Page 1

POWER DISTRIBUTION

JK Series

400A & 720A

Fixed Type

Medium Voltage

Motor Controllers

Page 2

MEDIUM VOLTAGE CONTROLLERS

JK400 Series

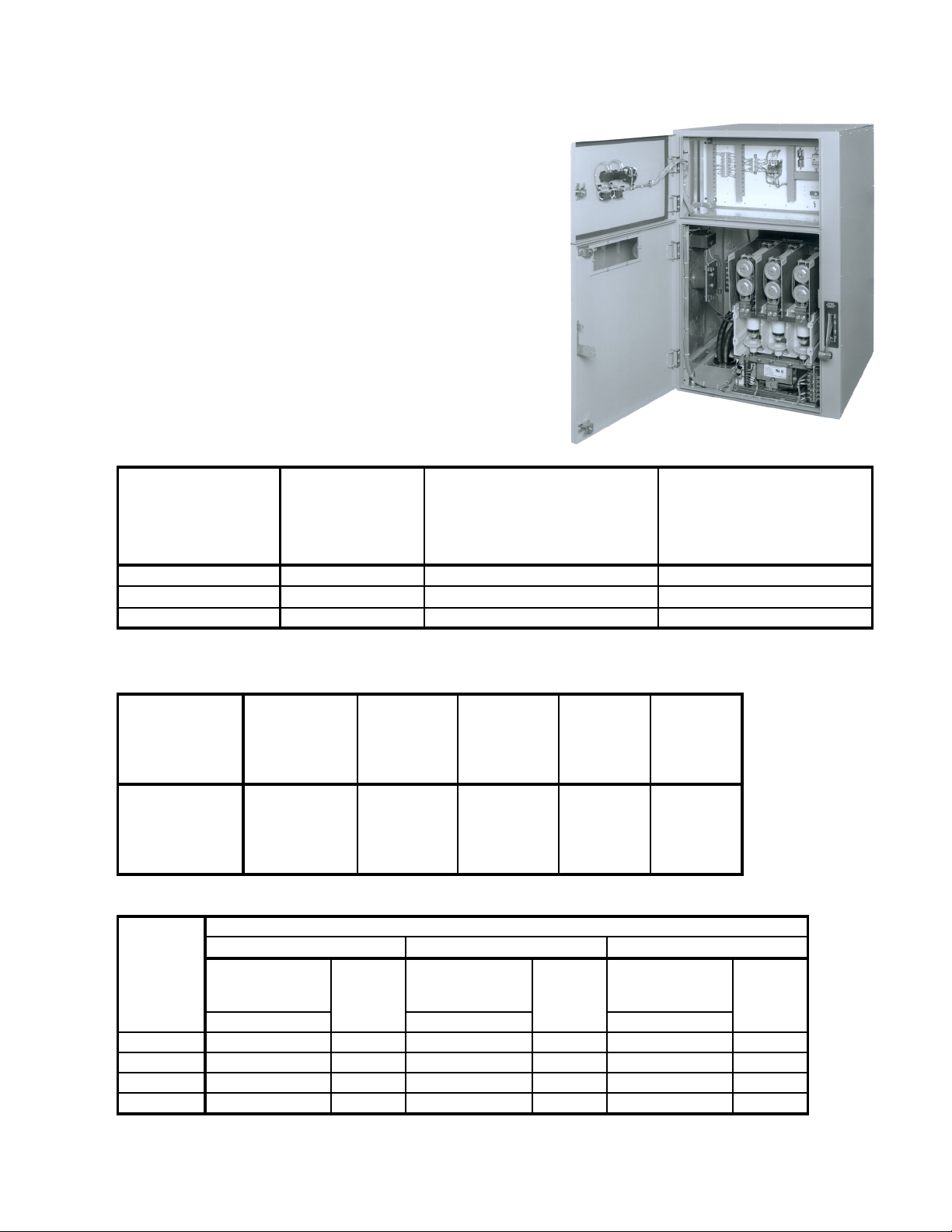

The JK400 Series of motor controller is the result

of extensive research and development. This

state-of-the-art controller was designed in

Houston, T exas, and is currently being manufactured under ISO 9001 standards in the same

manufacturing facility as Toshiba motors and

drives. The components in this new series have

been arranged in the most logical manner to

produce a tightly designed unit, and in the full

voltage type starters, uses no internal power

cables. This streamlined, space saving design

provides the ultimate in maintenance ease and

safety features.

These medium voltage controllers are available in

across-the-line or reduced voltage models for the

control of induction, wound rotor or synchronous

motors, transformers, or capacitors up to 6.6kV .

All controllers are designed to meet NEMA Class

E2 requirements. These fixed type controllers

are available in one or two high enclosures with

the following standard features:

Standard Features Full & Reduced

Voltage Controllers

T oshiba Medium V oltage V acuum Cont actor 400A

Bolted Pressure Switch Connections

30" Wide Footprint (Even in a T wo High Design)

Rigid 1 1 Gauge S teel Frame

Front Accessible Main Bus

Current Transformers

Current Limiting, High Interrupting Capacity ,

"R" Rated Motor Starting Fuses

Start and Stop Push Buttons

Run and Off Pilot Lights

Single Phase Ammeter

Control Power Transformer with Primary

and Secondary Fuses

Thermal Bimetallic Overload Relay

S eparate Medium and Low Voltage

Compartments

Built-in Run/T est Circuit

Mechanical and Electrical Interlocks

Isolated Low Voltage Compartment

The low voltage section is oversized and is at a

convenient height. This section is isolated from

the medium voltage section and includes:

Thermal Overload Protection Relay

Pilot Lights (door mounted)

Push Buttons (door mounted)

Single Phase Ammeter (door mounted)

CPT Secondary Fuses

Control T erminal Point s for Customer Connections

Timers (for Reduced V oltage Controllers)

Standard Options:

Metering & Metering Switches

Ground Fault Protection Relay

Phase Sequence Protection Relay

RTD Monitor/Relay

Solid State (2E) Protection Relay

(Overload/Single Phase)

S2E21 Multi-funtion Protection Relay

Visible, Bolted Pressure, Isolation Switch

Standard Features:

Bolted Pressure Isolation Switch

Less Resistance

Less Wear

Zero Insertion Pressure

Mechanical Interlocking System

Reduced Voltage Autotransformer

Controller

Additional Standard Features:

Shorting and Run, 400 Ampere, Vacuum

Contactors

NEMA Medium Duty, Three Winding, Copper

Wound Autotransformer with 50%, 65%, and

80% Taps

Adjustable Solid State Transition Timer

Adjustable Solid State Incomplete Sequence

Timer

If UL or CUL is required, specify when ordering.

Consult Factory for applicable models and options.

Page 3

g

r

MEDIUM VOLTAGE CONTROLLERS

p

JK400 Series

Toshiba's JK400 series complies with EEMAC,

NEMA, UL and CSA standards and is available in

non-reversing and reversing full voltage, autotransformer, reactor, multi-speed, synchronous and

wound rotor configurations. Latched contactors

are also available.

The JK400 series is available in the following

enclosed ratings:

360 amps

2300-6600 Volts

Up to 5,000 HP

Current Rating

Maximum

Continuous

Enclosure Type

Type 1 Ventilated 360 360 320

Type 1 Non-Ventilated 320 320 280

Type 12, 3, 3R 310 310 280

* Actual limits based on your specific application parameters. All specifications subject to change without notice.

Amperes*

46" and 61"

One-Hi

h Controlle

Maximum Continuous Amperes*

90" One-High Controller or Lower

Controller in a Two-High Stacking

Arrangement

Maximum Continuous

Amperes*

Upper Controller in a Two-High

Stacking Arrangement

Short Circuit & Withstand Capability

Interrupting

Capacity

(Symmetrical

Amperes)

50,000

@ 2.3 - 6.6 kV

Interrupting

Capacity

(Symmetrical

MVA)

200 @ 2.3 kV

350 @ 4.0 kV

400 @ 4.6 kV

570 @ 6.6 kV

Short Time

Capability

30 Seconds

(Amperes)

2400 6000 18.2 60

Short Time

Capability

1 Second

(Amperes)

Dielectric

Withstand

1 Minute

(kVAC)

Impulse

Voltage

Withstand

(kV)

Application Table

Enclosed

Maximum

Continuous

Current

(Amperes)

360 1500 1750 1500 2500 3000 2500 4000 5000 4000

320 1250 1500 1250 2250 2500 2250 3500 4500 3500

310 1250 1500 1250 2000 2500 2000 3500 4000 3500

280 1000 1250 1000 1750 2250 1750 3000 3500 3000

For transformer and capacitor load switching applications, consult factory.

2300 Volts, 3 Phase 4200 Volts, 3 Phase 6600 Volts, 3 Phase

Synchronous

Motors

0.8 PF 1.0 PF 0.8 PF 1.0 PF 0.8 PF 1.0 PF

Maximum Horse

Induction

Motors

Synchronous

ower at Utilization Voltage

Motors

Induction

Motors

Synchronous

Motors

Induction

Motors

Page 4

MEDIUM VOLTAGE CONTROLLERS

JK720 Series

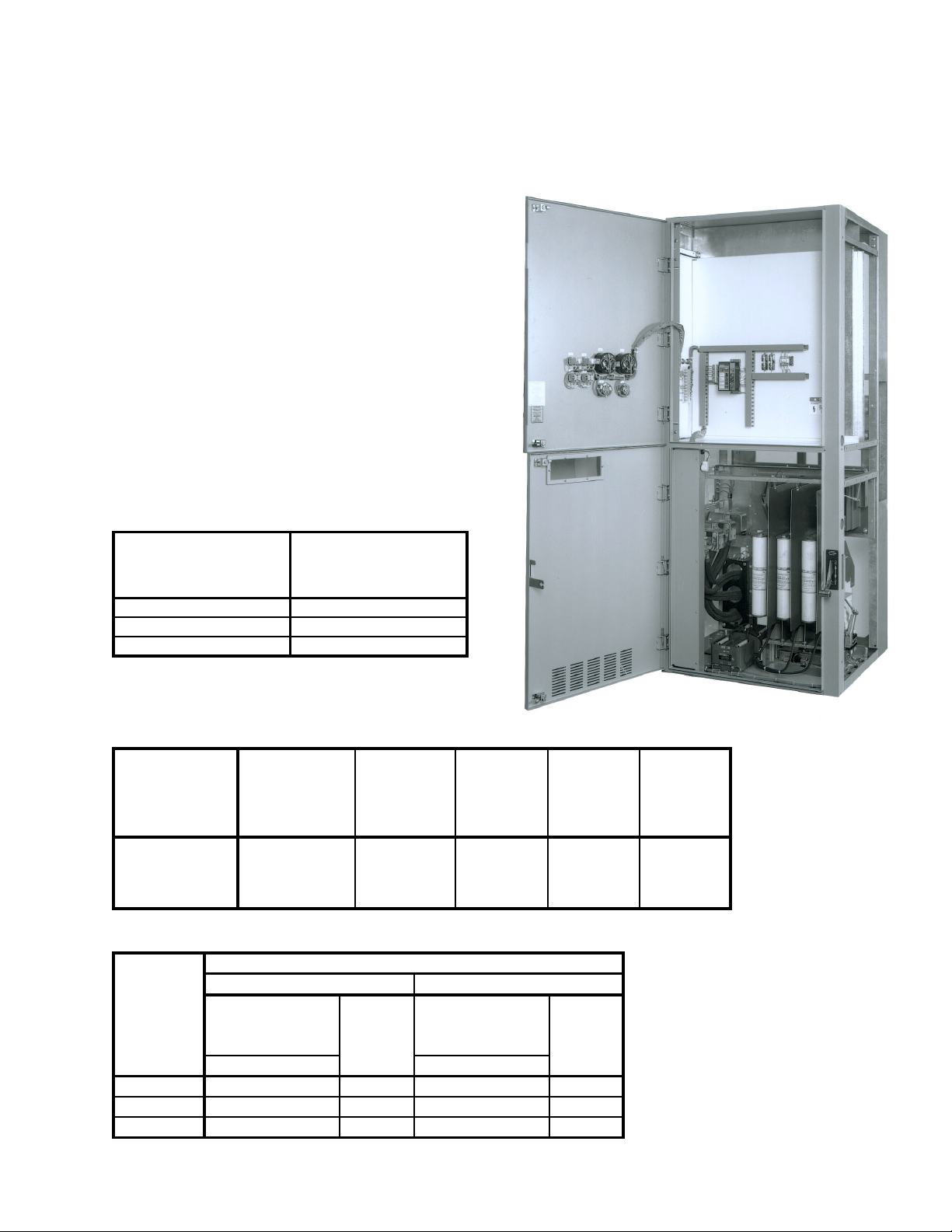

The new JK720 Series of motor controller is the

result of extensive research and development.

This state-of-the-art controller was designed in

Houston, T exas, and is currently being manufactured under ISO 9001 standards in the same

manufacturing facility as Toshiba motors and

drives. The components in this new series have

been arranged in the most logical manner to

produce a tightly designed unit. This streamlined, space saving design provides the ultimate

in maintenance ease and safety features.

These medium voltage controllers are available in

across-the-line or reduced voltage models for the

control of induction, wound rotor or synchronous

motors, transformers, or capacitors up to 4.8kV .

All controllers are designed to meet NEMA Class

E2 requirements. These fixed type controllers

are available in one high enclosures with the

following standard features:

Standard Features Full & Reduced

Voltage Controllers

T oshiba Medium V oltage Vacuum Contactor 720A

Bolted Pressure Switch Connections

36" Wide Footprint

Rigid 1 1 Gauge S teel Frame

Front Accessible Main Bus

Current Transformers

Current Limiting, High Interrupting Capacity ,

"R" Rated Motor Starting Fuses

Start and Stop Push Buttons

Run and Off Pilot Lights

Single Phase Ammeter

Control Power Transformer with Primary

and Secondary Fuses

Thermal Bimetallic Overload Relay

Separate Medium and Low Voltage

Compartments

Built-in Run/T est Circuit

Mechanical and Electrical Interlocks

Isolated Low Voltage Compartment

The low voltage section is oversized and is at a

convenient height. This section is isolated from

the medium voltage section and includes:

Thermal Overload Protection Relay

Pilot Lights (door mounted)

Push Buttons (door mounted)

Single Phase Ammeter (door mounted)

CPT Secondary Fuses

Control T erminal Point s for Customer Connections

Timers (for Reduced V oltage Controllers)

Standard Options:

Metering & Metering Switches

Ground Fault Protection Relay

Phase Sequence Protection Relay

RTD Monitor/Relay

Solid State (2E) Protection Relay

(Overload/Single Phase)

S2E21 Multi-funtion Protection Relay

Standard Features:

Bolted Pressure Isolation Switch

Less Resistance

Less Wear

Zero Insertion Pressure

Mechanical Interlocking System

Reduced Voltage Autotransformer

Controller

Additional Standard Features:

Shorting (400A) and Run (720A), V acuum

Contactors

NEMA Medium Duty , Three Winding, Copper

Wound Autotransformer with 50%, 65%, and

80% Taps

Adjustable Solid State Transition Timer

Adjustable Solid State Incomplete Sequence

Timer

If UL or CUL is required, specify when ordering.

Consult Factory for applicable models and options.

Page 5

MEDIUM VOLTAGE CONTROLLERS

A

JK720 Series

Toshiba's JK720 series complies with EEMAC,

NEMA, UL and CSA standards and is available in

non-reversing and reversing full voltage, autotransformer, reactor, multi-speed, synchronous and

wound rotor configurations. Latched contactors

are also available.

The JK720 series is available in the following

enclosed ratings:

720 amps

2300-4800 Volts

Up to 6,000 HP

Note: An Incoming Section is required for the JK720

FVNR, FVR and RVAT type starters, transformer

feeders and capacitor switching controllers.

Current Rating

Maximum Continuous

Enclosure Type

Type 1 Ventilated 720

Type 1 Non-Ventilated 650

Type 12 & 3R 600

Amperes*

One-High Controller

* Actual limits based on your specific application parameters.

All specifications subject to change without notice.

Short Circuit & Withstand Capability

Interrupting

Capacity

(Symmetrical

Amperes)

50,000

@ 2.3 - 4.6 kV

Interrupting

Capacity

(Symmetrical

MVA)

200 @ 2.3 kV

350 @ 4.0 kV

400 @ 4.6 kV

Short Time

Capability

30 Seconds

(Amperes)

4320 10,800

Short Time

Capability

1 Second

(Amperes)

Application Table

Enclosed

Maximum

Continuous

Current

(Amperes)

720 3000 3500 3000 5500 6000 5500

650 2750 3000 2750 5000 5500 5000

600 2500 2750 2500 4500 5000 4500

For transformer and capacitor load switching applications, consult factory.

0.8 PF 1.0 PF 0.8 PF 1.0 PF

Maximum Horsepower at Utilization Voltage

2300 Volts, 3 Phase 4200 Volts, 3 Phase

Synchronous

Motors

Induction

Motors

Synchronous

Motors

Dielectric

Withstand

1 Minute

(kV)

C 13.25

DC 19

Induction

Motors

Impulse

Voltage

Withstand

(kV)

60

Page 6

1. Standards

1.1 Basic controller shall comply with NEMA ICS3-1993, Part 2 (ICS2-324) and UL 347

Standards. Basic controller can be UL Listed and CSA Certified.

2. Structure

2.1 Dimensions

FVNR One-high - 30"W x 36"D x 46"H (no bus, small LV compartment)

FVNR One-high - 30"W x 36"D x 61"H (bus provision, large LV compartment)

FVNR One-high - 30"W x 36"D x 90"H (bus provision, empty upper MV compartment)

FVNR Two-high - 30"W x 36"D x 90"H

RVAT (up to 1250HP) - 36"W x 36"D x 90"H

RVAT (1250HP-4000HP) - 42"W x 36"D x 90"H

2.2 Fabrication

2.2.1 11 gauge frame with 16 gauge side, back and top sheets.

2.2.2 Front of cubicle to be an all-welded assembly. Remainder of frame to be bolted

construction.

JK Series Product Specification

400A MEDIUM VOLTAGE FIXED CONTROLLER

2.2.3 Back and top sheets to be removable for easy access for assembly and wiring.

2.2.4 Basic dimensions and squareness of cubicle to be controlled by accurately located NCpunches holes. With exception of welded front frame, cubicle should be capable of being

assembled without a fixture.

2.2.5 All doors shall be minimum 12 gauge steel.

2.2.6 All structural components shall be given a corrosion resistant finish by either galvanizing or

painting. Galvanized steel shall be used only for internal structural members or panels.

2.2.7 All panels used to mount low voltage devices shall be painted white for superior visibility.

Panels shall be easily removable or swing-out to provide access to horizontal bus mounted in the

middle rear of the cubicle.

2.3 General Arrangement of Components

2.3.1 Medium voltage compartments, low voltage compartments and power bus compartments

shall be isolated by grounded steel barriers.

2.3.2 Complete front accessibility to all components shall be provided for installation against

walls or for back-to-back arrangements.

2.3.3 Low voltage components shall be located so that components are accessible with medium

voltage doors closed. Low voltage compartment shall be sized with consideration to mounting

commonly used devices.

Page 7

2.4 Handling and Installation

2.4.1 Removable angles or eye bolts shall be provided at the top of the structure for lifting.

3. Power Bus

3.1 Horizontal power bus shall be located at the center rear of the cubicle, in the same location as

other JK Series controllers.

3.2 Horizontal power bus ratings of 1200 and 2000 amperes are available. Bus sizes shall match

those provided in other JK Series controllers.

3.3 Horizontal power bus shall be braced for 50kA RMS symmetrical.

3.4 Horizontal power bus shall be tin plated as standard with insulated bus and silver plating optional.

3.5 Bare copper 1/4 x 2 inch horizontal ground bus shall be available and the location shall match

other JK Series controllers.

3.6 Vertical power bus feeding 400 ampere controllers shall be 1/4 x 1-1/4 inch tin plated copper.

Insulated bus and silver plating are optional.

3.7 Horizontal power bus shall be front accessible by removing or swinging open a panel.

4. Medium Voltage Controllers - 400 Amperes

4.1 Medium Voltage Controller Compartment

4.1.1 The medium voltage controller compartment for controllers rated 400 amperes shall consist

of an isolation switch (4.2), a fixed mounted vacuum contactor (4.3), three fixed mounted power

fuses (4.4), three current transformers and a control power transformer with primary fuses.

Optionally a second control or potential transformer with primary fuses may be provided.

4.1.2 Internal power connections between power components shall be made using either high

voltage cable or bus bars.

4.1.3 Connection of customer's outgoing load cables shall be made to terminals mounted on the

rear of the medium voltage contactor. It shall be possible to terminate outgoing load cables with

the removal of the horizontally mounted power fuses. Sufficient wire bending space shall be

provided for terminating shielded cables as large as 1-2/0 per phase, or unshielded cables as

large as 1-350MCM per phase, top or bottom entry.

4.1.4 A zero sequence current transformer for ground fault sensing when required shall be

provided. It shall be located within the MV compartment where customer’s load cable can be

conveniently passed through the current transformer window prior to termination.

4.1.5 Three current transformers for metering and relaying shall be provided. These shall be of

the window type (or bar type as option) with burden capacity as required for operating the various

meters and relays.

4.1.6 Control power and optional potential transformers shall be of the encapsulated type with

primary fuses. Primary side of transformers shall be wired to the load side of the main controller

power fuses. Transformers shall be arranged to provide easy access for replacement of primary

fuses.

Page 8

4.2 Bolted Pressure Isolation Switch

4.2.1 A Toshiba type JK fixed mounted, gang-operated isolation switch shall be provided with

each controller to isolate the medium voltage compartment from the power source.

4.2.2 The switch shall be directly driven by an externally operable handle mounted on the right

hand flange of the cubicle. The handle shall provide positive indication of the position of the

switch.

4.2.3 The switch mechanism shall be designed such that in the closed position it provides the

equivalent of a bolted pressure joint at both ends of the movable blades, rather than relying on

spring pressure.

4.2.4 The line side of the switch shall be bus connected to the main horizontal power bus or to

the incoming terminals of the controller. The load side of the switch shall be bus connected to

the main controller power fuses.

4.2.5 The switch blades shall automatically ground the line side of the power fuses when the

switch is opened. This allows any stored energy in the controller load circuit to be discharged by

closing the contactor using test power.

4.2.6 It shall be possible to visually confirm that the switch blades are open and grounded by

viewing the blades through the viewing window with the medium voltage door closed. Also, there

shall be a mechanical operated flag (visible through the window in the medium voltage door)

displaying the switch in the “OPEN” position with the door closed.

4.2.7 A shutter mechanism shall automatically isolate the medium voltage compartment from all

live parts when the switch is opened.

4.2.8 The external operating handle for the isolation switch shall be designed to accept up to

three external padlocks in the OFF position.

4.2.9 The switch shall be capable of interrupting the no-load current of the largest control power

transformer which can be connected to it. The interrupting capability of the switch shall be a

minimum of 0.4 amperes at 110% of rated line voltage.

4.2.10 The switch shall be rated as follows:

400 amperes @ 7.2kV

4.2.11 The mechanical life of the switch and its operating mechanism shall be 10,000 operations

minimum.

4.2.12 All switch current-carrying parts shall be silver plated. An optional tin-over-silver plated

switch shall be available for use in paper mill applications.

4.3 Vacuum Contactor

4.3.1 The Toshiba HCV-5HA vacuum contactor shall be used in these controllers.

4.3.2 The contactor shall be bolted into the medium voltage compartment. It shall be arranged

such that the power connections are front-accessible so it can be unbolted and removed if

necessary for maintenance.

Page 9

4.3.3 Power connections from the isolation switch to the main power fuses shall be made using

bus bar. Connections from the contactor through the current transformers to the outgoing load

terminals shall be made using power cable furnished by others.

4.3.4 The contactor shall be available with an optional mechanical latch with provisions for

manual or electrical trip.

4.3.5 The contactor shall be mechanically and electrically interlocked with the isolation switch as

described in the section on interlocking (4.5).

4.4 Power Fuses

4.4.1 The power fuses shall be arranged horizontally at the top of the contactor unit. In this

position, the blown fuse indicators on the fuses shall be visible, through the viewing window, when

the medium voltage door is closed.

4.4.2 The fuse unit shall include either single or double barrel power fuses, R-rated or E-rated, 3"

diameter.

4.5 Interlocking

4.5.1 A mechanical interlock shall be provided between the vacuum contactor and the isolation

switch. The interlock shall prevent the isolation switch from being opened or closed unless the

main contacts of the contactor are opened.

4.5.2 The interlock described in 4.5.1 shall also operate in a manner such that it will prevent the

closing of the main contacts of the vacuum contactor unless the isolation switch is either fully

opened or fully closed.

4.5.3 An electrical interlock shall be provided as a backup to the mechanical interlock in 4.5.1.

This interlock shall switch off control power to the vacuum contactor at any isolating switch

position other than fully opened or fully closed.

4.5.4 A mechanical interlock shall be provided between the isolation switch and the medium

voltage compartment door. This interlock shall prevent the door from being opened unless the

isolating switch is in the fully open position.

4.5.5 The interlock described in 4.5.4 shall be capable of being circumvented in the event

emergency entrance to the controller is required. Circumventing the interlock shall require two

separate and distinct operations and shall require the use of a tool.

4.5.6 A mechanical interlock between the isolation switch and the medium voltage door shall be

provided to prevent the isolating switch from being closed when the door is open. This interlock

shall be capable of being circumvented only by the use of a tool.

4.5.7 An electrical interlock shall be provided to ensure the isolation switch does not open with

the control power transformer under load. This interlock shall be designed such that during

switch opening, the transformer secondary is disconnected prior to the opening of the switch

blades. Also, the isolating switch blades must close before the secondary load is reconnected.

4.5.8 An electrical interlock shall be provided to prevent the vacuum contactor from being closed

using external test power unless the isolation switch is fully opened and the secondary of the

normal control power transformer is disconnected from the control circuit to prevent backfeeding

the transformer.

Page 10

5. Ratings

5.1 Controller shall be rated as follows:

5.1.1 Interrupting Ratings:

400 Ampere Controller:

- contactor 7.0kA @ 6.9kV

- fused controller 50kA RMS Sym. @ 7.2kV

5.1.2 Continuous Thermal Ratings:

400 Ampere Controller:

200MVA @ 2.3kV

350MVA @ 4.0kV

400MVA @ 4.6kV

570MVA @ 6.6kV

Enclosure type Max. Continuous

Amperes

46” and 61” One-high

controller

Max. Continuous

Amperes

90” One-high controller or

Lower controller in a Two-

high stacking

Max. Continuous

Amperes

Upper controller in a

Two-high stacking

arrangement

arrangement

NEMA-1 Ventilated 360 360 320

NEMA-1 Non-ventilated 320 320 280

NEMA-12/3R 310 310 280

5.1.3 Short Time Thermal Rating:

400 Ampere Contactor: 2400A for 30 seconds

6000A for 1 second

5.1.4 Impulse Withstand:

400 Ampere Controller: 60kV

1.2 x 50 microsecond wave

Rev. 2, 2/16/1999

Page 11

1. Standards

1.1 Basic controller shall comply with NEMA ICS3-1993, Part 2 (ICS2-324) and UL 347

Standards. Basic controller can be UL/CUL Listed.

2. Structure

2.1 Dimensions

Across-the-Line (one-high) - 36"W x 36"D x 90"H

Reduced Voltage Autotransformer - (2) 36"W x 36"D x 90"H

2.2 Fabrication

2.2.1 11 gauge frame with 16 gauge side, back and top sheets.

2.2.2 Front of cubicle to be an all-welded assembly. Remainder of frame to be bolted

construction.

2.2.3 Side, back and top sheets to be removable for easy access for assembly and wiring.

2.2.4 Basic dimensions and squareness of cubicle to be controlled by accurately located NCpunches holes. With exception of welded front frame, cubicle should be capable of being

assembled without a fixture.

JK Series Product Specification

720A MEDIUM VOLTAGE FIXED CONTROLLER

2.2.5 All doors shall be minimum 12 gauge steel.

2.2.6 All structural components shall be given a corrosion resistant finish by either galvanizing or

painting. Galvanized steel shall be used only for internal structural members or panels.

2.2.7 All panels used to mount low voltage devices shall be painted white for superior visibility.

Panels shall be easily removable or swing-out to provide access to horizontal bus mounted in the

rear of the cubicle.

2.3 General Arrangement of Components

2.3.1 Medium voltage compartments, low voltage compartments, power bus compartments and

field conductor wireways shall be isolated by grounded steel barriers.

2.3.2 Complete front accessibility to all components shall be provided for installation against

walls or for back-to-back arrangements.

2.3.3 Low voltage components shall be located so that components are accessible with medium

voltage door closed. Low voltage compartment shall be sized with consideration to mounting

commonly used devices.

2.4 Handling and Installation

Page 12

2.4.1 Removable angles or eye bolts shall be provided at the top of the structure for lifting.

2.4.2 Optional removable sill channels shall be available.

3. Power Bus

3.1 Horizontal power bus shall be located at the center rear of the cubicle, in the same location as

other JK Series controllers.

3.2 Horizontal power bus ratings of 1200 and 2000 amperes shall be available. Bus sizes shall

match those provided in other JK Series controllers.

3.3 Horizontal power bus shall be braced for 50kA RMS symmetrical.

3.4 Horizontal power bus shall be tin plated as standard with silver plating optional.

3.5 Bare copper 1/4 x 2 inch horizontal ground bus shall be available and the location shall match

other JK Series controllers.

3.6 Vertical power bus feeding 720 ampere controllers shall be 3/8 x 2 inch tin plated copper. Silver

plating shall be optional.

3.7 Horizontal power bus shall be front accessible by removing or swinging open a panel.

4. Medium Voltage Controllers - 720 Amperes

4.1 Medium Voltage Controller Compartment

4.1.1 The medium voltage controller compartment for controllers rated 720 amperes shall consist

of an isolation switch (4.2), a fixed mounted vacuum contactor (4.3), three fixed mounted power

fuses (4.4), three current transformers and a control power transformer with primary fuses.

Optionally a second control or potential transformer with primary fuses may be provided.

4.1.2 Internal power connections between power components shall be made using either high

voltage cable or bus bars.

4.1.3 Connection of customer's outgoing load cables shall be made to terminals mounted on the

left side of the medium voltage compartment. It shall be possible to terminate outgoing load

cables without the removal of major components such as the vacuum contactor and power fuses.

Sufficient wire bending space shall be provided for terminating shielded cables as large as 2500MCM per phase, top or bottom entry.

4.1.4 A zero sequence current transformer for ground fault sensing when required shall be

provided. It shall be located such that factory installed internal power cables from all three

phases shall pass through its window. Ground current sensors for Toshiba 2E ground fault

module and Multilin ground fault relay shall be available as a minimum.

4.1.5 Three current transformers for metering and relaying shall be provided. These shall be of

the window type with burden capacity as required for operating the various meters and relays.

4.1.6 Control power and optional potential transformers shall be of the encapsulated type with

integral primary fuses. All transformers shall be rated 60kV BIL. Primary side of transformers

shall be wired to the load side of the main controller power fuses. Transformers shall be

arranged to provide easy access for replacement of primary fuses.

Page 13

4.2 Bolted Pressure Isolation Switch

4.2.1 A fixed mounted, gang-operated isolation switch shall be provided with each controller to

isolate the medium voltage compartment from the power source.

4.2.2 The switch shall be directly driven by an externally operable handle mounted on the right

hand flange of the cubicle. The handle shall provide positive indication of the position of the

switch.

4.2.3 The switch mechanism shall be designed such that in the closed position it provides the

equivalent of a bolted pressure joint at both ends of the movable blades, rather than relying on

spring pressure.

4.2.4 The line side of the switch shall be bus connected to the main horizontal power bus or to

the incoming terminals of the controller. The load side of the switch shall be bus connected to

the main controller power fuses.

4.2.5 The switch blades shall automatically ground the line side of the power fuses when the

switch is opened. This allows any stored energy in the controller load circuit to be discharged by

closing the contactor using test power.

4.2.6 It shall be possible to visually confirm that the switch blades are open and grounded by

viewing the blades through the viewing window with the medium voltage door closed. Also, there

shall be a mechanical operated flag (visible through the window in the medium voltage door)

displaying the switch in the “OPEN” position with the door closed.

4.2.7 A shutter mechanism shall automatically isolate the medium voltage compartment from all

live parts when the switch is opened.

4.2.8 The external operating handle for the isolation switch shall be designed to accept up to

three external padlocks in the OFF position.

4.2.9 The switch shall be capable of interrupting the no-load current of the largest control power

transformer which can be connected to it. The interrupting capability of the switch shall be a

minimum of 0.4 amperes at 110% of rated line voltage.

4.2.10 The switch shall be rated as follows:

720 amperes @ 5.0kV

4.2.11 The mechanical life of the switch and its operating mechanism shall be 10,000 operations

minimum.

4.2.12 All switch current-carrying parts shall be silver plated. An optional tin-over-silver plated

switch shall be available for use in paper mill applications.

4.3 Vacuum Contactor

4.3.1 The Toshiba CV-6KAU vacuum contactor shall be used in these controllers.

4.3.2 The contactor shall be bolted into the medium voltage compartment. It shall be arranged

such that the power connections are front-accessible so it can be unbolted and removed if

necessary for maintenance.

Page 14

4.3.3 Power connections from the isolation switch to the contactor shall be made using bus bar.

Connections from the contactor through the current transformers to the outgoing load terminals

shall be made using power cable.

4.3.4 The contactor shall be supplied with an optional mechanical latch with provisions for

manual or electrical trip.

4.3.5 The contactor shall be fully mechanically and electrically interlocked with the isolation

switch as described in the section on interlocking (4.5).

4.4 Power Fuses

4.4.1 Main current-limiting power fuses shall be provided for both motor starting (R rated) and

transformer feeder (E rated) applications.

4.4.2 Available fuse ratings for motor starting applications shall be Gould Type A051B2DAR0

rated 38R (630A), 5kV or A051B3DAR0 rated 57X (900A), 5kV.

4.4.3 Available fuse ratings for transformer feeder applications shall be Gould Type

A055C2D0R0-500E and 600E, and A055B3D0R0-750E and 900E, rated 5.5kV.

4.4.4 All power fuses shall employ bolt-in mounting.

4.4.5 The blown fuse indicators on the fuses shall be visible, through the viewing window, when

the medium voltage door is closed.

4.5 Interlocking

4.5.1 A mechanical interlock shall be provided between the vacuum contactor and the isolation

switch. The interlock shall prevent the isolation switch from being opened or closed unless the

main contacts of the contactor are opened.

4.5.2 The interlock described in 4.5.1 shall also operate in a manner such that it will prevent the

closing of the main contacts of the vacuum contactor unless the isolation switch is either fully

opened or fully closed.

4.5.3 An electrical interlock shall be provided as a backup to the mechanical interlock in 4.5.1.

This interlock shall switch off control power to the vacuum contactor at any switch position other

than fully opened or fully closed.

4.5.4 A mechanical interlock shall be provided between the isolation switch and the medium

voltage compartment door. This interlock shall prevent the door from being opened unless the

switch is in the fully open position.

4.5.5 The interlock described in 4.5.4 shall be capable of being circumvented in the event

emergency entrance to the controller is required. Circumventing the interlock shall require two

separate and distinct operations and shall require the use of a tool.

4.5.6 A mechanical interlock between the isolation switch and the medium voltage door shall be

provided to prevent the switch from being closed when the door is open. This interlock shall be

capable of being circumvented only by the use of a tool.

Page 15

4.5.7 An electrical interlock shall be provided to ensure the isolation switch does not open with

the control power transformer under load. This interlock shall be designed such that during

switch opening, the transformer secondary is disconnected prior to the opening of the switch

blades. Also, during switch closing, the switch blades must close before the secondary load is

reconnected.

4.5.8 An electrical interlock shall be provided to prevent the vacuum contactor from being closed

using external test power unless the isolation switch is fully opened and the secondary of the

normal control power transformer is disconnected from the control circuit to prevent backfeeding

the transformer.

5. Ratings

5.1 Controllers shall be rated as follows:

5.1.1 Interrupting Ratings

- Contactor 7.2kA @ 6.6kV Max.

- Controller 50kA RMS Sym. @ 5.0kV Max.

5.1.2 Continuous Current Ratings

N-1 Enclosure (Ventilated) 720A

N-1 Enclosure (Non-ventilated) 650A

N-12, 3, 3R Enclosure 600A

200MVA @ 2.3kV

350MVA @ 4.0kV

400MVA @ 4.6kV

5.1.3 Horsepower Ratings - Induction Motors (Approximate)

5.1.4 Short Time Current Ratings

5.1.5 Impulse Voltage Withstand

Rev. 5, 2/16/1999

@2.3kV@4.2kV

N-1 Enclosure (Ventilated) 3000 5500

N-1 Encl. (Non-ventilated) 2750 5000

N-12, 3, 3R Enclosure 2500 4500

4320A - 30 seconds

10,800A - 1 second

60kV

1.2 x 50 microsecond wave

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

North America Headquarters & Manufacturing Facilities (Houston, TX)

TOSHIBA - Quality by Design

Our company culture and history is strongly rooted in quality. Our designs are

technologically innovative and our products are manufactured from start to end

using only the highest quality foreign and domestic parts.

Product Warranty

Toshiba offers a comprehensive warranty program on its full line of industrial

products. Consult your salesperson or the factory for specific information.

Medium Voltage Motor

G7 Drive

Need to Know More?

Be sure to visit our website located at www.tic.toshiba.com for the latest

information on Toshiba products.

Customer Support Services

Toshiba offers 24 hour service nationwide. For assistance of any type,

call: 1-800-231-1412

ADJUSTABLE SPEED DRIVES MOTORS CONTROLS UPS INSTRUMENTATION PLC

Available Through:

INDUSTRIAL DIVISION

13131 West Little York Road, Houston, Texas 77041

Tel 713/466-0277 Fax 713/466-8773

US 800/231-1412 Canada 800/872-2192 Mexico 01/800/527-1204

www.tic.toshiba.com

Copyright 2/2005

*pacjKSBROCH050218*

Loading...

Loading...