Page 1

POWER DISTRIBUTION

Solid

State Starters

Medium Voltage

200-400-600-720A

JK Series

Page 2

SOLID STATE STARTER

JKSSS4+ Series

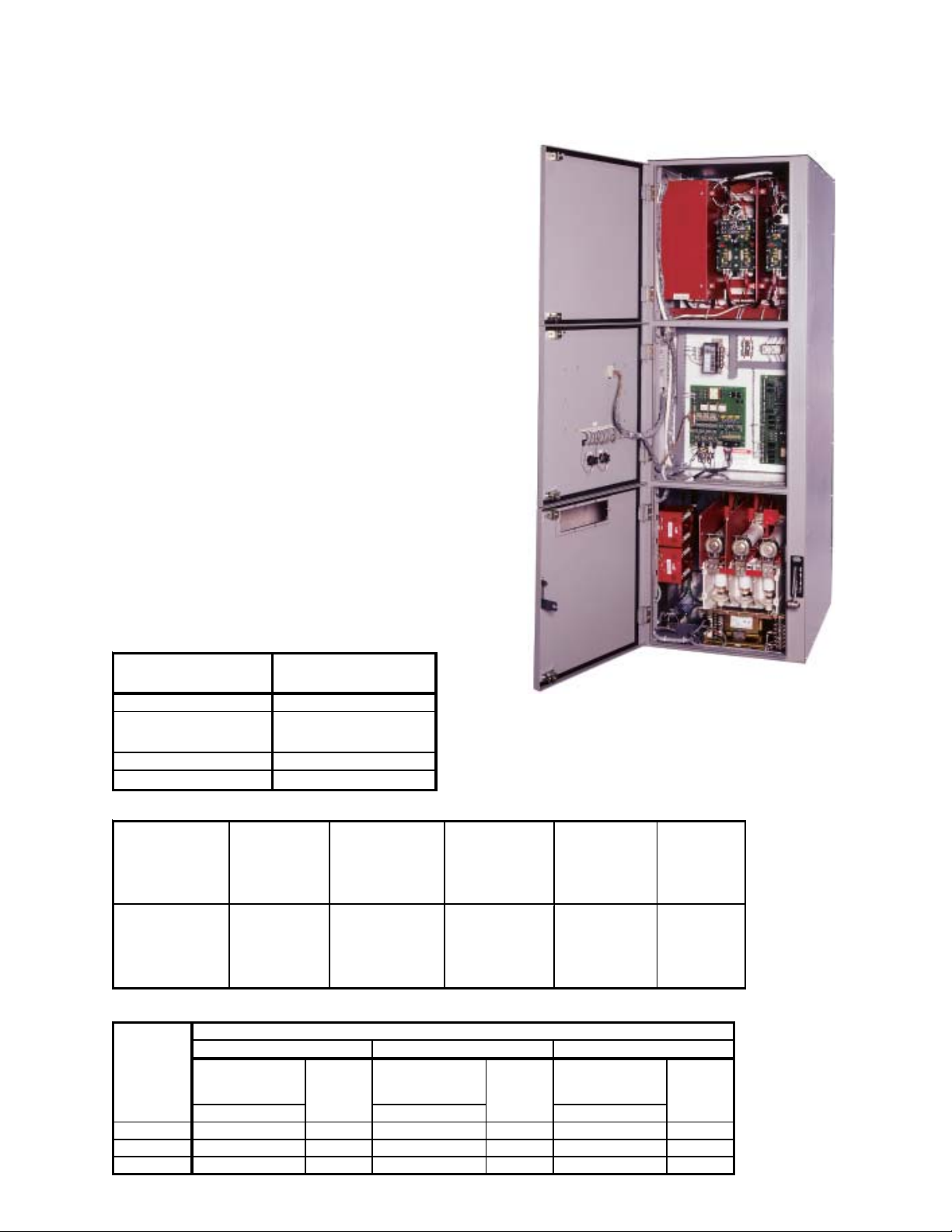

The JKSSS Series of motor starter is the result of

extensive research and development. This

streamlined, space saving design (only 30" wide)

provides the ultimate in maintenance ease and

safety features. These medium voltage solid state

starters are available for the control of induction,

wound rotor or synchronous motors, up to 6.9kV.

All starters are designed to meet NEMA Class E2

requirements.

Features

Soft Start

125% Continuous Duty

500% - 60 Seconds, 600% - 30 Seconnds

30" Wide Footprint

Digital Microprocessor Control

LCD Display w/Programming Keypad

Toshiba Medium Voltage Vacuum Contactors,

for Bypass and Input Isolation

Incoming, 400A JK Disconnect Switch - Bolted

Pressure Switch Connections

Current Limiting, High Interrupting Capacity,

"R" Rated Motor Starting Fuses

Two Stage Solid State Motor Protection

Starting: Programmable for Class 5 through 30

Running: Programmable for Class 5 through 30

Control Power Transformers with Primary and

Secondary Fuses

NEMA Type 1 Enclosure

Separate Medium and Low Voltage Compartments

Mechanical and Electrical Interlocks

Visible, Bolted Pressure, Isolation Switch

Less Resistance

Less Wear

Zero Insertion Pressure

Mechanical Interlocking System

Isolated Low Voltage Compartment

The low voltage section is oversized and is at a

convenient height. This section is isolated from

the medium voltage section.

Digital Control Module

LCD Display (two lines) and Status LEDs

(Power, Run, Alarm, Aux. Relays)

Programming Keypad (Non-volatile Memory)

Maintenance Data

Fault indications: Shorted SCR, Phase Loss, Shunt

Trip, Phase Imbalance, Phase Rotation, Overload,

Overtemp, Overcurrent, Short Circuit, Load Loss,

Ground Fault, Stator Phase Trip, RTD Trip, or Any Trip

Coast Down Time

Starts per Hour

Time Between Starts

Event History - Up to 60 events. Data includes

cause, date, time, phase and ground current.

Additional Features

Serial Communication Port:

RS485 or RS422 with Modbus RTU Protocol or

RS485 or RS422 with Windows Interface

Rugged Gate Firing Circuit Using Ring Transformer

Opto-isolated Inputs

Auxiliary Contacts - Form C, 5A @ 240Vac max.

Adjustments

Motor Full Load Ampere (FLA)

Dual Adjustments - Two independent settings

Initial Voltage 0 - 100% of nominal voltage

Current Limit 200 - 500% of motor FLA

Acceleration Time 1 - 120 seconds

Deceleration Time 1 - 60 seconds

Three custom Accel curves

Jog: 5 - 100% Volt., 1 - 20 sec., Current 100 - 500%

Kick Start: 10 - 100% Voltage, 0.1 - 2 sec.

Coast Down (Back Spin) Lockout Timer 1 - 60 min.

Starts-per-Hour Lockout Timer

1 - 10 successful starts per hour

1 - 60 min. between start attempts

Undercurrent 10 - 90% (with adjustable trip delay

1 - 60 sec.)

Overload Reset - Selectable Manual or Automatic

Two 4 - 20 mA Analog Outputs: Selectable from

Off, RPM, Hottest Non-Stator RTD, Hottest Stator

RTD, RMS Current, % of Motor Load

Options

Drawout Input Isolation, Vacuum Contactor

NEMA Type 12 or 3R Enclosure

1200 or 2000A Main Copper Bus

Available in MCC Lineups with Other JK Series

Starters (FVNR, FVR, RVAT, Synchronous, Etc.)

Available in MCC Lineups with Main Incoming

Disconnect Switch or Toshiba Vacuum

Circuit Breaker

The soft start is available as a controller only for

users which already have an existing full voltage

starter (disconnect switch, main power fuses &

contactor) and wants to add reduced voltage

starting and soft stop features.

PFC Contactor - Vacuum contactor for switching

Power Factor Correction Capacitor.

Manual (Full Voltage) Bypass Selection with solid

state protection (2E) or bimetallic overload.

If UL or CUL is required, specify when ordering.

Consult Factory for applicable models and options.

Page 3

SOLID STATE STARTER

JKSSS4+ Series

T oshiba's JKSSS4 series complies with EEMAC,

NEMA, UL and CSA standards and is available in

non-reversing and reversing, multi-speed, synchronous and wound rotor configurations.

The JKSSS4 series is available in the following

enclosed ratings:

360 Amps Max.

2300-6900 Volts

Protective Features

z Electronic Overload:

Retentive Thermal Memory

Dynamic Reset Memory

z Phase Imbalance/Single Phase

z Short Circuit

z Ground Fault - Optional

z RTD T emperature

z Phase Reversal/Phase Sequence

z Overcurrent

z Start s-per-Hour

z Shorted SCR

z Undercurrent/Loss of Load

z Starter Overtemperature

z Shorted SCR

z Undervoltage

z Overvoltage

Continuous Current

Enclosure T ype

Type 1 Ventilated 360A

Type 12 Ventilated w/

Fans & Type 12 Filters

Type 1 Non-Ventilated 300A

Type 12 & 3R 300A

Short Circuit & Withstand Capability

Max. Continuous Amps*

90" One-High Controller

310A

Interrupting

Capacity

(Symmetrical

Amperes)

Interrupting

Capacity

(Symmetrical

MVA)

Short Time

Capability

30 Seconds

(Amperes)

Short Time

Capability

1 Second

(Amperes)

Dielectric

Withstand

1 Min ute

(kVAC)

200 @ 2.3 kV

50,000

@ 2.3 - 6. 6 kV

350 @ 4.0 kV

400 @ 4.6 kV

2400 6000 18.2 60

570 @ 6.6 kV

Approximate Maximum Horsepower Based on Continuous Current

Enclosed

Maximum

Continuous

Current

(Amperes)

360 1500 1750 1500 2500 3000 3000 4000 5000 4500

320 1250 1500 1250 2250 2500 2500 3500 4000 4000

300 1000 1250 1000 2000 2500 2250 3000 3500 3500

Synchronous

0.8 PF 1.0 PF 0.8 PF 1.0 PF 0.8 PF 1.0 PF

2300V 4200V 6600V

Motors

Maximum Horsepower at Utilization Voltage

Induction

Motors

Synchronous

Motors

Induction

Motors

Synchronous

Motors

Impulse

Voltage

Withstand

(kV)

Induction

Motors

If UL or CUL is required,

specify when ordering.

Consult Factory for

applicable models and

options.

Page 4

SOLID STATE STARTER

JKSSS7+ Series

The new JKSSS7+ Series of motor starter is the

result of extensive research and development.

These medium voltage solid state starters are

available for the control of induction, wound rotor

or synchronous motors up to 4.8kV. All controllers are designed to meet NEMA Class E2

requirements.

Features

Soft Start

125% Continuous Duty

500% - 60 Seconds, 600% - 30 Seconds

Digital Microprocessor Control

LCD Display w/Programming Keypad

Toshiba Medium Voltage Vacuum Contactors,

for Bypass and Input Isolation

Incoming, 720A JK Disconnect Switch - Bolted

Pressure Switch Connections

Current Limiting, High Interrupting Capacity,

"R" Rated Motor Starting Fuses

Two Stage Solid State Motor Protection -

Starting: Programmable for Class 5 through 30

Running: Programmable for Class 5 through 30

Control Power Transformers with Primary and

Secondary Fuses

NEMA Type 1 Enclosure

Separate Medium and Low Voltage Compartments

Mechanical and Electrical Interlocks

Visible, Bolted Pressure, Isolation Switch

Less Resistance

Less Wear

Zero Insertion Pressure

Mechanical Interlocking System

Isolated Low Voltage Compartment

The low voltage section is oversized and is at a

convenient height. This section is isolated from

the medium voltage section.

Digital Control Module

LCD Display (two lines) and Status LEDs

(Power, Run, Alarm, Aux. Relays)

Programming Keypad (Non-volatile Memory)

Maintenance Data

Fault indications: Shorted SCR, Phase Loss, Shunt

Trip, Phase Imbalance, Phase Rotation, Overload,

Overtemp, Overcurrent, Short Circuit, Load Loss,

Ground Fault, Tach Accel Trip, Stator Phase Trip,

RTD Trip, or Any Trip

Coast Down Time

Starts per Hour

Time Between Starts

Any Lockout

Event History - Up to 60 events. Data includes

cause, date, time, phase and ground current.

Adjustments

Motor Full Load Ampere (FLA)

Dual Adjustments - Two independent settings

Initial Voltage 0 - 100% of nominal voltage

Current Limit 200 - 500% of motor FLA

Acceleration Time 1 - 120 seconds

Deceleration Time 1 - 60 seconds

Three custom Accel curves

Jog: 5 - 100% Volt., 1 - 20 sec., Current 100 - 500%

Kick Start: 10 - 100% Voltage, 0.1 - 2 sec.

Coast Down (Back Spin) Lockout Timer 1 - 60 min.

Starts-per-Hour Lockout Timer

1 - 10 successful starts per hour

1 - 60 min. between start attempts

Undercurrent 10 - 90% (w/1 - 60 sec trip delay)

Overload Reset - Selectable Manual or Automatic

Two 4 - 20 mA Analog Outputs: Selectable from

Off, RPM, Hottest Non-Stator RTD, Hottest Stator

RTD, RMS Current, % of Motor Load

Options

NEMA Type 12 or 3R Enclosure

1200 or 2000A Main Copper Bus

Available in MCC Lineups with Other JK Series

Starters (FVNR, FVR, RVAT, Synchronous, Etc.)

Available in MCC Lineups with Main Incoming

Disconnect Switch or Vacuum Circuit Breaker

The soft start is available as a controller only for

users which already have an existing full voltage

starter (disconnect switch, main power fuses &

contactor) and wants reduced voltage starting

and soft stop features.

PFC Contactor - Vacuum contactor for switching

Power Factor Correction Capacitor.

Manual (Full Voltage) Bypass Selection with solid

state protection (2E) or bimetallic overload.

Page 5

SOLID STATE STARTER

AC 13.25

Continuous

Induction

JKSSS7+ Series

T oshiba's JKSSS7 series complies with EEMAC,

NEMA, UL and CSA standards and is available for

induction, synchronous and wound rotor configurations.

The JKSSS7 series is available in the following enclosed ratings:

600 & 720 Amp s, 2300-4800 Volts, Up to 6,000 HP

Protective Features

Electronic Overload:

Retentive Thermal Memory w/Dynamic Reset Memory

Phase Imbalance/Single Phase

Short Circuit

Ground Fault - Optional

RTD T emperature

Phase Reversal/Phase Sequence

Overcurrent

Start s-per-Hour

Shorted SCR

Undercurrent/Loss of Load

Starter Overtemperature

Shorted SCR

Undervoltage

Overvoltage

Microprocessor Digital Control Unit (DCU) **

Programming Keypad:

Operator Control

System/Motor Protection

Serial Communication (RS485)

Statistical Data

LCD status and alarm display with Twelve LEDs

POWER - Indicates control power is present

RUN - Indicates unit/motor is running

ALARM - Lights in conjunction with AUX 2 to

indicate event or warn of possible critical condition

TRIP - Lights in conjunction with AUX 1 to

indicate a critical condition has occurred.

AUX 1-8 - Auxiliary unit relays

** Standard on all JKSSS4+ & JKSSS7+ models, 200-720A, 2300-6900V

Additional Features

Serial Communication Port:

RS485 or RS422 with Modbus RTU Protocol or

RS485 or RS422 with Windows Interface

Rugged Gate Firing Circuit Using Ring Transformer

Opto-isolated Inputs

Continuous Current

Maximum Continuous

Enclosure Type

Amperes*

One-High Controller

Type 1 Ventilated 720

Type 1 Non-Ventilated 650

Type 12 & 3R 600

Short Circuit & Withstand Capability

Interrupting

Capacity

(Symmetrical

Amperes)

50,000

@ 2.3 - 4.6 kV

Interrupting

Capacity

(Symmetrical

MVA)

200 @ 2.3 kV

350 @ 4.0 kV

400 @ 4.6 kV

Short Time

Capability

30 Seconds

(Amperes)

4320 10,800

Short Time

(Amperes)

Capability

1 Second

Dielectric

Withstand

1 Minute

(kV)

DC 19

Impulse

Voltage

Withstand

(kV)

60

Approximate Maximum Horsepower Based on Continuous Current

Enclosed

Maximum

Current

(Amperes)

720 3000 3500 3000 5500 6000 5500

650 2750 3000 2750 5000 5500 5000

600 2500 2750 2500 4500 5000 4500

Maximum Horsepower at Utilization Volt age

2300 Volts, 3 Phase 4200 Volts, 3 Phase

Synchronous

Motors

0.8 PF 1.0 PF 0.8 PF 1.0 PF

Induction

Motors

Synchronous

Motors

Motors

Metering **

Percent of FLA

Phase Current (A, B & C)

Average Current

Ground Fault Current (w/Optional GF

Protection)

Remaining Thermal Register

Thermal Capacity to Start

Average Start Time

Average St art Current

Measured Capacity to Start

Time Since Last Start

Line Frequency

Phase Order

Motor RPM

kW, kV A, kV AR, PF , MWHr

kW Demand, kVA Demand, kVAR

Demand, Amps Demand - (All Date/

Time Stamped)

** Standard on all JKSSS4+ & JKSSS7+

models, 200-720A, 2300-6900V

Page 6

Typical Dimensions and Mechanical Layout for 2300-4200V, 360A Max. Starter

Dimensions are for reference only.

Page 7

T ypical Dimensions and Mechanical Layout for 2300-4200V, 600A & 720A St arter

Dimensions are for reference only.

Page 8

*pacjKSss050218*

ADJUSTABLE SPEED DRIVES

MOTORS

CONTROLS UPS INSTRUMENTATION

PLC

INDUSTRIAL DIVISION

Tel 713/466-0277 Fax 713/466-8773

US 800/231-1412 Canada 800/872-2192 Mexico 01/800/527-1204

www.tic.toshiba.com

Copyright 2/2005

Available Through:

TOSHIBA - Quality by Design

Our company culture and history is strongly rooted on quality. Our designs

are technologically innovative and our products are manufactured from start to

end using only the highest quality foreign & domestic parts.

Toshiba offers a comprehensive warranty program on its full line of industrial

North America Headquarters & Manufacturing Facilities (Houston, TX)

Medium Voltage Motor

G7 Drive

Loading...

Loading...