Air to Air Heat Exchanger

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Installation Manual

Concealed microcomputer

control type

Model name:

VN-M150HE

VN-M250HE

VN-M350HE

VN-M500HE

VN-M650HE

VN-M800HE

VN-M1000HE

For commercial use

Installation Manual 1

Installation Manual xx

English

Xxxxx

1-EN 2-EN

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Air to Air Heat Exchanger

Installation Manual

–1–

Air to Air Heat Exchanger

Installation Manual

Original instruction

Thank you very much for purchasing TOSHIBA Air to Air Heat Exchanger.

Please read this owner’s manual carefully before using your Air to Air Heat Exchanger.

• Obtain the “Owner’s manual” and “Installation manual” from constructor (or dealer).

Request to constructor or dealer

• Please clearly explain the contents of the Owner’s manual and hand over it.

• Read this Installation Manual thoroughly to fully understand everything about your Toshiba Air to Air Heat

Exchanger and be able to install it properly.

• Ask a qualified installer or qualified service person to perform installation.

• System parts such as a wired remote controller (sold separately) are necessary for using this unit.

• After installation, perform a test operation and confirm the safety, then explain to the customer how to use

this unit. Give this installation manual to the customer and ask him/her to keep it with the owner's manual.

Handover to the Customer

• Hand the owner's manual and installation manual to the customer.

• Before the handover, explain fully to the customer the contents of the owner's manual.

Contents

1 Precautions for Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Accessory Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Cautions for Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4 Separately Sold Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5 Reference Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

6 Model List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Please read carefully through these instructions that contain important information which complies with the

“Machinery” Directive (Directive 2006/42/EC), and ensure that you understand them.

Generic Denomination: Air to Air Heat Exchanger

Definition of Qualified Installer or Qualified Service Person

The Air to Air Heat Exchanger must be installed, maintained, repaired and removed by a qualified installer or qualified service

person. When any of these jobs is to be done, ask a qualified installer or qualified service person to do them for you.

A qualified installer or qualified service person is an agent who has the qualifications and knowledge described in the table

below.

Agent Qualifications and knowledge which the agent must have

• Qualified installer • The qualified installer is a person who installs, maintains, relocates and removes the Air to Air Heat

• Qualified service

person

Exchanger made by Toshiba Carrier Corporation. He or she has been trained to install, maintain,

relocate and remove the Air to Air Heat Exchanger made by Toshiba Carrier Corporation or,

alternatively, he or she has been instructed in such operations by an individual or individuals who have

been trained and is thus thoroughly acquainted with the knowledge related to these operations.

• The qualified installer who is allowed to do the electrical work involv ed in installation, relo cation and

removal has the qualifications pertaining to this electrical work as stipulated by the local laws and

regulations, and he or she is a person who has been trained in matters relating to electrical work on

the Air to Air Heat Exchanger made by Toshiba Carrier Corporation or, alternatively, he or she has

been instructed in such matters by an individual or individuals who have been trained and is thus

thoroughly acquainted with the knowledge related to this work.

• The qualified installer who is allowed to work at heights has been trained in matters relating to working

at heights with the Air to Air Heat Exchanger made by Toshiba Carrier Corporation or, alternatively,

he or she has been instructed in such matters by an individual or individuals who have been trained

and is thus thoroughly acquainted with the knowledge related to this work.

• The qualified service person is a person who installs, repairs, maintains, relocates and removes the

Air to Air Heat Exchanger made by Toshiba Carrier Corporation. He or she has been trained to install,

repair, maintain, relocate and remove the Air to Air Heat Exchanger made by Toshiba Carrier

Corporation or, alternatively, he or she has been instructed in such operations by an individual or

individuals who have been trained and is thus thoroughly acquainted with the knowledge related to

these operations.

• The qualified service person who is allowed to do the electrical work involved in installation, repair,

relocation and removal has the qualifications pertaining to this electrical work as stipulated by the local

laws and regulations, and he or she is a person who has been trained in matters relating to electrical

work on the Air to Air Heat Exchanger made by Toshiba Carrier Corporation or, alternatively, he or she

has been instructed in such matters by an individual or individuals who have been trained and is thus

thoroughly acquainted with the knowledge related to this work.

• The qualified service person who is allowed to work at heights has been trained in matters relating to

working at heights with the Air to Air Heat Exchanger made by Toshiba Carrier Corporation or,

alternatively, he or she has been instructed in such matters by an individual or individuals who have

been trained and is thus thoroughly acquainted with the knowledge related to this work.

7 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

8 Electric Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

9 Installation Method for Each System Configuration . . . . . . . . . . . . . . . . . . . . . . . . 10

10 Advanced System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

11 Advanced Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

12 Test Run. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

13 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

14 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Air to Air Heat Exchanger

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Installation Manual

Air to Air Heat Exchanger

Installation Manual

Definition of Protective Gear

When the Air to Air Heat Exchanger is to be transported, installed, maintained, repaired or removed, wear

protective gloves and ‘safety’ work clothing.

In addition to such normal protective gear, wear the pr otective gear described be low when undertak ing the special

work detailed in the table below.

Failure to wear the proper protective gear is dangerous because you will be more susceptible to injury, burns,

electric shocks and other injuries.

Work undertaken Protective gear worn

All types of work Protective gloves

Electrical-related work Gloves to provide protection for electricians and from heat

Work done at heights (50 cm or more) Helmets for use in industry

Transportation of heavy objects Shoes with additional protective toe cap

‘Safety’ working clothing

Warning Indications on the Air to Air Heat Exchanger

Warning indication Description

WARNING

ELECTRICAL SHOCK HAZARD

Disconnect all remote

electric power supplies

before servicing.

WARNING

Moving parts.

Do not operate unit with

inspection cover removed.

Stop the unit before the servicing.

CAUTION

High temperature parts.

You might get burned

when removing this cover.

WARNING

ELECTRICAL SHOCK HAZARD

Disconnect all remote electric power supplies before servicing.

WARNING

Moving parts.

Do not operate unit with inspection cover removed.

Stop the unit before the servicing.

CAUTION

High temperature parts.

You might get burned when removing this cover.

1 Precautions for Safety

WARNING

General

• Before starting to install the Air to Air Heat Exchanger, read carefully through the Installation Manual, and follow its

instructions to install the Air to Air Heat Exchanger.

• Only a qualified installer(*1) or qualified service person(*1) is allowed to install the Air to Air Heat Exchanger. If the

Air to Air Heat Exchanger is installed by an unqualified individual, a fire, electric shocks, injury, water leakage, noise

and/or vibration may result.

• If using separately sold products, make sure to use Toshiba specified products only. Using unspecified products may

cause fire, electric shock, water leak or other failure.

• Before opening the electrical control cover or inspection cover of the Air to Air Heat Exchanger, set the circuit breaker

to the OFF position. Failure to set the circuit breaker to the OFF position may result in electric shocks through contact

with the interior parts. Only a qualified installer(*1) or qualified service person(*1) is allowed to remove the electrical

control cover or inspection cover of the Air to Air Heat Exchanger and do the work required.

• Before carrying out the installation, maintenance, repair or removal work, set the circuit breaker to the OFF position.

Otherwise, electric shocks may result.

• Place a “Work in progress” sign near the circuit breaker while the installation, maintenance, repair or removal work

is being carried out. There is a danger of electric shocks if the circuit breaker is set to ON by mistake.

• Only a qualified installer(*1) or qualified service person(*1) is allowed to undertake work at heights using a stand of

50 cm or more or to remove the electrical control cover or inspection cover of the Air to Air Heat Exchanger to

undertake work.

• Wear protective gloves and safety work clothing during installation, servicing and removal.

• When working at heights, use a ladder which complies with the ISO 14122 standard, and follow the procedure in the

ladder’s instructions. Also wear a helmet for use in industry as protective gear to undertake the work.

• When cleaning the filter or heat exchange element of the Air to Air Heat Exchanger, set the circuit breaker to OFF

without fail, and place a “Work in progress” sign near the circuit breaker before proceeding with the work.

• When working at heights, put a sign in place so that no-one will approach the work location, before proceeding with

the work. Parts and other objects may fall from above, possibly injuring a person below.

• The Air to Air Heat Exchanger must be transported in stable condition. In case an accident such as dropping of the

unit occurs while transporting the Air to Air Heat Exchanger, contact the dealer .

• Do not move or repair any unit by yourself. There is high voltage inside the unit. You may get electric shock when

removing the cover and main unit.

• Do not modify the products. Do not als o disa ssembl e or modi fy the par ts. It may caus e a fire, electr ic shoc k or inj ury.

• Confirm whether there is a risk of the Air to Air Heat Exchanger falling down during maintenance or repairing work.

• Before opening the Supply/Exhaust air grill, set the circuit breaker to the OFF position. Otherwise, your hand may be

caught in the rotating parts inside and an injury may result.

Selection of installation location

• Do not install the Air to Air Heat Exchanger in a location that may be subject to a risk of expire to a combustible gas.

If a combustible gas leaks and becomes concentrated around the unit, a fire may occur.

• When transporting the Air to Air Heat Exchanger, wear shoes with additional protective toe caps, protective gloves

and other protective clothing.

• When transporting the Air to Air Heat Exchanger, do not take hold of the bands around the packing carton. You may

injure yourself if the bands should break.

• Install the Air to Air Heat Exchanger at least 2.5 m above the floor level since otherwise the users may injure

themselves or receive electric shocks if they poke their fingers or other objects into the Air to Air Heat Exchanger

while it is running.

• Do not place any combustion appliance in a place where it is directly exposed to the wind of Air to Air Heat Exchanger,

otherwise it may cause im perfect combustion.

• Use a hand track or forklift to carry the unit. When carrying it by human power, have four persons or more; otherwise,

you may strain your back.

Installation

• When the Air to Air Heat Exchanger is to be suspended, the designated hanging bolts (M10 to M12) and nuts (M10

to M12) must be used.

• Install the Air to Air Heat Exchanger at enough strong places to withstand the weight of the unit. If the strength is not

enough, the unit may fall down resulting in injury.

• Follow the instructions in the Installation Manual to install the Air to Air Heat Exchanger. Failure to follow these

instructions may cause the product to fall down or topple over or give rise to noise, vibration, water leakage, etc.

EN

3-EN 4-EN

–2–

5-EN 6-EN

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Air to Air Heat Exchanger

Installation Manual

–3–

Air to Air Heat Exchanger

Installation Manual

Electrical wiring

• Only a qualified installer(*1) or qualified service person(*1) is allowed to carry out the electrical work of the Air to Air

Heat Exchanger. Under no circumstances must this work be done by an unqualified individual since failure to carry

out the work properly may result in electric shocks and/or electrical leaks.

• When repairing the electrical parts or undertaking other electrical jobs, wear gloves to provide protection for

electricians and from heat. Failure to wear this protective gear may result in burn.

• Use wiring that meets the specifications in the Installation Manual and the stipulations in the local regulations and

laws. Use of wiring which does not meet the specifications may give rise to electric shocks, electrical leakage,

smoking and/or a fire.

• Connect earth wire. (Grounding work)

Incomplete earthing causes an electric shock.

• Do not connect earth wires to gas pipes, water pipes, and lightning rods or earth wires for telephone wires.

• After completing the repair or relocation work, check that the earth wires are connected properly.

• Install a circuit breaker that meets the specifications in the installation manual and the stipulations in the local

regulations and laws. Use an exclusive power supply circuit for the Air to Air Heat Exchanger at the rated voltage.

• Install the circuit breaker where it can be easily accessed by the agent.

• When installing the circuit breaker outdoors, install one which is designed to be used outdoors.

• Under no circumstances must the power cable be extended. Connection trouble in the places where the cable is

extended may give rise to smoking and/or a fire.

• Electrical wiring work shall be conducted according to law and regulation in the community and installation manual.

Failure to do so may result in electrocution or short circuit.

• When carrying out electric connection, use the wire specified in the Installation Manual and connect and fix the wires

securely to prevent them applying external force to the terminals. Improper connection or fixing may result in fire.

Test run

• Before operating the Air to Air Heat Exchan ger after havin g completed the work, check that the electrical control cover

and inspection cover are closed, and set the circuit breaker to the ON position. You may receive an electric shock if

the power is turned on without first conducting these checks.

• When there is some kind of trouble (such as when an error display has appeared, there is a smell of burning,

abnormal sounds are heard, or water is leaking) has occurred in the Air to Air Heat Exchanger, do not touch the Air

to Air Heat Exchanger yourself but set the circuit breaker to the OFF position, and contact a qualified service person.

Take steps to ensure that the power will not be turned on (by marking “out of service” near the circuit breaker, for

instance) until qualified service person arrives. Continuing to use the Air to Air Heat Exchanger in the trouble status

may cause mechanical problems to escalate or result in electric shocks, etc.

• After the work has finished, use an insulation test er set (500V Megger) to check the resistance is 1 MΩ or more

between the charge section and the non-charge metal section (Earth section). If the resistance value is low, a disaster

such as a leak or electric shock is caused at user’s side.

• Upon completion of the installation work, check the insulation resistance. Then conduct a test run to check that the

Air to Air Heat Exchanger is operating properly.

Explanations given to user

• Upon completion of the installation work, tell the user where the circuit breaker is located. If the user does not know

where the circuit breaker is, he or she will not be able to turn it off in the event that trouble has occurred in the Air to

Air Heat Exchanger.

• After the installation work, follow the Owner’s Manual to explain to the customer how to use and maintain the unit.

• If there is a danger of the Air to Air Heat Exchanger falling, do not approach the Air to Air Heat Exchanger but set the

circuit breaker to the OFF position, and contact a qualified service person(*1) to have the repairs done. Do not set

the circuit breaker to the ON position until the repairs are completed.

Relocation

• Only a qualified installer(*1) or qualified service person(*1) is allowed to relocate the Air to Air Heat Exchan ger. It is

dangerous for the Air to Air Heat Exchanger to be relocated by an unqualified individual since a fire, electric shocks,

injury, water leakage, noise and/or vibration may result.

• The external air intake opening should be positioned away from the exhaust openings of combustion gases. The

intake of such gases could cause a lack of oxygen in the room.

The external air intake opening should not be pos itioned where discharged air may directly enter it.

A situation like this will lead to the room being contaminated and this may pose a health risk.

• Netting or something similar should be provided at the external air intake opening to prevent birds or other things

interfering with the unit.

• Nests or other foreign objects should be removed. That c ould cause a lack of oxygen in the room.

• To pierce the metal duct through the metal lath or the wire lath or the metal plate of the wooden facility, do not forget

to insulate electrically between the duct and the wall. Otherwise, it would cause an electric shock or an electric

leakage.

• Install the outdoor duct in a falling gradient toward the outside so as to prevent water from coming in. If it is not

installed so, the building is likely to be flooded, wetting the household effects.

• Heat-insulate the outdoor duct (including the indoor side, if necessary) to prevent dewing. If heat insulation is not

adequate, water likely goes indoor and wets the household properties.

• When it is high humid and high temperature inside the ceiling, a ventilation system must be installed inside the ceiling.

Otherwise, it could cause a fire or an electric leakage.

• Install the power line and the connecting line with accuracy so the power source cover may not float. If the installation

of the electrical control cover is inappropriate, the pin connection area is likely to cause a heat generation, a fire and

an electric shock due to dust or powder.

• Do not use the unit at the other voltages than the rated one. It could cause a fire or an elec tric sho ck.

• Do not install the unit in locations with large amounts of oily smoke, such as food preparation areas. It could cause a

fire.

• Do not install the unit at the place of a high temperature or a flame.

It could cause a heat generation or a fire.

• Do not install in locations with high humidity, such as close to bathroom or other similar environment. It could cause

an electric shock or an electric leakage or other troubles.

• Install an earth leakage breaker that is not tripped by shock waves.

If an earth leakage breaker is not installed, an electric shock may be caused.

• Do not install the unit and inside air int ake in a place such as a machin e factor y, chemi cal pl ant, or r esearc h insti tute,

where acids, alkaline, organic solvents, or coating materials are handled and toxic gases and/or corrosive gases may

be produced.

Otherwise gas poisoning may occur and/or the inside of the unit may be eroded or deteriorated. The deterioration

and erosion may result in an fire.

• After installation, switch off the circuit breaker for safety if the unit will not be used for a long time.

• Attach the parts such as the inspection cover securely.

Disposal

Dispose of Air to Air Heat Exchanger in accordance with the 2002/96/EC Directive WEEE (Waste Electrical and

Electronic Equipment).

(*1) Refer to the “Definition of Qualified Installer or Qualified Service Person.”

CAUTION

To Disconnect the Appliance from Main Power Supply.

• Means for disconnection having a contact separation in all poles at least 3 mm must be incorporated in the fixed

wiring in accordance with the wiring rules.

The installation fuse (All Types Can Be Used) must be used for the power supply line of this Air to Air

Heat Exchanger.

Air to Air Heat Exchanger

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Installation Manual

Air to Air Heat Exchanger

Installation Manual

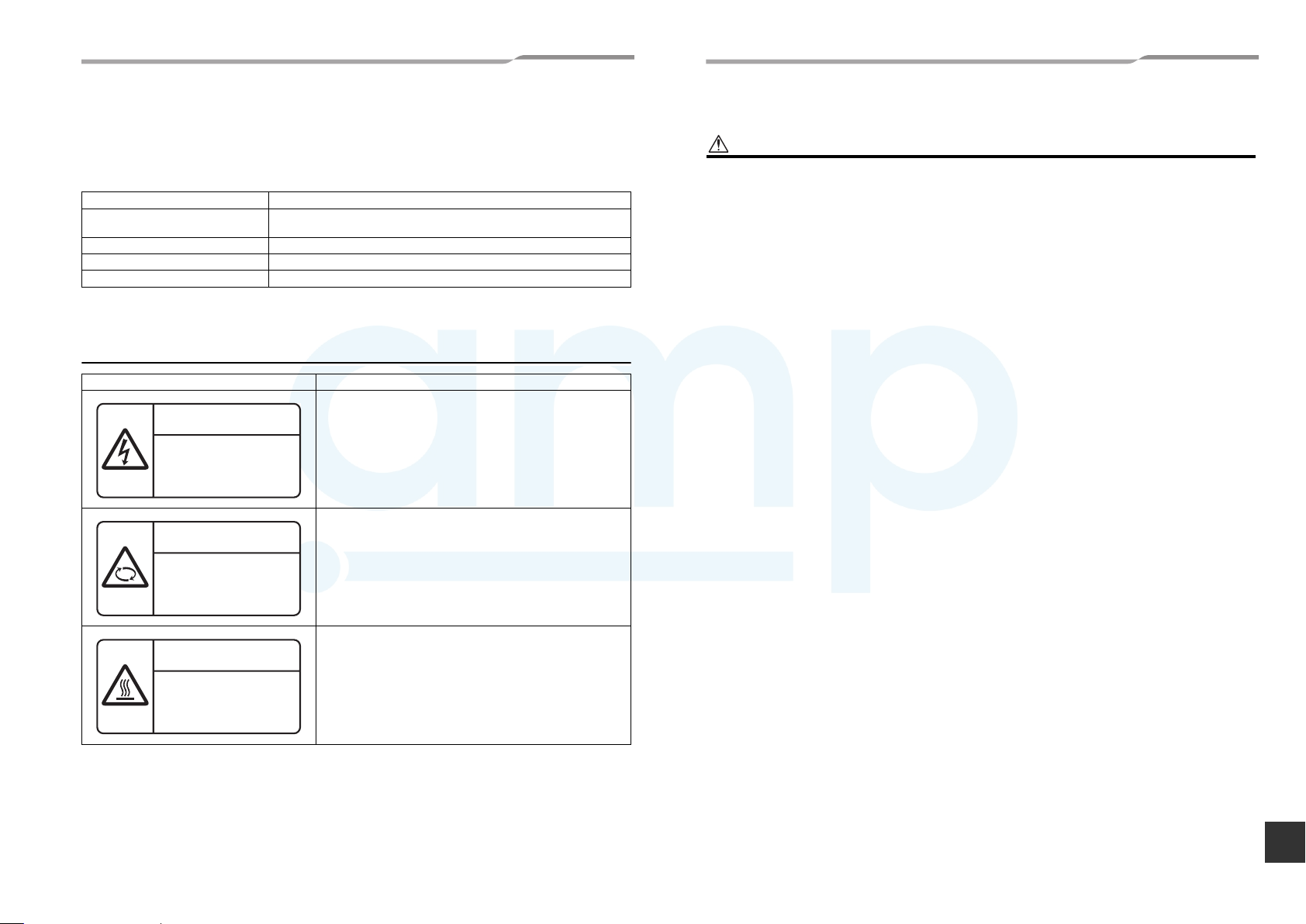

2 Accessory Parts

Name Quantity Shape Usage

Installation manual 1 — (Hand it to the customers.)

CD-ROM (Owner’s manual

and Installation manual)

Owner's manual 1 — (Hand it to the customers.)

Adapter 4 Connection parts for the duct

Screw 16/24 Screws for attaching the adapter

1—

(For other languages that do not appear in this manual, please refer

to the enclosed CD-ROM.)

3 Cautions for Installation

Make the inspection opening at the specific place on the ceiling so the constant cleaning or the equipment checking

of filter and heat exchange element can be performed.

• The inspection opening shown below is necessary to clean the heat exchange element and th e filt er as

required. If not cleaned, they are likely to get clogged, resulting in degradation of performance.

• Use forklift to carry in the Air to Air Heat Exchanger units and use winch or hoist at installation of them.

Unit: mm

B C

EA

(Exhaust

air)

Outdoor side

A

OA

(Outdoor

air)

150 to

250

600 or more

For the inspection of Filters,

Heat Exchange Elements,

Fans, Motors and Damper.

Inspection Opening 450 × 450

or more

RA (Return air)

Indoor side

Centre of gravity

SA (Supply air)

200

• Helmet must be worn to protect your head from falling objects.

Especially, when you work under an inspection opening, helmet must be worn to protect your head from

falling objects from the opening.

• Observe the following conditions when using the Air to Air Heat Exchanger.

Installation requirements : Temperature range −10°C to +40°C, relative humidity 80% or less

Outdoor air conditions : Temperature range −15°C to +43°C, relative humidity 80% or less

Return air conditions : Temperature range +5°C to +40°C, relative humidity 80% or less

Do not install the Air to Air Heat Exchanger in a place where flames can come into contact with the unit.

If the Air to Air Heat Exchanger is used for a long time without observing the conditions above, deterioration or

deformation of resin parts will occur and a malfunction may result.

• Dewing and frosting.

• In cold regions, the surface of the unit or the duct connector may be affected by condensation or frosting

depending on the outdoor air conditions or temperature/humidity of the ceiling cavity even though the

conditions for use are observed. In this case, add a heat insulator.

• Do not install the unit in a place where there is something that must not become wet. Depending on the

temperature or humidity of outdoor air and the installation place, water droplets may fall from the unit.

• As shown in the figure to the below, suppose a high temp absorbing air condition A and a low temp absorbing

air condition B are plotted on the air line figure, then a high temp a ir A is heat-exchanged by the unit and goes

out of the saturation curve as shown by Point C. In this case, the unit will be dewed o r frosted . To avoid th is,

heating a low temp air B up to B’ is required so as to get C’ below the saturation curve, before usin g the unit.

e

v

r

u

C

n

o

i

t

a

r

u

A

at

S

C

B

Dry-bulb temperature (°C)

C'

B'

Absolute humidity (kg/kg’)

• Refrain from the following duct installation works.

1) Excessive bending 2) Multi-times bending 3) Making the connecting duct

smaller

4) Bending near the exhaust air

duct

• Do not install it near the water-heater

• Do not use in bathrooms or food preparation areas or in similar condition place.

If the unit is used at the place of much soot and high humidity large amounts of oily smoke, the filter or the

heat exchange element gets clogged and it will be disable to be use.

• Duct length must be longer than 850 mm.

Model No. A (mm) B (mm) C (mm) Weight (kg)

VN-M150HE, M250HE 900 900 290 36 2

VN-M350HE 900 900 290 38 2

VN-M500HE, M650HE 1140 1140 350 53 2

VN-M800HE, M1000HE 1189 1189 400 70 2

7-EN 8-EN

Heat exchange

element

EN

–4–

9-EN 10-EN

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Air to Air Heat Exchanger

Installation Manual

–5–

Air to Air Heat Exchanger

Installation Manual

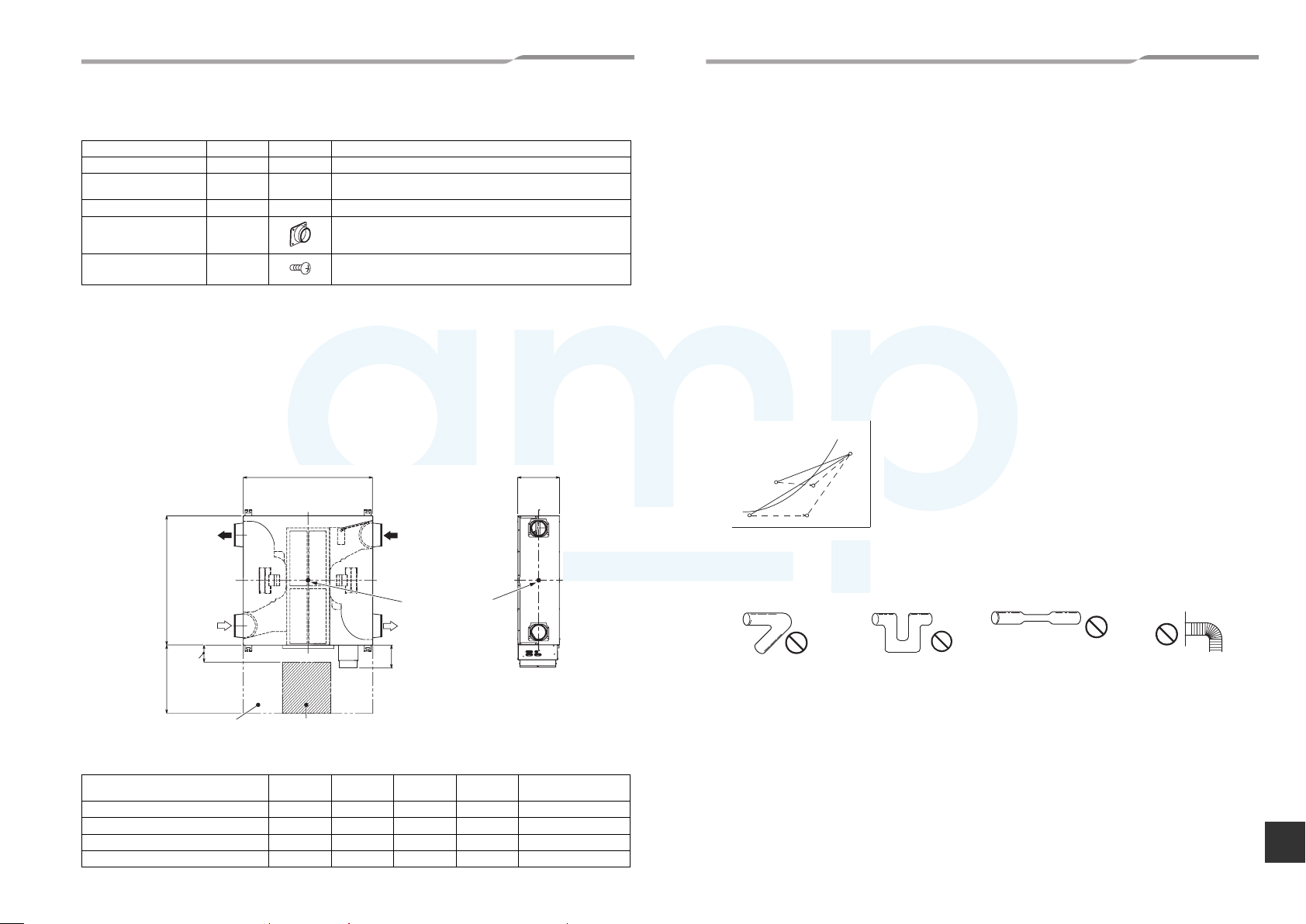

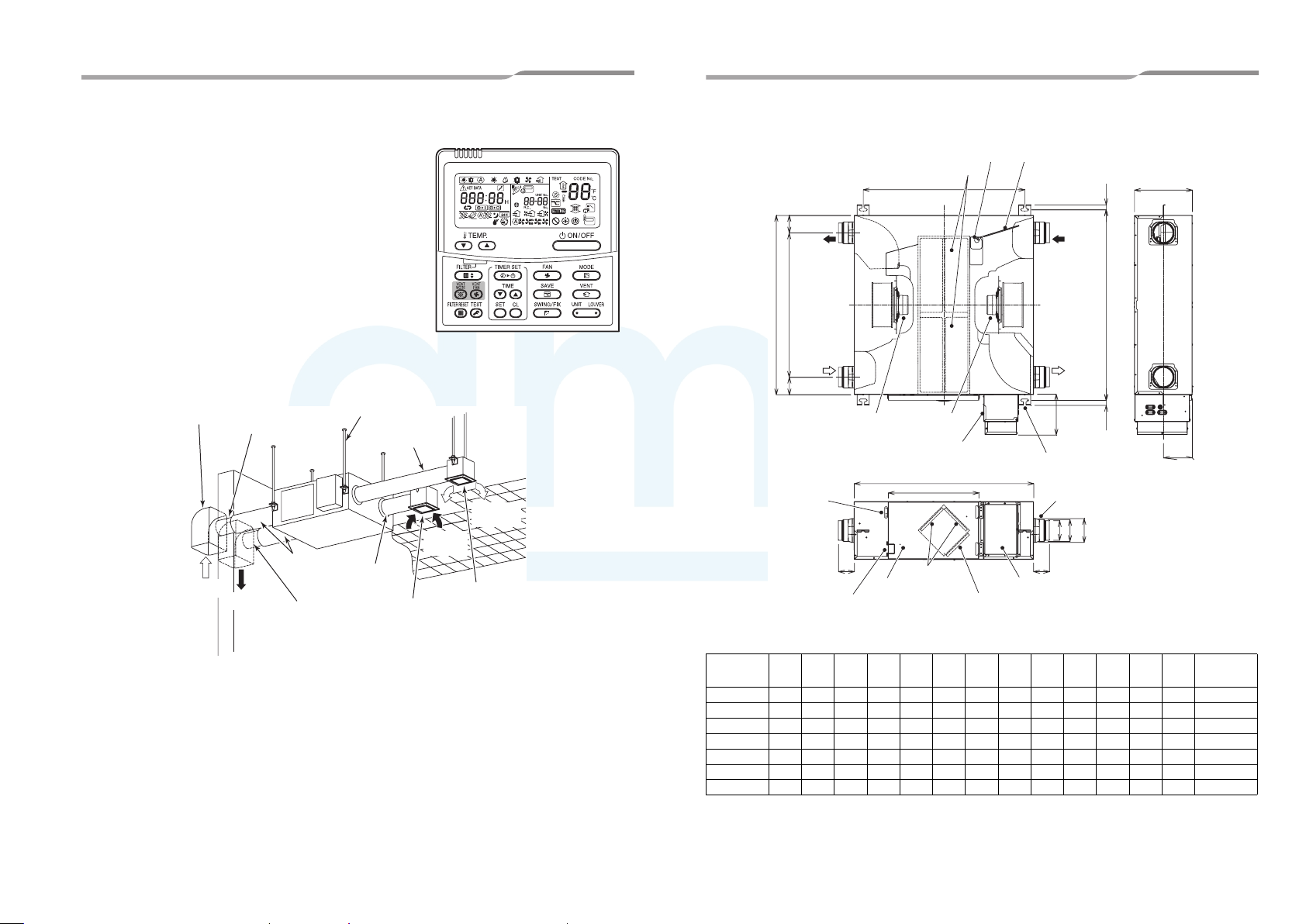

4 Separately Sold Parts

• Wired remote controller (for the Air to Air Heat Exchanger)

NRC-01HE (Sold separately)

Up to 8 units of the Air to Air Heat Exchanger can be operated us ing

this remote controller.

5 Reference Diagram

Pipe hood

OA (Outdoor air)

Outdoor air

intake duct

EA (Exhaust air)

Heat insulation

material

Hanging bolt

Exhaust air

duct

Supply air duct

Return air

intake duct

Room intake

opening

(Supply/

Exhaust Air

grille)

RA (Return

air)

Inside supply opening

(Supply/Exhaust Air grille)

SA (Supply

air)

6 Model List

Heat exchange element (2)

CC

EA

(Exhaust air)

Outdoor

A

B

side

OA

(Outdoor air)

Motor

(Exhaust air)

Fixed part of

inspection cover

H H

Fixing lever

Model nameABCDE FGH I JKLM

VN-M150HE 900 724 88 810 957 900 454 80 Ø98 Ø110 121 290 145 Ø100

VN-M250HE 900 670 115 810 957 900 454 97 Ø145 Ø158 162 290 145 Ø150

VN-M350HE 900 670 115 810 957 900 454 97 Ø145 Ø158 162 290 145 Ø150

VN-M500HE 1140 800 170 1050 1197 1140 454 80 Ø195 — Ø212 350 175 Ø200

VN-M650HE 1140 800 170 1050 1197 1140 454 80 Ø195 — Ø212 350 175 Ø200

VN-M800HE 1189 800 195 1099 1246 1189 454 85 Ø245 — Ø262 400 200 Ø250

VN-M1000HE 1189 800 195 1099 1246 1189 454 85 Ø245 — Ø262 400 200 Ø250

(Supply Air)

Inspection cover

Damper motor

D

Motor

Electrical control base

F

G

Filter (x 2)

High efficiency filter

(One for each element)

(sold separately)

Damper

RA

(Return air)

Indoor

side

SA

(Supply air)

200

Hanging bracket (4)

4 - 13 X30 Oval hole

Adapter (4)

I

J

K

Electrical control cover

25

E

25

L

M

Unit: mm

Applicable

duct nominal

diameter

Air to Air Heat Exchanger

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Installation Manual

Air to Air Heat Exchanger

Installation Manual

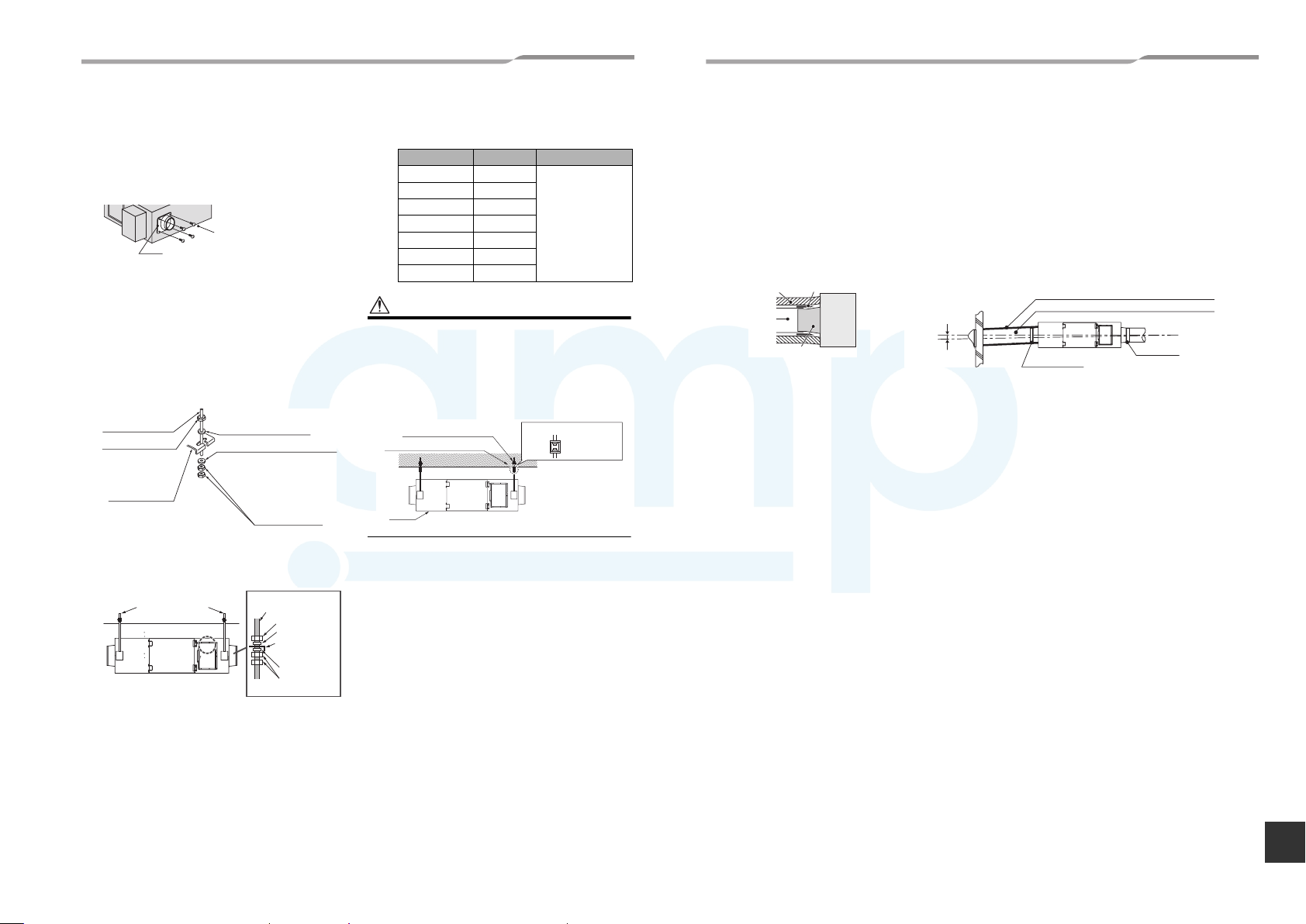

7 Installation

Attaching the adapter

• Attach the adapter to the unit using the accessory

screws (4 or 6).

Screws (accessory:

Adapter

Attaching the washer and the

nut

1) Preparation of the hanging bolt, nut, and

washer is required.

2) Attach the washer and the nut to the hanging

bolt (see the table on the below) according to

the diagram on the below.

Hanging bolt

(M10 or M12)

Nut (M10 or M12)

Hanging bracket

4 or 6 screws)

Washer (M10 or M12)

Washer (M10 or M12)

Use the washer just under

the hanging bracket to

prevent the bolt from

falling off.

Nut (M10 or M12)

Model name Weight (kg) Hanging bolt

VN-M150HE 36

VN-M250HE 36

VN-M350HE 38

VN-M500HE 53

VN-M650HE 53

VN-M800HE 70

VN-M1000HE 70

M10, M12

CAUTION

• Use a commercially available vibration-proof fixture

when the unit is installed in a place where preventing

vibration is necessary.

• Leave a space of 450mm x 450mm or more for

checking the filter, heat exchanging element, power

source, or motor. Refer to “Cautions for Installation”

for the location of the space required.

Hanging bolt

Vibration-proof fixture

Unit

Vibration-proof fixture

Duct Installation

• Duct installation is necessary to protect against access to live parts, rain water or contact with moving parts.

• Seal the junction of an adaptor and a duct with an aluminium tape firmly to prevent any air leakage.

• The room intake opening should be positioned as far as possible from the indoor supply opening.

• Use the specified ducts. (See the Model List)

• Install two outdoor ducts so they will be in the down gradient toward outdoor to prevent water from coming in.

(Gradient: 1/100~1/50) (See the figure below)

Heat-insulate two outdoor ducts (including outdoor air and exhaust air duct) to prevent dewing.

(Material: Glass Wool, Thickness-25mm) (See the figure below)

To pierce the metal duct through the metal lath or the wire lath or the metal plate of the wooden facility, insulate

electrically between the duct and the wall. (Refer to the laws and regulations of the country concerned and the

technical standard.)

Adapter

Aluminium tape

Unit

Slope

(1/100 to 1/50)

Heat insulator

Duct

• It is recommended that an electric damper is used together with the Air to Air Heat Exchanger, as wind may enter

the room while the unit is not in operation in windy places.

Heat insulator

(Insulates the adapter and the aluminium tape)

Outdoor air intake duct, Exhaust air duct

Aluminium tape

Aluminium tape

Fixing the unit

Hanging bolt

(M10 or M12)

Hanging bolt

Nut

Washer

Hanging

bracket

Washer

Nut

Cautions installing unit body

upside down

• The hanging bracket does not need to be replaced.

• The printed image is reversed.

1) Hang the hanging bracket on the hanging bolt,

then adjust the nut so that the unit is level.

2) Use a double nut and fasten it firmly so that the

nut does not become loose.

• If the unit is not installed properly, it will vibrate

and may pose a hazard.

• If the unit is not level, the damper unit will not

work properly.

• Install the unit firmly enough to support its own

weight.

11-EN 12-EN

–6–

EN

13-EN 14-EN

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Air to Air Heat Exchanger

Installation Manual

–7–

Air to Air Heat Exchanger

Installation Manual

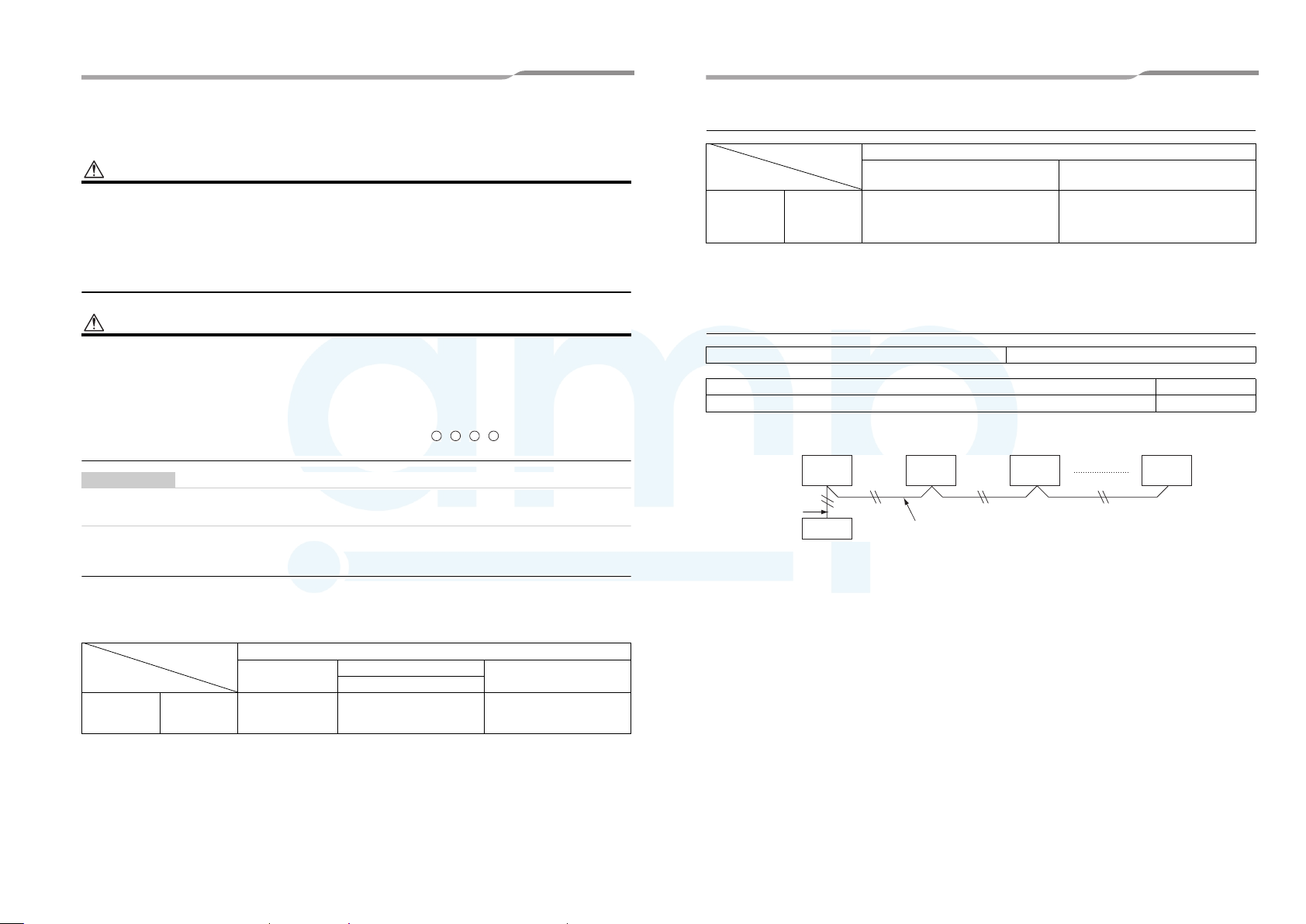

8 Electric Wiring

WARNING

1. Using the specified wires, ensure to connect the wires, and fix wires securely so that the external tension to

the wires do not affect the connecting part of the terminals.

Incomplete connection or fixation may cause a fire or other troubles.

2. Connect earth wire. (grounding work)

Incomplete earthing cause an electric shock.

Do not connect earth wires to gas pipes, water pipes, lightning rods or earth wires for telephone wires.

3. Appliance shall be installed in accordance with national wiring regulations.

Capacity shortage of power circuit or incomplete installation may cause an electric shock or a fire.

CAUTION

• If incorrect/incomplete wiring is carried out, it will cause an electrical fire or smoke.

• Install an earth leakage breaker that is not tripped by shock waves.

If an earth leakage breaker is not installed, an electric shock may be caused.

• Use the cord clamps attached to the product.

• Do not damage or scratch the conductive core and inner insulator of power and communication wires when peeling

them.

• Use the power and communication wire of specified thickness, type, and protective devices required.

• Do not connect 220-240V power to the communication terminal blocks ( , , , ) for control wiring.

(Otherwise, the system will fail.)

REQUIREMENT

• For power supply wiring, strictly conform to the Local Regulation in each country.

• After connecting wires to the terminal blocks, provide a trap and fix wires with the cord clamp.

Power and wiring Specifications

Power supply wire and communication wire should be locally procured.

U3U4A B

Communication wire

Item

Model name VN-

Air to Air Heat

Exchanger

*2:

• The length of the communication wire is the total length of the outdoor/indoor transition wire and wire of the central control

assuming that an interlocking system with the indoor unit or central control system is used.

• To prevent noise, use a 2 core shielded wire.

M150HE to

M1000HE

Central control wire (*2) Remote controller wire

2-core, non-polarity

Shielded wire

(Up to 1000m) 1.25 mm

(Up to 2000m) 2.0 mm

Communication wire

2

2

2-core, non-polarity

2

to 2.0 mm2

0.5 mm

Remote controller wiring

Remote controller wiring, remote controller inter-unit wiring 2-core, non-polarity: 0.5 mm

Total wire length of remote controller wiring and remote controller inter-unit wiring = L + L1 + L2 + ··· Ln Up to 500mm

Total wire length of remote controller inter-unit wiring = L1 + L2 + ··· Ln Up to 200mm

On the outside of the uni t, do not all ow the wire fo r the remote c ontroller (co mmunication wi re) and the w ire for AC220-24 0V to come into contact

or put them together in one electrical conduit; otherwise, the control system may have trouble due to noise.

Indoor unit

wiring

L

Remote

controller

Remote controller

* The total length of the remote controller inter-unit wiring is the same for both between the indoor units and

between the Air to Air Heat Exchanger.

Indoor unit

L1 L2 Ln

Remote controller inter-unit wiring

Air to Air

Heat

Exchanger

(Up to 8 units)

2

to 2.0 mm2

Air to Air

Heat

Exchanger

See the table below for the power supply specifications. If the capacity is too small, the unit will suffer from

overheating or burnout.

Item

Model name VN-

Air to Air Heat

Exchanger

*1: Prepare the exclusive power supply for the Air to Air Heat Exchanger

M150HE to

M1000HE

Power supply

220V-240V~, 50Hz

220V~, 60Hz

Power supply for Air to Air Heat Exchanger (*1)

Circuit breaker (switch)

Current rating (Fuse rating)

15A

Power supply wire

1.5 mm

(H07 RN-F or 60245 IEC 66)

3-core,

2

or 2.5 mm

2

Air to Air Heat Exchanger

A

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Installation Manual

Air to Air Heat Exchanger

Installation Manual

Connection diagram

Gray Light blue

M

FM1

1~

Connector

(White)

White

C C

White

Blue

Black

Connector

Orange

(White *6)

White

3

23

13

43F12

43F11

5

5

White

White

Red

Air to Air Heat

Exchanger

Earth

Code Part name

CN*** Connector

F01 Fuse

FM1 Air supplying motor

FM2 Air exhausting motor

DAM Damper motor

TRA TRA sensor

M

1~

Connector

(Black)

Yellow

Blue

Connector

Brown

(Red *6)

Red

43F22

55

White

White

Red

S(N)R(L)

Power supply for the Air

to Air Heat Exchanger

220-240V~, 50Hz

220V~, 60Hz

132

FM2

Yellow

43F21

Red

White

7

43F12

8

P01

Black

CN701

Black

TB1

1

(White)

F01

T3.15A

250V~

1

3

CN67

(Black)

represents the connector to switch between

Extra High and High.

TOA TOA sensor

RY701, RY702 Relay for air supplying motor

RY704, RY705 Relay for air exhausting motor

TB1 Terminal block (power supply)

TB2 Terminal block (communication)

TB3 Terminal block (external output)

777

43F21

43F11 43F22

888

Gray

Yellow

Blue

Light blue

Pink

Brown

3513

RY701

CN702

5

(Red)

Indoor control

RY705

RY702

circuit board

MCC1615

RY704

Code Part name

1. The dotted line represents a wire procured locally, and the dashed line represents an option sold separately.

2. represents a terminal block, represents a c onne ction terminal, and represents a connector on

the printed circuit board.

3. represents a protective earth.

4. represents a printed circuit board.

5. Using a no voltage a-contact input of the external input (sold separately), the following operations are available:

Between 1 and 2: Selecting the remote controller operation (Invalid/Valid)

Between 1 and 3: Adjusting the ventilation fan speed (Low/High)

Between 1 and 4: Selecting the ventilation mode (Bypass mode/Heat exchange mode)

Between 1 and 5: Operation (ON/OFF)

Use a microcurrent contact (DC12V, 1mA). In addition, ON/OFF operation is possible when using a voltage of

DC12V or 24V.

6. Blue wire (High) is connected as factory default. To switch to “Extra High”, connect black wire’s connector

instead of blue.

7. When the temperature of the outdoor air is below -10°C, the unit runs in the cold mode (the ventilator for air

supply runs intermittently). The unit cannot run when the temperature of the outdoor air is below -15°C. The

ventilator for air supply stops running and the ventilator for air exhaust also stops depending on the settings.

8. Even if “Bypass mode” is selected manually, the unit switches to “Heat exchange mode” automatically to prevent

condensation when the temperature of the outdo or air is below 15°C. However, “Byp ass mode” is still displayed.

+

+

M

2134

CN760

(White)

DAM

6

65

Power

supply

External output

(220-240V~, under 1A each)

Operation output

Common

External damper output

12 45

1

Abnormal/Bypass mode ou tpu t

3

TB3

White

Yellow

Blue

Black

Red

CN704

3 975

RY710

RY709

RY708

SW701

DC20V

DC12V

DC 5V

ON

OFF

SW702

ON

OFF

1

4322341

Wiring for central control Wiring for the remote

Code Part name

SW301, SW701

SW702, SW703

43F11, 43F12 Relay for air supplying motor

43F21, 43F22 Relay for air exhausting motor

*5 External input (sold

separately)

No voltage a-contact input

1 Common

2 Remote controller operation

3 Ventilation fan speed

4 Ventilation mode

5 Operation

Voltage DC (12V, 24V) input

5

213

1

4

52

CN705

CN706

1

Blue Blue

U3

DIP switch

CN105

(Brown)

CN106

(White)

CN041

2

3

1

Black

Black

U4

BA

controller

BA

SW301

ON

OFF

SW703

ON

OFF

CN040

(Blue) (Blue)

TB2

1

2

2

1

t°

2

1

t°

2

Wired remote

controller (sold

separately)

TR

TOA

Switches and connectors on the circuit board

Remove the 4 screws to detach the electrical control cover.

* Refer to "9. Installation Method for Each System Configuration" on page 10 about setting the switch.

Electrical control base

Screws (x 4)

Electrical control cover

Changeover switch

for the central

control address

SW703 (No. 3)

Fix: ON

Auto: OFF

ON

OFF

1ON2 3 4 1ON2 3 4

SW702 SW703

Changeover switch for th e

indoor unit address

SW702 (No.1 to 4), 703 (No. 1

and 2)

Changeover switch

for the group

address

SW703 (No.4)

Header (Individual:

ON

Follower: OFF

Changeover switch

for the terminator

SW301 (No.1)

100Ω: ON

None: OFF

ON

OFF

1ON2

SW301

Changeover switch for

pulse/static

SW701 (No.1)

Pulse: ON

Level: OFF

Connectors for the external

input

Remote ON/OFF adapter

(NRB-1HE: sold separately)

CN705(5P)

No voltage a-contact in put

(Remote controller

operation Invalid/Valid,

fan speed Low/High,

Ventilation mode Bypass/

Heat exchange, Operation

ON/OFF)

CN706(2P)

Voltage of DC12V or 24V

(ON/OFF)

ON

OFF

1ON2

SW701

15-EN 16-EN

–8–

EN

17-EN 18-EN

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Air to Air Heat Exchanger

Installation Manual

–9–

Air to Air Heat Exchanger

Installation Manual

Wire connection

In a central control system, connect

the copper braid shield of central

control wire (2-core shielded wire).

Communication wire

terminal block

Wiring for the central

control (U3, U4)

Wiring for the remote

controller (A, B)

Power supply terminal

block (R(L), S(N))

External output terminal

block (1, 2, 3, 4, 5)

Operation output

Common

External damper output (3-4)

Abnormal/Bypass mode

output (3-5)

U2

U1

BA

U4

U3

SR

Power supply wire Central control wire Remote controller wire

30

S(N)

R(L)

Earth line

30

40

1510

REQUIREMENT

• Pass the wires through the grommet of wiring connection holes of the Air to Air Heat Exchanger.

• Keep a margin (Approx. 100 mm) on a wire.

• The low-voltage circuit is provided for the remote controller.

• Rotate the electrical control base to open.

• Connect the power supply wire (R (L), S (N)) and the remote control wire (A, B).

• Connect the central control wire (U1/U3, U2/U4) or the external output terminal block (1 to 5) if necessary.

• Tighten the screws on the terminal board firmly, then fix the wiring on the electrical control box using the

accessory cord clamp.

• Perform earthing work.

Remote

controller wire

Central control

wire

Earth screw

Grommet

Power supply

wire

Electrical control

box

1510

Switching between Extra High and High

WARNING

• Turn off the circuit breaker before switching between Extra High and High.

When switching to Extra High, connect the black lead wire

(Extra High) to the connector.

* The blue lead wire (High) is connected as factory default.

* Connect the black lead wire both to the supplying air motor

(white connector) and the exhausting air motor (red

connector).

* Refer to “Connection diagram” for the connection method.

REQUIREMENT

• After connecting the black lead wire to the connectors, fix the

lead wires using the cord clip.

Cord clip

Blue lead wire

(High)

*Factory default

Exhaust air

(red connector)

Supply air

(white connector)

Remote Controller Wiring

• As the remote controller wire has non-polarity, there is no problem if connections to Air to Air Heat Exchanger

terminal blocks A and B are reversed.

Wiring diagram

Terminal block for remote

controller wiring of Air to Air

Heat Exchanger

A

B

Remote controller wire

(locally procured)

* For details of wiring/installation of the remote controller, refer to the Installation Manual enclosed to in the remote

controller.

Terminal block

Remote

A

controller

B

unit

Air to Air Heat Exchanger

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Installation Manual

Air to Air Heat Exchanger

Installation Manual

9 Installation Method for Each System

Configuration

D

Central control system

(When controlling the Air to Air Heat Exchanger only)

Settings and electric wiring differ depending on the system configuration. Perform electric wring according to the

system examples shown in the table below. (Refer to page 12 to 14 for details.)

System example Operation

A

Air to Air Heat Exchanger system

(One Air to Air Heat Exchanger is used.)

Air to Air

Heat

Exchanger

AB

AB AB

Remote controller for the Air to Air

Heat Exchanger

NRC-01HE

Remote controller for air conditioner

RBC-AMS41E

B

Air to Air Heat Exchanger system

(Multiple Air to Air Heat Exchangers are used.)

Air to Air

Heat

Exchanger

C

Air to Air Heat Exchanger system linked with air

conditioners

Outdoor

unit

Air

conditioner

Air to Air

Heat

Exchanger

AB AB

AB AB

Remote controller for the Air to Ai r

Heat Exchanger

NRC-01HE

Remote controller for air

conditioner

RBC-AMS41E

U1 U2

U1 U2 U1 U2

Air

conditioner

AB AB AB

Remote controller for air conditioner

AB

RBC-AMT32E, RBC-AMS41E

Remote controller for the Air to Air Heat

Exchanger

NRC-01HE

Air to Air

Heat

Exchanger

Air to Air

Heat

Exchanger

19-EN 20-EN

• Using the remote controller for the Air to Air Heat

Exchanger NRC-01HE, the unit can be started or stopped,

control the ventilation fan speed, and select the ventilation

mode.

• If two remote controllers are used, the latter operation

overrides the former and their indications always reflect the

result of the latter operation.

* The remote controllers for the air conditioners RBC-

AMT32E are not compatible with a system in which only

the Air to Air Heat Exchanger is used. Only on/off

operation is available for RBC-AMS41E.

• Using the remote controller for the Air to Air Heat

Exchanger NRC-01HE, the unit can be started or stopped,

control the ventilation fan speed, and select the ventilation

mode.

• If two remote controllers are used, the latter operation

overrides the former and their indications always reflect the

result of the latter operation and the settings of the header

unit.

* The remote controllers for the air conditioners RBC-

AMT32E are not compatible with a system in which only

the Air to Air Heat Exchanger is used. Only on/off

operation is available for RBC-AMS41E.

• The remote controller for the air conditioner or the Air to Air

Heat Exchanger can be used to ON/OFF the whole

system.

• The remote controller for the Air to Ai r Heat Exchanger

NRC-01HE can be used to control the ventilation fan speed

and ventilation mode of the Air to Air Heat Exchanger.

• The remote controller for air conditioner RBC-AMT32E and

RBC-AMS41E cannot be used to control the ventilation fan

speed or ventilation mode of the Air to Air Heat Exchanger.

• The remote controller for the air conditioner or the Air to Air

Heat Exchanger can be used to ON/OFF the Air to Air Heat

Exchanger separately.

AB

* Setting modifications are required for separate control.

AB

Refer to "11. Advanced Control" on page 19.

• If two remote controllers are used, the latter operation

overrides the former and their indications always reflect the

result of the latter operation. In addition, the indications of

the Air to Air Heat Exchanger always reflect the setting of

the unit with the smallest indoor unit address number.

–10–

U3 U4

U3 U4 U3 U4

Air to Air

Heat

Exchanger

AB

AB

Remote controller for the Air to Air Heat Exchanger

(NRC-01HE)

Remote controller for air conditioner (RBC-AMS41E)

E

Central control system

(When controlling the air conditioner and the Air to Air Heat

Exchanger separately)

Outdoor

unit

U1 U2

U3 U4

U1 U2 U1 U2

Air

conditioner

AB

AB

Remote controller for the

air conditioner

(RBC-AMT32E, RBCAMS41E)

F

Central control system

(When controlling the air conditioner and Air to Air Heat

Exchanger together)

Outdoor

unit

U1 U2

U3 U4 U3 U4

U1 U2 U1 U2

Air

conditioner

AB AB AB

AB

System example Operation

• The central controller can be used to ON/OFF the whole

system and separately ON/OFF groups of the Air to Air

Central controller for 64/128 units/groups

(TCB-SC642TLE2, BMS-CM1280TLE)

Air to Air

Heat

Exchanger

AB

AB

U3 U4

Air

conditioner

AB

AB

Air

conditioner

Remote controller for air

conditioner

(RBC-AMT32E, RBC-AMS41E)

Remote controller for the Air to Air

Heat Exchanger (NRC-01HE)

Air to Air

Heat

Exchanger

Central controller for 64/128

units/groups

(TCB-SC642TLE2, BMSCM1280TLE)

Air to Air

Heat

Exchanger

Remote controller for the Air to Ai r

Heat Exchanger (NRC-01HE)

Remote controller for air conditioner

(RBC-AMS41E)

Central controller for 64/128

units/groups

(TCB-SC642TLE2

BMS-CM1280TLE)

Air to Air

Heat

Exchanger

AB

AB

U3 U4

AB

AB

Air to Air

Exchanger

Air to Air

Heat

Exchanger

Air to Air

Exchanger

Heat

AB

AB

AB

AB

Heat

Heat Exchangers.

• The central controller cannot be used to control the

ventilation fan speed or ventilation mode of the Air to Air

Heat Exchanger.

• If the central controller and the remote controller for the Air

to Air Heat Exchanger are used, the latter operation

overrides the former.

• The remote controller for the Air to Air Heat Exchanger

(NRC-01HE) can be used to control the ventilation fan

speed and ventilation mode of the Air to Air Heat

Exchanger.

* The remote controllers for the air conditioners (RBC-

AMT32E) cannot be used to control the group of the Air

to Air Heat Exchangers. Only on/off operation is

available for RBC-AMS41E.

• The central controller can be used to ON/OFF the whole

system and separately ON/OFF groups of air conditioners

and the Air to Air Heat Exchangers. (Air conditioners and

Air to Air Heat Exchangers are not linked in this system.)

• The central controller cannot be used to control the

ventilation fan speed or ventilation mode of the Air to Air

Heat Exchanger.

• The operation of the central controller overrides that of the

remote controllers for the Air to Air Heat Exchangers and

the air conditioners. However, the operation of the remote

controller for the Air to Air Heat Exchanger does not affect

that of the remote controller for the air conditioner and vice

versa.

• The remote controller for the Air to Air Heat Exchanger

(NRC-01HE) can be used to control the group of the air

conditioners instead of using the remote controller for the

air conditioner.

• The remote controller for the Air to Air Heat Exchanger

(NRC-01HE) can be used to control the ventilation fan

speed and ventilation mode of the group of the Air to Air

Heat Exchangers.

* The remote controllers for the air conditioners (RBC-

AMT32E) cannot be used to control the group of the Air

to Air Heat Exchangers. Only on/off operation is

available for RBC-AMS41E.

• The central controller can be used to ON/OFF the whole

system. It can also be used to ON/OFF the Air to Air Heat

Exchanger separately (*).

• The central controller cannot be used to control the

ventilation fan speed or ventilation mode of the Air to Air

Heat Exchanger.

• If three control devices are used; the central controller and

the remote controllers for the Air to Air Heat Exchanger and

the air conditioner, the latter operation overrides the former

regardless of which device is used.

• The remote controller for the Air to Air Heat Exchanger

NRC-01HE can be used to control the ventilation fan speed

and ventilation mode of the Air to Air Heat Exchanger.

• If the remote controller for the air conditioner (RBC-

AB

AMT32E and RBC-AMS41E) is used; the ventilation fan

speed or ventilation mode of the Air to Air Heat Exchanger

can not be controlled.

AB

• The remote controller for the air conditioner or the Air to Air

Heat Exchanger can be used to ON/OFF the Air to Air Heat

Exchanger separately.

* Setting modifications are required for separate control.

Refer to “"11. Advanced Control" on page 19.

EN

21-EN 22-EN

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Air to Air Heat Exchanger

Installation Manual

–11–

Air to Air Heat Exchanger

Installation Manual

Air to Air Heat Exchanger system

System example —

Central control None

No. of Air to Air Heat

Exchangers

Operation together with the air

conditioners

Remote controller inter-unit

wiring

Central control wiring Not necessary

1.Line (system) address Fixed

2. Changing the indoor

unit address

No.1 to 4 of SW702

No.1 and 2 of SW703

3. Changing the group

address

No.4 of SW703

4.Fix/Automatic

changeover of the

central control

address

No.3 of SW703

Circuit board of the Air to Air Heat Exchanger

5. Changing the

terminator

No.1 of SW301

Checking before turning on

the power

Turning on the power Turn on the breaker of all the Air to Air Heat

Central control address

setting

A B C

1 Multiple 1 Multiple

No Yes

Not necessary Necessary

* The line (system) address is fixed as 31 for the Air to Air Heat Exchanger.

Not necessary

Factory default: 1

Necessary

Header (Individual):

ON

Complete the settings of the Air to Air Heat

Exchanger and wiring.

Exchangers.

Necessary

No duplication

Factory default: 1

Necessary

Header: ON (1unit)

Follower: OFF (the

other units)

* Settings of the

header unit reflect

the indications of

the remote

controller.

Air to Air Heat Exchanger system linked

Not necessary

Factory default: 1

Not necessary

Follower: OFF (all units)

* Settings of the follower unit with the smallest

indoor unit address number reflect the

indication of the remote controller.

Not necessary

Not necessary

None: OFF

• Complete the settings of the Air to Air Heat

Exchanger and wiring.

• Refer to the Installation Manual of the air

conditioner for the settings and wiring.

Turn on the Air to Air Heat Exchan ger first.

Refer to the Installation Manual of the air

conditioner for its power supply.

Not necessary

with air conditioners

Necessary

No duplication

Factory default: 1

Central control system

System example — —

Central control One Air to Air

No. of Air to Air Heat

Exchangers

Operation together with the air

conditioners

Remote controller inter-unit

wiring

Central control wiring Necessary (Header unit only) Not necessary

1.Line (system) address Fixed

2.Changing the indoor

unit address

No.1 to 4 of SW702

No.1 and 2 of SW703

3.Changing the group

address

No.4 of SW703

4.Fix/Automatic

changeover of the

central control

address

No.3 of SW703

Circuit board of the Air to Air Heat Exchanger

5.Changing the

terminator

No.1 of SW301

Checking before turning on

the power

Turning on the power Turn on the

Central control address

setting

D E F

Heat Exchanger

is used.

Multiple 1 Multiple 1 Multiple

Necessary Not necessary Necessary

* The line (system) address is fixed as 31 for the Air to Air Heat Exchanger.

Necessary

No duplication

Factory default: 1

Necessary

Header: ON

(1unit)

Follower: OFF

(the other units)

* Settings of the

header unit

reflect the

indications of

the remote

controller.

Necessary

100Ω: ON

(1 header unit

only)

Complete the

settings of the Air

to Air Heat

Exchanger and

wiring.

breaker of all the

Air to Air Heat

Exchangers.

Refer to the Installation Manual of the central control device.

When controlling the air conditioner

and the Air to Air Heat Exchanger

separately

No Yes

Not necessary

Factory default: 1

Necessary

Header

(Individual): ON

*Refer to the Installation Manual of the central control device.

Not necessary

OFF

* Adjust settings on the air conditioner.

• Complete the settings of the Air to Air Heat Exchanger and wiring.

• Refer to the Installation Manual of the air conditioner for the settings and

wiring.

Turn on the Air to Air Heat Exchanger first. Refer to the Installation Manual

of the air conditioner for its power supply.

Necessary

No duplication

Factory default: 1

Necessary

Header: ON

(1unit)

Follower: OFF

(the other units)

* Settings of the

header unit

reflect the

indications of

the remote

controller.

Not necessary

Auto: OFF

When controlling the air conditioner

and Air to Air Heat Exchanger

together

Not necessary

Factory default: 1

Not necessary

Follower: OFF (all units)

* Settings of the follower unit with

the smallest indoor unit address

number reflect the indication of the

remote controller.

Necessary

No duplication

Factory default: 1

Air to Air Heat Exchanger

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Installation Manual

Air to Air Heat Exchanger

Installation Manual

Changing the group address, indoor unit address, and central

control address

◆ About the switches on the circuit board of the Air to Air Heat Exchanger

SW702 SW703

Changing the indoor unit address

●: ON -: OFF

When there are multiple Air to Air

Heat Exchangers, do not duplicate

the value between No.1 to No.4 of

SW702 and between No.1 and No.2

of SW703. (Factory default: 1)

ON

OFF

1ON2 3 4 1ON2 3 4

Indoor unit address switch (¦: ON —: OFF)

Address switch number

SW702 SW703 SW702 SW703 SW702 SW703 SW702 SW703

1 2 3 4 1 2 1 2 3 4 1 2 1 2 3 4 1 2 1 2 3 4 1 2

Address

1 ——————17————¦ — 33—————¦ 49————¦¦

2 ¦ —————18 ¦ ———¦ — 34 ¦ ————¦ 50 ¦ ———¦¦

3—¦ ————19 — ¦ ——¦ — 35 — ¦ ———¦ 51 — ¦ ——¦¦

4 ¦¦————20 ¦¦——¦ — 36 ¦¦———¦ 52 ¦¦——¦¦

5——¦ ———21 — — ¦ — ¦ — 37 — — ¦ ——¦ 53 — — ¦ — ¦¦

6 ¦ — ¦ ———22 ¦ — ¦ — ¦ — 38 ¦ — ¦ ——¦ 54 ¦ — ¦ — ¦¦

7—¦¦———23 — ¦¦— ¦ — 39 — ¦¦——¦ 55 — ¦¦— ¦¦

8 ¦¦¦———24 ¦¦¦— ¦ — 40 ¦¦¦——¦ 56 ¦¦¦— ¦¦

9 ———¦ ——25 — — — ¦¦— 41 — — — ¦ — ¦ 57———¦¦¦

10 ¦ ——¦ ——26 ¦ ——¦¦— 42 ¦ ——¦ — ¦ 58 ¦ ——¦¦¦

11 — ¦ — ¦ ——27 — ¦ — ¦¦— 43 — ¦ — ¦ — ¦ 59 — ¦ — ¦¦¦

12 ¦¦— ¦ ——28 ¦¦— ¦¦— 44 ¦¦— ¦ — ¦ 60 ¦¦— ¦¦¦

13 — — ¦¦——29 — — ¦¦¦— 45 — — ¦¦— ¦ 61 — — ¦¦¦¦

14 ¦ — ¦¦——30 ¦ — ¦¦¦— 46 ¦ — ¦¦— ¦ 62 ¦ — ¦¦¦¦

15 — ¦¦¦——31 — ¦¦¦¦— 47 — ¦¦¦— ¦ 63 — ¦¦¦¦¦

16 ¦¦¦¦——32 ¦¦¦¦¦— 48 ¦¦¦¦— ¦ 64 ¦¦¦¦¦¦

Address switch number

Address

Address

Changing the group address

Header (Individual): ON Follower: OFF

• When the system equipped with the Air to Air

Heat Exchanger(s) only is used, s et only one

unit as the header unit.

• When the system equipped with the Air to Air

Heat Exchanger and air conditio ners is

used, be sure to set all the Air to Air Heat

Exchangers as follower units . (Factory

default: Follower)

Changing the central control address

Fixed: ON Auto: OFF

The settings do not need to be adjusted.

(Leave the value OFF.)

Address switch number

Address switch number

Address

Installing two remote controllers for the Air to Air Heat

Exchanger

For details on how to install the remote controller for the Air to Air Heat Exchanger, r efer to the I nstallation Manual

accessory with the remote controller.

One or multiple Air to Air Heat Exchanger(s) can be controlled b y using two re mote cont rollers. ( Up to two remo te

controllers can be installed.)

Remote controller (inside of the

back)

Follower remote

controller

Header remote

controller

21

* Set switch 2 to low.

Header remote

controller

21

21

DIP switch

Follower remote

controller

Header remote

controller

Follower remote

controller

21

21

DIP switch

How to install

To use two remote controllers, follow the procedure below.

1. Set one remote controller as the header (factory default).

2. Set the other remote controller as the follower using the DIP switch. After that, the remote controller works as

the follower.

Settings for each system configuration

NOTE

• The line (system) address is fixed as 31 for the Air to Air Heat Exchanger.

A

Air to Air Heat Exchanger system (One Air to Air Heat Exchanger is used.)

Air to Air Heat Exchanger

Earth

Power supply

LNU1U3U2U4

Remote controller

(header)

AB

ABAB

Remote controller

(follower)

Changing the group address (No.4 of SW703)

Settings for changing the group address are

necessary. Select “Header: ON”. (Factory default:

Follower)

* When “Header: ON” is selected, “Individual: ON”

will be selected in this system.

Changing the indoor unit address (No.1 to 4 of

SW702, No.1 and 2 of SW703)

The setting does not need to be adjusted. (Factory

default: 1)

23-EN 24-EN

–12–

EN

25-EN 26-EN

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Air to Air Heat Exchanger

Installation Manual

–13–

Air to Air Heat Exchanger

Installation Manual

B

Air to Air Heat Exchanger system (Multiple Air to Air Heat Exchangers are used.)

Air to Air Heat Exchanger

Earth EarthEarth

U1U3U2

LN LN LN

Remote controller

(header)

* For group control, install remote controller inter-unit wiring between the units.

* Up to 8 units can be installed for group control.

AB

U4

AB AB

Air to Air Heat Exchanger Air to Air Heat Exchanger

U1U3U2

AB

U4

Remote controller

inter-unit wiring

Power supplyPower supplyPower supply

Remote controller

(follower)

U1U3U2

U4

AB

Changing the group address (No.4 of SW703)

Settings for changing the group address are necessary. Select “Header: ON” for only one unit. Select “Follower”

for the other units.

* Settings of the header unit reflect the indications of the remote controller. (Factory default: Follower)

Changing the indoor unit address (No.1 to 4 of SW702, No.1 and 2 of SW703)

Settings for changing the indoor unit address are necessary. Do not duplicate the value. (1 to 64)

* The header unit does not need to be selected as “1”. (Factory default: 1)

C

Air to Air Heat Exchanger system linked with air conditioners

Power supply

Indoor unit

Power

supply

Remote controller

(header)

* For group control with air conditioners , install inter-unit wiring between the units.

* Up to 8 units can be installed for group control.

Outdoor unit

L1 L2 L3 N

U1 U2 U3 U4 U5 U6

Control wiring between indoor and outdoor units

LN

AB

Control wiring between indoor units

Indoor unit Air to Air Heat Exchanger

LN LN LN

Power

supply

Air to Air Heat Exchanger

U1U3U2

ABU1 U2ABU1 U2 AB

Power

supply

Remote controller

inter-unit wiring

AB

U4

Power

supply

Remote controller

(follower)

U1U3U2

U4

AB

Changing the group address (No.4 of SW703)

The settings of the group address does not need to be adjusted. Leave th e value “Follower: OFF”. (Factory default:

Follower)

* Settings of the follower unit with the smallest indoor unit address number reflect the indication of the remote

controller.

Changing the indoor unit address (No.1 to 4 of SW702, No.1 and 2 of SW703)

Settings for changing the indoor unit address are necessary. Do not duplicate the value. (1 to 64) (Factory default: 1)

D

Central control system (When controlling the Air to Air Heat Exchanger only)

For the settings of the central control address, refer to the Installation Manual of the central control device.

Power supply

Central controller

L N

U1U3U2

U4

Central control wiring

Air to Air Heat

Exchanger

U1U3U2

U4

LN

Power

supply

Remote controller

(header)

* Central control wiring must be connected to the header Air to Air Heat Exchanger unit only.

* For group control, install inter-unit wiring between the units.

* Up to 8 units can be installed for group control.

AB AB

AB

Power

supply

Remote controller

inter-unit wiring

Air to Air Heat

Exchanger

U1U3U2

U4

LN LN LN

Remote controller

(follower)

AB

Air to Air Heat

Exchanger

Power

supply

Remote controller

(header)

U1U3U2

U4

AB

Remote controller

inter-unit wiring

Air to Air Heat

Exchanger

Power

supply

Remote controller

(follower)

U1U3U2

AB

U4

ABAB

Changing the group address (No.4 of SW703)

Settings for changing the group address are necessary. Select “Header: ON” on the header unit of each group

which central control wiring is connected to. Select “Follower” for the other units.

* Settings of the header unit reflect the indications of the remote controller. (Factory default: Follower)

Changing the indoor unit address (No.1 to 4 of SW702, No.1 and 2 of SW703)

Settings for changing the indoor unit address are necessary. Do not duplicate the value. (1 to 64)

* The header unit does not need to be selected as “1”. (Factory default: 1)

Changing the terminator (No.1 of SW301)

Settings for changing the terminator are necessary. Select “ON” f or one of the header unit.

(Factory default: OFF)

100Ω: ON (1 header unit only)

None: OFF (the other uni ts)

SW301

ON

OFF

1ON2

Changing the

terminator

100Ω: ON

None: OFF

(Factory default: OFF)

Air to Air Heat Exchanger

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Installation Manual

Air to Air Heat Exchanger

Installation Manual

E

Central control system (When controlling the air conditioner and the Air to Air Heat Exchanger

separately)

For the settings of the central control address, refer to the Installation Manual of the central control device.

Power supply

L1 L2 L3 N

U1 U2 U3 U4 U5 U6

Indoor unit

LN

Power

supply

Remote controller

(header)

* Central control wiring of the Air to Air Heat Exchanger is necessary only for the header unit.

* For group control, install inter-unit wi ring between the units.

* Up to 8 units can be installed for group control.

Central

control

wiring

Control wiring

between indoor and

outdoor units

AB AB

Remote controller

inter-unit wiring

Changing the group address (No.4 of SW703)

Settings for changing the group address are necessary. Select “Header: ON” on the header unit of each group

which central control wiring is connected to. Select “Follower” for the other units.

* When “Header: ON” is selected, “Individual: ON” will be selected if only one Air to Air Heat Exchanger is

connected to this system.

* Settings of the header unit reflect the indications of the remote controller. (Factory default: Follower)

Changing the indoor unit address (No.1 to 4 of SW702, No.1 and 2 of SW703)

Settings for changing the indoor unit address are necessary. Do not duplicate the value. (1 to 64)

* The header unit does not need to be selected as “1”. (Factory default: 1)

Changing the terminator (No.1 of SW301)

* The settings do not need to be adjusted.

Power supply

Central controllerOutdoor unit

L N

U1U3U2

U4

Control wiring between

indoor units

Indoor unit

LN LN LN

Power

supply

Remote controller

(follower)

ABU1 U2ABU1 U2

Central control wiring

Air to Air Heat

Exchanger

Power

supply

Remote controller

(header)

U1U3U2

U4

AB

Remote controller

inter-unit wiring

Air to Air Heat

Exchanger

Power

supply

Remote controller

(follower)

U1U3U2

AB

U4

ABAB

F

Central control system (When controlling the air conditioner and Air to Air Heat Exchanger

together)

• For the settings of the central control address, refer to the Installation Manual of the central control device.

• Do not perform the central control wiring with the Air to Air Heat Exchanger.

Power supply

L1 L2 L3 N

U1 U2 U3 U4 U5 U6

Control wiring between indoor and outdoor units

Indoor unit

LN

Power

supply

Remote controller

(header)

* For group control with air conditioners, perform inter-unit wiring between the units.

* Up to 8 units can be installed for group control.

AB

Changing the group address (No.4 of SW703)

The settings of the group address does not need to be adjusted. Leave the value “Follower: OFF”. ( Factory default:

Follower)

* The settings of the follower unit with the smallest indoor unit address number reflect the indication of the remote

controller.

Changing the indoor unit address (No.1 to 4 of SW702, No.1 and 2 of SW703)

Settings for changing the indoor unit address are necessary. Do not duplicate the value. (1 to 64) (Factory default: 1)

Changing the terminator (No.1 of SW301)

* The settings do not need to be adjusted.

Central

control

wiring

Power supply

Central controllerOutdoor unit

L N

U1U3U2

U4

Control wiring between indoor units

ABU1 U2ABU1 U2

Air to Air Heat

Exchanger

Power

supply

Remote controller

inter-unit wiring

U1U3U2

AB

U4

Indoor unit

LN LN LN

Power

supply

Air to Air Heat

Exchanger

Power

supply

Remote controller

(follower)

U1U3U2

AB

U4

AB

27-EN 28-EN

–14–

EN

29-EN 30-EN

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Air to Air Heat Exchanger

Installation Manual

–15–

Air to Air Heat Exchanger

Installation Manual

10Advanced System

WARNING

• Use wiring that meets the specifications in the Installation Manual and the stipulations in the local regulations and

laws. Use of wiring which does not meet the specifications may give rise to electric shocks, electrical leakage,

smoking and/or a fire.

• When carrying out electric connection, use the wire specified in the Installation Manual and connect and fix the wire

securely to prevent them applying external force to the terminals. Improper connection of fixing may result in fire.

• Electrical wiring work shall be conducted according to law and regulation in the community and Installation Manual.

Failure to do so may result in electrocution or short circuit.

REQUIREMENT

For the connecting procedure and electric wiring of External Input (sold separately), refer to the Installation Manual of

Remote On/Off Adapter NRB-1HE.

1 When the operation is linked by a signal from an external device or remotely controlled On and

Off. (Separately sold External Input)

REQUIREMENT

Do not change the setting of the Air to Air Heat Exchanger single operation for Air to Air Heat Exchangersystem linked

with air conditione rs on page 19.

* Operating together if a command is sent to one of the units in the group.

* Setting for linked operation with external devices can be changed. Refer to the "Setting for linked operation with