FILE NO. A02-012

Revised on : 2005/Feb./15

SERVICE MANUAL

HEAT EXCHANGE VENTILATORS

VN-250SE

VN-350SE

VN-500SE

VN-800SE

VN-1KSAE

VN-500SE

PRINTED IN JAPAN, Jan.,2003 ToMo

CONTENTS

1. SAFETY CAUTIONS ................................................................................. 3

2. TECHNICAL POINTS (PERFORMANCE) ............................................... 7

3. REFERENCE DRAWING FOR INSTALLATION ...................................... 7

4. SPECIFICATIONS...................................................................................... 8

5. NAME AND DIMENSION OF EACH PARTS.......................................... 11

6. WIRING DIAGRAM .................................................................................. 12

7. OWNER’S MANUAL (EXTRACT) ........................................................... 13

8. INSTALLATION MANUAL (EXTRACT) .................................................. 19

9. HOW TO DIAGNOSE THE TROUBLE..................................................... 24

10. HOW TO REPLACE THE MAIN PARTS.................................................. 25

11. CHECK WHEN REPAIR WORK COMPLETED...................................... 28

12. Q & A FOR HEAT EXCHANGE VENTILATORS .................................... 29

13. EXPLODED VIEWS AND PARTS LIST .................................................. 30

– 2 –

1. SAFETY CAUTIONS

The important contents concerned to the safety are described on the ventilator body and in this Service manual.

Preserve the described items after understanding clearly the following contents (indications/illustration symbols)

and reading this manual thoroughly.

n Explanation of indications

Indication

DANGER

WARNING

CAUTION

Damage of property : expanded damage concerned to property/household effects or domestic animals/pets

*

Indicates the contents which a danger such as death or serious injury is caused in

emergency on the repair engineers or the surrounding third party by an incorrect work.

Indicates the contents which a possibility such as death or serious injury is caused on the

repair engineers or the surrounding third party by an incorrect work, or on the customers

by a trouble of the products.

Indicates the contents which occurrence of injury (*) or damage of property is supposed

on the repair engineers or the surrounding third party by an incorrect work, or on the

customers by a trouble of the products.

Meaning

n Explanation of illustration symbols

Illustration symbol Meaning

Indicates prohibition (Never do it.).

The concrete contents of prohibition are indicated with illustrations or descriptions near

the illustration symbol.

Indicates forced work (Necessarily do it.).

The concrete contents of forced work are indicated with illustrations or descriptions near

the illustration symbol.

Indicates cautions (including danger/warning).

The concrete contents of cautions are indicated with illustrations or descriptions near the

illustration symbol.

1-1. Warning and caution exclusive in service work

WARNING

• Be sure to ask the customers not to let children close to the work place.

The tools or disassembled parts may cause an injury on children.

• Be sure to turn off the breaker before work when power-ON is unnecessary such as a case of

disassembling.

If doing so, an electric shock may be caused.

• Use the substitute parts corresponded to the model for repair. And do not modify the products.

It causes an abnormal operation or a trouble resulted in leakage or fire, that is a cause of customers’

disaster.

• For connection of the cut lead cables, connect the cables with application terminals, direct the closed

end side upward, and then apply the draining process.

If the post-process of connection is not carried out, a cause of customers’ disaster such as leakage or fire

generates.

• After the work, check the insulation resistance between live part (pin of SL terminal) and non-current

carrying part (motor frame) using a insulation megger (500V) and confirm 10MW or more is kept.

If the insulation resistance is not confirmed, a cause of customers’ disaster such as leakage or fire generates.

CAUTION

• Use the protective materials such as gloves, etc. for check/repair inside of the unit.

If touching inside of the unit with bare hands, an injury may be caused.

– 3 –

1-2. DANGER/WARNING/CAUTION Described in Owner’s Manual

DANGER

• Do not use as an air circulators for open-type burners (heaters).

When gas or oil stoves are used in the home, separate equipment for circulating the air should be used.

WARNING

• When any abnormal condition (scorching smell or others) is found, stop the operation immediately

and keep the exclusive circuit breaker “OFF”.

If you continue the operation without removing the cause, it could cause an electric shock or a fire.

• When the system needs a repair, consult your dealer.

• When the system is checked and the power cable undergoes maintenance, stop the operation, and

switch the exclusive circuit breaker “OFF”.

The internal fan is revolving at high speeds and can cause serious injury. And when using a stepladder,

etc., make sure to fix it properly.

• The external air intake opening should be positioned away from the exhaust openings of combustion

gases etc.

The intake of such gasses could lead to a lack of oxygen in the room.

• If there is combustible gas leakage from other appliances, ventilate the room by opening windows.

If operation were to be attempted in such a situation, sparking at electrical contact points could cause an

explosion.

• Netting or something similar should be provided at the external air intake opening to prevent birds

etc. interfering with the unit.

Nests or other foreign objects should be removed. That could lead to a lack of oxygen in the room.

• If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a

similarly qualified person in order to avoid a hazard.

• The external air intake opening should not be positioned where discharged air may directly enter it.

A situation like this will lead to the room being contaminated and this may pose a health risk.

• When Heat Exchange Ventilators are relocated, contact your dealer or a professional installer.

Improper practice of installation could cause a drop of the unit, a water leakage, an electric shock or a

fire.

• Ask the sales office or the engineering shop to perform the work.

• Don't push a finger or a stick into the open-air inlet or the exhaust outlet.

A fan with a high rpm will injure you.

• Modification of the system is strictly prohibited.

Improper practice of repair could cause a water leakage, an electric shock or a fire.

• When the system needs a repair, consult your dealer.

– 4 –

CAUTION

• If Heat Exchange Ventilators are not used for a long period of time, keep the exclusive circuit

breaker “OFF” for safety reasons.

If the power is left on, any build-up of dust could cause a heat generation or a fire.

• The system should never be used for any other purposes than intended such as for preservation of

foods, flora and fauna, precision devices or work of art.

• It could cause deterioration of foods or other problems.

• Install at a stable place of sufficient strength.

Please note that there might be some places not strong enough to install due the structure of building.

• Provide an exclusive circuit breaker that can completely break contacts on all the poles by more

than 3mm through direct connection to the power terminals.

Depending upon the environment for installation, it becomes necessary to install an earth leakage

breaker. Unless the earth leakage breaker is installed, it could cause an electric shock.

• Ask the sales office or the engineering shop to perform the work.

• Never fail to install the unit inside the heat insulting walls or, in other words, in the space insulated

from the open air.

If you install it outside or in the space equivalent to the open-air conditions, dew is condensed inside the

body in the winter season.

• The filter should be cleaned regularly.

Dust or dirt building-up on it can lead to a lack of oxygen in the room.

• Use gloves when cleaning the filter or heat exchange element.

Doing so will reduce any possibility of injury.

• It is strictly prohibited to place a container of combustible gas or liquid near Heat Exchange Ventilators or to spray it directly with the gas or liquid.

It could cause a fire.

• Do not use outside the rated voltage.

It could cause a fire or an electric shock.

• Combustion apparatus should not be placed allowing a direct exposure to wind of Heat Exchange

Ventilators.

Incomplete combustion could occur on the apparatus.

• Don’t put a container of water on Heat Exchange Ventilators.

When water spills, it is likely to enter inside the unit and degrade electric insulation, possibly resulting in

an electric shock.

• Don’t incline Heat Exchange Ventilators when taking them out.

Otherwise, water remaining inside is likely to drop and wet the furniture or other property.

• Ask the sales office or the engineering shop to perform the work.

• Do not install in locations where harmful or corrosive gasses may be present (i.e. acidic, alkali,

organic solvent, paint gasses etc. from machinery or factories)

Installation in such a location could cause a gas-poisoning and a fire.

• Do not install in locations where oily smoke or soot may be present.

There is a possibility that oil will adhere to the filter, heat exchange

• Do not install in locations with high humidity, such as close to bathroom etc.

Installation in such a location could cause a breakdown.

• Don’t use benzene or metal brush when cleaning the filter and heat exchange element.

Otherwise, the unit will get unfit for use.

• Don’t blow directly against animals or plants.

Likely to cause bad effect on animals and plants.

element etc.

and make operation impossible.

• Do not wash Heat Exchange Ventilators with water.

It could cause an electric shock.

• Do not handle switches with a wet hand.

It could cause an electric shock.

– 5 –

1-3. WARNING/CAUTION Described in Installation Manual

WARNING

Never fail to ask the sales office from which you bought the unit or the installing service shop to install the

unit. If you install it by yourself, any inappropriate installing works would cause an electric shock or a fire.

Carry out the installing works accurately in line with this installation manual. Improper practice of installation

could cause an electric shocks or a fire.

Choose the installing place where is endurable in quality as well as in weight, then install the unit accurately

with adequate strength and completeness of installation in accordance with the installation manual.

Otherwise, it is likely to cause an electric shock, a fire, a drop of the unit, thus causing the injury on the

human body.

Carry out electrical work in accordance with the laws and regulations prevailing in the country concerned,

technical standard and explanation for work, and make absolutely sure that an exclusive circuit is used.

Any insufficient capacity of power circuit and improper work can result in electric shock and fire hazard.

The external air intake opening should be positioned away from the exhaust openings of combustion gases

etc. The intake of such gases could cause a lack of oxygen in the room.

Netting or something similar should be provided at the external air intake opening to prevent birds etc.

interfering with the unit. Nests or other foreign objects should be removed.

That could cause a lack of oxygen in the room.

When the system is checked and the power cable undergoes maintenance, stop the operation, and switch

the exclusive circuit breaker “OFF”. Otherwise, it could cause an electric shock.

Carry out the GND work. Never connect the GND wire to a gas pipe, a water supply pipe, a lightning conductor, a GND line of a telephone, etc. An incomplete GND wire is likely to cause an electric shock.

CAUTION

Provide an exclusive circuit breaker that can completely break contacts on all the poles by more than 3mm

through direct connection to the power terminals. Depending upon the environment for installation, it becomes necessary to install an earth leakage breaker.

When you want to pierce the metal duct through the metal lath or the wire lath or the metal plate of the

wooden facility, do not forget to insulate electrically between the duct and the wall.

Otherwise, it would cause an electric shock or an electric leakage.

Don’t use other parts than specified (including the auxiliary parts) for installing works.

If you do not use the specified parts, it is likely to cause a drop of the unit, a fire, an electric shock, etc.

Install the outdoor duct in a falling gradient toward the outside so as to prevent water from coming in.

If it is not installed so, the building is likely to be flooded, wetting the household effects.

Heat-insulate the outdoor duct (including the indoor side, if necessary) to prevent dewing.

If heat insulation is not adequate, water likely goes indoor and wets the household properties.

When it is high humid and high temperature inside the ceiling, a ventilation system must be installed inside

the ceiling. Otherwise, it could cause a fire or an electric leakage.

Connect the power line and the connecting line with accuracy using the specified cables and fix them firmly

so as not to put the outer stress of the cables on the pin connecting area.

Incomplete connection or fixing is likely to cause a heat generation or a fire.

Install the power line and the connecting line with accuracy so the power source cover may not float.

If the installation of the power source cover is inappropriate, the pin connection area is likely to cause a heat

generation, a fire and an electric shock due to dust or powder.

Never install the unit near the place where there is a fear of leakage of an inflammable gas.

If gas happens to leak and stays around the unit, it is likely to cause a fire.

Don’t use the unit at the other voltages than the rated one. It could cause a fire or an electric shock.

Do not install the unit in locations with large amounts of oily smoke, such as food preparation areas.

It could cause a fire.

Don’t install the unit at the place of a high temperature or a flame. It could cause a heat generation or a fire.

Do not install in locations where harmful or corrosive gasses may be present (i.e. acidic, alkali, organic

solvent, paint gasses etc. from machinery or factories).

Installation in such a location could cause a gas-poisoning and a fire.

Do not install in locations with high humidity, such as close to bathroom etc. It could cause an electric shock

or an electric leakage etc.

– 6 –

2. TECHNICAL POINTS (PERFORMANCE)

• Energy-saving ventilation to save the cooling/heating cost because the heat energy (outside

air load) to be lost by ventilation is effectively recovered.

• Compact construction to downside the cooling/heating equipment with size corresponding

to heat energy amount to be recovered because the outside air load can be vastly decreased.

• By using the heat exchanger, humidity control effect which sucks the humidity approached

to near the humidity in the room.

• Comfortable ventilation by simultaneous air suction/discharge which sucked air approached

to the temperature in the room and the stable ventilation to be performed even in the high

airtight room.

• Noise-proof effect to prevent entering of outside noise or flowing of noise to outside.

• Suction/discharge air system on straight line which is easy to be designed or installed.

• The high-level long filter is mounted to increase the effect of dust collection for removing.

( Weight: 82%)

• Reverse installation up and down is possible, which 2 units use the same check port.

• Especially powerful notch is mounted, which can increase air volume and is selectable in the

main unit.

• Only one check port is used for all the maintenance works.

3. REFERENCE DRAWING FOR INSTALLATION

Supply Air Duct

SA

(Supply Air)

RA

(Outside Air)

Inside Supply Opening

(Supply/Exhaust Air Grill)

Pipe Hood

OA

(Outside Air)

Outside Intake Duct

EA

(Exhaust Air)

Heat Insulation

Material

Ceiling Suspension Bolt

Room Intake Duct

Room Intake Opening

(Supply/Exhaust Air Grill)

Exhaust Air Duct

Pipe Hood

– 7 –

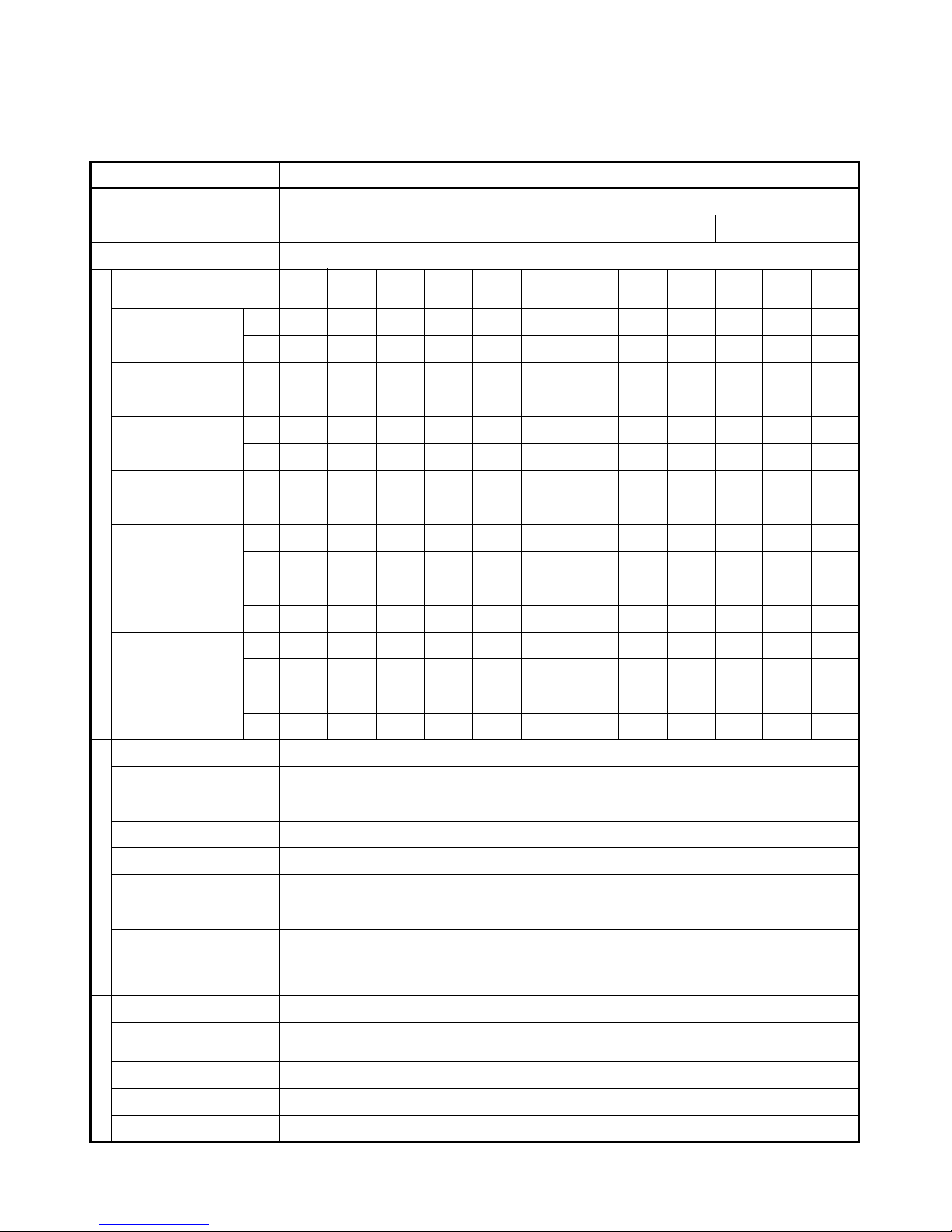

<VN-250SE, VN-350SE>

4. SPECIFICATIONS

Model

Type

Ventilation system

Rating

Current (A)

Power consumption (W)

Air volume (m³/H)

Static pressure (pa)

CharacteristicsConstruction

Noise (dB)

Temp. exchange rate (%)

VN-250SE VN-350SE

Concealed duct type

Heat exchange Normal ventilation Heat exchange Normal ventilation

50Hz 220 – 240V, 60Hz 220V

Extra

high high high high

0.48–0.5 0.46–0.48 0.37–0.39 0.47–0.5 0.46–0.480.37–0.390.63–0.65 0.59–0.6

50Hz

60Hz

0.59 0.55 0.39 0.59 0.55 0.39 0.85 0.75 0.67 0.83 0.74 0.67

104–119 99–114 79–90 103–119 98–114 79–90 137–154 124–137 117–128 133–151 119–132 113–125

50Hz

60Hz

128 118 78 128 118 7 7 178 149 132 176 145 131

250 250 170 250 250 170 350 350 280 350 350 280

50Hz

60Hz

250 250 135 250 250 135 350 350 240 350 350 240

90 80 37 90 80 37 95 65 42 95 65 42

50Hz

60Hz

125 100 30 125 100 30 155 90 43 155 90 43

27–28 26–27 21–22 27–28

50Hz

60Hz

28 26 21 28 26.5 21.5 33 30 22 33 30 23

75 75 77 ——— 75 75 77 ———

50Hz

60Hz

75 75 78 ——— 75 75 79 ———

High Low

Extra

High Low

26.5–27.5 21.5–22.5

Extra

31–32 29–30 25–26 31–32 30–31 26–27

High Low

0.56–0.57 0.61–0.63

Extra

0.57–0.6

High Low

0.54–0.56

(%)

In heating

In cooling

Enthalpy

exchange

rate

Frame

Motor

Sirocco fan

Heat exchanger

Filter

Adapter

Mounting pipe diam. (m m )

External dimension

(Length x Width x Height)

Product mass (kg)

Shape

Dimension

(Length x Width x Height)

Mass (kg)

Package

No. of stacked boxes

70 70 73 ——— 69 69 71 ———

50Hz

70 70 75 ——— 69 69 73 ———

60Hz

50Hz

63 63 66 ——— 66 66 69 ———

63 63 68 ——— 66 66 71 ———

60Hz

Zinc iron plate

4-pole capacitor dielectric motor (E type)

ABS resin

Combustion-proof sheet

Nonwoven fabric (Collection effect weighing method 82%)

ABS resin

Ø150

(mm)

(mm)

599 x 882 x 270 804 x 882 x 270

29 37

Corrugated board package/ventilator

335 x 1138 x 795 335 x 1138 x 1000

34 42

4

Accessory

• Installation Manual: 1, • Owner’s Manual: 1

– 8 –

<VN-500SE, VN-800SE>

Model

Type

Ventilation system

Rating

Current (A)

Power consumption (W)

Air volume (m³/H)

Static pressure (pa)

Characteristics

Noise (dB)

Temp. exchange rate (%)

VN-500SE VN-800SE

Concealed duct type

Heat exchange Normal ventilation Heat exchange Normal ventilation

50Hz 220 – 240V, 60Hz 220V

Extra

high high high high

0.86–0.9 0.79–0.81 0.72–0.73 0.84–0.88 0.76–0.77 0.71–0.73 1.51–1.54 1.48–1.5 1.44–1.46 1.47–1.5 1.45–1.48 1.41–1.43

50Hz

60Hz

1.14 1.0 0.81 1.12 0.96 0.8 2.05 1.92 1.68 2.04 1.87 1.68

188–214 169–188 151–166 184–210 161–182 145–164 316–347 309–329 302–327 309–337 300–325 297–316

50Hz

60Hz

244 202 162 243 196 161 424 391 347 417 387 346

500 500 370 500 500 370 800 800 650 800 800 650

50Hz

60Hz

500 500 310 500 500 310 800 800 575 800 800 575

105 70 38 105 70 38 140 110 70 140 110 70

50Hz

60Hz

165 85 33 165 85 33 190 100 50 190 100 50

33–34 31–32 25–26 34–35 32–33 26.5–27.5 38–39 36.5–37.5 32–34 38.5–39.5 37–38 33–35

50Hz

60Hz

35 31 23 36 33 24 39 36 31 39.5 37 31

75 75 77 ——— 75 75 76 ———

50Hz

60Hz

75 75 79 ——— 75 75 77 ———

High Low

Extra

High Low

Extra

High Low

Extra

High Low

(%)

In heating

In cooling

Enthalpy

exchange

rate

Frame

Motor

Sirocco fan

Heat exchanger

Filter

Adapter

Construction

Mounting pipe diam. (m m )

External dimension

(Length x Width x Height)

Product mass (kg)

Shape

Dimension

(Length x Width x Height)

Mass (kg)

Package

No. of stacked boxes

67 67 71 ——— 71 71 74 ———

50Hz

67 67 74 ——— 71 71 75 ———

60Hz

50Hz

62 62 67 ——— 65 65 68 ———

62 62 69 ——— 65 65 69 ———

60Hz

Zinc iron plate

4-pole capacitor dielectric motor (E type)

ABS resin

Combustion-proof sheet

Nonwoven fabric (Collection effect weighing method 82%)

Zinc iron plate

Ø200 Ø250

(mm)

(mm)

904 x 962 x 270 884 x 1322 x 388

43 71

Corrugated board package/ventilator

335 x 1218 x 1100 453 x 1538 x 1075

48 79

43

Accessory

• Installation Manual: 1, • Owner’s Manual: 1

– 9 –

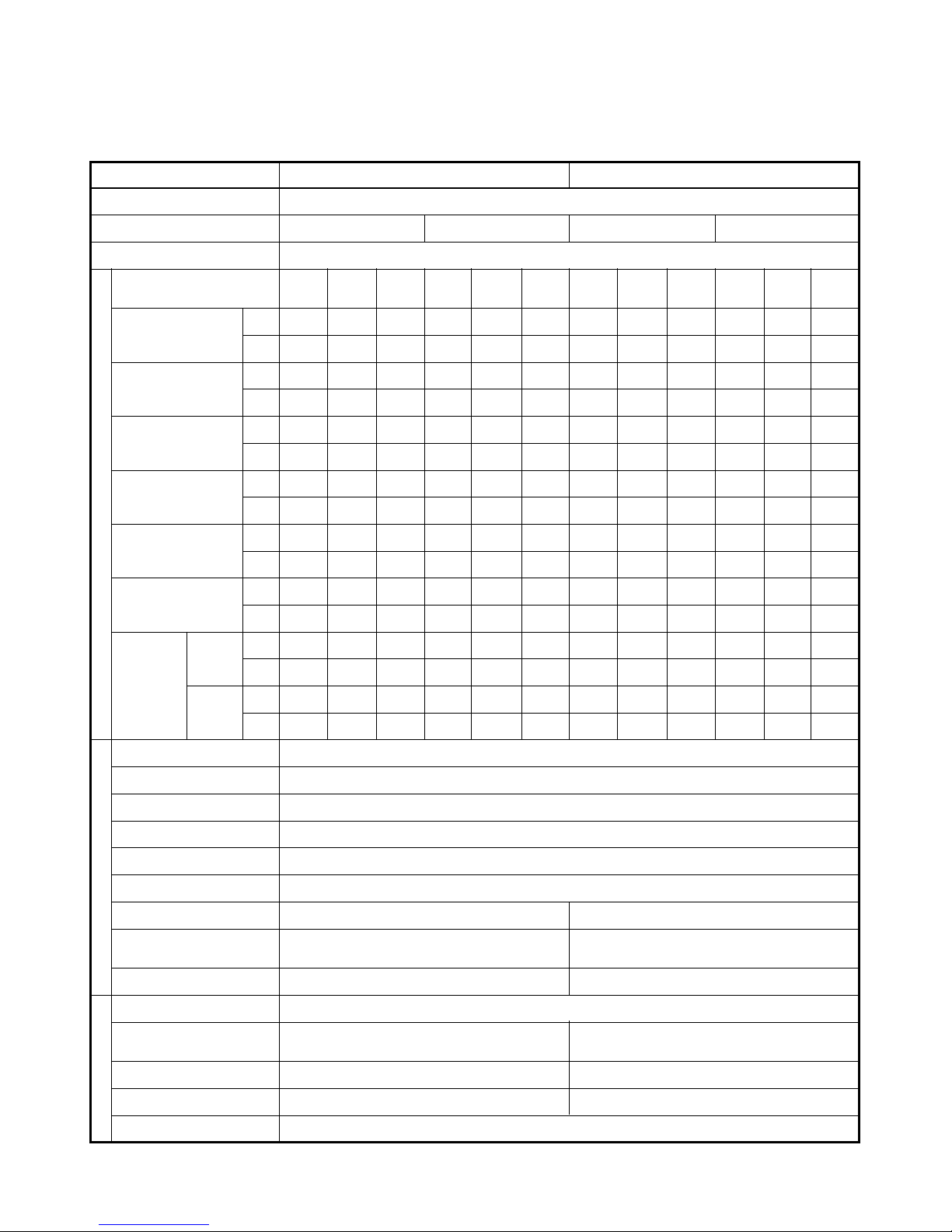

<VN-1KSAE>

Model

Type

Ventilation system

Rating

Current (A)

Power consumption (W )

Air volume (m²/H)

Static pressure (pa)

Noise (dB)

Characteristics

Temp. exchange rate (%)

Enthalpy exchange rate

Frame

Motor

Sirocco fan

Heat exchanger

(%)

In heating

In cooling

VN-1KSAE

Concealed duct type

Heat exchange Normal ventilation

50Hz 220 – 240V

Extra high High Low Extra high High Low

1.97–2.04 1.85–1.93 1.68–1.76 1.95–2.03 1.84–1.92 1.67–1.74

399–445 360–399 332–367 392–438 358–392 329–362

1000 1000 810 1000 1000 810

90 55 35 90 55 35

37.5–38.5 36–37 31–33 38–39 36.5–37.5 31.5–33.5

75 75 76 ———

71 71 73 ———

65 65 68 ———

Zinc iron plate

4-pole capacitor dielectric motor (E type)

ABS resin

Combustion-proof sheet

Filter

Adapter

Construction

Mounting pipe diam. (m m )

External dimension

(Length x Width x Height)

Product mass (kg)

Shape

Dimension

(Length x Width x Height)

Mass (kg)

Package

No. of stacked boxes

Accessory

(mm)

(mm)

Nonwoven fabric (Collection effect weighing method 82%)

Zinc iron plate

Ø250

1134 x 1322 x 388

83

Corrugated board package/ventilator

453 x 1538 x 1325

91

3

• Installation Manual: 1, • Owner’s Manual: 1

– 10 –

5. NAME AND DIMENSION OF EACH PARTS

<VN-250SE, VN-350SE, VN-500SE>

2

5

EA

(Exhaust Air)

A

IHJ

OA

(Outside Air)

CC

4

6

E

1

11

B

8

7

12

3

Model

VN-250SE

VN-350SE

VN-500SE

9

10

RA

(Room Air)

FG

SA

(Supply Air)

4-13 x 30

Oval Hole

Applicable Duct

P

N

Model

VN-250SE

VN-350SE

VN-500SE

Number

1

2

3

4

5

6

7

8

9

10

11

K

L

M

12

Note) Model VN-250SE has one Heat Exchange.

Nominal Diameter

Ø150

Ø200

Name

Frame

Adapter

Terminal

Inspection Cover

Fan Sirocco

Motor Fan

Heat Exchanger

Filter

Damper

Motor Damper

Ceiling Suspension Fixture

Electric Parts Lid

Quantity

1

4

1

1

2

2

2

2

1

1

4

1

Note

Note)

Unit: mm

PNMLKJIHGFECBA

Ø164Ø1442701591351423151421965581095882 599

Ø164Ø1442701591351624801621986081095882804

Ø210Ø194 7015913520250020219960890107962904

<VN-800SE, VN-1KSAE>

6

5

1

7

B

J

3

HIH

A

C

Model

VN-800SE

VN-1KSAE

EA

(Exhaust Air)

OA

(Outside Air)

11

2

4

E

4-13 x 30, Oval Hole

8

P

N

C

12

9

10

(Room Air)

(Supply Air)

Applicable Duct

M+2

VN-1KSAE

RA

FGG

SA

Model

VN-800SE

Number

1

2

3

4

5

6

7

8

9

K

L

M

10

11

12

Note) Model VN-1KSAE has one Heat Exchange.

Nominal Diameter

Ø250

Name

Frame

Adapter

Terminal

Inspection Cover

Fan Sirocco

Motor Fan

Heat Exchanger

Filter

Damper

Motor Damper

Ceiling Suspension Fixture

Electric Parts Lid

Quantity

1

4

1

1

2

2

3

2

1

1

4

1

Note

Note)

Unit: mm

PNMLKJIHGFECBA

Ø258Ø24538821819461242822819 9401250851322 884

Ø258Ø24238821819461267822819119012508513221134

– 11 –

6. WIRING DIAGRAM

<VN-250SE, VN-350SE,

VN-500SE>

Power Source

Divide the power lines running

to the switch and the main unit.

On the product. do not attach

more then one cable to each

terminal.

(1)

Switch

(To be procured

locally)

(2)

(3)

(4)

(5)

(6)

Operation Switch

(1) 0 (OFF)

(2) 1 (ON)

Air Flow Switch

(3) High

(4) Low

Function Select Switch

(5) Heat Exchange

Ventilation

(6) Normal Ventilation

To find out the function

of each switch.

CN–

SAFM

(LINE)

(NEUTRAL)

Red

Supply

Air Fan

Yellow

Blue

Low

High

1234567 12345678

1 2 3 4 5 6 7

Orange

Whte

Extra

High

Capacitor

Black

Common

Yellow

Low

CN–

EAFM

3

1

CN8 CN6 CN5CN7

NC

NO

RY5 RY2

CM

TM1

1

L

2

N

3

COMMON

4

LOW

5

HIGH

6

DAMPER

7

(Srcond main body)

TM1

1

L

Power Source

Third main body

N

LOW

HIGH

DAMPER

2

3

4

5

6

7

Exhaust

Air Fan

Blue

High

NO

CM

Damper

Red

Orange

Capacitor

Motor

MS

Whte

Extra

Black

High

4

1

NO

NC

CM

Common

RY3

Blue

12345

1234 51 2 3 4 5 6 78

RY4

Yellow

(Heat Exchange)

NC

NO

CM

White

(Normal)

RY5

Black

CN–DM

RY4

RY3

Model Power Source

VN-250SE

VN-350SE

220-240V~50Hz/

220V~60Hz

VN-500SE

RY2

Model Capacitor

VN-250SE 2.0µF 450VAC

VN-350SE 3.0µF 450VAC

VN-500SE 3.5µF 450VAC

<VN-800SE, VN-1KSAE>

Power Source

Divide the power lines running

to the switch and the main unit.

On the product. do not attach

more then one cable to each

terminal.

Operation Switch

(1) 0 (OFF)

(2) 1 (ON)

Air Flow Switch

(3) High

(4) Low

Function Select Switch

(5) Heat Exchange

Ventilation

(6) Normal Ventilation

To find out the function

of each switch.

(NEUTRAL)

(1)

(2)

(3)

(4)

(5)

(6)

Switch

(To be procured

locally)

CN–

SAFM

(LINE)

Third main body

Red

Supply

Air Fan

Orange

Yellow

Blue

Low

High

Whte

Extra

High

1234567 12345678

1 2 3 4 5 6 7

3

1

CN8 CN6 CN5CN7

NC

NO

RY5

CM

L

N

COMMON

LOW

HIGH

DAMPER

(Srcond main body)

Power Source

L

N

COMMON

LOW

HIGH

DAMPER

Capacitor

Black

Common

1

2

3

4

5

6

7

1

4

6

Yellow

Low

CN–

EAFM

RY2

TM1

2

3

5

7

TM1

Exhaust

Air Fan

Blue

High

NO

CM

4

1

NC

Red

Orange

Whte

Extra

High

Damper

Capacitor

Motor

MS

Black

Common

Blue

12345

1234 51 2 3 4 5 6 78

RY4

Yellow

(Heat Exchange)

NC

NO

CM

White

(Normal)

Black

CN–DM

RY4

NO

RY3

CM

NC

NO

RY1

CM

RY1

RY5

RY3

Model Power Source

VN-800SE

VN-1KSAE

220-240V~50Hz/

220V~60Hz

220-240V~50Hz/

RY2

Model Capacitor

VN-800SE 8.0µF 450VAC

VN-1KSAE 10.0µF 450VAC

– 12 –

7. OWNER’S MANUAL (EXTRACT)

7-1. Specific Caution Items

7-1-1. Checking Location of Installation

This Energy Recovery Ventilators have been designed especially for use in offices, conference rooms, etc.

Please check to ensure that neither the main unit nor the inlet-outlet grill are installed in any of the following locations.

Locations exposed to high temperatures or direct flame.

Avoid installing the Heat Exchange

Ventilators or the inlet-outlet grill in

locations which reach temperatures

of 40°C or above.

Usage under high temperature

conditions may cause distortion of

the filter or Heat Exchanger or

motor burn-out.

40˚C

Make sure that access is provided so that filter and Heat

Exchanger maintenance and periodic spot checks of

the unit can be easily carried out.

(Refer to the Model Installation for its space)

Locations with high humidity.

Do not install in high humidity

locations such as bathrooms.

Doing so may cause a breakdown

of the unit or an electric shock.

Locations with large amounts of oily

smoke, such as food preparation

areas.

The unit will become inoperable if

the filter or Heat Exchanger

become clogged with oil.

Interior Intake Vent

Oily

smoke

Do not install the unit in locations such as machinery or

chemical plants where it will be exposed to noxious

gases containing acids, alkali, organic solvents, paint

fumes, etc., to gases containing corrosive ingredients,

or where dust or oil mist will be produced.

If there are any problems concerning the location or installation of the unit, please consult either store from which it

was purchased or the agent who installed it.

7-1-2. When Using

Always be sure to use a filter.

Failure to do so may cause dust and dirt to build up on

the heat exchange element, lowering its efficiency and

rendering it inoperable.

Operate the switch with certainty.

In particular, suddenly turning the switch on and off will

not only cause improper operation of the unit, but will

also obversely affect the relay inside the switch, and

may damage it.

– 13 –

7-2. Model Installation

Outside Intake Duct

Pipe Hood

Supply Air Duct

Ceiling Suspension Bolt

Note that when installing a unit body

upside down, its printed indication is

in a reversed position.

7-2-1. Method of Use

• Use the operation switch to operate the unit.

0 (OFF) ..............the unit stop.

OA

(Outside Air)

(Exhaust Air)

Heat Insulation

Material

Pipe Hood

Room Intake Duct

EA

Room Intake Opening

(Supply/Exhaust Air Grill)

Exhaust Air Duct

RA

(Outside Air)

Inside Supply Opening

(Supply/Exhaust Air Grill)

1 (ON) ................the unit operates.

• Use the Air Flow switch to set to the desired air flow.

High ...................Turns to high air volume.

Low....................Turns to low air volume.

• Use the Function Select switch to set the ventilation mode.

Heat Exchange Ventilation Mode .....Open air is thermal-exchange with room air to bring it closer to a room

temperature and humidity, before taking it in the room.

Normal V entilation Mode ..................T o intake open air as it is.

SA

(Supply Air)

7-3. Maintenance Method

In order to prevent the reduced effectiveness of your Heat Exchange Ventilators, be sure to clean dirt and dust from the

filter and Heat Exchanger at regular intervals.

CAUTION

Be sure to turn the power off, and to

keep the exclusive breaker off

before carrying out maintenance

activities.

Switch

Turn off

Do not use the following items for

cleaning.

Gasoline

Thinner

Benzene

Do not immerse the filter or other

resin components in water 60°C or

above.

Water 60

or above

˚C

Avoid using heat to dry the filter, as

it may cause changes in shape or

quality.

Filter

Never use water on the motor, the

switch, or the Heat Exchanger.

Motor

Switch

Heat

Exchange

Element

Always be sure to use a filter.

Failure to do so may cause dust

and dirt to build up on the Heat

Exchanger, lowering its efficiency

and rendering it inoperable.

Metal brush

– 14 –

7-4. Maintenance Method

7-4-1. Model VN-250SE/VN-350SE/VN-500SE

• Stop the operation and keep the exclusive breaker “OFF”.

• Cleaning the filter (When required)

1) Enter the ceiling from the Inspection Opening for the Heat

Exchange Ventilators, and remove the screw on the inspection

cover.

2) Holding the Inspection Cover, turn two pieces of knob for 90°

and remove the cover.

3) There is a filter below the Heat Exchanger at two places,

respectively. Pull it toward you.

4) Either lightly strike the removed filter with your hand or

vacuum it with a vacuum cleaner to remo ve the dirt.

If it is very dirty, swish it back and forth in a solution of

lukewarm water and dish-washing (neutral) detergent.

5) Install the filter after thoroughly allowing it to dry naturally.

CAUTION

Avoid using heat to dry the filter, as this may cause changes in

the shape or quality of the filter.

Knob Position

Hook

Hook

Inspection

Cover

Inspection

Cover

• Whenever the filter was damaged, order the sales shop or the

engineering office. (Separately sold)

• Cleaning the Heat Exchanger.

(If you find it too much stained, clean it.)

1) Remove the filters.

2) Remove the two Heat Exchanger from the unit.

(Model VN-250SE has one Heat Exchange .)

CAUTION

• The weight of the Heat Exchanger is as shown in the table

below .

Hold it firmly to ensure that you do not drop it.

Model

VN-250SE

VN-350SE

VN-500SE

Weight (kg/piece)

4.5

3.4

3.7

Pieces to be used

1

2

2

When installed

(Closed)

Heat Exchanger

Filter

To remove

(Open)

– 15 –

3) Use a vacuum cleaner to remove dust and dirt from the

element’s surface.

CAUTION

• Use a brush attachment on the vacuum cleaner nozzle.

Clean with a light, brushing action.

Avoid using a hard nozzle as it may disfigure the heat ex-

change foils.

• Never use water to clean the Heat Exchanger.

• Whenever the Heat Exchanger was damaged, order the sales

shop or the engineering office. (Separately sold)

4) When cleaning is completed, return the Heat Exchanger and

filter to their former positions, and close the Inspection cover

and tighten the screw.

CAUTION

• Make absolutely sure to install the filter with an indication of

“ ” turned to wart the Heat Exchanger side.

Failure to do so will lead to clogging of the Heat Exchanger

foils and reduced performance.

• Insert the heat exchanger right side up, with the label marked

facing toward you.

ñ

Nozzle

Mark

– 16 –

7-4-2. Model VN-800SE/VN-1KSAE

Heat Exchanger

Grooved Rail

When installed

(Closed)

To remove

(Open)

Filter

Hook

Inspection Cover

Hook

Inspection Cover

Knob Position

• Stop the operation and keep the exclusive breaker "OFF".

• Cleaning the filter (When required)

1) Enter the ceiling from the Inspection Opening for the

Heat Exchange Ventilators, and remove the screw on

the inspection cover.

2) Holding the Inspection Cover, turn two pieces of knob

for 90° and remov e the cover.

3) There is a filter at two places, respectively.

Pull it toward you.

4) Either lightly strike the removed filter with your hand or

vacuum it with a vacuum cleaner to remo ve the dirt.

If it is very dirty, swish it back and forth in a solution of

lukewarm water and dish-washing (neutral) detergent.

5) Install the filter after thoroughly allowing it to dry natu-

rally. (Install them to fit well with the grooved rail)

CAUTION

Avoid using heat to dry the filter, as this may cause

changes in the shape or quality of the filter.

• Whenever the filter was damaged, order the sales shop

or the engineering office. (Separately sold)

• Cleaning the Heat Exchanger.

(If you find it too much stained, clean it.)

1) Remove the four Heat Exchanger from the unit.

(Model VN-800SE has three Heat Exchange.)

CAUTION

• The weight of the Heat Exchanger is as shown in the

table below.

Hold it firmly to ensure that you do not drop it.

Model

VN-800SE

VN-1KSAE

Weight (kg/piece)

4.0

4.0

Pieces to be used

3

4

– 17 –

2) Use a vacuum cleaner to remove dust and dirt from the

element's surface.

CAUTION

• Use a brush attachment on the vacuum cleaner nozzle.

Clean with a light, brushing action.

Avoid using a hard nozzle as it may disfigure the heat ex-

change foils.

• Never use water to clean the Heat Exchanger.

• Whenever the Heat Exchanger was damaged, order the sales

shop or the engineering office. (Separately sold)

3) When cleaning is completed, return the Heat Exchanger and

filter to their former positions, and close the Inspection cover

and tighten the screw.

CAUTION

• Make absolutely sure to install the filter with an indication of

“ ” turned toward the Heat Exchanger side.

Failure to do so will lead to clogging of the Heat Exchanger

foils and reduced performance.

• Please insert so that the stamp “ ” to be toward you.

Nozzle

Stamp

7-5. After-sales Service

• Request for Spot Checks

To ensure safe, correct usage, we suggest that you consider a maintenance contract.

For details, inquire at the store where you bought your unit, or at the agent which installed it.

• If You Think It’s Broken

Examine the unit as shown in the table below, and if you find any irregularities, shut it off immediately and

contact the store where you bought your unit or the agent who installed it to request servicing (or consultation).

Symptom

• No activity, even when

the switch is on.

• No air comes out.

• Is the fuse blown or the breaker tripped?

• Is the power out?

• Check whether or not there is dust on the filters and the Heat Exchanger.

(Clean it according to the Maintenance Method mentioned.)

Where to look

– 18 –

8. INSTALLATION MANUAL (EXTRACT)

8-1. Cautions for Operation

Never fail to make the inspection opening at the specific place on the ceiling so you can perform the constant cleaning or the equipment checking of filter and Heat Exchanger .

• The inspection opening shown below is necessary to clean the Heat Exchanger and the filter as required. If not cleaned, they are likely to get clogged, resulting in degradation of performance.

RA

(Room Air)

EA (Exhaust Air)

Heat Exchanger

A

Unit Body

SA

(Supply Air)

OA (Outside Air)

600

Maintenance Space

Inspection Opening : 450 Inspection Opening : 450

(For the inspection of Filters,

Heat Exchanger, Fans,

Motors and Damper.)

Heat Exchanger

RA

(Room Air)

EA (Exhaust Air)

Unit Body

SA

(Supply Air)

OA (Outside Air)

600A

Maintenance Space

(For the inspection of Filters,

Heat Exchanger, Fans,

Motors and Damper.)

Note) Model VN-250SE has one Heat Exchange. Note) Model VN-1KSAE has four Heat Exchange.

Unit : mm Unit : mm

Model

VN-250SE

VN-350SE

VN-500SE

A

599

804

904

Model

VN-800SE

VN-1KSAE

A

884

1134

• This Energy Recovery Ventilators should be installed at the place where a larger space than the sizes

shown below can be secured for the ceiling space.

• Don't install it near the water-heater.

• Refrain from the following duct installing works.

(1) Excessive bending

20

A

(2) Multi-times bending

Model

VN-250SE

VN-350SE

VN-500SE

– 19 –

Ceiling Space A

320

(3) Making the connecting duct smaller

Model

VN-800SE

VN-1KSAE

Unit : mm

Ceiling Space A

440

• Do not use in bathrooms or food preparation areas etc.

If you use the unit at the place of much soot and high humidity, the filter or the Heat Exchanger gets clogged

and disables you to use it.

• Use the Heat Exchange V entilator s in the ambient temperature of 40°C or less.

Never install the unit at the place where the flame likely reaches directly the unit. If you use it at the atmosphere of

more than 40°C for hours , it is likely to cause deterior ation or def ormation or damage of the resin part.

• Be careful of dewing and frosting.

As shown in the figure to the right, suppose a high temp. absorbing air condition A and a low temp absorbing air condition B are plotted on the air line

figure, then a high temp air A is heat-exchanged by the unit and goes out of

the saturation curve as shown by Point C. In this case, the unit will be dewed

or frosted. To avoid this, y ou are required to heat a low temp air B up to B' so

as to get C' below the saturation curve, before using the unit.

B

Saturation

curve

C

C'

B'

Dry-bulb temperature (˚C)

8-2. Local Procurements

• Switches are to be locally procured.

We recommend that you use a switch having more than 3mm distance to break contact and more than 15A

rated current.

A

Absolute humidity (kg/kg’)

8-3. Reference Sketch

Pipe Hood

(Outside Air)

OA

Outside Intake Duct

EA

(Exhaust Air)

Heat Insulation

Material

Pipe Hood

Ceiling Suspension Bolt

Room Intake Duct

Room Intake Opening

(Supply/Exhaust Air Grill)

Exhaust Air Duct

Supply Air Duct

RA

(Outside Air)

Inside Supply Opening

(Supply/Exhaust Air Grill)

Use conditions

Outdoor air conditions : Temperature range –10°C~40°C, relativ e humidity 85% or less

Indoor air conditions : Temperature range –10°C~40°C , relativ e humidity 85% or less

Installation requirements: Same as the indoor air conditions

• Indoor air here means air in air-conditioned living rooms. Its use in refrigerators or other places where

temperature can fluctuate greatly is prohibited even if a temperature range is acceptable.

SA

(Supply Air)

Example: Indoor air conditions

During cooling period : Temperature 27°C, relative humidity 50%

During heating period : Temperature 20°C, relativ e humidity 40%

– 20 –

8-3. Installation Method

8-3-1. Model Installation

• You are required to prepare the ceiling suspension bolts, nuts and washers .

• Install the unit firmly and horizontally enough to support its weight. (Fig. 1)

• If you do not fit it firmly, it is not only dangerous but also easily vibrated.

If it is not fitted horizontally, the damper unit becomes defective in operation.

CAUTION

• When you are required to be cautious on prevention of vibration,

we recommend you to use the anti-vibration ceiling suspension

fixtures.

• Never fail to make an inspection opening with 450 mm or more at

the place shown on the paragraph of “Cautions For Operation”, so

that you can inspect filters, Heat Exchanger, power source and

motors.

Ceiling Suspension Bolt

(Ø10 to Ø12)

Fig. 1

Nut

Washer

Ceiling Suspension

Fixture Washer

Nut

8-3-2. Cautions on Installing The Unit Body Upside Down

• Re-fit the ceiling suspension fixture in an opposite side. (If they are left as it is, the foolproof function of ceiling

suspension bolts do not work and will cause the danger of dropping of the unit.)

• Printed indication is in a reversed position.

In particular, be careful of the arrow mark [ ñ ] showing the direction of inserting a Heat Exchange.

8-4. Electric W orks

Have a specialized working contractor perform wiring in accordance with the laws and regulations of the country

concerned.

• Connect the broken lines in the wiring diagram.

• We recommend that you use a switch having more than 3 mm distance to break contact and more than 15A

rated current.

Damper

RY3

MS

Blue

12345

1234 51 2 3 4 5 6 78

RY4

Motor

Yellow

(Heat Exchange)

NC

NO

CM

White

(Normal)

RY5

RY2

Black

CN–DM

RY4

RY3

Model Power Source

VN-250SE

VN-350SE

VN-500SE

Model Capacitor

VN-250SE 2.0µF 450VAC

VN-350SE 3.0µF 450VAC

VN-500SE 3.5µF 450VAC

220-240V~50Hz/

220V~60Hz

Divide the power lines running

to the switch and the main unit.

On the product. do not attach

more then one cable to each

terminal.

Operation Switch

(1) 0 (OFF)

(2) 1 (ON)

Air Flow Switch

(3) High

(4) Low

Function Select Switch

(5) Heat Exchange

Ventilation

(6) Normal Ventilation

To find out the function

of each switch.

Power Source

(NEUTRAL)

(1)

(2)

(3)

(4)

(5)

(6)

Switch

(To be procured

locally)

Red

Supply

Air Fan

Orange

Yellow

Blue

Low

High

Whte

Extra

Black

High

3

1

NC

NO

CM

L

N

COMMON

LOW

HIGH

DAMPER

(Srcond main body)

L

N

LOW

HIGH

DAMPER

Common

1234567 12345678

CN–

1 2 3 4 5 6 7

SAFM

(LINE)

CN8 CN6 CN5CN7

RY5 RY2

Power Source

Third main body

Capacitor

CN–

EAFM

1

2

3

4

5

6

7

1

2

3

4

5

6

7

Yellow

Low

TM1

TM1

Exhaust

Blue

High

NO

CM

Air Fan

Red

Orange

Whte

Extra

High

4

1

NO

NC

CM

– 21 –

Capacitor

Black

Common

Divide the power lines running

to the switch and the main unit.

On the product. do not attach

more then one cable to each

terminal.

Operation Switch

(1) 0 (OFF)

(2) 1 (ON)

Air Flow Switch

(3) High

(4) Low

Function Select Switch

(5) Heat Exchange

Ventilation

(6) Normal Ventilation

To find out the function

of each switch.

Power Source

(LINE)

(NEUTRAL)

(1)

(2)

(3)

(4)

(5)

(6)

Switch

(To be procured

locally)

Red

Supply

Capacitor

Air Fan

Orange

Yellow

Blue

Low

High

Whte

Extra

Black

High

1234567 12345678

CN–

1 2 3 4 5 6 7

SAFM

CN8 CN6 CN5CN7

RY5

Power Source

Third main body

Common

3

1

NC

NO

CM

1

L

2

N

3

COMMON

4

LOW

5

HIGH

6

DAMPER

7

(Srcond main body)

L

N

COMMON

LOW

HIGH

DAMPER

CN–

EAFM

TM1

1

2

3

4

5

6

7

Yellow

Low

RY2

TM1

Exhaust

Air Fan

Blue

High

NO

CM

Damper

Capacitor

Black

Common

NC

RY1

RY3

MS

Blue

12345

1234 51 2 3 4 5 6 78

RY4

Motor

Yellow

(Heat Exchange)

NC

CM

Black

White

(Normal)

CN–DM

NO

RY4

RY3

RY1

RY5

RY2

Model Power Source

VN-800SE

VN-1KSAE

Model Capacitor

VN-800SE 8.0µF 450VAC

VN-1KSAE 10.0µF 450VAC

220-240V~50Hz/

220V~60Hz

220-240V~50Hz

Red

Orange

Whte

Extra

High

4

1

NO

NC

CM

NO

CM

• Use the polyvinyl chloride insulated and sheathed cables for fixed wiring having

1.6 mm to 2.0 mm in diameter or 2.0 mm² to 3.1 mm² in conformity with IEC 60227-4.

Ring

terminal

(Carry out the work based on the laws, regulations and technical standards of the

country concerned.)

Secure wire

• Follow the following steps for wiring.

• Unfasten two cover-fixing screws of the electrical equipment box,

open the box cover, and then connect wiring firmly.

properly

Stranded

wire

• Fit the cables from the terminal firmly with a cord clamber.

• When you need much airflow or a duct is long, change the wire connection from High to Extra High.

• Unfasten two cover-fixing screws of the electrical equipment box and open the box cover.

• Change CN6 to CN5 and CN8 to CN7 inside the Electric Parts Lid.

• It is possible to operate up to 10 units from one switch set.

Switching Connector

(CN8) (CN8) (CN8) (CN8)

Cover-fixing screws of the

Electric Parts Lid

Electric Parts Lid

CAUTION

• Use the power source corresponding to the name plate. Using a different power source may cause the

motor to burn out.

• Carry out grounding work according to the laws and regulations of the country concerned and the technical

standard.

• After completion of wiring, check again there are no wrong wirings before power ON.

– 22 –

8-5. Duct Installation

• Wind the junction of an adaptor and a duct with an aluminum tape firmly to prevent any air leakage.

• The room intake opening should be positioned as far as possible from the inside supply opening.

• Use the specified ducts. (See the Name and Dimension of Each Part.)

• Install two outdoor ducts so they will be in the down gradient toward outside to prevent water from coming in.

(Gradient: 1/100~1/50) (Fig. 2)

• Never fail to heat-insulate two outdoor ducts (including outside air and exhaust air duct) to prevent dewing.

(Material: Glass Wool, Thickness-25mm) (Fig. 2)

• When you want to pierce the metal duct through the metal lath or the wire lath or the metal plate of the wooden

facility, do not forget to insulate electrically between the duct and the wall.

(Refer to the laws and regulations of the country concerned and the technical standard.)

Heat Insulation Material (Insulate the Adapter and Aluminum Tape.)

Outside Intake Duct, Exhaust Air Duct

Gradient

(1/100 ~ 1/50)

Aluminum Tape Aluminum Tape

Fig. 2

8-6. Pilot Running

• On completion of installing works, never fail to check wirings and perform a pilot running.

• After completion of wiring, power ON and perform a pilot run according to the following steps for checking a

airflow condition and a damper operation.

• Check the opening and closing of a damper by opening the inspection cover of the side of the unit.

• Model VN-800SE, VN-1KSAE, two Fan Motors are stopped during an operation of the damper .

Each switch setting

Function Select Switch Air Flow Switch

1

2

Heat Exchange

Normal Ventilation

High (Extra High)

High (Extra High)

Low

Low

Airflow condition

Check if the air from inside

supply opening and the one

from room intake opening are

set to High (Extra High) and to

Low, respectively

Checking items

Damper

Open

(A Damper is beyond)

Close

(A Damper is near)

• In case that any abnormality occurs in a pilot running, its conceivable cause would be a wrong wiring.

Don’t lose time to switch the exclusive breaker to OFF and re-wire correctly.

Otherwise, it is likely to cause an electric shock.

– 23 –

9. HO W T O DIAGNOSE THE TROUBLE

<VN-250SE, VN-350SE, VN-500SE, VN-800SE, VN-1KSAE>

Phenomenon

Motor fan does not

revolve.

Abnormal sound is heard

from inside the main unit.

Check point

• Wall switch

• Lead wire

• Connecting section

• Motor fan

• Turning section of fan

sirocco

• Capacitor

• Relay

• Power supply

• Terminal block of wall

(Assembly of electric

parts stool)

• Motor fan

Cause

Connection failure, Incorrect connection

Wire disconnection

Contact failure

Motor revolution section

(Bearing) is locked.

Motor winding or temp. fuse

is disconnected.

Turning section of fan

sirocco is locked.

Capacitor trouble

Relay trouble

Abnormal power is applied.

Miswiring

Electromagnetic sound

(Buzzing of motor)

Measures

• Replace wall switch. Correct

connection.

• Replace motor fan.

• Connect surely. (Assembly of

electric parts stool, Fan)

• Replace motor fan.

• Remove locked part.

• Replace capacitor.

• Replace relay.

• Check power supply.

• Re-wire according to the

wiring diagram.

• Replace motor fan.

Motor fan revolution is

weak.

Damper does not open/

close.

• Fan sirocco

• Screws of each part of

main unit

• Filter

• Heat exchanger

• Capacitor

• Wall switch

• Lead wire

• Motor damper

• Damper

• Connector assembly

Bearing failure

Incomplete attachment of

fan sirocco

Suction of foreign matter

Deformed fan sirocco

Loosening of screw

(Resonance due to incomplete tightening)

Clogging of filter

Clogging of heat exchanger

Capacitor failure

Contact failure

Contact failure

Winding of motor damper is

disconnected.

Catching at sliding section

Contact failure

• Attach fan sirocco firmly.

• Remove foreign matter.

• Replace fan sirocco.

• Tighten screw firmly.

• Clean filter.

• Clean heat exchanger

• Replace capacitor.

• Ensure contact.

• Ensure contact.

• Replace motor damper.

• Correct catching.

• Replace connector assembly.

– 24 –

10. HOW TO REPLACE THE MAIN PARTS

Turn off the power supply.

Prohibition of modification.

Use appropriate repair parts.

WARNING

• Be sure to turn off the power supply of distribution panel, power board,

and etc. before the work when power-ON is unnecessary such as a case of

disassembling.

Otherwise an electric shock may be caused even if the wall switch is turned off

because it is a single cut switch.

• Do not modify the product.

Also do not use the disassembled, modified or repaired parts.

Otherwise it causes a fire, electric shock or injury.

• Use the substitute parts corresponded to the model for repair .

It causes an abnormal operation or a trouble resulting in leakage or fire, that is a

cause of customers’ disaster.

Use gloves.

CAUTION

• Use the protective materials such as gloves, etc. for check/repair inside the

unit.

If touching inside the unit with bare hands, an injury may be caused.

– 25 –

Position/Part Replace/Assembly procedure Description

WARNING

• Be sure to turn off the power supply of distribution panel, power

board, and etc. before the work when power-ON is unnecessary

Turn off

the power

supply.

such as a case of disassembling.

Otherwise an electric shock may be caused even if the wall switch is

turned off because it is a single cut switch.

• Filter 1), 2)

• Heat exchanger 1),

3)

• Fan sirocco 1) to 8)

• Motor fan 1) to 9)

• Damper

1), 2), 3),10), 11)

• Capacitor

12), 13), 14), 15)

• P.C. board assembly

(including terminal

block and relay)

12) to 16)

1) Remove the screw, turn the lock

knob by 90°, and then remove the lid

maintenance.

2) Remove the filter.

3) Remove the Heat Exchanger.

The weight of the heat

exchanger is 3 to 7kg.

Hold the Heat Exchanger hard

without dropping it.

4) Remove the screw and the rail.

5) Remove the partition board.

The figure is for VN-250SE. The configuration

differs according to the model.

Lid

maintenance

Screw

Heat

Exchanger

Screw

Partition

board

Lock

knob

Filter

6) Remove the connector.

7) Remove the screw fixing the fan unit.

8) Remove the nut and the fan sirocco.

Rail

Connector

Fan unit

Screw

Nut

Fan

sirocco

– 26 –

Position/Part Replace/Assembly procedure

9) Remove the screw fixing the motor

fan to remove the motor fan.

Description

Screw

Motor fan

10) Remove the connector of the damper

ass’y.

11) Remove the fixing screw of the

damper ass’y and slide the damper

leftward to remove it.

12) Remove the screw of the lid electric

parts.

Damper

Connector

Limit switch

Screw

Damper ass’y disassembling

Cam

Motor

damper

Screw

13) Open the lid electric parts.

14) Remove FASTON terminal connected

to the capacitor.

15) Remove the screw to remove the

capacitor.

16) Remove the connector and P.C. board

ass’y.

Perform wiring correctly according to

the wiring diagram.

Mounting

Perform mounting in the reverse procedure of removal.

– 27 –

FASTON

terminal

P.C. board

ass’y

Lid electric

parts

Screw

Capacitor

11. CHECK WHEN REPAIR WORK COMPLETED

Check after repair work

Check after reinstallation

WARNING

• After repair work, check whether there is a trouble or not referring to the

check points.

If the check is not performed, a fire, an electric shock or an injury occurs.

Before check, turn off the power supply of the distribution panel and power

board.

• After repair work, perform a test run to check whether there is smoke/

abnormal sound or not.

If the check is not performed, a fire, an electric shock or an injury occurs.

• After reinstallation, check the following items.

• The earth wire is correctly connected.

• The power supply cord is not pinched in the product.

• The installation is stable without inclination or wavering.

If the check is not performed, a fire, an electric shock or an injury occurs.

[Check Point]

When the product was repaired (replacement of parts, etc.), be sure to perform a test run and check there is no

trouble on the following items.

Item

(1) Insulation resistance

(2) Parts specified to

safety

(3) Process on lead

wire

(4) Tightening of screws

(5) Removal of foreign

matters in the unit

Check/Judgment

When measuring the insulation resistance between the common

pin of the terminal and the metal section of the main unit under

condition that the power supply cord is not connected, the insulation resistance keeps 10MΩ or more.

Especially check the following cases sufficiently.

• When the electric parts were replaced.

• Articles used at place with high humidity.

• Products used for 5 years or more.

If a part other than specified part is used, replace it with the

specified one.

Check whether there is slack or excessive tension of the lead wire

or not. Check the lead wire is connected firmly and the binding

process is surely performed.

Check the screws are surely tightened.

Check whether soldering chip, wire wastes, screws, and etc. are

remained or not in the unit.

And check there is no accumulation of dust in the unit.

Measuring device/

Sub-material

DC500V megger

(6) Check power supply

cable.

(7) Check mounting

status.

Check the damage of the terminal block.

Check whether the specified power supply cable is used or not.

Check strength of the product mounting section.

There is no loosening of the mounting nut, etc.

– 28 –

12. Q & A FOR HEAT EXCHANGE VENTILATORS

(Users are responsible for the following contents.)

Question

u Fan does not operate.

u Fan does not ventilate

(suction air).

Answer

•Is the electric wiring securely performed?

For this model, the terminal block for connection of cables is provided

to the side of the main unit. The connecting works between the power

supply and the switch and between the switch and the main unit are

performed by the special dealers. Incorrect cabling from the specified

switch and the switches disables to adjust the air volume. Therefore,

check the cable connection.

Are not the various filters clogged with dust, etc.?

•

Perform cleaning described in Owner’s Manual.

Is not the heat exchanger clogged with dust, etc.?

•

Especially in case that the mounting direction of the product is incorrect (indoor side and outdoor side), dust, etc. is clogged in a short time

because the indoor air and outdoor air do not pass through the filter but

flow directly in the heat exchanger.

SA

indoor side Outdoor (Out air) side

RA

Air flow

OA

EA

u Drop of heat exchange

effect

u Water drops on the

ceiling surface.

u Dew condensation

generates on surface of

the main unit.

Does not generate the dew condensation on the heat exchanger?

•

In the heat exchange, the temperature difference between indoor and

outdoor is widened. Therefore, in the heat exchanger , the de w condensation generates according to some conditions of temperature and humidity, and the dew condensation/freezing generates according to some

conditions of outdoor air . In these cases, the status returns to the original

status when temperature of the outdoor air ascends and thaws. For the

measures, heating of air at low-temperature side is necessary as described in Installation Manual.

Are thermal insulation process applied to 2 duct pipes (Air suction

•

OA and air dischar ge EA) at outdoor side?

Be sure to apply thermal insulation because the temperature difference

between indoor and outdoor is widened and the dew condensation may

generate according to some conditions of temperature and humidity.

Is the product installed horizontally?

•

If the product is slanted, various troubles may be caused.

Is not the ventilator operated with the normal ventilation in the

•

winter season?

If the ventilator is operated with the normal ventilation in the winter

season, the surface of the main unit is cooled with the outdoor air

resulting in dew condensation on the surface.

– 29 –

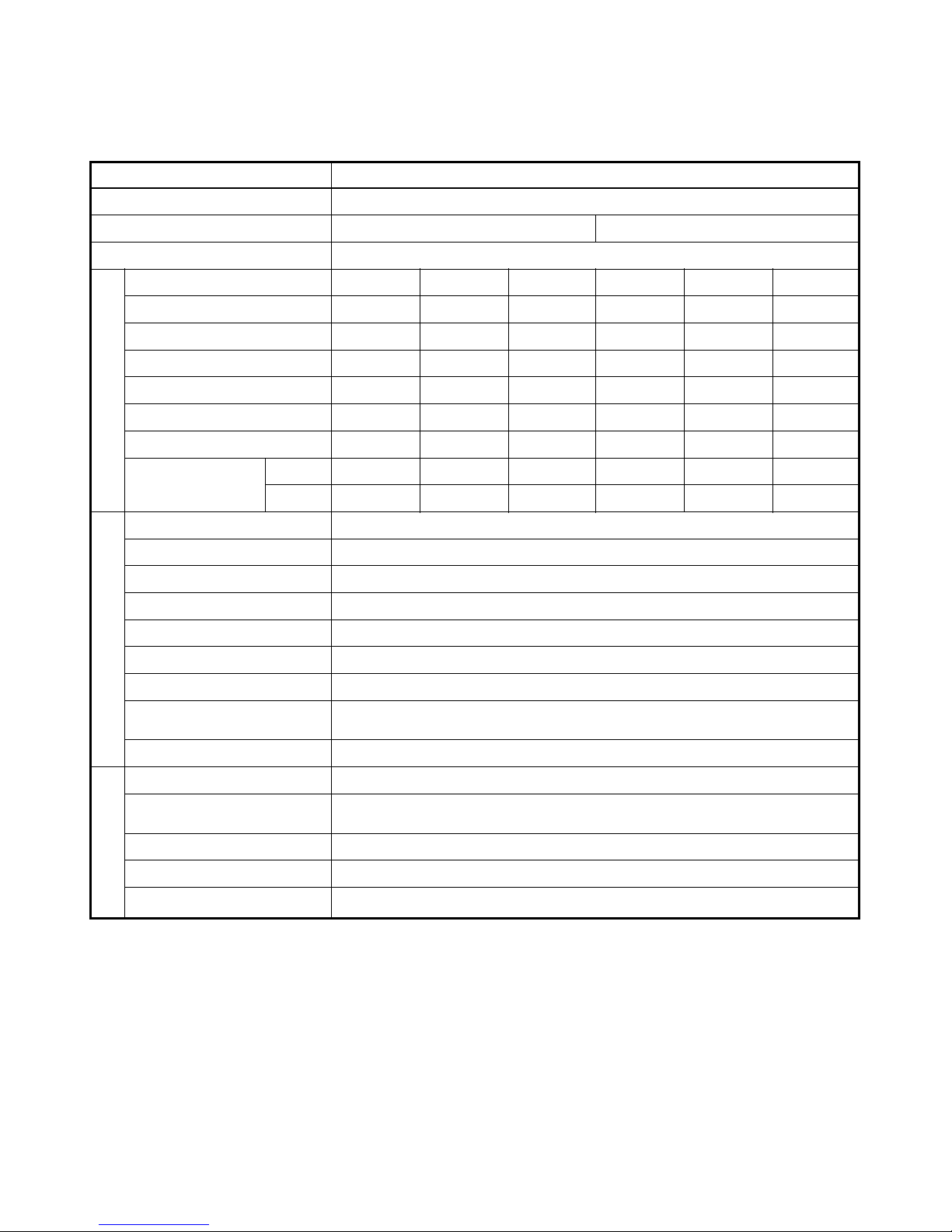

13. EXPLODED VIEWS AND PARTS LIST

19,18

1,2,10

50

31,32,

33,34,35

51

52,53

11,12

13,14,

15,16,17

20

3,4,5

45,46,

47,48,49

13,14,15,

16,17

26,27,

28,29

30

36

31,32,

33,34,35

6,7,8,9

43,44

42

21,22,

23,24,25

37,38,

39,40,41

1,2,10

18,19

54,55,

56,57,58

– 30 –

Location

No.

Part No. Description

Location

No.

Part No. Description

1 41120433 Fan, Sirocco

(VN-250SE, VN-350SE)

2 41120434 Fan, Sirocco

(VN-800SE, VN-1KSAE)

3 41118431 Adaptor

(VN-250SE, VN-350SE)

4 4118432 Adaptor (VN-500SE)

5 4118448 Adaptor

(VN-800SE, VN-1KSAE)

6 41114829 Heat Exchanger (VN-350SE)

7 41114830 Heat Exchanger (VN-250SE)

8 41114831 Heat Exchanger (VN-500SE)

8 41114840 Heat Exchanger

(VN-800SE, VN-1KSAE)

10 41120445 Fan, Sirocco (VN-500SE)

11 41112485 Lid, Maintenance

(VN-250SE, VN-350SE,

VN-500SE)

12 41112513 Lid, Maintenance

(VN-800SE, VN-1KSAE)

13 41114833 Filter (VN-250SE)

14 41114834 Filter (VN-350SE)

15 41114835 Filter (VN-500SE)

16 41114845 Filter (VN-800SE)

17 41114846 Filter (VN-1KSAE)

18 41118433 Nut, Dome Cap

(VN-250SE, VN-350SE,

VN-500SE)

19 41118451 Nut, Dome Cap

(VN-800SE, VN-1KSAE)

20 41118434 Knob, Lock

21 41171265 Capacitor, 2MFD , 450V

(VN-250SE)

22 41171266 Capacitor, 3MFD , 450V

(VN-350SE)

23 41171267 Capacitor, 3.5MFD , 450V

(VN-500SE)

24 41171268 Capacitor, 8MFD , 450V

(VN-800SE)

25 41171269 Capacitor, 10MFD , 450V

(VN-1KSAE)

26 41118531 Damper Ass’y (VN-250SE)

27 41118532 Damper Ass’y

(VN-350SE, VN-500SE)

28 41118533 Damper Ass’y (VN-800SE)

29 41118534 Damper Ass’y (VN-1KSAE)

30 41179475 Motor, Damper , A C 220–240V

31 41150975 Motor, F an, A C 220–240V,

50/60Hz (VN-250SE)

32 41150976 Motor, F an, A C 220–240V,

50/60Hz (VN-350SE)

33 41150977 Motor, F an, A C 220–240V,

50/60Hz (VN-500SE)

34 41150978 Motor, F an, A C 220–240V,

50/60Hz (VN-800SE)

35 41150979 Motor, F an, A C 220–240V,

50Hz (VN-1KSAE)

36 41170448 Switch, Limit

37 41179476 Wire, Ass’y (VN-250SE)

38 41179477 Wire, Ass’y (VN-350SE)

39 41179478 Wire, Ass’y (VN-500SE)

40 41179479 Wire, Ass’y (VN-800SE)

41 41179480 Wire, Ass’y (VN-1KSAE)

42 41112561 Lid, Electric Parts

43 41170449 P.C. Board Ass’y

(VN-250SE, VN-350SE,

VN-500SE)

44 41170450 P.C. Board Ass’y

(VN-800SE, VN-1KSAE)

45 41116677 Name Plate (VN-250SE)

46 41116678 Name Plate (VN-350SE)

47 41116679 Name Plate (VN-500SE)

48 41116680 Name Plate (VN-800SE)

49 41116681 Name Plate (VN-1KSAE)

50 4118S177 Owner’s Manual

51 4118S178 Installation Manual

52 4118S179 Wiring Diagram

(VN-250SE, VN-350SE,

VN-500SE)

53 4118S180 Wiring Diagram

(VN-800SE, VN-1KSAE)

54 4119B217 Packing (VN-250SE)

55 4119B218 Packing (VN-350SE)

56 4119B219 Packing (VN-500SE)

57 4119B220 Packing (VN-800SE)

58 4119B221 Packing (VN-1KSAE)

– 31 –

Loading...

Loading...