Toshiba HVK-6M40A, VK-6P32A, HVK-6P40A, VK-8M40A, VK-8P40A Installation Operation & Maintenance

...

lvlav.

31, 2012 9:lSAlVl

TOSHIBA

No

1530

P,

2

Document; GF0776{'I-B

INSTRUGTION$

IilSTALLATION

.

OPEFATION

.

MAINTENANCE

Type

VK

&

HVK

Series

Vacuum

Circuit

Breakers 5-15kV

APPLICABLE TYPE FORMS

(1200A) (20004)

(30004)

VK.6M32A VK.6P32A

I.IVK.6M32A

HVK-6P32A

VK.6M4OA VK.BP4OA

HVK-6M4OA HVK'6P4OA

VK"8M4OA

VK-8P4OA VK-8O40

HVK-8M4OA HVK-8P4OA

,VK.1OM25A2

VK-1OF25A2

HVK-lOM25A2

HVK-I0P26A2

VK-10M40A VK-10P40A VK-10040

HVK-1OM4OA HVK.IOP4OA

vK-6M50

vK-6P50 VK-6050

vK-10M50 VK-10P50 VK-10()50

NOTES:

t) The

designation of

H

before

vK

(i€.

HVKI

dsnot€s that the circuit braaker unit

was assembled

in the USA using domestic

and

foreigri

components.

All

'

relErgnces to modal numbere in thie manual will

be by the numbets following

the VK- and

HVK-.

2l Thi! manuel waB writtan

lor tha Toshiba typ€ form circuit

brsakers listed on

thi$

page

used in coniunction

with Toshiba

cells.

For

circuit

brsek6rs

utilized in

the convereion

of

othsr

equipment, a supplemental

i struction manu8l Should

be obEain6d

from lhe conversion manufacturer.

lssued 2/95.

Supemedee GF077401-A Deted 12194.

N4av.

31 2012

9: l5AlVl

t0, )tu

r,

1

INTRODUCTION

Page i

READ THIS MANUAL carefully

for imponant information about

safety, handling,

installation,

operation,

maintenrnce, and

parts

replacements for

spring-operation-type.

VK

and

HVK

series

vacuum

circuit breake6.

This manual

and all accompanying

drawhg$ should

b6 consid€r€d a

pgrmanent paft

of the equlpmgnt.

They should

be

readily

available

for /eview

and

reference

at all timos.

DIMENSIONS

shown in th€ manual are

metric and/or their 1,.S. equivalgnt.

INOUIRIES

should be addressed to;

Field

$ervice

Department

Toshiba lnternational Corporation

13.l31

West Littls York Road

Houston, Texas 77041

USA

Telephone:

1713't

466"0277

(800)

231-1412

(800)

527-12O4

(Cenada)

Fax:

|'7131

466"8773

ll[ffiFiliilC-l

uaa only Torhtba-authodzad

rBptacamont

padr.

nWiF-MiEl

tiris

equipment

is

de3igned and buitt

in

accordance

with

opptioable

sttetl

etandqrds

in 6l{sct on ttle date of manutactu.c. Unautho.hed

modElcadonr wlll

vold wattalty

and cEn ra:uh ln rwera lnJury, daath and

propsrty

dnmag6, Do not

mak6 nny moditicadons to

thi8

ecpipmefi without

tho

written

tpproval of

Toshiba.

6

TOSHIBA INTEFNATIONAL

CORPORATION,

1 995

t!1ay.31.2012

9:15Att1

No.

1510

P,

4

TABLE OF CONTENTS

Page ii

SAFETY

RECEIVING,STORAGEANDHANDLING

,........,,4

Receiving and Unpacking

.........4

Acc€pl6nca lnspection

,...4

Lifting for Handling and Moving

" "

'

5

Stotage,

..'.". t,

lnspection During Stolage

........-

6

GENERALDESCRIPTION

.,..,...7

gafety

Deviceg

........' I

lnterlock Lever , ,

........9

Sell Coupling Type Secondary

(Csntrol

Circuit)

Disconngcts

, .

'

. . 10

INSTALLATION

.,...,

11

Service Conditions

....

..'...... 11

Bating..

...... 11

Lifting tor lnstellation

',.'

13

Using the

Portable Lifter

...'.'.'. 13

Moving the Circuit Breaker in the Cell

.-.....15

PRE-ENERGIZATION

CHECK

..,, 18

General ,

.. ... .

18

Elactrical Checks .

...... t8

oPERATtoN

..,,"..,

19

Manual Operation.....

.'..'.". 19

Electrical Op€ration

.

'

... 20

Controf Ckcult

Oparation

..,.

'., , '

ZO

Closing Sequence.....

..'.20

Charging Sequence

'.......20

Tripping

(Oponing)

Saquanca

....."' 20

Mechanism Operation

....25

Closing .

,.......

25

Charging

.......' 25

Tripping ,

.......

25

Trip Frae

.""...25

MAINTENANCE

...,,, 26

Maintenance Progtam

.... 26

Maintgnanca R€cord

,

.,"

26

Servioing

Equipment

..... ?7

lnspaction

and Maintenance

Type3..

'..'.'.2e

lnspgction and

Mainlenanc€

lnterv8ls

'.

', ',.

30

Wipe Measutement

...

......

'..

36

Vacuum

Chack

,

..-...'

37

Troubleshoothg Guidelines

.,"".41

Replacement of

Parts .

... 44

Auxiliary Switch,

"'.'....45

Closing Coil

and Trip Coil

,

..

....

' ' '

47

Control Citcuit

Board .

..'..4S

Control Circuit Board Fuse

'."'

. . .. .

51

Feplacement

Pans List

...

53

CoNVERS|ONS

.

^....

54

WARBANTYandLIMITATIONOFLIABILITY

..'..'' 57

tvlav

31

2012 9:

l5Al!1

[1o

1530

P5

SAFETY

Page

1

IITJIPO

RTAI{T MESSAG

ES

R€ad

thls manual and follow

lt3 Instruotlons.

Signal

words

such as DANGER'

WAFNING

enrf CAUTION

will bB lollowsd

by imponam

safety information

that

must be catafullv

reviewed.

lndjcates a

situation which

will tesult

in

death,

serious iniury,

and

s€vsrB

propeny

damage

if

you

do

not follow

instructions'

|[mmiilG"l

M66n3 that

you

might be seriouslv

iniured

or

killod

if

you

do

not lollow

r-:'-J

instructions, S€vste

property

demage

tflight

also

occur.

A CAlmOil

: Mean3

that

you

might be

injured if

vou

do

not follow

instructions.

Equipment

damage

might elso occur.

NOTE:

Gives

you

nelpful

informallon'

SAFETY

CODE$

Comply

with all applicable

state and

local codes' Unless $upsrssdad

by etate and

local

codei, adhere

to all appliceble

ANSI, OSHA, IEEE,

NEMA and

National

Eteclrical

Cods

{NFPA

70) and'Maintenance

ProcEdures

in NFPA 708

standarde.

This includes sl6ndards

penalnlng

to

the manufaetu.e,

a88embly, installation,

grounding,

maintananca, conversion,

lating and ope€tion

of:

1

)

Metehclad switchgear

2) Power swltchge8r

3) MetaFclad

snd stEtion

typg cubiclE switchgsar

4) AC hiqh voltagB

circuit braakers

llav.

3I 2012

0,

15AM

No. 1530

P6

Page 2

SAFETY

READ ALL SAFETY SIGNS

Safety

slgns are

placed

on ths circuit

breaker

for

your

safety

and imtruction.

BeEd and follow tha

instructions in this

manual

and on tho safety

signs locatod

on rhe equipment.

Keep

the sefsty

sign viaible

and in

good

shape,

Never removg, damag6, or covat

any

safety sign.

ElDltagr|rtnfilrlclElrltr

ictllim.

eemre

orlanrrr

lta

E[Et

H^TNHEH'IE

r ArN.irfit'

m,tla

tFGaHtE

. tt clal tFq-llll

i-HirdE

. DEEdtgqt

trLrd

arqrc(ilt* Hlf,ln*f

a

irll

trdrlecEtd

hrb

. ffi lrrildr,iq

ntt

!.ltffilr

*flm

rrrlt

r[ ffiEF]a

!!

cltlrdhLilriFtLE

. btuhht!5ttrttll

dy-tCrttlUEl*'E

trf

rrE t&r'ClUfiFa

'd.aEr,

.

orF

tFtt cF#tbr

tdfr

FEAD tt€tnrJdflol{

t&lluAl BEFoRE ATTElptlE

THE

FoUOlltttt

pfiQOEltJfiES

uAr{rAl oFEE

s PmcEDt'Ae

To $lA*E

stf,Negl n

.g chlrliE f5t*

toqrl cevst

crd hE

(t1.

ii!

;htd. bro Soqbr

OF..fte.

BtEa

-l}

t& tlF fd

Dcttt

unfl a cH b tLtlll

erd sEtla

rr&or R.le ofiAndD

g.lqr).

Rd€ ldt{e

Fdt r'

ilttHr

l5t rtd

R€tbat 8o.ld

Csnr'

1rO.La!!FSREAIGRT

Fllhdlrat,(!

G eJfllll

Ctqi Es'b.lre

\irf, Tllql

R€rd

ctoeED

(is0

{td OlSCt{AffiED

0rn'}

7o OPB{ BRE

xE t h.lr

A. TflrP

gJftSL

Ch * hdr..li*dor

lr

Thrl h

@sl

(Glifit

rd ol8C+lrhOED

$nr.!

lfiftE

fhe Folci'rn C||t

R€sa

h Ef,+trsr Olttqg.

o.dgidl

*

rlE cLodta

gt

tTct{

lllfi 1'lr€ drEi

Er*. clllg4r'

aj-r!+*n Oa

The

cr.CElcc BUTllll

Yflt llro wTEH.rffi

lE\rEB Br*rr

D.i.doi Cl Tlta

dr6

E

gufltil

!\{l

lltelilP Jtlofi

D'F t'c5'

NsnLLAfn chElaol/^l.j

ITFEATOB t{$i FFd

OtSfi

RaED

(!lt{t}

Atld OpBl

GlE€o)

8.aort

lttc

gr*.

Cfi tf mH

lllo cjr Fentle<t

lErnn Tll. Ocl

(ffi).

N4av.

3I 2012

9: l5AlV

No

1530

P,

1

gAFETY

Page

3

OUALIFIED

OPERATORS

OilLY

only

quslified

persons

are to

lnstall, op€rate

or service

this €qulpmefi

accordjng

to all

applicabls

codes and established

safgty

practic6s.

A

quallfle

d

person

must:

1

)

Getelully

tead th6 entlte

iGtruction

tnanual.

2) Be $killed

in the

installation, construction

or opgration

of the Equipment

and awa/e Ol

the hazards involved.

3l

Be lrainad

and suthorized to $sf€ly

energizB,

de-enetgize,

clear,

ground,

lockout

8nd

tag circuits

ln accordEnce

wilh estSbli$hed

sefsty

practice.

4) Be trained ahd

Suthorized

to

parform

the service,

maiftenancs or

rspair of this

aquipment.

5)

Be

trained

in the

proper

care

and use of

protectiva

equipment

such as

rubber

glove$,

hsrd hat, safety

glassos,

face shield'

flash clothing, etc.

in

accordance

with

astabllshBd

practlces.

6)

Bp

tr9ln6d

in rendering

first aid.

Nlav

31. 2012 9:15AN4

No.

1530

P.

I

Page 4

RECEIVING, HANDLING

AND $TORAGE

RECEIVIIIo AND UIUPACKING

The

clrcuh breqker

unite

are aubjected to

fEctory

production

testlng

prlor

to

being

packed

and shipped.

ACCSPTAilCE IiI$PECNON

Confirm that

the

circuil breake, unit

is

oompleta,

conect as :pecified and undamaged

trom shipment 6nd

handling.

Upon

recelpt

of the

equipmBnt, do the

following:

1) Make

an

lmm€diat€ ircpeclion

for damag€

which miotx

have

occurred

durlng

Ehipment

(Fig.

1

).

lf

damage

is

discove.ed,

it

should

be notad with th€ carrier

prior

to

accepting

the

shipment

if

p+asibla.

2)

Carelully

unpack tha aquipmant sufficiently

to cheok

for missing

pens

or concealed

damage-

3l Keep the equipmefi

upright

(Flg.

2).

A

CAltflOil

r ltl.vat

hy th6

esripmam on lia

elde or upslde dwn. Tlf$

may

cause

equhmrm

drmrge to occur.

4) File

a

claim with the

csrrier

for

$ny

damaggd

or missing itsms €nd immediately

notily the

neaiest Toshlbe lnternational

Corporation representative.

IZffil

oo nor i6ral or en€rllze

eqrlpmEnt trat

has

bcan *rflagsd.

Drmegod

iquipmilt can fdl drdng operadon, tctultidg

in fire snd

exploEion.

5) lf the cucuit

braikor

haa

baen

utilized

for

rhe conveFion of olher equipmert, see the

CONVERSIONS

S6etion ot this manual.

Cofifirm th€t

yo{lr

conver8ion

msnufecturer

is in compliance with

thi$ section.

Flg. t lnspedl for Damaga

Fi!. Z Thb Circuit Brdsk8r Bhould

Uprighr

kept

llav.31

2012

9:16AM

No

1530

P9

RECEIVING,

HANDLING

AND STORAGE

Page 5

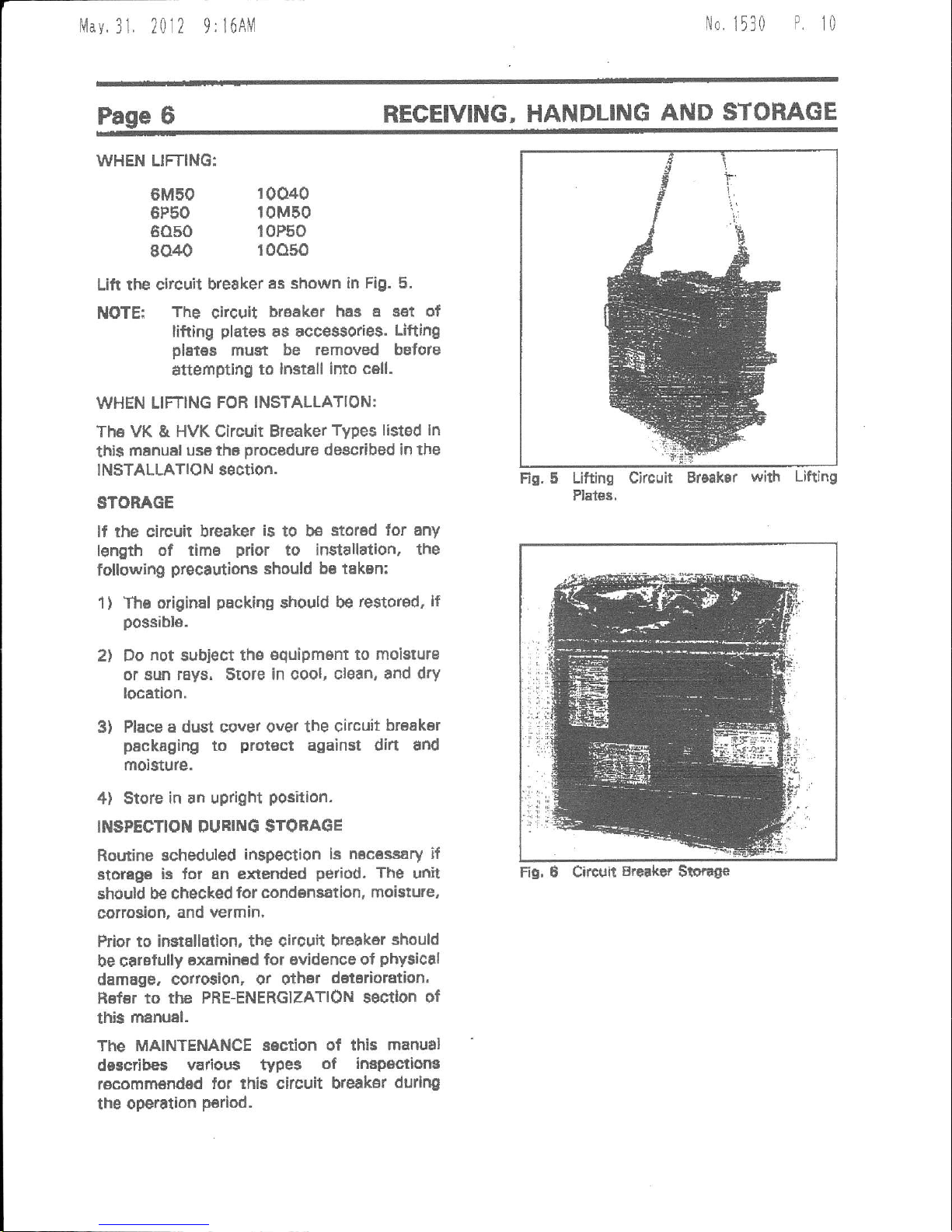

LIFTINd

FOR HANDLING

AND MOVING

When

handllng

and

movlng

the

circuit braskdr,

rhe suspension

technlques shown

ln this

saction

may b6 used. When installing

or

removing

th6 circuit braaker

from the csll

above

floor

level, refer

to the

"Lifting For

I nstaltation"

instructions

id the

I N$TALLATIO

N

Sgction

of thie mpnual,

ffmnlGl Do nor atbmpr instattation

of

the clrouit bteaker

above

floot leyel u3ing the

lifting

m€thod8 d€scdbed

ln thls section.

Alway$ u$e

e Tolhibe

Portsbla Llfter

for

lnstalladon,

Care and

csution

should ba

usad when

handling

the circuit

breaker units

to avoid

damage to tha aquipment

and

personal

injury.

Always

keep the circuit bf€aker

in e

genBrally

upright

position.

ACAUflON

!

when

littlng,

the oircuit

breekar

vvlll tllt rllghtly backwards.

Stand clear

of

the bteake.

whon

lifting or

you

may be

inlured,

Always use

lifting

equipmant

suilable for

handling ths weight of the

unit.

The

capability

of the

llfting equipment to

handle the size and

weight

of the ciicuit

br6aker should

be

confirmed

prior

to lifting,

A

CAlmON

I

Attempting

to

menually lift

the

circull bruakar

csn caure ledous injury

or

equiprro

t damtge.

Alwey: u:a

eultoHe llftlng

equJpmerTt,

FlE.

3

Lifting

the Cirouit

Hooks.

Breaker

with Lifting

Fig. 4 Circuit

Br6ehsr Tihing Beckward

whils

Lifting.

WHEN

LIFTING:

6M32A

6P32A

6M4OA

6P4OA

8M4OA

8P4OA

10M25A2

10P25A2

10M40A

10P40A

Lift ihe

circuit breaker as

shown

ih Fig. 3 end

Fig. 4.

li1av

31 2012 9:

l6AlVl

Itlo,

1 13 0

P

t0

WHEN LIFTING:

6M50

6P50

6050

8040

Lift the circuil

breaker

as shown in

Fig. 5.

The

circuit

braak€r

ha,B a eet of

lifting

plates

as accessories.

Ufting

pletes

must be

removed before

atterfiptlng

to lnstall into c6ll.

WHEN LIFTING FOR

INSTALLATION:

The VK & HVK Gircuit Breaker

Types listed ln

thi$

manual

us€ the

procedure

described

in the

INSTALLATION

section-

STORAGE

lf the

circuit breaker

is

to be

stored

lor any

length of

timB

prior

to installation,

the

following

precautiotar

should

be taken:

The original

packing

should be

restor€d, lf

possibl6.

Do

not

subject

th€

€quipmBnt

to moisturB

or aun

rays. srote in oool,

cl6an, and dry

locetlon.

Place a dust cover over

the circuit

br€ak6r

packaging

to

prot€ct

against dift

and

moisture.

$tote

in an upright

Position.

INSPECTION

OURING STORAGE

Rouine

scheduled

inspection ls nec6s34ry

if

storage

iE lor En extended

period.

The

dlit

should b€ checked

for condensation,

moi$ure,

cottogion,

and vermin,

ftior to instEllation,

the circuit breaker

should

be crrefully

6xamined

lor ovidence of

phy$ical

damage. cotto$ion,

or othsr

doteaioration.

Hof6r

to thc PRE-ENERGIZATION

ssctlon of

this

menual.

The MAINTENANCE

sEction of this

manual

describes

vatious typ$

of

impsc.tiong

recommsndsd

for this

circuit breaksr

durlng

the

operstlon

P€riod.

REGEIVING,

HANDLING

AND

STOHAGE

t

1

10040

10M50

10P50

roo50

NOTE:

Fig. 5

Lifting Circuit

Plat68,

with Lifting

1)

2t

3)

4)

Fig, e

Circuir

Breekef

S$.ag€

lvlav.

31 2012

9: 16AM

No

1530

P.

tl

GENERAL

DESCRIPTION

Page 7

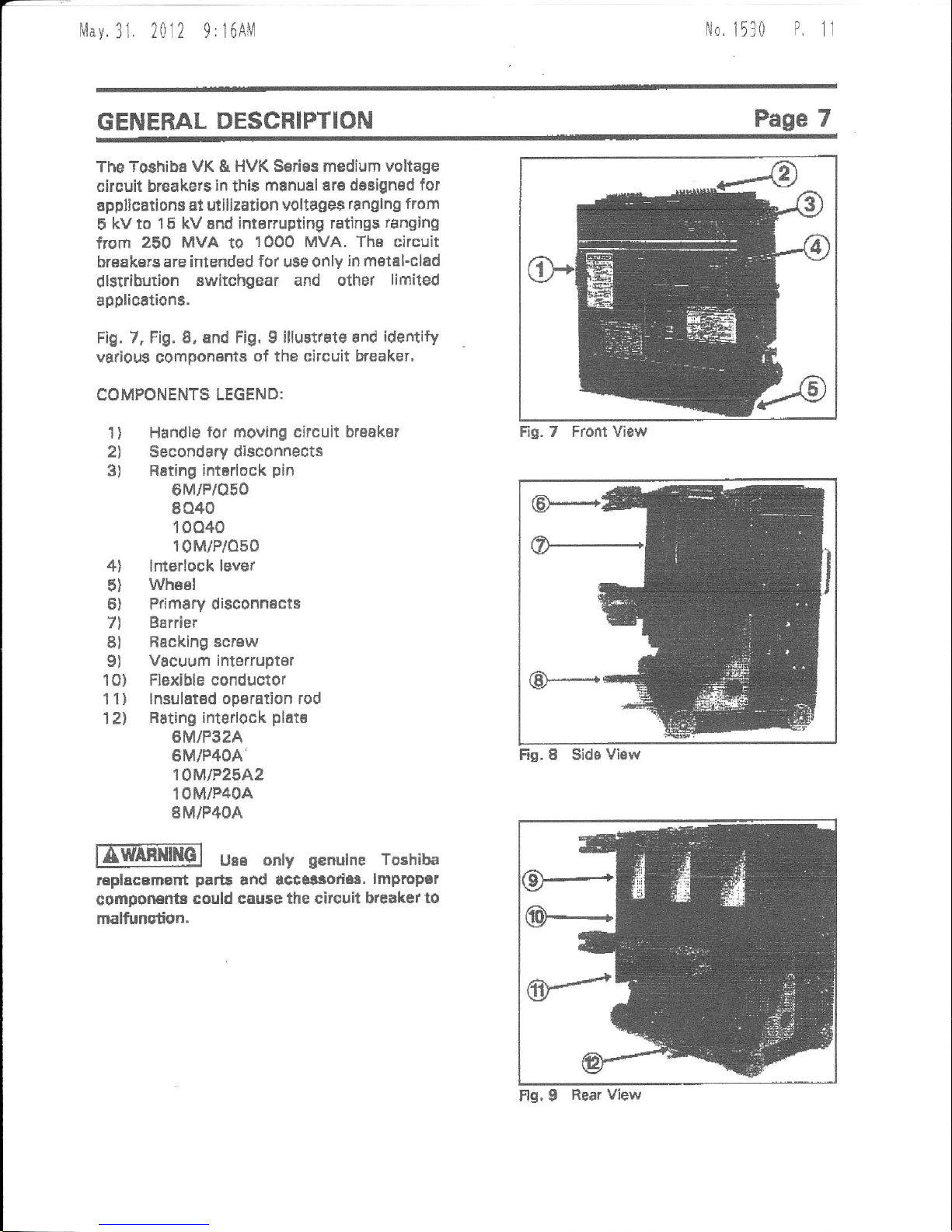

The Toshiba

VK

&

HVK Serias medium voltage

circuit breakers

in

thi6

manuel are dasigned

for

applica offi at utilization

voltages

ranglno from

5

kv to 15 kV and intorrupting ratings

ranging

from

250 MvA

to

1000 MVA. The circuit

breakarg are inlended

for

use only

in metal-clad

dlstriburion

switchgear and other

lifitited

applicttions.

Fig. 7, Fig. 8, and Fig,

g

illust.ate and

identify

various component8

of the circuit b'eaker,

COMPONENTS

LEGEND:

1

)

Handle

lor moving circuit breakar

2l Secondary disconnects

3) Rsting

intBrlock

pin

0M/P/oF0

8040

10040

10M/P/o50

4l lnterlock lever

5)

Whssl

6) Primary disconnscts

7l

Barrier

Bl

Rscking scrsw

9)

Vacuum interrupter

1O)

Flexible conductor

11) lnsulatsd

opsration rod

1Zl

Bating interlock

plat€

6M/P32A

6M/P4OA'

10M|P25A2

10M/P40A

8M/P4OA

UBE only

g€nulne

Toshiba

replacBm€nt

parE

and accatsod68.

lmproP€r

componEl'tr

could cauee the citcuit breaker

to

malfunction.

Fis. 8 Sids

View

Fio.

7 Front Viaw

Fls, I

Rear View

Mav.31

2012 9rl6AM

No,

1530

P.

12

SAFETY

DEI/ICES

Sat61y

inr€rlockg and

guards

sre

provid€d

as

an

iftegr8l

pen

ol th€ €quipment deslgn.

These devices are

provided

for

your

BafBty.

Never Defeat, Modfy or

Bypa*

any Satety

El6vlc53,

lmerloeks. or

operadng mechanfim.

Ttrt world

make

the

enripment

unsati. Flre. erploCon,

gevere

Ir{ury,

death, and

propafi

damage could

occul,

nml

Do not o'€rate th* equipm€nt

unle$s all soverE

and

panelr

sr€ ln

place-

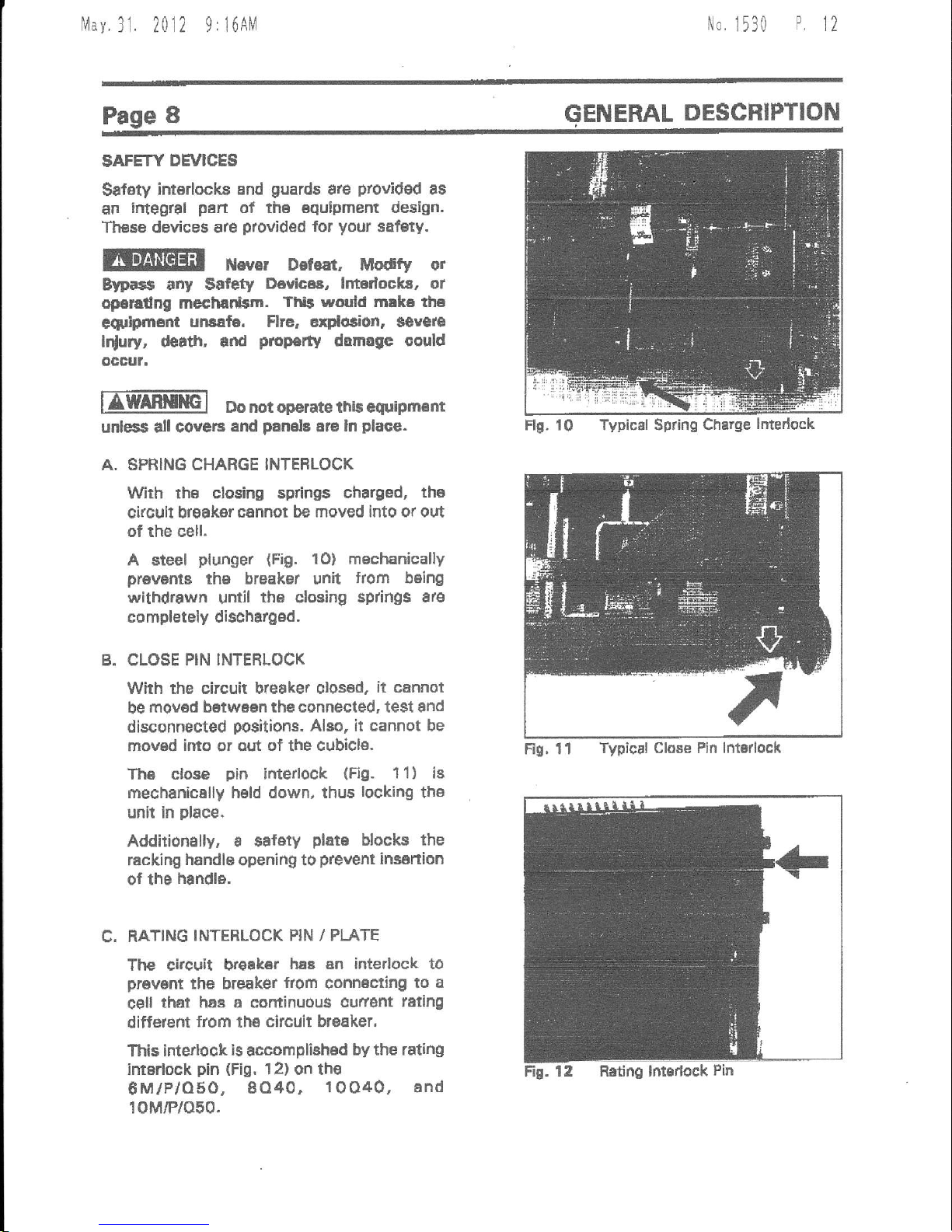

A. SPRING CHARGE INTEFLOCK

With the clesing springs

charged,

tha

circuft break€r

cannot be moved into or out

of the cell.

A steel

plunger

{Fig.

10} mechanically

prawms

th€

breakel unit

from being

withdrawn

until

thB

closing

sp ngs 8re

completely dischargod.

B. CLOSE

PIN INTERLOCK

With the circuit bteaker olosed,

it cannot

be

mov6d betwaen the connected, test and

disconnected

positiorc.

Alao, it cannot be

mov6d

into

or aut of the

cubicl6.

Th6 close

pin

ifiterlock

(Fig.

1 1

)

is

mechanically held down, thus

locking

the

unit in

place.

Addition€lly, a salety

plats

blocks the

racking handle opening to

prevent

insartion

0f

the

handle.

C. RATING

INTERLOCK PIN / PI-ATE

The citcuit H€ak€r

hsB sn interlock to

prevsnt

the breaker

fiom

conn6cting

to a

c€ll

that hae a cominuous

cufierrt

reling

difterent

from

the

circuit br6aker,

This intertock

is

accomplished

by the rating

intarlock

pin

(Fig,

l2) on the

8M/P/O50,

8O40.

1OO40, and

10M/P/O50.

ENERAL

DESCFIPTION

Rs, 11

Typical Close Pin lntorlock

Flg. 10 TypicNl Spring

Charge

lntedock

Mav.31,

2012

9:i6AM

No,

1530

P

t3

GENERAL

DESCRIPTION

Page

9

Ths intddock

ie accomplished

by a rating

interlook

plats

(Fig.

1 3) on the

6MlP32A,

eMlP4OA,

19MtP2gA2,

8M/P40A

and

10M/P40A.

INTENLOCK LEVER

The

interlock

lever

(Fig.

'14)

on the right side

of

the circuit

bleaker

front

panal

cannot be liftad

wh6n

thB circuit breaket

is clo$ed.

Belore

lifting th€

interlock lBvsr, vsrify

that the

opan-closed

indicator

reads

"OPEN'

(grosn).

when

tho interlock lever

is lifted, the

closing

action

is

blocked

boih

electrically

and

rnsch6nically.

wilh

the

interlock

lever up. the micloswitch

(Fig,

151 is

open, thus electricallY

prevsnting

the

circuit brsak€r from

being closed.

Fig,

13 Rating

lntorlock Plate

Fig,

14 lnterlock

Lever

f/av

31. 2012 9:17Ah1

No,

1530

P.

14

Page

1O

GENERAL

DESCRIPTION

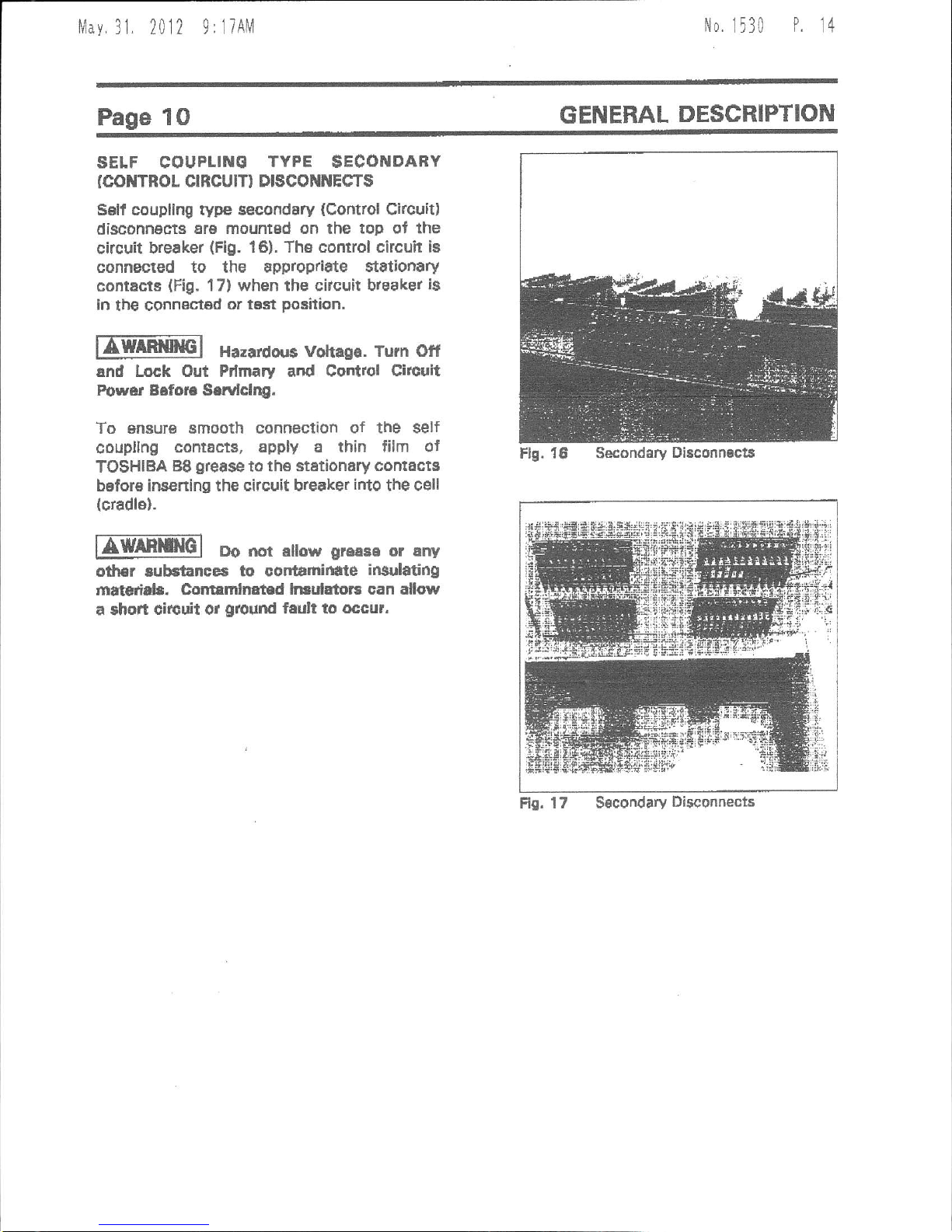

SELF COUPLINE

TYPE

$ECONDAEY

(col{TRor

crRcurr) DrscoililEcT$

Sslt coupllng

rype

secondary

(Control

Cl.cult)

disconnects

Er6 mountsd on the top of the

circuit breaker

(Fig.

16).

The comrol circuh ia

connected to the approp/idte $t8tionary

contacts

{Fig.

17} when the citcuit breake.

is

ln

tbe

connestsd

or t6st

position.

fA-l

Hazardorr6 votraga,

Turn otf

and Lock Out Pdmary and Control Circuit

Power B6for€ Sarvlclqg.

To snsur€ smooth connection

of the self

coupllng

contact8, apply a thin film ol

TOSHIBA

B8

grease

to

th€ stationary

cornacts

before insening the

circuit breaker

irto

the cell

(cradle).

nWAf,rcl

Do mt alow

greese

or any

od|3r aubstanccs to cortamid

te

insulating

mNtcriab. Colrtrmlnat

d ln ulatots can allow

a shon

circuit or

ground

fadt to occur.

Fr0.

17

Secondary

Disconnecis

Flg. 16 Secondary

Di8conn€ct8

lvlay.

31, 2012

9:lTAlVl

No

1530

P.

1t

INSTALLATION

Page

11

SERVICE

CONDITTOilS

EWAEtlilG-l

Do nqt ini1pll

rhis

aquipm.m

in areas

where unurual

serviae condition$

erist.

Using thiE €quipm€nt

ln othsr than uaual

aervlce

condffod$ can

relult in squipm€nt

fallura,

Toshibs

VK

&

HVK

$eri€s

Circuit Brsak€rt ara

intended

for

use

in u6ual servioe

conditions as

dellndd

by ANSI. The

temperatule of the air

(arfibient

air temp6raturs)

surrounding

the

Ewitchgear

should be

between the

limits of

-3OoC

l.22oF)

snd +4OoC

(104oF),

The

altitude of the equipffient

instsllation should

nor exceed

3300 ft

{100o

m},

IUOTE;

Temperature,

ehitutle ot othar

conditions outside

of the usual

limitt

may raquire derating

or other special

equiPment.

Contact ToEhiba

lntsrnational CorPoration

for

additional lntormstion.

RATIIVG

Prior

to

ln$tallation:

The

maximum fault curredt

capaoily

ol tho

powsr

sy3t6m

at thB

point

of

installstion

should be

verified. This

valug must not exceed

ths symmetrical

interruptino eapability

ot the

circult

bteaker.

Fig. 18 illuetrEtes

a typical

circuit breaket

nameplatg

and

ratings.

Do not exceed

the

tati

ga

$pecified

on

fi6 circult

braak€r nameplate

ot

aystem acces5orie5.

undefrated

equipment

can

fail

durlng oparallon caudng

flre, erploaion,

sgvgrg

inju

. d6rth,

ind

proP.dy

damagc,

To calculat€ .th€

required Symmetrical

lnterrupti

g

Capability.

usatheformula

in Note

4 and 5

of Table 1, All system

accss9origs

Buch as surge supprasaors,

lightning arlestols,

etc, should

be checked

to

varify thsir ratingi

capacity.

Flg. 18 Typical

Ciacuit Br3aker

Nsmsplac

1,,1av.31.

2012 9:17AM

N0.

1530

P

16

Idofiificdidr

RddVdlr

::;..itH6l

it:iji6flil;&l

i"i;6,1.{iri:

|-., i..i i:lc

.3frNt

ltl.i irE8li.i

"t:i

'.

Er!

r!t5! r

+.r'ri ,

r}'

H

f,..!H

V*{t

0t

!.Yl

tldt

3tln

{xv t

r4ahg

tffi)

r#*

r,iri{

Dty, V

!E

6a.d

Htr-

E

{rYl

t2f

Y*rt

nrrF

t

cat'

ht

\'hrg

tsr

lhr

rl

€oll

{At

ESA

Atrr

*sln

ht}rg

la

lls.

rvt

lrat

t4)'

F4ruy

VB

lvl

AIE2A

6Fil2A

4.16

!t.16

2SO

150

1,76

4.78

't.24

1,21

l9

to

60

m

1200

zxxt

29

za

I

3 2

E.a6

s,gt

3lt

3A

a0 6E

5A

al,tloA {rf

6goa

of

4.lE

!t.t6

s60

950

\7d

d76

t-d

I

O

te

IE

60

@

l roo

zu)

,t1

3

2

2

4.78

1.',1c

4t

4l

41

+1

SB

6E

Etfio

6F60

6(rc

4,16

4.16

ILI

E

Ito

360

361)

47',

+76

4.ta

l-lr

t.t3

t0

19

19

60

60

c0

t tod

20@

3000

tll

4t

4t

I

I

s

,

z

2

lto

a.o

40

43

att

49

49

a0

4S

7t

7t

7e

Ar,lbA

I'IIOA

80,to

tlf

7,4

7.2

300

6('0

500

d.:5

a.r3

a,z5

l.r5

LB

t.lE

36

3t

IE

95

tt

SE

I400

20s

gooo

33

t3

3

a

s

2

2

2

4.6

6,6

6,8

41

4i

a1

41

d6

66

6A

I6MfiA'

tot:lt l 13.4

500

5m

t6

l5

t

-30

tJo

36

t!

gE

s

I uao

zn

16

IE

3

s 7

I t.5

l t,3

,3

23

tt

t3

a7

t7

toM{an

't{tFttoa

roq40

tll'

1C.E

I

s.a

l3.a

750

7A

7

IE

ll

IE

t.ao

1.30

t

-so

a8

36

3t

6

t5

t6

1200

:000

3000

2A

28

2E

3

3

2 11.5

36

t6

86

3g

36

36

5S

EA

6E

roP4oA fil

lmto fl r

l!-6

13.8

1066

100(l

t3

IE

t.0

t-0

3C

36

t5

s

2o0o

3000

B7

37

a 2

1E

15

37

g7

l7

6A

F9

lotFo

totto

iooEo

19.t

13,t

t3,8

t 000

looo

1000

16

t5

l5

!

-lo

l,$

1.30

36

3!

36

s

E6

1206

2l'qt

30m

s7

g7

3

I

3

2

2

i t,5

I 1,5

116

49

.t6

4E

4{

*0

46

't7

77

17

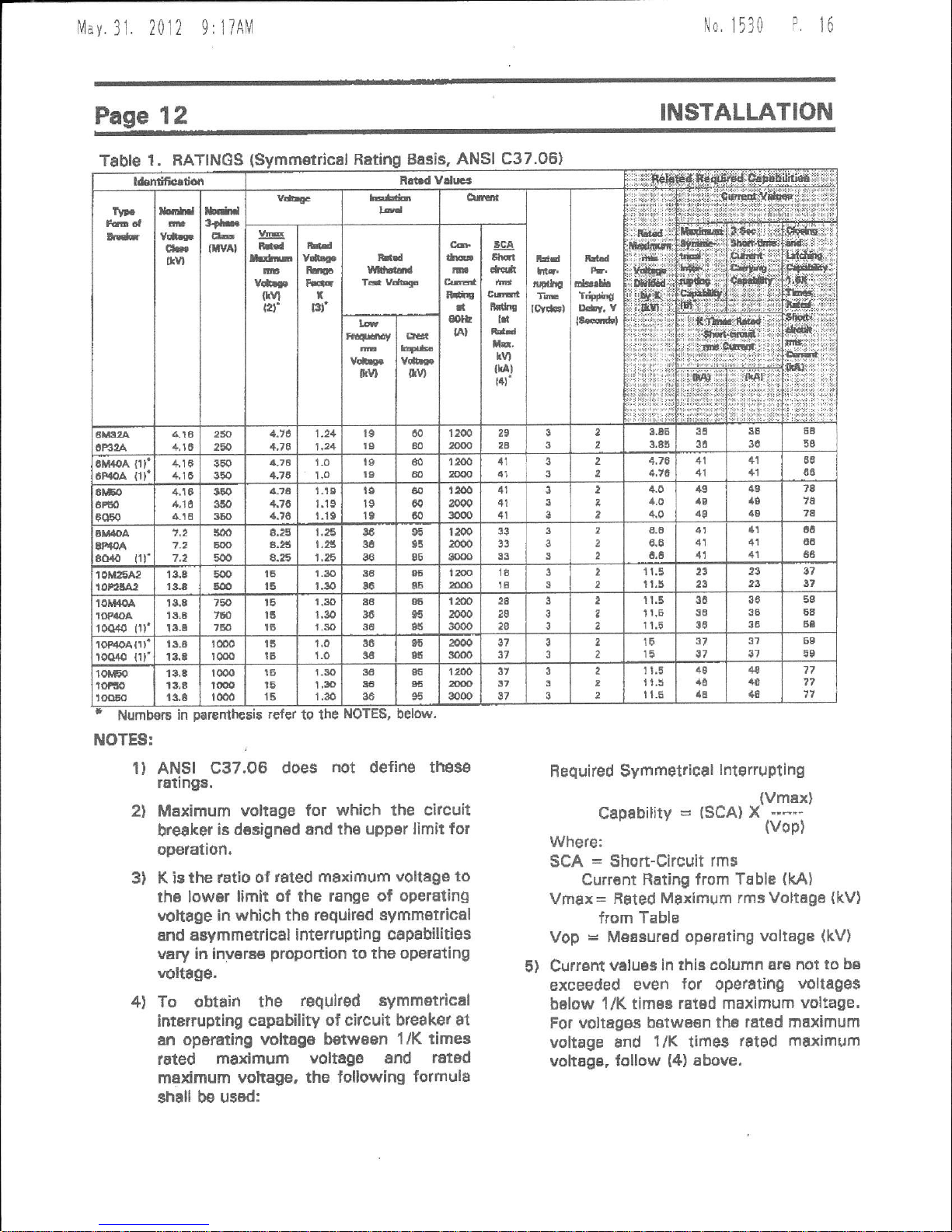

Table

1 . RATINGS

Numbol6

ITIOTES:

Basis,

ANSI C37.06)

r€fer

to the

r)

2l

3)

ANSI C37.OB

does

not

define

thes€

r6tings.

MEximum voltage

for which lhe circuit

breaker

i6 d€signed and th6

upper limit for

operation.

K ic

the

latio

of

rSted maximum

vollage to

th6 lowar limit

of the range ot

opetating

vohage

in which tha roguir€d

symm€trical

and asymmefiical

interrupting cap8bilitiss

vary in inv€rs€

proportion

to the oper€ting

voltSge.

To obtain the

requked symmetrical

interrupting capability

of citcuit breaker

at

an

operEting voltsga betwsBn

1/K times

Irted

m€ximum

voltage

snd

ratad

maximum vohage,

the tollowing formulS

shall be

usBd:

Required Symmetrical

lfierruptlng

(vmex)

Capability=(SCA)X*-*

(vop)

where:

SCA = Short-Circuit

rms

Currant

Rating from

Table

(kAl

Vmax=

Faled

Maximum rms Voltega

{kV}

from Table

Vop

=

Measured

operating

voltage

(kV)

5) Crlrrsnt

veluas in thb column

are not to

be

excEeded even

{or

operatihg

voltages

below

1/K tim6s

rated maximum voltage'

For voltages bstwBsn

the ratad maximum

voltage

8nd

l/K

times

rated maximum

voltage, lollow

{4)

above,

4)

Nlav

31. 2012 9:liAM

No.

1530

P

17

INSTALLATION

Page 13

LIFTING FOF INSTALLATIOil

lJnlika the

lifting

procedures

recommended

in

the

FECEIVING,

STORAGE AND HANDLING

section,

Lifting

for lnstallation

pulposas

raquires a different technique,

A Portablg

liftdr ss shown ln Fig. 19 should ba

used

for lhe insettion ot

removal

of a clrcuit

br€ak6r to th6 switchgear

compartment above

floor level,

Ths

ponable

lifter may also

be used to

trtnsport

ths circuit brsakar to 6nd

from th€

switchgear.

EWffiMt{6]

Do not

attempt to

irstar

ot

remova

a circult

breaker abova floor level

from

a

compartmefit by uting th6

lifting 6y68 or

plater,

Ure a To5hlba

portable

lifter,

lIffiEl

Dbcharge sprtngs

compt€rcly

ffilre

irHtallution.

A CAtmOil

: Alwaya lnsurs the

portibl€

llfter ls operated

on a

fififi

and

l€vel

Surface.

USIilO

THE PORTABLE LIFTER

1)

$et

wheel

stops to

the

lock€d

position.

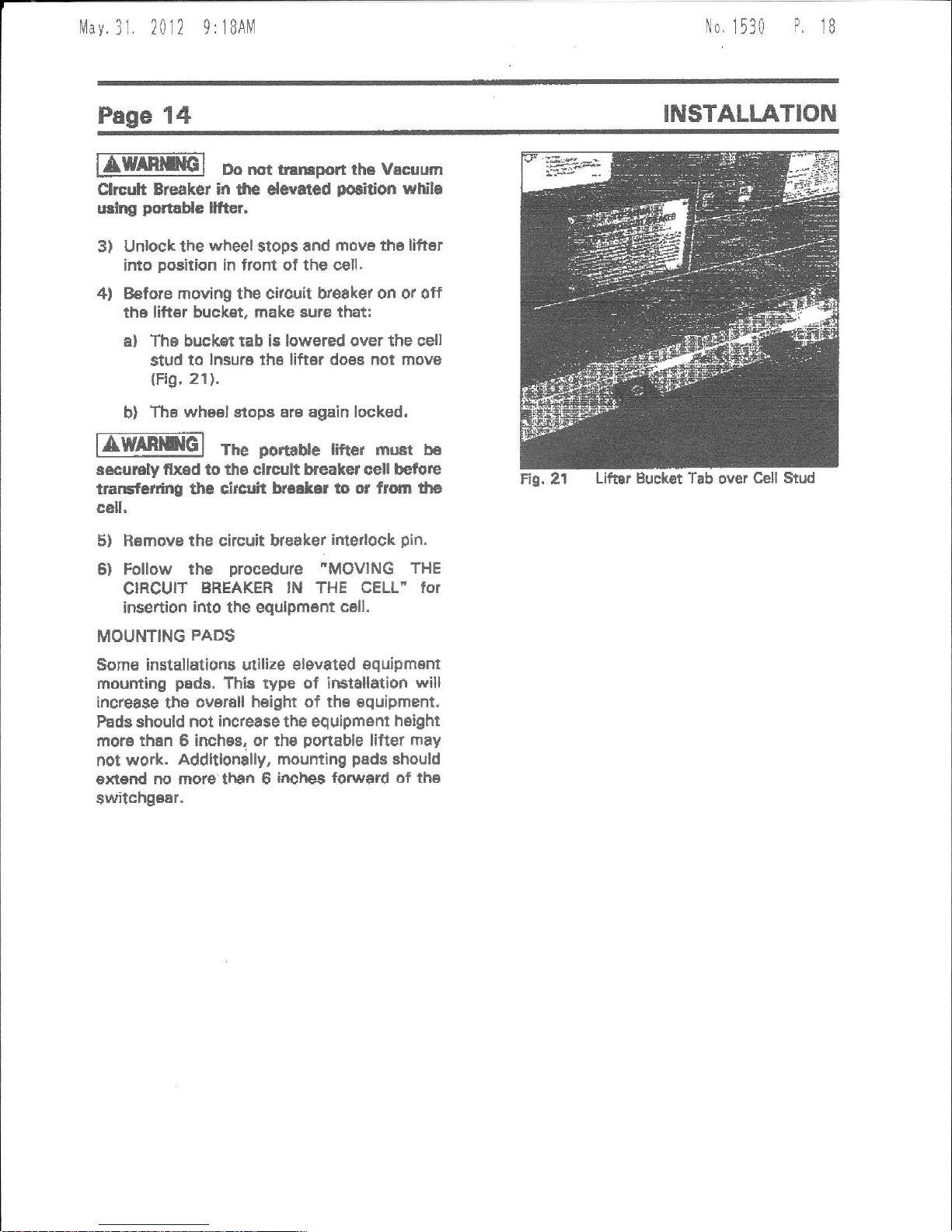

2) Place the circult,brsaksr

on lhs liltBr buckat

and

lock in

place

with

the

inte,look

pin

(Fig.

2o).

EEm[im]

Do nor traffipon

the circuit

breraker

without

th€ intsrlock

pln

lockad

ln

place,

Flg. 19

Po*able Lifter in use

ng.2O

Portable Lifter lntsrlock Pin

in Placg

klay

31. 2012

9:18AM

No.

1530

P

18

Page 14

INSTALLATION

lIffil

Do nar rrrEport the vac.um

Clrcuh

Ercaker in dle dc{iNted

pocition

whila

udru

por$lc

llfter,

3l Unlock

the

wheel

stops and

move the lifter

into

position

in front of

the

oell.

4l Before moving the citouit hreaket on or off

th6 liftor bucket, make sure that:

al The buckst tab is lowered over the sell

stud to

lnsure

the

lifter does not movs

(Fig,

21).

b)

Ths wheel stops Ere again locked.

nmmG]

The

porrdue

riftGr must b6

s€cu]€ly flx6d to ths clrcult breaket cell befu|e

traGfcrdng the cirllir't

k..ler lo or from lha

cell.

5) Ramove

the circuit bteaker

ifiterlock

pin.

6) Follow the

procedure

"MOVING

THE

CIRCUIT

EREAKER

lN

THE

GELL" for

insertion

into

the equlpment

cell.

MOUNTING

PADS

Some installations

utilize

elevated equipment

mounting

pads.

This ryp€ of irEtallation

will

increa$e

ths

ovorell heigtrt of thB Bquipment,

Pads should not increa$e the equlpmsnt

height

more

than 6 inches, or tho

ponable

lifter ftay

not work.

Addltlonally,

mounting

pads

should

ext€dd

no moru than 6

inches lorward of the

switchgBar.

Lifar Buckat Tab

over

Cell Stud

Eq,

2l

|!lav

3l.

20l2 9

r

lBAM

No,

1530

P

19

INSTALLATION

Page

15

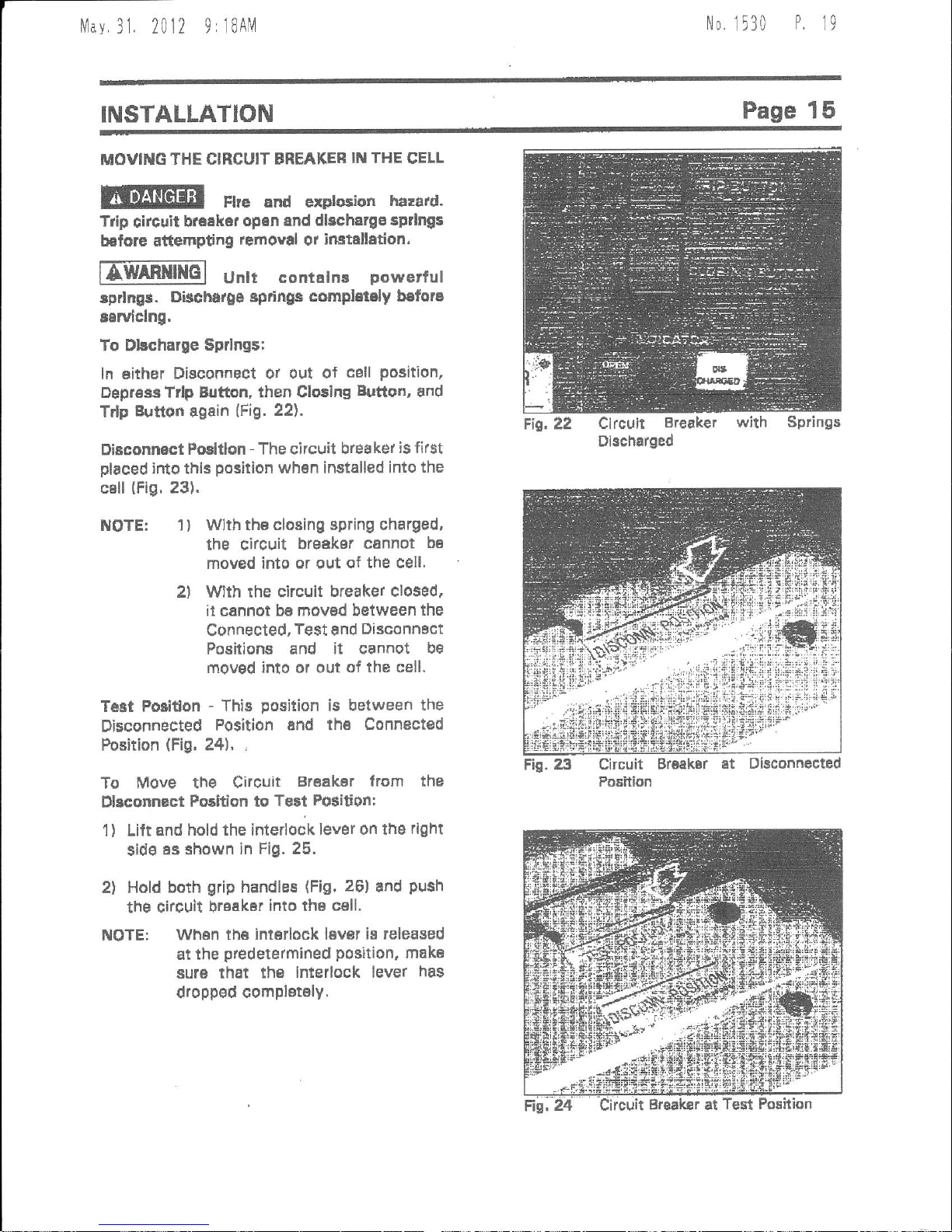

MOVING

THE CIRCUIT

BREAKER

IN THE

CELL

lilE@

Ftre and exptoiion

harard.

Trip

clrcuit

ba€ekar

opan and dlecharoa

sptlng$

b€lore

attempting

lemoyil

or

instellation.

ITMRNINGI

unh

conratns

powerrut

sprlngr.

Discturge ep,ingc

completely befora

rswlclng,

To Dkcharse

$prlngs;

ln either

Disconnect ot out

of

cell

position,

Dep.ess

Trlp Bjtton, then Clo3ing

Button,

and

Trlp

Eutton

again

(Fig.

22).

Disconnact

posltlon

-

The circuit

breaker

is first

placed

into

thlr

posilion

whsn installed

into the

cBll

(Fig.

231.

Fic. 22

Clrcult

Breaket

with

Dlscharged

Springs

NOTE:

2t

1)

T6Bt Poiiffon

Disconnected

Position

(Fig,

Wlth th€ closing spring charged,

the circuit

brgdker

cannot

bB

moved into or out

of the cell'

With rhe circuit

breaker closed.

it cannot

be moved between

the

Connected,

Test

snd

Disconnact

Positions and

it cannot

be

moved into ol oui

of the cell,

-

This

position

is between

the

Position and th6 Connected

24t,

,

Dbconnected

1)

To

Move the

circuir

Br€akEr trom

the

Dbconnact

Fosltlon to

Te3t

Position:

Lift and

hold the inlerlook lever

on ths

rlght

sid€

as shown in

Fig. 25.

Hold

both

grip

handles

Fig,

26]

and

push

the circuil

breaker

into the cell.

2l

Whsn

th6 interlock laver

is released

at the

predetermined

position,

mak€

sUrS that the

interlock lever

has

dropped

compl€t€ly.

Nlav

31.

2012 9:IBAM

No.

1530

0 1/\

Page

16

INSTALLATION

Conneated

Felition

-

ln thia

position,

the

circuit breaker

prim6ry

disconnect

bus stabs

afs

conn€ctod to rhe switchgeal

bus bars.

ln

moving the circuit

br€akdr

from rhe T€st

Po€idon to

trr€ Connccted Position:

1)

First cheak to

mak6 Eur6 th6

open-closad

indicator

reads

"OPEI{'

(green).

Flre and erdoSlon

hazard.

Trip

circuit

br€3kar

opin b€fors attempdrig

to

rack llre citcuit

beaker |trto tte Conn€ct€d

Posldon,

2) Lift

the

ifierlock levar.

3l Ineen

the racking handle

as $hown

in

Fig. 27.

4l Turn

the handle clockwise

(Fig.

28). The

cirouit breaker

will

move inward,

5l Stop

rotating the tacking

hsndle

when

the

raoking scr6w

thread h€s cleared

the

racking nw,

You will

heer e click sound

ae

th6

arrow at the lower

paft

of the cirouit

brsaker

comes in line whfi

the red line of

the Connected

Position hdicating

plal6

on

tha cell

floor

{Fig.

29}.

Remove

the

racking

nandle.

Check to

verify rha intedock

lerrer

has

dropped

completely.

Fig" 26

Gripping Circuit Bresker

HEndles

6)

7l

Fis. 25 Lifting

htarlock Lever

FlA. 27

lnsening Backing

Handle

|v1av.31.2012

9:l8AlM

No. 1530

P,

21

INSTALLATION

Page 17

WhEn drawing

out the circuit braakar

from the

Connected

Po6ition

to th6

Teit

Fosition:

1) Firit

check to mako sure the open-closed

indicetor

r6ads

'OPEN-

{gr6sn}.

Fire

and

exploaion

harerd.

Trlp clrcult breaket open bcfoa€

attsmptng to

r.ck

th6

clrcult

brraker out d th. Connected

Position.

2) Lift thB

int€rlock l€v6r.

A CNfiO{

: To avold equlpme t damage,

.lo not

push

the clo3lng button

lgrEenl

whlle

thc

lnterlock

Lever ii l;fted.

3) lnsen the raching handle

(Fig.

271,

4l Turn the

racking handle coufterclookwise

to mov€ ths circuit broakBr

to th8 Tert

Positj,on.

5)

Stop rotating th€ racking

handlo whsn the

raeking

$crew thread

has cleared the

racking

nut, You will hear a click

sound as

ths

arrow at th6 lowdr

pan

of the circuit

breaker

'$

aligned

with

ths

rsd llne of tn6

TEst Porldon indicaiing

line,

E) Rem0ve

the

racking handle.

7)

Check

to verify the lntarlock

levar has

dropped completEly.

Fig- 2a Turning Racking

Hendlg

Nlav

31. 2012

9:l9AM

No.

1530

P.

12

Page

18

PRE-ENERGIZATION

CHECK

OE

ERAL

BEFORE

ETIEEGIZITUG

THE

CIRCUIT

EFEAXER

for the

fir$t time,

lollow

the

procedure

below

to verify

that the aquipment

iB

properly

installed

and

funotional.

ISE@E

nu2arddu

voltage, Tum

ofr and

lock oui

dl

prim.ry

and control clrcltlt

por,\rsr

sources

tttiot

to

perforrning

ttlS

pre-

energlzadon

check.

nffil

Do not

orerfie

th6

6s$pm6nt

undl

a compleE

safEty inspecffon

hm been

mede.

nwARmG]

Do not enerEize

dsffaged

6qrlpm6nt

that ha3 noi

bsen repalred

or

vcrified,

Eml

Do

nat remove,

cover or

destsoy

iny safew

6igrB.

fllffigl Do not operEt€

th," .qrrpment

uftil all

pand$

and

Govelt

hav6 b6an

rcplaced.

n Prior

to

operating the

clrcuit

br€eker,

be

su.e that

thG citcuit breakel

unit

is installed

in the

correct cell.

tr

All block or

oth6r t€mporary

braces used

lor $hipment

must

be

removed,

E Before

alosing

,the

snclosure, all

mstal

chipe, scrap

wire snd othel

deblis

left

over

from

instelletion muBt

bs cleanad out.

E

Cover

all

unueed openings

in

the circuit

breaket.

cell

r all

ELEC'RICAt

CHECKS

nWARl|[Ql Eecrrical

shock

not

touch energlzed

components

u$ng

auxiliary

Power'

panels

and covars.

tr A

Eupply ot epEre

parts,

fuses, etc.

should

be

e3tsbllshrd.

I lnstructlon

manuals

snd

diagrams should

be collected

and

filed.

n

Replace

all

pans,

guards

and batriers

that

may have

b'een

rEmoved

during

wiring and

in$allation.

hazard.

Do

during

a tert

D An

6l6ctrical

insulation

tesistance test

should

be

performsd

to verify

that the

circuit brsaker

and

associated

fi€ltt wiling

arg

fres

from shon

circuits and

grounds,

Refe/tothe

MAINTENANCE

SEction of

this

manual

for additional

information.

EmllRlrB[q Hazardous

vortages

are

pr$ent

.luring dialEctrlc

testlng

whlch can

reault

ln serious

iniury

or

daath.

High

polentlal

taat3

should be

parformed

only by

qualified

peftonnel.

. All

switchos

dnd circuit

breakers

must be

sel

to the OFF

and/or OPEN

positlon

befors

Bnergiu

ing incoming

Powet'

the

llanual GLOBlllG

EUTfo

Fig.

3O

Typical From Circuit

Breaket

LeYout

lvlav

31 2012 9:

19A[1

No,

1530

P.

23

OPERATION

Page

19

MANUAL

OPERATION

ITWmmo]

powcrfl

spdns6, Do nor

place your

hends or iny

part

Of

your

body

inside

thi$ equipfient whlle any lndlcator

ahows

"CHARGED' {yallow)

or

'CLOSED'

kedl.

A.

Manual Chdrging of Closing

gpring

(Fio.31)

1l Rgmove

tho charging

handle

cover,

ldsert

the charging

handle into the

opening for th6 manual charging

handle.

2l

Rarchet

tha

h€ndl€

up and down

several tirnes

{u$u8lly

7

times) untii a

click

(latch)

sound is heard end tha

closing spring chargihg indicatot

changes

fioilt

"Dl$CHARGED"

(whitel

to

"CHARGED"

(yellow).

This is the

position

wh6rB th6 closing spring

is

charged and no

further

movement of

ths handl€ is required.

3) Remove the charging h6ndl6 and

r6plac6 ths cover

plat6

to the Opening.

NOTE:

The number

of times the

handle

must be opefsted

depends

on the

sngle of handla oparation.

B, Manual Closing Operation

Pueh the manualclosing button

(green)

and

th6 circuit braakBr will close

(Fig.

32).

At

this time the open-closed indicator

reads

"CLOSED"

(rad)

and

th€ spring charging

indicaror

turn3

to

"Dl$CHARGED"

(whlto).

A CAIIIIOII

: To

dvoid equipme r damage

do not

push

the closlng button

lgreenl

whlle

th3 clrcult braakar ia closad.

A CNmON

: To avold cqulpment damEge

do not

puNh

th. clo3ing button

lgrEEnl

whil6

the

ffp button

lred)

i$

depressed.

C.

Manual

Qpening

(Tripping)

Operation

Push the trip bwton

(red)

and the circuit

breaker will open,

The opan-closed

indicator

{Fig.

33} will

r6ad

"OPEN"

(greenl.

Fig,32

Fis. 3l Msnusl Chsqing

of Clo$ing Spring

Circuit Br6iksr

Clo€dd

Fig. 33 Circuit Breaker Trlpped

Open

tvlav.31.

2012 9:19AM

No.

1530

P.

24

Page

20

OPERATION

ELESTRICAL OPERATIOITI

Elsctrical

opetation can

ba carrisd

ofi at the

Ts$

or Connoctsd Pqsition.

when

tho

clrcuit

breaker

is

outside

of the cell,

it can be

operated

elegttically

by using

Toshiba

lntarnalional Cotpotdtion's

Sccgs$ory

lsEt

oabinet.

nffiq

powarfut

Spdngs. Do

nct

place

youl

hanrb or any

pan

of

your

body

imlda

the eqipment

whih

indicstor rhows

'CHARGED' lysllorv)

or

"CLOSED'

(r€dl.

Effiffil

66""L

crrcuit

breaker

namedate

for verification of

prop€t

oPeradng

Yohags,

A.

Eledtricel

Charging of Closing

Spting

Upon

applying

power

to tne

conlrol circuit,

the

charging

motor will immediately

start.

When

the sprlng

is

charg€d, the closing

spring charging

indicator

turns from

"DISCHARGED"

(white)

to

"CHABGED"

(yellowL

and

tie motor stops'

The spring

charging is now completod.

B,

Electrical Cloeing

Operation

When the

clo6ing switch

is turned to

"CLOSE"

position,

the

closing coil

will bs

immedidtely

enorgizod

and the circuit

bre€ker

will close. The open'close

indicator

wlll

th€n

tead

"CLOSED"

(redl.

After tho

clositrg

of the

brsek6r. tha

charging motol

will

immediately begin to

charg6

thg

olosing

dprings. Upon

rhe

completion

of

charging, the

closing

spring

charging

indicator

will read

"CHARGED"

(yellow).

6.

Electrlcal Opening

(Tripping)

Operation

Wh6n

the trlp switch

is

lurned

to

'TRIP"

position,

tha

trip coil will be

imrnedistely

energized and the

circuit

breaker will open,

wirh

ths open-closed

indicstor

reading

'OFEN'(greenl.

cor\lYRol ct RcutT oPEnAnoI\l

A, Closing Sequence

Th6

schematics $hown

in Fig. 34 thru

Fig.

36

r6fl6cts

the condition where:

1)

Ghatgtng

13

complate,

and

2)

Th€ circuit breaker

is

open.

IVOTE:

Thc closing

spring

immedi8tBlY

begins

chalging

when the control

circuit

is energizsd.

Pour€rful tprlngs

and movlng

geare,

Do not

plaae yout

hands

of

eny

part

of

your

body lnslde

the equlpment

whil6 tha

cl.cult brcNLGt

it chrrglng.

ln this condition,

the external

opBration

switch

cs(1|

is turned to

the

"closEi

position

causing:

1) Circuit

lL, b1,

LCS,

Y'b, X'b, CC to

energize

the

closing coil

CC,

in$tantlY,

end

2)

The circuit brsakar

closing

llm.

18

304O

mcec., at which

tiffie,

3)

Auxilidry

switch b1 opens,

4) Closing

coil CC, d€-€nergiz€8.

5) Auxiliary

relay

Y,

energizos,

completing

th€ anti-pumping

circuit.

B. Charging Sequence

At

the same

tima tha

circuit breaker

is

closed:

1) Limit switch, LS,

closes

2) Control

Felay X, enargizes

3) Circuit

LS, LS,

X-4, M,

X'4. F is

complered,

and

4) Charging

motdr

runs

(for

about 4

eec)

When oloslng

spring

is charged:

1) Limit switch,

LS,

opens.

2l

Control

r6lay

X, de-energizes.

C. Tripping

{Opening}

$equence

The

tripping

of the circuit breaker

involves

only

the a l

,

TC citcuit.

when the extelnal

oporation switch

GS(21

is

turnsd

to th6

"TFlP"

position:

1) Trip coil, TC,

engrglzss,

and

2) Chcult

brEake. opening

ot tripping

fime

is 15-20 maec,

At

which

time:

1) Auxiliary switch

A1,

opons

2) Trip

coil,

TC, de-anergizes

IIOTE:

FOr clrcuit

brsakers with different

valtagE combinationg

lor cloaing,

tripping

or charging,

consult

Toshiba

lntgrnational CorporEtion

tol

the

particulSr

schEmetic.

Mav

31, 2012

9:l9All

No, 1530

?.

2,

Page

22

OPERATION

FiC.

36 20S250

VDC

ContIol Circuit

Schematic

SYMBOL

DESCRIPTION

Auxiliary rslay coil

Y-b

Auxiliary

relay cofitedts

(N,0.)

x Conuol

relay coil

X-a Control

relay

contacts

{N.o.l

X.tt

Contlol

rclry contacts

(N,C.l

cc

Closing

coil

TC

Trip

coil

a1{5

Auxiliary contacrs

(N.O,l

bt-b5

4ur;11"ry

q6n166s

{N.C.}

M cherging

motor

LS

Limh switches

DI

-D5 Diodes

RI-R4

Resistors

IL lntor'lock switches

c

Cepscitor

F

Fuse

Lcg

Latch Checking

Switch

Hg,37

Legend for Co rol

Ckctrit Schamatics

Nlav

31. 2012

9:l9AM

No.

1530

P,

26

OPERATION

Page 23

l-8 SN" end doGlng

$dng

dlal!€d

t-5'oFF

Clodng €igr,Ll

slrn o{ dGln! op€rdion

Cdlnpleuon ot do8lng op€rdon

1.3

!Ol{i

rnd deing rgnrB

cfierged

Stai of healdng

operuisn

Flg.

38

Sequance of Opgration

l/av.

3l. 2012

9: 19Ali1

No.

1530

P.

21

Page 24

OPERATION

trip

cacch

trip

coil

c ioEing

sprilg

Cl

oei ng

Vac

lrum

inter!uptef

paddle

Closlng

eoil

CloEing

Trip

paddl€

catch

Wip6 rl)rl

CloElbE button

openisg

spring

\

I'taid

Ehaft

Flg. 39 Mechanist$

N1ay.

31

2012 9;

20AlV

No.

1530

P

28

OPERATION

Page 25

MECHANIgM

OPERATIOITI

fAlmml|Fl

Do not

modify or ovedosd

thc

clrcult

breaker operati

g

mechanism.

Slow

clo:ure

of the broaker could

re5ult

in file

and

explo6ion.

A. Closing

The

condition

shown

in Fig.

40 repressnts

the condition

whete the oircuit

breakst

ls

open

and the closing

spring i$ charged

(ready

for cloringl.

ln this condition,

tha

closing

catch

is

released by the

closing

button

or th8 closing

coil, the

closing

spring

csuses the cam

lo rotate

quickly

into the condilion

shown

in Fig.

41 in

which

the circuit breaker is

closed.

B, Charging

From

ths

closed condition

ol Fig.

41 only

the closing cam

is rotaled

by

tha

motor,

with thB

circuit breaker kept closed,

ufiil

the

roller on

th6 cam sngages with

the

catch.

Tripping

Wh6n

thB trip Bhaft ig released

by lhe trip

button or the trip

coil,

dll tha linke raturn

to

the original

open oondition

shown

in

Fig.40.

Trip Free

Whed the

trip crtch

ls r€lea3€d,

tho link

will

move to the trip

free condition Shown

in Fig.

42. When rha charging

operation is

completed,

the

link wili

asBums

the open

condition.

Fig.40

MechanismOpened

D.

Fig.41

MBchNniBm

lmmEdiBtBly

attef

Closing

by Signal

Fig.42

MschNnism

TriPPed

Free

ltlav

31 2012

9:20A1vl

No, 1530

P.29

MAI|uTEilATIICE

PROGRAI$

ln

ordgr

lo €nrur€

continued

reliable and safg

opefatlon

of

lh€

equipment, a

program

ol

routine

maintenance

must

be eetablished.

Operating

and environmental

conditions

will

u6ually dictst€

thE frEquency ol inspeotion

rBquired.

NFPA

R.lbllcatlon

708

'Electrical

Equipmsnt

Maintenance"

may be usad

as a

guide

for satting up thE

maintenance

prog6m.

f@@il

contact

with .netglzed

GomponeBt3

Gan caut€ ievere

iniury, .l€eth

and

Foperty

<lamege.

Tum-off

and look out

hlmary and

Corttol Citcuit

Powar bofore

Ser1,icing.

|AUARlllG-l

tmoropor

matnt€nEnc€ can

c*l86

selrEr€ lnJury.

dsath, and

prop.rty

damage.

Only

qualified

and

aut}odzed

peBons

are

to irstoll.

operatE,

or r€Mce

thls

eqripmBnt.

Do not

allow

grrlte

or lny

othsr

subetancs

to aontaminate

any

intularirq

materl6ls.

Gofteminated

lBulatots oan

allow

8 rhort clrcult

ot

ground

fauh to occul.

iIOTE: Refer to the SAFETY

section

of this

manual lor imPonant

information.

MAIII{TEIIAT{CE

HECORD

Keep

a

p6rman6nt

record

of all

maintenanca

work. At

a

minimum, this

r3cord should

lncluda

information on:

Item$

inspec-tlon

Repons of

any testing

Equipmem

condhion

Corrective

actions

or adiustmems

Dat6 of work

Comments

The

degrss

of detail of

the record

will

depend

somewhat

on the

operating

cond ions.

Teblg

2.

Gircuit

Breakor

Recommended

Torque Valuss

TablF

3. $witchgear

Rscoflmandad

Torque Values

1)

z',r,

3)

4t

5)

6)

Hardware

Size

Recomm6nded

Torque

M3

M4

M5

M6

M8

M10

M12

{kgf-cm)

10

20

40

80

200

350

450

(ft-tb)

0.7

1,4

2.S

5.8

16.5

26,0

33.0

Hardware

Size

BecommsndBd

Totque

1t4-20

5/16-18

3/8-16

1t2-13

(kgf-cm)

55-83

138-207

276-415

553-691

(ft-lb)

+E

10-15

20-30

40-50

ftlav

31 20l2

9: 2OAlVl

No

1530

P.

30

SERVICIITIG

EOI,IPMENT

For

your

safety,

turn ott and

lock out

main and

control

circuit

powel

betoae

servicing

th€

circuit

brsek6r.

Should

ssrvica to

thB circuit bleaker

bo

required

while

tho system

remains

energized,

enrome

caution ust be

sxarcisdd.

Al8o,

certain minimum

safety

procedu/es

mu$t be

followed:

1) Only

qualtfiad perronnel

should attempt

this

38rvic6.

2)

Oo not servic€ a

eircuit bteaker unit

while

connected

to ths

line lerminals.

withdraw

the de-energized

circuit

break€r from

the

anargiead main

bus before

sgrvicing.

Never sE.YicE the

olrsult

breaker

whlla ln the Cormeoted

Porition.

3) Verify

that the automatic

Iine tsrminal

Ehutters

are

closgd, Ilcver service

a unit

unless

the$6 Shutters

ara

fully closed.

4) ltleve.

perform

s6rvic€ on

or next to

exposed components

energizEd

with lin€

volteg6.

lIfimFildl

Fairure to adhere

ro rh€s€

ittety

pmc€durt3

can

tG8ult ln 5everc

iniury.

death ard $evere

prop€rty

damagB'

l!1av.

31.

2012 9:2OAM

No.

1530

0 11

,)

Page 28

MAINTENANCE

INSPECTION

AHD MAIIITENANCE

TYPE$

IUOTE: Refer to the

SAFETY sactlon

ot

this

manual lot impqnant

intormation.

For

points

and types

of

lubtication

refer to Fig. 43

A. Acc€ptancB lnspsction

This

inspaction confirme that the circuit

bredke.

unit

ie completa, corr€ct

as

epeciJied, and undamaged

from

Ehlpmant.

Th6

procEdure

for this in$pection

ls

outlined

in ths BECEIVING eEction of

this

manual.

B, Ftsfiol ln$pection

lnspection

of the condition

of th€ circuit

breaker

while energized.

1) Check

thar no unugual sounds or smolls

exists axternally.

C.

Vi$ual lnsp€otion

lnspection

perform.d

with thB circuit

breaker

withdrawn flom

ths

switchge8r

companm6nt.

I

)

Wiih front

covet removed, inspect

entire clrcult breaker

fot deformation,

ruai or any other

typss

ol

abnormalities-

D. Periodicel

lnapection

lnspec on

parformed

with the circuit

bteaker

withdrawn from the Bwitchg€ar

companment.

1l Psrform Visual lnspection.

2) Clean and lightly coat the contacting

gurfac€s

ol rh€ main conductive

pans

with

Toshiba

B8

greas€.

3) Close

and ttip circuit br€ek€r

manually

and alectrically to

insure

Proper

operation of

m€chaniom.

ChEck wiPe

measurement

(Pg.

361.

4)

lnspect to insure

lubricadon of sliding

end rotating

pans.

5)

LubricEt€

sliding and rotating

parts

with

machine oll

ts

r€quirod.

6)

Test

the clrcuit

breeksr to inaurB

that

primary

and

$econdary

circuit in3ulation

reeistances are

within Toshiba

lnternetlonal

Corporatian

specilications

(Pg.

35).

E, Detail lnspection

lnspection

performad

with

rhe circuit

breaker

drawn outside

of th€ switchgaat

compertm€nt.

1

I

Parform

Periodical lnspefiion.

2) Re-grease

sliding and

roteting

part8.

Feplac€ cotrBr

pins

and E{ings that

are

removed

with ngw ona8.

3)

Perform diol€ctrlc

test

(s6e

Vacuum

Chack

on Pg. 37)'

4) Test the circuit

bisak6r

to insure that

closing time

(Pg.

201,

openlng

timB

(Fg.

2O)

and minimum operating

voltages

tPg.

48)

of

bolh the

closa and trip coils

ar€

within

Toshiba lnternational

Corporation

sp€cifications.

F.

O\rernaul

Complete

di3assembly

of circuit breaker to

replace worn

pdrts

Es

required. Clsan and

re-greaae all

parts,

To

be

performed

only by

Toshiba

lntgrnational Corporation,

[1ay.31.

2012 9:2oAM

No.

1530

P,

32

Olh

or tO

vAc.+N: or-

O&

cr

:5C

,rcsir rA E6 cRlcsE

o#

cr

r&o

ro

Nor

-uERrcAiE

cl coN-AVl."lA-

t{,Tr OTIER Cr'-s Cl GiA{S:

b:tA| A

(sHcwN

DTSASSEVBLED)

:)fi:RNAL

Pc|l-r S

I\'TERNAL PCI^ES

Flg, 43 Points and

Type6

of

Lubricetion

Mav

31. 2012

9:2OAM

No.

1530

P.

33

Page

30

MAINTENANCE

INSPFCTIONANDMAINTST{AilCE

INTERVALS

Tho frsqu€ncy and

detail ot

the required

lnspefilons

will vary

depending on

th6

anvironment

of service and type

ot

inspection

to

be

performed.

Ueing Fig. 44 select

between

the

charts oJ op€rating

years

and operating

cycles

which

will reQuire thd

most fr€quant

inspections

and maintenance.

ln addhion,

when applying circuit

b.eakers

in

severe almospheric

sites such as

outdoor

companftents

,

dusty

gnvironm€nts

,

high

temperaturss

and/or

high humidity

the

inspection and

nrairtanenc6 frequency

should

ba. at a minimum,

twice as

oft€n.

lf th€

1 2th

year

overhaul

is not cetriBd

out, ths

Detsil lnspBction

should

be applied

in

the

cyeleE

of ths

Psriodical lnspaction

(every

3

years),

Should

the circuit

breeker

ba

subiEcted to a

sev€re

condition such

as drop,

collision,

earthquek6

or

fire contacr Toshiba

lnternational

corporation

for s compi6ts

inspection.

lgpldoh

&rpFfrn€ & Pra4llcl!tssn

Ctpdt

l6dnl

I

Frio.Hl

ItlHr

gerdot!

ln+€roolt

AcEsFsnEa i

PllEsnrEtsdl Clrd(

Vlllnll

Pdiddiod

I

0

1000

4000

0000

4@

5000

5000

7000

d0d0

9000

10000

Fic.

,*4

lnepection

Frequensy Schedule5

fffir@t

ablpdudE'ign

9.CtFd(Ublb#n

a uidcdrth

ol

[.

HanrE haddon

Fd.EB

6.R.{rE

7.

Dlalacllc Toa

Chsd(

ffir1!6?V&urlt

8. OprdB

Cll."dtHc

ll.sramst

g,

Oodvlda

D5*ni6t {d Hetdld

Fig.rlS lnepection

and

Maintenance

Tree

llav.31

2012 9:20AlVl

No

1530

P.

34

MAINTENANCE

Page 31

at

.v

(E

[,

rc

c..io6

-g-p(\

€€^-

FFE

oG

6N

.ct ;

Pd

o

tt

o

E

ts

o

o

o

!

cqi

PE

r-B

Etl

ond

tL-c

F.

oqrE

-ooi

cE8

.c .>

,:E-

B50h

O IJ{!

L

;olEE

5 Et

-Ct

3t

tl

E

o

A."

8H

9o

ss

dP

CE

+rlt

9E

oR

G-

fig

.EE

oo

lEc

si

_r

Ntr(:

:4C0.

E'E E

E.96

Ee_

!t

r: H

8EF

s-g

H

ohle

IECLf

!il

f,ft

.=B

9.8

luo

EC

9o

d

3b a

8E

-

8

Eol>

€HEE

EEE€

F

(J

o

.Bd

-a

+;

6E

fiE

6t-

E5

bE=

t;g

:€:

'i8E

EEEE

o

'6

6Ul

3EI$

9iE

Jcl6

.EEE

gIEE

oi,

Een

f€;

e

B

3

-c)

EE

Vrg

6r .=

g

.st

FE

E

oo

EE

*E

EE

JIE

EE

l,ra

'rE

oq

3!'

'l

qo

dg

o

ot

d

-t!

tGd

oEt_t

tc.F.

cr:8

!c@r

d;eFl

(J-c;rit

EXXO.

IJJOEla

Es

.t-

p9

EE

{',E

.g!

to

;83

E9g

tr- ct rl

o

E

!0

=

J

I

E

(J

8

.lr'9

oil

.e

8g

O.E

B

ET:

gEE

J

(J

6

(J

6

:

t,

IJ

o

.tr

()

E

.!

()

d)

E

U

(c

o

{,

qt

r'P

C

r-.P

OEE

E**

f !1 E

g€E

J

u

I

iJ

:t

lt,

5

J

t)

s

a

.q

E

o

I

C'

6

.c

(J

o

8e

o6

E}

,lE

,9E

F_C

o

c

9E

:.6

t, @

d.P

c,

r0J

838

'tl

a.l

fit

.E>E

EE€

EHE

ED

c

'd

ct

.E

o

-g

g)L

oo

JEI

vt

o

dL

tl

5

IA

g,

5

.D

o

HB

o6

otr

trd

ulE

E

c,

3

T'

E

ll-

o

o-

J

(J

t)

(J

o

:s

-

0lE

6'=

-l

l,

ts.= P

=

l!(J[d(,l

o

z

.A

J

d

llt

F

z

;

t)

z

z

r!

F

z

a

2

o

z

z

o

tr

C)

ut

c

ah

z

.F

o

F(.l

,EE

6E

TR

E6

!c

*-C

o.-

r.-

O

oc

!o

.t Tr

-Eo

tE

o:

so

96

1E

l!u

-o

{t

F5

flay.

31.

2012

9:20Al!1

N0.

1530

P

35

Page

32

MAINTENANCE

o

_v

c

=

o

E,

c{('(o

o o({

iFfl

t-t-v

o

E

o

E

s

=

a

o

E

CL

!t

c-->

6H;

I

oB

5C6

t.E s

ahSi

8r

-d

sfl

EH

FC

o

o

ad

CI

6

o

Pu

lio

ct6

oo

.EE

ah

F

o

o

6

o.

o

o

.E

,=

dt

q,

tr

e6

ori

IEE

ct

EC

E'6

.F

.E

e>

oll

bo-

EEE

TZEO

o

o

U'

f,t

3E

gE

'=o

E!.

b9

64

AE

o

c

o

-t6

IEF

e-

tto

6!J

-t,

Ir0

d E'6

o

E

6

.ia

o

o

E

oP

> e-a

b'c 0t

tt

_=

!l

o'a

trbo

I

eE

E'i ta

E''E .

6Pig

gEg.E

F

CT6

O

d)

5€

Ed!

()c

E>

3E

oQ

.E

ci

E.,e r

d',o,-g

3E;

{fi;

co

._

ED

>.c

P E'E

E8R

.ov

.D otE

.

E.efE

a-=6

ED

it

=

>

-:J-O

a, E= o

Ei{e

E.9du

EEAE

Or

tr

-a)

E.d

EE

-o=tD

-e4

6Jc

S":BH

q€

I

EE

gri;

FE

.aE

EFl-

FFEEH

aqooEdl

u) ca

ara

T'

c

o

att

:

E

o

c

o

-!!

=a

YF

o-

o6t

oQ

nt

'cl

E

5

9

rlt

.9;

'EE

oo

o.tr

o;

.l

c

o

o

E

att

o

o

€

a

f

E

E

.c

o

E

!

(t

o

E

(J

J

TJ

ID

"c

(t

EI

:

ab

dt

ttt

.4' I

(,

i:

O.C

aa

6EB

ET:

60.

9ti

.l

(,

I

t

o

:

-o

.t

tJ

o

E

o

F

f

p

J

C'

o

a)

!d

l

o

r'9

lo

g$

E

o

rri

it .E

c!

t'o

e?

6E

..v

o

c

E

o

E

E

o

g

!

o

E

.c

o

F

E

B

{

st

.E'j'

!r aJ

co

:rc

ot

68

E

F'

dsi9

A

E.E

BgE

(J

o.o

ta

tr

-g

a

o

EI

att

o

td

!rE

6h

an(D

de

c

FO

Oftt

Pi

EO.

t,/)6

oo

-!l

o-

60

uc

llF

fo

l.o

Ed

cr,

Fg

'6

o-

6rr

UE

E

tJ

o-

o

o

E

o

6

ib

'\'

cD

g

ct

o':i ia

o

!jYOI

fii5fi6

E>

cD6=

EEfiE

"8gEE

o

z,

-

C

o

o

c

o

E

o

I

o

c

o

ut

c

,6

!.

J4

ct

rD

E

(J

+

-c

.o

6

F

N1ay,31.

2012

9:2lAM

No.

1530

P.

36

MAINTENANCE

lt

it

E

g

o

E

ID

lq

rir

d-

t\

d)

ED

m

n.

o

EI

o

E

3

=

E+

htso

o-P

.>J.E

cI-o

o

qE

E

<tdtr

ED

tr

oE

E Ic

E

".o

CEE

oio

tr O, IJ

"-9-l

.g

F.q

;

>:c

-.=

H;

Ee

F.: bq

=---v

EE.Bsr*

fi.s E E-9

o

8.HE

'=

o ar.E

frE

sf;

}EEd

-E

'.=

:1 0

tr $F;

oP- o

,EE; E

P

fi;g€qE

FE.E:E

HF

':

oF

-e€.o

ti t!

0!

ln

Ed

gFF€

s_96-9

>oust

6

o

E

TJ

*

o

o

E

ttt

E

6

E

i

f

E

-b

o

o

o

o

i

o

o

E

t4

Ei

FE

ho

tso

ecl

o-

c,6

(g

I

c

o

i$

6

lr

E

o-

o.=

-c

dr

6q

!t

.i

*g

.sE

o

o

d,

an

.l,

o

6)

.c

(J

E

(}

d

ql

ff

g*Et*El;EE

:Ett

SEis

gS

g

fig€E?E'EEE

EH;cEic'E[;

.9d

ou

E,p

.l

6e,

EE

€s

tr!

tr

lll

{.1

c

uF

3rJ

EE

nL

o

lll

O.!E

FE

E

o

-c

o

E

*

o

()

g

u

!)

(l

E

o

c

o

EJ

oo

tro

3-c

l!t

c