SERVICE MANUAL

3LCD DATA PROJECTOR

TLP-X2000E/B/U/C

TLP-X2500E/B/U/C

FILE NO. 330-200711GR

TLP-X3000E/B/U/C

The above models are classified as green product (s) (*1), as indicated by the underlined serial number (s).

This Service Manual describes replacement parts for green product (s). When repairing any green product (s), use

the parts described in this manual and lead-free solder (*2).

For (*1) and (*2) , see the next page.

Published in Japan, July 2007 GREEN© TOSHIBA CORPORATION

I

C

ontents

Table of Contents

Chapter 1 1-1

Specifications 1-1

Using the Menus 1-3

Names of the Terminals on the Rear Panel 1-4

Name of each part on document camera 1-5

List of Supported Signals 1-6

Chapter 2 2-1

Replaceable Part Hierarchy 2-1

Required Tools 2-2

Parts Replacement 2-3

Replacement of optical parts 2-15

Chapter 3

SINGOWS 2000 3-1

Chapter 4 4-1

Firmware Upgrade 4-1

Chapter 5 5-1

Wiring Diagram 5-1

Block Diagram 5-2

Chapter 6 6-1

LED Display 6-1

Troubleshooting 6-2

Operation of Power Supply 6-9

Chapter 7 7-1

Electrical adjustment 7- 1

Chapter 8 8-1

Functional Test 8-1

3-1

Chapter 9 9-1

Spare Parts List 9-1

II

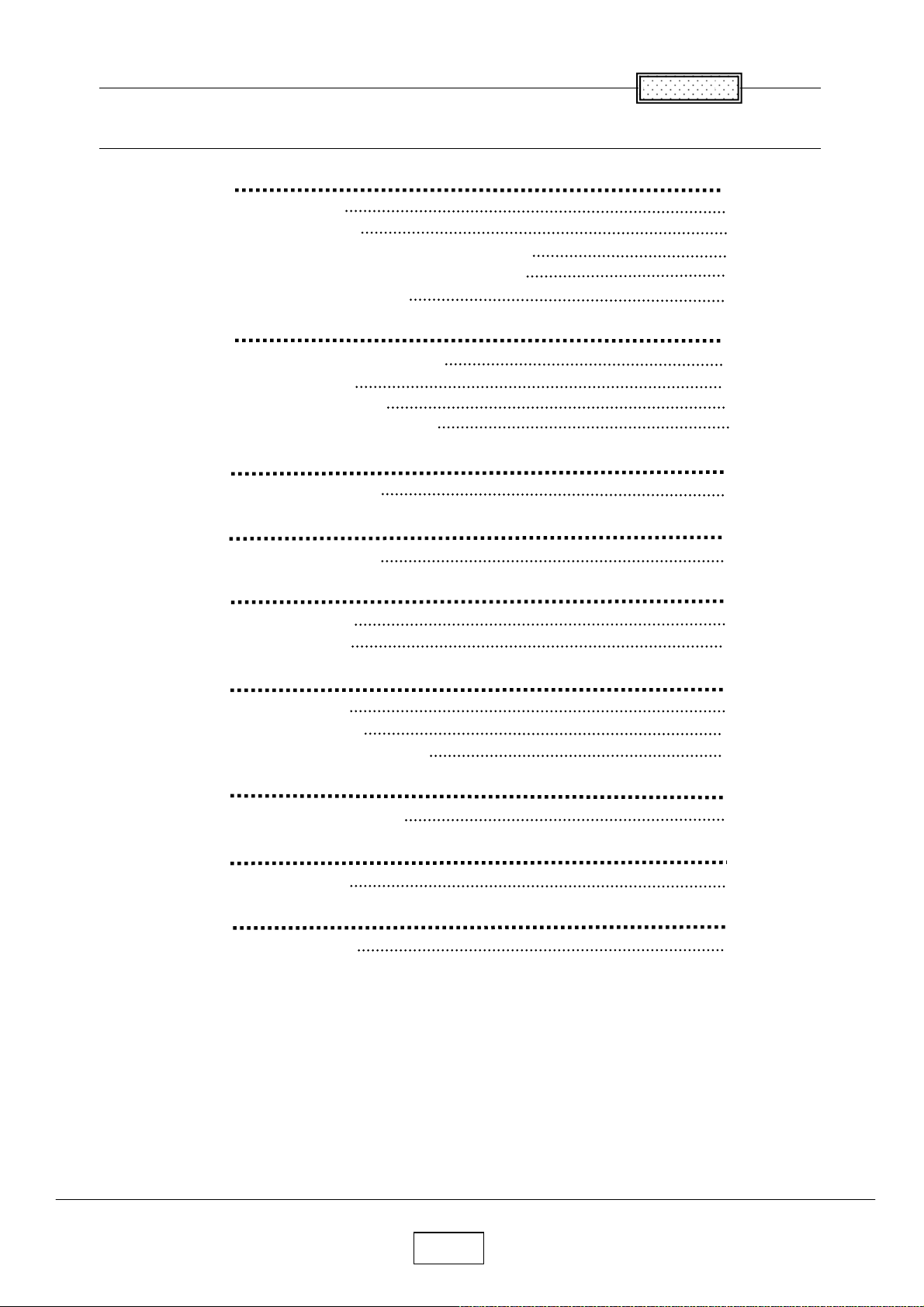

Chapter 1

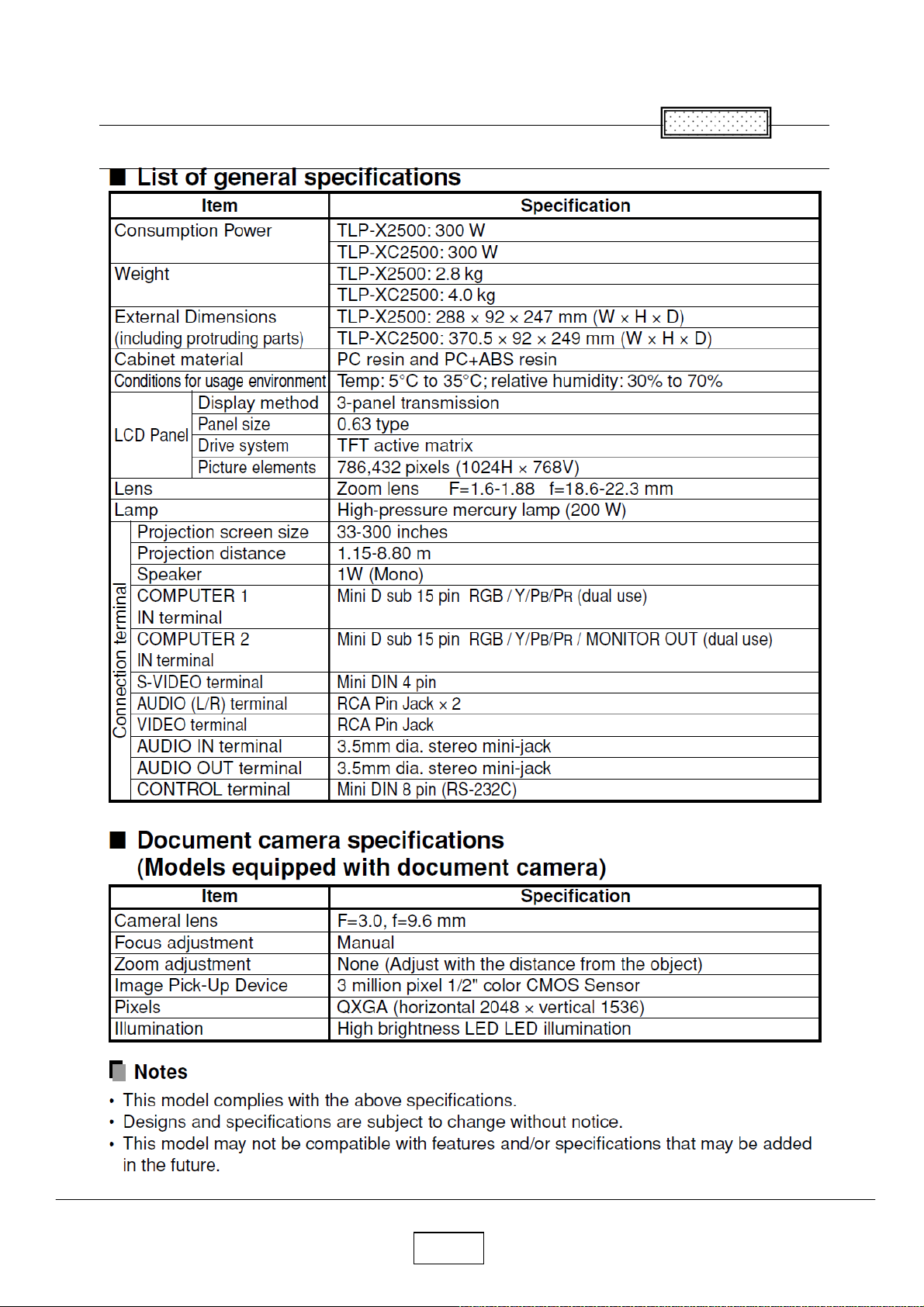

Specifications

Chapter 1

1-1a

Chapter 1

Specifications

Chapter 1

1-1b

Chapter 1

Specifications

Chapter 1

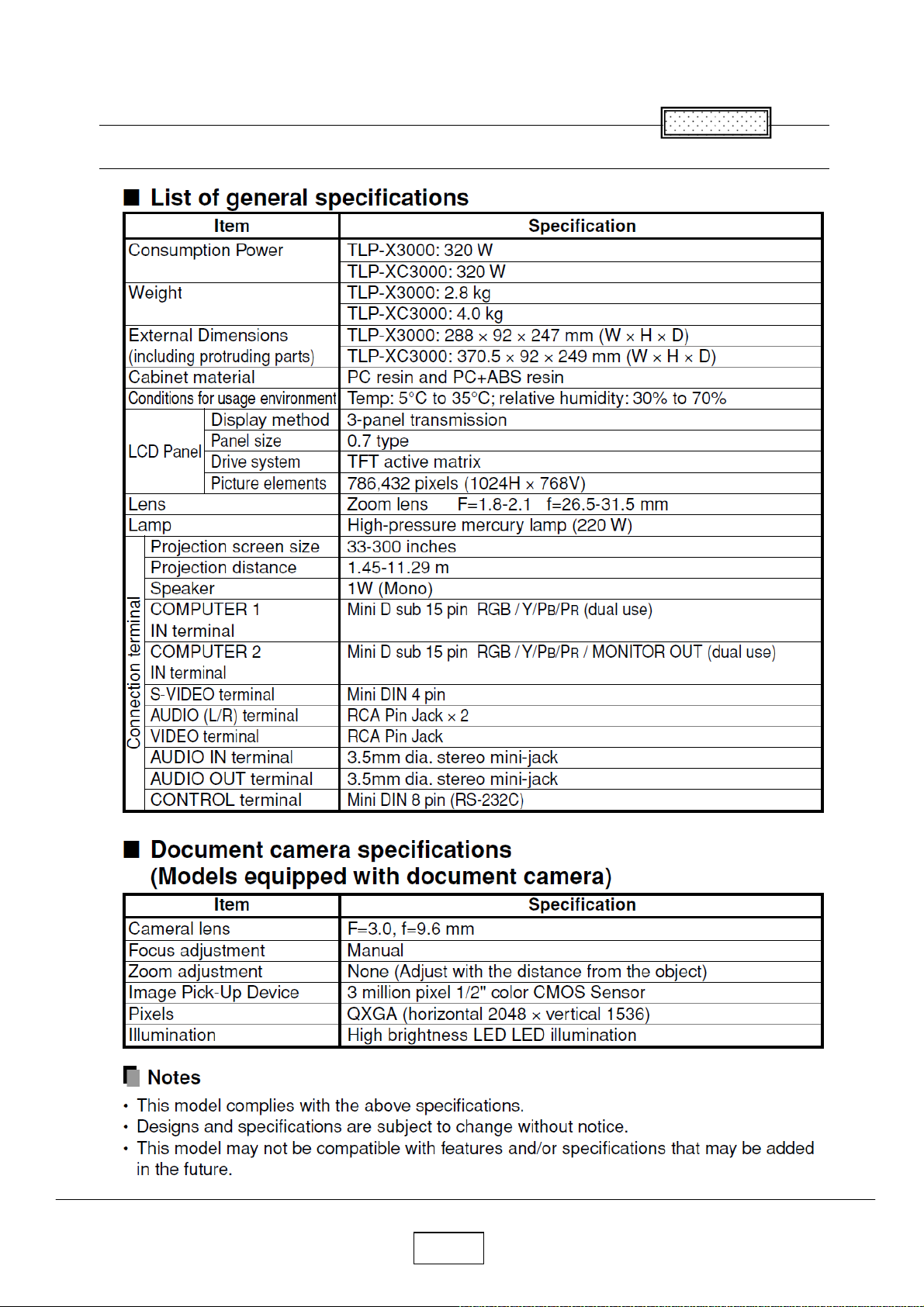

1-1c

Chapter 1

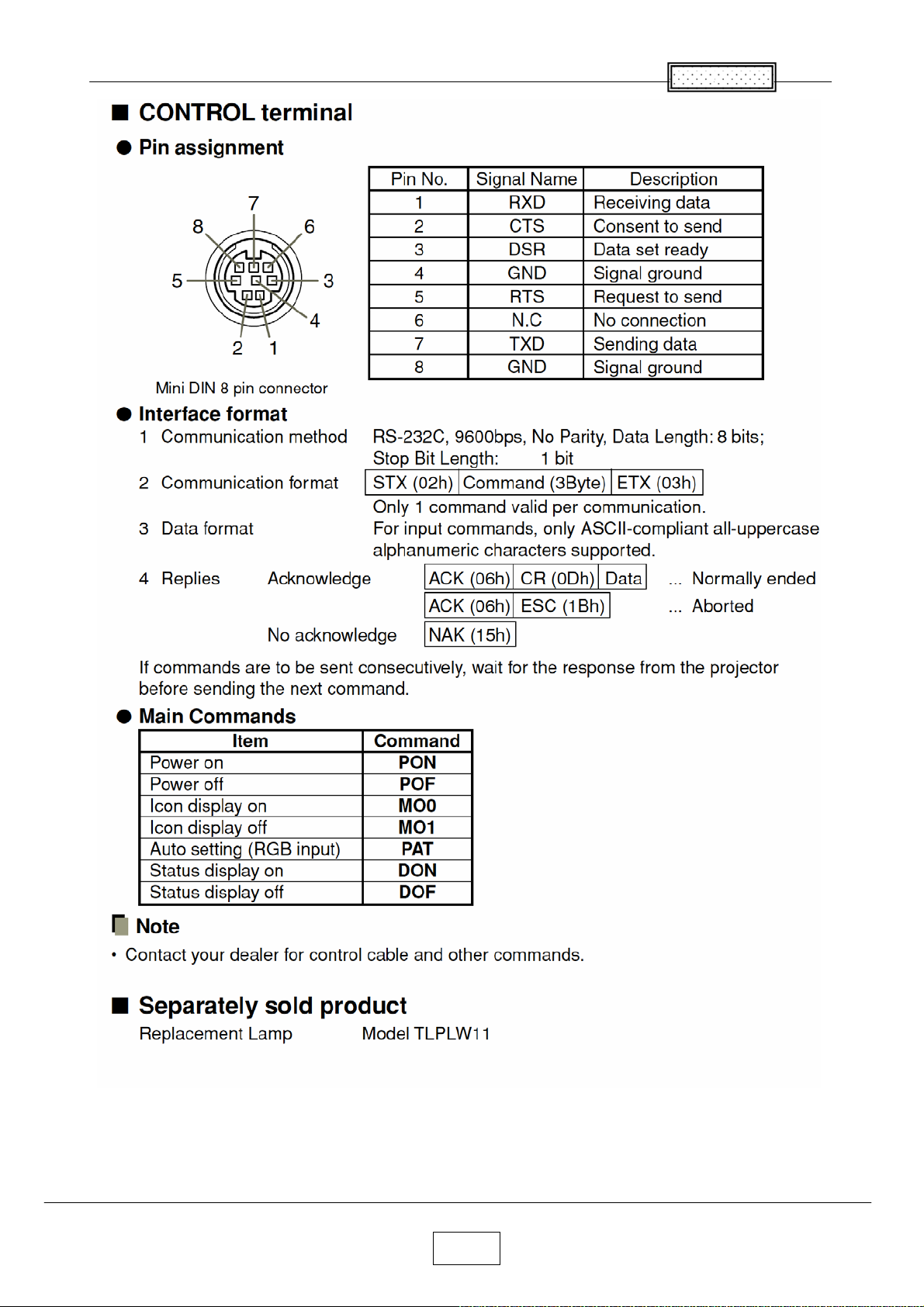

1-2

Using the Menus

Chapter 1

1-3

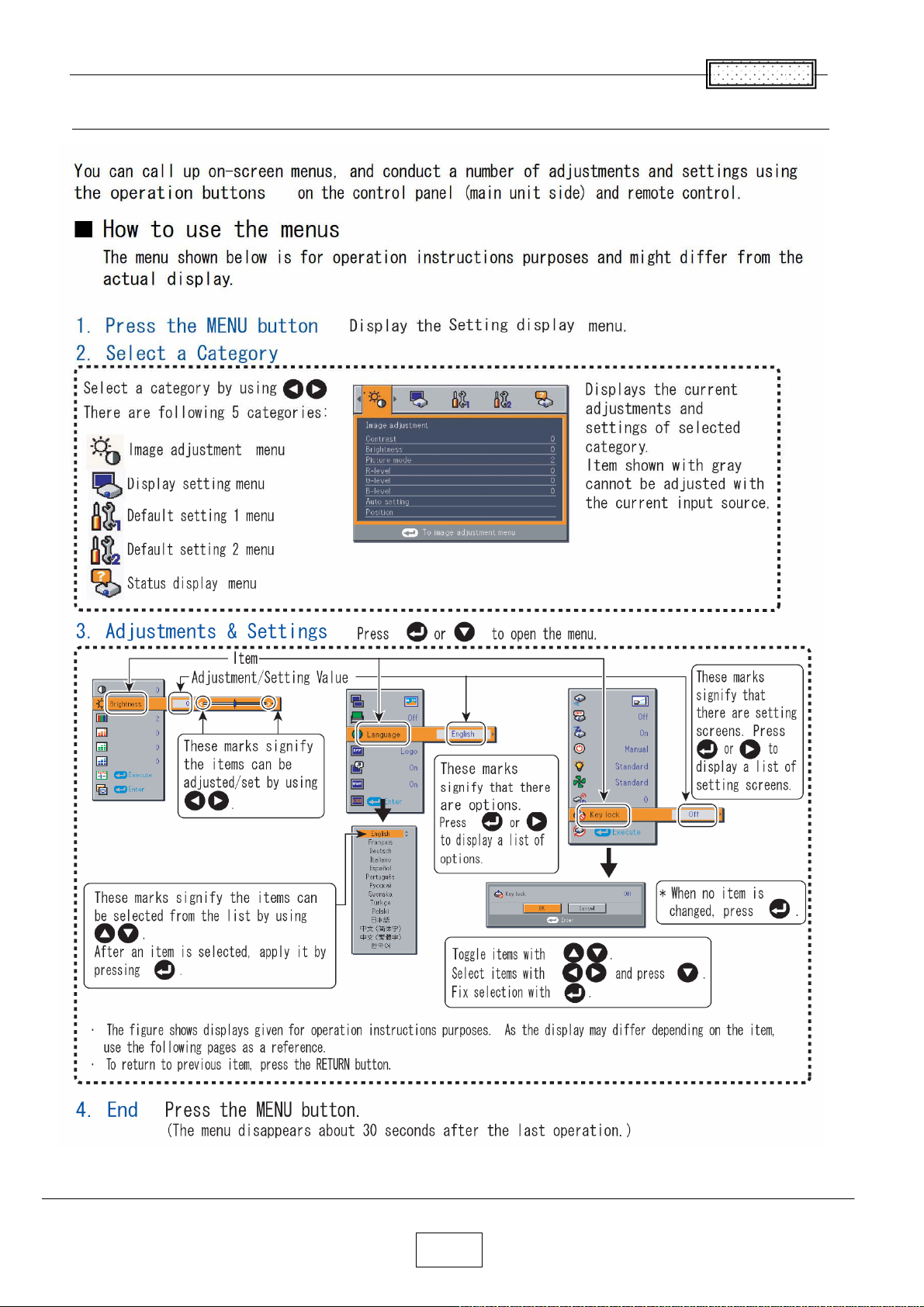

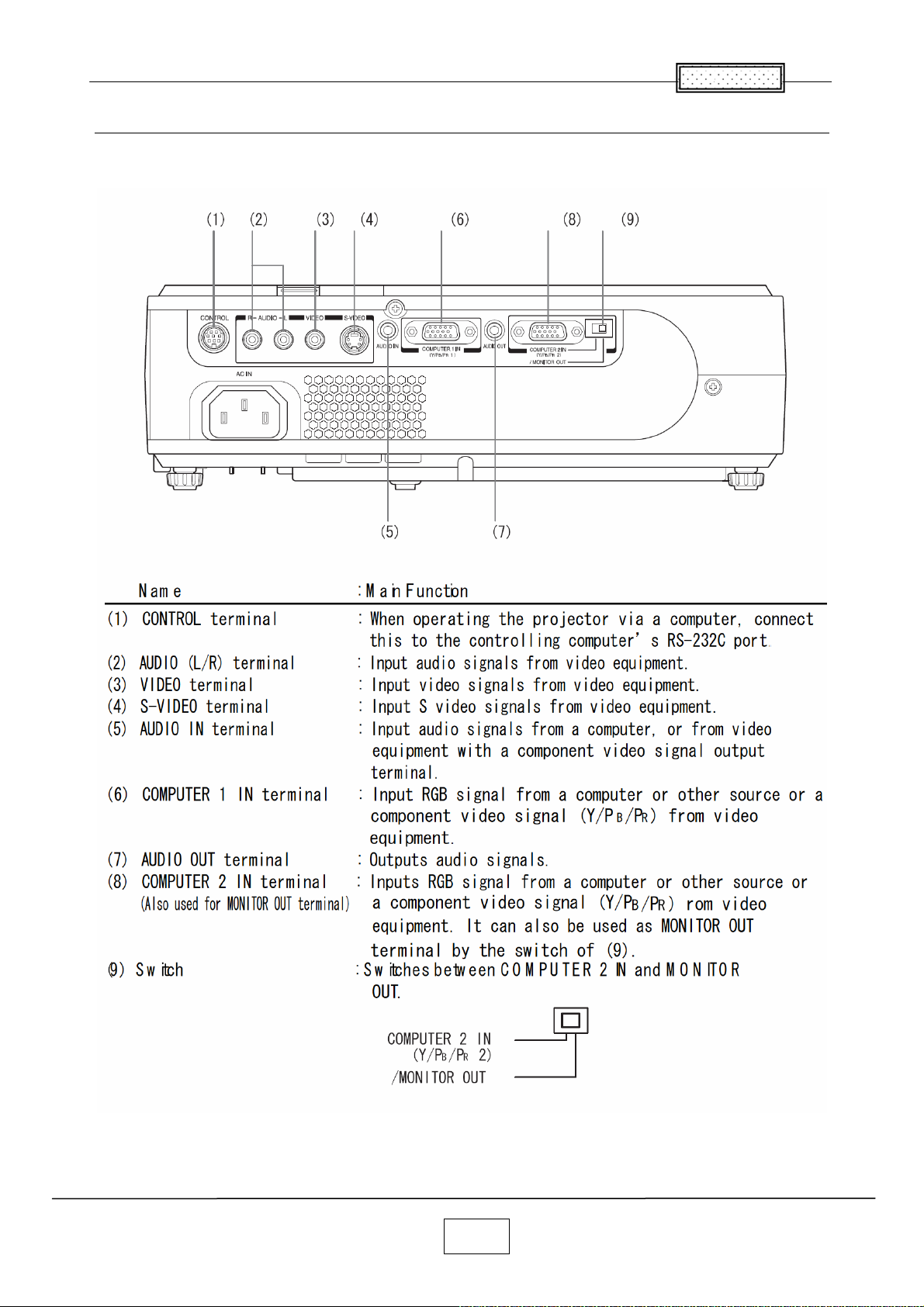

Chapter 1

Names of the Terminals on the Rear Panel

1-4

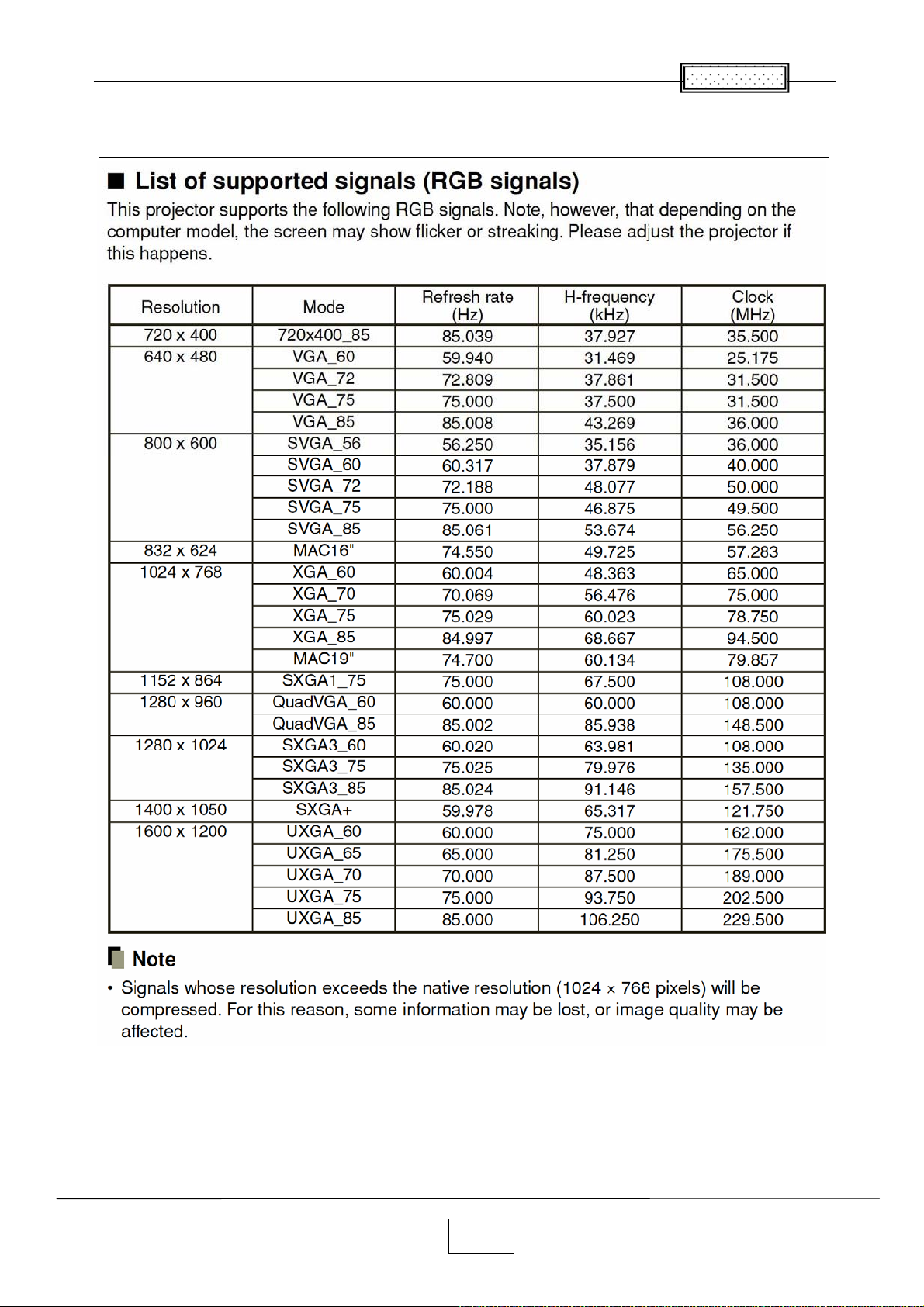

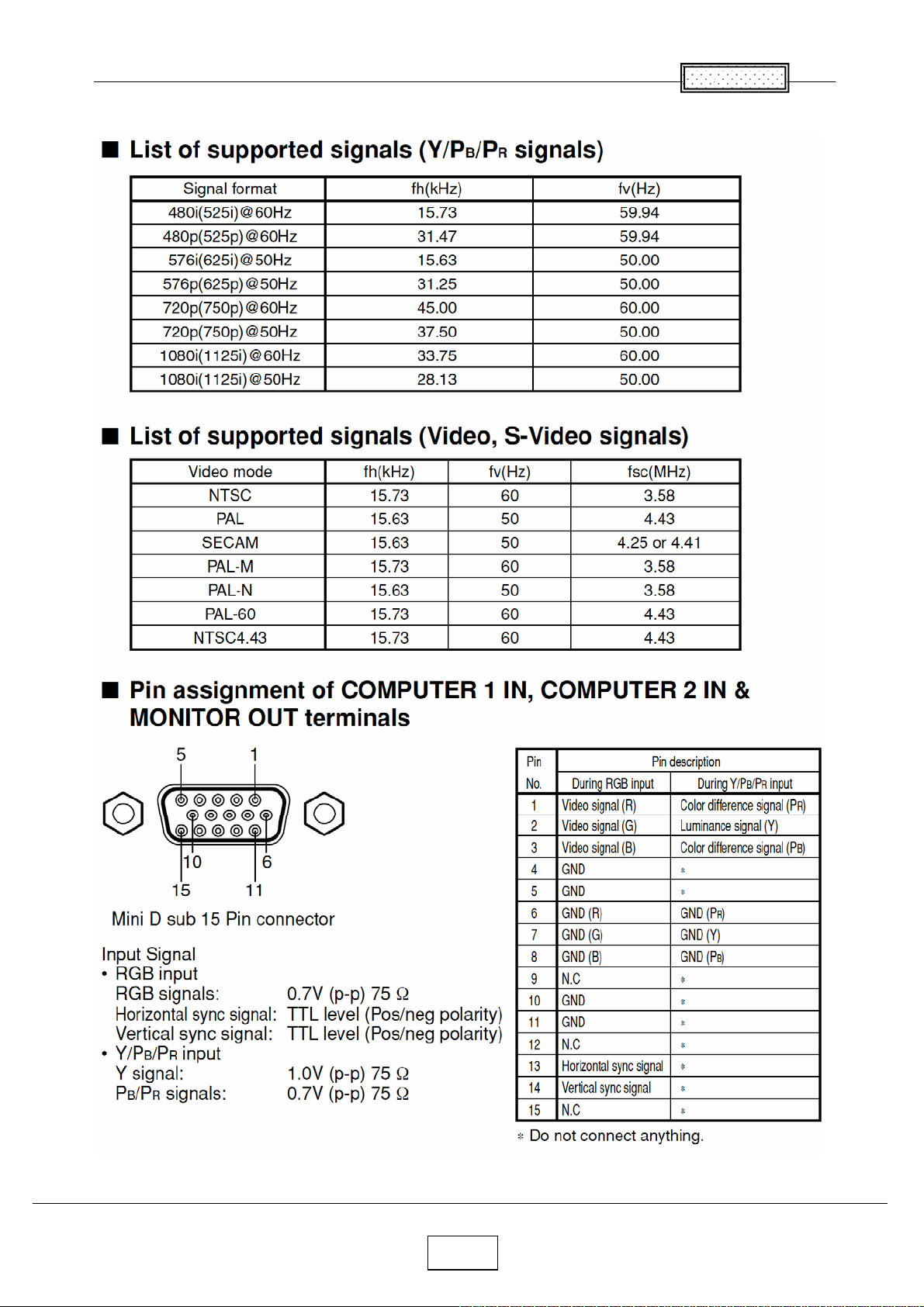

List of Supported Signals

Chapter 1

1-5

Chapter 1

1-6

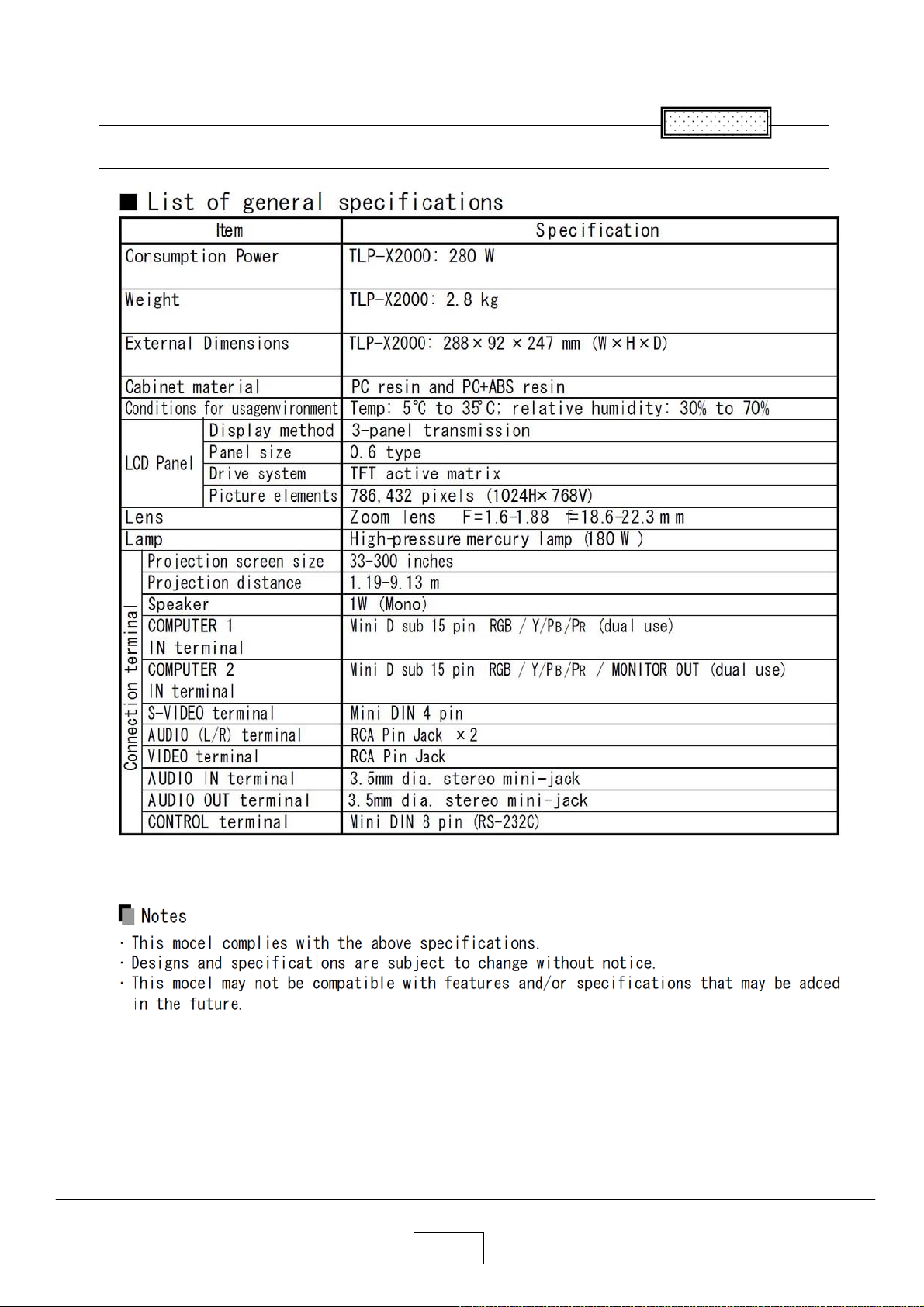

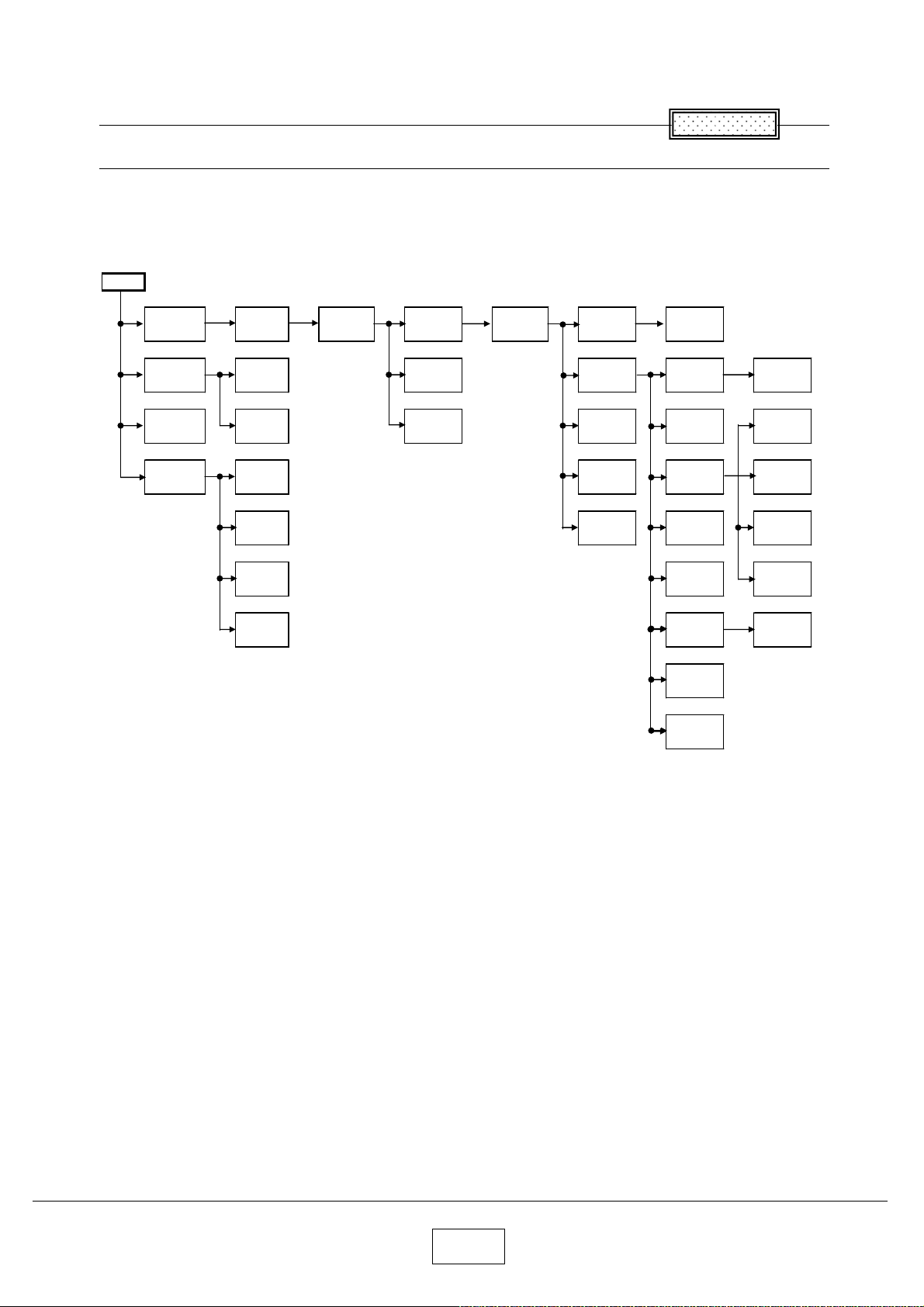

Chapter 2

2

Replaceable Part Hierarchy

Replaceable Part Hierarchy

The flow chart below shows what parts must be removed to access each replaceable part in the projector.

The parts on the first level (Ex.Lamp cover) are accessible without removing any other parts.

The move levels down that a part is, the more parts you need to remove in order to access it.

Start

Chapter

Lamp

cover

Control

panel

Lens cover

Camera

assy

Lamp

Bracket

LED

board

Speaker

Camera

Main

Camera

KEY

Camera

CMOS

Camera

LED

Top cover

PCB Main

Remocon

receiver

PCB

Sensor

Cover for

Power

Power

Main

Optical

Engine

Intake

Fan

Exhaust

Fan

Powe

Filter Fan

Front

panel

LCD Fan

Door SW

Balast &

FAN assy

Lens

Color

wheel

Power

Filter

LCD

Panel

LCD Filter

Foot ADJ

PBS Fan

Balast

Fan

Lamp

Driver

Rear

panel

Thermal

SW

2-1

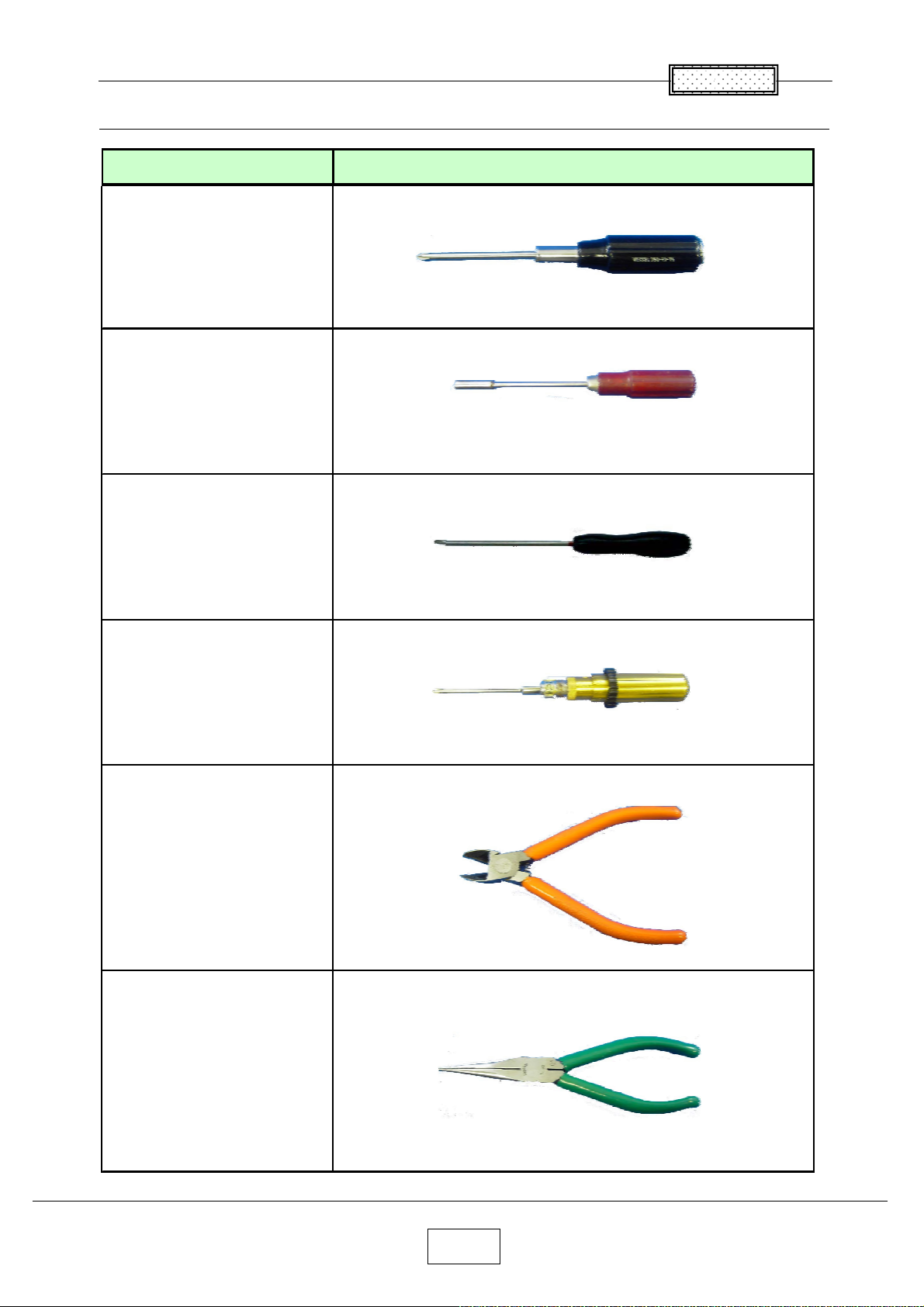

Required Tools

䋫

䋫

Item Photo

Driver bit (䋫) No 2

Box driver M3

Chapter 2

Driver bit (

Torque driver bit (

Nippers

) No 0

) No 2

Cutting pliers

2-2

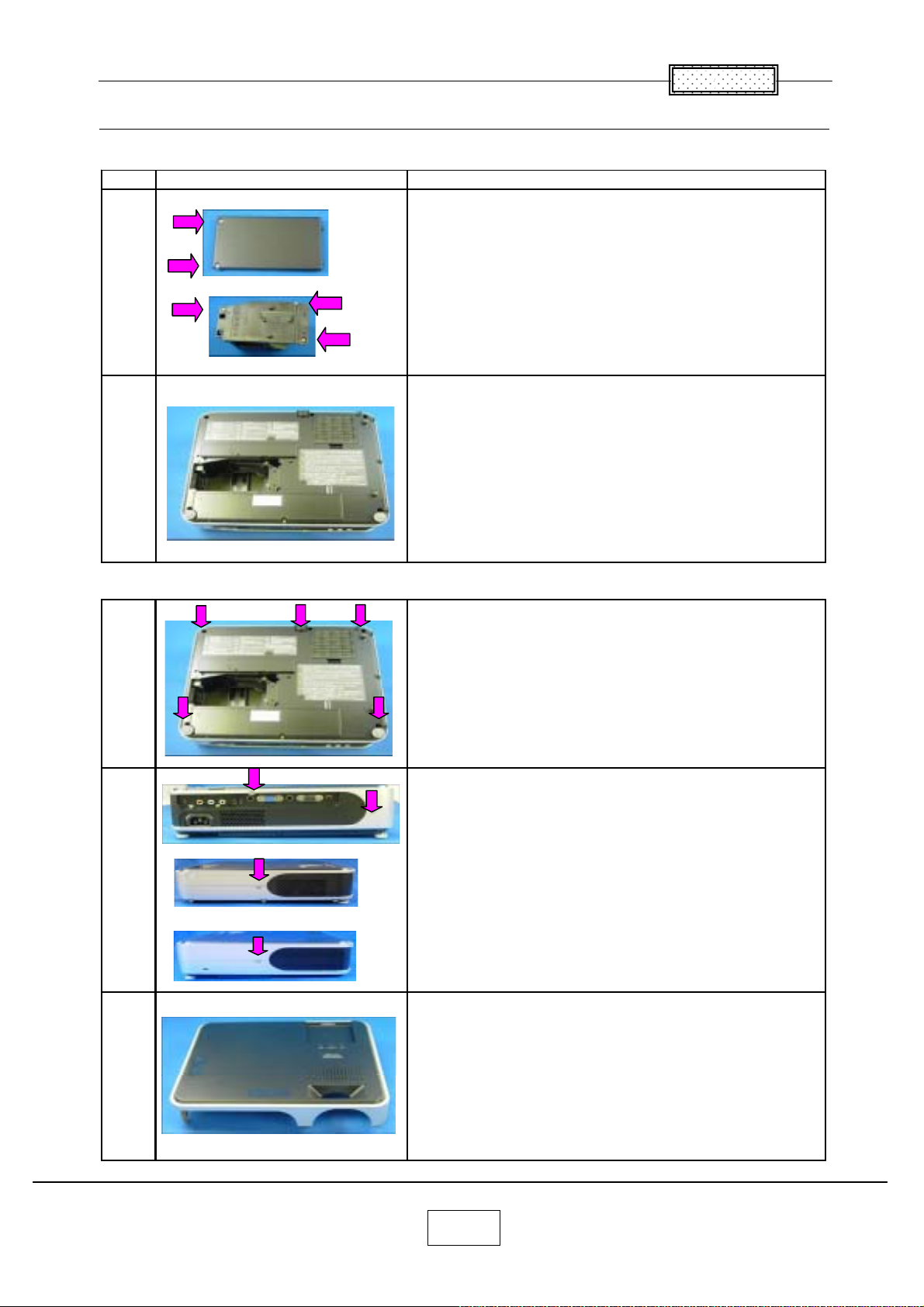

Parts Replacement

g

g

1.Lamp

No Fi

1

ure Explanation

Chapter 2

Remove two lamp cover screws.

Remove three lamp screws.

2

2.Top Cover

Lamp is pulled out.

Remove five screws at the bottom.

Remove two screws at the rear.

Remove a screw at the ri

ht.

Remove a screw at the left.

Top cover is removed.

3

2-3

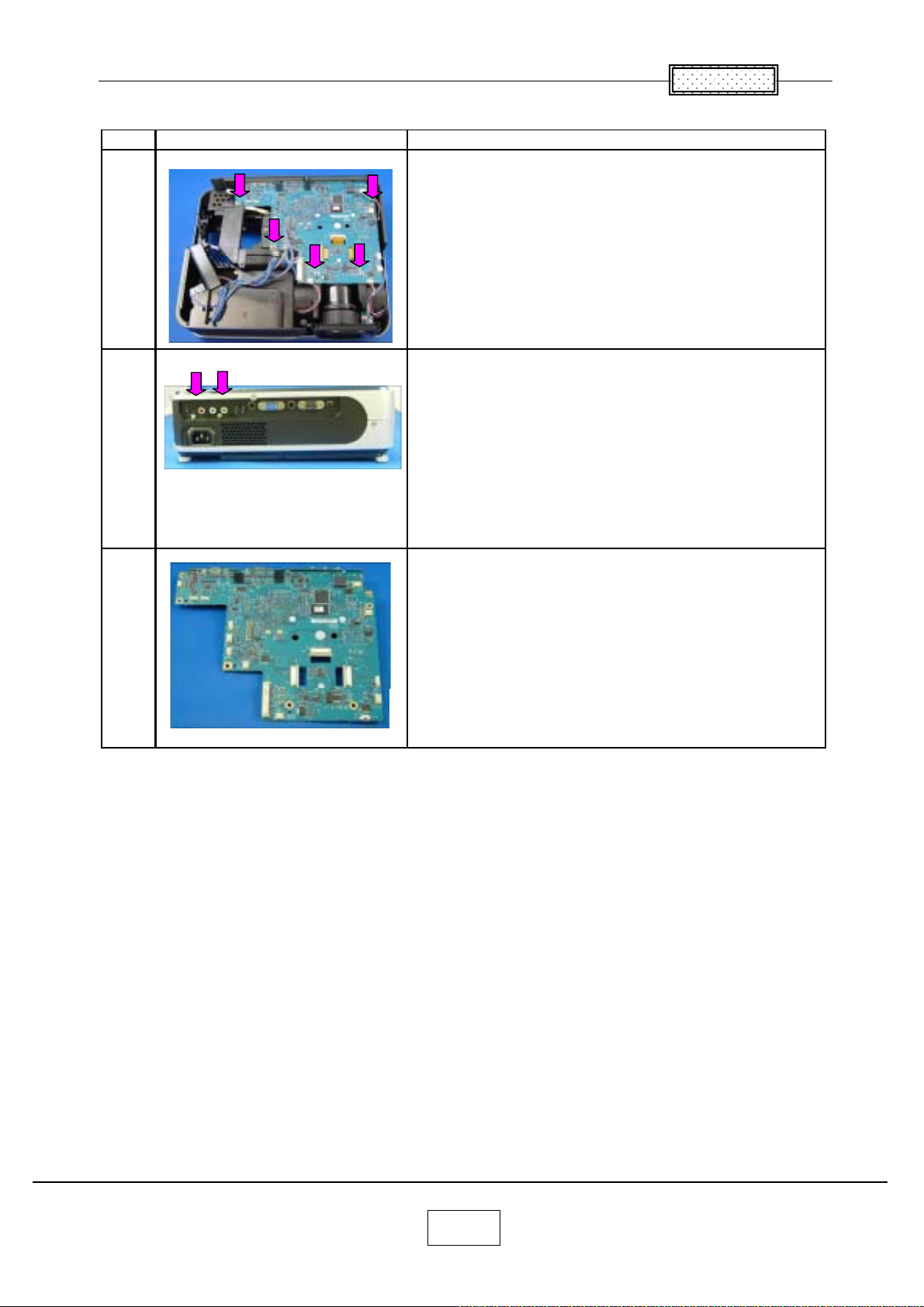

3.Main Board

Step Figure Explanation

All the connectors on a main board unit are removed.

Chapter 2

1

2

3

Remove five screws.

Remove two screws at the rear cover.

Main board is removed.

2-4

4.Main Power Unit

Step Figure Explanation

Remove four screws.

1

Cover & Power Intake FAN are removed.

Chapter 2

2

3

4

Remove two screws.

Power Intake FAN are removed.

Remove a screw.

5

Main Power Unit is taken out.

2-5

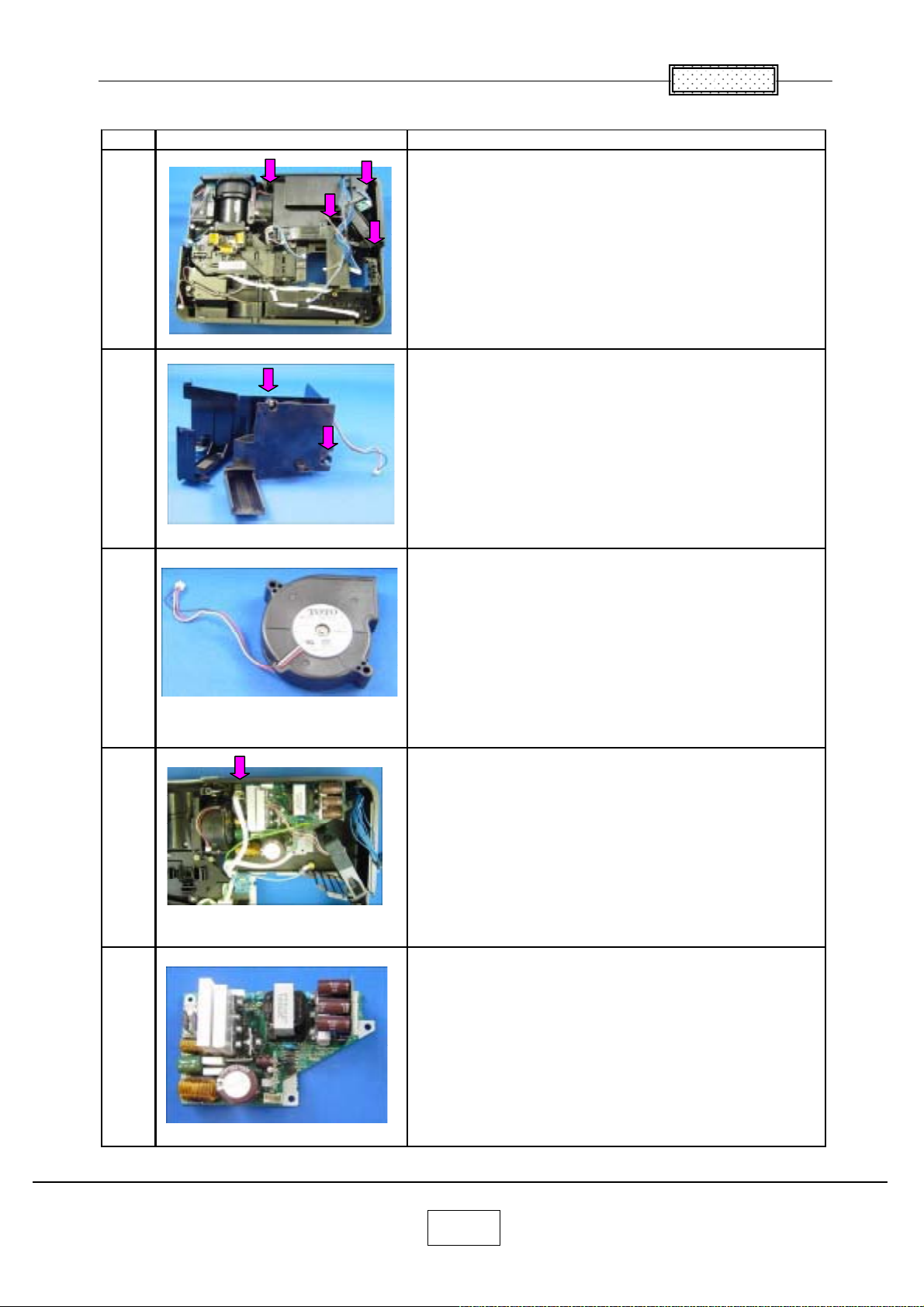

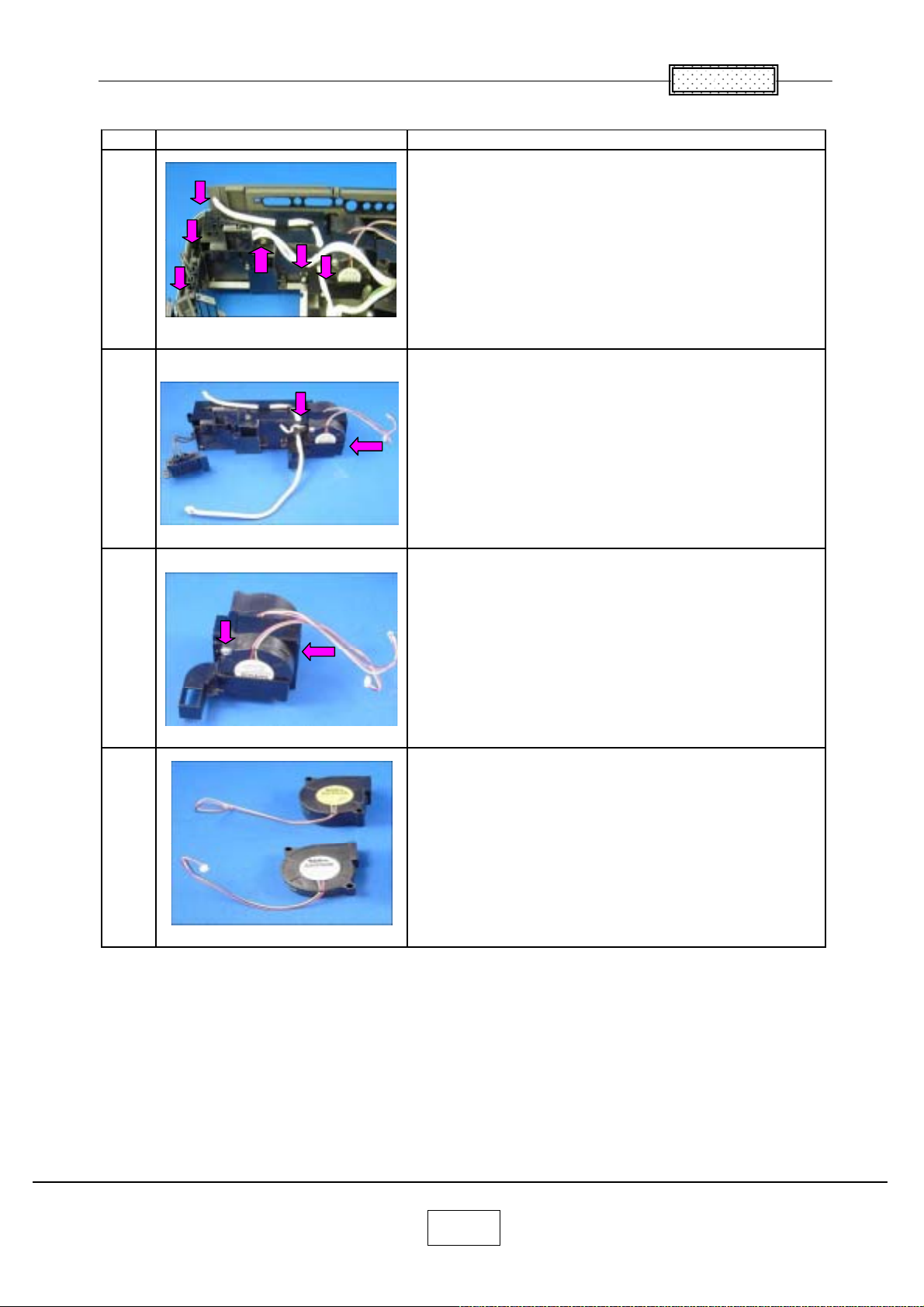

5.PBS & Ballast FANs

Step Figure Explanation

Remove six screws.

1

Balast & FAN assy is taken out.

Chapter 2

2

3

4

Remove two screws.

Remove two screws.

Ballast FANs are removed.

PBS FANs are removed.

2-6

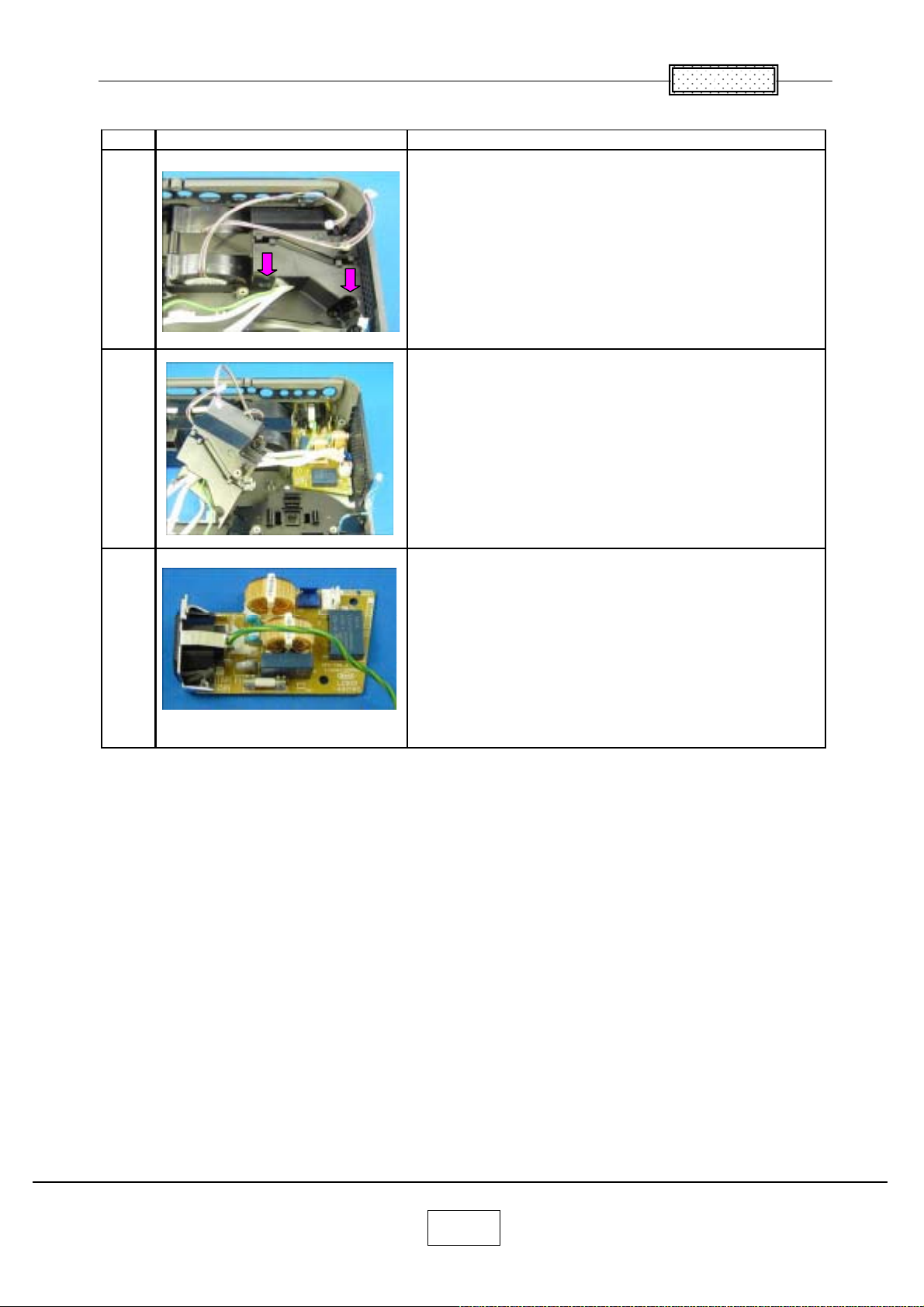

6.Exhaust Fan

Chapter 2

Remove no screw.

1

2

7.Ballast

1

Note.

May be very tight.

Exhaust Fan is removed.

Remove two screws.

2

3

Cover is removed.

Pinch a stud with cutting pliers. (4 points)

Then pull up PC Board.

Ballast is removed.

2-7

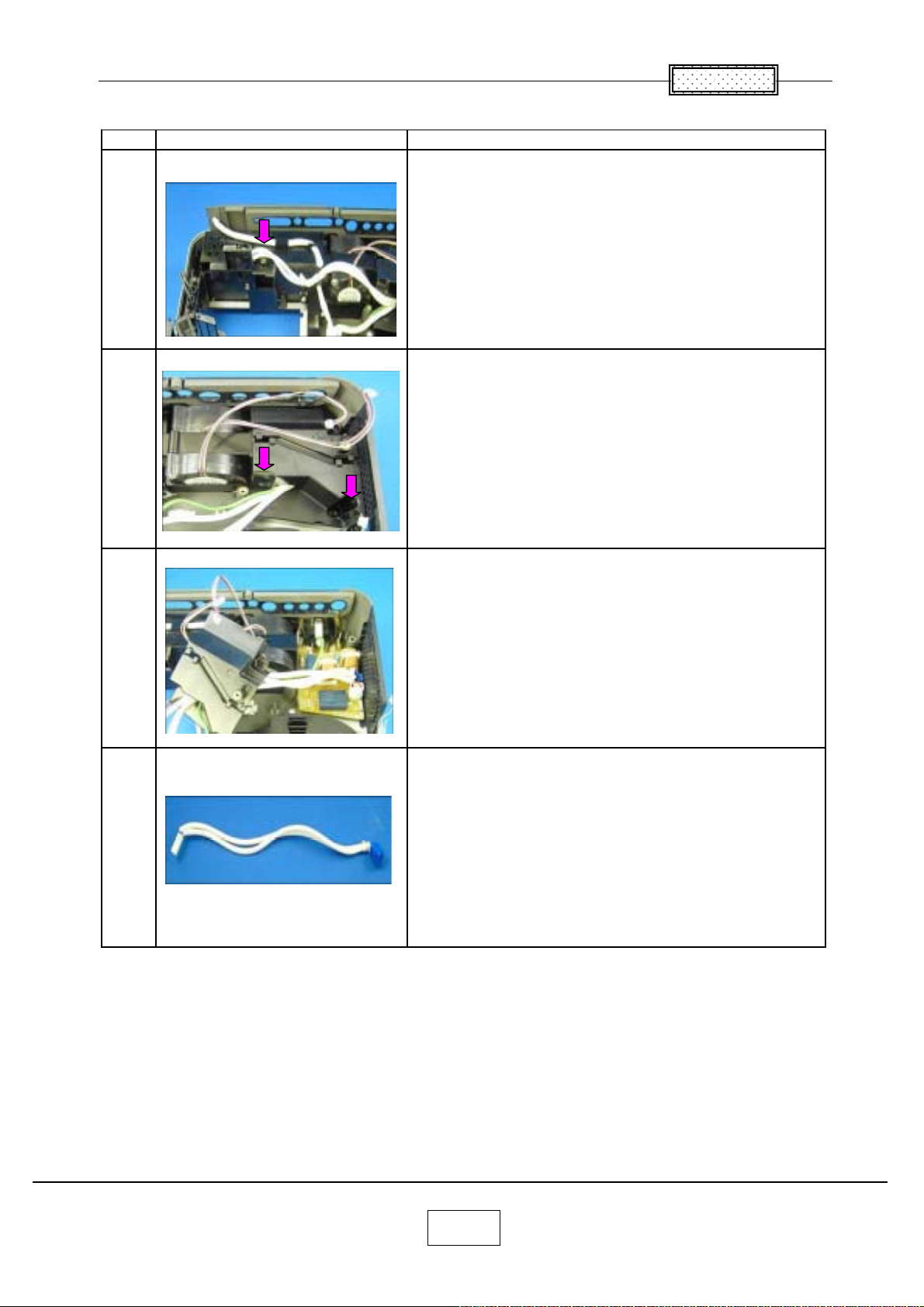

8.Filter Power

Step Figure Explanation

Remove two screws.

1

Cover is removed.

2

Chapter 2

3

Filter Power is taken out.

2-8

9.Thermal Switch

Step Figure Explanation

Remove a screws.

1

Remove two screws.

2

Chapter 2

3

4

Cover is removed.

Thermal Switch is removed.

2-9

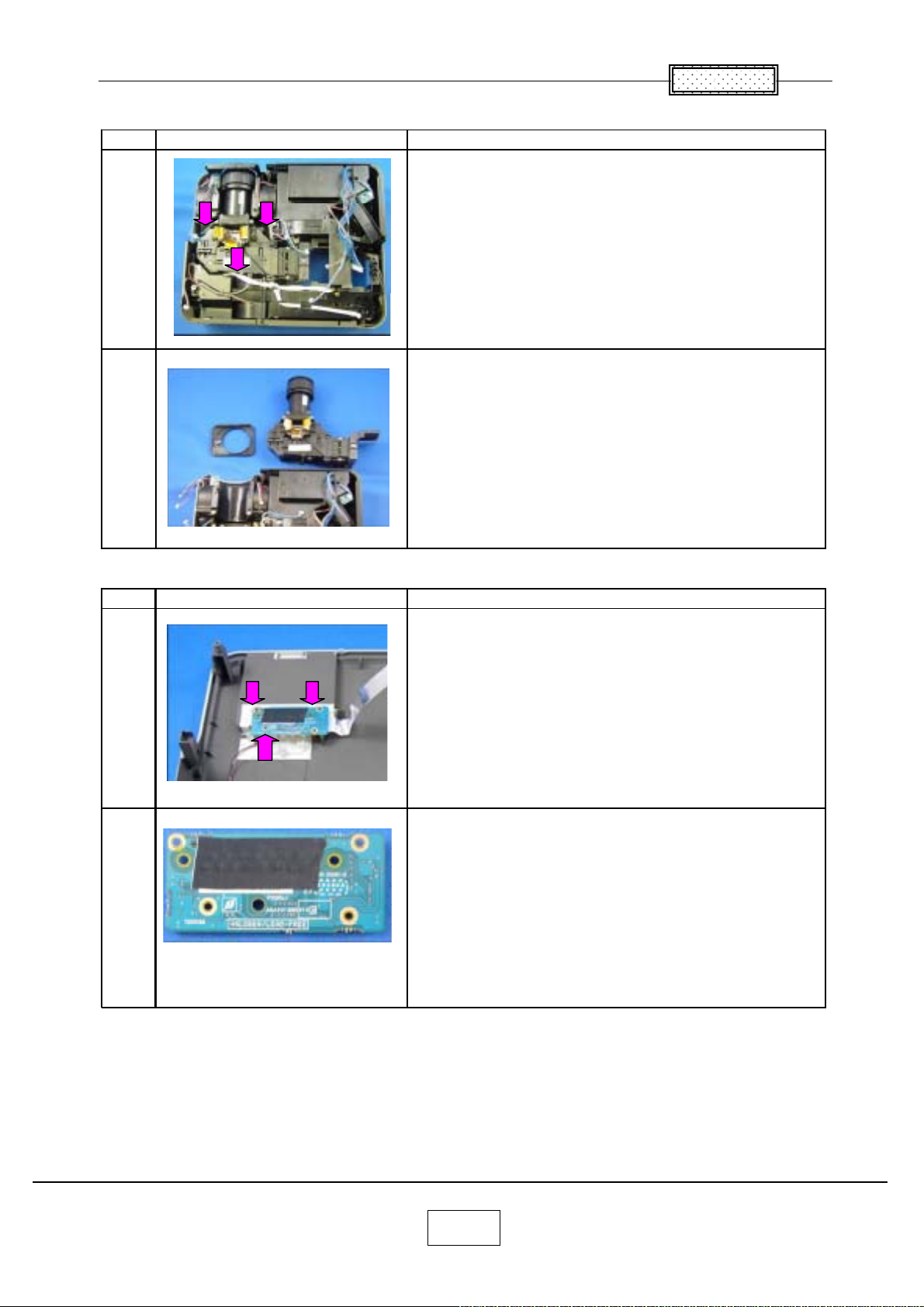

10.Optical Emgine

Step Figure Explanation

Remove three screws.

1

Optical Engine is taken out.

2

Chapter 2

11.Relay Board

Step Figure Explanation

Remove three screws.

1

Relay Board is removed.

2

2-10

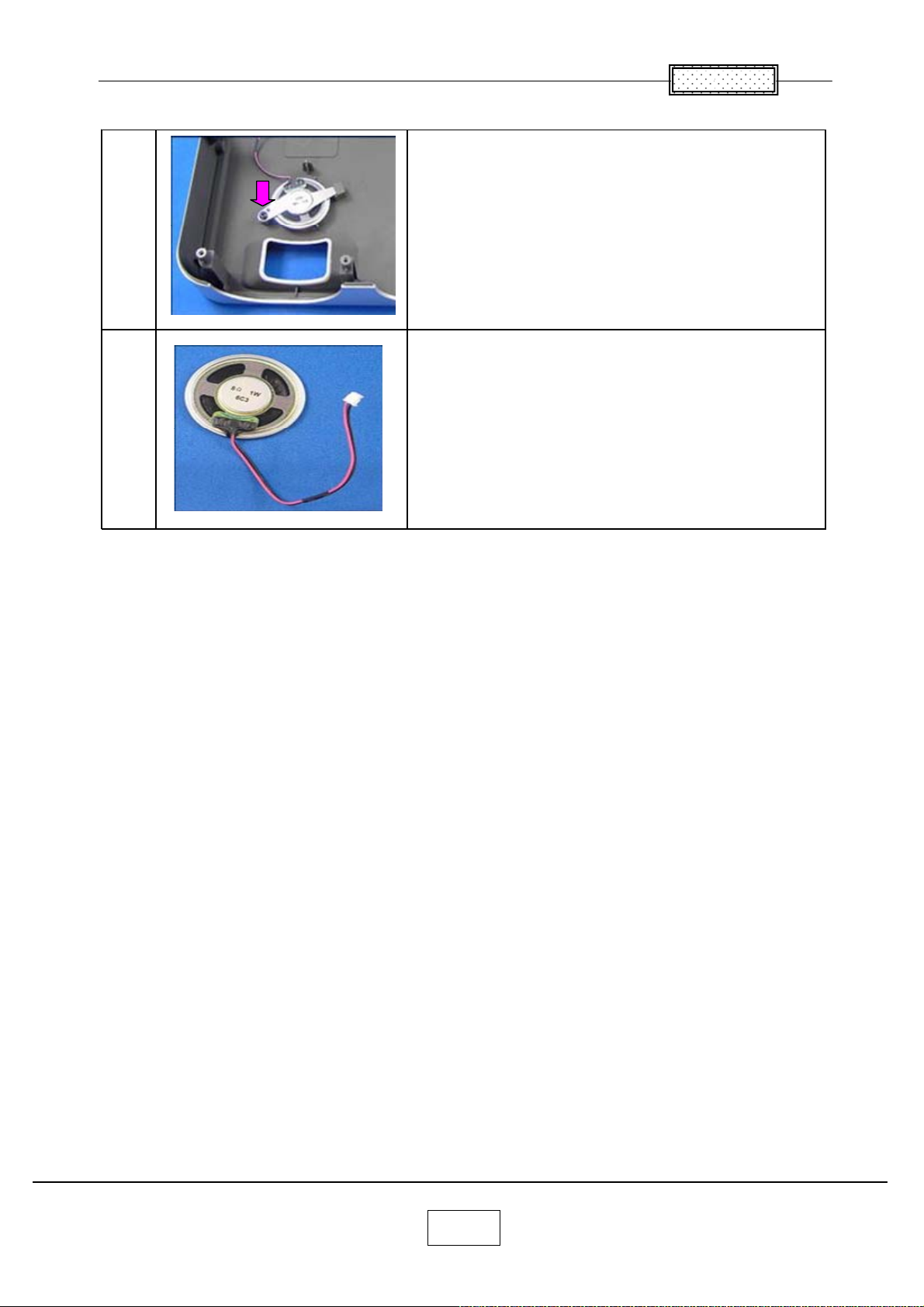

15.Speaker

1

2

Chapter 2

Remove a screws.

Speaker is removed.

2-11

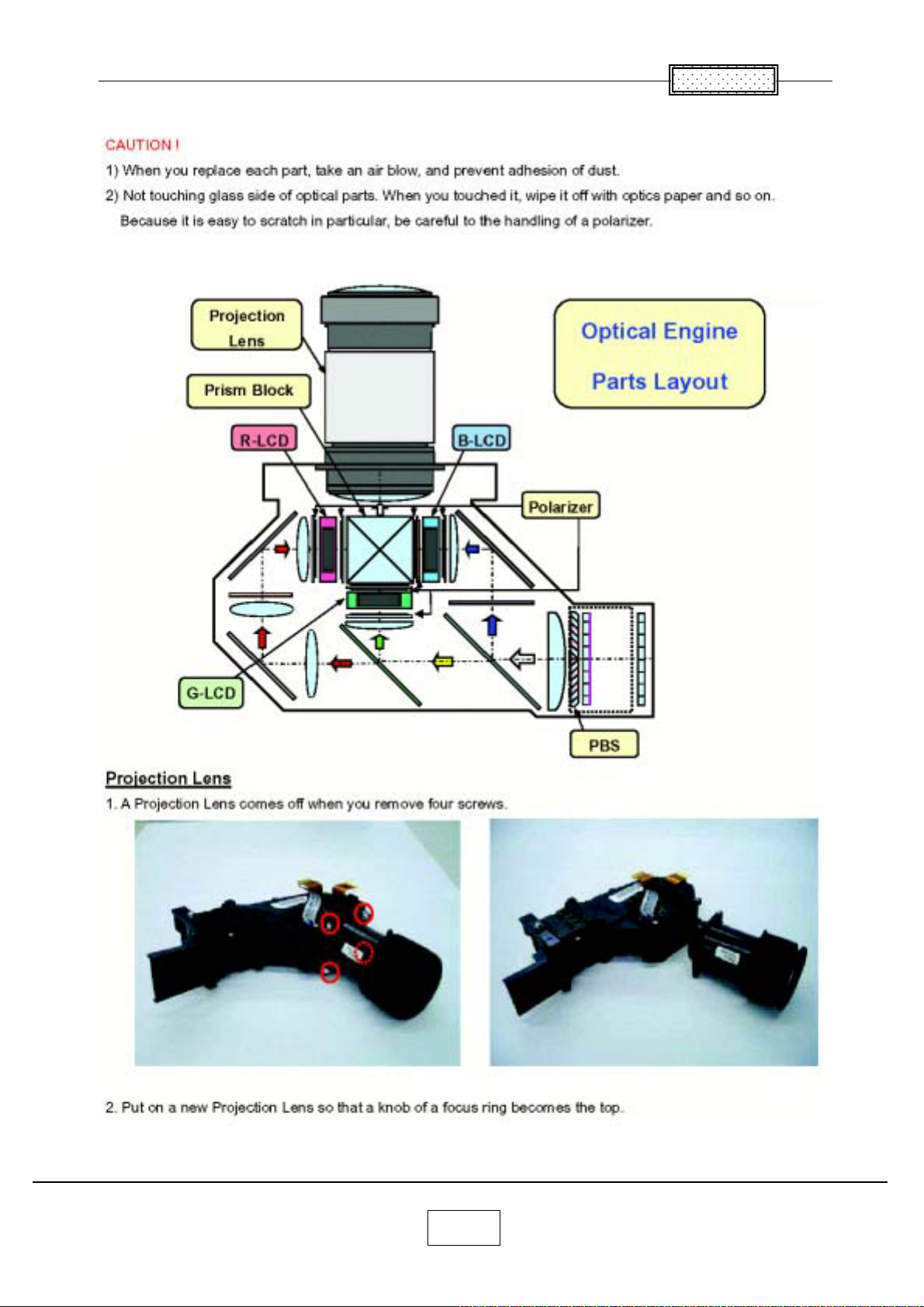

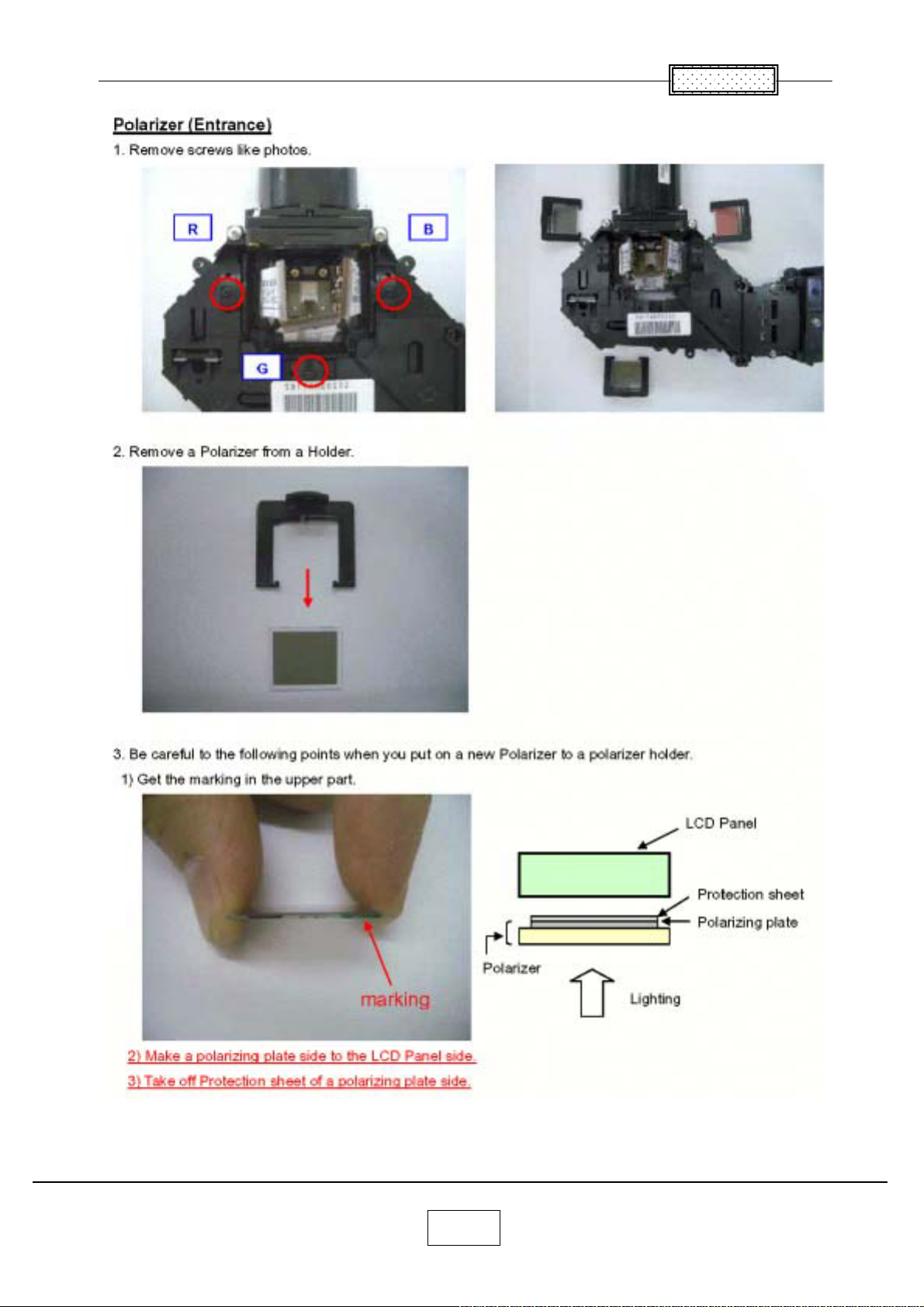

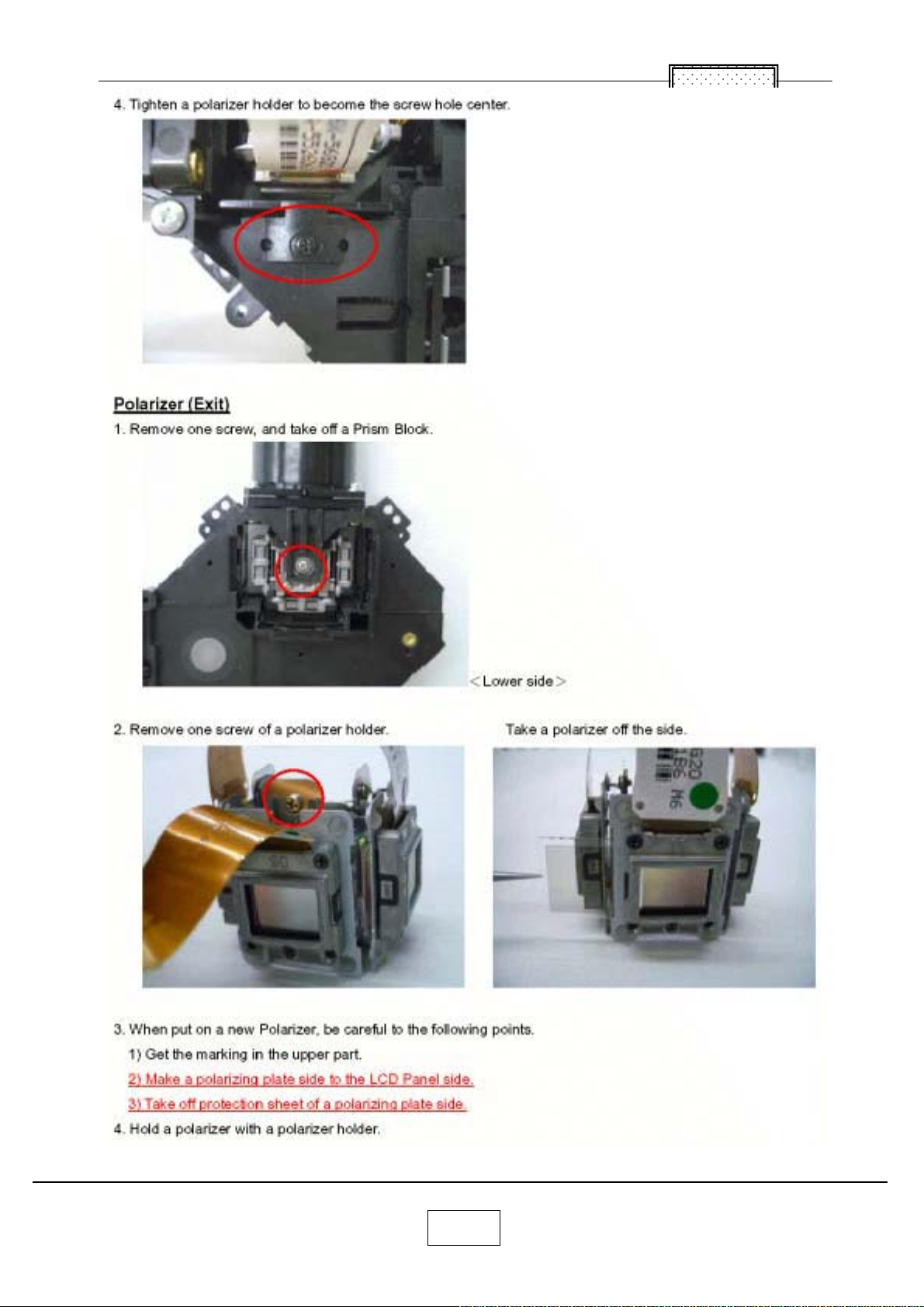

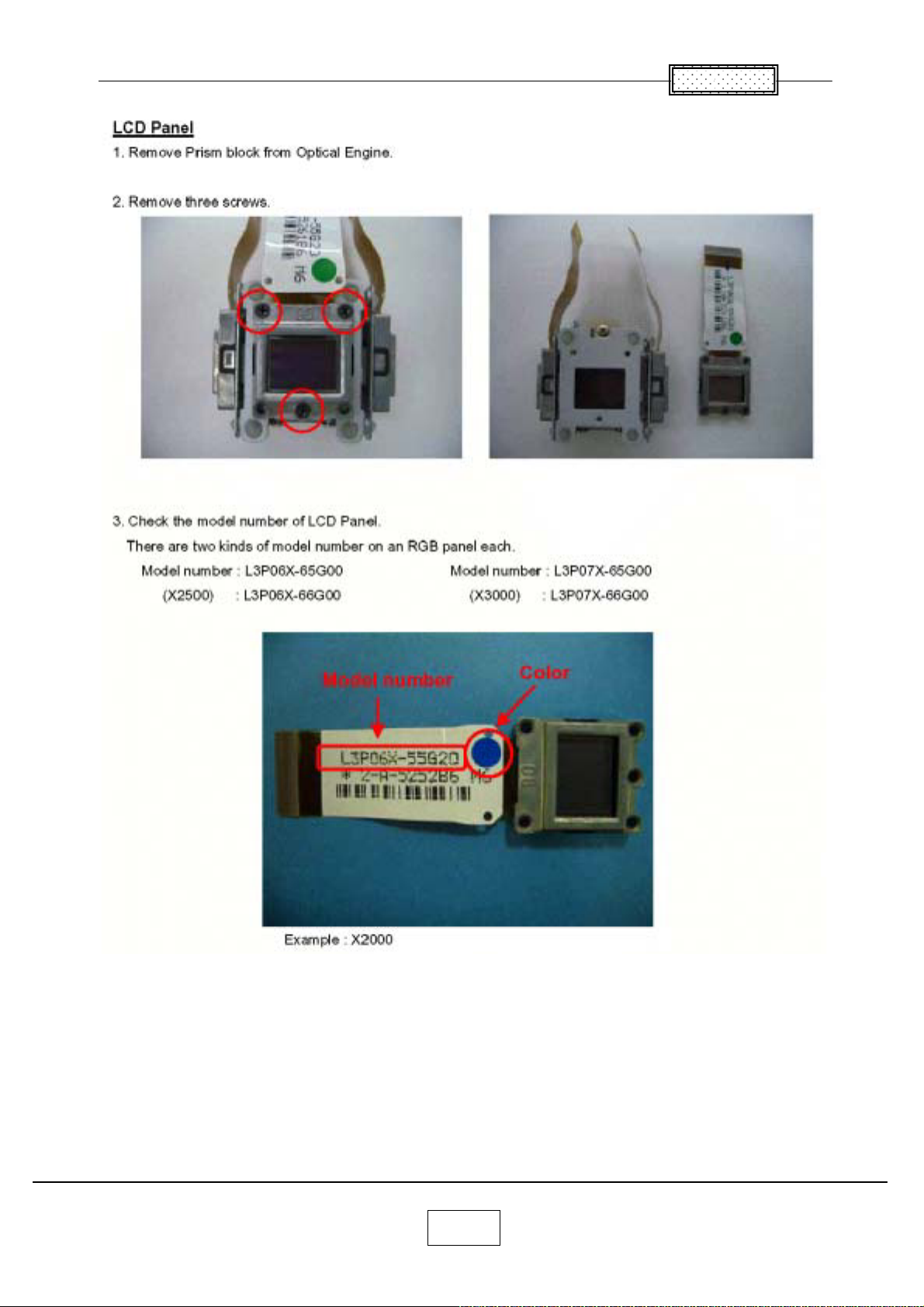

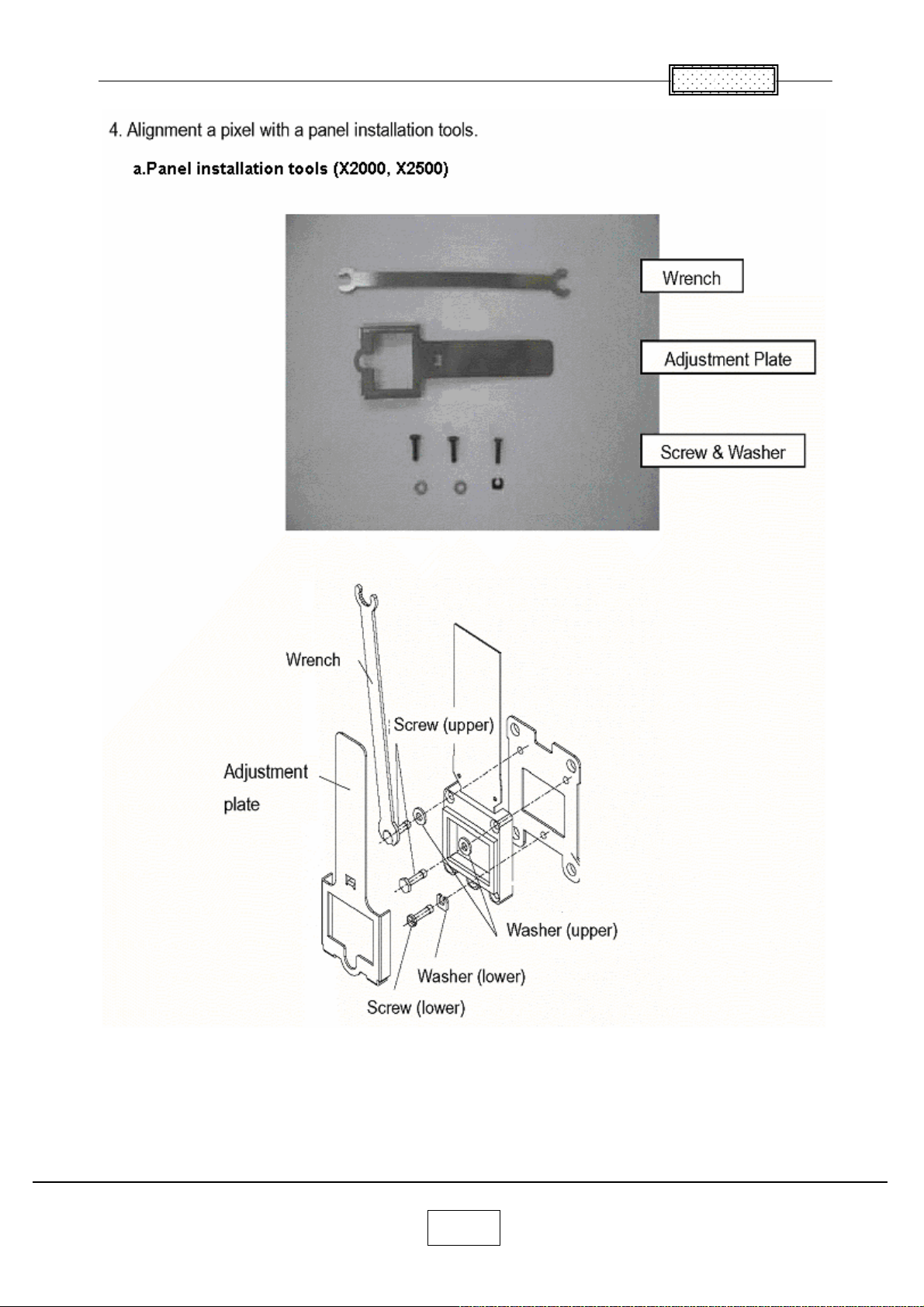

Replacement of Optical Parts

Chapter 2

2-12

Chapter 2

2-13

Chapter 2

2-14

Chapter 2

2-15

Chapter 2

2-16

Chapter 2

2-17

Chapter 2

2-18

Chapter 2

2-19

Chapter 3

SINGOWS 2000

Install the Software on the Computer

The software you download is bundled into one .MSI file.

Double-click the file to install the signal generating software.

Chapter 3

The Install Wizard appears,ready to begin the install process.

Click the next button.

3-1

The Select Installation Folder dialog box appears.

Navigate to the location where you stored the software files.

Click the next button.

The confirm Installation dialog box appears.

Click the next button.

3-2

The Installing software dialog box appears.

The Installation Complete dialog box appears.

Click the close button.

3-3

Startup the Software

Open Windows Exploler, navigate to the location where you stored the files, Then double click the

SINGOWS2000.EXE.

Moreover, even if it chooses the shortcut of the All programs of start, it can startup

.

3-4

Chapter 4

Chapter 4

Firmware Upgrade

Upgrade the software

Connect the control cable to the control terminal on the projector.

Then plug the RS232C connector on the other end of the cable into a RS232C port on the computer.

Open Windows Explorer navigate to the location where you stored the upgrade files, and then double click

the Firmware Upgrader.exe.

The Upgrade Wizard appears. Click the Choose button to open the Select File Dialog box.

In the Open File dialog box, select the .inf file, and then click Open button.

4-1

The upgrade file appears in the Select File box.

Select the COM port.

Chapter 4

Click Flash button.

4-2

Chapter 4

Press and hold the projector’ s [Input] and [Keystone] keys, and then plug in the power cord.

The projector starts the Firmware upgrade,

[LAMP], [ON/Standby] and [TEMP] LED’ s are RED blinking.

The computer begins downloading the upgrade files to the projector.

The process may take several minutes.

4-3

When the upgrade finishes normally, the following dialog box appears.

Chapter 4

Click the Close button.

The upgrade is complete.

4-4

Confirm the software upgrade

1. Power up the projector.

2. On the projector keypad, press the MENU key to display the menus.

3. Press button Right or Left arrow to highlight Setting display.

4. The Setting display dialog box display the software version.

These should match the upgrade version you downloaded.

Chapter 4

4-5

Chapter 5

Wiring Diagram

Chapter 5

5-1

Block Diagram

BLOCK DIAGRAM 1/2

Chapter 5

5-2

Block Diagram 2/2

Chapter 5

5-3

Chapter 6

6

LED Display

LED Display (Problems Shown on LED Indicator Combination)

Chapter

<Notes>

When each error occurs,after approx.one minute of abnormal display,

the projector turns to the standby state waiting for internal cool down.

[ L ] : LAMP, [ O ] : ON, [ T ] : TEMP

6-1

Troubleshooting

You use this section to diagnose problems with the projector. Choose the problem you

are trying to diagnose from the list below. The Power, Image and Audio sections

provide a variety of symptoms, while the other includes only one page.

1. For Power problems

2. For Image problems

3. For Audio problems

4. For Remote Control

5. For Keypad problems

6. For Menu problems

Troubleshooting Power Problems

The projector will not power up, only partially power up,

or will not remain powered up.

Chapter 6

What is the problem?

No stand by LED

No stand by LED

Check the Power cord and AC power outlet.

Check the Main power switch.

Check the Keypad cable has broken or not.

Check the connect cables inside the Unit.

No lamp

At least some fans are running.

Ye s

Does the projector power up?

No

Check the voltage of CN106 (Power IN) at Main board

And also check the voltage of CN201 (Power Out) at Power Supply

when it removes the cable from Main board.

Lamp or projector shuts off after

running a short period of time.

Problem resolved.

Is the power supply outputting?

Ye s

Replace the Main board

No

Replace the power supply

6-2

No lamp

Check the error code log at service mode

When there is the error code, refer to the LED error List.

When the error code is Lamp error (No.1), remove the lamp to see if it looks good.

There should be no ruptures, no bulges, and no cracks in the reflector.

Substitute a known good lamp if you want to be absolutely certain that the lamp is not the problem.

Replace the lamp.

Check the color wheel motor cable and color wheel sensor cable are connected to the Main board.

Chapter 6

Does lamp enable measure low?

(CN 111 3 P I N )

No

Is 370V (DC) input

of Ballast OK?

370V (DC): CN102 1PIN (RED)

(POWER SUPPLY SIDE)

Ye s

Ye s

Replace the ballast

Are DC power voltage levels

OK on the Main board

Ye s

Lamp or projector shuts off after running a Short period of time.

No

Replace the power supply

Replace the Main board

Note:

This is usually a thermal issue caused by excessively high internal temperature.

The high temperature could cause a component on the Main board or the power supply to fail when it gets hot.

No

Check the error code log at service mode

When there is the error code, refer to the LED error List.

Ye s

Are all fans running?

No

Replace the broken fan.

Ye s

Does the projector run property?

No

Replace the power supply

6-3

Replace the Main Board

Problem resolved

Troubleshooting Image Problems

The image is not correct.

The projector starts and runs normally.

The menus are accessible.

The lamp is lit.

Upgrade the software to the latest version or reinstall the projector software.

Confirm that all image adjustments are set to factory defaults

Confirm that the cable and source signal Are good.

What is the problem?

Chapter 6

No image at all.

Vertical or horizontal lines.

Sparkle picture.

Clusters of dark pixels.

Dim image

No image at all.

Vertical or horizontal lines.

Sparkly picture.

Clusters of dark pixels.

Replace the Main Board.

What is the problem?

No

Replace the optical engine

Bad or missing tint or color.

Missing logo,VGA,composite Video, or S-video.

Distorted image, noisy, rolling,torn,frozen,

” Plaid” repeated, or shifted image.

Ye s

Problem resolved

6-4

Dim image

Substitute known good lamp.

Image brighter?

No

Substitute known good Main board.

Image brighter?

No

Chapter 6

Ye s

Replace the lamp.

Ye s

Replace the Main Board

Replace the optical engine

Bad or missing tint or color.

Distorted image, excess noise, rolling, torn, frozen,” Plaid” image, repeated single image or shifted image.

Make sure cables are good.

Check the color wheel delay index value in the service mode.

Ye s

Image good?

Problem resolved

No

Replace the Main Board

6-5

Troubleshooting Audio Problems

No audio or distored audio from the speaker.

Make sure cables are good.

Chapter 6

Is audio OK?

No

What is the problem?

No audio from the speaker

No audio from the speaker.

Check the speaker resistance.

Does it measure around 16 ohms?

No

Replace the speaker

Ye s

Ye s

Problem resolved

Audio is distoyed

Connect a known good 16 ohms speaker

in place of the existing speaker.

No

Is audio OK?

Ye s

Replace the Main board.

Audio sounds scratchy or distored.

Verify that audio signal source and cables are good.

Ye s

Sound good?

No

Connect a known good 16 ohms speaker in the place of the existing speaker.

Ye s

Sound good?

No

Replace the Main board.

Problem resolved

Problem resolved

Problem resolved

6-6

Troubleshooting Remote Controller Problems

Infrared Remote Problem

Install known good batteries in the remote controller.

Ye s

Does the remote work?

No

Use a known good remote with the projector

Chapter 6

Problem resolved

Does the remote work?

No

Replace the Main board.

Troubleshooting Keypad Problems

Keypad does not

respond to key presses.

Is a known good Key B.

available for substitution?

Ye s

Substitute the good key board.

No

Problem resolved

Substitute a known

good Main board.

Ye s

Does the projector

Respond the key presses?

Does the projector

respond the key presses?

Ye s

Replace the key board.

No

Replace the Main board.

6-7

No

Replace the Main board.

Replace the key board.

Troubleshooting Menu Problems

Menu does not appear on screen.

Startup screen and other images appear normal.

Try pressing the Menu button on both the remote and keypad.

Chapter 6

Ye s

If the remote works and

the keypad doesn’ t, go to

Troubleshooting Keypad problems

Flash or re-flash the latest software into the projector.

Does the menu appear?

No

Does the menu appear?

No

Replace the Main.board.

Ye s

If the keypad works and

the remote doesn’ t, go to Troubleshooting

remote control problems

Ye s

Problem resolved

6-8

Chapter 6

Operation of Power Supply (APS-M602)

OUTLINE

This power circuit APS-T60 is composed of 2 units as shown as below. (Fig.1)

APS-T602 is composed of AC inlet and input line filters mainly.

APS-T603 is composed of rectifier circuits, PFC circuit and DC/DC converter circuit mainly.

The power circuit APS-T60 is supplied 100~240Vac and it supplies 5 power sources to load

circuits.

In case of the typical operation, it supplies 370V (260W max.) and 16V as Non-isolated output and

supplies 3 outputs as isolated output. 3 isolated outputs are 6V, 14V and 17V.

In case of the standby mode, 16V line is turned off. And the voltage of 370V line is varied to

voltagethat

rectified the AC source.

3 isolated outputs are not turned off.

+370V (non-isolated)

+16V (non-isolated)

0V (non-isolated)

to Ballast

Bridge

Rectifier

Circuit

Power

Factor

Correction

(PFC)

Circuit

Primary

+16V line

Rectifier

Circuit

DC/DC

Switching

Converter

Secondary

Rectifier

Circuit

Feedback

Control

+17V

+14V

+6V

GND

ST/OP

(ON/OFF

Control)

6–9

Chapter 6

OPERATION OF POWER SUPPLY

1. Transition from AC ON to Standby mode

When the AC source is supplied to this power circuit, the voltage rectified by D101 and smoothed by

C105 is supplied to VH pin of IC102 through R125.

VCC pin voltage of IC102 rises by current supplied to VCC pin through VH pin.

And then, IC102 starts up and the DC/DC converter begins to operate. (6V, 14V and 17V start up.)

* This DC/DC converter is a PWM switching circuit, which is composed of IC102, T201 and Q103 mainly.

2. Transition from Standby mode to Typical Operation mode

When the level of ST/OP pin in the connector CN201 is Low or open, only the DC/DC converter is in the

switching operation. Each output does not have the on/off control which works solo, except primary 16V

line. The voltage level of primary 370V line becomes voltage after smoothing through

circuit. (e.g. Input: 100Vac,

This status is standby mode.

When the level of ST/OP pin in the connector CN201 is High, Q105 is turned on through a photo-coupler

PC103, and then the primary 16V source is supplied to the Ballast and IC101 of PFC circuit.

Because VCC voltage of IC101 reaches

PFC circuit begins to operate. The voltage level of primary 370V line becomes approximately 370V which is

stable against variation of AC input voltage.

* ST/OP pin is a pin to control for switching mode between standby and typical operation.

Output: approx. 140Vdc)

threshold level of starting voltage, IC101 starts up activity and the

bridge rectifier

3. Protection against abnormal condition

If Overvoltage or overheat or overload happens, the DC/DC converter stops the switching operation by

putting IC102 into the latch mode. Every output (They are primary 16V, secondary 6V, 14V and 17V.) of

the DC/DC converter is turned off, and this is maintained. PFC circuit stops the switching operation

because +16V line which is power source for the control IC of PFC is turned off. The voltage of 370V line

varies to

About the latch mode of IC102

In normal operation, CS pin voltage of IC102 is clamped by an inside 4V zener diode.

Externally forcing CS pin voltage to increase to the threshold voltage, 8.2V, for the latch mode allows the

IC102 to stop its operation for protection.

When CS pin voltage reaches to 8.2V, the inside source in IC102 is turned off, and OUT pin (for gate

drive of FET in the DC/DC converter) is set to the Low level.

Then, the start-up circuit is activated again, and VCC voltage is held at approximately 22V. This status is

the latch mode of IC102. The latch mode is maintained as long as supply to VCC pin continues.

It takes time for the latch mode to be rest because charged C105 voltage is applied to the VH pin even if

IC102 have changed to the latch mode.

Cutting off the input voltage decreases VH pin voltage, supplying no current to the VCC pin.

Thereafter, the latch mode is reset when VCC drops below the OFF threshold level, 8V min.

voltage that rectified the AC source. (i.e. The boost stops.)

6–10

Chapter 6

OPERATION OF EACH SECTION

1. Input Line Filter

The Input line filter circuit is made up of capacitors (e.g. C1, C2, C101) and inductor chokes (e.g. L1, L2,

L101) on APS-T602 unit and a part of APS-T603 unit,

This section protects the noise generated by the power supply circuit from leaking out to AC line

and from entering of the external noise inside the power supply circuit.

This circuit is effective for both normal and common noise.

The fuse F1 becomes open in order to protect other parts, when excessive current flows in abnormal

conditions.

The connector CN2 is connected to thermal sensing element (e.g. thermal protector). Power Supply is

operated by CN2 shorted condition. In other words, when 2 terminals of CN2 become open by thermal

protector, power supply to subsequent circuit is shut off.

2. Power Factor Correction Circuit (PFC circuit)

The main parts of this switching converter are choke coil T101, switching MOSFET Q101, Q102, control

IC IC101 and diode D104. This circuit has mainly 4 functions as following.

a. Generate stable voltage

This PFC circuit operates so that the output always is set to 370Vdc(typ.). Actually, the switching

operation of Q101 and Q102 is controlled by IC101. Initial voltage setting of 370V output is set at

370Vdc(typ.) by VR101. (Input voltage: 100Vac, maximum load)

* Please don’ t turn although there are 2 variable resisters for this output voltage setup and for

the overvoltage protection setup. The case which needs to turn the volume means that the failure

mode cannot be repaired easily.

b. Reduce input harmonic current

Main purpose of Power Factor Correction Circuit is reducing input harmonic current by bringing the

input current waveform closer to a sine wave.

This circuit is CCM (Continuous Conduction Mode) PFC circuit which used resettable integrator.

The gate pulse width is adjusted per one cycle by detecting DC output voltage at the VF pin of IC101

and peak current at the ISNS pin of IC101. The amplitude and shape of the input current is controlled

so as to be proportional to and in phase with the input voltage.

c. Over current protection

The current sense pin ISNS of IC101 is the input to the current sense amplifier and the overcurrent

protection comparator.

There are essentially two levels of current limitation provided by the IC101. There is a “ soft” current

limit, which is essentially a duty cycle limiting fold back type: the converter duty cycle is limited to the

point where output power is limited and the output voltage begins to decrease. There is also a “peak”

current limit feature which immediately terminates the present drive pulse once the peak limit

threshold, = -1.0V, is exceeded.

d. Over voltage protection

The voltage in

the OVP pin of IC101.

drive signal.

proportion to output voltage by resistors R112, R113, R114, R115 and VR102 is added to

When the OVP threshold(7.49V(typ.)) is triggered, the IC101 will disable the gate

6–11

Chapter 6

3. DC/DC converter

The main parts of this switching converter are transformer T201, switching MOSFET Q103, control IC

IC102 and output diodes D201, D202 and D203. This converter is Fly Back type.

This means that energy is transferred from the primary to secondary when MOSFET Q103 is off.

The main output is 6V line and auxiliary output is 14V and 17V line.

a. Start up

When AC input is supplied to this power supply unit, power source of IC102 is supplied through R125.

And then IC102 begins switching operation and the converter starts up.

Once the converter starts up, power source of IC102 is supplied from

b. Output Voltage Control

Output voltage is controlled by Pulse Width Modulation (PWM).

The voltage divided by R208, R209, R210 and R223 in the 6V line is detected, and this voltage is

compared with the reference voltage of shunt regulator IC201. Photo coupler PC101 feeds back the

comparison from secondary to primary. And output voltage is adjusted by the level of current drawn

from the FB pin of IC102.

When 6V output voltage is above the control level, IC102 to shorten the on-time (duty cycle) of

MOSFET Q103. This cause the average output to decrease. When the output is below the control

level, on-time (duty cycle) is increase, thereby increasing the average output voltage.

auxiliary winding of T201.

c. Overcurrent Protection

If the power supply output becomes overload, the current of MOSFET Q103 is limited by the maximum

threshold voltage of the IS pin in IC102 and output voltage drops. If the state continues as it is, an

overload protection function of IC102 operates to stop the IC in the latch mode.

d. Overvoltage Protection

Overvoltage state is detected when output voltage exceeds the zener voltage of zener diode (ZD201,

ZD202, ZD203). When zener diode is in conduction state, through the photo coupler PC102, the CS

pin voltage of IC102 is increased

shut down.

e. Overheat Protection

The abnormality of heat sink temperature of Q101, Q102 and Q103 is detected by PTC thermistor

PR101. Through the diode D113, the CS pin voltage of IC102 is increased

for the latch mode

overload or FAN-Locked.

and power supply is shut down. It operates at the time of abnormal state such as

forcibly to the threshold level for the latch mode. And power supply is

forcibly to the threshold level

6–12

Chapter 6

6-13

Chapter 6

6-14

APS-M602 (ETXTS602MDA/MDE) Troubleshooting Faults

Chapter 6

6-15

Chapter 7

A

Electrical Adjustment

Preparation

< Test equipment >

1) Personal computer

(Windows PC, OS: Windows 98SE, ME, 2000, XP)

2) Signal generating software

SINGOWS2000.MSI (Installer)

3) Adjustment software

DPJAdjustmentTool_2500.exe

4) Cables

RGB Cable and Control (RS232C) Cable

5) A protractor for Vertical Auto Keystone Calibration

<For connection and setting of Personal computer>

1) Connection of personal computer

Connect the PC to computer 1 input and RS232C terminal as shown in following Fig.1

2) Set the screen resolution and refresh rate to XGA (1024x768) 60Hertz.

Set RGB output of the PC to CRT.

Chapter 7

Control cable

Fig.1

nd, to Control PC (the same PC)

7-1

Adj

The table below shows you the items to be adjusted according to the type of part you replaced.

ustment Points vs Part Replaced

Adjustment

Parts

Keystone

Special Key Operations

Sub

Contrast

Altitude

Pixel

(Convergence)

SINGOWS

2000

VCOM Gamma Shading

DPJAdjustmentTool_2500.exe

Chapter 7

Main Board

Optical Engine

LCD Panel

×

× × × ×

× × ×

:Adjustment is needed

× :Not necessary

<SAVE DATA to EEPROM > (Common on all adjustment)

Press the buttons,

[Up], [Down], [Left] and [Right] simultaneously.

When these buttons are accepted, all LED’s light orange or red blinking in order.

7-2

c

t

Proje

Plug in the power cord; turn on main power switch and the power of the projector.

or Setup

How to enter to the Factory Mode (TLP-X2500/XC2500/X3000/XC3000)

1) While the Volume adjustment bar is displayed on the screen, set value to [2],

and press the buttons,

[Input], [On/Standby] and [Keystone] simultaneously.

2) While the Volume adjustment bar is displayed on the screen, set value to [0],

and press the buttons,

[Input], [On/Standby] and [Keystone] simultaneously.

3) While the Volume adjustment bar is displayed on the screen, set value to [0],

and press the buttons,

[Input], [On/Standby] and [Keystone] simultaneously.

4) While the Volume adjustment bar is displayed on the screen, set value to [0],

and press the buttons,

[Input], [On/Standby] and [Keystone] simultaneously.

When the projector enters to the Service Mode, the buzzer beeps for 3 seconds.

If doesn’t beep, repeat from the beginning.

This mode maintains until you turn off the main power switch.

Chapter 7

7-3

How to display the Service status

After the projector has entered to the factory mode, press the buttons,

[Return] and [Up] simultaneously. Then, the following display appears.

If it doesn’t appear, repeat from the beginning.

This mode maintains until you turn off the Main power switch.

Chapter 7

FAN-1 is Z103 (Service part location No.). FAN-2 is Z102.

FAN-3 is Z104. FAN-4 is Z105. FA N-5 is Z101. FAN-6 is Z100.

Temp- 1 is Intake temperature. Te mp-2 is Exhaust temperature.

A number of Error log means an error ID.

7-4

<Keystone Calibration>

Press [Input] and [Up] buttons simultaneously.

For it initialize the value, Press [Keystone] button.

Set the projector on a level surface.

Press [Enter] button of the projector.

When the adjustment is successfully completed, values changes from default [0].

(Example: The following menu)

If it fails, values don’t change from default [0].

Chapter 7

7-5

Select the KC1 item by pressing [Down] button.

Keep projector on 30 degree.

Press [Enter] button of the projector.

When the adjustment is successfully completed, values changes from default [0].

(Example: The following menu)

If it fails, values don’t change from default [0].

Chapter 7

7-6

Select the KC2 item by pressing [Down] button.

Keep projector on -30 degree

Press [Enter] button of the projector.

When the adjustment is successfully completed, values changes from default [0].

(Example: The following menu)

If it fails, values don’t change from default [0].

<Note> When the projector is not tilted accurately +/- 30degree,

the adjustment values ([KC1] and [KC2]) do not change.

Chapter 7

7-7

Select the KC3 item by pressing [Down] button.

Set the projector on a level surface and perform heat-run for 30 minutes or more.

Press [Enter] button of the projector.

When the adjustment is successfully completed, values changes from default [0].

(Example: The following menu)

Chapter 7

7-8

<Sub Contrast>

Right - click to display the following color pallets. Click [White] button.

Note: Move the mouse cursor out of a screen to avoid the error

Select the Sub contrast item by pressing [Down] button.

Press [Enter] button of the projector.

When the adjustment is successfully completed, values changes from default [85].

(Example: The following menu)

If it fails, values don’t change from default [85].

Adjust Computer-1 input and Computer-2 input both.

.

Chapter 7

7-9

<Altitude>

Press [On/Standby] and [Up] buttons simultaneously.

For it initialize the value, Press [Keystone] button.

Select proper value by pressing the [Left] or [Right] button.

Factory setting is 0.

The value 1 is more than 500m (1,640ft) and under 1,000m (3,281ft).

The value 2 is more than 1,000m (3,281ft) and under 1,500m (4,921ft).

The value 3 is more than 1,500m (4,921ft) and under 2,000m (6,562ft).

The value 4 is more than 2,000m (6,562ft) and under 2,500m (8,202ft).

The value 5 is more than 2,500m (8,202ft) and under 3,000m (9,843ft).

The value 6 is more than 3,000m (9,843ft).

For example, in case of 2,700m altitude set the value to 5.

Press [Return] button.

7-10

<VCOM>

Connect the control cable to the control terminal on the projector.

Then plug the RS232C connector on the other end of the cable into a RS232C port on the computer.

Open Windows Explorer navigate to the location where you stored the Adjustment file,

and then double click the DPJAdjustmentTool_2500.exe.

The startup window appears.

Select the COM port. and click the [VCOM] button.

The following window appears.

Select the “R”.

7-11

The current data is displayed in DATA column.

Push (+1) or (-1) button.

Adjust the data to reduce the flicker to its minimum point.

By pushing the (+4) or (-4), the data is adjusted in greater steps.

After the adjustment, click the [Save] to save the data.

Select the “G”.

The current data is displayed in DATA column.

Push (+1) or (-1) button.

Adjust the data to reduce the flicker to its minimum point.

By pushing the (+4) or (-4), the data is adjusted in greater steps.

After the adjustment, click the [Save] to save the data.

7-12

Select the “B”.

The current data is displayed in DATA column.

Push (+1) or (-1) button.

Adjust the data to reduce the flicker to its minimum point.

By pushing the (+4) or (-4), the data is adjusted in greater steps.

After the adjustment, click the [Save] to save the data.

When adjustment of R, G and B finishes, click the [Close] button.

7-13

<Gamma>

Click the [GAMMA] button.

The following window appears.

Click the [Send] button.

Select the Gamma data file and click the [Open] button. (There are two files for R-type LCD and L-type LCD.)

7-14

After the transfer is completed, the following message appears.

Click [OK] button.

The transferred gamma data will be automatically saved.

7-15

<Shading>

Click the [SHADING] button.

The following window appears.

Click the [Send] button.

Select the Shading data file and click the [Open] button. (There are two files for R-type LCD and L-type LCD.)

7-16

After the transfer is completed, the following message appears.

Click [OK] button.

The transferred shading data will be automatically saved.

7-17

Chapter 8

8

Chapter

Functional Test

You perform the functional tests after you’ ve repaired the projector to make sure

All components of the projector operate properly.

You can also perform the functional tests if you’ re having trouble determining what is wrong with the projector.

Required Equipment

Equipment Notes

Video player Make sure the video player has an S-video Out port and cables.

The player should also have a Composite video port (RCA).

Toshiba strongly suggests you use a DVD player to test the Video quality. DVD players

reproduce colors better and project Sharper images. The least preferable is a VCR.If

you must use a VCR, make sure you use a commercially produces recoding

not one recorded from a broadcast source.

The VCR must include an S-Video connector in addition to a composite connector.

Commercially produced

video

Cables 1. RCA Pin jack cable for Composite video & audio.

Remote control Ensure that the remote has fresh AAA batteries.

Projector screen Use a flat screen, not a curved one.

Personal computer (PC)

You’ ll need the video in DVD, etc. format.

2. S-video cable.

3. RGB cable that come with the projector.

4. 3.5mm mini-jack cable for PC audio.

The stereo audio card should have either a 3.5mm stereo audio Jack or RCA left and

right output ports. The PC must have a CD-ROM and must have outputs for RGBHV,

VESA, D-sub15pin.

Before beginning

Make sure the work surface where you perform the functional tests is level and clean.

Place the projector on a soft surface (such as an anti-static mat) when running the tests.

Connect the following the I/O panel on the projector.

1. Video player through Composite Video and S-video ports.

2. Audio sources through Audio ports (RCA) or 3.5mm mini-jack.

3. Personal computer through RGB cable

.

8-1

Perform the following tests

Test Verification

Chapter 8

Power Up

Connect AC power, and turn the unit on.

Cosmetics and mechanicals

Adjust the projector so that the image is Square.

Make sure the lens is at a 90 degree angle to the wall.

Composite video from video source

Connect the yellow composite (RCA) video Connector to

the projector. (Ensure that no other video source is

connected to the projector)

S-Video from video source

Connect the S-Video cable to the projector.

Disconnect the yellow composite (RCA) Video connector.

Image keystone adjustment

Connect a video source to the projector.

Audio from audio source

Connect the audio cable to the projector.

Manual source selection

Manually select a connected source.

Verify that the proper splash (logo) screen Appears.

Verify image quality.

Verify that the elevator and leveling foot Are functional.

Verify that the focus and zoom rings operate properly.

Verify cosmetics.

Verify that the video automatically synchronizes.

Verify there is no distortion, noise or other abnormalities.

Verify that the video automatically synchronizes.

Verify there is no distortion, noise or other abnormalities.

Verify that image responds properly when

You adjust the keystone setting.

Verify that audio source plays through the projector’ s speaker.

Verify that the volume controls function correctly.

Verify that the projector switches to the manually-selected

source.

Verify that the video automatically synchronizes.

Verify there is no distortion, noise or other abnormalities.

Software Version / Lamp time Used

Navigate through the Basic menu to the Setup menu.

Navigate to the Service menu.

Select info from the Service menu.

Verify software version

Verify the keys are not sticky.

Verify that the software version is current and that the lamp

is within its service life.

8-2

Test Verification

Chapter 8

Focus

SINGOWS2000

Cross Hatch image.

Color Wheel Index Delay

SINGOWS2000

Color bar image.

Verify that the image synchronizes properly through the computer 1 input.

Verify that image focuses through the full zoom range.

Verify there are no problems.

Verify that the image synchronizes properly through the computer 1 input.

Verify that the color is located in a line.

Verify there are no problems

8-3

Test Verification

DMD Images

SINGOWS2000

White image (Level 100%)

SINGOWS2000

Black image (Level 0%)

Verify that each image synchronizes properly through the computer

1 input.

SINGOWS2000

SMPTE image

System Reset

On the keypad, press the Menu key.

Navigate through the basic menu to the default

setting menu.

Select Reset all.

Power Down

After all tests are complete turn the power off

and disconnect all cables.

Attach the lens cap.

Verify there are no problems

Verify that the image synchronizes after system reset.

Verify unit is powered off before disconnecting cables.

8-4

Chapter 9

A

A

A

Spare Parts List

Exploded View

100:Assy Cover Top

Chapter 9

$&$6($66<

&2175 2/83

U006:KEY Board

$&$6($66<

&217/2:(5

B131:Cover Ballast

Z105:Exhaus t FAN

P801:Main Power

B111:Panel Front

Lamp (Not Service parts)

B110:Panel Rear

U001:PCB FXMA2

P800:Filter Power

Z200:Optical Engine

Z101:Panel FAN A

Z100:Panel FAN B

B100:Cover BTM

220:Lens Cap

210:Cover Lamp

9-1

㧥

Exploded View(Optics Block)

Chapter

㪞㪇㪇㪈㪆㪞㪇㪇㪉

㪣㪚㪛㩷㪧㪘㪥㪜㪣

㪱㪉㪇㪉㪞㪑㪧㪦㪣㪘㪩㪰㪱㪜㪩㩷㪦㪬㪫㪄

㪱㪉㪇㪉㪩㪑㪧㪦㪣㪘㪩㪰㪱㪜㪩㩷㪦㪬㪫㪄

㪩㪇㪇㪈㪆㪩㪇㪇㪈

㪣㪚㪛㩷㪧㪘㪥㪜㪣

㪱㪉㪇㪈㪙㪑㪧㪦㪣㪘㪩㪰㪱㪜㪩㩷㪠㪥㪄

㪱㪉㪇㪊㪑㪌㪐㪈㪧㪙㪪

㪱㪈㪇㪇㪑㪦㪧㪫㪠㪚㪪㩷㪙㪣㪦㪚㪢

㪙㪇㪇㪈㪆㪙㪇㪇㪉

㪣㪚㪛㩷㪧㪘㪥㪜㪣

㪱㪉㪇㪉㪙㪑㪧㪦㪣㪘㪩㪰㪱㪜㪩

㪱㪉㪇㪇㪑㪧㪩㪠㪪㪤

㪱㪉㪇㪈㪙㪑㪧㪦㪣㪘㪩㪰㪱㪜㪩㩷㪠㪥㪄

㪱㪉㪇㪈㪩㪑㪧㪦㪣㪘㪩㪰㪱㪜㪩㩷㪠㪥㪄

㪱㪉㪇㪌㪑㪌㪐㪈㪣㪜㪥㪪

9-2

㧥

Other Parts

Chapter

9-3

Chapter

㧥

Spare parts list (TLP-X2000) GREEN

No Location Description

1

A100 COVER ASSY, TOP

2

A101 SCREW, 2.0 X 4.0 MM

3

A102A SCREW

4

A110 CASE ASSY, CONTROL UP

5

A110A SCREW, 2.0 X 4.0 MM

6

A111 CASE ASSY, CONT LOWER

7

A111A SCREW, 2.0 X 4.0 MM

8

A210 COVER ASSY, LAMP

9

A220 CAP, LENS

10

A230 COVER ASSY, FILTER BOTTOM

11

A304 LABEL, CAUTION

12

A305 LABEL, CAUTION HOT BLACK

13

A306 LABEL, LABEL CAUTION, LENS BLACK

14

A307 LABEL, CARTON,TLP-X2000

15

A308 LABEL, TOP TAG

16

A310 LABEL, CASE LOWER, X2000

17

A401 CARTON BOX, X2000

18

A401B SHEET, PROTECTIVE 700X300

19

A405 SOFT CASE, X2000

20

B001 LCD PANEL, L3P06X-56G20B

21

B002 LCD PANEL, L3P06X-55G20B

22

B100 COVER ASSY, BOTTOM

24

B101 SCREW

25

B111 PANEL, FRONT

26

B112 PANEL, SIDE

27

B113 PANEL ASSY, LENS

28

B120 PLATE, AC-IN

29

B131 COVER, LAMP

30

B141 AIR DUCT, POWER FAN

31

B170 AIR DUCT

32

CN105 CONNECTOR, 1.25MM PITCH W TO B

33

CN108 CONNECTOR, 1.25MM PITCH W TO B

34

CN503 CONNECTOR, D-SUB, DZ11A92-ND201-7F

35

E255 LENS, ANLC03T

36

E270 HOLDER ASSY, LAMP

37

G001 LCD PANEL, L3P06X-55G20G

38

G002 LCD PANEL, L3P06X-56G20G

39

IC100 IC, PW 190-10L, IMAGE PROCESSOR

40

IC101 IC, BD87A29FVM-TR, VOLTAGE DETECTOR

IC104

41

IC105

42

43

IC108 IC, 24LC128T-I/SNG

44

IC1100 IC, PNA4612M01TH, PD WITH REMOTE CONT

45

IC111 IC, TC7SH08FU(TE85L,F)

46

IC112 IC, L3232ECV-16Z-T

IC119

47

IC1200

48

49

IC122 IC, TC7SH08FU(TE85L,F)

50

IC123 IC, TC7SH08FU(TE85L,F)

IC, PQ1MX55M2SPQ, LOW VOLTAGE

REGULATOR

IC, TK11150CSCL-G, POSITIVE LDO

REGULATOR

IC, LTC3701EGN#TRPBF, DC/DC

CONTROLLER

IC, G751-2RDF, TEMPERATURE SENSOR AND

THERMAL WATCHDOG

EBUCH

Part No

75004216

70391261

23738144

75004217

70391261

75004218

70391261

75004221

75004222

75004223

75004197

75004198

75004200

75004195

75004196

75004201

75004232

75004234

75004233

75004158

75004155

75004219

23738144

75004225

75004226

75004227

75004230

75004220

75004229

75004228

75002110

75002110

75004141

75004215

75004231

75004154

75004157

75004414

75004425

75004417

75004418

75004412

75001241

75001245

75004413

75004148

75004147

75001245

75001245

9-4

Chapter

㧥

No Location Description

51

IC124 IC, SN74AHCT1G08DCKR, 2 INPUT AND GATE

52

IC125 IC, SN74AHCT1G08DCKR, 2 INPUT AND GATE

53

IC126 IC, BD4843G-TR, VOLTAGE DETECTOR

54

IC127 IC, TC7SH08FU(TE85L,F)

55

IC129 IC, TC7SH08FU(TE85L,F)

IC1300

56

57

IC350 IC, TC7WBD126AFK(T5L,F, DUAL BUS SWITCH

IC351

58

IC352

59

60

IC353 IC, PQ200WNA1ZPH, VOLTAGE REGULATOR

61

IC354 IC, PQ200WNA1ZPH, VOLTAGE REGULATOR

62

IC355 IC, PQ200WNA1ZPH, VOLTAGE REGULATOR

63

IC356 IC, PQ200WNA1ZPH, VOLTAGE REGULATOR

64

IC357 IC, PQ200WNA1ZPH, VOLTAGE REGULATOR

65

IC358 IC, M62334FP DF5J, D/A CONVERTER

66

IC359 IC, PQ200WNA1ZPH, VOLTAGE REGULATOR

67

IC501 IC, XC95144XL-10TQG100C-X2000

68

IC502 IC, MXD2020EL-T/R, ACCELEROMETER

69

IC503 IC, MAX4885ETJ+TG40, ANALOG SWITCH

70

IC504 IC, EL4340IUZ-T7, MULTIPLEXING AMPLIFIER

IC505

71

72

IC506 IC, EL4332CSZ-T7, VIDEO MULTIPLEXING

73

IC507 IC, EL5106IW Z-T7, GAIN AMPLIFIER

74

IC508 IC, EL5106IW Z-T7, GAIN AMPLIFIER

IC509

75

IC510

76

77

IC511 IC, ISL59885ISZ-T7, VIDEO SYNC SEPARATOR

78

IC512 IC, ISL59885ISZ-T7, VIDEO SYNC SEPARATOR

79

IC513 IC, BU9882FV-WE2, 2KBIT EEPROM

80

IC514 IC, MM1565AFBE, VOLTAGE REGULATOR

IC515

81

82

IC6001 IC, NJM2370U1-09-TE1, VOLTAGE REGULATOR

83

IC6002 IC, NJM2370U1-09-TE1, VOLTAGE REGULATOR

IC6003

84

IC6004

85

86

IC6005 IC, NJW1142AV(TE1), AUDIO PROCESSOR

87

IC6010 IC, EL1883ISZ-T7, SYNC SEPARATOR

88

IC6011 IC, EL1883ISZ-T7, SYNC SEPARATOR

89

IC6012 IC, TC7SH08FU(TE85L,F)

90

IC6021 IC, TC7SH08FU(TE85L,F)

91

IC701 IC, PQ20VZ1UJ00H, LOW VOLTAGE REGULATOR

92

IC702 IC, TC7SH08FU(TE85L,F)

IC703

93

94

IC704 IC, L3E07072K0A, TFT-LCD CONTROLLER

95

IC801 IC, L3E06100D0B, TFT-LCD CONTROLLER

96

IC831 IC, L3E06100D0B, TFT-LCD CONTROLLER

97

IC861 IC, L3E06100D0B, TFT-LCD CONTROLLER

98

J6001 CONNECTOR, LAP5300-0110F

99

MJ02 WIRE HARNESS, THERMAL SWITCH

100

P800 PC BOARD ASSY, LINE-FILTER, APS-T602

IC, G751-2RDF, TEMPERATURE SENSOR AND

THERMAL WATCHDOG

IC, G768BF, TEMPERATURE SENSOR AND

FAN CONTROLLER

IC, G794D5U, TEMPERATURE SENSOR AND

4FAN CONTROLLER

IC, SN74LVC2G17DCKR, DUAL SCHMITT-TRIGGER

BUFFER

IC, SN74LVC2G17DCKR, DUAL SCHMITT-TRIGGER

BUFFER

IC, SN74LVC2G17DCKR, DUAL

SCHMITT-TRIGGER BUFFER

IC, LM2660MM, SWITCHED CAPACITOR

VOLTAGE CON

IC, NJM2886DL3-05(TE1), LOW DROPOUT

VOLTAGE REGULATOR

IC, TPA2005D1DGNRG4, AUDIO POWER

AMPLIFIER

IC, BA10324AFV-E2,QUAD OPERATIONAL

AMPLIFIER

Part No

EBUCH

75004410

75004410

75004150

75001245

75001245

75004147

75001220

75004146

75004421

75004422

75004422

75004422

75004422

75004422

75001226

75004422

75004143

75004419

75004151

75004429

75004411

75001323

75004430

75004430

75004411

75004411

75004424

75004424

75004415

75004420

75001237

75001239

75001239

75004427

75004428

75004426

75004423

75004423

75001245

75001245

75004416

75001245

75004149

75004145

75004144

75004144

75004144

75004140

75005121

23122519

9-5

Chapter

㧥

No Location Description

101

P801 PC BOARD ASSY, MAIN POWER, APS-T603

P850

102

Q101

103

104

R001 LCD PANEL, L3P06X-56G20R

105

R002 LCD PANEL, L3P06X-55G20R

106

S1605 SWITCH, TACT, TSW-6A-1-16-T50

107

S501 SWITCH, SLIDE, SLD-12-500

108

SP200 SPEAKER, RFF-0401C-02

109

U001 PC BOARD ASSY, MAIN, FX2MA2

U002

110

U003

111

112

U004 PC BOARD ASSY, SENSOR, FX2SE2

113

U005 PC BOARD ASSY, DOOR SWITCH, FX2DR2

114

U006 PC BOARD ASSY, KEY, FX2KY2

115

U007 PC BOARD ASSY, RELAY BOARD, FX2RL2

116

Y100 CABLE, RGB, BLUE

Y200

117

118

Y200 OWNER'S MANUAL, TLP-X2000C

119

Y201 CD-ROM, OWNERS MANUAL, X2000 SIRIES

120

Y260 POWER CORD, CEE 250V 6A, 3M

121

Y260 POWER CORD, UL 125V 10A, 3M

122

Y260 POWER CORD, GB250V10A

123

Y260 POWER CORD, UK250V6A

124

Y700 REMOCON HAND UNIT, CT-90264

125

Y702 REMOCON RECIVER, IR, MOUS, CR-916

126

Z100 FAN, TYF450FJ06

127

Z100 OPTICS BLOCK, CJ591TA

128

Z101 FAN, TYF400FJ10

129

Z102 FAN, D05F-12BS2 02A

130

Z103 FAN, TYF310FJ11

131

Z104 FAN, D05F-12PS7 01A(EX)

132

Z105 FAN, D07R-12TH 03A(EX)

133

Z200 OPTICS BLOCK, 591SUB

134

Z201B OPTICS BLOCK, 591IN-B

135

Z201G OPTICS BLOCK, 591IN-G

136

Z201R OPTICS BLOCK, 591IN-R

137

Z202B OPTICS BLOCK, 591OUT-B

138

Z202G OPTICS BLOCK, 591OUT-G

139

Z202R OPTICS BLOCK, 591OUT-R

140

Z203 LENS, 591PBS

141

Z205 LENS, 591LENS

PC BOARD ASSY, LAMP POWER,

PS-240A-MS-120-22H

TRANSISTOR, UM6K1NTN, N-CH MOS FET

MODULE

PC BOARD ASSY, REMOCON RECEIVER,

FX2RE2

PC BOARD ASSY, EXHAUST SENSOR,

FX2EX2

OWNERS MANUAL ASSY, X2000, MULTI

LANGUAGE

Part No

EBUCH

23122520

75004203

75004142

75004156

75004153

75004139

75004138

23351359

75004132

75004133

75004134

75004135

75004136

75004137

75004131

23368955

75004235 75004235 75004235

-----

23372167

-----

-----

----- 23372337

----- ----75004236

----- ----- -----

-----

----- -----

23372148

----- ----75004204

23306621

75004190

75004205

75004160

23125960

75004159

75004191

75004192

75004207

75004210

75004209

75004208

75004213

75004212

75004211

75004214

75004206

-----

75004975

-----

23372155

9-6

Chapter

㧥

(

)

(

)

(

)

(

)

(

)

(

Spare parts list (TLP-X2500) GREEN

No Location Description

1 A100

2 A101

3 A102A

4 A110

5 A110A

6 A111

7 A111A

8 A210

9 A220

10 A230

11 A401

12 A405

13 B001

14 B002

15 B100

16 B111

17 B112

18 B113

19 B120

20 B131

21 B141

22 B170

23 CN105

24 CN108

25 CN503

26 E255

27 E270

28 G001

29 G002

30 IC100

31 IC101

32 IC104

33 IC105

34 IC107

35 IC1100

36 IC111

37 IC112

38 IC119

39 IC1200

40 IC122

41 IC123

42 IC124

43 IC125

44 IC126

45 IC127

46 IC129

47 IC1300

48 IC350

49 IC351

50 IC352

COVER ASSY, TOP

SCREW, 2.0 X 4.0 MM

SCREW

CASE ASSY, CONTROL UP

SCREW, 2.0 X 4.0 MM

CASE ASSY, CONT LOWER

SCREW, 2.0 X 4.0 MM

COVER ASSY, LAMP

CAP, LENS

COVER ASSY, FILTER BOTTOM

CARTON BOX, X2000

SOFT CASE, X2000

LCD PANEL, L3P06X-66G00B

LCD PANEL, L3P06X-65G00B

COVER ASSY, BOTTOM

PANEL, FRONT

PANEL, SIDE

PANEL ASSY, LENS

PLATE, AC-IN

COVER, LAMP

AIR DUCT, POWER FAN

AIR DUCT

CONNECTOR, 1.25MM PITCH W TO B

CONNECTOR, 1.25MM PITCH W TO B

CONNECTOR, D-SUB, DZ11A92-ND201-7F

LENS, ANLC03T

HOLDER ASSY, LAMP

LCD PANEL, L3P06X-65G00G

LCD PANEL, L3P06X-66G00G

IC, PW190-10L, IMAGE PROCESSOR

IC, BD87A29FVM-TR, VOLTAGE DETECTOR

IC, PQ1MX55M2SPQ, LOW VOLTAGE

REGULATOR

IC, TK11150CSCL-G, POSITIVE LDO

REGULATOR

IC, ES29LV160ET-70TGI

IC, PNA4612M01TH, PD WITH REMOTE CONT

IC, TC7SH08FU

IC, L3232ECV-16Z-T

IC, LTC3701EGN#TRPBF, DC/DC CONTROLLER

IC, G751-2RDF, TEMPERATURE SENSOR AND

THERMAL WATCHDOG

IC, TC7SH08FU

IC, TC7SH08FU

IC, SN74AHCT1G08DCKR, 2 INPUT AND GATE

IC, SN74AHCT1G08DCKR, 2 INPUT AND GATE

IC, BD4843G-TR, VOLTAGE DETECTOR

IC, TC7SH08FU

IC, TC7SH08FU

IC, G751-2RDF, TEMPERATURE SENSOR AND

THERMAL WATCHDOG

IC, TC7WBD126AFK

IC, G768BF, TEMPERATURE SENSOR AND

FAN CONTROLLER

IC, G794D5U, TEMPERATURE SENSOR AND

4FAN CONTROLLER

TE85L,F

TE85L,F

TE85L,F

TE85L,F

TE85L,F

T5L,F, DUAL BUS SWITCH

EBUCH

Part No

75004216

70391261

23738144

75004217

70391261

75004218

70391261

75004221

75004222

75004223

75004232

75004233

75004771

75004767

75004219

75004225

75004226

75004227

75004230

75004220

75004229

75004228

75002110

75002110

75004141

75004215

75004231

75004766

75004769

75004414

75004425

75004417

75004418

75004763

75001241

75001245

75004413

75004148

75004147

75001245

75001245

75004410

75004410

75004150

75001245

75001245

75004147

75001220

75004146

75004421

9-7

Chapter

㧥

(

(

)

(

)

(

)

No Location Description

51 IC353

52 IC354

53 IC355

54 IC356

55 IC357

56 IC358

57 IC359

58 IC501

59 IC502

60 IC503

61 IC504

62 IC505

63 IC506

64 IC507

65 IC508

66 IC509

67 IC510

68 IC511

69 IC512

70 IC513

71 IC514

72 IC515

73 IC6001

74 IC6002

75 IC6003

76 IC6004

77 IC6005

78 IC6010

79 IC6011

80 IC6012

81 IC6021

82 IC701

83 IC702

84 IC703

85 IC704

86 IC801

87 IC802

88 IC831

89 IC832

90 IC861

91 IC862

92 J6001

93 MJ02

94 P800

95 P801

96 P850

97 Q101

98 R001

99 R002

100 S1605

IC, PQ200WNA1ZPH, VOLTAGE REGULATOR

IC, PQ200WNA1ZPH, VOLTAGE REGULATOR

IC, PQ200WNA1ZPH, VOLTAGE REGULATOR

IC, PQ200WNA1ZPH, VOLTAGE REGULATOR

IC, PQ200WNA1ZPH, VOLTAGE REGULATOR

IC, M62334FP DF5J, D/A CONVERTER

IC, PQ200WNA1ZPH, VOLTAGE REGULATOR

IC, XC95144XL-10TQG100C-X2000

IC, MXD2020EL-T/R, ACCELEROMETER

IC, MAX4885ETJ+TG40, ANALOG SWITCH

IC, EL4340IUZ-T7, MULTIPLEXING AMPLIFIER

IC, SN74LVC2G17DCKR, DUAL SCHMITT-TRIGGER

BUFFER

IC, EL4332CSZ-T7, VIDEO MULTIPLEXING

IC, EL5106IWZ-T7, GAIN AMPLIFIER

IC, EL5106IWZ-T7, GAIN AMPLIFIER

IC, SN74LVC2G17DCKR, DUAL SCHMITT-TRIGGER

BUFFER

IC, SN74LVC2G17DCKR, DUAL SCHMITT-TRIGGER

BUFFER

IC, ISL59885ISZ-T7, VIDEO SYNC SEPARATOR

IC, ISL59885ISZ-T7, VIDEO SYNC SEPARATOR

IC, BU9882FV-WE2, 2KBIT EEPROM

IC, MM1565AFBE, VOLTAGE REGULATOR

IC, LM2660MM, SWITCHED CAPACITOR VOLTAGE

IC, NJM2370U1-09-TE1, VOLTAGE REGULATOR

IC, NJM2370U1-09-TE1, VOLTAGE REGULATOR

IC, NJM2886DL3-05(TE1), LOW DROPOUT

VOLTAGE REGULATOR

IC, TPA2005D1DGNRG4, AUDIO POWER

AMPLIFIER

IC, NJW1142AV

IC, EL1883ISZ-T7, SYNC SEPARATOR

IC, EL1883ISZ-T7, SYNC SEPARATOR

IC, TC7SH08FU

IC, TC7SH08FU

IC, PQ20VZ1UJ00H, LOW VOLTAGE

REGULATOR

IC, R1172H121D-T1-F, VOLTAGE REGULATOR

IC, TC7SH08FU

IC, L3E07110K0A,TIMING PULSE GENERATOR

IC, L3E06150S2A,TFT-LCD CONTROLLER

IC, L3E01060P0A

IC, L3E06150S2A,TFT-LCD CONTROLLER

IC, L3E01060P0A

IC, L3E06150S2A,TFT-LCD CONTROLLER

IC, L3E01060P0A

CONNECTOR, LAP5300-0110F

SWITCH, THERMAL SWITCH WITH WIRE

HARNESS

PC BOARD ASSY, LINE-FILTER, APS-T602

PC BOARD ASSY, MAIN POWER, APS-T603

PC BOARD ASSY, LAMP POWER,

PS-240A-MS-120-22H

TRANSISTOR, UM6K1NTN, N-CH MOS FET

MODULE

LCD PANEL, L3P06X-66G00R

LCD PANEL, L3P06X-65G00R

SWITCH, TACT, TSW-6A-1-16-T50

TE1), AUDIO PROCESSOR

TE85L,F

TE85L,F

TE85L,F

Part No

EBUCH

75004422

75004422

75004422

75004422

75004422

75001226

75004422

75004143

75004419

75004151

75004429

75004411

75001323

75004430

75004430

75004411

75004411

75004424

75004424

75004415

75004420

75001237

75001239

75001239

75004427

75004428

75004426

75004423

75004423

75001245

75001245

75004416

75004762

75001245

75004760

75004761

75004759

75004761

75004759

75004761

75004759

75004140

75005121

23122519

23122520

75004203

75004142

75004768

75004764

75004139

9-8

Chapter

㧥

A

A

A

(EX)

(EX)

No Location

101 S501

102 SP200

103 U001

104 U002

105 U003

106 U004

107 U005

108 U006

109 U007

110 Y100

111 Y200

112 Y200

113 Y205

114 Y260

115 Y260

116 Y260

117 Y260

118 Y700

119 Y702

120 Z100

121 Z100

122 Z101

123 Z102

124 Z103

125 Z104

126 Z105

127 Z200

128 Z201B

129 Z201G

130 Z201R

131 Z202B

132 Z202G

133 Z202R

134 Z203

135 Z205

Description

SWITCH, SLIDE, SLD-12-500

SPEAKER, RFF-0401C-02

PC BOARD ASSY, MAIN, FX5MA2, TLP-X2500

PC BOARD ASSY, REMOCON, FX5RE2,

TLP-X2500

PC BOARD ASSY, EXTERNAL, FX5EX2,

TLP-X2500

PC BOARD ASSY, SENSOR, FX5SE2,

TLP-X2500

PC BOARD ASSY, DOOR SWITCH, FX5DR2,

TLP-X2500

PC BOARD ASSY, KEY, FX5KY2, TLP-X2500

PC BOARD ASSY, FX2RL2

CABLE, RGB, BLUE

OWNERS MANUAL, X2500U/E/B/J

OWNERS MANUAL, X2500C

OWNER'S MANUAL, X2000SERIES ERRAT

POWER CORD, CEE250V6A 3M

POWER CORD, UL125V10A 3M

POWER CORD SET, UK250V6

POWER CORD, GB250V10A

REMOCON HAND UNIT, CT-90266

REMOCON RECIVER, IR, MOUS, CR-916

FAN, TYF450FJ06

OPTICAL BLOCK, ENGINE, CJ590TA

FAN, TYF400FJ10

FAN, D05F-12BS2 02

FAN, TYF310FJ11

FAN, D05F-12PS7 01A

FAN, D07R-12TH 03A

OPTICAL BLOCK, SUB ASSY, 590SUB

POLARIZER, 591IN-B

POLARIZER, 591IN-G

POLARIZER, 591IN-R

POLARIZER, 591OUT-B

POLARIZER, 591OUT-G

POLARIZER, 591OUT-R

LENS, 591PBS

LENS, 591LENS

Part No

EBUCH

75004138

23351359

75004673

75004674

75004675

75004676

75004677

75004678

75004131

23368955

75004777

----- ----- ----- 75005669

75004435

23372167 ----- ----- -----

----- ----- 23372148 -----

----- 23372337 ----- -----

----- ----- ----- 23372155

75004774

23306621

75004190

75004775

75004160

23125960

75004159

75004191

75004192

75004776

75004210

75004209

75004208

75004213

75004212

75004211

75004214

75004206

-----

9-9

Chapter

㧥

Spare parts list (TLP-X3000) GREEN

No Location Description

1 A100 COVER ASSY, TOP

2 A101 SCREW, 2.0 X 4.0 MM

3 A102A SCREW

4 A110 CASE ASSY, CONTROL UP

5 A110A SCREW, 2.0 X 4.0 MM

6 A111 CASE ASSY, CONT LOWER

7 A111A SCREW, 2.0 X 4.0 MM

8 A210 COVER ASSY, LAMP

9 A220 LENS CAP, 07 MDN

10 A230 COVER ASSY, FILTER BOTTOM

11 A301 LABEL, RATING, X3000

12 A401 CARTON BOX, X2000

13 A405 SOFT CASE, X2000

14 A502 LABEL

15 B001 LCD PANEL, L3P07X-66G00B

16 B002 LCD PANEL, L3P07X-65G00B

17 B100 COVER ASSY, BOTTOM

18 B111 PANEL, FRONT

19 B112 PANEL, SIDE

20 B113 PANEL ASSY, LENS

21 B120 PLATE, AC-IN

22 B131 COVER, LAMP

23 B141 AIR DUCT, POWER FAN

24 B170 AIR DUCT

25 CN105 CONNECTOR, 1.25MM PITCH W TO B

26 CN108 CONNECTOR, 1.25MM PITCH W TO B

27 CN503 CONNECTOR, D-SUB, DZ11A92-ND201-7F

28 E270 HOLDER ASSY, LAMP

29 G001 LCD PANEL, L3P07X-65G00G

30 G002 LCD PANEL, L3P07X-66G00G

31 IC100 IC, PW190-10L, IMAGE PROCESSOR

32 IC101 IC, BD87A29FVM-TR, VOLTAGE DETECTOR

33 IC104

34 IC105

35 IC107 IC, ES29LV160ET-70TGI

36 IC1100 IC, PNA4612M01TH, PD WITH REMOTE CONT

37 IC111 IC, TC7SH08FU(TE85L,F)

38 IC112 IC, L3232ECV-16Z-T

39 IC119

40 IC1200

41 IC122 IC, TC7SH08FU(TE85L,F)

42 IC123 IC, TC7SH08FU(TE85L,F)

43 IC124 IC, SN74AHCT1G08DCKR, 2 INPUT AND GATE

44 IC125 IC, SN74AHCT1G08DCKR, 2 INPUT AND GATE

45 IC126 IC, BD4843G-TR, VOLTAGE DETECTOR

46 IC127 IC, TC7SH08FU(TE85L,F)

47 IC129 IC, TC7SH08FU(TE85L,F)

48 IC1300

49 IC350

IC, PQ1MX55M2SPQ, LOW VOLTAGE

REGULATOR

IC, TK11150CSCL-G, POSITIVE LDO

REGULATOR

IC, LTC3701EGN#TRPBF, DC/DC

CONTROLLER

IC, G751-2RDF, TEMPERATURE SENSOR AND

THERMAL WATCHDOG

IC, G751-2RDF, TEMPERATURE SENSOR AND

THERMAL WATCHDOG

IC, TC7WBD126AFK(T5L,F, DUAL BUS

SWITCH

EBUCH

Part No

75004216

70391261

23738144

75004217

70391261

75004218

70391261

75004221

75005367

75004223

75005357

75004232

75004233

23564859

75005356

75005353

75004219

75004225

75004226

75004227

75004230

75004220

75004229

75004228

75002110

75002110

75004141

75004231

75005352

75005355

75004414

75004425

75004417

75004418

75004763

75001241

75001245

75004413

75004148

75004147

75001245

75001245

75004410

75004410

75004150

75001245

75001245

75004147

75001220

9-10

Chapter

㧥

No Location Description

50 IC351

51 IC352

52 IC353 IC, PQ200WNA1ZPH, VOLTAGE REGULATOR

53 IC354 IC, PQ200WNA1ZPH, VOLTAGE REGULATOR

54 IC355 IC, PQ200WNA1ZPH, VOLTAGE REGULATOR

55 IC356 IC, PQ200WNA1ZPH, VOLTAGE REGULATOR

56 IC357 IC, PQ200WNA1ZPH, VOLTAGE REGULATOR

57 IC358 IC, M62334FP DF5J, D/A CONVERTER

58 IC359 IC, PQ200WNA1ZPH, VOLTAGE REGULATOR

59 IC501 IC, XC95144XL-10TQG100C-X2000

60 IC502 IC, MXD2020EL-T/R, ACCELEROMETER

61 IC503 IC, MAX4885ETJ+TG40, ANALOG SWITCH

62 IC504 IC, EL4340IUZ-T7, MULTIPLEXING AMPLIFIER

63 IC505

64 IC506 IC, EL4332CSZ-T7, VIDEO MULTIPLEXING

65 IC507 IC, EL5106IWZ-T7, GAIN AMPLIFIER

66 IC508 IC, EL5106IWZ-T7, GAIN AMPLIFIER

67 IC509

68 IC510

69 IC511 IC, ISL59885ISZ-T7, VIDEO SYNC SEPARATOR

70 IC512 IC, ISL59885ISZ-T7, VIDEO SYNC SEPARATOR

71 IC513 IC, BU9882FV-WE2, 2KBIT EEPROM

72 IC514 IC, MM1565AFBE, VOLTAGE REGULATOR

73 IC515

74 IC6001

75 IC6002

76 IC6003

77 IC6004

78 IC6005 IC, NJW1142AV(TE1), AUDIO PROCESSOR

79 IC6010 IC, EL1883ISZ-T7, SYNC SEPARATOR

80 IC6011 IC, EL1883ISZ-T7, SYNC SEPARATOR

81 IC6012 IC, TC7SH08FU(TE85L,F)

82 IC6021 IC, TC7SH08FU(TE85L,F)

83 IC701

84 IC702 IC, R1172H121D-T1-F, VOLTAGE REGULATOR

85 IC703 IC, TC7SH08FU(TE85L,F)

86 IC704 IC, L3E07110K0A,TIMING PULSE GENERATOR

87 IC801 IC, L3E06150S2A,TFT-LCD CONTROLLER

88 IC802 IC, L3E01060P0A

89 IC831 IC, L3E06150S2A,TFT-LCD CONTROLLER

90 IC832 IC, L3E01060P0A

91 IC861 IC, L3E06150S2A,TFT-LCD CONTROLLER

92 IC862 IC, L3E01060P0A

93 J6001 CONNECTOR, LAP5300-0110F

94 MJ02

95 P800 PC BOARD ASSY, LINE-FILTER, APS-T602

IC, G768BF, TEMPERATURE SENSOR AND

FAN CONTROLLER

IC, G794D5U, TEMPERATURE SENSOR AND

4FAN CONTROLLER

IC, SN74LVC2G17DCKR, DUAL SCHMITTTRIGGER BUFFER

IC, SN74LVC2G17DCKR, DUAL SCHMITTTRIGGER BUFFER

IC, SN74LVC2G17DCKR, DUAL SCHMITTTRIGGER BUFFER

IC, LM2660MM, SWITCHED CAPACITOR

VOLTAGE CON

IC, NJM2370U1-09-TE1, VOLTAGE

REGULATOR

IC, NJM2370U1-09-TE1, VOLTAGE

REGULATOR

IC, NJM2886DL3-05(TE1), LOW DROPOUT

VOLTAGE REGULATOR

IC, TPA2005D1DGNRG4, AUDIO POWER

AMPLIFIER

IC, PQ20VZ1UJ00H, LOW VOLTAGE

REGULATOR

SWITCH, THERMAL SWITCH WITH WIRE

HARNESS

Part No

EBUCH

75004146

75004421

75004422

75004422

75004422

75004422

75004422

75001226

75004422

75004143

75004419

75004151

75004429

75004411

75001323

75004430

75004430

75004411

75004411

75004424

75004424

75004415

75004420

75001237

75001239

75001239

75004427

75004428

75004426

75004423

75004423

75001245

75001245

75004416

75004762

75001245

75004760

75004761

75004759

75004761

75004759

75004761

75004759

75004140

75005121

23122519

9-11

Chapter

㧥

,

No Location Description

96 P801 PC BOARD ASSY, MAIN POW ER, APS-T603

97 P850

98 Q101

99 R001 LCD PANEL, L3P07X-66G00R

100 R002 LCD PANEL, L3P07X-65G00R

101 S1605 SWITCH, TACT, TSW -6A-1-16-T50

102 S501 SW ITCH, SLIDE, SLD-12-500

103 SP200 SPEAKER, RFF-0401C-02

104 U001 PC BOARD ASSY, MAIN, FX5MA2, TLP-X3000

105 U002 PC BOARD ASSY, RELAY, FX5RE2, TLP-X3000

106 U003

107 U004

108 U005

109 U006 PC BOARD ASSY, KEY, FX5KY2, TLP-X3000

110 U007 PC BOARD ASSY, RELAY, FX2RL2

111 Y100 CABLE, RGB, BLUE

112 Y200

113 Y200 OWNERS MANUAL, CHINESE, X3000C ----- ----- ----- 75005668

114 Y260 POWER CORD, UL 125V 10A, 3M ----- 23372148 ----115 Y260 POWER CORD, EU 23372167 ----- ----- ----116 Y260 POWER CORD, UK 23372337 ----- ----117 Y260 POWER CORD, CHINA ----- ----- ----- 23372155

118 Y700 REMOCON HAND UNIT, CT-90266

119 Y702 REMOCON RECIVER, IR, MOUS, CR-916

120 Z100 FAN, TYF450FJ06

121 Z100 OPTICAL BLOCK, CJ589TA

122 Z101 FAN, TYF400FJ10

123 Z102 FAN, D05F-12BS2 02A

124 Z103 FAN, TYF310FJ11

125 Z104 FAN, D05F-12PS7 01A(EX)

126 Z105 FAN, D07R-12TH 03A(EX)

127 Z200 OPTICAL BLOCK, SUB ASSY, 589SUB

128 Z201B POLARIZER, 591IN-B

129 Z201G POLARIZER, 591IN-G

130 Z201R POLARIZER, 591IN-R

131 Z202B OPTICAL FILTER, 589OUT-B

132 Z202G OPTICAL FILTER, 589OUT-G

133 Z202R OPTICAL FILTER, 589OUT-R

134 Z205 LENS, 589LENS

PC BOARD ASSY, LAMP POWER,

PS-240A-MS-120-22H

TRANSISTOR, UM6K1NTN, N-CH MOS FET

MODULE

PC BOARD ASSY, EXHAUST SENSOR,

FX5EX2

PC BOARD ASSY, SENSOR, FX5SE2,

TLP-X3000

PC BOARD ASSY, DOOR SWITCH, FX5DR2,

TLP-X3000

OWNERS MANUAL, CD-ROM AND BOOKLET,

X3000UEBJ

TLP-X3000

EBUCH

Part No

23122520

75004203

75004142

75005354

75005351

75004139

75004138

23351359

75005345

75005346

75005347

75005348

75005349

75005350

75004131

23368955

75005368

75004774

23306621

75004190

75005360

75004160

23125960

75004159

75004191

75004192

75005362

75004210

75004209

75004208

75005365

75005364

75005363

75005361

9-12

TOSHIBA CORPORATION

1-1, SHIBAURA 1-CHOME, MINATO-KU, TOKYO 105-8001, JAPAN

Loading...

Loading...