SERVICE MANUAL

FILE NO. 330-200515GR

DOCUMENT CAMERA

TLP-C001

The above models are classified as green product (s) (*1), as indicated by the underlined serial number (s).

This Service Manual describes replacement parts for green product (s). When repairing any green product (s), use

the parts described in this manual and lead-free solder (*2).

For (*1) and (*2) , see the next page.

Published in Japan, December 2005 GREEN© TOSHIBA CORPORATION

(*1) GREEN PRODUCT PROCUREMENT

The EC is actively promoting the WEEE & RoHS Directives that define standards for

recycling and reuse of Waste Electrical and Electronic Equipment and for the Restriction of

the use of certain Hazardous Substances. From July 1, 2006, the RoHS Directive will prohibit

any marketing of new products containing lead.

Increasing attention is given to issues related to the global environmental. Toshiba

Corporation recognizes environmental protection as a key management tasks, and is doing

its utmost to enhance and improve the quality and scope of its environmental activities. In

line with this, Toshiba proactively promotes Green Procurement, and seeks to purchase and

use products, parts and materials that have low environmental impacts. Green procurement

of parts is not only confined to manufacture. The same green parts used in manufacture

must also be used as replacement parts.

(*2) LEAD-FREE SOLDER

This product is manufactured using lead-free solder as a part of a movement within the CE

industry at large to be environmentally responsible. Lead-free solder must be used in the

servicing and repair of this product.

WARNING

This product is manufactured using lead free solder.

DO NOT USE LEAD BASED SOLDER TO REPAIR THIS PRODUCT

!

The melting temperature of lead-free solder is higher than that of leaded solder by 86°F to

104 °F (30°C to 40°C). Use of a soldering iron designed for lead-based solders to repair

product made with lead-free solder may result in damage to the component and or PCB

being soldered. Great care should be made to ensure high-quality soldering when servicing

this product—especially when soldering large components, through-hole pins, and on

PCBs—as the level of heat required to melt lead-free solder is high.

1

SECTION 1

PART REPLACEMENT

1.LOCATION OF MAIN PARTS

E002: CAMERA HEAD ASSY

A004: LABEL, SPEC

A002: BOTTOM COVER

U001: MAIN PCB

A005: FOOT, RUBBER

A001: TOP COVER ASSY

U002: KEYPAD PCB

U003: IR RECEIVER

B001: SPRING+BEARING

E001: ARM ASSEMBLY

A003: CAMERA HEAD COVER KIT

ARM

BOTTOM COVER

CAMERA

TOP COVER

2

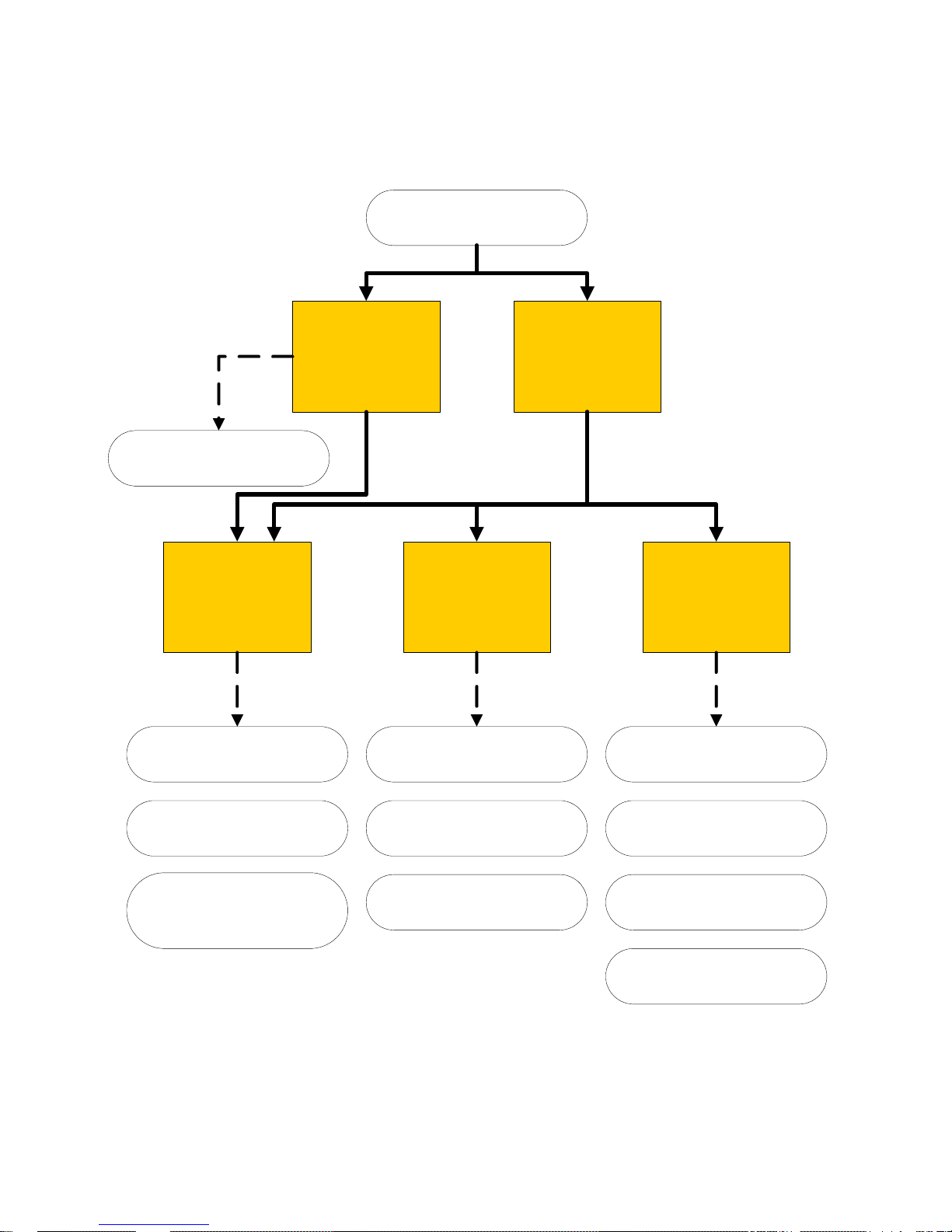

2.ASSEMBLY INSTRUCTION

3-2

BASE

ASSEMBLY

TLPC001

UNIT

3-5

BOTTOM

COVER

ASSEMBLY

3-4

TOP COVER

ASSEMBLY

3-3

ARM

ASSEMBLY

3-1

CAMERA

ASSEMBLY

U002

KEYPAD PCB

U001

MAIN PCB

E002

CAMERA HEAD ASSY

E001

ARM ASSEMBLY

B001

SPRING+BEARING

A005

FOOT, RUBBER

A004

LABEL, SPEC

A003

CAMERA HEAD

COVER KIT

A002

BOTTOM COVER

A001

TOP COVER ASSY

U003

IR RECEIVER

3

Cautions Before Servicing

Electronic parts are susceptible to static electricity and may easily be damaged, so

do not forget to take proper grounding treatment as required.

Many screws are used inside the unit. To prevent missing, dropping, etc. of the

screws, always use a magnetized screwdriver in servicing. Several kinds of screws

are used and some of them need special cautions. That is, take care of the tapping

screws securing molded parts and fine pitch screws used to secure metal parts. If

they are used improperly, the screw holes will be easily damaged and the parts can

not be fixed.

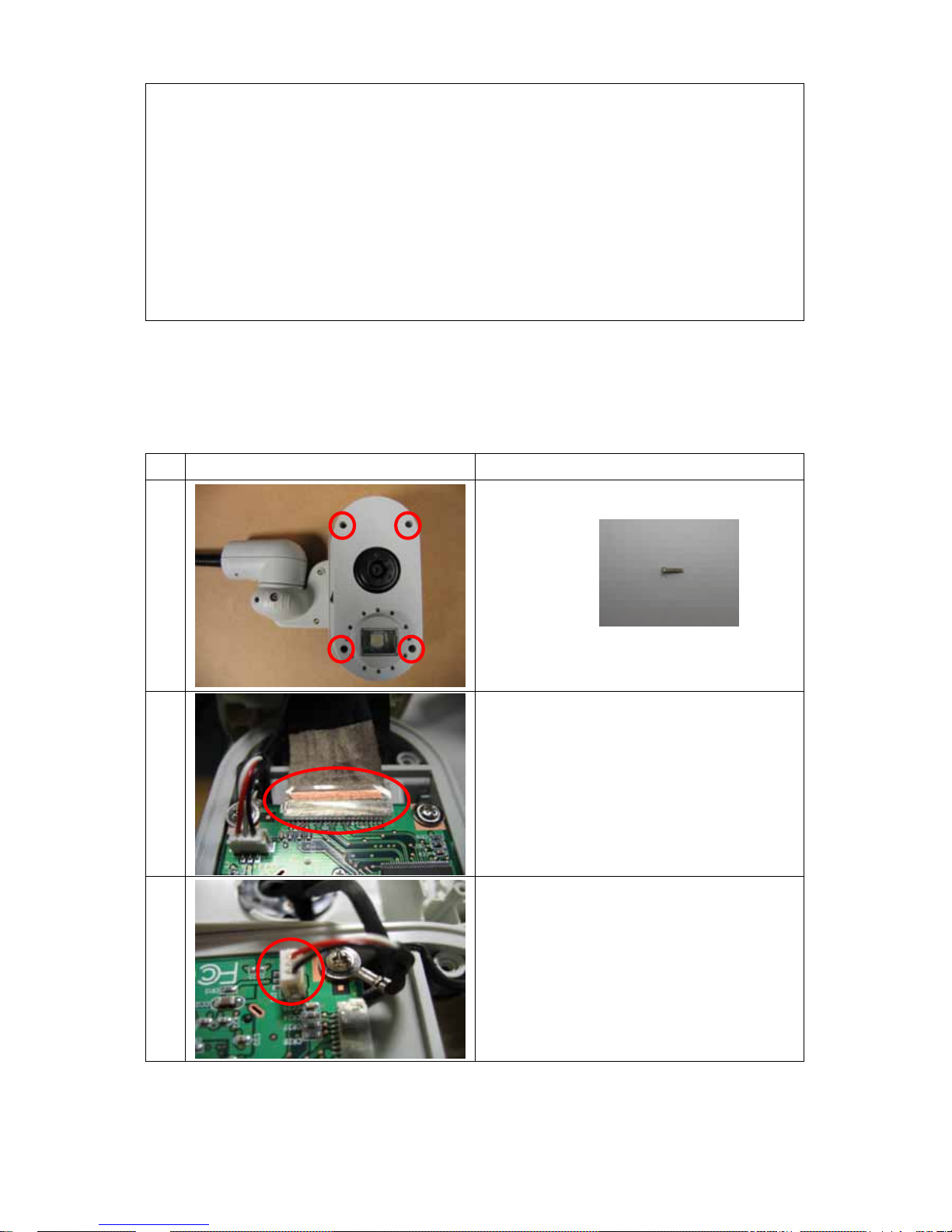

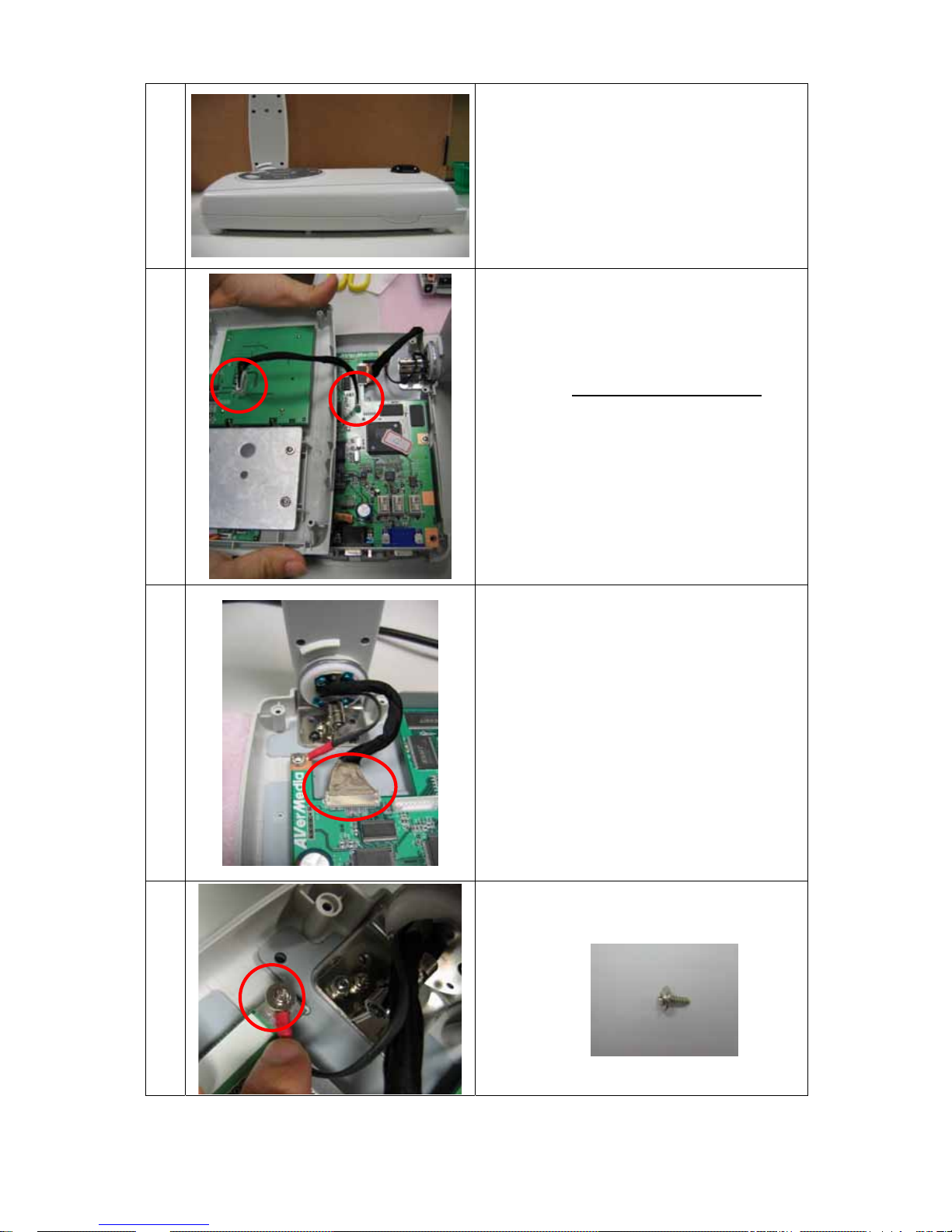

3.REPLACEMENT OF MECHANICAL PARTS

3-1 Camera Assembly

Step Figure Explanation

1 Remove four S-1 (force:1.8~2lb).

2 1.Tear off the sticker on the cable,

2.Remove the cable.

3 Remove the 3pin cable.

4

4 Remove the S-2 (force:2.8~3lb) that

connected with “CAMERA HEAD

ASSY”[23587758]

Note: Go to 3-3 Arm Assembly for the

further assembly instruction.

5

3-2 Base Assembly

Step Figure Explanation

1

Remove four “FOOT,

RUBBER”[23587753]

2 Remove five S-3 (force:2.8~3lb).

3 1.Tear off the sticker “LABEL,

SPEC”[23587754]

2.Remove two S-4 (force:4.8~5lb).

4 Remove the fixture metal.

6

5 Open the top cover from the base.

6

Remove the cable which is connected with

top cover and the base.

Note: Go to 3-4 Top Cover Assembly

for

the further assembly instruction.

7

Tear off the sticker on the cable and

disconnect it.

Note: Be careful for the direction of

connector when connect the cable back

with mainboard

8 Remove the S-2 (force:2.8~3lb) which is

connected with arm assembly and base.

7

9 Remove two S-5 (force:4.8-5lb)

Note: Go to 3-3 Arm Assembly

and 3-5

Bottom Cover Assembly for the further

assembly instruction.

8

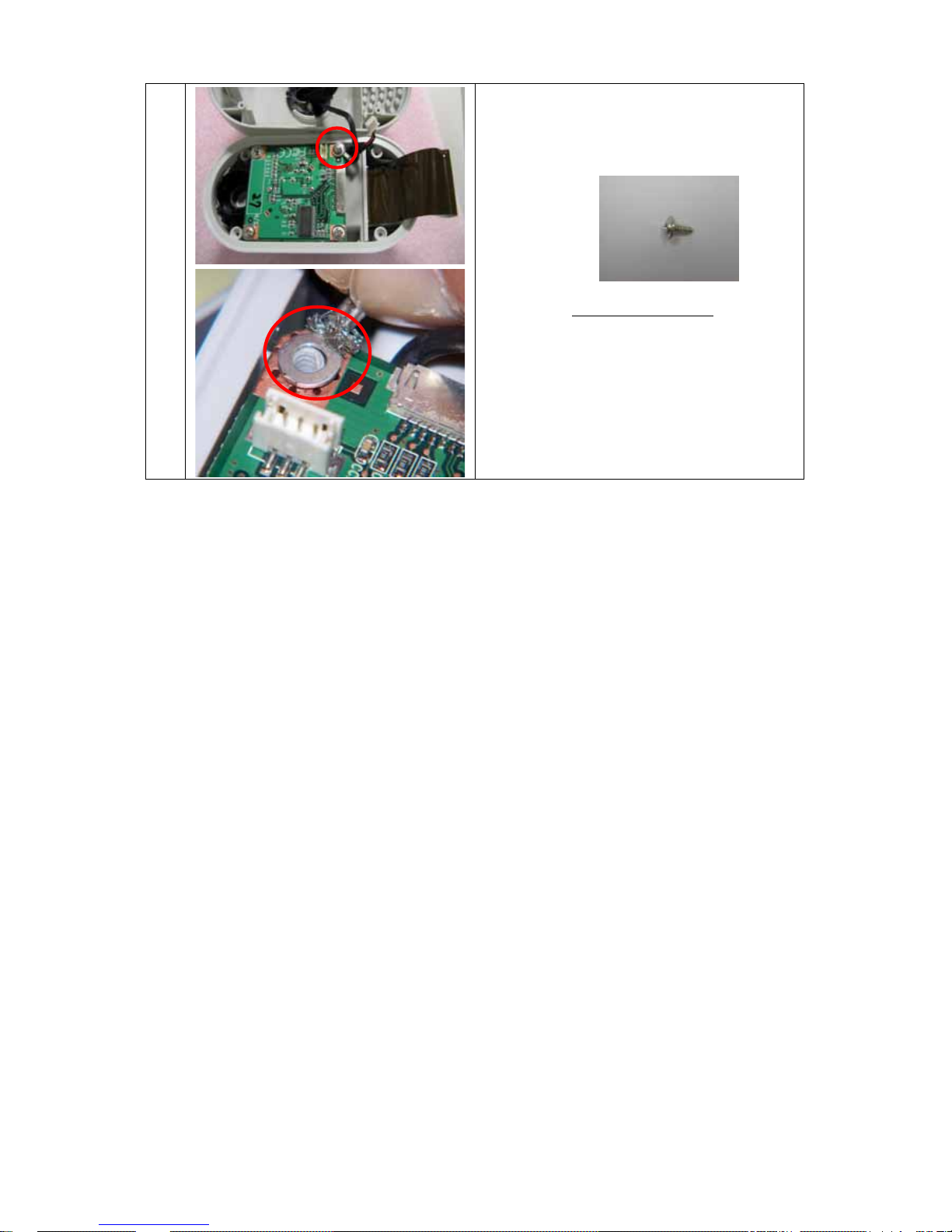

3-3 Arm Assembly

Step Figure Explanation

1 1.Remove three S-1 (force:1.8~2lb)

2.Remove one S-9 (force:4.8~5lb)

2 Remove one S-1 (force:1.8~2lb)

3 Remove two S-6 (force:2.8~3lb)

Note: The black rotation pad should be

assembled with the right position.

4 Take off the camera head - “CAMERA

HEAD COVER KIT”[23587753] and

remove the

“SPRING+BEARING”[23587756]

S-1

S-1

S-1

S-9

9

5 1.Remove two S-2 (force:2.8~3lb)

2.Take off the joint cover-“CAMERA HEAD

COVER KIT”[23587753]

10

3-4 Top Cover Assembly

Step Figure Explanation

1 1.Remove four S-2 (force:2.8~3lb)

2.Take off two metal plates

2 Remove the cable which is connected with

“IR RECEIVER”[23587761] and “KEY

PAD PCB”[23587760]

Note: Please put the cable into the track of

case when connect it back

3 1.Remove four S-1 (force:0.8~1lb)

2.Take off “KEY PAD PCB”[23587760]

4 1.Remove two S-7 (force:0.8~1lb)

2.Take off “KEY PAD PCB”[23587760]

11

3-5 Bottom Cover Assembly

Step Figure Explanation

1 Remove four S-8 (force:2.8~3lb)

2 1.Remove three S-2 (force:2.8~3lb)

2.Take off “MAIN PCB”[23587759]

3 1.Remove one S-2 (force:2.8~3lb)

2.Take off the bottom plate

4 Remove two metal plates

12

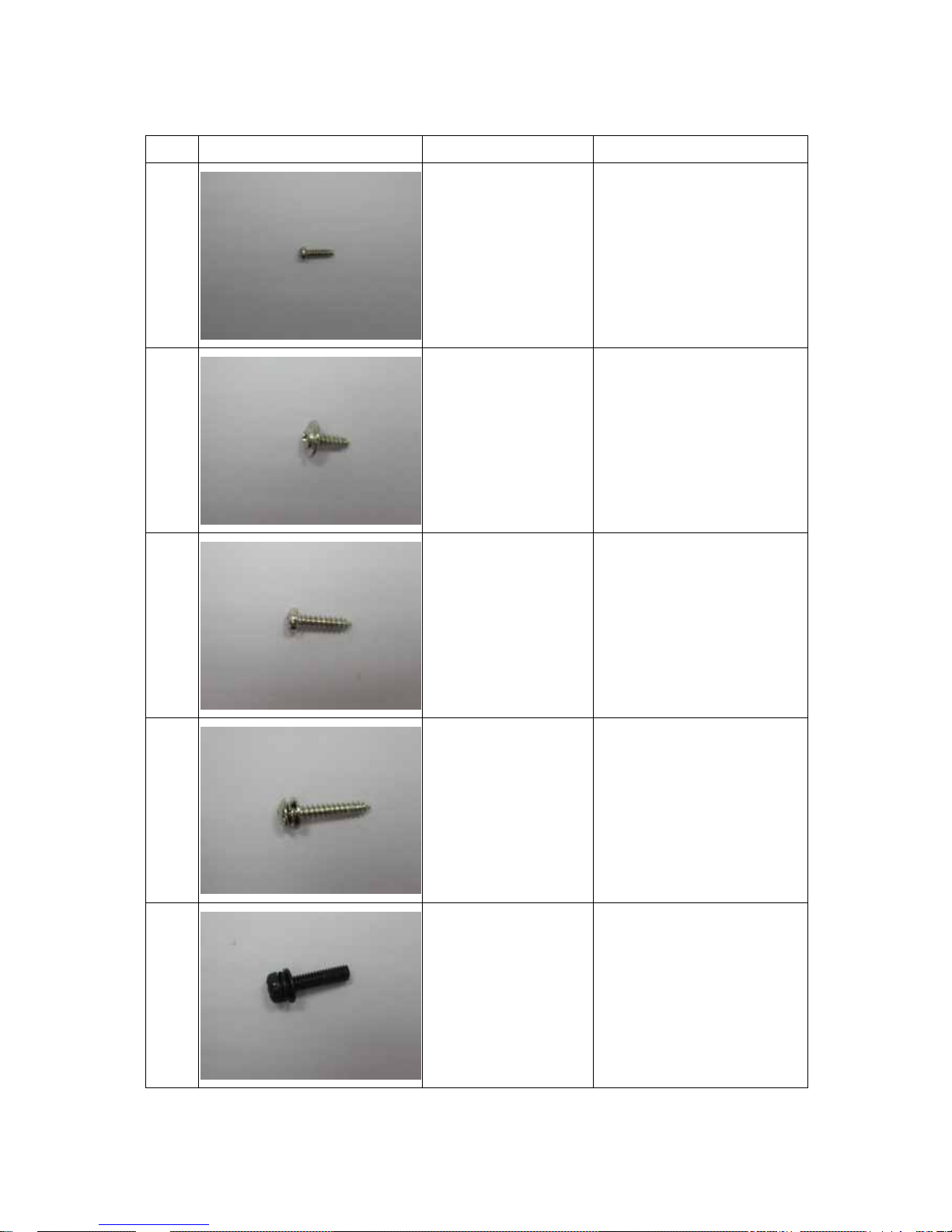

3-6 Screws

Type FORM SIZE Location

S-1 T2x7 Camera Assembly(4)

Arm Assembly(4)

Top Cover Assembly(4)

S-2 T2.6x8 Camera Assembly(1)

Base Assembly(1)

Arm Assembly(2)

Top Cover Assembly(4)

Bottom Cover Assembly(4)

S-3 T2.6x14 Base Assembly(5)

S-4 T2.6x15 Base Assembly(2)

S-5 M3x12 Base Assembly(2)

13

S-6 T2.6x8 Arm Assembly(2)

S-7 M2x4 Top Cover Assembly(2)

S-8 M4.75x7 Bottom Cover Assembly(4)

S-9 M3x7 Arm Assembly(1)

14

SECTION 2

SERVICING DIAGRAMS

1.TROUBLE SHOOTING

1-1.Debuging Function

BUTTON FUNCTION DESCRIPTION

“ZOOM –”+

“ ”

EDID checking

(ON/OFF)

To recognize Toshiba projector, if the display is

not admitted by TSB, the image will disappear

after 10 seconds.

“ZOOM –” +

“ ”

Test Pattern

(ON/OFF)

Run the Camera DSP test pattern

“ZOOM –“ +

“ ”

Debug Mode Enter the Debug mode (See the following

explanation)

“ZOOM –“ +

“ ”

Remote Control

(ON/OFF)

Enable the remote control function

NOTE:

1. Debug Mode:

SELECTION DESCRIPTION

MX88L284 System Register

Default Back to the factory setting

FPGA System Register

CMOS Sensor System Register

ISP Update FW ( See 3) I2C

EEPROM-Version Check FW version

MXIC-Block0 Test MXIC Pattern Pattern

MXIC-Restore Close the MXIC Pattern

Auto Test Test Test EEPROM in

2. Press two buttons at the same time and last for 3 seconds at least to active the

debugging function.

3. Press “INPUT” to close the menu of Debug mode.

15

1-2.Trouble Shooting

CAUSE CHECK POINT CHECK ITEM JUDGE

A. Power supply (NG)

=>Power supply is NG

(OK)

=>Check next step

Power is not on 1.Power supply is

connected well.

2.No light on

“ON/Standby” LED

B. Keypad PCB

connection with

+3.3V

(NG)

=>KEYPAD PCB or

Cable1 (2-1) is NG

(OK)

=>MAIN PCB is NG

Standby mode

couldn’t be

powered on

”ON/Standby” LED Color keeps on

orange

=>KEYPAD PCB or MAIN

PCB is NG

MAIN PCB display MXIC Pattern

(See1-1)

(NG)

=>MAIN PCB is NG

(OK)

=>Check next step

Display is

abnormal

Camera DSP

display

Test Pattern

(See1-1)

(NG)

=>CAMERA HEAD ASSY

or Cable1(2-1) is NG

(OK)

=>MAIN PCB is NG

Flicker Switch FLICKER SW

(50/60 Hz)

(OK)

=>Normal

(NG)

=>Check next step

MAIN PCB display MXIC Pattern

(See1-1)

(NG)

=>MAIN PCB is NG

(OK)

=>Check next step

Display with

waved line

Camera DSP

display

Test Pattern

(See1-1)

(NG)

=>CAMERA HEAD ASSY

or Cable1(2-1) is NG

(OK)

=>MAIN PCB is NG

16

Message

display is wrong

when turn on

1.The display is

magnified to 190%

2.The “190%”

appear position is

wrong

Check the FW

version (See 1-1)

=>Update the FW

(See 3)

LED on the

Camera is not

lighted

LED SW LED lamp =>CAMERA HEAD ASSY

is NG

17

2.CONNECTOR PIN ASSIGNMENT

2-1.U001 (MAIN PCB-J5)<->E002 (CAMERA PCB-CJ1):

It is included in E002: ARM ASSEMBLY

U001 DEFINITION E002 DEFINITION SIGNAL FORMAT

1 LIGHT LIGHT 20 (ON) +3.3V / (OFF) 0V

2 GND GND 19 0V

3 SSCL SCLK 18 0 V to +3.3V (Pulse)

4 SSDA SDATA 17 0 V to +3.3V (Pulse)

5 GND GND 16 0V

6 RAM TA- 15 200mV(Swing)

7 RAP TA+ 14 200mV(Swing)

8 GND GND 13 0V

9 RBM TB- 12 200mV(Swing)

10 RBP TB+ 11 200mV(Swing)

11 GND GND 10 0V

12 RCLKM TCLK- 9 200mV(Swing)

13 RCLKP TCLK+ 8 200mV(Swing)

14 GND GND 7 0V

15 5V 5V 6 +5V

16 5V 5V 5 +5V

17 5V 5V 4 +5V

18 3V7 3V7 3 +3.7V

19 3V7 3V7 2 +3.7V

20 3V7 3V7 1 +3.7V

2-2.U001 (MAIN PCB-J3)<->U002 (KEYPAD PCB-KJ2)

U001 DEFINITION U002 DEFINITION SIGNAL FORMAT

1 REMOTE REMOTE 9 0 V to +3.3V (Pulse)

2 KEY-DO KEY-DO 8 0 V to +3.3V (Pulse)

3 KEY-CLK KEY-CLK 7 0 V to +3.3V (Pulse)

4 KEY-LED KEY-LED 6 0 V to +3.3V (Pulse)

5 KEY-DI KEY-DI 5 0 V to +3.3V (Pulse)

6 3V3 3V3 4 +3.3V

7 3V3 3V3 3 +3.3V

18

8 GND GND 2 0V

9 GND GND 1 0V

3.U002 (KEY PAD PCB-KJ1)<->U003 (IR RECEIVER-RJ1)

U001 DEFINITION U002 DEFINITION SIGNAL FORMAT

1 3V3 POWER 5 +3.3V

2 GND GND 4 0 V

3 IRA IR1 3 0 V to +3.3V (Pulse)

4 IRB IR2 2 0 V to +3.3V (Pulse)

5 IRC IR3 1 0 V to +3.3V (Pulse)

19

3.BLOCK DIADRAM

U001:

MAIN PCB

U002:

KEYPAD PCB

U003:

IR RECEIVER

E002:

CAMERA HEAD

ASSY

RGB IN:

TO COMPUTER

POWER JACK:

+15V IN

RGB OUT:

TO PROJECTOR

FLICKER SW:

50Hz/60Hz

CABLE3:

5PIN(2-3)

CABLE1(E001):

ARM ASSEMBLY(2-1)

CABLE2:

9PIN(2-2)

20

4.CIRCUIT DIAGRAM

4-1.U001:MAIN PCB

4-2.E002: CAMERA HEAD ASSY

21

4-3. P0D1_ISP module

22

SECTION 3

PART LIST

NOTICE

The part number must be used when ordering parts in order to assist in processing, be sure

to include the model number and description.

Parts marked # are of chip type and mounted on original PC boards.

How ever, when they are placed for servicing works, use discrete parts listed on the parts list.

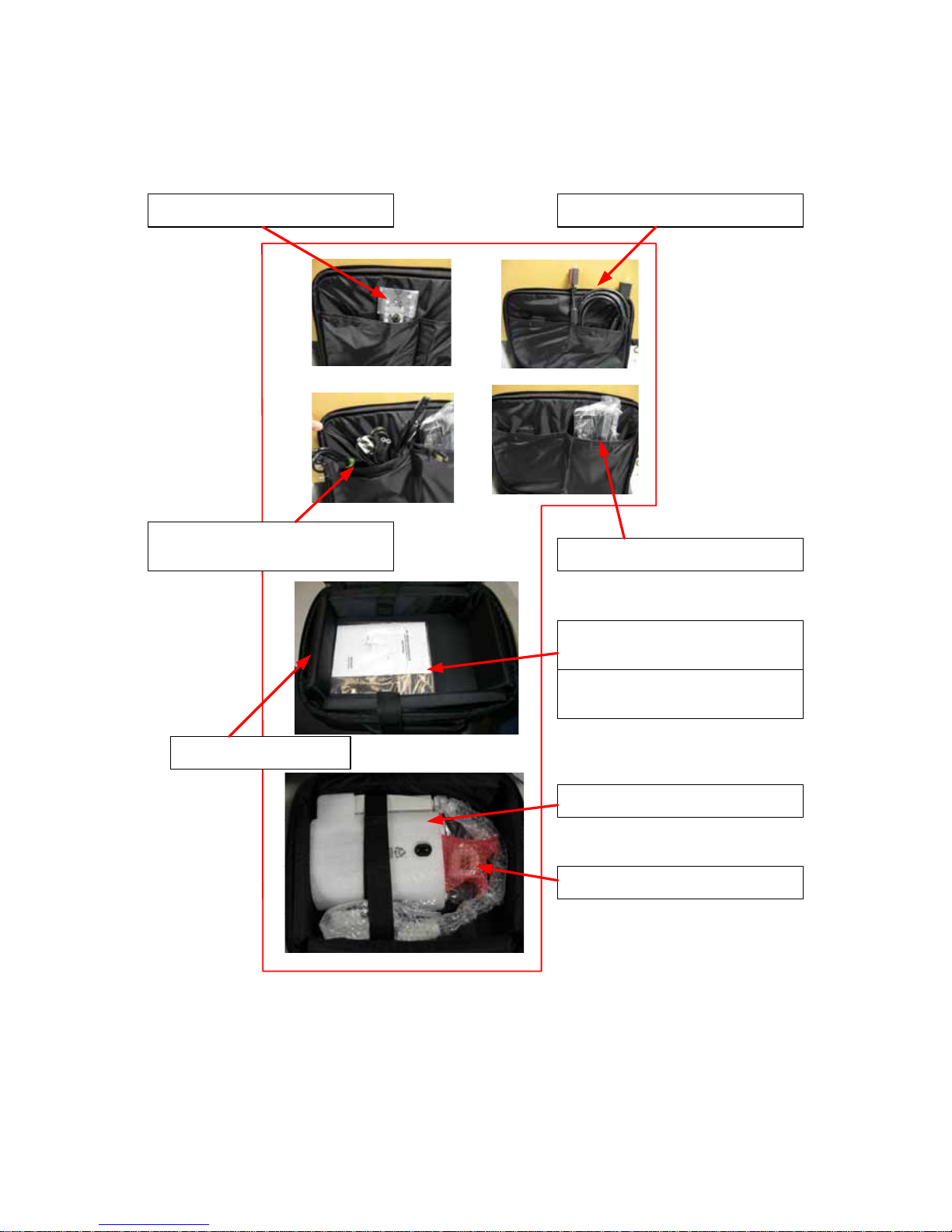

1.PACKING ASSEMBLY

1-1 Carton Assembly

Y005: CARTON BOX

Y006: INSERT

SOFT CASE ASSEMBLY

Y006: INSERT

23

1-2 Soft Case Assembly

Y002: USERS MANUALHARD COPY

Y008-Y0012: POWER

CARD

Y013: RGB CABLE

Y007: AC ADAPTER

Y004: REMOTE CONTROL

Y003: USERS MANUAL-CD

Y014: LED HOOD

TLPC001 UNIT

Y001: SOFT CASE

24

2.SPARE PARTS LIST

2-1.Accessories

LOCATION

NO

DESCRIPTION PARTS NO FIGURE

Y001

SOFT CASE

23587762

Y002

USERS MANUAL-HARD COPY

23587763

Y003

USERS MANUAL-CD

23587764

Y004

REMOTE CONTROL

23587765

Y005

CARTON BOX

23587766

25

Y006

INSERT

23587767

Y007

AC ADAPTER

23587768

Y008

POWER CORD-EU

23587769

Y009

POWER CORD-JP

23587770

Y010

POWER CORD-US

23587771

Y011

POWER CORD-CHINA

23587772

26

Y012

POWER CORD-UK

23587773

Y013

RGB CABLE

23587774

Y014

LED HOOD

23587775

27

2-2.Main Unit Parts

LOCATION

NO

DESCRIPTION PARTS NO FIGURE

A001

TOP COVER ASSY

23587751

A002

BOTTOM COVER

23587752

A003

CAMERA HEAD COVER KIT

23587753

28

A004

LABEL,SPEC

23587754

A005

FOOT,RUBBER

23587755

B001

SPRING+BEARING

23587756

E001

ARM ASSEMBL Y

23587757

E002

CAMERA HEAD ASSY

23587758

29

U001

MAIN PCB

23587759

U002

KEY PAD PCB

23587760

U003

IR RECEIVER

23587761

30

2-3 Label

A004-1: LABEL, SPEC A004-2: LABEL, SPEC

31

TOS

1--1, SHIBAURA 1-- CHOME, MINATO -- KU, TOKYO 105 -- 8001, JAPAN

H

IBA CORPORATION

Loading...

Loading...