Page 1

FILE NO. 336-9707

TECHNICAL TRAINING MANUAL

3 LCD D ATA PROJECTOR

TLP511U

TLP510U

TLP511E

TLP510E

PRINTED IN JAPAN, Nov., 1997

S

Page 2

CONTENTS

1. MAIN POWER SUPPLY

CIRCUIT .....................................1-1

1-1. Description .................................................1-1

1-2. Output Control ..........................................1-1

1-3. Voltage Switching ...................................... 1-1

1-4. Over-voltage Protection............................ 1-1

1-5. Over-current Protection ........................... 1-2

1-6. Overheat Protection ..................................1-2

2. LAMP POWER SUPPLY

CIRCUIT (LAMP DRIVER).....2-1

2-1. Configuration.............................................2-1

3. OPTICAL SYSTEM...................3 -1

3-1. Configuration.............................................3-1

4. R.G.B. DRIVE CIRCUIT...........4-1

4-1. Outline ........................................................ 4-1

4-2. Operation Description .............................. 4-3

5. MICROPROCESSOR................5-1

5-1. System Outline...........................................5-1

5-2. System Microprocessor.............................5-3

5-3. Power Supply Reset Process..................... 5-4

5-4. Non-volatile Memory Process ..................5-4

5-5. Remote Control Reception Process..........5-4

5-6. RS-232C T ransmission/

Reception Process...................................... 5-4

5-7. Status Read Process .................................. 5-4

5-8. Status Display Process ..............................5-5

5-9. On-screen Display Process........................ 5-5

5-10. Video System Control Process.................. 5-6

5-11. Panel System Control Process.................. 5-6

5-12. Drive System Control Process.................. 5-7

5-13. Various Display Modes .............................5-7

5-14. Applicable Signal.......................................5-8

5-15. RS-232C Control Method ......................... 5-9

6. DIGITAL CIRCUIT ...................6-1

6-1. Outline ........................................................ 6-1

6-2. Each IC Description ..................................6-3

7. VIDEO SIGNAL PROCESS

CIRCUIT .....................................7-1

7-1. Circuit Component.................................... 7-1

7-2. Input Signal Switch Section...................... 7-3

7-3. Video Demodulation Block....................... 7-5

7-4. RGB Signal Amplification Section.........7-12

7-5. Microprocessor Interface .......................7-14

8. CCD CAMERA CIRCUIT

(For TLP511)...............................8 -1

8-1. Outline ........................................................ 8-1

9. FLUORESCENT LAMP

INVERTER CIRCUIT

(For TLP511)...............................9 -1

9-1. Operation Description .............................. 9-1

9-2. Troubleshooting .........................................9-2

9-3. Circuit Diagram......................................... 9-3

i

Page 3

1. MAIN POWER SUPPLY CIRCUIT

1-3. Voltage Switching

1-1. Description

This power supply boosts up at boost-up-converter just

after bridge-rectifying AC input voltage, supplies the

voltage smoothed to DC 350V to the lamp output. Then

current resonance DC-DC converter which uses the DC

350V as an input converts the voltage and supplies S6V,

+6V, +10V, +13V, +15.5V and –12V.

The boost-up-converter control IC, IC301, stabilizes AC

rectified voltage to DC 350V. The current resonance DCDC converter, IC303, turns FET Q102 and Q103 “ON/

OFF” alternately using the drive transformer T103 and

converts the voltage to secondary side through the

converter transformer T101. At this time, the voltage of

S6V at the secondary side is detected by IC402, the

negative feedback to IC303 is carried out at photo

coupler PH301 and then the voltage is stabilized. Other

outputs are determined by the turn ratio of secondary

side of T101, and the voltage rectified, smoothed, but not

stabilized are stabilized through the series regulator.

(+10V is stabilized at IC203, +13V at IC202, +15.5V at

IC201.)

The voltage rectified and smoothed by D105 and C113 at

primary winding of T101 is supplied as a VCC voltage of

IC301, IC302 and IC303 on primary side ICs, and also

the voltage rectified and smoothed by D106 and C114 is

supplied as a gate bias voltage of D306 TRIAC (triode

AC switch) which short-circuits the inrush current

limiting resistor R305. Therefore, when the electric

current resonance DC-DC converter stops to oscillate, the

VCC voltage is not supplied so that the boost-upconverter stops to operate.

1-2. Output Control

When the voltage switching terminal of connector C

opens, pin 1 develops low, since the pin 2 of IC401 is 6V,

higher than pin 2 (3V), the voltage adjusted to 16.3V is

directly developed from IC201, since the status of Q205

turns off. When the voltage switching terminal develops

ground potential, since pin 2 of IC401 develops 0V and

the voltage of pin 2 develops low, pin 1 develops high,

Q205 turns on, voltage-set-up resistor of R201 is shortcircuited and the voltage of IC201 rises from 16.3V to

18.0V.

1-4. Over-voltage Pr otection

When the negative feedback circuit of current resonance

DC-DC converter is shut down, the secondary side

voltage control is unable to operate, the voltage begins to

develop high without any restriction. At this time, when

the voltage of S6V and +6V exceeds 8.5V, the base of

transistor Q401 is biased through the zener diode D201,

and turns on, and then the voltage higher than 7V is

added to pin 6 (OVP) of IC303 through the photo coupler

PH302. When the voltage higher than 7V is added to pin

6, IC303 is latched, all outputs are shut down. ( Boostup-converter stops simultaneously, too.)

When the voltage is added to +10V, +13V, +15.5V lines

from external side, (exceeding +15V for +10V line, 13V

for +13 line and 20V for +15.5V line), on each line

respectively through the zener diodes D202, D203 and

D204, the base voltage of Q401 is biased passing, IC303

is latched in the same way as the above-mentioned, all

outputs are shut down. When releasing the latch operation, stop to supply the commercial power supply and

then re-supply the commercial power after more than

approx. 120 seconds.

When the output control 1 and 2 of connector A develops

low, the voltage of approx. 14V is added to Q203 gate

and pins 4 of IC203, IC201, and IC202 through R205

and R206 respectively, since the transistors Q201 and

Q202 turn off. In this case, Q204, IC201, IC202 and

IC203 turn off, the voltages of +6V, +10V, +15.5V and

+13V are not developed.

When the output control 1 and 2 develop high, the

transistors Q201 and Q202 turn on, so no voltage is

added to the gate Q203, IC201, IC202 and IC203,

described above, and the voltage of +6V, +10V, –15.5V

and +13V are developed.

1-1

Page 4

1-5. Over-curr ent Protection

In S6V and +6V lines, the voltage drop owing to the

current flowing in L203 is detected by pins 5 and 6 of

IC401, when the total current amount exceeds 8A, pin 7

develops high and the voltage biasses the base voltage of

transistor Q401 passing through the zener diode D402

and diode D401. In the same way as described in the

item of the over-voltage protection, IC303 is latched and

all outputs are shutdown. The method to release the latch

operation is the same as the item of the over-voltage

protection.

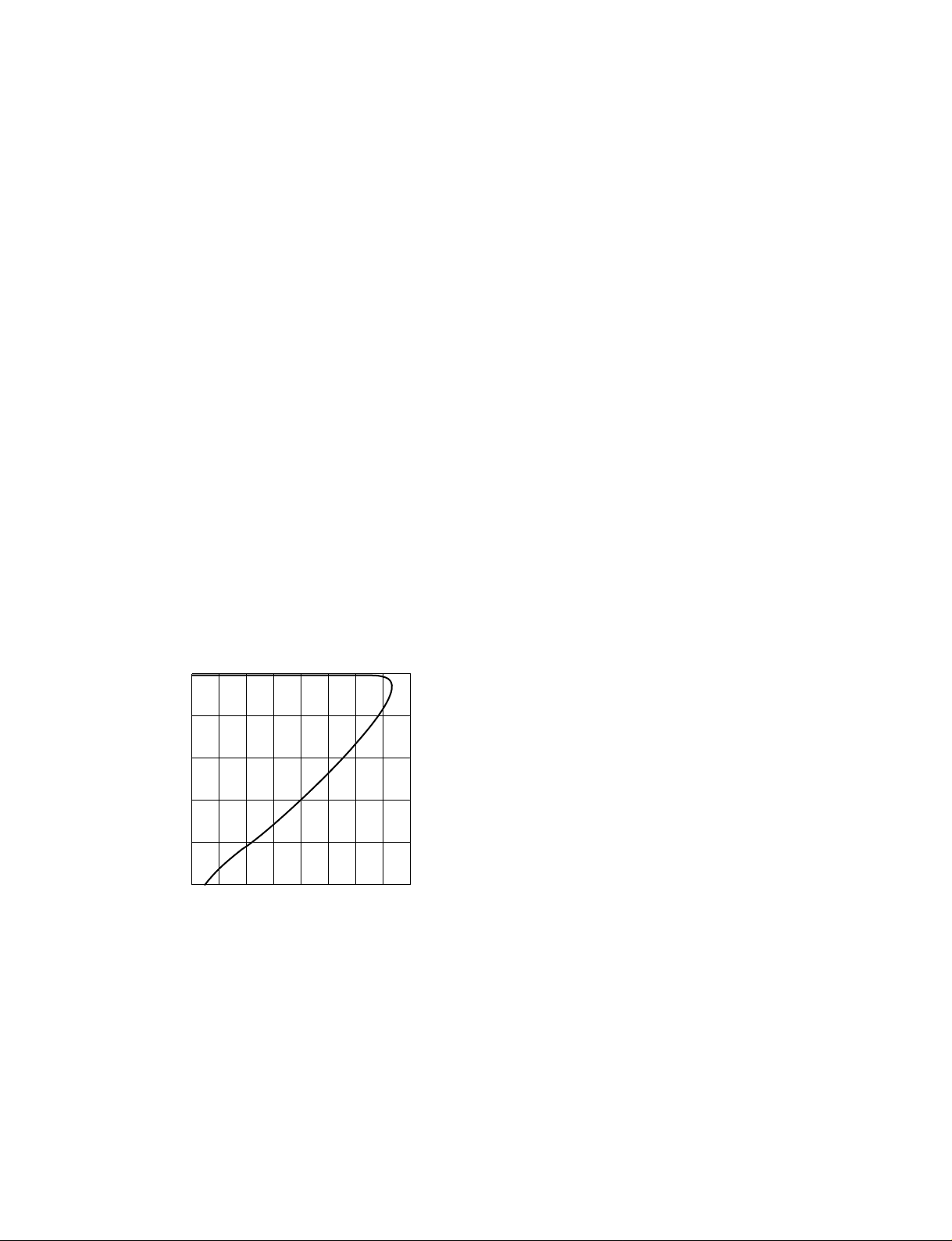

Over-current protection at +10V, +13V, +15.5V lines are

carried out by the over-current protection characteristic

provided with the series regulator ICs (IC203, IC202 and

IC201). Refer to Fig. 1-5-1.

In this case, as only the line short-circuiting or overloading is protected, no effect appears on other outputs. The

protection is released by removing the over current

flowing condition.

When short-circuiting or overloading continues, the IC

overheats and the overheat protection circuit inside the

IC works to shut down the output voltage. In this case,

the overheat protection is released by unloading the

current and removing the overheat of IC.

100

80

60

40

20

Relative output voltage (%)

0

0 1.0 2.0 3.0 4.0

Output current Io (A)

Fig. 1-5-1

<Supplement>

The over-current protection for lamp output detects the

voltage drop of the current detection resistor R113 at

between pins 9 and 10 of IC302. When voltage switching

terminal of connector C opens (at 16.3V), the photo

coupler PH303 turns off since pin 1 of IC401 develops

low and the voltage of drop voltage at R113 is directly

compared at pin 10 of IC302. When the lamp output

current is from 0.7 to 0.9A, pin 8 develops high and the

voltage higher than 7V is added to pin 6 of IC303. Then

IC303 is latched and all outputs are shut down.

When the voltage switching terminal of connector C

develops the ground potential (at 18.0V), pin 1 of IC401

develops high, PH303 turns on and the voltage of drop

voltage at R113 and the voltage divided by R317 and

R327 are compared at pin 10 of IC302. When the lamp

output is from 1.05 to 1.35A, pin 8 of IC302 develops

high, IC303 is latched and all outputs are shut down. The

method to release the latch operation is the same as the

over-voltage protection description.

1-6. Overheat Protection

As an overheat protection of the power supply, the

temperature of switching FET Q301 of the boost-upconverter is detected. Positive characteristic thermistor

TH301 for temperature detection is attached on the heat

sink of Q301. When Q301 is overheated owing to the

overload and/or defect of cooling fan, etc., the resistor

value of TH301 increases abruptly, while the surface

temperature exceeds approx. 120°C. Then the transistor

Q302 turns on, the voltage higher than 7V is added to the

pin 6 (OVP) of IC303, IC303 is latched and all outputs

are shut down.

When releasing the latch operation, stop to supply the

commercial power by canceling, cool enough after more

than approx. 120 seconds, and then re-supply the

commercial power.

1-2

Page 5

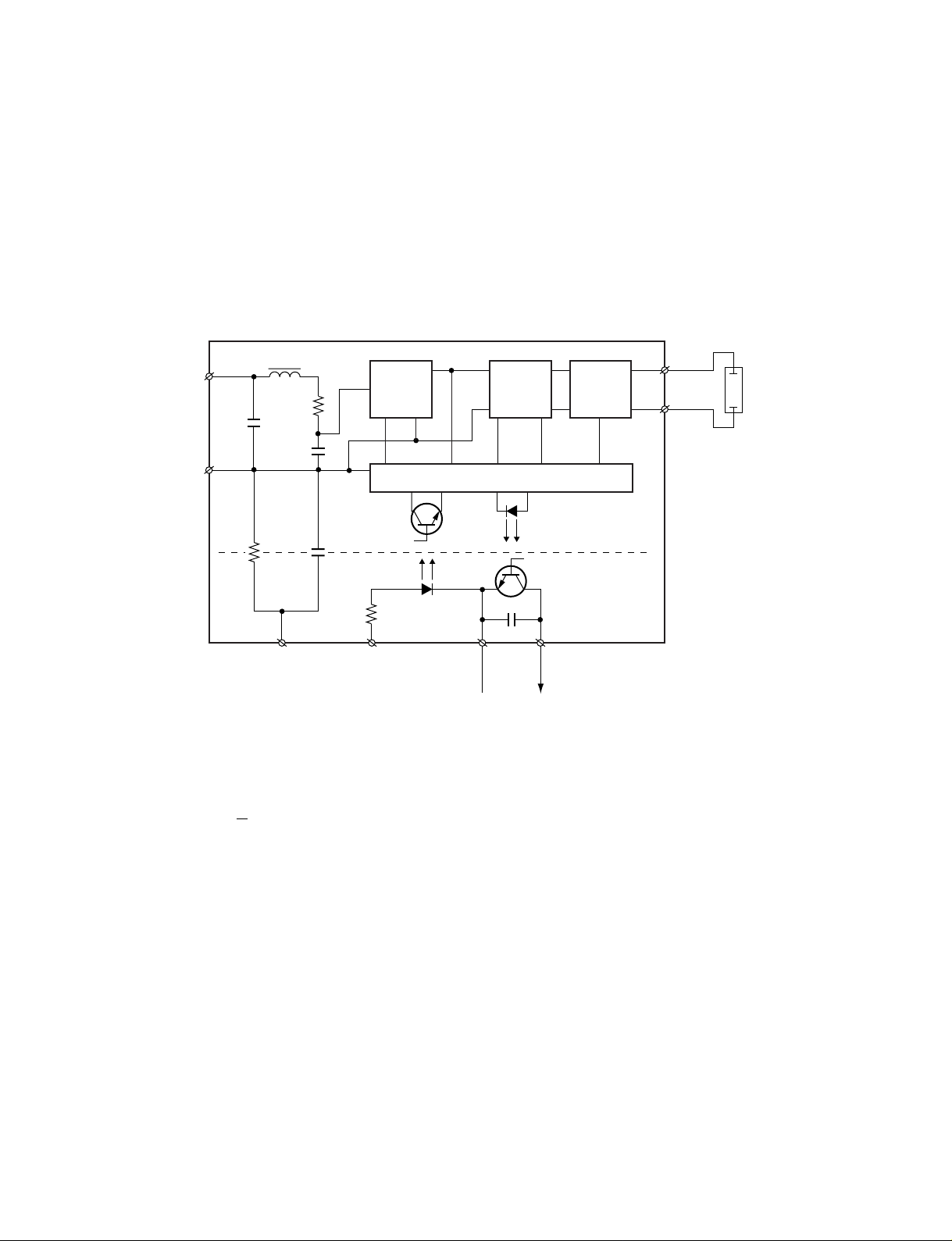

2. LAMP POWER SUPPLY CIRCUIT

(LAMP DRIVER)

2-1. Configuration

The lamp power supply cicrcuit receives a DC220 to

390V (primary side) from the system power supply and

provides a AC voltage (70 to 100VAC at ever turning on

the lamp) to turn on the lamp. Fig. 2-1-1 shows the block

diagram.

Lamp Driver

L1

Stabilizer Igniter

R1

C1

Power

input

C2

CsRs

CB3

EMC GND

(optional)

I122

1K

CB2-1

SCI

The DC voltage is supplied to CB1 from the main power

supply unit through an interlock switch. This voltage

becomes AC input x 2Ö2 (= 340V for AC120V input)

when the lamp is off. CB2 is a connector for the lamp on

control signal input (SCI) and lamp off control signal

output (FLAG). When +5V is applied to SCI (CB2-1) in

the standby on, I122 FET transistor turns on, the igniter

develops a high voltage pulse (5 to 25 kV), and the lamp

starts to light up.

Commu-

tator

Control

100nF

CB2-2

Common Flag

Fig. 2-1-1

The pulse normally continues to be developed until the

lamp turns on (for max. 3s.). But if the lamp does not

turn on, I121 does not turn on, the voltage of CB2-3

develops high. I121 turns on and develops low after the

lamp turned on, the igniter circuit stops the operation.

Then the AC70 to 100V is applied to the lamp.

I121

L1

L2

Lamp

Mains

isolated

2-1

Page 6

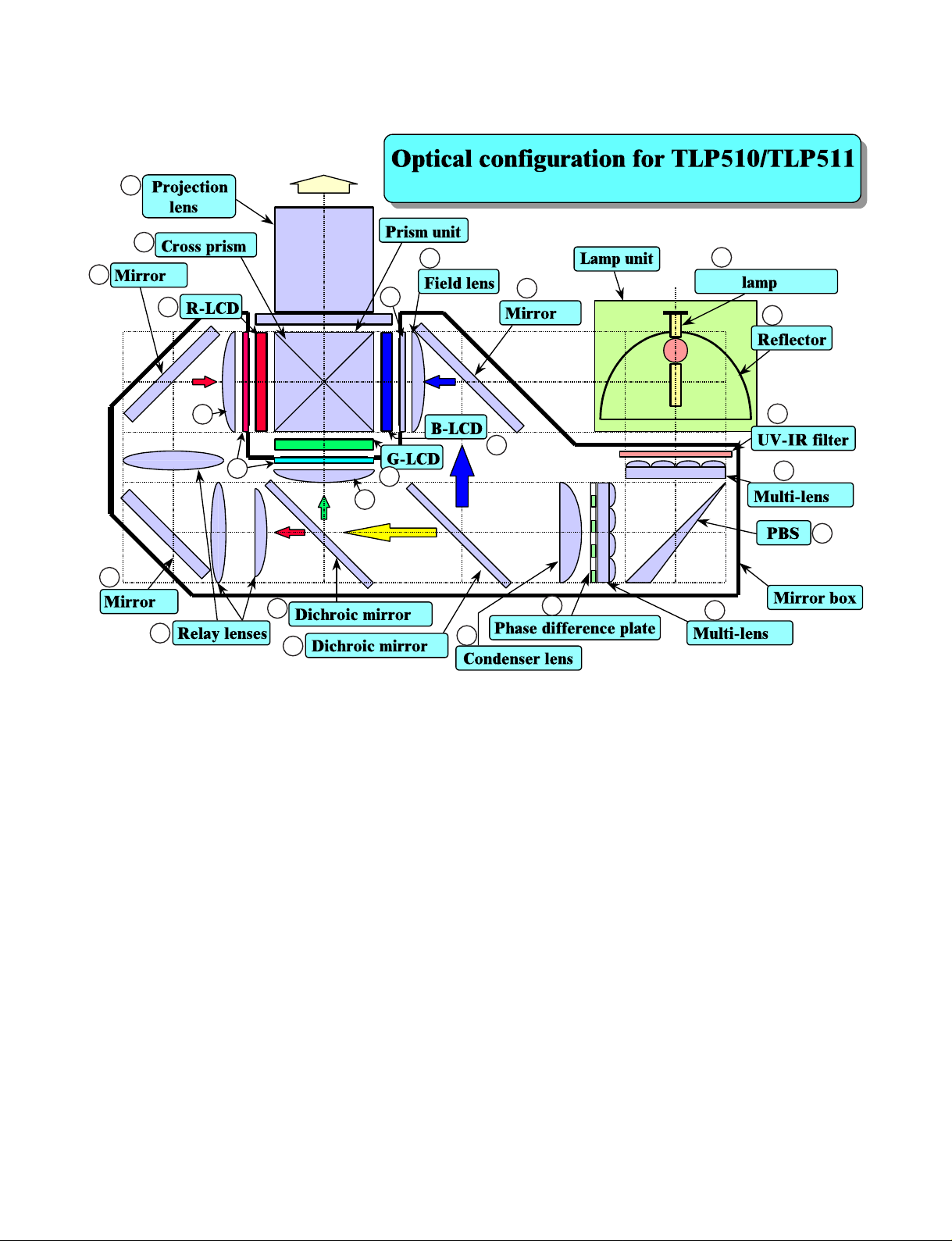

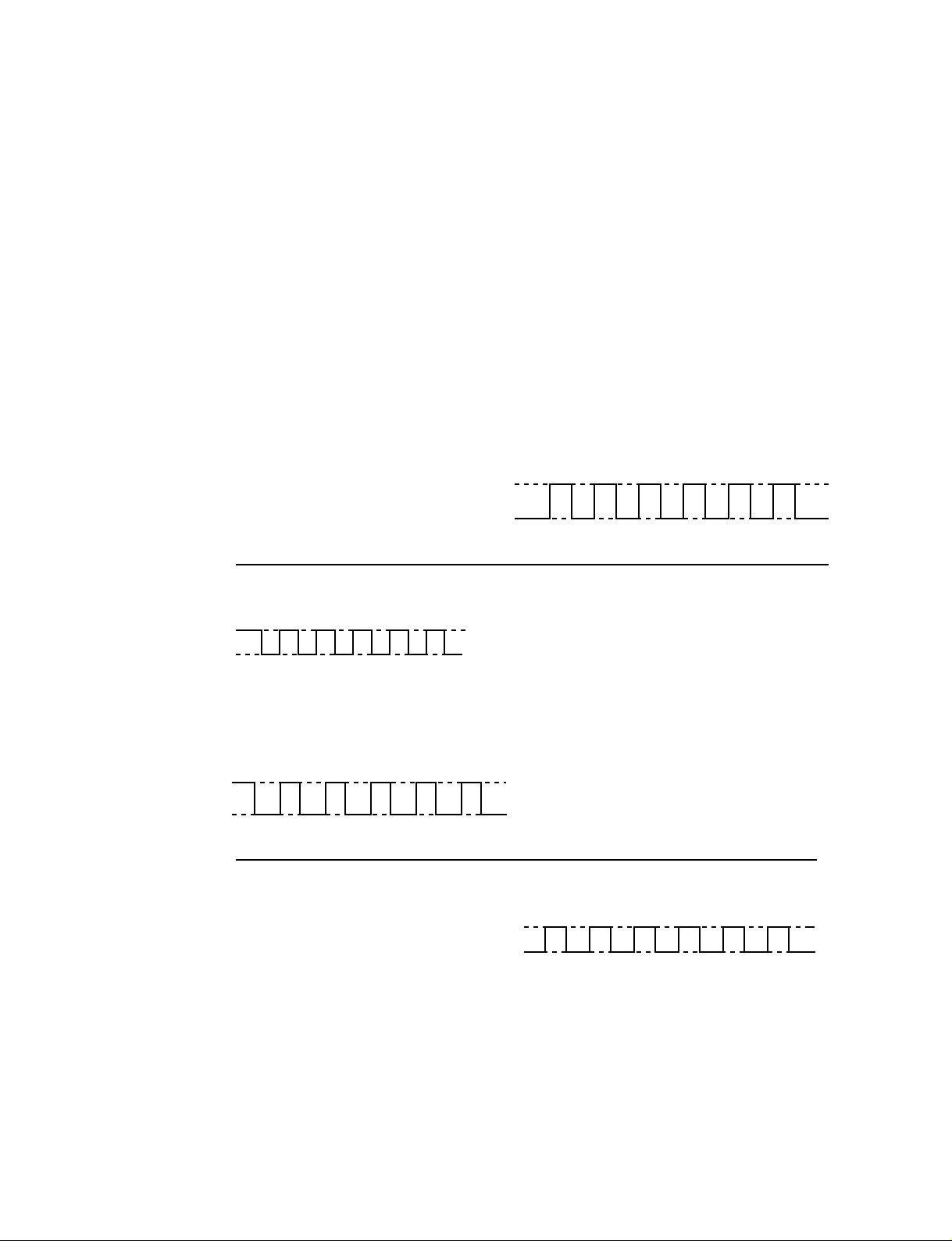

3. OPTICAL SYSTEM

3-1. Configuration

Lamp

unit

Mirror

box

unit

Prism

unit

Projection

lens

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Name

UHP lamp

Parabolic

reflector

UV IR filter

Multi-lenses

A, B

Polarization

light beam

splitter (PBS)

Phase

difference

plate

Condenser

lens

Dichroic

mirror

Full reflection

mirror

Field lens

Relay lens

Incident side

polarized

plate/Phase

difference

plate

Liquid crystal

panel

Cross prism

Projection

lens

Description

Light source of the optical system. AC lighting system 120W, arc length 1.3 mm.

As the arc length is shorter than the conventional metal halide lamp, the light source

operates as an ideal light point source and this improves the light convergence factor.

Also, the color temperature gets higher and this allows to reproduce more natural

white color.

Parabolic reflector converges light emitted from the UHP lamp forward in approximate

parallel light beams and illuminates the liquid crystal panel.

Optical filter to pass necessary visible rays and cut unnecessary ultraviolet rays and

infrared rays among light emitted from the UHP lamp.

Tw o multi-lenses A and B allow a circular beam light emitted from the light source to

illuminate the square liquid crystal panel evenly, thus providing projected pictures

with less brightness variation.

Separates the illuminating light from the light source into P polarization light and S

polarization light and leads both light to the multi-lens B with a little angle.

Converts the polarization direction of incident light via the multi-lens B into another

direction. Here, P polarization light waveform separated by PBS is converted into

another S polarization light waveform.

Converges the illuminating light emitted from the light source into the liquid crystal

panel.

Separates the white light emitted from the light source into RGB three primary colors.

The white light emitted from the light source reflects B light using a dichroic mirror 1

and the RG lights pass through the dichroic mirror 1. Of the RG lights passed, G light

is reflected by the dichroic mirror 2 and R light passes.

Reflection mirror to lead the R and B lights separated by the dichroic mirrors 1 and 2

to the liquid crystal panel.

Light transmitted through liquid crystal panel is converged in direction of focal point

and effectively entered entrance pupil of the projection lens.

In the R axis optical path which is longer than those of G, B, the relay lens works as

a correction lens to arrange the illumination distribution of the liquid crystal panel

surface with that of other liquid crystal panel.

The illumination lights separated into RGB have the S polarizing waveform component in processing the PBS and phase difference plate operation previously described.

The incident side polarized plate arranges the illumination light more effective direct

polarizing waveform. The phase difference plate used works to converge the S

polarizing waveform into the P polarizing waveform which fits to the transparent axis

of the liquid crystal panel.

Since the phase difference plate possesses the wavelength characteristics for light,

each RGB axis employs exclusive phase difference plate. These polarizing plates

and difference plates are constructed in one plate by attaching each other, and put

on a glass plate.

To increase the color pur ity ratio of three primar y colors, the glass plate possess the

dichroic filter characteristics for RG axis.

Light exit side polarized plate is put on the light exit plane. When no signal voltage is

applied, the polarization direction of transmission light rotates by 90 degrees. When a

voltage is applied, the polarization direction is controlled owing to the voltage

applied. That is, the liquid crystal panel employs such general TN type liquid crystal.

In this model, the incidence/exit polarization plate is placed (in normally white mode)

so that the light transmission amount becomes maximum (white) when no voltage is

added and the light transmission amount becomes minimum (black) when maximum

voltage is added.

According to the liquid crystal panel specification, exclusive panel for each RGB axis

is employed and shown by identification seals.

Works to mix RGB lights passed through the liquid crystal panel.

Demodulated by the video signal on the liquid crystal panel and projects pictures

displayed on the liquid crystal at a screen. Light axis of the projection lens is set at

upper side of center of the liquid crystal panel and this realizes easy viewing of the

panel because the projected screen position is upper than the unit position. The

projected light shows S polarizing waveform and is compatible with the polarizing

screen.

The projection lens employs the zoom & focus system and allows to project enlarging

a picture upto maximum approx. 300 inch.

3-1

Page 7

15

XGA 1.3 inch 3 plates system

14

10

9

9

11

-2

13

-3

10

12

12

9

-1

13

13

10

8

8

-2

-1

7

6

1

UHP (120W)

2

3

4

A

5

4

B

Fig. 3-1-1 Optical configuration diagram

3-2

Page 8

4. R.G.B. DRIVE CIRCUIT

1

1022 1023 1024

23

1st line

768 lines

768th line

1024 pixels

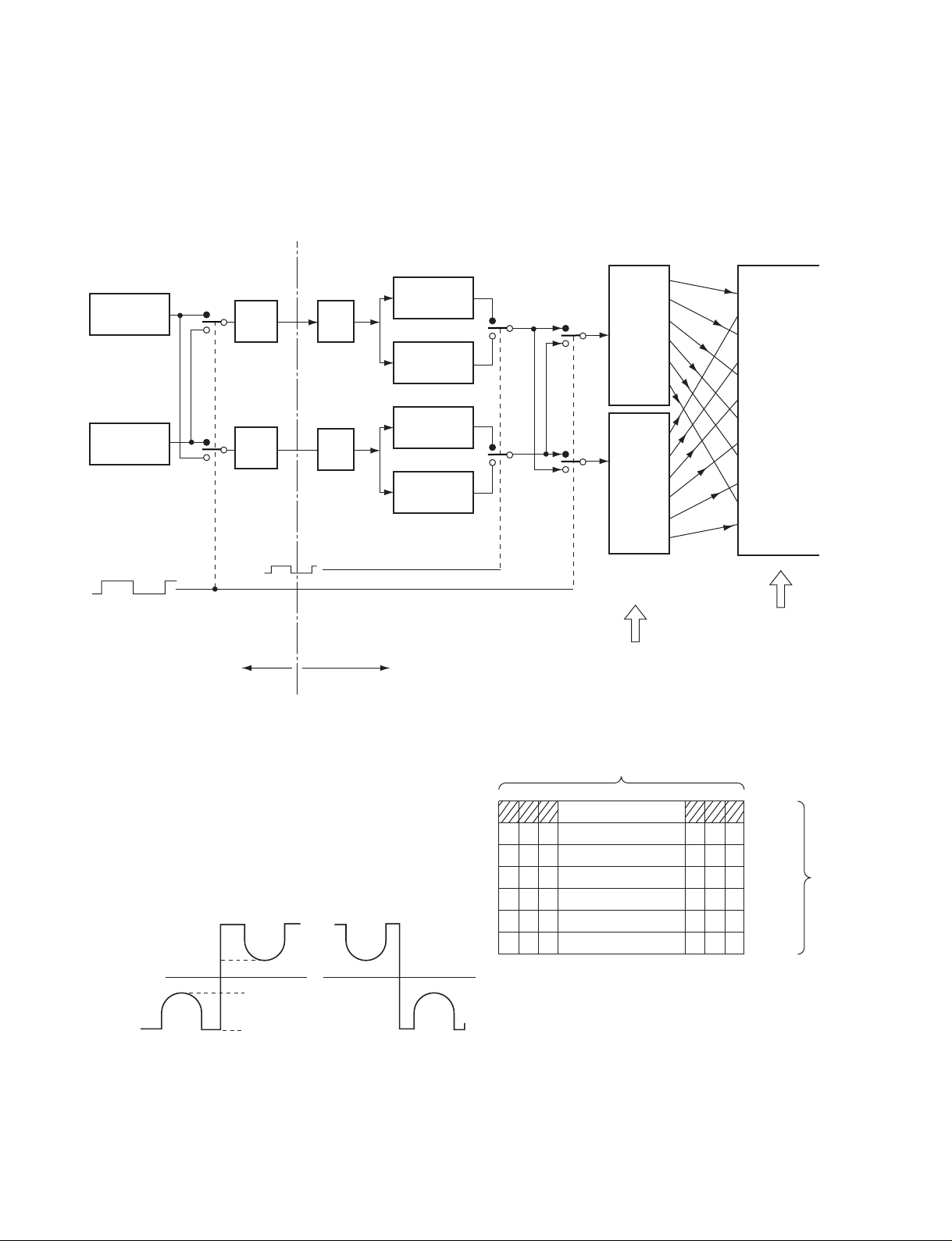

4-1. Outline

The outline of RGB drive circuit is described below

using the G process of the RGB drive circuit as an

example.

Odd number

pixel memory

Even number

pixel memory

Frame inverted

Digital PC board Drive PC board

SW2

SW1

1

DAC1 Amp.

2

1

DAC2

2

Q502

Q504

Amp.

Line inverted

Q505,Q506,Q507

Normal

amp.1

Q508,Q509,Q510

Inverted

amp.1

Q511,Q512,Q513

Normal

amp.2

Q523,Q524,Q510

Inverted

amp.2

1

2

1

2

Q514

SW3

Q514

SW4

Exclusive for odd number pixel

Q515

SW5

1

2

1

2

12-phase decomposite

Q516

&

Sample hold

1

Q515

SW6

even number pixel

&

Sample hold

2

Q517

Exclusive for

6-Phase decomposite

6-Phase decomposite

(12-phase collectively input)

Panel

VIDEO

input

12-phase composite

1

2

3

4

5

6

7

8

9

10

11

12

In the panel, 1024 pixels are arranged in a horizontal

direction and 768 lines of the pixels are in a vertical as

shown in Fig. 4-1-2.

As an H inverted drive system is employed, the panel

input signal waveform is as shown in Fig. 4-1-3.

Black level

White level

Center voltage

1st line

2nd line

White level

Black level

1st frame 2nd frame

Fig. 4-1-3

1st line

2nd line

Fig. 4-1-1

Fig. 4-1-2

4-1

Page 9

The signal as shown in Fig. 4-1-1 is separated into the

odd and even pixels at the digital PC board. After the

signal process is carried out in the drive PC board, the

odd and even pixel signals are synthesized to

decomposite the signal on the panel.

Referring to Fig. 4-1-1, the operation principle is

described.

When assuming;

1) the signal passing through DAC1 ® Q502 ® Normal

amp. 1 ® SW31 ® SW5 ® Q516 to the positive

phase 1,

2) the signal passing through DAC1 ® Q502 ® inverted

amp. 1 ® SW32 ® SW5 ® Q516 to the inverted

phase 1,

<1st frame>

3) the signal passing through DAC2 ® Q504 ® Normal

amp. 1 ® SW41 ® SW6 ® Q517 to the positive

phase 2 and

4) the signal passing through DAC2 ® Q504 ® inverted

amp. 2 ® SW42 ® SW6 ® Q517 to inverted phase

2,

the AC and DC levels of the positive phases 1, 2 and the

inverted phases 1, 2 are expected to be the same.

However, each voltage will vary slightly owing to the

adjustment variation. In this case, each frame signal is

assumed as follows.

Center voltage

Normal phase 1

voltage

Normal phase 2

voltage

<2nd line>

Inverted phase 2

voltage

Inverted phase 1

voltage

Center voltage

Inverted phase

2 voltage

Inverted phase

1 voltage

12345 6 7 8 9 10 11 12 Pixel

1st line

1 2 3 4 5 6 7 8 9 10 11 12 Pixel

1st line

Normal phase 1

voltage

Normal phase 2

voltage

123

1 2 3 4 5 6 7 8 9 10 11 12 Pixel

456789101112 Pixel

2nd line

2nd line

As shown in Fig. 4-1-4, even if a slight level difference

occurs among the positive phases 1, 2 and inverted

phases 1, 2 signals (approx. 100 mV), the level difference will be decreased visually by reducing the level

Fig. 4-1-4

variation of the same line between each frame and

inverting the pixel voltage of the adjacent lines (1st line

and 2nd line) between each frame.

4-2

Page 10

4-2. Operation Description

The video signal of the odd number pixel (even number

pixel) is sent to Q501 (Q503) base and supplied to pin 16

of Q502 (Q504), LM1201M. The signal is clamped at

pin 16 and the pedestal voltage is adjusted at pin 6 after

the DC level is stabilized and then AC level is adjusted at

pin 3.

The signal is developed from pin 8, supplied to the buffer

circuits of Q505 – Q507 and Q511 – Q513, and supplied

to the inverted circuits of Q508, Q509, Q510, Q523,

Q525 and Q510. These signals are supplied to pins 5, 6,

8, 13, 15 and 16 of 12 phases development IC.

CXA2504N, Q516 and Q517 of sample-and-hold passing

through the SW circuit composed of Q514 and Q515.

The signals are developed from pins 37, 35, 33, 25 and

23 for each input.

The signals at pins 4, 7, 14 are used as bias input and the

bias inputs set the center DC voltage of output equal to

the bias voltage.

Q519 works to suppress the noise occurred at 12 phases

collective input process of the panel.

4-2-1. Outline of Liquid Crystal Panel

The liquid crystal panel module is an active matrix panel

with a built-in driver of multi-crystal silicon. The liquid

crystal panel module is designed for use of color projectors in combination with an enlargement projection

system and dichroic mirror.

<Basic specification>

(1) Screen size 26.624 (W) x 19.968 (H)

(2) Pixel number 1024 (W) x 768 (H)

(3) Applicable to XGA

(4) Monochrome panel

(5) Drive system H inverted drive

(6) Dot clock 65 MHz

(7) Inverted function for UP/DOWN/LEFT/RIGHT di-

rections

4-2-2. Basic Component

Pin No.

1

2

3

4

5

6

7

8

9

Name

DT

CLY

CLY

VDDY

NRS2

NRS1

LCCOM

VID11

VID9

Pin No.

10

11

12

13

14

15

16

17

18

Table 4-2-1 Terminal description

Name

VID7

VID5

VID3

VID1

VSSX

CLX

CLX

DX

VDDX

Pin No.

19

20

21

22

23

24

25

26

27

Name

DIRX

DIRX

ENB2

ENB1

VSSX

VID2

VID4

VID6

VID8

Pin No.

28

29

30

31

32

33

34

35

36

Name

VID10

VID12

LCCOM

N.C.

NRG

DY

DIRY

DIRY

VSSY

4-3

Page 11

Table 4-2-2 Input terminal function description

Name

DX

CLX, CLX

DIRX, DIRX

ENB1 – ENB2

VID1 – VID12

DY

CLY , CLY

DIRY, DIRY

LCCOM

VDDX

VDD Y

VSSX

VSSY

NRG

NRS1 – NRS2

Function

Start pulse input ter minal of X shift register composing X driver.

Transfer clock input terminal X shift register composing X driver

X driver driving direction switch input terminal (DIRX = H R shift, DIRX = L L shift)

X driver enable pulse input terminal

X driver video signal input terminal

Start pulse input ter minal of Y shift register composing Y dr iver.

Transfer clock input terminal of Y shift register composing Y driver.

Transfer clock input terminal of Y shift register composing Y driver. (DIRX = H Down shift,

DIRX = L Up shift)

Diagonal electrode potential input terminal of liquid crystal panel

X driver positive power supply input terminal

Y driver positive power supply input terminal

X driver negative power supply input terminal

Y driver negative power supply input terminal

Drive signal input terminal for auxiliary signal circuit

Auxiliary signal input terminal

4-4

Page 12

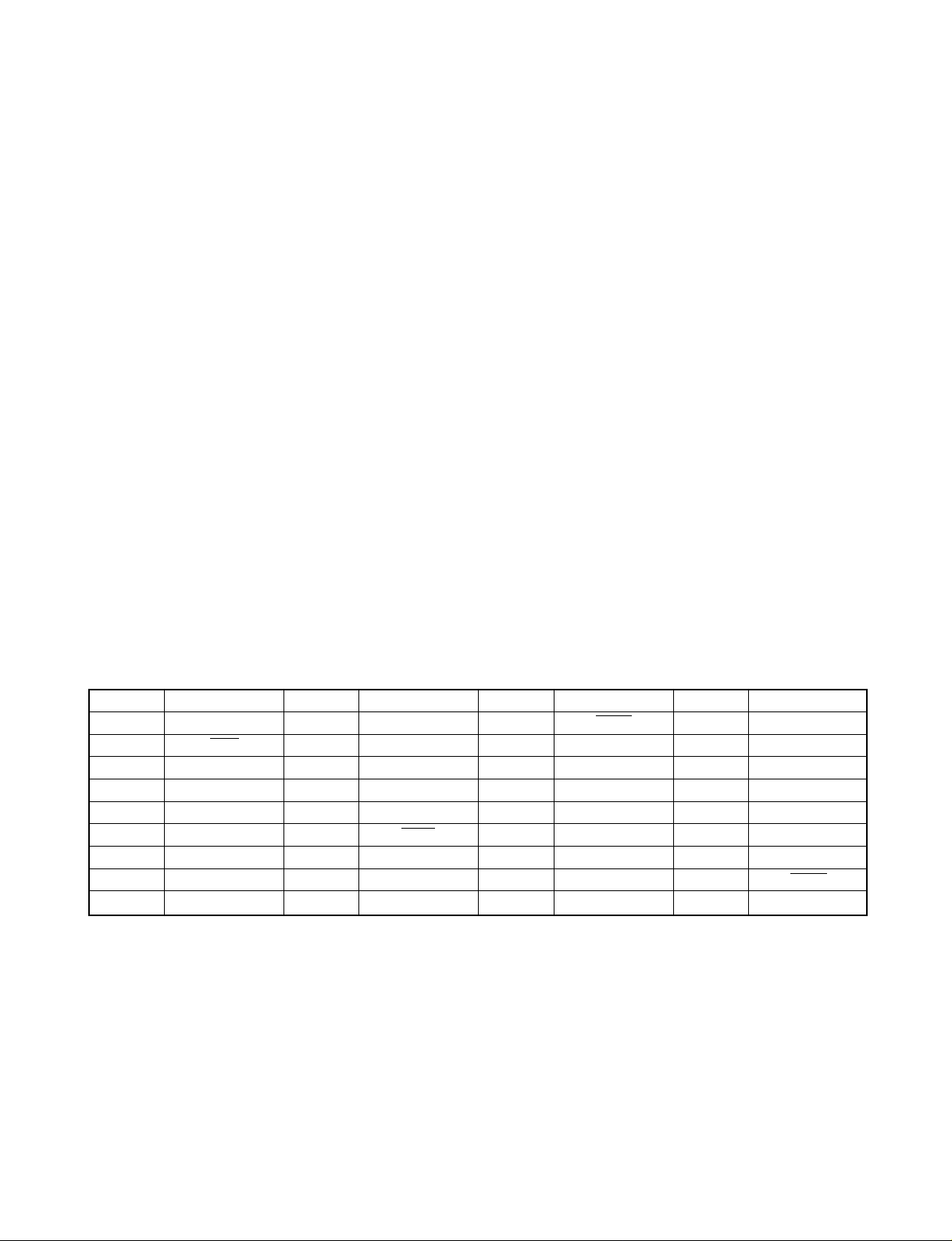

5. MICROPROCESSOR

5-1. System Outline

The system microprocessor has features as shown below.

In considering easy maintenance for specification

modification, etc., the program content is written in the

built-in non-volatile memory.

The program is also developed in considering use of

structured notation, parts modularity, and multi filling

system.

Major functions of the system microprocessor are as

follows.

5-1-1. System Control

• Microprocessor program write process

• Non-volatile memory control process

• Remote control reception process

• RS-232C transmission/reception process

• Status read process

• On-screen display process

5-1-3. Adjustment Control

• Video controls (high & low brightness ratio,

brightness, color density, tint, sharpness)

• Panel adjustments (V position, H position,

phase, clock, user registration, user read-out)

• Mode adjustments (Wide, MIC, OSD mute,

projection)

• Language adjustments (English, Japanese,

French, German, Spanish, Italian)

5-1-4. Adjustment Control at Factory Delivery

• Video sub adjustments (RGB gain, sub-bright)

• Drive adjustments (each item for panel controls,

RGB trimming)

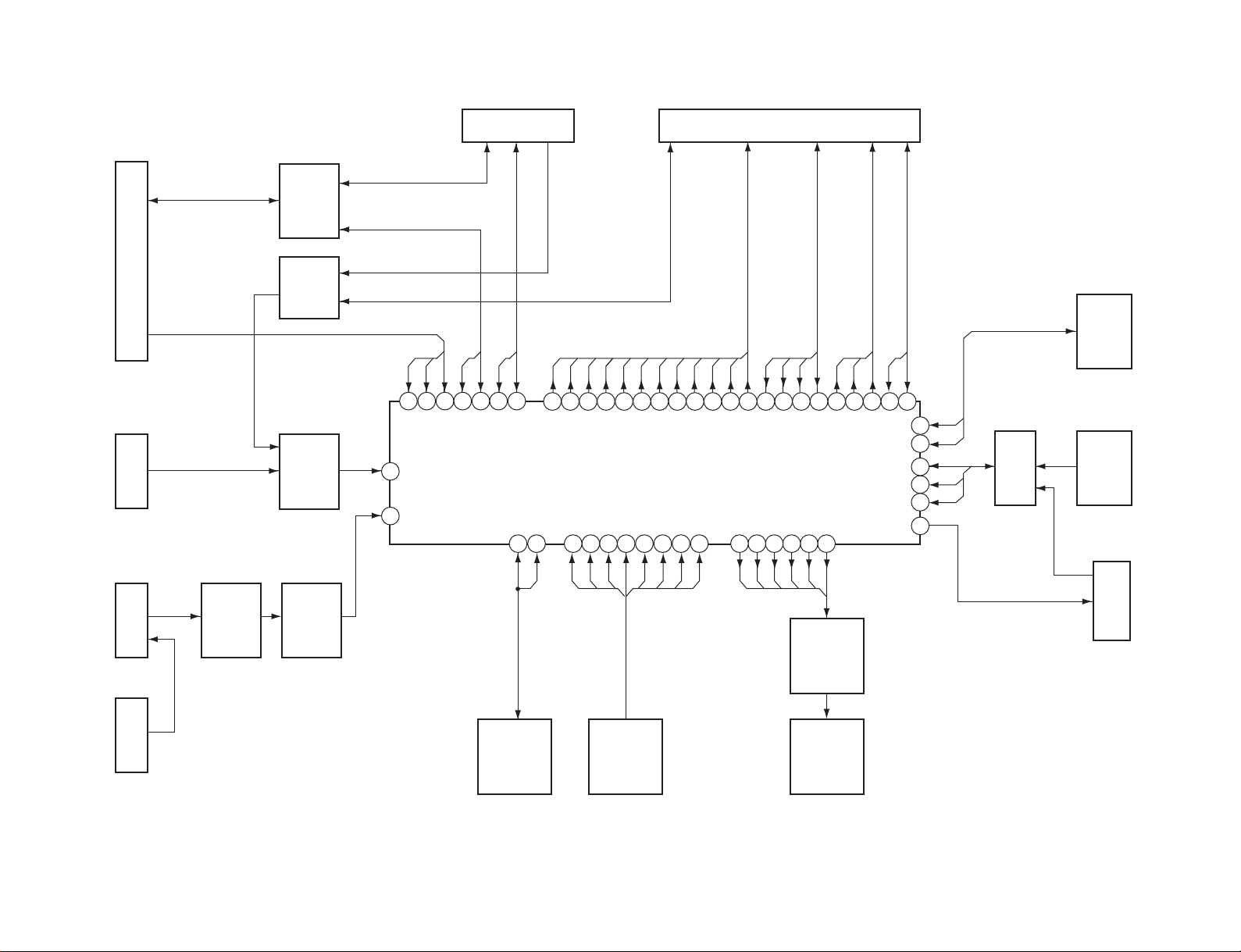

Fig. 5-1-1 shows the system block diagram.

5-1-2. Normal Control

• Power ON/OFF

(Main/Fan/Lamp)

• Input switch (RGB/Video/Camera)

• Sound volume control UP/DOWN

• Menu

• Adjust (Up/Down/Left/Right)

• All mute ON/OFF

• Audio mute ON/OFF

• Display ON/OFF

• Freeze ON/OFF

• Resize ON/OFF

• Focus UP/DOWN

(at camera use)

• Zoom UP/DOWN

(at camera use)

5-1

Page 13

PL004PL010

5-2

PL001

2

/

3

/

PL006 QL003

PQ20VZ1U

PL001

HC125

QL012

HC125

QL005PL003

HC14

QL004

RN5VD27A

19

2

/

2

/

5

/

DRIVE

SENSOR

PL009

/

/

/

2

2

10117978457

77

QL002

HD64F3337YF16

1

16 17 24232221

25 26 27 28 44

12

/

/

4

4342414039

/

3

2

/

55596063646566676869707172747576

54

496162

58

57

53

52

51

48

6

/

2

QL010

HC165

3

/

PL002

/

2

CAT24C16J

QL006

/

8

SW LED

Fig. 5-1-1 System block diagram

HC541

6

/

QL007

Page 14

5-2. System Microprocessor

The system microprocessor QL002 employs an 8 bit

micro-controller (HD64F3337YF16).

In this system microprocessor, a program area is provided inside the non-volatile memory.

Table 5-2-1 Terminal functions of the system microprocessor

Using an exclusive data-writer allows easy maintenance

of the system microprocessor when specification modification, bug correction, etc. will occur.

Table 5-2-1 shows the terminal functions of the system

microprocessor.

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Name

RES

XTAL

EXTAL

MD1

MD0

NMI

FVPF

VCC1

WDT

RXD0

TXD0

GND1

SDA

f

SEL

EEPCK

EEPDT

VD

REMOCON

AUX

KEY0

KEY1

KEY2

KEY3

KEY4

KEY5

KEY6

KEY7

AVCC

AD0

AD1

AD2

AD3

AD4

AD5

AD6

AD7

AGND

LED0

LED1

Function

Reset input

Clock input for oscillation

Clock output for oscillation

Mode 1

Mode 2

Priority interruption

Memory write voltage

Digital power supply

Not used

RS-232C reception for camera

RS-232C transfer for camera

Digital ground

Not used

Oscillation clock

Remote controller selection

Non-volatile memory clock

Non-volatile memory data

Not used

Remote controller reception

Not used

Key input 0

Key input 1

Key input 2

Key input 3

Key input 4

Key input 5

Key input 6

Key input 7

Analog power supply

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Analog ground

LED data 0

LED data 1

I/O

O

O

O

I/O

O

O

O

I/O

O

O

O

Pin No.

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

Name

LED2

LED3

LED4

LED5

MAIN. PW

FAN. PW

V

CC2

LAMP. PW

OSDL

DDCV

SENL

SENC

SEND

VD0C

VD0D

GND2

DRVC

DRVD

OSDC

OSDD

PLLU

SYGL

SYGC

SYGD

D0

D1

D2

D3

D4

D5

D6

D7

GND3

CLK

R/W

ENB

RST

TXD1

RXD1

SCL

Function

LED data 2

LED data 3

LED data 4

LED data 5

Main power supply swtich

Fan power supply switch

Digital power supply

Lamp power supply switch

OSD load

Not used

Sensor load

Used for sensor

Used for sensor

Video I2C clock

Video I2C data

Digital ground

Drive I2C clock

Drive I2C data

OSD clock

OSD data

PLL enable

SYG load

SYG clock

SYG data

T-FORC data 0

T-FORC data 1

T-FORC data 2

T-FORC data 3

T-FORC data 4

T-FORC data 5

T-FORC data 6

T-FORC data 7

Digital ground

T-FORC clock

T-FORC read/write

T-FORC enable

T-FORC reset

RS-232C transfer for control

RS-232C reception for control

Not used

I/O

O

O

O

O

O

O

I

O

O

I

O

O

I

O

I/O

I

O

O

O

O

O

O

O

I/O

O

O

O

O

O

O

O

O

I

O

O

O

O

O

I

O

5-3

Page 15

5-3. Power Supply Reset Process

5-5. Remote Control Reception Process

In the power supply reset process, power supply reset IC

(RN5VD27A), QL004 is employed.

The reset IC,QL004, develops the reset signal when the

power supply voltage for the microprocessor varies and

becomes lower than the specified voltage, and sends the

signal to the reset terminal of the system microprocessor

(QL002).

5-4. Non-volatile Memory Control Process

In the non-volatile memory process, data reading and

saving for various adjustments are carried out on the

non-volatile memory, QL006 (CAT24C16J).

When the power (AC) is on, all the adjustment data are

read out by the system microprocessor (QL002), then the

previous status is realized.

When saving the data, all the adjustment data are written

by the system microprocessor (QL002), then the current

status is preserved.

However, if a failure (such as power interruption due to

lightning, etc.) occurs during the adjustment data writing,

a data error may occur. If the data is determined as

incorrect, the initial data memorized on the system

microprocessor (QL002) is read out and stored on the

non-volatile memory.

In the remote control reception process, a remote control

unit (CT-9925) connected to the remote control terminal

emits a remote control signal and a remote control signal

receive section on the front panel, the rear panel or the

camera arm (for TLP511) decodes the signal.

The remote control signals for rear panel and camera

section (for TLP511) are selected by QL012 buffer

(TC74HC125AF). Then both signals are mixed with the

remote control signal for front panel through QL005

buffer (74HC14AF).

Finally, the signal mixed is supplied to the remote control

terminal of the system microprocessor (QL002).

5-6. RS-232C Transmission/Reception

Process

In the RS-232C transmission/reception process, an RS232C signal entered through the RS-232C connector (DSUB 9P) is decoded in the RS-232C interface

(mPD4721), and fed to RXD1 terminal of the system

microprocessor (QL002).

In the RS-232C transmission process, RS-232C signal

developed from TXD0 terminal of the system microprocessor (QL002) is decoded in the RS-232C interface

(mPD4721) and fed to the camera microprocessor

section.

Signal name

Pin No.

QL010

(L)

(H)

A

11

FAN1. ER

Abnormal

Normal

5-7. Status Read Process

In the status read process, the following status shown in

the table below are read by QL010 (74HC165AF) and

the error process corresponding to each status is carried

out.

Table 5-7-1 shows the contents of the status read signals

and the logic.

Table 5-7-1 The contents of the status read signals and the logic

B

12

FAN1. SW

Normal

Abnormal

C

13

FAN2. ER

Abnormal

Normal

D

14

E

3

TEMP1. ER

Normal

Abnormal

F

4

G

5

LAMP. ER

Abnormal

Normal

H

6

MAIN. ER

Abnormal

Normal

5-4

Page 16

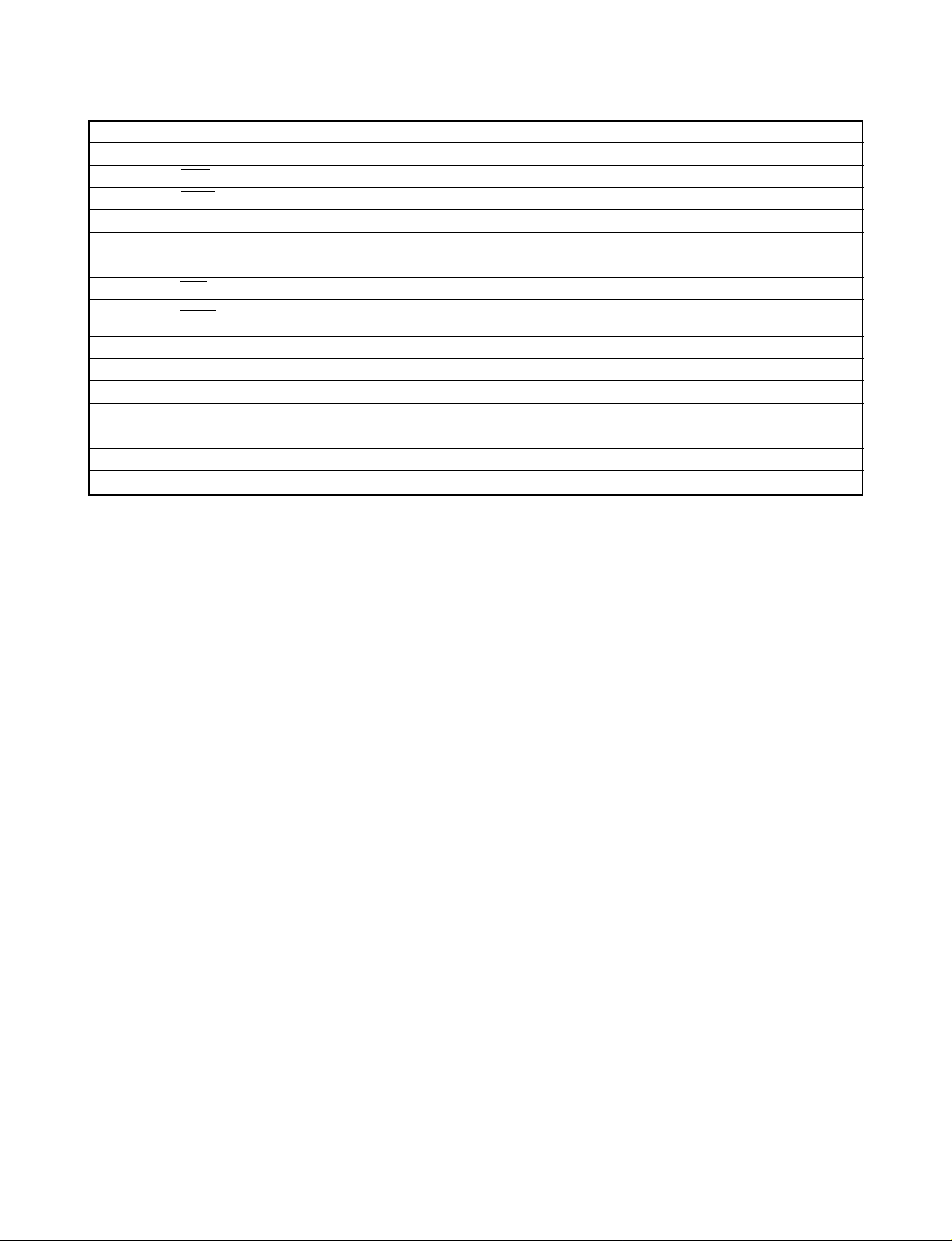

5-8. Status Display Process

5-9. On-screen Display Process

In the status display process, two-color lighting LEDs of

DL037, DL038 and DL039 turn ON for each kind of

status shown in the table below by using LED0 to LED5

terminal output of the microprocessor.

Table 5-8-1 Contents of the status display signals and the logic

ON

X

Green

Red

Orange

Green

Green

Green

Green

Orange

Red

Red

Red

Red

Red

Red

Red

LAMP

X

Green

Red

X

X

(Green)

Green

X

(Green)

X

Red

Orange

X

X

X

X

TEMP

X

Green

Red

X

X

X

X

X

X

X

X

X

(Red)

(Orange)

(Green)

Red

Stand-by power supply

abnormality

Non-volatile memory OK

Non-volatile memory NG

Stand-by

Lamp ON

Lamp Heat-up

Lamp Lighting

Lamp OFF

Lamp cool-down

Main power supply

abnormality

Lamp no-lighting

Lamp lighting-lifetime

Suction fan stop

Exhaust fan stop

Fan filter open

Temperature sensor

abnormality

Function

In the on-screen display process, control signals are

supplied to the OSD display IC QX003 (CD0016AM),

and the OSD display IC generates character display

signals at the timing determined by VD, HD and clock

supplied to the IC separately.

Status

At AC cord plugged

At AC cord plugged

At AC cord plugged

At power off

At power on

At power on

During power on

At power off

At power off

At power On/During

At power On/During

At power on

At power on

At power on

Ever

Ever

Countermeasure

Repair

Normal

At initial time

Normal

Normal

Normal

Normal

Normal

Normal

Repair

Repair or preparation failure

Operates after approx. 2500 H

operation

Repair

Repair

Close

Lower internal temperature of

the unit.

5-5

X: Lighting OFF

( ): Blinking

Page 17

5-10. Video System Contr ol Pr ocess

5-11. Panel System Control Process

In the video system control process, control signals are

supplied to various video system process ICs shown in

the table below. Table 5-10-1 shows the I2C control for

each kind of video system.

Table 5-10-1 I2C control for each kind of video system

Part No.

QV001

QV002

QV005

QV008

QV007

QV045

QB025

QV057

Type name

CXA1855Q

(Custom: $90)

TC9090N

(Custom: $B2)

TDA9141

(Custom: $8A)

TDA4780

(Custom: $88)

TDA4672

(Custom: $88)

CXA1315M

(Custom: $40)

CXA1315M

(Custom: $44)

M62320FP

(Custom: $71)

I/O SW process

Color signal process (3D Y/C separation)

Sync detection process (Custom: $8B)

Signal kinds identification (NTSC/PAL/SECAM, etc.)

Video control (Density, hue)

Video control (Sharpness control)

Input SW, MIC SW

Volume, mute, MIC gain

Brightness, contrast, RGB gain

Sync information

Camera ON/OFF (for TLP511), focus, zoom reading

Fan switch open

The panel system control process supplies various

control signals to the panel system control ICs shown in

the table below.

Table 5-11-1 shows the IC control for each kind of panel

system.

Process

Part No.

QX004

QX007

QX204

QX404

QX604

QX001

QX002

Table 5-11-1 IC control for each kind of panel system

Type name

SYG

(TC160G54AF1137)

CXA3106

TFORC

(TC203E2651AF-01)

M62320FP

(Custom: $78)

M62320FP

(Custom: $7A)

Process

Various kinds of screen display process (position, picture frame,

property)

Screen position control (Vertical position, horizontal position)

Screen position control (sampling phase, sampling frequency)

Picture frame control (R)

Picture frame control (G)

Picture frame control (B)

Panel mode control

A/D sample phase (R)

A/D sample phase (G)

A/D sample phase (B)

5-6

Page 18

5-12. Drive System Control Process

In the drive system control process, the control signal is

supplied to each kind of drive system process ICs shown

in the the table below.

Table 5-12-1 Each kind of the drive system IC control

Table 5-12-1 shows each kind of the drive system IC

control.

Part No.

Q701

Q702

Q703

Q704

Q705

Type name

M62399FP

(Custom: $90)

M62399FP

(Custom: $92)

M62399FP

(Custom: $94)

M62399FP

(Custom: $96)

M62399FP

(Custom: $98)

Process relative to R drive

Process relative to G drive

Process relative to B drive

Process relative to VCOM, NR

Process relative to NR, Bias

5-13. Various Display Modes

In this system, various LED display patterns are provided

in relation to the display modes shown in Table 5-8-1.

Operation processes from the status of AC cord plugged

to that of power on and power off will be given below.

(1) Data of the non-volatile memory are checked when

the AC cord is plugged, and all the LED are turned

on in red in the initial use. In second or later use, all

the LEDs are turned on in green and the unit enters

the standby status.

(2) In the standby status, only the ON/STANDBY LED

is turned on in orange, and the main power is off

and the lamp power is also off.

(3) When the power is on by pressing the ON/

STANDBY key, the unit enters a normal status in

passing through following processes.

1) The main power is on, and ON/STANDBY LED

turns on in green.

2) The fan power is on, and the fan starts to rotate.

3) The lamp power is on, and LAMP LED blinks

in green for about 3s.

4) With the lamp turned on, LAMP LED turns on

in green and the unit enters the normal status.

(4) If the lamp does not turn on, ON/STANDBY LED

turns on in orange, and the LAMP LED blinks in

green for about 1 min. and then the unit returns to

the standby status.

Process

(5) In the normal status, ON/STANDBY LED and the

LAMP LED are turned on in green, and the main

power and the lamp power are turned on.

(6) When the power is turned off by pressing the ON/

STANDBY key, the unit enters the standby status in

passing through following processes.

1) When the lamp power is turned off, ON/

STANDBY LED turns on in orange.

2) The LAMP LED blinks in green for about 1

min. For this period the lamp can not be turned

on again by the ON/STANDBY key.

3) When blinking of the LAMP LED stops, only

the ON/STANDBY LED turns on in orange.

After this, the lamp can be turned on again by

the ON/STANDBY key.

(7) Moreover, the fan works for about 2 min. to lower

temperature of the unit. When the main power turns

off, the fan also stops and returns to the standby

status.

(8) If an error occurs due to some causes, the ON/

STANDBY LED turns on in red, and the error

information is kept in the display status of the

LAMP and TEMP LEDs. When the error is

detected, the unit enters the standby status after

cooling down process for about 2 min. In this case,

if the error status continues, the error display is also

kept and any key entry is not accepted.

5-7

Page 19

5-14. Applicable Signal

Various kinds of signals are used as the applicable

signals in the preset mode (standard value) as shown in

Table 5-14-1. For the signals not fit to the preset modes,

a user mode is provided.

In the preset modes, the applicable signals are based on

the VESA standard, so the sample frequency (CLOCK

adjustment in the panel menu) is not used, but the

adjustment is allowed only in the user mode.

Table 5-14-1 Applicable signal

In other mode, the signal line number is detected to allow

the separate adjustment in the VGA system (basically

effective for line number of 480 lines), SVGA system

(basically effective for line number of 600 lines) and

XGA system (basically effective for line number of 768

lines).

In the user mode of SGA system (900 line system and

1024 line system), the input signal is applicable to the

plain display mode. That is, the signal is displayed in

different two ways owing to the line number in vertical

direction.

Mode

NTSC

PAL

V60

V72

V75

V85

M13

24K

T70

T70

T70

T70

T85

T85

T85

S56

S60

S72

S75

S85

M16

X60

X70

X75

X85

M21

SXGA1

SXGA2

Signal

Content

NTSC

PAL

VGA 60 Hz

VGA 72 Hz

VGA 75 Hz

VGA 85 Hz

MAC-13”

PC98-STD

VGA 70 Hz

VGA 70 Hz

VGA 70 Hz

VGA 70 Hz

VGA 85 Hz

VGA 85 Hz

VGA 85 Hz

SVGA 56 Hz

SVGA 60 Hz

SVGA 72 Hz

SVGA 75 Hz

SVGA 85 Hz

MAC-16”

XGA 60 Hz

XGA 70 Hz

XGA 75 Hz

XGA 85 Hz

MAC-21”

1152 system

1280 system

Resolution Frequency All Operation

H

664

756

640

640

640

640

640

640

720

720

640

640

640

640

720

800

800

800

800

800

832

1024

1024

1024

1024

1152

1152

1280

V

484

574

480

480

480

480

480

400

350

400

350

400

350

400

400

600

600

600

600

600

624

768

768

768

768

870

864

1024

H (kHz)

15.734

15.625

31.470

37.861

37.500

43.269

35.000

24.830

31.470

31.470

31.470

31.470

37.861

37.861

37.927

35.156

37.879

48.077

46.875

53.674

49.724

48.363

56.476

60.023

68.677

100.000

108.000

135.000

V (Hz)

59.940

50.000

59.940

72.809

75.000

85.008

66.667

56.420

70.020

70.020

70.020

70.020

85.080

85.080

85.039

56.250

60.317

72.188

75.000

85.061

74.550

60.004

70.069

75.029

84.997

68.653

67.500

79.976

Clock

(MHz)

12.590

12.500

25.175

31,500

31.500

36.000

30.240

21.053

28.322

28.322

28.322

28.322

31.500

31.500

35.500

36.000

40.000

50.000

49.500

56.250

57.283

65.000

75.000

78.750

94.500

75.030

75.000

75.025

H

800

800

800

832

840

832

864

848

900

900

800

800

832

832

936

1024

1056

1040

1056

1048

1152

1344

1328

1312

1376

1456

1600

1688

525

625

525

520

500

509

525

444

450

450

450

450

445

445

446

625

628

666

625

631

667

806

806

800

808

915

900

1066

Sync

V

H/V

N/N

N/N

N/N

N/N

N/N

N/N

N/N

N/N

P/N

N/P

P/N

N/P

P/N

N/P

N/P

N/N

N/N

N/N

N/N

N/N

N/N

N/N

N/N

N/N

N/N

N/N

N/N

N/N

Corre-

spondence

O

O

O

O

O

O

O

O

D

D

O

O

O

O

D

O

O

O

O

O

O

O

O

O

O

X

X

X

Remarks

Video input

Video input

Plain display

Plain display

Plain display

• In the sync column of Table 3-14-1, P shows the positive polarity and N shows the negative polarity.

• In the operation column, O shows a standard mode, D

shows pull-in mode, X shows plain display mode.

5-8

Page 20

5-15. RS-232C Control Method

Table 5-15-1 RS-232C connection signals

Signals are connected to the RS-232C connector in a

straight format as shown in Table 5-15-1 RS-232C

connection signals. This is because a crossing connection is provided inside the unit. Communication conditions are set to meet the conditions given in Table 5-15-2.

Table 5-15-3 shows the command list of RS-232C.

When transmitting the command, be always sure to keep

100 ms interval between each command. Moreover, the

process time is required for a while when turning the

power ON/OFF and/or selecting the input mode. So in

such cases, also be always sure to keep enough intervals

between the commands.

Table 5-15-2 RS-232C communication conditions

Item

Communication system

Communication type

Transmission speed 9600 baud, No par ity, Data length 8 bit, Stop bit: 1 bit

STX (1 byte) + CMD (3 byte) + ETX (1 byte) = 1 block

STX is 02h, ETX is 03h, CMD is command string (Uppercase character)

Pin No.

2

3

4

5

6

7

8

Conditions

Signal name

RXD

TXD

DTR

S. G

DSR

RTS

CTS

Signal content

Receive data

Transmit data

Data terminal ready

Signal ground

Data set ready

Transmission request

Transmission enable

I/O

I

O

O

I

I

O

I

5-9

Page 21

Table 5-15-3 RS-232C command list

Item

Normal status

RGB

Camera (for TLP511)

Common adjustment

Video

Command

PON

POF

IN1

IN2

IN3

VUP

VDW

DON

DOF

MON

MOF

AON

AOF

FON

FOF

RON

ROF

CFU

CFD

CZU

CZD

ALF

ARG

AUP

ADW

RST

SAV

VCN

VBR

VCL

VTN

VSH

Content

Power supply ON

Power supply OFF

Video input

RGB input

Camera input

Volume UP

V olume DOWN

Display ON

Display OFF

All Mute ON

All Mute OFF

Audio Mute ON

Audio Mute OFF

Freeze ON

Freeze OFF

Resize ON

Resize OFF

Focus UP

Focus DOWN

Zoom UP

Zoom DOWN

Menu left shift/

adjustment value

DOWN

Menu right shift/

adjustment value UP

Menu up shift

Menu down shift

Standard setting for

each item

Adjustment value

storing

Contrast

Bright

Color

Tint

Sharp

Item

Panel

Mode

Language

Camera

Command

PVP

PHP

PPH

PCK

PL0

PL1

PL2

PL3

PL4

PL5

PS0

PS1

PS2

PS3

PS4

PS5

MW1

MW0

MM1

MM0

MO1

MO0

PJ0

PJ1

PJ2

PJ3

LEN

LJP

LFR

LGR

LSP

LIT

CSH

CSL

SIR

Content

Vertical position

Horizontal position

Sampling phase

Sampling frequency

Wide ON

Wide OFF

MIC ON

MIC OFF

OSD mute ON

OSD mute OFF

Floor mounted front

projection

Ceiling mounted front

projection

Floor mounted rear

projection

Ceiling munted rear

projection

English display

Japanese display

French display

German display

Spanish display

Italian display

High sensitivity ON

High sensitivity OFF

Iris adjustment

5-10

Page 22

6. DIGITAL CIRCUIT

6-1. Outline

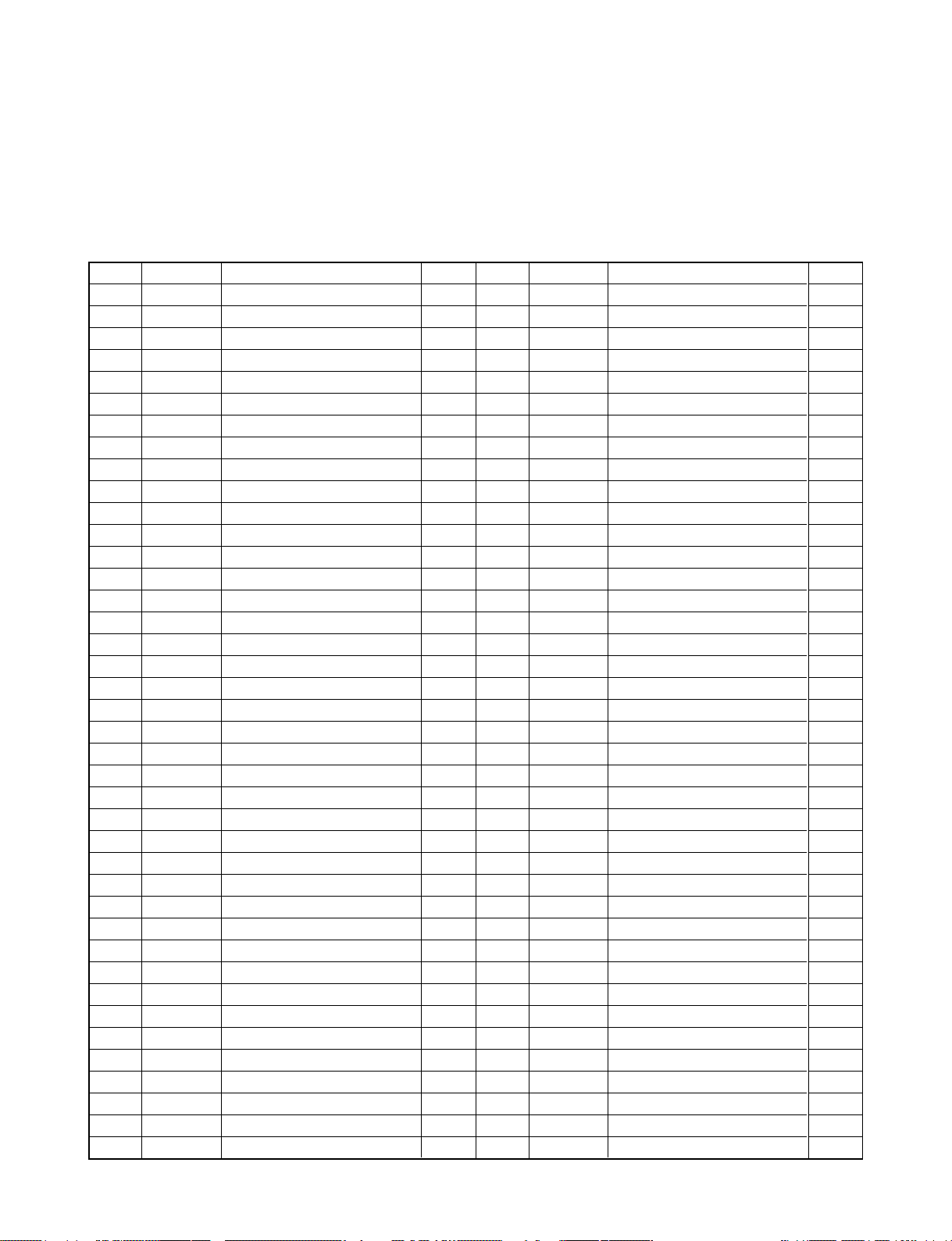

A Configuration of digital circuit is shown in Fig. 6-1-1.

The functions of digital circuit are described on the

following pages.

QX202, 203, 205, 206

MB814265/HM514265

(MEMORY)

R signal

(2.0V - 4.0V)

G signal

(2.0V - 4.0V)

B signal

(2.0V - 4.0V)

FREEZE

(MPU or camera)

VD

HD

For RGB signal

For VIDEO signal

QX201

CXA3026Q

(A/D CONV.)

CLK (PECL)

QX028

CXA3106Q

(PLL IC)

QX029

TLC2932

(PLL IC)

1/2 CLK

R CHANNEL

VD (INPUT)

HD (INPUT)

1/2 CLK

QX204

TC203E2651AF-01

(T-FORC)

G CHANNEL (RX4**, CX4**, QX4**)

B CHANNEL (RX6**, CX6**, QX6**)

42 MHz

System clock

for T-FORC

ZX003

42 MHz

X'tal OSC

QX004

TC160G54AF1137

(SYG)

Reference clock

for signal format

measurement

EPM7064LC68

(EXCHANGE)

VD (PANEL)

HD (PANEL)

LCD panel

clock

Reference

clock for

LCD drive

ZX003

32.5 MHz

X'tal OSC

QX207

QX003

ON SCREEN

DISPLAY

QX009

EMP7160ELC84

(TIMING)

MB40950

(D/A CONV.)

QX008

TLC2932

(PLL IC)

QX208

R signal

(3.0V - 5.0V)

G signal

(3.0V - 5.0V)

B signal

(3.0V - 5.0V)

Timing signals

for LCD drive

Fig. 6-1-1

6-1

Page 23

6-1-1. PLL Circuit

The PLL circuit develops the clock signal synchronized

with the horizontal sync signal, using the horizontal sync

signal entered.

For RGB signals, a highly stable CXA3106 (QX028) is

used. For video signal, a highly traceable TLC2932

(QX029) is used.

6-1-4. Gamma Correction Circuit

The gamma correction is carried out in the digital circuit.

So the digital circuit develops the signal corrected in

gamma.

The gamma correction circuit is built in the T-FORC

(QX207, QX407 and QX607) and the gamma correction

characteristics are set by the microprocessor using a bus.

6-1-2. Video Signal Format Con version

The LCD panel used for the unit requires a non-interlace

signal of 65 Hz dot clock entered. Accordingly, all the

RGB signals are converted into XGA 60 Hz format (Dot

clock = 65 MHz). In the same way, the video signal

(interlace signal) is converted into a non-interlace signal

with 64 MHz dot clock in keeping the vertical sync

signal frequency. These processes are carried out by the

newly developed ICs T-FORC (QX207, QX407 and

QX607) and memories (QX202, QX203, QX205,

QX206, QX402, QX403, QX405, QX406, QX602,

QX603, QX605 and QX606).

Furthermore, as the clock of XGA signal reaches approx.

80 MHz (max.), all signal processes are carried out in

parallel for even and odd pixels grouped. The video

signal entered is converted into the digital video signals

for two systems by the A/D converters (QX204, QX401

and QX601).

The signals divided into two systems are processed in

parallel in stages after the digital circuit. In case of the

process carried out in parallel as described above, if the

characteristics between two systems differ, the vertical

stripes will appear on the screen. In order to reduce this

vertical stripes, the signal system used is exchanged for

every one line and one field by the EXCHANGE PLD

(QX207, QX407 and QX607). The signals exchanged are

returned to the original order just before reaching the

LCD panel.

6-1-5. Panel Driving Timing Signal Generation

The driving for LCD panel requires various kinds of

timing signals. These timing signals are generated in the

digital circuit and especially generated by the timing

generation PLD (QX009).

6-1-6. ON-SCREEN Character Generation

The ON-SCREEN character timing signal is generated

and superimposed inside the digital circuit. So the signal

composed of the ON-SCREEN character is developed

from the digital circuit.

6-1-7. Signal Format Measurement

The RGB signals consist of various kinds of signal

formats, and the timing signal, enlargement ratio and etc.

must be switched corresponding to each signal format.

For this purpose, the signal format identification is

carried out by measuring the HD signal frequency

entered and the line number per 1 frame. This circuit is

built in the SYG (QX004) and the processed result is

read by the microprocessor through the bus line.

6-1-3. Screen Size Enlargement and Reduction

The pixel number of the LCD panel used for the unit is

1024 x 768 pixels. As for a signal entered, various kinds

of signals are used ranging from 640 x 480 pixels of

VGA signal to 1280 x 1024 pixels of SXGA signal. In

this unit, these signals are displayed on the whole screen

by enlarging/reducing the signals. The enlargement/

reduction process are also carried out by the ICs T-FORC

(QX207, QX407 and QX607) and memories (QX202,

QX203, QX205, QX206, QX402, QX403, QX405,

QX406, QX602, QX603, QX605 and QX606).

6-2

Page 24

6-2. Each IC Description

6-2-1. PLL IC CXA3106Q (QX028) for RGB Signals

A configuration of CXA3106Q is shown in Fig. 6-2-1.

The PLL IC of CXA3106Q is an IC with high performance and low jitter, and can generate the clock signal

synchronized with the horizontal sync signal of max. 120

MHz.

RC 1 RC 2

VCO

(TTL)

VCO

(PECL)

SYNC

(TTL)

SYNC

(PECL)

HOLD

(TTL)

TTLIN

PECLIN

TTLIN

PECLIN

TTLIN

DAC CONTROL REGISTER

POLARITY

1 bit

DETECTOR

1 bit

PHASE

ON/OFF

1 bit

READ OUT

TTLOUT

CHARGE

PUMP

2 bits

1/16 20/16 CLK

DELAY

5 bits

1/256 1/4096

PROGRAMMABLE

COUNTER

12 bits

ON/OFF

TTLOUT TTLIN

FINE

1 bit

The VCO, phase comparator, loop filter and frequency

dividing circuit are built in the IC, so the IC can generate

the clock signal by itself.

1 bit

VCO MUX

1 bit

LATCH

LOGIC

2 bits

SYNTHESIZER

POWER SAVE

1 bit

1 - 4 CLK

COARSE

DELAY

2 bits 1 bit

DIV

POLARITY

REST

1/2

WHOLE CHIP

POWER WAVE

ON/OFF

ON/OFF

ON/OFF

ON/OFF

ON/OFF

ON/OFF

TTLOUT

PECLOUT

1 bit

TTLOUT

1 bit

TTLOUT

PECLOUT

1 bit

TTLOUT

1 bit

TTLOUT

PECLOUT

1 bit

UNLOCK

DETECT

PECL

DSYNC

(TTL)

DSYNC

(PECL)

CLK

(TTL)

NCLK

(TTL)

CLK

(PECL)

CLK/2

(TTL)

NCLK/2

(TTL)

CLK/2

(PECL)

UNLOCK

VBB

1 REF

SENABLE SCLK SDATA SEROUT DIVOUT TLOAD CS

Fig. 6-2-1

6-3

Page 25

6-2-2. PLL IC TLC2932 (QX029) for Video Signal

The PLL IC of TLC2932 is composed of a phase

comparator and a VCO. As a frequency dividing circuit is

not built in, so the IC works as a PLL circuit by connecting to the external VCO terminal of QX028 and using the

frequency dividing circuit of QX028.

6-2-3. Sync Process IC SYG (QX004)

A configuration of the SYG component is shown in Fig.

6-2-2. The SYG IC is used as a sync process IC and

composed of the timing generation circuit for 2 systems,

one for the input signal and the other is for the panel

display, and the input signal measurement circuit. The IC

supplies the HD/VD signal to each IC and the IC works

on the timing signal basis. Also, the field identification at

video signal is carried out by the IC. In the unit, as the

PLL circuit is independent from the SYG, the sync signal

(DSYNC) enters from the PLL circuit to pin 139. The pin

is connected to the reset terminal of the horizontal

counter (for input signal).

6-2-4. Timing Signal Generation PLD (QX009)

A configuration of timing signal generation PLD is

shown in Fig. 6-2-3. The timing generation PLD generates the clock pulse and the timing signal to drive the

panel. As the signal timing and clock differ owing to the

inverted driving for top/bottom/left/right of panel and

kinds of input signals, the mode signal controls the

timing signal generation PLD.

PLL IC

QX008

AD CLK/2

32.5 MHz

Mode

CLK, HD, VD

PLL

CIRCUIT

SW

MODE

DECODER

PANEL TIMING

GENERATOR

PCLK

Timing signals

for

LCD panel

Fig. 6-2-3

32.5 MHz

HD, VD

SIGNAL FORMAT

BUS

INTERFACE

MPU

Fig. 6-2-2

MEASUREMENT

TIMING SIGNAL

GENERATOR 1

TIMING SIGNAL

GENERATOR 2

6-2-5. A/D Converter CXA3026Q

(QX201, QX401 and QX601)

A configuration of CXA3026Q is shown in Fig. 6-2-4.

The max. conversion speed of 120 MHz is supported by

CXA3026Q, A/D converter.

A frequency dividing circuit is built in the A/D converter

and the converter develops the data for two systems. The

clock speed is fast, so that the clock signal to be entered

is a differential input of PECL level. The input level of

analog signal ranges from 2.0 to 4.0V.

6-4

Page 26

V

RT

V

RM3

V

RM2

V

V

RM1

V

RB

(ECL)

CLK

(TTL)

INV

R1

R/2

R

R

0

1

6 bits

R

R

R

63

64

65

8 bits 8 bits

LATCH A

TTLOUT

6 bits

R

R

R

IN

R

126

127

128

129

ENCODER

6 bits

6 bits LATCH + ENCODER

R

R

R

191

192

193

6 bits

8 bits

LATCH B

TTLOUT

R

R

R/2

254

255

(LSB)

P1D0

P1D1

P1D2

P1D3

P1D4

P1D5

P1D6

P1D7

(MSB)

(LSB)

P2D0

P2D1

P2D2

P2D3

P2D4

P2D5

P2D6

P2D7

R2

DELAY

(MSB)

1/2

(ECL)

NRSET

(TTL)

SELECTOR

Fig. 6-2-4

6-5

SELECT

TTL

OUT

CLK OUT

Page 27

6-2-6. Picture Size of View Conversion IC T-FORC

(QX204, QX404, QX604)

A configuration of T-FORC is shown in Fig. 6-2-5. The

T-FORC is a newly developed picture size conversion IC.

By using the IC, smooth picture enlargement and

reduction, and format conversion will be made. Also, a

gamma correction circuit is built in the IC.

Video

signal

Video

signal

SEL

SW

SW

OSD, OSDI, PBLK

OSD SW

BLANKING SW

Video

signal

Video

signal

Memory Freeze

MEMORY

INTERFACE

FORMAT

CONVERTER

MEMORY

INTERFACE

Memory MPU

GAMMA

(LOOK UP

TABLE)

INTERFACE

OSD SW

BLK SW

(NOT USED)

BUS

Input CLK

System CLK

(42 MHz)

Panel CLK

(32.5 MHz)

Fig. 6-2-5

6-2-7. Memory

The memory uses four general 4 M bits EDO-DRAMs

(256k x 16 bits) per 1 channel.

From

timing PLD

PANEL TIMING

TRIM

MPU

To LCD panel

(ENB, DX)

Fig. 6-2-6

6-2-9. D/A Converter

MB40950 is a 10 bits 3 channels D/A converter of which

max. conversion speed is 60 MHz. In order to reduce the

difference of two systems of each RGB channel, each

RGB channel possesses one IC respectively. So one

channel of 3 channels D/A converter built in the IC is not

used. The output signal level ranges from 3.0 to 5.0V.

6-2-8. Exchange PLD

A configuration of timing signal generation PLD is

shown in Fig. 6-2-6. In the unit, the signal process is

carried out in parallel by dividing the process into two

systems. In order to reduce the characteristic difference

between these two systems, the signals of both systems

are switched for every 1 line and 1 frame. The PLD

carries out the process. Also, the ON-SCREEN display

signal superimposing, addition of non-display section for

top and bottom and left and right, etc. are carried out by

the PLD.

6-6

Page 28

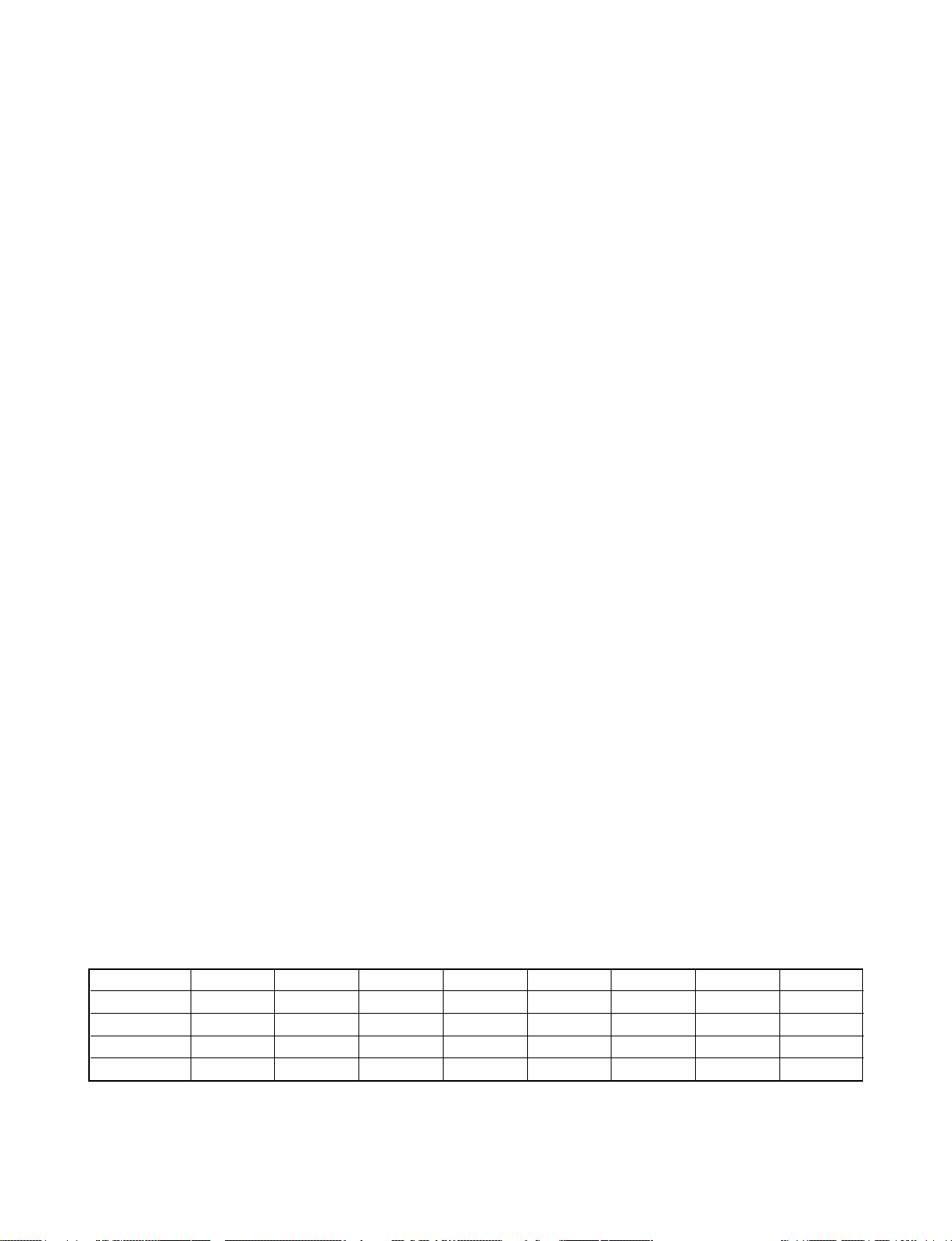

7. VIDEO CIRCUIT

7-1. Circuit Component

The video circuit performs selection of input signals,

video signal (NTSC, PAL, SECAM) demodulation to

RGB signals, RGB input signal amplification and audio

signal amplification.

Fig. 7-1-1 shows the block diagram.

7-1-1. Input Signal SW Section

<Video input section>

All the video and audio signals entered are sent to the

input SW IC (except for RGB signals). In the input SW

IC, the signals are switched corresponding to the

composite, Y/C and color modes (NTSC, PAL SECAM

and BLACK & WHITE) respecti vely. Processing routes

for the composite video signals are changed depending

on the color modes (NTSC, P AL, SECAM and BLACK &

WHITE). Y/C signals, SECAM and Black & White

signals are supplied to the video color process IC in the

next stage passing through the input SW IC. NTSC, PAL

and 4.43 NTSC color signals only are separated into the

luminance Y signal and color C signal by the digital

comb filter and then enter the input SW IC again as the

Y/C signals.

In the cases other than described above, when the power

is on or the input switching occurs, the signals are

supplied to the video/color process IC as a composite

video signal passing through the input SW IC.

<RGB input section>

The RGB signals entered are divided in two systems; the

internal signal process and external output systems.

The signals for the external output system enter 75 ohm

driver IC and then enter D-sub 15 pin for output. The

RGB signals for internal signal process system enter the

mute IC. When the video signal is selected, the RGB

signals are muted by the mute IC output.

7-1-2. Video Demodulation Section

In the video demodulation section, the composite video

signal and Y/C signals are demodulated into the RGB

signals.

In the video/color process IC, the color demodulation is

carried out corresponding to the color mode of the video

signal entered. The applicable color modes are NTSC,

4.43 NTSC, P AL and SECAM.

The mode identification is automatically carried out by

the video/color process IC.

When the power turns on and the input is switched, the

composite video signal passing through the input SW IC

enters and the color mode is determined. The microprocessor detects the result of color mode determination and

sets a corresponding color mode. The color difference

signal demodulated by the video/color process IC is

developed after processed its phase and signal level via

1H delay IC.

The luminance signal enters the picture quality correction IC and the color difference signal enters the RGB

demodulation IC via the delay line for matching with

the luminance signal.

In the RGB demodulation IC, the gamma correction,

color adjustment, etc. are carried out as well as the

luminance color difference signal is demodulated to the

RGB signals.

7-1-3. RGB Signal Amplification Section

In the RGB signal amplification section, the RGB input

signals and the video signal demodulated to the RGB

signals are switched and the contrast and brightness

adjustments are carried out. Further, the gain adjustment

for each RGB signal is also carried out.

The sync signals of the RGB signals correspond to

HD,VD, composite sync (CS) and SYNC ON G signals.

7-1-4. Audio Signal Amplification Section

The audio signal inputs of the video and RGB inputs

correspond to L and R stereo input. After switching the

input, the signal develops at the audio terminal through

the output buffer circuit. After L and R signals are mixed,

the sound volume control IC controls its level, thus

controlled signal is amplified to the sufficient level to

drive the speaker by the audio output IC, and then sent

to the speaker.

7-1

Page 29

7-2

Fig. 7-1-1 Block diagram

Page 30

7-2. Input Signal Switch Section

The signal SW section works as a circuit to supply the

signal to the signal process section in the next stage and

each output terminal by switching the signal entered

(video, audio).

Each input signal is sent to QV001 (CXA1855Q) as

shown in Fig. 7-2-1. The IC control is carried out by I2C

bus.

7-2-1. Video Signal

The composite video signal enters pins 43 (V1) and 45

(Y1) at the same time. When the composite signal

entered is a NTSC/PAL color signal, pin 43 (V1) is

selected. When it is either a SECAM or Black & White

signal and when the input switching is carried out, pin

45 (Y1) is selected.

This is because the composite signal is supplied to the

video/color process IC in the next stage passing through

the Y/C separation IC QV002 (TC9090AN) when the

composite signal is either SECAM or black & white

signal and when the input switching is carried out.

This is also because in the Y/C separation IC QV002

(TC9090AN), the SECAM signal cannot be separated

into Y and C signals, and it is not necessary for the Black

& White signal to be separated in Y and C signals.

The signal developed from pin 34 is Y/C-se parated by Y/

C separation IC QV002 (TC9090AN) and then enters the

signal SW IC QV001 (CXA1855Q) again. (Pin 31 (Y),

pin 29 (C))

The Y/C signals entered from S terminal enter pins 3 and

5 respectively.

VIDEO

VIDEO

AUDIO

L

R

43

V1

Y1

45

44

LV1

RV1

46

QV001

CXA1855Q

V OUT 1

In case of TLP511, the video signal from the camera

section is supplied as Y/C signals and enters pins 9 and

11 respectively.

The video signal selected finally develops from pins 37

(Y) and 29 (C) respectively.

7-2-2. Audio Signal

The audio signal employs two input systems; one is for

video signal and the other is for RGB signals. Each

system is applicable to L and R stereo inputs respectively.

The audio signal for the video signal is selected when

the video signal is selected and the audio signal for RGB

signals is selected when the RGB signals are selected.

The audio signal selected develops from pins 33 (L) and

32 (R).

7-2-3. RGB Signal

The RGB signals are entered using a high density D-SUB

15 and separated in two systems for the internal signal

process and the external output signal. The external

output signal develops at PV002 (RGB output connector) via QB007 (6 dB amp.). When the power turns on,

the RGB output signals always develop if any signal

enters at the RGB input terminal.

On the other hand, the internal process signals for the

RGB signals enter QB004, QB005 and QB006, respectively. The input signal switch IC controls to mute the

RGB input signals when selecting the video input.

QV002

TC9090AN

Y IN 1

C IN 1

34

31

29

COMB

FILTER

S1/S2

CAMERA

RGB

AUDIO

Y

S

C

Y

C

L

R

3

Y2

5

C2

S2

6

9

Y3

C3

11

25

LEV

REV

26

Y OUT 1

C OUT 1

L OUT 1

R OUT 1

SCL

SDA

37

39

33

32

13

14

QV005

TDA9141

AUDIO

Microprocessor

Fig. 7-2-1

7-3

Page 31

TV

EV

V1

V2

V3

Y1

Y2

Y3

C1

C2

C3

41

27

43

45

47

11

6 dB

1

7

3

9

5

6 dB

0 dB

0 dB

6 dB

6 dB

6 dB

0 dB

0 dB

6 dB

6 dB

6 dB

6 dB

34

31

37

35

39

29

23

21

24

19

17

38

30

VOUT1

YIN1

YOUT1

TRAP1

COUT1

CIN1

VOUT2

YOUT2

TRAP2

COUT2

VOUT3

Vcc

GND

LTV

LEV

LV1

LV2

LV3

RTV

REV

RV1

RV2

RV3

42

25

44

2

8

40

26

46

4

10

BIAS

6 dB

6 dB

6 dB

6 dB

6 dB

Logic

6 dB

Fig. 7-2-2 Internal block diagram of CXA1855Q

36

33

32

22

20

18

16

13

14

15

48

6

12

28

BIAS

LOUT1

ROUT1

LOUT2

ROUT2

LOUT3

ROUT3

SCL

SDA

ADR

S1

S2

S3

MUTE

7-4

Page 32

7-3. Video Demodulation Block

Table 7-3-1 Terminal function of TC9090AN

7-3-1. Y/C Separation Circuit

This circuit separates Y and C signals from a composite

video signal. Fig. 7-3-1 shows the pin configuration of

TC9090AN and Fig. 7-3-2 shows the block diagram.

The composite video signal enters pin 3. A fsc (3.58/

4.43 MHz) developed from the video/color IC enters pin

19 and is converted into a 4fsc of the drive clock

frequency inside the IC. The composite video signal

entered is processed at a rate of the clock frequency of

the IC and output as Y and C signal.

V

REFH

V

SS1

ADIN

DD1

V

V

REFL

BIAS1

P/S

SDA

SCL

RESET

TEST1

TEST2

KILLER

PLLSEL

1

2

3

4

5 24

6 23

7 22

8 21

9 20

10 19

11 18

12 17

13 16

14 15

28

27

26

25

SS4

V

V

DD4

V

REF1

Y

OUT

BIAS2

OUT

C

BIAS3

2/1V

VFIL

CKIN

V

DD2

V

SS2

V

SS3

V

DD3

DD

Fig. 7-3-1 Pin configuration of TC9090AN

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Name

V

REFH

V

SS1

ADIN

V

DD1

V

REFL

BIAS1

P/S

SDA

SCL

RESET

TEST1

TEST2

KILLER

PLLSEL

V

DD3

V

SS3

V

SS2

V

DD2

CKIN

VFIL

2/1 V

DD

BIAS3

C

OUT

BIAS2

Y

OUT

V

REF1

V

DD4