Page 1

FILE NO. 330-9904

S

SERVICE MANUAL

3LCD DATA PROJECTOR

TLP450E, TLP451E

TLP650E, TLP651E

TLP450U, TLP451U

TLP650U, TLP651U

TLP451, TLP651

PRINTED IN JAPAN, Oct., 1999

Page 2

CONTENTS

SAFETY PRECAUTIONS .............................................................. I

IMPORTANT PRECAUTIONS .................................................... I

IMPORTANT SAFETY INSTRUCTIONS.............................. II

PART REPLACEMENT AND ADJUSTMENT PROCEDURES

SECTION 1

1 . LOCATION OF MAIN PARTS ......................................... 1 - 1

2 . LO CAT IO N OF PC BOA RD S ........................................... 1 - 1

3 . REPLACEMENT OF MECHANICAL PARTS ............ 1 - 2

3-1. Camera Arm Assembly (Only for TLP451/651) ........ 1- 2

3-2. Lamp Assembly ................................................................. 1 -2

3-3. Front Cover and Top Cover .......................................... 1 -3

3-4. Main PC Board ................................................................. 1-3

3-5. RGB PC Board .................................................................. 1 - 3

3-6. Handle and Fan Assembly............................................... 1-4

3-7. Power Supply Unit ............................................................ 1-4

3-8. Filter Assembly .................................................................. 1-5

3-9. Lamp House ....................................................................... 1- 5

3-10.Optical Engine .................................................................. 1 -5

SECTION 2

SERVICING DIAGRAMS

1 . PART CONFIGURATION AND THEIR SYMBOLS 2- 1

1-1. Replacing Subminiature “CHIP” Parts ....................... 2-1

1-2. Precoutions for Part Replacement ................................ 2- 2

1-3. Solid Resistor Indication.................................................. 2-2

1-4. Capacitance Indication .................................................... 2- 2

1-5. Inductor Indication........................................................... 2-3

1-6. Waveform and Voltage Measurement.......................... 2- 3

2 . EACH SIGNAL FLOW ........................................................ 2- 4

2-1. Operation at RGB Signal Input ..................................... 2- 4

2-2. Video Signal ....................................................................... 2- 4

2-3. Operation at Y/Pb/Pr Signal and HDTV Signal Input2-5

2-4. Camera Input Operation ................................................ 2-5

2-5. Camera Overlay Signal ................................................... 2 - 5

3. BLOCK DIAGRAMS ............................................................ 2 - 7

3-1. RGB Block Diagram ........................................................ 2-7

3-2. Input Block Diagram........................................................ 2-8

3-3. Main Block Diagram ........................................................ 2- 9

3-4. Digital Block Diagram ................................................... 2-11

4 . PRINTED WIRING BOARD AND

SCHEMATIC DIAGRAM ................................................. 2-12

3-11. Input PC Board ............................................................... 1 -6

3-12. Lens .................................................................................... 1 - 6

3-13. Mirror Box ....................................................................... 1-6

3-14. LCD Block and LCD Panel ........................................... 1 - 7

3-15. CAM SW PC Board (Only for TLP451/651) ............ 1- 9

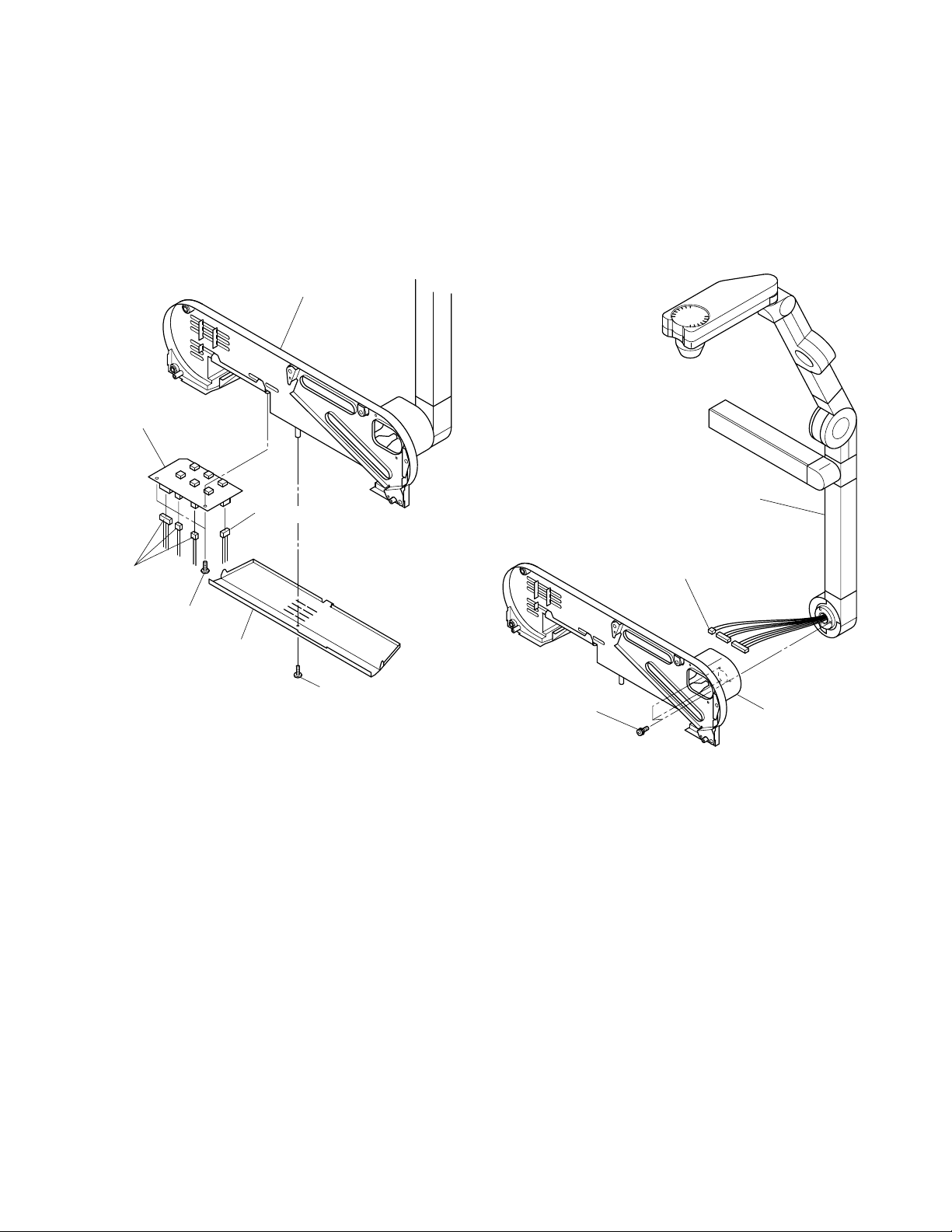

3-16. Arm Assembly (Only for TLP451/651) ...................... 1- 9

3-17. Switch (Only for TLP451/651) .................................. 1-10

3-18. Camera PC Board (Only for TLP451/651) ............. 1-10

3-19. Lamp PC Board (TLP451/651) .................................. 1-10

4 . ELECTRICAL ADJUSTMENT ....................................... 1-11

4-1. LCD Drive Adjustment .................................................. 1-12

5 . LED DISPLAY ...................................................................... 1-16

5 . CIRCUIT DIAGRAMS ...................................................... 2-15

5-1. Drive Circuit Diagram (for TLP650, TLP651) ........ 2-15

5-2. Drive Circuit Diagram (for TLP450, TLP451) ........ 2-19

5-3. Main Circuit Diagram (for TLP650, TLP651) ......... 2-23

5-4. Main Circuit Diagram (for TLP450, TLP451) ......... 2-27

5-5. Micon Circuit Diagram ................................................. 2-31

5-6. RGB Circuit Diagram .................................................... 2-35

5-7. Input Circuit Diagram ................................................... 2-39

5-8. Power Supply Circuit Diagram .................................... 2-42

5-9. Camera Interface Circuit Diagram ............................ 2-45

5-10. ............................................ FAN Control Circuit Diagram

2-47

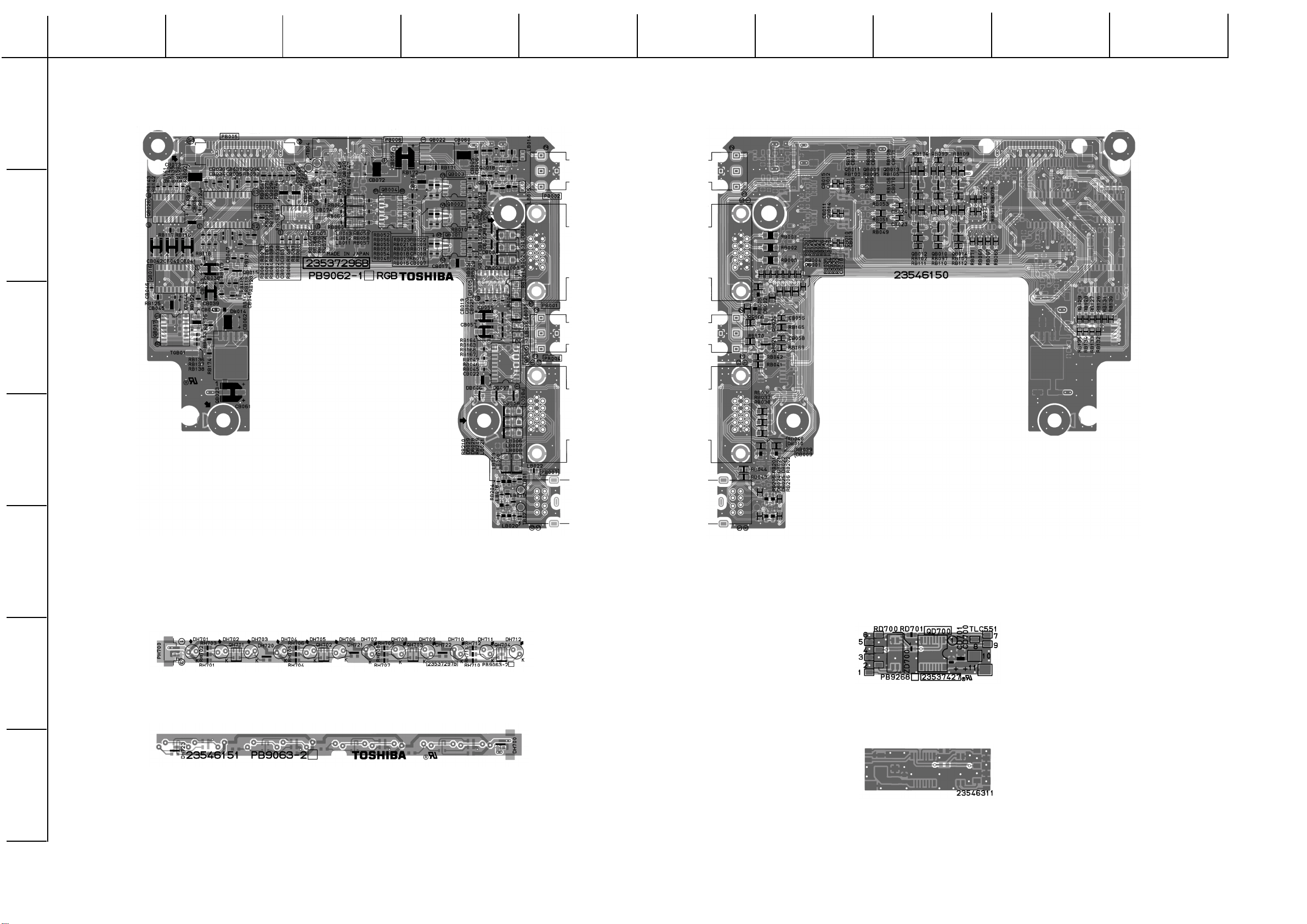

6. PC BOARDS ......................................................................... 2-49

6-1. Input PC Board ............................................................... 2-49

6-2. CAM Switch PC Board .................................................. 2-50

6-3. Main PC Board ............................................................... 2-51

6-4. RGB PC Board ................................................................ 2-55

6-5. LED PC Board ................................................................ 2-55

6-6. Sub Digital PC Board .................................................... 2-56

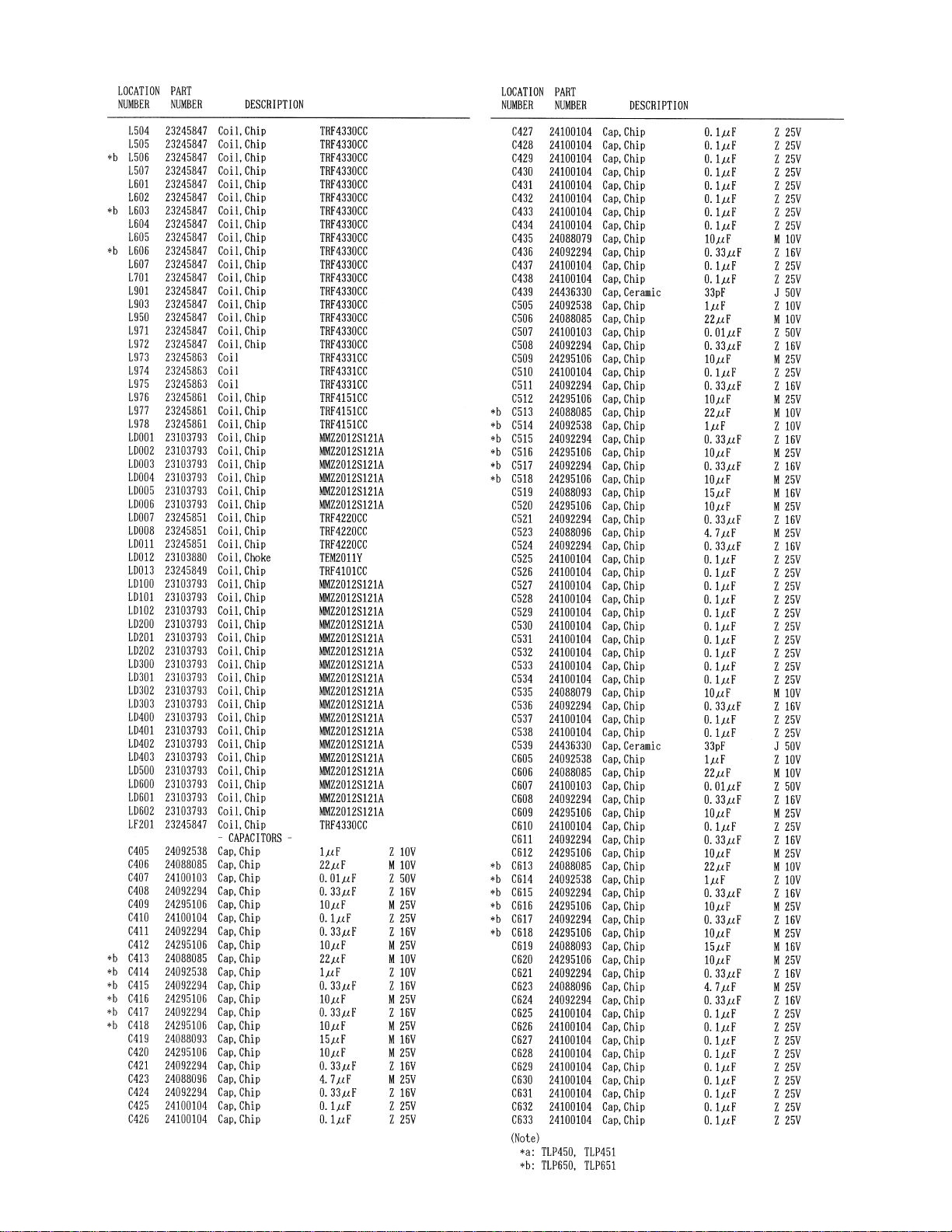

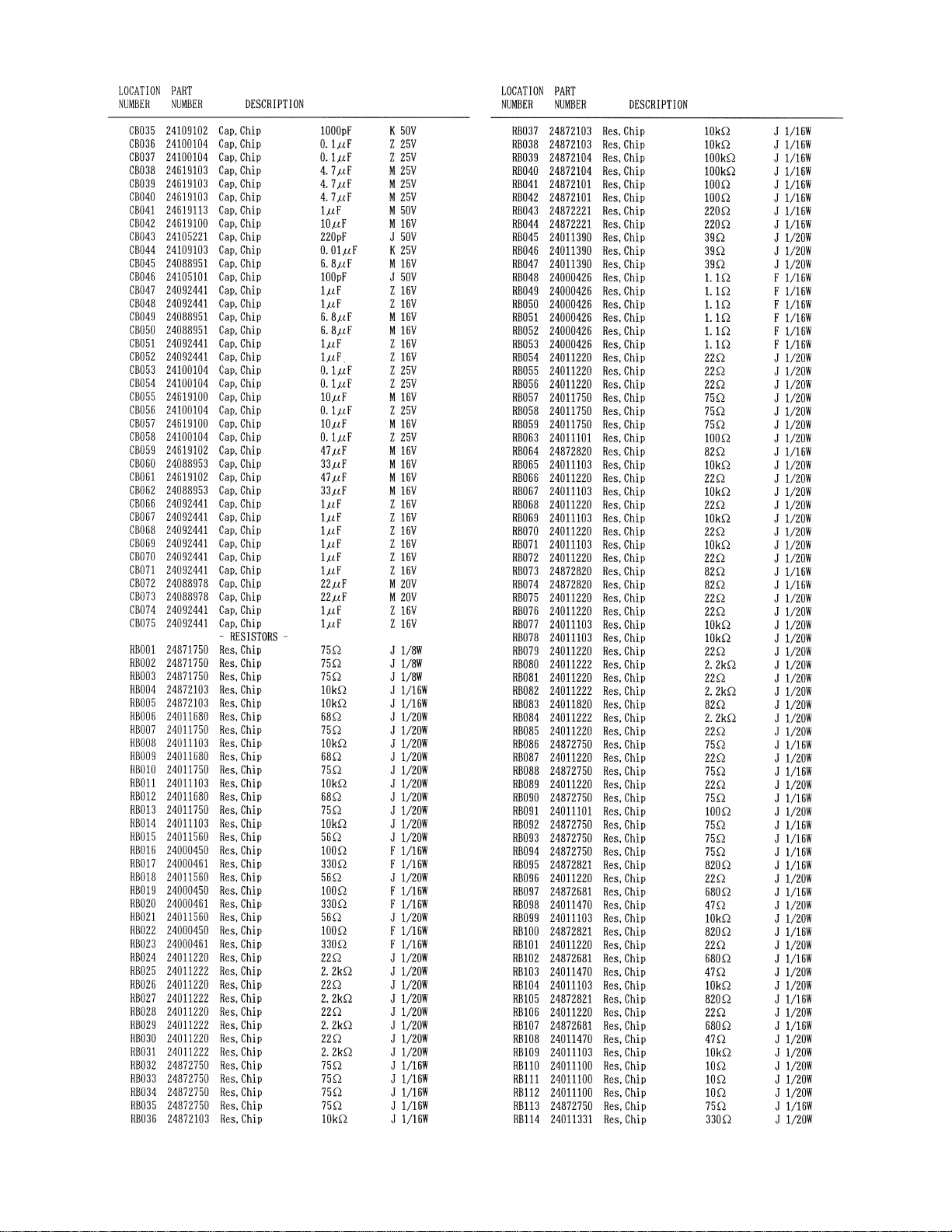

PARTS LIST

1. SAFETY PRECAUTION...................................................... 3 -1

2. NOTICE ..................................................................................... 3 -1

3 . ABBREVIATIONS.................................................................. 3- 1

3-1. Integrated Circuit (IC) .................................................... 3- 1

3-2. Capacitor (Cap) ................................................................ 3-1

3-3. Resistor (Res) ..................................................................... 3-1

SECTION 3

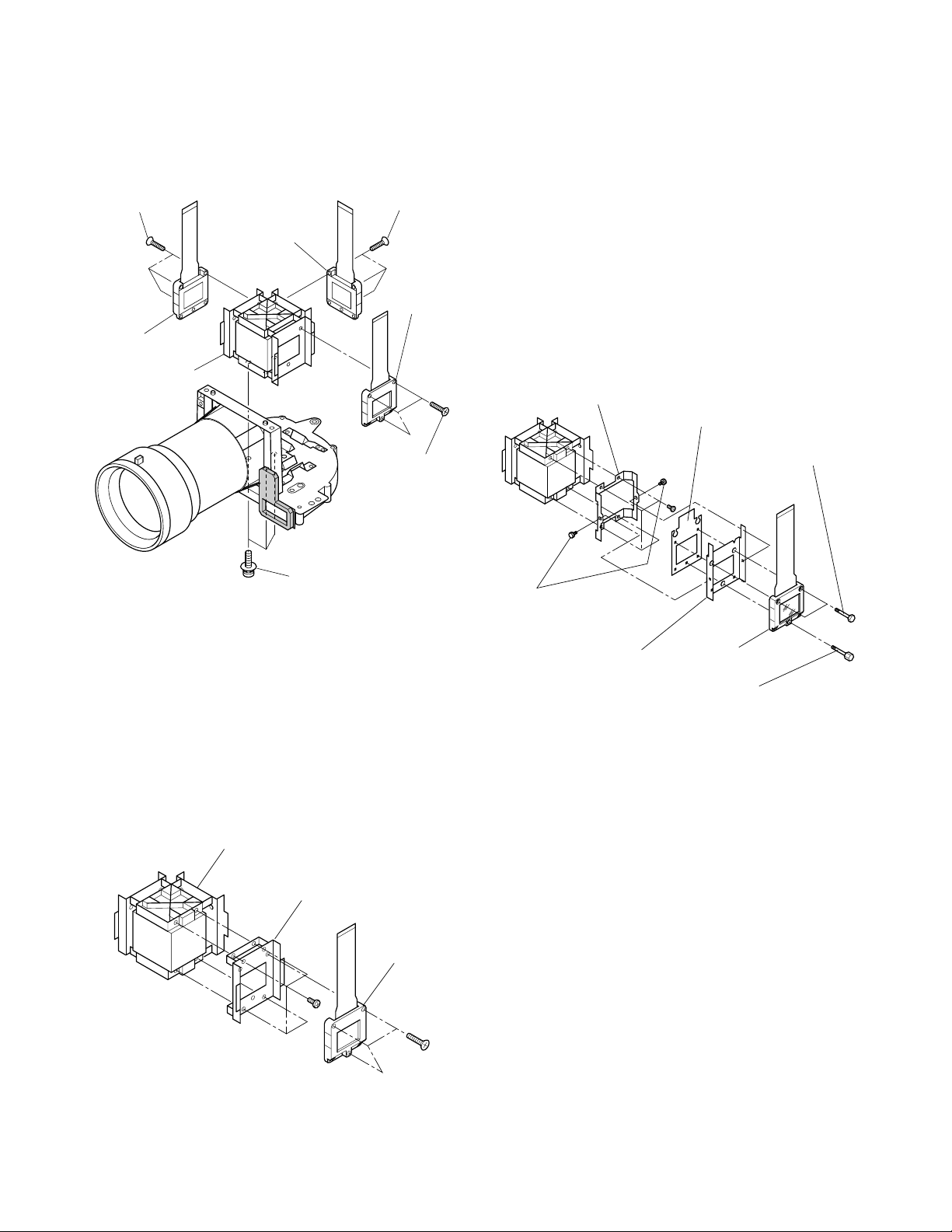

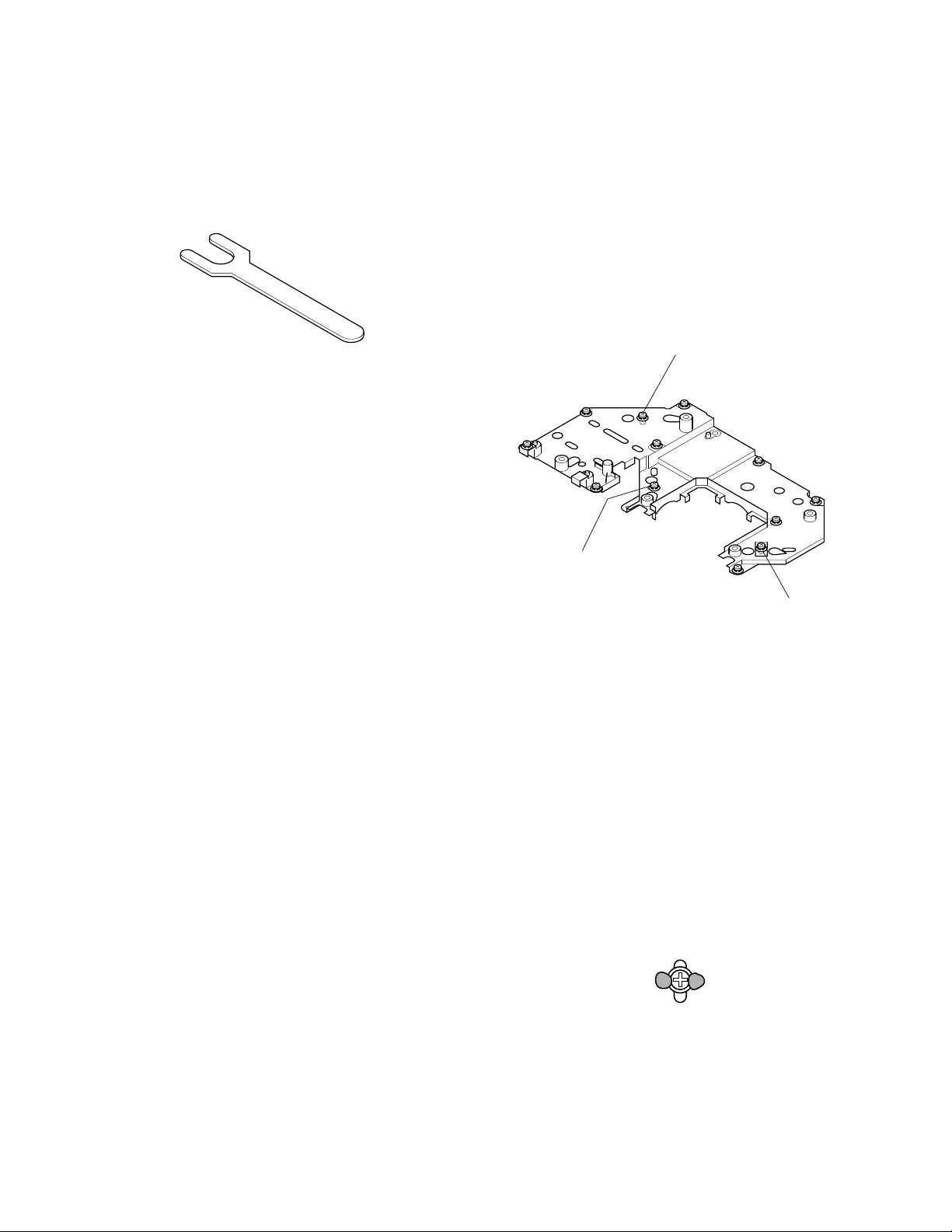

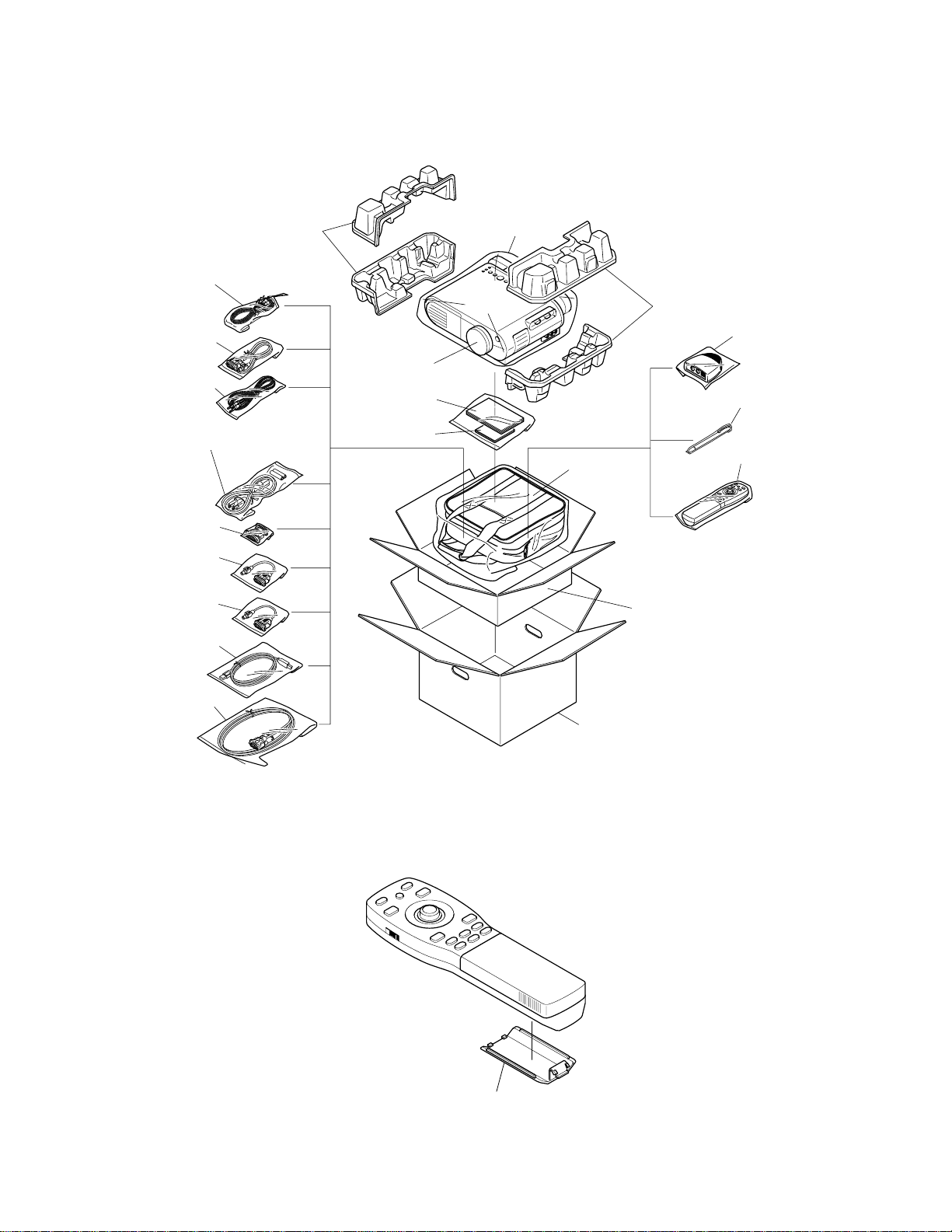

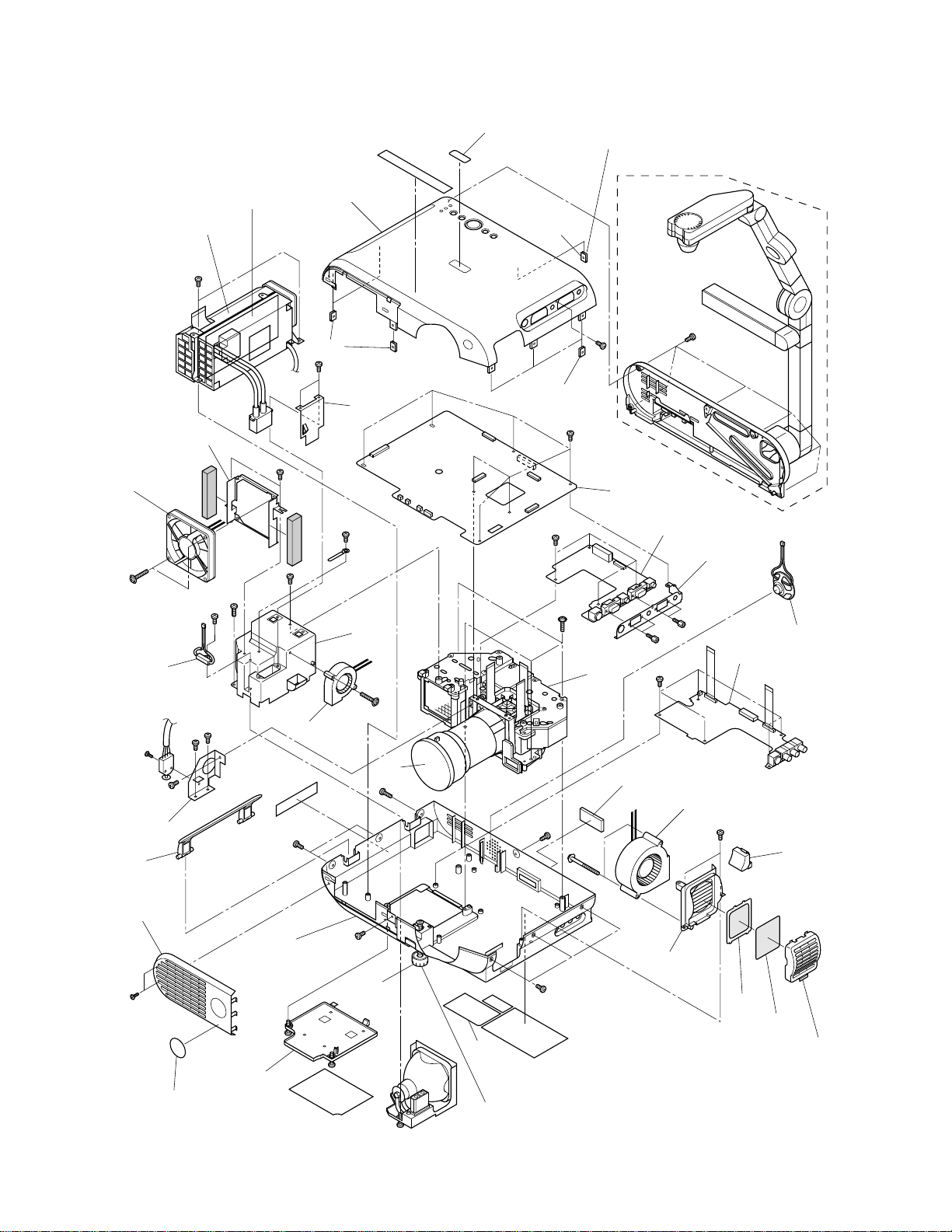

4 . EXPLODED VIEWS .............................................................. 3-2

4-1. Packing Assembly ............................................................. 3- 2

4-2. Remote Control Unit........................................................ 3-2

4-3. Chassis Assembly ............................................................... 3 -3

4-4. Arm Assembly (TLP451, TLP651) ................................ 3-4

5 . PARTS LIST ............................................................................. 3- 5

Page 3

ADJUSTMENT PROCEDURES

PART REPLACEMENT AND

SECTION 1

PART REPLACEMENT AND

ADJUSTMENT PROCEDURES

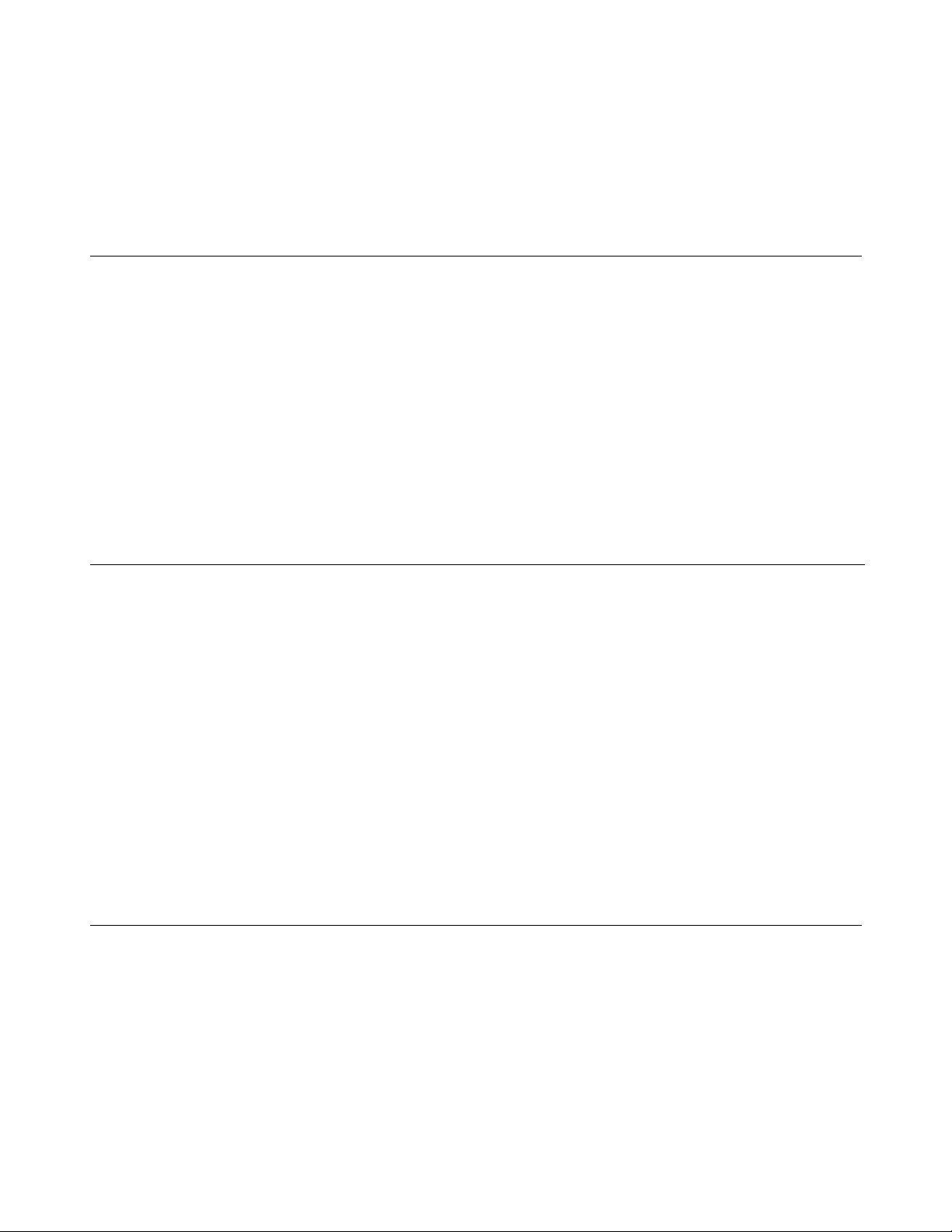

1. LOCATION OF MAIN PARTS

E200 Optical Engine

B180 Lamp House

P800 Power Unit

Z101 Fan

SECTION 1

TLP451/651

PC300 Camera

Unit Assembly

SC01 Arm Position

Detection Switch

P100 Thermal Lead Switch

Projection Lens

2. LOCATION OF PC BOARDS

U007 Sub Digital

U001 Main PC Board

LCD Block

Filter

Fig. 1-1-1

TLP451/651

U0032 LED PC Board

U0031 CAM

Switch PC Board

Fig. 1-2-1

1-1

U0021RGB PC Board

U0022 Input PC Board

Page 4

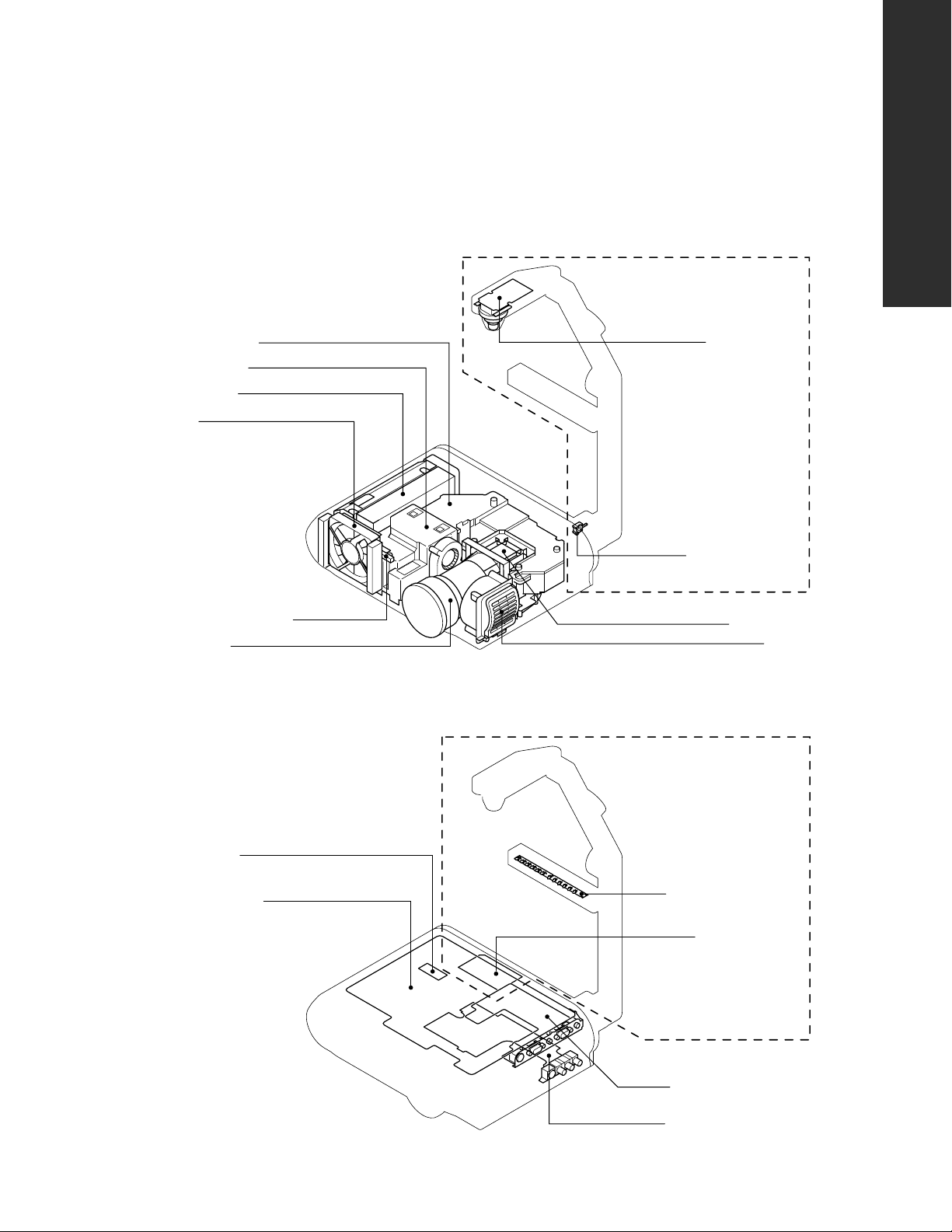

CAUTIONS BEFORE STARTING SERVICING

Electronic parts are susceptible to static electricity and may easily damaged, so do not forget to take a proper

grounding treatment as required.

Many screws are used inside the unit. To prevent missing, dropping, etc. of the screws, always use a magnetized

screwdriver in servicing. Several kinds of screws are used and some of them need special cautions. That is, take care

of the tapping screws securing molded parts and fine pitch screws used to secure metal parts. If they are used

improperly, the screw holes will be easily damaged and the parts can not be fixed.

3. REPLACEMENT OF MECHANICAL PARTS

3-1. Camera Arm Assembly

(Only for TLP451/651)

1. Remove six screws (1) and remove the camera arm

assembly (2).

2. Remove the connector (3) connecting to the main

unit.

Screws (1)

Camera arm

assembly (2)

Main unit

3-2. Lamp Assembly

1. Loosen two screws (1) and remove the cover (2).

2. Pull down the handle to remove the lamp assembly (3).

Lamp assembly (3)

Handle

Fig. 1-3-1

Cover (2)

Connector (3)

Screws (1)

(Loosen.)

Fig. 1-3-2

1-2

Page 5

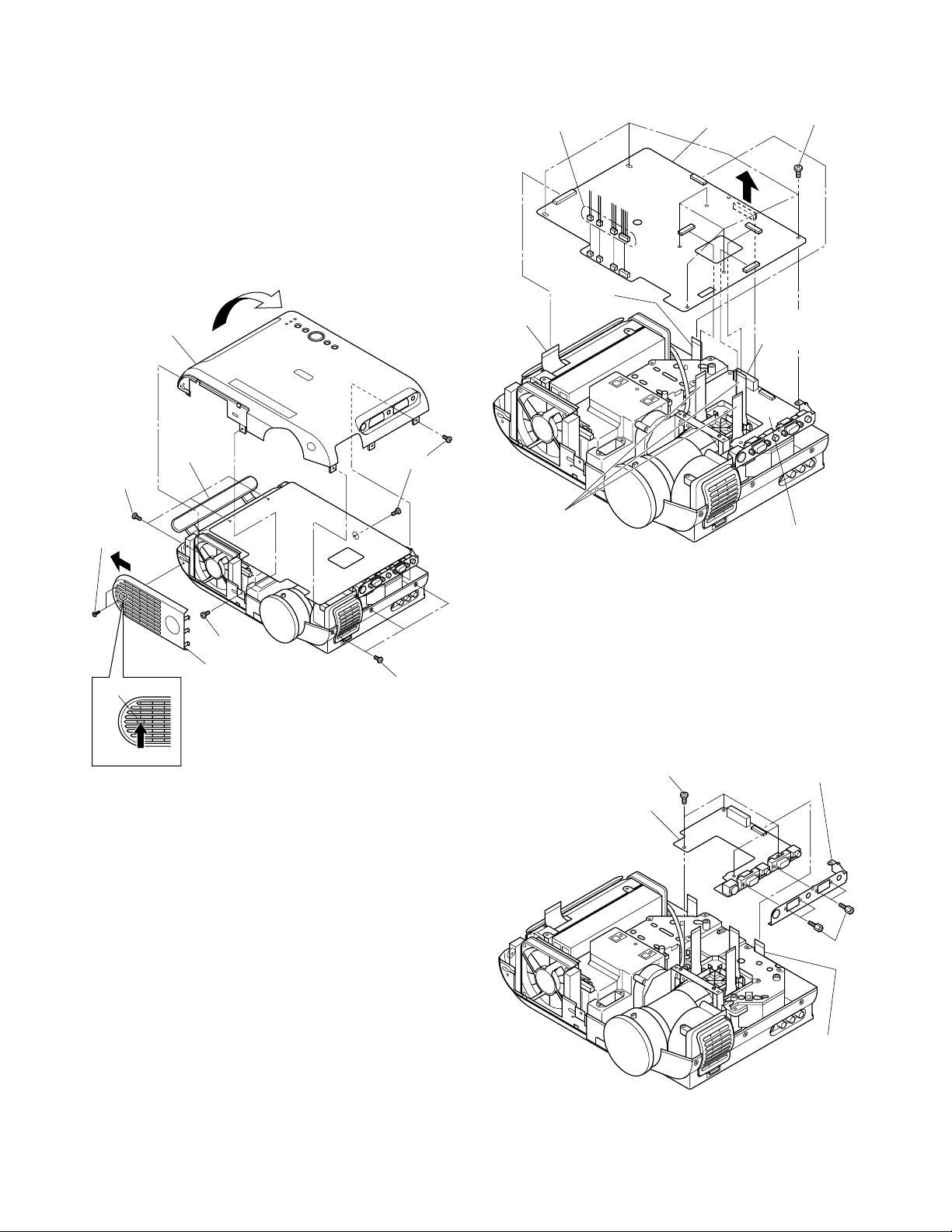

3-3. Front Cover and Top Cover

Connectors (2)

Main PC board (1)

Screws (4)

Connector on

RGB PC board (5)

RGB PC board (5)

FFC (3)

FFC (3)

FFCs (3)

1. Remove two screws (1) and remove the front cover (2)

by sliding the portion A pushed with a thin bar in the

arrow B direction.

2. Remove nine screws (3).

3. Push the handle (4) to one side and remove the top

cover (5) by rotating in the arrow C direction.

Screws (3)

Top cover (5)

Screws (1)

B

A

Push

C

Handle (4)

Screws (3)

Front cover (2)

Fig. 1-3-3

Screws (3)

Screw (3)

Fig. 1-3-4

3-5. RGB PC Board

1. Remove the FFC (1).

2. Remove four screws (2) and RGB PC board (3).

3. Remove four screws (4) and remove the cover (5) from

the RGB PC board (3).

Screws (2)

RGB PC board (3)

Cover (5)

3-4. Main PC Board

1. Remove four connectors (2) and five FFCs (3)

connected to the main PC board (1).

2. Remove seven screws (4).

3. Lift the main PC board (1) upward and remove the

main PC board (1) from the RGB PC board (5).

Screws (4)

FFC (1)

Fig. 1-3-5

1-3

Page 6

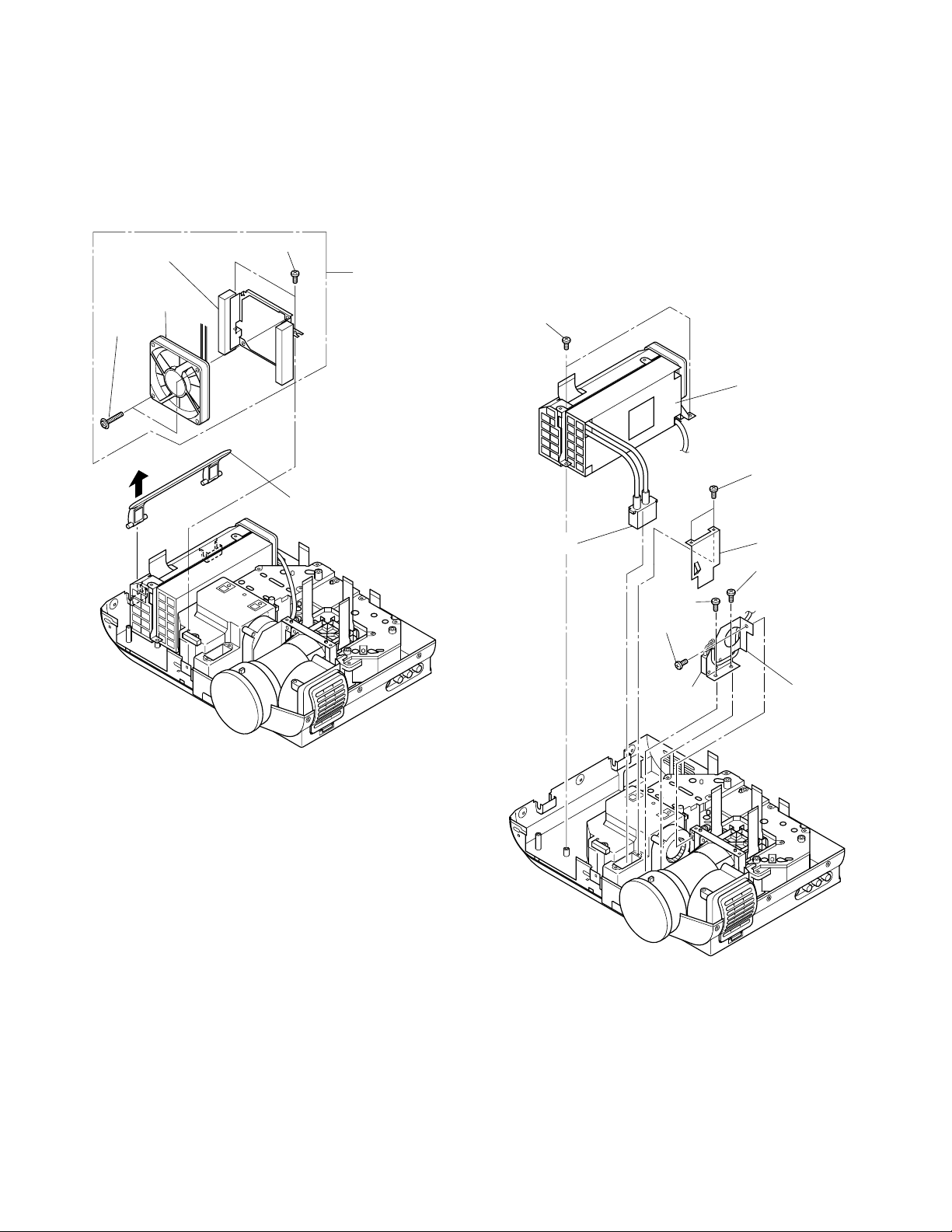

3-6. Handle and Fan Assembly

1. Pull out the handle (1) upward.

2. Remove two screws (2) and fan assembly (3).

3. Remove two screws (4) and then remove the fan (5)

from the fan bracket (6).

Fan bracket (6)

Fan (5)

Screws (4)

Screws (2)

Fan assembly (3)

Handle (1)

3-7. Power Supply Unit

1. Remove two screws (1) and then remove the shield

plate (2) and the socket (3). (Do not lose the shield

plate (2).)

2. Remove two screws (4) and remove the power supply

unit (5).

3. Remove two screws (6) and one screw (7) and remove

the interlocking switch and plate (8).

Screws (4)

Power supply unit (5)

Screws (1)

Fig. 1-3-6

Socket (3)

Screw (7)

Screw (6)

Interlocking

switch (8)

Shield plate (2)

Screw(6)

Interlocking

switch plate (8)

1-4

Fig. 1-3-7

Page 7

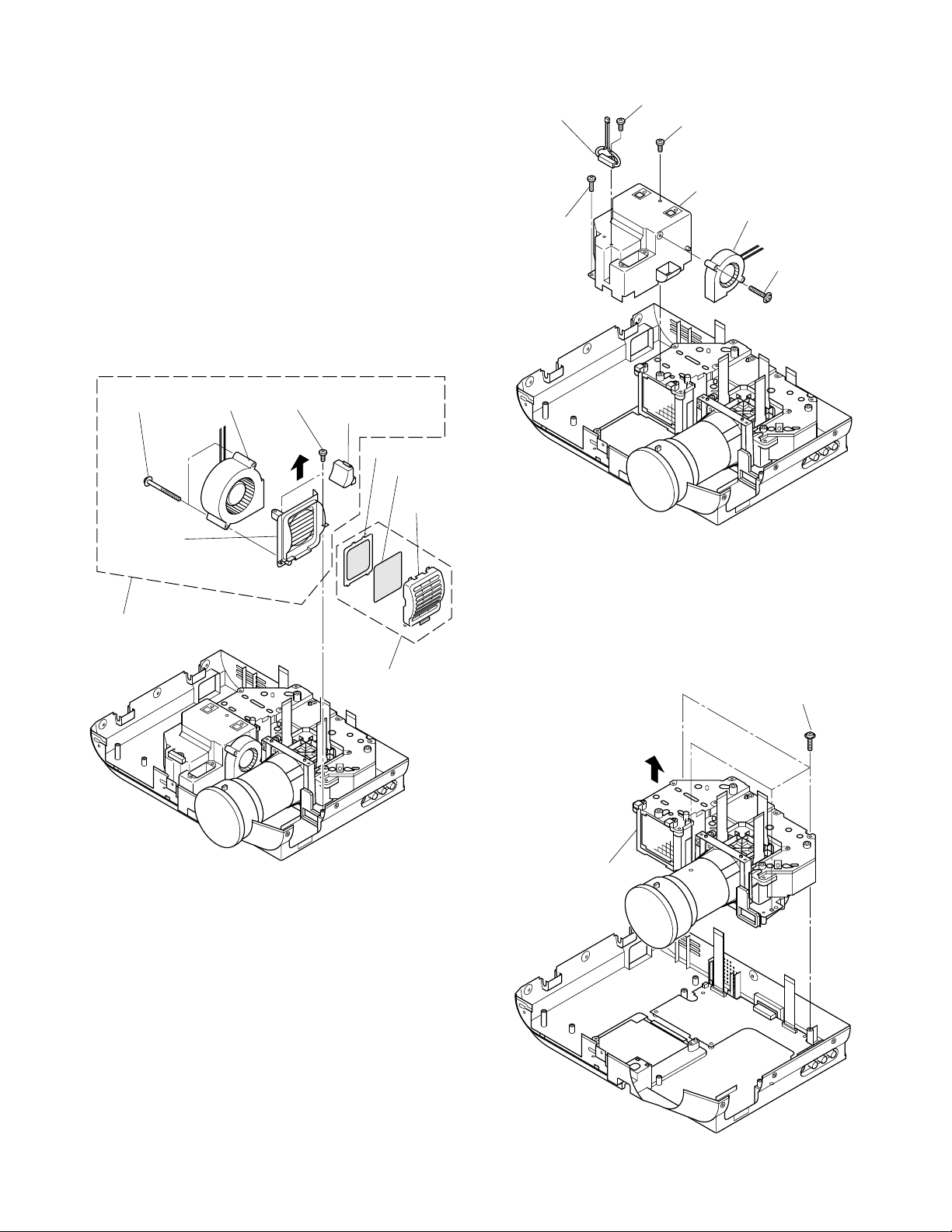

3-8. Filter Assembly

1. Remove the filter cover (1) from the suction fan

holder (2).

2. Remove the filters (3) and (4) from the filter cover (1).

(When replacing and/or cleaning the filter, note the

arrangement of the filters. Refer to Fig. A)

3. Remove two screws (5) and pull out the filter assem-

bly (6) upward.

4. Remove two screws (7) and remove the fan (8).

5. Remove the suction fan mouse piece (9) from the

suction fan holder (2).

Temperature

sensor switch (5)

Screw (2)

Screw (4)

Screw (1)

Lamp house (3)

Fan (7)

Screw (6)

Screws (7)

Suction fan

holder (2)

Filter

assembly (6)

Fan (8)

Screws (5)

Suction fan

mouse piece (9)

Filter (4)

Filter (3)

Filter

cover (1)

Replacement

filter

Fig. A

Fig. 1-3-9

3-10. Optical Engine

1. Remove four screws (1).

2. Remove the optical engine (2) by lifting upward.

Screws (1)

Fig. 1-3-8

3-9. Lamp House

1. Remove one screw (1) and (2) and then remove the

lamp house (3).

2. Remove one screw (4) and then remove the tempera-

ture sensor switch (5).

3. Remove one screw (6) and then remove the fan (7).

Optical engine (2)

Fig. 1-3-10

1-5

Page 8

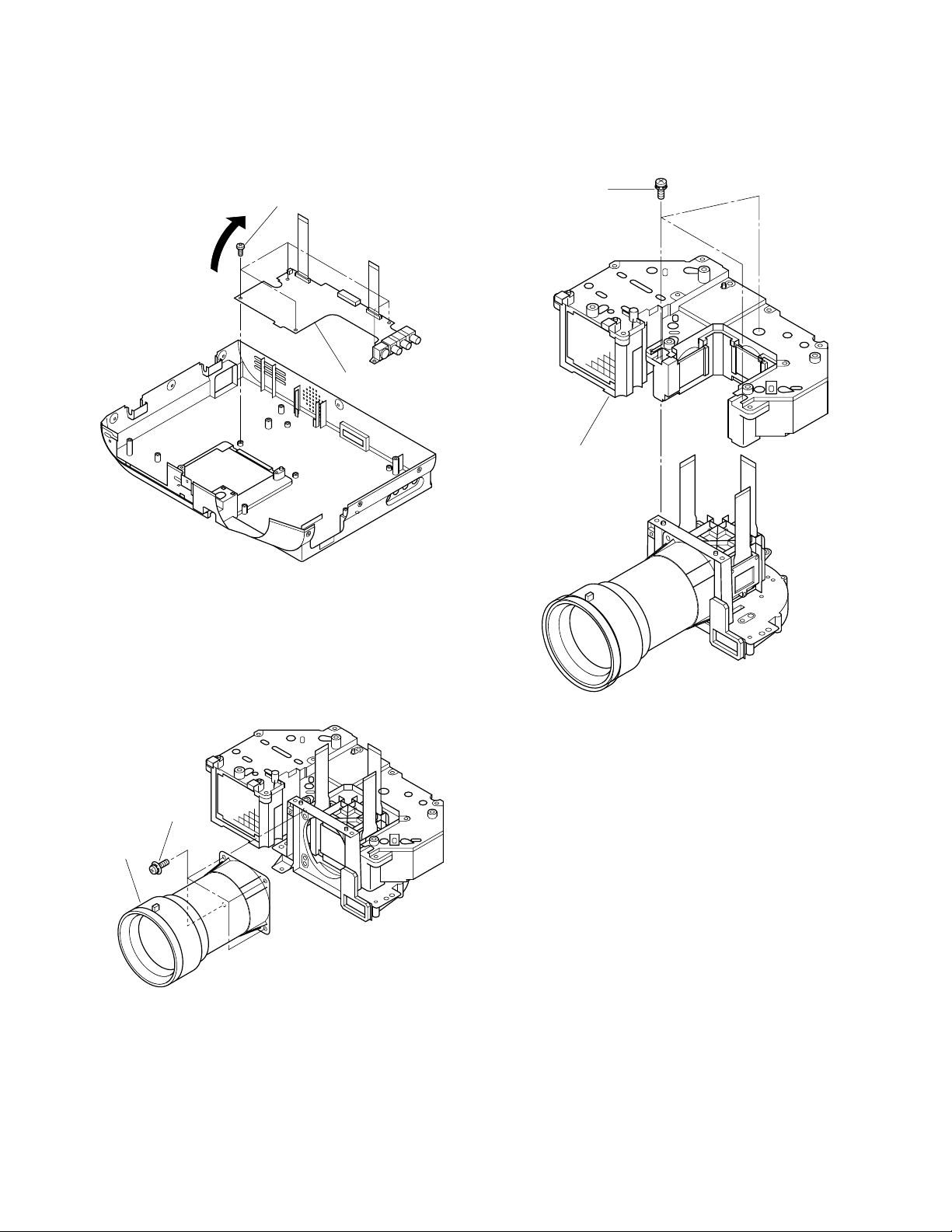

3-11. Input PC Board

1. Remove five screws (1).

2. Remove the input PC board (2) by turning the arrow

direction.

Screws (1)

Input PC board (2)

3-13. Mirror Box

1. Remove three screws (1) and then remove the mirror

box (2).

Screws (1)

Mirror box (2)

Fig. 1-3-11

3-12. Lens

1. Remove four screws (1) and then remove the lens (2).

Screws (1)

Lens (2)

Fig. 1-3-12

Fig. 1-3-13

1-6

Page 9

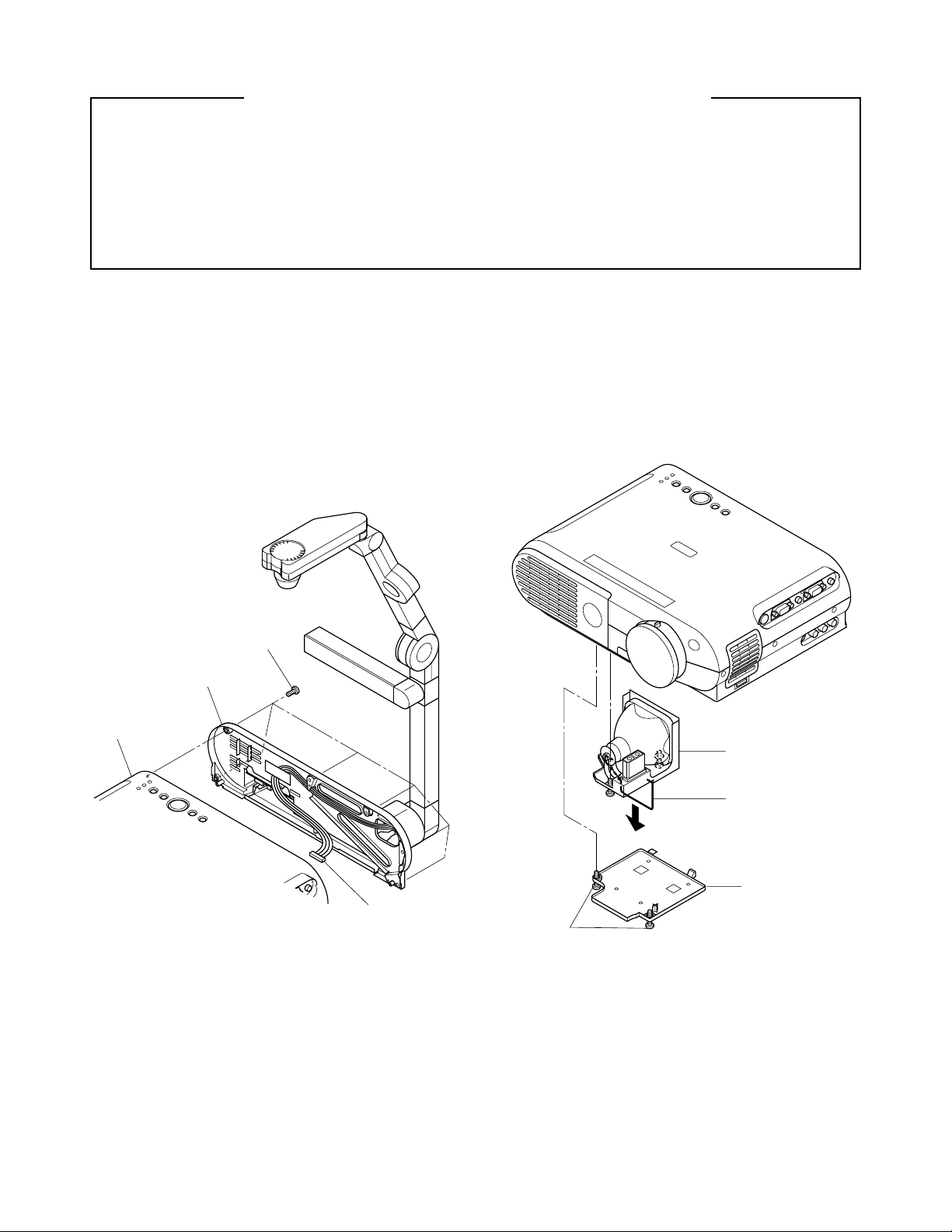

3-14. LCD Block and LCD Panel

Holder support

Adjusting screws S (x2)

Z rotation plate

L lower adjusting screw (x1)

L upper adjusting

screw (x2)

XY shifting plate

Panel

1. Remove three screws (1) and remove the LCD block (2).

2. Remove three screws (3) and remove the LCD panel (4).

Screws (3)

LCD panel (4)

LCD panel (4)

LCD block (2)

Screws (3)

LCD

panel (4)

Screws (3)

3. Mount a holder support for the service holder at the

location of the panel holder removed. (Use screws

removed in step 2.) (Refer to Fig. 1-3-16 for the

following steps.)

4. Mount a new panel on the XY shifting plate with the

Z rotation plate placed between them. (Use L upper

and lower adjustment screws.) At this time, fix them so

that two holes on the panel lower side are matched

with the holes on the Z rotation plate.

5. Mount the Z rotation plate on the holder support.

(Use S adjustment screws.) Tighten the S adjustment

screws lightly.

3-14-1. Panel Replacement and Adjustment

< Replacement procedures >

1. Remove the prism block from the optical engine.

2. Remove the panel and the panel holder from the

prism block. (Refer to Fig. 1-3-15.)

Screws (1)

Fig. 1-3-14

Procedures

Prism block

Panel holder

Panel

Fig. 1-3-15 Prism block exploded views

Fig. 1-3-16 Mounting view of a holder for service

< Panel adjustment procedures >

– carried out with a cross hatch signal (RGB input)

received.

(1) Panel focus adjustment

– carried out with a single color (panel color replaced)

status.

1. Shift the Z rotation plate by holding its handles

located on the upper sides with fingers or a long-nose

pliers, etc. and adjust to obtain the best focus at the

whole screen. At this time, adjust the screen center

focus by shifting the Z rotation plate entirely back

and forth, the left/right screen focus balance by

shifting the rotation plate to left/right rotation

directions and the upper/lower screen focus balance

by shifting it to upper/lower rotation directions.

1-7

Page 10

2. Tighten the S adjusting screws with a wrench for

servicing and fix the Z rotation plate. (Refer to Fig. 1-

3-17.) If the focus adjusted is upset when fixing,

loosen the S adjusting screws and perform the

adjustment in step 1 again.

Fig. 1-3-17 Service wrench

3. Repeat the steps 1 and 2 until the Z rotation plate is

fixed in the best focus condition. Finally, fix the Z

rotation plate perfectly by tightening the S adjusting

screws further with a long-nose plier, etc.

< Holder fixing >

1. Apply screw lock to the S adjusting screws.

2. Fix the Z rotation plate and the holder support, and

the Z rotation plate to the XY shifting plate by using

a silicone bond at the appropriate locations.

3-14-2. Mirror Adjustment Procedures

(After polarizing plate replacement)

1. Loosen screws fixing three mirror holder (WM, RM,

BM).

WM fixing screw

(2) Picture element adjustment

(Convergence adjustment)

– Superimposing pictures on R and B panels with a

picture on G panel.

1. Loosen the upper and lower L adjusting screws fixing

the panel.

2. Shift the XY shifting plate by holding its upper

portion with fingers or a long-nose plier, etc. and

adjust to superimpose the picture on the panel

replaced on that of the G panel.

For the relation between the picture and the XY

shifting plate shifting directions, the picture shifts to

the left when the XY shifting plate shifts to the left

seeing from the incident side of the panel (the picture

shifts to the right when the XY shifting plate shifts to

the right direction.), and the picture shifts to the lower

direction when the XY shifting plate shifts to the

upper direction (the picture shifts to the upper

direction, when the XY shifting plate shifts to the

lower direction.).

3. Fix the panel by tightening the upper/lower L

adjusting screws with a wrench for servicing. If a

focus is upset when fixing the panel, loosen the

upper/lower L adjusting screws and perform the step 2

again.

4. Repeat the steps 2 and 3 until the panel is fixed with

the picture superimposed in the best condition.

RM fixing screw

BM fixing screw

Fig. 1-3-18

2. Set G single color screen. Move the WM fixing screw

along the long hole and fix it where the upper and

lower edges of the screen does not show the dark

band.

3. Set R single color screen. Fix the RM fixing screw in

the same way as shown in step 2.

4. Set B single color screen. Fix BM fixing screw in the

same way as shown in step 2.

5. Apply screw lock to each fixing screw. (For the screw

lock position, refer to the figure shown below.)

Fig. 1-3-19

1-8

Page 11

3-15. CAM SW PC Board

(Only for TLP451/651)

1. Remove one screw (1) and remove the cover (2).

2. Remove four connectors (4) connected to the CAM

SW PC board (3).

3. Remove two screws (5) and remove the CAM SW PC

board (3).

Base cover

CAM SW

PC board (3)

3-16. Arm Assembly

(Only for TLP451/651)

1. Remove three screws (1) and remove the arm assem-

bly (2).

2. Pull out three connectors (3) connected from the arm

assembly (2) from the base cover (4).

Connectors (4)

Screws (5)

Connector (4)

Cover (2)

Fig. 1-3-20

Screw (1)

Screws (1)

Arm assembly (2)

Connectors (3)

Base cover (4)

Fig. 1-3-21

1-9

Page 12

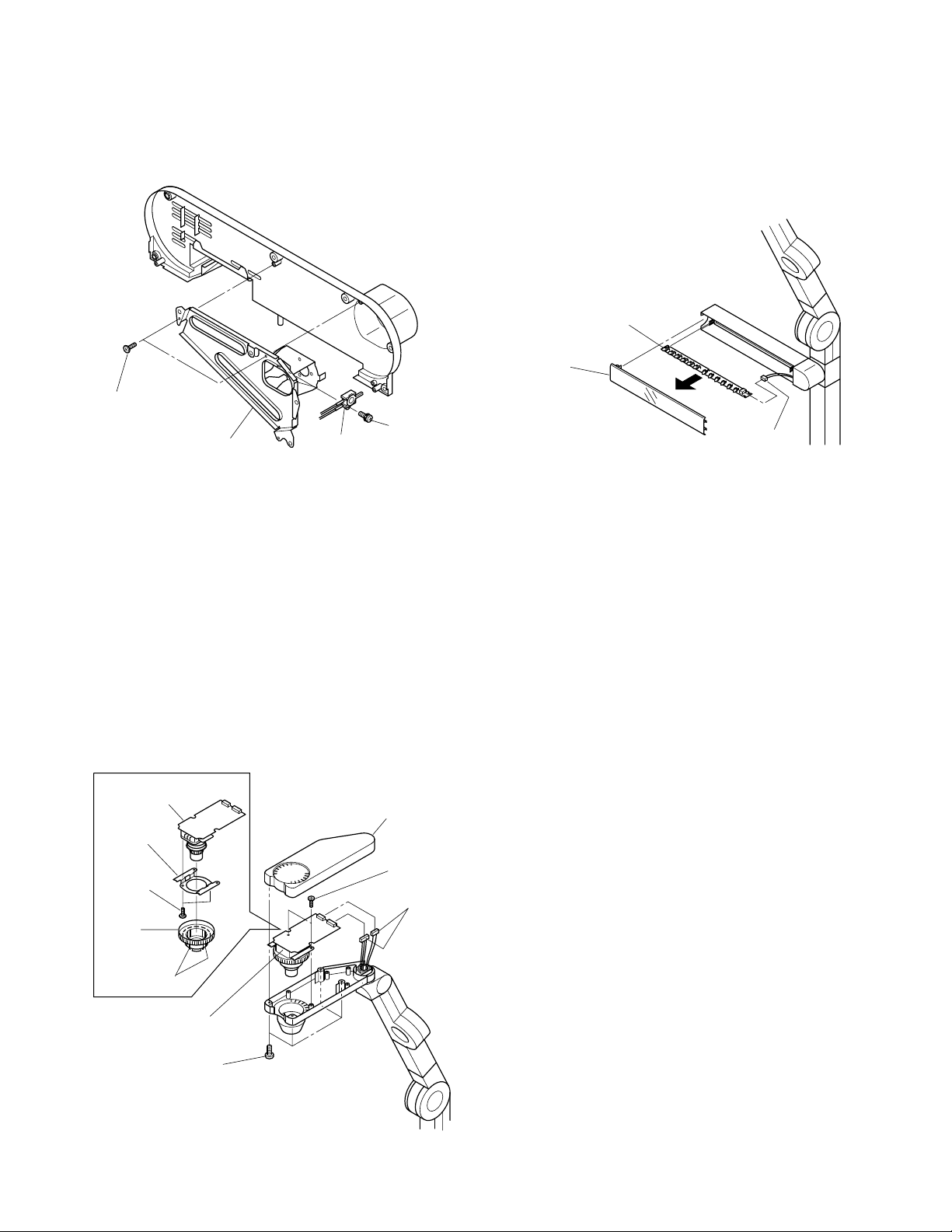

3-17. Switch (Only for TLP451/651)

1. Remove two screws (1) and remove the base plate (2).

2. Remove one screw (3) and remove the switch (4).

Screws (1)

3-19. Lamp PC Board (TLP451/651)

1. Remove the lamp cover (1).

2. Pull out the lamp PC board (2) in the arrow direction.

3. Unplug the connector (3).

Lamp PC board (2)

Lamp

cover (1)

Base plate (2)

Switch (4)

Screw (3)

Fig. 1-3-22

3-18. Camera PC Board

(Only for TLP451/651)

1. Remove four screws (1) and remove the cover (2).

2. Remove two connectors (3).

3. Remove two screws (4) and remove the camera

block (5).

4. Remove the focus ring (6) by releasing the claws (A).

5. Remove two screws (7) and remove the camera base

(9) from the camera PC board assembly (8).

Camera PC board

assembly (8)

Camera

base (9)

Screws (7)

Focus

ring (6)

Cover (2)

Screws (4)

Connectors (3)

Connector (3)

Fig. 1-3-24

Claws (A)

Camera block (5)

Screws (1)

Fig. 1-3-23

1-10

Page 13

Normal Adjust

AMP

DLY

CNT

GAIN

NRSH

WMS NRSL DIRX DIRY WMC WMD VRL VRH

CALR BLKLIM CLPLEV BCOM GCOM RCOM SIGCEN

Setting Shading Contents Bus Cont Screen Data SpecialDrive

Drive

Gamma

Drive

GAM

/ TEST

W1D

POSCONT1

POSCONT2

DIR

/ INV

AMP BIAS

GAM WHP GAM B1P GAM B2P GAM WHG GAM B1G GAM B2G SUB CONT

Reset

Reset

R

G

B

R

G

B

R

G

B

R

G

B

R

G

B

R

G

B

R

G

B

R

G

B

R

G

B

W1E W1F

Send CMD Receive CMD

4. ELECTRICAL ADJUSTMENT

< Test Equipments and Test Jigs >

• Oscilloscope

• Digital voltmeter

• Adjustment software TLP65CTLS.EXE

• Color luminance meter (BM-5)

• Personal computer

• Signal generator

• Multi-point luminance meter

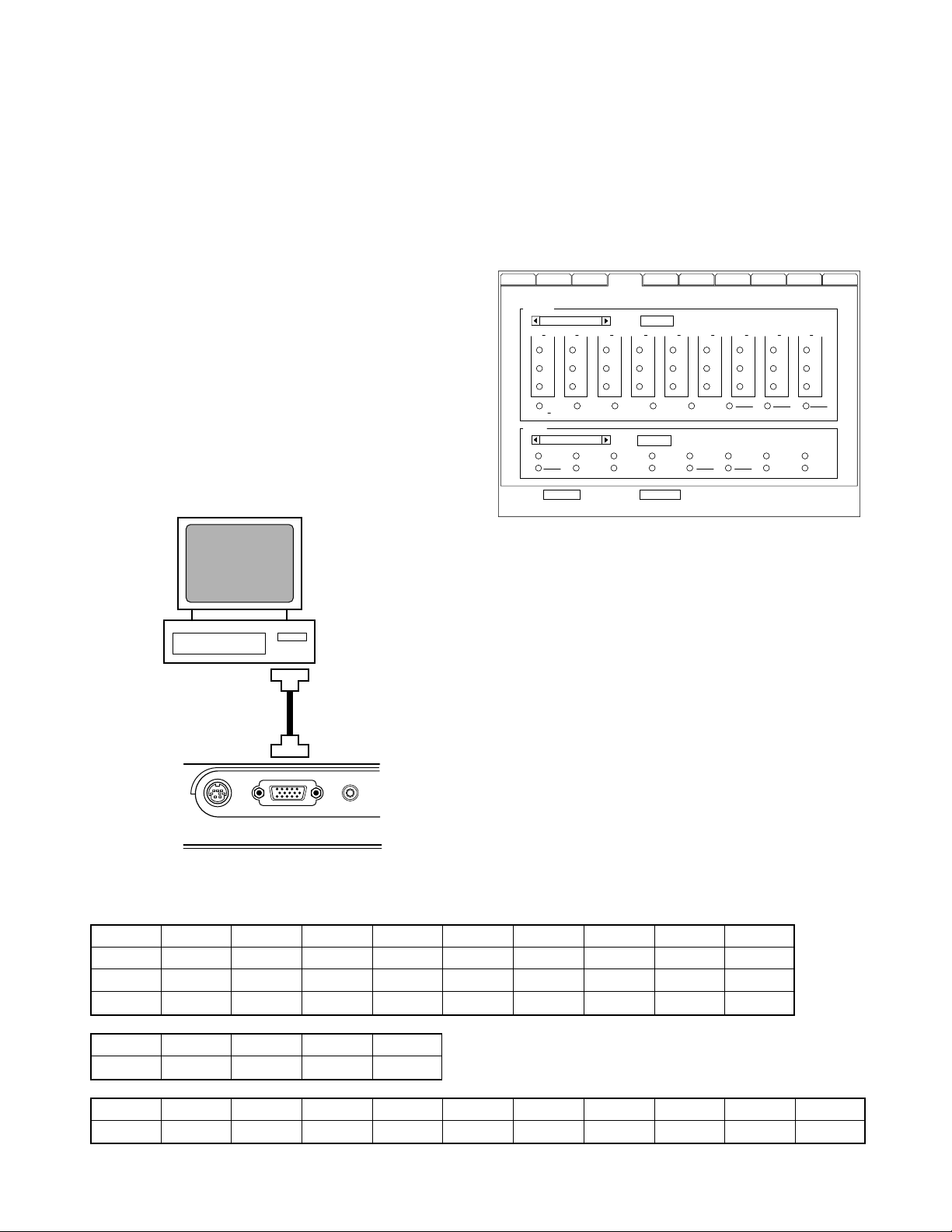

< Connection and Setting of Personal Computer >

(1) Connection of personal computer

1) Connect a computer as shown in Fig. 1-4-1, and

then perform the adjustment using the adjustment

software TLP65CTLS.EXE. (When using a drive C,

type C: ¥TLP65CTLS.EXE and press enter key.)

(2) Adjustment software usage

The electrical adjustment is carried out by using the

adjustment software. For the adjustment command items

in the adjustment procedures, set the command by

referring the following contents.

First, start the software and select the "Drive" tab. Then

the following display appears.

RS-232C

CONTROL

AMP_GAIN

R

G

B

DLY_CNT

W18

NRSH

WM0

GAM/TEST

W00

W01

W02

W19

CALR

WM1

RS-232C

Fig.1-4-1

AMP_BIAS

W03

W04

W05

POS_CONT1

W1A

BLKLIM

WM2

RGB AUDIO

MONITOR OUTPUT

GAM_WHP

W06

W07

W08

POS_CONT2

W1B

CLPLEV

WM3

GAM_B1P

W09

W0A

W0B

DIR/INV

W1C

BCOM

WM4

Fig. 1-4-2

The adjustment command setting enables to be carried

out by clicking radio button(s) on this screen. The

following list shows the adjustment command setting. By

referring to the list, set the adjustment command.

GAM_B2P

W0C

W0D

W0E

GCOM

WM5

GAM_WHG

W0F

W10

W11

RCOM

WM6

GAM_B1G

W12

W13

W14

SIGCEN

WM7

GAM_B2G

W15

W16

W17

NRSL

WM9

SUB_CONT

VGR

VGG

VGB

DIRX

WMA

1-11

DIRY

WMB

Page 14

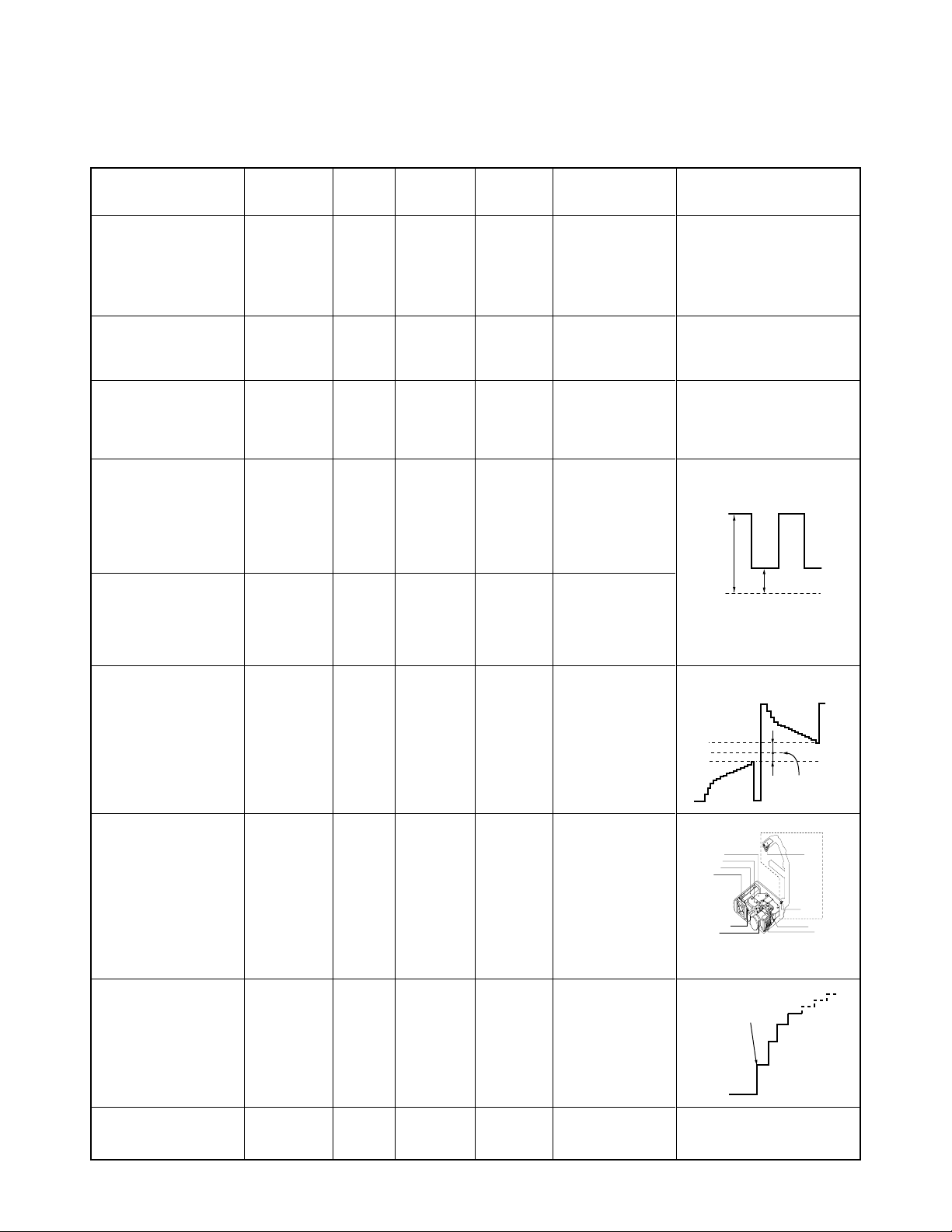

4-1. LCD Drive Adjustment

• Save the data in each step.

Adjust Items

1. Input level check

1-1. Input level

adjustment of

RGB signals

1-2. Input level

adjustment of

video signal

1-3. Input level

adjustment of

Y/Pb/Pr signal

2. NRS adjustment

2-1. Vertical stripe

adjustment

2-2. NRS level

confirmation

3. Center voltage

adjustment

Input Signal

16-stairstep

waveform

Gray scale or

stairstep

waveform

Gray scale or

stairstep

waveform

Window

signal with all

white 50% in

peripherals

and all black

at center.

Window

signal with all

white 50% in

peripherals

and all black

at center.

16-stairstep

waveform

Test

Equip-

ment

Oscillo-

scope

Oscillo-

scope

Oscillo-

scope

Oscillo-

scope

Oscillo-

scope

Oscillo-

scope

Table 1-4-1

Test Point

TP701 (R)

TP702 (G)

TP703 (B)

TP701

TP702

TP703

TP701 (R)

TP702 (G)

TP703 (B)

TP403 (R)

TP503 (G)

TP603 (B)

TP403 (R)

TP503 (G)

TP603 (B)

TP402 (R)

TP502 (G)

TP602 (B)

Adjust

mode

VGR

VGG

VGB

VGR

VGG

VGB

VGR

VGG

VGB

WM0

(WM9)

WM7

Adjust Value

• 1.2V ± 20 mV

between pedestal

and white level of

16th stairstep

waveform.

• 1.15V ± 20 mV

between pedestal

and white peak

level.

• 1.15V ± 20 mV

between pedestal

and white peak

level.

• Adjust so that the

vertical stripe

disappears.

Adjust at TP503.

• Confirm the base

level of the

amplitude should

be approx. 1.6V.

• Adjust for A = B

as shown in

illustration right.

( ) : confirmation only.

Note

• RGB input.

• Trigger the scope at TP901

(H period).

• Video input.

• Trigger the scope at TP901

(H period).

• Trigger the scope at TP901

(H period).

• Select “Y/Pb/Pr” in “RGB

input” on “Setting” menu of

the adjustment software.

B

GND

A

A = Approx. 1.6V

B = 5.5V to 8.0V

• Trigger the scope at TP901

(H period).

4. Gamma adjustment

4-1. RGB bias

adjustment

4-2. RGB black gamma

adjustment

4-3. Ghost adjustment

16-stairstep

waveform

16-stairstep

waveform

SMPTE signal

Oscillo-

scope

Oscillo-

scope

––––

TP402 (R)

TP502 (G)

TP602 (B)

TP402 (R)

TP502 (G)

TP602 (B)

––––

W03

W04

W05

W0C

W0D

W0E

(W1A)

• Adjust the 16th

stairstep waveform for following

values:

5.65 ± 20 mV

• Adjust the 2nd

stairstep waveform for following

values:

2.6V ± 20 mV

• If ghost is high,

adjust in W1A

mode.

A

B

7.0V DC

(center)

TLP451/651

E200 Optical Engine

B180 Lamp House

P800 Power Unit

Z101 Fan

P100 Thermal Lead Switch

Projection Lens

PC300 Camera

Unit Assembly

SC01 Arm Position

Detection Switch

LCD Block

Filter

• Trigger the scope at TP901

(H period).

2nd stairstep

1-12

Page 15

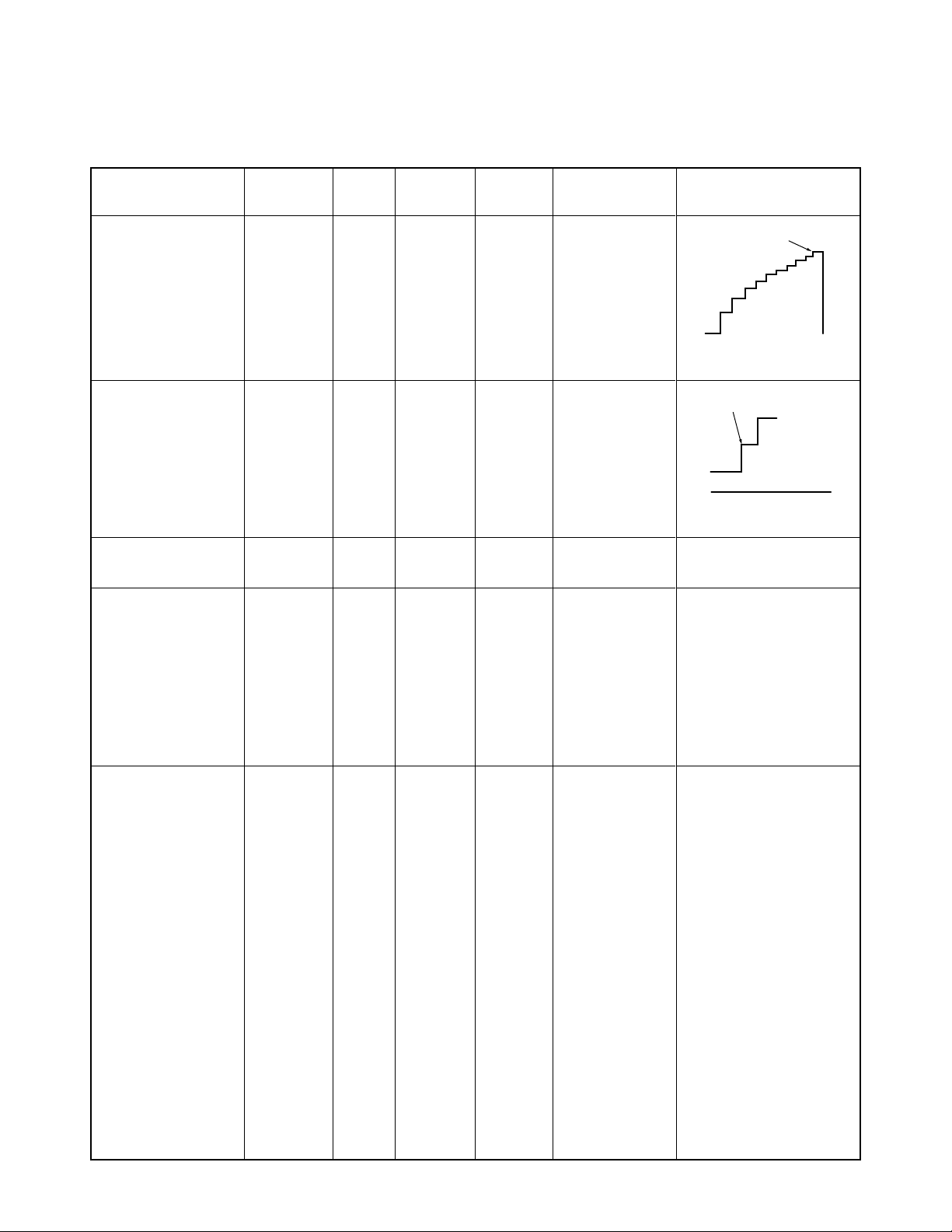

Table 1-4-2

Adjust Items

5. Gamma correction at

video input

5-1. Video bias

adjustment

5-2. Video black

gamma adjustment

5-3. Ghost adjustment

6. Common voltage

adjustment

6-1. Common voltage

adjustment 1

6-2. Common voltage

adjustment 2

Input Signal

10-stairstep

waveform

10-stairstep

waveform

Retma signal

Adjustment

signal

Adjustment

signal

Test

Equip-

ment

Oscillo-

scope

Oscillo-

scope

––––

Oscillo-

scope,

confirm

on the

screen.

Oscillo-

scope,

confirm

on the

screen.

Test Point

TP402 (R)

TP502 (G)

TP602 (B)

TP402 (R)

TP502 (G)

TP602 (B)

––––

––––

––––

Adjust

mode

W03

W04

W05

W0C

W0D

W0E

(W1A)

WM4

WM5

WM6

WM4

WM5

WM6

Adjust Value

• Adjust the 10th

stairstep waveform for following

values:

5.3 ± 20 mV

• Adjust the second

stairstep waveform for following

values:

2.75 ± 20 mV

• If ghost is high,

adjust in W1A

mode.

• Select “Standard”

in Projection

mode on “Setting”

menu.

• Adjust so that the

flicker for each R,

G, B signal

becomes

minimum.

• Invert Up/Down

contents

displayed on the

screen.

• Select “Rear

Ceiling” in

Projection mode

on “Setting”

menu.

• Adjust so that the

flicker for each R,

G, B signal

becomes

minimum.

• After adjustment,

click the standard

button (PJ0) on

the setting screen

and return to the

standard status.

Note

10th stairstep

• Trigger the scope at TP901

(H period).

Second stair step

• Trigger the scope at TP901

(H period).

1-13

Page 16

Table 1-4-3

Adjust Items

7. White balance

adjustment

Input Signal

All white 50%

signal

10-stairstep

video signal

16-stairstep

RGB signal

1. Lay the unit in a dark room and input all white 50% signal, video 10-stairstep signal or RGB 16-stairstep

signal.

2. Affix the standard white board WS-2 on the top center of screen, or suspend it adjacent to the screen

from above.

3. Set the color luminance meter (BM-5) with more than 30 min. heat-run operation performed, so that color

temperature on the WS-2 can be measured.

4. Measure the color temperature by using the BM-5 and adjust with W03 and W05 in the adjustment menu

to obtain the value within the range of X = 0.285 ± 0.01 and Y = 0.310 ± 0.01.

Adjustment standard

a. Adjust Y by using in W05 mode.

b. Adjust X by using in W03 mode.

Color temperature: 8500

duv...less than 0.005

Test

Equip-

ment

Color

lumi-

nance

meter

(BM-5)

Test Point

Shown

below

Adjust

mode

W03

W04

W05

Adjust Value

• Shown below.

Note

8. White level adjustment at RGB input

5. Input all white 100% signal.

Measure the luminance and the color temperature and record them.

6. Perform the steps 1 to 4 for the video input.

7. Enter 16 steps at RGB input and 10 steps at Video input. Then check the color temperature on black

side and adjust W0C and W0E if required. (Adjustment range should be within ±3 steps.)

Window

signal with

center 98%

and periph-

eral 100%.

–––– –––– W03

W04

W05

• Adjust W03, W04

and W05 in the

same way

(modifying the

same data

amount) so that

98% white

appears a little.

1-14

Page 17

30

°

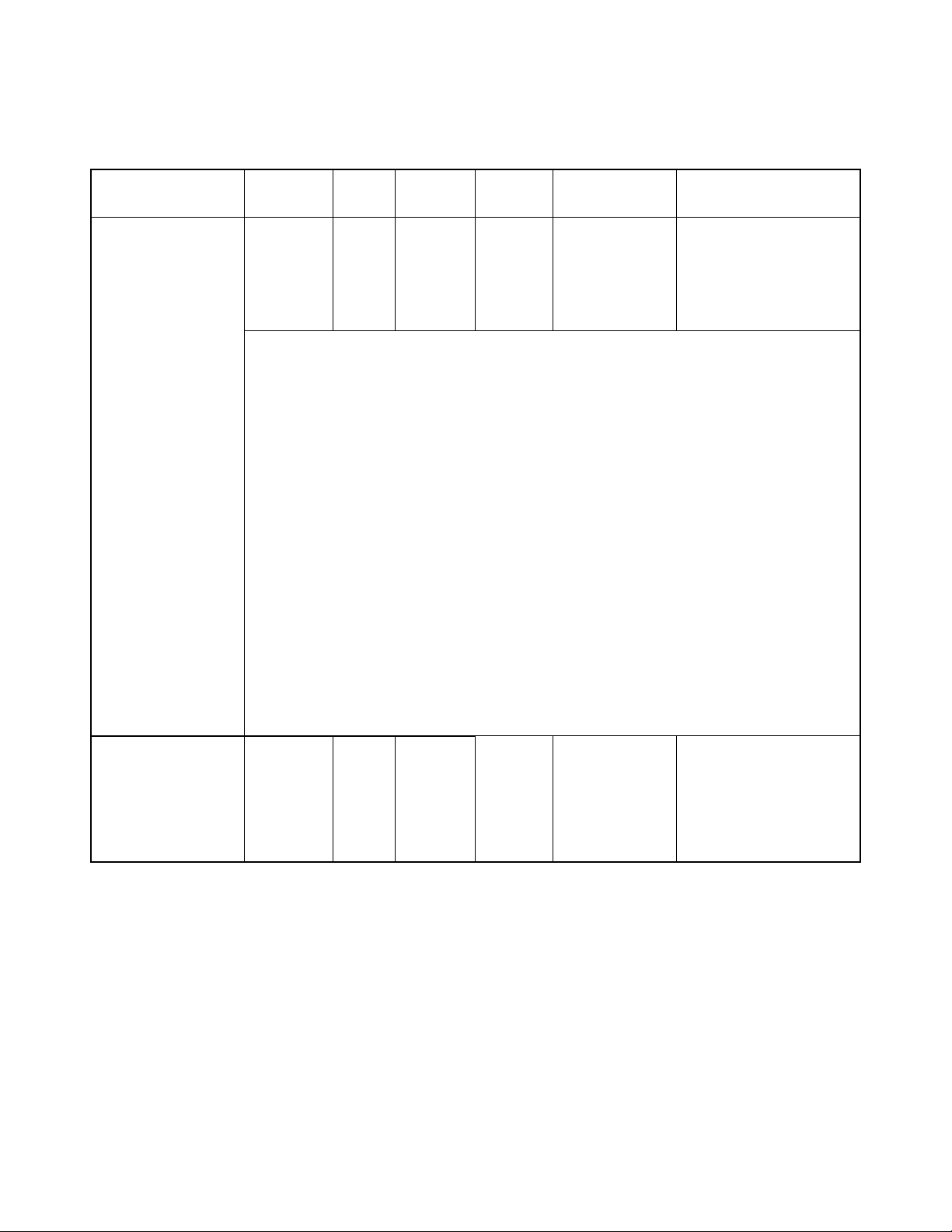

• Perform the following adjustment when replacing the main PC board (PB9061) and/or the microprocessor QXXX.

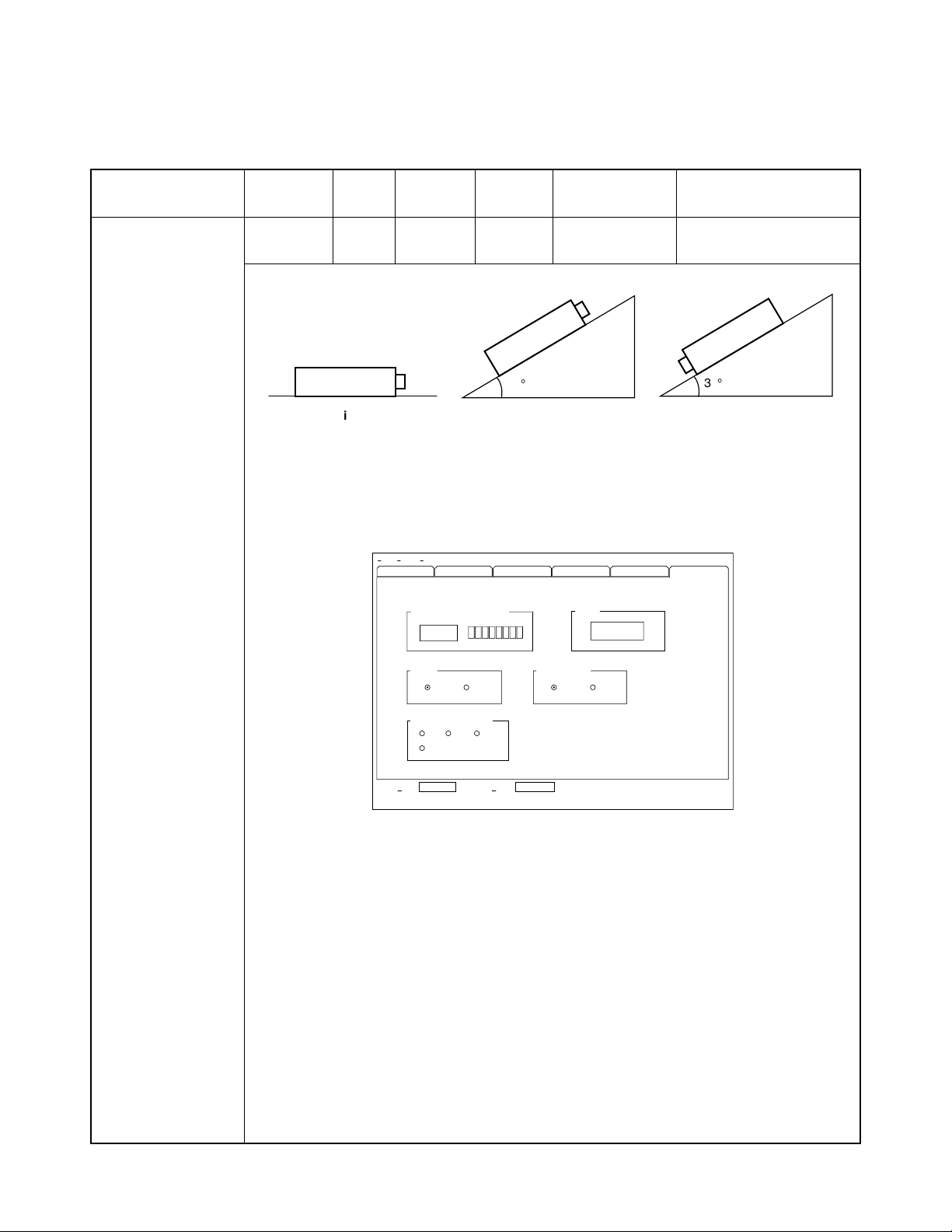

Table 1-4-4

Adjust Items

9. Slantness sensor

correction data

setting

Input Signal

––––

Test

Equip-

ment

––––

Test Point

––––

Adjust

mode

––––

30

°

Adjust Value

––––

Note

Fig. 1 Fig. 2 Fig. 3

1. Leave the unit for more than 3 hours to cool down enough.

2. Connect TLP450/451/650/651 to a personal computer by using a RS-232 cable. Set TLP450/451/650/

651 in the standby status.

3. Start the slantness sensor correction data setting software (menu) on the personal computer.

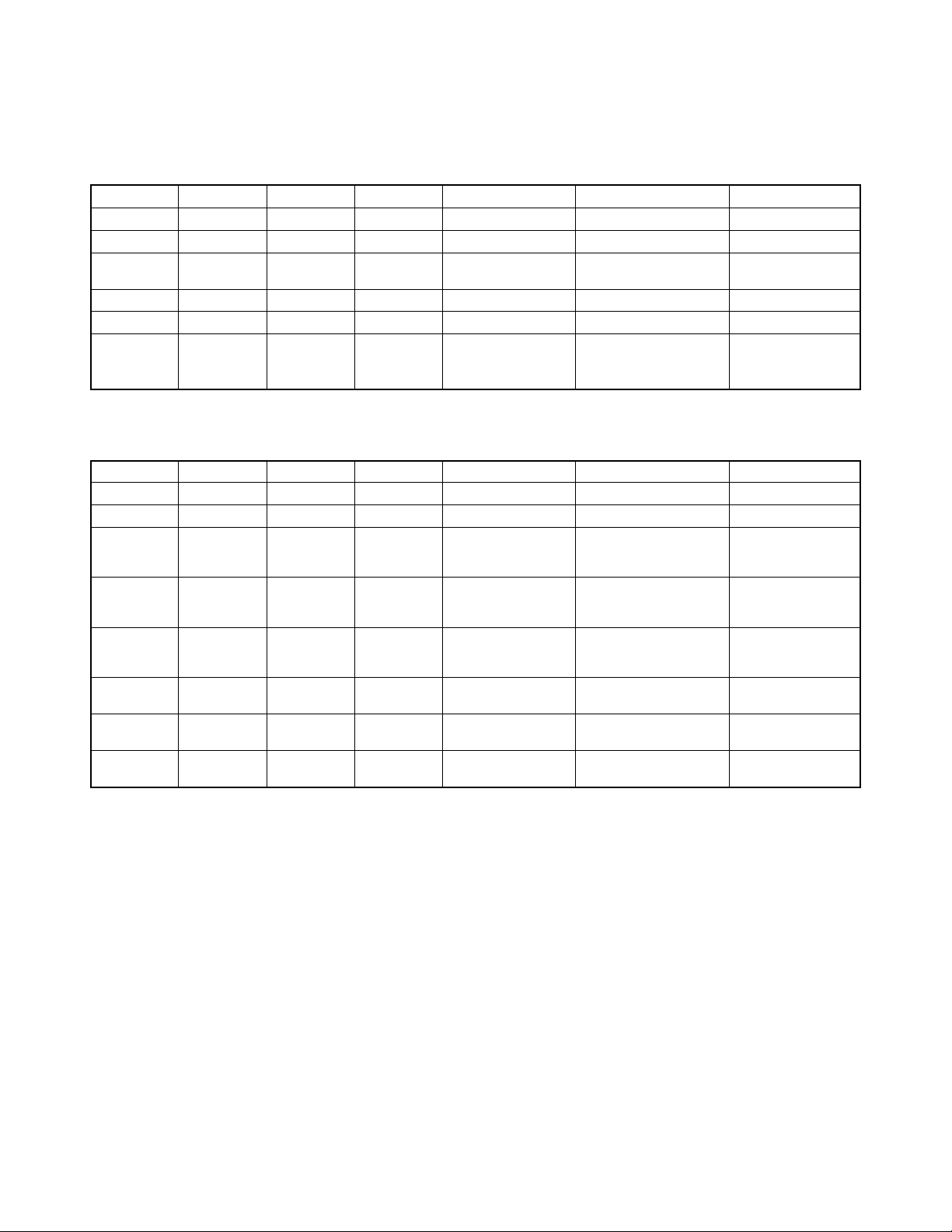

P

Save Help

ort

Normal

Special

Adjust

All data read (X command) Timer

Read

Setting Drive Data Read

Initialize

Special

Send CMD

Option

Off

On Off On

Keystone format (Deg)

0

+30 -30

0 (High-temp)

Receive CMD

TOSHIBA logo

Fig. 4

4. Place TLP450/451/650/651 to be adjusted horizontally on a flat table and click “0” of keystone format

(Deg) on the menu and store the data at the horizontal position. (Refer to Fig. 1.)

5. Place TLP450/451/650/651 to be adjusted on a table with 30 degrees slanted and its projection lens

directed upward. Then click “+30” of keystone format (Deg) on the menu and store the data of +30

degrees position. (Refer to Fig. 2.)

6. Place TLP450/451/650/651 to be adjusted on a table with 30 degrees slanted and its projection lens

directed downward. Then click “–30” of keystone format (Deg) on the menu and store the data of –30

degrees position (Refer to Fig. 3.). At this time, the data is written on the flash ROM of the TLP450/

451/650/651.

7. After heat-running for more than 1 hour with the power turned on, place TLP450/451/650/651 horizontally

and click “0 (High-temp)” of keystone format (Deg) to save the horizontal position data at high temperature.

8. Stretch the height adjusting legs on the front side of TLP450/451/650/651 fully, turn on the projector and

start projecting on the screen.

Adjust the focus roughly and push the automatic keystone button on the remote controller. Check to see

the image projected is more rectangular with less trapezoidal in comparison with the shape before

pushing the keystone button.

1-15

Page 18

5. LED DISPLAY

X: Lighting off, Color: Contents shown by lighting in the color, (Color): Contents shown by blinking in the color

Table 1-5-1 Normal operation

Status

Normal

Normal

Normal

Normal

Normal

Normal

Status

Error

Error

Error

Error

Error

Error

Error

Error

Power

Orange

Green

Green

Green

Orange

Orange

Power

Red

Red

Red

Red

Red

Red

Red

Red

Lamp

X

X

(Green)

Green

Green

(Green)

Lamp

X

Red

Orange

X

X

X

X

X

Temp

X

X

X

X

X

X

Contents

Standby status

Power on

Lamp is heating up.

Lamp lighting

Power off

Lamp is cooling

down.

Table 1-5-2 Error operation

Temp

X

X

X

(Red)

(Orange)

(Green)

Red

Orange

Contents

Main power error

Lamp not lighting

Lamp fan stop

Suction fan stop

Exhaust fan stop

Filter open

Temperature sensor

1 abnormality

Temperature sensor

2 abnormality

Remarks

At normal power off

Various power on

Lamp power is being

confirmed.

At normal power on

Various power off

For approx. 1 min.

(Impossible to light on

again.)

Remarks

Only at power on.

Only at power on.

Only at power on.

Only at power on.

Only at power on.

Only at power on.

Only at power on.

Only at power on.

Additional notice

Additional notice

Operation is carried

out below 30 °C in the

old control.

Operation is carried

out below 30 °C in the

old control.

Operation is carried

out below 30 °C in the

old control.

Not used in the

current control.

1-16

Page 19

SECTION 2

TWEEZERS

SERVICING DIAGRAMS

1. PART CONFIGURATION AND THEIR SYMBOLS

1-1. Replacing Subminiature "CHIP" Parts

1-1-1. Required Tools:

1. Fine tipped, well insulated soldering “pencil”, about

30 Watts.

2. Tweezers.

3. Blower type hair dryer.

1-1-2. Soldering Cautions:

1. Do not apply heat for more than 3s.

2. Avoid using a rubbing stroke when soldering.

3. Discard removed chips; do no reuse them.

4. Supplementary cementing is not required.

5. Use care not to scratch or otherwise damage the chips.

1-1-3. Removal (Resistors, Capacitors, etc.):

1. Melt the solder at one side.

1-1-4. Removal (Transistors, Diodes, etc.):

1. Melt the solder of one lead.

Fig. 2-1-4

2. Lift the side of that lead upward.

Fig. 2-1-5

3. Simultaneously heat solder the two remaining leads

and lift part to remove.

SERVICING DIAGRAMS

SECTION 2

Fig. 2-1-1

2. Grasp the part with tweezers and melt the solder at the

other side.

TWEEZERS

Fig. 2-1-2

3. Remove the part with a twisting motion.

Fig. 2-1-6

1-1-5. Preheating (Except for semiconductors):

Immediately before installing new resistors or capacitors,

use a blower type hair dryer and preheat the part for about

two min. at approximately 150°C.

1-1-6. Replacement:

1. Presolder the contact points of the circuit pattern.

Fig. 2-1-7

2. Press the part downward with tweezers and apply the

soldering pencil as indicated in the figure.

TWEEZERS

Fig. 2-1-3

2-1

Fig. 2-1-8

Page 20

1-2. Precautions for Part Replacement

100k

Rated Wattage Type Tolerance

100µ

Temperature

response

Rated

voltage

Tolerance

• In the schematic diagram, parts marked (ex.

F801) are critical part to meet the safety regulations,

so always use the parts bearing specified part codes

(SN) when replacing them.

1-3. Solid Resistor Indication

Unit None ........... Ω

k ...........kΩ

M ........... MΩ

Tolerance None ........... ±5%

B ........... ±0.1%

C ........... ±0.25%

D ...........±0.5%

F ...........±1%

G ...........±2%

K ...........±10%

M ........... ±20%

Rated Wattage (1) Chip Parts

None .........1/16W

(2) Other Parts

None .........1/6W

Other than above, described in the Circuit Diagram.

Type None ........... Carbon film

S ...........Solid

R ........... Oxide metal film

W ........... Metal film

W ........... Cement

FR ...........Fusible

• Using the parts other than those specified shall

violate the regulations, and may cause troubles such

as operation failures, fire etc.

Fig. 2-1-9

1-4. Capacitance Indication

Symbol

Unit None ........... F

Rated voltage None ........... 50V

Tolerance (1) Ceramic, plastic, and film capacitors of which

Temperature characteristic None ........... SL

(Ceramic capacitor) For others, temperature characteristics are

+

........... Electrolytic, Special electrolytic

NP

........... Non polarity electrolytic

........... Ceramic, plastic

M

........... Film

........... Trimmer

µ ........... µF

p ...........pF

For other than 50V and electrolytic capacitors,

described in the Circuit Diagram.

capacitance are more than 10 pF.

None ........... ±5% or more

B ........... ±0.1%

C ........... ±0.25%

D ...........±0.5%

F ........... ±1%

G ...........±2%

(2) Ceramic, plastic, and film capacitors of which

capacitance are 10 pF or less.

None ........... more than ±5% pF

B ........... ±0.1 pF

C ........... ±0.25 pF

(3) Electrolytic, Trimmer

Tolerance is not described.

described. (For capacitors of 0.01 µF and

no indications are described as F.)

Fig. 2-1-10

2-2

Page 21

1-5. Inductor Indication

Unit None ........... Η

µ ........... µH

m ........... mH

Tolerance None ........... ±5%

B ........... ±0.1%

C ........... ±0.25%

D ........... ±0.5%

F ........... ±1%

G ........... ±2%

K ........... ±10%

M ........... ±20%

Type PL ........... Peaking

For other, model name is described.

1-6. Waveform and Voltage Measurement

• Measurement of waveform and voltage at each

section in the color circuits was conducted with

sufficient service color bar signal being received and

reproduced in normal conditions.

• Waveforms and voltage values for the remaining

circuit were measured with a broadcasting signal

normally received, so they may vary slightly accord-

ing to the programs being received. Use them as a

measure for servicing.

• All voltage values except the waveforms are ex-

pressed in DC and measured by a digital voltmeter.

10µ

Type Tolerance

Fig. 2-1-11

2-3

Page 22

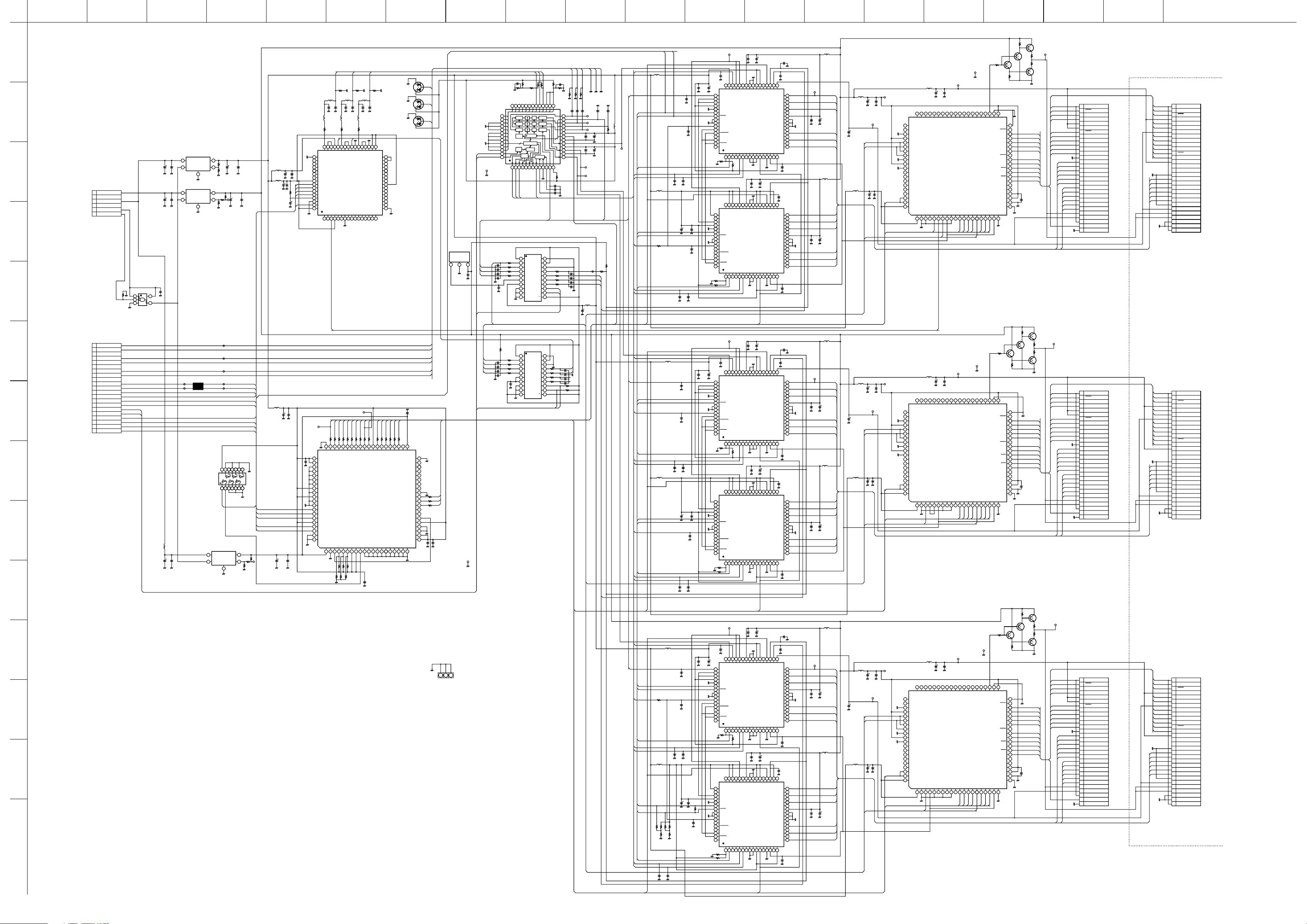

2. EACH SIGNAL FLOW

2-1. Operation at RGB Signal Input

The RGB signal is entered from PB001 on the RGB PC

board and sent to the main PC board after passing

through the MUTE circuit and the low pass circuit. The

low pass circuit is provided to prevent a moire from

occurring when the real sampling operation is not

executed. Usually, a selector selects a signal not passed

through the low pass filter, but selects the signal passed

through the low pass filter since the real sampling is not

carried out for a signal higher than SXGA85 Hz. The

RGB signal entered passes through a buffer and develops

PB003.

In the main PC board, the RGB input signal is converted

to a digital signal in A/D+PLL (QD300). The A/D

converter is used in the parallel mode, so the output

becomes 16 bits per 1 channel and its clock rate is a half

of the sampling clock. The digital RGB signal is enlarged

or reduced by the scaller (QD500) and converted into a

format of fv=60Hz, panel resolution (TLP65x: 1024 x

768, TLP45x: 800 x 600). The scaller output signal is a

RGB signal of 10 bits per 1 channel, converted into the

analog signal by the D/A converter and fed to the drive

circuit. The scaller (QD500) also performs the contrast/

brightness control and keystone correction in addition to

the enlargement or reduction process for the video signal

entered.

The clock signal for the input system is generated in the

A/D+PLL (QD300) and that for LCD panel drive system

is in the 2nd PLL (QD402) circuit.

In the drive circuit, the pre-driver circuit amplifies the

signal and performs a gamma correction. The correction

signal sent from the color uniformity correction IC

(Q971) enters the BIAS control terminal of the pre-driver

(Q701) and the color uniformity is corrected by entering

the correction signal corresponding to the screen position

of the input signal. The signal corrected in the gamma is

inverted its polarity and sampled & held in six phase

signals by the sample & hold IC (Q401, Q501, Q601) and

then fed to the LCD panel. The XGA panel used for

TLP650/651 employs 12 phase driving system, so two

sample & hold ICs are used per one channel. (Since

TLP450/451 employs 6 phase driving system, one

sample & hold IC is used per one channel.)

The panel driving timing signal is generated in the

timing generator IC (Q203) with a clock signal and HD/

VD signal supplied from the digital circuit. The Up/Down

and Left/Right display inversion on the LCD panel (for

ceiling mounting and rear projection status) is carried out

by changing the timing signal generated by the timing

generator. The timing signal used for this LCD panel

requires a 15V in the amplitude, so the signal is con-

verted into the timing signal of 15V amplitude by the

level shifter and drives the LCD panel. The drive circuit

operation is carried out in the same way regardless of the

kinds of input signals. So the operation description for

other input signals is omitted.

2-2. Video Signal

The video signals, S-video and composite video signals,

are sent to the main PC board in passing through the

input PC board through the connector and the buffers.

The signal sent to the main PC board enters the video

decoder IC (QD200) and the decoder develops 8 bit

signal (27 MHz clock) multiplexed with the Y/Cb/Cr

components. The signal switching between S-video and

composite video signals is carried out by a selector built-

in the video decoder. The Y/Cb/Cr signal input for the

scaller IC are 8 bit Y signal + 8 bit Cb/Cr signal. The 8 bit

Y/Cb/Cr signal (27 MHz) in QD405 is converted into a

16 bit Y signal + Cb/Cr signal (13.5 MHz) and enters the

scaller IC. In the scaller IC, the digital matrix circuit

converts the Y/Cb/Cr signal into the R/G/B signals.

After that, the signal process is carried out in the same

way as those for the RGB signal input. That is, the key

stone correction, enlargement/reduction process and

contrast/brightness control are carried out and fed to the

drive circuit.

The process relating to the sync is also carried by the

video decoder IC and the clock signal for input system is

also generated.

Furthermore, when the video signal of fv=50Hz, such as

PAL signal, etc. enters, the panel drive operation is

carried out by using the signal of fv=50Hz.

2-4

Page 23

2-3. Operation at Y/Pb/Pr Signal and

HDTV Signal Input

Y/Cb/Cr signal (DVD player output) or HDTV signal

enters from PB001 and reaches the A/D converter

(QD100) for Y/Cb/Cr (Y/Pb/Pr) signal after passing

through the low pass circuit. The A/D converter develops

16 bit signal of 8bit Y signal + 8bit Cb/Cr (Pb/Pr) and

enters the scaller IC through the selector for the signal

and that from the video decoder inside QD405. The

process following to the scaller IC is the same as that of

the video signal process.

The process relating to the sync process at Y/Cb/Cr signal

(DVD player output) input (clock generation) is carried

out by the video decoder and the clock generation at

HDTV signal input is by the A/D+PLL (QD300).

2-4. Camera Input Operation

A camera input enters the A/D converter for Y/Cb/Cr (Y/

Pb/Pr) signal through an exclusive connector and is

processed as a Y/Cb/Cr signal input. The camera signal is

a Y/Cb/Cr signal of fh=11.8 kHz and fv=15 Hz.

The clock generation is carried out in the A/D+PLL

(QD300).

2-5. Camera Overlay Signal

The camera overlay signal usually enters the A/D

converter for Y/Cb/Cr signal (Y/Pb/Pr) through an

exclusive connector in the same way as that of camera

input.

The A/D converter output enters QD405 and the red and

blue components of the signal are extracted by the level

slice circuit. Thus processed signal is converted into the

signal synchronizing with the LCD panel output timing

by using a memory (QD46). Then the signal is over-

lapped with the on-screen signal and the signal over-

lapped is fed to the on-screen signal input of the scaller

IC, and overlapped with the main video output signal. At

this time, the clock generation for overlay signal input

system is carried out by the PLL circuit exclusive for the

overlay.

As described above, the A/D converter for Y/Cb/Cr (Y/Pb/

Pr) signal is used for the overlay signal input, so the

signal which is usually processed by the A/D converter

for Y/Cb/Cr (Y/Pb/Pr) signal, that is, Y/Cb/Cr signal (DVD

player output), cannot be overlaid at the HDTV signal

input.

2-5

Page 24

This page is not printed.

2-6

Page 25

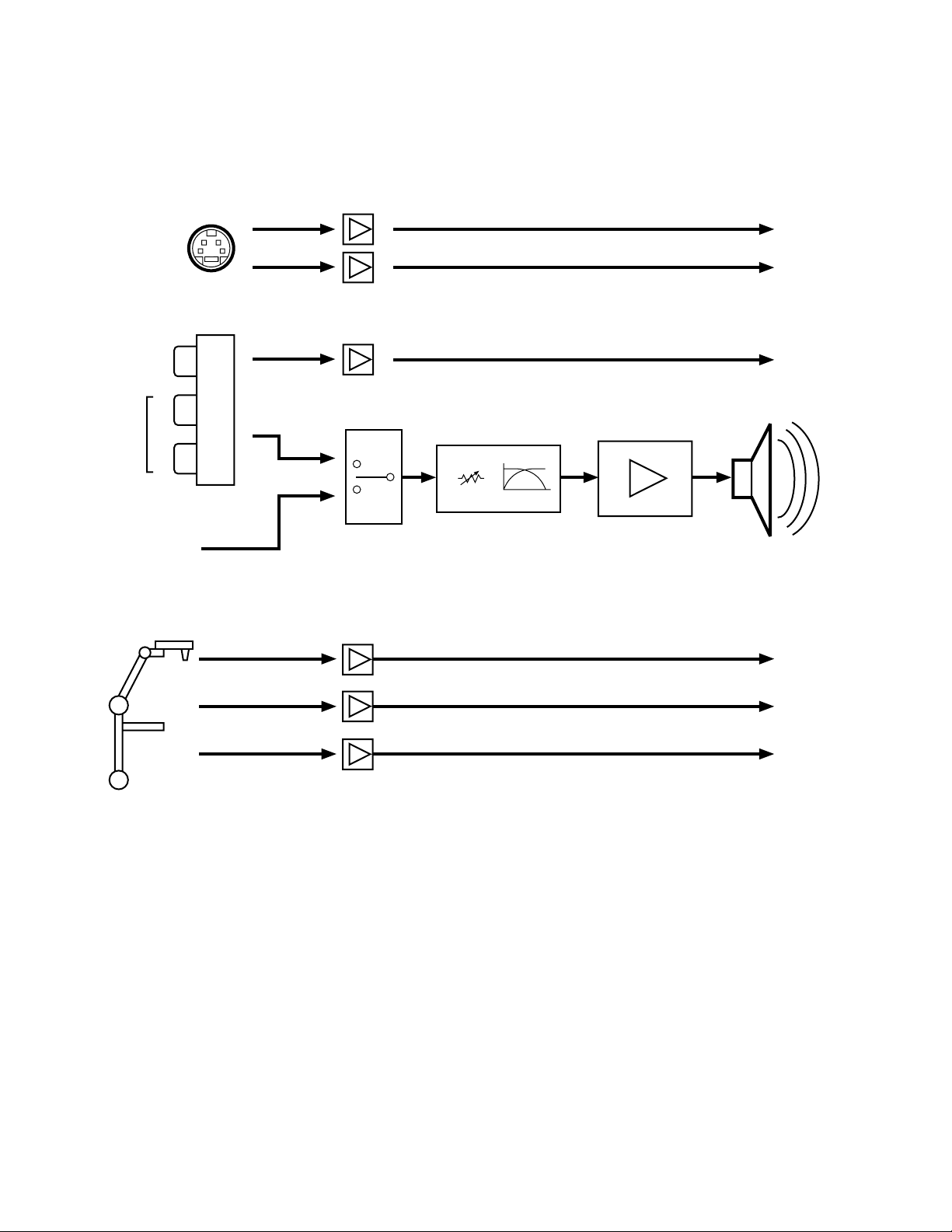

3. BLOCK DIAGRAMS

3-1. RGB Block Diagram

RGB In

(PB001)

RGB Out

(PB003)

Sound in

(PB002)

QB005

Buffer

HD, VD

G Channel only

QB001-3

Mute

QB017

Interface

QB016

Sync

Process

Low Pass Filter

Sync Status

HD, VD

Control Bus

QB008

Selector

QB007

Selector

QB026

Selector

Video Sisnal

HD,VD

RGB out

(To Main)

YPbPr/YUV out

(To Main)

Camera in

(From Input)

Camera

Sync out

(To Main)

Main Sync out

(To Main)

Control Bus

Sound out

(PB004)

RS-232C

(PB007)

Fig. 2-3-1

2-7

Page 26

3-2. Input Block Diagram

Audio

Video

S-Video

S-Y

S-C

QA01

QA02

QA03

Video

QA06

Selector

QA09

Vol. & Tone

QA10

Power Amp

Speaker

To main board

To main board

QA14

QA15

QA16

(Emitter Follower)

Y

Cb

Cr

Camera

Audio (PC)

from RGB board

Fig. 2-3-2

2-8

Page 27

3-3. Main Block Diagram

3-3. Digital Block Diagram

Video

S - Video

Camera

HDTV

DVD

RGB

SYNC

QL020

TEMP SENSOR

QL021

TEMP SENSOR

24.567 MHz

QD200

VIDEO

DECODER

QD100

A/D

(YPbPr)

Overlay Clock

Video Clock

EXT Clk in

QD300

A/D+PLL

(RGB)

Control BUS Signals

Video Data (8bit)

YPbPr Data (16bit)

Camera, HDTV, DVD

Main Clock (input)

RGB Data (48bit)

ZD004

80MHz OSC

QD407

PLL for

Overlay

QD405

Timing GEN

Timing Generator

Data SW(YUV/YPbPr)

Form Convert(8bit 16bit)

Overtay Control

Tilt Sensor interace

Camera, HDTV, DVD, Vide o

YUV/Ypbpr Data (16bit)

QD500

SCALER

Enlarge Shrink

YUV RGB convert

Contrast Bright Control

Keystone Cortect

QD501-3

SD-RAM (16M)

QD406

Memory for

Overlay

QD001

Tilt

Sensor

QD401

OSD

GEN

QD402

2nd

PLL

HD, VD for LCD Panel

Panel Clock (TTL)

65X:65MHz 45X:40MHz

RGB Data (30bit)

QD600

D/A

RGB Signal

Q203

Timing GEN

for LCD

Panel Clock (PECL)

65X:32.5MHz 45X:40MHz

Q971

Shading

Correct

Q701

Pre-Driver

Gamma

Amp

1H 1H

Timing Signal for LCD Panel

Q407

Timing Signal

Level Shift

5V 15V

Q401, (402)*

Sample & Hold

Invert

Q507

Timing Signal

Level Shift

5V 15V

Q501, (502)*

Sample & Hold

Invert

Q607

Timing Signal

Level Shift

5V 15V

Q601, (602)*

Sample&Hold

Invert

1H

RED

Panel

GREEN

Panel

BLUE

Panel

Video signal

(Y/Pb/Pr 8bit)

Y/Pb/Pr, HDTV signal

(Y,Pb/Pr 16bit)

RGB signal

(Each RGB 16bit : 48bit)

8bit 16bit

conv.

Various kinds of

timing signal

generation circuit

Y, Pb/Pr 16bit

Y/Pb/Pr RGB

Digital matrix

Level

slice

PLL circuit for

overlay

Overlay signal

process

On-screen

signal

process

On-screen signal

superimposing

QD406

Memory

On-screen

character

generation

circuit

QD401

QD500

RGB signal

(Each RGB 10bit : 30bit)

KEY SWITCH

LED

REMOTE

CONTROL

RECEIVER

(FRONT/REAR)

I/F

QL005

MICRO

CONTROLLER

QL018

RAM

QL011

EEPROM

POWER

ON

QL015

RS232C

INTERFACE

QL016

RS232C

INTERFACE

LAMP ON CAMERA

UNIT

EXTERNAL

CONNECTOR

PF006

PF014

11V

7V

QF001

FAN CONTROL

QF003

FAN CONTROL

OPTICAL

ENGINE FAN

LAMP FAN

EXHAUST

FAN

INTAKE FAN

Fig. 2-3-3

Keystone

correction

Contrast / Brightness

control

Enlargement / Reduction

process

Memory

QD501-3

Fig. 2-3-4

Page 28

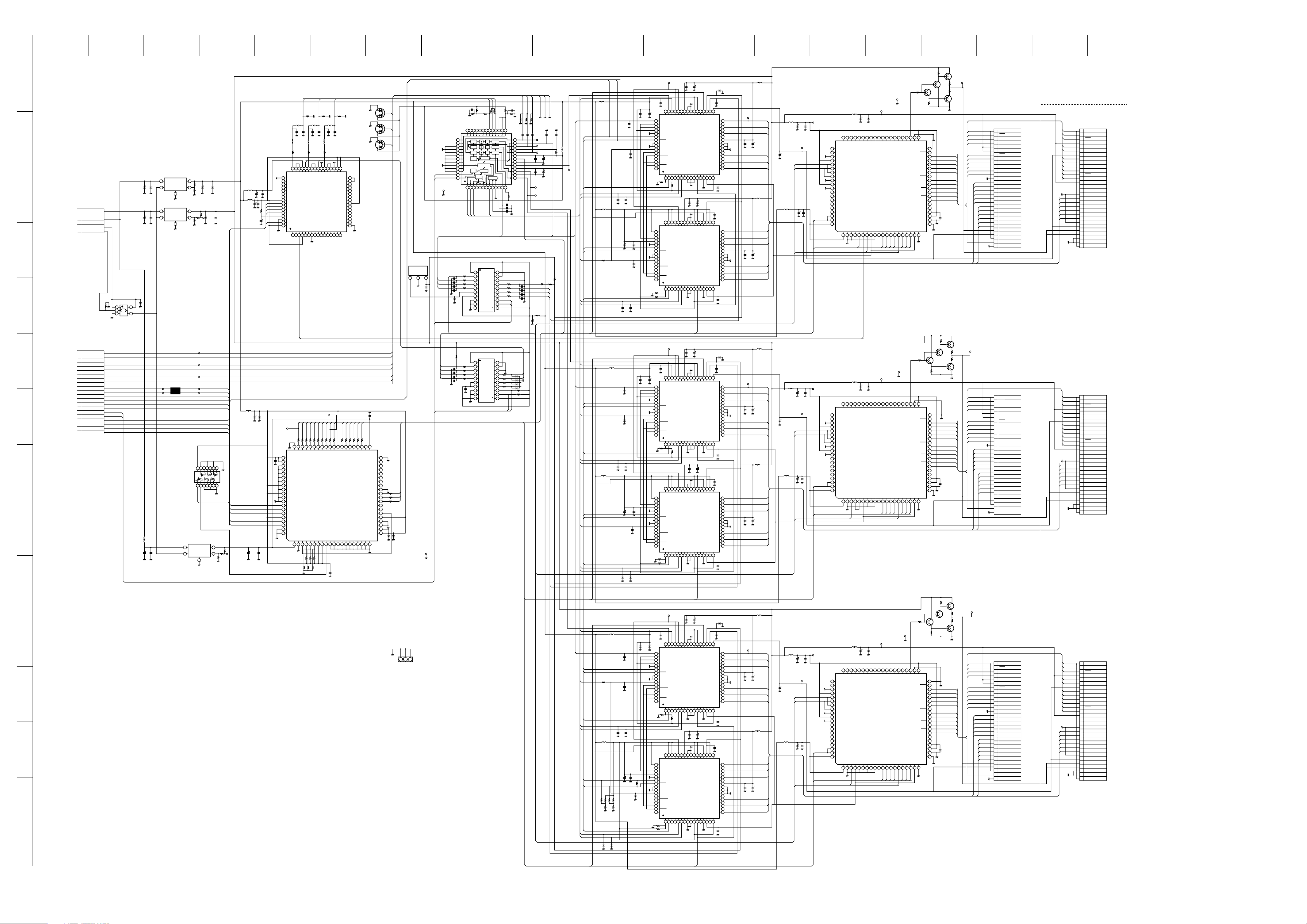

4. PRINTED WIRING BOARD AND SCHEMATIC DIAGRAM

UHP-LAMP

THERMAL-SW

LCD-R

LCD-G

LCD-B

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

P401

16

DY

-CLY

CLY

NRG

VDDY

VDDX

-CLX

CLX

DX

ENB2

ENB1

DIRX

VSSX

VID1

VID2

DY

-CLY

CLY

NRG

VDDY

VDDX

-CLX

CLX

DX

ENB2

ENB1

DIRX

VSSX

VID1

VID2

DY

-CLY

CLY

NRG

VDDY

VDDX

-CLX

CLX

DX

ENB2

ENB1

DIRX

VSSX

VID1

VID2

for for

VID3

17

VID4

18

VID5

19

VID6

20

VID7

21

VID8

22

VID9

23

VID10

24

VID11

25

VID12

26

NRS

27

LCCOM

28

DY

29

DIRY

30

VSSY

P501

16

VID3

17

VID4

18

VID5

19

VID6

20

VID7

21

VID8

22

VID9

23

VID10

24

VID11

25

VID12

26

NRS

27

LCCOM

28

DY

29

DIRY

30

VSSY

P601

16

VID3

17

VID4

18

VID5

19

VID6

20

VID7

21

VID8

22

VID9

23

VID10

24

VID11

25

VID12

26

NRS

27

LCCOM

28

DY

29

DIRY

30

VSSY

TLP650/651 TLP450/451

1

DY

2

CLY

3

-CLY

4

VDDY

5

NRG

6

DIRY

7

LCCOM

8

ENB1

9

ENB2

10

DIRX

11

CLX

12

-CLX

13

DX

14

VDDX

15

N.C.

1

DY

2

CLY

3

-CLY

4

VDDY

5

NRG

6

DIRY

7

LCCOM

8

ENB1

9

ENB2

10

DIRX

11

CLX

12

-CLX

13

DX

14

VDDX

15

N.C.

1

DY

2

CLY

3

-CLY

4

VDDY

5

NRG

6

DIRY

7

LCCOM

8

ENB1

9

ENB2

10

DIRX

11

CLX

12

-CLX

13

DX

14

VDDX

15

N.C.

P402

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

P502

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

P602

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

N.C.

VSSX

VID1

VID2

VID3

VID4

VID5

VID6

VSSX

LCCOM

NRS1

NRS2

VSSY

VSSY

DY

N.C.

VSSX

VID1

VID2

VID3

VID4

VID5

VID6

VSSX

LCCOM

NRS1

NRS2

VSSY

VSSY

DY

N.C.

VSSX

VID1

VID2

VID3

VID4

VID5

VID6

VSSX

LCCOM

NRS1

NRS2

VSSY

VSSY

DY

FLASH(WRITER)

GND

TXD

RXD

RES

VIN

VPP

MOD

GND

SEL

123456789

PL001

EXHAUST-FAN

+13.4V

FAN(G )

N.C.

123

PF001

PB9061

INTAKE-FAN

+13.4V

FAN(G )

123

PF002

U001

MAIN

LAMP-

INTAKE-FAN

N.C.

N.C.

4

+7V

123

PF003

U007

OPTICAL-

INTAKE-FAN

+11V

FAN(G )

N.C.

FAN(G )

12345

PF005

DIGITAL

DRIVE

MICON

FAN-CONTROL

SENCOR

N.C.

N.C.

SW1

1

PD004

SW2

2

PD001

1

S6V

2

S6V

3

S6V

4

S6V

5

S6V

6

S6V

7

GND

8

GND

9

GND

10

GND

11

GND

12

GND

13

S15V

14

S15V

15

GND

16

GND

S18V

17

S18V

18

19

GND

20

GND

-7V

21

GND

22

23

FAN-P OW ER

24

LAMP-POWER

25

GND

26

LAMP-ERROR

CN201

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

FAN-P OW ER

24

LAMP-POWER

25

26

LAMP-ERROR

S6V

S6V

S6V

S6V

S6V

S6V

GND

GND

GND

GND

GND

GND

S15V

S15V

GND

GND

S18V

S18V

GND

GND

-7V

GND

GND

CN202

1

LAMP-PW

2

GND

3

LAMP-ER

CN101

1

350V(LAMP)

2

1

LAMP-PW

2

GND

3

LAMP-ER

1

350V(LAMP)

2

GND

GND

LAMP-DRIVER

INTERLOCK-SW

SUB-DIGITAL

PB9268

1

2

3

P901

N.C.(GND)

N.C.(GND)

N.C.(GND)

MAIN-POWER

P800

APS-128A

AC-INLET

PC300

CAMERA-UNIT

CONTROL

AUDIO-OUTPUT

RGB-OUTPUT

AUDIO-INPUT

RGB-INPUT

PB007

PB004

PB003

PB002

PB001

S6V

S6V

GND

GND

GND

CAM-HD

6

2

Y

Y-G N DPBPB-GNDPRPR-GND

345

1

S6V

S6V

GND

10

789

111213

GND

GND

CAM-HD

10

PD003

PB005

PR

PB

Y

PR-GND

PB-GND

Y-G N D

123456789

11121314151617181920212223242526272829303132333435363738394041

U0021

PB9062-1

N.C.

N.C.

FWP

GND

GND

CAM-VD

24

22

18

14

GND

GND

GND

GND

GND

Y-SYNC

23

192021

151617

N.C.

N.C.

FWP

GND

GND

CAM-VD

GND

GND

GND

GND

GND

Y-SYNC

RGB

RXD232

R

252627

RXD232

R

N.C.

-7V

-7V

N.C.

RTS232

D-HD

373839

RTS232

D-HD

GND

GND

50

48

44

40

SDA

SCL

V.Y

V.C

+18V

S6V

S6V

S6V

GND

GND

MAIN-HD

MAIN-VD

STS-SCL

STS-SDA

49

454647

414243

PB006 PA03

+9V

N.C.

-7V

-7V

GND

44

42

GND

GND

MAIN-HD

MAIN-VD

4546474849

43

1

N.C.

GND

50

STS-SCL

STS-SDA

+9V

2

GND

3

GND

4

AUDIO/LOUT

5

GND

6

AUDIO/ROUT

7

GND

8

GND

9

RGB/LIN

10

GND

11

RGB/RIN

12

GND

13

GND

14

GND

15

GND

16

GND

17

CAMERA/Y

18

GND

19

CAMERA/B-Y

20

GND

21

CAMERA/R-Y

22

GND

23

CAMERA/H

24

GND

25

CAMERA/V

26

GND

27

GND

28

N.C.

29

N.C.

30

+9V

1

+9V

2

GND

3

GND

4

AUDIO/LOUT

5

GND

6

AUDIO/ROUT

7

GND

8

GND

9

RGB/LIN

10

GND

11

RGB/RIN

12

GND

13

GND

14

GND

15

GND

16

GND

17

CAMERA/Y

18

GND

19

CAMERA/B-Y

20

GND

21

CAMERA/R-Y

22

GND

23

CAMERA/H

24

GND

25

CAMERA/V

26

GND

27

GND

28

N.C.

29

N.C.

30

S6V

PD002

123456789

S6V

S6V

S6V

S6V

PA 0 5

123456789

INPUT(VIDEO)

+18V

GND

GND

GND

GND

GND

GND

GND

GND

101112131415161718192021222324252627282930

+18V

+18V

GND

GND

GND

GND

101112131415161718192021222324252627282930

U0022

PB9062-2

PA 0 1

CVBS

GND

GND

GND

GND

CAMERA-ON

CAMERA/TX

V.Y

V.C

CVBS

GND

GND

GND

GND

CAMERA-ON

CAMERA/TX

PA 0 2

S15V

N.C.

GND

GND

CAMERA/RX

REMOCON

CAMERA/RX

REMOCON

POWER-ON

PA 0 4

CAMERA/Y

1

GND

SDA

SCL

S15V

N.C.

GND

GND

POWER-ON

2

3

CAMERA/R-Y

CAMERA/B-Y

4

GND

5

CAMERA/V

6

CAMERA/H

7

N.C.(GND)

8

REMOCON REMOCON

9

GND

10

SDA SDA

11

GND

12

SCL SCL

13

GND

14

POWER-ON POWRE-ON

15

GND

16

CAMERA/RXD

17

S6V

18

CAMERA/TXD

19

S6V

20

21

CAMERA-ON

+18V

22

GND

23

S15V

24

GND

25

S15V

26

SP(+)

SP(-)

N.C.

PA 0 6

123

PH002

1

2

3

4

5

6

7

8

9

10

11

12

13

14

+18V

15

16

17

18

S15V

19

S15V

20

GND

GND

GND

GND

RXD

S6V

TXD

S6V

GND

N.C.(GND)

N.C.(+18V)

GND

GND

GND

GND

GND

TXD232

CTS232

36

32

28

G

B

R-GND

G-GND

B-GND

333435

293031

GND

GND

GND

TXD232

CTS232

G

B

R-GND

G-GND

B-GND

IK-K81LC

GND

GND

CAMERA/Y

CAMERA/R-Y

CAMERA/B-Y

CAMERA/V

P102

1234567

CAMERA/H

U0031

CAMERA

INTERFACE

PB9063-1

+9V

P101

12345

+9V

PH004

12345

TXD

GND

+4V

N.C.

6RXD

+4V

6

+13.5V +13.5V

1

GND GND

2

3

PH003

RXD

TXD

GND

GND

PH700

1

2

3

GNDGND

U0032

LED

PB9063-2

PH001

ARM-SW

1

GND

2

ARM-SW

S-VIDEO

CVBS

(For TLP451, TLP651)

Fig. 2-4-1

TLP650 WIRING

AUDIO-L

AUDIO-R

2-12 2-13 2-14

Page 29

A

B

C

D

E

F

G

H

J

K

L

M

N

123456789 1710 11 12 13 14 15 16 18 19 20

Q404

R409

100

2SC4116Y

42

41

DGND

ENBY2IN

DIRXIN

19

20

R509

100

2SC4116Y

42

41

DGND

ENBY2IN

DIRXIN

19

20

R609

100

2SC4116Y

42

41

DGND

ENBY2IN

DIRXIN

19

20

2SA1586Y

R410

Q405

3.3k

2SC3265Y

TP403

R412

3.3

R413

2SA1298Y

Q504

2SA1586Y

R510

3.3k

Q604

2SA1586Y

R610

3.3k

Q406

PDIRYR

PNRGR

PENBX1R

PENBX2R

PDIRXR

PDXR

PCLXR

PXCLXR

PCLYR

PXCLYR

PDYR

C438

0.1 `

Q506

2SA1298Y

PDIRYG

PNRGG

PENBX1G

PENBX2G

PDIRXG

PDXG

PCLXG

PXCLXG

PCLYG

PXCLYG

PDYG

C538

0.1 `

Q606

2SA1298Y

PDIRYB

PNRGB

PENBX1B

PENBX2B

PDIRXB

PDXB

PCLXB

PXCLXB

PCLYB

PXCLYB

PDYB

C638

0.1 `

3.3

Q505

2SC3265Y

R512

3.3

R513

3.3

Q605

2SC3265Y

R612

3.3

R613

3.3

PDYR

PXCLYR

PCLYR

PNRGR

PXCLXR

PCLXR

PDXR

PENBX2R

PENBX1R

PDIRXR

RVSIG1

RVSIG2

RVSIG3

RVSIG4

RVSIG5

RVSIG6

RVSIG7

RVSIG8

RVSIG9

RVSIG10

RVSIG11

RVSIG12

PDIRYR

P401

1

DY

2

CLY

3

CLY

4

NRG

5

VDDY

6

VDDX

7

CLX

8

CLX

9

DX

10

ENB2

11

ENB1

12

DIRX

13

VSSX

14

VID1

15

VID2

16

VID3

17

VID4

18

VID5

19

VID6

20

VID7

21

VID8

22

VID9

23

VID10

24

VID11

25

VID12

26

NRS

27

LCCOM

28

DY

29

DIRY

30

VSSY

PDYR

PCLYR

PXCLYR

PNRGR

PDIRYR

PENBX1R

PENBX2R

PDIRXR

PCLXR

PXCLXR

PDXR

RVSIG1

RVSIG3

RVSIG5

RVSIG7

RVSIG9

RVSIG1 1

P402

KETSU

1

DY

2

CLY

3

CLY

4

VDDY

5

NRG

6

DIRY

7

LCCOM

8

ENB1

9

ENB2

10

DIRX

11

CLX

12

CLX

13

DX

14

VDDX

15

N.C

16

N.C

17

VSSX

18

VID1

19

VID2

20

VID3

21

VID4

22

VID5

23

VID6

24

VSSX

25

LCCOM

26

NRS1

27

NRS2

28

VSSY

29

VSSY

30

DY

TP503

P502

PDYG

PXCLYG

PCLYG

PNRGG

PXCLXG

PCLXG

PDXG

PENBX2G

PENBX1G

PDIRXG

GVSIG1

GVSIG2

GVSIG3

GVSIG4

GVSIG5

GVSIG6

GVSIG7

GVSIG8

GVSIG9

GVSIG10

GVSIG11

GVSIG12

PDIRYG

P501

1

DY

2

CLY

3

CLY

4

NRG

5

VDDY

6

VDDX

7

CLX

8

CLX

9

DX

10

ENB2

11

ENB1

12

DIRX

13

VSSX

14

VID1

15

VID2

16

VID3

17

VID4

18

VID5

19

VID6

20

VID7

21

VID8

22

VID9

23

VID10

24

VID11

25

VID12

26

NRS

27

LCCOM

28

DY

29

DIRY

30

VSSY

PDYG

PCLYG

PXCLYG

PNRGG

PDIRYG

PENBX1G

PENBX2G

PDIRXG

PCLXG

PXCLXG

PDXG

GVSIG1

GVSIG3

GVSIG5

GVSIG7

GVSIG9

GVSIG11

KETSU

1

DY

2

CLY

3

CLY

4

VDDY

5

NRG

6

DIRY

7

LCCOM

8

ENB1

9

ENB2

10

DIRX

11

CLX

12

CLX

13

DX

14

VDDX

15

N.C

16

N.C

17

VSSX

18

VID1

19

VID2

20

VID3

21

VID4

22

VID5

23

VID6

24

VSSX

25

LCCOM

26

NRS1

27

NRS2

28

VSSY

29

VSSY

30

DY

TP603

BVSIG1

BVSIG3

BVSIG5

BVSIG7

BVSIG9

BVSIG11

P602

KETSU

1

DY

2

CLY

3

CLY

4

VDDY

5

NRG

6

DIRY

7

LCCOM

8

ENB1

9

ENB2

10

DIRX

11

CLX

12

CLX

13

DX

14

VDDX

15

N.C

16

N.C

17

VSSX

18

VID1

19

VID2

20

VID3

21

VID4

22

VID5

23

VID6

24

VSSX

25

LCCOM

26

NRS1

27

NRS2

28

VSSY

29

VSSY

30

DY

PDYB

PXCLYB

PCLYB

PNRGB

PXCLXB

PCLXB

PDXB

PENBX2B

PENBX1B

PDIRXB

BVSIG1

BVSIG2

BVSIG3

BVSIG4

BVSIG5

BVSIG6

BVSIG7

BVSIG8

BVSIG9

BVSIG10

BVSIG11

BVSIG12

PNRS1B

PDIRYB

P601

1

DY

2

CLY

3

CLY

4

NRG

5

VDDY

6

VDDX

7

CLX

8

CLX

9

DX

10

ENB2

11

ENB1

12

DIRX

13

VSSX

14

VID1

15

VID2

16

VID3

17

VID4

18

VID5

19

VID6

20

VID7

21

VID8

22

VID9

23

VID10

24

VID11

25

VID12

26

NRS

27

LCCOM

28

DY

29

DIRY

30

VSSY

PDYB

PCLYB

PXCLYB

PNRGB

PDIRYB

PENBX1B

PENBX2B

PDIRXB

PCLXB

PXCLXB

PDXB

Q403

R411

3.3k

VDD1

DGND

DIRY

DIRY

NRG

ENBX1

ENBX2

DIRX

DIRX

DX

CLX

CLX

CLY

CLY

DY

ENBY1

ENBY2

25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

VDD2

VDD2

DGND

21 22 23 24

ENBY1IN

Q503

R511

3.3k

VDD1

DGND

40

DIRY

DIRY

38 39

NRG

ENBX1

36 37

ENBX2

DIRX

34 35

DIRX

DX

32 33

CLX

CLX

30 31

CLY

CLY

28 29

DY

ENBY1

26 27

ENBY2

25

VDD2

24

VDD2

DGND

22 23

21

ENBY1IN

Q603

R611

3.3k

VDD1

DGND

40

DIRY

DIRY

38 39

NRG

ENBX1

36 37

ENBX2

DIRX

34 35

DIRX

DX

32 33

CLX

CLX

30 31

CLY

CLY

28 29

DY

ENBY1

26 27

ENBY2

25

VDD2

24

VDD2

DGND

22 23

21

ENBY1IN

SVGA MODEL

Fig. 2-5-1

5. CIRCUIT DIAGRAMS

C408

5-1. Drive Circuit Diagram (for TLP650, TLP651)

PQ20VZ1U

1

IN OUT

2

CTL Vref

PQ20VZ1U

1

IN OUT

2

CTL Vref

Q950

GND

5

Q951

GND

5

C951

1 `

T

C950

10 ` 25V

DUMMY12

1

S18V

2

3

S6V

4

5

+5VS

6

D-POWER-ON

123

VDD

GND

R964

100k

Q955

TC7S08F

C955

0.1 `

C954

33 ` 25V

C970

0.1 `

45

OMCLK OXMCLK

B.BIAS

G.BIAS

R.BIAS

BGND

R.BIAS

G.BIAS

R976

1.5k

L975

L974

330 `

330 `

C983

C984

C981

330p

680p

330p

L977

L978

150 `

150 `

R975

R973

100

100

VRH

47

46

45

44

43

42

48

DVSS2

AOUT0

DACI0

DACO0

AVDD

VRH

AOUT1

3

4

3

R952

4

R954

1k

+5VDRIVE

R950

3k

C952

C953

33 ` 10V

1 `

R951

1k

10k

R953

1.5k

+15.5V

C956

C957

33 ` 25V

1 `

G026

T10 ` 10V

C971

T10 ` 10V

L971

T

33 `

L972

T

33 `

C973

C974

1 `

R977

T

C985

10 ` 10V

49

N.C

50

N.C

51

C972

1 `

10k

3WBENB4

3WBCLK

3WBDTO

PHSYNC

SHDCLK

N.C

52

N.C

53

N.C

54

N.C

55

DVDD2

56

SCTR

57

SCLK

58

SDAT

59

HSYNC

60

XCLR

61

DVSS3

62

CKI

63

SLCK

64

DACI1

Q971

CXD3503R

N.C

N.C

VST

HST

DWN

RGT

CTRL

1

2

3

4

5

6

7

B.BIAS

R974

R972

1.5k

1.5k

L973

330 `

C980

C982

C979

680p

680p

330p

L976

150 `

R971

100

VRL

36

35

41

DACO1

TEST0

8

34

40

VRL

TEST1

9

33

39

37

38

OLIM

DACO2

AVSS

DVSS1

AOUT2

DVDD1

DACI2

DACK1

DACK0

DOUT25

DOUT24

DOUT23

DOUT22

DOUT21

DOUT20

DVDD0

DOUT15

DOUT14

DOUT13

DOUT12

DOUT11

DOUT10

DVSS0

DOUT03

DOUT05

DOUT02

DOUT04

TEST2

DOUT00

DOUT01

13

16

14

15

12

10

11

D701

1SS226

D702

1SS226

D703

1SS226

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

BIN

GGND

GIN

RGND

RIN

DRIVE-SCL

DRIVE-SDA

TG701

Q701

CXA2111R

GAMG-B2P

GAMB-B2P

GAMR-WHG

GAMG-WHG

GAMB-WHG

GAMR-B1G

GAMG-B1G

GAMB-B1G

GAMR-B2G

GAMG-B2G

GAMB-B2G

SCL

SDA

40

41

42

43

44

45

46

47

48

49

50

51

52

C715

0.1 `

R711

R712

3.3k

GAMR-B2P

GAMB-B1P

GAMG-B1P

GAMR-B1P

GAMB-WHP

38

37

36

39

CLAMP AMP DRIVER

CLAMP AMP DRIVER

CLAMP AMP DRIVER

CLAMP

Cont

DAC/Control

Input

I/F

Output

I/F

1

2

3

4

DLY-CNT

DIR-CNT

INV-CNT

POS-CNT1

POS-CNT2

POS1

DLY

POS2

35

.AMP ADJ

I2CBus

5

R709

3.3k

C714

AMPBBAIS

PRG/SID

V33

V33

0.1 `

R715

KETSU

AMPGBAIS

AMPRBIAS

AMPBGAIN

29

32

31

30

8

9

11

10

PRGLEV

SIDLEV

PRGPLS

BIN

GIN

RIN

BGND

GGND

KETSU

R710

1.5k

KETSU

R702

R701

AMPGGAIN

AMPRGAIN

1 `

28

27

C703

C702

BIN

26

CLPLEV

25

GIN

24

ATT

23

RIN

22

Vcc

21

CLPPLS

20

GND

19

ROUT

18

PVcc

17

GOUT

16

PGND

15

BOUT

14

13

12

R706

BLKLIM

GAMOFF

10k

C712 0.1 `

C711 0.1 `

C710 0.1 `

BLKLIM

CLP2

RGND

R703 KETSU

1 `

1 `

C701

C704

1 `

C706

1 `

C709

C713

0.1 `

0.1 `

TP703

TP702

R705

TP701

10k

T

C705

T10 ` 10V

T

C707

T10 ` 10V

TP705

TP706

CLPLEV

R714

KETSU

1.5k

R713

KETSU

GAMG-WHP

GAMR-WHP

34

33