Toshiba TLP-250, TLP-250C, TLP-251, TLP-251C, TLP-550 Service Manual

...

FILE NO. 330-200103

SUPPLEMENT

SERVICE MANUAL

3LCD DATA PROJECTOR

TLP-250/251/250C/251C

TLP-550/551/550C/551C

PART REPLACEMENT AND

N

800

Y

E

N

OUSING

S

L

N

Y

D

ADJUSTMENT PROCEDURES

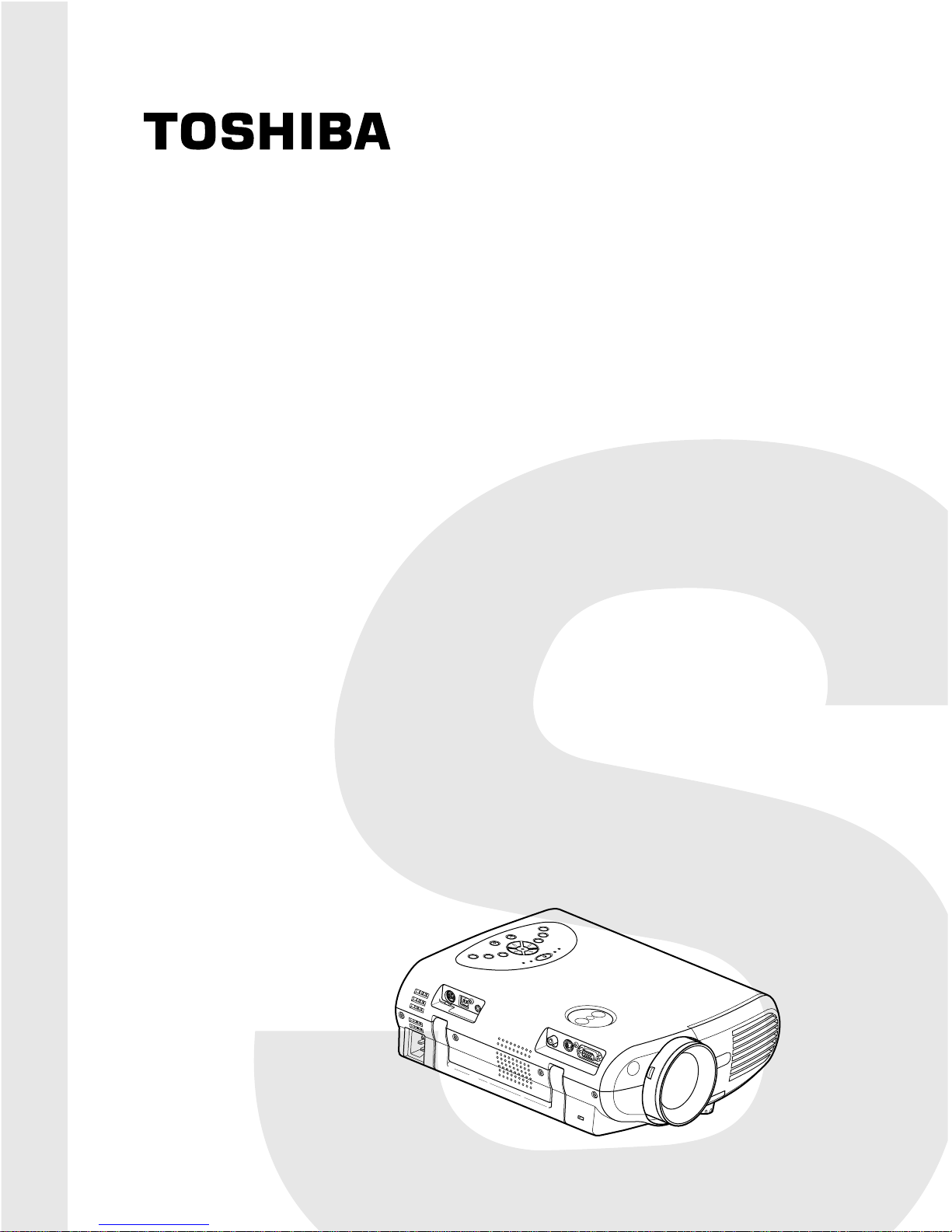

1. LOCATION OF MAIN PARTS

SECTION 1

PEAKER B

LCD BLOCK

E201A: PROJECTION LE

E200: OPTICAL ENGIN

Z100: INTAKE FA

LAMP H

Z101: EXHAUST FA

P

: POWER SUPPL

BALLAST POWER SUPPL

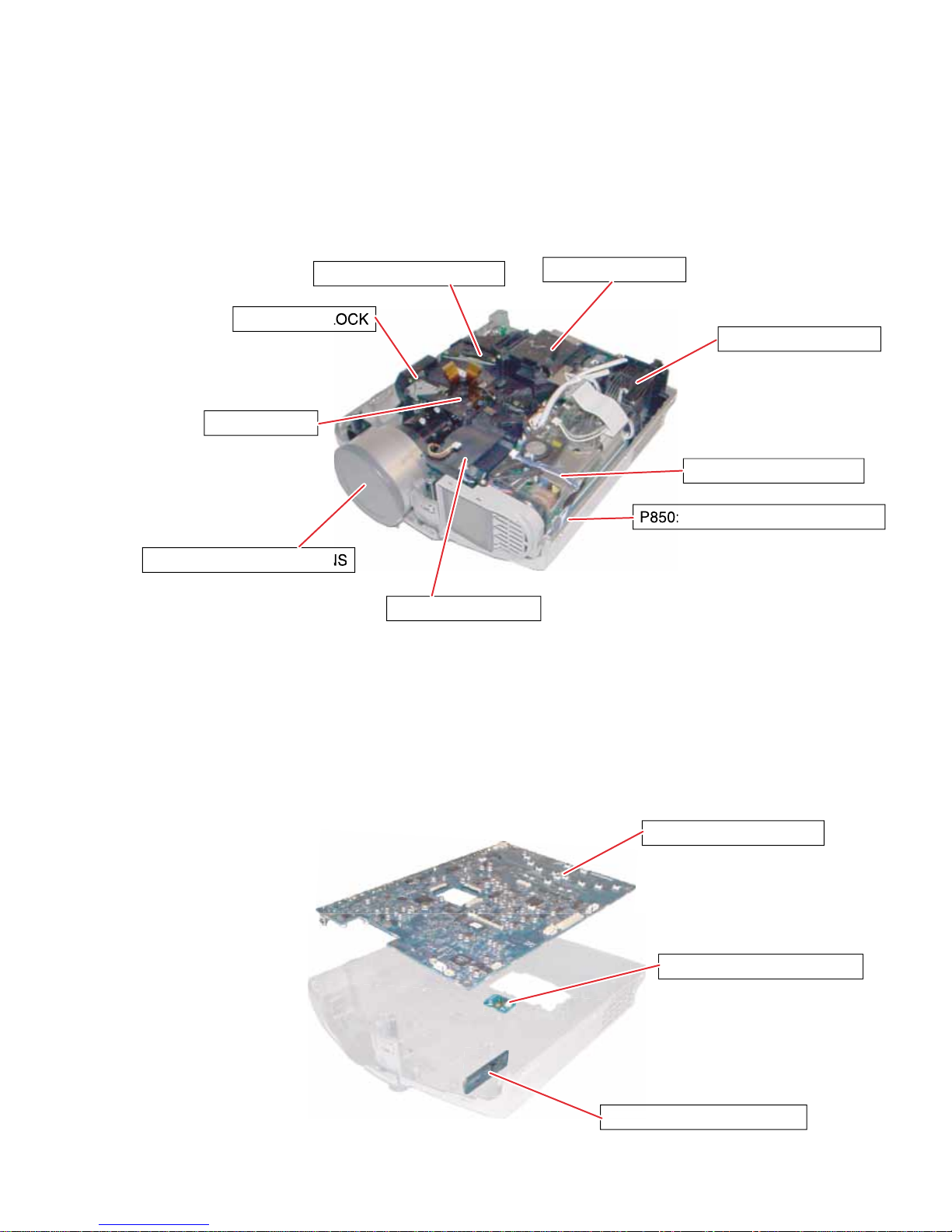

2. LOCATION OF PC BOARD

1: MAIN PC BOAR

U003: SWITCH PC BOARD

1-1

CAUTIONS BEFORE SERVICING

Electronic parts are susceptible to static electricity and may easily be damaged, so do not forget to take

proper grounding treatment as required.

Many screws are used inside the unit. To prevent missing, dropping, etc. of the screws, always use a

magnetized screwdriver in servicing. Several kinds of screws are used and some of them need special

cautions. That is, take care of the tapping screws securing molded parts and fine pitch screws used to

secure metal parts. If they are used improperly, the screw holes will be easily damaged and the parts can

not be fixed.

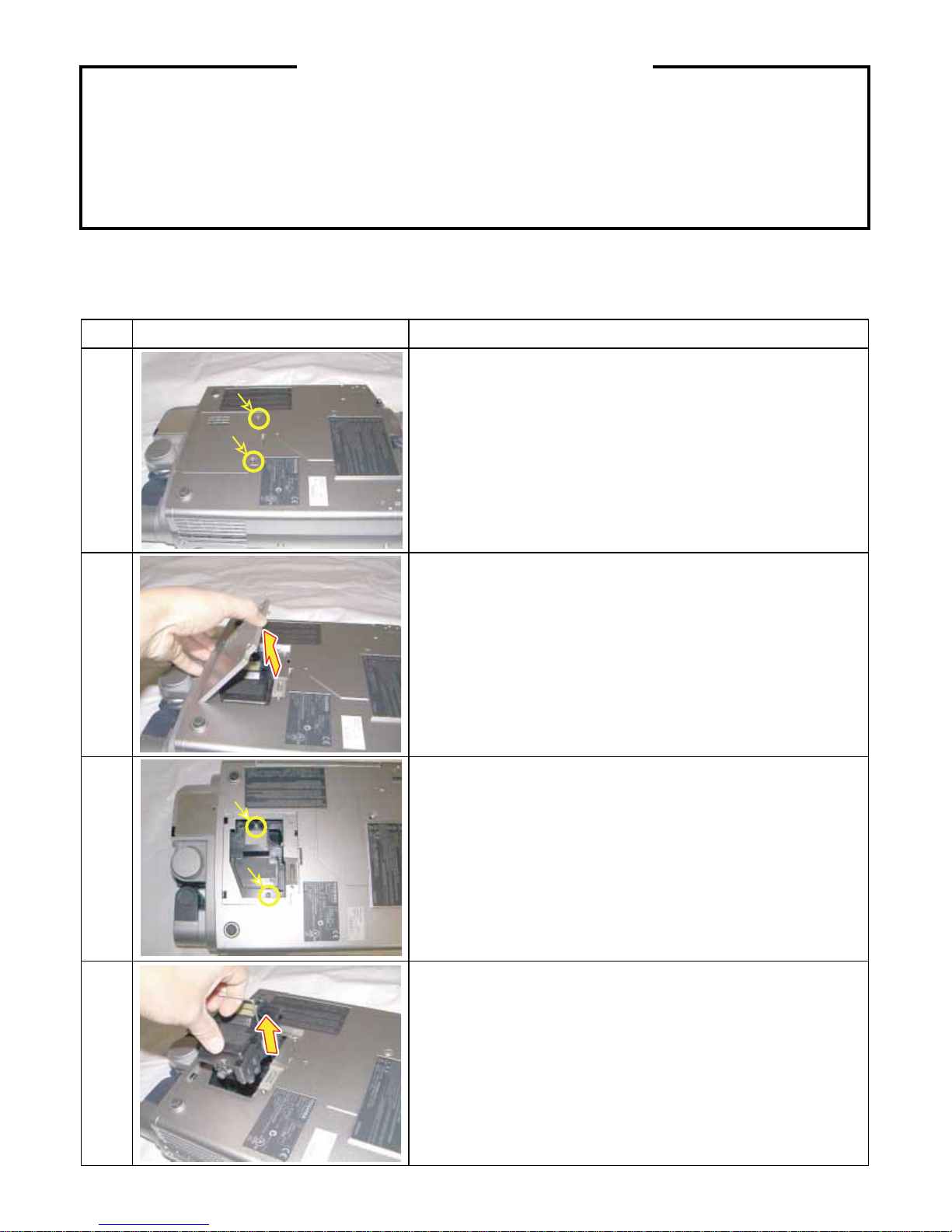

3. REPLACEMENT OF MECHANICAL PARTS

3-1. Lamp Assembly

Step Figure

1

2

Explanation

Loosen 2 screws (M3 x 8).

These screws are retained with split washers.

Remove the lamp cover.

3

4

Loosen 2 screws that secure the lamp module (M3 x 8).

These screws are retained with split washers.

Lift the lamp module and slide out from the projector.

1-2

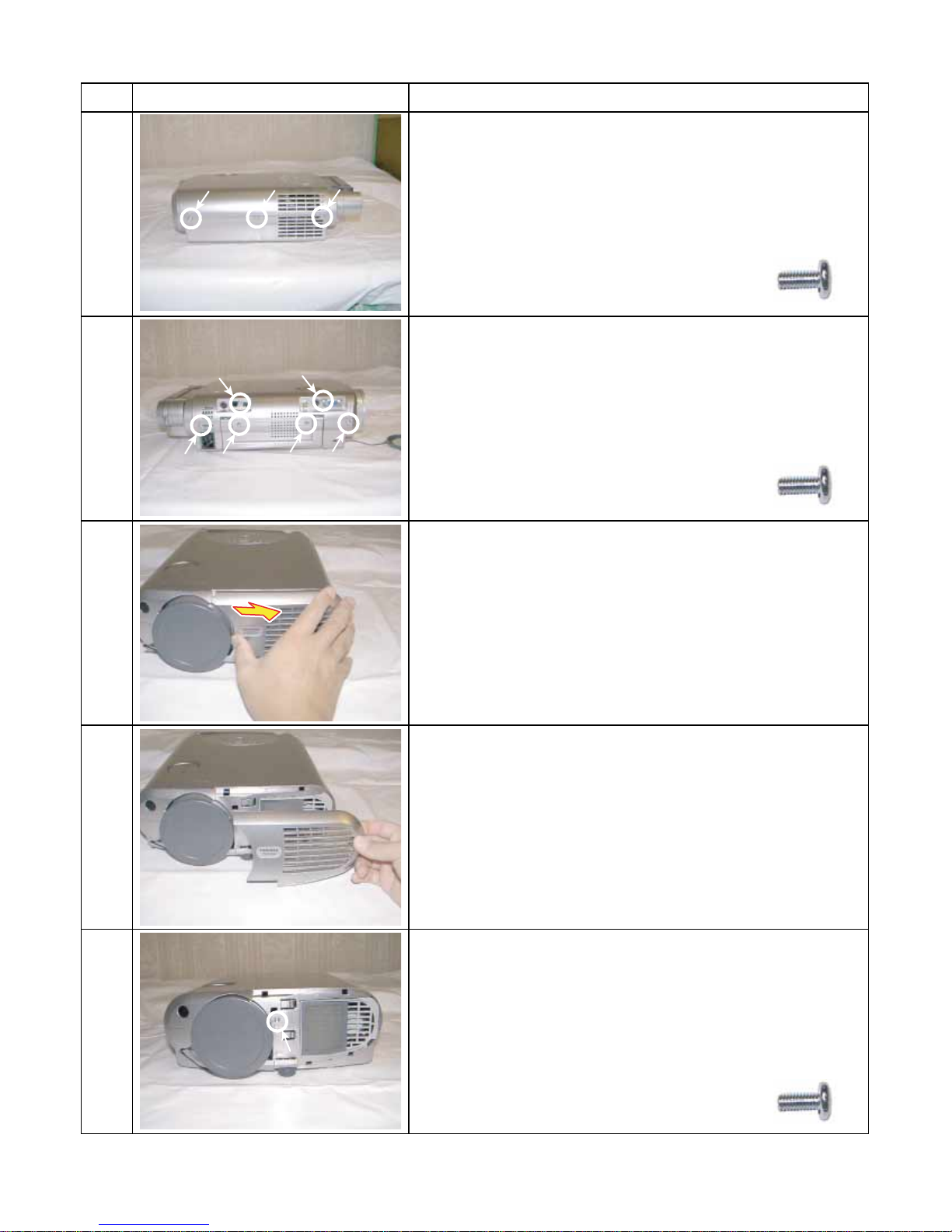

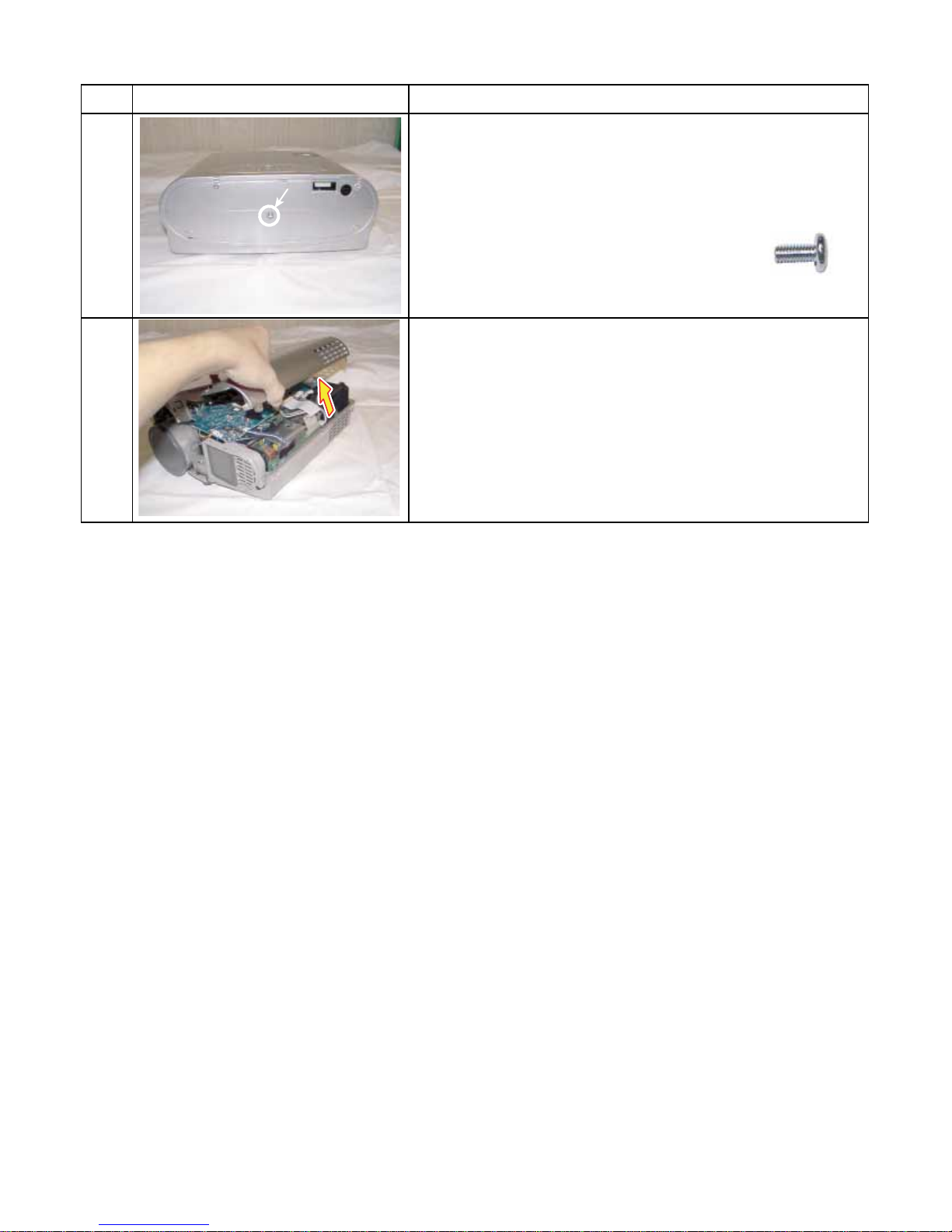

3-2. T op Cover

Step Figure Explanation

[Left Side]

Remove 3 screws (M3 x 6).

1

[Right Side]

Remove 6 screws (M3 x 6).

2

Screw : type [M-1]

Screw : type [M-1]

3

4

[Front]

Slide front cover to the right.

Remove front cover.

Remove 1 screw (M3 x 6).

5

Screw : type [M-1]

1-3

3-2. Top Cover (Continued)

Step Figure Explanation

[Rear]

Remove 1 screws (M2 x 6).

6

Top cover can be removed by lifting left edge.

7

Screw : type [M-1]

1-4

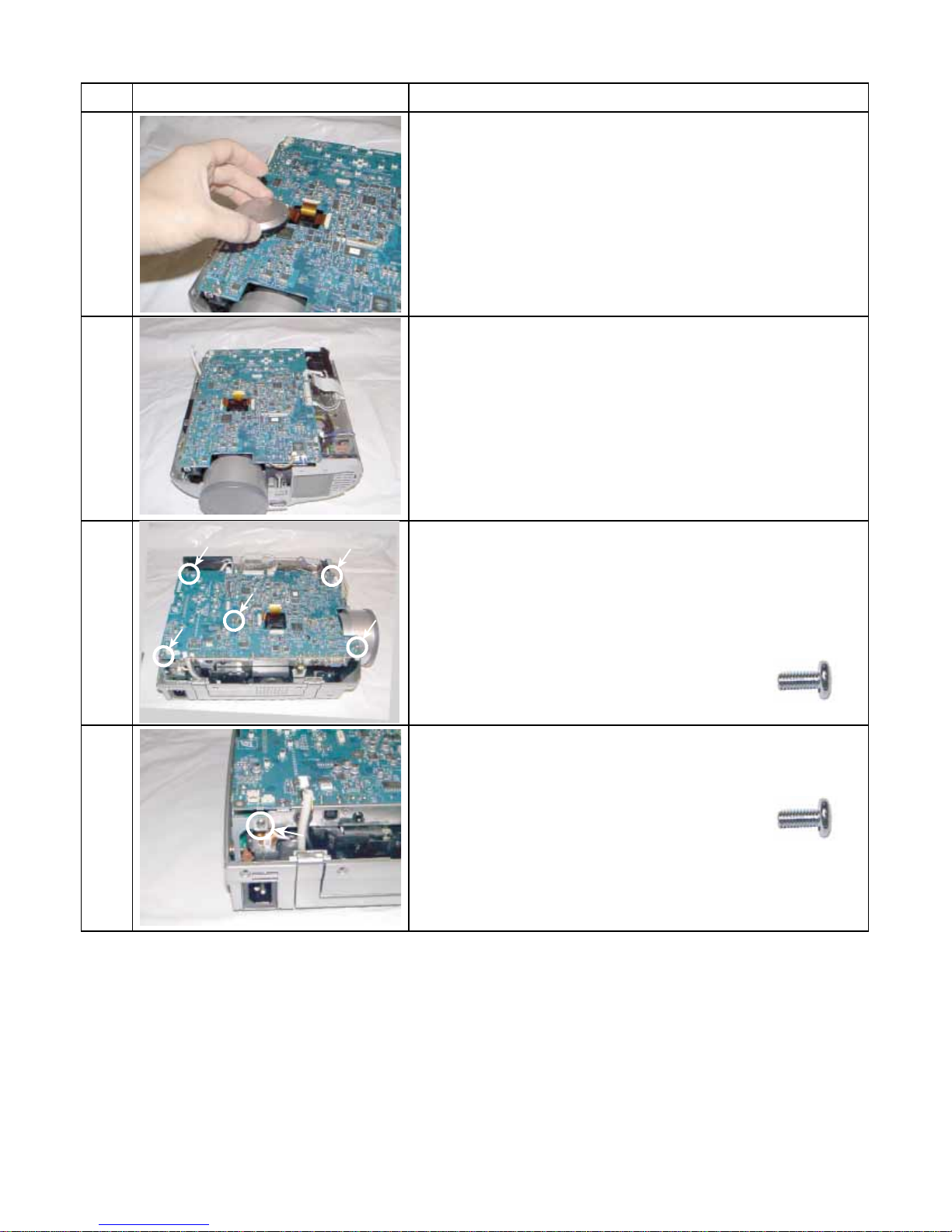

3-3. Main PC Board

Step Figure Explanation

Remove lens shift dial.

1

Remove all cables and connectors.

2

3

4

Remove 5 screws (M3 x 6).

Screw : type [M-1]

Remove 1 screws (M3 x 6).

Screw : type [M-1]

[Note]

The screw here is also fixing the grand wire.

1-5

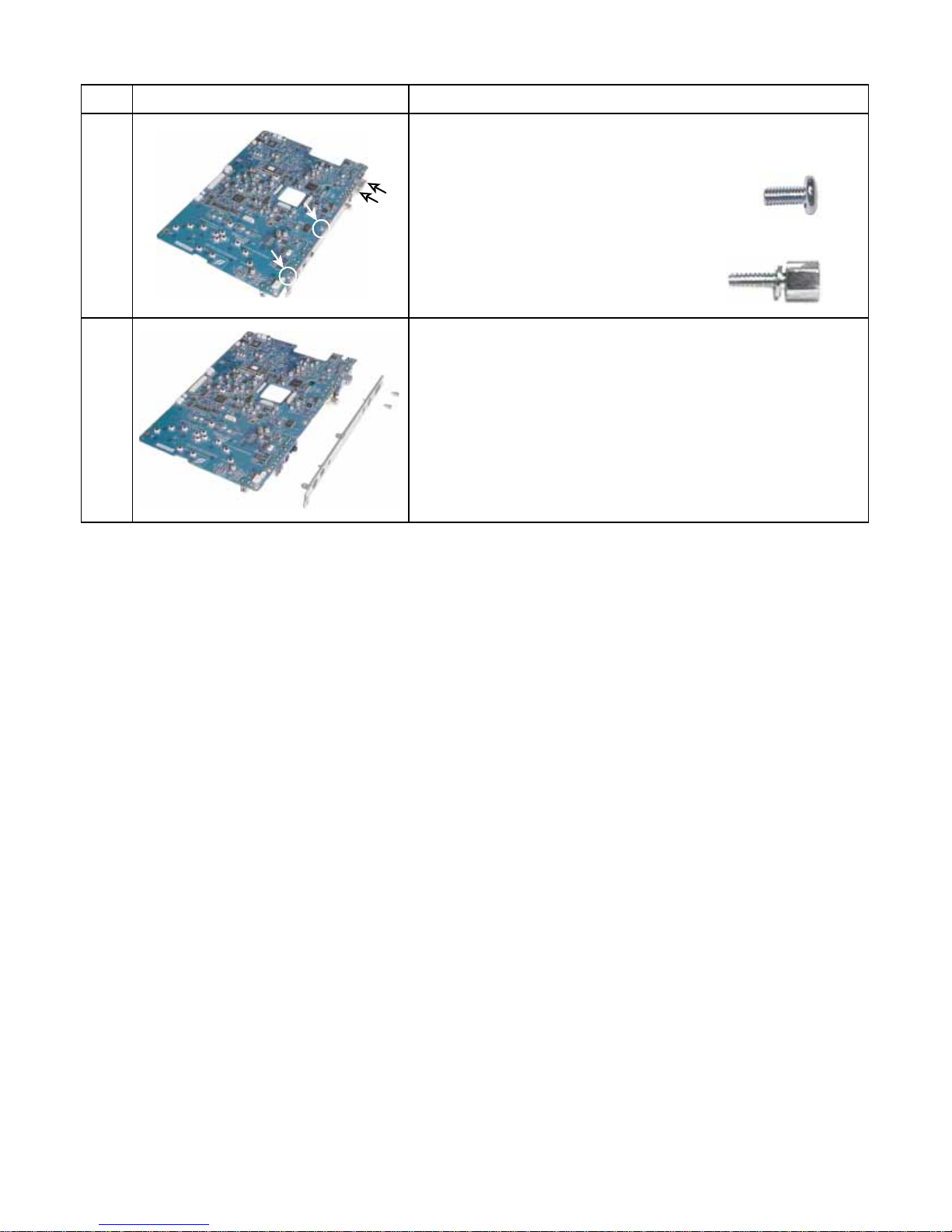

3-3. Main PC Board (Continued)

y

]

Step Figure Explanation

Remove 2 screws (M3 x 6).

Screw : type [M-1]

5

6

Remove 2 screws (M3 x 8).

Remove metal plate.

Screw : t

pe [M-10

1-6

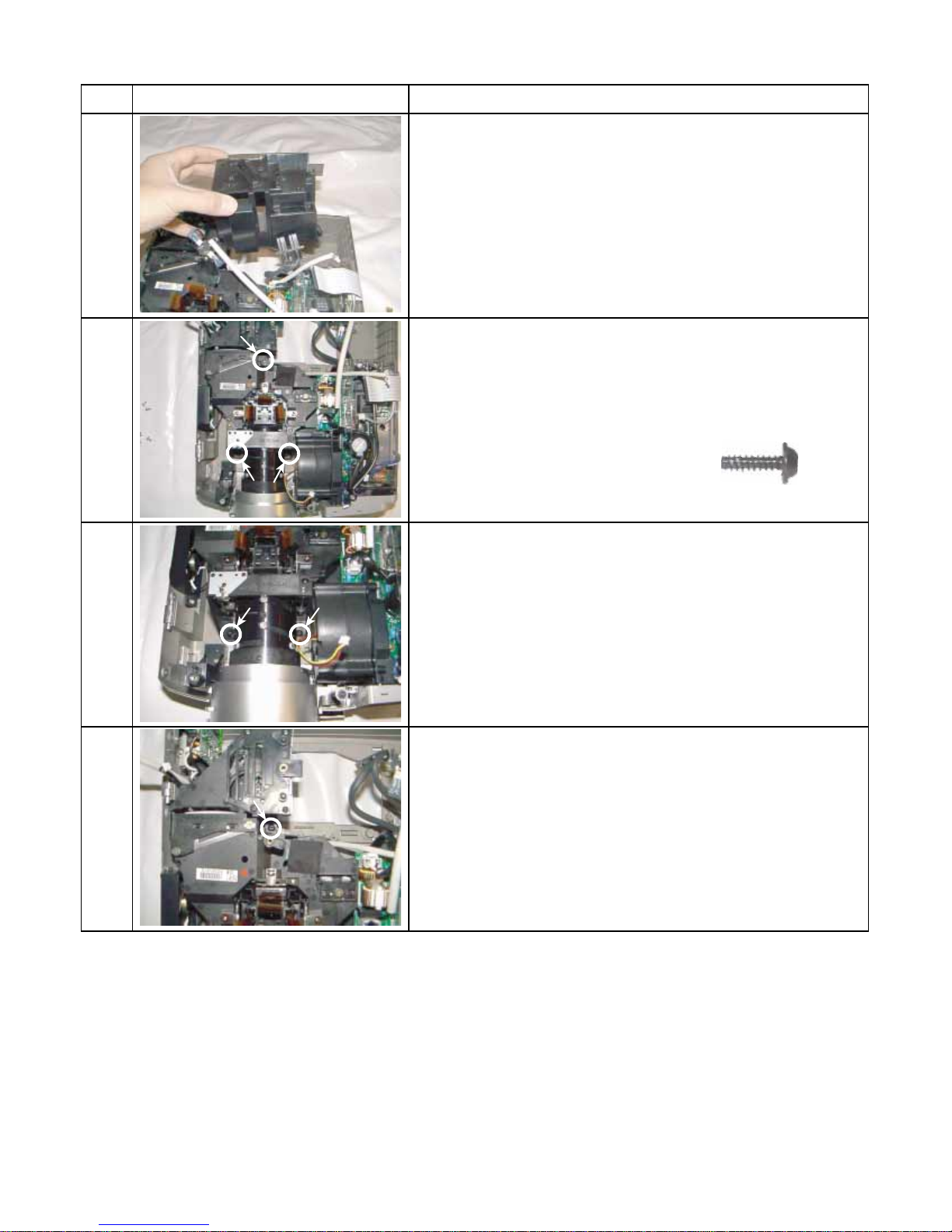

3-4. Optical Engine

Step Figure Explanation

1

2

Remove 1 screw (M3 x 6).......A

Screw : type [M-1]

A

B

Remove 2 screws (3 x 8)......B

Screw : type [M-2]

B

Remove 2 screws (3 x 8)

Screw : type [M-2]

Remove Thermal switch.

3

4

5

Remove metal plate.

Remove 2 screws (3 x 8)

Screw : type [M-2]

1-7

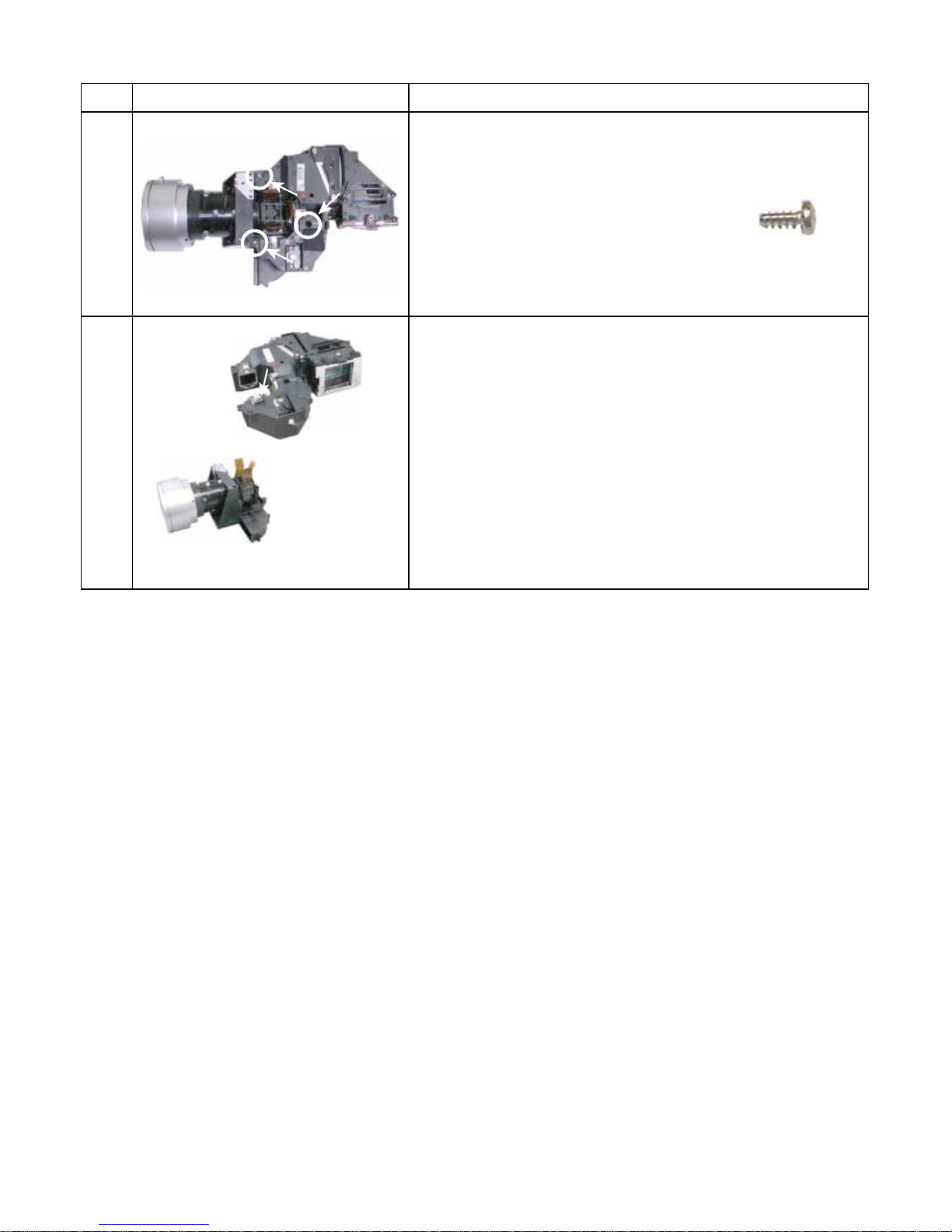

3-4. Optical Engine (Continued)

Step Figure Explanation

Remove lamp housing.

6

b

Remove 3 screws (M3 x 15).

7

7a

7b

Screw : type [M-4]

a

1-8

3-4. Optical Engine (Continued)

Step Figure Explanation

Remove 3 screws (M3 x 8) .

8

Separate the main frame and sub frame from the engine

block.

9

Screw : type [M-2]

Main frame

1-9

3-5. MULTI-PBS (Polarizing Beam Splitter)

y

]

Lamp

Step Figure Explanation

B

Remove 3 screws (M3 x 15) ....A

Screw : type [M-8]

1

2

3

A

Remove 1 screws (M2.5 x 15) ....B

Screw : t

Press the Multi-PBS up from cooling space.

Remove the Multi-PBS.

pe [M-9

4

Prism

Lamp

Lamp

[Note]

Make sure the direction of the PBS when you install.

TOP VIEW

PBS

Rotation Film

Lamp SIDE

Prism SIDE

Multi Lens

1-10

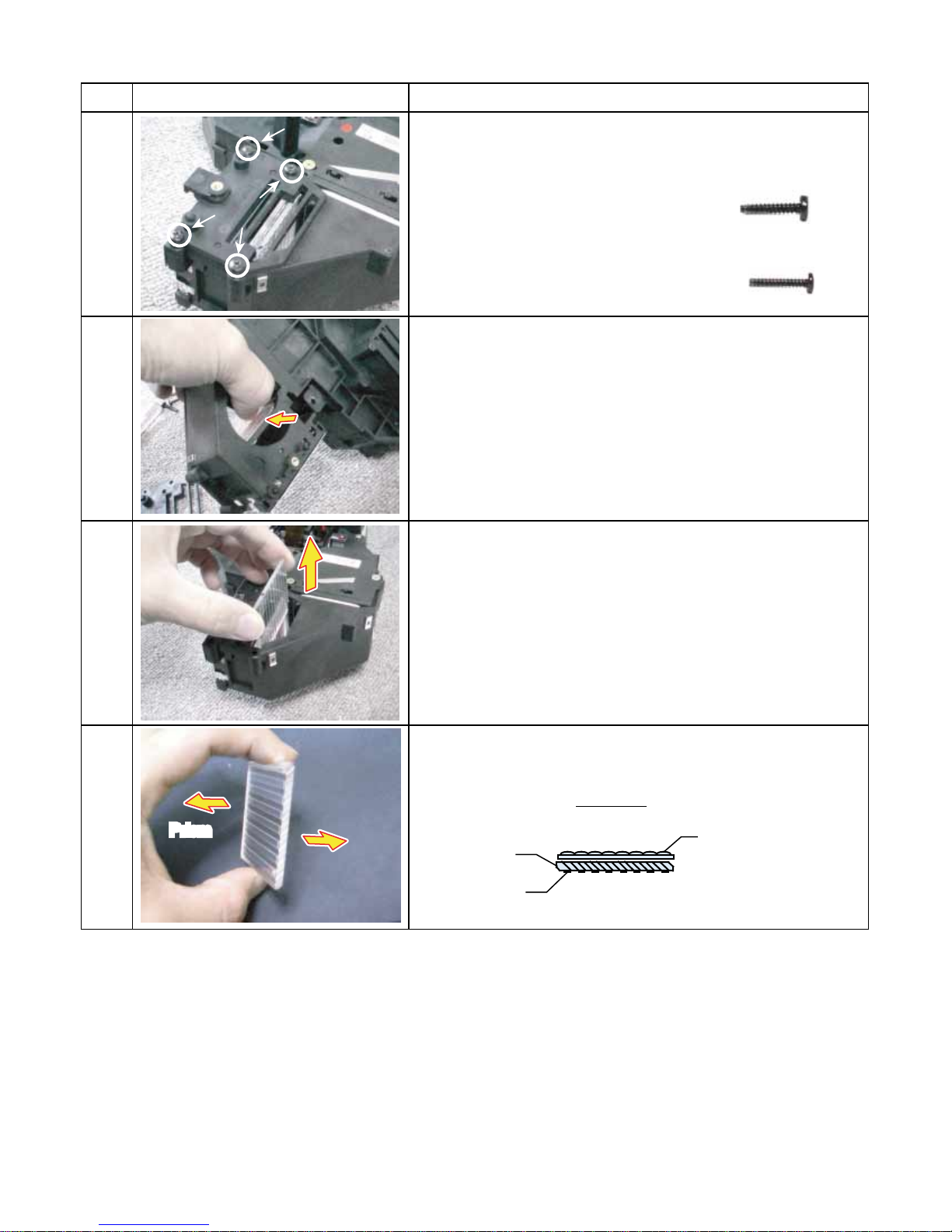

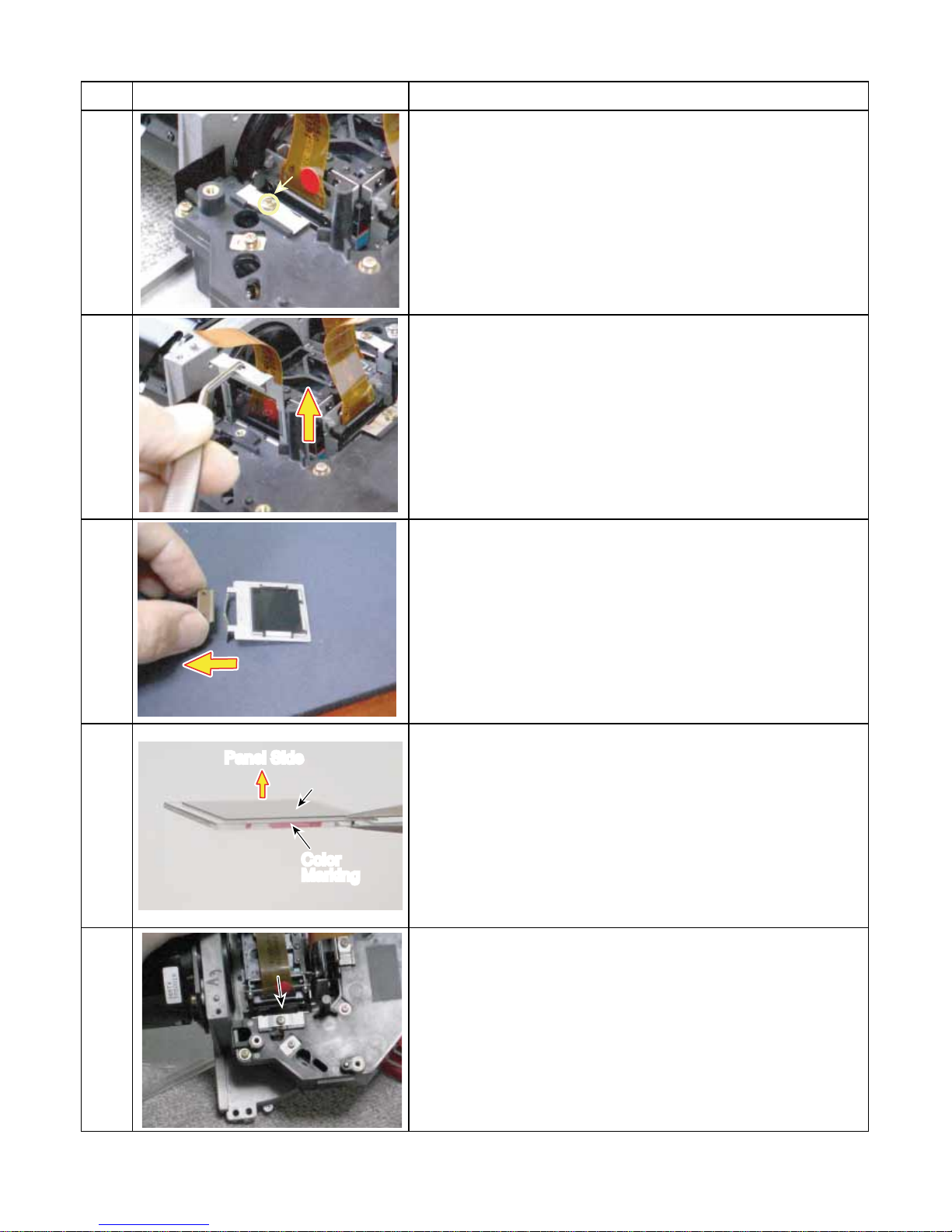

3-6. Polarized Plate

polarizer film

Step Figure Explanation

Remve the one screw.

1

Remove the stopper.

2

3

4

Panel Side

polarizer film

polarizer film

Color

Marking

Remove the holder and polarized plate.

[Note]

The film side must be faced to the LCD panel when installing

and the color must be related with the color of LCD panel.

Tighten a screw in the position where 100% black image

screen gets the darkest.

5

1-11

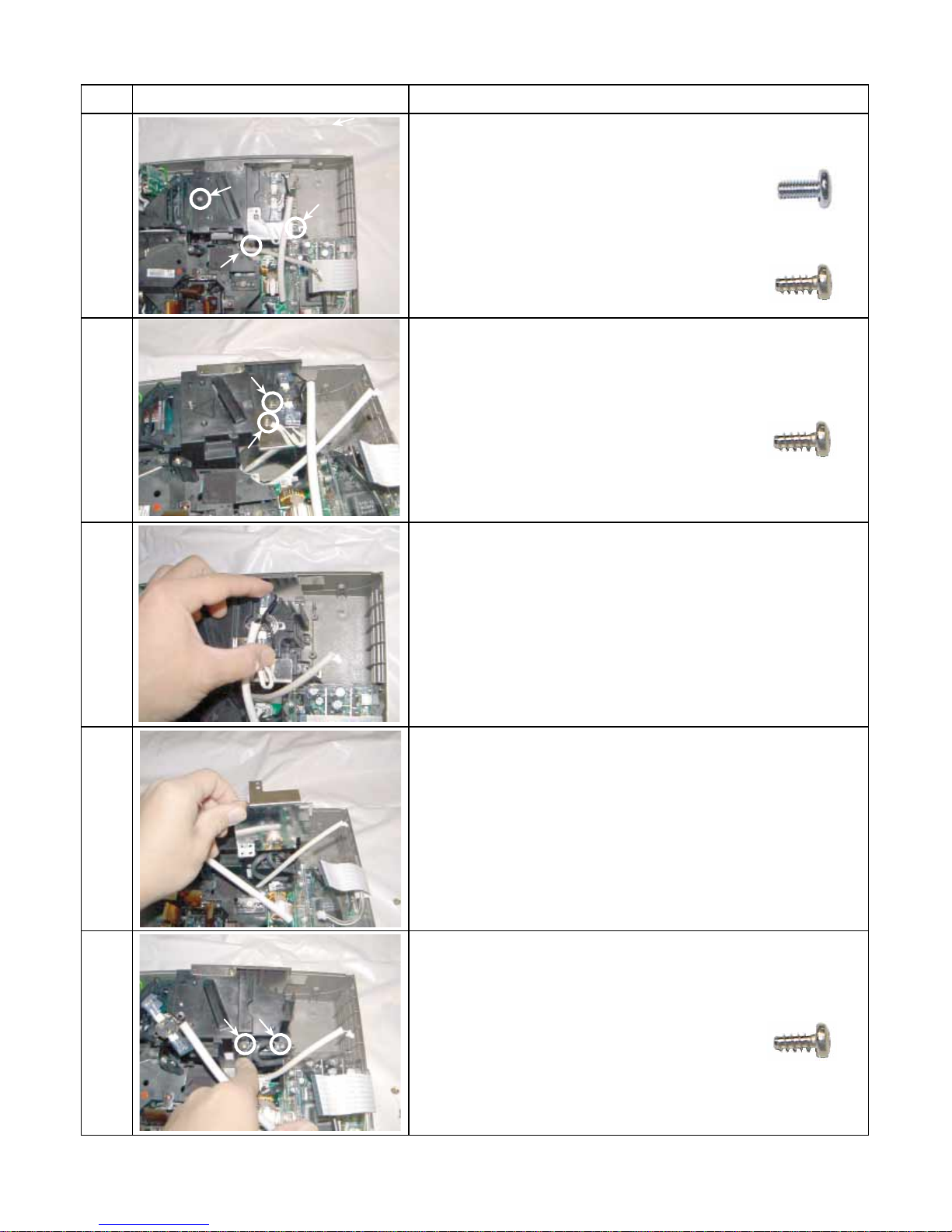

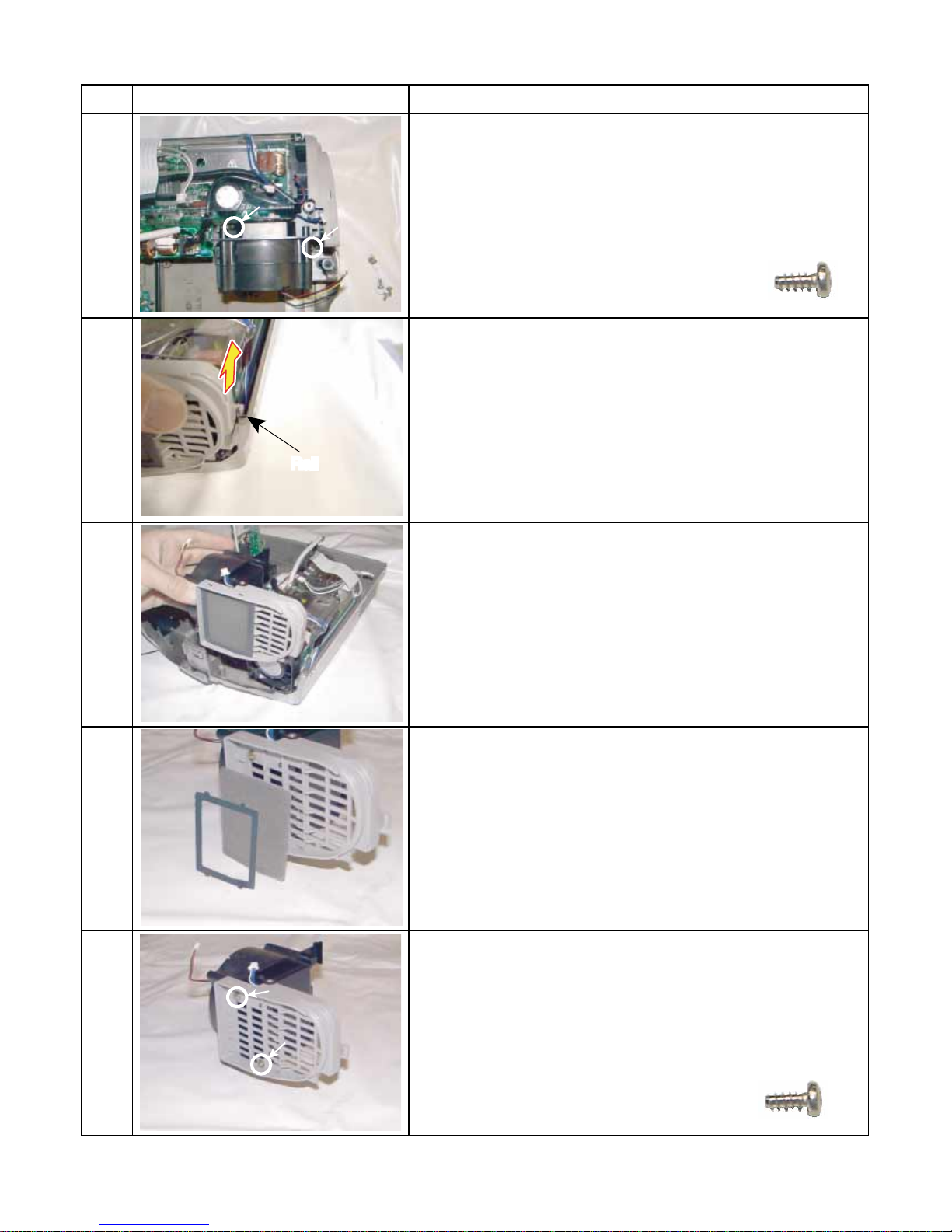

3-7. Intake Fan

Step Figure Explanation

Remove 2 screw (3 x 8).

1

Remove intake fan block from the bottom cabinet.( It pulls

up along with a rail. )

2

Rail

Screw : type [M-2]

3

4

Remove filter block from the bottom cabinet.

The filter is split like this.

Remove 2 screws (3 x 8).

5

Screw : type [M-2]

1-12

3-7. Intake Fan (Continued)

Step Figure Explanation

Remove 2 screw (3 x 47).

6

The Intake fan block is split like this.

7

Screw : type [M-5]

1-13

Loading...

Loading...