Toshiba Tl000LE User Manual

1.1 GENERAL

The Toshiba

technology, high speed, excellent legibility, IBM

Tl000LE

The

Tl000LE

The

80C86-2 microprocessor with a 16-bit data width on the data bus line. The standard random

access memory (RAM) capacity is I-Mbyte with the ability to insert

memory cards; thus, the system can have up to 9 Mbytes

The TlOooLE system unit consists

Tl000LE

is so small it defines a new class

uses the MS-DOS version 3.30 operating system and contains a powerful

• System board/memory board

• 3.5-inch floppy disk drive (FDD) that supports two memory formats:

1.44-Mbyte double-sided, high-density, double-track (2HD)

720-Kbyte double-sided, double-density, double-track (2DD)

• 2.5-inch hard disk drive (HDD) with 20-Mbyte capacity

• IBM enhanced keyboard compatibility

• Sidelit liquid crystal display (LCD)

• Power supply system consisting

is one

of

the lightest portable computers available offering high

PC/XT compatibility, and battery operation.

of

portables called notebook computers.

1-,2-,4-

of

RAM.

of

the following features:

of

an AC adapter and batteries

or

8-Mbyte

The LCD supports

color attribute combinations.

Connecting ports for optional equipment are provided on the rear panel

parallel port, serial port, and expansion bus connector are all provided for.

640 x 400 pixels with color/graphics adapter (CGA) compatibility and two

1-1

Figure

TlOOOLE

system unit

of

the system. A

1-3

1.2

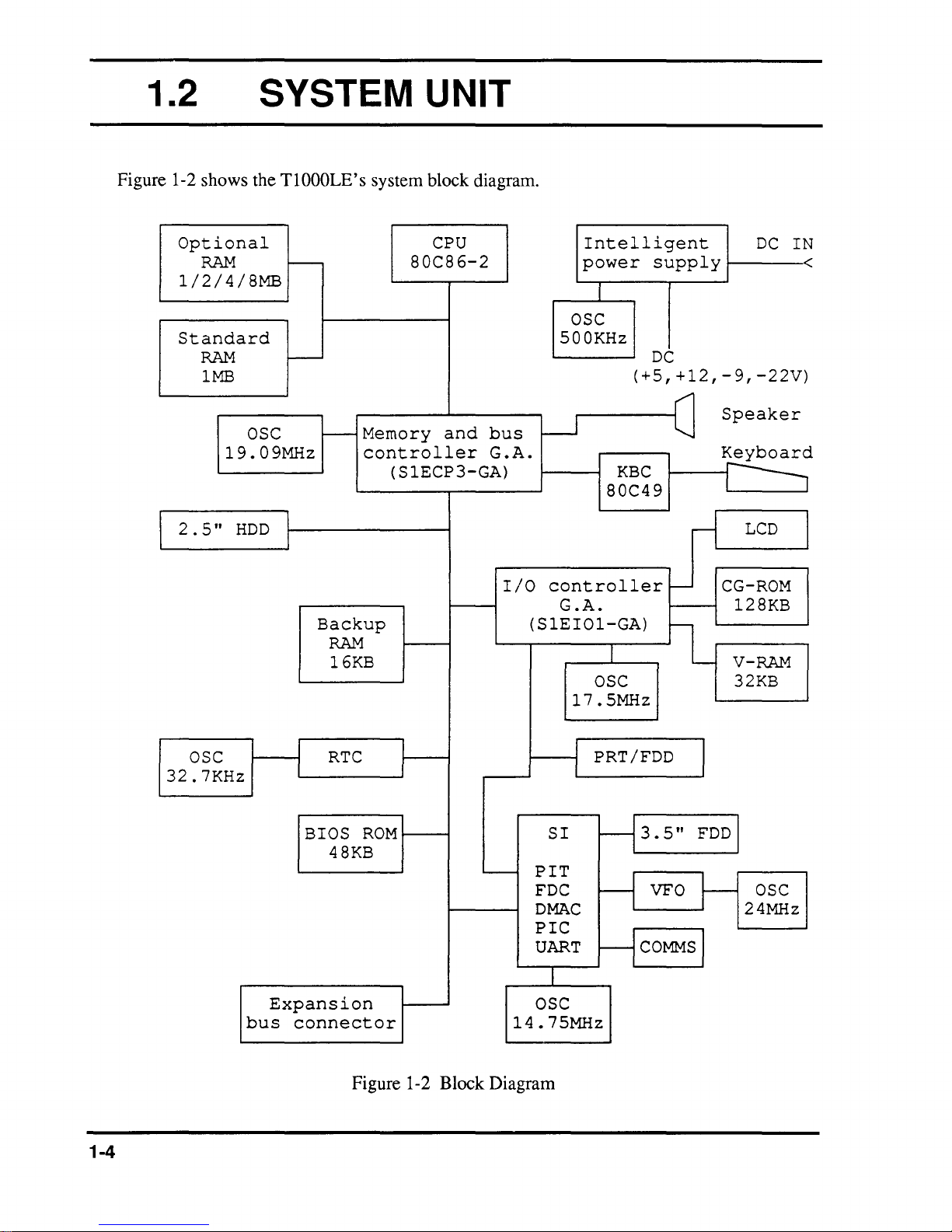

Figure 1-2 shows the T1000LE's system block diagram.

SYSTEM UNIT

Optional

RAM

1/2/4/8MB

Standard

RAM

1MB

OSC

19.09MHz

2.5"

HDD

r--

I---

I---

Memory

controller

Backup

RAM

16KB

CPU

80C86-2

and

bus

G.A.

(SlECP3-GA)

OSC

500KHz

W

I/O

controller

G

.A.

(SlEI01-GA)

17.5MHz

Intelligent

power

OSC

supply

DC

(+5,+12,-9,-22V)

KBC

80C49

Speaker

~

r-1

-

~

CG-ROM

128KB

V-RAM

32KB

DC

LCD

I N

<

I

1-4

OSC

32.7KHz

Expansion

bus

connector

RTC

BIOS

48KB

ROM

'---

Figure 1-2 Block Diagram

PIT

FDC

DMAC

PIC

UART

OSC

14.75MHz

SI

PRT/FDD

3

-1

-1

5

.

VFO

COMMS

-1

"

J

FDD

t-

I

OSC

24MHz

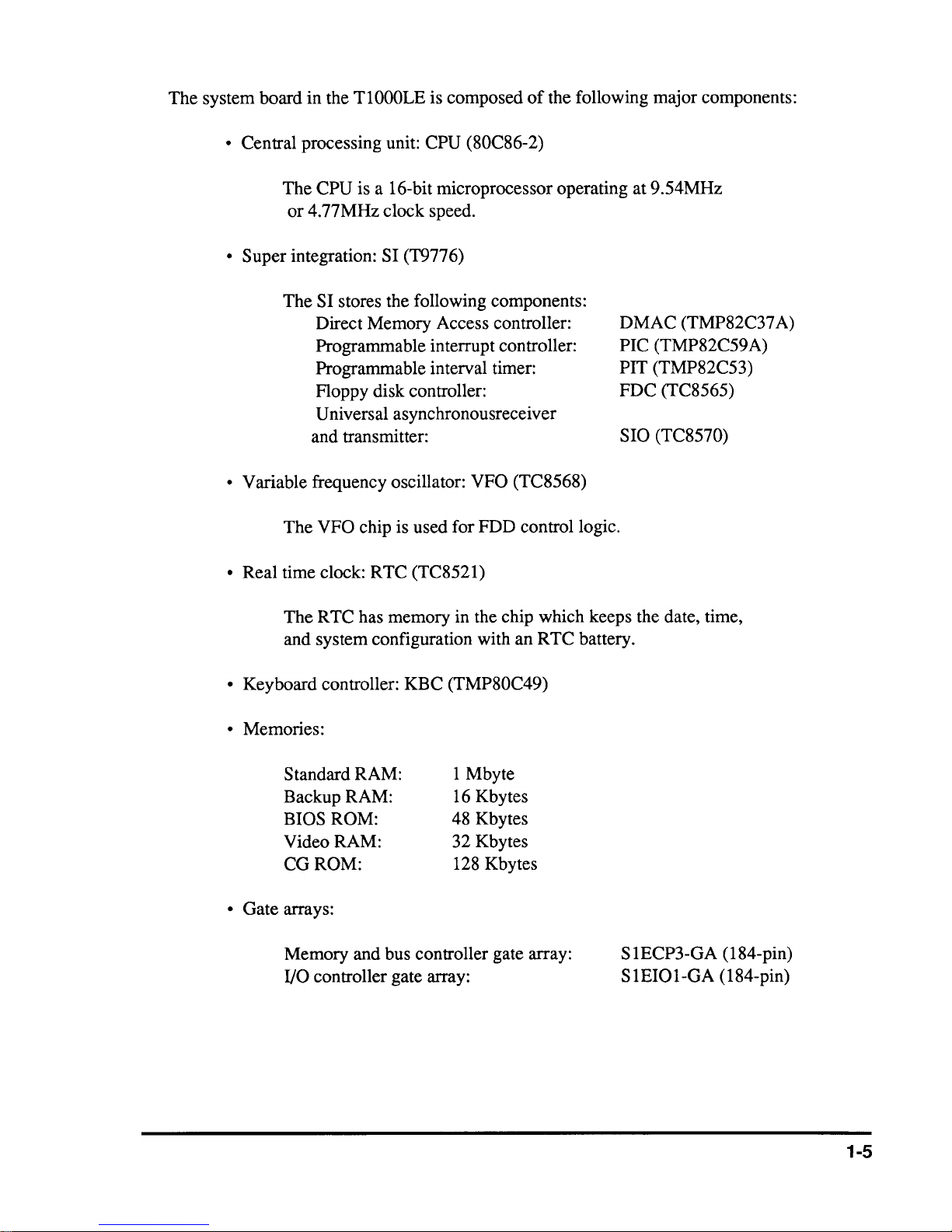

The system board in the

• Central processing unit: CPU (80C86-2)

The

CPU is a 16-bit microprocessor operating at 9.54MHz

or

4.77MHz clock speed.

• Super integration: SI (T9776)

The

SI stores the following components:

Direct Memory Access controller:

Programmable interrupt controller:

Programmable interval timer:

Floppy disk controller:

Universal asynchronousreceiver

and transmitter:

• Variable frequency oscillator: VFO (TC8568)

VFO chip is used for FDD control logic.

The

TlOOOLE

is composed

of

the following major components:

DMAC (TMP82C37

PIC (TMP82C59A)

PIT (TMP82C53)

FDC (TC8565)

SIO (TC8570)

A)

• Real time clock: RTC (TC8521)

The R TC has memory in the chip which keeps the date, time,

and system configuration with an RTC battery.

• Keyboard controller: KBC (TMP80C49)

• Memories:

Standard RAM:

Backup RAM:

BIOS ROM:

Video RAM:

CGROM:

I Mbyte

16

Kbytes

48 Kbytes

32 Kbytes

128 Kbytes

• Gate arrays:

Memory and bus controller gate array:

I/O controller gate array:

SIECP3-GA (184-pin)

S

lEIOI-GA

(184-pin)

1-5

• Oscillators: OSC

32.768KHz OSC

19.0909lMHz

(Xl)

is used for the RTC.

OSC (X2) is used for the CPU.

l4.7456MHz OSC (X3) is used for the SIO.

24MHz OSC (X4) is used for the VFO.

l7.5MHz

500KHz OSC

The

OSC (X5) is used for the LCD.

location

(X50l)

of

these OSCs are shown in Appendix A.

is used for the CPU

of

the intelligent power supply.

1-6

1.3

3.5-INCH FLOPPY DISK

DRIVE

The 3.5-inch floppy disk drive (FDD) is a high perionnance, reliable, and thin drive that

supports

The FDD is shown in Figure 1-3 and its specifications are described in Table 1-1.

720-Kbyte (fonnatted) 2DD and 1.44-Mbyte (fonnatted) 3.5-inch floppy diskettes.

Storage

Unformatted

Formatted

Number

Number

Access

Track

Average

Head

Rotation

Data

Recording

Recording

Recording

transfer

Item

capacity

of

heads

of

cylinders

time

to

settling

speed

method

track

density

Table

track

rate

density

Figure 1-3 3.5-inch FDD

1-1

3.5-inch FDD specifications

2-Mbyte

(Kbyte)

2,000

1,440

(ms)

181

time

(rpm)

(Kbps)

MFM

modulation)

(bpi)

(bpi)

360

500

(modified

135

17,430

Specifications

mode

2

80

3

15

1-Mbyte

1,000

720

80

181

15

360

300

frequency

135

8720

mode

2

3

1-7

1.4

2.S-INCH HARD DISK

DRIVE

The 20-Mbyte (formatted) hard disk drive (HDD) is a random access storage device. It is

equipped with a non-removal 2.5-inch magnetic disk and mini-Winchester type magnetic

heads.

The HDD is shown in Figure 1-4 and its specifications are described in Table 1-2.

Storage

Formatted

Number

Data

Data

Track

Track

Sectors

Access

Rotation

Data

Interleave

Recording

Recording

surfaces

heads

per

density

Track

Average

Maximum

transfer

To/from

(bpi)

Item

capacity

of

disks

surface

per

time

to

speed

method

density

Figure 1-4 2.5-inch HDD

Table 1-2 2.5-inch HDD specifications

JDE2825P

(Mbytes)

(tpi)

track

(ms)

track

(rpm)

rate

media

(bps)

( ID)

1,465

3,109

(Run

39,665

21.4

1

2 2

2 2

581

36

8 5

25 25

45

3,433

10

M

1:1

2-7

RLL

length

code

limited)

I

34,816

CP2024

21.4

1

653

1,700

33

40

10

M

1:1

1-8

1.5 KEYBOARD

The 82- (USA)

connected to the keyboard controller on the system board through a

keyboard is shown in Figure 1-5.

Optional keyboard configurations are illustrated in Appendix

or

84- (European) keyboard is mounted on the system unit. The keyboard is

E.

20-pin flat cable. The

Figure 1-5 Keyboard

1-9

1.6

SIDELIT LIQUID CRYSTAL

DISPLAY

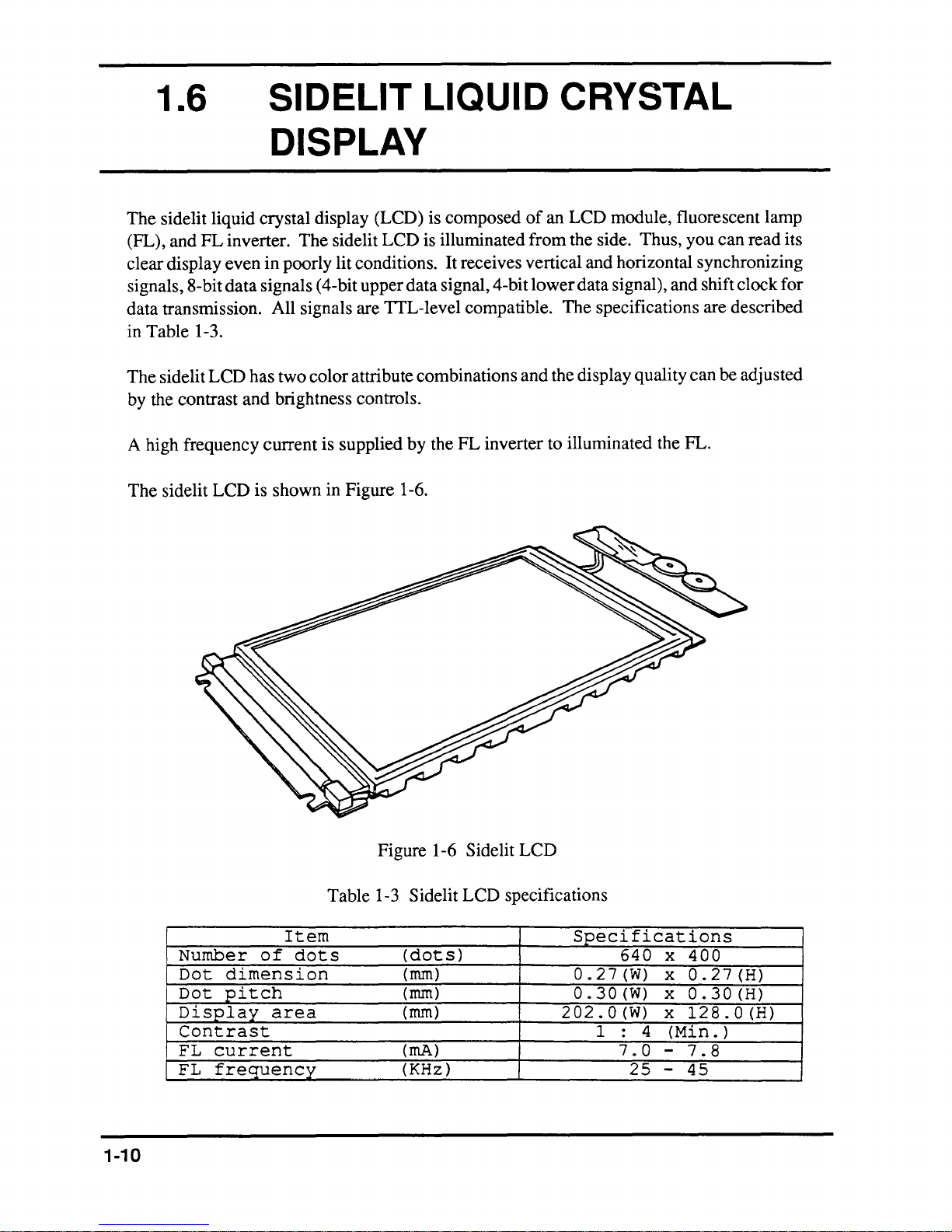

The

sidelit liquid crystal display (LCD) is

(FL),

and

FL

inverter.

1-3.

LCD

even

data

has

and

clear display

signals, 8-bit

data

transmission. All signals are TTL-level compatible.

Table

in

The

sidelit

by

the contrast

The

sidelit

in

poorly lit conditions. It receives vertical

signals (4-bit upper data signal, 4-bit

two

color

brightness controls.

LCD

attribute combinations

composed

is illuminated

of

an

LCD

module, fluorescent lamp

from

the side. Thus, you

and

horizontal synchronizing

lower

data

signal), and shift clock

The

specifications are described

and

the display quality

can

can

be adjusted

read

its

for

A high frequency

The

sidelit

LCD

current

is

shown

is supplied

in Figure 1-6.

by

Figure 1-6

the

FL

inverter to illuminated the FL.

Sidelit

LCD

Item

Number

Dot

Dot

Display

of

dots

dimension

pitch

area

Contrast

FL

current

FL

frequency

1-10

Table

1-3 Sidelit

(dots)

(rnm)

(rnm)

(rnm)

(rnA)

(KHz)

LCD

specifications

Specifications

640

0.27(W)

0.30(W)

202.0(W)

1

4

:

7.0

25

x

400

x

0.27(H)

x

0.30(H)

x

128.0(H)

(Min.

-

7.8

-

45

)

2.1

The problem isolation procedures described in Part 2 are used to isolate defective field

replaceable units (FRUs). The FRUs covered are:

GENERAL

1.

2. System board

3.

4.

5.

6.

Test program operations are described in Part 3 and detailed replacement procedures are

described in Part

The following items are necessary for implementing the problem isolation procedures:

1.

2. Phillips head screwdriver

3.

4. Cleaning disk kit (for FDD testing)

5. Printer port LED

6.

7. Multimeter

Power supply unit

FDD

HDD

Keyboard

Display

4.

T1000LE Diagnostics Disk

Work disk (for FDD testing)

RS-232-C, printer wraparound connectors

The problem isolation flowchart described in Section 2.2 can

isolation procedures are necessary to isolate a

TlOOOLE

problem.

be used to determine which

2-3

2.2

PROBLEM ISOLATION

FLOWCHART

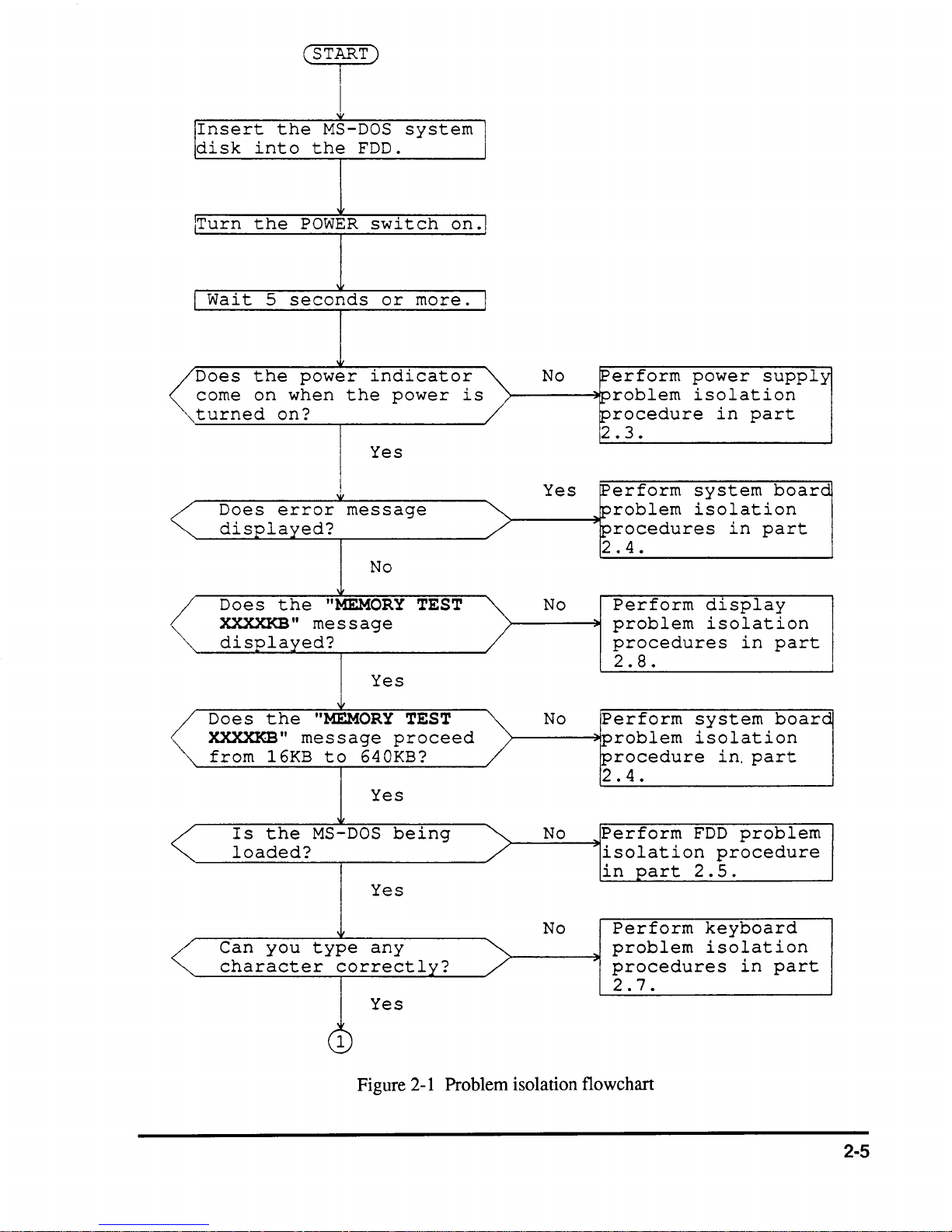

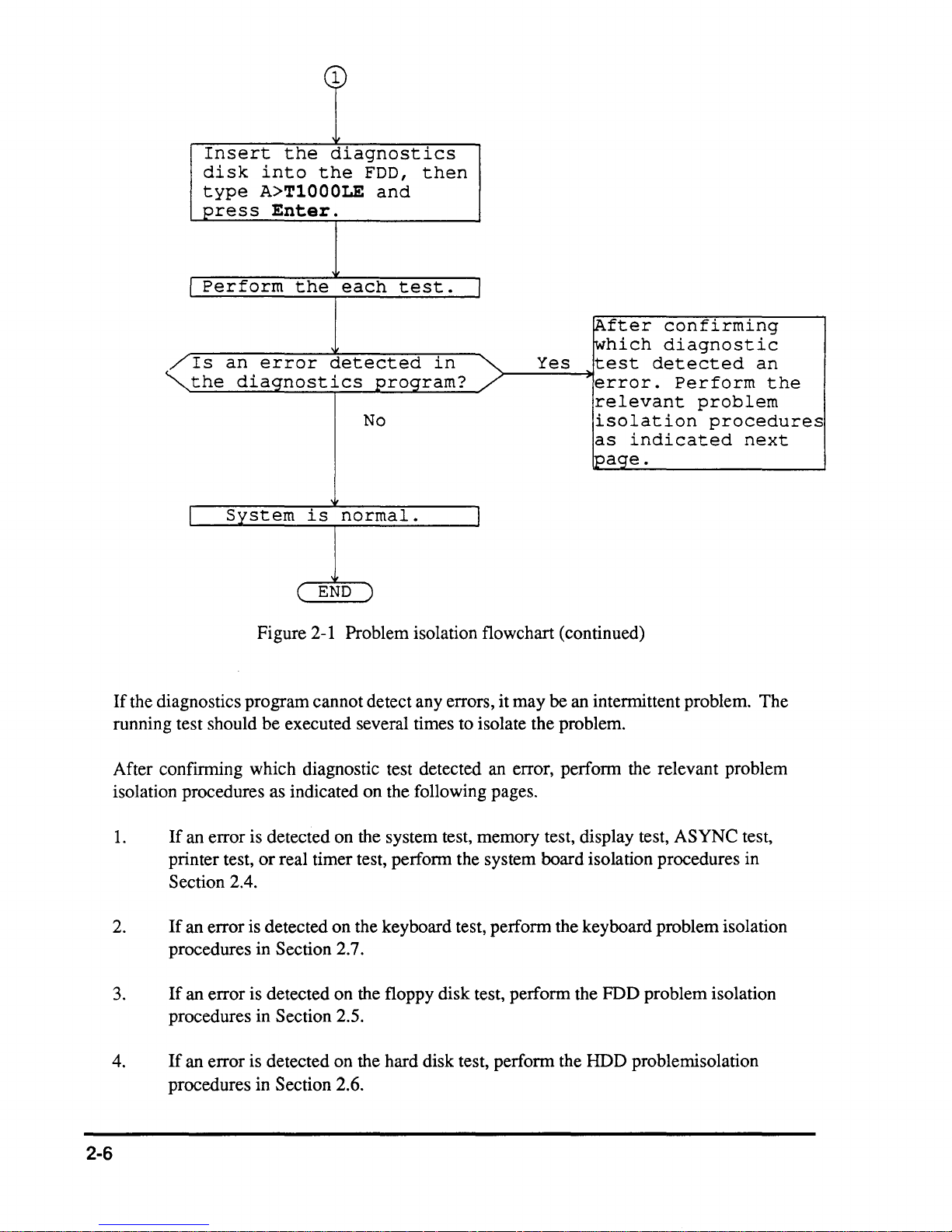

The flowchart in Figure 2-1 is used as a guide for determining which FRU is defective. Please

confIrm

the following before performing the flowchart procedures.

1.

2.

Disconnect all optional equipment.

Remove any disk in the FDD.

2-4

!IInsert

disk

the

into

(STjT)

I

'It'

MS-DOS

the

FDD.

system

!

lTurn

I

Wait

Does

corne

turned

Does

displayed?

Does

XXXXKB"

displayed?

the

5

the

on

POWER

seconds

power

when

on?

error

the

message

switch

or

indicator

the

power

Yes

message

No

"MEMORY

Yes

on.1

more.

TEST

is

J

No

Yes

No

~erform

~roblem

procedure

2.3.

~erform

problem

procedures

2

.4.

Perform

problem

procedures

2 . 8 .

power

isolation

in

part

system

isolation

in

display

isolation

in

supply

board

part

part

Does

XXXXKB"

from

Is

the

16KB

the

loaded?

Can

you

character

"MEMORY

message

to

640KB?

Yes

MS-DOS

Yes

type

any

correctly?

Yes

,

1

Figure

TEST

proceed

being

2-1

Problem

No

No

No

isolation

Perform

problem

procedure

2.4.

Perform

isolation

in

part

Perform

problem

procedures

2.7.

flowchart

system

isolation

in,

part

FDD

problem

procedure

2.5.

keyboard

isolation

in

board

part

2-5

1

Insert

disk

type

press

Perform

Is

an

the

diagnostics

System

the

into

diagnostics

the

A>T1000LE

Enter.

the

each

error

is

(

END)

detected

normal.

FDD,

then

and

test.

program?

No

in

I

Yes

After

which

test

error.

relevant

isolation

as

confirming

diagnostic

detected

Perform

problem

indicated

an

the

procedures

next

page.

Figure 2-1 Problem isolation flowchart (continued)

If

the diagnostics program cannot detect any errors,

running test should be executed several times to isolate the problem.

After confirming which diagnostic test detected an error, perform the relevant problem

isolation procedures as indicated on the following pages.

1.

2.

3.

4.

If

an error is detected on the system test, memory test, display test, ASYNC test,

printer test,

Section 2.4.

If

an error is detected on the keyboard test, perform the keyboard problem isolation

procedures in Section 2.7.

If

an error is detected on the floppy disk test, perform the FDD problem isolation

procedures in Section 2.5.

If

an error is detected on the hard disk test, perform the HDD problemisolation

procedures in Section 2.6.

or

real timer test, perform the system board isolation procedures in

it

may be an intermittent problem. The

2-6

2.3

POWER SUPPLY PROBLEM

ISOLATION PROCEDURES

This section describes how to determine

PROCEDURE I and continue with the other procedures as instructed. The procedures

described in this section are:

PROCEDURE

PROCEDURE

PROCEDURE

1:

2:

3:

Indicator Check

Connector, Cable, and Power Switch Check

Replacement Check

if

the power supply is defective. Start with

2-7

PROCEDURE 1

Indicator Check

The indicator labeled

connect the A C adapter to the T

is abnonnal, this indicator blinks red

(1)

If

the DC IN indicator blinks red

the system, see Check

(2)

If

the DC IN indicator blinks red

"DC

IN" lights red

if

power is supplied from the AC adapter when you

l000LE and a wall outlet.

or

does not glow.

or

does not glow before the power is turned on to

1.

or

does not glow after the power is turned on to the

If

the A C adapter's output voltage

system, see Check 2. Also, check the power output circuits to the system.

Check 1

Unplug the AC adapter from the wall outlet and system. Reconnect the AC

adapter to the system and wall outlet, then restart the system.

Check 2

still exists, perfonn Check

Check the AC adapter voltage supplied to the system using the multimeter.

2.

it is not nonnal (DC + 12V), the AC adapter may be damaged. Replace it with

a new AC adapter.

If

the problem still exists, perfonn PROCEDURE

check the battery charge circuits.

The indicator labeled

or

lights green (when the battery pack is fully charged)

adapter when you connect the battery pack to the system.

"Battery" lights orange (while the AC adapter is charging the battery)

if

power is supplied from the AC

If

only the battery pack is connected

to the system, this indicator lights green (the battery pack is in use)

is low), and

if

this indicator blinks red, the battery pack is completely discharged.

If

the problem

2.

or

lights red (the battery

If

Also,

(1)

If

the battery indicator blinks or does not glow when you connect the AC adapter to

the system, see Check

(2)

If

the battery indicator blinks or does not glow when you disconnect the AC adapter

to the system, see Check

Check 3

Check that the battery pack is correctly connected to the system.

problem still exists, perfonn Check 4.

Check 4

Connect the AC adapter to the system and wait

problem still exists, perfonn Check 5.

Check 5

Replace the battery pack with a known good battery pack.

exists, perfonn

2-8

3.

6.

Also, check the power output circuits to the system.

30 minutes or

If

the problem still

PROCEDURE

2.

Also, check the battery charge circuits.

so.

If

If

the

the

Check 6

Check that the battery pack is correctly connected to the system.

problem still exists, perfonn Check 7.

If

the

Check 7

Replace the battery pack with a known good one.

perfonn

PROCEDURE 2.

If

the problem still exists,

2-9

PROCEDURE 2

and

Connector, Cable,

The battery pack is connected directly to the power supply board and an optional battery cable

is connected to the system board through the power supply board on the back

The sub battery and power switch cable are connected directly to the system board. Any

these cables may be disconnected

cables. Disassembly procedures are described in

Power Switch Check

or

damaged. Disassemble the system unit to checking the

Part 4.

of

the top cover.

of

Check 1

Check 2

Check 3

Check that the following cables are correctly connected to the system board,

power supply board, and LED board.

LED board

PS board PJ802

Power switch --------> System board

If

any

of

If

the problem still exists, perform Check 2.

Recheck the above cables using the multimeter.

damaged, replace them and restart the system.

perform Check

Check the power switch contact using the multimeter.

contact is bad, replace the power switch with a new one and restart the system.

If

the problem still exists, perform PROCEDURE 3.

PJ601 <--------> System board

PJ602 <--------> PS board

PJ603 <--------> System board

<--------

PJ805 <--------> DC jack

these cables are disconnected, connect them and restart the system.

3.

> System board

PJ503

PJ803

PJ505

PJ502

PJ702

PJ501

If

any

of

the cables look

If

the problem still exists,

If

the power switch

2-10

PROCEDURE 3

Replacement Check

In this system unit, the power board, DC-IN board, LED board, and system board are

connected with the power supply circuits, and the LED board is connected with the indicator

circuits. Any

voltages and/or replace them. Replacement procedures are described in Part 4.

of

these boards may be damaged. Perform Checks 1 through 4 to check the

Check 1

Check 2

Check 3

Check 4

Replace the DC-IN board with a new one and restart the system.

problem still exists, perform Check

Replace the power board with a new one and restart the system.

2.

If

the problem

still exists, perform Check 3.

Replace the LED board with a new one and- restart the system.

If

the problem

still exists, perform Check 4.

Replace the system board with a new one.

If

the problem still exists, other

units may be damaged. Continue troubleshooting the system unit.

If

the

2-11

2.4 SYSTEM BOARD PROBLEM

ISOLATION PROCEDURES

This section describes how to detennine

PROCEDURE 1 and continue with the other procedures as instructed. The procedures

described in this section are:

PROCEDURE

PROCEDURE

PROCEDURE

1:

2:

3:

Message and Beep Sound Check

Printer Port LED Check

Test Program Check

if

the system board is defective. Start with

2-12

PROCEDUREl

Message

After the power is turned on, the system performs the initial reliability test (IRT) which is a

program stored in

the system board.

If

an error message appears on the screen, perform Check

the screen, perform

Check 1

Check 2

and

Beep Sound Check

BIOS ROM on the system board. The IRT tests and initializes each IC on

1,

and

if

nothing is displayed on

PROCEDURE

If

the following error message appears on the screen, press any key. This

program confirms the current system configuration and the configuration

stored to RTC memory.

appear. You can easily set the current configuration in the RTC memory by

pressing any key.

***SYSTEM CONFIGURATION ERROR***

A

checksum

Press

If

the following message appears, press any key. At this time the resumed data

will be erased.

any

2.

If

they are different, the following message will

If

another error message appears, perform Check

error

key

If

another error message appears, perform Check

occurred

for

default

in

set

the

configuration

....

2.

RAM.

3.

WARNING:

PRESS

ANY

RESUME

KEY

TO

FAILURE.

CONTINUE.

2-13

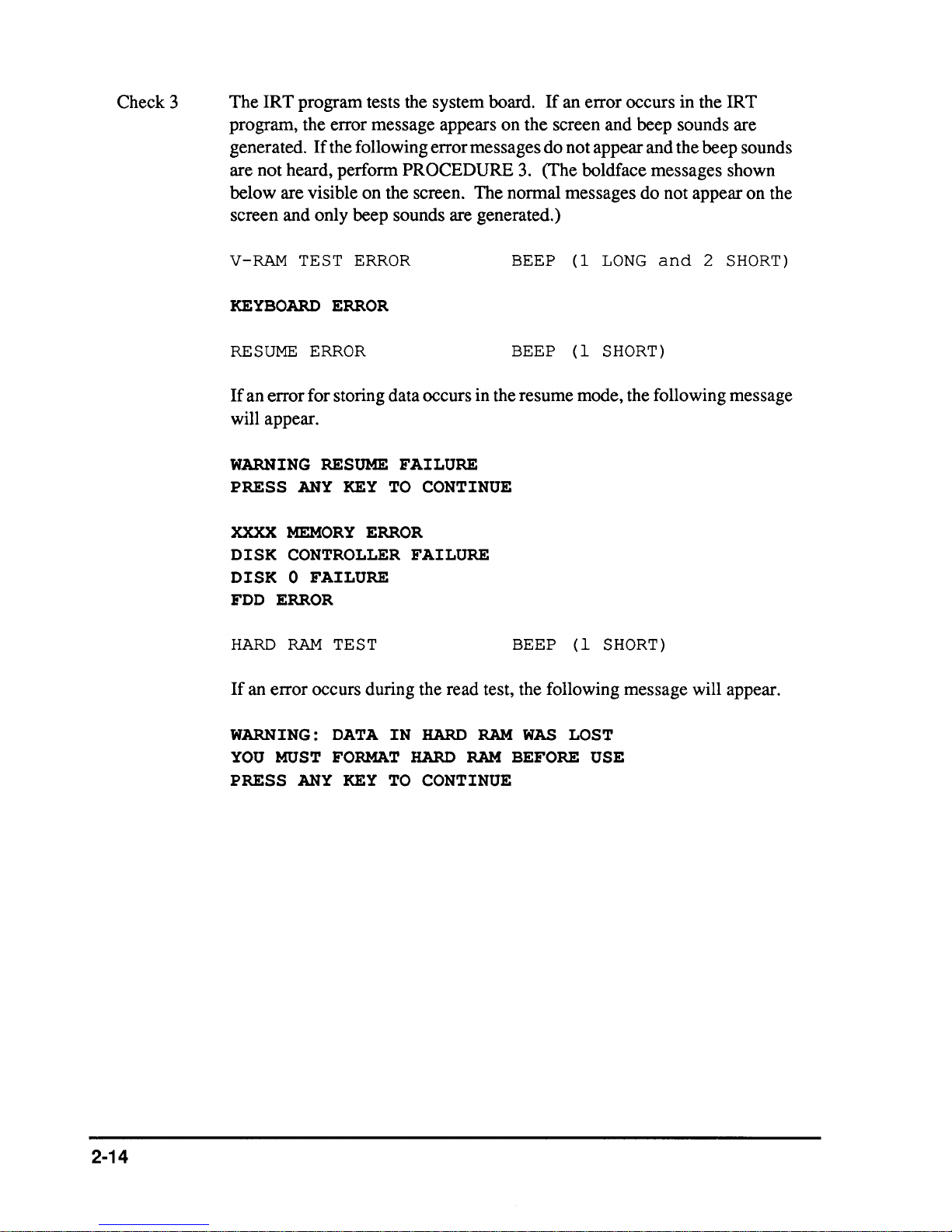

Check 3

The IRT program tests the system board.

program, the error message appears on the screen and beep sounds are

generated.

are not heard, perform

below are visible on the screen. The normal messages do not appear on the

screen and only beep sounds are generated.)

If

the following error messages do not appear and the beep sounds

PROCEDURE

If

an error occurs in the IRT

3.

(The boldface messages shown

V-RAM

KEYBOARD

RESUME

If

an error for storing data occurs in the resume mode, the following message

will appear.

WARNING

PRESS

XXXX

DISK

DISK

FDD

HARD

If

an error occurs during the read test, the following message will appear.

TEST

ERROR

ERROR

ERROR

RESUME

ANY

KEY

MEMORY

ERROR

CONTROLLER

0 FAILURE

ERROR

RAM

TEST BEEP (1

FAILURE

TO

CONTINUE

FAILURE

BEEP (1

BEEP (1

LONG

SHORT)

SHORT)

and

2

SHORT)

2-14

WARNING:

YOU

MUST

PRESS

ANY

DATA

IN

FORMAT

KEY

TO

HARD

HARD

RAM

RAM

CONTINUE

WAS

LOST

BEFORE USE

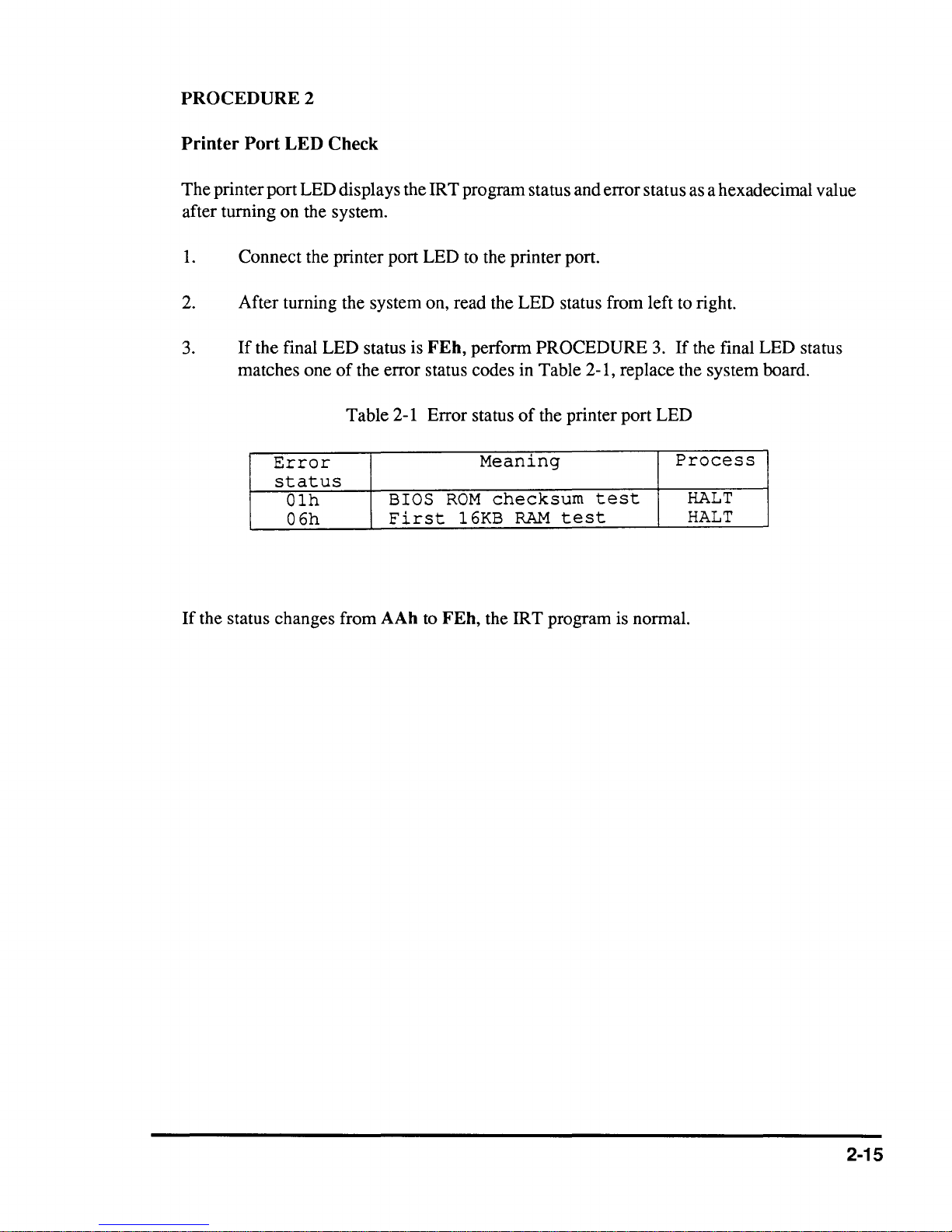

PROCEDURE

2

Printer

Port

LED

Check

The printer port LED displays the IRT program status and error status

after turning on the system.

1.

Connect the printer port LED to the printer port.

2. After turning the system on, read the LED status from left

3.

If

the final LED status is

of

matches one

the error status codes in Table 2-1, replace the system board.

Table 2-1 Error status

Error

FEh,

perform PROCEDURE

of

the printer port LED

Meaning

3.

If

Process

status

Olh

06h

BIOS

First

ROM

l6KB

checksum

RAM

test

test

as

a hexadecimal value

to

right.

the final LED status

HALT

HALT

If

the status changes from AAh

to

FEh,

the IR T program is normal.

2-15

PROCEDURE 3

Test Program Check

The test program which is stored in the

TlOOOLE

Diagnostics Disk has several programs

for testing the system board. Perform the following tests. Detailed operation is described

in Part

3.

System test

Memory test

Display test

Printer test

ASYNC test

Real timer test

If

an error is detected during the above tests, replace the system board.

If

the problem still

exists, another unit may be defective. Continue troubleshooting the system unit.

2-16

2.5

FLOPPY DISK DRIVE

PROBLEM ISOLATION

PROCEDURES

This section describes how to determine

PROCEDURE 1 and continue with the other procedures as instructed. The procedures

described in this section are:

PROCEDURE

PROCEDURE

PROCEDURE

1:

2:

3:

Format Check

Test Program Check

Connector Check

if

the floppy disk drive is defective. Start with

2-17

PROCEDUREl

Format

Prepare a new floppy disk by fonnatting

If

the floppy disk does not fonnat correctly, check the following items.

Check 1

Check 2

Check 3

Check

it

using the MS-DOS

Check that the FDD indicator lights.

3.

If

it

lights,

Check that the

When

When

If

If

the media type is 2DD, use the FORMAT/3 command.

the media type is 2HD, use the FORMAT command.

the

FORMAT

the

FORMAT

still exists,

perfonn

MS-DOS

Check 2.

FORMAT

command was used correctly,

command was not used correctly,

perfonn

Check 3.

Ifitdoes

command was used correctly.

FORMAT

not light, perfonn PROCEDURE

perfonn

Clean thereadlwrite head using the 3.5-inch FDD cleaning kit.

still exists,

perfonn

PROCEDURE 2.

try

command.

Check 3.

again.

If

the problem

If

the problem

2-18

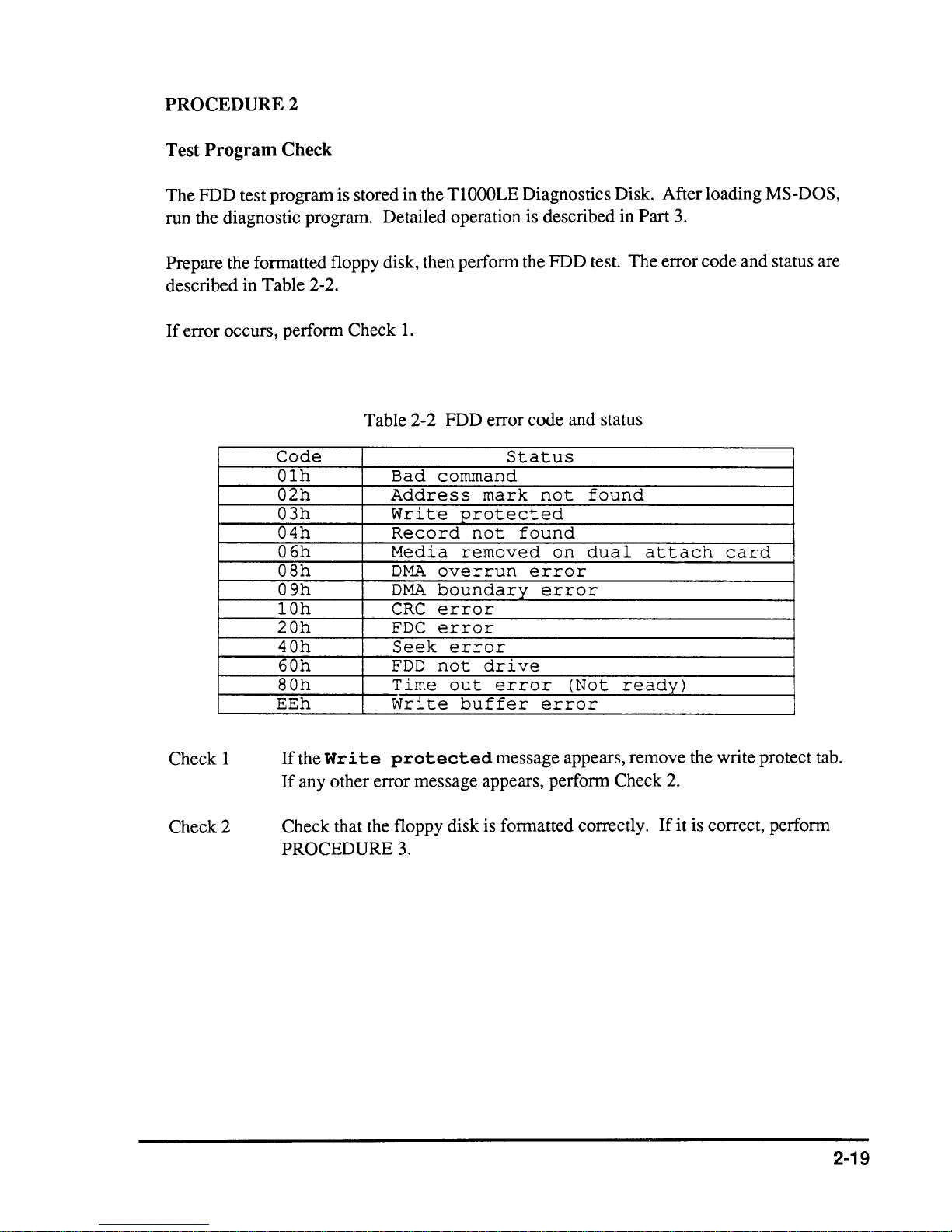

PROCEDURE 2

Test Program Check

The FDD test program is stored in the

run the diagnostic program. Detailed operation is described in Part 3.

Prepare the formatted floppy disk, then perform the FDD test. The error code and status are

described in Table 2-2.

If

error occurs, perform Check

Table 2-2 FDD error code and status

Code

Olh

02h

03h

04h

06h

OSh

09h

lOh

20h

40h

60h

SOh

EEh

Bad

Address

Write

Record

Media

DMA

DMA

CRC

FDC

Seek

FDD

Time

Write

1.

command

overrun

boundary

error

error

not

TlOOOLE

Status

mark

protected

not

removed

error

drive

out

error

buffer

Diagnostics Disk. After loading MS-DOS,

not

found

found

on

dual

attach

card

error

error

(Not

ready)

error

Check 1

Check 2

If

the

Wr i te

U any other error message appears, perform Check 2.

Check that the floppy disk is formatted correctly.

PROCEDURE 3.

protected

message appears, remove the write protect tab.

If

it is correct, perform

2-19

PROCEDURE 3

Connector Check

The FDD is connected to the system unit by the FDD cable. This cable may

be disconnected

from the system unit. Disassemble the system unit and check the FDD cable. Disassembly

procedures are described in

Check 1

Check that the following cable is correctly connected to the system board.

FDD 1 cable

If

this cable is disconnected, connect it to the system unit and perfonn

PROCEDURE 1 and 2.

Check 2

The FDD may be defective. Replace it with a new FDD, then perfonn

PROCEDURE 1 and 2.

Check 3

The system board may

Part 4.

-------> System board PJ5

If

the problem still exists, perfonn Check

If

the problem still exists, perfonn Check 3.

be defective. Replace it with a new system board.

2.

2-20

2.6 HARD DISK DRIVE PROBLEM

ISOLATION PROCEDURES

This section describes how to determine if the hard disk drive is defective. Start with

PROCEDURE 1 and continue with the other procedures

described in this section are:

as

instructed. The procedures

PROCEDURE

PROCEDURE

PROCEDURE

CAUTION: The contents

problem isolation procedures. Before continuing, transferthe contents

the hard disk to floppy disks. This can be done with the MS-DOS BACKUP command. (See the MS-DOS

1:

2:

3:

Logical Format Check

Test Program Check

Connector Check

of

the hard disk will

be

erased by performing the HDD

manualfor

details.)

of

2-21

PROCEDUREl

Logical Format Check

Using the MS-DOS system disk, make a partition

command. Then format the hard disk by using the

Is

after FORMAT to transfer the system program.

If

normal operation is restored, the HDD is normal.

perform

PROCEDURE

2.

of

the hard disk by using the FDISK

FORMAT command. At this time enter

If

normal operation is not restored,

2-22

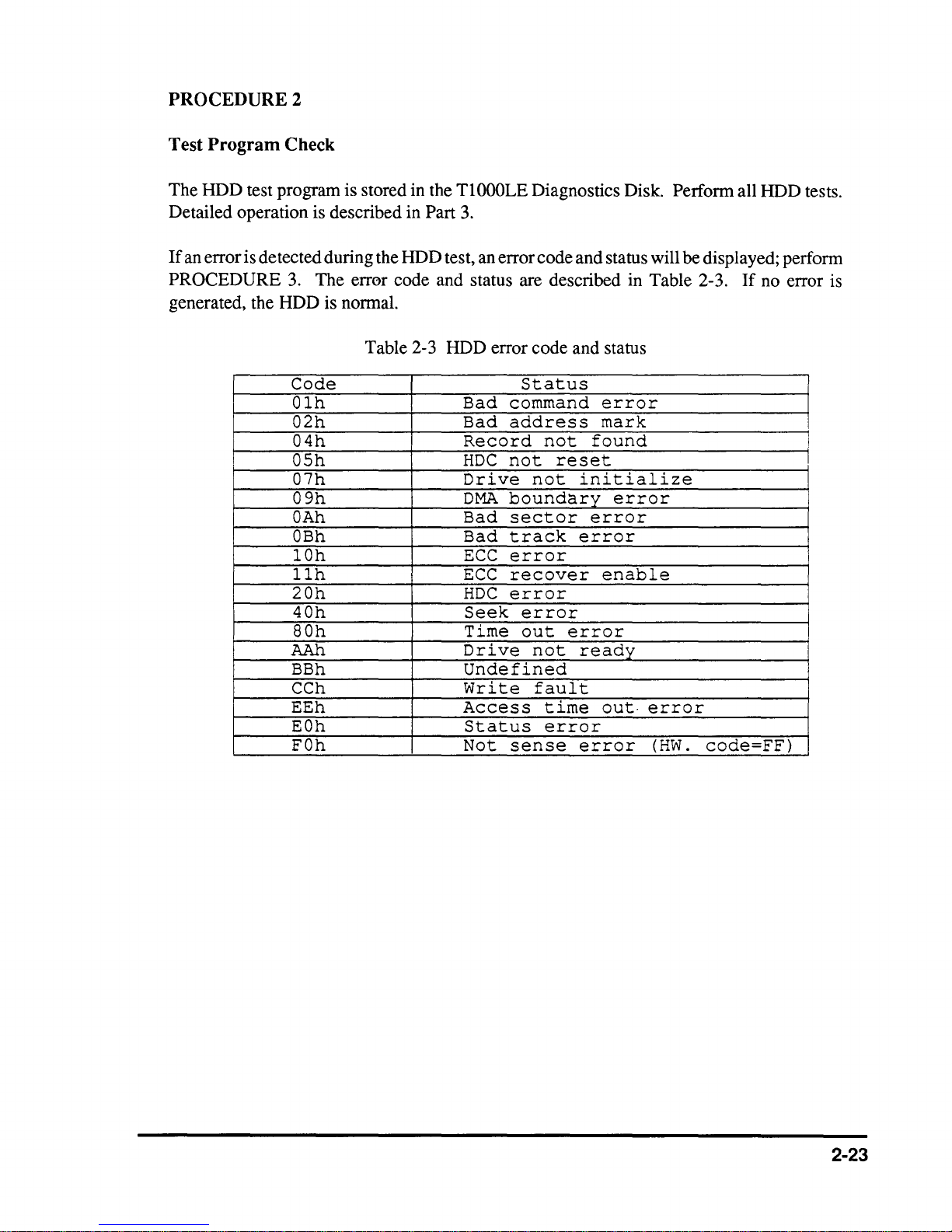

PROCEDURE

Test

Program

2

Check

The HDD test program is stored in the

Detailed operation is described in

If

an error is detected during the HDD test, an error code and status will be displayed; perform

PROCEDURE 3. The err0r code and status are described in Table 2-3.

generated, the HDD is normal.

Table 2-3 HDD error code and status

Code

Olh

02h

04h

OSh

07h

09h

OAh

OBh

lOh

llh

20h

40h

SOh

AAh

BBh

CCh

EEh

EOh

FOh

TlOOOLE

Part

3.

Bad

Bad

Record

HDC

Drive

DMA

Bad

Bad

ECC

ECC

HDC

Seek

Time

Drive

Undefined

Write

Access

Status

Not

Diagnostics Disk. Perform all HDD tests.

If

no error is

Status

command

address

not

not

not

boundary

sector

track

error

mark

found

reset

initialize

error

error

error

error

recover

enable

error

error

out

error

not

ready

fault

time

out·

error

error

sense

error

(HW.

code=FF)

I

2-23

PROCEDURE

3

Connector Check

The

packed HDD is connected to the system board by the HDD connector. Disassemble the

system unit and check the

is disconnected, connect

problem still exists, perform Check

HDD.

it

to the system board and perform PROCEDURES I and 2.

Detailed procedures are described in Part 4.

If

1.

this cable

If

the

Check I

Check 2

The HDD may be damaged. Replace the HDD unit with a new one.

still occurs, perform Check

The

system board may be damaged. Replace the system board with a new one.

2.

If

the error

2-24

Loading...

Loading...