Page 1

Intelligent Image Sensor

iIS-010 series

TK6234A5 : iIS-010

TK6238A7 : iIS-011

TK6240A5 : iIS-012

ProductSpecification

1. Product Description·································2

2. Features ···················································2

3. Configuration···········································4

4. Name and Function of Parts·····················6

5. Specification············································9

6. External View········································22

• Restriction For Use·································26

• Precautions ·············································27

• Exemption Clauses ·································27

The contents of this product specification may be revised without notice to reflect future product

modifications. Please confirm the functions and the spec ifica tio ns on the latest specification sheet.

(Total 29 pages)

D4130145B

Page 2

iIS-010 series product specification

Ver. B (Oct. 12 2004)

1. Product Description

"intelligent image sensor" iIS-010 series is an integrated image processing system consists of CCD

camera head, control unit, and application software. iIS-010 series is a pre-packaged solution designed to

simplify the deployment of machine vision in industrial applications.

2. Features

(1) High measurement accuracy

High measurement precision finds small defects in manufactured parts.

(2) Double speed VGA sensor

Remote head VGA sensor connected through a single cable with all camera electronics contained

within the iIS assembly. The camera electronics support a 60Hz progressive scan frame rate.

(3) Interface for industrial applications

Industrial and intelligent I/O interfaces for part type (job code), part inspection, part decision and light

control.

(4) Standard interfaces

Standard serial and Ethernet 10/100baseT communication interfaces for configuration and data

reporting.

(5) Graphical user interface

Intuitive step-by-step configuration and monitoring GUI, accessible through a standard Microsoft

browser page and available in two languages (English and Japanese).

(6) Local Scaling / Global Scaling

Simple calibration procedure which factors out both perspective and non-linear lens distortions,

provides high measurement accuracy. And measurement in metric, English or pixel, supports unique

system requirements.

(7) History reports

Customer-defined history reports including parts images records information on recent passed, failed

and reworked parts; key measures; specifics on which part failed to enable diagnosis. Provides a history

of recent good and bad label images enables you to monitor and spot error trends on a line.

2

D4130145B

Page 3

iIS-010 series product specification

Ver. B (Oct. 12 2004)

(8) Gauge Application

Comprehensive set of gauging tools gives you the ability to precisely and accurately measure lines,

angles between lines, ellipses and circles (center, circularity or out-of-round, nicks, major and minor

axes),arcs (centers and lengths), Annuli, thread spacing (“wave tool ”),multiple measures of length and

spacing of parts such as pins on an electrical connector (“rake tools ”),and other part measures.

(9) Label Application

User-defined features including label rotation, movement, rejection thresholds enables you to define

your label quality criteria. All settings are quickly defined and changed using a sliding bar from “lower”

to “higher”. Automatic learning of good labels, using a proprietary neural net learns labels and variations.

3

D4130145B

Page 4

iIS-010 series product specification

3. Configuration

Hardware

iIS-010 Camera Head: 20mm square type ···················································1

Camera cable: Direct Fixing (2m) ··················································1

*Cable fixing direction: (viewed from rear) Right

Control Unit (iIS-010 series compatible)········································1

iIS-011 Camera Head: φ17mm type ····························································1

Camera cable: Separated type (2m) ················································ 1

*Cable fixing direction: (viewed from rear) Rear

Control Unit (iIS-010 series compatible)········································1

iIS-012 Camera Head: C mount head type ··················································1

Camera cable: Direct Fixing (2m) ··················································1

*Cable fixing direction: (viewed from rear) Right

Ver. B (Oct. 12 2004)

Control Unit (iIS-010 series compatible)········································1

・Accessories

Ethernet crossover cable KB-10T5-03CK (Sanwa-supply, 3m) ·············································1

DIN rail mounting kit CKD-80 (Takachi Denki)································································2

Screws for the mounting kit PB3X10BS-NI················································································4

Plug for power cable 39860-1002 (MOLEX, 2 terminal type)··········································1

Plug for parallel I/O cable 1-1546208-5 (AMP/Buchanan, 15 pin type)··································· 1

Floppy Disk Including switching applica t ion file················································1

Operation Manuals Basics (Japanese)············································································1

Basics (English)··············································································1

Applications (Japanese)··································································1

Applications (English)···································································· 1

Calibration sheet A4 size ··························································································· 1

* Ethernet® is a trademark of Xerox Corporation U.S.

4

D4130145B

Page 5

iIS-010 series product specification

Software

iIS Web pages for viewing on Internet Explorer® (Installed)

iWorks(Gauge) Application for Gauge (Auto download from the control unit)

iWorks(Label) Application for Label (Auto download from the control unit)

iAssistant Application for Upgrade (Auto download from the control unit)

iServer Application for monitoring connection status (Installed)

HTML Help Microsoft® online help for Gauge / Label application

Switch To Gauge Binary File for switching to Gauge (including in the floppy disk)

Switch to Label Binary File for switching to Label (including in the floppy disk)

Others ActiveX® control libraries (Auto download from the control unit)

* Microsoft®, Windows®, Microsoft® Internet Explorer, and ActiveX® are registered trademarks

of Microsoft Corporation, U.S., in the U.S. and other countries.

Ver. B (Oct. 12 2004)

Optional Accessories

Camera Lens

For iIS-010 Dedicated lenses (M10.5 P0.5 female)

For iIS-011 Dedicated lenses (M15.5 P0.5 male)

For iIS-012 C mount lenses

Camera mounting kit

For iIS-010 CPT4310A / CPT4310B

For iIS-011 CPT5130

For iIS-012 CPT5110

*Please contact your dealer / distributor for details of option units.

Peripheral Devices (compatibility verified)

DC Power supply PS5R-D24 (Idec)

PC DynaBook 2590X (Windows® 2000 Japanese / English)

Local Display RDF17S (Mitsubishi)

*Please contact your dealer / distributor for the other peripheral devices.

5

D4130145B

Page 6

iIS-010 series product specification

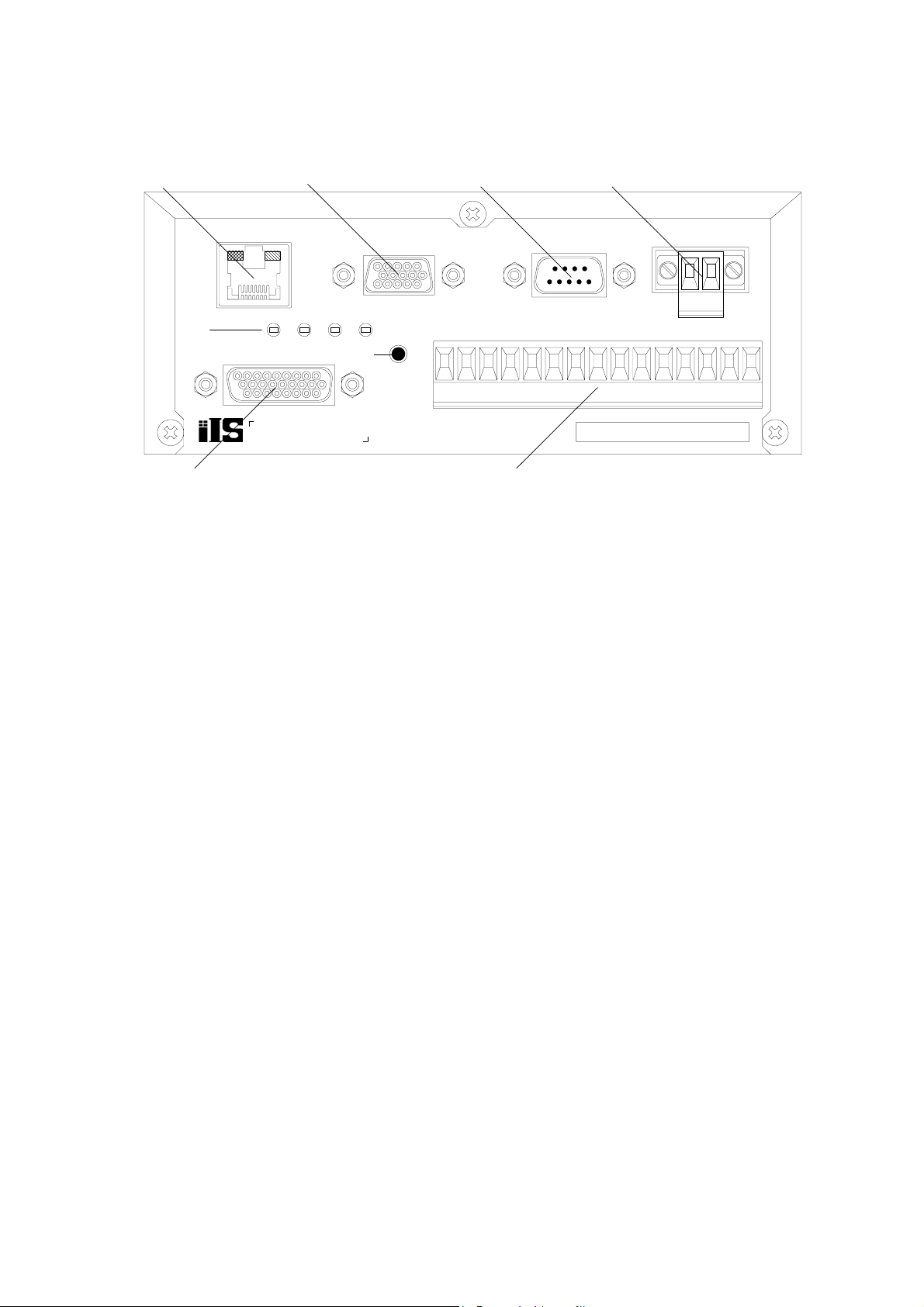

4. Name and Function of Parts

Ver. B (Oct. 12 2004)

1

ETHERNET

5

2

POWER LED1 LED2 LED3

CAMERA

DISPLAY RS232C

RESET

7

010

6

Figure 1. Control unit (Front-panel side)

1. RJ45 connector for Ethernet Connect with PC or PLC by using Ethernet cable.

2. Local Display connector

3 4

RDY

STR

GPO2

GPO1

GPO3

8

GPO0

COM1

TRIG

D.TRIG

POWER

GPI1

GPI0

V+

COM0

V-

GPI3

GPI2

SEL

A XGA Monitor can be connected directly to the control unit, for local display of the camera image.

3. RS-232C connector Connect with PC or PLC by using the crossover RS-232C cable.

4. Power connector Connect the DC Power Supply (+24V DC ±10%) to the control unit power connector.

5. LED indicator

POWER: power-on indicator - steady green

LED1: server “heartbeat” - slow flashing green

LED2: acquisition (frame) done (or processing start) ‐ rapid flashing green

LED3: reserved for future use ‐ steady off

6. Camera connector Connect the control unit and camera head with the camera cable provided with iIS-010 series kits.

7. Reset button Reset the control unit or reset to the factory default.

6

D4130145B

Page 7

iIS-010 series product specification

8. Parallel I/O 8 inputs and 7 outputs parallel I/O.

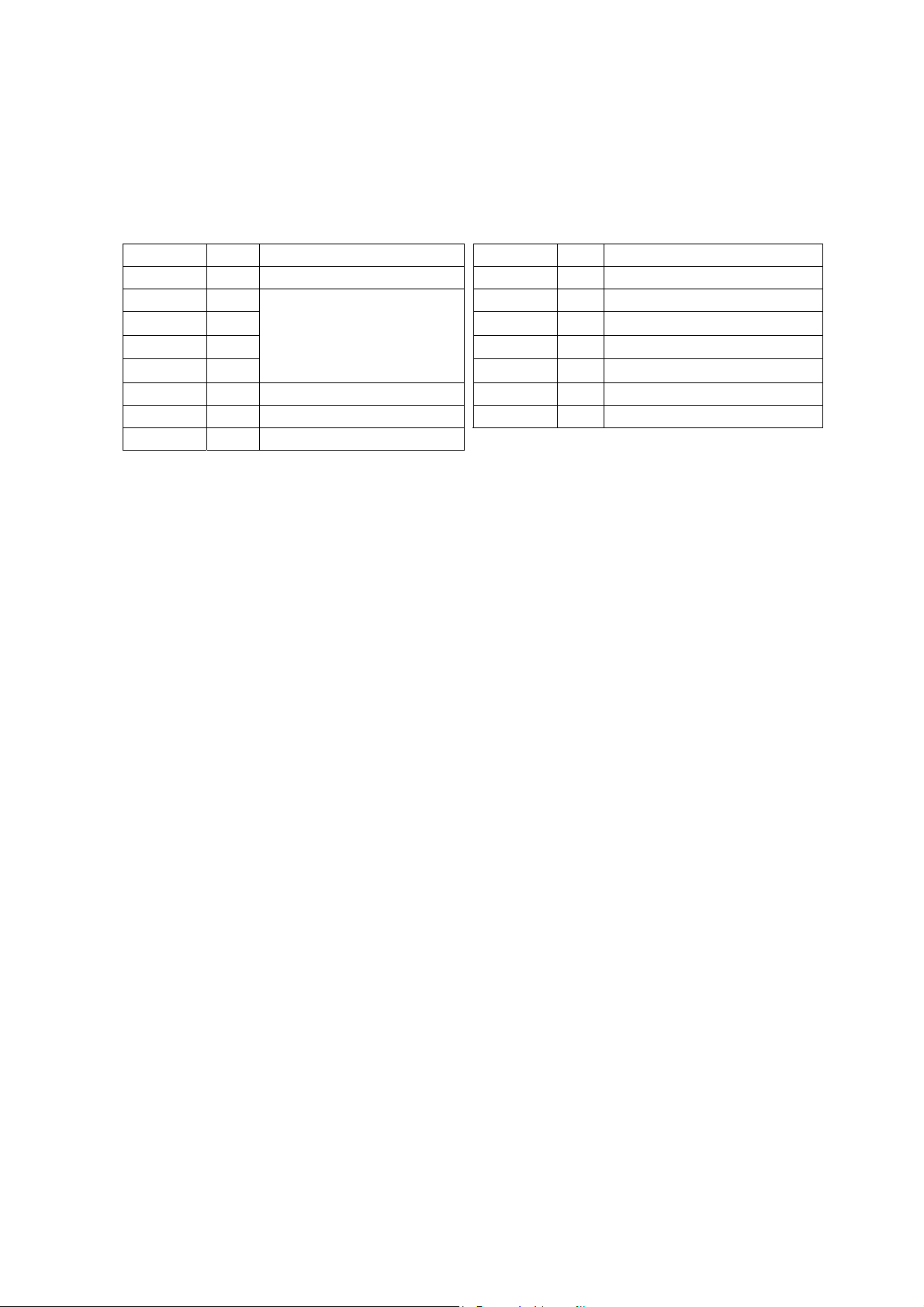

Table 1. Parallel I/O terminal functions

Ver. B (Oct. 12 2004)

NAME I/O Function Name I/O Function

I

COM0

GPI0

GPI1

GPI2

GPI3

SEL

D.TRIG

TRIG

COM0: Common input for all other inputs.

GPI0 ~ 3: 4 inputs for solution selection. This is a BCD code representing 16 different solutions that

Common for inputs COM1

I

I

Select solution input

(4bit, ID00~15)

I

I

I

Change solution input STR

I

Decision trigger input RDY

I

Inspection trigger input

GPO0

GPO1

GPO2

GPO3

O

Common for outputs

O

Result (Pass) output

O

RESERVE

O

O

O

O

Result (Recycle) output

Result (Reject) output

Strobe pulse output

Ready signal output

can be loaded.

SEL: 1 input for job change - This input will generate an interrupt to the CPU informing it that a

line changeover is taking place. The system will then load one of 16 predefined solutions

according to the BCD code present on the job selection inputs. During this process, the

ready signal will go OFF indicating a busy state.

D.TRIG: 1 decision trigger input representing detection of a valid part to make a decision on.

Decisions are queued following every inspection.

TRIG 1 inspection trigger input representing detection of a valid part to inspect.

COM1: Common output for all other outputs.

GPO0 ~ 3: 4 outputs for pass, fail, rework and reserve

STR: 1 strobe light control with offset and pulse width programmable.

RDY: 1 ready indicator. This OUTPUT will be active when the iIS system is available to process

parts. It is a level sensitive signal where a ON indicates the system is available and a OFF

indicates that it is busy, not configured or unable to continue due to a catastrophic event.

7

D4130145B

Page 8

iIS-010 series product specification

Ver. B (Oct. 12 2004)

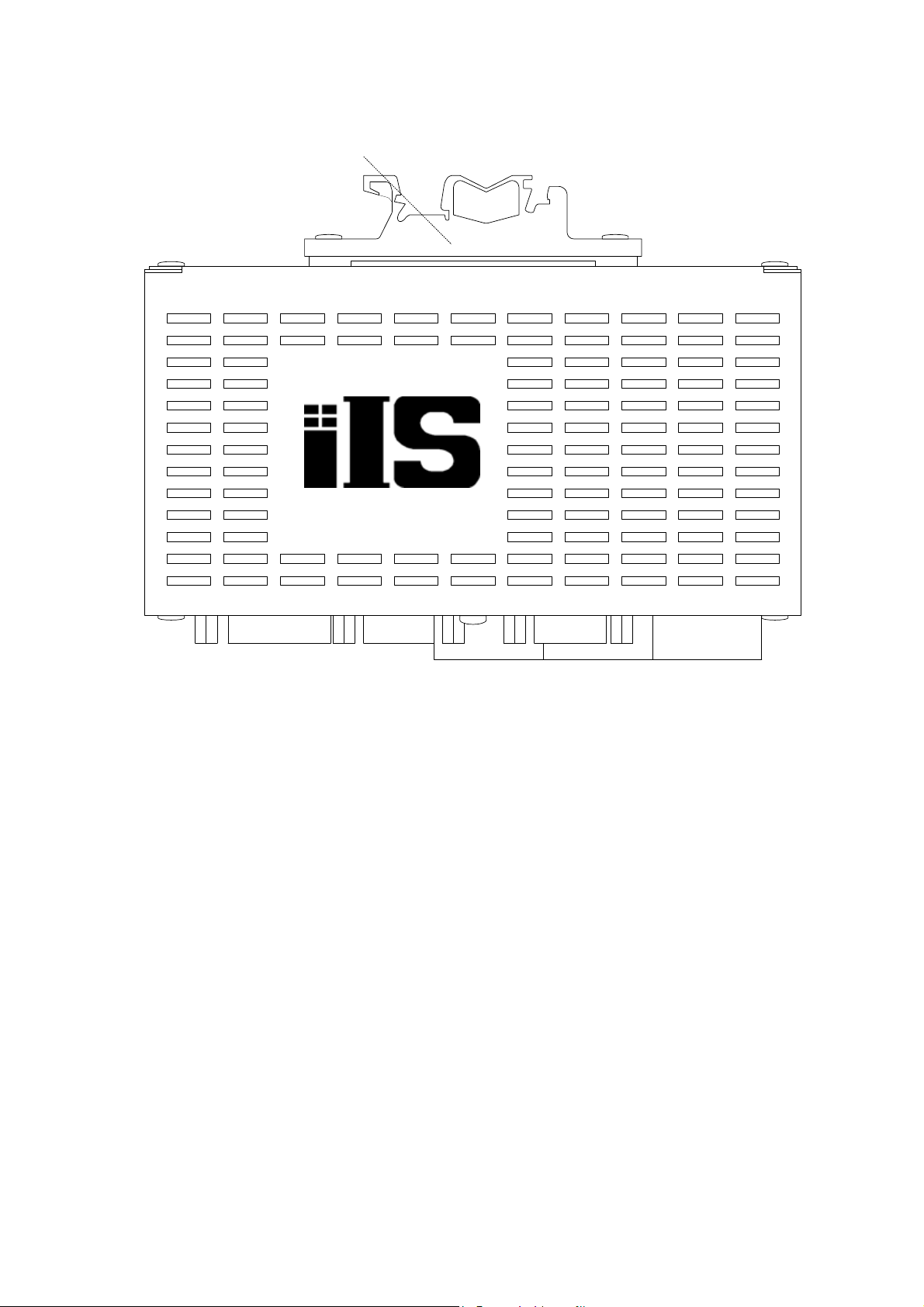

9

9. Mounting kits for DIN rail You can mount with 32mm / 35mm width type DIN rail.

Figure 2. Control unit (top view)

8

D4130145B

Page 9

iIS-010 series product specification

5. Specification

[General Specification]

Ver. B (Oct. 12 2004)

Power Supply +24V DC ±10% (Ripple voltage: 50mV

Power Consumption 10W or less (+24V DC)

Operating T emperature 0 °C ~ +40 °C

Operating Humidity 30 % ~ 85 %RH (No condensing)

Storage Temperature -20 °C ~ +60 °C

Storage Humidtity 10 % 95 %RH (No condensing)

EMC conditions (Electro-Magnetic Compatibility)

(Electro-Magnetic Interference) EN50081-2 (Examination level: EN55011-A) Conformity

EMI

(Electro-Magnetic Susceptibility) EN61000-6-2 Conformity

EMS

* Conformity of EMC conditions

About the conformity of the EMC standard of this machine, it has guaranteed in the cond itions

combined with the peripheral devices of the 3rd clause.

When used combining parts other than specification of our company, I ask you to have final

EMC conformity checked of a visitor with a machine and the whole equipment.

[Camera head specification]

Image sensor All Pixel's Data Read-out Interline CCD

Total pixels 692 (H) × 504 (V)

or less)

P-P

Valid pixels 648 (H) × 494 (V)

Unit cell size 7.4 (µm) × 7.4 (µm)

Sensitivity 400lx, F5.6 (Exposure time = 1/60s)

External Dimensions

iIS-010 20 (W) × 20 (H) × 25 (D) mm

iIS-011 φ17 × 36.2 (D) mm

iIS-012 φ35 × 40 (D) mm

Lens mount

iIS-010 Special mount (M10.5 P0.5 female)

iIS-011 Special mount (M15.5 P0.5 male)

iIS-012 C mount

Weight

iIS-010 Approx. 19g (Excluding cable)

iIS-011 Approx. 16g (Excluding cable)

iIS-012 Approx. 55g (Excluding cable)

Camera cable length 2m (iIS-010 series)

9

D4130145B

Page 10

iIS-010 series product specification

Ver. B (Oct. 12 2004)

Relative Spectrum Response (*Including lens characteristics, Excluding light source characteristics)

Sensitivity

Wave Length(nm)

Figure 3. Relative Spectrum Response

[Control Unit]

Camera input 1

V ideo output pixels 640 (H) × 480 (V)

Quantization 10bit gray scale

Processing 8bit gray scale

Video format Non-Interlace

Sensor Trigger mode Selectable Internal Timer or External trigger

Exposure time Settable from 1 to 1024 (1 step = Approx. 60µs)

Brightness Approx. 3 ~ 19 LSB (8 bit)

Contrast Approx. ±4dB

Processor 266MHz Intel compatible SOC processor

Memory 64MB image acquisition and processing

32MB program and solution (job) storage

Device Name NS2***** (Default)

IP address 192.168.0.100 (Default)

Subnet Mask 255.255.0.0 (Default)

MAC address 00-01-0D-**-**-** (* Unique ID)

DHCP Disabled (Default)

DHCP server Not Available (Default)

Primary WINS server 000.000.000.000 (Settable on the web page)

10

D4130145B

Page 11

iIS-010 series product specification

Secondary WINS server Not Available (Default)

Interfaces

Ethernet 1ch

Connector RJ-45

Table 2. Ethernet connector pin assignment

Pin # I/O Teminal function

1 O TD+ (Transmit data +)

2 O TD- (Transmit data -)

3 I RD+ (Receive data +)

4 - NC

5 - NC

6 I RD- (Transmit data -)

7 - NC

8 - NC

Connection Type 10/100 BaseT Ethernet

Ver. B (Oct. 12 2004)

IEEE 802.3 compatible

10/100 BaseT Auto Sence

Protocol HTTP, ICMP, DHCP, TCP/IP

LED indicator Orange indicates for working on 100BaseT

Green indicates for working on 10BaseT

Light on indicates for linking Ethern et

Blink indicates for working communication

Cables Twisted Pair (Category 5e or greater)

Maximum cable length 100m (Unshielded Twisted Pair cable)

DISPLAY 1ch

Connector D-SUB 15 pin, Right Angle, female

Table 3. Local Display connector pin assignment

Pin # Terminal Function Pin # Terminal Function

1 Red Data 9 NC

2 Green Data 10 GND

3 Blue Data 11 NC

4 NC 12 NC

5 GND 13 HSYNC

6 GND 14 VSYNC

7 GND 15 NC

8 GND

Scanning type Progressive

Video signal level 0.7V

(75Ω terminated)

P-P

11

D4130145B

Page 12

iIS-010 series product specification

Ver. B (Oct. 12 2004)

for sync on green, 1.0 V

(Video signal: 0.7 V

(75 Ω terminated)

P-P

, sync signal: 0.3 V

P-P

P-P

)

Sync signal Separate sync

Horizontal sync frequency 56.4kHz

Vertical sync frequency 70Hz

Image resolution 1024 × 768 × 16bpp

Sampling resolving power R=5bit, G=6bit, B=5bit

RS-232C 1ch

Connector D-SUB 9pin, Male

Table 4. RS-232C connector pin assignment

Pin # I/O Description Pin # I/O Description

1 - NC 6 - NC

2 I RX (Receive Data) 7 - NC

3 O TX (Transmit Data) 8 - NC

4 - NC 9 - NC

5 - Ground

Control type RS-232C (Non-procedure)

Bit rate 110 / 300 / 600 / 1200 / 2400 / 4800 / 9600 / 19200 / 38400 /

57600 / 115200 bps

*230400 / 460800 / 921600 bps are not supported.

Data bits 5 / 6 / 7 / 8

Stop bits 1 / 1.5 / 2

Parity Odd / Even / None / Mark / Space

Flow Control None

Parallel I/O 8 inputs (COM0 / GPI0 ~ 3 / SEL / D.TRIG / TRIG)

7 outputs (COM1 / GPO0 ~ 3 / STR / RDY)

Connector Terminal Block (1-1546208-5 supplied by AMP)

IOPWR BOARD

COM0

All other inputs

Ferrite A

650Ω / 1W

Ferrite B

0.1µF/50V

Chassis Ground

1000pF/50V

Input circuit

12

PS2805 (NEC)

Signal Groud

D4130145B

Page 13

iIS-010 series product specification

Rated input voltage 25V (1ch)

Input voltage range 0V to 25V

Input voltage level ON: 5V to 25V

OFF: 0.8V or less

Input current level ON: 5mA to 20mA

OFF: 1.9mA or less

Control signal inputs 3ch

TRIG Inspection Trigger input

D.TRIG Decision Trigger input

SEL Change Solution input

Polarity Positive

Minimum pulse width 200µs

Select Solution Inputs 4ch

Ver. B (Oct. 12 2004)

Table 5. Select Solution Inputs

GPI3 GPI2 GPI1 GPI0

ID_00 OFF OFF OFF OFF

ID_01 OFF OFF OFF ON

ID_02 OFF OFF ON OFF

ID_03 OFF OFF ON ON

ID_04 OFF ON OFF OFF

ID_05 OFF ON OFF ON

ID_06 OFF ON ON OFF

ID_07 OFF ON ON ON

ID_08 ON OFF OFF OFF

ID_09 ON OFF OFF ON

ID_10 ON OFF ON OFF

ID_11 ON OFF ON ON

ID_12 ON ON OFF OFF

ID_13 ON ON OFF ON

ID_14 ON ON ON OFF

ID_15 ON ON ON ON

13

D4130145B

Page 14

iIS-010 series product specification

Ver. B (Oct. 12 2004)

IOPWR BOARD

220Ω

PS2805 (NEC)

Signal Ground

Ferrite B

Ferrite A

1000pF/50V

0.1µF/50V

Chassis Ground

Output circuit

Rated Voltage 80V (Collector to Emitter)

Reverse voltage -6V (Emitter to Collector)

Total Power Dissipation 120mW

Load voltage range 5V to 24V

Rated output current 50mA

Decision outputs 4ch

GPO0 Pass output

GPO1 RESERVE

GPO2 Recycle output

GPO3 Reject output

All other Output

COM1

Light control output (STR) 1ch

READY output (RDY) 1ch

OFF: Booting the control unit / When changing solution

ON: After boot, start application / After changing solution

External Dimensions 150 (W) × 60 (H) × 80 (D)

Weight Approx. 500g (Excluding DIN rail mounting kits)

14

D4130145B

Page 15

iIS-010 series product specification

[Example Installation]

PC

or

LAN

TXRXTX

RX

ETHERNET

LOCAL

DISPLAY

Ver. B (Oct. 12 2004)

PC / PLC

TXRXTX

RX

RS-232C

DC Power Supply

24V DC +/- 10%

1A or more

CAMERA

External

Control Devices

*The length of the power line between the control unit and DC power supply must be less than

10m, and use twisted-pair wire.

[Client PC system requirements]

Operating System Microsoft® Windows® NT 4.0 SP5 or later,

Microsoft® Windows® 2000 SP3 or later,

Microsoft® Windows® XP SP1

Web Browser Microsoft Internet Explorer 6.0 or later

(ActiveX control supported)

History Log Viewer Hilgraeve HyperTerminal for Conditional/strings output

Microsoft EXCEL for the History log of CSV type

PC type X86 compatible

Interface Ethernet (Static or Dynamic addressing)

RJ-45 type connector

* The PC control program may not work for the effect installed software for application and

driver. The workaround for this problem is to be done by users at their own risk.

15

D4130145B

Page 16

iIS-010 series product specification

[Software function specification - on Internet Explorer (Ver.1.2.0.0)]

Select Language English / Japanese

Devise Setup

Network Alias Naming a network name your control unit

Network Settings Selectable using DHCP or Static IP Address

Monitor Monitoring inspections from the web

Upgrade Software Upgrades / Backup / Restore

Switch to Gauge or Label

Open iWorks Open Gauge or Label application window

HistoryLog V iew ing data output

File logging (CSV type)

Table 6. CSV file output format (Gauge application)

Ver. B (Oct. 12 2004)

ABCD E

1 Inspection Number N Time Stamp T

2 Inspection Number N +1 Time S tamp T

3 Inspection Number N +2 Time S tamp T

.. .. . .

.. .. . .

Result Measured Value V

1

Result Measured Value V

2

Result Measured Value V

3

Measured V alue V

N1

Measured V alue V

(N+1)1

Measured V alue V

(N+2)1

N2

(N+1)2

(N+2)2

Inspection Number Parts Inspection Number

Time Stamp Inspection time taken from Client PC (HH:MM:SS)

Result Pass/ Recycle / Fail

Measured value The values for each measurement.

Measurements sort in ascii order

Significant digit: 3

Table 7. CSV file output format (Label application)

ABCDE

1 Inspection Number N Time Stamp T

2 Inspection Number N+ 1 Time Stamp T

3 Inspection Number N+ 2 Time Stamp T

.. . . . .

.. . . . .

Fai led Area F

1

Fai led Area F

2

Fai led Area F

3

N

(N+1)

(N+2)

Angle Of fset A

Angle Of fset A

Angle Of fset A

N

(N+1)

(N+2)

R esult Ba rcode String

R esult Ba rcode String

R esult Ba rcode String

F

Inspection Number Parts Inspection Number

….

…

…

…

…

…

.

.

Time Stamp Inspection time taken from Client PC (HH:MM:SS)

Failed Area How much of the Label's area failed (%, significant digit: 3)

Angle offset How much of the Label's angle failed (degree, significant digit: 3)

Result Pass / Recycle/ Fail

Barcode String Barcode string output if you enabled the barcode reader

16

D4130145B

Page 17

iIS-010 series product specification

Password Protection For preventing others from changing your Solution

[Software Function Specification: Gauge/Label in common specifications (Ver.1.2.0.0)]

Camera image Displaying on the right panel of the application window

Camera Image size 640 × 480 pixel

Zoom in / Zoom out Zoom in / Zoom out buttons

Cursor Location Displaying X-Y coordinate at mouse cursor location

Pixel Intensity Displaying Pixel intensity at mouse cursor location (0 ~ 255)

Solution ID Displaying Current Solution ID (00 ~ 15)

Online Help Microsoft® HTML Help

Setup Status Bar Displaying current status

(Not configured / Stopped / Ready to Run / Running)

Select solution panel Starting new solution

Loading last saved solution

Ver. B (Oct. 12 200

4)

Importing solution from network client

Setup Sensor panel

Sensor Trigger mode Selectable Internal Trigger or External Tr igger

Internal Trigger period Settable from 35ms to 1000ms (1 step = 1ms)

Inspection Trigger Delay Settable from 0ms to 1500ms (1 step = 1ms)

Light Control

Duration Settable from 0ms to 64ms (1 step = 1 ms)

Offset Settable from 0µs to 2000µs (1 step = 1µs)

Local display refresh rate Every 100 / Continuous / None

Exposure Selectable from 1 to 1024 (1 step = 60.0µs)

Brightness 0% ~ 100%

Contrast 0% ~ 100% (with inverting contrast function)

* Due to the level variation characteristics of the control amplifier, incremental change amount

per step is not uniform.

Decision panel

Action when Images are skipped Ignore / Stop when count reaches set value / Pass / Recycle / Reject

Action when frames are failed Ignore / Stop when continuous or total count reaches set value

Setup Outputs panel

History Log Selectable Enable or Disable

Decision output

Output timing Selectable Immediate or Decision sensor

Rejection Delay Settable from 0ms to 1500ms (1 step = 1ms)

Duration Settable from 0.1ms to 1000.0ms (1 step = 0.1ms)

17

D4130145B

Page 18

iIS-010 series product specification

Conditional output Selectable Disable or Enable

if (Condition) Create / Edit Condition

Then (Send) Add / Edit Output string

To (Destination) Add / Edit Destination

Serial (COM3) port settings

Bit rate Selectable 110 / 300 / 600 / 1200 / 2400 / 4800 / 9600 / 19200 /

38400 / 57600 / 115200bps

*230400 / 460800 / 921600bps are not supported.

Data Bits Selectable 5 / 6 / 7 /8

Parity Selectable Odd / Even / None / Mark / Space

Stop bit Selectable 1/ 1.5 / 2

Flow control None

TCP/IP

Control unit role Selectable "as client" or "as server"

Ver. B (Oct. 12 200

4)

As client Define device IP address

As server Alter or reassign Port Number

*The reliability of controlling external devices (such as a conveyer, a kicker or etc.) on the

product line via Ethernet is NOT guaranteed.

Inspection status Selectable Ready to Run / Running

Monitoring

Statistics Information Displaying parts inspected number

Displaying parts skipped number

Displaying Pass / Recycle / Reject parts number

Inspection Information Displaying set upped inspection information

Processing Time Displaying the total time take to find (search) and inspect the part

Reset Product line and Statistics

History Recall Showing history records for inspected parts

Saving image Bitmap image

Image Data / Data Only / Nothing

Saving Solution

To the Control Unit memory Up to 16 solutions

Settable Solution description (Up to 127 letters)

Export Saving to PC or a network device

Deleting saved Solution All / Current solution / Single Solution

[Software function specifications: Gaug e Application (V er .1.2.0.0)]

Calibration Measurement in real units with the calibration sheet

18

D4130145B

Page 19

iIS-010 series product specification

Take a picture Taking a still or frozen picture

Location setup

Position / Angle Settable search area and search pattern

Origin Properties Moving the origin to another location

Locator Properties Confidence / Position / X / Y/ Rotation

Naming each measurements

Setting Tolerance

Edge Sensitivity Settable from 1 to 100

Inspection tools

Perpend Line-Line measure the perpendicular distance between two edges

Line-Line measure the distance bet ween two edges

Point-Point measure the distance between two points

Point-Line measure the distance betwee n one edge and one point

Angle measure the angle between two edges

Ver. B (Oct. 12 200

4)

Corner define a corner point, or measure the angle between two edges.

Circle define a point, or measure the diameter or circularity of a circle

Circle-Circle measure the distance between 2 circle centers

Circle-Line measure the distance from a circle center to an edge

Point-Circle measure the distance between a circle and one point

Concentric Circles measure the distance from each circle center, to the average center

Ruler Properties Naming measurement

Setting Tolerance (settable units on the measurement)

Settable Accuracy from 2 to 50

Track locator (Enable / Disable)

Angle Properties Naming measurement

Setting Tolerance

Settable Accuracy from 2 to 50

Track locator (Enable / Disable)

Circle Properties Diameter / Circularity

Naming measurement

Setting Tolerance (settable units on the measurement)

Settable Accuracy from 8 to 72

Track locator (Enable / Disable)

Concentricity Properties Naming measurement

Setting Tolerance

More inspection tools

ROI (Region of Interest) Selectable the shape (Line / Rectangle / Circle / Poly)

19

D4130145B

Page 20

iIS-010 series product specification

Count count the number of objects in a ROI

Count Properties Count / Area

Naming measurement

Setting Tolerance (settable units on the measurement)

Selectable defecting bright object or dark object

Settable Inspection Area / Length / Height

Rejecting objects that touch edges (Enable / Disable)

Track locator (Enable / Disable)

Setting Sensitivity from 0 to 100

Edge count Counting the edges crossed, along a line or the outline of the ROI.

Edge Count Properties Count / Average Separation / Min / Max

Naming measurement

Setting Tolerance

Selectable transition (Dark-Light / Light-Dark / Both)

Ver. B (Oct. 12 200

4)

Track locator (Enable / Disable)

Setting Sensitivity from 0 to 100

Intensity Avg. / Min / Max /Std. Dev.

measure pixel intensities in a ROI and calculate statistics

Statistics Properties Naming measurement

Setting Tolerance

Track locator (Enable / Disable)

Eraser delete a measurement

Tip Window gives hints on drawing measurements

Color settings changing colors of the measurement tools and graphics

to suit your preference

(HighLight1 / Actua l Edge / U ser Dr aw n /

User Drawn Same Tool / Gauge Point / Construct /

Control Point / Landmark / Landmark 2 /

Landmark Search / Pass / Warning / Reject)

Saving good parts image Windows® Bitmap Image

Decision outputs setting Define the conditions for part acceptance, recycling or rejections

Monitoring

Statistics Information Displaying parts inspected number

Displaying parts skipped number

Displaying Pass / Recycle / Reject parts number

Inspection Information Displaying each measured value

Processing Time Displaying the total time take to find (search) and inspect the part

20

D4130145B

Page 21

iIS-010 series product specification

Reset Product line and Statistics

History Log Recent 8 images and data of Pass / Recycle / Reject

Saving current parts image Windows® Bitmap Image

Display Image and Data / Data only / Nothing

[Software Function Specifications: iWorks Label (Ver.1.2.0.0)]

Take a Picture Taking a still or frozen picture

Inspection Area Settings Setting inspection area

Setting search areas

Define any areas to ignore

Barcode Reading (Optional) Enable / Disable

Barcode change None / Change

Inputting Barcode Value If applicable

Inspecting as Part of the Label Enable / Disable

Ver. B (Oct. 12 200

4)

Barcode Inspection Settings Report Every Read / Report Only If Error

Inspection Settings

Label Locator On / Off

Label Rotation Tolerance Settable ±5° (Maximum, 1step=0.25°)

Acceptable Tolerance Contrast / Failed area

Learning Good Parts

Acceptable T olerance Differences

Forgetting Learned Images

Monitoring Inspections

Statistics Information Displaying parts inspected number

Displaying parts skipped number

Displaying Pass / Recycle / Reject parts number

Processing Time Displaying the total time take to find (search) and inspect the part

Inspection Information Label Quality

Angle Offset

Displaying barcode string (if you enabled the barcode reader)

Reset Product line and Statistics

History Log Recent 8 images and data of Pass / Recycle / Reject / Learn mode

Display Image and Data / Data only / Nothing

Saving current image Windows® Bitmap image format (*.BMP)

* For detailed information operating procedures, see the operation manuals.

* The design and specification may change without prior notice.

21

D4130145B

Page 22

iIS-010 series product specification

6. External View

Ver. B (Oct. 12 200

4)

iIS-010 series control unit - external view

22

D4130145B

Page 23

iIS-010 series product specification

Ver. B (Oct. 12 200

4)

iIS-010

20mm square camera head - external view

23

D4130145B

Page 24

iIS-010 series product specification

Ver. B (Oct. 12 200

4)

iIS-011

φ17mm camera head- external view

24

D4130145B

Page 25

iIS-010 series product specification

Ver. B (Oct. 12 200

4)

iIS-012

C mount camera head - external view

25

D4130145B

Page 26

iIS-010 series product specification

Ver. B (Oct. 12 200

• Restriction For Use

• Should the equipment be used in the following conditions or environments, give consideration to safety

measures and inform us of such usage:

1. Use of the equipment in the conditions or environment contrary to those specified, or use outdoors.

2. Use of the equipment in applications expected to cause potential hazard to peop le or property, which

require special safety measures to be adopted.

• This product can be used under diverse operating conditions. Determination of applicability of

equipment or devices concerned shall be determined after analysis or testing as necessary by the designer

of such equipment or devices, or personal related to the specifications. Such designer or personal shall

assure the performance and safety of the equipment or devices.

• Do NOT place your device near any noises generating source. Correct result outputs may be not obtained

causes the inputted data are disturbed. Take extra precautions against electromagnetic-wave-interference

if the camera is used with a servomotor, inverter, or other electromagnetic-wave-generating equipment.

4)

• This product is not designed or manufactured to be used for control of equipment directly concerned with

human life(*1) or equipment relating to maintenance of public services/functions involving factors of

safety(*2). Therefore, the product shall not be used for such applications.

(*1): Equipment directly concerned with human life refer to:

Medical equipment such as life-support systems, equipment for operating theaters.

Exhaust control equipment for exhaust gases such as toxic fumes or smoke.

Equipment mandatory to be installed by various laws and regulations such as the Fire Act or

Building Standard Law.

Equipment related to the above.

(*2): Equipment relating to maintenance of public service/functions involving factors of safety refer to:

Traffic control systems for air transportation, railways, roads, or marine transportation.

Equipment for nuclear power generation.

Equipment related to the above.

Although sufficient check is performed about translation of these specifications, we will apply a Japanese

sentence, if a doubt should occur.

26

D4130145B

Page 27

iIS-010 series product specification

Ver. B (Oct. 12 200

• Precautions

• The contents of this manual may not be reproduced in whole or in part without prior written consent from

TELI (Tokyo Electronic Industry Co., Ltd.).

• The contents of this manual may be revised without notice to reflect future product modifications.

• If the CCD Camera or the system using the CCD Camera is subject to strategic products or technologies as

set forth in Foreign Exchange and Foreign Trade Control Laws, an export license by the Japanese

Government is required before it can be transported to other countries.

• While every precaution has been taken in the preparation of the operation manual to ensure accuracy and

completeness, some errors may remain. Please contact TELI if you find any inaccuracies or ambiguities.

• Before connecting and using any other with the CCD Camera, please read the operation manual for the

equipment to familiarize yourself with usage precautions and correct operating procedures.

• Some files and data are copyrighted or protected by other rights. Make sure you are familiar with pertinent

responsibility and liability issues before duplicating or distributing such data. TELI assumes no

responsibility or liability for illegal handling of data or problems involving copyrighted printed matter.

4)

• If used in conjunction with equipment not previously verified for compatibility by TELI, the CCD Camera

may become defective, break down, or operate unreliably. In these cases, the purchaser may be required to

bear the cost of any repairs. For information on hardware compatibility, please contact TELI, or a TELI

dealer or distributor.

• Exemption Clauses

• TELI assumes no responsibility or liability for damage arising from fire, earthquake, an act by a third

party or other accidents, or intentional or careless error or misuse by the user, or use under abnormal

conditions.

• TELI assumes no responsibility or liability for incidental damages (e.g., loss of business profits or

interruption of business) arising from use of or inability to use the camera equipment.

• TELI assumes no responsibility or liability in the case damages or losses are caused by failure to observe

the information contained in the operation manual and specifications.

• TELI assumes no responsibility or liability in the case damages or losses are caused by use contrary to the

instructions in this operation manual and specifications.

• TELI does NOT guarantee the items that are not described in the specification.

• TELI assumes no responsibility or liability in the case damages or losses are caused by malfunction or

other problems resulting from use of equipment or software that is not specified.

• TELI assumes no responsibility or liability in the case damages or losses are caused by repair or

modification conducted by the customer or any unauthorized third party (such as an unauthorized service

representative).

• The CCD Camera is not designed for use in mission-critical or life-support applications, facilities, or

equipment, such as medical equipment, nuclear facilities and equipment, aerospace equipment, or

27

D4130145B

Page 28

iIS-010 series product specification

Ver. B (Oct. 12 200

transportation facilities and equipment, or any other application, facility, or equipment that requires

extreme reliability. TELI assumes no responsibility or liability for injury, fire, or consequential damages

arising from failure of the CCD camera in such applications.

• Expenses we bear on this product shall be limited to the individual price of the product.

4)

28

D4130145B

Page 29

Head Office: 7-1, 4 chome, Asahigaoka, Hino-shi, Tokyo, 191-0065, Japan

(Overseas Sales Department)

Phone: +81-42-589-8771 Fax: +81-42-589-8774

http://www.toshiba-teli.co.jp

URL:

iIS-010 series - Product Specification October 2004

29

D4130145B

Loading...

Loading...