INSTRUCTION MANUAL

INSTALLATION – OPERATION - MAINTENANCE

TE2 Series

Low Voltage

DOCUMENT: NBZ0004 Rev.0

Digital

Solid State Soft Starter

18 – 1250A

Issued: 11/18

Firmware Version 1.32

Basic Installation and Operation Guide

TE2 Series Digital Solid State Soft Starters 18 – 1250A

This Page Intentionally Left Blank

Basic Installation and Operation Guide

TE2 Series Digital Solid State Soft Starters 18 – 1250A

Important Notice

The instructions contained in this manual are not intended to cover all details or variations in equipment

types nor may it provide for every possible contingency concerning the installation, operations, or

maintenance of this equipment. Should additional information be required, contact your Toshiba

Customer Support Center.

The contents of this manual shall not become a part of or modify any prior or existing agreement,

commitment, or relationship. The sales contract contains the entire obligation of Toshiba International

Corporation. The warranty contained in the contract between the parties is the sole warranty of Toshiba

International Corporation and any statements contained herein do not create new warranties or modify

the existing warranty.

Any electrical or mechanical modifications to this equipment without the prior written consent of

Toshiba International Corporation may void all warranties or other safety certifications.

Unauthorized modifications may also result in safety hazard or equipment damage.

Misuse of this equipment could result in injury and equipment damage. In no event will Toshiba

International Corporation be responsible or liable for direct, indirect, special, or consequential

damage or injury that may result from the misuse of this equipment.

About This Manual

Every effort has been made to provide accurate and concise information to you, our customer.

At Toshiba International Corporation we are continuously striving for better ways to meet the constantly

changing needs of our customers. E-mail your comments, questions, or concerns about this publication

to tic-controls@toshiba.com.

Basic Installation and Operation Guide

TE2 Series Digital Solid State Soft Starters 18 – 1250A

Purpose and Scope of Manual

This manual provides information on how to safely install, operate, maintain, and dispose of your TE2

solid state starter. The information provided in this manual is applicable to the TE2 starter only.

This manual provides information on the various features and functions of this powerful device,

including:

• Installation

• Operation

• Mechanical and electrical specifications.

Included is a section on general safety instructions that describe the warning labels and symbols that

are used on the device and throughout the manual. Read the manual completely before installing,

operating, performing maintenance, or disposing of this equipment.

This manual and the accompanying drawings should be considered a permanent part of the equipment

and should be readily available for reference and review. Dimensions shown in the manual are in

imperial units and/or the metric equivalent. Connection drawings within this document convey the typical

topology of the TE starter.

Because of our commitment to continuous improvement, Toshiba International Corporation reserves the

right, without prior notice, to update information, make product changes, or to discontinue any product or

service identified in this publication.

Toshiba International Corporation (TIC) shall not be liable for direct, indirect, special, or

consequential damages resulting from the use of the information contained within this manual.

This manual is copyrighted. No part of this manual may be photocopied or reproduced in any form

without the prior written consent of Toshiba International Corporation.

© Copyright 2018 Toshiba International Corporation.

All rights reserved.

Printed in the U.S.A.

TOSHIBA® is a registered trademark of Toshiba Corporation. All other product or trade references

appearing in this manual are registered trademarks of their respective owners.

Basic Installation and Operation Guide

TE2 Series Digital Solid State Soft Starters 18 – 1250A

Contacting TIC’s Customer Support Center

Toshiba International Corporation’s Customer Support Center can be contacted to obtain help in

resolving any system problem that you may experience or to provide application information.

The Support Center is open from 8 a.m. to 5 p.m. (CST), Monday through Friday. The Center’s toll free

number is US (800) 231-1412/Fax (713) 937-9349 CAN (800) 872-2192 MEX 01 (800) 527-1204.

For after-hours support follow the directions of the outgoing message when calling.

To contact Toshiba International Corporation, address all correspondence to:

Field Service Department

Toshiba International Corporation

13131 West Little York Road

Houston, Texas 77041-9990

For further information on Toshiba International Corporation’s products and services, please visit our

website at www.toshiba.com/tic.

TOSHIBA INTERNATIONAL CORPORATION

TE2 Solid State Starter

Please complete the following information for your records and retain this manual.

Model Number: _____________________________________________________________________

Serial Number: _____________________________________________________________________

Project Number (if applicable):_________________________________________________________

Date of Installation: _________________________________________________________________

Inspected By: _____________________________________________________________________

Name of Application: ________________________________________________________________

DANGER

General Safety Information

DO NOT attempt to install, operate, maintain, or dispose of this equipment until you have read and

understood all of the product safety information and directions that are contained in this manual.

Safety Alert Symbol

The Safety Alert Symbol is comprised of an equilateral triangle enclosing an exclamation mark. This

indicates that a potential personal injury hazard exists.

Important Messages/Signal Words

Listed below are the signal words that are used throughout this manual followed by their descriptions

and associated symbols. When the words DANGER, WARNING, and CAUTION are used in this

manual, they will be followed by important safety information that must be carefully followed.

The word DANGER preceded by the safety alert symbol indicates that an imminently hazardous

situation exists that, if not avoided will result in serious injury to personnel or loss of life. If instructions

are not followed precisely, it will result in serious injury to personnel or loss of life.

The word WARNING preceded by the safety alert symbol indicates that a potentially hazardous situation

exists that, if not avoided or if instructions are not followed precisely, could result in serious injury to

personnel or loss of life.

WARNING!

The word CAUTION proceeded by the safety alert symbol indicates that a potentially hazardous

situation exists that, if not avoided or if instructions are not followed precisely, may result in minor or

moderate injury.

CAUTION

The word NOTE indicates information considered important, but no hazard-related (e.g. messages

relating to property damage).

NOTE

Basic Installation and Operation Guide

TE2 Series Digital Solid State Soft Starters 18 – 1250A

Equipment Warning Labels

DO NOT attempt to install, operate, perform maintenance, or dispose of this equipment, until you have

read and understood all of the product labels, and user directions, that are contained in this manual.

Warning labels that are attached to the equipment will include the exclamation mark within a triangle.

DO NOT remove or cover any of these labels. If the labels are damaged or if additional labels are

required, contact the Toshiba Customer Support Center.

Labels attached to the equipment are there to provide useful information or to indicate an imminently

hazardous situation that may result in serious injury, severe property and equipment damage, or loss of

life if safe procedures or methods are not followed as outlined in this manual.

Qualified Personnel

Installation, operation, and maintenance shall be performed by Qualified Personnel ONLY. A Qualified

Person is one that has the skills and knowledge relating to the construction, installation, operation, and

maintenance of the electrical equipment and has received safety training on the hazards involved (Refer

to the latest edition of NFPA 70E for additional safety requirements).

A qualified person must:

1) Read this entire manual carefull.

2) Be skilled in the installation, construction and operation of the starter, the equipment being driven,

and the hazards involved.

3) Be able to recognize and properly address hazards associated with the application of motor-driven

equipment.

4) Be trained and authorized to safely energize, de-energize, clear, ground, lock-out/tag-out circuits and

equipment, and clear faults in accordance with established safety practices.

5) Be trained and authorized to perform the service, maintenance or repair of this equipment.

6) Be trained in the proper care and use of protective equipment such as safety shoes, rubber gloves,

hard hat, safety glasses, face shield, flash clothing, etc., in accordance with established safety practices.

7) Be trained in rendering first aid.

For further information on workplace safety, visit www.osha.gov.

Safety Codes

WARNING! All installations must comply with all applicable state and local codes.

In the United States, installations must adhere to all applicable National Electric

Code (NFPA 70) standards.

Installations must follow all instructions provided in this manual.

Failure to follow all applicable codes, standards, or the instructions in this manual

May cause accidents resulting in death or severe injuries.

Basic Installation and Operation Guide

TE2 Series Digital Solid State Soft Starters 18 – 1250A

DANGER

Modifications

WARNING Never attempt to modify the starter.

Any attempted modification may impair the performance of the starter.

Any attempted modification may cause accidents that result in death or severe

Injuries.

Equipment Inspection

• Upon receipt of the equipment, inspect the packaging and equipment for shipping damage.

• Carefully unpack the equipment and check for parts that may have been (concealed) damaged during

shipping, or missing parts. If any discrepancies are discovered, it should be noted with the carrier prior

to accepting the shipment, if possible. File a claim with the carrier if necessary and immediately notify

your Toshiba Customer Support Center.

• DO NOT install the starter if damaged or if it is missing any component(s).

• Ensure the rated capacity and model number specified on the nameplate conform to the order

specifications.

• Inspections may be required after moving the equipment.

• Contact your Toshiba Customer Support Center to report discrepancies or for assistance if required.

Handling and Storage

• Use proper lifting techniques when moving the breaker; including properly sizing up the load, getting

assistance, and using a forklift if required.

• Store in a well-ventilated location and preferably in the original packaging if the equipment will not be

used upon receipt.

• Store in a cool, clean, and dry location. Avoid storage locations with extreme temperatures, rapid

temperature changes, high humidity, moisture, dust, corrosive gases, or metal particles.

• The storage temperature range of the breaker is 23° to 104° F (-5° to 40° C).

• DO NOT store the unit in places that are exposed to outside weather conditions (e.g., wind, rain,

snow).

• Store in an upright position.

HAZARDOUS VOLTAGE

Will cause severe injury, death, fire, explosion and property damage.

• Disconnect and lock out Primary and Control Circuit Power before installing or servicing.

• Keep all panels and covers securely in place.

• Never Defeat, Modify or Bypass and Safety Interlocks.

• Qualified Personnel only.

Disposal

Never dispose of electrical components via incineration. Contact your state environmental agency for details on

disposal of electrical components and packaging in your area.

Table of Contents

Chapter 1 - Introduction

Chapter 2 - Installation

Chapter 3 - Motor Overload Protection

Chapter 4 - Connections

Chapter 5 - Programming

Chapter 6 - Start-up

Chapter 7 - Fault Conditions

Appendices

Appendix 1: Ramp Profile Details …………………………………………………………………... 71

Appendix 2: Pump-Flex

Appendix 3: Parameter Lock / User Password Instructions …………………………………….. 77

Appendix 4: External Overload Relay Application……………………………………………..... 79

Appendix 5: Soft Starter Settings Record ………………………….…………….………………... 84

Decel Mode Application Considerations ……………………………...

1.1 General Description ………………………..

1.2 Sizes and Ratings …………………………..

2.1 Receiving and Unpacking ………………….

2.2 Choosing a Location ………………….........

2.3 Initial Unit Inspection …………………........

2.4 SERVICE WARNING! ……………………..

2.5 Mounting and Cleaning …………………….

2.6 Power Terminations ………………………..

2.7 Remote Keypad Mounting…………............

2.8 Dimensions ……………………………........

3.1 Solid State Overload Protection …………..

3.2 NEMA Class Trip Curves …………….........

4.1 Power Connections ………………………...

4.2 Control Connections ………………………..

5.1 Introduction ……………………………….....

5.2 Digital Interface ……………………………..

5.3 Display Modes ………………………………

5.4 Program Mode ………………………………

5.4.5 Fault Mode …………………………….

5.5 The TE2 Function List ………………......

5.6 Function Descriptions ………………………

5.6.1 Motor and Overload Functions ………

5.6.2 Starting Modes…………………………

5.6.3 Jog Mode…………………….. ……….

5.6.4 Kick Start Mode ……………………….

5.6.5 Pump-Flex Decel Mode ………………

5.6.6 Restart Delay ………………………….

5.6.7 Voltage Protection …………………….

5.6.8 Current and Ground Fault Protection..

5.6.9 Lockouts, Reset & Internal Protection

5.6.10 Output Relays …………………………

5.6.11 Serial Communications……………….

5.6.12 System Settings ………………………

5.6.13 Fault History and Statistical Data……

5.6.14 Phase Protection Settings……..….….

5.6.15 Motor Power Protection Settings…….

5.6.16 Analog Output………………………….

5.6.17 Display & System Settings……………

6.1 Basic Startup ………………………………..

6.2 Start-up Check List …………………………

6.3 Sequence of Operation ………………........

6.4 Testing with a smaller motor ………………

7.1 Fault Codes and Numbers ……………......

7.2 Fault Explanation …………….....................

Page

1

4

5

5

5

6

6

7

9

10

11

13

15

16

23

23

24

25

28

30

37

37

39

42

43

44

45

45

47

50

54

55

56

58

60

61

62

64

65

66

66

67

67

70

74

Chapter 1 - Introduction

Acceleration Adjustments

Dual Ramp Settings

Deceleration Adjustments

1.1 General Description

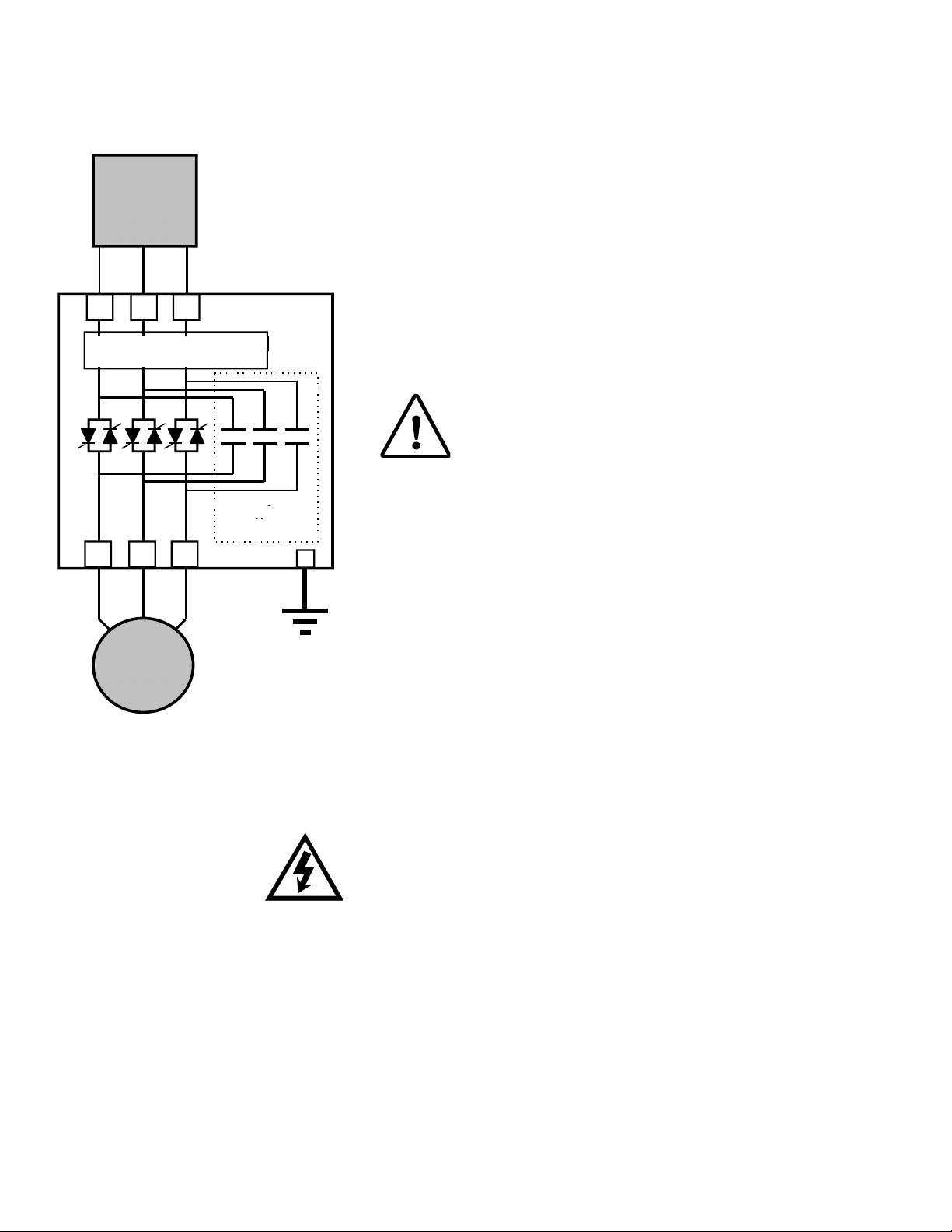

The TE2 Series is a digitally programmable solid-state reduced voltage

soft starter. Its six SCR design features a voltage/current ramp with an

anti-oscillation circuit for smooth load acceleration. The SCRs are sized

to withstand starting currents of 500% for 20 seconds (Standard Duty)

and up to 500% for 60 seconds (Heavy Duty). The TE2 Series features

smooth, stepless ramp control, which reduces motor inrush current and

excessive wear on the mechanical drive train components. The TE2

Series includes a programming keypad for setting operating parameters

for the ideal starting cycle and protection features, plus easy to

understand diagnostic LEDs. Starting torque, ramp time, current limit,

dual ramp, and Decel control are standard features on the TE2 Series.

By simply adjusting the units’ starting torque, ramp time, and current

limit functions, the starting electrical characteristics of the motor can be

matched to the mechanical characteristics of the drive train for

controlled acceleration of the load. The TE2 Series includes solid-state

electronic overload protection in addition to numerous other protective

features. It requires 120VAC (220VAC optional) control power and uses

dry contact inputs for Start / Stop control. Programmable auxiliary

contacts and provisions for interlocking are also included.

1.1.1 Control Features

Programmable Ramp Types:

Voltage Ramp (VR) or closed loop Current Ramp (CR)

Initial Values: 0 - 100% of line voltage (VR)

or 0 - 600% of motor FLA (CR)

Ramp Time: 1 to 120 seconds

Current Limit: 200 - 600% (VR or CR)

4 Options:

Ramps 1 & 2 = VR.

Ramp 1 = VR, Ramp 2 = CR.

Ramps 1 & 2 = CR.

Ramp 1 = CR, Ramp 2 = VR.

Dual Ramp Control:

Ramp #1 = Default.

Ramp #2 = Selectable via dry contact input.

Begin Decel Level: 0 - 100% of line voltage

Stop Level: 0 to 1% less than Begin Decel Level

Decel Time: 1 - 60 seconds

Programmable to Decel or coast to stop upon overload trip.

Jog function selected via dry contact closure input.

Jog Settings

Kick Start Settings

Jog Voltage: 5 - 100%

Time of Jog Voltage: 1 - 20 seconds

Jog Current: 100 - 500%

Kick Voltage: 10 - 100%

Kick Time: 0.1 - 2 seconds

TE2 Series Digital Solid State Soft Starter User Manual 1 | Page

1.1.2 Advanced Motor Protection Features

Thermal Model Electronic

Overload Protection

Two Stage

Overload Curves

Overload Reset Manual (default) or automatic.

Retentive Thermal Memory

Dynamic Reset Capacity

Current Imbalance Trip

Over Current Trip

(Electronic Shear Pin)

Voltage Protection

Phase Loss

Phase Rotation

Power Protection

Equipment Ground Fault

Protection

A sophisticated Thermal Model of the motor operation is created in the

microprocessor to accurately track all starting, stopping, and running conditions,

thus, providing maximum motor protection.

Starting: Programmable for Class 5 through 30

Run: Programmable for Class 5 through 30 when "At-Speed" is detected.

Overload circuit retains thermal condition of the motor regardless of control

power status. Unit uses real time clock to adjust for off time.

Overload will not reset until thermal capacity available in the motor is enough for

a successful restart. Starter learns and retains this information by monitoring

previous successful starts.

Trip Level: 5 - 30% Imbalance in any two phases.

Trip Delay: 1 -20 seconds.

Trip Level: 100 - 300% of FLA

Trip Delay: 1 - 20 seconds

Over Voltage Trip Level: 1 - 10% of Line Voltage.

Under Voltage Trip Level: 1 - 20% of Line Voltage.

Separate Under Voltage levels for Start and Run modes.

Voltage Imbalance Trip Level: 1 - 30% Phase Difference.

Voltage Imbalance Trip Delays: 1 - 20 seconds.

Phase Loss trip: Any phase current less than 12% of unit CT value.

Can be disabled in programming for testing with smaller loads.

Phase Rotation Trip: ABC, ACB or insensitive.

Phase Protection Trip Delays: 1 - 3 seconds.

Motor kW Trip Settings: Over / Under Trip.

Under kW Trip Level: 20 - 100% of calculated motor kW.

kW Trip Delay: 1 - 9999 minutes.

PF Trip Setting: Lead, Lag or Lead/Lag.

PF Trip Level: 0.01 - 1.0 (cos. θ).

PF Trip Delay Time 1 - 2 seconds.

Type: Residual Current Method.

Range: 5 - 90% of unit CT ratio.

Trip Delay: 1 - 60 seconds.

Load Loss Trip

Coast Down (Back Spin)

Lockout Timer

Starts-per-hour Lockout 1 - 10 successful starts per hour.

Minimum Time between

Starts Lockout

Restart Delay

Auto Reset

Power Device Monitoring

Under Current Trip Level: 10 - 90% of motor FLA.

Trip Delay: 1 - 60 seconds.

Prevents restart when motor may be spinning backwards.

Coast Down Time Range: 1 - 3600 seconds.

Range: 1 - 60 minutes between start attempts.

Sequential Start Feature for restarting delay after a power outage ends.

1-999 seconds after a power loss.

Can be programmed to attempt resetting after selected faults.

0 - 10 Attempts, in 1 minute cycles.

Shorted SCR Lockout (1 shorted SCR) and independent Shunt Trip (multiple

shorted SCRs). Can be disabled in programming.

TE2 Series Digital Solid State Soft Starter User Manual 2 | Page

1.1.3 Design Specifications

Type of Load: Three - phase AC induction motors.

AC Supply Voltage: Universal, 208 - 600VAC ±10%, 50/60 Hz.

Power Ratings: 9 - 1250 Amps, 7.5 - 1000 HP @ 460V.

Unit Capacity - Continuous Max. Amp rating is UL Listed continuous rating.

Unit Capacity - Overload Rating

(Percent of motor FLA)

Power Circuit

SCR Firing Angle Detection

SCR PIV Ratings

(Peak Inverse Voltage)

Transient Protection RC snubber dV/dt networks on each phase.

Cooling Fan assisted convection.

Bypass Contactor Standard on all units.

Bypass Contactor Rating Shunt rated or can be sized for Line start rating.

Bypass Contactor Control Integral control is included, but contactor can be externally controlled as well.

Ambient Condition Design

Control Power 120VAC (customer supplied), 240VAC optional.

Inputs 6 Dry (voltage free) contact inputs using 24VDC from an internal power supply.

Programmable Relay Outputs

Output Relay Contact Rating 5 Amps, 240VAC max. (1200VA).

Programmable Analog Outputs

Dedicated Fault Output

500% - 60 seconds.

6 SCRs, full phase angle firing using a hard fire firing circuit to avoid motor

transient problems.

6 pulse Independent Locked Phase Tracking with Auto-synchronization,

prevents misfiring on unstable source frequency.

1600V

0° to 40°C (32° to 122°F)

5 - 95% relative humidity.

0 - 3300 ft. (1000m) above sea level without derating.

3 relays, 2 each Form C (SPDT), 1 each Form A (SPST).

Can be programmed for 32 functions, with delays or flashing.

1 analog output 4-20mA

Can be programmed for 12 functions with scaling.

AC Triac solid state switch.

240VAC, 50mA max.

Approvals UL Listed, Canadian UL (cUL) Listed CE Approved. UL 60947-4-2

TE2 Series Digital Solid State Soft Starter User Manual 3 | Page

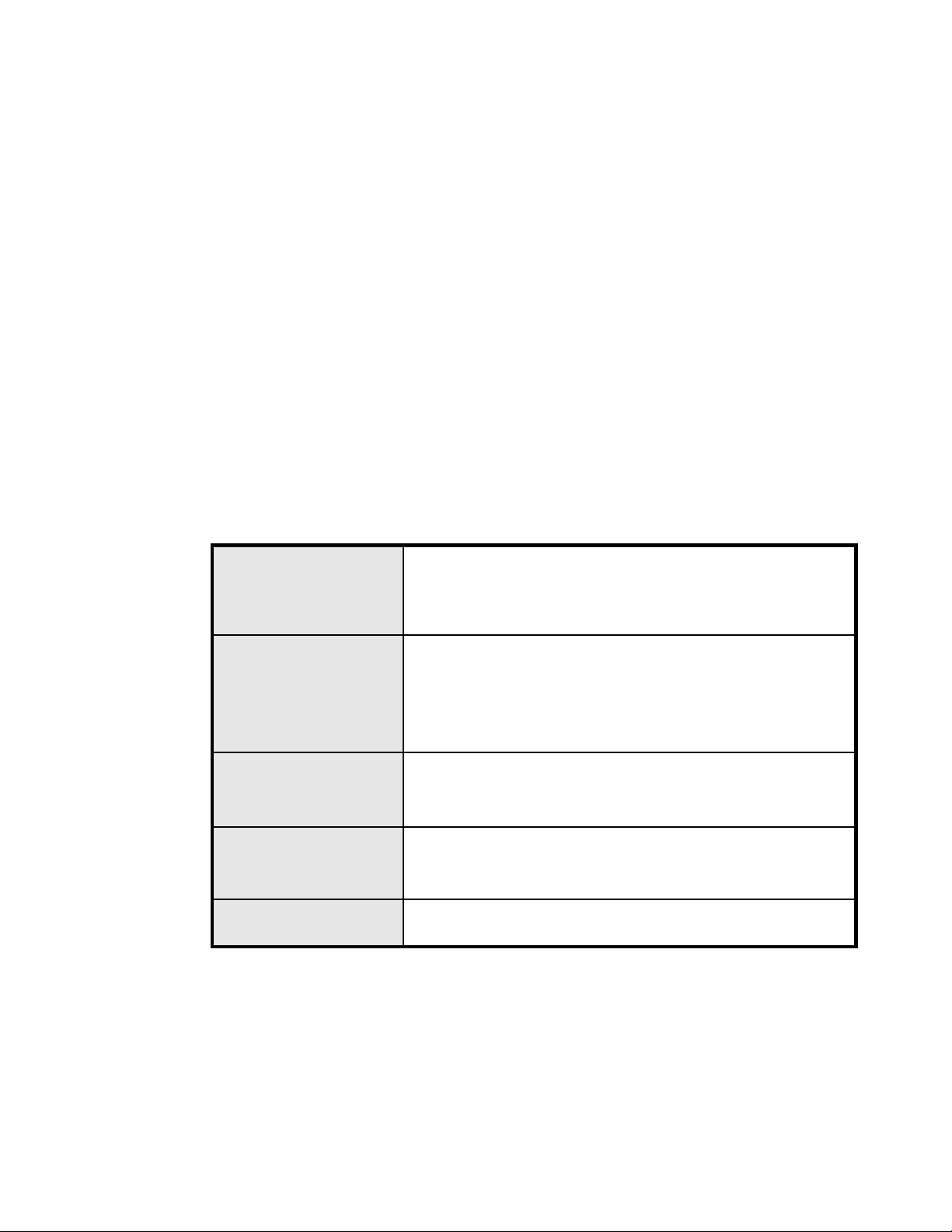

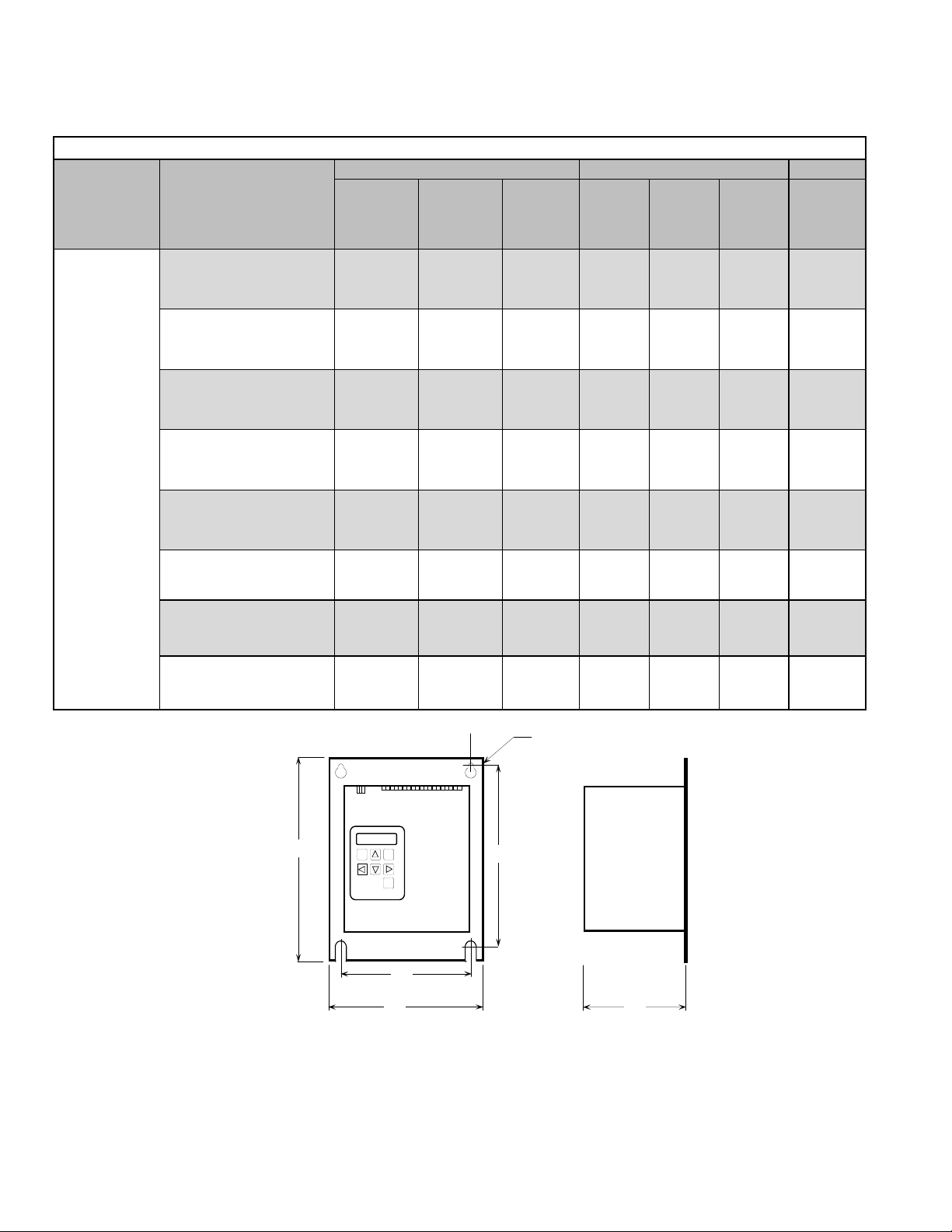

Table 1.2 TE2 Series Range

Model

Number

TE2-18-BP 9 - 18

TE2-28-BP 14 - 28

TE2-39-BP 19 - 39

TE2-48-BP 24 - 48

TE2-62-BP 36 - 62

TE2-78-BP 39 - 78

TE2-92-BP 46 - 92

TE2-112-BP 56 - 112

TE2-150-BP 75 - 150

TE2-160-BP 80 - 160

TE2-210-BP 105 - 210

TE2-275-BP 138 - 275

TE2-361-BP 181 - 361

TE2-450-BP 225 - 450

TE2-550-BP 275 - 550

TE2-600-BP 300 - 600

TE2-862-BP 431 - 862

TE2-900-BP 450 - 900

TE2-1006-BP 503 - 1006

TE2-1250-BP 625 - 1250

Current

Range

Min.- Max.

1.2 Sizes and Ratings

The Toshiba TE2 Series starters are current rated controllers. Max.

Amp ratings are for continuous duty and must not be exceeded. Always

check the motor nameplate FLA and Service Factor to ensure proper

sizing.

Each size has an adjustable current range of 50% to 100% of the Max

Amp rating. Table 1.2 shows the Current Ratings available.

1.2.1 Selecting for Service Factor Utilization

Many NEMA design motors include a design rating referred to

as Service Factor (SF) that may allow continuous operation

above the nameplate current rating. If using this Service

Factor, the TE2 Series starter must be sized for the total amps

used. For proper selection of the TE2 Series starter when

using SF continuously, multiply the nameplate FLA by the

stated Service Factor, or use stated Service Factor Amps

(SFA) if listed on the nameplate. The following excerpt is from

the NEMA MG-1 standards for AC Motors that describes the

issues concerning the use of Service Factor ratings.

"When an induction motor is operated at any service factor

greater than 1.0, it may have efficiency, power factor and

speed different than those at rated load. Locked rotor torque

and current and breakdown torque will remain the same. A

motor operating continuously at any service factor greater than

1.0 will have a reduced life expectancy compared to operating

at its nameplate horsepower."

When using this feature, simply program the TE2 Series

Service Factor (F002) to the nameplate rating. (See section

5.6.1.) All other adjustments to the protection circuits are done

automatically within the TE2 Series.

1.2.2 Selecting for Across the Line Bypass

If you need to be able to start the motor Across-the-Line when

the TE2 Series electronics are out of service, the starter can

also be selected based upon the rating of the Bypass

Contactor. Some users may also elect to size their Bypass

Contactors per NEMA guidelines. When doing this, please

refer to the Product Selection Guide for details and notes, and

see Appendix 4 for special considerations regarding Overload

Protection.

1.2.3 The TE2…-BP Series starters include the ability to connect a

dry contact directly to the Bypass Contactor coil control circuit.

These terminals are covered when shipped and should be used

ONLY when necessary for Emergency Bypass operation and with

an external Overload Relay. See Appendix 4 for additional

information.

No field wiring to these terminals is necessary if this feature is not

used.

TE2 Series Digital Solid State Soft Starter User Manual 4 | Page

Chapter 2 - Installation

2.1 Receiving and Unpacking

Upon receipt of the product, you should immediately do the following:

Carefully unpack the unit from the shipping carton and inspect it for

shipping damage. If damaged, notify the freight carrier and file a

claim within 15 days of receipt.

Verify that the model number on the unit matches your purchase

order.

Confirm that the ratings nameplate on the unit match or are greater

than the motors’ HP and current rating with which it is to be used.

2.2 Choosing a Location

Proper location of the TE2 Series is necessary to achieve specified

performance and normal operational lifetime. The TE2 Series should

always be installed in an area where the following conditions exist:

Ambient operating temperature: 0 to 40°C (32 to 104°F)

Protected from rain, moisture, and direct sun.

Humidity: 5 to 95% non-condensing.

Free from metallic particles, conductive dust, and corrosive gas.

Free from excessive vibration. (below 0.5G)

Open panel units must be mounted in the appropriate type of

enclosure. Enclosure size and type must be suitable to dissipate

heat generated by the soft starter and any other components

mounted inside with it.

Care should always be taken to maximize the available space

inside of the enclosure. See section 2.5.1 or contact factory for

assistance in sizing enclosures.

2.3 Initial Unit Inspection

Make a complete visual check of the unit for damage that may have

occurred during shipping and handling. Do not attempt to continue

installation or start up the unit if it is damaged.

Check for loose mechanical assemblies or broken wires which may

have occurred during transportation or handling. Loose electrical

connections will increase resistance and cause the unit to function

improperly.

Prior to beginning the installation, verify that the motor and TE2

Series unit is rated for the proper amperage and voltage.

TE2 Series Digital Solid State Soft Starter User Manual 5 | Page

2.4 SERVICE WARNING!

r

Do not service equipment with voltage applied! The unit can be the

source of fatal electrical shocks! To avoid shock hazard,

disconnect main power and control power before working on the

unit. Warning labels must be attached to terminals, enclosure and

control panel to meet local codes. Use Lockout tags such as the

one shown when servicing equipment.

2.5 Mounting and Cleaning

When drilling or punching holes in the enclosure, cover the electrical

assembly to prevent metal filings from becoming lodged in areas which

can cause clearance reduction or actual electrical shorts. After work is

complete, thoroughly clean, vacuum the area, and re-inspect the unit for

foreign material.

2.5.1 Clearances

Make sure there is sufficient clearance all around the unit for cooling,

wiring, and maintenance purposes. To conserve panel space, the TE2

Series - BP models were designed for close clearances of only 1 inch

(25mm) on either side. A minimum clearance of 4 inches (100 mm) on

the top and bottom is necessary to maximize effective airflow and

cooling. Also the unit must be installed with its heat sink ribs oriented

vertically and running parallel to the mounting surface. Keep in mind

that these are minimums. NEC or local codes may require more

clearance, particularly for the power terminals.

4" minimum ( 100 mm )

1" minimum (25 mm )

TE2 Series

Starte

4" minimum ( 100 mm )

1" minimum (25 mm )

Figure 2.5: TE2 minimum mounting clearances

TE2

Series Digital Solid State Soft Starter User Manual 6 | Page

TE2 -18 ~

TE2 -48

(38.07 mm)

Line

Line Load

R/L1 S/L2 T/L3

1.50"

0.45"

(11.42 mm)

Load

V/T2

U/T1 W/ T3/

1.10"

(27.92 mm)

WARNING!

Remove all sources of power before cleaning the unit.

In dirty or contaminated atmospheres, the unit should be cleaned on a

regular basis to ensure proper cooling. Do not use any chemicals to

clean the unit. To remove surface dust, use clean, dry compressed air

only, 80 to 100 psi. A three-inch, high quality, dry paintbrush is helpful to

loosen up the dust prior to using compressed air on the unit. Do not use

wire brushes or other conductive cleaning materials

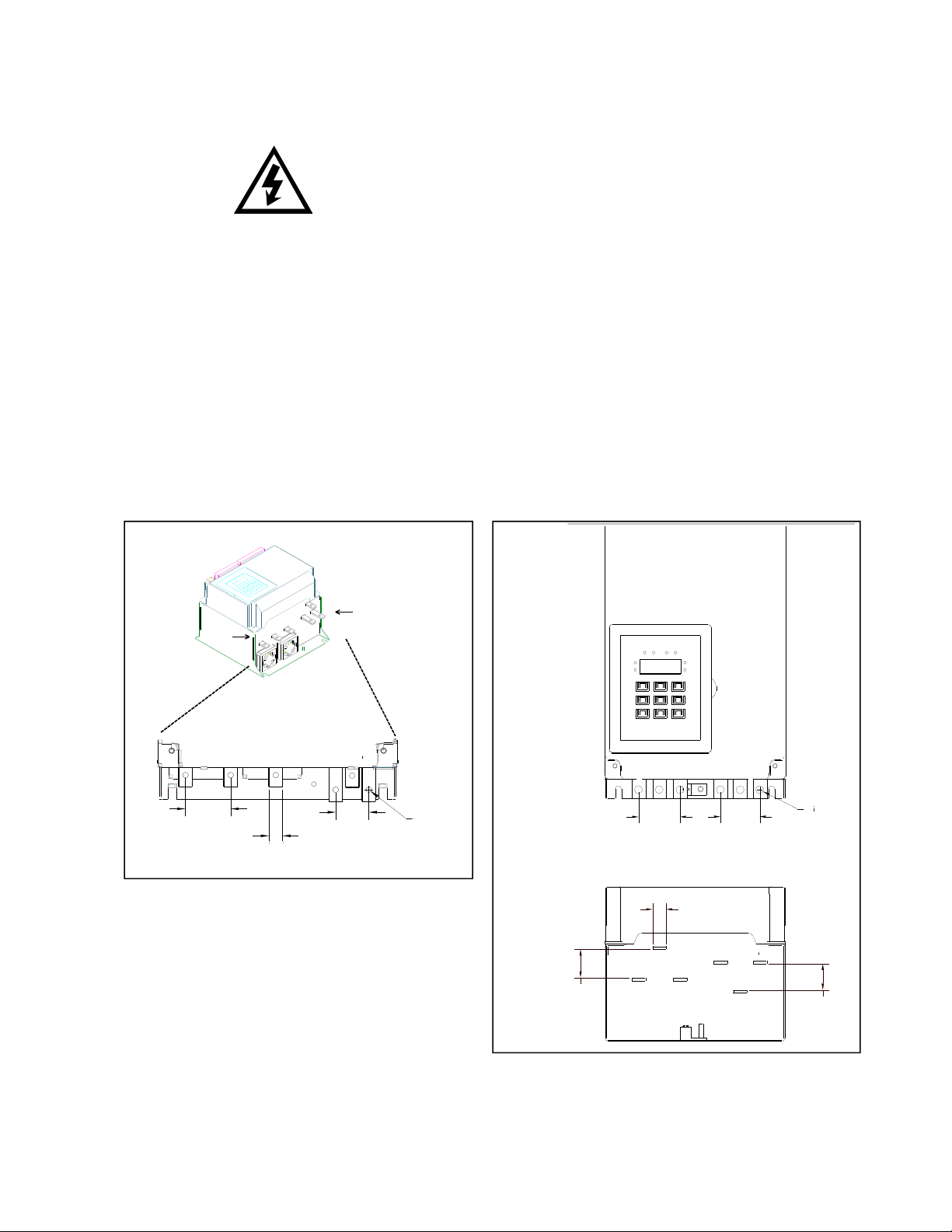

2.6 Power Terminations

All line and load power terminations are to be made to the tin plated

copper Bus Tabs located on each unit. Bus tabs are pre-drilled to

accept industry standard bolts. Toshiba recommends using crimp-on

ring lugs, although mechanical compression lugs are suitable as well.

The following diagrams show sizes of the bus tab holes and critical

spacing between them for determining the size of lug that can be used.

Note: All wiring must be sized according to local and national code

standards.

TE2-62 ~

TE2 -112

0.19"

(4.82 mm)

Line Load

1.82"

(46.19 mm)

(43.91 mm)

1.73"

0.38"

(9.64 mm)

1.23"

(31.22 mm)

R/L1 T/L3

0.60"

(15.23 mm)

S/L2

Line Load

U/T1 W /T3

V/T2

1.13"

(28.68 mm)

Figure 2.6.1 Critical clearances for bus tab connections

TE2

Series Digital Solid State Soft Starter User Manual 7 | Page

Figure 2.6.2 Critical clearances for bus tab connections

2.6 Power Connections (cont.)

/T3V

TE2 -150 ~

TE2 -160

Line Load

0.38"

1.52"

(38.58 mm)

1.54"

(39.09 mm)

2.81"

(71.32 mm)

(9.64 mm)

0.14"

(3.55 mm)

T/L3

R/L1

S/L2

Line Load

0.60"

(15.23 mm)

U/T1

W

/T2

Figure 2.6.3 Critical clearances for bus tab connections

Note: Consult factory for bus tab critical dimensions for units 210A and above

TE2 Series Digital Solid State Soft Starter User Manual 8 | Page

2.6.1 Power Terminals:

r

r

r

Connection points are bus tabs with pre-drilled holes (see below).

Suggested wire sizes and tightening torques for factory-supplied

connectors using conductors rated for 75C are shown in the chart

below. Always consult local and national codes along with industry

standard practices for proper wires sizes and terminations to

accommodate voltage drop and ambient conditions.

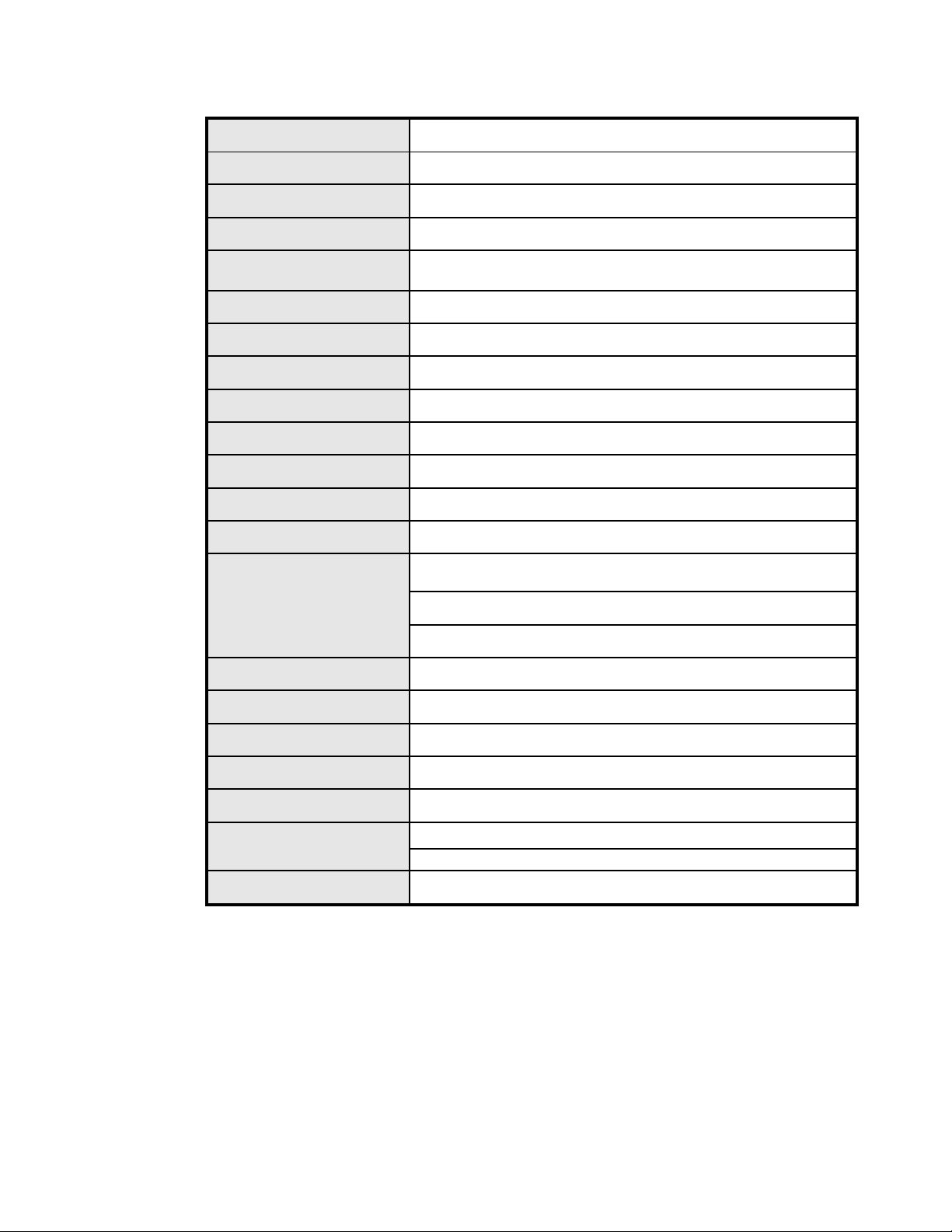

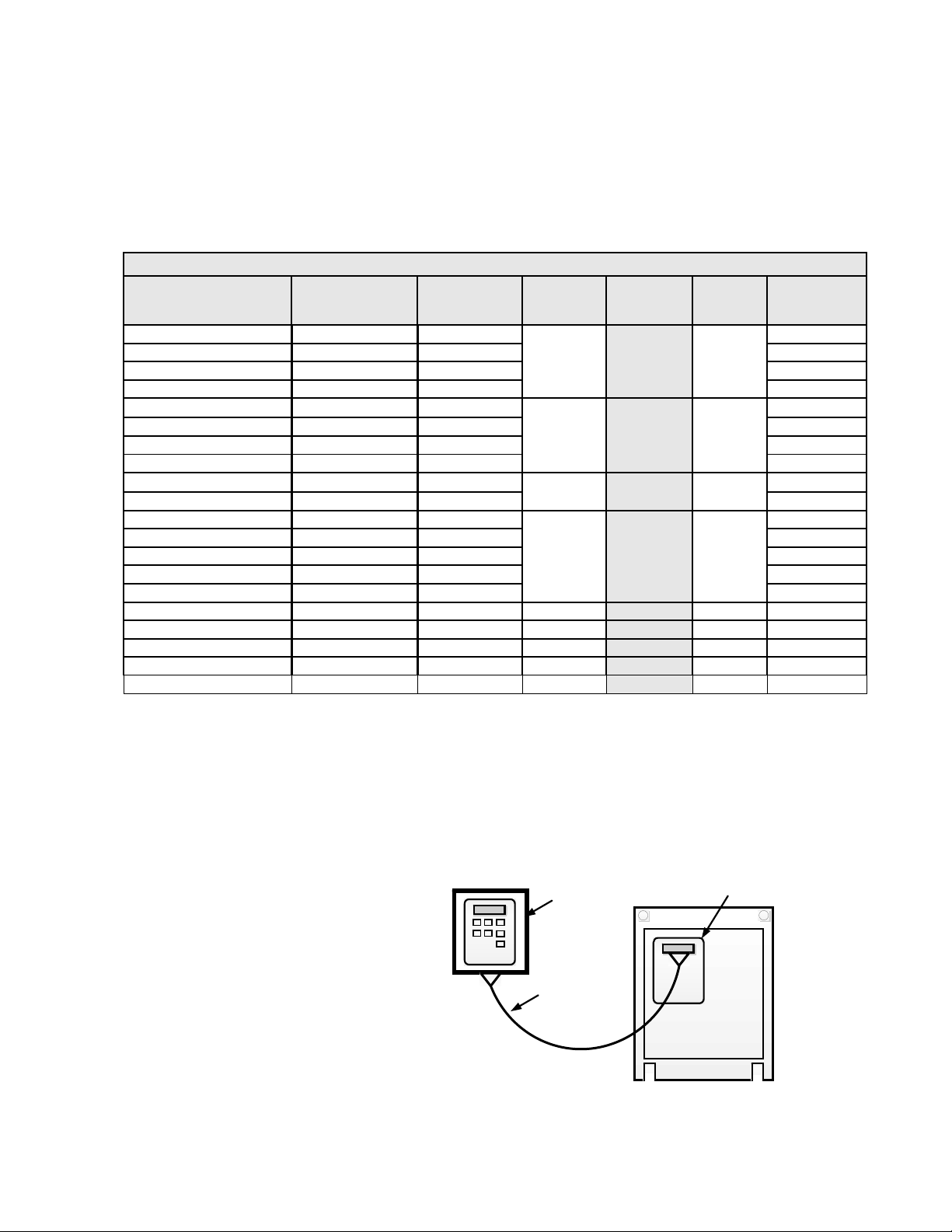

Table 2.6: TE2 Series Wire Ranges and Torque Specifications

Model

Number

TE2-18-BP 9 - 18 10

TE2-28-BP 14 - 28 8

TE2-39-BP 19 - 39 8

TE2-48-BP 24 - 48 6

TE2-62-BP 36 - 62 4

TE2-78-BP 39 - 78 3 35

TE2-92-BP 46 - 92 2 35

TE2-112-BP 56 - 112 1 50

TE2-150-BP 75 - 150 2/0

TE2-160-BP 80 - 160 3/0 95

TE2-210-BP 105 - 210 250

TE2-275-BP 138 - 275 350 kCMIL 185

TE2-361-BP 180 - 361 2 x 300 kCMIL 2 x 150

TE2-450-BP 225 - 450 2 x 300 kCMIL 2 x 150

TE2-550-BP 275 - 550 2 x 400 kCMIL 2 x 240

TE2-600-BP 300 - 600

TE2-862-BP 431 - 862

TE2-900-BP 450 - 900

TE2-1006-BP 503 - 1006

TE2-1250-BP 625 - 1250

Current Range

Min.- Max.

Note: TBD = To Be Determined at a later date

Suggested

Wire Size

AWG

2 x 500 kCMIL TBD

3 x 400 kCMIL TBD

3 x 500 kCMIL TBD

4 x 350 kCMIL TBD

4 x 500 kCMIL TBD

Tightening

Torque

in.-lbs.

35

45

80

200

Screw / Bolt

Size

1 x M5

(included)

1 x M8

(included)

1 x M8

(included)

1 x 0.38" hole

(M10)

for User

supplied

lugs

TBD TBD 2 x 300

TBD TBD 3 x 240

TBD TBD 3 x 300

TBD TBD 4 x 185

TBD TBD 4 x 300

Tightening

Torque

Nm

4

5

9

15

Suggested

Wire Size

ISOmm2

6

10

10

16

25

70

150

2.7 Remote Keypad Mounting

The keypad / operator interface unit can be remotely mounted up to 10ft

(3 meters) away from the starter, i.e. on the enclosure door. A remote

mounting kit is necessary, which consists of an adaptor plate, a

doorframe for NEMA 1 or NEMA 12 enclosures and a pre-assembled

ribbon cable available in 1-meter length increments. Detailed assembly

instructions and an enclosure cutout template are included with the kit.

See Product Selection Guide for part numbers of the available kits.

NEMA12

Door Frame

Figure 2.7

Remote Keypad Mounting Kit

Components

Adaptor Plate

Ribbon Cable,

3 Me ter s

1, 2, o

(3. 28, 6.56, o

9.84 feet.)

TE 2 Starte

TE2 Series Digital Solid State Soft Starter User Manual 9 | Page

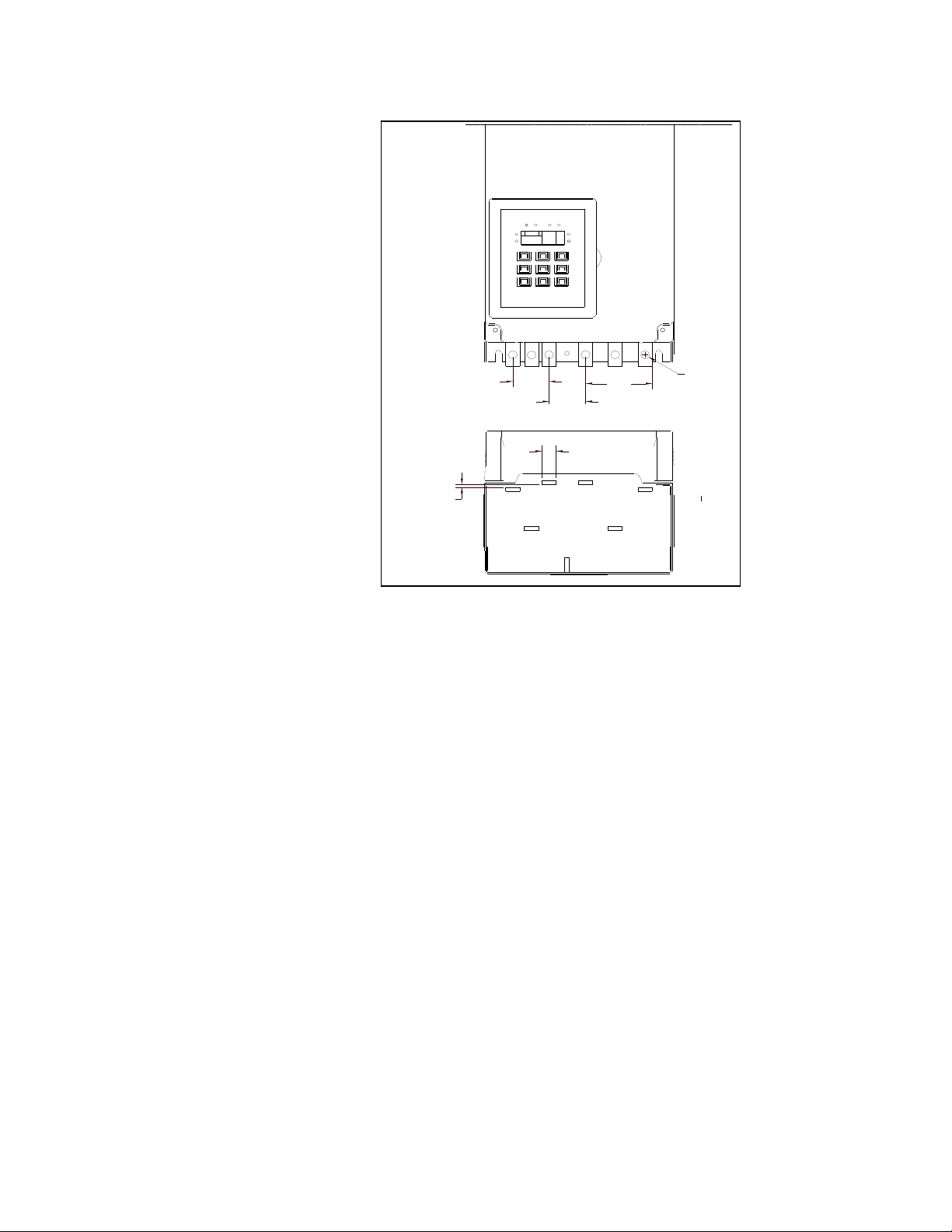

2.8 Dimensions (consult price catalog for enclosed units)

Table 2.8: TE2 Dimensions and Weights

Overall Mounting

Enclosure Model Number

TE2-18-BP through

TE2-48-BP

TE2-62-BP through

TE2-112-BP

TE2-150-BP and

TE2-160-BP

Panel (open)

with integral

TE2 -210-BP and

TE2-275-BP

bypass

contactor

TE2-361-BP and

TE2-450-BP

TE2-550-BP through

TE2 -600-BP

TE2-862-BP through

TE2-900-BP

A

Inches

(mm)

8.85

(230)

14.00

(355.6)

19.00

(487.9)

28.10

(723.9)

29.30

(744)

29.50

(786.9)

44.25

(1124)

B

Inches

(mm)

8.00

(203)

8.00

(203)

8.00

(203)

12.5

(317.5)

12.5

(317.5)

12.5

(317.5)

25.5

(647.7)

C

Inches

(mm)

6.65

(169.7)

6.65

(169.7)

6.65

(169.7)

9.1

(229.4)

9.1

(229.4)

9.1

(229.9)

11.86

(301.3)

D

Inches

(mm)

8.06

(204.7)

13.25

(336.6)

18.25

(463.6)

27.38

(695.5)

27.38

(695.5)

27.38

(695.5)

43.00

(1092.2)

E

Inches

(mm)

7.00

(177.8)

6.75

(171.5)

6.75

(171.5)

10.75

(273.1)

10.75

(273.1)

10.75

(273.1)

23.00

(584.2)

F

Inches

(mm)

0.22

(5.6)

0.28

(7.1)

0.28

(7.1)

0.40

(10.2)

0.40

(10.2)

0.40

(10.2)

0.40

(10.2)

Weight

lbs

(kg)

13

(5.9)

23

(10.4)

35

(15.9)

90

(40.9)

105

(47.7)

120

(55)

Contact

Factory

TE2-1006-BP through

TE2 -1250-BP

50.77

(1182.6)

25.5

(716.3)

13.28

(332.7)

Fdia.

42.75

(1095.9)

23.25

(590.5)

0.40

(10.2)

Contact

Factory

Figure 2.8: TE2 Dimensions

A

~ ~

D

~

E

B

C

TE2 Series Digital Solid State Soft Starter User Manual 10 | Page

Chapter 3 - Motor Overload Protection

3.1 Solid State Overload Protection

MOTOR FLA (F001)

must be programmed

for unit to operate!

Examples:

H100

100% Thermal

Capacity remaining

at rest

H057

57% Thermal Capacity

remaining after starter

(43% used)

The TE2 Series Starter provides true U.L. listed I

Protection as a built-in function of the main digital processor for

maximum motor protection. It mimics the tripping action of a bi-metallic

overload relay, with the accuracy and repeatability of a digital control

system. It is adjustable over a wide range and is easily be programmed

to different trip curves.

3.1.1 Thermal Memory

The TE2 Series microprocessor uses a sophisticated “Thermal

Register” in the digital memory to keep track of motor heating and

cooling over time regardless of the starter’s power status. By using nonvolatile memory, the TE2 Series does not “forget” that the motor has

been running even if power to the starter is turned off and turned back

on. Continuous overload protection is provided based on the true

thermal condition of the motor.

3.1.2 Thermal Capacity

The Thermal Register is displayed as a percentage. This percentage is

the motor’s remaining thermal capacity. The percentage value begins at

100; showing that the motor is cool (has 100% of its capacity available).

As the motor heats up or moves toward an overload condition, the

percentage begins to drop. The Thermal Capacity is derived from the

programmed motor nameplate Full Load Amps (FLA) in Function F001,

the Service Factor rating in Function F002, and the Overload Trip Class

in Functions F003 and F004. Setting these functions to the proper

values provides maximum protection and eliminates nuisance tripping.

The Remaining Thermal Capacity is viewed by using the UP or DOWN

arrow keys when in the Status Display mode. From the default Phase A

Current screen (dot on right side), press the UP arrow key 4 times to

display [H100] meaning there is 100% of the Thermal Capacity (H =

Heat capacity) remaining in the motor. After starting or running, the

motor will use this capacity and the display will show a lower number.

For example, after a cold start, the display may read [H065] which

indicates that the motor has 65% of its thermal capacity remaining (35%

used). The Status Display screens cycle back to the beginning, so the

Down arrow keys can access this display as well.

3.1.2.a Motor Full Load (FLA) Setting

Use Function F001 to enter motor FLA as indicated on the motor

nameplate. (Do not calculate for service factor, this is programmed

separately in F002).

Note:

All TE2 Series starters are shipped from the factory with F001 set

to a default value of 0000. If F001 is left at the factory default, the

unit will not operate. If the user attempts to start the TE2 Series

without entering the motor nameplate FLA, the starter will Fault and

the display will read “nFLA” (no Full Load Amps).

2

t Thermal Overload

TE2

Series Digital Solid State Soft Starter User Manual 11 | Page

3.1.3 Disabling the Overload Protection

The Overload Protection feature can be disabled if necessary. When

using external devices such as Motor Protection Relays or when the

TE2 Series is wired downstream from an existing starter, this feature

can be disabled to prevent conflicts with external Overload Protection

devices. When the TE2 Series is controlling multiple motors, the built-in

Overload Protection must be disabled and individual thermal overload

relays must be installed on the motor leads going to each motor (see

Appendix 4 for additional details). To disable the Overload Protection

function, use F005.

WARNING!

Do NOT disable Overload Protection unless another Thermal

Overload Protection device exists in the circuit for all three

phases. Running a motor without Overload Protection presents serious

risk of motor damage or fire.

3.1.3.a Manual Reset

The factory default setting is Manual Reset. This means that when

the Overload Trip is activated, the starter cannot be restarted

without pressing the Reset key. The Overload Trip will not reset

until the motor cools down (see 3.1.3.d). The Manual Reset function

is also “trip free”. Holding in the Reset key will not prevent the

Overload Trip from activating and protecting the motor.

Note:

When the Overload Trip activates, the Overload LED will be on

solid. When the motor cools down, the LED will begin to flash,

indicating that the Overload Trip can be reset.

3.1.3.b Automatic Reset

If Automatic Reset is necessary, change from Manual Reset to

Automatic Reset by using Function F005. (See Section 5 for

details). In this mode, a 3-wire control circuit will be capable of

restart when the TE2 Series has reset itself after the cool down

period.

WARNING!

Two-wire control systems may restart without warning when Auto

Reset of the Overload Protection is selected. Extreme caution

should be exercised. To prevent automatic restarting with 2-wire

control systems, use external interlocking to provide sufficient

warning and safety to operators. A Warning Label similar to that

shown below (and the one provided in the packet with this manual)

must be located where visible (on the starter enclosure and/or the

driven equipment) as required by local code.

WARNING: M OT OR CONNECT ED T O T HIS EQUIPM ENT

MAY ST ART AUT OMAT ICALLY WIT HOUT WARNING

TE2 Series Digital Solid State Soft Starter User Manual 12 | Page

3.1.3.c Overload Protection During Bypass

When an integral Bypass Contactor is used to shunt power around

the SCRs in the TE2 Series (as in the TE2…-BP version), overload

protection is maintained as long as the TE2 Series is directly

controlling the contactor. No additional Overload Relay is

necessary for normal operation.

When the Bypass Contactor on a TE2…-BP Series has been

selected to be used for Across-the-Line restart (reference section

1.2.3), supplemental overload protection is necessary. For this

application, refer to the External Overload Relay Applications

supplement and wiring diagram in Appendix 4.

3.1.3.d Dynamic Reset Capacity

The TE2 Series includes the ability to dynamically track the

Thermal Capacity needed for a successful restart after an overload

trip. It averages the Thermal Capacity consumed in the previous

three successful starts, and calculates a Thermal Capacity to Start

(viewed in Function F059). After tripping on Overload, the Thermal

Register must have regained the amount recorded in F059 before a

Reset will be allowed. If the display reads [Inh] when attempting to

reset an overload trip, it is indicating that the starter is Inhibited from

being reset.

Refer to details of Function F071 for information on emergency

override of lockouts such as this.

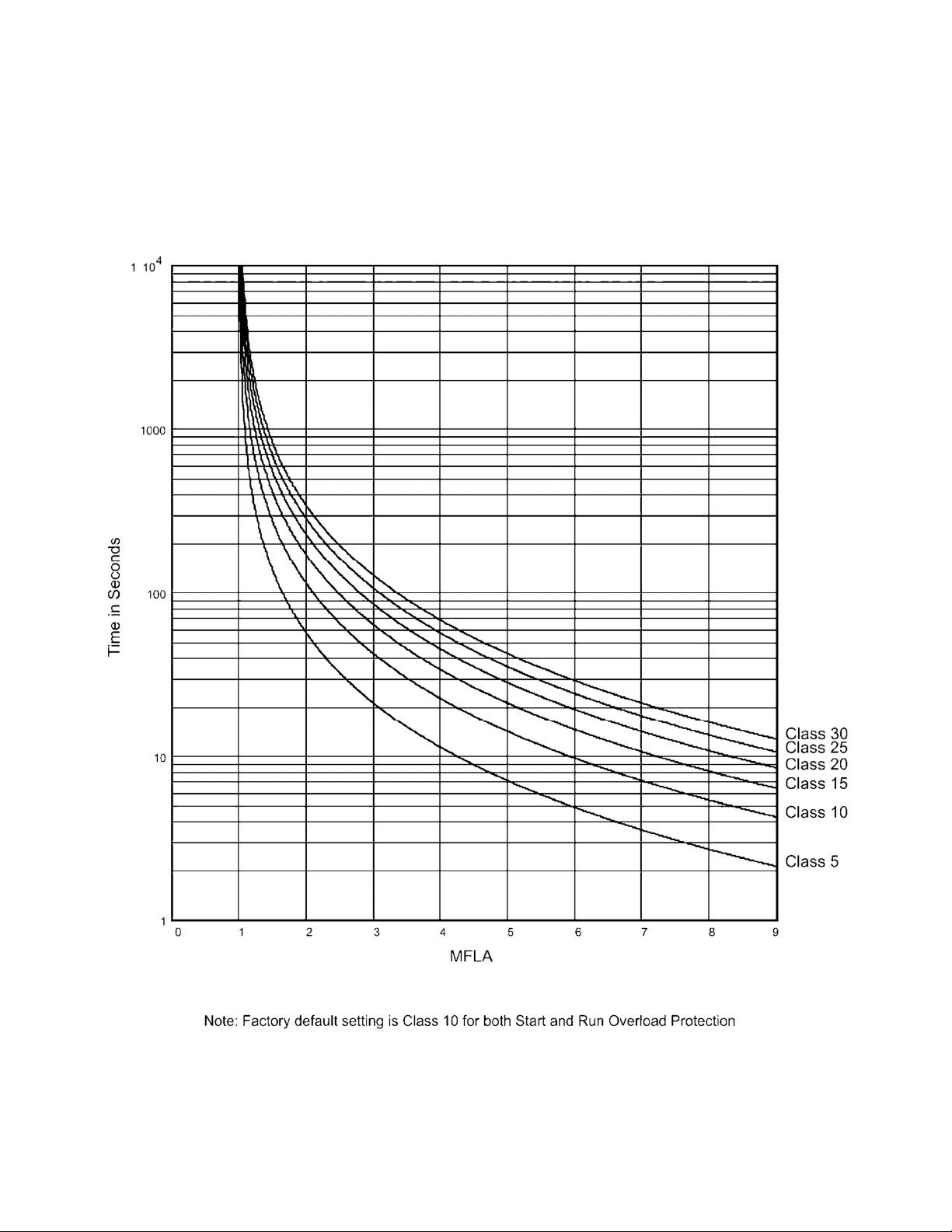

3.2 NEMA Class Trip Curves

NEMA Class trip curves are based on a common tripping point of 600%

of motor Full Load Amps (FLA). Curves vary by the amount of time

before the unit trips. As an example, a Class 20 curve will trip in 20

seconds at 600% of FLA. The factory default setting of Class 10 will trip

in 10 seconds at 600% of FLA.

3.2.1 Dual Overload Trip Curves

The TE2 Series Soft Starter provides two separate Overload Trip

Protection Curves, one for starting and one for running conditions. The

starter’s At-Speed detection circuit determines when the motor has

reached full speed. When the At-Speed condition is reached, the

overload trip curve will shift from the Start to the Run level, as

programmed in Functions F003 and F004. See Section 5.6.1 for

programming details.

3.2.2 Starting Overload Trip Curve

During the start mode, Overload Trip Curves are selectable from NEMA

Class 5 through Class 30 only. The default setting of Class 10 allows

protection for the overload capacity of the soft starter as well as the

motor. Use a higher Trip Class only if nuisance tripping occurs with the

default setting.

TE2 Series Digital Solid State Soft Starter User Manual 13 | Page

3.2.3 Running Overload Curve

During the Run mode, Overload Trip curves are selectable from NEMA

Class 5, 10, 15, 20, 25, and 30. Program the appropriate curve

according to the characteristics of your motor and load.

3.2.4 Overload Trip Curve Chart

TE2

Series Digital Solid State Soft Starter User Manual 14 | Page

Figure 3.2.4: TE2 Series Overload Trip Curves

Chapter 4 - Connections

r

r

/

V /

Disconnect

o

Circuit

Breaker

R /

L1

U /

T1

T2

S /

L2

T

TE2 Starte

L3

Solid State

Overload

W /

T3

.

.

Integral

Bypass

Contactor*

.

G

MTR

4.1.2 Power Factor Correction Capacitors

Power factor correction capacitors can be connected to motors

TE2 Power Connections

Figure 4.1:

4.1 Power Connections

Refer to national and local code for wire sizing and length, connect

power conductors to the unit input terminals marked L1, L2, L3 (R, S, T

for IEC users). Use appropriate compression or mechanical lugs for

termination to these bus tabs. Avoid routing power wires over the

control board or display. Connect the motor leads to the unit terminals

marked T1, T2, T3 (U, V, W for IEC users). If control power is present,

but line power is disconnected from L1, L2, L3, the display will show

[n3PH] indicating “no 3 Phase”.

Caution!

Never interchange input and output connections to

the unit. This could cause excessive voltage in the

control logic circuit and may damage the unit.

4.1.1 Bypass Contactor

Bypass Contactors are integral (built-in) on all TE2 sizes. See sections

1.2.3, 3.1.3.c, and Appendix 4 for more details on contactor control and

overload protection details.

controlled by TE2 Series starters; however they must be off-line during

ramping. Connect PFC capacitors to the Line side of the starter with a

separate capacitor control contactor.

WARNING!

Never connect power factor correction capacitors on the load side

of the unit. The SCRs will be seriously damaged if capacitors are

located on the load side.

4.1.3 Grounding

Connect the ground cable to the ground terminal as labeled on the unit.

Refer to the National Electrical Code or your local Code for the proper

ground wire size, and be sure that the ground connector is connected to

earth ground.

TE2

Series Digital Solid State Soft Starter User Manual 15 | Page

4.1.4 Testing

The TE2 Series can be tested with a load smaller than the motor it was

originally selected to control, however additional steps must be taken to

avoid tripping on Phase Current Loss. See section 5.6.8.a under “Phase

Loss Protection” for additional details on performing this task.

Notes:

The unit cannot be tested without a motor or other test load

connected to the load side of the unit. It may be necessary to use a

load bank to test the unit without a motor.

Line voltage will appear across the output terminals if there is no

motor or load connected to the unit.

4.1.5 Lightning Protection

As with all electronic power controllers, protection from damage by

lightning surges is recommended in areas where lightning is a

significant problem. Stationary SPDs (Surge Protection Device) should

be considered and utilized on the input power source. The best method

of protection is to have an Isolation Contactor in front of the starter that

is open when the soft starter is not in use. Enclosed versions may be

provided with a surge protection device.

4.2 Control Connections

Control connections on the TE2 Series starter are divided into 2 groups.

With the unit oriented vertically, TB1 is a 12-point DC terminal block (on

the left), and TB2 is a 10-point AC terminal block (on the right side).

These are removable terminal blocks for ease of connection and

servicing, and are provided with different spacing (pitch) between the

header pins, so they are not interchangeable. Following are descriptions

of control connection points.

Note:

Terminal numbers are shown on the side of the first and last

terminal of each block. An additional 3 point terminal on the far left

side is for serial communication connections (see section 5.6.10).

TE2

Series Digital Solid State Soft Starter User Manual 16 | Page

Figure 4.2: Control Terminal Blocks

1

NC NO. C

2

NC NO. C3NO. C

Control Power Supply Connection

Figure 4.2.1

TB-2

4.2.1 AC Control Power Supply Connection

120VAC

Supply

1

A1 A2

Separate AC Control Power supply is required to power the electronics

of the TE2 Series starter. The standard is 120VAC, but 240VAC

(optional) can be ordered if necessary for your line power supply

configuration. The control voltage must be connected to terminals

marked A1 and A2 of TB-2 as shown in figure 4.2.1 (these are also

Terminal No.’s 21 and 22). This control voltage must be customer

supplied, unless an optional control power transformer (see table below)

has been supplied with the unit.

Table 3: TE2 Series AC Control Power VA Requirements

TE2…-BP

Model

TE2-18 to 48 48 (inc. in PCB) 95 9 100

TE2-62 to 112 48 (inc. in PCB) 220 17 250

TE2-150 to 160 48 72 298 12.3 500

TE2-210 to 276 48 100 380 11.6 500

TE2-360 to 450 48 150 571 14 750

TE2-550 48 200 1000 29 1000

PC

Boards

Fans

-BP: Bypass

Contactor

Inrush

-BP: Bypass

Contactor

Sealed

Recommended

minimum

CPT

Rating

4.2.1.a Control Power Requirements

When sizing a control power transformer for the TE2…-BP Series

starter use the above chart for minimum sizes or supply capacity.

Any additional control devices powered by the same CPT must be

added to the above values to ensure proper operation of the Bypass

Contactor.

4.2.1.b Control Fusing

The output relay contacts (TB2) must be protected from currents in

excess of 5A by either using fuses or other suitable current

protection devices.

A dedicated fault output for use in PLC or interposing relay control

is available on TB1. This opto-isolated Triac switch is rated for

50mA max., 10-250V AC. Any circuit connected to it must be fused

accordingly.

TE2 Series Digital Solid State Soft Starter User Manual 17 | Page

4.2.2 Three-Wire Control Connection

For standard 3-wire control, connect dry (voltage free) contacts for the

Stop / Start buttons as shown on the diagram directly above the terminal

strip. Connect the N.O. contact of the Start button to Terminal 1 (far left

terminal), the common point between the Stop and Start to Terminal 2

nd

(2

from left) and the N.C. from the Stop button to Terminal 3 (3rd from

left).

4.2.2.a Seal In Contact

The TE2 Series uses an internally pre-wired “seal-in” contact

around the Start button (Terminals 1 and 2). No external relay or

auxiliary output connection is necessary.

4.2.3 Two Wire Control: Relay / PLC Connection

An alternate connection for automated or unattended operation replaces

the start/stop push buttons by connecting a dry (voltage free)

maintained contact closure between terminals 1 and 3 as shown in

Figure 4.2.3. When this contact is closed, the TE2 Series starter will

start and run. When it is opened, it is the same as a Stop command.

4.2.3.a Automatic Functions and 2-Wire Control

When using the Auto Reset functions (F052 - F053), special

consideration must be given to using 2-wire control. Refer to section

5.6.8 for details on using Auto-Reset functions.

Note:

When a maintained contact is used for start/stop, it is advisable to

set the overload relay to the manual reset position. This will prevent

the motor from restarting if the thermal overload trips and then cools

down.

CAUTION!

Control Terminals 1-10 of TB1 are configured using solid state

devices powered internally with a 24VDC power supply. To prevent

damage to the TE2 Series control board, use dry (unpowered)

contact closures only when connecting to these terminals.

If existing 120VAC or other powered control circuit must be

interfaced, use isolating relays.

4.2.4 Interlock Connection

TB1 provides a connection point for an external dry (voltage free) N.C.

(Normally Closed) interlock device between terminals 4 and 5.

Examples where this interlock connection would be used include low oil,

high temperature, or excess vibration dropout from user supplied

devices. A factory-installed jumper is provided which allows the TE2

Series unit to operate if external interlocks are not used. If this jumper is

removed and an interlock is not used, the TE2 Series unit will not

function.

TE2

Series Digital Solid State Soft Starter User Manual 18 | Page

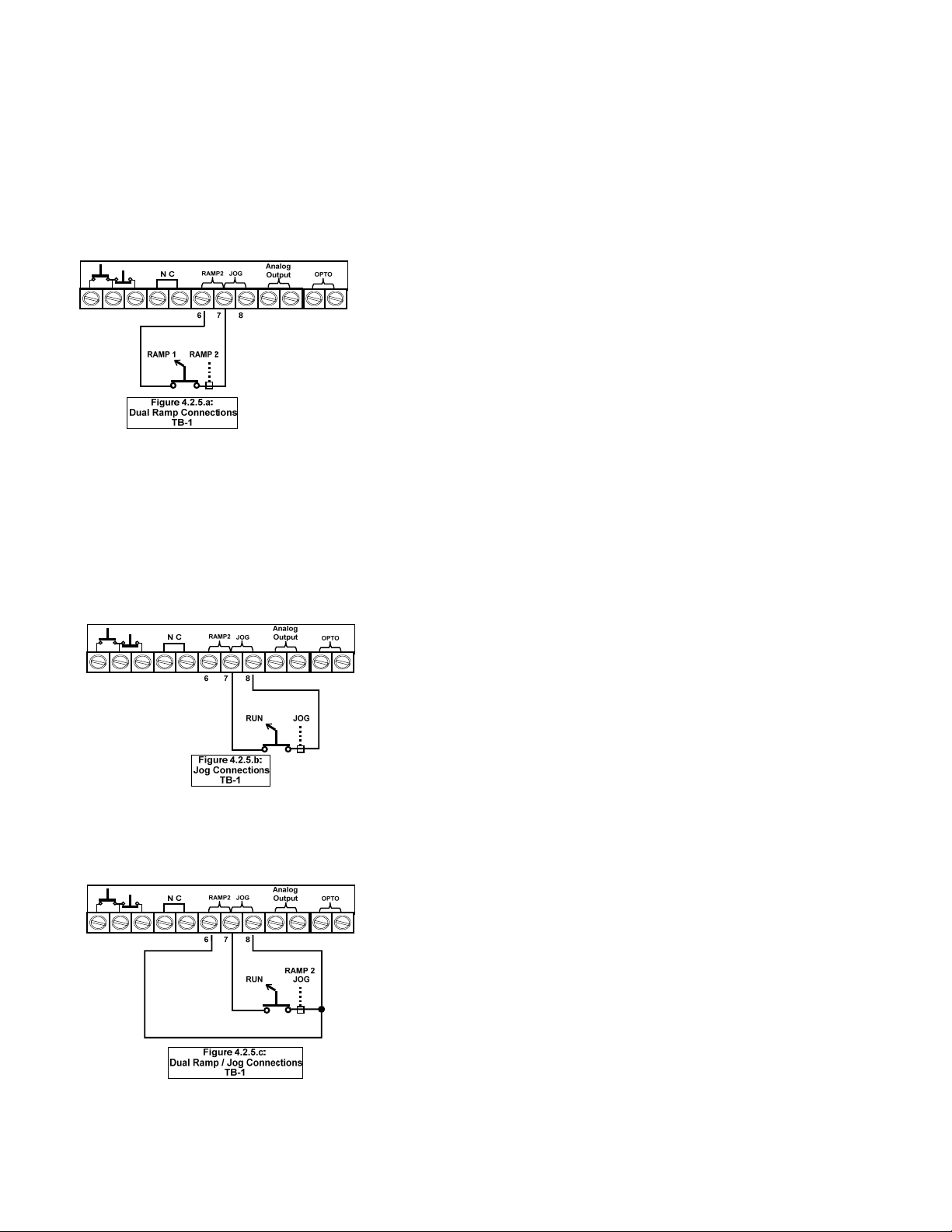

Note: Ramp 2 terminals are defaulted as

“External Reset”, see parameter F113 for

other options.

Note: Jog terminals are defaulted as

“External Lockout, Normally Closed”, see

parameter F113 for other options.

4.2.5 Enabling the Dual Ramp and Jog Features

TB1 includes provisions for enabling the Dual Ramp and Jog functions

by using external contact closures. Both features use a common

+24VDC from Terminal 7. However, they can be used independently of

each other or together. See sections 5.6.2 and 5.6.3 for full function

descriptions and setup.

4.2.5.a Dual Ramp Command

Closing a dry (voltage free) contact between TB1, terminals 6 and 7

will enable Ramp 2, and the TE2 Series starter will respond to the

settings for Ramp 2 in F015 - F018. If no contact closure is present,

the TE2 Series starter defaults to the Ramp 1 parameters (F011 -

F014). See Section 5.6.2.a for setup of the Dual Ramp Feature.

The Dual Ramp feature is useful in instances where the load

changes significantly. Example: a loaded or unloaded conveyor belt.

The characteristics for starting an unloaded conveyor can be

programmed for Ramp 1. The characteristics for starting a loaded

conveyor can be programmed for Ramp 2. Ramp 2 can also be

programmed for Full Voltage / Across-the-Line starting by setting

the ramp time to 0 and Current to 600%.

Dual Ramp is also useful in 2-speed motor applications. Simply use

an auxiliary contact from one of the speed contactors to select

Ramp 2 so that separate ramp profiles can be used.

Dual Ramp input can also be configured as a “Remote reset”

(See parameter F113 and associated table)

4.2.5.b Jog / Remote Command

Connecting a dry (voltage free) contact between TB1, Terminals 7

and 8 will enable the Jog feature. A Start command (Run Command

or Start button) is required to activate the Jog feature. See Section

5.6.3 for setup of the Jog Function.

The Jog feature can be used for tasks such as lining up machines

for blade or bit changes, or inching belts along to check tracking.

This input is also used to change the function of the Serial

Communications port control through F068. For additional

information, see instructions of that function in section 5.6.11.

Jog input can be also configured as:

“Remote” (via comm. link) / “Local” (T-strip), Start stop control.

“External Lockout” (N.O.)

“External Lockout” (N.C.)

(See parameter F113 and associated table)

4.2.5.c Using Both Commands

It may be useful to initialize the Ramp 2 and Jog command

simultaneously when jogging. If this is the case, terminals 6 and 8

can be jumped together and controlled with one contact closure to

Terminal 7 (the common 24VDC).

TE2 Series Digital Solid State Soft Starter User Manual 19 | Page

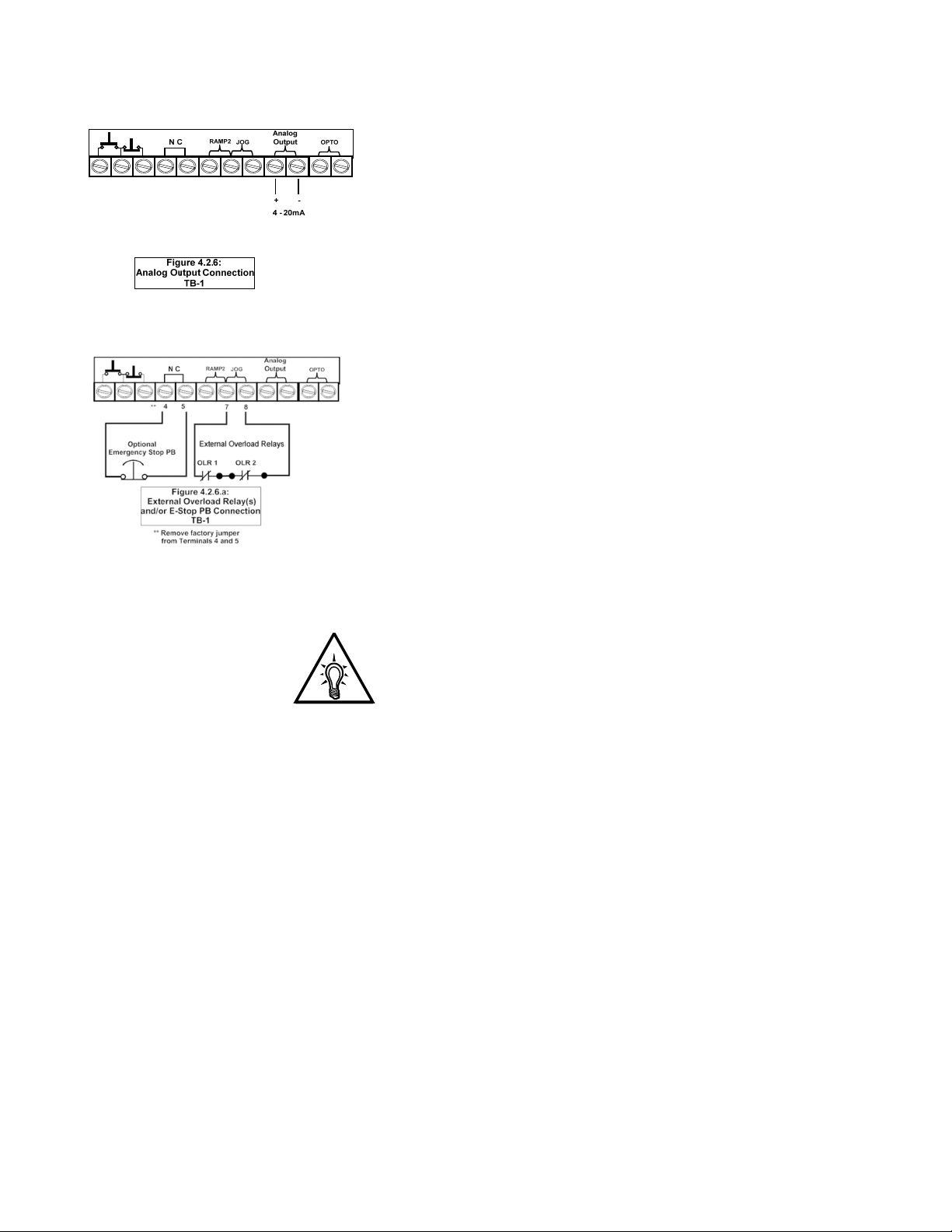

4.2.6 Analog Output (4-20mA)

The TE2 Series starter provides a 4 to 20 milliamp output signal that

can be set to monitor different parameter values using F108 and scaled

with parameter F109 and F110. See section 5.5.16.

4.2.6.a External Overload Relay Connection

If an external Overload Relay (OLR) is used (see Section 3.1.3.c and

Appendix 4), connect the N.C. aux. contact of the OLR across the

Jog input (TB1 terminals 7&8), and re-program the Jog input for

“External Lockout N/C”, by changing F113 per table in sect 5.6.17.

When the external OLR trips, the contact will open. This indicates an

immediate Overload to the starter, which trips and displays [LcA,

Lcc, or Lcd] depending on operation mode when the overload trips.

If multiple OLRs are used, i.e. multiple motors controlled by the same

TE2 Series starter, simply wire the Aux Contacts in series as shown

in Figure 4.2.6.a. See Appendix 4 for additional information.

Note:

This feature is especially useful when using Deceleration Control

because it will immediately shut off power to the motor even if

Deceleration is active. If used this way, the trip indication will be

[LcA, Lcc, or Lcd] depending on the operation mode when the trip

is issued.

TE2

Series Digital Solid State Soft Starter User Manual 20 | Page

Internal Connections

K3

1

NC NO. C

13 14 15 16 17 18 19 20

AUX.

RELA Y # 1

2

NC NO. C3NO. C

AUX.

RELA Y #2

Figure 4.2.8

Auxiliary Relay Conne ctions

TB-2

K5K4

AUX.

RELA Y #3

1

A1 A2

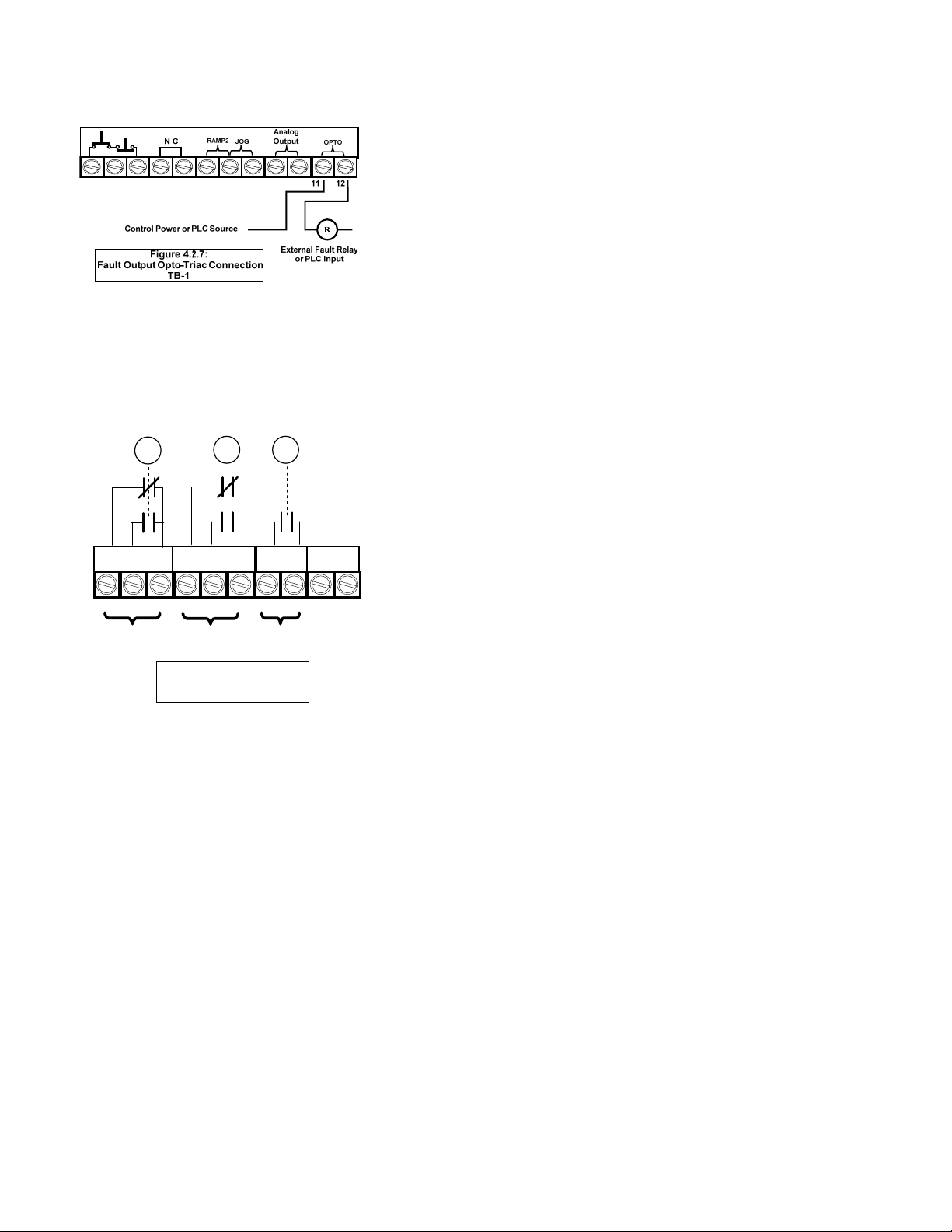

4.2.7 Fault Signal

An optically isolated Triac output is dedicated as a fault indicator on

TB1, terminals 11 and 12, labeled “Opto”. The output Triac switch is

rated for 10 - 250VAC, 50 mA (maximum). If the three programmable

Output Auxiliary Relays are being used for other functions, this output

can easily be hooked up to a PLC or small external relay to provide a

Fault signal. This Fault Output operation is permanently fixed at “Any

Trip”, duplicating the relay setting 22 as shown in Table 5.6.9.

This output is permanently set to this function and is not

programmable.

4.2.8 Output (Auxiliary) Relay Contacts

Three programmable auxiliary relays are on TB2. The TE2 Series

starter comes with three programmable dry relay output contacts.

Outputs 1 and 2 are Form C (SPDT), with a Common, N.O. and N.C.

Output 3 is a Form A, (SPST), N.O. contact. It is not necessary to use

the programmable output auxiliary relays in the Start / Stop circuit. An

internal seal-in relay is provided elsewhere (see 4.2.2.a). Toshiba

recommends fusing all outputs with external fuses.

The relays are rated for 240VAC, 5 A and 1200 VA.

Factory default settings for these relays are as follows:

AUX 1 - Run / Stop (see F060).This contact changes state upon a

Start command, returns to normal on Stop (or Begin Decel if active).

AUX 2 - At-Speed / Stop (see F061).This contact changes state

upon the TE2 Series detecting At-Speed, and returns to normal on

Stop. At-Speed is determined by the TE2 Series detecting the

current dropping after reaching End-of-Ramp, or a maximum of 30

seconds after Start.

AUX 3 - Any Trip (see F062) This contact closes when any trip

condition 5 - 21 (as defined in Table 5.6.9) occurs.

All relays can be reprogrammed for a wide variety of functions.

See Section 5.6.9 for additional relay programming details.

TE2 Series Digital Solid State Soft Starter User Manual 21 | Page

4.2.9 Bypass Contactor Control

On TE2…-BP version (and NEMA 12 enclosures) starters, an internal

dedicated connection is used at the factory for automatically controlling

the Bypass Contactor. Field wiring for Bypass Contactor operation is not

required.

4.2.9.a Independent Bypass Contactor Control

The TE2…-BP Series starters use standard industrial contactors

that can be controlled independently of the starter electronics if

necessary. When doing so, it is necessary to size the starter based

upon the ATL (Across-the-Line) selection chart so that the

contactors are rated for ATL duty instead of normal Shunt Duty.

Supplemental overload protection will be required (see section

3.1.3.c).

Units have external terminal blocks marked for this purpose (see

Appendix 4 for drawings). A dry (voltage free) contact closure

between these terminals will close the bypass contactor

immediately. The Bypass Contactor coil voltage is the same as the

control voltage (120VAC unless the optional 240VAC control is

specified), and the voltage on these terminals is the same as the

coil voltage.

No field wiring is necessary to these terminals if this feature is

not used.

For all other styles of TE2 Series, the At-Speed signaling can be

programmed into any of the three Output relays (section 4.2.8 and

Table 5.6.9).

TE2 Series Digital Solid State Soft Starter User Manual 22 | Page

Chapter 5 - Programming

5.1 Introduction

It is best to operate the motor at its full load starting conditions to

MOTOR FLA (F001)

must be programmed

for unit to operate!

Figure 5.2: Digital Interface

achieve the proper time, torque and ramp settings. Initial factory settings

are set to accommodate general motor applications and provide basic

motor protection. Advanced features must be enabled via programming.

The only parameter that MUST be set by the user is motor FLA (F001).

5.2 Digital Interface

The TE2 Series Soft Starter includes a digital keypad with eight LEDs,

seven command keys, and an LED display with four alphanumeric

digits.

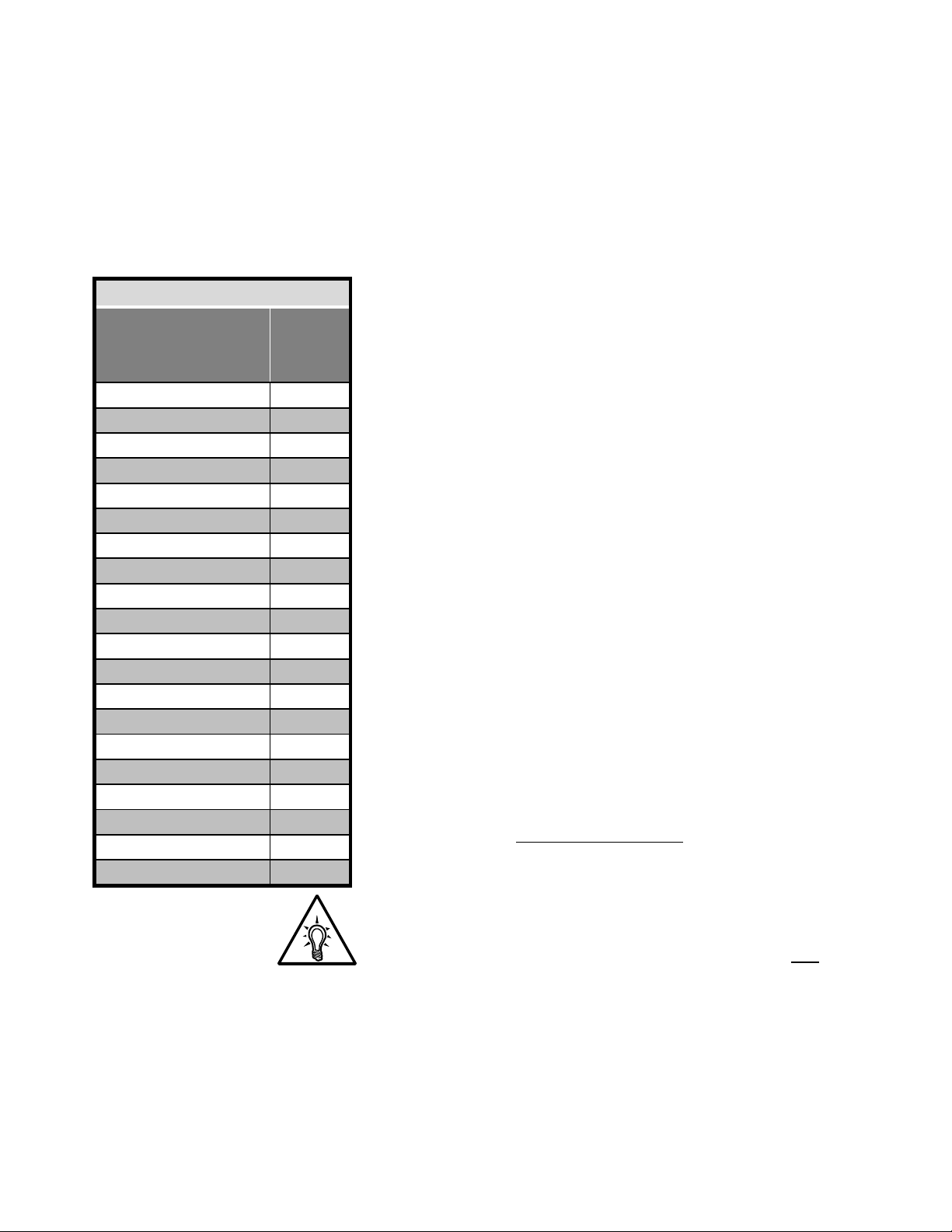

Table 5.2: TE2 Series Display Features

Reset Clears the Trip indication and releases the Trip Relay.

Fn Enters or exits the Program Mode.

Navigates through the Status Display Mode, scrolls up

and down through the Function List, increases or

decreases the value of the active (flashing) digit and

scrolls through the fault history. When entering values,

holding the key down for more than 2 seconds will

activate Auto-step, which increases its rate the longer

the key is held down.

Each keypress shifts the active (flashing) digit to the

right or left by one position, allowing you to change

higher values of functions without waiting to Auto-step

though large numbers.

Control power is available at A1 and A2

The motor is at full power and the Bypass Contactor

has been commanded to pull in.

The SCRs are at full conduction and current has

dropped.

Power is flowing to the motor in the Off mode. See

section 5.6.8.a for additional information.

There is no voltage drop across at least one SCR

phase assembly, indicating that at least one SCR is

shorted. See section 8 for additional information.

Overcurrent LED lights for three sets of fault conditions:

1) During start, the unit saw current exceeded the

normal rate of increase in the first 250ms.

2) During Run, current exceeded either the OC setting

in F042 for the delay set in F043. This LED will be

accompanied by oCA, oCC or oCd on the display.

3) The unit has seen a Short Circuit exceeding 10x

FLA for 12.5ms. This LED will be accompanied by

SCA, SCC or SCD display.

One or more of the phase currents dropped below the

threshold during starting or running.

Starter has tripped due to excess heat sink

temperature. This will automatically reset.

Starter has tripped due to the Thermal Register

reaching 0000. The Overload must reset before this

fault can be cleared.

4 digit 7 segment display with a decimal point on the

right side indicating Phase A.

Keys

Green

LEDs

Yellow

LEDs

Display

Up and

Down

Arrows

Right

and Left

Arrows

Power

On

At

Speed

Shunt

Trip

Shorted

SCR

Over

Current

Phase

Loss

Over

Temp

Over

Load

8888.

TE2 Series Digital Solid State Soft Starter User Manual 23 | Page

5.3 Display Modes

There are three modes of display: The Status Display Mode, the

Program Mode, and the Fault Mode.

5.3.1 Status Display Mode (Default Display)

The Status Display Mode displays five “screens” of information. Motor

Currents (3 phases), Remaining Thermal Capacity and Ground Current.

This is also the entry screen for going into the Program Mode.

Status mode:

[0000.] The initial display on power up is four digits and the decimal.

This indicates the motor current for Phase A of the motor.

[0000] Scroll UP to display four digits only (no decimal). This indicates

the motor current for Phase B. While viewing Phase B, press the UP

arrow again to view Phase C current.

[G000] Scroll UP to display the “G”. This shows the value of the current

flowing to ground on the motor leads.

[H000] Scroll UP to display the “H”. This indicates the value of the

remaining thermal capacity percentage of the motor (i.e. H070 = 70%

remaining thermal capacity).

Example: Figure 5.3.1

Reading the Status Display

[0120.] Indicates Phase A is drawing 120 amps.

Press the UP arrow

[0121] Indicates Phase B is drawing 121 amps.

NOTE: Decimal points are not present in the

readouts for Phases B and C.

Press the UP arrow

[0120] Indicates Phase C is drawing 120 amps.

Press the UP arrow

[G002] Indicates that there are 2 amps of current flowing to

ground in the motor leads or motor.

Press the UP arrow

[H083] Indicates the motor has 83% of its thermal capacity

remaining (H = Heat).

Press the UP arrow

[0120.] Loop back to Phase A current indication

TE2

Series Digital Solid State Soft Starter User Manual 24 | Page

5.4 Program Mode

The starter must be OFF (Motor Stopped) in order to enter the Program

Mode. Use the Program Mode to view or change Function (Fn) settings.

To enter the Program Mode, press the [Fn] key once from the Status

Screen described in 5.3.1 above. The first time you enter the Program

Mode after power has been cycled to the starter, the initial function

[F001] should be displayed with the selected digit flashing. If the TE2

Series starter has been programmed and power to the unit has not

been cycled, the readout will display the last function viewed or

changed. To change to a different function, use the arrow keys.

5.4.1 Viewing Function Programming and Values

While in the RUN Mode, the programming of each individual function

and metering values can be viewed, but no changes are allowed. Each

Function is signified by the letter "F" at the beginning of the data. The 4digit value of the function follows after pushing the (READ/ENTER) key.

• [F001] The “F” indicates the programmable Function.

• [0000] This is the present setting of the applicable function. This

display may include decimals between digits depending on the function

setting’s range and incremental steps.

Example: Figure 5.4.1

Viewing a Function’s Set Value:

Motor FLA Setting

[0000.] Indicates that Phase A is drawing no current

(unit is in Off mode).

Press the Fn key

[F001] Indicates that this is Function 001 (Motor FLA).

Press Read / Enter key

to view the F001’s value

[0306] Indicates that the programmed motor FLA is

360 Amps.

Press the Fn key

to return to the function

[F001] Indicates that you have returned to the Function

Select screen.

Press the Fn key again

to return to the Status Display Mode

[0000.] Indicates that Phase A is drawing no current

(unit is in Off mode).

Note:

If password protection has been enabled, the operator will need to

obtain password access before function settings can be changed.

See Section 5.6.12 and Appendix 3.

Display

Shows...

Pre ss

Key...

Fn

READ

ENTER

Fn

Fn

0000.

F001

0360

F0 0 1

0000.

Figure 5.4.1:

Vie w ing a Function's Se t Va lue

Means...

Default Display:

Phase A Current

Sele cting

Function #1

Fn 1 Value:

FLA = 360A

Return to Function

# Selection

Return to

Default Display

Without Change

TE2 Series Digital Solid State Soft Starter User Manual 25 | Page

5.4.2 Enabling Password Protection / Parameter Lock

The TE2 Series starter is shipped with the password protection disabled

(F070 = 0). If it becomes necessary to prevent parameters from being

changed inadvertently, set the password in function F070. See

Appendix 3 for details. If the display reads [ Loc] when the

[READ/ENTER] key is pressed, the parameter lock is enabled.

5.4.3 Changing a Function’s Set Value

From the instructions above, after pressing the [READ/ENTER] key the

display will show the value of that function with one digit flashing

(usually the rightmost digit). Flashing indicates this is the digit to be

altered (similar to cursor position). Use the UP arrow key to increment

the value of the flashing digit. Use the DOWN arrow key to decrement

the value of the flashing digit. Use the LEFT or RIGHT arrow to select

the next digit to be altered. Values can only be changed within the

Adjustment Range of the function parameter.

Example 1: Figure 5.4.3

Viewing a Function’s Set Value

[0000.] Indicates Phase A is drawing no current

(unit is in Off mode).

Press the [Fn] key

[F001] Indicates this is Function 001 (Motor FLA).

Press [READ/ENTER] key

to view the F001 value

[0048] Indicates the programmed motor FLA is 48 Amps.

The right most digit (8) is flashing, indicating that

this is the digit that you will alter (cursor position).

Press the UP Arrow key

to increase this digit value

[0049] Indicates you have increased the right most digit

to a value of 9.

Press the LEFT Arrow key

to shift left to the next digit

[0049] The second digit from the right is now flashing,

indicating a new cursor position.

Press the UP Arrow key

to increase this digit value

[0059] Indicates you have increased the 2

nd

to right digit

to a value of 5 (10’s place).

Press [READ/ENTER] key

to store the new value

[End] The word “End” will flash briefly to indicate that

the new value has been entered and accepted.

After flashing once, the display will revert to

showing the Function number.

Example 1: Setting the Motor FLA

Change FLA from 48 to 59A

Pre ss

Key...

Fn

READ

ENTER

READ

ENTER

Display

Shows...

0000.

F0 0 1

0048

0049

0049

0059

End

F001

Figure 5.4.3:

Changing a Function Va lue

Me ans...

Phase A

Curr e nt

Function #1

Se le cte d

Previous Setting

of Function #1

New Value of

First Digit

Cursor (flashing)

Position Shift

New Value of

Second Digit

Value Accepte d

(flashes once)

Retur n to

Function # Display

TE2 Series Digital Solid State Soft Starter User Manual 26 | Page

5.4.3.a Changing a Value by Increments

Although it may be easier to shift the cursor position, it is also

possible to increase or decrease values by pressing the UP or

DOWN arrow keys successively. This will change the Function

value by the incremental amount associated with that Function. The

Function List shows increment values for each Function.

Example 2: Figure 5.4.3.a

Changing a Function’s Value by Increments

[0000.] Indicates that Phase A is drawing no current

(unit is in Off mode).

Press the [Fn] key

[F001] Indicates that this is Function 001 (Motor FLA).

The right most digit (1) is flashing, indicating this

is the digit that you will alter (cursor position).

Press the UP Arrow key twice

to increase this digit value to 3

[F003] Indicates that this is Function 003

(OL Class During Start).

Press [READ/ENTER] key

to view the F003 value

[0010] Indicates that the programmed OL is Class 10

during the Start Mode. Cursor flashing on right

most digit.

Press the UP Arrow key

to increase this digit value

[0015] Indicates that you have increased the Function

value by the increment assigned to it, a value of 5

in this case.

Press the UP Arrow key again

to increase this digit value

[0020] Indicates that you have again increased the

Function value by the increment assigned to it.

Press [READ/ENTER] key

to store the new value

[End] The word “End” will flash briefly to indicate that

the new value has been entered and accepted.

After flashing once, the display will revert to

showing the Function number.

5.4.4 Storing the Altered Value of a Function

Once the desired value is displayed, press the [READ/ENTER] key.

This stores the value in memory. The readout momentarily displays

[End] and then returns to the function code.

Caution!

If the Fn key is pressed or power is lost before the [READ/ENTER]

key is pressed, the TE2 Series Starter will not store the selected

value in memory.

Example 2: Setting the OL Curve

During Start

Change from Class 10 to Class 20

Display

Shows...

x2

0000.

F0 0 1

F003

0010

Pre ss

Key...

Fn

READ

ENTER

0015

0020

READ

ENTER

End

F003

Changing a Function Va lue by Inc reme nts

Figure 5.4. 3.a :

Me ans...

Phase A

Curr e nt

Function #1

Displayed

New Value of

First Digit

Previous Setting

of Function #3

Value Incre ased

by 1 Incre ment

Value Incre ased

by 1 Incre ment

Value Accepte d

(flashes once)