查询TB62300FG供应商

TOSHIBA BiCD IC Silicon Monolithic

TB62300FG

Dual Full-Bridge Driver for DC Motor

The TB62300FG is a dual brushed DC motors driver IC

employing a chopper-based forward/reverse full-bridge

mechanism. It controls two brushed DC motors at high precision.

The motor supply voltage is up to 40 V and the V

voltage is 5.0 V.

Features

• A single IC can drive two brushed DC motors.

• Monolithic Bi-CMOS IC

• Low ON-resistance (R

• Selectable current control: PWM current control using the

PHASE pin or serial control

• 5-bit DA converter for specifying current value and 2-bit DA converter for determining torque

• MIXED DECAY mode enables specification of current decay rate in four steps.

• Self-oscillation chopping frequency with external resistor and capacitor

• High-speed chopping at 100 kHz or higher

• ISD, TSD, and POR (V

• Charge pump circuit (two external capacitors) for driving output

• 36-pin package: HSOP36 with heat sink

• Output voltage: 40 V (max)

• Output current: 2.5 A max (in steady-state phase) or 8 A max (pulsed output)

) = 0.3 Ω (Tj = 25°C at 2.0 A typ.)

on

) protection circuits

DD/VM

supply

DD

Weight: 0.79 g (typ.)

TB62300FG

Note: The values specified in this document are designed values, which are not guaranteed.

1

2005-04-04

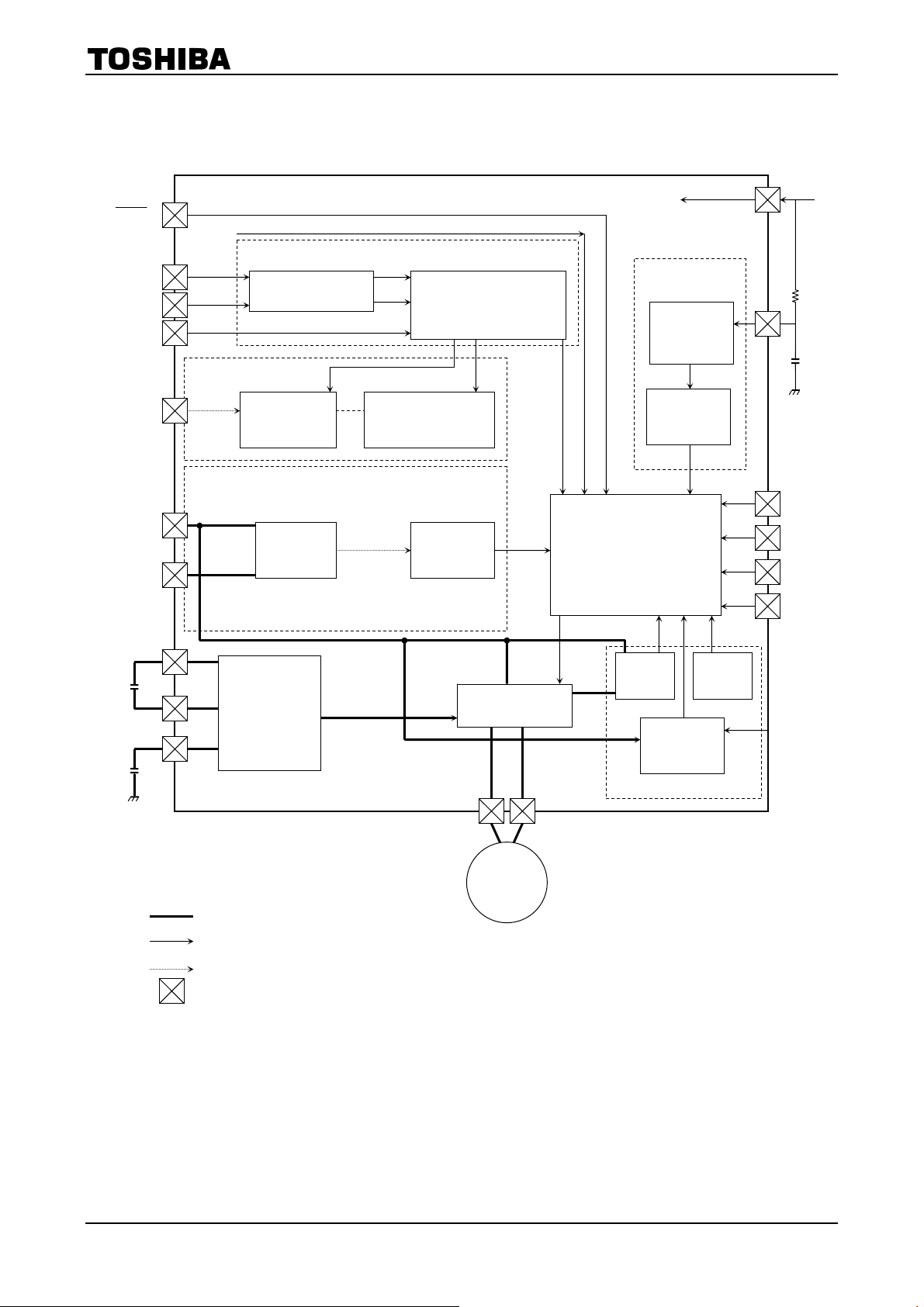

Block Diagram

TB62300FG

1.

Sleep

DATA

STROBE

Overview (for single axis)

Current control data logic circuit

Circuits used to set current value

CLK

V

ref

R

VM

Mixed decay timming,

table logic circuit

Current feedback circuit

S

16-bit shift register

Current range

controller

(2-bit D/A)

V

circuit

RS

Current value controller

(5-bit D/A)

16-bit latch

RS comparator

circuit

Chopping reference

circuit

Chopping

waveform

generator

circuit

Waveform

squaring

circuit

Output control circuit

Mixed decay control

Output pre driver

VDD

CR

MODE

PHASE

ENABLE

BRAKE

Ccp 2

Ccp 1

Charge pump

circuit

High-voltage (VM)

Logic data

Analog data

IC pin

Output circuit

(H-bridge)

Brushed DC

Motor

Out X

ISD

circuit

V

DDR/VMR

circuit

Protection circuit

TSD

circuit

2

2005-04-04

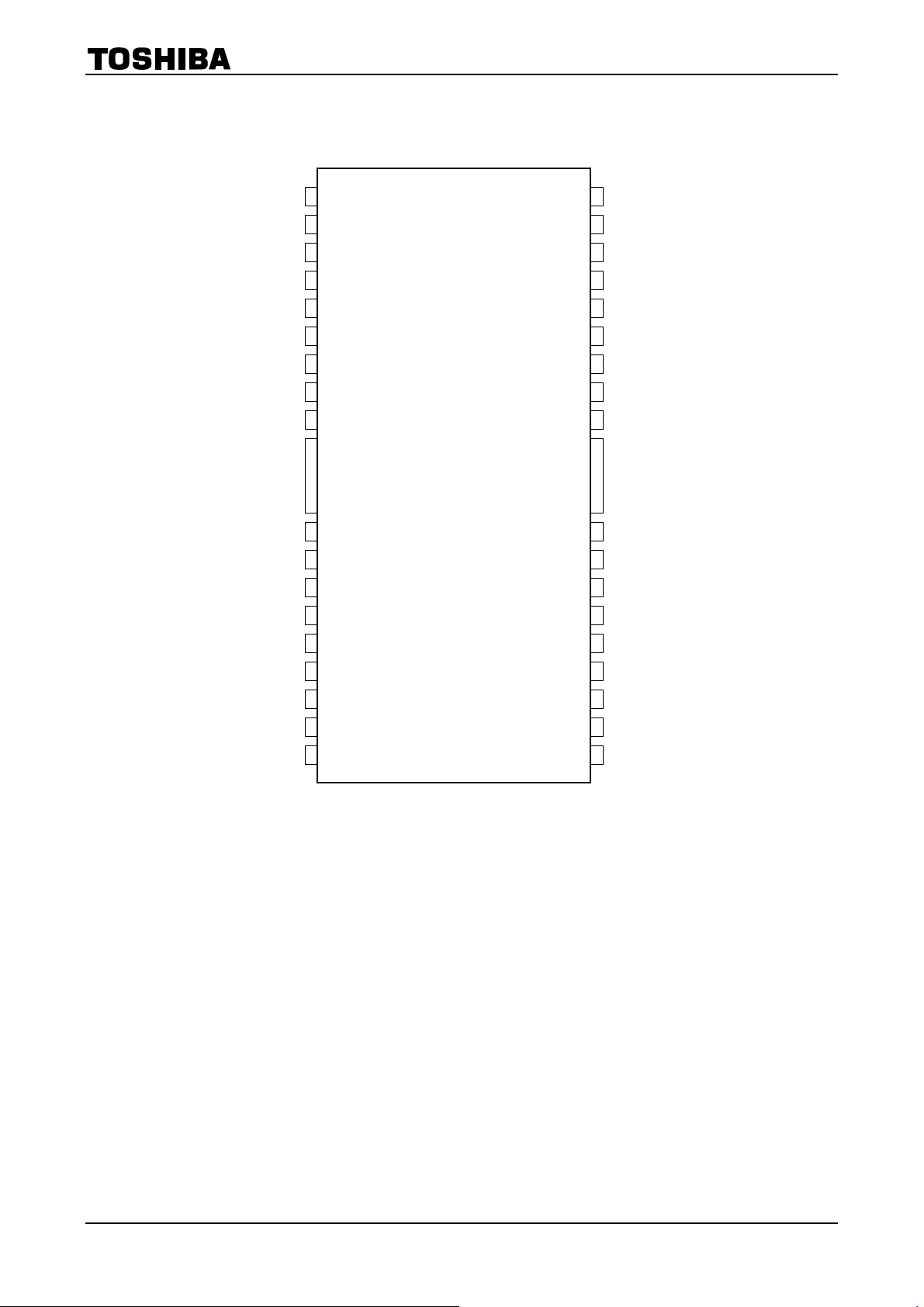

Pin Assignment

TB62300FG

R

S A

V

REF A

V

REF B

CR

V

M

Ccp 1

Ccp 2

Ccp 3

VDD

LGND

NC

TSTO

TSTI

BRAKE A

BRAKE B

1

2

3

4

5

6

7

8

9

10

11

12

13

14

36

R

35

SLEEP

34

ENABLE B

33

ENABLE A

32

PHASE B

31

PHASE A

30

DATA B

29

DATA A

28

CLK B

LGND

27

CLK A

26

STROBE B

25

STROBE A

24

MODE B

23

MODE A

S B

22

21

20

19

NC

OUT B

PGND

OUT B

−

+

OUT A

PGND

OUT A

NC

15

16

−

17

18

+

Note: When designing a ground line, make sure that all ground pins are connected to the same ground trail and

remember to take heat radiation into account.

When pins that are used to toggle between modes are controlled by a switch, pull up or down the pins to avoid

high impedance.

The IC may be destroyed due to short circuit between outputs, to supply, or to ground. Design output lines,

V

(VM) lines and ground lines with great care.

DD

When power supply pins (V

, RS, OUT, P-GND, VSS and CCP) that are exposed to high current, or logic input

M

pins are not connected correctly, excessive current or malfunction may cause the IC to break down.

3

2005-04-04

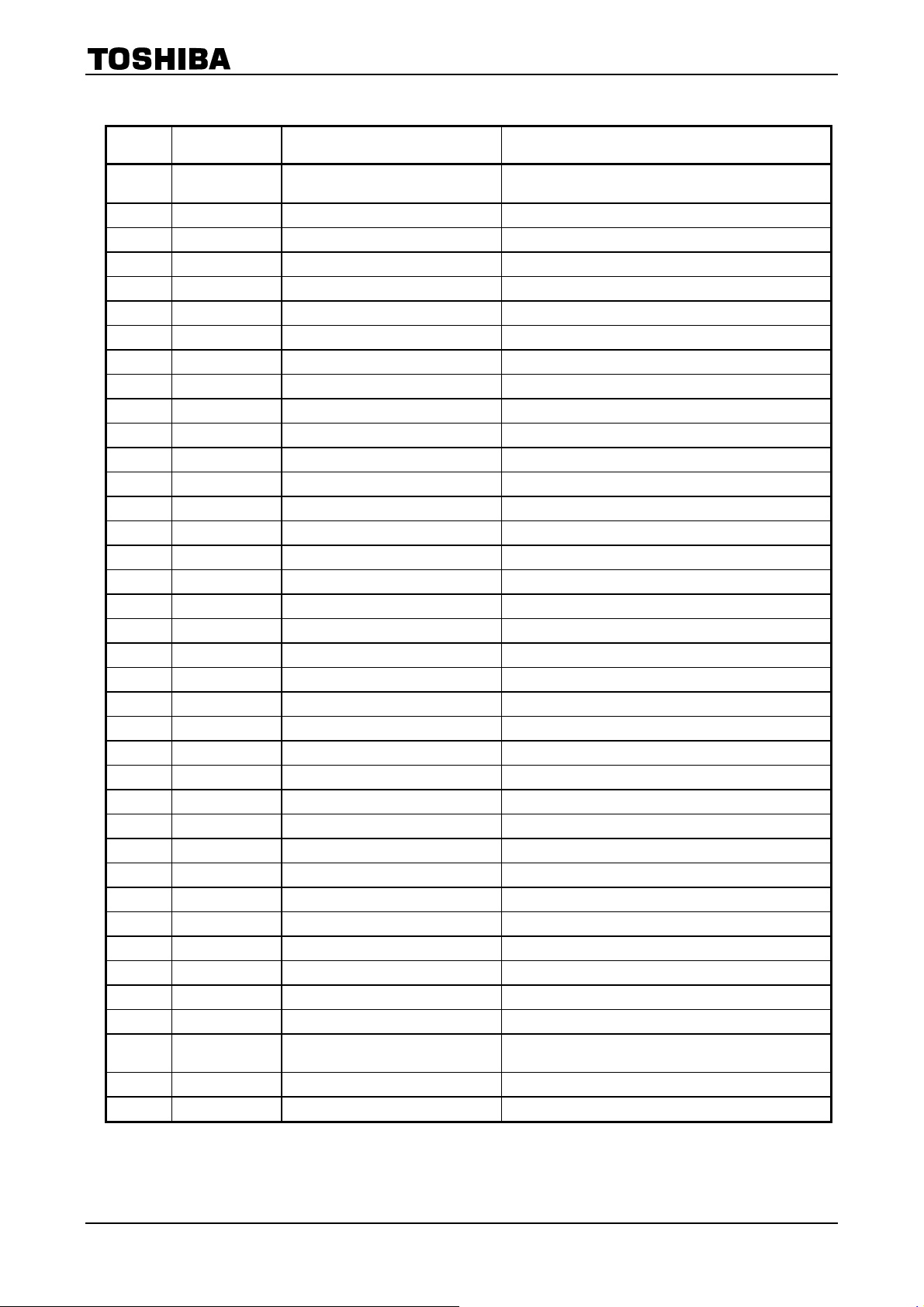

Pin Description

TB62300FG

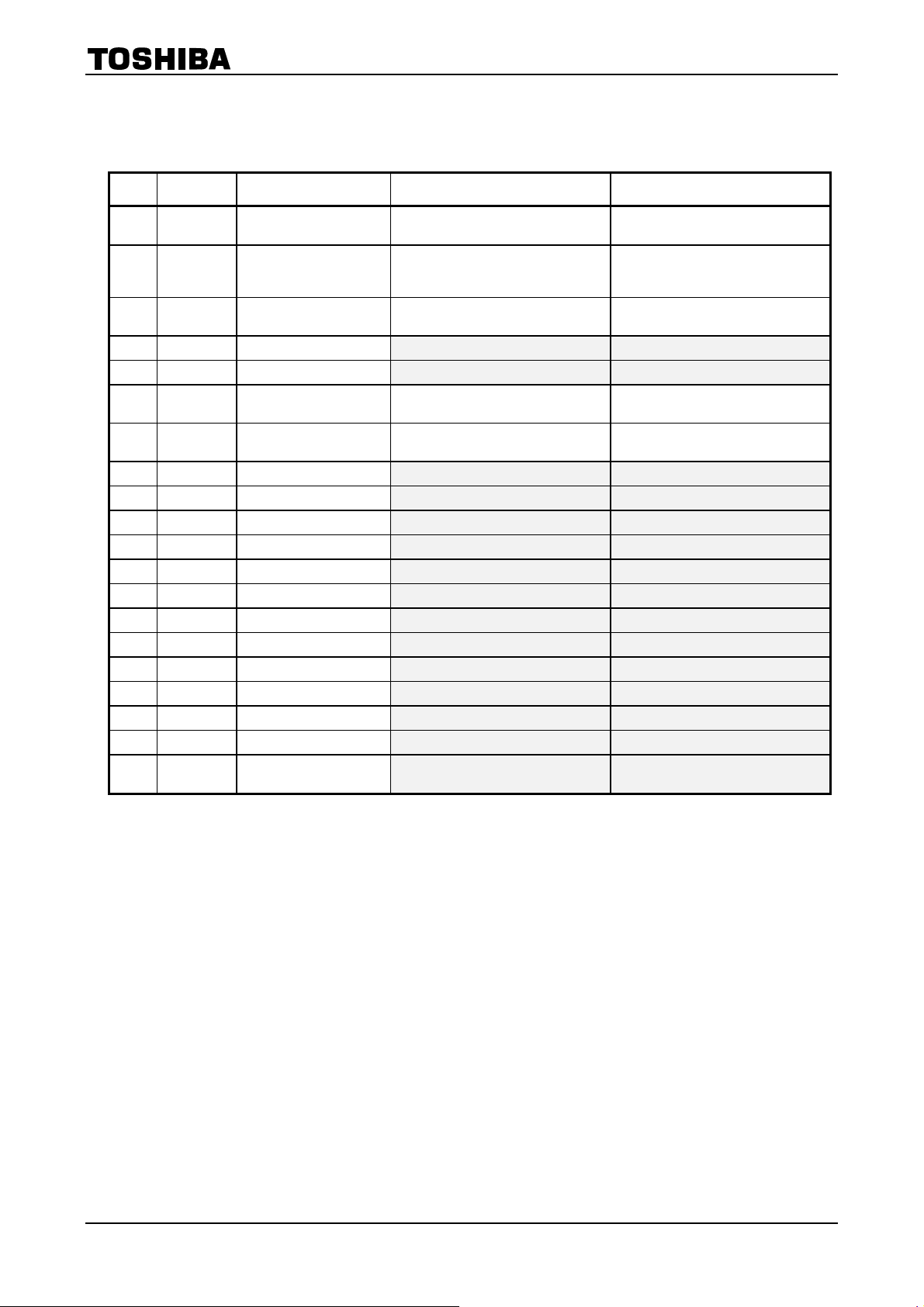

Pin

Number

1 R

2 V

3 V

4 CR External chopping reference pin Pin used to set the chopping frequency

5 VM Supply voltage monitor pin Monitor (reference) pin for motor supply voltage

6 Ccp 1 Charge pump capacitor pin Pin for connecting a charge pump capacitor

7 Ccp 2 Charge pump capacitor pin Pin for connecting a charge pump capacitor

8 Ccp 3 Charge pump capacitor pin Pin for connecting a charge pump capacitor

9 VDD Logic power supply Logic supply current input pin

10 NC NC pin Note: Usually, leave this pin open.

11 TSTO Test pin (usually not used) Note: Usually, leave this pin open.

12 TSTI Test pin (usually not used) Note: Usually, connect this pin to LGND.

13 BRAKE A A-ch brake mode pin Forced brake mode

14 BRAKE B B-ch brake mode pin Forced brake mode

15 NC NC pin Note: Usually, leave this pin open.

16 OUT A − A-ch negative output pin A − output pin

17

18

19 OUT B + B-ch positive output pin B + output pin

20 PGND VM ground Power ground

21 OUT B − B-ch negative output pin B − output pin

22 NC NC pin Note: Usually, leave this pin open.

23 MODE A A-ch data mode switching pin Pin used to toggle between serial input and PWM control

24 MODE B B-ch data mode switching pin Pin used to toggle between serial input and PWM control

25 STROBE A A-ch latch signal input pin Data input: latched on rising edge

26 STROBE B B-ch latch signal input pin Data input: latched on rising edge

27 CLK A A-ch clock input pin Data input: referred to rising edge

28 CLK B B-ch clock input pin Data input: referred to rising edge

29 DATA A A-ch data input pin Data input:

30 DATA B B-ch data input pin Data input:

31 PHASE A A-ch phase switching pin PWM signal input pin:

32 PHASE B B-ch phase switching pin PWM signal input pin::

33 ENABLE A A-ch output forced OFF pin L: output stopped

34 ENABLE B B-ch output forced OFF pin L: output stopped

35 SLEEP Operation stopped mode Internal logic cleared and charge pump stopped

36 R

FIN1 LGND Logic ground Logic ground

FIN2 LGND Logic ground Logic ground

Symbol Function Remarks

S A

A-ch reference voltage input pin Reference power supply pin for A-axis current

REF A

B-ch reference voltage input pin Reference power supply pin for B-axis current

REF B

PGND

+

OUT A

S B

A-ch output power supply pin (current

detection pin)

VM ground Power ground

A-ch positive output pin A

B-ch output power supply pin (current

detection pin)

Reference pin for A-axis supply voltage

+ output pin

Reference pin for B-axis supply voltage

4

2005-04-04

TB62300FG

Pin Description

(Supplementary)

Pull-up/pull-down status and operation within the IC for input pins

Pin

Number

10 NC Open

11 TSTO Output pin (usually low)

12 TSTI

13 BRAKE A No pull-up or down

14 BRAKE B No pull-up or down

15 NC Open

22 NC Open

23 MODE A No pull-up or down

24 MODE B No pull-up or down

25 STROBE A No pull-up or down

26 STROBE B No pull-up or down

27 CLK A No pull-up or down

28 CLK B No pull-up or down

29 DATA A No pull-up or down

30 DATA B No pull-up or down

31 PHASE A No pull-up or down

32 PHASE B No pull-up or down

33 ENABLE A No pull-up or down

34 ENABLE B No pull-up or down

35 SLEEP Pull-down with a 50-kΩ

Symbol Internal Pull-up/down Output Operation at High Output Operation at Low

Does not affect normal operation of

the IC.

Does not affect normal operation of

the IC (with the same withstand

Input pin (no pull-up or

down)

resistor

voltage as for V

Toshiba test mode Normal operation mode

Does not affect normal operation of

the IC.

Does not affect normal operation of

the IC.

DD

).

Does not affect normal operation of

the IC.

Does not affect normal operation of

the IC.

Does not affect normal operation of

the IC.

Does not affect normal operation of

the IC.

5

2005-04-04

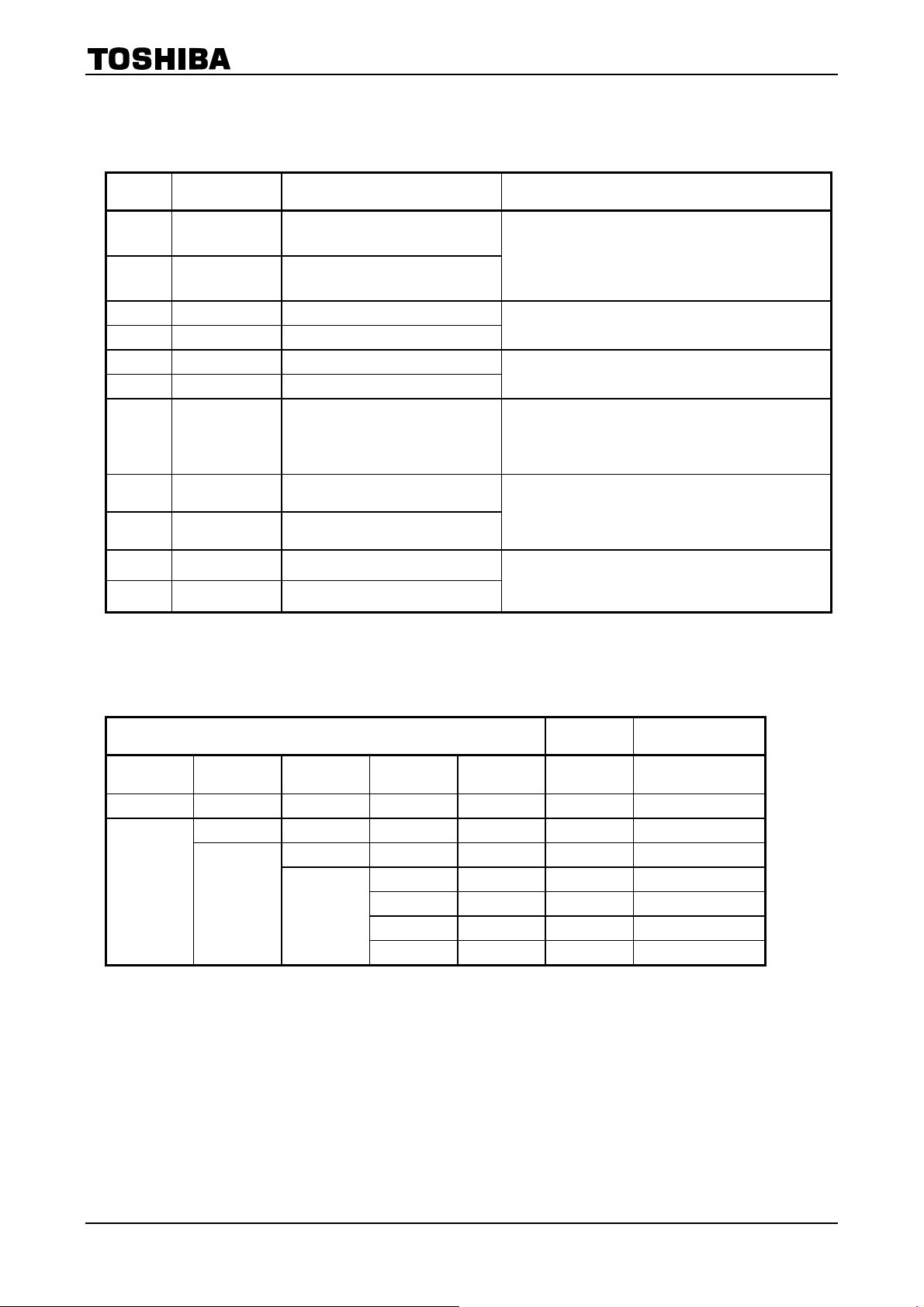

Truth Table (1)

Pin logic overview

Pin

Number

23 MODE A A-ch data mode switching pin

24 MODE B B-ch data mode switching pin

25 STROBE A A-ch latch signal input pin

26 STROBE B B-ch latch signal input pin

31 PHASE A A-ch phase switching pin

32 PHASE B B-ch phase switching pin

35 SLEEP Operation stopped mode

33 ENABLE A A-ch output forced OFF pin

34 ENABLE B B-ch output forced OFF pin

13 BRAKE A A-ch brake mode pin

14 BRAKE B B-ch brake mode pin

Symbol Function Logic

Truth Table (2)

TB62300FG

H : Serial signal input control

L : PWM control

Note: When PWM control is selected, serial data

bits D0 to D6 are valid while D7 to D13 are

invalid.

H : Latched on rising edge

L : Pass-through

H : Positive phase

L : Negative phase

H : Sleep released

L : Sleep state

All internal circuits, including charge pumps, are

stopped.

H : Output enabled

Output transistors turned on

L : Output disabled

Output transistors turned off

H : Brake applied

PHASE and ENABLE pins disabled

L : Brake released

Overall logic

SLEEP ENABLE

0 X X X X X Sleep mode

1

External Pins Serial Status

A/B

0 X X X X Disable mode

1

BRAKE

A/B

1 X X X Breake ON

0

MODE

A/B

0 1 X Forward

0 0 X Reverse

1 X 1 Forward

1 X 0 Reverse

PHASE

A/B

PHASE

6

2005-04-04

IC State for Each Function

Function Internal Logic Output Charge Pump OSC Recovery Time

TB62300FG

SLEEP Reset OFF OFF OFF t

ENABLE Maintained OFF Operating Operating N/A

POR Reset

ISD Reset OFF OFF OFF t

TSD Reset OFF OFF OFF t

OFF OFF OFF t

ONG

ONG

ONG

ONG

Serial Input Signals

Order of data

input

Data Bit Name Function

0 TBlank 0 0

1 TBlank 1 1

2 TBlank 2

3 Torque 0

4 Torque 1

5 Decay mode 0 1

6 Decay mode 1

7 Current 0 1

8 Current 1 1

9 Current 2 1

10 Current 3 1

11 Current 4

12 Phase Switch phase 0 Negative Disabled

13 ⎯ ⎯ ⎯ ⎯ ⎯

14 ⎯ ⎯ ⎯ ⎯ ⎯

15 ⎯ ⎯ ⎯ ⎯ ⎯

Set blanking time to prevent

false detection due to noise

Set current range

Set decay mode

Set current

= 2.0 ms (typ.)/4.0 ms (max)

= 2.0 ms (typ.)/4.0 ms (max)

= 2.0 ms (typ.)/4.0 ms (max)

= 2.0 ms (typ.)/4.0 ms (max)

Initial

Value

1

0

0

0

1

Initial State

÷ fchop ÷ 16 × 7 Enabled

1

25% Enabled

Mixed decay mode

(37.5%)

100% Disabled

When PWM is

Operating

Enabled

Strobe

Data

Clock

Register

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

A15 A14 A13 A12 A11 A10 A9 A8 A7 A6 A5 A4 A3 A2 A1 A0

Notes on TBlank Setting

When using PWM control and serial control simultaneously, constant-current chopping may be disabled

depending on the TBlank setting. Using constant-current chopping requires the following phase width in

Fast Decay mode:

(TBlank setting + 2/fcr) × 2

7

2005-04-04

TB62300FG

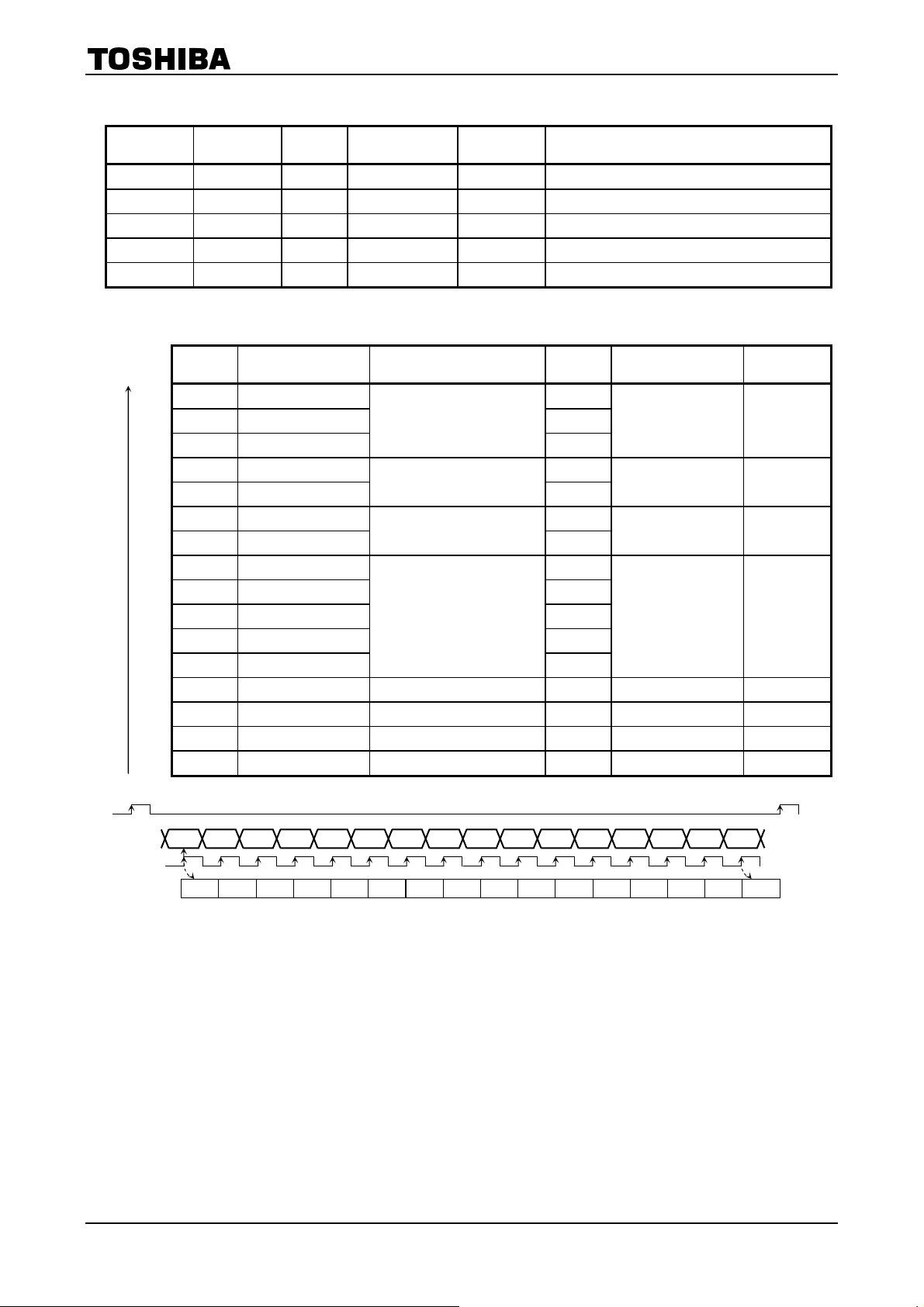

Setting Table (1): D0, D1, D2

Blanking time settings

Data Bit Name Function TBlank 2 TBlank 1 TBlank 0 Setting TBlank (typ.)

0

1

2

TBlank 0

TBlank 1

TBlank 2

Set blanking time to prevent

false detection due to noise

0 0 0 1 ÷ f

0 0 1 1 ÷ f

0 1 0 1 ÷ f

0 1 1 1 ÷ f

1 0 0 1 ÷ f

1 0 1 1 ÷ f

1 1 0 1 ÷ f

1 1 1 1

Setting Table (2): D3, D4

Torque settings

Data Bit Name Function Torque 1 Torque 0 Setting Torque (typ.)

3

4

Torque 0

Torque 1

Set current range

0 0 25%

0 1 50%

1 0 75%

1 1 100%

Setting Table (3): D5, D6

÷ f

Chop

Chop

Chop

Chop

Chop

Chop

Chop

Chop

÷ 16 × 1

÷ 16 × 2

÷ 16 × 3

÷ 16 × 4

÷ 16 × 5

÷ 16 × 6

÷ 16 × 7

÷ 16 × 8

Decay mode settings

Data Bit Name Function

5

6

Decay mode 0

Decay mode 1

Set decay mode

Torque

Mode 1

0 0 Slow decay mode

0 1 Mixed decay mode: 37.5%

1 0 Mixed decay mode: 75.0%

1 1 Fast decay mode

Torque

Mode 0

Setting Decay Mode

8

2005-04-04

TB62300FG

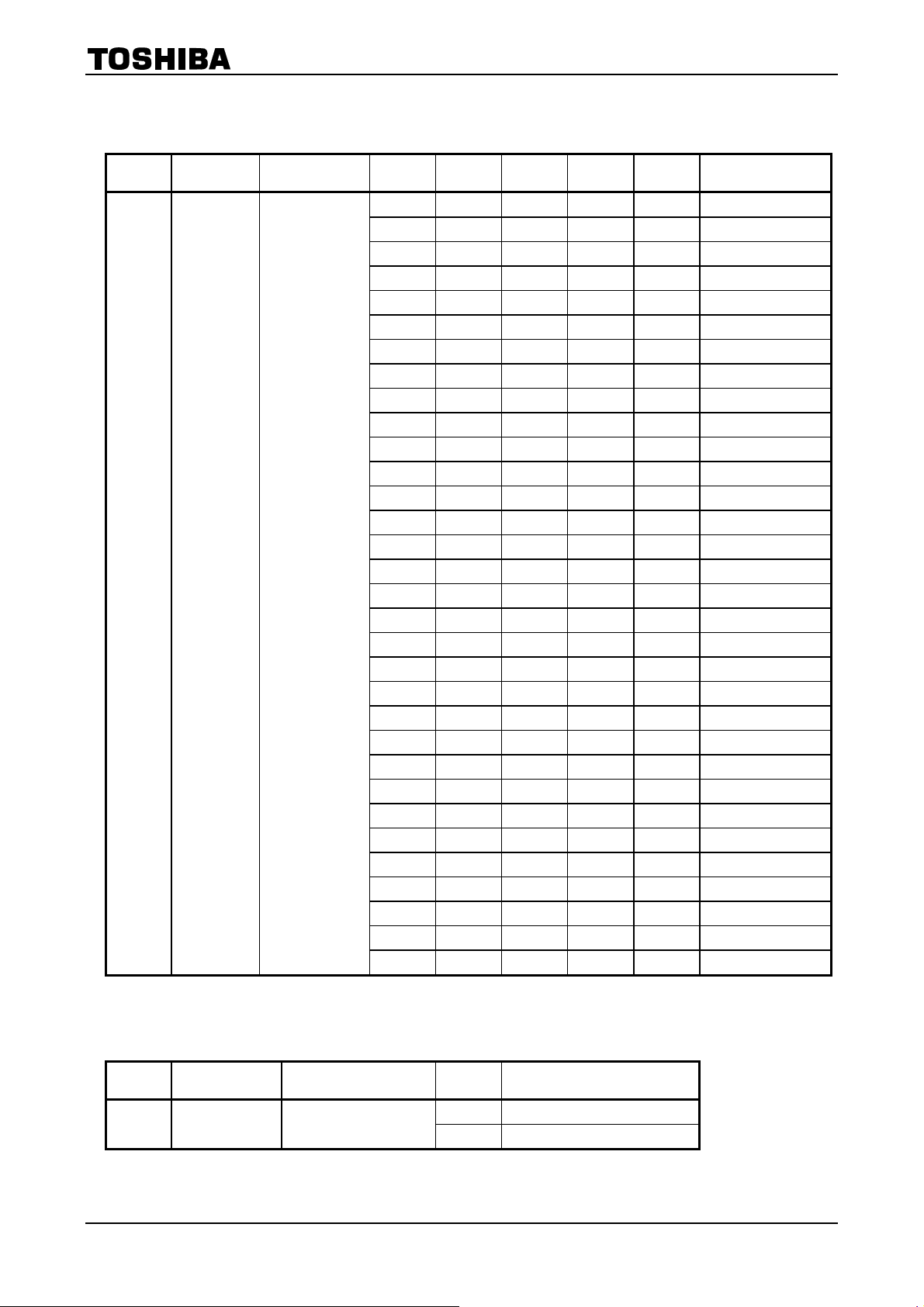

Setting Table (4): D7, D8, D9, D10, D11

Current settings

Data Bit Name Function Current 4 Current 3 Current 2 Current 1 Current 0 Setting Current

7

8

9

10

11

Current 0

Current 1

Current 2

Current 3

Current 4

Set current

Setting Table (5): D12

0 0 0 0 0 0%

0 0 0 0 1 3%

0 0 0 1 0 6%

0 0 0 1 1 9%

0 0 1 0 0 12%

0 0 1 0 1 16%

0 0 1 1 0 19%

0 0 1 1 1 22%

0 1 0 0 0 25%

0 1 0 0 1 29%

0 1 0 1 0 32%

0 1 0 1 1 35%

0 1 1 0 0 38%

0 1 1 0 1 41%

0 1 1 1 0 45%

0 1 1 1 1 48%

1 0 0 0 0 51%

1 0 0 0 1 54%

1 0 0 1 0 58%

1 0 0 1 1 61%

1 0 1 0 0 64%

1 0 1 0 1 67%

1 0 1 1 0 70%

1 0 1 1 1 74%

1 1 0 0 0 77%

1 1 0 0 1 80%

1 1 0 1 0 83%

1 1 0 1 1 87%

1 1 1 0 0 90%

1 1 1 0 1 93%

1 1 1 1 0 96%

1 1 1 1 1 100%

Phase settings

Data Bit Name Function Phase Setting Phase

12 Phase Switch phase

0 Negative

1 Positive

9

2005-04-04

TB62300FG

2005-04-04

1 2 3 4 5 6 ・・・・・

*16)

chop

(f

CR

PHASE

f

PWM Operation

Input range for fcr clock

Internal reset signal

1/fcr*2

*2

Example:

1/fcr

Phase Blank Time

*TBlank

*2 + 1/fcr*TBlank

1/fcr

Example: 1/fcr

Serial Blanking Time

Total Blanking Time

Output control signal

frequency.

chop

is 16 times the f

cr

・PHASE is an external signal.

・The internal reset signal resets the internal clocks and counters.

・Phase Blank Time is time between either edge of the external PHASE signal and the leading edge of serial blanking time.

Notes: ・f

The output H bridge is driven by an external PHASE signal.

Description

It, however, also uses the fcr signal, generated with external CR, to generate blanking time and Mixed Decay time. The above logic is configured to handle the two

signals, PHASE and fcr, which are asynchronous to each other. The logic generates internal reset signal edges from external PHASE edges, resulting in the width

equal to two fcr cycles.

The fcr-based counter assumes the first fcr falling edge following the PHASE edge as the first count. The maximum phase difference between the PHASE and fcr

signals is, therefore, one fcr cycle. The serial blanking time starts at the second count based on the fcr clock (The first three samples of serial blanking time signal must be 000).

The last stage output is switched by the edge of the external PHASE signal. That means there is an interval of two fcr cycles before the set blanking time starts.

To cover the interval, the logic generates the time between the PHASE signal edge and blanking time start as phase blank time, during which comparison is masked

difference between PHASE and fcr (up to two fcr cycles).

off in the same way as in blanking time.

Consequently, the blanking time as viewed from outside the IC is within the range from one fcr cycle (TBlank (000)) to eight fcr cycles (TBlank (111)) + I phase

10

TB62300FG

Absolute Maximum Ratings

Characteristics Symbol Test Condition Rating Unit

Logic supply voltage VDD ⎯ −0.4 to 7.0 V

Maximum output voltage VM ⎯ 40 V

Peak output current

(Note: preliminary specification)

Continuous output current I

Logic input voltage VIN ⎯ −0.5 to VDD V

Current detection pin voltage VRS ⎯ V

Power dissipation PD

Operating temperature T

Storage temperature T

Junction temperature Tj ⎯ 150 °C

Note: When T

= 45°C, Tj = 150°C and θja = 32°C

opr

(T

= 25°C)

opr

I

OUT (Peak)tW

OUT (Cont)

⎯ −40 to 85 °C

opr

⎯ −55 to 150 °C

stg

≤ 500 ns 8.0 A

⎯ 2.5 A

± 4.5 V V

M

IC alone 1.4 W

When mounted on a board

(Note)

3.2 W

Recommended Operating Conditions

Characteristics Symbol Test Condition Min Typ. Max Unit

(T

= 0 to 85°C)

opr

Supply voltage (Note 1) VDD ⎯ 4.5 5.0 5.5 V

Output voltage (Note 1) VM VDD = 5.0 V 18.0 24.0 33.0 V

I

Output current

(Note: preliminary specification)

Logic input voltage range VIN ⎯ 0 ⎯ VDDV

Clock frequency f

Chopping frequency f

V

reference voltage V

ref

Current detection pin voltage VRS VDD = 5.0 V 0 ±1.0 ±1.5 V

Junction temperature Tj ⎯ ⎯ ⎯ 120 °C

Oscillator capacitor C

Oscillator resistor R

Charge pump capacitor A C

Charge pump capacitor B C

Input rise and fall rate (Note 2) tri/tfi ⎯ ⎯ 0.1 5.0 µs

OUT (Peak)VM

I

OUT (Cont)VM

VDD = 5.0 V 1.0 25.0 MHz

CLK

VDD = 5.0 V 20 30 150 kHz

chop

VM = 24.0 V, T

ref

⎯ ⎯ 270 ⎯ pF

OSC

⎯ ⎯ 3.9 ⎯ kΩ

OSC

⎯ ⎯ 0.22 ⎯ µF

CPA

⎯ ⎯ 0.022 ⎯ µF

CPB

= 33.0 V, tw ≤ 500 ns ⎯ 6.4 7.2 A

= 33.0 V ⎯ 1.5 1.8 A

= 100% 2.0 3.0 V

ORQUE

DD

Note 1: Do not reduce VDD to 0 V (ground) while VM voltage is applied. Such an attempt may damage the IC

because there is a current path from the V

not applied. Leaving V

open (Hi-Z) is less likely to damage the IC, although it is not recommended.

DD

pin to VDD pin and the internal logic is undefined when VDD is

M

Note 2: The circuit configuration of this IC cannot handle extremely slow data input (on pins BREAK A, BREAK B,

SLEEP, ENABLE A, ENABLE B, PHASE A, PHASE B, DATA A, DATA B, CLK A, CLK B, STROBE A,

STROBE B, MODE A, and MODE B). Applying a slow signal having a period longer than 5 µs may cause

the IC to oscillate.

(1) Calculating the current

= 1/3 × V

I

OUT

where 1/3 is the V

(V) × (Torque (%) ÷ RRS (Ω) ) × Current (%)

ref

(GAIN):V

ref

attenuation ratio.

ref

(2) Calculating the oscillation frequency

= 1/(KA) × (C × R + KB × C)) × [Hz]

f

CR

KA = 0.523, KB = 600, f

= fCR/16 [Hz]

chop

[Example] When C

= 270 pF and R

OSC

= 3.9 kΩ: fCR = 1.57 MHz and f

OSC

= 1.57/16 = 98.4 kHz

chop

V

11

2005-04-04

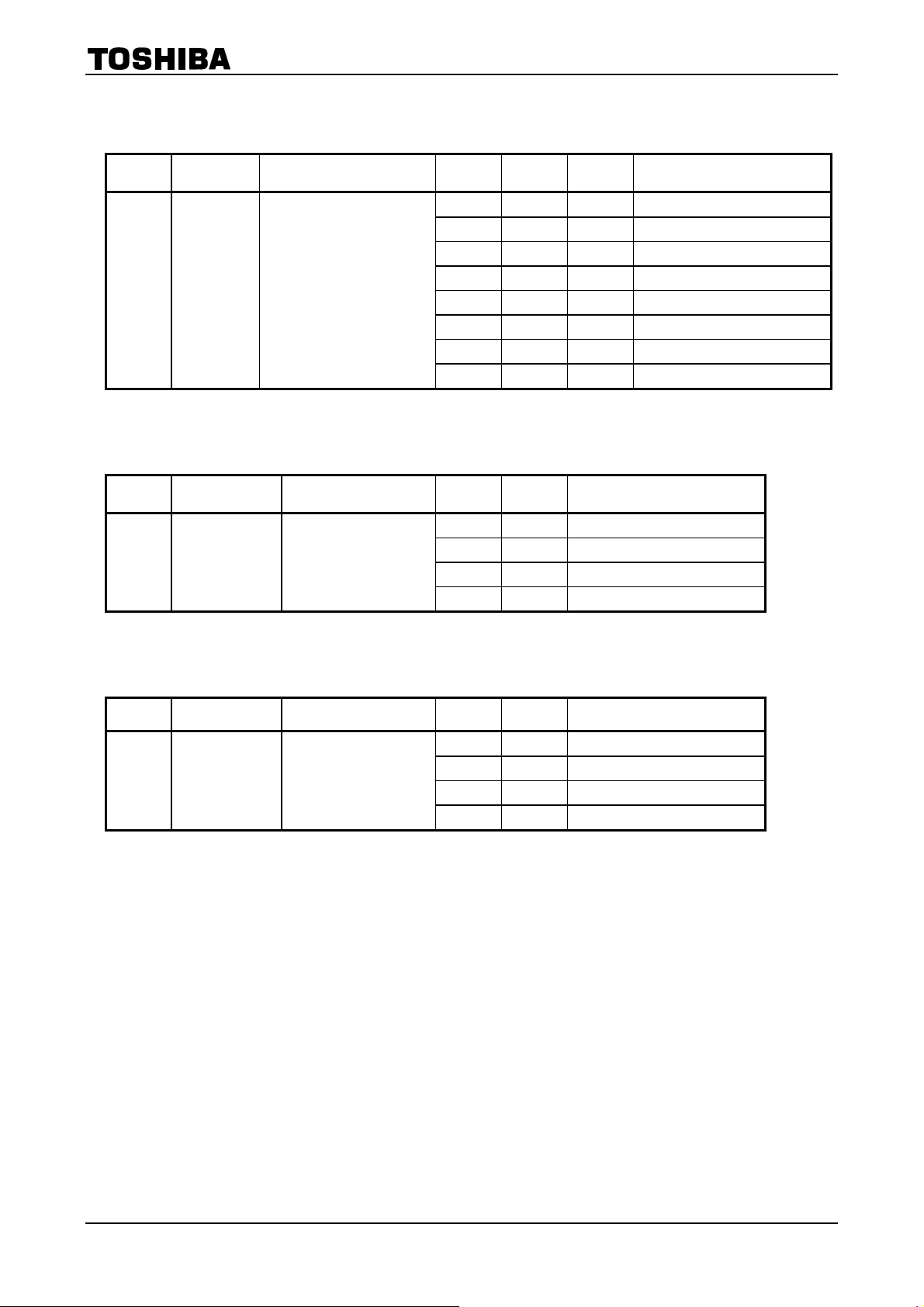

Electrical Characteristics 1

TB62300FG

DC Characteristics

Characteristics Symbol

Input voltage

Input current

Current consumed by logic power

supply

VM current consumption

(unless otherwise specified, VM = 24 V, VDD = 5.0 V, T

High V

Low V

I

IH1

I

IL1

I

IH2

I

IL2

I

DD1

I

DD2

IM1

IM2

Test

Circuit

IH

DC

IL

DC

DC

DC

Test Condition Min Typ. Max Unit

CLK, STROBE, DATA, MODE,

2.0 ⎯

PHASE, ENABLE and PHASE

pins

CLK, STROBE, DATA, MODE,

⎯ ⎯ 0.8

⎯ ⎯ 1.0

PHASE, ENABLE and PHASE

pins

⎯ ⎯

⎯ ⎯

SLEEP pin

⎯ ⎯

VDD = 5.0 V, fcr stopped ⎯ 3.0 4.5

In SLEEP mode

Output open, f

logic operating, V

V

= 24 V, all output stages

M

CLK

DD

= 1 kHz,

= 5 V,

stopped, charge pump charged

Output open, f

CLK

= 4 kHz,

internal logic operating

(100-kHz chopping), output

stages operating without load,

charge pump charged

0.3 1.0

⎯ 4.3 7.0

⎯ 20.0 28.0

= 25℃)

opr

⎯

1.0

200.0

1.0

V

µA

µA

mA

mA

Output standby current Upper I

Output bias current Upper I

Output leakage current Lower I

High V

Comparator reference

voltage ratio

Mid

High

Mid

Low

Low

V

V

V

I

M3

OH

OB

OL

RS (H)

RS (MH)

RS (ML)

RS (L)

In SLEEP mode ⎯ 0.5 1.0

VRS = VM = 24 V, V

ENABLE

DATA

VRS = VM = 24 V, V

DC

ENABLE

DATA

V

= Low,

= All low

= Low,

= All low

= VM = Ccp A = V

RS

= 24 V, SLEEP= Low

V

= 3.0 V, V

ref

TORQUE

V

= 3.0 V, V

ref

TORQUE

= 11 = 100% set

= 10 = 75% set

DC

V

= 3.0 V, V

ref

TORQUE

V

= 3.0 V, V

ref

TORQUE

= 01 = 50% set

= 00 = 25% set

= 0 V,

out

= 24 V,

out

out

(gain) = 1/3.0

ref

(gain) = 1/3.0

ref

(gain) = 1/3.0

ref

(gain) = 1/3.0

ref

−400 ⎯ ⎯

−200 ⎯ ⎯

⎯ ⎯ 1.0

µA

⎯ 100 ⎯

73 75 77

%

48 50 52

23 25 27

12

2005-04-04

TB62300FG

Electrical Characteristics 2

DC Characteristics

Characteristics Symbol

Output current interchannel error ∆I

Output current setting error ∆I

RS pin current I

Output transistor drain-source

ON-resistance

V

input voltage V

REF

unless otherwise specified,

(

OUT1

OUT2

RS

RON1

RON1

RON2

RON2

ref

Test

Circuit

DC

DC I

DC µA

DC

DC

VM = 24 V, VDD = 5.0 V, T

Test Condition Min Typ. Max Unit

Error in output current between

channels (I

= 1.5 A −5.0 ⎯ 5.0 %

OUT

= 1.5 A, VDD = 5.0 V,

I

OUT

T

= 25 °C, forward direction

j

= 1.5 A, VDD = 5.0 V,

I

OUT

T

= 25 °C, reverse direction

j

= 1.5 A, VDD = 5.0 V,

I

OUT

T

= 105 °C, forward direction

j

= 1.5 A, VDD = 5.0 V,

I

OUT

T

= 105 °C, reverse direction

j

= 24 V, VDD = 5.0 V,

V

M

ENABLE, output operation

OUT

= 1.5 A)

−5.0 ⎯ 5.0

⎯ 0.3 0.4

⎯ 0.3 0.4

⎯ 0.4 0.55

⎯ 0.4 0.55

2.0

= 25℃)

opr

⎯ V

DD

%

Ω

V

= 3.0 V,

V

ref

V

input current I

REF

V

attenuation ratio

REF

TSD operating temperature (Note 1) TjTSD DC VDD = 5 V, VM = 24 V 130 ⎯ 170 °C

Overcurrent protection circuit

operating current

Output OFF mode supply voltage

ref

V

ref

(GAIN)

ISD DC V

Vpor

(V

)

DD

Vpor

(V

)

M

DC

DC

DC V

DC V

V

= 24 V, VDD = 5.0 V,

M

SLEEP

= 3.0 V,

V

ref

V

= 24 V, VDD = 5.0 V,

M

SLEEP

= 5 V, VM = 24 V ⎯ 6.0 ⎯ A

DD

= 24 V ⎯ 3.0 ⎯

M

= 5 V ⎯ 15.0 ⎯

DD

⎯ ⎯ 100 µA

1/2.82 1/3 1/3.18 ⎯

V

Note 1: Thermal shutdown (TSD) circuit

When the IC junction temperature reaches the specified value and the TSD circuit is activated, the internal

reset circuit turns output off. The TSD activation temperature can be set within the range from 130°C (min)

to 170°C (max). Once the TSD circuit is activated, output is stopped until a pulse (L to H to L) is

subsequently applied to the SLEEP pin. The charge pump is halted while the TSD circuit is active.

The TSD circuit does not include hysteresis. Applying a pulse (L to H to L) to the SLEEP pin deactivates the

circuit.

Note 2: Overcurrent protection circuit (ISD)

This circuit is activated when a current pulse exceeding the specified output value is applied for a period of

1/2f

CHOP

(min) to f

CHOP

(max).

The circuit activates the internal reset circuit to turn output off.

Once it is activated, output is stopped until a pulse (L to H to L) is subsequently applied to the SLEEP pin.

While the ISD circuit is active, the IC is placed in SLEEP mode with the charge pump halted.

13

2005-04-04

TB62300FG

AC Characteristics

(T

= 25°C, VM = 24 V, VDD = 5 V

opr

Characteristics Symbol

Clock frequency f

Minimum clock pulse width

Minimum STROBE pulse width

Minimum SLEEP pulse width t

Phase difference between PHASE

signal and fcr

Blanking time for preventing false

detection

Data setup time

Data hold time

STROBE setup time (relative to CLK)

STROBE hold time (relative to CLK)

CLK

tw (t

CLK

t

wp

t

wn

t

WSTROBE

t

STROBE (H)

t

STROBE (L)

WSTROBE

tp AC

t

BLNIK

t

sSIN-CLK

t

sST-CLK

t

hSIN-CLK

t

hST-CLK

t

sSSB-CLK

t

hSB-CLK

Test

Circuit

with load of

Test Condition Min Typ. Max Unit

6.8 mH/5.7 Ω)

⎯ 1.0 ⎯ 25.0 MHz

)

AC

AC

AC t

⎯ ⎯ 1/f

(Note 1) ⎯ 300 ⎯ ns

40.0 ⎯ ⎯

20.0 ⎯ ⎯

20.0

⎯ ⎯

40.0 ⎯ ⎯

20.0 ⎯ ⎯

20.0

ONG

⎯ ⎯

⎯ ⎯ ns

CR

20.0 ⎯ ⎯

AC

20.0 ⎯ ⎯

20.0

⎯ ⎯

AC

AC

AC

20.0

⎯ ⎯

20.0 ⎯ ⎯

20.0 ⎯ ⎯

ns

ns

ns

ns

ns

ns

⎯ 40.0 100

⎯ 40.0 100

⎯ 100 200

⎯ 580 1000

AC

⎯ 100 200

C

osc

= 270 pF, R

= 3.9 kΩ 1.1 1.3 1.5 MHz

osc

⎯ 350 700

⎯ 1000 2000

⎯ 350 700

20.0 ⎯ 150.0 kHz

When f

= 480 kHz ⎯ 30.0 ⎯ kHz

CR

AC ⎯ 2.0 4.0 ms

Output transistor switching time

CR reference signal oscillation

frequency

f

chop (min)

Chopping frequency

f

chop (typ.)

f

chop (max)

Oscillation frequency f

Charge pump rise time t

t

t

t

pLH

t

pHL

t

pLZ

t

pHZ

t

pZL

t

pZH

f

CR

chop

ONG

f

f

Note 1: The blanking time is internally fixed but it can be elongated by applying a serial blanking time signal.

ns

14

2005-04-04

TB62300FG

Test Circuit

R

osc

5 V

C

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

osc

LGND

(DC)

= 3.6 kΩ

= 560 pF

I

DD1IDD2

A

A

A

A

A

LGND

A

A

A

A

A

A

A

A

A

A

A

V

DD

CR

STROBE A

CLK A

DATA A

STROBE B

CLK B

DATA B

SLEEP

LGND

(F

PHASE A

PHASE B

ENABLE A

ENABLE B

MODE A

MODE B

BRAKE A

BRAKE B

A

V

ref

V

B

ref

V

M

R

RS A

A

A

)

IN

B

B

R

RS B

P-GND

Ccp 3Ccp 2Ccp 1

A

A

I

RS

I

ref

A

I

ref

A

IM1, IM2, I

V

I

OUT1, 2

DC Motor

PGND

M3

V

RS

M

M

R

RS A

DC Motor

R

RS B

SGND

ref

V

ref

V

0.22

0.22

3 V

LGND

3 V

LGND

Ω

Ω

100 µF

I

I

I

OL

OH

OB

A

1 µF

1 µF

24 V

Ccp 2

0.022

µF

LGND

Ccp 1

V

0.22

µF

15

2005-04-04

TB62300FG

µ

Test Circuit

f

, tw (t

CLK

t

wSTROBE

t

sSIN-CLK

f

,

chop

fosc

R

osc

5 V

C

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

osc

SGND

(AC)

), twp, twn,

CLK

, t

STROBE (H)

, t

sST-CLK

= 3.6 kΩ

= 560 pF

, t

hSIN-CLK

, t

STROBE (L)

LGND

A

A

A

A

A

A

A

A

, t

hST-CLK

,

V

DD

CR

STROBE A

CLK A

DATA A

STROBE B

CLK B

DATA B

SLEEP

V

SS

(F

PHASE A

PHASE B

ENABLE A

ENABLE B

MODE A

MODE B

BRAKE A

BRAKE B

I

I

A

RS

ref

A

V

I

OUT1, 2

DC Motor

V

RS

M

M

R

RS A

DC Motor

R

RS B

PGND

ref

3 V

V

LGND

ref

3 V

V

LGND

I

OL

I

OH

I

OB

Ω

Ω

F

100

A

1.0

1.0

1 µF

1 µF

t

BLNIK

24 V

A

V

ref

V

B

ref

V

M

R

RS A

A

)

IN

Ccp 3Ccp 2Ccp 1

A

B

B

R

RS B

P-GND PGND

Ccp 1

V

0.22

µF

Ccp 2

0.022

t

ONG

µF

16

2005-04-04

AC Test Waveforms

TB62300FG

DATA

CLOCK

STROBE

SLEEP

PHASE

Out A

PHASE

ENABLE

DATA 15 50% DATA 0 DATA 1

tw (t

CLK)

twntwn t

t

sDATA

t

hDATA

sSTROBE

50%

t

50%

t

wSTROBE

50%

t

pLH

50%

dCLOOK

50%

t

wSLEEP

t

pHL

Out A

t

pZH

t

pHZ

t

pZL

t

pLZ

17

2005-04-04

TB62300FG

Waveform in Mixed Decay Mode

(Current Waveform)

f

f

chop

Internal

CR CLK

signal

I

OUT

Set current

value

25%

Mixed

Decay

Mode

NF

MDT (Mixed Decay Timming) point

Output Transistor Operating Mode

V

M

chop

Set current value

RNF

V

V

M

NF

M

R

U1

ON

L1

OFF

RS

RS pin

U2

(Note)

Load

PGND

Charge mode Slow mode Fast mode

OFF

L2

ON

U1

OFF

L1

R

Output Transistor Operation Functions

CLK U1 U2 L1 L2

Charge ON OFF OFF ON

Slow OFF OFF ON ON

Fast OFF ON ON OFF

RS

RS pin RS pin

(Note)

Load

U2

OFF

L2

ON

PGND

U1

OFF

L1

ONON

(Note)

Load

RRS

U2

ON

L2

OFF

PGND

Note: The above table is an example where current flows in the direction of the arrows in the above figures.

When the current flows in the opposite direction of the arrows, see the table below.

CLK U1 U2 L1 L2

Charge OFF ON ON OFF

Slow OFF OFF ON ON

Fast ON OFF OFF ON

18

2005-04-04

TB62300FG

Power Supply Sequence

V

DD

V

M

Internal reset

V

V

V

GND

VM

V

V

GND

Non-reset

Reset

DD (max)

DD (min)

DDR

M (min)

MR

(Recommended)

SLEEP input

(Note1)

Note 1: If V

internally reset.

This is a protective measure against malfunction. Likewise, if V

regulation voltage is applied to V

To avoid malfunction, when turning on V

recommended.

It takes time for the output control charge pump circuit to stabilize. Wait up to t

before driving a motor.

Note 2: When the V

such a case, the charge pump circuit cannot operate properly because of insufficient voltage. The IC should

be held in SLEEP mode until V

Note 3: Since V

At that time, a current of several mA flows due to a current path between V

When the output voltage is high, make sure that the specified voltage is applied to V

H

L

Takes up to t

Non-operable area

drops to the level of the V

DD

value is between 3.3 to 5.5 V, the internal reset is released, thus output may be active. In

M

= 0 V and VM = voltage within the rating are applied, output is turned off by internal reset.

DD

or below while the specified voltage is applied to the VM pin, the IC is

DDR

, the IC is internally reset as a protective measure against malfunction.

DD

reaches 13 V or more.

M

or VDD, applying a signal to the SLEEP pin at the above timing is

M

until operable

ONG

drops to the level of VMR or below while

M

time after power on

ONG

and VDD.

M

DD

.

19

2005-04-04

TB62300FG

PD – Ta

Transient thermal resistance

(1) HSOP36 R

(2) When mounted on a board (140 mm × 70 mm × 1.6 mm: 38°C/W: typ.)

(Package power dissipation)

3.5

3

2.5

(W)

D

2

1.5

(1)

1

Power dissipation P

0.5

0

0

25 50 75 100 125 150

without a board (96°C/W)

th (j-a)

P

– Ta

D

(2)

Ambient temperature Ta (°C)

Note: R

th (j-a)

: 8.5°C/W

20

2005-04-04

TB62300FG

Relationship between VM and VH

Note: VDD = 5 V

Ccp 1 = 0.22 µF, Ccp 2 = 0.022 µF, f

(Care must be taken about the temperature charges of charge pump capacitor.)

50

V

40

30

voltage Charge up voltage VM voltage

H

Apply SLEEP signal.

(charge pump voltage)

= 150 kHz

chop

V

– VH (& Vcharge UP)

M

Charge pump

output voltage

voltage, charge up voltage (V)

20

H

V

10

VMR

Recommended operation area

Usable area

0

0

2 3 10 20 30 404 5 6 7 8 9 11 12 13 14 15 16 17 18 21 22 23 24 25 2619 27 28 29 31 32 33 34 35 36 37 38 39 1

Supply voltage VM (V)

VM voltage

Maximum rating

Charge pump voltage VH = VDD + VM (= Ccp A) (V)

(Maximum rating is V

(7 V) + VM (40 V))

DD

21

2005-04-04

Operation of Charge Pump Circuit

VDD = 5 V

RS

TB62300FG

R

RS

= 24 V

V

M

V

M

V

H

Ccp A

7

Comparator

and

Controller

Output

Output

H switch

i2

Di2

r2

V

Di3

Di1

(1)

z

T

T

r1

i1

(2)

Ccp B

Ccp 2

0.022

(2)

R

1

Ccp C

µF

Ccp 1

0.22

µF

VH = VM + VDD = charge pump voltage

i1 = charge pump current

i2 = gate block power dissipation

• Initial charging

(1) When RESET is released, T

(2) After T

is turned off and Tr2 is turned on, and Ccp 1 is charged from Ccp 2 via Di2.

r1

(3) When the voltage difference between V

reaches V

or higher, operation halts (in the steady-state phase).

DD

is turned on and Tr2 turned off. Ccp 2 is charged from VM via Di1.

r1

and VH (Ccp A pin voltage = charge pump voltage)

M

• Actual operation

(4) The charge of Ccp 1 charge is used at f

switching and the potential of VH drops.

chop

(5) The circuit is charged up by the operations of (1) and (2) above.

Output switching

Initial charging Steady-state phase

V

H

V

M

(1)

(2) (3)

(4)

t

(5)

(4)

(5)

22

2005-04-04

Charge Pump Rise Time

TB62300FG

V

M

STANDBY

+ VM

V

DD

+ (VDD × 90%)

V

M

5 V

0 V

t

: Time taken for capacitor Ccp 2 (charging capacitor) to fill up Ccp 1 (storing capacitor) to VM + VDD

ONG

after a reset is released.

The internal circuits cannot drive the gates correctly until the voltage of Ccp 1 reaches V

Be sure to wait for t

Basically, the larger the Ccp 1 capacitance is, the smaller the voltage fluctuation is, though the

initial charge up time is longer.

The smaller the Ccp 1 capacitance is, the shorter the initial charge-up time is, but the voltage

fluctuation is larger.

Depending on the combination of capacitors (especially with small capacitance), voltage may not be

sufficiently boosted. When the voltage does not increase sufficiently, R

lower than the reference value, which raises the temperature.

Thus, use the capacitors under the capacitor combination conditions (Ccp 1 = 0.22 µF, Ccp 2 = 0.022

µF) recommended by Toshiba.

Ccp 1 voltage

50%

t

ONG

+ VDD.

M

or longer before driving the motors.

ONG

of output DMOS becomes

ON

23

2005-04-04

External Capacitor for Charge Pump

TB62300FG

When driving a motor while VDD = 5 V, f

= 150 kHz, L = 10 mH under the conditions of V

chop

= 27 V and

M

2.0 A, the logical values for Ccp 1 and Ccp 2 are as shown in the graph below:

Ccp 1 – Ccp 2

0.05

0.045

0.04

0.035

0.03

0.025

0.02

0.015

Ccp 2 capacitance (µF)

0.01

0.005

0

0

0.05 0.1 0.15 0.2 0.25 0.35 0.4

Applicable range

Recommended

0.3

Ccp 1 capacitance (µF)

value

0.45 0.5

Choose Ccp 1 and Ccp 2 to be combined from the above applicable range. We recommend Ccp 1:Ccp 2 at

10:1 or more. (If our recommended values (Ccp = 0.22 µF, C cp 2 = 0.022 µF) are used, the drive conditions in

the specification sheet are satisfied. (There is no capacitor temperature characteristic as a condition.)

When setting the constants, make sure that the charge pump voltage is not below the specified value and

set the constants with a margin (the larger Ccp 1 and Ccp 2, the more the margin).

Some capacitors exhibit a large change in capacitance according to the temperature. Make sure the above

capacitance is obtained under the IC ambient temperature.

24

2005-04-04

Recommended Application Circuit

µ

µ

The values of external constants are example recommended values. For values under different input

conditions, see the above-mentioned recommended operating conditions.

(The following shows an example when fcho = 501 Hz (CR frequency = 800 kHz and constant-current

limiter = 2.27 A) with serial signals placed in initial status.)

V

F

10

SGND

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

R

osc

C

osc

= 3.6 kΩ

= 560 pF

LGND

DD

CR

STROBE A

CLK A

DATA A

STROBE B

CLK B

DATA B

SLEEP

LGND

(F

PHASE A

PHASE B

ENABLE A

ENABLE B

MODE A

MODE B

BRAKE A

BRAKE B

)

IN

Ccp 3Ccp 2Ccp 1

V

ref

V

ref

V

R

RS A

R

RS B

P-GND

TB62300FG

A

B

M

A

A

M DC Motor

B

B

M

PGND

R

RS A

DC Motor

R

RS B

LGND

ref

V

0.11

0.11

3 V

LGND

Ω

Ω

100 µF

F

1

24 V

Ccp 2

0.022

µF

LGND

Ccp 1

0.22

µF

Note: It is recommended to add bypass capacitors as required.

Make sure that all gound pins are connected to the same ground rail.

STROBE, CLK, and DATA must be tied to LGND if serial input is not used for settings or motor control.

Because there may be short circuits between outputs, to supply, or to ground, be careful when designing

output lines, V

(VM) lines, and ground lines.

DD

25

2005-04-04

TB62300FG

Connection Diagram

3 V

3 V 10 µF

10 µF

3.9 k

24 V

100 µF

5 V

10 µF

(when external forced PWM mode is used)

0.5 Ω

Ω

270 pF

0.022

0.22 µF

5 V

NC

µF

1

2

3

4

5

6

7

8

9

10

R

S A

V

REF A

V

REF B

CR

V

M

Ccp 1

Ccp 2

Ccp 3

V

DD

LGND

TEST A

R

SLEEP

ENABLE B

ENABLE A

PHASE B

PHASE A

DATA B

DATA A

CLK B

LGND

CLK A

S B

0.5 Ω

36

35

34

33

32

31

30

29

28

27

NC

PGND

26

25

24

23

22

21

−

20

19

M M

NC

TEST B

11

TEST C

12

13

BRAKE A

BRAKE B

14

15

NC

16

OUT A

17

PGND

18

OUT A

−

+

: Signal from central unit

STROBE B

STROBE A

MODE B

MODE A

OUT B

OUT B +

26

2005-04-04

Package Dimensions

HSOP36-P-450-0.65

TB62300FG

Unit: mm

Weight: 0.79 g (typ.)

27

2005-04-04

TB62300FG

RESTRICTIONS ON PRODUCT USE

• The information contained herein is subject to change without notice.

• The information contained herein is presented only as a guide for the applications of our products. No

responsibility is assumed by TOSHIBA for any infringements of patents or other rights of the third parties which

may result from its use. No license is granted by implication or otherwise under any patent or patent rights of

TOSHIBA or others.

• TOSHIBA is continually working to improve the quality and reliability of its products. Nevertheless, semiconductor

devices in general can malfunction or fail due to their inherent electrical sensitivity and vulnerability to physical

stress. It is the responsibility of the buyer, when utilizing TOSHIBA products, to comply with the standards of

safety in making a safe design for the entire system, and to avoid situations in which a malfunction or failure of

such TOSHIBA products could cause loss of human life, bodily injury or damage to property.

In developing your designs, please ensure that TOSHIBA products are used within specified operating ranges as

set forth in the most recent TOSHIBA products specifications. Also, please keep in mind the precautions and

conditions set forth in the “Handling Guide for Semiconductor Devices,” or “TOSHIBA Semiconductor Reliability

Handbook” etc..

• The TOSHIBA products listed in this document are intended for usage in general electronics applications

(computer, personal equipment, office equipment, measuring equipment, industrial robotics, domestic appliances,

etc.). These TOSHIBA products are neither intended nor warranted for usage in equipment that requires

extraordinarily high quality and/or reliability or a malfunction or failure of which may cause loss of human life or

bodily injury (“Unintended Usage”). Unintended Usage include atomic energy control instruments, airplane or

spaceship instruments, transportation instruments, traffic signal instruments, combustion control instruments,

medical instruments, all types of safety devices, etc.. Unintended Usage of TOSHIBA products listed in this

document shall be made at the customer’s own risk.

030619EBA

• The products described in this document are subject to the foreign exchange and foreign trade laws.

• TOSHIBA products should not be embedded to the downstream products which are prohibited to be produced

and sold, under any law and regulations.

28

2005-04-04

Loading...

Loading...