y

查询TB62209F供应商

TB62209F

TOSHIBA BiCD Processor IC Silicon Monolithic

Preliminar

T B 6 2 2 0 9 F

Stepping Motor Driver IC Using PWM Chopper Type

The TB62209F is a stepping motor driver driven by chopper

micro-step pseudo sine wave.

The TB62209F integrates a decoder for CLK input in micro

steps as a system to facilitate driving a two-phase stepping motor

using micro-step pseudo sine waves. Micro-step pseudo sine

waves are optimal for driving stepping motors with low-torque

ripples and at low oscillation. Thus, the TB62209F can easily

drive stepping motors with low-torque ripples and at high

efficiency.

Also, TB62209F consists output steps by DMOS (Power MOS

FET), and that makes possible to control the output power

dissipation much lower than ordinary IC with bipolar transistor output.

The IC supports Mixed Decay mode for switching the attenuation ratio at chopping. The switching time for the

attenuation ratio can be switched in four stages according to the load.

Features

Weight: g (typ.)

• Bipolar stepping motor can be controlled by a single driver IC

• Monolithic BiCD IC

• Low ON-resistance of R

• Built-in decoder and 4-bit DA converters for micro steps

• Built-in ISD, TSD, V

• Built-in charge pump circuit (two external capacitors)

• 36-pin power flat package (HSOP36-P-450-0.65)

• Output voltage: 40 V max

• Output current: 1.8 A/phase max

• 2-phase, 1-2 (type 2) phase, W1-2 phase, 2W1-2 phase, 4W1-2 phase, or motor lock mode can be selected.

• Built-in Mixed Decay mode enables specification of four-stage attenuation ratio.

• Chopping frequency can be set by external resistors and capacitors.

High-speed chopping possible at 100 kHz or higher.

Note: When using the IC, pay attention to thermal conditions. These devices are easy damage by high static

voltage. In regards to this, please handle with care.

= 0.5 Ω (Tj = 25°C @1.0 A: typ.)

on

&VM power monitor (reset) circuit for protection

DD

1

2001-09-05

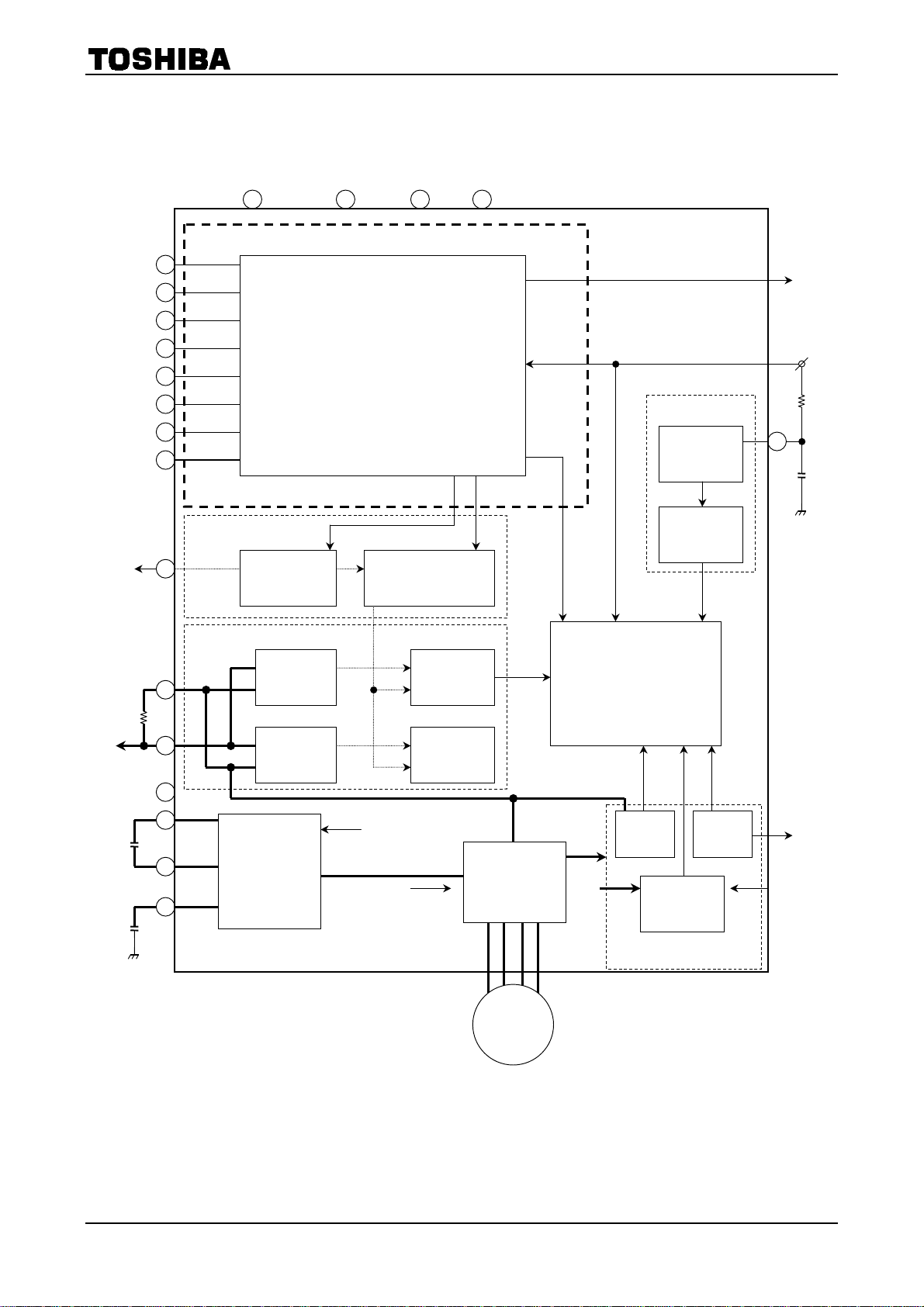

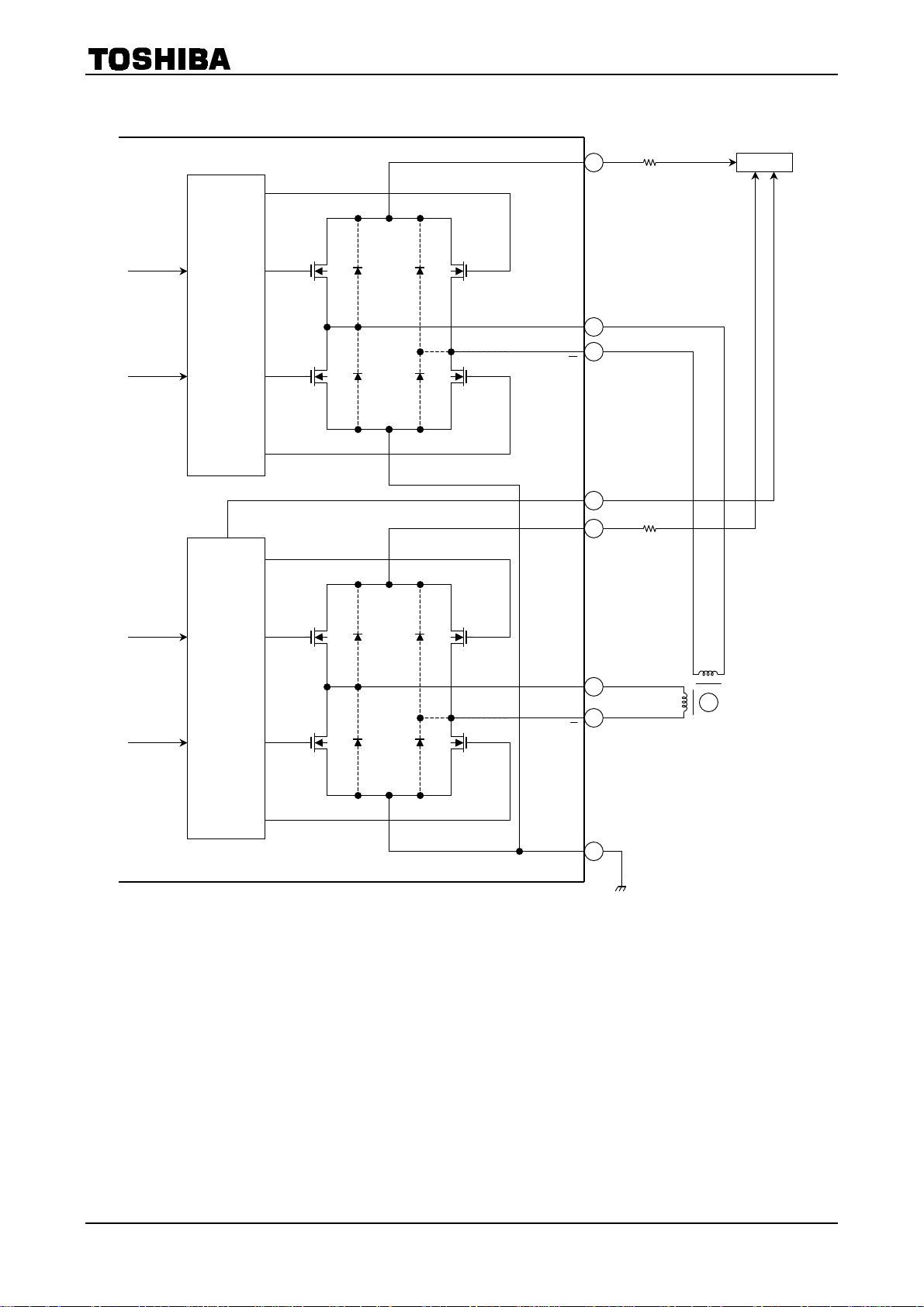

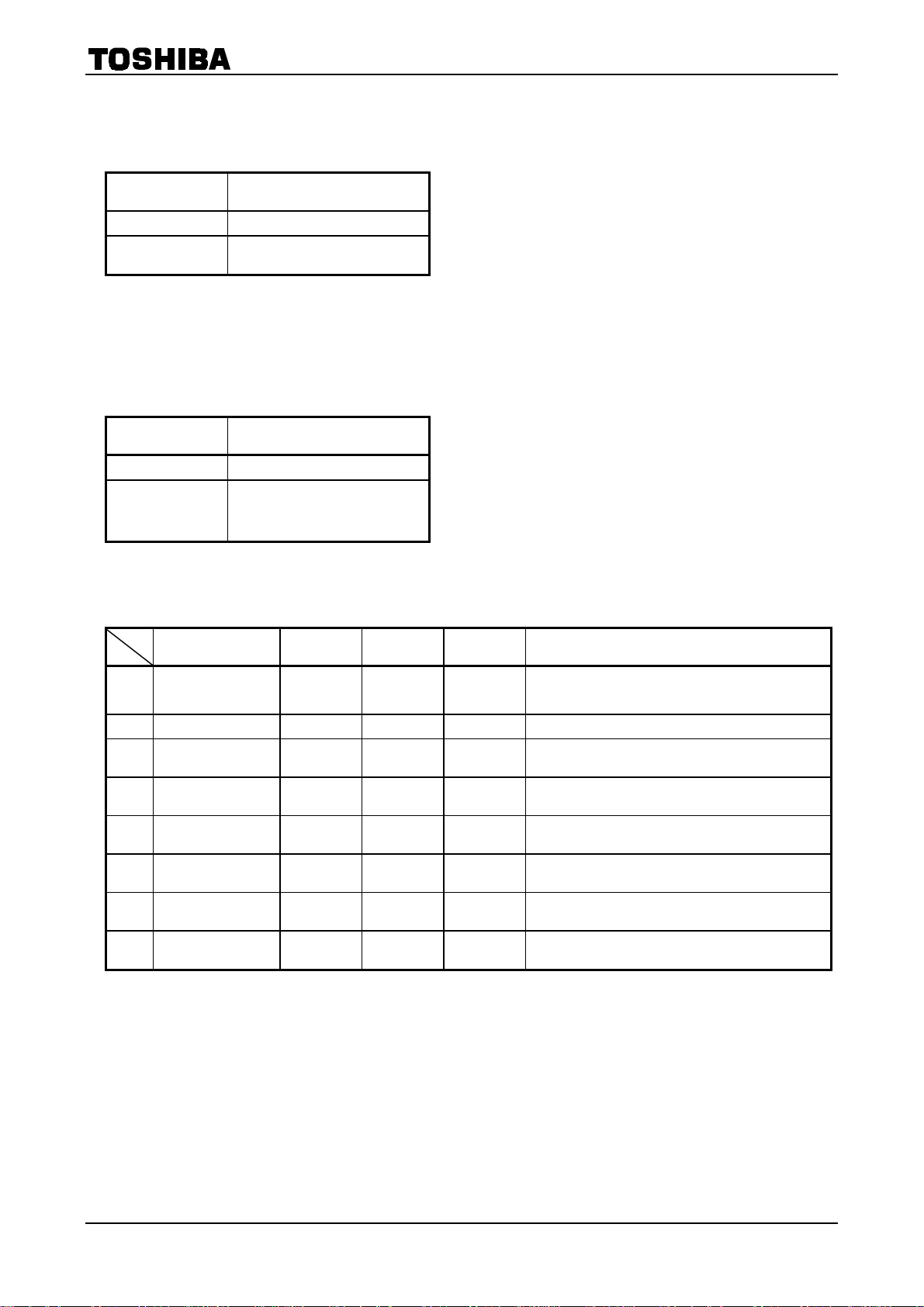

Block Diagram

f

1. Overview

TB62209F

RESET

CW/CCW

ENABLE

STANDBY

D MODE 3

D MODE 2

D MODE 1

CLK

V

re

TORQUE 1

Current Level Set

TORQUE 2 MDT 1 MDT 2

Micro-step decorder

Torque control

4-bit DA

(sine angle control)

V

DD

Chopper OSC

OCS

CR-CLK

converter

MO

CR

V

M

Ccp C

Ccp B

Ccp A

Current Feedback (×2)

V

R

S

V

M

Charge

Pump

Unit

RS 1

V

RS 2

STANDBY

ENABLE V

R

S COMP 1

R

S COMP 2

(Mixed Decay control)

Output (H-bridge)

× 2

Stepping

Moter

Output control

ISD

V

DDR/VMR

V

M

protect

Protection Unit

TSD

DD

TSD

protect

2

2001-09-05

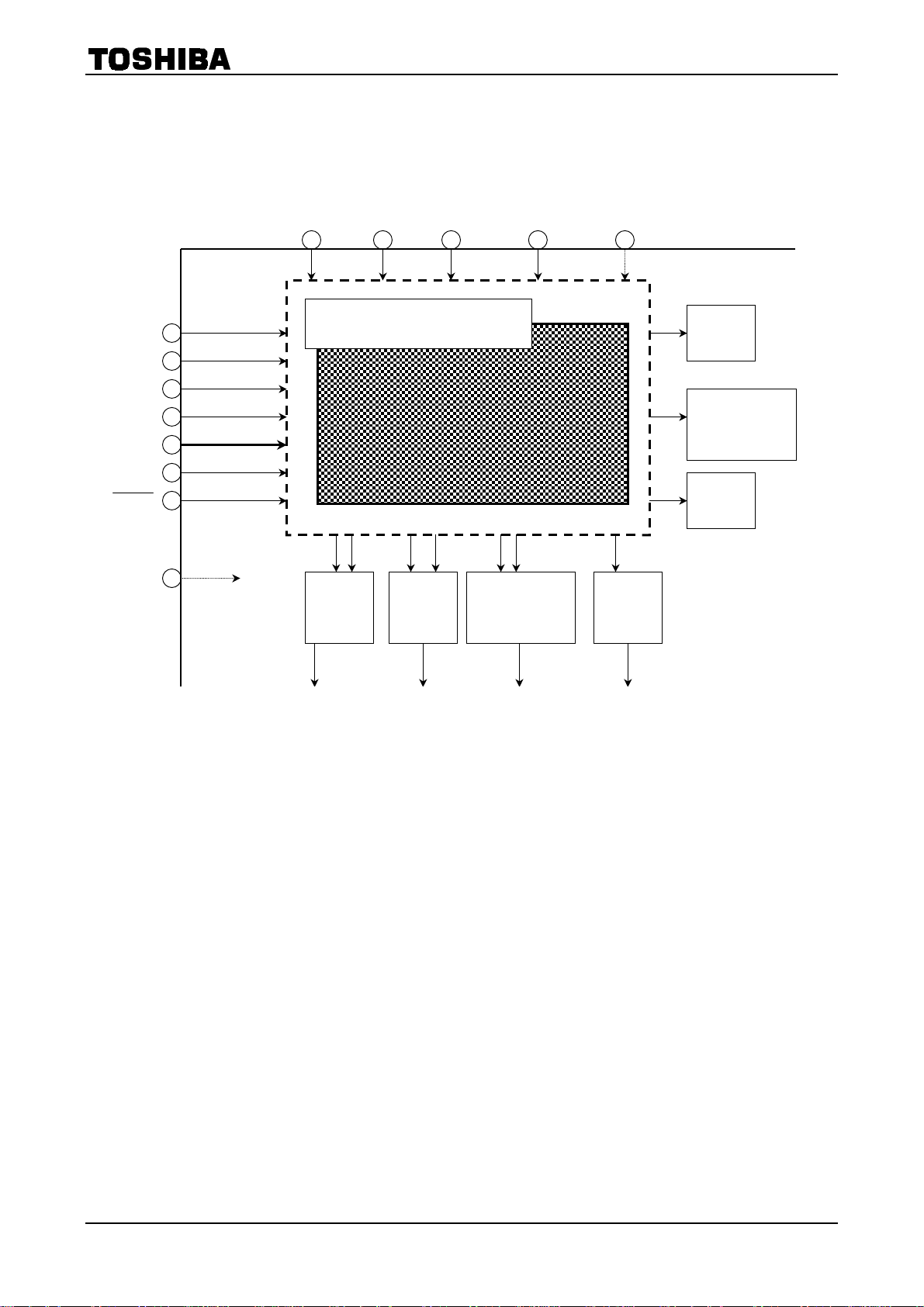

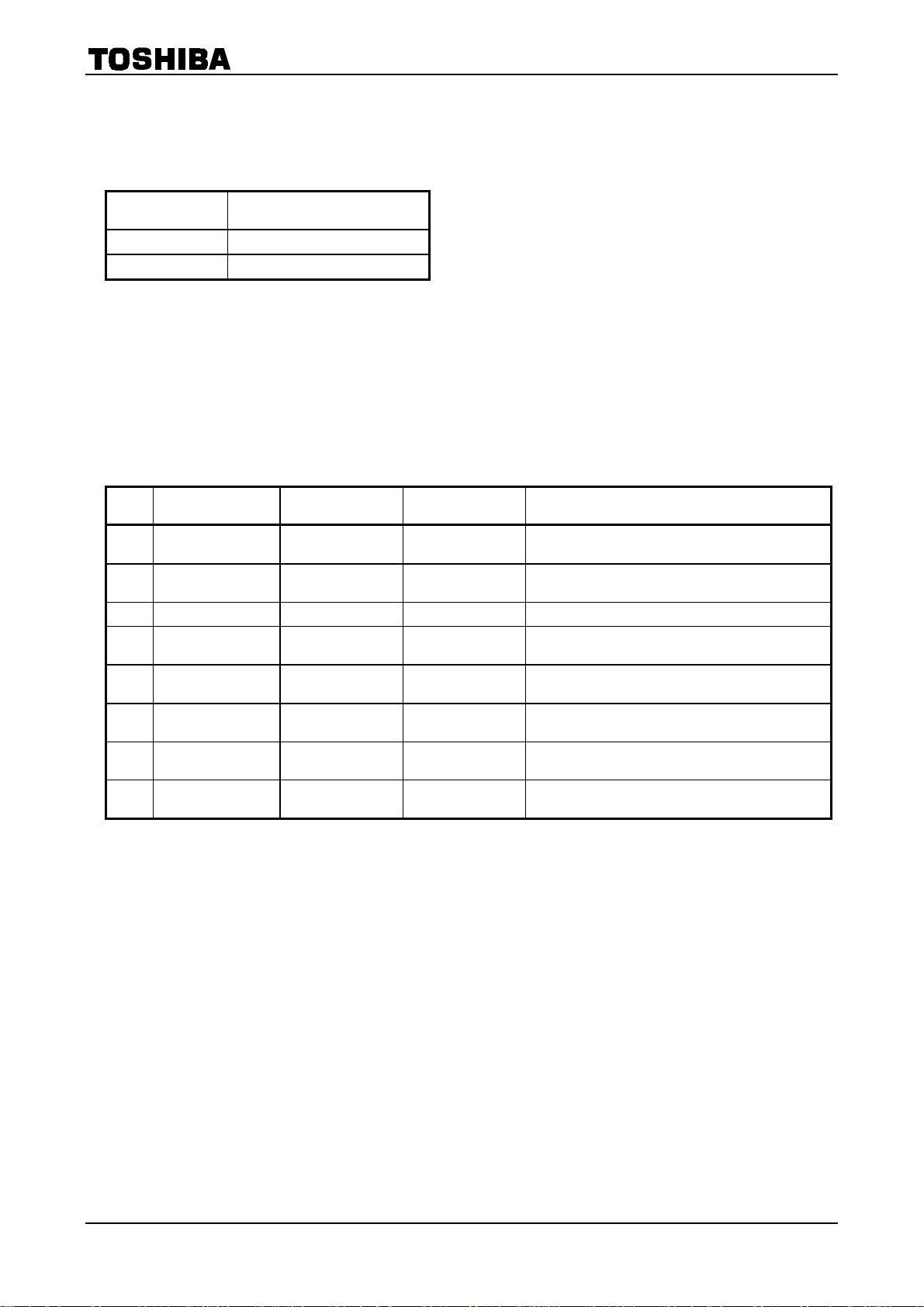

2. LOGIC UNIT A/B (C/D unit is the same as A/B unit)

Function

This circuit is used to input from the DATA pins micro-step current setting

them to the subsequent stage. By switching the SETUP pin, the data in the mixed decay

can be overwritten.

MDT 1 MDT 2

TORQUE 1 TORQUE 2

TB62209F

data and to transfer

timing table

DATA MODE

D MODE 1

D MODE 2

D MODE 3

CW/CCW

CLK

STANDBY

RESET

ENABLE

Output

control

circuit

Torque

× 2 bits

Current

feedback

circuit

Micro-step decoder

Decay

× 2 bits

B unit side

Mixed

Decay

circuit

Micro-step

current data

× 4 bits

B unit side

DA circuit

Phase

× 1 bit

B unit side

Output

control

circuit

Decay

× 2 bits

A unit side

Micro-step

current data

× 4 bits

A unit side

Phase

× 1 bit

A unit side

3

2001-09-05

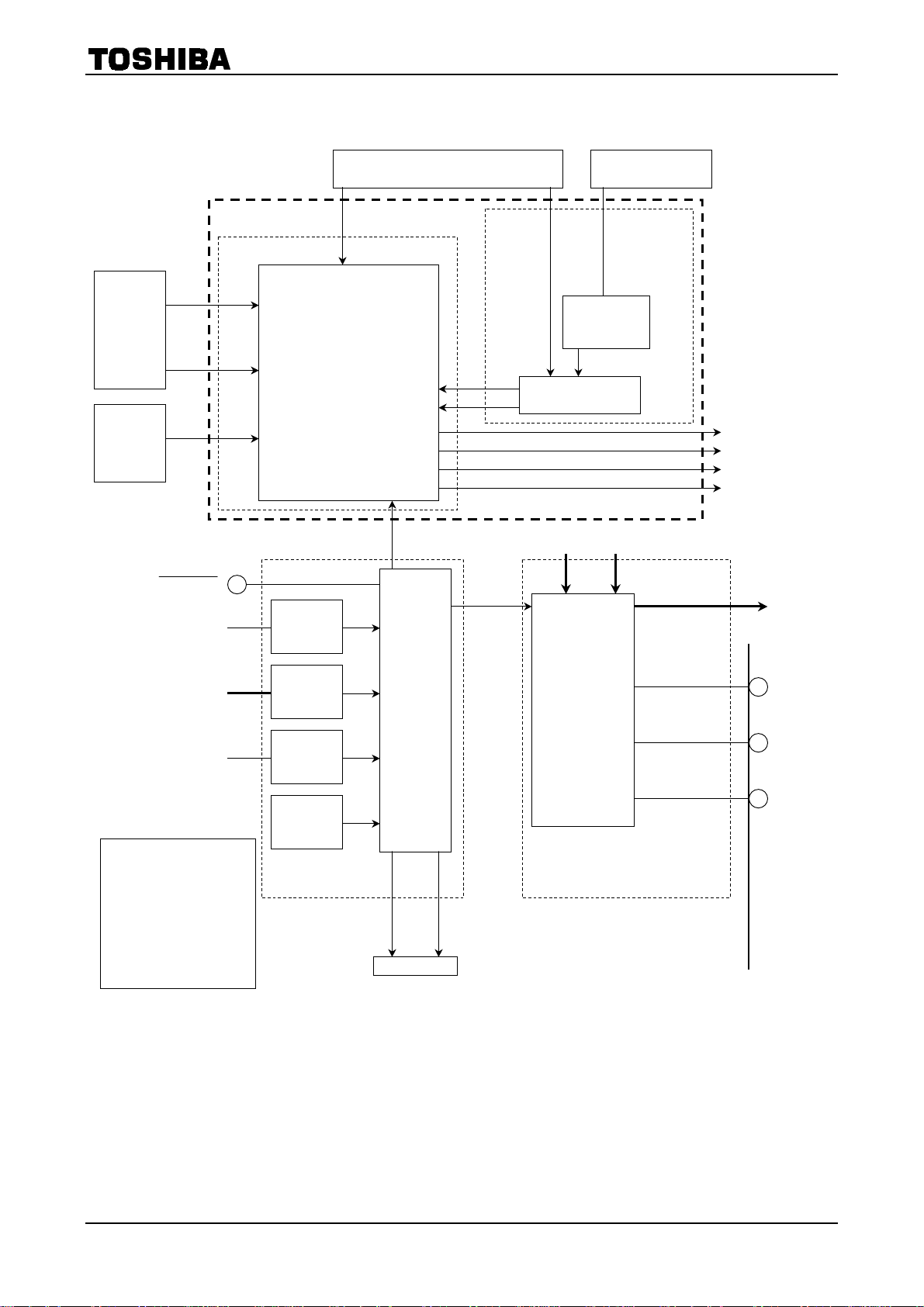

3. Current feedback circuit and current setting circuit

Function

The current setting circuit is used to set the reference voltage of the output current using the current

setting decoder.

The current feedback circuit is used to output to the output control circuit the relation between the

set current value and

current setting circuit with the potential difference generated when current flows through the current

sense resistor connected between R

The chopping waveform generator circuit to which CR is connected is used to generate clock used as

reference for the chopping frequency.

TORQUE

0, 1

output current. This is done by comparing the reference voltage output to the

and VM.

S

Decoder

Unit

CURRENT

0-3

TB62209F

V

ref

R

S

100%

85%

70%

50%

Torque

control

circuit

Current setting

circuit

DA circuit

VRS circuit 1

(detects

potential

difference

between

RS and VM)

Micro-step

15

current

14

setting

13

selector

12

11

circuit

10

9

8

7

6

5

4

4-bit

3

DA

2

circuit

1

0

R

S COMP

circuit

1

(Note 1)

Chopping waveform

Waveform shaping circuit

Chopping reference circuit

Output stop signal (ALL OFF)

generator circuit

<Use in Charge mode>

NF

(set current

reached signal)

CR

Mixed

Decay

timing

circuit

Output

control

circuit

V

M

Current feedbackcircuit

VRS circuit 2

(detects

potential

difference

between

VM and RS)

R

S COMP

circuit

2

(Note 2)

RNF

(set current

monitor signal)

<Use in FAST MODE>

Note 1: R

S COMP1

: Compares the set current with the output current and outputs a signal when the output

current reaches the set current.

Note 2: R

S COMP2

: Compares the set current with the output current at the end of Fast mode during chopping.

Outputs a signal when the set current is below the output current.

4

2001-09-05

4. Output control circuit, current feedback circuit and current setting circuit

TB62209F

Current

feedback

circuit

Current

setting

circuit

STANDBY

Output pin

V

V

DD

Output control circuit

NF set current

reached signal

RNF set current

monitor signal

Output stop

signal

ISD

circuit

M

VMR

circuit

V

DDR

circuit

Micro-step current setting

decoder circuit

PHASE

Mixed

Decay

timing

Charge Start

U1

U2

L1

L2

Output RESET signal

Internal

stop

signal

select

circuit

Charge

DECAY

MODE

pump

halt

signal

CR counter

CR Serector

VDD VM

Charge

pump

circuit

Chopping

reference circuit

Mixed

Decay

timing

circuit

Power supply for

upper drive output

VH

Output circuit

Output

circuit

Cop A

Cop B

V

: VDD power on

DDR

Reset

VMR: VM power on Reset

ISD: Current shutdown

circuit

TSD: Thermal shutdown

circuit

Note: The STANDBY pins are pulled down in the IC by 10-kΩ resistor.

When not using the pin, connect it to GND. Otherwise, malfunction may occur.

TSD

circuit

Protection

circuit

Micro-step current

setup latch

clear signal

LOGIC

Mixed Decay

timing table clear

signal

5

Cop C

2001-09-05

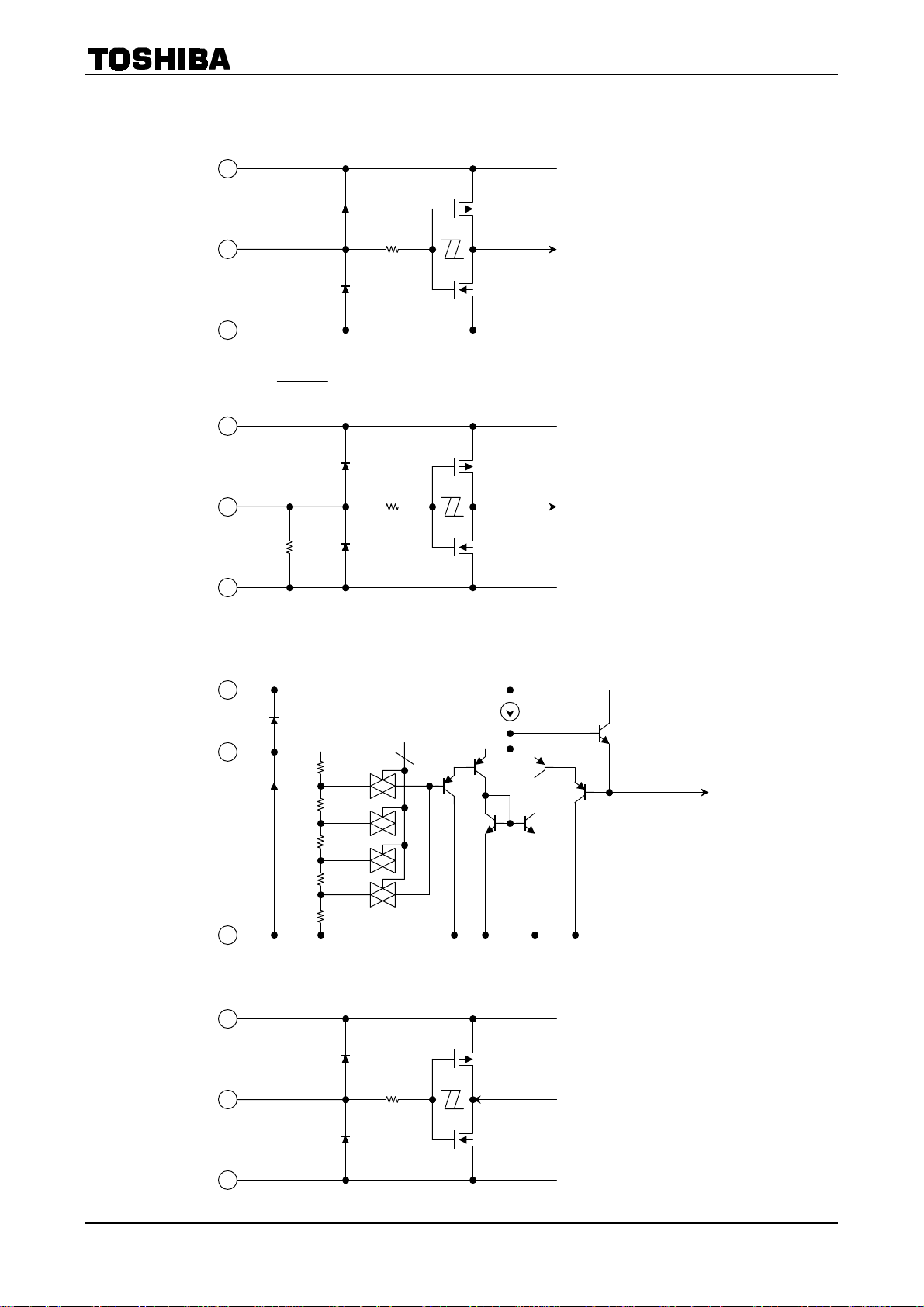

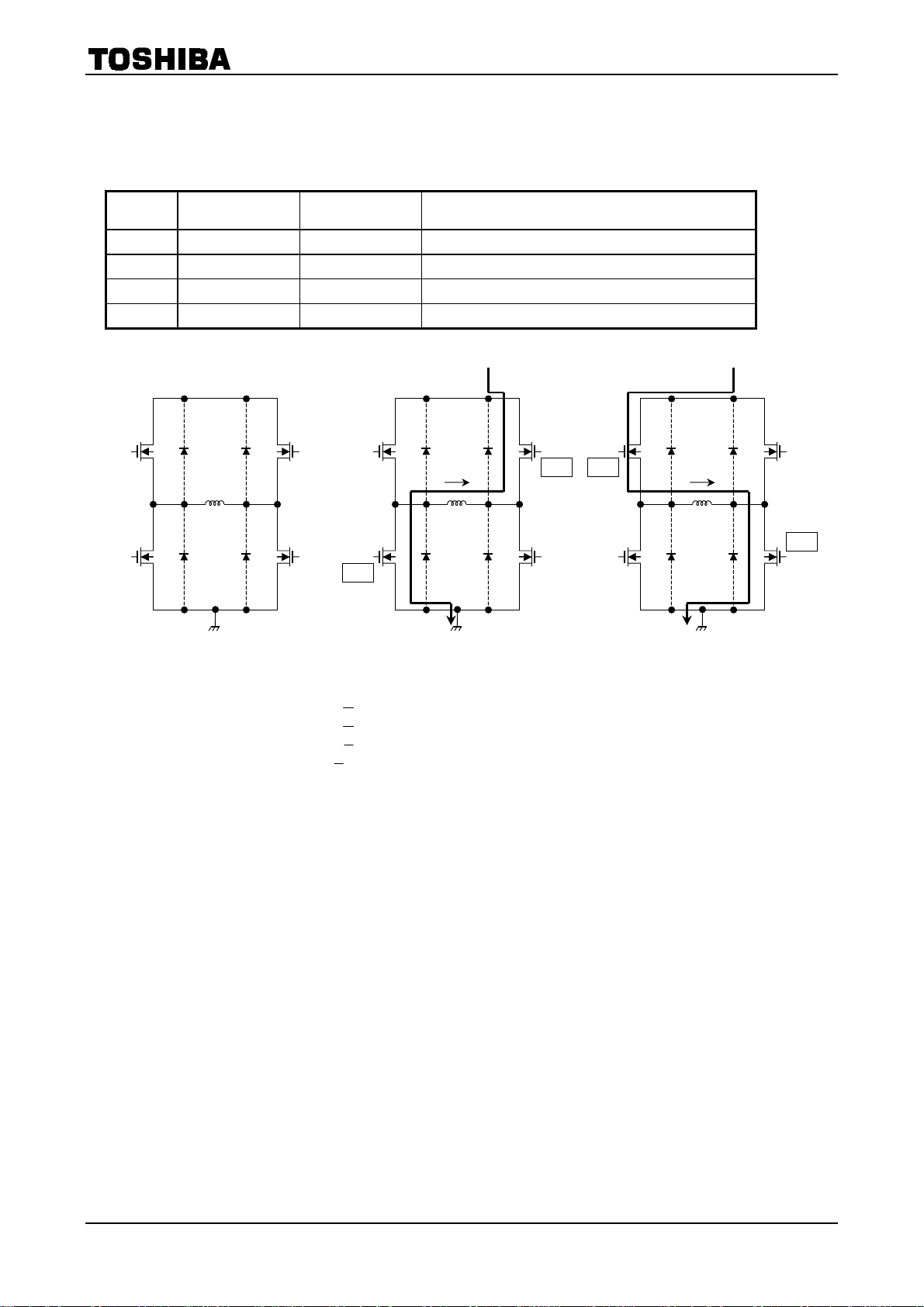

5. Output equivalent circuit (A/B unit (C/D unit is the same as A/B unit)

TB62209F

From output

control

circuit

From output

control

circuit

Power

supply

for upper

drive output

(VH)

U1

U2

L1

L2

Output

driver

circuit

Phase A

Power

supply

for upper

drive output

(VH)

U1

U2

L1

L2

Output

driver

circuit

Phase B

U1

L1

U1

L1

U2

L2

U2

L2

Output A

Output

Output B

Output

R

S A

A

RSB

B

R

RS A

V

M B

R

RS B

PGND

To VM

M

Note: The diode on the dotted line is parasitic diode.

6

2001-09-05

6. Input equivalent circuit

1. Input circuit (CLK, TORQUE, MDT, CW/CCW, DATA MODE, Decay Mode)

V

DD

IN

150 Ω

To Logic IC

TB62209F

2. Input circuit (

3. V

V

SS

V

DD

IN

V

SS

input circuit

ref

V

DD

IN

RESET

100 kΩ

, ENABLE, STANDBY)

150 Ω

2

GND

To Logic IC

GND

V

SS

4. Output circuit (MO, PROTECT)

V

DD

OUT

V

SS

150 Ω

To DA circuit

GND

GND

7

2001-09-05

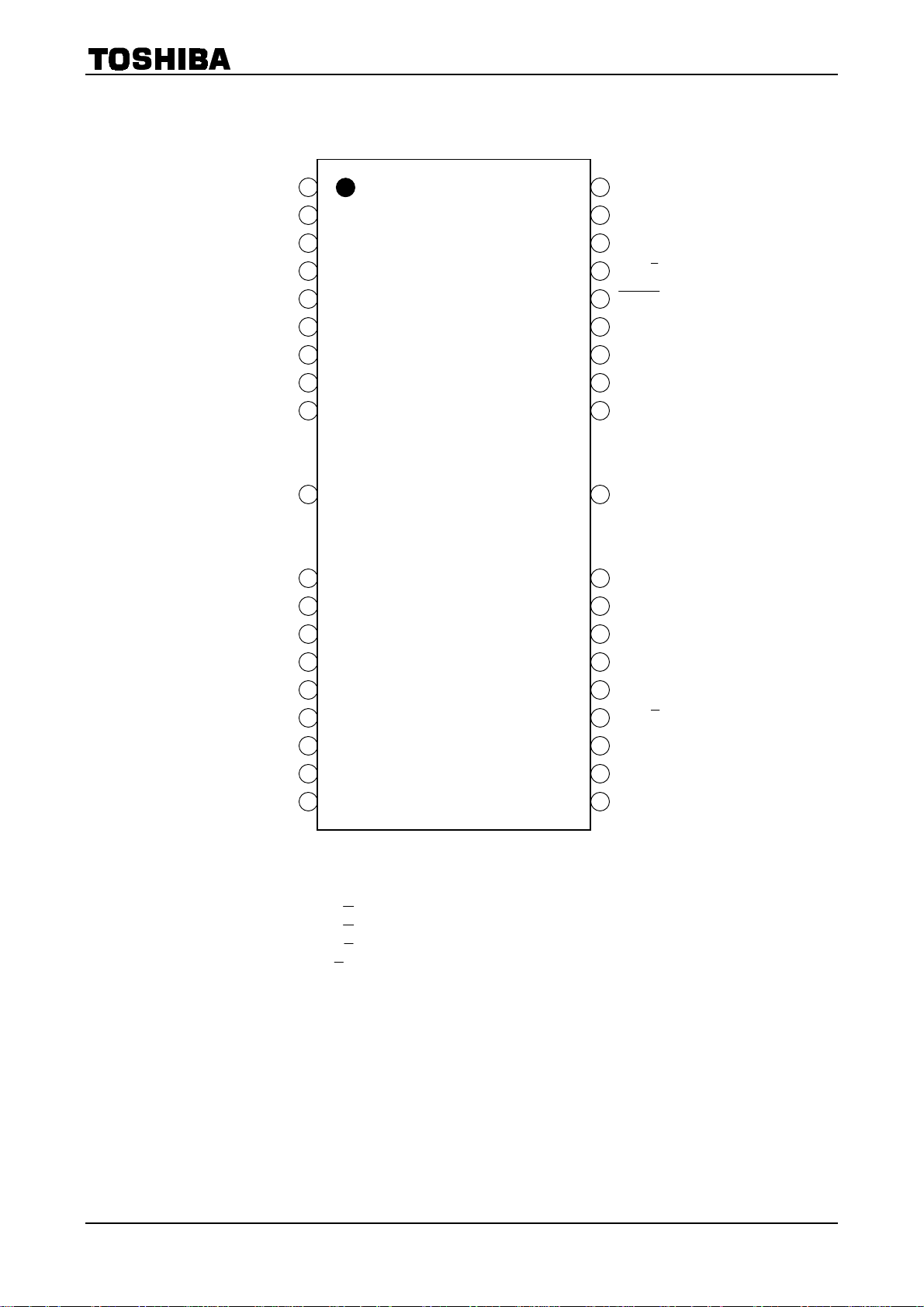

TB62209F

f

Y

Pin Assignment

(top view)

DD

re

S B

1 D MODE 1

2 D MODE 2

3 D MODE 3

4 CW/CCW

5 V

6 V

7 NC

8 NC

9 R

(FIN)

TB62209F

36

CR

35

CLK

34 ENABLE

33 OUT B

32 RESET

31 DATA MODE

30 NC

29 OUT B

28 PGND

(FIN)

10R

S A

11NC

12NC

13VM

14STANDB

15Ccp A

16Ccp B

17Ccp C

18MO

Pin Assignment for PWM in Data Mode

D MODE 1 → GA+ (OUT A, A)

D MODE 2 → GA− (OUT A,

D MODE 3 → GB+ (OUT B,

CW/CCW → GB− (OUT B,

Note: Pin assignment above is different at data mode and PWM.

A)

B)

B)

27 PGND

26 OUT A

25 NC

24 MDT 2

23 MDT 1

22 OUT A

21 TORQUE2

20 TORQUE1

19 PROTECT

8

2001-09-05

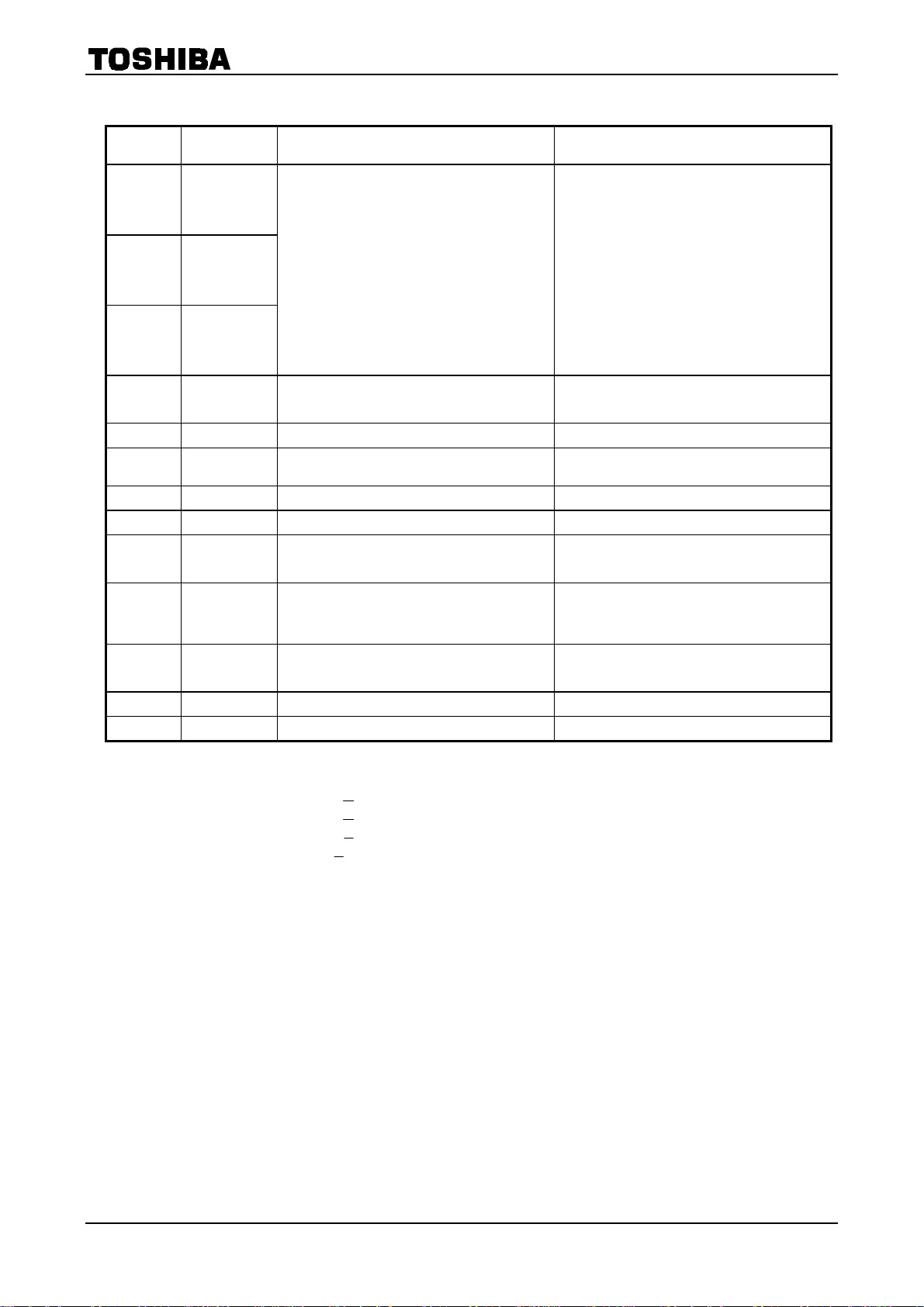

Pin Description 1

Pin Number Symbol Function Remarks

D MODE 3, 2, 1 =

1 D MODE 1

2 D MODE 2

3 D MODE 3

4 CW/CCW Sets motor rotation direction

5 VDD Logic power supply connecting pin Connect to logic power supply (5 V).

6 V

7 NC Not connected Not wired

8 NC Not connected Not wired

9 R

FIN FIN FIN Logic ground pin

10 R

11 NC Not connected Not wired

12 NC Not connected Not wired

ref

S B

S A

Motor drive mode setting pin

Reference power supply pin for setting output

current

Unit-B power supply pin

(connecting pin for power detection resistor)

Unit-A power supply pin

(pin connecting power detection resistor)

LLL: Same function as that of STANDBY pin

LLH: Motor Lock mode

LHL: 2-Phase Excitation mode

LHH: 1-2 Phase Excitation (A) mode

HLL: 1-2 Phase Excitation (B) mode

HLH: W1-2 Phase Excitation mode

HHL: 2W1-2 Phase Excitation mode

HHH: 4W1-2 Phase Excitation mode

CW: Forward rotation

CCW: Reverse rotation

Connect to supply voltage for setting current.

Connect current sensing resistor between this

pin and V

Connect to power ground.

The pin functions as a heat sink. Design pattern

taking heat into consideration.

Connect current sensing resistor between this

pin and V

.

M

.

M

Pin Assignment for PWM in Data Mode

TB62209F

D MODE 1 → GA+ (OUT A, A)

D MODE 2 → GA− (OUT A,

D MODE 3 → GB+ (OUT B,

CW/CCW → GB− (OUT B,

A)

B)

B)

9

2001-09-05

Pin Description 2

Pin Number Symbol Function Remarks

13 VM Motor power supply monitor pin Connect to motor power supply.

14

15 Ccp A

16 Ccp B

17 Ccp C (charging side)

18 MO Electrical angle (0°) monitor pin

19 PROTECT TSD operation detector pin

20 TORQUE 1

21 TORQUE 2

22 OUT A Channel A output pin

23 MDT 2

24 MDT 1

STANDBY

All-function-initializing and Low Power

Dissipation mode pin

Pin connecting capacitor for boosting output

stage drive power supply (storage side

connected to GND)

Pin connecting capacitor for boosting output

stage drive power supply

Motor torque switch setting pin

Mixed Decay mode setting pins

H: Normal operation

L: Operation halted

Charge pump output halted

Connect capacitor for charge pump (storage

side) V

Connect capacitor for charge pump (charging

side) between this pin and Ccp C.

Connect capacitor for charge pump (charging

side between this pin and Ccp B.

Outputs High level in 4W1-2, 2W1-2, W1-2, or

1-2 Phase Excitation mode with electrical angle

of 0° (phase B: 100%, phase A: 0%).

In 2-Phase Excitation mode, outputs High level

with electrical angle of 0° (phase B: 100%,

phase A: 100%).

Detects thermal shut down (TSD) and outputs

High level.

Torque 2, 1 = HH: 100%

LH: 85%

HL: 70%

LL: 50%

MDT 2, 1 = HH: 100%

HL: 75%

LH: 37.5%

LL: 12.5%

and VDD are generated.

M

TB62209F

10

2001-09-05

Pin Description 3

Pin Number Symbol Function Remarks

25 NC Not connected Not wired

26 OUT A Channel A output pin

27 PGND Power ground pin Connect all power ground pins and VSS to GND.

FIN FIN Logic ground pin

28 PGND Power ground pin Connect all power ground pins to GND.

29 OUT B Channel B output pin

30 NC Not connected Not wired

31 DATA MODE Clock input and PWM

32 RESET Initializes electrical angle.

33 OUT B Channel B output pin

34 ENABLE Output enable pin Forcibly turns all output transistors off.

35 CLK

36 CR

Inputs CLK for determining number of motor

rotations.

Chopping reference frequency reference pin (for

setting chopping frequency)

The pin functions as a heat sink. Design pattern

taking heat into consideration.

H: Controls external PWM.

L: CLK-IN mode

We recommend this pin normally be used as

CLK-IN mode pin (Low).

In PWM mode, functions such as constant

current control do not operate.

Forcibly initializes electrical angle.

At this time we recommend ENABLE pin be set

to Low to prevent misoperation.

H: Resets electrical angle.

L: Normal operation

Electrical angle is incremented by one for each

CLK input.

CLK is reflected at rising edge.

Determines chopping frequency.

TB62209F

11

2001-09-05

1. Function of CW/CCW

CW/CCW switches the direction of stepping motor rotation.

Input Function

H Forward (CW)

L Reverse (CCW)

2. Function of MDT 1/MDT 2

MDT 1/MDT 2 specifies the current attenuation speed at constant current control.

The larger the rate (%), the larger the attenuation of the current. Also, the peak current value (current

ripple) becomes larger. (Typical value is 37.5%.)

MDT 2 MDT 1 Function

L L 12.5% Mixed Decay mode

L H 37.5% Mixed Decay mode

H L 75% Mixed Decay mode

H H 100% Mixed Decay mode (Fast Decay mode)

3. Function of TORQUE X

TORQUE X changes the current peak value in four steps. Used to change the value of the current used,

for example, at startup and fixed-speed rotation.

TB62209F

TORQUE 2 TORQUE 1 Comparator Reference Voltage

H H 100%

L H 85%

H L 70%

L L 50%

4. Function of RESET (forced initialization of electrical angle)

With the CLK input method (decoder method), unless CLKs are counted, except MO, where the electrical

angle is at that time is not known. Thus, this method is used to forcibly initialize the electrical angle.

For example, used to change the excitation mode to another drive mode during output from MO

(electrical angle = 0°).

Input Function

H Initializes electrical angle to 0°

L Normal operation

12

2001-09-05

5. Function of ENABLE (output operation)

ENABLE forcibly turns OFF all output transistors at operation.

Data such as electrical angle and operating mode are all retained.

Input Function

H Operation enabled (active)

L

Output halted (operation other

than output active)

6. Function of STANDBY

STANDBY halts the charge pump circuit (power supply booster circuit) as well as halting output.

We recommend setting to Standby mode at power on.

(At this time, data on the electrical angle are retained.)

Input Function

H Operation enabled (active)

Output halted (Low Power

L

Dissipation mode)

Charge pump halted

7. Functions of Excitation Modes

TB62209F

Excitation Mode DM3 DM2 DM1 Remarks

1

2 Motor Lock mode 0 0 1 Locks only at 0° electrical angle.

3

4

5

6

7

8

Low Power

Dissipation mode

2-Phase Excitation

mode

1-2 Phase Excitation

(A)

1-2 Phase Excitation

(B)

W1-2 Phase

Excitation

2W1-2 Phase

Excitation

4W1-2 Phase

Excitation

0 0 0

0 1 0 45° → 135° → 225° → 315° → 45°

0 1 1 Low-torque, 1-bit micro-step change

1 0 0 High-torque, 1-bit micro-step change

1 0 1 2-bit micro-step change

1 1 0 3-bit micro-step change

1 1 1 4-bit micro-step change

Standby mode

Charge pump halted

13

2001-09-05

8. Function of DATA MODE

DATA MODE switches external duty control (forced PWM control) and constant current CLK-IN control.

In Phase mode, H-bridge can be forcibly inverted and output only can be turned off. Constant current drive

including micro-step drive can only be controlled in CLK-IN mode.

Input Function

H PHASE MODE

L CLK-IN MODE

Note 1: Normally, use CLK-IN mode.

9. Electrical Angle Setting immediately after Initialization

In Initialize mode (immediately after RESET is released), the following currents are set.

In Low Power Dissipation mode, the internal decoder continues incrementing the electrical angle but

current is not output.

Note that the initial electrical angle value in 2-Phase Excitation mode differs from that in nW1-2 (n = 0,

1, 2, 4) Phase Excitation mode.

Excitation Mode IB (%) IA (%) Remarks

TB62209F

1

2 Motor Lock mode 100 0

3 2-Phase Excitation 100 100 45°

4

5

6

7

8

Low Power

Dissipation mode

1-2 Phase Excitation

(A)

1-2 Phase Excitation

(B)

W1-2 Phase

Excitation

2W1-2 Phase

Excitation

4W1-2 Phase

Excitation

100 0 Electrical angle incremented but no current output

Electrical angle incremented but no motor rotation

due to no IA output

100 0 0°

100 0 0°

100 0 0°

100 0 0°

100 0 0°

Note 2: Where, IB = 100% and IA = 0%, the electrical angle is 0°. Where, IB = 0% and IA = 100%, the electrical

angle is +90°.

14

2001-09-05

10. Function of DATA MODE (Phase A mode used for explanation)

DATA MODE inputs the external PWM signal (duty signal) and controls the current. Functions such as

constant current control and overcurrent protector do not operate.

Use this mode only when control cannot be performed in CLK-IN mode.

GA+ GA− Output State

(1) L L Output off

(2) L H A+ phase: Low A− phase: High

(3) H L A+ phase: High A− phase: Low

(4) H H Output off

(1)・(4)

(2)

TB62209F

(3)

U1

OFF

L1

OFF

PGND

Note: Output is off at (1) and (4).

D MODE 1 → GA+ (OUT A,

D MODE 2 → GA− (OUT A,

D MODE 3 → GB+ (OUT B,

CW/CCW → GB− (OUT B,

U2

OFF

L2

OFF

A)

A)

B)

B)

U1

OFF

L1

ON

(Note)

Load

PGND

U2

ON

L2

OFF

U1

ON

OFF

L1

(Note)

Load

U2

OFF

ON

L2

PGND

15

2001-09-05

TB62209F

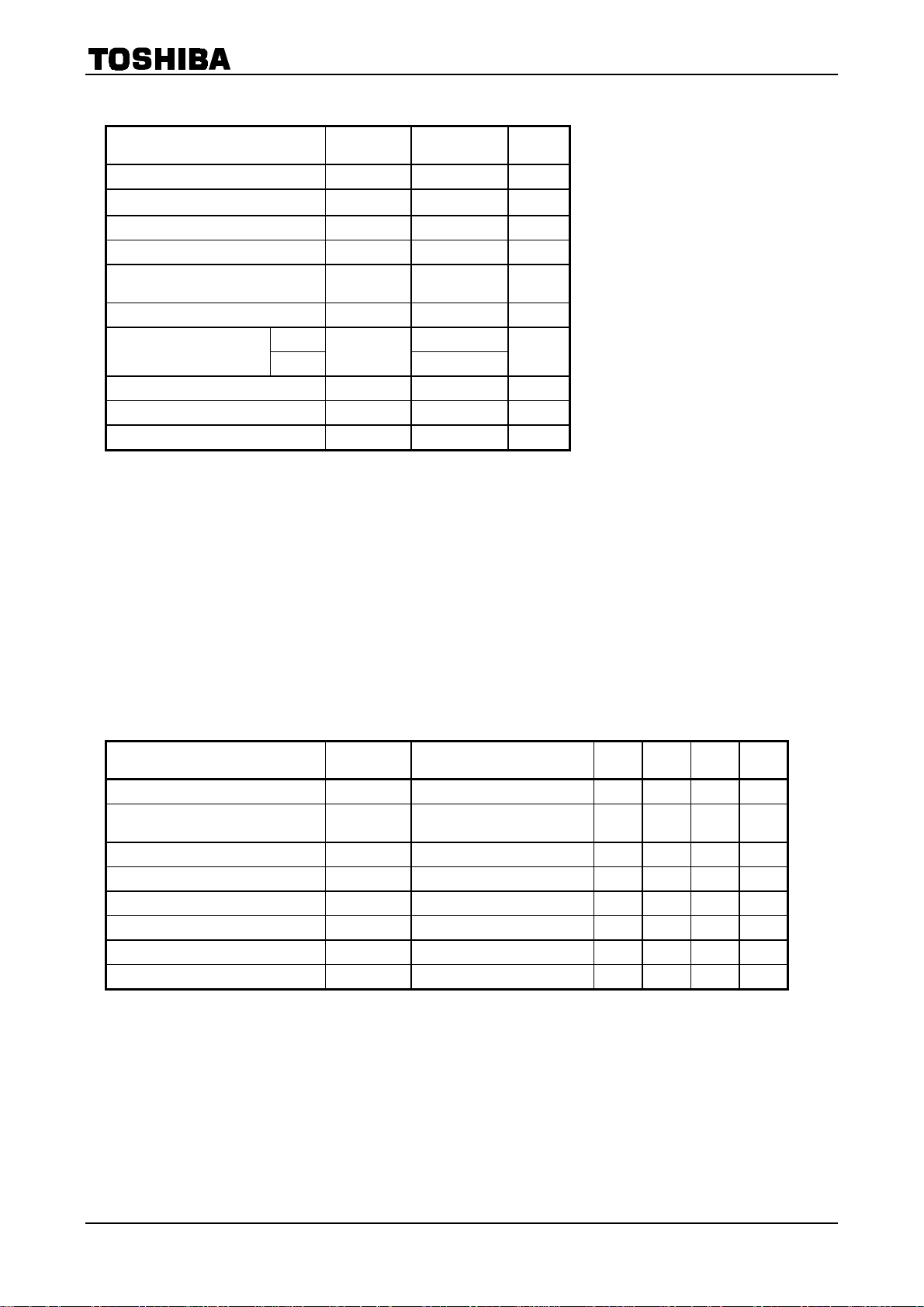

Maximum Ratings

Characteristics Symbol Rating Unit

Logic supply voltage V

Motor supply voltage VM 40

Output current (Note 1) I

Current detect pin voltage VRS V

Charge pump pin maximum voltage

(CCP1 Pin)

Logic input voltage (Note 2) VIN to VDD + 0.4 V

Power dissipation

Operating temperature T

Storage temperature T

Junction temperature Tj 150 °C

(Ta ==== 25°C)

(Note 3) 1.4

(Note 4)

DD

1.8 A/phase

OUT

V

V

H

PD

−40 to 85 °C

opr

−55 to 150 °C

stg

7 V

± 4.5 V V

M

+ 7.0 V

M

3.2

W

V

Note 1: Perform thermal calculations for the maximum current value under normal conditions. Use the IC at 1.5 A or

less per phase.

The current velue maybe controled according to the ambient temperature or board conditions.

Note 2: Input 7 V or less as V

IN

.

Note 3: Measured for the IC only. (Ta = 25°C)

Note 4: Measured when mounted on the board. (Ta = 25°C)

Ta: IC ambient temperature

T

: IC ambient temperature when starting operation

opr

Tj: IC chip temperature during operation Tj (max) is controlled by TSD (thermal shut down circuit)

Recommended Operating Conditions

Characteristics Symbol Test Condition Min Typ. Max Unit

Power supply voltage VDD 4.5 5.0 5.5 V

Motor supply voltage VM

Output current I

Logic input voltage VIN GND VDD V

Clock frequency f

Chopping frequency f

Reference voltage V

Current detect pin voltage VRS VDD = 5.0 V 0 ±1.0 ±4.5 V

OUT (1)

CLK

chop

ref

(Ta ==== 0 to 85°C, (Note 5))

= 5.0 V, Ccp1 = 0.22 µF,

V

DD

Ccp2 = 0.02 µF

Ta = 25°C, per phase 1.2 1.5 A

VDD = 5.0 V 1.0 150 KHz

VDD = 5.0 V 50 100 150 KHz

VM = 24 V, Torque = 100% 2.0 3.0 VDD V

20 24 34 V

Note 5: Because the maximum value of Tj is 120°C, recommended maximum current usage is below 120°C.

16

2001-09-05

TB62209F

Electrical Characteristics1

(unless otherwise specified, Ta ==== 25°C, VDD ==== 5 V, VM ==== 24 V)

Characteristics Symbol

HIGH V

IN (H)

Input voltage

LOW V

Input hysteresis voltage V

Input current 1

IN (L)

IN (HIS)

I

Data input pins with resistor 1.0

IN (H)

I

35 50 75

IN (H)

I

IN (L)

I

DD1

Power dissipation (VDD Pin)

I

DD2

IM1

Power dissipation (VM Pin)

Output standby

current

Output bias

current

Output leakage

current

Upper I

Upper I

Lower I

IM2

I

M3

OH

OB

OL

HIGH

(Refer-

ence)

Comparator

reference

voltage ratio

MID

HIGH

MID

LOW

LOW V

Output current differential ∆I

Output current setting differential ∆I

V

RS (H)

V

RS (MH)

V

RS (ML)

RS (L)

OUT1

OUT2

RS pin current IRS

R

ON (D-S) 1

R

Output transistor drain-source

ON (D-S) 1

ON-resistance

R

ON (D-S) 2

R

ON (D-S) 2

Test

Circuit

2.0 VDD

Data input pins

Test Condition Min Typ. Max Unit

V

DD

+ 0.4

GND

− 0.4

GND 0.8

Data input pins 200 400 700 mV

Data input pins without resistor

1.0

V

= 5 V (STROBE,

DD

DATA = L),

Logic, output all off

Output OPEN, f

LOGIC ACTIVE, V

Charge Pump = charged

RESET

CLK

= L,

= 1.0 kHz

= 5 V,

DD

RESET

,

1.0 2.0 3.0

1.0 2.5 3.5

Output OPEN (STROBE,

, DATA = L),

RESET

= L, Logic, output all off,

RESET

1.0 2.0 3.0

Charge Pump = no operation

Output OPEN, f

LOGIC ACTIVE, V

V

= 24 V, Output off,

M

Charge Pump = charged

Output OPEN, f

LOGIC ACTIVE, 100 kHz

chopping (emulation), Output

CLK

CLK

= 1 kHz

= 5 V,

DD

= 4 kHz

2.0 4.0 5.0

10 13

OPEN,

Charge Pump = charged

V

= VM = 24 V, V

RS

STANDBY = H,

OUT

RESET

= 0 V,

= L

−200 −150 µA

CLK = L

= 0 V, STANDBY = H,

V

I

OUT

= L, CLK = L

RESET

= VM = CcpA = V

V

RS

= 24 V, LOGIC IN = ALL = L

V

= 3.0 V, V

ref

TORQUE = (H) = 100% set

= 3.0 V, V

V

ref

TORQUE = (MH) = 85% set

= 3.0 V, V

V

ref

TORQUE = (ML) = 70% set

= 3.0 V, V

V

ref

TORQUE = (L) = 50% set

OUT

(Gain) = 1/5.0

ref

(Gain) = 1/5.0

ref

(Gain) = 1/5.0

ref

(Gain) = 1/5.0

ref

Differences between output

current channels

= 1000 mA −5 5 %

OUT

= 24 V, VM = 24 V

V

RS

= L (RESET state)

RESET

I

= 1.0 A, VDD = 5.0 V

OUT

T

= 25°C, Drain-Source

j

I

= 1.0 A, VDD = 5.0 V

OUT

T

= 25°C, Source-Drain

j

I

= 1.0 A, VDD = 5.0 V

OUT

T

= 105°C, Drain-Source

j

= 1.0 A, VDD = 5.0 V

I

OUT

T

= 105°C, Source-Drain

j

−100 −50 µA

1.0 1.0 µA

100

83 85 87

68 70 72

48 50 52

−5 5 %

1 2 µA

0.5 0.6

0.5 0.6

0.6 0.75

0.6 0.75

V

µA

mA

mA

%

Ω

17

2001-09-05

TB62209F

Electrical Characteristics 2

Characteristics Symbol

Chopper current Vector

(Ta ==== 25°C, VDD ==== 5 V, VM ==== 24 V, I

==== 1.0 A)

OUT

Test

Circuit

Test Condition Min Typ. Max Unit

θA = 90 (θ16) 100

θA = 84 (θ15) 100

θA = 79 (θ14) 93 98

θA = 73 (θ13) 91 96

θA = 68 (θ12) 87 92 97

θA = 62 (θ11) 83 88 93

θA = 56 (θ10) 78 83 88

θA = 51 (θ9) 72 77 82

θA = 45 (θ8) 66 71 76

θA = 40 (θ7) 58 63 68

θA = 34 (θ6) 51 56 61

θA = 28 (θ5) 42 47 52

θA = 23 (θ4) 33 38 43

θA = 17 (θ3) 24 29 34

θA = 11 (θ2) 15 20 25

θA = 6 (θ1) 5 10 15

θA = 0 (θ0)

%

0

18

2001-09-05

TB62209F

Electrical Characteristics 3 (unless otherwise specified, Ta ==== 25°C, VDD ==== 5 V, VM ==== 24 V)

Characteristics Symbol

V

input voltage V

ref

V

input current I

ref

V

attenuation ratio V

ref

TSD temperature (Note 1) TjTSD VDD = 5 V, VM = 24 V 130 170 °C

TSD return temperature difference

(Note 1)

VDD return voltage V

VM return voltage VMR 11 VDD = 5 V, STANDBY = H 2.0 3.5 5.0 V

Over current protected circuit

operation current (Note 2)

High temperature monitor pin

output current

Electrical angle monitor pin output

current

High temperature monitor pin

output voltage

Electrical angle monitor pin output

voltage

ref

ref

(GAIN)

ref

∆T

TSD TjTSD = 130 to 170°C

j

DDR

ISD V

I

protect

I

MO

V

protect (H)

V

protect (L)

V

MO2 (H)

V

MO2 (L)

Test

Circuit

9

9

10 VM = 24 V, STANDBY = H 2.0 3.0 4.0 V

12

12

12

12

Test Condition Min Typ. Max Unit

= 24 V, VDD = 5 V,

V

M

STANDBY = H,

Output on, CLK = 1 kHz

STANDBY = H,

Output off, V

V

= 5 V, V

DD

V

= 24 V, VDD = 5 V,

M

STANDBY = H,

Output on, V

− 1.0 V

= 5 V, VM = 24 V 3.0 A

DD

= 5 V,

V

DD

TSD = operating condition

= 5 V,

V

DD

electrical angle = 0°

(IB = 100%, IA = 0%)

= 5 V,

V

DD

TSD = operating condition

= 5 V,

V

DD

TSD = not operating

condition

V

= 5 V,

DD

electrical angle = except 0°

(IB = 100%, IA = Except 0%

set)

= 5 V,

V

DD

electrical angle = 0°

(IB = 100%, IA = 0%)

RESET = L,

RESET

= 24 V,

M

= 3.0 V

ref

RESET

= 2.0 to VDD

ref

2.0 V

= L,

20 35 50 µA

= L,

1/4.8 1/5.0 1/5.2

TSD

T

TjTSD

j

− 50

− 35

1.0 3.0 5.0 mA

1.0 3.0 5.0 mA

DD

TjTSD

− 20

V

°C

V

V

Note 1: Thermal shut down (TSD) circuit

When the IC junction temperature reaches the specified value and the TSD circuit is activated, the internal

reset circuit is activated switching the outputs of both motors to off.

When the temperature is set between 130 (min) to 170°C (max), the TSD circuit operates.

When the TSD circuit is activated, the charge pump is halted, and TROTECT pin outputs V

Even if the TSD circuit is activated and Standby goes H → L → H instantaneously, the IC is not reset until

the IC junction temperature drops −20°C (typ.) below the TSD operating temperature (hysteresis function).

Note 2: Overcurrent protection circuit

When current exceeding the specified value flows to the output, the internal reset circuit is activated, and the

ISD turns off the output.

Until the Standby signal goes Low to High, the overcurrent protection circuit remains activated.

During ISD, IC turns Standby mode and the charge pump halts.

19

voltage.

DD

2001-09-05

TB62209F

AC Characteristics

Characteristics Symbol

Clock frequency f

Minimum clock pulse width

Output transistor switching

characteristic

Transistor switching characteristics

(MO, PROTECT)

Noise rejection dead band time t

CR reference signal oscillation

frequency

Chopping frequency range

Chopping frequency f

Charge pump rise time t

(Ta ==== 25°C, VM ==== 24 V, VDD ==== 5 V, 6.8 mH/5.7 ΩΩΩΩ)

Test

Circuit

120 kHz

CLK

tw (t

) 100

CLK

twp 50

t

50

wn

tr Output Load: 6.8 mH/5.7 Ω 100

tf 100

t

CLK to OUT 1000

pLH

t

Output Load: 6.8 mH/5.7 Ω 2000

pHL

t

CR to OUT 500

pLH

Output Load: 6.8 mH/5.7 Ω 1000

t

pHL

tr 20

tf 20

t

20

pLH

20

t

pHL

I

BRANK

f

C

CR

f

chop (min)

f

chop (max)

chop

ONG

Test Condition Min Typ. Max Unit

= 1.0 A 200 300 400 ns

OUT

= 560 pF, R

osc

V

= 24 V, VDD = 5 V,

M

Output ACTIVE (I

Step fixed, Ccp1 = 0.22 µF,

Ccp2 = 0.01 µF

Output ACTIVE (I

CR CLK = 800 kHz

Ccp = 0.22 µF, Ccp = 0.01 µF

VM = 24 V, VDD = 5 V,

STANDBY = ON → OFF

= 3.6 kΩ 800 kHz

osc

= 1.0 A)

OUT

OUT

= 1.0 A),

40 100 150 kHz

100 kHz

100 200 µs

µs

ns

ns

20

2001-09-05

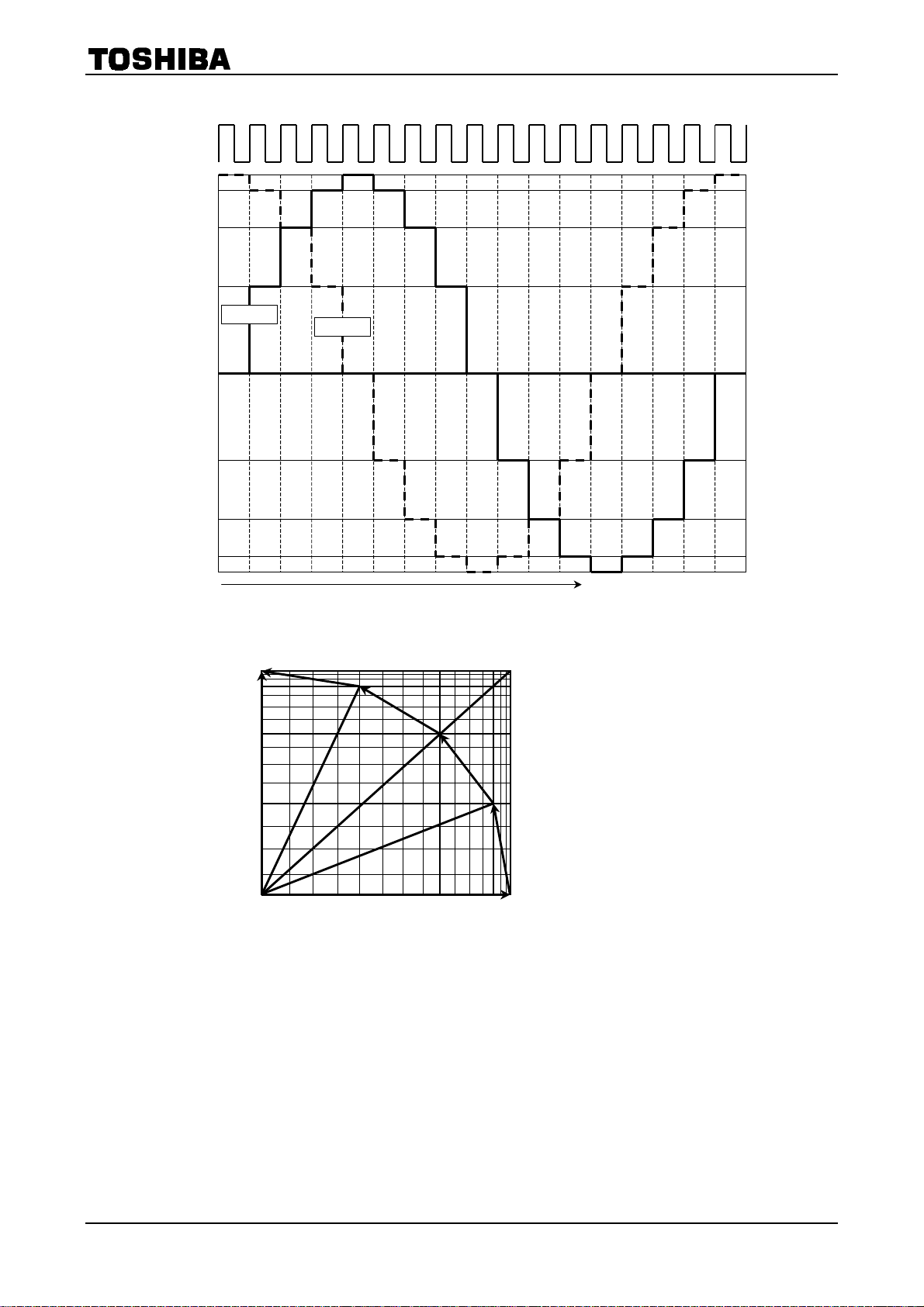

1. Current Waveform and Setting of Mixed Decay Mode

At constant current control, in current amplitude (pulsating current) Decay mode, a point from 0 to 3 can

be set using 2-bit parallel data.

NF is the point where the output current reaches the set current value. RNF is the timing for monitoring

the set current.

The smaller the MDT value, the smaller the current ripple (peak current value). Note that current decay

capability deteriorates.

f

CR pin

internal

CLK

waveform

DECAY MODE 0

12.5%

MIXED

DECAY

MODE

NF

Charge mode → NF: set current value reached → Slow mode

→ Mixed decay timing → Fast mode → current monitored

(when set current value > output current) Charge mode

chop

Set current value

TB62209F

MDT

RNF

37.5%

MIXED

DECAY

MODE

DECAY MODE 2

75%

MIXED

DECAY

MODE

DECAY MODE 3

FAST

DECAY

MODE

NF

Charge mode → NF: set current value reached → Slow mode

→ Mixed decay timing → Fast mode → current monitored

(when set current value > output current) Charge mode

NF

MDT

Charge mode → NF: set current value reached → Slow mode

→ Mixed decay timing → Fast mode → current monitored

(when set current value > output current) Charge mode

MDT

Set current value DECAY MODE 1

Set current value

Set current value

RNF

RNF

RNF

Fast mode → RNF: current monitored (when set current value

> output current) Charge mode → Fast mode

100% 75% 50% 25% 0

RNF

21

2001-09-05

2. CURRENT MODES

(MIXED ((((SLOW ++++ FAST) DECAY MODE Effect)

• Current value in increasing (Sine wave)

Set current

value

Sine wave in decreasing (When using MIXED DECAY Mode with large attenuation ratio (MDT%) at

attenuation)

Set current

value

Slow Slow

Set current

Slow Slow

Fast Charge

Charge

value

Fast Charge

Fast

TB62209F

Slow

Fast

Charge

Because current attenuates so quickly, the current

immediately follows the set current value.

Charge

Slow

Fast

Set current

value

Charge

Fast

Set current

value

Slow

Fast

Charge

Slow

Fast

• Sine wave in decreasing (When using MIXED DECAY Mode with small attenuation ratio (MDT%) at

attenuation)

Because current attenuates slowly, it takes a long time

for the current to follow the set current value (or the

current does not follow).

Fast

Charge

Fast

Charge

Fast

Charge

Slow

Fast

Slow

Charge

Set current

value

If RNF, current watching point, was the set current value (output current) in the mixed decay mode and

in the fast decay mode, there is no charge mode but the slow + fast mode (slow to fast is at MDT) in the

next chopping cycle.

Note: The above charts are schematics. The actual current transient responses are curves.

22

2001-09-05

3. MIXED DECAY MODE waveform (Current Waveform)

TB62209F

Internal

CR CLK

signal

I

OUT

Set current

value

25%

MIXED

DECAY

MODE

I

OUT

f

f

chop

NF

MDT (MIXED DECAY TIMING) point

• When NF is after MIXED DECAY TIMING

f

f

chop

Set current value

RNF

Fast Decay mode after Charge mode

Set current value

NF

chop

chop

NF

Set current

value

25%

MIXED

DECAY

MODE

Set current

value

I

OUT

25%

MIXED

DECAY

MODE

MDT (MIXED DECAY TIMING) point

NF

NF

CLK signal input

• In MIXED DECAY MODE, when the output current > the set current value

f

f

chop

NF

RNF

Set current value

f

chop

Because the set current value is the output

current, no CHARGE MODE in the next cycle.

(Charge cancel function)

RNF

MDT (MIXED DECAY TIMING) point

chop

RNF

NF

CLK signal input

23

2001-09-05

4. FAST DECAY MODE waveform

f

chop

Set current

value

I

OUT

TB62209F

FAST

DECAY

MODE

(100%

MIXED

DECAY

MODE)

Because the set current value is the output

current, FAST DECAY MODE in the next

cycle. (Charge cancel function)

RNF

Because the set current value is the output

current, CHARGE MODE → NF → FAST

DECAY MODE in the next cycle.

CLK signal input

Set current value

RNF

NF

The output current to the motor is in supply voltage mode after the current value set by V

Torque reached at the set current value.

RNF

, RRS, or

ref

24

2001-09-05

5. CLK SIGNAL, INTERNAL CR CLK, AND OUTPUT CURRENT waveform

g

(When CLK signal is input in SLOW DECAY MODE)

12.5% MIXED DECAY MODE

f

Internal

CR CLK

si

nal

f

chop

f

chop

chop

TB62209F

Set current value

I

OUT

NF

MDT

Set current value

NF

MDT

RNF

RNF

CLK signal input

Reset CR-CLK counter here

Momentarily enters CHARGE MODE

When CLK signal is input, the chopping counter (CR-CLK counter) is forced to reset at the next CR-CLK

timing.

Because of this, compared with a method in which the counter is not reset, response to the input data is

faster.

The delay time, the theoretical value in the logic portion, is expected to be a one-cycle CR waveform: 5 µs

at 100 kHz CHOPPING.

When the CR counter is reset due to CLK signal input, CHARGE MODE is entered momentarily due to

current comparison.

Note: In FAST DECAY MODE, too, CHARGE MODE is entered momentarily due to current comparison.

25

2001-09-05

6. STROBE SIGNAL, INTERNAL CR CLK, AND OUTPUT CURRENT waveform

(When CLK signal is input in CHARGE MODE)

12.5% MIXED DECAY MODE

f

Internal

CR CLK

signal

Set current

value

I

OUT

f

chop

f

chop

MDT

NF

Set current value

RNF

chop

MDT

TB62209F

RNF

CLK signal input

Reset CR-CLK counter here

Momentarily enters CHARGE MODE

26

2001-09-05

7. STROBE SIGNAL, INTERNAL CR CLK, AND OUTPUT CURRENT waveform

(When STROBE signal is input in FAST DECAY MODE)

12.5% MIXED DECAY MODE

f

Internal

CR CLK

signal

f

chop

f

chop

chop

TB62209F

Set current

value

I

OUT

NF

MDT

Set current value

MDT

NF

MDT

RNF

RNF

STROBE signal input

Reset CR-CLK counter here

Momentarily enters CHARGE MODE

27

2001-09-05

8. CLK SIGNAL, INTERNAL CR CLK, AND OUTPUT CURRENT waveform

(When CLK signal is input in 2 EXCITATION MODE)

12.5% MIXED DECAY MODE

f

Set current

value

I

OUT

f

chop

f

chop

chop

TB62209F

0

RNF

Set current value

CLK signal input

Reset CR-CLK counter here

NF

RNF

NF

MDT

28

2001-09-05

TB62209F

Current Discharge Path when

In Slow Mode, when all output transistors are forced to switch off, coil energy is discharged in the

following MODES:

Note: Parasitic diodes are located on dotted lines. In normal MIXED DECAY MODE, the current does not flow

to the parasitic diodes.

V

M

R

RS

RS pin

U1

ON

OFF

L1

(Note)

Load

PGND

U2

OFF

ON

L2

OFF

ENABLE

U1

ON

L1

Input During Operation

V

M

R

RS

RS pin

U2

(Note)

Load

PGND

OFF

Input

L2

ON

ENABLE

U1

OFF

L1

OFF

power supply

V

M

R

RS

RS pin

(Note)

Load

U2

OFF

L2

OFF

PGND

Charge mode Slow mode Forced OFF mode

As shown in the figure at right, an output transistor has parasitic diodes.

To discharge energy from the coil, each transistor is switched on allowing current to flow in the reverse

direction to that in normal operation. As a result, the parasitic diodes are not used. If all the output

transistors are forced to switch off, the energy of the coil is discharged via the parasitic diodes.

29

2001-09-05

Output Transistor Operating Mode

V

M

TB62209F

V

M

V

M

U1

ON

L1

OFF

R

RS

RS pin

U2

(Note)

Load

PGND

Charge mode Slow mode Fast mode

OFF

L2

ON

U1

OFF

L1

R

RS

RS pin

(Note)

Load

PGND

Output Transistor Operation Functions

CLK U1 U2 L1 L2

CHARGE ON OFF OFF ON

SLOW OFF OFF ON ON

FAST OFF ON ON OFF

U2

OFF

L2

ON

U1

OFF

L1

ON ON

R

RS pin

(Note)

Load

PGND

RS

U2

ON

L2

OFF

Note: The above table is an example where current flows in the direction of the arrows in the above figures.

When the current flows in the opposite direction of the arrows, see the table below.

CLK U1 U2 L1 L2

CHARGE OFF ON ON OFF

SLOW OFF OFF ON ON

FAST ON OFF OFF ON

30

2001-09-05

TB62209F

Power Supply Sequence

V

DD (max)

V

DD (min)

V

V

DD

V

M

Internal reset

DDR

GND

VM

V

M (min)

V

MR

GND

NON-RESET

RESET

(Recommended)

STANDBY

INPUT (Note 1)

STANDBY

H

L

Takes up to t

until operable.

ONG

Non-operable area

Note 1: If the V

drops to the level of the V

DD

or below while the specified voltage is input to the VM pin, the IC is

DDR

internally reset.

This is a protective measure against malfunction. Likewise, if the V

while regulation voltage is input to the V

, the IC is internally reset as a protective measure against

DD

drops to the level of the VMR or below

M

malfunction.

To avoid malfunction, when turning on V

or VDD, to input the Standby signal at the above timing is

M

recommended.

It takes time for the output control charge pump circuit to stabilize. Wait up to t

time after power on

ONG

before driving the motors.

Note 2: When the V

value is between 3.3 to 5.5 V, the internal reset is released, thus output may be on. In such a

M

case, the charge pump cannot drive stably because of insufficient voltage. The Standby state should be

maintained until V

reaches 13 V or more.

M

Note 3: Since VDD = 0 V and VM = voltage within the rating are applied, output is turned off by internal reset.

At that time, a current of several mA flows due to the Pass between V

When voltage increases on V

output, make sure that specified voltage is input.

DD

and VDD.

M

31

2001-09-05

How to Calculate Set Current

This IC controls constant current in CLK-IN mode.

At that time, the maximum current value (set current value) can be determined by setting the sensing

resistor (R

1/5.0 is V

) and reference voltage (V

RS

(max) OUT

(gain): V

ref

I

1

5.0

(V) V

ref

attenuation ratio. (For the specifications, see the electrical characteristics.)

ref

).

ref

××=

=

)Ω(

R

RS

50%) 70, 85, 100, (Torque Torque

For example, when inputting V

= 3 V and torque = 100% to output I

ref

or more) is required.

How to Calculate the Chopping and OSC Frequencies

At constant current control, this IC chops frequency using the oscillation waveform (saw tooth waveform)

determined by external capacitor and resistor as a reference.

The TB62209F requires an oscillation frequency of eight times the chopping frequency.

The oscillation frequency is calculated as follows:

TB62209F

100×

= 0.8 A, RRS = 0.75 Ω (0.5 W

OUT

=

f

CR

For example, when C

At this time, the chopping frequency f

f

= fCR/8 = 101

chop

When determining the chopping frequency, make the setting taking the above into consideration.

IC Power Dissipation

IC power dissipation is classified into two: power consumed by transistors in the output block and power

consumed by the logic block and the charge pump circuit.

• Power consumed by the Power Transistor (calculated with R

In Charge mode, Fast Decay mode, or Slow Decay mode, power is consumed by the upper and lower

transistors of the H bridges.

The following expression expresses the power consumed by the transistors of a H bridge.

P (out) = 2 (T

The average power dissipation for output under 4-bit micro step operation (phase difference between

phases A and B is 90°) is determined by expression (1).

Thus, power dissipation for output per unit is determined as follows (2) under the conditions below.

R

= 0.60 Ω (at 1.0 A)

ON

I

(Peak: max) = 1.0 A

OUT

V

= 24 V

M

V

= 5 V

DD

P (out) = 2 (T

Power consumed by the logic block and IM

The following standard values are used as power dissipation of the logic block and IM at operation.

I (LOGIC) = 4.0 mA (typ.):

I (I

) = 15.0 mA (typ.): operation/unit

M3

I (I

) = 4.0 mA (typ.): stop/unit

M1

The logic block is connected to V

V

and current consumed by output switching) is connected to VM (24 V). Power dissipation is

M

calculated as follows:

P (Logic&IM) = 5 (V) × 0.004 (A) + 24 (V) × 0.015 (A) = 0.38 (W)................. (3)

Thus, the total power dissipation (P) is

P = P (out) + P (Logic&IM) = 1.51 (W)

Power dissipation at standby is determined as follows:

P (standby) + P (out) = 24 (V) × 0.004 (A) + 5 (V) × 0.004 (A) = 0.116 (W)

For thermal design on the board, evaluate by mounting the IC.

1

= 560 pF and R

osc

kHz

) × I

r

OUT

) × 1.02 (A) × 0.60 (Ω) = 1.20 (W).............................................. (2)

r

×+××

C)600R(C0.523

= 3.6 kΩ are connected, fCR = 813 kHz.

osc

is calculated as follows:

chop

(A) × VDS (V) = 2 × I

(5 V). IM (total of current consumed by the circuits connected to

DD

= 0.60 Ω)

ON

2

× RON.............................. (1)

OUT

32

2001-09-05

Test Waveforms

p

p

TB62209F

CK

V

M

GND

tCK t

t

LH

50%

10%

tr t

CK

90% 90%

t

HL

f

50%

10%

Figure 1 Timing Waveforms and Names

33

2001-09-05

OSC (CR)

OUTPUT

Voltage A

OUTPUT

A

Voltage

Set current

OSC-Charge Delay

H

L

H

L

H

L

50%

t

chop

TB62209F

OSC-Fast Delay

50%

50%

OUTPUT

CR Waveform

Internal CR CLK

Waveform

Current

L

OSC-charge delay:

Charge

Slow Fast

Because the rising edge level of the OSC waveform is used for converting the OSC waveform to the

internal CR CLK, a delay of up to 1.25 ns (@f

= 100 kHz: fCR = 400 kHz) occurs between the OSC

chop

waveform and the internal CR CLK.

CR-CR CLK delay

Figure 2 Timing Waveforms and Names (CR and output)

34

2001-09-05

Relationship between Drive Mode Input Timing and MO

CLK Waveform

MO Waveform

• If drive mode input changes before MO timing

Drive Mode Input

Waveform (1)

Drive Mode Input

Internal Reflection (1)

TB62209F

Parallel set signal is reflected.

• If drive mode input changes after MO timing

Drive Mode Input

Waveform (2)

Drive Mode Input

Internal Reflection (2)

Parallel set signal occurs after the rising edge of CLK, therefore, it is not reflected. The drive mode is

changed when the electrical angle becomes 0°.

Note: The TB62209F uses the drive mode change reserve method to prevent the motor from step out when

changing drive modes.

Note that the following rules apply when switching drive modes at or near the MO signal output

timing.

35

2001-09-05

Reflecting Points of Signals

TB62209F

2-Phase Excitation mode 45° (MO)

1-2 Phase Excitation mode

W1-2 Phase Excitation

mode

2W1-2 Phase Excitation

mode

4W1-2 Phase Excitation

mode

Point where Drive Mode

Setting Reflected

Before half-clock of phase

B = phase A = 100%

0° (MO)

Before half-clock of phase

B = 100%

CW/CCW

At rising edge of CLK input

At rising edge of CLK input

Other parallel set signals can be changed at any time (they are reflected immediately).

Recommended Point for Switching Drive Mode

CLK Waveform

MO Waveform

When Drive Mode

Data Switching

can be Input

Drive mode reflected

During MO output (phase data halted) to forcibly switch drive modes, a function to set

and to initialize the electrical angle is required.

RESET

= Low

36

2001-09-05

TB62209F

PD – Ta

(1) HSOP36 R

(2) When mounted on the board (140 mm × 70 mm × 1.6 mm: 38°C/W: typ.)

Note: R

(Package power dissipation)

3.5

3

2.5

(W)

D

2

1.5

(1)

1

Power dissipation P

0.5

0

0

25 50 75 100 125 150

only (96°C/W)

th (j-a)

8.5°C/W

th (j-a):

– Ta

P

D

(2)

Ambient temperature Ta (°C)

37

2001-09-05

TB62209F

Relationship between VM and VH

50

V

40

30

voltage charge up voltage VM voltage

H

Input STANDBY

VMR

(charge pump voltage)

– VH (&Vcharge UP)

V

M

Charge pump

voltage

VM voltage

voltage, charge up voltage (V)

20

H

V

10

0

0

2 3 10 20 30 404 5 6 7 8 9 11 12 13 14 15 16 17 18 21 22 23 24 25 2619 27 28 29 31 32 33 34 35 36 37 38 391

Supply voltage VM (V)

H

= 150 kHz

chop

Note: V

DD

= 5 V

Ccp 1 = 0.22 µF, Ccp 2 = 0.022 µF, f

Charge pump voltage V

(Be aware the temperature charges of charge pump capacitor.)

Maximum rating

Usable area

Recommended operation area

= VDD + VM (= Ccp A) (V)

38

2001-09-05

Operation of Charge Pump Circuit

R

VDD = 5 V

S

TB62209F

R

RS

VM

V

M

= 24 V

V

H

Ccp A

7

Comparator

&

Controller

Output

Output

H switch

i2

Tr1

T

r2

V

Di3

Di2

Di1

(1)

z

i1

(2)

Ccp B

Ccp 2

(2)

R

1

0.01 µF

Ccp C

Ccp 1

0.22 µF

VH = VM + VDD = charge pump voltage

i1 = charge pump current

i2 = gate block power dissipation

• Initial charging

(1) When RESET is released, T

is turned ON and Tr2 turned OFF. Ccp 2 is charged from Ccp 2 via

r1

Di1.

(2) T

(3) When the voltage difference between V

is turned OFF, Tr2 is turned ON, and Ccp 1 is charged from Ccp 2 via Di2.

r1

and VH (Ccp A pin voltage = charge pump voltage)

M

reaches V

or higher, operation halts (Steady state).

DD

• Actual operation

(4) Ccp 1 charge is used at f

switching and the VH potential drops.

chop

(5) Charges up by (1) and (2) above.

Output switching

Initial charging Steady state

V

H

V

M

(1)

(2) (3)

(4)

t

(5)

(4)

(5)

39

2001-09-05

Charge Pump Rise Time

TB62209F

VM + (VDD × 90%)

STANDBY

t

:

ONG

Time taken for capacitor Ccp 2 (charging capacitor) to fill up Ccp 1 (storing capacitor) to VM + VDD after

a reset is released.

The internal IC cannot drive the gates correctly until the voltage of Ccp 1 reaches V

wait for t

Basically, the larger the Ccp 1 capacitance, the smaller the voltage fluctuation, though the initial charge

up time is longer.

The smaller the Ccp 1 capacitance, the shorter the initial charge-up time but the voltage fluctuation is

larger.

Depending on the combination of capacitors (especially with small capacitance), voltage may not be

sufficiently boosted. When the voltage does not increase sufficiently, output DMOS R

the normal, and it raises the temperature.

Thus, use the capacitors under the capacitor combination conditions (Ccp 1 = 0.22 µF, Cc p 2 = 0.02 µF)

recommended by Toshiba.

+ V

V

DD

M

V

M

5 V

50%

0 V

t

ONG

or longer before driving the motors.

ONG

ON

Ccp 1 voltage

+ VDD. Be sure to

M

turns lower than

40

2001-09-05

External Capacitor for Charge Pump

TB62209F

When driving the stepping motor with VDD = 5 V, f

= 150 kHz, L = 10 mH under the conditions of V

chop

M

= 13 V and 1.5 A, the logical values for Ccp 1 and Ccp 2 are as shown in the graph below:

Ccp 1 – Ccp 2

0.05

0.045

0.04

0.035

0.03

0.025

0.02

0.015

Ccp 2 capacitance (µF)

0.01

0.005

0

0

0.05 0.1 0.15 0.2 0.25 0.35 0.4

Applicable range

Recommended

0.3

Ccp 1 capacitance (µF)

value

0.45 0.5

Choose Ccp 1 and Ccp 2 to be combined from the above applicable range. We recommend Ccp 1:Ccp 2 at

10:1 or more. (If our recommended values (Ccp = 0.22 µF, C cp 2 = 0.02 µF) are used, the drive conditions in

the specification sheet are satisfied. (There is no capacitor temperature characteristic as a condition.)

When setting the constants, make sure that the charge pump voltage is not below the specified value and

set the constants with a margin (the larger Ccp 1 and Ccp 2, the more the margin).

Some capacitors exhibit a large change in capacitance according to the temperature. Make sure the above

capacitance is obtained under the usage environment temperature.

41

2001-09-05

TB62209F

(1) Low Power Dissipation mode

Low Power Dissipation mode turns off phases A and B, and also halts the charge pump.

Operation is the same as that when the STANDBY pin is set to Low.

(2) Motor Lock mode

Motor Lock mode turns phase B output only off with phase A off.

From reset, with IA = 0 and IB = 100%, the normal 4W1-2 phase operating current is output.

Use this mode when you want to hold (lock) the rotor at any desired value.

(3) 2-Phase Excitation mode

100

[%]

Phase B

0

Phase A

−100

STEP

2-Phase Excitation Mode (typ.A)

100

IA (%)

0

100

IB (%)

Electrical angle 360° = 4 CLKs

Note: 2-phase excitation has a large load change due to motor induced electromotive force. If a mode in

which the current attenuation capability (current control capability) is small is used, current increase

due to induced electromotive force may not be suppressed. In such a case, use a mode in which

the mixed decay ratio is large.

We recommend 37.5% Mixed Decay mode as the initial value (general condition).

42

2001-09-05

TB62209F

K

(4) 1-2 Phase Excitation mode (a)

MO

CL

100

[%]

Phase B

Phase A

0

−100

STEP

100

1-2 Phase Excitation Mode (typ.A)

IA (%)

0

IB (%)

100

Electrical angle 360° = 8 CLKs

43

2001-09-05

TB62209F

(5) 1-2 Phase Excitation mode (b)

MO

CLK

100

[%]

71

Phase A

Phase B

0

−71

−100

STEP

1-2 Phase Excitation Mode (typ.B)

100

71

IA (%)

0

IB (%)

71

100

Electrical angle 360° = 8 CLKs

44

2001-09-05

TB62209F

(6) W1-2 Phase Excitation mode

[%]

100

92

71

38

Phase A

Phase B

0

−38

−71

−92

−100

STEP

W1-2 Phase Excitation Mode

(2-bit micro step)

100

92

71

IA (%)

38

0

38

IB (%)

71

92

100

Electrical angle 360° = 16 CLKs

45

2001-09-05

TB62209F

(7) 2W1-2 Phase Excitation mode

[%]

100

96

88

71

Phase A

56

38

20

0

−20

Phase B

−38

−56

−71

−83

−92

−98

−100

STEP

2W 1-2 Phase Excitation Mode

100

98

92

83

(3-bit micro step)

71

56

IA (%)

38

20

92 100 0

71 38

IB (%)

98

83 56 20

Electrical angle 360° = 32 CLKs

46

2001-09-05

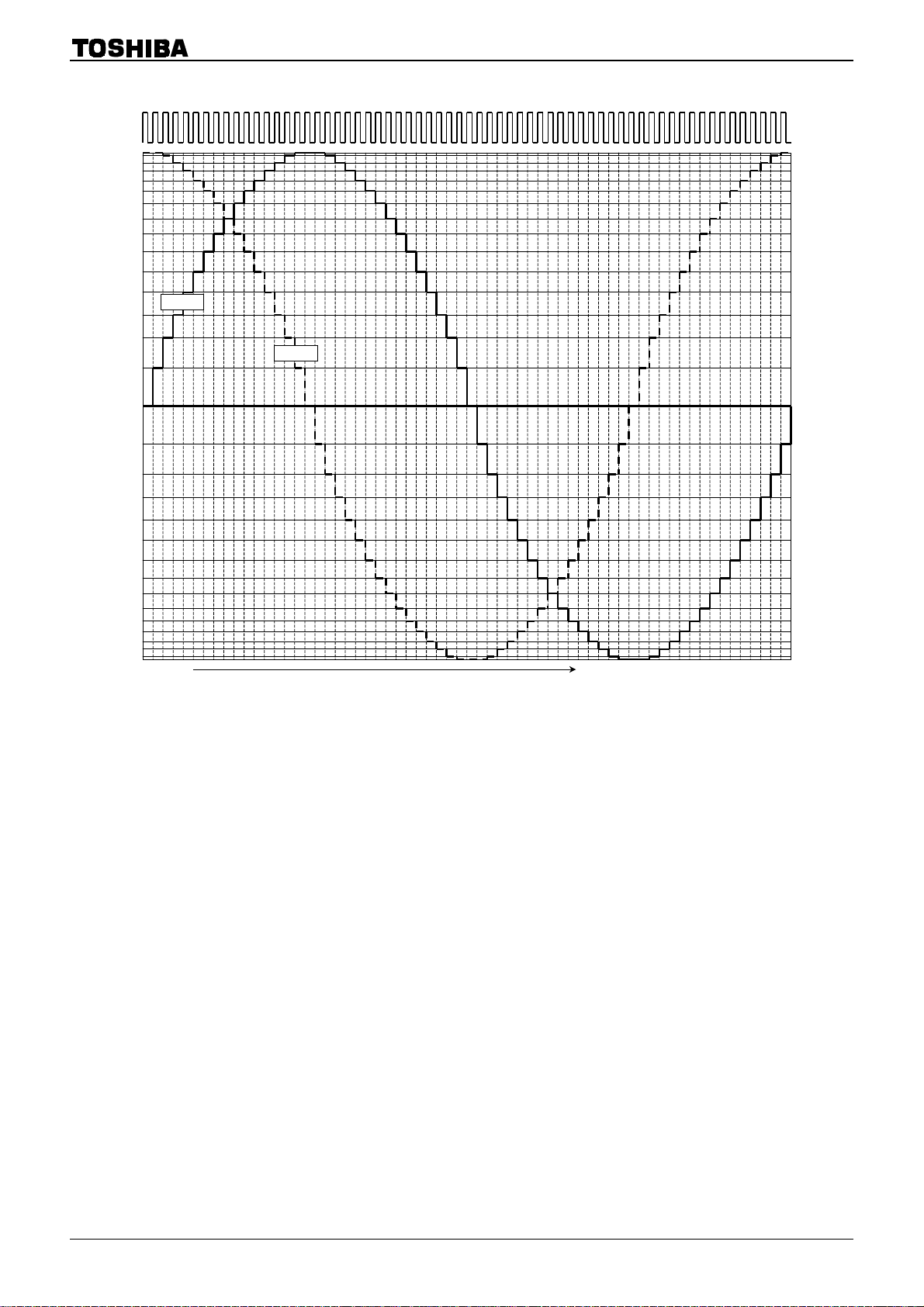

(8) 4W1-2 Phase Excitation mode

[%]

100

98

96

92

88

83

77

71

63

56

47

38

Phase A

29

20

10

0

−10

−20

−29

−38

−47

−56

−63

−71

−77

−83

−88

−92

−96

−98

−100

Electrical angle 360° = 64 CLKs

TB62209F

Phase B

STEP

2001-09-05 47

TB62209F

4-Bit Micro Step Output Current Vector Locus

X = 16

100

98

96

92

88

83

77

71

63

56

47

IA (%)

38

X = 15

X = 14

X = 13

X = 12

X = 11

CCW

(Normalizing each step to 90°°°°)

CW

X = 10

X = 9

X = 8

X = 7

X = 6

X = 5

X = 4

29

20

θX

10

0

10 20 29 38 47 56 63 71 77 83 88 92 96 98 100

θX

X = 3

X = 2

X = 1

X = 0

IB (%)

For input data, see the current function examples.

48

2001-09-05

Recommended Application Circuit

The values for the devices are all recommended values. For values under each input condition, see the

above-mentioned recommended operating conditions.

R

= 3.6 kΩ

osc

CR

C

= 560 pF

osc

V

DD

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

5 V

0 V

PGND

DATA MODE

CLK

ENABLE

CW/CCW

RESET

P-GND

DMODE 1

DMODE 2

DMODE 3

MDT 1

MDT 2

STANDBY

V

ref AB

V

R

RS A

R

RS B

V

SS

(FIN)

PROTECT

MO

M

A

A

B

B

SGND

OPEN

OPEN

TORQUE 1

TORQUE 2

DATA MODE

M

5 V

0 V

5 V

0 V

5 V

0 V

3 V

V

ref AB

R

0.66 Ω

RS A

STEPPING

MOTER

0.66 Ω R

RS B

TB62209F

1 µF

SGND

SGND

5 V

10 µF

Ccp 1

0.22 µF

SGND

Ccp C Ccp B Ccp A

Ccp 2

0.01 µF

100 µF

SGND

Note: Adding bypass capacitors is recommended.

Make sure that GND wiring has only one contact point, and to design the pattern that allows the heat

radiation.

To control setting pins in each mode by SW, make sure to pull down or pull up them to avoid high

impedance.

To input the data, see the section on the recommended input data.

Because there may be shorts between outputs, shorts to supply, or shorts to ground, be careful when

designing output lines, V

(VM) lines, and GND lines.

DD

24 V

49

2001-09-05

Package Dimensions

HSOP36-P-450-0.65 Unit: mm

TB62209F

Weight: g (typ.)

50

2001-09-05

TB62209F

RESTRICTIONS ON PRODUCT USE

• TOSHIBA is continually working to improve the quality and reliability of its products. Nevertheless, semiconductor

devices in general can malfunction or fail due to their inherent electrical sensitivity and vulnerability to physical

stress. It is the responsibility of the buyer, when utilizing TOSHIBA products, to comply with the standards of

safety in making a safe design for the entire system, and to avoid situations in which a malfunction or failure of

such TOSHIBA products could cause loss of human life, bodily injury or damage to property.

In developing your designs, please ensure that TOSHIBA products are used within specified operating ranges as

set forth in the most recent TOSHIBA products specifications. Also, please keep in mind the precautions and

conditions set forth in the “Handling Guide for Semiconductor Devices,” or “TOSHIBA Semiconductor Reliability

Handbook” etc..

• The TOSHIBA products listed in this document are intended for usage in general electronics applications

(computer, personal equipment, office equipment, measuring equipment, industrial robotics, domestic appliances,

etc.). These TOSHIBA products are neither intended nor warranted for usage in equipment that requires

extraordinarily high quality and/or reliability or a malfunction or failure of which may cause loss of human life or

bodily injury (“Unintended Usage”). Unintended Usage include atomic energy control instruments, airplane or

spaceship instruments, transportation instruments, traffic signal instruments, combustion control instruments,

medical instruments, all types of safety devices, etc.. Unintended Usage of TOSHIBA products listed in this

document shall be made at the customer’s own risk.

• The products described in this document are subject to the foreign exchange and foreign trade laws.

• The information contained herein is presented only as a guide for the applications of our products. No

responsibility is assumed by TOSHIBA CORPORATION for any infringements of intellectual property or other

rights of the third parties which may result from its use. No license is granted by implication or otherwise under

any intellectual property or other rights of TOSHIBA CORPORATION or others.

000707EBA

• The information contained herein is subject to change without notice.

51

2001-09-05

Loading...

Loading...