查询TA2145AF供应商

TOSHIBA Bipolar Lin ear I nt egrated Circuit Silicon Monolith ic

TA2145AF

3 V Stereo Headphone Amplifier (3 V USE)

The TA2145AF is developed for play-back stereo headphone

equipments (3 V USE).

It is built in dual preamplifiers, dual OCL power amplifiers,

motor governor, DC volume control and preamplifier on/off switch

etc.

Features

· Built-in preamplifier

Input coupling condenser-less

Built-in input capacitor for reducing buzz noise

Low noise: V

Preamplifier on/off switch.

· Built-in power amplifier

OCL (Output condenser-less)

Voltage gain: G

· Built-in motor governor (Current proportion type)

· Built-in DC volume control function

ATT = 82dB (Ta = 25°C, typ.)

· Built-in bass boost function

· Low supply current (V

· Quiescent supply current

PRE + PW: I

GVN: ICC = 2.5 mA

· 0.1 mW × 2 ch output

I

CC1

I

CC2

· 0.5 mW × 2 ch output

I

CC3

I

CC4

· Operating supply voltage range (Ta = 25°C)

V

CC (opr)

GVN V

CC (opr)

= 1.2 µVrms (typ.)

ni

= 31 dB (typ.)

V

= 3 V, f = 1 kHz, PRE OUT = 100 mVrms, Ta = 25°C, typ.)

CC

= 8.5 mA

CCQ

= 9.8 mA (RL = 32 Ω)

= 10.5 mA (RL = 16 Ω)

= 14.0 mA (RL = 32 Ω)

= 16.5 mA (RL = 16 Ω)

= 1.8~3.6 V

= 2.1~3.6 V (Motor voltage = 1.8 V)

Weight: 0.32 g (typ.)

TA2145AF

1

2002-04-19

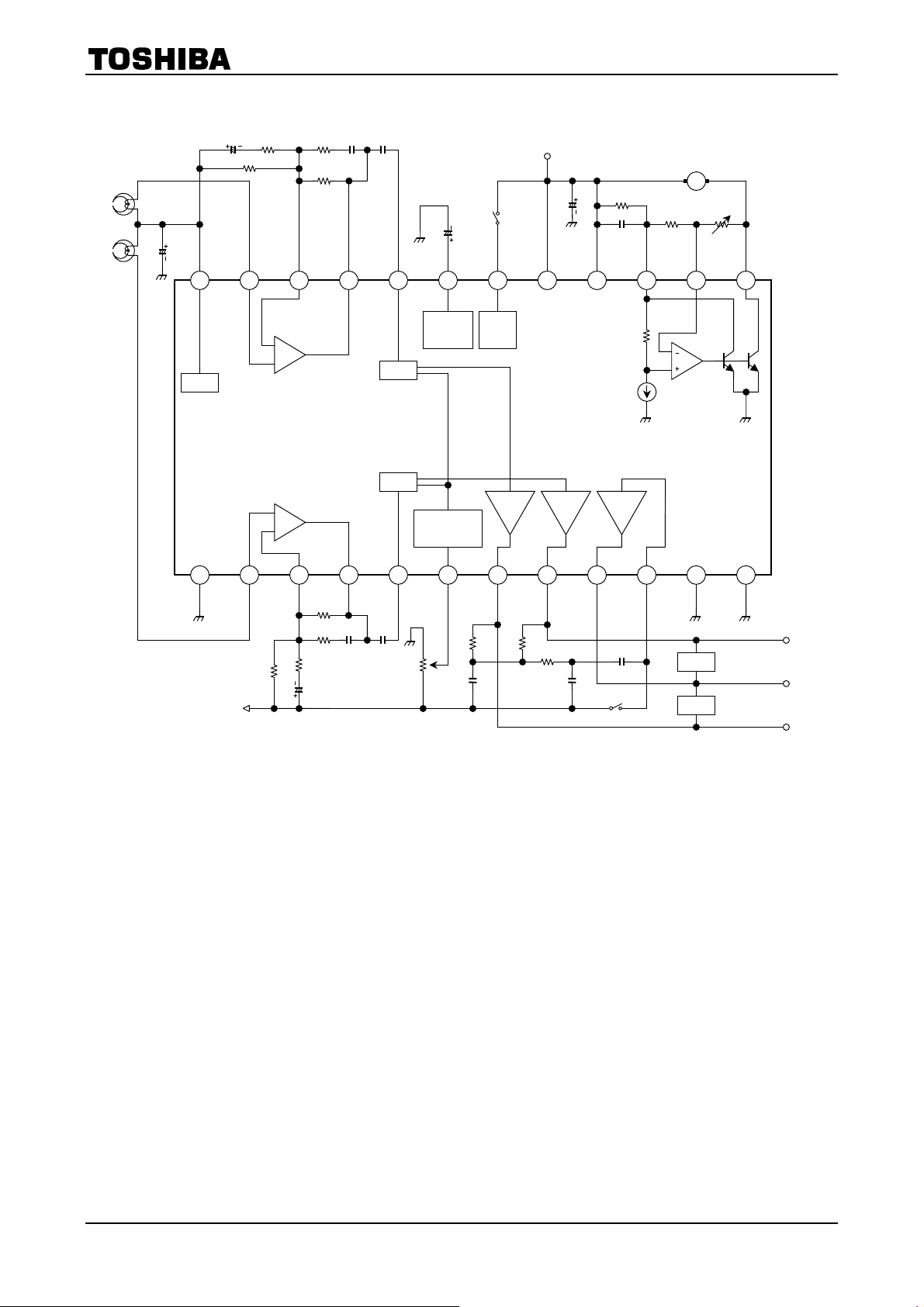

Block Diagram

TA2145AF

M

PRE:

OFF

V

REF

IN

23

NFB

B

22 24

PRE

B

PRE

OUT

PW

IN

B

B

RIPPLE

FILTER

RF

IN

PRE

SW

PRE

SW

V

CC

GVN

V

161718192021

Rt

CC

15 14 13

GVN

CTL

GVN

OUT

VOL.

V

REF

VOL.

PRE

A

VOL.

PWB PWA PWC

CONTROL

1

PRE

GND

2 3

IN

A

NFA

4 5

PRE

OUT

A

6 7 8

PW

IN

V

CTL

A

OUT

B

OUT

9

A

C

10

OUT

PW

IN

C

11 12

PW

GND

GVN

GND

OUT

A

RL

OUT

OUT

C

B

V

REF

BST SW

BST: OFF

RL

2

2002-04-19

TA2145AF

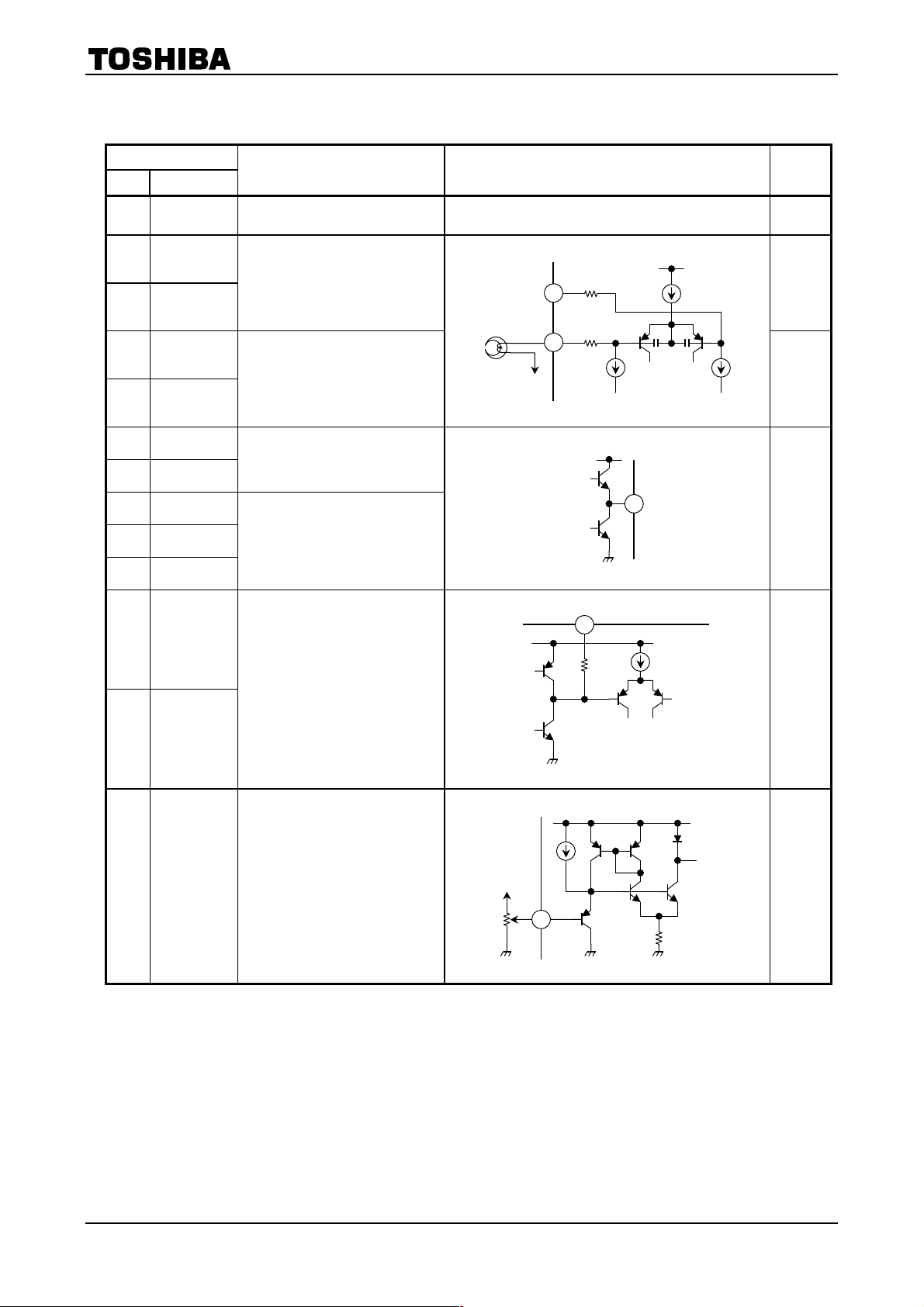

Terminal Explanation

circuit, V

No. Name

1 PRE GND

2 INA

23 INB

3 NFA

22 NFB

4 PRE OUTA

21 PRE OUTB

7 OUTB

8 OUTA

==== 3 V, Ta ==== 25°C)

CC

Terminal

The GND, except for power drive

stage and motor governer stage.

Input of preamplifier 1.2

NF of preamplifier

Output of preamplifier

Output of power amplifier

(Terminal Voltage: Typical terminal voltage at no signal with test

Terminal

Function Internal Circuit

¾ 0

RF

500 W

3

500 W

2

V

REF

V

CC

4

Voltage

(v)

1.2

1.2

9 OUTC

5 PW INA

20 PW INB

6 V

The terminal of DC volume control

CTL

Input of power amplifier

5

RF

10 kW

V

REF

VCC

1.2

V

REF

6

¾

3

2002-04-19

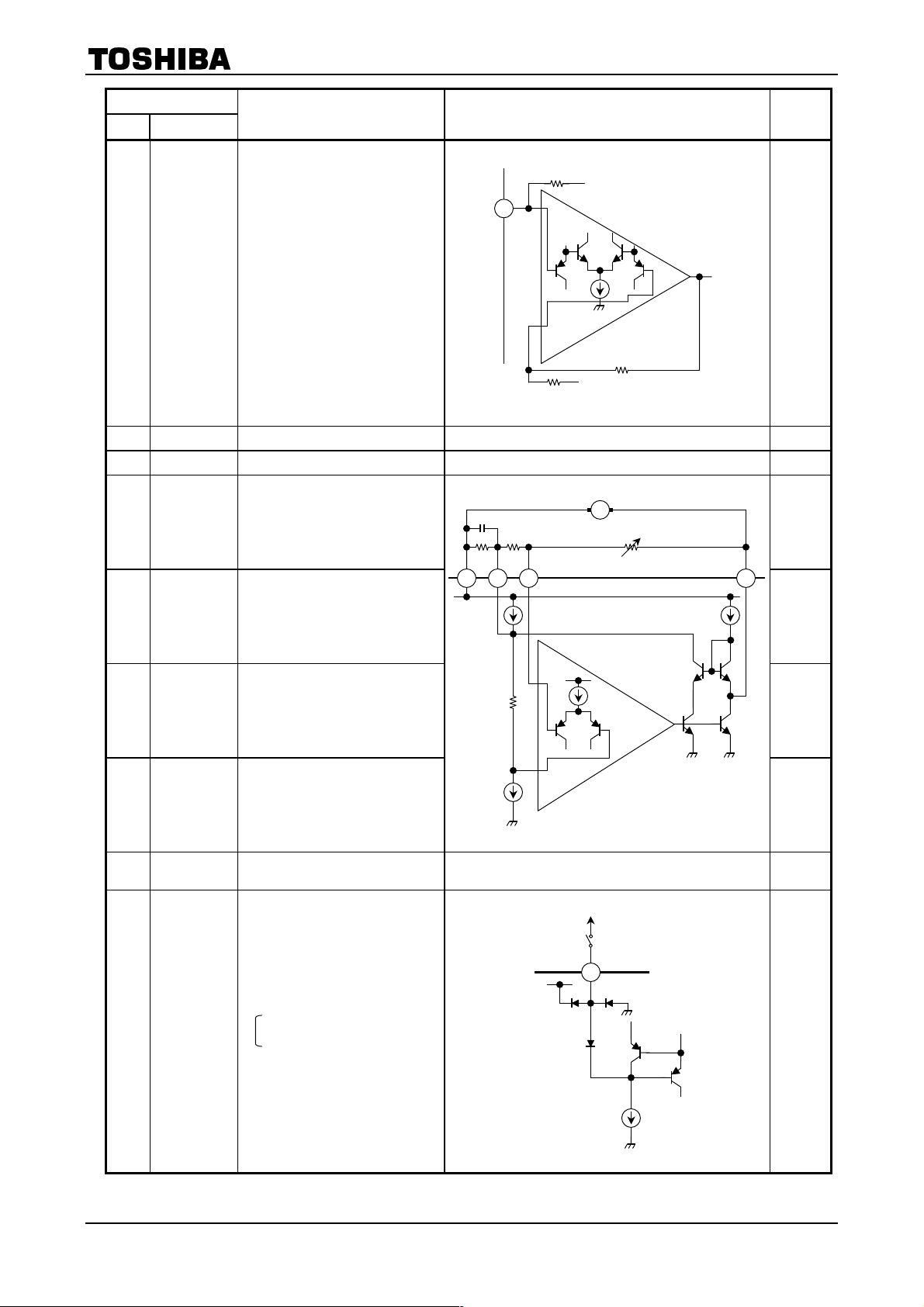

TA2145AF

Terminal

No. Name

10 PW INC Input of center amplifier

11 PW GND GND for power drive stage ¾ 0

12 GVN GND GND for motor governor stage ¾ 0

13 GVN OUT Motor terminal ¾

Function Internal Circuit

20 kW

10

V

REF

30 kW

V

2 kW

REF

M

Terminal

Voltage

1.2

(v)

1416 15

14 GVN CTL The terminal of motor speed control ¾

15 Rt

16 GVN VCC VCC for motor governor stage

17 VCC

18 PRE SW

The terminal of amateur

compensation resistor

for preamplifier stage and

V

CC

power amplifier stage.

Muting switch of preamplifier

Preamp. on: “L” level/open

Preamp. off: “H” level

Refer to application note

¾ 3

18

13

¾

¾

3

4

2002-04-19

TA2145AF

Terminal

No. Name

19 RF IN Ripple filter of power supply 2.5

Reference voltage

24 V

REF

Preamplifier and power amplifier

operate on this reference.

Function Internal Circuit

19 24

VCC

4 kW

4.7 kW 1.3 kW

10 kW

Terminal

Voltage

(v)

1.2

5

2002-04-19

TA2145AF

Application Note

· VCC and GND

This IC has two V

terminals and three GND terminals. Pattern layout should be designed carefully to

CC

reduce the common impedance.

· V

CC

V

(pin 17) -----------------Preamplifier stage and power amplifier stage.

CC

GVN V

(pin 16) --------- Motor governor stage.

CC

· GND

PRE GND (pin 1)------------Preamplifier stage, and power amplifier stage except for the power drive stage.

PW GND (pin 11) -----------Power drive stage of power amplifier.

GVN GND (pin 12) ---------Motor governor stage.

· V

REF

It is necessary to stabilize the V

circuit, because the internal circuit operate on this reference.

REF

· RF IN

As this terminal is an input terminal of the ripple filter, it cannot supply a power supply to other ICs etc.

· Preamplifier

Input signal should be applied to V

standard, otherwise pop noise become bigger when VCC is turned on

REF

and off.

· Power amplifier

It is necessary to insert the coupling capacitor through the PW IN terminal. In case that DC current or DC

voltage is applied to the PW IN terminal, the internal circuit has unbalance and the power amplifier doesn’t

operate normally.

· Operating supply voltage range of motor governor stage

As for the minimum of operating supply voltage range, the motor voltage is 1.8 V.

In case that it is more than 1.8 V, the low voltage performance becomes bad.

· PRE SW sensitivity (Ta = 25°C)

PRE SW

4

(V)

18

3

2

1.8 V

1.5 V

1

Terminal DC voltage V

0.5 V

0 1.5 2.0 2.5 3.5 4.0 3.0

Supply voltage VCC (V)

“H”

PRE AMP: OFF

3.6 V

3.0 V

1.2 V

6

2002-04-19

TA2145AF

Maximum Ratings

Characteristic Symbol Rating Unit

Supply voltage V

Power dissipation PD

Output current (PW AMP.) I

Output current (GVN) I

Operating temperature T

Storage temperature T

(Ta ==== 25°C)

CC

(Note 1) 400

(Note 2) 925

O (PW)

O (GVN)

-25~75 °C

opr

stg

4 V

200 mA

700 mA

-55~150 °C

mW

Note 1: IC only: Derated above Ta = 25°C in the proportion 3.2 mW/°C

Note 2: IC + PCB (TOSHIBA typical PCB): Derated above Ta = 25°C in the proportion7.4 mW/°C

7

2002-04-19

Electrical Characteristics

(Unless otherwise specified, VCC ==== 3 V, Ta ==== 25°C, f ==== 1 kHz, SW2: a, SW5: OPEN

Preamplifier: R

Power amplifier: R

Motor governor: I

==== 2.2 kWWWW, RL ==== 10 kWWWW, SW1: ON, SW3: b, SW4: b

g

==== 600 WWWW, RL ==== 16 WWWW, Vol.: max, SW1: OPEN, SW3: a, SW4: a

g

==== 100 mA, SW1: OPEN, SW3: b, SW4: b)

m

TA2145AF

Characteristic Symbol

Quiescent supply current

Open loop voltage gain G

Closed loop voltage gain G

Maximum output voltage V

Total harmonic distortion THD1 ¾ Vo = -10dBV ¾ 0.02 0.3 %

Equivalent input noise

voltage

Cross talk CT1 ¾ V

Pre amp.

Ripple rejection ratio RR1 ¾ fr = 100 Hz, Vr = -20dBV ¾ 48 ¾ dB

Preamplifier muting

attenuation

Preamplifier on voltage V

Preamplifier off voltage V

Voltage gain G

Channel balance CB ¾ Vo = -10dBV -1.5 0 +1.5 dB

Output power 1 P

Output power 2 P

Total harmonic distortion THD2 ¾ Po = 1m W ¾ 0.5 ¾ %

Output noise voltage V

Power amp.

Ripple rejection ratio RR2 ¾ fr = 100 Hz, Vr = -20dBV ¾ 52 ¾ dB

Cross talk CT2 ¾ Vo = -10dBV ¾ 32 ¾ dB

Dc volume maximum

attenuation

Supply current I

Saturation voltage V

Reference voltage ,V

Reference voltage

fluctuation 1

Reference voltage

fluctuation 2

Reference voltage

fluctuation 3

Motor governor

Current ratio K ¾ ¾ 34.5 37.5 40.5

Current ratio fluctuation 1 ,K1 ¾ VCC = 2.1~3.6 V ¾ 0.25 ¾ %/V

Current ratio fluctuation 2 ,K2 ¾ Im = 25~250 mA ¾ 0.08 ¾ %/mA

Current ratio fluctuation 3 ,K3 ¾ Ta = -25~75°C ¾ 0.005 ¾ %/°C

I

CCQ1

I

CCQ2

VO

VC

om

V

ATT1 ¾ V

18 (ON)

18 (OFF)

ATT2 ¾

CC

CE (sat)

,V

REF1

,V

REF2

,V

REF3

ni

V

o1

o2

no

REF

Test

circuit

Pre off, V

¾

SW4: b, SW5: ON

¾ Vin = 0, Vol.: min, SW4: b ¾ 8.5 14.5

¾ Vo = -10dBV, SW2: b ¾ 86 ¾ dB

¾ Vo = -10dBV ¾ 35 ¾ dB

¾ THD = 1% 550 720 ¾ mVrms

= 2.2 kW, SW1: OPEN

R

g

BPF = 20 Hz~20 kHz,

¾

NAB (G

= -10dBV ¾ 70 ¾ dB

o

= -10dBV, SW5: OPEN ® ON ¾ 80 ¾ dB

o

¾ 0 ¾ 0.5 V

V

CC

¾

¾ Vo = -10dBV 29 31 33 dB

¾ RL = 16 W, THD = 10% 17 28 ¾ mW

¾ RL = 32 W, THD = 10% ¾ 20 ¾ mW

= 600 W, SW3: b

R

g

¾

BPF = 20 Hz~20 kHz

Vo = -10dBV, SW4: a®b

(Vol.: max ® min)

¾ Im = 0 ¾ 2.5 3.5 mA

¾ Im = 200 mA ¾ ¾ 0.5 V

¾ Im = 100 mA 0.76 0.81 0.86 V

¾ VCC = 2.1~3.6 V ¾ 0.25 ¾ %/V

¾ Im = 25~250 mA ¾ 0.003 ¾ %/mA

¾ Ta = -25~75°C ¾ 0.005 ¾ %/°C

Test condition Min Typ. Max Unit

= 0, Vol.: min,

in

= 35dB, f = 1 kHz)

V

= 1.8 V

¾ 7.5 13

¾ 1.2 2.4 mVrms

1.5 ¾ 1.8 V

¾ 270 400 mVrms

¾ 82 ¾ dB

mA

8

2002-04-19

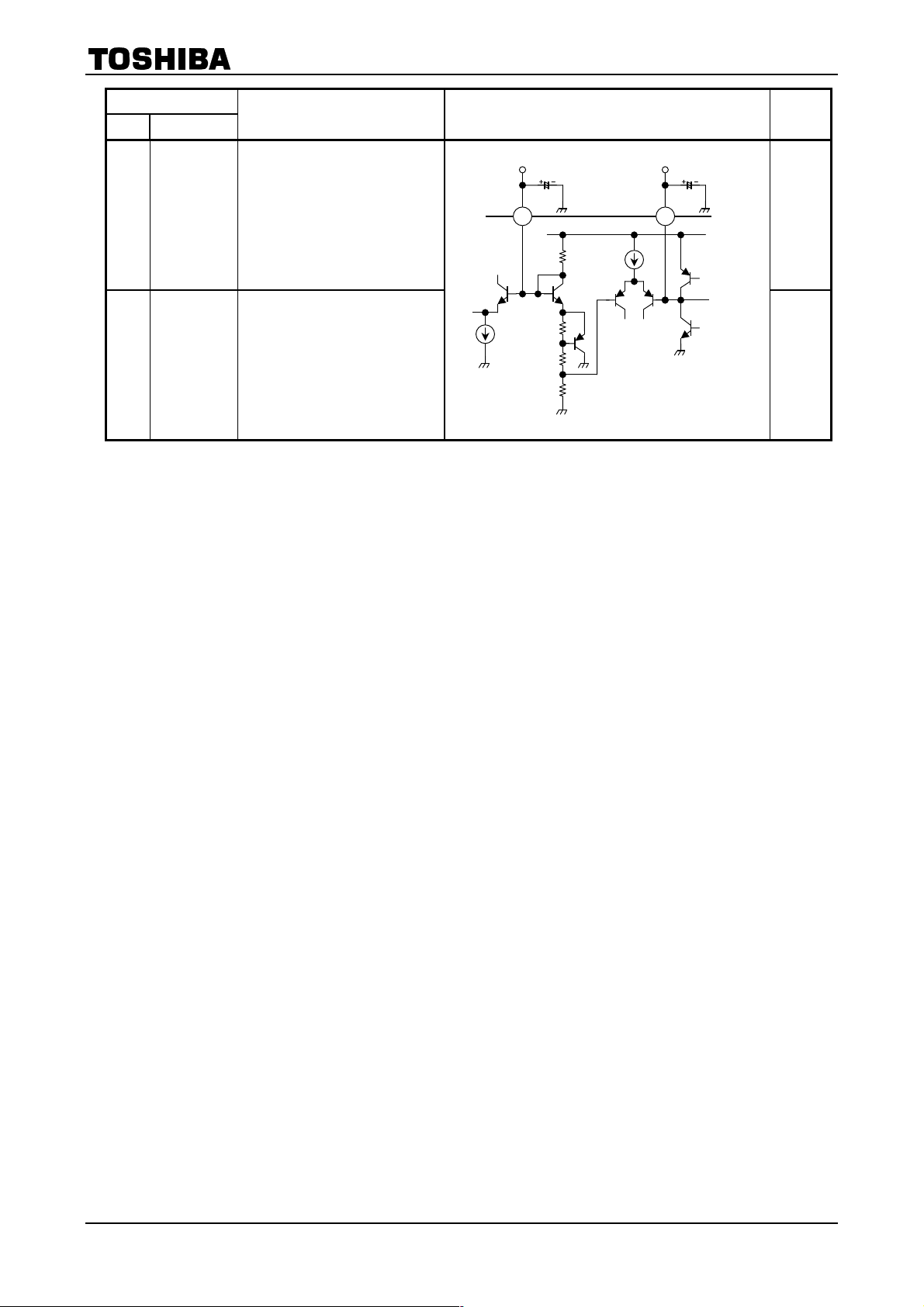

Test Circuit

PRE INB

SW1b

Rg = 600 W

22 mF

PRE

IN

A

SW1a

Rg = 600 W

2.2 kW

1000 pF

2.2 kW

1000 pF

220 mF

22 mF

470 kW

REF

PRE OUTB

SW2b

(b) (a)

8200 pF

470 W

INB V

NF

V

REF

18 kW

470 kW

PRE

B

OUT

TA2145AF

Rg = 600 W

PW IN

10 kW

(a)

B

SW3b

(b)

600 W

1 mF

1 mF

100 mF

PW

RF IN PRESWPW

IN

B

B

TA2145AF

V

REF

SW5

V

CC

47 mF

180 W

47 mF

1 mF

GVN

V

V

CC

Rt

CC

5 W

3.6 kW 5 kW

14 13 15 16171819202122 23 24

GVN

GVN

PRE

GND

1

IN

PRE

NF

A

OUT

A

PW

V

IN

A

A

OUTBOUTAOUT

CTL

PW

PW

GVN

IN

GND

C

C

10 9876543 2

GND

11 12

470 kW

470 kW

22 mF

470 W

220 mF

8200 pF

(b) (a)

SW2a

PRE OUTA

18 kW

SW4

(a) (b)

10 kW

1 mF

1 mF

(a)

Rg = 600 W

RL

R

PW OUT

L

PW OUT

SW3a

PW OUT

10 kW

PW IN

V

REF

600 W

A

(b)

V

REF

A

C

B

9

2002-04-19

TA2145AF

Characteristic Curves

(mA)

CCQ

16

(mA)

12

CC

8

4

Supply current I

Quiescent supply current I

0

0

1.5 2.0 2.5 3.5 4.0 3.0

Supply voltage VCC (V)

PRE G

100

80

(dB)

(dB)

VC

VO

60

40

20

Open loop voltage G

Closed loop voltage G

0

10 100 1 k 100 k10 k

)

rms

(mV

om

1000

500

PRE

THD = 1%

200

Maximum output voltage V

100

0 1.5 2.0 2.5 3.5 4.0 3.0

Supply voltage VCC (V)

, ICC – VCC

I

CCQ

I

(PRE + PW, Vol.: min)

CCQ1

I

(PW only, Vol.: min)

CCQ2

ICC (GVN: Im = 0)

, GVC – f

VO

Frequency f (Hz)

Vom – V

( Unless otherwise specifi ed, VCC ==== 3 V, Ta ==== 25°C, f ==== 1 kHz,

Preamplifier: R

Power amplifier: R

Motor governor: I

Vo = -10dBV

GVO

GVC

CC

==== 2.2 kWWWW, RL ==== 10 kWWWW

g

==== 600 WWWW, RL ==== 16 WWWW, Vol. ==== max

g

==== 100 mA)

m

– VCC

V

2.5

2.0

(V)

O (DC)

1.5

1.0

0.5

Output DC voltage V

0

0 1.5 2.0 2.5 3.5 4.0 3.0

O (DC)

V

, PW OUT, PRE OUT

REF

Supply voltage VCC (V)

PRE

40

50

60

Cross talk CT (dB)

70

80

10 100 1 k 100 k10 k

CT – f

Frequency f (Hz)

PRE

10

3

1

3

0.1

0.03

Total harmonic distortion THD (%)

0.01

1 10 100 100001000

Output voltage Vo (mVrms)

THD – Vo

f = 10 kHz

f = 100 Hz

f = 1 kHz

Vo = -10dBV

10

2002-04-19

TA2145AF

PRE V

20

)

rms

10

(mV

ni

5

2

1

Equivalent input noise V

0.5

0 1.5 2.0 2.5 3.5 4.0 3.0

Supply voltage VCC (V)

PW G

60

Vo = -10dBV

50

(dB)

V

40

Voltage G

BST = OFF

30

BST = ON

20

20 100 1 k 100 k10 k

Frequency f (Hz)

PW P

100

THD = 10%

(mW)

o

10

Output power P

2

0 1.5 2.0 2.5 3.5 4.0 3.0

Supply voltage VCC (V)

ni

o

RL = 16 W

– VCC

– f

V

– VCC

32 W

PRE RR – V

10

fr = 100 Hz

20

Vr = -20dBV

30

40

50

60

Ripple rejection ratio RR (dB)

70

80

0 1.5 2.0 2.5 3.5 4.0 3.0

Supply voltage VCC (V)

CC

PW CT – f

Vo = -10dBV

0

10

20

30

40

Cross talk CT (dB)

50

60

BST = OFF

20 100 1 k 10 k 100 k

BST = ON

Frequency f (Hz)

PW THD – P

30

VCC = 3 V

RL = 16 W

10

3

1

Total harmonic distortion THD (%)

0.2

0.2 1 100 10

1 kHz

Output power Po (mW)

f = 10 kHz

100 Hz

o

11

2002-04-19

TA2145AF

PW V

10

Volume Resistance (Pin@-GND)

Ratio = Volume resistance

-10

0dB = -10dBV

(mW)

o

-30

-50

Output voltage V

-70

-90

0 0.2 0.4 0.8 1 0.6

40

Resistance (Pin@-GND)

Volume ratio

50

0dB = -10dBV, Vr = -20dBV

=

Volume resistance

60

70

Ripple rejection ratio RR (dB)

80

0 0.2 0.4 0.8 1 0.6

(mV)

REF

GVN DV

10

5

0

-5

current ratio fluctuation DK

Reference voltage fluctuation DV

-10

0 50 100 250 300 200 150

Motor current Im (mA)

– Vol.

o

Volume ratio

RR – Vol.

Volume ratio

, DK – Im

REF

DV

REF

DK

PW V

500

Volume Resistance (Pin@-GND)

)

300

Ratio = Volume resistance

rms

(mV

no

100

50

30

Output noise voltage V

10

0 0.2 0.4 0.8 1 0.6

– Vol.

no

Volume ratio

DV

GVN

7.5

(mV)

5.0

REF

2.5

0.0

-2.5

-5.0

Current ratio fluctuation DK

Reference voltage fluctuation DV

-7.5

1.5 2.0 2.5 3.5 4.0 3.0

Supply voltage VCC (V)

, DK – V

REF

DV

REF

CC

DK

, ICC – Ta

I

16

12

(mA)

(mA)

CC

CCQ

Quiescent Supply current I

Supply current I

8

4

0

-20 0 60 80 40 20

CCQ

I

(PRE + PW, Vol. = min)

CCQ1

I

(PW only, Vol. = min)

CCQ2

I

(GVN: Im = 0)

CC

Ambient temperature Ta (°C)

12

2002-04-19

TA2145AF

1.5

(V)

1

O (DC)

0.5

Output voltage V

0

-20 0 20 60 80 40

Ambient temperature Ta (°C)

PRE THD – Ta

1

Vo = -10dBV

0.1

0.01

Total harmonic distortion THD (%)

0.001

-20 0 20 60 80 40

Ambient temperature Ta (°C)

PW

10

5

Po = 1 mW

2

1

0.5

0.2

Total harmonic distortion THD (%)

0.1

-20 0 20 60 80 40

Ambient temperature Ta (°C)

V

O (DC)

V

, PW OUT, PRE OUT

REF

THD – Ta

– Ta

PRE G

40

GV: Vo = -10dBV

Vom: THD = 1%

38

(dB)

V

36

34

Voltage gain G

32

30

-20 0 20 60 80 40

Ambient temperature Ta (°C)

, Vom – Ta

V

Vom

GV

800

760

(mVrms)

om

720

680

640

Maximum output voltage V

600

PW

35

GV: Vo = -10dBV

Po: THD = 10%

(dB)

V

30

Voltage G

25

-20 0 20 60 80 40

Ambient temperature Ta (°C)

GV, Po – Ta

GV

Po

50

40

30

20

10

(mW)

o

Output Power P

DV

GVN

6

(mV)

4

REF

2

0

-2

-4

Current ratio fluctuation DK

Reference voltage fluctuation DV

-6

DK

DV

REF

-20 0 20 60 80 40

Ambient temperature Ta (°C)

REF

, DK – Ta

13

2002-04-19

TA2145AF

p

k

k

m

m

m

m

p

m

m

k

Application Circuit

PRE IN

B

PRE IN

A

F

1000

F

1000

F

22

V

REF

470

IN

V

CC

F

F

F

23

470 W 22

18 kW

470 kW

22 24

NFB

8200 pF 1

PRE

OUT

W

B

F

F

100

B

RF

IN

TA2145AF

PW

IN

B

PRE

SW

PRE

OFF

PW

V

CC

47

0.1

180 W

161718192021

GVN

V

Rt

CC

M

W 1 mF

3.6

W

5

15 14 13

GVN

CTL

GVN

OUT

V

REF

PRE

GND

1

IN

A

2 3

22 mF

NFA

470 kW

470 W

470 kW

18 kW

8200 pF

PRE

OUT

A

4 5

1 mF

PW

IN

V

CTL

A

6 7 8

10 kW

9

0.1 mF

PW

IN

C

BST: OFF

OUT

33 kW

OUT

B

12 kW

33 kW

0.1 mF

OUT

A

0.1 mF

BST SW

10

C

PW

GND

11 12

RL

RL

GVN

GND

OUT

OUT

OUT

A

C

B

14

2002-04-19

Package Dimensions

TA2145AF

Weight: 0.32 g (typ.)

15

2002-04-19

TA2145AF

A

RESTRICTIONS ON PRODUCT USE

· TOSHIBA is continually working to improve the quality and reliability of its products. Nevertheless, semiconductor

devices in general can malfunction or fail due to their inherent electrical sensitivity and vulnerability to physical

stress. It is the responsibility of the buyer, when utilizing TOSHIBA products, to comply with the standards of

safety in making a safe design for the entire system, and to avoid situations in which a malfunction or failure of

such TOSHIBA products could cause loss of human life, bodily injury or damage to property.

In developing your designs, please ensure that TOSHIBA products are used within specified operating ranges as

set forth in the most recent TOSHIBA products specifications. Also, please keep in mind the precautions and

conditions set forth in the “Handling Guide for Semiconductor Devices,” or “TOSHIBA Semiconductor Reliability

Handbook” etc..

· The TOSHIBA products listed in this document are intended for usage in general electronics applications

(computer, personal equipment, office equipment, measuring equipment, industrial robotics, domestic appliances,

etc.). These TOSHIBA products are neither intended nor warranted for usage in equipment that requires

extraordinarily high quality and/or reliability or a malfunction or failure of which may cause loss of human life or

bodily injury (“Unintended Usage”). Unintended Usage include atomic energy control instruments, airplane or

spaceship instruments, transportation instruments, traffic signal instruments, combustion control instruments,

medical instruments, all types of safety devices, etc.. Unintended Usage of TOSHIBA products listed in this

document shall be made at the customer’s own risk.

· The products described in this document are subject to the foreign exchange and foreign trade laws.

· The information contained herein is presented only as a guide for the applications of our products. No

responsibility is assumed by TOSHIBA CORPORATION for any infringements of intellectual property or other

rights of the third parties which may result from its use. No license is granted by implication or otherwise under

any intellectual property or other rights of TOSHIBA CORPORATION or others.

000707EB

· The information contained herein is subject to change without notice.

16

2002-04-19

This datasheet has been download from:

www.datasheetcatalog.com

Datasheets for electronics components.

Loading...

Loading...