TOSHIBA

4200FA

UNINTERRUPTIBLE POWER SYSTEM

THREE-PHASE 75 / 80 kVA UPS

MANUFACTURED IN THE U.S.A.

Document Number: 56418-002

Date: December, 2004

USERS MANUAL

TOSHIBA

4200FA

THREE-PHASE 75/80 kVA

UNINTERRUPTIBL E POWER SYSTEM

OPERATION MANUAL

FOR MODELS

T42#3F750XAXXN, T42#3F750FAXXN,

T42#3F800XAXXN, T42#3F800FAXXN.

TOSHIBA

INTERNATIONAL CORPORATION

INDUSTRIAL DIVISION

13131 West Little York Rd., Houston, Texas 77041

TOSHIBA

IMPORTANT NOTICE

The Instructi ons cont ained in this manual are not int ended to cover all of

the details or vari ations in equipment or to provide for every possible

contingency to be m et in connec tion with installation, operation, or

maintenance. Should further information be required or should particular

problems arise which are not covered sufficiently the matter should be

referred to the local Toshiba sales office.

The contents of this instruction manual shall not become a part of or

modify any prior or exi sting equipment, commitment, or relationship. The

sales contract contains the entire obligat ion of Toshiba Internati onal

Corporation’s UPS Division. The warranty contained in the contract

between the parties is the sole warranty of Toshiba International

Corporation’s UPS Division, and any statement s cont ained herein do not

create new warranti es or modify the existing warranty.

Any Electrical or mechanical modifications to this equipment

without prior written consent of Toshiba International

Corporation will void all warranties and may void UL/CUL

listing. Unauthorized modifications may also result in

equipment damage, personal injury, or loss of life.

UNINTERRUPTIBLE POWER SYSTEM

If additional i nformation or technical assistance is required call Toshiba’s

Customer Serv ic e Depar tment toll free at 1-800-231-1412, or write to: Toshiba

International Corporation, 13131 W. Littl e Y or k Rd., Houston, TX 77041-9990.

Please complete the following inform ation f or your rec or ds. Unless otherwise

specified on the warranty c ar d, the warranty period for the UPS or UPS part is

36 months from the shipment date (see TIC bill of lading).

Unless otherwise speci fied on the warranty card, the warranty period for a

UPS battery is 24 months from the shipm ent date (see TIC bill of lading).

Keep this manual with the UPS equipment.

Job Number:

Model Number:

Serial Number:

Application:

Shipping Date:

Date of Installation:

Inspected By:

2

TOSHIBA

TABLE OF CONTENTS

IMPORTANT NOTICE.......................................................................................................2

TABLE OF CONTENTS....................................................................................................3

Purpose and Scope of Manual .......................................................................................5

Contacting Toshiba’ s Customer Support Center..........................................................5

GENERAL SAFETY INSTRUCTIONS..............................................................................6

EQUIPMENT WARNING LABELS....................................................................................8

IMPORTANT SAFETY INSTRUCTIONS.........................................................................10

1.0 Product Description.............................................................................................13

1.1 Theory of Operati on ...................................................................................................................13

1.2 Application and use.................................................................................................................... 13

1.3 Power Backup............................................................................................................................13

1.4 Power Conditioning....................................................................................................................13

2.0 Unpacking/Inspection/Storage/Disposal............................................................14

2.1 Unpacking the new UPS equipment:...........................................................................................14

2.2 Inspection of the new UPS equipment ........................................................................................15

2.3 Storage of UPS equipm ent.........................................................................................................15

2.4 Disposal.....................................................................................................................................15

3.0 Precautions...........................................................................................................16

3.1 Installation Precautions................................................................................................................16

3.2 Pre-start Precautions..................................................................................................................17

3.3 Ope r a ting P re c a u t io n s................................................................................................................17

4.0 UPS Connections .................................................................................................18

4.1 UPS Power and Control Connections........................................................................................ 18

4.1.1...Recommended Wir e Size and Tightening Torque For UPS Input and Output Terminals.........19

4.1.2...Power Connection Cable Routing..........................................................................................20

4.1.3...Dual Input Configuration........................................................................................................28

4.2 Control Circ uit and Ex ternal Battery Interface Connections .........................................................29

4.2.1...Recommended Wir e Size and Tightening Torque UPS Control and B att er y Interface.............29

4.3 Communication Interface............................................................................................................30

4.3.1...Remote Contact....................................................................................................................30

4.3.2...RS-232C............................................................................................................................... 31

4.3.3...UPS Shutdown (v i a RS-232C)...............................................................................................31

5.0 Specifications.......................................................................................................32

5.1 Specifications – 4200FA 75kVA with Internal T r ansformer..........................................................32

5.2 Specifications – 4200FA 75kVA without Inter nal Transformer .....................................................33

5.3 Specifications – 4200FA 80kVA with Internal T r ansformer..........................................................34

5.4 Specifications – 4200FA 80kVA without Inter nal Transformer .....................................................35

6.0 Operating the UPS................................................................................................36

6.1 Ope r a ting th e UPS..................................................................................................................... 36

6.1.1...AC Input Mode (normal operation).........................................................................................36

6.1.2...Circuit-bypass Mode..............................................................................................................36

6.1.3...Battery Back u p Mod e............................................................................................................37

6.2 Battery Backup Time and Discharge Process .............................................................................38

6.3 Battery Low Voltage T ol er anc es .................................................................................................38

6.4 Battery Recharging.....................................................................................................................39

6.5 Front Panel Layout (All Units).....................................................................................................40

6.6 EPO ( Emergen cy P o wer Off) Function .......................................................................................41

6.7 Au d ible Ala rm Functions.............................................................................................................41

6.8 Light Emitting Di ode ( LE D) Functions......................................................................................... 42

6.8.1...Light Emitting Di ode ( LE D) System S tatus.............................................................................42

6.9 Liquid Crystal Display (LCD) Functions.......................................................................................43

3

TOSHIBA

6.9.1...Line-1 System Messages...................................................................................................... 43

6.9.2...Line-2 System Fault Messages ............................................................................................. 43

6.9.3...Line-3 System Messages...................................................................................................... 43

6.9.4...Line-4 System Messages...................................................................................................... 44

6.10 Initial Battery Charge ................................................................................................................. 45

6.11 S tart-up Procedure..................................................................................................................... 46

6.12 S hutdown Procedure..................................................................................................................47

6.13 K ey pad Overview....................................................................................................................... 48

6.14 Key Functions............................................................................................................................49

6.14.1.MONI.................................................................................................................................... 49

6.14.2.IN..........................................................................................................................................49

6.14.3.OUT...................................................................................................................................... 49

6.14.4.BATT Key............................................................................................................................. 50

6.14.5.MENU, F1, ENTER, UP, & DOWN Keys...............................................................................50

6.14.6.BATT TEST Key...................................................................................................................50

6.14.7.BUZZ STOP Key...................................................................................................................51

6.14.8.RESET Key..........................................................................................................................51

6.15 M enu Data Screens................................................................................................................... 52

6.15.1. Setti ngs for Calendar and Clock............................................................................................52

6.15.2.Adjusting Buzzer Volume......................................................................................................52

6.15.3.Settings for Display Duration................................................................................................. 53

6.15.4.Run Switch Select ................................................................................................................. 53

6.15.5.Serial Com Station Address..................................................................................................54

6.15.6. Output Voltage Adjustment ................................................................................................... 54

6.15.7. Charge Mode Select ............................................................................................................. 55

6.15.8.Reset to Default Settings.......................................................................................................55

6.16 Overload Operation....................................................................................................................56

6.17 Backup History & Faul t History...................................................................................................57

7.0 UPS Protection System........................................................................................59

7.1 System Protection Features.......................................................................................................59

7.2 System Protection Functi ons...................................................................................................... 59

8.0 Preventive and Scheduled Maintenance / Part Replacement............................60

8.1 Preventiv e Maintenance............................................................................................................. 60

8.2 Parts Replacement....................................................................................................................60

9.0 External Dimensions / Shipping Weights ...........................................................61

9.1 External Dimensions..................................................................................................................61

9.2 Shipping Dimensions.................................................................................................................62

9.3 Sh ipping Weigh ts....................................................................................................................... 62

4

TOSHIBA

Purpose and Scope of Manual

This manual provides information on how to safely i nstall, operate, and maint ain y our TIC power electronics

product. Thi s manual includes a section on General Safety Instructions that describes the warning label s

and symbols that are used throughout the manual. Read the m anual c om pletely before installing,

operating, or performing maintenance on t his equi pment.

This manual and the acc om panyi ng dr awings should be considered a permanent part of the equipment and

should be readil y av ailable for reference and review. Dimensions shown in the manual ar e in m etric and/or

the English equivalent.

Toshiba Inter national Corporation r eserves the right, without prior notice, to update inform ation, make

product changes, or t o discontinue any product or service identified in this publ ic ation.

TOSHIBA is a registered t r adem ar k of the Toshiba Corporation. All other product or trade refer enc es

appearing in this manual are registered tr adem arks of their respective owners.

Toshiba International Corporation (TIC) shall not be liable for technical or editorial omissions or

mistakes in this manual. Nor shall it be liable for incidental o r consequential damages result ing

from the use of information contained in this manual.

This manual is copyri ghted. No part of this manual may be photocopied or reproduced in any form without

the prior written consent of Toshiba Inter national Corporation.

© Copyright 2004 Toshi ba International Corporation.

All rights reserved.

Printed in the U.S.A.

Contacting Toshiba’s Customer Support Center

Toshiba’s Customer Support Center can be cont acted to obtain help in resolving any Uninterruptible

Power System problem that you may experi enc e or to pr ov ide application inform ation.

The center is open from 8 a.m. to 5 p.m. (CST ), Monday t hrough Friday. The Support Cent er ’s toll free

number is US (800) 231-1412/Fax (713) 846-5212.

You may contact Toshiba by wri ting to:

Toshiba Inter national Corporation

13131 West Little York Road

Houston Texas 77041-9990

Attn: UPS Product Manager

For further inf ormation on Toshiba’s products and services, please visit our website at

www.tic.toshiba.com.

5

TOSHIBA

GENERAL SAFETY INSTRUCTIONS

DO NOT attempt to install, operate, maintain or di spose of this equipment until you have read and

understood all of the product safety inf ormati on and dir ections that are cont ained in this manual.

Safety Alert Symbol

The Safety Alert Symbol indicates that a potenti al per sonal injury hazard exists. The symbol is comprised

of an equilateral tr iangle enclosing an excl am ation mark.

Signal Words

Listed below are the signal words that are used throughout this manual followed by their descriptions and

associated sym bols. When the words DANGER, WARNING and ATTENTION are used in this manual they

will be foll owed by important safety informati on that must be carefully adhered to.

Warnings in this manual may appear in any of the following ways:

1) Danger warning

precedes the word “DANGE R.” The Danger warning symbol is used to indicate situations,

locations, and conditions that exist and will cause serious injury or deat h.

─

The danger symbol is an exclamation mar k enclosed in a triangle, which

DANGER

2) Caution warning ─ The caution symbol is an exclamati on m ark enclosed in a triangle, which

precedes the word “CAUTION.” The Caution warning sym bol is used to i ndicate situations and

conditions that c an c ause operat or injury and/or equipm ent damage.

CAUTION

3) Attention warning ─ The attention warning symbol is an exclamation mark enclosed in a

triangle which pr ec edes the word “ATTENTION.” The Att ention warning symbol is used to

indicate situations and conditions that c an c ause operat or injury and/or equi pm ent damage.

ATTENTION

Other warning symbols may appear along with the Danger and Caution symbol and are used to specif y

special hazards. These warnings describe particular areas where special care and/or procedures are

required i n order t o pr ev ent seri ous injury and possible death.

1) Electrical w ar ning

Electri c al warni ng symbol is used to indicate high voltage locations and conditi ons that may

cause serious inj ur y or death if the proper precautions are not observed.

2) Explosion warning

triangle. The Explosion warning symbol i s used to indicate locations and condi tions where

─

The electrical warning sym bol is a lighting bolt enclosed i n a tri angle. The

─

The explosion warning sym bol is an explosion image enclosed in a

6

TOSHIBA

molten exploding parts that may cause serious inj ur y or death if the proper precautions are not

observed.

7

TOSHIBA

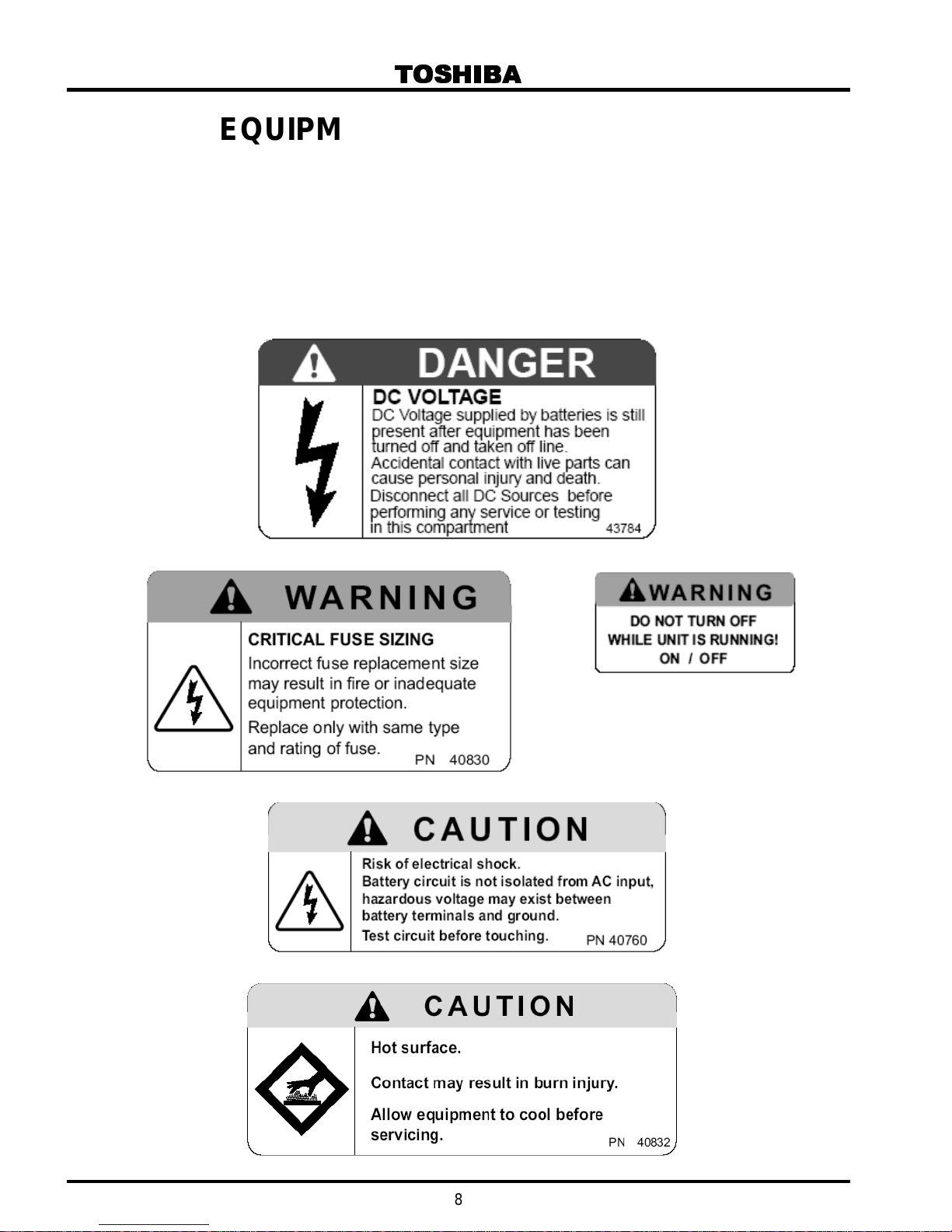

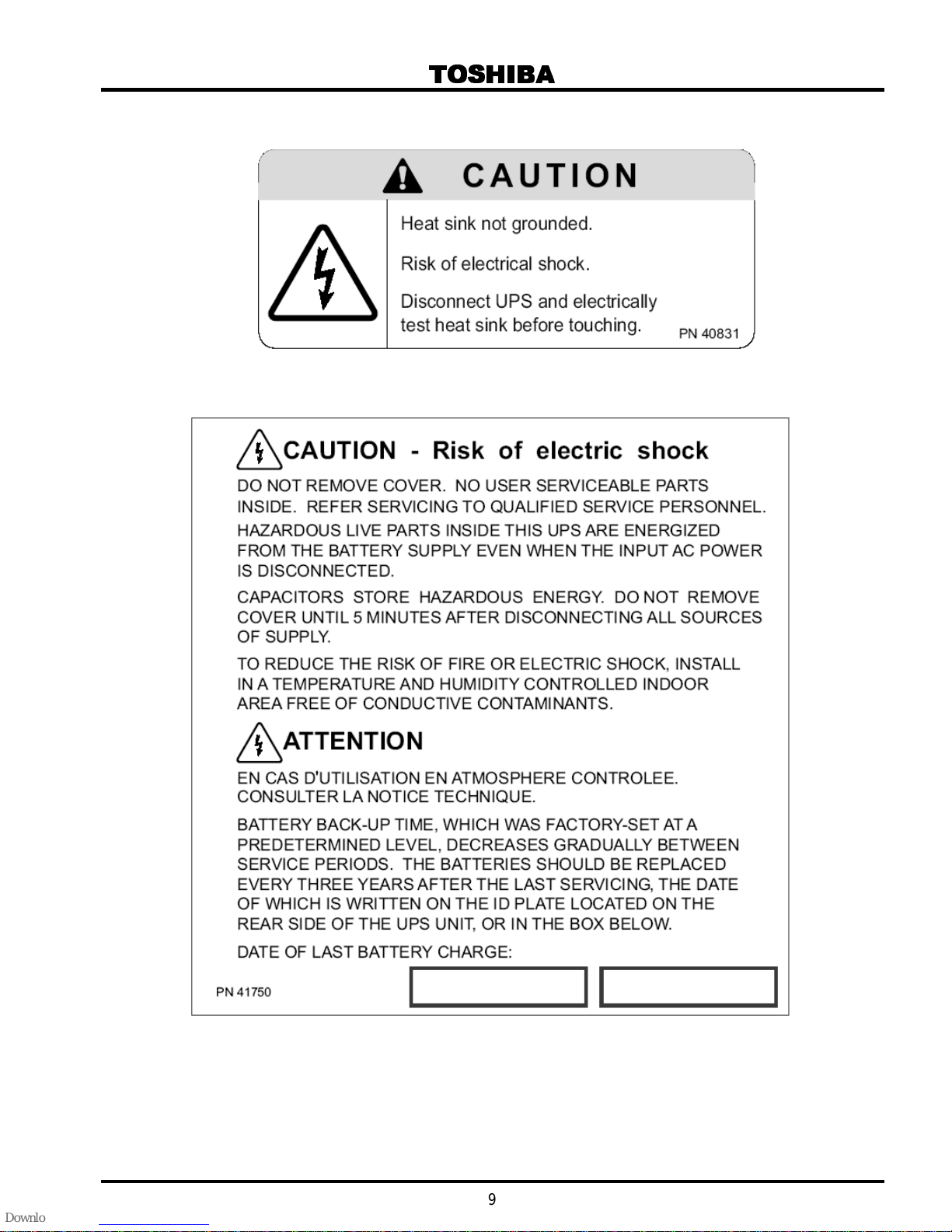

EQUIPMENT WARNING LABELS

DO NOT attempt to install, operate, maintain or di spose of this equipment until you have read and

understood all of the product warnings and user direct ions that are contai ned in this instruction manual.

Shown below are examples of warni ng labels that may be found attached to the equipment. DO NOT

remove or cover any of the labels. If the labels are damaged or if additional labels are required, contact

your Toshiba representative for additional labels.

The following ar e ex am ples of the warning labels that may be found on the equipment. The labels are ther e

to provide useful information or to indic ate an imminently hazardous situat ion that may result in serious

injury, severe property and equipment damage, or death if the instructions are not followed.

8

TOSHIBA

9

TOSHIBA

SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

This manual contains important instructions

that should be followed during the

installation, operation, and maintenance of the UPS and its batteries. Turn off, lockout, and tagout all

power sources befor e pr oc eeding to connect the power wiring t o the equipment or when performing

maintenance. Hardwire type UPS units are not equipped wit h an over-current protection device nor an

output disconnect for the AC output. Theref or e, a cir c ui t breaker should be provided by the user

between the UPS output and t he l oad input. This device should be rat ed as follows:

Device Type 75kVA 80kVA

Rated Output 208/120VAC 208/120VAC

Device Rating 240V, 270A 240V, 300A

The maximum ambient t em per ature in which the UPS unit should be operated is 40°C (104°F).

The nominal batter y v oltage is 288VDC.

Only a qualified Toshi ba Repr esentative who is knowledgeable in batteries and the required precautions

should only perf orm bat tery servicing. Keep unauthorized personnel away fr om batt eries. To arrange for

battery replac em ent, contact your nearest Toshi ba authorized service c enter.

Qualified Personnel ONLY

A Qualified Person i s one that has the skills and knowledge relating the construction, installation, operation

and maintenance of the elec trical equipment and has received safety training on the hazar ds i nvolved

(Refer to the latest edition of NFPA 70E for additional safety requirements).

Qualified Personnel Shall:

1) Have carefully read t he entire operation manual.

2) Be trained and authorized to safely energize, de-ener gize, ground, l ockout/tagout circuits and

equipment, and clear faults in accordance with established safety practices.

3) Be trained in the proper c ar e and use of pr otective equipment such as safety shoes, rubber gloves,

hard hats, safety glasses, face shields, fl ash clothing, etc., in acc or danc e with established safety

practices.

4) Be trained in rendering first aid.

5) Be knowledgeable of batteries and the requir ed pr ec autions.

For further info rmat io n of workpl ace saf ety visit www.osha.go v.

Refer to the Battery System M anual when scheduling batter y maintenance or battery replacem ent.

DANGER

indirect, or c onsequential damage or injury that may result from the use of this equipm ent.

Misuse of this equi pm ent could result in injury and equi pm ent damage.

In no event will Toshi ba Cor por ation be responsible or l iable for direct,

CAUTION

CAUTION

Do not open or mutilat e the bat teries. Released elect r ol yte is tox ic and

harmful to the eyes and skin.

Do not dispose of the batteries in a fire. The batteri es may

explode.

10

TOSHIBA

CAUTION

and/or flam e. An author iz ed technician must perform annual pr ev entative maintenanc e.

CAUTION

resulting in secondary faults such as odor, smoke, and fire.

CAUTION

unauthorized per sonnel away from the batteries.

CAUTION

reliability of your UPS system. Refer to service manual.

DANGER

when working with batteries:

This unit contains sealed lead acid batteries. Lac k of prev entative

maintenance could result in batteri es exploding and emitting gasses

Failure to replace a battery before it becomes exhausted may cause

the case to crack; possibl y r eleasi ng electrolyte f r om the batt er y

Only personnel knowledgeable of batteries and the r equired

precautions should perform install ation and servicing of batt eri es. K eep

Proper maintenance to the battery system of this unit m ust be done by

a qualified service technician. Thi s is essential to the safety and

A battery can present a risk of electrical shock and high short

circuit current .

The following pr ec autions should be observed

TO BE PERFORMED BY QUALIFIED PERSONNEL ONLY!

1) Verify that t he UPS is off and i s di sconnected from the power source.

2) Remove watches, rings, or other metal objects.

3) Use tools with insulated handles to prevent inadv er tent shorts.

4) Wear rubber gl ov es and boots.

5) Do not place tools or m etal parts on top of the batteries.

6) Determine if the batt ery is inadvertently grounded. If inadvertently gr ounded, remove

source of ground.

electrical shock.

removed during installation and maintenance.

7) Verify circ uit polarities prior to maki ng c onnec tions.

8) Disconnect charging source and load prior t o connecting or disconnecting t erminals.

9) VRLA batteries cont ain an explosive mixture of hydr ogen gas. Do not smoke, or create a flame

or spark in the immedi ate area of the batteries. This inc ludes stat ic electricity from the body.

10) Do not attempt to open the batteries in order to add water or sample the specific gravit y of t he

electroly te. The batteries are valve- r egulated lead acid type and such servici ng is not possible

without damagi ng the battery.

11) Use proper lifting means when moving bat teries and wear all appropriate safety clothing and

equipment.

12) Do not dispose of lead acid batteries except through channels in accordance with local, state

and federal regulations.

Contact with any part of a grounded b at tery can result in

The likelihood of such shock will be reduced if such grounds are

11

TOSHIBA

INSTRUCTIONS IMPORTANTES CONCERNANT

LA SÉCURITÉ

CONSERVER CES INSTRUCTIONS

ATTENTION

ATTENTION

Un battery puet présenter un r isque de choc électri que, de brûlure

par transfer t d’ énergie.

L’élimination des batteries est règl em entèe. Consultar les codes

locaux à cet effet

Cette notice contient des

instructions importantes

concernant la sécur té

12

1.0 Product Description

1.1 Theory of Operation

An Uninterruptible Power System (UPS) is a system t hat is installed between the commerci al

power and the load equi pment. The UPS provides steady AC output power duri ng c om m er ci al

power fluctuations and interruptions.

During normal operation the UPS receives comm ercial AC power and removes any high

voltage spik es and tr ansi ents caused by switching or faults on the main utility. The result of this

process is maxim um power conditioning and regul ation of the power applied to the load.

If the AC power supplied t o the UPS dr ops bel ow a specif ied voltage level, the batteries of the

UPS are automati c ally switc hed on and will supply power to the load. This insures that the

loads connected to t he UPS c ontinue to receive power with no inter r uption. This power is

provided for a peri od long enough to ensure that the load can be shut down in an orderly

fashion. This prevents loss of data and possible damage to the hardware or software.

When AC input power becom es available again, normal system oper ation resumes and the

UPS battery-char ge c y cl e r esumes.

1.2 Application and use

Toshiba's 4200FA Uninterruptible Power Systems (UPS) pr ov ide c ontinuous computer grade

AC power in a compact and effi ci ent high-performance unit. The UPS assures safe, reliable

operation of critical office equipment, ranging from personal c om puters to mini-computers to

local area networks (LAN). All units feature an audible alarm that sounds if the batt er y v oltage

drops below standard during use. This is an additional ai d to help in retaining the valuable

office data banks, and all units allow for computer interfacing.

TOSHIBA

1.3 Power Backup

During an electri c al power failure the batteries of the UPS unit supply DC power to the inverter

that supports the l oad equipment automatically , without interrupti on. For example, when used

to support a computer , a UPS backup assures addi tional time to complete your activity and

store data after a power f ailure occurs.

1.4 Power Conditioning

While commercial power i s present, the UPS supplies conditioned power to the load while

maintaining the batteries in a charged condi tion. The UPS protects the connect ed load against

the normal everyday pr oblems associated with heav y use of raw commerci al power, including

power sags, surges, signal interference, and spi kes. This protection keeps power-l ine problems

from reaching your load where i t can cause equipment to operate erratically, or damage

software or hardware.

13

TOSHIBA

2.0 Unpacking/Inspection/Storage/Disposal

2.1 Unpacking the UPS Equipment

1) Upon receipt of t he UPS, a careful inspection for shipping damage should be made.

2) For units shipped in a c r ate, r em ov e the screws that at tach the shipping crat e panels to

each other and to the pallet. Remove the crate and foam packing materi al.

3) Unbolt the unit fr om t he shi pping pallet.

4) Lift the UPS from the pallet usi ng a forklift that has suffici ent capacity. Approach the

UPS only from the front or rear.

14

2.2 UPS Equipment Insp ection

ATTENTION

UPS Equipment Insp ection

Upon receipt of the UPS, a car eful inspection for shipping damage should be made. Use

caution when rem ov ing unit from pallet. Refer to labels or docum entation attached to

packing material.

After Uncrating

1) Check the unit for loose, brok en, bent or other damaged parts. If damage has occurred

during shipment, keep all original crating and pac king materials for ret ur n to t he

shipping agent. The equipment warranty will not apply to units that are damaged

during shipment.

2) Check to see that the rat ed c apaci ty and the model number specifi ed on the nameplate

conform to the order specif ications.

2.3 Storage of the UPS Equipment

If the UPS equipment is t o be subject to long or short-term storage, the f ol lowing guidelines

should be used.

Avoid:

1) Storage in sites subject to extreme changes in temper ature or high humidity.

2) Storage in sites subject to exposure of high lev els of dust or metal par ticles.

3) Storage on incli ned floor surfaces or in sites subject to excessive vibration.

TOSHIBA

2.4 Disposal

Before Storing:

1) Allow the UPS to be operated for 24 hours to ensure that the batteries are fully

charged.

2) Stop the unit (see Stopping the UPS in section 6.12).

3) Place the MCCB switch of t he UPS in the OFF positi on ( see section 4.1for

location).

Storing:

1) Store within t he temper ature range of –20°C to 40°C (-4°F to 104°F).

2) For best results, stor e the UPS in the original shipping c ontainer and place on

a wood or metal pallet.

3) The optimum storage temperature is 21°C (70°F). Higher am bient

temperatures cause UPS bat teries to require rec harging more frequently.

After Storing:

1) If stored in an ambient temper ature less than 20°C (68°F); rec har ge the

batteries every 9 months.

2) If stored in an ambient temper ature of 20°C to 30°C (68°F to 86°F); recharge

the batteries every 6 months.

3) If stored in an ambient temper ature of 30°C to 40°C (86°F to 104°F); r ec har ge

the batteries every 3 months.

Please contact y our state env ironmental agency for details on proper disposal of el ectrical

components and packaging in your particular ar ea.

It is illegal to dump lead-acid batteries in landfills or dispose

of imprope r ly . Pl ease hel p our E arth by contacting the

environment al pr otection agencies in your ar ea, t he battery

manufacturer , or call Toshiba toll-fr ee at ( 800) 231- 1412 for more

information about recycling batteri es.

15

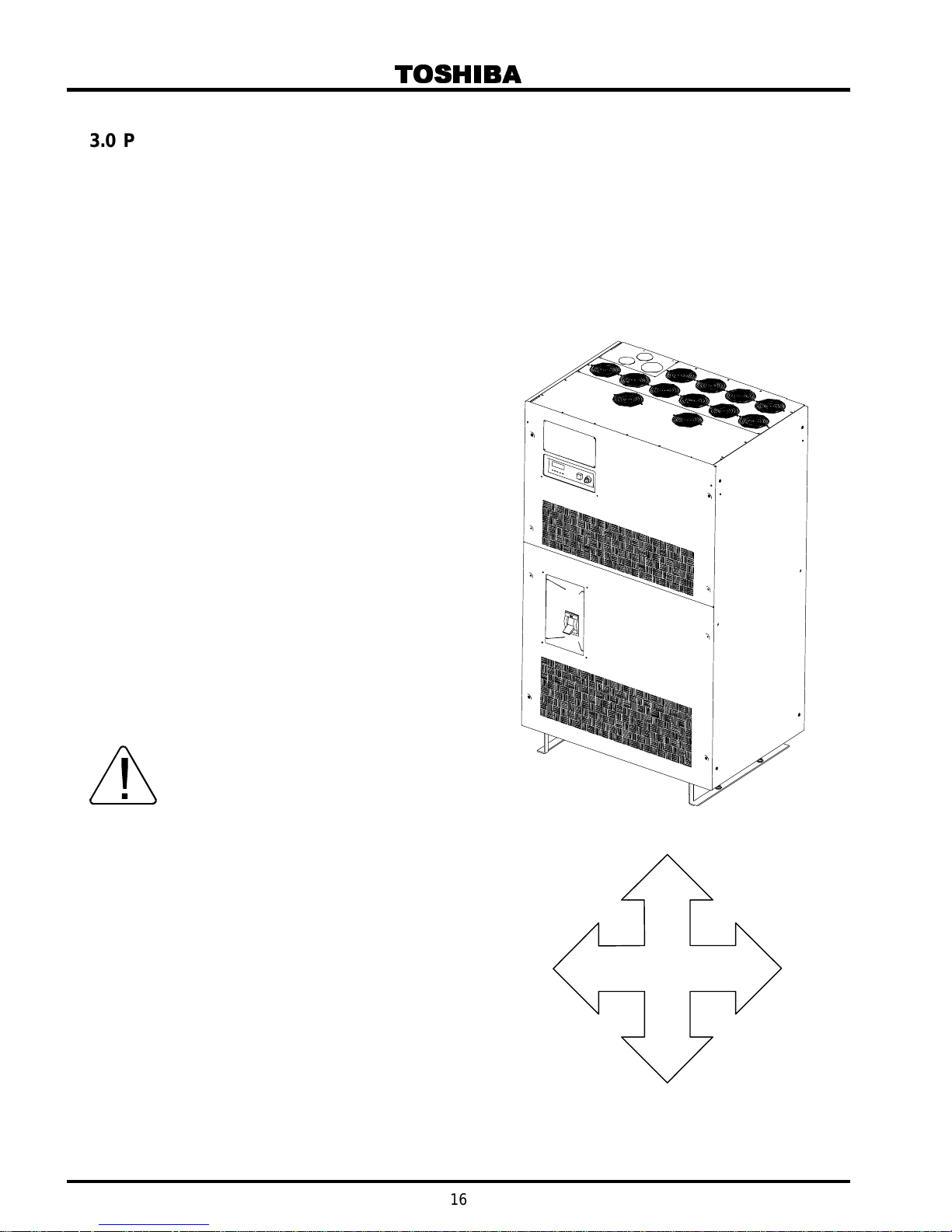

3.0 Precautions

Because of the exter nal dimensions of the 4200FA UPS and the way the outer panels are to

be removed; onl y a minimum amount of space around the unit is requir ed for v entilation and

maintenance access. Figure 3.1 shows the minimum clearanc es required for proper UPS

installation.

3.1 Installation P recautions

1) Install the UPS in a stable, level, and upright positi on that is free of vibration.

2) Install the UPS in a well ventilated location with the required allowances for v entilation

and servicing as shown in fi gur e 3.1.

3) Install the UPS where the ambient

temperature is within the correct

operating range ( see the UP S

Specifications in section 5.1). Verify that

the ventilation and air conditioni ng

system at the site is capable of

removing the heat gener ated by the

UPS unit (see Section, 5.1

Specifications, "Environment " ). Ambient

temperature r ange for operating the

UPS is 0°C – 40°C (32°F – 104°F);

25°C (77°F) is the reco mmend ed

operating temperature for maximum

battery life.

4) Do not install the UPS in a locati on that

is subject to high humi dity.

5) Do not allow the UPS to be exposed to

direct sunli ght.

6) Do not install the UPS in areas that are

subject to contamination such as high

levels of air bor ne dust, metal particles,

or flammable gasses.

7) Avoid install ation near sources of

electric al noise and always ensure that

the earth ground is intact to prevent

electrical shock and help prevent

electric al noise.

8) Do not install the UPS in an area t hat

may expose the UPS to water or that

may allow any foreign matter to get

inside.

9) This UPS generat es and radiates radiofrequency energy dur ing operation.

There is no guarantee that the UPS will

not influence some sensitive devices

that are operati ng cl ose by. If such

interfer ence is experienced, the UPS

should be installed farther away from

the affected equi pment and/or powered

from a different source than the affected

equipment.

10) The user should prov ide output over

current protection for hardwired UPS

versions. See S afety Instructions on

page 10 for the corr ect dev ic e r ating.

TOSHIBA

REAR

0” (0mm)

TOP

LEFT

0” (0mm)

22” (550 mm)

FRONT

28” (700 mm)

RIGHT

0” (0mm)

Figure 3.1

16

11) After ensuring that all power sources are turned off and isolated in accordance wit h

reset.

established loc k out/tagout procedures, connec t power source wiring of the cor r ec t

voltage to the input terminals of the UPS. Connect the output t erminals of the UPS to an

applicable load type application (ref er to NEC Arti cl e 300 – Wiri ng M ethods and Article

310 – Conductors For Gener al Wiring). Size the branch circuit conductors in accordanc e

with NEC table 310.16.

3.2 Pre-start Precautions

Before connecting the UPS to a power source; move the MCCB switch (ON/OFF ) to the OFF

position and move the oper ation RUN/STOP key switch, on the front panel ( S ee S ection 6.5

for location), to the STOP position.

3.3 Operating Precautions

1) The UPS should not be powered up until the entire Operati on Manual has been read.

2) The input power source voltage must be within +10% to -30% of the rated input voltage.

The input frequenc y m ust be within the rated input frequency r ange. Voltages and

frequencies outsi de of the permissible range m ay activate the internal prot ec tion device.

3) The UPS should not be used with a load that has a rated input greater than the r ated

UPS output.

4) Do not use the UPS to provi de power to motor s that require high starting cur r ent or a

long starting time such as vacuum cleaners or machine tools (over sizing for loc k ed rotor

current required).

5) Do not insert metal objects or combustible materi als i n the ventilation slots of t he UPS.

6) Do not place, hang, or paste any objec ts on the top or on the exterior surfaces of the

UPS.

7) The capacitors of the UPS maintain a residual charge f or a whil e aft er turning off the

UPS. The requir ed discharge time for each UPS typeform is provided via a cabinet label

and a CHARGE LED. Wait for at least the mi nim um tim e indic ated on the label and

ensure that the CHARGE LED has gone out before removing the front panel of the UPS

once the UPS power has been turned off .

8) Do not attempt to disassembl e, modify, or repair the UPS. Call y our Toshiba sal es

representative for repair information.

9) Turn the power on only aft er att ac hing ALL the covers and DO NOT remove any covers

of the UPS when the power is on.

10) If the UPS should emit smoke or an unusual odor or sound, turn the power off

immediately.

11) The heat sink and other components may become extremely hot to the touch. Allow the

unit to cool before c oming into contact with these items.

12) Warning si gns should be placed on or near the load to let people k now that the load is

being powered by the UPS.

13) Additional warnings and notific ations shall be posted at the equipm ent installation

location as deem ed r equir ed by Qualified Pe r s on ne l.

TOSHIBA

CAUTION

UPS will conti nue to prov ide power to the load. The unit must be in Bypass mode and then

the breaker tur ned to the OFF position for the UPS to shut down power to the l oad.

CAUTION

When the UPS is in the Inverter m ode, t ur ning the breaker to the OFF

position will cause the unit to go into the battery back up mode. The

Do not EPO (Emergency Power OFF ) the UP S and then r eset the

breaker until the UPS has been fully discharged. T he UPS could be

damaged if the unit is not f ull y powered do wn before the breaker is

17

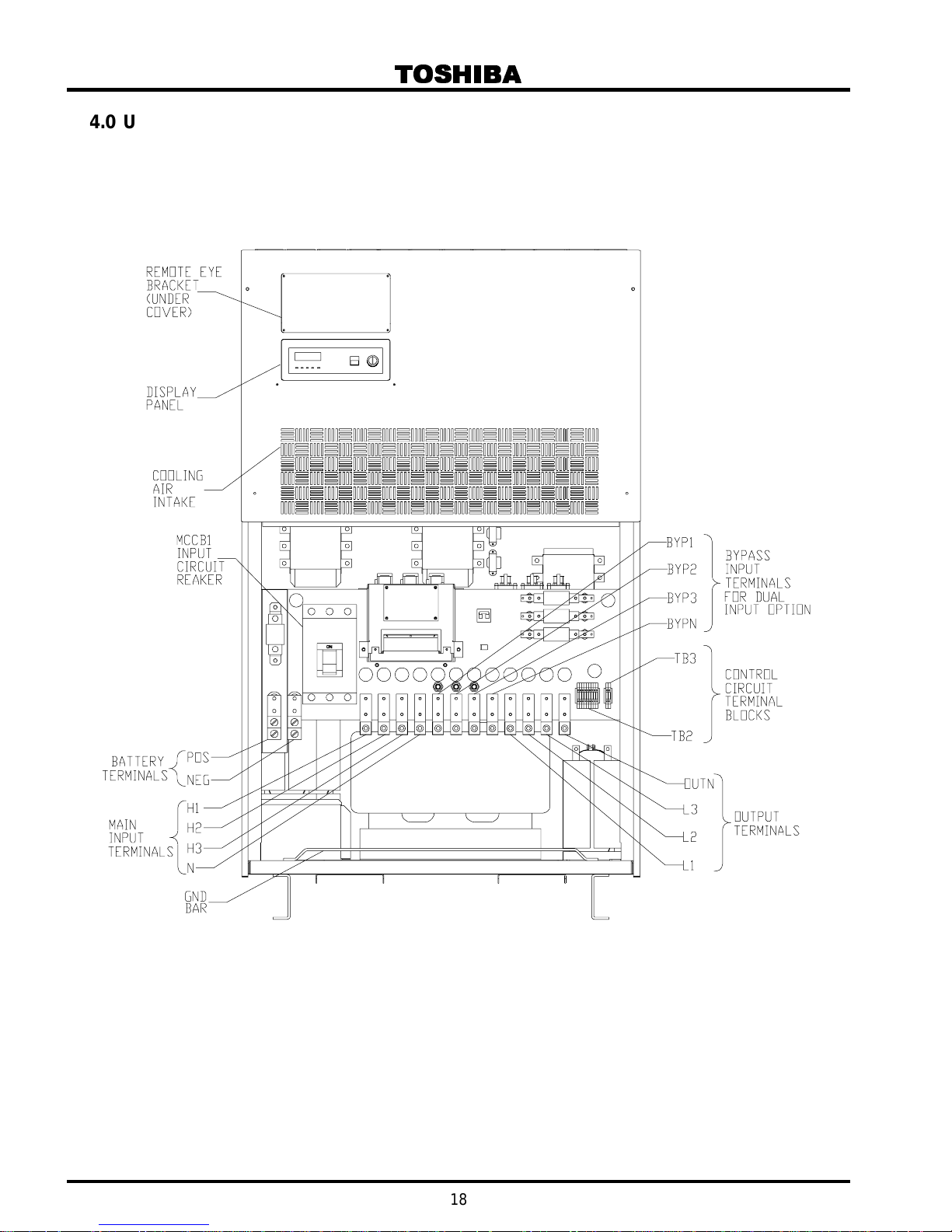

4.0 UPS Connections

4.1 UPS Power and Control Connection s

The following illustration shows the wiring c onnec tions to the input and output termi nation

points and the Control Cir c uit Terminal Blocks for the 4200FA 75/80 kVA UPS.

TOSHIBA

18

TOSHIBA

4.1.1 Recommended Wire Size and Tightening Torque for UPS Input/Output Terminals

Minimum/Maximum Wire Size and Tightening Torque

of UPS Input and Output Terminals

Main Input &

Bypass Input

208VAC 300MCM to 500MCM 400MCM to 500MCM 375

380, 400, 415VAC 2/0 to 500MCM 400MCM to 500MCM 375

480VAC 1/0 to 500MCM 400MCM to 500MCM 375

600VAC 1/0 to 500MCM 400MCM to 500MCM 375

Output

208V/120VAC 300MCM to 500MCM 400MCM to 500MCM 375

Battery Circuit AWG

288VDC Nominal 400MCM to 600MCM 500

BYP1, BYP2, BYP3)

AWG

(H1 – H3,

AWG

(L1, L2, L3)

(POS, NEG)

AWG

(N, BYPN)

AWG

(OUTN)

Tighte ni ng Torque

(in-lbs.)

Tighte ni ng Torque

(in-lbs.)

Tighte ni ng Torque

(in-lbs.)

Input/Output

Ground

All wire sizes are per NEC

Use copper wiring with at least 90°C rated insulat ion

Neutral Conductors are rated @ 1.73 or 200% of phase conductors, per NEC

Note 1: Use a UL listed lug suitable for the wire size used.

Note 2: Use tightening torque recommended by m anufacturer of lug used.

AWG

(GND)

2 minimum (see note 1) (see note 2)

19

Tighte ni ng Torque

(in-lbs.)

4.1.2 Power Connection Cab le Routing

1) Use separate met al c onduits for routing the input power, output power, battery, and

control circuits.

2) A separate ground cable shoul d be r un inside of the conduit wit h the input power, output

power, and control circuits.

3) Always ground the unit to prevent electrical shock and to help reduce electrical noise.

4) Follow wire size and tightening torque recomm endations provided in thi s manual.

TOSHIBA

CAUTION

THE METAL OF A CONDUIT IS NOT AN ACCEPTABLE

GROUND

Single Input UPS with input transformer. Shown with bottom cable entry

configuration.

20

TOSHIBA

Dual Input UPS with input transformer. Shown with bottom cable entry

configuration.

21

TOSHIBA

Single Input UPS with no transformers. Shown with bottom cable entry

configuration.

22

TOSHIBA

Dual Input UPS with no transformers. Shown with bottom cable entry

configuration.

23

TOSHIBA

Single Input UPS with input transformer. Shown with top cable entry configuration.

24

TOSHIBA

Dual Input UPS with input transformer. Shown with top cable entry configuration.

25

TOSHIBA

Single Input UPS with no transformers. Shown with top cable entry configuration.

26

TOSHIBA

Dual Input UPS with no transformers. Shown with top cable entry configuration.

27

4.1.3 Dual Input Configuration

Units are shipped from the factory wired for single input configuration. For those requiring

a dual input confi gur ation see below. This change should only be performed by factory

trained service p ersonnel and not by the end user.

TOSHIBA

Bypass jumpers are fac tory installed on bypass bus bars.

Single In p ut C onfiguration

Move wires from bypass bus bars to stand offs to configure for dual input.

Dual Input Configur a tion

28

TOSHIBA

4.2 Control Circuit and External Battery Int erf ace Con nections

The following illustrates the wiri ng connections of the Control Circuits and Battery Interfac e

Circuits.

4.2.1 Recommended Wire Size and Tightening Torque UPS Control and Battery Interface

Minimum Wire Siz e and Tight ening Torque for UPS Control and Batt ery Interface Circuits

TERMINAL (TERMINAL #) AWG TIGHTENING TORQUE

*UPS CONTROL CIRCUITS (1-18) 14-16 8 in-lbs.

*BATTERY CONTROL CIRCUITS (3-6) 14-16 8 in-lbs.

*Indicates Class 1 wi r in g metho d i s to be used.

USE MINIMUM 75° C COPPER WIRING

29

4.3 Communication Interface

4.3.1 Remote Contact

The remote contact interface is a standard feature and is available as dry switch

contacts through a DB9 male connector located on the bac k side of the UPS (see

Section 9 for DB9 connector location). The following schem atic shows the contact

state and pin assignm ent for each signal and the associated DB9 c onnec tor pinout.

5 System Common

6 Bypass Active

7 Battery Voltage Low

TOSHIBA

DB9 Male Connector Outline

(facing connector)

1 2 3 4 5

8 UPS On-line

9

Battery Discharge

4

1

Fault Signal Detect

2

Notes:

1) Switches are shown in their inactive states (if batt er y voltage is low pin 7 will be connected to System

Common).

2) Contacts are resistive loads rated at 30 VDC, 0.1A (125VAC 3A ).

3) Pin 3 is not used.

6 7 8 9

30

4.3.2 RS-232C

The RS-232C serial communication interf ac e is available via a DB9 female

connector located on the rear of the UPS (see Section 9 for DB9 connector

location). This interface allows control of the UPS from a personal computer

running special Toshiba software. The comput er and the UPS are connected

through a serial RS-232C communication port. The avail able data from the UPS,

via the RS-232C comm unic ation link is shown below.

Operating Conditions

UPS Operating Stat us

(Described as Yes or No)

Fault Detail s

(Described as Occurr ed or Not O c c urred)

TOSHIBA

Input Voltage

Output Voltage

Output Current

Battery Voltage

Input Frequency

Output Frequency

Utility Power OK

Low Battery Voltage Det ec ted

UPS in BYPASS Mode

UPS in NORMAL Mode

Input and Output Frequenc y S y nc hr oniz ed

UPD FAULT Occurred

DC Bus Over-Current

DC Bus Over-Voltage

DC Bus Under-Voltage

Input Over-Curr ent

Overheat

Overload Being Timed

Overload (all owable time exceeded)

Output Over- V oltage (during Normal Mode)

Output Under-V oltage (during Normal Mode)

The connector pin assignment and female connector outline are illustrat ed below.

Pin I/O Symbol Description

1 This pin is not used

2 Input RXD Receive D at a

3 Output TXD Transmit Data

4 Output DTR Data Terminal Ready

5 - SG Signal Ground

6 Input DSR Data Set Ready

7 Output RTS Request To Send

8 Input CTS Clear To Send

9 This pin is not used

4.3.3 UPS Shutdown (via RS-232C)

When the UPS is operating from its internal batteries, a S hutdown order can be

sent to the UPS telling i t t o turn OFF aft er a user-specif ied amount of time. This

function can allow you to stop discharging the UPS batt eri es af ter an orderly

system shutdown has been completed. The UPS can be programmed to turn OFF

up to 8 minutes after the S hutdown command is given. This command can be

cancelled before the specified time has elapsed by following the directions listed

on the RS232 screen.

DB9 Female connector outline

(facing connector)

54321

9876

31

TOSHIBA

328VDC (

2%) wi th 2.28V/cel l

3% (0-100% unbalanced load)

5V Manually from front key pad

4° (unbalanced load)

0.1% in free running mode

3% (transfer of bypa ss to inve rter)

0 to 40

C; optimal operating temperature is 25

C

5.0 Specifications

5.1 Specificati on s – 4200FA 75kVA with Internal Transf ormer

Model Number T42#3F750@AXXN

Rated Output Capacity 75kVA

External Dimensions 44 inch W x 31 inch D x 74 inch H

Weight 2150 pounds

Rated Voltage # = (B-208, H- 220, C-240, N-380,T-400/415, D-480, M-600 )Vac

Voltage Variation +10% to –15% ; (-15% to –30%) ****

Rated Frequency 50/60 Hz

Num ber P hases / Wires 3 Ph ase / 3 Wi re

Main Input

Optional

Bypass

Input

Battery

Output

Environment

(**) Batt er y b ac ku p tim e m ay v ary depen di ng on th e operating c ondi t ion s an d am bi ent temp erature at th e inst allati on sit e. A n initial

charge time of 24 hrs is necessary to obtain proper battery performance level before the unit is placed in operation.

(***) At 6600-ft (2000 m) above sea level, output capacity should be derated by 3% (Consult factory for higher elevations).

(****) Prolonged operation at this level requires derating of the maximum operating temperature to 35°C.

* Power Factor G r eater than 0.99 when in inverter mode

Required Input Power 70kW when in inverter mode

Walk-in Function From 20% to 100% over 5 seconds

Inrush Current Less than 12 times rated current under synchronous operation

Current Limit 115% maximum

* Harmonic Current s Less than 3% THD

Rated Voltage @ = (X-n/a, F-208)Vac

Voltage Variation +10% to –15%

Rated Frequency 50/60 Hz

Num ber P hases / Wires 3 Ph ase / 4 Wi re + GN D

DC Nominal (Voltage Range) 288VDC (230 to 332VDC)

Float Charge (Regulation)

Ripple Voltage 2% R.M.S.

**Rated Back-up Time Refer to Battery System Manual

Rated Charge Current 20.0 Amps ****

Rated Voltage 208 / 120 VAC

Rated Current 208 Amps

Rated Power Factor 0.8 lagging

Number Phases / Wires 3-phase / 4 W ire + GND

Voltage Regulation

(phase-phase)

Voltage Adjustment Range

Phase Displacement

Rated Frequency 50 / 60 Hz

Frequency Regulation

Frequency Synchronous

Operation Range

Frequency Slew Rate 1 Hz/s to 3 Hz/s

Voltage Transients

(Recovery time: 50 mS)

Inverter Overload Capacity 125% 30sec ; 150% 5sec

Bypass Overload Capacit y 1000% 10msec; 125% 10min.

Crest Factor 2.5

Neutral Line Conductor 1.73 times line rating

Harmonic Voltage Distortion 1.5% max (linear load)

Inrush Current protection Automatic transfer to bypass, then retransfer to inverter

Efficiency AC/DC/ AC: 87% typical; DC/AC: 90% typical

Heat loss to be r emoved 40,000Btu/hr (10kcal · kg/hr)

Audible Noise 75 dB (A) at 1 meter from the units front display

Operating T emperatu re

Operating Humidity Less than 90% RH (non-condensing)

Altitude *** Less than 1000 meters

Items marked with an (*) are specified at rated conditions under balanced linear loads.

± 2% (0-100% balanced load)

±

±

± 2° (0-100% balanced load)

±

± .5/1.0/1.5 Hz (± 1.0 Hz. std.)

switch selectable by qualified technician

± 3% (100% load step change)

± 5% (loss or return of input voltage)

±

°

±

±

°

32

TOSHIBA

328VDC (

2%) wi th 2.28V/cel l

3% (0-100% unbalanced load)

5V Manually from front key pad

4° (unbalanced load)

0.1% in free running mode

3% (transfer of bypa ss to inve rter)

0 to 40

C; optimal operating temperature is 25

C

5.2 Specificati on s – 4200FA 75kVA without Internal Transformer

Model Number T42F3F750@AXXN

Rated Output Capacity 75kVA

External Dimensions 44 inch W x 31 inch D x 74 inch H

Weight 1560 pounds

Rated Voltage 208 Vac

Voltage Variation +10% to –15% ; (-15% to –30%) ****

Rated Frequency 50/60 Hz

Num ber P hases / Wires 3 Ph ase / 3 Wi re

Main Input

Optional

Bypass

Input

Battery

Output

Environment

(**) Batt er y b ac ku p tim e m ay v ary depen di ng on th e operating c ondi t ion s an d am bi ent temp erature at th e inst allati on sit e. A n initial

charge time of 24 hrs is necessary to obtain proper battery performance level before the unit is placed in operation.

(***) At 6600-ft (2000 m) above sea level, output capacity should be derated by 3% (Consult factory for higher elevations).

(****) Prolonged operation at this level requires derating of the maximum operating temperature to 35°C.

* Power Factor G r eater than 0.99 when in inverter mode

Required Input Power 70kW when in inverter mode

Walk-in Function From 20% to 100% over 5 seconds

Inrush Current Less than 12 times rated current under synchronous operation

Current Limit 115% maximum

* Harmonic Current s Less than 3% THD

Rated Voltage @ = (X-n/a, F-208)Vac

Voltage Variation +10% to –15%

Rated Frequency 50/60 Hz

Num ber P hases / Wires 3 Ph ase / 4 Wi re + GN D

DC Nominal (Voltage Range) 288VDC (230 to 332VDC)

Float Charge (Regulation)

Ripple Voltage 2% R.M.S.

**Rated Back-up Time Refer to Battery System Manual

Rated Charge Current 20.0 Amps ****

Rated Voltage 208 / 120 VAC

Rated Current 208 Amps

Rated Power Factor 0.8 lagging

Number Phases / Wires 3-phase / 4 W ire + GND

Voltage Regulation

(phase-phase)

Voltage Adjustment Range

Phase Displacement

Rated Frequency 50 / 60 Hz

Frequency Regulation

Frequency Synchronous

Operation Range

Frequency Slew Rate 1 Hz/s to 3 Hz/s

Voltage Transients

(Recovery time: 50 mS)

Inverter Overload Capacity 125% 30sec ; 150% 5sec

Bypass Overload Capacit y 1000% 10msec; 125% 10min.

Crest Factor 2.5

Neutral Line Conductor 1.73 times line rating

Harmonic Voltage Distortion 1.5% max (linear load)

Inrush Current protection Automatic transfer to bypass, then retransfer to inverter

Efficiency AC/DC/ AC: 87% typical; DC/AC: 90% typical

Heat loss to be r emoved 40,000Btu/hr (10kcal · kg/hr)

Audible Noise 75 dB (A) at 1 meter from the units front display

Operating T emperatu re

Operating Humidity Less than 90% RH (non-condensing)

Altitude *** Less than 1000 meters

Items marked with an (*) are specified at rated conditions under balanced linear loads.

± 2% (0-100% balanced load)

±

±

± 2° (0-100% balanced load)

±

± .5/1.0/1.5 Hz (± 1.0 Hz. std.)

switch selectable by qualified technician

± 3% (100% load step change)

± 5% (loss or return of input voltage)

±

°

±

±

°

33

TOSHIBA

328VDC (

2%) wi th 2.28V/cel l

3% (0-100% unbalanced load)

5V Manually from front key pad

4° (unbalanced load)

0.1% in free running mode

3% (transfer of bypa ss to inve rter)

0 to 40

C; optimal operating temperature is 25

C

5.3 Specificati on s – 4200FA 80kVA with Internal Transf ormer

Model Number T42#3F800@AXXN

Rated Output Capacity 80kVA

External Dimensions 44 inch W x 31 inch D x 74 inch H

Weight 2150 pounds

Rated Voltage # = (B-208, H- 220, C-240, N-380,T-400/415, D-480, M-600 )Vac

Voltage Variation +10% to –15% ; (-15% to –30%) ****

Rated Frequency 50/60 Hz

Num ber P hases / Wires 3 Ph ase / 3 Wi re

Main Input

Optional

Bypass Input

Battery

Output

Environment

(**) Batt er y b ac ku p tim e m ay v ary depen di ng on th e operating c ondi t ion s an d am bi ent temp erature at th e inst allati on sit e. A n initial

charge time of 24 hrs is necessary to obtain proper battery performance level before the unit is placed in operation.

(***) At 6600-ft (2000 m) above sea level, output capacity should be derated by 3% (Consult Factory for higher elevations).

(****) Prolonged operation at this level requires derating of the maximum operating temperature to 35°C.

* Power Factor G r eater than 0.99 when in inverter mode

Required Input Power 75kW when in inverter mode

Walk-in Function From 20% to 100% over 5 seconds

Inrush Current Less than 12 times rated current under synchronous operation

Current Limit 115% maximum

* Harmonic Current s Less than 3% THD

Rated Voltage @ = (X-n/a, F-208)Vac

Voltage Variation +10% to –15%

Rated Frequency 50/60 Hz

Num ber P hases / Wires 3 Ph ase / 4 Wi re + GN D

DC Nominal (Voltage Range) 288VDC (230 to 332VDC)

Float Charge (Regulation)

Ripple Voltage 2% R.M.S.

**Rated Back-up Time Refer to Battery System Manual

Rated Charge Current 20.0 Amps ****

Rated Voltage 208 / 120 VAC

Rated Current 223 Amps

Rated Power Factor 0.8 lagging

Number Phases / Wires 3-phase / 4 W ire + GND

Voltage Regulation

(phase-phase)

Voltage Adjustment Range

Phase Displacement

Rated Frequency 50 / 60 Hz

Frequency Regulation

Frequency Synchronous

Operation Range

Frequency Slew Rate 1 Hz/s to 3 Hz/s

Voltage Transients

(Recovery time: 50 mS)

Inverter Overload Capacity 125% 30sec ; 150% 5sec

Bypass Overload Capacit y 1000% 10msec; 125% 10min.

Crest Factor 2.5

Neutral Line Conductor 1.73 times line rating

Harmonic Voltage Distortion 1.5% max (linear load)

Inrush Current protection Automatic transfer to bypass, then retransfer to inverter

Efficiency AC/DC/ AC: 87% typical; DC/AC: 90% typical

Heat loss to be r emoved 40,000Btu/hr (10kcal · kg/hr)

Audible Noise 75 dB (A) at 1 meter from the units front display

Operating T emperatu re

Operating Humidity Less than 90% RH (non-condensing)

Altitude *** Less than 1000 meters

Items marked with an (*) are specified at rated conditions under balanced linear loads.

± 2% (0-100% balanced load)

±

±

± 2° (0-100% balanced load)

±

± .5/1.0/1.5 Hz (± 1.0 Hz. std.)

switch selectable by qualified technician

± 3% (100% load step change)

± 5% (loss or return of input voltage)

±

°

±

±

°

34

TOSHIBA

328VDC (

2%) wi th 2.28V/cel l

3% (0-100% unbalanced load)

5V Manually from front key pad

4° (unbalanced load)

0.1% in free running mode

3% (transfer of bypa ss to inve rter)

0 to 40

C; optimal operating temperature is 25

C

5.4 Specificati on s – 4200FA 80kVA without Internal Transformer

Model Number T42F3F750@AXXN

Rated Output Capacity 80kVA

External Dimensions 44 inch W x 31 inch D x 74 inch H

Weight 1560 pounds

Rated Voltage 208 Vac

Voltage Variation +10% to –15% ; (-15% to –30%) ****

Rated Frequency 50/60 Hz

Num ber P hases / Wires 3 Ph ase / 3 Wi re

Main Input

Optional

Bypass

Input

Battery

Output

Environment

(**) Batt er y b ac ku p tim e m ay v ary depen di ng on th e operating c ondi t ions and am bi en t tem perature at the inst al l at i on sit e. A n initial

charge time of 24 hrs is necessary to obtain proper battery performance level before the unit is placed in operation.

(***) At 6600-ft (2000 m) above sea level, output capacity should be derated by 3% (Consult factory for higher elevations).

(****) Prolonged operation at this level requires derating of the maximum Operating Temperature to 35°C.

* Power Factor G r eater than 0.99 when in inverter mode

Required Input Power 75kW when in inverter mode

Walk-in Function From 20% to 100% over 5 seconds

Inrush Current Less than 12 times rated current under synchronous operation

Current Limit 115% maximum

* Harmonic Current s Less than 3% THD

Rated Voltage @ = (X-n/a, F-208)Vac

Voltage Variation +10% to –15%

Rated Frequency 50/60 Hz

Num ber P hases / Wires 3 Ph ase / 4 Wi re + GN D

DC Nominal (Voltage Range) 288VDC (230 to 332VDC)

Float Charge (Regulation)

Ripple Voltage 2% R.M.S.

**Rated Back-up Time Refer to Battery System Manual

Rated Charge Current 20.0 Amps ****

Rated Voltage 208 / 120 VAC

Rated Current 223 Amps

Rated Power Factor 0.8 lagging

Number Phases / Wires 3-phase / 4 W ire + GND

Voltage Regulation

(phase-phase)

Voltage Adjustment Range

Phase Displacement

Rated Frequency 50 / 60 Hz

Frequency Regulation

Frequency Synchronous

Operation Range

Frequency Slew Rate 1 Hz/s to 3 Hz/s

Voltage Transients

(Recovery time: 50 mS)

Inverter Overload Capacity 125% 30sec ; 150% 5sec

Bypass Overload Capacit y 1000% 10msec; 125% 10min.

Crest Factor 2.5

Neutral Line Conductor 1.73 times line rating

Harmonic Voltage Distortion 1.5% max (linear load)

Inrush Current protection Automatic transfer to bypass, then retransfer to inverter

Efficiency AC/DC/ AC: 87% typical; DC/AC: 90% typical

Heat loss to be r emoved 40,000Btu/hr (10kcal · kg/hr)

Audible Noise 75 dB (A) at 1 meter from the units front display

Operating T emperatu re

Operating Humidity Less than 90% RH (non-condensing)

Altitude *** Less than 1000 meters

Items marked with an (*) are specified at rated conditions under balanced linear loads.

± 2% (0-100% balanced load)

±

±

± 2° (0-100% balanced load)

±

± .5/1.0/1.5 Hz (± 1.0 Hz. std.)

switch selectable by qualified technician

± 3% (100% load step change)

± 5% (loss or return of input voltage)

±

°

±

±

°

35

6.0 Operating the UPS

6.1 Operating the UPS

6.1.1 AC Input Mode (normal operation)

The following illustration shows circuit power flow when the UPS is operati ng normally in the

AC input mode. The conver ter of the UPS, including a boost chopper ci r c uit, converts the AC

input power to DC power. The boost c hopper c ircuit maintains a constant voltage and

provides current lim iting for battery chargi ng. It also supplies a DC voltage of the proper lev el

to the inverter section. The inverter secti on generates a high quality sine wav e output

voltage. The UPS batteries always maintai n a charge during normal UPS operation.

TOSHIBA

Power Flow

Isolating

Input

Power

XFMR

6.1.2 Bypass Mode

If the UPS detects an overload or develops an internal fault , power flow is automatic ally

switched from the main ci r c uit of the UPS to the By pass ci r c uit. Power flow through the

Bypass is shown in the following illustrati on. This changeover occurs automatically in less

than 4 milliseconds. The s witching period is not long enough to cause interruptions to oc c ur

in most loads. If the power flow is tr ansferred to the bypass circ uit because of an overload

and the overload condition ends within a specifi ed peri od of time, normal operation wil l

resume automati c ally (see Section 6.16 Overl oad Oper ation).

If the power flow is transferred to the bypass circui t due t o a fault c ondition, the power flow

must be transfer r ed m anually from the Bypass circuit back to the i nv erter circuit after the

fault is cleared ( see Section 6.11 Start-up Procedur e) .

Static

Bypass

MCCB

Converter Inverter

Charger/

Chopper

External

Batteries

Power flow in AC input mode for the 4200FA 75/80 kVA UPS

Output

Power

Power Flow

Isolating

Input

Power

XFMR

Power flow in circuit -bypass mode for the 4200FA 75/80 kVA UPS

MCCB

Static

Bypass

Converter Inverter

Charger/

Chopper

External

Batteries

36

Output

Power

6.1.3 Battery Backup Mod e

The following illustration shows power flow during the battery backup mode. In the event of

an AC power failur e the batter ies of the UPS instantly begin supplying DC power to the UPS

to the main inverter circuit. This circuit c onv ert s the DC power i nto AC power. The AC power

is availabl e at t he output of t he unit. This back-up process will continue until the UPS battery

voltage drops bel ow a specif ic minimum level. At which time the batteries cease supplyi ng

power to the load.

This minimum level is the shutdown voltage minimum (V min). The rated battery voltage

table on page 33 shows (V min). The bat tery backup time and discharge proces s i s

explained in S ection 6.2.

TOSHIBA

Power Flow

Input

Power

Static

Bypass

Charger/

Chopper

External

Batteries

Isolating

XFMR

MCCB

Converter Inverter

Power flow in battery backup mod e for the 4200 FA 75/80 kVA UPS

Output

Power

37

TOSHIBA

6.2 Battery Backup Time and Disch arge Process

The UPS system, when used in conj unc tion with a Toshiba designed Battery System, is

designed to provi de several minutes of back-up time for the 4200FA UPS (Refer to the

Battery System M anual for back-up times). These times are valid for full-load oper ation. At

half-load operat ion the batteries can provide approximately 2 times the specified value. The

exact times will depend on the UPS model used, condition of the batt eri es, amount and type

of load, temper ature, and other variables.

CAUTION

The following illustration shows the battery discharge process at full load c onditions.

Contact your Toshiba sal es repres entative if using bat tery systems

other than Toshi ba- desi gned battery systems to determine compliance.

Using other systems may void the warranty and/or the saf ety

certifications.

6.3 Battery Low Volt age Tolerances

Excessive discharge will cause the UPS batter y volt age to drop below tolerable levels. The

table below list s the normal operating voltage, the voltage levels at which the low-voltage

alarm will sound, and the low-voltage level at which an automatic shut down will occur .

Nominal Voltage 288 VDC

Alarm Voltage 252 VDC

Shutdown Voltage min. 216 VDC

38

6.4 Battery Recharging

The illustration below shows the battery rec har ge pr oc ess af ter a full discharge.

TOSHIBA

The recharge process typically consists of three periods. During the fi r st period, the charging

current is maintained at approximately 20.0 amperes. This current is the maximum value that

can be used to charge the batteries (for minimal rec har ge time) while assuring safet y and

long battery life.

In the second period, constant-voltage c ontrol starts and the current gr adually decreases as

the batteries charge to the fully charged state.

In the third peri od, a t ri ckle current continues to fl ow into the batteries to maintai n the f ully

charged status at the normal DC Voltage level.

A full recharge requires approximatel y 24 hours (90% rec har ge in 10 hours) after a complet e

discharge.

The following table shows the rated maximum and minimum battery voltages, and the

charge current for each of the sizes for 75°C operati on.

Rated Battery Voltages

V float

V min

I charge

332 VDC

214 VDC

20.0 Amps

39

6.5 Front Panel Layout (All Units)

Line-1

TOSHIBA

4-line liquid crystal

display screen

(see Section 6. 9)

Line-2

Line-3

Line-4

Green light- emit ting

diodes (LED)

(see Section 6. 8)

INV BYP BATT FAULT

AC IN

Red light-emitting

diode (LED)

(see Section 6. 8)

Emergency

Power Off swi tch

(see Section 6. 6)

BATT F1

MONI

INPUT

BUZZ

STOP

RESET

BATT

OUTPUT

TEST

MENU ENTER

12-key Data entry key pad

(see Section 6. 13)

RUN/STOP

key switch

EPO RUNSTOP

ON LINE

UNINTERUPTIB LE POW ER SYSTEM

UPS

4200

FA

40

TOSHIBA

6.6 EPO (Emergency Power Off) Functi on

The 4200FA UPS system is equi pped with terminals for receiv ing an emergency power-off

(EPO) closed contact switc h c ommand from two locations: (1) a rem ote loc ation (see

Section 4.2 Terminal Block Details) and (2) fr om a fr ont panel mounted EPO switch (see

Section 6.5 Front P anel Lay out).

This safety f eature enables quick shutdown of the UPS AC output and bat tery circuits.

Typically the em er genc y power off switch is installed in a central location that is easily

accessible to personnel concerned with the operation of the UPS unit and the equi pm ent

connected to it. The EPO function is initiated by pressing the switch to the closed Shutdown

position. The effect of using the EPO switch is the same whether t he UP S unit is in the AC

input mode (see Section 6.1.1), battery backup mode ( see Sec tion 6.1.3), or the circuit

bypass mode (see Section 6.1.2). See EMERGENCY OFF screen in Secti on 6.12

Shutdown Procedure. T he following figure shows the UPS condition after applicati on of t he

EPO switch. Use the Start-up Procedure (see Section 6.11) for rest ar ting the unit.

Power Flow

Isolating

Input

Power

XFMR

6.7 Audible Alarm Functions

While in the battery backup mode, during a fault, duri ng a low batt er y condition, or if the

system is in an overload condition, an audible al arm will sound. The following tabl e shows

the audible alarm pattern for each condition. Time interv als are shown in seconds. The

audible alarm c an be stopped by pressi ng the BUZZ STOP key (see Section 6.5 Front Panel

Layout).

Condition Audible pattern

UPS in Battery Backup Mode

(Battery Voltage 100-90%)

TRIPPED

MCCB

OFF

Static

Bypass

Converter Inverter

OFF OFF

Charger/

Chopper

OFF

External

Batteries

1 S7 S

Output

Power

UPS Low Battery

(Battery Volt age < 90%)

Overload

Fault

1 S 1 S

.5 S.5 S

.5 S.5 S

41

6.8 User Notification LEDs

The following is a li st of t he user-notification LEDs and their function.

On when the UPS is not in an input over-voltage condition, input under-voltage condition, or

power failure state. If there is an input power failure this LED is off. If there is no power

failure and the input voltage is in an over-volt age c ondition, the AC IN LED will flicker on and

off rapidly (0.4 sec on and 0.4 sec off). If there is no power failure and the input voltage is in

an under-voltage c ondition the AC IN LED will be off.

On when the UPS inverter is operat ing.

On when the UPS is in the static bypass mode.

On when the UPS is in the batter y-discharge mode. If the battery is l ow duri ng a batt er y

discharge, the B ATT lamp will flicker on and off slowly ( 1.2 second on and 1.2 second of f).

The BATT LED will go off if the battery voltage reaches the shutdown level during the

battery-discharge mode.

TOSHIBA

On when the UPS is experiencing a fault.

6.8.1 LED System Status

The following table shows the UPS system status that can be determined by

decoding the on and off condition of the LED lamps. It should be used in

conjunction with the LCD display (see Section 6.9) and the audible alarms (see

Section 6.7) f or t otal system monitoring.

LED ON/OFF STATUS LED ON/OFF STATUS

Normal UPS Operation

(UPS on-line, no abnorm al c onditions)

AC IN

INV

BYP

BATT

FAULT

Bypass Operation; UPS Fault

AC IN

INV

BYP

BATT

FAULT

Battery Back-up; (Battery Voltage Low)

AC IN

INV

BYP

BATT

FAULT

ON

ON

OFF

OFF

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON (Blinking)

OFF

Output Shutdown

(After Emergenc y Power Off rec eived (EPO))

AC IN

BYP

BATT

FAULT

Fatal Communicati on E r r or

(Display t o Control Interface)

AC IN

BYP

BATT

FAULT

INV

INV

OFF

OFF

OFF

OFF

OFF

ALL ON OR

FLICKERING

RAPIDLY

42

6.9 LCD Functions

The LCD display is a 4-line by 20- c har ac ter display. The LCD display c onv ey s system

operational i nformation. It should be used in conjunc tion with the LED display (see Secti on

6.8) and the audible al arms (see Section 6.7) for total system monitoring.

Listed below are the t y pes of user-notificati on messages that are available f or each line of

the LCD display screen and a description of each. This message display ed is determined by

the UPS operating mode and conditions. These messages are shown i n the following line

message tables.

6.9.1 Line-1 System Messages

Line-1 messages are based on the operating mode. The following table shows all

allowable Line-1 messages, which occur while starting up and while in main

monitor (MONI) screen mode.

Display Message Description

- UPS START UP -

- BYPASS OPERATION -

- UPS ON-LINE -

- BATTERY DISCHARGE -

- O UTPUT SHUTDOWN -

- BATTERY BACKUP -

TOSHIBA

LINE-1 MESSAGES

Displayed when UPS is i n the start-up condition

or display board is resett ing.

Displayed when the UPS is in Bypass

Operation.

Displayed when the inverter is running, and no

Utility abnormal exists.

Displayed duri ng Utility abnormal; inverter is

supplying power f r om batt eri es. ( U nit shuts

down after V (min.) i s reached.

Displayed duri ng power failure if V (min.) is

reached, or an EPO is received, or after

completion of Start-Up Sequence of the Inverter

and Bypass is not av ailable.

Displayed during input power failure.

6.9.2 Line-2 System Fault Messages

Line-2 fault messages are automatically displayed when a system fault is detect ed.

Display Message

DCUV DC Under-voltage

DCOC DC Over - c ur rent

DCUB DC Unbalanced

DCOV DC Over-voltage

EERR Main EEPROM error

OH Overheat (internal)

OL Output Overload

IVUV Inv erter Under -voltage

IVOV Inverter O ver -voltage

6.9.3 Line-3 System Messages

Line–3 messages show load curr ent information, and user sel ec ted instructions.

LINE-2 MESSAGES

Meaning

43

6.9.4 Line-4 System Messages

Line-4 messages ref lect the UPS operating conditi ons. Warning messages will be

displayed when an abnormal operating condition occurs. The following t able shows

the allowable Li ne- 4 m essages.

Displayed Message Meaning

PHEI

I/O NOT SYNCHRONIZE

* AUTOTRAN SFER *

* BATTERY LOW *

* UPS OL: REDUCE LOAD *

* DCOC *

* DCOV *

* DCUB *

* UPS OL *

* INOV *

* INUV *

* BATTOH *OR MCCB-B OPEN

* UPS OK *

* DISCHARGE CURR=###% *

* TRANSFER INHIBITED *

* EMERGENCY OFF *

* UPS OUTPUT DISABLED *

* FAULT(S) DETECTED *

Note:

1) Line-4 will be blank when the BATT key is pressed during battery back up m ode

with normal batt er y v oltage.

TOSHIBA

Line-4 Messages

Displayed when input P hase rot ation is not wired for

clockwise rotation.

Displayed when input and output frequencies are not

synchronized. ( abnormal)

Displayed when auto-tr ansfer to bypass is active (i.e.

current limit r eac hed) . (abnormal)

Displayed when battery voltage is low (abnormal ) or

the UPS batteri es have f ailed self-diagnostic test.

(abnormal)

Displayed when UPS has tri pped due to an overload

condition. (abnormal)

Displayed when the UPS has an internal failure.

(abnormal)

Displayed when the UPS has an int ernal DC bus

over-voltage. (abnormal)

Displayed when the UPS has an int ernal DC bus

unbalance refer enc ed to Neutral. (abnormal )

Displayed when UPS has tri pped due to an overload

condition. (abnormal)

Displayed when inverter output over-volt age has

occurred. (abnormal)

Displayed when inverter output under-v oltage has

occurred. (abnormal)

Displayed when the optional battery over -tem p

sensor has annunciated, or if the external batter y

disconnect is open. ( V erify TB3-5,6)

Displayed when none of the above abnormal

conditions are present. ( nor mal)

Displayed when none of the above abnormal

conditions are present and t he UP S is in battery

discharge mode. (normal backup)

Displayed when key switc h posi tion is changed and

frequency is not synchr onized. (abnormal)

Displayed when an emergenc y ( E PO) si gnal is

received.

Displayed when UPS has normally shutdown.

Displayed when a fault or faults have occurred.

(abnormal)

2) The # symbol signifies num eri c al v al ues or ot her information suppli ed by t he UPS.

44

6.10 Initial Battery Charge

The battery of the UPS must be char ged before it is used for the first time or if the unit has

not been used (AC power source rem oved) for more than 10 days. Use the following

procedure to rechar ge the battery of the UPS.

1) Switch on power at the UPS i nput distribution panel.

2) Move the MCCB1 power switch to On (see Section 4 for location). Not e: The

3) With the key switch in t he STOP posi tion, the AC IN and the BYP lamp will be

TOSHIBA

battery chargi ng ci r c uit is now activated. The AC IN lamp will be on. The LCD

display (see Secti on 6.5 "Front Panel Layout") will display the following

message:

- UPS START UP -

> PLEASE WAIT

on and the LCD display will show the following message:

- BYPASS OPERATION OUTPUT VOLTAGE=208V

>CURRENT 100/100/100%

(DATE) DAY (TIME)

4) Turn the Key Switch to RUN and the UPS performs the Automatic Batter y Test

(The Automatic B att er y Test is performed only when the software is enabl ed

for this functi on. The default setting is Disabled) .

(Allow 24 hours for the batteries to fully charge).

Should the Automati c Battery Test fail and the LOW BATTERY message is

displayed use the following procedure:

1) Turn the key switch to STOP.

2) Allow 24 hours for t he batt eri es to c har ge and, upon completion, m ov e the

MCCB switch (see Section 4 for location) to off.

3) Repeat Initi al B att ery Charge procedure (a fail ur e indic ates battery

replacement r equir ed) .

45

6.11 Start-up Procedure

The UPS batteries m ust be c har ged before the UPS is used for the first time or if the unit has

not been used (ac power source rem oved) for more than 10 days (Refer to S ection 6.10).

If the batteries are c har ged perform the start-up pr oc edur e as follows: