T300MVi

ADJUSTABLE SPEED MOTOR DRIVE

INSTRUCTION MANUAL

TOSHIBA INTERNATIONAL CORPORATION

Document Number: IF08CZ00

June, 2009

MEDIUM VOLTAGE

TOSHIBA INTERNATIONAL CORPORATION

13131 WEST LITTLE YORK

HOUSTON, TEXAS 77041

Tel: 1-713-466-0277

1-800-231-1412

Printed in U.S.A.

- ii -

Important Notice

The instructions contained in this manual are not intended to cover all details or variations in

equipment types, nor may it provide for every possible contingency concerning the installation, operation, or

maintenance of this equipment. Should additional information be required contact your Toshiba

representative.

The contents of this manual shall not become a part of or modify any prior or existing agreement,

commitment, or relationship. The sales contract contains the entire obligation of Toshiba International

Corporation. The warranty contained in the contract between the parties is the sole warranty of Toshiba

International Corporation and any statements contained herein do not create new warranties or modify the

existing warranty.

Any electrical or mechanical modifications to this equipment without prior written consent of

Toshiba International Corporation will void all warranties and may void the UL/CUL listing or other

safety certifications. Unauthorized modifications may also result in a safety hazard or equipment

damage.

Misuse of this equipment could result in injury and equipment damage. In no event will

Toshiba Corporation be responsible or liable for either indirect or consequential damage or injury

that may result from the misuse of this equipment.

TOSHIBA INTERNATIONAL CORPORATION

Adjustable Spe ed D rive

Please complete th e Warra nty Card suppl ied w ith the ASD and retu r n it to Tos h iba by prep aid ma il. This w ill

activate the 12 month warranty from the date of installation; but, shall not exceed 18 months from the date of

purchase.

Complete the following information about the drive and r etain it for your records.

Model Number:

Serial Number:

Project Number (if applicable):

Date of Installation:

Inspected By:

Name of Application:

- iii -

Manual’s Purpose and Scope

This manual provides information on how to safely install, operate, and maintain your TIC power

electronics product. This manual includes a section of general safety instructions that describes the warning

labels and symbols that are used throughout the manual. Read the manual completely before installing,

operating, or performing maintenance on this equipment.

This manual and the accompanying drawings should be considered a permane nt part of the

equipment and should be readily available for reference and review. Dimensions shown in the manual are in

metric and/or the English equivalent.

Toshiba International Corporation reserves the right, without prior notice, to update information,

make product changes, or to discontinue any product or service identified in this publication.

TOSHIBA is a registered trademark of the Toshiba Corporation. All other product or trade

references appearing in this manual are registered trademarks of their respective owners.

Toshiba International Corporation (TIC) shall not be liable for direct, indirect, special, or

consequential damages resulting from the use of the information contained within this manual.

This manual is copyrighted. No part of this manual may be photocopied or reproduced in any form

without the prior written consent of Toshiba International Corporation.

© Copyright 2006 Toshiba International Corporation.

All rights reserved.

Printed in the U.S.A.

Contacting Toshiba’s Customer Support Center

Toshiba’s Customer Support Center can be contacted to obtain help in resolving any Adjustable

Speed Drive system problem that you may experience or to provide application information.

The center is open from 8 a.m. to 5 p.m. (CST), Monday through Friday. The Support Center’s toll

free number is US (800) 231-1412/Fax (713) 466-8773 — Canada (80 0) 527-1204.

You may also contact Toshiba by writing to:

Toshiba International Corporation

13131 West Little York Road

Houston, Texas 77041-9990

Attn: ASD Product Manager.

For further information on Toshiba’s products and services, please visit our website at

www.toshiba.com/ind

.

- iv -

General Safety Instructions

DO NOT attempt to install, operate, maintain or dispose of this equipment until you have read and

understood all of the product safety information and directions that are contained in this manual.

Safety Alert Symbol

The Safety Alert Symbol indicates that a potential personal injury hazard exists. The symbol is

comprised of an equilateral triangle enclosing an exclamation mark.

Signal Words

Listed below are the signal words that are used throughout this manual followed by their

descriptions and associated symbols. When the words DANGER, WARNING and CAUTION are used in

this manual they will be followed by important safety information that must be adhered to.

The word DANGER preceded by the safety alert symbol indicates that an imminently hazardous

situation exists that, if not avoided, will result in death or serious injury to personnel.

DANGER

The word WARNING preceded by the safety alert symbol indicates that a potentially hazardous

situation exists that, if not avoided, could result in death or serious injury to personnel.

WARNING

The word CAUTION preceded by the safety alert symbol indicates that a potentially hazardous

situation exists which, if not avoided, may result in minor or moderate injury.

CAUTION

The word CAUTION without the safety alert symbol indicates a potentially hazardous situation

exists which, if not avoided, may result in equipment and property damage.

CAUTION

- v -

Special Symbols

To identify special hazards, other symbols may appear in conjunction with the DANGER,

WARNING and CAUTION signal words. These symbols indicate areas that require special and/or strict

adherence to the procedures to prevent serious injury to personnel or death.

Electrical Hazard Symbol

A symbol which indicates a hazard of injury from

electrical shock or burn. It is comprised of an equilateral

triangle enclosing a lightning bolt.

Explosion Hazard Symbol

A symbol which indicates a hazard of injury from

exploding parts. It is comprised of an equilateral triangle

enclosing an explosion image.

- vi -

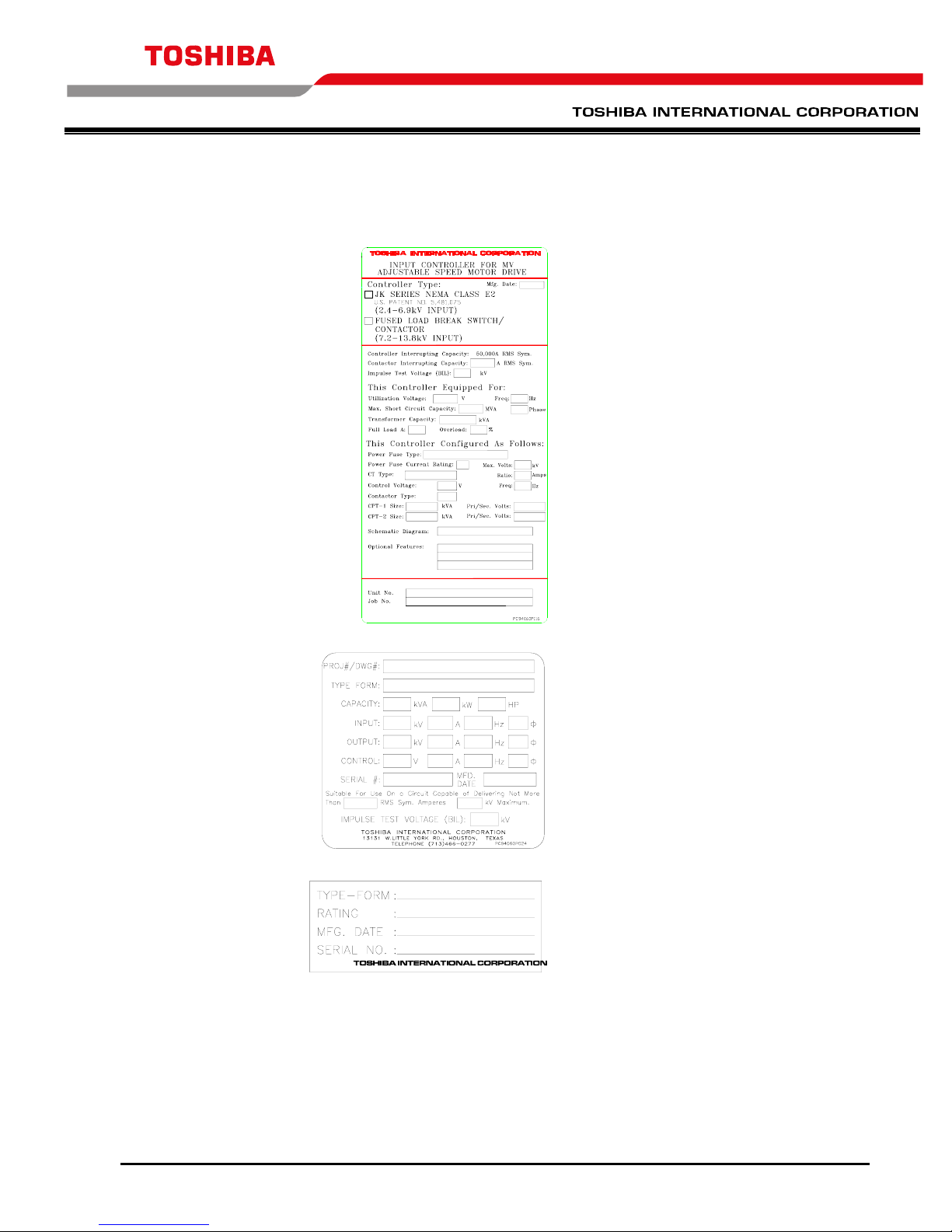

Equipment Labels (Safety, Rating, Information)

DO NOT attempt to install, operate, perform maintenance, or dispose of this equipment until you

have read and understood all of the product labels and user directions that are contained in this manual.

Shown below are examples of safety labels that may be found attached to the equipment. DO NOT

remove or cover any of the labels. If the labels are damaged or if additional labels are required, contact your

Toshiba representative for additional labels.

Labels attached to the equipment are there to provide useful information or to indicate an

imminently hazardous situation that may result in serious injury, severe property and equipment damage, or

death if the instructions are not followed.

SAFETY labels that will be found on the equipment are shown below:

- vii -

RATING labels that will be found on the equipment are shown below:

Input Controller Rating Label

Note: If no input controller is

supplied, this label will not be

present. Refer to label on upstream

equipment for rating data.

Adjustable Speed Drive Rating Label

Inverter Power Module Rating Label

Note:

The above labels are shown blank. The labels affixed to the equipment will be filled in with rating data

specific to the actual unit(s) furnished. Complete rating data is also provided on the rating sheet included

in the supplementary drawing packet. Ensure that all rating data matches the power system and the

driven load connected to the equipment.

- viii -

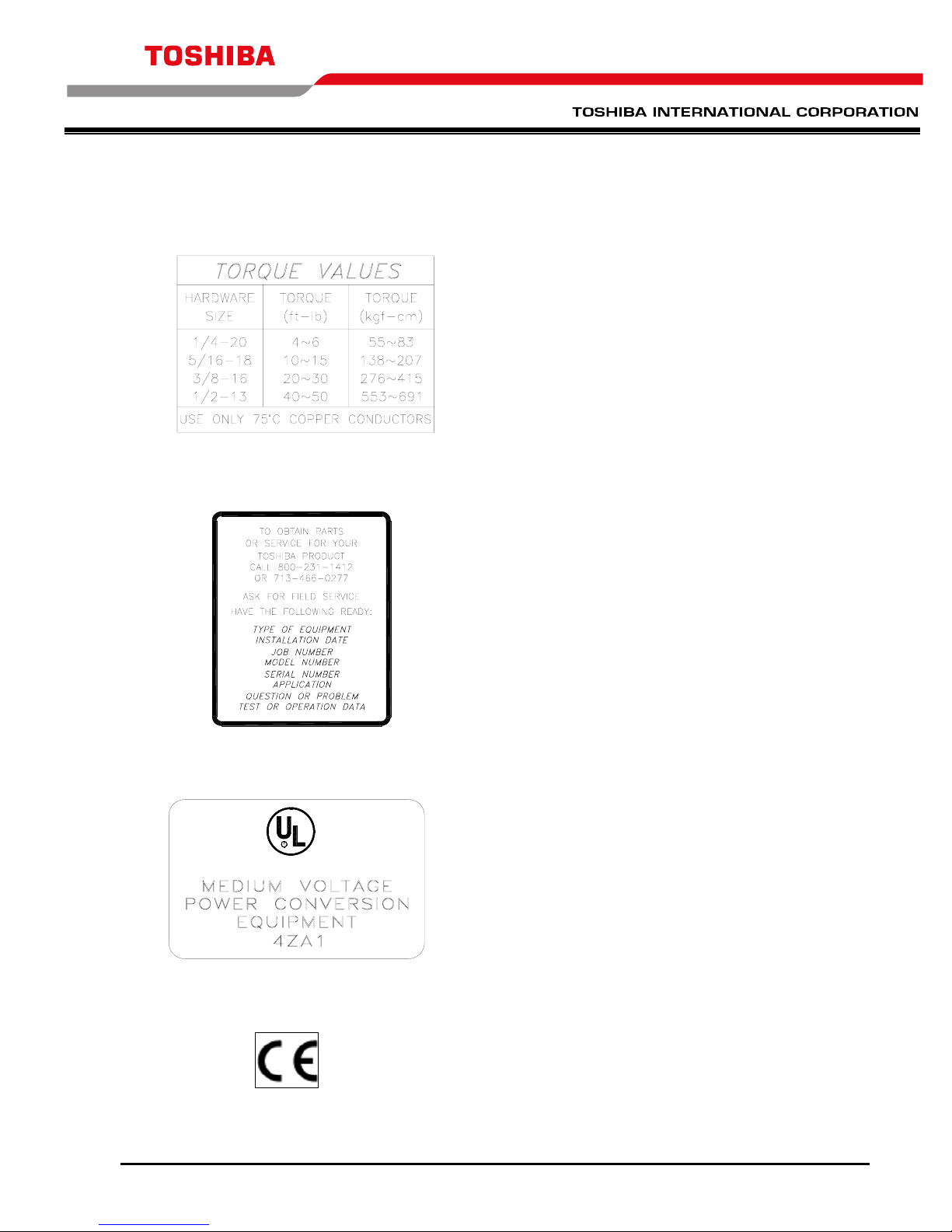

p

INFORMATION labels that will be found on the equipment are shown below:

Torque Label

LISTED

Service Label

USC

UL Label

(for UL Listed drives)

CE Label

(for drives designed

for use in the

ean Union)

Euro

- ix -

Qualified Personnel

Installation, operation, and maintenance shall be performed by Qualified Personnel Only. A

Qualified Person is one that has the skills and knowledge relating to the construction, installation,

operation, and maintenance of the electrical equipment and has received safety training on the hazards

involved. In the U.S., refer to the latest edition of NFPA 70E for additional safety requirements. Outside the

U.S., follow all applicable national and local safety practices.

Qualified Personnel shall:

• Have read the entire operation manual.

• Be familiar with the construction and function of the ASD, the equipment being driven, and the

hazards involved.

• Able to recognize and properly address hazards associated with the application of motor-driven

equipment.

• Be trained and authorized to safely energize, de-energize, ground, lockout/tagout circuits and

equipment, and clear faults in accordance with established safety practices.

• Be trained in the proper care and use of protective equipment such as safety shoes, rubber

gloves, hard hats, safety glasses, face shields, flash clothing, etc., in accordance with established

safety practices.

• Be trained in rendering first aid.

For further information on workplace safety in the U.S. visit www.osha.gov

refer to your existing plant safety regulations.

Equipment Inspection

• Upon receipt of the equipment inspect the packaging and equipment for shipping damage.

• Carefully unpack the equipment and check for parts that were damaged from shipping, missing

parts, or concealed damage. If any discrepancies are discovered, it should be noted with the carrier

prior to accepting the shipment, if possible. File a claim with the carrier if necessary and

immediately notify your Toshiba representative.

• DO NOT install or energize equipment that has been damaged. Damaged equipment may fail

during operation resulting in further equipment damage or personal injury.

• Check to see that the rated capacity and the model number specified on the nameplate conform

to the order specifications.

• Modification of this equipment is dangerous and must not be performed except by factory trained

representatives. When modifications are required contact your Toshib a representative.

• Inspections may be required before and after moving installed equipment.

. Outside the U.S.,

• Keep the equipment in an upright position as indicated on the shipping carton.

• Contact your Toshiba representative for assistance if required.

- x -

Handling and Storage

• Use proper lifting techniques when moving the ASD; including properly sizing up the load, getting

assistance, and using a forklift if required.

• Store in a well-ventilated covered location and preferably in the original carton if the equipment

will not be used upon receipt.

• Store in a cool, clean, and dry location. Avoid storage locations with extreme temperatures, rapid

temperature changes, high humidity, moisture, dust, corrosive gases, or metal particles.

• Do not store the unit in places that are exposed to outside weather conditions (i.e., wind, rain,

snow, etc.).

• Store in an upright position as indicated on the shipping carton.

• Include any other product-specific requirements.

Disposal

Never dispose of electrical components via incineration. Contact your state environmental agency

for details on disposal of electrical components and packaging in your area.

- xi -

Installation Precautions

Location and Ambient Requirements

• Adequate personnel working space and adequate illumination must be provided for adjustment,

inspection, and maintenance of the equipment. In the U.S., refer to NEC Article 110-34 for

requirements. Outside the U.S., follow applicable local electrical code requirements.

• Avoid installation in areas where vibration, heat, humidity, dust, fibers, steel particles, explosive/

corrosive mists or gases, or sources of electrical noise are present.

• Do not install the ASD where it may be exposed to flammable chemicals or gasses, water,

solvents, or other fluids.

• The installation location shall not be exposed to direct sunlight.

• Allow proper clearance spaces for installation. Do not obstruct the ventilation openings. Refer to

the recommended minimum installation dimensions as shown on the enclosure outline drawings.

• The ambient operating temperature shall be between 0 and 40

Mounting Requirements

• Only Qualified Personnel should install this equipment.

o

C (32 and 105 oF).

• Install the unit in a secure upright position in a well-ventilated area.

• A noncombustible insulating floor or mat should be provided in the area immediately surrounding

the electrical system at the place where maintenance operations are to be performed.

• Equipment should be installed according to all applicable national, regional, and industry codes

and standards. In the U.S., installation of the equipment should conform to NEC Article 110

Requirements For Electrical Installations and to OSHA requirements..

• In the U.S., installation practices should conform to the latest revision of NFPA 70E Electrical

Safety Requirements for Employee Workplaces. Outside the U.S., applicable national and local

installation safety practices should be followed.

- xii -

Conductor Routing and Grounding

• Use separate metal conduits for routing the input power, output power, and control circuits.

• A separate ground cable should be run inside the conduit with the input power, output power, and

control circuits.

• DO NOT connect control terminal strip return marked CC to earth ground.

• Always ground the unit to prevent electrical shock and to help reduce electrical noise.

• It is the responsibility of the person installing the ASD or the electrical maintenance personnel to

provide proper grounding and branch circuit protection in accordance with all applicable national

and local electrical codes (in the U.S. refer to the 2005 NEC).

WARNING

The Metal Of Conduit Is Not An Acceptable Ground.

Connections

WARNING

Contact With Energized Wiring Will Cause Severe Injury Or Death.

• Turn off, lockout, and tagout all power sources before proceeding to connect the power wiring to

the equipment.

• After ensuring that all power sources are turned off and isolated in accordance with established

lockout/tagout procedures, connect three-phase power source wiring of the correct voltage to the

correct input terminals and connect the output terminals to a motor of the correct voltage and type

for the application. In the U.S., refer to NEC Article 300 – Wiring Methods and Article 310 –

Conductors For General Wiring and size the branch circuit condu ctors in acco rdance with NEC

Table 310.16. Outside the U.S., follow your national and local electrical codes.

• If multiple conductors that are smaller than the recommended sizes are used in parallel for the

input or output power, each branch of the parallel set shall have its own conduit and not share its

conduit with other parallel sets (i.e., place U1, V1, and W1 in one conduit and U2, V2, and W2 in

another) (refer to NEC Article 300.20 and Article 310.4 for U.S. requirements). National and local

electrical codes should be referenced if three or more power conductors are run in the same conduit

(in the U.S. refer to 2002 NEC Article 310 adjustment factors on page 70-142). Outside the U.S.,

consult your national and local electrical codes for additional requirements for running multiple

conductors.

• Ensure that the 3 phase input power is Not connected to the output of the ASD. This will damage

the ASD and may cause injury to personnel.

• Do not install the ASD if it is damaged or if it is missing any component(s).

• Turn the power on only after attaching and/or securing the front cover.

• Ensure the correct phase sequence and the desired direction of motor rotation in the Bypass

mode (if applicable).

- xiii -

Protection

• Ensure that primary protection exists for the input wiring to the equipment. This protection must be

able to interrupt the available fault current from the power line. The equipment may or may not be

equipped with an input disconnect (option).

• All cable entry openings must be sealed to reduce the risk of entry by vermin and to allow for

maximum cooling efficiency.

• Follow all warnings and precautions and do not exceed equipment ratings.

• If using multiple motors provide separate overload protection for each motor and use V/f control.

• External dynamic braking resistors, if supplied, must be thermally protected.

• It is the responsibility of the person installing the ASD or the electrical maintenance personnel to

setup the Emergency Off braking system of the ASD. The function of the Emergency Off braking

function is to remove output power from the drive in the event of an emergency. A supplemental

braking system may also be engaged in the event of an emergency.

Note: A supplemental emergency stopping system should be used with the ASD.

Emergency stopping should not be a task of the ASD alone.

System Integration Precautions

The following precautions are provided as general guidelines for the setup of the ASD within the

system.

• The Toshiba ASD is a general-purpose product. It is a system component only and the system

design should take this into consideration. Please contact Toshiba for application-specific

information and for training support.

• The Toshiba ASD is part of a larger system and the safe operation of the device will depend on

observing certain precautions and performing proper system integration.

• A detailed system analysis and job safety analysis should be performed by the systems designer

and/or systems integrator before the installation of the ASD component. Contact Toshiba for options

availability and for application-specific system integration information if required.

Personnel Protection

• Installation, operation, and maintenance shall be performed by Qualified Personnel Only.

• A thorough understanding of the ASD will be required before the installation, operation, or

maintenance of the ASD.

WARNING

• Rotating machinery and live conductors can be hazardous and shall not come into contact with

humans. Personnel should be protected from all rotating machinery and electrical hazards at all

times.

- xiv -

• Insulators, machine guards, and electrical safeguards may fail or be defeated by the purposeful or

inadvertent actions of workers. Insulators, machine guards, and electrical safeguards are to be

inspected (and tested where possible) at installation and periodically after installation for potential

hazardous conditions.

• Do not allow personnel near rotating machinery. Warning signs to this effect shall be posted at or

near the machinery.

• Do not allow personnel near electrical conductors. Human contact with electrical conductors can

be fatal. Warning signs to this effect shall be posted at or near the hazard.

• Personal protection equipment shall be provided and used to protect employees from any hazards

inherent to system operation.

- xv -

System Setup Requirements

• When using the ASD as an integral part of a larger system, it is the responsibility of the ASD

installer or maintenance personnel to ensure that there is a fail-safe in place, i.e., an arrangement

designed to switch the system to a safe condition if there is a fault or failure.

• System safety features should be employed and designed into the integrated system in a manner

such that system operation, even in the event of system failure, will not cause harm or result in

personnel injury or system damage (i.e., E-Off, Auto-Restart settings, System Interlocks, etc.).

• The programming setup and system configuration of the ASD may allow it to start the motor

unexpectedly. A familiarity with the Auto-restart settings is a requirement to use this product.

• Improperly designed or improperly installed system interlocks may render the motor unable to

start or stop on command.

• The failure of external or ancillary components may cause intermittent system operation, i.e.; the

system may start the motor without warning.

• There may be thermal or physical properties, or ancillary devices integrated into the overall

system that may allow for the ASD to start the motor without warning. Signs at the equipment

installation must be posted to this effect.

• If a secondary magnetic contactor (MC) is used between the ASD and the load, it should be

interlocked to halt the ASD before the secondary contact opens. If the output contactor is used for

bypass operation, it must be interlocked such that commercial power is never applied to the ASD

output terminals (U, V, and W).

• Power factor improvement capacitors or surge absorbers must not be installed on the output of

the ASD.

• Use of the built-in system protective features is highly recommended (i.e., E-Off, Overload

Protection, etc.).

• The operating controls and system status indicators should be clearly readable and positioned

where the operator can see them without obstruction.

• Additional warnings and notifications shall be posted at the equipment installation location as

deemed required by Qualified Personnel.

- xvi -

Operational and Maintenance Precautions

• Turn off, lockout, and tagout the main power, the control power, and instrumentation connections

before inspecting or servicing the drive, or opening the door of the enclosure.

• Turn off, lockout, and tagout the main power, the control power, and instrumentation connections

before proceeding to disconnect or connect the power wiring to the equipment.

• The capacitors of the ASD maintain a residual charge for a period of time after turning the ASD

off. The required time for each ASD typeform is indicated with a cabinet label and a Charge LED.

Wait for at least the minimum time indicated on the label and ensure that the Charge LED has gone

out before opening the door of the ASD once the ASD power has been turned off.

• Do Not attempt to disassemble, modify, or repair the ASD. Call your Toshiba sales representative

for repair information.

• Do not place any objects inside of the ASD.

• Turn the power on only after attaching (or closing) the front cover and Do Not remove the front

cover of the ASD when the power is on.

• If the ASD should emit smoke or an unusual odor or sound, turn the power off immediately.

• The heat sink and other components may become extremely hot to the touch. Allow the unit to

cool before coming in contact with these items.

• Remove power from the ASD during extended periods of non-use.

• The system should be inspected periodically for damaged or improperly functioning parts,

cleanliness, and to ensure that the connectors are tightened securely.

WARNING

• Ensure that the Run functions (F, R, Preset Speed, etc.) of the ASD are off before performing a

Reset. The post-reset settings may allow the ASD to start unexpectedly.

• In the event of a power failure, the motor may restart after power is restored.

• Retry or Reset settings may allow the motor to start unexpectedly. Warnings to this effect should

be clearly posted near the ASD and motor.

DO NOT install, operate, perform maintenance, or dispose of this equipment until you have read

and understood all of the product warnings and user directions. Failure to do so may result in

equipment damage, operator injury, or loss of life.

- xvii -

This page intentionally left blank.

- xviii -

CONTENTS

INTRODUCTION................................................................................................................ 1

INITIAL COMMISSIONING................................................................................................ 2

Confirmation of Wiring..................................................................................................... 2

Start-Up and Test............................................................................................................ 2

Cautions on Changing Setting Parameters..................................................................... 3

INSPECTIONS AND MAINTENANCE............................................................................... 4

Daily Inspections............................................................................................................. 4

Regular Inspections ........................................................................................................ 4

Main Components............................................................................................................5

Cautions on Handling Printed Wiring Boards .............................................................. 5

Parts to be Regularly Renewed....................................................................................... 6

Recommended Spare Parts............................................................................................ 7

Preparations for Inspection and Maintenance of Equipment (Powering-Off)................... 8

Recovery after Inspection and Maintenance of Equipment (Powering-On)..................... 9

OVERVIEW................................................................................................................... 10

Display/Keypad (MVi-EOi) ............................................................................................ 10

MVi-EOI Diagram.......................................................................................................... 10

How to Handle Faults....................................................................................................... 12

Description of Terminology ........................................................................................... 12

General Specifications (Structure) .................................................................................13

Altitude and Temperature De-rating.............................................................................. 14

Motor Cable Length....................................................................................................... 14

General Specifications (Electrical) .................................................................................15

General Specifications (Control) ....................................................................................16

Rating Specifications..................................................................................................... 18

Protective Functions...................................................................................................... 19

General Cubicle Structure............................................................................................. 21

Cubicle Structure and Dimensions.................................................................................21

Dimensions and Weights of Equipment ........................................................................ 22

INTERFACE..................................................................................................................... 24

Power Supply Interface and Ground............................................................................. 24

Motor Interface.............................................................................................................. 25

Speed Sensor Interface (Option)................................................................................... 25

Resolver.........................................................................................................................25

PG (Pulse Generator) ....................................................................................................25

Pulse Signal Output ...................................................................................................... 26

Digital Input...................................................................................................................26

Digital Output ................................................................................................................ 29

Analog Input.................................................................................................................. 29

Analog Output............................................................................................................... 30

General-purpose Analog Output ....................................................................................30

Additional Analog Outputs..............................................................................................31

Motor Mounted Fan Circuit............................................................................................ 31

CIRCUIT OPERATION .................................................................................................... 32

Main Circuit Configuration............................................................................................. 32

- xix -

Control .......................................................................................................................... 34

Vector Control Block Diagram........................................................................................34

Speed Reference...........................................................................................................35

Speed Control................................................................................................................36

Simulator Follower Control (SFC, optional control used with a speed sensor)...............37

Torque Reference and Current Reference.....................................................................37

IQ Limit (Torque current limit).........................................................................................38

D-Q Axis Current Control ...............................................................................................39

Output Voltage References............................................................................................40

Speed Feedback (Option)..............................................................................................41

Resolver.................................................................................................................... 41

PG............................................................................................................................. 41

Control Board Configuration.......................................................................................... 42

OPERATION.................................................................................................................... 43

Pre-Operation Check Points ......................................................................................... 44

Powering-On................................................................................................................. 44

Operation...................................................................................................................... 44

Normal Operation...........................................................................................................44

Powering-Off................................................................................................................. 44

DATA CONTROL............................................................................................................. 45

Setting Data .................................................................................................................. 45

FAULT AND RECOVERY................................................................................................ 45

Cautions when Handling Faults..................................................................................... 45

Repair ........................................................................................................................... 46

Cautions on Repair ........................................................................................................46

DRIVE INSTALLATION DRAWINGS............................................................................... 47

Frame 0 4160V module lifting and installation .............................................................. 47

Frame 1 4160V drive lifting and assembly .................................................................... 47

Frame 1 drive lifting and assembly (cont’d)................................................................... 48

Frame 1 2400V module lifting and installation .............................................................. 49

Frame 1 4160V module lifting and installation .............................................................. 49

Frame 2 drive lifting and assembly................................................................................ 50

Frame 2 drive main cable installation............................................................................ 51

Frame 2 module lifting................................................................................................... 52

Frame 2 4160V module installation............................................................................... 53

Frame 3 drive lifting and assembly................................................................................ 54

Frame 3 drive main cable installation............................................................................ 55

Frame 3 2400V module installation............................................................................... 57

Frame 3 4160V module installation............................................................................... 58

Frame 4 drive lifting and assembly................................................................................ 59

Frame 4 drive main cable installation............................................................................ 60

Frame 4 module lifting................................................................................................... 61

Frame 4 2400V module installation............................................................................... 62

Frame 4 4160V module installation............................................................................... 63

Frame G4P drive lifting and assembly .......................................................................... 64

Frame G4P drive main cable installation....................................................................... 65

- xx -

Frame G4P module lifting and installation..................................................................... 66

Frame G4P module lifting and installation continued.................................................... 67

Frame H4P drive lifting and assembly........................................................................... 68

Frame H4P drive main cable installation....................................................................... 69

Frame H4P module lifting and installation..................................................................... 70

Frame H4P module lifting and installation continued .................................................... 71

Frame B2 2400V module lifting and installation Type 1................................................ 72

Frame B2 2400V module lifting and installation Type 2................................................ 73

- xxi -

INTRODUCTION

Thank you for purchasing the T300MVi Medium Voltage ASD. This adjustable frequency, solidstate AC drive features a 3φ input isolation transformer with a 24-pulse converter design, a 32 -bit CPU, and

a three-unit power module inverter section providing a 5 level output for 4160/3300V drives and 3 level

output for 2400V drives. The T300MVi also features as standard, an 8 key Control Panel with a LCD screen

and 2 discrete LED lamps to indicate Ready, Run, Local, Remote and Alarm/Fault.

On most power systems, this drive will meet IEEE-519-1992 harmonic regulation guidelines without

installing additional harmonic filters. The input power factor is typically 0.95. The multi-level output

produces a more sinusoidal voltage and reduces stress on the motor win ding insulation. This drive uses

high capacity 3300V IGBTs to improve reliability, reduce switching losses, and improve control performance.

The PP7 control processor and 6-layer control board achieves high integration a nd reliability.

- 1

INITIAL COMMISSIONING

The drive should be commissioned by qualified personnel only. Below are some general steps

required for commissioning.

CAUTION

Confirmation of Wiring

Make the following final checks before applying power to the unit:

1) Confirm that source power is connected to terminals L1, L2, L3 (R, S, T). Connection of

incoming source power to any other terminals will damage the drive. Other control voltages

may be required. Consult your custom equipment diagrams shipped with the drive for any

other requirements.

2) Verify that the power modules are properly installed and that there was no damage during

shipping or handling.

3) Verify that there are no loose connections or wires and that all of the required shipping split

connections have been made.

4) Verify all external control circuit wiring is complete and properly connected.

5) The 3-phase source power should be within the correct voltage and frequency tolerances.

6) The motor leads must be connected to terminals T1, T2, T3 (U, V, W).

7) Make sure there are no short circuits or inadvertent grounds and tighten any loose connector

terminal screws.

CAUTION

Start-Up and Test

Prior to releasing the drive system for regular operation after installation, the system must

be adjusted and tested by qualified personnel. This assures correct operation of the equipment for

reasons of reliable and safe performance. It is important to make arrange ments for such a check and that

time is allowed for it.

CAUTION

- 2

Cautions on Changing Setting Parameters

The setting data of the T300MVi MV is saved in an EEPROM, non-volatile memory. When the

micro controller initializes at power-up, it reads the EEPROM data and copie s it to the RAM (Rando m

Access Memory). From then on, the micro controller controls the drive using the values in the RAM.

When the setting parameters are changed, by the display-keypad or personal computer ("su pport

tool"), only the execution parameters in RAM are changed. If they need to be stored, they must be manually

written to the EEPROM. Without this operation, the next initialization or power up will cause them to be

replaced by the old data.

When a write to the EEPROM is performed, write processing may take 30 seconds. Turning off the

control power supply during write processing will make both the RAM and EEPROM data abnormal. When

the power is turned on again, this abnormal data will result in an error ("CHECK ERROR") preventing the

drive from running. If such an error occurs, the settings must be reloaded from a saved file. If no setting file

exists, the drive must be re-commissioned.

CAUTION

Do not turn off the control power supply under any circumstances while

writing data to the EEPROM.

- 3

INSPECTIONS AND MAINTENANCE

Maintenance and inspection is a particularly effective means to help prevent failures an d reduce

down time. Creating equipment specific inspection and maintenance check sheets can help to perform

maintenance and inspection effectively. Detailed inspections and regular maintenance should be carried

out in short cycles initially until a schedule reflecting the site-specific conditions can be determined.

For items that are too high to reach, use a step ladder to gain access. Do not attempt to climb on

the equipment.

CAUTION

DANGER

Daily Inspections

Daily inspections consist mainly of visual inspections on the following items. These observations

should be made with all of the cubicle doors closed and safety covers installed. Any abnormalities

discovered should immediately be repaired.

1) Check the temperature, the humidity, the presence of corrosive or explosive gases, and the

presence of dust in the area.

2) Check for any abnormal sound or vibration of the reactor, transformer, or cooling fans.

3) Check for abnormal odors such as the smell of burning insulating materials.

Regular Inspections

Carry out regular inspections with power off, locked out, and with confirmation that the bus voltage

is completely discharged. Use power lockout/tagout procedure on the disconnecting means in

accordance with applicable local electrical codes (in the U.S., see 2002 NEC Article 430-1 01) before

performing any drive maintenance.

The first thing to do in maintenance and inspection is cleaning. Cleaning should be carried out

according to the conditions of the equipment. Before starting cleaning, turn off the power supply and check

that the main circuit voltage is reduced to 0. Clean dust with a vacuum, dry

cloths. Note that excessive air pressure when blowing out equipment may damage parts and wiring. Do

not use solvents to clean the drive. Substances stuck to the circuits, which cannot be removed by

blowing, should be wiped away using a cloth. As a basic rule, cleaning should start from the upper parts

and end at the lower parts. Cleaning of the lower parts last will allow proper removal of substances that

could drop from the upper parts.

CAUTION

DANGER

compressed air, and clean dry

- 4

INSPECTIONS AND MAINTENANCE

(cont’d)

Main Components

1) Cooling fan - Check to see if there is any abnormality with airflow, increased fan noise, etc.

2) Air filter - Visually check if the air filter is clogged. Gently tap it outside the room to remove loose

dust. To remove caked on dirt use water and a gentle detergent, rinse it with clean water and dry it.

Otherwise replace it with a new one. Cleaning with solvents is not recommended.

3) Main circuit parts and entire cubicle - Check to see if dust is stuck to the cubicl e interior or if there

is any discoloration, heat generation, abnormal sound, leakage, odor or damage with the reactor,

transformer, contactors, cables and connections, fuses, capacitors, lightening arrestor s, and

resistors. Check to see that no wires or mounted parts are broken, disconnected, loose or

damaged. High voltage standoffs, insulators, and cable can be cleaned with isopropyl alcohol.

4) Printed Wiring Boards - The boards, which are made up of ICs and electronic components, must

be protected from dust, corrosive gases and extreme temperatures. Pay attention to the installation

environment of the equipment. Regular inspections, the proper cleaning, and maintenance in an

optimal environment is essential for circuit boards. Since most of the components and parts are

small and vulnerable to external forces, when cleaning them, use a brush to carefully wipe off dust.

Inspect the boards for signs of component damage, heating, and corrosion.

Cautions on Handling Printed Wiring Boards

a) All maintenance work on the board should be carried out at least 15 minutes after all

power supplies are turned off to allow the capacitors on the boards to discharge.

b) When removing the board, disconnect all the connectors and wires and remove the

mounting screws from the upper part of the board first. At this time, be careful not to drop

the boards or screws. When setting the board down, place it on a static free surface. Be

careful not to damage any components.

c) When attaching the board, do so in the order opposite to the removing procedure. Be

sure that all of the connectors and wires are connected correctly.

d) New boards are shipped in an anti-static bag. Use this bag to store them.

Note that the anti-static coating is only on the inner side of the bag.

5) Check the protection functions for proper operation (Door switches, OH, E-stop...)

6) Check the insulation resistance of the medium voltage circuits.

CAUTION

- 5

INSPECTIONS AND MAINTENANCE

(cont’d)

CAUTION

Parts to be Regularly Renewed

To use the T300MVi for a maximum period of time, it is necessary to regularly renew (replace)

components whose characteristics have deteriorated. The table below shows the parts used for the inverter

equipment whose regular renewal is recommended and their recommended re newal period.

Parts to be Regularly Renewed

Product name Recommended

renewal period

Cooling fan

Air filter 6 months Can also be cleaned.

Aluminum Electrolytic

Capacitors

On Circuit Boards

Oil-filled capacitor

Main circuit

Control power supply 7 years

Main circuit 7 years Fuse

Control circuit 7 years

3 years Sooner if dust or dirt

7 years

20 years

Remarks

damages bearings

Contact Toshiba for

replacement of these

devices

- 6

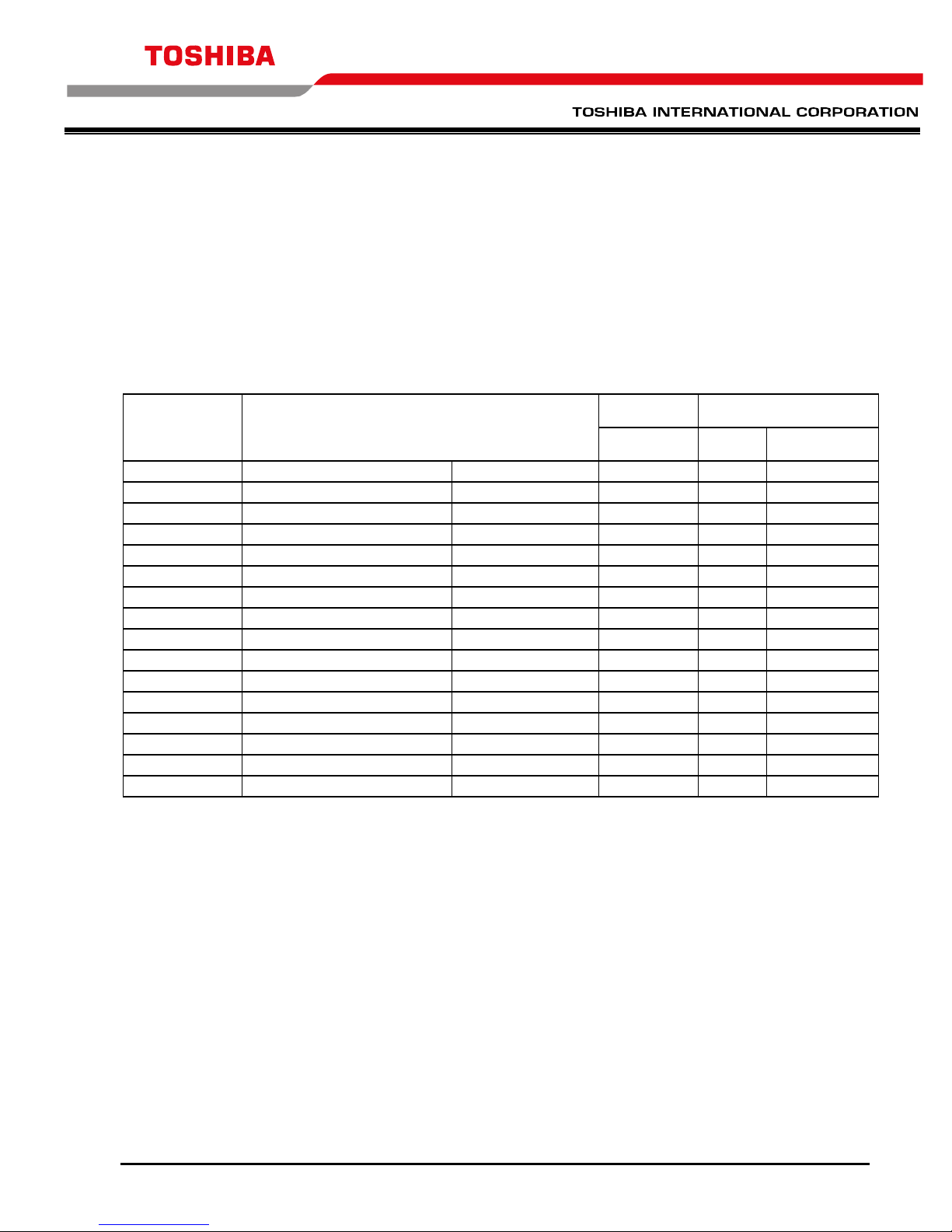

Recommended Spare Parts

Spare parts are an important part of downtime reduction. When parts in the drive have failed, onhand spare parts are necessary to shorten the mean time to repair (MTTR). Since repla cement of discrete

components is time consuming, it is recommended that entire assemblies be replaced. Recommended

spare parts common to all drives are shown in the following tables. The recommende d spare rate and

minimum amount can serve as references for the minimum number of spare parts relative to the total

number of drives on site. It is recommended that the quantity be determined in accordance with the number

drives on site. Many other parts are job specific. It is up to the end user to determine what other parts may

be needed.

Recommended Common Spare Parts **

Number of

Product name Model/Rating

CTR Control board ARND-3110(*) 1 each 10% 1

GSD Gate signal distribution board ARND-3126B 1 each 10% 1

OLB Optical gate signal board ARND-8205(*) 3 each 10% 1

XIO External input/output board ARND-8120(*) 1 each 10% 1

VDET Voltage detection board ARND-3127(*) 3 each 10% 1

IPAD Keypad interface board PC61910PP114A 1 each 10% 1

DISP Display/keypad PC61910P116 1 each 10% 1

PS1 Control power supply FYX900/63T-BGEE 1 each 10% 1

GDI Earth fault detection ARND-8126A 1 each 10% 1

TEX Twin expansion board PC61910P123(*) 1/0 10% 1

Control Fuses * * 2 each 10% 2

Main Fuses * * 3 each 10% 3

Pt fuses * * 4 each 10% 4

Rectifier fuses * * 36/12 10% 4/2

Power modules*** * * 3 10% 1

Cooling Fans * * * 10% 1

* This data is job/inverter specific. Check the drawings for the specific inverter for this information.

** This is a general list of spares. Check the specific job drawings for other components that may need to be

spared.

parts per drive

4160V/2300V

*** It is recommended that failed power modules be replaced as a unit and that the failed modules

be returned to Toshiba for repair and testing.

Recommended spare parts

Spare

rate

Recommended

Min Q’ty

- 7

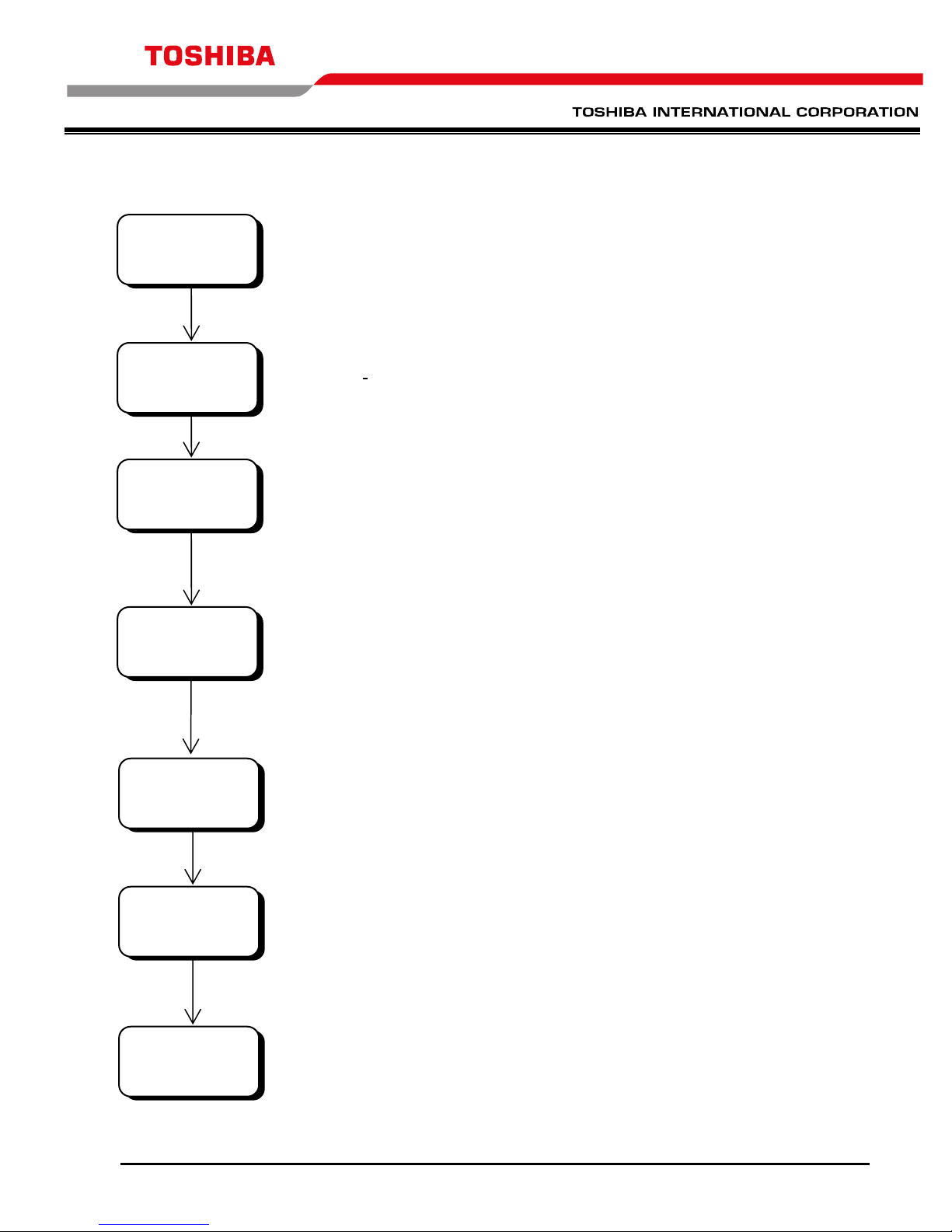

Preparations for Inspection and Maintenance of Equipment (Powering-Off)

Stop the

equipment

Main power

OFF

Control power

OFF

Wait for DC bus

discharge

Voltage check

Grounding

Work

1) Stop the equipment and check that the motor has

completely stopped.

2) Press the interlock switch on the operation panel (See Fig. 1 in the next section).

The light on the switch should turn on.

3) Turn off

power.

4) Turn off and lock out the control power supply.

5) Turn off an lock out any other job specific power feeding the drive.

6) Wait for 15 minutes or more for the bus to discharge.

7) Verify that all power is removed by measuring the main, the DC bus, the control,

and any other external source voltage levels with properly rated measuring

equipment.

Note! A meter rated for 5kV is required to safely check the main circuit

voltages.

8) Ground the 3-phase input power supply terminal at the main circuit input

terminals. (Grounding is automatic when the equipment is supplied with a JK type

incoming starter.)

9) Perform the necessary maintenance.

the external main power supply. Disconnect and lockout the main

- 8

g

Recovery after Inspection and Maintenance of Equipment (Powering-On)

Check for tools.

Remove the

rounding rod

Close the door

Control power

supply ON

Main power

supply ON

Prepare

operation of

equipment

1) Check the drive to make sure no tools or other foreign objects were left in the

drive.

2) Remove any grounding devices that may have been attached to the main

circuit input terminal.

3) Replace any safety barriers or covers that were removed for maintenance. Close

the and latch all doors. Operation of the equipment cannot start when the door of

the main circuit related cubicles is open.

4) Turn on

5) Turn on any other external power suppy sources.

6)Turn on

7) After safety checks, prepare for the operation.

Press the interlock switch on the operation panel (See Fig. 1 in the next section).

(When the LED is turned off, the interlock is off. If the drive is ready, it

will start if commanded).)

the control power supply.

the external main power supply.

- 9

OVERVIEW

Display/Keypad (MVi-EOi)

The following figure shows the display/keypad of the equipment. Refer to the keypad operation

manual for more details on its use.

MVi-EOI Diagram

1

2

4

5

3

6

13 14 15

Figure 1.

789

11

10

12

- 10

1. Graphical LCD – Displays user information in text and numerical form.

2. Local/Remote LED – This green LED is illuminated when in local mode, and extinguished while in

remote mode.

3. Status LED:

• Not ready and not running – Both Red and Green off.

• Ready and not running – Green LED only

• Ready and running – Red LED only.

• Fault – Fast blinking Red LED. (2.0 Hz).

• Alarm – Slow blinking red if running or, green if not running. (0.67 Hz).

• Test mode – Alternating red and green when in ready or running condition. (2.0 Hz).

4. LOCAL/REMOTE Key – Toggles between Local and Remote mode while the drive is not running. Press

and hold the key for two seconds to toggle modes.

5. MON/PRG Key – This key will cycle through the tabs (see figure 2).

6. RUN Key – Initiates a start command when the ASD is in local mode, and the MVi-EOI is in the Main

Tab.

7. ENTER Key – Selects a menu item to be changed or accepts and writes the changed data of a selected

field. While in the Main Tab, press and hold this key for two seconds to toggle the direction of the motor.

8. ESCAPE Key – This multi-function Escape key allows the user to cancel changes made to a

programming filed if pressed while the field is selected (highlighted), returns the user to the previous

level of the menu tree, and cycles through the display tabs.

9. STOP key – This initiates a stop request when operating in local mode, and is functional in all screens.

When double pressed within 1.5 seconds, it initiates a (gate block) coast to stop. This function always

works. The drive must be reset after a double-press stop.

10. UP key – Scrolls up a menu listing and increments a selected field’s parameter data.

11. DOWN key – Scrolls down a menu listing and decrements a selected field’s parameter data.

12. Encoder – This multi-function device scrolls up and down a menu listing, increments/decrements the

data in a selected programming parameter field, and functions as the Enter key when pressed.

13. Commissioning Tool Port – Ethernet port used for communication to the commissioning and support tool

(Wi-Tool).

14. RESET Pushbutton – This pushbutton is used to clear inverter faults and alarms displayed on the LCD.

15. INTERLOCK Pushbutton – This pushbutton is used to disable the inverter via a hard-wired circuit. The

pushbutton is illuminated while the inverter is interlocked, and extinguished for normal operation.

Operating the INTERLOCK pushbutton will result in an inverter gate block and free-run deceleration of

the load.

- 11

How to Handle Faults

In the event of a fault, the following measures should be taken:

(1) Record the fault message shown on the display on the operation panel.

(2) Collect the trace back data, if the commissioning software package was purchased.

(3) See the Fault and Recovery section.

Description of Terminology

This section describes the special terms used in this manual.

Description of Terminology

Term Meaning

Power

module

IGD board

OLB board

VDET board

GSD board Gate Signal Distributor. Board that distributes gate signals to each output phase.

CTR board Inverter main control board

TEX board

EEPROM Electrical Erasable Programmable Read Only Memory

IGBT Insulated Gate Bipolar Transistor

LCD Liquid Crystal Display

LED Light Emitting Diode

MCCB Molded Case Circuit Breaker

PP7

PSM

RAM Random Access Memory

Initialize

Interface Means by which this equipment transfers signals to/from external devices.

Inverter

Overload Operation at a current output that exceeds the continuos rating of the equipment.

Display-

keypad

Load Refers to a motor that receives power from this equipment.

A single-phase DC-fed inverter module using IGBTs.

IGBT Gate Driver Board. Converts gate signals sent in optical signal form to

electric signals.

Optical Link Board. Converts gate signals from electric to optical signals for

isolation.

Voltage Detection Board. Board that measures analog voltage signals and

converts them to optical signals.

Twin Expansion Board. Distributes the gate signals to the power modules for

twin drives.

Power electronics Processor for Various Inverter control Integration (VII=7).

Toshiba dedicated power electronics control 32-bit micro-controller.

Switching power supply that providing ±15 VDC and +5 VDC for boards.

Act of initialization. When the control power switch is turned from OFF to ON the

inverter equipment initializes data and circuits.

Inverse converter that converts DC power to AC power.

(DC → AC conversion)

Operational panel installed on the cubicle surface that is used for data display

and basic operations.

- 12

A

General Specifications (Structure)

The general specifications (structure) of the equipment are shown in the following table.

General Specifications (Structure)

Item Standard specification Additional optional

specification

Applicable standard UL, NEMA

Ambient

conditions

Temperature

0 to 40°C

Humidity Max 95%, no condensation

Altitude 1000 m Max. above sea level

Installation

Indoors

location

Vibration 10 to 50 Hz, 0.5 G or less

Corrosive

factors

Hydrogen Sulfide (H2S) 0.001 PPM

Sulfur Dioxide (SO2) 0.05 PPM

Chlorine gas (Cl2) 0.1 PPM

Ammonia gas (NH3) 0.1 PPM

Nitrogen Dioxide (NO2) 0.02 PPM

Nitrogen Oxide (NOx) 0.02 PPM

Ozone (O3) 0.002 PPM

) 0.1 mg/m

1

Paint color Cubicle

Hydrochloric acid mist (HCl

ANSI 61 Gray Consult factory for

surface

Cubicle structure Front maintenance,

stand-alone cubicles

NEMA 1,

structure

Forced ventilated

With channel base

Air filter Front mounte d

This is a list of

3

optional colors

Cubicle protective

Remarks

t no time should

the drive be

subjected to

conditions that

would allow

condensation to

form on the

components.

corrosive agents

know to attack

the drive

components.

Other agents

may also have

adverse effects

on the drive.

- 13

Altitude and Temperature De-rating

Altitude Derate Chart **

Altitude % Amp Output Derate

3,300’ 0.0%

4,000’ 2.0%

4,500’ 3.3%

5,000’ 4.7%

6,000’ 7.5%

7,000’ 10.2%

8,000’ 12.9%

9,000’ 15.7%

10,000’ 18.4%

** Applications above 5000 feet may also require special magnetics. Consult Toshiba Engineering.

Temperature Derate Chart

Ambient Temperature % Amp Output Derate

40 C

45 C

50 C

0.0%

7.5%

15.0%

Motor Cable Length

Below are cable length guidelines for use with most standard industrial motors.

Suggested Maximum Output Cable Distances

AC Motor Voltage Drive Output Voltage Max lead length

without filter

2300 2400V 0-1000 ft

2300/4000 2400V 0-1000 ft

4000V or 2300/4000 4160V 0-1000 ft

CAUTION

(1) Older motors, or motors with marginal insulation systems, may require filters to help reduce the stress on

the insulation system. Consult Toshiba application engineering.

(2) Exceeding the peak voltage and allowable rise time of the motor insulation system will reduce motor life

expectancy. To insure good insulation life, consult with the motor supplier to determine motor insulation

ratings and allowable maximum output lead distance. Long lead lengths b etween the motor and drive may

require that filters be added to the drive output.

- 14

A

T

Y

Y

General Specifications (Electrical)

The general (electrical) specifications of the equipment are shown in the following table.

General (Electrical) Specifications

Item Standard specification Standard

Optional

Specification

Frame Sizes

Motor driven by this equipment Squirrel-cage induction

Main

power

supply

Control

power

supply

circuit

Others

Input supply voltage

and range of

fluctuation

Output voltage 0 ~ Rated Voltage

Supply voltage

frequency

PWM frequency 2048Hz 4160V

Regeneration system Not available

Overload capacity 100% - continuous

Ground protection Yes

Receptacle No Yes

Motor cooling fan

control

Cabinet space heater No

Cabinet internal light No

Maximum Sound

Level

4160V

2400V

motor

Rated Voltage ±10%

Rated Frequency ±5%

Internally supplied 480 V,

60 Hz

1024Hz 2400V

110-115% - 60 sec

(Depends upon frame size

and drive rating)

No

Less than 80 dBA,

measured 3 ft (1 m) from

equipment

Frame 0

Frame 1

Frame 2

Frame 3

Frame 4

Frame G4P

Frame H4P

Frame 0

Frame 1

Frame B2

Frame 3

Frame 4

See ratings

480 V, 60 Hz

Voltage

fluctuation

range: ±10%

Main

125%,

dditional

Optional

Specification

150%,

175%,

200%,

225%,

250%

es

es

Remarks

table for

specific kVA

ratings

available

he higher OL

ratings require

a reduction in

continuous

capacity

- 15

General Specifications (Control)

The general (control) specifications are shown in the following table.

General Control Specifications

Item Standard

specification

Maximum output frequency 75 Hz 120 Hz

Speed sensor (PG pulse output) No Yes

Basic

control

performance

Basic control system Volts/Hertz

Operation control range 3%-100% 1%-100% Limited by motor

Field weakening control 1:1.5 1:5 Vector Control

Additional

optional

specification

Sensor Type

Vector

Sensorless

Vector

Remarks

Sensor type vector

control uses a resolver

or a PG. The maximum

PG freq. is 10kHz.

heating

Operation

specification

Speed accuracy

Speed resolution 1/25000

Acceleration/deceleration

time

Restart after

instantaneous interruption

±0.5% ±0.01%

(Digital setting)

0.1 – 3276.7 sec,

acceleration/dec

eleration

independent

setting

Possible

(more than 5

cycles

interruption

causes shut

down)

Analog setting

1/1000.

Isolation

transducer

recommended.

Drive can not

Under-voltage

trip at 75%

level

regenerate

- 16

General Control Specifications Continued:

General Control Specifications

Item Standard specification Option Remarks

Transmission

Cubicle

display/

operation

Operation

Connector Personal computer connection Ethernet

Analog signal output

Analog signal input

Digital input/output

Commissioning and

Maintenance Tool

PC interface None MODBUS

Comissionin

g/Maintenan

ce Tool

LED 1 lamp READY: Operation preparation

LED 2 lamp ON - Keypad control

LCD display 128x64 Pixel Graphical LCD display

apparatus

Ethernet (with modular jack attached to

keypad)

completed (Green)

RUN: Inverter in operation (Red)

ALARM/FAULT:

Alarm slow flashing/Fault fast flashing

OFF - Other than keypad control

Backlit type interlock switch: 1

Unlit reset switch: 1

Operation via 8 key keypad and a

15pulse/30detent incremental encoder

modular jack

±10VDC x 3 programmable channels

on XIO board

±10VDC x 5 programmable channels

on terminal strip

±10VDC x 2 fixed channels on

terminal strip

±10VDC x 2 channels

Input: 8 dry contact inputs

7 Programmable:

1 dry contact 24-110Vdc 48-120Vac

6 dry contact 24Vdc

1 Fixed:

1 dry contact 24-110Vdc 48-120Vac

Output: Programmable

1 open collector 24VDC-50mA max

5 open collector 24/50VDC-50mA max

Parameter

DEVICE_NET

PROFIBUS

TL-S20

READY and

RUN light

colors can be

reversed by

changing an

EIO parameter

Connected

Connected

Fixed contact is

24V contact

setting, fault

data display,

etc.

Requires

optional board.

measuring

equipment must

be isolated from

ground

source

equipment must

be isolated from

ground

always used for

interlocking

control function

always used for

internal control

functions

Optional

Software

Package

- 17

Rating Specifications

NEMA Type 1 Standard Ratings Table

Standard

Model

M3A22030S 300 233 268 64 74 0

M3A22035S 350 272 313 75 86 0

M3A22040S 400 311 357 86 99 0

M3A22045S 450 350 402 97 111 0

M3A22050S 500 389 447 107 124 0

M3A22060S 600 466 536 129 148 1

M3A22070S 700 544 625 150 173 1

M3A22080S 800 622 715 172 198 1

M3A22090S 900 699 804 193 222 1

M3A22100S 1000 777 893 215 247 1

M32A22060S 600 466 536 129 148 B2

M32A22070S 700 544 625 150 173 B2

M32A22080S 800 622 715 172 198 B2

M32A22090S 900 699 804 193 222 B2

M32A22100S 1000 777 893 215 247 B2

M3A22125S 1250 971 1116 269 309 3

M3A22150S 1500 1166 1340 322 371 3

M3A22175S 1750 1360 1563 376 432 3

M3A22200S 2000 1554 1786 430 494 3

M3A22225S 2250 1748 2010 483 556 4

M3A22250S 2500 1943 2233 537 618 4

M3A22300S

M3A44030S 300 233 268 37 43 0

M3A44035S 350 272 313 43 50 0

M3A44040S 400 311 357 50 57 0

M3A44045S 450 350 402 56 64 0

M3A44050S 500 389 447 62 71 0

M3A44060S 600 466 536 74 86 0

M3A44070S 700 544 625 87 100 0

M3A44080S 800 622 715 99 114 0

M3A44090S 900 699 804 112 128 0

M3A4410ES 1000 777 893 124 136 0

M3A44100S 1000 777 893 124 143 1

M3A44125S 1250 971 1116 155 178 1

M3A44150S 1500 1166 1340 186 214 1

M3A44175S 1750 1360 1563 217 249 1

M3A44200S 2000 1554 1786 248 273 1

M3A44225S 2250 1748 2010 279 321 2

M3A44250S 2500 1943 2233 310 356 2

M3A44300S 3000 2331 2680 372 428 3

M3A44350S 3500 2720 3126 434 499 3

M3A44400S 4000 3108 3573 496 570 4

M3A44450S 4500 3497 4019 558 642 4

M3A44500S 5000 3885 4466 620 713 4

M3A44550S 5500 4274 4913 682 784 4

M3A44600S 6000 4663 5359 744 818 4

M3AP44700S 7000 5440 6252 868 998 G4P

M3AP44800S 8000 6217 7146 992 1141 H4P

M3AP44900S 9000 6994 8039 1116 1283 H4P

M3AP4410KS

Specifications subject to change without notice. Inverter performance data is based on a typical 4 pole motor operating

at 0.87 pf and 0.96 efficiency.

Input

Voltage

2400 V

4160 V

Motor

Hp

10000 7771 8932 1240 1426 H4P

Output

kW

3000 2331 2680 645 741 4

Output

KVA

Output Current

100%

Overload Current

110~115%-60 s. Frame

Output Voltage

& Frequency

0~2400 V

0~75 Hz

0~4160 V

0~75 Hz

- 18

Protective Functions

The main protective functions are shown in the following table. For other faults or more details,

refer to the troubleshooting manual.

Protective Function Table

Item Abbreviation

Input main switch open AC_MCCB O O

No load connected AC_NL O O

Output main switch closed

without signal (Welded)

Output main switch opened

during operation

Output main switch open timer ACSW_T O O

Brake healthy B_HLTY O O

External trip from input breaker BLA O O

Brake release fault BR_F O O

Equipment ventilation fan stop C_FN O O O

Equipment ventilation fan stop

timer

Current limit timer CL_T O O

Current limit alarm CL_TA O O

Control power supply loss CPSF O O*

CPU error CPU_A or M O O*

U or W phase feedback error CURU or W O O*

Door open DS_T O O*

Encoder feedback error ENCODER_F O O*

Rectifier fuse fault FUSE_xP

Ground fault alarm GR_A_ O O O

Ground fault trip GR_T_ O O

External interlock IL O O

Motor cooling fan stop timer M_FN_T O O

Motor cooling fan stop M_FN O O O O

Motor overheat M_OH O O O O

Motor overheat alarm M_OH_A O O O

Main power supply loss MPSF O O*

Main power supply loss MPSF_MV O O*

Motor temperature sensor error MTMP_S O O O

AC over-current OCA O O*

Power Module phase over-

current

Power Module IGBT over-

current

Power Module overheat OH_T_x O O*

Transformer over heat OH_TR O O*

ACSW_C

ACSW_F

C_FN_T

FUSE_xN

OCD_x

OCD_xA1

OCD_xA4

OCD_xB1

OCD_xB4

Hardware

Detection

O O*

Software

Detection

O O

O O

O O*

O O*

Heavy Fault

Coast

to stop

Decel

stop

Medium

Fault

Stop

request

Light

Fault

Alarm

Start

Interlock

O

- 19

Overload alarm OL_A O O

Overload (5 minutes) OL5 O O

Overload (20 minutes) OL20 O O

Over speed OSS O O*

Output frequency high OSS_F0 O O*

DC bus over-voltage

positive/negative

Panel safety switch P_SW O O

Parameter setting error PARA_ERR O O

PLL phase error PHASE_ERR O O

PLD error PLD_ERR O O*

PLL error PLL O O*

Pre-charge CTT trip PRE_CTT O O

Pre-charge CTT alarm PRE_CTT_F O O O

Rectifier failure REC_F O O*

Reverse rotation failure REV_ROT_F O O*

Rotation/start failure ROTATE_FAIL O O*

Soft stall SOFT_STL O

Speed feedback error SP_ERR O O*

Speed feedback error2 SP_ERR2 O O*

Speed reference lost SP_LOST O O O

Speed reference lost alarm SP_LOST_A O O O

Motor turning start interlock SP_SIL O

Spare input 1-4 SPA1-4 O O* O O

Spare input 1-4 timer SPA1-4_T O O* O O

System configuration error SYS_ERR O O

Communication error 1-4 TL_F1-4 O O O

Main under-voltage UV_MPSF O O

DC under-voltage start interlock UV_SIL O O O

DC under-voltage trip UVD O O

External safety switch UVS O O

Input voltage phase loss VAC_PH_LOSS O O

Output current phase loss VINV_PH_LOSS O O

OV_xP

OV_xN

O O*

(Note 1) Hardware Detection: Items for which all IGBTs are directly turned off by hardware.

Detection: Items for which protective interlock operation is performed by detecting errors via software.

(Note 2) "O" marks in the interlock operation fields can be selected by parameter setting.

"*" indicates that the equipment outputs the trip signal to input main circuit breaker.

Software

“x” indicates the phase (U,V,W).

- 20

General Cubicle Structure

The configuration and dimensions of the equipment are described below.

Cubicle Structure and Dimensions

The equipment is made up of one or more cabinets containing the transformer, incoming terminals,

converter section, and the inverter section. All components can all be accessed from the front.

This outline is for the standard Frame 1 model. For details of this and other ratings, see the outline

drawing of each product.

POWER

ISOLATION

SWITCH

O

N

O

F

F

HEIGHT

TRANSFORMER/CONVERTER CUBICLEINVERTER/CONTROL

WIDTH DEPTH

Dimensional Outline of 4160V- Frame 1 Cubicle

(See the following page for dimensions)

General structure

1) All cubicles have a structure that allows maintenance from the front. Rear maintenance access is

not required. The cubicles may be placed within 1" of the rear wall.

2) Provide a maintenance space of at least 72 inches (1829 mm) in front of the cubicles.

3) Provide a clearance of at least 24 inches (610 mm) above the exhaust fans.

4) The following are not included in the dimensions on the next page:

a) Handle projections

b) Door mounted device projections

c) Fastener projections

- 21

Dimensions and Weights of Equipment

Dimensions and weights of the complete drive, including the power modules

Standard Model

Number

M3A22030-050S 103.7 (2634)

M3A22060-100S 103.7 (2634)

M32A22060-100S 103.7 (2634)

M3A22125-200S 103.7 (2634)

M3A22250-300S 103.7 (2634)

M3A44030-10ES 103.7 (2634)

M3A44100-200S 103.7 (2634)

M3A44225-250S 103.7 (2634)

M3A44300-350S 103.7 (2634)

M3A44400-600S 103.7 (2634)

M3AP44700S 103.7 (2634)

M3AP44800-10KS 103.7 (2634)

Standard Model

M3A22030-050S N/A 6000 (2722)

M3A22060-100S

M32A22060-100S

M3A22125-200S

M3A22250-300S

M3A44030-10ES

M3A44100-200S

M3A44225-250S

M3A44300-350S

M3A44400-600S

M3AP44700S

M3AP44800-10KS

“*” Inverter and converter sections combined into one cubicle.

“**” Maximum weight for the frame size with the standard transformer and no options. Consult the

factory for weights for non-standard inverters, as they are job specific.

H

Number

W

Input

Sect

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

51 (1295)

51 (1295)

Weight

Input

lbs (kg)

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

3000 (1364)

3100 (1409)

Dimensions – inches (mm)

W

Conv

Sect 1

74 (1880) N/A *

74 (1*(880)

74 (1880)

90 (2286)

111 (2819)

74 (1880)

74 (1880)

90 (2286)

90 (2286)

111 (2819)

118.5 (3010)

92.5 (2350) 100 (2540) 111 (2819)

Weight

Conv1**

lbs (kg)

6500 (2949)

6000 (2722)

10500 (4763)

13000 (5897)

7600 (3447)

10500 (4763)

12000 (5443)

14000 (6350)

24000 (10909)

23500 (10682) N/A 8300 (3772) 3000 (1364)

20500 (9318) 20500 (9318) 9600 (4364) 3500 (1591)

W

Conv

Sect 2

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

W

Inv

Sect

48 (1219)

*

84 (2134)

111 (2819)

*

48 (1219)

74 (1880)

84 (2134)

111 (2819)

90 (2286)

Weight

Conv2**

lbs (kg)

N/A * N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

2500 (1134)

4500 (2041)

6000 (2722)

2500 (1134)

4500 (2041)

6000 (2722)

6300 (2858)

W

Output

Sect

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

48 (1219)

48 (1219)

Weight

Inv**

lbs (kg)

*

*

74 (1880) 43.4 (1102)

122 (3099) 43.4 (1102)

74 (1880) 43.4 (1102)

174 (4420) 49.5 (1257)

222 (5639) 49.5 (1257)

74 (1880) 43.4 (1102)

122 (3099) 43.4 (1102)

164 (4166) 49.5 (1257)

174 (4420) 49.5 (1257)

222 (5639) 49.5 (1257)

307.5 (7811) 60 (1524)

402.5 (10224) 60 (1524)

Weight

Output

lbs (kg)

W

total

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

D

- 22

Dimensions and weights of the inverter power modules

Drive Model Number

Module Dimensions – inches (mm)

Width Depth Height

M3A22030-050S 9.64 (245) 27.00 (686) 24.21 (615) 120 (54)

M3A22060-100S 11.60 (295) 30.18 (767) 31.55 (801) 235 (107)

M32A22060-100S 9.88 (251) 26.75 (679) 11.13 (283) 71 (32)

M3A22125-200S 24.00 (610) 38.00 (965) 35.34 (898) 512 (232)

M3A22250-300S 31.20 (792) 35.40 (899) 38.61 (981) 650 (295)

M3A44030-090S 9.64 (245) 27.00 (686) 24.21 (615) 140 (64)

M3A44100-200S 11.60 (295) 30.18 (767) 31.55 (801) 260 (118)

M3A44225-250S 16.65 (423) 35.40 (899) 38.61 (981) 400 (181)

M3A44300-350S 24.00 (610) 38.00 (965) 35.34 (898) 580 (263)

M3A44400-600S 31.20 (792) 35.40 (899) 38.61 (981) 800 (363)

M3AP44700S 24.00 (610) 38.00 (965) 35.34 (898) 580 (263)

M3AP44800-10KS 31.20 (792) 35.40 (899) 38.61 (981) 800 (363)

Weight

lbs (kg)

- 23

Speed sensor

Temperature sensor

INTERFACE

The interface between the drive system and external devices is divided into two categori es: power

supply system and control system.

Power Supply Interface and Ground

The power supplies required are the main circuit input of 2400/4160V and (option al) control power

supply of AC480V-60 Hz.

The following figure shows a recommended grounding circuit for the related equipment. Grounding

is intended not only for safety but also to reduce noise problems. The control ground bus is mounted on

insulated standoffs. It may be separated from the power ground and run separately to the earth ground with

insulated cable if noise problems are encountered with auxiliary control devices.

Grounding must follow local and national codes by attaching a properly sized ground conductor

to the drive equipment.