Page 1

TOSHIBA

UM-TS03***-E002

PROGRAMMABLE CONTROLLER

PROSEC T3

USER’S MANUAL

- HARDWARE -

Contents

Toshiba Corporation

Page 2

Important Information

Misuse of this equipment can result in property damage or human injury.

Because controlled system applications vary widely, you should satisfy yourself

as to the acceptability of this equipment for your intended purpose.

In no event will Toshiba Corporation be responsible or liable for either indirect

or consequential damage or injury that may result from the use of this equipment.

No patent liability is assumed by Toshiba Corporation with respect to use of

information, illustrations, circuits, equipment or examples of application in this

publication.

Toshiba Corporation reserves the right to make changes and improvements to this

publication and/or related products at any time without notice. No obligation shall be

incurred other than as noted in this publication.

This publication is copyrighted and contains proprietary material. No part of this book

may be reproduced, stored in a retrieval system, or transmitted, in any form or by any

means — electrical, mechanical, photocopying, recording, or otherwise — without

obtaining prior written permission from Toshiba Corporation.

©TOSHIBA Corporation 1992. All rights reserved

PROSEC and TOSLINE are registered trademarks of TOSHIBA Corporation.

Publication number: UM-TS03***-E002

1st edition Aug. 1992, 3rd edition Sept. 1997

Page 3

Safety Precautions

This manual is prepared for users of Toshiba’s Programmable Controller PROSEC T3.

Read this manual thoroughly before using the T3. Also, keep this manual and related manuals so

that you can read them anytime while the T3 is in operation.

General Information

1. The T3 has been designed and manufactured for use in an industrial environment.

However, the T3 is not intended to be used for systems which may endanger human life.

Consult Toshiba if you intend to use the T3 for a special application, such as

transportation machines, medical apparatus, aviation and space systems, nuclear

controls, submarine systems, etc.

2. The T3 has been manufactured under strict quality control. However, to keep safety of

overall automated system, fail-safe systems should be considered outside the T3.

3. In installation, wiring, operation and maintenance of the T3, it is assumed that the users

have general knowledge of industrial electric control systems.

If this product is handled or operated improperly, electrical shock, fire or damage to this

product could result.

4. This manual has been written for users who are familiar with Programmable Controllers

and industrial control equipment. Contact Toshiba if you have any questions about this

manual.

5. Sample programs and circuits described in this manual are provided for explaining the

operations and applications oi the T3. You should test completely if you use them as a

part of your application system.

Hazard Classifications

In the following pages, the following two hazard classifications are used to explain the

safety precautions.

As. WARNING indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

A\ PAl mON Indicates a potentially hazardous situation which, if not avoided, may

^ result in minor or moderate injury. It may also be used to alert

against unsafe practices.

Even a precaution is classified as CAUTION, it may cause serious results depending on

the situation. Observe all the safety precautions described on this manual.

User’s manual - Hardware

Page 4

Safety Precautions

Installation:

1. Excess temperature, humidity, vibration, shocks, or dusty and corrosive gas

environment can cause electrical shock, fire or malfunction. Install and use the T3 in

the environment described in this manual.

2. Improper installation directions or insufficient installation can cause fire or the units to

drop, install the T3 in accordance with the instructions described in this manual.

3. Turn off power before installing or removing any units, modules or terminal blocks.

Failure to do so can cause electrical shock or damage to the T3 and related

equipment.

4. Entering wire scraps or other foreign debris into to the T3 and related equipment can

cause fire or malfunction. Pay attention to prevent entering them into the T3 and

related equipment during installation and wiring.

Safety Precautions

A CAUTION

Wiring:

1. Turn off power before wiring to minimize the risk of electrical shock.

2. Exposed conductive parts of wire can cause electrical shock. Use crimp-style

3. Operation without grounding may cause electrical shock or malfunction. Connect the

4. Applying excess power voltage to the T3 can cause explosion or fire. Apply power of

5. Improper wiring can cause fire, electrical shock or malfunction. Observe local

II PROSEC T3

A CAUTION

terminals with insulating sheath or insulating tape to cover the conductive parts. Also

close the terminal covers securely on the terminal blocks when wiring has been

completed.

ground terminal on the T3 to the system ground.

the specified ratings described in this manual.

regulations on wiring and grounding.

Page 5

Safety Precautions

Operation:

A WARNING

1. Configure emergency stop and safety interlocking circuits outside the T3. Otherwise,

malfunction of the T3 can cause injury or serious accidents.

A CAUTION

2. Operate the T3 and the related modules with closing the terminal covers. Keep hands

away from terminals while power on, to avoid the risk of electrical shock.

3. When you attempt to perform force outputs, RUN/HALT controls, etc. during operation,

carefully check for safety.

4. Turn on power to the T3 before turning on power to the loads. Failure to do so may

cause unexpected behavior of the loads.

5. Set operation mode switches of the T3 and I/O modules. Improper switch settings may

cause malfunction of the T3 and related equipment.

6. Do not use any modules of the T3 for the purpose other than specified. This can

cause electrical shock or injury.

7. Configure the external circuit so that the external power required for output modules

and power to the loads are switched on/off simultaneously.

Also, turn off power to the loads before turning off power to the T3.

8. Install fuses appropriate to the load current in the external circuits for the relay output

modules. Failure to do so can cause fire in case of load over-current.

9. Check for proper connections on wires, connectors and modules. Insufficient contact

can cause malfunction or damage to the T3 and related equipment.

10. Turn off power immediately if the T3 is emitting smoke or odor. Operation under such

condition can cause fire or electrical shock.

Also unauthorized repairing will cause fire or serious accidents. Do not attempt to

repair. Contact Toshiba for repairing.

User’s manual - Hardware ¡11

Page 6

Safety Precautions

Maintenance:

A CAUTION

1. Do not charge, disassemble, dispose in a fire nor short-circuit the batteries. It can

cause explosion or fire. Observe local regulations for disposal of them.

2. Turn off power before removing or replacing units, terminal blocks or wires. Failure to

do so can cause electrical shock or damage to the T3 and related equipment.

3. Replace a blown fuse with a specified one. Failure to do so can cause fire or damage

to the T3.

4. Perform daily checks, periodical checks and cleaning to maintain the system in normal

condition and to prevent unnecessary troubles.

5. Check by referring ‘Troubleshooting” section of this manual, when operating

improperly. Contact Toshiba for repairing if the T3 or related equipment is failed.

Toshiba will not guarantee proper operation nor safety for unauthorized repairing.

6. The contact reliability of the relays used in the relay output module will reduce if the

switching exceeds the specified life. Replace the module if exceeded.

7. Replace the battery every 2 years to maintain the T3’s program and data normally.

8. Do not modify the T3 and related equipment in hardware nor software. This can cause

fire, electrical shock or injury.

9. Pay special attention for safety if you attempt to measure circuit voltage at the T3’s

terminal.

10. Turn off power before replacing modules. Failure to do so can cause electrical shock

or damage to the T3 and related equipment.

If you attempt to replace an I/O module while power on (by using on-line I/O

replacement function), carefully check for safety.

IV PROSEC T3

Page 7

Safety Label

The safety label as shown on the right is

attached to the power terminal of the T3.

Safety Precautions

A CAUTION

Remove the mount paper before wiring.

Peel off the label from the mount paper

and stick It near the power terminals

where it can be readily seen.

Contact Toshiba if the label is damaged.

Do not touch terminals

A

Hazardous voltage can ^lock, bum or cause death.

Do not touch termirials while power on.

Read related manual thoroughly for safety.

Stick this seal on unit or near unit

Take off this sheet before wiring.

while power on.

3

User’s manual - Hardware V

Page 8

VI PROSEC ТЗ

Page 9

Before reading this manuai

FOR SAFETY To use the T3 safely, read this section carefully before use.

1. Only use the T3 after first carefully reading this Manual and

related guides.

2. Do not use in any of the following environments, as they will

cause malfunctions:-

(1 ) Where the ambient temperature of the T3 (the temperature

inside the panel) is 0"C or below or 55“C or above

(2) Where the ambient humidity of the T3 (the humidity inside the

panel) is 20% or less or 90% or more

(3) Where condensation may form due to severe changes of

temperature

(4) Where there are vibration or violent shocks

(5) Where there are corrosive gases or flammable gases

(6) Where there is dust,salinity or iron content

(7) Where there is direct sunlight

3. Pay attention to the following at the T3 installation site:-

(1 ) For safety in maintenance and operation, keep a distance of

at least 200mm from high-voltage equipment (high-voltage

lines) and power equipment (power lines), or separate by a

shield such as a steel plate.

(2) Keep the expansion cables separate from other povv'er

sources when wiring. In particular, separate by at least

200mm from high-power lines.

(3) Provide an air space of at least 70mm around the units for

ventilation.

(4) install the units vertically.

4. The T3 power supply module is a dedicated module for the T3.

Do not use it on its own for other purposes.

5. For the wiring to the module, use crimp-style terminals fitted with

reverse power sheaths. When it is not possible to use crimp-style

terminals fitted with sheaths, cover with insulating tape and

ensure that the conducting parts are<iot exposed.

User's manual - Hardware

1

Page 10

Before reading this manual

^ This is the warning mark for dangerous locations. It is attached

to the equipment in positions where there is a risk of electric

shock and in positions where there is a risk of damage to the

equipment through wrong wiring.

Take the following precautions where there is a A mark>

(1) Hazardous voltage can shock or cause severe injury if you

(2) For safety, always switch off power when wiring and during

(3) Wire the power input terminals correctly and do not apply

touch the power input terminals while power on. Do not

touch the power input terminals.

maintenance and inspections.

voltages in excess of the specified voltage limits, since this

will cause the equipment damege.

2 PROSEC T3

Page 11

Before reading this manual

The purpose of this

manual

This manual explains the hardware of the programmable controller

PROSEC T3. The explanation covers the configuration,

specification, installation, wiring, maintenance and service.

Scope of this manual This manual covers the following basic parts of the T3 system.

T3 main body: CPU module

Power supply module

Rack

Expansion interface module

Basic Dl/0 : 32 points DC input module (12-24 Vdc)

64 points DC input module (24 Vdc)

32 points AC input module (100-120 Vac, 200-240 Vac)

16 points DC output module (12-24 Vdc)

32 points DC output module (12-24 Vdc)

64 points DC output module (5-24 Vdc)

16 points AC output module (100-240 Vac)

32 points AC output module (100-240 Vac)

32 points relay output module (240 Vac/24 Vdc)

16 points isolated relay output module (240 Vac/24 Vdc)

User's manual - Hardware

Page 12

Before reading this manuai

Related manuals The following related manuals are available for the T3.

T3 User's Manual - Hardware

This manual covers the T3‘s main body and basic I/O - their

specifications, handling, maintenance and services.

T3 User's Manual - Functions

This document explains the functions of the T3 and how to use

them. The necessary information to create user program is covered

in this volume.

T-series Instruction Set

This manuai provides the detailed specifications of instructions for

Toshiba's T-series Programmable Controllers.

T-PDS Basic Operation Manuai

This manual explains how to install the T-series program

development system (T-PDS) into your personal computer and

provides basic programming operations.

T-PDS Command Reference Manual

This manual explains each command of the T-series program

development system (T-PDS) in detail.

T-series Computer Link Function

This manual explains the specification and handling method of the

T-series Programmable Controller's Computer Link function.

4 PROSEC T3

Page 13

Before reading this manuai

Note and caution

symbols

Terminology

Users of this manual should pay special attention to information

preceded by the following symbols.

NOTE Calls the reader's attention to information considered

important for full understandings of programming

procedures and/or operation of the equipment.

CAUTION Calls the reader's attention to conditions or practices that

could damage the equipment or render It temporarily

inoperative.

AWG American Wire Gage

ASCI! American Standard Code for Information Interchange

CPU Central Processing Unit

EEPROM Electrically Erasable Programmable Read Only Memory

IF Interface

I/O Input/Output

LED Light-Emitting Diode

ms millisecond

NEMA National Electrical Manufacturers' Association

PLC Programmable Controller

PS Power supply

RAM Random Access Memory

ROM Read Only Memory

jj. s microsecond

Vac ac voltage

Vdc dc voltage

User's manual - Hardware

Page 14

Contents

1. System Configuration.............................................................................. 9

1.1 T3 hardware configuration....................................................................... 9

1.2 Unit configuration ..................................................................................11

1.3 Power supply module

1.4 CPU module...........................................................................................15

1.5 Rack....................................................................................................... 19

1.6 Expansion interface module ..................................................................20

1.7 Expansion cable.....................................................................................21

1.8 List of I/O modules .................................................................................22

1.9 Examining the power supply capacity

2. Specification............................................................................................26

2.1 General specifications

2.2 External dimensions...............................................................................27

2.3 I/O module specifications

3. Precautions for I/O Modules...................................................................48

3.1 Precautions for DC input modules .........................................................48

3.2 Precautions for AC input modules

3.3 Precautions for DC output modules........................................................53

3.4 Precautions for AC output modules .......................................................55

3.5 Precautions for relay output modules ................................................... 56

............................................................................

....................................................

..........................................................................

......................................................................

........................................................

13

23

26

28

51

4. Installation and Wiring ...........................................................................57

4.1 Installation environment

4.2 Installing units ....................................................................................... 58

4.3 Mounting modules..................................................................................59

4.4 Connecting expansion units

4.5 Grounding...............................................................................................62

4.6 Wiring of the power supply

4.7 I/O wiring............................................................................................... 67

5. Maintenance and Checking....................................................................69

5.1 Daily checking items ............................................................................. 69

5.2 Periodical checking items ..................................................................... 70

5.3 Maintenance parts

5.4 Replacing battery ................................................................................. 71

5.5 Replacing fuses..................................................................................... 72

5.6 IC memory card handling

........................................................................

..................................................................

.....................................................................

...............................................................................

.....................................................................

57

60

65

71

74

6 PROSEC T3

Page 15

Contents

6. Troubleshooting..........................................................75

6.1 Troubleshooting procedure.....................................................................75

6.2 Checking the power supply

6.3 Checking the CPU..................................................................................77

6.4 Checking program.................................................................................. 77

6.5 Checking input........................................................................................78

6.6 Checking output......................................................................................79

6.7 Troubles due to external factors

6.8 I/O module replacement during operation .............................................81

6.9 List of self-diagnostic items

....................................................................

.............................................................

....................................................................

76

80

82

User s manual - Hardware 7

Page 16

1. System Configuration

8 PROSEC T3

Page 17

1. System Configuration

1.1

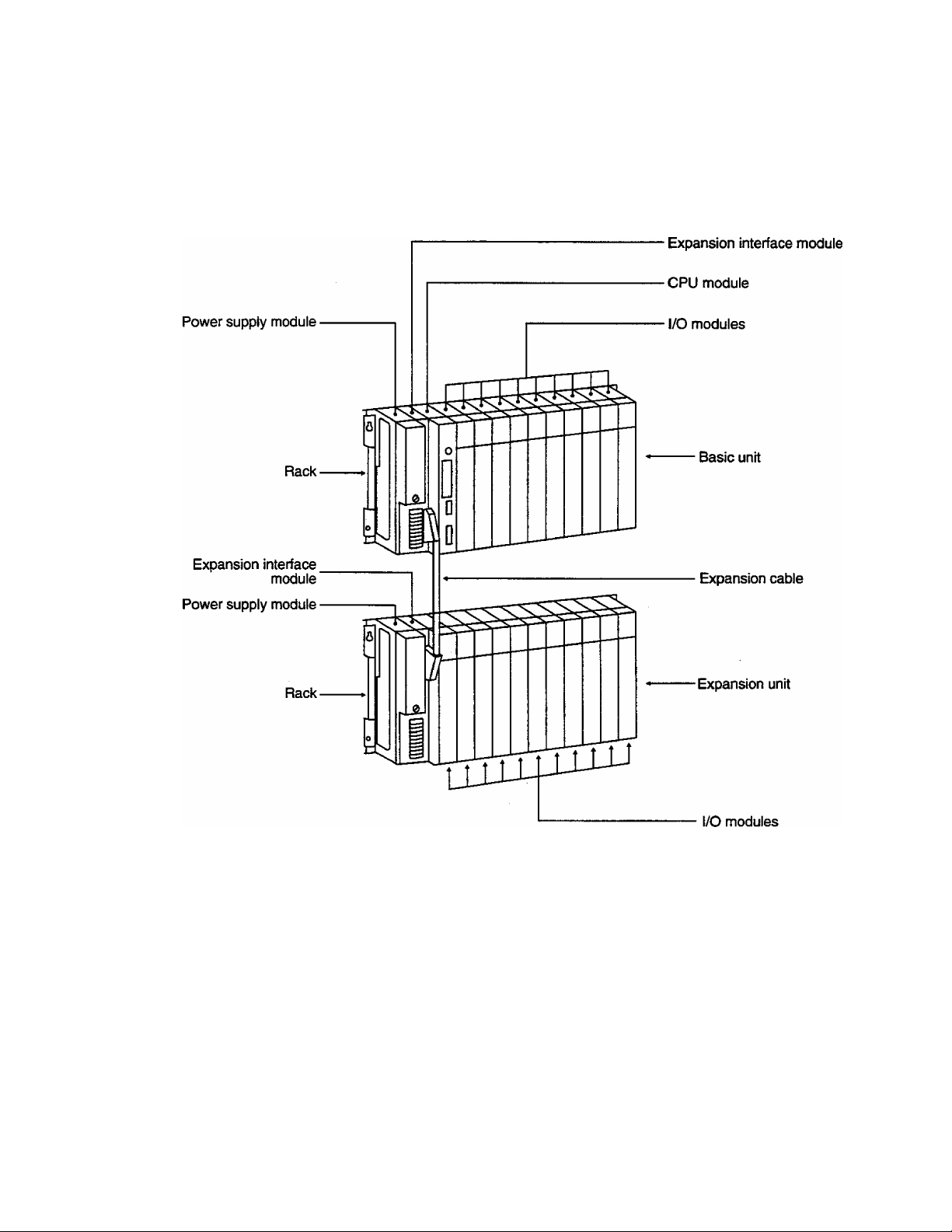

T3 hardware The T3 consists of the rack (s), the power supply modules (s), the

configuration CPU module, the expansion interface module (s), the expansion

cables (s) and I/O modules (s).

User's manual • Hardware

Page 18

1. System Configuration

The modules which configure the T3 system are listed below,

(except I/O modules)

Power supply module

CPU module

Rack

Type Description

PS361

1

2

PS332

Type

1

PU315 RAM

2 PU325

Type

1

BU31A

BU315

2

BU35B

3

4

BU356

Power supply voltage : 100-120 Vac/200-240 Vac,

common for basic and expansion units

Power supply voltage: 24 Vdc,

common for basic and expansion units

RAM+EEPROM

For basic

unit

For expansbn

unit

Description

Description

10 slots for I/O modules

5 slots for I/O modules

11 slots for I/O modules

6 slots for I/O modules

Expansion interface module

Type

1

IF311

2

IF351

3

IF312

4 IF352

IF353

5

For basic

unit

Fcx expansion

unit

For basic

unit

For middle

expan^n unit

For end

expansion unit

Description

Standard type,

2m maximum between the units,

total 6 m maximum

Long-distance type,

total 40 m maximum

Expansion cable

Type

1

CS3R5 0.5m

2 CS301 Im

CS302

3

4

CL3R5 0.5m

CL301

5

6 CU05 5m Long-distance type,

7 CL310

CL320

8

CL340

9

2m

1m

10m

20m

40m

Description

Standard type,

both-end connector (50-pin)

both^nd connector (68-pin)

10

PROSECT3

Page 19

1.2

Unit configuration

1. System Configuration

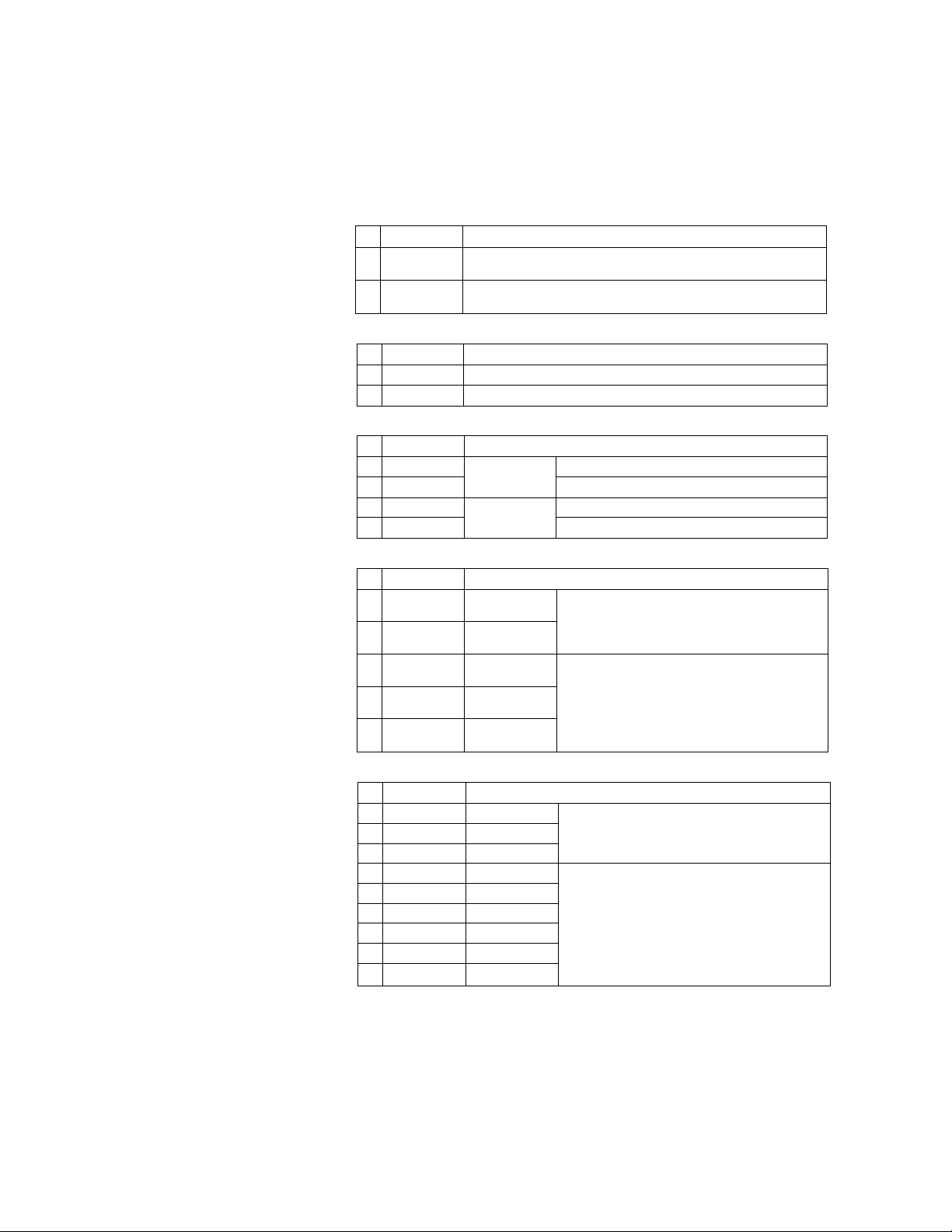

(1) Minimum configuration of the T3

c 1 1 1 1 1 i I 1 1 1

p

1

p

/ / / / / / / / /

s

/

u

0 0 0 0 0 0 0 0 0 0

Basic unit (10 t/0 rack)

320 points (32-point I/O)

Basic unit (5 I/O rack)

160 points (32-point I/O)

The minimum configuration of the T3 is one basic unit. In this

case, no expansion interface module is needed.

(2) Maximum configuration of the T3

Number of l/Q points (when 32point I/O modules are used)

320 points (10 I/O rack)

160 points (5 t/O rad()

1

672 points (11 I/O rack)

/

/ : / :

352 points (6 t/O rack)

0

1 (

1 I

1 (

1024 points (11 I/O rack)

544 points (6 I/O rack)

c 1 ! 1 1 1

p 1

1

p / / / / /

p

s

p 1

s

c¡1

c]

1

r

c

u 0

0

0 0 0 0

Expansion unit No.1

1 1 1 1 1 1 1

/ /

/ / /

0

0 0 0 0 0

Expansion unit No.2

Basic unit

11(1

(1(1

1 1 1 : 1 ; 1 : 1

/;/:/:/;/

0 : 0 : 0 ; 0 ; 0

till

(III

( ( ( 1

/

( 1

J 1

J 1

; 1 : 1 ; 1 ;

/

; / :

: 0 :

1 1

( 1

( (

1 1

1 1

1 1

0:0:

Expansion un t No.3

p

s F

□

i/1/1

!

0 0

/1/

0

0

1

/1/

0

o

1376 points (11 I/O rack)

736 points (6 I/O tack)

Up to three expansion units can be connected to the basic unit.

There is no limitation in combining different size of racks.

The expansion interface module is needed for each unit,

(indicated as "IF" in the figure)

The expansion interface module is dedicated for basic or

expansion units

User's manual - Hardware

11

Page 20

1. System Configuration

If the Standard type expansion is used, all expansion interface

modules must be the standard type. In this case, the maximum

length of the expansion cable is 2m between units, 6m total.

If the long-distance type expansion is used, all expansion

interface modules must be the long-distance type. In this case,

the maximum length of the expansion cable is total 40m.

If the standard type expansion is used, the necessity of the

power supply modules on the expansion units is determined

depending on the internal current consumption. (See 1.9

Examining the power supply capacity)

The power supply mode plug of the expansion interface module

must be set according to the power supply module mounting

status.

If the long-distance type expansion is used, all expansion units

should have the power supply modules.

The dedicated expansion cables are available for the standard

expansion and for the long-distance expansion, respectively.

12 PROSEC T3

Page 21

1.3

Power supply module

1. System Configuration

The following table shows that two types of power supply modules

are available, depending on the power supply voltage. These

modules can be used for both the basic unit and the expansion unit.

The power supply module is mounted in the extreme left of the rack.

However, the expansion rack that is connected to the standard

expansion IF may not need the power supply module. For details,

see 1.9 Examining the power supply capaci^.

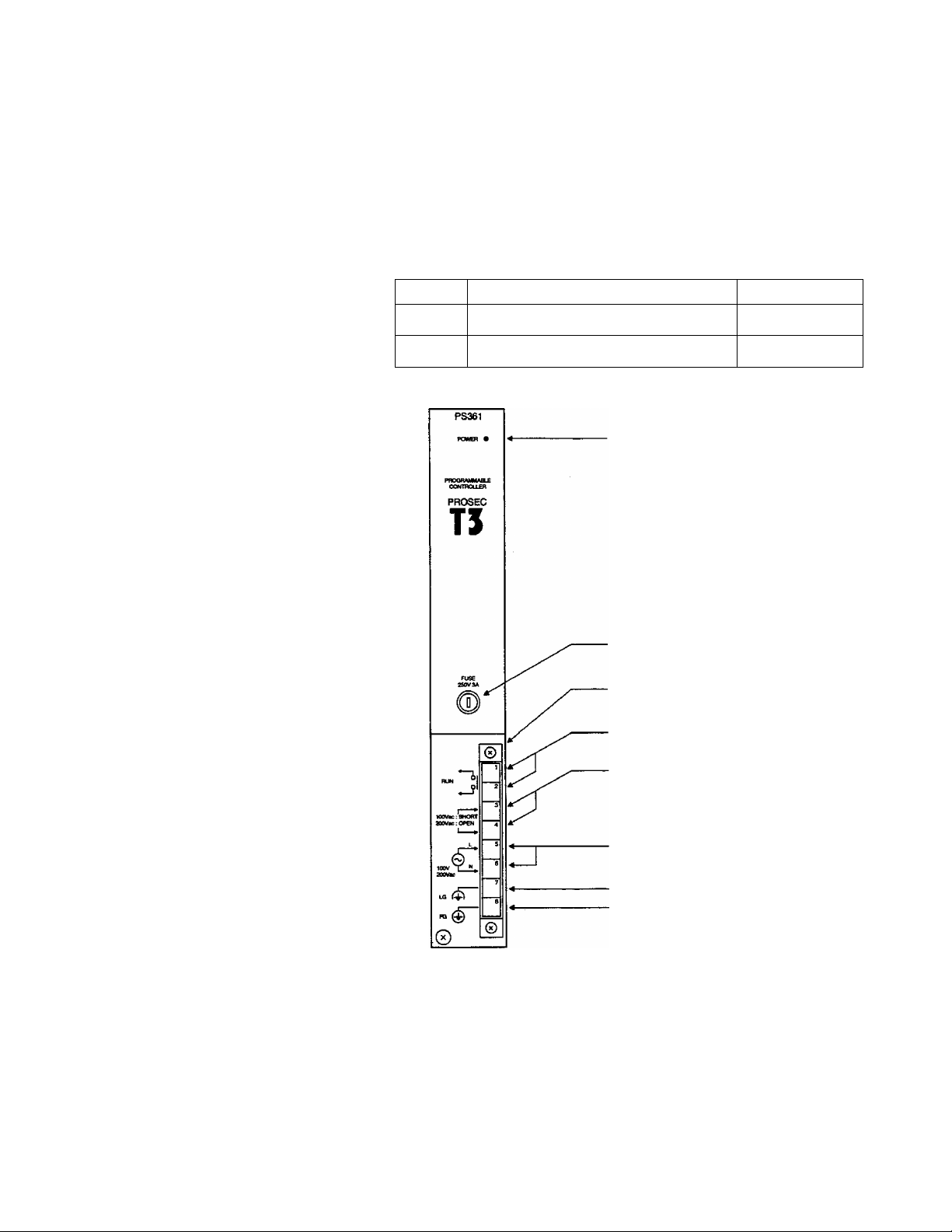

Type

PS361

PS332

Rated voltage

100-120 Vac/200-240 Vac (selectable)

24 Vdc

POWER LED

Fuse

Tenninal block eject screw

(on top at bottom)

Run signal output terminals

Frequency

50/60 Hz

Voltage switch terminals

(100 to 120 Vac... ^ort\

1200 to 240 Vac... open)

Power su|:^ly input terminais

Line filter ground terminal

Frame ground terminal

\

Module fixing screw

User's manual - Hardware

13

Page 22

1. System Configuration

POWER LED (green):

This LED is lit when the internal 5 Vdc power supply is normal.

Fuse:

For PS361 ...250 Vac-3A (with one spare fuse)

For PS332...250 Vac-6A (with one spare fuse)

Run signal output terminals

Built-in NO contact which closes when T3 is in RUN mode.

Contact output...240 Vac/24 Vdc-2A (max.)

(can also be used on the expansion unit)

Voltage switch terminals:

These terminals are shorted or opened, depending on the power

supply voltage (with a short-circuit bar).

100 to 120 Vac...short

200 to 240 Vac...open

Power supply input terminals :

These terminals are used to connect the power supply line.

Line filter ground terminal (LG):

This terminal is a neutral point for the primary line filter of the power

supply, (grounding terminal)

Frame ground terminal (FG):

This terminal is connected to the frame of the T3. (grounding

terminal)

The terminal is connected, via a capacitor, to the signal ground (SG)

of the internal circuit.

CAUTION (1) Correctly set the voltage switch terminals, otherwise

▼AT

the module will be damaged.

(2) For details, see 2.1 General Specifications, for the

external power supply conditions.

(3) The screw size for the terminal is M3.5. For details

of the wiring, see 4.5, Grounding, and 4.6, Wiring of

the Power Supply.

14 PROSEC T3

Page 23

1. System Configuration

1.4

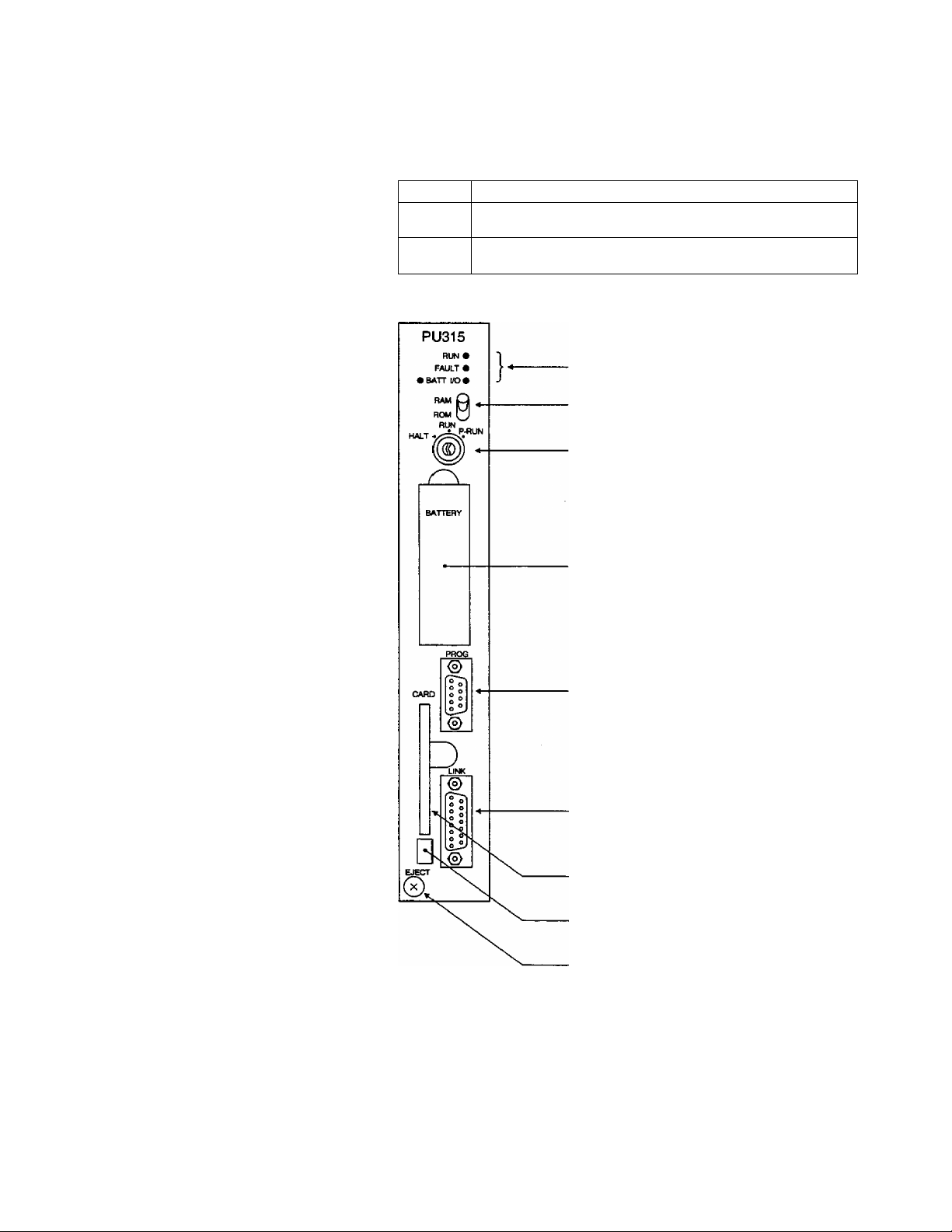

CPU module As shown in the table below, the CPU module is available in two

types.

Type Specification

PU315

PU325

PU315/PU325

RAM (battery backup), 32K steps for user program,

ladder diagram, SFC

EEPROM+RAM (battery backup), 32K steps for user program,

ladder diagram, SFC

Status display LED (RUN, FAULT. I/O, BATT)

RAM/ROM switch

Operation mode switch (HALT/RUN/P-RUN)

Battery cover

RS232C port for the programmer

(D-Sub 9-pin female connector)

RS485 port for the computer iink

(D-Sub 15-pin female connector)

1C memory card slot

IC memory card ejection button

Module fixing screw

User's manual - Hardware

15

Page 24

1. System Configuration

Status display LED:

Lit User program is executing (in the RUN mode)

RUN

(green)

Blink

Not lit Execution is stopped (in the HALT mode or in the ERROR mode)

Execution is stopped (in the HOLD mode)

Ut

FAULT

(red)

I/O

(red)

ВАТТ

(green)

Blink

Not lit

Ut

Blink Hardware initialization error

Not lit

Ut Normal battery voltage

Not lit Battery voltage becomes low

RAM/ROM switch

Position at

power ON

RAM

ROM

Typed

CPU

PU315

PU325

PU315

PU325

CPU/program error

Hardware initialization error

Normal

I/O error

Normal

Operation of the CPU

(program transfer at power ON)

Program transfer is not executed.

When an tC memory card which stores user program is

inserted, contents d the 1C memory card is transferred

to RAM. (When the operation mode switch is in P-RUN,

the program transfer is not executed.)

When an 1C memory card is not inserted or when the 1C

memory card does not contain a user program, program

transfer is not executed.

When an 1C memory card that stores user program has

been inserted, contents of the 1C memory card is

transferred to RAM. (When the operation mode switch

is in P-RUN, the program transfer is not executed.)

When an 1C memory card is not inserted, or when the 1C

memory card inserted does not contain a user program,

the contents of the EEPROM will be transferred to RAM.

(When the operation mode switch is in P-RUN, the

program transfer is not executed)

16 PROSEC T3

By using the RAM/ROM switch and the operation mode switch

together, the user can select a initial operation mode when power

is applied. For details,-see the next page.

Page 25

1. System Configuration

Operation mode switch :

Position of

the switch

User program execution is hatted (HALT mode).

HALT

RUN

P-RUN

Changing the operation mode by the programmer is invalid.

Normally programming is done in this state.

When the operation mode switch is changed to RUN,

the user program execution is started (the RUN mode).

Changing the operation mode from the programmer is possible.

When the operation mode switch is changed to P-RUN,

user program execution is started (the RUN mode).

Changing the operation mode from the programmer is possible.

The user program and leading 4K words of data registers (D)

are write-protected.

The table below shows the initial operation modes after power ON

depending on the Operation mode switch and RAM/ROM switch

status.

Function

RAM/ROM

switch

RAM

ROM

Mode

switch

HALT HALT

RUN HALT

P-RUN HALT

HALT

RUN

P-RUN RUN

Mode after

power on

HALT

RUN

Remarks

The CPU module is started in the HALT

mode and then waits for the RUN

command from the programmer,

or for a change-over of ttie operation

mode switch (->HALT->RUN).

The user program is transferred in

accordance with the conditions

mentioned in the table on the preceding

page.

The program transfer is not executed.

The CPU module is started based on

the contents of RAM.

NOTE (1) When power is turned on while the RAM/ROM switch

BAM, user program execution will not be started.

Regardless of the type of CPU module, therefore, the

RAM/ROM switch should be set to ROM for normal

operation.

(2) When the Operation mode switch is changed to RUN

while theRAM/ROM switch is in ROM, the program

transfer is executed, according to the conditions

mentioned in the table on the preceding page, before

the CPU module starts operation.

(3) For details on operation modes, see "T3 User's

Manual-Functions" in a separate volume.

User's manual - Hardware 17

Page 26

1. System Configuration

Battery cover:

A batteiy has been installed inside this cover at the factory

shipment. The battery keeps the RAM contents (user program and

user data) and supports the clock-calendar operation during power

OFF.(See 5.4 Replacing battery)

RS232C port for the programmer :

The T-series programmer (T-PDS or HP911) is connected to the T3

through this port. Dedicated connection cables are available.

RS485 port for the computer link:

The CPU module has the computer link function as standard.

By using this function, T3 can communicate with a host computer or

an intelligent equipment through RS485 interface. For details of the

computer link function, see separate "T-series Computer Link

Funciton Operation Manual".

IC memory card slot:

Optional !C memory card (type : ME914) is inserted into this slot.

By installing the IC memory card, user program back-up/switchover

or user data expansion become available. Refer to 5.6 IC memory

card handling.

18 PROSEC T3

Page 27

1.5

Rack

1. System Configuration

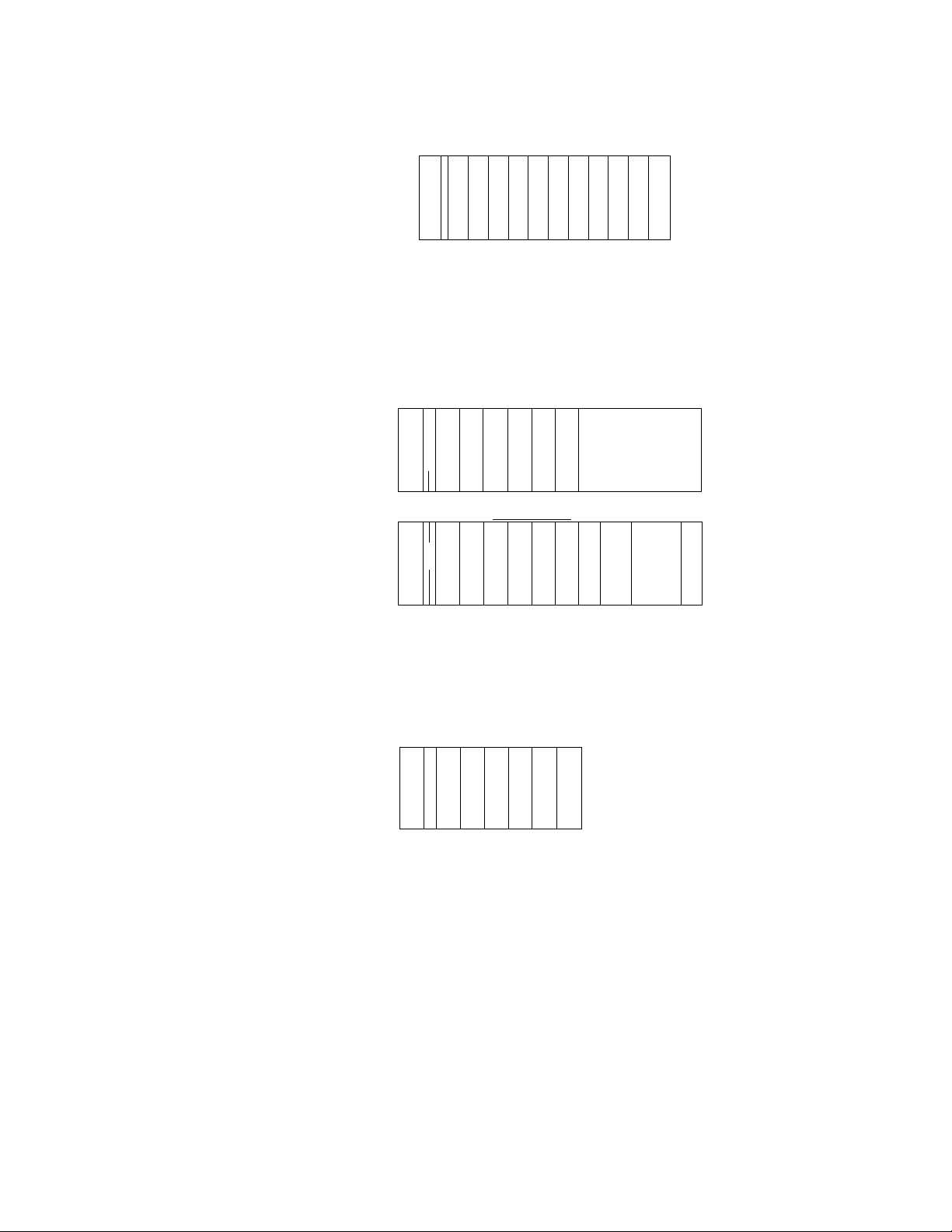

As described in the table below, in total four racks are available :

two racks are for the basic unit, and two racks, for the expansion

unit.

Type

BU31A

BU315

BU35B

BU356 PS X1,IF X1,I /0X6

Use

For

basic

unit

For

expansion

unit

Number of modules mountable

PSX1, IFX1, CPUX1,1/0X10

PS XI.IF XI.C PUX I, 1/0X5

PS XI.IF XI, 1/0X11

) "PS" and "IF" in the above table indicate the power supply

module and the expansion interface module respectively.

I II I I I

BU315

BU356

• The connector on the extreme-left slot of the rack is dedicated to

the power supply module, and the connector next to the right

slot is dedicated to the expansion interface module. The third

connector from the extreme left slot of the basic unit rack

(BU31A, BU315) is dedicated to the CPU module.

CAUTION Place a cap on each of the connectors where no module

is mounted so that no foreign material will enter.

User's manual - Hardware

19

Page 28

1. System Configuration

1.6

Expansion interface

module

If the expansion units are used, the expansion interface modules

must be mounted in each of the basic unit and the expansion units.

There are basically two types of expansion interface modules-the

standard type and the long-distance type. What type to use will

depend on the cable distance. The dedicated expansion interface

module must be mounted on each of the basic unit and the

expansion units.

Type

IF311

IF351

IF312

IF352

IF353

Use

For

basic unit

For

etqjansion unit

For

basic unit

For middle

expansion unit

For end

expansion unit

IF311

(standard type, tor basic unit)

iF311

OUT

iS.

Standard type

2m maximum between two units,

6m maximum in total cable length

Long-distance type

40m maximum in total cable length

(standard type, for expansion unit)

Expansion connector (IN)

Connected to tiie preceding unit

Expansion connector (OUT)

Connected to the next unit.

Remark

IF351

1F351

&

V

IN

OUT

20 PROSEC T3

Page 29

1. System Configuration

Since there is no compatibility between the standard type and

the long-distance type, these two types cannot be mixed in one

T3 configuration.

The standard type expansion cable and the long-distance type

expansion cable are not compatible with each other. (See

Section 1.7 Expansion Cable.)

If the standard type is used, whether a power supply module is

necessary for the expansion unit will depend on the internal 5

Vdc current consumption. (See Section 1.9 Examining the

power supply capacity.)

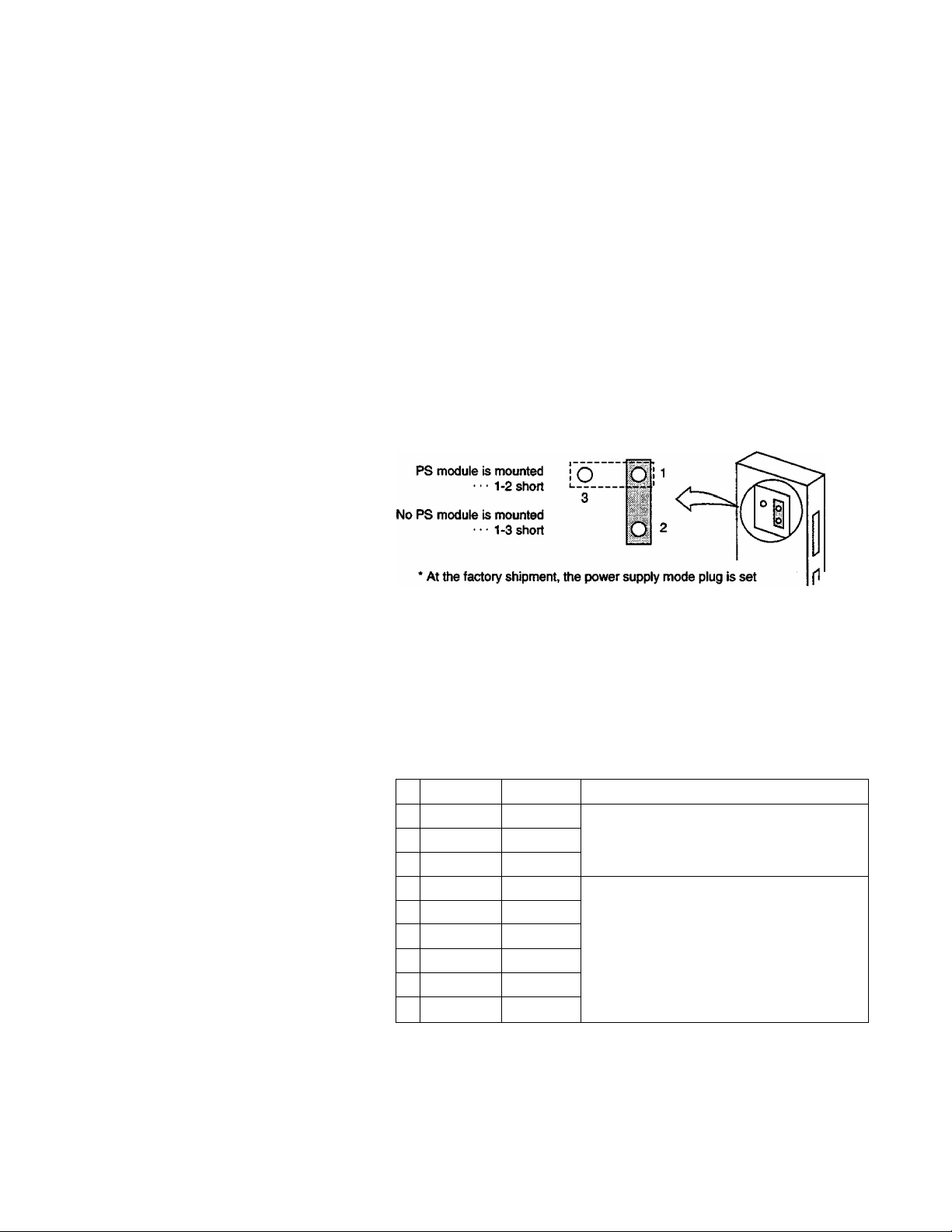

For the IF351, change the power supply mode plug as shown in

the figure below (depending on whether a power supply module

has been mounted on its own unit).

IF351

1.7

Expansion cable

to 1-2 shorted (witii a power supply).

For the long-distance type, a power supply module is needed for

each of the expansion units.

In the long-distance type, the IF312 is for basic unit, the IF352 is

for middle expansion units and the IF353 is for the end

expansion unit.

The following types of expansion cables are available.

Type

1

CS3R5

2

CS301

3

CS302 2m

4

CL3R5 0.5m

.5

GL301 1m

6

CL305

7

CL310

8

CL320 20m

9

CL340 40m

Cable length Remarks

0.5m

1m

5m

10m

Standard type

With both-end connectors (50-pin)

Long-distance type

With both-end connectors (68-pin)

Front

User’s manual - Hardware

21

Page 30

1. System Configuration

1.8

List of I/O Modules

This manual explains the basic I/O modules in the list below and

how to use them.

Type

DI334

DI334H

D1335

DI335H

IN354

IN364

D0333

D0334

D0335

AC363

AC364

R0364

R0363S

DC

input

AC

input

DC

output

AC

output

Relay

output

Specification

32 points (8 pts common), 12 to 24 Vdc,

10 mA/point

32 points (8 pts common), 12 to 24 Vdc,

10 mA/point, high-speed response

64 points (8 pts common), 24 Vdc,

5 mA/point

64 points (8 pts common), 24 Vdc,

5 mA/point, high-speed response

32 points (8 pts common), 100 to 120 Vac,

10 mA/point

32 points (8 pts common), 200 to 240 Vac,

10 mA/point

16 points (8 pts common), 12 to 24 Vdc,

2 A/point, 5 A/common

32 points (16 pts common), 12 to 24 Vac,

0.5 A/point, 5 A/common

64 points (8 pts common), 5 to 24 Vdc,

100 mA/point

16 points (8 pts common), 100 to 240 Vac,

2 Appoint, 5 A/common

32 points (16 pts common), 100 to 240 Vac,

0.5 A/point, 3.2 A/common, 5 A/module

32 points (8 pts common), 240 Vac/24 Vdc,

2 A/point, 5 A/common

16 points (isolated contact), 240 Vac/24 Vdc,

2 A/point

22 PROSEC T3

For details on the specification of I/O modules, see 2.3, I/O

module specifications.

Carefully read the Cautions described In Section 3 for applying

I/O modules.

The I/O module can be mounted in any I/O slot functionally.

However, to improve noise-immunity for the entire system, it is

recommended to separate the low voltage 1/Os and the power

I/Os. (See 4.7, I/O Wiring.)

Page 31

1.9

Examining the power

supply capacity

1. System Configuration

The maximum output current (5 Vdc) of the power supply module

(PS361/PS332) is 7 A. (5.1V at factory setting)

In the standard type expansion configuration, if the power supply

module of the previous unit can supply 5 Vdc to the following units,

no power supply module for the following expansion units is

necessary.

In this case, however, there may be a voltage drop of the 5 Vdc

power caused by the resistance of the expansion cable. The

minimum limit voltage is 4.75 Vdc. It should also be considered.

Basic unit

Internal S Vdc current

consumption

^PU+IF+l/0 {A)=lo[A]

Exfsansion cable

resistance

= Ro [Q]

Internal 5 Vdc current

consumption

==IF+l/0 (BHi[A]

Expansion cable

resistance

= Ri [Q]

internal 5 Vdc current

consumption

=IF+l/0 (C)=l2[A]

Expansion cable

resistance

= R2 [Q]

Internal 5 Vdc current

consumption

=IF+l/0 (D)=l3lA]

Concerning the above figures, the following conditions (1) and (2)

must be satisfied so that the expansion units N0.1 through 3 can be

mounted in the slots using no power supply of their own.

(1) lo+li+l2+l3<7A

(2) 5.1-RoX(li+l2+l3)-RiX{h+l3)-R2Xl3> 4.75V

If either of the above conditions is not satisfied, a power supply

module is needed for the expansion unit.

If a power supply module is mounted on the expansion unit, the

power supply module will supply 5 Vdc to the own unit and to the

following expansion units, disconnecting 5 Vdc line from the

previous unit (OV line is common).

User's manual - Hardware

23

Page 32

1. System Configuration

For example, if the user is going to mount a power supply module

on the expansion unit No.2, check that the following conditions are

satisfied.

(1) lo+li<7A

(2) 5.1-RoXh > 4.75V

(3) l2+l3 < 7A

(4) 5.1-R2Xl3>4.75V

Additional power supply modules may be mounted on the units

even though the power supply capacity has enough margin.

NOTE (1) Correctly set the power supply mode plug of the

\~ZiX7 expansion interface module (IF351) according to a

Conditions for the power supply

capacity of the basic unit

Conditions for the power supply

capacity of expansion unit No.2

power supply module to be mounted on the unit. If

the setting is wrong, the T3 will not work normally.

(For details, see 1.6 Expansion interface module.)

(2) For the long-distance expansion interface module,

each of the units must be equipped with a power

supply module.

The table below shows the resistance values (typical value) of

expansion cables.

Cable

length

0.5m

1m

2m

Part No.

CS3R5

CS301

CS302

Resistance

value

38m Q

66m Q

112mQ

Remarks

Standard type

With both-end connectors

(50-pin)

24 PROSEC T3

Page 33

1. System Configuration

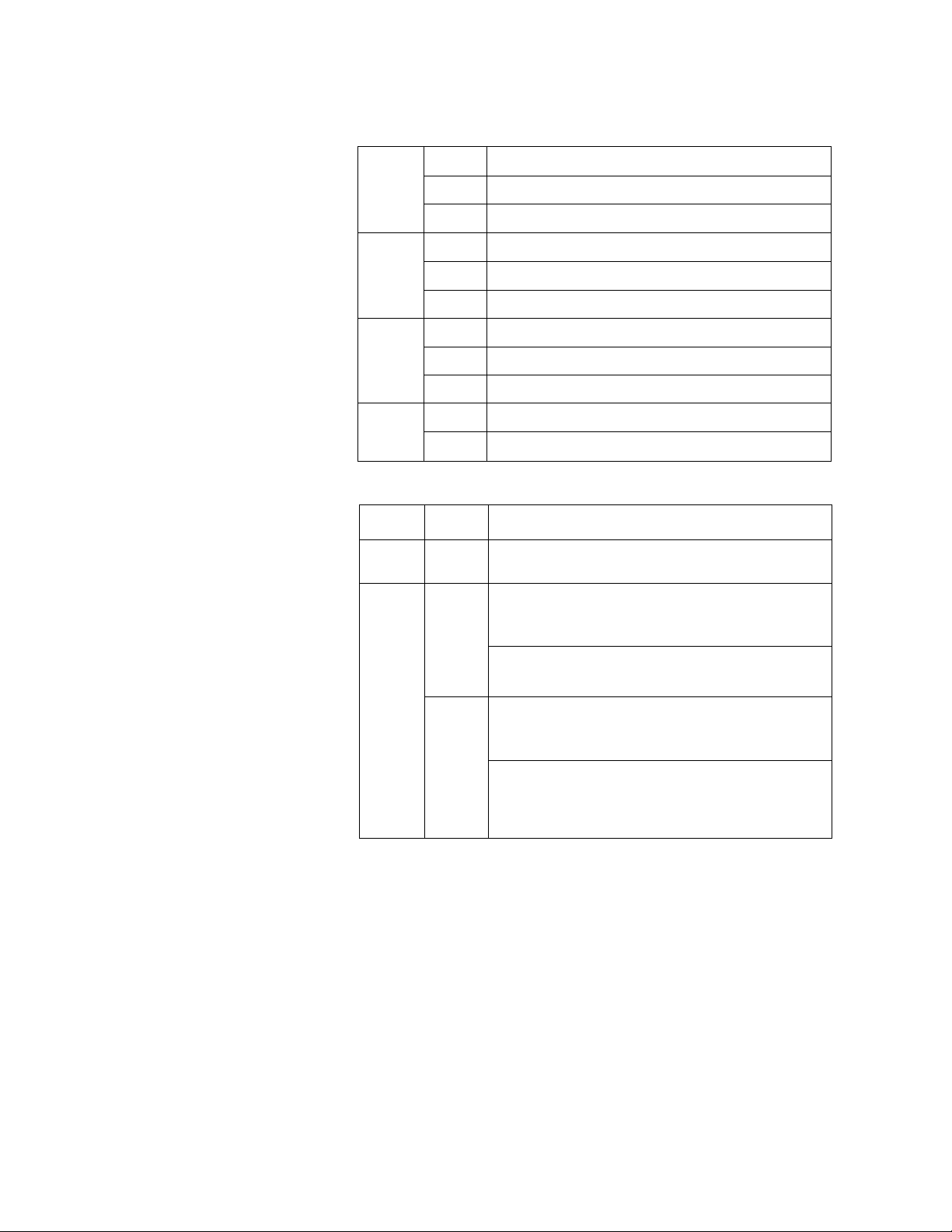

The table below lists the internal 5 Vdc current consumption (max.)

of the module for calculating allowable power capacity.

Internal 5-

Type

Expansion

interface

CPU

DC

input

AC

input

DC

output

AC

output

Relay

output

Special

I/O

Data link

Name

Standard expansion interface

(for basic unit)

Standard expansion interface

(for expansion unit)

Long-distance expansion interface

(for basic unit)

Long-distance expansion interface

(for middle expansion unit)

Long-distance expansion interface

(for end expansion unit)

CPU (RAM)

CPU (EEPROM+RAM)

32-point DC input

32-point DC input

(high-speed response)

64-point DC input

64-point DC input

(high-speed response)

32-point AC input (100 to 120 Vac)

32-point AC input (200 to 240 Vac)

16-point DC ou^ut (12 to 24 Vdc)

32-point DC output (12 to 24 Vdc)

64-point DC output (5 to 24 Vdc)

16-point AC output (100 to 240 Vac)

32-point AC ou^ut (100 to 240 Vac)

32-point relay output

10-point relay output (Isolated)

Analog Input (8 channels)

Analog output

(4 channels)

Pulse input (2 channels)

DC input (8 pts) with status change

detection

ASCII interface

TOSL1NE-S20

TOSLINE-F10 (master)

Voltage

Current DA374 180 mA

Coaxial

Optic

Coaxial/optic

Part No.

IF311 20 mA

IF351 20 mA

IF312 800 mA

IF352 700 mA

IF353 700 mA

PU315 2.5 A

PU325 2.5 A

DI334 100 mA

DI334H 100 mA

DI335 170 mA

DI335H

IN354

IN364 120 mA

D0333

D0334 210 mA

D0335

AC363

AC364 800 mA

R0364 170 mA

R0363S 100 mA

AD368

DA364

P1312 800 mA

CD332 300 mA

AS311

SN321 800 mA

SN322 800 mA

SN323 800 mA

MS311

volt current

ccxisumption

170 mA

120 mA

320 mA

400 mA

530 mA

460 mA

180 mA

1 A

1 A

Note) The current consumption of the T3 CPU modules (2.5 A max.) is

the value when the handy programmer (HP911) is connected.

When the HP911 is not connected, it is 1.5 A max.

User's manual - Hardware

25

Page 34

2. Specification

2.1

General Specifications

Item Specification

Rated

voltage

Voltage

tolerance

Rated

>.

o.

frequency

CL

3

ai

Frequency

k.

<i)

tolerance

1

CL

Retentive power

Interruption

Power

consumption

Inrush

current

Insulation

resistance

Withstand

voltage

Operating

temperature

Storage

temperature

Ambient

humidity

(1) 100 to 120 Vac/200 to 240 Vac

(2) 24 Vdc

(1) 85 to 132 Vac/170 to 264 Vac

(2) 20.4 to 28.8 Vdc

(1)50/60 Hz

(1)47 to 63 Hz

10 ms or less

(1) 80 VA or less

(2) 50 W or less

(1) 10 A/100 Vac, 20 A/200 Vac

(2) 6 A

10 MQ or more (500 Vdc)

1500 Vac for 1 minute

0 to 5Sr

-20 to 75*C

20 to 90% RH

Remarks

Switchable

Max. load

conditions of one

PS module

Between power

terminals and FG

Between power

terminals and FG

No condensation

26 PROSEC T3

Atmosphere No corrosive gases

Dust

Vibration

immunity

Shock

immunity

Noise

immunity

Grounding

Structure

Cooling

10 mg/m3 or less

16.7 Hz, 3 mmp-p, 30 seconds

98 m/s2, 3 times, in X, Y, Z

directions

1500 Vp-p, 1 M s (noise simulator

method) NEMA ICS3-304

100Q or less

Control panel built-in t^

Natural cooling

Approx. 7.6 kg

Weight

Approx. 4.7 kg

No power

No power

Power supply noise

Basic unit with

10 I/O modules

Basic unit with

five I/O modules

Page 35

2.2

External Dimensions

2. Specification

Basic unit (10 I/O slots)

4-^6

Expansion unit (11 I/O slots)

4-^6

Basic unit (5 I/O slots)

4-^6

Expansion unit (6 I/O slots)

4^^6

User's manual - Hardware

units: mm

27

Page 36

2. Specification

I/O module

specifications

32-point DC input

2.3

Type

Category

input type

Number of input points

insulating method

Rated input voltage

Range of input voltage

Rated input current

Input impedance

Opera

tion

voltage

Delay

Min. ON voltage

Max. OFF voltage

OFF-ON

ON — OFF

Input signal display

External connection

No. of commons

No. of input points

per common

Polarity of common

Derating condition

Internal cunent

consumption

Insulation resistance

Withstand voltage

Weight

Internal circuit

DI334

DC input

Current sinking/sourdng

32 points. 2-word input (X 2 W)

Photo-coupler

12to24Vdc

10 to 26.4 Vdc

10 mA (at 24 Vdc)

2.4 KQ (at 24 Vdc)

9.6V

3.5V

10 ms or less

15 ms or less

LED display for all points, lit at ON, internal logic side

38-pin removable tenninal block, M3.5

4 (insulated between commons)

8 points/common

No Polarity

See NOTE on the next pate

5 Vdc, 100 mA or less

10 MQ or more (500 Vdc)

1500 Vac, 1 minute (between commons, between

internal and external circuits)

420g

DI334H

1 ms or less

1.5 ms or less

28 PROSEC T3

Page 37

2. Specification

32-point DC input

(cont'd)

Terminal connections

—^S)— Input power "Hh" 12 to 24 VdC

supply |^|j

NOTE The number of simultaneous ON input points will be

restricted according to the ambient temperature and

input voltage, as described in the figure below.

Number of simultaneous ON input points

Amt»ent temperature

(C)

User's manual - Hardware 29

Page 38

2. Specification

64-point DC input

30 PROSEC T3

Page 39

64-point DC input

(cont'd)

2. Specification

NOTE Type of the connector of the module side:

FCN-365P040-AU (Fujitsu)

Connectors (2, soldering types) of the cable side are

attached as standard.

User's manual - Hardware

31

Page 40

2. Specification

32-point AC input

Type

Category

Number of input points

insulating method

Rated input voltage

Range of input voltage

Frequency

Rated input current

input impedance

Opera

tion

voltage

Min. ON voltage

Max, OFF voltage

OFF - ON

Delay

ON — OFF

Input signal display

External connection

No. of commons

No. of input points

per common

Derating condition

Internal current

consumption

insulation resistance

Withstand voltage

Weight

Internal circuit

IN354

AC input

32 points, 2-word input (X 2 W)

Photo-coupler

100 to 120 Vac

85 to 132 Vac

50/60Hz(47to63Hz)

10mA(at100Vac,50Hz)

10 KQ (50Hz),

8 KQ (60Hz)

70 Vac

25 Vac

15 ms or less

15 ms or less

LED display for all points, lit at ON, internal logic side

38-pin removable terminal block, M3.5

4 (insulated between commons)

8 points per common

None

5 Vdc, 120 mA or less

10 M Q or more (500 Vdc)

1500 Vac, 1 minute (between commons, between

internal and external droiits)

480g

200 to 240 Vac

170 to 264 Vac

10 mA (at 200 Vac, 50Hz)

22 kD (50 Hz),

18 kQ (60 Hz)

140 Vac

50 Vac

IN364

32 PROSEC T3

Page 41

2. Specification

32-point AC input

(cont'd)

Terminal connections

Input power

supply

too to 120 Vdc

200 to 240 Vdc

User's manual - Hardware 33

Page 42

2. Specification

16-point DC output

Type

Category

Output type

No. of output points

Insulating method

Rated input voltage

Range of load voltage

Max. load current

Voltage drop at ON

Leakage current at OFF

Delay

Output signal display

Module status display

External connection

No. of commons

No. of output points

per common

Common polarity

Derating condition

Internal current

consumption

Insulation resistance

W№stand voltage

Built-in fuse

Surge suppressor

Weight

Internal circuit

OFF - ON

ON — OFF

D0333

Transistor output

Current sinking

16 points, 1-word input (Y 1 W)

Photo-coupler

12 to 24 Vdc

10to30Vdc

2 A/point, 5 A/common

1.5 V or less (at 24 Vdc)

0.1 mA or less (at 24 Vdc)

1 ms or less

1 ms or less

LED display for all points, lit at ON, internal logic side

Fusing/extemal abnormal power supply LED

(FL, FH), lit at abnormal state

20-pin removable terminal block, M3.5

2 (insulated between commons)

8 points per common

negative (-) polarity

See NOTE on the next page

5 Vdc, 320 mA or less

10 MQ (500 Vdc)

1500 Vac, 1 minute (between commons, between

internal and external drcuits)

6 A/commonX2

Diode

41 Og

_______________

34 PROSEC T3

Page 43

2. Specification

16-point DC output

(cont'd)

Terminal connections

—□□—

_ 1

_ . 1

. 1

_ . 1

-........1

--------1

___

--------I

___

]

------

1

___

1

-----

1

___

1

-----

____

-------1

___

1

-----

1

___

1

___

------

1

___

1

___

1

-----

1

___

1

-----

1

___

1

___

1

1

1

1

1. ..

t

1

1

1

1

i

i

i

1

1

1

1

1

1

1

1

1

1

_ll

_____

u

1

2

3

4

5

6

7

LP

I ■

11

LC

A

B

C

D

B

F

HP

HC

10

e

11

9

12

13

14

15

16

17

18

_||_

19

20

Load pow№ SLpply:

12to24Vdc

NOTE The maximum load current has the following restrictions,

depending on the ambient temperature.

Load currant

GO Ambient temperature

rC)

User's manual - Hardware

35

Page 44

2. Specification

32-point DC output

Type

Category

Output type

No. of output points

Insulating method

Rated load voltage

Range of load voltage

Max. load current

Voltage drop at ON

Leakage current at OFF

Delay

Output signal display

Module status display

External connection

No. of commons

No. of output points

per common

Common polarity

Derating condition

Internal current

consumption

Insulation resistance

Withstand voltage

Built-in fuse

Surge suppressor

Weight

Internal circuit

OFF - ON

ON - OFF

D0334

Transistor output

Current sinking

32 points, 2-word output (Y 2 W)

Photo-coupler

12 to 24Vdc

10 to 30Vdc

0.5 A/point, 5 A/common

1.5 V or less

0.1 mA or less (at 24 Vdc)

1 ms or less

1 ms or less

L£D display for all points, lit at ON, internal logic side

Fusing/extemai abnormal power supply LED

(FL. FH), lit at abnormal state

38-pin removable terminal block, M3.5

2 (insulated between commons)

16 points per common

negative (-) polarity

See NOTE on the ne)d page

5 Vdc, 210 mA or less

10 MQ (500 Vdc)

1500 Vac, 1 minute (between commons, between

internal and external circuits)

6 A/common X2

Diode

530g

_________

36 PROSEC T3

Page 45

2. Specification

32-point DC output

(cont'd)

Terminal connections

Load power supply :

Hi-

12to24Vdc

NOTE Maximum load current has the following restrictions,

depending on the ambient temperature.

Load current

0.5 A/point

5 A/common

10 20 30 40 50 60 Ambient temperature

0.4 A/point

4 A/common

CC)

User's manual - Hardware 37

Page 46

2. Specification

64-point DC output

Type

Category

Output type

No. of output points

Insulating method

Rated input voltage

Range of load voltage

Max. load current

Voltage drop at ON

Leakage current at OFF

Delay

Output signal display

Module status display

Externa! connection

No. of commons

No. of output points

per common

Common polarity

Derating condition

Intemai current

consumption

insulation resistance

Withstand voltage

Built-in fuse

Surge suppressor

Weight

Intemai circuit

OFF - ON

ON — OFF

D0335

Transistor output

Current sinking

64 points, 4-word output (Y 4 W)

Photo-coupler

5 Vdc/12 to 24 Vdc

4.5 to 9.5 Vdc/9-6 to 26.4 Vdc

0.1 A/point (9.6 to 26.4 Vdc)

0.05 A/point (4.5 to 9.5 Vdc)

0.4 V or less

0.1 mA or less (at 24 Vdc)

1 ms or less

1 ms or less

LED display for ali points, lit at ON, intemai logic side

None

40-pin connectorX2

8 (insulated between commons)

8 points per common

negative (-) polarity

None

5 Vdc, 400 mA or less

10 MO or less (500 Vdc)

1500 Vac, 1 minute

(between intemai and external circuits)

None

Diode

550g (including connectors)

38 PROSEC T3

CN1

CN2

Page 47

64-point DC output

(cont'd)

2. Specification

NOTE Type of the connector on the module side :

FCN-365P040-AU (Fujitsu)

The connectors (two, soldering types) of the cable side

are attached as standard.

User's manual - Hardware

39

Page 48

2. Specification

16-point AC output

Type

Category

No. of output points

Insulating rpethod

Rated load voltage

Range of load voltage

Max. load current

Voltage drop at ON

Leakage current at OFF

Min. load current

Max. innjsh current

Delay

Output signal display

Module status di^lay

External connection

No. of commons

No. of output points

per common

Derating condition

Internal current

consumption

insulation resistance

Withstand voltage

Built-in fuse

Surge suppressor

Weight

Internal circuit

OFF — ON

ON OFF

AC363

Triac output

16 points, 1-word output (Y 1 W)

Photo-coupler

100 to 240 Vac (50/60 Hz)

24 to 264 Vac (47 to 63 Hz)

2 A/points, 5 A/common

1.5 V or less

1.0 mA or less (at 100 Vac, 50 Hz)

2.4 mA or less (at 200 Vac, 60 Hz)

100 mA (24 Vac), 50 mA (100 to 240 Vac)

20 A/20 ms (point), 40 A/20 ms (common)

1 ms or less

1 ms+1/2cycle or less

LED di^lay for all points, iit at ON, interna) logic side

Fusing display LED (FL, FH), lit at fusing

20-pln removable terminal block, M3.5

2 (insulated between commons)

8 points per common

See NOTE on die next page

5 Vdc, 530 mA or less

lOMQor less (500 Vdc)

1500 Vac, 1 minute (between commons between

interna) and external circuits)

6 A/common X2

CR snubber circuit, varistor

500g

40 PROSEC T3

Page 49

16-poìnt AC output

(cont'd)

2. Specification

NOTE Maximum load current has the following restrictions,

depending on the ambient temperature.

Load current

40 50 60 Ambient temperature

(t)

User's manual - Hardware

41

Page 50

2. Specification

32-point AC output

Type

Category

No. of output points

Insulating method

Rated load voltage

Range of load voltage

Max. load current

Voltage drop at ON

Leakage current at OFF

Min. load current

Max. inrush current

Delay

Output signal display

Module status display

External connection

No. of commons

No. of output points

per common

Derating condition

Internal current

consumption

Insulation resistance

Withstand voltage

Built-in fuse

Surge suppressor

Weight

Internal circuit

OFF —ON

ON — OFF

AC364

Triac output

32 points, 2-word output (Y 2 W)

Photo-coupler

100 to 240 Vac (50/60 Hz)

24 to 264 Vac (47 to 63 Hz)

0.5 A/point, 3.2 A/common, 5 A/modute

1.5 V or less

0.8 mA or less (at 100 Vac, 50 Hz)

1.6 mA or less (at 200 Vac, 50 Hz)

100 mA (24 Vac), 50 mA (100 to 240 Vac)

20 A/20 ms (points and common)

1 ms or less

1 ms+1^cycle or less

LED display for all points, lit at ON, internal logic side

Fusing display LED (FL, FH), lit at fusing

38-pin removable terminal block, M3.5

2 (insulated between commons)

16 points per common

None

5 Vdc, 800 mA or less

10 MQ or less (500 Vdc)

1500 Vac, 1 minute (between commons, between

internal and external circuits)

6 A/commonX2

CR snu№er circuit

540g

42 PROSEC T3

Page 51

2. Specification

32-point AC output

(cont'd)

Terminal connections

Load power supply

100to240Vdc

NOTE Minimum 24 Vac can be used as the load voltage.

However, if ioad voltage becomes 85 Vac or less, the

fusing detection circuit may work, in this case, aithough

AC output operation has no problem, the fusing display

LED (FL, FH) will light.

User's manual - Hardware 43

Page 52

2. Specification

32-point relay output

Type

Category

Output

No. of output points

Insulating method

Rated toad voltage

Range of load voltage

Max. load current

Contact ON resistance

Leakage current at OFF

Min. load current

Delay

Output signal display

Module status display

External connection

No. of commons

No. of output points

per common

Internal current

consumption

External

power

for relay

Mechanical life

Electrical contact life

insulation resistance

Withstand voltage

Built-in fuse

Weight

Internal drcuit

OFF ON

ON — OFF

Rated voltage

Rated current

Voltage range

R0364

Electromechanical relay output

NO-contact

32 points, 2-word output (Y 2 W)

Photo-coupler

240 Vac/24 Vdc

Up to 264 Vac/125 Vdc

2 A/point (resistive load), 5 A/common

50 mQ or less (initial value)

None

5 Vdc, 10 mA (50 mW or more)

10 ms or less

10 ms or less

LED display for all points, lit at ON, internal logic side

^normal external power suF^ly display LED (F),

tit at abnormal state

38-pin removable terminal block, M3.5

4 (insulated between commons)

8 points per common

5 Vdc, 170 mA or less

24 Vdc

300 mA (24 Vdc, at all points ON)

21.6 to 26.4 Vdc

20 million times or more

See the next page

10 MQ or more (500 Vdc)

1500 Vac, 1 minute (between commons, between

internal and external circuits)

None

51 Og

_____

44 PROSEC T3

OCOM

Page 53

2. Specification

32-point relay output

(cont'd)

Terminal connections

Load poMer supply

240Vai/24Vdc

Hi- 24Vdc for relay

driving

SwitcNng life

(10,000 bTnes)

NOTE The following figures indicate life curves of the output

relay. The data are based on 1800 switching times/hour.

For more frequently operation, the life of the output relay

will become shorter.

AC load

Switchirig life

(10,000 times)

DC load

Switching

Cunent

User's manual - Hardware 45

Page 54

2. Specification

16-point isolated relay

output

Type

Category

Output type

No. of output points

Insulating method

Rated load voltage

Range of load voltage

Max. load current

Contact ON resistance

Leakage current at OFF

Min. load current

Delay

Output signal display

Module status display

External connection

Common connection

Internal current

consumption

External

power

for relay

Mechanical life

Electrical contact life

Insulation resistance

Withstand voltage

Built-in fuse

Weight

Internal circuit

OFF - ON

ON OFF

Rated voltage

Rated current

Voltage range

R0363S

Electromechanical relay output

NO-contact

16 points, 1-word output (Y 1 W)

Photo-coupler

240Vac/24Vdc

Up to 264 Vac/125 Vdc

2 A/point

50 mQ or less (initial value)

None

5 Vdc, 10 mA (50 mW or more)

10 ms or less

10 ms or less

LED di^lay for all points, lit at ON, internal logic side

^normal external power supply display LED (F),

lit at abnormal state

38-pin removable terminal block, M3.5

16-point isolated contact

5 Vdc, 100 mA or less

24 Vdc

145 mA (24 Vdc, at all points ON)

21.6 Vdc to 26.4 Vdc

20 million times or more

See the next page

10 MQ or more (500 Vdc)

1500 Vac, 1 minute (between the points, between

internal and external circuits)

None

450g

46 PROSEC T3

Page 55

2. Specification

16-point isolated

relay output

(cont'd)

Terminal connections

Load power suppty

240Vac/24VdC

:

-J|_ 24Vdc for retay

' driving

Switching life

(10,000 tiines)

NOTE The following figures indicates life curves of the output

relay. The data are based on 1800 switching times/hour.

For more frequently operation, the life of the output relay

will become shorter.

AC load

Switching life

(10,000 times)

DC load

0,2 0.3 0.5 0.7

1.5 2 Current

Swit^ng

User's manual - Hardware

47

Page 56

3. Precautions for I/O Modules

3.1

Precautions for DC

Input modules

(1) Read conditions for the ON/OFFchanges of the input signals are:

Input ON time^ON delay time (OFF->ON)+lnput reading cycle

input OFF time^OFF delay time (ON->OFF)+lnput

Where the “input reading cycle“ means PLC scan cycle for the

refresh input, or the execution interval of a direct input instruction

when the instruction is used.

(2) For some external contacts, the input current (10 mA/24V for

DI334; 5 mA/24V for DI335) of modules may not be able to

maintain contact reliability. In this case, install a bleeder resistor

between the input and common terminals to increase the contact

current.

(An example of selecting a bieeder resistor R)

Input voltage V=24 Vdc

Input module DI334 (10 mA/24 Vdc)

When the contact requires 50 mA current;

Resistance value R of a bleeder resistor=0.6[kQ]

Wattage P of the bleeder resistor=3[W]

y-

reading cycle

Contact Input module

—

---

------

0 O—'

t

”

—\

ill

COM

II

V

wi

Wattage P> X(2.5~3)

R

48 PROSEC T3

(3) If a switch with an LED display is used, the current (leakage

current) through the LED may cause the erroneous input (always

ON). In this case, install a bleeder resistor to lower the input

impedance.

LED

(Example of selecting a bieeder resistor R)

When the voltage between input terminals is Vd at the switch

OFF state (with no bleeder resistor), the resistance (R) and the

wattage (P) of the bleeder resistor can be selected as follows.

Page 57

3. Precautions for I/O Modules

(V-Vd) Vo

R<

V(Vd-Vo)

P= (2.5~3)

In case of DI334,

V=24 Vdc, Vo=3-5 Vdc, Zi=2.4 kCl

If Vd=5 Vdc, R can be calculated as follows.

R[kQ]<_l

As a result,

R<4.4[kQ]->3kQ

P=(2.5~3)X

Also, when the bleeder resistor is selected in the above manner,

the contact current at the switch ON state should be checked.

Contact current=24[V]X

(4) If the two-wire proximity switch and other solid-state switches

are used, be sure that there is no possibility of mis-inputting

because of the leakage current, as in procedure (3). (See (3) for

details on how to select a bleeder resistor.)

Also in this case, because of the effect of the saturation voltage

(voltage drop) at ON, regardless of whether the switch is ON,

the input terminal voltage may not be able to reach the ON

voltage, thereby failing to read as input ON.

if input voltage is low or if input wiring is too long, special

measures are necessary.

Two-wire proximity switch , ^ module

(24-5) X3.5

----------1-----24X(5-3.5)

2 V: Input voltage

yL

R

X2.4IkQ]

{2AW

3000[Q]

Vo: Max. OFF voltage of the input module

Z i: Input impedance of the input module

0.5W

2.4IkQ]+R

2.4[kQ]XR

^18[mA]

Cable resistance (R) moouie

■ CD---

----------

6

if the cable resistance value is expressed as R[Q], Vd[V] for the

voltage drop of the proximity switch, and Zi[Q] for the input

impedance of the input module, the voltage Vi[V] applied

between the input module terminals will be as expressed below

(when the proximity switch is ON):

V-Vd

Vi=

2R+Zi

If the above Vi is lower than the minimum ON voltage of the

input module, input voltage V must be raised or the value of the

cable resistor R must be made smaller.

Zi

User's manual - Hardware 49

Page 58

3. Precautions for I/O Modules

(5) Because the input filter time constant of the high-speed

response input module (DI334H, D1335H) is set to small, the

input module may read the wrong input due to chattering of the

contact. Use the high-speed response input module to connect

with solid-state devices. Also, take measures to suppress noise.

(6) If input wiring is too long, take measures to prevent erroneous

input caused by noise, as follows.

•Wiring length must be minimized. Do not make unnecessary

loops.

•Keep the input wires away, at least 200 mm, from power

cables and high frequency lines, or shield the input cables

with a metal plate.

•If possible, use relays at the leading in the control panel.

•For some cases, use a shielded cable or twisted-pair cable.

•Install a bleeder resistor to reduce input impedance.

(7) If dynamic scan input is configured using a DC input module and

a DC output module, in addition to the response-delay of output

and input, consider the difference of timing caused by the PLC

scan. Moreover, diodes must be installed to prevent erroneous

input caused by detour circuit, (the figure below is an example of

4X4 input)

Input module

:k

Output module

:k

For example, when contact a is ON, the change timing between

output 0 and input 0 is as follows :

PLC scan cycle

-Output 0 ^internal)

Output 0 (external)

Input 0 (external)

Input 0 (internal)

T1 : Output response

T2: Input response

Note that the change timing of output 0 and input 0 will be

affected with the scan time of the PLC and the response time of

input and output.

67a oTe 6jj 6|n

"6| n

K

^

^

delay

delay

50 PROSEC T3

Page 59

3.2

Precautions in applying

AC input modules

3. Precautions for I/O Modules

(1) The conditions to read the ON/OFF state of the input signal are

as follows:

Input ON time^ON delay time (OFF->ON)+input reading cycle

Input OFF time^OFF delay time (ON->OFF)+lnput reading

cycle

The input reading cycle means PLC scan cycle for the refresh

input, or the execution interval of the direct input instruction

when using a direct input instruction.

(2) When an AC output sensor is connected to the I/O module, due

to the leakage current from the sensor at OFF, there may be a

voltage which exceeds the maximum OFF voltage between the

input terminals. This will make the PLC unable to read input

OFF when the sensor is OFF. In this case, install a bleeder

resistor between the input terminals to lower the input

impedance.

For selecting a bleeder resistor, refer to 3.1 (3).

(3) if external lines for AC input become longer with using a multi

core cable, induced current may flow to an open wire from

charged wires due to the electrostatic capacity of the cable,

causing an erroneous ON input. In this case, install a bleeder

resistor between the input terminals to lower the input

impedance. Or, you had better apply the DC input.

User's manual > Hardware

51

Page 60

3. Precautions for I/O Modules

(4) If the AC lines are installed in parallel with high frequency or

power lines, induced current may cause erroneous input. In this

case, take necessary countermeasures as follows:

• Change the installation route of AC input lines so that

they are not parallel with power lines and high

frequency lines.

• Use twisted-pair cables as input lines.

• Use shielded cables as input lines.

• Use relays at the leading in the control panel (the relay

must satisfy larger ON current).

• Install a bleeder resistor to lower the input impedance.

(5) If the input module and an inductive load are connected in

parallel, a surge voltage generated at both-ends of the load

when the contact is changed to OFF may cause a malfunction of

the PLC. In this case, install a surge absorption element in

parallel with the load to suppress the surge voltage.

----------------------------------------------------------

Input module

-

)

-

---------

Inductive load

-0^

^ ^ Surge absorption element (snubber circuit, etc.)

Hl-O-

)

52 PROSEC T3

Page 61

3.3

Precautions for DC

output modules

3. Precautions for I/O Modules

(1) The DC output module needs an externa! power supply to drive

output transistors. For each common, connect the load power to

the appropriate terminal. (For details, see 2.3, I/O module

specifications)

If the wrong polarity of the power supply to the terminal is

connected, the module will be damaged. Check the polarity

before connection.

For the D0333 and D0334 modules, if their built-in fuse is

blown out or if the external power supply is not supplied, the

front LED (FL, FH) of the module lights.

(2) Protection coordination against over-current of DC output

module

Type of module

D0333

<16-point output)

D0334

(32-point output)

D0335

(64-point output)

A fuse of 6 A per common (8 points) is built in mis DC

output module. For an overload and load short-cir

cult, the transistor will not be protected. This fuse,

however, protects the DC output module and the

external cable from burn-out.

A fuse of 6 A per common (16 points) is built in this DC

output module. For an overload and load short-circuit,

the transistor will not be protected. This fuse, however,

protects the nrodule and the external cable from bumout.

Because a protection fuse is not built in this DC output

module, the load short-circuit, etc. will cause bum-out

of the module and external cable, Therefore, install an

appropriate fuse on the outside to prevent accidental

bum-out.

Protection

(3) A diode as shown in the figure below is built in to protect the

transistor from transient overvoltage.

D: Bypasses transient overvoltage to the power supply and

suppresses the voltage between the collector and emitter of the

transistor.

User's manual - Hardware

53

Page 62

3. Precautions for I/O Modules

(4) If a capacitive load is connected, rush current will flow when

output is changed to ON.

At that time, necessary measures must be taken to protect the

output transistor from being destroyed by the rush current.

To limit the rush current there are two effective measures. One

is to connect a resistor to the load in series. The other is to apply