Page 1

PROGRAMMABLE CONTROLLER

PROSEC T2N

USER’S MANUAL

- Basic Hardware and Function -

UM-TS02N**-E001

Toshiba Corporation

Page 2

Important Information

Misuse of this equipment can result in property damage or human injury.

Because controlled system applications vary widely, you should satisfy yourself

as to the acceptability of this equipment for your intended purpose.

In no event will Toshiba Corporation be responsible or liable for either indirect

or consequential damage or injury that may result from the use of this equipment.

No patent liability is assumed by Toshiba Corporation with respect to use of

information, illustrations, circuits, equipment or examples of application in this

publication.

Toshiba Corporation reserves the right to make changes and improvements to this

publication and/or related products at any time without notice. No obligation shall be

incurred other than as noted in this publication.

This publication is copyrighted and contains proprietary material. No part of this book

may be reproduced, stored in a retrieval system, or transmitted, in any form or by any

means electrical, mechanical, photocopying, recording, or otherwise without

obtaining prior written permission from Toshiba Corporation.

© TOSHIBA Corporation 1997. All rights reserved

PROSEC and TOSLINE are registered trademarks of TOSHIBA Corporation.

IBM and Windows are registered trademarks of International Business Machines Corporation.

MS-DOS and Windows are registered trademarks of Microsoft Corporation.

Ethernet is a registered trademark of Xerox Corporation.

DeviceNet is a trademark of the Open DeviceNet Vender Association, Inc.

Publication number: UM-TS02N∗∗-E001

1st edition December 1997

-

i

-

Page 3

Introduction

CE Marking

The Programmable Controller PROSEC T2N (hereafter called T2N) complies with the

requirements of the EMC Directive 89/336/EEC and the Low Voltage Directive 72/23/EEC under

the condition of use according to the instructions described in this manual.

The contents of the conformity are shown below.

Application of : EMC - 89/336/EEC(as amended by 91/263/EEC and 92/31/EEC)

Council Directive : LVD - 72/23/EEC

Manufacture’s Name : TOSHIBA CORPORATION, FUCHU WORKS

Manufacture’s address : 1, TOSHIBA-CHO,

FUCHU-SHI, TOKYO 183,

JAPAN

declares, that the product

Product Name : Programmable Controller , T2N Series

Model Number : TPU215N*S,TPU235N*S,TPU245N*S,TBU228N*S

Product Options : All

conforms to the following Product Specifications:

EMC : Radiated Interference EN55011 Class A Group 1

Mains Interference EN55011 Class A Group 1

Radiated Susceptibility ENV50140

Conducted RFI Susceptibility ENV50141, IEC1000-4-6

Electrostatic Discharge IEC1000-4-2

Electrical Fast Transient IEC1000-4-4

LVD : EN61131-2 : 1995

3,10 Dielectric Properties

4 Mechanical Requirements

-

ii

-

Page 4

Introduction

!

WARNING

!

CAUTION

Safety Precautions

This manual is prepared for users of Toshiba’s Programmable Controller T2N.

Read this manual thoroughly before using the T2N. Also, keep this manual and related manuals so

that you can read them anytime while the T2N is in operation.

General Information

1. The T2N has been designed and manufactured for use in an industrial environment.

However, the T2N is not intended to be used for systems which may endanger human

life. Consult Toshiba if you intend to use the T2N for a special application, such as

transportation machines, medical apparatus, aviation and space systems, nuclear

controls, submarine systems, etc.

2. The T2N has been manufactured under strict quality control. However, to keep safety of

overall automated system, fail-safe systems should be considered outside the T2N.

3. In installation, wiring, operation and maintenance of the T2N, it is assumed that the users

have general knowledge of industrial electric control systems.

If this product is handled or operated improperly, electrical shock, fire or damage to this

product could result.

4. This manual has been written for users who are familiar with Programmable Controllers

and industrial control equipment. Contact Toshiba if you have any questions about this

manual.

5. Sample programs and circuits described in this manual are provided for explaining the

operations and applications of the T2N. You should test completely if you use them as a

part of your application system.

Hazard Classifications

In this manual, the following two hazard classifications are used to explain the safety

precautions.

Even a precaution is classified as CAUTION, it may cause serious results depending on the

situation. Observe all the safety precautions described on this manual.

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. It may also be used to alert

against unsafe practices.

-

iii

-

Page 5

Safety Precautions

!

CAUTION

Installation:

1. Excess temperature, humidity, vibration, shocks, or dusty and corrosive gas

environment can cause electrical shock, fire or malfunction. Install and use the T2N

and related equipment in the environment described in this manual.

2. Improper installation directions or insufficient installation can cause fire or the units to

drop. Install the T2N and related equipment in accordance with the instructions

described in this manual.

3. Turn off power before installing or removing any units, modules, racks or terminal

blocks. Failure to do so can cause electrical shock or damage to the T2N and related

equipment.

Introduction

Safety Precautions

4. Entering wire scraps or other foreign debris into to the T2N and related equipment can

cause fire or malfunction. Pay attention to prevent entering them into the T2N and

related equipment during installation and wiring.

5. Turn off power immediately if the T2N or related equipment is emitting smoke or odor.

Operation under such situation can cause fire or electrical shock. Also unauthorized

repairing will cause fire or serious accidents. Do not attempt to repair. Contact Toshiba

for repairing.

6. The T2N must be installed in an enclosure. The user should consider to prevent

contact with careless touch to the live parts of this product in during operation or

maintenance.

7. The Protective ground terminal of the T2N must be connected to an external protective

earth.

8. The computer which is connected to the T2N must be connected to an external

protective earth properly.

9. The external cables, including for data transmission, which are prepared by the user

are outside of the scope of this document.

-

iv

-

Page 6

Introduction

!

CAUTION

!

WARNING

!

CAUTION

Wiring:

1. Turn off power before wiring to minimize the risk of electrical shock.

2. Exposed conductive parts of wire can cause electrical shock. Use crimp-style terminals

with insulating sheath or insulating tape to cover the conductive parts. Also close the

terminal covers securely on the terminal blocks when wiring has been completed.

3. Operation without grounding may cause electrical shock or malfunction. Connect the

ground terminal on the T2N to the system ground.

4. Applying excess power voltage to the T2N can cause explosion or fire. Apply power of

the specified ratings described in the manual.

Safety Precautions

5. Improper wiring can cause fire, electrical shock or malfunction. Observe local

regulations on wiring and grounding.

Operation:

1. Configure emergency stop and safety interlocking circuits outside the T2N. Otherwise,

malfunction of the T2N can cause injury or serious accidents.

2. Operate the T2N and the related modules with closing the terminal covers. Keep hands

away from terminals while power on, to avoid the risk of electrical shock.

3. When you attempt to perform force outputs, RUN/HALT controls, etc. during operation,

carefully check for safety.

4. Turn on power to the T2N before turning on power to the loads. Failure to do so may

cause unexpected behavior of the loads.

5. Do not use any modules of the T2N for the purpose other than specified. This can

cause electrical shock or injury.

6. Do not modify the T2N and related equipment in hardware nor software. This can

cause fire, electrical shock or injury.

7. Configure the external circuit so that the external power required for output modules

and power to the loads are switched on/off simultaneously.

Also, turn off power to the loads before turning off power to the T2N.

-

v

-

Page 7

Introduction

!

CAUTION

!

WARNING

!

CAUTION

Safety Precautions

Operation (continued):

8. Install fuses appropriate to the load current in the external circuits for the outputs.

Failure to do so can cause fire in case of load over-current.

9. Check for proper connections on wires, connectors and modules. Insufficient contact

can cause malfunction or damage to the T2N and related equipment.

Maintenance:

1. Do not charge, disassemble, dispose in a fire nor short-circuit the batteries. It can be

cause explosion or fire. Observe local regulations for disposal of them.

2. Turn off power before removing or replacing units, modules, terminal blocks or wires.

Failure to do so can cause electrical shock or damage to the T2N and related

equipment.

3. Replace a blown fuse with a specified one. Failure to do so can cause fire or damage

to the T2N.

4. Do not insert your finger into the rack’s ventilation hole during power on. This can

cause electrical shock.

5. Do not disassemble the T2N because there are hazardous voltage parts inside.

6. Perform daily checks, periodical checks and cleaning to maintain the system in normal

condition and to prevent unnecessary troubles.

7. Check by referring “Troubleshooting” section of this manual when operating

improperly. Contact Toshiba for repairing if the T2N or related equipment is failed.

Toshiba will not guarantee proper operation nor safety for unauthorized repairing.

8. The contact reliability of the output relays will reduce if the switching exceeds the

specified life. Replace the unit or module if exceeded.

9. Replace batteries in accordance with instructions described in the manual.

Failure to do so can cause system accidents.

-

vi

-

Page 8

Introduction

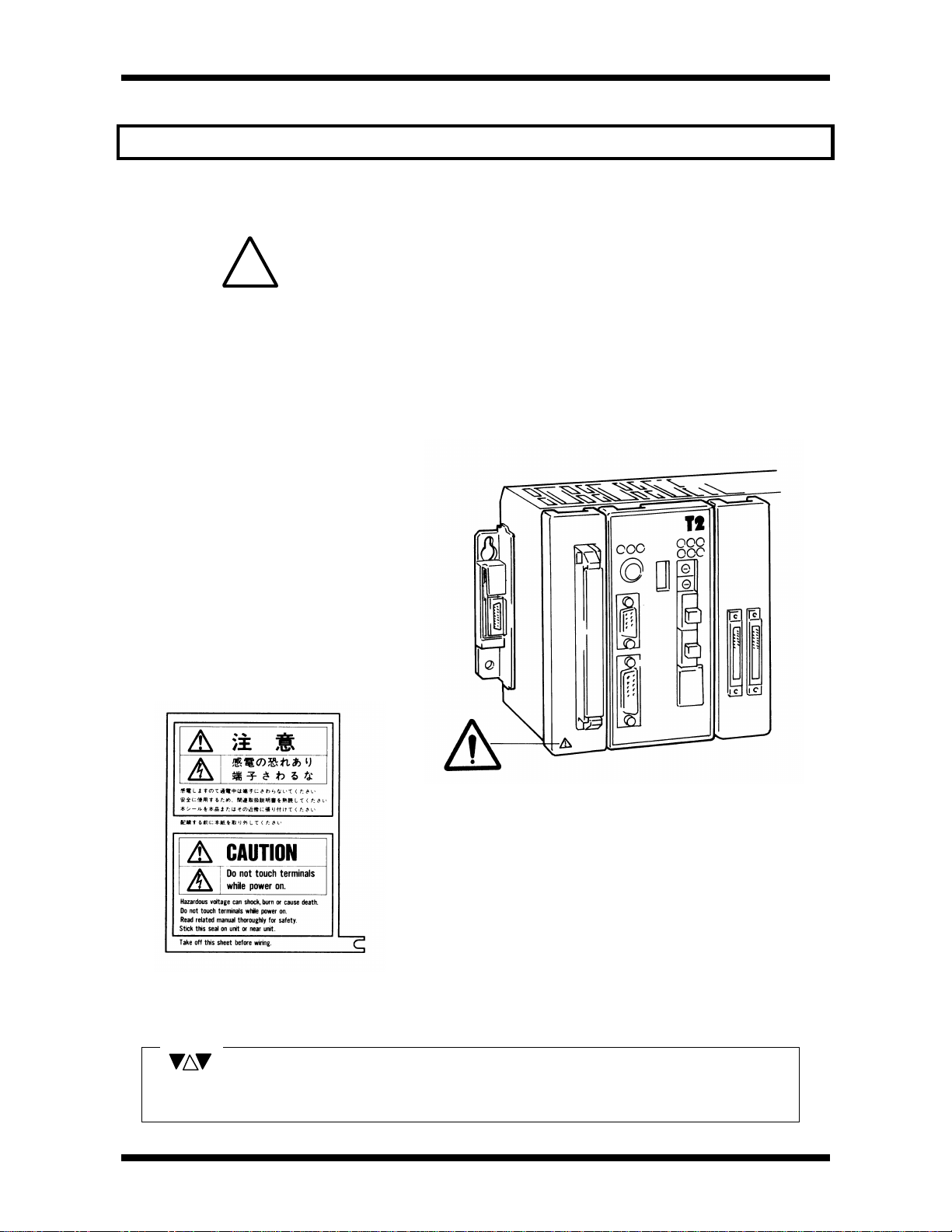

Markings used on the T2N and in this manual

Warning Mark on the T2N

This is the warning mark for dangerous location. It is attached to the equipment in

positions where there is a risk of electric shock and in positions where there is a risk

damage to the equipment through wrong wiring.

!

Take the following precautions where there is this mark.

(1) Keep hands away from terminals ,especially the input terminall of power supply while power on, to avoid

the risk of electrical shock.

(2) Turn off power before installing or removing modules, terminal blocks or wires.

(3) Applying excess power voltage to the T2N can cause explosion or fire. Apply power of the specified ratings

described in this manual.

Safety Label

The safety label as shown on the left is

attached to the power terminal of the T2N.

Remove the mount paper before wiring.

Peel off the label from the mount paper

and stick it near the power terminals

where it can be readily seen.

NOTE

This mark is printed in places in this manual which should always be read carefully.

Read them carefully.

-

vii

-

Page 9

About This Manual

NOTE

This manual has been prepared for first-time users of Toshiba’s Programmable Controller

T2N to enable a full understanding of the configuration of the equipment, and to enable the

user to obtain the maximum benefits of the equipment.

This manual introduces the T2N system configuration, and explains the specifications,

installation and wiring for T2N’s basic hardware. This manual provides the information for

designing T2N user program, such as T2N internal operation, memory configuration, I/O

allocation. Information for maintenance and troubleshooting are also provided in this

manual.

The specifications of the enhanced communication function, and how to use them, are

explained in separate manual. Read T2E/T2N User’s Manual-Enhanced communication

function. (UM-TS02E**-E003)

In addition, the T2N’s computer link function is also covered by separate manual. Read Tseries Computer Link Operation Manual for details.

Related Manuals

About This Manual

The following related manuals are available for T2N. Besides this manual, read the

following manuals for your better understanding.

T2N User’s Manual - Basic Hardware and Function - UM-TS02N**-E001

T2E/T2N User’s Manual - Enhanced communication function - UM-TS02E**-E003

TOSLINE-S20LP T2N/T3H Stations Instruction Manual -6F3B0356

Built-in Ethernet Module for T2N (PU235N/245N) Instruction Manual

T-series Instruction Set - UM-TS03***-E004

T-PDS for Windows Basic Operation Manual - UM-TS03***-E038

T-PDS Basic Operation Manual (MS-DOS) - UM-TS03***-E006

T-PDS Command Reference Manual (MS-DOS) - UM-TS03***-E007

T-PDS Ver.2.0 Expanded Functions (MS-DOS) - UM-TS03***-E028

T-Series Handy Programmer (HP911) Operation Manual - UM-TS03***-E025

T-series Computer Link Operation Manual - UM-TS03***-E008

1 Axis positioning controller Manual - UM-EX100**-E011

T2 Communication Interface Module (CF211) Manual - UM-TS02***-E013

T2/EX100 Computer Link Module (CL11) Manual - UG-TS02***-E015

TOSLINE-S20 User’s Manual - UM-TLS20**-E001

TOSLINE-F10 User’s Manual - UM-TLF10**-E001

Other than the listed above, some T2N elated manuals for special I/O modules

and data transmission modules are available. Contact Toshiba for more

information.

-6F3B0362

-

viii

-

Page 10

About This Manual

Terminology

The following is a list of abbreviations and acronyms used in this manual.

µs microsecond

ASCII American Standard Code For Information Interchange

AWG American Wire Gage

BCC Block Check Code

CCW Counter-Clockwise

CPU Central Processing Unit

CW Clockwise

EEPROM Electrically Erasable Programmable Read Only Memory

H hexadecimal (when it appears in front of an alphanumeric string)

I/O Input/Output

LED Light Emitting Diode

LSB Least Significant Bit

ms millisecond

MSB Most Significant Bit

PWM Pulse Width Modulation

RAM Random Access Memory

ROM Read Only Memory

Vac AC voltage

Vdc DC voltage

-

ix

-

Page 11

Contents

Important Information

Introduction

About This Manual

PART 1 HARDWARE

1. SYSTEM CONFIGURATION

1.1 System Configuration....................................................................................................................................................................... 3

1.2 Power Supply Module...................................................................................................................................................................... 6

1.3 CPU Module............................................................................................................................................................................................ 8

1.4 Communication Port...................................................................................................................................................................... 13

1.5 Racks......................................................................................................................................................................................................... 15

1.6 Expansion Cable.............................................................................................................................................................................. 16

1.7 I/O Modules.......................................................................................................................................................................................... 17

1.8 Data Transmission Modules.................................................................................................................................................... 18

1.9 Built-in networking............................................................................................................................................................................20

Contents

2. SPECIFICATION

2.1 General Specifications................................................................................................................................................................. 21

2.2 External Dimensions...................................................................................................................................................................... 22

2.3 I/O Module Specifications.......................................................................................................................................................... 23

3. APPLICATION PRECAUTIONS FOR I/O MODULES

3.1 Input Modules - Application Precautions....................................................................................................................... 51

3.2 DC Output Module - Application Precautions............................................................................................................ 53

3.3 Triac Output Module - Application Precautions........................................................................................................ 56

3.4 Relay Output Module - Application Precautions...................................................................................................... 56

3.5 Analog Input Module - Application Precautions....................................................................................................... 57

3.6 Analog Output Module - Application Precautions................................................................................................... 58

-

x

-

Page 12

Contents

4. INSTALLATION AND WIRING

4.1 Operating Environment................................................................................................................................................................ 59

4.2 Installing the Rack........................................................................................................................................................................... 60

4.3 Mounting the Modules.................................................................................................................................................................. 61

4.4 Connecting the Expansion Unit............................................................................................................................................. 61

4.5 Grounding.............................................................................................................................................................................................. 62

4.6 Grounding Methods........................................................................................................................................................................ 63

4.7 Wiring the Power Supply............................................................................................................................................................ 65

4.8 I/O Wiring............................................................................................................................................................................................... 66

4.9 Power up/down Sequence........................................................................................................................................................ 68

4.10 Safty Circuit....................................................................................................................................................................................... 69

5. MAINTENANCE AND CHECKS

5.1 Daily Checks........................................................................................................................................................................................ 70

5.2 Periodic Checks................................................................................................................................................................................ 72

5.3 Spare Parts to Keep in Stock................................................................................................................................................. 73

5.4 Battery Replacement..................................................................................................................................................................... 74

5.5 Fuse Replacement.......................................................................................................................................................................... 76

6. TROUBLESHOOTING

6.1 Troubleshooting Procedure...................................................................................................................................................... 77

6.2 Power Supply Check..................................................................................................................................................................... 78

6.3 CPU Check........................................................................................................................................................................................... 79

6.4 Program Check.................................................................................................................................................................................. 79

6.5 Input Check........................................................................................................................................................................................... 80

6.6 Output Check...................................................................................................................................................................................... 81

6.7 Faults Due to External Problems......................................................................................................................................... 82

6.8 List of Items for Self-Diagnostic check............................................................................................................................ 83

-

xi

-

Page 13

PART 2 FUNCTIONS

1. OVERVIEW

1.1 T2N System Configuration........................................................................................................................................................ 95

1.2 Functional Specifications........................................................................................................................................................... 97

2. INTERNAL OPERATIONS

2.1 Basic Internal Operation Flow................................................................................................................................................ 98

2.2 System Initialization........................................................................................................................................................................ 99

2.3 Mode Control.....................................................................................................................................................................................101

2.4 Scan Control...................................................................................................................................................................................... 104

2.4.1 Scan Mode........................................................................................................................................................................106

2.4.2 Batch I/O Processing................................................................................................................................................108

2.4.3 Timer Update...................................................................................................................................................................110

2.5 Peripheral Support........................................................................................................................................................................ 111

2.6 Programming Support Functions....................................................................................................................................... 112

Contents

3. USER PROGRAM RUNNING CONTROL

3.1 Program Classification............................................................................................................................................................... 115

3.2 Sub-program control....................................................................................................................................................................116

3.3 Interrupt Program control.........................................................................................................................................................116

4. PERIPHERAL MEMORY SUPPORT

4.1 EEPROM Support..........................................................................................................................................................................118

5. RAS FUNCTION

5.1 Overview............................................................................................................................................................................................... 119

5.2 Diagnostics.......................................................................................................................................................................................... 119

5.3 Event History......................................................................................................................................................................................122

5.4 Memory Protect Function.........................................................................................................................................................124

5.5 Execution State Monitoring....................................................................................................................................................125

5.6 Debug Support Function..........................................................................................................................................................127

5.7 System Diagnostics...................................................................................................................................................................... 129

-

xii

-

Page 14

Contents

PART 3 USER PROGRAMS

1. OVERVIEW

1.1 Aim of Part 3...................................................................................................................................................................................... 135

1.2 User Memory Configuration................................................................................................................................................... 135

2. USER PROGRAM CONFIGURATION

2.1 Overview............................................................................................................................................................................................... 137

2.2 System Information.......................................................................................................................................................................139

2.3 User Program....................................................................................................................................................................................142

2.3.1 Main Program.................................................................................................................................................................143

2.3.2 Sub-Program...................................................................................................................................................................144

2.3.3 Interrupt Program.........................................................................................................................................................145

2.3.4 Sub-Routines..................................................................................................................................................................146

3. USER DATA

3.1 Overview............................................................................................................................................................................................... 149

3.2 Registers and Devices............................................................................................................................................................... 152

3.3 Processing Register Data........................................................................................................................................................176

3.4 Index Modification.......................................................................................................................................................................... 183

3.5 Digit Designation.............................................................................................................................................................................186

4. I/O ALLOCATION

4.1 Overview............................................................................................................................................................................................... 189

4.2 Setting of Unit No..........................................................................................................................................................................191

4.3 Methods of Input/Output Allocation..................................................................................................................................192

4.4 Register and Module Correspondence.........................................................................................................................197

5. PROGRAM LANGUAGE

5.1 Overview............................................................................................................................................................................................... 199

5.2 Laddser Diagram............................................................................................................................................................................202

5.3 SFC...........................................................................................................................................................................................................209

5.4 Programming Precautions....................................................................................................................................................... 224

5.5 List of Instructions..........................................................................................................................................................................226

Ordering Information......................................................................................................................................................................................255

Index................................................................................................................................................................................................................................257

-

xiii

-

Page 15

Features

Networking & Communication PLC Easy to use high technology

There are three types of CPUs in the T2N.

PU215N : Standard type

PU235N : Standard type + built-in Ethernet

PU245N : Standard type + built-in Ethernet + built-in TOSLINE-S20LP

nNetworking

lEthernet connection

The T2N CPU modules (PU235N and PU245N) have built-in Ethernet interface

(10Base-T). Through the Ethernet, the T2N can communicate with higher level

controllers (computer, workstation, etc.) or other PLCs including T2N.

lTOSLINE-S20LP connection

The T2N CPU module (PU245N) has built-in TOSLINE-S20LP (Loop version)

in the CPU module. TOSLINE-S20LP is a high-reliability double-loop fiber optic network.

Features

lHigh speed industrial LAN

The T2N can be connected to Toshiba’s high speed industrial LANs (Local Area

Networks) TOSLINE-S20 and TOSLINE-F10. The TOSLINE series are suited for real

time control data linkage. Through these networks, the T2N can exchange data with

Toshiba’s various equipment, such as, DCS system, other T-series PLCs, Inverters, etc.

lDeviceNet support

A DeviceNet scanner module is available for the T2N. The DeviceNet scanner module

can read/write data to any other manufacturer’s OVDA certified devices (I/O blocks,

Inverters to include Toshiba’s G3, air manifold, sensors, etc.).

-

xiv

-

Page 16

Features

nEnhanced communication

The T2N has RS-232C/RS485 serial communication port. Either interface can be selected.

Using this port, one of the following communication functions can be used.

lComputer link mode :Connection with higher level computer, MMI/SCADA system,

modem, etc.

lData link mode :Easy data linkage between two T2Ns or T2E .

lFree ASCII mode :Active communication between serial ASCII devices. (bar code

readers, etc.).

nProgrammer port function

The T2N’s RS-232C programmer port supports the T-series computer link protocol. This

results in easy connection to a higher level computer, an operator interface unit, a modem,

etc.

n High speed processing

The T2N excels at applications where high speed processing is required.

• 0.33µs/contact • 0.44µs/coil

• 1.2µs/16-bit transfer• 1.63µs/16-bit addition

n Advanced instruction set

The T2N offers 24 basic relay-ladder instructions and 192 function block instructions,

including the following.

• Arithmetic operation • Data manipulations • Trigonometric functions

• PID/ramp/integral • Subroutine call • For-Next loop

• Averaging/filtering • ASCII↔Hex conversion • Floating-point math

n Two programming Languages

The T2N supports two programming languages: Ladder Diagram (LD) and Sequential

Function Chart (SFC). By selecting the appropriate language, or combination of the two,

program development time can be greatly reduced.

n Sufficient capacity

The T2N has 24K steps program memory and controls up to 2,048 I/O points.

-

xv

-

Page 17

PART1

HARDWARE

Page 18

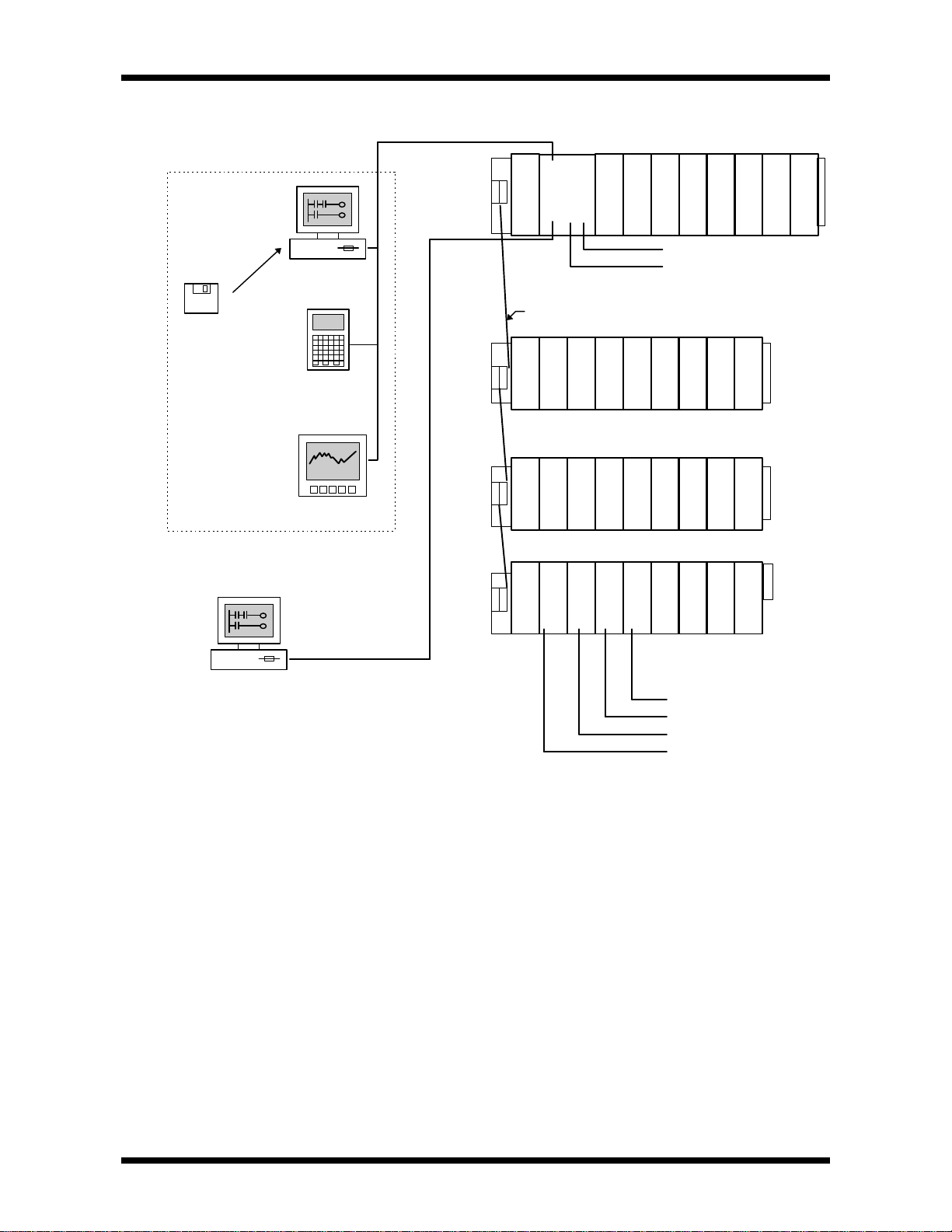

1.1

(IBM compatible)

System Configuration

Peripherals

T-series Program

Development

System(T-PDS)*2

software

Handy Programmer

LCD Display etc.

Personal

Computer

HP911

1.System Configuration

Basic Unit

C

P

U

Power Supply

*1 Ethernet

*1 TOSLINE-S20LP

Expansion Cable

Expansion Unit

Power SupplyPower Supply

Expansion Unit

T

T

T

L

L

L

30

F

S

Power Supply

Personal

Computer

•Computer Link

•Serial I/F

•Data Link

(Dual T2E/T2Ns can be

communicated each other)

Up to a maximum of 3 expansion units can be connected.

Note *1: Ethernet which is built-in PU235N and PU245N

TOSLINE-S20LP which is built-in PU245N

*2: T-PDS (MS-DOS) software V2.06 or later is available for the T2N.

T-PDS (Windows) software V1.2 or later is available for the T2N.

Expansion Unit

D

N

Data transmission module

DeviceNet Scanner

TOSLINE-S20(Optic/wire)

TOSLINE-F10(wire)

TOSLINE-30(Optic/wire)

User’s manual 3

Page 19

1.System Configuration

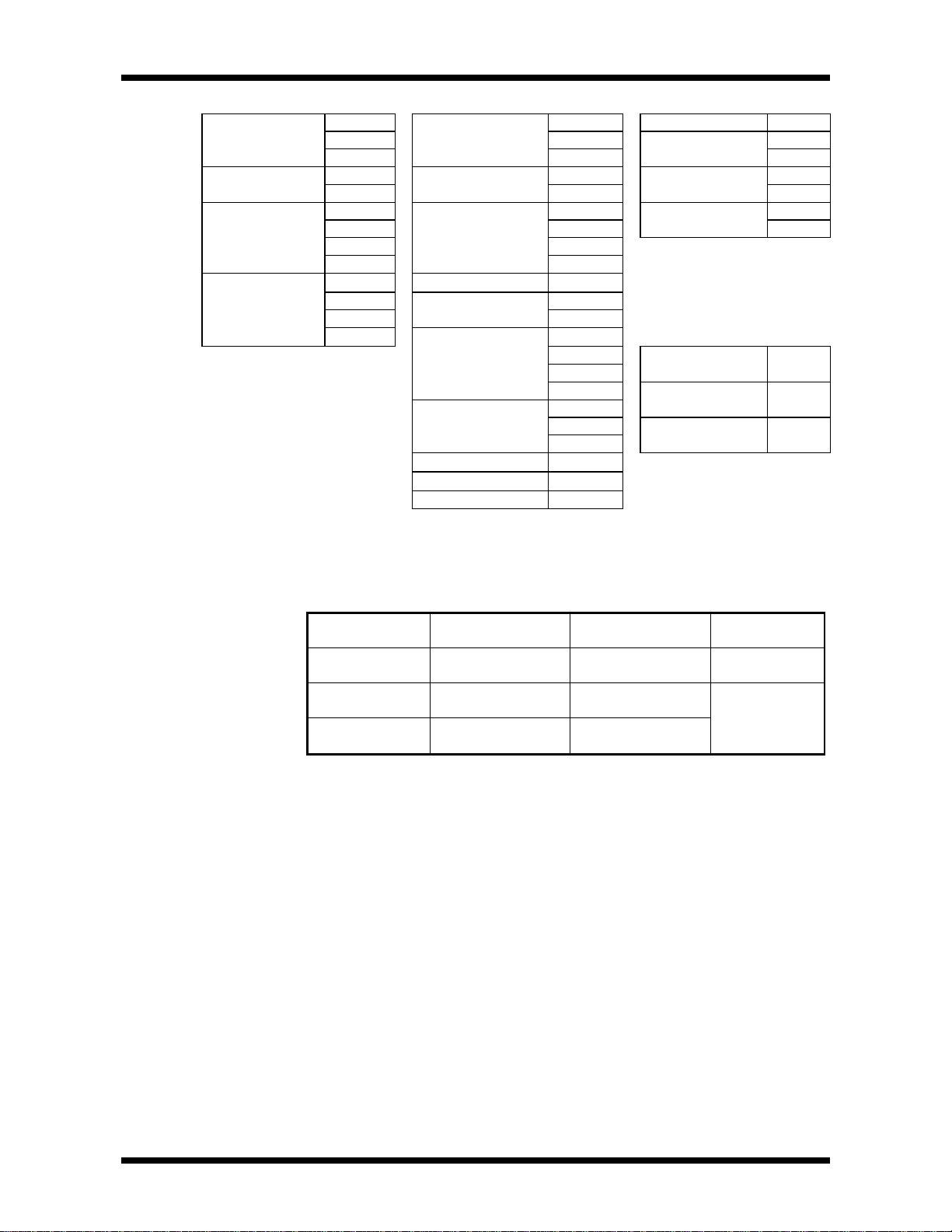

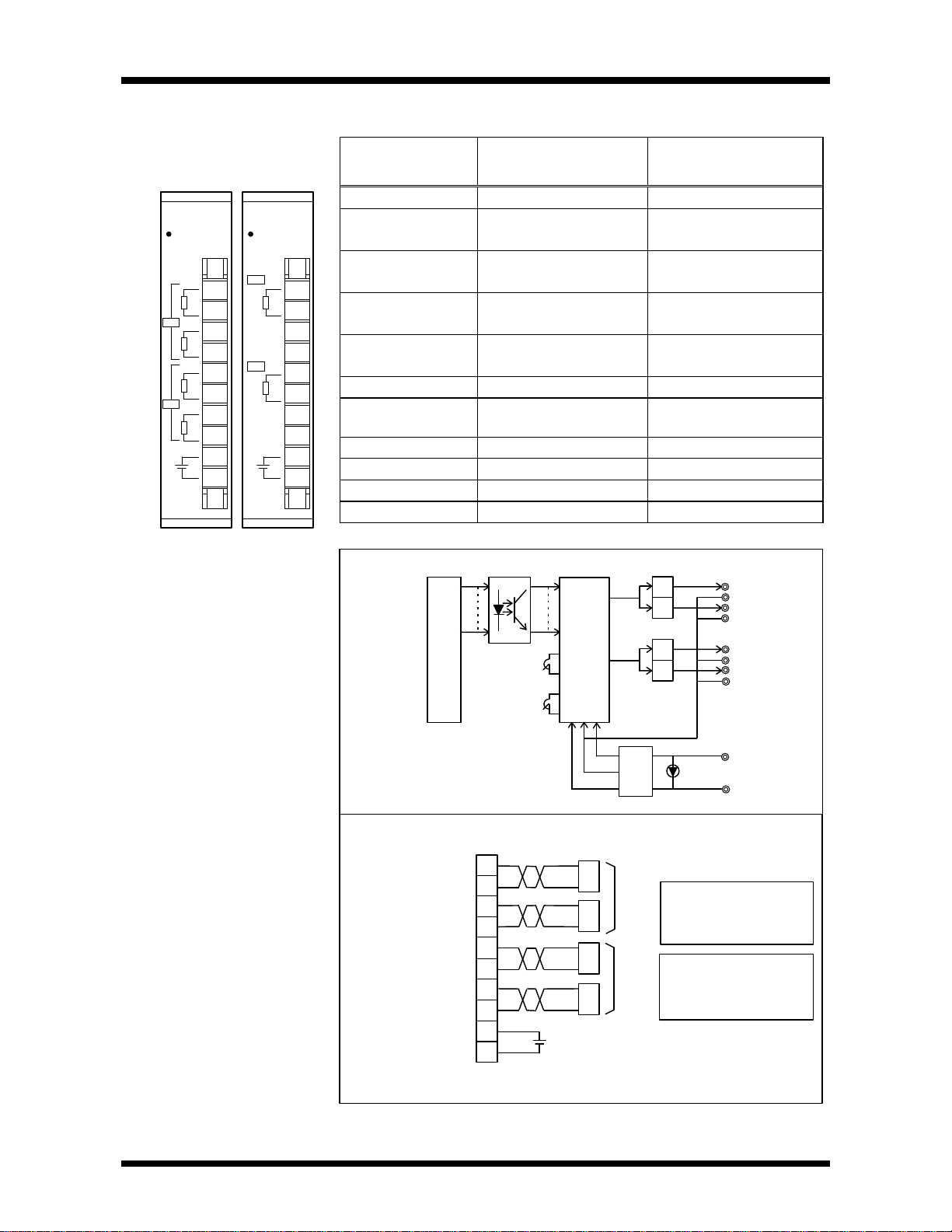

•Basic Configuration •I/O module •Data transmission Module

Rack BU268 DI32 SN221

Power Supply PS261 AC input IN51 TOSLINE-F10 MS211

Module PS31 IN61 RS211

CPU Module DO32

Expansion Cable CAR5 Relay output RO61

BU228N DC input DI31

BU266 DI235

PU215N Transistor output DO31 LK11

PU235N DO235

PU245N DO233P

CAR3 Triac output AC61

CAR7 RO62

CS2RF AI21

Analog input AI31

AI22

AI32

AO31

AO22Analog output

AO32

Pulse input PI21

Positioning module MC11

Serial interface CF211

DeviceNet scanner

TOSLINE-S20

TOSLINE-30

•Programming Tool

T-PDS

(for MS-DOS)

T-PDS

(for Windows)

Handy

Programmer

DN211

SN222A

LK12

MM33I1

MW33E1

HP911

Minimum and Maximum configuration are shown on next page.

As mentioned in Section 1.5 ,the following racks are available.

Part Number Application Number of Module

Installation

TBU228N*S Dedicated to the

Basic unit

TBU268**S For expansion unit 8

TBU266**S For expansion unit 6

8

Remarks

4 PROSEC T2N

Page 20

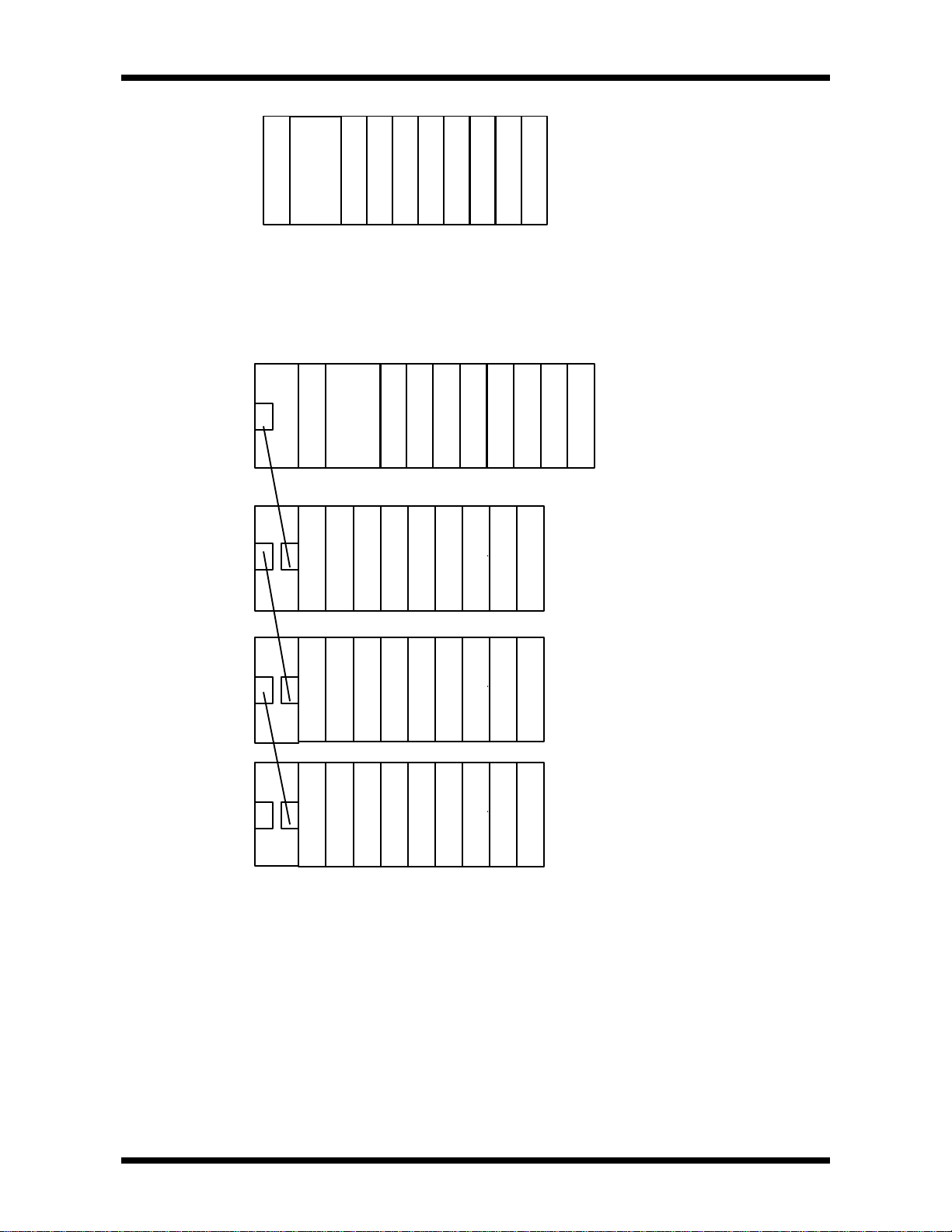

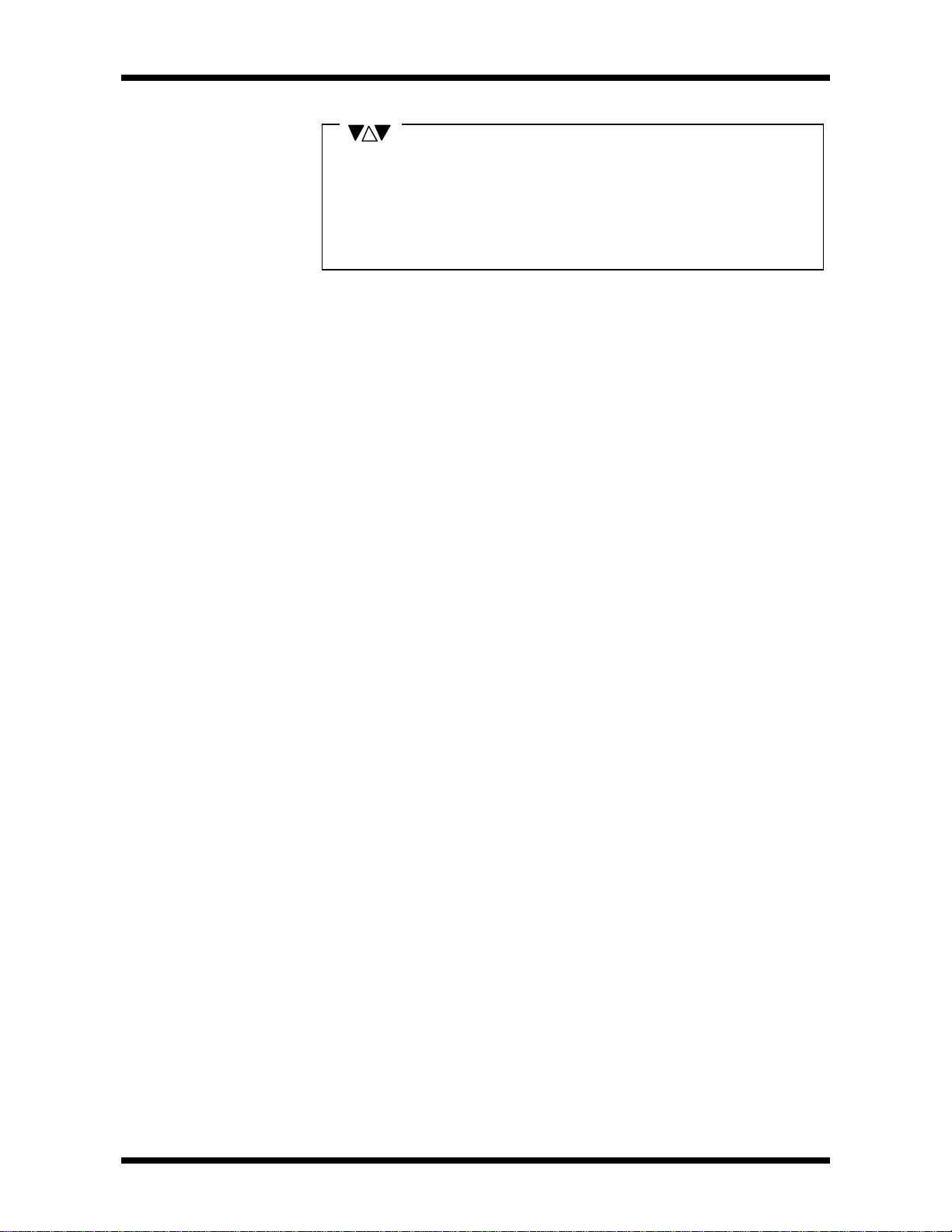

1)Minimum Configuration

/

/

/

/

/

1.System Configuration

CPU

Power Supply

Basic unit with 8 I/O modules(BU228N)

2) Maximum Configuration

I/O/I/O/I/OOI/O/I/O

Basic unit

CPU

Power Supply

Expansion Unit No.1

I/O/I/O/I/O/I/O/I/O/I/O/I/O/I/O

I/O/I/O/I/O/I/O/I/O/I/O/I/O/I/O

Power Supply

Expansion Unit No.2

I/O/I/O/I/O

Number of I/O module

8 I/O modules(BU228N)

8 I/O modules(BU268)

6 I/O modules(BU266)

8 I/O modules(BU268)

6 I/O modules(BU266)

I/O/I/O/I/O/I/O/I/O/I/O/I/O/I/O

Power Supply

Expansion Unit No.3

8 I/O modules(BU268)

6 I/O modules(BU266)

I/O/I/O/I/O/I/O/I/O/I/O/I/O/I/O

Power Supply

• Up to a maximum of 3 expansion units can be connected.

• There is no limit on combinations of the types of the rack.

• When one BU228N and three BU268 are used ,a maximum of 32 I/O modules can be

controlled by the T2N CPU.

User’s manual 5

Page 21

1.System Configuration

TOSHIBA

OUT

OUTNCNC

IN

1.2

Power Supply Module Power supply modules are mounted on the left -end slots of all units. There are

two types according to the power voltage. Select one as required.

Model Power Voltage Output Rating Weight

TPS261**S 100 - 240Vac

(+10%/-15%)

EX10*MPS31 24Vdc

(+20%/-15%)

Internal 5V power supply : 2.5A (max.)

External power supply : 24V,+10%/-10%

0.5A (max.)

(Internal + external total 15W or less)

Approx.

300g

Power LED

POWER

24Vdc

+

External 24Vdc

output terminals

-

RUN

Terminal block

Run signal output

terminals

eject levers

LG

FG

L

N

Line filter ground terminal

Frame ground terminal

Power supply

terminals

• External 24Vdc Output Terminals

These terminals can be used to supply 24Vdc power to external devices such as

sensors or relay output modules. 24Vdc(±10%)-0.5A(max.)

• Run Signal Output Terminals

When the T2N is in the operating mode(RUN), built-in contact is closed.

240Vac(+10%)/24Vdc(+20%)-2A(max.)

(Can also be used on expansion units)

• Power Supply Terminals

Connect to the power supply line. (See 4.7 Wiring the power supply).

• Line Filter Ground Terminal / Frame Ground Terminal

These are grounding terminals. (See 4.6 Grounding methods).

NOTE

1. The maximum rated output of the power supply module is 15W, this includes the

internal 5Vdc and external 24Vdc output combined. Configure the system, referring to

the Module Current Consumption Table on the next page, so that the following equation

is satisfied.

15W≥5V × Total 5V current (max. 2.5A) + 24V × external 24V current (max. 0.5V)

2. Do not connect the external 24V supply terminals to the other power supply systems,

and do not run the wiring over long distances.

3. This power supply module is dedicated power supply for the T2N and T2E/T2/EX100.

Do not use it by itself for other purposes.

6 PROSEC T2N

Page 22

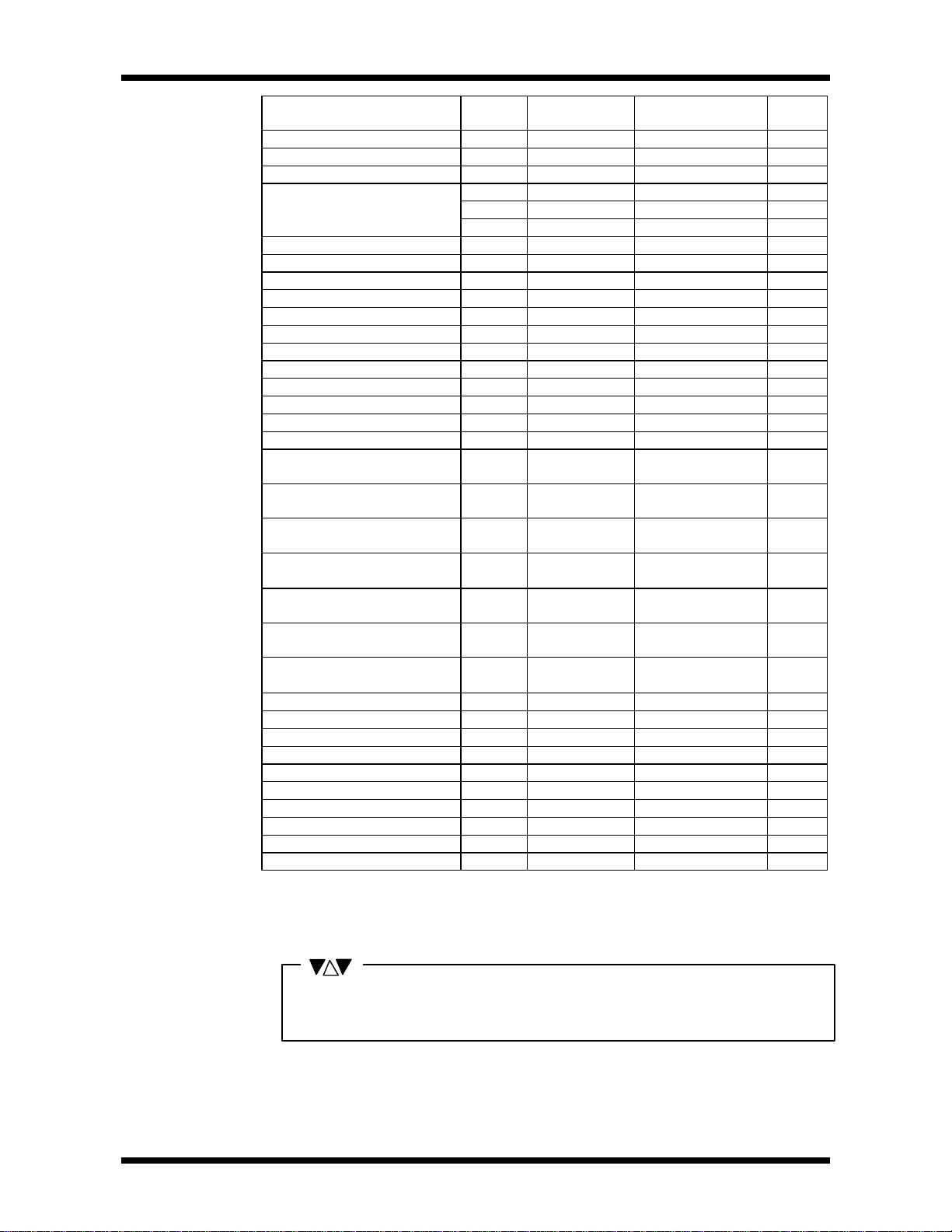

1.System Configuration

Module Current

Consumption Table

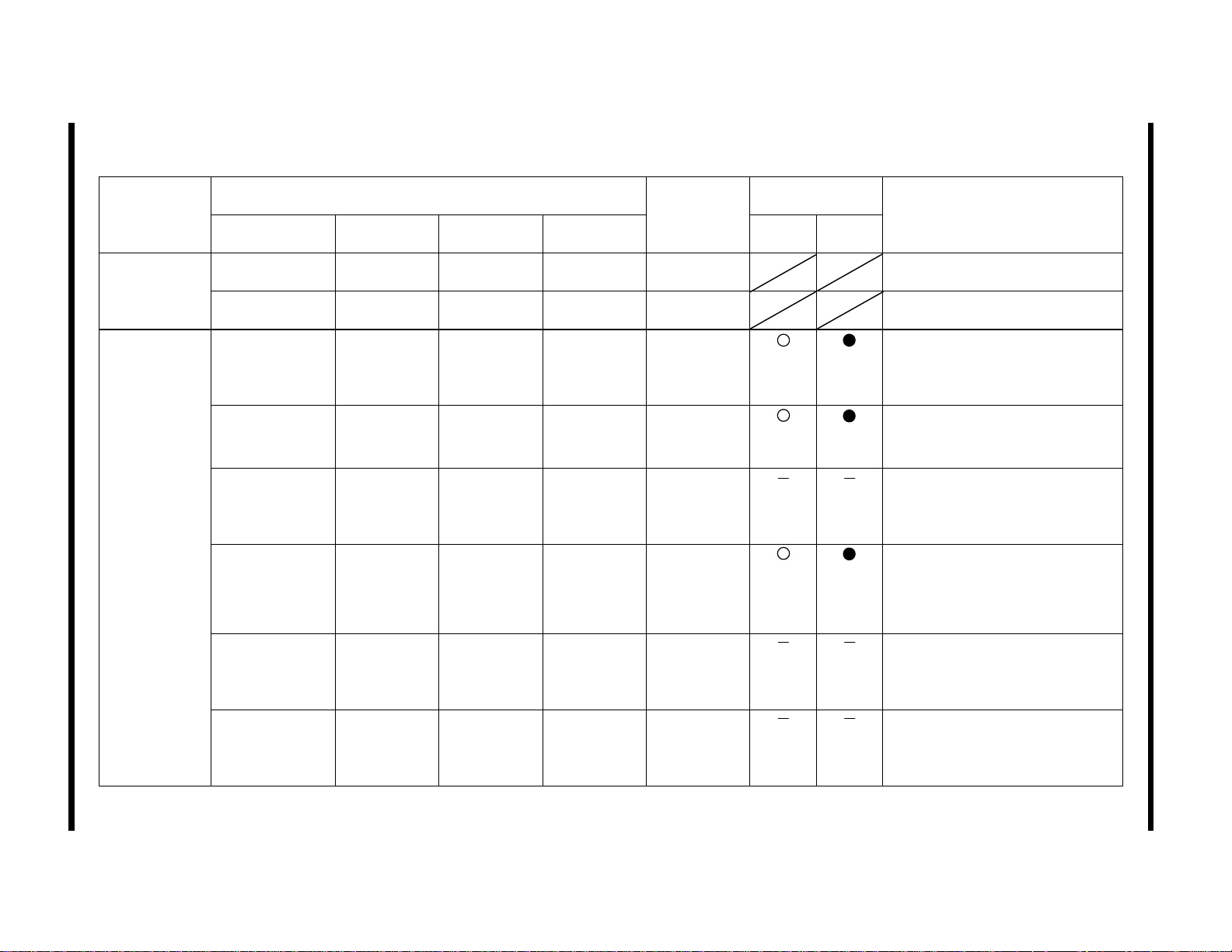

Name Model Internal 5Vdc External 24Vdc Weight

(approx.)

CPU PU215N 800mA or less - 300g

CPU(Ether) PU235N 1500mA or less - 400g

CPU(Ether+TOSLINE-S20LP) PU245N 2000mA or less - 400g

BU228N 50mA or less - 1600g

Rack BU268 50mA or less - 1500g

BU266 50mA or less - 1400g

16-point DC/AC input(12-24V) DI31 15mA or less - 200g

32-point DC input(24V) DI32 80mA or less - 200g

64-point DC input(24V) DI235 100mA or less - 250g

16-point AC input(100-120V) IN51 15mA or less - 250g

16-point AC input(200-240V) IN61 15mA or less - 250g

12-point relay output RO61 50mA or less DC24V, 140mA 250g

8-point isolated relay output RO62 40mA or less DC24V, 100mA 250g

16-point transistor output DO31 60mA or less DC5-24V, 35mA 200g

32-point transistor output DO32 250mA or less DC5-24V, 100mA 200g

64-point transistor output DO235 250mA or less - 250g

16-point transistor (PNP) DO233P 60mA or less - 200g

12-point triac output AC61 300mA or less - 200g

4ch analog input (8bit)

(4-20mA/1-5V)

4ch analog input (12bit)

(4-20mA/1-5V)

4ch analog input (8bit)

(0-10V)

4ch analog input (12bit)

(±10V)

2ch analog output (8bit)

(4-20mA/1-5V/0-10V)

2ch analog output (12bit)

(4-20mA/1-5V)

2ch analog output (12bit)

(±10V)

1ch pulse input PI21 80mA or less - 200g

Position control MC11 200mA or less DC12/24V, 100mA 250g

Serial Interface CF211 550mA or less - 200g

TOSLINE-30(wire) LK11 250mA or less - 200g

TOSLINE-30(optical) LK12 200mA or less - 200g

TOSLINE-S20(wire) SN221 600mA or less - 250g

TOSLINE-S20(optical) SN222A 700mA or less - 250g

TOSLINE-F10(Master Station) MS211 600mA or less - 250g

TOSLINE-F10(Remote Station) RS211 600mA or less - 250g

Devicenet scanner DN211 500mA or less - 200g

AI21 50mA or less DC12/24V, 50mA 200g

AI22 50mA or less DC24V, 50mA 200g

AI31 50mA or less DC12/24V, 50mA 200g

AI32 50mA or less DC24V, 50mA 200g

AO31 70mA or less DC24V, 90mA 200g

AO22 170mA or less DC24V, 90mA 200g

AO32 170mA or less DC24V, 90mA 200g

NOTE

The external 24Vdc in the Table are not power supplies for input/output signals.

They are the power supplies required for module operation.

User’s manual 7

Page 23

1.System Configuration

(SRUN. SONL, SACC)

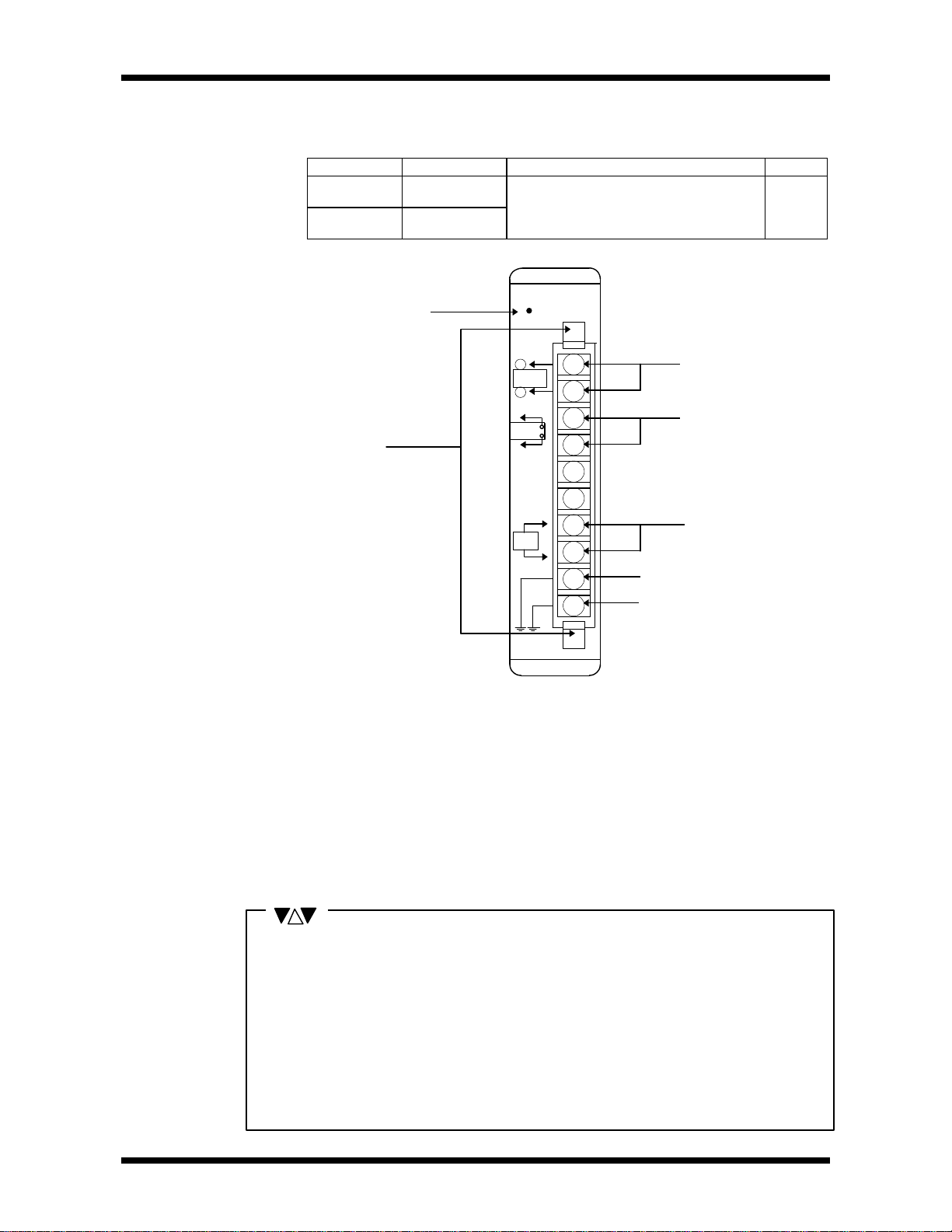

1.3 CPU Module There are three types of CPU modules with functions as shown below.

Type Specification

PU215N RAM(battery back-up) + EEPROM, User program 23.5k step,

ladder, SFC, real time clock, enhanced communication function

PU235N PU215’s function + Ethernet

PU245N PU215’s function + Ethernet + TOSLINE-S20LP

Status display LED

(RUN, FauLT, BATtery)

Operation Mode Switch

(HALT, RUN, P-RUN)

Setting Switches of

Operation Mode

Programmer port connector

(RS232C)

Communication port connector

(RS232C/RS485)

Ethernet status display

(ERUN, ET/R, EACC)

TOSLINE-S20LP status

display

Station address switches

for TOSLINE-S20LP

Communication connectors

for TOSLINE-S20LP

Communication connectors

for Ethernet

8 PROSEC T2N

Status display LEDs : Show operation states of the T2N

RUN

(Green)

FAULT

(Red)

BAT

(Green)

Status display LEDs : Show operation states of the Ethernet/TOSLINE-S20LP

For details of operation mode, see Ethernet/TOSLINE-S20LP user’s manual.

These all LED’s color is green.

ERUN Operating state (Ethernet)

ET/R Data transmission/receive state (Ethernet)

EACC T2N’s accessing state for Ethernet

SRUN Operating state (TOSLINE-S20LP)

SONL Online state of TOSLINE-S20LP

SACC T2N’s accessing state for TOSLINE-S20LP

Lit Operating state (RUN Mode)

Blink HOLD Mode

Out Stopped state (HALT Mode) or Error Mode

Lit CPU abnormal

Blink Program abnormal

Out Normal

Lit Battery normal

Blink Battery getting abnormal

Out Battery abnormal or no battery

Page 24

1.System Configuration

P/S

ROM

R/S

CM0

CM1

COM

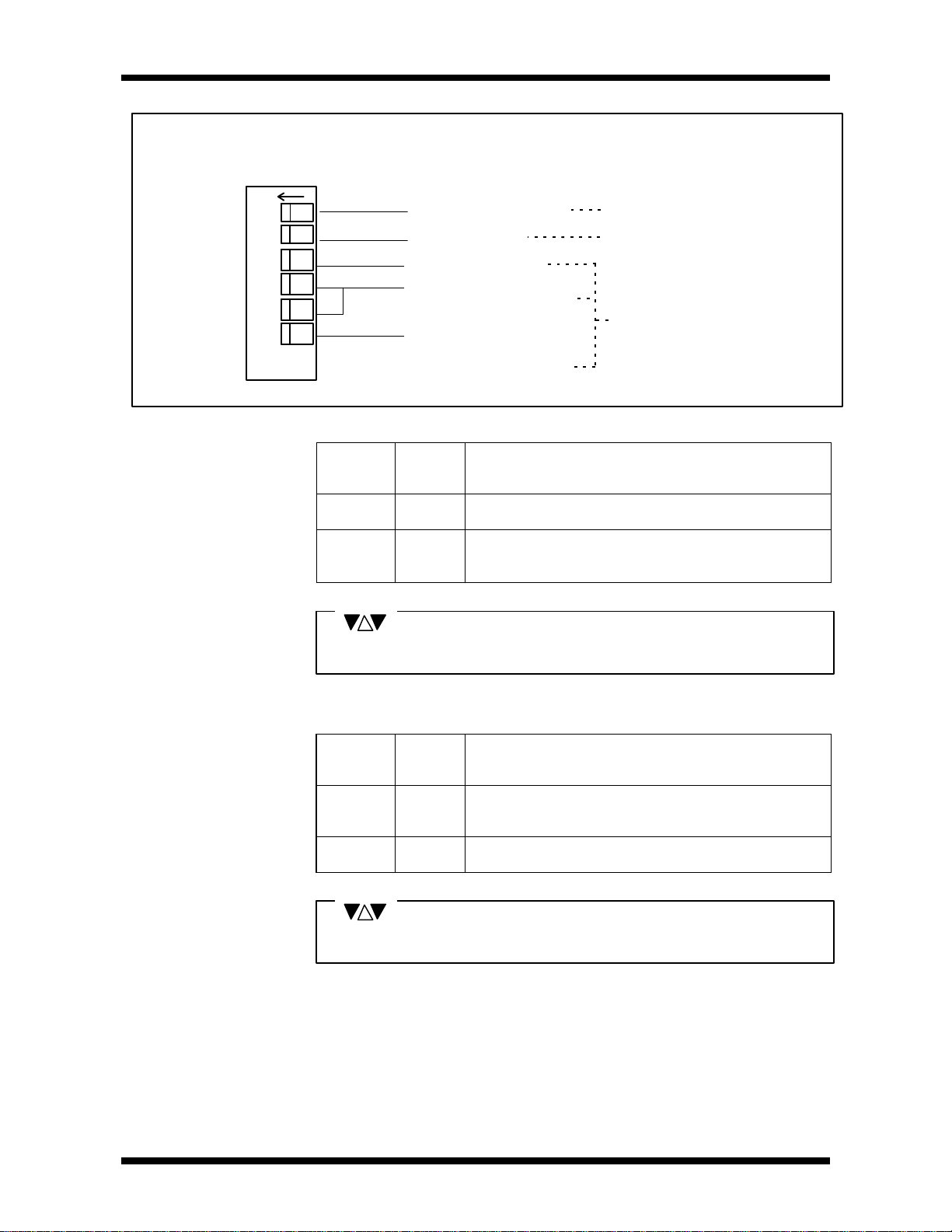

• Setting Switches of Operation Mode

These switches are provided on the CPU front panel. They control the

following functions.

OFF

1

2

3

4

5

6

Programmer/S-LS Switch This switch can be changed anytime

ROM/RAM Switch CPU reads this status when power

RUN/Stand-by Switch

Selection Switch of optional

Communication function

Programmer Port

Parity

(1) Programmer/S-LS(selection) Switch

Setting

Position

SW.1

OFF T-PDS T-PDS direct connection mode : Operate as the

ON S-LS S-LS connection mode : Operate as the tool for setting

Function CPU operation

(Communication support on Programmer port)

Programmer.

parameter for TL-S20LP.Or operate as the remote

programmer T-PDS via TL-S20LP.

is changed from OFF to ON or when

operation mode is changed to RUN.

CPU reads these switches status

only when power turns to ON.

NOTE

Programmer/S-LS (selection) switch is set to Programmer at the factory.

(2) ROM/RAM Switch

Setting

Position

SW.2

OFF ROM Starts up after the content of the EEPROM has been

ON RAM Starts up on the content of the RAM.

Function

CPU operation

at power up and at the beginning of the RUN mode

transferred to the RAM.

(Transfer is not executed when P-RUN is selected.)

(No program transfer)

NOTE

The ROM/RAM switch is set to ROM at the factory.

User’s Manual 9

Page 25

1.System Configuration

(3) RUN/Stand-by Switch

The RUN/Stand-by switch is set to RUN at the factory.

(4)(5)Selection Switch of optional Communication function

Setting Position Operation

Setting

Position

SW.3

Function Operation

Mode

Switch

HALT HALTOFF Automatic

RUN

RUN RUN Automatic RUN start occurs.

HALTON Stand-by

RUN

Mode after

power up

HALT

Remarks

Starts up in HALT mode. Ready

to start operation by RUN command from the programmer or by

shifting the operation mode

switch.(→HALT→RUN)

NOTE

Function

SW.4 SW.5

OFF OFF Computer Link The T2N can communicate with a master

computer using T-series computer link

protocol.

ON OFF Data Link The T2N executes data link with other T2N.

OFF ON Free ASCII The T2N can communicate with external

devices using ASCII code.

ON ON Reserved No operation.

NOTE

1. These switches are set to computer link function at the factory.

2. For details of the operation mode, see Section 1.4.

(6)Programmer Port Parity

Setting

Position

SW.6

OFF Odd Parity 8 bit Data, 9600bps, Data length is 11bit.

ON No Parity 8 bit Data, 9600bps, Data length is 10bit.

Function Remarks

NOTE

The Programmer Port Parity switch is set to Odd Parity at the factory.

The T2N can connect to Modem by using this switch.

Control signals (CTS,DTR,etc) should be set to No Use at the modem side.

Response of the T2N can be delayed on the programmer port using SW38

(Programmer port response delay mode register).

10 PROSEC T2N

Page 26

1.System Configuration

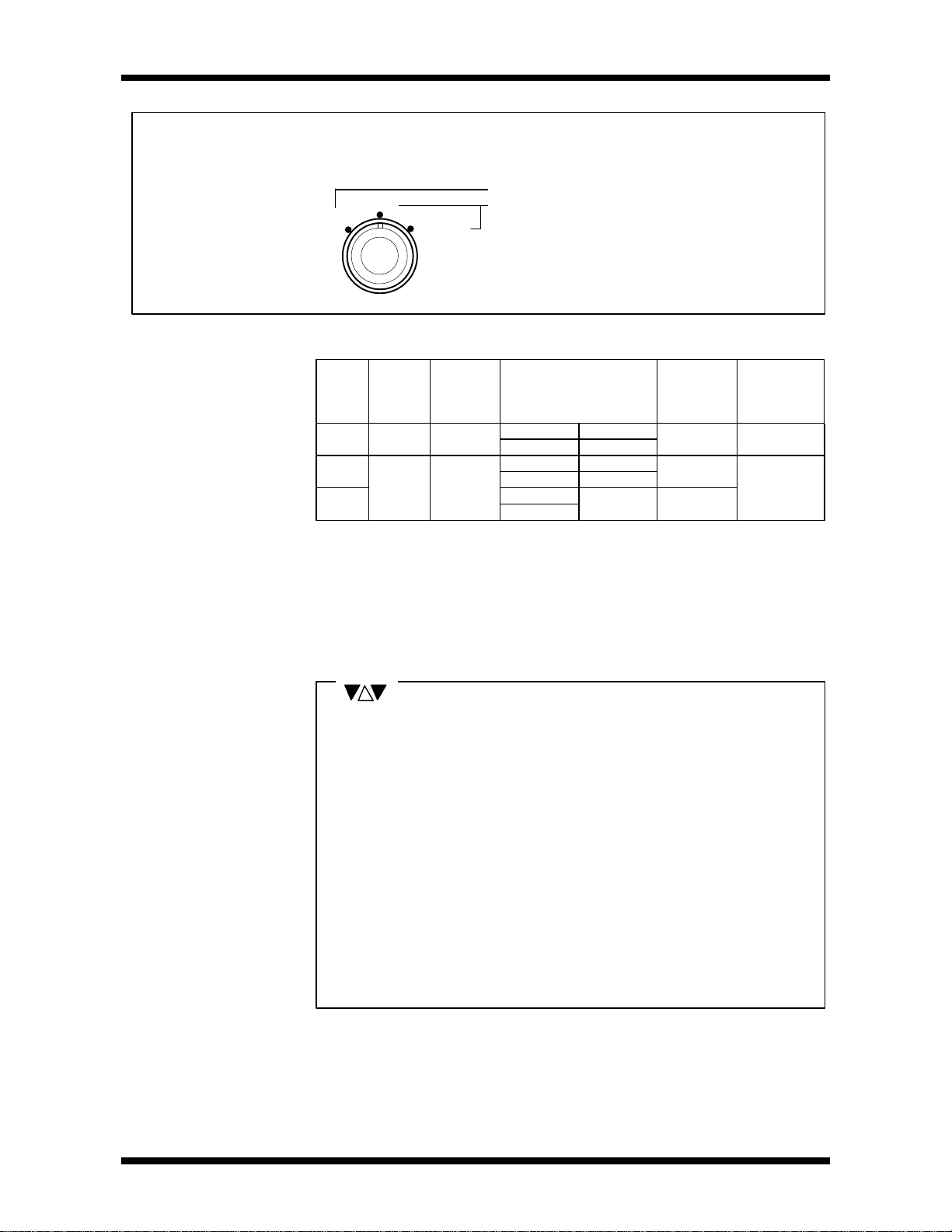

• Operation Mode Switch

The Operation Mode Switch is provided on the CPU module.

This switch controls T2N operation (RUN/P-RUN/HALT).

Stop user program execution (HALT mode)

HALT

CPU status is shown below after power up or after the operation mode is

changed to RUN from HALT.

Setting

Position

P-RUN

User

Program

Executed RUN

Operation

RUN

Start user program execution (RUN mode)

Mode

Initial Load

Program

exe : executed

- :not executed

SW.2:OFF exeHALT Stopped HALT

SW.2:ON SW.2:OFF exeRUN

SW.2:ON SW.2:OFFP-RUN

SW.2:ON

- protect

Memory

Protection

No protect not available

No protect

Operation

Mode Change

programmer

available

by the

As shown the above table, initial load (program transfer into EEPROM from RAM)

performs in the RUN mode when setting SW.2 to OFF except P-RUN position.

NOTE

1. The operation mode switch is set to HALT at the factory.

2. “P-RUN” is state that the operation mode switch set to P-RUN.

The user program and the first half of data register (D0000 to D2047) are

in the write protect mode and user can’t write or change them.

3. Normally, the programming is carried out in the HALT mode.

4. When shifting to the RUN mode with the ROM/RAM switch in the ROM

position , operation will commerce after program transfer has been

executed. (that is, it is called initial load.)

5. For details of the operation mode, see Part2, Section 2.3.

6. When the operation mode switch is changed quickly from HALT to P-RUN,

program transfer is interrupted.

Turn to P-RUN after the RUN LED is lit.

7. The RAM is backed up by battery of the T2N. When the battery voltage

drops and the T2N can’t keep retentive area in the RAM, CPU clears all the

retentive data.

Then CPU checks user program BCC. If error is detected, CPU registered

error.

User’s Manual 11

Page 27

1.System Configuration

• Programmer Port

The programmer (T-PDS or HP911) is connected to this programmer port.

Connector type of CPU side is female , 9-pin D-SUB connector.

The T2N’s RS232C programmer port can accept the computer link protocol

(data read/write). This results in easy connection to a higher level computer,

an operator interface unit, etc. directly.

General specifications and the connector pin assignment of programmer port

are shown below.

For details of T-series computer link protocol, see T-series User’s manual

- Computer Link (UM-TS03***-E008).

Communication specifications

Item Specifications

Interface Conforms to RS232C

Configuration One to One

Transmission distance 15m max.

Transmission speed 9600bps (fixed)

Frame format Start bit 1bit

Data 8bit

Parity odd/none (selected by SW.6)

stop bit 1bit

Supported command DR (Data Read)

DW (Data Write)

ST (Status read)

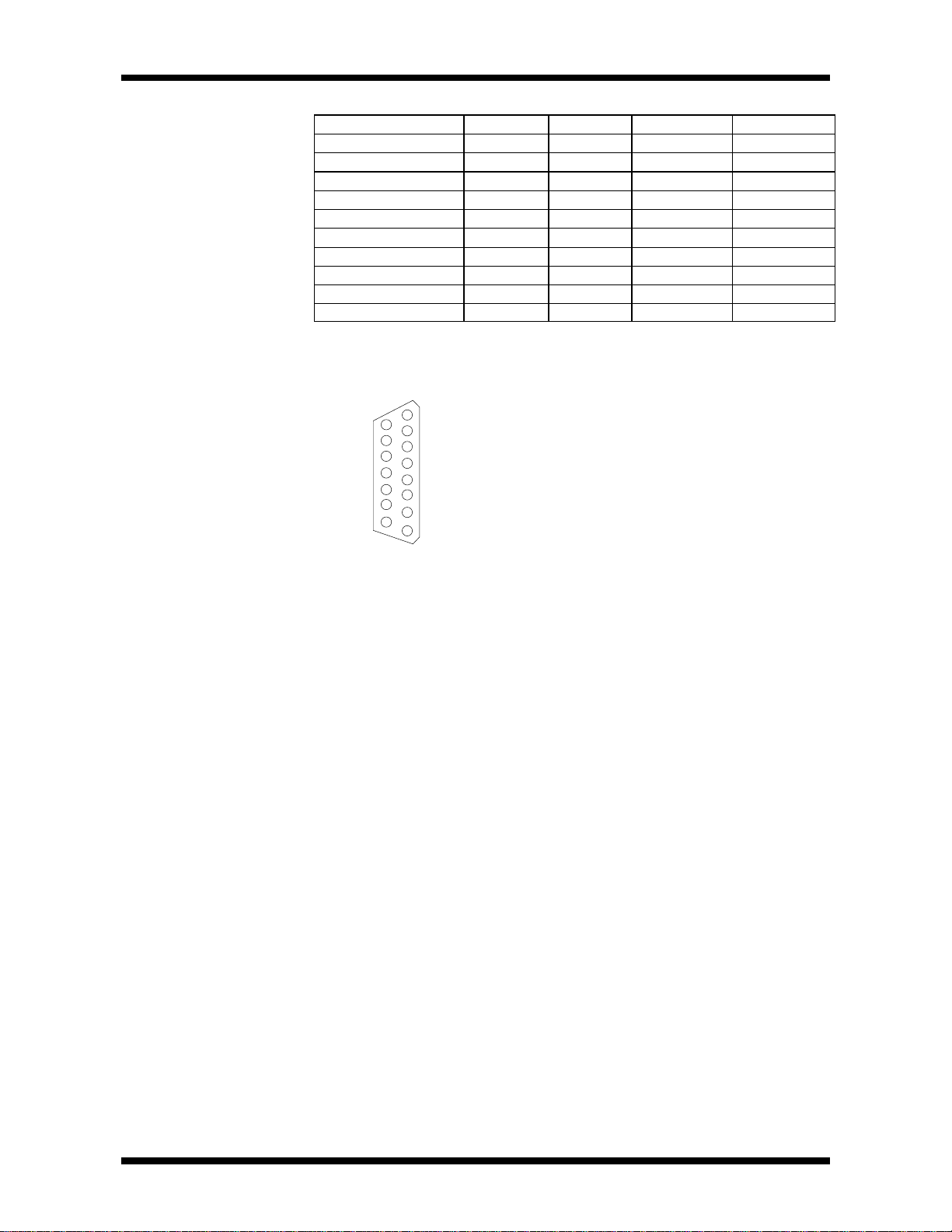

Pin assignment of programmer port

Signals No. of pins Symbols Direction

Transmission data 3 TXD

Receive data 2 RXD

Signal ground 5 SG T2N -- Host

Request To Send 7 RTS

Clear To Send 8 CTS

T2N → Host

T2N ← Host

T2N → Host

T2N ← Host

NOTE

Other pins except the above table should not be connected.

12 PROSEC T2N

Page 28

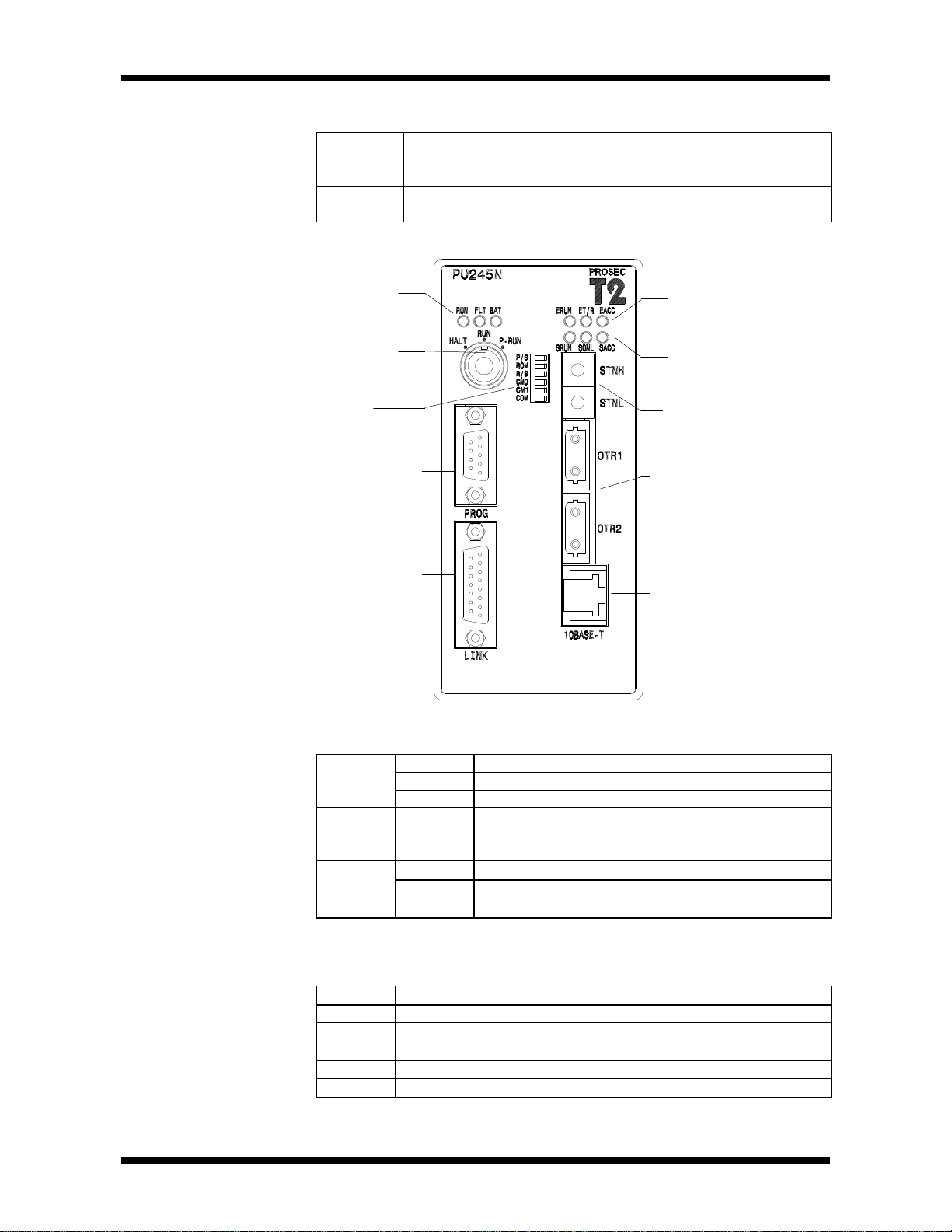

1.4

Communication port

1.System Configuration

The T2N supports enhanced communication functions. Either RS485 or

RS232C can be selected for this communication port by using selection

switches.

There are three communication functions in the T2N.

One of them can be selected by setting swithches CM0/CM1 (SW.4/SW.5).

Function Operation

Computer Link This performs to connect between a Host computer and

up to 32 T2Ns, using RS485.

(one to one ,using RS232C)

Data Link This performs to connect two T2E/T2Ns.

They share 32W data with each other.

Free ASCII This performs to connect between the external devices

such as inverter, etc. and the T2N.

For details of these functions and usage method, see T2E/T2N User’s manual

- Enhanced communication function -(UM-TS02E**-E003).

• Switch settinf of communication port.

Setting Position

Dip-SW.1

OFF Conforms to RS485.

ON Conforms to RS232C.

Communication port interface.

NOTE

These swithes are set to RS485 at the factory.

User’s Manual 13

Page 29

1.System Configuration

• Pin assignment of communication port (LINK).

Transmission data 5 TXD RS232C

Receive data 12 RXD RS232C

Request To Send 6 RTS RS232C

Clear To Send 14 CTS RS232C

Signal Ground 7,8,15 SG RS232C/485 T2N - Host

Transmission data A 3 TXA RS485

Transmission data B 11 TXB RS485

Receive data A 2 RXA RS485

Receive data B 10 RXB RS485

No Connection 1,4,9,13 NC

Signals No. of pins Symbols Interface Direction

T2N→Host

T2N←Host

T2N→Host

T2N←Host

T2N→Host

T2N→Host

T2N←Host

T2N←Host

D-SUB 15pin connector.

15

8

9

1

14 PROSEC T2N

Page 30

1.System Configuration

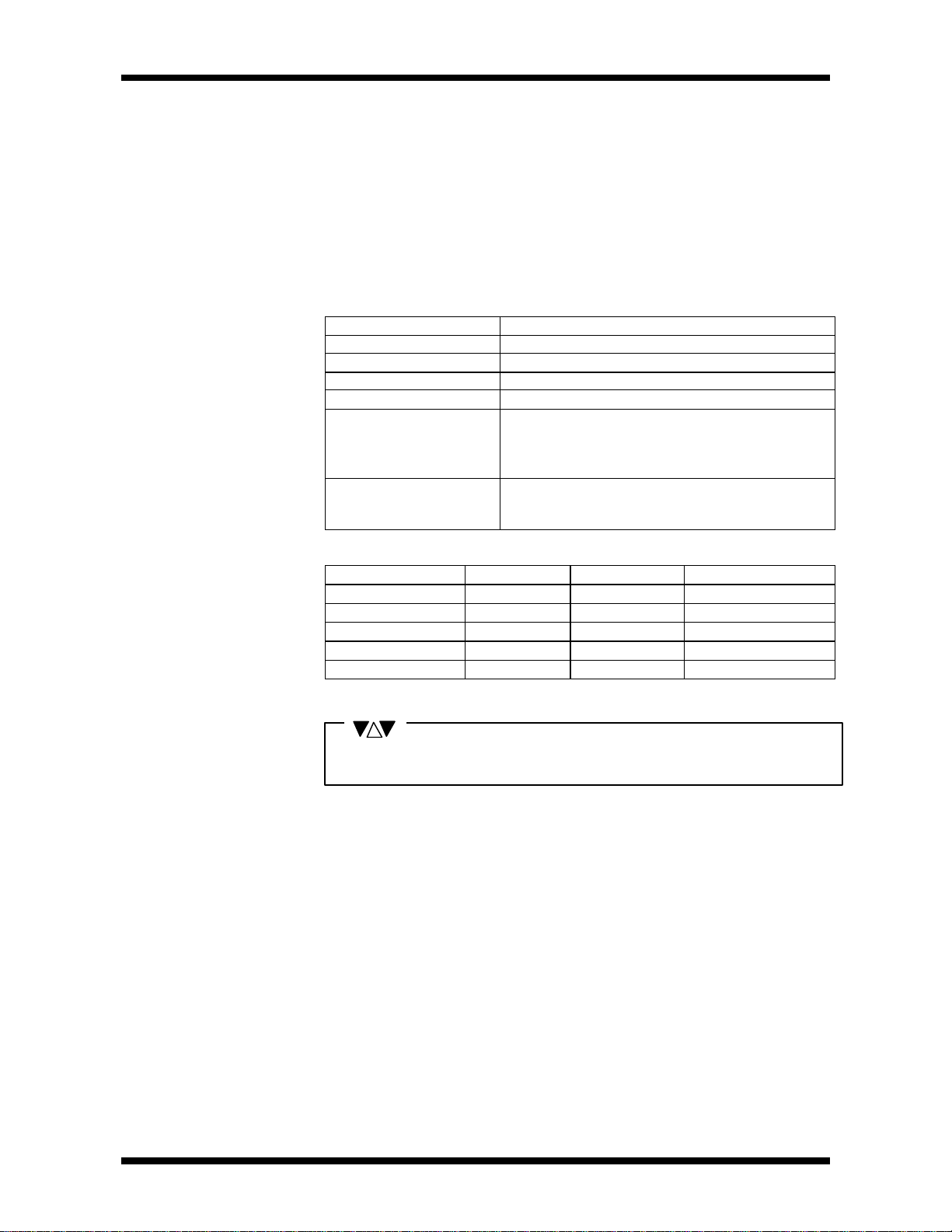

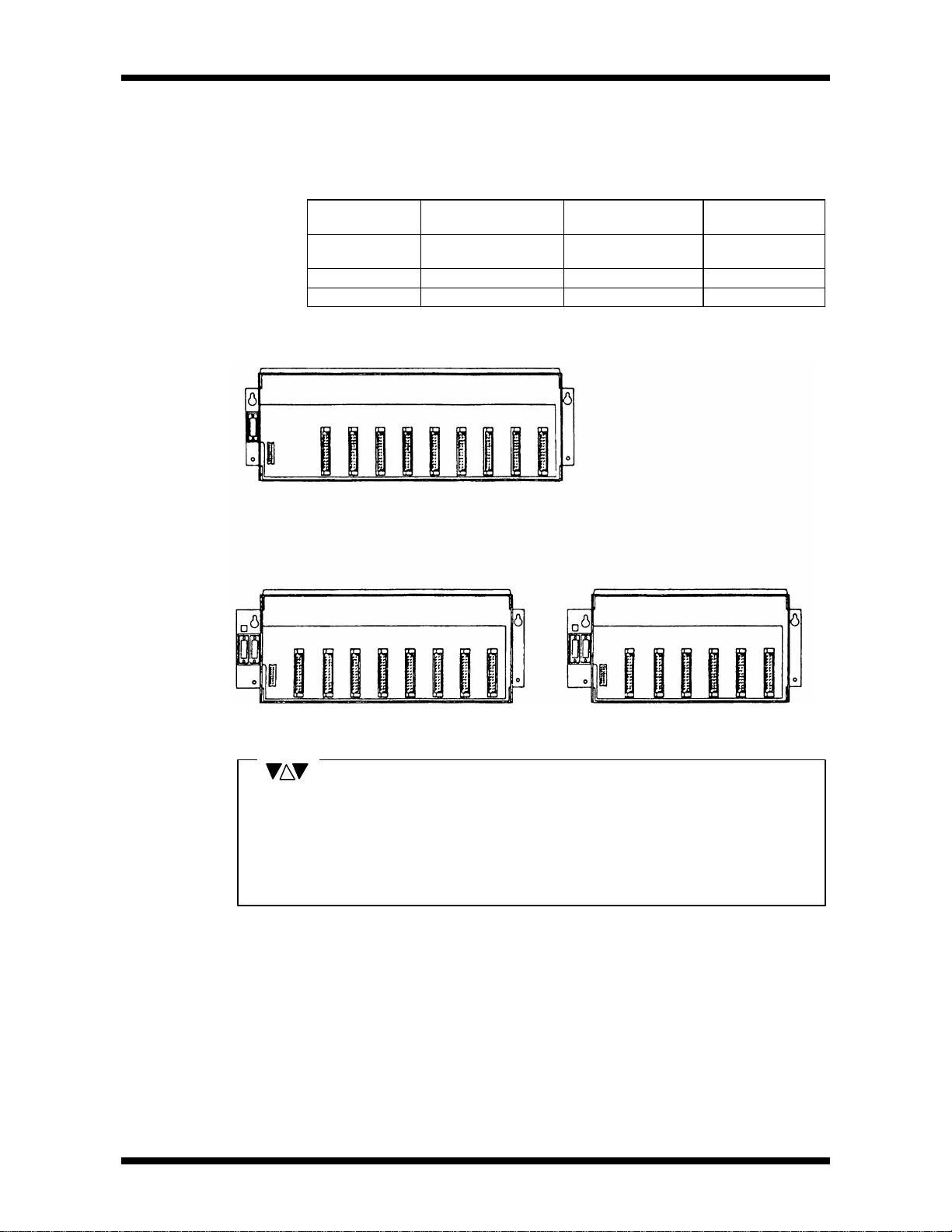

1.5 Racks As mentioned in Section 1.1, the rack is available in the three types as follows.

The BU228N is for the basic unit, and the BU268/BU266 are for the expansion

unit.

BU228N

Type Application Number of Module

Installation

BU228N Dedicated to the

Basic unit

BU268 For expansion unit 8

BU266 For expansion unit 6

8

BU266BU268

Remarks

NOTE

1. Two expansion connectors are provided in the BU268 and the BU266. The right side

connector is for connecting the basic unit/previous expansion unit.

The left side connector is for connecting the next expansion unit.

2. Use a blind slot cover (EX10*ABP1) to prevent debris from entering in the rack

where no I/O modules is mounted .

User’s Manual 15

Page 31

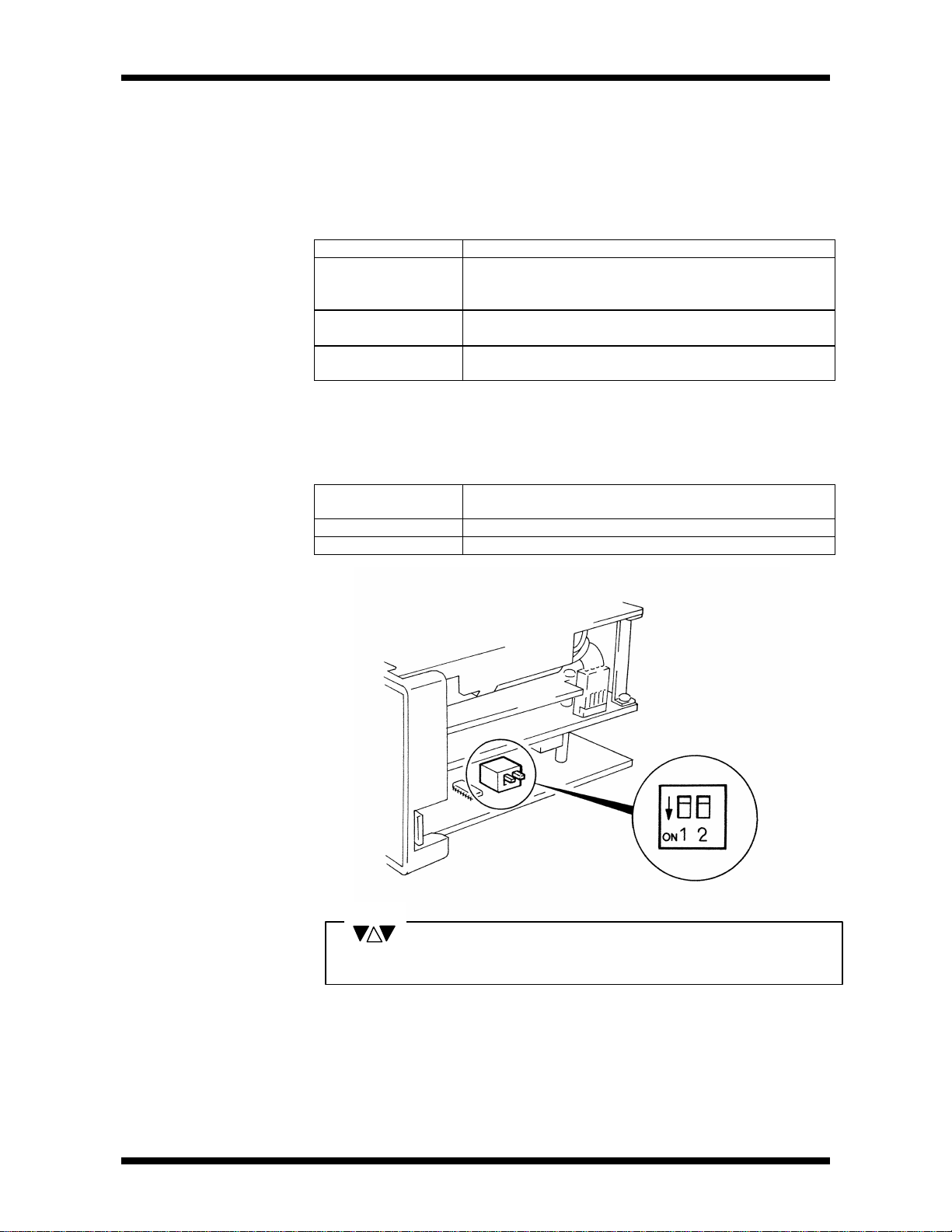

1.System Configuration

• Setting the Unit No.

When using the BU268 or the BU266 for dedicated expansion units,

set the Unit No. before operating. The setting is carried out by a rotary switch

in the upper part of the expansion connector on the left hand side of the rack.

NOTE

The rack used for : Switch Setting

Expansion Units Set in the order 1>2>3, starting from the

unit closest to the basic unit

1. Switches will be set at 0 at the factory.

2. Be careful not to duplicate Unit Nos. on units.

3. Do not use setting 4 - 9, as these are not for use.

1.6

Expansion Cables These are used for connecting the basic unit and the expansion units.

They are available in the following four lengths.

Type Length

CAR3 30cm

CAR5 50cm

CAR7 70cm

CS2RF 1.5m

NOTE

The maximum cable length between units is 1.5m.

The maximum total cable length is 4.5m.

16 PROSEC T2N

Page 32

1.System Configuration

1.7

I/O Modules Various types of I/O modules are available for the T2N, as shown in the

following table. Thus, it can respond to a wide variety of applications.

I/O modules can be mounted in any slot in the rack, and in any order.

(See Section 4.8 for recommended arrangements)

Input/Output status

display LEDs

Terminal block

eject levers

Type Description Specification

DI31 DC/AC input 16-point (16 points per common),12-24V dc/ac

DI32 DC input 32-point (8 points per common),24Vdc

DI235 DC input 64-point (8 points per common),24Vdc

IN51 16-point (16 points per common),100-120Vac

IN61

RO61 12-point (4 points per common),

RO62

DO31 16-point (16 points per common),5-24Vdc

DO32 32-point (8 points per common),5-24Vdc

DO235 64-point (8 points per common),5-24Vdc

DO233P

AC61 Triac output 12-point (4 points per common),100-240Vac

AI21 4-channel (not isolated between channels),

AI31

AI22 4-channel (not isolated between channels),

AI32

AC input

Relay output

Transistor output

Analog input

(8bit)

Analog input

(12bit)

16-point (16 points per common),200-240Vac

240Vac(+10%)/DC24V(+20%),

2A/point,4A/4 points common (max.)

8-point (each point isolated),

240Vac(+10%)/DC24V(+20%), 2A/point (max.)

1A/point, 1.2A/4 points (max.)

0.1A/point, 0.8A/8 points common (max.)

0.1A/point, 0.8A/8 points common (max.)

16-point (16 points per common),12-24Vdc

0.5A/point, 0.6A/2-element SSR (max.)

1-5V/4-20mA, 8bit resolution

4-channel (not isolated between channels),

0-10V ,8bit resolution

1-5V/4-20mA, 12bit resolution

4-channel (not isolated between channels),

-10V - +10V ,12bit resolution

Input/Output terminal block

(10-pin/18-pin)

User’s Manual 17

Page 33

1.System Configuration

Type Description Specification

AO31 Analog output

(8bit)

AO22 4-channel (not isolated between channels),

Analog output

AO32

PI21 Pulse input 1-channel (two phase, with zero marker),

MC11 Single-axis

CF211 Serial Interface RS-232C 1port,

(12bit)

positioning

NOTE

For detailed specifications of each I/O module, see Section 2.3 I/O Module

Specifications.

1.8

Data Transmission By applying the following 4 types of data transmission module according to the

Module system requirements, the T2N can configure the flexible and efficient control

systems.

2-channel (not isolated between channels),

1-5V/0-10V/4-20mA, 8bit resolution

4-20mA /1-5V,12bit resolution

4-channel (not isolated between channels),

-10V - +10V,12bit resolution

5/12Vdc, 100kpps (max), 24bit counter

1 axis, 100kpps(max.), position data memory

capacity 64 points

Common memory 160W×2

• TOSLINE-F10

PLC to PLC data linkage and remote I/O systems are configured by the

TOSLINE-F10 data transmission equipment.

Up to 8 T2 stations can be mounted in any slots, in the same way as I/O modules.

MS211/RS211

(High-speed setting)

Topology Bus (twisted-pair cable)

Transmission speed 750kbps 250kbps

Transmission Distance 500m 1km

Number of stations max. 32stations

Transmission capacity 32 words (L/LW)

Response speed 7ms(when 32 words) 12ms(when 32 words)

MS211/RS211

(Long-distance setting)

18 PROSEC T2N

Page 34

1.System Configuration

• TOSLINE-S20

The TOSLINE-S20 is a Local Area Network (LAN) for factory automation systems.

It can achieve high-speed data linkage between PLCs and communication between

industrial computers.

One T2 station can be mounted in any slot, in the same way as an I/O module.

SN221 and SN222A are allocated as optional card in the T2N.

Therefore READ/WRITE instructions should be used to access data of TOSLINE-S20

modules, because the link registers are not assigned.

SN221

(Co-Axial Cable)

Topology Bus

Transmission speed 2 Mbps

Transmission Distance 1km 10km

(1km between stations)

Number of stations Max. 64 stations

Response speed Minimum 5ms in scan transmission

• TOSLINE-30

The T2N can use the TOSLINE-30.

It is effective when connecting EX series systems to the T2N.

Up to 4 T2 stations can be mounted in any slots, in the same way as I/O modules.

The link relay/register(Z/W) is assigned for the TOSLINE-30, the same as the

TOSLINE-S20LP. If the TOSLINE-S20LP is used together with the TOSLINE-30,

the link registers assigned to the TOSLINE-30 (starting with W0000) should not

allocate for the TOSLINE-S20LP.

LK11

(Twisted-pair Cable)

Topology Bus Star

Transmission speed 187.5kbps 375kbps

Transmission Distance 1km 2km

Number of stations MAX. 17 stations MAX. 16 stations

Transmission capacity 8/16/32 words W0000-W0127

SN222A

(Optical Fiber Cable)

LK12

(Optical Fiber Cable)

(1km between stations)

Response speed 25ms(when 32words) 19.2ms(when 32words)

• DeviceNet (Scanner)

The DeviceNet is a field network. It can achieve data linkage between the T2N and

any ODVA certified devices.

The T2N can use the DeviceNet scanner module.

It is effective for connecting DeviceNet systems to the T2N.

The T2N stations can be mounted in any slots, in the same way as for I/O

modules.

DN211

(Twisted-pair Cable)

Topology Bus

Transmission speed 125kHz 250kHz 500kHz

Transmission Distance 500m 250m 100m

Number of stations Max. 64 stations

User’s Manual 19

Page 35

1.System Configuration

1.9

Built-in networking The T2N has built-in networking as follows.

Type TOSLINE-S20LP Ethernet

PU215N - PU235N - Built-in

PU245N Built-in Built-in

For details of networking, see the following manuals.

Ethernet Built-in Ethernet Module for T2N (PU235N/245N)

Instruction Manual 6F3B0362

TOSLINE-S20LP TOSLINE-S20LP T2N / T3H Stations

Instruction Manual 6F3B0356

• Ethernet

The Ethernet is a standard Local Area Network (LAN) not only for OA but also for

factory automation systems.

It can achieve high-speed data linkage between PLCs and communication with

higher level computers (workstation/personal computer). The T2N supports T-series

computer link function, PLC data link function and socket interface function.

The T2N has 10BASE-T interface for the Ethernet.

Topology Bus

Transmission speed 10Mbps

between nodes 200m(one HUB) 1700m(four HUBs)Transmission

Distance

Number of nodes Max. 1 node/1 segment

Communication Function (2) T-series PLC link

between segments 100m

(1) T-series computer link

(3) Socket interface

Specifications

• TOSLINE-S20LP

The TOSLINE-S20LP is a Local Area Network (LAN).

It can achieve high-speed data linkage between PLCs.

The TOSLINE-S20LP is a double-loop system using optical fibers and can

continue data linkage if any problem is occured in one loop.

Transmission data capacity is expanded to 4k words.

Specifications

Topology Double-Loop

Transmission speed 2Mbps

between stations 1km (4km using the optical repeater)Transmission

Distance

Number of stations Max. 64 stations/loop

Transmission capacity 4,096words

Response speed Min. 5ms in scan transmission

total 30km

W0000-W2047 (Z/W) and any 2048word

registers (using XFER instruction)

(1) Scan transmissionCommunication Function

(2) Message transmission

20 PROSEC T2N

Page 36

2.1

General Specification

2.Specification

Item Specification Remarks

Rated Voltage (1)100-240Vac PS261

(2)24Vdc PS31

(1)85 - 264Vac PS261Voltage

Fluctuation

Range

Power Supply

Frequency

Frequency

Fluctuation

Range

Retentive

power

Power Supply

interruption

Power

consumption

Inrush current (1) 15A(at 100Vac) or less

Insulation

resistance

Withstand voltage 1500Vac - 1minute *1

temperature

Ambient humidity

Atmosphere No corrosive gases

Dust 10mg/m

Vibration immunity 16.7Hz-3mm p-p

Shock immunity 98m/s2 (10g) (3 shocks per axis, on 3

Noise immunity

Grounding

Construction Installed in control panel

Cooling Natural air cooling

Notes *1 Insulated Circuits

• between Power supply circuit and I/O circuit

• between Accessible metal parts and Power supply circuit

• between Accessible metal parts and I/O circuit

• between SELV circuit and Power supply

• between SELV circuit and I/O circuit

(2)20.4 - 28.8Vdc PS31

(1)50/60Hz

(1)47 - 63Hz

10ms or less

(at maximum load for one power supply

module)

(1)53VA or less PS261

(2)22W or less PS31

35A(at 240Vac) or less

(2)30A/10ms or less PS31

10MΩor more

(between power terminals and

ground terminals)

0 to 55°C

-20 to 75°C

20∼90%RH no condensation

Sulphurous acid gas 0.05ppm or less

Hydrogen sulphide 0.01ppm or less

(3 mutually perpendicular awes)

mutually perpendicular awes)

1000Vp-p /1µs

Complied for EMC Directive of CE marking

Grounding resistance 100Ω or less

3

or less

PS261

operationAmbient

storage

Accessible metal parts: Racks, Protective ground terminal, etc.

SELV (Safety Extra Low Voltage) circuit: Internal logic circuit

The accessible metal parts of the peripherals which are connected

to the programmable controller by the standard cable are

connected to the Protective ground terminal, or double insulated.

User’s manual 21

Page 37

2.Specification

External dimensions

Basic dedicated unit (BU228N)

Expansion unit (BU266) Eexpansion unit (BU268)

2.2

When 16-point I/O module installed

When 32/64-point I/O, MC11 installed

22 PROSEC T2N

Page 38

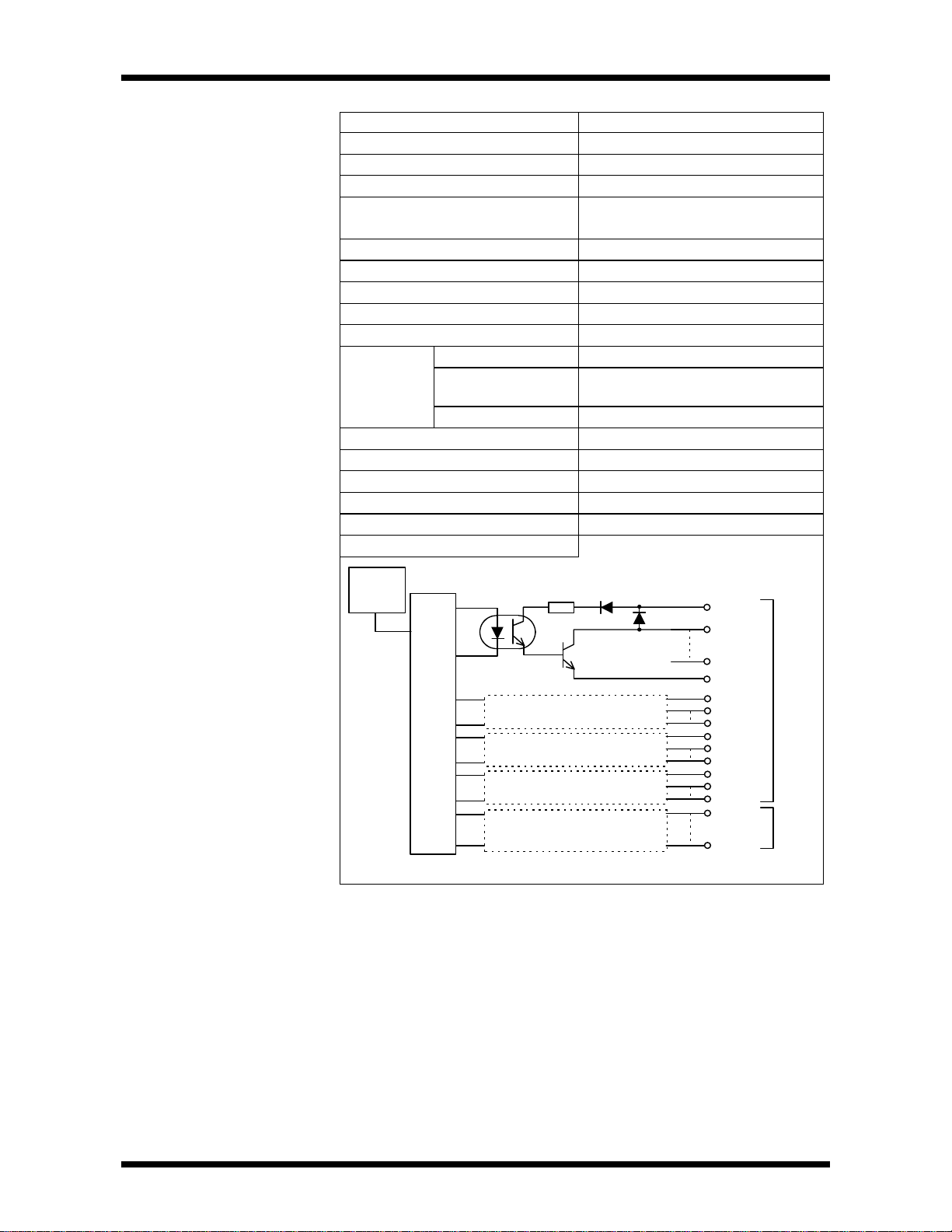

2.3

Circuit Configuration

........

........

CO

2

0

1

F

N

H

LED Display

COM

COM

COM

I/O Module

Specifications

16-point DC/AC input

D I 3 1

0 1 2 3 4 5 6 7

8 9 A B C D E F

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

2.Specification

Item

%

Input Voltage Range

12 - 24V

+ 10

dc/ac(50/60Hz)

%

− 15

Minimum ON Voltage 9.6V or more

Maximum OFF Voltage 3.6V or less (leak current 0.7mA or less)

Input Current(Type) Approx.8mA (at 24Vdc)

No. of input point 16 points/common

N Mode 10ms or less (dc) / 20ms or less (ac)ON Delay

H Mode 1.5ms or less (dc)

N Mode 10ms or less (dc) / 15ms or less (ac)OFF Delay

H Mode 1.5ms or less (dc)

Withstand Voltage 1500Vac / 1minute

Current Consumption 15mA (5Vdc) or less

Weight Approx. 200g

DI31

(EX10*MDI31)

* Filter

Selection

12-24Vac/dc IN

Terminal Connections

Internal Circuit

* Filter Selection(jumper plug setting)

N ; Standard DC/AC common use(set at the factory)

H ; High-speed DC input only

0

1

3

5

7

9

B

D

2

4

6

8

A

C

E

F

12-24V

User’s manual 23

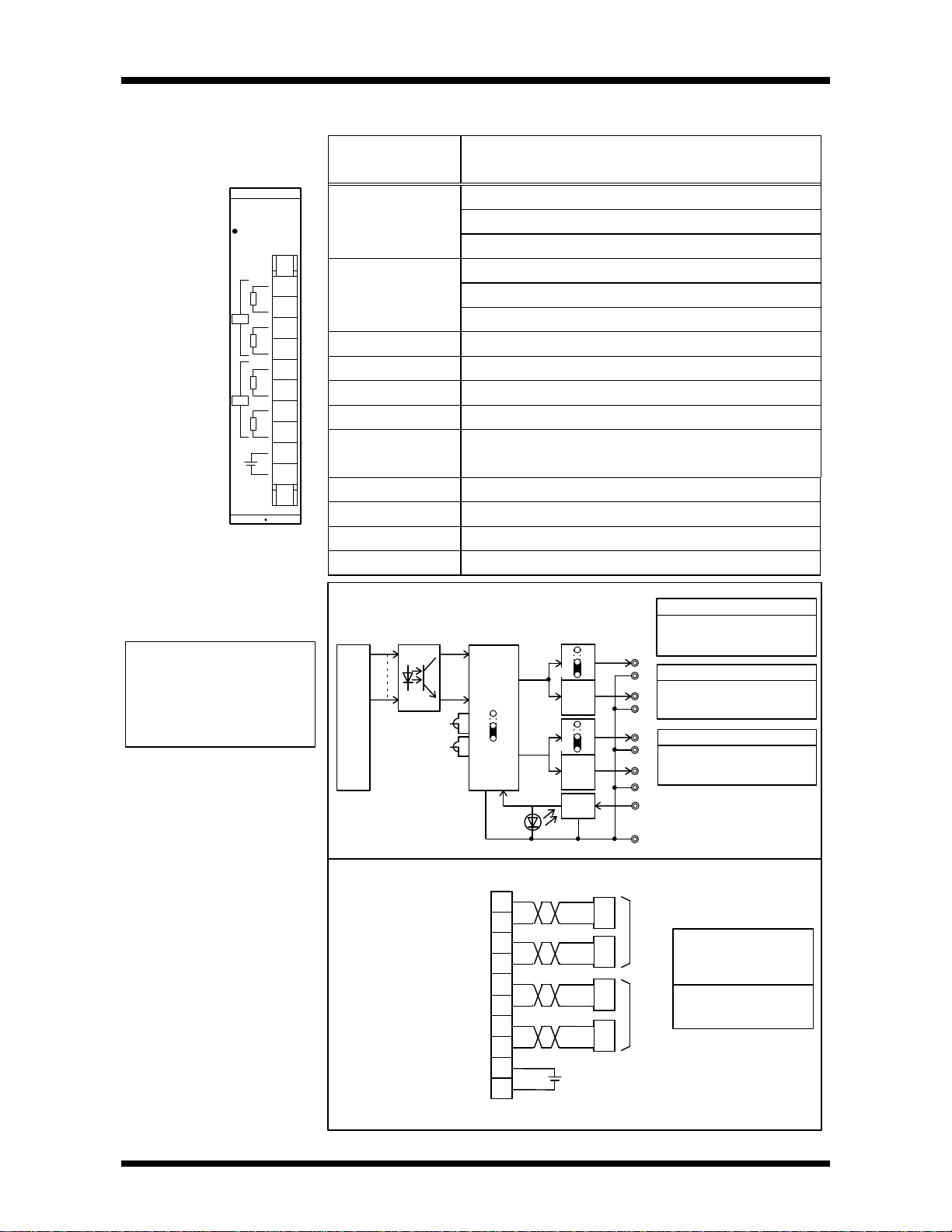

Page 39

2.Specification

CN1(XWn)

CN2(XWn+1)

1

12121

CN2

CN1

A B

B A

32-point DC input

D I 3 2

CN1

0 1 2 3 4 5 6 7

8 9 A B C D E F

0 1 2 3 4 5 6 7

8 9 A B C D E F

CN2

24Vdc IN

Item

Input Voltage Range

Minimum ON Voltage

Maximum OFF Voltage

Input Current

Number of Input point

ON Delay

OFF Delay

N Mode

H Mode 1.5msec or less

N Mode

H Mode 1.5msec or less

24Vdc ± 10% - 15%

18.0V

6.0V

Approx 5mA(at 24Vdc)

32points

10msec or less

10msec or less

(EX10*MD132)

External Connections 2 x 24pin connectors

Number of commons 4

Common

Configuration

Number of Input points

per Common

8 points

Common Polarity No Polarity

Withstand voltage 1500Vac / 1 minute

Current Consumption 80mA (5Vdc) or less

Weight Approx. 200 g

Circuit Configuration

0

1

7

COM

Internal circuit

LED display

Selection of the filter constant can be set in

16-point units (CN1, CN2) by DIP switch

setting. (set on N mode at the factory)

Switch

OFF ON Application

No.

1 N mode H mode CN1(XWn)

2 N mode H mode CN1(XWn+1)

Terminal Connections

+

B A

COMlNC

12 12

F

11 11

D

10 10

B

9 9

9

8 8

NC

7 7

NC

6 6

NC

5 5

7

4 4

5

3 3

3

2 2

1

1 1

E

C

A

8

NC

NC

COM0

6

4

2

0

+

+

+

+

DI32

+

+

COM2

+

COM3

+

A B

1

0

1 1

2

3

2 2

4

5

3 3

7

6

4 4

NC

5 5

NC

NC

NC

6 6

NC

7 7

9

8

8 8

B

A

9 9

D

C

10 10

E

F

11 11

12 12

NC

NOTE

Connectors on the Module: FCN-365P024-AU (made by Fujitsu)

Cable side connectors:

Soldering type (standard attached)

Connector FCN-361J024-AU (made by Fujitsu)

Connector cover FCN-360C024-E (made by Fujitsu)

24 PROSEC T2N

Page 40

2.Specification

CN2

CN1

64-point DC input.

Item DI235

Input Voltage Range

24Vdc

− 15

%

%

+ 10

Input Current Apporx.4mA(at 24Vdc)

Input Impedance

5.8kΩ(24Vdc)

Minimum ON Voltage 16V

Maximum OFF Voltage 5V

ON delay 10ms or less than

OFF delay 15ms or less than

External Connections

2 × 40 pin connectors

Number of Commons 8

Common

Configuration

Number of Input

Points per Common

8 points

Common Polarity No Polarity

Derating Condition See next page

Current Consumption 100mA (5Vdc) or less

Withstand voltage 1500Vac/ 1 minute

Weight Approx. 250g

Circuit Configuration

0L

7L

LC0

8L

LC1

0H

HC0

8H

HC1

0L

LC0

8L

LC1

0H

HC0

8H

HC1

LED

∼

display

Internal Circuit

User’s manual 25

Page 41

2.Specification

NC

NC

PS

FL

FH

PS

0H

0L

FL

A B

B A

L

H

PSPSPS

PS

PSPSPS

H

L

Terminal Connections

CN1

(B)(A)

20 20

NC

19 19

HC1

18 18

17 17

EH

16 16

DH

15 15

CH

14 14

BH

13 13

AH

12 12

9H

11 11

8H

10 10

HC0

9 9

7H

8 8

6H

7 7

5H

6 6

4H

5 5

3H

4 4

2H

3 3

1H

2 2

0H

1 1

NC

LC1

EL

DL

CL

BL

AL

9L

8L

LC0

7L

6L

5L

4L

3L

2L

1L

0L

1L

2L

3L

4L

5L

6L

7L

LC0

8L

9L

AL

BL

CL

DL

EL

LC1

NC

NC

CN2

(A)(B)

1 1

2 2

3 3

4 4

5 5

6 6

7 7

8 8

9 9

10 10

11 11

12 12

13 13

14 14

15 15

16 16

17 17

18 18

19 19

20 20

1H

2H

3H

4H

5H

6H

7H

HC0

8H

9H

AH

BH

CH

DH

EH

FH

HC1

NC

NC

CN2

CN1

CN1-L=XWn

CN1-H=XWn+1

CN2-L=XWn+2

CN2-H=XWn+3

20

1

20

1

: Power Supply

24Vdc

Connectors on the Module : FCN-365P040/AU (made by Fujitsu)

Cable side connectors : Soldering type (standard attached)

Connector : FCN-361J040-AU (made by Fujitsu)

Connector cover : FCN-360C040-E (made by Fujitsu)

Derating Condition

Number of input ON points (per 1 conncctor)

32 (100%)

26 (80%)

20 (60%)

0 10 20 30 40 50 60

21.6Vdc or less

24Vdc

26.4Vdc

Ambient temperature

26 PROSEC T2N

Page 42

2.Specification

201

F

COM

COM

COM

........

........

*

16-point AC input

IN51

0 1 2 3 4 5 6 7

8 9 A B C D E F

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

100-120Vac IN

Item

Input Voltage Range

(Sine wave)

Minimum ON voltage

(Sine wave)

Maximum OFF voltage

(Sine wave)

IN51

(EX10*MIN51)

100-120Vac + 10%

(50/60Hz)

-

15%

200-240Vac + 10%

(50/60Hz)

80Vac or more 160Vac or more

30Vac or less

(leak current 2mA or less)

60Vac or less

(leak current 2mA or less)

IN61

(EX10*MIN61)

-

15%

Input Current(Sine wave) Approx 7mA (100V-50Hz) Approx 6mA (200V-50Hz)

Number of Input Points 16 points (single common)

16 points (single common)

ON Delay (Sine wave) 20mS or less 20mS or less

OFF Delay (Sine wave)

15mS or less 15mS or less

Voltage lnsulation 1500Vac / 1 minute 1500Vac / 1 minute

Current Consumption 15mA (5Vdc) or less 15mA (5Vdc) or less

Weight Approx 250g Approx 250g

Circuit Configuration

Intermal

circuit

LED

indication

Terminal connections

1

3

5

7

9

B

D

2

4

6

8

A

C

E

F

COM

0

*

IN51 : 100-120Vac (50/60HZ)

IN61 : 200-240Vac (50/60HZ)

User’s manual 27

Page 43

2.Specification

1.ON/OFF life of relays: Electrical 100,000 times

display

CI

NC

C2

C3

COIL

........

....

12-point Relay Output

RO61

0 1 2 3 4 5 6 7

8 9 A B

0

1

2

3

4

5

6

7

+

8

9

A

B

-

24Vd

RELAY OUT

Item

RO61

(EX10*MRO61)

Load voltage 24Vdc, +20%(MAX)/240Vac, + 10%(MAX)

Maximum load 2A/point (resistive load), 1A/point (inductive load), 4A/4points

common

Minmum load 50mW (5V or more)

Number of output points 12 points (4 points / common)

ON delay 10ms or less

OFF delay 15ms or less

Leakage current When OFF 0mA

Withstand voltage 1500Vac / 1 minute

Current consumption 50mA (5Vdc) or less

External relay Coil

Power required

24Vdc +/- 10% - 140mA/all points ON (10mA/point)

Weight Approx 250g

Circuit Configuration

Internal

circuit

LED

1

2

3

C

4

7

C

8

B

C

Terminal Connections

28 PROSEC T2N

1

3

2

C1

4

0

24V

5

7

+

9

B

-

6

C2

8

A

C3

NOTE

Mechanical 20 million times

2.No overload protection fuses are built into this module.Therefore

connect fuses externally suitable to the current capacity.

Page 44

2.Specification

........

8-point Isolated

Relay Output

RO62

0 1 2 3 4 5 6 7

0

1

2

3

4

5