Page 1

DeviceNet Module DN211 for

PROSEC - T2/T2E/T2N

Instruction Manual

(Appendix3 DN211A)

6 F 3 B 0 3 6 4

REQUIREMENTS

• Read this instruction manual carefully before operating.

• Keep the manual aside to use when necessary.

• Pack the manual with the DN211 when transferring or

reselling.

January, 2001

© 2001 Toshiba Corporation

All rights reserved

UM-TS02***E16

Page 2

6 F 3 B 0 3 6 4

© Copyright 1998 by Toshiba Corporation Tokyo, Japan

Toshiba Corporation reserves the right to make changes and improvements

to this publication and/or related products at any time without notice. No

obligation shall be incurred, except as noted in this publication.

This publication is copyrighted and contains proprietary material. No part of

this book may be reproduced, stored in a retrieval system, or transmitted in

any form or by any means — electrical, mechanical, by photocopying,

recording, or otherwise — without obtaining prior written permission from

Toshiba.

Important Information

Misuse of this equipment can result in property damage or human injury.

Because controlled system applications vary widely, you should satisfy

yourself as to the acceptabillity of this equipment for your intended purpose. In

no event will Toshiba Corporation be responsible or liable for either indirect or

consequential damage or injury that may result from the use of this

equipment.

No patent liability is assumed by Toshiba Corporation with respect to the use

of information, illustration, circuits equipment, of application examples in this

publication.

1

Page 3

Safety Precautions

Thank you for purchasing Toshiba's DeviceNet module (DN211) for programmable controllers

PROSEC-T2 series (T2/T2E/T2N). This instruction manual describes the handling, precautions

and operation of the DN211.

Be sure to carefully read this manual and all of other related documents to learn the safety

precautions, notes, and knowledge about the DN211 before its installation, operation, or

inspection. This will allow you to operate your DN211 comfortably.

Important Information

1. Toshiba's DN211 is designed and manufactured for use with general industrial

equipment(manufacture line control devices, machine tools, etc.); it is not intended for use

with equipment and systems which will endanger people's life during operation.

Contact the Toshiba dealer in advance when you are going to use your DN211 for special

applications such as transport vehicles(train, etc.), medical equipment, aerospace equipment,

nuclear power control equipment, underwater relay equipment, or other similar applications.

6 F 3 B 0 3 6 4

2. Toshiba's DN211 is manufactured under strict quality control. However, be sure to install

safety systems to minimize the effect of a possible accident before you apply your DN211 to

the equipment which will endanger people's life or cause serious damage on the surroundings

if the DN211 should break down.

3. Toshiba's DN211 is meant for those who have general knowledge of handling control

equipment, especially the knowledge about installation, wiring, operation, and maintenance of

the DN211. Incorrect handling of the DN211 can cause electric shock, fire, failure, or/and

malfunction. Therefore, don't engage in the installation, wiring, operation, or maintenance of

the DN211 if your knowledge including electrical knowledge is not enough to handle control

equipment. Instead, ask the qualified person to do such work.

4. This instruction manual and accompanying documents are meant for those who have general

knowledge about the programmable controller and how to handle control equipment. If you

have any questions on the content of this manual, don't hesitate to contact the Toshiba dealer.

2

Page 4

Safety Precautions (continued)

[Warning indication]

This instruction manual has the following important indications and symbols to prevent bodily injury

and property damage during operation. Be familiar with these safety indications to follow during

operation. After reading the text, keep the manual aside to consult when necessary.

Description of Safety Signs

Indication Meaning

Indicates misuse of the handling could cause a

DANGER

CAUTION

fatal accident or serious injury.

Indicates misuse of the handling could cause

injury or material damage.

6 F 3 B 0 3 6 4

Injury means a hurt, burn, or electric shock, which requires neither hospitalization nor long-term

medical treatment by visits. Some of the CAUTION items, however, could bring about grave

consequences depending on the situation. So be sure to always follow the CAUTION instructions.

3

Page 5

Safety Precautions (continued)

•

Precaution for operation

DANGER

1. Configure an emergency-stop circuit, interlock circuit, and/or other similar safety

circuits outside the PC and DN211.

If the PC or DN211 gets failed or malfunctioned, it can cause an accident which will

lead to bodily injury and/or mechanical damage.

T2/T2E/T2N User’s Manuals

3. Preparation for Operation

(hardware)

CAUTION

2. Secure the safe environment before executing program modification, forcible output,

RUN, or HALT instruction during operation. An operational mistake can cause

mechanical damage or accident.

T2/T2E/T2N User’s Manuals

3. Preparation for Operation

(hardware)

6 F 3 B 0 3 6 4

•

DIP switch for setting the operating mode/communication rate

CAUTION

1. Set and keep "OSEN" on the DIP switch to OFF. Setting it to ON can get failed or

malfunctioned.

2. When you set "BUSOFF" on the DIP switch to OFF, transmission will restart

automatically even when busoff occurs. Unless the cause of the DN211's busoff

(cause of communication error) is solved, however, busoff may get repeated.

3. When you set both of communication rate DR0 and DR1 to ON and turn on the power

of the T2/T2E/T2N, "Communication Rate Setting Failed" will appear with the

following indications:

• The "MS" LED is blinking red.

• "F7" and the local station node address are being displayed alternately on the

7-segment LED.

To clear these indications, set DR0 and DR1 correctly and, issue a reset request or

turn OFF and ON the power.

4. Set the communication rates of your nodes being connected to the network, to the

same communication rate. Setting different communication rates on your

different nodes will cause slave devices or the DN211 to get malfunctioned,

resulting in no communication started.

Read the relevant manuals and descriptions to set the communication rate of your

slave devices.

5. Don't change over the communication rates while your T2/T2E/T2N is rising just after

the turning on power. In particular, never change the communication rate while

communicating with slave devices. Failing to do so will cause "Communication Rate

Setting Failed" to appear.

To clear this indication, set the DIP switch to the correct setting and, issue a reset

request or turn OFF and ON the power.

3.2.1 DIP Switch for Setting the Operation Mode/Communication Rate

4

Page 6

Safety Precautions (continued)

•

Rotary switch for setting the node address

CAUTION

1. When you set a value within 64 to 99 to the node address of your DN211 and turn ON

the power of your T2/T2E/T2N, "Node Address Setting Failed" will appear with the

following indications:

• The "MS" LED is blinking red.

• "F6" and the local station node address are being displayed alternately on the

7-segment LED.

To clear these indications, set the correct value to the node address and, issue a

reset request or turn OFF and ON the power.

2. If your DN211 node address has the same value with another node and when the

DN211 comes into run state, "Node Address Duplicated" will appear with the following

indications:

• The "MS" LED is lighting red and/or the "NS" LED is lighting red.

• "70" and the local station node address are being displayed alternately on the

7-segment LED.

6 F 3 B 0 3 6 4

To clear these indications, set the correct value to the node address and, issue a

reset request or turn OFF and ON the power.

3.2.2 Rotary Switch for Node Address Setting

•

Mounting in the base unit

CAUTION

1. Since the DN211 is designed for Toshiba's T2 series, be sure to mount your

DN211 in the base unit, instead of using it in stand-alone; don't use it for other

applications. Unauthorized applications can cause electric shock, bodily injury,

and/or mechanical malfunction.

2. Be sure to turn OFF the power (on the T2 side and network side) before attaching or

detaching the DN211 and/or the terminal block. Failing to do so will cause electric

shock, malfunction, and/or failure.

3. Keep the DN211 free from foreign matter such as electric-wire waste. Failing to do so

could cause fire, failure, and/or malfunction.

4. Check the connectors, cables, and base unit of the DN211, for their firm connection

and mounting using stoppers and screws. Note loose connection or mounting can be

shaky or easily disconnected off, resulting in failure or malfunction of the DN211.

3.3 Mounting in the Base Unit

5

Page 7

Safety Precautions (continued)

•

Connection with the network

CAUTION

1. Don't engage in attaching or detaching the DeviceNet cable with the network side

connector during network operation. Failing to do so can cause reverse connection

or short circuit of the network power, resulting in no communication with other nodes.

2. When you connect the DeviceNet cable with the network side connector, be sure not

to make the wrong connection. Failing to do so can cause short circuit of the network

power, resulting in no communication with other nodes.

3. Neither attach nor detach the network side connector with the device side connector

on the DN211 front panel while T2/T2E/T2N is rising just after the power is turned ON.

Failing to do so can cause the DN211 to fail or malfunction.

4. Attaching the opposite end of the network side connector with/from the device side

connector is not possible because of the specific form. Trying connecting the wrong

end by excessive force can damage both the network side connector and the device

side connector.

6 F 3 B 0 3 6 4

5. Be sure not to wire the cable in too tightly stretched state or in bent state.

Also, don't put heavy stuff on the cable. Otherwise, the cable could break.

6. Ask the qualified expert for the installation work of the DeviceNet cables because it

requires sufficient safety and noise-suppression measures. Refer to DeviceNet

Volume I, Release 1.3, for the standard installation.

3.4 Connection with the Network

6

Page 8

Safety Precautions (continued)

•

Turning ON/OFF the power of master/slave and the network

CAUTION

1. Be sure to turn ON the network power before turning ON the power of the DeviceNet

devices.

Some nodes of the slave devices use the network power as the operation power while

other slave devices indicate an error when their work power is not supplied.

Therefore, be sure to switch ON the network power. Also note unless the network

power is switched ON, your DN211 cannot start communication with slave devices.

2. Be sure the network power is supplied to all the nodes being connected with the

network. The node to which no network power is supplied could cause

communication obstacle to other nodes.

3. Make sure the power of all slave devices is switched ON before the DN211 begins

communication. When the DN211 begins communication while the power of a slave

device is not switched ON, the DN211 will display an error message of no response

from that device.

6 F 3 B 0 3 6 4

4. While network communications are operating, don’t shut OFF the network power.

Failing to do so will cause the entire network communications to stop and, one of the

nodes become busoff state.

5. Switch OFF the T2/T2E/T2N side power at last after the DN211 begins

communications. This helps the master device (DN211) to be recognized from the

network and prevents slave devices from malfunctioning.

3.5 The Network Power/Grounding

7

Page 9

Safety Precautions (continued)

Relating to the following sections:

•

How to handle your DN211 (software)

•

Examples of DN211 applications

•

RAS information

CAUTION

1. Chapter 4 describes the subjects necessary for using diverse functions of the DN211

from the T2/T2E/T2N. Chapter 5 describes, based on the subjects explained in

Chapter 4, setting the DN211 parameters, activating transmission,

inputting/outputting data with slave devices, and the procedure for reading RAS

information including event history, and sample programs.

Write programs after understanding the contents. As sample programs are basic,

you need to examine your programs from beginning to end before applying them to

actual systems.

6 F 3 B 0 3 6 4

4. How to Handle Your DN211 (software)

5. Examples of DN211 Applications

6. RAS Information (except RAS area on communication memory)

•

Allocation of slave device data to input/output data area

CAUTION

1. When a slave device has odd transmission/reception bytes in size, the actual size

plus 1 byte are allocated to the DN211 input/output area.

2. When you add a new slave device, enter a new value larger than the node addresses

of the present slave devices. For Figure 4.8, enter a value larger than "41" for the

node address of a new slave. If the node address of a new slave device is set to "18",

allocating data area of node addresses 20/30/40 will be shifted.

3. Don't change the input/output data size for slave devices (FLEX-I/O, etc.) which are

flexible in data allocation size. If changed, the slave devices with a node address

larger than that of the slave device changed data size will be shifted in their data

allocation.

4.4 Allocating Slave Device Data to the Input/Output Data Area

•

Operating mode of the T2/T2E/T2N and the DN211

CAUTION

1. If the T2/T2E/T2N turns into HALT/ERROR mode, the DN211 in run mode becomes

standby mode.

4.6.1 DN211 Operation Mode

5. Examples of DN211 Applications

8

Page 10

Safety Precautions (continued)

•

Action when your DN211 is reset

CAUTION

1. Neither issue a request from the T2/T2E/T2N to DN211 while the DN211 is being

reset nor execute data input/output. Otherwise, the instruction requested will be

completed abnormal (error of station mode abnormal), or the module self-check will

fail turning into down mode.

•

Setting slave device parameters

CAUTION

1. The parameter setting request (slave device) sets the parameters of slave devices

on to the non-volatile memory in the DN211. As long as the slave devices

configuration is unchanged, you don’t need to execute this request every time when

the power is switched ON. In addition, when the parameters of the slave device

requested and the parameters of the slave device in the non-volatile memory are

same, this setting request is not executed.

6 F 3 B 0 3 6 4

[4.6.2 Reset Request]

2. When the slave devices configuration needs to be changed, delete the salve devices

parameters using a reset request before setting new slave devices parameters.

3. The number of times available for setting slave devices parameters in the nonvolatile memory of the DN211 is 300 times.

4. The DN211 has the following restriction for transmitting "0 byte" to a slave device

from the DN211.

• When a slave device comes into no communication state with the DN211 due to

some reason (for example, the power of the slave device is OFF; the connector is

disconnected, etc.), the DN211 cannot recognize the slave device is abnormal.

Even after the cause of the failed communications is solved, the DN211 and the

slave device cannot communicate with each other.

Note: The above restriction of the present DN211 will be solved by a version-up of the

internal software.

4.6.4 Parameter Setting Request (slave device)

•

Installation environment and mounting in the base unit

CAUTION

1. Apply the environment specified in the User’s Manual of the T2/T2E/T2N.

When using your DN211 in the environment other than specified, the DN211 can

cause electric shock, fire, failure, and/or malfunction.

2. Mount your DN211 in the way specified in the User’s Manual of the T2/T2E/T2N.

If mounted in the direction other than specified or if mounted incorrectly, the DN211

could fall off, or cause fire, failure, and/or malfunction.

8.1 Installation Environment and Mounting in the Base Unit

9

Page 11

Safety Precautions (continued)

•

Mounting/removing the module

CAUTION

1. Since the DN211 is designed for the T2 series, be sure to attach it to the base unit.

Don't use your DN211 in stand-alone state or to other applications.

Failing to do so could cause electric shock, injury, and/or failure.

2. Be sure to turn OFF the power before mounting, removing, wiring, or un-wiring the

DN211. Failing to do so can cause electric shock, malfunction, and/or failure.

3. Keep your DN211 free from foreign matter such as electric-wire waste. Failing to do

so could cause fire, failure, and/or malfunction.

4. Check the connectors and cables and the DN211 mount in the base unit, for their firm

connections and mount using stoppers/screws. Loose connection and mounting

becomes shaky and disconnected, resulting in failure or malfunction.

8.2 Mounting/Removing the Module

6 F 3 B 0 3 6 4

•

Wiring the power and grounding

CAUTION

1. Be sure to turn OFF the power before wiring cables. Failing to do so could cause

electric shock.

2. Use crimp-on connectors with sheath or cover the conducting part with tape when

wiring your T2/T2E/T2N power module. Also, handle the terminal block cover

correctly to avoid fall-off and damage when fixing. Be sure to fix the cover on the

terminal block when completing the wiring. If the conducting part is exposed, you can

have electric shock.

3. Be sure to have grounding. When not grounded, electric shock and/or malfunction

can occur.

4. Make sure the wiring is correct when connecting the DeviceNet cables to the network

side connector. The short circuit of the network power, etc. can fail communication

with other nodes.

5. When you are going to detach or connect the network side connector to/from the

device side connector on the DN211 front panel, don't engage yourself while the

T2/T2E/T2N side power is rising. Failing to do so can cause the DN211 to fail or

malfunction.

6. Attaching the opposite end of the network side connector with/from the device side

connector is not possible because of the specific form. Trying connecting the wrong

end by excessive force can damage both the network side connector and the device

side connector.

7. Ask a qualified person to wire cables. Incorrect wiring can cause fire, failure, and/or

electric shock.

8.3 Power Unit Wiring/Grounding

10

Page 12

Safety Precautions (continued)

•

Basic caution in network Installation

CAUTION

1. Ask the qualified subcontractor for sufficient safety and noise-suppression

measures when installing the DeviceNet cable.

Refer to DeviceNet Volume I, Release1.3, for the standard installation.

2. It is recommended to consign a subcontractor specialized in safety measures and

standards.

3. Avoid the network components of the DeviceNet cable from being installed in a noisy

environment. When installing, be sure to furnish noise-suppression measures as

described in the following section.

•

Maintenance

6 F 3 B 0 3 6 4

8.4 Network Installation

CAUTION

1. Be sure to turn OFF the power mounting or removing the module, terminal block, and

cable. Failing to do so can cause electric shock, malfunction, and/or failure.

2. Carry out daily check, periodical check, and cleaning to keep the system in normal

condition.

3. If your DN211 does not operate normally, refer to "7. Troubleshooting" to identify the

cause of the trouble.

Contact a Toshiba's branch office (or dealer) or service agency for returning your

DN211 for repair when failed. Operation and safety of your DN211 can be

guaranteed only when repaired by Toshiba or a Toshiba's authorized service

agency.

4. Neither try to disassemble nor modify the hardware of the module. Similarly, don't

modify the software by any means. Failing to do so could cause fire, electric shock,

and/or injury due to failure or malfunctioning.

5. Make sure you are safe when measuring the voltage on the connector of the module.

Failing to do so could cause electric shock.

6. Stop the network and turn OFF the T2/T2E/T2N side power before replacing the

module.

Failing to do so could cause electric shock, malfunction, and/or failure.

7. Don't use your DN211 in abnormal condition such as smoking or nasty smelling.

Failing to do so could cause fire, electric shock, and/or failure.

If such an abnormal condition happens, turn OFF all the power supplies immediately

and contact a Toshiba branch office (or dealer) or authorized service agency.

Since it is very dangerous, don't engage yourself in modifying or repairing your

DN211 by any means.

Appendix (maintenance)

11

Page 13

Usage Recommendations

Usage Recommendation

This section puts together the knowledge and handling manners necessary for correct operation.

Read the section carefully and be familiar with equipment knowledge, safety information, and

notes.

•

Network cnfiguration

Usage Recommendation

1. Don't make a network configuration whose extended trunk line and drop lines have

no node being connected.

2. Don't attach a terminal resistor to the node. It could cause communication error.

3. Attach a terminal resistor to both ends of the trunk line; don't attach a terminal

resistor on the end of a drop line. Attach only to both ends of the trunk line.

1.2 Network Configuration of the DeviceNet

6 F 3 B 0 3 6 4

•

Switch setting

Usage Recommendation

1. Use a small minus screwdriver for changing the value of the DIP switch.

3.2.1 DIP Switch for Setting the Operation Mode/Communication Rate

Usage Recommendation

1. Use a small minus screwdriver for changing values of the rotary switch.

3.2.2 Rotary Switch for Node Address Setting

•

Connecting your DN211 with the network side connector

1. Loosen the cable fixing screws on the connector before inserting a cable into the

network side connector. The cable cannot be fixed when the screws are kept

tightened.

2. Colors corresponding to cable colors are printed by the device side connector of the

DN211. Match the cable colors with the printed colors to have correct wiring.

3. The DN211 and the DN311 (DeviceNet module for T3/T3H) have different directions

for attaching the network side connector.

4. DeviceNet cable, power tap, and device tap (connecting the trunk line with drop

lines) are necessary when constructing a system using a DeviceNet. Refer to "3.6

The Network Components" for detail.

Some of the network components must be prepared by the user.

5. When you use the network side connector that has the upper and lower rows with

holes for cables (at the left-side Figure 3.5), the connector protrudes from the leftside DN211 about 5mm. When you attach or detach the left-side module of DN211,

you must detach the connector from DN211.

3.4.2 Connecting Network Side Connector to the DN211

12

Page 14

Usage Recommendations (continued)

•

Network power configuration

Usage Recommendation

1. Consider not only current capacity of the trunk line but also current capacity of drop

lines when you install a node on a drop line.

2. In particular, when you are connecting nodes in daisy chain on a drop line, be careful

not to have insufficient current capacity.

3. Use a network power whose capacity is much larger than the total current

consumption necessary for the network.

3.5.2 How to Configure Network Power Units

•

Network power unit

Usage Recommendation

6 F 3 B 0 3 6 4

1. Use a network power whose capacity is much larger than the total current

consumption necessary for the network.

3.5.3 The Network Power Unit(24Vdc)

•

Registering your DN211 module

Usage Recommendation

1. When your DN211 is going to be I/O registered in the T2/T2E/T2N, leave blank for

the slot where the DN211 is installed.

After automatic allocation is performed, the DN211-installed slot is left blank.

4. How to Handle Your DN211 (software)

•

Node address of your DN211

Usage Recommendation

1. Set the node address of your DN211 to a value smaller than the node addresses of

slave devices(because of the feature of CAN currently used in the DeviceNet).

4.6.3 Parameter Setting Request (local node)

•

How to solve overrun errors

Usage Recommendation

1. Reduce the network communication speed when an overrun error occurs (500 kbps

-> 250 kbps -> 125 kbps).

7. Troubleshooting (Data Communication with Slave Devices)

13

Page 15

About This Manual

Thank you for purchasing Toshiba's programmable controller PROSEC-T2 series (T2/T2E/T2N).

This manual describes the specification, handing manners, and sample programs of the DeviceNet

module (called as the "DN211") used for PROSEC-T2 series. Read this manual to handle and

operate your DN211 correctly.

This manual consists of the following chapters:

Chapter 1: Overview of the DeviceNet Module

Outlines functions of the DN211, specification, and application systems, etc. Read this chapter to

know basic performances of the DN211.

Chapter 2: Names and Functions of DN211 Parts

Describes the names and functions of DN211 parts. Read this chapter carefully since important

information, required for hardware settings in the next chapter, is included in this chapter.

6 F 3 B 0 3 6 4

Chapter 3: Preparation for Operation (hardware)

Describes the hardware preparation and setting necessary for your DN211 operation.

Chapter 4: How to Handle Your DN211 (software)

Explains accessing the DN211 from the T2/T2E/T2N and software settings.

Chapter 5: Examples of DN211 Applications

Describes sample programs of handling the DN/211 explained in Chapter 4.

Chapter 6: RAS Information (except RAS area on communication memory)

Describes the formats and contents of RAS information on the DN211 (except for RAS area on

communication memory).

Chapter 7: Troubleshooting

Explains possible causes and solutions when your DN211 malfunctions.

Chapter 8: Installation/Wiring Work

Explains how to install your DN211 and T2/T2E/T2N, how to wire transmission cables, and how to

arrange other preparation work.

Appendix

Describes the maintenance and check items and the execution time of READ/WRITE instructions

of the T2/T2E/T2N.

14

Page 16

6 F 3 B 0 3 6 4

In addition to this instruction manual, the following descriptions about the T2/T2E/T2N, instruction

words, programmer, and computer link procedure transmission are also prepared for your reading.

• T2 User’s Manual Basic Hardware and Function (UM-TS02***-E001)

Describes hardware (basic unit, basic I/O) and the main unit functions of the T2.

• T2E User’s Manual Basic Hardware and Function (UM-TS02E**-E001)

Describes hardware (basic unit, basic I/O) and the main unit function of the T2E.

• T2E User’s Manual Enhanced Communication Function(UM-TS02E**-E003)

Describes the functions and how to handle the optional communication card for the T2E.

• T2N User’s Manual Basic Hardware and Function (UM-TS02N**-E001)

Describes hardware (basic unit, basic I/O) and the main unit functions of the T2E.

• Instruction Manual TOSLINE-S20LP T2N/T3H Stations (6F3B0356)

Describes the system configuration of the T2N built-in data link system "TOSLINE-S20LP"

and its device configuration, and the functions, performances, and handling of "TOSLINES20LP."

• Built-in Ethernet Module for T2N (PU235N/245N) Instruction Manual (6F3B0362)

Describes the Ethernet built-in T2N and the handling.

• T-Series Instruction Set (UM-TS03***-E004)

Explains a detailed specification of instruction words about the ladder diagram and SFC

programming languages, which are supported by Toshiba's T-series.

• T-Series Computer Link Operation Manual (UM-TS03***-E008)

Describes the specification and operating manners for the computer link function built in

Toshiba's T-series CPU.

Registered Trademarks:

n DeviceNet is a registered trademark of ODVA (Open DeviceNet Vendor Association).

n PowerTap, T-Port Tap, DeviceBox Tap, and FLEX I/0 are registered trademarks of RockWell

Automation Co., Ltd.

n COMBICON is a registered trademark of Phoenix Contact Corporation.

15

Page 17

Contents

1. Overview of The DeviceNet Module ..................................................................19

1.1 Features and System Configuration Examples of the DeviceNet Module (DN211)19

1.2 Network Configuration of DeviceNet..................................................................21

1.3 Conformity Specification and Trademarks .........................................................25

1.4 The Basic Functions ...........................................................................................26

1.5 The DN211 Specification ....................................................................................30

6 F 3 B 0 3 6 4

1.2.1 The Network Configuration .......................................................................21

1.2.2 Trunk Line/Drop Line and Maximum Cable Length...................................22

1.2.3 The Terminal Resistor ..............................................................................24

1.4.1 The Polling Instruction/Response Mode...................................................26

1.4.2 The Bit Strobe Instruction/Response Mode..............................................27

1.4.3 Synchronization/Asynchronous Mode and Data Update Cycle .................28

1.5.1 The Function Specification .......................................................................30

1.5.2 Number of Mounting Modules ...................................................................31

2. Names and Functions of DN211 Parts.............................................................33

2.1 Outer Dimensions and Sizes ..............................................................................33

2.2 Names of DN211 Parts........................................................................................34

2.3 Functions of DN211 Parts....................................................................................36

3. Preparation for Operation (hardware)...............................................................38

3.1 DN211 Setting Flowchart (hardware)..................................................................38

3.2 Switch Setting ....................................................................................................39

3.2.1 DIP Switch for Setting the Operation Mode/Communication Rate .............39

3.2.2 Rotary Switch for Node Address Setting ...................................................41

3.3 Mounting in the Base Unit ..................................................................................42

3.4 Connection with the Network.............................................................................43

3.4.1 Connecting DeviceNet Cables to Network Side Connectors.....................44

3.4.2 Connecting the Network Side Connector to the DN211............................45

3.5 The Network Power/Grounding ..........................................................................47

3.5.1 The Network Power Mechanism................................................................47

3.5.2 How to Configure Network Power Units .....................................................48

3.5.3 The Network Power Unit (24 Vdc) .............................................................54

3.5.4 The Network Grounding ...........................................................................55

3.5.5 Procedure for Switching-ON/Shutting-OFF the Power ..............................56

3.6 The Network Components.................................................................................57

4. How to Handle Your DN211 (software).............................................................60

4.1 Configuration of the DN211 Communication Memory .........................................61

4.2 The Input/Output Data Area................................................................................62

4.3 The RAS Information Area .................................................................................66

16

Page 18

6 F 3 B 0 3 6 4

4.4 Allocating Slave Device Data to the Input/Output Data Area..............................75

4.5 The Semaphore Area .........................................................................................76

4.6 Requests to the DN211 ........................................................................................79

4.6.1 The DN211 Operation Modes...................................................................80

4.6.2 Reset Request .........................................................................................81

4.6.3 Parameter Setting Request (local node) ..................................................82

4.6.4 Parameter Setting Request (slave device)...............................................85

4.6.5 Operation Mode Control Request.............................................................88

4.6.6 RAS Information Read Request................................................................89

4.6.7 Time Setting Request ...............................................................................90

4.7 Completion Status..............................................................................................91

5. Example of DN211 Applications.........................................................................92

5.1 The DN211 Operation Order...............................................................................92

5.2 Module Setting Procedure .................................................................................93

5.2.1 Accessing the DN211 in Module Setting ...................................................94

5.2.2 Configuration of a Module Setting Sample Program.................................96

5.2.3 Reset Request .........................................................................................97

5.2.4 Parameter Setting Request (local node) ..................................................99

5.2.5 Parameter Setting Request (slave device).............................................100

5.2.6 Operation Mode Control Request...........................................................106

5.2.7 RAS Information Read ............................................................................111

5.2.8 Time Setting Request .............................................................................114

5.3 Slave Data Input/Output................................................................................... 116

5.3.1 Slave Device Check ...............................................................................116

5.3.2 Asynchronous Mode Data Input/Output..................................................117

5.3.3 Synchronous Mode Data Input/Output ...................................................122

6. RAS Information (except RAS area on communication memory)..........129

6.1 Module Status / Network Status LED (MS/NS)................................................... 130

6.2 Indications of the 7-Segment LED ....................................................................131

6.3 RAS Information Reading Data ........................................................................ 133

6.3.1 The RAS Counter ...................................................................................133

6.3.2 Event History..........................................................................................136

6.3.3 Execution Node Information ....................................................................139

7. Troubleshooting..................................................................................................141

7.1 When Starting up the Module .......................................................................... 141

7.2 Reset Request (scan list clear).......................................................................... 142

7.3 When the Module Doesn't Become Run Mode ................................................. 143

7.4 Data Communication with Slave Devices......................................................... 146

17

Page 19

6 F 3 B 0 3 6 4

8. Installation/Wiring Work.....................................................................................148

8.1 Installation Environment and Mounting in the Base Unit.................................. 148

8.2 Mounting/Removing the Module ...................................................................... 148

8.3 Power Unit Wiring/Grounding.......................................................................... 149

8.3.1 Power Unit Wiring...................................................................................149

8.3.2 Grounding..............................................................................................149

8.4 Network Installation ......................................................................................... 150

8.4.1 Installation Gists Outside the Board .......................................................150

8.4.2 Installation Gists Inside the Board ..........................................................153

Appendix

Appendix 1 Maintenance and Inspection......................................................154

Appendix 2 READ/WRITE Instruction Execution Time ..................................156

Appendix 3 DN211A ..……….………………………………………………………...157

18

Page 20

6 F 3 B 0 3 6 4

1. Overview of the DeviceNet Module

1.1 Features and System Configuration Examples of the DeviceNet Module (DN211)

This section describes the features and system configuration examples of the DeviceNet module

(DN211) for the programmable controller PROSEC-T2 series (T2/T2E/T2N). The DN211 is an

interface module for connecting the DeviceNet, which is a device level network for FA, to the

PROSEC-T2 series.

Hereafter, the programmable controllers PROSEC−T2, PROSEC-T2E, and PROSEC-T2N are

respectively called the "T2", "T2E", and "T2N". Likewise, the DeviceNet module for the T2 series

is also called the "DN211."

(1) Conformed with DeviceNet

DeviceNet is a standardized device level network for factory automation(FA), developed by

RockWell Automation Co. in USA. A nonprofit organization, called ODVA (Open DeviceNet

Vendor Association), is serving as the center for the maintenance/extension of the DeviceNet

specification and for conformable products introduction.

The DN211, functioning as the master (parent station) device on a DeviceNet, performs data

input/output between the master device and the DeviceNet slave (child station) devices, which are

developed by different makers (vendors) in and outside Japan and conform with the DeviceNet, to

interface such slave devices with the T2/T2E/T2N .

(2) Input/Output Data Size, Number of Slave Devices, communication Rate and Network

Length

A DN211 allows a DeviceNet to have one network to be connected. The sizes of inputting and

outputting data, allowed between a DN211 and slave devices are 128 words for input and 128

words for output (one word = 16 points).

Input data and output data, so far as each of them is within 128 words in total, can be exchanged

data with up to 63 slave devices. (Since the amount of data outputted to a slave device and the

amount of data inputted from a slave device vary depending on the slave device, check the slave

device specification of data size).

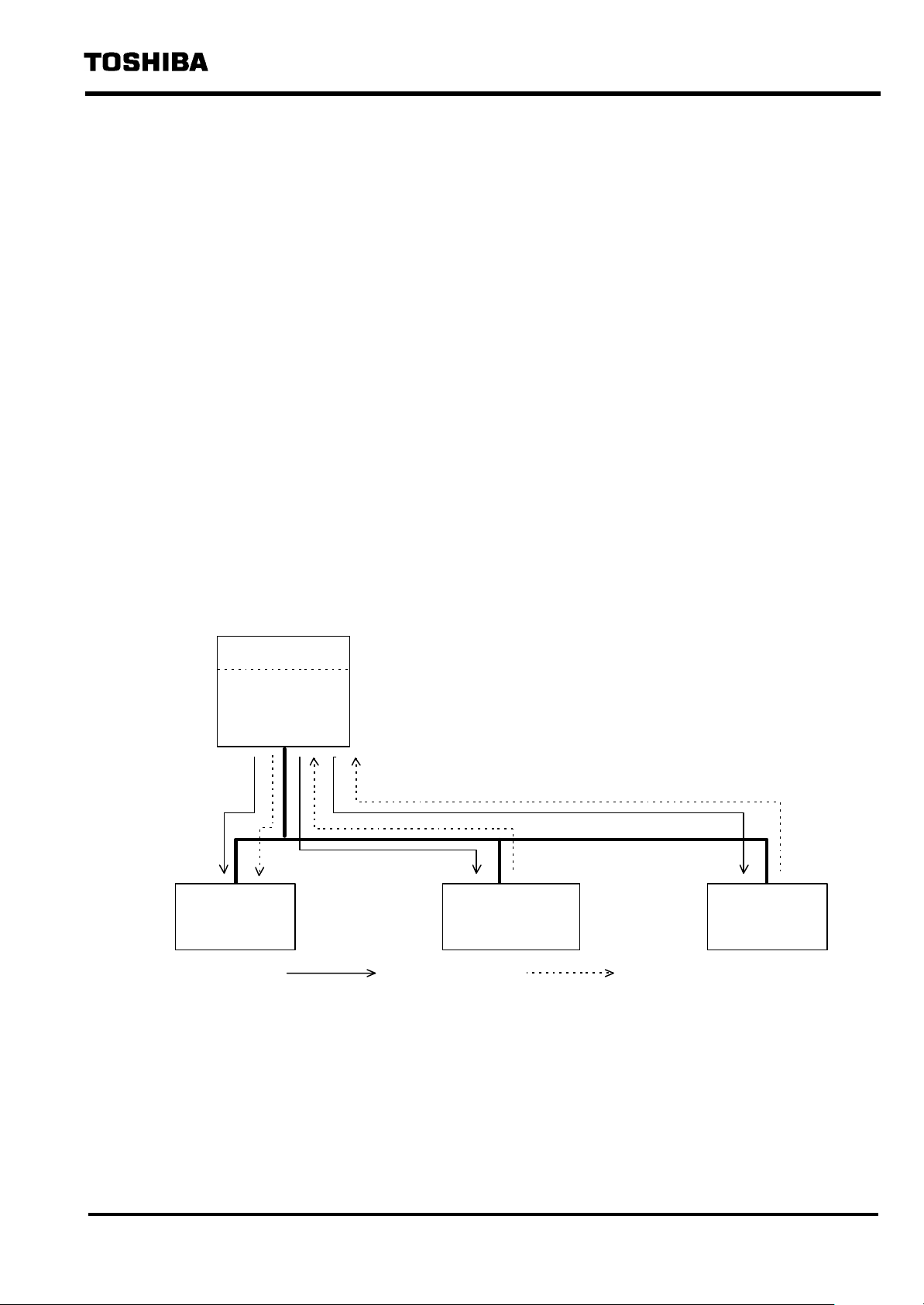

The definition of input data and output data, dealt in this book, is shown in the following figures.

Output data : T2/T2E/T2N → DN211 → Slave device

Input data : T2/T2E/T2N ← DN211 ← Slave device

Figure 1.1 Definition of Output Data and Input Data

Three types of communication rates, namely 500 kbps, 250 kbps and 125 kbps are available. The

maximum network length varies depending on the communication rate (l00 m for 500 kbps, 250 m

for 250 kbps, and 500 m for 125 kbps).

The detail is explained in "1.2 Network Configuration of DeviceNet."

19

Page 21

(3) Means of Inputting/Outputting Data

1

Input/Output

Input/Output

Input/Output

The DN211 supports "polling instruction/response" and "bit strobe instruction/response," both of

which are specified in the DeviceNet specification as the means of inputting/outputting data

to/from slave devices. The details of "polling instruction/response" and " bit strobe

instruction/response" are explained in "1.4 The Basic Functions."

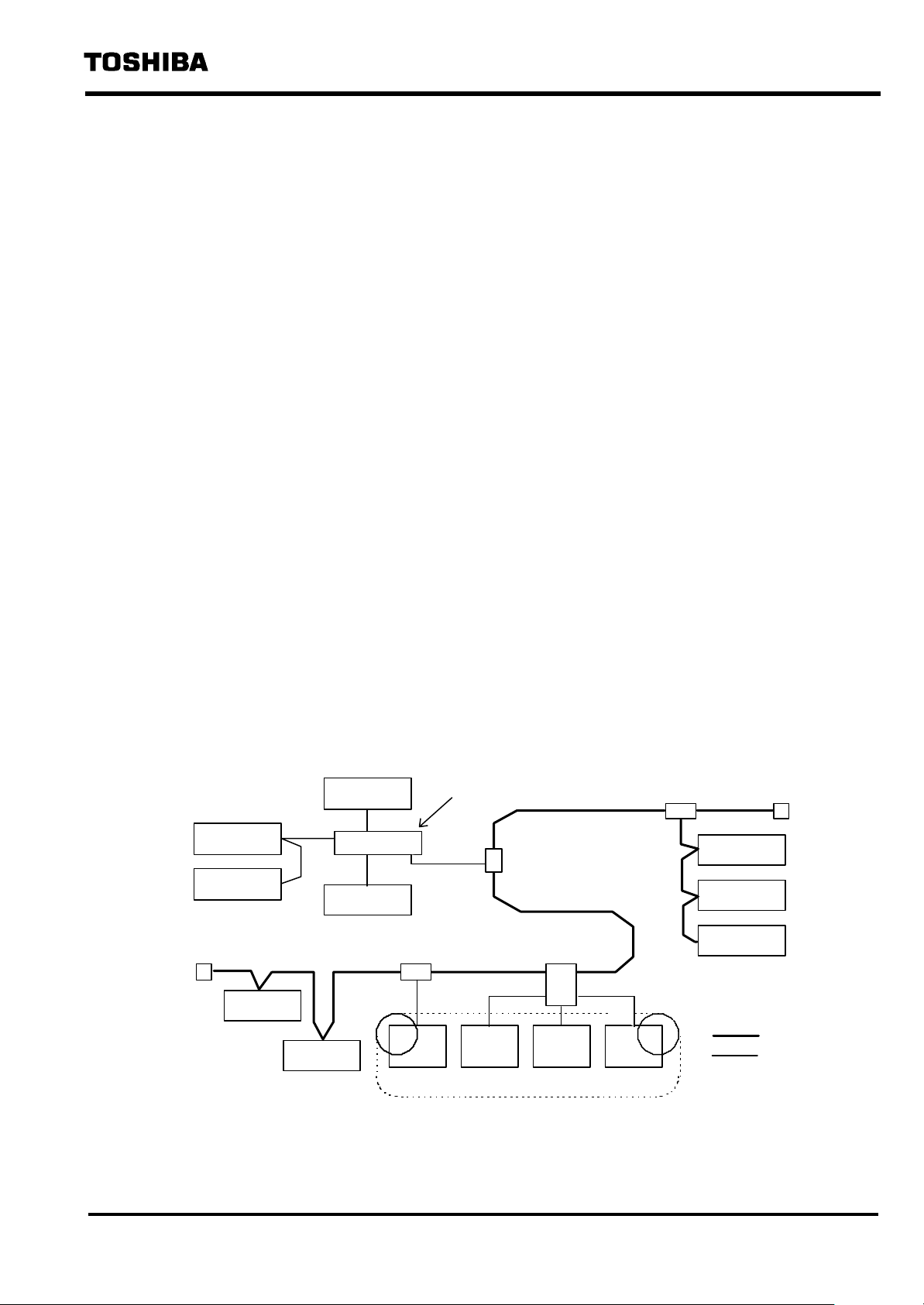

(4) Examples of the System Configuration

This section describes a typical system configuration using the DN211, which is mounted on the

I/O slot of the T2/T2E/T2N. The DN211 allows the T2/T2E/T2N to exchange data with slave

devices on the DeviceNet.

In the following example, the DN211 is connected with slave devices, such as input/output devices,

sensor, and drive unit, which conforms with the DeviceNet specification. Moreover, a Toshiba's

original control LAN (TOSLINE-S20) is used to connect the T2/T2E/T2N with a higher-rank

controller.

A number of wiring combinations meeting the installation environment are available because the T

branch topology and the multi-drop topology are combinable when wiring a DeviceNet.

High-rank computer

T2N: PROSEC − T2N

T2E: PROSEC − T2E

S20: TOSLINE − S20

6 F 3 B 0 3 6 4

S

T

2

2

0

E

DeviceNet

device

Input/Output device

Sensor

Ethernet

TOSLINE−S20

D

T

2

N

D

N

N

2

2

1

1

1

DeviceNet

device

Sensor

Drive unitDrive unit

Sensor

device

Figure 1.2 Example of the System Configuration

20

Page 22

1.2 Network Configuration of DeviceNet

Terminal

resistor

Terminal

resistor

This section describes the network configuration of the DeviceNet.

1.2.1 The Network Configuration

The network configuration of a DeviceNet consists of a trunk line and drop lines as shown in Figure

1.3.

(1) The Nodes

The nodes of the DeviceNet in Figure 1.3 have slave devices such as input/output devices, sensors,

and drive units, and a master device such as the DN211, to exchange data with each other. One

network can have up to 64 nodes and one master device. Physical arrangement of a master device

and slave devices has no particular restrictions.

Each of the DeviceNet devices on a network has a unique number (NA: node address) to identify

the node from the other nodes. The node address values must be within 0 to 63 in decimal scale,

and the node addresses in the network must be different from the others.

(2) The Trunk Line

According to the DeviceNet specification, a trunk line is a cable which connects nodes located

most distant. The trunk line can have nodes directly-connected with it (connection with no drop

line). The length of the trunk line varies depending on the communication rate of the network. The

both ends of the trunk line need a terminal resistor.

6 F 3 B 0 3 6 4

(3) The Drop Line

All the cables branched from taps on the trunk line fall on drop lines. The drop line has a maximum

length of 6 meters (from tap to most distant node) regardless of the communication rate on the

network (The total extension of drop lines varies depending on the communication rate on the

network). A drop line can have one or more nodes connected. The following three types of node

configurations are available, as shown in Figure 1.3.

a) Configuration of drop lines short from the tap/multiport tap

b) Configuration of multidrops on a drop line

c) Configuration of branches on a drop line (no branch configuration for the trunk line)

Branch configuration

Node 35

Node 30

Node 0

Node 45

Node 40

Multiport tap

Tap

Tap Multiport tap

Tap

Node 50

Node 55

Node 60

Multidrop

configuration

No drop line

Node

25

Node 5

Node

10

Node

15

Short drop line configuration

Node

20

Figure 1.3 Example of DeviceNet Network Configuration

21

Trunk line

Drop line

Page 23

1.2.2 Trunk Line/Drop Line and Maximum Cable Length

Terminal

resistor

Short drop line configuration

Terminal

resistor

The DeviceNet specification stipulates the Thick Cable and the Thin Cable. For detail, see

DeviceNet Volume I. Currently, cables conforming with the standards of the Thick Cable and Thin

Cable are available in the commercial market. Buy ones which meet the configuration of your

network (Details are explained in "3.6 The Network Components").

(1) The Trunk Line

The trunk line of a DeviceNet consists of a Thick Cable or a Thin Cable (their mixture is also

possible). Since the Thin Cable is flexible compared with the Thick Cable, wiring the cable is easy.

Conversely, the Thick Cable allows longer network cabling than the Thin Cable. A maximum of the

trunk line length varies depending on the type of cable used and the communication rate on the

network. For details, see "3 The Maximum Network Length."

(2) The Drop Line

The drop lines of a DeviceNet consists of Thin Cables. Table 1.1 lists the length of drop lines and

the total length. A node on a drop line can be configured in a short drop line configuration/multidrops configuration/short brunch configuration. Figure 1.4 shows how to calculate the drop line

length and the total length by different configurations.

Table 1.1 Maximum Drop Line Length

6 F 3 B 0 3 6 4

Communication

Rate

125 kbps 156 meters

250 kbps 6 meters 78 meters

500 kbps 39 meters

Branch configuration

Node 35

Node 30

Node 0

Node 45

i

Node 5

Node 40

Drop Line Total Extension by Network

Multiport tap

g

f

h

Tap Multiport tap

a

Node

10

Node

15

Tap

b

Node

20

e

d

c

Node

25

Tap

Node 50

Node 55

Node 60

Multidrop

configuration

Individual drop line length: a ≤ 6 m, b ≤ 6 m, c ≤ 6 m, and d ≤ 6 m (short drop line configuration)

e ≤ 6 m (multi-drops configuration)

f + g ≤ 6 m, f + h ≤ 6 m, f + i ≤ 6 m (branch configuration)

Total of drop lines extended : a + b + c + d + e + f + g + h + i

Figure 1.4 Example of Calculating the Drop Line Length

22

Page 24

(3) The Maximum Cable Length

Terminal

Terminal

Terminal

Terminal

The distance between two nodes on the network cannot exceed the "Maximum cable length"

specified in the DeviceNet specification. In Figure 1.4, the distance from node 0 to node 60 is not

allowed to exceed the "Maximum cable length."

The "Maximum cable length" varies depending on the communication rate of the

network and the type of the cable used for the trunk line.

a) Table 1. 2 lists the maximum cable length for the case that the trunk line consists of a Thick

Cable alone and no drop line is connected on it (that is, all nodes are connected on the trunk line),

as shown in Figure 1.5. In this case, "maximum trunk line length between node 0 and node n" =

"maximum cable length."

Moreover, when the "maximum trunk line length between node 0 and node n" = "maximum

cable length," no new node can be attached outside node 0 and node n..

6 F 3 B 0 3 6 4

resistor

Figure 1.5 Distance Between Two Nodes on a Network With No Drop Line

Table 1.2 Maximum Cable Length (Thick Cable/Thin Cable alone)

Communication

Rate

125 kbps 500 m 100 m

250 kbps 250 m 100 m

500 kbps 100 m 100 m

Distance between two nodes ≤ Maximum cable length

• • • • • • • • •

Thick Cable

alone

Thin Cable alone

Node nNode 3Node 2Node 0

resistor

b) Figure 1.6 shows the maximum distance between two nodes in the case that a Thick Cable

or Thin Cable alone is used for the trunk line and that drop lines are used.

Table 1.2. lists the maximum cable length. In this case, the "maximum trunk line length

between two nodes" is as follows:

Maximum trunk line length between two nodes

= Maximum cable length

(value in Table 1.2)

− Total length of drop lines for both ends nodes of trunk line

For Figure 1.6, the maximum trunk line length between node 0 and node n is equal to the

maximum cable length (value in Table 1.2) minus total length of drop lines for node 0 and

node n.

resistor

Node 0

Distance between two nodes ≤ Maximum cable length

Node 3Node 2

23

• • • • • • • • •

Node n

resistor

Page 25

6 F 3 B 0 3 6 4

Figure 1.6 Distance Between Two Nodes on a Network with Drop Lines

24

Page 26

6 F 3 B 0 3 6 4

Terminal

Terminal

c) Figure 1.7 shows the maximum distance between two nodes in the case that the trunk line

consists of Thick Cable and Thin Cables and that drop lines are connected. Use the formulas in

Table 1.3. for calculating the maximum cable length.

In this case, the "maximum trunk line length between two nodes" is represented in the

following formula:

Maximum trunk line length between two nodes

= Maximum cable length (value in Table 1.3)

− Total length of drop lines for the nodes at

both ends of trunk line

For Figure 1.7, the maximum trunk line length between node 0 and node n is equal to the

maximum cable length (value in Table 1.3) minus the total length of the drop lines for node 0 and

node n.

Distance between two nodes ≤ Maximum cable length

resistor

Figure 1.7 Distance Between Two Nodes on a Network with Drop Lines

Table 1.3 Maximum Cable Length (Mixture of Thick Cable/Thin Cable)

Communication

Rate

125 kbps L-thick + 5 × L-thin ≤ 500 m

250 kbps L-thick + 2.5 × L-thin ≤ 250 m

500 kbps L-thick + L-thin ≤ 100 m

L-thin: Length of trunk line using thin cable (m)

L-thick: Length of trunk line using thick cable (m)

1.2.3 The Terminal Resistor

The DeviceNet needs a terminal resistor on both ends of the trunk line in order to reduce signal

reflections and stabilize communications. The specifications of the terminal resistor are as follows:

L-thin L-thick

• • • • • • • • •• • • • • • • • •

Calculation Formula

resistor

Node nNode 3Node 0

• 121Ω

• 1% of the metal film

• 1/4 W

Terminal resistors conforming with the above specifications are available in the commercial market.

See "3 .6 The Network Components."

Usage Recommendation

1. Don't make a network configuration whose extended trunk line and drop lines have no node

being connected.

2. Don't attach a terminal resistor to the node. It could cause communication error.

3. Attach a terminal resistor to both ends of the trunk line; don't attach a terminal resistor on the

25

Page 27

end of a drop line. Attach only to both ends of the trunk line.

6 F 3 B 0 3 6 4

26

Page 28

1.3 Conformity Specification and Trademarks

DeviceNet is a standardized device level network for factory automation (FA), which is developed

by RockWell Automation Co., Ltd. in USA. Currently, a nonprofit organization called ODVA

(Open DeviceNet Vendor Association) is serving as the center for the maintenance and extensions

of DeviceNet and introduction of conformable products.

The DeviceNet specification has Volume I: DeviceNet Communication Model and Protocol, and

Volume II: DeviceNet Device Profiles and Object Library, in which the hardware and software

specifications are defined.

The DeviceNet specification that the DN211 conforms with is found in Volume I, Release 1.3, and

Volume II, Release 1.2.

Trademarks:

n DeviceNet is a registered trademark of ODVA (Open DeviceNet Vendor Association).

n PowerTap, T-Port Tap, DeviceBox Tap, and FLEX I/0 are registered trademarks of RockWell

Automation Co., Ltd.

6 F 3 B 0 3 6 4

n COMBICON is a registered trademark of Phoenix Contact Corporation.

27

Page 29

1.4 The Basic Functions

Node identification number that individual DeviceNet

devices have in the DeviceNet network. The values

This section describes the following two functions for communicating between the DN211 and

slave devices.

1) Polling instruction/response mode

2) Bit strobe instruction/response mode

1.4.1 The Polling Instruction/Response Mode

The polling instruction/response mode is used for exchanging an arbitrary size of data between the

master device ⇔ slave devices. The master device has information on slaves devices (items of

scan list, such as node address, input/output data volume, etc.) on the network.

For polling instructions, based on such information, the master device outputs an arbitrary size of

data to slave devices. Slave devices transmit response data (arbitrary data size) to a polling

instruction to the master device (polling response).

It depends on the specification of a slave device how the slave device interprets the polling

instruction and what data the slave device transmits as the polling response. For this

communication function, it is prerequisite that the slave device supports the polling

instruction/response mode. (Almost all the slave devices on the DeviceNet support this

communication system).

6 F 3 B 0 3 6 4

(1) The Polling Instruction

The example in Figure 1.8 indicates the DN211 is polling sensors, inputting sensor input information,

and trying to send output control data to the actuator. How to write polling output data to the

DN211 from the T2/T2E/T2N is found in "5. Communication with Slave Devices."

T2/T2E/T2N

Master

DN211

NA = 1

Slave 1

Proximity sensor

NA = 19

NA (Node Address):

range from 0 to 63 in decimal scale.

In the DeviceNet network, the node addresses of the

devices must be unique and different from each other.

Slave 3

Optoelectronic sensor

NA = 22

Polling responsePolling instruction /

Slave 5

Actuator

NA = 52

Figure 1.8 Example of Polling Instruction/Response Mode

(2) The Polling Response

A slave device which received a polling instruction transmits an arbitrary size of response data to

the master device. The content of response data varies depending on the specification of the slave

device. The mechanism the T2/T2E/T2N reads polling response data from the DN211 is explained

in"5. Communication with Slave Devices."

28

Page 30

1.4.2 The Bit Strobe Instruction/Response Mode

NA = 23

NA = 22

The bit strobe instruction/response mode is used for exchanging a small size of data between the

master device ⇔ slave devices. In the bit strobe instruction, based on the information obtained

from the scan list, the master device broadcasts 1-bit output data to individual slave devices.

These individual devices transmit data (0-8 bytes) in response to the bit strobe instruction to the

master device (bit strobe response).

It depends on the specification of a slave device how the salve device interprets a bit strobe

instruction and what data the slave device transmits to the bit strobe response.

For this communication function, it is prerequisite that the slave device supports the bit strobe

instruction/response mode.

(1) The Bit Strobe Instruction

Broadcasts data to bit strobe instruction/response mode supporting slave devices on the network.

The bit strobe instruction contains 64-bit output data, and each of the 64 bits is assigned to

individual node addresses on the network (Figure 1. 9).

The example in Figure 1.9 indicates the DN211 is inputting sensor information by the bit strobe

mode and trying to send output control data to the actuator. The way of writing output data in bit

strobe from the T2/T2E/T2N to the DN211 is explained in "5. Communication with Salve Devices."

6 F 3 B 0 3 6 4

T2/T2E/T2N

Master

DN211

NA = 1

Slave 1

Proximity sensor

NA = 19

Slave 2

Proximity sensor

NA = 21

Figure 1.9 Example of the Bit Strobe Instruction/Response Mode

(2) The Bit Strobe Response

Slave 3

Photoelectric

sensor

Bit strobe instruction data

Bit number

Slave 4

Photoelectric

sensor

Bit strobe responseBit strobe instruction /

Slave 5

Actuator

NA = 52

• • • •• • • •• • • •

6351 5219 20 21 22 23 240 1

A slave device which received the bit strobe instruction transmits 0 to 8 byte response data to the

master device. The contents of response data varies depending on the specification of the slave

device. The way the T2/T2E/T2N reads bit-strobe response data from the DN211 is described in

"5. Communication with Slave Devices."

29

Page 31

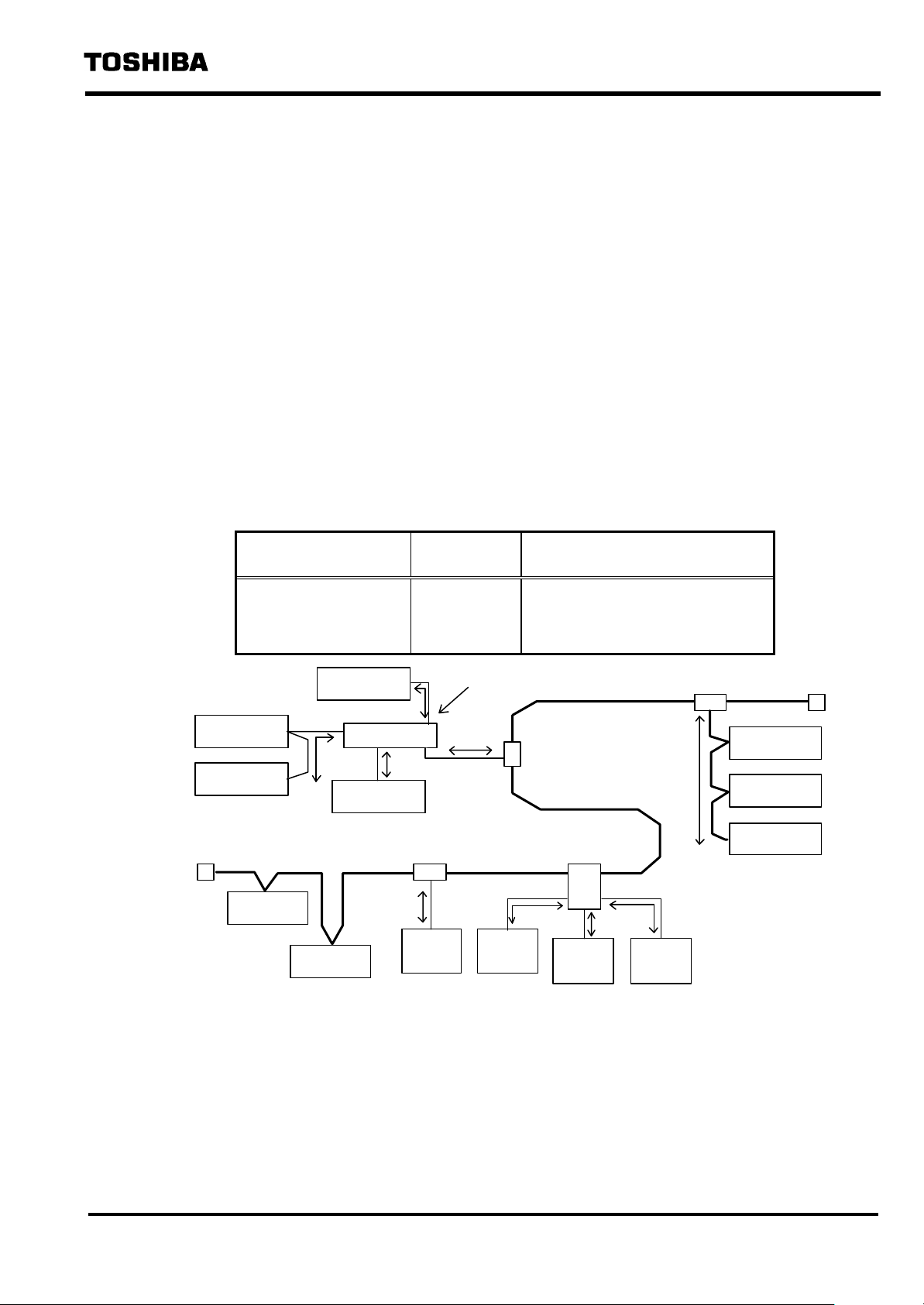

1.4.3 Synchronization/Asynchronous Mode and Data Update Cycle

data

T2N

As explained in the preceding section, the communication function between the DN211 and slave

devices has the polling instruction/response mode and the bit strobe instruction/response mode.

Data can be exchanged between the T2/T2E/T2N and the DN211 in synchronous mode or

asynchronous mode. This section describes the synchronous mode/asynchronous mode.

(1) The synchronous mode

At output: The T2/T2E/T2N writes output data to slave devices into the DN211 beforehand, and

activates a polling instruction/bit strobe instruction. When the polling instruction/bit

strobe instruction is activated, the DN211 sends the output data to slave devices.

At input: The DN211 receives data from slave devices by a polling response/bit strobe response.

After having received data from all slave devices, the DN211 arranges input data

before notifying the input completion to the T2/T2E/T2N. If the T2/T2E/T2N is reading

input data, it will check for the input completion by the DN211 before reading the input

data.

T2/T2E/T2N Data Update Cycle

6 F 3 B 0 3 6 4

T2/

TE2/

DN211

Slave

Output

Input

data

Output

instruction

Output

processing

Response Response

Input

completion

Iutput

processing

Output

data

Output

instruction

Output

processing

Input

completion

Intput

processing

Output data and input data exchanged between the T2/T2E/T2N ⇔ the DN211 are

synchronizing with the output/input cycles of the T2/T2E/T2N side program. For this reason, the

size of synchronous data value is equal to one-time output/input data to all slave devices.

30

Page 32

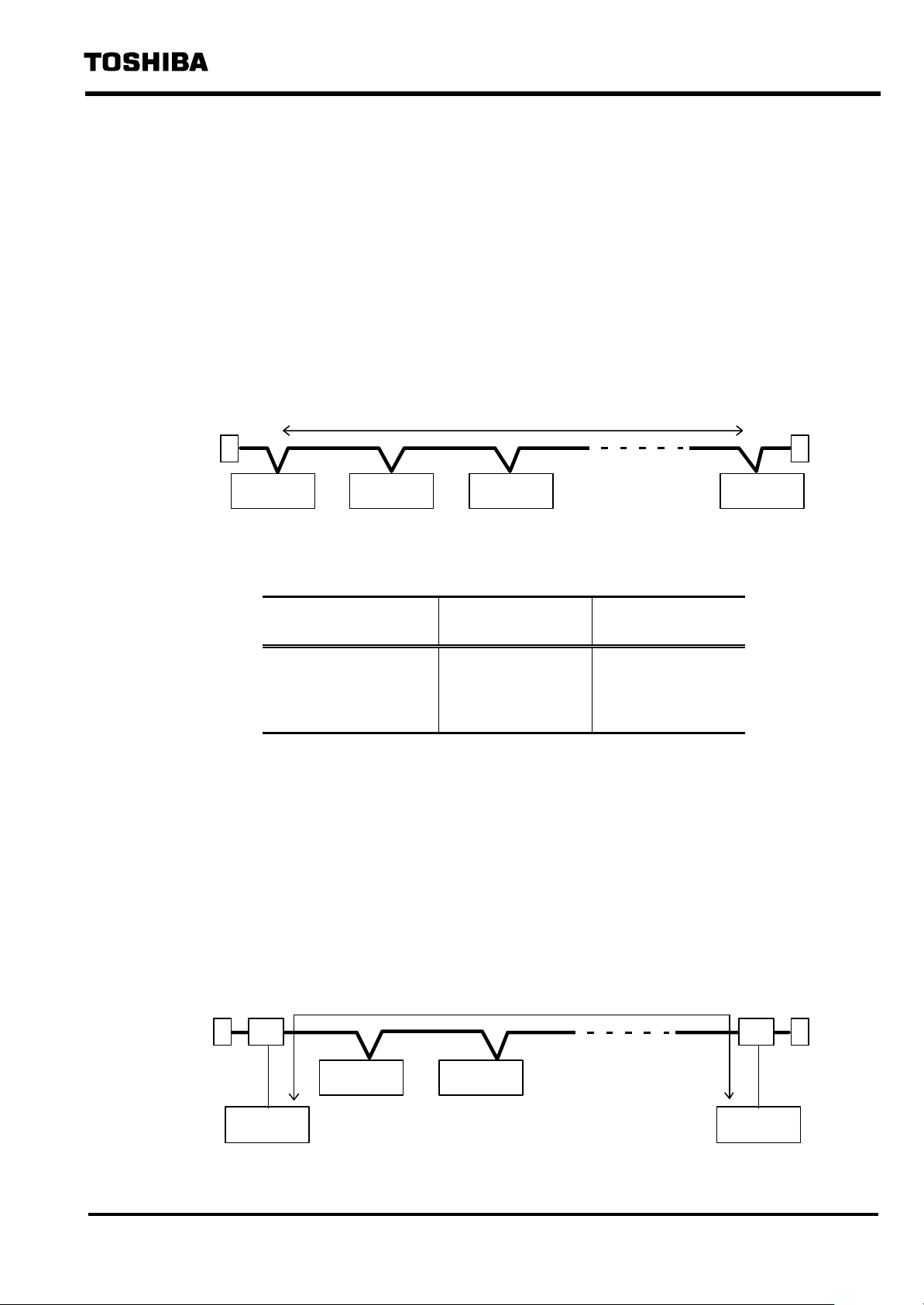

(2) The asynchronous mode

T2N

data

At output: The T2/T2E/T2N writes output data to slave devices into the DN211. Disregarding the

timing of the T2/T2E/T2N's output data writing, the DN211 sends, by the scanning

cycle at the local station, written output data to a slave device. Unless output data is

updated by the T2/T2E/T2N, the DN211 sends the same data to slave devices.

At input: The DN211 receives data from slave devices by a polling response/bit strobe response.

After having received data from all slave devices, the DN211 updates input data. The

DN211 doesn't notify the completion of the data reception to the T2/T2E/T2N.

Disregarding the timing of input data update by the DN211, the T2/T2E/T2N reads

input data.

T2/T2E/T2N Data Update Cycle

T2/

T2E/

Output

Input

data

DN211 scan

6 F 3 B 0 3 6 4

Output

data

DN211

Slave

Output

processing

Response

Iutput

processing

Output

processing

Response

Intput

processing

Outpu

processing

Response

Intput

processing

Outpu

processing

Transfer of output data and input data between the T2/T2E/T2N ⇔ the DN211 and the transfer

between the DN211 ⇔ slave devices are asynchronous. Transfer between the T2/T2E/T2N ⇔

the DN211 are synchronizes with the scan cycle by the T2/T2E/T2N side, while the transfer

between the DN211 ⇔ slave devices are synchronizes with the scan cycle in the DN211.

Although data are secured by the byte (8 bits), the sequence program is simplified for data transfer

processing, compared with the synchronous mode. When the scan cycle by the DN211 side is

shorter than the scan cycle by the T2/T2E/T2N, delay of data update time between the

T2/T2E/T2N ⇔ slave devices becomes smaller.

The scan time by the DN211 varies depending on the number of slave devices being connected,

size of transmission data by the slave device, and the performances of the slave device being

connected.

31

Page 33

1.5 The DN211 Specification

1.5.1 The Function Specification

Table 1.4 lists the function specification of the DN211. The general specification of the DN211

conforms with the T2/T2E/T2N main unit.

Table 1.4 Function Specification

Item Specification

Module form (pet name) DN211

Transmission specification Conformed with the DeviceNet

Media access system CSMA/NBA system (note)

Modulation Baseband

Transmission path Bus topology

Data rate 125 kbps 250 kbps 500 kbps

Max. network length 500 m 250 m 100 m

Max. number of nodes 64 units/network (1 master device, 63 slave devices)

Connector MSTBP 2.5/5-STF-5.08 AB GY AU SO

Connection cable DeviceNet THICK cable (thick cable)

Communication function 1. Polling instruction/response mode

RAS function 1. Self-check when the power is ON

Current consumption [mA] T2/T2E/T2N side (DC5V): 500 mA

Outer dimensions [mm] 32.5 (W) × 138 (H) × 102.1 (D)

Weight [g] 200

Board specification One slot (slot width)

Mounting T2/T2E/T2N base unit (basic/extension)

Number of modules See "1.5.2 Number of Mounting Modules."

Access READ/WRITE instruction (module control, data input/output)

Note: CSMA/NBA : Carrier Sense Multiple Access with Non-destructive Bitwise Arbitration

6 F 3 B 0 3 6 4

TMSTBP 2.5/5-STF-5.08 AB GY AU

Phoenix Contact Corporation

DeviceNet THIN cable (thin cable)

(synchronous/asynchronous)

2. Bit strobe instruction/response mode

(synchronous/asynchronous)

ROM, RAM, and CAN controllers

DN211 communication memory for T2/T2E/T2N

2. RAS information on the T2/T2E/T2N interface buffer memory

3. Information by reading RAS information

• Event trace

• CAN controller (circuit) information

4. Time setting function

5. Displaying the module status/network status on the 7segment LED on the front panel

Network side (DC 24 V): 90 mA

I/O slot

32

Page 34

1.5.2 Number of Mounting Modules

This section describes the number of the DN211 units available on the T2/T2E/T2N and the

instruction execution time when accessing the DN211 from the T2/T2E/T2N.

(1) Number of DN211 Units Available

The number of the DN211 units available on the T2/T2E/T2N system varies depending on the

power capacity of the T2 power module and the current consumption of the entire T2/T2E/T2N

system.

Table 1.5 5Vdc Power/Current consumption

Power module (PS261) 5 Vdc power 2500 mA

T2 CPU module (PU224) 5 Vdc current consumption 800 mA

T2E CPU module (PU234E) with optional card 5 Vdc current consumption 800 mA

T2N CPU module (PU245N) with optional card 5 Vdc current consumption 2000 mA

6 F 3 B 0 3 6 4

(when no external 24 Vdc is used)

DN211 5 Vdc current consumption 500 mA

For the T2/T2E:

Number of mounting basic base units: (2500-800) ÷ 500 = 3.4 → 3 units

Number of extended base units: 2500 ÷ 500 = 5 → 5 units

The maximum configuration of the T2 and the T2E is equal to basic base unit × 1 unit + extended

base unit × 3 unit; thus, the number of mounting DN211 units available reaches 18 units.

For the T2N:

Number of mounting basic base units: (2500-2000) ÷ 500 = 1 → 1 unit

Number of extended base units: 2500 ÷ 500 = 5 → 5 units

The maximum configuration of the T2N is equal to basic base unit × 1 unit + extended base unit ×

3 unit; thus, the number of mounting DN211 units available reaches 16 units.

The maximum number of the DN211 units available on your system varies depending on

the number of non-DN211 modules mounted.

33

Page 35

6 F 3 B 0 3 6 4

(2) Instruction execution time when accessing the DN211 from the T2/T2E/T2N

When outputting data to slave devices from the T2/T2E/T2N through the DN211, the WRITE

instruction writes the output data in the DN211 from the T2/T2E/T2N. When inputting data from

slave devices through the DN211, the READ instruction reads from the DN211.

Table 1.6 lists the instruction execution times of the T2/T2E/T2N.

The DN211 has 128 words for the output data area (area where output data to slave devices are

stored) and 128 words for the input data area (area where input data from slave devices are

stored).

Table 1.7 lists the execution times for the WRITE/READ instructions by the T2/T2E/T2N when

accessing 128 words. When input/output data with slave devices is smaller than 128 words, the

instruction execution time becomes shorter.

Conversely, when accessing the output data area/input data area several times, the sum of

instruction execution times increases depending on the number of accessed times (the output data

area/input data area is explained in "4.2 The Input/Output Data Area.")

Table 1.6 READ/WRITE Instruction Execution Time (μs)

T2 T2E/T2N

READ instruction

WRITE instruction

N: Number of transfer words

Table 1.7 Maximum Execution Time for DN211 Access (ms)

READ instruction

WRITE instruction

Total 4.51 2.93

720 + 9.0 × N

721 + 15.0 × N

(128 words for input/output)

T2 T2E/T2N

1.87

2.64

430 + 5.6 × N

427 + 10.6 × N

1.15

1.78

The values in Table 1.7 indicate times for accessing the DN211. When you are mounting more than

one DN211 unit, calculate and total the instruction execution times to access individual

DN211 units.

One unit of T2/T2E/T2N cannot cover the entire DN211 units being mounted when the

total of the sum times necessary for the T2/T2E/T2N's accessing the DN211 units and

the sum time necessary for input, output, and internal processing except for accessing

the DN211 units are larger than the response time that your system requires.

In this case, divide your T2/T2E/T2N to mount DN211 units, depending on your system

configuration.

34

Page 36

6 F 3 B 0 3 6 4

2. Names and Functions of DN211 Parts

This chapter explains the names and functions of DN211 parts.

2.1 Outer Dimensions and Sizes

Figure 2.1 Outer Dimensions and Sizes (unit: mm)

35

Page 37

2.2 Names of DN211 Parts

1 2 3 4

DeviceNet

7-segment LED for node address / error code indication

D N 2 1 1

6 F 3 B 0 3 6 4

Black

Blue

White

Red

MS NS

NA / ERROR

LOADER

ON

1

OSEN

2

BUSOFF

3

DR1

4

LED for module status / network status indication

DIP switch for operation mode / communication rate

setting

Test connector (D-Sub, 9-pin)

Device side connector (connecting the DeviceNet)

Figure 2.2 Appearance (front panel)

36

Page 38

6 F 3 B 0 3 6 4

NA-H NA-L

Rotary switch for setting node addresses

Figure 2.3 Appearance (side view)

37

Page 39

2.3 Functions of DN211 Parts

(1) LED for module status/network status indication (MS/NS)

This LED can light green/red. By making a distinction between green and red and lighting and

blinking, the DN211's module status (MS) and network status (NS) are indicated.

6 F 3 B 0 3 6 4

LED Indication

status

MS Not lit • No power is supplied to the DN211.

Green lighting • The DN211 is operating normally.

Green blinking • The DN211 is reading switch settings.

Red blinking • The DN211 is encountering a recoverable trouble.

Red lighting • The DN211 is encountering a non-recoverable trouble (down

NS Not lit • No power is supplied to the DN211 (check MS).

Meaning of the indication (main trouble)

• Though the power is supplied to the DN211, the module doesn't

become run mode (∗ 1).

When the 7-segment LED for node address/error code indicates the

local station node address, the power is supplied.

→ Switch setting abnormal (DIP switch/rotary switch), etc.

status).

You may need to replace the module.

• Though the power is supplied to the DN211, the module doesn't

become run mode ( ∗ 1); check MS.

• The DN211 is encountering a non-recoverable trouble (down

status); check MS.

• No network power is supplied to the DN211.

Green lighting • The DN211 is normally communicating with slave devices.

Green blinking • No communication between the DN211 and slave devices is

established.

• No slave devices are registered in the DN211.

Red blinking • No communication is established with more than one slave devices.

Red lighting • The DN211 communication is stopped due to busoff (∗ 2).

• Communication is stopped due to the node address duplicated.

(* 1) See " 4.6 Requests to the DN211" for the run mode.

(* 2) Busoff: Individual nodes on the DeviceNet check for abnormal transmission paths; when the local

node is judged to be the cause of the abnormal transmission path, the local node is separated from

the transmission path. This state is called busoff.

38

Page 40

(2) 7-Segment LED for Node Address/Error Code Indication (NA/ERROR)

While the DN211 is normally transmitting data with slave devices the local station node address is

displayed.

Node address: A node identification number that the DeviceNet devices (nodes) linked to the

network have. The values range within 0 to 63 in decimal scale. In a DeviceNet, the

node address of a node linked to the network must be unique.

In the following cases, module or network status is displayed in combination of this LED and the

LED for module status/network status indication.

• A trouble occur on the DN211 or on the network.

• An error occurs when the T2/T2E/T2N requests.

(Parameter setting and operation mode controlling, etc. are performed by the request from the

T2/T2E/T2N.)

• The DN211 is downed.

See "6.2 Indications of the 7-Segment LED" for the combinations and meanings of this LED and

the LED for module status/network status indication.

6 F 3 B 0 3 6 4

(3) DIP switch for setting the operation mode/communication rate

This DIP switch is used for setting the operation mode at DN211 busoff and a communication rate

on the network (500 kbps/250 kbps, 125 kbps).

"3.2 Switch Setting" explains the contents of the DIP switch and how to set it.

(4) Rotary switch for node address setting (NA-H/NA-L)

Is used for setting node addresses in the network of the DeviceNet.

The DN211 can have a node address within 0 to 63 (decimal scale) unless the node address doesn't

duplicate with another node address (slave device) in the network.

"3.2 Switch Setting" explains how to set the rotary switch.

(5) The test connector

This connector is only for maintenance. You may not use it.

(6) The device side connector (for DeviceNet connection)

This connector is for connecting the DeviceNet cable to the DN211.

"3.4 Connection with the Network" explains how to connect cables.

39

Page 41

3. Preparation for Operation (hardware)

3.1 DN211 Setting Flowchart (hardware)

DANGER

1. Configure an emergency-stop circuit, interlock circuit, and/or other similar safety circuits

outside the PC and DN211.

If the PC or DN211 gets failed or malfunctioned, it can cause an accident which will lead to

bodily injury and/or mechanical damage.

CAUTION

2. Secure the safe environment before executing program modification, forcible output, RUN, or

HALT instruction during operation. An operational mistake can cause mechanical damage or

accident

The following flowchart shows the DN211 setting.

6 F 3 B 0 3 6 4

Start

Setting your DN211's node address /

operation mode / communication rate

Mounting the DN211 on the I/O slot of the

T2/T2E/T2N

Connecting the DN211 to the network

Supplying the network power to the DN211

Supplying the T2/T2E/T2N power

Set the node address for the DN211 with the rotary

switch on the side. Also set the operation mode and

communication rate with the DIP switch on the front

panel.

See '3.2 Switch Setting" for detail.

Mount the DN211 into the I/O slot of the T2/T2E/T2N

base unit.

See "Mounting module" in the Main Unit User’s Manual

for detail.

Using the network side connector (attached to DN211),

connect the DeviceNet cables to the DN211. See "3.4

Connection with the Network" for detail.

Supply the communication power for the DeviceNet

devices through the network cable.

See "3.5 The Network Power / Grounding" for detail.

After completing the above work, switch ON the power

of the T2/T2E/T2N.

See "Grounding" and "Power-supply Wiring" in the

Main Unit User’s Manual for the details of powersupply wiring / grounding.

End

Figure 3.1 DN211 Setting Flowchart

40

Page 42

3.2 Switch Setting

LOADER

The DN211 has a DIP switch on the front panel and a rotary switch on the side. These switches

are used for setting the operation mode, communication rate, and node address of the DN211.

3.2.1 DIP Switch for Setting the Operation Mode/Communication Rate

∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼∼

6 F 3 B 0 3 6 4

ON

1 2 3 4

1

OSEN

2

BUSOFF

3

DR1

4

DR0

← DIP switch for setting the operation

mode/communication rate

Factory setting: OFF