1.1 Features

The Toshiba T200/T200CS Pen Computer uses extensive Large Scale Integration (LSI), and

Complementary Metal-Oxide Semiconductor (CMOS) technology to provide minimum size

and weight, low power usage and high reliability. These computers include the following:

❑ Microprocessor

The T200/T200CS uses an SL Enhanced Intel 486DX2-40 microprocessor that

operates at 40 MHz and 3.3 volts.

❑ Math co-processor

The T200/T200CS has a math co-processor stored in the i486DX2 microprocessor.

❑ Cache memory

The T200/T200CS has an 8 KB cache memory stored in the i486DX2 microprocessor.

❑ Disk storage

The T200/T200CS has an internal 1.8-inch IDE 80 Megabyte (MB) Hard Disk Drive

(HDD).

❑ Memory

The T200/T200CS comes standard with 4 MB of CMOS RAM. This includes 640

KB of conventional memory and 3,328 KB of extended memory, which can be utilized

as expanded memory compatible with Lotus/Intel/Microsoft Expanded Memory

Specifications (LIM-EMS).

❑ Display screen

The T200 has a 9.5-inch high resolution monochrome Liquid Crystal Display (LCD)

which displays 640x480 pixels with a 16-level gray scale, and an electromagnetic

derivative tablet (transreflective).

The T200CS has a 9.5-inch high resolution Supertwist Nematic (STN) color LCD

which displays 640x480 pixels and 256 colors, and an electromagnetic derivative

tablet.

The T200/T200CS internal display controller supports Video Graphics Array (VGA)

on the internal/external display and Super VGA (SVGA) on the external display.

❑ Batteries

The T200/T200CS has three different batteries: a main battery, a backup battery, and

a Real Time Clock (RTC) battery.

T200/T200CS 1-1

❑ Exp. memory slot

An optional 4, 8, or 16 MB memory card can be installed in the memory slot.

❑ PC card slot (Type II, Type III)

The T200/T200CS has two PC card slots which support Personal Computer Memory

Card International Association (PCMCIA) standard version release 2.0 and MiNC

Toshiba modem card.

❑ FDD port

An optional external 3.5-inch Floppy Disk Drive (FDD) supports 2HD (1.44 Mbytes)

floppy disks and 2DD (720 Kbytes) floppy disks.

❑ Printer port

The T200/T200CS's Centronics-compatible printer interface port can be connected to

the printer through a parallel printer cable.

❑ Serial port

The T200/T200CS has one 9-pin serial interface port.

❑ Ext. keyboard port

The T200/T200CS has an external keyboard interface port for connection with a PS/2compatible keyboard.

❑ Ext. monitor port

The T200/T200CS has an external monitor interface port for connection with an

analog VGA or SVGA display.

❑ 72-pin Expansion port

The T200/T200CS has a 72-pin Expansion port which enables connection of a 72-pin

Expansion connector. The Expansion port allows connection of a PS/2 keyboard,

external monitor, printer, serial I/O and optional 3.5-inch FDD.

❑ Stylus

The T200/T200CS has one cordless stylus (pen), which is used to enter information

into the computer. The stylus does not need batteries.

1-2 T200/T200CS

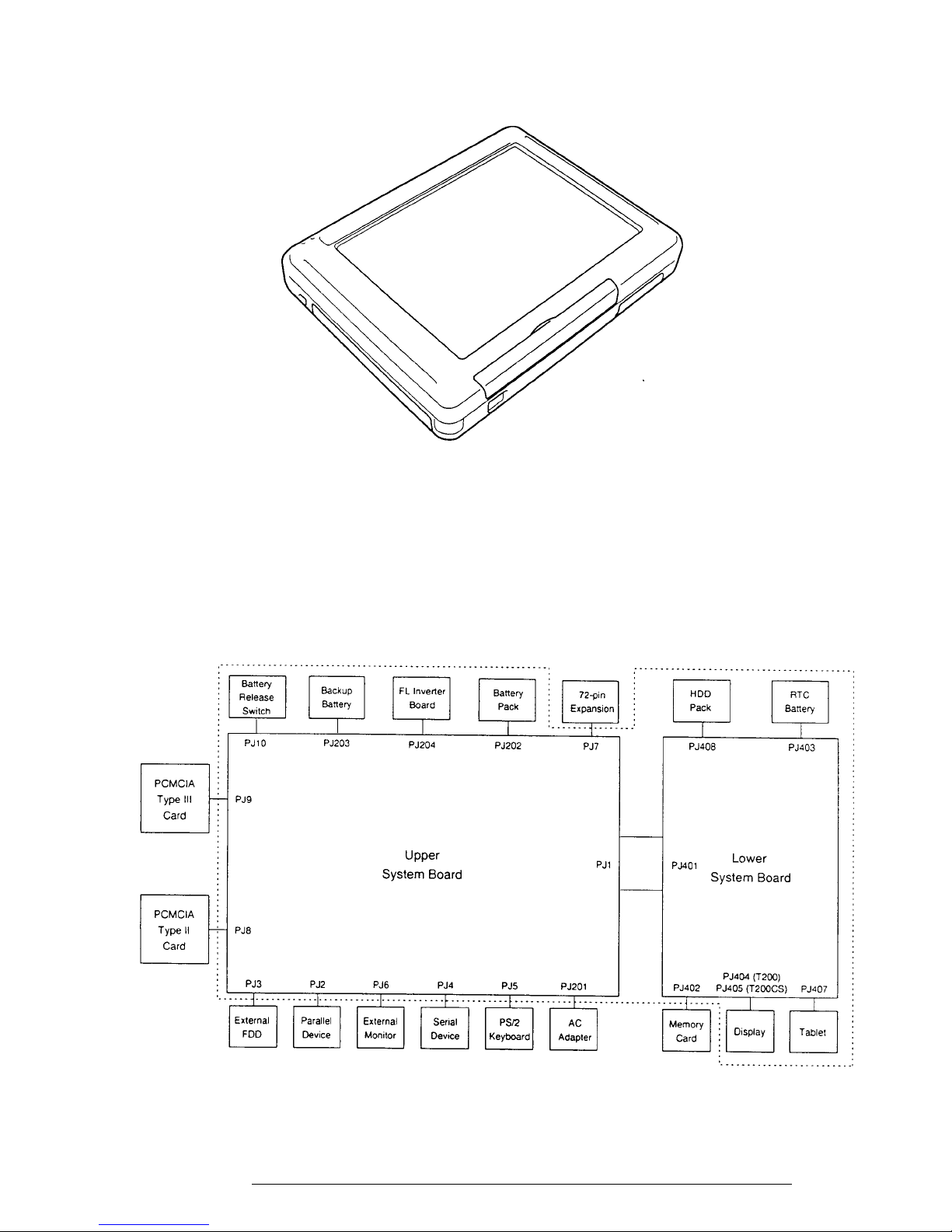

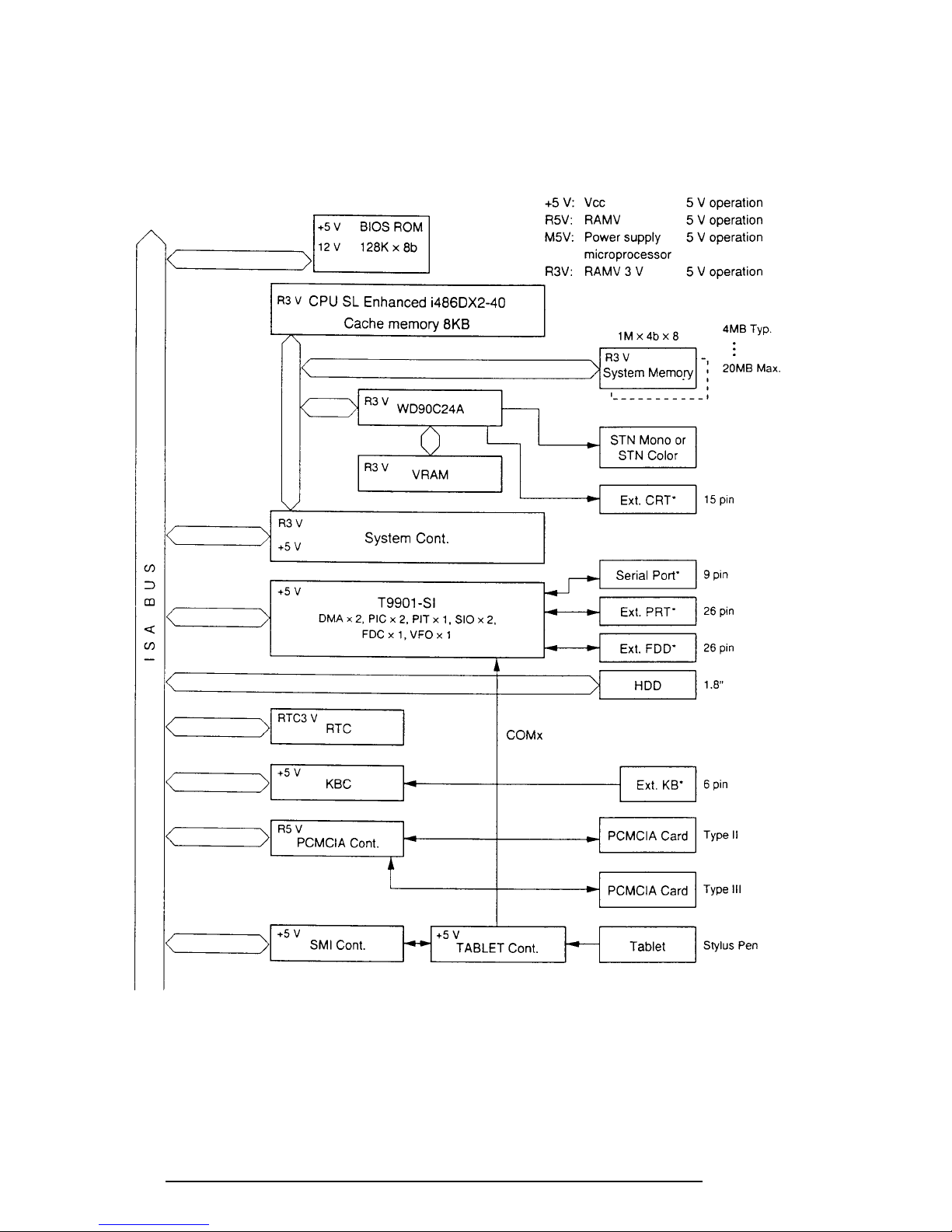

The T200/T200CS Pen Computer is shown in Figure 1-1. Its system configuration is shown

in Figure 1-2.

Figure 1-1 T200/T200CS Pen Computer

Figure 1-2 T200/T200CS System Unit Configuration

T200/T200CS 1-3

1.2 System Unit Block Diagram

Figure 1-3 is a block diagram of the computer's system unit.

* These port signals also output to the 72-pin Expansion port.

1-4 T200/T200CS

Figure 1-3 Block Diagram

The computer's system board is composed of the following major components:

❑ SL Enhanced i486DX2-40

❑ Super Integration (SI) T9901, which stores the following components:

• Two Direct Memory Access Controllers (DMAC): 82C37

• Two Programmable Interrupt Controllers (PIC): 82C59

• One Programmable Interval Timer (PIT): 82C54

• One Floppy Disk Controller (FDC): TC8565

• Two Serial Input/Output Controllers (SIO): TC8570

• One Variable Frequency Oscillator (VFO): TC8568

• One I/O Controller

• One Printer Port Controller

• One Speaker Controller

❑ A Real Time Clock (RTC)

One T9934 chip with 128 bytes of memory is used. Fourteen bytes of memory are

used for the calendar and clock and the remaining 114 bytes for system configuration

data.

OSC (X2) generates 32.768 KHz for RTC.

❑ A Keyboard Controller (KBC)

One 80C42 chip is used. This KBC includes the keyboard interface controller and

controls the external keyboard.

❑ The following memories:

Standard RAM: 4 MB

Cache memory: 8 KB (inside CPU)

BIOS ROM: 128 KB (96 KB are used)

This ROM contains Initial Reliability Test (IRT),

Basic Input/Output System (BIOS), and video BIOS.

Video RAM: 256 KB

Optional memory cards expand memory to a maximum of 20 MB.

VGA display controller (WD90C24A)

❑

This controller controls internal VGA display and external SVGA compatible display.

❑ Clock Generator receives 14.31818 MHz (X3) and generates the following frequen-

cies:

• 20 MHz for the CPU (CPU operates at 40MHz.)

• 14.7477 MHz for the COM

• 24 MHz for the FDC and VFO

• 16 MHz is used for the System Controller GA

• 14.31818 MHz is used for the T9901 (SI)

T200/T200CS 1-5

❑ Gate Arrays

System Controller Gate Array

This gate array has the following functions:

• CPU Controller

• Memory Controller

-DRAM Controller

-Compatible Bus Interface Controller

• SMI Controller

• VL Bus Controller

• Bus Controller

-Compatible Bus Interface Controller

-Compatible Access Controller

-DMA Controller

-I/O Controller

• Address Latch Controller

-32-Bit to 16-Bit Controller

-Address Latch

-DMA Address Generator

-Refresh Address Generator

• I/O Register

-Compatible I/O Port

-Saving the data of the Register (in resume) Controller

-Toshiba Special Register

• Processing Speed Controller

• Data Bus Change Controller

• Data Latch

PCMCIA Controller Gate Array

This gate array has the following functions:

• Memory Card Controller

-PCMCIA IC Card Controller

-Toshiba Modem Card Controller

1-6 T200/T200CS

SMI Controller Gate Array

This gate array has the following functions:

• Tablet Controller

-Tablet Microprocessor Communication Controller

-SMI Controller

• Others

-Contrast Adjust PWM Controller

T200/T200CS 1-7

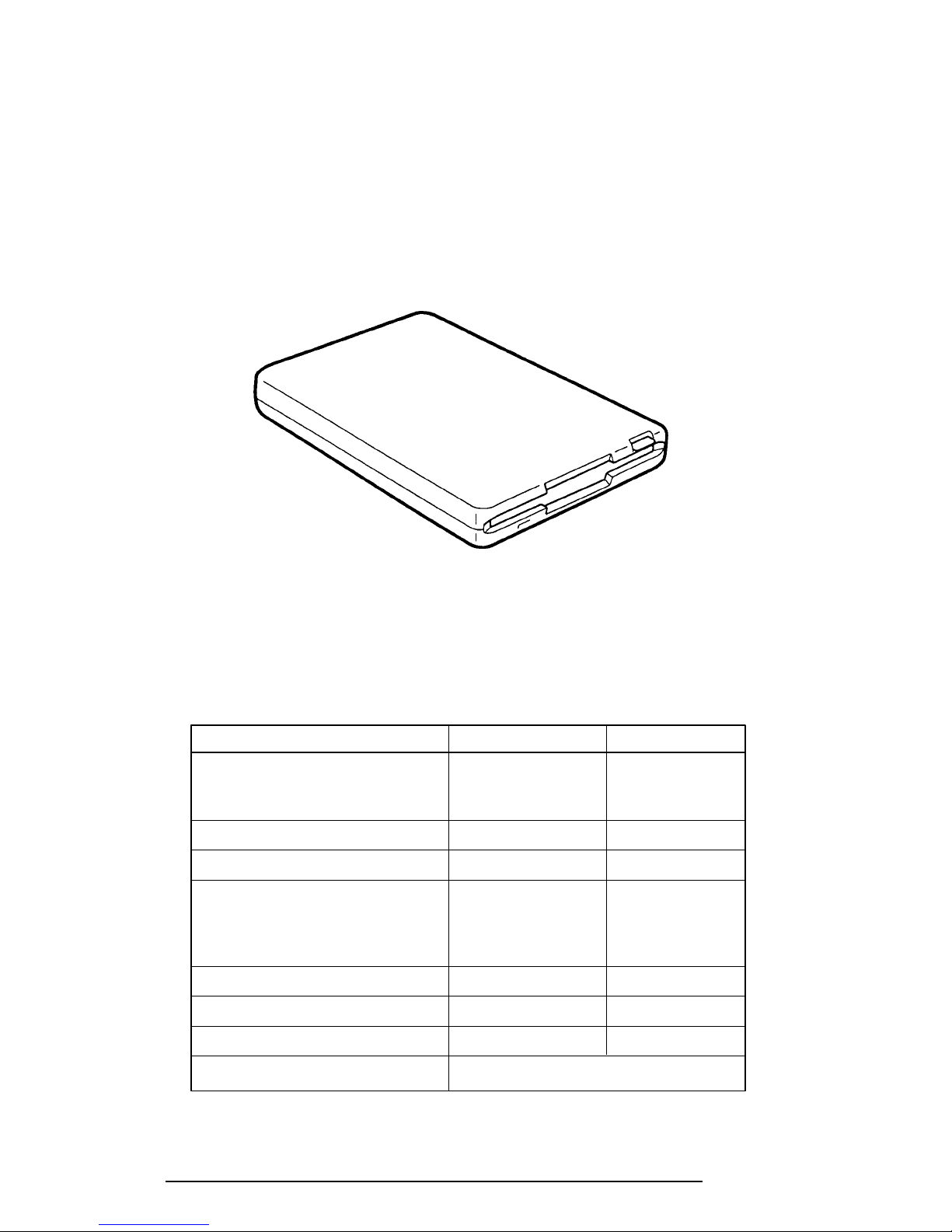

1.3 Optional External 3.5-inch Floppy Disk Drive

The computer's optional 3.5-inch Floppy Disk Drive (FDD) is a thin, high-performance

reliable drive that supports 720-KB (formatted) 2DD and 1.44-MB (formatted) 2HD 3.5-inch

floppy disks.

The computer's FDD is shown in Figure 1-4. The specifications for the FDD are provided in

Table 1-1.

Figure 1-4 3.5-Inch FDD

Table 1-1 3.5-Inch FDD Specifications

Item 2-MB mode 1-MB mode

Storage capacity (KB)

Unformatted 2,000 1,000

Formatted 1,474 737

Number of heads 2 2

Number of cylinders 80 80

Access time (ms)

Track to track 3 3

Average 181 181

Head settling time 15 15

Recording track density (tpi) 135 135

Data transfer rate (Kbps) 500 250

Rotation speed (rpm) 300 300

Recording method Modified Frequency Modulation (MFM)

1-8 T200/T200CS

1.4 1.8-inch Hard Disk Drive

The computer’s 80-MB (formatted) Hard Disk Drive (HDD) is a random access non-volatile

storage device. It has a non-removable 1.8-inch magnetic disk and mini-winchester type

magnetic heads.

The HDD is shown in Figure 1-5. Specifications for the HDD are provided in Table 1-2.

Figure 1-5 1.8-Inch HDD

Table 1-2 1.8-Inch HDD Specifications

Item 80 MB

(ZA1094)

Storage capacity (MB)

Formatted 85.0

Number of disks 2

Data heads 3

Data surfaces 3

Tracks per surface 2,750

Sectors per track 20

Bytes per sector 512

Access time (ms)

Track to track 8

Average 18

Maximum 35

Rotation speed (rpm) 3,571

Data transfer rate (bps)

To/from media 2.5M

Interleave 1:1

T200/T200CS 1-9

Recording method 1-7 RLL

1.5 Monochrome LCD

The monochrome LCD is composed of an LCD module, a Fluorescent Lamp (FL), and an FL

inverter board.

1.5.1 Monochrome LCD Module

The computer's monochrome LCD supports 640 x 480 pixels with a video controller and 16

levels of gray. The video controller includes the functions of the VGA and SVGA for external

display.

The LCD receives vertical and horizontal synchronizing signals, 8-bit data signals (4-bit upper

block data signal and 4-bit lower block data signal), and shift clock for data transmission. All

signals are CMOS-level compatible.

The sidelit LCD is shown in Figure 1-6 and its specifications are provided in Table 1-3.

Figure 1-6 Monochrome LCD

Table 1-3 Monochrome LCD Specifications

Item Specifications

Number of dots (dots) 640 x 480

Dot pitch (mm) 0.27 (W) x 0.27 (H)

Display area (mm) 196 (W) x 147.6 (H)

Contrast 10:1 (typically)

FL current (mA) 5.5 (r.m.s.)

FL frequency (KHz) 39

1-10 T200/T200CS

1.5.2 Monochrome LCD Fluorescent Lamp (FL) Inverter Board

The FL inverter board supplies the high-frequency current needed to illuminate the LCD's FL.

The FL inverter board is shown in Figure 1-7 and its specifications are provided in Table 1-4.

Figure 1-7 Monochrome LCD FL Inverter Board

Table 1-4 Monochrome LCD FL Inverter Board Specifications

Item Specifications

Input Voltage (VDC) 5

Power (W) 2.7

Output Voltage (VAC) 1,100 (r.m.s)

Current (mA) 5.5 (r.m.s)

Frequency (KHz) 39

T200/T200CS 1-11

1.6 STN Color LCD

The STN Color Liquid Crystal Display (LCD) contains an LCD module, a Fluorescent Lamp

(FL), and an FL inverter board.

1.6.1 STN Color LCD Module

The computer's STN color LCD supports 640x480 pixels with a video controller. This video

controller includes the functions of VGA and SVGA for external display.

The LCD receives vertical and horizontal synchronizing signals, 16-bit data signal (8-bit upper

block data signal, 8-bit lower block data signal), display enable signal, and shift clock for data

transmission. All signals are CMOS-level compatible.

The STN LCD is shown in Figure 1-8. The LCD specifications are provided in Table 1-5.

Figure 1-8 STN Color LCD

Table 1-5 STN Color LCD Specifications

Item Specifications

Number of Dots (dots) 640x480

Dot pitch (mm) 0.3(W)x0.3(H)

Display area (mm) 195 (W)x147 (H)

Contrast 18:1 (Typically)

FL current (mA) 6.0 (r.m.s.)

FL frequency (KHz) 47

1-12 T200/T200CS

1.6.2 STN Color LCD Fluorescent Lamp (FL) Inverter Board

The FL inverter board supplies high frequency current to light the LCD’s Fluorescent Lamp.

The FL inverter board is shown in Figure 1-9 and its specifications are described in Table 1-6.

Figure 1-9 STN Color LCD FL Inverter Board

Table 1-6 STN Color LCD FL Inverter Board Specifications

Item Specifications

Input Voltage (VDC) 5

Power (W) 4

Output Voltage (VAC) 1,100 (r.m.s.)

Current (mA) 6.0 (r.m.s.)

Frequency (KHz) 47

T200/T200CS 1-13

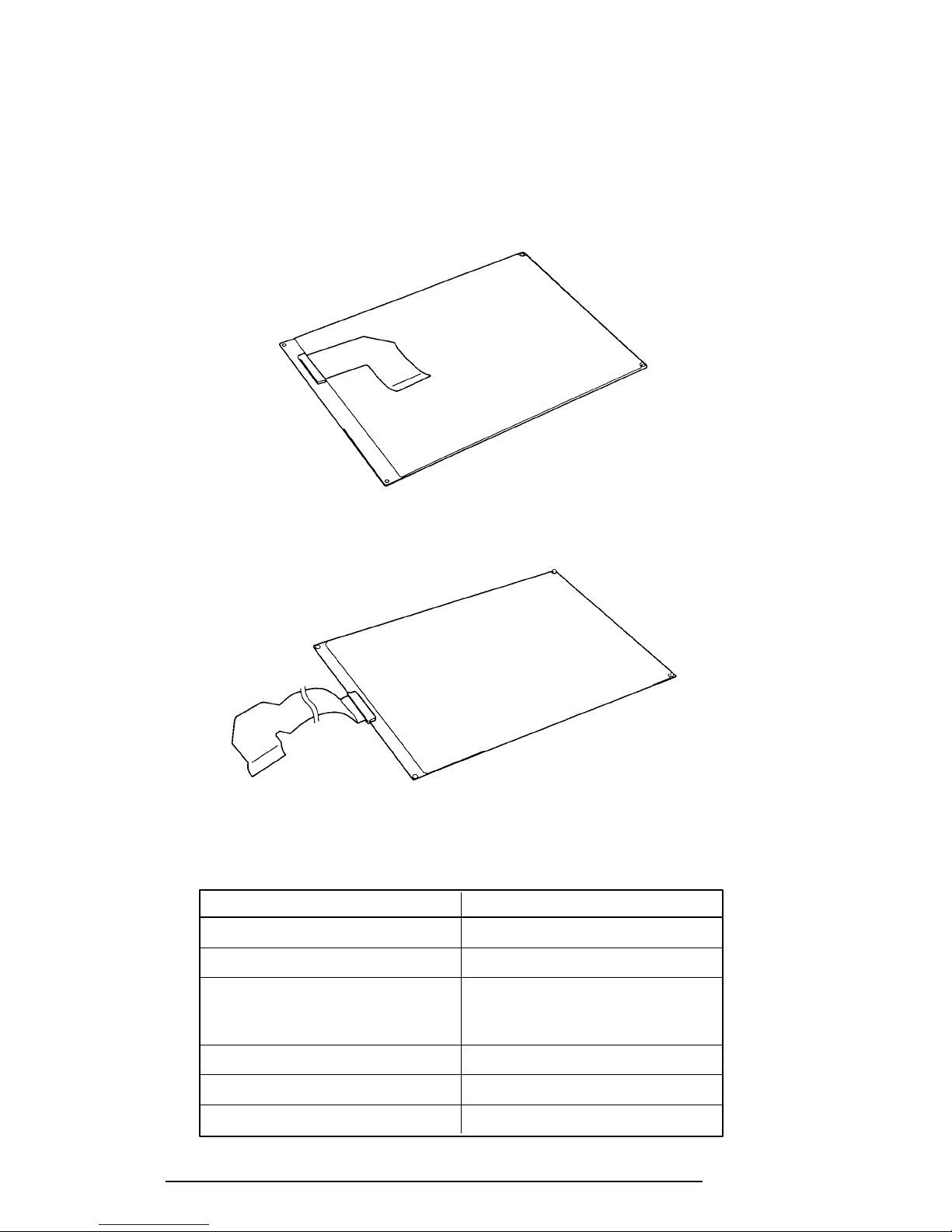

1.7 Tablet

The tablet is the internal digitizer, which also acts as the interface between the stylus and the

computer.

The tablets are shown in Figures 1-10 and 1-11 and their specifications are provided in Table

1-7.

Figure 1-10 T200 Tablet

Item Specifications

Material Electromagnetic derivative

Voltage (VDC) 5V

Current (mA) 30 (In use)

Resolution (mm) 0.1

Precision (mm) ±0.4

Data transfer (point/sec) 205

1-14 T200/T200CS

Figure 1-11 T200CS Tablet

Table 1-7 Tablet Specifications

23 (In suspend)

5.2 (In sleep)

1.8 Power Supply

The power supply supplies five kinds of voltages to the computer's system board. The

computer's power supply has one microprocessor and it operates at 500 Hz. It contains the

following functions:

1. Determines if the AC adapter or battery is connected to the computer.

2. Detects DC output and circuit malfunctions.

3. Controls the LED icon and speaker.

4. Turns the battery charging system on and off and detects a fully charged

battery.

5. Determines if the power can be turned on and off.

6. Provides more accurate detection of a low battery.

7. Calculates the remaining battery capacity.

The power supply output rating is specified in Table 1-8.

Table 1-8 Power Supply Output Rating

DC Regulation Maximum

Use for Name voltage tolerance current Ripple

System logic, FDD, HDD VCC +5 ±5 1,720 100

RS-232C, Flash ROM 12V +12 ±5 120 240

RAM, CPU B3V +3.3 ±5 1243 100

RS-232C -9V -9 15 15 150

(V) (%) (mA) (mV)

T200/T200CS 1-15

1.9 Batteries

The computer has three types of batteries:

❑ Main battery pack

❑ Backup battery

❑ Real Time Clock (RTC) battery

Battery specifications are provided in Table 1-9.

Table 1-9 Battery Specifications

Battery name Material Output voltage Capacity

Main battery pack Lithium-Ion 10.8 V 3,000 mAH

Backup battery Nickel Metal Hydride 3.6 V 120 mAH

RTC battery Lithium-Vanadium 3.0 V 50 mAH

1.9.1 Main Battery

The removable main battery pack is the primary power source when the AC adapter is not

attached. The main battery recharges the backup battery when system power is on. The

backup and main battery maintain the state of the computer system when AutoResume is

enabled. The main battery is shown in Figure 1-12.

1-16 T200/T200CS

Figure 1-12 Main Battery

❏ Battery Indicator

The battery indicator is located on the top cover of the computer. The indicator shows the

status of the removable battery pack, power supply, and AC adapter. The status of each can

be determined by color:

Orange The battery is being charged or an AC adapter is attached.

Green The battery is fully charged. (An AC adapter is attached.)

No light The AC adapter is disconnected from the computer or is connected, but

cannot charge the battery for one of the following reasons:

❏ The battery is extremely hot. Allow the computer and the battery to

reach room temperature before attempting to charge the battery.

❏ The battery is almost fully discharged and will not begin

charging until a few minutes after the AC adapter is connected.

❏ The AC adapter is not receiving power.

T200/T200CS 1-17

1.9.2 Battery Charging Control

Battery charging is controlled by a power supply microprocessor mounted on the power

supply. The microprocessor turns charging on or off and detects a full charge when the AC

adapter and main battery pack are attached to the computer. The system charges the main

battery pack using quick or trickle charge.

❏ Quick Battery Charge

When the AC adapter is attached, there are two types of charge: quick charge when the

system is powered off and trickle charge when powered on. Table 1-10 gives quick charging

time requirements.

Table 1-10 Time Required For Quick Charges

Charge Charging time

Quick charge About 3 hours

(power off)

Quick charge About 8 hours

(power on)

If one of the following occurs, the battery quick charge process stops.

1. The battery becomes fully charged.

2. The AC adapter or battery is removed.

3. The battery or AC adapter output voltage is abnormal.

4. The charge current is abnormal.

❏ Trickle Battery Charge

When the main battery is fully charged and the AC adapter is attached, the power supply

microprocessor changes quick charge to trickle charge.

1-18 T200/T200CS

1.9.3 Backup Battery

The backup battery maintains data for AutoResume. The power source used to back up

AutoResume data is determined according to the following priority:

AC adapter > Main battery > Backup battery

The backup battery is charged by the main battery or AC adapter when the system is powered

on. Table 1-11 shows the charging time and data preservation period of the backup battery.

Table 1-11 Backup Battery Charging/Data Preservation Time

Time

Charging Time Power On 10 H

Power Off 10 H

(with AC Adapter or main battery)

Power Off Doesn’t charge

(Without AC Adapter and main battery)

Data preservation period (full charge) 8 H

1.9.4 RTC Battery

The RTC battery provides power to keep the current date, time, and other setup information

in memory while the computer is turned off. Table 1-12 shows the charging time and data

preservation period of the RTC battery.

Table 1-12 RTC Battery Charging/Data Preservation Time

Time

Charging Time Power On 48 H

Power Off Doesn’t charge

Data preservation period (full charge) 1 month

T200/T200CS 1-19

1.10 Stylus

The stylus is used to enter information into the computer by writing directly onto the screen.

You can write letters or numerals to enter data, draw gestures to enter commands, or tap to

select from menus.

The stylus is shown in Figure 1-13.

Figure 1-13 The Stylus

1-20 T200/T200CS

2.1 Troubleshooting

Chapter 2 describes how to determine if a Field Replaceable Unit (FRU) is causing a malfunction. FRUs covered are:

1. System Board

2. Floppy Disk Drive

3. Hard Disk Drive

4. Display Module

5. Tablet

Diagnostics Disk operations are described in Chapter 3 and detailed replacement procedures

are given in Chapter 4.

The following tools are necessary for troubleshooting:

1. T200/T200CS Diagnostics Disk

2. Phillips-head screwdriver (2 mm)

3. 2DD or 2HD formatted work disk for FDD testing

4. Printer port LED

5. RS-232-C wraparound connector

6. Printer wraparound connector

7. Multimeter

8. Parallel cable (standard equipment)

9. External PS/2-type keyboard

10. Optional external 3.5-inch FDD

T200/T200CS 2-1

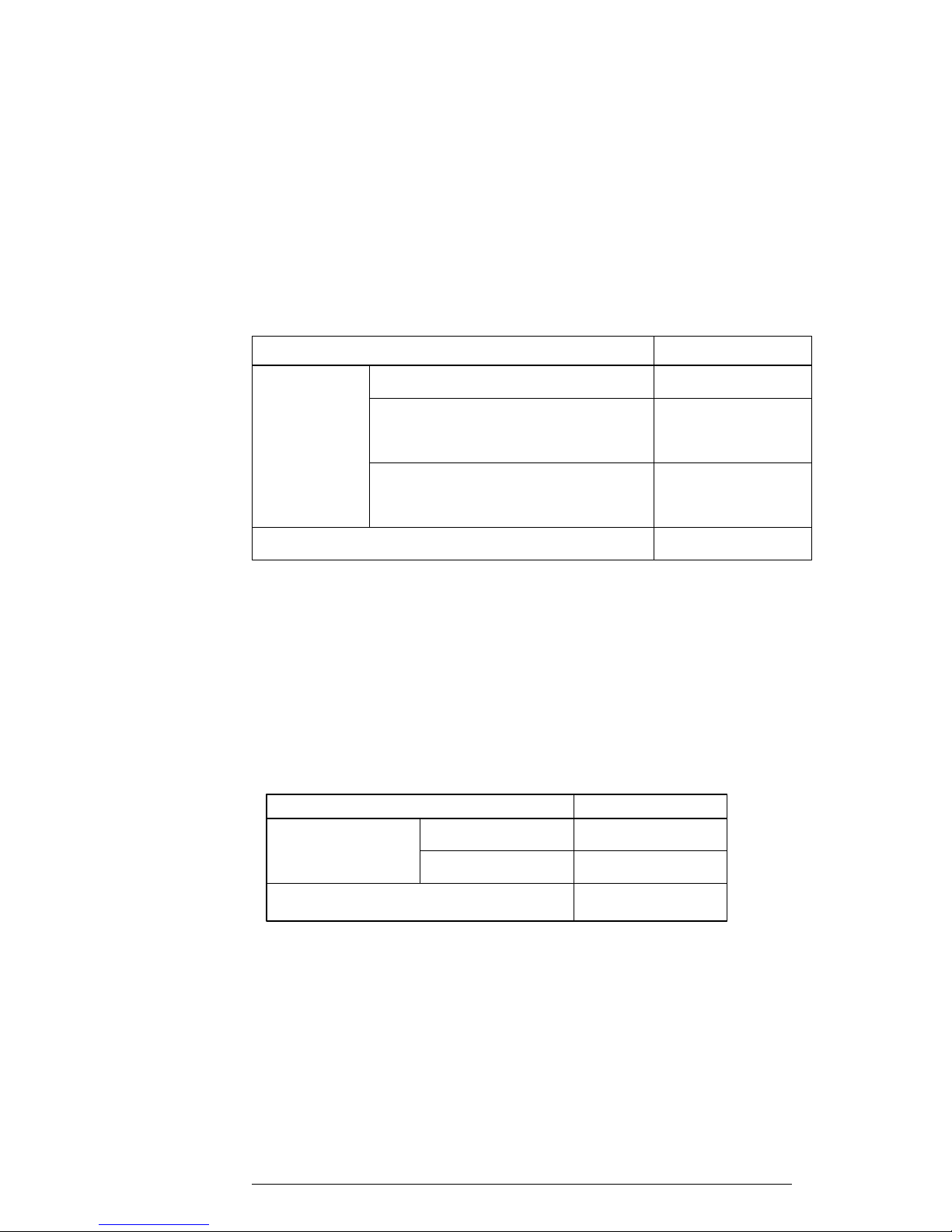

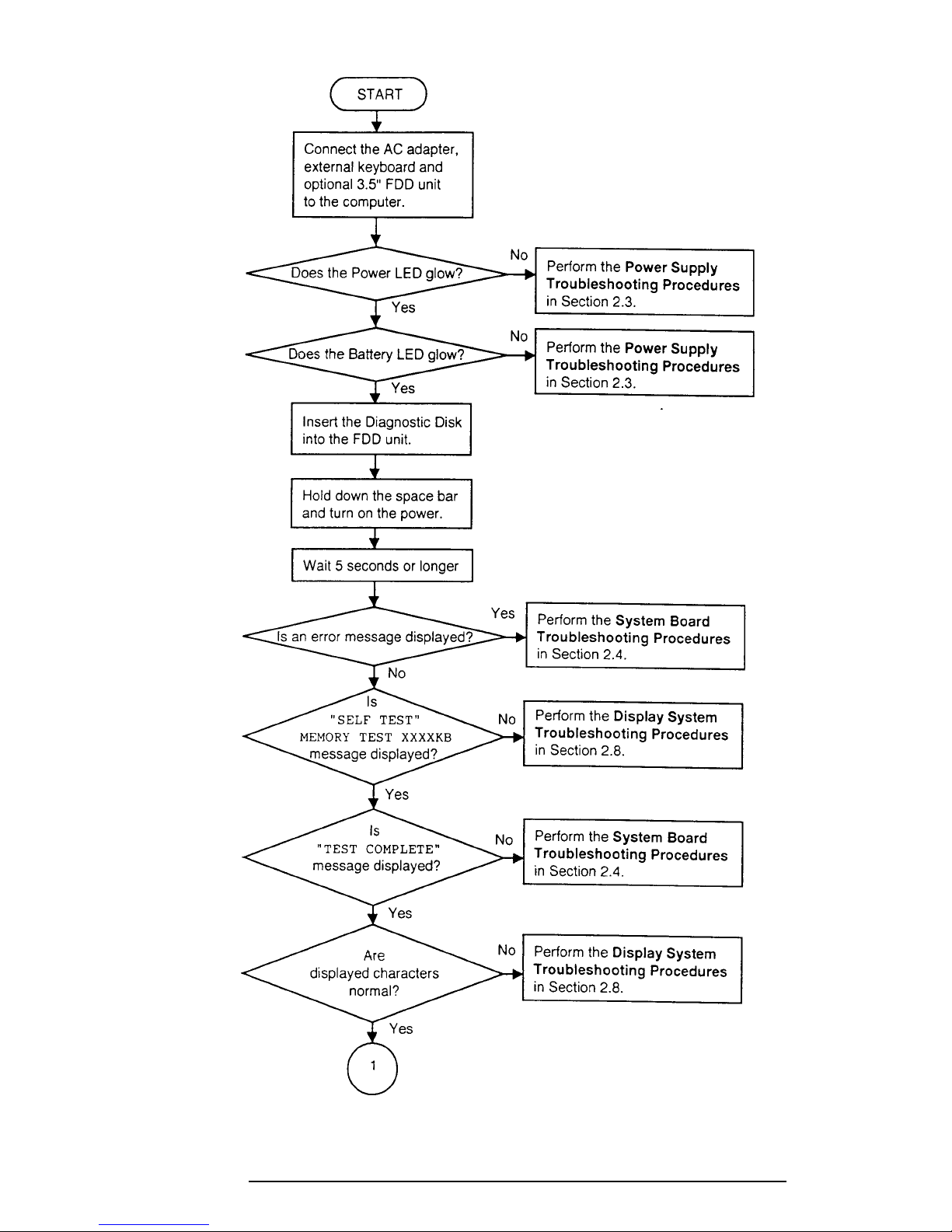

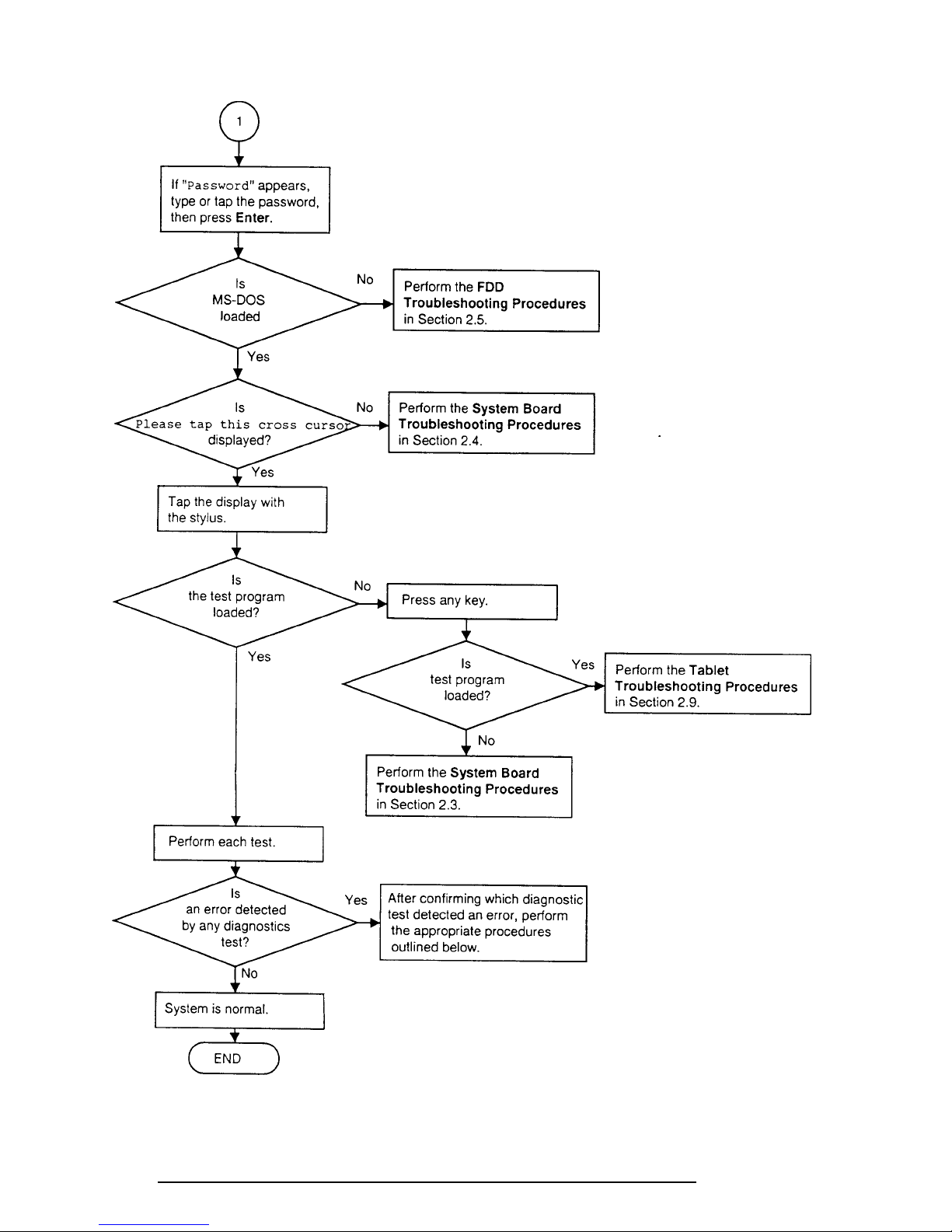

2.2 Troubleshooting Flowchart

Use the flowchart in Figure 2-1 as a guide to determine which procedures to execute. Before

going through the flowchart steps, verify the following:

❑ Ask the user if a password is registered, and if it is, ask him or her to enter the pass-

word. If the user has forgotten the password, connect the printer port wraparound

board (F31PRT), then turn the POWER switch on. The computer will skip the password function.

❑ Make sure all optional equipment is disconnected.

2-2 T200/T200CS

T200/T200CS 2-3

Figure 2-1 Troubleshooting Flowchart (1/2)

Figure 2-1 Troubleshooting Flowchart (2/2)

2-4 T200/T200CS

If the diagnostics program cannot detect an error, the problem may be intermittent. The

Running Test program should be executed several times to isolate the problem. Check the

Log Utilities function to confirm which diagnostic test detected an error(s), then perform the

appropriate procedures as follows:

1. If an error is detected on the system test, memory test, display test, ASYNC test,

printer test, or real timer test, perform the system board troubleshooting procedures in Section 2.4.

2. If an error is detected on the keyboard test, perform the keyboard troubleshooting

procedures in Section 2.7.

3. If an error is detected on the floppy disk test, perform the floppy disk drive

troubleshooting procedures in Section 2.5.

4. If an error is detected on the hard disk test, perform the hard disk drive troubleshooting procedures in Section 2.6.

5. If an error is detected on the tablet test, perform the tablet troubleshooting procedures in Section 2.9.

T200/T200CS 2-5

2.3 Power Supply Troubleshooting

The power supply controls many functions and components. To determine if the power

supply is functioning properly, start with Procedure 1 and continue as instructed. The procedures described in this section are:

Procedure 1: Power LED Indicator Check

Procedure 2: Battery LED Indicator Check

Procedure 3: PCB Replacement Check

2-6 T200/T200CS

Procedure 1 Power LED Indicator Check

The AC adapter converts AC to DC power and contains a charging circuit for charging the

batteries. The adapter connects to the Power socket connector on the back side of the computer. When the AC adapter is connected and power is off, the AC adapter charges the

batteries.

The Power LED displays whether or not the AC adapter is connected and supplying power.

❑ When the Power LED is green, the AC adapter is connected and supplying power to

the computer.

❑ If the Power LED does not light, the AC adapter is not supplying power to the com-

puter or the AC adapter is not attached to the computer, go to Check 1.

❑ If the Power LED is flashing orange, the AC adapter voltage supply is abnormal or the

power supply is not functioning properly, go to Check 2.

If any of the above indicator conditions are abnormal, make sure the Power LED indicator

lights are not burned out before performing the following checks:

Check 1 Make sure the correct AC adapter cable is firmly plugged into the Power socket

on the back of the computer.

Check 2 If the Power LED flashes orange when the AC adapter is connected, its voltage

output is abnormal. Connect a new AC adapter and turn the computer on again to

verify the indicator condition. If the problem still exists, perform Check 3.

Check 3 The battery pack may be malfunctioning. Replace the battery pack with a new one

and turn the computer on again. If the problem persists, perform Check 4.

Check 4 Place the computer in an environment between –20°C and 70°C until at ambient

temperature. Repeat the steps which caused abnormal operation. If the same

problem persists, perform Procedure 3.

T200/T200CS 2-7

Procedure 2 Battery LED Indicator Check

The battery LED indicator shows battery charging status. The LED, identified by a battery

icon on the front of the computer, glows orange when the AC adapter is charging the battery

pack.

❑ If the Battery LED indicator glows green, the AC adapter is connected and the battery

is fully charged.

❑ If the Battery LED indicator glows orange, the AC adapter is connected and the

battery is being charged.

❑ If the Battery LED indicator does not glow, go to Check 1.

Check 1 Make sure the AC adapter cable and AC cord are firmly plugged into the Power

socket and wall outlet. If connected correctly, go to Check 2.

Check 2 Make sure the battery pack is installed correctly. Go to Check 3 if it is.

Check 3 Remove the battery pack and check that the battery terminal is clean and not bent.

❑ If the terminal appears dirty, clean gently with a cotton swab dipped in

alcohol.

❑ If the terminal looks bent or damaged, replace the upper system board.

❑ If the battery terminal is clean and not bent, go to Check 4.

Check 4 Connect a new AC adapter. If the Battery LED indicator still does not glow, go

to Check 5.

Check 5 Install a new battery pack. If the Battery LED indicator still does not glow, go to

Procedure 3.

2-8 T200/T200CS

Procedure 3 PCB Replacement Check

The power supply is mounted on the upper system board. The upper system board may be

damaged. Disassemble the computer following the steps described in Chapter 4, Replacement

Procedures, then perform the following checks.

Check 1 Replace the upper system board with a new one and restart the system. If the

problem still exists, go to Check 2.

Check 2 Replace the lower system board with a new one and restart the system. If the

problem persists, other FRUs may be damaged.

T200/T200CS 2-9

2.4 System Board Troubleshooting

This section describes how to determine if the system board is defective or not functioning

properly. Start with Procedure 1 and continue as instructed. The procedures provided are:

Procedure 1: Message Check

Procedure 2: Printer Port LED Check on Boot Mode

Procedure 3: Printer Port LED Check on Resume Mode

Procedure 4: Diagnostic Test Program Execution Check

Procedure 5: Connection and Replacement Check

2-10 T200/T200CS

Procedure 1 Message Check

When power is turned on while the space bar is held down, the system performs the Initial

Reliability Test (IRT) resident in BIOS ROM. IRT tests and initializes each IC on the system

board.

❑ If an error message is shown on the display, perform Check 1.

❑ If there is no error message, go to Procedure 2.

❑ If the test program is properly loaded, go to Procedure 3.

Check 1 If one of the following error messages is displayed on the screen, tap the display or

press the F1 key as instructed. These errors occur when the system configuration

preserved in RTC memory (CMOS-type memory) is not the same as the actual

configuration or when data is lost.

Tapping the display or pressing the F1 key as instructed causes the SETUP menu

to appear. If error message (b) appears often when power is turned on, replace

the RTC battery. If any other error message is displayed, perform Check 2.

(a) *** Error in CMOS. Bad HDD type ***

Check system. Then tap any point on the screen

with the stylus or press [F1] key.

(b) *** Error in CMOS. Bad battery ***

Check system. Then tap any point on the screen

with the stylus or press [F1] key.

(c) *** Error in CMOS. Bad check sum ***

Check system. Then tap any point on the screen

with the stylus or press [F1] key.

(d) *** Error in CMOS. Bad memory configuration ***

Check system. Then tap any point on the screen

with the stylus or press [F1] key.

(e) *** Error in CMOS. Bad time function ***

Check system. Then tap any point on the screen

with the stylus or press [F1] key.

Check 2 If the following error message is displayed, tap the display or press any key as the

message instructs.

WARNING: RESUME FAILURE.

TAP ANY POINT ON SCREEN WITH STYLUS PEN OR PRESS

ANY KEY TO CONTINUE.

The error message appears when data stored in RAM under the resume function is

lost because the battery is discharged or the system board is damaged. Go to

Procedure 2.

If any other message appears, perform Check 3.

T200/T200CS 2-11

Check 3 The IRT checks the system board. When the IRT detects an error, the system

stops or an error message appears.

❑ If one of the following error messages; (1) through (17), (19), (20), (25) or

(26), is displayed, replace the system board.

❑ If error message (18) is displayed, go to the Keyboard Troubleshooting

Procedures in Section 2.7.

❑ If error message (21) or (22) is displayed, go to the HDD Troubleshooting

Procedures in Section 2.6.

❑ If error message (23) or (24) is displayed, go to the FDD Troubleshooting

Procedures in Section 2.5.

(1) CPU ERROR

(2) SYSTEM ROM CHECK SUM ERROR

(3) PIT ERROR

(4) MEMORY REFRESH ERROR

(5) TIMER OUT ERROR

(6) FIRST 64KB MEMORY ERROR

(7) FIRST 64KB MEMORY PARITY ERROR

(8) VRAM ERROR

(9) KBC ERROR

(10) SYSTEM MEMORY ERROR

(11) SYSTEM MEMORY PARITY ERROR

(12) EXTENDED MEMORY ERROR

(13) EXTENDED MEMORY PARITY ERROR

(14) DMA PAGE REGISTER ERROR

(15) DMAC #1 ERROR

(16) DMAC #2 ERROR

(17) PIC #1 ERROR

(18) PIC #2 ERROR

(19) KEYBOARD ERROR

(20) HDC ERROR

(21) HDD #0 ERROR

(22) HDD #1 ERROR

(23) NO FDD ERROR

(24) FDC ERROR

(25) TIMER INTERRUPT ERROR

(26) RTC UPDATE ERROR

2-12 T200/T200CS

Procedure 2 Printer Port LED Check on Boot Mode

The printer port LED displays IRT and test status by turning lights on and off as an eight-digit

binary value for boot mode. Figure 2-2 shows the printer port LED.

NOTE: When performing this check, the Power-up Mode option in the SETUP program must be set to boot mode.

Figure 2-2 Printer Port LED

To use the printer port LED, follow these steps:

1. Turn on the computer's power, then set to boot mode.

2. Turn off the computer's power.

3. Connect the parallel cable (standard equipment) to the PRT port.

4. Plug the printer port LED into the computer's parallel cable.

5. Connect the external keyboard to the KB port.

6. Hold down the space bar and turn on the computer's power.

7. Read the LED status from left to right.

8. Convert the status from binary to hexadecimal notation.

9. If final LED status is FFh (normal status), go to Procedure 3.

10. If final LED status matches any of the test status values in Table 2-1, perform

Check 1.

NOTE: If an error condition is detected by the IRT, the printer port LED displays an

error code after the IRT ends. For example, when the printer port LED displays 1F

and halts, the IRT has already completed display initialization. In this instance, the

IRT indicated an error was detected during system memory test.

T200/T200CS 2-13

Table 2-1 Printer Port LED Boot Mode Error Status (1/2)

Error status Test item Message

System test 01H Test start

02H PIT test end

03H SM-RAM stack enable

04H CMOS test end

05H KBC initialization, self-test-

skip-request-test and

tablet initialization end

06H DRAM size test end

07H System BIOS ROM/RAM

copy end

08H Display control end

09H Test end

0AH∗ First 64KB memory test FIRST 64KB MEMORY ERROR

0BH** System memory -

initialization

0CH System initialization 0DH Interrupt vector -

initialization

18H PIC initialization -

1FH Display initialization CRTC ERROR

VRAM ERROR

READ DATA = XXXXXXXXH

WRITE DATA = XXXXXXXXH

25H System memory test SYSTEM MEMORY ERROR

ADDRESS = XXXXXXXXH

READ DATA = XXXXXXXXH

WRITE DATA = XXXXXXXXH

SYSTEM MEMORY PARITY ERROR

ADDRESS = XXXX0000H - XXXXFFFFH

30H (Error) Extended memory test EXTENDED MEMORY ERROR

33H (Normal) ADDRESS = XXXXXXXXH

READ DATA = XXXXXXXXH

WRITE DATA = XXXXXXXXH

EXTENDED MEMORY PARITY ERROR

ADDRESS = XXXX0000H - XXXXFFFFH

40H* DMA page register test DMA PAGE REGISTER ERROR

READ DATA = XXH

WRITE DATA = XXH

41H* DMAC test DMAC #1 ERROR

READ DATA = XXXXH

WRITE DATA = XXXXH

42H DMAC initialization -

2-14 T200/T200CS

DMAC #2 ERROR

READ DATA = XXXXH

WRITE DATA = XXXXH

Table 2-1 Printer Port LED Boot Mode Error Status (2/2)

Error status Test item Message

4AH* PIC test PIC #1 ERROR

READ DATA = XXH

WRITE DATA = XXH

PIC #2 ERROR

READ DATA = XXH

WRITE DATA = XXH

50H Mouse initialization 55H KBC initialization KBC ERROR

5AH Boot password1 -

(checks for access right)

60H HDD initialization HDC ERROR

HDC #0 ERROR

HDC #1 ERROR

65H FDD initialization NO FDD ERROR

FDD ERROR

70H Printer test 80H RS-232-C test 90H Timer initialization TIMER INTERRUPT ERROR

RTC UPDATE ERROR

A0H NDP initialization A6H Expansion I/O ROM C0H Boot password2 -

(checks for no access right)

FEH Pre-boot setup FFH Expansion system ROM -

NOTES:

* These error codes are not displayed on hot boot mode.

** This error code is not displayed on cold boot mode.

Check 1 If any of the following error codes are displayed, go to Procedure 5.

01h, 02h, 03h, 04h, 05h, 06h, 07h, 08h, 09h, 0Ah, 0Bh, 0Ch, 0Dh, 18h, 1Fh,

25h, 30h, 33h, 40h, 41h, 42h, 4Ah, 50h, 55h, 5Ah, 60h, 65h, 70h, 80h, 90h,

A0h, A6h, C0h, FEh

Check 2 If error code 5Ah is displayed, go to the HDD Troubleshooting Procedures in

Section 2.6.

Check 3 If error code 60h is displayed, go to the FDD Troubleshooting Procedures in

Section 2.5.

T200/T200CS 2-15

Procedure 3 Printer Port LED Check on Resume Mode

The printer port LED displays IRT and test status by turning lights on and off as an eight-digit

binary value for resume mode.

NOTE: When performing this check, the Power-up option in the SETUP program

must be set to resume mode.

To use the printer port LED, follow these steps:

1. Turn on the computer's power, then set to resume mode.

2. Turn off the computer's power.

3. Connect the parallel cable (standard equipment) to the PRT port.

4. Plug the printer port LED into the parallel cable.

5. Connect the external keyboard to the KB port.

6. Turn on the computer's power.

7. Read the LED status from left to right.

.

8. Convert the status from binary to hexadecimal notation.

9. If final LED status is FFh (normal status), go to Procedure 3.

10. If final LED status matches any of the test status values in Table 2-2, perform

Check 1.

Table 2-2 Printer Port LED Resume Mode Error Status

Error status Meaning of status

00H RAM BIOS error

F0H Press the reset switch.

F1H Suspend process error (The system will suspend while FDD is accessed, etc.)

F2H The system has optional ROM, or optional card (CGA, MDA).

F4H Backup RAM checksum error

F5H Main memory checksum error

F6H Video RAM checksum error

F7H Extended memory checksum error

F8H Backup RAM checksum error

F9H Main memory checksum error

FAH Video RAM checksum error

FBH Extended memory checksum error

FDH Card modem error (Card modem will be removed while system is in resume, etc.)

FEH Password error (The password will be erased before it is suspended.)

2-16 T200/T200CS

Procedure 4 Diagnostic Test Program Execution Check

Execute the following tests from the Diagnostic Test Menu. Refer to Chapter 3, Tests and

Diagnostics, for more information on how to perform the tests.

1. System test

2. Memory test

3. Printer test

4. ASYNC test

5. Real Timer test

6. PCMCIA test

7. Tablet test

8. NDP test

If an error is detected during the tests, go to Procedure 5.

T200/T200CS 2-17

Procedure 5 Connection and Replacement Check

The system board(s) may be disconnected or damaged. Disassemble the computer following

the steps described in Chapter 4, Replacement Procedures, and check the connection between

the upper system board and lower system board, and other components. After checking the

connection, perform the following checks.

If the IRT test (Boot mode) detects any of the following codes, go to Check 1.

FFH (first), 01H, 04H, 06H, 07H, 08H, 0BH, 0CH, 0DH, 18H, 30H, 33H, 40H,

41H, 42H, 4AH, 50H, 5AH, 60H, 65H, 70H, 80H, 90H, A0H, C0H, FEH

If the IRT test (Boot mode) detects any of the following codes, go to Check 2.

02H, 03H, 05H, 09H, 0AH, 1FH, 55H, A6H

If the IRT test (Resume mode) detects any of the following codes, go to Check 1.

00H, F0H, F1H, F2H, F6H, FAH, FDH

If the IRT test (Resume mode) detects any of the following codes, go to Check 2.

F4H, F5H, F7H, F8H, F9H, FBH, FEH

If any of the following diagnostic tests detects an error, go to Check 1.

System test

NDP test

Printer test

Async test

PCMCIA test

If any of the following diagnostic tests detects an error, go to Check 2.

Memory test

Real Timer test

Tablet test

Check 1 Replace the upper system board with a new one. If the problem still exists, replace

the lower system board with a new one. Refer to Chapter 4 for instructions on

how to remove and replace the upper and lower system boards.

Check 2 Replace the lower system board with a new one. If the problem still exists, replace

the upper system board with a new one. Refer to Chapter 4 for instructions on

how to remove and replace the upper and lower system boards.

2-18 T200/T200CS

2.5 Floppy Disk Drive Troubleshooting

This section describes how to determine if the computer's optional external 3.5-inch floppy

disk drive is functioning properly. If the test program can be loaded, go to Procedure 3.

Otherwise, perform the steps below starting with Procedure 1 and continue as required.

Procedure 1: Functioning External FDD Check

Procedure 2: FDD Connection Check

Procedure 3: Diagnostic Test Program Execution Check

Procedure 1 Functioning External FDD Check

Connect a functioning external 3.5-inch FDD to the computer's FDD port. Check the FDD

operation. If the FDD is operating properly, the user's FDD is malfunctioning. If the FDD

does not operate properly, go to Procedure 2.

Procedure 2 FDD Connection Check

Make sure the external 3.5-inch FDD cable is firmly connected to the FDD port. If this cable

is disconnected, connect it to the FDD port. If the FDD is not functioning properly, replace

the upper system board with a new one and re-start the system. If the problem still exists,

replace the lower system board.

T200/T200CS 2-19

Procedure 3 Diagnostic Test Program Execution Check

The FDD Diagnostic Test program is stored on the T200/T200CS Diagnostics Disk. Run the

diagnostic program. Refer to Chapter 3, Tests and Diagnostics, for more information about

the diagnostics test procedures.

FDD test error codes and their status names are listed in Table 2-3. Verify that the floppy

disk in the FDD is formatted correctly and the write protect tab is disabled. If any other

errors occur while the FDD diagnostics test is executing, go to Check 1.

Table 2-3 Floppy Disk Drive Error Code and Status

Code Status

01h Bad command

02h Address mark not found

03h Write protected

04h Record not found

06h Media removed

08h DMA overrun error

09h DMA boundary error

10h CRC error

20h FDC error

40h Seek error

60h FDD not drive error

80h Time out error

EEh Write buffer error

FFh Data compare error

Check 1 If the following message is displayed, disable the write protect tab on the floppy

disk. If any other message appears, perform Check 2.

Write protected

Check 2 Replace the upper system board with a new one and re-start the system. If the

problem still exists, replace the lower system board.

2-20 T200/T200CS

2.6 Hard Disk Drive Troubleshooting

To determine if the HDD is functioning properly, perform the procedures below starting with

Procedure 1 and continue as instructed.

Procedure 1: Partition Check

Procedure 2: Message Check

Procedure 3: Format Check

Procedure 4: Diagnostic Test Program Execution Check

CAUTION: The contents of the hard disk will be erased when the HDD troubleshooting procedures are executed. Transfer the contents of the hard disk to a floppy disk(s)

using the Toshiba MS-DOS BACKUP command. Refer to the Toshiba MS-DOS

Manual for more information about how to perform the BACKUP command.

Procedure 1 Partition Check

Insert the Toshiba MS-DOS system disk and turn on the computer, then perform the following checks:

Check 1 Type C: and press Enter. Go to Check 2 if the drive will not change to C. Go to

Procedure 2 if the drive changes to C.

Check 2 Type FDISK and press Enter. Choose Display Partition Information from the

FDISK menu. If drive C is listed, go to Check 3. If drive C is not listed, return to

the FDISK menu and choose the option to create a DOS partition on drive C.

Then recheck the system. If the problem still exists, go to Procedure 2.

Check 3 If drive C is listed as active in the FDISK menu, go to Check 4. If drive C is not

listed as active, return to the FDISK menu and choose the option to set the active

partition for drive C. Then recheck the system. If the problem still exists, go to

Procedure 2.

Check 4 Remove the system disk from the FDD and cold boot the computer. If the prob-

lem still exists, go to Procedure 2. Otherwise, the HDD is operating normally.

T200/T200CS 2-21

Procedure 2 Message Check

When the HDD does not function properly, some of the following error messages may appear

on the display. Start with Check 1 below and perform other checks as instructed.

Check 1 If any of the following messages appear, perform Check 2. If the following mes-

sages do not appear, perform Check 4:

HDC ERROR

(After 5 seconds this message will disappear.)

or

HDD #0 ERROR

(After 5 seconds this message will disappear.)

or

HDD #1 ERROR

(After 5 seconds this message will disappear.)

Check 2 If either of the following messages appears, perform Procedure 3. If the following

messages do not appear, perform Check 3.

Insert system disk in drive

Press any key when ready .....

or

Non-System disk or disk error

Replace and press any key

Check 3 Using the Toshiba MS-DOS system disk, install a system program on the hard disk

using the SYS command.

If the following message appears on the display, the system program has been

transferred to the HDD. Restart the computer. If the error message still appears,

perform Check 4.

System transferred

Check 4 The HDD is connected to the system board. Disassemble the computer as de-

scribed in Chapter 4, Replacement Procedures. If the HDD is disconnected, reattach it to the system board and return to Procedure 1. If the HDD is firmly

connected to the system board, perform Procedure 3.

2-22 T200/T200CS

Procedure 3 Format Check

The HDD is formatted using the low-level format program and the MS-DOS FORMAT

program. To format the HDD, start with Check 1 below and perform other steps as required.

Check 1 Using the Toshiba MS-DOS system disk, partition the hard disk using the FDISK

command. Format the hard disk using FORMAT C:/S/U to transfer the system

program to the HDD. If the following message appears on the display, the HDD

is formatted.

Format complete

If any other error message appears on the display, refer to the Toshiba MS-DOS

Manual for more information and perform Check 2.

Check 2 Using the T200/T200CS Diagnostic Disk, format the HDD with a low-level

format option. Refer to Chapter 3, Tests and Diagnostics, for more information

about the diagnostic program.

If the following message appears on the display, the HDD low-level format is

complete. Partition and format the HDD using the MS-DOS FORMAT command.

Format complete

If the HDD cannot be formatted using the Test and Diagnostic program, go to

Procedure 4.

T200/T200CS 2-23

Procedure 4 Diagnostic Test Program Execution Check

The HDD test program is stored on the T200/T200CS Diagnostics Disk. Perform all of the

HDD tests in the Hard Disk Drive Test. Refer to Chapter 3, Tests and Diagnostics, for more

information about the HDD test program.

If an error is detected during the HDD test, an error code and status will be displayed; perform Check 1. Error codes and status are listed in Table 2-4. If an error code is not

generated, the HDD is operating properly.

Table 2-4 Hard Disk Drive Error Code and Status

Code Status

01h Bad command

02h Address mark not found

04h Record not found

05h HDC not reset error

07h Drive not initialized

08h HDC overrun (DRQ)

09h DMA boundary error

0Ah Bad sector

0Bh Bad track error

10h ECC error

11h ECC recover enable

20h HDC error

40h Seek error

80h Time out error

AAh Drive not ready

BBh Undefined error

CCh Write fault

E0h Status error

EEh Access time out error

FFh Data compare error

Check 1 Replace the HDD unit following the instructions in Chapter 4, Replacement

Procedures. If the HDD is still not functioning properly, perform Check 2.

Check 2 Replace the lower system board following the instructions in Chapter 4, Replace-

ment Procedures. If the problem still exists, replace the upper system board.

2-24 T200/T200CS

2.7 Keyboard Troubleshooting

To determine if the keyboard is functioning properly, perform the following procedures. Start

with Procedure 1 and continue as instructed.

Procedure 1: Functioning Keyboard Check

Procedure 2: External Keyboard Connection Check

Procedure 3: Diagnostic Test Program Execution Check

Procedure 1 Functioning Keyboard Check

Connect a functioning keyboard to the computer's KB port. Check the keyboard's functions.

If the keyboard is functioning properly, the user's keyboard is malfunctioning. If the keyboard

is not functioning properly, go to Procedure 2.

Procedure 2 External Keyboard Connection Check

Make sure the external keyboard cable is firmly connected to the KB port. If this cable is

disconnected or loose, connect it to the KB port. If the external keyboard still does not

function properly, go to Procedure 3.

Procedure 3 Diagnostic Test Program Execution Check

Execute the Keyboard Test in the Diagnostic Program. Refer to Chapter 3, Tests and

Diagnostics, for more information on how to perform the test program.

If an error occurs, replace the upper system board with a new one and re-start the system. If

the problem still exists, replace the lower system board.

T200/T200CS 2-25

2.8 Display Troubleshooting

This section describes how to determine if the display is functioning properly. Start with

Procedure 1 and continue as instructed.

Procedure 1: Brightness and Contrast Control Check

Procedure 2: External CRT Check

Procedure 3: Diagnostic Test Program Execution Check

Procedure 4: Connector Check

Procedure 5: Replacement Check

Use the checklist below to determine which procedure to begin with:

❑ Display is dark

: Go to Procedure 1

❑ Backlight does not light.

Characters are not displayed.

Abnormal lines are displayed.

Some pixels do not light.

If the backlight lights but no characters are displayed.

: Go to Procedure 4

❑ Any other problem.

: Go to Procedure 3

Procedure 1 Brightness and Contrast Control Check

Change the brightness and contrast by tapping the adjust point of the display with the stylus.

If the brightness and contrast do not change, go to Procedure 4.

Procedure 2 External CRT Check

Connect the external CRT to the computer's external monitor port, then boot the computer.

If the external CRT works correctly, the internal LCD display may be damaged. Go to Procedure 4.

If the external CRT appears to have the same problem as the internal LCD, the display controller may be damaged. Go to Procedure 3.

2-26 T200/T200CS

Procedure 3 Diagnostic Test Program Execution Check

The Display Test program is stored on the T200/T200CS Diagnostic Disk. This program

checks the display controller on the system board. After loading Toshiba MS-DOS, run the

Diagnostic Program. Refer to Chapter 3, Tests and Diagnostics, for details.

If an error is detected, go to Procedure 4. If an error is not detected, the display is functioning properly.

T200/T200CS 2-27

Procedure 4 Connector Check

The display system has an LCD panel, FL unit, tablet, and FL inverter board. These components are connected to the system board.

Disassemble the display unit and check the cable connections shown in Figures 2-3 and 2-4.

Refer to Chapter 4, Replacement Procedures, for more information about how to disassemble

the computer.

If any of these cables is not connected, firmly re-connect it and repeat Procedures 1, 2, and 3.

If the problem still exists, perform Procedure 5.

Figure 2-3 T200 Display Connection

Figure 2-4 T200CS Display Connection

2-28 T200/T200CS

Procedure 5 Replacement Check

The FL inverter board, display module, and system board are connected to the display circuits.

Any of these components may be damaged. Refer to Chapter 4, Replacement Procedures, for

disassembly instructions and then perform the following checks:

❑ If the FL does not light, perform Check 1.

❑ If characters are not displayed clearly, perform Check 1.

❑ If some screen functions do not operate properly, perform Check 1.

Check 1 Replace the display module and test the display again. If the problem persists,

perform Check 2.

Check 2 Replace the FL inverter board and test the display again. If the problem persists,

perform Check 3.

Check 3 Replace the display cable and test the display again. If the problem persists,

perform Check 4.

Check 4 The upper system board may be damaged. Replace the upper system board and

test the display again. If the problem persists, perform Check 5.

Check 5 The lower system board may be damaged. Replace the lower system board.

T200/T200CS 2-29

2.9 Tablet Troubleshooting

To determine if the tablet is functioning properly, perform the following procedures. Before

diagnosing the tablet, however, try using it. If the writing does not feel right, replace the

stylus tip. If it still has trouble, start with Procedure 1.

Procedure 1: Diagnostic Test Program Execution Check

Procedure 2: Connector and Replacement Check

Procedure 1 Diagnostic Test Program Execution Check

Execute the Tablet Test of the Diagnostic Program. Refer to Chapter 3, Tests and Diagnostics, for more information on how to perform the test program.

If an error occurs, go to Procedure 2.

Procedure 2: Connector and Replacement Check

The tablet is connected to the system board by a cable. This cable may be disconnected or

damaged. Disassemble the computer as described in Chapter 4, Replacement Procedures, and

perform the following checks:

Check 1 Make sure the tablet cable is not damaged and is connected to the lower system

board. If this cable is damaged, replace it with a new one. If the cable is disconnected, firmly re-connect it. Perform Procedure 1 again. If the tablet is still not

functioning properly, perform Check 2.

Check 2 The tablet may be damaged. Replace the tablet with a new one. Refer to Chapter

4, Replacement Procedures, for more information. If the tablet is still not functioning properly, perform Check 3.

Check 3 The lower system board may be damaged. Replace the lower system board. Refer

to the instructions in Chapter 4, Replacement Procedures for more information. If

the tablet is still not functioning, replace the upper system board.

2-30 T200/T200CS

3.1 The Diagnostic Test

This chapter explains how to use the T200/T200CS's Diagnostic Test program to test hardware module functions. The Diagnostics Test Program is stored on the Diagnostic Disk. The

Diagnostic Test consists of 20 programs grouped into the Service Program Module (DIAGNOSTICS MENU) and Test Program Module (DIAGNOSTIC TESTS).

The DIAGNOSTICS MENU consists of the following eight functions:

❑ DIAGNOSTIC TEST

❑ HARD DISK FORMAT

❑ HEAD CLEANING

❑ LOG UTILITIES

❑ RUNNING TEST

❑ FDD UTILITIES

❑ SYSTEM CONFIGURATION

❑ SETUP

The DIAGNOSTIC TESTS menu contains the following twelve functional tests:

❑ SYSTEM TEST

❑ MEMORY TEST

❑ KEYBOARD TEST

❑ DISPLAY TEST

❑ FLOPPY DISK TEST

❑ PRINTER TEST

❑ ASYNC TEST

❑ HARD DISK TEST

❑ REAL TIMER TEST

❑ PCMCIA TEST

❑ TABLET TEST

❑ NDP TEST

The following equipment is needed to perform some test programs.

❑ T200/T200CS Diagnostics Disk (all tests)

❑ Optional external 3.5-inch FDD

❑ Formatted working disk for the floppy disk drive test

❑ Cleaning kit to clean floppy disk drive heads (Head Cleaning)

❑ Printer wraparound connector for the printer wraparound (Printer) test

❑ RS-232C wraparound connector for the RS-232C port wraparound (ASYNC) test

❑ Parallel cable for the printer wraparound (Printer) test

❑ External PS/2 type keyboard (Keyboard test)

❑ PCMCIA wraparound connector for the I/O card (PCMCIA) test

❑ Stylus

The following sections detail DIAGNOSTIC TESTS menu tests. Refer to sections 3.18

through 3.24 for detailed information on the other Service Program Module functions.

T200, T200CS 3-1

3.2 Executing the Diagnostic Test

To start the Diagnostic Test Program follow the steps below. The Diagnostic Test Program

can be executed with either the stylus or an optional keyboard.

1. Connect an optional 3.5-inch floppy disk drive.

2. Connect an external keyboard (Keyboard Test), RS-232C wraparound connector

(Async Test), parallel cable (Printer Test), PCMCIA wraparound connector

(PCMCIA Test), and printer wraparound connector (Printer Test) to each port.

3. Insert the Diagnostic disk and turn on the computer.

4. A cross-hair cursor will appear. Tap the cursor or press Enter.

The following menu will appear:

TOSHIBA Personal Computer XXXXX DIAGNOSTICS

Version 1.XX (C) Copyright TOSHIBA Corp. 19XX

DIAGNOSTICS MENU :

1 - DIAGNOSTIC TEST

2 - HARD DISK FORMAT

3 4 - HEAD CLEANING

5 - LOG UTILITIES

6 - RUNNING TEST

7 - FDD UTILITIES

8 - SYSTEM CONFIGURATION

9 - EXIT TO MS-DOS

0 - SETUP

Break Break

0 A

1 B

2 C

3 D

4 E

5 F

6

7 Up-Aw

8 Dn-Aw

9 R-Aw

R L-Aw

BS Esc

↑ ↓ → ← : Select items Enter : Specify Esc : Exit

NOTES: • To use the stylus, tap the appropriate number or command in the

menu at right. "Up-Aw" is up arrow, "Dn-Aw" is down arrow, "R-Aw'"

is right arrow, "L-Aw" is left arrow, "Esc" is escape and "BS" is back

space.

• To use a keyboard, set the highlight bar to the desired test, and press

Enter.

• To exit the menu, tap or press Esc. If a test program is in progress,

tap "Break" or press Ctrl+Break to exit the test program.

3-2 T200, T200CS

Enter Enter

5. To execute the DIAGNOSTIC TEST MENU from the DIAGNOSTICS MENU,

move the highlight bar to 1, then tap or press Enter. The following DIAGNOSTIC TEST MENU will appear:

TOSHIBA Personal Computer XXXXX DIAGNOSTICS

Version 1.XX (C) Copyright TOSHIBA Corp. 19XX

DIAGNOSTICS TEST MENU :

1 - SYSTEM TEST

2 - MEMORY FORMAT

3 - KEYBOARD TEST

4 - DISPLAY TEST

5 - FLOPPY DISK TEST

6 - PRINTER TEST

7 - ASYNC TEST

8 - HARD DISK TEST

9 - REAL TIMER TEST

10 - PCMCIA TEST

11 TABLET TEST

12 - NDP TEST

88 - ERROR RETRY COUNT SET : ( FDD & HDD )

99 - EXIT TO DIAGNOSTICS MENU

Break Break

0 A

1 B

2 C

3 D

4 E

5 F

6

7 Up-Aw

8 Dn-Aw

9 R-Aw

R L-Aw

BS Esc

↑ ↓ → ← : Select items Enter : Specify Esc : Exit

Enter Enter

Refer to sections 3.4 through 3.15 for detailed descriptions of Diagnostic Tests 1

through 12. Function 88 sets the floppy disk drive and hard disk drive error retry

count. Function 99 exits the submenus of the Diagnostic Test and returns to the

DIAGNOSTICS MENU.

T200, T200CS 3-3

6. Move the highlight bar to the option you want to execute and tap or press Enter.

When you select SYSTEM TEST, the following message will appear:

SYSTEM TEST TTSSDSS

SUB TEST : XX

PASS COUNT : XXXXX ERROR COUNT: XXXXX

WRITE DATA : XX READ DATA : XX

ADDRESS : XXXXX STATUS : XXX

error status name

SUB-TEST MENU :

01 - ROM checksumum

02 - HW status

03 - Version check

99 - Exit to DIAGNOSTIC TEST MENU

Break Break

0 A

1 B

2 C

3 D

4 E

5 F

6

7 Up-Aw

8 Dn-Aw

9 R-Aw

R L-Aw

BS Esc

↑ ↓ → ← : Select items Enter : Specify Esc : Exit

Enter Enter

3-4 T200, T200CS

7. Move the highlight bar to the desired option from the subtest menu and tap or

press Enter. The following message will appear:

TEST LOOP : YES NO

Selecting YES increases the pass counter by one each time the test cycle ends and

restarts.

Selecting NO returns the sub-test menu to the main menu after the test is complete.

8. After making the Test Loop selection, the following message will appear:

ERROR STOP: YES NO

Selecting YES stops the test program when an error is found and displays the

operation guide on the right side of the display screen as shown below:

ERROR STATUS NAME [[ HALT OPERATION ]]

1: Test end

2: Continue

3: Retry

These three selections have the following functions:

1: Terminates the test program and exits to the subtest menu.

2: Continues the test.

3: Restarts the test from the beginning.

Selecting NO keeps the test running even if an error is found.

9. Move the highlight bar to the desired option and tap or press Enter.

Table 3-1 in Section 3.3 describes the function of each test on the subtest menu.

Table 3-3 in Section 3.16 describes the error codes and error status for each error.

T200, T200CS 3-5

3.3 Subtest Names

Table 3-1 lists subtest names for each test program in the DIAGNOSTIC TESTS menu.

Table 3-1 Subtest Names (1/2)

No. Test name Subtest No. Subtest item

1 SYSTEM 01 ROM checksum

02 H/W status

03 Version check

2 MEMORY 01 RAM constant data

02 RAM address pattern data

03 RAM refresh

04 Protected mode

05 Memory module

06 Backup memory

07 Cache memory

3 KEYBOARD 01 Pressed key code display

4 DISPLAY 01 VRAM read/write

02 Character attributes

03 Character set

04 80x25/30 Character display

05 320x200 Graphics display

06 640x200 Graphics display

07 640x350/400/480 Graphics display

08 Display page

09 “H” pattern display/Border color

10 DAC pallet

11 VGA color graphics display

5 FDD 01 Sequential read

02 Sequential read/write

03 Random address/data

04 Write specified address

05 Read specified address

6 PRINTER 01 Ripple pattern

02 Function

03 Wraparound

3-6 T200, T200CS

Table 3-1 Subtest Names (2/2)

No. Test name Subtest No. Subtest item

7 ASYNC 01 Wraparound (board)

02 Board (#1) <=> board (#2)

03 Point to point (send)

04 Point to point (receive)

05 Interrupt test

8 HDD 01 Sequential read

02 Address uniqueness

03 Random address/data

04 Cross talk & peak shift

05 Write/read/compare (CE)

06 Write specified address

07 Read specified address

08 ECC circuit

09 Sequential write

10 W-R-C specified address

9 REAL TIMER 01 Real time

02 Backup memory

03 Real time carry

10 PCMCIA 01 I/O card test (PCMCIA)

11 TABLET 01 TABLET ADJUST

02 9POINT test

03 CURSOR MOVING test

04 WRITE DOT test

12 NDP 01 NDP test

T200, T200CS 3-7

3.4 System Test

To execute the System Test, select 1 from the DIAGNOSTIC TESTS menu and tap or press

Enter. The system test contains three subtests. Select a subtest and tap or press Enter.

Subtest 01 ROM checksum

ROM checksum tests the system board from address F0000h to FFFFFh

(64KB).

Subtest 02 H/W status

This test reads and displays hardware status as shown below:

76543210

H/W status = 10001000

Bit7 ... =

Bit6 ... CPU clock = 40MHz

Bit5 ... Notch signal = 2HD

Bit4 ... FDD type = 2MB

Bit3 ... =

Bit2 ... Drive A/B = Ext. = B

Bit1 ... External FDD = OFF

Bit0 ... Internal FDD = 2HD

Table 3-2 lists hardware bit status for each bit tested. Press Enter to return to

the Subtest Menu.

Table 3-2 Hardware Bit Status

Bit H/W status 1 0

7 Reserved — —

6 CPU clock speed 20 MHz 40 MHz

5 Media type 2DD 2HD

4 FDD type 1.6 MB 2 MB

3 Reserved — —

2 Drive A/B Ext. = A Ext. = B

1 External FDD ON OFF

0 Internal FDD 2DD 2HD

3-8 T200, T200CS

Subtest 03 Version check

This subtest checks versions for the following items:

❑ BIOS ROM

❑ BOOT ROM

❑ KBC version

❑ PS microprocessor

The subtest compares the items to test program reference data. When the read

information is lower than the reference data, the speaker sounds, and the

following screen image is displayed. Press the S key to exit. The display is

unchanged if the read information is higher.

ROM-BIOS = V1.00 : OK V1.10

ROM(BOOT) = V1.00 : OK V1.00

KBC Version = V1.26 : NG V1.00

PS Micom Version = V1.35 : OK V1.35

Reference data

Current data

T200, T200CS 3-9

3.5 Memory Test

To execute the Memory Test, select 2 from the DIAGNOSTIC TESTS menu and tap or press

Enter. Select a subtest to execute and tap or press Enter.

Subtest 01 RAM constant data (real mode)

This subtest writes constant data to conventional memory (0 to 640 KB), then

reads the new data and compares the result with original data.

Constant data is FFFFh, AAAAh, 5555h, and 0000h.

Subtest 02 RAM address pattern data (real mode)

This subtest writes address pattern data created by the exclusive-ORing

(XORing) to the address segment and address offset in conventional memory

(program end to 640 KB), then reads the new data and compares the result

with original data.

Subtest 03 RAM refresh (real mode)

This subtest writes a 256-byte unit of constant data to conventional memory (0

to 640 KB) then reads the new data and compares the result with original data.

Constant data is AAAAh and 5555h.

NOTE: There is a short delay between write and read operations, depending on

data size.

Subtest 04 Protected mode

This subtest writes constant data and address data to extended memory (from

100000h to the maximum address) then reads new data and compares the

result with original data.

3-10 T200, T200CS

Subtest 05 Memory module

NOTE: To execute this subtest, an optional memory card must be installed in the

computer.

This subtest functions the same as subtest 04 but is used for testing an optional

memory card. Memory module capacity is 2, 4, 8, or 16 MB.

After selecting subtest 05, the following message will appear:

Extended memory size (1:2 MB,2:4 MB,3:8 MB,4:16 MB) ?

Select the number corresponding to the installed memory card.

Subtest 06 Backup Memory

This subtest writes constant data to memory from address C8000h to CFFFFh,

then reads new data and compares the result with original data.

Constant data is 0000h, 5555h, AAAAh, and FFFFh.

Subtest 07 Cache memory

To test cache memory, a pass-through write-read comparison of ‘5A’ data is

run repeatedly to a test area ('7000':'Program' size to '7000':='7FFF' (32 KB))

to check hit-miss ratio (on/off status). One test takes 3 seconds.

Number of miss hit < Number of hit → OK

Number of miss hit > Number of hit → Fail

T200, T200CS 3-11

3.6 Keyboard Test

To execute the Keyboard Test, select 3 from the DIAGNOSTIC TESTS menu, tap or press

Enter, and follow the directions displayed on the screen. Subtest 01 tests keyboard actions.

Tap or press Enter to select the subtest.

Subtest 01 Pressed key code display

When a key is pressed, the scan code, character code, and key top name are

displayed on the screen in the format shown below. The Ins, Caps Lock,

Num Lock, Scroll Lock, Alt, Ctrl, Left Shift, and Right Shift keys are

displayed in reverse screen mode when pressed. Scan codes, character codes,

and key top names are shown in Appendix E.

KEYBOARD TEST IN PROGRESS 301000

Scan code =

Character code =

Keytop =

Ins Lock Caps Lock Num Lock Scroll Lock

Alt Ctrl Left Shift Right Shift

PRESS [Enter] KEY

3-12 T200, T200CS

3.7 Display Test

To execute the Display Test, select 4 from the DIAGNOSTIC TESTS menu and tap or press

Enter. Eleven subtests test the display in various modes. Select a subtest and tap or press

Enter.

NOTE: In the Display Test, the screen does not display "Break" or "Enter." Tap

the upper right corner of the screen to enter "Break" or the lower right corner to enter

"Enter."

Subtest 01 VRAM Read/Write

This subtest writes constant data FFFFh, AAAAh, 5555h, 0000h and address

data to video RAM (1MB). (CGA (B8000H ~ BFFFFH: 32KB) and VGA

(A0000H ~ AFFFFH:64KB*4*4)). This data is then read from the video

RAM and compared to original data.

Subtest 02 Character Attributes (mode 1, 13h)

This subtest displays four character attribute modes; normal, intensified,

reverse, and blinking. The character attribute modes display foreground and

intensified color (16 colors or 16-level gray scale) using black, blue, red,

magenta, green, cyan, yellow, and white from the color display. The following

display appears when the subtest is executed.

CHARACTER ATTRIBUTES

NEXT LINE SHOWS NORMAL DISPLAY.

NNNNNNNNNNNNNNNNNNNNNNNNNNNNNN

NEXT LINE SHOWS INTENSIFIED DISPLAY.

IIIIIIIIIIIIIIIIIIIIIIIIIIIIII

NEXT LINE SHOWS REVERSE DISPLAY. RRR

R RRRRRRRRRRRRRRRRRRRRRRRRRRRRRR

NEXT LINE SHOWS BLINKING DISPLAY

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

00 08 ; BLACK

01 09 ; BLUE

04 0C ; RED

05 0D ; MAGENTA

02 0A ; GREEN

03 0B ; CYAN

06 0E ; YELLOW

07 0F ; WHITE

PRESS [Enter] KEY

T200, T200CS 3-13

Pressing Enter causes 16 colors or gray scales of mode 13h to appear in the

320x200 graphics mode as shown below:

320*200 GRAPHICS DISPLAY [ 13 ]

BLACK

BLUE

GREEN

CYAN

RED

MAGENTA

BROWN

WHITE

GRAY

LIGHT BLUE

LIGHT GREEN

LIGHT CYAN

LIGHT RED

LIGHT MAGENTA

YELLOW

INTENSE WHITE

PRESS [Enter] KEY

Pressing Enter toggles between the two displays.

To exit to the DISPLAY TEST menu, press Ctrl + Break.

Subtest 03 Character Set

In this subtest, the character set (address 00h to FFh) is displayed in the 40x25

character mode as shown below.

PRESS [Enter] KEY

To exit to the DISPLAY TEST menu, press Ctrl + Break.

3-14 T200, T200CS

Subtest 04 80x25/30 Character Display (mode 3, 12)

In this subtest, the character string is displayed shifting one character to the right,

line by line in the 80x25 and 80x30 character modes as shown below.

80*XX CHARACTER DISPLAY

012345678901234567890123456789012345678901234567890123456789012345678901234567

!”#$%&’()*+,-./0123456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_‘abcdefghijklm

!”#$%&’()*+,-./0123456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_‘abcdefghijklmn

“#$%&’()*+,-./0123456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_`abcdefghijklmno

#$%&’()*+,-./0123456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_‘abcdefghijklmnop

$%&’()*+,-./0123456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_‘abcdefghijklmnopq

%&’()*+,-./0123456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_‘abcdefghijklmnopqr

&’()*+,-./0123456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_‘abcdefghijklmnopqrs

‘()*+,-./0123456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_`abcdefghijklmnopqrst

()*+,-./0123456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_‘abcdefghijklmnopqrstu

)*+,-./0123456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_‘abcdefghijklmnopqrstuv

*+,-./0123456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_‘abcdefghijklmnopqrstuvw

+,-./0123456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_‘abcdefghijklmnopqrstuvwx

,-./0123456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_‘abcdefghijklmnopqrstuvwxy

-./0123456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_‘abcdefghijklmnopqrstuvwxyz

./0123456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_‘abcdefghijklmnopqrstuvwxyz{

/0123456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_‘abcdefghijklmnopqrstuvwxyz{|

0123456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_‘abcdefghijklmnopqrstuvwxyz{|}

123456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_‘abcdefghijklmnopqrstuvwxyz{|}~

23456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_‘abcdefghijklmnopqrstuvwxyz{|}~∆

3456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_‘abcdefghijklmnopqrstuvwxyz{|}~∆

456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_‘abcdefghijklmnopqrstuvwxyz{|}~∆Çü

PRESS[ENTER]KEY

Pressing Enter toggles between tests. To exit to the DISPLAY TEST menu, press

Ctrl + Break.

Subtest 05 320x200 Graphics Display (mode 4,D)

This subtest displays two color sets for the color display in 320x200 dot graphics

mode 4 and D. One example is shown below:

320*200 GRAPHICS DISPLAY

COLOR SET X : [X]

GREEN RED BROWN

CYAN MAGENTA WHITE

PRESS [Enter] KEY

Pressing Enter toggles between tests. To exit to the DISPLAY TEST menu, press

Ctrl + Break.

T200, T200CS 3-15

Subtest 06 640x200 Graphics Display (mode 6, E)

This subtest displays even, odd, and all dots in 640x200 dot graphics mode 6 and E

as shown below:

640*200 GRAPHICS DISPLAY : [x]

EVEN DOTS ODD DOTS ALL DOTS

DRIVEN DRIVEN DRIVEN

PRESS [ENTER] KEY

To exit to the DISPLAY TEST menu, press Ctrl + Break.

Subtest 07 640x350/400/480 Graphics Display (mode 10, 74, 12)

This subtest displays even, odd, and all dots in 640x350, 640x400 and 640x480

dot graphics mode 10, 74, 12 as shown below:

640*XXX GRAPHICS DISPLAY

EVEN DOTS ODD DOTS ALL DOTS

DRIVEN DRIVEN DRIVEN

PRESS [ENTER] KEY

Press Enter to change displayed image size. To exit to the DISPLAY TEST

menu, press Ctrl + Break.

3-16 T200, T200CS

Subtest 08 Display Page

This subtest confirms that pages can be changed in order from 0 through 7 in 40x25

character mode.

DISPLAY PAGE 0

0000000000000000000000000000000000000000

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0000000000000000000000000000000000000000

Press Ctrl + Break to exit after test completion and return to the DISPLAY

TEST menu.

Subtest 09 H Pattern Display/Border Color

This subtest displays 2000 H characters on the entire screen, as shown below.

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

Pressing Enter displays the following message:

Setting the color CRT (1:yes/2:no)

If an external CRT is connected to the computer, choose 1 to display the following

message:

[Border color test (press [Enter] key 7 times)]

Press Enter to execute the border color test.

To exit to the DISPLAY TEST menu, press Ctrl + Break.

T200, T200CS 3-17

Subtest 10 DAC Pallet

This subtest writes the ‘2A’ and ‘15’ data to 6 bits of 256x3 (RGB), then reads

new data and compares the result with original data.

[ DAC pallet W-R-CMP test ] = (about 5 seconds)

[ Processor latch test ]

Processor latch test (1:256 times, 2:endless) ?

To exit, press Ctrl + Break. Then press Enter.

Subtest 11 VGA color graphics display

This subtest displays eight screens. The first screen shows many colors (mode 13)

at once. The next three display 64 shades (mode 13) of red, green, and blue

successively. Next, a single screen displays many colors (mode 5F). The last three

display 256 shades of red, green and blue.

Press Enter to change the display. Press Ctrl + Break to exit.

3-18 T200, T200CS

3.8 Floppy Disk Test

CAUTION: Before running the floppy disk test, prepare a formatted work disk. Remove the Diagnostics Disk and insert a work disk into the FDD. The contents of the

floppy disk will be erased.

To execute the Floppy Disk Test, select 5 from the DIAGNOSTIC TESTS menu, tap or press

Enter, and follow the directions displayed on the screen. Five subtests test the internal floppy disk

drive. The following messages will appear after the Floppy Disk Test is selected. Answer each

question with an appropriate response to execute the test.

1. Select the test drive number of the floppy disk drive to be tested and tap or press

Enter.

Test drive number select : FDD#1 FDD#2 FDD1&2

2. Select the media type of the floppy disk to be tested, and tap or press Enter.

Media in drive #X mode : 2DD 2D, 2D-2HD 2HD

3. Select the track to start the test on and tap or press Enter. Tapping or pressing

Enter alone sets the start track to zero.

Test start track (Enter:0/dd:00-79) ?

4. The floppy disk test menu will appear after the start track number is selected. Select a

subtest number and tap or press Enter. The following message will appear during the

test.

FLOPPY DISK XXXXXXX

SUB-TEST : XX

PASS COUNT : XXXXX ERROR COUNT : XXXXX

WRITE DATA : XX READ DATA : XX

ADDRESS : XXXXXX STATUS : XXX

The first three digits in the ADDRESS number indicate the cylinder being tested. The

fourth indicates the head, and the last two indicate the sector being tested.

The first digit in the STATUS number indicates the drive being tested and the last two

indicate the error status code as explained in Table 3-3.

T200, T200CS 3-19

Subtest 01 Sequential Read

This subtest performs a Cyclic Redundancy Check (CRC) that continuously reads

all tracks on a floppy disk. The following tracks are read according to the media

type in the FDD:

Double-sided, double-density (2D): Tracks 0 to 39.

Double-sided, double-density, double-track (2DD) and double-sided,

high-density, double-track (2HD): Tracks 0 to 79.

A start track is specified when the FDD test is started from the Diagnostic Test

Menu. Refer to step 3 at the beginning of this section to set the start track.

Subtest 02 Sequential Read/Write

This subtest continuously writes data pattern B5ADADh to all the specified tracks

selected in subtest 01. Data is then read and compared to the original data.

Subtest 03 Random Address/Data

This subtest writes random data to random addresses on all tracks defined in

subtest 01. Data is then read and compared to the original data.

Subtest 04 Write Specified Address

This subtest writes specified data to a specified track, head, and address.

When this subtest is selected, the following prompts appear on the screen in succession.

TEST DATA ??

TRACK NO ??

HEAD NO ??

Subtest 05 Read Specified Address

This subtest reads data from a specified track, head, and address.

When this subtest is selected, the following prompts appear on the screen in succession.

TRACK NO ??

HEAD NO ?

3-20 T200, T200CS

3.9 Printer Test

To execute the Printer Test, select 6 from the DIAGNOSTIC TESTS menu, tap or press

Enter, and follow the directions displayed on the screen. Three subtests test printer output.

NOTE: An IBM-compatible printer with a parallel cable must be connected to the

system to execute this test.

The following message will appear when the printer test is selected:

channel#1 = XXXXh

channel#2 = XXXXh

channel#3 = XXXXh

Select the channel number (1-3) ?

The printer I/O port address is specified by the XXXXh number. The T200/T200CS supports

three printer channels. Select the appropriate printer channel number, and tap or press Enter

to execute a subtest.

Subtest 01 Ripple Pattern

This subtest prints characters for codes 20h through 7Eh line-by-line while