Page 1

6F3B0253

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

UM-TS01∗∗∗-E031

PROGRAMMABLE CONTROLLER

PROSEC

T1- 16S

USER’S MANUAL

−−−− Basic Hardware and Function −−−−

TOSHIBA CORPORATION

Page 2

Important Information

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Misuse of this equipment can result in property damage or human injury.

Because controlled system applications vary widely, you should satisfy yourself

as to the acceptability of this equipment for your intended purpose.

In no event will Toshiba Corporation be responsible or liable for either indirect

or consequential dam age or inju ry that may result from the use of this equipment.

No patent liability is assumed by Toshiba Corporation with respect to use of

information, illustrations, circuits, equipment or examples of applic ation in this

publication.

Toshiba Corporation reserves the right to make changes and improvements to this

publication and/or related products at any time without notice. No obligation shall be

incurred other than as noted in this publication.

This publication is copyrighted and contains proprietary material. No part of this book

may be reproduced, stored in a retrieval system, or transmitted, in any form or by any

means elect rical, mechani c al, photocopying, recording, or otherwise without

obtaining prior written permission from Toshiba Corp oration.

6F3B0253

© TOSHIB A Corpor ation 2001. A ll rights reserv ed

IBM is a registered tr ademark of International B usi ness Machi nes Corpor ation.

MS-DOS and Windows are registered trademarks of Microsoft Corporation.

Publication number: UM-TS01∗∗∗-E031

1st edition A pril 2001, 2nd edition November 2001

Page 3

6F3B0253

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

CE Marking

The Programmable Controller PROSEC T1-16S (hereafter called T1-16S) complies with the

requirements of the EMC Directive 89/336/EEC and Low Voltage Directive 72/23/EEC under the

condition of use according to the instructions described in this manual.

The conte nts of the conformity are sho wn below .

Application of EMC : 89/336/EEC (as amended by 91/263/EEC and 92/31/EEC)

Council Directive LVD : 72/23/EEC (as amended by 93/68/EEC)

Manufacture’s Name : Toshiba Corporation,

Fuchu Operations-Social Infrastructure Systems

Address : 1, Toshiba-Cho

Fuchu-shi

TOKYO 183-8511

Japan

declares, that the product

Product Name : Programmable Controller , T1-16S

Model Number : TDR116S6S, TDR116S6C

TDR116S3S, TDR116S3C

conforms to the following Product Specifications:

EMC

Radiated Interference : EN 55011 Group 1 Class A

Mains Interference : EN 55011 Group 1 Class A

Radiated Susceptibility : ENV50140

Conducted RFI Susceptibility : ENV50141, IEC100-4-6.

Electrostatic Discharge : IEC1000-4-2

Electrical Fast Transient : IEC1000-4-4

LVD : EN61131-2:1995 3.10 Dielectric Properties

4. Mechanical Requirements

Supplementary information :

(1) Included Handy Programmer THP911A*S.

(2) Included each type of associated input/output unit in a typical configuration.

(3) Product must be installed in accordance with manufacturers instructions

Basic Hardware and Function

1

Page 4

6F3B0253

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

UL/c-UL Listing

The Programmable Controller PROSEC T1-16S (hereafter called T1-16S) is UL/c-UL listed as

shown below.

UL and c-UL Listing

File Number : E95637

Product Na me : Programmable Controller , T1-16S

Product Covered : Main Unit

TDR116S6S, TDR116S6C,

TDR116S3S, TDR116S3C

I/O module

TDI116M*S, TDD116M*S, TDO116M*S,

TAD121M*S, TAD131M*S, TDA121M*S, TDA131M*S,

TFR112M*S

Peripherals

TRM102**S, TCU111**S, THP911A*S

UL and c-UL Listing For Use in Hazardous Locations

File Number : E184034

Product Na me : Programmable Controller , T1-16S

Product Covered : Main Unit

TDR116S6S, TDR116S6C

Locations Class : Class I, Division 2, Groups A, B, C, D

Important Notice : 1. THIS EQU I PMENT IS S U ITABLE F OR USE I N CLASS I,

DIVISION 2, GROUPS A, B, C, D OR NON-HAZARDOUS

LOCATIONS ONLY.

2. WARNING - EXPLOSION HAZARD - SUBSTITUTION OF

COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS I,

DIVISION 2.

3. WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT

EQUIPMENT UNLESS POWER HAS BEEN SWITCHED OFF

OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

T1-16S User’s Manual

2

Page 5

Safety Precautions

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

This manual is prepared for users of Toshiba’s Programmable Controller T1-16S.

Read this manual thoroughly before using the T1-16S. Also, keep this manual and related

manuals so that you can read them anytime while the T1-16S is in operation.

General Information

1. The T1-16S has been designed and manufactured for use in an industrial

environment. However, the T1-16S is not intended to be used for systems which may

endanger human life. Consult Toshiba if you intend to use the T1-16S for a special

application, such as transportation machines, medical apparatus, aviation and space

systems, nuclear controls, submarine syste ms, etc.

2. The T1-16S has been manufactured under strict qualit y control. However, to keep

safety of overall automated system, fail-safe systems should be considered outside

the T1-16S.

3. In installation, wiring, operation and maintenance of the T1-16S, it is assumed that the

users have general knowledg e of industrial electric control systems.

If this product is handled or operated improperly, electric al shock , fire o r da m age to

this product could result.

4. This manual has been written for users who are familiar with Programmable

Controllers and industrial control equipment. Contact Toshiba if you have any

questions about this manual.

5. Sample programs and circuits described in this manual are provided for explaining the

operations and applications of the T1-16S. You should test completely if you use them

as a part of your application system.

6F3B0253

Hazard Classifications

In this manual, the following two hazard classifications are used to explain the safety

precautions.

!

WARNING

!

CAUTION

Even a precaution is classified as CAUTION, it may cause serious results depending on

the situation. Observe all the safety precautions described on this manual.

Indicates a potentially hazardous situation which, if not avoided, could

result in death o r serious injury.

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. It may also be used to alert

against unsafe practices.

Basic Hardware and Function

3

Page 6

Safety Precautions

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Installation:

!

CAUTION

1. Excess temperature, humidity, vibration, shocks, or dusty and corrosive gas

environment can cause electrical shock, fire or malfunction. Install and use the T116S and related equipment in the environment described in this manual.

2. Improper installation directions or insufficient installation can cause fire or the units

to drop. Install the T1-16S and related equipment in accordance with the instructions

described in this manual.

3. Turn off power before installing or removing any units, modules, racks, terminal

blocks or battery. Failure to do so can cause electrical shock or damage to the T116S and related equipment.

6F3B0253

4. Entering wire scra ps or other f o reign debris into t o the T1 -1 6S and related

equipment can cause fire or malfunction. Pay attention to prevent entering them into

the T1-16S and related equipment during installation and wiring.

5. Turn off power immediately if the T1-16S or related equipment is emitting smoke or

odor. Operation under such situation can cause fire or electrical shock. Also

unauthorized repairing will cause fire or serious accidents. Do not a ttemp t to repair.

Contact Toshiba for repairing.

Wiring:

!

CAUTION

1. Turn off power before wiring to minimize the risk of electrical shock .

2. Exposed conductive parts of wire can cause electrical shock. Use crimp-style

terminals with insulating sheath or insulating tape to cover the conductive parts. Also

close the terminal covers securely on the terminal blocks when wiring has been

completed.

3. Operation without grounding may cause electrical shock or malfunction. Connect the

ground terminal on the T1-16S to the system ground.

4. Applying excess power voltage to the T1-16S can cause explosion or fire. Apply

power of the specified ratings described in the manual.

5. Improper wiring can cause fire, electrical shock or malfunction. Observe local

regulations on wiring and grounding.

T1-16S User’s Manual

4

Page 7

Safety Precautions

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Operation:

!

WARNING

1. Configure emergency stop and safety interlocking circuits outside the T1-16 S.

Otherwise, malfunction of the T1-16S can cause injury or serious accidents.

!

CAUTION

2. Operate the T1-16S and the related modules with closing the terminal covers. Keep

hands away from terminals while power on, to avoid the risk of electrical shock.

6F3B0253

3. When you attempt to perform force outputs, RUN/HALT controls, etc. duri ng

operation, carefully check for safety.

4. Turn on power to the T1-16S b e fore turning on power to the loads. Failure to do so

may cause unexpected behavior of the loads.

5. Do not use any modules of the T1-16S for the purpose other than specified. This

can cause electrical shock or injury.

6. Do not modify the T1-16S and related equipment in hardware nor software. This can

cause fire, electrical shock or injury.

7. Configure the external circuit so that the external 24 Vdc power required for

transistor output circuits and power to the loads are switched on/off simultaneously.

Also, turn off power to the loads before turning off power to the T1-16S.

8. Install fuses appropriate to the load current in the external circuits for the outputs.

Failure to do so can cause fire in case of load over-current.

9. Check for proper connections on wires, connectors and modules. Insufficient contact

can cause malfunction or damage to the T1-16S and related equipment.

Basic Hardware and Function

5

Page 8

Safety Precautions

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Maintenance:

!

CAUTION

1. Turn off power before removing or replacing units, modules, terminal blocks or wires.

Failure to do so can cause electrical shock or damage to the T1-16S and related

equipment.

2. When you remove both input and output terminal blocks with wires for maintenance

purpose, pay attention to prevent inserting them upside down.

3. Touch a grounded metal part to discharge the static electricity on your body before

touching the equipment.

6F3B0253

4. Otherwise, charged static electricity on your body can cause malfunction or failure.

5. Do not disassemble the T1-16S because there are hazardous voltage parts inside.

6. Perform daily checks, periodical checks and cleaning to maintain the system in

normal condition and to prevent unnecessary troubles.

7. Check by referring “Troubleshooting” section of this manual when operating

improperly. Contact Toshiba for repairing if the T1-16S or related equipment is failed.

Toshiba will not guarantee proper operation nor safety for unauthorized repairing.

8. The contact relia b ility of the output relays will reduce if the switching exceeds the

specified life. Replace the unit or module if exceeded.

9. The battery used in T1-16S may present a risk of fire of chemical burn if mistreated.

Do not recharge, disassemble, heat above 100ºC (212ºF), or incinerate.

10. Replace battery with CR2032 only. Use of another battery may present a risk of fire

or explosi on.

11. Dispose of used battery promptly. Keep away from children. Do not disassemble

and do not dispose of in fire.

T1-16S User’s Manual

6

Page 9

Safety Label

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

The safety label as shown on the right is

attached to the power terminal of the

T1-16S.

Remove the mount paper before wiring.

Peel off the label from the mount paper

and stick it near the power terminals

where it can be r eadily seen.

Contact Toshiba if the label is damaged.

Safety Precautions

CAUTION

!

Do not touch ter min al s

while power on.

Hazardous voltage can shock, burn or cause death.

Do not touch terminals while power on.

Read related manual thoroughly for safety.

Stick this seal on unit or near unit.

Take off this sheet before wiring.

6F3B0253

Basic Hardware and Function

7

Page 10

About This Manual

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

About This Manual

This manual has been prepared for first-time users of Toshiba’s Programmable Controller

T1-16S to enable a full understanding of the configuration of the equipment, and to

enable the user to obtain the maximum benefits o f the equipment.

This manual introduces the T1-16S, and explains the system configuration,

specifications, in stallation and wiring for T1-16S’s basic hardware. This manual provides

the information for designing T1-16S user program, such as the internal operation,

memory configuration, I/O allocation and programming instructions. Information for

maintenance and troubleshooting are also provided in this manual.

The T1-16S’s computer link function and T1-16S’s multi-purpose communication

functions are covered by the separate manual. Read the T1-16S User’s Manual Communication Function - for details.

Inside This Manual

6F3B0253

This manual consists of 10 main sections and an appendix.

Section 1 outlines the T1-16S configuration. To fully understand the T1-16S, it is

important to read this section carefully. Sections 2, to 4 describe the hardware used in

designin g ex t ernal circuits and panels. Sections 5 to 7 are mainly concerned with

software . S ection 8 exp la in s the T1-16S’s special I/O functions. S ec ti ons 9 and 10

describe the maintenance procedure for the T1-16S, to ensure safe operation and long

service life .

Related Manuals

The following related manuals are available for T1-16S. Besides this manual, read the

following manuals for your better understanding.

T1-16S User’s Manual

- Basic Hardware and Function - (this manual)

- I/O Modules -

- Communication Function T-Series Handy Pro g r ammer (H P911) Op erat ion Man ual

T-Series Program Development System (T-PDS) User’s Manual

UM-TS01∗∗∗-E031

UM-TS01∗∗∗-E034

UM-TS01∗∗∗-E033

UM-TS03∗∗∗-E025

UM-TS03∗∗∗-E045

8

T1-16S User’s Manual

Page 11

Terminology

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

The following is a list of abbreviations and acronyms used in this manual.

µµµµs microsecond

ASCII American Standard Code For Information Interchange

AWG American Wire Gage

BCC Block Check Code

CCW Counter-Clockwise

CPU Central Proc essing Unit

CW Clockwise

EEPROM Electrically Erasable Programmable Read Only Memory

H hexadecimal (when it appears in front of an alphanumeric string)

I/O Input/Output

LED Light Emitting Diode

LSB Least Significant Bit

ms millisecond

MSB Most Significant Bit

PWM Pulse Width Modulation

RAM Random Access Memory

ROM Read Only Memory

Vac AC voltage

Vdc DC voltage

6F3B0253

About This Manual

Basic Hardware and Function

9

Page 12

Contents

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Contents

Safety Precau t ions .................................................................................. 3

About This Manual .................................................................................. 8

1. System Configuration .................................................................... 13

1.1 Introducing the T1-16S ................................................................ 14

1.2 Features .............................................................................................. 16

1.3 System configuration .......................................................................... 19

1.4 I/O expansion ...................................................................................... 20

1.5 Components........................................................................................ 21

1.5.1 Basic unit ......................................................................................... 21

1.5.2 I/O modules ...................................................................................... 25

1.5.3 Options ............................................................................................ 26

1.6 Programmer port function .................................................................. 27

1.7 RS-485 port communication function ................................................. 28

1.8 Real-time data link system ................................................................. 32

1.9 Peripheral tools .................................................................................. 33

6F3B0253

2. Specifications .................................................................................. 37

2.1 General specifications ........................................................................ 38

2.2 Functional specifications .................................................................... 40

2.3 I/O specifications ................................................................................ 42

2.4 External dimensions ........................................................................... 46

3. I/O Application Precautions .......................................................... 47

3.1 Application precautions for input signals ............................................ 48

3.2 Application precautions for output signals .......................................... 50

4. Installation and Wiring ................................................................... 53

4.1 Environmental conditions ................................................................... 54

4.2 Installing the unit ................................................................................. 55

4.3 Wiring terminals .................................................................................. 57

4.4 Grounding ........................................................................................... 58

4.5 Power supply wir i ng ............................................................................ 59

4.6 I/O wiring ............................................................................................ 61

T1-16S User’s Manual

10

Page 13

Contents

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

5. Operating System Overview ......................................................... 63

5.1 Operation modes ................................................................................ 64

5.2 About the built-in EEPROM ................................................................ 66

5.3 Scanning ............................................................................................. 69

6. Programming Information ............................................................. 73

6.1 Devices and registers ......................................................................... 74

6.2 Index modification ............................................................................... 86

6.3 Real-time clock/calendar .................................................................... 88

6.4 I/O allocation ....................................................................................... 89

6.5 T1-16S memory mode setting.............................................................. 91

6.6 User program configurati on ................................................................ 92

6.6.1 Main program .................................................................................. 94

6.6.2 Sub-program #1 .............................................................................. 95

6.6.3 Timer interrupt program .................................................................. 95

6.6.4 I/O interrupt programs ..................................................................... 96

6.6.5 Subroutines .................................................................................... 97

6.7 Programming language ...................................................................... 98

6.8 Program executi on sequence ............................................................ 99

6.9 On-line debug support functions ........................................................ 100

6.10 Password protection ........................................................................... 103

6F3B0253

7. Instructions ...................................................................................... 105

7.1 List of instructions .............................................................................. 106

7.2 Instruction specifications .................................................................... 116

8. Special I/O Functi o n s .................................................................... 255

8.1 Special I/O function overview ............................................................. 256

8.2 Variable input filter constant .............................................................. 260

8.3 High speed counter ............................................................................ 261

8.3.1 Single phase up-counter ................................................................. 262

8.3.2 Single phase speed-counter ............................................................ 263

8.3.3 Quadrature bi-pulse counter ............................................................ 265

8.4 Interrupt input function ........................................................................ 268

8.5 Analog setting function ....................................................................... 270

8.6 Pulse output function .......................................................................... 271

8.7 PWM output function .......................................................................... 273

9. Maintenance and Checks .............................................................. 275

9.1 Precautions during operation ............................................................. 276

9.2 Daily checks ........................................................................................ 277

9.3 Periodic checks ................................................................................... 278

9.4 Maintenance parts ............................................................................... 279

9.5 Battery................................................................................................. 280

Basic Hardware and Function

11

Page 14

Contents

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10. Troubleshooting .............................................................................. 281

10.1 Troubleshooting procedure ................................................................ 282

10.1.1 Power supply check ......................................................................... 283

10.1.2 CPU check ....................................................................................... 284

10.1.3 Program check ................................................................................. 284

10.1.4 Input check ....................................................................................... 285

10.1.5 Output check .................................................................................... 286

10.1.6 Environmental problem .................................................................... 287

10.2 Self-diagnostic items .......................................................................... 288

Appendix ......................................................................................................... 293

A.1 List of models and types ..................................................................... 294

A.2 Instruction index ................................................................................. 295

6F3B0253

T1-16S User’s Manual

12

Page 15

Section 1

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

System Configuration

6F3B0253

1.1 Introducing the T1-16S, 14

1.2 Features, 16

1.3 System configuration, 19

1.4 I/O expansion, 20

1.5 Components, 21

1.6 Computer link system, 27

1.7 T1-16S Communication function, 28

1.8 Real-time data link system, 32

1.9 Peripheral tools, 33

Basic Hardware and Function

13

Page 16

1. System Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1.1 Introducing the T1-16S

The T1-16 is compact, block style, high-performance programmable controller with a

range of 16 to 144 input and output points.

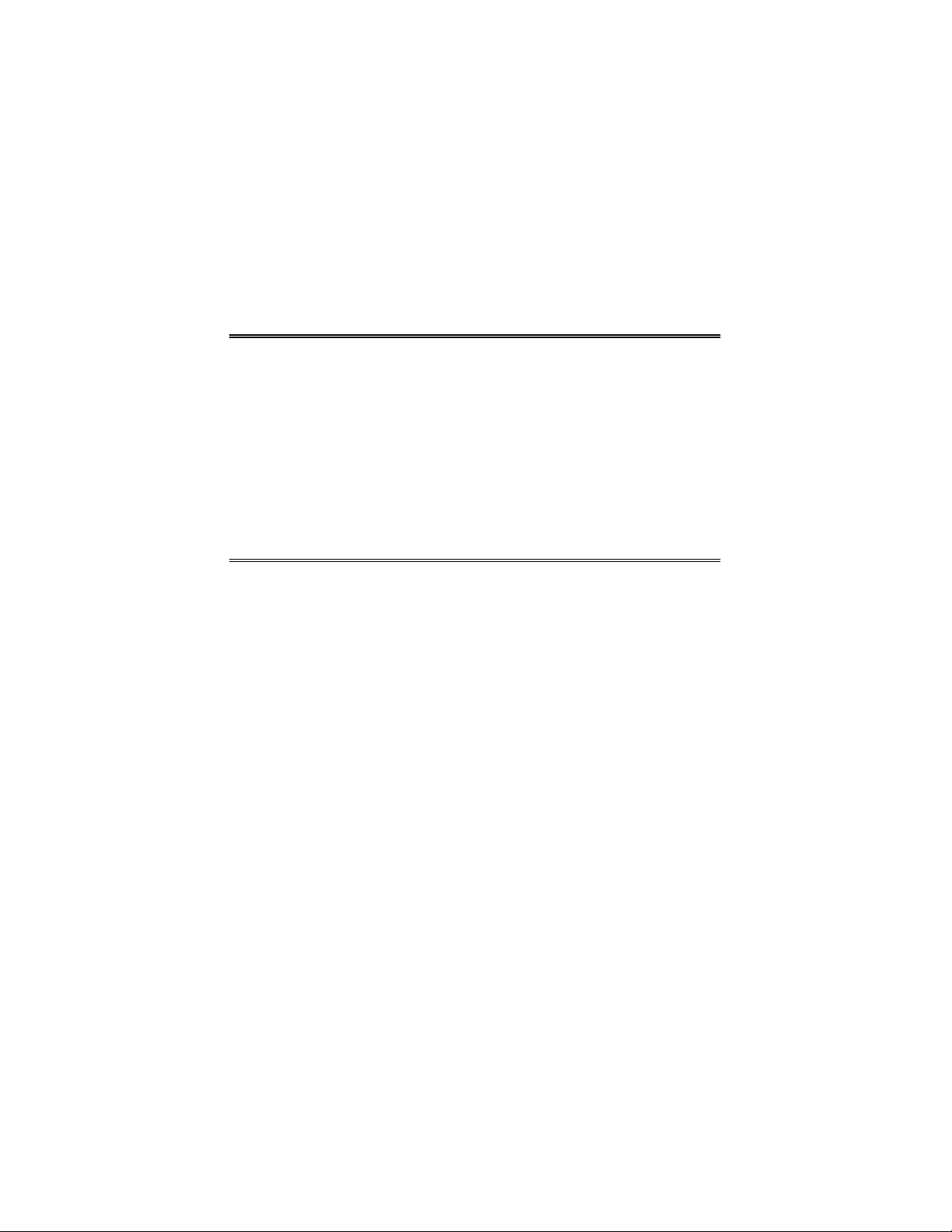

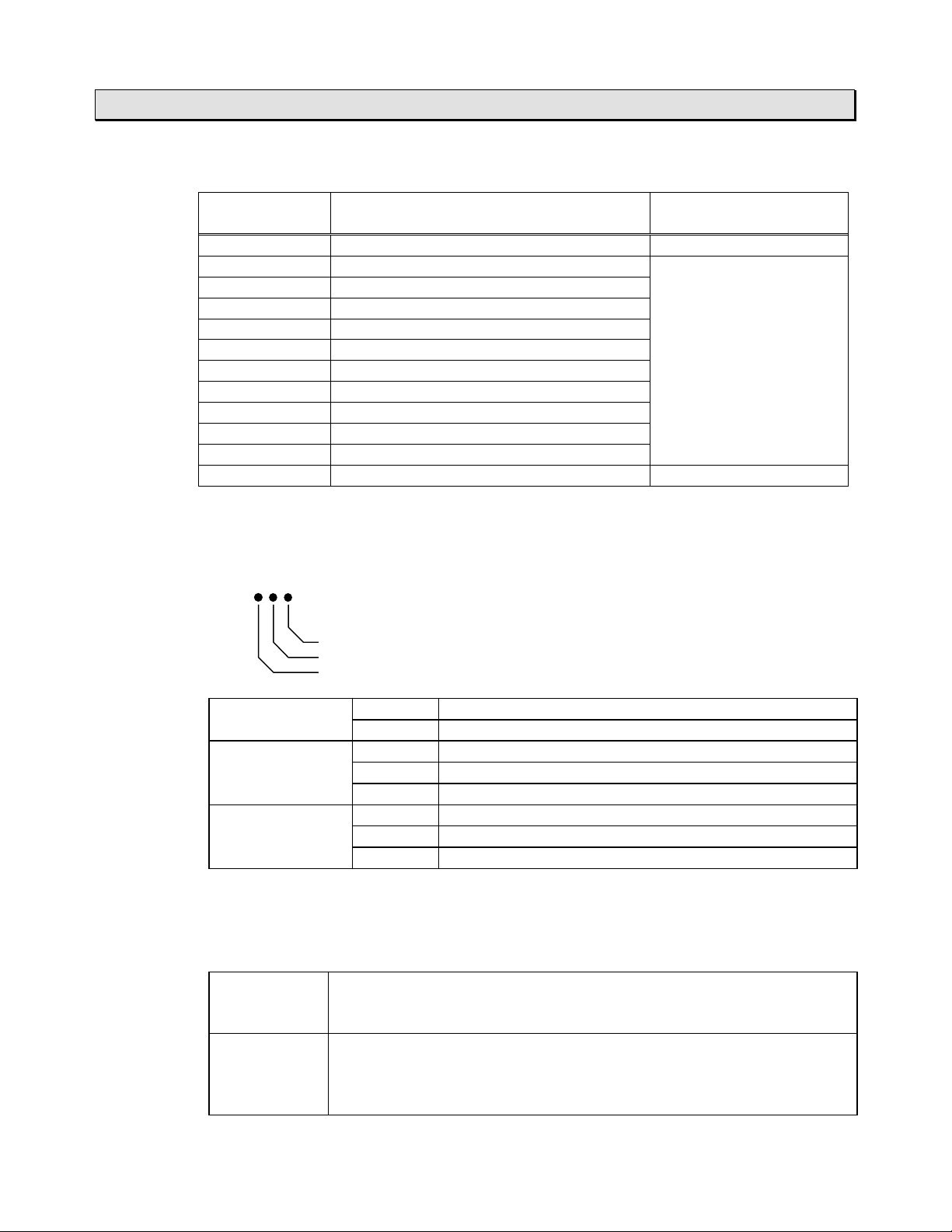

The figu re below shows the T1 Series line-up. The T1 Series consists of the total 16

types.

T1 Series T1 T1-16 T1-MDR16

T1-MAR16

T1-MDR16D

T1-28 T1-MDR28

T1-MAR28

T1-MDR28D

T1-40 T1-MDR40

T1-MAR40

T1-MDR40D

T1S T1-16S T1-MDR16SS

T1-MDR16SC

T1-MDR16SSD

T1-MDR16SCD

T1-40S T1-MDR40S

T1-MAR40S

T1-MDR40SD

6F3B0253

I/O points:

The T1 Series are available in five models, T1-16, T1-28, T1-40, T1-40S and T116S. Each model has the following I/O points.

T1-16S T1-28 T 1-40 T1-40S

14 points

(12 relay plus

16 points

(14 relay plus 2 solid-state)

Input

Output

T1-16

8 points 14 points 24 points

8 points

(6 relay plus 2 slid-state)

2 slid-state)

Expansion

No Up to 8 I/O

modules.

Total up to

No 2 option cards plus

1 expansion rack or unit.

Total up to 382 points.

144 points.

The T1-16S can expand its I/O points by connecting I/O modules. Up to eight I/O

modules can be connected. If eight 16-point I/O modules are connected to the T116S, it can control up to 144 points.

T1-16S User’s Manual

14

Page 17

6F3B0253

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1. System Configuration

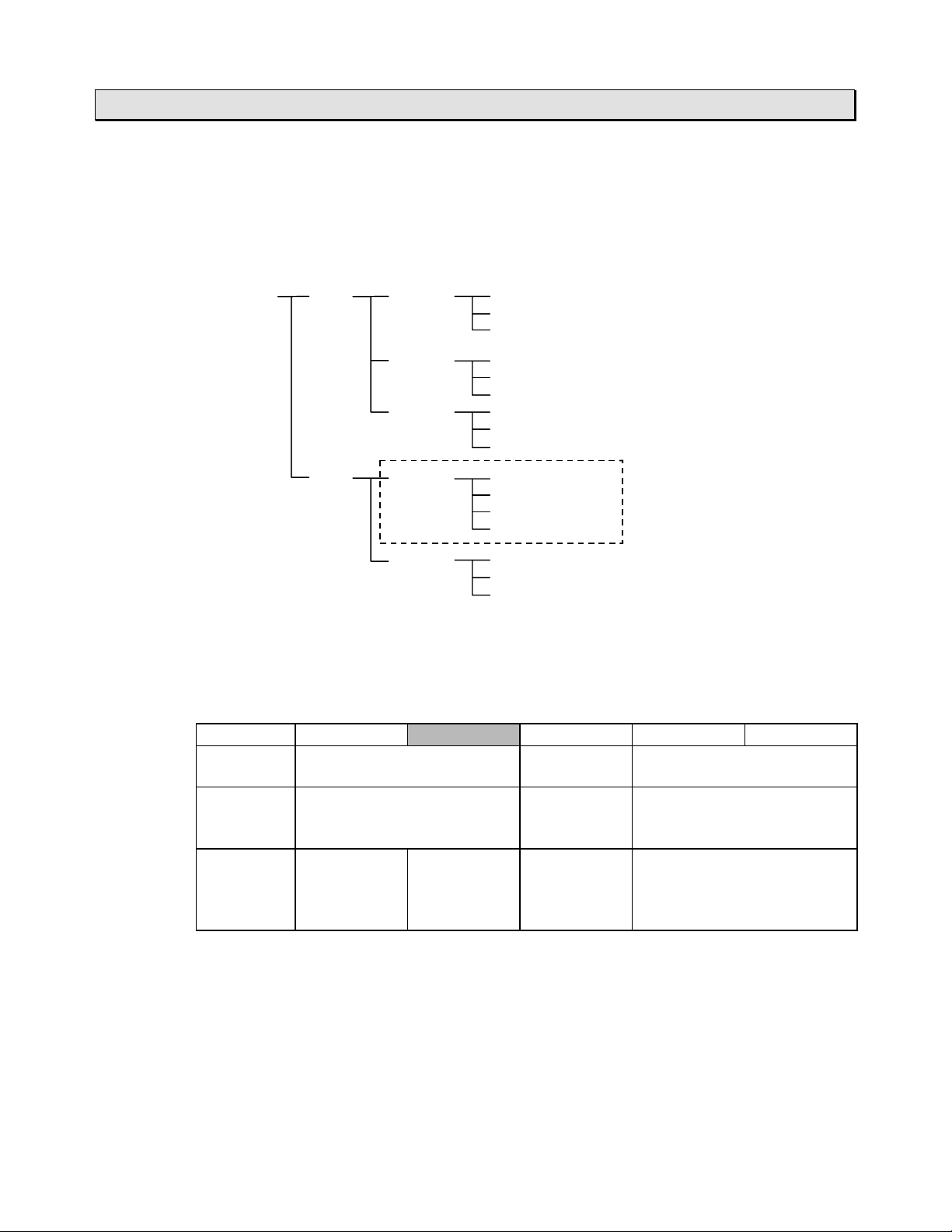

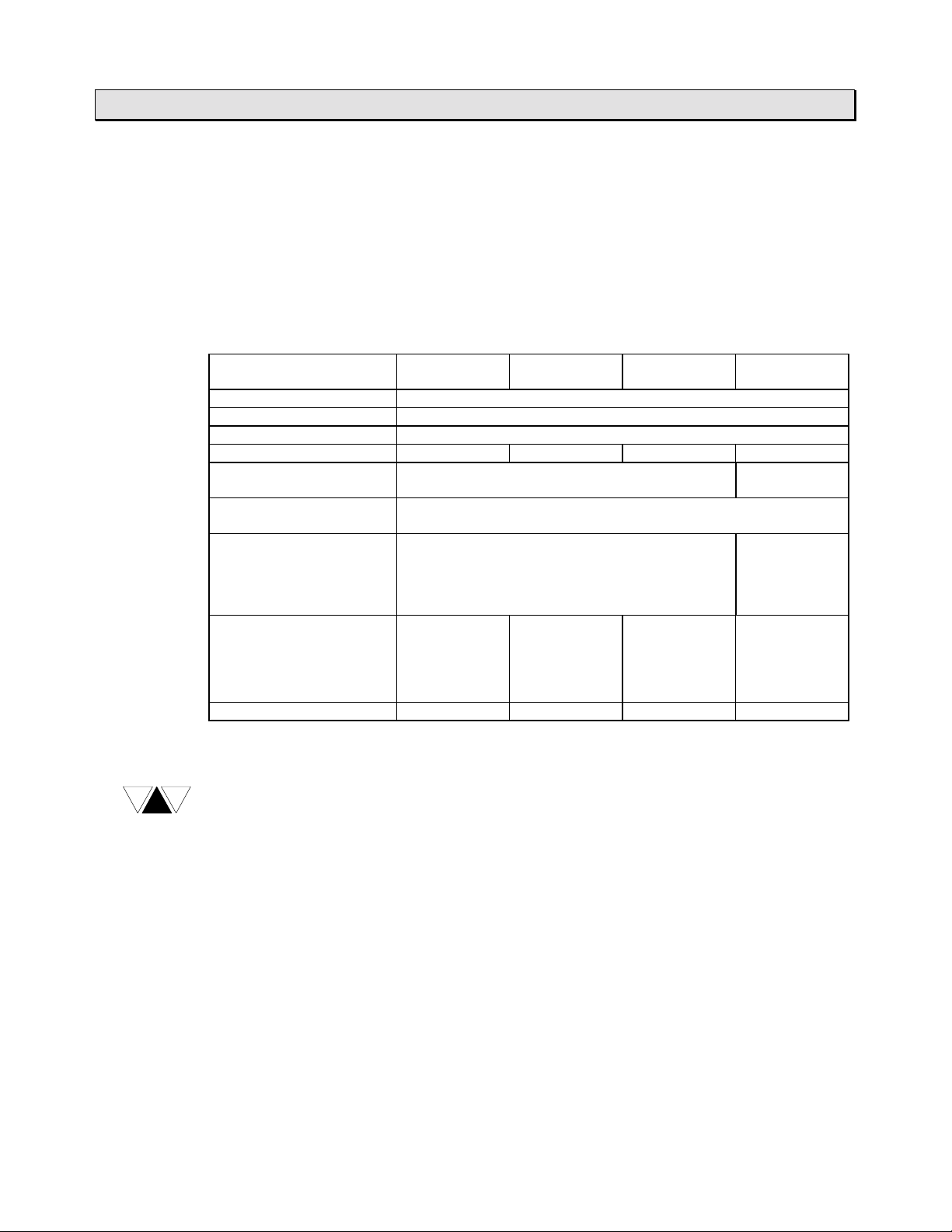

Mem o r y cap acity:

Program memory capacity of th e T1 is 2 k steps. And that of the T1S is 8 k steps.

W hole th e program and a part of data registers are stored in built-in EEPROM.

T1-16/28/40 T1-40S

Memory

Program

capacity

Data capacity

EEPROM

back-up

RAM back-up

(at 25°C)

(at 77°F)

Control functions:

In addition to the basic relay ladder functi ons , the T1/T1S provides functions such as

data operations, arithmetic operations, various functions, etc. Furthermore, its highspeed counter functions, pulse output functions and data communication functions

allow its application to a wide scope of control systems.

Language

Number of

instructions

Subroutines

Execution speed

Real-time

clock/calendar

Communication

RAM (for execution) and EEPROM (for back -up)

2 k steps 8 k steps

(4 k mode or 8 k mode)

Auxiliary relay: 1024 points

Timer: 64 points

Counter: 64 points

Data register: 1024 words

Program and leading 512

words of Data register

Capacitor: 6 hours or more Capacitor: 168 hours

T1-16/28/40 T1-40S

Ladder diagram w ith function block

Basic: 17 types

Function: 76 types

16

(nesting not allowed)

1.4 µs/contact, 2.3 µs/coil, 4.2 µs/transfer, 6.5 µs/addition

No Yes (year, month, day, week, hours,

RS-232C

(programmer port)

Auxiliary relay: 4096 points

Timer: 256 points

Counter: 256 points

Data register: 4096 words

Program and the user specified range of

Data register (0 to 2048 words)

or more

Basic: 21 types

Function: 99 types

256

(up to 3 levels of nesting)

minutes, seconds)

RS-232C (programmer por t),

RS-485 (multi-purpose)

T1-16S

Capacitor: 1 hour

or more

Battery: 2 years

or more

T1-16S

Basic: 21 types

Function: 97 types

Construction:

The T1-16S is a compact, easy-handling block style programmable controller. The

T1-16S has all of the features of a block style controller. In addition, the T1-16S has

modular expandability. The T1-16S provides flexibility into the block style controller.

Series compatibility:

Programming instructions are upward compatible in the T-Series programmable

controllers. The T1/T1S programs can be used for other models of the T-Series, T2,

T2E, T2N, T3 and T3H. Peripheral tools can also be shared.

Basic Hardware and Function

15

Page 18

1. System Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1.2 Features

I/O module support:

The T1-16S has an interface for connecting the I/O modules. Up to eight modules

can be connected to the T1-16S.

By using the 16 points I/O module, the T1-16S can control up to 144 I/O points.

Built-in high-speed counter:

Two single-phase or one quadrature (2-phase) pulses can be counted. The

acceptable pulse rate is up to 5 kHz. (DC input type only)

Built-in analog setting adjusters:

Two analog setting adjusters are provided on the T1-16S. This allows operators to

adjust time or other control parameters easily using a screwdriver.

High speed processing:

Sophisticated machine control applications require high speed data manipulations.

The T1-16S is designed to meet these requirements.

• 1.4 µs per contact • 2.3 µs per coil

• 4.2 µs per 16-bit transfer • 6.5 µs per 16-bit addition

The T1-16S also supports interrupt input function (DC input type only). This allows

immediate operation independent of program scan.

6F3B0253

Hi gh performance s oftware:

The T1-16S offers 21 basic ladder instructions and 97 function instructions.

Subroutines, Interrupt functions, Indirect addressing, For/Next loops, Pre-derivative

real PID, etc. are standard on the T1-16S. These functions allow the T1-16S to be

applied to the most demanding control applications.

Battery-less operation:

The T1-16S has a standard built-in EEPROM, permitting operation without need of a

battery. Also, the variable data can be written into and/or read from the EEPROM,

providing completely maintenance-free back-up operation.

This fun ct ion is an impo rt a nt feature f or OEMs, because it can eliminate the need for

changing the battery every few years.

(Optional battery is also available to back-up real-time clock and retentive data)

T1-16S User’s Manual

16

Page 19

6F3B0253

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1. System Configuration

Pulse output / PWM output:

One point of variable frequency pulses (max. 5 kHz) or variable duty pulses can be

output. These functions can be used to drive a stepping motor or to simulate an

analog output. (DC input type only)

Built-in computer link function:

The T1-16S’s RS-232C programmer port can accept the computer link protocol (data

read/write). This results in easy connection to a higher level computer, an operator

interface unit, etc.

The parity setting of the programmer port can be selected either odd or none. The

none parity mode is provided especially for telephone modem connection. Using

modems, remote programming/monitoring is available.

Real-time control data li nk net wo rk:

By connecting the TOSLINE-F10 remote module (FR112M) to the T1 -16S, highspeed data link network can be established. In this network, upper T-series PLC

model (T2/T2E/T2N or T3/T3H) works as master and up to 16 T1-16Ss can be

connected as remote. Each T1-16S can exchange data with the master through 1

word input and 1 word output. The transmission speed can be selected either 750

kbps or 250 kbps.

Sampling trace f unction:

The sampling trace is the function to collect the user specified data every user

specified timing (minimum every scan), and to display the collected data on the

programmer screen in time chart and/or trend graph format. This function is useful

for checking the input signals changing.

Password protection:

By registering your passwords, four levels of protection is available according to the

security levels required for your application.

Level 4: Reading/writing program and writing data are prohibited

Level 3: Reading/writing program are prohibited

Level 2: Writ ing program is prohibi ted

Level 1: No protection (changing passwords is available only in this level)

Two points of solid-state output:

Each model of the T1-16S has two points of solid-state output (transistors for DC

input type and triacs for AC input type). These solid-state outputs are suitabl e for

frequent switching application.

Basic Hardware and Function

17

Page 20

1. System Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

DIN rail mounting:

The T1-16S is equipped with brackets for mounting on a standard 35 mm DI N rail.

The T1-16S can be mounted on a DIN rail as well as sc rew mounting.

On-line program changes:

When the T1-16S’s memory mode is set to 4 k steps mode, on-line (in RUN mode)

program changes are available. Furthermore, program writing into the built-in

EEPROM is also available in RUN mode. These functions are useful in program

debugging stage.

Real-time clock/calendar function: (Enhanced model only)

The T1-16S has the real-time-clock/calendar function (year, month, day, day of the

week, hours, minutes, seconds) that can be used for performing scheduled

operations, data gathering with time stamps, etc. To back-up the real-time

clock/calendar data, use of the optional battery is recommended.

RS-485 multi-purpose communication port: (Enhanced model only)

The T1-16S has an RS-485 multi-purpose communication port. Using this port, one

of the following communication modes can be selected.

•••• Computer link mode: T-series computer link protocol can be used in this mode.

Up to 32 T1-16Ss can be connected to a master computer. By using this mode,

MMI/SCADA system can be easily configured.

•••• Dat a link mode: Two PLCs (any combination of T1S, T2E or T2N) can be

directly linked together. This direct link is inexpensive, easily configured and

requires no spec ial programming.

•••• Free ASCII mode: User defined ASCII messages can be transmitted and

received through this port. A terminal, printer, bar-code reader, or other serial

ASCII device can be directly connected.

•••• Inverter connection mode: This mode is specially provided to communicate with

Toshiba Inverters (ASDs) VF-A7/G7/S9 series. By using this function, the T1-16S

can control and monitor the connected Inverters.

6F3B0253

T1-16S User’s Manual

18

Page 21

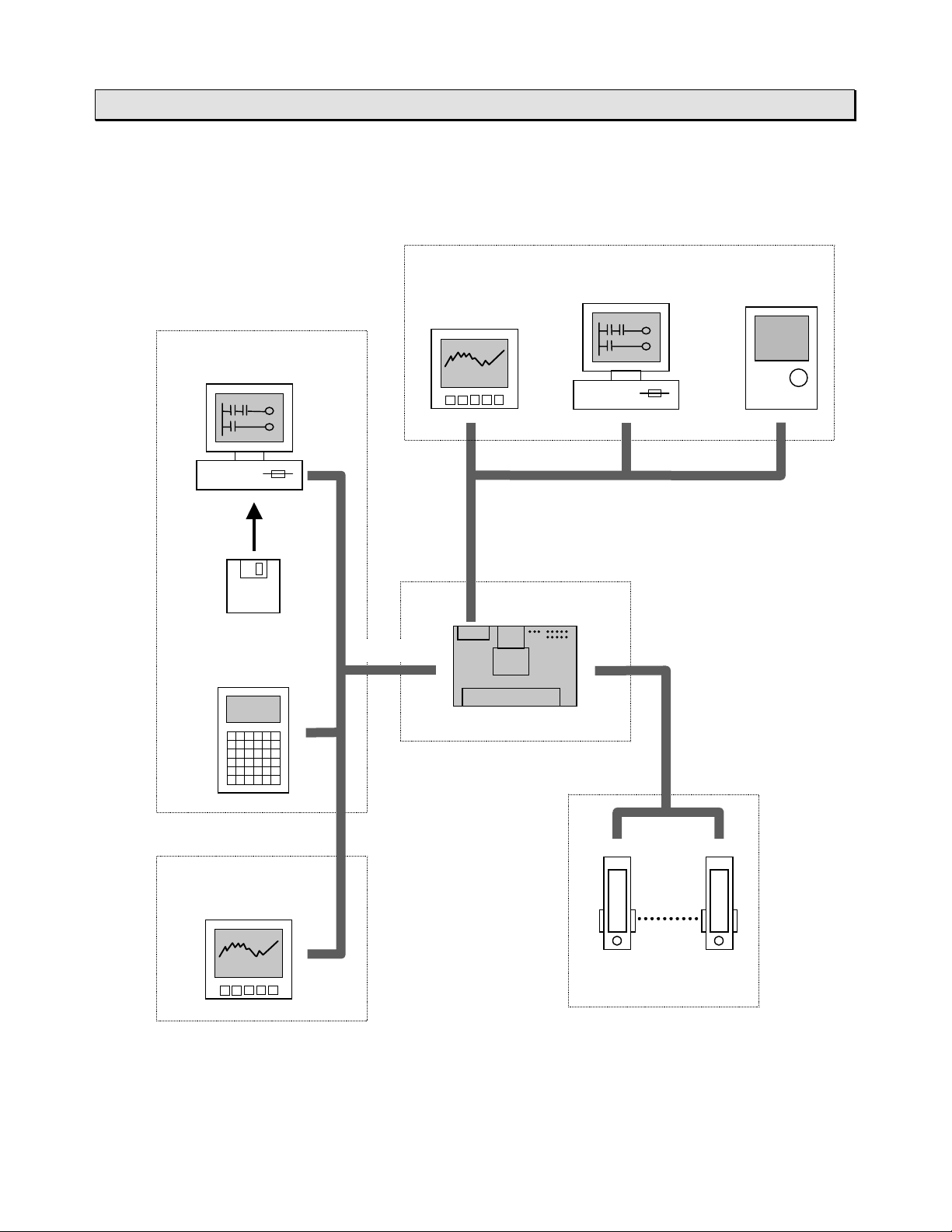

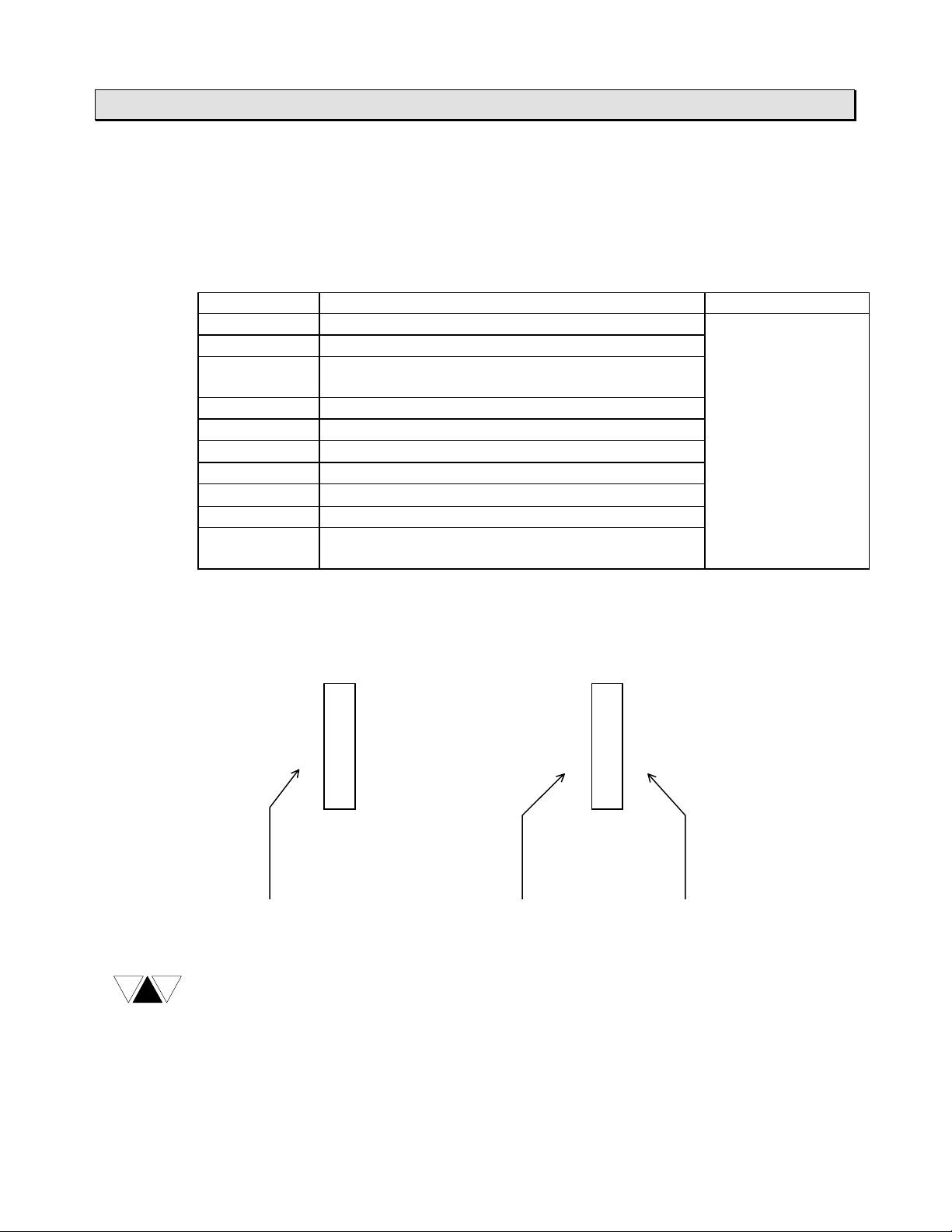

1.3 System configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

The fo llo win g figure sho ws the T1-16S system configuration .

Peripheral tool

IBM-PC compatible

personal computer

MMI/SCADA

system

1. System Configuration

IBM-PC compatible

personal computer

6F3B0253

Inverter

T-PDS

software

Handy programmer

HP911A

Comput er link fun c t i on

MMI/SCADA

system

RS485 (Standard type only)

T1-16S basic unit

T1-16S

RS232C

I/O modules

8 modules max.

Basic Hardware and Function

19

Page 22

1. System Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

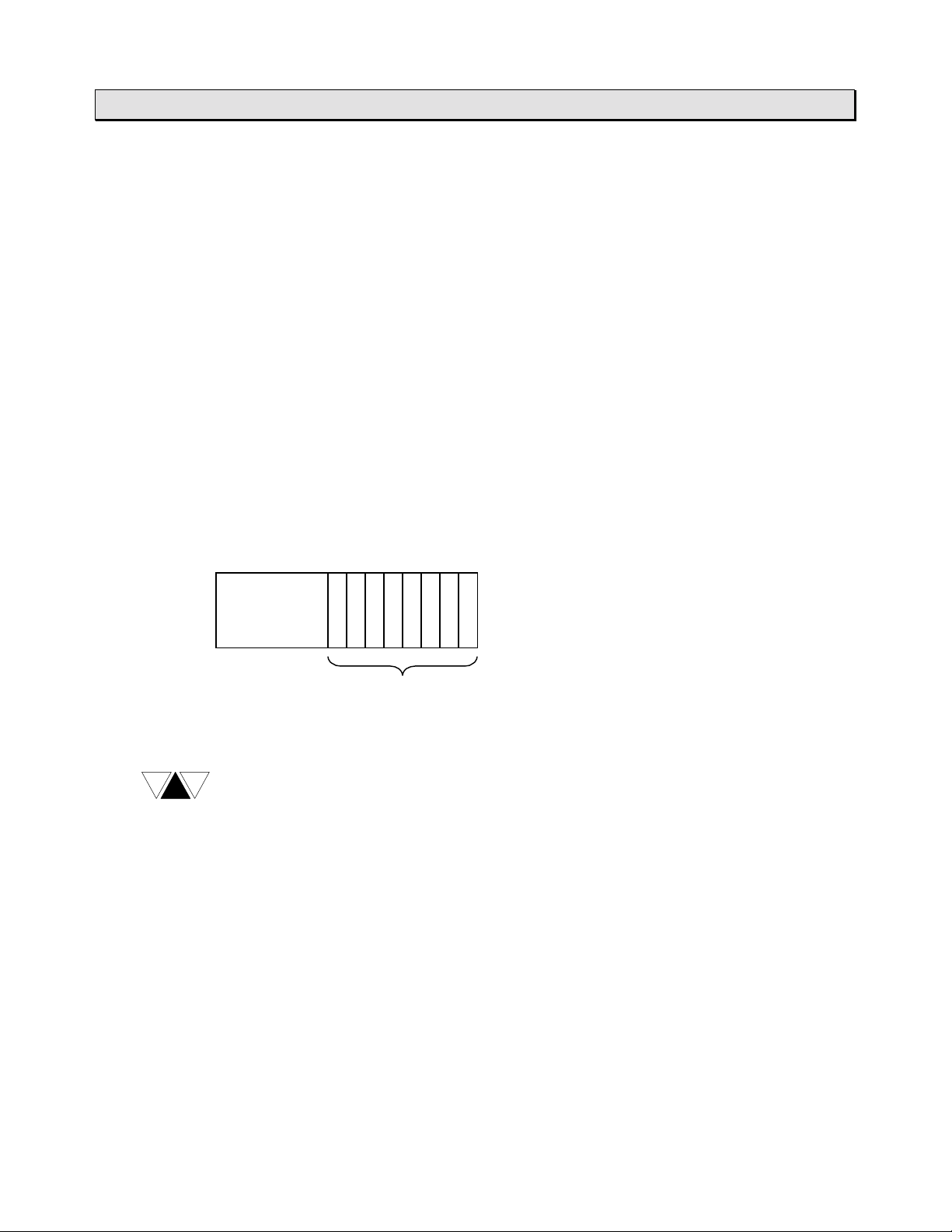

1.4 I/O expansion

The T1-16S provides I/O expandability by connecting the I/O modules. Up to eight

I/O modules can be connected.

Available I/O modules

DI116M: 16 points DC input

DO116M: 16 points DC output

DD116M: 8 points DC input + 8 points DC output

RO108M: 8 points relay output

AD121M: 1 channel analog input (0 to 5V or 0 to 20mA)

AD131M: 1 channel analog input (-10 to +10V)

DA121M: 1 channel analog output (0 to 20mA)

DA131M: 1 channel analog output (-10 to +10V)

TC111M: 1 channel thermocouple input (type K, J, E, or ±50mV)

FR112M: TOSLINE-F10 remote station

6F3B0253

T1-16S maximum configuration

T1-16S

main unit

Up to 8 I/O modules

NOTE

(1) The 5Vdc power to the I/O modules is supplied from the main unit. The main

unit can supply maximum 1.5A of the 5Vdc power to the I/O modules. Check

the current consumption of each I/O module used. Refer to section 2.1.

(2) The connecting order of the I/O modules is not restricted except TOSLINE-

F10 remote station FR112M. When the FR112M is used, it must be the right

end module.

(3) If more than 8 I/O modules are connected, the T1-16S cannot operate

normally.

T1-16S User’s Manual

20

Page 23

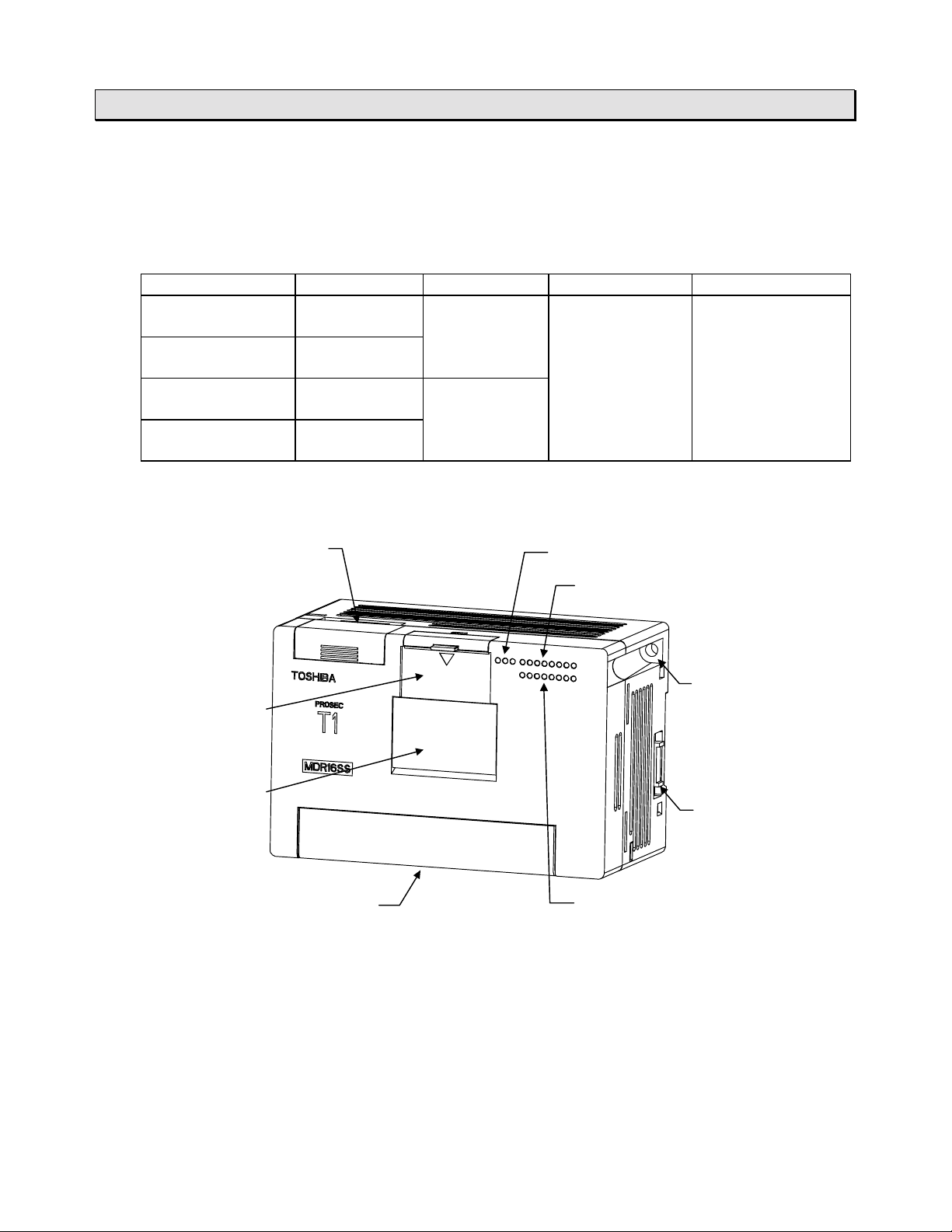

1.5 Components

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1.5.1 Basic unit

The T1-16S is available in four types as shown in the following table.

Type

T1-MDR16SS

(Enhanced model)

T1-MDR16SC

(Standard model)

T1-MDR16SSD

(Enhanced model)

T1-MDR16SCD

(Standard model)

Link/ Calendar Power supply

100-240 Vac,

Yes

No

Yes

No

50/60 Hz

24 Vdc

6F3B0253

1. System Configuration

Input

8 points - 24 Vdc 6 points - relay,

Output

2 points - transistor

Link terminals

(Enhanced model only)

Programmer

port cover

Battery holder

cover

Power s upply and

input/output terminals

Operati on status LED s

I/O status LEDs (Low side)

Mounting hole

Expantion

connector

I/O status LEDs (High side)

Basic Hardware and Function

21

Page 24

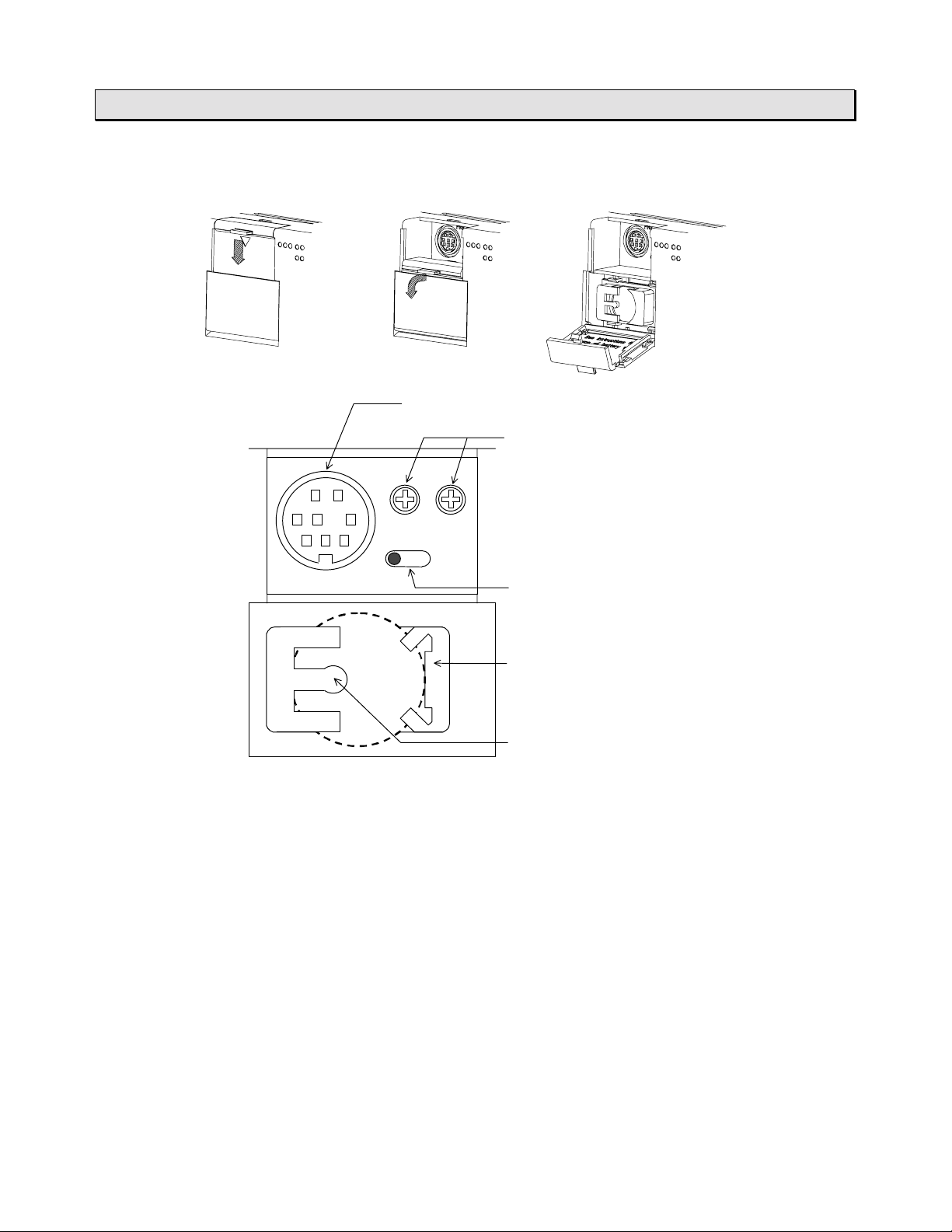

1. System Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

♦ Behind the programmer port cover

6F3B0253

Programmer port conne ctor

Analog setting adjusters

(V0 and V1)

PRG

V1 V0

H/R

Mode c ontrol switch

(HALT / RUN)

Battery holder

Battery type: CR2032

(Optional)

A tab for battery eject

Power supply terminals:

Connect the power cable and grounding wire. The terminal screw size is M3.

See sections 4.4 and 4.5 for wiring.

Input terminals:

Connect input signal wires. The terminal screw size is M3. See section 2.4 for

details.

Output terminals:

Connect output signal wires. The terminal screw size is M3. See section 2.4 for

details.

T1-16S User’s Manual

22

Page 25

1. System Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

I/O status LEDs:

Indicates the ON/OFF status of each I/O signal. (color: red)

SW54 setting

value

0 (default)

1

2

3

4

5

6

7

8

9

10

Others

Operation status LEDs:

Indicates the operation status of the T1-16S.

I/O intending for an indication

Basic unit (L: X000-007, H: Y020-027)

I/O module slot 0

I/O module slot 1

I/O module slot 2

I/O module slot 3

I/O module slot 4

I/O module slot 5

I/O module slot 6

I/O module slot 7

TOSLINE-F10 (FR112M), Low 1 word

TOSLINE-F10 (FR112M), High 1 word

Basic unit (L: X000-007, H: Y020-027)

6F3B0253

Note

It indicates these at the

time of only RUN

mode.

FLT

RUN

PWR

PWR

(Power) (green)

RUN (green)

FLT

(Fault) (red)

Mode control switch:

Controls the operation modes of the T1-16S.

H (HALT)

Lit

Not lit

Lit

Blinking HOLD mode

Not lit

Lit

Blinking Hardware error (programmer c annot be connected)

Not lit

When the switch is turned to H (HALT) side, the T1-16S stops

Internal 5 Vdc power is norm al.

Internal 5 Vdc power is not normal.

RUN mode (in operation)

HALT mode or ERROR mode

ERROR mode

Normal

program execution (HALT mode). In this position, RUN/HALT

command from the programmer is disabled.

R (RUN)

When the switch is turned to R (RUN) side, the T1-16S starts

program execution. This is the position during normal operation.

In this positio n, RUN/HALT command f rom the programmer is also

available.

Basic Hardware and Function

23

Page 26

1. System Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Analog setting adjusters:

Two analog setting adjusters are provided. The V0 value is stored in SW30 and the

V1 value is stored in SW31. The converted value range is 0 to 1000. Refer to section

8.5 for details of the analog setting function.

Programmer port connector:

Used to connect the programmer cable. The interface is RS-232C. This port c an also

be used for the computer link function. Refer to section 1.6 for more information

about the computer link function.

Expansion connector:

Used to connect the I/O module.

RS-485 port (Enhanced model only):

Used to connect a computer (SCADA system), operator interface unit, other T1-16S,

or many kinds of serial ASCII devices including Toshiba’s Inverter through RS-485

interface. Refer to section 1.7 for more information about the T1-16S’s RS-485 multi-

purpose communication functions.

Mounting holes:

Used to fix the T1-16S on a mounting frame by screws. The mounting holes are

provided at two opposite corners .

DIN rail bracket:

The DIN rail bracket is provided at the rear for mounting the T1-16S on a 35 mm DIN

T1

rail. See section 4.2 for installing the unit.

6F3B0253

Use two M4 screws for mounting. See section 4.2 for

installing the unit.

T1-16S User’s Manual

24

Page 27

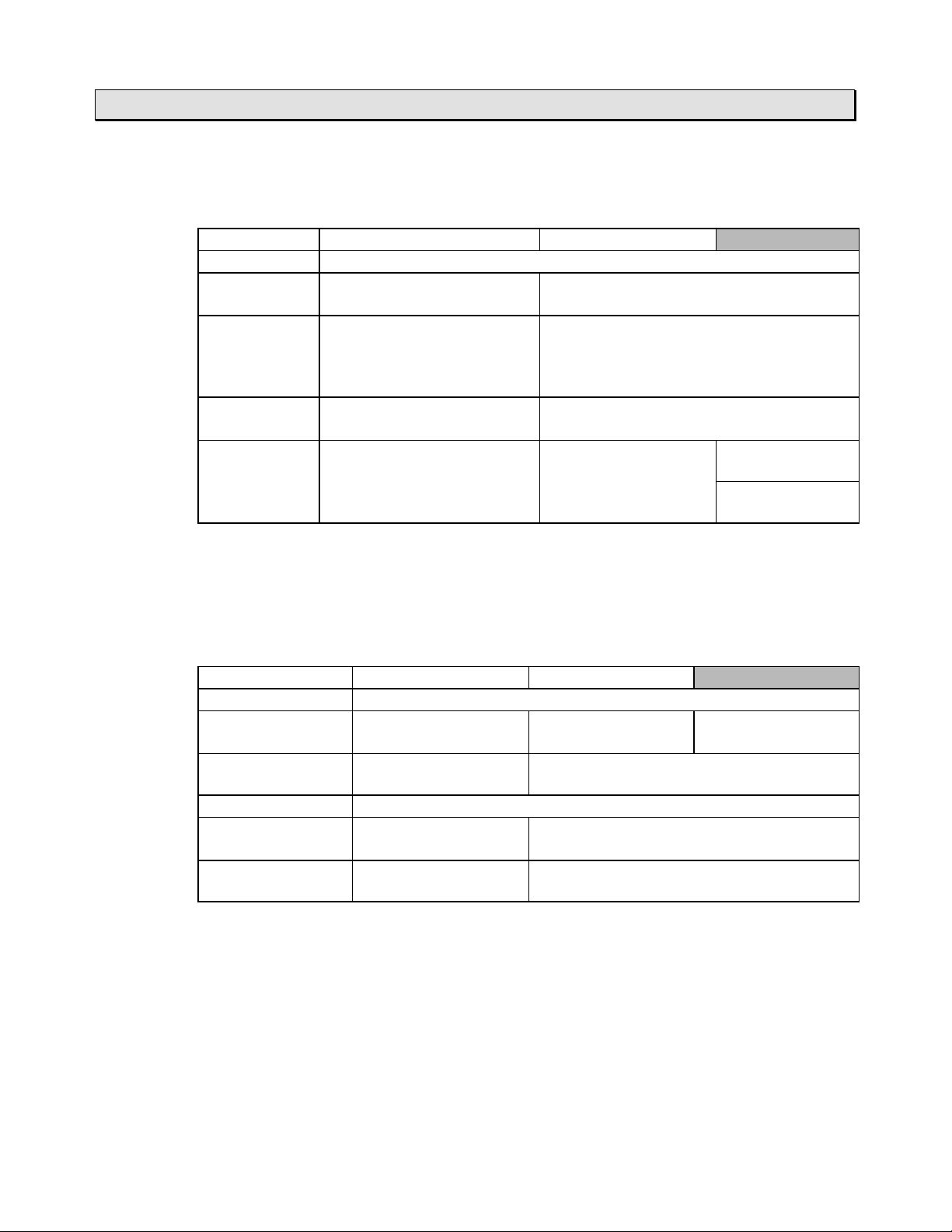

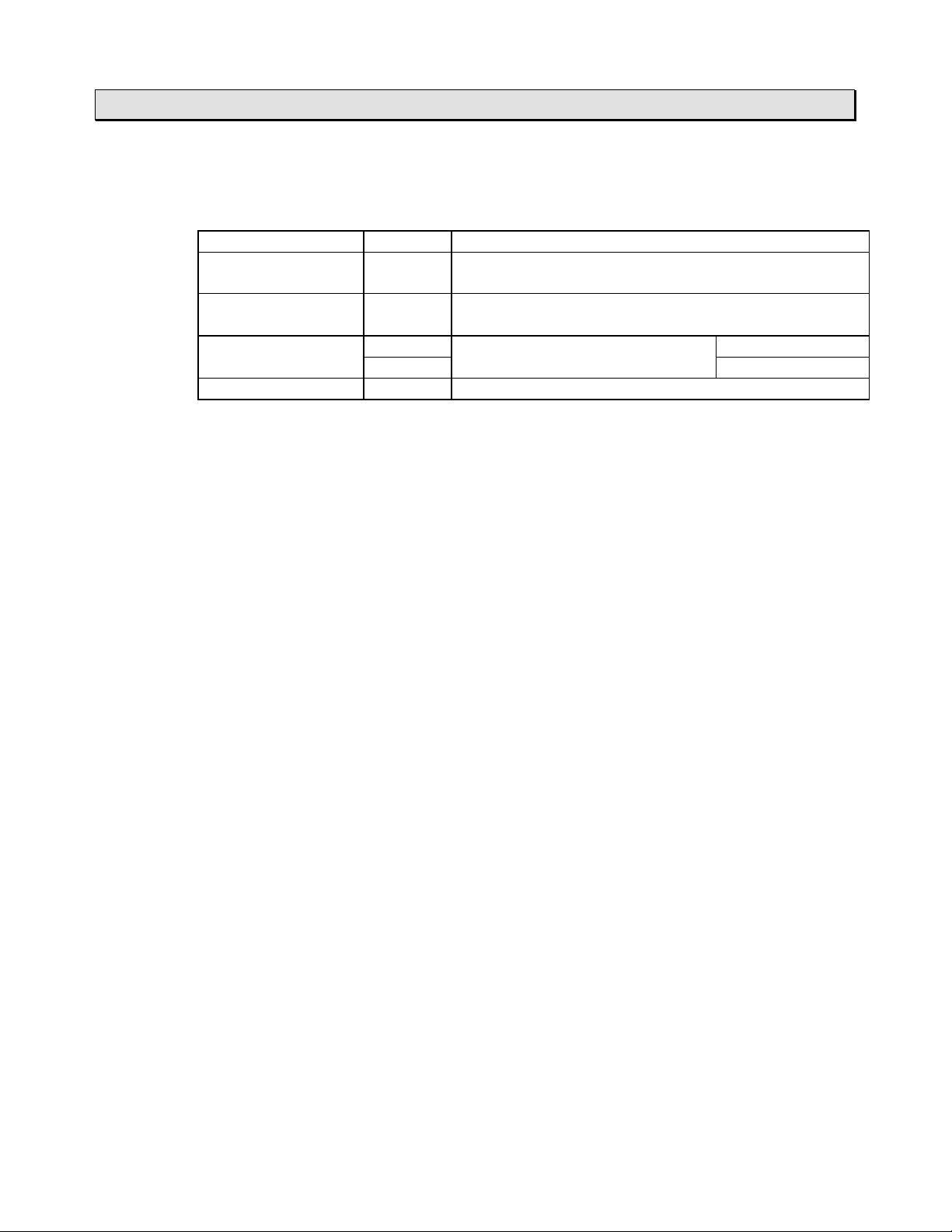

1.5.2 I/O modules

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

The T1-16S can connect up to eight I/O modules.

The following 10 types of the I/O modules are available.

For specification details of the I/O modules, refer to the separate manual “T1-16S

User’s Manual − I/O Modules −“.

DI116M

DO116M

DD116M

RO108M

AD121M

AD131M

DA121M

DA131M

TC111M

FR112M

Type

1. System Configuration

Description

16 points input, 24Vdc – 5mA

16 points output, 24Vdc – 100mA

8 points input, 24Vdc - 5mA

+ 8 points output, 24Vdc – 100mA

8 points relay output, 24Vdc/240Vac - 1A

1 channel analog input, 0 to 5V / 0 to 20mA

1 channel analog input, ±10V

1 channel analog output, 0 to 20mA

1 channel analog output, ±10V

1 channel thermo-couple input

TOSLINE-F10 remote station,

1 word input + 1 word output

FR112M

Other I/O modules

6F3B0253

Power supply

Supplied from the

basic unit (5 Vdc)

Expantion connector Expantion connectors

NOTE

(1) If more than 8 I/O modules are connected, T1-16S cannot operate normally.

(2) The TOSLINE-F10 remote station module (FR112M) must be connected at the

right end. Tow or more FR112Ms cannot be used together.

Basic Hardware and Function

25

Page 28

1. System Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1.5.3 Options

The following optional items are available.

Item

Cable for

programming tool

Programm er port

connector

Option card I/O

connector

Back-up battery

6F3B0253

Type

CJ105

PT16S

PT15S

PT15F

CR2032 For memory b ack up. (A v ailable on the market.)

For T-PDS, 5 m length

For RS-232C computer link , with 2 m cable

Cable side connector for

DI116M, DO116M, or DD116M

Description

Soldering type

Flat cable type

T1-16S User’s Manual

26

Page 29

1.6 Programmer port function

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

The interface of the T1-16S’s programmer port is RS-232C. Normally this port is

used to connect the programmer. However, this port can also be used for the

computer li nk function.

The computer link is a data communication function between computer or operator

interface unit and the T1-16S. The data in the T1-16S can be read and written by

creating simple communication program on the computer. The computer link protocol

of the T1-16S is published in “T1-16S User’s Manual − Communication Function −”.

Item

Interface

Transmission system

Synchronization

Transmission speed

Transmission distance

Framing

Protocol

Transmission delay option 0 to 300 ms

By using the multi-drop adapter (CU111), multiple T1-16Ss can be connected on an

RS-485 line. The T-series PLC programming software (T-PDS) can also be used in

this configuration.

1. System Configuration

Specifications

Conforms to RS-232C

Half-duplex

Start-stop system (asynchronous)

9600 bps (fixed)

15 m max.

Start bit:

Data bits:

Parity:

Stop bit:

T-series computer link (ASCII )

Programmer (binary)

1 bit

8 bits (fixed)

Odd or none

1 bit (fix ed)

6F3B0253

Operator Interface

RS-232C

C

U

T1-16S

T1-16S

Master Computer

RS-485 (1 km max.)

C

U

T1-16S

Max. 32 T1-16Ss

C

U

T1-16S

Basic Hardware and Function

27

Page 30

1. System Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1.7 RS-485 port communication function

The T1-16S enhanced model has an RS-485 multi-purpose communication port.

This port can work independent of the programmer port.

By using this communication port, one of the following four communication modes is

available, computer link mode, data link mode, free ASCII mode, and Inverter

connection mode.

For details of these functions, refer to the separate manual “T1-16S User’s Manual −

Communication Function −”.

Item

Interface

Transmission system Half-duplex

Synchronization

Transmission code

Transmission speed

Transmission

distance

Framing

Protocol

Link configuration

Computer

Conforms to RS-458

Start-stop system (asynchronous)

ASCII/binary ASCII

300, 600, 1200, 2400, 4800, 9600, or

19200 bps

1 km max.

Start bit: 1 bit

Data bits: 7 or 8 bits

Parity: Odd, even, or none

Stop bit: 1 or 2 bits

T-series

computer

link (ASCII),

Programmer

(binary)

1-to-N

link

Free ASCII

User

defined

ASCII

messages

N/A

Inverter

connection

Binary

Inverter VFA7/G7/S9

binary

protocol

1-to-N

6F3B0253

Data link

Binary

19200 bps

(fixed)

Special

Special

1-to-1

NOTE

T1-16S standard model does not have the RS-485 interface.

T1-16S User’s Manual

28

Page 31

6F3B0253

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1. System Configuration

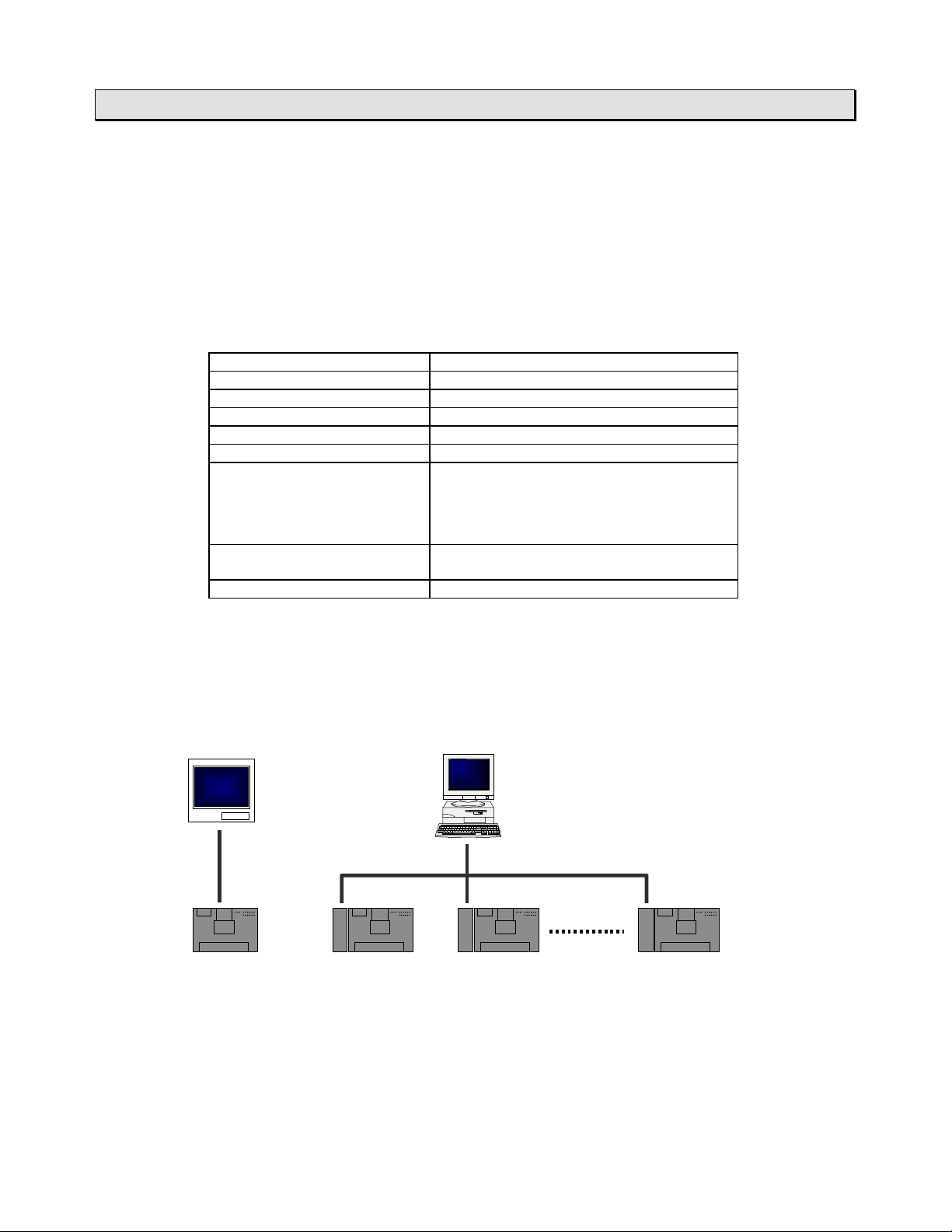

Computer link mode

T-series computer link protocol can be used in this mode. A maximum of 32 T1-16Ss

can be connected to a master computer.

By using this mode, all the T1-16S’s data can be accessed by a master computer.

The T-series PLC programming sof t wa re (T-PDS ) can als o be used in this

configuration.

Master Computer

T1-16S

RS-485 (1 km max.)

T1-16S T1-16S

Max. 32 T1-16Ss

T1-16S

Data link mode

Two PLCs (any combination of T1-16S, T2E or T2N) can be directly linked together.

This direct link is inexpensive, easily configured and requires no special

programming. Data registers D0000 to D0031 are used for the data transfer.

T1-16S

Station No. 1

D0000

D0015

D0016

RS-485 (1 km max.)

T1S

T1

Station No. 2

D0000

D0015

D0016

D0031

D0031

Basic Hardware and Function

29

Page 32

1. System Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Free ASCII mode

The free ASCII mode is used to connect between the T1-16S and various serial

ASCII devices, such as a micro computer, bar code reader, printer, display, etc.

By using this mode, the T1-16S can work as a communication master. Therefore, the

T1-16S c a n communic ate with other PLCs u s in g the computer link protocol .

T1-16S

6F3B0253

RS-485 (1 km max.)

• Bar-code reader

• ID system

• Weigh scale

• Power meter

• Printer

• Others

T1-16S User’s Manual

30

Page 33

6F3B0253

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1. System Configuration

Free ASCII mode

The T1-16S's Inverter connection mode is a special function to monitor/control the

Toshiba Inverters (ASDs) VF-A7/G7/S9 through the RS-485 line.

Using this mode, the T1-16S can perform the following functions for the Inverters

connected on the RS-485 line without any special communication program.

• Monitoring − Operating frequency and Terminal status

• Control − Run/Stop/Jog, Forward/Reverse, Frequency reference, etc.

• Parameter read/write

• Broadcast command

T1-16S

RS-485 (1 km max.)

RS485 adapter

888

VF-A7 VF-S9VF-A7

888

888 888

VF-S9

888 888

VF-S9 VF-S9

(Max. 64 Inverters)

Basic Hardware and Function

31

Page 34

1. System Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1.8 Real-time data link system

TOSLINE-F10

TOSLINE-F10 is a high speed data transmission system suited for small points I/O

distribution system. By inserting the TOSLINE-F10 remote module (FR112M), the

T1-16S can work as a remote station of the TOSLINE-F10 network. On this network,

the T1-16S sends 1 word data to the master station and receives 1 word data from

the master station.

Item

Topology

Transmission distance

(without repeater)

Transmission speed

Scan transmission

capacity

Scan cycle

Error checking

NOTE

Typical data link configuration

The figu re below s hows the ty pical data link c onfiguration.

(1) Refer to the separate “T1 User’s Manual − Option Card and I/O

Module −“ for details of the TOSLINE-F10 remote card (FR112).

(2) Refer to the separate TOSLINE-F10 User’s Manual for details of

TOSLINE-F10 system specifica t io n s

High speed mode

Bus (terminated at both ends)

500 m max. (total)

750 kbps

512 points (32 words) max.

7 ms/32 words

CRC check

overall TOSLINE-F10 system.

Master

computer

Long distance mode

1 km max. (total)

250 kbps

12 ms/32 words

6F3B0253

T2E

(master)

TOSLINE-F10

T1-16S T1-16S

Operator interface units

T1-16S User’s Manual

32

T2E

(remote)

RI/O RI/O T1-16S

RI/O: remote I/O

Page 35

1.9 Peripheral tools

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

The following peripheral tools are available for the T1-16S.

T-Series Program D e velopment System (T-PDS)

The T-Series Program Development System (T-PDS) is a software which runs on

any IBM-PC compatible personal computers such as Toshiba’s Notebook computers.

The same T-PDS software supports on-line/off-line programming, debugging and

program documentation for all the T-Series programmable controllers T1/T1S,

T2/T2E/T2N, T3/T3H and S2T.

• User-friendly program editor includes cut & paste, address search & replace,

program bloc k move/copy, etc.

• Group programming − part program development by multiple designers and

merging them into a complete program − enhance the software productivity.

• Powerful monitoring, I/O force and data set functions fully support your program

debugging.

• Do c umentat ion of program s wit h commentary makes your maintenance work

easy.

• Remote monitoring/programming via modem (radio/phone) is possible.

The table below s hows t he T-PDS versions that support the T1-16S.

T-PDS for Windows TMW33E1SS Ver 1.0 or later

T-PDS for MS-DOS TMM33I1SS Ver 1.61 or later

*1) The T1-16S can be used with these versions. However, in this case, there are

the following functional limitations.

• The program si z e setting is only available as 2 k. It is set to 4 k mode in the

• Some of the added instructions (MAVE, DFL, HTOA, ATOH) may not be

NOTE

6F3B0253

1. System Configuration

Type Part number Versions avail able for

T1-16S.

edited/monitored. (depending on the version)

The connection cable for the T1-16S is different from that for upper T-Series

PLCs. These cables are supplied separately.

Connection cable for T1-16S ... Type: CJ105, 5 m length

Connection cable for T2/T3 …. Type: CJ905, 5 m length

T1-16/28/40 T1-40S/T1-16S

*1)

*1)

Ver 1.2 or later

Ver 2.1 or later

Basic Hardware and Function

33

Page 36

1. System Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

T-Series Handy Programmer (HP911A)

The HP911A is a hand-held programmer, that can be used to program the T1-16S

using ladder diagram. Its portability makes it ideal for maintenance use at remote

locations.

The HP911A has the following features.

• The HP911A supports ladder diagram programming of T-Series programmable

controllers T1-16S, T2/T2E/T2N and T3.

• Built-in EEPROM allows program copy between T-Series controllers.

• Two display modes are available,

- Normal: 5 lines and 12 columns

- Zoom: Full device description

• On-line data set and I/O f o rce are useful for system checking.

• Backlit LCD display allows operation in dim light.

6F3B0253

There are two types of the Handy Programmer (HP911) depending on the cable

included with.

Type Part number Cable included with Versions available for T1-16S

HP911A

HP911

THP911A∗S

THP911∗∗S

2 m cable for T1-16S Ver 1.1 or later

2 m cable for the upper

T-series PLCs

Ver 1.1 or later

The T1-16S can be used with the HP911(A). However, there are the following

functional limitations.

• The program si z e setting is only available as 2 k. It is set to 4 k mode in the T116S.

• Some of the added instructions (MAVE, DFL, HTOA, ATOH) cannot be

edited/monitored.

NOTE

A 2 m connection cable for the T1-16S (Type: CJ102) is supplied with the

HP911A. The cable for the T2/T3 is available separately. (Type: CJ902, 2 m

length)

T1-16S User’s Manual

34

Page 37

Program Storage Module (RM102)

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

6F3B0253

1. System Configuration

The program storage module (RM102) is an

external memory for storing the T1-16S

program. By using the RM102, program saving

from the T1-16S to the RM102, and program

loading from the RM102 to the T1-16S can be

done without need of a programmer.

Because the RM102 has an EEPROM,

maintenance-free program storage and quick

saving/loading are available.

Multi-drop adapter (CU111)

The T1-16S’s RS-232C programmer port

supports the computer link function.

When two or more T1-16Ss are connected with

a master computer, the multi-drop adapter

(CU111) can be used. (One-to-N configuration)

The CU111 is an RS-232C/RS-485 converter

specially designed for the T1-16S’s

programmer port.

Basic Hardware and Function

35

Page 38

6F3B0253

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

T1-16S User’s Manual

36

Page 39

Section 2

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Specifications

6F3B0253

2.1 General specifications, 38

2.2 Functional specifications, 40

2.3 I/O specifications, 42

2.4 Ext ernal dimensions, 46

Basic Hardware and Function 37

Page 40

2. Specifications

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

2.1 General specifications

Item T1-16S

Power supply voltage 100 to 240Vac (+10/-15%), 50/60 Hz

Power consumption 45VA or less

Inrush current 50A or less (at 240Vac, cold start)

Output

rating

AC Power type

(Note)

Power supply voltage 24Vdc (+20/-15%)

Power consumption 18W or less

Inrush current 25A or less (at 24Vdc)

DC Power type

5Vdc output rating (Note) 1.5A (for I/O module)

Retentive power interruption 10ms or less

Insulation resistance 10MΩ or more

Withstand voltage 1500Vac - 1 minute

Ambient temperature 0 to 55°C (operation), -20 to 75°C (storage)

Ambient humidity 5 to 95%RH, no condensation

Noise immunity 1000Vp-p/1µs, Conform to EMC Directive 89/336/EEC

Vibration immunity 9.8m/s2 (1g)

Shock immunity 98m/s2 (10g)

Approximate weight 500g

24Vdc

(24Vdc, ±10%)

5Vdc 1.5A (for I/O module)

6F3B0253

0.2A (for external devices and/or for input signals)

(between power terminals and ground terminal)

(for 30 minute s per axis, on 3 mut ually perpendicular axes)

(3 shocks per axis, on 3 mu tually perpendicular axes)

NOTE

(1) 24Vdc service power output is not provided on the DC power supply type.

(2) The maximum output current of the 5Vdc is 1.5A. However there is the following

restrictions, depending on the conditions.

• When HP911 is used:

→ Redused by 0.2A

• When RS-485 port is used:

→ Reduced by 0.1A

(A)

1.5

1.0

5Vdc

• When 24Vdc service power is used:

→ Refer to the right chart.

maximum load current

24Vdc service power

0.2 (A)0.1

38 T1-16S User’s Manual

Page 41

6F3B0253

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

2. Specifications

NOTE

(3) The 5Vdc current consumption of each I/O modules is described below.

Check that the total 5Vdc current consumption is within the limit.

Model Specifications 5Vdc consumer

current

DI116M 16points, 24Vdc-5mA input. 50mA

DO116M 16points, 24Vdc-100mA output. 50mA

DD116M 8points, 24Vdc-5mA input.

8points, 24Vdc-100mA output.

RO108M 8 points, 24Vdc/240Vac – 1A relay output 260mA

AD121M 1ch. 12bit analog input.

(0 to 20mA, 0 to 5V)

AD131M 1ch. 12bit analog input. (±10V) 260mA

DA121M 1ch. 12bit analog output.

(0 to 20mA, 0 to 5V)

DA131M 1ch. 12bit analog output. (±10V) 240mA

TC111M 1ch. 12bit thermo couple input. 400mA

FR112M TOSLINE-F10 remote station. 100mA

50mA

260mA

350mA

Basic Hardware and Function 39

Page 42

2. Specifications

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

2.2 Functional specifications

Item T1-16S

Control method Stored program, cyclic scan system

Scan system Floating scan or constant scan (10 – 200ms, 10ms unit s)

I/O update Batch I/O refresh

Program memory (Note) RAM and EEPROM (no back-up battery required)

Program capac i ty 8K steps

Programming language Ladder diagram with function block

Instructions Basic: 21

Execution speed

Program t ypes

User data

back-up

I/O register 512 points/ 32 words (X/XW, Y/YW)

Auxiliary relay 4096 points/ 256 words (R/RW)

Special r el ay 1024 points/ 64 words (S/S W)

Timer 256 points (T./T)

Counter 256 points (C./C)

Data register 4096 words (D)

Index r egister 3 words (I, J, K)

Capacitor 1 hour (at 25°C)Memory

Battery (option) Max. 2 years.

6F3B0253

(direct I/O instruction available at basic unit’s I/O)

(4K or 8K mode)

Function: 97

1.4µs/contact, 2.3µs/coil,

4.2µs/16-bit transfer, 6.5µs/16-bit addition

1 main program

1 sub-program (initial program)

1 timer interrupt (interval: 5 to 1000ms, 5ms units )

4 I/O interrupt (high-speed counter and interrupt input)

256 subroutines (up to 3 levels of nesting)

64 at 0.01s, 192 at 0.1s

Min. 6 months. (Note)

NOTE

(1) The user program stored in the EEPROM is transferred to the RAM

(2) The data of RAM and calendar IC are backed up by built-in capacitor

(3) When the optional battery is used, replace the battery periodically with

time per day

40 T1-16S User’s Manual

when power is turned on. Therefore, if the program is modified, it is

necessary to issue the EEPROM Write command from the programming

tool. O t herwise, the modified program is over-written by original

EEPROM contents at the next initial load timing.

and optional battery.

refe rrin g to the table below .

Annual average air temperature

Under 30°C (86°F) Over 30°C (86°F)

Over 8 hours 2 years 1 yearOperation

Under 8 hours 1 year 6 months

Page 43

Functional spec ifications (cont’d)

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Item T1-16S

I/O capacity 16 points (basic)

+128 points (I/O modules)

Input 24Vdc input (8 points)I/O type

Output Relay (6 points) + transistor (2 points)

I/O terminal block Fixed

Real-time clock

/calendar

Special I/O functions

(Note)

Communications

interface

Debug support

function

Yes, ±60 s/month at 25°C

(Enhanced model only)

• High speed counter, 2 single or 1 quadrature

• Interrupt input, 2 points

• Adjustable analog register, 2 points

• Pulse output, CW+CCW or pulse+direction

• PWM output

• 1 port RS-232C (programmer port)

- for Programmer or Computer link connection

• 1 port RS-485 (Enhanced model only)

- Programmer

- Computer link

- Data link

- Free ASCII

• TOSLINE-F1 0 remote (by I/O module)

• Sampling trace, 8 devices and 3 register - 256 times

• On-line programming

• On-line EEPROM write

6F3B0253

2. Specifications

NOTE

(1) High-speed counter, interrupt input, pulse output and PWM output are

available in the DC input types.

(2) High-speed counter and interrupt input cannot be used simultaneously.

(3) Pulse output and PWM output cannot be used simultaneously.

Basic Hardware and Function 41

Page 44

2. Specifications

0 C

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

2.3 I/O specifications

• Input specifications

Input type DC input, current source/sink

Number of input points 8 points (8 points/common)

Rated input voltage 24Vdc, +10/-15 %

Rated input current 7mA (at 24Vdc)

Min. ON voltage 15V dc

Max. O FF voltage 5Vdc

ON delay time 0 to 15ms

OFF delay time 0 to 15ms

Input signal display LED display for all points, lit at ON, internal logic

External connecti on Removable termi nal block, M3

Withstand voltage 1500Vac, 1 minute

Internal c i r cuit

6F3B0253

Item Specifications

*1

*1

side

(between internal and external circuits)

LED

7

Internal cir cuit

*1: User can change the input ON/OFF delay time of the DC input.

The setting range is 0 to 15ms. (Default value = 10ms) Refer to section 8.2.

42 T1-16S User’s Manual

Page 45

• Input signal connections

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

T1-16S

6F3B0253

2. Specifications

DC IN

Service power

24Vdc

NOTE

L

C

−

NCN

+ 2422206

31

0

42

Vin

75

C C

2321

26

2725

24Vdc

24Vdc input

The 24Vdc service power output is not provided on the DC power supply type.

Basic Hardware and Function 43

Page 46

2. Specifications

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

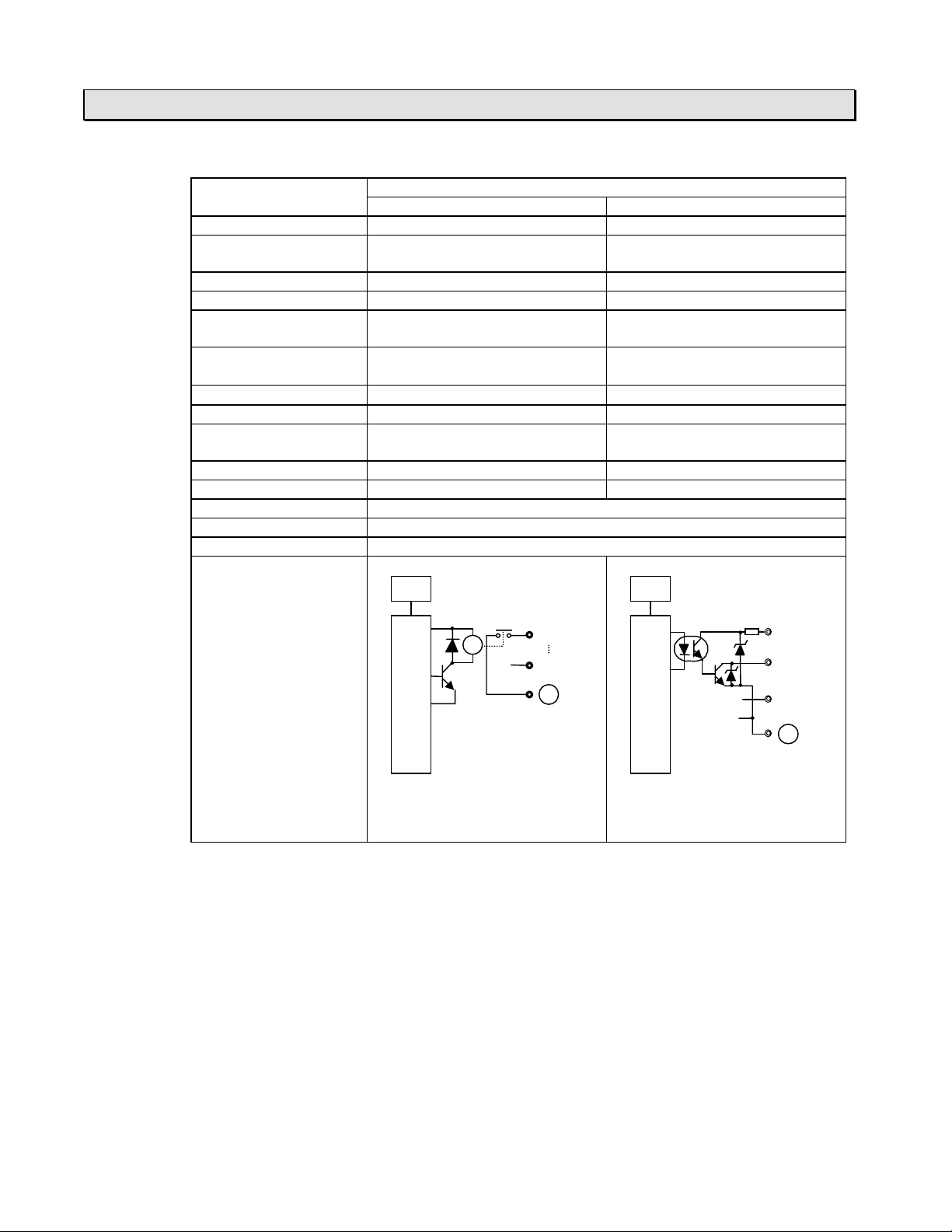

• Output specifications

Output ty pe Relay contact, no rmally open Transistor output, curr ent sink

Number of output points 6 points

Rated load voltage 240Vac/24Vdc (max.) 24Vdc

Range of load voltage Max. 264Vac/125Vdc 20.0 - 28.0Vdc

Maximum l oad current 2A /poi nt (resisti ve),

ON resistance

Voltage drop at ON

Leakage current at OFF None 0.1mA or less

Minim um load 5Vdc, 10mA

ON delay time 10ms or less 0.1ms or less

OFF del ay t ime 10ms or less 0.1m s or l ess

Input signal display LED display f or all points, lit at ON, i nternal logic side

External connecti on Removable terminal bl oc k, M3

Withstand voltage 1500Vac, 1 minute (between internal and external circuits)

Internal c i r cuit

Relay output Transistor output

(6 pts/common)

4A/common

50mΩ or less

(init i al v al ue)

(50mW)

LED

6F3B0253

SpecificationsItem

2 points

(2 poi nts/ common)

0.5A/point (resistive)

−

−

0.5V or less

−

LED

Ry

Internal c ircu it

*1: The switching life of the relay output is as follows.

20 million times or more (mechanical)

100 thousand times or more (electrical, at maximum rated voltage and current)

22

27

C

Internal circuit

Vin

20

21

C

44 T1-16S User’s Manual

Page 47

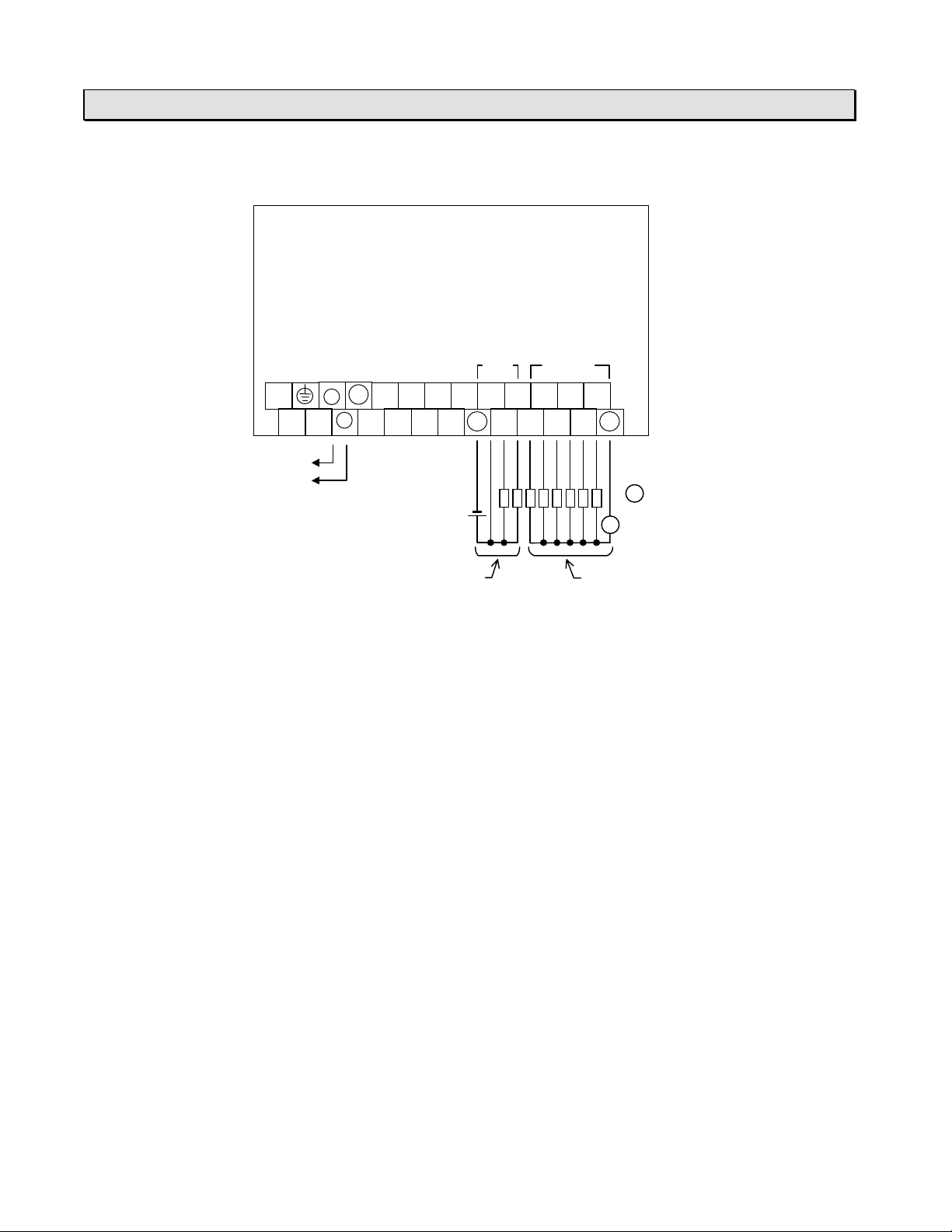

• Output signal connections

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

T1-16S

6F3B0253

2. Specifications

L

N

Service power

24Vdc

C

−

NC

+ 24 22 20 6

Transister output

DC OUT

3 1

0

4 2

24Vdc

Vin

7 5

C

+

RELAY OUT

23 21

26

27 25

C

PS

240Vac/24Vdc (max.)

PS

Relay output

Basic Hardware and Function 45

Page 48

2. Specifications

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

2.4 External dimensions

♦ T1-16S

6F3B0253

♦ I/O module

[mm]

[mm]

46 T1-16S User’s Manual

Page 49

Section 3

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

I/O Application Precautions

6F3B0253

3.1 Application precautions for input signals, 48

3.2 Application precautions for output signals, 50

Basic Hardware and Function 47

Page 50

3. I/O Application Precautions

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

3.1 Application precautions for input signals

6F3B0253

!

WARNING

Configure emergency stop and safety interlocking circuits outside the

T1-16S. Otherwise, malfunction of the T1-16S can cause injury or serious

accidents.

(1) Minimum ON/OFF time of the input signal

The following conditions guarantee correct reading of the ON/OFF state of the input

signal:

Input ON time: ON delay time + the t ime for one scan

Input OFF time: OFF delay time + the time for one scan

The ON and OFF times of the input signals must be longer than these intervals.

(2) Increasing the contact current

The reliab ilit y of some contacts cannot be guaranteed by the specified input current. In

this case, install an external bleeder resistor to increase the contact current.

Bleeder resistor

I

I

V

R

1

I2

T1

input

circuit

V

R

=

−

II

Wattage

1

2

V

>×

3

R

(3) Connecting transistor output device

An example of connecting a transistor output device to T1-16S’s input circuit is shown

below.

For NPN open collector

•

48 T1-16S User’s Manual

For PNP open collector

•

C

T1

input

circuit

C

T1

input

circuit

Page 51

3. I/O Application Precautions

circuit

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

(4) Countermeasures against leakage current

When a switch with an LED or sensor is used, the input sometimes cannot recognize

that the switch is off due to the current leakage. In this case, install a bleeder resistor

to reduce input impedance.

6F3B0253

LE

Bleeder resistor

T1

input

C

Select a bleeder resistor according to the following criteria:

(a) The voltage between the input terminals must be lower than the OFF voltage

when the sensor is switched off.

(b) The current must be within the allowable range when the sensor is switched on.

(c) Calculate the wattage of the bleeder resistor by multiplying the current when the

sensor is switched on times three.

Basic Hardware and Function 49

Page 52

3. I/O Application Precautions

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

3.2 Application precautions for output signals

6F3B0253

!

WARNING

Configure emergency stop and safety interlocking circuits outside the

T1-16S. Otherwise, malfunction of the T1-16S can cause injury or serious

accidents

!

CAUTION

1. Turn on power to the T1-16S before turning on power to the loads.

Failure to do so may cause unexpected behavior of the loads.

2. Con figure the exter nal circuit s o that the external 24Vdc power required

for the transistor output circuits and power to the loads are switched

on/off simultaneously. Also, turn off power to the loads before turning off

power to the T1-16S.

3. Install fuses appropriate to the load current in the external circuits for the

outputs. Failure to do so can cause fire in case of load over-current.

(1) 2 points of solid-state output

The leading 2 points of output (Y020 and Y021) are solid-state outputs, transistors on

the DC input types.

These solid-state outputs are suited for frequent switching applications.

Note that the specifications of the solid-state outputs and other outputs (relays) are

different.

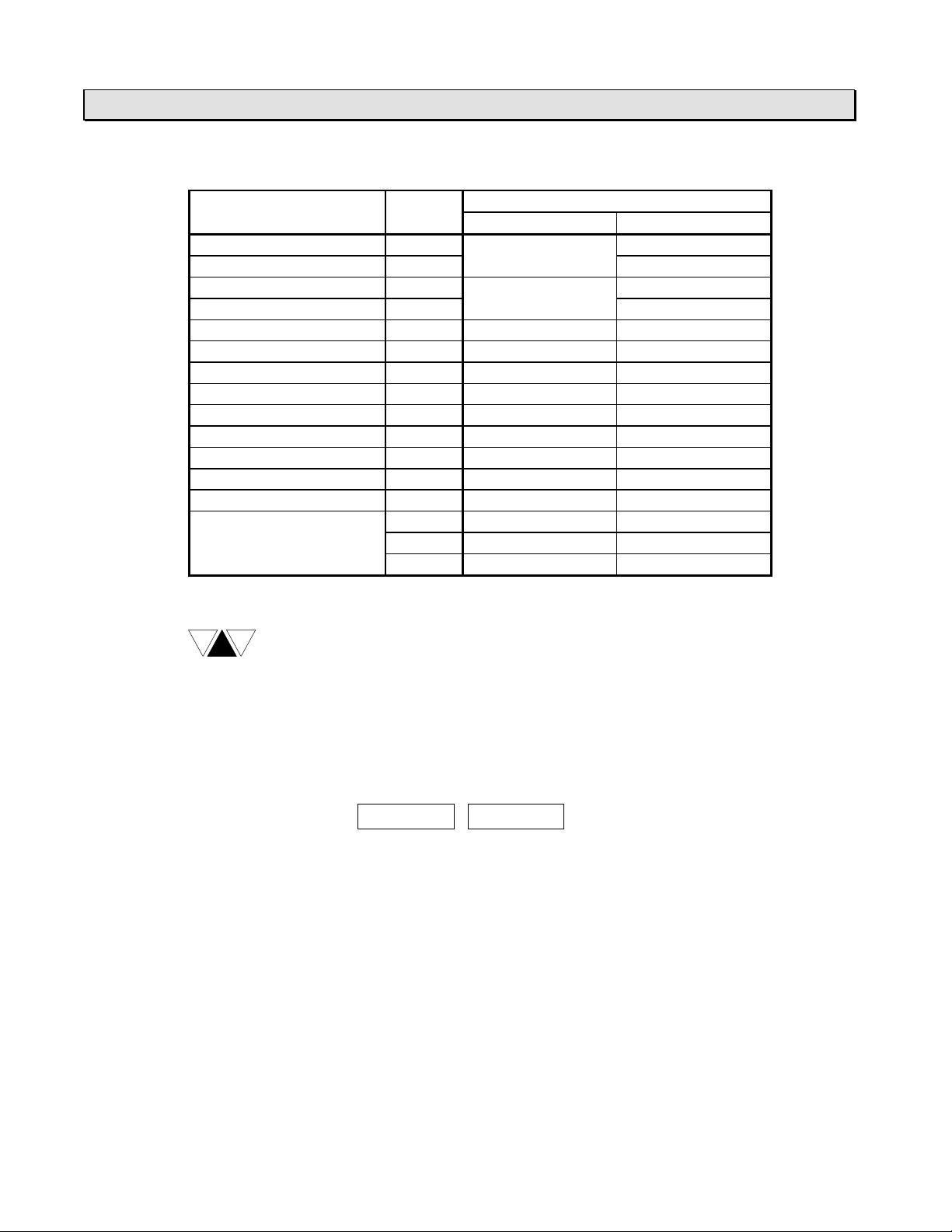

(2) Switching life of output relays

Expected relay life is more than 100,000 electrical cycles at rated maximum voltage

and current, and more than 20 million mechanical cycles. The expected contact life

(electrical cycles) is shown on the table below.

Load

voltage

AC 110Vac, 2A 340 DC 24Vdc, 2A 280

load

COSφ = 1

110Vac, 2A 150 24Vdc, 2A 60

COSφ = 0.7

220Vac, 2A 220 48Vdc, 1A 200

COSφ = 1

220Vac, 2A 100 L/R = 15 ms 0.2A 420

COSφ = 0.7

Load

current

Expected life

(thousand)

Load

voltage

Load

current

Expected life

(thousand)

1A 720 load L/R = 0 ms 1A 600

0.5A 1,600 0.5A 1,300

1A 320 L/R = 15 ms 1A 150

0.5A 700 0.5A 350

1A 500 L/R = 0 ms 0.5A 420

0.5A 1,100 48Vdc, 0.5A 130

1A 210 110Vdc, 0.5A 200

0.5A 460 L/R = 0 ms 0.2A 550

110Vdc, 0.2A 150

L/R = 15 ms 0.1A 350

50 T1-16S User’s Manual

Page 53

3. I/O Application Precautions

circuit

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

(3) Over-current protection

The output circuit of the T1-16S does not contain protective fuses. Fuses rated for the

output should be provided by the user.

6F3B0253

T1

Load