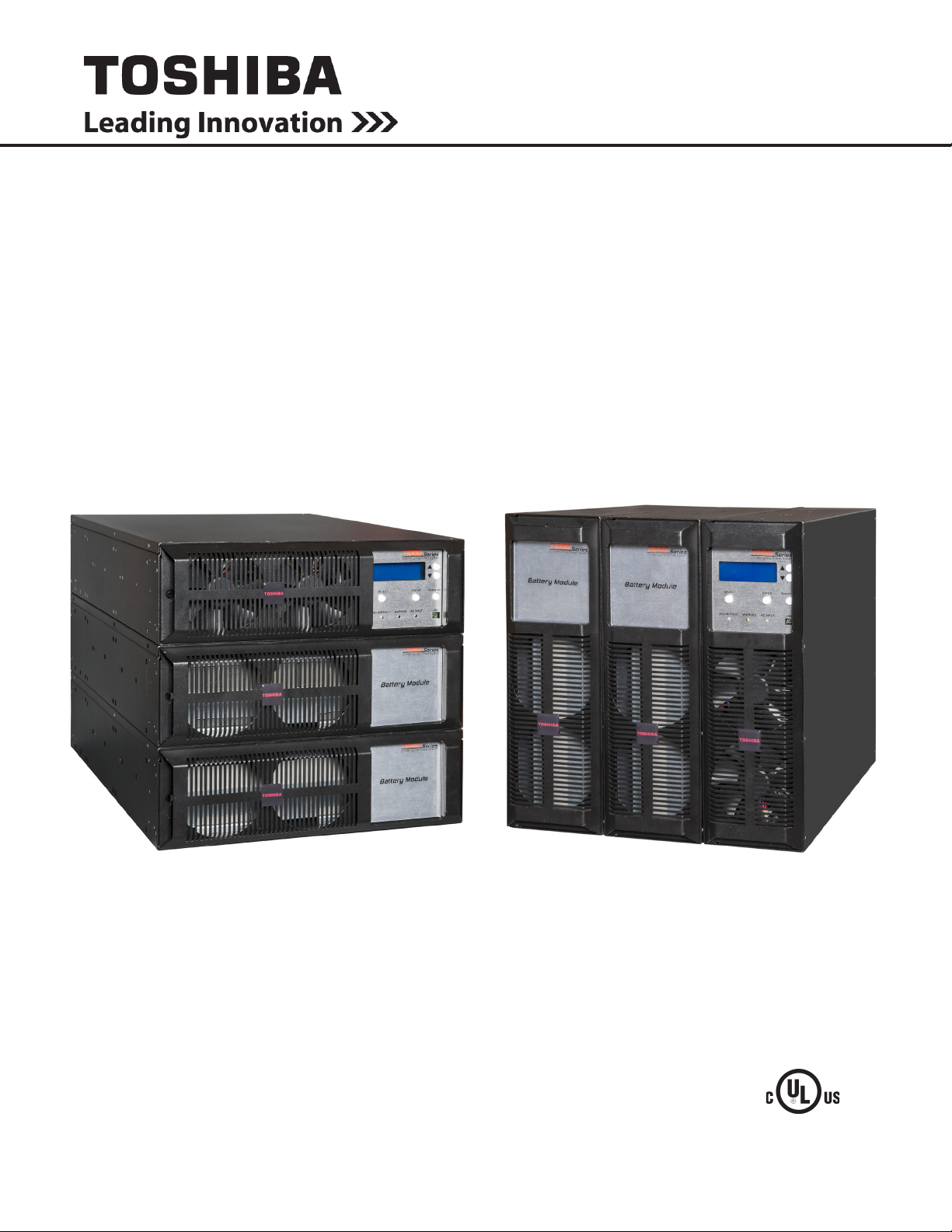

Toshiba t1000 Installation And Operation Manual

UNINTERRUPTIBLE POWER SYSTEM (UPS)

T1000 Series

UPS INSTALLATION AND OPERATION

MANUAL

SINGLE PHASE - 6 KVA

Rackmount

Conguration

Part # 91074-002

July 2015

Manufactured in the USA

© Copyright 2015 TOSHIBA International Corporation

All rights reserved.

Tower

Conguration

b

T1000 Series UPS Installation and Operation Manual – 91074-002

Product Use and Warranty Restrictions

The Toshiba products listed in this document are intended for usage in general electronics applications

(computer, personal equipment, ofce equipment, measuring equipment, industrial robotics, domestic

appliances, etc.). These Toshiba products are neither intended nor warranted for usage in equipment that

requires extraordinarily high quality and/or reliability or where a malfunction or failure may cause loss

of human life or bodily injury (Unintended Usage). Unintended Usage includes atomic energy control

instruments, airplane or spaceship instruments, transportation instruments, trafc signal instruments,

combustion control instruments, life-support equipment, all types of safety devices, etc. Unintended Usage

of Toshiba products listed in this document shall be made at the customer’s own risk.

NOTICE

PLEASE INFORM A TOSHIBA INTERNATIONAL CORPORATION REPRESENTATIVE IN

CASE OF INCONSISTENCIES, OMISSIONS, OR QUESTIONS.

The instructions contained in this manual are not intended to cover all of the details or variations in

equipment, or to provide for every possible contingency concerning installation, operation, or maintenance.

Should further information be required or if problems arise which are not covered sufciently, contact your

Toshiba sales ofce.

The contents of this instruction manual shall not become a part of or modify any prior or existing agreement,

commitment, or relationship. The sales contract contains the entire obligation of Toshiba International

Corporation/Social Infrastructure Systems Group/Power Electronics Division/UPS Business Unit, hereafter

referred to as Toshiba UPS. The warranty contained in the contract between the parties is the sole warranty

of Toshiba UPS and any statements contained herein DO NOT create new warranties or modify the existing

warranty.

Any electrical or mechanical modications to this equipment without prior written consent of Toshiba UPS

will void all warranties and may void the UL/CUL listing. Unauthorized modications can also result in

personal injury, loss of life, or destruction of the equipment.

QUALIFIED PERSONNEL ONLY

Qualied Personnel are those who have the skills and knowledge relating to the construction,

installation, operation, and maintenance of the electrical equipment and have received safety

training on the hazards involved (Refer to the latest edition of NFPA 70E for additional safety

requirements).

T1000 Series UPS Installation and Operation Manual – 91074-002

UNINTERRUPTIBLE POWER SYSTEM (UPS)

Please complete the following information and retain for your records.

Unless otherwise specied, the warranty period for the UPS or UPS part is 36 months from the shipment

date (see Toshiba International Corporation bill of lading).

Unless otherwise specied, the warranty period for a UPS battery is 24 months from the shipment date (see

Toshiba International Corporation bill of lading).

JOB NUMBER

MODEL NUMBER

SERIAL NUMBER

APPLICATION

SHIPMENT DATE

INSTALLATION DATE

INSPECTED BY

T1000 Series UPS Installation and Operation Manual – 91074-002

Purpose

This manual provides information on how to safely install your Toshiba International Corporation power

electronics product. This manual includes a section of general safety instructions that describes the warning

labels and symbols that are used throughout the manual. Read the manual completely before installing,

operating, or performing maintenance on this equipment.

This manual and the accompanying drawings should be considered a permanent part of the equipment and

should be readily available for reference and review. Dimensions shown in the manual are in metric and/or

the English customary equivalent.

Toshiba International Corporation reserves the right, without prior notice, to update information, make

product changes, or discontinue any product or service identied in this publication.

Toshiba is a registered trademark of the Toshiba Corporation. All other product or trade references appearing

in this manual are registered trademarks of their respective owners.

Toshiba International Corporation shall not be liable for direct, indirect, special, or consequential damages

resulting from the use of the information contained within this manual.

This manual is copyrighted. No part of this manual may be photocopied or reproduced in any form without

the prior written consent of Toshiba International Corporation.

© Copyright 2015 Toshiba International Corporation

All rights reserved.

Printed in the U.S.A.

Toshiba Customer Support Center

Contact the Toshiba Customer Support Center for assistance with application information or for any

problems that you may experience with your Uninterruptible Power System (UPS).

Toshiba Customer Support Center

8 a.m. to 5 p.m. (CST) – Monday through Friday

USA Toll Free (877) 867-8773 – Field Service Tech Support

USA Toll Free (855) 803-7087 – Pre-sales Application Support

Fax (713) 896-5212

Email: ToshibaUPS@tic.toshiba.com

You may also contact Toshiba by writing to:

TOSHIBA INTERNATIONAL CORPORATION

SOCIAL INFRASTRUCTURE SYSTEMS GROUP

POWER ELECTRONICS DIVISION - UPS

13131 West Little York Road

Houston, Texas 77041-9990

Attn: T1000 Product Manager

For further information on Toshiba products and services, please visit our website at:

www.toshiba.com/tic/industrial/uninterruptible-power-systems

T1000 Series UPS Installation and Operation Manual – 91074-002

This page intentionally left blank.

f

T1000 Series UPS Installation and Operation Manual – 91074-002

Table of Contents

1. General Safety Instructions ........................................................................1

1.1 Symbols ............................................................................................1

1.2 Signal Words ....................................................................................2

1.3 Regulatory Compliance Statement ...................................................2

2. Equipment Warning Labels ........................................................................3

3. Important Safety Instructions .....................................................................5

3.1 Qualied Personnel Only ..................................................................6

4. Inspection/Storage/Disposal ......................................................................7

4.1 Inspection .........................................................................................7

4.2 Unpacking .........................................................................................7

4.3 Storage .............................................................................................7

4.4 Disposal ............................................................................................7

5. Installation Precautions ..............................................................................8

5.1 Conductor Routing and Grounding ...................................................9

6. Installation....................................................................................................10

6.1 Module Arrangement ........................................................................10

6.2 System Installation............................................................................11

6.3 Tower Installation with Cap ...............................................................12

6.4 Rackmount Installation - Bracket Mounting Holes ............................13

6.5 4-Post Rack Installation Instructions ................................................13

7. Wiring the System .......................................................................................16

7.1 Layout - Power Module ....................................................................16

7.2 Layout - Battery Module (w/ Outlet Panel) .......................................17

7.3 Layout - Transformer Module ...........................................................18

7.4 Power Module Cable Size and Tightening Torque ............................ 18

8. Operating Precautions ................................................................................21

9. Control Panel ...............................................................................................22

9.1 Control Panel Layout ........................................................................22

9.2 Light Emitting Diodes (LED) .............................................................23

9.3 LCD Display - Open the Main Menu .................................................23

9.4 LCD Display - Menu/Sub-Menu Navigation ......................................24

9.5 LCD Display - Sub-Menu/Parameter Navigation ..............................25

10. UPS Operation ...........................................................................................26

10.1 Initial Startup .................................................................................26

10.2 Startup (Normal) ...........................................................................27

10.3 Bypass ..........................................................................................27

10.4 Shutdown ......................................................................................28

T1000 Series UPS Installation and Operation Manual – 91074-002

i

11. System Description ...................................................................................29

11.1 Application and Use ........................................................................29

11.2 Power Backup ................................................................................. 29

11.3 Power Conditioning ......................................................................... 29

12. Operating Modes .......................................................................................30

12.1 Static-Bypass (Stop operation) .......................................................30

12.2 On-Line (Run operation) ...............................................................30

12.3 Battery Backup (On batteries) ........................................................31

12.4 EPO (Emergency Power Off) Function ...........................................31

12.5 Cold Start (On Batteries) ................................................................32

12.6 Frequency Conversion Mode (CVCF) ............................................32

12.7 Battery Backup Time and Discharge Process ..............................33

12.8 Battery Low Voltage Tolerances .....................................................33

12.9 Battery Recharging .........................................................................34

12.10 Battery Test ................................................................................... 35

13. Control Panel Menu Trees ........................................................................36

13.1 Control Panel Navigation and Menu Access...................................36

13.2 Top Menu - Sub-Menu Tree ............................................................37

13.3 Monitor Sub-Menu/Parameter Tree ................................................38

13.4 Setting Sub-Menu/Parameter Tree .................................................39

13.5 Records Sub-Menu/Parameter Tree ...............................................40

14. Operation....................................................................................................41

14.1 Cold Start ........................................................................................41

14.2 EPO and Remote Stop ...................................................................41

15. Communication Interfaces .......................................................................43

15.1 Remote Contacts ............................................................................43

15.2 (Optional) RemotEye® Network Card ..............................................44

15.3 (Optional) Google ChromeTM Browser App ..................................... 45

15.4 (Optional) EMD ...............................................................................46

16. UPS Protection System.............................................................................47

16.1 UPS Protection Devices .................................................................47

16.2 UPS Protection Devices Fault Response ......................................47

16.3 System Fault Messages .................................................................49

16.4 System Warning Messages ............................................................50

16.5 System Mode Messages ................................................................52

16.6 System Status Messages ...............................................................53

17. Preventive Maintenance/Parts Replacement ..........................................54

17.1 Preventive Maintenance .................................................................54

17.2 LCD Display Cleaning.....................................................................54

17.3 Battery Replacement ....................................................................54

ii

T1000 Series UPS Installation and Operation Manual – 91074-002

17.4 Part Replacement ...........................................................................54

18. Shipping Weights/Dimensions .................................................................55

18.1 Unit and Shipping Weights .............................................................55

18.2 Shipping Dimensions .....................................................................55

Appendix A: T1000 Specications .................................................................A-1

Appendix B: T1000 Menu Table ......................................................................B-1

Appendix C: T1000 Dimensional Drawings...................................................C-1

Appendix D: T1000 Packing Lists and Kit Contents ....................................D-1

Inter-Module Cabling Identication ..........................................................D-1

Appendix E: T1000 Optional Installation Kit Instructions ...........................E-1

E.1 Optional 3-Module Tower Cap Kit - 93178 .......................................E-1

E.2 Optional Tower Caster Kit - 90508 ...................................................E-2

E.3 Optional T1000 2-Post Rack Fixed Installation Kit - 92801 ..............E-5

E.4 Optional T1000 4-Post Rack Slide Installation Kit - 92800 ...............E-8

E.5 Optional T1000 2-Post Rack Slide Installation Kit - 90400 ...............E-11

Index ..................................................................................................................I-1

T1000 Series UPS Installation and Operation Manual – 91074-002

iii

This page intentionally left blank.

iv

T1000 Series UPS Installation and Operation Manual – 91074-002

1. General Safety Instructions

DO NOT attempt to transport, install, operate, maintain or dispose of this equipment until you have read and

understood all of the product safety information provided in this manual.

1.1 Symbols

The symbols listed below are used throughout this manual. When symbols are used in this manual they will

include important safety information that must be carefully followed.

Safety Alert Symbol indicates that a potential

personal injury hazard exists.

Prohibited Symbol indicates DO NOT take action.

Mandatory Symbol indicates that the following

instruction is required.

Ground Symbol indicates the location of the

equipment grounding conductor.

Electrical – Voltage & Shock Hazard Symbol

indicates parts inside may cause electric shock.

Explosion Hazard Symbol indicates parts may

explode.

Heavy Lift Hazard Symbol indicates object

requires two- or more man lift, or lifting aid.

T1000 Series UPS Installation and Operation Manual – 91074-002

1

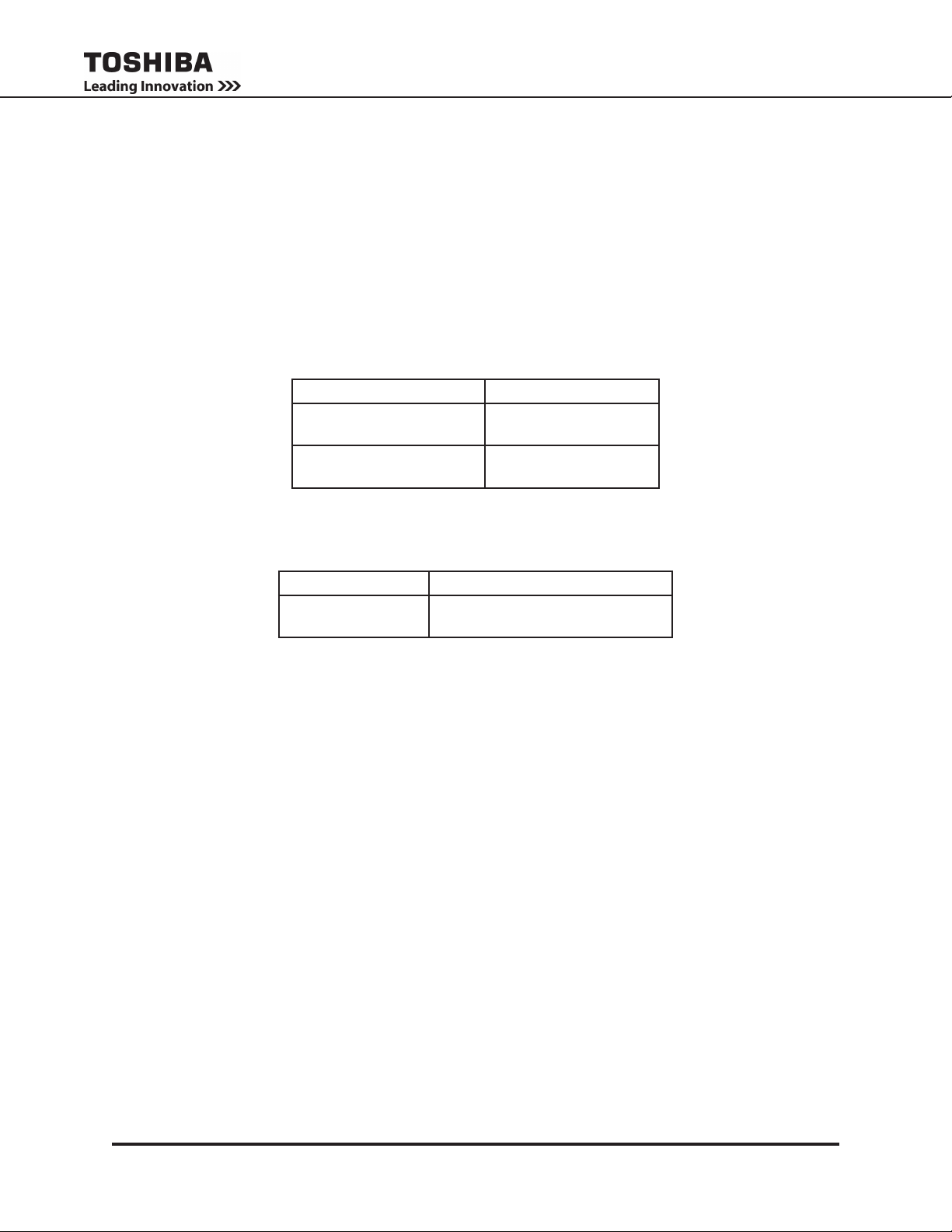

1.2 Signal Words

The signal words listed below are used throughout this manual. When the words DANGER, WARNING,

CAUTION and NOTICE are used in this manual they will include important safety information that must be

carefully followed.

The word DANGER in capital letters preceded by

DANGER

WARNING

CAUTION

the safety alert symbol indicates that an imminently

hazardous situation exists, and if not avoided

will result in loss of life or serious injury to

personnel.

The word WARNING in capital letters preceded by

the safety alert symbol indicates that a potentially

hazardous situation exists, and if not avoided

may result in loss of life or serious injury to

personnel.

The word CAUTION in capital letters preceded by

the safety alert symbol indicates that a potentially

hazardous situation exists, and if not avoided may

result in minor or moderate injury.

The word NOTICE in capital letters without the safety

NOTICE

alert symbol indicates a potentially hazardous

situation exists, and if not avoided may result in

equipment and property damage.

1.3 Regulatory Compliance Statement

FCC Class A Notice

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy, and if it is not installed and used in accordance with the

instruction manual, it may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference, in which case the user will be required to correct

the interference at his own expense.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause undesired

operation.

Notice: The FCC regulations provide that changes or modications made to this device that are not

approved by Toshiba International Corporation may void the authority granted to the user by the FCC to

operate this equipment.

EMC Directive Class A Note

This UPS is commercial in design and not intended for use at anytime in a Residential Environment.

2

T1000 Series UPS Installation and Operation Manual – 91074-002

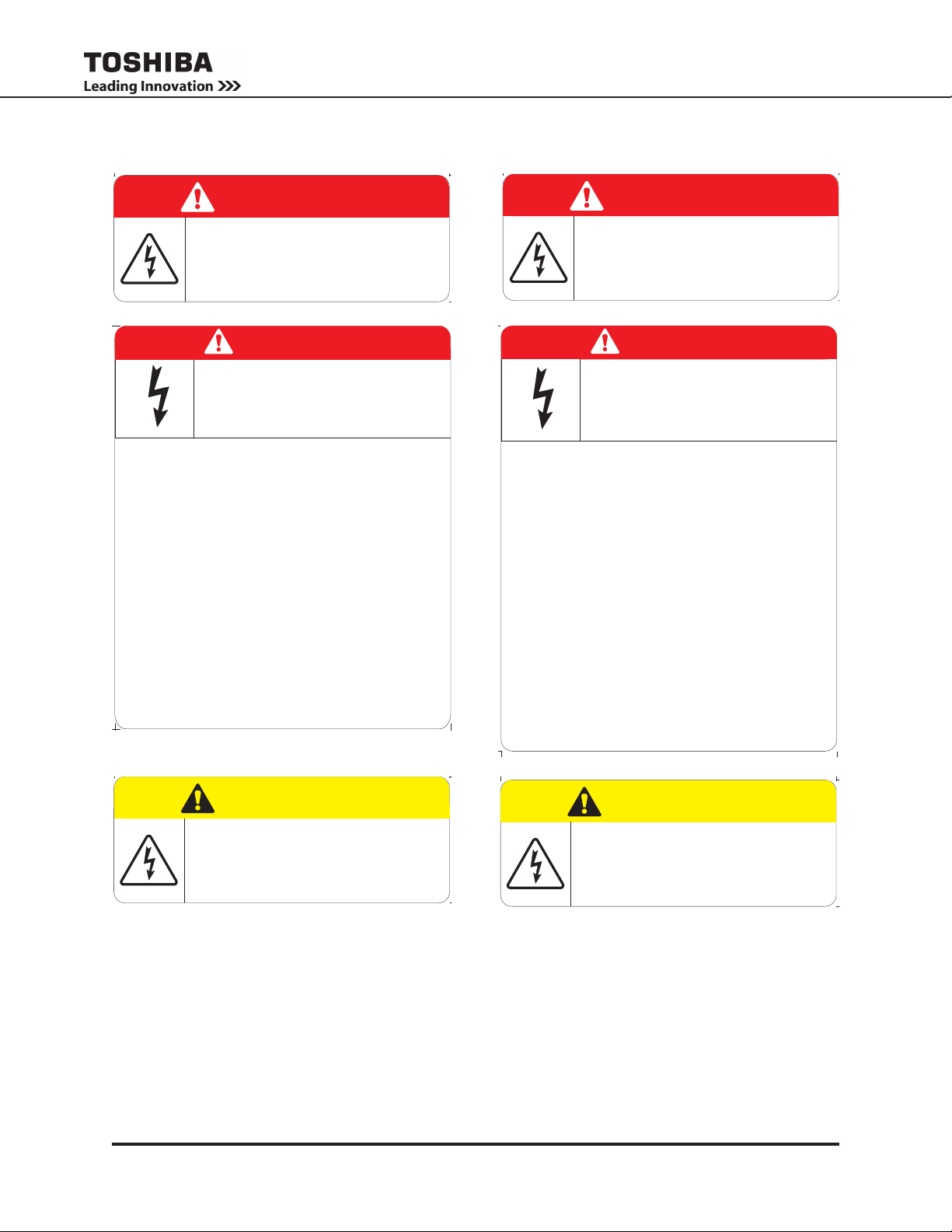

2. Equipment Warning Labels

WARNING AREA

TEXT AREA

WARNING AREA

TEXT AREA

WARNING AREA

TEXT AREA

WARNING AREA

TEXT AREA

WARNING AREA

TEXT AREA

WARNING AREA

TEXT AREA

The following pages show examples of warning labels that may be attached to either the interior or exterior

of the Power (UPS), Battery, or Transformer Modules. Do not remove or cover any of the labels. If the

labels are damaged or if additional labels are required, contact your equipment representative for additional

labels.

These labels in both English and French are placed to provide useful information or to indicate an imminently hazardous situation that may result in severe equipment/property damage, serious injury, or loss of

life if instructions are not followed.

LABELS IN ENGLISH ÉTIQUETTES EN FRANÇAIS

DANGER

AC VOLTAGE

This UPS receives power from more

than one source. Disconnect all AC

sources before performing any service

or testing inside this unit

48082

DANGER

RISK OF ELECTRIC SHOCK

Capacitors stay charged after power

has been shut off.

Accidental contact with live parts can

cause personal injury and death.

Turn off and lock out all power sources.

WAIT AT LEAST FIVE (5) MINUTES

for power to dissipate, then check

voltage before servicing.

57275

DANGER

DC VOLTAGE

DC Voltage supplied by batteries is still

present after equipment has been

turned off and taken off line.

Accidental contact with live parts can

cause personal injury and death.

Disconnect all DC Sources before

performing any service or testing

in this compartment.

43784

DANGER

TENSION AC

Cette UPS est alimentée par plus d´une

source. Débrancher toutes les sources

AC avant d´effectuer des entretiens ou

des tests à l´intérieur de cette unité.

90630

DANGER

RISQUE DE CHOC ÉLECTRIQUE

Les condensateurs restent chargés après

coupure de l´alimentation. Tout contact

accidental avec des composants sous

tension électrique peut provoquer des

blessures ou la mort. Fermer et verrouiller

toutes les sources d´alimentation.

ATTENDRE AU MOINS (5) MINUTES

pour laisser décharger les condensateurs,

puis vérifier la tension électrique avant

l´entretien.

90624

DANGER

TENSION DC

Tension DC fournie par des batteries

est encore présente après que le

matériel a été éteint et mis hors linge.

Tout contact accidentel avec des

composants sous tension peut causer

des blessures et la mort.

Débrancher toutes les sources DC

avant d´effectuer des réparations ou

des tests dans ce compartiment.

90632

FIGURE 2-1: EQUIPMENT WARNING LABELS

T1000 Series UPS Installation and Operation Manual – 91074-002

3

0.75"

2.00"

0.75"

2.00"

WARNING AREA

TEXT AREA

WARNING AREA

TEXT AREA

0.75"

2.00"

0.75"

2.00"

LABELS IN ENGLISH ÉTIQUETTES EN FRANÇAIS

DANGER

Risk of electrical shock.

Live terminals on batteries.

Do not touch uninsulated battery

terminal.

PN 40759

DANGER

HAZARDOUS VOLTAGES

Hazardous voltages are used in the operation

of this equipment and could cause severe personal

injury or loss of life.

The following precautions should be observed to

reduce the risk of injury or death.

Only qualified technicians familiar with this equipment and the

information supplied with it should be permitted to install and

operate this equipment.

Installation of electrical equipment must be done in

accordance with National Electrical Code and any other state

or local codes. Proper grounding and conductor sizing must

be installed for safe operation.

During operation, keep all covers in place and cabinet

doors shut.

When performing visual inspections and maintenance, if

possible, be sure the UPS is turned off and the incoming

AC feed is turned off and locked out.

The UPS and Battery Cabinet will have hazardous

voltages present even after the AC feed is turned off.

If it is necessary to make measurements with the power

on, do not touch any electrical connection points. Remove

all jewelry from wrists and fingers. Make sure test equipment

is in good, safe operating condition.

While servicing, stand on some type of insulation, and be

sure not to be grounded.

Follow the safety instructions given in the equipment manual

carefully and observe all danger, warning and caution notices.

40308

DANGER

Risque de choc électrique.

Bornes de batteries sous tension.

Ne pas toucher de borne de batterie non

isolée.

PN 90637

DANGER

TENSIONS DANGEREUSES

Des tensions dangereuses sont utilisées dans

l´opération de cet appareil et pourraient causer

des blessures graves ou des pertes de vie.

Les mesures de sécurité suivantes doivent être

observées pour réduire le risque de blessure ou de

Seulement des techniciens qualifiés et familiarisés avec ce

matériel, ainsi que la documentation fournie avec elle,

devraient être autorisés à installer et à utiliser cet équipement.

L´installation de l´équipement électrique doit être effectuée

selon les normes électriques reconnues par les organismes

nationaux ou provinciaux accrédités. Une bonne mise à la

terre et un calibre de câble approprié doivent être installés

pour un fonctionnement sécuritaire.

Pendant le fonctionnement, maintenir tous les couvercles en

place et les portes de l´armoire fermées.

Lors des inspections visuelles et d´entretien, si possible,

vérifier que l´UPS soit éteinte et que l´alimentation AC est

éteninte et verrouillée.

L´UPS et l´armoire de batterie auront des tensions

dangereuses présentes même après avoir coupé

l´alimentation AC.

Si des mesures sur l´appareil sous tension doivent être

effectuées, ne toucher à aucun point de connexion

électrique. Retirer tous les bijoux des poignets et des doigts.

S´assurer que l´équipement de test est en bon êtat de

fonctionnement.

.

Lors des opérations de maintenance, l´opérateur doit se tenir

sur une surface isolée non reliée à la mise à la terre.

Suivre attentivement les consignes de sécurité indiquées

dans le manuel d´opération et respecter tous les avis de

danger, les avertissements et les mises en garde.

mort.

90638

CAUTION

Risk of electrical shock.

Battery circuit is not isolated from AC input,

hazardous voltage may exist between

battery terminals and ground.

Test circuit before touching.

PN 40760

ATTENTION

Risque de choc électrique.

Le circuit de la batterie n´est pas isolé de

l´entrée AC, des tensions dangereuses

peuvent exister entre les bornes de la

batterie et la masse.

Tester le circuit avant de toucher.

PN 90636

FIGURE 2-1: (CONT.) EQUIPMENT WARNING LABELS

4

T1000 Series UPS Installation and Operation Manual – 91074-002

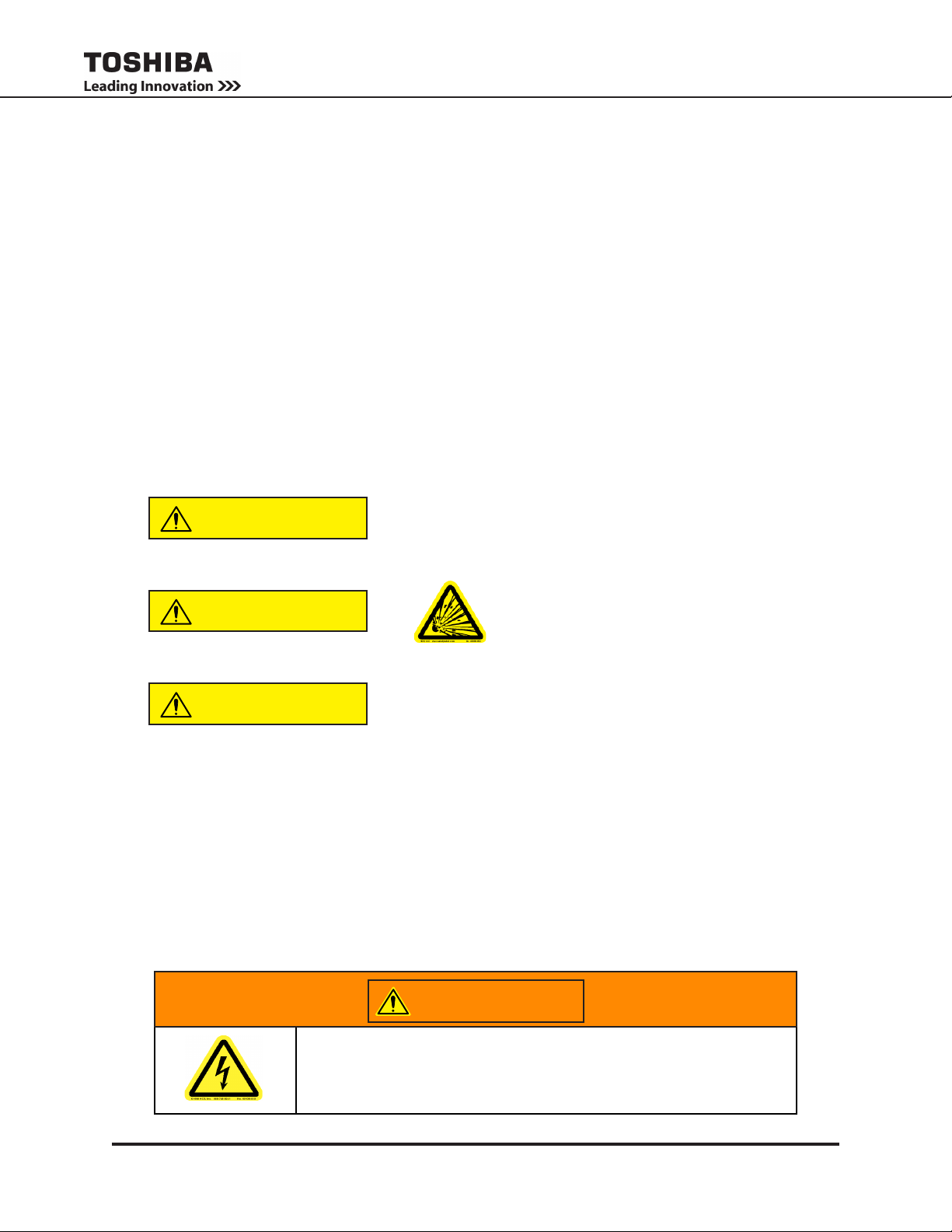

3. Important Safety Instructions

This manual contains important instructions that should be followed during the installation and maintenance

of the UPS and its batteries.

The T1000 Series UPS is a modular single-phase double conversion system. Each of the rackmount

modules is 3U (Three Standard Rack Units) high.

UPS systems are not equipped with an over-current protection device nor an output disconnect for the AC

output. Circuit breakers should be provided by the user between the UPS Input and utility power, and the

UPS output and the load input. This device should be rated as follows:

240/208 VAC RATING* 6 kVA

Input Breaker

240 V / 208 V 40 A

Output Breaker

240V / 208V 40 A

* Ratings are for a 80% rated device.

The nominal battery voltages for these models is as follows:

UNIT BATTERY VOLTAGE

6 kVA

Servicing the batteries should only be performed by a qualied factory authorized representative who is

knowledgeable about batteries and the required precautions. Keep unauthorized personnel away from

batteries. To arrange for battery replacement, contact Toshiba Customer Support Center.

1. Turn off, lockout, and tagout all equipment before connecting the power wiring to the equipment or

when performing maintenance.

2. The maximum ambient operating temperature is 104 °F (40 °C). UPS will go to Bypass when it

overheats.

3. Access panels should only be removed by authorized Toshiba eld Service personnel.

4. UPS servicing should be performed by qualied Toshiba representatives only.

5. Battery servicing should be performed by qualied Toshiba representatives only.

6. Contact your Toshiba authorized service center for battery replacement.

216 Vdc (Nominal)

(1 string of 18 x 12V batteries)

T1000 Series UPS Installation and Operation Manual – 91074-002

5

3.1 Qualied Personnel Only

Qualied personnel are those who have the skills and knowledge relating to the construction,

installation, operation, and maintenance of the electrical equipment and have received safety

training on the hazards involved (Refer to the latest edition of NFPA 70E for additional safety

requirements).

Qualied personnel shall:

1. Have read the entire operation manual.

2. Be trained and authorized to safely energize, de-energize, ground, lockout and tag circuits

and equipment, and clear faults in accordance with established safety practices.

3. Be trained in the proper care and use of protective equipment such as safety shoes, rubber

gloves, hard hats, safety glasses, face shields, ash clothing, etc., in accordance with

established safety practices.

4. Be trained in rendering rst aid.

5. Be knowledgeable about batteries and their required handling and maintenance precautions.

For further information about workplace safety visit www.osha.gov.

Misuse of this equipment may result in human injury

CAUTION

and equipment damage. In no event will Toshiba

Corporation be responsible or liable for either

indirect or consequential damage or injury that may

result from the misuse of this equipment.

CAUTION

CAUTION

To be performed by Qualied Personnel Only:

DO NOT open or mutilate the batteries. Released

electrolyte is harmful to the eyes and skin and could

also be toxic.

DO NOT dispose of the battery module in

a re. The batteries inside may explode.

1. Verify that the UPS is off and that the power is disconnected from the power source.

2. Remove watches, rings or other metal objects.

3. Use tools with insulated handles to prevent inadvertent shorts.

4. Wear rubber safety gloves and boots.

5. DO NOT place tools or any metal parts on top of batteries.

6. Determine if the battery is inadvertently grounded. If inadvertently grounded, remove source of

ground.

WARNING

Contact with any part of a grounded battery can result in

electrical shock.

The likelihood of shock will be reduced if such grounds are removed

prior to installation or maintenance.

6

T1000 Series UPS Installation and Operation Manual – 91074-002

4. Inspection/Storage/Disposal

4.1 Inspection

Inspect for shipping damage upon receipt of the UPS. Use caution when removing the unit from the pallet.

Refer to labels or documentation attached to packing material.

4.2 Unpacking

Check the unit for loose, broken, bent or otherwise damaged parts. If damage has occurred during shipping,

keep all original crating and packing materials for return to the shipping agent. The warranty does not apply

to damage incurred during shipping. Ensure that the rated capacity and the model number specied on the

nameplate conform to the order specications.

4.3 Storage

During periods of non-use, the following guidelines are recommended for storage.

Storage Preparation

1. Power up the UPS and allow it to operate with no load for 24 hours to fully charge the

batteries.

2. Stop the unit (See Section 12.1 Bypass/Stop Operation).

3. Place the MCCB switch (Fig. 7-1 (1)) in the Off position.

Storing Conditions

• For best results, store the UPS in the original shipping container and place on a wood

or metal pallet.

• Storage temperature: -4 – 104 °F (-20 – 40 °C).

• The optimum storage temperature is 70 °F (21 °C). A higher ambient temperature will

require recharging more frequently during storage.

Avoid storage locations that:

• Are subject to extreme temperature changes or high humidity.

• Are subject to high levels of dust or metal particles.

• Are subject to excessive vibration.

• Have inclined oor surfaces.

Storage Maintenance

• If stored at an ambient temperature less than 68 °F (20 °C), recharge the batteries every

9 months.

• If stored at an ambient temperature of 68 – 86 °F (20 – 30 °C), recharge the batteries

every 6 months.

• If stored at an ambient temperature of 86 – 104 °F (30 – 40 °C), recharge the batteries

every 3 months.

4.4 Disposal

Contact your local or state environmental agency for details on disposal of electrical components and

packaging in your particular area.

It is illegal to dump lead-acid batteries in landlls or dispose of improperly.

Please help our Earth by contacting the environmental protection agencies in your area, the battery

manufacturer, or call Toshiba toll-free at (877) 867-8773 for more information about recycling.

T1000 Series UPS Installation and Operation Manual – 91074-002

7

5. Installation Precautions

NOTICE

1. Observe the following environmental restrictions:

• Install the unit in a well-ventilated location.

• Install the unit where the ambient temperature is within the range specied in Appendix A -

“Specications”.

• DO NOT install the UPS in areas that are subject to high humidity.

• DO NOT install the UPS in areas that allow exposure to direct sunlight.

• DO NOT install the UPS in areas that allow exposure to high levels of airborne dust, metal

particles, or ammable gases.

• DO NOT install the UPS in areas near sources of electrical noise. Ensuring a proper earth ground

will reduce the effects of electrical noise and will reduce the potential for electrical shock.

• DO NOT install the UPS in areas that would allow uids or any foreign object to get inside the

UPS.

2. Install the unit in a stable, level and upright position that is free of excessive vibration.

3. Follow the instructions on the unpacking label afxed to the exterior of the UPS.

4. Tower Unit with Caster Kit Option Only: Once the installation is complete, screw down the UPS

leveling feet located next to the front and back casters, until the unit is no longer resting on the

casters.

5. The UPS generates and can radiate radio-frequency energy during operation. Although RFI noise

lters are installed inside of the unit, there is no guarantee that the UPS will not inuence some

sensitive devices that are operating near by. If such interference is experienced, the UPS should be

installed farther away from the affected equipment and/or powered from a different source than that

of the affected equipment.

6. It is the responsibility of the installer of this equipment to provide a suitable disconnect for the Control

Panel supplying power to this equipment.

This disconnect must:

Be suitable for the Voltage and Full Load Ampere Rating of all downstream equipment supplied by

the Panel;

The supply disconnecting device shall be one of the following types:

• Switch-disconnect, with or without fuses, in accordance with IEC 60947-3, utilization category

AC-23B or DC-23B

• As above, except one that has an auxiliary contact that in all cases causes switching devices

to break the load circuit before the opening of the main contacts of the disconnect.

• A circuit breaker suitable as an isolation device per IEC 60947-2

• Any other switching device in accordance with an IEC product standard that also meets the

isolation requirements of IEC 60947-1 and is appropriate for on-load switching of motors or

other inductive loads;

Be approved for use as a disconnect for the country in which this equipment is installed.

Be provided with a Lock Out Tag Out capability in the Off (Down) position.

8

T1000 Series UPS Installation and Operation Manual – 91074-002

7. Allow 5 minutes after power is removed for internal capacitors to fully discharge before attempting

to service the unit.

8. The user should provide output over-current protection for hardwired UPS systems. See “Appendix

A: T1000 Specications” on page A-1A-2 for the device rating.

9. After ensuring that all power sources are turned off and isolated in accordance with established

lockout/tagout procedures, connect the power source wiring of the correct voltage to the input

terminals of the UPS.

10. Hardwire Only: Connect the output terminals of the UPS to the load in line with local wiring

regulations. Size the branch circuit conductors in accordance with NEC Table 310.16.

5.1 Conductor Routing and Grounding

1. Use separate metal conduits for routing the input power, output power, and control circuits.

2. Follow the wire size and tightening torque specications listed on Table 7-4.

3. Always ground the unit to reduce the potential for electrical shock and to help reduce electrical

noise.

4. A separate ground cable should be run inside the conduit with the input power, output power, and

control circuits.

WARNING

METAL OF CONDUIT IS NOT AN ACCEPTABLE GROUND.

T1000 Series UPS Installation and Operation Manual – 91074-002

9

6. Installation

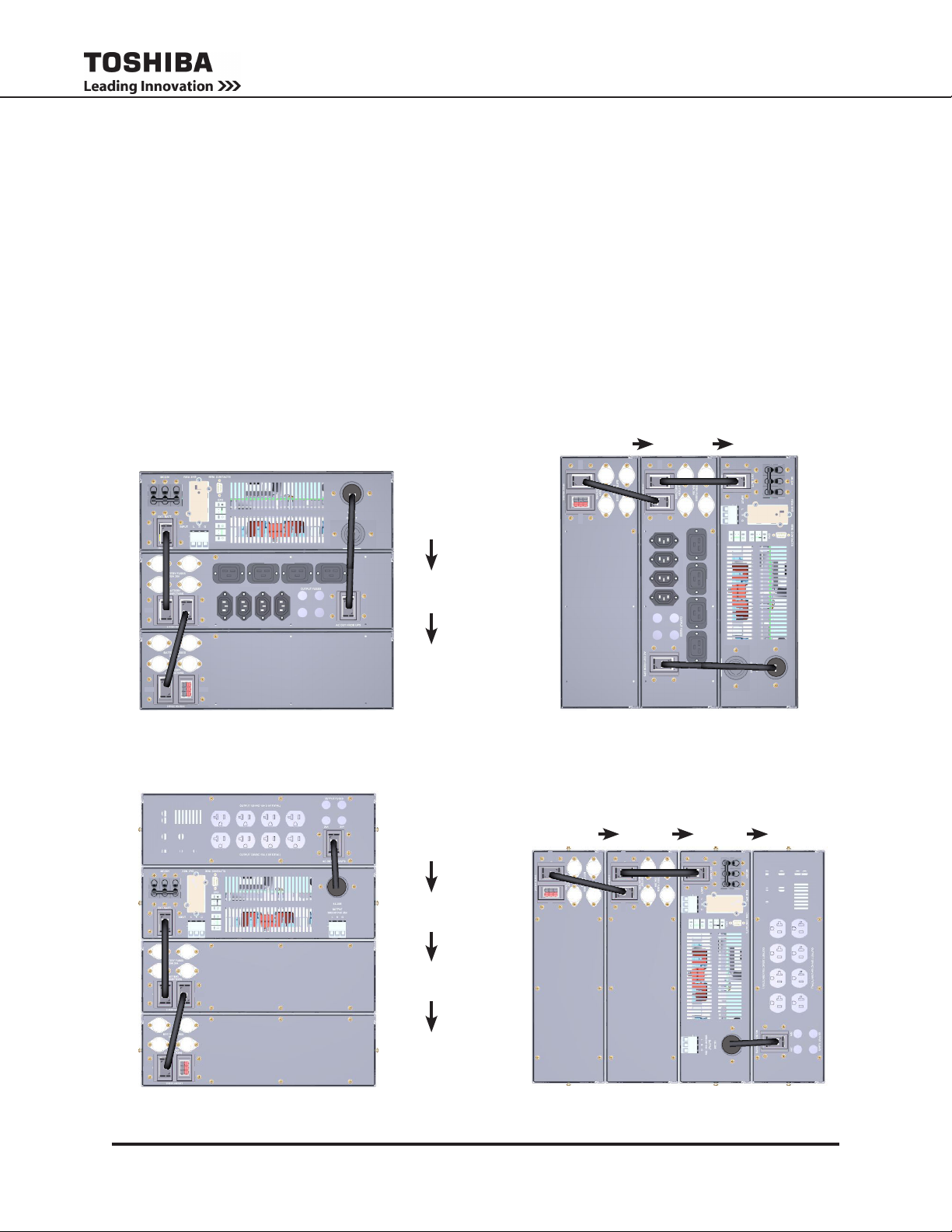

6.1 Module Arrangement

The T1000 Series UPS consists of a Power (UPS) module, optional Battery module(s), and optional

Transformer module for output other than 240/208 V. These modules can be purchased in either a rackmount or tower conguration.

Module arrangement is determined by the length of the factory-supplied inter-module cables. The Modules should be arranged in the following order as viewed from the front: top-to-bottom for Rackmount

(Fig. 6-1, Fig. 6-2); left-to-right for Tower (Fig. 6-3, Fig. 6-4).

NOTE: If a Transformer module is used, then the battery module(s) may, or may not, have an output

panel.

OUTPUT 240VAC 15A

CN12A CN12B

REAR VIEW

CN12A CN12B

OUTPUT 240VAC 10A

10A 15A

10A

15A

FIGURE 6-1: RACKMOUNT 240V

SYSTEM WITH C-13/C-19 PANEL

POWER

MODULE

BATTERY

MODULE 1

BATTERY

MODULE 2

OUT

TRANSFORMER

MODULE

BATTERY

MODULE 2

CN12A CN12B

REAR VIEW

BATTERY

MODULE 1

CN12A CN12B

10A

10A 15A

15A

OUTPUT 240VAC 10A

OUTPUT 240VAC 15A

FIGURE 6-3: TOWER 240V

SYSTEM WITH C-13/C-19 PANEL

BATTERY

MODULE 2

CN12A CN12B

BATTERY

MODULE 1

CN12A CN12B

POWER

MODULE

POWER

MODULE

OUT

TRANSFORMER

MODULE

REAR VIEW

CN12A CN12B

CN12A CN12B

FIGURE 6-2: RACKMOUNT 120V

TEM WITH TRANSFORMER MODULE

10

OUT

SYS-

POWER

MODULE

BATTERY

REAR VIEW

MODULE 1

BATTERY

MODULE 2

FIGURE 6-4: TOWER 120V

WITH TRANSFORMER MODULE

SYSTEM

OUT

T1000 Series UPS Installation and Operation Manual – 91074-002

6.2 System Installation

The T1000 Series Power (UPS) module, optional Battery module(s), and optional Transformer module can

be purchased in either a rackmount or tower conguration. All three modules are a standard 3U (3 Rack

Units) tall, and t a standard 19 in. rack.

TOWER CONFIGURATION:

In the tower conguration, the orientation of the modules are rotated 90 degrees counter-clockwise,

placing the ventilation openings on the bottom. A slip-on Tower Cap is used to provide physical stability

for systems of two or more tower modules, including tower systems with optional casters. (Figure 6-5)

• OPTIONAL: TOWER CAPS

Each 2-Module tower system comes with a Tower Cap that helps maintain physical tower stability.

Optional 3-Module Tower Caps are available for larger systems.

• OPTIONAL: CASTERS

An optional caster kit may also be purchased with each module to facilitate relocating the system

before and after installation.

RACKMOUNT CONFIGURATION:

Each rackmount conguration module ships with a 4-Post

Rack Fixed Mounting Kit, P/N 92802, for mounting the

module in a standard 19 inch rack.

Other rack mounting kit congurations are available: (Fig-

ure 6-6)

• OPTIONAL: 2-POST RACK FIXED MOUNTING KIT

Hardware for mounting system modules in a standard

19 inch 2-post rack. See Appendix E.

• OPTIONAL: 4-POST RACK SLIDE MOUNTING KIT

Hardware for mounting system modules in a standard

19 inch 4-post rack with fully extending slide rails. See

Appendix E.

• OPTIONAL: 2-POST RACK SLIDE MOUNTING KIT

Hardware for mounting system modules in a standard

19 inch 2-post rack with fully extending slide rails. See

Appendix E.

2-POST RACK

FIXED INST.

2-POST RACK

WITH SLIDES

4-POST RACK

FIXED INST.

4-POST RACK

WITH SLIDES

TOWER WITH CAP

FIGURE 6-5: TOWER

INSTALLATION OPTIONS

T1000 Series UPS Installation and Operation Manual – 91074-002

TOWER WITH CAP AND CASTERS

FIGURE 6-6: RACK

INSTALLATION OPTIONS

11

6.3 Tower Installation with Cap

The Tower conguration modules are arranged side by side, and secured by a press-t cap over the assembly. If the optional Caster Kit is available, see Appendix E2 for installation.

1. Unpack the T1000 modules and set them in the desired location with the faceplates at the top as

shown below.

2. Facing the front of the modules, arrange them left to right in the following order (See Fig. 6-1 - 6-4):

• Transformer Module (if available)

• Power Module

• Battery Module with output panel(if available)

• Second Battery Module without output panel (if available)

NOTE: There is a Tower Cap for 2-, and 3-module tower systems. Fig. 6-7 shows Tower Cap installation for a 2-module system.

3. Press the T1000 Tower Cap over the tower modules (Fig. 6-7).

4. The T1000 tower is ready for interconnecting cable installation.

5. Go to Section 7 for cabling instructions.

A CB

FIGURE. 6-7: INSTALL CAP ON TWO MODULE TOWER SYSTEM

12

T1000 Series UPS Installation and Operation Manual – 91074-002

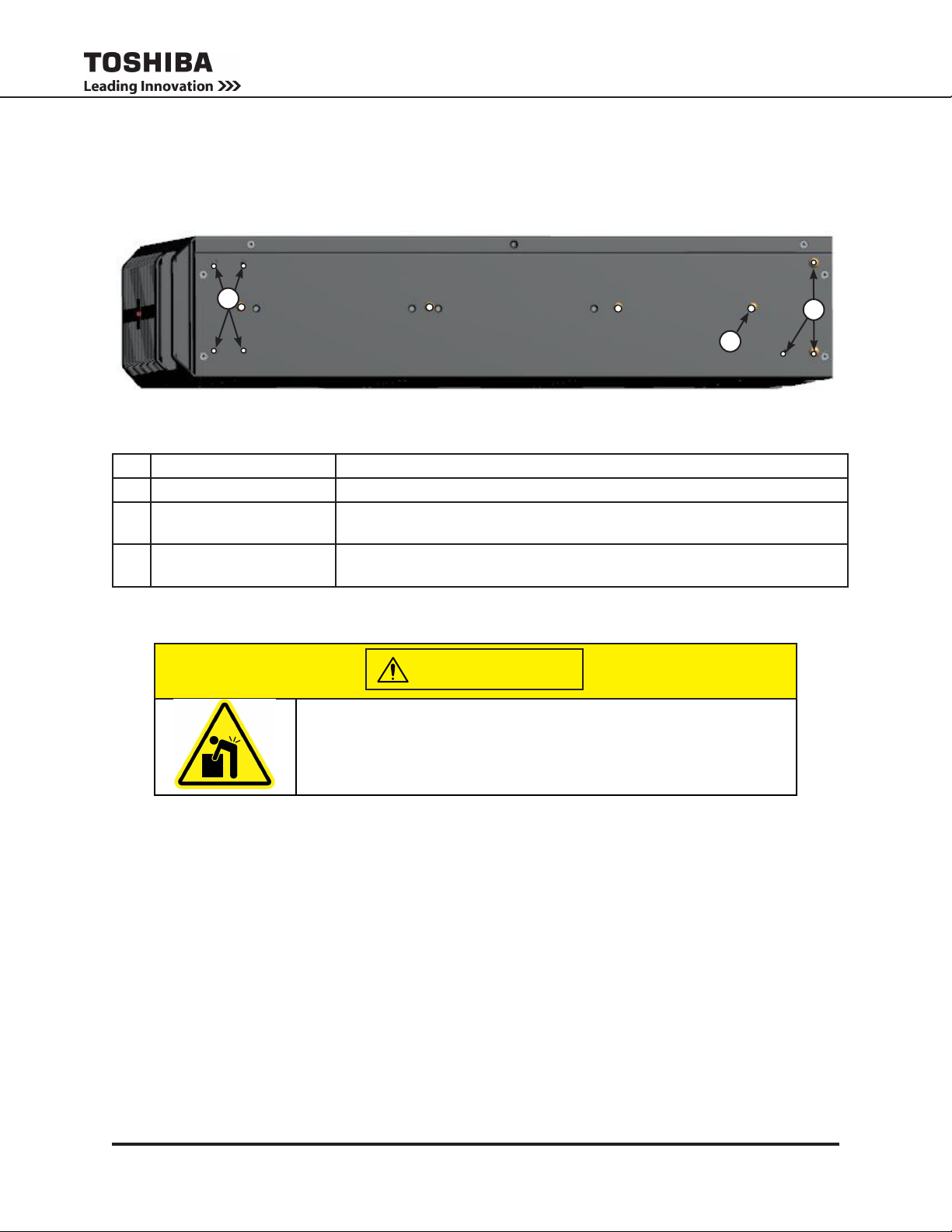

6.4 Rackmount Installation - Bracket Mounting Holes

The Power Module, Battery Module, and Transformer Module all come with the mounting bracket holes

located symmetrically on each side. See Fig. 6-8 for the hole locations. Table 6-1 lists the mounting hardware for the bracket holes.

1

3

FIGURE. 6-8: RACKMOUNT BRACKET MOUNTING HOLES

TABLE 6-1 RACKMOUNT BRACKET MOUNTING HOLES AND HARDWARE

No. Accepts (per side) Used for

1 4 x Phillips 8-32 x 1/4” Mount for front bracket 68844 used for 4-Post xed mounting

2 3 x Phillips 8-32 x 1/4” Mount for rear bracket 92746 used for 4-Post Fixed Mounting Brackets

(Kit 92802),

3 1 x Phillips 10-32 x 1/2” Mount for rear bracket 92746 used for 4-Post Fixed Mounting Brackets

(Kit 92802),

2

CAUTION

Heavy object

Can cause muscle strain or back injury.

Use lifting aids and proper lifting techniques when handling or

installing T1000 Modules.

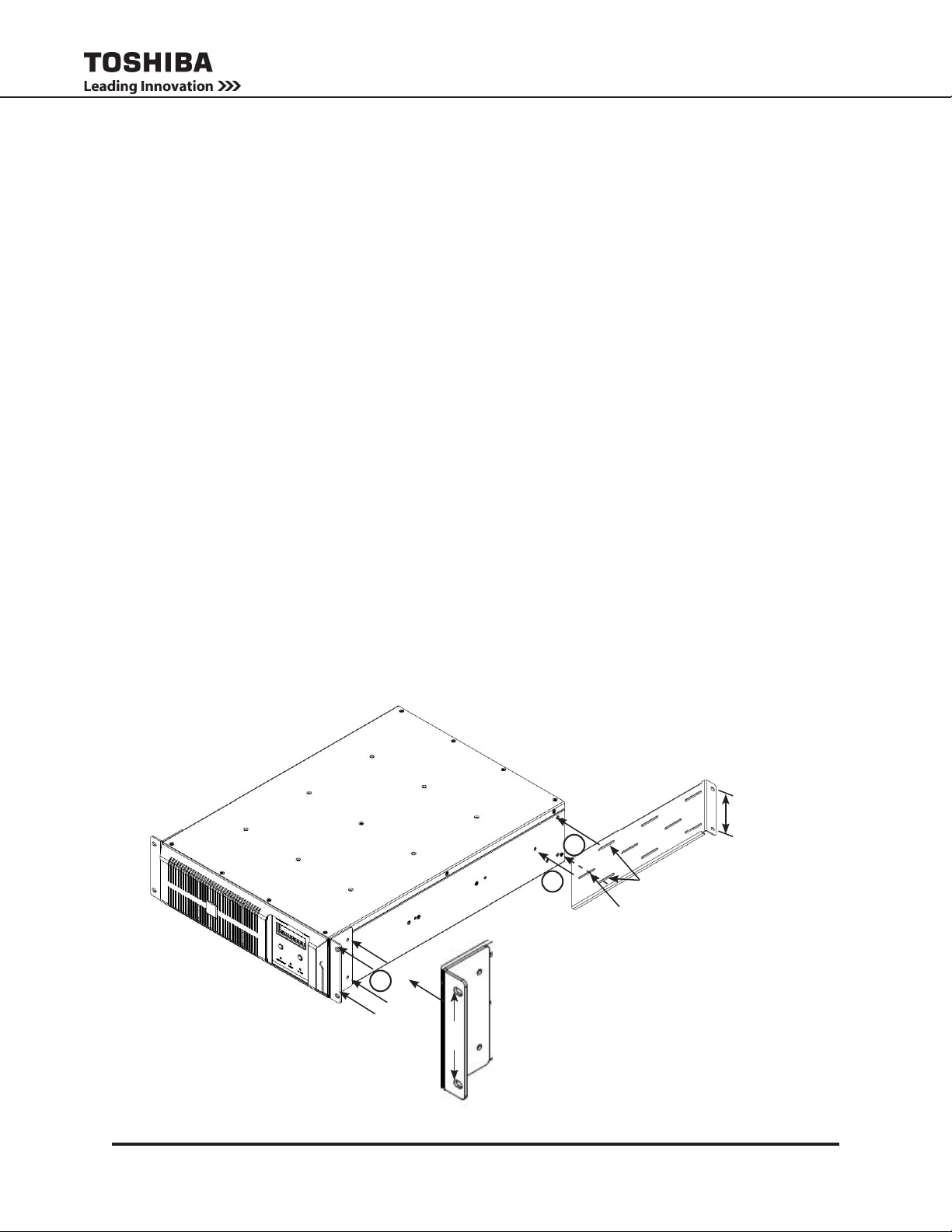

6.5 4-Post Rack Installation Instructions

Use the 4-Post Fixed Rackmount Kit 92802 (1 kit per module) to mount the T1000 module in a 19-inch,

4-Post rack as follows.

Contents - Fixed 4-Post Rack Installation Kit (92802)

1 ea.: T1000 Fixed 4-Post Rack Installation Instructions - 94036

2 ea.: 68844 - Ear Chassis Mounting

2 ea.: 92746 - Bracket, Rear Fixed Mounting, 4-Post, Black

(Hardware Kit 93863)

12 ea.: Cage Nut, 1/4”-20

12 ea.: Hex bolt, Sems, 1/4”-20 x 5/8”

12 ea.: Screw, PHP (Pan Head Phillips) 10-32 x 1/2” St Box

4 ea.: Screw, PHP 8-32 x 1/4” St Zi

Prepare the 4-Post Rack

1. Clip the cage nuts (PC76315P501 Cage Nut, 1/4”-20) from the 93863 kit over the rack rail mounting

T1000 Series UPS Installation and Operation Manual – 91074-002

13

holes at the desired level. Clip 2 cage nuts spaced vertically 4 in. apart on each Post.

2. If more than one module is being installed for the T1000 system, install the next pair of cage nuts 3

Rack Units (5 1/4”) above the rst set of cage nuts for the next module.

3. Repeat Steps 1-2 for each T1000 module to be installed. Continue until cage nuts for all the modules

in the system have been clipped on the 4-Post rack.

Prepare the Module(s)

4. Attach the front and rear bracket to the left and right sides of the T1000 module as shown in Fig. 6-9.

Use the mounting hardware from Kit 93863 to secure the brackets to the mounting holes indicated in

Fig. 6-8 and Table 6-1.

5. Secure the Front Brackets, P/N 68844, to the left and right front side of the module at Fig. 6-9 (1) using

four Phillips 8-32 x 1/4” screws.

6. Secure the Rear Brackets, P/N 92746, to the left and right rear side of the module at Fig. 6-9 (2) using

1 Phillips 8-32 x 1/4” screw each in the top and bottom slot, and use a Phillips 10-32 x 1/2” in the center

slot (Fig. 6-9 (3)).

Install the Module(s) in the 4-Post Rack

CAUTION: Battery Modules weight 150 lb. (68 kg). Use lifting aids and proper lifting techniques.

7. Follow the vertical arrangement of T1000 modules as discussed in Section 6.1. Mount the lowest module in the 4-Post rack to the bottom pair of cage nuts on each Post using the 1/4”-20 x 5/8” hex bolts,

(P/N 33798).

8. Repeat Step 7 for the remaining modules, working from bottom to top. (Fig. 6-10)

9. Go to Section 7 for cabling instructions.

14

Rear Bracket

92746

2

3

Center Slots - use one ea.

Phillips 10-32 x 1/2” screws

Front Bracket

1

4 in.

FIGURE. 6-9: FIXED MOUNTING BRACKETS - 4-POST RACK

T1000 Series UPS Installation and Operation Manual – 91074-002

68844

Four ea.

Phillips 8-32 x 1/4” screws

4 in.

Side Slots - use two ea.

Phillips 8-32 x 1/4” screws

FIGURE. 6-10: 4-POST RACK - FIXED

T1000 Series UPS Installation and Operation Manual – 91074-002

15

7. Wiring the System

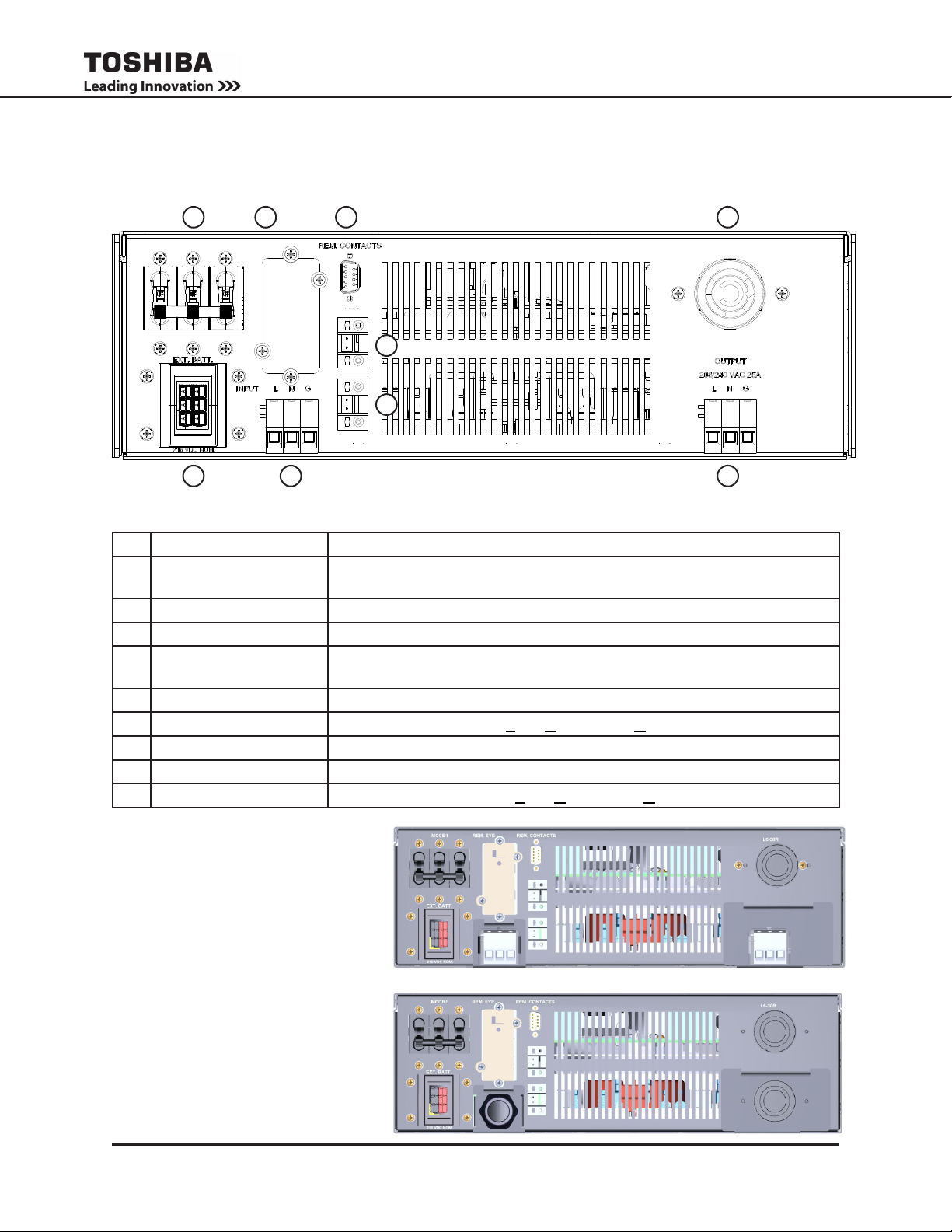

7.1 Layout - Power Module

1 2

INPUT MCCB1

208V/240VAC 30A

REMOTEYE

EPO 240V

REM. STOP

43

USE COPPER 75°C MIN.

CONDUCTORS ONLY

8

SEE INSTRUCTION MANUAL FOR WIRING

TERMINATION AND TIGHTENING TORQUE

OUTPUT L6-30R

208/240VAC 25A

7

65

FIGURE 7-1: POWER MODULE BACK PANEL LAYOUT

9

TABLE 7-1: POWER MODULE BACK PANEL LAYOUT

No. Label Function

1 INPUT MCCB1

Main On/Off circuit breaker.

208V/240VDC 30A

2 REMOTEYE Cover plate for RemotEye® circuit card slot.

3 REM. CONTACTS Dry contacts DB9 connector.

4 OUTPUT L6-30R

Output receptacle for L6-30P cord (alternate output for 208/240 only)

208/240VAC 25A

5 EXT. BATTERY External Battery Module Anderson receptacle.

6 INPUT L N G Hardwire input terminals Line, Neutral, and Ground. (TB1)

7 REM. STOP Remote Stop Contacts. (TB4) (10 VDC)

8 EPO 240V Remote Emergency Power Off (EPO) Contacts. (TB3) (240/208 VAC)

9 OUTPUT L N G Hardwire output terminals Line, Neutral, and Ground. (TB2)

FIGURE 7-2: POWER MODULE -

HARDWIRED CONFIGURATION

(P/N T1P0A6000GVG,

T1P0A6000GVGR3)

3-Post Input Terminal Block, and

one each 3-Post Output Terminal

EPO 240V

REM. STOP

Block and NEMA L6-30R outlet.

FIGURE 7-3: POWER MODULE WITH

6-50P LINECORD (-L1) OPTION

(P/N T1P0A6000GVGL1,

T1P0A6000GVGR3L1)

Input Power Cord #10-3SO 6-50P

and two each NEMA L6-30R outlets.

16

EPO 240V

REM. STOP

T1000 Series UPS Installation and Operation Manual – 91074-002

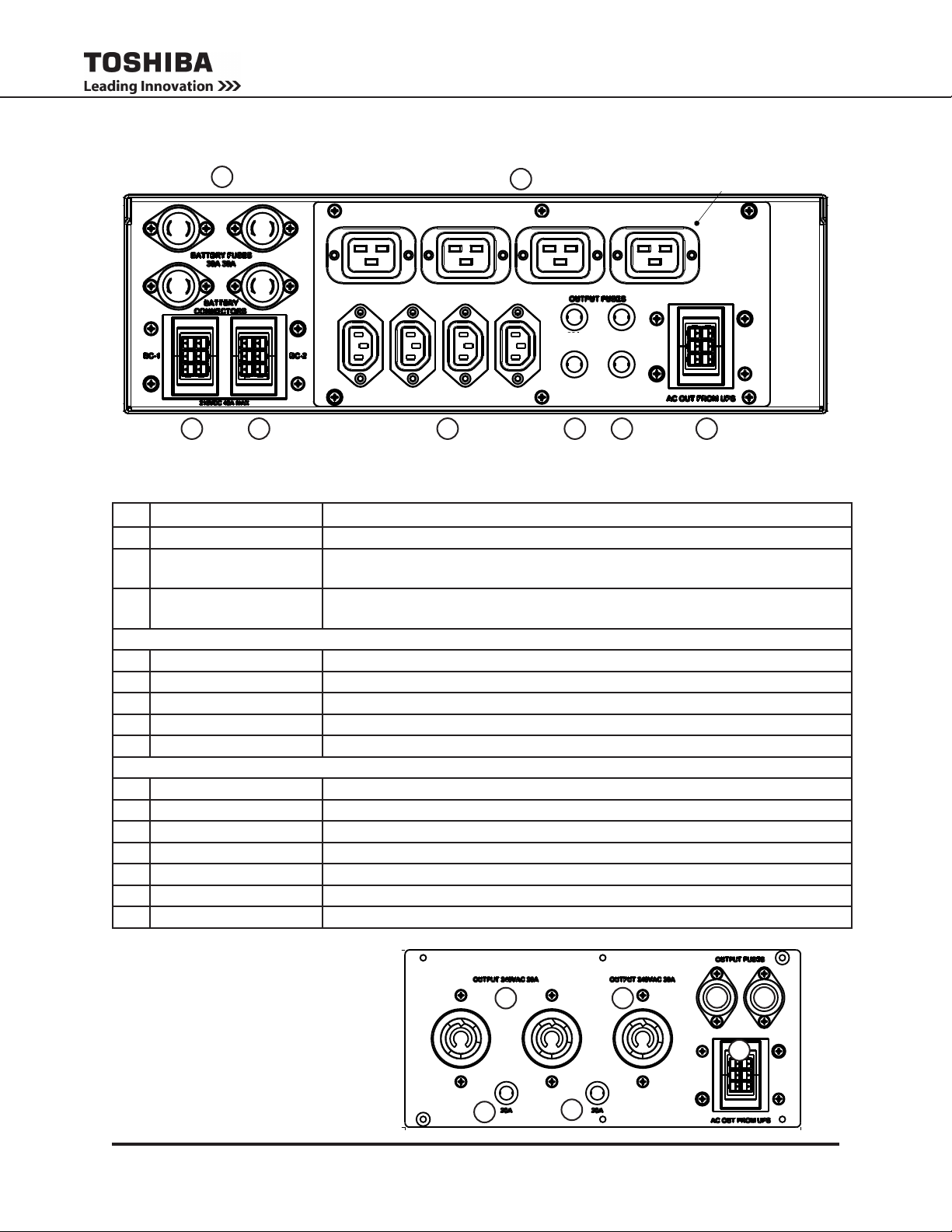

7.2 Layout - Battery Module (w/ Outlet Panel)

O/P PANEL C-13 & C19

905000

1

OUTPUT 240VAC 10A

CN12A CN12B

4

OUTPUT 240VAC 15A

10A

10A

15A

15A

6532 7 8

FIGURE 7-4: BATTERY MODULE WITH P1 OUTLET PANEL - LAYOUT

TABLE 7-2: BATTERY MODULE - BACK PANEL LAYOUT

No. Label Function

1 BATTERY FUSES Battery Fuses, 4 ea. (500V, 30A)

2 CN12A Battery cable Anderson Receptacle (w/ Int. Thermistor) - Connect to Power

Module “Ext. Battery”.

3 CN12B Battery cable Anderson Receptacle - Connect to second Battery

Module CN12A or CN12B

P1 OPTIONAL OUTLET PANEL 91425: C-13 & C-19

4 OUTPUT 240VAC 15A Outlet Receptacles: 4 ea. IEC C-19, (250V, 20A N. Aamerica., 15A INT.).

5 OUTPUT 240VAC 10A Outlet Receptacles: 4 ea. IEC C-13, (250V, 10A N.Aamerica., 10A INT.).

6 OUTLET FUSES 15A Outlet Fuses for IEC C-19 receptacles. (250V, 15A)

7 OUTLET FUSES 10A Outlet Fuses for IEC C-13 receptacles. (500V, 10A)

8 AC OUT FROM UPS Anderson receptacle for UPS output cable.

P2 OPTIONAL OUTLET PANEL 91427: NEMA L6-20R & L6-30R

8 AC OUT FROM UPS Anderson receptacle for UPS output cable.

9 OUTPUT 240VAC 20A Outlet Receptacles: 2 ea. NEMA L6-20R, (250V, 20A).

10 OUTPUT 240VAC 30A Outlet Receptacle: 1 ea. NEMA L6-30R, (250V, 30A).

11 OUTLET FUSE 20A Outlet Fuse for NEMA L6-20R receptacle (250V, 20A).

12 OUTLET FUSE 20A Outlet Fuse for NEMA L6-20R receptacles (250V, 20A).

13 OUTLET FUSE 30A Outlet Fuses for NEMA L6-30R receptacle (500/600V, 30A).

14 OUTLET FUSE 30A Outlet Fuses for NEMA L6-30R receptacles (500/600V, 30A).

FIGURE 7-4: BATTERY MODULE

OUTPUT PANEL P2 - LAYOUT

9

11

T1000 Series UPS Installation and Operation Manual – 91074-002

12

10

13

14

20A 30A

8

17

7.3 Layout - Transformer Module

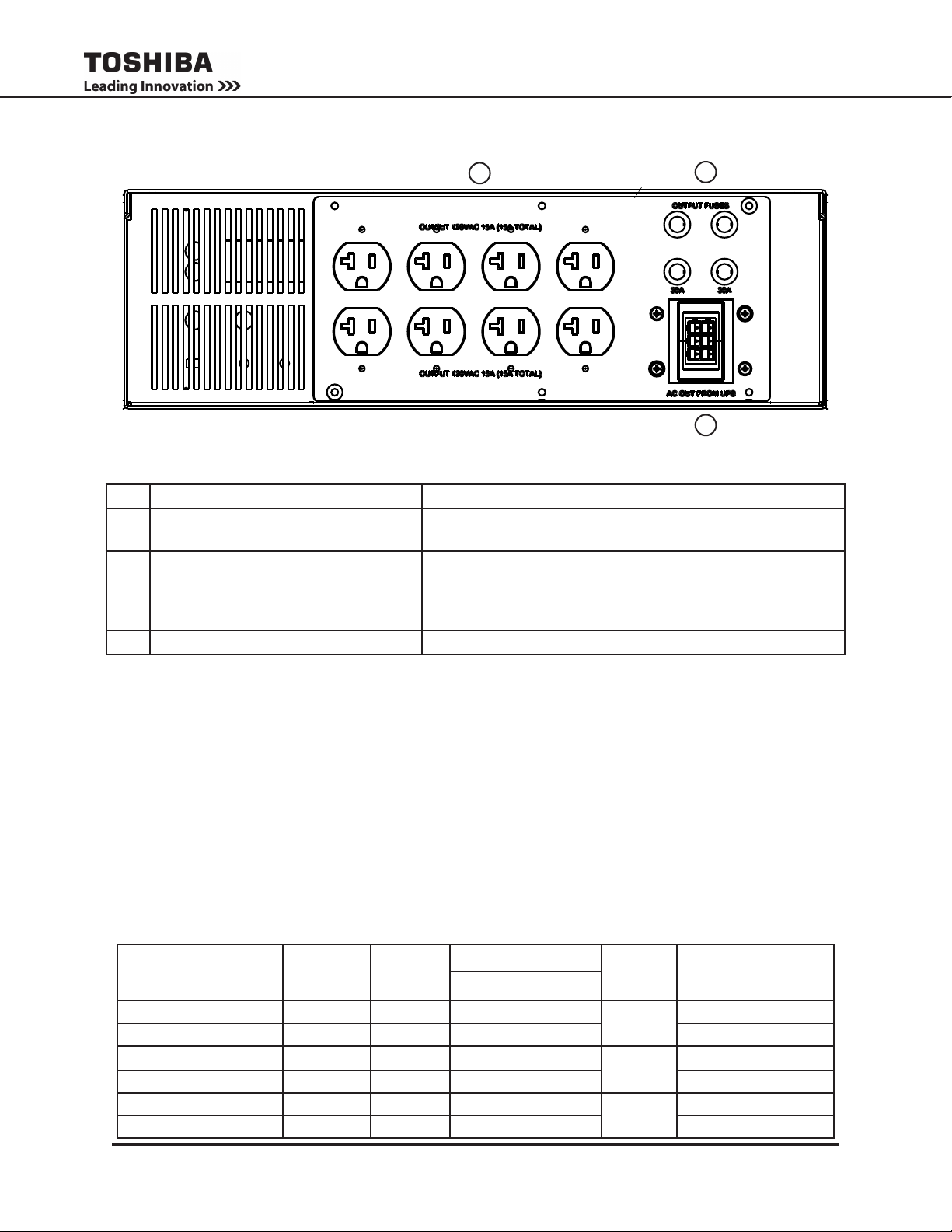

OUTPUT PANEL 8X 5-20R

91426

4.875

10.875

4.875

10.875

C-13, (250V 15A) & C-19, (250V 20A)

NEMA 5-20R, (125V 20A) (XFMR MODULE)

NEMA L6-20R, (250V 20A) L6-30R, (250V 30A)

BLANK PANEL

ASSY: 91427; PANEL: 90502

ASSY: 91425; PANEL: 90500

1

2

FIGURE 7-5: TRANSFORMER MODULE - BACK PANEL LAYOUT

TABLE 7-3: TRANSFORMER MODULE BATTERY MODULE - BACK PANEL LAYOUT

No. Label Function

1 OUTPUT 120VAC 20A Output Receptacle Panel: 4 duplex NEMA 5-20R (250V,

2 OUTPUT FUSES Fuses, 4 ea. ,(250V, 20A)

3 AC OUT FROM UPS Anderson receptacle for UPS output cable.

7.4 Power Module Cable Size and Tightening Torque

The Battery Modules and Transformer modules come with their own inter-module cabling included.

See Fig. 7.5.

Only the Power Module Input terminals need to have wiring installed.

The Power Module Output terminal wired using either:

• Factory-supplied inter-module cables

• Customer-supplied hardwire cables

Use the following table to select the recommended wire size and terminal lug tightening torque for I/O wire

connections.

3

20A)

(4 Line fuses, one for each pair NEMA 5-20R. Total current

limit for each pair receptacles is 20A.

Total output from all receptacles must not exceed 50 A)

TABLE 7-4: POWER MODULE CABLE SIZING AND TERMINAL TORQUE SPECIFICATIONS- HARDWIRE

Terminal

AC Input Line, Neutral L, N 24 - 6 10 - 8 0.43 in

AC Input Ground G 24 - 6 10 - 8 11 - 21 (1.2 - 2.4)

AC Output Line, Neutral L, N 24 - 6 10 - 8 0.43 in

AC Output Ground G 24 - 6 10 - 8 11 - 21 (1.2 - 2.4)

EPO Switch (Plug) 30 - 12 18 - 16 0.27 in

Remote Switch (Plug) 30 - 12 18 - 16 3.5 - 4.4 (0.4 - 0.5)

18

(USE COPPER 75°C MIN. CONDUCTORS ONLY)

Terminal

Number

Terminal

Capacity

(AWG)

Recommended Wire

T1000 Series UPS Installation and Operation Manual – 91074-002

6 kVA

Stripping

Length

in (mm)

(11 mm)

(11 mm)

(7 mm)

Tightening Torque

lb.-in. (N•m)

11 - 21 (1.2 - 2.4)

11 - 21 (1.2 - 2.4)

3.5 - 4.4 (0.4 - 0.5)

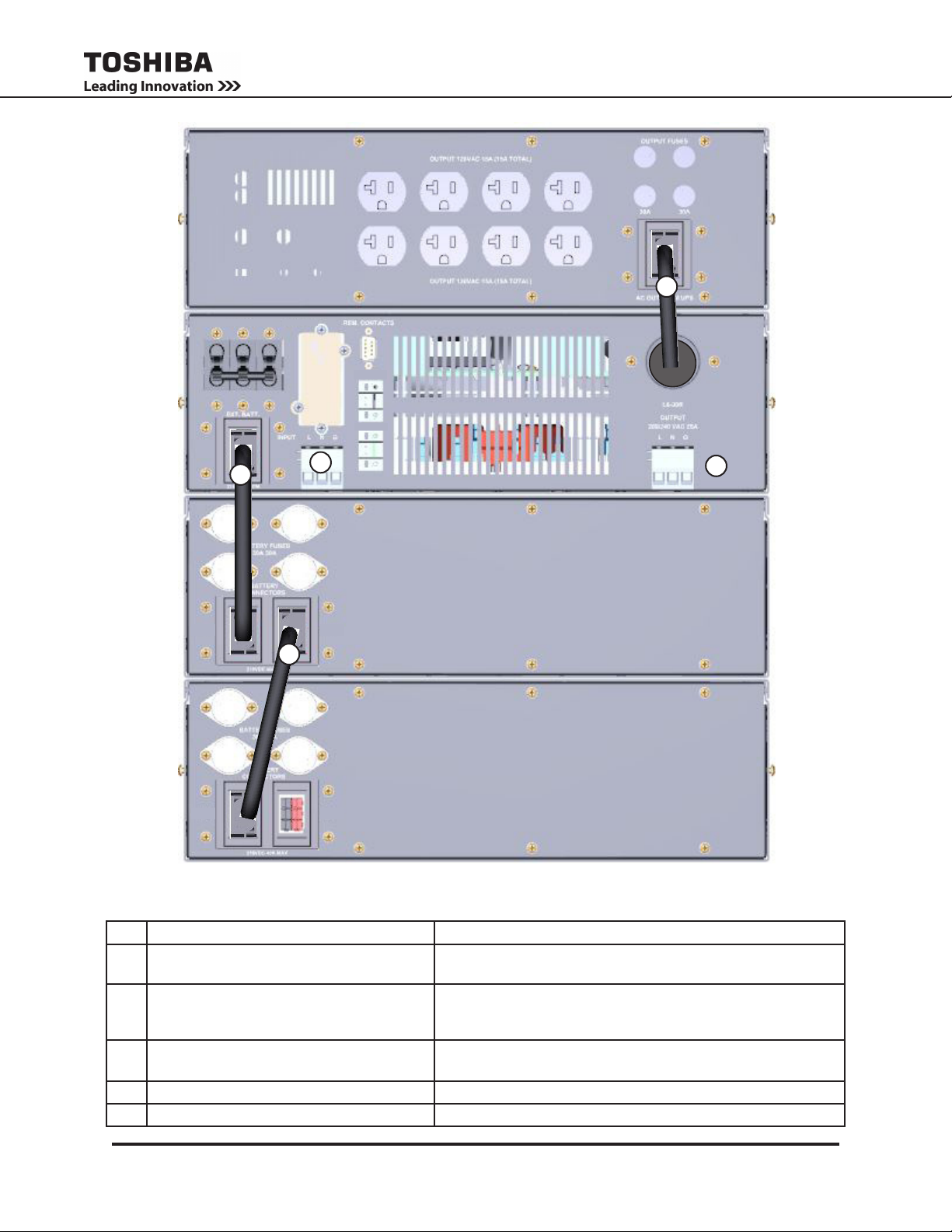

3

INPUT MCCB1

CN12A CN12B

REMOTEYE

1

5

2

EPO 240V

REM. STOP

4

CN12A CN12B

FIGURE 7-5: FACTORY SUPPLIED CABLING GUIDE - W/ 120V XFMER MODULE

TABLE 7-5: 120V SYSTEM CABLING SPECIFICATIONS

No. Item Function

1 92855 Battery Connector Cable Factory Supplied - Connects Power Module EXT BATT to Batt

Module BC1 CN12A to using keyed Anderson Connectors.

2 92855 Battery Connector Cable Factory Supplied - Connects Batt Module BC1 CN12B to either

Batt Module BC2 CN12A or Batt Module BC2 CN12B using

keyed Anderson Connectors.

3 92858 (240V) and 92883 (208V) Power

Module L6-30 Output to Xfmr Module Cable

4 TB2 240V Hardwire Output User Supplied (two wire plus ground)

5 TB1 240V Hardwire Input User Supplied (two wire plus ground)

T1000 Series UPS Installation and Operation Manual – 91074-002

Both Factory Supplied - L6-30P twistlock to Xfmr Module keyed

Anderson Connector.

19

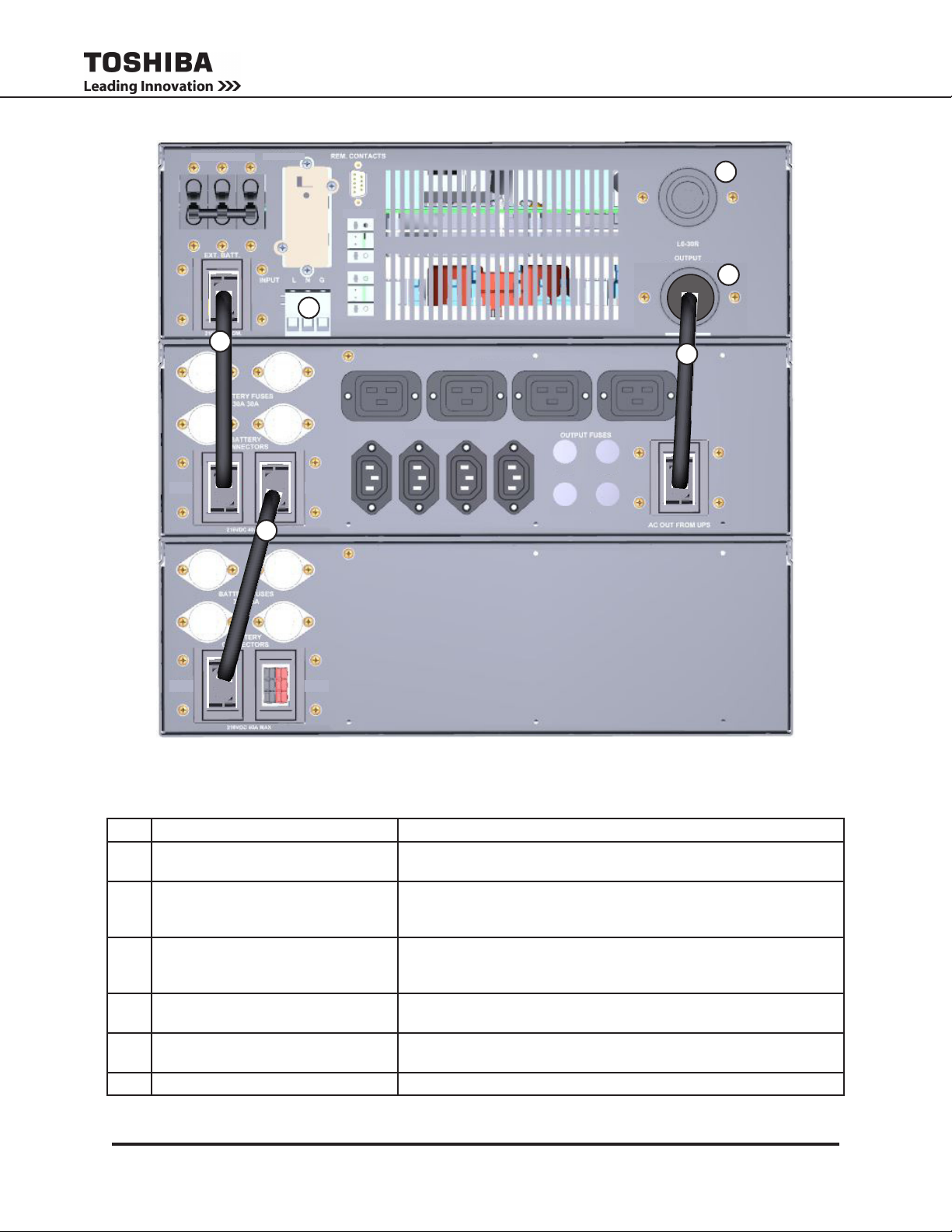

INPUT MCCB1

REMOTEYE

5

EPO 240V

6

1

CN12A CN12B

2

CN12A CN12B

REM. STOP

OUTPUT 240VAC 10A

OUTPUT 240VAC 15A

10A 15A

10A

4

3

15A

FIGURE 7-6: FACTORY SUPPLIED CABLING GUIDE - W/ BC OUTPUT PANEL

TABLE 7-6: 240V SYSTEM CABLING SPECIFICATIONS

No. Item Function

1 92855 DC Connector Cable: Batt

Module 1 to Pwr Module

2 92855 DC Connector Cable: Batt

Module 1 to Batt Module 2

3 92858 AC Connector Cable: Power

Module L6-30R Output to Batt Mod-

ule Output Panel P1/P2

4 Output L6-30R Receptacle Panel User Selectable - Can be either a L6-30 Receptacle or a 3-Post, 3

5 Output L6-30R Receptacle Accommodates L6-30P twistlock cord (alternate output for 208/240

6 TB1 240V Hardwire Input User Supplied (two wire plus ground)

20

Factory Supplied - Connects Power Module EXT BATT to Batt Module

BC1 CN12A to using keyed Anderson Connectors.

Factory Supplied - Connects Batt Module BC1 CN12B to either Batt

Module BC2 CN12A or Batt Module BC2 CN12B using keyed Ander-

son Connectors.

Both Factory Supplied - L6-30P twistlock to Xfmr Module keyed Anderson Connector.

wire terminal 240V output.

only).

T1000 Series UPS Installation and Operation Manual – 91074-002

Loading...

Loading...