Page 1

TEC Electronic Computing Scale

SL-5300 SERIES

Owner's Manual

Page 2

This equipment has been tested and foun d to comply with the limits f or a Class A digital d evice,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

prot ection against harmful interference when the equipm ent is operated i n a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance wi th the instruction manual, may cause harmful inter ference

to ra dio communications. Operations of this equipment in a resi dential ar ea is likely t o caus e

harmful i nterference in which case the user will be required to correct the interference at his own

expense. (for USA only)

Changes or modifications not expressly approved by manufacturer for compliance could void the

user’s authority to operate the equipment.

“This Class A digital apparatus meets all requirements of the Canadian Interf erence-Causing

Equipment Regulations.” “Cet ap pareil numéique de la classe A respecte toutes les exigen ces

du Rèlement sur le materiel brouilleur du Canada.”

Some procedures described in this manual may be i llegal in various state jurisdic tions. When

there are optional setti ngs to enable various functions or to disable functions. Please ensure that

the optional settings for scale operation meet the local re quirements of weights and measures. If

you are uncertain of specific items, contact the state or county office of weights and measures for

clarification.

(for CANADA only)

Copyright © 2004

by TOSHIBA TEC CORPORATION

All Rights Reserved

570 Ohito, Ohito-cho, Tagata-gun, Shizuoka-ken, JAPAN

Page 3

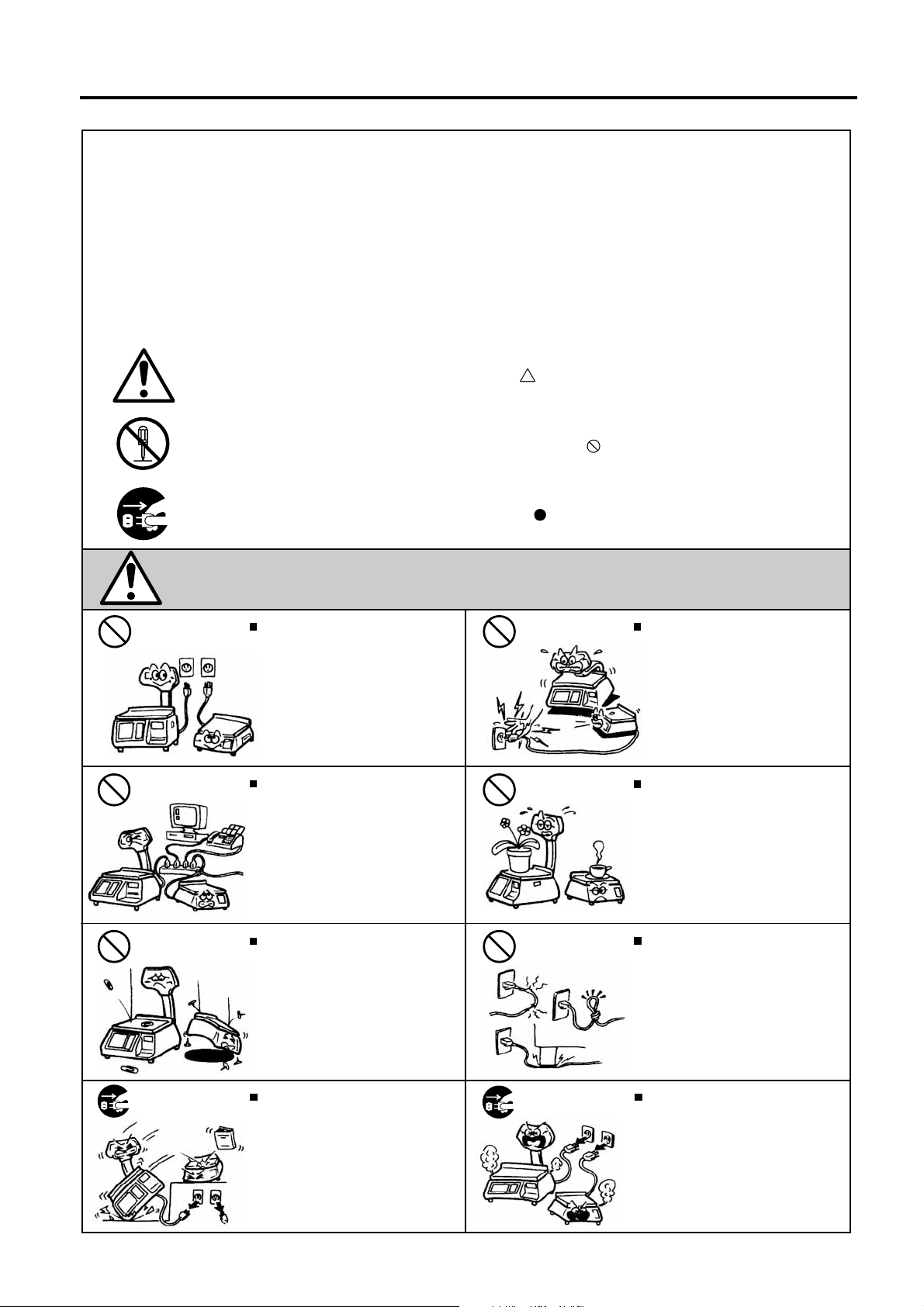

Safety Summary

Safety Summary

Personal safety in handling or maintaining the equipment is extremely important. Warnings and Cautions

necessary for safe handling are included in this manual. All warnings and cautions contained in this manual

should be read and understood before handling or maintaining the equipment.

Do not attempt to effect repairs or modifications to this equipment. If a fault occurs that cannot be rectified

using the procedures described in this manual, turn off the power, unplug the machine, then contact your

authorized TOSHIBA TEC representative for assistance.

Meanings of Each Symbol

This symbol indicates warning items (including cautions).

Specific warning contents are drawn inside the symbol.

(The symbol on the left indicates a general caution.)

This symbol indicates prohibited actions (prohibited items).

Specific prohibited contents are drawn inside or near the symbol.

(The symbol on the left indicates “no disassembling”.)

This symbol indicates actions which must be performed.

Specific instructions are drawn inside or near the symbol.

(The symbol on the left indicates “disconnect the power cord plug from the outlet”.)

EO1-31009

W ARNING

Any other than the

specified AC voltage is

prohibited.

Prohibited

Prohibited

Do not use voltages other than

the voltage (AC) specified on the

rating plate, as this may cause fire

or electric shock.

If the machines share the same

outlet with any other electrical

appliances which consume large

amounts of power, the voltage will

fluctuate widely each time these

appliances operate. Be sure to

provide an exclusive outlet for the

machine as this may cause fire or

electric shock.

Do not insert or drop metal,

flammable or other foreign objects

into the machines through the

ventilation slits, as this may cause

fire or electric shock.

This indicates that there is the risk of death or serious injury if the

machines are improperly handled contrary to this indication.

Prohibited

Prohibited

Prohibited

Do not plug in or unplug the power

cord plug with wet hands as this may

cause electric shock.

Do not place metal objects or

water-filled containers such as

flower vases, flower pots or mugs,

etc. on top of the machines. If metal

objects or spilled liquid enter the

machines, this may cause fire or

electric shock.

Do not scratch, damage or modify

the power cords. Also, do not place

heavy objects on, pull on, or

excessively bend the cords, as this

may cause fire or electrical shock.

Disconnect

the plug.

If the machines are dropped or their

cabinets damaged, first turn off the

power switches and disconnect the

power cord plugs from the outlet, and

then contact your authorized

TOSHIBA TEC representative for

assistance. Continued use of the

machine in that condition may cause

fire or electric shock.

Disconnect

the plug.

Continued use of the machines in an

abnormal condition such as when the

machines are producing smoke or

strange smells may cause fire or elec-

tric shock. In these cases, immediately turn off the power switches and

disconnect the power cord plugs from

the outlet. Then, contact your authorized TOSHIBA TEC representative for

assistance.

(i)

Page 4

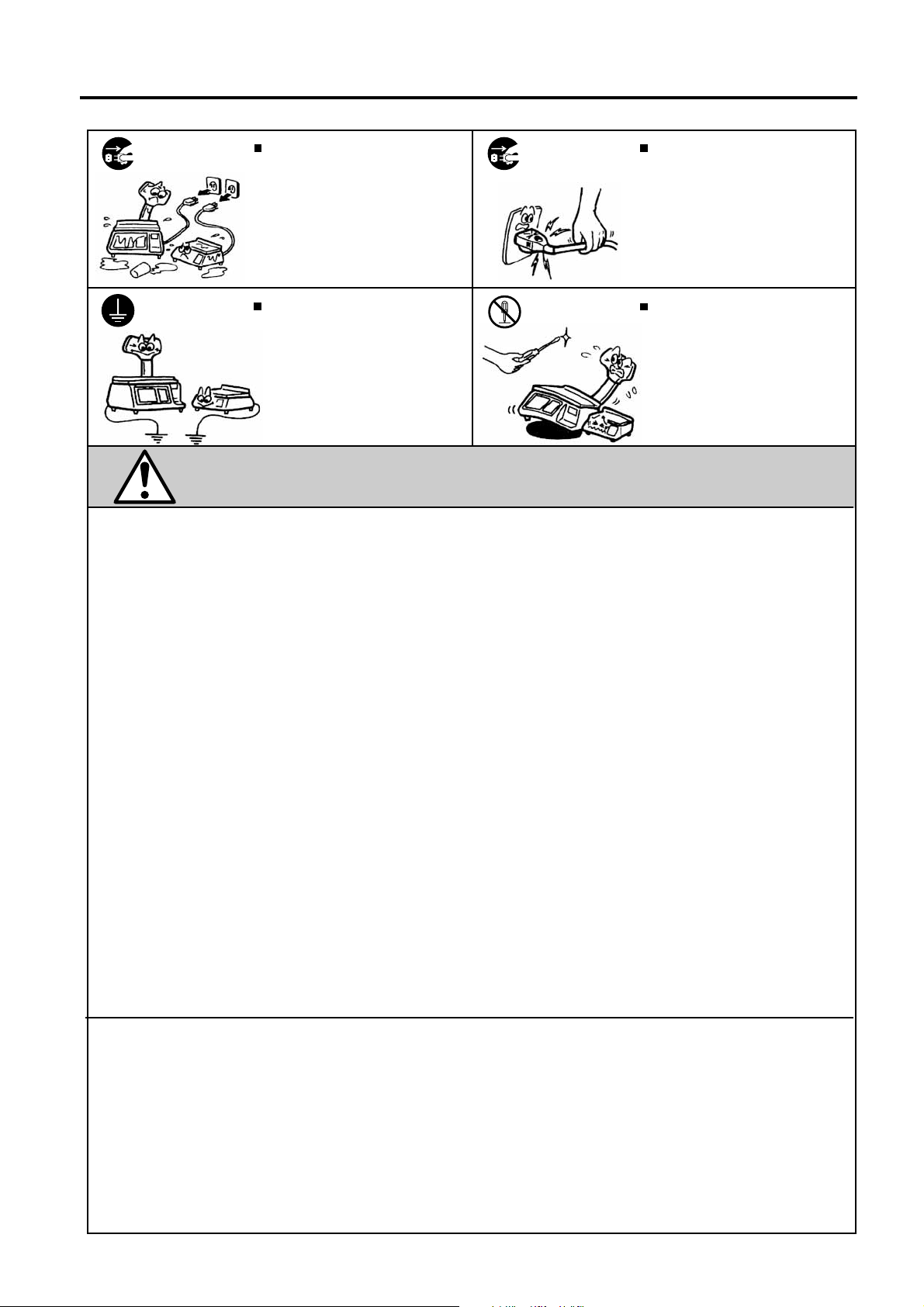

Safety Summary

EO1-31009

Disconnect

the plug.

Connect a

grounding

wire.

If foreign objects (metal fragments,

water, liquids) enter the machines,

first turn off the power switches and

disconnect the power cord plugs from

the outlet, and then contact your

authorized TOSHIBA TEC representative for assistance. Continued

use of the machine in that condition

may cause fire or electric shock.

Ensure that the equipment is

properly grounded. Extension cables

should also be grounded. Fire or

electric shock could occur on

improperly grounded equipment.

Disconnect

the plug.

No disassembling.

When unplugging the power cords,

be sure to hold and pull on the plug

portion. Pulling on the cord portion

may cut or expose the internal wires

and cause fire or electric shock.

Do not remove covers, repair or

modify the machine by yourself. You

may be injured by high voltage, very

hot parts or sharp edges inside the

machine.

This indicates that there is the risk of personal Injury or damage to

CA UTION

objects if the machines are improperly handled contrary to this indication.

Precautions

The following precautions will help to ensure that this machine will continue to function correctly.

• Try to avoid locations that have the following adverse conditions:

* Temperatures out of the specification * Direct sunlight * High humidity

* Shared power source * Excessive vibration * Dust/Gas

• Do not subject the machine to sudden shocks.

• Do not press the keys too hard. Keys will operate correctly if they are touched lightly.

• Clean the cover and keyboard, etc. by wiping with a dry cloth or a cloth soaked with detergent and wrung out

thoroughly. Never use thinner or other volatile solvent for cleaning.

• To ensure that the scale is operating correctly, place a known weight on the platter and check it for correct

weight measurement. This should be done every morning before starting normal operations.

• When moving the machine, take hold of the case and lift the machine. Never hold the remote unit.

• Do not place the machines on unstable or slanted surfaces, as they may drop or fall and cause injury.

• USE ONLY TOSHIBA TEC SPECIFIED paper.

• DO NOT STORE the paper or ribbons where they might be exposed to direct sunlight, high temperatures,

high humidity, dust, or gas.

• Ensure the machine is operated on a level surface.

• Any data stored in the memory of the machine could be lost during a machine fault.

• Try to avoid using this equipment on the same power supply as high voltage equipment or equipment likely to

cause mains interference.

• Unplug the machine whenever you are working inside it or cleaning it.

• Keep your work environment static free.

• Do not place heavy objects on top of the machines, as these items may become unbalanced and fall causing

injury.

• Do not block the ventilation slits of the machines, as this will cause heat to build up inside the machines and

may cause fire.

• Do not lean against the machine. It may fall on you and could cause injury.

• Care must be taken not to injure yourself with the printer paper cutter.

• Unplug the machine when it is not used for a long period of time.

Request Regarding Maintenance

• Utilize our maintenance services.

After purchasing the machine, contact your authorized TOSHIBA TEC representative for assistance once a

year to have the inside of the machine cleaned. Otherwise, dust will build up inside the machines and may

cause a fire or a malfunction. Cleaning is particularly effective before humid rainy seasons.

• Our preventive maintenance service performs the periodic checks and other work required to maintain the

quality and performance of the machines, preventing accidents beforehand.

For details, please consult your authorized TOSHIBA TEC representative for assistance.

• Using insecticides and other chemicals

Do not expose the machines to insecticides or other volatile solvents. This will cause the cabinet or other

parts to deteriorate or cause the paint to peel.

(ii)

Page 5

EO1-31009

TABLE OF CONTENTS

Page

1. INTRODUCTION .................................................................................................................... 1-1

1.1 Applicable Model......................................................................................................... 1-2

1.2 Accessories................................................................................................................. 1-2

2. SPECIFICATIONS.................................................................................................................. 2-1

2.1 Scale........................................................................................................................... 2-1

2.2 Option.......................................................................................................................... 2-2

3. APPEARANCE....................................................................................................................... 3-1

3.1 Dimensions.................................................................................................................. 3-1

3.2 Scale........................................................................................................................... 3-1

3.3 Label Cassette.............................................................................................................3-1

3.4 Connector Panel.......................................................................................................... 3-2

4. PROCEDURE BEFORE DAILY OPERATION........................................................................ 4-1

4.1 Installation of the Scale................................................................................................ 4-1

4.2 Preparation.................................................................................................................. 4-1

5. INSERTING THE POWER CORD .......................................................................................... 5-1

6. LEVEL ADJUSTMENT........................................................................................................... 6-1

7. TURNING THE POWER ON/OFF........................................................................................... 7-1

7.1 Turning the Power ON................................................................................................. 7-1

7.2 Turning the Power OFF............................................................................................... 7-2

8. LOADING/REPLACING THE MEDIA..................................................................................... 8-1

9. OPERATION PANEL ............................................................................................................. 9-1

9.1 Operational Precautions.............................................................................................. 9-1

9.2 Tilt Angle Adjustment................................................................................................... 9-1

9.3 Layout of the Operation Panel..................................................................................... 9-2

10. CUSTOMER’S DISPLAY.......................................................................................................10-1

10.1 US Model....................................................................................................................10-1

10.2 CA Model....................................................................................................................10-2

10.3 Spanish Display Sticker..............................................................................................10-3

11. DAILY MAINTENANCE.........................................................................................................11-1

11.1 Cleaning.....................................................................................................................11-1

11.1.1 Print Head.......................................................................................................11-1

11.1.2 Platen and Media Roll Holder .........................................................................11-2

11.1.3 Covers and Platter..........................................................................................11-2

11.1.4 Operation Panel ..............................................................................................11-2

11.2 Removing the Jammed Media....................................................................................11-3

11.3 Media Guide Adjustment ............................................................................................11-4

12. PC CARD HANDLING...........................................................................................................12-1

12.1 Inserting the PC Card.................................................................................................12-1

12.2 Ejecting the PC Card..................................................................................................12-1

13. OUTLINE OF MAIN MENU....................................................................................................13-1

Page 6

EO1-31009

14. PROGRAMMING MODE.......................................................................................................14-1

14.1 Edit Screen................................................................................................................14- 2

14.2 PLU Data Setting.......................................................................................................14- 4

14.3 Department Setting...................................................................................................14-12

14.4 Ingredient Setting.....................................................................................................14-13

14.5 Nutrition Facts Setting ..............................................................................................14-14

14.5.1 Serving Size Setting......................................................................................14-18

14.5.2 Calories Setting ............................................................................................14-18

14.5.3 Nutrition Setting 1/2......................................................................................14-20

14.5.4 Nutrition Setting 2/2......................................................................................14-21

14.5.5 Additional Title Change 1/2...........................................................................14-23

14.5.6 Additional Title Change 2/2...........................................................................14-24

14.5.7 Footnote Setting ...........................................................................................14-25

14.6 Recipe Setting..........................................................................................................14-26

14.7 Grade Line Setting....................................................................................................14-28

14.8 Message/Information Setting....................................................................................14-29

14.9 Store Name/Address Setting....................................................................................14-30

14.10 Scrolling Message Setting........................................................................................14-31

14.11 Combination Report Setting......................................................................................14-33

14.12 Vendor Setting..........................................................................................................14-42

14.13 SFKC Setting............................................................................................................14-43

14.14 Idiom Setting............................................................................................................14-48

14.15 Combination Label Setting........................................................................................14-49

14.16 Promotion Setting.....................................................................................................14-51

14.17 Schedule Setting ......................................................................................................14-53

14.18 Inline (LAN Master/Satellite System) Setting............................................................14-55

14.19 DLL (LAN Master/Satellite System) Setting..............................................................14-56

14.20 Operator’s Hint Setting .............................................................................................14-58

14.21 Changing the Unit Price............................................................................................14-60

15. SETUP MODE.......................................................................................................................15-1

15.1 Date/Time Setting......................................................................................................15- 2

15.2 Label Format Setting.................................................................................................15- 3

15.2.1 Free Format Arrangement .............................................................................15- 6

15.2.2 Label Format List..........................................................................................15-10

15.2.3 Format Copy and New Format No. Addition..................................................15-10

15.2.4 Format Reset................................................................................................15-11

15.3 Bar Code Format Setting..........................................................................................15-30

15.4 Memory Card Operation...........................................................................................15-33

15.4.1 Save/Load Operation....................................................................................15-34

15.4.2 Memory Card Format....................................................................................15-37

15.4.3 Clear File in Scale Memory...........................................................................15-38

15.4.4 Memory Card Copy.......................................................................................15-39

15.5 PLU Data Maintenance.............................................................................................15-40

15.6 Password Assignment..............................................................................................15-47

15.7 Wireless LAN............................................................................................................15-48

15.7.1 Wireless LAN Setup......................................................................................15-49

15.7.2 Wireless LAN Status Check.......................................................................... 15-51

16. REGISTRATION MODE........................................................................................................16-1

16.1 Programming for the Registration Mode....................................................................16- 3

16.1.1 Print Item Selection........................................................................................16- 4

16.1.2 Label Format Selection..................................................................................16- 5

16.1.3 Mode Change................................................................................................16- 5

16.1.4 PLU Library....................................................................................................16- 6

16.1.5 Temporary Date Change ...............................................................................16- 8

Page 7

EO1-31009

e

16.1.6 Special Information Assignment.....................................................................16- 9

16.1.7 Logo Assignment..........................................................................................16-10

16.1.8 Grade Line Assignment................................................................................16-11

16.1.9 Scrolling Message Setting ............................................................................16-12

16.1.10 Store Name/Address Assignment...............................................................16-13

16.1.11 Operation Panel Brightness Adjustment......................................................16-14

16.2 Basic Operations......................................................................................................16-15

16.2.1 Zero Count Setting........................................................................................16-15

16.2.2 Calling a PLU................................................................................................16-16

16.2.3 Weighing Commodities and Issuing Labels...................................................16-18

16.2.4 Tare Subtraction/Cancellation/Save..............................................................16-19

16.2.5 Void..............................................................................................................16-24

16.2.6 Vendor Log-in...............................................................................................16-24

16.2.7 Unit Price Set and Change............................................................................16-26

16.2.8 Changing the Unit of Weight (CA model only)...............................................16-28

16.2.9 Label Issue Count Setting.............................................................................16-29

16.2.10 Test Print....................................................................................................16-30

16.2.11 Speed Key Screen Change.........................................................................16-30

16.3 By Count Operations ................................................................................................16-31

16.3.1 When Using the Quantity Preset to the PLU.................................................16-31

16.3.2 When Invalidating the Quantity and

Changing the Unit Price Preset to the PLU...................................................16-32

16.3.3 Batch Print Operation....................................................................................16-36

16.4 Fix Price Operation (US model only).........................................................................16-38

16.5 Issuing Net Weight Statement Label (US model only)...............................................16-39

16.6 Sales Promotion.......................................................................................................16-41

16.7 Average Portion Cost................................................................................................16-43

16.8 Operator’s Hint.........................................................................................................16-45

17. REGISTRATION MARK DOWN MODE ................................................................................17-1

18. REGISTRATION REWRAP MODE .......................................................................................18-1

19. REPORT/RESET MODE.......................................................................................................19-1

19.1 Label Mode Total Memory Report/Reset...................................................................19- 3

19.2 Programmed Data Report.........................................................................................19-13

19.3 Combination Report..................................................................................................19-19

19.4 Total Data Transmission...........................................................................................19-21

20. TRAINING MODE..................................................................................................................20-1

21. SLEEP MODE.......................................................................................................................21-1

22. SLIDE SHOW MODE ............................................................................................................22-1

23. TROUBLESHOOTING ..........................................................................................................23-1

24. ERROR MESSAGE TABLE..................................................................................................24-1

CAUTION!

1. This manual may not be copied in whole or in par t without prior written per mission of TOSHIBA TEC.

2. The contents of this manual may be changed without notification.

3. Please refer to your local Authorised Service representative with regard to any queries you may hav

in this manual.

Page 8

1. INTRODUCTION EO1-31009

1. INTRODUCTION

1. INTRODUCTION

Thank you for purchasing the TOSHIBA TEC SL-5300 Series Electr onic Com put ing Scale.

TEC SL-5300 series has many features and functions designed for user friendliness as well as

complete customer satisfaction. We believe t hat your needs will now be fully satisfied, and you will

have total reliability in price calculations.

Please read carefully and understand this manual to help gain maxim um performance of this product.

For most queries please refer to this m anual and keep it safe for future refer ence.

This scale has the following features:

[Operation Panel and Customer’s Display]

A 10.4-inch color TFT, a touch screen panel, and the tilt mechanism are adopted for the operat ion

panel, which provide wide viewing angle and much higher degree of operability.

The customer’s display is a built-in 2-row 5x7 dots by 20 columns vacuum fluorescent display (VFD). It

can be replaced with an optional display unit, such as a built-in 256x64-dot VFD and r em ote type

display.

[Printer]

Adoption of the front loading label cassette m akes t he m edia r eplacement easier and extra space for

the scale side unnecessary.

The printer can print up to 80-mm-wide labels with the maximum print speed of 4”/sec., allowing

production of a variety of print formats.

[Firmware]

The firmware of this machine enables the following functions.

1. Average unit price can be printed.

2. PLU library listed in alphabetic order

3. Sales promotion time schedule

4. “+Tax” can be printed on the label.

5. Some nutrition facts templat es ar e pr ovided.

6. Store coupon can be printed on the label.

7.Slide show is displayed on the operation panel.

8. Wireless LAN function is optionally available.

[Interface]

One RS-232C port and two slots of PCMCIA inter face are provided as standard. The PCMCIA

interface accommodates an Ethernet 10BASET ( LAN) and ATA card.

[Options]

The following options are available to this scale.

MEMO PC Board: PLU memory can be expanded up to 4MB.

Built-in 256x64-dot VFD: Replacing t he standard 5x7-dot VFD with the 256x64-dot VFD will m ake

the customers’ visibilities higher.

Remote Display: Two types of remote display: 5x7-dot VFD and 256x64- dot VFD ar e

available so that you can choose one according to your budget.

1- 1

Page 9

1. INTRODUCTION EO1-31009

SL-5300 SERIES

Owner's Manual

For end user's in the U.S.A.

SCALE/PRINTER

QUALITY CONTROL REPORT

1.1 Applicable Model

1.1 Applicable Model

• SL-5300-30M-US

• SL-5300-15M-CA

The description of the model number is as follows.

SL-5300-30M-US

Destination country/Region code

Ex) US, CA

Max. Capacity

30M: 30 lbs (decimal pound/multi-interval)

15M: 15 kg (multi-inter val)

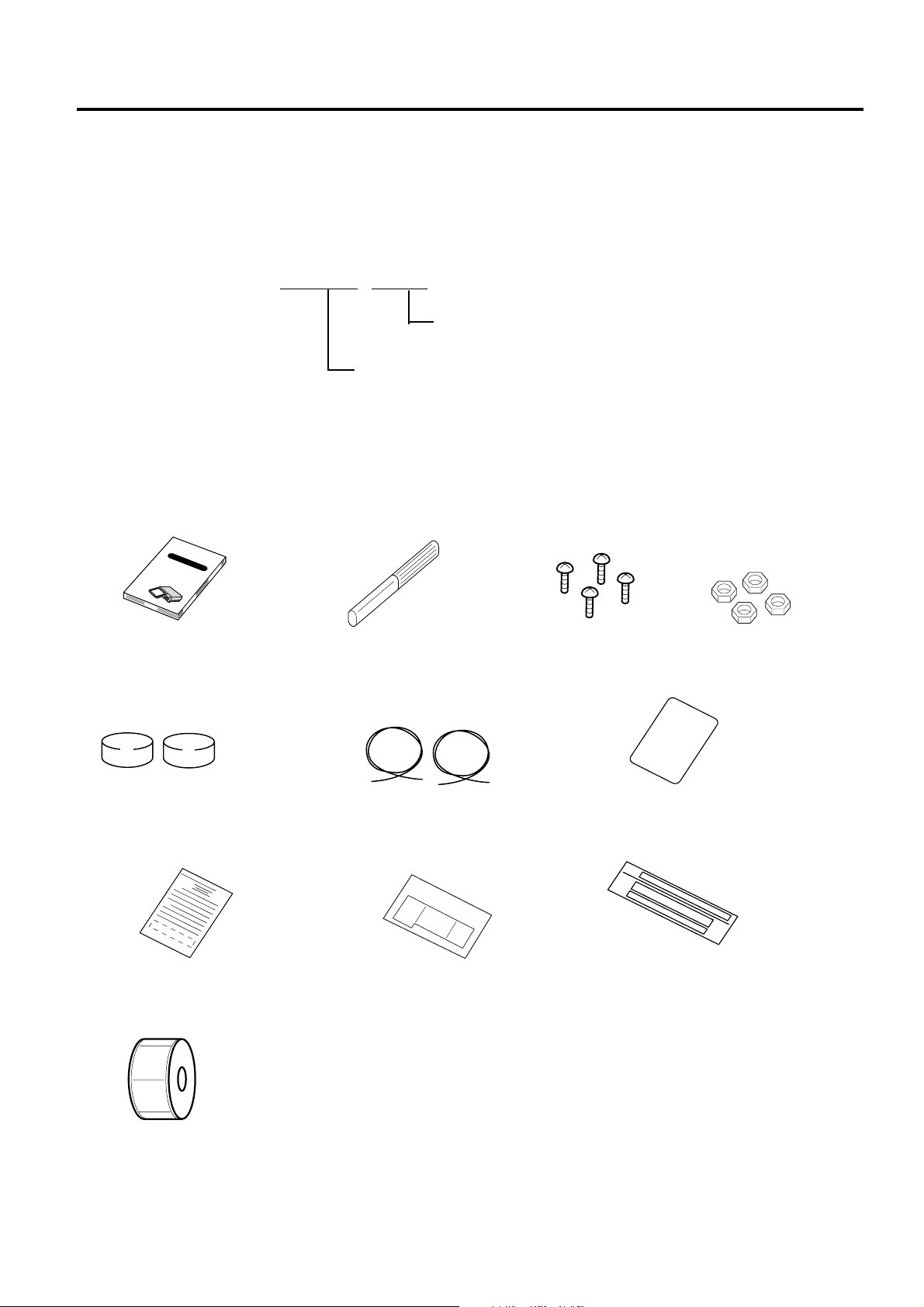

1.2 Accessories

When unpacking, please check that the following accessories are supplied with the scale.

Owner’s Manual Print Head Cleaner TR-4x10 Screw N-8 Nut

(1 copy) (1 pcs.) (4 pcs.) (4 pcs.)

Sealing Lead Stranded Wire Sealing Cover Label

(2 pc.) (260 mm x 2 pcs.) (1 pc.)

Warranty Instruction Quality Control Report Spanish Display Sticker

(1 pc., US model only) (1 pc., US model only) (1 pc., CA model only)

Label (1 roll)

1- 2

Page 10

2. SPECIFICATION

EO1-31009

2.1 Scale

2. SPECIFICATION

2.1 Scale

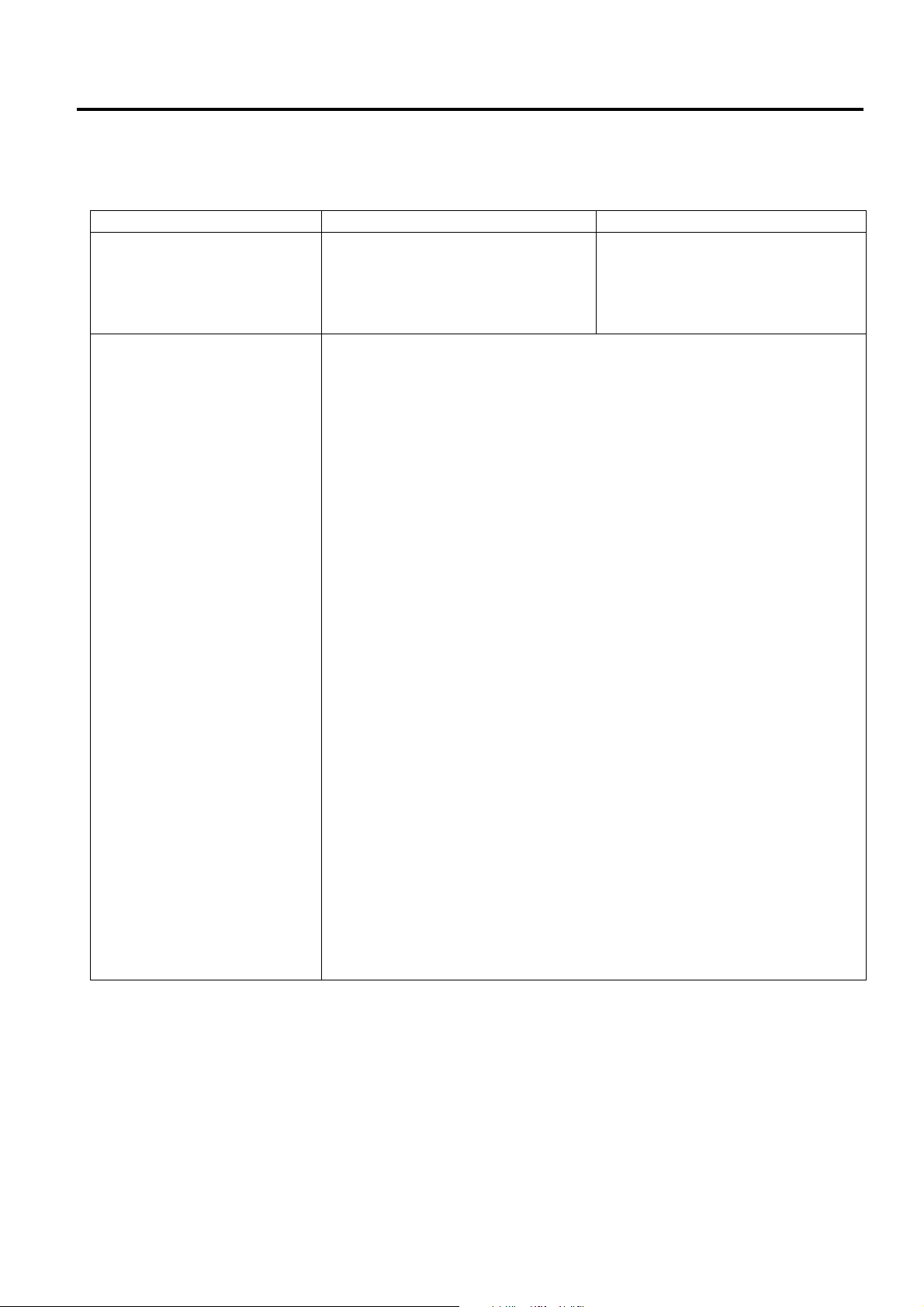

Item 30 lb scale (US model) 15 kg scale (CA model)

Maximum capacity

Minimum Scale Division

Maximum Tare

Display Range

Unit Price Pre-settable

Minimum Price Display

Power Requirement

Power Consumption

Temperature Limits

Relative Humidity

Message Display

Unit Price

Total Price

Touch Panel

Capacity of PLU Memory

Print Head

Media Issue Method

Dot Density

Print Speed

Available Media width

Recommended Media

Thermal label

Variable length label

Thermal receipt

Interface

Dimensions (Approx.)

Weight

NOTE: The CA model is changeable between 30-lb scale and 15-kg scale as program option. For details,

please contact the nearest TOSHIBA TEC service representative.

30 lb

0.005 lb (0 to 15 lb)

0.01 lb (15 to 30 lb)

2 lb

0 to 30.05 lb

15 kg

0.002 kg (0 to 6 kg)

0.005 kg (6 to 15 kg)

1 kg

0 to 15.025 kg

$0.01 to $99.99

$0.01

AC 85V to 138V, 50/60 Hz±2%

90W/1.5A (when printing), 40W/0.6A (St and- by)

23°F to 95°F (-5°C to +35°C)

30% to 80% (No condensation)

Operator’s display: 10.4 inch color TFT display (640x480 dots)

Customer’s display: 5x7 dots 20 characters x 2 lines VFD (Standar d)

256x64 dots Full dot display (Opt ion)

4 digits

5 digits

Thin Film Resistor

2300 PLUs (standard), 17300 PLUs max. (Opt ion)

Thermal Print Head

Strip/Batch

203 dots/inch (8 dots/mm)

Supersensitive label: 4 inches/sec. (102 mm/sec.)

Normal sensitive label: 3 inches/sec. (76 mm/sec.)

1.89 to 3.15 inches (Variable length labels 1.89 or 2.24 inches)

48 mm to 80 mm (Variable length labels 48 mm or 57 mm)

VHTS, VHNS,GFTS,GFNS (OSP)/Outer diameter: ∅3.94 inches

(100mm) (Max.)

VHTS, VHNS,GFTS,GFNS (OSP)/Outer diameter: ∅3.94 inches

(100mm) (Max.)

PD-152R, PD-150R (OJI PAPER)/ Outer diameter: ∅3.15 inches

(80mm) (Max.)

PCMCIA interface 2 slots (LAN, ATA card, Wireless LAN)

RS-232C interface 1 channel

17.7 inches (W)x Max. 18.4 inches (D) x Min. 6. 1 inches ( H)

450 mm (W) x Max. 468 mm (D) x Min. 155 m m (H)

36.6 lb (16.6 kg)

2- 1

Page 11

2. SPECIFICATION

EO1-31009

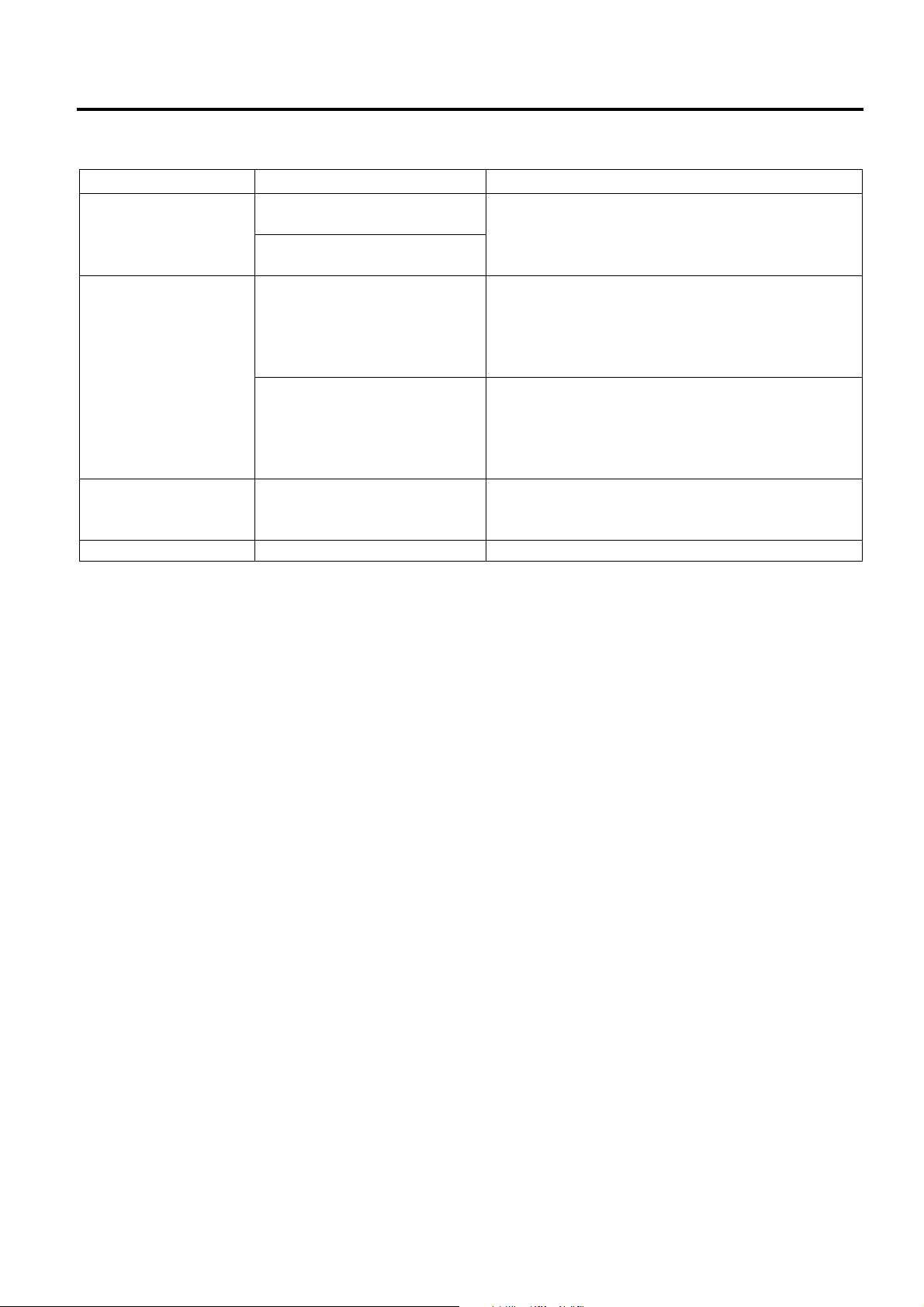

2.2 Option

2.2 Option

Option Name Model No. Description

Built-in Customer’s

Display

Remote Customer’s

Display (Pole Type)

MEMO PC Board OP-5300-PIGGYBACK-1MB PLU Memory expansion PC board containing

Label Cassette KS-53 A spare label cassette

NOTE: To purchase these options, please contact the nearest TOSHIBA TEC service representative or

sales agent.

OP-5300-FBIU-US

(US model)

OP-5300-FBIU-CA

(CA model)

A 256x64-dot Vacuum Fluorescent Display

(VFD). Installing this display in place of the

standard 5x7-dot VFD enhances the customers’

visibility.

OP-5300-57PIU A 5x7-dot VFD (20 characters x 2 lines) remo t e

type customer’s display. When this option is

used, the standard customer’s display does not

work. Please take the height of the remote

display into consideration.

OP-5300-FPIU A 256x64-dot VFD remote type customer’s

display. When this option is used, the standard

customer’s display does not work. Please take

the height of the remote display into

consideration.

1M byte RAM as standard. The memory can be

expanded up to 4M bytes (Max. 17300 PLUs).

2- 2

Page 12

3. APPEARANCE EO1-31009

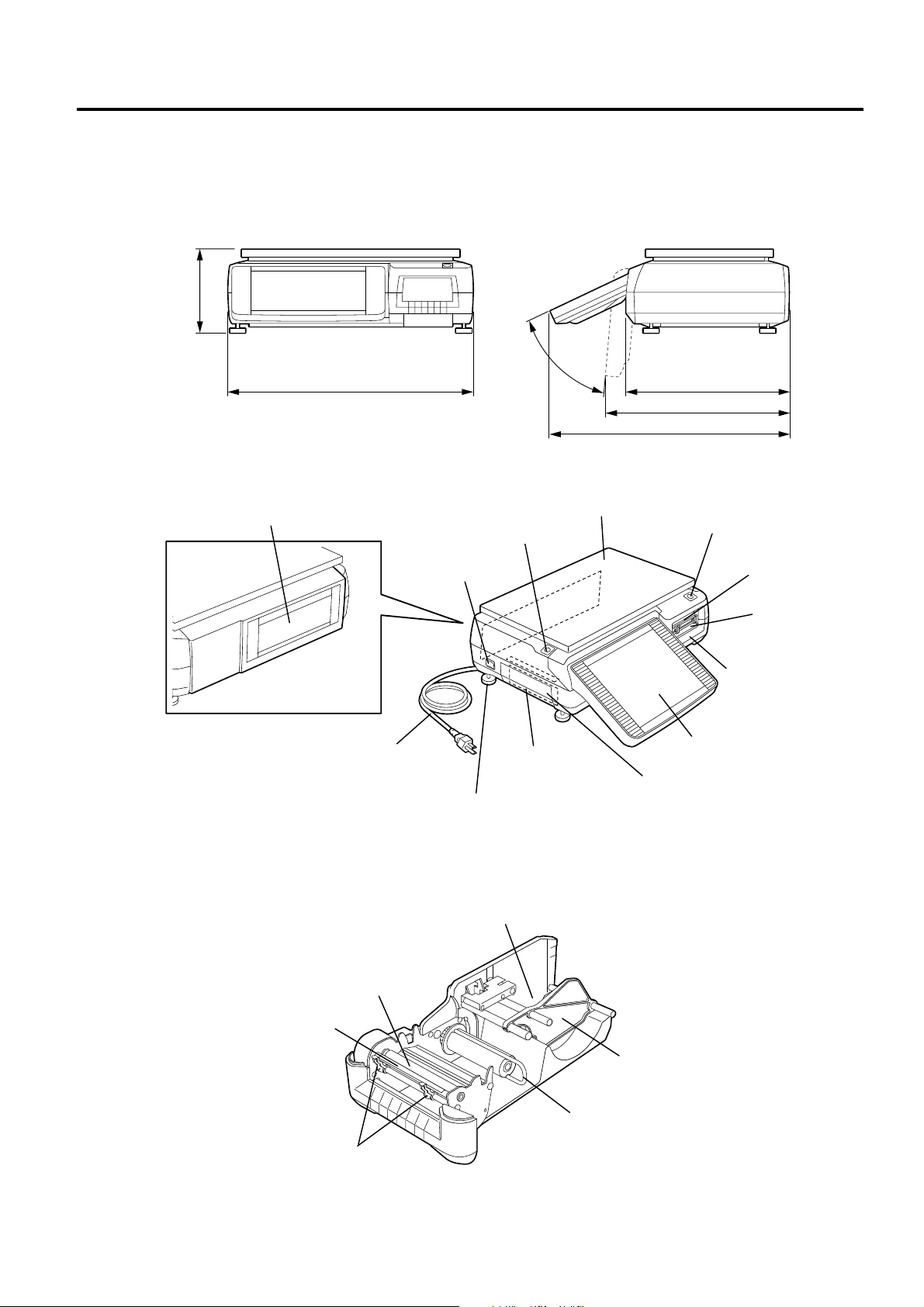

3.1 Dimensions

3. APPEARANCE

3.1 Dimensions

155 - 180

3.2 Scale

Customer’s Display

450

Power Cord

Level Gauge

Power Switch

Interface Cover

Adjustable Leg

25° - 85°

Platter

Connector Panel

310

410

464

Feed Button

Operation Panel

Cutter

Media Outlet

Label Cassette

3.3 Label Cassette

Strip Plate

Media Guide

Media Roll Holder

Platen

Media Roll Stopper

Backing Paper Stopper

3- 1

Page 13

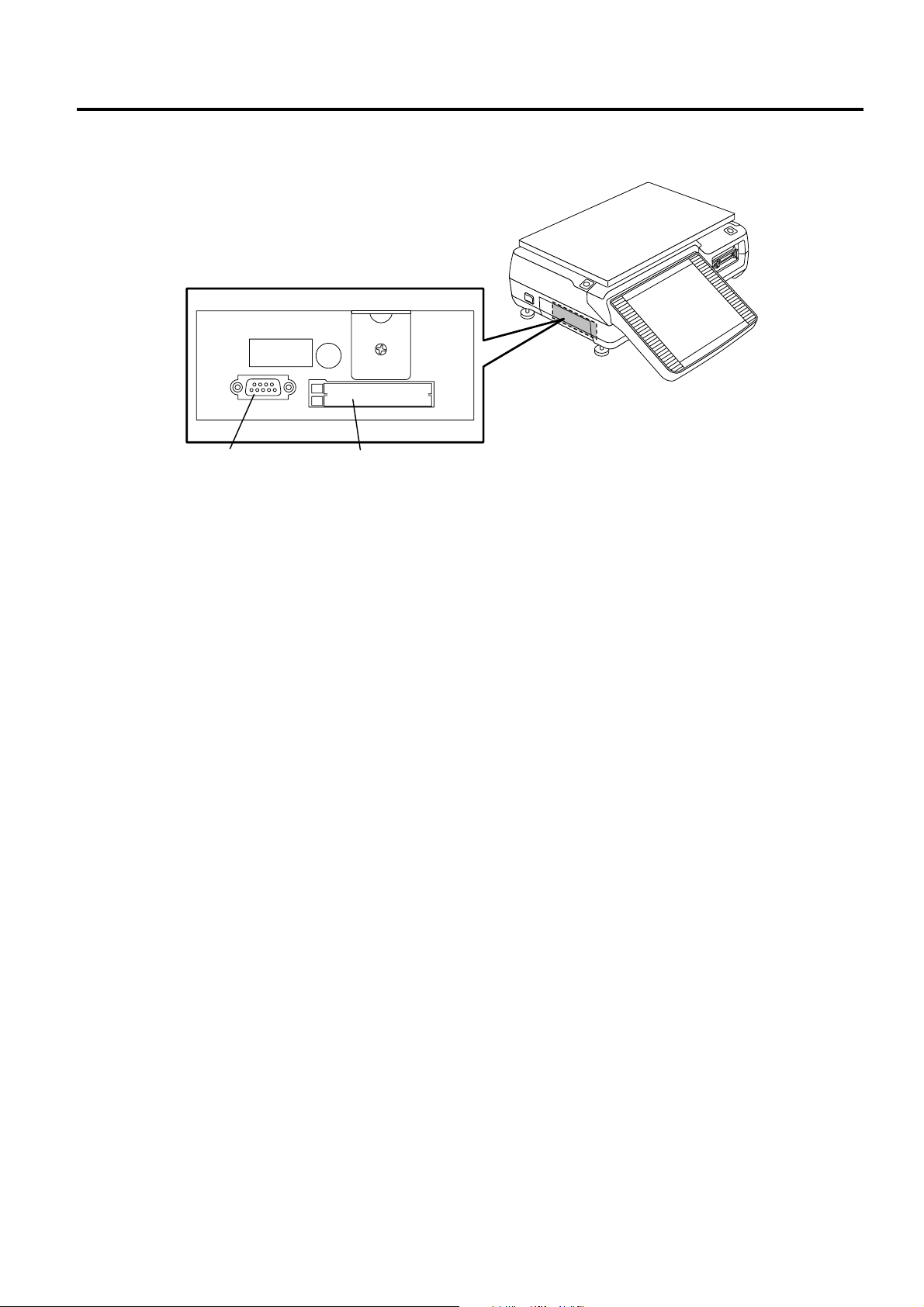

3. APPEARANCE EO1-31009

(

3.4 Connector Panel

3.4 Connector Panel

Serial Port

COM1)

PC Card Slot

3- 2

Page 14

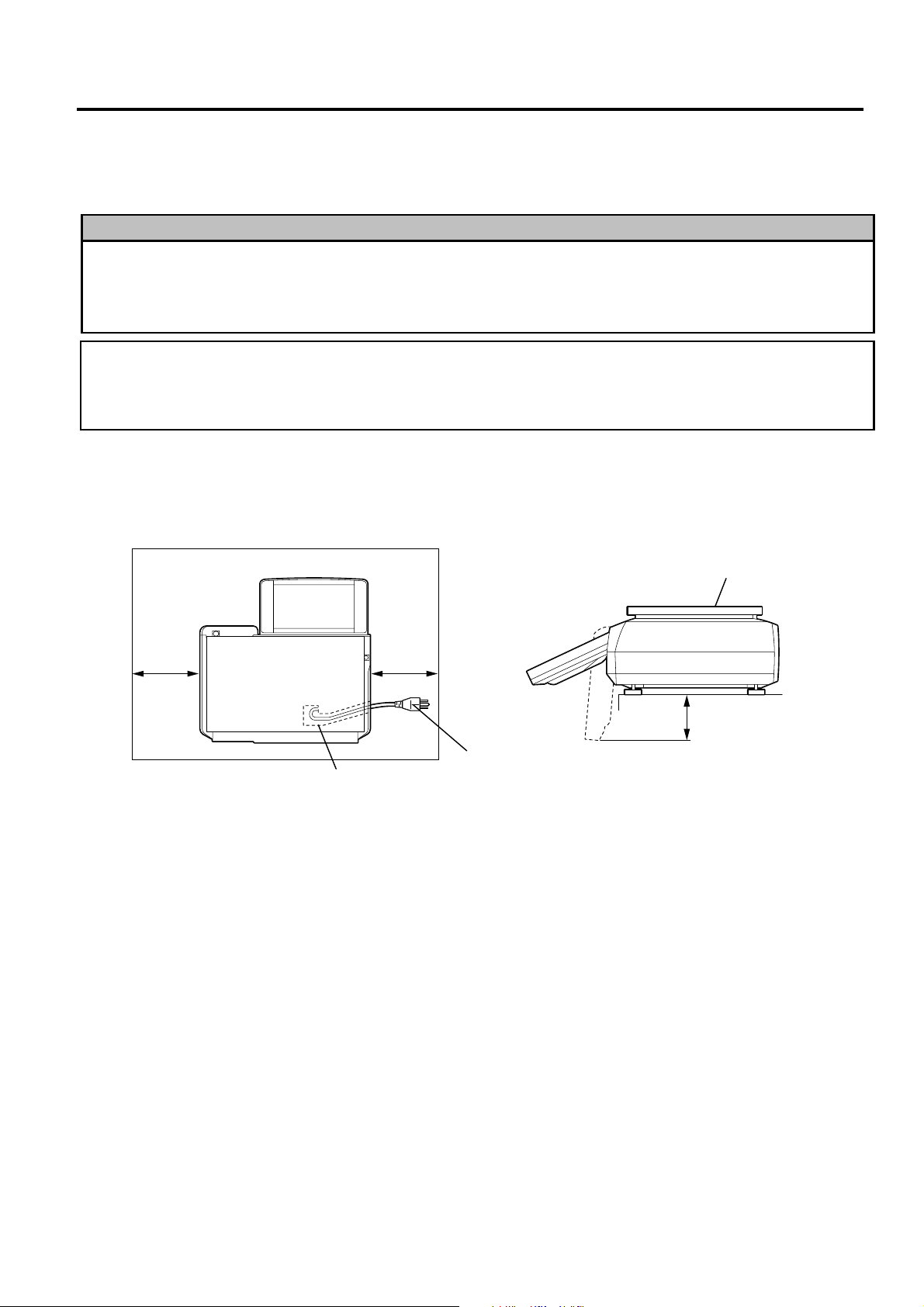

4. PROCEDURE BEFORE DAILY OPERATION EO1-31009

e

4.1 Installation of the Scale

4. PROCEDURE BEFORE DAILY OPERATION

4.1 Installation of the Scale

When installing the scale, avoid locations that have the following adver se conditions. Failure to do this

may cause a fire, electric shock, or injury.

Direct sunlight, high temperature, high humidity, rapid temperatur e change, vibrations, dust, near a

device generating magnetism or electromagnet ic wave, near fire or moisture, unst able t able.

WARNING!

CAUTION!

Basically, the power cord should come out from the left side of the scale being fitted into the ditch of th

scale bottom. If it cannot, car e m ust be taken when adjusting the adjustable legs so as not to squash

the power cord.

Install the scale on the well-ventilated, plane and level sur f ace. Be sure to provide enough space

around the scale as follows for easy operation.

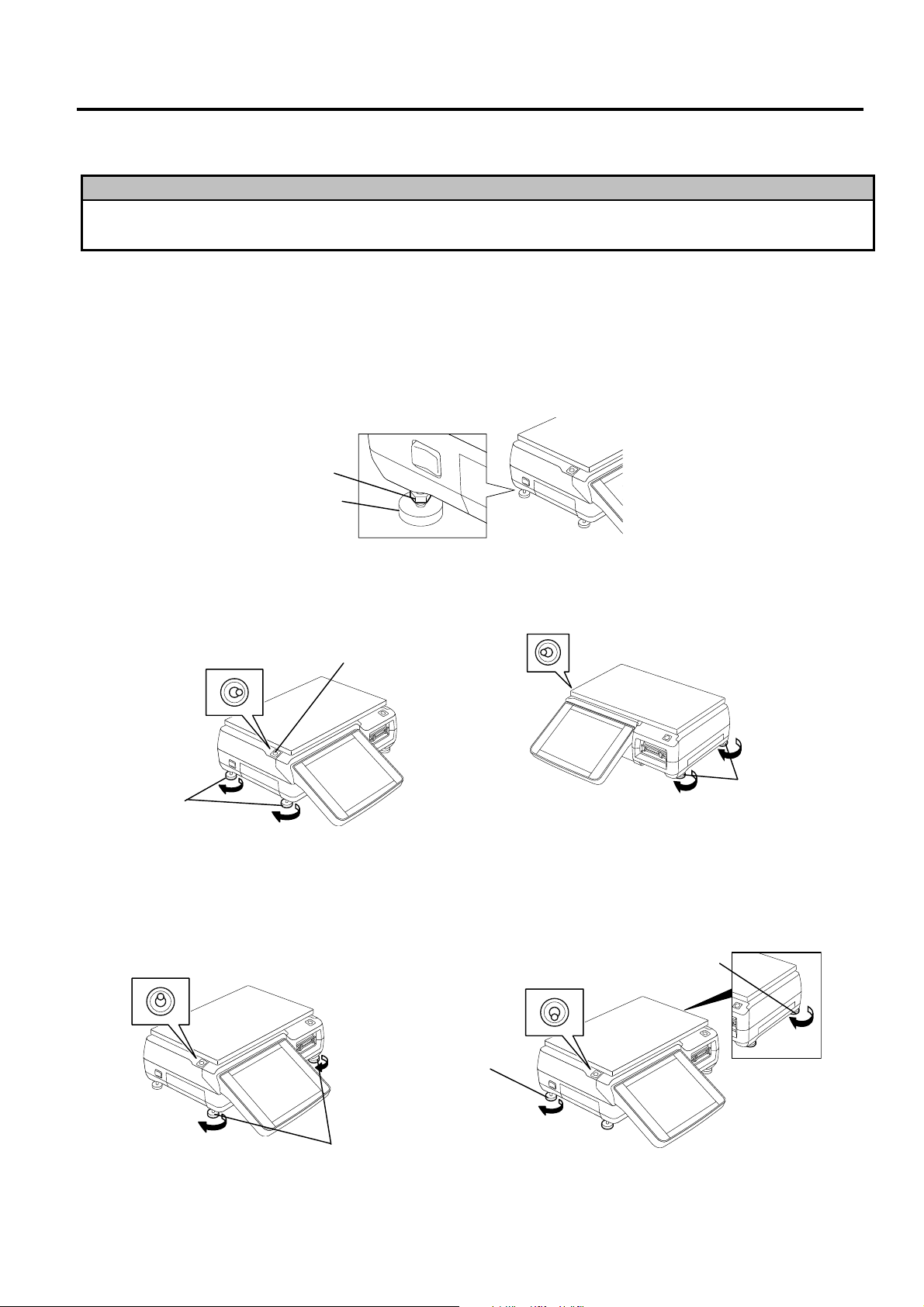

As viewed from the top As viewed from the right side

Platter

50 mm 50 mm

NOTES:

1. Remove anything that touches or may touch the platter around the scale. Failure to do this may cause

incorrect weighing operation.

2. Avoid the location where the scale is subject to the direct wind from the air conditioner. Failure to do this

may cause incorrect weighing operation.

3. TOSHIBA TEC will not guarantee any problems with t he scale and t he per ipher al devices caused by

installation or removal of the peripherals by yourself.

Ditch

Power Cord

150 mm

4.2 Preparation

Before starting the business hours, perf or m the following preparatory operations.

1. Plug in the scale. (Refer t o Sect ion 5.)

2. Adjust the level of the scale. ( Ref er t o Section 6.)

3. Turn ON the power switch. ( Ref er to Section 7.)

4. Adjust the angle of the operation panel. (Refer to Section 9.)

5. Load the media. (Refer t o Section 8.)

After the business hour is over, clean the scale.

1. Turn OFF the power switch. (Refer to Section 7.)

2. Clean the scale. (Refer t o Sect ion 11.)

4- 1

Page 15

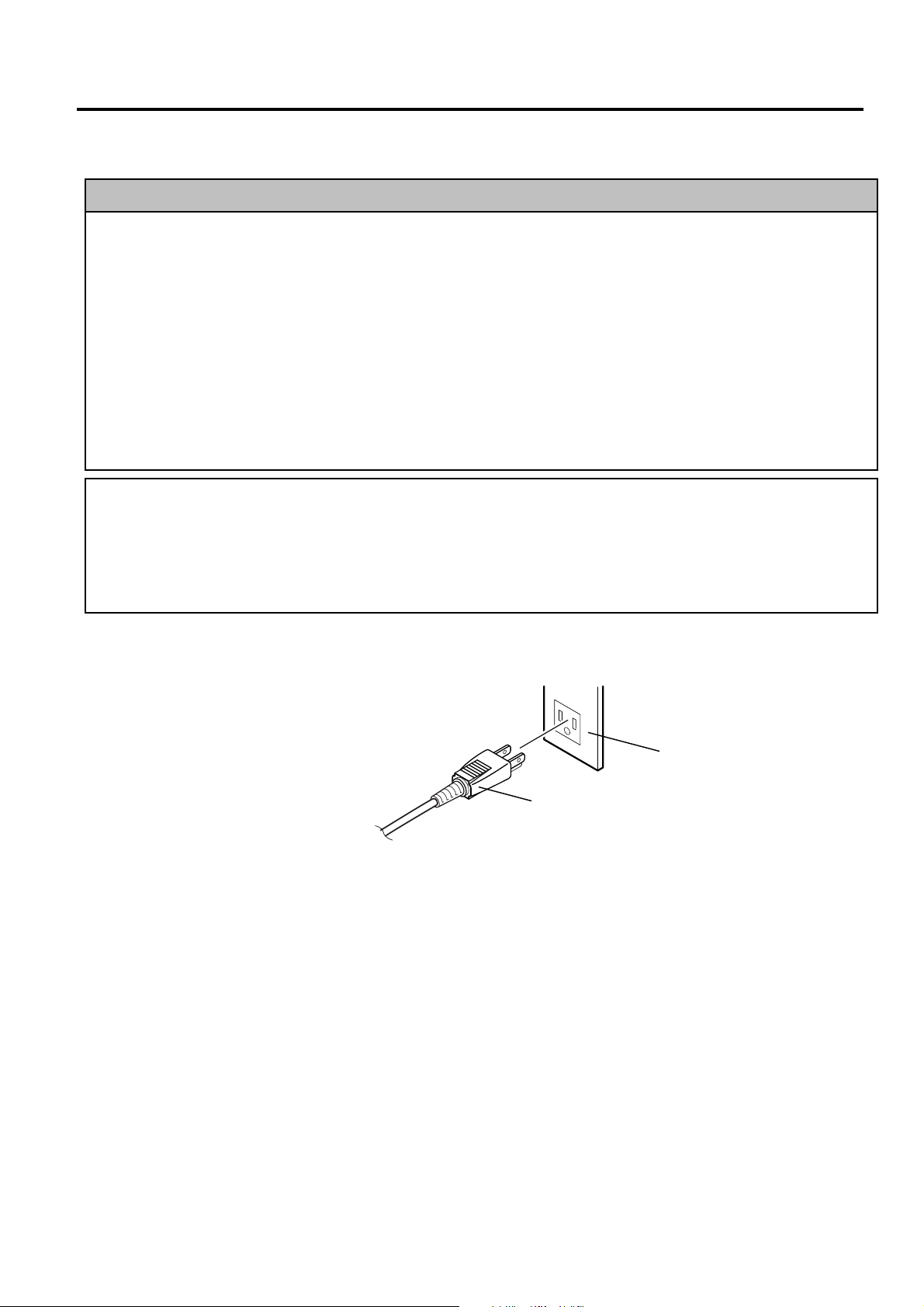

5. INSERTING THE POWER CORD EO1-31009

5. INSERTING THE PO WER CORD

5. INSERTING THE POWER CORD

1. Be sure to insert t he power plug into the rated outlet. Failure to do this may cause fire or electric

shock.

2. Do not share the same out let with any other electrical appliances or do not use an extension cor d.

Over capacity may cause fire or electric shock.

3. Do not excessively bend, pull on, damage, place a heavy object on, or heat the power cord.

Damaged power cord may cause fire or electric shock.

4. Do not plug in or unplug the power cor d wit h wet hands, as this may cause an electric shock.

5. Be sure to fully insert the power plug into the AC outlet. Failure to do t his may cause fire or electric

shock.

6. Be sure to hold and pull on the plug when disconnecting t he power cor d. Pulling on the cord instead

of the plug may break the internal wires, which may cause fire or electric shock.

7. Clean the plug for a few t im es a year . The power plug may collect dirt and this may cause fire.

WARNING!

CAUTION!

1. Do not share the AC outlet with any other electrical appliances that consume a large am ount of

power. Doing so may affect the operat ion of t his machine as the voltage will fluctuate widely each

time these appliances operate.

2. Be sure to turn O FF the power before plug in the power cord. Failure t o do t his m ay cause a shortcircuit resulting in a machine failure.

1. Make sure that the power swit ch is in the OFF position.

2. Insert the power plug into t he AC outlet completely.

AC Outlet

Power Plug

5- 1

Page 16

6. LEVEL ADJUSTMENT EO1-31009

6. LEVEL ADJUSTMENT

6. LEVEL ADJUSTMENT

Care must be taken not to squash the power cord by the scale when adjusting the level, as this may

cause electric shock or fire.

WARNING!

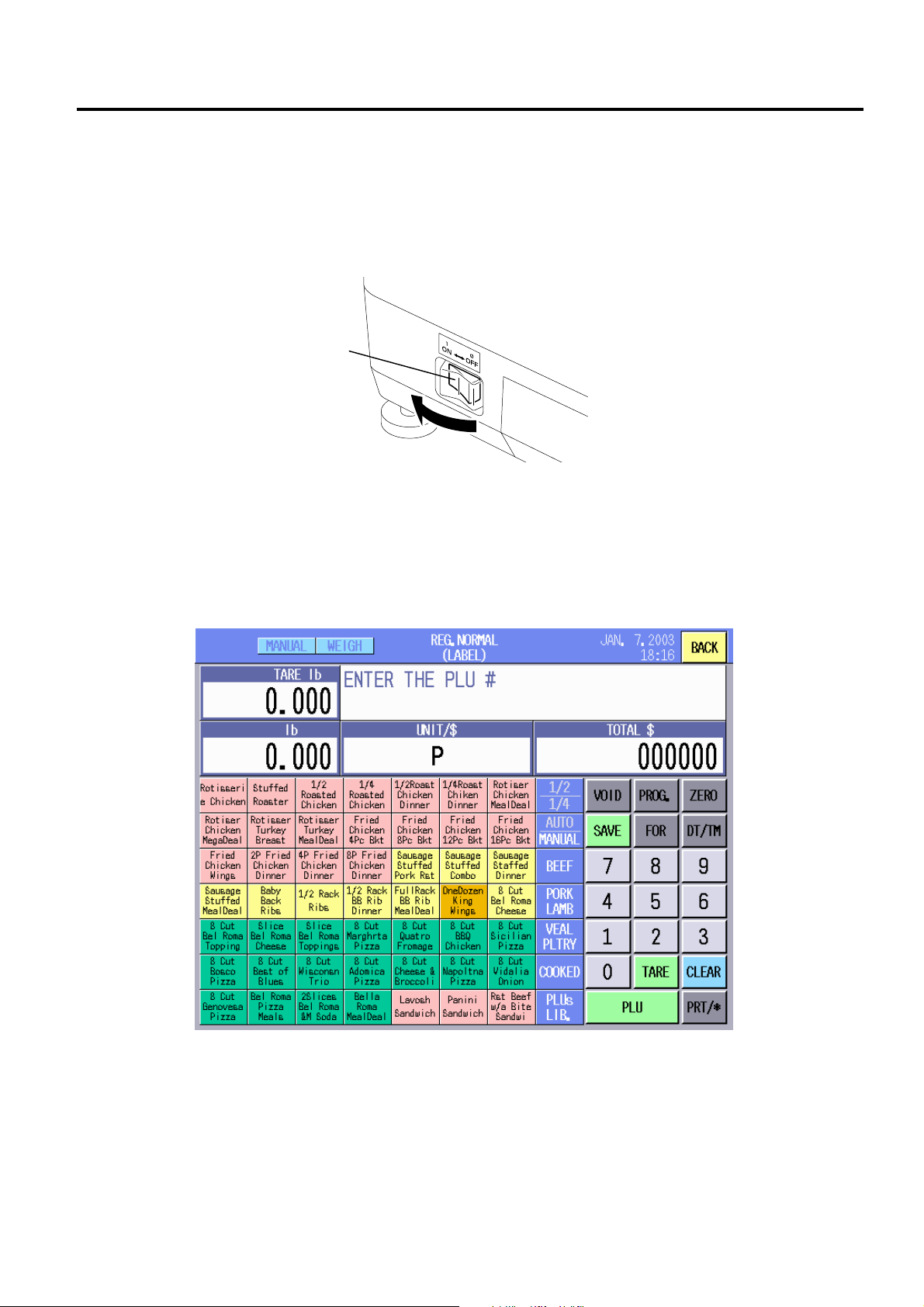

For correct weighing operations, be sure to level t he scale. Turn the four adjustable legs so that the

bubble in the level gauge is positioned at the center.

NOTES:

1. Make sure that the scale is leveled before the business hour starts.

2. To prevent the level adjustment from being changed unconsciously and the power cord from being

squashed, fixing the adjustable legs with the enclosed nuts is recommended.

Adjustable Leg

Nut

• When the bubble is positioned rightward.

Tur n the left adjustable legs clockwise, or

turn the right adjustable legs

• When the bubble is positioned leftward.

Tur n the right adjustable legs clockwise, or turn

the left adjustable legs counterclockwise.

counterclockwise.

Level Gauge

Left Adjustable

Legs

Right Adjustable Legs

• When the bubble is positioned backward.

Turn the front adjustable legs clockwise, or

turn the rear adjustable legs

counterclockwise.

•••• When the bubble is positioned frontward.

Tur n the rear adjustable legs clockwise, or turn

the front adjustable legs counterclockwise.

Rear Adjustable Leg

Rear Adjustable Leg

Front Adjustable Legs

6- 1

Page 17

7. TURNING THE POWER ON/OFF EO1-31009

7.1 Turning the Power ON

7. TURNING THE POWER ON/OFF

7.1 Turning the Power ON

1. Make sure that the power plug is f ully inser ted into the AC outlet.

2. Make sure that nothing is placed on the plat ter, and then turn ON the power swit ch.

NOTE: While the power switch is ON, the memory backup battery is charged. Therefore, data in t he

memory may be deleted if the battery voltage drops. Consult your TOSHIBA TEC service

representative in case the scale will not be used for a long period of time ( mor e t han 30 days) .

3. The last display before turning OFF t he switch follows about 10-second scanning display.

NOTE: If the power does not turn on or an error message appears, refer to Section 23,

TROUBLESHOOTING or Section 24, ERRO R MESSAGE TABLE.

Power Switch

7- 1

Page 18

7. TURNING THE POWER ON/OFF EO1-31009

7.2 Turning the Power OFF

7.2 Turning the Power OFF

CAUTION!

1. Do not turn off the power during printing. Doing so may cause a paper jam or machine failure.

2. Do not turn off the power in the middle of operation. Doing so may cause a malfunction.

3. Do not turn off the power while the PC card is being accessed. Doing so may destroy t he

data in the PC card.

1. Make sure that the Registr ation Mode Initial screen or Main Menu is displayed.

2. Turn OFF the power switch.

Power Switch

7- 2

Page 19

8. LOADING/REPLACING THE MEDIA EO1-31009

8. LOADING/REPLACING THE MEDIA

8. LOADING/REPLACING THE MEDIA

WARNING!

1. Do not touch the print head or around the print head, or you may get bur ned as t he pr int head

becomes very hot during printing.

2. Do not touch the cutter blade, as this may cause injury.

3. Firmly hold the bott om of the label cassette when pulling it out. Failure to do this m ay cause the

label cassette to drop, resulting in injur y .

CAUTION!

Do not push down or hit the print head, as this m ay cause a m achine f ailur e.

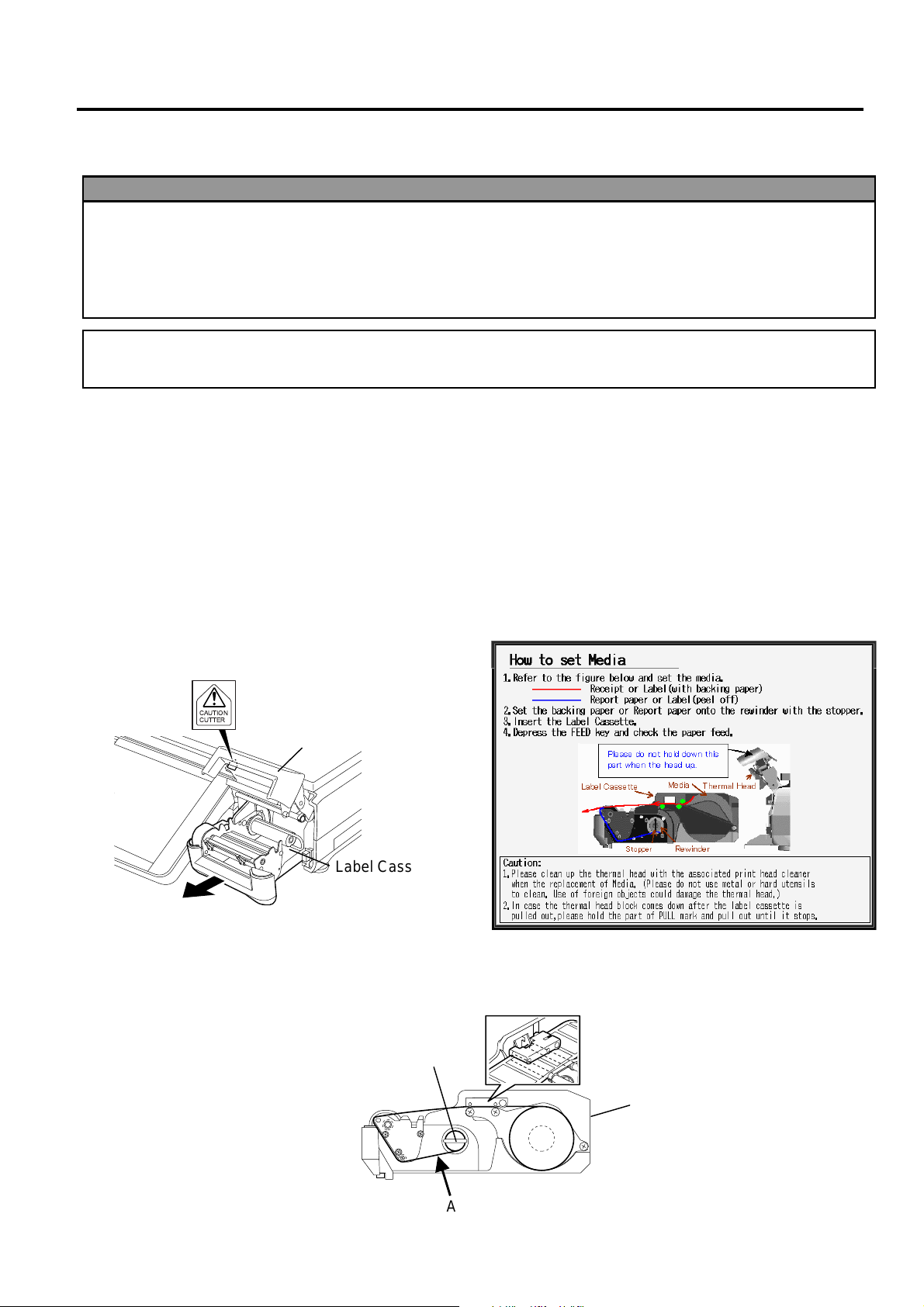

In this section how to load or replace the label is described. Please use TOSHIBA TEC-approved

labels only. For the label specification, refer to Section 2.1.

NOTES:

1. The label loading procedure differs according to the issue modes: Batch and Strip.

2. When purchasing the labels, contact the nearest TOSHIBA TEC service representative.

3. The loading procedure of receipt is same as that of the label. (Receipts are used in the Report and Reset

mode.)

1. Pull out the label cassette. See the label loading procedur e displayed on t he oper ation panel just

for your reference.

Caution symbol for the cutter blade

(Please refer to WARNING!)

CAUTION

CUTTER

Print Head Block

Label Cassette

NOTE: When replacing the label, first cut the backing paper at the position of arrow A, remove the

backing paper stopper, move the media roll stopper to the right, and remove the label roll and

the backing paper roll from the label cassette.

Backing Paper Stopper

Label Cassette

A

8- 1

Page 20

8. LOADING/REPLACING THE MEDIA EO1-31009

WIDTH

8. LOADING/REPLACING THE MEDIA

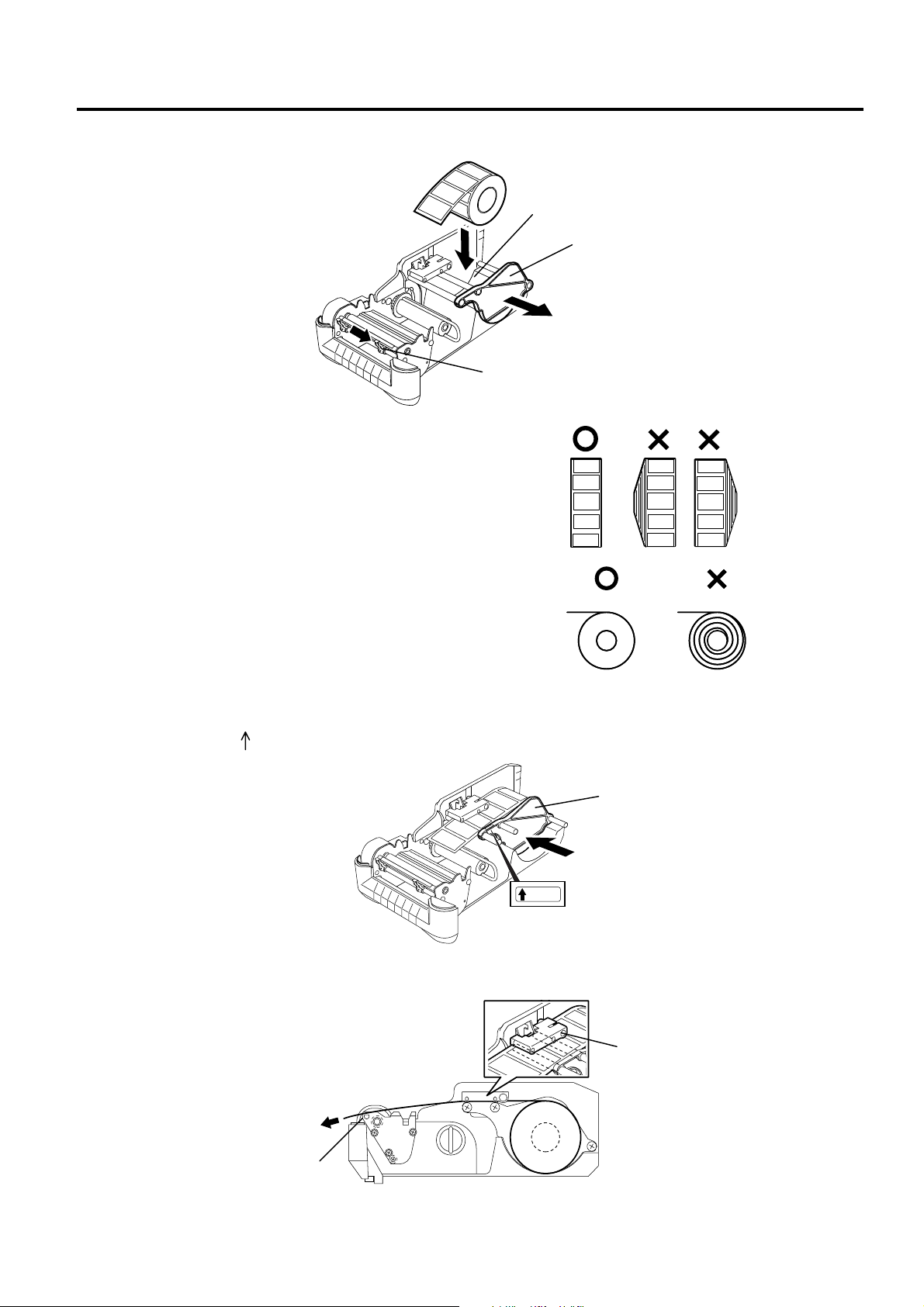

2. Move the media guide and the media roll stopper t o the right and place a label roll into the label

roll holder.

Label Roll Holder

Media Roll Stopper

NOTES: 1. When the inner part of the label roll is protruding,

flatten it on a level surface.

2. Do not use labels rolled loose, as this may

cause a paper jam. Re-roll the label tightly.

Media Guide

3. Move the media roll stopper t o t he label edge. Make sure that the label roll stopper’s f r ont part,

where the label “ WIDTH” is attached, is set along with the label edge.

4. Pull the top end of the label past the strip plate so that the labels pass under the pinch roller unit.

Strip Plate

Media Roll Stopper

Pinch Roller Unit

8- 2

Page 21

8. LOADING/REPLACING THE MEDIA EO1-31009

8. LOADING/REPLACING THE MEDIA

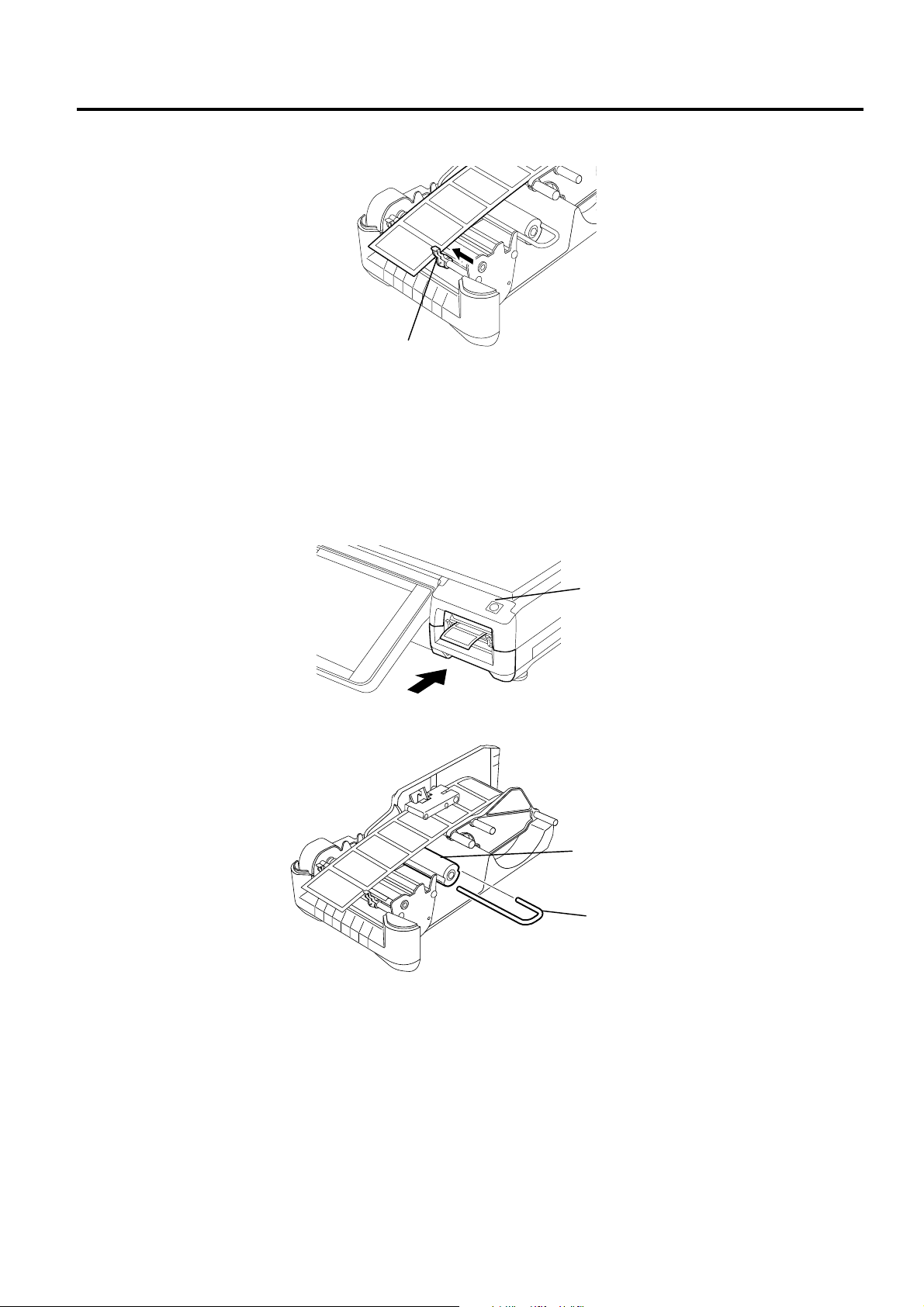

5. Move the media guide to the label edge.

Media Guide

NOTE: When the labels are issued in strip mode, provide about 1 mm gap between the backing paper

edge and the media guide.

6. To issue the label in the strip mode, skip t his st ep. To issue the label in the batch mode, push the

label cassette into the scale with the top edge of t he label pr otruding from the media outlet. Pr ess

the [FEED] button to check that the labels are fed properly. Now the label loading for t he bat ch

mode is completed.

FEED Button

7. When using the strip issue, remove the backing paper stopper from the take-up shaft.

Take-up Shaft

Backing Paper Stopper

8- 3

Page 22

8. LOADING/REPLACING THE MEDIA EO1-31009

8. LOADING/REPLACING THE MEDIA

8. Remove enough labels from the leading edge of t he label stock to leave 40 - 50 cm of backing

paper. Thread the backing paper through the print er as shown below, and fix the top edge of the

backing paper to the take-up shaft with t he backing paper st opper . Then turn the take-up shaft

counterclockwise for a few times.

9. Push back the label cassette into the scale, and press t he [FEED] button to check that t he labels

are fed properly.

8- 4

Page 23

9. OPERATION PANEL EO1-31009

9.1 Operational Precautions

9. OPERATION PANEL

9.1 Operational Precautions

The operation panel should be operated carefully. Follow the precautions provided below.

1. Though the operation panel is water - proof constructed, do not touch it with wet fingers or hands.

Doing so may cause electric shock or machine failure.

2. Should the liquid crystal leak out of the operation panel, do not touch it or you may have a r ash. If it

is attached to your skin or clothes, wash it away im m ediat ely with clean water.

CAUTION!

1. Operate the oper ation panel only with fingers. Do not use a sharp object like a pen, as t his m ay

cause a machine failure.

2. Just press the touch scr een panel lightly. Do not hit or give excessive pressure to the oper at ion

panel, as this may cause a machine failure.

3. Do not place anything on the operat ion panel. Doing so may cause a machine failure.

WARNING!

9.2 Ti lt Angle Adjustment

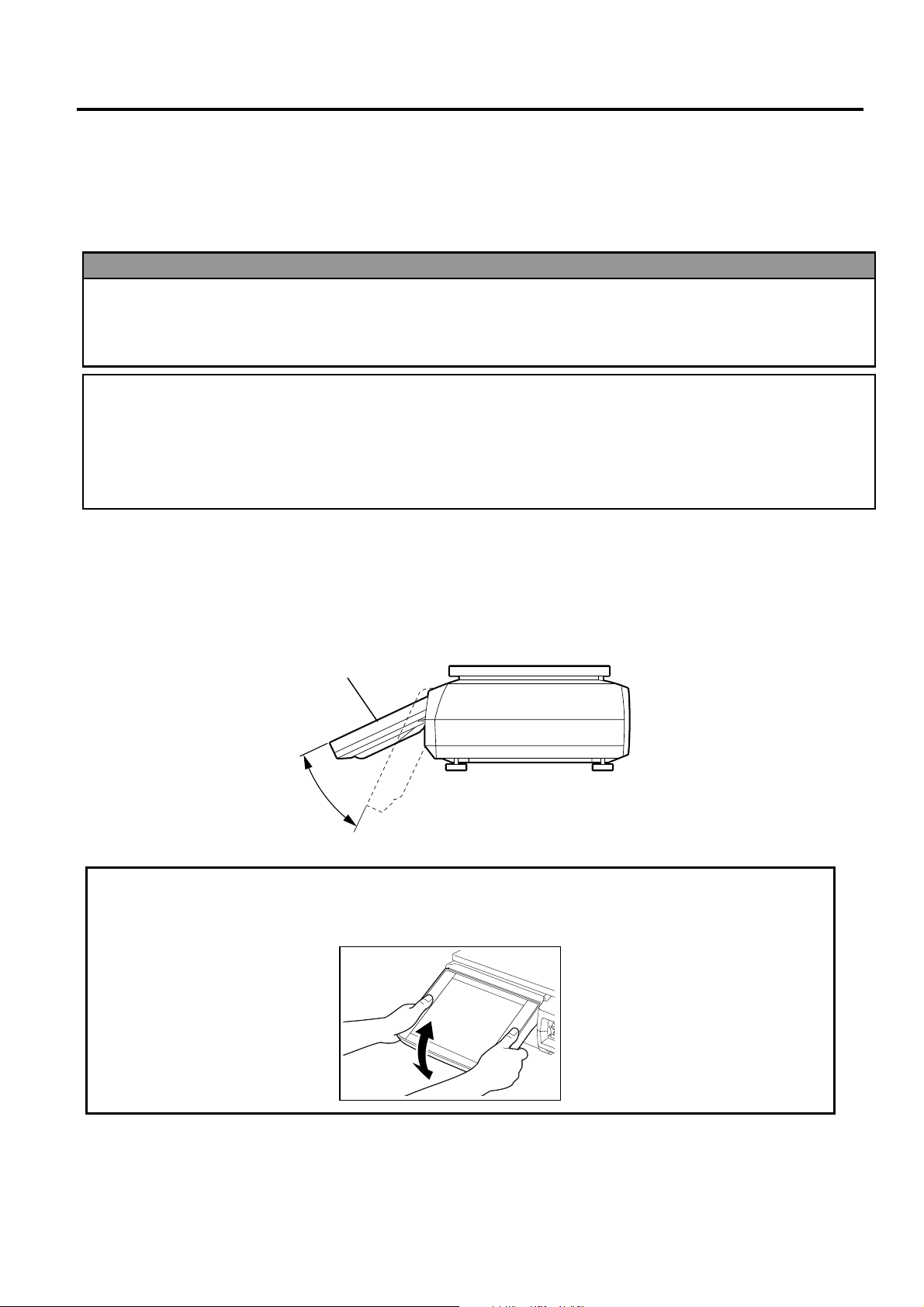

The tilt angle of the operation panel can be freely adjust ed in a r ange of 25° to 65°. Adjust the angle to

your best position so that the reflection of t he r oom light or outside light is minimized and you can

operate the operation panel at ease.

CAUTION!

Be sure to hold the frame of the operation panel when adjusting the tilt angle. Excessive

pressure to the display may cause a machine failure.

Operation Panel

25°

65°

9- 1

Page 24

9. OPERATION PANEL EO1-31009

(11)

(10)

(10)

(11)

(2)

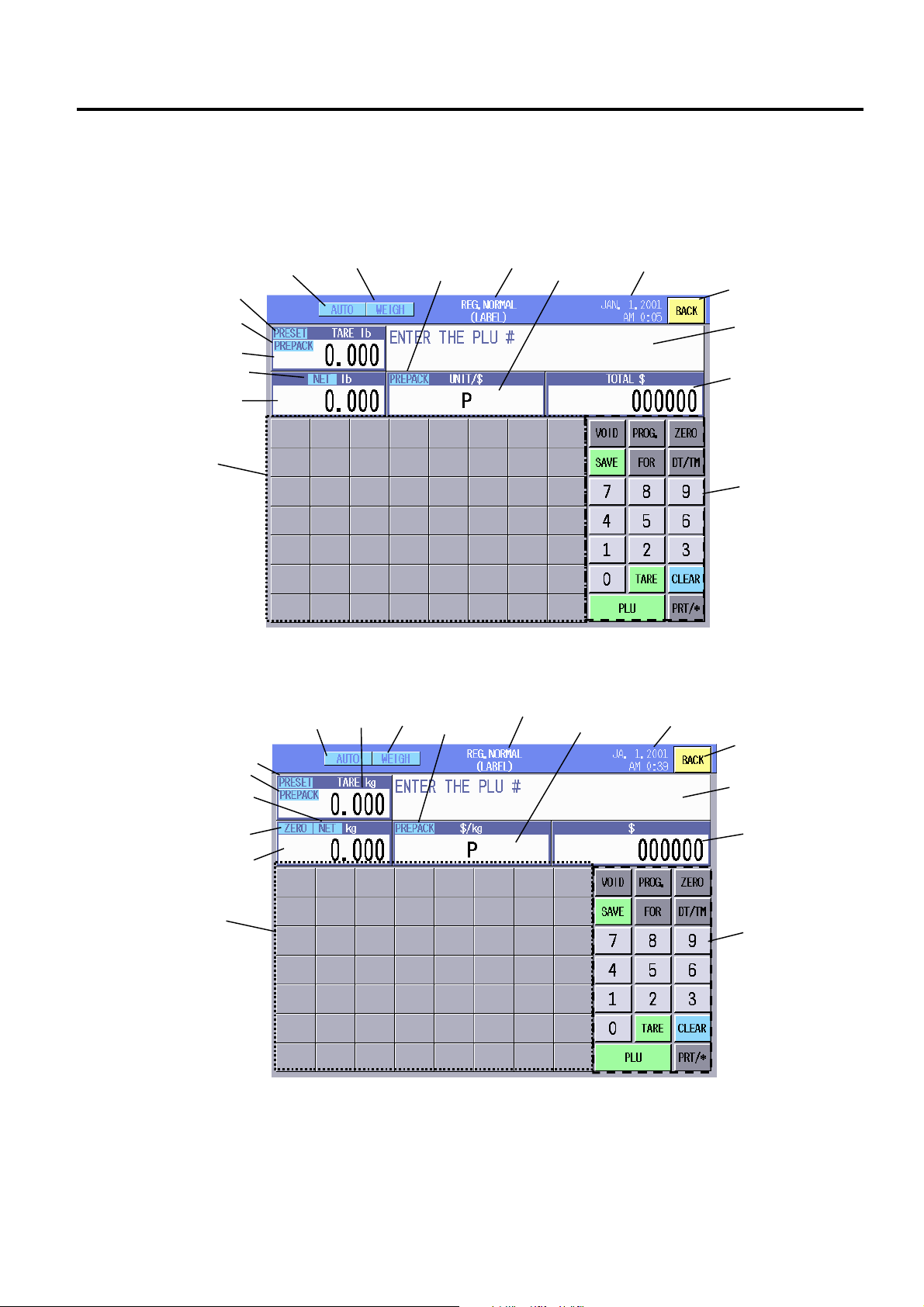

9.3 Layout of the Operation Panel

9.3 Layout of the Operation Panel

This section describes the layout of the screen displayed in the operation panel. The screen differs

according to the modes and menus. The examples shown below are those t hat appear in the

Registration mode.

1) US Model

(8)

2) CA Model

(8)

(1)

(14)

(2)

(15)

(3)

(14)

(15)

(17)

(3)

(1)

(13)

(13)

(16)

(16)

(6)

(6)

(12)

(4)

(5)

(7)

(9)

(12)

(4)

(5)

(7)

(9)

9- 2

Page 25

9. OPERATION PANEL EO1-31009

9.3 Layout of the Operation Panel

(1) Preset tare lamp: Lights when a tare preset to the PLU is called. (See NOTE.)

(2) Tare: Max. 4-digit tare is displayed.

(3) Weight: Max. 5-digit weight including “−“ mark is displayed.

(4) BACK key: Used to return to the previous screen.

(5) Commodity: A commodity name is displayed.

(6) Unit price: Max. 4-digit unit price is displayed.

(7) Total price: Max. 5-digit total price is displayed.

(8) Speed keys: You can freely program these keys by SFKC setting.

(9) Function keys: You can freely program these keys by SFKC setting.

(10) Scale mode: Current state of the scale is displayed (Weigh/By-count/Fix).

(11) Operating mode: Current operating mode is displayed (REG. NORMAL (Label)/REG. MARK

DOWN/REG. REWRAP).

(12) Date and Time

(13) AUTO/MANUAL lamp: The current label issue method is displayed.

(14) PREPACK (tare) lamp: Lights when the called PLU data or tare is retained.

(15) NET lamp: Lights when a tare is entered. In this case, a net weight will be displayed

on the Weight area.

(16) PREPACK (Unit Price) lamp: Lights when the called PLU data is retained.

(17) ZERO lamp: Lights when a tare is not set or nothing is placed on the platter (weight is

zero).

NOTE: With the initial settings, PLU preset tare function cannot be used. I f you desire t o use this function,

please contact the nearest TOSHIBA TEC service representative or sales agent.

9- 3

Page 26

10. CUSTOMER’S DISPLAY

10. CUSTOMER’S DISPLAY

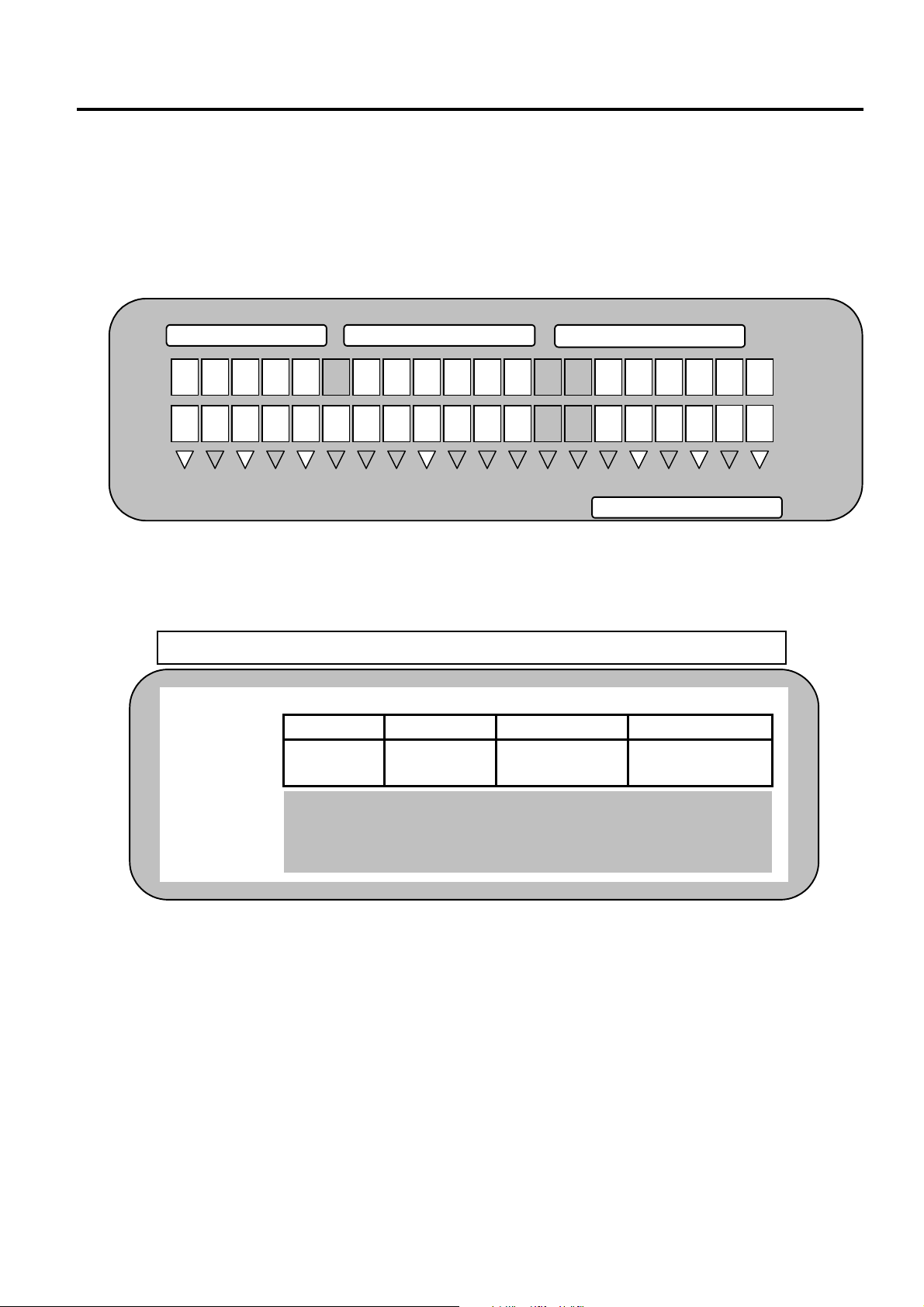

10.1 US Model

• 5x7-dot Built-in Display (Standard)

• 5x7-dot Remote Display (OP-5300-57PIU)

EO1-31009

10.1 US Model

TARE lb PRICE/lb $ WEIGHT lb

CAPACITY 0-15 lb e= d=0.005 lb 15-30 lb e=d=0.01 lb

SCROLLING MESSAGE INDICATES SCALE AT ZERO.

0 . 0 0 0

0 . 0 0 0

P

E N T E R

P L U

#

0 0 0 0

0 0

%/T

PRESET-T

PREPACK

NET

REG. M/D R/W

TOTAL PRICE $

256x64-dot Built-in Display (OP-5300-FBIU-US)

•

256x64-dot Remote Display (OP-5300-FPIU)

•

<REG.>

MANU. WEIGH JN.01.02 17:45

TARE lb UNIT/$ lb TOTAL $

P-TARE

% TARE

PREPACK

ENTER THE PLU #

NOTE: Regarding the Remote Display, US, CA, and Spanish display stickers are enclosed in t he optional

kits so that you can choose the appropriate one from them. For the installation of t he opt ional kits,

please contact the nearest TOSHIBA TEC service representative or sales agent.

CAPACITY 0-15 lb e= d=0.005 lb 15-30 lb e=d=0.01 lb

SCROLLING MESSAGE INDICATES SCALE AT ZERO.

000000 P 0.000 0.000

10- 1

Page 27

10. CUSTOMER’S DISPLAY EO1-31009

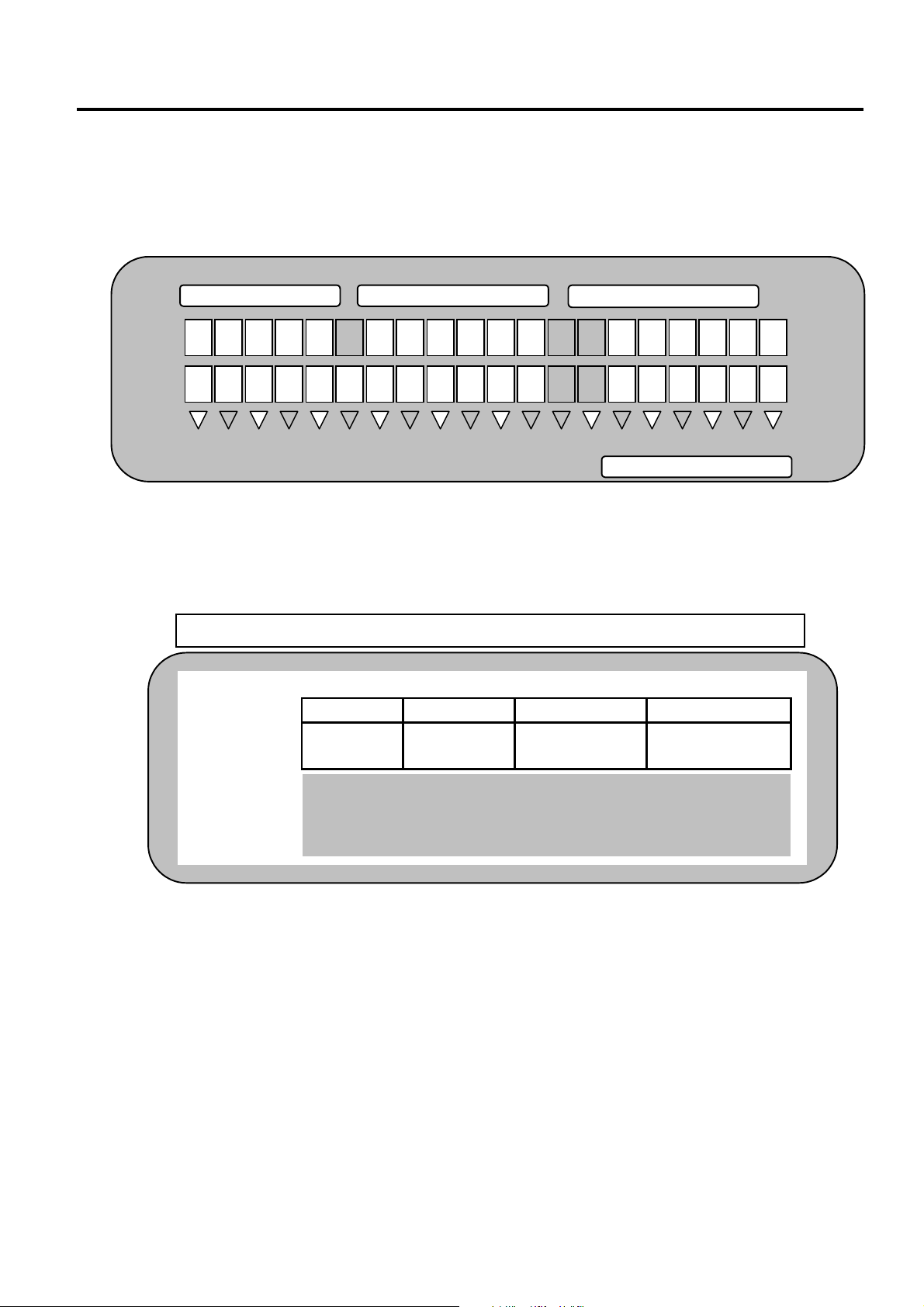

10.2 CA Model

10.2 CA Model

• 5x7-dot Built-in Display (Standard)

• 5x7-dot Remote Display (OP-5300-57PIU)

TARE PRICE/PRIX $ WEIGHT/POIDS

CAPACITY 0-6 kg e=d=0.002 kg 6-15 lb e=d=0.005 kg

CAPACITÉ 0–15 lb e=d-0.005 lb 15-30 lb e=d=0.01 lb

0 . 0 0 0

0 . 0 0 0

P

E N T E R

P L U

#

0 0 0 0 0 0

PRESET T

PROG.-T

%T

PRÉ-EMBALLÉ

PREPACK

ZERO/

ZÉRO

NET kg

lb

100g

REG.

TOTAL $

M/D

R/W

• 256-64-dot Built-in Display (OP-5300-FBIU-CA)

• 256-64-dot Remote Display (OP-5300-FPIU)

<REG.> MANU. WEIGH JN.01.02 17:45

TARE kg $/ kg kg $

ZERO

P-TARE

% TARE

PREPACK

ENTER THE PLU #

NOTE: Regarding the Remote Displays, US, CA, and Spanish display stickers are enclosed in optional

kits so that you can choose the appropriate one from them. For the inst allat ion of t he opt ional kit s ,

please contact the nearest TOSHIBA TEC service representative or sales agent.

CAPACITY 0-6 kg e=d=0.002 kg 6-15 lb e=d=0.005 kg

CAPACITÉ 0–15 lb e=d-0.005 lb 15-30 lb e=d=0.01 lb

000000 P 0.000 0.000

10- 2

Page 28

10. CUSTOMER’S DISPLAY EO1-31009

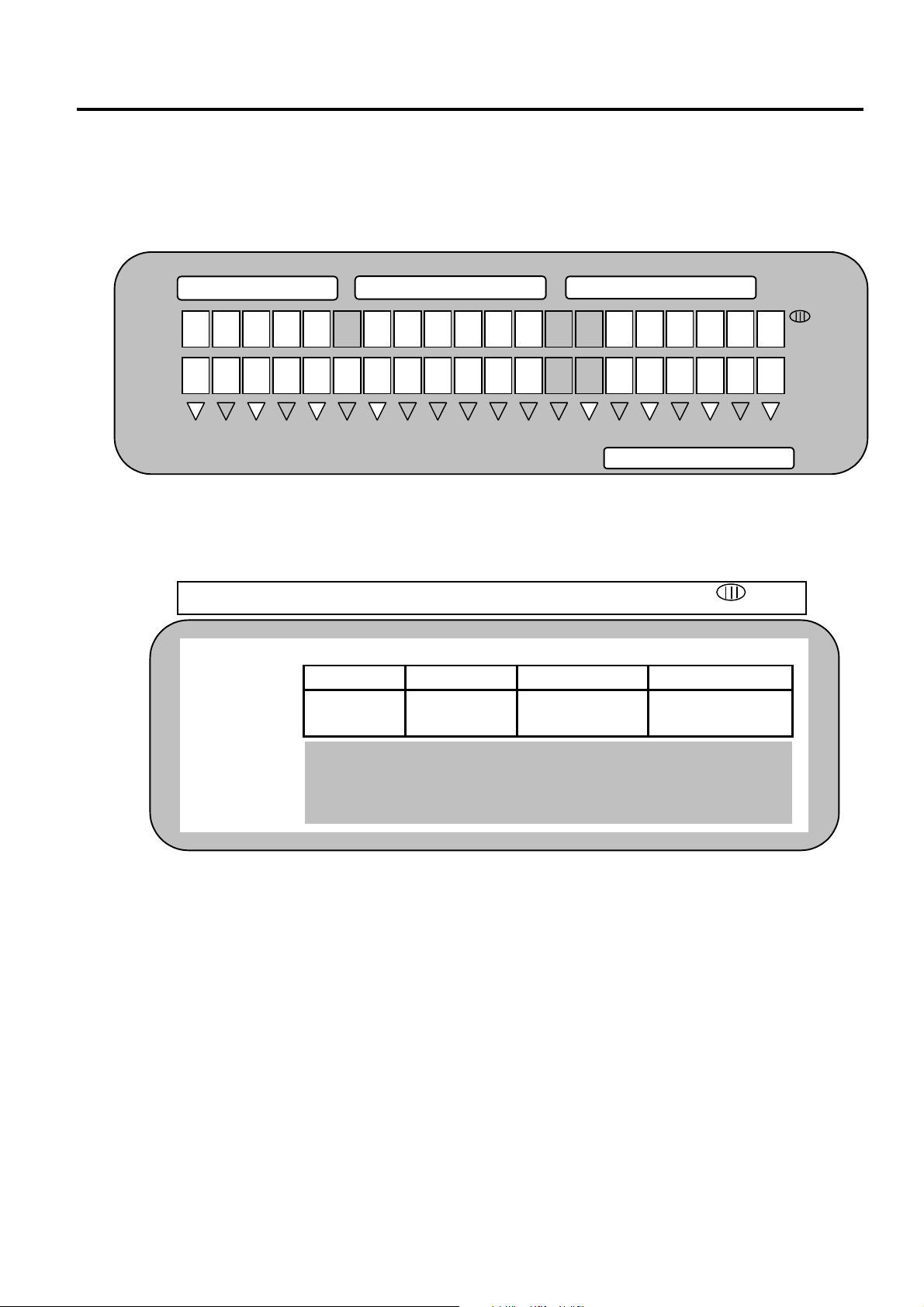

10.3 Spanish Display Sticker

10.3 Spanish Display Sticker

• 5x7-dot Built-in Display (Standard)

• 5x7-dot Remote Display (OP-5300-57PIU)

TARA kg

0 . 0 0 0

PESO kg

E N T E R

TARE

PREDEFINIDA

%/T

FIJO

CERO 100g

• 256x64-dot Built-in Display (OP-5300-FBIU-CA)

• 256x64-dot Remote Display (OP-5300- FPI U)

NOTES:

1. Regarding the Built-in Displays, the Spanish display sticker is enclosed in the CA model machine.

Please contact the nearest TOSHIBA TEC service representative or sales agent when you desire to

use the Spanish display sticker.

2. Regarding the Remote Displays, US, CA, and Spanish display stickers are enclosed in the optional kits

so that you can choose the appropriate one from them. For the installat ion of the optional kits, please

contact the nearest TOSHIBA TEC service representative or sales agent.

CAPACIDAO 0-6 kg e=d=0.002 kg 6-15 kg e=d=0.005 kg TARA T= -1 kg Min. 0.04 kg

<REG.> MANU. WEIGH 01.06.02 17:45

TARE kg $/ kg kg $

ZERO

P-TARE

% TARE

PREPACK

ENTER THE PLU #

CAPACIDAO 0-6 kg e=d=0.002 kg 6-15 kg e=d=0.005 kg TARA T= -1 kg

PRECIO UNITARIO $/kg

0 . 0 0 0

P L U

#

0 0 0 0 0 0

REG. M/D R/W

PRECIO TOTAL $

P

Max 15 kg

Max 15 kg

Min. 0.04 kg

000000 P 0.000 0.000

10- 3

Page 29

11. DAILY MAINTENANCE

EO1-31009

11.1. Cleaning

11. DAILY MAINTENANCE

Please clean the machine every day after the business hour finished so t hat you can always obtain

satisfactory performance of t he machine. Since the print head and the platen easily get dirt y, cleaning

is recommended whenever the media is replaced.

1. Do not pour water over t he scale or wipe it with soaked cloth. If water enters into the machine

inside, a fire or electric shock may occur.

2. Be sure to turn of f the power before cleaning. Failure to do this m ay cause a f ir e or electric shock.

3. Do not use thinner or benzine f or cleaning, as this may cause a fire.

4. Do not touch the print head or around it just after printing. You m ay get bur ned as the print head

becomes very hot during printing.

CAUTION!

1. Do not use a sharp object for cleaning the print head or platen. Doing so may damage them ,

causing a print failure or machine failur e.

2. Do not use thinner or benzine f or cleaning. Doing so may cause a print failure, machine failur e, or

discoloration.

3. Do not touch the print head element, as static electricity may dam age the print head.

4. Care must be taken not to give excessive pressure or shock to the platter and oper at ion panel.

Doing so may cause a machine failure.

5. Do not scratch or dam age t he operation panel with a sharp or hard object. Doing so may cause a

machine failure.

WARNING!

11.1 Cleaning

11.1.1 Print Head

1. Turn off the power switch.

2. Pull out the label cassette.

3. Clean the print head element (shaded par t in the figure below) with a print head cleaner enclosed

with the scale.

NOTE: Please purchase the print head cleaner (P/No. 24089500013) from your authorized TOSHIBA

TEC service representative.

Print Head Element

Print Head

Label cassette

Print Head Cleaner

11- 1

Page 30

11. DAILY MAINTENANCE

EO1-31009

11.1. Cleaning

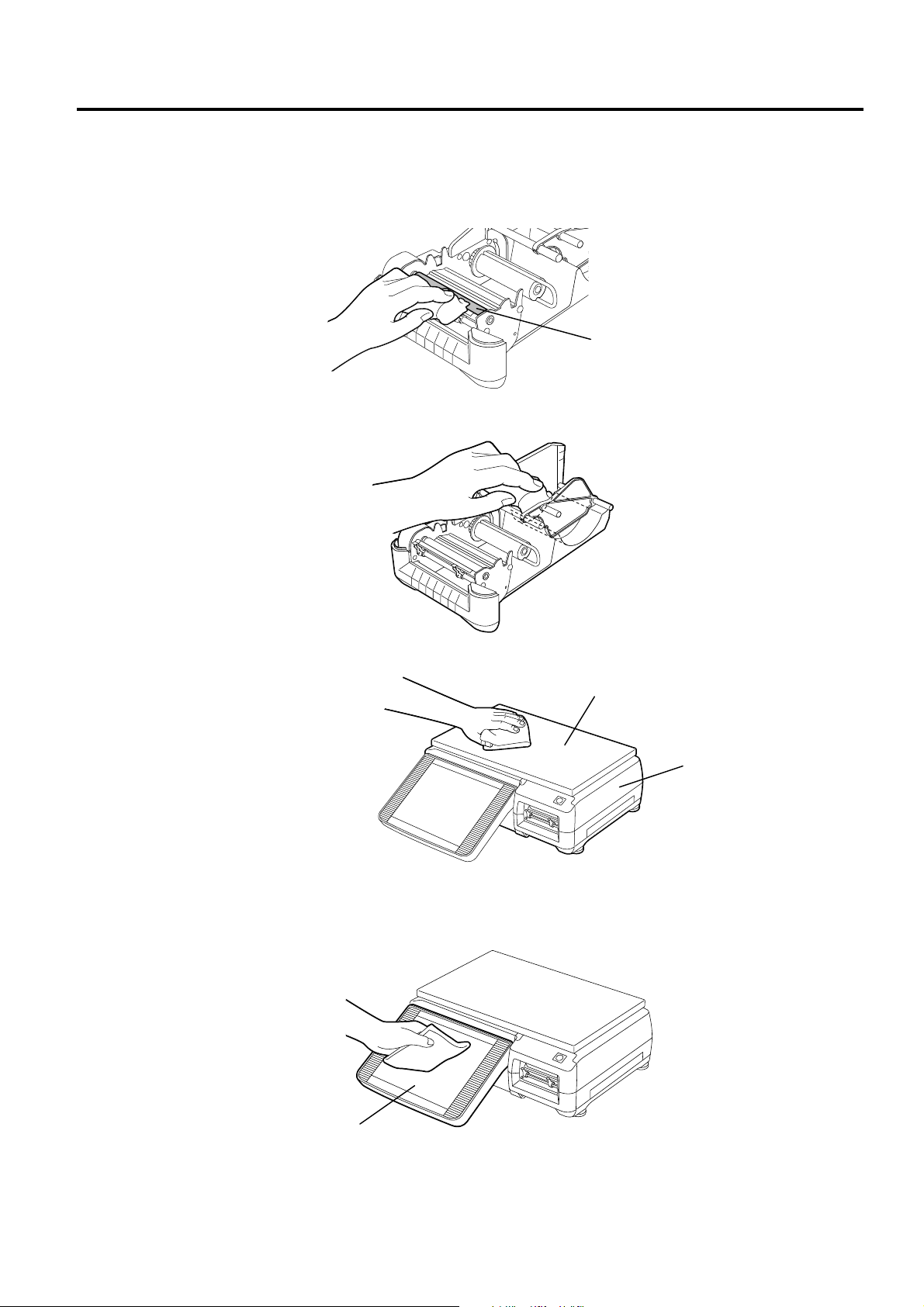

11.1.2 Platen and Media Roll Holder

1. Turn off the power switch.

2. Pull out the label cassette and remove the media roll.

3. Wipe the platen with a soft cloth slightly moistened with alcohol.

4. Wipe out any dust or paper particles f r om t he media roll holder with a slightly moistened soft clot h.

Platen

11.1.3 Covers and Platter

1. Turn off the power switch.

2. Wipe the covers and platter with a dry soft cloth. For dirty parts, use a slightly moistened soft cloth.

11.1.4 Operation Panel

1. Turn off the power switch.

2. Wipe the surface of the operation panel wit h a dr y sof t cloth. For dirty parts, use a com m ercially

available OA cleaner.

Platter

Cover

Operation Panel

11- 2

Page 31

11. DAILY MAINTENANCE

11.2. Removing the Jammed M edi a

EO1-31009

11.2 Removing the Jammed Media

1. Turn off the power switch.

2. Pull out the label cassette.

CAUTION!

Do not push down or hit the print head block, as this m ay cause a m achine f ailur e.

3. Remove the jammed media.

4. Re-load the label roll correctly, and push the label casset t e into the scale with the top edge of the

label protruding from the media outlet . (Refer to Section 8. Loading/Replacing the M edia. )

Print Head Block

Label Cassette

Label Cassette

11- 3

Page 32

11. DAILY MAINTENANCE

11.3. Media Guide Adjustment

EO1-31009

11.3 Media Guide Adjustment

When the label skews in the strip mode, adjust the media guides so that a 1-mm clearance is given

between each guide and the backing paper edge.

1. Set the left side media guide at 2 mm from the left end. If t he media guide touches the backing

paper, move it left for about 1 mm.

2 mm

2. Set the right side media guide at about 1 mm f rom the right edge of the backing paper.

Right Side Media Guide

Left Side Media Guide

11- 4

Page 33

12. PC CARD HANDLING

12.1. Inserting the PC Card

EO1-31009

12. PC CARD HANDLING

This scale allows a use of commercially available PC cards (conforming to Types I to III). Regarding

the available PC card types, please refer to your TO SHI BA TEC service representative.

In this section, how to insert or eject a PC car d is descr ibed.

CAUTION!

1. Do not insert or eject a PC car d while the scale power is on. Doing so may destroy the data stor ed

in the PC card or PC card itself.

2. Do not eject a PC card or t ur n off the power while the PC card is being accessed. Doing so may

destroy the data stored in the PC card or PC card itself.

NOTES: 1. PC cards of Type I to Type III conforming to PCMCIA2.1JEIDA4.2 are available. However,

two Type III PC cards cannot be used at the same time.

2. For details of PC card handling, please refer to each PC card’s instruction.

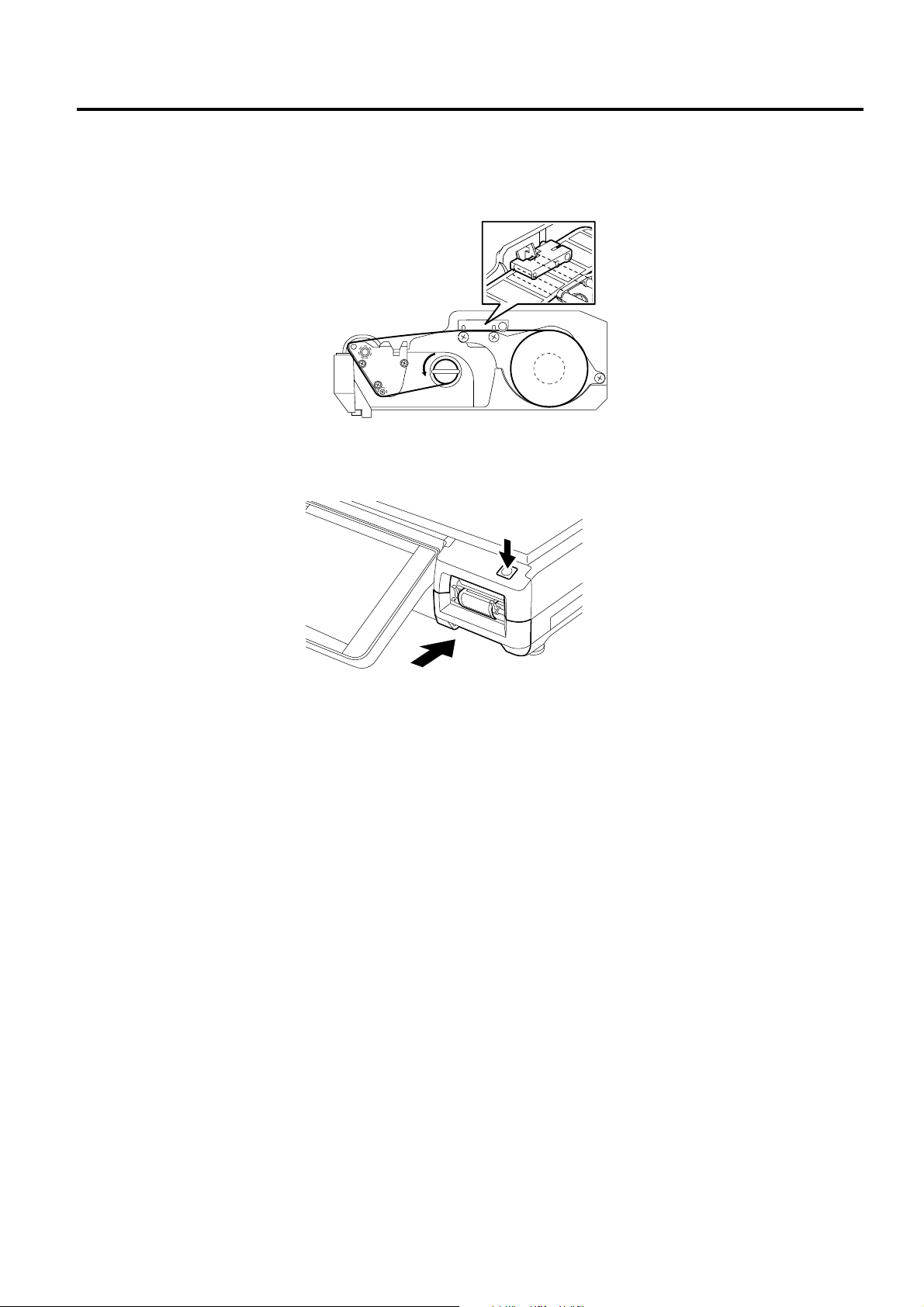

12.1 Inserting the PC Card

1. Turn off the power switch, and open t he int er face cover by pushing the portion indicated by the

arrow.

2. Hold the PC card so that the front side f aces up and t he arrow mark points to the card slot, and

slowly insert it into the slot until it st ops.

PC Card Slot

3. Turn on the power switch.

Interface Cover

Arrow

Mark

PC Card

12.2 Ejecting the PC Card

1. First, make sure that t he PC car d is not being accessed, then, turn off the power swit ch.

2. Press the eject button and the PC card will pop out of t he card slot. Pull it out straight.

Eject Button

PC Card

12- 1

Page 34

13. OUTLINE OF MAIN MENU

13. OUTLINE OF MAIN MENU

EO1-31009

13. OUTLINE OF MAIN MENU

This section outlines the main menu of this scale.

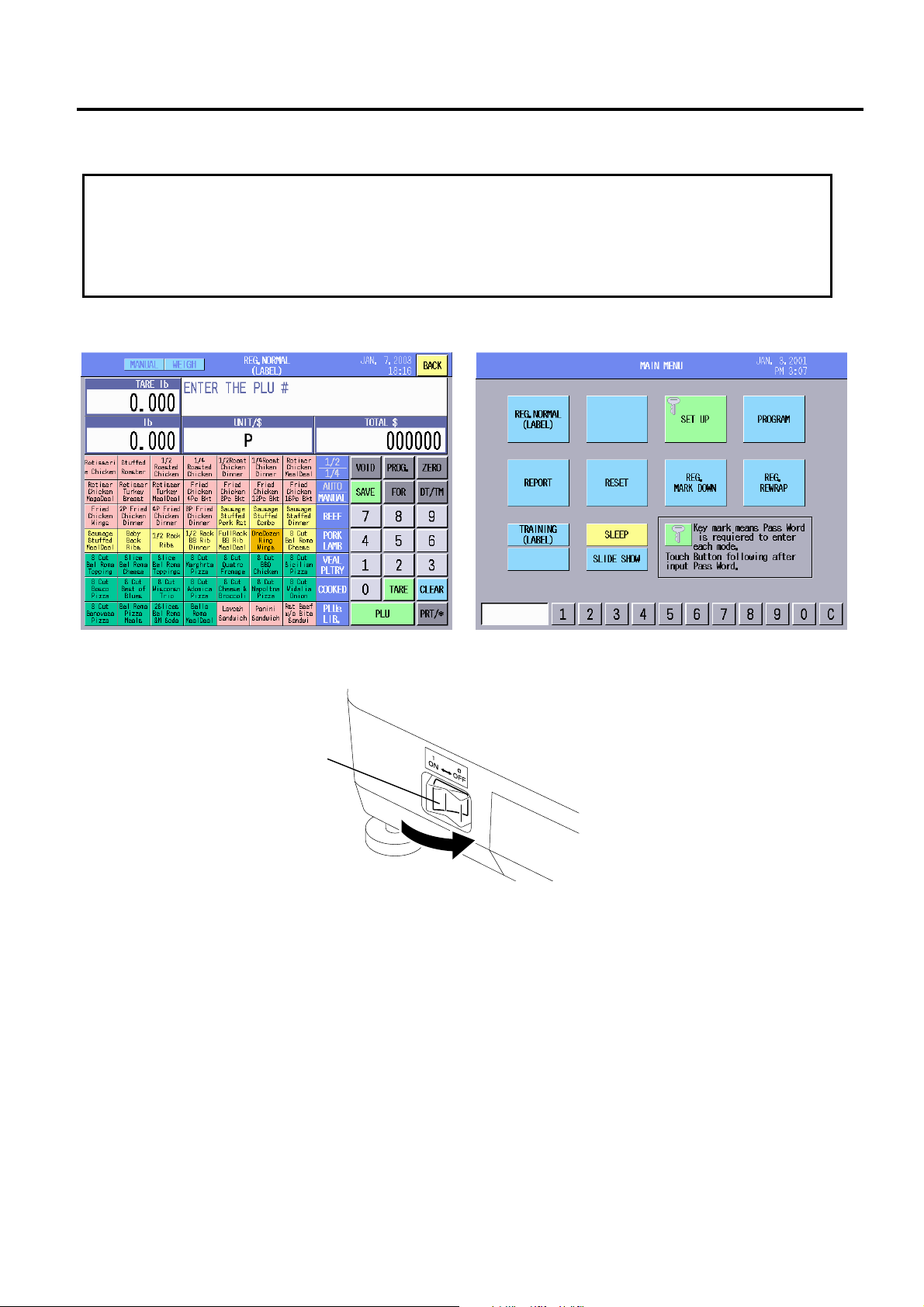

1. After turning on the power switch, the operation panel will show the last screen of Regist r ation

Mode that was used just before the power off. It takes about 15 seconds.

2. Touching the [BACK] key causes the main menu to appear. Select t he desir ed m enu by touching

its key.

1

4

9

8

10

5

2

3

7

6

13- 1

Page 35

13. OUTLINE OF MAIN MENU

13. OUTLINE OF MAIN MENU

EO1-31009

The following table describes the contents of the m ain m enu and t heir functions.

Key Mode Function Refer to

1 REG.NORMAL

(LABEL)

In this mode, you can perform daily operat ions, such as,

weighing commodities, calling the registered PLUs, and

Section

16

issuing the desired number of labels. You can also change

the PLU data, select the print item s, and adjust the feed

amount, sensor sensitivity, and print tone.

2 SET UP In this mode, you can set the date/time, print items, label feed

amount, sensor sensitivity, print tone, label format, bar code

Section

15

types, print titles, password, et c. You can also read/write data

from/to the PC card.

3 PROGRAM In this mode, you can program the various settings required for

the daily operation, such as, unit price, ingredient, commodity

Section

14

name, message, store name and address, t are, SFKC, etc.

4 REPORT In this mode, you can check the total memory or issue the X

report of the totals registered in Registration Mode (NORMAL,

MARK DOWN, REWRAP). Also, it is possible t o send t he

registered data from the satellite scales to the master scale.

Section

19

5 RESET In this mode, you can r eset the total memory, issue the Z

report of the totals registered in Registration Mode (NORMAL,

MARK DOWN, REWRAP).

6 REG. MARK DOWN In this mode, the prices are reduced f r om the usual prices.

The transaction data in this mode will be stored separat ely

Section

17

from the Registration NORMAL (LABEL) Mode.

7 REG. REWRAP In this mode, rewrapped products are registered. The

transaction data in this mode will be stored separately from the

Section

18

Registration NORMAL (LABEL) Mode.

8 TRAINING (LABEL) This mode is a training mode intended for operators to lear n

how to operate this scale. Any operations performed in this

Section

20

mode will not change the data in the memor y.

9 SLEEP This is an energy saving mode that may be used when the

machine is not used for a long time.

10 SLIDE SHOW In this mode, programmed image data is displayed on the

operation panel.

Section

21

Section

22

The modes protected by the password are displayed with a key symbol. To enter these modes, first

input the password with the numeric keys, then touch the desired menu key.

NOTE: The Set Up mode has been protected by the initial settings. To enter the Set Up mode, t he mast er

password is required. For details, please contact the nearest TOSHIBA TEC service representat ive

or sales agent.

13- 2

Page 36

14. PROGRAMMING MODE EO1-31009

14. PROGRAMMING

MODE

14. PROGRAMMING MODE

In the Programming Mode, you can program various data required for the daily operation.

The following Programming Mode Main Menu screen will appear when the [PROGRAM] key of the

main menu is touched.

Programming Mode Main Menu screen

Numeric

Display area

The following keys will be used throughout the Programming Mode. As many other keys appear on the

screens hereinafter, refer to the following sections.

Key Functions

Key Function

BACK Used to return to the previous screen.

0 - 9 Used to input numeric data. The input number is displayed on the Numeric window on

the left side of the “1” key.

C Used to clear the input numeric data.

Used to scroll the screen.

Menu

PLU data

Department

Ingredient

Nutrition

Recipe

Grade line

............................

........................

...........................

.............................

...............................

..........................

Message/Information

Store name/address

Scrolling message

...........

..............

Combination report/reset

NOTE: The DLL (LAN) key is not displayed unless the scale is set t o be t he mast er. Ref er to the Inline

(LAN) mode for how to set the scale to the master.

Section 14.2 Vendor

Section 14.3 SFKC

Section 14.4 Idiom

Section 14.5 Confirmation Label

Section 14.6 Promotion

Section 14.7 Schedule............................. Section 14.17

.........

Section 14.8 Inline (LAN)

Section 14.9 DLL (LAN)

Section 14.10 Operator’s Hint

...

Section 14.11 Unit Price Change

................................

..................................

...................................

..............

............................

........................

..........................

....................

...............

Section 14.12

Section 14.13

Section 14.14

Section 14.15

Section 14.16

Section 14.18

Section 14.19

Section 14.20

Section 14.21

Back key

Scroll Bar

Clear key

Numeric keys

14- 1

Page 37

14. PROGRAMMING MODE EO1-31009

14.1 Edit Screen

14.1 Edit Screen

The Edit screen will appear when setting commodity names, department names, ingredient, nutrition

facts, recipe, grade lines, store messages, store name, address, vendors, etc. It can be used like a PC

keyboard.

Specified Code

Alphanumeric keys

Shift key

(Upper/Lower)

Bold/Normal key

Insert/Overwrite key

EURO Sign 1

EURO Sign 2

Space key

Key Functions

Key Function

Alphanumeric keys Used to input alphabets, numbers, and symbols.

Shift (upper/lower) Used to switch the case between the upper cases and the lower cases.

Bold/Normal Used to switch the font style between norm al and bold f ace.

Font style is not changed per character, but per line.

Insert/Overwrite Used to switch the typing mode between the insert and overwrite.

Space Used to insert a space.

Back space Used to delete the character in front of the cursor.

ENTER Used to add another line.

Used to move the cursor.

Del. Used to delete the selected character.

EURO Sign 1

EURO Sign 2

Used to show European characters or symbols.

Euro Sign 1 Euro Sign 2

Cursor

Del. key

Cancel key

Back Space key

Enter key

Cursor keys

Idiom key

Paste key

Copy key

Cancel Used to cancel the entry.

Copy Used to choose the character(s) to be copied. Touch this key when the cursor

is on the first and last characters of t he copy r ange.

Paste Used to paste the copied characters to the position of the cursor.

Idiom Used to call the idiom list (list of frequently used words)

14- 2

Page 38

14. PROGRAMMING MODE EO1-31009

14.1 Edit Screen

NOTES: 1. How to copy and paste

(1) Move t he cur s or t o the first character of the copy r ange, and then touch the [Copy]

key.

(2) Move t he cur s or t o the last character of the copy range, and t hen touch the [Copy]

key.

The copy range is shaded.

(3) Move t he cur s or t o the position where the selected copy range is pasted, and then

touch the [Paste] key.

(4) The selected copy r ange is copied.

2. How to apply boldface

Move the cursor to the line where bold is applied, and t he t ouch the [Bold] key. The

applied line is displayed in red.

3. Idiom

When the [Idiom] key is touched, the I diom list will appear. Select the desired idiom by

touching its area. Regarding the Idiom set t ing, r ef er to Section 14.14.

Idiom area

14- 3

Page 39

14. PROGRAMMING MODE

14.2 PLU Data Setting

EO1-31009

14.2 PLU Data Setting

A PLU (Price Look Up) includes not only a commodity name, but unit price, tare, shelf life, nutrition

facts, ingredient, etc. You can progr am or change the PLU data with this menu.

The following screen will appear when the [PLU data] key of the Programming Mode Main Menu is

touched. Since this menu consists of 3 screens, change the scr een wit h t he scroll key.

First screen

PLU No. and Dept. No. area

AUTO CODE area

MODE FLAG area

WEIGH

FIX

BY-COUNT

TARE LIMIT area

Key Functions

PLU# Used to call a registered PLU data.

Comm. Short Used to shorten the PLU’s commodity name. The shortened names are used as

PLUs Lib. Used to call the index of the commodity names.

ADD Used to add a new PLU.

NEXT PLU Used to call the PLU of next number.

LAST PLU Used to call the PLU of preceding number.

COPY Used to copy the PLU data to a new PLU.

DELETE Used t o delete the PLU data.

CHANGE PLU# Used to change the PLU No.

Commodity Name Area

Unit Price area

1ST. PRICE

2ND. PRICE

(Unused)

PIECES

Unit Price Flag area

per lb

per 1/2lb

per 1/4lb

per 1kg

per 100g

Tare area

PLU TARE

% TARE

COMPULSORY

YES or NO key

CHANGE PLU# key

DELETE key

COPY key

PLU# key

PLUs Lib. key

Comm. Short key

LAST PLU key

NEXT PLU key

ADD key

Key Function

the speed key names in SFKC setting.

14- 4

Page 40

14. PROGRAMMING MODE

Procedure

Item Procedure

Adding a new PLU 1. Input a new PLU No. (max. 6 digits)

2. Touch the [ADD] key.

NOTE: The top 2-digit number is the department No. There is no zero

suppression.

Calling a registered PLU 1. Input the PLU No. (max. 6 digits ) wit h the numeric keys.

2. Touch the [PLU#] key.

Commodity name 1. Touch the Commodity Name area.

2. The Edit screen will appear.

3. Edit a commodity name (max. 32 char act ers by 4 lines).

EO1-31009

14.2 PLU Data Setting

Making the commodity

name shorter

To shorten a single PLU’s name:

1. Call the PLU.

2. Touch the [Comm. Short] key.

3. The sub screen will appear.

4. Touch the [Single] key.

To shorten the all PLU names:

1. Touch the [Comm. Short] key.

2. The sub screen will appear.

3. Touch the [ALL] key.

NOTES:

1. A PLU name is shortened to 24 characters max.

2. The shortened commodity name is displayed in the Shortened commodity

name area. The commodity names can be also shortened by manual entry.

(Refer to the second screen on page 14-8.)

14- 5

Page 41

14. PROGRAMMING MODE

Item Procedure

14.2 PLU Data Setting

EO1-31009

Auto Code,

UPC

To set the auto code:

1. Touch the Auto code area.

2. The auto code setting screen will appear.

3. Input an Auto code (max. 6 digits).

4. Touch the [Decision] key.

To set the UPC:

1. Input a UPC (max. 6 digits).

2. Touch the UPC area.

Decision key

Asterisk key

NOTES:

1. Default: 000000

2. When the auto code has been entered, the UPC will become the same

number with the auto code.

3. When asterisks (*) are included in the auto code, the input code for UPC

can displace them, selected from the lowest digit. See t he examples below.

Example 1: Auto code = 123***, Input code for UPC = 6543

Example 2: Auto code = 98**54, Input code for UPC = 0211

Unit price 1. I nput a 4-digit number.

2. Touch the “1

st

Price” area.

nd

NOTE: The 2

Price cannot be used at present.

Unit price flag In case of the lb scale (US model):

Select “per 1lb”, ‘per 1/2 lb”, or “per 1/4lb”.

In case of the kg scale (CA model):

Select “per 1kg” or “per 100g”.

NOTE: Only “per 1kg” is selectable unless the initial settings are changed.

When “per 100g” is required, please contact the nearest TOSHIBA TEC

service representative or sales agent.

Mode flag Select “WEIGH”, “FIX”, or “BY-COUNT”.

NOTE: When “BY-COUNT” is selected, t he “ PI ECES” ar ea will need a

numeric data. Input the number for the “PIECES” area.

14- 6

Page 42

14. PROGRAMMING MODE

Item Procedure

14.2 PLU Data Setting

EO1-31009

Tare,

%Tare

Input a numeric data (max. 2lb for lb scale, 1kg for kg scale, or 99.9%

for %Tare).

NOTES:

1. With the initial settings, Preset tare and %Tare function is not available.

When these functions are required, contact the nearest TOSHIBA TEC

service representative or sales agent.

2. %Tare data exceeding the tare limit results in an error.

3. When the NET statement labels are to be issued, enter the net weight (0 –

480 oz) to the PLU tare area.

Tare Limit 1. Input a numeric data in the following range:

Lb scale: 0.000 – 2.000lb (Default: 2.000lb)

Kg scale: 0.000kg – 1.000kg (Default: 1.000kg)

2. Touch the Tare Limit area.

3. The confirmation screen will appear.

4. Touch the [Go] key to enter the data. To cancel, touch the [Cancel]

key.

NOTES:

1. With the initial settings, this funct ion is not available. When this function is

required, contact the nearest TOSHIBA TEC service representative or sales

agent.

2. If the actual tare exceeds the tare limit, an error occurs.

Compulsory tare

subtraction

Select YES or NO.

YES: Tare subtraction is compulsory.

NO: Tare subtraction is not compulsory.

NOTE: With the initial settings, YES cannot be selected. When this function

is required, contact the nearest TOSHIBA TEC service representative or

sales agent.

14- 7

Page 43

14. PROGRAMMING MODE

Second screen

SHELF LIFE area

PROMOTION area

LOGO area

LOGO1

LOGO2

LOGO3

Coupon LOGO

SAFE HANDLING area

OPERATOR’S HINT area

Procedure

Item Procedure

14.2 PLU Data Setting

Shortened Commodity Name area

EO1-31009

Relish area

FSP area

Discount $

Discount %

Bonus LOGO

FSP LOGO

GRADE LINE area

Shelf Life 1. Input a numeric data (max. 999 days).

2. Touch the “SHELF LIFE” area.

Relish 1. Input a numeric data (max. 999 days).

2. Touch the “RELISH” area.

Promotion 1. Input a sales promotion number. (1 – 99)*

2. Touch the PROMOTION area.

Or,

1. Touch the PROMOTION area.

2. The promotion list will appear.

3. Select the desired promotion number.

For details of the sales promotion, ref er to Section 14.16.

Grade Line 1. Input a grade line number (1 – 99)*.

2. Touch the GRADE LINE area.

Or,

1. Touch the GRADE LINE area.

2. The grade line list will appear.

3. Select the desired grade line from the list .

For details of the grade line, refer t o Section 14.7.

Operator’s Hint 1. Input an operator’s hint number ( 1 – 99) *.

2. Touch the OPERATOR’S HINT area.

Or,

1. Touch the OPERATOR’S HINT area.

2. The operator’s hint list will appear.

3. Select the desired operator’s hint fr om the list.

For details of the operator’s hint, r ef er to Section 14.20.

*: To clear the entered number, input “0”.

14- 8

Page 44

14. PROGRAMMING MODE

Item Procedure

FSP (Frequent Shoppers) To set the sale promotion schedule No.:

1. Input a schedule No. (1 – 99)*

2. Touch the FSP schedule area.

Or,

1. Touch the FSP schedule area.

2. The schedule list will appear.

3. Touch the desired schedule from the list.

For details of the schedule, refer to Sect ion 14.17.

To set the discount amount:

1. Input a numeric data (max. 999.99).

2. Touch the Discount area (left side).

To set the discount rate:

1. Input a numeric data (max. 99.9%).

2. Touch the Discount area (right side).

NOTES:

1. With the initial settings, the FSP function is not available. When this

function is required, contact the nearest TOSHIBA TEC service

representative or sales agent.

2. For the BONUS logo and FSP logo settings, refer to the NOTES for the

LOGO setting on the following page. However, the logo print area is limited

to the following size:

104 dots

118 dots

256 dots

3. The Bonus logo’s print area is shared by LOGO 3. Usually LOGO 3 takes

precedence over the Bonus logo except during the FSP schedule time

range.

4. The FSP logo’s print area is shared by Coupon logo. Usually Coupon

logo takes precedence over the FSP logo except during the FSP schedule

time range.

64 dots

EO1-31009

14.2 PLU Data Setting

Shortened Commodity

Name

1. Touch the Shortened commodity name area.

2. Input a short commodity name ( m ax. 24 characters) on the Edit

screen.

NOTE: When the commodity name is shortened by using t he [Comm.

Short] key, the first 24 characters of the commodity name are

automatically displayed in the Shortened commodity name area.

*: To clear the entered number, input “0”.

14- 9

Page 45

14. PROGRAMMING MODE EO1-31009

14.2 PLU Data Setting

Item Procedure

LOGO 1. Input a logo number (0000 – 9999)

2. Touch the LOGO area.

Or,

1. Touch the LOGO area.

2. The logo list will appear.

3. Select the desired logo number

from the list.

NOTES:

1. Max. 3 logos can be set to one PLU.

2. Logos can be called only from the flash memory card (ATA card).