Page 1

TEC Software Solution

SCALE VIEW V4

Owner’s Manual

Original Oct, 2004

(Revised )

TEC

Document No. OM-SW4

TOSHIBA TEC AMERICA RETAIL INFORMATION SYSTEMS, INC.

Page 2

TOSHIBA TEC AMERICA RETAIL INFOMATION SYSTEMS, INC. provides this publication as is without

warranty of any kind, either expressed or implied. This publication could include

technical inaccuracies or typographical errors. Changes are periodically made to the

information herein; these changes will be incorporated in new editions of the publication.

TOSHIBA TEC AMERICA RETAIL INFOMATION SYSTEMS, INC. may make improvements and/or changes in

the product(s) and/or program(s) described in this publication at any time.

Last Revised October 15, 2004

Page 3

Table of Contents

Getting Started

Creating the Databases ........................................................................................................1

PLU Maintenance Form ........................................................................................................2

Data Maintenance

PLU Maintenance

Add New PLU..................................................................................................................3

Saving PLU’s...................................................................................................................4

Editing PLU’s...................................................................................................................4

Delete a PLU ...................................................................................................................5

Ingredient Maintenance

Add/Enter Ingredients......................................................................................................6

Search Function...............................................................................................................8

Maximum Characters per Line.........................................................................................9

Insert Function.................................................................................................................9

Copy Current SL9000 Ingredient to SL5300 Ingredient Number ...................................10

Add New SL5300 Ingredient Number ............................................................................10

Import Ingredient Message............................................................................................10

Saving Ingredients.........................................................................................................11

Deleting Ingredients.......................................................................................................11

Nutrition Maintenance

Edit SL9000 Nutrition Message .....................................................................................12

Edit SL5300 Nutrition Message .....................................................................................13

Nutrition Templates........................................................................................................14

Search Nutrition Numbers..............................................................................................14

Add Nutrition Numbers................................................................................................... 14

Import Nutrition Numbers...............................................................................................14

Saving Nutrition Messages............................................................................................15

Deleting Nutrition Messages..........................................................................................15

Scheduled Batches

Send All Batches................................................................................................................. 16

Delete an Individual PLU.....................................................................................................16

Delete Multiple PLU’s..........................................................................................................17

Delete an Individual Ingredient Number (SL5300 Only)......................................................18

Delete a Range of Ingredient Numbers (SL5300 Only).......................................................18

Delete an Individual Nutrition Number (SL5300 Only).........................................................19

Delete a Range of Nutrition Numbers (SL5300 Only) .........................................................19

i

Page 4

Table of Contents

Main Menu

Sort/Search Database.........................................................................................................20

Sending Batches.................................................................................................................20

Set Back Function...............................................................................................................21

View ....................................................................................................................................22

Log......................................................................................................................................22

Reports

PLU Price Report...........................................................................................................23

PLU Detail Report..........................................................................................................23

PLU SPrice Report ........................................................................................................24

SL9000 Reports

PLU/Nutri Batch Report .................................................................................................24

SL9000 Ing Report.........................................................................................................25

SL9000 Nutr Report.......................................................................................................25

SL9000 Ing Batch Report...............................................................................................26

SL5300 Reports

SL5300 Ing Report.........................................................................................................26

SL5300 Nutr Report.......................................................................................................27

SL5300 Ing Batch Report...............................................................................................27

SL5300 Nutr Batch Report.............................................................................................28

SL5300 PLU Ingr No Report..........................................................................................28

SL5300 Nutr No Report .................................................................................................29

Error Messages.......................................................................................................................31

ii

Page 5

Scale View V4.0 Owner’s Manual

Getting Started

Getting Started

Creating the Databases

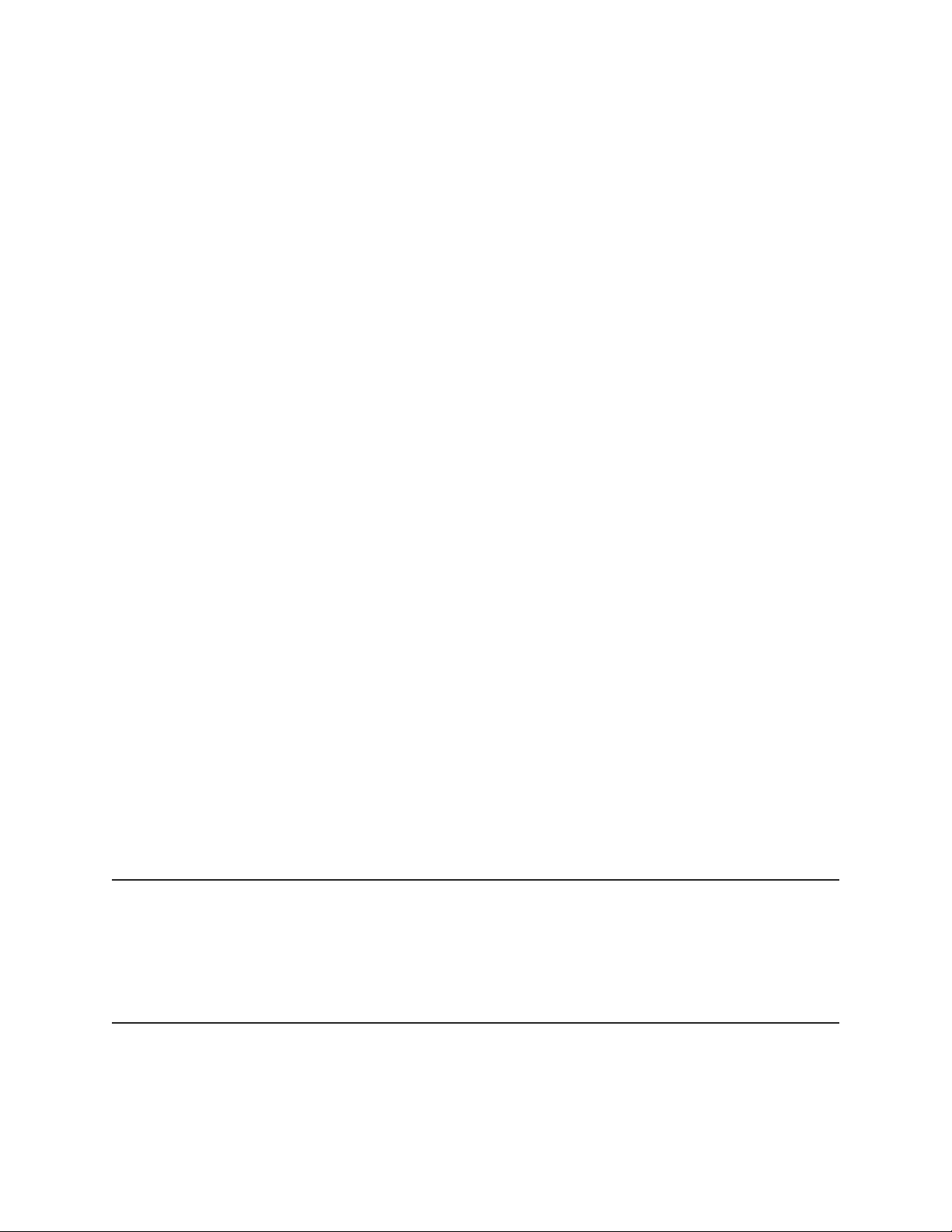

When Scale View is installed the PLU, Ingredient and Nutrition databases are empty. The

screen below shows an empty PLU database.

The PLU, Ingredient or Nutrition databases can be created by either of the following methods:

1.) Uploading and then Importing the information from one scale or any number of

scales.

Note: This method should only be performed by the installing TEC Dealer.

2.) Manually inputting the information using the appropriate data maintenance form

The Upload and Import method is usually used during the initial installation and setup of the

software. If you have had your software installed and the databases are not populated and you

wish to use the Upload and Import method to populate them, please contact your authorized

TEC Dealer.

If you simply wish to add or change information in your existing database or build the database

from scratch, you should use the appropriate PLU, Ingredient or Nutrition data maintenance

form and input that information manually. To start to build your database from scratch you would

simply “double-click” anywhere below the title PLU Table in the screen above.

18-Oct-04 Page 1

Page 6

Getting Started

Scale View V4.0 Owner’s Manual

PLU Maintenance Form

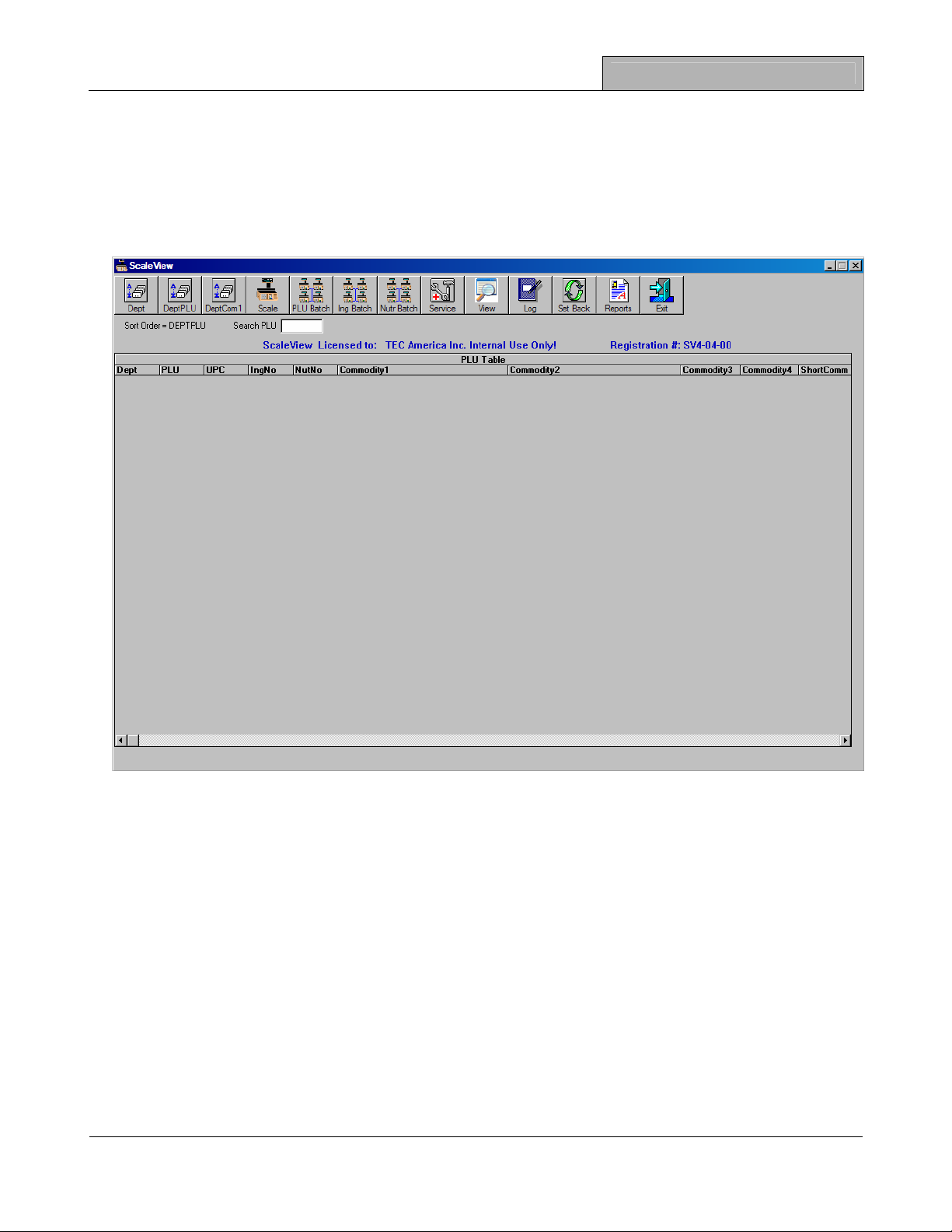

You should see the PLU Maintenance Form shown below. For those of you familiar with other

versions of Scale View you will notice that the PLU Maintenance Form contains some changes.

A lot of these changes have been incorporated to support the new SL5300 Series Scale along

with the SL9000 Series Scales that were previously supported.

You will notice several blue fields. These blue fields are only used by the SL5300 Series Scale.

The fields that are titled in magenta are used only in the SL9000 Series. The fields that are titled

in black are used for both the SL5300 and SL9000 Series Scales. Since you can have both

types of scales, an SL9000 and SL5300 in the same department you may use a combination of

these different colored fields when programming a PLU. Scale View will send the appropriate

information down to the scale based on the scale type.

Also notice that when you place your cursor over a text box you will get a pop up box that gives

you the acceptable format and limitations for that particular field.

Page 2 18-Oct-04

Page 7

Scale View V4.0 Owner’s Manual

Data Maintenance

Data Maintenance

Add New PLU

The Add New PLU button allows you to add a new PLU number to the database.

The status of your PLU database will determine what happens when you press the

Add New PLU button. For example, if your PLU database is empty and you have

just “double-clicked” on the PLU Table screen you will see the PLU Maintenance

Form with PLU Number 000001 with a Commodity Descriptor of ADDNEW and a department

number of 000001. If you depress the Add New PLU button at this moment you will get a pop-up

warning telling you that the PLU has not been saved and asking you if you want to save it. If you

answer YES, the PLU Number 000001 ADDNEW will be saved to the database in department

number 000001. If you answer NO, the PLU Number field will be blanked and the cursor will be

placed in the PLU Number field so you may add a new PLU number to department 000001. If

you “double-click” on the PLU Table screen and you already have PLU’s in your database, you

will be adding a new PLU to the department number of the PLU you “double-clicked” on. If you

press the Add New PLU button at this point, the PLU Number field will blank and the cursor will

be placed there for you to add a new PLU number. Please keep in mind that if you do not want

this new PLU to be in the current department you must change the department number prior to

saving this PLU.

After you have entered a PLU Number enter all the other appropriate information for this PLU.

You may move to the other fields by depressing the TAB key or moving the mouse pointer to

the desired field and clicking there. Notice that some fields have an explanation or limitation

statement at the bottom of the PLU Maintenance Form.

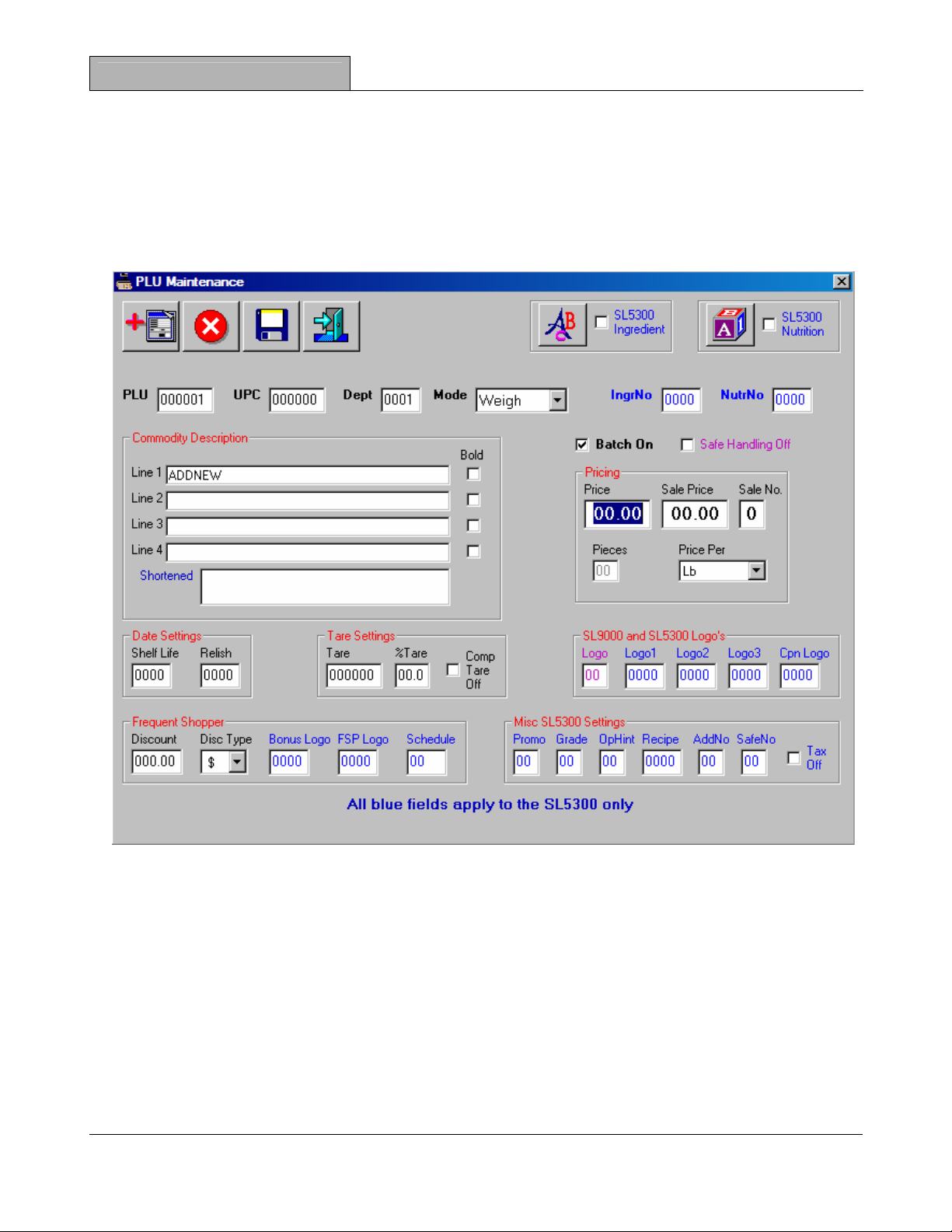

Miscellaneous Field Requirements:

Field Requirement

PLU Price, Sale Price

or Frequent Shopper

Discount Price

These price fields do not require you to enter a decimal point.

They will automatically format the number that is entered to 2

decimal places.

Commodity Line 1 This field must have at least 1 character space entered due to

database sort index requirements. If you attempt to save a

PLU without at least 1 character space entered you will get a

pop up window reminding you of the requirement.

Tare Weight The tare weight field entry must follow the minimum

incremental weighing capacity setup of the scale. For

example, if the scale is setup to weigh 0 – 15 lb in 0.005 lb

increments then the tare weight field must be entered in

increments of 5. If the scale is setup to weigh in 0.01lb

increments then the tare weight should be entered in

increments of 1. Failure to use the correct tare weight

increments will not result in an error during downloading but

will result in a PLU DATA ERROR when recalling the PLU.

Note: If scale types are mixed in a department all scales

must be set to weigh in the same minimum increments.

Ingredient or Nutrition Ingredient or Nutrition information can only be entered if the

PLU has been saved

18-Oct-04 Page 3

Page 8

Data Maintenance

Scale View V4.0 Owner’s Manual

Field Requirement

Unit Price When the unit price of a Weigh Mode PLU is set to $00.00 you

must set the Price Per field to Lb Open. When the unit price of

a By Count Mode PLU is set to $00.00 you must set the

Pieces field to “0” and the Price Per field to Lb Open. Failure

to do this will result in PLU DATA ERROR when recalling

those PLU’s.

Sale Price If the Sale Price field is set to any number larger than $00.00

when downloading the entire PLU file or a PLU Batch to the

scale the Sale Price field will be sent as the unit price. If the

Sale Price is set to $00.00 then the unit price field entry will be

sent to the scale.

Sale Number The software allows for up to 9 different Sale Batches for the

entire PLU database. This feature will be discussed in the Set

Back section of this manual.

Shortened

Commodity Name

This box is only used for the SFKC name on the SL5300. It

has a limit of 24 characters and spaces maximum. It may also

be multiple lines. Keep in mind that a carriage return is

counted as a character.

Batch On/Off Box This box indicates the status of a PLU’s Batch flag. If it is

checked it means the PLU is part of a pending batch. If it is

not checked then the PLU is not part of a pending batch.

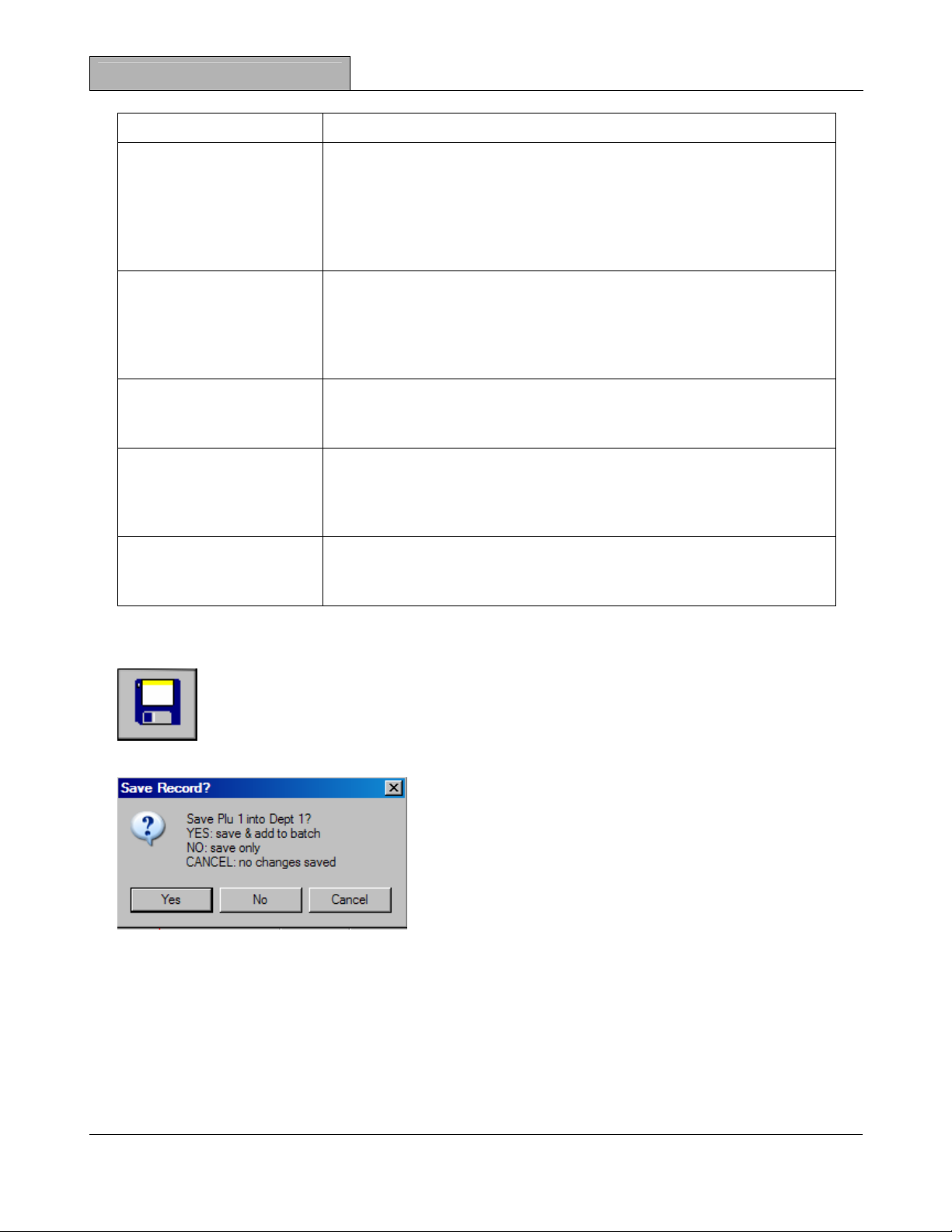

Saving PLU’s

After you have entered all of the appropriate information for a PLU you will need to

save it to the database. This is done by depressing the Save button at the top of

the PLU Maintenance Form. Once you have depressed the Save button you will be

prompted with three options.

If you answer YES, the PLU will be saved to the

database and added to a PLU batch.

If you answer NO, the PLU will be saved to the

database but will not be added to a PLU batch.

If you answer CANCEL then the information you have

programmed will be discarded and the PLU will not be

added to the database.

Editing PLU’s

To edit a PLU, simply “double-click” on the desired PLU in the database. Make the necessary

changes and then click the Save button. When editing the PLU you may change any information

except the PLU number. If the PLU belongs in another department, change the department

number and depress the Save button. You should then delete the original PLU.

Page 4 18-Oct-04

Page 9

Scale View V4.0 Owner’s Manual

Data Maintenance

Keep in mind that you can take advantage of the special features in a scale by using the same

techniques when editing PLU’s in Scale View. For example, if you only place information on

Commodity Line 1 and Commodity Line 3 in a PLU and the total number of characters on each

line is less than 25, the printed Commodity Name will be in large letters.

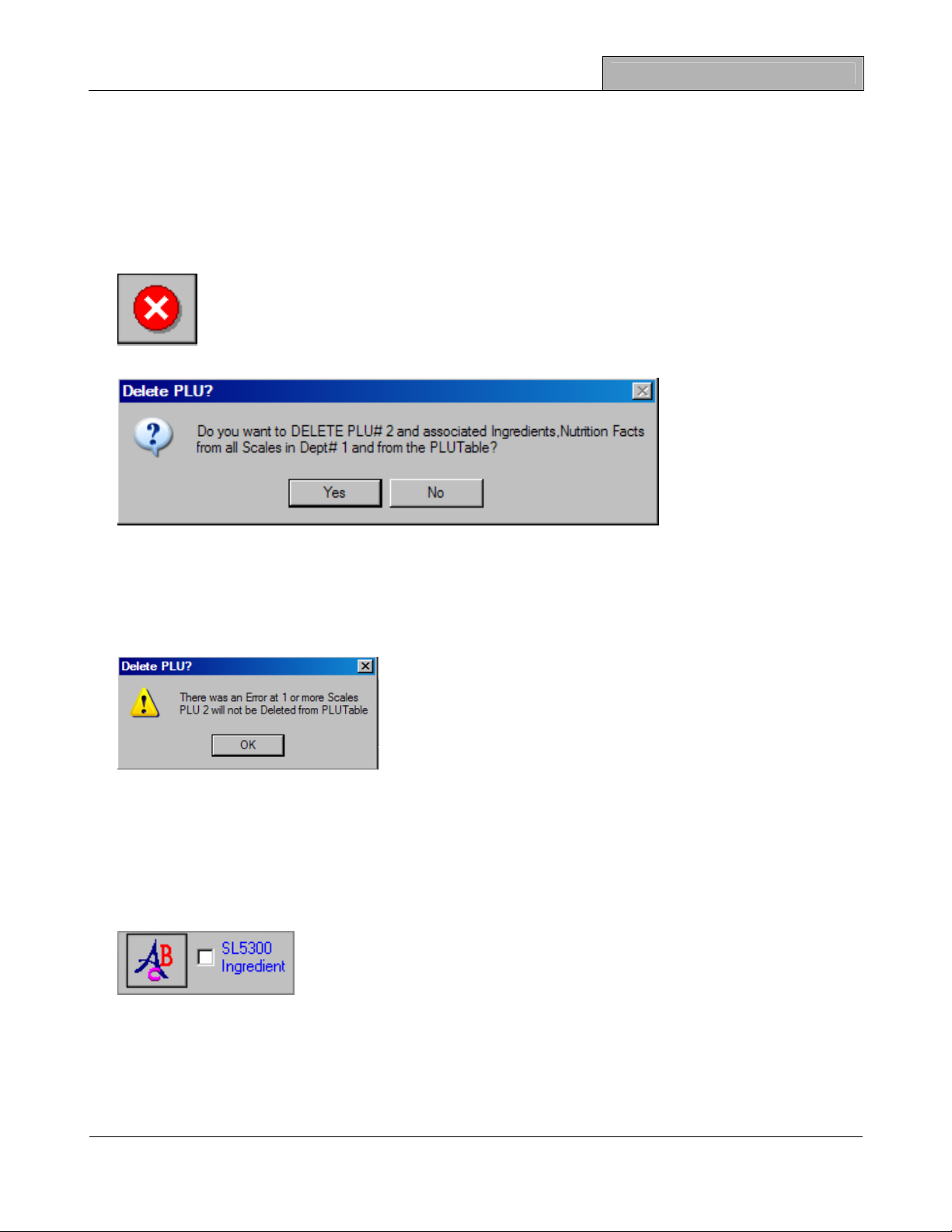

Delete PLU

PLU’s are deleted individually and not by batches when using the Delete PLU

button. To delete a PLU “double-click” on it in the database and the PLU

Maintenance Form will appear. Click on the Delete PLU button and a message box

will appear.

Before you click on YES make sure that the correct PLU has been selected for deletion. The

selected PLU, and its associated Ingredients and Nutrition information (if applicable) will be

deleted from all scales in the department. If communications is successful to all scales in the

department, the PLU and its associated Ingredients and Nutrition information will be deleted

from the database.

If there is any error at any scale with the exception of

“PLU DOES NOT EXIST” the PLU and its associated

Ingredients and Nutrition information will remain in the

database.

Hint: To delete a PLU when there is no scale connected, do not have a scale assigned in the

Scale Table to the same department of the PLU to be deleted.

Ingredient Maintenance

Ingredient Maintenance is performed based on the scale model. The

Edit Ingredient button has a check box on it. If the check box is left

unchecked when you click on it you will be editing an Ingredient

Message for the SL5300 Scale. The SL5300 stores Ingredients

separate from the PLU information and uses Ingredient Numbers (INGRNO). These Ingredient

Numbers may be linked to an Individual PLU or the same Ingredient Number may be linked to

several different PLU’s. There are other unique ingredient maintenance features available that

we will discuss later.

18-Oct-04 Page 5

Page 10

Data Maintenance

Scale View V4.0 Owner’s Manual

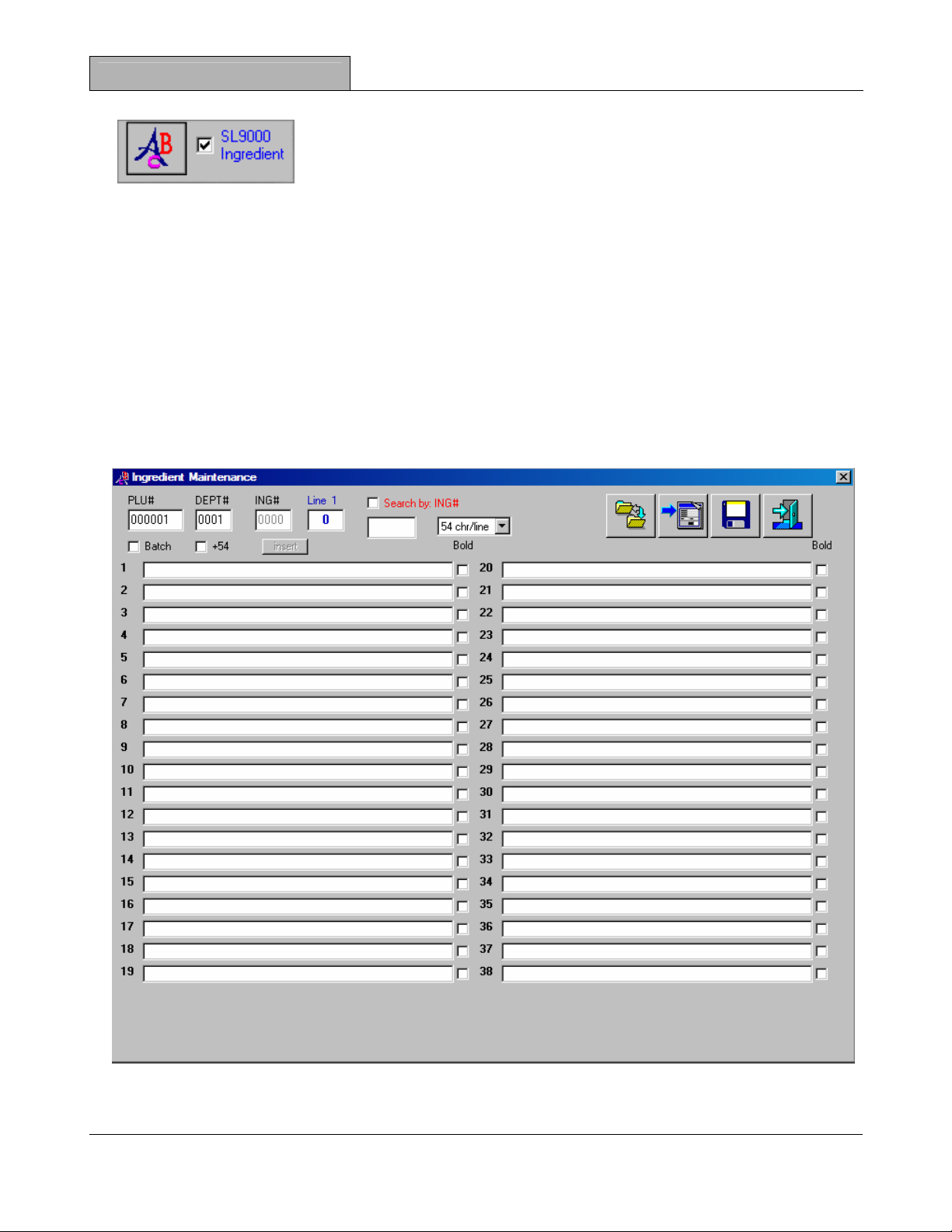

If you click on the check box and then click on the Edit Ingredient

button you will be editing an Ingredient Message for the SL9000 Scale.

An ingredient message that is programmed for a PLU in the SL9000

is automatically attached to the PLU record. The SL9000 does not

use Ingredient Numbers like the SL5300.

Add/Edit Ingredient Messages

The status of the check box next to the Ingredient Edit button will determine the Ingredient Edit

Screen that will appear when the button is depressed. Since there are differences in the

methods of how each scale manages its Ingredient Messages there will also be differences in

these Ingredient Edit screens.

In the SL9000 Ingredient Edit screen shown below you will notice that the Ingredient Number

field is grayed out but the PLU Number and Department Number fields are highlighted.

Remember, in the SL9000 we do not use Ingredient Numbers; the PLU record contains the

Ingredient Message information.

Page 6 18-Oct-04

Page 11

Scale View V4.0 Owner’s Manual

Data Maintenance

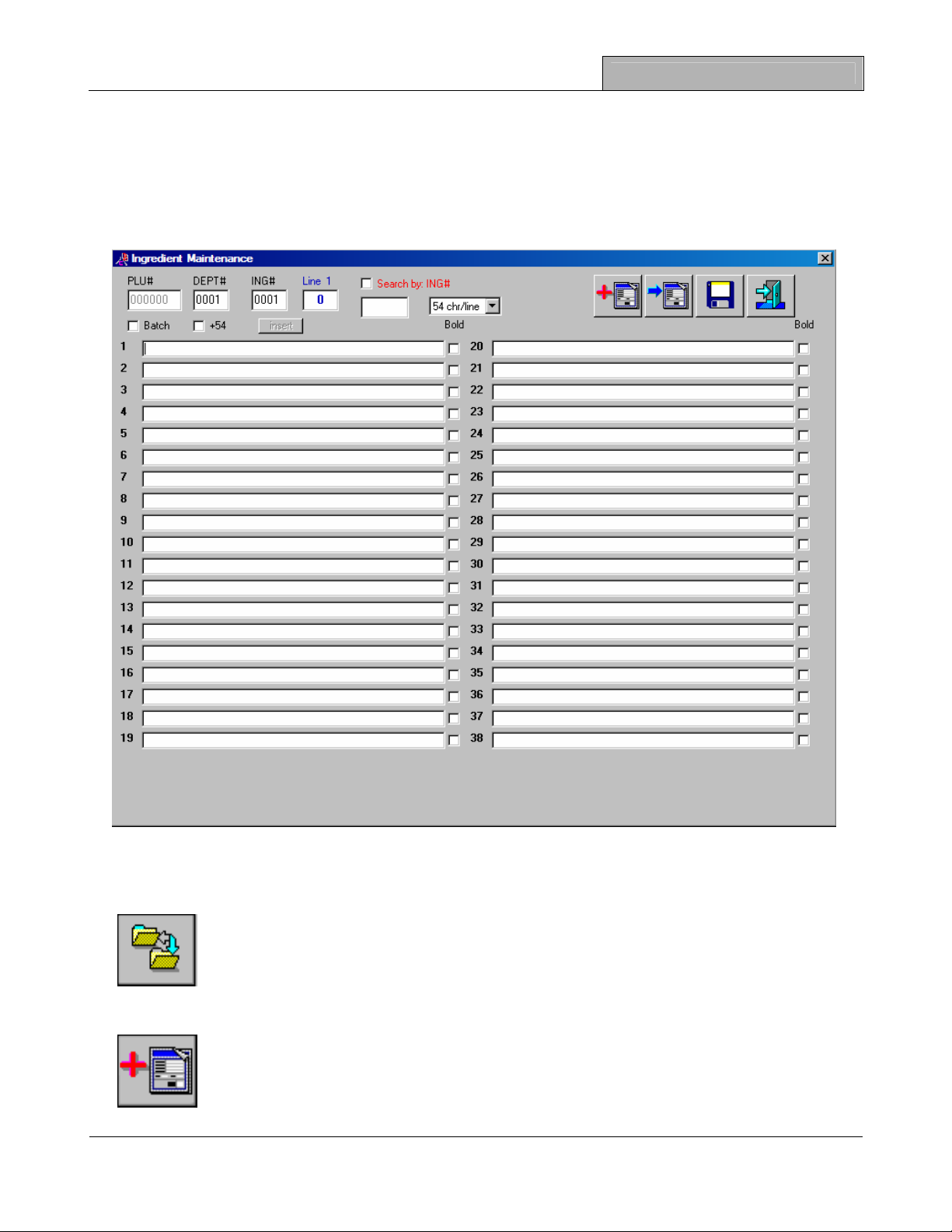

Note that in the SL5300 Ingredient Edit screen the PLU Number is grayed out and the

Department Number and Ingredient Number fields are highlighted. This is because the SL5300

uses the Ingredient Number when storing Ingredient Messages. This Ingredient Number is used

to provide a link in the PLU to the Ingredient Message stored in the Ingredient memory area in

the scale.

The other differences in the Ingredient Edit screens of the SL9000 and the SL5300 are:

Copy Current SL9000 Ingredient Message to Selected Ingredient Number button

This button allows you to copy the SL9000 Ingredient Message that is currently

displayed to an Ingredient Number that will be used in the SL5300. This function

provides an easy way to create Ingredient Messages for the SL5300 from existing

SL9000 Ingredient Messages.

Add New SL5300 Ingredient Number button

This button allows you to create a new SL5300 Ingredient Number. This may be

done without having to assign the message to a PLU number. These functions will

be explained in more detail in the paragraphs to follow.

18-Oct-04 Page 7

Page 12

Data Maintenance

Scale View V4.0 Owner’s Manual

With the exception of the two items mentioned previously, the Ingredient Message Edit Screen

functions are the same for both the SL5300 and the SL9000 model scales. There are some new

features in the Ingredient Message Edit function that make creating and editing Ingredient

Messages much easier. Please keep in mind that even though these new features may be

available for both scale models in Scale View they may not necessarily provide any true

functionality in a particular scale.

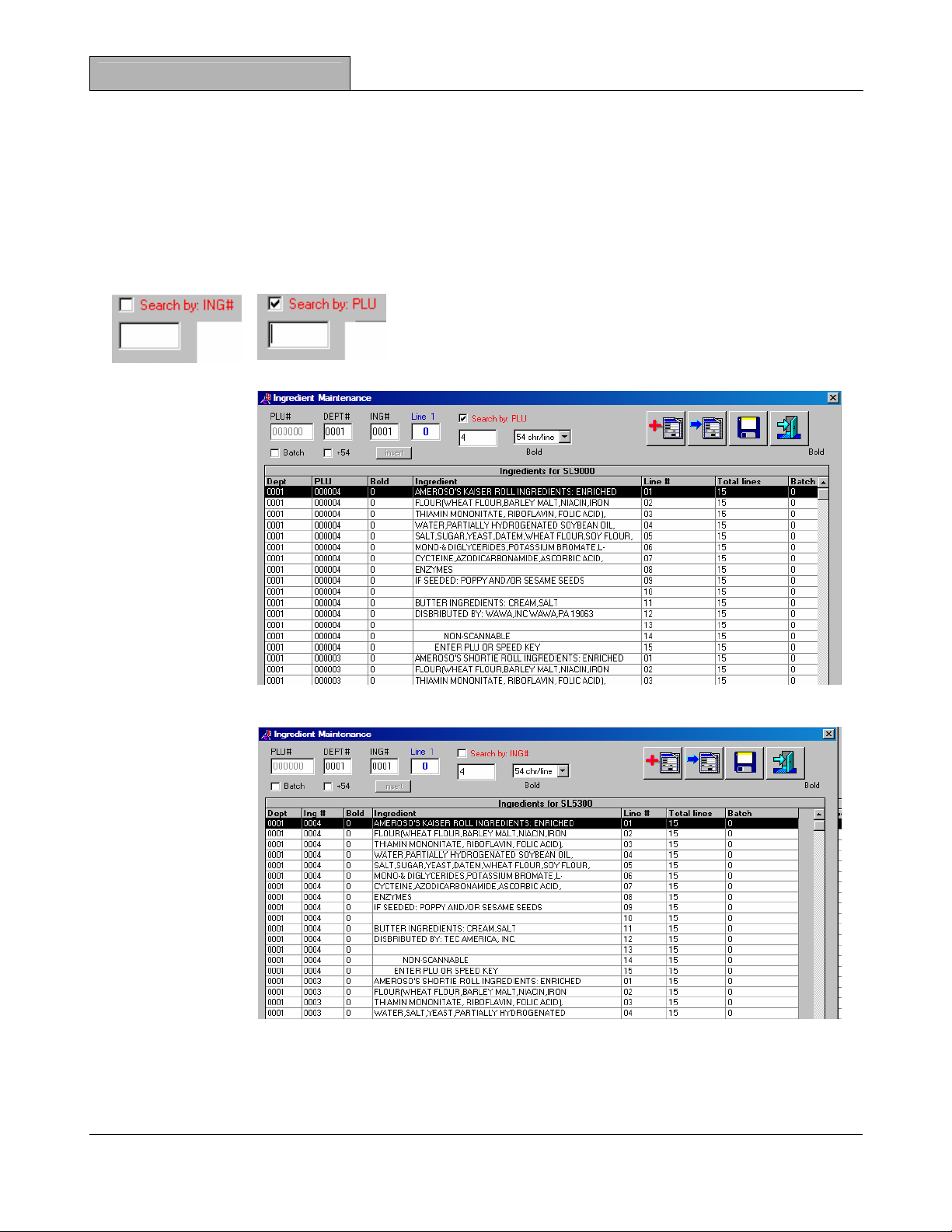

Search Function

By using the search function you can navigate to different

Ingredient Messages. This allows you to edit or view the

entire Ingredient Message database. You can select

Search by PLU for SL9000 Ingredient Messages or

Search by Ingredient # for the SL5300 by checking or unchecking the check box. In the text box

you can enter

either the

number (PLU for

SL9000 or

Ingredient for

SL5300) or [A]

for all

departments or

[D] for the

current

department and

the Ingredient

table will appear.

When the PLU

or Ingredient

number has

been entered, the Ingredient table will show that Ingredient Message and the three previous

Ingredient

Messages in the

file. You may

scroll to the

desired PLU or

Ingredient

number and

“double-click” on

any Ingredient

line for that

number and the

Ingredient table

will disappear

and the selected

Ingredient

Message is now

ready to edit. You may also adjust the column widths in the Ingredient table and the widths will

be saved permanently when you exit the maintenance screen.

Page 8 18-Oct-04

Page 13

Scale View V4.0 Owner’s Manual

Data Maintenance

Maximum Characters per Line

Another feature that is available in the Ingredient Message Edit function is the

ability to set the maximum number of characters allowed for each line in the

Ingredient Message. This feature can be used to ensure that Ingredient

Messages contain the correct number of characters that can be printed on a

certain label width. For example, if the label width that is being used in a

particular department is always the same then the maximum number of characters capable of

being printed on that size label can be set in the Ingredient Message maintenance screen. This

can help prevent missing or truncated information. The SL9000 and the SL5300 have the

capability of using 48mm or 57mm label widths. The 48mm label has a maximum printable

character width of 45 and the 57mm label has a maximum printable character width of 54.

The SL5300 can also use an 80mm label. By using the 36 character per line setting, the 80mm

label is capable of having both the Ingredient Message and Nutrition Information printed side by

side on the same label.

Note: This setting remains after closing the Ingredient Maintenance screen. If an

Ingredient is selected for editing that has more characters per line than the character per

line setting those lines will be truncated. To make use of this function you should set the

characters per line to the desired setting, exit the Ingredient Maintenance screen and then

re-enter the Ingredient Maintenance screen. After editing the shortened character per line

Ingredient Messages you should reset the character per line setting to the maximum

characters per line needed for other Ingredient Messages in the database. This will

prevent inadvertent truncating of Ingredient Messages.

Insert Function

The need may arise to insert words, characters or spaces into an

ingredient line once they have been created. This need may occur

even if the ingredient line already contains the maximum number of

characters allowed. To accomplish the inserting of words, characters or spaces into lines of an

existing Ingredient message click the +54 box. (This could also be +45 or +36 depending on the

current character per line setting) After checking this box the Insert button will be enabled and

all Ingredient lines will accept any number of characters that are entered. When editing is

complete simply click on the Insert button. Any Ingredient line that contains more than the

maximum allowable characters will have those characters wrapped onto the next line. Any

subsequent lines that receive “overflow” characters will automatically be adjusted until line 38 is

reached. Any “overflow” from line 38 will simply be discarded.

You may perform this Insert function one line at a time or you may edit multiple lines and then

press the Insert button. If the end of the line of “overflow” contains a dash, the dash will be

removed. If the end of the “overflow” does not contain a space a dash is added. Confirm that all

Ingredient lines are correct and click the Save button. If any Ingredient lines are not acceptable

simply exit and all changes will be removed.

The Insert function may also be used in conjunction with the maximum characters per line

function to convert larger number of characters per line to smaller ones. For example, a 54

characters per line Ingredient Message can be converted to a 36 characters per line message

by selecting the 36 characters per line and then clicking on the +36 checkbox. Now click on the

Insert button. The Ingredient Message will be converted to 36 characters per line. (Remember

to set the characters per line setting back to the largest size required by your database.)

18-Oct-04 Page 9

Page 14

Data Maintenance

Scale View V4.0 Owner’s Manual

When both the SL9000 and the SL5300 are programmed in the same department and contain

Ingredients, a set of Ingredients will be required for each scale. This is necessary because of

the differences in memory management in each scale. There is a special feature in Scale View

that allows you to maintain these separate Ingredient databases very easily.

Copy Current SL9000 Ingredient Message to Selected Ingredient Number button

This button will only appear if the Ingredient Message you are adding or editing is

an SL9000 type. This feature will allow you to copy an existing SL9000 Ingredient

Message to any Ingredient Number in the SL5300 Ingredient database. To do this

you will need to program the SL9000 Ingredient Message and click Save. Then go

back into the Ingredient Maintenance screen and select that Ingredient Message. Click on the

Copy Current Ingredient Message to Selected Ingredient Number button and enter the desired

SL5300 Ingredient Number. Click OK. The Ingredient Message has been copied to the SL5300

Ingredient database under the Ingredient Number you entered.

Note: If the SL5300 Ingredient Number that you enter already exists in the SL5300

Ingredient database the existing SL5300 Ingredient Number will be overwritten without

any warning. Therefore, unless you wish to overwrite an existing Ingredient message in

the database please ensure that it does not already exist.

Add New SL5300 Ingredient Number button

This button will only appear if the Ingredient Message you are adding or editing is

an SL5300 type. Since the Ingredient Numbers in the SL5300 do not require a PLU

number to already exist before they can be programmed, they may be added at

anytime using this button. Click on the button and then enter an Ingredient Number.

Enter Ingredient lines as necessary and then click Save. If the Ingredient Number you have

chosen already exists a warning message will appear. Decide if you wish to overwrite the

existing Ingredient Number or not. If you select No, then the entered information will be

discarded and you will be returned to the PLU Maintenance screen.

Import Ingredient from Existing PLU or Ingredient Number

This button allows you to Import an existing SL9000 Ingredient Message or an

existing SL5300 Ingredient Number into the current Ingredient Message being

edited.

Enter the SL5300 INGNO and Department

Number of the Ingredient Message that you want

to import and press the Import button. That

INGNO message will now be displayed in the

Ingredient Message Maintenance screen and can

be edited.

If you wish to import an SL9000 Ingredient

Message you would enter the PLU Number and

Department Number and press the Import button.

Make sure that you enter the desired Department

Number of the Ingredient Message you are trying

to import or you may not get the correct

Ingredient Message.

Page 10 18-Oct-04

Page 15

Scale View V4.0 Owner’s Manual

Data Maintenance

Saving Ingredients

After you have entered all the necessary lines of your Ingredient Message you will

need to save the information to the appropriate database. To do this simply press

the Save button at the top of the Ingredient Message maintenance form. You will

be prompted with three choices.

If you answer YES the Ingredient Message will be

saved to the database and added to a batch.

If you answer NO the Ingredient Message will be

saved to the database only.

If you answer CANCEL all changes will be discarded.

Deleting Ingredients

To delete an SL9000 Ingredient Message but not delete the PLU you must first delete all of the

currently programmed Ingredient Lines for that PLU. Then insert one space on Line 1 of that

PLU’s Ingredient Message. Save the Ingredient Message by selecting the YES option. This will

save the Ingredient Message to the database and add that Ingredient Message to an Ingredient

Batch for that department. Send the Ingredient Batch to the Scale and the Ingredient Message

for that PLU will be removed.

In the SL5300 Deleting an Ingredient Number is quite different. Since the Ingredient Number is

not part of the PLU record it may be deleted without affecting any PLU or PLU’s to which it has

been linked. In Scale View to delete an SL5300 Ingredient Number you can use the Scheduled

Batch function or if you have a password you can use the SL5300 Delete function under the

Service Menu. (This is explained in detail in the Scale View Dealer’s Manual)

Nutrition Maintenance

Nutrition Information editing is based on the scale model. The Edit

Nutrition button has a check box on it. If the check box is left

unchecked when you click on it you will be editing a Nutrition

Message for the SL5300. The SL5300 stores Nutrition Information

separate from the PLU information and uses Nutrition Information Numbers (NutrNo). These

Nutrition Numbers may be linked to an individual PLU or the same Nutrition Number may be

linked to several different PLU numbers. The SL5300 has some special Nutrition editing

features that will be discussed later in this document.

If you click on the check box and then click on the Edit Nutrition button

you will be editing an SL9000 Nutrition Message. The SL9000

Nutrition Messages are different from the SL5300 Nutrition Messages

and therefore are maintained by different maintenance screens and

stored in a separate database.

18-Oct-04 Page 11

Page 16

Data Maintenance

Scale View V4.0 Owner’s Manual

Add/Edit Nutrition

There are separate databases for the SL9000 Nutrition Information and the SL5300 Nutrition

Information because the SL5300 has multiple Nutrition Information templates available.(See

SL5300 Owner’s Manual). Also the databases are separate because the SL9000 Nutrition

Information is stored with the PLU record and the SL5300 stores Nutrition Information in a

separate area of memory.

Editing SL9000 Nutrition Information

The SL9000 Nutrition Information Maintenance screen allows for only one type of Nutrition

template. This Nutrition Information is stored with the PLU and is attached to a department.

The TAB key is used to

navigate from one field to

another. To go in reverse press

and hold the SHIFT key while

pressing the TAB key.

Nutrition Information may be

imported from an existing PLU

by depressing the Import button

once. Then input the desired

Department and PLU Number.

Depress the Import button

again to Import the information

or you may press the Close

button to abort the Import.

To save the Nutrition

Information press the Save

button. The Nutrition Save

function is the same as the PLU

or Ingredient Save function.

Keep in mind that the Nutrition

Message will be saved with the

PLU number in the department.

Field Limitations

Field Requirements

Serving Size Field limited to 30 characters and spaces including

field title characters. Template allows for 18

characters which when added to the 12 characters

for the field title equals 30.

Page 12 18-Oct-04

Page 17

Scale View V4.0 Owner’s Manual

Data Maintenance

Field Requirements

Servings per Container Field limited to 30 characters and spaces including

field title characters. Template allows for 18 but only

the first 8 will be accepted and printed due to the

length of the title field characters (22).

Calories, Calories from Fat Field limited to 4 characters.

Total Fat, Saturated Fat, Cholesterol,

Sodium, Total Carbs, Fiber, Sugars,

Field limited to 5 characters. May include one

decimal point as one of 5 characters.

Protein

Vitamin A, Vitamin C, Calcium, Iron Field limited to 4 characters. No decimal point.

Editing SL5300 Nutrition Information

The SL5300 Nutrition Edit Maintenance screen provides support for the SL5300’s enhanced

Nutrition Information Templates. Nutrition Information stored in the database may be linked to

an individual PLU or to multiple PLU’s by the use of Nutrition Information numbers.

The TAB key is used to navigate

from one field to another. To go in

reverse press and hold the SHIFT

key while pressing the TAB key.

Field Limitations

Field Requirements

Serving Size Field limited to 32 characters and spaces including

field title characters. Template allows for 20

characters which when added to the 12 characters

for the field title equals 32.

18-Oct-04 Page 13

Page 18

Data Maintenance

Scale View V4.0 Owner’s Manual

Field Requirements

Servings per Container Field limited to 32 characters and spaces including

field title characters. Template allows for 20 but only

the first 10 will be accepted and printed due to the

length of the title field characters (22).

Calories, Calories from Fat Field limited to 4 characters. May include one

decimal point as one of 4 characters.

Total Fat, Saturated Fat, Cholesterol,

Sodium, Total Carbs, Fiber, Sugars,

Field limited to 5 characters. May include one

decimal point as one of 5 characters.

Protein

Vitamin A, Vitamin C, Calcium, Iron Field limited to 4 characters. May include one

decimal point as one of 4 characters.

Nutrition Templates

The SL5300 supports multiple Nutrition Templates. The Nutrition

Template may be selected for different reasons. One reason may be

size or layout style so it will fit on a particular label. This functionality

means that the Nutrition Information numbers can only be used in the

SL5300. For examples of each of the different templates refer to the

SL5300 Owner’s Manual.

Search Nutrition Number

The Search Nutrition Number function works like the Ingredient Number

search function. The only difference is that the Search Nutrition Number

will only return Nutrition Information stored in the SL5300 Nutrition

database. This results from the differences in the available templates for the SL5300 as

opposed to the SL9000 scale.

Add New Nutrition Number

The Add New Nutrition Number button allows us to add Nutrition Information

numbers without having a PLU programmed first. This is possible due to the way

the SL5300 stores information. Determine the desired Department you want to add

the new Nutrition Information to and enter it in the Department Number field.

Depress the Add New Nutrition button and enter the desired NutrNo. Enter the appropriate

Nutritional Information and depress the Save button.

Import Nutrition Number

The Import Nutrition Number function will only allow you to import other SL5300

Nutrition Information. Depress the Import Nutrition Number button and then enter

the desired Department number and the desired NutrNo. Depress the Import

button again.

Page 14 18-Oct-04

Page 19

Scale View V4.0 Owner’s Manual

Data Maintenance

Saving Nutrition

After you have entered all appropriate Nutrition Information press the Save button.

You will be prompted with three options just like the PLU and Ingredient save

functions.

If you answer YES the Nutrition Information will be

saved to the database and added to a batch.

If you answer NO the Nutrition Information will only

be saved to the database.

If you answer CANCEL the Nutrition Information will

be discarded.

Delete Nutrition

Deleting Nutrition Information for an SL9000 scale can not be done through Scale View unless

the entire PLU is deleted. To delete just the Nutrition Information and not the PLU on an SL9000

you must perform the delete Nutrition operation at the scale.

In the SL5300 Deleting a Nutrition Number is quite different. Since the Nutrition Number is not

part of the PLU record it may be deleted without affecting any PLU or PLU’s to which it has

been linked. In Scale View to delete an SL5300 Nutrition Number you can use the Scheduled

Batch function or if you have a password you can use the SL5300 Delete function under the

Service Menu. (This is explained in detail in the Scale View Dealer’s Manual.)

18-Oct-04 Page 15

Page 20

Scheduled Batches

Scale View V4.0 Owner’s Manual

Scheduled Batches

Sending Batches using the Windows

Scheduled batches can be performed using the Windows

appropriate version Windows

®

Manual or the Help Menu for scheduled task setup procedures.

Each department will require separate scheduled tasks. Scheduled tasks will not execute

correctly if Scale View is in operation. To verify the correct execution of scheduled tasks use the

Log button on the Scale View Main Menu.

Send All Batches

To send all pending PLU, Ingredient and Nutrition batches for a department follow the Windows

Task Scheduler instructions for adding a task and add the command line switch as shown.

Where 1 represents the department number. There is a space after the “ mark and before the

word batch.

This will result in all pending batches for department 1 to be sent at the time entered in the

scheduled task. If you want to send batches for multiple departments you would need to create

separate scheduled tasks for each department and substitute the appropriate department

number in the command line switch. (i.e., batch,2; batch,3; etc.) Keep in mind that each

scheduled task may take some time depending on the number of items in a batch and the

number of batch types. Therefore, you should allow enough time between scheduled tasks to

ensure each task can be performed.

Delete an Individual PLU

To delete an individual PLU for a department follow the Windows

for adding a task and add the command line switch as shown.

Where 1 represents the department number and 8001 represents the PLU number in that

department to be deleted. There is a space between the “ mark and delplu.

This will result in PLU number 8001 in department 1 being deleted from the database and the

scales in department 1 if there are no problems with communications. (i.e., scale turned off,

scale disconnected from the network, etc.) If there are any problems with communications to

any scale in the department the PLU will not be deleted from the database. It will be deleted

from any scale that had successful communications.

®

Task Scheduler

®

Task Scheduler. Please refer to the

batch,1

®

Task Scheduler instructions

delplu,1,8001

®

Page 16 18-Oct-04

Page 21

Scale View V4.0 Owner’s Manual

Scheduled Batches

Delete Multiple PLU’s

To delete multiple PLU’s for a department follow the Windows

adding a task and add the command line switch as shown.

The 1 is fixed. (department information is included in the “delete.txt” file.) There is a space

between the “ mark and delete.

To delete multiple PLU’s in the department you will need to create a file named “delete.txt”. The

“delete.txt” file can be created using Windows

®

Notepad. The PLU’s you want to delete should

be added to the file by entering the department number, PLU number then pressing the enter

key.

Ex.)

1,1001

1,1002

1,3010

1,5005

1,6000

At the end of each PLU number the enter key was depressed. After all the PLU’s you wish to

delete are entered save the file as “delete.txt” in C:\Program Files\ScaleView\FTP.

Note: The path shown is the location if you used the default directory during the Scale

View installation procedure. If you did not use the default directory when installing Scale

View you will need to save the “delete.txt” file in the FTP folder located in the path where

you installed Scale View. If the “delete.txt” file is not located in the correct folder it will not

be executed and the PLU’s you wanted to delete will not be deleted.

Executing this command will result in all PLU numbers included in the “delete.txt” file being

deleted from the database and all departmental scales if there are not any communications

problems. (i.e., scale turned off, scale disconnected from the network, etc.) If there are any

problems with communications to any scale in the department the PLU’s will not be deleted from

the database. The PLU’s will be deleted from any scale that had successful communications.

®

Task Scheduler instructions for

delete,1

18-Oct-04 Page 17

Page 22

Scheduled Batches

Scale View V4.0 Owner’s Manual

Delete Ingredient Numbers (SL5300 Only)

In the SL5300 scales you can delete Ingredient Numbers without deleting PLU’s because they

are stored in separate areas of memory. This is not the case in the SL9000 scales, to delete an

Ingredient Message in the SL9000 you will need to delete the PLU.

We also have the capability in the SL5300 to delete either a single Ingredient Number in a

department or a range of Ingredient Numbers in the department. Each option is explained below.

Delete a Single Ingredient Number (SL5300 Only)

To delete a single Ingredient Number in a department follow the Windows

instructions for adding a task and add the command line switch as shown.

deling,1,5,5

Where 1 is the department number; 5 is the starting Ingredient Number and 5 is also the ending

Ingredient Number. There is a space between the “ mark and the word deling.

This will result in Ingredient Number 5 being deleted in the database and all departmental

scales if there are no communications problems. (i.e., scale turned off, scale disconnected from

the network, etc.) If there are problems with communications to any scale in the department the

Ingredient Number will not be deleted from the database. The Ingredient Number will be deleted

from any scale that had successful communications.

Deleting a Range of Ingredient Numbers (SL5300 Only)

To delete a range of Ingredient Numbers in a department follow the Windows

instructions for adding a task and add the command line switch as shown.

deling,1,10,100

Where 1 is the department number; 10 is the starting Ingredient Number and 100 is the ending

Ingredient Number. There is a space between the “ mark and the word deling.

This will result in Ingredient Numbers in the range between 10 and 100 being deleted in the

database and all departmental scales. This includes Ingredient Numbers 10 and 100. If there

are communications problems with any scale in the department the Ingredient Numbers will not

be deleted from the database. The Ingredient Numbers will be deleted from any scale that had

successful communications.

®

Task Scheduler

®

Task Scheduler

Page 18 18-Oct-04

Page 23

Scale View V4.0 Owner’s Manual

Scheduled Batches

Delete Nutrition Numbers (SL5300 Only)

In the SL5300 scales you can delete Nutrition Numbers without deleting PLU’s because they

are stored in separate areas of memory. This is not the case in the SL9000 scales, to delete a

Nutrition Message in the SL9000 you will need to delete the PLU.

We also have the capability in the SL5300 to delete either a single Nutrition Number in a

department or a range of Nutrition Numbers in the department. Each option is explained below.

Delete a Single Nutrition Number (SL5300 Only)

To delete a single Nutrition Number in a department follow the Windows

instructions for adding a task and add the command line switch as shown.

delnutr,1,5,5

Where 1 is the department number; 5 is the starting Nutrition Number and 5 is also the ending

Nutrition Number. There is a space between the “ mark and the word delnutr.

This will result in Nutrition Number 5 being deleted in the database and all departmental scales

if there are no communications problems. (i.e., scale turned off, scale disconnected from the

network, etc.) If there are problems with communications to any scale in the department the

Nutrition Number will not be deleted from the database. The Nutrition Number will be deleted

from any scale that had successful communications.

Deleting a Range of Nutrition Numbers (SL5300 Only)

To delete a range of Nutrition Numbers in a department follow the Windows

instructions for adding a task and add the command line switch as shown.

delnutr,1,10,100

Where 1 is the department number; 10 is the starting Nutrition Number and 100 is the ending

Nutrition Number. There is a space between the “ mark and the word delnutr.

This will result in Nutrition Numbers in the range between 10 and 100 being deleted in the

database and all departmental scales. This includes Nutrition Numbers 10 and 100. If there are

communications problems with any scale in the department the Nutrition Numbers will not be

deleted from the database. The Nutrition Numbers will be deleted from any scale that had

successful communications.

®

Task Scheduler

®

Task Scheduler

18-Oct-04 Page 19

Page 24

Main Menu

Scale View V4.0 Owner’s Manual

Main Menu

Sort/Search Database

There are six ways to sort the database; the default sort order is

DEPTPLU. Anytime Scale View is opened, the database will be

sorted and displayed by DEPTPLU. The first button sorts by either

Department Number or PLU Number. When sorting by Dept, the

PLU numbers might not be listed in numerical order and when

sorting by PLU the Department numbers might not be in

numerical order. The second button sorts the database by either

DEPTPLU or DEPTUPC. The DEPTPLU sorts the database by

the Department number first and then by PLU number within that Department. The DEPTUPC

sorts the database by the Department number first and then the UPC number within that

Department. The third button sorts the database by either DEPTCOM1 or DEPTBATCH. The

DEPTCOM1 will sort the database by the Department number first and then alphabetically sorts

that Department by the first line of the PLU’s commodity name. The DEPTBATCH sorts the

database by the Department number and then by the PLU Batch flag.

There is a status description located below these sort buttons that

displays the current sort method selection. As different sort

options are selected this description will change accordingly.

To search the database for a specific PLU, enter the PLU Number in the

text box (no enter key required). The database will be searched after

every number entered. The PLU number that is less than or equal to the number entered will be

highlighted. Valid number entries in this search field are 1 through 999999.

Sending Batches

In Scale View the term “batch” refers to any record in the

database that has its “batch” checkbox checked. There are

“batch” checkboxes for PLU’s, Ingredients and Nutrition

Information. Anytime you press the Save button when you Add or

Edit a PLU, Ingredient or Nutrition item you are given the option of saving the item to the

database and adding it to an appropriate “batch” type for that item. If you select the YES option

when saving an item it will have its “batch” flag set and will be added to that department’s

current batch for that type of item. There is another option to set the “batch” flag for an item.

This option is available in the maintenance screen for all the item types. You can check the

“batch” checkbox in the maintenance screen for an item and then select the NO option when

you are saving that item and it will have its “batch” flag set. (The normal procedure when adding

or editing an item would be to save it and select the YES option which would automatically set

the “batch” flag but if the only change desired is to add the item to a batch you could use this

method.) In the PLU table the “batch” status of a PLU will show a “1” in the “batch” column.

There are no indications for the status of an Ingredient batch or Nutrition type batch in the PLU

table. The only method of determining and viewing Ingredient and Nutrition batches is by using

the Report function.

Page 20 18-Oct-04

Page 25

Scale View V4.0 Owner’s Manual

Main Menu

When one of the Batch buttons is depressed a window

will open asking you to select the department to which

you want to send all pending batches. Select the

appropriate department and press the yes button. If

there are any pending batches of any type that have not

been sent to the scales in that department they will be

sent now. After batches have been sent successfully to

all scales in the department, the “batch” flags for the

items in those batches will be reset. This will only

happen if communications to all scales in that

department were successful. If there was a communication failure to any scale in the selected

department the “batch” flags for those departmental items will not be reset. The communication

problem should be corrected and the batches for that department resent.

If there are no pending batches of any type for a department that is selected there will be no

attempted communications with that department’s scales.

Note: If the PLU batch includes any new PLU’s for a department be sure to download the

PLU batch first and then any Ingredient and Nutrition batches.

Set Back Function

The Set Back function is used in conjunction with the PLU Sale Price and Sale

Number fields in the PLU Maintenance screen. It provides a method of resetting all

PLU items that have been placed on sale by the Sale Number.

When performing PLU maintenance enter a Sale Price and a

Sale Number (1 – 9) for the desired PLU. If the PLU is saved

to the database using the YES option it will have its “batch”

flag set. The next time a PLU Batch Download or a Complete

File Download (Service Menu) is executed for this department

the Sale Price that was entered for the PLU will be downloaded to the scales in that department.

Note: If there is a Sale Price entered for a PLU it will be downloaded during a batch

download for the department or a complete file download for a scale instead of the current

price entry. To use the current price field during a download make sure the Sale Price field

is set to all zeroes.

When the Sale Price is over and the original prices

need to be restored simply press the Set Back button

and select the desired Sale Number.

Note: This will set all Sale Price field entries for this

Sale Number back to all zeroes. This affects all

PLU’s associated with this Sale Number regardless

of the department to which they are assigned.

18-Oct-04 Page 21

Page 26

Main Menu

Scale View V4.0 Owner’s Manual

After selecting the desired Sale Number press the YES button. A confirmation screen will

appear; press the YES button and all of the PLU’s associated with this Sale Number will have

their Sale Price and Sale Number fields set back to all zeroes.

Selecting YES will also set the “batch” flag for the PLU’s that had a Sale Price. To send the

updated prices to a scale, click on the PLU Batch Download button and select the appropriate

department number. Keep in mind that you must execute the PLU Batch Download for each

department that had PLU’s with this Sale Number associated with them.

View

The View button expands the PLU table to show all programmed fields for PLU’s. If

it is depressed again it will truncate the programmed fields view. Please note that

the columns used in the PLU table are manually adjustable. Once they are

adjusted there widths will be permanently saved.

Log

All communications attempts whether they are successful or unsuccessful will be

recorded into the Log file (tmcc.log). This recording includes both uploads and

downloads from a scale. To view the Log file simply click on the Log button. The

Log file will open showing all communications records to and from scales in the

system. Some errors may not be the result of a communication problem. For

example, “DATA ERROR…Dept 1 PLU 1” means that there is a conflict between the

programmed PLU data and a scale setting (usually tare or price per field).

After closing the Log file the Log button will change to the Clear Log button. At this

point you should decide if you want to clear the Log file or not. Depress the Clear

Log button and you will get a decision screen.

If you don’t want to clear the log file at this time depress the NO

button and the Clear Log button will revert back to the Log button

and the Log file will remain intact.

If you want to clear the Log file then depress the YES button and

the Log file will be cleared.

The Log file should be cleared on a regular basis. If the size of

the Log file exceeds 40Kbytes a warning message will be displayed. Every time Scale View is

started a copy of the Log file is saved in a file named tmcc.sav. If the Log file is cleared by

mistake, exit Scale View; rename the tmcc.sav file to tmcc.log and re-start Scale View. If you

are not sure how to accomplish this you should call your authorized TEC dealer representative.

Page 22 18-Oct-04

Page 27

Scale View V4.0 Owner’s Manual

Main Menu

Reports

There are several reports available in Scale View. These reports can be displayed

on the screen, printed to a connected printer or exported in various file formats.

There are reports that can be performed on both scale models and some only used

for the SL5300. All reports available are programmed data only, there are no

financial report capabilities in Scale View V4.0.0.

PLU Reports

PLU Price Report provides the department number and all PLU‘s with their current programmed price. It also displays Commodity Line 1 and 3 of the PLU descriptor.

PLU Detail Report provides all programmed information for a PLU. The PLU’s are listed numerically by PLU and include all data except the Ingredient and Nutrition Information.

18-Oct-04 Page 23

Page 28

Main Menu

Scale View V4.0 Owner’s Manual

PLU SPrice Report provides a list of all items by department number then PLU number. It includes the current price field and the Sale Price field with the Sale Number. It also shows Commodity Line 1 of the PLU’s descriptor.

SL9000 Reports

PLU/NUTRI Batch Report displays a list of all PLU’s by department and their PLU “batch” and Nutrition “batch” flag status.

Page 24 18-Oct-04

Page 29

Scale View V4.0 Owner’s Manual

Main Menu

SL9000 Ing Report shows a list by department of all SL9000 PLU’s in the database and their Ingredient Message.

SL9000 Nutr Report displays a list by department of all SL9000 PLU’s in the database and the Nutrition Information programmed for those PLU’s.

18-Oct-04 Page 25

Page 30

Main Menu

Scale View V4.0 Owner’s Manual

SL9000 Ing Batch Report provides a listing of all SL9000 PLU’s in the database that have an Ingredient “batch” flag turned on. The department number, PLU number, first line of the Ingredient Message and the “batch” flag status are displayed.

SL5300 Reports

SL5300 Ing Report provides a list by department of all SL5300 Ingredient Numbers that are in the database.

Page 26 18-Oct-04

Page 31

Scale View V4.0 Owner’s Manual

Main Menu

SL5300 Nutr Report displays a list by department of all SL5300 Nutrition Numbers stored in the database. All programmed Nutrition Information for the Nutrition Number is shown.

SL5300 Ing Batch Report provides a list by department of all Ingredient Numbers with their Ingredient Number “batch” flags turned on.

18-Oct-04 Page 27

Page 32

Main Menu

Scale View V4.0 Owner’s Manual

SL5300 Nutr Batch Report displays a list by department of all Nutrition Numbers in the database with their Nutrition Information “batch” flags turned on.

SL5300 PLU Ingr No Report uses the PLU Detail report to display the SL5300 PLU programmed data including the Ingredient Number programmed for each PLU.

Page 28 18-Oct-04

Page 33

Scale View V4.0 Owner’s Manual

Main Menu

SL5300 PLU Nutr No Report uses the PLU Detail report to display the SL5300 PLU programmed data including the Nutrition Number programmed for each PLU.

Choosing a Report

To select a specific report press the Report button on the Main Menu. The Report Selection

screen will appear. Depending on the report type select you will have the option of selecting the

report to run in an individual department or all departments. If you are attempting to run the PLU

Sale Price report you will be allowed to choose from an Individual Sale Number, a range of Sale

Numbers or all Sale Numbers. This is different due to Sale Numbers having the ability to be

programmed on PLU’s in different departments.

18-Oct-04 Page 29

Page 34

Main Menu

Scale View V4.0 Owner’s Manual

Reports may be viewed on the screen in different magnifications or printed to any attached

printer. They also may be exported in several different formats. These functions are

accomplished by clicking on the appropriate buttons on the bottom of the report screen.

Export Options

Viewing Size

Export Report

Print Report

Page 30 18-Oct-04

Page 35

Scale View V4.0 Owner’s Manual

Error Messages

Error Message Explanation

Error Messages

Mismatch Data Length

SL9000DRV.EXE is not

found

Terminal Busy

Invalid Port Number

Cannot Open Port

TMCC text file format is incorrect – check Scale

Table file format version against setting in scale

(Initial set 9 bit 7: 1 = Version 2.3; 2 = Version 2.8).

Refer to Scale Table settings and Initial Set

Information.

This is the TMCC driver (SL9000DRV.EXE). This

error may display when running the Scale View for

the first time. Start Windows Explorer, go to

“c:\program files\scaleview\” and double click on the

driver icon. A new window will open, click on File in

new window and then on Exit. This registers the

driver in Windows. This error may occur with Demo

CD and some Windows versions, like Windows XP.

The master scale is in the middle of LON command

or in the middle of reset. If this is not the case, status

clear scale in question.

The COM port selected for the PC in the Scale Table

doesn’t exist. Select another COM port.

The COM port selected for the PC in the Scale Table

is malfunctioning or is currently being used by

another program. Try re-booting or select another

COM port.

Error Closing Port

Select Failed in

Command Sequence

Poll Failed in Get Data

Sequence

Poll Failed in

Command Sequence

Expected Ack: Send

Command

Expected Ack: Send

Message

The COM port selected for the PC in the Scale Table

is malfunctioning or is currently being used by

another program. Select another COM port.

The selected scale is not responding - check scales

Initial sets and “Online” status, Scale View Scale

Table configuration, cabling or Level Converter.

Selected scale stopped communicating. Check

cabling, Level Converter, scales Initial sets, and

Scale View Scale Table configuration.

PC stopped communicating with scale. Check

cabling, Level Converter, scales Initial sets, and

Scale View Scale Table configuration.

Check cabling, Level Converter, scales Initial Sets,

and Scale View Scale Table Configuration. May see

this error with USB to RS-232 adapter, which is not

supported

Check cabling, Level Converter, scales Initial Sets,

and Scale View Scale Table configuration.

18-Oct-04 Page 31

Page 36

Error Messages

Scale View V4.0 Owner’s Manual

“Run Time error 76”

when trying to access

TMCC log

An error occurs when

requesting a report

Scale Not

Communicating

The file “notepad.exe” is not found in the default

directory. The default directory for Scale View for

“notepad.exe” is “C:\Windows”. This error usually

occurs with Windows NT, Windows NT WS and

Windows NT 2000.

To correct this first confirm that there is not a

“Windows” subdirectory. If there is no “Windows”

subdirectory you must create one and copy the file

“notepad.exe” into it. This should take care of this

error.

“Unable to connect, incorrect session parameters.”

Or Microsoft Access opens and requests a

password.

These problems occur because of a conflict between

different versions of Crystal Reports installed by

other programs.

Contact your TEC Representative for assistance.

In Scale View V4.0 this error indicates that there is a

problem with a Scale’s IP address. This problem

could be that it isn’t programmed in the scale or in

Scale View’s Scale Table correctly. Check the Scale

View Scale Table configuration and the Scale’s IP

address.

Page 32 18-Oct-04

Page 37

Page 38

TOSHIBA TEC AMERICA RETAIL INFORMATION SYSTEMS, INC.

4401-A Bankers Circle

Atlanta, GA 30360

PRINTED IN USA

E

OM-SV4

Loading...

Loading...