Page 1

TOSHIBA

MOTOR

MODEL

PROTECTION

S2E21

RELAY

Page 2

TOSHIBA'S

for

all

motor

event

1

data

TEMPERATURE

.

.

Every motor

temperature

protection

2

.

Relay

.

SIMPLE

programming

easytofollow

with

integral

MOTOR

TOSHIBA

motor

applications.It

application

similation

OPERATION

programmer,

protection

SIMILATION

is

used

is

made

instructions,

relay,

all

FOR

the

OVERLOAD

has

protected

overload

for

simple

large

or

LCD

computer

by

PROTECTION

MODEL

Model

by

by

S2E21,isa

protective

FEATURES

clear,

display

.

features

total

motor

necessary,

MAINTENANCE

4

.

Rotor

and

starts,

before

S

.

MONITORING

Built-in

tenance

RELAY

S2E21

protection

includingadisplay

stator

running

trip,

running

memory

procedures

monitoring

and

DATA

temperatures,

historyofkey

time,

event

SYSTEM

card

data

supports on-going

.

of

number

parameters

.

package

running

of

main-

ALL

TYPES

overload,

3

.

Thermal

overcurrent,

locked

PROTECTIVE

Feature

Overload

Short

Instantaneous

Overcurrent

Current

Unbalance

Stator

Bearing

Overtemperature

Undercurrent

Zero

Ground

Locked

Starting

Repeated

Two

Inputs

Fault

rotor,

Circuit

-

Phase

and/or

Sequence

Fault

Rotor

Time

Starting

Auxiliary

for

External

Relays

and

OF

PROTECTION

instantaneous

current

repeated

FUNCTIONS

Overcurrent

Failure

unbalance,

starting

DeviceNo.

49

50

51

46

38/49

37

50G/51

48

66

overcurrent,

undercurrent,

ground

and

ITEMS

Control

Rated

frequency

Rated

current

Applicable

environment

Performance

G

Output

fault

power

Contact

.

supply

Ambient

Humidity

Altitude

Dielectric

Current

withstand

Vibration

withstand

Shock

G

.

COMMUNICATIONS

Standard

dard

for

temp

.

strength

withstand

RS485

all

relays

RATINGS

DESCRIPTION

AC

DC

50/60

1A/5A

-10to+60°C

-20to+60°Cinstorage

20to85%

2000m

AC

1.3x

40xrated current

16.7Hz,

(3

10G3directions,

TRIP

LOCK

ALARM

ERROR

communication

.

100V-120V

100V-125V

Hz

CT

secondary

RH

(6600ft)

2000V,

directions,2hours)

rated

total

for1min

current

1C

1

C

1

C

1C

portisstan

current

and

transportation)

condensation)

no

max

.

.

continuously

1

sec

for

amplitude

2 hours

(FAIL-SAFE/NON-FAIL-SAFE)

(FAIL-SAFE/NON-FAIL-SAFE)

(FAIL-SAFE/NON-FAIL-SAFE)

(FAIL-SAFE/NON-FAIL-SAFE)

.

.

3mm

Page 3

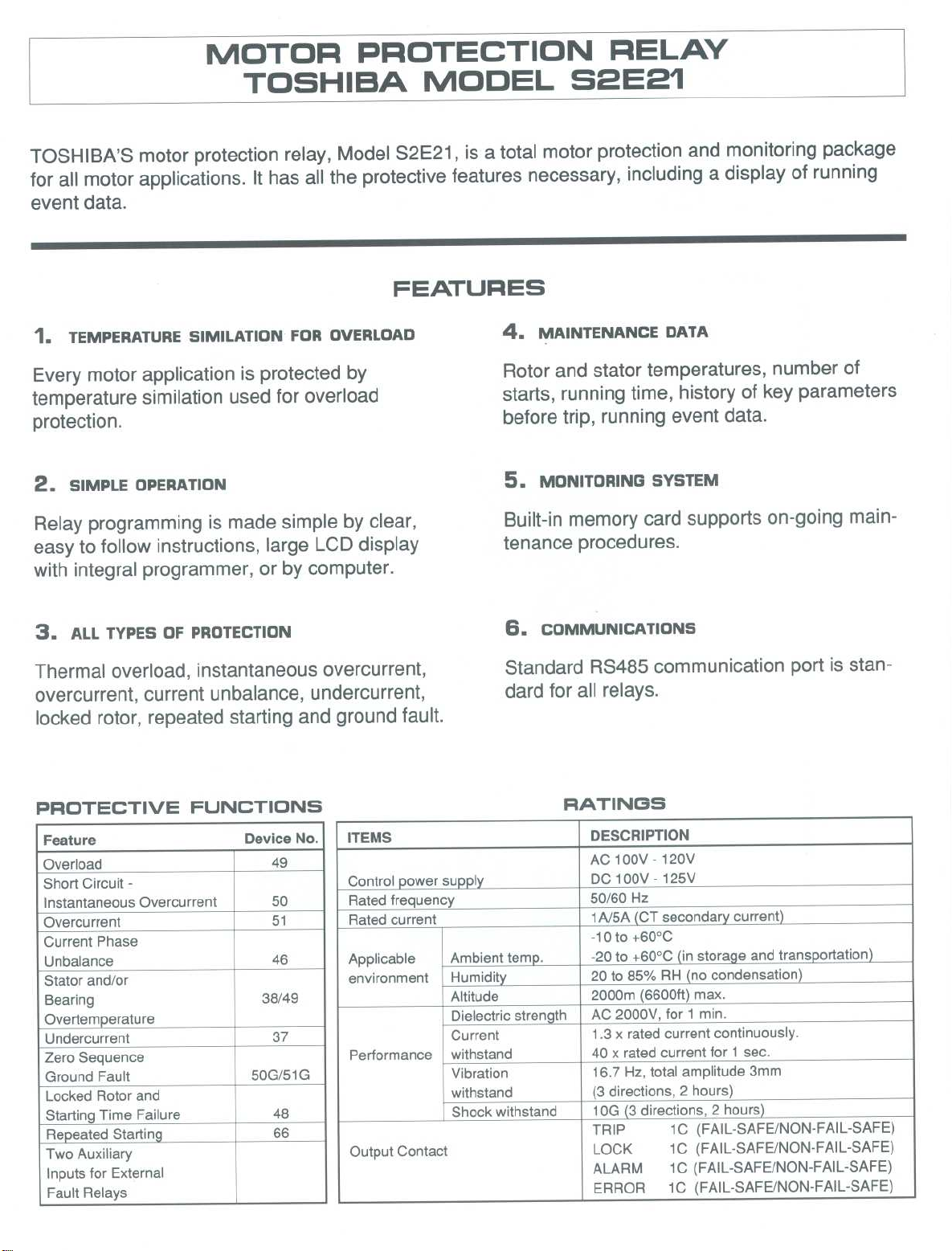

APPLICATION

Allowable

rise

Permissible

rise (9s)

Rated

temperature

rise

Ambient

(temperature)

START

II

II

II

I

I

11

1

1

I

Full

load

I

--

Over

load

--

-

_________

Relay

PRE-ALARM

Trip

LEVEL-

Time

-

t

Page 4

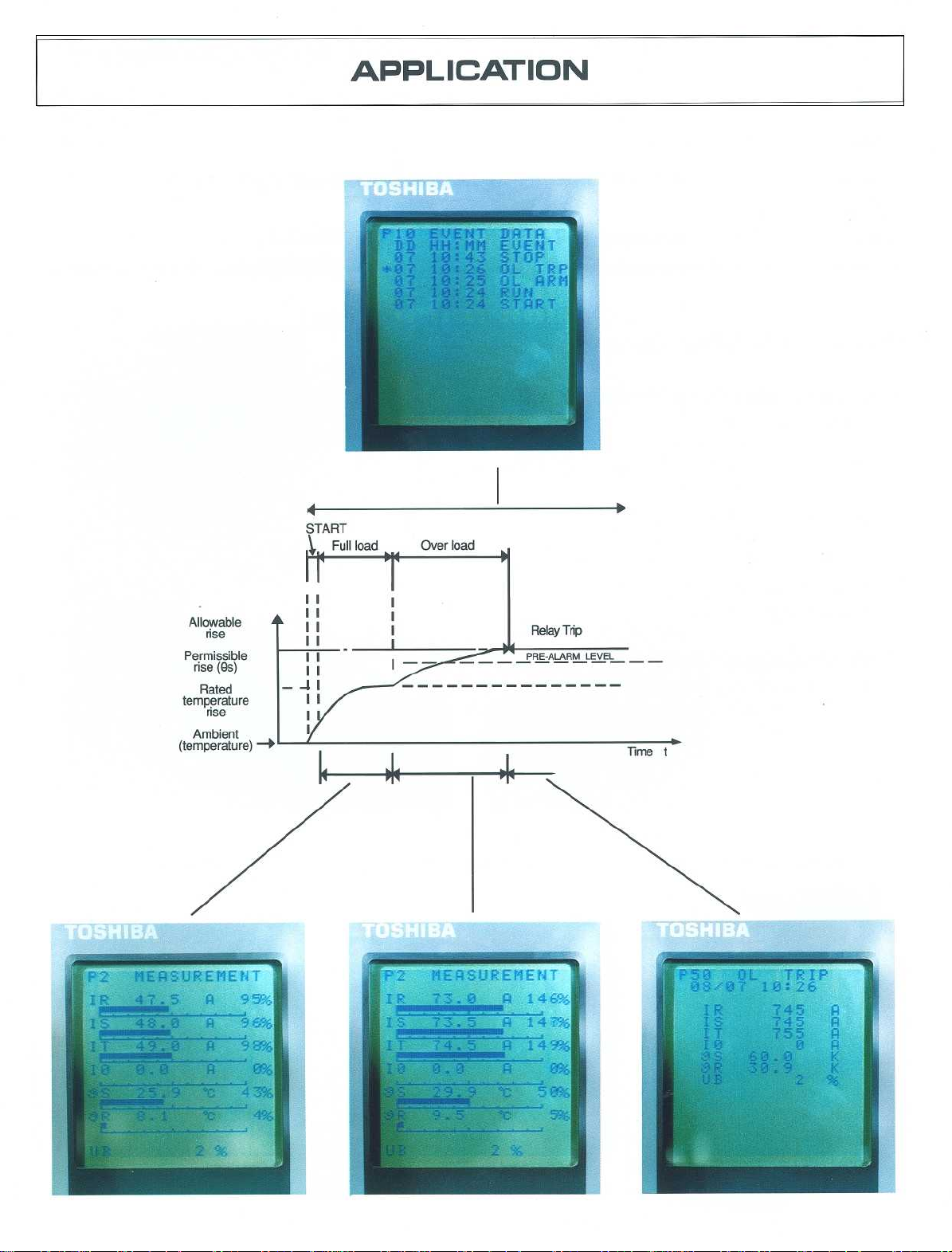

OPERATION

Simple,

Standard

drawn

Memory

RunningMonitor

OverloadDetection

Error

straightforward

relayisdrawout

out

.

cardisincludedasa

Stop-Lightisoff

Run-Lightison

Starting-Light

Light

blinks3times/second

Indicator

Lighted

when

blinksin1

relay

operation

(steady)

detects

.

construction.CT

standard

(red)

second

(red)

self-checking

accessory

intervals

connections

.

error

are

shorted

automatically

when

relay

is

Trip

Indicator

Lighted

relaytotrip.LCD

trip

occurred

when

any

.

(yellow)

protective

display

will

function

show

what

causes

type

of

Page 5

LCD

DISPLAY

OPERATION

Each

information

cellisassignedaseparate

displayisperformed

cursor

Auto-shutoff

4

Set

changed,

key

minutes

points

.

feature

.

are

protectedbyPASSWORD

exceptbypersonnel

by pressing

LCD

.

displayisturned

`Page'

and

authorized

LCD

DISPLAY

page

display.Selecting

then

either

off

automaticallyifno

ID

security

with

the

feature.Settings

correct

the

page

password

SAMPLES

the

number

new

LCD

may

.

view

or

the

Down

page

or

the

to

Up

screenisselected

be

viewed,

but not

desired

within

INDICATION

Function

Ammeter

Calculated

temperature

stator,

Unbalanced

ratio

RTD

temperature

3

Phase

starting

Average

starting

Starting

Average

starting

rotor

current

current

time

time

rise

Display

Page

P2

P2

P2

P3

P4

P4

P4

P4

Description

Range

Accuracy

Updated

Digital

2diits

3

digits,

Type:Pt

Ni

100

Range:-20to200°C,1°C

Len

the

IRst Starting

ISst

ITst

Ist

Tst

TAVst

Three Phase

0.05-17 x

CT

+2

.5%atCT&ZCT

0.5sec

and

analog

8 channel counter 14

100

ohm,Ni120

1000m3300ft

bar

ohm,Pt100

ohm

last

start

Average

last5starts

Starting

Average

last5starts

.

ohm

step

current

value

time

value

(JIS),

of

of

of last

of

Zero

0

.005-1

Rating

start

Function

.7 x

ZCT

INDICATION

Function

Running

Maximum

current

Start

Total

time

Event

Daily

Maximum

starts

Trip

Current

Machine

Date/Time

value

counter

running

display

start

day

data

trend

Display

Page

Time P4

ID PO

P4

P4

P4

P10

P5

P6

P50

P51

P52

P53

PO

Code

Trun

I

MAX

Nst

Ttrun

-

-

-

-

-

MACH

ID

-

Description

Running

Timeoflast

Maximum

monitored

Countertocount

numberofstarts

Total

of

Displays

Start

Dayand

maximum

(highest

Data

Current

1to10 sec.before

Individual

or

DATE

running

motor

counter

days

display

motor

and

current

time

last

14 events

for

of operation

number

starts

3 days)

at trip

value

display

codeofS2E21

TIME

value

the

last

starts

trip

start

of

Page 6

PROTECTION

Overload

tific

calculation

The

measured

protection,

temperature

line

stant.These

method

If

RTD's

heating

heating

be

offers

are

and

and

calculatedbythe

locked

performed

simulation

currents,

values

are

complete

presentinthe

cooling time

cooling time

relayinauto-learning

rotor

protection,

by the

relay,

protection

the

motor

constantly

protection

motor

thermal

monitored

for

the

constantofany

constants

START

by

and

simulating

method

calculates

heating time

by

the

all

motor

applications

auto-learning

typeofmotor,

an

operator.Starting

mode

.

repeat

start

real-world

constant,

relay

function

eliminating

protection

temperatures

the

rotor

and

and

andcompared

.

will

allow the

the

currents

are

.

stator

the

motor

to

relaytoread

need

and

acceleration

accomplished

heat

rise

cooling

the set

trip

the

for

programming

time

byascien-

based

time

on

con-

points.This

actual

the

may

also

Ambient

(temperature)

Time

t

Page 7

1

Function

PROTECTION

Overload

Instantaneous

Over

current

Overcurrent

Phase

unbalance

Under

current

Ground

Locked

Repeated

fault

rotor

start

External

fault

input

Description

Rated

curren

Heat

time constant

Cooling

Allowable

Operating

Operating

Operating

Operating

Operating

time

temperature

current

time

current

time

current

(Minimum)

Unbalance

Operating

Operating

Operating

Operating

Operating

Starting

Starting

Allowable

ratio

time

current

time

current

time

current

time

locked

Automatically

conditions

2

external

and

fault

:

:

constant

:

:

:

t

:

:

:

:

:

:

:

:

set

:

set

:

rotor

calculated

thermal

input

ports

:

rise

of

stator:60

time

:

based

on motor

capabilityofmotor

2A

-

2000A

10

-

165

Min

.

10

-

500

Min

.

-

125°C

5-17 x

50ms

1.5-10x

0.3- 1

0.5x

(3Q)

Rated

or

less

Rated

Sec

.

Rated

Average)

current

5-30%

4

sec.of

less

0.3-0.8xRated

1 -

5

sec.±

10%

0

.05-.40

0.1- 1

0

.1

Others:±

1.51 1 -

operation

.5

sec

sec

. :+40%-0%

20%

15 x

60

sec

130sec

x

ZCT

.

Rated

.

.

history,

.

current

±

current

±

10%

current±10%

Pri

.Rating±10%

current

present

15%

±

5%-

Curve

No

1

2

3

4

.

10,000

1,000

U

N

m

E

c

0

am

a

O

T

Overload

Heating

constant

(min)

10

10

165

165

Overload

Curve

4

Examples

3

1

2

C~i%::al

100

.rt

10

MOM

https://manualmachine.com/~IIIII~~~111111~~~~11111~~~111111

~1

N11

111110111

1

.

.lm

1I

a

WE!

Pl~~

ME_

.

...ll{

~~~IIIIII~~~IIIIII~~miIIIIMIIIII

0

.1

0

.1

time

1

--~

Multiples

Curve

Examples

Allowable

temperature

(IC)

125

125

125

125

10

Units

of

rise

100

Current

(Times)

Rated

temperature

(IC)

10

100

10

100

1,000

rise

Time

(sec)

Short-circuit,

1000

100

U

0)

am

E

c

0

a)

Q

O

j

0

0

.01

Unbalance

12

s

4

i

5 10 15

Underbalance

Overcurrent,

and

Undercurrent

c

m

®r.

Time

(sec)

I

.II

I

111111

10

Units

of

Current

Overcurrent

Short-Circuit

1111111

100

(Times)

Ground

0

.5

5 10

15

Zero

(Ratio

against

1111

1,000

Fault

20 25

square

ZCT

-

HI

Curve

30 35

current(~)

primary

40

rating)

45

~~

10

-_

~~

1

.

...r

II

. .

._____1111

l

.

nOE

M

.1

0

.1

1

Multiples

Curve

20 25

30 35

(%)

Page 8

Set

Point

Item

CT

rating

ZCT

rating

Rated

current

Heating

constantofstator

Cooling

Allowable

temperature

Rated

INST

OC

OC

Unbalance

UC

UC

G.F.

G

Allowable

time

Starting

Starting

Data

communication

time

time constantofstator

stator

rise

stator

temperature

operating

operating

operating

operating

operating

operating

.F.operating

in

COLD

current

current

time

ratio

current

time

current

time

locked

condition

current

time

SET

rotor

rise

POINT

Page

P20

P20

P20

P21

P21

P21

P21

P22

P22

P22

P23

P23 IUC

P23

P24

P24

P25

P25

P25

P26

Code

ZCT

TR

TD

6SM

9SN

I

INST

IOC

TOC

TUC

IOCG

TOCG

TSC

IST

TST

CT

UB

IN

-

LIST

Value

5-2000

50-100

40-100%

10-165

10-500

60-125

125

10

-

5-17 x

1.5-

10 x

0.3- 1

SEC

5-30%

30-80%xIN

1 -5SEC

5-40%xZCT

0.1- 1.5SEC

1 -

130

1.5-

15 x

1 -60SEC

SlaveNo.:1

Parity:None,

Remote

A

A

MIN

MIN

DEG

(RISE)

DEG

RISE

IN

IN

SEC

IN

-31

Even

set:No/Yes

Factory

Set Point

5A

50A

40%

10

MIN

10

MIN

60

C

50

C

0

OFF

0

OFF

0.3SEC

0

OFF

0(OFF)

1

SEC

0

OFF

0.1SEC

0(OFF)

6 times

1

SEC

1

0

(NONE)

0 (NO)

IN

Description

Motor

protection

Motor

protection

Motor

protection

Motor

protection

Motor

protection

Motor

protection

Motor

protection

Monitor software

Converter

Memory

Reader

Memorycar

card

./Writer

d

relay

relay

relay

relay

relay

relay

relay

Memory

Alarm,

Output

configuration

Analog

RTD

Auto-learning

card

reset

output

ORDERING

Order

Code

S2E21-C1

S2E21-ClAA

S2E21

S2E21-C1

S2E21-C1

S2E21-C1

S2E21-C1 AF

S2E21

4D9E0054GOO1

4D9E

A

-C1AB

AC

AD

AE

-SE

4D9E0054GOO2

0057GOO

level

1

ModelNo.

ADP-6237B

MZA5001

MCA5101

AAA

BAA

P27

P28

P33

P29

P30

P31

P32

P34 P34

-

-

-

-

-

ATD

RTD1-8

INFORMATION

Function

Standard

WithDGfor

WithDGfor

WithDGfor

WithDGfor

WithDGof

WithDGof

3.5inch

Necessary,

Necessary,

from

S-RAM,

ungrounded

ungrounded

10A

10A

capacitory

capacitory

2HDFDD

when

when

computer

32-kbyte,40pin

grounded

grounded

data

memory

- -

Output

selection

fail-safe/non-fail-safe

Output

selection

RTD

selection

IST

:

Tst

:

TR

:

TD

:

system

system

system

system

voltage

voltage

communication

card

Off/On

50Hz

60Hz

60Hz

50Hz

division

type

50Hz

division

type

60Hz

(RS485)

usedinprogramming

used

OL

Trip

non-fail-safe

0

NONE

0

NONE

OFF

Accessory

Memory

Memory

Test

plug

Quantity

Cable

Cable

card

card

(Qty

(Qty

1

for

1)

1)

Items

DDG

(Qty

(Qty

1)

1)

(Qty

1)

Page 9

MONITOR

SYSTEM

TOSHIBA'S

MONITOR

Easy

operation.All

MAIN

MENU

monitor

SYSTEM

system

items

can be

are

2

3

usedtoplan

selected

Relay

selection

Set

point

Information

from

the

and

menu

implement

w

.

a motor

Bon

Bo~

Boom

Boom

Boom

2

3

2

3

4

5

maintenance

PC:J3100,

CONVERTER:ADP-6237B

MEMORY

CARD:MCA5101BAA

READER/WRITER

Protection

RTD

Output

relay

configuration

ID

Relay

status

Event

history

Numberofstarts

Trip/alarm

Relay

information

selection

program

R

T3100

:

MZA5001AAA

.

History

5

Trip

Print

Relay

Initialize

9

Configuration

End

curves

out

operation

memory

card

2

3

4

2

3

2

3

Current

Temperature

RTD

Time

Data

Reset

Time

Parameter

Communication

Communication

Directory

MS-DOS

history

history

span

selection

clear

setting

setting

rise

history

selection

test

Page 10

DIMENSIONS

External

89

IR

Dimensions

(3 .50)

171-

of

S2E21-C1A*(without

4-o6(0

.236)

holes4-o 6(0.236)

CUTOUT

N

N

N

07

N

DETAIL

DG)

ao

t0

N

O

N

hales

External

U

J

36161

(1

.417)

DIMENSIONSINMM

.339)26

(6

(INCHES)

(1

.024)

267

295

(10

D

(11

Dimensions

.512)

.614)

of

S2E21-C1A

4-o 6(0.236)

N

N

Of

N

(1

.417)

DIMENSIONSINMM

holes

CUTOUT

[](with

4-e 6(0.236)

DETAIL

.024)

(1

(INCHES)

DG)

holes

O

f0

N

O

N

L~Q

CONNECTION

'W's

4%

[tStDUExromxxER

oixECrLrmsExtxEUr

-

(u)

(u1.~4t7wK

'~

<

t

-IF7

[ormx~

to

~}L~

21

.o16

xatwG)

Page 11

NOTES

Page 12

TOSHIBA

TOSHIBA

INDUSTRIAL

13131

(713)

Tel

:

U.S. :

World

TOSHIBA

1-1,

Shibaura

Telex:J22587

Fax:456-1631

OVERSEAS

Mexico

Wien,

Wellington,

TOSHIBA

Pty.Ltd.:

Toshiba

Limited:London

"

For

"

The

L-A-001-97

INTERNATIONAL

DIVISION

West

Little

466-0277

800-231-1412

Wide

Web

CORPORATION

1-Chome,

TOSHIBA

City,

Caracas,

Berlin,

Hong

Johannesburg,

INTERNATIONAL

Sydney,

International

further

data

giveninthis

YorkRd.,

Fax:(713)

CANADA:800-872-2192

Http

://www

Minato-Ku,

Cable:Toshiba Tokyo

OFFICES

information,

Rio de

Kong,

:

Bangkok,

Beijing,

Melbourne

Company

Houston,

.tic

Janiero,

catalog

CORPORATION

Texas

466-8773

.toshiba

Tokyo,

Buenos

Manila,

Tipei,

CORPORATION

please

77041

Telex

.co

m

105,

Phone

Aires,

Jakarta,

Guangzhou

contact

are

subject

COPYRIGHT

:

Japan

762078

457-4900

:

London,

Sydney,

your

nearestToshiba

to

change

©

1997

without

TOSHIBA

Representative

notice

.

INTERNATIONAL

.

COPORATION

PrintedinU.S.A

.

Loading...

Loading...