Page 1

Page 2

TOSHIBA

1.

2.

*N*ROD”CT[ON

GENERA,, SpECIF~CAT]ON

2.1

Rat,& Performance

2.2

Functions

2.3

Pr,ot~tion Curves

........................................................

................................................

..............................................

......................................................

..............................................

6F9EOlll

CONTENTS

Page

-j-

3

4

5

17

3.

APPEARANCE AND CONFIGURATION

3.1

SZEZl-ClA*

3.2

S2.E21-ClA[

4.

MODNTlNO

4.1

AND CONNECTION

MolJnting

4.2 Co~yj&ion

HANDLING

5.

lnijtal1 ing Battery

5.1

5.2 Turning Power On

(without

1 (with

.......................................................

.....................................................

............................................................

...............................................

5.3 Basic Operation of Screen

5.4 Registration of

5.5 Menu

...........................................................

5.6 Measurement

5.7 Event

5.8 Setting

5.9 Testing

5.10

Failure

..........................................................

........................................................

........................................................

Information

ID

....................................................

5.11 Hand1 ing of Memory Card

5.12 Directional Ground Unit

6.

MAINTENANCE AND INSPECTION

6.1 Periodic Inspection

6.2

6.3

Troubleshooting

Berlch Test

.................................................

......................................................

........................................

.......................................

DG)

........................................

DG)

.............................................

..........................

......................................

.............................................

............................................

........................................

(DG)

..........................................

............................................

:.

.................

...................................

18

18

21

27

27

30

38

38

38

39

44

46

47

54

56

81

83

86

91

92

92

96

I,,,,

7.

PROTECTIVE DETECTION SCHEME

7.1 Overload Unit

7.2

Locfked Rotor hit

Reptitive

7.3

..................................................

...........................

Starting

.........................................

.............................................

7.4 Detection of Starting Current and Starting Time

...............

..-.c

.................

105

105

109

113

114

7.5 Detection of the Heating Time Constant and

Cocli

ing Time Constant

7.6 Setting Based on Fundamental Information

Setting For Reduce Voltage Starting .............................

7.7

APPENDIX A

Rev

2

2

g

>

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

TYPE

S2E21-ClAU

...........................................

........................

VERSION 1.01

115

117

120

121

-l-

Page 3

TOSHIBA

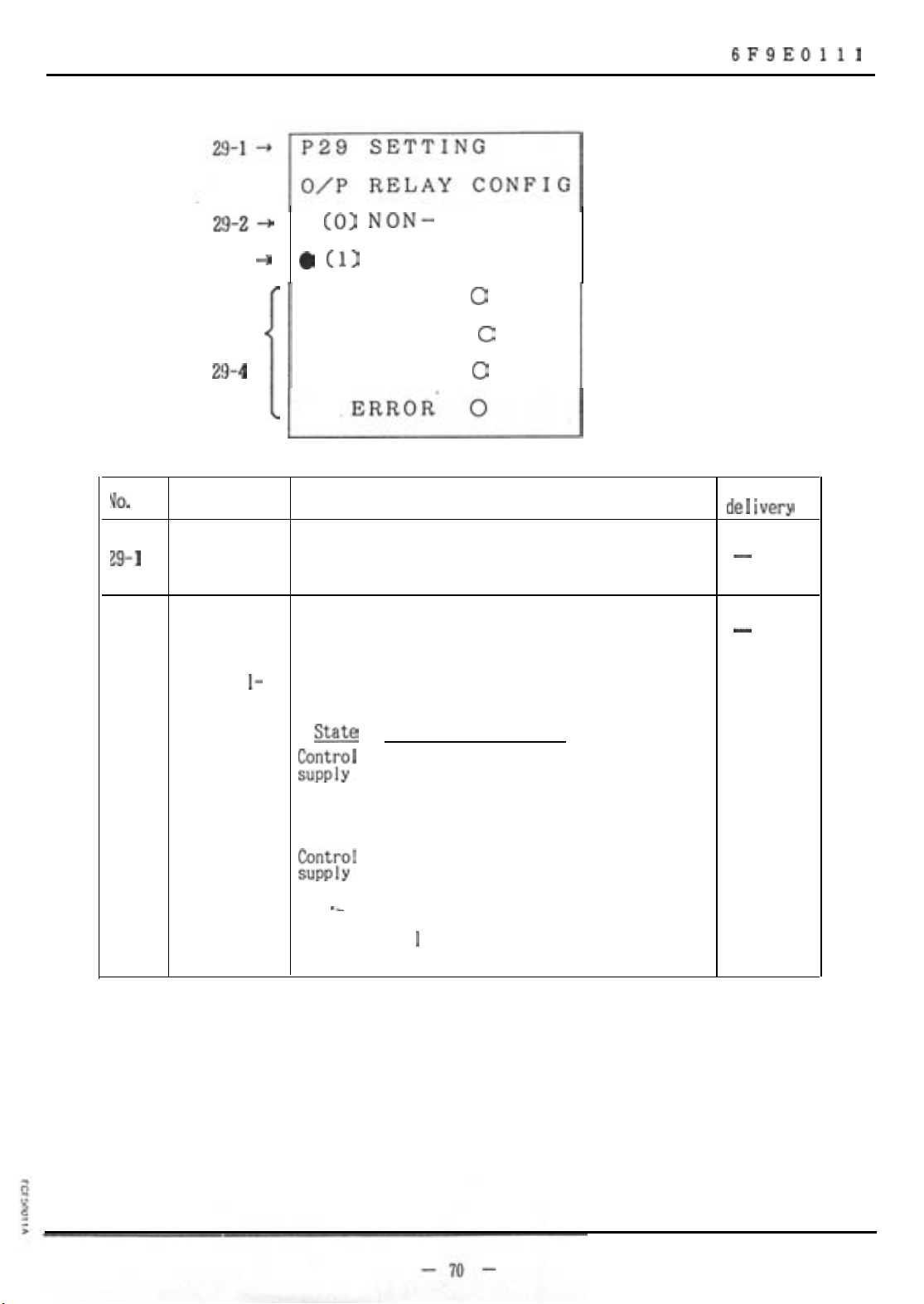

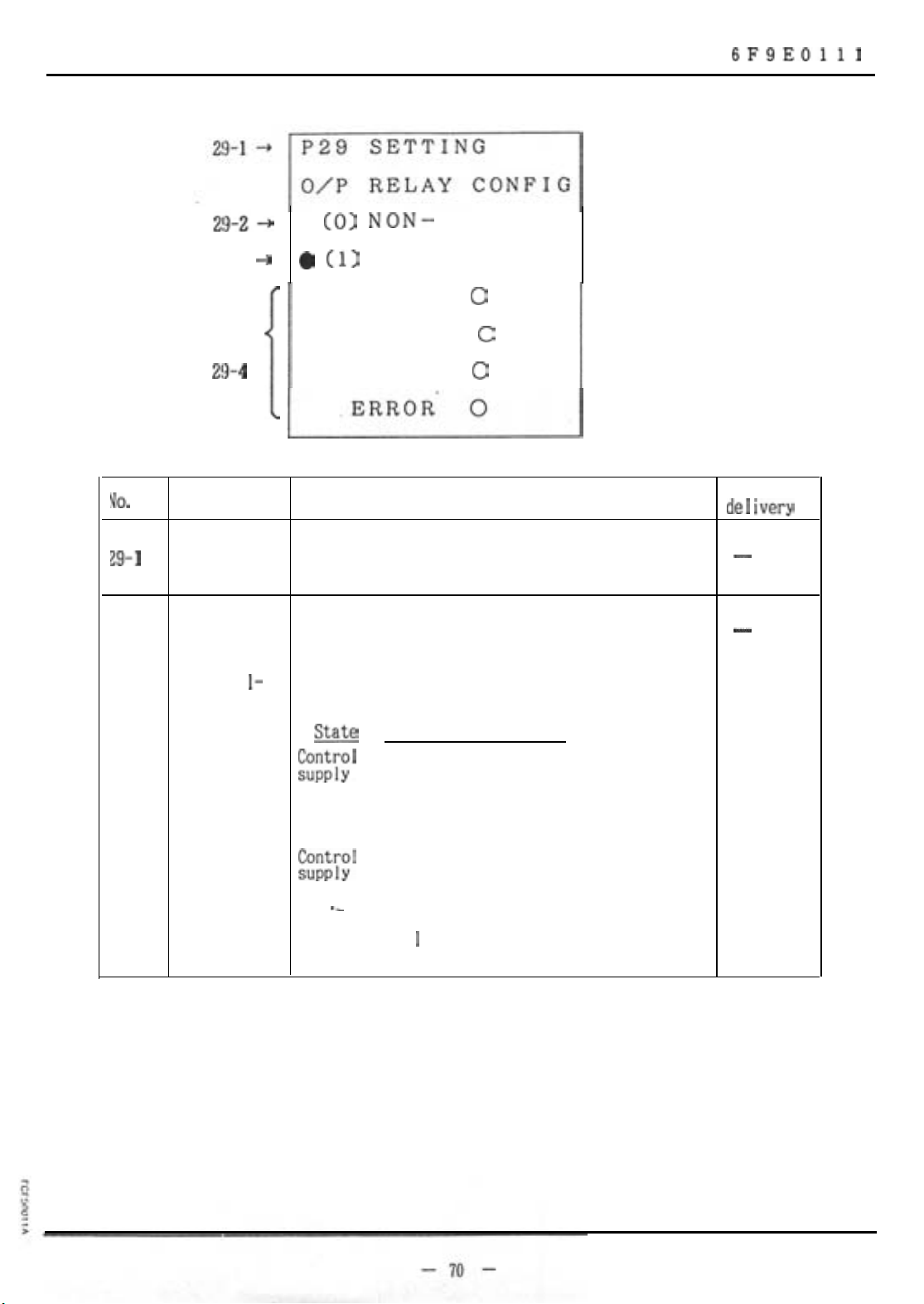

29-3

--)

0

(0) NON-

0 (1)

FAIL-SAFE

6F9EOlll

FAIL-SAFE

VO.

29-l

29-2

TRIP

ALARM

2!J-4

i

Item

Setting

Energized-on The output relay is energized on operation.

operation

(Non-fai

safe)

Description

Sets the operation mode of the output relay.

The state of output contact is shown below in

I-

the case of tripping.

E$r;’

not

provided

State

LOCK

a-contact b-contact

Open Closed

0

0

0

State at

de1 ivery

-

-

:%;’

provided

.-

Trip

Open Closed

C 1 osed Open

Page 4

TOSHIBA

6F9EOlll

i0.

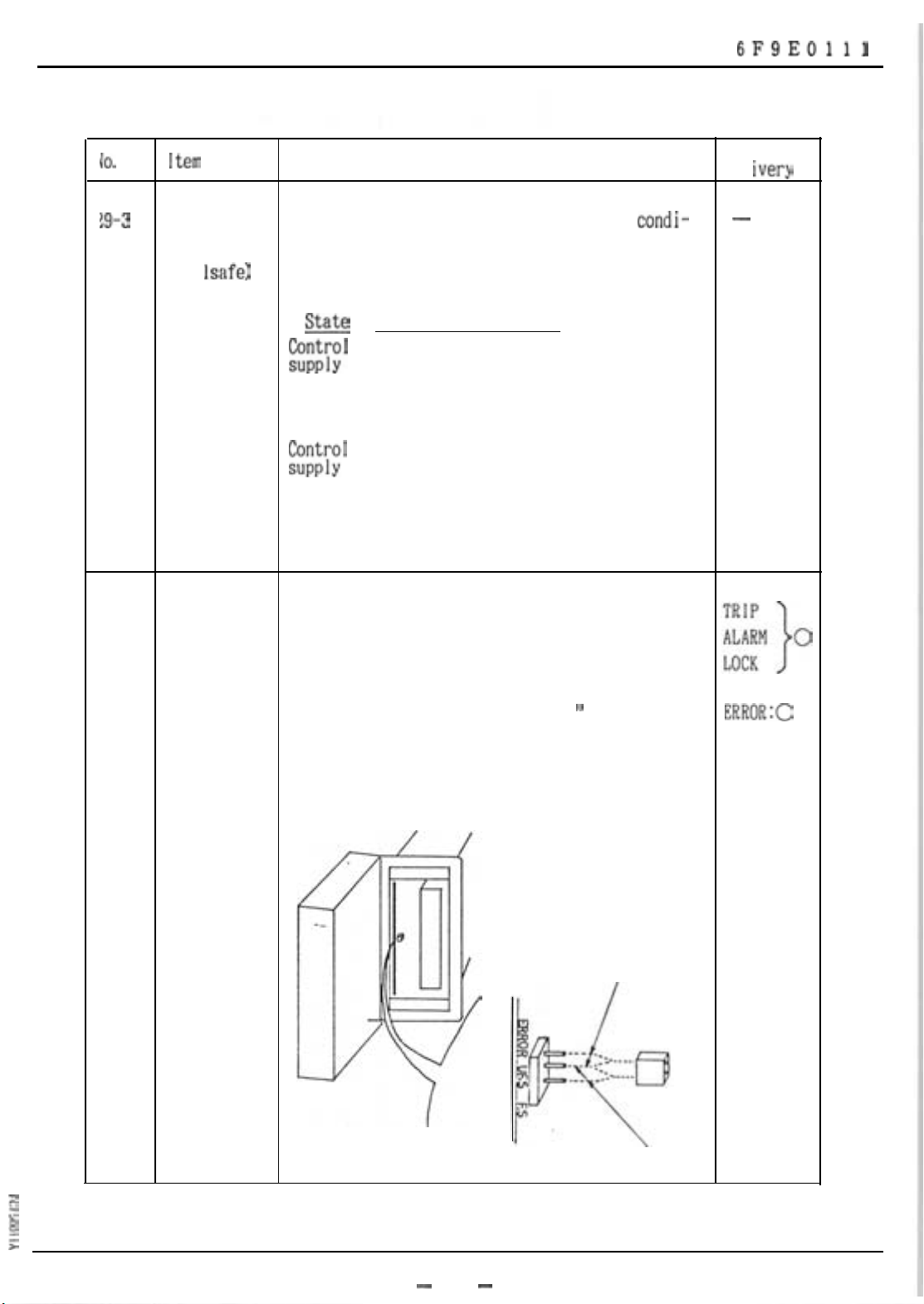

29-3

!9-4

Item

Description

Continuously The output relay is energized at normal

energized

(fai

Isafe)

tion. The state of output contact is shown below

in the case of tripping.

m

a-contact b-contact

Open Closed

t%;’

not

provided

Closed

Open

&$;’

provided

Setting

Trip

Selects between continuously energized and

Open Closed

energized-on-operation for 3 outputs-trip.

alarm, and lock.

Setting is made by moving the cursor to this

position and entering “0” or “1.

‘*

condi-

State at

de I ivery

-

ERROR:0

The setting of the error output is made in

hardware.

Non-fail-safe

fail-safe

-

71

-

Page 5

TOSHIBA

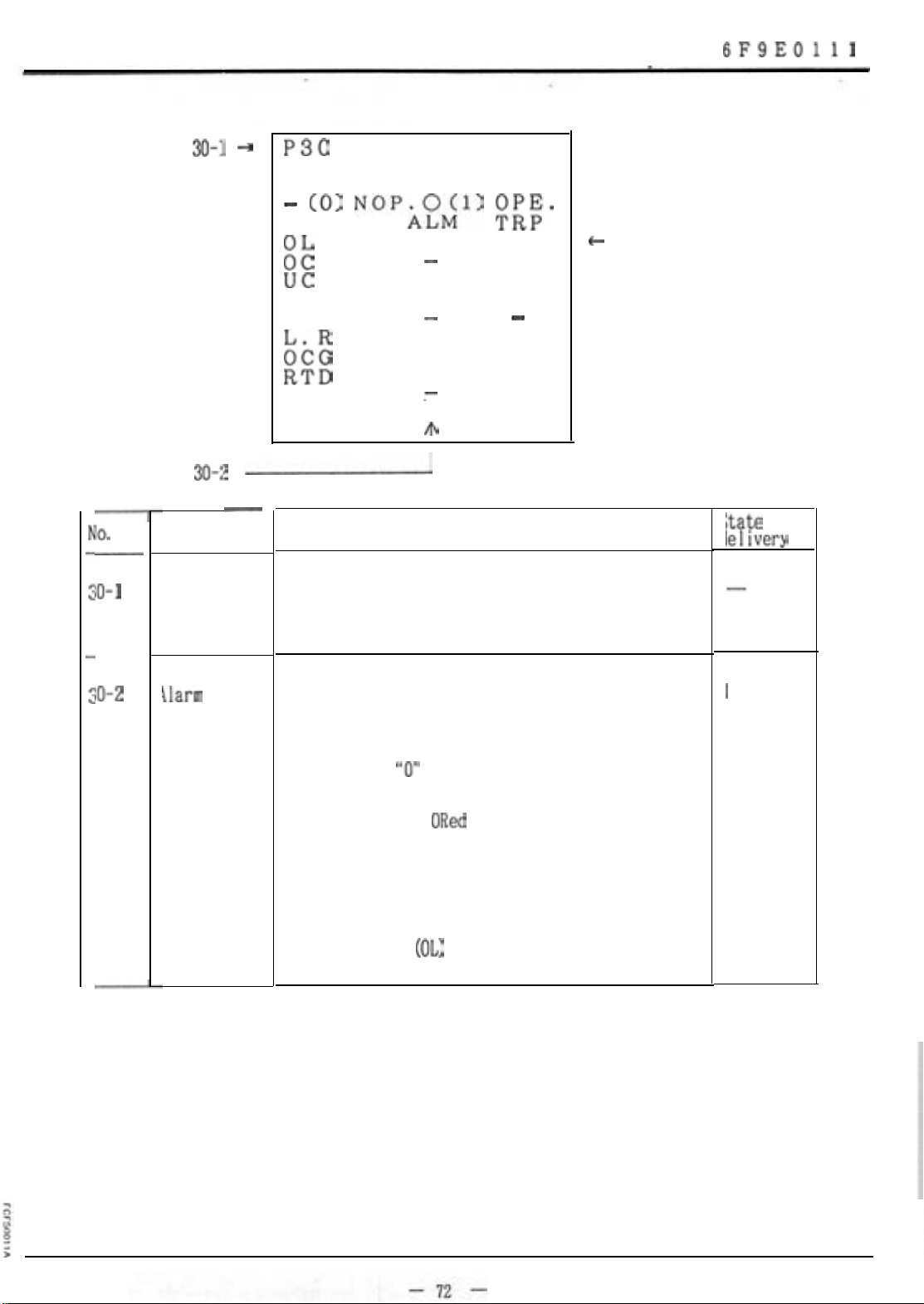

30-l +

P30

SETTING

RY O/P SEL.

- (01 NOPi.&

E%

-

UC

INST

UB

g

- -

6F9EOlll

;;;.

+

0

30-3

D-1

&2

30-3 A

Item

jetting

\larm

output

SPARE1

-

SPARE2

m

-

Description

Sets the operation condition for the output

relay.

Selects a unit that drives the alarm output

relay when an alarm is detected.

Enter either

The output is an

from the unit that drives the alarm output

relay.

"0"

(not operate) or "1" (operate).

ORed

output of alarm detections

Zate at

leiivery

I

Locked-rotor has no alarm. But it isdetected

as an overload

(OL)

alarm instead.

Page 6

TOSHIBA

6F9EOlll

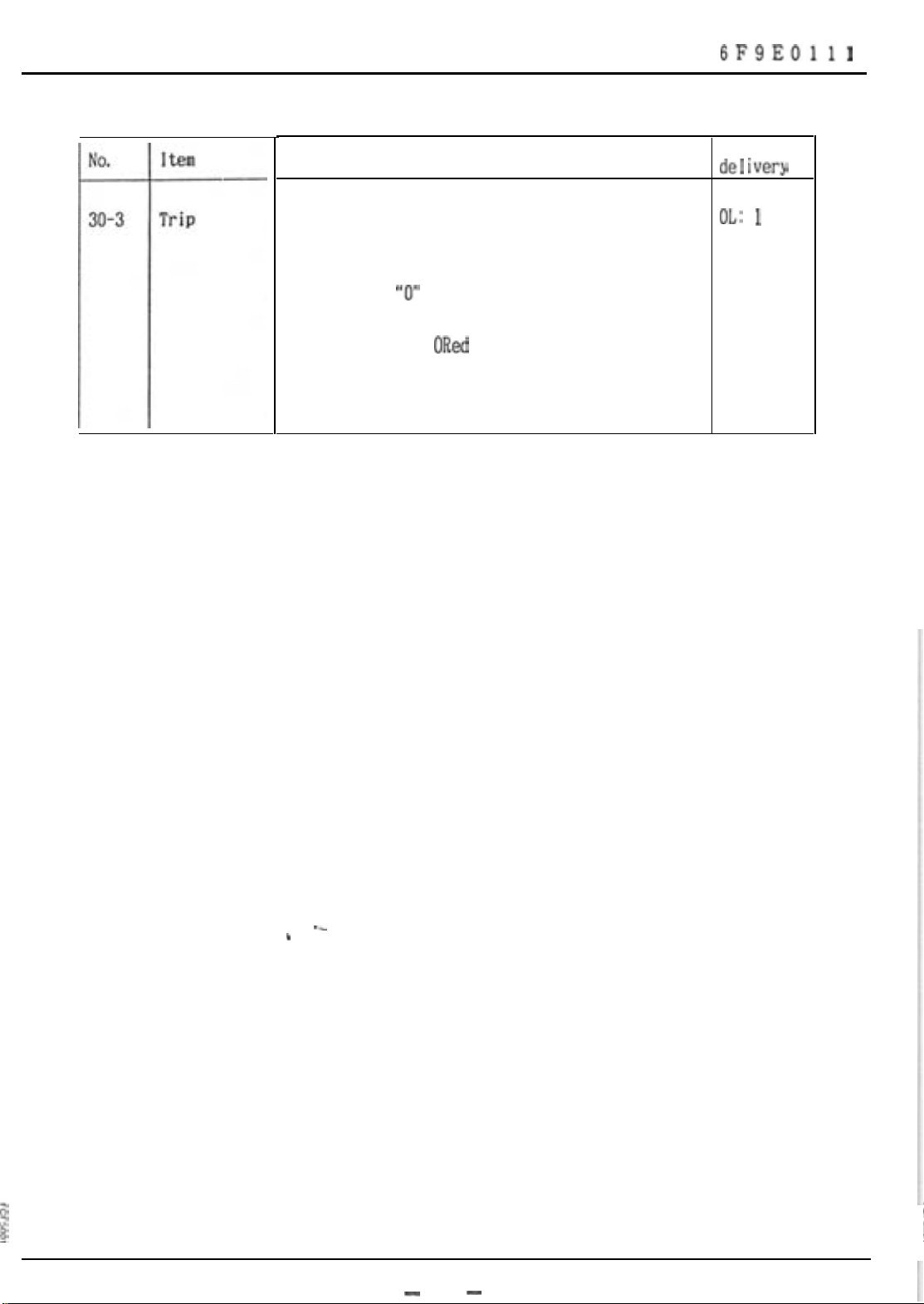

No.

30-3

item

Trip

Description

Specifies a unit that drives the trip output

relay when a trip is detected.

Enter either

The output is an

from the unit that drives the trip output

relay.

I-

“0”

(not operate) or “1” (operate).

ORed

output of trip detections

State at

de1 ivery

OL: 1

Others:

--

.

-

13

-

Page 7

TOSHIBA

6F9EOlll

No.

31-1

31-1

--t

31-2 ‘+

I tern

Setting

P31 SETTING

ATD O/P = 2

“1’14;”

2=IS

3=IT

4=IAV

5=es

6=8R

Description

Selects an analog transducer output.

7=RTDl

8=RTD2

9=RTD3

1

O=RTD4

ll=RTD5

12=RTD6

13=RTD7

14=RTD8

.15=10

>

State at

delivery

-

31-2

transducer

output

Ana I og

transdwer

output

IR

IS

IT

IAV

8.3

BR

Selects a measuring unit that outputs data to

the analog transducer.

I

4mA -

0

A

‘or

CT RATIO

I

0°C - BSM

oc

-

20

mA

(No.20-2)

(No. 21-6)

200

"C

transducer

xltput

RTDl

RTD2

RTD3

RTD4

RTD5

RTD6

RTDt?

10

-2o'c -

4mA

OA

0

-

-

20

mA

2OO'C

ZCT RATIO

(No.20-3)

-

14

-

Page 8

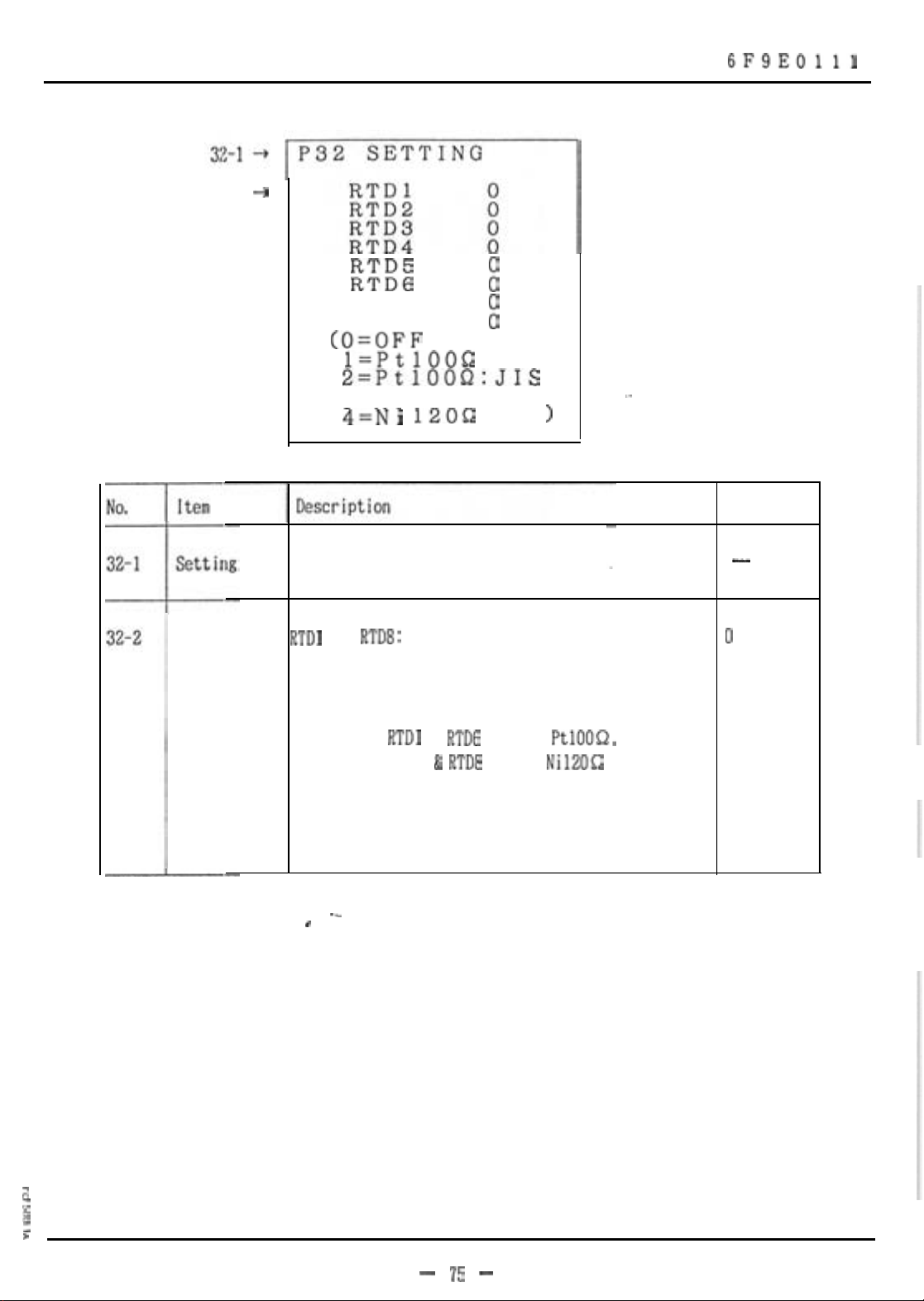

TOSHIBA

32-2

6F9EOlll

+

Kind of RTD

EE

:

RTD7

RTD8

:

(O=OFF

l=PtlooQ

2=PtlOOQ:JIS

3=Ni

4=Ni 12062

Sets the kind of RTD.

RTDl

to

type. Different RTD types can be selected on

one relay.

Example:

10062

RTD8:

Selects the corresponding RTD

RTDl

to

RTDG

can be

RTD? &

individual relay.

RTDB

can be

>

PtlOOQ,

Nil2062

-.

and

on one

State at

delivery

-

0

Set to 0 (OFF) those channels that are not used.

--

.

z

g

I

>

- 75 -

Page 9

TOSHIBA

6F9EOlll

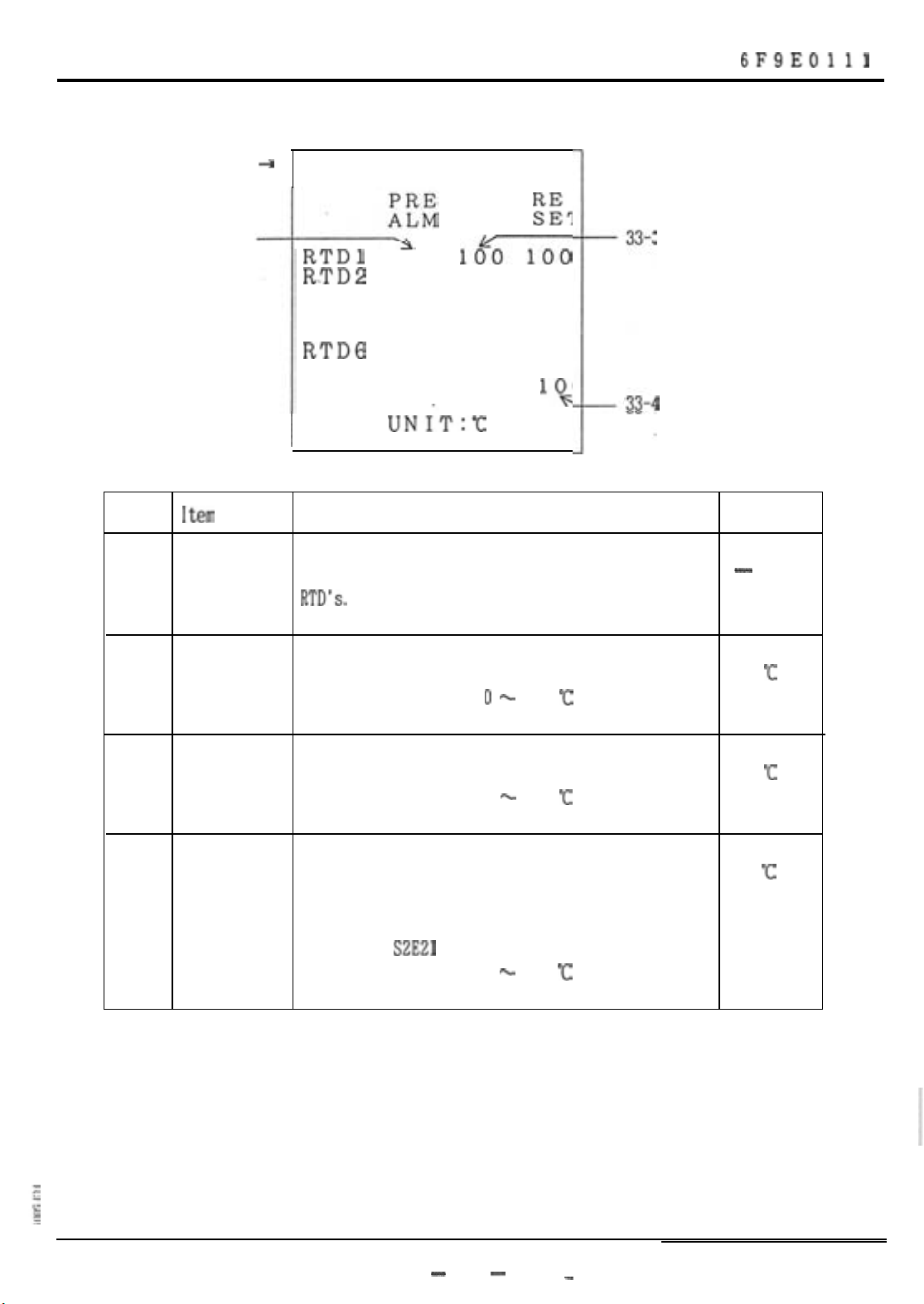

No.

33-l

33-1

33-2

Item Description

Setting Sets the alarm, trip and reset levels for the

P33 SETTING

+

TRP

RTDl

R.TD2

RTD3

RTD4 100 100 100

RTD5

RTDG

RTD7

RTD8

100

100 100 100

100 100 100

100 100 100

100 100 100

100 100 100

100 100

UNIT:C

10%

I

RTD's.

ti%T

33-3

102

.33-4

1.

State at

delivery

-

33-2

33-3 Trip level

33-4

Alarm level Sets alarm detection temperature for each RTD.

Reset level Sets a reset temperature for each RTD. 100

100

'C

Setting range: 0 - 200

Sets trip detection temperature for each RTD.

Setting range: 0 - 200

After the temperature goes below the reset

level. the S2E21 can then be reset.

Setting range: 0 - 200

'c

"c

C

100

'c

'c

-

76

-

-

Page 10

TOSHIBA

6F9EOlll

lo.

34-l

34-1

34-Z --)

34-3

34-4

34-5

I

tern

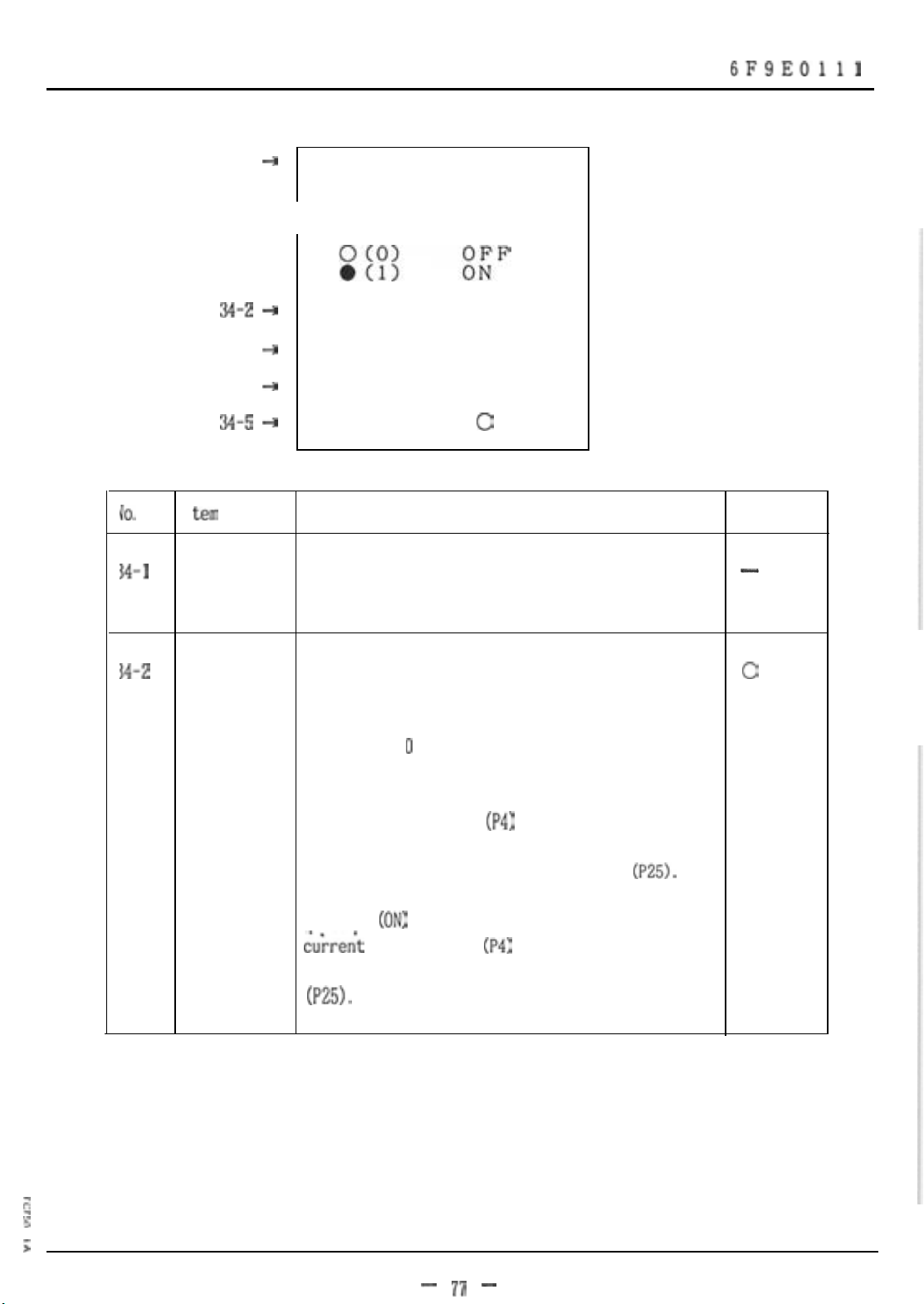

Setting Sets whether or not automatic detection is

P34 SETTING

+

*AUTO LEARNING*

1st

--t

+

+

Description

needed.

Tst 0

TR 0

TD

0

0

State at

de I i very

-

34-2

Starting Automatically detects the starting current and

current

specifies whether or not the detected value is

taken as the starting current setting.

Enter either 0 (OFF) or 1 (ON).

When 0 (OFF) is entered, the detected starting

current is displayed

not the detected value, is used as the setting

value in the starting current setting

When 1

d&rent

setting value in the starting current setting

(P25).

(ON)

is entered, the detected starting

is displayed

(P4)

but the input value,

(P25).

(P4)

and also taken as the

0

$

z

3

i

- 17 -

Page 11

TOSHIBA

6F9EOlll

No.

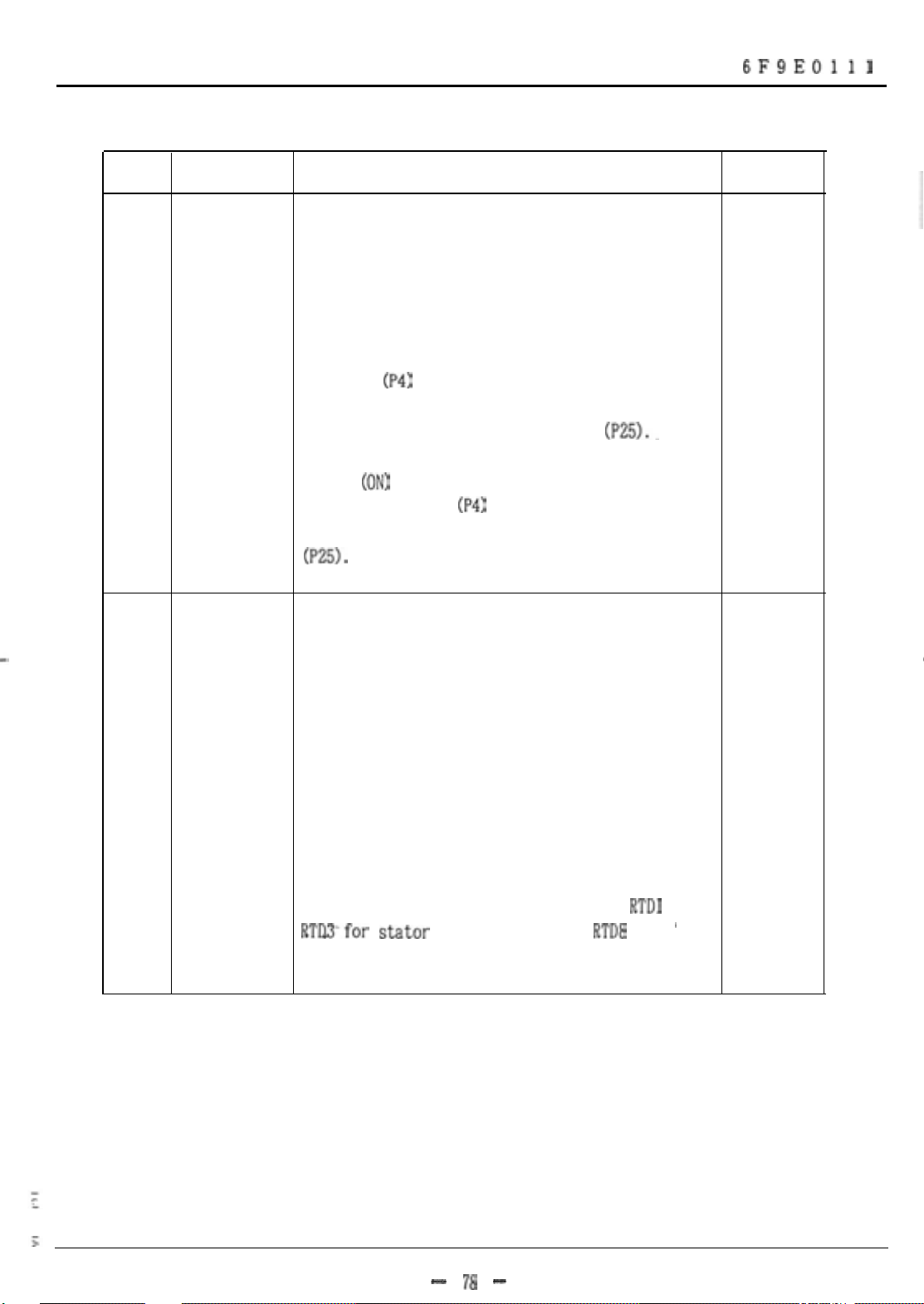

34-3

34-4

Item

starting

time

Heating time Automatically detects the heating time constant

constant

Description

Automatically detects the starting time and

specifies whether or not the detected starting

time is used as the setting value.

Enter either 0 (OFF) or 1 (ON).

When 0 (OFF) is entered, the starting time is

displayed

not the detected value, is used as the-setting

value in the starting time setting

When 1

time is displayed

setting value in the starting time setting

(P25).

and specifies whether or not the detected value

is taken as the heating time constant setting.

(P4)

but the input setting value;

(P25)..

(ON)

is entered, the detected starting

(P4)

and also taken as the

State at

delivery

0

0

When 1 (ON) is entered, the heating time

constant is automatically detected and the

detected value is taken as the setting value.

Upon completion of detection, this setting

automatically turns off.

Automatic detection requires input of

RTDPfor

ambient temperature.

stator

temperature, and

RTD8

RTDl

to

for

'

- 18 -

Page 12

TOSHIBA

6F9EOlll

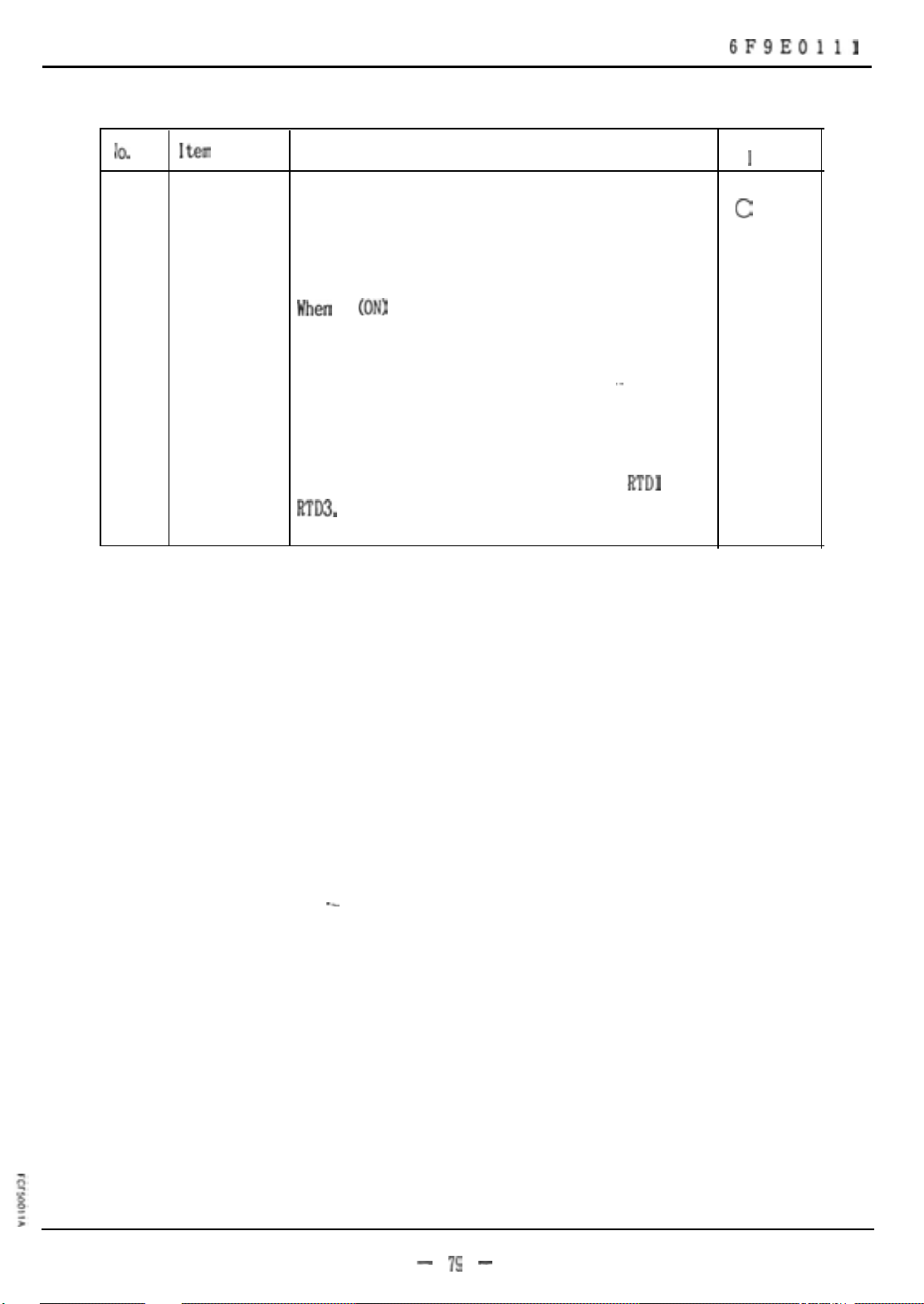

IO.

14-5

Item

Description

Cooling time Automatically detects the cooling time constant

constant

and specifies whether or not the detected value

is taken as the cooling time constant setting.

When

1

(ON)

is entered, the cooling time

constant is automatically detected and the

detected value is taken as the setting value.

.-

Upon completion of detection, this setting

automatically turns off.

Automatic detection requires input of

RTD3.

and RTD8 for ambient temperature.

RTDl

to

State at

de 1 i very

0

--

- 19 -

Page 13

TOSHIBA

6F9EOlll

I

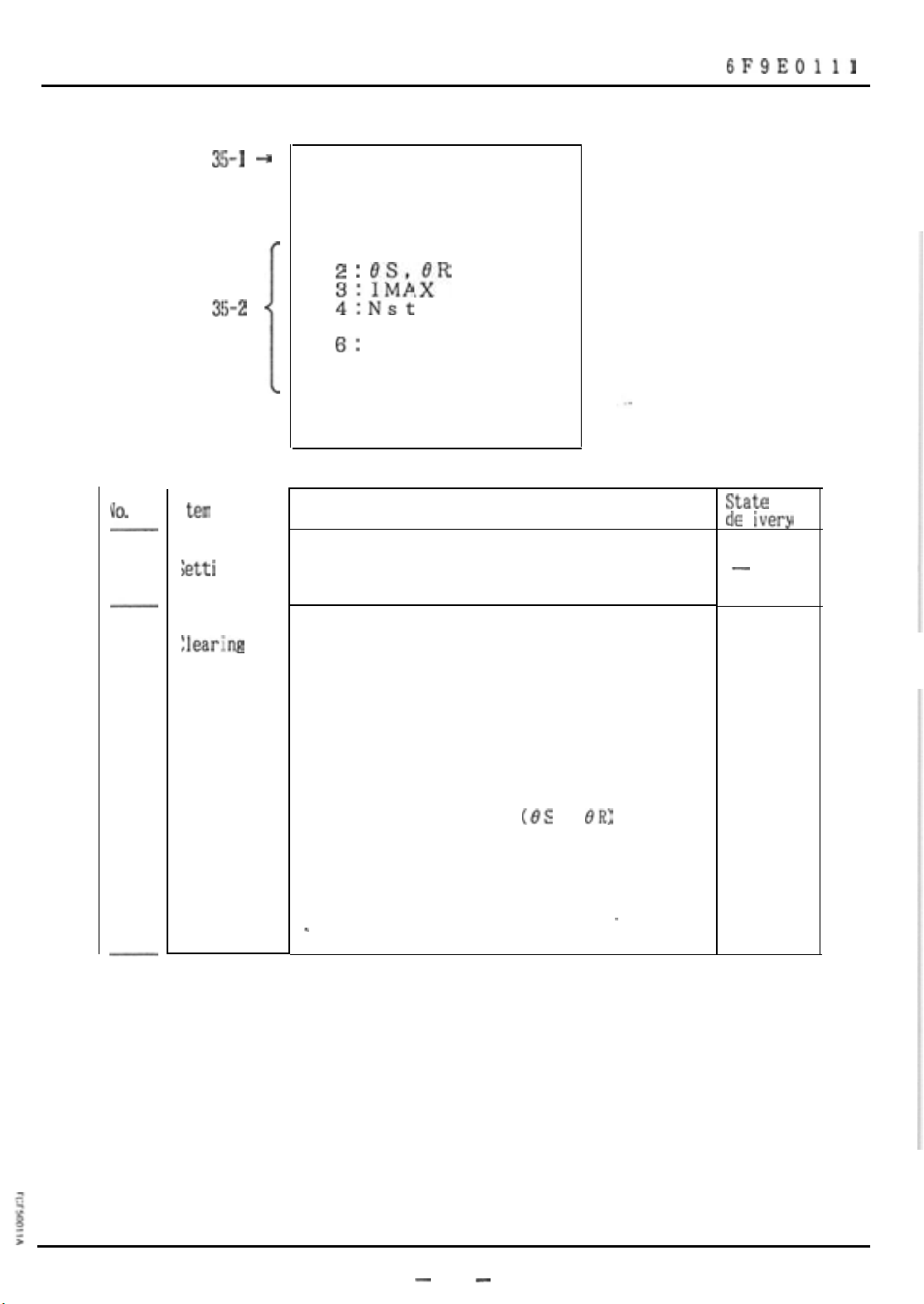

UO.

35-1

3!i-1 --)

P35 SETTING

Clear data 0

(1 : ALL

: : ELii”

3!+2

4iNst

5:Ttrun

6:

7 : LEARNED TD

1

8 : MAX STARTS)

-:

tern

Description

--

Iett i

ng

Clears accumulated data and held data.

--

LEARNED TR

itate

le

I ivery

-

at

35-2

:lear:ing

Entering the numbers of items whose data you

want cleared causes the corresponding data to be

cleared.

Example:

1. Data may be required to be reset (cleared)

due to a new motor installation.

2. Temperature data only

(0.3

or

OR)

may be

required to be reset for an emergency

restart. Caution should be taken in

resetting this data. Motor damage may

_

--

result.

-

-

80

-

Page 14

TOSHIBA

5.9 Testing

I

UO.

--

1 tern

M-1

110-2

40-3 +

P40

+

*

*o/p*

Description

TESTING

I/P*

RESET

SPARE1

SPARE2

ATD 4

(4-2

0

:

mA

OmA)

6F9EOlll

Zate

at

le

I ivery

10-I

10-2

Testing

Input

Perform tests on the input/output circuit.

Displays the state of contact input from the

terminal block.

Displays 0 when there is an input: and

Displays 0 when there is no input.

The 3-phase input and zero-phase input are

checked with the current value displayed on P2.

--

^ --

-

-

-

81

-

Page 15

TOSHIBA

6F9EOlll

Description

Changes the outpit of the analog transduser.

Press

a current value

analog transducer.

The output current is checked externally.

[EXE1

key. The cursor appears, and enter

(4-20 mA)

to be output from the

State at

delivery

.-

-

-

82

-

Page 16

TOSHIBA

5.10 Failure Information

6F9EOlll

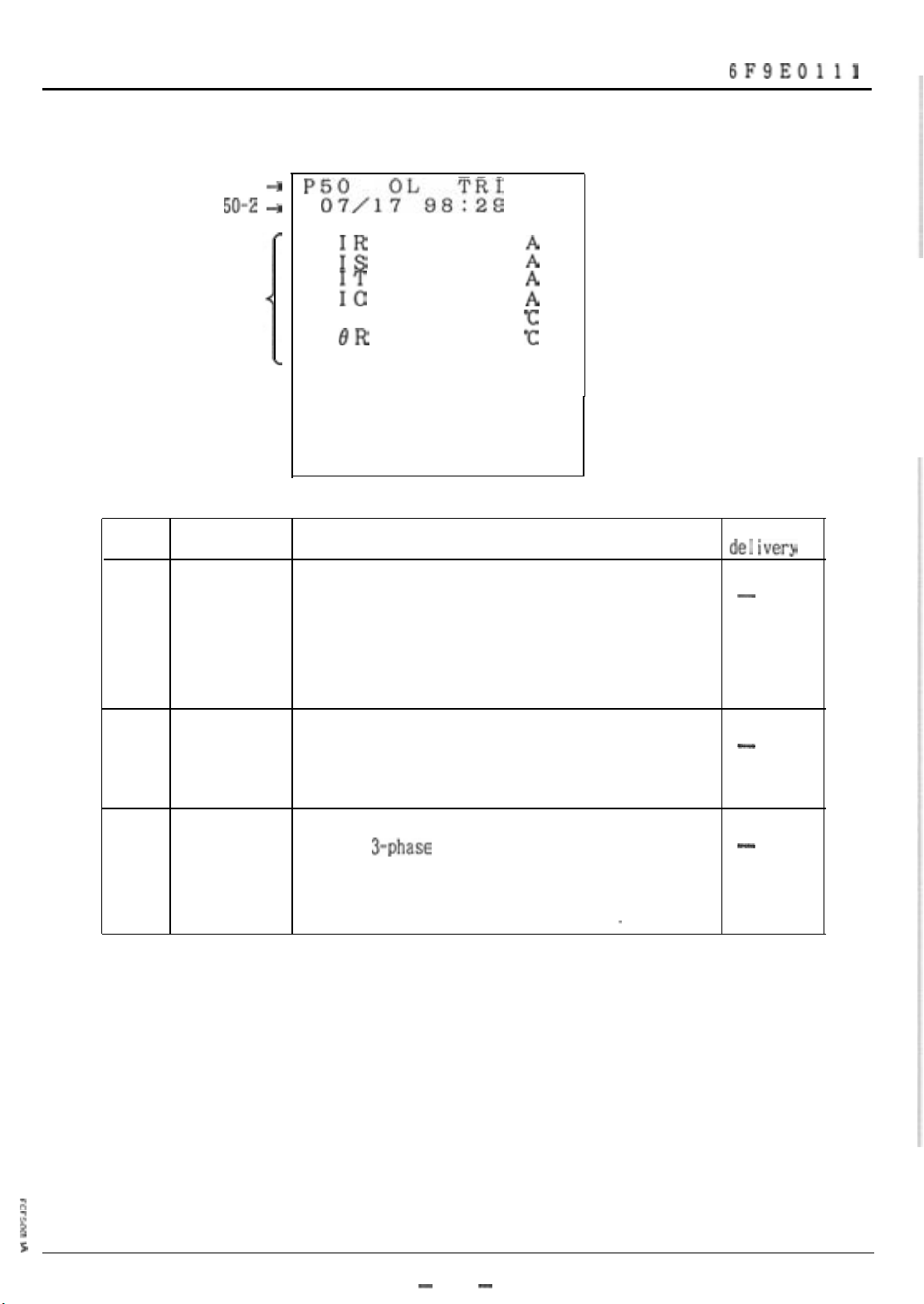

No.

50-l

50-l

50-Z

50-3

Item

Trip

information

+ P50

-3

07dL88:28

:z

128 130

::

132 0

TRIP

2

2

es 60.0

BR

23.2

UB 2%

Description

Displays information at the date and time of the

latest current-associated trip.

:

State at

de1 ivery

-

50-2

50-3

Cause of trip is displayed.

Time

Dispiayes the date and time at which the trip

occurred.

information Displays

temperature rise and unbalance factor at the

trip.

--

3-phase

current. zero-phase current,

-

-

-

:

$

I:

>

-

83

-

Page 17

TOSHIBA

6F9EOlll

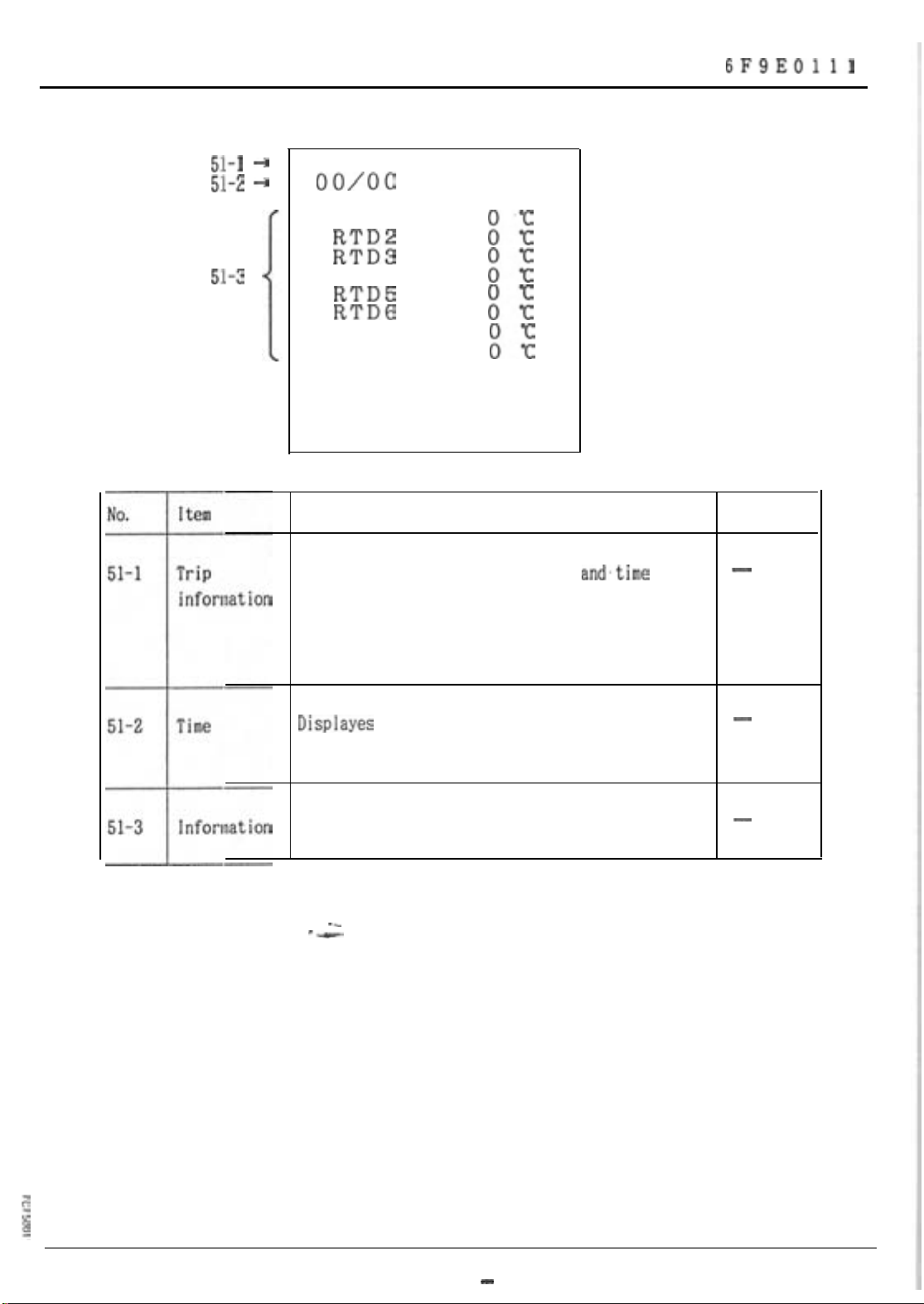

5:1-1 +

5:1-z +

5:1-3

P51

oo/oo

00: 00

TRIP

RTD 1

::

Ez

RTD4

::

RTD5

RTDG

E

RTD7

RTD8

E

Description

Displays information at the date

latest trip.

and.time

of the

State at

delivery

-

RTD number. that has tripped is displayed.

Displayes

the date and time at which the trip

occurred.

Displays temperature of each RTD at trip.

--

--

-

-

- 84

-

Page 18

TOSHIBA

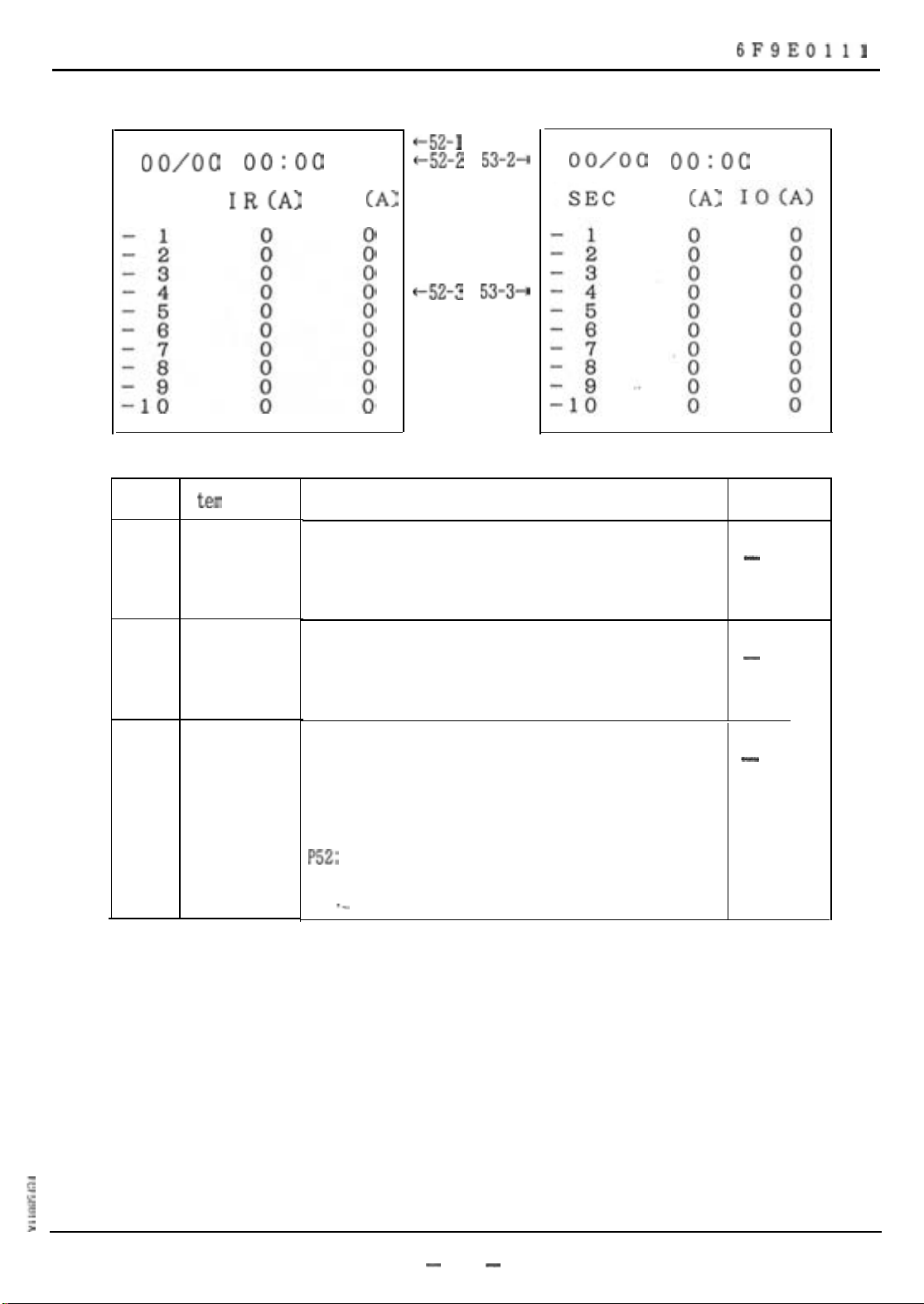

P52 TRIP CURRENT

oo/oo

0o:oo

+52-l

53-1-r

~52-2 53-2+

6F9EOlll

P53 TRIP CURRENT

oo/oo

0o:oo

SEC

No.

52-1

53-l

52-2

53-2

IR(A)

I

tern

Trip current

trend

Time

IS

(A)

IT

(A)

-52-3 53-3-9

Description

Displays the current trend immediately before

the trip

Displays the date time at which the trip

occurred.

State at

delivery

-

-

52-3

53-3

Current

trend

Displays 10 seconds of 1 second interval current

trend before trip.

Current of R-phase and S-phase are displayed on

P52:

and current of T-phase and zero-phase are

displayed on P53.

-_

-

-

85

-

Page 19

TOSHIBA

6F9EOlll

5.11 Handling of

The

SZE21s

Hemory

Card

each have a dedicated memory card, which is used for backup of

S2E21

settings and as information media for the monitor system (purchased separately)

that includes personal computers.

The specifications of the memory card are

shown in Table 5.

5.11.1 Sack up of Setting

The memory card is utilized as a backup of the setting of

the.S2E21.

Procedure for backup

1.

Cancel the write-pretect for the

&x

5.11.3

2.

Insert the memory card into the

&I:

5.11.3

Initialize the memory card.

3.

(See

5.8 P27.

(2j.j

(3). )

)

memory

S2E21.

card.

4.

Store the contents of setting into the memory card.

See

5.8 P27.

5.

Turn on the write-protect for the memory card.

Gef!

5.11.3

)

(2j.j

The memory card uses S-RAM card with a battery backup that prevents the contents

of the backup from being lost when you pull the memory card from the

S2E21.

The battery backup also allows the memory card to be inserted or withdrawn during

the operation of the

S@l.

---

CAUTION: Removing the memory card from the

S2E21

and storing it alone may result

in the loss of the backed-up contents when the backup battery is

exhausted.

The memory card must be left inserted in the

S2E21.

$

g

:

-

86

-

Page 20

TOSHIBA

Procedure for loading the backed-up settings of the memory card into the SZE21.

6F9EOlll

Register the MACH. ID and PASS ID of the

1.

(MACH. ID and PASS ID must be the same as those when the settings were

backed up in the memory card.)

(See 5.3.3. 5.4.)

Insert the memory card into the

2.

(See 5.11.3

3.

Load the backed-up contents from the memory card into the S2E21.

The contents of settings backed up by the memory card are those stored by the

above backup procedure.

the contents of the memory card do not automatically change.

to perform the store operation again.

Prior to the loading of the backed-up settings, comparison is made of the

MACH. ID and PASS ID between the memory card and the S2E21.

numbers do not agree, the backed-up settings will not be loaded into the S2E21.

5.11.2 Memory Card As Information Media

(3j.j

After this, when the settings of the S2E21 are changed,

S2E21.

S2E21.

You are reguired

When these ID

The memory card may be used as information media for the monitor system including

personal computers and for the

For detail, see the manual for the monitor system.

S2E21.

-

87

-

Page 21

TOSHIBA

Table 4 Memory Card Specifications

Item Description

Manufacturer Toshiba

Type

Memory type

Capacity

Scheme Memory bus scheme

Pin number 40 pins

Battery

Battery life Not in relay Approx. 2 years

5.11.3 Handling of Memory Card

MCA 5101BAA

S-RAM

32

kbytes

type

Inserted

Lithium coin battery (3

Greater than 10 years

V)

in relay W/control power on relay

Approx. 2 years

W/no power to relay

6F9EOlll

The memory card should be handled as follows.

(1)

Inst,alling

1)

battery:

Open the battery holder cover of the

memory card with the screwdriver

supplied.

2)

Place the attached battery in the

battery holder, with the positive

polarity

3)

Close the battery holder cover in the

process reverse to step

(t)

facing up.

._

---

1).

_I

n

2

:

-

88

-

Page 22

TOSHIBA

(2)

Write-protecting the memory card:

The memory card is provided with a writeprotect switch for preventing inadvertent

writing. Turn on the write-protect switch

(to set the write-protect) except when

storing the data into the memory card.

To set the write-protect:

Move the write-protect switch to the right

side (to align with the

mark-7’).

This

djzjables writing into the memory card.

To cancel the write-protect:

Move the write-protect switch to the left

side (away from the mark

“V”).

This

enables writing into the memory card.

6F9EOlll

---

-_

-

89 -

Page 23

TOSHIBA

29-3

--)

0

(0) NON-

0 (1)

FAIL-SAFE

6F9EOlll

FAIL-SAFE

VO.

29-l

29-2

TRIP

ALARM

2!J-4

i

Item

Setting

Energized-on The output relay is energized on operation.

operation

(Non-fai

safe)

Description

Sets the operation mode of the output relay.

The state of output contact is shown below in

I-

the case of tripping.

E$r;’

not

provided

State

LOCK

a-contact b-contact

Open Closed

0

0

0

State at

de1 ivery

-

-

:%;’

provided

.-

Trip

Open Closed

C 1 osed Open

Page 24

TOSHIBA

6F9EOlll

i0.

29-3

!9-4

Item

Description

Continuously The output relay is energized at normal

energized

(fai

Isafe)

tion. The state of output contact is shown below

in the case of tripping.

m

a-contact b-contact

Open Closed

t%;’

not

provided

Closed

Open

&$;’

provided

Setting

Trip

Selects between continuously energized and

Open Closed

energized-on-operation for 3 outputs-trip.

alarm, and lock.

Setting is made by moving the cursor to this

position and entering “0” or “1.

‘*

condi-

State at

de I ivery

-

ERROR:0

The setting of the error output is made in

hardware.

Non-fail-safe

fail-safe

-

71

-

Page 25

TOSHIBA

30-l +

P30

SETTING

RY O/P SEL.

- (01 NOPi.&

E%

-

UC

INST

UB

g

- -

6F9EOlll

;;;.

+

0

30-3

D-1

&2

30-3 A

Item

jetting

\larm

output

SPARE1

-

SPARE2

m

-

Description

Sets the operation condition for the output

relay.

Selects a unit that drives the alarm output

relay when an alarm is detected.

Enter either

The output is an

from the unit that drives the alarm output

relay.

"0"

(not operate) or "1" (operate).

ORed

output of alarm detections

Zate at

leiivery

I

Locked-rotor has no alarm. But it isdetected

as an overload

(OL)

alarm instead.

Page 26

TOSHIBA

6F9EOlll

No.

30-3

item

Trip

Description

Specifies a unit that drives the trip output

relay when a trip is detected.

Enter either

The output is an

from the unit that drives the trip output

relay.

I-

“0”

(not operate) or “1” (operate).

ORed

output of trip detections

State at

de1 ivery

OL: 1

Others:

--

.

-

13

-

Page 27

TOSHIBA

6F9EOlll

No.

31-1

31-1

--t

31-2 ‘+

I tern

Setting

P31 SETTING

ATD O/P = 2

“1’14;”

2=IS

3=IT

4=IAV

5=es

6=8R

Description

Selects an analog transducer output.

7=RTDl

8=RTD2

9=RTD3

1

O=RTD4

ll=RTD5

12=RTD6

13=RTD7

14=RTD8

.15=10

>

State at

delivery

-

31-2

transducer

output

Ana I og

transdwer

output

IR

IS

IT

IAV

8.3

BR

Selects a measuring unit that outputs data to

the analog transducer.

I

4mA -

0

A

‘or

CT RATIO

I

0°C - BSM

oc

-

20

mA

(No.20-2)

(No. 21-6)

200

"C

transducer

xltput

RTDl

RTD2

RTD3

RTD4

RTD5

RTD6

RTDt?

10

-2o'c -

4mA

OA

0

-

-

20

mA

2OO'C

ZCT RATIO

(No.20-3)

-

14

-

Page 28

TOSHIBA

32-2

6F9EOlll

+

Kind of RTD

EE

:

RTD7

RTD8

:

(O=OFF

l=PtlooQ

2=PtlOOQ:JIS

3=Ni

4=Ni 12062

Sets the kind of RTD.

RTDl

to

type. Different RTD types can be selected on

one relay.

Example:

10062

RTD8:

Selects the corresponding RTD

RTDl

to

RTDG

can be

RTD? &

individual relay.

RTDB

can be

>

PtlOOQ,

Nil2062

-.

and

on one

State at

delivery

-

0

Set to 0 (OFF) those channels that are not used.

--

.

z

g

I

>

- 75 -

Page 29

TOSHIBA

6F9EOlll

No.

33-l

33-1

33-2

Item Description

Setting Sets the alarm, trip and reset levels for the

P33 SETTING

+

TRP

RTDl

R.TD2

RTD3

RTD4 100 100 100

RTD5

RTDG

RTD7

RTD8

100

100 100 100

100 100 100

100 100 100

100 100 100

100 100 100

100 100

UNIT:C

10%

I

RTD's.

ti%T

33-3

102

.33-4

1.

State at

delivery

-

33-2

33-3 Trip level

33-4

Alarm level Sets alarm detection temperature for each RTD.

Reset level Sets a reset temperature for each RTD. 100

100

'C

Setting range: 0 - 200

Sets trip detection temperature for each RTD.

Setting range: 0 - 200

After the temperature goes below the reset

level. the S2E21 can then be reset.

Setting range: 0 - 200

'c

"c

C

100

'c

'c

-

76

-

-

Page 30

TOSHIBA

6F9EOlll

lo.

34-l

34-1

34-Z --)

34-3

34-4

34-5

I

tern

Setting Sets whether or not automatic detection is

P34 SETTING

+

*AUTO LEARNING*

1st

--t

+

+

Description

needed.

Tst 0

TR 0

TD

0

0

State at

de I i very

-

34-2

Starting Automatically detects the starting current and

current

specifies whether or not the detected value is

taken as the starting current setting.

Enter either 0 (OFF) or 1 (ON).

When 0 (OFF) is entered, the detected starting

current is displayed

not the detected value, is used as the setting

value in the starting current setting

When 1

d&rent

setting value in the starting current setting

(P25).

(ON)

is entered, the detected starting

is displayed

(P4)

but the input value,

(P25).

(P4)

and also taken as the

0

$

z

3

i

- 17 -

Page 31

TOSHIBA

6F9EOlll

No.

34-3

34-4

Item

starting

time

Heating time Automatically detects the heating time constant

constant

Description

Automatically detects the starting time and

specifies whether or not the detected starting

time is used as the setting value.

Enter either 0 (OFF) or 1 (ON).

When 0 (OFF) is entered, the starting time is

displayed

not the detected value, is used as the-setting

value in the starting time setting

When 1

time is displayed

setting value in the starting time setting

(P25).

and specifies whether or not the detected value

is taken as the heating time constant setting.

(P4)

but the input setting value;

(P25)..

(ON)

is entered, the detected starting

(P4)

and also taken as the

State at

delivery

0

0

When 1 (ON) is entered, the heating time

constant is automatically detected and the

detected value is taken as the setting value.

Upon completion of detection, this setting

automatically turns off.

Automatic detection requires input of

RTDPfor

ambient temperature.

stator

temperature, and

RTD8

RTDl

to

for

'

- 18 -

Page 32

TOSHIBA

6F9EOlll

IO.

14-5

Item

Description

Cooling time Automatically detects the cooling time constant

constant

and specifies whether or not the detected value

is taken as the cooling time constant setting.

When

1

(ON)

is entered, the cooling time

constant is automatically detected and the

detected value is taken as the setting value.

.-

Upon completion of detection, this setting

automatically turns off.

Automatic detection requires input of

RTD3.

and RTD8 for ambient temperature.

RTDl

to

State at

de 1 i very

0

--

- 19 -

Page 33

TOSHIBA

6F9EOlll

I

UO.

35-1

3!i-1 --)

P35 SETTING

Clear data 0

(1 : ALL

: : ELii”

3!+2

4iNst

5:Ttrun

6:

7 : LEARNED TD

1

8 : MAX STARTS)

-:

tern

Description

--

Iett i

ng

Clears accumulated data and held data.

--

LEARNED TR

itate

le

I ivery

-

at

35-2

:lear:ing

Entering the numbers of items whose data you

want cleared causes the corresponding data to be

cleared.

Example:

1. Data may be required to be reset (cleared)

due to a new motor installation.

2. Temperature data only

(0.3

or

OR)

may be

required to be reset for an emergency

restart. Caution should be taken in

resetting this data. Motor damage may

_

--

result.

-

-

80

-

Page 34

TOSHIBA

5.9 Testing

I

UO.

--

1 tern

M-1

110-2

40-3 +

P40

+

*

*o/p*

Description

TESTING

I/P*

RESET

SPARE1

SPARE2

ATD 4

(4-2

0

:

mA

OmA)

6F9EOlll

Zate

at

le

I ivery

10-I

10-2

Testing

Input

Perform tests on the input/output circuit.

Displays the state of contact input from the

terminal block.

Displays 0 when there is an input: and

Displays 0 when there is no input.

The 3-phase input and zero-phase input are

checked with the current value displayed on P2.

--

^ --

-

-

-

81

-

Page 35

TOSHIBA

6F9EOlll

Description

Changes the outpit of the analog transduser.

Press

a current value

analog transducer.

The output current is checked externally.

[EXE1

key. The cursor appears, and enter

(4-20 mA)

to be output from the

State at

delivery

.-

-

-

82

-

Page 36

TOSHIBA

5.10 Failure Information

6F9EOlll

No.

50-l

50-l

50-Z

50-3

Item

Trip

information

+ P50

-3

07dL88:28

:z

128 130

::

132 0

TRIP

2

2

es 60.0

BR

23.2

UB 2%

Description

Displays information at the date and time of the

latest current-associated trip.

:

State at

de1 ivery

-

50-2

50-3

Cause of trip is displayed.

Time

Dispiayes the date and time at which the trip

occurred.

information Displays

temperature rise and unbalance factor at the

trip.

--

3-phase

current. zero-phase current,

-

-

-

:

$

I:

>

-

83

-

Page 37

TOSHIBA

6F9EOlll

5:1-1 +

5:1-z +

5:1-3

P51

oo/oo

00: 00

TRIP

RTD 1

::

Ez

RTD4

::

RTD5

RTDG

E

RTD7

RTD8

E

Description

Displays information at the date

latest trip.

and.time

of the

State at

delivery

-

RTD number. that has tripped is displayed.

Displayes

the date and time at which the trip

occurred.

Displays temperature of each RTD at trip.

--

--

-

-

- 84

-

Page 38

TOSHIBA

P52 TRIP CURRENT

oo/oo

0o:oo

+52-l

53-1-r

~52-2 53-2+

6F9EOlll

P53 TRIP CURRENT

oo/oo

0o:oo

SEC

No.

52-1

53-l

52-2

53-2

IR(A)

I

tern

Trip current

trend

Time

IS

(A)

IT

(A)

-52-3 53-3-9

Description

Displays the current trend immediately before

the trip

Displays the date time at which the trip

occurred.

State at

delivery

-

-

52-3

53-3

Current

trend

Displays 10 seconds of 1 second interval current

trend before trip.

Current of R-phase and S-phase are displayed on

P52:

and current of T-phase and zero-phase are

displayed on P53.

-_

-

-

85

-

Page 39

TOSHIBA

6F9EOlll

5.11 Handling of

The

SZE21s

Hemory

Card

each have a dedicated memory card, which is used for backup of

S2E21

settings and as information media for the monitor system (purchased separately)

that includes personal computers.

The specifications of the memory card are

shown in Table 5.

5.11.1 Sack up of Setting

The memory card is utilized as a backup of the setting of

the.S2E21.

Procedure for backup

1.

Cancel the write-pretect for the

&x

5.11.3

2.

Insert the memory card into the

&I:

5.11.3

Initialize the memory card.

3.

(See

5.8 P27.

(2j.j

(3). )

)

memory

S2E21.

card.

4.

Store the contents of setting into the memory card.

See

5.8 P27.

5.

Turn on the write-protect for the memory card.

Gef!

5.11.3

)

(2j.j

The memory card uses S-RAM card with a battery backup that prevents the contents

of the backup from being lost when you pull the memory card from the

S2E21.

The battery backup also allows the memory card to be inserted or withdrawn during

the operation of the

S@l.

---

CAUTION: Removing the memory card from the

S2E21

and storing it alone may result

in the loss of the backed-up contents when the backup battery is

exhausted.

The memory card must be left inserted in the

S2E21.

$

g

:

-

86

-

Page 40

TOSHIBA

Procedure for loading the backed-up settings of the memory card into the SZE21.

6F9EOlll

Register the MACH. ID and PASS ID of the

1.

(MACH. ID and PASS ID must be the same as those when the settings were

backed up in the memory card.)

(See 5.3.3. 5.4.)

Insert the memory card into the

2.

(See 5.11.3

3.

Load the backed-up contents from the memory card into the S2E21.

The contents of settings backed up by the memory card are those stored by the

above backup procedure.

the contents of the memory card do not automatically change.

to perform the store operation again.

Prior to the loading of the backed-up settings, comparison is made of the

MACH. ID and PASS ID between the memory card and the S2E21.

numbers do not agree, the backed-up settings will not be loaded into the S2E21.

5.11.2 Memory Card As Information Media

(3j.j

After this, when the settings of the S2E21 are changed,

S2E21.

S2E21.

You are reguired

When these ID

The memory card may be used as information media for the monitor system including

personal computers and for the

For detail, see the manual for the monitor system.

S2E21.

-

87

-

Page 41

TOSHIBA

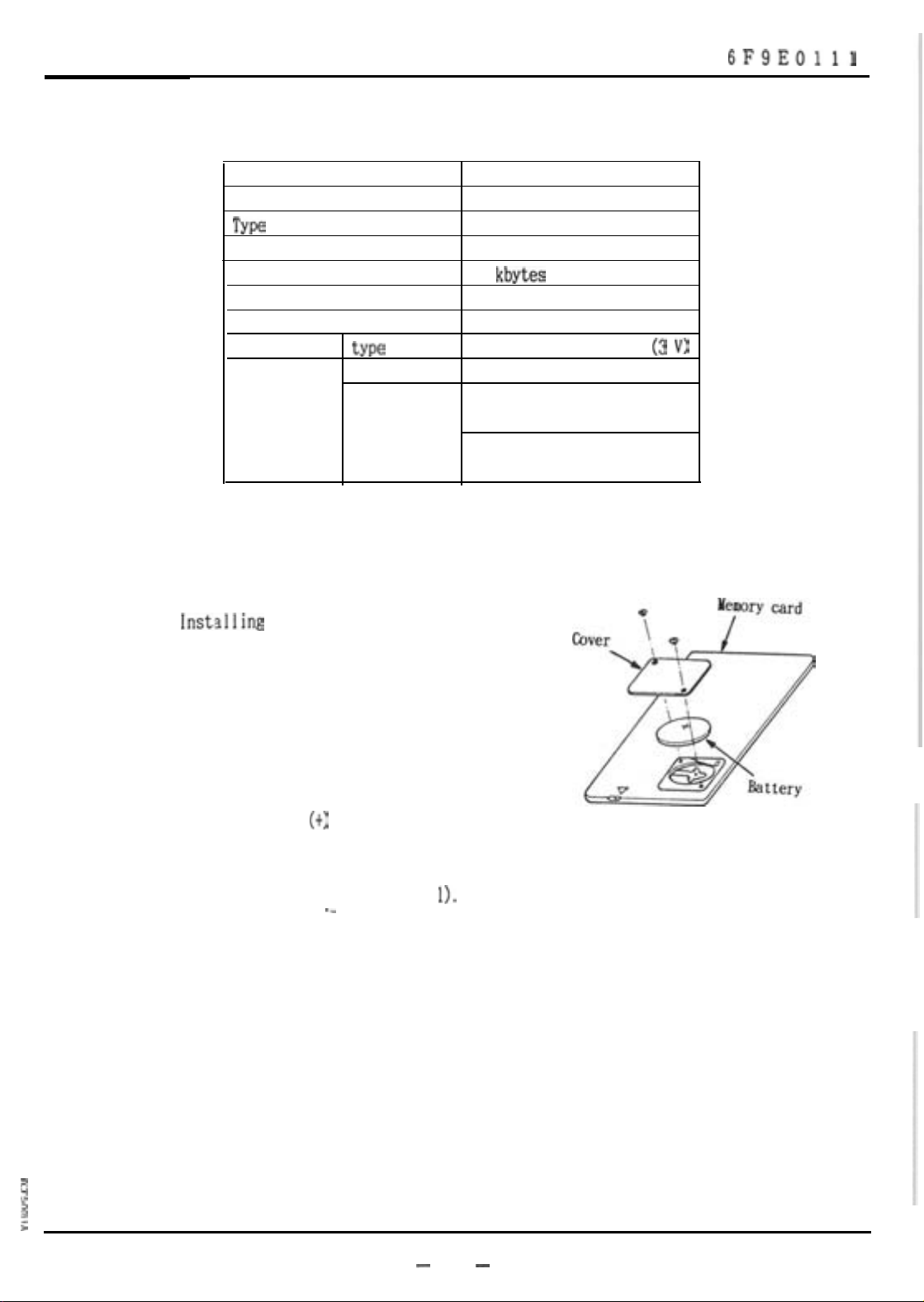

Table 4 Memory Card Specifications

Item Description

Manufacturer Toshiba

Type

Memory type

Capacity

Scheme Memory bus scheme

Pin number 40 pins

Battery

Battery life Not in relay Approx. 2 years

5.11.3 Handling of Memory Card

MCA 5101BAA

S-RAM

32

kbytes

type

Inserted

Lithium coin battery (3

Greater than 10 years

V)

in relay W/control power on relay

Approx. 2 years

W/no power to relay

6F9EOlll

The memory card should be handled as follows.

(1)

Inst,alling

1)

battery:

Open the battery holder cover of the

memory card with the screwdriver

supplied.

2)

Place the attached battery in the

battery holder, with the positive

polarity

3)

Close the battery holder cover in the

process reverse to step

(t)

facing up.

._

---

1).

_I

n

2

:

-

88

-

Page 42

TOSHIBA

(2)

Write-protecting the memory card:

The memory card is provided with a writeprotect switch for preventing inadvertent

writing. Turn on the write-protect switch

(to set the write-protect) except when

storing the data into the memory card.

To set the write-protect:

Move the write-protect switch to the right

side (to align with the

mark-7’).

This

djzjables writing into the memory card.

To cancel the write-protect:

Move the write-protect switch to the left

side (away from the mark

“V”).

This

enables writing into the memory card.

6F9EOlll

---

-_

-

89 -

Page 43

TOSHIBA

6F9EOlll

(3)

Inserting and withdrawing the memory card

to/from

the

SZE21:

Inserting the memory card:

F’ul

I forward the right end of the door of

the display control section to open it and

then perform the following.

Insert the memory card into the guide

1)

with the upper surface of the card

facing toward the right;

21

Be sure to insert the memory card to

the full stop.

Printed circuit

bard

-

When inserted fully, the memory card

3)

end becomes aligned with the front and

Before insertion

of the printed circuit board.

If the memory card still projects from

the board (card is not fully inserted),

push it further to the complete stop.

Withdrawing the memory card:

Reverse the

ins&ion

process.

After insertion

(fully inserted)

Page 44

TOSHIBA

6F9EOlll

5.12 Directional Ground Unit

The

direc:tional

For detail, see the next manuals.

1)

6F9E10107

2) 6F9E:0108

3)

6F9E0109

The terminal numbers

for SZE21 in this manual.

The front external views of the three directional ground modules are shown in

Figure 14.

ground unit has three kinds of directional ground modules.

for ungrounded system

for 10 A grounded system

for capacitor-voltage-division type

(DG)

47 to 66 in the above manuals are read ai D47 to D66

;I

$

:

0

‘000

b)hground

Fifure 14 Front External View of Directional Ground Modules

-

91

system

-

0

.

‘000

cjmgmm systen

kapacitor-voltage-

division type)

Page 45

TOSHIBA

MAINTENANCE AND INSPECTION

6.

This chapter summarizes the method of maintenance and inspection for assuring

normal operation of the SZE21 for a long period of service. Consult this chapter

when you make periodic inspection and troubleshooting.

6.1 Periodic Inspection

Inspection of the SZE21 should be done according to the following criteria.

6.1.1 Inspection Interval

(a)

About 1 year when the environments is relatively good (in normal electric

rooms).

6F9EOlll

(b)

About 6 months when the environment is very bad.

--

-

92

-

Page 46

TOSHIBA

6.1.2 Inspection Item

(a)

(b)

6F9EOlll

Dust and dirt

When the surrounding portions of the conductors are dirty, wipe them clean

with dry cloth. Never use organic solvents such as gasoline or benzine.

Loose screws

Retighten loose screws with screwdriver.

Check of settings

Cc)

Check the settings against the setting table.

Characteristic and operation check

Cd)

When required, a check should be made of the protection characteristic.

Others

(e)

Check for abnormal indication, damages or other abnormalities.

6.1.3 Replacing Parts

The

follolving

(1)

LCD Indicator

Replacement interval: about 5000 hours of lighting

parts should be replaced periodically.

.-

Parts to be replaced:

Part code Part name Remark

4D9E0054G003

-..

--

Liquid crystal TOSHIBA

display TLX-341AX

with special connector

- 93 -

Page 47

TOSHIBA

6F9EOl

11

Method of replacement:

1)

Turn off the control supply for

2)

Open the display section.

3)

Disconnect the LCD wire at the

connector.

4)

Remove the four screws that fix the

LCD and then remove the LCD.

5)

Moount a new LCD and fasten the set

screws.

6)

Connect the LCD wire to the connector.

(2)

Battery

Replacement interval: Approximately every 2 years.

-

SZE21.

LCD

LCDmoduk

Parts to be replaced:

Part code Part name

CR 2025

equivalent

Method of replacement:

1)

Turn off the control

S2E21.

2)

Open the

3)

Remove the battery from the battery

holder.

d&tay

Lithium coin battery 3 V

supply

for the

section.

Rating

Removing

the

Battery

Battery holder

battery

-

94

-

Page 48

TOSHIBA

Install the new battery.

4)

5)

Reset the calendar and clock.

6F9EOlll

Installing the

batt&

--

--

-

95

-

Page 49

TOSHIBA

6.2 Troubleshooting

6F9EOlll

Phenomenon

lothing

In

iisplay

appears

the LCD

Check point

Power LED is off. Control power is

Error LED

Operation of the key Normal.

pad has not been

done for about

4 min.

Open the door panel

and check if

there is a loose

connection between

the LCD display and

the door panel or

between the door

panel and the relay

body.

is'l.it.

Possible cause

off or incorrect.

There is an

internal problem and turn it on again.

with the relay. If LED remains lit,

Bad connection.

-Turn control power off

What to do

If the control power

connection is wrong,

correct it. (See

Section 4.2.)

consult nearest

TOSHIBA.

Press the

(See Section 5.3.5.)

Connect firmly. (See

Section 6.1.3.)

[EXE]

key.

Displ&

are faint. reduced.

LCD display used for LCD life

more than expired.

5000 hours.

characters Brightness

-

96

-

Adjust brigtness.

(See Section 5.3.4.)

Replace LCD display.

(See Section 6.1.3.)

Page 50

TOSHIBA

6F9EOlll

Phenomenon

-

:D

indicates

l8.

-

Ir

I

LCD indicator

or

I

PO

Second cannot

be set.

-

Or

1

P2

The

displa:y

does not

change while

the metered

value changes.

Check point

3rror LED is lit.

3rror

LED is not

lit.

Lt

lower part of

CD,

‘ >>>SELECT

is indicated.

P2

<<<"

Possible cause

Setting value is

incorrct.

Normal.

Normal.

The page is being

turned.

#hat to do

Press the [EXE] key

and enter all setting

values again. (NOTE)

Display other pages.

(See Section 5.3.1.)

The second setting

is not provided.

Press the

change to the display

mode.

[EXE1

key

tc

8 R remains

0.

UB remains

0.

On

/

P3

999 is

displayed.

On

P4

I s t

and

T s t

remain at 0.

NOTE: Pressing the [EXE] key returns the setting to those values set at time

(4-3)

(4-4)

of delivery.

I'SC (25-2)

'25 is 0 (OFF).

UB (23-2)

'23 is 0 (OFF).

s

item measured

n the temperature

*an@ between

lnd 2E?

lotor

has not been

;tarted

'ive

times. and

earned function is

:elected.

on

on

2OC

more than

Normal.

Normal.

Cable

conection

bad.

Normal.

Change value from

Change value from

is

Firmly connect cable

and connector.

The measured value is

displayed after the

motor is started five

times.

zerc

zero

-

97

-

Page 51

TOSHIBA

6F9EOlll

Phenomenon

Dn P28

-

PRE-ALM set-

ting of

does not go

below 100%.

3n P30

-

Cursor will

move to

1 N S T and U

-

Trip output

fails to be

produced.

1JC

A.LM

of

na

B

Check point

-

Protection function

is locked.

Output is not

selected at RY O/P

SEL

(P30).

.

Possible cause

Normal.

Normal.

Normal.

Normal.

What to do

PRE-ALM setting of UC

has a range between

100% and 300%.

ALM setting is not

provided for I NST

and UB.

Activate the

protective function.

Select(l) to activate.

-

Alarm output

is not

produced.

In O/P RELAY

(P29).

the logic is

inverted.

External connection

is incorrect or

I oose.

Protection function

is locked.

--

--

lutput

is not

selected-at RY O/P

SEL (P30).

In O/P RELAY

(P29).

the logic is

inverted.

3xternal

is incorrect or

I oose.

CONPIG

CONFIG

connection

Normal.

Bad connection.

Normal.

Normal.

Normal.

Bad connection.

Match the logic.

Make proper

connection.

Activate the

protective function.

Select(l) to activate.

Match the logic.

Make proper

connection.

Page 52

TOSHIBA

6F9EOlll

'henomenon

Cannot be

reset.

Transducer On

output does

not change.

Check point

Trip state

continues

INST.

After OL. the reset Normal.

level

and B R

still exceeded.

ATD

not set.

P40 is displayed. Normal. Change to page other

LIB. OCG)

(28-4)

P31.

(OC.

UC.

of 19 S

(2-3).is

O/Pis

Possible cause Hhat to do

Normal. Stop the motor and

correct the problem.

Hait

for the motor to

cool.

CAUTION: Since the

motor is overheated,

take utmost caution

Normal. Enter the necessary

setting.

than

P40.

On

P25,

REP is

activated 'when (25-2) is set lower setting.

the motor is

than T s t

TSC

(25-5).

incorrect setting. Enter the correct

-

99

-

Page 53

TOSHIBA

6.3 Bench Test

6F9EOlll

1

ten

Operat- Gradually increase

ing

point

IL

Operat- 1) On

ing

time

Test method

current and record the

current value when the

RUN LED begins blinking BSM:

at 0.3 s intervals. temperature rise

P2.

check that

OS is0.

it is not 0. either

wait, or on

clear

2)

Apply 6 times the

rated current

abruptly and

measure the time it

takes for the relay

to trip.

0s.

When

P35.

(IN)

Decision Test

OSM

?5F

I

N

BSN:

Stator

temperature rise

-60 x TR x L

1=6x1,,

TR: Heating time constant

!d

current

Stator

rated

*10x

allowable

"(1 -'E +',

circuit

(single

phase)

Figure 15

Figure 15

*lG%

Operat- Gradually increase the Setting value

ing

point current value when the

)C

Operat- 1) Apply the rated

ing

time

current and measure the

relay trips.

-L

Setting value

current

2) Apply current 1.5

times the setting

value

measure the time it

takes for the relay

to trip.

(I&

(IN).

and

- 100 -

*5%

*10X

Figure 15

Figure 15

Page 54

TOSHIBA

6F9EOlll

r

-

UC

-

Item

Operat-

ing

point

Operat-

ing

time

Test method Decision

Apply rated current and

gradually lower the

current. Measure the

current value at which

the relay trips.

1)

Apply the rated

current

2)

Quickly reduce the

current to 20% of

the rated current

and measure the time

it akes for the

relay tc trip.

(IN).

Setting value

Setting value

*lo%

*10X.‘

Test

circuit

(single

chase)

Figure 15

Figure 15

Operat-

ing

point

Operat-

ing

time

Gradually reduce the

current and measure the

current value at which

the relay trips.

Quickly apply current

two times the setting

value

the time it takes for

the relay to trip.

(I>>)

and measure

.-

--

Setting value

50 ms or less

3~15% Figure 15

Figure 15

Page 55

TOSHIBA

6F9EOlll

Item

Qperat-

ing

point the current value at

JB

Clperat- 1) Apply the rated

ing

time

Unbal- 1)

ante

factor

Slowly reduce the

Test method

current and measure

which the relay trips.

current

2) Quickly change

current in one phase

to 0 and measure the

time it takes for

the relay to trip.

Apply the rated

current

2)

Change current in

one phase and

measure the current value.

at which the relay

trips.

(IN).

--

--

(IN).

Decision Test

75%

rtlO%

of the rated

current

Less than 4 s. Figure 16

I II -

The calculated value must be

within

Example: When the setting

1 I: Measured current value.

(IN)

IAVE

I x

loo%

IN

*5%

of the setting

value is 30%. the

calculated value

must be in the

range of 25 to 35%.

circuit

(single

phase)

Figure 16

Figure 16

-

102

-

Page 56

TOSHIBA

6F9EOlll

Item

Opet-at- 1) On

ing

time

1.

R

Operat- 1) On

ing

point not zero, either

!EP

Test method

P2,

check that

8 R is 0. When

not 0. clear

2)

Quickly increase the TSC: Allowable starting-time

applied current from

0 to 3 times the

rated current (IN)

and measure the time

it takes for the

relay to trip.

P2.

check that

B R is 0. When

wait or clear 8 R

on P35.

OR.

Decision

(-$$'

1st:

' - TX

Tst: Starting time

x TX

Starting current

Tst

-

(set) +10X

*10x

Test

circuit

(single

phase)

Figure 15

Figure 15

2)

Apply the starting

current

measure the % value

of 6'R on P2 when

the lock output is

produced.

(1st)

and

--

--

-

103

-

Page 57

TOSHIBA

6F9EOlll

Figure 15 Test Circuit

Figure 16 Test Circuit

(1)

(2)

Figure 17 Test Circuit

c

-

104

(3)

-

Page 58

TOSHIBA

PROTECTIVE DETECTION SCHEME

7.

6F9EOlll

This chapter describes how the protective unit of the

SZE21

7.1 Overload Unit

This is a function to thermally protect the motor insulations.

be protected is mainly the

stator.

Changes in

stator

temperature when the motor

is in operation and at rest are represented by the following formula.

[During operation]

0

1

(t)

= 6

l=(lt). (I-e-‘/Y

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...*........*..

where

e

i (t)

: Temperature rise in time t

Bm(1t.j:

TR:

Final temperature rise that occurs when the

continuously and which is determined by

the.magnitude

Motor’s heating time constant

stator

[At rest]

detects failures.

The component to

(1)

current It flows

of It.

0 Z(t)

= 0

d(D) .e-“ro

where

82(t):

0 (0)

TD:

Temperature rise in time t

: Temperature rise when the motor is at rest (t =

Motor’s cooling time constant

The equations

(1)

and

--

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(2)

0).

(2)

are represented in the following diagrams.

--

Page 59

TOSHIBA

6F9EOlll

0

(a) During operation

In other words, the

to a certain temperature that is determined by the current magnitude.

motor is stopped, the

This relay determines whether the motor is running or at rest by checking the

presence of the

or (2) to simulate the heated condition of the motor.

The

stator

are successively

simulation in response to the changes in the motor operating condition.

Figure 16 shows a timechart that represents changes in the simulated temperature

rise in response to changes in the motor operating condition (current changes).

current is samlped at predetermined intervals and the sampled currents

stator

fed

to the calculation process in order to perform the thermal

Time

Figure 15

stator

temperature rises exponentially during motor operation

stator

current.

0

(b)

At reset

Stator

temperature falls down to the ambient temperature.

Then it performs the calculation of equation (1)

temperature rise

Time

When the

--

--

- 106-

Page 60

TOSHIBA

6F9EOlll

CUrI-ellt

t

Starting current -----

Rated current ----

Temperature rise

t

Allowable

rise

tenpreture

(OS)

Raced tenpreture

rise

(ON)

Ambient temperature 0

Full load operation

start

I

_

I

: :

: :

: :

: :

: :

: :

: I

Norlnal

Overload operation

/

Relay operating point

load operation

stop

+

Time t

--.-.-.-.-.-.-.

+

Time t

Figure 16 Simulated Temperature Rise Timechart

In Figure 16. the allowable temperature rise

insulation design of the motor and is defined in Table 5 by JIS-4004 and NEMA

MGl-1.65.

Table 5 Insulation Class and Allowable

Temperature Rise

--

--

Insulation class

E: il

Class B

Class F

Class H

*( ):

(0SM)

is a value dependent on the

Allowable temperature

rise 8s YC)

%i

;;i (105)'

NEMA

Page 61

TOSHIBA

6F9EOlll

The rated temperature rise

rated current (full laod current). This value is usually submitted by a motor

manufacturer as test data.

This relay requires setting of the motor's heating time constant and the cooling

time constant. These values are also supplied as the motor data. When they are

not shown. request them from the motor manufacturer.

As a reference. the standard values of Toshiba motors are shown in Table 6.

Table 6 Heating Time Constant of Motor

(Toshiba Standard Values)

Motor kind Time constant

Totally

enclosed

outer fan 2 poles 4 pole

--

Frame

4

-

%“’

(8SN)

represents a temperature rise for the motor's

(minute)

1

Other than totally Heating 1 Cooling

enclosed outer fan 1 TR

or more

355

400 355 45

450-630 400-630 60

-

30

TD

I I

I 3xTR

~~!LJ

560,

710

--

?/l,or

-

--

?O,or

-

90

120

Page 62

TOSHIBA

7.2 Locked Rotor Unit

The Locked Rotor Unit (L.R) has a main function of protecting the rotor of

a motor as opposed to the Overload (OL) which protects the stator of the motor.

6F9EOlll

In providing protection, the

and rotor in a motor independently because each has different thermal

characteristics.

For the load currents that are below about 2.5 times the rated current, the

heat of the motor is produced mainly by the

currents, the rotor produces most of the heat,

For this reason. the S2E21 performs the temperature rise simulation for the

rotor as follows:

(1)

When the load current is less than 2.5 times the rated current

(0 <

I (0 < 2.5 x

The temperature rise 0 R of the rotor is made to converge into the

temperature rise 8 S of the

(i) When

e

R(t) =

OR(t) < 0

IN)

e

S (1 -

:

S:

S2E21

simulates temperature rises of the

e-9

stator,

stator

by the heating time constant (TR)

. . . . . . . . . . . . . . . . . . . . . . . . . . ..*.......

and for higher load

stator

(3)

e

es

1‘

(ii) When

8

R(t)<TR(O)

OR(t) > 0s:

-_

-

es) e-“TR + es

. . . ..I.................. (4)

Page 63

TOSHIBA

6F9EOlll

Where

(2)

When the load current is higher than 2.5 times the rated current

(2.5 x IN <

From the heating characteristic during locking that isdetermined by the

motor starting current (1st) and the allowable locking time. the temperature rise of the rotor is simulated.

When at time 0 the rotor is locked, then

BR(t)

6R:

temperature rise of the rotor at time t CC)

~9

S: temperature rise of the

TR:

I(t)):

=

heating time constant of the motor (minute) (set value)

eR(O) + (,st

l(t),

) .

-

1

.

TSC

stator

elm.

at time t (C)

t

. . . . . . . . . . . . . ...(5)

Where 0 R(t): temperature rise of the rotor at time t

OR(O):

In*

1st: _

TSC:

9

When

The operation characteristic (operating time) in the locked state varies

depending on the heated condition of the motor and the conducting current.

OR(t)

=

temperature rise of the rotor before the rotor is

locked (C)

load current at time t (A)

starting current (A) (setting value)

allowable locking time in the cold state

(setting value)

RM:

allowable temperature rise of the rotor CC)

(fixed at

9~

the trip operation is carried out.,

-

110

2OO'C)

-

('C)

(set)

Page 64

TOSHIBA

6F9EOlll

When the starting current is flowing in the locked state. the operating

time will be as follows:

(i)

In cold condition (motor is cool):

In equation

since

the operating time is TX

TX:

(ii:)

In hot condition (motor is running at the rated load):

In equation

since 9

the operating time will be

6’R(O)

allowable locking time in cold state

(5).

= 0.

(5),

R(O) = BSN,

(set).

T~H =

(set)

CORM - BSN

e

RM

(setting value)

*

TSC

(set).

Where

6’SN:

rated temperature rise value

TSH:

allowable locking time in hot condition

-_

--

(set)

(setting value)

(set)

>

TSH

T

L---J

i:

g

i

-

111

-

Page 65

TOSHIBA

6F9EOlll

(iii) In

operati,ng

In reality, 0

this case is given by:

TOP = s~lll - OR@)

Where TOP:

condition:

R(O)

falls between 0 and

6’

RM

operating time

*

TSC

kec).

BSN.

The operating time in

--

--

-

112

-

Page 66

TOSHIBA

7.3 Repetitive Starting

When the motor is started, the repetitive starting protection checks the

starting current and the starting time to see if the temperature rise exceeds

the rotor':; allowable temperature rise.

the rotor is exceeded, this protective function issues a lock signal to

prevent the motor from starting.

The rotor heating caused by a single starting is expressed by the following

equation:

6F9EOlll

If the allowable temperature rise of

E .

However, if at starting

Tst

FE'

Where Tst:

Hence, when there is no margin defined in

rise BR(i;) and the allowable rotor temperature rise

issued.

e

($)2

B

RM

TSC: allowable rotor locking time

9

1st: starting current (A) (setting value)

RM - 8R(t) 5 E

.

BRM ..: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

l(t) = 1st.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..I . . . . . . . . . . . . . . . . . . .

motor starting time

nM:

allowable rotor temperature rise

.-

then the following holds:

(set)

(setting value)

(set)

(6b)

between the rotor's temperature

~?RM,

.

(3~

(setting value)

(rc)

(fixed at

a lock output is

200°C)

&)

(6b)

Page 67

TOSHIBA

7.4 Detection of Starting Current and Starting Time

The SZE21 checks a motor current to detect whether the motor is stopped.

starting, running or overloaded.

The detection conditions are as follows:

6F9EOlll

(1)

Stopped:

(2)

Starting:

(3)

Running:

(4) Overloaded: Not during the starting period, when the motor current exceeds

When the motor current is less than 5% of the motor's rated

current

From the time when the motor current exceeds 1.5 times the

motor rated current

until the motor current falls below 1.5 times the motor

rated current.

Not during the starting period. when the motor current is

higher than 5% of the motor rated current. but lower than a

current that will trigger the overload

the operating value for the overload

(IN).

(IN)

as it leaves the stopped condition

(OL)

function.

(OL)

function.

__________

’

I

________

----~---------~----.~-.-----.--.~----.--------~~~---~.-.~-.--.

L

(1) Starting current

The starting current is a current value that exists 100 ms after the relay

has detected that the motor is starting. The starting current is obtained

by taking an average of five starting currents.

(2) Starting time

The time 2 shown in the diagram above is taken as a starting time.

sta"ting time is obtained by taking an average of five starting times.

________.

I(

_____

er

(1) ., (2) .I,

4.

--

--

_________________------

m:g;e::ting

_______________________

current

(3)

-

114

-

-----_-

I, (4) J, (3) J, (1) T

4.

I.

_

A-.

O.D5

x IN

point

T,he

,

Page 68

TOSHIBA

7.5 Detection of the Heating Time Constant and Cooling Time Constant

CAUTION:

Detecting the heating time constant and the cooling time

constant requires three

for measuring the ambient temperature to determine the

motor temperature rise.

care should be taken of the following points:

(1)

The RTD for measuring the ambient temperature

provides a reference temperature for determining the

motor temperature rise, so make sure that you measure

the ambient temperature precisely.

The measuring error of the ambient temperature will

have great effect on the detection accuracy of the

heating time constant and the cooling time constant.

RTDs

in the winding and one RTD

To enhance the detection accuracy,

6F9EOlll

(a)

Do not allow the RTD to be affected by heat

from the motor.

(b)

Keep the RTD free from direct sun rays or

radiant heat.

(c)

Keep the RTD free from influences of cool air

and drafts.

(d)

Keep the RTD free from moisture or high humidity.

(2)

To maintain a required level of accuracy, the heating

time constant and the cooling time constantare

detected under the conditions described later.

The motor must be able to be operated in ways that

meet thm_;tuirements.

The relationship between the motor temperature rise and the heating time

constant is given in equation

temperature and the cooling time constant is given in equation (2).

(1)

and the relationship between the motor

-

115

-

Page 69

TOSHIBA

6F9EOlll

01(t) and

determined by measuring the motor winding temperature and the ambient

temperature using the

The

S2E21

RTDl, RTD2, and RTD3 and also the ambient temperature at RTD8 to determine

the heating time constant and the cooling time constant from the motor

temperature rises. The accuracy of calculating these time constants is

about *10X.

From equation

TR =

-

From equation

TD=---

6'2Ct.j

represent the motor temperature rises, which can be

RTDs.

receives signals from the three

(I).

the heating time constant is expressed as

t2 - tl

e

(It) - eiw

‘ "

‘e

(It) -

e

(2).

the cooling time constant is given by

t2 -. t,

ezct,j

--

Ln 02M

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

k2)

B

(It)

is determined by the motor current.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RTDs

in the winding at its inputs

(1')

(2')

At each start and stop of the motor, the heating time constant and the

cooling time constant are detected over a length of time equivalent to

these time constants.

the heating time constant and the cooling time constant.

[Requirements for detecting the heating time constant]

-

The

olotor

is sufficiently cool.

-

The

olotor current--is

-

The

[Requirements for detecting the cooling time constant]

-

The motor is sufficiently heated.

nlotor

is

Five measurements are taken and averaged to determine

large enough (not too lightly loaded).

n~t'?Cerloaded.

- 116-

Page 70

TOSHIBA

6F9EOlll

7.6 Settings

When setting the protective characteristics of the SZE21 according to fundamental

information alone that you can obtain from the rating nameplate of the motor, the

following steps should be taken.

In this case. however, use overly conservative characteristics to ensure the

motor safety.

the actual motor temperature rises.

To perform accurate temperature rise simulation and protection, it is necessary

to set the motor constants.

Fundanenta.1

llased

on Fundamental Information

Note that the temperature rises (6 S, 8 R) are different from

information:

IMFLC:

motor rated current

CT

CT:

cecondary

(A)

current (A)

0SM: allowable motor temperature rise

TSC :

Tst:

1st: starting current

20-Z: CT ratio (given)

20-3:

20-4: rated

21-2: Setting of the heating time constant

allowable motor locking time during cold condition

starting time

ZCT

ratio 50 A

This does not affect the protection characteristics.

cZ%it

This is calculated by the following equation:

lN

=

TR

(min) )

Hhen Tst is less than 3, setting should be

TR = 10

(set)

(A)

setting (IN).

kc (A)/CT (A)

(TR)

3 x Tst

(min)

-

21-4: Setting of the cooling time constant

It should be set to 0

-117 -

(TD

= 3 x

(TD)

TR)

Page 71

TOSHIBA

6F9EOlll

21-6: Setting of the allowable motor locking time

Setting depends on the insulation class of the winding.

Table 5 (Table Al).

21-T: Setting of the rated temperature rise

OSN

=

6SM f

1.2

Under this condition, the operating point of OL is given by

1.1 x

22-2: Setting of the INST current

This function should be locked when a combination starter is

used as the motor starter.

When switchgear incorporating a circuit breaker is used as the

starter, the following characteristics should be coordinated

during the setting procedure:

-

-

- Suitchgear!~

IrnFLC

Motor starting current

Motor inrush current

(

(C)

(I>>)

overcurrent relay characteristics

'(6SMj

(6'SN)

See

n

51

!

>

22-3: Setting of INST time

This is fixed at 0.05 s.

22-4: Setting of OC current

OC is not for the motor protection but for the protection of

equipment connected to the motor. OC is locked when the

equipment protection is not needed.

When OC is

22-5: Setting of OC time

Set Oc time to 0.3 s.

--

23-2: Setting of unbalance factor

Set UB to 5%.

23-3: Setting of UC current

UC is not for the motor protection, but for preventing

:an

underload or less of load condition.

When not necessary, it is locked.

When needed, set to 80

It is recommended however that you measure

the no-load current

CT>))

(10~)

equired.

--

set to 1.5 (times).

(Tot)

(1"~)

OJB)

(%).

INK

and set the UC current to 1.2 x

INLC.

-- 118

-

Page 72

TOSHIBA

6F9EOlll

23-4: Setting of UC time

Set to 1

24-2: Setting of OCG current

To prevent undesired operation, Set to 10

24-3: Setting of OCG time

Set to 0.1 s.

25-2: Setting of allowable locking time in cold condition

Given value (Consult motor manufacturer>

25-3: Starting current

See motor data.

Or after one start, read screen P4. (See page

25-4: Starting time

Varies per application. (motor, load,type of starter)

-

calculate based on motor torque and load .

-

Or after one start, read screen P4. (See page

(TUG)

s.

(IO,,)

(%).

(TO&

(TSC)

(1st)

50.4-2.)

(Tst)

50.4-4.)

-..

--

g

2

>

- 119-

Page 73

TOSHIBA

'7.7 Settings For Reduce Voltage Starting

For reduce voltage starting, the actual starting current is different from

the nameplate of the motor.

Perform the following steps for setting of TSC. 1st and Tst for locked-rotor

protection. In this case, Auto learning function of Tst and 1st should not

be turned on.

6F9EOlll

25-2: Setting of allowable locked-rotor time in cold condition

Given value (Consult motor manufacturer)

25-3: Starting current

See motor data (at full voltage.)

25-4: Starting time

-

Convert the actual starting time to setting value based 1st.

Tst = (

Where Tst : starting time (setting value)

- Actual starting time should be calculate based on motor torque

and load. or after one start read screen P4. (See manual page 50,

4-4.)

(1st)

(Tst.)

Ist.act

-

1st

Tst.act :

1st : starting current (motor data at full voltage)

I&act

)* * Tst.act

actual starting time at reduced voltage.

: actual starting current at reduced voltage.

(TSC)

-

Actual starting current should be calculated, or after one start

re&reen

Following the above procedure protects the motor under a full voltage