Page 1

E6581323

④

LCD Remote Keypad

Instruction Manual

RKP004Z

Notice

1. Please see to it that this instruction manual reaches the actual user of the LCD remote

keypad without fail.

2. Be sure to read this instruction manual carefully before installing and using the LCD remote

keypad. After reading the manual, be sure to store it.

Page 2

Introduction

Introduction

Thank you for purchasing a LCD remote keypad (RKP004Z) designed specifically for

Toshiba VF-AS1/PS1 series industrial inverters.

The use of this LCD remote keypad (also referred to as the unit, the product and the

remote keypad) equipped with a high-resolution liquid crystal display with back lighting

makes it easier to set parameters or monitor the operation.

The unit can be mounted easily on an inverter's operation panel, and on a board by

means of an optional attachment. Moreover, using the unit along with a dedicated

interconnect cable makes it possible to operate the inverter by remote control.

This instruction manual mainly explains how to use the keys on the LCD remote keypad.

For details of parameters available, refer to the instruction manual included with your

inverter.

Warning

● Never connect the unit to any inverter other than a VF-AS1/PS1 series

inverter or any communications device. Do not use any cable other than

Prohibited

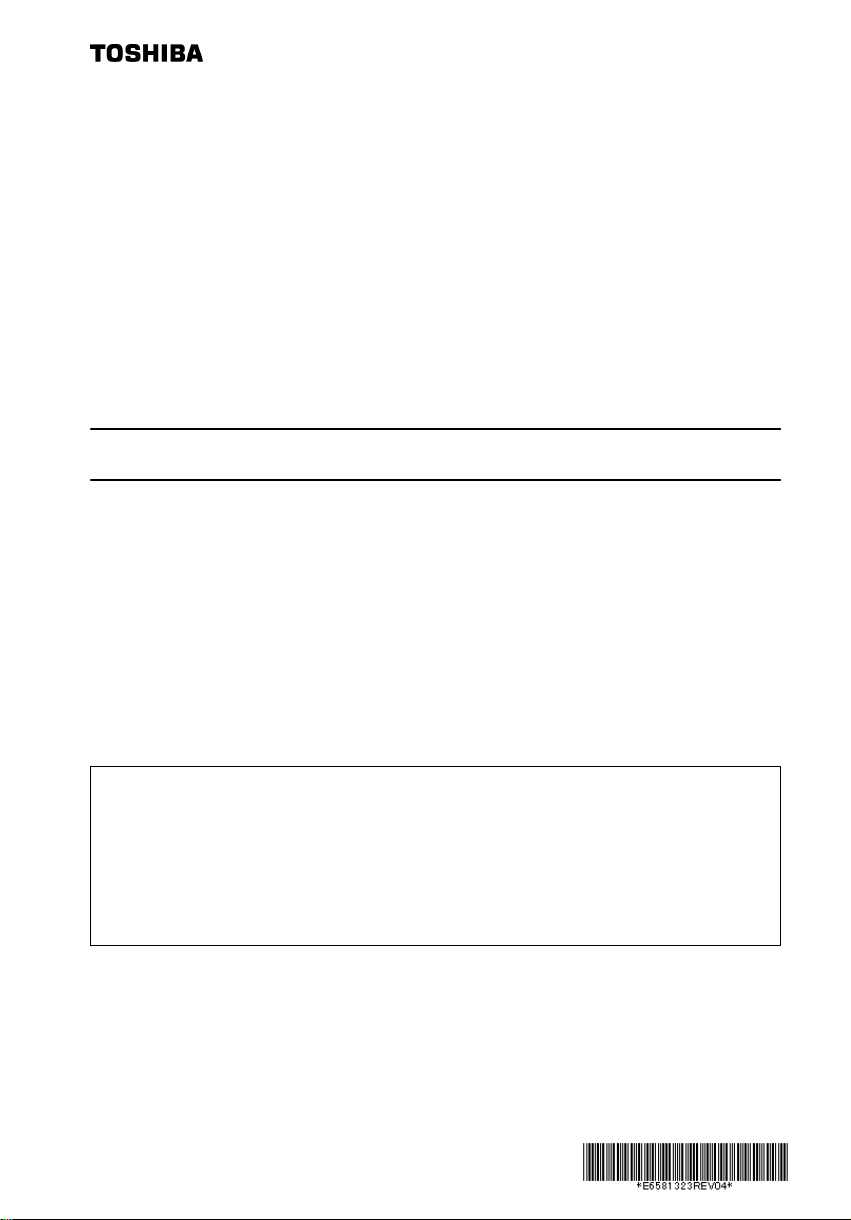

Explanation of model code

RKP

Check product purchase

Before using the unit, make sure all the following items are packaged with the

product.

an optional interconnect cable designed specifically for the unit.

Failure to observe this might cause the unit to break down and result in

an electric shook or fire.

004 Z - 3

Revision No.

Cable length (Z: No cable)

Optional LCD keypad

Optional remote keypad

Product (rem ote keypad)

(RKP004Z)

Instruction Manual

This manual

ⅰ

(1)

Page 3

Introduction

Optional products

The products listed below are optionally available. Purchase these cables and

attachments separately.

Product Model number Product Model number

Interconnect cable

Interconnect cable

Interconnect cable

Interconnect cable

You can install the LCD remote keypad to the inverter or operate the inverter by

remote control combining optional products.

⇒ For details, refer to “2. Installing the LCD remote keypad.

«Installation on an inverter (no optional products required)»

CAB0071

(1m)

CAB0073

(3m)

CAB0075

(5m)

CAB00710

(10m)

Connector

IP54 attachment

IP65 attachment

- -

CNT001Z

SBP006Z

SBP007Z

”

RKP004Z

«Installation on a board»

+ +

RKP004Z SBP006Z CAB0

«Installation on a board (protective structure)»

+ + +

RKP004Z SBP006Z SBP007Z CAB0

«Remote control»

+ +

RKP004Z CNT001Z CAB0

: 071, 073, 075, 0710

ⅱ

Page 4

Safety precautions

Safety precautions

On the inverter and in its instruction manual, important information is contained for

preventing injuries to users, damages to assets, and for proper use of the device.

Read the instruction manual attached to the inverter along with this instruction manual

to completely understand the safety precautions, the symbols and indications shown

below. Please adhere to the contents of these manuals at all times.

Explanation of markings

Marking Meaning of marking

Warning

Caution

Indicates that errors in operation may lead to death or serious injury.

Indicates that errors in operation may lead to injury (*1) to people or that these

errors may cause damage to physical property. (*2)

(*1) Such things as injury, burns or shock that will not require hospitalization or long

periods of outpatient treatment.

(*2) Physical property damage refers to wide-ranging damage to assets and materials.

Meanings of symbols

Marking Meaning of marking

Indicates prohibition (Don't do it).

What is prohibited will be described in or near the symbol in either text or picture

form.

Indicates something mandatory (must be done).

What is mandatory will be described in or near the symbol in either text or picture

form.

Indicates warning.

What is warned will be described in or near the symbol in either text or picture

form.

Indicates caution.

What the caution should be applied to will be described in or near the symbol in

either text or picture form.

Limitation of use

Safety precaution

● Never use this unit with any device other than TOSVERT series inverters. Doing so may

cause an accident.

ⅲ

Page 5

Safety precautions

Handling in general

Never

Disassem

Prohibited

● Never disassemble, modify or repair the product.

Disassembling the product may cause electric shocks, fire or injuries.

ble

For repairs, call your sales/repair agency.

● Do not put or insert foreign objects such as waste cable, bars, or wires into the

product.

It may lead to electric shocks or fire.

● Do not splash water over the product, and do not wipe the body with a wet cloth.

It may lead to electric shocks or fire.

Mandatory

● Turn off input power before wiring.

Wait at least 15 minutes and check to make sure that the charge lamp (on the

inverter unit) is no longer lit.

● Turn off the power immediately in case of any abnormalities such as smoke,

smell or abnormal noise.

Neglect of these conditions may lead to fire.

For repairs, call your sales/repair agency.

Transportation and installation

Prohibited

Mandatory

● Do not install or operate the inverter if it is damaged or any part of it is missing.

Operating a defective inverter may lead to electric shocks or fire.

For repairs, call your sales/repair agency.

● Do not put any flammable material near the product.

It may catch fire due to the product sparking in the case of a malfunction.

●Electrical construction work must be done by a qualified expert.

Connection of input power by someone who does not have expert knowledge

may result in fire or electric shock.

●Operate under the environmental conditions prescribed in the instruction

manual.

Operations under any other conditions may result in malfunction.

●An emergency stop device must be installed that fits with system specifications

(e.g. shut off input power then engage mechanical brake).

Operation cannot be stopped immediately by the inverter or Remote Keypad

alone, thus risking an accident or injury.

●Use the Toshiba-specified cable for connecting this optional unit. (Refer to page

ⅱ.)

The use of any other option may result in an accident.

●Do not install the product in any place subject to vibrations or it may fall.

Prohibited

This may lead to the product falling and causing injury.

Warning

Warning

Caution

ⅳ

Page 6

Safety precautions

Operations

●Do not apply a dropping shock or other physical shocks.

Prohibited

Otherwise, damage or malfunction will result.

●Do not pull on the cable and connector

It may cause damage or error.

●Even if this product is deactivated by an unusual event such as tripping, an

operating error, power outage, etc. do not bring any regions of your body into

contact with the inverter terminals when power is supplied to the inverter.

Contact during the power-on status of the inverter can result in electric shock.

●Use an additional safety device with your inverter or system to prevent a

Mandatory

serious accident due to the unit malfunctions. Usage without an additional

safety device may cause an accident.

●Make sure to check that the parameter data from this product is not

accidentally copied to the wrong inverter.

Usage with wrong parameter may result in an accident.

●Set up “Communication error trip time (F803, F804, see the inverter instruction

Mandatory

manual for details)” to stop the inverter when Remote Keypad is deactivated by

an unusual event such as tripping, an operating error, power outage, failure,

etc. Deactivated Remote Keypad may cause an accident, if the

“Communication error trip time” is not properly set up.

Disposal

●If you dispose off this unit, have it done by a specialist in industrial waste

Mandatory

disposal*. Improper disposal may result in explosion of capacitors or produce

noxious gases, resulting in injury.

(*) Persons who specialize in the processing of waste and known as “Industrial

Waste Product Collectors and Transporters” or “Industrial Waste Disposal

Persons.” If the collection, transport and disposal of industrial waste is done by

someone who is not licensed for that job, it is a punishable violation of the law

(Laws in regard to cleaning and processing of waste materials).

Notes on operations

●Avoid installing in a place where ambient temperature or/and humidity change

sharply.

●Keep the interconnect cable separate from the power cable of the inverter to

prevent the inverter from malfunctioning due to electromagnetic noise.

●It is recommended to install the unit on the panel board of a cabinet if it is used

as a remote operation panel. Improperly installed units may result in damage

and malfunction.

Warning

Caution

Caution

Notes

ⅲ

ⅴ

Page 7

1. Names and functions ······················································································ 1-1

2. Installing the LCD remote keypad ································································· 2-1

2. 1 Installing the remote keypad to the inverter········································ 2-1

2. 2 Installing the remote keypad to the board (optional)·························· 2-2

2. 3 Remote control (optional)······································································ 2-3

3. Setting to be made when turning on the unit for the first time ·················· 3-1

4. About available modes ··················································································· 4-1

5. Operation in Top View Mode ·········································································· 5-1

5. 1 Setting a panel operation frequency ···················································· 5-1

5. 2 Using an EASY key function·································································· 5-2

5. 3 Selecting a language to be displayed··················································· 5-4

5. 4 Performing jog run ················································································· 5-5

5. 5 Emergency stop/reset operation··························································· 5-6

6. Operation in Parameter Setup Mode····························································· 6-1

6. 1 Searching for the change histories of parameters

(History function) ···················································································· 6-1

6. 2 Setting a basic parameter ······································································ 6-2

6. 3 Setting an extended parameter····························································· 6-3

6. 4 Searching for parameters whose settings were changed

(Search for changed settings) ····························································· 6-4

7. Operation in Status Monitor Mode ································································ 7-1

7. 1 Displaying details of an item monitored ·············································· 7-2

8. Operation in a copy function ········································································· 8-1

8.1 Copy to LCD ····························································································· 8-2

8.2 Copy to inverter ······················································································· 8-3

8.3 Confirm a memory information ······························································ 8-4

9. List of function key functions ········································································ 9-1

10. Specifications ································································································ 10-1

11. Before making a service call ······································································ 11-1

12. Warranty ······································································································· 12-1

Contents

ⅵ

Page 8

1. Names and functions

(2)

(3)

(4)

(5)

1. Names and functions

(1)

(9)

(8)

(6)

(7)

(10)

(1) LCD panel

For an explanation of windows displayed, see the next page.

(2) to (5) [F1] to [F4] function keys

The function of each function key varies depending on the window currently

displayed.

⇒ Refer to the next page and “8. List of function key functions”

(6) [ESC] key

Each time this key is pressed, modes change from one to another. Also, pressing

this key brings you back to the window one level higher in the window hierarchy.

(7) [FWD/REV] key

Each time this key is pressed, the direction of operation changes between forward

run and reverse run.

(To use this key, parameter settings need to be changed. ⇒ Refer to page 1-3.)

(8) [RUN] key

Starts operation.

(To use this key, parameter settings need to be changed. ⇒ Refer to page 1-3.)

(9) [STOP/RESET] key

Stops operation.

(To use this key, parameter settings need to be changed. ⇒ Refer to page 1-3.)

In case the inverter has tripped, pressing this key twice in a row resets the inverter.

* If multiple commands are entered by pressing the three keys [F2], [F3] and [F4] or

[ESC], [FWD] and [RUN] in rapid succession, a stop command will be issued

instead to stop operation.

(10) Control dial

In a menu window, turn the dial clockwise or counterclockwise to select a menu item

(the item selected is highlighted) and press the dial to confirm the menu item

selected.

Turn the dial clockwise (+) to select an item that follows the item currently selected.

Turn the dial counterclockwise (-) to select an item that precedes the item currently

selected.

Selecting a menu item by turning the dial clockwise or counterclockwise and confirm

the item selected by pressing the dial are referred to as “select/confirm an item.”

*1

1-1

Page 9

1. Names and functions

p

In a value setting window, turn the dial clockwise or counterclockwise to increment or

decrement the value displayed, and press the dial to confirm the value specified.

Turn the dial clockwise (+) to increment the value.

Turn the dial counterclockwise (-) to decrement the value.

Turning the dial clockwise or counterclockwise to increment or decrement the value

displayed and pressing the dial to confirm the value specified are referred to as

“specify/confirm a value.”

*1: When the control dial is pressed, it performs the same function as the [ENT] key

on the inverter’s main operation panel.

*2: Some settings are executed only by tuning the control dial.

LCD panel

This section explains the features of windows available, using the top window of

Status Monitor Mode as an example.

Status Monitor Mode

Rotative direction FWD

Frequency referen ce 60.0Hz

Output current 90%

Input voltage 99%

Output voltage 99%

To

(1) Displays the mode currently selected.

(1)

Real-time information

Prm

(2)

(3)

(4)

(5)

(6)

(2) Displays the operating status of the inverter in a graphical symbol.

(rotating) : In operation

: Operation impossible (While the frequency is set at 0Hz, the

EOFF (blinking) : Waiting for emergency stop operation

(3) Displays the title or status of the window.

(4) Displays settings both in a menu form and numerically, or a list of various kinds of

information.

(5) Displays the function assigned to each function key in an abbreviation or graphical

symbol.

The abbreviations and graphical symbols in the window correspond to the [F1] to

[F4] keys, respectively starting from the left.

Top :

In this example, pressing the [F1] key displays the Top View Mode window.

: In this example, pressing the [F2] key displays the previous window.

: In this example, pressing the [F3] key displays the next window.

Prm : In this example, pressing the [F4] key displays the Parameter Setting Mode

window.

⇒ Refer to “8. List of function key functions”

(6) Graphical symbols displayed vary depending on whether there are windows that

precede or follow the current window.

: There are windows that precede and/or follow the current window.

: There is no window that precedes or follows the current window.

[RUN] key is pressed.)

*2

1-2

Page 10

1. Names and functions

About the change of parameter settings

By default, the inverter is set with parameters to the mode in which it controls the

operation of the machine via a terminal board. Moreover, the inverter is set so that

the switching between forward run and reverse run cannot be performed using its

operation panel.

To operate the inverter using this unit, parameter settings need to be changed, as

described below.

Parameter CMOd (Command input mode) =1 (Pane/LCD-option)

Parameter FMOd (Frequency input mode 1) =4 (Pane/LCD-option)

Parameter Fr (Panel FWD/REV selection) =2 (Forward (switchable)),

3 (Reverse (switchable))

This change of parameter settings makes it possible to start operation using the

[RUN] key, to stop operation using the [STOP/RESET] key, and to switch between

forward run and reverse run using the [FWD/REV] key.

Furthermore, it allows you to set an operation frequency using the control dial.

⇒ Refer to “5.1 Setting a panel operation frequency.”

1-3

Page 11

2. Installing the LCD remote keypad

The LCD remote keypad can be installed on the inverter and on the board (optional).

Using this LCD remote keypad along with a dedicated interconnect cable makes it

possible to operate the inverter by remote control (optional).

2. Installing the LCD remote keypad

2.1 Installing the remote keypad to the inverter

Turn off the inverter, and then follow these steps.

1 Remove the serial RS485 port cover

from the inverter’s main operation

panel.

To detach the cover, wrench it open using

a flat-blade screwdriver or any other

flat-tipped tool.

2 Mount the remote keypad on the

inverter’s main operation panel.

Insert the connector on the remote

keypad into the RS485 port while pushing

in the lock knobs, and then release the

lock knobs to secure the remote keypad.

3 Make sure the remote keypad is fixed

securely to the inverter.

2-1

Page 12

2. Installing the LCD remote keypad

2.2 Installing the remote keypad to the board (optional)

The remote keypad can be mounted on a board by means of an IP54 attachment

(optional).

If an IP65 attachment (optional) is used in combination with an IP54 attachment, the

remote keypad can be installed where it may be splashed with water.

Warning

● Never connect the unit to any inverter other than a VF-AS1/PS1 series

Prohibited

Turn off the inverter, as shown in the figure below.

inverter or any communication device. Do not use any cable other than

an optional interconnect cable designed specifically for the unit.

If the correct cable was not used, this might cause the unit to break down

and result in an electric shook or fire.

Tapping screws (4 pieces)

Used to secure the attachment.

Make a hole in the board, as shown in

the figure below.

115

104 5.55.5 4-Ф3.5

5

100

114.5

IP54 attachment

(optional)

Remote keypad

Dedicated interconnect cable

(optional)

* The pin configuration of the dedicated

IP65 attachment (optional)

Used to be attached to the IP54 attachment

interconnect cable is different from that of

any other commercially available cable.

Therefore, be sure to use the dedicated

interconnect cable.

*Leave a space of 45mm or more

for the interconnect cable.

*

2-2

Page 13

2.2 Remote control (optional)

Connecting the remote keypad to the inverter unit with a dedicated interconnect cable

and a connector (optional) makes it possible to operate the inverter from a distant

point up to 5m from it.

● Never connect the unit to any inverter other than a VF-AS1/PS1 series

Prohibited

Turn off the inverter, as shown in the figure below.

inverter or any communication device. Do not use any cable other than

an optional interconnect cable designed specifically for the unit.

If the correct cable was not used, this might cause the unit to break down

and result in an electric shook or fire.

<Inverter unit>

*Leave a space of 60mm or more

for the interconnect cable.

2. Installing the LCD remote keypad

Warning

Connector (optional)

Serial RS485

connector (2-wire)

< Remote keypad >

Dedicated interconnect

cable (optional)

* The pin configuration of the dedicated interconnect

cable is different from that of any other commercially

available cable.

Therefore, be sure to use the dedicated interconnect

cable.

2-3

*

Page 14

4. 標準モニタモードでの操作

g

3. Setting to be made when turning on the unit for the first time

When the unit is turned on at the first time after purchase, the Language Selection

window shown below appears on the LCD panel. In this window, select the language

you want to display on the screen.

1 The Language Selection window appears on

the screen.

This window appears only when the unit is turned

on at the first time after purchase.

2 Select the desired language using the control

dial and push the dial.

(In this example, English is selected. There is no

need to select/confirm the language.)

3 The Startup window is displayed and soon

replaced by the top window of Top View Mode.

Language selection

English

Deutsch

Portuguese

Language selection

English

Deutsch

Portuguese

インバータ⇒パネル

CONNECTION IN PROGRESS

*

V1.1 IE04

*: This window shows the

version of the installed

software. The contents of

the window may be

somewhat different from

those of your LCD panel.

Top View Mode

FWD 0.0H z STOP

0.0 Hz

Quick ---

3-1

Ln

Page 15

5. 標準モニタモード

gory

p

g

4. About available modes

The LCD remote keypad offers the following three modes, just as with the inverter’s

main operation panel.

(1) Top View Mode

When the remote keypad is turned on, it enters this mode first.

The top window displays the operating status.

In this mode, you can set a panel operation frequency, use a function key as the

EASY key, and so on.

⇒ Refer to “5. Operation in Top View Mode.”

(2) Parameter Setup Mode

This mode allows you to set parameters.

⇒ Refer to “6. Parameter Setup Mode.”

(3) Status Monitor Mode

This mode allows you to monitor various kinds of statuses and information, such

as the operating status of the inverter and information on the terminal board.

⇒ Refer to “7. Operation in Status Monitor Mode.”

The figures below show the top windows of these modes.

To change from one mode to another, press the [ESC] key.

FWD 60.0 Hz STOP

Top View Mode

ESC

0.0 Hz

Quick ---

Ln

Top View Mode

ESC

Status Monitor Mode

Real-time informat ion

Rotative direction FWD

Frequency reference 60.0Hz

Output current 0%

Input voltage 99%

Output voltage 0%

Top Prm

Status Monitor Mode

Parameter Setup Mode

Cate

History function

Basic Parameters

Extended Parameters

Changed Parameters

To

Parameter Setup Mode

Selection

Mon

* When Quick mode is selected

ESC

with the EASY key, other

windows are displayed.

4-1

Page 16

5. Operation in Top View Mode

g

5. Operation in Top View Mode

When the remote keypad is turned on, it enters this mode first, which allows you to

monitor the operating status, set an operation frequency, use a function key as the

EASY key, and switch between languages.

When Panel Jog Run is selected, a jog run frequency also can be specified in this

mode.

Explanation of the top window

Display of commands

executed

Display of

operating status

• Display of commands executed:

“FWD” or “REV” is displayed to indicate the

direction of rotation.

To p Vi ew Mo de

FWD 60.0 Hz RUN

The operation frequency is displayed in the form

of “

Hz.”

• Display of operating status:

“RUN” is displayed during operation.

“STOP” is displayed during a stop.

“Trip” is displayed in the event of tripping.

• Display of output frequency:

The operation frequency is displayed in the form of

“.

Hz.”

• Display of alarm/tripping:

If an error or tripping occurs, an error or trip code is displayed.

• Display of error/tripping message:

If an error or tripping occurs, an error or trip message is displayed.

60.0 Hz

Overheat alarm

Quick

Display of output frequency

Display of alarm/tripping

Ln

F1 F2

---

Display of

error/tripping

message

Functions of function keys

F1

: Switches between Quick mode and Standard Setting mode.

F2

: Brings you to the Language selection window.

5.1 Setting a panel operation frequency

When Frequency input mode1 (parameter FMOd=4) as a frequency setting mode, an

operation frequency can be set with the remote keypad.

1 Press the control dial.

The panel frequency window appears.

The current operation frequency setting is displayed

at the center of the window.

The current output frequency is displayed in the

upper right section of the window.

The minimum allowable frequency (min) and the

maximum allowable frequency (max) are displayed

at the bottom of the window.

Functions of function keys

The functions keys allow you to select the position or decimal place of each figure

(operation frequency) you want to increment or decrement with the control dial.

F1

: Selects the position of hundreds.

F2

: Selects the position of tens.

F3

: Selects the position of ones.

: Selects the first decimal place.

F4

Basic Parameters

FC

Panel frequency

Output frequency

0.0Hz

0.0Hz

min=0.0 max=60.0

×100 ×1000 ×10 ×1

F1 F2 F3 F4

5-1

Page 17

5. Operation in Top View Mode

g

2 After selecting the position of a figure you want

to change, specify/confirm another figure with

the control dial.

(In this example, a frequency of 30.0Hz is specified.)

Functions of function keys

The functions keys allow you to select the position

or decimal place of each figure (operation

frequency) you want to increment or decrement with

the control dial.

F1

: Selects the position of hundreds.

F2

: Selects the position of tens.

F3

: Selects the position of ones.

F4

: Selects the first decimal place.

Basic Parameters

Panel frequency

Output frequency 0.0Hz

30.0Hz

min=0.0 max=60.0

×1000 ×10 ×1

×100

F1

F2 F3

When you confirm the frequency specified, the screen goes back to the top window

of Top View Mode.

To change the frequency during operation

Press the control dial during operation to display the operation panel operation

frequency menu and turn the control dial to change the setting.

5.2 Using an EASY key function

The [F1] function key can be used as a substitute for the EASY key on the inverter’s

main operation panel. When the name of the function assigned to the [F1] key is

displayed in the lower left corner of the window, the [F1] key can be used as the EASY

key.

“Quick” : Function of switching between Quick

mode and Standard Setting mode

(parameter F750=0)

“Panel” : Function of switching between Operation

Panel and Remote

(parameter F750=2)

(When used with a VF-AS1 inverter)

“Loc/Rem” : Function of switching between Local and

Remote

(parameter F750=2)

(When used with a VF-PS1 inverter)

“Update” : Function of updating the Peak/Minimum

Hold setting

(parameter F750=3)

* The shortcut key function (parameter F750=1)

cannot be used. Even if the parameter is so set, the

name of the function is not displayed on the screen.

Top View Mode

FWD 60.0 Hz STOP

Quick

Quick

Panel

inverter)

Loc/Rem

inverter)

Ln

(When used with a VF-AS1

(When used with a VF-PS1

FC

F4

0.0 Hz

---

5-2

Page 18

5. Operation in Top View Mode

(1) Function of switching between Quick mode and Standard Setting mode

<Standard Setting mode selected when power is turned on (parameter PSEL=0)>

• When power is turned on, ”Quick” is displayed. (If the [F1] key is not pressed.)

When the unit enters Parameter Setup Mode in this situation, the ordinary top

window of Parameter Setup Mode appears.

• If the [F1] key is pressed while “Quick” is displayed, “Quick” is switched from

normal to reverse video “ ”. (If the [F1] key is pressed.)

Quick

When the unit enters Parameter Setup Mode in this situation, the Quick mode

window appears instead of the top window of Parameter Setup Mode.

<Quick mode selected when power is turned on (parameter PSEL=1)>

• When power is turned on, “ ” is displayed in reverse video. (If the [F1] key

Quick

is not pressed.)

When the unit enters Parameter Setup Mode in this situation, the Quick mode

window appears instead of the top window of Parameter Setup Mode.

• If the [F1] key is pressed when “ ” is displayed in reverse video, “Quick” is

Quick

switched from reverse to normal video. (If the [F1] key is pressed.)

When the unit enters Parameter Setup Mode in this situation, the ordinary top

window of Parameter Setup Mode appears.

<Always Quick mode (parameter PSEL=2)>

• “ ” is displayed in reverse video.

Quick

When the unit enters Parameter Setup Mode in this situation, the Quick mode

window appears instead of the top window of Parameter Setup Mode.

* In this situation, the [F1] key is inoperative.

(2) Operation Panel and Remote

(When used with a VF-AS1 inverter)

• “Panel” is displayed. (If the [F1] key is not pressed.)

In this situation, operation can be performed by remote control by means of the

terminal board.

• If the [F1] key is pressed while “Panel” is displayed, “Panel” is switched from

normal to reverse video “ ”. (If the [F1] key is pressed.)

Panel

In this situation, operation can be performed using keys on the remote keypad.

There is no need to switch to Panel Operation mode by changing parameter

settings.

* The switching between operation modes cannot be done during operation.

(3) Operation Panel and Remote

• “Loc/ ” is displayed. (If the [F1] key is not pressed.)

Rem

(When used with a VF-PS1 inverter)

In this situation, operation can be performed by remote control by means of the

terminal board.

• If the [F1] key is pressed while “Panel” is displayed, “Loc/ ” is switched from

normal to reverse video “ /Rem”. (If the [F1] key is pressed.)

Loc

Rem

In this situation, operation can be performed using keys on the remote keypad.

There is no need to switch to Local Operation mode by changing parameter

settings.

* The switching between operation modes cannot be done during operation.

5-3

Page 19

5. Operation in Top View Mode

(4) Peak/Minimum Hold setting

• “Update” is displayed. (If the [F1] key is not pressed.)

The instant the [F1] key is pressed in this situation, a measurement for peak

hold/minimum hold starts. When the [F1] key is pressed, “ ” is displayed

Update

in reverse video. (If the [F1] key is pressed.)

5.3 Selecting a language to be displayed

A language to be displayed on the screen can be selected.

In this window, the language selected when turning on the remote keypad for the first

time can also be changed to the other language.

Note) When an application CPU version of VFAS1 is less than V104, you cannot choose

it other than English and Japanese.

1 Press the [F2] (Lng) key.

The Language selection window appears on the

screen.

Select/confirm the desired language with the

control dial.

Functions of function keys

F1

: Brings you to the Top View Mode.

2 Select/confirm the desired language with the

control dial.

(In this example, Japanese is selected.)

Functions of function keys

F1

: Brings you to the Top View Mode.

Language selection

V English

Deutsch

Portuguese

F1

Language selection

English

V

Deutsch

Portuguese

F1

Top

To p

5-4

Page 20

5. Operation in Top View Mode

g

g

5.4 Performing jog run

When Panel Jog Run is selected (parameter F262=1, CMOd=1), “JOG” is displayed in

the lower right corner of the window. When “JOG” is displayed, jog run can be

performed using the [F4] key.

The switching to jog run cannot be performed during operation. When switching to Jog

Run mode, operation has to be stopped temporarily.

1 Press the [F4] key to carry out jog run.

The jog run frequency is displayed on the screen.

(In this example, the operation frequency is set at

5.0Hz.)

Operation continues as long as the [F4] key is

pressed, and it stops when the [F4] key is

released.

Functions of function keys

F1

: Switches between Quick mode and Standard

Setting mode.

F2

: Brings you to the Language selection window.

F4

: Executes a jog run command.

Top View Mode

FWD 60.0 Hz STOP

0.0 Hz

Quick

Top View Mode

FWD 60.0 Hz JOG

Ln

JOG

5.0 Hz

Quick

Ln

F1 F2 F4

JOG

5-5

Page 21

5. Operation in Top View Mode

g

g

g

5.5 Emergency stop/reset operation

To make an emergency stop or to reset the inverter, follow these steps. An emergency

stop can be made when operation is performed with the terminal board (parameter

CMOd=0, 2, 3 or 4).

1 Press the [STOP/RESET] key, which displays

the blinking code “EOFF” in the upper right

corner of the window.

2 Then press the [STOP/RESET] key again.

The Emergency Stop window appears and the

blinking code “E” is displayed.

3 Then press the [STOP/RESET] key again.

The Trip window appears and the blinking code

“CLr” is displayed in it.

Top View Mode EOFF

FWD 60.0 Hz RUN

60.0 Hz

Emergency stop?

Quick

Top View Mode

FWD 60.0 Hz Trip

Quick

Top View Mode

FWD 60.0 Hz Trip

Ln

Emergency stop

Ln

CLr

Trip reset? (STOP-Key)

Quick

Ln

4 Last of all, press the [STOP/RESET] key once

again to reset the inverter.

---

E

---

---

5-6

Page 22

6. Operation in Parameter Setup Mode

p

p

p

A

A

6. Operation in Parameter Setup Mode

In this mode, you can set basic parameters and extended parameters.

This mode also allows you to use the history function (inverter’s parameter ) and

the changed parameter search function (inverter’s parameter ) easily by simply

selecting the desired function from a menu.

Functions of function keys

F1

: Brings you to the Top View Mode.

F4

: Brings you to the Status Monitor Mode.

Parameter Setup Mode

Category Selection

History function

Basic Parameters

Extended Parameters

Changed Parameters

To

F1 F4

Mon

When Quick mode is selected

The window shown in the figure at right appears

when Quick mode is selected using the EASY key

function.

This window displays the parameter currently

selected for Quick mode.

Functions of function keys

F1

: Brings you to the Top View Mode.

F2

: Displays the previous window.

F3

: Displays the next window.

F4

: Brings you to the Status Monitor Mode.

Parameter Setup Mode

Quick mode

U4 :Automatic function set

Pt :V/f control mode

FH :Maximum frequency

CC :Acceleration time 1

DEC :Deceleration time 1

To

F1 F2 F3 F4

Mon

6.1 Searching for the change histories of parameters

(History function)

The change histories of up to 5 parameters can also be displayed in a list form in order

of novelty.

1 Select/confirm “History function” using the

control dial.

Change histories are displayed in a list form in

order of novelty.

If the number of change histories exceed 5,

change histories except the 5 latest ones are

deleted in the order in which changes were made.

Functions of function keys

F1

: Brings you to the Top View Mode.

In this window, settings can be changed.

Pressing the control dial displays the Parameter Setting window, in which you can

change settings as required.

⇒ For the steps to be followed, see the following pages.

Parameter Setup Mode

History function

vL :Base frequency 1

CMOd :Command input mode

---- :There is no history

---- :There is no history

---- :There is no history

To

F1

6-1

Page 23

6.2 Setting a basic parameter

60.0

p

A

A

A

When Quick mode is selected using the EASY key function, skip step 1.

Go straight to step 2.

1 Select/confirm “Basic parameters” using the

control dial.

The Basic Parameters window appears.

Functions of function keys

F1

: Brings you to the Top View Mode.

F2

: Displays the previous window.

F3

: Displays the next window.

2 Select/confirm the parameter setting you want

to change, using the control dial.

(Ex. Select/confirm “Command input mode”

and “Base frequency 1.”

The Parameter Setting window appears.

If the setting selected is changed by selecting a

menu item, the menu item selected is highlighted

and marked with a checkmark.

Functions of function keys

F2

: Displays the previous window.

F3

: Displays the next window.

If the setting selected is changed by specifying a

value, the value specified is displayed. In addition,

the minimum allowable value (min) and the

maximum allowable value (max) are also

displayed at the bottom of the window.

Functions of function keys

The functions keys allow you to select the position

or decimal place of each figure (operation

frequency) you want to increment or decrement

with the control dial.

F1

: Selects the position of hundreds.

F2

: Selects the position of tens.

F3

: Selects the position of ones.

F4

: Selects the first decimal place.

6. Operation in Parameter Setup Mode

Parameter Setup Mode

Basic Parameters

U1 :Automatic acc/dec

U2 :Automatic torque boost

U4 :Automatic function set

CMOd :Command input mode

FMOd :Frequency input mode 1

To

F1 F2 F3

If the setting selected is

●

changed by selecting a menu

item

Basic Parameters

Command input mode

0 :Terminal 口

1 :Panel / LCD-option

2 :RS485-2wire

3 :RS485-3wire

CMOd

F2 F3

∨

● If the setting selected is

changed by specifying a

value

Basic Parameters

vL

Base frequency 1

min=25.0 max=500.0

×100

×1000

F1 F2 F3 F4

Hz

×1

×10

6-2

Page 24

6. Operation in Parameter Setup Mode

90.0

●

3 Using the control dial, select/confirm the

setting you want to change by selecting a

menu item or specifying a value.

(In this example, “Panel / LCD-option” is

selected and confirmed or a frequency of

90.0Hz is specified and confirmed.)

When the change you made is saved, the title of

the parameter stops blinking and the screen

returns to the previous window.

If the setting selected is

changed by selecting a

menu item

Basic Parameters

Command input mode

0 :Terminal

1 :Panel / L CD-option 口

2 :RS485-2wire

3

:RS485-3wire

CMOd

∨

● If the setting selected is

changed by specifying a

value

Basic Parameters

vL

Base frequency 1

min=25.0 max=500.0

×1000

×100

Hz

×1

×10

6.3 Setting an extended parameter

1 Select/confirm “Extended parameters” using

the control dial.

The Extended Parameters window appears.

Functions of function keys

F1

: Displays parameters in the number range of

900.

The number displayed decrements each time

this key is pressed.

F2

: Displays the previous window.

F3

: Displays the next window.

F4

: Displays parameters in the number range of

Parameter Setup Mode

Extended Parameters

F100 :Low-speed signal freq

F101 :Speed reach frequency

F102 :Speed reach freq band

F105 :Priority of FWD/REV

F106 :Input terminal priority

F9-- F2--

F1 F2 F3 F4

200.

The number displayed increments each time

this key is pressed.

2 Change the parameter setting.

To do this, perform steps 2 and 3 in the “6.2 Setting a basic parameter” section.

6-3

Page 25

6. Operation in Parameter Setup Mode

p

6.4 Searching for parameters whose settings were

changed (Search for changed settings)

The remote keypad is capable of displaying parameters whose current settings are

different from their default settings, and their current settings.

1 Select/confirm “Changed Parameters” using

the control dial.

The Changed Parameters window appears.

Functions of function keys

F1

: Brings you to the Top View Mode.

F3

: Displays, in reverse order, parameters whose

setting were changed.

: Displays, in normal order, parameters whose

F4

setting were changed.

2 Search for the desired parameter by pressing

the [F3] or [F4] key repeatedly.

The title, function and current setting of the

parameter selected are displayed.

Functions of function keys

F1

: Brings you to the Top View Mode.

F3

: Displays, in reverse order, parameters whose

setting were changed.

F4

: Displays, in normal order, parameters whose

setting were changed.

In this window, settings can be changed.

Pressing the control dial displays the Parameter Setting window, in which you can

change settings as required.

⇒ For the operation procedure, see the previous sections.

Parameter Setup Mode

Changed Parameters

[U - - -]

Waiting for search

To

F1 F3 F4

Parameter Setup Mode

Changed Parameters

[CMOd]

Command input mode

1 :Panel / LCD-option

Top Back Next

F1 F3 F4

Back Next

6-4

Page 26

7. Operation in Status Monitor mode

p

7. Operation in Status Monitor Mode

In this mode, you can monitor various kinds of statuses and information, such as the

operating status of the inverter, information on the terminal board, and trip information.

Functions of function keys

F1

: Brings you to the Top View Mode.

F2

: Displays the previous window.

F3

: Displays the next window.

F4

: Brings you to the Parameter Setup Mode.

Status Monitor Mode

Real-time informat ion

Rotative direction FWD

Frequency reference 60.0Hz

Output current 22%

Input voltage 99%

Output voltage 50%

To

F1 F2 F3 F4

Prm

Here are the items that can be monitored in this mode and an explanation of them.

These items are the same as those that can be monitored with the inverter’s main

operation panel.

Items displayed Description

Rotative direction

Frequency reference

*1, *2

*1

*1

*1

*1, *2

*1, *2

*1, *2

Output current

Input voltage

Output voltage

To rq u e

PBr overload

Inverter overload

Motor overload

Input terminal 1 :

S4,S3…R,F

Input terminal 2 :

L8,L7…L1

Output terminal 1 :

FL…OUT2

Output terminal 2 :

R4…OT3

Version of APP-CPU

Version of MOT-CPU

Past trip # 1 (latest)

Past trip # 2

Past trip # 3

Past trip # 4

Parts replacement alarm

Cumulative run time

Rotating direction -

*1

Set value and current value of parameter F711 v

Set value and current value of parameter F712 v

Set value and current value of parameter F713 v

Set value and current value of parameter F714 v

Set value and current value of parameter F715 v

Set value and current value of parameter F716 v

Set value and current value of parameter F717 v

Set value and current value of parameter F718 v

Input terminal board information (Standard

terminal board)

Input terminal board information (Optional

terminal board)

Output terminal board information (Standard

terminal board)

Output terminal board information (Optional

terminal board)

CPU version information (Application) CPU version information (Motor) Trip history information 1 (latest) v

Trip history information 2 v

Trip history information 3 v

Trip history information 4 v

Parts replacement alarm information v

Cumulative run time -

Display

of details

v

v

v

v

*1: The display item shows the case of a default setting.

*2: These items are not displayed when the LCD panel is used with a VF-PS1 inverter.

7-1

Page 27

7. Operation in Status Monitor Mode

p

p

p

7. 1 Displaying details of an item monitored

1 Select/confirm the desired item using the

control dial.

(Ex. Select/confirm “Output current”)

The monitor window of the item selected appears.

* Depending on the item selected, no monitor

window may be displayed.

Functions of function keys

F1

: Brings you to the Top View Mode.

F4

: Brings you to the Parameter Setup Mode.

How to use monitor windows

Monitor windows can be broadly classified under the

following three types.

<Type of window 1: Displays a value and a

graph>

This type of window displays an analog value,

such as an output frequency, output current or

output voltage. (Ex. “Output current”)

It displays the current value both numerically and

in a graph form.

In addition, the minimum allowable value (min)

and the maximum allowable value (max) are also

displayed at the bottom of the window.

<Type of window 2: Displays information in a

graph form>

This type of window displays input/output terminal

information and a life alarm in a graph form. (Ex.

“Input terminal : S4, S3...R, F”)

It displays the ON/OFF status of each terminal

signal and the ON/OFF status of an alarm signal in

a graph form.

If the arrow

is moved to a terminal or alarm

symbol, the name of the function assigned to the

terminal or the name of the alarm is displayed.

<Type of window 3: Displays information in a list

form>

This type of window displays detailed trip

information. (Ex. Past trip # 1 (latest))

It displays the conditions under which the inverter

was operated at the occurrence of tripping.

Status Monitor Mode

min=0 max=185

Status Monitor Mode

min=0 max=185

ON

OFF

To

* This illustration shows the

information displayed when the

LCD panel is connected to an

VF-AS1 inverter.

E :Emergency stop

Sequence number 1

Output frequency 25.0Hz

Rotative direction FWD

Frequency reference 30.0Hz

Output current 40%

Output current

22%

To

Prm

F1 F4

Output current

22%

Top Prm

Status Monitor Mode

Input terminal 1 : S4,S3…R,F

S4 S3 S2 S1 RES ST R F

Forward run

Prm

Past trip # 1 (latest)

To

Prm

7-2

Page 28

8. Operation by a copy function

op

ode

8. Operation in a copy function

The copy function can be used when "Copy" is displayed on the upper part of the F3 key.

The copy function works by the latest combination of LCD Remote Keypad (RKP004Z rev.2 or

later) with the Inverter version of APP-CPU is V136 or more of VFAS1, V614 or more of

VFPS1. When either is old, this function does not work.

Version of APP-CPU

Limitation in copy function use

VFAS1 VFPS1

V134

or less

V136

or more

V612

or less

V614

or more

RKP004Z-1or0 Disabled Disabled Disabled Disabled LCD type form

After RKP004Z-2 Disabled Enabled Disabled Enabled

Moreover, it is not possible to copy normally in the following cases even if the copy

function can be used.

1) It is not possible to copy, when the inverter form differs,.

2) It is not possible to copy to the inverter while driving.

3) It is not possible to copy, when a minimum unit of the frequency is different.

4) It is necessary to reset up the parameters after the copy when copying between the

inverters from which capacity differs.

5) It is necessary to reset power supply after the copy when the unit of time differs.

Explanation of the top window

• Display of commands executed:

“FWD” or “REV” is displayed to indicate the direction of

rotation.

The operation frequency is displayed in the form of

Hz.”

“.

Display of

commands

T

FWD 60.0 Hz RUN

View M

Display of

operating status

• Display of operating status:

“RUN” is displayed during operation.

“STOP” is displayed during a stop.

“Trip” is displayed in the event of tripping.

• Display of output frequency:

The operation frequency is displayed in the form of

“.

Hz.”

• Display of alarm/tripping:

If an error or tripping occurs, an error or trip code is displayed.

• Display of error/tripping message:

60.0 Hz

Overheat alarm

Quick Copy

Lng

F1 F2 F3

Display of output frequency

Display of alarm/tripping

Display of error/tripping message

---

If an error or tripping occurs, an error or trip message is displayed

Functions of function keys

F1

:Switches between Quick mode and Standard Setting mode

F2

:Brings you to the Language selection window.

:Brings you to Copy mode window.

F3

8-1

Page 29

8. Operation by a copy function

p

y

p

y

p

y

y

p

8. 1 Copy to LCD

Push the F3 key on an initial screen and the copy mode screen is displayed. It is not

possible to drive with the [RUN] key in the following 3~5 screen display.

1 Select the memory saving group using the

control dial.

2 Select copy direction [Copy to the LCD

memory] using the control dial.

Memory - B

To

[Copy to the LCD memory]

To

Copy Mode

Group selection

Memory - A

Copy Mode

Memor

- A

Copy direction

[Copy to the inverter]

3 Display of copy waiting

Copy starts when the [F4] key is input.

Please push F4 key

when starting

[LCD メモリへコピー]

Copy Mode

Memor

- A

[Copy to the LCD memory]

Waiting

To

4 Display of copy loading(fixed screen)

Copy finishes in 1 minute. When the copy

is not completed even if it waits 2 minutes

or more, please reset a power supply and

copy again.

Note) The status display(

)doesn't rotate when

Now loading.

Please wait for about 1 min.

[LCD メモリへコピー]

Copy Mode

- A

[Copy to the LCD memory]

Memor

Loading

copying it while driving until the copy is completed.

5 Display of copy finish

Return to the copy direction window

as above “2” when press the ESC key

after copy.

Copy was completed normally.

Please push ESC-key.

CRC code:6AE3

Copy Mode

Memor

[Copy to the LCD memory]

To

- A

Finish

Info

Star t

F4

8-2

Page 30

8. Operation by a copy function

y

p

p

p

y

y

p

y

8. 2 Copy to inverter

There is no data in LCD, and copy it to LCD at the time of purchase.

(Chap.: 8.1)

Push the F3 key on an initial screen and the copy mode screen is displayed. It is not

possible to drive with the [RUN] key in the following 3~5 screen display.

1 Select the memory saving group using the

control dial.

2 Select copy direction [Copy to the inverter

memory] using the control dial.

It is not possible to copy to the inverter

when there is no information in the selected

memory. Copy to the LCD first

(ref.: Chapter 8.1).

3 Display of copy waiting

Copy starts when the [F4] key is input

Memory - B

To

[Cop y to the LCD memory]

Top

Please push F4 key

when starting

[LCD メモリへコピー]

To

Copy Mode

Grou

selection

Memory - A

Copy Mode

Memor

Group selection

[Copy to the inverter]

Copy Mode

Memor

[Copy to the inverter]

Waiting

Info

- A

- A

Star t

F4

4 Display of copy loading(fixed screen)

Copy finishes in 1 minute. . When the copy

is not completed even if it waits 2 minutes

or more, please reset a power supply and

copy again.

Copy Mode

- A

Memor

[Copy to the inverter]

5 Display of copy finish

Return to the copy direction window

as above “2” when press the ESC key

after copy.

.

Copy was completed normally.

Please push ESC-key.

CRC code:6AE3

Copy Mode

Memor

[Copy to the inverter]

Finish

To

- A

8-3

Page 31

8. Operation by a copy function

p

p

y

p

p

8. 3 Confirm a memory information

There is no data in LCD, and copy it to LCD at the time of purchase.

(Chap.: 8.1)

Push the F3 key on an initial screen and the copy mode screen is displayed.

1 Select the memory saving group that you

want to confirm using the

control dial.

Memory - B

2 Push the [F4] key.

Memory - B

3 Displays detail information in the LCD

memory.

Typ e: Displays VFAS1 or VFPS1.

Rating:Displays voltage and capacity.

Version of APP-CPU:

Displays CPU version for the application.

The total parameter might differ when CPU version is different.

CRC code:

The CRC code is calculated from the communication data. It is detected whether it

normally copies to the inverter by agreeing with the CRC in the memory code and

the CRC in the copy completion display when copying it to the inverter.

Type : VFAS1

Rating : 200V-3.7kW

Version of APP-CPU : v136

CRC code : 6AE3

Copy Mode

Grou

Memory - A

To

Copy Mode

Group selection

Memory - A

To

Copy Mode

Memor

Inverter informat ion

To

selection

Info

Info

F4

- A

Star t

8-4

Page 32

10. Warranty

g

9. List of function key functions

The abbreviations and graphic symbols displayed at the bottom of the window refer to

the functions of function keys, and the pressing a function key performs the

corresponding function.

The abbreviations and graphical symbols in the window

correspond to the [F1] to [F4] keys, respectively starting from the left.

0.0 Hz

Press the [F1] key to perform this function.

Press the [F2] key to perform this function.

Press the [F3] key to perform this function.

Press the [F4] key to perform this function.

Here are the functions keys available and their functions.

Function

key

[F1] key Far left

[F2] key Left center

[F3] key

[F4] key Far right

Display

position

Right

center

Display

Item

Function

displayed

Quick

Panel

Loc/Rem Switches between Local and Remote. 5-2

Update Measurements for Peak/Minimum Hold starts. 5-2

Top Brings you to the Top View Mode. 4-1

F9-- ~ F1--

×1000 Selects the position of hundreds. 5-1

Lng Brings you to the Language selection window. 5-4

Displays the previous window. 6-1

×100 Selects the position of tens. 5-1

Displays the next window. 6-1

×10 Selects the position of ones. 5-1

Back

Copy Brings you to the copy mode. 8-1

--- No function. Mon Brings you to the Top View Mode. 4-1

Prm Brings you to the Parameter Setup Mode. 4-1

F1-- ~ F9--

×1 Selects the first decimal place. 5-1

Next

JOG Executes a jog run command. 5-5

Info Brings you to the memory information. 8-3

Switches between Quick mode and Standard Setting

mode.

Switches between Operation Panel and Remote.

Displays parameters in the number range of 900 ~

displays parameters in the number range of 100.

Displays, in reverse order, parameters whose setting

were changed.

Displays parameters in the number range of 100 ~

displays parameters in the number range of 900.

Displays, in normal order, parameters whose setting

were changed.

FWD 60.0 Hz STOP

Top View Mode

Quick ---

Ln

Reference

5-2

5-2

6-3

6-4

6-3

6-4

9-1

Page 33

7. 状態モニタモードでの操作

10. Specifications

Item Specifications

Model number RKP004Z

Applicable model VF-AS1/PS1 inverter unit

Communication

setting

Use environments Indoors, an altitude of 3000m or less, where the product will

Ambient temperature -10 to +60°C

Storage temperature -25 to +65°C

Relative humidity 20 to 93% (no condensation and absence of vapor)

Vibration 5.9m/s2 (0.6G) or less (10 to 55Hz) (compliant with JIS C

Cooling method Self-cooling

Outside dimensions (unit: mm)

Baud rate: 19200 bps (F800=1)

Communication type: 2-wire RS485

Parity: even (F801=1)

not be exposed to direct sunlight, corrosive or explosive

gases, vapor, coarse particulates including dust, and where

there is no grinding fluid or grinding oil nearby

60068-2-6)

98 26

107

10-1

Page 34

8. Before making a service call

11. Before making a service call

If a problem occurs, follow the instructions in this table to track down and eliminate the

cause of the problem.

Problems Possible causes Remedies

Nothing is displayed on the

screen.

The Startup window

appears, but the message

“CONNECTION IN

PROGRESS” does not out

and the screen does not turn

to the next window.

Although line information is

displayed on the screen,

textual information is not

displayed. Or some

characters are not displayed

correctly.

The error code E-17 (key

failure alarm) is displayed.

Operation cannot be

controlled with the [RUN]

key or the [STOP/RESET]

key.

Operation can be controlled

with the [RUN] key and the

[STOP/RESET], but the

direction of rotation cannot

be changed with the

[FWD/REV] key.

The inverter has tripped

because of a communication

error (Err5).

Although the [STOP/RESET]

key was not pressed, the

machine stopped operating.

• The inverter connected is not

turned on or it is not connected

securely.

• A cable other than a dedicated

one is used.

• The communication speed

setting or parity setting of the

inverter is different from that of

the unit.

• Connection may be broken

during communication.

• If the unit uses an old language

database, the codes shown

below may be displayed.

<Ex.>

“F123” “:004” “M301”

• The same key is pushes more

than 20 seconds.

• Panel Operation mode is not

enabled.

• The operation frequency is set

at 0.0Hz.

• The basic parameter Fr (panel

FWD/REV selection) is set to 0

or 1.

• F803 (com time-out time) is

turned ON (enabled).

* By default, the function of

measuring the time for a

time-out is turned off (disabled).

• Multiple commands have been

entered because the three keys

[F2], [F3] and [F4] or [ESC],

[FWD] and [RUN] were pressed

in rapid succession.

• The [STOP/RESET] key may be

broken and held in the ON

position.

• Check whether the inverter is turned

on.

• Check the interconnect cable and the

connector for loosening.

• Use a dedicated cable.

• Set the communication speed and the

parity, as specified below.

F800 (communication speed) = 1

(19,200 bps)

F801 (parity) = 1 (even parity)

Then turn the unit off and then back on

to reset it.

• Move to another window by pressing

the [ESC] key to reload textual

information, and check the cable and

the connector for loosening.

• This phenomenon does not mean that

the unit is faulty.

• Check whether the key operates

normally. If it does not operate

normally, it has to be repaired.

• Change the setting of the basic

parameter COMd (command input

mode) to 1 (Panel / LCD-option).

• Set an operation frequency according

to the setting of the basic parameter

FMOd (frequency input mode 1).

When performing operation at the

frequency set with the extension

operation panel (see section 5.1), set

FMOd to 4 (Panel / LCD-option).

• Change the setting of the parameter Fr

(panel FWD/REV selection) to 2 or 3.

• Connection may be broken during

communication. Check the cable and

the connector for loosening.

• Check to see if multiple commands

have been entered as a result of

pressing the three keys in rapid

succession.

• Check whether the key operates

normally. If it does not operate

normally, it has to be repaired.

11- 1

Page 35

11. Before making a service call

r

Problems Possible causes Remedies

Using a copy function is not

possible.

Memory data error message

is displayed.

Disconnection error

message is displayed when

the copy function is used.

"TOSHIBA" screen is

momentarily displayed when

using copy function or the

confirmation of the memory

information.

“----“ is displayed when using

the confirmation of the memo

information function.

German cannot be selected. • APP-CPU version of VFAS1 is

• APP-CPU and the LCD type

form may not be appropriate.

• Something is wrong with the

internal memory.

• Connection may be broken

during communication.

• This phenomenon appears only

once when using copy function

for the first time.

• It occurs when LCD has no

information or communication

signal between LCD and the

inverter is disconnected while

copying to the LCD.

less than V104.

• When APP-CPU and the LCD type form

are not appropriate the copy function

cannot be used.

• Copy to the LCD again. (ref. Chapter 8)

• Check the cable and the connector,

then copy again.

• Does not appear after doing copy to the

LCD one time(ref. Chapter 8.1).

• Copy to the LCD. (ref. Chapter 8)

• German can be selected by using

APP-CPU version of VFAS1 is V106 or

greater.

11- 2

Page 36

10. Warranty

12. Warranty

Any part of the unit that proves defective will be repaired and adjusted free of charge

under the following conditions:

1. If the product breaks down within one year after delivery, although it is installed and

handled properly, and if the breakdown is undoubtedly attributable to a defect in

designing or manufacturing by Toshiba, the product shall be repaired free of charge.

2. This warranty applies only to the delivered unit.

3. For the following kinds of failure or damage, the repair cost shall be borne by the

customer even within the warranty period.

(1) Failure or damage caused by misuse, or unauthorized repairs or modification

(2) Failure or damage caused by the drop of the product after purchase or rough

handling during transportation

(3) Failure or damage caused by fire, salty water or wind, corrosive gas, earthquake,

storm or flood, lightning, abnormal voltage supply, or other natural disasters

(4) Damage caused by using the product for a purpose unauthorized for it as an

external operation panel

4. If there are any warranty conditions otherwise provided for, those conditions will

govern.

12-1

Loading...

Loading...