Toshiba RAV-M242A-E, RAV-M242A Service Manual

SERVICE MANUAL

ROOM AIR-CONDITIONER

FILE NO. A10–9801

PRINTED IN JAPAN, Mar.,1998 ToMo

SUPPLEMENT

Unit A

Unit B

RAS-13SK-E

(or RAS-13SKX)

RAV-M242A-E

(or RAV-M242A)

RAV-M242A-E

SPLIT WALL TYPE

(Combination with RAS-13SK-E)

RAV-M242A

(Combination with RAS-13SKX)

– 2 –

CONTENTS

1. SPECIFICATIONS.......................................................................................................................... 3

2. CONSTRUCTION VIEWS .............................................................................................................. 4

3. WIRING DIAGRAM ........................................................................................................................5

4. SPECIFICATIONS OF ELECTRICAL PARTS ...............................................................................6

5. REFRIGERANT PIPING DIAGRAM ..............................................................................................7

6. UNIT INSTALLATION.....................................................................................................................9

7. TROUBLESHOOTING CHART....................................................................................................10

7-1. What to be Prechecked First ......................................................................................................... 10

7-2. Primary Judgement of Tr ouble Sources ....................................................................................... 11

7-3. Troubleshooting Flo wc harts.......................................................................................................... 15

7-4. How to Check the Remote Contr ol (Including the Indoor P.C. Board)........................................ 20

7-5. P.C. Board Layout........................................................................................................................... 23

8. EXPLODED VIEWS AND PARTS LIST .......................................................................................25

8-1. Indoor Unit ...................................................................................................................................... 25

8-2. Outdoor Unit ................................................................................................................................... 26

– 3 –

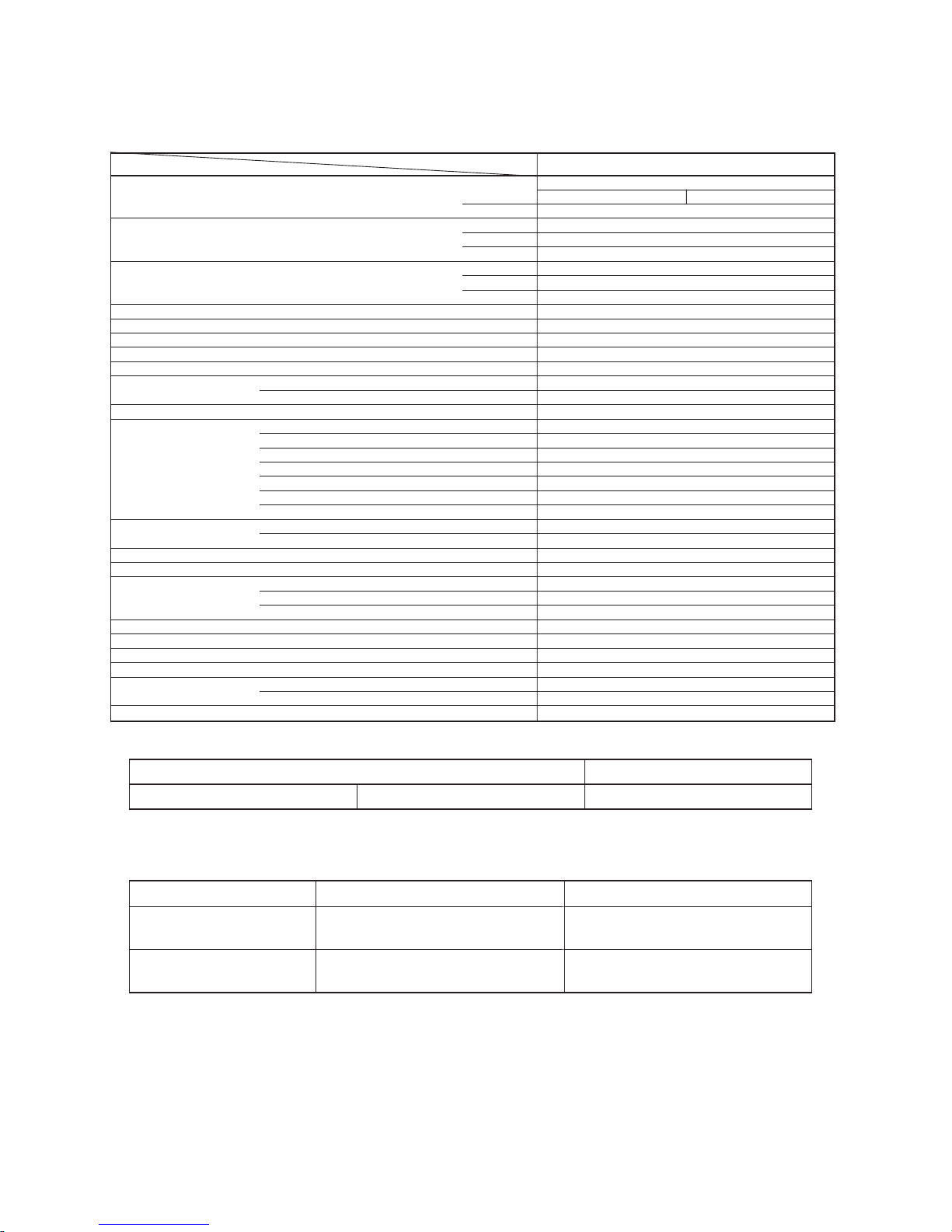

1. SPECIFICATIONS

RAV-M242A-E / RAV-M242A

2 indoor unit

AB

12, 200 x 2

6, 100

24, 400

7,1

1

220 – 240

50

2,46

99

10,8

68

53

R-22

0,95 + 0,95

Capillary tube

ø12,7 (1/2")

Flare

ø6,4 (1/4")

Flare

7,6 (25)

15 (48)

2 ( 7 )

5 (16)

5 (16)

RAS-13SK-E or RAS-13SKX

RAV-M242A-E or RAV-M242A

790 (2 – 7 1/8)

880 (2 – 9 1/8)

310 (1 – 1/4)

70 (154,3)

Finned tube

Propeller fan

63

PH160X2-4L

1,100

Fuse, inner overload-relay

Model

Item

Operation Unit

*1 BTU/h

kcal/h

Cooling capacity *1 BTU/h

kW

Phase

Power source V

Hz

Power consumption Cooling kW

Power factor Cooling %

Running current Cooling A

Starting current Cooling A

Operating noise (SPL*4) dB (A)

Refrigerant

Name of refrigerant

Charge volume kg

Refrigerant control

Gas side size mm (in.)

Coupler style

Liquid side size mm (in.)

Coupler style

Standard length m (ft)

Maximum length (One-way) *2 m (ft)

Minimum length m (ft)

Maximum height

Indoor unit higher m (ft)

Outdoor unit higher m (ft)

INDOOR UNIT MODEL

OUTDOOR UNIT MODEL

Height mm (ft-in.)

Dimensions Width mm (ft-in.)

Depth mm (ft-in.)

Net weight kg (Ibs)

Condenser type

Condenser fan type

Fan motor output W

Compressor

Model

Output W

Protective device

Condenser air inlet temperature

35°C DB (95°F DB)

Evaporator air inlet temperature

27°C DB (80°F DB) 19,0°C WB (66°F WB)

Note 1: Cooling capacity is based on the following temperature conditions.

Note 2: These mean equivalent length.

Note 3: Operating range of the units

Note 4: SPL: Sound Pressure Level

Note 5: Specifications are subject to change without notice.

Remark:

• Be sure to refer to the service manual file No. A00-9701 for the indoor unit RAS-13SKX (or RAS-13SK-E) to be

connected.

Condenser air inlet temperature

43°C DB (109°F DB)

21°C DB (70°F DB)

Evaporator air inlet temperature

32°C DB, 22,5°C WB

(95°F DB, 73°F WB)

21°C DB, 15,5°C WB

(70°F DB, 60°F WB)

Maximum

Minimum

– 4 –

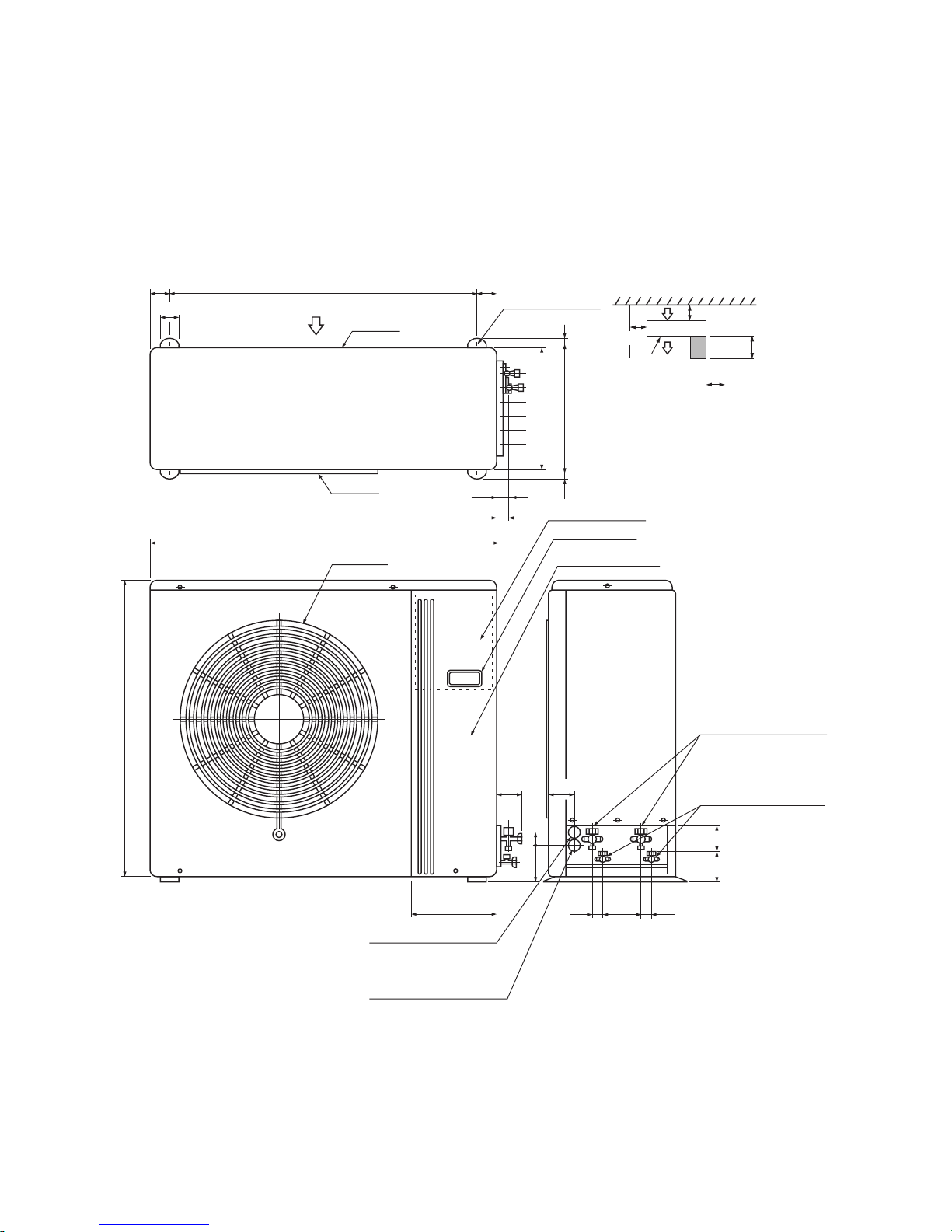

2. CONSTRUCTION VIEWS

Outdoor Unit

RAV-M242A-E (or RAV-M242A)

340 1212

310

45

36

31

79045

50

Air inlet

Air outlet

880

257

70 57

34

Refrigerant piping joint

(Gas side 2-ø12,7)

Refrigerant piping joint

(Liquid side 2-ø6,4)

3486

Power supply cord hole

(ø19 knockout hole)

Inter-unit wiring cord hole

(

ø28 knockout hole

)

65 60

107 33

790

Air outlet

Electric parts box

Carrying handle

(Both side)

Electric parts cover

100

Outlet

(Space for wiring

and piping)

100

Space required for service

Space for service

When installing, the inlet is

to be faced the wall side.

300

500

Anchor bolt hole

(4-12x18 long hole)

– 5 –

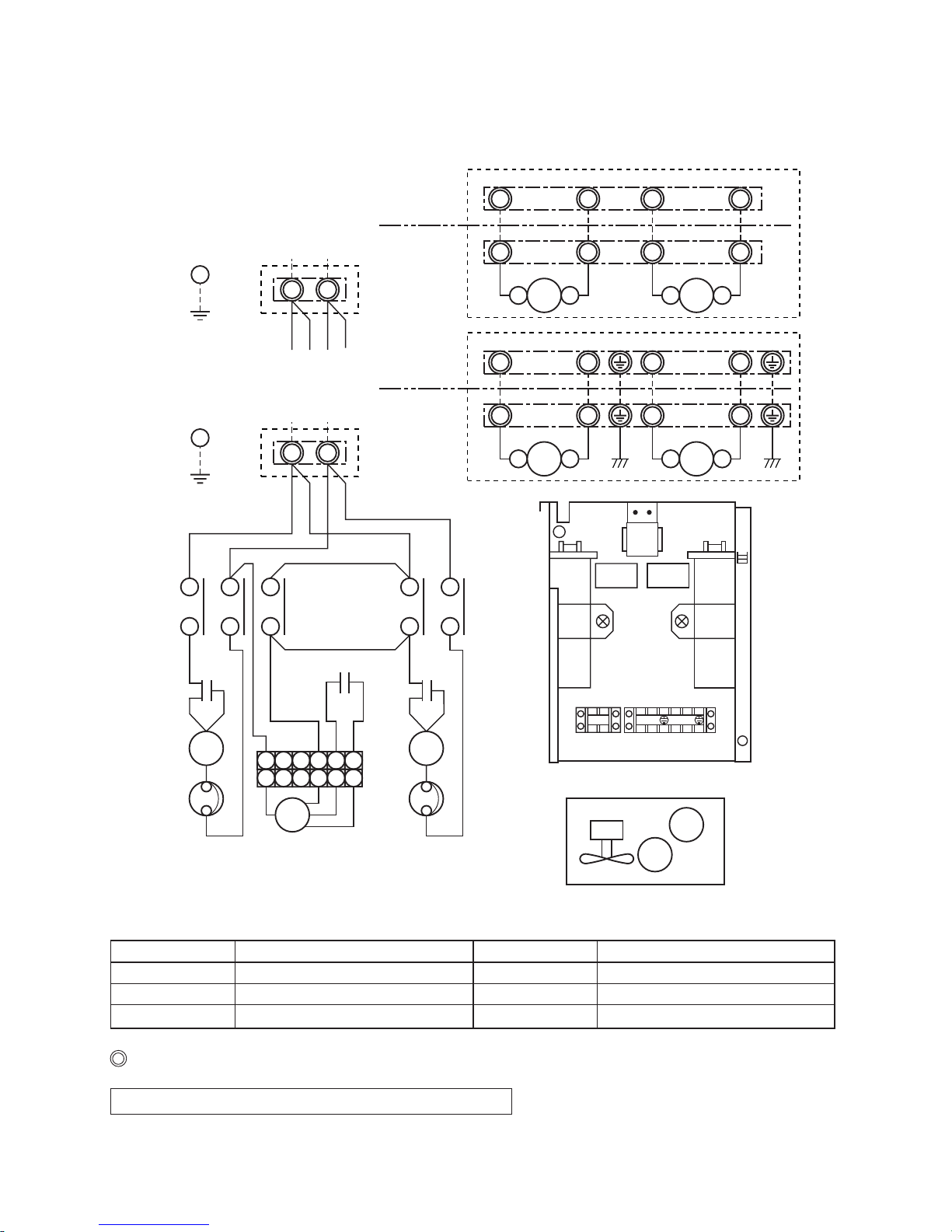

3. WIRING DIAGRAM

Shows terminal block and figures show terminal numbers.

Broken lines show wiring at site.

Don't operate the units with the magnetic contactor pushed.

Symbol Name

CM1, 2 Compressor

FMo Fan moter

RCc1, 2 Running capacitor (Compressor)

Symbol Name

RCo Running capacitor (Fan motor)

51C1, 2 Overload relay

52C1, 2 Magnetic contacto

11

L N

12

CM1

RCo1

RCo

WHI

BLK

BLK

RED

RED

51C1

52C1 52C2

220-240V 1Ph 50Hz

power supply

Outdoor Unit

Earth screw

Indoor Unit

131415

16

6

11

12

CM2

RCo2

WHI

BLK

BLK

RED

RED

51C2

13

14

A B

5 4 3 2 1

6 5 4 3 2 1

FMo

1 2 1

52C1 A B52C2

Unit A Unit B

2

1 2 1 2

A B

1 2 1

52C1

A B

52C2

Unit A Unit B

2

1 2 1 2

(Electrical Parts Box)

Parts Position

(Fan Motor, Compressor,Coil)

RCo

52C2

RCc2RCc1

52C1

NL2121

CM1

FMo

CM2

Outdoor Unit

Indoor Unit

A N

220-240V 1Ph 50Hz

power supply

Earth screw

RAV-M242A

RAV-M242A-E

– 6 –

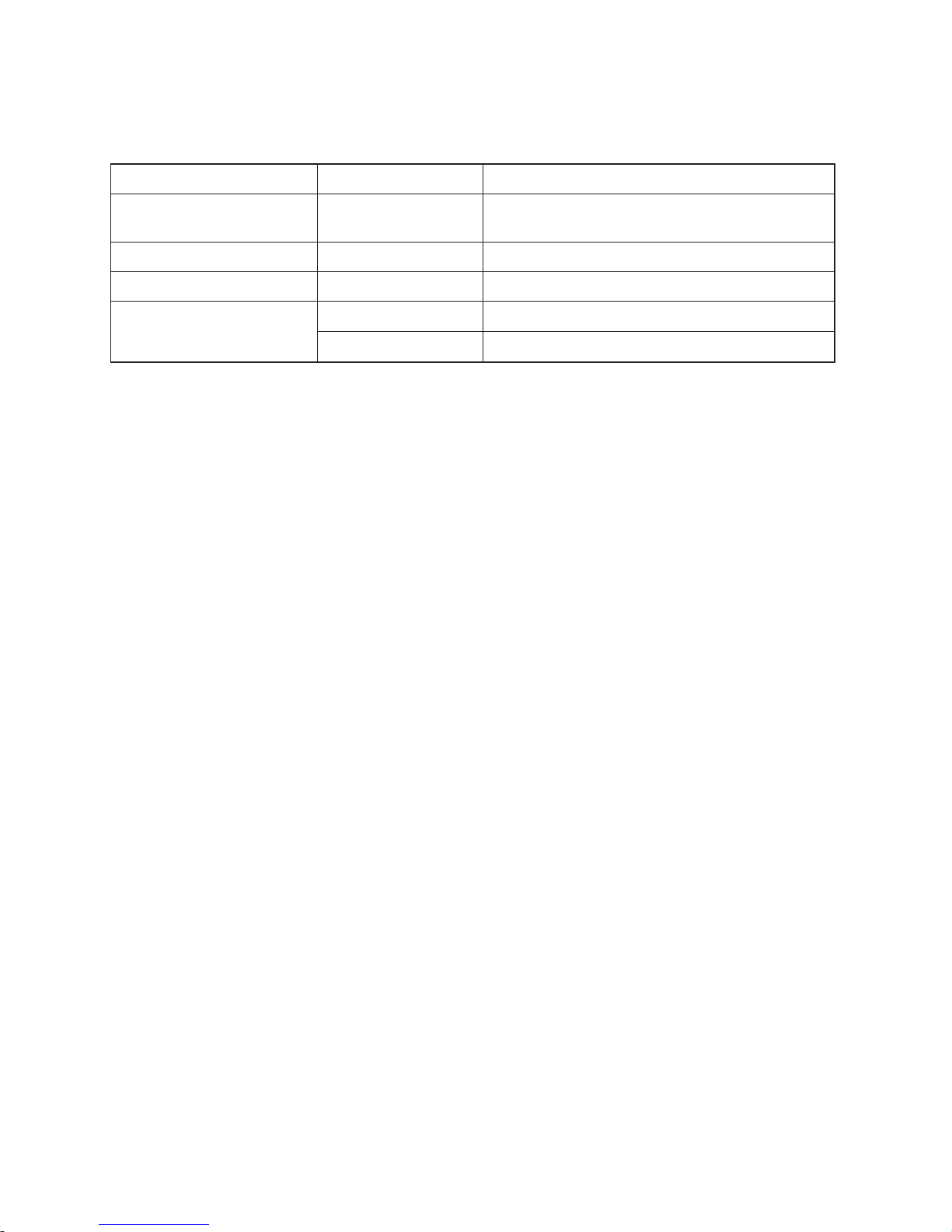

4. SPECIFICATIONS OF ELECTRICAL PARTS

Parts name Type Specifications

Compressor 1, 2

PH160X2-4L

Output 1,1 kW, 2 pole, 1 φ, 220 – 240 V, 50 Hz

Winding resistance: Main coil 2,2 Ω, Aux. coil 3,8 Ω

Fan motor STF-200-63B Output 63 W, 6 pole, 1 φ, 220 – 240 V, 50 Hz

Magnetic contactor VC20FA AC 240 V

Capacitor

MT-40MP356W For compressor 1, 2, AC 400 V, 35 µF

EAG45M355UF1 For fan motor, AC 450 V, 3,5 µF

– 7 –

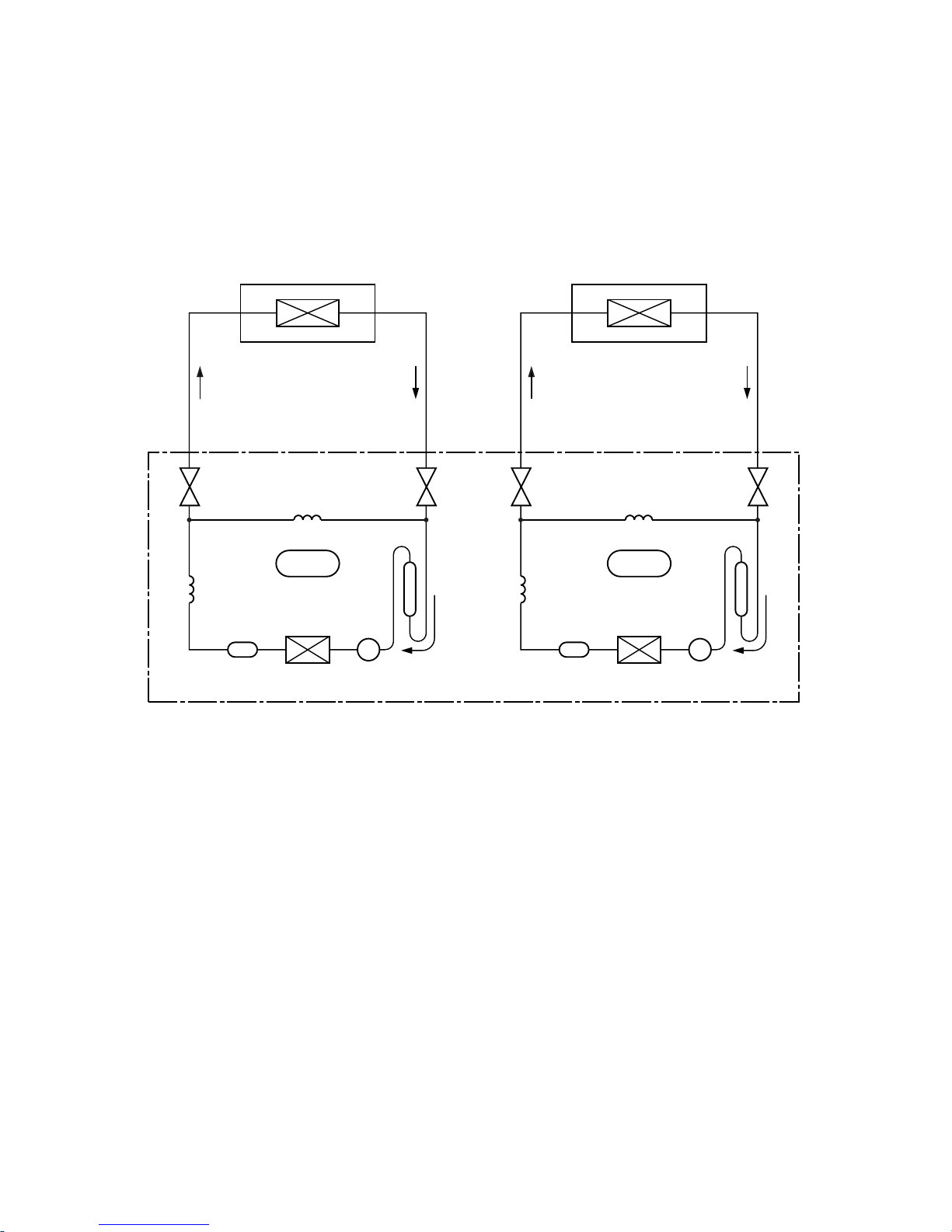

5. REFRIGERANT PIPING DIAGRAM

Evaporator

(Indoor unit A)

(RAS-13SK)

CYCLE 1

Condenser

Dryer

Compressor 1

Accumulator

Refrigerant pipe

(Liquld side)

φ6,4mm

Packed

valve

Capillary tube

φ1,7 x 600

Packed

valve

Refrigerant pipe

(Gas side)

φ12,7mm

Outdoor Unit

Capillary tube

φ0,6 x 600

Evaporator

(Indoor unit B)

(RAS-13SK)

CYCLE 2

Condenser

Dryer

Compressor 2

Accumulator

Refrigerant pipe

(Liquld side)

φ6,4mm

Packed

valve

Capillary tube

φ1,7 x 600

Packed

valve

Refrigerant pipe

(Gas side)

φ12,7mm

Capillary tube

φ0,6 x 600

– 8 –

Model

Connectable indoor Permissible piping Permissible piping

Remarks

unit number length ( 1, 2) head (H)

RAS-13SK-E

2 15m 5m Fig. 5-1

(or RAS-13SKX)

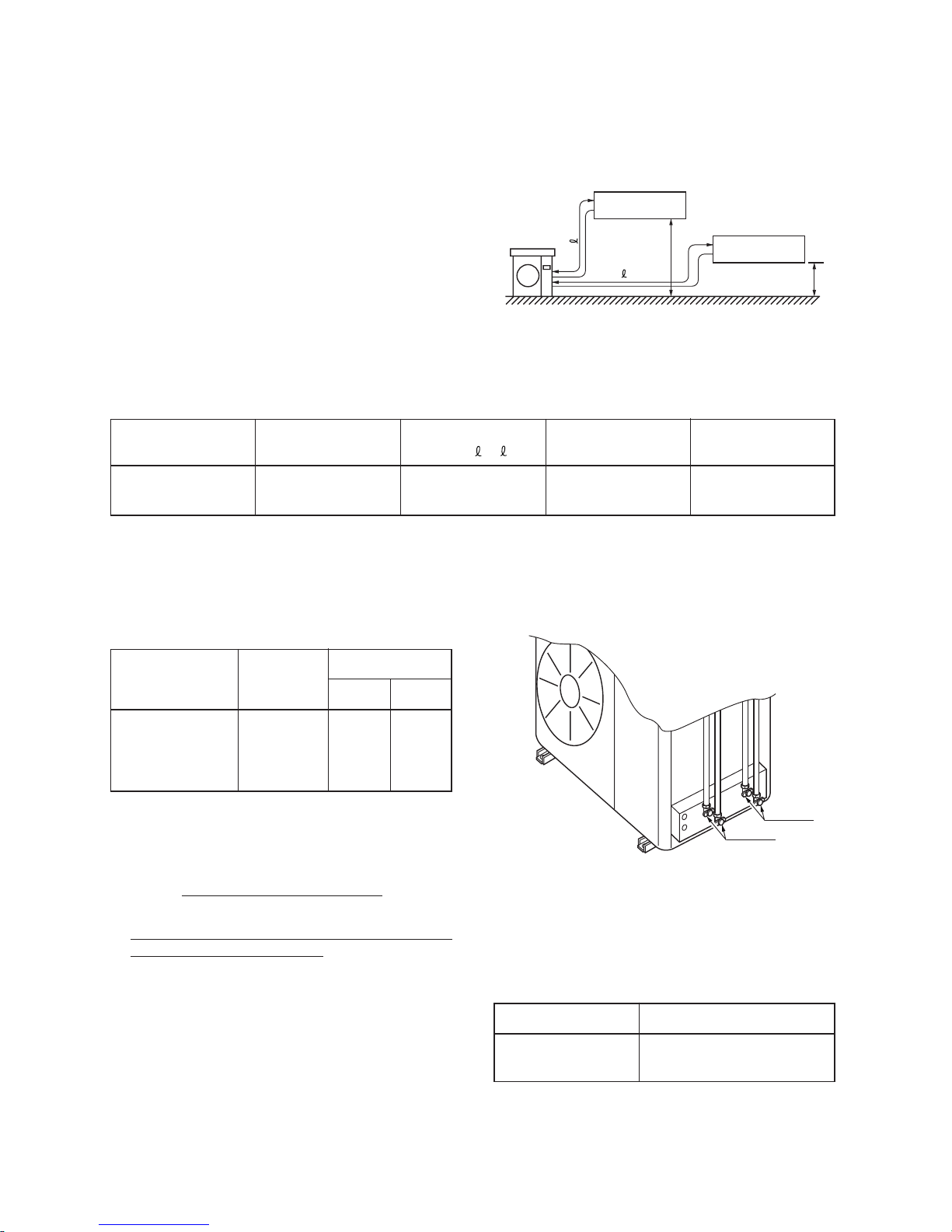

5-1. Refrigerant Piping

5-1-1. Permissible Piping Length and Head

The minimum inter-unit refrigerant piping length shall

be 2m.

Limit the number of bends in the refrigerant piping to

10 or less.

Fig. 5-1

Table 5-1

5-1-2. Piping Material and Sizes

Table 5-2

Piping material

Phosphate deoxidized copper

seamless pipes for

air conditioners

Model

RAS13SK-E

(or RAS13SKX)

Piping size (mm)

Larger Smaller

12,7 6,4

5-1-3. Air Purging

• Subject the refrigerant tube of outdoor and indoor

units to air purge with a vacuum pump.

• Do not carry out this air purge by using the refrigerant filled in the outdoor unit.

• To handle valves, a 5mm hexagon wrench is

needed.

5-1-4. Refrigerant Pipe Connecting Position

H

H

Unit A

2

1

RAS-13SK-E

(or RAS-13SKX)

Unit B

RAS-13SK-E

(or RAS-13SKX)

Model Addition per meter

RAV-M242A-E

No need

(or RAV-M242A)

Fig. 5-2

5-1-5. Additional Refrigerant Quantities

Table 5-3

Unit B

Unit A

– 9 –

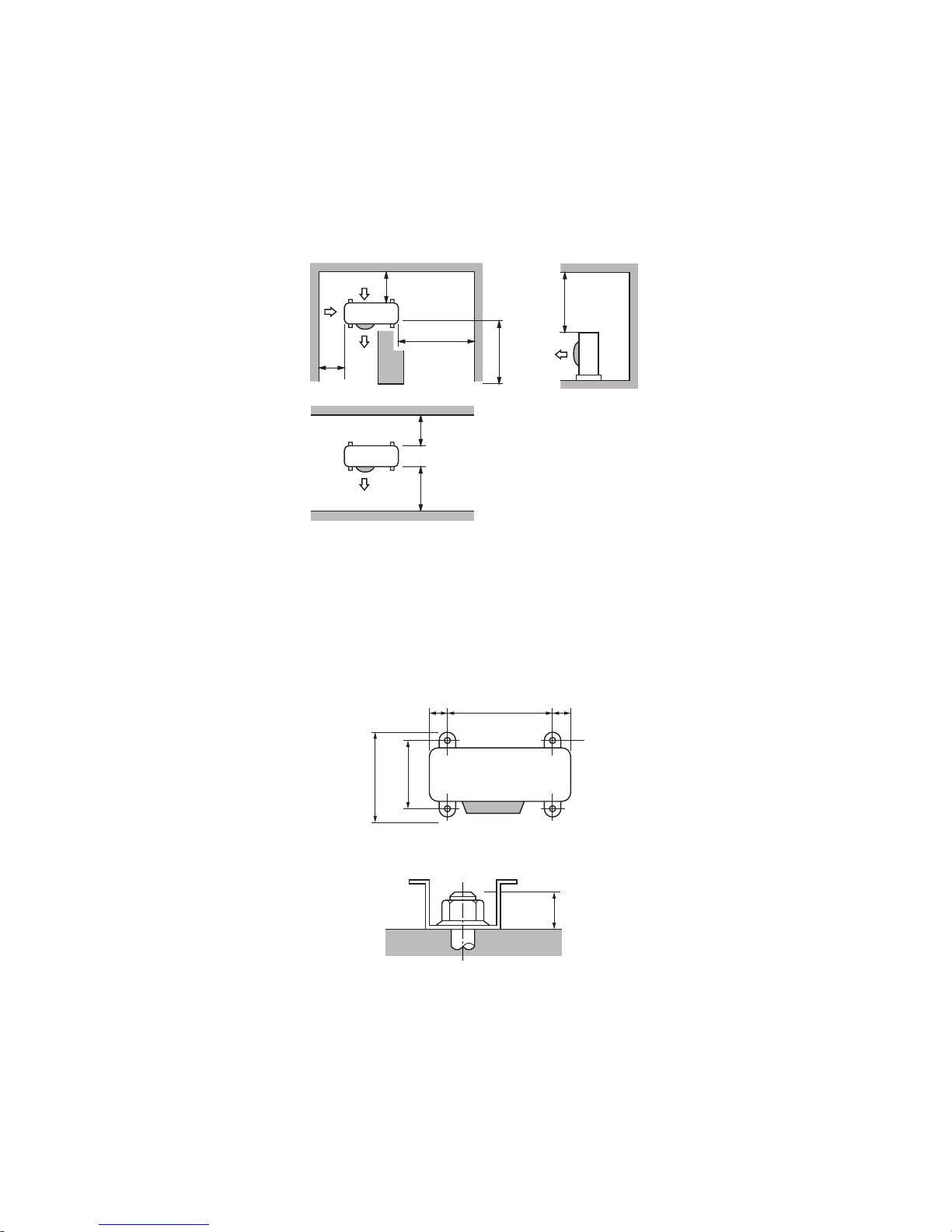

6. UNIT INSTALLATION

Service Space

Ensure that there is sufficient space around the outdoor unit for installation and servicing.

Fig. 6-1

• Do not install in a place that can increase the vibration and amplify the noise level of the units.

• Be sure to fix the outdoor unit with four (4) M10 anchor bolts according to f oundation drawings below.

45 45790

340

15

364

100 or more

500 or more

500 or more

300 or more

100 or more

500 or more

100

or more

Fig. 6-2

Loading...

Loading...