Toshiba RAV-CT100-M, RAV-CT150-M, RAV-CT200-M, RAV-CT100-L, RAV-CT150-L Installation And Owner's Manual

...

TOSHIBA Carrier (UK) Ltd.

For commercial use

RAV-CT100/150/200/250BH-M/L

DX Air Curtain Built-in (Medium / Large)

RAV-CT100/150/200/250CH-M/L

DX Air Curtain Free-Hanging (Medium / Large)

RAV-CT100/150/200/250UH-M/L

DX Air Curtain Cassette (Medium / Large)

DX Air Curtain

Installation and Owner's manual

Model name:

ENGLISH

1

DX Air Curtain

Contents

Please read this Installation Manual carefully before installing the DX Air Curtain.

ADOPTION OF R410A REFRIGERANT

This Air Conditioner is a type which adopts a HFC refrigerant (R410A) instead of the conventional

refrigerant R22 in order to prevent destruction of the ozone layer.

This appliance is for commercial use only and should not be accessible to the general public.

Children should be supervised to ensure that they do not play with the appliance.

Contents

1

INSTALLER: APPLICATION _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2

2

INSTALLER: PRECAUTIONS FOR SAFETY _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3

3

INSTALLER: INSTALLATION _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3

4

INSTALLER: ELECTRICAL WORK _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6

5

INSTALLER: APPLICABLE CONTROLS _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9

6

INSTALLER: TEST RUN _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

15

7

INSTALLER: TROUBLE SHOOTING _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

16

8

INSTALLER: MAINTENANCE GUIDELINES _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

19

9

INSTALLER: OPTIONAL PARTS _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

20

10

INSTALLER: TECHNICAL SPECIFICATIONS _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

21

11

INSTALLER: TECHNICAL DRAWINGS _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

22

12

INSTALLER: DECLARATION OF CONFORMITY_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

25

13

INSTALLER: SERVICE PARTS _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

26

14

OWNER: PRECAUTIONS FOR SAFETY _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

27

15

OWNER: REMOTE CONTROLLER _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

28

16

OWNER: CORRECT USAGE _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

31

17

OWNER: TIMER OPERATION _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

33

18

OWNER: MAINTENANCE _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

34

19

OWNER: AIR CONDITIONER OPERATIONS AND PERFORMANCE _ _ _ _ _ _ _ _ _ _

36

• This Manual describes the installation method of the DX Air Curtain.

• You must also refer to the Installation Manual attached to the Toshiba outdoor unit.

This appliance is not intended for use by person (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety.

This symbol mark is for EU countries only. This symbol mark is according to the directive 2002/96/EC Article

10 Information for users and Annex IV.

This product is designed and manufactured with high quality materials and components which can be

recycled and reused.

This symbol means that electrical and electronic equipment, at the end-of-life, should be disposed of

separately from your household waste.

Please dispose of this equipment at your local community waste collection / recycling centre.

In the European Union there are separate collection systems for used electrical and electronic product.

2

DX Air Curtain

Installer

1 APPLICATION

Every air curtain is manufactured conforming with European directives and the latest standards. Air curtains prevent air

currents and draughts and produce a comfortable environment in the door entrance area

The air curtains are manufactured to the latest technical standards and regulations. The quality controls include

material and function controls and ensure a quality product with a long life span.

The air curtains are built to CE guide lines.

The fan-motors used in the Air Curtain comply with ErP 2013 (Commission Regulation (EU) No 327/2011).

Correct installation is of paramount importance. This includes that unit and control are also used in the correct

environment. The air curtains and controls are manufactured for indoor use only.

Do not install in humid, aggressive or explosive areas. During the installation the unit has to be kept clean and dry.

Applications:

DX Air curtains are only applicable:-

For indoor areas (shops, warehouses, exhibition halls, or banks, etc.)

Installed in false ceilings or free hanging

DX Air curtains must not be installed:-

In humid areas like swimming pools

Areas with danger of explosion

Areas with aggressive air

Areas with extreme high dust exposure

Vertically (Only horizontally hung installations are permitted)

Twin / Triple Restriction:

To ensure reliable operation DX Air Curtains must be connected to a single outdoor unit (no twin or triple installations).

Model Range:

Built-in unit (BH)

Suitable for installation in the ceiling space above the door, only the inlet

grille and discharge outlet will be visible.

Door widths: 1.0m, 1.5m, 2.0m and 2.5m

2 versions offered: Medium (Door height range: 2.5m to 3.0m)

Large (Door height range: 2.7m to 3.2m)

Free-Hanging unit (CH)

Suitable for installation above the door, where whole unit will be visible.

Door widths: 1.0m, 1.5m, 2.0m and 2.5m

2 versions offered: Medium (Door height range: 2.5m to 3.0m)

Large (Door height range: 2.7m to 3.2m)

Cassette unit (UH)

Suitable for installation where the ceiling space is limited above the door,

the full panel will be visible.

Door widths: 1.0m, 1.5m, 2.0m and 2.5m

2 versions offered: Medium (Door height range: 2.5m to 3.0m)

Large (Door height range: 2.7m to 3.2m)

"Air On" Temperature Limits: Minimum 15°CDB / Maximum 28°CDB

In Heating mode (reverse cycle) when the outdoor unit is producing hot gas, the DX coil in the Air Curtain is effectively

the condenser. Air temperatures flowing across the coil below this level, can cause over condensing of the refrigerant.

This can result in liquid being returned to the compressor which will cause a mechanical failure of the outdoor unit. Low

air temperatures will also cause the unit to use it's defrost mode more often

3

DX Air Curtain

Installer

M (Medium)

2.5 – 3.0 m

L (Large)

2.7 – 3.2 m

Refrigerant (R410A) Air Conditioner Installation

To Disconnect the Appliance from Main Power Supply

Ceiling mounting kit

Electrical connections

Inlet grill

Access cover

Door

frame

External

wall

2 PRECAUTIONS FOR SAFETY

• Ensure that all Local, National and International regulations are satisfied.

• Read this "PRECAUTIONS FOR SAFETY" carefully before installation.

• The precautions described below include the important items regarding safety. Observe them without fail.

• After the installation work, perform a trial operation to check for any problem.

• Follow the installation manual to explain how to use and maintain the unit to the customer.

• Turn off the main power supply switch (or breaker) before the unit maintenance.

• Ask the customer to keep the installation manual.

• THIS AIR CONDITIONER ADOPTS THE HFC REFRIGERANT (R410A) WHICH DOES NOT DESTROY OZONE

LAYER.

The characteristics of R410A refrigerant are; easy to absorb water, oxidizing membrane or oil, and its pressure is

approx. 1.6 times higher than that of refrigerant R22. Accompanied with the new refrigerant, refrigerating oil has also

been changed. Therefore, during installation work, be sure that water, dust, former refrigerant, or refrigerating oil does

not enter the refrigerating cycle.

To prevent charging an incorrect refrigerant and refrigerating oil, the sizes of connecting sections of charging port of

the main unit and installation tools are changed from those of conventional refrigerant.

Accordingly the exclusive tools are required for the new refrigerant (R410A).

For connecting pipes, use new and clean piping designed for R410A, and please care so that water or dust does not

enter. Moreover, do not use the existing piping because there are problems with the pressure-resistance force and

impurity in it.

This appliance must be connected to the main power supply by means of a switch with a constant separation of at least

3mm.

3 INSTALLATION

POSITIONING OF THE AIR CURTAIN

The unit should be installed as close as possible to the wall and

as flush as possible to the top of the door.

The outlet flow should always be free and not interrupted or

obstructed.

Don‘t exceed the recommended installation height recommended

per type. Type plate can be found on the inside of the access

panel.

Installation height

Type Door Height Range

• DO NOT STAND UNDERNEATH THE UNIT WHILE LIFTED OR DURING INSTALLATION

• DO ONLY USE APPROPRIATE TOOLS FOR LIFTING AND INSTALLING

• FOLLOW ALL LOCAL RULES AND REGULATIONS

4

DX Air Curtain

Installer

Pressure

Fa

DX Coil

Inlet plenum

Access

Free-Hanging (CH)

Built-in (BH)

Cassette (UH)

Ceiling mounting kit

Electrical connections

Inlet grill

Access cover

Door

frame

External

wall

Ceiling mounting

kit

Electrical

connections

Inlet grill

Access cover

Door

frame

External

wall

Ceiling mounting kit

Electrical connections

Inlet grill

Access cover

Door

frame

External

wall

The access panel and E-Box cover has to be accessible at all times!

In all situations the accessibility of the unit over the whole length of

the unit has to be ensured.

Please refer to the technical drawings for dimensions.

For installation within a c eiling void it has to be ensured that the

access panel between in and out let grille is accessible over the

whole length of the unit.

The sliding type (BH) sections have to be fixed at the desired height

(use methods suitable to avoid vibrations).

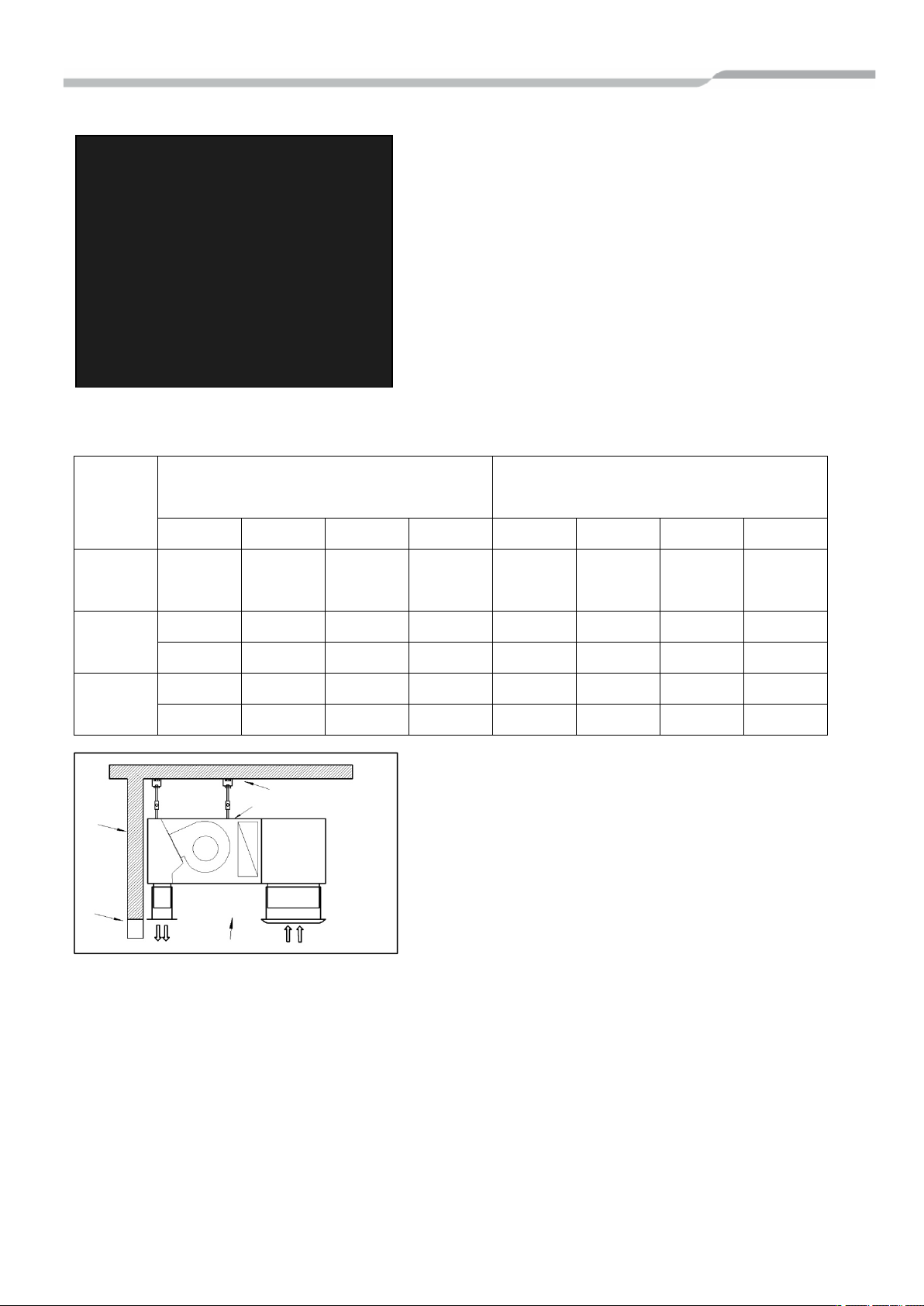

CEILING MOUNTING

Please use the fixing points. The number of fixing points depends on model and length of the air curtain.

Model

Free-Hanging (CH)

(RAV-)

CT100 CT150 CT200 CT250 CT100 CT150 CT200 CT250

Fixing

points

1.0m 1.5m 2.0m 2.5m 1.0m 1.5m 2.0m 2.5m

M M M

4

L L L - L L L -

- - -

6

- - - L - - - L

Built-in (BH)

-

M

Cassette (UH)

M M M

- - -

-

M

5

DX Air Curtain

Installer

CODE

DESCRIPTION

DETAILS

3871

Ceiling mounting kit (1,0m / 1,5m / 2,0m)

M8 x 4

4034

Ceiling mounting kit (2,5m)

M8 x 6

Lock nut M 8

Hanging rod M 8

length 1 m

lock nut M 8

Spanner nut M 8

Set screw M 8 with left-hand and right-hand

Lock nut M 8

FLARE NUT CONNECTION

The Air Curtain is fitted with R410A Flare Nuts and is charged with

Nitrogen Gas (1 barg) when shipped.

Please refer to the installation Manual attached to the Toshiba

Outdoor unit for flare nut instructions.

Gas Pipe External ∅15.9mm

Liquid Pipe External ∅9.5mm (Remove Schrader pipe)

OPTIONAL CEILING MOUNTING KIT

Ceiling mounting kit with vibration absorber and sound insulation bracket:-

Setting range 30

Wall plugs are not included in the delivery!

When choosing the wall plug, please refer to the weight of the unit and the certification of the material

When assembling the spanner nut, please make sure that all hanging rods and set screws are properly fitted together.

All parts must be countered with a lock nut.

6

DX Air Curtain

Installer

• Do not turn on the power of the indoor unit until

4 ELECTRICAL WORK

WARNING

1. Using the specified wires, ensure to connect

the wires, and fix wires securely so that the

external tension to the wires do not affect the

connecting part of the terminals.

Incomplete connection or fixation may cause a fire,

etc.

2. Be sure to connect earth wire (grounding work).

Incomplete grounding cause an electric shock.

Do not connect ground wires to gas pipes, water

pipes, lightning rods or ground wires for telephone

wires.

3. Appliance shall be installed in accordance with

national wiring regulations.

Capacity shortage of power circuit or incomplete

installation may cause an electric shock or a fire.

CAUTION

• This indoor unit has no power cord.

• If incorrect / incomplete wiring is carried out, it will

cause an electrical fire or smoke.

• Install an earth leakage breaker.

If an earth leakage breaker is not installed, an

electric shock may be caused.

• Be sure to use the cord clamps attached to the

product.

• Do not damage or scratch the conductive core and

inner insulator of power and inter-connecting wires

when peeling them.

• Use the power cord and inter-connecting wire of

specified thickness, type and protective devices

required

REQUIREMENT

• For power supply wiring, strictly conform to the

Local Regulation for each country.

• For wiring of power supply of the outdoor units,

follow the Installation manual of each outdoor unit.

• Never connect 220-240V power to the terminal

blocks ( , etc) for control wiring (otherwise the

system will fail).

• Perform the electric wiring so that it does not come

in to contact with the high-temperature part of the

pipe.

The coating may melt in an accident

• After connecting wires to the terminal blocks, be

sure to leave sufficient wire before fixing with the

cord clamp.

• Run the refrigerant piping and control wiring line in

the same line.

vacuuming of the refrigerant pipes is completed.

Remote controller wiring

2-core non polarity wire is used for the remote

controller wiring.

How to wire

1. Connect the wires from the terminal block on the

outdoor unit to the same numbered terminal on

the DX Air Curtain terminal block. Use wires to

H07 RH-F or 60245 IEC 66 (1.5mm

2. In the case of unsheathed redundant cords

(conductors) be sure to insulate with electrical

insulation tape.

Fix them so that they do not touch any electrical

or metal parts.

REQUIREMENT

• Be sure to connect the wires matching the

terminal numbers. Incorrect connection causes a

trouble.

• Be sure to pass the wires through the bushing of

the wiring connection port of the DX e Msm- dop m"ialM1 eMthe MMMMMM

2

or more).

8

DX Air Curtain

Installer

WIRING DIAGRAM

9

DX Air Curtain

Installer

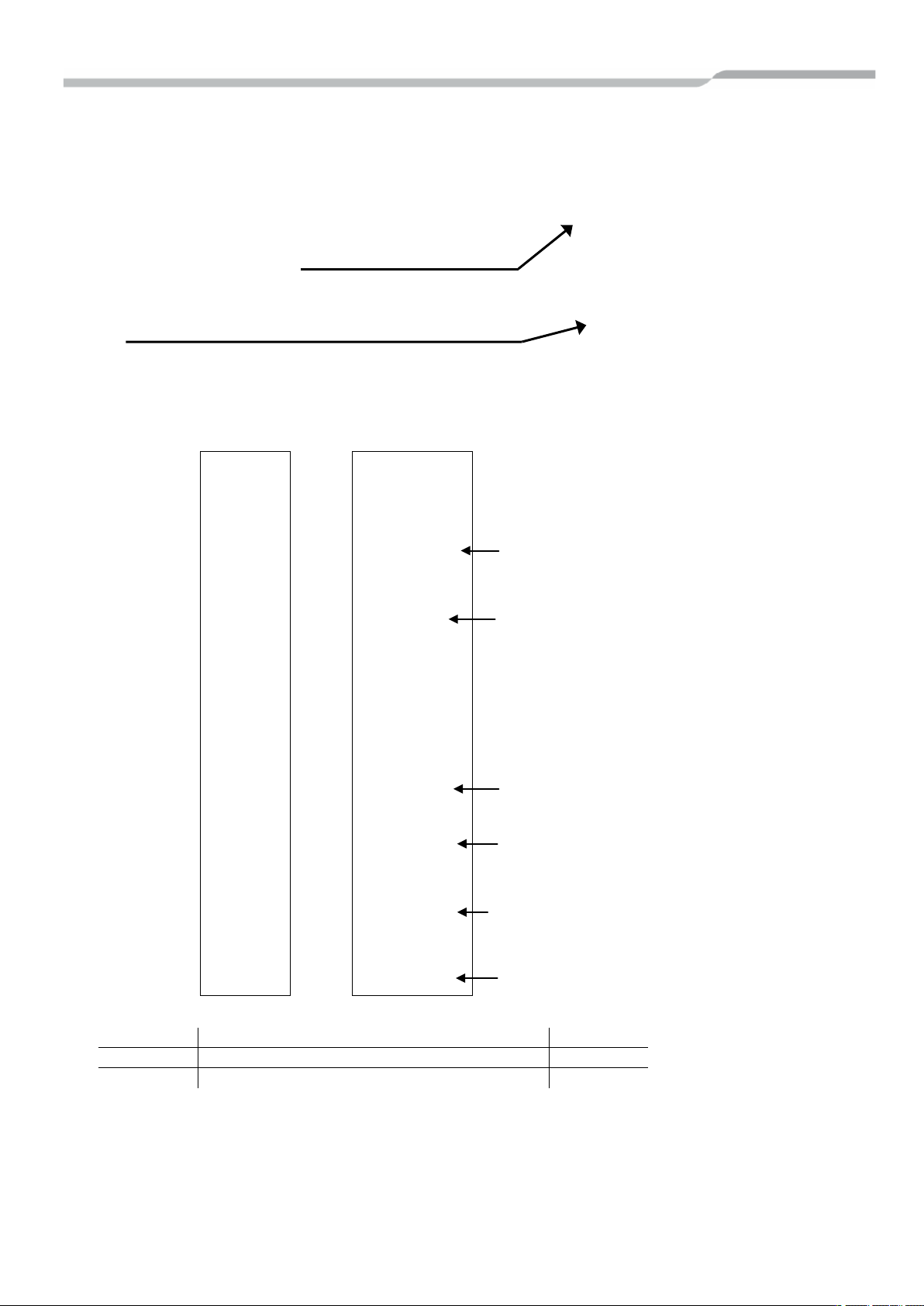

Approx. 5 minutes

Power

Remote

flashes

goes out

Approx. 1 minutes

Power

Remote

flashes

goes out

5 APPLICABLE CONTROLS

REQUIREMENT

• When you use this air conditioner for the first time,

it takes approx. 5 minutes until the remote

controller becomes available after power-on. This

is normal.

<When the power is turned on for the first time

after installation>

It takes approx. 5 minutes until the remote

controller becomes available.

Changing of settings for

applicable controls

Basic procedure for changing settings

Change the settings while the air conditioner is not

working.

(Be sure to stop the air conditioner before making

settings).

on

controller

is available

<When the power is turned on for the second

(or later) time>

It takes approx. 1 minute until the remote

controller becomes available.

on

• Normal settings were made when the unit was

shipped from factory.

Change the indoor unit as required.

• Use the wired remote controller to change the

settings.

• The settings cannot be changed using the wireless

remote controller, sub remote controller, or remote

controller-less system (for central remote controller

only).

Therefore, install the wired remote controller to

change the settings.

controller

is available

Procedure 1

Push + + buttons simultaneously for at

least 4 seconds.

After a while, the display flashes as shown in the

figure.

Confirm that the CODE No. is [10].

• If the CODE No. is not [10] push button to

erase the display content and repeat the

procedure from the beginning.

(No operation of the remote controller is accepted

for a while after button is pushed).

(While air conditioners are operated under the

group control, "ALL" is displayed first. When

is pushed, the indoor unit number

displayed following "ALL" is the header unit).

(* Display content varies with the

indoor unit model).

10

DX Air Curtain

Installer

Procedure 2

Procedure 5

DIRTY FILTER ALARM

(Disabled)

CENTRAL CONTROL ADDRESS

(Unset)

AUTO MODE

(Disabled)

POWER ADDRESS

(Unset)

DEVICE ADDRESS

(Unset)

GROUP ADDRESS

(Unset)

AVAILABLE MODE

(Heating & Fan Only)

DX Air Curtain Configuration

Each time you push button, indoor unit

numbers in the control group change cyclically.

Select the indoor unit you want to change settings for.

The fan of the selected unit runs and the louvers start

swinging. You can confirm the indoor unit for which

you want to change settings.

Procedure 3

Using "TEMP", buttons, specify CODE

NO. [ ].

Procedure 4

Using timer "TIME" buttons, select SET

DATA [ ].

Push button. When the display changes from

flashing to lit, the setup is completed.

• To change settings of another indoor unit, repeat

from procedure 2.

• To change other settings of the selected indoor unit,

repeat from procedure 3.

Use button to clear the settings.

To make settings after button was pushed,

repeat from procedure 2.

Procedure 6

When settings have been completed, push button

to determine the settings.

When button is pushed, flashes and then

the display content disappears and the air conditioner

enters the normal stop mode.

(While is flashing, no operation of the remote

controller is accepted).

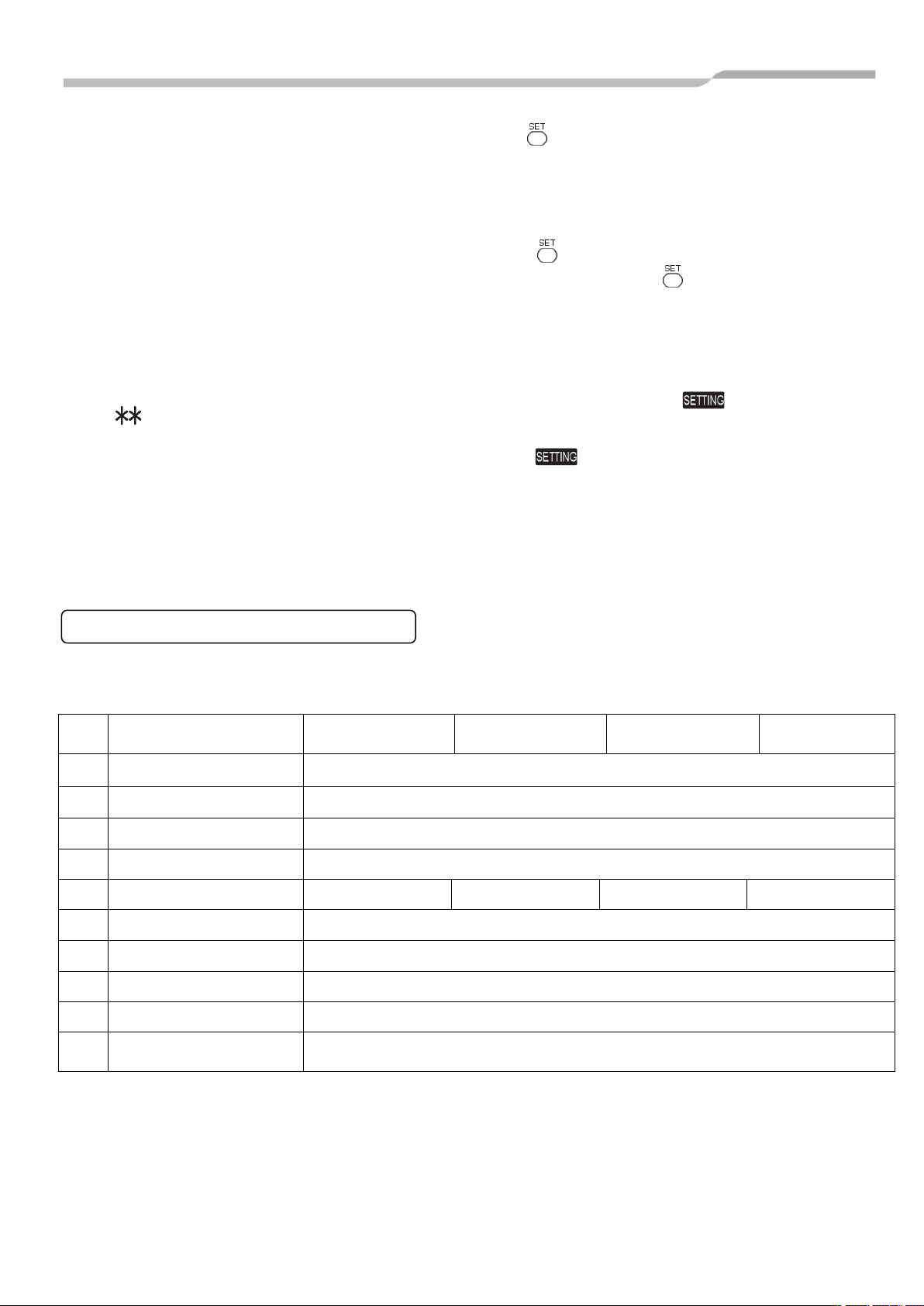

The circuit board of the DX AIR CURTAIN is configured at the factory. For reference these are the settings used. Any

changes must be set using the DN code menu.

Follow to the basic operation procedure (1 → 2 → 3 → 4 → 5 → 6).

DN

CODE

01

03

0d

10 DEVICE TYPE

11 CAPACITY CODE

12

13

14

2d

9b

* 0099 = address not assigned (system addresses are assigned during the automatic addressing by the system.

Central addresses can be assigned automatically with a central remote control or manually. Subsequent

modifications may lead to malfunction.)

DX AIR CURTAIN MODEL

(RAV-****-M/L)

FAN CONTROL

(Disabled)

CT100BH/CH/UH CT150BH/CH/UH CT200BH/CH/UH CT250BH/CH/UH

0000

0099*

0001

0004

0012 0015 0017 0018

0099*

0099*

0099*

0009

0001 (Fan motor operates during defrost cycle)

(To stop fan motor operation during defrost cycle change to 0000)

11

DX Air Curtain

Installer

To secure better effect of

Setup Data

Detection temp shift value

0000

No shift

0001

+1°C

0002

+2°C (at shipment from factory)

0003

+3°C

0004

+4°C

0005

+5°C

0006

+6°C

Group Control

Outdoor unit Outdoor unit Outdoor unit Outdoor unit Outdoor unit

heating

When it is difficult to obtain satisfactory heating

due to installation place of the indoor unit or

structure of the room, the detection temperature

of heating can be raised. Also use the circulator,

etc. to circulate heat air near the ceiling.

Follow to the basic procedure

(1→2→3→4→5→6).

• For the CODE No. in Procedure 3, specify

[06].

• For the set data in Procedure 4, select the

setup data of shift value of detection

temperature to be set up from the table

below.

In case of group control for system of multiple units.

One remote controller can control maximum 8 indoor units

as a group.

▼ In case of group control in single system.

Indoor unit Indoor unit Indoor unit Indoor unit Indoor unit

(Max. 8 units)

Remote controller Finish of address setup by Power- ON

• For wiring procedure and wiring method of the individual

line (Identical refrigerant line) system, follow to

"Electrical work".

• Wiring between lines is performed in the following

procedure.

Connect the terminal block (A/B) of the indoor unit

connected with a remote controller to the terminal blocks

(A/B) of the indoor units of other indoor units by wiring

the inter-unit wire of the remote controller.

• When the power supply has been turned on, the

automatic address setup starts and which indicates that

address is being set up on the display part. during setup

of automatic address, the remote controller operation is

not accepted.

Required time up to the finish of automatic

addressing is approx. 5 minutes.

NOTE

In some cases, it is necessary to change the address

manually after setup of the automatic address according to

the system configuration of the group control.

12

DX Air Curtain

Installer

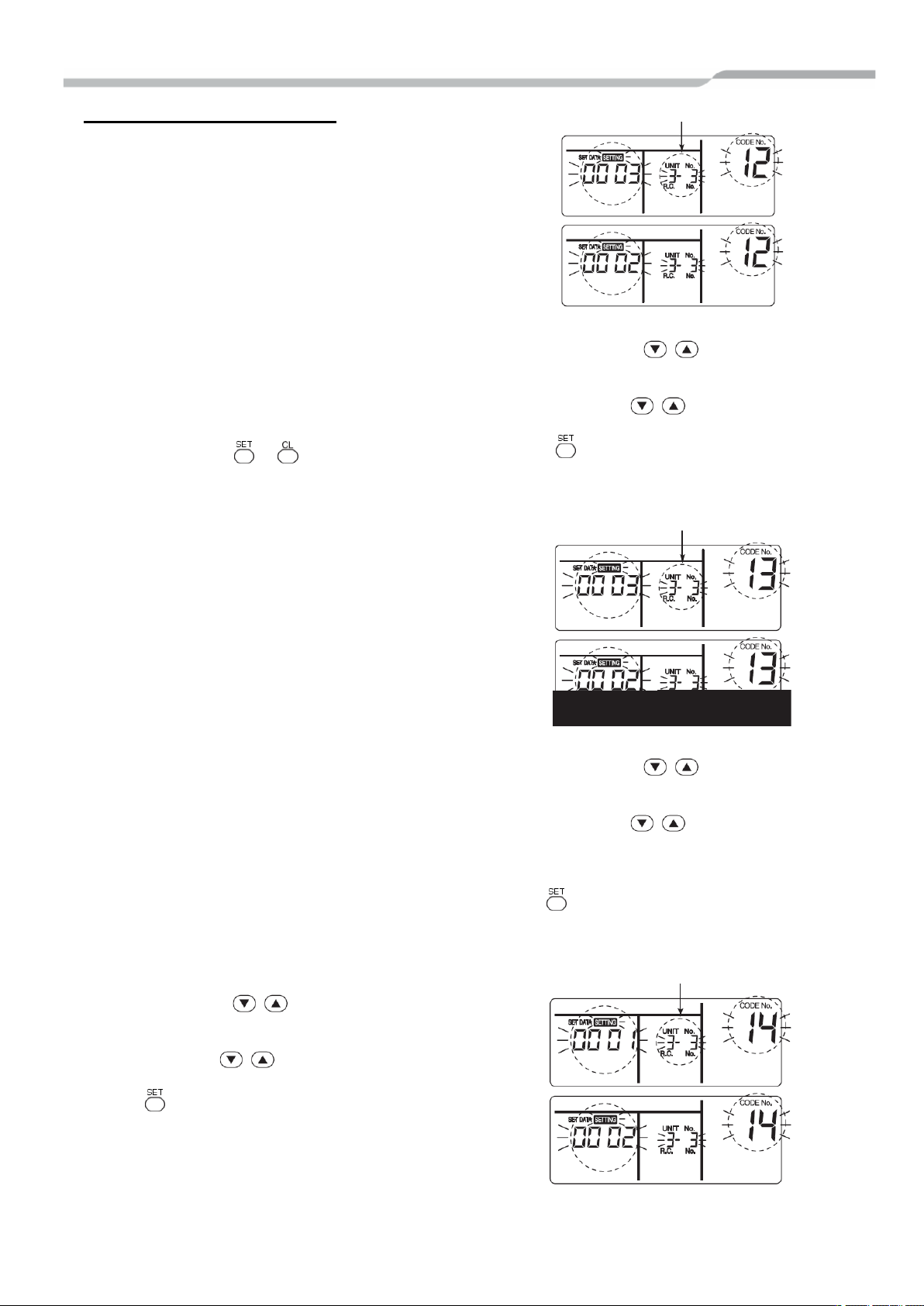

Group Control procedure example

Indoor unit No. before setup change is displayed.

(* Display changes according to

Manual address setup procedure

While the operation stops, change the setup.

(Be sure to stop operation of the unit).

Procedure 1

Push simultaneously + + buttons for 4

seconds or more. After a while, the display part

flashes as shown below. Check the displayed CODE

No. is [10].

• When the CODE No. is other than [10], push

button to erase the display and repeat procedure

from the first step.

(After pushing button, operation of the remote

controller is not accepted for approx. 1 minute).

(For group control, No. of the first displayed indoor

unit becomes the header unit).

the model No. of indoor unit.)

Procedure 2

Every pushing button, the indoor unit No. in

the group control is displayed in order. Select the

indoor unit of which setup is changed.

In this time, the position of the indoor unit of which

setup is changed can be confirmed because fan of

the selected indoor unit operate.

Procedure 3

1. Using temp. setup buttons, specify CODE

No. [12].

(CODE No. [12]: Line address).

2. Using timer time buttons, change the line

address from [3] to [2].

3. Push button.

In this time, the setup finishes when the display

changes from flashing to lighting.

Procedure 4

1. Using temp. setup buttons, specify

CODE No. [13].

(CODE No. [13]: Indoor address)

2. Using timer time buttons, change the

indoor address form [3] to [2].

3. Push button.

In this time, the setup finishes when the display

changes from flashing to lighting.

Indoor unit No. before setup change is displayed

Procedure 5

1. Using temp. setup buttons, specify

CODE No. [14].

(CODE No. [14]: Group address).

2. Using timer time buttons, change the

setup data from [0001] to [0002].

(Setup data [Header unit: 0001] [Follower unit:

0002])

3. Push button.

In this time, the setup finishes when display

changes from flashing to lighting.

Indoor unit No. before setup change is displayed

Loading...

Loading...