Toshiba RAS-13YKH-ES, RAS-07YKHE, RAS-07YAH-ES, RAS-07YAH-E, RAS-10YKH-E SERVICE MANUAL

...

SERVICE MANUAL

AIR-CONDITIONER

SPLIT WALL TYPE

RAS-07YKH-E/RAS-07YAH-E

FILE NO. DAS-SM-00-003

SUPPLEMENT

RAS-10YKH-E

/

RAS-10YAH-E

RAS-13YKH-E / RAS-13YAH-E

RAS-07YKH-ES/RAS-07YAH-ES

RAS-10YKH-ES / RAS-10YAH-ES

RAS-13YKH-ES / RAS-13YAH-ES

CONTENTS

1. SPECIFICATIONS.................................................................................... 3

2. CONSTRUCTION VIEWS ....................................................................... 7

3. WIRING DIAGRAM ................................................................................ 10

4. SPECIFICATIONS OF ELECTRICAL PARTS ..................................... 12

5. REFRIGERANT CYCLE DIAGRAM ..................................................... 15

6. CONTROL BLOCK DIAGRAM ............................................................. 21

7. OPERATION DESCRIPTIONS................................................................ 22

8. INSTALLATION PROCEDURE .............................................................. 30

9. TROUBLESHOOTING CHART.............................................................. 44

10. PART REPLACEMENT.......................................................................... 60

11. EXPLODED VIEWS AND PARTS LIST .............................................. 65

– 2 –

1. SPECIFICATIONS

RAS-10YKH-E / RAS-10YAH-E, RAS-13YKH-E / RAS-13YAH-E

MODEL

ITEM

Capacity kW *1

Phase Single

V220–240Power source

Hz 50

Power consumpt i on kW 0,98–1,02 0,89–0,91 1,26–1,30 1,19–1,27

Power fac tor % 95–90 95–88 98–92 95–93

Running current

Starting c urr e nt A 19 14 25 25

Moisture remov a l lit/h 1,2 2,0

Noise

(SPL at 1 me te r )

Refrigerant

Refrig erant control Capillary tube

Interconnection pipe

Condensate drain pipe Outer diameter mm 16

INDOOR UNIT RAS-10YKH-E RAS-13YKH-E

Net weight kg 8

Evap orator type Finned tube

Indoor fan type Cross flow fan

Fan motor output W 20

Air filter Polypropylene net filter (Washable)

OUTDOOR UNIT RAS-10YAH-E RAS-13YAH-E

Net weight kg 31 42

Condenser type Finned tube

Outdoor fan type Propeller

Air flow rate (220–240V) m³/h 1500–1700 1690–1730

Fan motor output W 18 28

Compressor

Safety device Fuse, Overload relay

Auto l ouver Yes

Usable outdoor temperature range °C21–43 -5–21 21–43 -5–21

Indoor/Outdoor A

Indoor (H/M/L) dB (A) 41 / 36 / 29 41 / 36 / 29 44 / 39 / 34 44 / 39 / 34

Outdoor (220–240V) dB (A) 47–49 47–49 49 / 51 49 / 51

Name of refrigerant R-22

Rated volume kg 0,74 0,88

Gas side size mm 9,52 12,7

Connection type Flare connection

Liquid side size mm 6,35

Connection type Flare connection

Maximum length (of one way) m *210 15

Maximum he ight differenc e

Indoor un it

Outdoor unit

Height mm 265

Width mm 790Dimensions

Depth mm 189

High fan m³/h 600 650

Medium fan m³/h 500 560Air flow rate

Low fan m³/h 400 510

Height mm 530 538

Width mm 770 780Dimensions

Depth mm 200 300

Model PH120T1-4C PH170T2-4L2

Output W 750 1100

↑

↓

V220V–240V 220V–240V 220V–240V 220V–240V

m

RAS-10YKH-E/10YAH-E RAS-13YKH-E/13YAH-E

Cooling Heating Cooling Heating

220V–240V 220V–240V 220V–240V 220V–240V

2,65–2,70 3,00–3,10 3,45–3,50 4,00–4,10

0,11/4,58 - 0,11/4,61 0,11/4,17 - 0,11/4,22 0,15/5,70 - 0,15/5,75 0,15 /5,54 - 0,15/5,44

56

Specifications are subject to change without notice.

– 3 –

RAS-10YKH-ES / RAS-10YAH-ES, RAS-13YKH-ES / RAS-13YAH-ES

MODEL

ITEM

Capacity kW *1

Phase Single

V220–240Power source

Hz 50

Power consumpt ion kW 0,98–1,02 0,89–0,91 1,26–1,30 1,19–1,27

Power f acto r % 9 5–90 95–88 98–94 97–93

Runnin g cur r ent

Starti ng current A 19 14 25 25

Moisture removal lit/h 1,2 2,0

Noise

(SPL at 1 me t er)

Refrigerant

Refrigerant control Capillary tube

Interconnection pipe

Condensate drain pipe Outer diameter mm 16

INDOOR UNIT RAS-10YKH-ES RAS-13YKH-ES

Net weight kg 8

Evap orator type Finned tube

Indoor fa n type Cross flow fa n

Fan motor output W 20

Air filter Polypropylene net filter (Washable)

OUTDOOR UNIT RAS-13YAH-E RAS-13YAH-ES

Net weight kg 31 42

Condenser type Finned tube

Outdoor fan type Propeller

Air flow rate (220–240V) m³/h 1500–1700 1690–1730

Fan motor output W 18 28

Compressor

Safety device Fuse, Overload relay

Aut o louve r Yes

Usable outdoo r te m perature range °C21–43 -5–21 21–43 -5–21

Indoor/Outdoor A

Indoor (H/M/L) dB (A) 41 / 36 / 29 41 / 36 / 29 44 / 39 / 34 44 / 39 / 34

Outdoor (220–240V) dB (A) 47–49 47–49 49 / 51 49 / 51

Name of refrigerant R-410A

Rated volume kg 0,69 0,80

Gas side size mm 9,52

Connection type Flare connection

Liquid side size mm 6,35

Connection type Flare connection

Maximum length (of one way) m *210 15

Maximum height differenc e

Indoor unit

Outdoor unit

Height mm 265

Width mm 790Dimensions

Depth mm 189

High fan m³/h 600 650

Medium fan m ³/h 500 560Air flow rate

Low fan m³/h 400 510

Height mm 530 538

Width mm 770 780Dimensions

Depth mm 200 300

Model PA118X1T-4FZ PA160X2T-4FM

Output W 750 1100

↑

↓

V220V–240V

m

RAS- 10 YKH- ES/10YAH-ES RAS-13YKH-ES/13YAH-ES

Cooling Heating Cooling Heating

220V–240V

2,65–2,70 3,00–3,10 3,45–3,50 4,00–4,10

0,11/4,44 - 0,11/4,46 0,11/4,15 - 0,11/4,10 0,15 /5,70 - 0,15/5,61 0,15 /5,43 - 0,15/5,54

56

Specifications are subject to change without notice.

– 4 –

Note :

• Capacity is based on the follo wing temperature conditions.

1

*

TEMPERATURE

Indoor unit inlet air temperature

Outdoor unit inlet air temperature

Notes : *2 CHARGELESS

RAS-07YKH-E, RAS-07YKH-ES, RAS-10YKH-E, RAS-10YKH-ES

• No additional refrigerant required.

• This air conditioner accepts a connection piping length of up to 10m and a head of up to 5m.

• There is no need to add the refrigerant as long as the total length of the connection piping is up to 10m.

RAS-13YKH-E, RAS-13YKH-ES

• No additional refrigerant required.

• This air conditioner accepts a connection piping length of up to 15m and a head of up to 6m.

• There is no need to add the refrigerant as long as the total length of the connection piping is up to 15m.

CONDITION COOLING HEATING

(DB) 27 °C 20 °C

(WB) 19 °C 12 °C

(DB) 35 °C 7 °C

(WB) 24 °C 6 °C

– 6 –

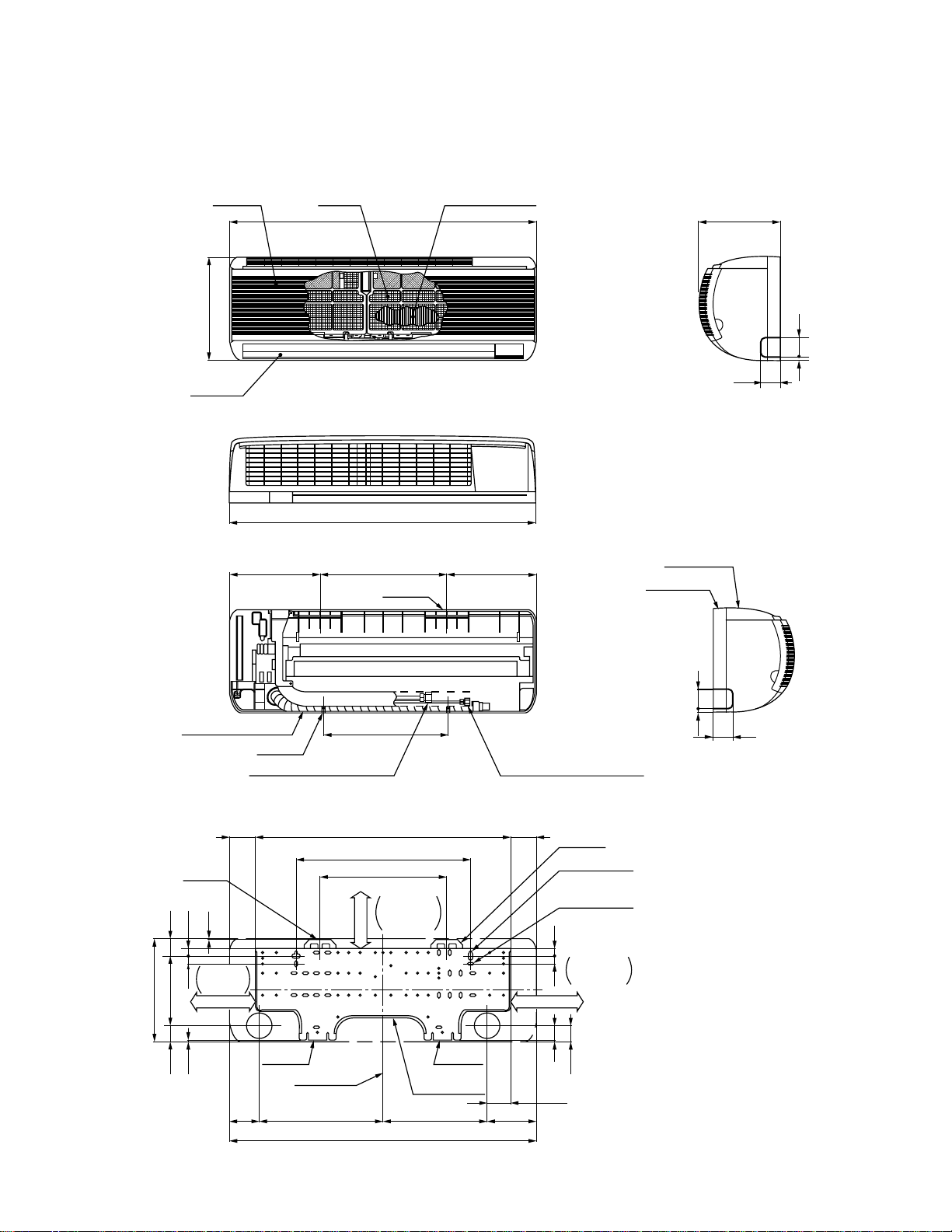

2-1. Indoor Unit

2. CONSTRUCTION VIEWS

Air inlet

265

Air outlet

Air filter

790

790

232 326 232

Hanger

Heat exchanger

Front panel

Back body

189

47

Knock out system

50

10

Drain hose (0,54m)

Hanger

Connecting pipe (0,39m)

(Flare Ø9,52)

(Flare Ø12,7 for 13YKH-E only)

Hanger

46

2,5

Minimum

distance

17 20

265

to wall

120 or more 120 or more

178,5

3,5

40,5

Center line

321

65965,5

450

326

66 or more

Minimum

distance

to ceiling

HangerHanger

Installation

plate outline

790

Connecting pipe (0,49m)

(Flare Ø6,35)

65,5

12626931976

Hanger

For stud bolt

(Ø8~Ø10)

For stud bolt

(Ø6)

Minimum

distance

20 2037

to wall

40,5

60,5

50

47

10

Knock out system

– 7 –

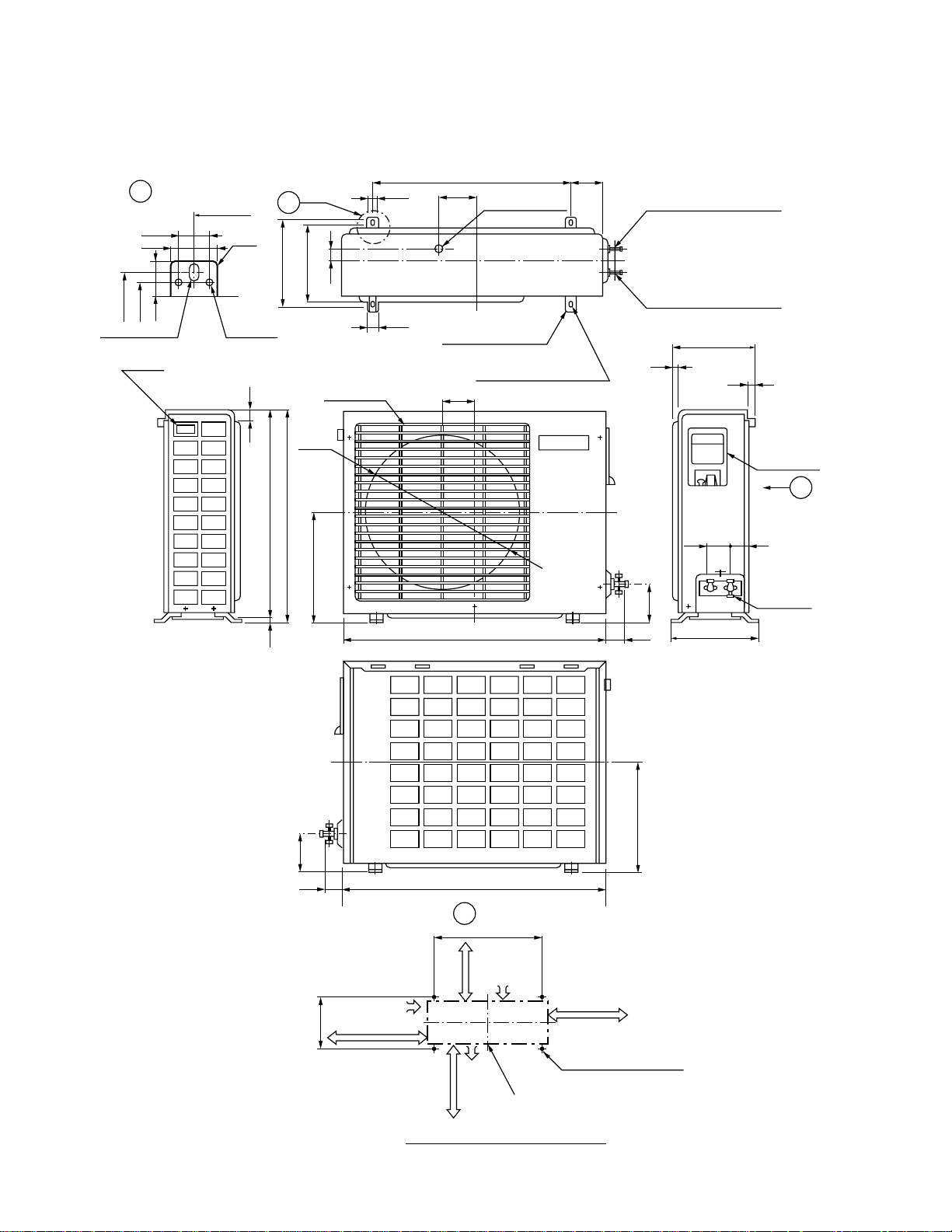

2-2. Outdoor Unit

RAS-07YKH-E, RAS-07YKH-ES, RAS-10YKH-E, RAS-10YKH-ES

600 85

Detail Drawing

A

36

50

216

230

25

Ø11x14 Hole

Handle

600

R10

Ø6 Hole

11

A

230

216

Fan guard

36

30

50

111

Ø25 Drain hole

8-Ø6 Holes

(For fixing the outdoor unit)

4-Ø11x14 Long holes

(For anchor bolt Ø8-Ø10)

111

Gas side (flare Ø9,52)

Liquid side (flare Ø6,35)

200

12

11

525

5

530

Ø420

268

89

59

TOSHIBA

770 59

770

268

89

Electric

parts cover

Z

54 62

Service

port

250

230

Inlet port

100 or more

View

Z

600

Inlet port

45 or more

Visible outline

of the product

Outlet

port

Center

400 or more

Mounting dimension of anchor bolt

port

600 or more

(Minimum distance

of the wall)

4-Ø11x14 Long holes

(For anchor bolt Ø8-Ø10)

– 8 –

RAS-13YAH-E, RAS-13YAH-ES

Detail Drawing

A

325

301

Ø11x14 hole

Handle

300

50

36

600

R10

23

Ø6 hole

538

52,5

325

Fan guard

Ø420

A

Ø25 Drain outlet

120

6-Ø11x14 hole (for Ø8-Ø10 anchor bolt)

600

780

90

Gas side

(Flare Ø12,7 for 13YAH-E,

Flare Ø9,52 for 13YAH-ES)

Liquid side (Flare Ø6,35)

8-Ø6 hole(for fixing outdoor unit)

Electric parts cover

59

27

100

(8,5)

130

325 (pitch)

342

54

61

Z

Service

port

(8,5)

Installation dimension

100 or more

325

100 or more

Z

Air outlet

View

600

Air inlet

600 or more

– 9 –

600 or more

4xØ11x14 Long holes (for Ø8-Ø10 anchor bolt)

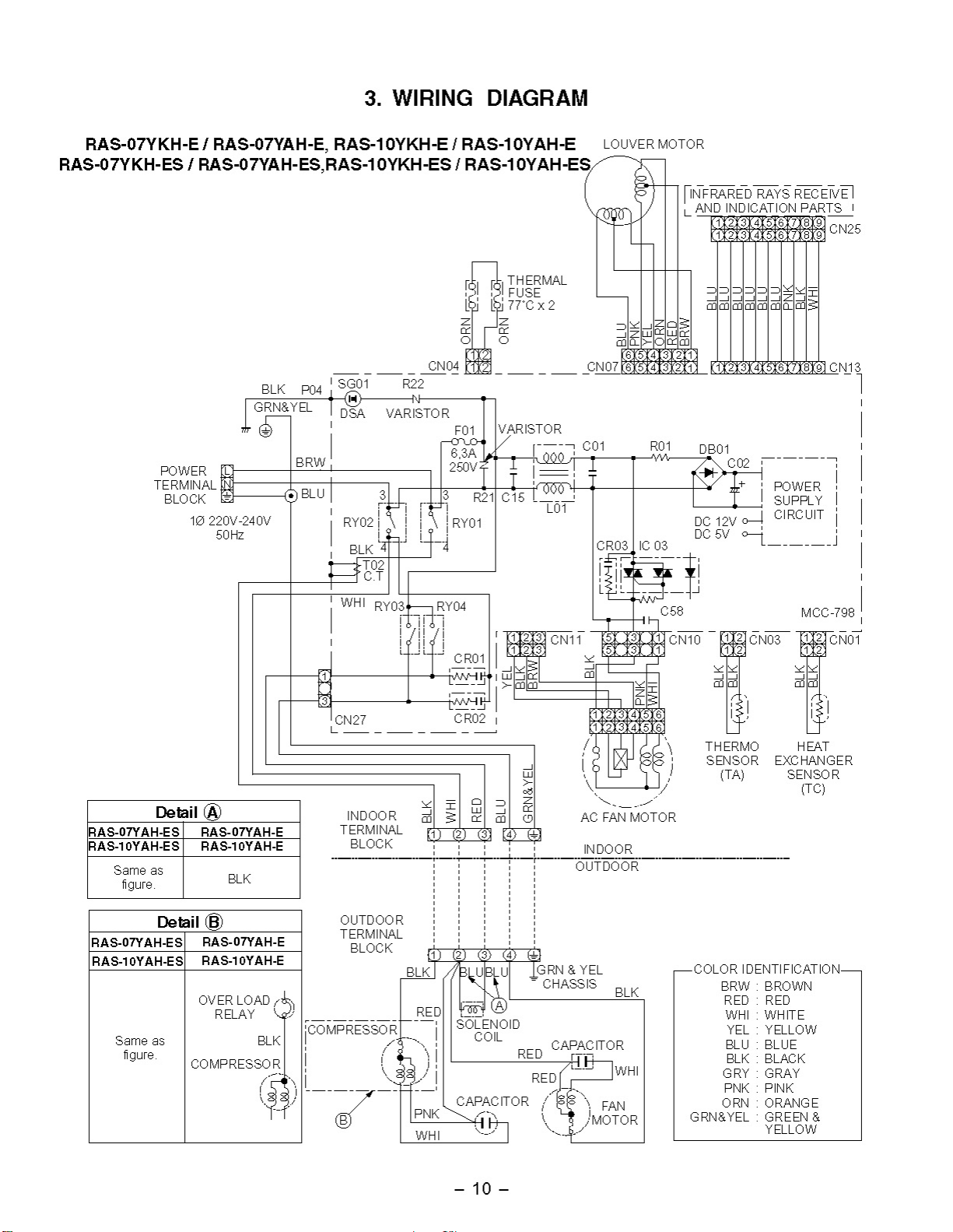

07 07

07

07

RAS-13YKH-E / RAS-13YAH-E

RAS-13YKH-ES / RAS-13YAH-ES

P04

BRW

BLU

1

3

SG01

DSA

POWER

TERMINAL

BLOCK

Ø 220V-240V

BLK

GRN&YEL

L

N

50Hz

RY02

BLK

WHI

VARISTOR

3

4

T02

C.T

R22

CN04

250V

3

4

RY04RY03

F01

6,3A

RY01

CR01

CR02

ORN

2

1

1

2

R21

THERMAL

FUSE

77˚C x 2

ORN

C15

L01

23

1

23

1

YEL

BLK

BRW

LOUVER MOTOR

INFRARED RAYS RECEIVE

AND INDICATION PARTS

6

7

5

CN07

C01

BLU

6

6

PNK

4

5

4

5

R01

YEL

ORN

RED

3

2

3

2

BRW

1

1

DB01

1

BLU

BLU

BLU

4433221

BLU

4321

5

BLU

5

6

BLU

6

7

PNK

7

8

8

BLK

8

9

9

WHI

9

CN25

CN13

C02

POWER

SUPPLY

2

2

BLK

CN03CN10

CIRCUIT

MCC-798

2

1

2

1

BLK

BLK

HEAT

EXCHANGER

SENSOR

DC 12V

CR03 IC 03

DC 5V

C58

CN11 CN01

5 3 1

5 3 1

BLK

PNK

1

23456

1

23456

WHI

1

1

BLK

THERMO

SENSOR

(TA)

(TC)

Detail A

RAS-13YAH-ES RAS-13YAH-E

Same as

figure.

BLK

Detail B

RAS-13YAH-ES

Same as

figure.

RAS-13YAH-E

OVER LOAD

RELAY

BLK

THERMOSTAT

FOR

COMPRESSOR

BLK

COMPRESSOR

INDOOR

TERMINAL

BLOCK

OUTDOOR

TERMINAL

BLOCK

COMPRESSOR

B

WHI

BLK

RED

321

321

BLK BLUBLU

RED

A

SOLENOID

COIL

CAPACITOR

PNK

WHI

– 11 –

BLU

4

4

RED

GRN&YEL

OUTDOOR

GRN & YEL

CHASSIS

CAPACITOR

RED

AC FAN MOTOR

INDOOR

BLK

WHI

FAN

MOTOR

COLOR IDENTIFICATION

:

BROWN

BRW

:

RED

RED

:

WHITE

WHI

:

YELLOW

YEL

:

BLUE

BLU

:

BLACK

BLK

:

GRAY

GRY

:

PINK

PNK

:

ORANGE

ORN

GRN&YEL

:

GREEN &

YELLOW

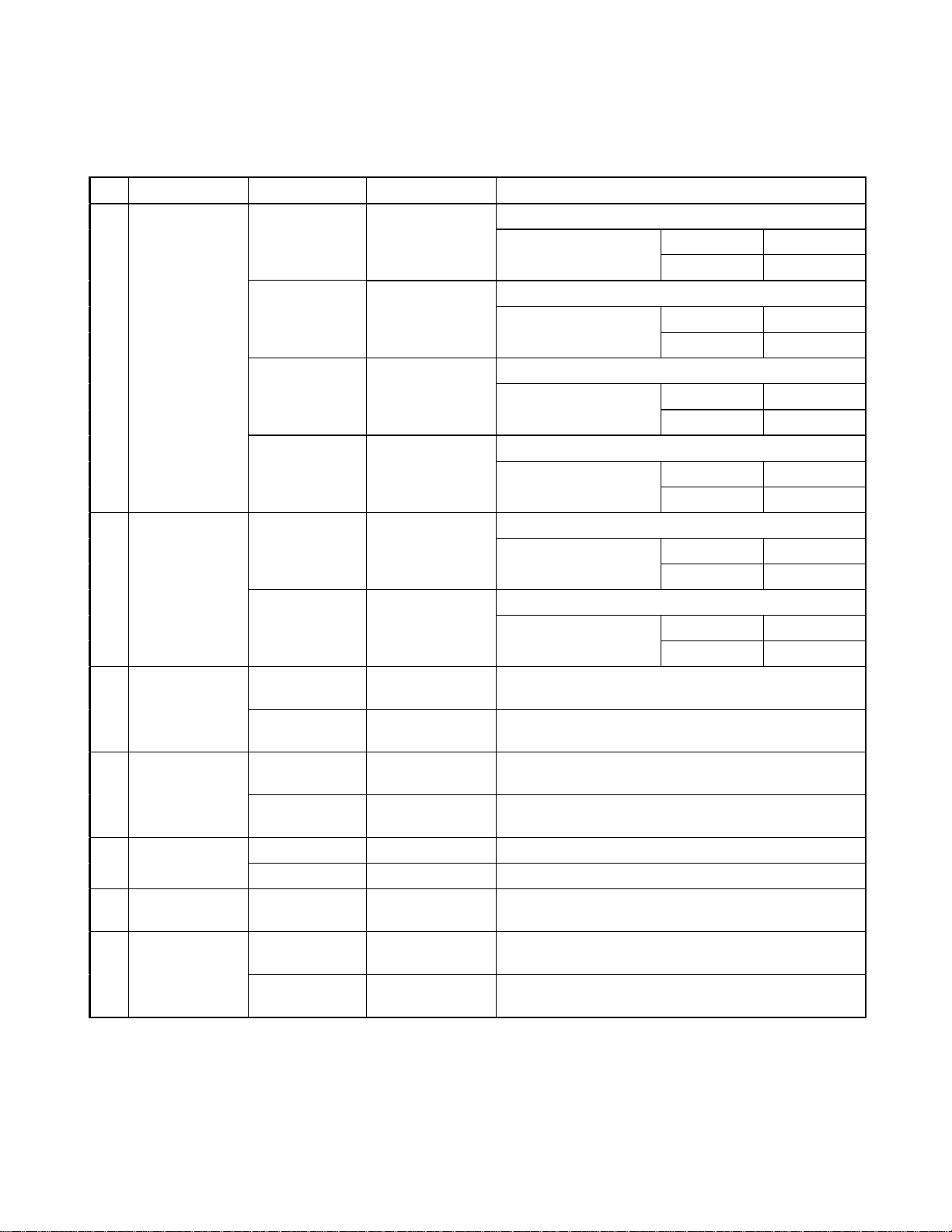

4-2. Outdoor Unit

RAS-10YAH-E, RAS-10YAH-ES

RAS-13YAH-E, RAS-13YAH-ES

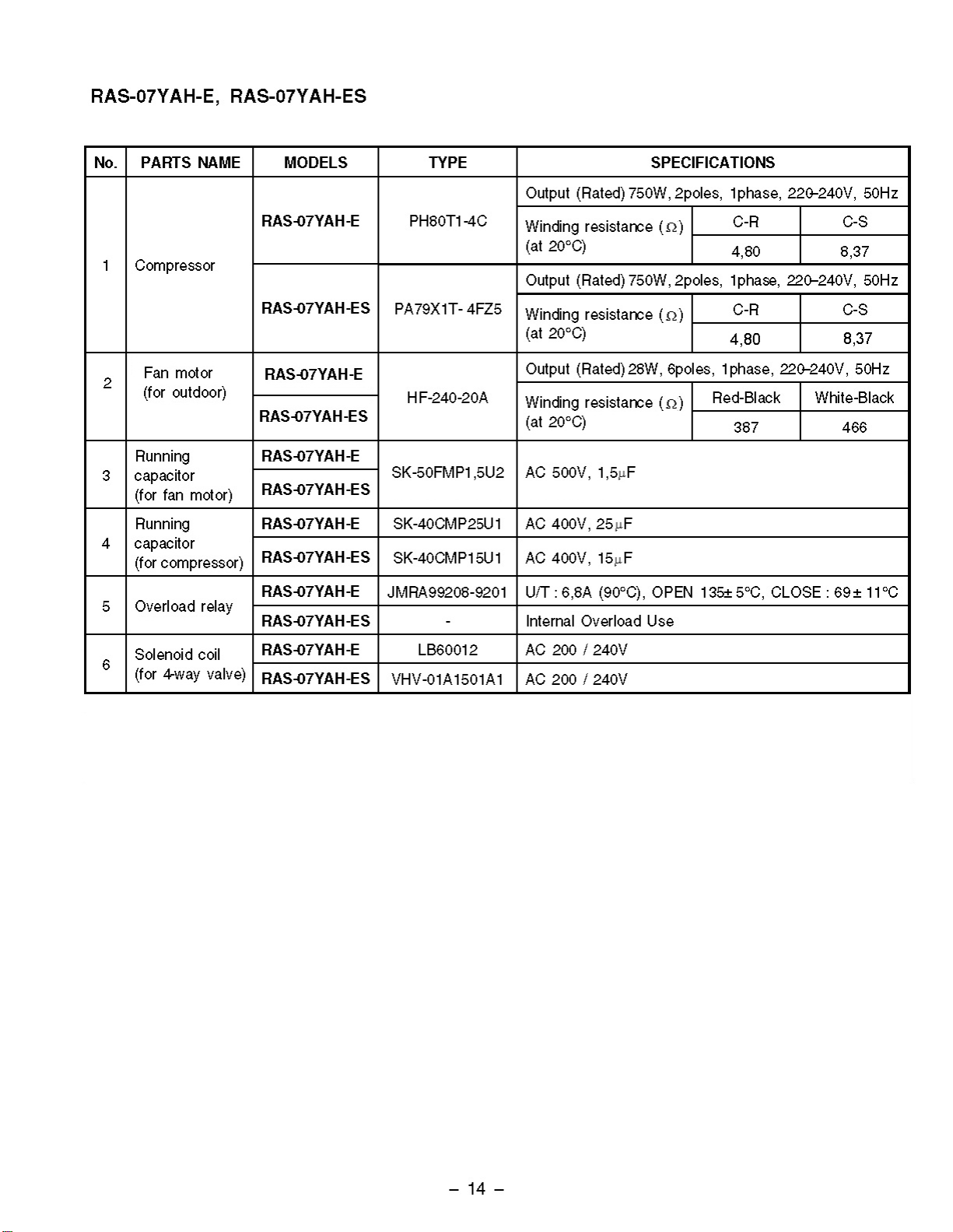

No. PARTS NAME MODELS TYPE SPECIFICATIONS

Output (Rated) 750W, 2poles, 1phase, 220–240V, 50Hz

1 Compressor

Fan mot or

2

(for outd oor)

Running

3

capacitor

(for fan motor)

Running

4

capacitor

(for compressor)

5 Overload relay

Thermostat

6

(for com p ressor)

Solenoid coil

7

(for 4-way valve)

RAS-10YAH-E

RAS-13YAH-E

RAS-10YAH-ES

RAS-13YAH-ES

RAS-10YAH-E

RAS-10YAH-ES

RAS-13YAH-E

RAS-13YAH-ES

RAS-10YAH-E

RAS-10YAH-ES

RAS-13YAH-E

RAS-13YAH-ES

RAS-10YAH-E

RAS-10YAH-ES

RAS-13YAH-E

RAS-13YAH-ES

RAS-10YAH-E

RAS-13YAH-E

RAS-10YAH-E

RAS-10YAH-E

RAS-13YAH-E

RAS-10YAH-ES

RAS-13YAH-ES

PH120T1-4C

PH170T2-4L2

PA118X1T-4FZ

PA160X2T-4FM

UE6-21SJ5P

AF-230-28P

SK-50FMP1,5U1 AC 500V, 1,5mF

SK-50FMP1,5U2 AC 500V, 1,5mF

SK-40CMP25U1 AC 400V, 25mF

SK-40CMP35U1 AC 400V, 35mF

JMRA99269-9200 U/T : 6,8A (90°C), OPEN 135 ± 5°C, CLO S E : 69 ± 11°C

JMRA99257-920 0 U/T : 8,0A (80°C), OPEN 145 ± 5°C, CLOSE : 75 ± 11°C

CS-7 OFF : 130°C, ON : 70°C

LB60012 AC 200 / 240V

VHV-01A1501A1 AC 200 / 240V

Winding resista n ce (W)

(at 20°C)

Output (Rated) 1 100W, 2poles, 1phase , 220–240V, 50Hz

Winding resista n ce (W)

(at 20°C)

Output (Rated) 750W, 2poles, 1phase, 220–240V, 50Hz

Winding resista n ce (W)

(at 20°C)

Output (Rated) 1 100W, 2poles, 1phase , 220–240V, 50Hz

Winding resista n ce (W)

(at 20°C)

Output (Rated) 1 8W, 6poles, 1phase , 220–240V, 50Hz

Winding resista n ce (W)

(at 20°C)

Output (Rated) 2 8W, 6poles, 1phase , 220–240V, 50Hz

Winding resista n ce (W)

(at 20°C)

C-R C-S

4,53 8,73

C-R C-S

2,22 3,04

C-R C-S

3,17 5,18

C-R C-S

2,26 3,53

Red-Black White-Black

370 370

Red-Black White-Black

198 160

– 13 –

5. REFRIGERANT CYCLE DIAGRAM

RAS-10YKH-E / RAS-10YAH-E

Indoor unit

Cooling

0,39m

(Connecting pipe)

ø9,52

O.D.:9,52mm O.D.:6,35mm

Cooling

Heating

Heating

P

Packed valve

(ø9,52)

Heating

4-way valve

Cooling

Compressor

PH120T

Accumulator

1

-4C

Evaporator

Cross flow fan

Dryer

T

0,49m

(Connecting pipe)

ø6,35

Packed valve

(ø6,35)

Capillary tube

ø1,5x500

Condenser

Refrigerant

R-22 0,74kg

Fan speed

(indoor)

Ambient temp.

conditions DB/WB (°C)

Indoor Outdoor

50Hz

Cooling

Heating

Standard

pressure P

(kg/cm²G)

Propeller fan

Outdoor unit

Surface temp. of heat

exchanger interchanging

pipe T (°C)

Mark( )means check points of Gas Leak

Standard 15,0 40,0 High 21/ - 7/6

High temperature *119–23 52,0–59,0 Low 27/ - 21/15Heating

Low temperature 12,5 35,0 High 21/ - -10/-10

Standard 6,0 12,0 High 27/19 35/24

High temperature 6,5 15,0 High 32/23 43/26Cooling

Low temperature 4,0 2,0 Low 21/15 21/15

Note : Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor.)

1 : During heating ov erload, the high temperature limit control operation is included.

*

– 15 –

RAS-13YKH-E / RAS-13YAH-E

Indoor unit

Cooling

0,49m

(Connecting pipe)

ø12,7

O.D.:12,7mm O.D.:6,35mm

Cooling

Heating

Heating

P

Packed valve

(ø12,7)

Gas container connection (Reinstall etc.)

Heating

4-way valve

Cooling

Compressor

PH170T2-4L2

Accumulator

Heat exchanger

Cross flow fan

Condenser

T

Capillary tube

ø0,6x1500

Capillary tube

ø1,7x400

0,39m

(Connecting pipe)

ø6,35

Packed valve

(ø6,35)

Capillary tube

ø1,2x400

Refrigerant

R-22 0,88kg

Fan speed

(indoor)

Ambient temp.

conditions DB/WB (°C)

Indoor Outdoor

50Hz

Cooling

Heating

Standard

pressure P

(kg/cm²G)

Propeller fan

Outdoor unit

Surface temp. of heat

exchanger interchanging

pipe T (°C)

Mark( )means check points of Gas Leak

Standard 15,0 43,0 High 21/ - 7/6

High temperature *119–23 52,0–59,0 Low 27/ - 21/15Heating

Low temperature 12,5 35,0 High 21/ - -10/-10

Standard 5,0 10,0 High 27/19 35/24

High temperature 6,0 14,0 High 32/23 43/26Cooling

Low temperature 4,0 2,0 Low 21/15 21/15

Note : Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor.)

1 : During heating ov erload, the high temperature limit control operation is included.

*

– 16 –

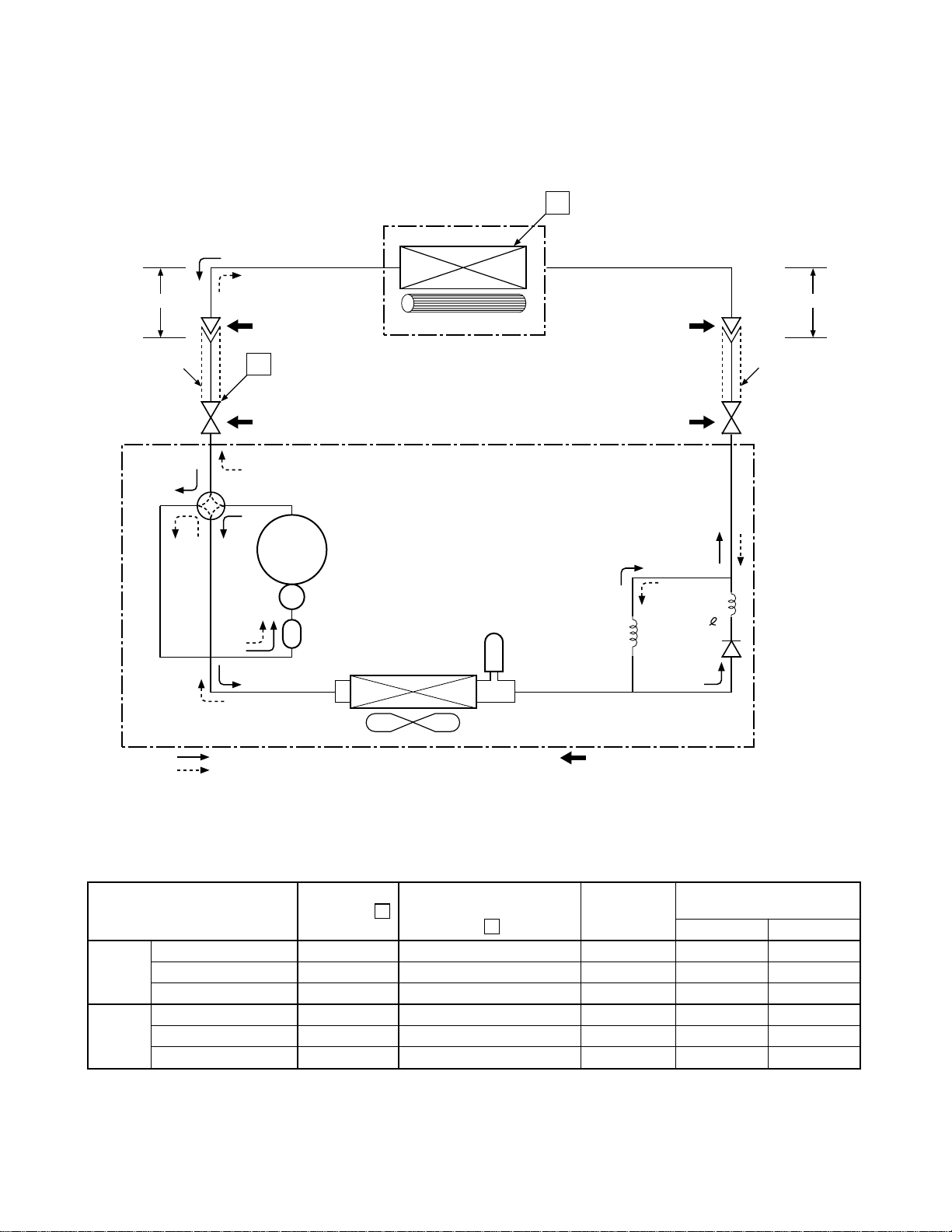

RAS-07YKH-E / RAS-07YAH-E

Indoor unit

Cooling

0,39m

(Connecting pipe)

ø9,52

O.D.:9,52mm O.D.:6,35mm

Cooling

Heating

Heating

P

Packed valve

(ø9,52)

Heating

4-way valve

Cooling

Compressor

PH80T

Accumulator

1

-4C

Evaporator

Cross flow fan

Dryer

T

0,49m

(Connecting pipe)

ø6,35

Packed valve

(ø6,35)

Capillary tube

ø1,5x1400

Condenser

Refrigerant

R-22 0,63kg

Fan speed

(indoor)

Ambient temp.

conditions DB/WB (°C)

Indoor Outdoor

50Hz

Cooling

Heating

Standard

pressure P

(kg/cm²G)

Propeller fan

Outdoor unit

Surface temp. of heat

exchanger interchanging

pipe T (°C)

Mark( )means check points of Gas Leak

Standard 15,0 40,0 High 21/ - 7/6

High temperature *119–23 52,0–59,0 Low 27/ - 21/15Heating

Low temperature 12,5 35,0 High 21/ - -10/-10

Standard 6,0 12,0 High 27/19 35/24

High temperature 6,5 15,0 High 32/23 43/26Cooling

Low temperature 4,0 2,0 Low 21/15 21/15

Note : Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor.)

1 : During heating overload, the high temperature limit control operation is included.

*

– 17 –

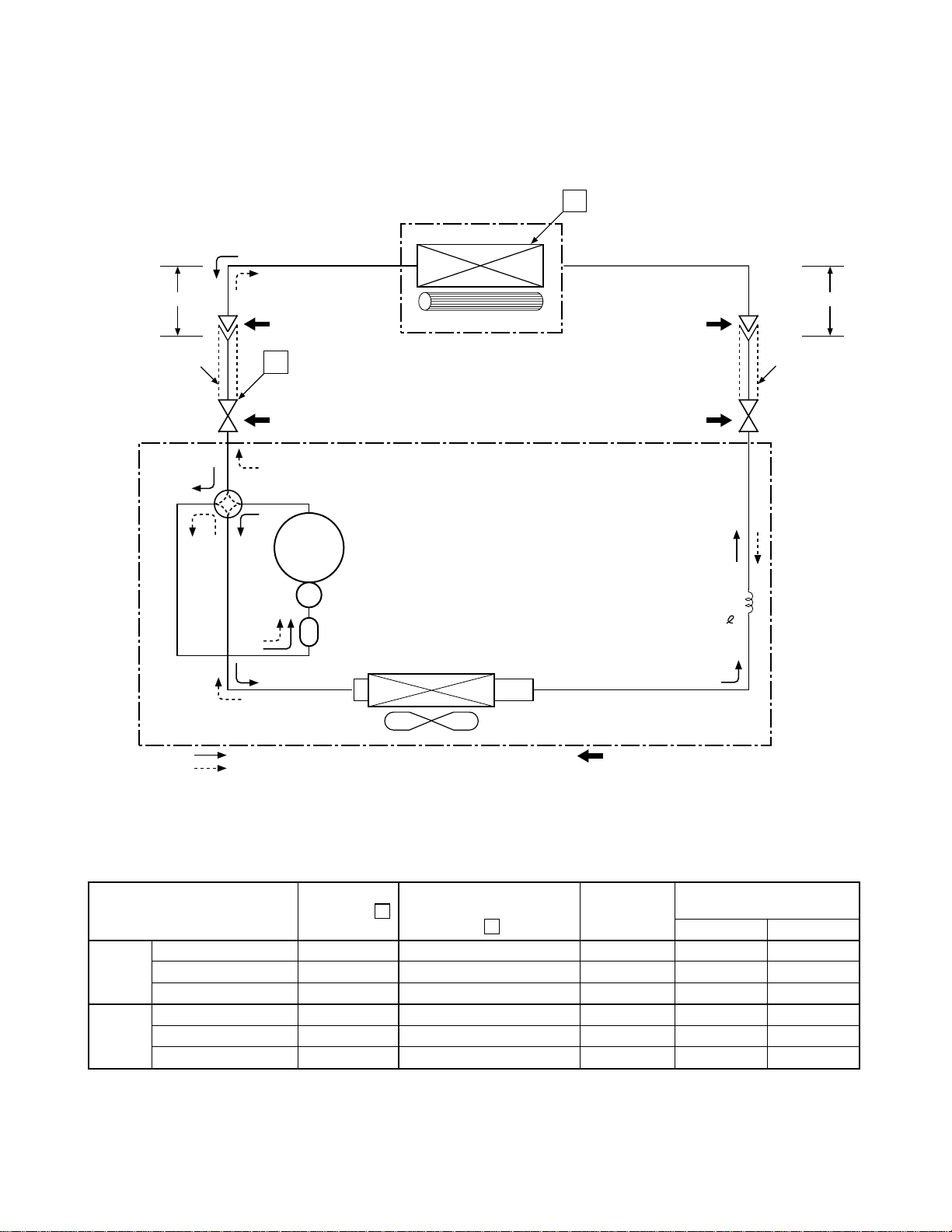

RAS-10YKH-ES / RAS-10YAH-ES

Indoor unit

Cooling

0,39m

(Connecting pipe)

ø9,52

O.D.:9,52mm O.D.:6,35mm

Cooling

Heating

Heating

P

Packed valve

(ø9,52)

Heating

4-way valve

Cooling

Compressor

Muffler

PA118X1T-4FZ

Accumulator

Condenser

Evaporator

Cross flow fan

Dryer

T

Capillary tube

ø1,2x400

0,49m

(Connecting pipe)

ø6,35

Packed valve

(ø6,35)

Muffler

Capillary tube

ø0,8x400

Refrigerant

R-410A 0,69kg

Fan speed

(indoor)

Ambient temp.

conditions DB/WB (°C)

Indoor Outdoor

50Hz

Cooling

Heating

Standard

pressure P

(MPaG)

Propeller fan

Outdoor unit

Surface temp. of heat

exchanger interchanging

pipe T (°C)

Mark( )means check points of Gas Leak

Standard 2,5 43,0 High 20/ - 7/6

High temperature *13,1–3,6 51,0–58,0 Low 27/ - 21/15Heating

Low temperature 2,2 36,0 High 20/ - -10/-10

Standard 0,9 10,0 High 27/19 35/24

High temperature 1,1 16,0 High 32/23 43/26Cooling

Low temperature 0,6 2,0 Low 21/15 21/15

Note : Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor.)

1 : During heating ov erload, the high temperature limit control operation is included.

*

– 18 –

RAS-13YKH-ES / RAS-13YAH-ES

Indoor unit

Cooling

0,49m

(Connecting pipe)

ø9,52

O.D.:9,52mm O.D.:6,35mm

Cooling

Heating

P

Packed valve

(ø9,52)

Gas container connection (Reinstall etc.)

Heating

4-way valve

Cooling

Muffler

Compressor

PA160X2T-4FM

Heat exchanger

Cross flow fan

Dryer

Condenser

T

Packed valve

Capillary tube

ø1,2x1200

(Note)

Maximum pipe length is 15m

Maximum pipe head is 6m

0,39m

(Connecting pipe)

ø6,35

(ø6,35)

Capillary tube

ø1,5x500

Refrigerant

R-410A 0,80kg

Fan speed

(indoor)

Ambient temp.

conditions DB/WB (°C)

Indoor Outdoor

50Hz

Cooling

Heating

Outdoor unit

Standard

pressure P

(MPaG)

Propeller fan

Mark( )means check points of Gas Leak

Surface temp. of heat

exchanger interchanging

pipe T (°C)

Standard 2,7 43,0 High 20/ - 7/6

High temperature *13,2–3,6 52,0–57,0 Low 27/ - 21/15Heating

Low temperature 2,0 30,0 High 20/ - -10/-10

Standard 0,9 11,0 High 27/19 35/24

High temperature 1,0 14,0 High 32/23 43/26Cooling

Low temperature 0,6 2,0 Low 21/15 21/15

Note : Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor.)

1 : During heating ov erload, the high temperature limit control operation is included.

*

– 19 –

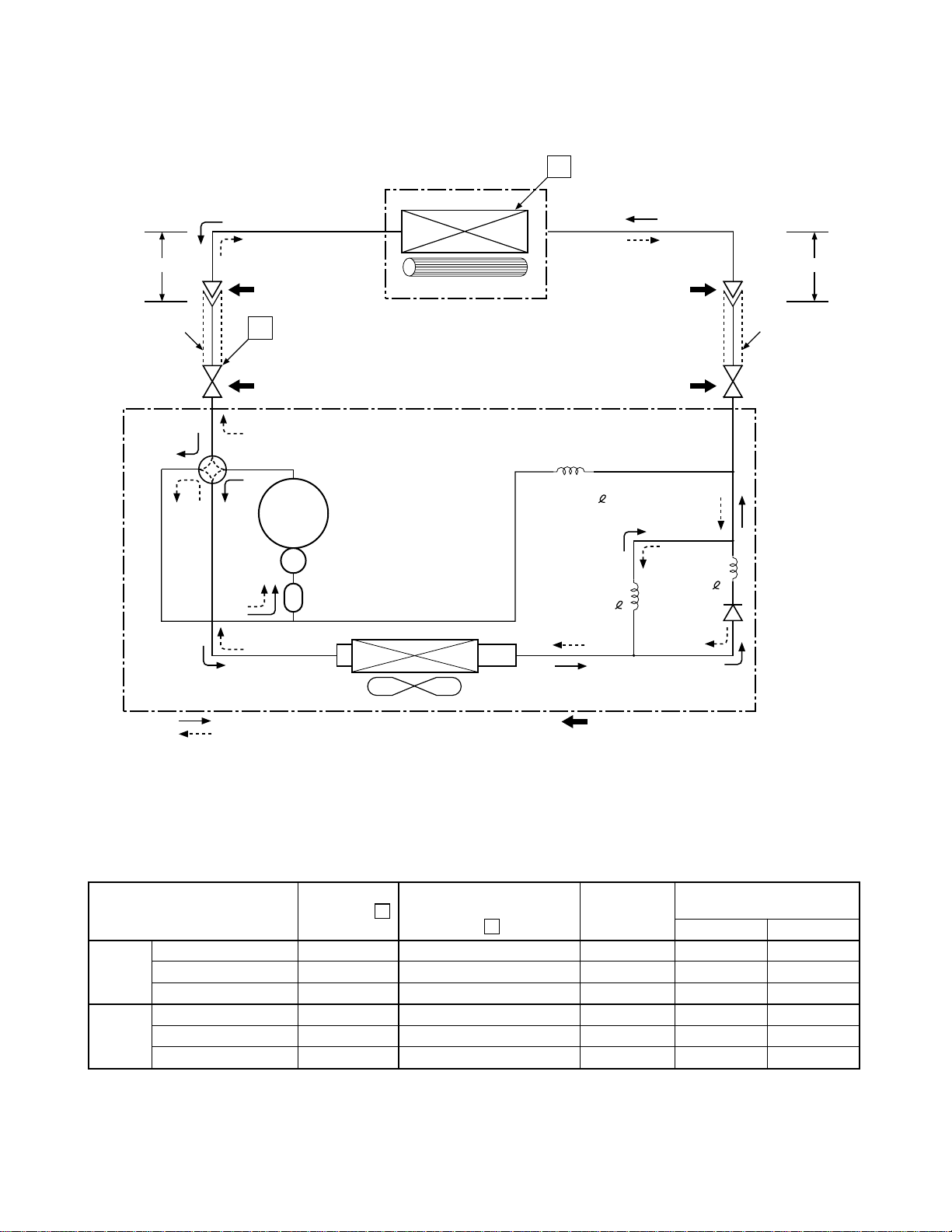

RAS-07YKH-ES / RAS-07YAH-ES

Indoor unit

Cooling

0,39m

(Connecting pipe)

ø9,52

O.D.:9,52mm O.D.:6,35mm

Cooling

Heating

Heating

P

Packed valve

(ø9,52)

Heating

4-way valve

Cooling

Compressor

PA79X1T-4FZ5

Accumulator

Evaporator

Cross flow fan

Dryer

T

0,49m

(Connecting pipe)

ø6,35

Packed valve

(ø6,35)

Capillary tube

ø1,2x900

Condenser

Refrigerant

R-410A 0,73kg

Fan speed

(indoor)

Ambient temp.

conditions DB/WB (°C)

Indoor Outdoor

50Hz

Cooling

Heating

Standard

pressure P

(kg/cm²G)

Propeller fan

Outdoor unit

Surface temp. of heat

exchanger interchanging

pipe T (°C)

Mark( )means check points of Gas Leak

Standard 2,5 43,0 High 20/ - 7/6

High temperature *1 3,1-3,6 51,0–58,0 Low 27/ - 21/15Heating

Low temperature 2,2 36,0 High 20/ - -10/-10

Standard 0,9 10,0 High 27/19 35/24

High temperature 1,1 16,0 High 32/23 43/26Cooling

Low temperature 0,6 2,0 Low 21/15 21/15

Note : Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor.)

1 : During heating ov erload, the high temperature limit control operation is included.

*

– 20 –

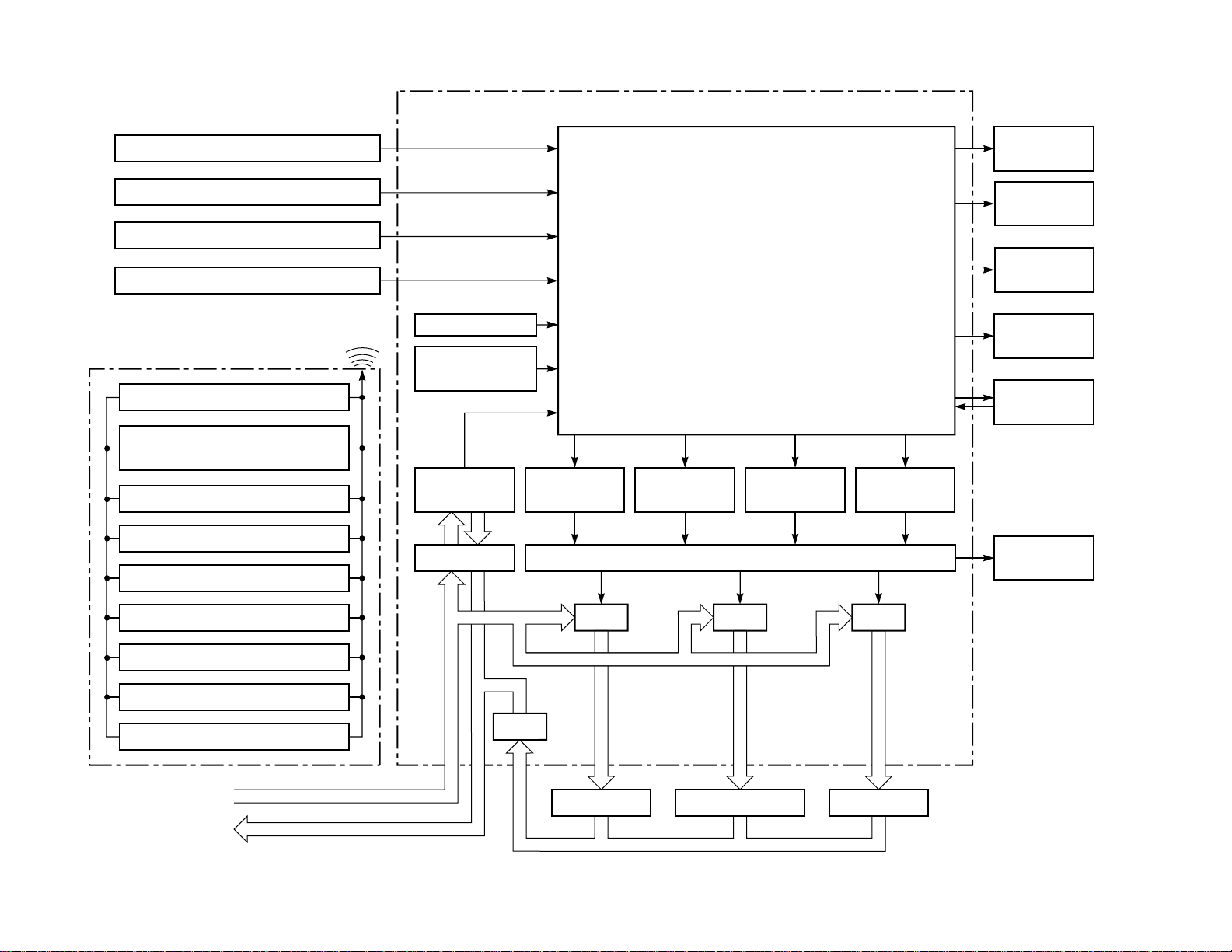

Main Unit Control Panel

C. P. U

Heat Exchanger Sensor

Thermo. Sensor

Current Sensor

(Compressor Current)

Infrared Rays Signal Receiver

Functions

• Louver Control

• 3-minutes Delay at Restart for Compressor

Operation

Display

Timer

Display

ECONO.

Sign Display

6. CONTROL BLOCK DIAGRAM

Infrared

Rays

Remote Control

Operation (START/STOP)

– 21 –

Operation Mode Selection

AUTO, COOL, DRY, HEAT, FAN ONLY

Thermo. Setting

Fan Speed Selection

ON TIMER Setting

Initializing Circuit

Clock Frequency

Oscillator Circuit

Power Supply

Circuit

Noise Filter

• Motor Revolution Control

• Processing

(Temperature Processing)

• Timer

Compressor

ON/OFF Signal

Outdoor Fan

ON/OFF Signal

Relay Driver, Louver Driver

4-Way Valve

ON/OFF Signal

PRE-DEF.

Sign Display

Indoor

Fan Motor

Louver

ON/OFF Signal

Louver

Motor

OFF TIMER Setting

Louver AUTO Swing

Louver Direction Setting

ECONO.

AC 220/230/240V ~

50Hz

Relay

RY02

Compressor

RelayRelayRelay

RY01 RY03 RY04

4-Way ValveOutdoor Fan Motor

7. OPERATION DESCRIPTIONS

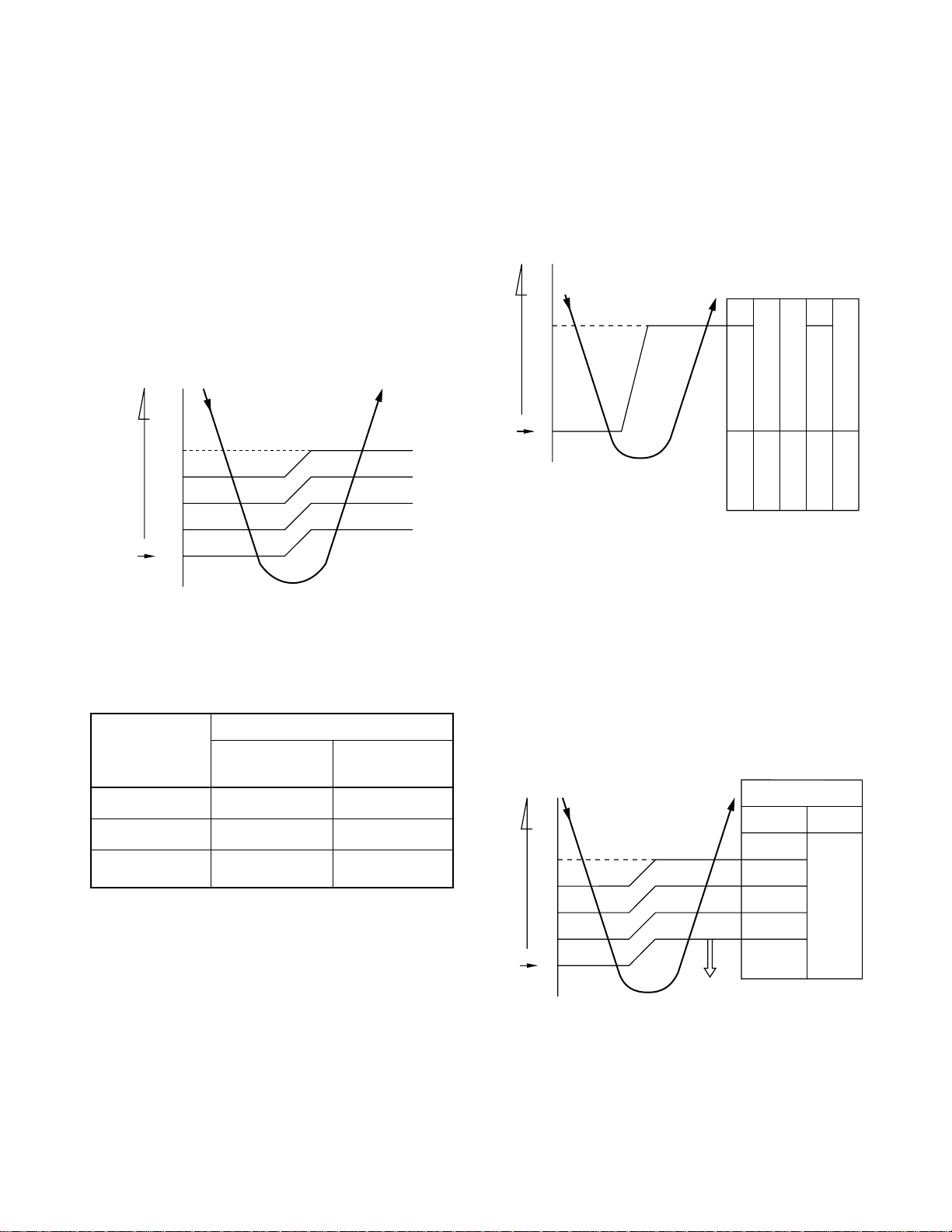

7-1. FAN ONLY Operation

(MODE of the remote control : FAN ONLY)

(1) During this mode, the rela y RY01 is always

turned off so that only the indoor fan is operated.

R Y02 is always turnd on.

7-2. COOL Operation

(MODE of the remote control : COOL)

(1) Compressor, 4-way valve, outdoor fan and

operation display are controlled as shown in Fig.

7-2-1.

1) When the F AN is set to AUTO, the indoor fan

motor operates as shown in Fig. 7-1-1.

2) When the F AN is set to LOW, MED, or HIGH,

the indoor fan motor operates with a constant

+1

ON

in volume as listed in Table 7-1-1.

OFF

ON ON

OFF

(Room temp. – Set temp.)

Set

0

temp.

Fig. 7-2-1

(RY02)

(RY01)

Compressor

Common relay

(Room temp. – Set temp.)

Set

temp.

28

27

26

25

24

HIGH

MED

LOW(+)

LOW

LOW

(2) Rela ys RY01 and RY02 are turned on to ener-

gize the outdoor unit, and a cool operation is

carried out.

Fig. 7-1-1 Auto setting of air volume

1) When the F AN is set to AUTO, the indoor fan

motor operates as shown in Fig. 7-2-2.

Table 7-1-1 Manual setting of FAN SPEED

2) When the F AN is set to LOW, MED, or HIGH,

the indoor fan motor operates with a constant

Indication of

FAN SPEED

3

HIGH Air volume (m

/hr)

RAS-10YKH-E RAS13-YKH-E

in volume as listed in Table 7-1-1.

RAS-10YKH-ES RAS13-YKH-ES

LOW

MED

HIGH

*For model : RAS-07YKH-E, RAS-07YKH-ES LOW(+)

(2) Once the setting is made, the operation mode is

memorized in the microcomputer so that the

same operation can be effected thereafter simply

400 (430)* 510

500 (490)* 560

600 (550)* 650

(Room temp. – Set temp.)

Set

temp.

+4

+3

+2

+1

0

RY01

OFF

FAN

AUTO

HIGH

MED

LOW

LOW

(continuous)

by pushing the START/STOP b utton.

Fig. 7-2-2

ON

OFF

(RY04)

(RY03)

4-way valve

Outdoor fan

OPERATION

Manual

According

to the set

position

display

– 22 –

(3) Once the setting is made, the operation mode is

memorized in the microcomputer so that the

same operation can be effected thereafter simply

by pushing the START/STOP button.

Loading...

Loading...