Toshiba RAS-B10UFV-E, RAS-137SKV-E5, RAS-167SKV-E5, RAS-B16N3KVP-E, RAS-B13UFV-E Technical Handbook

...

Version 14.1.3

24 Hour Technical Helpline: 0870 843 0333

Fault & DN Code Apps: Android & iPhone

Web Page toshiba-calc.co.uk/fault-codes/

Fault Code Text Service: 07624 803 017

technical.enquiries@toshiba-ac.com

Technical HandBook

Page 2 of 78

Index Page

Make Up of Model Number 3

Mechanical Specifications-RAS R410A Outdoor Units 4

Performance & Electrical Specifications - RAS R410A Single Splits 4

Performance & Electrical Specifications - RAS R410A Multi Splits 4

RAS R410A Multi Split System Combinations 5

Acoustic Data - RAS Indoor Units 5

RAS - Auto Restart Function 6

Fault Codes - RAS “N” Series 6

Mechanical Specifications - DI/SDI R410A Single Splits 7

Performance & Electrical Specifications - DI / SDI R410A Single Splits 7

Electrical Specifications - DI/SDI R410A Multi Splits 8

Acoustic Data – DI/SDI Indoor Units 8

Mechanical & Electrical Data - Air-to-Air Heat Exchangers 9

Digital/Super Digital Replacement Refrigerant Pipe Sizing 10

Digital/Super Digital Inverter Multi Split System Combinations 11

Digital/Super Digital Inverter Twin Splits 12

Digital/Super Digital Inverter Triple Splits 14

Digital Inverter Quad Splits 16

Digital/Super Digital Multi Split System Wiring Schematic 17

VRF System Make Up Chart 18

Electrical Data - VRF Outdoor Units 19

VRF Additional Refrigerant Charge Amount 19

VRF Additional Refrigerant Charge Calculations 20

Acoustic Data - MMY Indoor Units 23

Common Sensor Characteristics 24

Trouble Shooting - RAV Series 25

Apps Store Fault Codes - All Commercial & VRF Systems 28

Fault Codes – All Commercial & VRF Systems 29

Error Detected by TCC-Link Central Controller 43

Step By Step Wiping/Re-addressing Of VRF Systems 44

Priority Mode (SMMSi Only) 44

Outdoor Fan High Static Pressure Setup 44

Compressor or Outdoor Fan Motor Backup Isolation Setting 44

VRF Rotary Dial Data Display SMMSi, SHRMi & Mini SMMS 45

TCC-net Controller Guidelines 46

System Configuration Menu 47

TCCJ Optional Control Accessories 49

TCC-Net Control - Standard Wired Controller 50

Controller Configuration - Remote Controller RBC-AMT32E & RBC-AMS41E 51

Data Retrieval Guide - Remote Controllers RBC-AMT32E, RBC-AMS41E & RBC-AMS51E 52

Simplified Instructions for RBC-AMS41E Remote Controller 54

Time, Temperature & Mode Setting for RBC-AMS41E Remote Controller 55

Simplified Instructions for RBC-AMS51E Remote Controller 56

Fault Code Guide for RBC-AMS51E Remote Controller 57

Data Retrieval Guide - RBC-AMS51E Remote Controller 58

Relocation of Room Temperature Sensing from Return Air to Remote Controller 59

Automatic Restart after Power Failure 60

Condition Setting (Day, Time, Mode & Temperature) 62

Delete Settings for each Day 63

Copy Settings for Previous Day 63

Holiday Day Omit Setting 64

Energy Saving Function 64

VN Air to Air Heat Exchangers 66

VN Air to Air Heat Exchanger Configurations 68

Automatic Zone Registration Using the Central Remote Controller (TCB-SC642TLE) 69

Network Addressing DI/SDI and VRF Systems 70

Integration with AI Network Control 76

Second Controller 76

Temperature Sensing 76

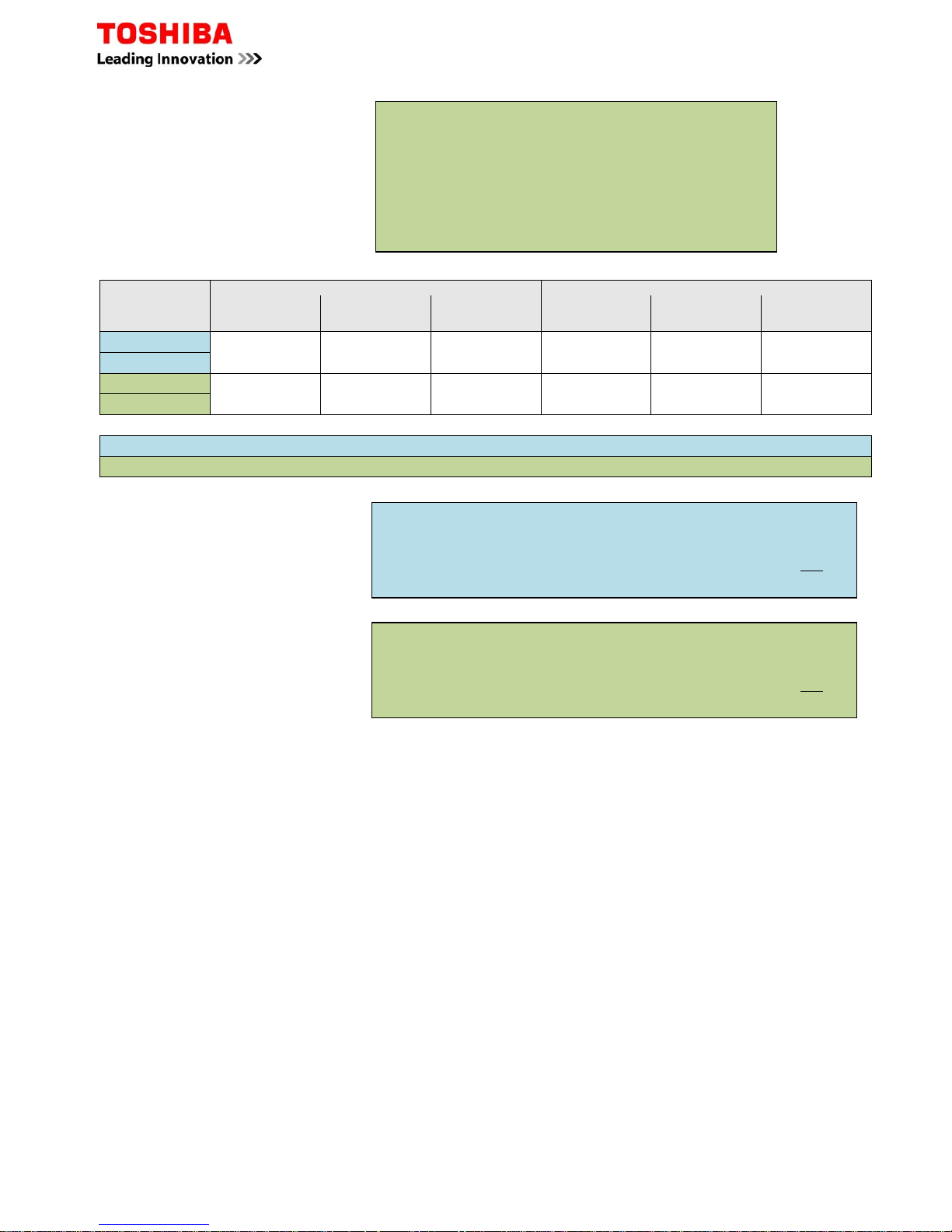

E = CE marked

P = Made in Thailand

T = Twin rotary compressor

V = Single rotary compressor

R = Infrared option

Style

X = Flexi (Low Wall or Under-slung)

K = Hi Wall, C = Ceiling Suspended

U = Cassette, B = Ducted

A = Outdoor

RAV/RAS Products

RAS - 16 7 SK_PE

Digital/Super Digital Inverter

RAV-SM566KRTP-E

SMMSi/SHRMi

MMYMAP 1204HT8E

Modular Multi Indoor Units

MM* - AP 056 4 BH E

009= 2.8kW 012= 3.6kW 015= 4.5kW 018= 5.6kW 024= 7.1kW 027= 8kW 030= 9kW 036= 11.2kW 048= 14kW 056= 16kW

*Style

U = Cassette, F = Tall Floor standing

D = Ducted, C = Ceiling suspended

K = High Wall, L = Floor standing

Refrigerant R410A

Capacity Rank

MMY = Modular Multi

M = Single module

No mark = Combined model

Refrigerant R410A

Capacity rank HP x 10

E = CE marked

Three phase power supply

Capacity variable unit (Inverter)

H = Heat pump (two pipe)

F = Heat recovery (three pipe)

Development series

RAV = Light Commercial Range

SM = Digital Inverter

SP = Super Digital Inverter

Nominal Duty (kW) i.e. 56 = 5.6kW

Generation: 0 = original

3 = 3

rd

Update etc

RAV = Light Commercial Range

RAS = Small Office / Domestic

Approx Duty (x 1000 = BTU)

Generation

RAV use numbers i.e. 0,1,2,3,4,5

RAS use letters i.e. U,E,S,Y

E = CE marked

P = Made in Plymouth

Blank = Single Phase Power Supply

8 = Three Phase Power Supply

H = HP (RAV)

N = Chassis Type, K = High Wall

L = Console Type, C = Ceiling suspended

S = Low Wall, F = Tall Floor

B = Ducted Type, U = Four Way Cassette

A = Outdoor Unit TU = Two Way Cassette

E = CE marked

Style

WH = 2-way discharge, H = Heat pump

SH = 1-way discharge, SPH = Slim Duct

BH = Standard duct

Development series

Make Up of Model Number

Page 3 of 78

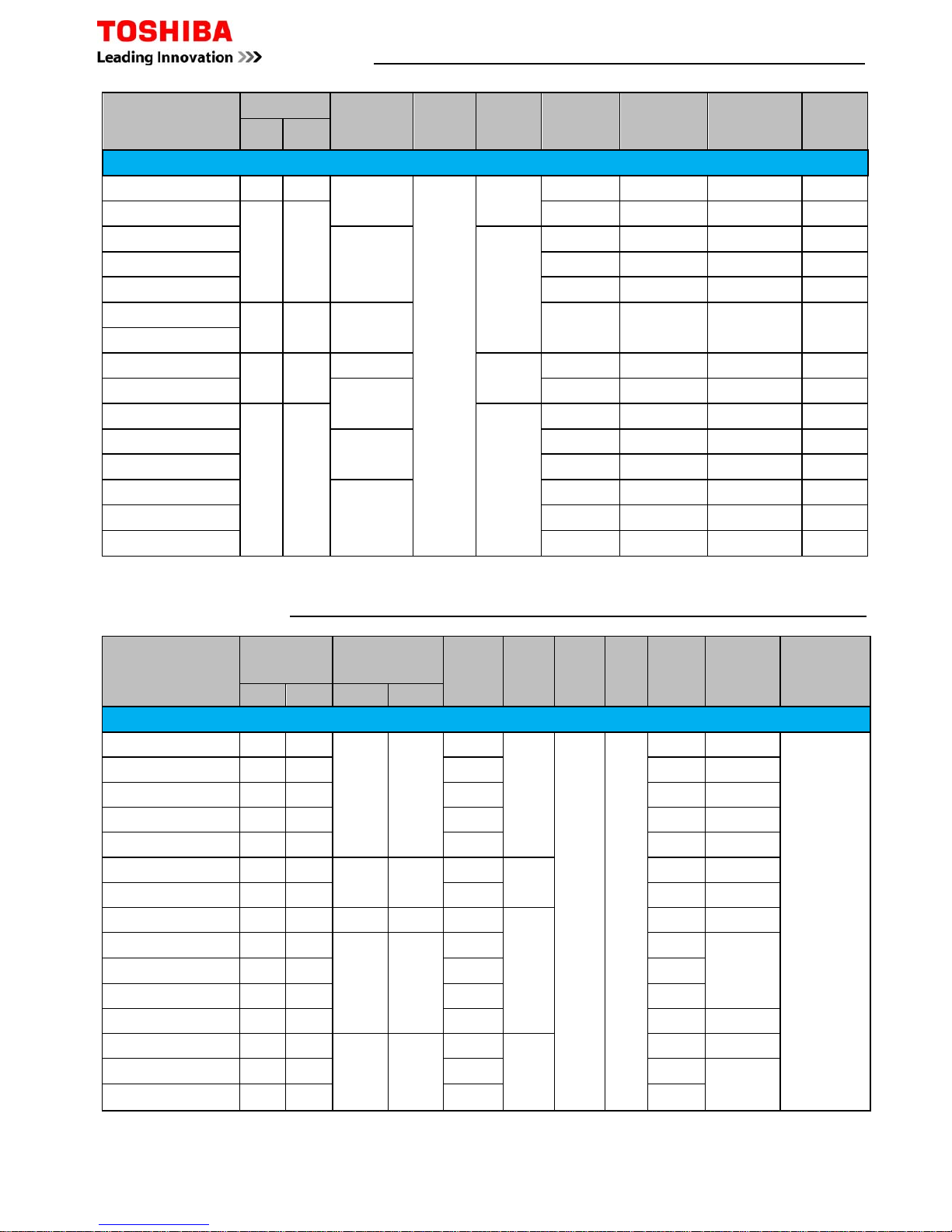

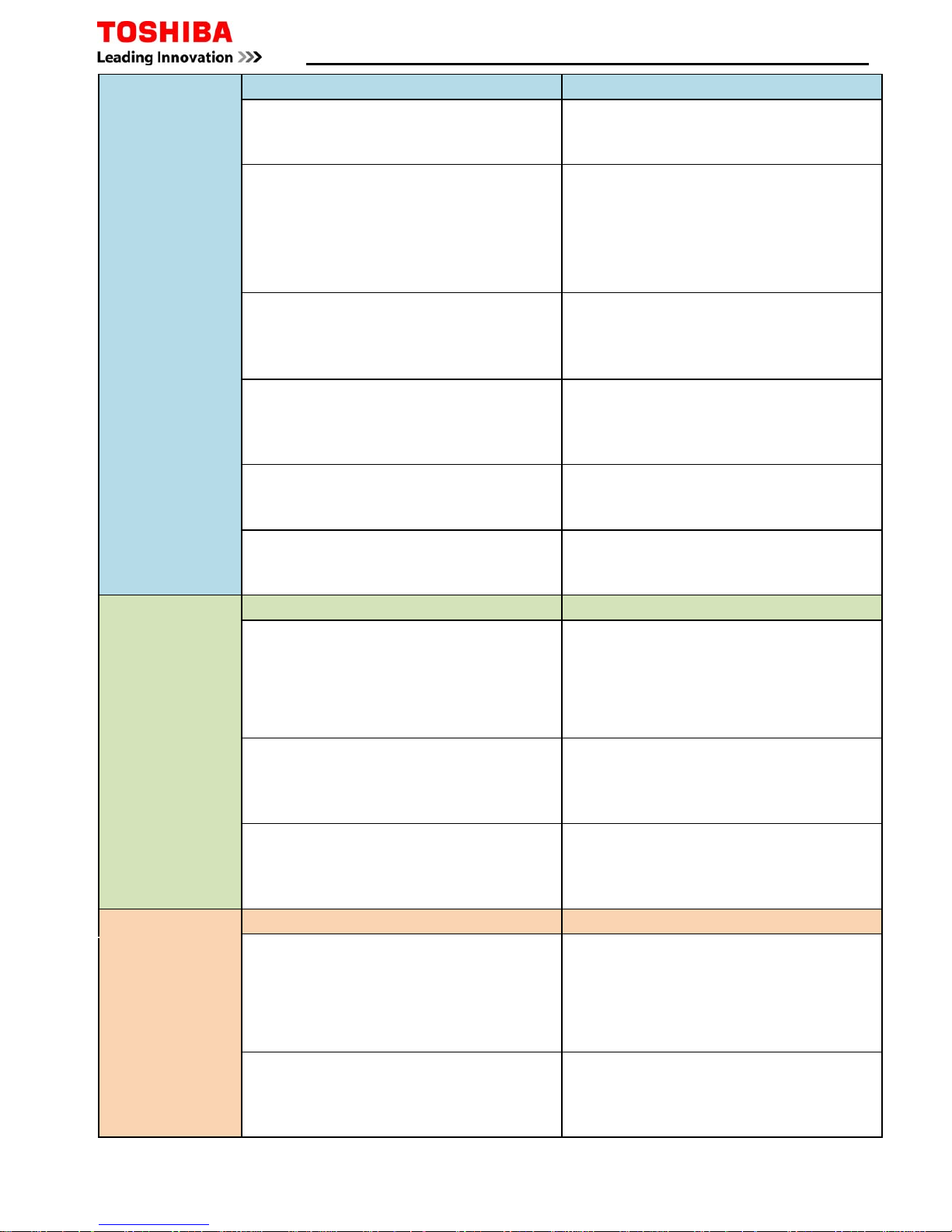

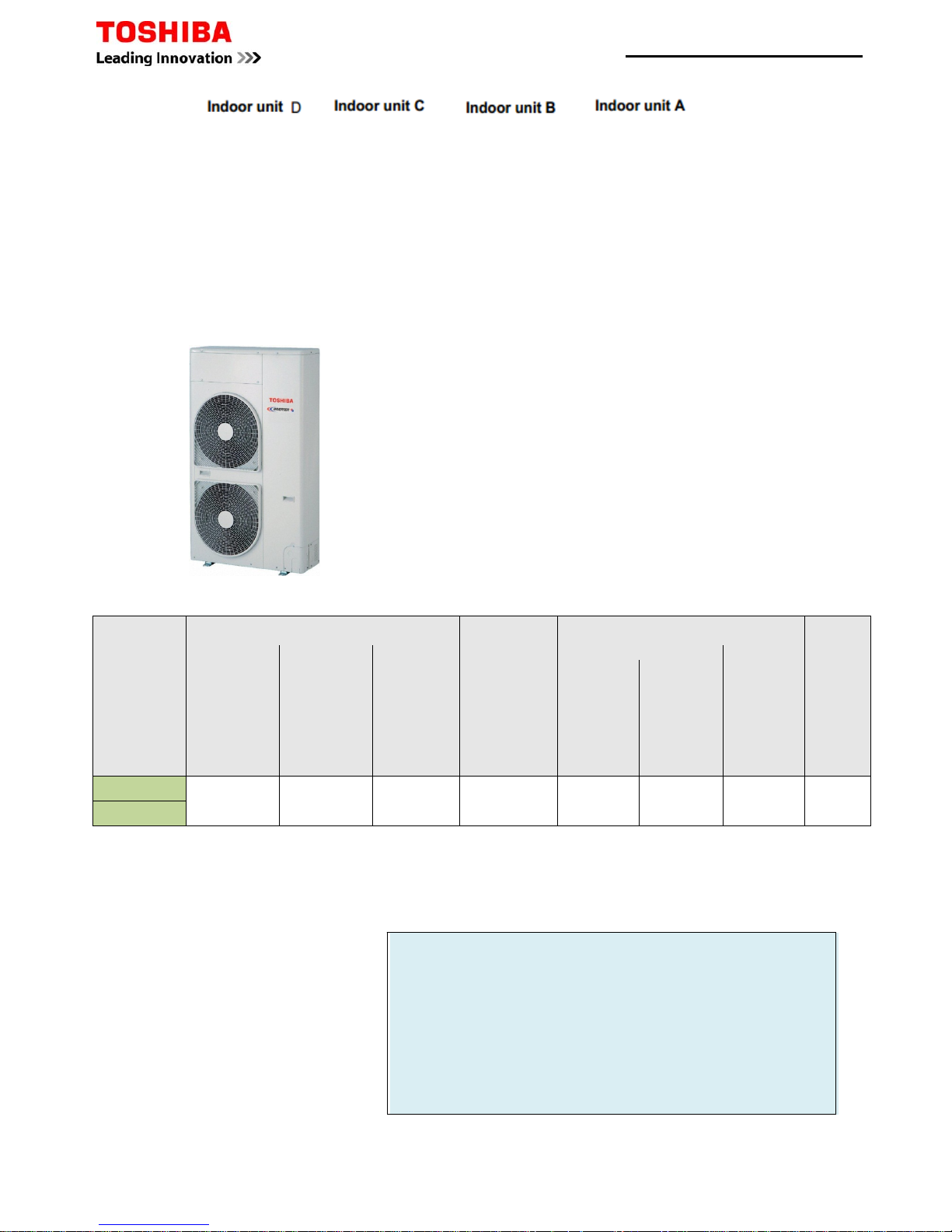

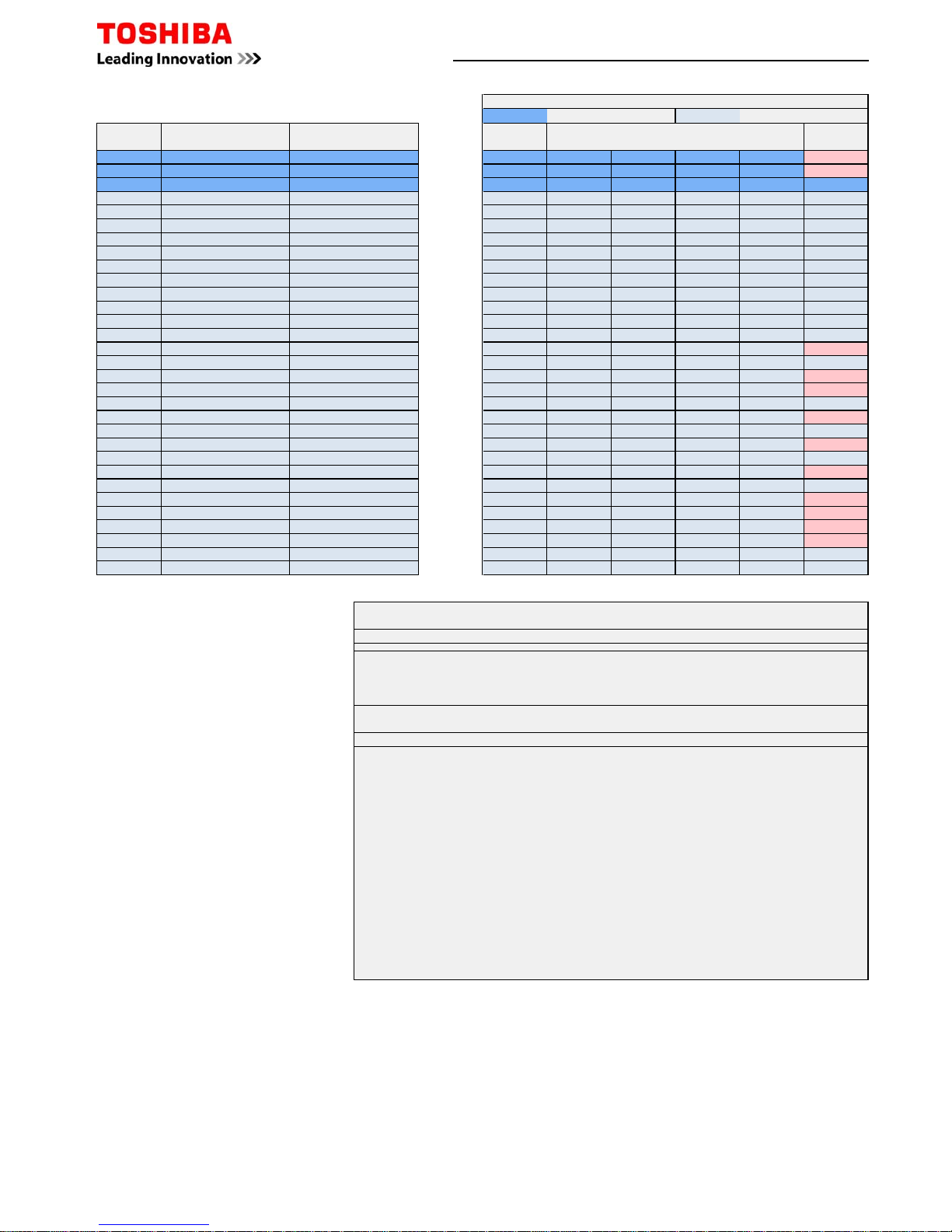

Mechanical Specifications - RAS R410A Outdoor Units

Page 4 of 78

Model

Pipe Sizes

Min/Max

Pipe Sep

(m)

Max

Height

Separation

Pre-

charge

(m)

Add

Charge

(g/m)

Base

Charge

(kg)

Dimensions

(mm)

Weight

(kg)

Liquid Suction

RAS Outdoor Units

RAS-107SAV

-

E6

1/4

3/8 2/15 8 15 N/A 0.63 530x660x240

27

RAS-137SAV

-E630

RAS-167SAV

-E51/2

2/20

10 15

20

1.05

550x780x290

40

RAS-10N3AVP

-

E

3/8

2/25 630x800x300 41

RAS-13N3AVP

-ERAS

-

16N3AVPE

1/2

RAS-10N3AV2

-

E

3/8

2/20 10 15 550x780x290

33

RAS-13N3AV2

-ERAS-16N3AV2

-E1/239RAS

-

M14GVAE

3/8

2/30 10 20

0.90

550x780x290

36

RAS-M18UAV

-

E

1/2

1.20

41

RAS-3M26UAV

-

E

70

15 40

2.40

890x900x320

69

RAS-4M27UAV

-ERAS-5M34UAV

-E180

2.99

75

Performance & Electrical Specifications - RAS R410A Single Splits

Model

Capacity

(kW)

Sensible

Capacity

(kW)

Energy

Rating

Cool/Heat Phase

PowerToSoft

Start

Max

Current

Suggested

Fuse Size

Interconnect

Cable

Cool Heat

RAS Split Systems

RAS-107SAV-E6

2.50 3.20

2.13 A/A

1Ph + N Outdoor Yes

4.19 10

3Core + Earth

RAS-137SAV-E6 3.15 3.60 2.51 A/A 5.37 10

RAS-167SAV-E5 4.87 4.65 3.70 A+/A 7.58 16

RAS-10N3AVP-E

3.30 4.62

2.48 A+++/A+++ 3.42 10

RAS-13N3AVP-E 4.07 4.91 3.05 A++/A+ 4.78 10

RAS-16N3AVP-E

4.50 5.80

3.38 A++/A+ 7.12 16

RAS-10N3AV2-E

3.02 3.60

2.53 A++/A+ 3.60 10

RAS-13N3AV2-E 3.99 4.05 2.79 A++/A 5.66 10

RAS-18N3AV2-E

5.55 4.73

3.89 A+/A 8.79 16

Performance & Electrical Specifications - RAS R410A Multi Splits

Model

Min-Max

Indoors

Capacity (kW)

Energy

Rating

Cool/Heat

Phase

PowerToSoft

Start

Max

Current

Suggested

Fuse Size

Interconnect

Cable

Cool Heat

RAS Multi Systems

RAS-M14GAV-E 1 - 2 1.10 - 4.50 0.90 - 5.20 A+/A

1Ph + N Outdoor Yes

5.47 16

3Core +Earth

RAS-M18UAV-E 2 - 2 1.40 - 6.20 0.90 - 8.30 A++/A++ 7.93 16

RAS-3M26UAV-E 2 - 3 4.10 - 9.00 2.00 - 11.2 A++/A+ 11.37 20

RAS-4M27UAV-E 2 - 4 4.20 - 9.30 3.00 - 11.7 A++/A+ 11.99 20

RAS-5M34UAV-E1 2 - 5 3.70 - 11.0 3.40 - 14.0 A++/A+ 15.22 25

RAS R410A Multi Split System Combinations Examples

Unit 1 Unit 2 Unit 3 Unit 4 Unit 5

10 (1.95kw)

10 (1.95kw)

13 (2.33kw)

10 (1.95kw)

10 (2.55kw)

10 (2.55kw)

13 (2.95kw)

10 (2.15kw)

13 (2.55kw)

13 (2.55kw)

16 (3.19kw)

10 (1.91kw)

16 (2.85kw)

13 (2.35kw)

10 (2.40kw)

10 (2.40kw)

10 (2.40kw)

13 (3.01kw)

10 (2.20kw)

10 (2.20kw)

16 (3.36kw)

10 (2.02kw)

10 (2.02kw)

18 (3.56kw)

10 (1.92kw)

10 (1.92kw)

13 (2.10kw)

13 (2.10kw)

10 (1.98kw)

16 (3.06kw)

13 (2.51kw)

10 (1.83kw)

18 (3.25kw)

13 (2.40kw)

10 (1.50kw)

16 (2.85kw)

16 (2.85kw)

10 (1.10kw)

18 (3.03kw)

16 (2.30kw)

10 (1.64kw)

13 (2.40kw)

13 (2.40kw)

13 (2.40kw)

16 (2.80kw)

13 (2.30kw)

13 (2.30kw)

18 (2.98kw)

13 (2.21kw)

13 (2.21kw)

16 (2.66kw)

16 (2.66kw)

13 (2.19kw)

18 (2.84kw)

16 (2.56kw)

13 (2.10kw)

16 (2.50kw)

16 (2.50kw)

16 (2.50kw)

18 (2.68kw)

16 (2.41kw)

16 (2.41kw)

10 (1.98kw)

10 (1.98kw)

10 (1.98kw)

10 (1.98kw)

13 (2.48kw)

10 (1.81kw)

10 (1.81kw)

10 (1.81kw)

13 (2.28kw)

13 (2.28kw)

13 (1.60kw)

10 (1.60kw)

13 (2.00kw)

13 (2.00kw)

13 (2.00kw)

13 (2.00kw)

16 (2.82kw)

10 (1.69kw)

10 (1.69kw)

10 (1.69kw)

16 (2.61kw)

13 (2.15kw)

10 (1.50kw)

10 (1.50kw)

16 (2.40kw)

13 (2.03kw)

13 (2.03kw)

10 (1.48kw)

16 (2.50kw)

16 (2.50kw)

10 (1.50kw)

10 (1.50kw)

18 (3.02kw)

10 (1.63kw)

10 (1.63kw)

10 (1.63kw)

18 (2.80kw)

13 (2.00kw)

10 (1.51kw)

10 (1.51kw)

18 (2.65kw)

13 (1.96kw)

13 (1.96kw)

10 (1.43kw)

18 (2.68kw)

16 (2.42kw)

10 (1.45kw)

10 (1.45kw)

10 (1.98kw)

10 (1.98kw)

10 (1.98kw)

10 (1.98kw)

10 (1.98kw)

13 (2.53kw)

10 (1.84kw)

10 (1.84kw)

10 (1.84kw)

10 (1.84kw)

13 (2.36kw)

13 (2.36kw)

10 (1.20kw)

10 (1.20kw)

10 (1.20kw)

13 (2.22kw)

13 (2.22kw)

13 (2.22kw)

10 (1.62kw)

10 (1.62kw)

13 (2.09kw)

13 (2.09kw)

13 (2.09kw)

13 (2.09kw)

10 (1.53kw)

13 (2.00kw)

13 (2.00kw)

13 (2.00kw)

13 (2.00kw)

13 (2.00kw)

16 (2.91kw)

10 (1.50kw)

10 (1.50kw)

10 (1.50kw)

10 (1.50kw)

16 (2.61kw)

13 (2.61kw)

10 (1.56kw)

10 (1.56kw)

10 (1.56kw)

16 (2.58kw)

13 (2.12kw)

13 (2.12kw)

10 (1.55kw)

10 (1.55kw)

16 (2.46kw)

13 (2.02kw)

13 (2.02kw)

13 (2.02kw)

10 (1.48kw)

16 (2.33kw)

13 (1.92kw)

13 (1.92kw)

13 (1.92kw)

13 (1.92kw)

16 (2.61kw)

16 (2.61kw)

10 (1.56kw)

10 (1.56kw)

10 (1.56kw)

16 (2.49kw)

16 (2.49kw)

13 (2.04kw)

10 (1.49kw)

10 (1.49kw)

16 (2.36kw)

16 (2.36kw)

13 (1.94kw)

13 (1.94kw)

10 (1.41kw)

18 (3.13kw)

10 (1.69kw)

10 (1.69kw)

10 (1.69kw)

10 (1.69kw)

18 (2.95kw)

13 (2.18kw)

10 (1.59kw)

10 (1.59kw)

10 (1.59kw)

18 (2.80kw)

13 (2.06kw)

13 (2.06kw)

10 (1.50kw)

10 (1.50kw)

18 (2.66kw)

13 (1.90kw)

13 (1.90kw)

13 (1.90kw)

10 (1.44kw)

*** Outdoor Unit will operate with 1 indoor unit connected ***

RAS-3M26UAV-E

7.5 kW

RAS-4M27UAV-E

8.0 kW

RAS-5M34UAV-E1

10.0 kW

Indoor Unit Size & Duty

Outdoor Unit

RAS Multi-Split System Combinations Examples

RAS-M14GAV-E

4.5 kW

RAS-M18UAV-E

5.3 kW

Outdoor Model Type

2 - Room Multi outdoor unit X X X X

2 - Room Multi outdoor unit O O O O

3 - Room Multi outdoor unit O O O O

4 - Room Multi outdoor unit O O O O

5 - Room Multi outdoor unit O O O O

Outdoor Unit Combination of 4-way Air Discharge Cassette

O Combination available, X Combination unavailable

RAS-M14GAV-E

RAS-M18UAV-E

RAS-3M26UAV-E

RAS-4M27UAV-E

RAS-5M34UAV-E1

Acoustic Data

–

RAS Indoor Units

Page 5 of 78

RAS Indoor Units

Model

High

dB(A)

Med

dB(A)

Low

dB(A)

RAS-107SKV-E5

40 35 30

RAS-137SKV-E5

40 34 28

RAS-167SKV-E5

45 40 31

RAS-B10N3KVP-E 43 35 27

RAS-B13N3KVP-E 43 35 27

RAS-B16N3KVP-E

45 38 29

RAS-B10UFV-E

39 32 26

RAS-B13UFV-E

40 33 27

RAS-B18UFV-E 46 40 34

RAS-B10N3KV2-E

39 33 26

RAS-B13N3KV2-E

40 33 26

RAS-B16N3KV2-E

45 40 30

RAS-M10SMUV-E

37 33 30

RAS-M13SMUV-E 38 34 30

RAS-M16SMUV-E 40 37 31

The indoor unit is equipped with an automatic restart facility that allows the unit to restart, at the last set operating conditions, after a power

failure. The operation will resume without warning three minutes after power is restored.

This feature is not set up when these systems are shipped from the factory, therefore it will need to be activated by the installing company.

Generally the process is the same for all RAS products since approx 2001 and is as follows:

To initiate auto restart:

1. Turn the power on. Green On/Off light will flash.

2. Set the system to operate using the remote controller. Green On/Off light will be on constantly.

3. Press and hold down the temporary button for three seconds.

4. The indoor unit will bleep three times to acknowledge set up. In most cases the green light changes to orange.

5. The system will continue to operate during this set up.

6. After set up the system may be stopped using the remote controller.

To cancel auto restart:

1. The system is operating. Green On/Off light will be on constantly.

2. Stop the system operating using the remote controller. Green On/Off light will extinguish.

3. Press and hold down the temporary button for three seconds.

4. The indoor unit will bleep three times to acknowledge cancellation.

5. The system will have stopped operating.

This feature cannot be set if the timer is in operation.

The louver will not swing, if it was previously set, when the system auto restarts.

Fault Codes – RAS “N” Series

Do Not turn off the power supply before reading the fault codes, doing so will clear the diagnostic memory. Caution

must be taken when removing the access covers as high voltages are present.

Fault codes are displayed through the LEDs flashing at 5 times per second. Note, the green LED will flash once per

second when the system is initially powered.

More specific codes may be obtained, while in the fault mode through the wireless controller

1. Press CHK to enter service mode

2. Navigate through TIMER buttons until all LEDs flash, accompanied by the internal buzzer – compare the

displayed code with the table below

3. Press CLR button to clear the existing fault code (controller displays 7F)

4. Press ON/OFF button to exit service mode.

Initial

code/display

Code Description

01

0C

TA sensor open or short circuit

0d

TC sensor open or short circuit

11

Indoor fan motor problem

12

Indoor PCB problem

01

04

Indoor to outdoor communication (includes compressor thermostat)

05

Indoor to outdoor communication

02

14

Inverter low voltage or short circuit protection

16

Compressor position circuit

17

Compressor current detected during off-cycle

18

TE or TS sensor open or short circuit

19

Td sensor open or short circuit

1A

Outdoor fan motor problem

1b

TE sensor fault

1C

Compressor drive circuit

03

07

Indoor to outdoor communication (includes compressor thermostat)

08

Indoor heat exchanger changes temperature – but in wrong direction

1d

Compressor locked rotor current protection

1E

Compressor - high discharge temperature

1F

Compressor current remains too high – after current release

RAS – Auto Restart Function

Page 6 of 78

Page 7 of 78

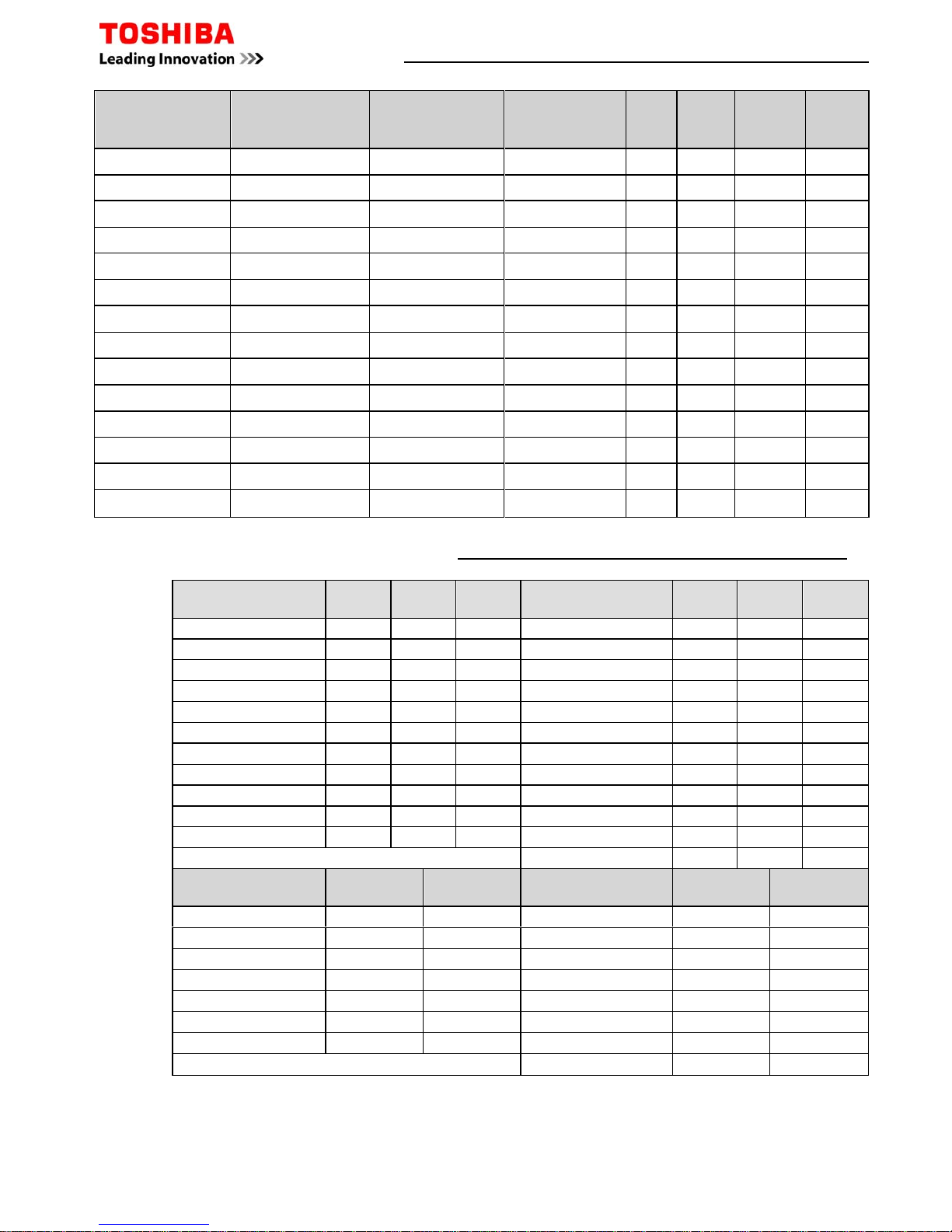

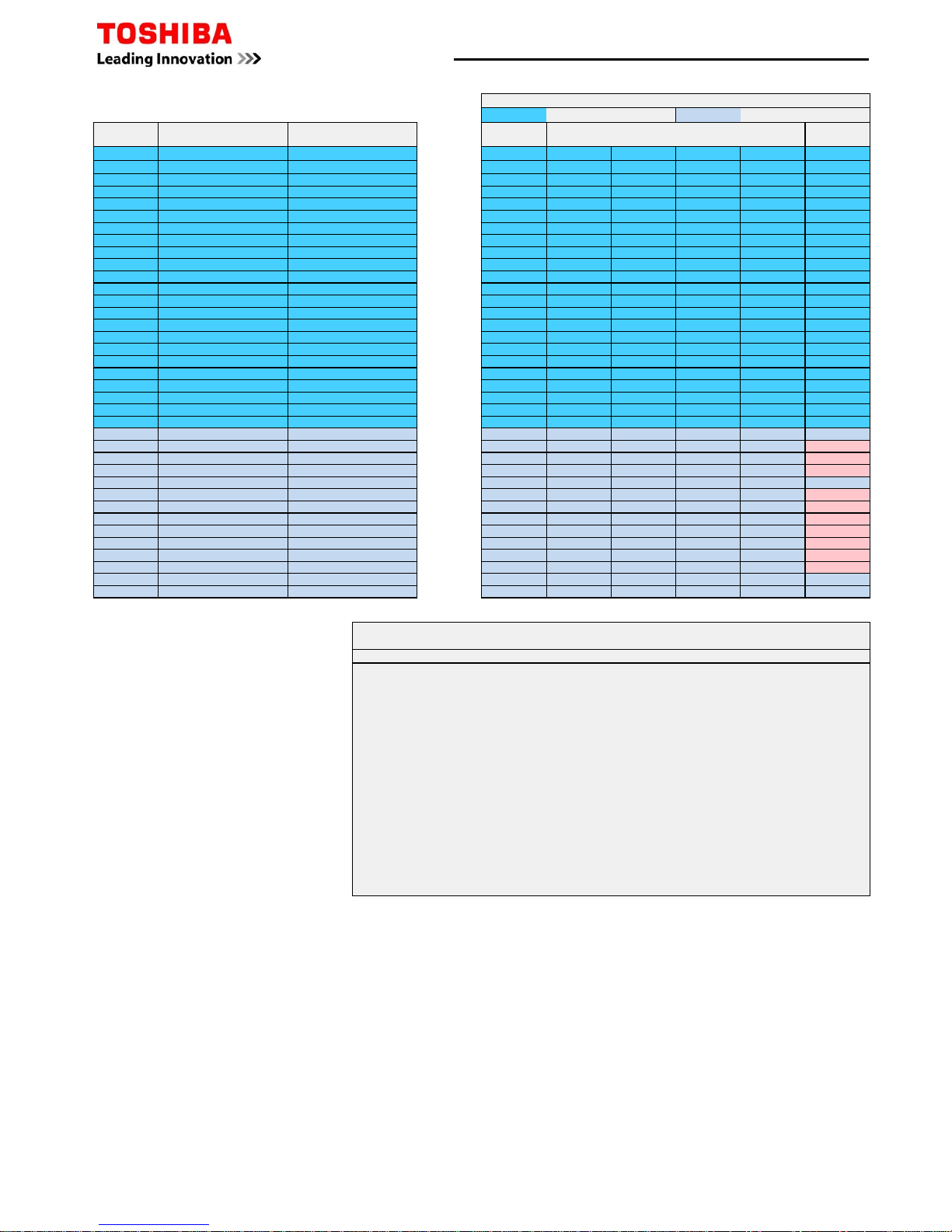

Mechanical Specifications - DI / SDI R410A Single Splits

Model

Pipe Sizes

Min/Max

Pipe Sep

(m)

Max

Height

Separation

Pre-

charge

(m)

Add

Charge

(g/m)

Base

Charge

(kg)

Dimensions

(mm)

Weight

(kg)

Liquid Suction

Commercial Range

RAV-SM564ATP-E

1/4 1/2

5/30

30

20

20 1.0 550x780x290 40

RAV-SM804ATP-E

3/8 5/8

40 1.7 550x780x290 44

RAV-SM1104ATP-E

5/50

30

40 2.8 890x900x320 68

RAV-SM1404ATP-E

40 2.8 890x900x320 68

RAV-SM1603AT-E

40 3.1 1340x900x320 99

RAV-SM2244AT8-E

1/2 1 1/8

7.5/70 80 5.9 1540x900x320 134

RAV-SM2804AT8-E

RAV-SP404ATP-E

1/4 1/2

5/30

20

20 1.0 550x780x290 40

RAV-SP564ATP-E

5/50

20 1.4 550x780x290 44

RAV-SP804ATP-E

3/8 5/8

30

40 2.1 890x900x320 63

RAV-SP1104AT-E

3/75

40 3.1 1340x900x320 93

RAV-SP1404AT-E

40 3.1 1340x900x320 93

RAV-SP1104AT8-E

3/75

40 3.1 1340x900x320 95

RAV-SP1404AT8-E

40 3.1 1340x900x320 95

RAV-SP1604AT8-E

40 3.1 1340x900x320 95

Performance & Electrical Specifications - DI / SDI R410A Single Splits

Model

Capacity kW

Ambient

Range °C

Energy

Rating

Cool/Heat

Phase

Power

To

Soft

Start

Max

Current

Suggested

Fuse Size

Interconnect

Cable

Cool Heat Cool Heat

Commercial Range

RAV-SM564ATP-E

5.00 5.30

46 to -15 15 to -15

A/A

1Ph + N

Outdoor Yes

8.95

16

3Core + Earth

RAV-SM804ATP-E

6.70 7.70 A/A 11.43 16

RAV-SM1104ATP-E

10.00 11.20 A/A 15.18

20

RAV-SM1404ATP-E

12.00 12.80

A/A

21.30 32

RAV-SM1603AT-E

14.00 16.00 B/A 23.90 32

RAV-SM2244AT8-E

20.00 22.40

46 to -20 15 to -20

D/B

3Ph + N

18.00 16

RAV-SM2804AT8-E

23.00 27.00

D/C

20.00 20

RAV-SP404ATP-E

3.60 4.00 43 to -15 15 to -15

A/A

1Ph + N

15.00 10

RAV-SP564ATP-E

5.30 5.60

43 to -15 15 to -20

A/A 13.30

16

RAV-SP804ATP-E

7.10 8.00 A/A 20.30

RAV-SP1104AT-E

10.00 11.20 A/A 20.50

RAV-SP1404AT-E

12.50 14.00 A/A 20.50 25

RAV-SP1104AT8-E

10.00 11.20

46 to -15 15 to -20

A/A

3Ph + N

14.70 10

RAV-SP1404AT8-E

12.50 14.00 A/A 14.70

16

RAV-SP1604AT8-E

14.00 16.00 B/A 14.70

Electrical Specifications - DI / SDI R410A Multi Splits

Page 8 of 78

Model Outdoor Twin Indoor Triple Indoor Quad Indoor Phase

Power

To

Suggested

Fused Size

Inter-

Connecting

Cable

RAV-SM80ATP-E RAV-SM40*T(P)-E

N/A N/A 1Ph-N Outdoor 16 3C+E

RAV-SM1104ATP-E RAV-SM56*T(P)-E N/A N/A

1Ph-N Outdoor 20 3C+E

RAV-SM1404ATP-E RAV-SM80*T(P)-E

N/A N/A 1Ph-N Outdoor 32 3C+E

RAV-SM1603AT-E RAV-SM80*T(P)-E RAV-SM56*T(P)-E

N/A 1Ph-N Outdoor 32 3C+E

RAV-SM2244AT8-E RAV-SM110*T(P)-E RAV-SM80*T(P)-E RAV-SM56*T(P)-E

3Ph-N Outdoor 16 3C+E

RAV-SM2244AT8-E RAV-SM110*T(P)-E RAV-SM80*T(P)-E RAV-SM56*T(P)-E

3Ph-N Outdoor 16 3C+E

RAV-SM2804AT8-E RAV-SM140*T(P)-E RAV-SM80*T(P)-E RAV-SM80*T(P)-E

3Ph-N Outdoor 20 3C+E

RAV-SM2804AT8-E RAV-SM140*T(P)-E RAV-SM80*T(P)-E RAV-SM80*T(P)-E

3Ph-N Outdoor 20 3C+E

RAV-SP804ATP-E RAV-SM40*T(P)-E

N/A N/A 1Ph-N Outdoor 16 3C+E

RAV-SP1104AT-E RAV-SM56*T(P)-E N/A N/A

1Ph-N Outdoor 16 3C+E

RAV-SP1104AT8-E RAV-SM56*T(P)-E

N/A N/A 3Ph-N Outdoor 10 3C+E

RAV-SP1404AT-E RAV-SM80*T(P)-E

N/A N/A 1Ph-N Outdoor 25 3C+E

RAV-SP1404AT8-E RAV-SM80*T(P)-E N/A N/A

3Ph-N Outdoor 16 3C+E

RAV-SP1604AT8-E RAV-SM80*T(P)-E RAV-SM56*T(P)-E

N/A 3Ph-N Outdoor 16 3C+E

Acoustic Data – DI/SDI Indoor/Outdoor Units

Model Indoor

High

dB(A)

Med

dB(A)

Low

dB(A)

Model Indoor

High

dB(A)

Med

dB(A)

Low

dB(A)

RAV-SM562KRT-E

54 51 48

RAV-SM566BT-E

33 29 25

RAV-SM806KRT-E

60 56 51

RAV-SM806BT-E

34 30 26

RAV-SM564UTP-E

32 29 28

RAV-SM1106BT-E

40 36 33

RAV-SM804UTP-E

35 31 28

RAV-SM1406BT-E

40 36 33

RAV-SM1104UTP-E

58 53 48

RAV-SM1606BT-E

40 36 33

RAV-SM1404UTP-E

44 38 34

RAV-SM567CTP-E

37 35 28

RAV-SM1604UTP-E

45 40 36

RAV-SM807CTP-E

41 36 29

RAV-SM404MUT-E

55 51 46

RAV-SM1107CTP-E

44 38 32

RAV-SM564MUT-E

55 51 46

RAV-SM1407CTP-E

46 41 35

RAV-SM404SDT-E

39 36 33

RAV-SM1607CTP-E

46 41 35

RAV-SM564SDT-E

45 40 36

RAV-SM2242DT-E

54 - -

RAV-SM2802DT-E

55 - -

Model Outdoor

Cooling

dB(A)

Heating

dB(A)

Model Outdoor

Cooling

dB(A)

Heating

dB(A)

RAV-SM564ATP-E

46 48

RAV-SP404ATP-E

45 47

RAV-SM804ATP-E

48 52

RAV-SP564ATP-E

47 48

RAV-SM1104ATP-E

53 54

RAV-SP804ATP-E

48 49

RAV-SM1404ATP-E

54 55

RAV-SP1104AT-E

49 50

RAV-SM1603AT-E

51 53

RAV-SP1404AT-E

51 52

RAV-SM2244AT8-E

56 57

RAV-SP1104AT8-E

49 50

RAV-SM2804AT8-E

57 58

RAV-SP1404AT8-E

51 52

RAV-SP1604AT8-E

51 53

Page 9 of 78

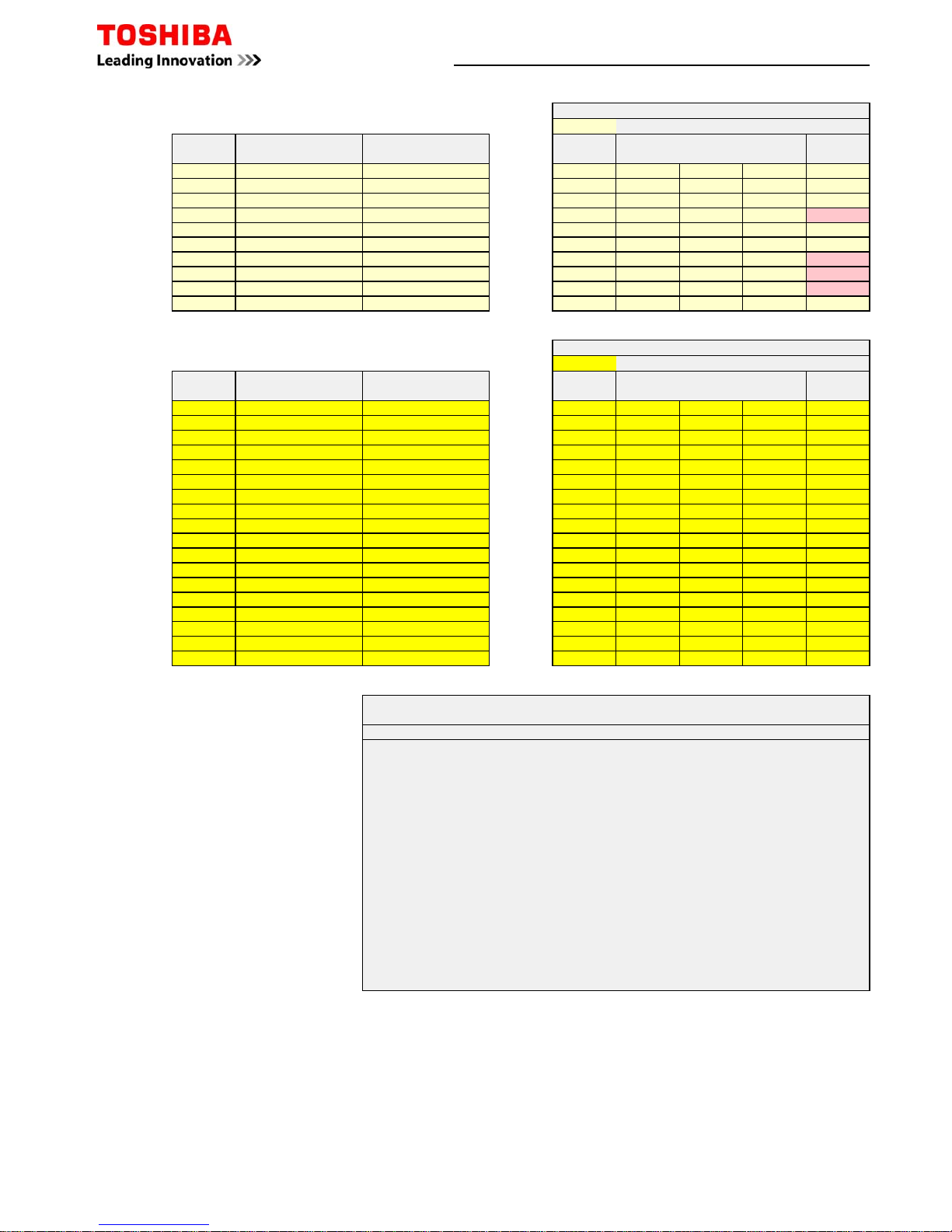

Mechanical & Electrical Data - Air-to-Air Heat Exchangers

Model

(Standard)

Power

Consumption

Low/High (W)

(L/H) Air

Volume

(m³/hr)

Static

Pressure

(Pa)

Dimensions Weight

(kg)

Duct

(mm)

1-ph+n

Fuse

Size

VN-M150HE 42 - 78 110 - 150 47 -102 900x900x290 36 100 3

VN-M250HE 52 - 138 155 - 250 28 - 98 900x900x290 36 150 3

VN-M350HE 82 - 182 210 - 350 65 -125 900x900x290 38 150 3

VN-M500HE 128 - 238 390 - 500 62 -150 1140x1140x350 53 200 3

VN-M650HE 178 - 290 520 - 650 61 -107 1140x1140x350 53 200 5

VN-M800HE 286 - 383 700 - 800 76 -158 1189x1189x400 70 250 5

VN-M1000HE 353 - 569 755 - 1000 84 -150 1189x1189x400 70 250 5

VN-M1500HE 570 - 786 1200 - 1500 112 -156 1189x1189x810 143 250 13

VN-M2000HE 702 - 1154 1400 - 2000 110 -143 1189x1189x810 143 250 13

Model

(DX Coil)

Capacity

Power

Consumption

Low/High (W

)

(L/H) Air

Volume

(m³/hr)

Static

Pressure

(Pa)

Dimensions Weight

(kg)

Duct

(mm)

1ph+n

Fuse

Size

Cool Heat

MMD-VN502HEXE 4.10 5.53

235 - 300 440 - 500 115 - 120 430x1140x1690 84 200 3

MMD-VN802HEXE 6.56 8.61 335 - 505 640 - 800 105 - 120 430x1189x1739 100 250 3

MMD-VN1002HEXE 8.25 10.90 485 - 550 820 - 950 105 - 135 430x1189x1739 101 250 3

Model

(DX Coil & Humidifier)

Capacity

Humidifier

(Kg/hr)

Power

Consumption

Low/High (W

)

(L/H) Air

Volume

(m³/hr)

Static

Pressure

(Pa)

Dimensions

Weight

(kg)

Duct

(mm)

1ph+n

Fuse

Size

Cool Heat

MMD-VNK502HEXE 4.10 5.53

3.0 240 - 305 440 - 500 85 - 95 430x1140x1690 91 200 3

MMD-VNK802HEXE 6.56 8.61 5.0 350 - 530 640 - 800 85 - 105 430x1189x1739

111 250 3

MMD-VNK1002HEXE 8.25 10.90 6.0 520 - 575 820 - 950 90 - 115 430x1189x1739

112 250 5

H x W* x D

H x W* x D

H x W* x D

* Width dimension excludes 200mm electrical box

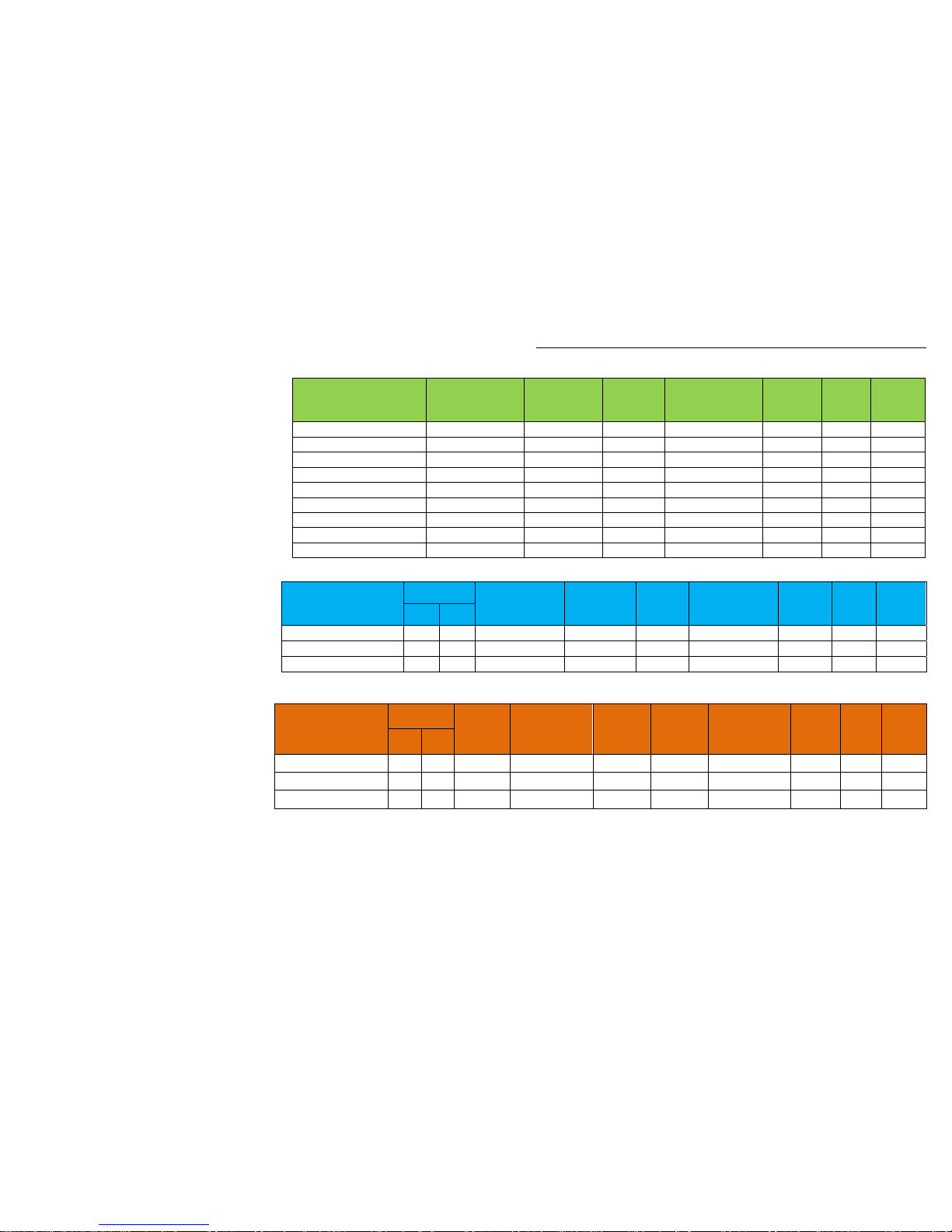

Digital/Super Digital R410A Replacement Technology Refrigerant Pipe Sizing

Length Pre-charged Length Pre-charged Length Pre-charged Length Pre-charged Length Pre-charged

m m m m m m m m m m

SP40430203020302020102010

SP45430203020302020102010

SP5645020502020102010

DI Series 3

SM5635020502020102010

Length Pre-charged Length Pre-charged Length Pre-charged Length Pre-charged Length Pre-charged Length Pre-charged Length Pre-charged

m m m m m m m m m m m m m m

SP80430203020503050305030

SP11047530753025152515

SP14047530753025152515

SM804

202020203020302030

20

SM1104

50305030251525

15

SM1404

50305030251525

15

SM1604

50305030251525

15

Length Pre-charged Length Pre-charged Length Pre-charged Length Pre-charged

m m m m m m m m

SM2244

70307030502050

20

SM2804

70307030502050

20

Performance capacity is reduced due to the effect of gas pipe size being smaller than standard connection

Normal Pipe Sizes

Not Compatible

5/8 - 15.9 (1-size larger) 1/2 - 12.7 (STD) 5/8 - 15.9 (1-size larger)

1/4 - 6.4 (STD) 3/8 - 9.5 (1-size large)

3/8 - 9.5 (1-size smaller) 1/2 - 12.7 (STD)

1/2 - 12.7 (1-size smaller) 5/8 - 15.9 (STD) 1/2 - 12.7 (1-size smaller)

Maximum Pipe Distance

SDI Series 4

1/4 - 6.4 (1-size smaller) 3/8 - 9.5 (STD)

5/8 - 15.9 (STD) 3/4 - 19.1 (1-size larger) 5/8 - 15.9 (STD) 3/4 - 19.1 (1-size larger)

1/2 - 12.7 (1-size larger)

7/8 - 22.2 (1-size smaller) 1 1/8 - 28.6 (STD) 7/8 - 22.2 (1-size smaller) 1 1/8 - 28.6 (STD)

Maximum Pipe Distance

SDI Series 4

DI Series 4

Liquid Pipe Size inch" or mm 1/2 - 12.7 (STD) 5/8 - 15.9 (1-size larger)

SDI Series 4

Gas Pipe Size inch" or mm

Liquid Pipe Size inch" or mm

Liquid Pipe Size inch" or mm

Gas Pipe Size inch" or mm

Maximum Pipe Distance

Gas Pipe Size inch" or mm

Applicable Refrigerants

Existing Plant

R22

R407C

R417A

R404A

R134a

R12

Page 10 of 78

Digital / Super Digital Inverter Multi Split System Combinations

Page 11 of 78

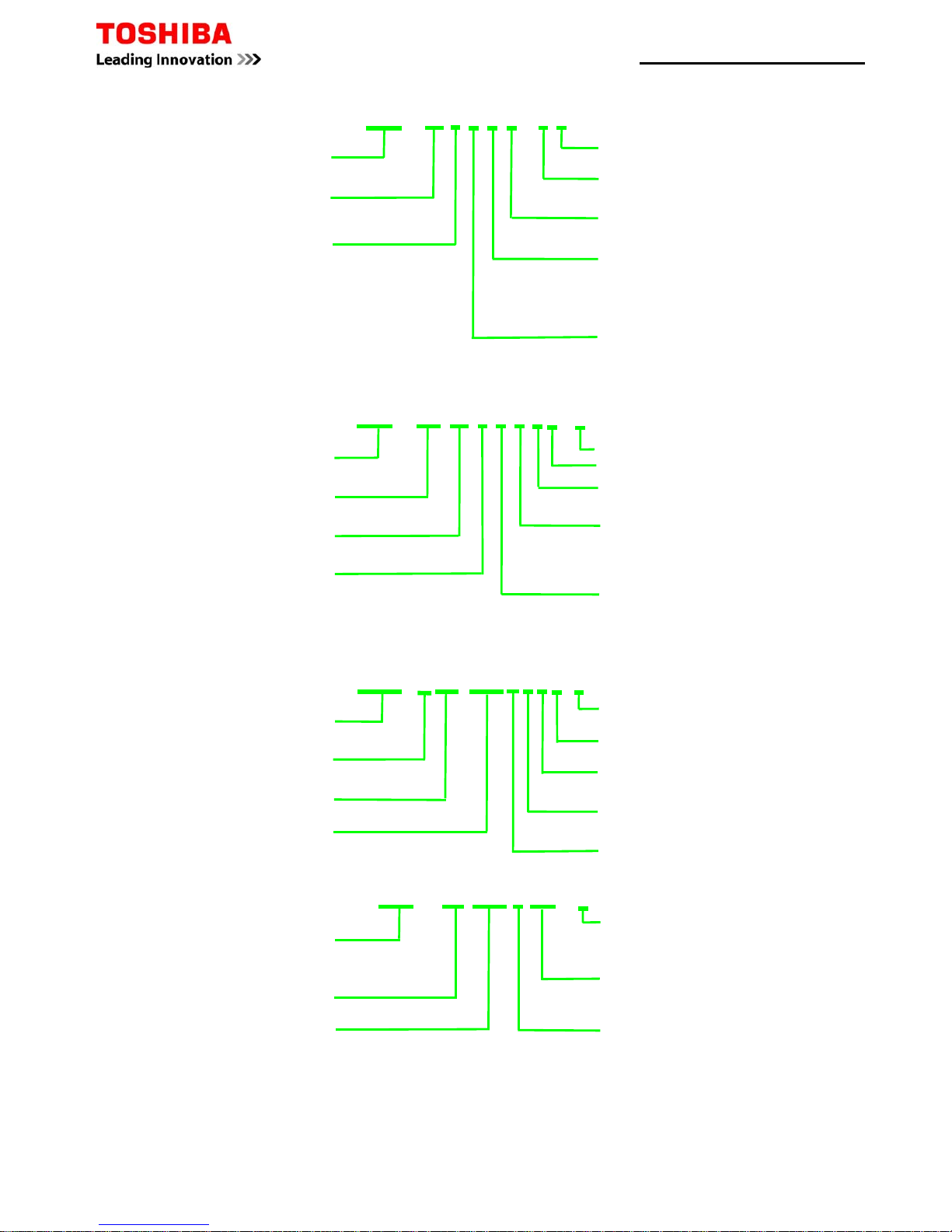

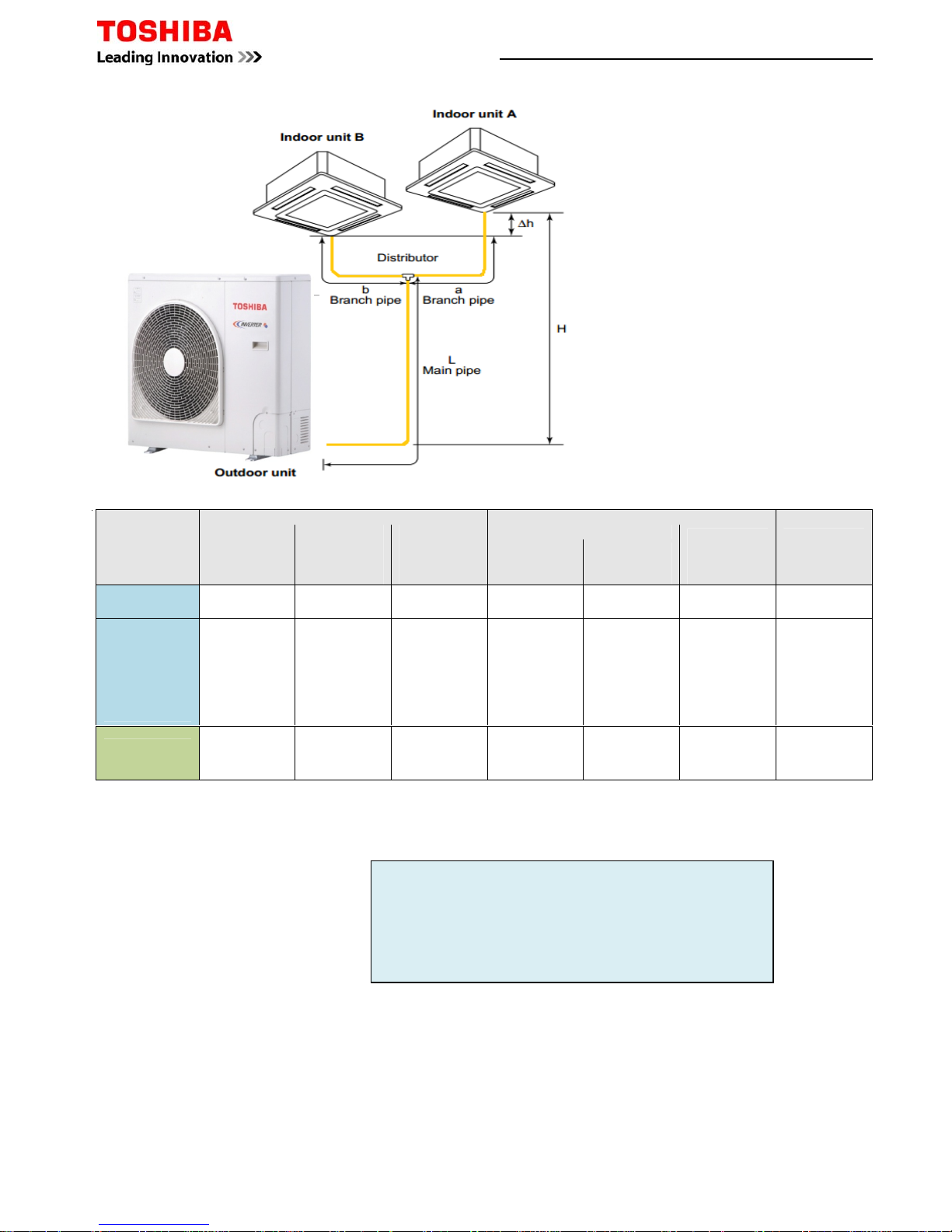

Twin Split Systems

1 x Outdoor Unit

2 x Indoor Units

RAV-SM804ATP-E

RAV-SP804ATP-E

RA V - SM 4 04M UT -E

RA V - SM 4 04SDT -E

RA V - SM 4 06B T -E

RAV-SM1104ATP-E

RAV-SP1104AT-E

RAV-SP1104AT8-E

RA V - SM5 6 4 U T P-E

RA V - SM5 6 4 M U T -E

RA V - SM5 6 7 C T P-E

RA V - SM5 6 6 B T - E

RA V - SM5 6 4 S D T -E

RA V - SM5 6 6 K R T -E

RAV-SM1404ATP-E

RAV-SP1404AT-E

RAV-SP1404AT8-E

RAV-SM804UTP-E

RAV-SM807CTP-E

RAV-SM806BT-E

RAV-SM806KRT-E

RAV-SM1603AT-E

RAV-SP1604AT8-E

RA V - SM8 0 4 U T P-E

RA V - SM8 0 7 C T P-E

RA V - SM8 0 6 B T - E

RA V - SM8 0 6 K R T -E

RAV-SM2244AT8-E

RAV-SM1107CTP-E

RAV-SM1104UTP-E

RAV-SM1106BT-E

RAV-SM2804AT8-E

RAV-SM1407CTP-E

RAV-SM1404UTP-E

RAV-SM1406BT-E

Triple Split Systems

1 x Outdoor Unit

3 x Indoor Units

RAV-SM1603AT-E

RAV-SP1604AT8-E

RA V - SM 5 6 4 U T P- E

RA V - SM 5 6 4 MU T -E

RA V - SM 5 6 7 CT P- E

RA V - SM 5 6 6 B T -E

RA V - SM 5 6 4 SD T -E

RA V - SM 5 6 6 K R T -E

RAV-SM2244AT8-E

RA V - SM 8 0 4 U T P- E

RA V - SM 8 0 4 B T -E

RA V - SM 8 0 7 CT P- E

RA V - SM 8 0 6 K R T -E

RAV-SM2804AT8-E

RA V - SM 8 0 4 U T P- E

RA V - SM 8 0 6 B T -E

RA V - SM 8 0 7 CT P- E

RA V - SM 8 0 6 K R T -E

Quad Split Systems

1 x Outdoor Unit

4 x

Indoor Units

RAV-SM2244AT8-E

RA V - SM 5 6 4 U T P- E

RA V - SM 5 6 4 MU T -E

RA V - SM 5 6 7 CT P- E

RA V - SM 5 6 6 B T -E

RA V - SM 5 6 4 SD T -E

RA V - SM 5 6 6 K R T -E

RAV-SM2804AT8-E

RA V - SM 8 0 4 U T P- E

RA V - SM 8 0 7 CT P- E

RA V - SM 8 0 6 B T -E

RA V - SM 8 0 6 K R T -E

Pipe Specifications

*

Total length of pipe between furthest indoor and outdoor unit.

†

Maximum distance of Branch pipe from main pipe distributor to furthest indoor unit.

‡

Maximum subtractive distance between pipe branches. Example: -

Example 1

Installed length main pipe L to distributor=38m

Installed length branch a=12m

Installed length branch b=10m

Example 2

Installed length main pipe L to distributor=40m

Installed length branch a=14m

Installed length branch b=2m

Example 1

Total pipe length L + a 38 + 12= 50m

Subtractive pipe length a – b 12 - 10= 2m

Example 2

Total pipe length L + a 40 + 14= 64m

Subtractive pipe length a – b 14 - 2= 12m

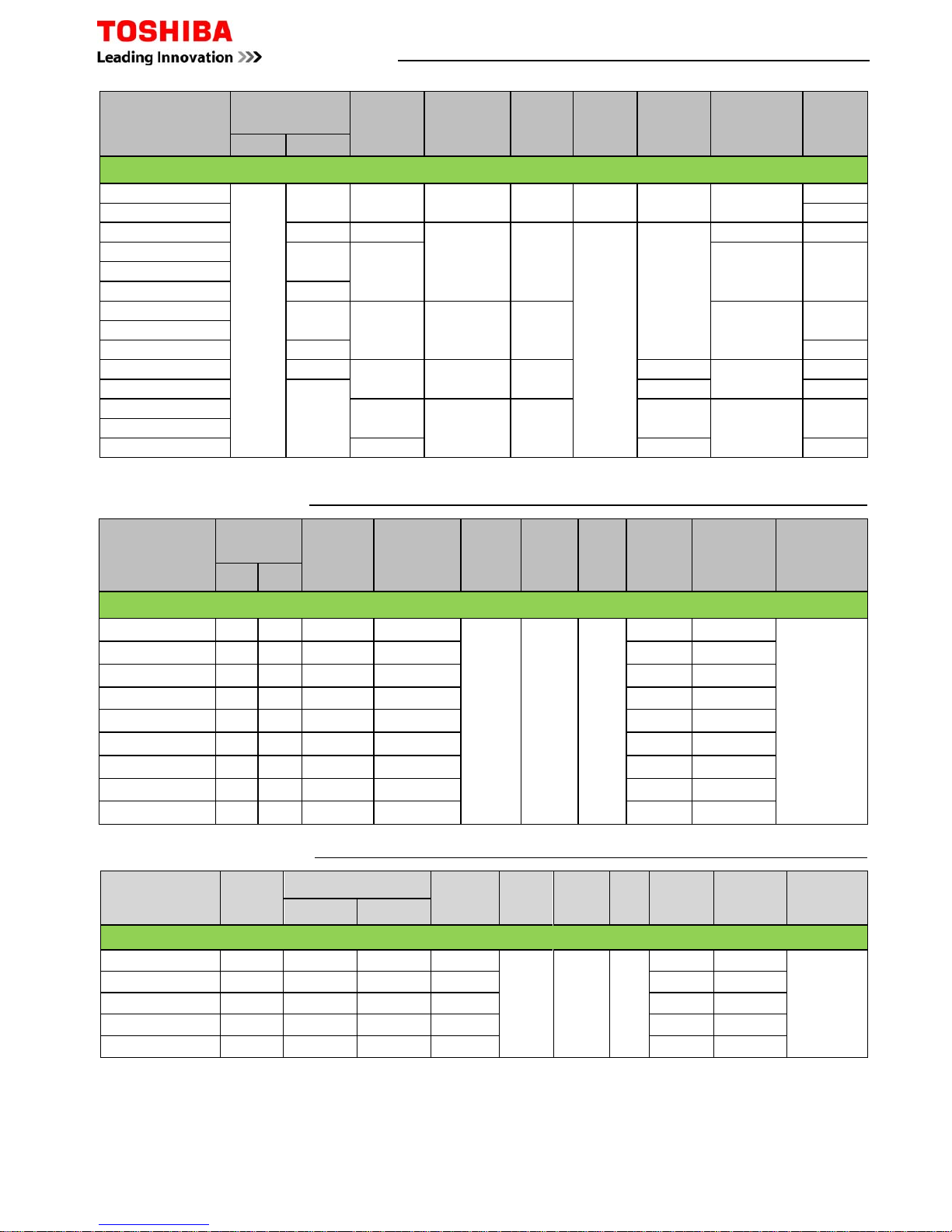

Digital / Super Digital Inverter Twin Splits

Model

(RAV-)

Allowable Piping Length (m)

Height Difference

(m)

Number of

Bent Portions

Maximum

or Less

*Total Length

(L+a or L+b)

Maximum

†Branch Piping

a or b to

Furthest Indoor

Maximum

‡Subtractive

Piping Length

a-b or b-a

Maximum

Indoor Unit

-

Outdoor Unit (H)

Indoor Unit

Height

Difference (Δh)

Maximum

Outdoor Unit

Higher

Maximum

Indoor Unit

Higher

Maximum

SM804ATP-E 30 10 5 30 30 0.5 10

SM1104ATP-E

SM1404ATP-E

SM1603AT-E

SP804ATP-E

SP1104AT(8)-E

SP1404AT(8)-E

SP1604AT8-E

50 15 10 30 30 0.5 10

SM2244AT8-E

SM2804AT8-E

70 20 10 30 30 0.5 10

Page 12 of 78

Example 3

Installed length main pipe L to distributor=50m

Installed length branch a=12m

Installed length branch b=10m

Example 4

Installed length main pipe L to distributor=60m

Installed length branch a=14m

Installed length branch b=2m

Additional Charge

Example 1

Installed length main pipe L to distributor=38m

Installed length branch a=12m

Installed length branch b=10m

Model

(RAV-)

Main Pipes Branch Pipes

Sizes (“)

Gas/Liquid

Pre-charge (m)

Add Amount

(kg/m) – [ ]

Sizes (“)

Gas/Liquid

Pre-charge (m)

Add Amount

(kg/m) – [ ß ]

SM804ATP-E

5/8 - 3/8 18 0.040 1/2 - 1/4 2 0.020

SP804ATP-E

SM1104ATP-E

5/8 - 3/8 18 0.040 1/2 - 1/4 2 0.020

SP1104AT(8)-E

SM1404ATP-E

5/8 - 3/8 18 0.040 5/8 - 3/8 2 0.040

SP1404AT(8)-E

SM1603AT-E

5/8 - 3/8 28 0.040 5/8 - 3/8 2 0.040

SP1604AT8-E

SM2244AT8-E

1 1/8 - 1/2 28 0.080 5/8 - 3/8 4 0.040

SM2804AT8-E

Gas calculation - [Main pipe] (L-18) x + [Branch Pipe] (a+b - 4) x ß = additional charge

Gas calculation - [Main pipe] (L-28) x + [Branch Pipe] (a+b - 4) x ß= additional charge

Example 1 using SM1104ATP-E

Total pipe length L - 18 x

38 - 18 =20 x 0.040= 0.80 +

Branch pipe length a + b x ß 12 + 10 - 4 =18 x 0.020= 0.36

Add Amount 1.16 kg

Example 3

Total pipe length L + a 50 + 12= 62m

Subtractive pipe length a – b 12 - 10= 2m

Example 4

Total pipe length L + a 60 + 14= 74m

Subtractive pipe length a – b 14 - 2= 12m

Example 1 using SM2804AT8-E

Total pipe length L - 28 x

38 - 28 =10 x 0.080= 0.80 +

Branch pipe length a + b x ß 12 + 10 - 4 =18 x 0.040= 0.72

Add Amount 1.52 kg

Page 13 of 78

Factor

Factor

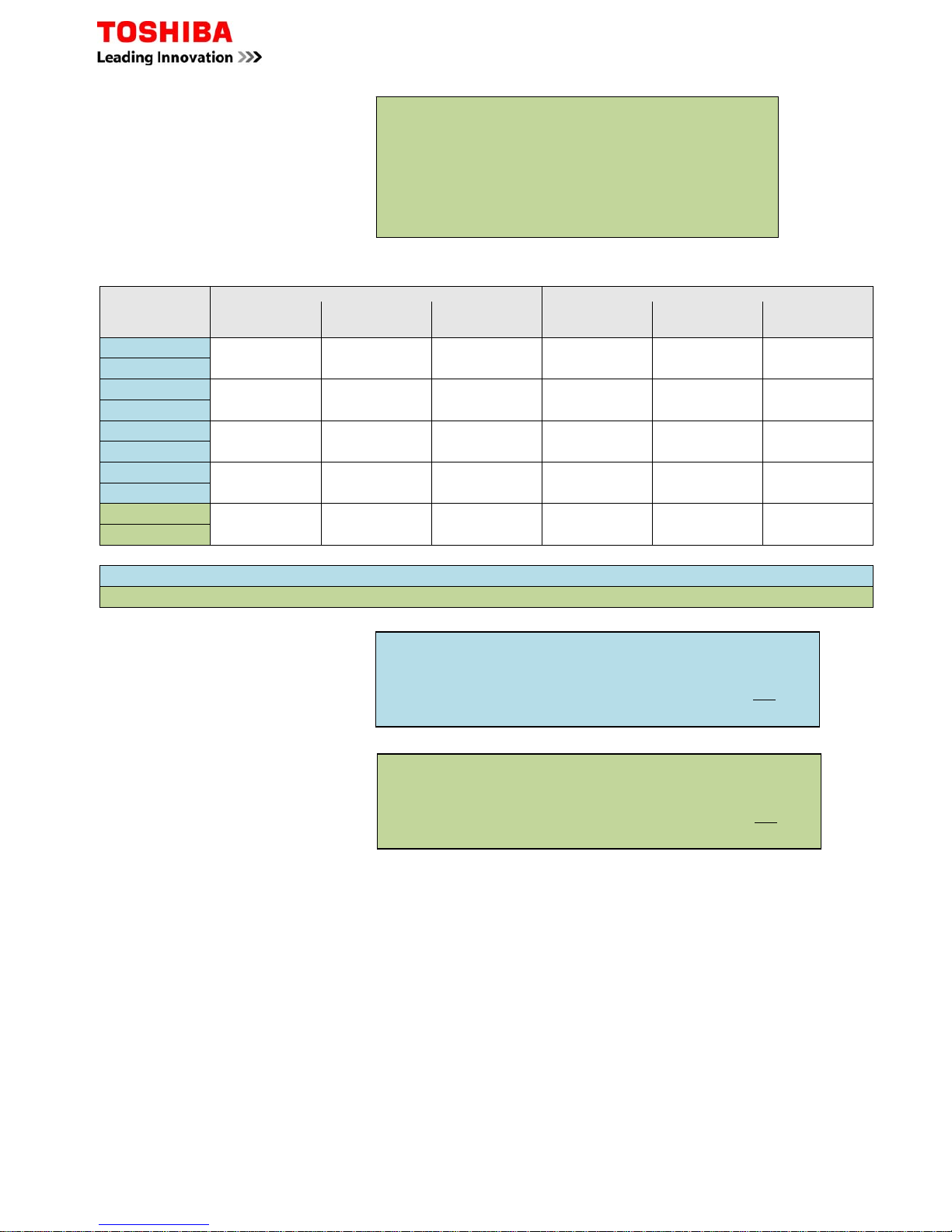

Pipe Specifications

Model (RAV-)

Allowable Piping Lengths (m) Height Difference (m)

Number of

Bent portions

Maximum

or Less

*

Total Length

La + Lb

La + Lc

Maximum

†

Branch Piping

La, Lb or Lc to

Furthest Indoor

Maximum

‡

Subtractive

Piping Length

Lb - La

Lb - Lc

Maximum

Indoor Unit - Outdoor Unit (H)

Indoor Unit

Height

Difference (∆h)

Maximum

Outdoor Unit

Higher

Maximum

Indoor Unit

Higher

Maximum

SM1603AT-E

50 15 10 30 30 0.5 10

SP1604AT8-E

SM2244AT8-E

70 20 10 30 30 0.5 10

SM2804AT8-E

*

Total length of pipe between furthest indoor and outdoor unit.

†

Maximum distance of Branch pipe from main pipe distributor to furthest indoor unit.

‡

Maximum subtractive distance between pipe branches. Example: -

Example 1

Installed length main pipe L to distributor=38m

Installed length branch a=12m

Installed length branch b=10m

Installed length branch c=12m

Example 2

Installed length main pipe L to distributor=40m

Installed length branch a=15m

Installed length branch b=4m

Installed length branch c=12m

Example 1

Total pipe length L + a 38 + 12= 50m

Subtractive pipe length a – b 12 - 10= 2m

Subtractive pipe length c – b 12 - 10= 2m

Example 2

Total pipe length L + a 40 + 15= 55m

Subtractive pipe length a – b 15 - 4= 11m

Subtractive pipe length c – b 12 - 4= 8m

Digital / Super Digital Inverter Triple Splits

Page 14 of 78

Example 3

Installed length main pipe L to distributor=40m

Installed length branch a=12m

Installed length branch b=12m

Installed length branch c=10m

Example 4

Installed length main pipe L to distributor=50m

Installed length branch a=20m

Installed length branch b=3m

Installed length branch c=5m

Additional Charge

Model (RAV-)

Main Pipes Branch Pipes

Sizes (“)

Gas/Liquid

Pre-charge (m)

Add Amount

(kg/m) – [ ]

Sizes (“)

Gas/Liquid

Pre-charge (m)

Add Amount

(g/m) – [ ß ]

SM1603AT-E

5/8 – 3/8 28 0.040 5/8 – 3/8

6 0.040

SP1604AT8-E

SM2244AT8-E

1 1/8 – 1/2 28 0.080 5/8 – 3/8 6 0.040

SM2804AT8-E

Gas calculation - [Main pipe] (L-28) x + [Branch Pipe] (a+b+c - 6) x ß = additional charge

Gas calculation - [Main pipe] (L-28) x + [Branch Pipe] (a+b+c - 6) x ß= additional charge

Example 1

Installed length main pipe L to distributor=38m

Installed length branch a=12m

Installed length branch b=10m

Installed length branch c=12m

Example 3

Total pipe length L + a 40 + 12= 52m

Subtractive pipe length a – b 12 - 12= 0m

Subtractive pipe length c – b 12 - 10= 2m

Example 4

Total pipe length L + a 50 + 20= 70m

Subtractive pipe length a – b 20 - 3= 15m

Subtractive pipe length c – b 5 - 3= 2m

Example 1 above using SM1603AT-E

Total pipe length L - 28 x

38 - 28 =10 x 0.040= 0.40 +

Branch pipe length a + b + c x ß 12+10+ 12- 6 =28 x 0.040= 1.12

Add Amount 1.52 kg

Example 1 above using SM2804AT8-E

Total pipe length L - 28 x

38 - 18 =20 x 0.080= 0.80 +

Branch pipe length a + b + c x ß 12+10+ 12- 6 =28 x 0.040= 1.12

Add Amount 1.92 kg

Page 15 of 78

Factor

Factor

Example 1

Total pipe length L + b + c 20 + 10 + 5= 35m

Branch length b + d 10 + 5= 15m

Branch length a + e 10 + 5= 15m

Branch length a + f 10 + 5= 15m

Subtractive pipe length c+b - d+b 5+10 - 5+10= 0m

Subtractive pipe length c+b - e+a 5+10 - 5+10= 0m

Subtractive pipe length c+b - f+a 5+10 - 5+10= 0m

Subtractive pipe length d+b - e+a 5+10 - 5+10= 0m

Subtractive pipe length d+b - f+a 5+10 - 5+10= 0m

Subtractive pipe length e+a - f+a 5+10 - 5+10= 0m

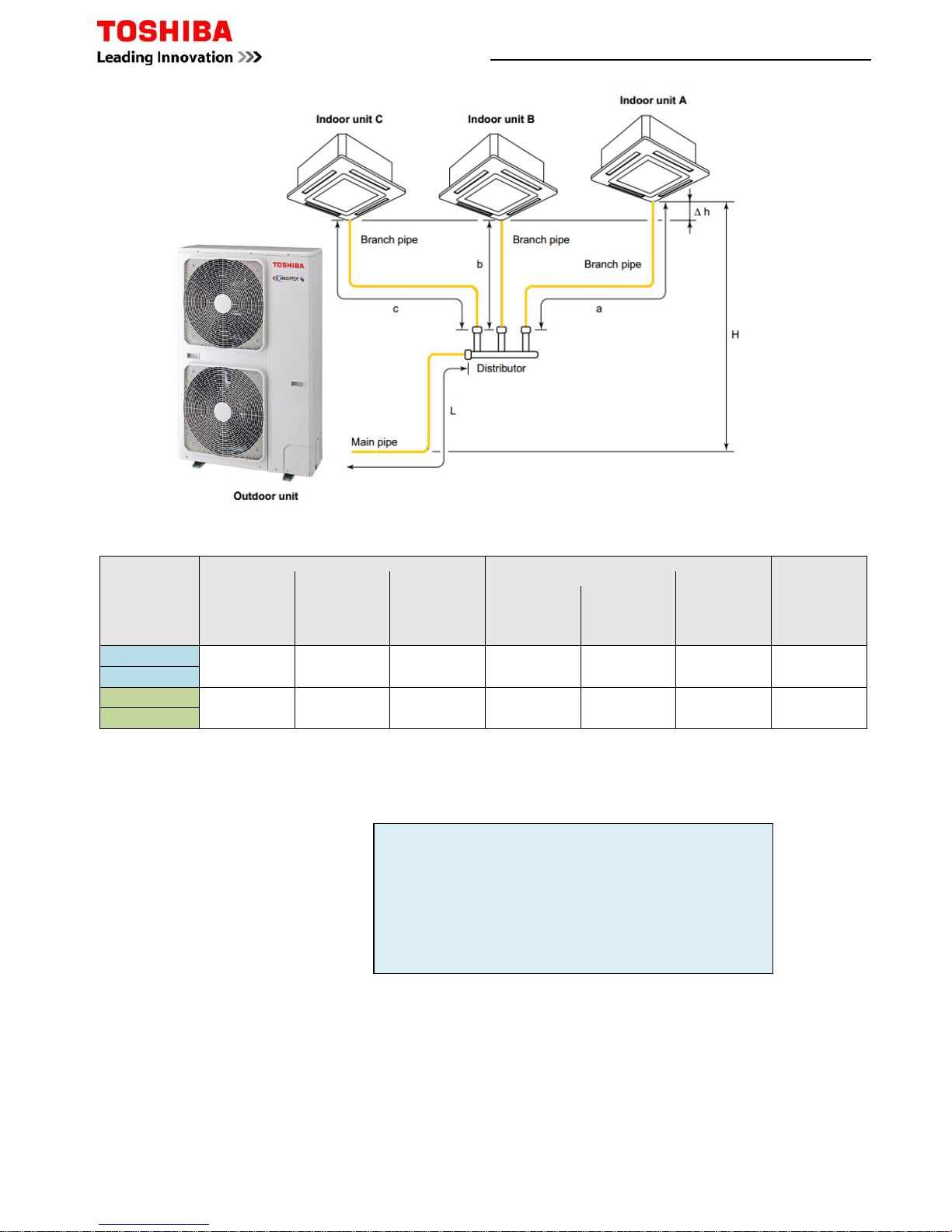

Pipe Specifications

Model (RAV-)

Allowable Piping Lengths (m)

Height Difference (m)

Number of

Bent

portions

Maximum

or Less

*

Total Length

(L+b+c) or

(L+b+d) or

(L+a+e) or

(L+a+f)

Maximum

†

Branch Piping

c, d, e & f to

Furthest Indoor

Maximum

¥Branch Piping

b+c

b+d

a+e

a+f

Maximum

‡

Subtractive

Branch Piping

(c+b) - (d+b)

(c+b) - (e+a)

(c+b) - (f+a)

(d+b) - (e+a)

(d+b) - (f+a)

(e+a) - (f+a)

Maximum

Outdoor Unit-Indoor Unit(H)

Indoor unit

height

difference

(∆h)

Maximum

Outdoor Unit

higher

Maximum

Indoor Unit

higher

Maximum

SM2244AT8-E

70 15 20 6 30 30 0.5 10

SM2804AT8-E

*

Total length of pipe between furthest indoor and outdoor unit.

†

Maximum distance of Branch pipe from main pipe distributor to furthest indoor unit.

¥ Maximum pipe distance between Branched pairs

‡

Maximum subtractive distance between pipe branches. Example:

Example 1

Installed length main pipe L to distributor=20m

Installed length branch b=10m

Installed length branch c=5m

Installed length branch d=5m

Installed length branch a=10m

Installed length branch e=5m

Installed length branch f=5m

Digital Inverter Quad Splits

Page 16 of 78

Page 17 of 78

Interconnecting Cables

3 Core+Earth Power connected to terminals

2 Core+Earth Power connected to terminals

2 Core Control connected to terminals A + B

Example 2

Total pipe length L + b + c 50+ 15+ 10 = 75m

Branch length b + c 15+ 10 = 25m

Branch length b + d 15+ 6 = 21m

Branch length a + e 15+ 5 = 20m

Branch length a + f 15+ 10 = 25m

Subtractive pipe length c+b - d+b 10+ 15- 6+ 15 = 4m

Subtractive pipe length c+b - e+a 10+ 15- 5+ 15 = 5m

Subtractive pipe length c+b - f+a 10+ 15- 10+ 15 = 0m

Subtractive pipe length d+b - e+a 6+ 15- 5+ 15 = 1m

Subtractive pipe length d+b - f+a 6+ 15- 10+ 15 = 1m

Subtractive pipe length e+a - f+a 6+ 15- 10+ 15 = 1m

Example 2

Installed length main pipe L to distributor=50m

Installed length branch b=15m

Installed length branch c=10m

Installed length branch d=6m

Installed length branch a=15m

Installed length branch e=5m

Installed length branch f=10m

Additional Charge

Example 1

Installed length main pipe L to distributor=20m

Installed length branch b=10m

Installed length branch c=5m

Installed length branch d=5m

Installed length branch a=10m

Installed length branch e=5m

Installed length branch f=5m

Model

Main Pipes Branch pipes

Sizes (“)

Gas/Liquid

Pre-charge (m) Add amount

(kg/m) – []

Sizes (“)

Gas/Liquid

Pre-charge (m) Add amount

(g/m) – [ß]

Sizes (“)

Gas/Liquid

Add amount

(g/m) – [γ]

SM2244AT8-E 1 1/8 – 1/2 28 0.080 5/8 – 3/8 4 0.040 1/2 – 1/4 0.020

SM2804AT8-E 1 1/8 – 1/2 28 0.080 5/8 – 3/8 4 0.040 5/8 – 3/8 0.040

Gas calculation - [Main pipe] (L-28) x + [Branch Pipe] (a + b - 4) x ß + (c+d+e+f) x

γ

= additional charge

Gas calculation - [Main pipe] (L-28) x + [Branch Pipe] (a + b - 4) x ß + (c+d+e+f) x

γ

= additional charge

Example 1 using SM2804AT8-E

Total pipe length L - 28 x

20 - 28 =-8 x 0.080= -0.64 +

Branch pipe length a + b 4 x ß 10+10- 4 =16 x 0.040= 0.64 +

Branch pipe length c + d + e + f x

γ 5+5+5+5 =20 x 0.040= 0.80

Add Amount 0.80 kg

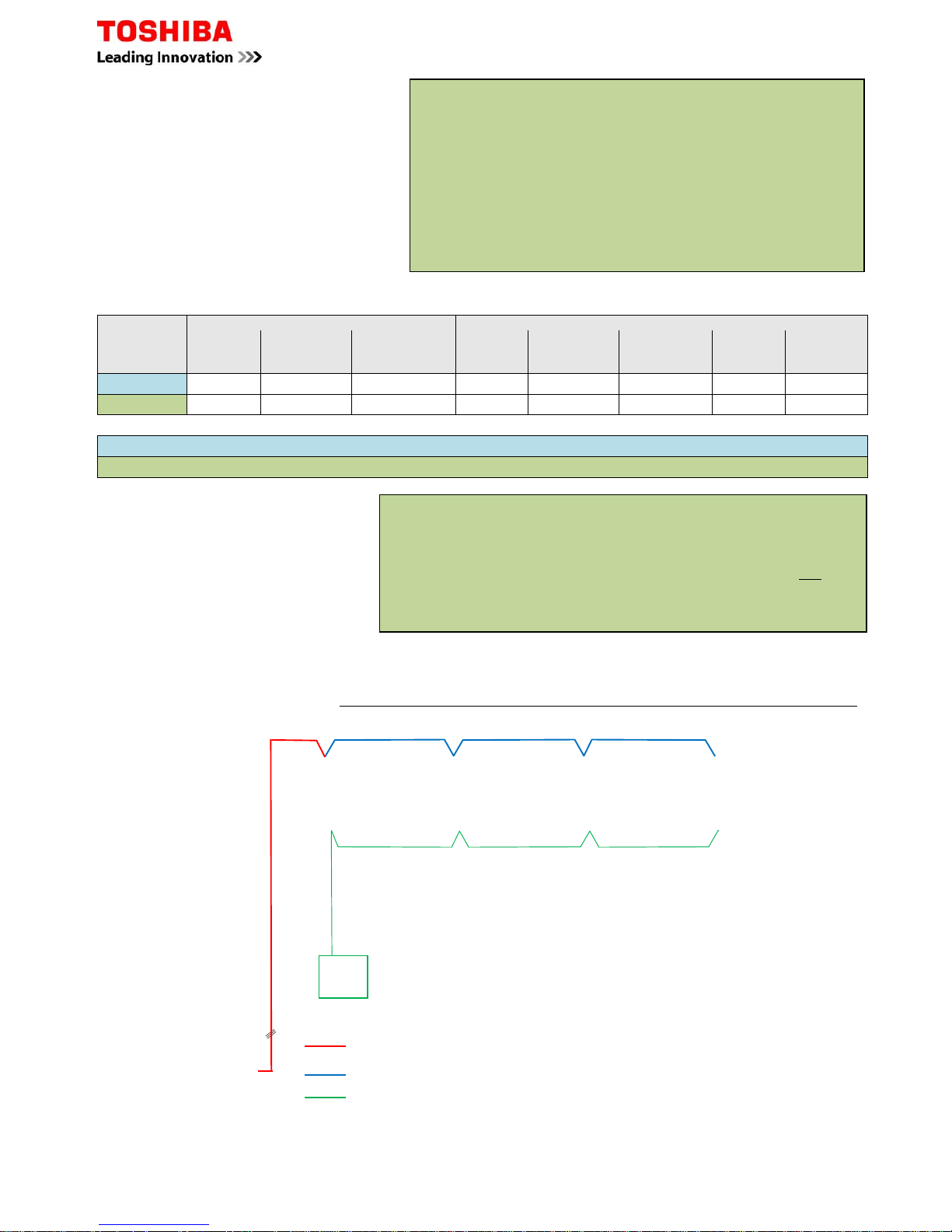

Configuration same for Twin, Triple & Quad combinations.

A common controller will be used, individual controls is not possible.

Master to Slave power supply.

Indoor Unit B

Indoor Unit CIndoor Unit D

Indoor Unit A

Remote

Controller

Digital / Super Digital Multi Split System Wiring Schematic

Factor

Factor

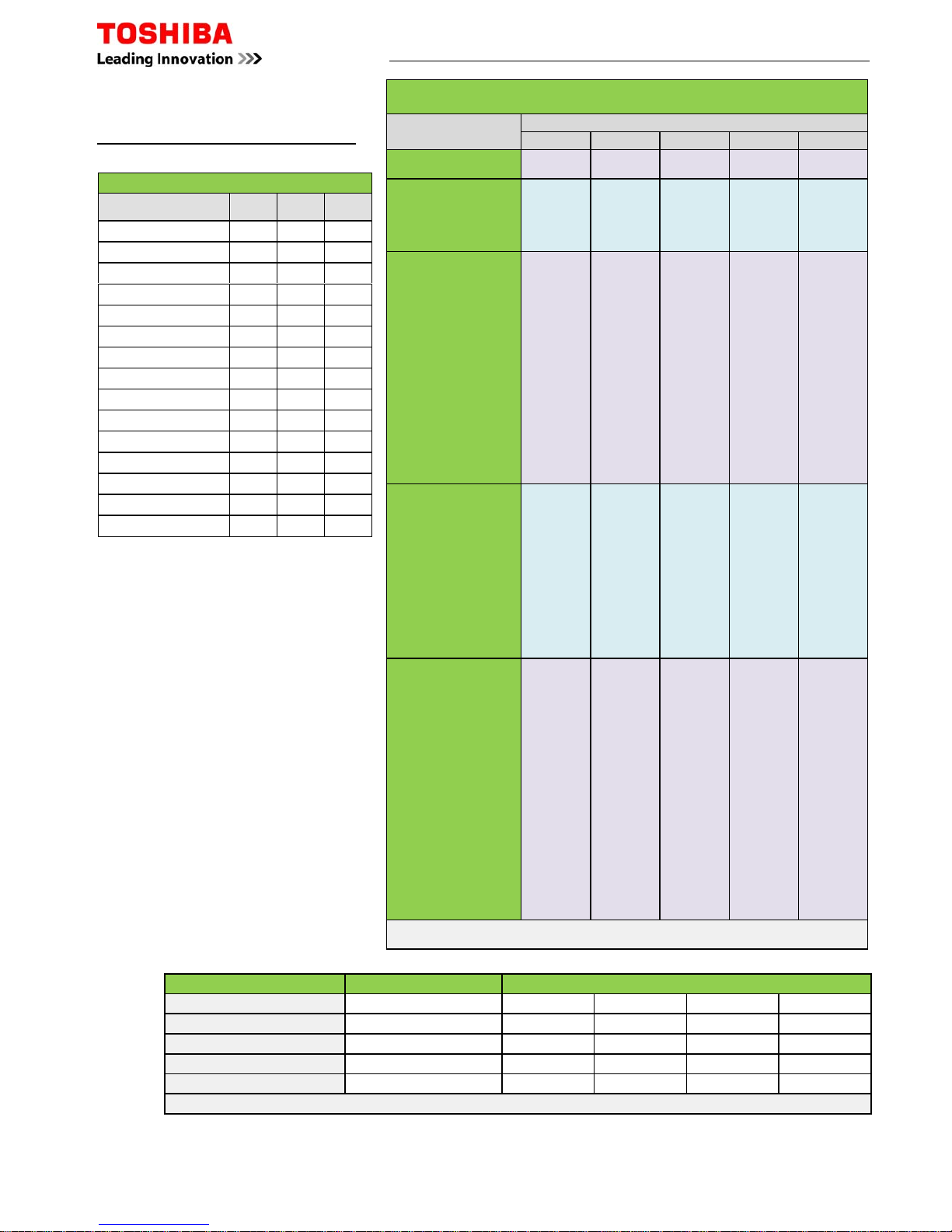

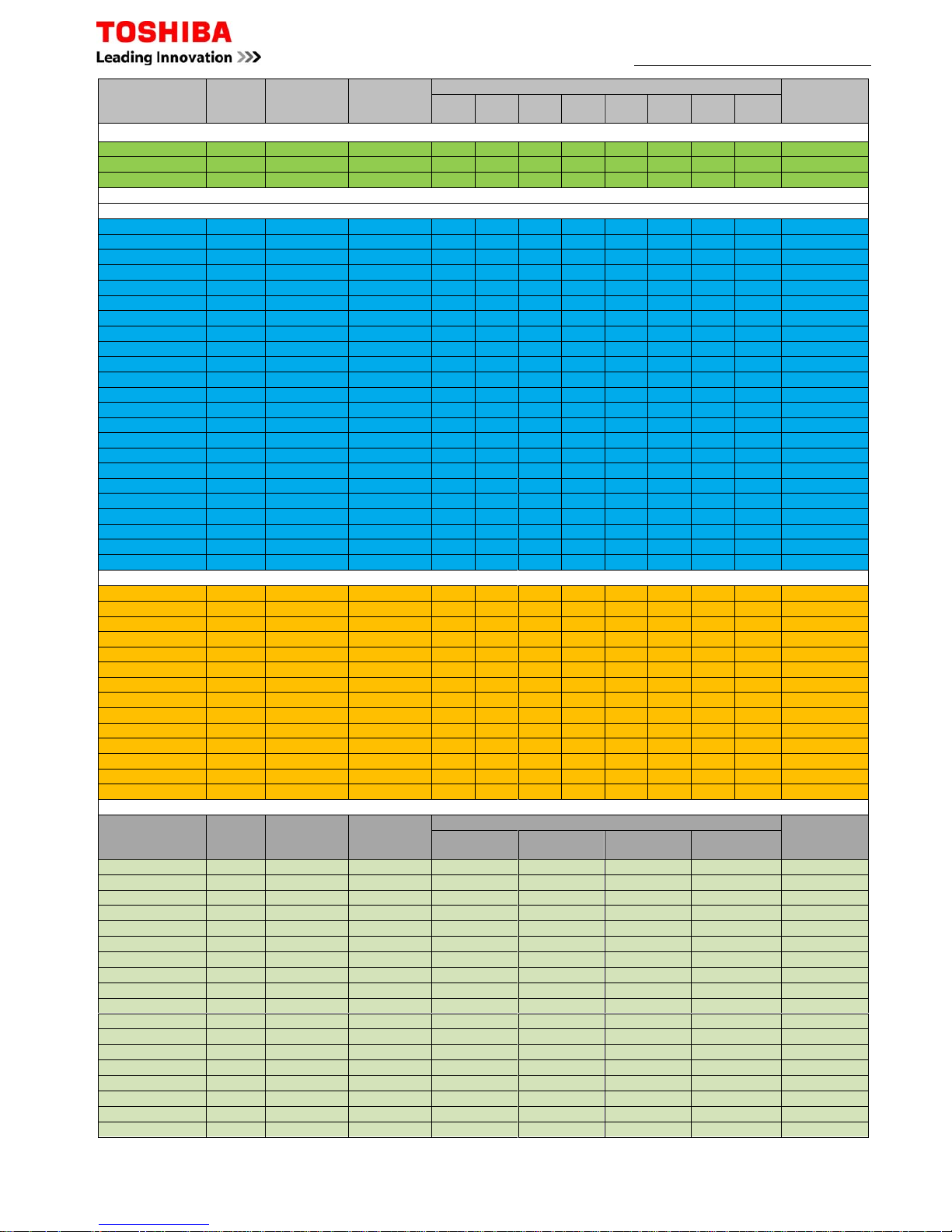

VRF System Make Up Chart

Model

Reference

MMY

Duty

HP

Cooling

Capacity

kW

Heating

Capacity

kW

Outdoor Unit Combination

Max.

Indoor

Units

0401 0501 0601 0804 1004 1204 1404 1604

Mini SMMS MCY

MAP0401HT

4

12.1

12.516

MAP0501HT 5 14.0 16.0 1 8

MAP0601HT 6 15.5 18.0 1 9

Note:- MAP0401HT, MAP0501HT & MAP601HT are

NOT

Modular

SMMSiHeat Pump MMY

MAP0501HT8-E 5 14.0 16.0 1 1 8

MAP0601HT8-E 6 16.0 18.0 10

MAP0804HT8-E 8 22.4 25.0 1 13

MAP1004HT8-E 10 28.0 31.5 1 16

MAP1204HT8-E 12 33.5 37.5 1 20

MAP1404HT8-E 14 40.0 45.0 1 23

MAP1604HT8-E 16 45.0 50.0 1 27

AP1814HT8-E 18 50.4 56.5 1 1 30

AP2014HT8-E 20 56.0 63.0 2 33

AP2214HT8-E 22 61.5 69.0 1 1 37

AP2414HT8-E 24 68.0 76.5 2 40

AP2614HT8E

26

73.0

81.511

43

AP2814HT8-E 28 78.5 88.0 1 1 47

AP3014HT8-E 30 85.0 95.0 1 1 48

AP3214HT8-E 32 90.0 100.0 2 48

AP3414HT8E

34

96.0

108.0

1248

AP3614HT8-E 36 101.0 113.0 3 48

AP3814HT8E

38

106.5

119.5

111

48

AP4014HT8-E 40 112.0 127.0 2 1 48

AP4214HT8-E 42 118.0 132.0 1 1 1 48

AP4414HT8-E 44 123.5 138.0 1 2 48

AP4614HT8-E 46 130.0 145.0 1 2 48

AP4814HT8-E 48 135.0 150.0 3 48

SMMSiHigh Efficiency Heat Pump MMY

AP1624HT8-E 16 45.0 50.0 2 27

AP2424HT8-E 24 68.0 76.5 3 40

AP2624HT8-E 26 73.0 81.5 2 1 43

AP2824HT8-E 28 78.5 88.0 1 2 47

AP3024HT8-E 30 85.0 95.0 3 48

AP3224HT8-E 32 90.0 100.0 4 48

AP3424HT8-E 34 96.0 108.0 3 1 48

AP3624HT8-E 36 101.0 113.0 2 2 48

AP3824HT8-E 38 106.5 119.5 1 3 48

AP4024HT8-E 40 112.0 126.5 4 48

AP4224HT8-E 42 118.0 132.0 3 1 48

AP4424HT8-E 44 123.5 138.0 2 2 48

AP4624HT8-E 46 130.0 145.0 1 3 48

AP4824HT8-E 48 135.0 150.0 4 48

SHRMiHeat Recovery MMY

Model

Reference

MMY

Duty

HP

Cooling

Capacity

Kw

Heating

Capacity

kW

Outdoor Unit Combination

Max.

Indoor

Units

0804 1004 1204 1404

MAP0804FT8-E 8 22.4 25.0 1 13

MAP1004FT8-E 10 28.0 31.5 1 16

MAP1204FT8-E 12 33.5 37.5 1 20

MAP1404FT8-E 14 40.0 45.0 1 23

AP1614FT8-E 16 45.0 50.0 2 27

AP1814FT8-E 18 50.4 56.5 1 1 30

AP2014FT8-E 20 56.0 63.0 2 33

AP2214FT8-E 22 61.5 69.0 1 1 37

AP2414FT8-E 24 68.0 76.5 1 1 40

AP2614FT8-E 26 73.0 81.5 1 1 43

AP2814FT8-E 28 78.5 88.0 2 47

AP3014FT8-E 30 85.0 95.0 3 48

AP3214FT8-E 32 90.0 100.0 2 1 48

AP3414FT8-E 34 96.0 108.0 2 1 48

AP3614FT8-E 36 101.0 113.0 3 48

AP3814FT8-E 38 106.5 119.5 2 1 48

AP4014FT8-E 40 112.0 127.0 1 2 48

AP4214FT8-E 42 118.0 132.0 3 48

Page 18 of 78

Electrical Data – VRF Outdoor Units

Model (Outdoor) HP Phase

Power

To

Soft

Start

Suggested

Fuse Size

Fuse

Type

Inter-Connecting

Cable

Mini SMMS

MCY-MAP0401HT 4 1Ph-N

Indoor + Outdoor

Y 20 C 2C Screened

MCY-MAP0501HT 5 1Ph-N

Indoor + Outdoor

Y 25 C 2C Screened

MCY-MAP0601HT 6 1Ph-N

Indoor + Outdoor

Y 32 C 2C Screened

SMMS

MMY-MAP0501HT8-E 5 3Ph-N Indoor + Outdoor Y 16 C 2C Screened

MMY-MAP0601HT8-E 6 3Ph-N

Indoor + Outdoor

Y 16

C

2C Screened

SMMS

i

MMY-MAP0804HT8-E 8 3Ph-N

Indoor + Outdoor

Y 16 C 2C Screened

MMY-MAP1004HT8-E 10 3Ph-N Indoor + Outdoor Y 16 C 2C Screened

MMY-MAP1204HT8-E 12 3Ph-N

Indoor + Outdoor

Y 25 C 2C Screened

MMY-MAP1404HT8-E 14 3Ph-N

Indoor + Outdoor

Y 25 C 2C Screened

MMY-MAP1604HT8-E 16 3Ph-N

Indoor + Outdoor

Y 32 C 2C Screened

SHRM

i

MMY-MAP0804FT8-E 8 3Ph-N

Indoor + Outdoor

Y 16 C 2C Screened

MMY-MAP1004FT8-E 10 3Ph-N

Indoor + Outdoor

Y 20 C 2C Screened

MMY-MAP1204FT8-E 12 3Ph-N

Indoor + Outdoor

Y 20 C 2C Screened

MMY-MAP1404FT8-E 14 3Ph-N

Indoor + Outdoor

Y 25 C 2C Screened

VRF Additional Refrigerant Charge Amount

Indoor Unit

Model

Capacity

Code HP

Capacity

Code kW

007 0.8

2.2

009 1

2.8

012 1.25

3.6

015 1.7

4.5

018 2

5.6

024 2.5

7.1

027 3

8.0

030 3.2

9.0

036 4

11.2

048 5

14.0

056 6

16.0

072 8

22.4

096 10

28.0

Capacity Data – VRF Indoor Units

Liquid

SMMS SHRM

Pipe Size

Mini SMMS

SMMS

i

SHRM

i

inch" - mm kg/m kg/m kg/m

1/4 - 6.4 0.025 0.025 0.0325

3/8 - 9.5 0.055 0.055 0.0715

1/2 - 12.7 0.105 0.1365

5/8 - 15.9 0.160 0.2080

3/4 - 19.1 0.250 0.3250

7/8 - 22.2 0.350 0.4550

Additonal Refrigerant Charge Amount

Page 19 of 78

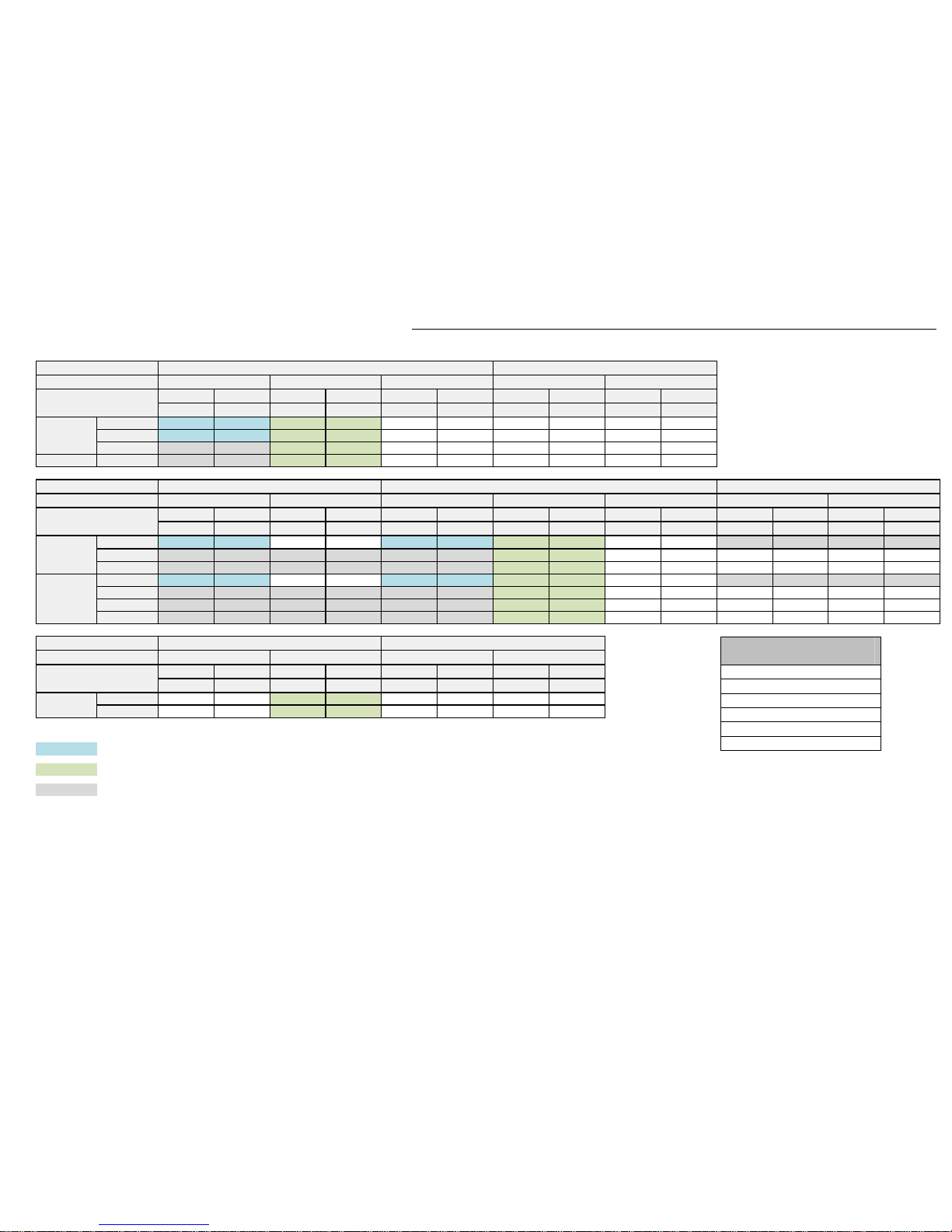

VRF Additional Refrigerant Charge Calculations

Page 20 of 78

Correction

1 2 3 4 Factor kg

4 4 4 -0.8

5 5 5 -0.4

6 6 6 0

5 5 5 0

6 6 6 0

8 8 8 1.5

10 10 10 2.5

12 12 12 3.5

14 14 8 6 0

16 16 8 8 0

18 18 10 8 0

20 20 10 10 3

22 22 8 8 6 0

22 22 12 10 5

24 24 8 8 8 -4

24 24 12 12 7

26 26 10 8 8 -4

28 28 10 10 8 -2

30 30 10 10 10 0

32 32 8 8 8 8 -6

32 32 12 10 10 1

34 34 10 8 8 8 -6

34 34 12 12 10 3

36 36 10 10 8 8 -6

36 36 12 12 12 4

38 38 10 10 10 8 -6

40 40 10 10 10 10 -5

42 42 12 10 10 10 -4

44 44 12 12 10 10 -2

46 46 12 12 12 10 0

48 48 12 12 12 12 2

Refrigerant

Length

0.0250 x =

0.0550 x =

Additional amount of refrigerant =

Refrigerant

Length

0.025 x =

0.055 x =

0.105 x =

0.160 x =

0.250 x =

0.350 x =

Additional amount of refrigerant =

Total System Charge =

Base Charge + Additional Refrigerant Charge + HP Correction Factor

HP

MAP0501HT8-E

MAP0601HT8-E

SMMS

12.5

12.5

Base Charge kg

Trim Charge

Mini SMMS

SMMS

Condenser Combinations

HP

MAP1001HT8-E

AP3001HT8-E

AP3201HT8-E

AP3211HT8-E

kg

kg

MAP0801HT8-E

MCY-MAP0401HT

MCY-MAP0601HT

7.2

7.2

MCY-MAP0501HT

7.2

8.5

8.5

AP4001HT8-E

AP4201HT8-E

AP4401HT8-E

AP4601HT8-E

AP4801HT8-E

AP3401HT8-E

AP3411HT8-E

AP3601HT8-E

AP3611HT8-E

AP3801HT8-E

MAP1201HT8-E

AP1401HT8-E

AP1601HT8-E

AP1801HT8-E

AP2001HT8-E

AP2201HT8-E

AP2211HT8-E

AP2401HT8-E

AP2411HT8-E

AP2601HT8-E

AP2801HT8-E

kg

x

Additional Refrigerant Charge Amount kg/m

Calculation of Additional Refrigerant Charge SMMS

kg

1/4 - 6.4

3/8 - 9.5

Additional Amount of

Calculation of Additional Refrigerant Charge Mini SMMS

Liquid Line Pipe Diameter Ø

50.0

50.0

50.0

50.0

Liquid Line Pipe Diameter Ø

Additional Amount of

1/4 - 6.4 kg

21.0

25.0

25.0

25.0

33.5

25.0

37.5

25.0

37.5

37.5

37.5

50.0

37.5

50.0

3/8 - 9.5 kg

Additional refrigerant

charge amount at site

Note: if a negative result occurs the additonal refrigerant amount is 0 kg

12.5

37.5

50.0

37.5

50.0

50.0

*** No additional refrigerant charge or change to Factory charge is required ***

3/4 - 19.1 kg

1/2 - 12.7 kg

5/8 - 15.9 kg

=

Real Length of Liquid Line m

+

HP Correction Factor kg

7/8 - 22.2 kg

VRF Additional Refrigerant Charge Calculations

Page 21 of 78

Correction

HP1234

Factor kg

5 5 5 0

6 6 6 0

888

1.5

101010

2.5

121212

3.51414148.516161610.518181080202010103222216105242412127.5

262616108.5

282816129.5

3030161411.5

3232161612.5

3434121210

3

3636121212

4

3838161210

6

4040161212

7

4242161412

8

4444161612

10

4646161614

12

4848161616

14

1616880

2424888

-4

26261088

-4

282810108

-2

3030101010

0

32328888-6

343410888-6

3636101088-638381010108-6404010101010-5424212101010-4444412121010-2464612121210

0

4848121212122

Refrigerant

Length

0.025 x =

0.055 x =

0.105 x =

0.160 x =

0.250 x =

0.350 x =

Additional amount of refrigerant =

Total System Charge =

Base Charge + Additional Refrigerant Charge + HP Correction Factor

Trim Charge

SMMS & SMMS

i

SMMS

i

High Efficiency

HP SMMS & SMMS

i

Base Charge kg

MAP0804HT8-E

11.5

MAP1004HT8-E

11.5

MAP1204HT8-E

11.5

MAP0501HT8-E

8.5

Condenser Combinations

MAP0601HT8-E

8.5

AP4814HT8-E

23.0

23.0

23.0

23.0

23.0

23.0

23.0

23.0

34.5

34.5

AP3614HT8-E

AP3814HT8-E

AP4014HT8-E

AP4214HT8-E

AP4414HT8-E

AP4614HT8-E

MAP1404HT8-E

MAP1604HT8-E

11.5

11.5

AP1814HT8-E

AP2014HT8-E

AP2214HT8-E

AP2414HT8-E

AP2614HT8-E

AP2814HT8-E

AP3014HT8-E

AP3214HT8-E

AP3414HT8-E

34.5

23.0

34.5

34.5

34.5

34.5

34.5

34.5

34.5

34.5

46.0

46.0

46.0

46.0

46.0

34.5

46.0

46.0

46.0

46.0

AP3224HT8-E

AP3424HT8-E

AP3624HT8-E

AP3824HT8-E

AP4024HT8-E

AP1624HT8-E

AP2424HT8-E

AP2624HT8-E

AP2824HT8-E

AP3024HT8-E

Liquid Line Pipe Diameter Ø

Additional Amount of

1/4 - 6.4 kg

3/8 - 9.5 kg

AP4224HT8-E

AP4424HT8-E

AP4624HT8-E

AP4824HT8-E

Calculation of Additional Refrigerant Charge SMMSi & High Efficiency

7/8 - 22.2 kg

kg

1/2 - 12.7 kg

5/8 - 15.9 kg

3/4 - 19.1 kg

charge amount at site

Real Length of Liquid Line m

Note: if a negative result occurs the additonal refrigerant amount is 0 kg

*** No additional refrigerant charge or change to Factory charge is required ***

Additional refrigerant

Additional Refrigerant Charge Amount kg/m

=x+

HP Correction Factor kg

VRF Additional Refrigerant Charge Calculations

Correction

HP 1 2 3 Factor kg

8 8 8 2

10 10 10 2.5

12 12 12 3

16 16 8 8 -1.5

18 18 10 8 0

20 20 10 10 2

24 24 8 8 8 -4.5

26 26 10 8 8 -3

28 28 10 10 8 -1.5

30 30 10 10 10 0

Correction

HP 1 2 3 Factor kg

8 8 8 2

10 10 10 3

12 12 12 8

14 14 14 10

16 16 8 8 0

18 18 10 8 1.5

20 20 10 10 3.5

22 22 12 10 7.5

24 24 14 10 8.5

26 26 14 12 11

28 28 14 14 12

30 30 10 10 10 2.5

32 32 12 10 10 5

34 34 14 10 10 6

36 36 12 12 12 8

38 38 14 12 12 9.5

40 40 14 14 12 11

42 42 14 14 14 12.5

Refrigerant

Length

0.0325 x =

0.0715 x =

0.1365 x =

0.2080 x =

0.3250 x =

0.4550 x =

Additional amount of refrigerant =

Total System Charge =

Base Charge + Additional Refrigerant Charge + HP Correction Factor

Trim Charge

SHRM

i

Condenser Combinations

Trim Charge

SHRM

HP SHRM Base Charge kg

MAP0802FT8-E

11.5

Condenser Combinations

HP SHRM

i

Base Charge kg

MAP0804FT8-E

11.0

MAP1004FT8-E

MAP1204FT8-E

MAP1404FT8-E

11.0

AP2214FT8-E

AP2414FT8-E

AP2614FT8-E

AP2814FT8-E

AP3014FT8-E

11.0

11.0

AP1614FT8-E

AP1814FT8-E

AP2014FT8-E

22.0

22.0

22.0

22.0

22.0

22.0

22.0

33.0

33.0

MAP2602HT8-E

34.5

MAP2802HT8-E

34.5

MAP1602HT8-E

23.0

MAP1802HT8-E

23.0

MAP2002HT8-E

23.0

MAP2402HT8-E

34.5

AP4214FT8-E

33.0

33.0

33.0

33.0

33.0

AP3214FT8-E

AP3414FT8-E

AP3614FT8-E

AP3814FT8-E

AP4014FT8-E

MAP1002FT8-E

11.5

MAP1202FT8-E

11.5

1/4 - 6.4 kg

kg

1/2 - 12.7 kg

Calculation of Additional Refrigerant Charge SHRMi

Liquid Line Pipe Diameter Ø

Additional Amount of

MAP3002HT8-E

34.5

*** No additional refrigerant charge or change to Factory charge is required ***

3/8 - 9.5

5/8 - 15.9 kg

3/4 - 19.1 kg

7/8 - 22.2 kg

Additional refrigerant

Additional Refrigerant Charge Amount kg/m

=x+

HP Correction Factor kg

charge amount at site

Real Length of Liquid Line m

Note: if a negative result occurs the additonal refrigerant amount is 0 kg

kg

Page 22 of 78

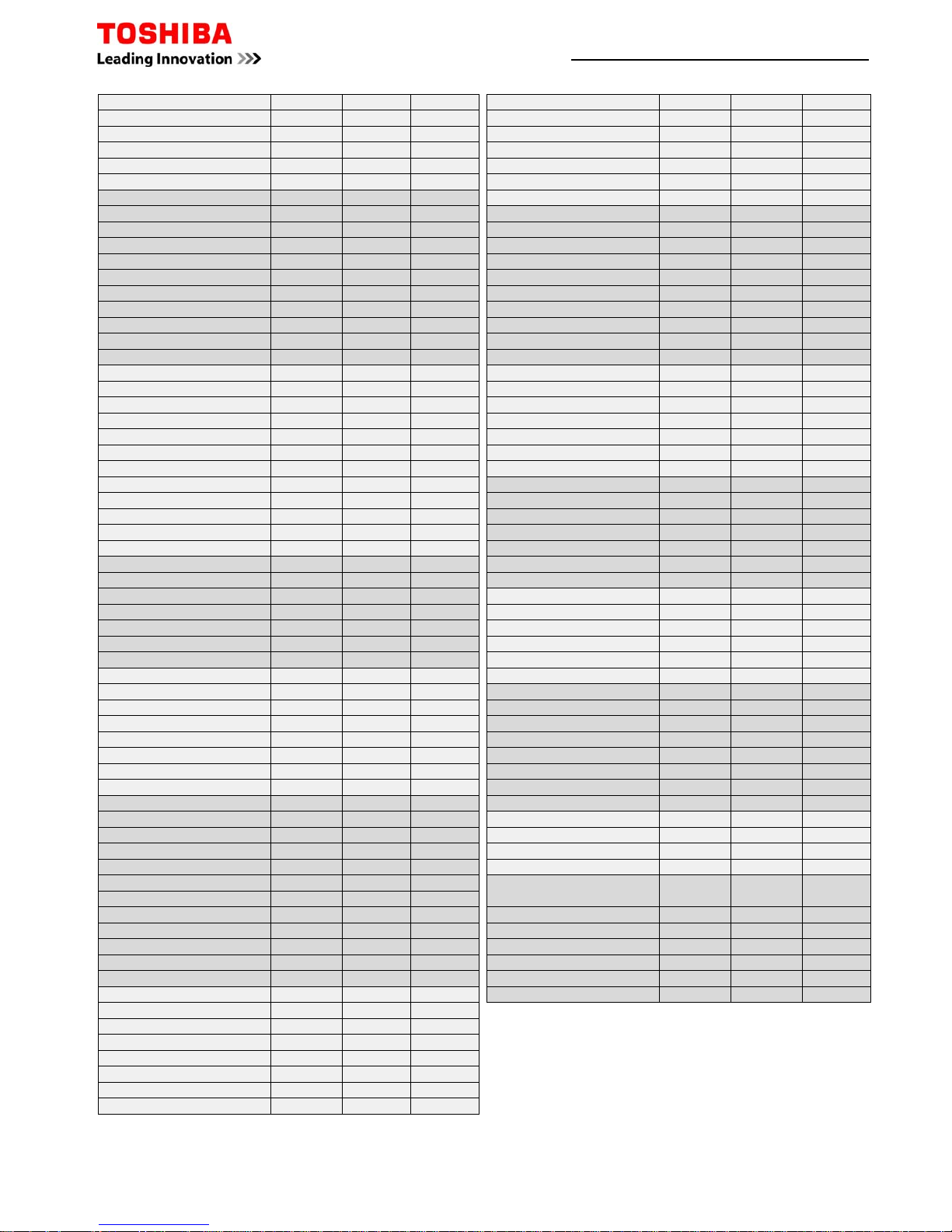

Acoustic Data - MMY Indoor Units

Page 23 of 78

4 Way Compact Cassette High dB(A) Med dB(A) Low dB(A) Ceiling Suspended High dB(A) Med dB(A) Low dB(A)

MMU-AP0074MH-E 36 32 28 MMC-AP0154H-E 35 32 30

MMU-AP0094MH-E 37 33 28 MMC-AP0184H-E 36 33 30

MMU-AP0124MH-E 37 33 29 MMC-AP0244H-E 38 36 33

MMU-AP0154MH-E 40 35 30 MMC-AP0274H-E 38 36 33

MMU-AP0184MH-E 44 39 34 MMC-AP0364H-E 41 38 35

4 Way Cassette High dB(A) Med dB(A) Low dB(A) MMC-AP0484H-E 43 40 37

MMU-AP0094HP-E 30 29 27 High Wall High dB(A) Med dB(A) Low dB(A)

MMU-AP0124HP-E 30 29 27 MMK-AP0073H 35 31 28

MMU-AP0154HP-E 31 29 27 MMK-AP0093H 37 32 28

MMU-AP0184HP-E 32 29 27 MMK-AP0123H 37 32 28

MMU-AP0244HP-E 35 31 28 MMK-AP0153H 41 36 33

MMU-AP0274HP-E 35 31 28 MMK-AP0183H 41 36 33

MMU-AP0304HP-E 38 33 30 MMK-AP0243H 46 39 34

MMU-AP0364HP-E 43 38 32 MMK-AP0074MH-E 35 32 29

MMU-AP0484HP-E 46 38 33 MMK-AP0094MH-E 36 33 29

MMU-AP0564HP-E 46 40 33 MMK-AP0124MH-E 37 33 29

2 Way Cassette High dB(A) Med dB(A) Low dB(A) Concealed Chassis High dB(A) Med dB(A) Low dB(A)

MMU-AP0072WH 34 32 30 MML-AP0074BH-E 36 34 32

MMU-AP0092WH 34 32 30 MML-AP0094BH-E 36 34 32

MMU-AP0122WH 34 32 30 MML-AP0124BH-E 36 34 32

MMU-AP0152WH 35 33 30 MML-AP0154BH-E 36 34 32

MMU-AP0182WH 35 33 30 MML-AP0184BH-E 36 34 32

MMU-AP0242WH 38 35 33 MML-AP0244BH-E 42 37 33

MMU-AP0272WH 38 35 33 Floor Mounted Console High dB(A) Med dB(A) Low dB(A)

MMU-AP0302WH 40 37 34 MML-AP0074H-E 39 37 35

MMU-AP0362WH 42 39 36 MML-AP0094H-E 39 37 35

MMU-AP0482WH 43 40 37 MML-AP0124H-E 45 41 38

MMU-AP0562WH 46 42 39 MML-AP0154H-E 45 41 38

1 Way Cassette High dB(A) Med dB(A) Low dB(A) MML-AP0184H-E 49 44 39

MMU-AP0074YH-E 42 39 34 MML-AP0244H-E 49 44 39

MMU-AP0094YH-E 42 39 34 Bi-Flow Console High dB(A) Med dB(A) Low dB(A)

MMU-AP0124YH-E 42 39 34 MML-AP0074NH-E 38 32 26

MMU-AP0154SH-E 37 35 32 MML-AP0094NH-E 38 32 26

MMU-AP0184SH-E 38 36 34 MML-AP0124NH-E 40 34 29

MMU-AP0244SH-E 45 41 37 MML-AP0154NH-E 43 37 31

Slim Ducted High dB(A) Med dB(A) Low dB(A) MML-AP0184NH-E 47 40 34

MMD-AP0074SPH-E 36 33 30 Floor Mounted Cabinet High dB(A) Med dB(A) Low dB(A)

MMD-AP0094SPH-E 36 33 30 MMF-AP0154H-E 46 43 38

MMD-AP0124SPH-E 38 35 32 MMF-AP0184H-E 46 43 38

MMD-AP0154SPH-E 39 36 33 MMF-AP0244H-E 49 45 40

MMD-AP0184SPH-E 40 38 36 MMF-AP0274H-E 49 45 40

MMD-AP0244SPH-E 49 47 44 MMF-AP0364H-E 51 48 44

MMD-AP0274SPH-E 49 47 44 MMF-AP0484H-E 54 50 46

Standard Ducted High dB(A) Med dB(A) Low dB(A) MMF-AP0564H-E 54 50 46

MMD-AP0076BH-E 29 26 23 Fresh Air Intake High dB(A) Med dB(A) Low dB(A)

MMD-AP0096BH-E 30 26 23 MMD-AP0481HFE 45 43 41

MMD-AP0126BH-E 30 26 23 MMD-AP0721HFE 46 45 44

MMD-AP0156BH-E 33 29 25 MMD-AP0961HFE 46 45 44

MMD-AP0186BH-E 33 29 25 Extra

MMD-AP0246BH-E 36 31 27 Air to Air Heat Exchanger High dB(A) High dB(A) Low dB(A)

MMD-AP0276BH-E 36 31 27 MMD-VN502HEXE 37 36 34

MMD-AP0306BH-E 36 31 27 MMD-VN802HEXE 41 40 38

MMD-AP0366BH-E 40 36 33 MMD-VN1002HEXE 43 42 40

MMD-AP0486BH-E 40 36 33 MMD-VNK502HEXE 36 35 33

MMD-AP0566BH-E 40 36 33 MMD-VNK802HEXE 40 39 38

High Static Ducted High dB(A) Med dB(A) Low dB(A) MMD-VNK1002HEXE 42 41 39

MMD-AP0184H-E 40 37 33

MMD-AP0244H-E 44 40 36

Sound Pressure Levels measured in an anechoic chamber in

accordance with JSI B8616

MMD-AP0274H-E 44 40 36

MMD-AP0364H-E 44 40 36

MMD-AP0484H-E 44 40 36

MMD-AP0724H-E 50 49 48

MMD-AP0964H-E 51 50 49

Common Sensor Characteristics

There are eight commonly used sensors in the RAS and RAV systems.

Ta = Return Air Sensor; indoor unit Tc = Coil Sensor; indoor unit

TL = Liquid Pipe Sensor (fan speed); outdoor unit TE = Heat Exchange Sensor (defrost); outdoor unit

Td = Discharge Pipe Sensor; outdoor unit To = Ambient

Ts = Suction Tk = Oil sensor

The Ta,Tc,TL and TE sensors all share the same resistance versus temperature characteristic. They differ however

in electrical connections and sensing head style, therefore it is important to quote the full model type number

when ordering any replacement sensors.

The Td sensor has a different resistance characteristic because its sensing range is that much higher than the

others.

Sensor -10 -5 0 5 10 15 20 25 30 35 40 45 50 55 60 100 ºC

Ta,Tc,TL,TE

To, Ts

60.3 45.3 34.5 26.4 20.5 16 12.5 10 8 6.5 5.3 4.3 3.6 2.9 2.4 - KΩ

Td, Tk - - - - 103 80.5 63 50 - - - - 17.9 - - 3.4 kΩ

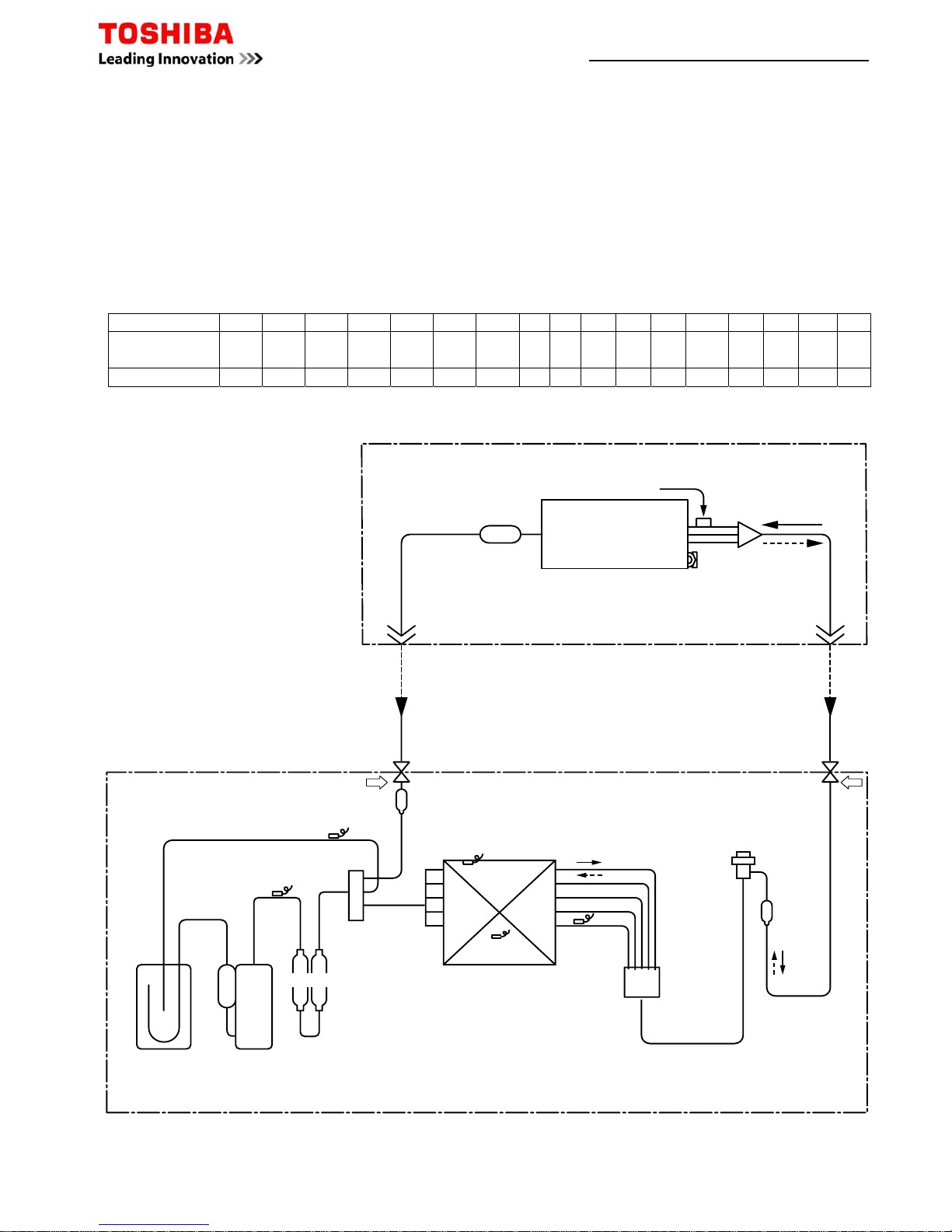

Indoor unit

Outdoor unit

Distributor

(Strainer incorporated)

TCJ sensor

Air heat exchanger

Strainer

Strainer

TC sensor

Strainer

Ball valve

Outer dia. ØA

Packed valve

Outer dia. ØB

Max.

50m

Min.

5m

TS sensor

TD sensor

TO sensor

TE

sensor

Distributor

4-way valve

(STF-0213Z

Ø25 × L210

Ø25 × L180

Twin Rotary

compressor

(DA220A2F – 20L)

Accumulator

(2500cc)

Heat exchanger

Outer side

Ø8, 2 rows, 20 steps

FP1.3 flat fin

Inner side

Ø9.52 row, 30 steps

FP1.5 flat fin

R410A 2.5kg

Muffler

Refrigerant pipe

at gas side

Ø15.9

Packet valve

Refrigerant pipe

at liquid side

Ø9.5

Packet valve

PMV

(Pulse Motor Valve)

(UKV-25D22)

Example for location of Sensors

TL sensor

Page 24 of 78

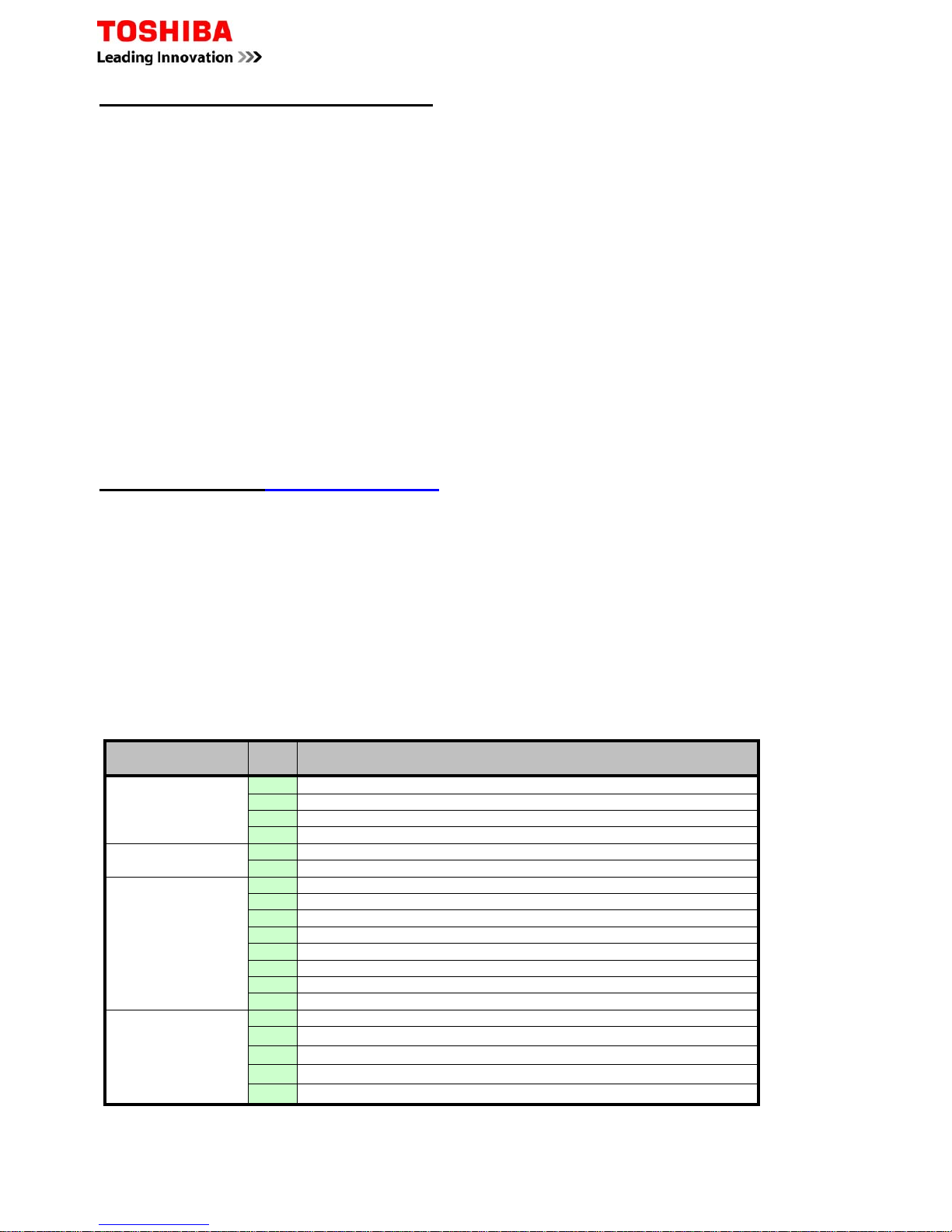

Stopped because of error of other indoor unit in a group

(Check codes of E03/L03/L07/L08)

Outdoor unit: Outdoor unit error

Protective device of

Outdoor unit: Inverter Idc operation ∗1

Outdoor unit: Position detection error

outdoor unit worked.

Outdoor unit high pressure protection

4-way valve system error (Indoor or outdoor unit judged.)

Negative phase detection error

Heat sink overheat error Outdoor unit error

Gas leak detection error

Outdoor unit discharge temp. error

Protective device of

∗1

Outdoor high pressure system error

outdoor unit worked.

Overflow was detected.

Protective device of indoor unit worked.

Indoor DC fan error

Miswiring between indoor unit and outdoor unit or connection erorr

(Communication stop between indoor and outdoor units)

Wire connection error between indoor units, Indoor power OFF

(Communication stop between indoor master and follower or between main

and sub indoor twin)

Communication error between CPUs on indoor unit P.C. board

Duplicated indoor unit No.

Setup error

Duplicated master units of remote controller

Receiving error

Receiving unit

Miswiring or wire connection error

Sending error

Communication stop

between receiving unit and indoor unit

Power supply OFF or miswiring between receiving unit and indoor unit

P31

Cause of trouble occurrence

P29

P26

P22

P20

P19

P15

P07

P05

P04

P03

P12

P10

E04

E18

E10

E09

E08

E03

E02

E01

—

Alternate flash

Check code

Operation

Timer Ready

Alternate flash

Operation

Timer Ready

Flash

Operation

Timer Ready

Flash

Operation

Timer Ready

No indication at all

Operation

Timer Ready

: Flash (0.5 sec.)

: Go on, : Go off,

Lamp indication

Lamp indication

Operation

Timer Ready

Alternate flash

Operation

Timer Ready

Alternate flash

Operation

Timer Ready

Simultaneous flash

Operation

Timer Ready

Simultaneous flash

Operation

Timer Ready

Flash

Operation

Timer Ready

Simultaneous flash

Operation

Timer Ready

Simultaneous flash

Check code

F01

F02

P10

F04

F06

F07

F08

F12

F13

F15

F29

F31

H01

H02

H03

H04

H06

L03

L07

L08

L09

L10

L20

L29

L30

L31

Cause of trouble occurrence

Heat exchanger sensor (TCJ) error

Heat exchanger sensor (TC) error Indoor unit sensor error

Heat exchanger sensor (TA) error

Discharge temp. sensor (TD) error

Temp. sensor (TE) error

Temp. sensor (TL) error

Temp. sensor (TO) error Sensor error of outdoor unit ∗1

Temp. sensor (TS) error

Temp. sensor (TH) error

Temp. Sensor miswiring (TE, TS)

Indoor EEPROM error

Outdoor EEPROM error

Compressor break down

Compressor lock

Current detection circuit error Outdoor compressor system error ∗1

Case thermostat worked.

Outdoor unit low pressure system error

Duplicated master indoor units

There is indoor unit of group connection → AUTO address

in individual indoor unit.

* If group construction and

Unsetting of group address

address are not normal

Missed setting when power supply turned on,

(Unset indoor capacity) automatically goes to address

setup mode.

Unset model type (Service board)

Duplicated indoor central addresses

Outdoor unit and other error Others

Outside interlock error

Negative phase error

Operation

Timer Ready

Simultaneous flash

Operation

Timer Ready

Alternate flash

—

—

During test run

Disagreement of cool/heat

(Automatic cool/heat setting to automatic cool/heat prohibited

model, or setting of heating to cooling-only model)

Page 25 of 78

Indoor Lamp Indication for Trouble Shooting - RAV Series

–

<I

Check Code List (Indoor)

¡

: Go on, ¥ : Flash, l : Go off ALT (Alternate): Alternate flashing when there are two flashing LED SIM (Simultaneous): Simultaneous flashing when there are two flashing LED

(Indoor unit detected)

²

When this warning was detected before group construction/address check finish at power supply was turned on, the mode shifts automatically to AUT O address setup mode .

(Remote controller detected)

(Central control devices detected)

Check code indication

TCC-LINK central &

Wired remote controller

E03

E04

E08

E10

E18

F01

F02

F10

F29

L03

L07

L08

L09

L20

L30

P01

P10

P12

P19

P31

Indoor Sensor lamp indication

Block indication

Operation

Timer Ready Flash

¥

ll

ll

¥

¥

ll

¥

ll

¥

ll

¥¥

l

ALT

¥¥

l

ALT

¥¥

l

ALT

¥¥

l

SIM

¥

l

¥

SIM

¥

l

¥

SIM

¥

l

¥

SIM

¥

l

¥

SIM

¥¡¥

SIM

¥¡¥

SIM

l

¥¥

ALT

l

¥¥

ALT

l

¥¥

ALT

¥

l

¥

ALT

¥

l

¥

ALT

Representative defective position

Regular communication error between indoor and

remote controller

Indoor/Outdoor serial error

Duplicated indoor addresses

²

Communication error between indoor MCU

Regular communication error between

indoor master and follower units

Indoor unit, Heat exchanger (TCJ) error

Indoor unit, Heat exchanger (TC) error

Indoor unit, Room temp. sensor (TA) error

Indoor unit, other indoor P.C. board error

Duplicated setting of indoor group master unit

²

There is group cable in individual indoor unit.

²

Unset indoor group address

²

Unset indoor capacity

Duplicated central control system address

Outside error input to indoor unit (Interlock)

Indoor unit, AC fan error

Indoor unit, overflow detection

Indoor unit, DC fan error

4-way valve system error

Other indoor unit error

Explanation of error contents

No communication from remote controller and network adapter

(Also no communication from central control system)

There is error on serial communication between indoor and outdoor units

Same address as yours was detected.

MCU communication error between main motor and micro computer

Regular communication between indoor master and follower units is impossible,

Communication between twin master (main) and follower (sub) units is impossible.

Open/short was detected on heat exchanger (TCJ).

Open/short was detected on heat exchanger (TC).

Open/short was detected on room temp. sensor (TA).

EEPROM error (Other error may be detected. If no error, automatic address is repeated.

There are multiple master units in a group.

When even one group connection indoor unit exists in individual indoor unit.

Indoor group address is unset.

Capacity of indoor unit is unset.

Duplicated setting of central control system address

Abnormal stop by outside error (CN80) input

An error of indoor AC fan was detected. (Fan motor thermal relay worked.)

Float switch worked.

Indoor DC fan error (Over-current/Lock, etc.) was detected.

In heating operation, an error was detected by temp. down of indoor heat exchanger sensor.

Follower unit in group cannot operate by warning from [E03/L03/L07/L08] of master unit.

Air conditioner operation

Automatic Operation

reset

continuation

¡

×

¡

×

¡

×

¡

×

¡

×

¡

×

¡

×

¡

×

××

××

××

××

××

¡

×

××

××

××

××

¡

×

¡

×

Check code indication

Wired remote controller

E01

E02

E09

Indoor Sensor lamp indication

Block indication

Operation

Timer Ready Flash

¥

ll

¥

ll

¥

ll

Representative defective position

No master remote controller, Remote controller

communication (Receive) error

Remote controller communication (Send) error

Duplicated master remote controller

Explanation of error contents

Signal cannot be received from indoor unit. Master remote controller was not set.

(including 2 remote controllers)

Signal cannot be sent to indoor unit.

In 2-remote controller control, both were set as master. (Indoor master unit stops warning

and follower unit continues operation.)

Air conditioner operation

Automatic Operation

reset

continuation

——

——

×

Check code indication

TCC-LINK central

C05

C06

C12

P30

Indoor Sensor lamp indication

Block indication

Operation

Timer Ready Flash

Is not displayed.

(Common use of

remote controller, etc.)

—

By warning unit

(Above-mentioned)

Representative defective position

Central control system communication (send) error

Central control system communication (receive) error

General-purpose device control interface batched warning

Group follower unit is defective.

Explanation of error contents

Signal sending operation of central control system is impossible.

There are multiple same central devices. (AI-NET)

Signal receiving operation of central control system is impossible.

An error on device connected to general-purpose device control interface of exclusiv e to

TCC-LINK/AI-NET

Group follower unit is defective .

(For remote controller, above-mentioned [∗∗∗] details are displayed with unit No.

Air conditioner operation

Automatic Operation

reset

continuation

——

——

——

——

NOTE: Even for the same contents of error such as communication error, the display of check code may differ according to detection device.When remote controller or central controller detects an error, it is not necessarily

related to operation of the air conditioner. In this list, the check codes that outdoor unit detects are not described.

Page 26 of 78

Indoor Lamp Indication for Trouble Shooting - RAV Series

–

<

Check Code List (Outdoor)

¡

: Go on, ¥ : Flash, l : Go off

ALT (Alternate): Alternate flashing when there are two flashing LED SIM (Simultaneous): Simultaneous flashing when there are two flashing LED

²

When this warning was detected before group construction/address check finish at power supply was turned on, the mode shifts automatically to AUTO address setup mode.

Remote

controller

indication

F04

F06

F08

F07

F12

F13

F15

F31

H01

H02

H03

H04

L10

L29

P03

P04

P05

P07

P15

P20

P22

P26

P29

E01

E02

E03

E04

E08

E09

E10

E18

L03

L07

L08

L09

L30

P19

Indoor Sensor lamp part

Block indication

Operation

Timer Ready Flash

¥¥¡

ALT

¥¥¡

ALT

¥¥¡

ALT

¥¥¡

ALT

¥¥¡

ALT

¥¥¡

ALT

¥¥¡

ALT

¥¥¡

SIM

l

¥

l

l

¥

l

l

¥

l

l

¥

l

¥¡¥

SIM

¥¡¥

SIM

¥

l

¥

ALT

¥

l

¥

ALT

¥

l

¥

ALT

¥

l

¥

ALT

¥

l

¥

ALT

¥

l

¥

ALT

¥

l

¥

ALT

¥

l

¥

ALT

¥

l

¥

ALT

¥

ll

¥

ll

¥

ll

ll

¥

¥

ll

¥

ll

¥

ll

¥

ll

¥

l

¥

SIM

¥

l

¥

SIM

¥

l

¥

SIM

¥

l

¥

SIM

¥¡¥

SIM

¥

l

¥

ALT

Representative defective position

Outdoor unit Discharge temp. sensor (TD) error

Outdoor unit Temp. sensor (TE, TS, TL) error

Outdoor unit Outside temp. sensor (TO) error

Outdoor unit Temp. sensor (TL) error

Outdoor unit Temp. sensor (TS) error

Outdoor unit Temp. sensor (TH) error

Outdoor unit Misconnection of temp. sensor (TE, TS)

Outdoor unit EEPROM error

Outdoor unit Compressor break down

Outdoor unit Compressor lock

Outdoor unit Current detection circuit error

Outdoor unit Case thermostat operation

Outdoor unit Setting error of service P.C. board type

Outdoor unit Other outdoor unit error

Outdoor unit Discharge temp. error

Outdoor unit

High pressure system error, Pow er supply voltage error

Power supply error

Outdoor unit Heat sink overheat

Gas leak detection

Outdoor unit High pressure system error

Outdoor unit Outdoor fan error

Outdoor unit Inverter Idc operation

Outdoor unit Position detection error

No remote controller master unit

Remote controller communication error

Remote controller send error

Regular communication error between indoor and

remote controller

Indoor/Outdoor serial error

Duplicated indoor addresses

²

Duplicated main remote controllers

Communication error between CPU

Regular communication error between master and

follower indoor units

Duplicated indoor master units

²

There is group cable in individual indoor unit.

²

Unset indoor group address

²

Unset indoor capacity

Outside error input to indoor unit (Interlock)

4-way valve inverse error

Detection

Outdoor

Outdoor

Outdoor

Outdoor

Outdoor

Outdoor

Outdoor

Outdoor

Outdoor

Outdoor

Outdoor

Outdoor

Outdoor

Outdoor

Outdoor

Outdoor

Outdoor

Outdoor

Outdoor

Outdoor

Outdoor

Outdoor

Outdoor

Remote

controller

Remote

controller

Indoor

Indoor

Indoor

Remote

controller

Indoor

Indoor

Indoor

Indoor

Indoor

Indoor

Indoor

Indoor

Outdoor

Explanation of error contents

Open/Short of discharge temp. sensor was detected.

Open/Short of heat exchanger temp. sensor was detected.

Miswiring between TE sensor and TS sensor

Open/Short of outside temp. sensor was detected.

Open/Short of heat exchanger temp. sensor was detected.

Open/Short of suction temp. sensor was detected.

Open/Short of heat sink temp. sensor (Board installed) was detected.

Misconnection of outdoor heat exchanger temp. sensor and suction temp. sensor was detected.

Outdoor P.C. board part (EEPROM) error was detected.

When reached min-Hz by current release control, short-circuited current (Idc) after

DC excitation was detected.

Compressor lock was detected.

Current detection circuit error

Case thermostat operation was detected.

When outdoor service P.C. board was used, model type select jumper setting was inappropriate.

1) Defective parts on outdoor P.C. board (MCU comm unication, EEPROM, TH sensor error)

2) When outdoor service P.C. board was used, model type selection was inappropriate.

3) Other error (Heat sink abnormal overheat, gas leak, 4-way valve inverse error) w as detected.

Error was detected by discharge temp. release control.

When case thermostat worked, error was detected by high release control from indoor/

outdoor heat exchanger temp. sensor. Power supply voltage error

Power supply voltage error

Abnormal overheat was detected by outdoor heat sink temp. sensor.

Abnormal overheat of discharge temp. or suction temp. was detected.

Error was detected by high release control from indoor/outdoor heat exchanger temp. sensor.