Page 1

SERVICE MANUAL

DATA WALL PROJECTION UNIT

CONTENTS

P503DL

1

Page 2

SAFETY PRECAUTIONS FOR USER·············································· 3

PRECAUTIONS FOR USE AND MAINTENANCE ···························· 8

GENERAL DESCRIPTIONS ····························································· 9

FEATURES ·················································································· 9

P503DL DIMENSIONS ······························································10

·······································································································

FUNCTION of I/O PANEL····························································11

FUNCTION of POWER PANEL ····················································11

POWER SWITCH AND POWER INDICATOR·····························12

SPECIFICATIONS ·······································································13

ACCEPTABLE SIGNAL TYPE ·····················································14

ACCEPTABLE RGB INPUT SIGNAL TIMING······························15

CONNECTION AT A MULTI-PROJECTION SYSTEM··················16

DISASSEMBLE ·················································································19

1. HOW TO REP LACE THE LAMP··············································19

2. Air Filter····················································································20

3. Cabinet Disassemble ·····························································20

4. Location of Key Components and Function Module ·················21

5. Wiring between Function Unit··················································22

6. Light Engine Block···································································23

ADJUSTMENT··················································································23

1. DLP ENGINE adjustment·························································23

LENS FOCUS adjustment························································23

ENGINE MOUNT adjustment preparation································24

2. ENGINE MOUNT adjustment ·················································25

3. ELECTRONICS ADJUSTMENT OR SETTING························27

3-1. Input Signal selection·························································28

3-2. Adjust Mode········································································28

3-3. Saving adjustments····························································28

3-4. Adjustment parameters·······················································28

3-5. Internal Test Pattern ···························································28

3-6. White Balance adjustment··················································28

3-7. Gain and Off- Set·································································28

3-8. Clock frequency adjustment and phase adjustment···········29

3-9. Image position adjustment ··················································29

3-10. Screen Mode Selection····················································29

3-11. On-Screen-Display, OSD··················································29

3-12. Video Enhancer································································30

3-13. Picture in Picture ······························································30

3-14. Image orientation······························································30

3-15. Status Indication·······························································30

3-16. Factory Reset STD key ····················································30

3-17. Color Mix adjustment························································30

4. Multiple Screen Wall system (example)···································30

5. ID Assignment (example)·························································30

5-1. Clearing I.D. ·······································································30

5-2. Setting I.D.··········································································30

5-3. Selecting I.D.······································································31

6. Magnification············································································31

7. Function in Special mode···········································31

7-1. Auto-Adjust On-Off················································31

7-2. Picture in Picture ···················································31

7-3. OSD color ·····························································31

7-4. Power On delay····················································31

7-5. Firmware Version ··················································31

7-6. Lamp Timer History···············································32

7-7. Current Lamp Timer indication ······························32

7-8. Lamp Timer Reset·················································32

8. Function in Service mode···········································32

8-1. OSD Mute·····························································32

8-2. Screen Mode Lock················································32

8-3. Picture Smoothing Filter········································32

Electric Circuit Explanation·················································32

1. RGB/Control PCB ······················································33

2. DMD Driver PCB························································33

3. Power Supply PCB ····················································33

4. Lamp Ballast PCB······················································33

5. RS232C Control PCB·················································33

6. Video PCB································································· 33

APPENDIX

1. P503DL control board LED status································34

Overall Block Diagram ················································35

2. Control via RS- 232C -Command Protocol List ·············36

3. Trouble shooting hints··················································39

4. PARTS LIST ·································································40

·························································································

·························································································

2

Page 3

SAFETY PRECAUTION

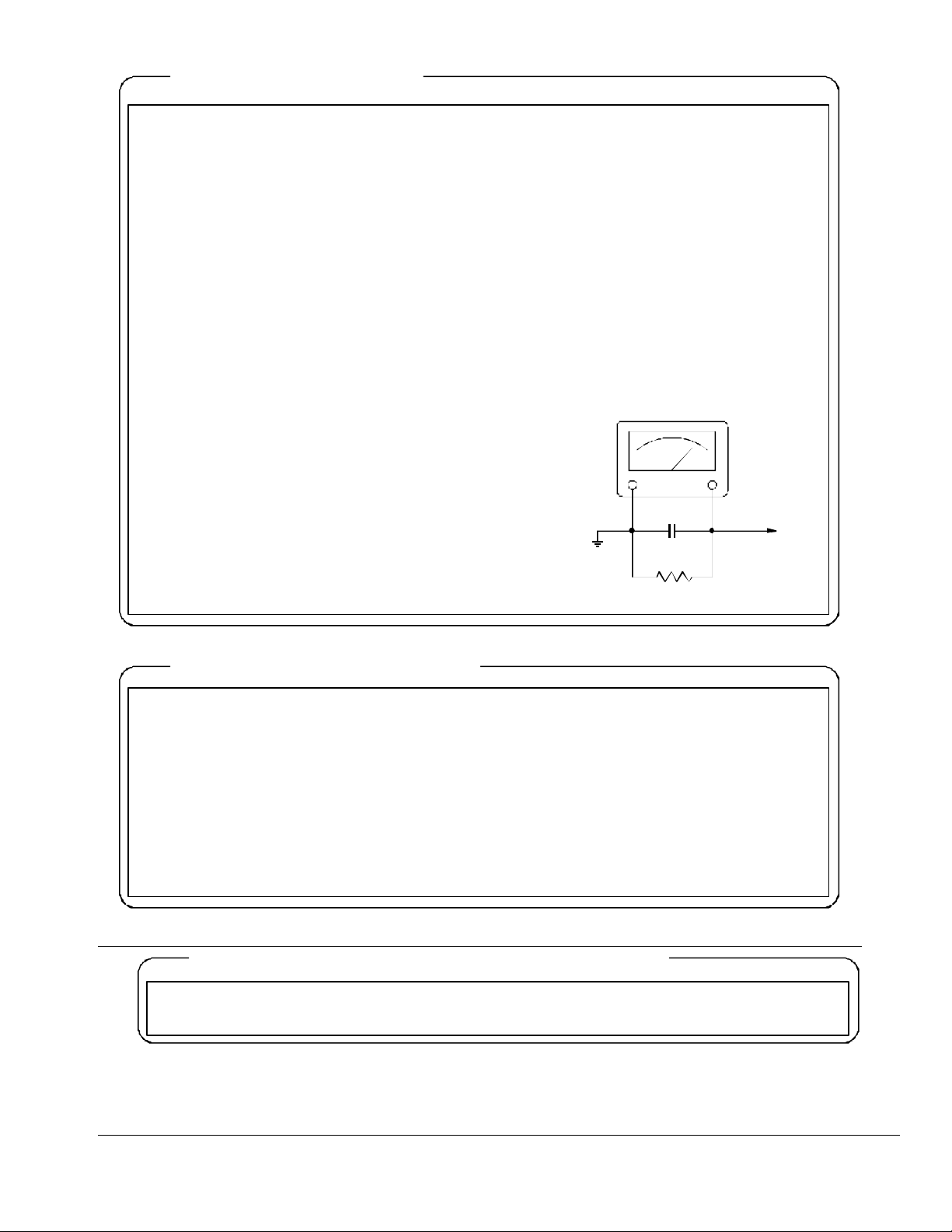

WARNING: Service should not be attempted by anyone unfamiliar with the necessary precautions on this

projector. The following are the necessary precautions to be observed before servicing this chassis.

1. An isolation Transformer should be connected in the power line between the projector and the AC line

before any service is performed on the projector.

2. When replacing a chassis in the cabinet, always be certain that all the protective devices are put back in

place, such as; non-metallic control knobs, insulating covers, shields, isolation resistor-capacitor network

etc.

3. Before returning the set to the customer, always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as terminals, screwheads, metal overlays, control shafts etc. to be sure

the set is safe to operate without danger of electrical shock. Plug the AC line cord directly into a AC outlet

(do not use a line isolation transformer during this check). Use an AC voltmeter having 5000-ohm per volt

or more sensitivity in the following manner: Connect a 1500-ohm 10W resistor, paralleled by a 0.15-MFD,

AC type capacitor, between a known good earth ground (water pipe, conduit, etc.) and the

exposed metallic parts, one at a time. Measure the AC

voltage across the combination of 1500-ohm resistor

and 0.15-MFD capacitor. Reverse the AC plug at the

AC outlet and repeat AC voltage measurements for

each exposed metallic part. Voltage measured must

not exceed 5.25V(rms). This corresponds to

3.5mA(AC). Any value exceeding this limit constitutes

a potential shock hazard and must be corrected

immediately.

Good earth ground

such as a water

pipe, conduit, etc.

AC VOLTMETER

0.15MFD

Place this probe on

each exposed

metallic part.

1500 ohm

10 watt

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These

characteristics are often passed unnoticed by a visual inspection and the protection afforded by them cannot

necessarily be obtained by using replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are identified in this manual and its

supplements; electrical components having such features are identified by the international hazard symbols

on the schematic diagram and the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The use of substitute

replacement parts which do not have the same safety characteristics as specified in the parts list may create

shock, fire or other hazards.

ULTRAVIOLET DANGER IN SERVICE MODE

Eye damage may result from directly viewing the light produced by the lamp used in this product. Always turn

off lamp before opening this cover. Ultraviolet radiation eye protection required during servicing.

3

Page 4

SAFETY PRECAUTIONS FOR USER

WARNING

On the product and in the operation manual, precautions are presented to use this equipment safely, in

order to protect you and other persons from injury and to protect from property damage.

Indications and symbols for such precautions are as shown below.

WARNING

Wrong operation or incorrect handling by ignoring this notice may result in

Wrong operation or incorrect handling by ignoring this notice may result in

death or serious injury of users and third parties.

serious injury of users, third parties and damage to property.

First things to be observed

When installing or move the equipment:

Installation or transportation of this equipment shall be entrusted to vendors qualified by " Toshiba

Lightning and Technology ".

Installation and transportation by parties other than qualified dealers may result in injury or damage of the

equipment. Also, improper power connection may result in fire disasters.

For installation notes, please refer to the section entitled "Items to be confirmed with a qualified dealer

before installation".

Items to be observed upon use of this equipment

For abnormality or trouble

WARNING

If during operation the unit emits smoke or odor, cut off the power circuit breaker immediately and

disconnect the power plug from the outlet.

After confirming smoke has stopped, contact your dealer for repair.

If you should continue using the equipment, fire or electric shocks may result.

When no image appears on the screen, cut off the power circuit breaker immediately and disconnect the

power plug from the outlet.

If you should continue using the equipment, fire or electric shocks may result. Contact your dealer for

repair.

If water or a foreign matter should get into the equipment, cut off the power circuit breaker immediately

and disconnect the power plug from the outlet.

If you should continue using the equipment, fire or electric shocks may result. Contact your dealer for

repair.

If the equipment should fall down or the cabinet is broken, cut off the power circuit breaker immediately

and disconnect the power plug from the outlet.

If you should continue using the equipm ent, fire or electric shocks may result. Contact your dealer for

repair.

4

Page 5

Equipment Use

SAFETY PRECAUTIONS FOR USER

WARNING

Do not remove the rear cabinet cover, as there are high-voltage parts in the unit. Touching components

inside may result in electric shocks.

End user should not repair or reconstruct the equipment.

Never attempt to do so, otherwise fire disaster or electric shocks may result. For repair, contact your dealer.

Do not damage, break, modify, bend forcibly, tug, t wist, bundle, place heavy weights on or heat the power

cable.

If the equipment is used with damaged power cable, fire disaster or electric shocks may result.

If the cable is damaged, contact your dealer for repair.

Do not insert or drop metals, liquids or combustible materials into the equipment through the vent holes,

etc. Fire disaster or electric shocks may result.

Do not place items on the equipment. These may fall from the unit, resulting in injury or other damage.

Do not obstruct any of the ventilation holes. Should metals or liquids get into the equipment, fire or electric

shocks may result.

Do not humidify the atmosphere around the unit. Do not place a humidifier near or under the unit.

High humidity may cause fire or electric shocks. Also, the screen may be degraded and broken, resulting in

injury.

CAUTION

When disconnecting the power plug, do not pull the power cable.

Make sure to hold the plug to disconnect. If you pull the cable, the cable may be damaged, causing fire or

electric shocks.

Do not connect/disconnect the power plug with wet hands. It may cause electric shocks.

Do not step on the equipment, or place heavy items on it.

This may cause the unit to fall possibly causing injury or damage, which may also cause fire or electric

shocks.

When leaving the equipment out of use for a long time, make sure to disconnect the power plug from the

outlet for safety.

When the power supply is turned off by the controller and the equipment is placed in “stand-by” mode,

electricity is still consumed and parts of the circuitry are still “live”.

If the equipment is not to be used for extended periods, shut off the power by main power switch and isolate

from the main power supply to avoid any unexpected problems, which may cause fire or other damage.

Do not block the vent ports of the equipment, or obstruct airflow around the equipment.

When the vent ports are blocked, temperature inside will rise and cause fire disaster. For example, avoid

using the equipment under the following conditions.

(1) Cover the equipment with a cloth or curtain.

(2) Place packages around the equipment or stand things against the equipment.

(3) Operating the equipment in an enclosed cabinet, without adequate ventilation.

(4) Operating the equipment in a manner or environment outside the published specifications.

Do not expose the equipment to oily smoke or steam, or use the equipment in dusty atmosphere.

Do not expose the equipment to wind and rain. This may cause damage to the unit, which can result in

electric shocks or other injury.

The screen may drop or fall down due to wind, excessive vibration etc. and cause injury or damage.

5

Page 6

For servicing, maintenance and inspection

SAFETY PRECAUTIONS FOR USER

WARNING

If dust or dirt is visible on the blades or the blade clamping face of the power plug, clean the plug or blade

clamping face before connection. Otherwise, fire may occur due to lowering of insulation of the power plug.

CAUTION

Make a maintenance contract with the dealer and entrust the dealer with periodical inspection and

adjustment.

If the equipment is left for long time without cleaning, dust inside the equipment may build up and the unit

may malfunction, possibly causing fire, electric shocks or other third party damage.

Servicing of the equipment must only be performed after disconnecting the power plug from the outlet.

Otherwise electric shocks resulting in death or injury may occur.

Pay attention to all connection cables. Injury may occur by being caught by or stumbling on the cables.

In addition, the equipment may fall down, resulting in injury or damage.

Items to be confirmed with the qualified dealer before installation

WARNING

This equipment has been designed exclusively for indoor use. Do not use the equipment

outdoors; fire or electric shocks may result.

Do not install the equipment on or in unstable locations. The equipment may drop or fall down, resulting in

injury.

When mounting the equipment on a wall or other vertical surface, ensure that all fixings are secure and that

the surface the equipment is being fastened to, is perpendicular and capable of supporting the additional

lord.

When mounting the equipment from a ceiling or other overhead horizontal surface, ensure that all fixings

are secure and able to support the load. Also ensure that the horizontal surface can support the additional

load and that any fixings used do not cause a trip or other safety hazard.

Confirm that the installation procedure are undertaken with sufficient allowance and consideration for the

total weight/load of all the units installed in the event of outside influences such as earthquakes, explosions

or other factors.

Always ensure that installation does not cause or create a safety hazard by being placed too low, so that a

passer-by can hit the unit with their head or other body part by accident.

If the installation is unstable, the equipment may drop or fall down, resulting in injury.

Do not install the equipment at places exposed to direct sunshine, or where temperature rises, such as a

place near heater, etc.

If the temperature inside the equipment rises, fire may result.

Do not use the equipment in places with high humidity, such as a bathroom or a place nea r a humidifier.

It may cause fire or electric shocks. Also, the screen may become broken, resulting in injury.

Do not use the equipment with power voltages other than the one indicated on the equipment.

otherwise, fire or electric shocks may result.

Ma ke sure to install a circuit breaker in the power supply line exclusively for the equipment.

otherwise, fire may occur because the power supply cannot be cut off immediately when trouble or

abnormality occurs in the equipment.

The socket-outlet shall be installed near the equipment and shall be easily accessible.

6

Page 7

SAFETY PRECAUTIONS FOR USER

Make sure to provide ground line from the ground terminal of the power plug.

Otherwise, electric shocks may result.

Always calculate the total loading of any installed equipment and ensure that the power supply, (sockets or

other outlets) are suitable for the installation. Failure to do so may cause fire or electric shocks due to

overload.

Do not place or store anything on the equipment. If metals, liquid or other objects should get inside the

equipment, fire or electric shocks may result. Also, any heavy items placed on the top of the units may fall

down, resulting in injury or damage.

Secure the equipment to the building. The wall to be attached needs to have strong and rigid construction.

A high position projection system may topple during an earthquake. Human life and property may sustain

great damage if a system topples. Prevent toppling and accidents. Following offers some examples of how to

avoid topplin g. Use the most appropriate one for the installation conditions.

CAUTION

Do not block the vent ports of the equipment, or obstruct

airflow around the equipment.

When the vent ports are blocked, temperature inside cube

will rise and cause fire disaster. For example, do not use

the equipment in the following conditions.

(1) Install the equipment in places with poor ventilation.

(2) Place the equipment facing up, sideways, or upside -down.

(3) Place the equipment on a carpet or bedding.

(4) Cover the equipment with a cloth or curtain.

(5) Place packages around the equipment or lean/place items

against the equipment.

(6) Placing the equipment on a table, unstable base or directly

against a wall. Rear access is required for periodic

maintenance or inspection.

(7) Do not place the equipment where it may be exposed to

dust, oily smoke or steam such as a cooking area, etc..

(8) Do not place the equipment where it may be exposed to

wind and rain.

The screen may drop or fall down due to wind and cause

injury. Or rain may result in fire or electric shocks.

7

Page 8

PRECAUTIONS FOR USE AND MAINTENANCE

Request to User

Plastic Screen

The P503DL screen is made of a plastic material and can be easily scratched. During manufacture and

packing, every care is taken to ensure that no hard objects that could scratch or otherwise cause damage are

allowed to touch the screen when opening the carton box and taking out the product. Please exercise

caution, when unpacking the unit to prevent the packing material or other items from scratching and

rubbing the screen to avoid (i) damage to the screen and (ii) generation of static electricity which may attract

dust particles onto the screen.

Precautions on Use

Connection of a grounded cable

Ground the projection unit in order to prevent electric shock with 3-core power cable. There is greater danger

of electric shock when multi projection units are used without ground wire connected.

Condensation

When room temperature rises rapidly (or the Dat a Display projection unit is moved from a cold place to a

hot place), condensation may form on the lens, causing picture distortion or color fade-out. In such case, wait

for a while (with keeping power ON) until the condensation clears.

About cooling fan and color wheel motor

The axial cooling fan and also color wheel motor in the projection unit should be considered a consumable

item and need to be replaced after about one or two years of use or whenever noise or other symptoms of

breakdown are apparent. Contact your dealer for the replacement work.

** Air filter equipped at air intake needs periodical cleaning. A clogged air filter will result in temperature

build up inside the P503DL cabinet. Possibly in excess of stated operating specification, th is may lead to

malfunction or reduced equipment life.

Maintenance

Do not use solvent or paint thinner

If these are used, coating layer may peel off or deteriorate. If rubber or plastic comes into contact with the

projection unit for a long time, the projection unit may be stained.

Care of the screen

After switching the power supply off, gently wipe the screen with a soft cotton cloth. Since the screen

surface is easily scratched, this may also build up an electronic static charge. Do not rub it with a hard

object; the screen may be easily damaged. Never use a chemical duster.

Care of the cabinet

After switching the power supply off, wipe gently with soft cloth.

When using a chemical duster, follow the maker's precautions.

Care of the air filter

The air intake filter should be regarded as a consumable and changed on periodic bases, depending on the

operating conditions. If or when the filter becomes clogged (by oily smoke etc) replacement of the filter is

recommended.

For a temporally remedy, the filter may be cleaned by an oil removal cleaner, detergent used in a kitchen

or a diluted vinegar solution.

8

Page 9

GENERAL DESCRIPTIONS

FEATURES

l Digital Light Processing TM (DLP TM) by Texas Instruments

P503DL is a projection unit using the Texas Instruments’ Digital Mirror Device (DMD) TM optical element.

The DLP TM, Digital Light Processing TM engine is constructed with the DMD chip, with XGA resolution.

l Input capability

From PC video output card, SVGA signal is best suitable but some others are also compatible.

Incoming PC signal timing should be followed the VESA standard.

SVGA signal is reproduced on screen without having any scaling function.

The other frequencies are converted to XGA resolution inside the cube. See note 1.

In case of SXGA resolution such as 1280x1024, an original aspect ration of 5:4 is changed to DLP aspect

ratio of 4:3 so that picture may have different shape in this resolution.

l Internal magnification

A multi -screen system can be formed easily with an internal magnification up to x6 magnification.

l Superior image quality

* Native resolution of XGA, 1024 x 768 pixels

* No burn-in unlike projection tube

* High Contrast image by 12 -degree mirror flip Double Data Rate DMD chip

l Easy installation and maintenance

* Convergence free between colors

* Steady geometric alignment

* Engine installed at factory

l Easy replacement 10,000/6000 H (Survival rate of 50%) UHP 100/120W selectable lamp power,

See note 2

l Low power consumption

100W UHP lamp is used for light source, ballast power selection of 100W/120W is possible.

Total power consumption is less than 200W.

l Highly reliable control system

Projection system can be controlled with a PC via RS232C cable. Also most of the

control/adjustment is possible to do with optional wired remote control, CT-90000.

RS232C IN/OUT are equipped to send command and also for communication between cubes.

l Mechanical function

Screen escutcheon can be removed from front. The mullion size is 1.0mm. When adjacent cube

is attached, total mullion size becomes 2.5mm including gap in between.

Note 1: This does not mean that all the signals are accepted. For acceptable signals, refer to the later page in

Note 2: The lamp is expected to last more than 8000H, with the recent information, it will be more than 10000H, with

Acceptable Signal Type and also Acceptable RGB input Signal Timing.

survival rate of 50% at 100W power selection, however, the actual life of each lamp varies depending on

conditions of use. For warranty and exchange of lamp, please check with your dealer/distributor.

9

Page 10

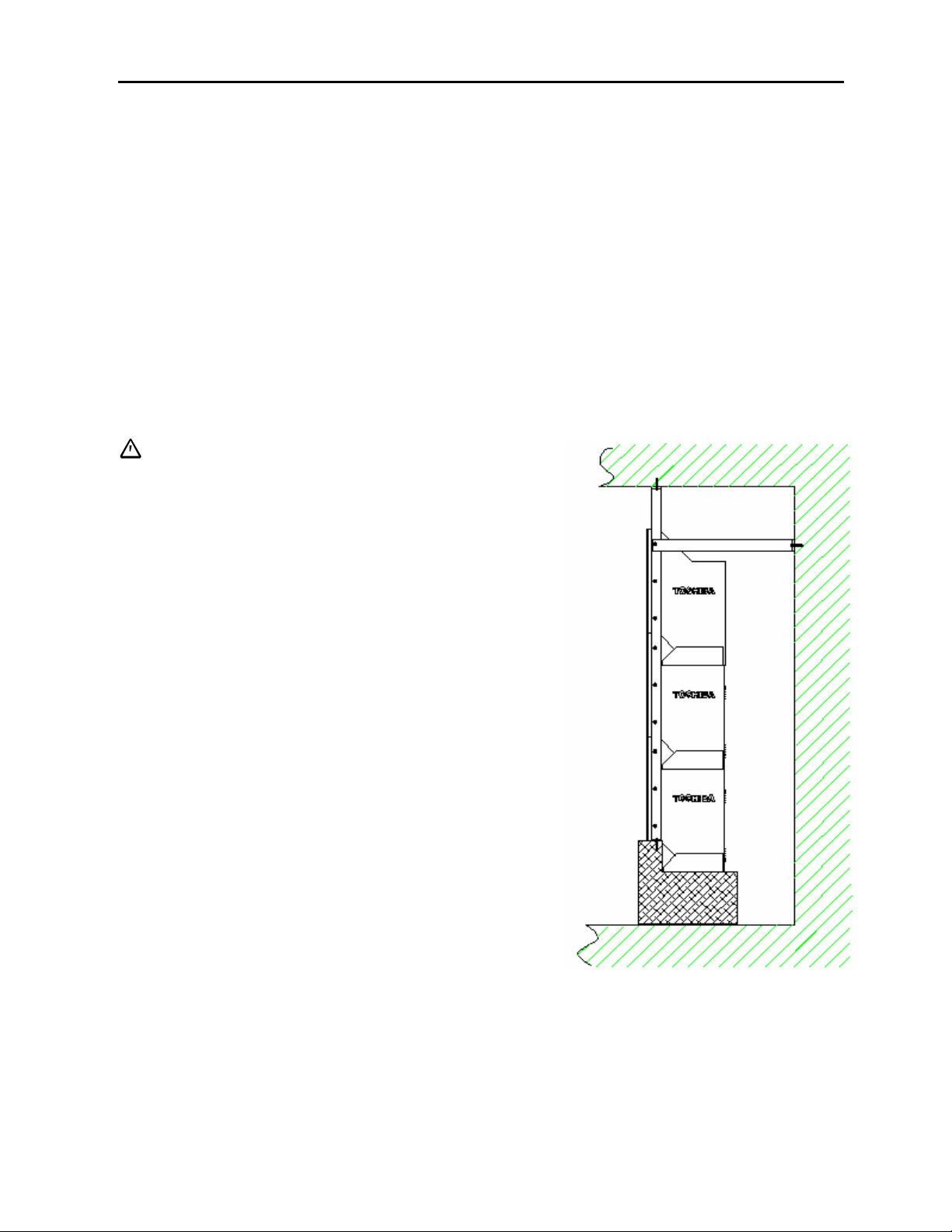

P503DL DIMENSIONS

Size: mm (inch)

Front Rear

[? ? ]

0.5 (0.02)

1016 (40.0)

0.5 (0.02)

0.5 (0.02)0.5 (0.02)

762 (30.0)

Side

550 (21.7)

[? ? ]

Top

[? ? ]

1050 (41.3)

550 (21.7)

[? ? ]

10

Page 11

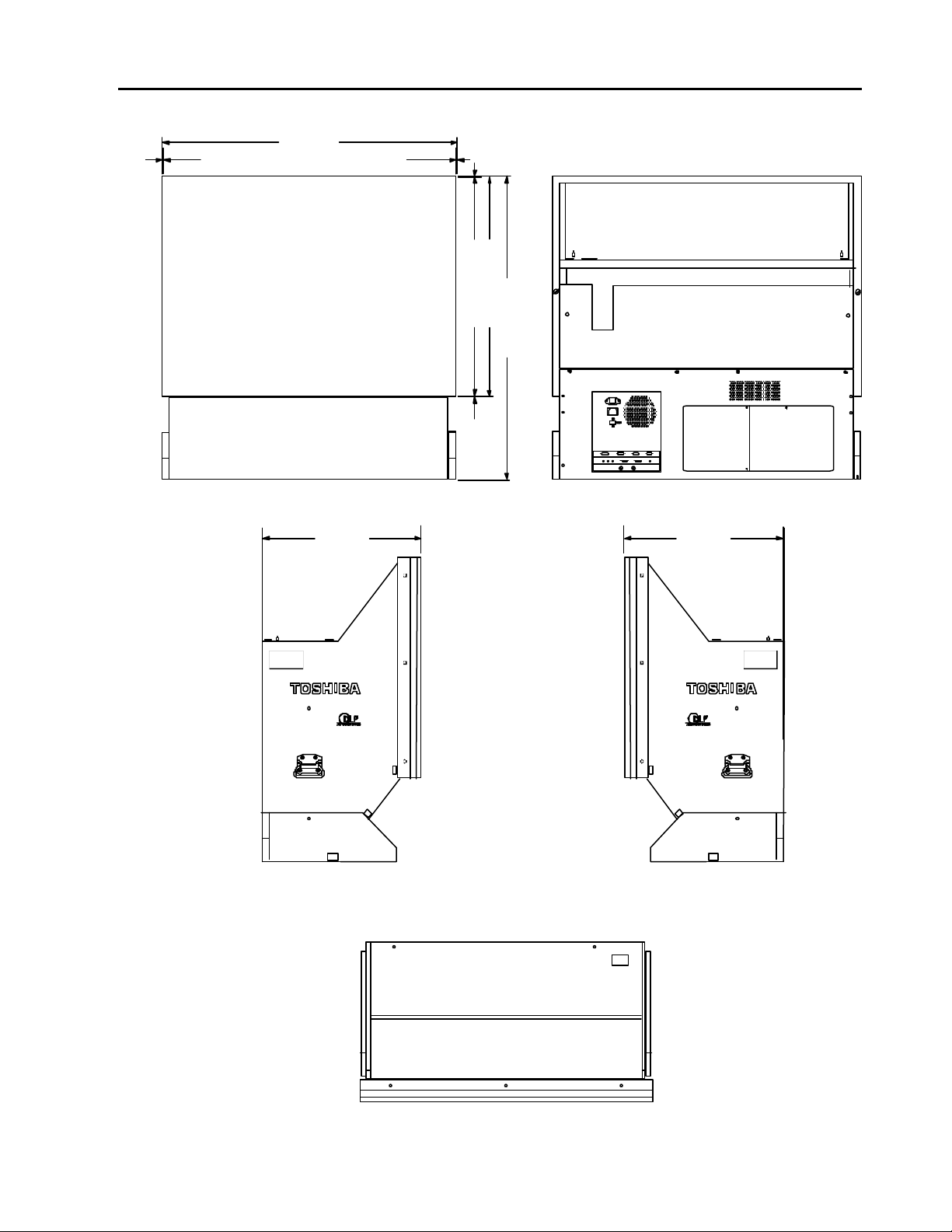

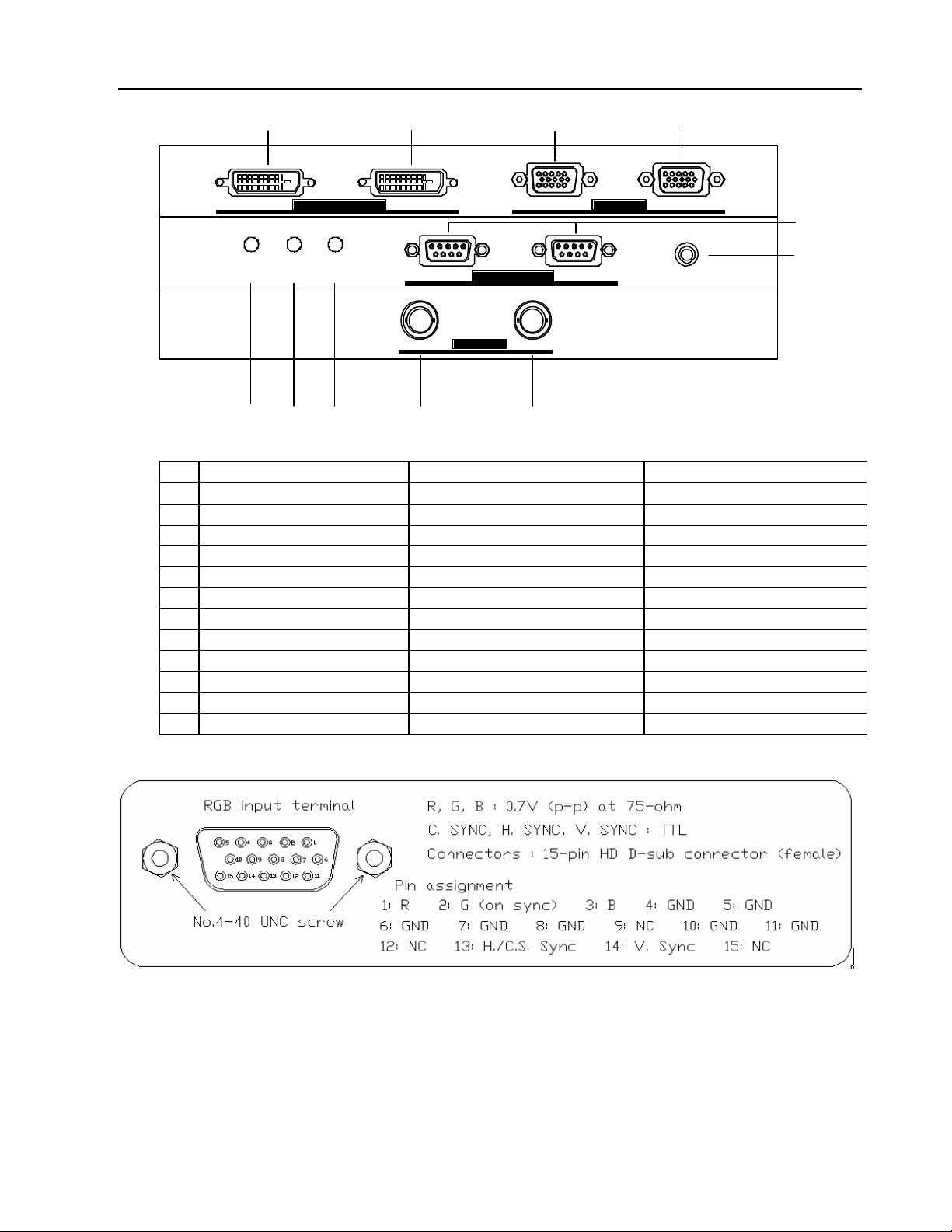

FUNCTION OF I/O PANEL

(7)

(6)

(5)

(10)

(11)

(1) (2) (3) (4)

OUT IN RGB 2 RGB 1DIGITAL SIGNAL LINK RGB INPUT

POWER FAN LAMP REMOTE

OUT

CONTROL RS-232C

VIDEO

(8)

(9)

INOUT

IN

No. Name Function Remarks

1 DVI Digital Output DVI Link (switched) Output Digital pins of DVI connector

2 DVI Digital Input DVI Input (Link or PC) Digital pins of DVI connector

3 RGB-2 Inp ut terminal RGB-HV signal Input D-sub HD 15 -pin (female)

4 RGB-1 Input terminal RGB-HV signal D-sub HD 15 -pin (female)

5 Power Indicator Power status indication Green/Red two colors LED

6 Fan Indicator Fan status indication Green LED

7 Lamp Indicator Fan status indication Green LED

8 RS232C Output RS232C Communication D-sub 9- pin (male)

8 RS232C Input RS232C Communication D-sub 9-pin (female)

9 Remote control Input jack Wired remote control 3.5mm stereo Mini Jack

10 Video Output Composite Video thru- Output BNC connector

11 Video Input Composite Video Input BNC connector

Note: Video signal: not fully compatible

Basic model does not include Video input terminal since the moving picture displayed with this

unit may not have full compatibility and picture will not display all the pictures supplied, it may

appear as missing field, picture lacks smooth movement

11

Page 12

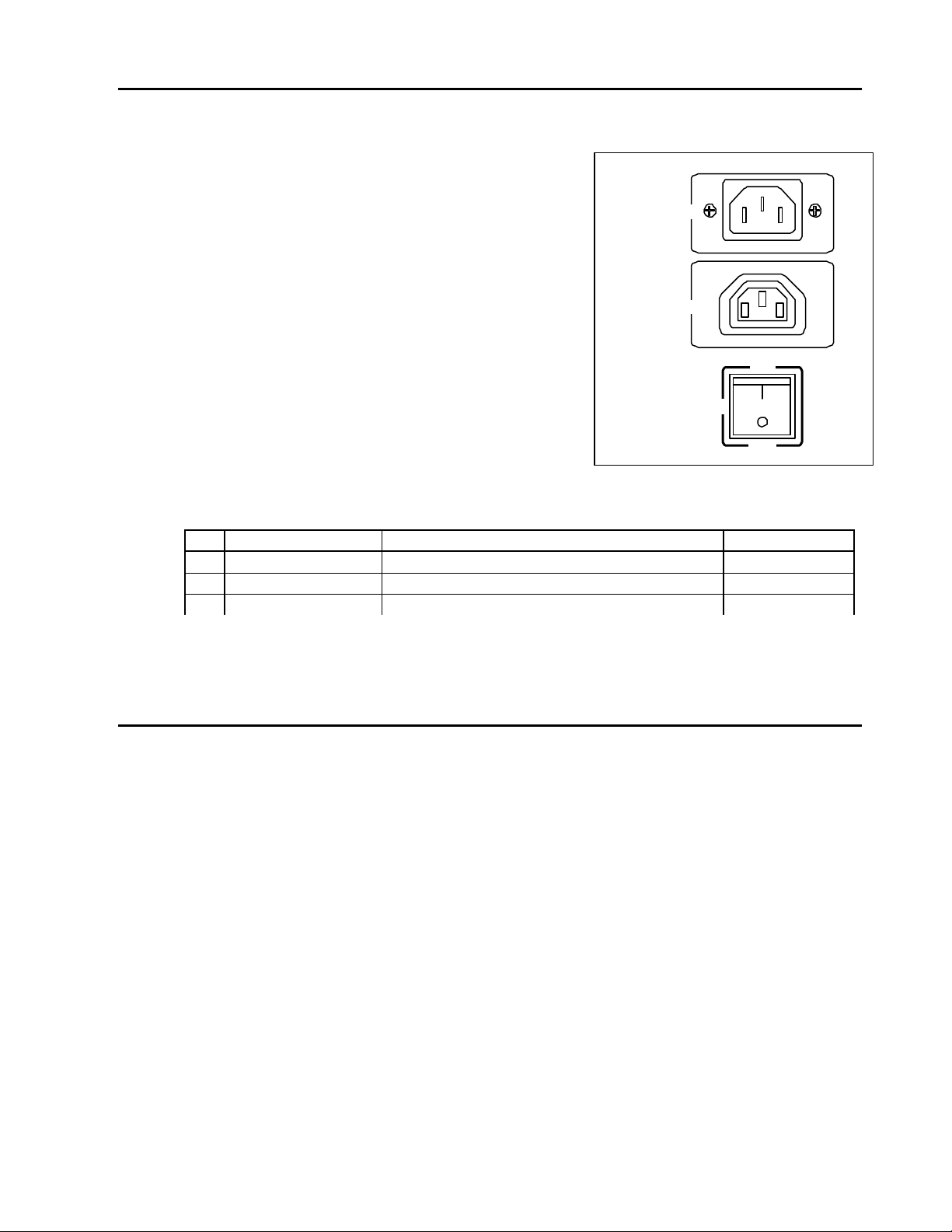

FUNCTION OF POWER PANEL

No.

1

2

3

Note 1: The AC outlet supplies un- switched power source to a

second unit in a multi-projection system.

Do not use it for any other purpose. Serial connection

using this power outlet must be maximum of four units

including the 1st unit.

Note 2: The plug type of the projection unit power cable may not

AC INLET

AC100~ 240 50/60Hz

AC100~ 240 50/60Hz

match the AC outlet. When power is to be supplied

to another unit from this AC outlet, please purchase

necessary power cable.

AC OUT INLET

UNSWITCHED 8A MAX

Note 3: About Power Supply cord

The Power Supply cord must be in accordance with

the applicable standards.

A three-core cord, one for ground, must be used.

POWER

The power cord must be at least 1.0mm2 and H05VV-F.

Name Function Remarks

Power Switch Turn ON and OFF main power ON/OFF

AC Inlet AC 100-240V, 50/60Hz input 3P plug

AC Outlet AC outlet, un -switched, max 8A 3P socket

POWER SWITCH AND POWER INDICATOR

AC power source is turned-on/off with the Power Switch. When the Power Switch is turned-on, the Power

Lamp LED Indicator lights in green, Fan indicator by green and some periods later, green at Lamp when

lamp is ON and the projection unit enters active state.

It takes about 30 seconds typically till an image is shown after Power Switch is turned -on.

In the active state, it is possible to power on/off with an external controller. When power is turned-off with

an external controller, the Power Indicator LED lights in red color and a projection unit enters standby

state.

Interval from turn-off to turn-on shall be more than 30 seconds. If the interval is not enough, the lamp

may not strike, longer the wait time, lamp life risk becomes less. If the user continues to repeat this

short wait re-strike, it may shorten the life of the lamp.

The power/lamp/fan indicators also indicate failure information of the projection unit by blinking light.

The later page at appendix list shows the lamp status.

( 2)

( 3)

ON

(1 )

OFF

12

Page 13

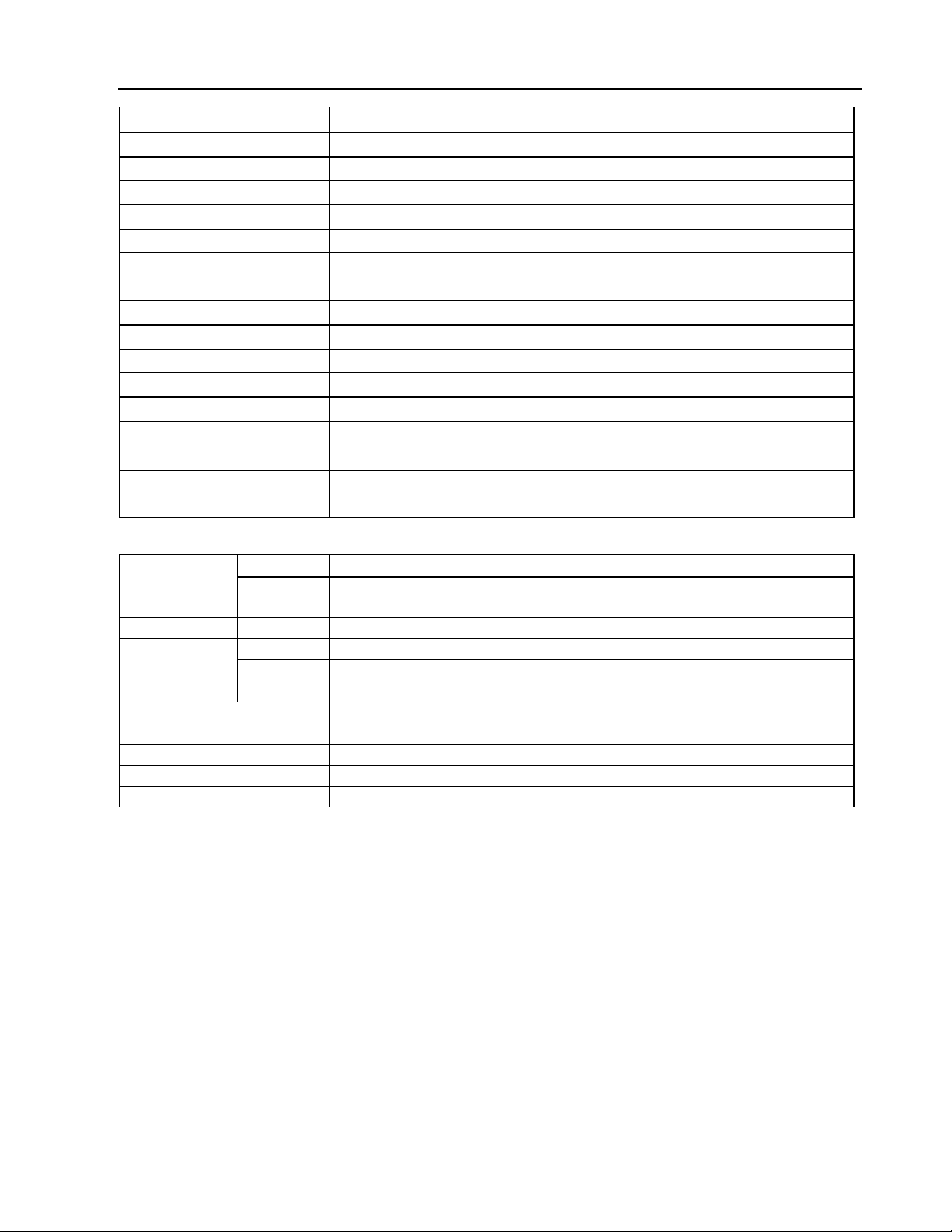

SPECIFICATIONS

Model name P503DL

Type 50- inch rear projection unit

Acceptable signals Refer to page 13 and page 14.

Image device 1 chip XGA Digital Mirror Device

Light source 100W/120W switch selectable UHP lamp

Resolution 1024 x 768 dots (Include part hidden with screen frame)

Brightness 500cd/m2 (Typ.) by 120W operation

Screen Fresnel sheet (internal), Lenticular sheet (external)

Screen frame 1 mm average (2.5mm between cubes when two are attached)

Viewing Angle Horizontal: Min. 150 degrees, Vertical: Min. 60 degrees

Operating temperature 5 -35 ? (41-95 F)

Operating humidity 30-70 % (Relative humidity non-condensing)

Power requirement AC100-240V, 50/60Hz, 200W (200VA)

Dimens ions 1016 (W) x 1050 (H) x 550 (D) mm (40.0 x 41.3 x 21.7 inch)

Weight about 63kg (139 lbs)

Accessories Owner’s Manual, Assembly screws

Video Input Terminal Video Composite Input: BNC

Level Video Input: 1.0Vp-p composite video, PAL/NTSC

DVI Input DVI signal from PC or Link, No HDCP compatible

RGB Inputs Terminal RGB input: HD D-sub 15pin (female) connector

Level R/G/B signal: 0.7Vp-p (75-ohm termination)

H.SYNC / V.SYNC signals: TTL

External control System: RS-232C, Terminal: D- sub 9pin (female) connector x 1

Speed: 1200, 2400, 4800, 9600 baud

Communication Link System: RS-232C, Terminal: D -sub 9pin connector x 2 for IN and OUT

Remote Control Terminal 3.5mm terminal for optional CT-90000 Remote Controller

The DVI i nput is compatible for PC signal but for 1080i HDCP.

DVI connector and RS232C cables are included as accessories. RS232C cable is common type and if

cubes are assembled more than 10 sets, RS232C communication error may become obvious by means of

its standard, length limitation. In such case, using better and thicker wire may extend the cable length

or possibly use buffered splitter and separate the wiring into two or more branch will result better

communication.

DVI output signal is possible to make link for any selected input but this DVI output comes after its

frequency converted digital output, having several frames of signal delay. Thus quick movement

such as moving video may result signal delay added by each cubes and picture may not match while

moving image displayed.

The specifications and design of this product are subject to change without notice.

(R)

Double Data Rate type

13

Page 14

ACCEPTABLE SIGNAL TYPE

59.94

50.00

55.90

85.08

60.02

The following are acceptable input signal types. Projection unit automatically distinguishes mode

according to frequency of input signal. All the signals accepted are displayed on screen with 1024x768 dot

by internal resolution converter. The Digital Signal Link function may not support NTSC/PAL/SECAM

signal supplied from RGB-1 and RGB-2 input terminal. Also, Digital Signal Link function may not

support unstable signal either.

Format Type Mode H. Freq. V. Freq. Input Sync Pol. Scan Type Input

Resolution H/V Terminal

NTSC 358-443 Standard NTSC2 15.734

PAL SECAM PAL2 15.625

NEC PC98 @56Hz NEC- 24k 24.820

VGA Graphic 350 lines @70Hz Text- 70 31.469 70.087 640 x 350

VGA Graphic 400 lines @70Hz Text- 70 31.467 70.087 640 x 400 N/P Non interlaced RGB IN

VESA 640 x 350 @85Hz TEXT85 37.861

VESA 640 x 400 @85Hz TEXT85 37.861 85.080 640 x 400

VESA 720 x 400 @85Hz TEXT85 37.927 85.039 720 x 400

VGA 640 x 480 @50Hz VGA50 26.250 50.000 640 x 480 N/N Non interlaced RGB IN

VESA 640 x 480 @60Hz VGA60 31.469 59.940 640 x 480

VESA 640 x 480 @72Hz VGA72 37.861 72.809 640 x 480

VESA 640 x 480 @75Hz VGA75 37.50 75.000 640 x 480

VESA 640 x 480 @85Hz VGA85 43.269 85.008 640 x 480

Macintosh 13 Inch Mode @67Hz MAC13 35.000 66.667 640 x 480

SVGA 800 x 600 @50Hz SVGA50 31.400 50.000 800 x 600 N/N Non interlaced RGB IN

VESA 800 x 600 @56Hz SVGA56 35.156 56.250 800 x 600

VESA 800 x 600 @60Hz SVGA60 37.879 60.317 800 x 600

VESA 800 x 600 @72Hz SVGA72 48.077 72.188 800 x 600

VESA 800 x 600 @75Hz SVGA75 46.875 75.000 800 x 600

VESA 800 x 600 @85Hz SVGA85 53.674 85.061 800 x 600

Macintosh 16 Inch Mode @75Hz MAC16 49.725 74.550 832 x 624

XGA 1024 x 768 @50Hz XGA50 40.300 50.000 1024 x 768 N/N Non interlaced RGB IN

VESA 1024 x 768 @43Hz XGA43 35.522 43.479 1024 x 768 P/P Interlaced RGB IN

VESA 1024 x 768 @60Hz XGA60 48.363 60.004 1024 x 768 N/N Non interlaced RGB IN

VESA 1024 x 768 @70Hz XGA70 56.476 70.069 1024 x 768 N/N Non interlaced RGB IN

VESA 1024 x 768 @75Hz XGA75 60.023 75.029 1024 x 768 P/P Non interlaced RGB IN

VESA 1024 x 768 @85Hz XGA85 68.677 84.997 1024 x 768 N/N Non interlaced RGB IN

Macintosh 19 Inch Mode @75Hz MAC19 60.135 74.700 1024 x 768 N/N Non interlaced RGB IN

SXGA 1280 x 1024 @50Hz SXGA50 53.000 50.000 1280 x 1024

VESA 1280 x 1024 @60Hz SXGA60 63.981.

VESA 1280 x 1024 @75Hz SXGA75 79.976 75.025 1280 x 1024

SEGA 640 x 480 @60Hz SEGA60 31.678 79.770 640 x 480 N/N Non interlaced RGB IN

Bowling 430 x 252 @60Hz 15.78 15.780 60.692 430 x 252 N/N Non interlaced RGB IN

Timing C 640 x 480 @60Hz Tri-F60 31.469 59.941 640 x 480 N/N Non interlaced RGB IN

480p 720 x 480 @60Hz 480p 31.542 60.080 856 x 525 N/N Non interlaced RGB IN

720p 1280 x 720 @60Hz 720p 45.000 60.000 1650 x 750 N/N Non interlaced RGB IN

EDTV 720 x 480 @60Hz EDTV 31.469 59.941 858 x 525 N/N Non interlaced RGB IN

Note 1: In composite sync or sync- on-green signal, H sync signal must be inserted into V sync signal.

No good Good

N/N Interlaced Video IN

N/N Interlaced Video IN

640 x 400

640 x 350

1280 x 1024

N/N Non interlaced RGB IN

P/N Non interlaced RGB IN

P/N Non interlaced RGB IN

N/P Non interlaced RGB IN

N/N Non interlaced RGB IN

N/N Non interlaced RGB IN

N/N Non interlaced RGB IN

N/N Non interlaced RGB IN

N/N Non interlaced RGB IN

- / - Non interlaced RGB IN

P/P Non interlaced RGB IN

P/P Non interlaced RGB IN

P/P Non interlaced RGB IN

P/P Non interlaced RGB IN

P/P Non interlaced RGB IN

- / - Non interlaced RGB IN

N/N Non interlaced RGB IN

N/N Non interlaced RGB IN

P/P Non interlaced RGB IN

Note 2: In H/V separation sync signal, V sync signal must not be included H sync signal or equalization

pulse. Also, H sync signal must not included V sync signal and equalization pulse.

14

Page 15

V sync signal

59.94

50

85

118

TEXT70

48

382

TEXT70

48

132

TEXT70

54

382

TEXT70

54

132

TEXT85

96

323

TEXT85

96

13

TEXT85

13

40

50.00

182

40

59.94

182

173

75

13

80

13

96

86435

33

88

1056

14

1024

56.2536

12

88

1056

14

64

1040

376

1056

75

13

1048

13

224

1152

74.55

13

No good Good

No good (Equalization pulse)

H sync signal

Note 3: When composite sync or sync-on- green signal is supplied, horizontal frequency must be 31 kHz or

higher.

Note 4: Sync signal : Horizontal Positive or Negative. Minimum H. sync width : 1µS

Vertical Positive or Negative. Minimum V. sync width : 2H

ACCEPTABLE RGB INPUT SIGNAL TIMING

Following are acceptable RGB input signal timings which have been tested by Toshiba. These are timings

checked on the RGB input terminals of projection unit. If signal supplied is not exactly the same as one of

the followings but is simile to one, it may be accepted by adjustment of projection unit.

When picture caused horizontal jitter or display position difference, adjust the projection unit with optional

controller. However, when signal cable used or other factors have problems, timing may cause trouble and

picture will not be stable. When signal is not stable, each function of projection unit will not be guaranteed

for good picture display.

R,G,B

H.Sync

Mode Input A B C D E fH fV Clock G H I J K

Resolution

NTSC 2 15.734

PAL 2 15.625

NEC24

k 640 x 400

640 x 350

640 x 400

720 x 350

720 x 400

640 x 350

640 x 400

720 x 400 108 720 36 72 936 37.927 85.039 35.500

VGA50 640 x 480

VGA60 640 x 480

VGA72 640 x 480 120 640 32 40 832 37.861 72.809 31.5

VGA75 640 x 480 120 640 16 64 840 37.5

VGA85 640 x 480

MAC13 640 x 480

SVGA5

0 800 x 600

SVGA5

6 800 x 600 128 800 24 72

SVGA6

0

SVGA7

2 800 x 600

SVGA7

5 800 x 600 160 800 16 80

SVGA8

5

MAC16 832 x 624

800 x 600

800 x 600 152 800 32 64

(Pixels) (Pixels) (Pixels) (Pixels) (Pixels

Horizontal Timing

A B C

R,G,B

V.Sync

D

640 59 64 848 24.820 55.900 21.053

640 14 96 800 31.469 70.087 25.175

640 14 96 800 31.469 70.087 25.175

720 18 108 900 31.469 70.087 28.322

720 18 108 900 31.469 70.087 28.322

640 32 64 832 37.861 85.080 31.500

640 32 64 832 37.861 85.039 35.500

640 24 96 800

640 24 96 800 31.469

640 56 56 832 43.269 85.008 36

640 64 64

800 40 128

800 40 128

800 56 120

832 32 64

E

) (kHz) (Hz) (MHz) (Lines) (Lines) (Lines) (Lines) (Lines)

26..25

0

66.667 30.24

31.40 50.0 33.158

35.156

37.879 60.317 40

48.079 72.188 50

46.875

53.674 85.061 56.25

49.725

15

Vertical Timing

G H I

J

16.521

16.406

21.00

25.175

31.5

49.5

57.283

K

25 400

60 350

35 400

60 350

35 400

60 350

41 400

42 400

25 480

25 480

20 480

16 480

25 480

39 480

23 600

22 600

23 600

23 600

21 600

27 600

39 624

440

449

449

449

449

445

445

446

525

525

520

500

509

525

628

625

628

666

625

631

667

Page 16

1024

1344

36

1024

1344

60.004

36

144

1024

1328

36

1024

1312

13

1024

1376

13

1024

1328

43

1280

1688

13

1066

1280

1688

60.02

13

1066

1280

1688

13

1066

87

143

46

24

96

56

96

1024

1650

55

59

66

A C

? ?

A C

? ?

Wired remote control

RGB

-

2 signal

AC power

This is one of the example of connection

XGA50 1024 x 768 160

XGA60 1024 x 768 160

XGA70 1024 x 768

XGA75 1024 x 768 176

XGA85 1024 x 768 208

MAC19 1024 x 768 172

24 136

24 136

24 136

16 96

48 96

34 96

40.30 50.0 54.163

48.363

65

56.476 70.069 75

60.023 75.029 78.75

68.677 84.997 94.5

60.135 74.7 79.86

29 768

29 768

29 768

28 768

36 768

30 768

SXGA5

0

1280 x 1024

248

48 112

53.30 50.0 89.97

38 1024

SXGA6

0 1280 x 1024

248

48 112

63.981

108

38 1024

SXGA7

5 1280 x 1024

248

16 144

79.976 75.025 135

38 1024

SEGA6

0

640 x 480

15.78 430 x 252

Tri-F60 640 x 480 116 640 38 64 858 31.469 59.941 27.000

480p 720 x 480

720p 1280 x 720 270

EDTV 720 x 480

640 43 82 852 31.678 59.770 26.990

430 10 33 519 15.780 60.692 8.190

720 16 64 856 31.542 60.080 27.000

260 96

45.000 60.000 74.250

720 16 63 858 31.469 59.941 27.000

33 480

2 252

30 480

30 480

20 720

33 480

Note 1: The clock pulse is made in projection unit automatically. External clock input is not equipped.

Note 2: When 15kHz NTSC/PAL signal is supplied to the RGB input terminal, the Digital Signal Link function is not guaranteed for correct

signal transfer.

Note 3: When signal except standard type (for example, played back software with a copy guard or a special effect play of VCR, etc.) is

supplied to the RGB input terminal, projection unit may not function properly.

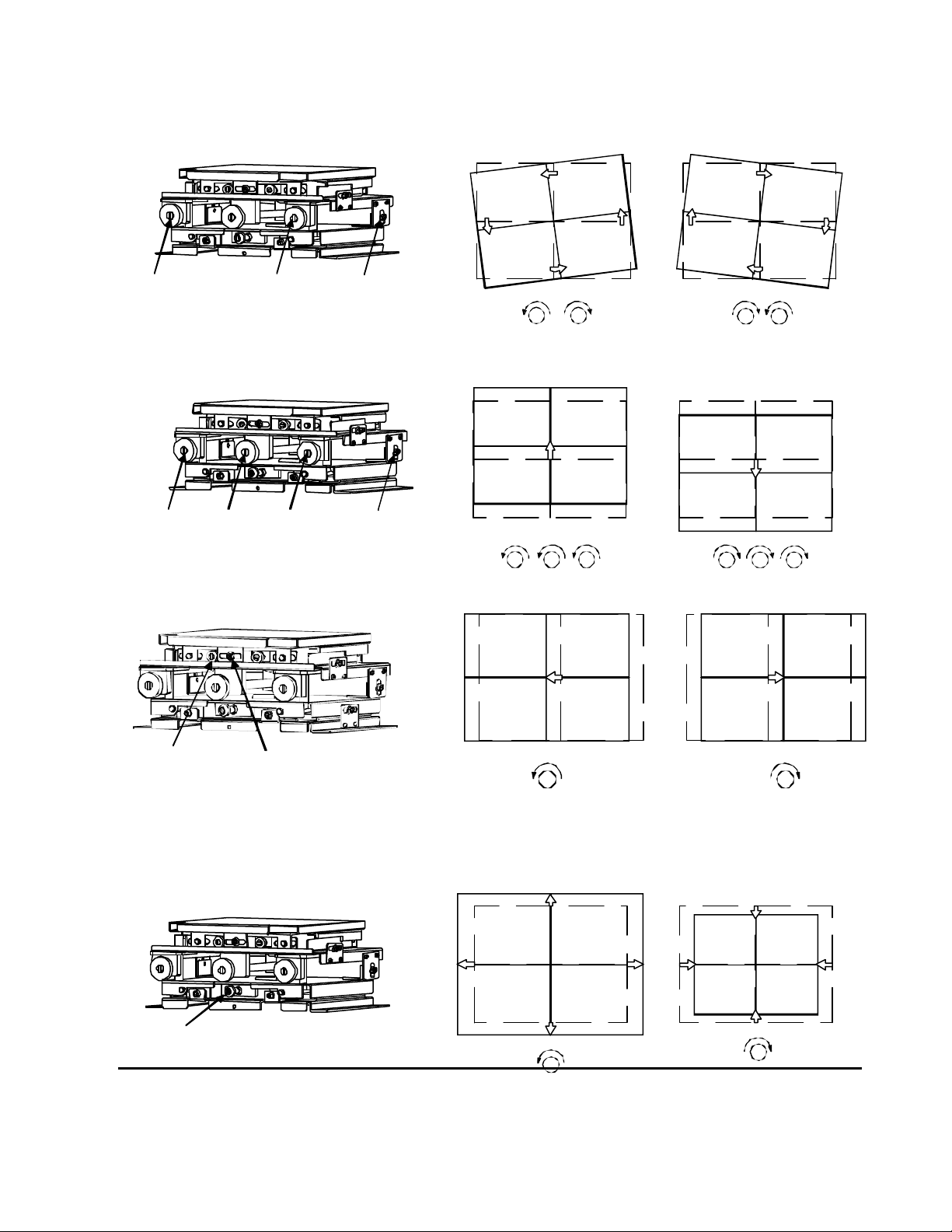

CONNECTION AT A MULTI PROJECTION SYSTEM

806

806

806

800

808

805

530

260

525

525

750

525

? ? ? ? ? ? ? ? ?

R G B? ? -1

RG B? ? -2

? ? ? ? ?

Video signal

OUT IN RGB 2 RGB 1DIGITAL SIGNAL LINK RGB INPUT

AC INLET

15A 125V/250V AC

AC OUTLET

AC100V-240V 50/60Hz

UNSWITCHED MAX 10A

A C ? ?

RGB-1 signal

OUT IN RGB 2 RGB 1DIGITAL SIGNAL LINK RGB INPUT

AC INLET

15A 125V/250V AC

AC OUTLET

AC100V-240V 50/60Hz

UNSWITCHED MAX 10A

Digital Lin k

DIGITAL SIGNAL LINK RGB INPUT

CONTROL RS-232C INOUTPOWER FAN LAMP REMOTE

VIDEO

OUT IN

OUT IN RGB 2 RGB 1

RS232C link

Unit-4 Unit-3

AC INLET

15A 125V/250V AC

AC OUTLET

AC100V-240V 50/60Hz

UNSWITCHED MAX 10A

A C ? ?

CONTROL RS-232C INOUTPOWER FAN LAMP REMOTE

VIDEOOUT IN VIDEOOUT IN

Unit-1

OUT IN RGB 2 RGB 1DIGITAL SIGNAL LINK RGB INPUT

Unit-2

AC INLET

15A 125V/250V AC

AC OUTLET

AC100V-240V 50/60Hz

UNSWITCHED MAX 10A

AC power

CONTROL RS-232C INOUTPOWER FAN LAMP REMOTE

VIDEOOUT IN

CONTROL RS-232C INOUTPOWER FAN LAMP REMOTE

16

for a multi-projection system using four

projection units.

In this example, signal sources are

supplied from composite video signal to

video-card and signal from a PC is

connected to each cubes by signal links.

The optional wired remote controller is

connected to Unit-1 and all the units

could be controlled by the remote

control through System Bus-Link when

RS232C communication links are daisy

chain connected.

The final RS232C output should not

return to 1st cube.

When both, RS232C control signal and

CT-90000 wired remote control are

connected, the remote control has a

priority over PC, RS-232C connection

thus PC control is not possible.

AC power source

This can be also possible to link up to 4 sets

by separately purchasing 6ft monitor power

interconnect cable

MULTIPLE CONNECTION

Page 17

Left side

Note: Maximum len

gth of the RS232C cable in total length is about 20

-

30 meters.

With this model DVI output is possible to form signal link connection by daisy

-

chain connection of

If the length becomes much more than its specification, the communication error may occur.

When some miss-reading of commands start to occur, then use better quality wire than its standard

may reduce trouble and possible to extend the communication wire length.

Using RS232C signal buffer distributor and separate the cable connection into two or more will also

Reduce miss- communication troubles.

DVI cables. When this feature is used, several frames of signal delay will occur by each cube’s

electronic circuit so that when moving picture is supplied, picture junction may not match.

When the set is opened from its carton box, 1st thing to do is to

remove the screen protection metal plate attached at the corners.

Note: * Pay attention not to touch the screen.

* When temporally place the screen, avoid screen

Screen protectors

? ? ? ? ? ? ? ? ? ? ?

touching to the other objects or materials.

The screen is locked by small tab at sides and screw attached

to the tab need to rotate to un-lock the screen frame.

The picture shows the

screws which are vertical

Screen Lock screws

Right side

slit, this position make

the screen lock released.

When this screw slit is

rotated to 90-deg. horizontal,

the screen frame is locked.

Another arrow with two points

Indicat e the push rod position.

3)

Screen Lock screw The screen can be removed by

? ? ? ? ? ? ? ?

holding both sides of the frame

and pull forward gently.

When wall assembled, then it

3)

2)

1)

is impossible to hold both sides

3)

of the frame thus, one person at

? ? ?

Guide rail front and another person at back

and at back person needs to push

the rod by long push pole.

3)

Any long push bar or pole can be

Screen Assembly used but strong, not easily bend

? ? ? ? ? ? ? ? ?

pole is needed.

3)

MULTIPLE CONNECTION

When attaching the screen, confirm the screen lock screw slit if it is placed vertical position so that the

17

Page 18

screen lock is un-locked and open before attaching the screen.

This is an example of 4 sets attached together by 2x2 configuration. When 4 sets are combined together

with the screws fastened, a gap between cubes becomes small and also stable for entire wall.

The internal locking screws need to be fastened while front screen has removed, carefully watching

frame of each cubes. Do not tighten the screws very strong, aluminum frame may be deformed by

such strong fastenings.

M8 screw 20mm long Hex key screw

Tightening torque: 20-25N.m

At the back of the each cubes, there are two small

plates located top portion at both sides and they

can be used to fasten cubes horizontally or vertically

for rear enforcement.

To do this, remove one of the screw, make loose for

another and rotate the plate then fasten to adjacent

cubes together.

As for the connection of wires, refer to the previous page, page 15 for one of the example.

The following left example shows the connection to use internal magnification capability and right

Example indicates the combination with external signal processor.

18

Page 19

DISASSEMBLE

? ? ? ? ? ? ?

? ? ? ? ? ? ?

e: When the lamp unit is not placed correctly, brightness or other picture performance may not be

DISASSEMBLY

Lamp housing

L

amp unit

Note: Lamp housing and Lamp may be

5) Attach new lamp at the

1. HOW TO REPLACE THE LAMP

1) Turn off the power switch and disconnect AC cord.

Make loose 3 screws at the lamp door.

2) Open Lamp door as right picture arrows show.

3) Rotate Locking Lever as shown as

arrow (1) below.

4) Gently pull the lamp housing

?

to the right as picture below, Lamp door screws

arrow (2) shows.

?

Lamp door

Screws are shown enlarged

hot, be careful when touch to it.

?

?

Do not touch lamp glass shield, an

oil particle from finger may affect

picture quality or lamp may be

damaged.

Wipe and clean lamp glass shield

?

?

?

? ? ? ? ?

surface before its installation if it

was not clean.

Lock Lever

guide rail shown as right

Lock lever

then slide as arrow (1) shows.

Lock lever needs to be at un-lock

?

position, then push in the lamp

holder at the right place.

Lock the Lock ring by lock lever

as arrow (2).

?

Lamp Unit

Not

Achieved to the specification. Make sure that the lamp is nicel y fit and fastened.

Check also if the lamp power supply connector is securely inserted.

6) Attach lamp door.

7) Turn ON the power switch, connect PC with software, Cube commander, or remote control, then

enter to the ADJUST mode à SPECIAL mode à F à STD thus the lamp timer is reset.

? ? ? ? ? ?

Guide rail

19

Page 20

? ?

2. AIR FILTER

Air filter needs to be maintained periodically by washing it or replace when the filter is damaged.

1) Turn off the power switch and remove one screw.

2) Lift up and pull the air filter case from its pocket

as arrow in the picture shows.

3) Wash and clean the filter and dry it.

3. Place the clean filter at its original place.

4.Fasten the screw.

Note:

This filter cleaning may be necessary to check and clean

in every 3 months of period.

Filter case

Continuous usage of clogged filter will affect to raise the internal

temperature and may reduce the life of the components. Screw

3. CABINET DISASSEMBLE

1) When mechanical position adjustments are needed, only the small door may be open to do.

This is located at almost center position.

Right side is lamp replacement door which

has door switch to shut off lamp when

opened.

2) When all the mechanism and electronics

area to be shown, then, the rear panel

needs to remove as right picture.

3) Location of the light engine or other

parts, the next chapter explains them.

Front and rear portion are fastened with

many screws to avoid electronic emission

radiation.

Use all the parts and screws to assemble to

have the same condition and reduce excessive

emission from the electronics parts.

Refer to next page picture for following

When Lamp ballast needs to remove, take 3 screws

out and pull it up. When I/O control box needs to be removed, after removing screws, pull

forward a little, sometimes, it may be convenient to remove ballast unit before this.

? ?? ? ? ? ? ?

DISASSEMBLE

20

Page 21

4. LOCATION OF KEY COMPONENTS AND FUNCTION MODULE

Power

module

Lamp Ballast

(A) Left-Right position adjustment

This illustration indicates the key components

? ? ? ? ? ?

? ? ? ? ?

Power Module

Control Module

Lamp power

DLP? ? ? ?

(1)..... ? ? ? ? ?

(2)..... D M D? ? ? ?

shown after rear panel has removed.

? ? ? ? ? ? ?

? ? ? ? ? ? ? ? ?

(2)

(4)

(1)

(3)..... ? ? ? ? ? ? ?

(4)..... ? ? ? ? ? ?

(5)..... ? ? ? ? ?

selection switch

is at here à

(5)

DLP Light Engine

(1) Projection Lens

(2) DMD Control Board

(3) Lamp unit

(4) Input signal connector

(5) Exhaust Fan

(3)

? ? ? ? ? ? ? ? ? ? ?

Control Module

Right picture shows the

screws used to fasten each

blocks.

Removing the screws

written, every unit can be

removed.

This picture shows enlarged

screw size, actual screws are

much small.

DISASSEMBLE

(B)

(A)

Engine Mount,

Adjustment platform

? ? ? ? ? ? ? ? (? ? ? ?? ? )

(A).......... ? ? ? ? ? ?

(B).......... ? ? ? ? ? ? ? ? ? ? ? ?

(C).......... ? ? ? ? ? ? ?

(D).......... ? ? ? ? ? ? ?

? ? ? ? ? ? ?

(C)

(D)

(B)

(B) Top to bottom Trapezoid, position

adjustment

(C) Right to left Trapezoid adjustment

(D) Picture Size adjustment

? ? ? ? ? ? ? ? ?

Lamp Ballast

DLP? ? ? ?

DLP Light Engine

21

Page 22

5. WIRING BETWEEN FUNCTION BLOCKS

Note:

Colors of drawing are not

Representing the color of wires

Note: 100W/120W lamp power selection ** selection of lamp power while lit will damage lamp**

At the left side of the optical engine, there is a slide switch located and indicated that the lamp power

switch is set to 100W position. Do not change the switch while powered. Turn off and select the switch.

DIASSEMBLE

22

Page 23

6. LIGHT ENGINE BLOCK

Lamp Ballast

30-pin connector

50-p

in connector

Power connector

(A)

(B)

(J)

(C)

(F)

(K)

? ? ? ?

? ?

? ? ? ?

? ? ?

? ?(? ? ? ?

? ?

)

focus

adjustment knob

CAUTION

Be careful to prevent the ESD (Electro Static Discharge) before touching the DLP Engine.

If ESD happened, important key components including DMD device may easily damaged.

This electro -static destruction will not be covered by Texas Instruments guarantee.

For ESD prevention, use conductive wrist strap and connect the wire to the metal frame of the

projection engine.

The light engine is

5 0 ? ? ? ? ? ?

3 0 ? ? ? ? ? ?

Placed on the mechanical

Adjustment platform.

When adjustments for

picture position or

distortion are necessary,

electronics adjustments will

not compensate the image.

connector

? ? ? ? ? ? ? ?

Lamp power

selection à

switch locates

here

To perform, mechanism adjustments

are necessary. The adjustment table

(platform) needs to be adjusted at the

right place but before doing this

adjustment, it is important to set

an electronic position adjustment

should be at the center.

Light Engine

placement

guide pins

at bottom

ADJUSTMENT

. 1. DLP Engine adjustment

(E)(D)

When DLP E ngine is replaced, most of occasion,

following adjustments are needed.

New DLP engine may have some position

displacement. The engine mount base

has limited adjustment range but enable

to cover most of position adjustment.

1) Loosen and release the screw tension

which are used to fasten engine mount

base (E) (I) (J) (K), to avoid any

displacement during transportation.

2) Lens Focus Adjustment

Before doing mechanical position adjustment,

Check if optical focus is out or not.

If the displayed picture, possibly using internal

Test signal, cross-hatch, did not appear sharp,

Then lens focus needs to re -touched

? ? ? ? ?

Lamp power

connector

(H) (I)

? ? ? ?

23

Page 24

ADJUSTMENT

(G2)

(1) Locate the screw at the lens barrel to adjust focus

(2) Rotate thumb screw to counter clockwise, then move the screw head to and fro to rotate so that

lens focus can be adjusted.

(3) Tighten the same screw to clockwise to fix the adjustment.

(4) Engine mount adjustment preparation

(5) Before doing Engine Mount mechanical adjustment, it is better to adjust an electronic position

adjustment at the center.

Use remote control or Cube adjustment software and enter Adjust mode, then perform H-V position

adjustment, then place at the center of the range so that electronically, it is at the center.

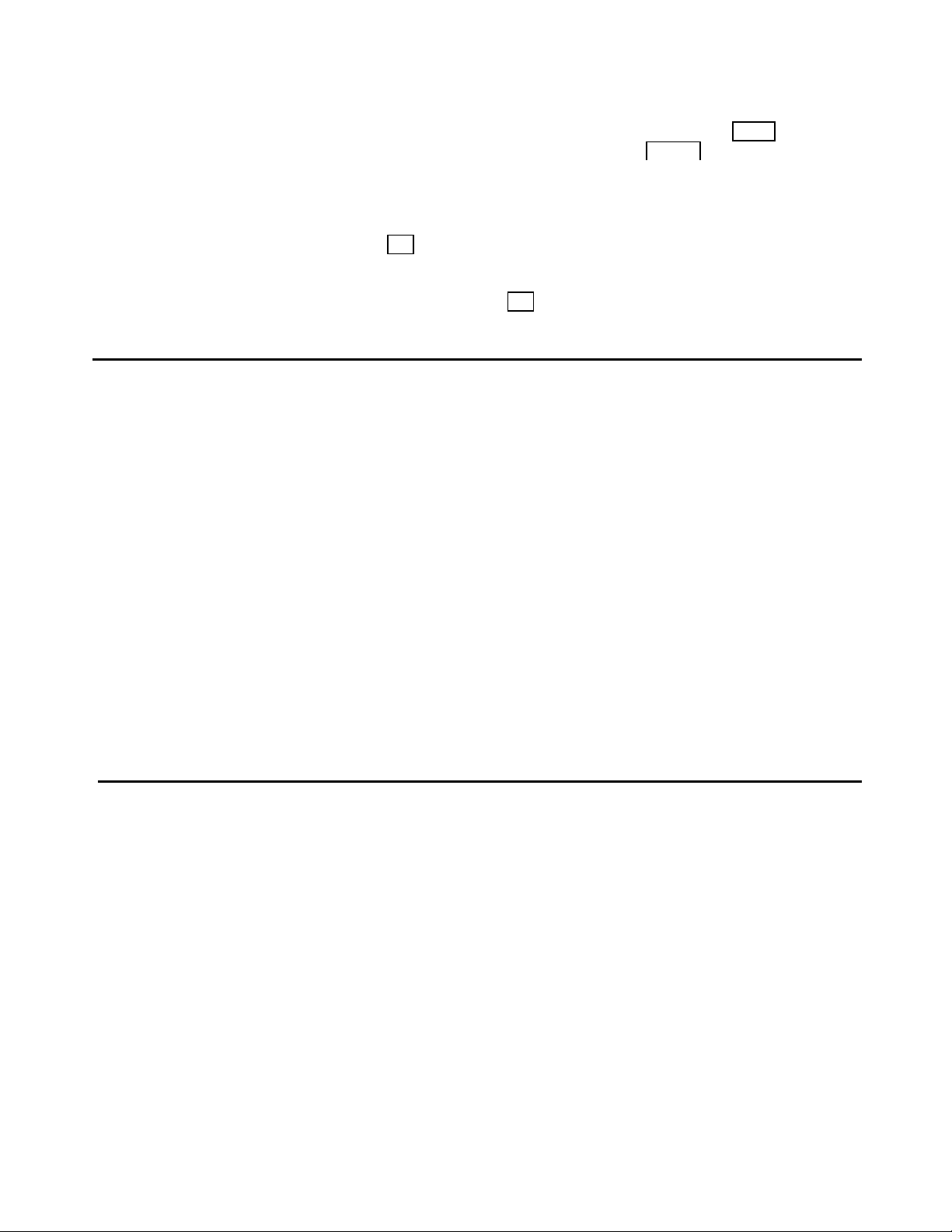

2 . ENGINE MOUNT ADJUSTMENT

1) Use internal test signal, TEST.P #07, thus full frame cross-hatch image appears on the screen

2) Left to Right Trapezoid adjustments can be performed by rotating (H) screw.

By doing this Adjustment, horizontal position will move but disregard its movement of position.

Obtain parallel image at top and bottom, then re-adjust position after this trapezoid adjustment.

When top/bottom parallel adjustment is done, tighten (J) screw.

? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?

Image movement is shown when observed from behind of the set.

(H)

(I)

H

H

3) Top to Bottom Trapezoid can be compensated by the small mirror at (G1) (G2) screws.

The picture is on the next page.

There are total of 8 screws which are not so much touching to the mirror and these s crews

Will add mirror bend thus the image distortion can be compensated but this top/bottom is

Basically done by these G1 and G2 screws. Adjust the image by rotating the screw so that left

and right becomes parallel.

By doing this adjustment, vertical position will change but do not worry about position

displacement. Obtaining parallel at right/left is important, then adjust position.

(G1)

ADJUSTMENT

G1 G2 G2G1

24

Page 25

4) Picture rotation adjustment

Make loose of (J) screw and rotate the screw (A) and (B) to the same amount but the opposite

direction so that picture rotation can be changed. If rotated to the same direction Vertical

position will change. Tighten (J) after the adjustment.

(A) (B)

5) Vertical position adjustment

(J)

A B

Make loose the (J) screw and rotate (A) (B) (C) screws for the same amount, vertical position

adjustment could be done. Tighten (J) after the adjustment.

6) Horizontal position adjustment

(A) (B)

(C)

(J)

A CCAB

Loosen screw (E) and adjust (D) screw for horizontal position. Tighten (E) after the adjustment.

7) Image size adjustment

(D)

(E)

D D

Rotate (F) screw so that entire table will move to front or back. Placing the adjustment table far

from the screen will make the picture size bigger and closer the table will result the size sm aller.

Adjust the size to the point that 2 pixels will be hidden by mullion. The outside line of the internal

test signal will appear for 6 pixels thickness in the image.

Do not adjust this if mechanism comes to an end, further adjustment will damage the mechanism.

(F)

F

ADJUSTMENT

Above adjustments will do positioning and also sizing. The position could be compensated by the

electronic adjustment but the size needs to be done mechanically. It is better to make mechanical

adjustment as much as possible so that any different magnification, the image will appear right.

25

BA

B

F

Page 26

8) Upper portion Pin-cushion adjustment

This adjustment is to bent the mirror and make the adjustment, do not over do it.

This adjustment is easy to do while cube is not assembled to wall but even assembled, it is possible

to perform removing the screen of the cube, attached on it.

Important Notice:

Do not exceed the adjustment too much, when mechanism comes to an end of its adjustment area,

there is no stopper mechanism provided and further forcing to do so will make fatal damage to the

mechanism.

These mechanical adjustments are important to display all the light coming out from engine to

the full screen. If this mechanism adjustment is not good, picture may not appear in full screen

however by electronic position and capture may possible to display.

Still, the 1st adjustment to obtain the full image is not an electronics but mechanism.

After performing all the mechanical adjustments, then electronic adjustment could be started.

Here is the summary of the adjustments.

1. Mechanical position adjustment by internal or external flat-field picture. Before this adjustment,

it is better to reset all the electronic position adjustments at the center/reset value.

2. Electronic Picture Position adjustment by external signal, there may be a little differences between

internal and external signal positions so that the signal which is generated from the PC which will

be used, is the best to supply.

3. After the position adjustments, then, color balance adjustment would be performed.

DMD drive condition can be changed by “Cutoff” and “Drive”. These adjustments could be

Done by internal test signal.

Then, “Offset” and “Gain” are provided to compensate the difference of signal level from PC.

3. Electronics Adjustment or Setting

Selection or adjustment can be performed using optional Remote Control, model CT-90000 or no

Ob ligation, user-risk freeware, “Cube Commander”.

Not all keys are used for adjustment.

Connect the remote control to the REMOTE jack (3.5mm stereo jack) on the projector.

26

Page 27

This chart is indicating the

This remote control is compatible for most of Toshiba data -wall display cube.

The GUI of cube commander is also similar layout of the push buttons so that once the position of

these key pads are getting familiar, both can be used without any difficulty.

Difference between this remote control and software is, the ID number access, this is caused by the

command generation CPU, in a PC which the software is installed or use the CPU in the cube.

stand-by mode ßà normal mode ßà adjust mode ßà special mode

Power Power Cut -off 1: Auto-Adj on-off

Digital Drive 7: Picture in Picture

Video1 Gain 8, A, B, C: OSD color

RGB1 Off-set 9: Power Delay time

ID mode RGB2 Contrast D: Firmware Version

ID.ALL White Balance Brightness E: Lamp Timer History

ID.SEL Adjust Color F: Current Lamp timer

ID.SET Call Tint

ID.CLR STD Sharpness

Adjust * MODE (0-9) Phase ßà service mode

(Mag. Memory) Clock 0:

Capture 1: OSD Mute

Magnification 2: Screen mode Lock

Layout 4: Picture smoothing filter

Position C:

Test pattern

Mode

Flip

Call

functions and also which button

7: Color Mix (color coordinate) 4=R, 5=G, 6=B

can be selected.

* MODE button makes to recall

Magnification memorized at

0-9 memory positions (ref P36)

ADJUSTMENT

3-1. Input Signal selectio n

Sources are selected by pressing the relevant source button: RGB1 RGB2 or VIDEO.

To select and display video picture, the video input adaptor need to be installed.

The screen will mute for approximately 5-7 seconds following source selection.

Source sele ction is basically possible in Normal Mode.

27

Page 28

3-2. Adjust Mode

Press ADJUST to enter Adjust Mode.

To exit Adjust Mode press ADJUST twice (one press will request confirmation that

you wish to exit Adjust Mode).

3-3. Saving adjustments

Adjusted value will be memorized into its non -volatile memory when WRITE button is clicked.

In case if the new adjustment value is not acceptable, simply shut off the power by rocker switch

so that this new adjusted value will be erased and go back to “before adjustment” value.

3-4. Adjustment parameters

All parameters except ‘Layout’ can be adjusted using the ? ? ? ? buttons.

‘Layout’ position is adjusted using the ´ ` < > buttons.

3-5. Internal Test Pattern

Test Patterns can be accessed by pressing TEST.P in Adjust Mode.

Continuously pressing TEST.P button will cycle through the available patterns or individual

patterns can be selected by entering the relevant two digits number as 0 7 TEST.P for direct

number access for test signal #7.

3-6. White Balance adjustment

There are three independent memories for white balance adjustments, press WB in NORMAL mode

to select the desired memory (WB1, WB2 or WB3) before making adjustments.

There are two stages for white balance or color balance adjustment to allow adjustment of

low-signal-level and high-signal-level portions of the image.

For low-signal level adjustment, 10-20% IRE signal is required and this should be provided by

the signal source to be used (i.e. if video is the source, a video test pattern generator should be

used and if computer is the main source, test pattern generating software should be used).

BRIGHTNESS will control the overall brightness of the image and CUTOFF then followed by

ADJ.R, ADJ.G and ADJ.B can be used to adjust the relative intensities of red, green and

blue.

For high-signal level adjustment, around 70-80 -90% IRE signal is required.

CONTRAST will control the overall level of the image and DRIVE followed by ADJ.R, ADJ.G and

ADJ.B can be used to adjust the relative intensities of red, green and blue.

3-7. Gain and Offset

The previous adjustments as cutoff, drive, contrast or brightness act on the digital signal

(after the A/D converter) and assume a signal level of 0.7V p -p was supplied.

It is also possible to adjust the analogue signal (before the A/D converter) but these

adjustments should be kept to the default values in most cases of connecting one PC.

While DVI connection is used, this adjustment is not available.

ADJUSTMENT

In case if the display is connected to multiple output card or such equipment having several

individual outputs as video-wall processor, offset/gain adjustments w ill be the right an basic

adjustment to compensate each signal level difference from each outputs.

OFFSET then following by ADJ.R, ADJ.G and ADJ.B can be used for the low-signal-level

adjustment and GAIN , then ADJ.R , ADJ.G and ADJ.B for the high-level adjustment.

Adjustment hint: Cutoff and Drive adjustments can be done using internal test signal.

28

Page 29

Display flat field test signal and press “cutoff” or “drive”, then adjustment is possible.

In case of “offset” and “Gain” adjustments are placed at early signal process area and internal test

signal is generated later stage than this adjustment, thus flat field test signal needs to generate

from PC. Thus PC needs to have such signal generation software installed.

These color balance adjustments need to repeat several times from low signal level,

Then perform high signal level, again, returning back to low, then high level signal.

Repeat them several times to achieve better color balance.

This is the general idea of adjustments:

DVI input: only “Cutoff” and “Drive” by internal test signal or from PC

RGB1 or RGB2, one PC: “Cutoff” “Drive” by internal test signal or signal from PC and then, also

“Offset” “Gain” by signal from PC for sub-adjustment

RGB1 or RGB2 using video-wall processor: “Cutoff” “Drive” by internal test signal and “Offset”

“Gain” by the test signal comes from PC

In this case, Offset and Gain adjustments are much more important to

perform.

Video input: “Cutoff” “Drive” by internal test signal and possibly “Brightness” and

“Contrast” if needed by the signal from source

3-8. Clock frequency adjustment and phase adjustment

Supply fine pitch signal (such as Windows shut -down screen) and adjust CLOCK and PHASE

to eliminate moiré an d jitter.

3-9. Image position adjustment

Initial image position should be adjusted using the mechanical adjustments with internal test picture

while electronic positions are at center so that all the unmagnified images appear at the same

position. Use POSI to electronically shift the image and CAP to select the position of the image for

magnification.

3-10. Screen Mode (frequency) Selection

Incoming signals are automatically synchronized and the relevant timing data is stored in memory so that

this data can be read out each time a particular source is recognized. RGB1 and RGB2 settings are

memorized separately. There are total of 10 signal memory areas available, additional frequencies differ

from VESA standard, they will be memorized for next time synchronization.

3-11. On-Screen-Display, OSD

The default condition is for the OSD to be on, this can be switched off by pressing the CALL button in

Adjust Mode.

ADJUSTMENT

It is possible to change the color of the OSD:

SPECIAL A = red, SPECIAL B = green, SPECIAL C = blue, SPECIAL 8 = white.

3-12. Video Enhancer

When video input is selected, the following adjustments are available: COLOR , TINT (NTSC only)

and SHARP

3-13. Picture in Picture

This is a feature which opens a small window and insert video image. The video signal input

Terminal adaptor need to place. The PC image is the base and small window has video signal

29

Page 30

Image, they cannot be changed. Get into Special mode by SPECIAL and 7 buttons will guide

to this feature. PIP picture position can be changed by arrow keys.

3-14. Image Orientation

The image orientation can be flipped up, down, left and right using the FLIP key.

3-15. Status Indication

Pressing CALL in Normal Mode will display general information such as input selection and source

frequency.

Pressing SPECIAL and then D in Adjust Mode will display software version and date.

SPECIAL F will display the lamp timer and SPECIA L E will display lamp history.

3-16. Factory reset STD key

This key need to be careful since all the adjustment data will be reset if pushed.

There is an on-screen-display indicating if this function would be performed or not.

Pressing this button again will erase all the adjustments and data are reset.

3-17. Color Mix adjustment (Color coordinate Control)

This is to compensate the color difference for example, when red picture is displayed on multiple

screens and reds are different as pure red vs orange red. An ideal condition is to have all the same

pure red all over the screens but in case if orange-red appeared at once cube, then other cube can be

color compensated to add some greens so that other red can be matched to the orange-red so that all

the colors can be matched same. Opposite operation, making orange to red is impossible.

Use 7 button while in Adjust mode, then click 4 for Red primary color and select ADJ.G for

the color to be mixed in case of above situation. The prima ry color would be 5 for Green, 6 for Blue

and ADJ.R , ADJ.G or ADJ.B will select the color to be mixed.

4. Multiple Screen Wall system (example)

The picture shows 2x2 wall by one PC displaying picture,

using internal magnification capability.

To make this image by internal signal processor, MAG

need to be set to 2x2 and left top cube need to have

Layout of 1 -1. The cube at right bottom needs to have

Layout of 2 -2. Small position adjustment may be needed

to match the picture. When using internal magnification

capability, still, all the cubes need to receive the same signal

and DVI digital link will cover this part, using DVI cables.

When cube need to control or any adjustment needed, then each cube need to have its ID #

different from the others so that the command can be sent to the right ID # cube.

This picture effect (ex. 2x2) can be memorized as User Magnification Pattern (p -36).

ADJUSTMENT

5. ID Assignment (example)

IDs should be assigned before connecting the RS232C control link cables and if ID has assigned

already and want to change, it must be cleared at first befo re they can be re-assigned.

5-1. Clearing I.D.

Press ADJUST to enter Adjust Mode and then press ID.ALL to enter I.D. Mode, press ID.SEL

3 times and then press ID.CLR to erase the current I.D.

5-2. Setting I.D.

Press ID.ALL so that ‘INPUT ID NUMBER’ appears and enter the desired 2 digits I.D. using the

alpha-numeric keys. Press ID.SEL 3 times and then ID.SET to assign the I.D. – the OSD will

disappear and the unit will return to Normal Mode.

30

Page 31

5-3 Selecting I.D.

If using Cube Commander software simply select the two digits I.D. for the cube you wish to control.

If using remote control it is necessary to press ID.SEL to access the correct menu for I.D. selection

and control.

If ID.ALL is pressed instead of an alpha-numeric key ‘X’ will appear, pressing ID.ALL twice will

display ‘XX’ (two wild cards) which will allow to control of all units simultaneously.

6. Magnification

To magnify the image, press MAG in Adjust Mode to change the magnification factor then type H+V

magnification numbers as needed such as 1x1, 2x2… It is also possible to select the magnification

factor for uneven magnification as 4x3 for example, horizontal of x4 and vertical of x3 magnification.

To make this magnification effective, MAG needs to be clicked again.

Once the desired magnification has been selected press LAYOUT followed by ´ ` < > to select

the portion of the image to be displayed. If the picture will not match at the mullion area, then

POSI. will cover the adjustment. Then, to memorize this picture, press WRITE .

7. Function in Special mode

7-1. Auto-Adjust On-Off

This is to select if automatic centering function, of frequency converter, necessary or not.

Auto center may have a chance to shift the image when power is completely down and on again.

7-2. Picture in Picture

By using 7 key after entering Special mode, Picture in Picture is possible. Always, the base picture

is PC signal supplied to RGB input and small window picture is the signal supplied to Video input,

composite signal.

7-3. OSD color

On screen display color can be changed by 8 : wh ite, A : red, B : green or C : blue in

Special mode.

7-4. Power On delay

By the setting of small power on timing to avoid the same time of lamp trigger, power supply can

be set from 0-sec to 4.5-sec. This delay time is not accurate since the lamp may not ignite by the

1st trigger all the time. Entering SPECIAL mode, then click 9 makes to change the Delay time.

7-5. Firmware version

Using D button in Special mode, the system Firm-ware version could be displayed.

ADJUSTMENT

7-6. Lamp Timer History

By E button, Lamp usage timer history could be displayed.

7-7. Current Lamp Timer indication

This mode will display only one lamp display, the current lamp. When lamp timer needs to reset,

Entering to this mode will conduct to the further operation.

7-8. Lamp Timer Reset

While in Special mode, F will indicate the current lamp timer and using STD button twice,

then WRITE button, the current timer count will stop and starts from new counter reading.

8. Function in Service mode

8-1. OSD Mute

This is similar as like as CALL button clicked while in Adjust mode, OSD would be erased or

displayed on the screen by 1 button while in Service mode. Even when OSD is erased, still the

31

Page 32

function is continue to operate as in the same operation mode. One of the good way to use this

operation is, in normal condition, OSD appears when Input is selected in Normal mode. Some user

may not like this, then enter this mode or other method is, enter Adjust mode, then click CALL so

that OSD will disappear even in the system is in Adjust mode. Then click WRITE button to

memorize this function.

8-2. Screen mode Lock

This could be used only when one designated PC used, so that the same PC picture will appear always

correct but not for the other PC. Use 2 button while in Service mode

8-3. Picture smoothing filter