FILE NO. 140-200108

SERVICE MANUAL

COLOR TELEVISION/

VIDEO CASSETTE RECORDER

MV19L4

SERVICING NOTICES ON CHECKING

As for the places which need special attentions,

they are indicated with the labels or seals on the

cabinet, chassis and parts. Make sure to keep the

indications and notices in the operation manual.

2. AVOID AN ELECTRIC SHOCK

There is a high voltage part inside. Avoid an

electric shock while the electric current is

flowing.

3. USE THE DESIGNATED PARTS

The parts in this equipment have the specific

characters of incombustibility and withstand

voltage for safety. Therefore, the part which is

replaced should be used the part which has

the same character.

Especially as to the important parts for safety

which is indicated in the circuit diagram or the

table of parts as a mark, the designated

parts must be used.

4. PUT PARTS AND WIRES IN THE

ORIGINAL POSITION AFTER

ASSEMBLING OR WIRING

There are parts which use the insulation

material such as a tube or tape for safety, or

which are assembled in the condition that

these do not contact with the printed board.

The inside wiring is designed not to get closer

to the pyrogenic parts and high voltage parts.

Therefore, put these parts in the original

positions.

5. TAKE CARE TO DEAL WITH THE

CATHODE-RAY TUBE

In the condition that an explosion-proof cathoderay tube is set in this equipment, safety is

secured against implosion. However, when

removing it or serving from backward, it is

dangerous to give a shock. Take enough care to

deal with it.

6. AVOID AN X-RAY1. KEEP THE NOTICES

Safety is secured against an X-ray by considering about the cathode-ray tube and the high

voltage peripheral circuit, etc.

Therefore, when repairing the high voltage peripheral circuit, use the designated parts and

make sure not modify the circuit.

Repairing except indicates causes rising of high

voltage, and it emits an X-ray from the cathoderay tube.

PERFORM A SAFETY CHECK AFTER

7.

SERVICING

Confirm that the screws, parts and wiring which

were removed in order to service are put in the

original positions, or whether there are the

portions which are deteriorated around the

serviced places serviced or not. Check the

insulation between the antenna terminal or

external metal and the AC cord plug blades.

And be sure the safety of that.

(INSULATION CHECK PROCEDURE)

1.

Unplug the plug from the AC outlet.

2.

Remove the antenna terminal on TV and turn

on the TV.

3.

Insulation resistance between the cord plug

terminals and the eternal exposure metal

[Note 2] should be more than 1M ohm by

using the 500V insulation resistance meter

[Note 1].

4.

If the insulation resistance is less than 1M

ohm, the inspection repair should be

required.

[Note 1]

If you have not the 500V insulation

resistance meter, use a Tester.

[Note 2]

External exposure metal: Antenna terminal

Earphone jack

HOW TO ORDER PARTS

Please include the following informations when you order parts. (Particularly the VERSION LETTER.)

1. MODEL NUMBER and VERSION LETTER

The MODEL NUMBER can be found on the back of each product and the VERSION LETTER can be

found at the end of the SERIAL NUMBER.

2. PART NO. and DESCRIPTION

You can find it in your SERVICE MANUAL.

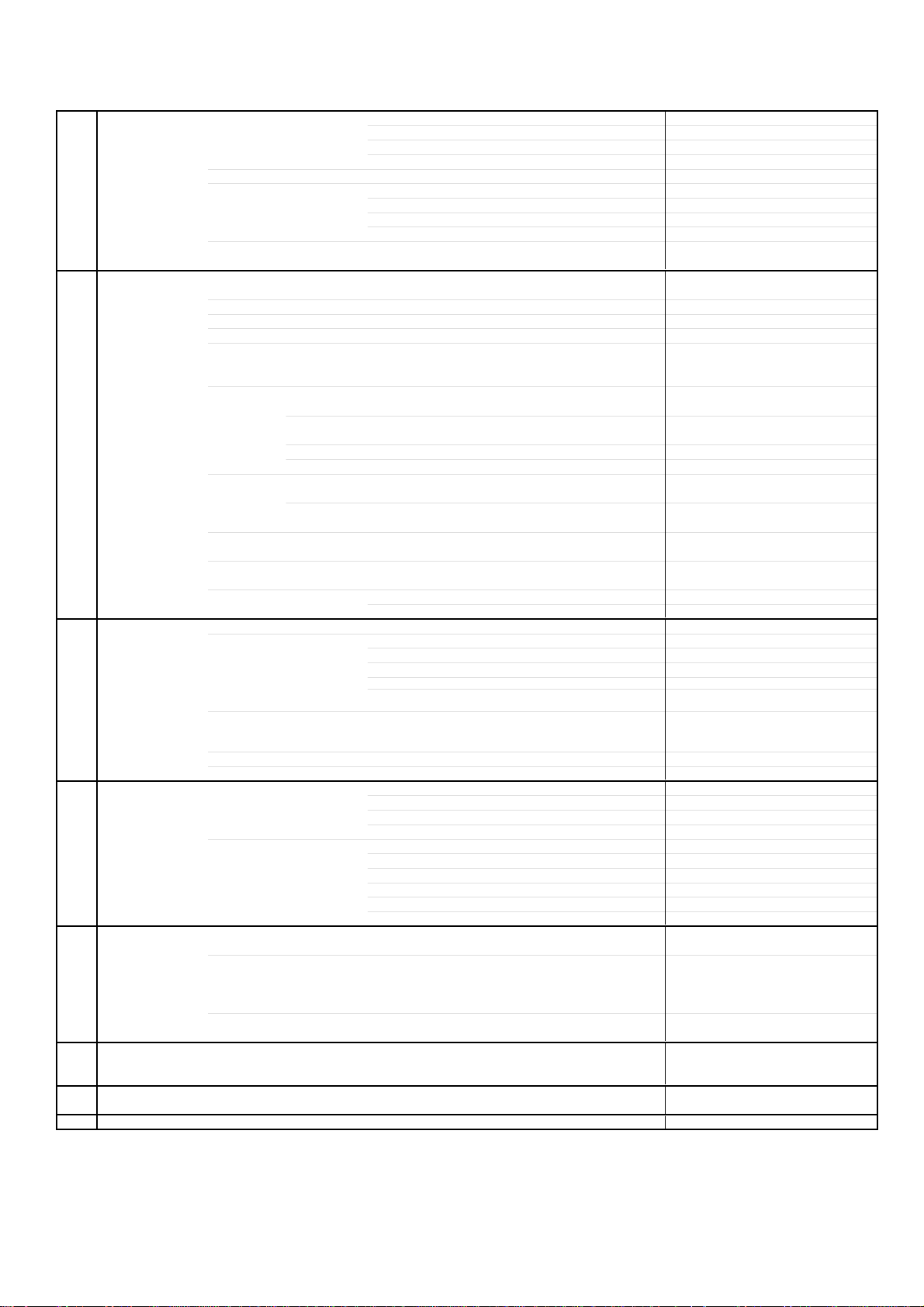

GENERAL SPECIFICATIONS

I

VHF/UHF

J~W,

I

Pi

(FP) 4

G-1 TV CRT CRT Size / Visual Size 19 inch / 480.0mmV

System CRT Type Normal

Color System NTSC

Speaker 1Speaker

Sound Output MAX 1.5 W

G-2 VCR System VHS

System Player / Recorder

Video System NTSC

Hi-Fi STEREO No

NTSC PB Deck DECK OVD-6S

Heads Video Head 4 Head

FM Audio Head No

Audio /Control Mono/Yes

Erase(Full Track Erase) Yes

Tape Rec PAL Speed NTSC SP/SLP(EP)

Play PAL -

Fast Forward / Rewind Time (Approx.) FF:4'50"/REW:2'30"

Forward/Reverse NTSC or PAL-M SP/SLP(EP)=3x,5x/9x,15x

Picture Search

Slow Speed Frame Advance 1/10

G-3 Tuning Broadcasting System US Sysytem M

System Tuner and System 1Tuner

Receive CH Destination USA+CATV

ntermediate

Frequency Sound(FS) 41.25MHz

Preset CH No

Stereo/Dual TV Sound No

G-4 Signal Video Signal Input Level 1 V p-p/75 ohm

Audio Signal Input Level RCA-8dB/50Kohm

Hi-Fi Audio Signal Dynamic Range : More than -

G-5 Power Power Source AC 120V 60Hz

Power Consumption at AC 86 W at 120V 60Hz

Protector Power Fuse Yes

G-6 Regulation Safety UL

G-7 Temperature Operation +5oC ~ +40oC

G-8 Operating Humidity Less then 80% RH

Deflection 90 degree

Magnetic Field BV/BH +0.45G / 0.18G

Position Front

Size 3 inch

Impedance 8 ohm

10%(Typical) 1.0 W

Loading System Front

Motor 3

NTSC SP/SLP(EP)

Cassette at T-120

Slow 1/10

Tuning System F-Synth

nput Impedance

CH Coverage

cture

FP-FS 4.5MHz

Output Level S/N Ratio (Weighted) 50 dB

Horizontal Resolution at SP Mode 220 Lines

Output Level -

Wow And Flutter : Less than Channel Separation : More than Harmonic Distortion : Less than -

DC -

at DC Stand by (at AC) 5 W at 120V 60 Hz

Per Year -

Dew Sensor

Radiation FCC

X-Radiation DHHS

Storage -20oC ~ +60oC

75 ohm

2~69, 4A,A-5~A-1, A~I,

5.75MHz

W+1~W+84

No

GENERAL SPECIFICATIONS

G-9 On Screen Menu Yes

Display Menu Type Character

G-CODE(or SHOWVIEW or PLUSCODE)No. Entry

Clock Yes

CH/AV Yes

Tape Counter(Linear Counter) Yes

Tape Speed Yes

Sleep Time Yes

Stereo/Audio Output

Control Volume Yes

Level Bright / Contrast / Sharpness / Color Yes

Auto Tracking/Manual Tracking Yes

Caption / Text Yes

Index

Muting Yes

Hi-Fi ,SAP

Repeat Yes

Zero Return

DEW

G-10 OSD Language English French Spanish

G-11 Clock,Timer Calendar 1990/1/1 ~ 2081/12/31

and Timer Timer Events 8 prog/ 1 month

Back-up One Touch Recording Max Time 5 Hours

OTPB Valid Time No

Sleep Timer Max Time 120

On/Off Timer Program(On Timer / Off Timer) 1

Auto Shut Off No Signal 15

Timer Back-up (at Power Off Mode) 5

Timer Rec Set Yes

Channel Setup Yes

TV/CATV Yes

Auto ch Memory Yes

Add/Delete Yes

Guide ch Set

TV Setup Yes

V-chip Set Yes

On/Off Timer Set Yes

Picture Yes

Audio

Sap On/Off

Auto Repeat On/Off Yes

System Setup Yes

Clock Set Yes

Language Yes

Auto Clock On/Off Yes

Standard Time Yes

Daylight Saving Time Yes

Commercial Advance

Marking On/Off

Blueback On/Off

Playback Auto/Manual

Unmarked Tape

Movie Advance

Go To Movie

Go To Preview

Bilingal

SAP

Tint Yes

Bass/Treble/Balance

Manual Tracking Yes

Play/Stop/FF/Rew/Rec/OTR/T-Rec/Pause/Eject/Tape In (Symbol Mark)

OSD Language Setting English

Step 10

No Operation -

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

Yes

No

No

No

No

min.

min.

prog.

min.

sec.

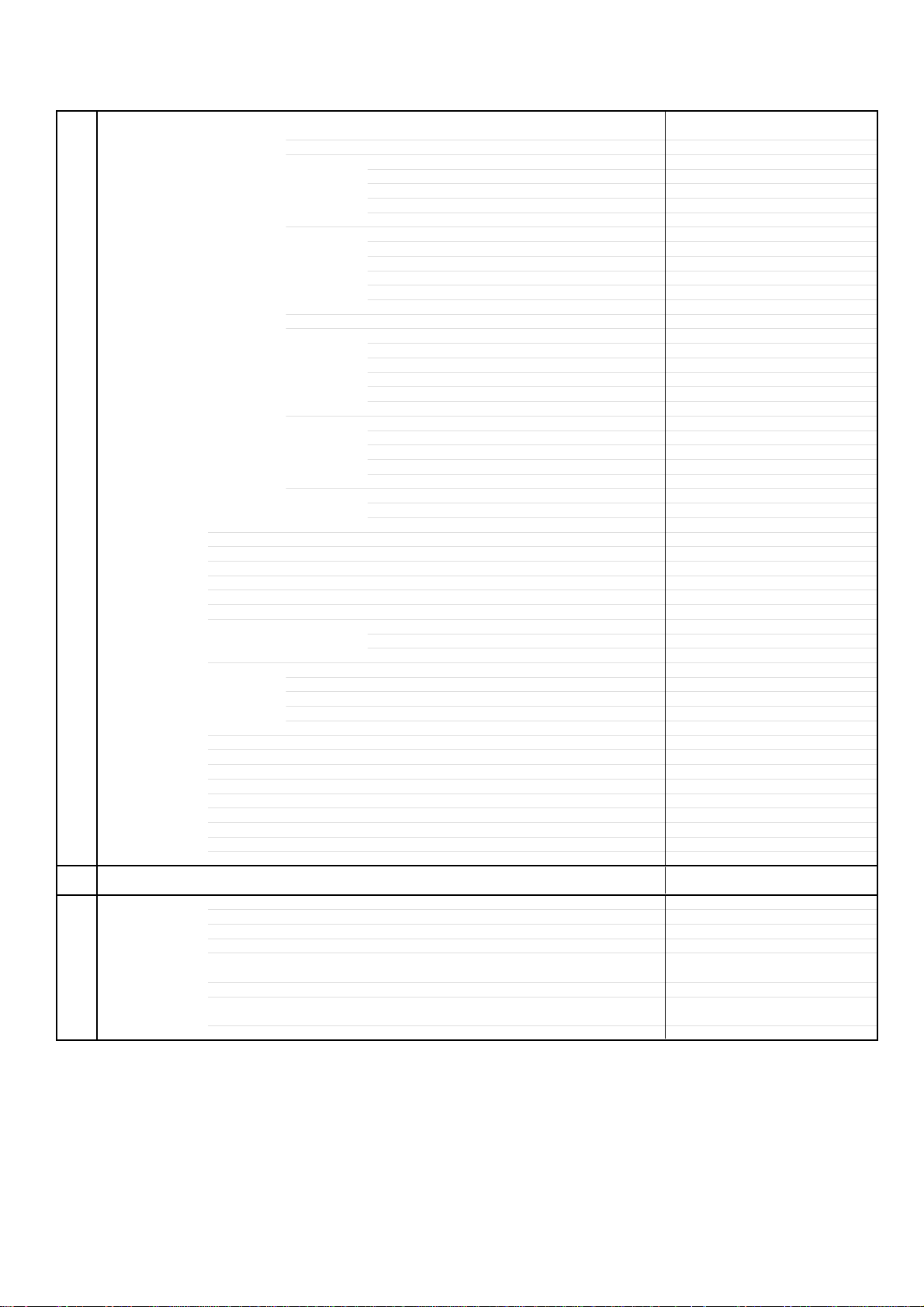

GENERAL SPECIFICATIONS

G-12 Remote Unit RC-DQ

Control Glow in Dark Remocon Yes

Format NEC

Custom Code 40-BFh , 44-BBh

Power Source Voltage(D.C) 3V

UM size x pcs UM-4 x 2 pcs

Total Keys 43

Keys Power Yes

1 Yes

2 Yes

3 Yes

4 Yes

5 Yes

6 Yes

7 Yes

8 Yes

9 Yes

0 Yes

CH Up Yes

CH Down Yes

Volume Up Yes

Volume Down Yes

Input Select Yes

Play Yes

F.Fwd Yes

Rew Yes

Pause/Still Yes

Stop Yes

Rec/OTR Yes(2Keys)

Eject Yes

Counter Reset Yes

Speed Yes

Timer Rec Yes(2Keys)

TV Monitor

Quick View Yes

Program Yes

Slow Yes

Auto Tracking Yes

Set/Tracking+ Yes

Set/ Tracking - Yes

Menu Yes

Enter Yes

Cancel Yes

Call Yes

TV/Caption/Text Yes

Sleep Timer Yes

Muting Yes

Zero Return Yes

CM Skip Yes

Audio Select

G-13 Features Auto Head Cleaning Yes

Auto Tracking Yes

HQ (VHS Standard High Quality) Yes

Auto Power On, Auto Play, Auto Rewind, Auto Eject Yes

VIDEO PLUS+(SHOWVIEW,G-CODE)

Auto Clock Yes

Forward / Reverse Picture Search Yes

One Touch Playback

Auto CH Memory Yes

Closed Caption Yes

TV Auto Shut off Function Yes

End Call

Index Search

SQPB

CATV Yes

CM Skip(30sec x 6 Times) Yes

Comb Filter

TV Monitor

Program Extend

Choke Coil

Energy Star Yes

Dirty Head

V-chip USA V-chip Yes

CANADA V-chip

CM Advance

Movie Advance

FBT Leak Test Protect Yes

Keys

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

GENERAL SPECIFICATIONS

G-14 Accessories Owner's Manual Language English

Remote Control Unit Yes

Rod Antenna

Loop Antenna

U/V Mixer

DC Car Cord (Center+)

Guarantee Card

Warning Sheet

Circuit Diagram

Antenna Change Plug

Service Facility List

Important Safeguard

Dew/AHC Caution Sheet

AC Plug Adapter

Quick Set-up Sheet

Battery Yes

AC Cord

AV Cord (2Pin-1Pin)

Registration Card Yes

ESP Card Yes

300 ohm to 75 ohm Antenna Adapter Yes

G-15 Interface Switch Power Yes

Indicator Power

Key Light up Rec/OTR

Terminals Front Video Input RCAx1

Rear Video Input

G-16 Set Size Approx. W x D x H (mm) 489 x 462 x 480

G-17 Weight Net (Approx.) 19.0 kg

w/Guarantee Card Yes

Poles Terminal w/300 ohm to 75 ohm Antenna Adapter -

Terminal -

UM size x pcs UM-4 x 2 pcs

Play Yes

Pause/Still

System Select

One Touch Playback

Channel Up Yes

Channel Down Yes

F.FWD/Cue Yes

Eject/Stop Yes

Main Power SW

Volume Up Yes

Volume Down Yes

Rew/Rev Yes

Rec/OTR Yes

Input Select Yes

Rec/OTR

T-Rec

On Timer

CS

One Touch Playback

Play

Audio Input RCAx1

Other Terminal Head Phone(Stereo & Mono, ?3.5)

Audio Input

Video Output

Audio Output

Euro Scart

Diversity

Ext Speaker

DC Jack 12V(Center +)

VHF/UHF Antenna Input

AC Inlet

Gross (Approx.) 22.0 kg

F Type

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

Red

Red

Red

No

No

No

No

No

No

No

No

No

No

No

No

No

No

(41.8 lbs)

(48.5 lbs)

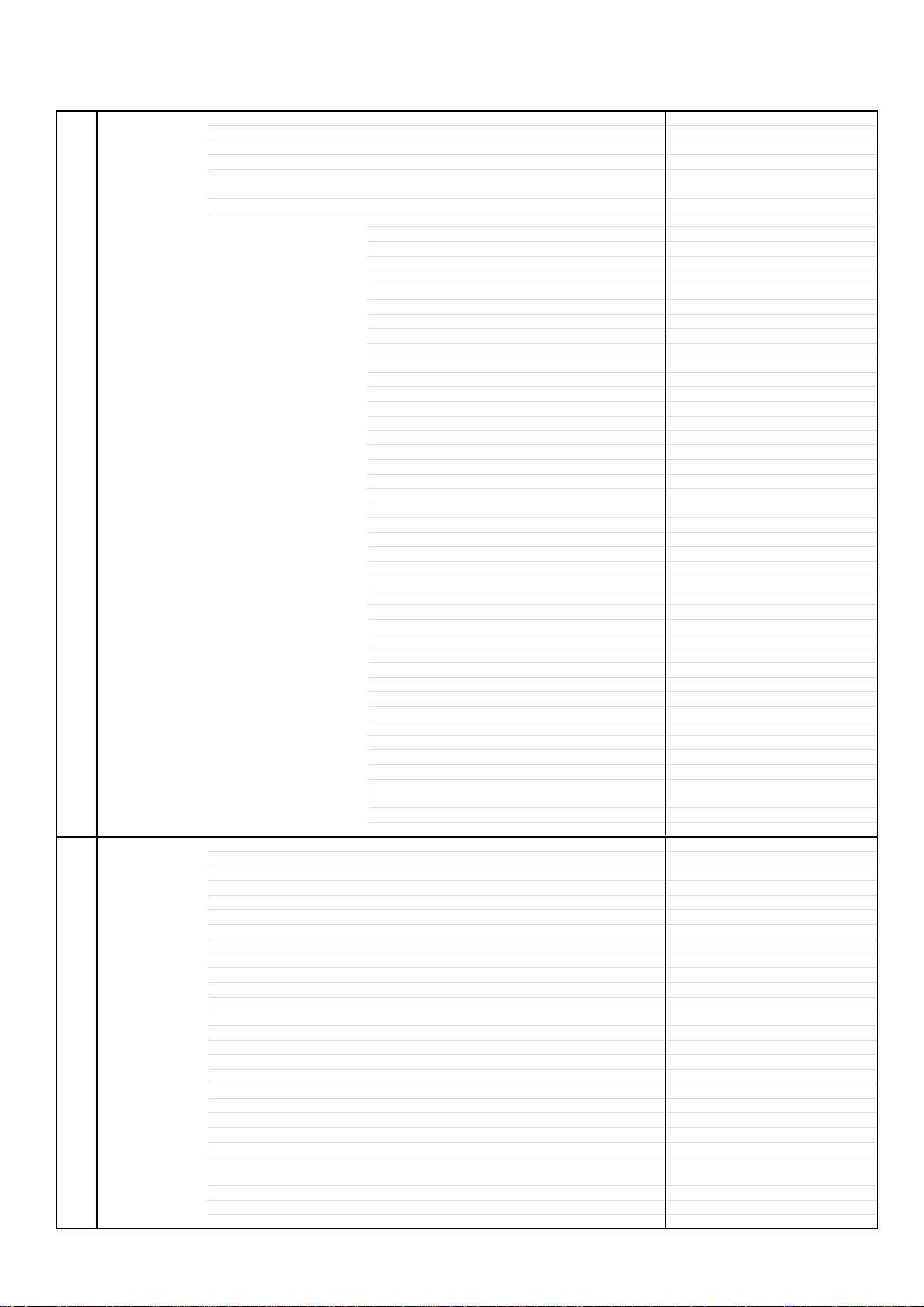

GENERAL SPECIFICATIONS

G-18 Carton Master Carton

Gift Box Yes

Drop Test Natural Dropping At

Container Stuffing(40' container) 352

G-19 Cabinet Material Cabinet Front PS 94V0 DECABROM

Content Material Dimensions W x D x H(mm) Description of Origin -

Material Double/White

Dimensions W x D x H(mm) 559 x 538 x 555

Design As per Buyer's

Description of Origin Yes

1 Corner / 3 Edges / 6 Surfaces

Height (cm) 46

Cabinet Rear PS 94V0 DECABROM

Jack Panel PS 94V0

No

Sets

DISASSEMBLY INSTRUCTIONS

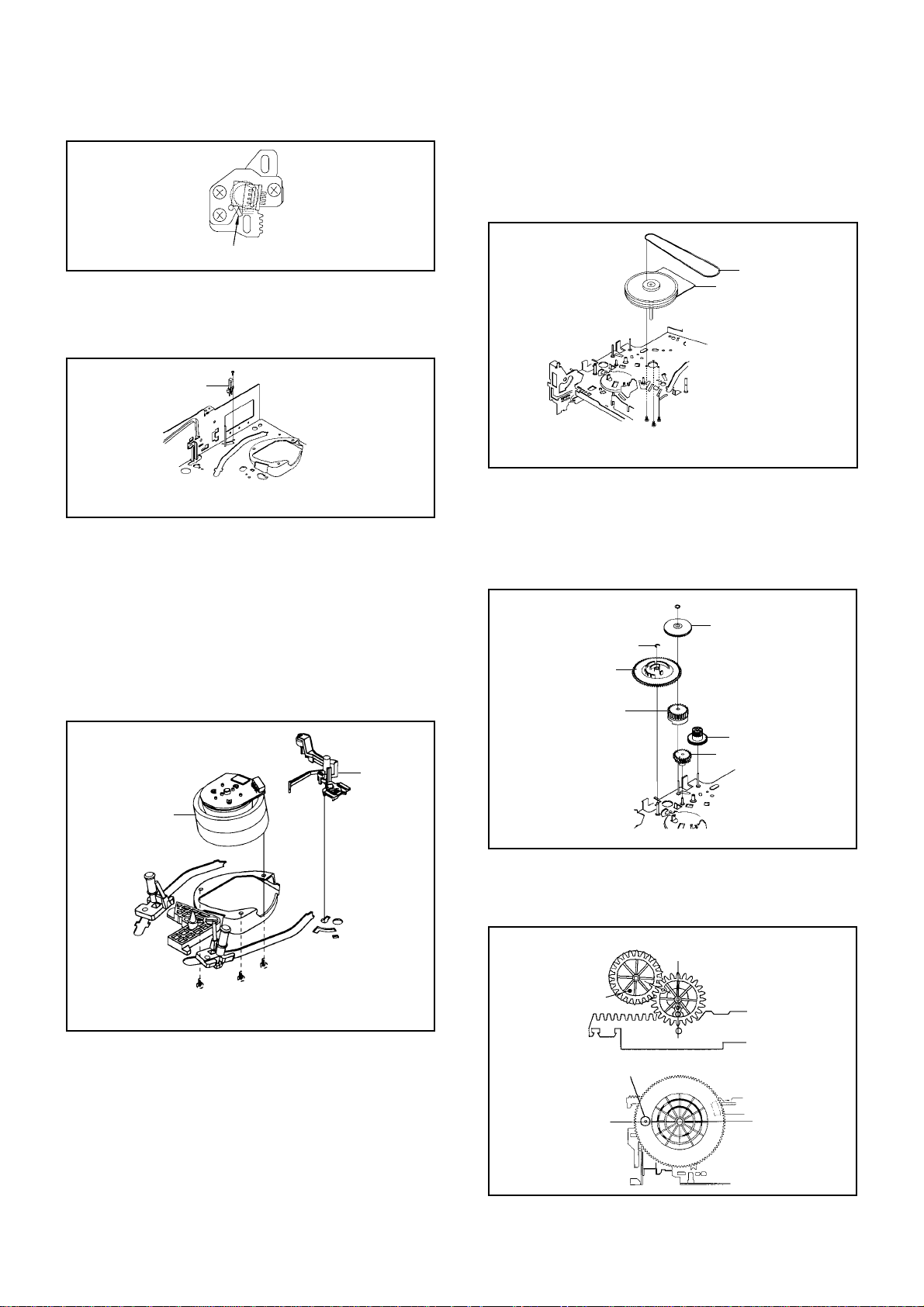

1. REMOVAL OF MECHANICAL PARTS

AND P.C. BOARDS

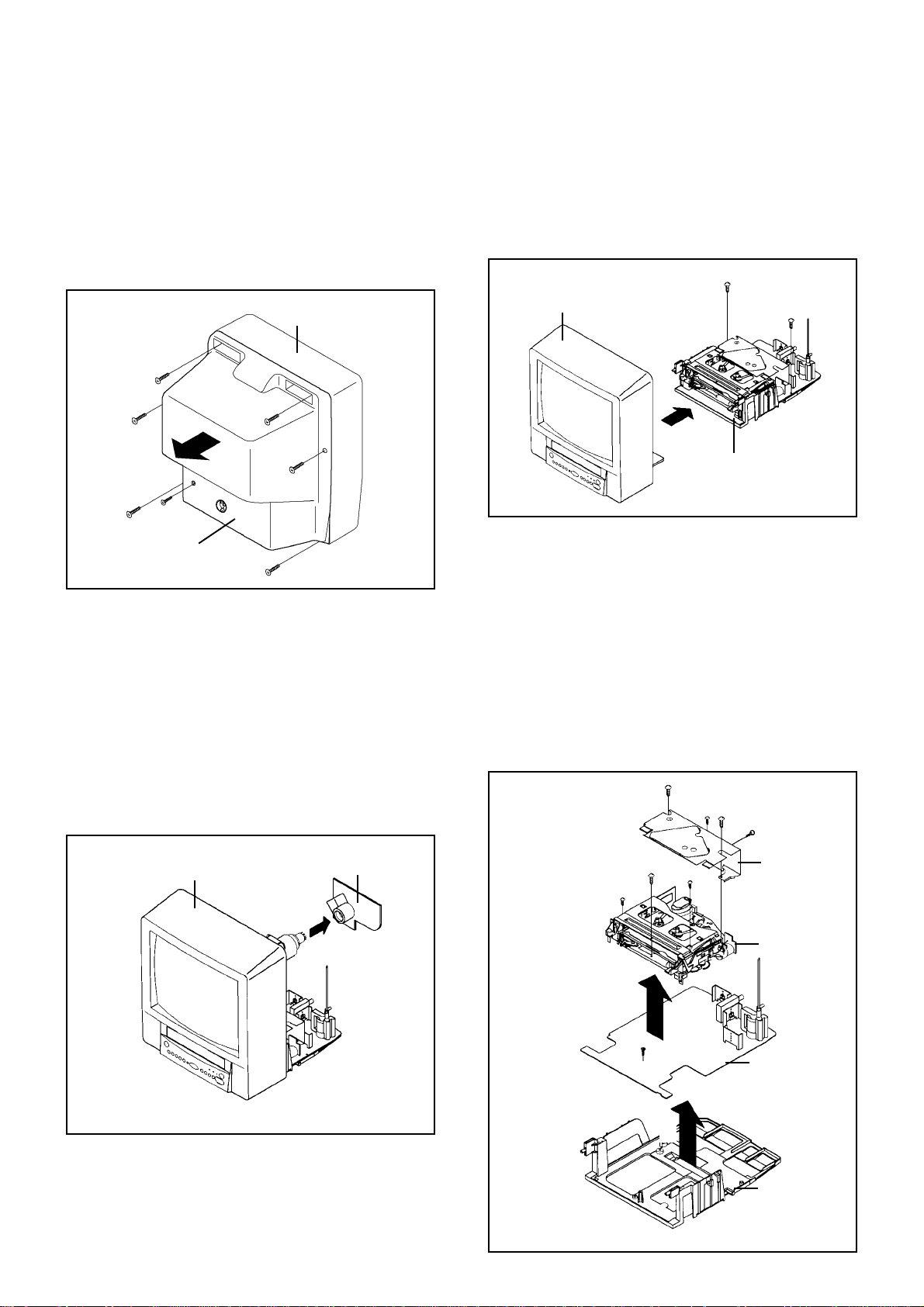

1-1: BACK CABINET (Refer to Fig. 1-1)

1.

Remove the 6 screws 1.

2.

Remove the screw 2.

3.

Remove the AC cord from the AC cord hook 3.

4.

Remove the Back Cabinet in the direction of arrow.

Front Cabinet

1

1

1

2

Back Cabinet

1-2: CRT PCB (Refer to Fig. 1-2)

CAUTION: BEFORE REMOVING THE ANODE CAP,

DISCHARGE ELECTRICITY BECAUSE IT

CONTAINS HIGH VOLTAGE.

BEFORE ATTEMPTING TO REMOVE OR

REPAIR ANY PCB, UNPLUG THE POWER

CORD FROM THE AC SOURCE.

1.

Remove the Anode Cap.

(Refer to REMOVAL OF ANODE CAP)

2.

Disconnect the following connectors:

(CP801 and CP851B).

3.

Remove the CRT PCB in the direction of arrow.

1

1

1

3

Fig. 1-1

1-3: TV/VCR BLOCK (Refer to Fig. 1-3)

1.

Remove the 2 screws 1.

2.

Disconnect the following connectors:

(CP352, CP353, CP354, CP401, CP502 and CP503).

3.

Unlock the support 2.

4.

Remove the TV/VCR Block in the direction of arrow.

1

Front Cabinet

1

2

UP TO

RELEASE

TV/VCR Block

Fig. 1-3

1-4: DECK CHASSIS AND SYSCON PCB

(Refer to Fig. 1-4)

1.

Remove the 3 screws 1.

2.

Remove the 2 screws 2.

3.

Remove the screw 3.

4.

Remove the screw 4.

5.

Disconnect the following connectors:

(CP1004, CP1005, CP1006, CP4001, CP4002 and

CP4003).

6.

Remove the Deck Chassis and Deck Shield Plate in the

direction of arrow (A).

7.

Remove the screw 5.

8.

Remove the Syscon PCB in the direction of arrow (B).

1

3

1

4

Front Cabinet

CRT PCB

Fig. 1-2

Deck Shield Plate

1

2

(A)

5

2

Deck Chassis

Syscon PCB

(B)

Deck Holder

Fig. 1-4

DISASSEMBLY INSTRUCTIONS

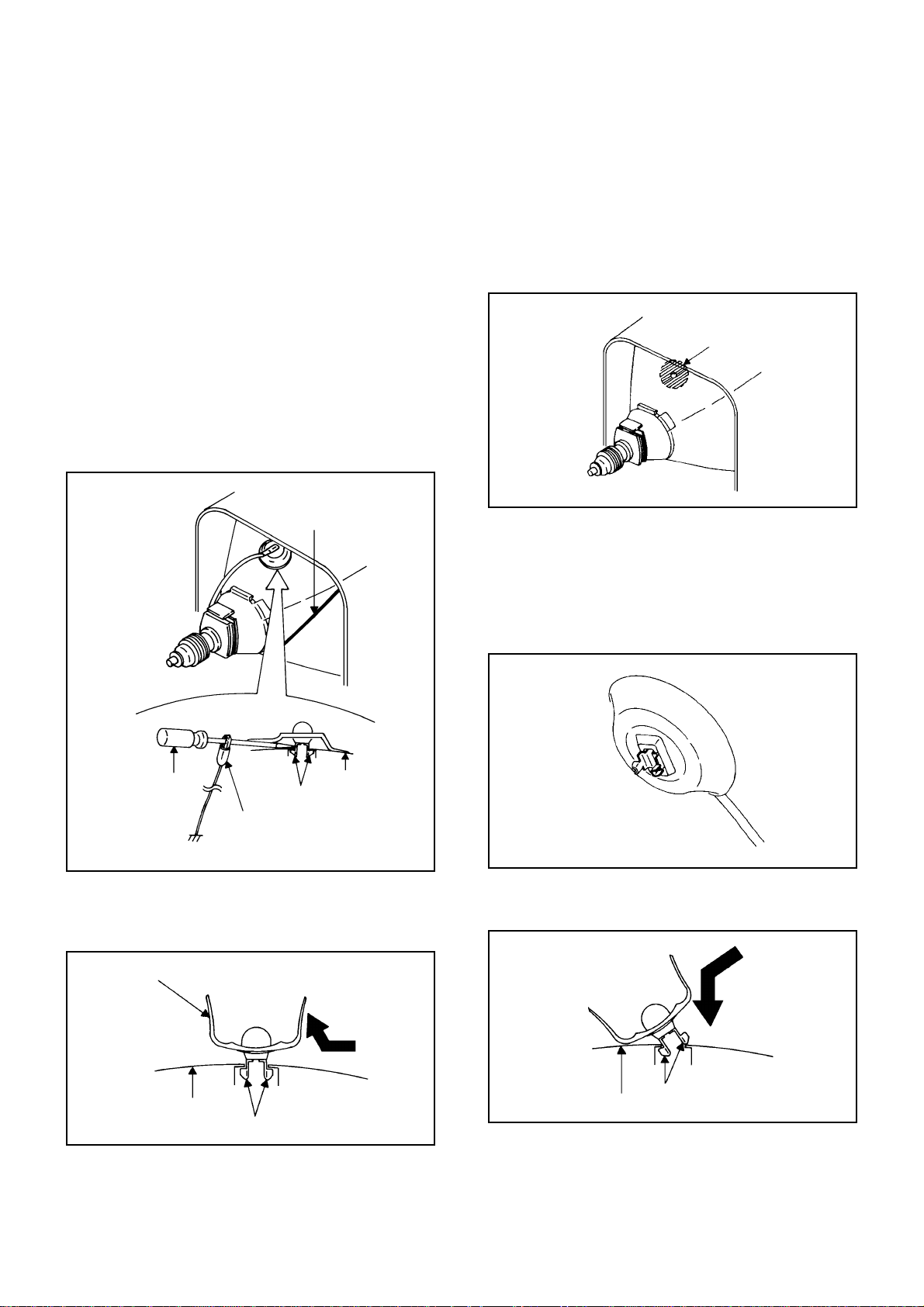

2. REMOVAL OF DECK PARTS

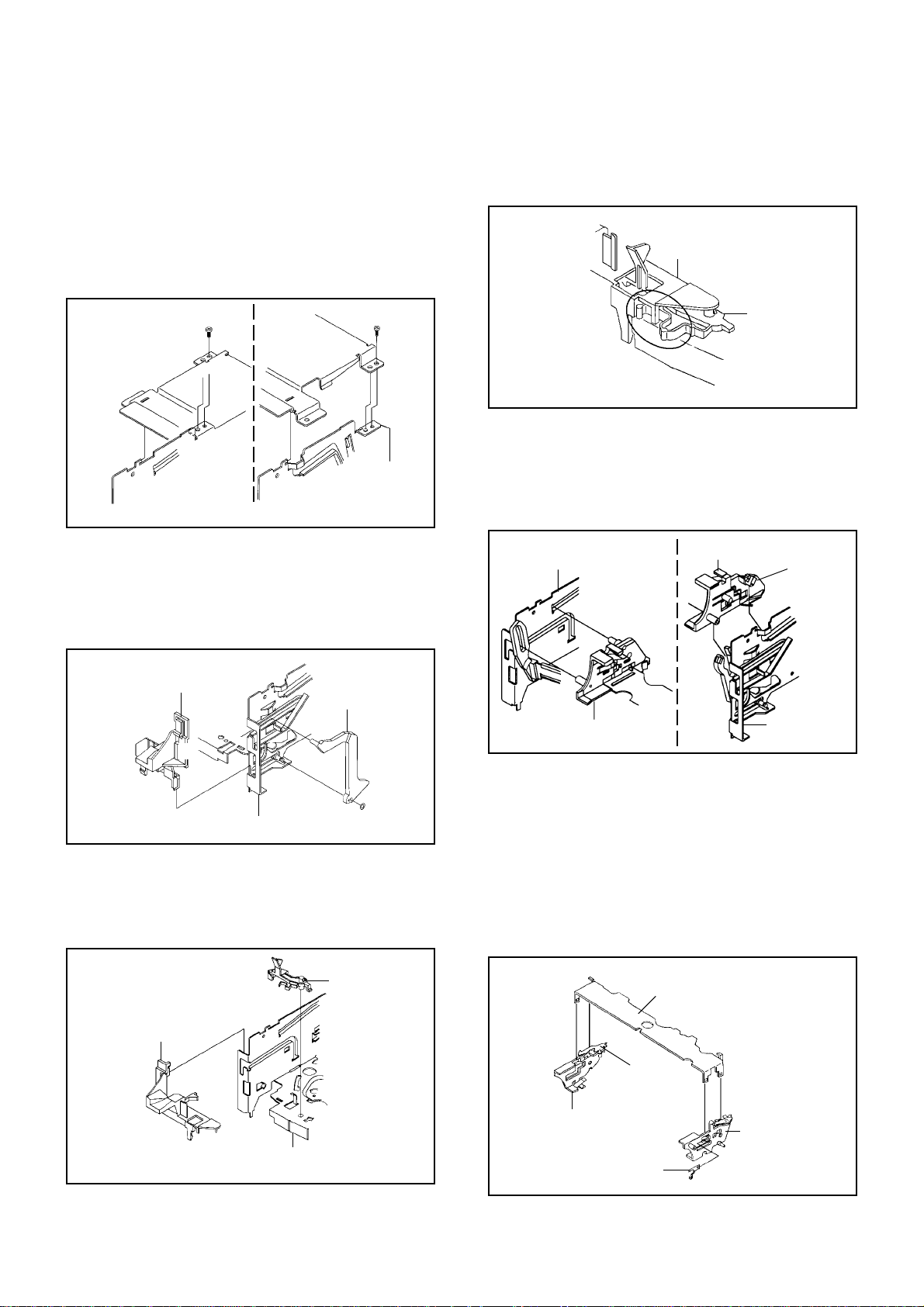

2-1: TOP BRACKET (Refer to Fig. 2-1)

Remove the 2 screws 1.

1.

Slide the 2 supports 2 and remove the Top Bracket.

2.

NOTE

When you install the Top Bracket, install the screw (1)

first, then install the screw (2).

(2)

1

Top Bracket

2

Main Chassis

• Screw Torque: 5 ± 0.5kgf•cm

Top Bracket

2

Main Chassis

2-2: FLAP LEVER/TAPE GUIDE R (Refer to Fig. 2-2)

Move the Cassette Holder Ass'y to the back side.

1.

Remove the Polyslider Washer 1.

2.

Remove the Flap Lever.

3.

Unlock the 3 supports 2 and remove the Tape Guide R.

4.

(1)

1

Fig. 2-1

NOTE

When you install the Tape Guide L, install as shown in the

circle of Fig. 2-3-B. (Refer to Fig. 2-3-B)

Tape Guide L

REC Lever

• The REC Lever is not installed on the Video Cassette Player.

Fig. 2-3-B

2-4: CASSETTE HOLDER ASS'Y (Refer to Fig. 2-4)

Move the Cassette Holder Ass'y to the front side so that

1.

the Link Ass'y doesn't slip out.

Push the Locker R to remove the Cassette Side R.

2.

Remove the Cassette Side L.

3.

Main Chassis

Cassette Side R

Locker R

Tape Guide R

Flap Lever

2

2

2

Main Chassis

1

Fig. 2-2

2-3: TAPE GUIDE L (Refer to Fig. 2-3-A)

Move the Cassette Holder Ass'y to the back side.

1.

Unlock the 2 supports 1 and remove the Tape Guide L.

2.

Remove the REC Lever. (Recorder only)

3.

REC Lever

Tape Guide L

1

1

• The REC Lever is not installed on the Video Cassette Player.

Main Chassis

Fig. 2-3-A

Cassette Side L

Main Chassis

Fig. 2-4

2-5: CASSETTE SIDE L/R (Refer to Fig. 2-5)

Unlock the 4 supports 1 and then remove the Cassette

1.

Side L/R.

Remove the Cassette Earth Spring.

2.

NOTE

1.2.When you install the Cassette Side R, be sure to move

the Locker R after installing.

After the installation of the Cassette Holder, then install

the Cassette Earth Spring.

1

1

Cassette Side R

Cassette Earth Spring

Cassette Holder

Locker R

1

1

Cassette Side L

Fig. 2-5

DISASSEMBLY INSTRUCTIONS

2-6: LINK UNIT (Refer to Fig. 2-6)

Set the Link Unit to the Eject position.

1.

Remove the (A) side of the Link Unit first, then remove

2.

the (B) side.

Link Unit

(B)

(A)

Main Chassis

Link Unit

Main Chassis

2-7: LOADING MOTOR ASS'Y (Refer to Fig. 2-7)

Remove the Link Lever.

1.

Remove the screw 1.

2.

Remove the Loading Motor Ass'y.

3.

Unlock the 2 supports 2 and remove the Deck PCB

4.

(BOT).

Fig. 2-6

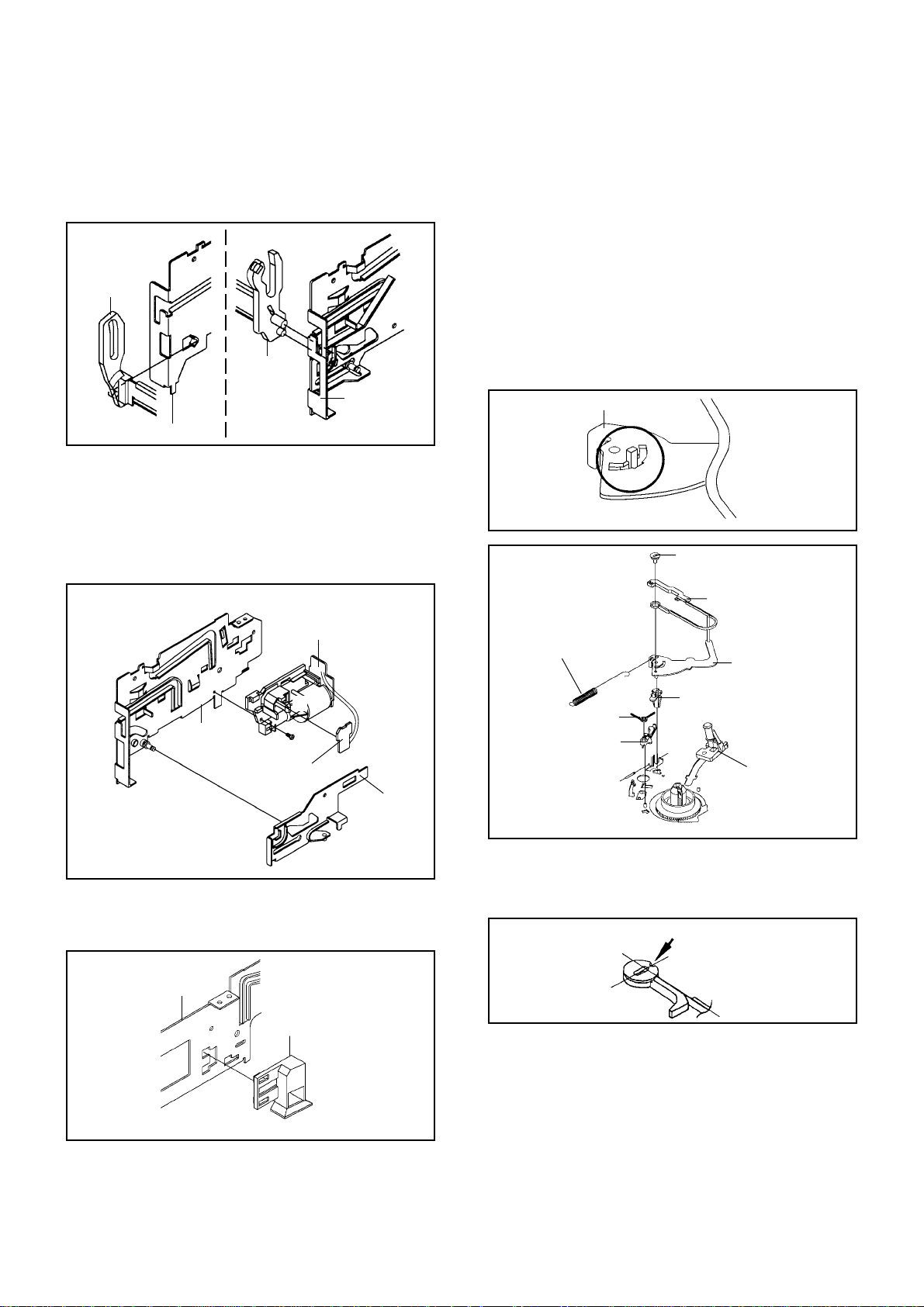

2-9: TENSION ASS'Y (Refer to Fig. 2-9-B)

Turn the Middle Gear clockwise so that the Tension

1.

Holder hook, is set to the position of Fig. 2-9-A to more

the Tension Arm Ass'y.

Remove the Tension Spring.

2.

Unlock the support 1 and remove the Tension Arm

3.

Ass'y.

Remove the Tension Adjust.

4.

Unlock the 2 supports 2 and remove the Tension Band

5.

Ass'y.

Float the hook 3 and turn it clockwise then remove the

6.

Tension Holder.

Remove the SS Brake Spring.

7.

Remove the SS Arm Brake.

8.

Tension Arm Ass'y

Fig. 2-9-A

Tension Adjust

2

2

Tension Band Ass'y

Loading Motor Ass'y

2

Main Chassis

1

Deck PCB

(BOT)

• Screw Torque: 5 ± 0.5kgf•cm

2-8: SENSOR COVER L3 (Refer to Fig. 2-8)

Unlock the support 1 and remove the Sensor Cover L3.1.

Main Chassis

Sensor Cover L3

Link Lever

Fig. 2-7

Tension Spring

SS Brake Spring

SS Arm Brake

1

3

Tension Holder

Tension Arm Ass'y

Inclined S Ass'y

Fig. 2-9-B

NOTE

When you install the Tension Adjust, install as shown in

Fig. 2-9-C. (Refer to Fig. 2-9-C)

Adjust the direction of the Marker to inside.

Fig. 2-9-C

1

Fig. 2-8

DISASSEMBLY INSTRUCTIONS

2-10: T BRAKE ASS'Y (Refer to Fig. 2-10)

1.2.Remove the T Brake Spring.

Turn the T Brake Ass'y clockwise and bend the hook

section to remove it.

T Brake Ass'y

Hook section

T Brake Spring

Fig. 2-10

2-11: S REEL/T REEL (Refer to Fig. 2-11)

Remove the S Reel and T Reel.

1.

Remove the 2 Polyslider Washers 1.

2.

NOTE

Take care not to damage the gears of the S Reel and T

1.

Reel.

The Polyslider Washer may be remained on the back of

2.

the reel.

Take care not to damage the shaft.

3.

Do not touch the section "A" of S Reel and T Reel. (Use

4.

gloves.) (Refer to Fig. 2-11) Do not adhere the stains

on it.

When you install the reel, clean the shaft and oil it. (If

5.

you do not oil, noise may be heard in FF/REW mode.)

After installing the reel, adjust the height of the reel.

6.

(Refer to MECHANICAL ADJUSTMENT)

S Reel

(A)

1

T Reel

(A)

1

P5 Spring

P5-3 Arm Ass'y

• Screw Torque: 5 ± 0.5kgf•cm

1

2

Cassette Opener

2

Pinch Roller Block

Pinch Roller Arm Spring

Pinch Roller Lever Ass'y

Main Chassis

Fig. 2-12-A

NOTE

Do not touch the Pinch Roller. (Use gloves.)

1.

When you install the Pinch Roller Block, install as shown

2.

in the circle of Fig. 2-12-B. (Refer to Fig. 2-12-B)

Fig. 2-12-B

2-13: A/C HEAD (Refer to Fig. 2-13-A)

Remove the screw 1.

1.

Remove the A/C Head Base.

2.

Remove the 3 screws 2.

3.

Remove the A/C Head and A/C Head Spring.

4.

NOTE

Do not touch the A/C Head. (Use gloves.)

1.

When you install the A/C Head Spring, install as shown

2.

in Fig. 2-13-B. (Refer to Fig. 2-13-B)

When you install the A/C Head, tighten the screw (1)

3.

first, then tighten the screw (2), finally tighten the screw

(3).

2-12: PINCH ROLLER BLOCK/P5-3 ARM ASS'Y

(Refer to Fig. 2-12-A)

Remove the P5 Spring.

1.

Remove the screw 1.

2.

Unlock the 2 supports 2 and remove the Cassette

3.

Opener.

Remove the Pinch Roller Block, Pinch Roller Arm

4.

Spring, Pinch Roller Lever Ass'y and P5-3 Arm Ass'y.

Fig. 2-11

(3)

(1)

2

2

(2)

1

• Screw Torque: 5 ± 0.5kgf•cm (Screw 1)

2

A/C Head

A/C Head Spring

A/C Head Base

Fig. 2-13-A

DISASSEMBLY INSTRUCTIONS

2-16: CAPSTAN DD UNIT (Refer to Fig. 2-16)

Remove the Capstan Belt.

1.

Remove the 3 screws 1.

2.

Remove the Capstan DD Unit.

3.

Spring Position

Fig. 2-13-B

2-14: FE HEAD (RECORDER ONLY) (Refer to Fig. 2-14)

Remove the screw 1.

1.

Remove the FE Head.

2.

FE Head

• The FE Head is not installed on the Video Cassette Player.

• Screw Torque: 4 ± 0.5kgf•cm

1

Fig. 2-14

2-15: AHC ASS'Y/CYLINDER UNIT ASS'Y

(Refer to Fig. 2-15)

Unlock the support 1 and remove the AHC Ass'y.

1.

Remove the 3 screws 2.

2.

Remove the Cylinder Unit Ass'y.

3.

NOTE

When you install the Cylinder Unit Ass'y, tighten the

screws from (1) to (3) in order while pulling the Ass'y

toward the left front direction.

AHC Ass'y

Capstan Belt

Capstan DD Unit

1

1

1

• Screw Torque: 5 ± 0.5kgf•cm

Fig. 2-16

2-17: MIDDLE GEAR/MAIN CAM (Refer to Fig. 2-17- A)

Remove the Polyslider Washer 1, then remove the

1.

Middle Gear.

Remove the E-Ring, then remove the Main Cam, P5

2.

Cam, Pinch Roller Cam and Joint Gear.

1

Middle Gear

E-Ring

Main Cam

Pinch Roller Cam

Joint Gear

P5 Cam

Cylinder Unit Ass'y

2

(2)

• Screw Torque: 3 ± 0.5kgf•cm

1

Fig. 2-17-A

NOTE

When you install the Pinch Roller Cam, P5 Cam and Main

Cam, align each marker. (Refer to Fig. 2-17- B)

Pinch Roller Cam

(1)

2

2

(3)

Check the hole of Main

Chassis can be seen.

P5 Cam

Fig. 2-15

Main Cam

Marker

Fig. 2-17-B

DISASSEMBLY INSTRUCTIONS

2-18: CLUTCH ASS'Y (Refer to Fig. 2-18)

Remove the Capstan Brake Spring.

1.

Remove the Polyslider Washer 1.

2.

Remove the Clutch Ass'y, Ring Spring and Coupling

3.

Gear.

Unlock the 2 supports 2 and remove the Clutch Lever.

4.

1

Clutch Ass'y

Capstan Brake Spring

Ring Spring

Coupling Gear

Clutch Lever

2

2

Fig. 2-18

2- 1 9 : LOADING GEAR S/T ASS'Y (Refer to Fig. 2-19-A)

Remove the E-Ring 1 and remove the Main Loading

1.

Gear.

Slide the Main Rod and remove the Spring Holder.

2.

Remove the Main Rod, Tension Lever, Clutch Actuator,

3.

Idler Arm Ass'y.

Remove the screw 2.

4.

Remove the LED Reflecter.

5.

Remove the Loading Arm S Ass'y and Loading Arm T

6.

Ass'y.

Remove the Loading Gear S and Loading Gear T.

7.

Remove the Loading Gear Spring.

8.

Spring Holder

1

Main Loading Gear

Tension Lever

Loading Gear T

Loading Gear

Spring

Loading Arm T Ass'y

Loading Gear S

Loading Gear

Spring

Idler Arm Ass'y

LED Reflecter

Clutch Actuator

Main Rod

2

NOTES

1. When you install the Loading Arm S Ass'y, Loading Arm

T Ass'y and Main Loading Gear, align each marker.

(Refer to Fig. 2-19-B)

Marker

Main Loading Gear

Marker

Loading Arm T Ass'y

Loading Arm S Ass'y

Fig. 2-19-B

2. When you install the Clutch Actuator, install as shown in

the circle of Fig. 2-19-C. (Refer to Fig. 2-19-C)

Clutch Actuator

Fig. 2-19-C

2-20: INCLINED S/T ASS'Y (Refer to Fig. 2-20)

Remove the Cap P4.

1.

Remove the screw 1.

2.

Unlock the support 2 and remove the Loading Gear

3.

Holder.

Remove the Inclined S Unit.

4.

Remove the Inclined T Unit.

5.

NOTE

Do not touch the roller of Guide Roller.

1

Inclined S Unit

Loading Gear Holder

2

Inclined T Unit

• Screw Torque: 5 ± 0.5kgf•cm

Loading Arm S Ass'y

Fig. 2-19-A

• Screw Torque: 2.5 ± 0.5kgf•cm

Cap P4

Fig. 2-20

DISASSEMBLY INSTRUCTIONS

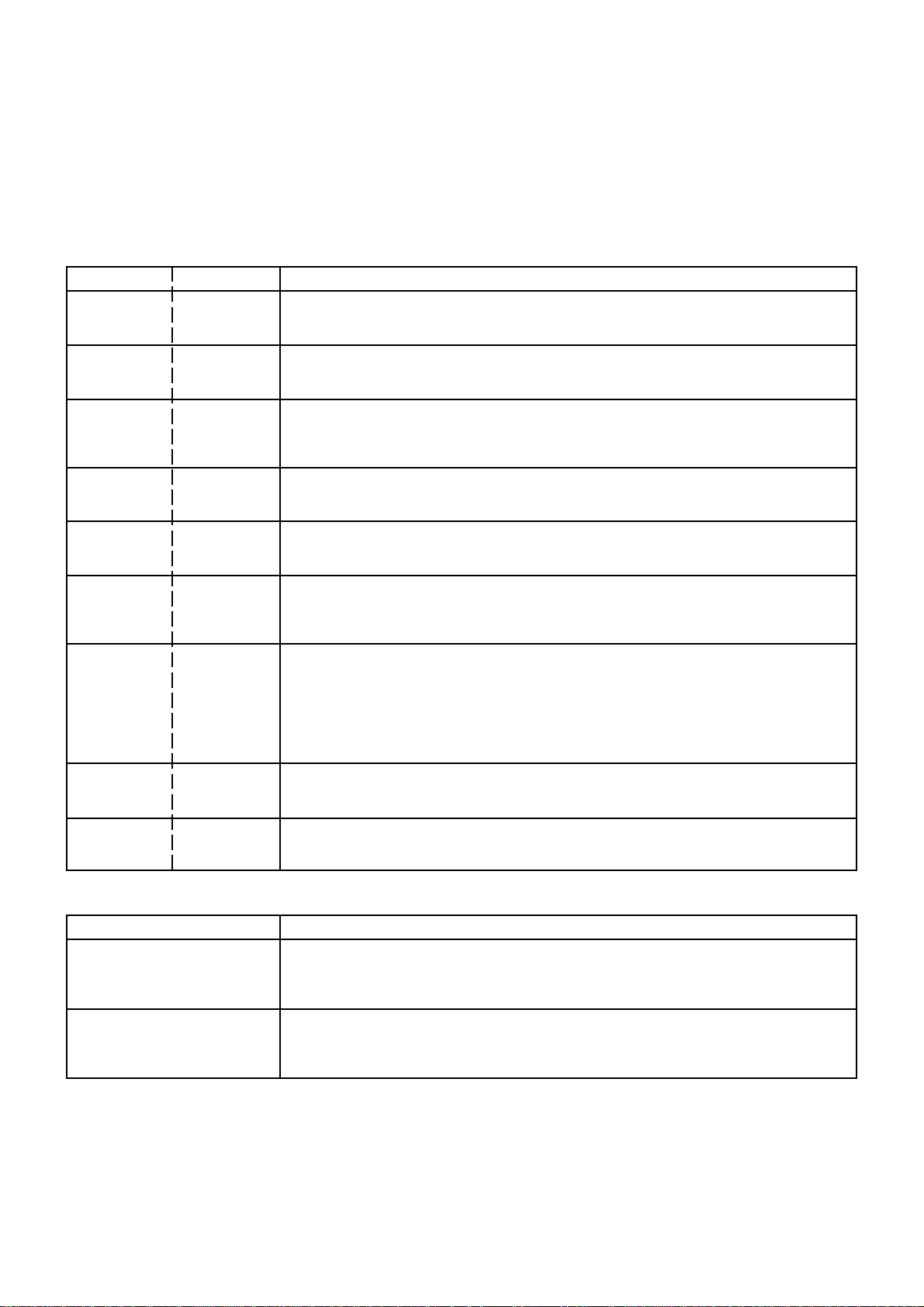

3. REMOVAL OF ANODE CAP

Read the following NOTED items before starting work.

*

After turning the power off there might still be a potential

voltage that is very dangerous. When removing the

Anode Cap, make sure to discharge the Anode Cap's

potential voltage.

*

Do not use pliers to loosen or tighten the Anode Cap

terminal, this may cause the spring to be damaged.

REMOVAL

1. Follow the steps as follows to discharge the Anode Cap.

(Refer to Fig. 3-1.)

Connect one end of an Alligator Clip to the metal part of a

flat-blade screwdriver and the other end to ground.

While holding the plastic part of the insulated Screwdriver,

touch the support of the Anode with the tip of the

Screwdriver.

A cracking noise will be heard as the voltage is discharged.

GND on the CRT

3. After one side is removed, pull in the opposite direction to

remove the other.

NOTE

Take care not to damage the Rubber Cap.

INSTALLATION

1. Clean the spot where the cap was located with a small

amount of alcohol. (Refer to Fig. 3-3.)

Location of Anode Cap

Fig. 3-3

NOTE

Confirm that there is no dirt, dust, etc. at the spot where

the cap was located.

2.3.Arrange the wire of the Anode Cap and make sure the

wire is not twisted.

Turn over the Rubber Cap. (Refer to Fig. 3-4.)

Screwdriver

Alligator Clip

GND on the CRT

Flip up the sides of the Rubber Cap in the direction of the

2.

arrow and remove one side of the support.

(Refer to Fig. 3-2.)

Rubber Cap

CRT

Support

Support

CRT

Fig. 3-1

Fig. 3-2

Fig. 3-4

4. Insert one end of the Anode Support into the anode button,

then the other as shown in Fig. 3-5.

Support

CRT

5.6.Confirm that the Support is securely connected.

Put on the Rubber Cap without moving any parts.

Fig. 3-5

A

A/C

ACC

AE

AFC

AFT

AFT DET

AGC

AMP

ANT

A.PB

APC

ASS'Y

AT

AUTO

A/V

B

BGP

BOT

BPF

BRAKE SOL

BUFF

B/W

C

C

CASE

CAP

CARR

CH

CLK

CLOCK (SY-SE)

COMB

CONV

CPM

CTL

CYL

CYL-M

CYL SENS

D

DATA (SY-CE)

dB

DC

DD Unit

DEMOD

DET

DEV

E

E

EF

EMPH

ENC

ENV

EOT

EQ

EXT

F

F

FBC

FE

FF

FG

FL SW

FM

FSC

FWD

G

GEN

GND

H

H.P.F

KEY TO ABBREVIATIONS

:

Audio/Control

:

Automatic Color Control

:

Audio Erase

:

Automatic Frequency Control

:

Automatic Fine Tuning

:

Automatic Fine Tuning Detect

:

Automatic Gain Control

:

Amplifier

:

Antenna

:

Audio Playback

:

Automatic Phase Control

:

Assembly

:

All Time

:

Automatic

:

Audio/Video

:

Burst Gate Pulse

:

Beginning of Tape

:

Bandpass Filter

:

Brake Solenoid

:

Buffer

:

Black and White

:

Capacitance, Collector

:

Cassette

:

Capstan

:

Carrier

:

Channel

:

Clock

:

Clock (Syscon to Servo)

:

Combination, Comb Filter

:

Converter

:

Capstan Motor

:

Control

:

Cylinder

:

Cylinder-Motor

:

Cylinder-Sensor

:

Data (Syscon to Servo)

:

Decibel

:

Direct Current

:

Direct Drive Motor Unit

:

Demodulator

:

Detector

:

Deviation

:

Emitter

:

Emitter Follower

:

Emphasis

:

Encoder

:

Envelope

:

End of Tape

:

Equalizer

:

External

:

Fuse

:

Feed Back Clamp

:

Full Erase

:

Fast Forward, Flipflop

:

Frequency Generator

:

Front Loading Switch

:

Frequency Modulation

:

Frequency Sub Carrier

:

Forward

:

Generator

:

Ground

:

High Pass Filter

H.SW

Hz

I

IC

IF

IND

INV

K

KIL

L

L

LED

LIMIT AMP

LM, LDM

LP

L.P.F

LUMI.

M

M

MAX

MINI

MIX

MM

MOD

MPX

MS SW

N

NC

NR

O

OSC

OPE

P

PB

PB CTL

PB-C

PB-Y

PCB

P. CON

PD

PG

P-P

R

R

REC

REC-C

REC-Y

REEL BRK

REEL S

REF

REG

REW

REV, RVS

RF

RMC

RY

S

S. CLK

S. COM

S. DATA

SEG

SEL

SENS

SER

SI

SIF

SO

SOL

SP

STB

SW

:

Head Switch

:

Hertz

:

Integrated Circuit

:

Intermediate Frequency

:

Indicator

:

Inverter

:

Killer

:

Left

:

Light Emitting Diode

:

Limiter Amplifier

:

Loading Motor

:

Long Play

:

Low Pass Filter

:

Luminance

:

Motor

:

Maximum

:

Minimum

:

Mixer, mixing

:

Monostable Multivibrator

:

Modulator, Modulation

:

Multiplexer, Multiplex

:

Mecha State Switch

:

Non Connection

:

Noise Reduction

:

Oscillator

:

Operation

:

Playback

:

Playback Control

:

Playback-Chrominance

:

Playback-Luminance

:

Printed Circuit Board

:

Power Control

:

Phase Detector

:

Pulse Generator

:

Peak-to Peak

:

Right

:

Recording

:

Recording-Chrominance

:

Recording-Luminance

:

Reel Brake

:

Reel Sensor

:

Reference

:

Regulated, Regulator

:

Rewind

:

Reverse

:

Radio Frequency

:

Remote Control

:

Relay

:

Serial Clock

:

Sensor Common

:

Serial Data

:

Segment

:

Select, Selector

:

Sensor

:

Search Mode

:

Serial Input

:

Sound Intermediate Frequency

:

Serial Output

:

Solenoid

:

Standard Play

:

Serial Strobe

:

Switch

S

SYNC

SYNC SEP

T

TR

TRAC

TRICK PB

TP

U

UNREG

V

V

VCO

VIF

VP

V.PB

VR

V.REC

VSF

VSR

VSS

V-SYNC

VT

X

X'TAL

Y

Y/C

KEY TO ABBREVIATIONS

:

Synchronization

:

Sync Separator, Separation

:

Transistor

:

Tracking

:

Trick Playback

:

Test Point

:

Unregulated

:

Volt

:

Voltage Controlled Oscillator

:

Video Intermediate Frequency

:

Vertical Pulse, Voltage Display

:

Video Playback

:

Variable Resistor

:

Video Recording

:

Visual Search Fast Forward

:

Visual Search Rewind

:

Voltage Super Source

:

Vertical-Synchronization

:

Voltage Tuning

:

Crystal

:

Luminance/Chrominance

SERVICE MODE LIST

This unit provided with the following SERVICE MODES so you can repair, examine and adjust easily.

To enter SERVICE MODE, unplug AC cord till lost actual clock time. Then press and hold Vol (-) button of main unit and

remocon key simultaneously.

The both pressing of set key and remote control key will not be possible if clock has been set. To reset clock, either unplug

AC cord and allow at least 5 seconds before Power On.

Set Key Remocon Key Operations

VOL. (-) MIN

VOL. (-) MIN 1

VOL. (-) MIN

VOL. (-) MIN

VOL. (-) MIN 4

VOL. (-) MIN

VOL. (-) MIN

0

2

3

5

6

Releasing of V-CHIP PASSWORD.

Initialization of the factory.

NOTE: Do not use this for the normal servicing.

Horizontal position adjustment of OSD.

NOTE: Also can be adjusted by using the Adjustment MENU.

Refer to the "ELECTRICAL ADJUSTMENT" (OSD HORIZONTAL).

Adjust the PG SHIFTER automatically.

Refer to the "ELECTRICAL ADJUSTMENT" (PG SHIFTER).

Adjust the PG SHIFTER manually.

Refer to the "ELECTRICAL ADJUSTMENT" (PG SHIFTER).

Adjusting of the Tracking to the center position.

NOTE: Also can be adjusted by pressing the ATR button for more than 2 seconds

during PLAY.

POWER ON total hours and PLAY/REC total hours are displayed on the screen.

Refer to the "PREVENTIVE CHECKS AND SERVICE INTERVALS" (CONFIRMATION

OF USING HOURS).

Can be checked of the INITIAL DATA of MEMORY IC.

Refer to the "NOTE FOR THE REPLACING OF MEMORY IC".

VOL. (-) MIN 8

VOL. (-) MIN 9

Method Operations

Press the ATR button on the

remote control for more than

2 seconds during PLAY.

Make the short circuit between

the test point of SERVICE and

the GND.

Writing of EEPROM initial data.

NOTE: Do not use this for the normal servicing.

Display of the Adjustment MENU on the screen.

Refer to the "ELECTRICAL ADJUSTMENT" (On-Screen Display Adjustment).

Adjusting of the Tracking to the center position.

Refer to the "MECHANICAL ADJUSTMENT" (GUIDE ROLLER) and "ELECTRICAL

ADJUSTMENT" (PG SHIFTER).

The EOT/BOT/Reel sensor do not work at this moment.

Refer to the "PREPARATION FOR SERVICING"

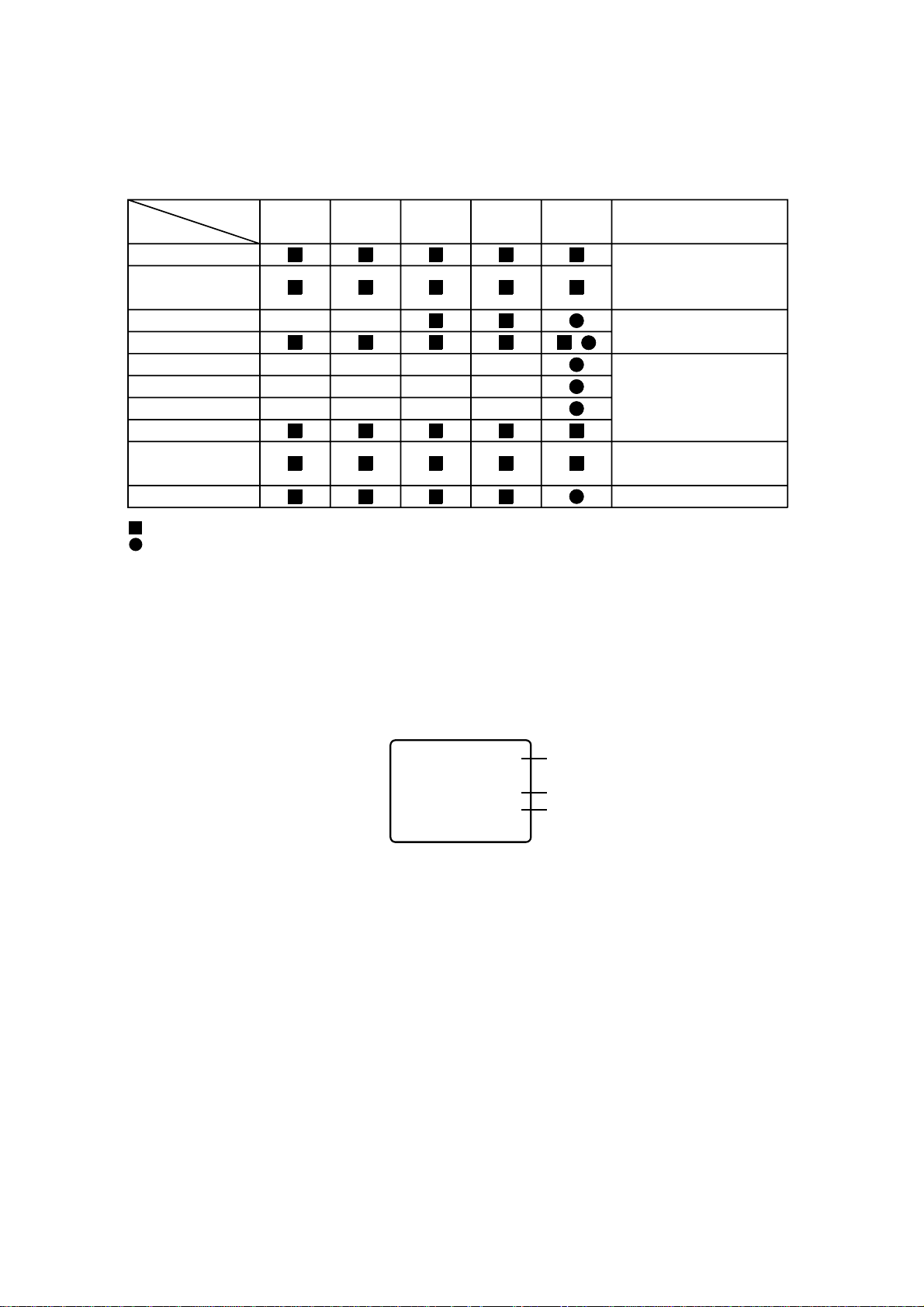

PREVENTIVE CHECKS AND SERVICE INTERVALS

The following standard table depends on environmental conditions and usage. Unless maintenance is properly

carried out, the following service intervals may be quite shortened as harmful effects may be had on other parts.

Also, long term storage or misuse may cause transformation and aging of rubber parts.

Time

Parts Name

Audio Control Head

Full Erase Head

(Recorder only)

Capstan Belt

Pinch Roller

Capstan DD Unit

Loading Motor

Tension Band

Capstan Shaft

Tape Running

Guide Post

Cylinder Unit

: Clean

: Replace

500

hours

1,000

hours

1,500

hours

2,000

hours

3,000

hours

Notes

Clean those parts in

contact with the tape.

Clean the rubber, and parts

which the rubber touches.

Replace when rolling

becomes abnormal.

Clean the Head

CONFIRMATION OF USING HOURS

POWER ON total hours and PLAY/REC total hours can be checked on the screen.

Total hours are displayed in 16 system of notation.

NOTE: The confirmation of using hours will not be possible if clock has been set. To reset clock, either unplug

AC cord and allow at least 5 seconds before Power On.

1.

Set the VOLUME to minimum.

2.

While holding down VOLUME button on front cabinet, press key 6 on remote control simultaneously.

3.

After the confirmation of using hours, turn off the power.

INIT 00 83

POWER ON

PLAY/REC

(16 x 16 x 16 x thousands digit value) + (16 x 16 x hundreds digit value) + (16 x tens digit value) + (ones digit value)

0010

0003

Initial setting content of MEMORY IC.

POWER ON total hours.

PLAY/REC total hours.

PREVENTIVE CHECKS AND SERVICE INTERVALS

CLEANING

NOTE

After cleaning the heads with isopropyl alcohol, do not

run a tape until the heads dry completely. If the heads

are not completely dry and alcohol gets on the tape,

damage may occur.

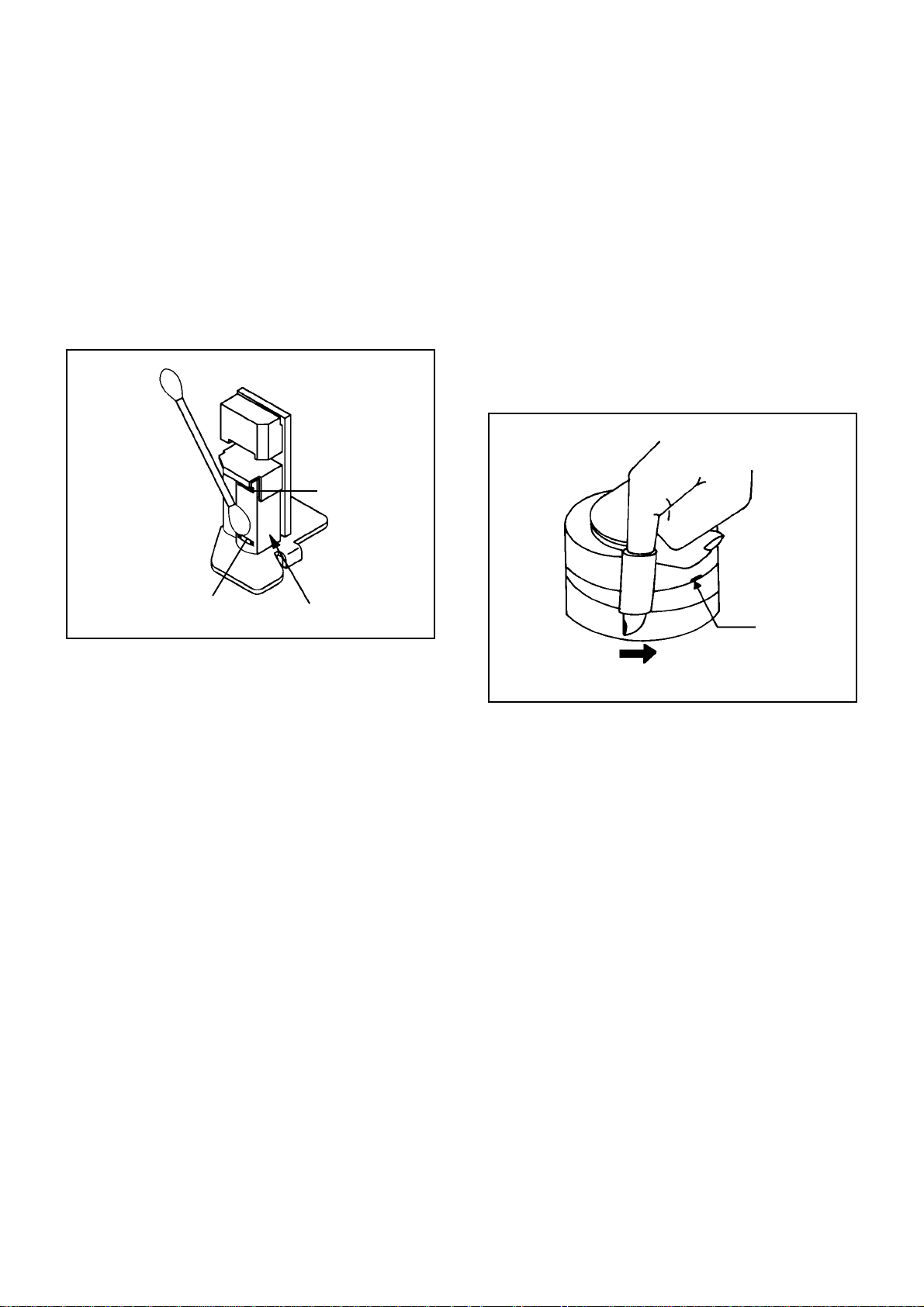

1. AUDIO CONTROL HEAD

Clean the Audio Control Head with the cotton stick

soaked by alcohol. Clean the full erase head in the

same manner. (Refer to the figure below.)

Head

2. TAPE RUNNING SYSTEM

When cleaning the tape transport system, use the

gauze moistened with isopropyl alcohol.

3. CYLINDER

Wrap a piece of chamois around your finger. Dip it in

isopropyl alcohol. Hold it to the cylinder head softly.

Turn the cylinder head counterclockwise to clean it (in

the direction of the arrow). (Refer to the figure below.)

NOTE

Do not exert force against the cylinder head. Do not move

the chamois upward or downward on the head.

Use the chamois one by one.

Head

Audio Control Head

Cylinder Head

Loading...

Loading...