Toshiba MV13K2 Owner’s Manual

TO SH IBA _ _o._o__oooo_

SERVICE MANUAL

COLOR TELEVISION/

VIDEO CASSETTE RECORDER

SERVICING NOTICES ON CHECKING

1. KEEP THE NOTICES

Asfor the placeswhichneed specialattentions,

they are indicatedwiththe labels or sealsonthe

cabinet,chassisandpads.Make suretokeepthe

indicationsend n_loes inthe opamtionmanual.

2. AVOID AN ELECTRIC SHOCK

There is a highvoltage part inside.Avoidan

electricshockwhilethe electriccurrentis

flowing.

3. USE THE DESIGNATED PARTS

The parts inthisequipment havethe specific

charactersof Incombustibilityand withstand

voltageforsafety. Therafore, the partwhich is

replacedshouldbe used the part which has

the same chemcter.

Especiallyas to the importantparts forsafety

which is indicatedin the cimultdiagramor the

tableof padsas a Z_ mark,the designated

pads must be used.

4. PUT PARTS AND WIRES IN THE

ORIGINAL POSITION AFTER

ASSEMBUNG OR WIRING

There are pads which use the insulation

meteriblsuchas atube ortape for safety, or

whichare assembledin the conditionthat

these de not contactwiththe pdntadboard.

The insidewidngis designed notto get cinsor

tothe pyrogenicpads and highvoltage parts.

Therefore, put thesepads in the originaf

positions.

5. TAKE CARE TO DEAL WITH THE

CATHODE-RAY TUBE

Inthe conditionthat an explosion-proofcathode-

raytube is set in this equipment, safetyis

securedagainstimplosion.However, when

removingitor sendng frombackward,it is

dangerousto give a shock.Take enoughcare to

deal withit.

6. AVOID AN X-RAY

Safetyle securedagainstan X-ray byconsider-

ing about the cathode-ray tube and the high

voltagepedphorsicircuit,etc.

Therefore, when rapalflngthe high voltagepe-

dpheral circuit, use the designated parts and

makesure notrnodifythe cimuit.

Repaidngexcept indicatescausesdsingof high

voltage,and itomits an X-rayfrom the cathode-

raytube.

7. PERFORM A SAFETY CHECK AFTER

SERVICING

Confirmthatthe screws,pads and wiring which

were removedinorder to sendce am putin the

odginalpositions,or whetherthereare the

portions which am deteriorated aroundthe

serviced placesserviced ornot.Checkthe

insuletionbetweenthe antennaterminalor

external metal and the AC cord plugblades.

Andbe sum the safetyofthat.

(INSULA'nONCHECKPROCEDURE)

1. Unplugthe plugfrom_ ACoutlet.

2. Removethealdenna turmlnsl on TV andturn

an the'rV.

3. Insulationresistancebetweenthe cordplug

terminals end the etemaf exposure metal

LTlote2] should be mere than 1M ohm by

using the 500V insulationreslstance meter

[Note1].

4. If the insulationresistance is lessthan 1M

ohm,the inspectionrepairshouldbe

required.

[Nob 1]

Ifyou heve notthe 500V insulation

resistancemeter,use a Tester.

[Note=]

Externalexposuremetal:Antennaterminal

Earphonejack

HOW TO ORDER PARTS

Please includethe fonowlngioformetionswhenyouorder pads. (Particularlythe VERSION LE'I-i'ER.)

1oMODEL NUMBER andVERSION LETTER

The MODEL NUMBERcanbe foundon the beck of eachproductandthe VERSION LETTER canbe

found atthe end of the SERIAL NUMBER.

2. PART NO. and DESCRIPTION

You can findit th your SERVICE MANUAL.

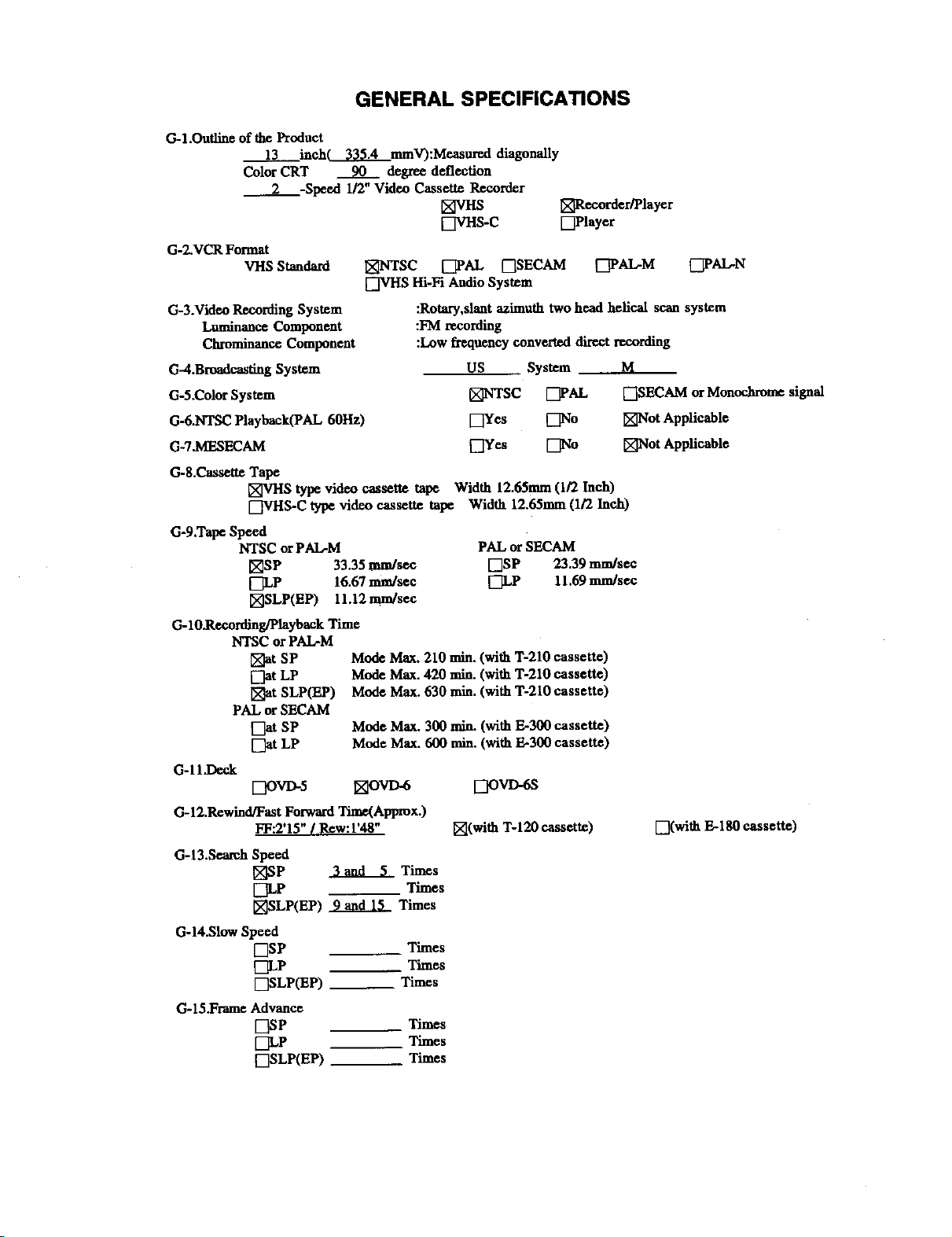

GENERAL SPECIFICATIONS

G-1.Outline of the Product

13 inchC 335.4 mmV):Measured diagonally

Color CRT 90 degree deflection

2 -Speed 1/2" Video Cassette Recorder

G-2.VCR Format

VHS Standard 1_€1"SC [_[PAL ["ISECAM [Z]PAI._M {_PAL-N

[_VI-IS Hi-Fi Audio System

G-3.Video Recording System

Luminance Component

Chrominance Component

G-4.Brcodcasting System

G-5,Color System

G-6.NTSC Playback(PAL 60Hz)

G-7_MESECAM

G-8.Cassette Tape

_]VHS type video cassette tape Width 12.65mm (1/2 Inch)

[_NI-IS-C type video cassette tape Width 12.65mm (1/2 Inch)

Go9.Tapo Speed

G-10.Recordm"g/Playback Time

NTSC or PAL-M PAL or SECAM

[_SP 33.35 ram/see [_SP 23.39 ram/see

[_[LP 16.67 mm/see [_[LP 11.69 mm/see

[_SLP(EP) 11.12 mm/see

NTSC or PALM

_at SP

[-]at LP

_at SLP(EP)

Mode Max. 210 rain. (with T-210 cassette)

Mode Max. 420 min. (with T-210 cassette)

Mode Max. 630 rain. (with T-210 cassette)

PAL or SECAM

Flat SP

LP

G-1 l.De_k

Mode Max. 300 rain. (with E-300 cassette)

Mode Max. 600 rain. (with E-300 cassette)

OVD-5 Novas OVD-6S

G-12.Rewind/Fast Forward Time(Approx.)

FF:2'I5" / Rew: I'48" [X](with T-120 cassette)

G-13.Sen_h Speed

[_]SP 3aod 5 Times

[_LP Times

[_SLP(EP) 9_d15 Times

G-14.Slow Speed

[_SP Times

[_LP Times

[TSLP(EP) Times

G- 15.Frame Advance

[_SP Times

[_SLP(EP). Times

[_VHS l_Reeorder/Player

E]VHS-C [_Player

:Rotary,slant azimuth two head helical scan system

:FM recording

:Low frequency convea_l direct recording

US System M

[_ITSC E]PAL [-]SECAM or Monochrome signal

ElYes [-]No l_€ot Applicable

[_!es _o _qot Applicable

IT(withE-180 cassette)

Times

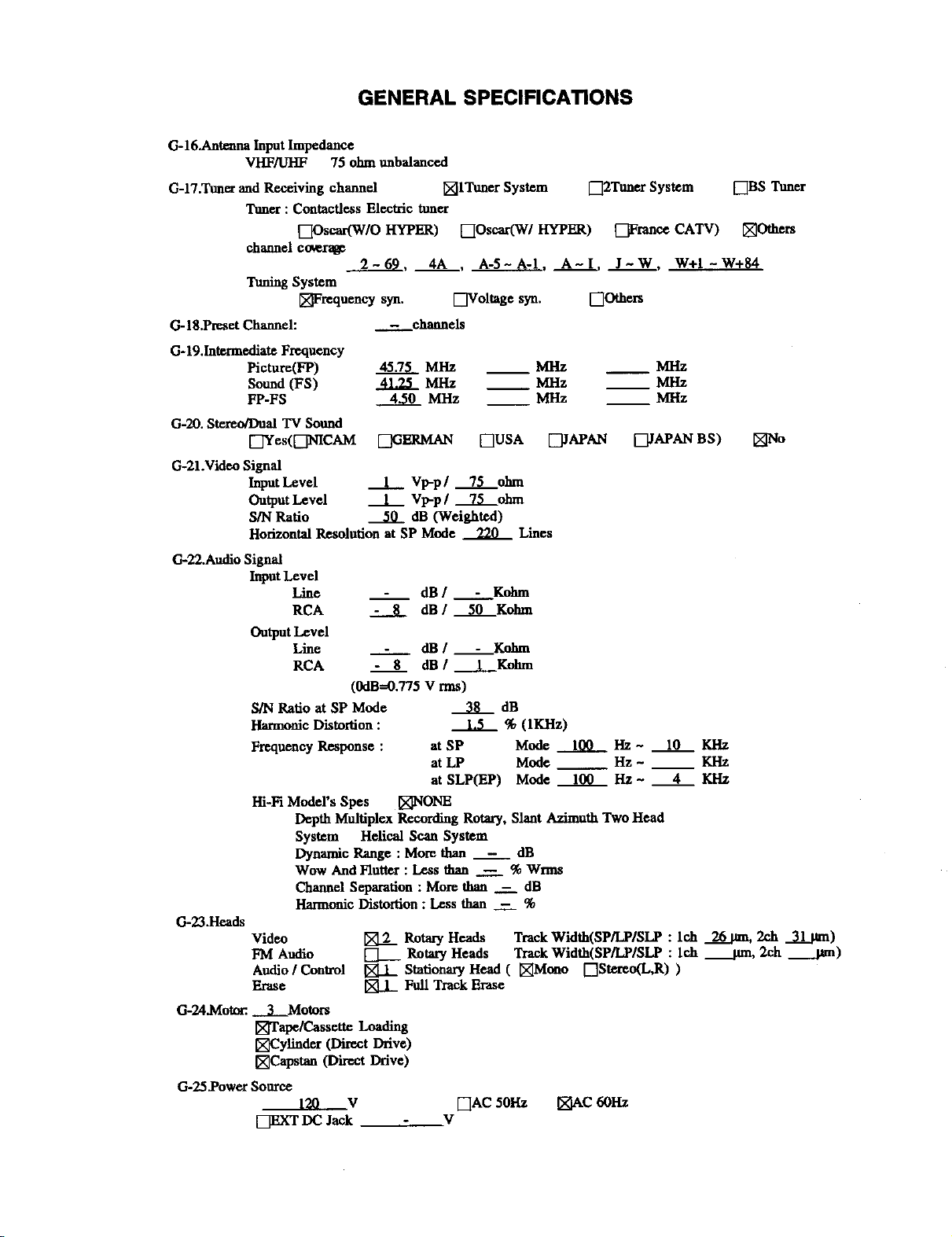

GENERAL SPECIFICATIONS

G-16,Antenna Input Impedance

VHF/UHF 75 ohm unbalanced

G=17.Tuner and Rec._ving ehaunel _]lTuner System

Tuner : Contaefless Electric tuner

[_)_'w/o HYPI_.) FIO_(W/HYPER) _rence CATV) []Others

channel co_r_

2-69, 4A , A-5-A-I, A-I, J-W, W+I-W+84

TuningSystem

_Frequency syn. E_/ultage syn. [-]Others

G-18.Preset Channel: chaunels

G- 19.1ntermediate Frequency

Pieture(FP) 45.75 MHz __ Ml-lz

Sound (FS) 41.25 MHz __ MHz

FP-FS 4.50 MHz __ MHz

G-20. Stereo/Dual "IV Sound

CyYes(_,_ICAM [_ERMAN []USA [JAPAN

G-21.Video Signal

Input Level _..L_ Vp-p / 75 ohm

Output Level ..._1._ Vp-p / 75 ohm

S/N Ratio 50 dB (Weighted)

Horizontal Resolution at SP Mode 220 Lines

G-22.Audio Signal

Input Level

Line dB/ - Kohm

RCA - 8 dB/ 50 Kohm

Output Level

Line

RCA - 8 dB/ ..._J Kohm

S/N Ratio at SP Mode 38 dB

Harmonic Distortion : 1.5 % (IKHz)

Frequency Response : at SP Mode 100 Hz ~ 10 KHz

Hi-Fi Model's Spes _NONE

Depth Multiplex Recording Rotary, Slant A_muth TWo Head

System Helical Scan System

Dynamic Range : More than - dB

Wow And Flutter : Less than _ % Wrms

Channel Separation : More than _=_ dB

Harmonic Distortion : Less than _----_-%

G-23.Heads

Video

FM Audio

Audio / Control

Erase

G-24.Motm:__3_Motors

[_rape/Cassalte Loading

[_Cylinder (Direct Drive)

C_Capstan(Direct Drive)

G-25_PowerSource

120 V []AC 50ttz _]AC 60Hz

E_XTDCJack V

dB/ - Kohm

(0dB=0.775 V t-ms)

at LP Mode Hz - __ KHz

at SLP(EP) Mode 100 Hz ~ _ KI-Iz

Rotary Heads Track Width(SP/LP/SLP : lch _ 2c,h _)

Rotary Heads Treck Width(SP/LP/SLP : lch ....._tun, 2ch _)

Stationary Head ( _;_Muno ["]Sterun(L,R) )

FUll Track Erase

["]2Tuner System FIBS Tuner

MHz

MHz

MHz

DJAPAN BS) [_,1o

GENERAL SPECIFICATIONS

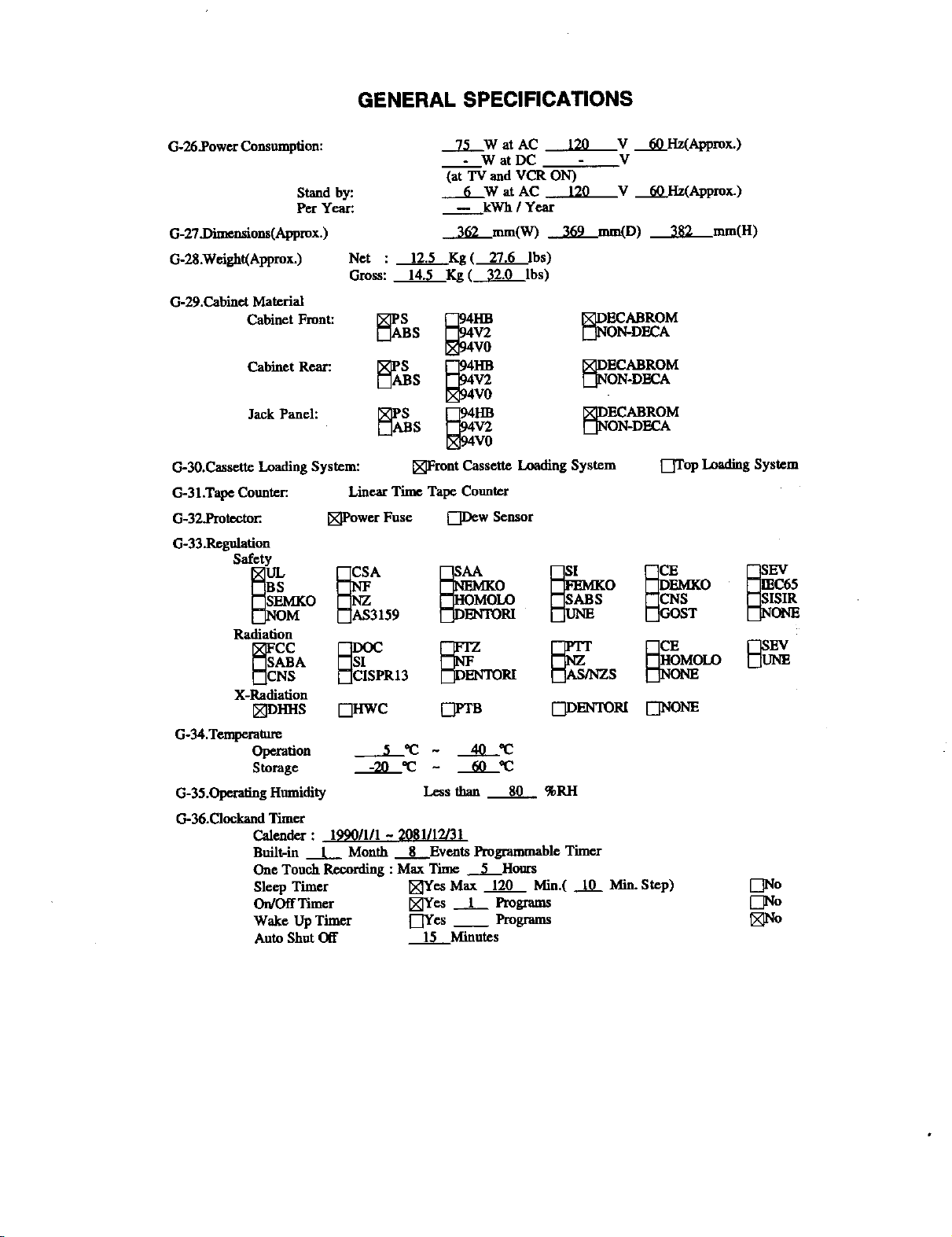

G-26.PowerConsumption:

Stand by:

Per Year:

G-27_mansions(Approx.)

G-28.Weight(Approx.) Net

G-29.Cablnet Material

Cabinet Front: _IASBS _0 [_DECABROM[_ION.DECA

Cabinet Ranr: _PA_Ss _vvH_0 _i'€ON-DECA[_DECABROM

JackPaneh _PA_Ss _0 [_ON-DECA_I)ECABROM

G-30.Cassette Loading System: [_¢mnt Cassette Landing System [_Top loading System

G-31 .TapeCounter:.

G-32.Protector. _ower Fuse [_ew Sensor

G-33.Regulation

Safety

_oE_M O [-]AS31'9 _DENTORI _E S BCosT _I_N_

Radiation

: 12.5 Kg( 27.6 lbs)

Gross: 14.5 Kg ( 32.0 Ibs)

Linear Time Tape Counter

75 W atAC 120 V 60 Hz(Appmx.)

- WatDC - V

(atTV and VCR ON)-

6 W at AC 120 V 60 Hz(Appmx.)

-- kwh I Year

362 mm(W) 369 ram(D) 392 ram(H)

[_HOMOLO CNS

NS [_CISPRI3

X-Ra_'ation

_HaS [_rwc [I_PTB [2Dm_roPaC_NONE

G-34.Tempemtnm

Operation 5 °C ~ 40 °C

Smmge -20 "C 60 '_2

G-35.OF.m_g Humidity

G-36.Clochand Timer

Calender : 19901111 ~ 2081112/31

Buih-in _ Month ......_L Evants Programmable Timer

One Touch Recording : Max Time _Hours

Sleep Timer l_Yes Max 120 Min.( 10 Mitt. Step)

On/Off Timer [_Yes l_.!._ Programs

Wake Up Timer [_Yes __ Programs

Auto ShutOff l..._..._Minut_s

Less than 80 %RH

[_o

[_o

No

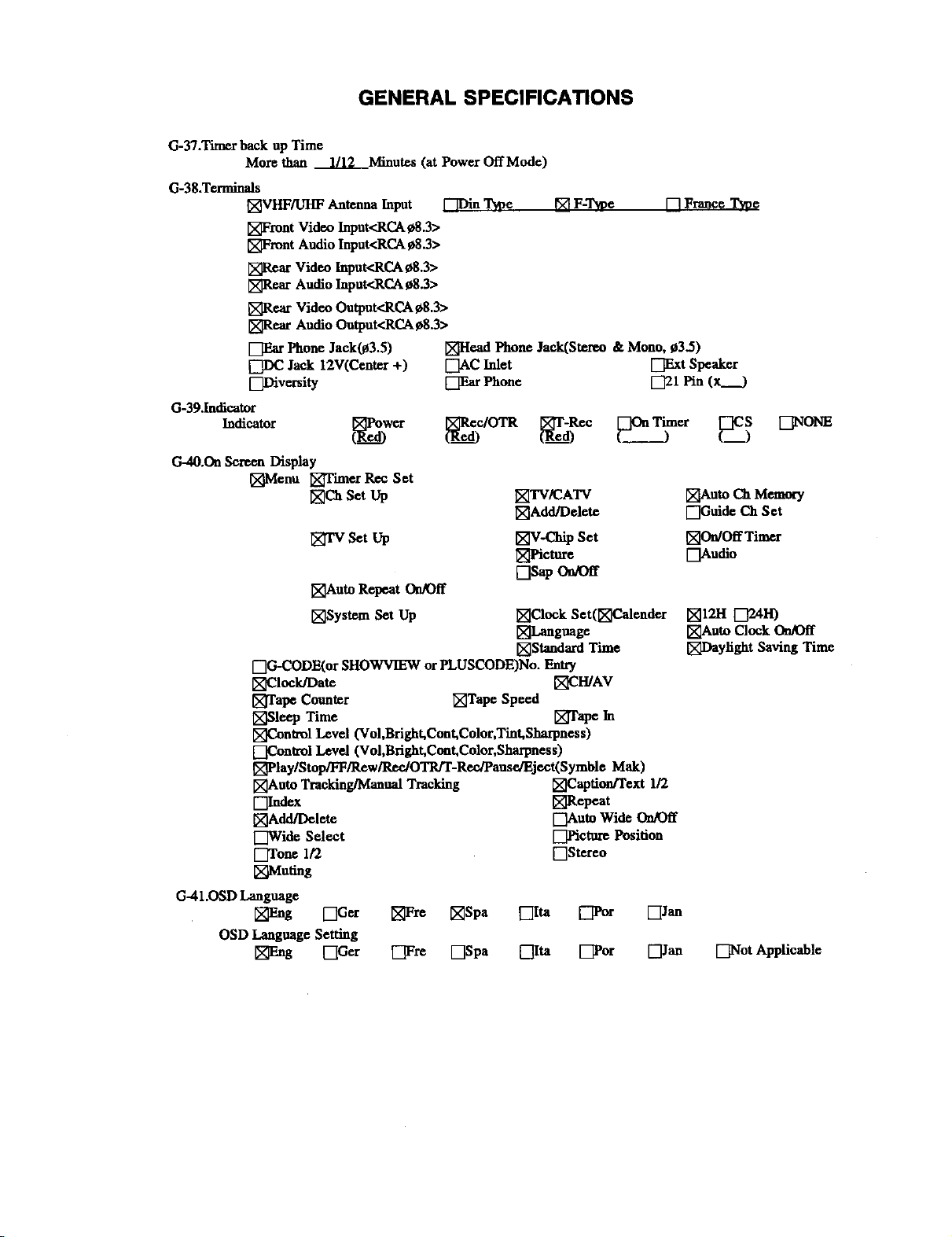

G-37.Timer back up Time

More than 1/12 Minntes (atPower OffMod¢)

G-38.Tcrrninals

_tHF/UHF Antenna Input _ T_e

_mnt Video Input<RCA _8.3>

_Fmnt Audio Input<RCA_8.3>

_7,car Video Input<RCAo8.3>

Audio Inpot<RCA _8.3>

_Rear Video Output<RCA €8.3>

_Rear Audio Output<RCA_8.3>

EJEar Phone Jack(_3.5)

_C Jack 12V(Center +)

[=]Diversi_

G-39.in_mr

Indica_r

G-40.OnScreen Display

[_V_enu _'l'imer RJ:¢ Set

GENERAL SPECIFICATIONS

F-T_e _ France Typ_

_Head Phone Jack(Stereo & Mono, ¢3.5)

[_AC Inlet [_,xt Speaker

Phone _21 Pin (x_._)

[Ch Set Up

Set Up C_v-C_ip Set [On/OffTimer

[_Auto Repeat On/Off

_TV/CATV

[Add/Delete

_!_Picture []Audio

fTSap On_r

[Z_qONE

[]Auto _ Memory

V]GuideC.hSet

_G-CODE(or SHOWVIEW or PLUSCODE)No. Entry

[Clock/Date _C/-//AV

[Tape Counter _]Tap¢ Speed

[Sleop Time _Tape In

[Control Level (Vol,Bright,Cnnt, Color,Tint, Sharpness)

[_ntrol Level (Vol,Bright, Cnnt, Color,Sharlmess)

_Play/S top/FF/Rew/RedOTRfr~Rec/Pause,/Ej ect(Symblc Mak)

[_Auto Tracking/Manual Tracking [5_']Captinnfrext 1/2

VlIndex [_Repeat

[_kdd/Dclete [_]Auto Wide On/Off

[Z]Wide Select [_Pictm'€ Position

[_l'oncI/2 [_Stereo

_[nting

G-41.OSD Language

OSD Language Setting

C_.ng [-]Ger E]Fre [_Spa _Ita [_Por

[]System Set Up _Clock Set([Calender

_].,angnnge

[_Standard Time

[_Ger [_Fre _Spa _]Ita [_Por

_12H [=]24H)

[_AutoClock On/Off

[_)aylight Saving Time

_Jan

[-]Jan [_ot Applicable

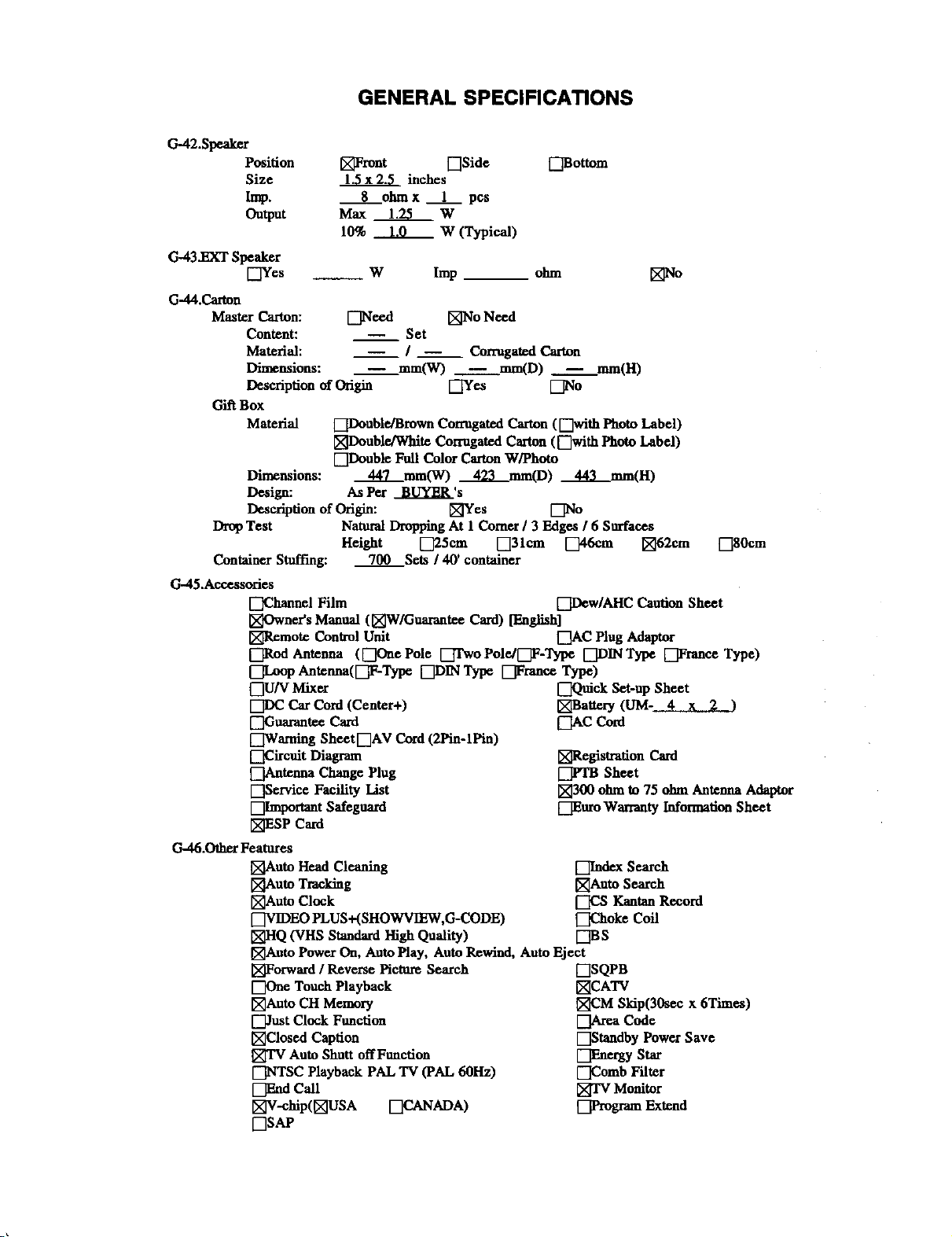

GENERAL SPECIFICATIONS

G-42.Spnaher

Position _mnt [-']Side

Size 1.5x 2.5 inches

Imp. 8 ohmx 1 pcs

Output Max 1.25 w

10_ LOW (Typical)

G-43_XT Speaker

[Yes __ W Imp ohm _4o

G-44.Carton

Master Carton: [_qeod _]No Need

Content: -- Set

Material: -- / _ Corrugated Carton

Dimensions: -- ram(W) -- ram(D) -- mm(H)

Description of Origin [_Yes [_o

Gift Box

Material _Double/Brown Corrugated Carton ( F'Twith Photo Label)

_;_Double./White Corrugated Carton ([_with Photo Label)

[-]Double Full Color Carton W/Photo

Dimonsions: _7 ram(W) 423 mm(D) _3 ram(H)

Design: As Per BUYER's

Description of Origin: _t'es [_o

Drop Test Natural Dropping At 1 Comer / 3 Edges / 6 Surfaees

Height [-_25em [31cm [46cm [_62cm

Container Stuffing: 700 Sets / 40' container

G-45.Aecessories

_Channel Film _Dew/AHC Caution Sheet

_Owner's Manna] (_W/Gnarantee Card) [English]

_mote Control Unit E]AC Plug Adaptor

Antenna (_)nePole _UwoPole/_F-Type [_DINType _lance Type)

Antenna(_-_ DDIN_ pranee Type)

_U/V Mixer

[DC Car Cord (Center+)

D3uarantee Card

I-]Warning SheetNAV Cord (2Pin-lPin)

[_]Circnit Diagram

_-_Antenna Change Plug

[-]Service Facility List

[_Important Safeguard

[_SP Card

G-46.Othar Features

_Auto Head Cleaning

_Auto Tracking

[5_Auto Clock

_tIDEO PLUS +(SHOWVIEW, G--CODE)

_HQ (VHS Standard High Quality)

[_Auto Power On, Auto Play, Auto Rewind, Auto Eject

_orward / Reverse Picture Search

[_One Touch Playback

[]Auto CH Memory

[-TJust Clock Function

[_Closed Caption

Auto Shutt offFunodon

_qTSC Playbac_ PAL TV (PAL 60Hz)

[Z odCall

_l-chip([_USA []CANADA)

[]-]SAP

[_-JBottom

I-"[80cm

[_Quiek Set-up Sheet

_Battery (UM-_

[_AC Cord

_gisWation Card

[_FB Sheet

_300 ohm to75 ohmAntenna Adaptor

[_Euro Warranty InformationSheet

_Index Search

[_Auto Search

C_CS Kanton Record

_._hoke Coil

VTSQPB

[CATV

[CM Skip(30secx 6Times)

[_AreaCode

F]StandbyPower Save

[_mergy Star

[Comb Filter

Monitor

[Program _tend

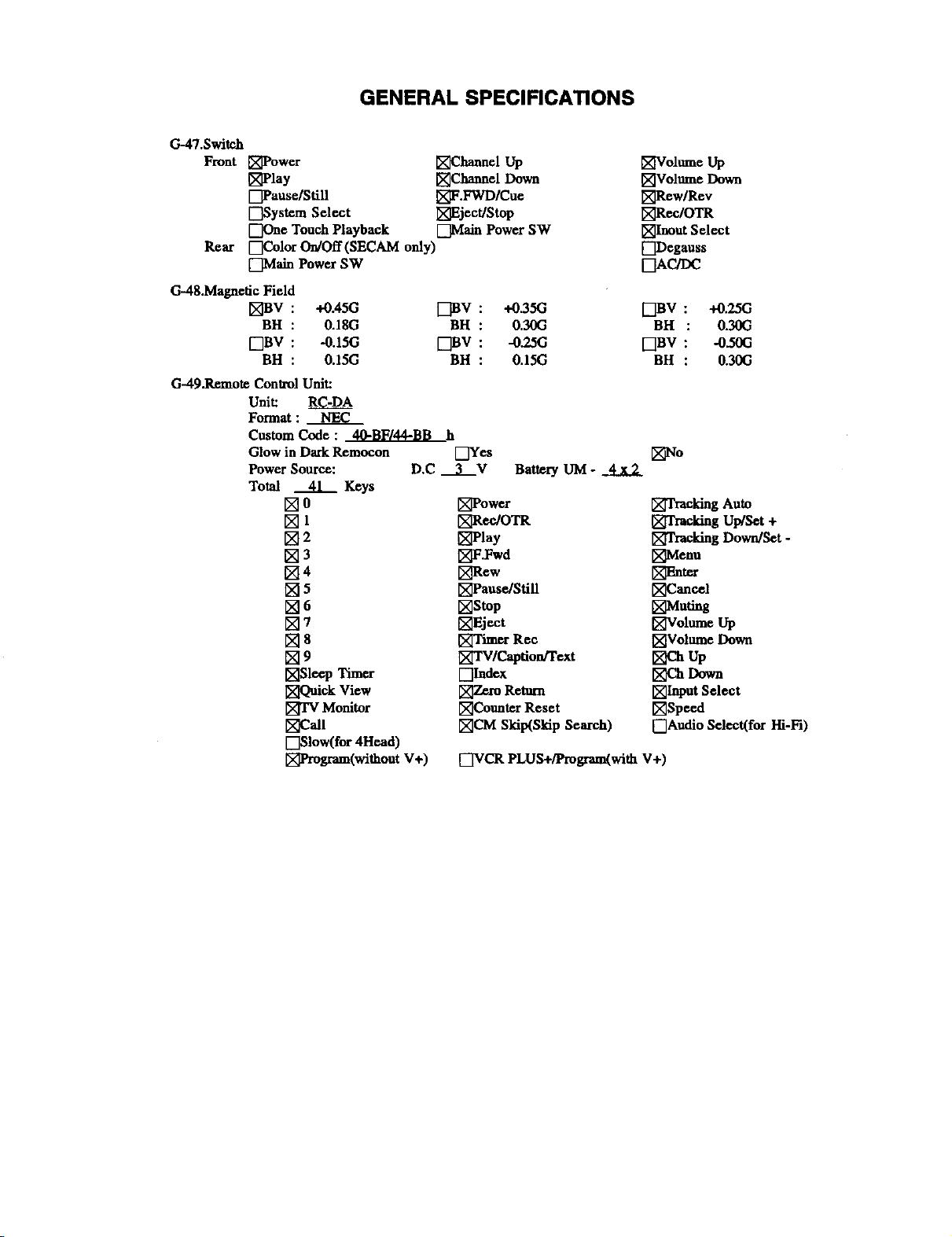

G-47.Switch

Front [_Power

[_Play

_Pausv/Still

E]System Select

[-]One Touch Playback

Rear DCnior On/Off(SECAM only)

E_vi',fin Power SW

G..48.Magnetic Field

[_]BV : +0.45G [_BV : +0.35(3 [Z]BV : +0.25G

BH : 0.18(3 BH : 0.30G BH : 0.30(3

[-]BV : -0.15G [Z]BV : -0.23G [_BV : -0..50(3

BH : 0.15G BH : 0.15G BH : 0.30G

G-49._mote Control Unit:

Unit: RC-DA

Format : NEt_

Custom Code : _BF/,_BB h

Glow in Dark Remocon [_Yes

Power Source: D.C _V

Total 41 Keys

[]0

_2

[]3

[]4

_5

_6

_7

[]8

_9

[_Sleep Timer

l_Qnick View

_TV Monitor

[_Call

I_Slow( for 4Head)

[_ogram(without V+)

GENERAL SPECIFICATIONS

_Channel Up

[_Channcl Down

[_F.FWD/Cu¢

_ject/Stop

[3_,Iain PowerSW

Battery UM- 4x2

_Power

[_P.ee/OTR

[_Play

[_F.Fwd

[_Rew

_C)ause/StiU

[_Stop

[_Eject

[_I'imer Rec

_V/Capfion/'rext

I--IIndex

E_]Zero Return

[_Counter Reset

[_CM Sklp(Sklp Search)

[_VCR PLUS+/Program(with V+)

[_IVolumeUp

[_Volume Down

l_Rew/Rev

I_]Ree/OTR

[_Inout Select

[_I)egauss

C]AC/I)C

_l'racking Auto

_'raddng Up/Set +

[_'mcking Down/Set -

_,_nnu

_t_

[_Can_l

[_Muting

_Volume Up

_olame Down

_C_Up

t_c_ i)own

[_Input Select

[_Speed

[-]Audio Select(fur Hi-Fi)

DISASSEMBLY INSTRUCTIONS

1. REMOVAL OF MECHANICAL PARTS

AND P.C. BOARDS

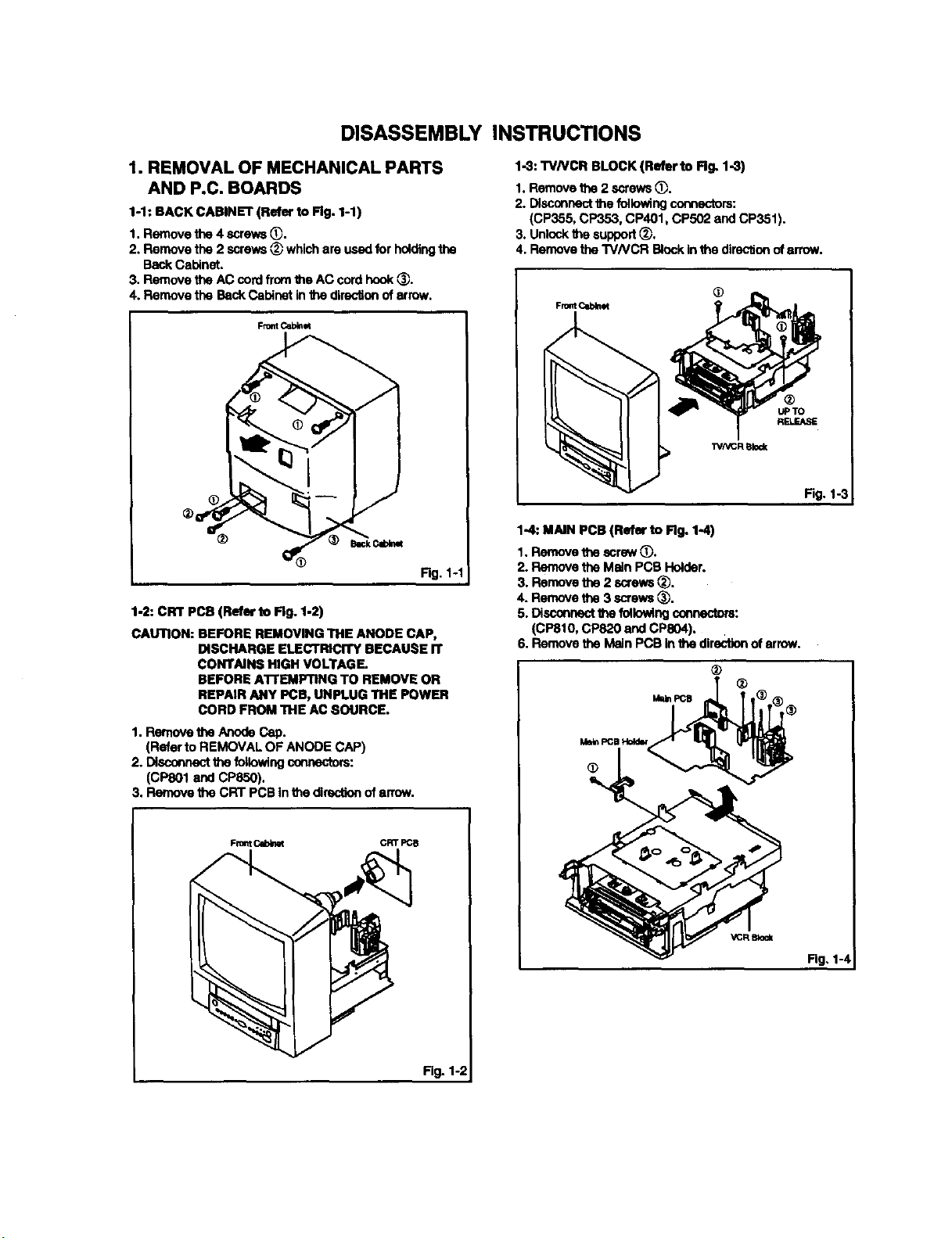

1-1: BACK CABINET (Refer to Fig. 1-1)

1. Removethe 4 screwsO.

2. Remove the 2 screws_ whichare usedfor holdingthe

BackCabinet.

3. Remove the ACcordfromthe AC cord hook_,,_j.

4. Remove the BackCabinet inthedirectionof errow.

From Cabinet

1-2: CRT PCR (Referto Fig. 1-2)

CAUTION: BEFORE REMOVINGTHE ANODE CAP,

DISCHARGE ELECTI_CITY BECAUSE IT

CONTAINS HIGHVOLTAGE.

BEFORE A'n'EMPTING TO REMOVE OR

REPAIR ANY PCR,UNPLUG THE POWER

CORD FROMTHE AC SOURCE.

1. Rernovethe AnodeCap.

(Referto REMOVAL OF ANODE CAP)

2. DIsconnectthe followingconnectors:

(CP801 and CP850).

3. Rernovethe CRT PCBIn the dirsctionof arrow.

1-3:TVNCR BLOCK(Refer to Fig. 1-3)

1. Removethe2 screws_).

2. DIsconnect thefollowingconnectors:

(CP355, CP353, CP401, CP502 andCP351).

3. Unlockthe support_.

4. Removethe TVNCR B_ockinthe direcUonof arrow.

Fro_tP.4ddeet

TVNCR I_bck

Fig. 1-3

1-4: MAIN PCB (Refer to Fig. 1-4)

1. Removethe screw_).

2. Removethe Main PCB Holder.

3. Removethe 2 screws_.

4. Removethe 3 screws_).

5. DIsconnect thefollowing connectors:

(CP810, CP820 and CP804).

6. Removethe Main PCBin thedirectionofarrow.

FromCabin_ CRT PCB

Fig. 1--_

DISASSEMBLY INSTRUCTIONS

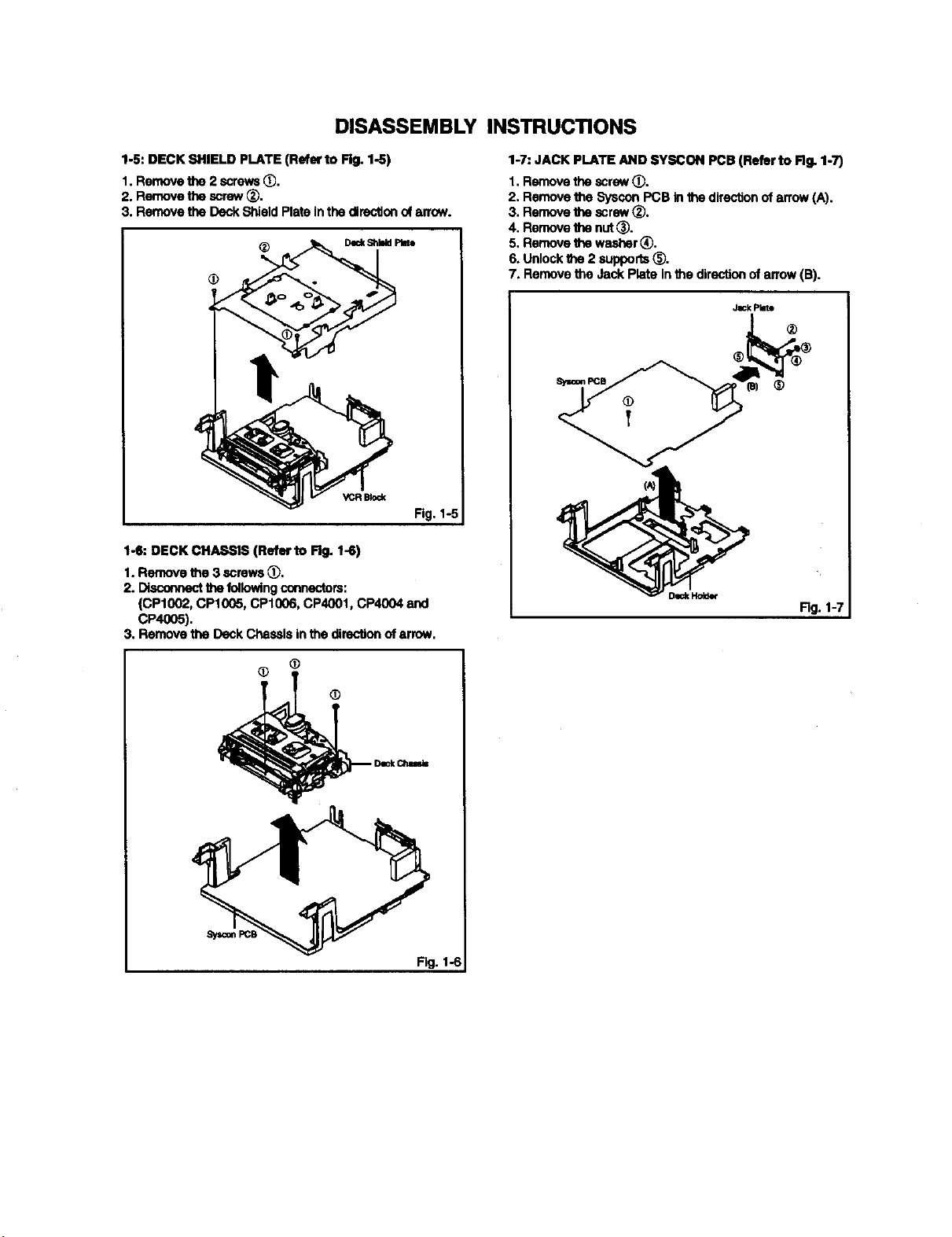

1-5: DECK SHIELD PLATE (Refer to Fig. 1-5)

I. Removethe 2 screws_.

2. Removethe screw_.

3. Remove the Deck ShieldPlateinthe directionofarrow.

VCRBlock

Fig. 1-5

1-6: DECK CHASSIS (Refer to Fig. 1-5)

1.Remove the 3 screws_.

2. Disconnectthe followingconnectors:

(CP1002, CP1005, CP1006,CP4001, CP4004 and

CP4005).

3. Removethe DeckChassisinthe directionofarrow.

1-7: JACK PLATE AND SYSCON PCB (Refer to Rg. 1-7)

1. Removethe screw(_.

2. Removethe SysconPCB inthe directionof arrow(A).

3. Removethe screw_.

4. Removethe nut_.

5. Rernovethe washer®.

6. Unlockthe 2 supports(_).

7. Removethe Jack PlateInthe directionof arrow(B).

®

Fig. 1-7

Fig. 1-5

DISASSEMBLY INSTRUCTIONS

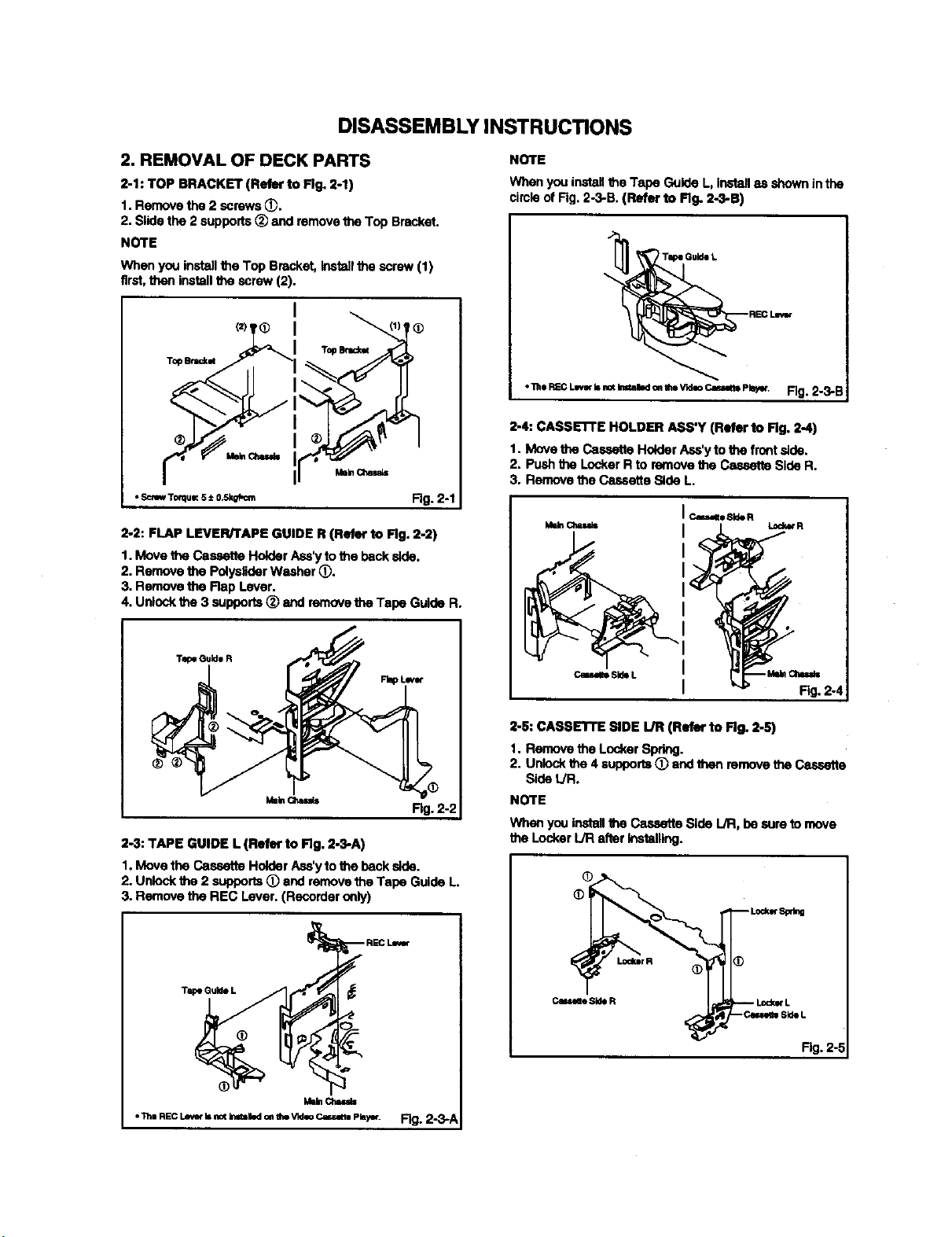

2. REMOVAL OF DECK PARTS

2-1: TOP BRACKET (Refer to Fig. 2-1)

1. Removethe 2 screws_.

2. Slidethe 2 supports_ and removethe Top Bracket.

NOTE

When youinstallthe Top Bracket, installthe screw (1)

first,then installthe screw (2).

I

(')?® I _"_) T®

._._1 T_=_ _L

I

t_ v =,_ow. ir___

_11 _._c_,=,

•s=w Tuq._5* o.skGe_._m Fig.2-1

2-2: FLAP LEVER/TAPE GUIDE R (Refer to Fig. 2-2)

1. Movethe Cassette HolderAss'./to the beck side.

2. Removethe PolysliderWasher _.

3. Removethe Rap Lever.

4. Unlock_ 3 supports_ and removethe Tape Guide R.

NOTE

Whenyou installtheTape Guide L, installas showninthe

cimleof Rg. 2-3-B. (Refer to Fig. 2-3-B)

2"4: CASSETrE HOLDER ASS'Y (Refer to Fig. 2-4)

1. Movethe Cassette HolderAss'yto the frontside.

2. Pushthe LockerR to removethe CassetteSide R.

3. Removethe CassetteSide L.

Mar Chss_=

Mab Chss_s

2-3: TAPE GUIDE L (Refer to Fig. 2-3-A)

1. Movethe CassetteHolder Aas'yto the beck side.

2. Unlockthe 2 supports(_)and removethe Tape GuideL

3. Remove the REC Lever. (Recorder only)

kbb

, _11mRECLm_"b not _IKI ottWteVidmoCeu_lo pkwy. Fig. 2-3-A

Fig.2-2

_SIde L

2-5: CASSETTE SIDE UR (Refer to Fig. 2-5)

1. Removethe Locker Spring.

2. Unlockthe 4 supports(_ and then removethe Cassette

Side L/R.

NOTE

Whenyou installthe CassetteSide L/R, be sure tomove

the LockerL/R after Installing.

Lodmr R

Fig. 2-.=

DISASSEMBLY INSTRUCTIONS

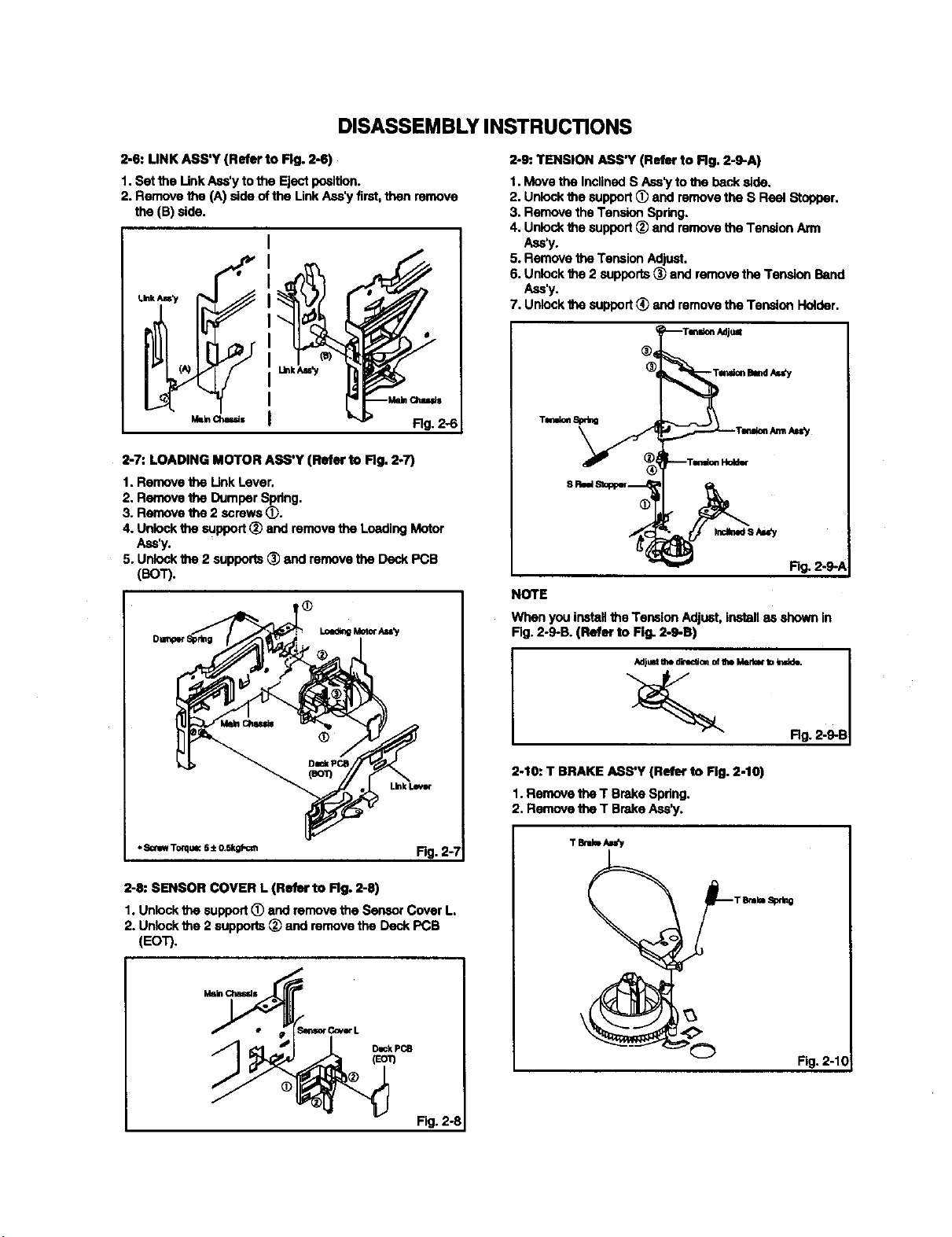

2-6: UNK ASS'Y (Refer to Fig. 2-6)

1. Setthe Unk Ass'yto the Eject position.

2. Removethe (A) sideofthe LinkAss'yfirst,then remove

the (B) side.

2-7: LOADING MOTOR ASS'Y (Refer to Fig.2-7)

1. Removethe LinkLever.

2. Removethe DumperSpdng.

3. Removethe 2 screws_.

4. Unlockthe support_j end removethe LoadingMotor

Ass'y.

5. Unlockthe 2 supports_ andremove the Deck PCB

(BOT).

2-9: TENSION ASS'Y (Refer to Fig. 2-9-A)

1. Movethe InclinedS Ass'ytothe backside.

2. Unlockthe support_) and remove the S Reel Stopper.

3. Removethe Tension Spring.

4. Unlockthe support_) and remove the TensionArm

Ass',/.

5. Removethe Tension Adjust.

6. Unlockthe 2 supports _ and removethe Tension Band

Ass'y.

7. Unlockthe support_, endremove the Tension Holder.

P_Tanskm Adjust

--Tin Hddw

®

sR=dStopp_--._

i

Rg. 2-9-

NOTE

Whenyou installthe TensionAdjust,installas shownin

Fig. 2-9-B. (Refer to Fig. 2-9-B)

•s_w Toq._s±0.r_-=_ Rg. 2-?

2-8: SENSOR COVER L (Refer to Fig. 2-8)

1. Unlockthe support(_ and remove the SensorCover L.

2. Unlockthe 2 supports _j and removethe Deck PCB

(EOT).

Msln Chards

m coelr L

DeckPC8

AdjustI_e dim_loq of 1he Merk_ to k_xJL

Fig. 2-9-B

2-10: T BRAKE ASS'Y (Refer to Fig. 2-10)

1.Remove theT BrakeSpring.

2. Remove the T BrakeAss_J.

T Bmkl/_¢y

Rg- 2-1<

Fig. 2-8

DISASSEMBLY INSTRUCTIONS

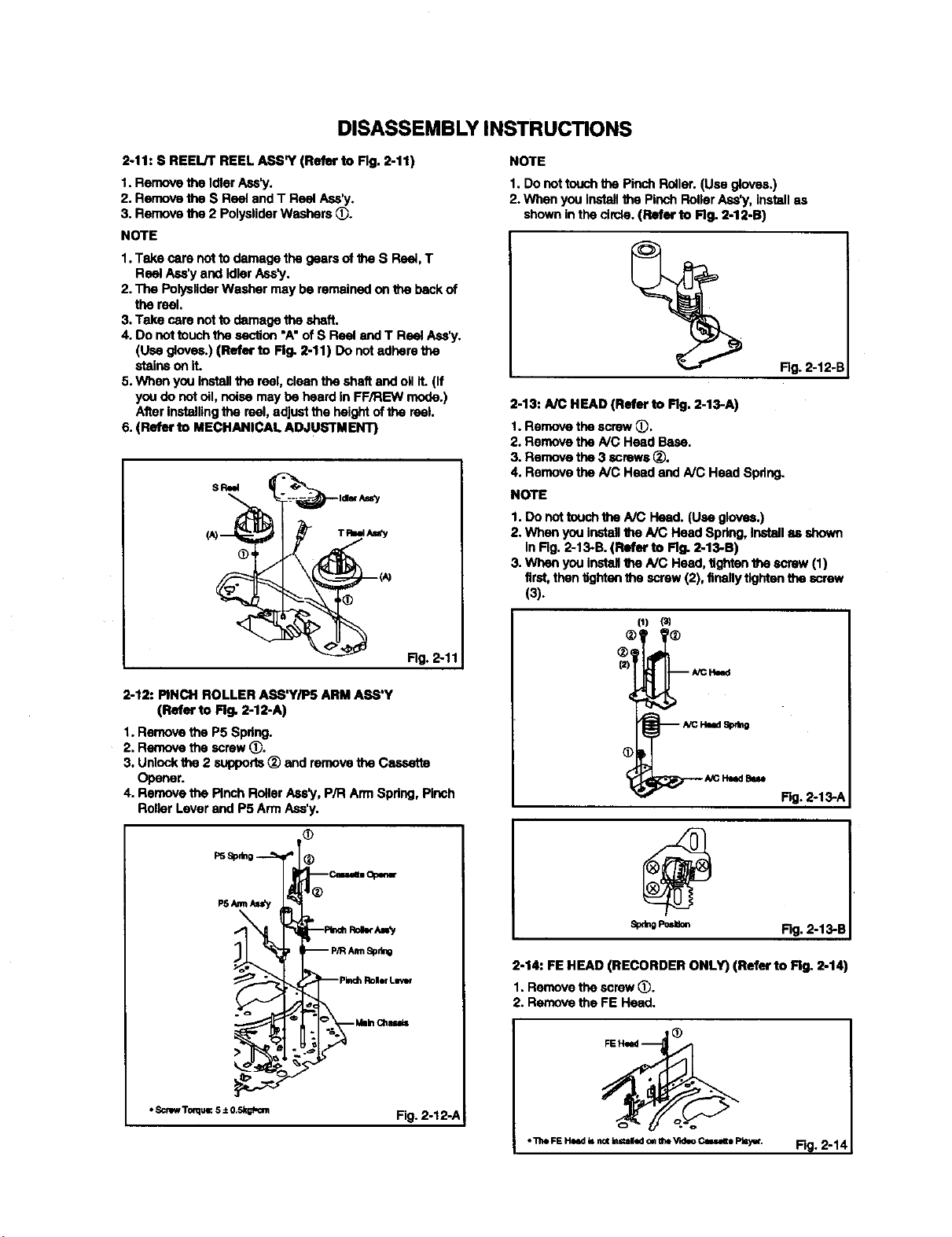

2-11: S REEL/T REEL ASS'Y (Refer to Fig. 2-11)

1. Removethe Idler Ass'y.

2. Removethe S Reel and T Reel Ass_/.

3. Removethe 2 PolysliderWashers_.

NOTE

1.Take care notto darnegethe gears of the S Re_, T

Reel Ass'y and IdlerAss_J.

2.The PolysliderWasher may be remained on the back of

the reel.

3.Take care notto damage the shaft.

4. Do nottouchthe section"A"ofS Reel and T Rse_Ass'y.

(Use glovee.) (Refer to Fig. 2-11) Do notadhere the

stainson it.

5. Whenyou installthe reel, cleanthe shaftand oHit. (If

youdo notoil, noise mayhe heard in FF/REW mode.)

Afterinstallingthe reel,adjustthe height ofthe reel.

6. (Refer to MECHANICAL ADJUSTMENT)

SP,Md

TR,_k_y

®

NOTE

1. Donot touchthe Pinch Roller.(Use gloves.)

2. When you In_tallthe PinchRollerAss'y,Installas

showninthe circle.(Refer to Pig.2-12-B)

Fig.2-12-B

2-13: A/C READ (Refer to Fig. 2-13-A)

1. Remove the screw _,

2. Remove the A/C Heed Base.

3. Remove the 3 screws (_.

4. Remove the A/C Head and A/C Head Spdng-

NOTE

1. Donot touchthe A/C Head. (Usegloves.)

2. When you InstaUthe A/C Heed Spdng- Installas shown

inFig. 2-13-B. (Refer to Pig. 2-13-B)

3. When you installthe/VC Head, tightenthe screw (1)

first,then tightenthe screw (2), finallytightenthe screw

(3).

(1) (3)

Rg._11

2-12: PINCH ROLLER ASS'Y/P5 ARM ASS'Y

(Refer to Fig. 2-12-A)

1. Remove the P5 Spdng.

2. Remove the screw_.

3. Unlockthe 2 suppods_ end removethe Cassette

Opener.

4. Remove the PinchRollerAss_J,P/R ArmSpdng, Pinch

RollerLever and P5 ArmAss'y.

PSsPr__c_a, op,,_r

AMSpr_

Mllbch_

P__ Rolar Lm_r

°

Pig- 2-13-A

s_r_ Fig. 2-13-B

2-14: FE HEAD (RECORDER ONLY) (Refer to Fig. 2-14)

1. Removethe screw _.

2. Removethe FE Head.

• 3crow TO_lU_ 5 ± 0.5_

Fig.2-12-A

FIQ._14

DISASSEMBLY INSTRUCTIONS

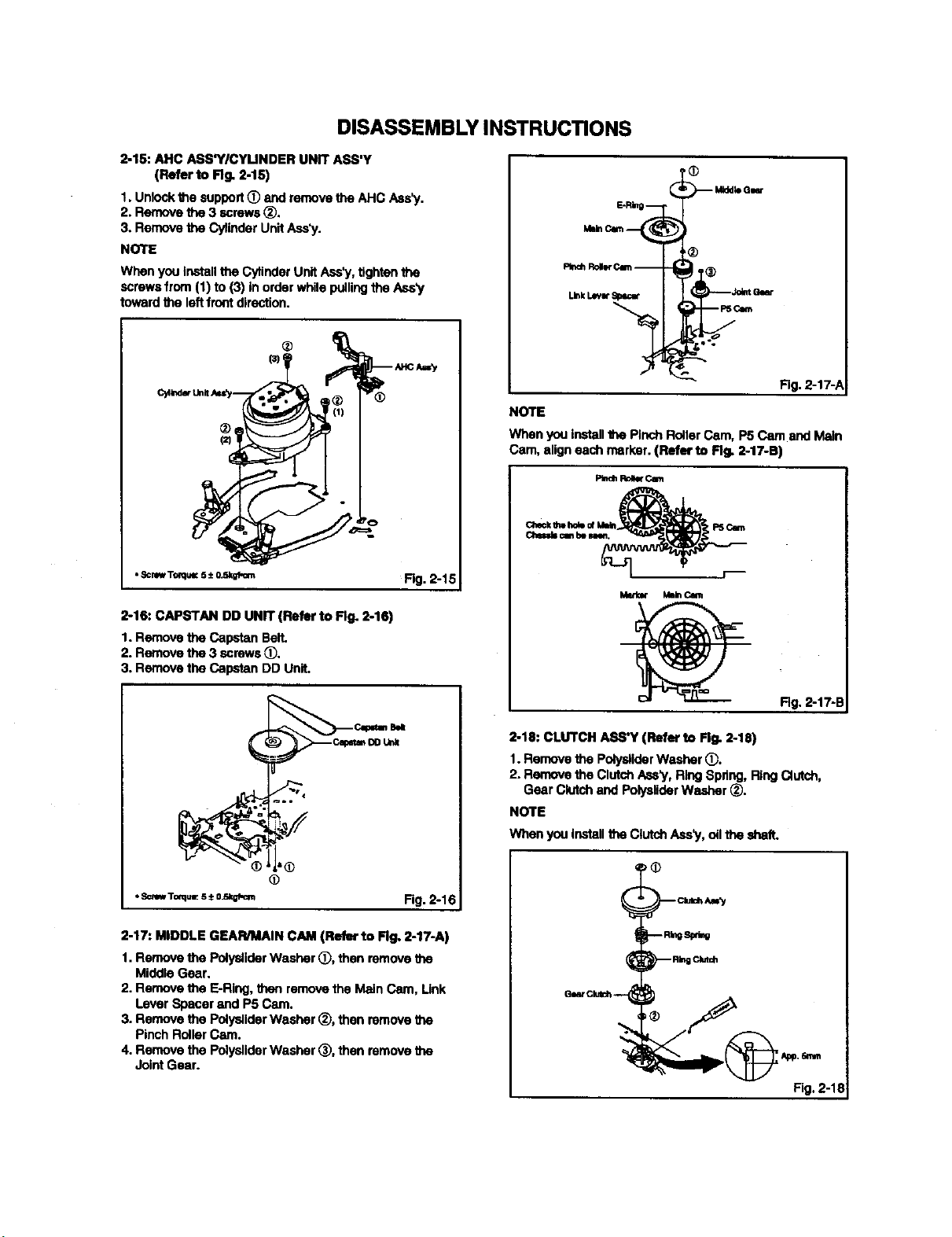

2-15: AHC ASS'Y/CYLINDER UNIT ASS'Y

(Refer to Fig. 2-15)

1. Unlockthe support(_)and removethe AHC Ass'y.

2. Removethe 3 screws(_).

3. Removethe CylinderUnit Ass'y.

NOTE

When youinstallthe CytinderUnitAss'y,tightenthe

screws from (1) to(3) In orderwhilepullingthe Ass'y

towardthe leftfrontdirection.

(3)

E-Ring _ M_ddle G_r

Meln Cem _)

Fig. 2-17-A

NOTE

When youinstallthe Pinch Roller Cam, P5 Cam and Main

Cam, aligneach marker.(Refer to Fig. 2-17-B)

P_h Rdk_Cwn

_k thoholo0f Mtin PsCem

• ScrmvTo_qu_5 ± 0_skgf,cm

Fig. 2-15

2-15: CAPSTAN DD UNIT (Refer to Fig. 2-16)

1. Removethe Capstan Belt.

2. Removethe 3 screws _).

3. Removethe Capstan DD Unit.

Fig.2-16

2-17: MIDDLE GEAR/MAIN CAM (Refer to Fig. 2-17-A)

1. Removethe PolysliderWasher (_, then removethe

Middle Gear.

2. Removethe E-Ring, then removethe Main Cam, Link

Lever Spacerand P5 Cam.

3. Remove the Polys_iderWasher _), then removethe

PinchRoller Cam.

4. Remove the PolyslidorWasher _), then remove

JointGear.

Merkw Ma_ Cam

Fig.2-17-B

2-18: CLUTCH ASS'Y (Refer to Fig. 2-18)

1. Removethe PolysllderWasher _.

2. Removethe ClutchAss_j,RingSpring, Ring Qutch,

Gear Clutchand Polysider Washer (_.

NOTE

When youinstallthe ClutchAss'y, ollthe shaft.

)®

c_

|

_--- Rlng SCdl_

_R_C_h

GeL" Clutch -_

Fig. 2-1

DISASSEMBLY INSTRUCTIONS

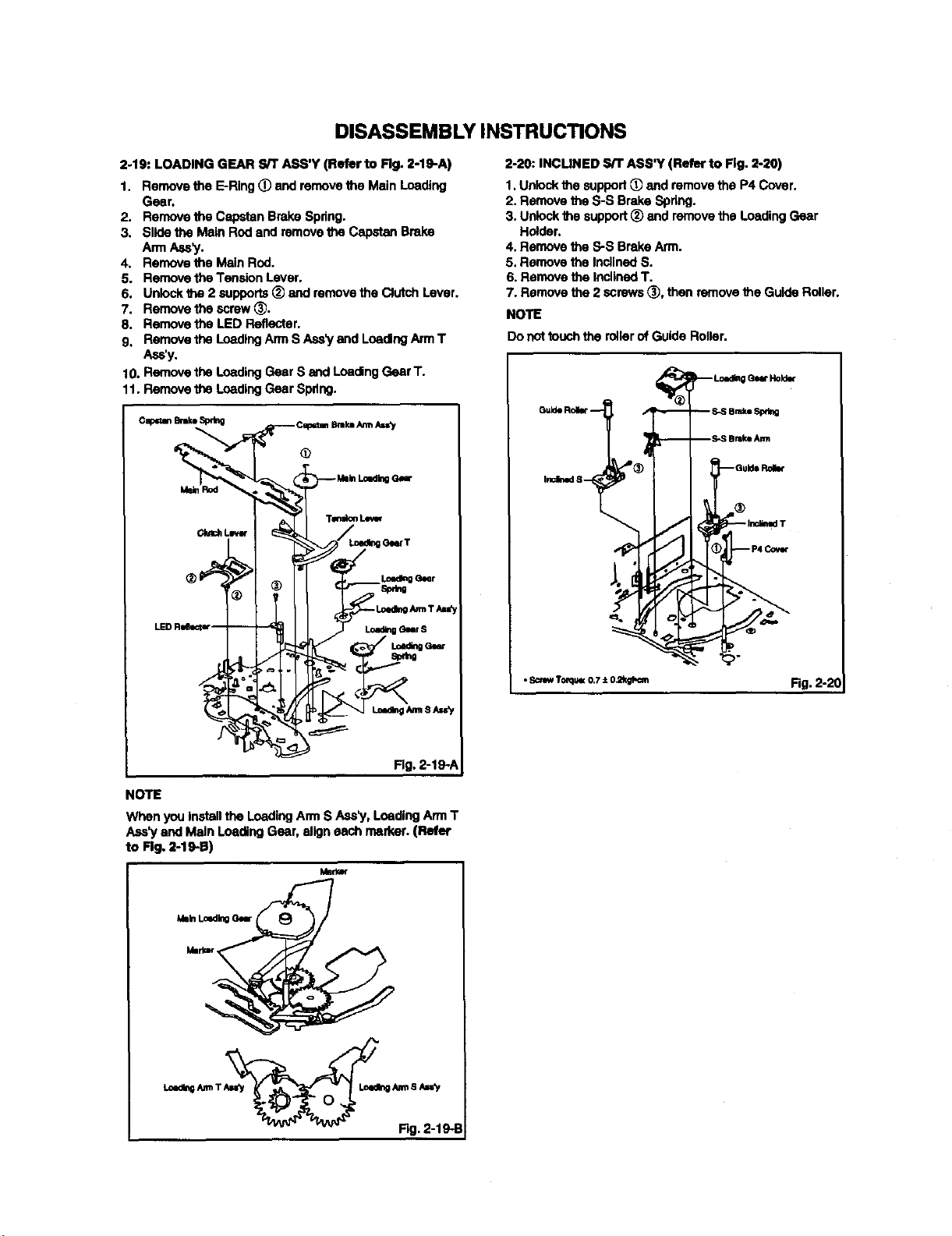

2-19: LOADING GEAR S/T ASS'Y (Refer to Fig"2-19-A)

1. Removethe E-Ring (_ and removethe Main Loading

Gear.

2. Remove the Capstan BrakeSpring.

3. Slidethe Main Rodand removethe Capstan Brake

ArmAss_J.

4. Remove the Main Rod.

5. Removethe Tension Lever.

6. Unlockthe 2 supports(_ and removethe Clutch Lever.

7. Removethe screw_j.

8. Removethe LEDReflscter.

9. Removethe Loading Arm S Ass_Jand LoadingArmT

Ass'y.

10. Removethe LoadingGear S andLoadingGear T.

11. Removethe LoadingGear Spring.

capaa,a_h spd.g

_-_ _ Loed_etT

2-20: INCUNED s/r ASS'Y (Refer to Fig. 2-20)

1. Unlock the support _ and remove the P4 Cover.

2. Remove the S-S Brake Spdng.

3. Unlock the support _ and remove the Loading Gear

Holder.

4. Remove the S-S Brake Arm.

5. Remove the Inclined S.

6. Remove the Inclined T.

7. Remove the 2 screws _, then remove the Guide Roller.

NOTE

Do nottouch the milerof Guide Roller.

Gu_e Roll_ -- _'_ _,A_,,.,_ _b_ Met

S-S Bmko Arm

Ind_dT

LED Rmlk_mr-- --

_rS

Rg. 2-19-A

NOTE

Whenyou Installthe LoadingArmS Ass_, LoadingArmT

Ass_/and Main LoadingGear, aligneach mad(en (Refer

to Fig. 2-19-B)

MadOr

Me_Loed__

Fig. 2-19-B

DISASSEMBLY INSTRUCTIONS

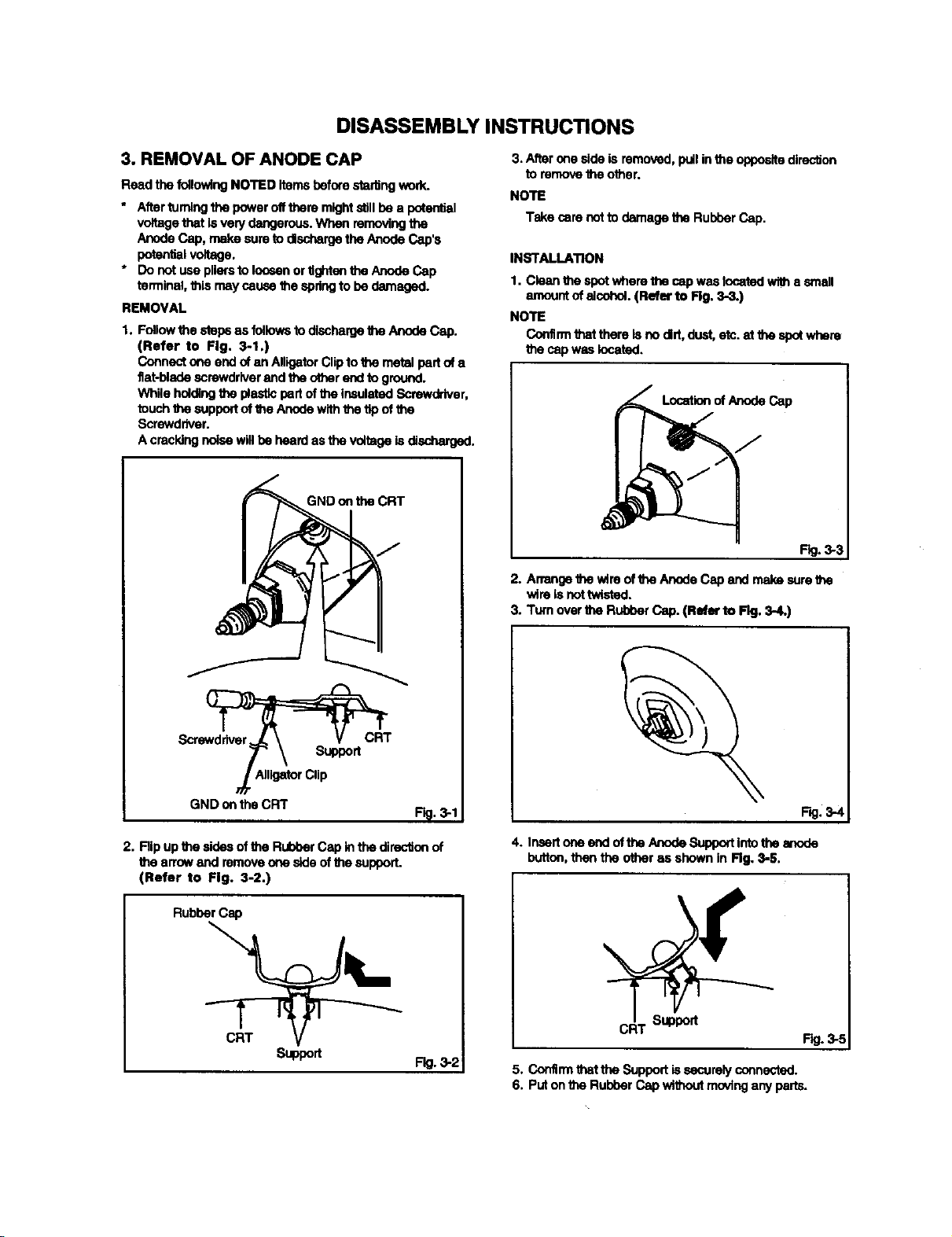

3. REMOVAL OF ANODE CAP

Readthe followingNOTED itemsbeforestaring wod_

• Afterturningthepowerofftheremightstillbe a potonbel

voltagethat isverydangerous.When removingthe

AnodeCap, make sure to dischargetheAnodeCap's

poten_alvoltage.

* Do not usepUersto loosenortightenthe AnodeCap

terminal,thismay causethe apring to bedamaged.

REMOVAL

1. Followthe stopaasfollowsto dischargetheAnode Cap.

(Refer to Fig. 3-1.)

Connectone end ofan AlligatorClipto the metalpad of a

fiat-bladescrewdriverandtheotherend to ground.

While holdingthe plasticpartof the insulatedScrewdriver,

touchthe supportofthe Anodewiththe tipof the

Screwdriver.

A crackingnoisewillbe heard as the voltageisdischarged.

GNDontheCRT

3.Afteronesideis removed,pullinthe opposite direclJon

toremovetheother.

NOTE

Takecarenotto damagetheRubberCap.

INSTALLATION

1. Cleanthe spotwherethe capwas locatedwith8 small

amountofsicohol.(Referto Fig.3-3.)

NOTE

Confirmthatthere is no dirt,dust,etc. at the spotwhere

the cap was located.

cap

Fig.3-3

2. Arranpathe wire of the AnodeCap and rnakesure the

wire is notbeistod.

3. Turnoverthe RubberCap. (Refer to Fig. 3-4.)

Screwdriver CRT

Alligator Clip

GND onthe CRT

2. Rip upthe sidesofthe RubberCap Inthe directionof

the arrowand removeone sideof the support.

(Refer to Fig. 3-2.)

RubberCap

CRT

Support

Support

Fill. 3-1

Fig.3-2

F_. 3-4

4. Insertoneond of the AnodeSupportIntothe al_de

button,then the otheras shownin Fig,3-5.

Fig.3-5

5. Confirmthatthe Supportis securelyconnected.

6. Put onthe RubberCap withoutmovingany parts.

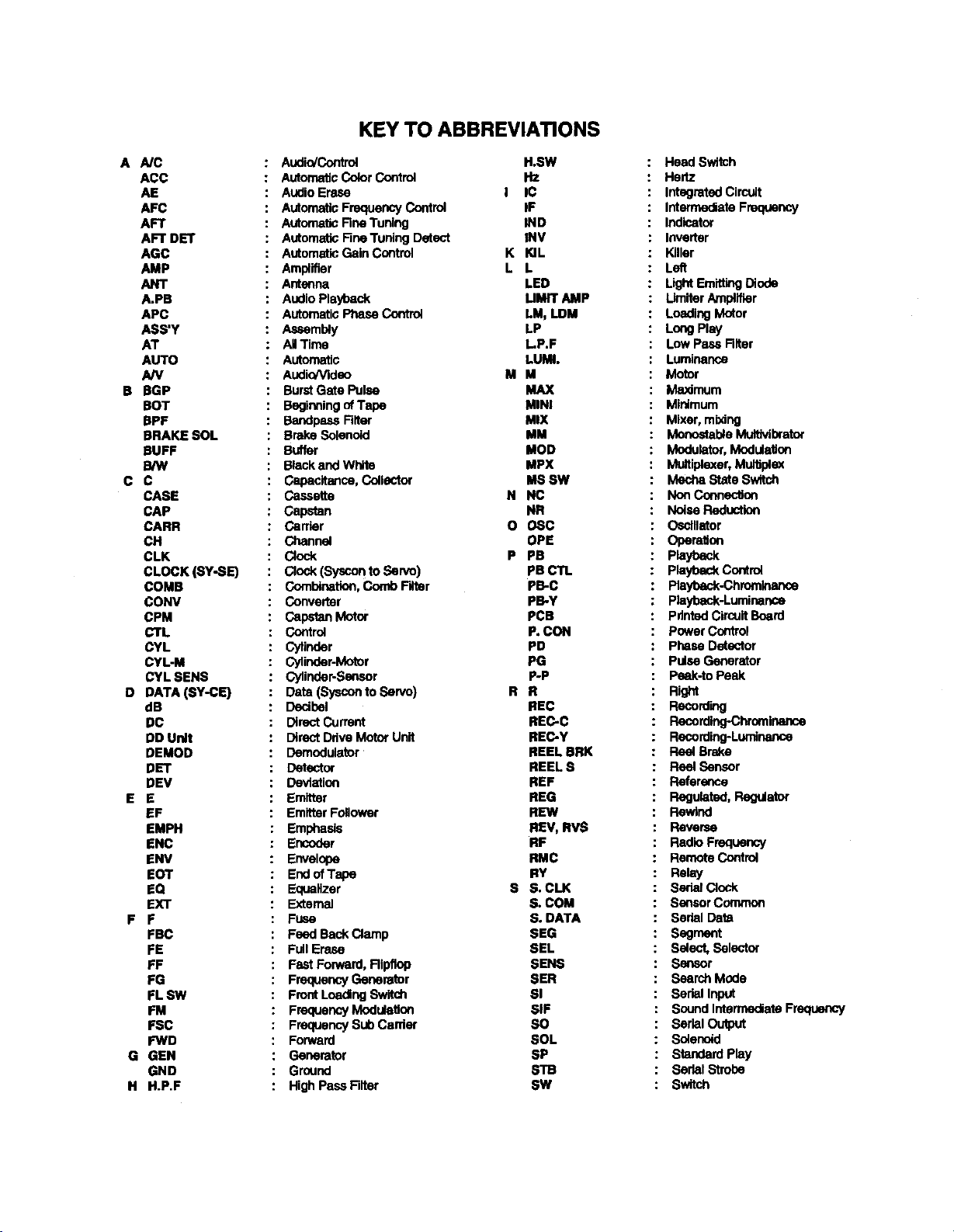

KEY TO ABBREVIATIONS

A NC

ACC

AE

AFC

AFT

AFT DET

AGC

AMP

ANT

A.PB

APC

ASS'Y

AT

AUTO

AN

B BGP

BOT

BPF

BRAKE SOL

BUFF

B/W

C C

CASE

CAP

CARR

CH

CLK

CLOCK (SY-SE)

COMB

CONV

CPM

C'rL

CYL

CYL-M

CYL SENS

D DATA (SY-CE)

dB

DC

DD Unit

DEMOD

DET

DEV

E E

EF

EMPH

ENC

ENV

EOT

EQ

EXT

F F

FBC

FE

FF

FG

FLSW

FM

FSC

FWD

G GEN

GND

H H.P.F

Audto/Control H.SW

AutomaticColorControl Hz

AudioErase I IC

AutomaticFrequencyControl IF

Automaf_cRne Tuning IND

AutomaticRne Tuning Detect if,iV

Automa,c GainControl K KIL

Amplifier L L

Antenna LED

AudioPlayback UMIT AMP

AutomaticPhaseContr_ LM, LDM

Assembly LP

AllTime LP.F

Automatic LUMI.

Audio/Video M M

BurstGate Pulse MAX

BeginningofTape MINI

BandpassFiller MIX

Brake Solenoid MM

Buffer MOO

Blackand White MPX

Capacitance,Collector MS SW

Cassette N NC

Capstan NR

Carder O OSC

Chann_ OPE

Clock P PB

Clock (Syscon to Servo) PB CTL

Combination,Comb Filter PB-C

Conveder PB-Y

Ca_ Motor PCB

Control P.CON

Cylinder PD

Cylinder-Motor PG

Cylinder-Sensor P-P

Data (Sysconto Serve) R R

Decibel REC

DirectCurrent REC-C

Direct Drive MotorUnit REC-Y

Demodulator REEL BRK

Detector REEL S

Devtation REF

Emitter REG

EmitterF_ower REW

Emphasis REV, RVS

Enouder RF

Envelope RMC

EndofTape RY

Equalizer S S. CLK

Extemal S, COM

Ft_e S. DATA

Feed BackClamp SEG

FullErase SEL

FastForward,Rlpflop SENS

FrequencyGenerator SER

FrontLoading Switch $1

FrequencyModulation SIF

FrequencySubCanter SO

Forward SOL

Generator SP

Ground s'rB

HighPass Filter SW

HeadSwitch

Hertz

IntegratedCimult

IntermediateFrequency

Indicator

Inverter

Killer

Left

LightEmittingDiode

Limiter Amplifier

LoadingMofor

LongPlay

LowPassRlter

Luminance

Motor

Maximum

Minimum

Mixer,mixing

MonoetableMultlvlbrator

Modulator,Modulation

Multiplexer,Multiplex

Mecha State Switch

NonConnection

NoiseReduction

Oscillator

Operallon

Piayback

PiaybackContret

Playback-Chromlnanna

Playback-Luminance

PrintedCircuitBoard

PowerCor_ol

phase Detector

Pulse Generator

Peak-to Peak

Right

Recording

Recordlng-Chromlnance

Recording-Lurninanna

Reel Brake

Reel Sensor

Reference

Reguiatod,Reg_o_

Rewind

Reverse

Radio Frequency

Remote Control

Relay

SerialClock

SensorCommon

SerialData

Segment

Select,Selector

Sensor

SearchMode

SerialInput

SoundIntennadi_e Frequency

SerialOutput

Solenoid

StandardPlay

SerialStrobe

Switch

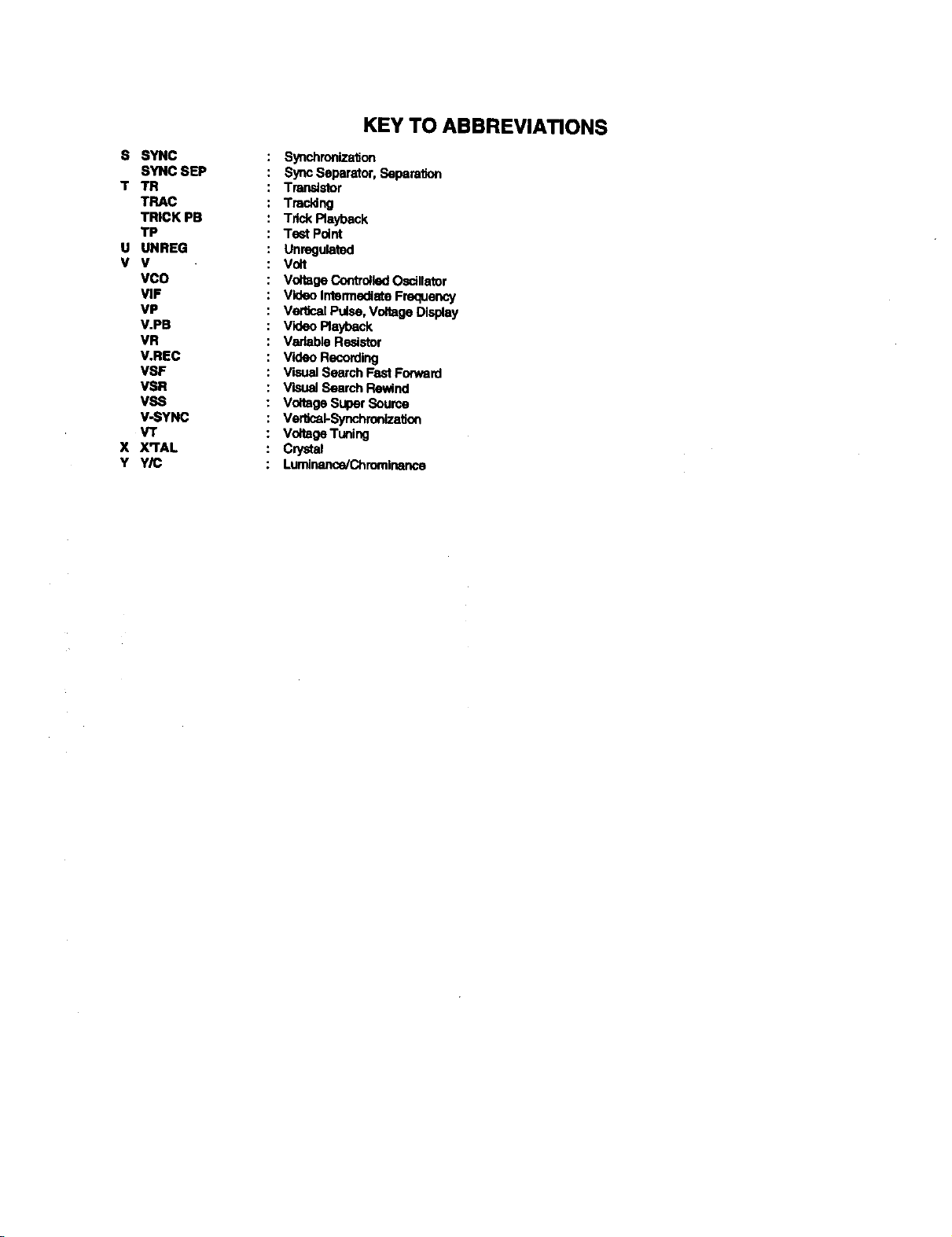

$ SYNC

$YNCSEP

T TR

TRAC

TRICKPB

TP

U UNREG

V V

VCO

VIF

VP

V.PB

VR

V.REC

VSF

VSR

VSS

V-SYNC

VT

X X'I"AL

Y WC

KEY TO ABBREVIATIONS

Synchronization

SyncSeparator,Separa_on

Transistor

Tracking

TrickRayback

Test Point

Unregulated

Volt

VoltageControlledOscillator

VideoIntermediateFrequency

VerUcalPulse, VoltageDisplay

VideoPlayback

VariableResistor

VideoRecording

Visual SearchFast Forward

VisualSearch Rewind

VoltageSuper Source

Vertical-SynchrordzalJon

VoltageTuning

Crystal

Luminance/Ctlrominence

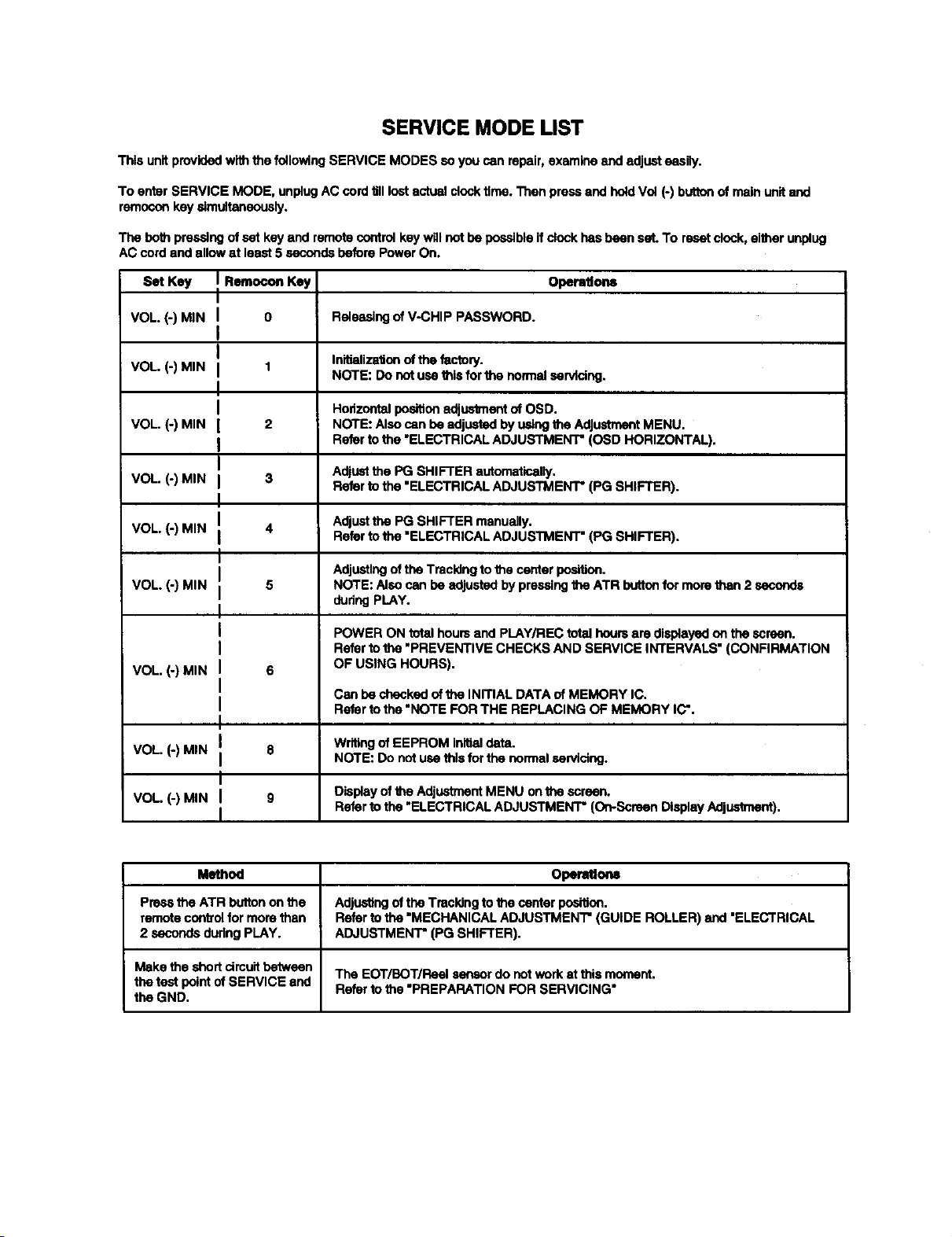

SERVICE MODE LIST

This unitprovidedwiththe followingSERVICE MODES so you can repair,examineand adjusteasily.

To enter SERVICE MODE, unplugACcord tilllost actualclocktime. Then pressand holdVol (-) buttonof main unitand

remocan key simultaneously.

The bothpressingof set keyand remotecontrolkeywill not bepossibleifclockhasbeen set. To resetdock, eitherunplug

AC cord and allowat least5 secondsbefore PowerOn.

Set Key I Remocon Key Operatlons

I

VOL (-) MIN I 0 Raieselngof V-CHIP PASSWORD.

I

I

VOL. (-) MIN I 1

Initialization of the factory.

NOTE: Do not use this for the normal ssrvidng.

I

VOL. (-) MIN

VOL. (-)MIN

VOL. (-)MIN

I

I 2

I

I

I 3

I

Horizontaipositionadjustment of OSD.

NOTE: Alsocan be adjustedby uaingthe AdjustmentMENU.

Refertothe "ELECTRICALADJUSTMENT" (OSD HORIZONTAL).

Adjustthe PG SHIFTER automatically.

Referto the "ELECTRICAL ADJUSTMENT" (PG SHIFTER).

Adjustthe PG SHIFTER manually.

Refertothe "ELECTRICALADJUSTMENT" (PG SHIFTER).

I

VOL (-) MIN

I °

I

I POWER ON total hoursand PLAY/REC totalhours are displayedon the screen.

I Referto the "PREVENTIVE CHECKS AND SERVICE INTERVALS" (CONFIRMATION

VOL. (-) MIN I 6 OF USING HOURS).

I Canbe checked ofthe INITIALDATA of MEMORY IC.

I Referto the "NOTE FOR THE REPLACING OF MEMORY IC'.

I

VOL. (-)MIN ! 8 Writingof EEPROM initial data.

VOL. (-) MIN I 9 Displayof the AdjustmentMENU onthe scrann.

I

I

I Referto the "ELECTRICAL ADJUSTMENT" (On-Screen DisplayAdjustment).

Adjustingof the Trackingto the centerposition.

NOTE: Alsocan be adjustedby pressingthe ATR buttonfor more than 2 seconds

dudngPLAY.

NOTE: Do notusethis forthe normalservicing.

Method OpemUons

Presethe ATR buttononthe Adjustingof the Trackingto the conter position.

remotecontrolfor more than Refer to the "MECHANICALADJUSTMENT" (GUIDE ROLLER)and "ELECTRICAL

2 secondsdudng PLAY. ADJUSTMENT" (PG SHIFTER).

Make the shortdrcuit between The EOT/BOT/Ranl sensordo notworkat this moment.

the test pointof SERVICE and Refer to the "PREPARATION FOR SERVICING"

the GND.

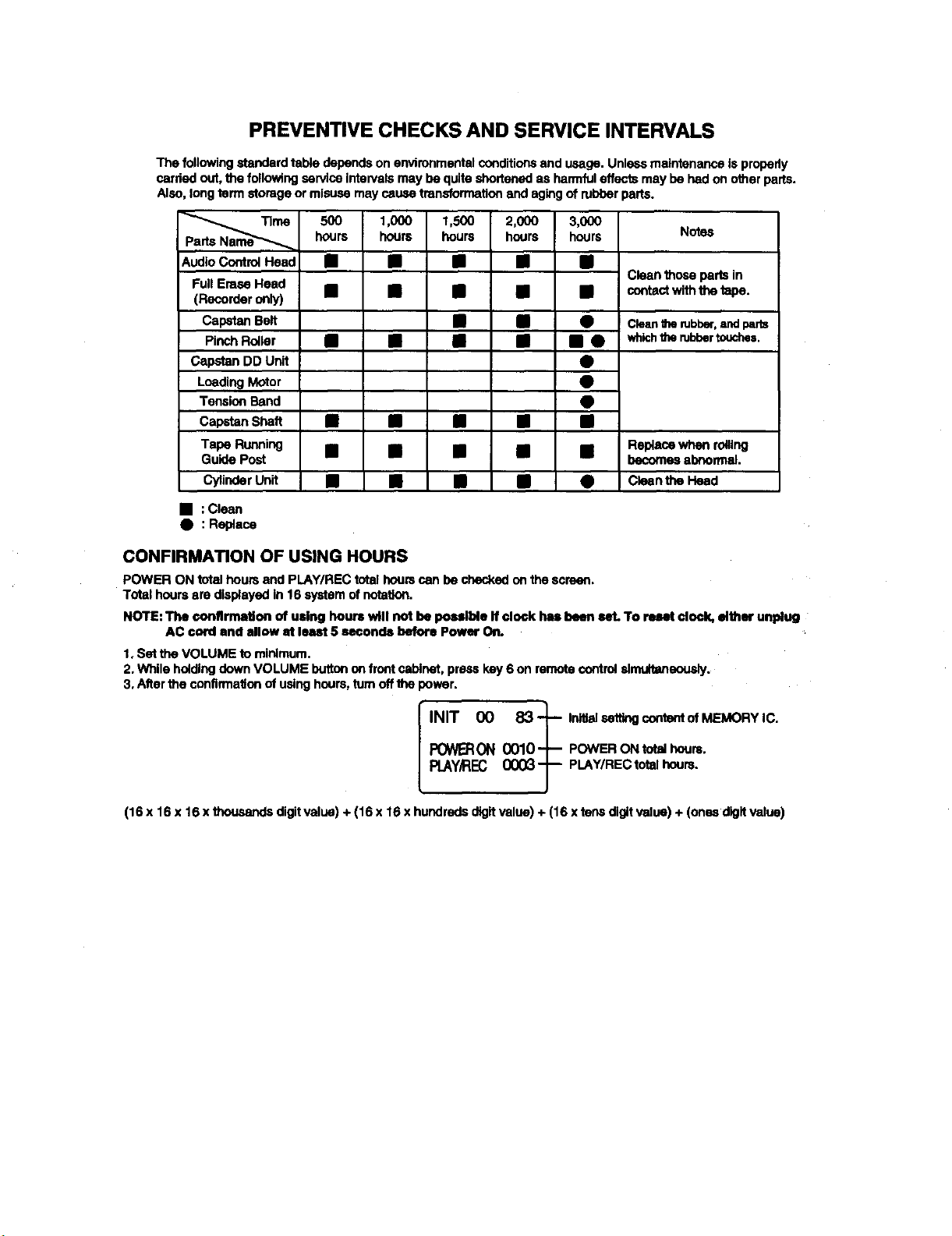

PREVENTIVE CHECKS AND SERVICE INTERVALS

The followingstandard table dependsonenvironmentalconditionsand usage. Unlessmaintenanceis propady

carded out, the fnilov_ngservice intervalsmay be quiteshortened as harmfuleffectsmay be hadon otherparts.

Also,long term storage ormisuse may causetransformationandaging of rubberparts.

TTIme 500 1,000 1,500 2,000 3,000

AudioControlHeed • • • • •

Full Emes Head

(Recorderonly) • • • •

Capstan Belt • • •

PinchRo_ler • • • • • •

Capstan DD Unit •

LoadingMotor •

Tension Band •

hours hours hours hours hours

• centastwi*hthe*ape,

Clean those parts in

Clean the rubber, and parts

whichrite rubbertou_ss.

Notes

cap=anShaft • • • • •

Tape Running • • • • •

Guide Post

CylinderUnit • • • • •

Replacewhen roiling

becomesabnormal.

Clean the Head

• :Clean

• : Replace

CONFIRMATION OF USING HOURS

POWER ON total hoursand PLAY/REC total hourscan be checked onthe screen.

Total hours are displayedin 16 systemof notation.

NOTE:The €onfirmation of using hours will not be posslMe If clo_k has been set. To reset dock, either unplug

AC cord and allow at least 5 seconds before Power On.

1.Set the VOLUME to minimum.

2, WhileholdingdownVOLUME buttonon frontcabinet, presskey 6 on remote controlslmuftanenusiy.

3.After the cenflnnaflonof usinghours,turn offthe )ower.

INIT 00 83-_-- InltlalsattingcoetantofMEMORYIC.

POW_0N 0010--I-- POWERONto_bourn.

/

PLAY_EC 0003 T PLAY/RECtotalhours.

(16 x 16 x 16x thousandsdigitvalue) + (16 x 16 xhundredsdigitvalue)+ (16 x tens digitvalue) + (ones digitvalue)

PREVENTIVE CHECKS AND SERVICE INTERVALS

CLEANING

NOTE

Aftercleaning the heads withIsopropyl alcohol,do not

runa tape undlthe headsdrycompletely,ff _ heads

are not completelydry and alcohol getson thetape,

damage may occur.

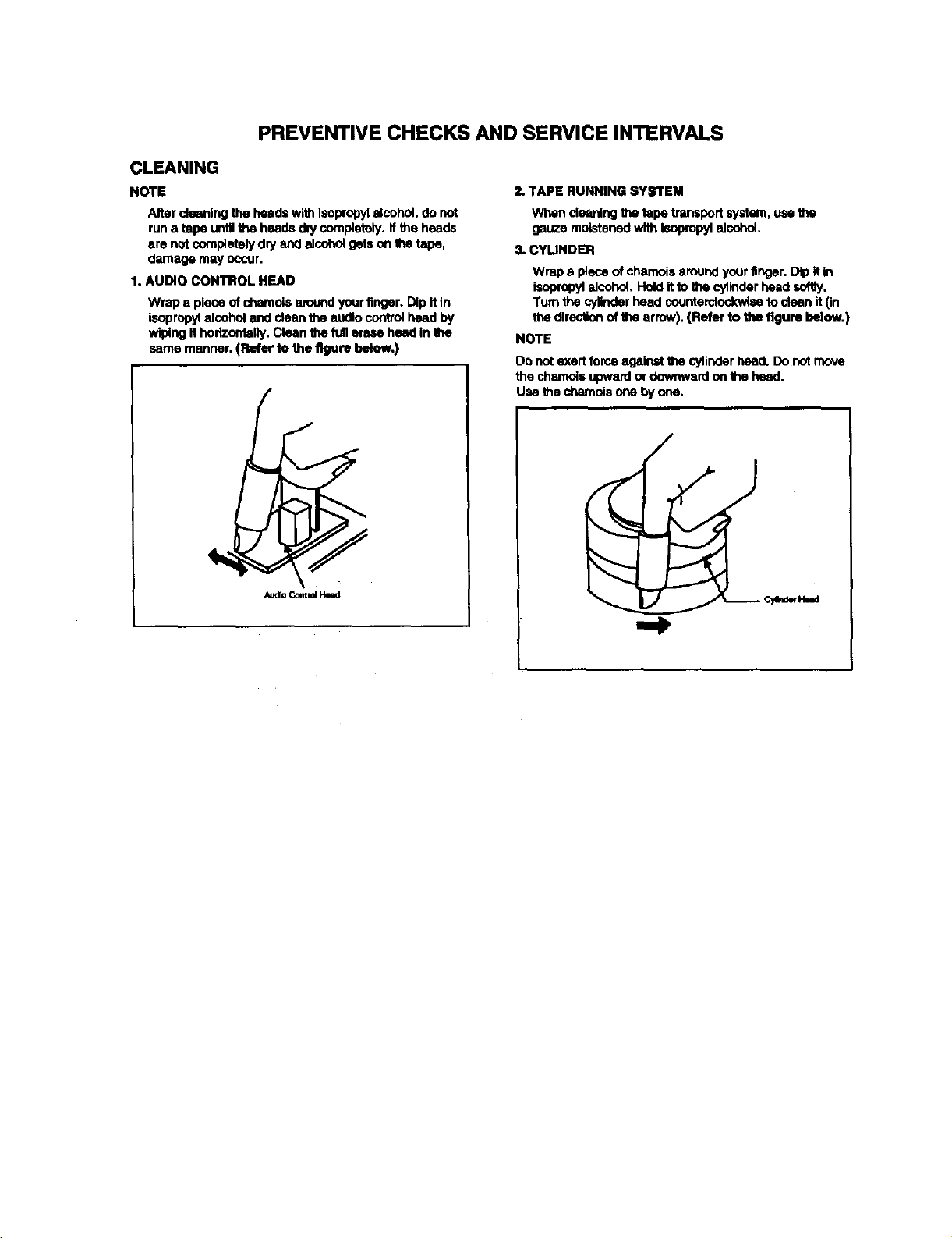

1. AUDIO CONTROL HEAD

Wrap a piece of chamoisaroundyour finger. Dipit in

isopropylalcoholand dean the audiocontrolhead by

wipingit horizontally.Cleanthe fullerase head inthe

same manner. (Refer to the figure below.)

2.TAPE RUNNING SYSTEM

When deaning the tape lmnsportsystem,use the

gauze moistenedwith isoprapylalcohol.

3. CYUNDER

Wrap a piece of chamoisaround yourfinger. Dipit in

isopropylalcohol. Hold it to the cytlnderheedsof_.

Turnthe cylinderheadcounterclockwiseto clean it(in

the dlrec_onof the arrow). (Refer to the ftgure below.)

NOTE

De not exert forceagainst the cylinderhead, Do not move

the chamois upwardordownward on 1hehead.

Use thechemoleone byone.

_do Con :i Heed

Loading...

Loading...