Page 1

File No. 31100005

Page 2

Copyright 2000

TOSHIBA TEC CORPORATION

Page 3

General Precautions for Installation/Servicing/Maintenance for the MR-3011/3012

The installation and service should be done by a qualified service technician.

1. When installing the MR-3011/3012 to the Plain Paper Copier, be sure to follow

the instructions described in the "Unpacking/Set-Up Procedure for the MR-3011/

3012" booklet which comes with each unit of the MR-3011/3012.

2. The MR-3011/3012 should be installed by an authorized/qualified person.

3. Before starting installation, servicing or maintenance work, be sure to turn off

and unplug the copier first.

4. When servicing or maintaining the MR-3011/3012, be careful about the rotating

or operation sections such as gears, pulleys, sprockets, cams, belts, etc.

5. When parts are disassembled, reassembly is basically the reverse of disassembly unless otherwise noted in this manual or other related materials. Be careful

not to reassemble small parts such as screws, washers, pins, E-rings, toothed

washers to the wrong places.

6. Basically, the machine should not be operated with any parts removed or disassembled.

7. Delicate parts for preventing safety hazard problems (such as breakers,

thermofuses, fuses, door switches, sensors, etc. if any) should be handled/

installed/adjusted correctly.

8. Use suitable measuring instruments and tools.

9. During servicing or maintenance work, be sure to check the serial No. plate and

other cautionary labels (if any) to see if they are clean and firmly fixed. If not,

take appropriate actions.

10. The PC board must be stored in an anti-electrostatic bag and handled carefully

using a wristband, because the ICs on it may be damaged due to static electricity. Before using the wrist band, pull out the power cord plug of the copier and

make sure that there is no uninsulated charged objects in the vicinity.

11. For the recovery and disposal of used MR-3011/3012s, consumable parts and

packing materials, it is recommended that the relevant local regulations/rules

should be followed.

12. After completing installation, servicing and maintenance of the MR-3011/3012,

return the MR-3011/3012 to its original state, and check operation.

Page 4

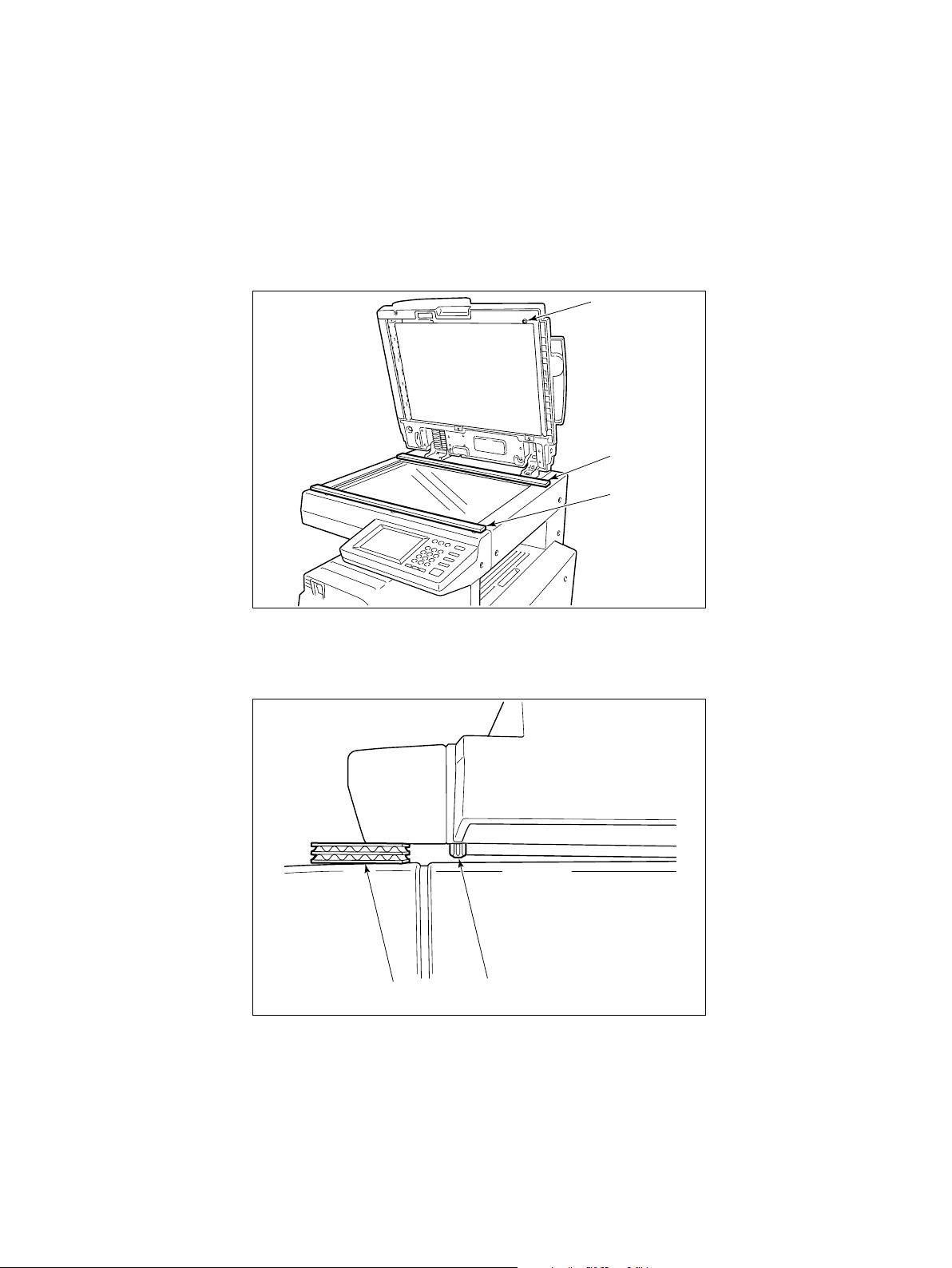

PREPARATION FOR TRANSPORTATION OF COPIER

Before transporting a copier on which mounts the MR-3011/3012, take off the MR3011/3012 or insert a gaggers underneath the MR-3011/3012 as shown in the

following figures.

1. Use pieces of the corrugated board came in the package of MR-3011/3012 or

equivalent as the gaggers. Insert the gaggers as shown in the figure, then close

the MR-3011/3012.

Height positioning

stud

Gagger

Gagger

2. Make sure that the height positioning stud is not in contact with the original

glass.

Gagger

The height positioning stud is not

in contact with the original glass.

Page 5

CONTENTS

1. SPECIFICATION ......................................................................................... 1-1

2. CONFIGURATION....................................................................................... 2-1

3. SECTIONAL VIEW AND DRIVE SYSTEM.................................................. 3-1

3.1 Sectional View ....................................................................................... 3-1

3.2 Drive System ......................................................................................... 3-2

4. SYMBOLS AND LAYOUT OF ELECTRICAL PARTS /

DIAGRAM OF SIGNAL BLOCKS................................................................ 4-1

4.1 Symbols................................................................................................. 4-1

4.2 Layout of Electrical Parts ....................................................................... 4-3

4.3 Diagram of Signal Blocks....................................................................... 4-4

4.4 Description of Interface Signals............................................................. 4-5

5. DESCRIPTION OF OPERATIONS .............................................................. 5-1

5.1 Single Side Feeding .............................................................................. 5-1

5.2 Duplex Feeding...................................................................................... 5-5

5.3 Single Side Feeding (for Mixed Sized Originals).................................... 5-14

6. JAMMING.................................................................................................... 6-1

6.1 Feeding Jam .......................................................................................... 6-1

6.2 Transpor t Jam........................................................................................ 6-1

6.3 Exit Jam................................................................................................. 6-2

6.4 Reversing Jam....................................................................................... 6-2

7. ORIGINAL SIZE DETECTION..................................................................... 7-1

7.1 Method of Original Size Detection (for Standard Sized Originals)..... 7-1

7.2 Relation between Status of Sensor and Original Size

(for Standard Sized Originals) ........................................................... 7-3

7.3 Method of Original Size Detection (for Mixed Sized Original)............ 7-4

7.4 Relation between Status of Sensor and Original Size

(for Mixed Sized Originals) ................................................................ 7-5

8. FLOW CHART ............................................................................................. 8-1

9. TIMING CHART........................................................................................... 9-1

10. DESCRIPTION OF CIRCUITS .................................................................... 10-1

10.1 Input Circuits for Original Length Sensor, Read Sensor

and Reverse Sensor .............................................................................. 10-1

10.2 Irruptive Current Control Circuit............................................................. 10-2

10.3 Drive Circuit for Read Motor .................................................................. 10-3

10.4 Drive Circuit for Reverse Motor.............................................................. 10-4

October 2000 © TOSHIBA TEC MR-3011/3012 CONTENTS

i

Page 6

10.5 Drive Circuit for Feed Motor................................................................... 10-5

10.6 Current Control Circuit for Feed Motor................................................... 10-6

10.7 Drive Circuit for Fan Motor..................................................................... 10-6

10.8 Drive Circuit for Reverse Solenoid......................................................... 10-7

10.9 Reset Circuit .......................................................................................... 10-7

10.10 EEPROM Circuit.................................................................................... 10-8

11. DESCRIPTION OF INPUT/OUTPUT SIGNALS.......................................... 11-1

11.1 REQ Signal, ACK Signal and TxD Signal .............................................. 11-1

11.2 DF-ACK Signal, DF-REQ Signal and RxD Signal.................................. 11-2

11.3 Input Circuits for Sensors ...................................................................... 11-3

12. DISASSEMBLY AND ADJUSTMENT .......................................................... 12-1

12.1 Pickup Roller and Feed Roller ............................................................... 12-1

12.2 Separation Roller................................................................................... 12-2

12.3 Reverse Solenoid .................................................................................. 12-3

12.4 Drive System ......................................................................................... 12-4

12.4.1 Fan motor .......................................................................................... 12-4

12.4.2 Read motor(MR-3011) ...................................................................... 12-5

12.4.3 Read motor(MR-3012) ...................................................................... 12-7

12.4.4 RADF open/close switch ................................................................... 12-8

12.4.5 Feed motor ........................................................................................ 12-9

12.4.6 Reverse motor................................................................................... 12-10

12.4.7 RADF open/close sensor .................................................................. 12-10

12.4.8 PC board ........................................................................................... 12-10

12.4.9 Jam access cover switch ................................................................... 12-10

12.4.10 Feed motor clock sensor .................................................................. 12-11

12.5 Tray sensor ............................................................................................ 12-11

12.6 Empty Sensor, Registration Sensor, Original Width Sensor and

Original Length Sensor.......................................................................... 12-12

12.7 Read Sensor.......................................................................................... 12-13

12.8 Exit Sensor ............................................................................................ 12-13

12.9 Reverse Sensor ..................................................................................... 12-14

12.10 Adjustment of registration...................................................................... 12-15

12.11 Adjustment of original registration for reversing operation..................... 12-16

12.12 Adjustment of reverse solenoid ............................................................. 12-17

12.13 Adjustment of RADF open/close switch................................................. 12-18

12.14 Adjustment of RADF open/close sensor................................................ 12-19

12.15 Adjustment of image skew..................................................................... 12-20

12.16 Adjustment of height (RADF)................................................................. 12-21

12.17 Initialization of EEPROM and Adjustment of Sensors ........................... 12-22

12.18 Attachment of Mylars............................................................................. 12-23

13. SERVICE ..................................................................................................... 13-1

13.1 Troubleshooting for Mechanical Errors .................................................. 13-1

13.2 Troubleshooting for Electrical Errors...................................................... 13-3

October 2000 © TOSHIBA TEC MR-3011/3012 CONTENTS

ii

Page 7

14. ASSEMBLY OF PC BOARD........................................................................ 14-1

15. PERIODIC MAINTENANCE ........................................................................ 15-1

16. CIRCUIT DIAGRAM / HARNESS DIAGRAM .............................................. 16-1

16.1 Circuit Diagram (MR-3011).................................................................... 16-1

16.2 Circuit Diagram (MR-3012).................................................................... 16-2

16.3 Control PC Board Circuit ....................................................................... 16-3

16.4 Harness Diagram (MR-3011)................................................................. 16-4

16.5 Harness Diagram (MR-3012)................................................................. 16-5

October 2000 © TOSHIBA TEC MR-3011/3012 CONTENTS

iii

Page 8

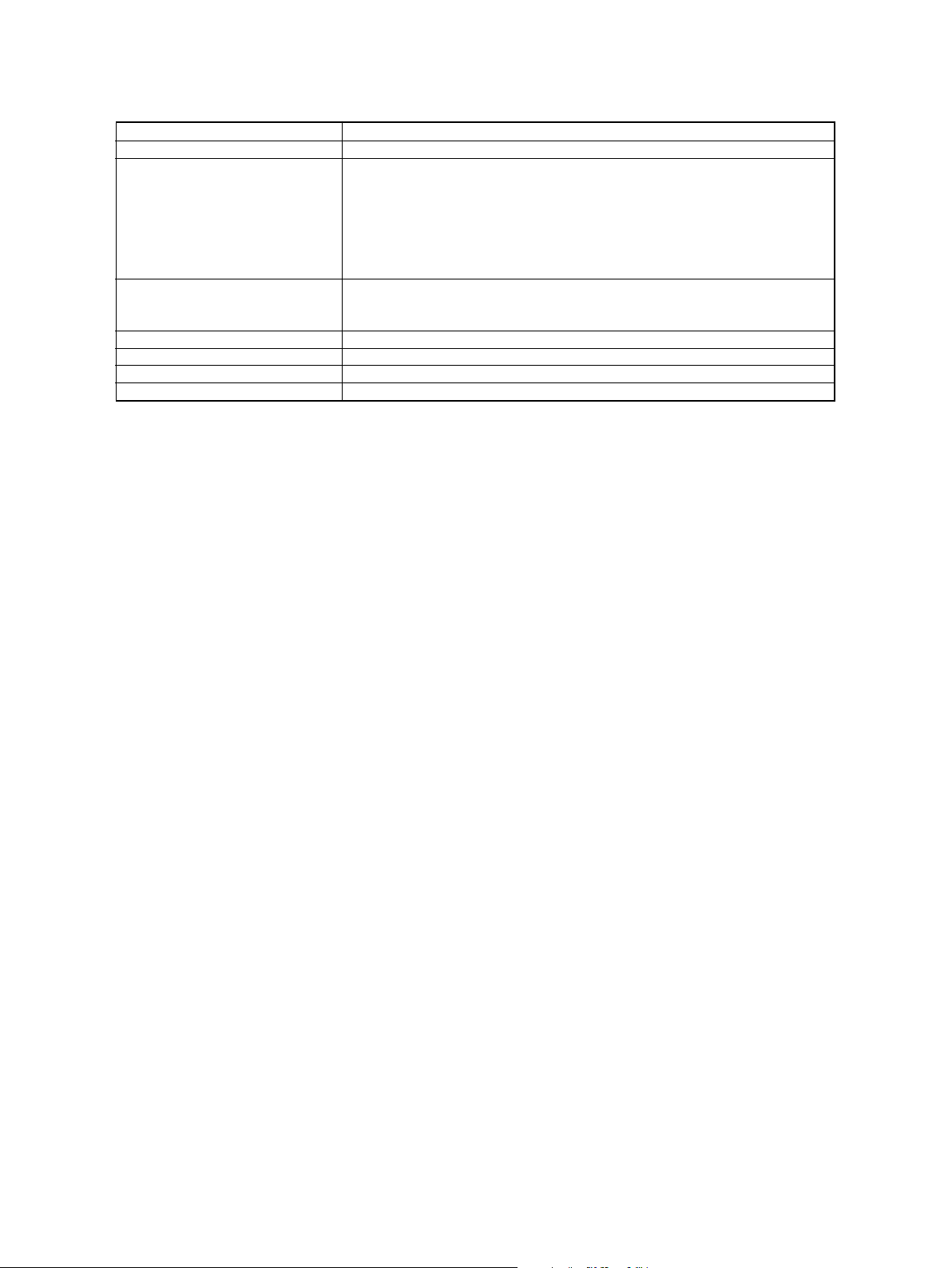

1. SPECIFICATION

Model Name

Capacity of Original Feeding Tray

Feed Speed

Acceptable Original Size

Power Source

Power Consumption

Dimensions

Weight

*Specification and appearance are subject to change without notice due to enhancedment of product quality.

MR-3011/MR-3012

Up to 100 sheets

MR-3011:

Approx.16 sheets/min. (A4 or Letter, feed widthwise) [DP1600]

Approx.20 sheets/min. (A4 or Letter, feed widthwise) [DP2000]

Approx.25 sheets/min. (A4 or Letter, feed widthwise) [DP2500]

MR-3012:

Approx.35 sheets/min. (A4 or Letter, feed widthwise) [DP3500]

Approx.45 sheets/min. (A4 or Letter, feed widthwise) [DP4500]

Smallest...A5-R

Largest...A3

Thickness...50g/m2~127g/m2 (13.3lb~33.8lb)

Power supplied from the copier

48W

W557 × D497.3 × H165 (W22 inches × D19.6 inches × H6.5inches)

Approx.13.6kg or 29.9lb

October 2000 © TOSHIBA TEC MR-3011/3012 SPECIFICATION

1-1

Page 9

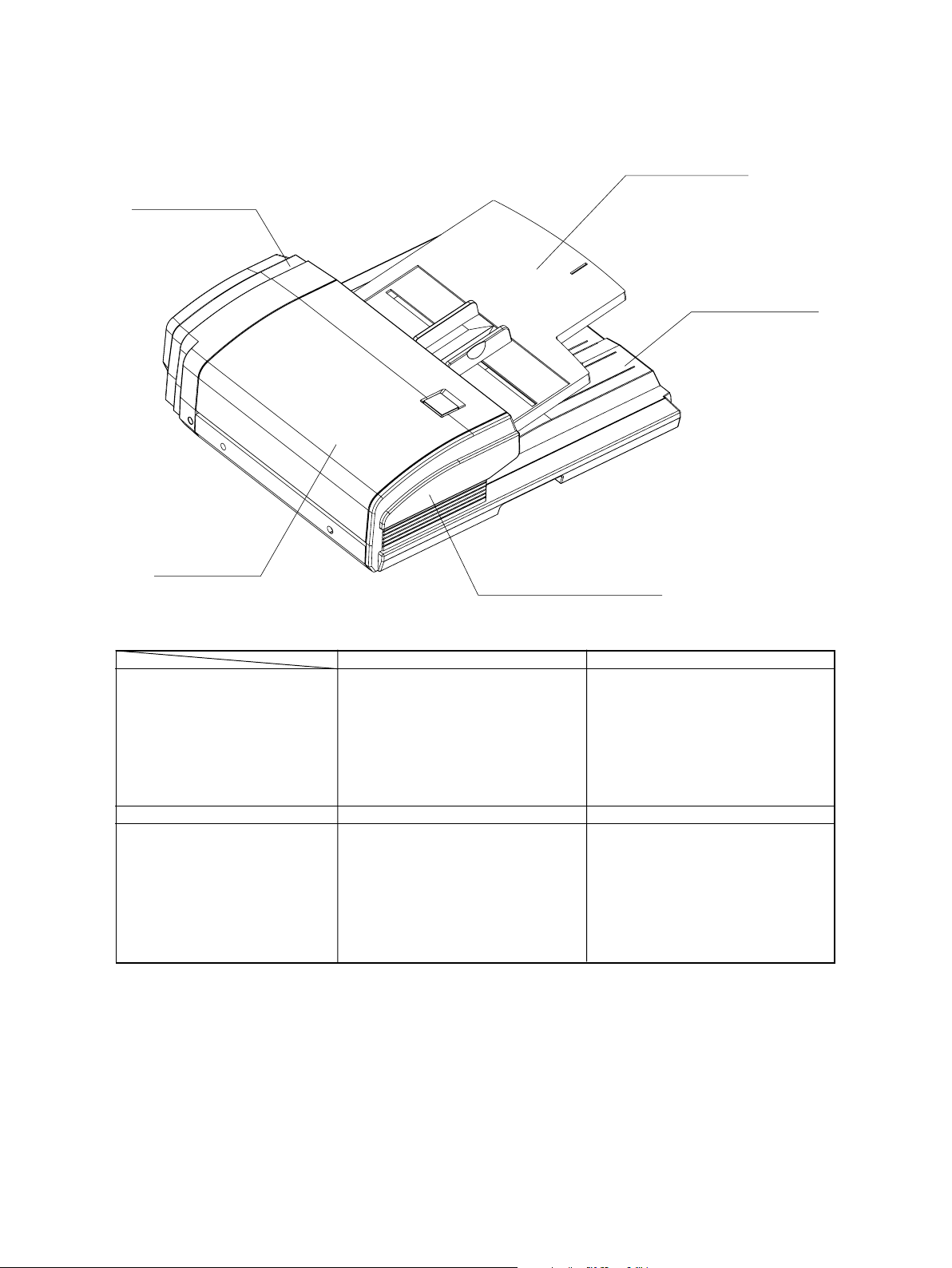

2. CONFIGURATION

Drive/control section

Original feeding tray

Original receiving tray

Jam access cover

Feeding/transportation section

Original feeding tray section

Drive/control section

Mechanical

• Jam access cover

• Pickup roller

• Feed roller

• Separation roller

• Registration roller

• Read roller

• Reverse roller

• Exit roller

• Original feeding tray

Feeding/transportation section

Electrical parts

• Empty sensor

• Original length sensor

• Registration sensor

• Original width sensor

• Read sensor

• Reverse sensor

• Exit sensor

• Tray sensor

• Feed motor

• Read motor

• Reverse motor

• Reverse solenoid

• RADF open/close sensor

• RADF open/close switch

• Jam access cover switch

• PC board

October 2000 © TOSHIBA TEC MR-3011/3012 CONFIGURATION

2-1

Page 10

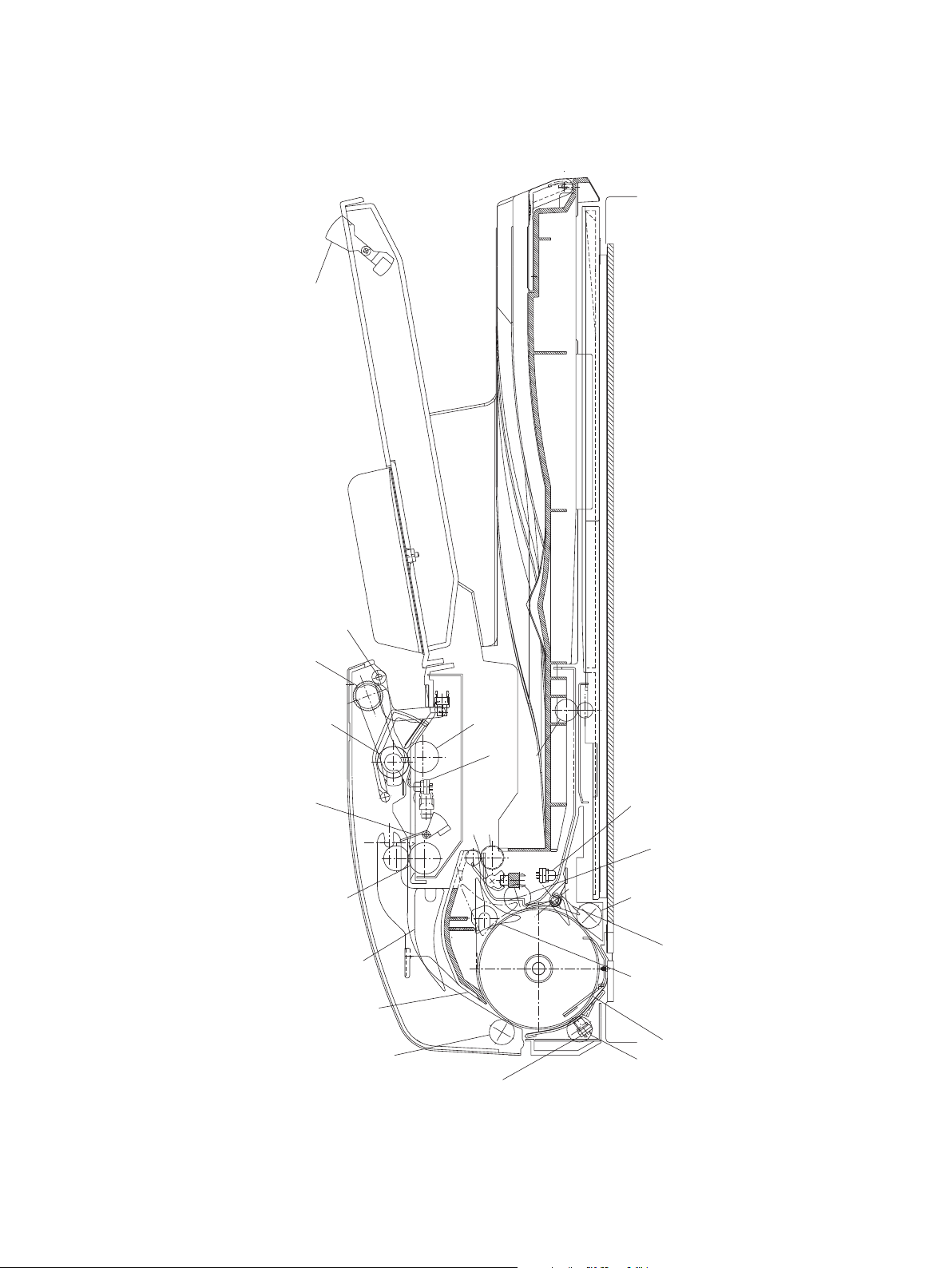

3. SECTIONAL VIEW AND DRIVE SYSTEM

3.1 Sectional View

Tray sensor

Empty lever

Pickup roller

Feed roller

Registration sensor

Original width sensor

Registration roller

Flapper

Reverse guide

Small roller1

Separation roller

Original length

sensor

Exit sensor

Read

Reverse roller

Exit roller

sensor

Reverse sensor

Small roller4

Small roller3

3

Reverse flapper

Exit flapper

Read roller

Small roller2

October 2000 © TOSHIBA TEC MR-3011/3012 SECTIONAL VIEW

3-1

Page 11

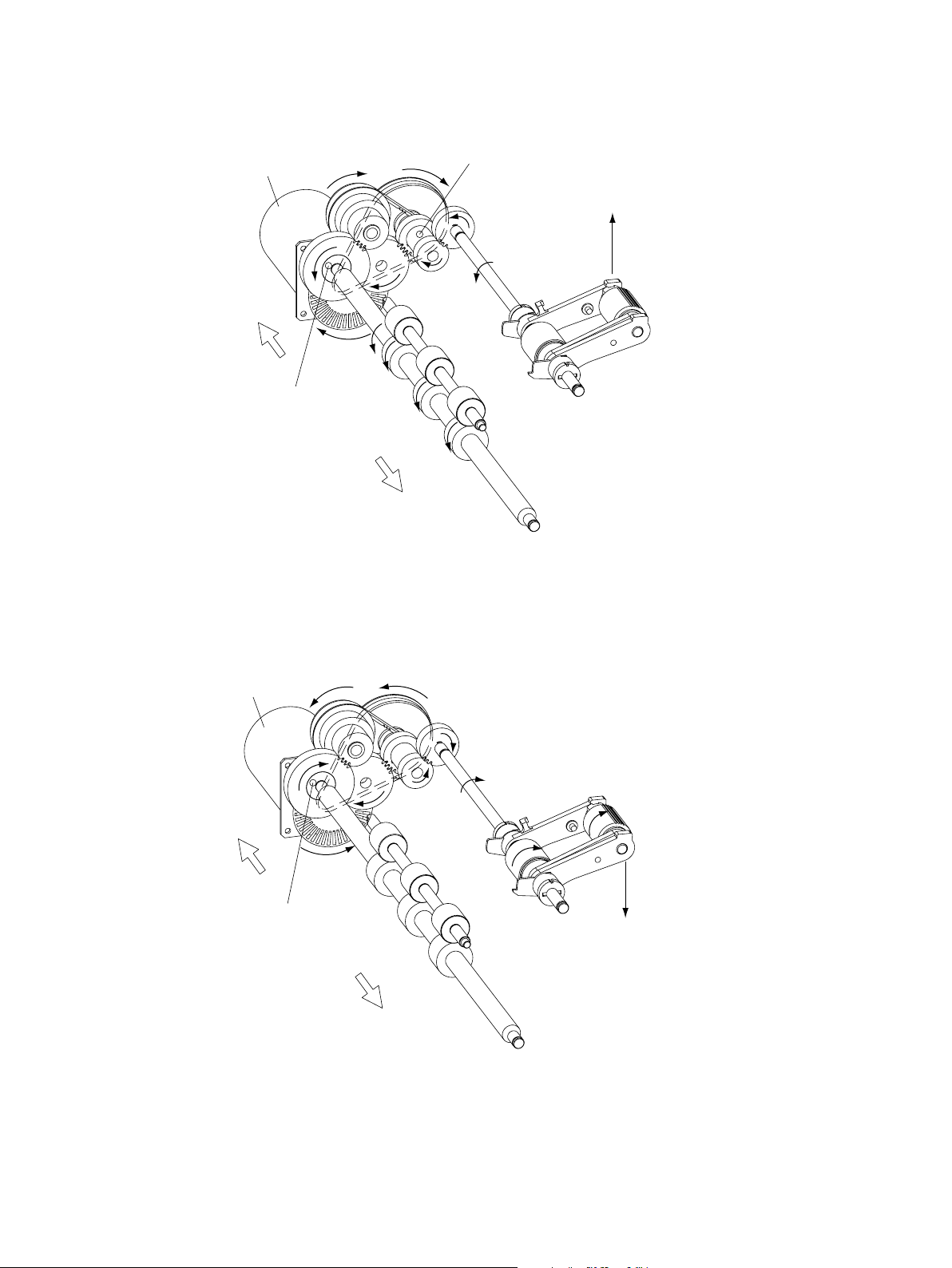

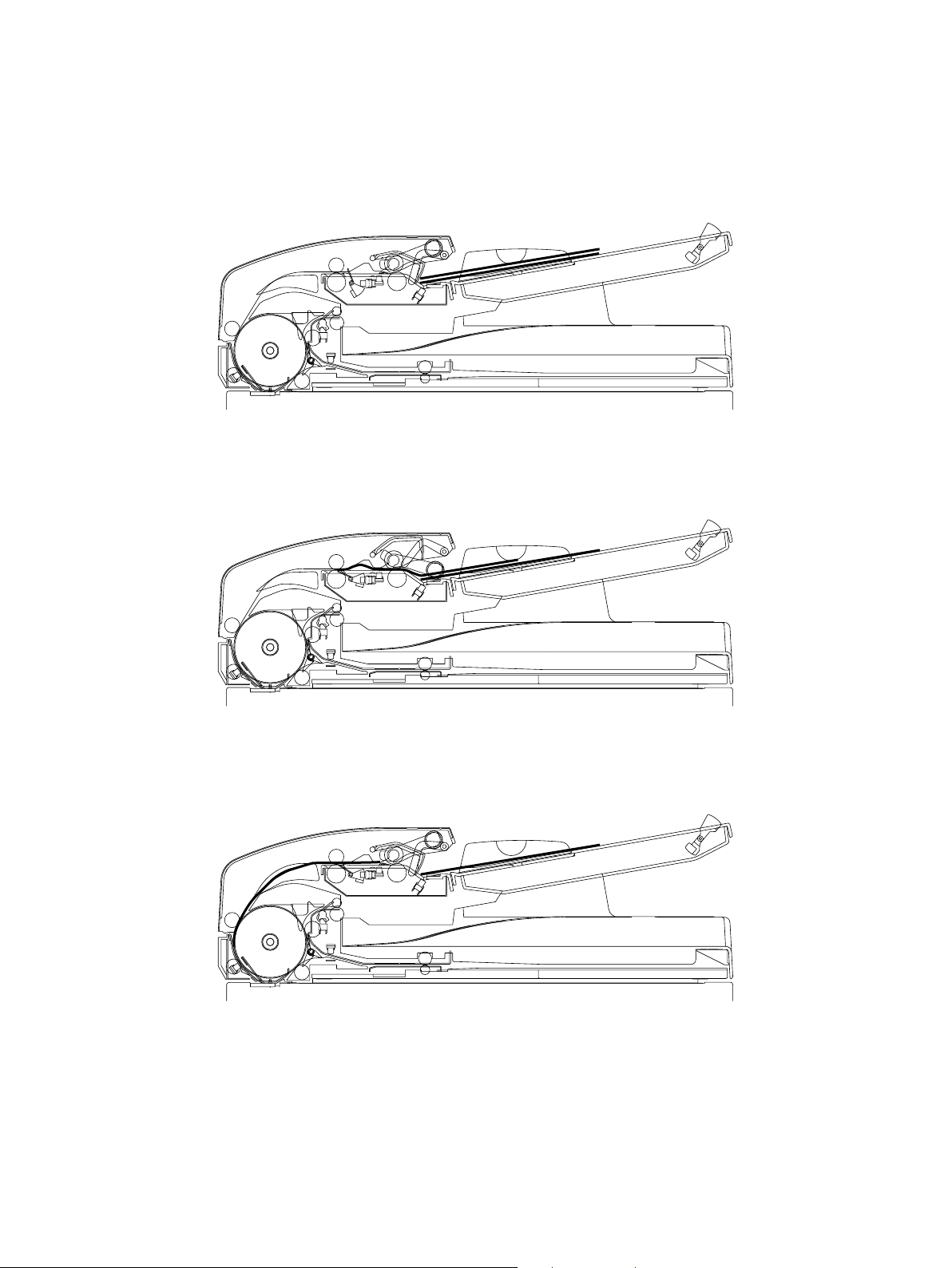

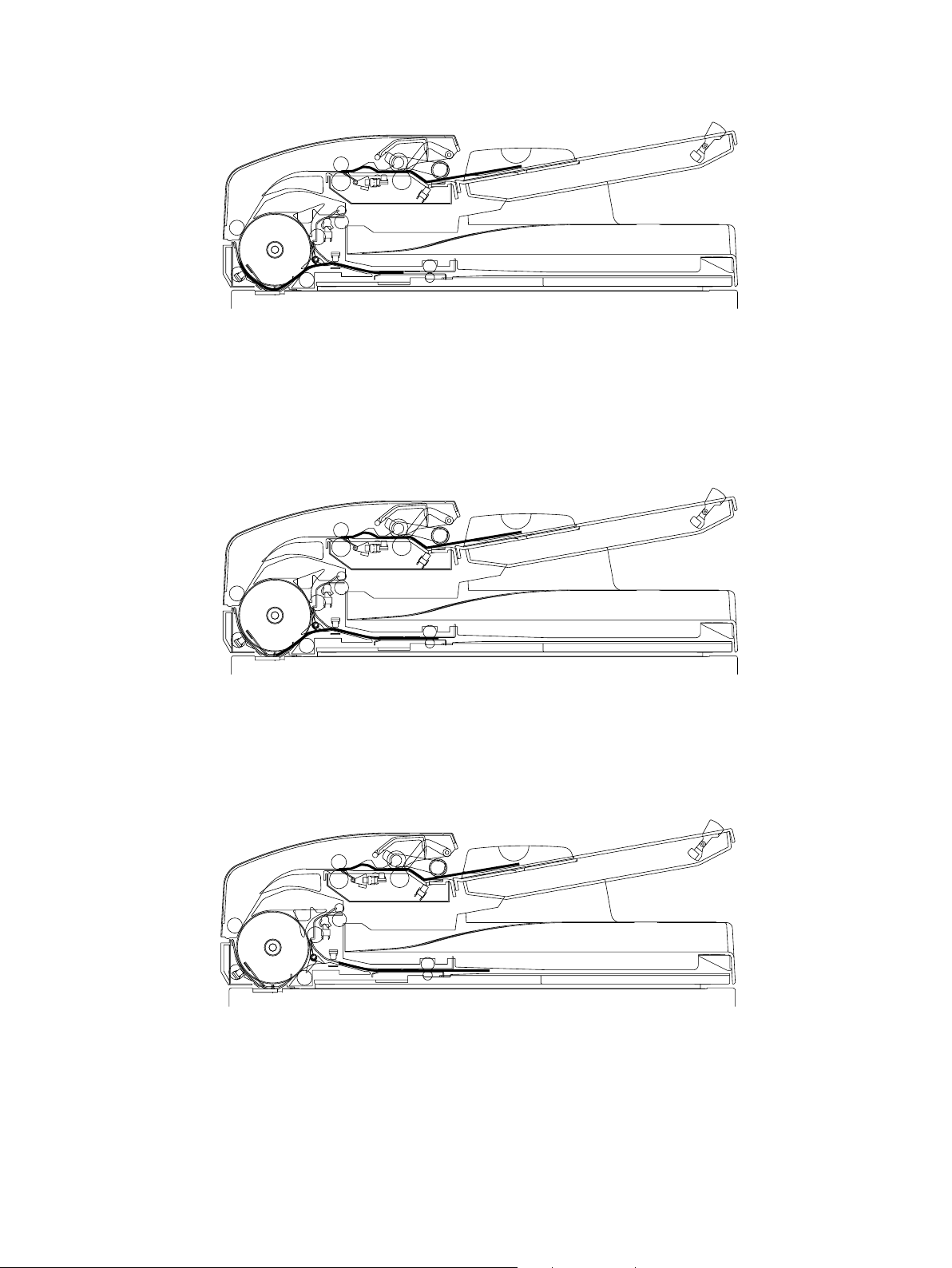

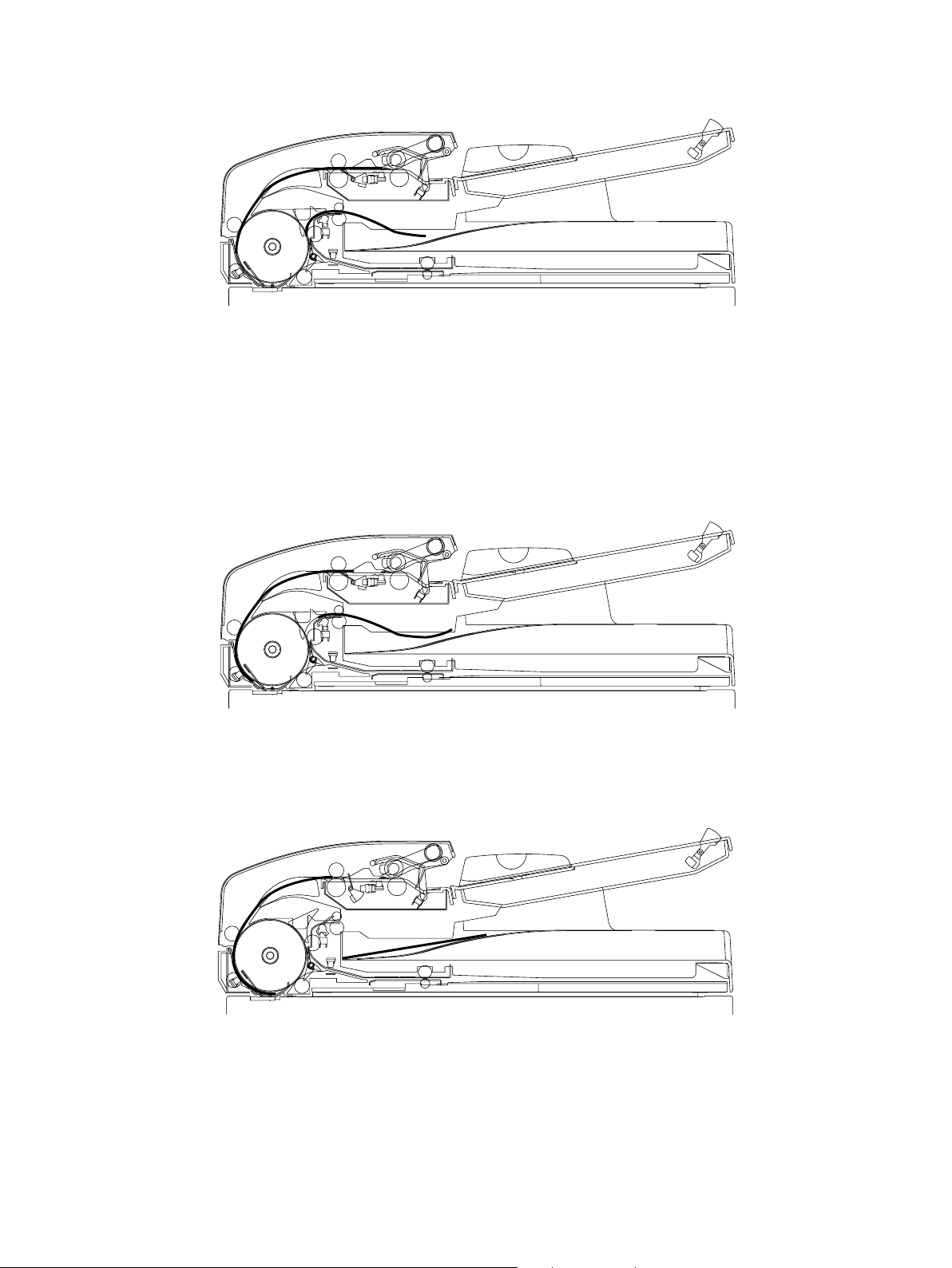

3.2 Drive System

(1) Feed motor rotating clockwise (as seen from the front side)

Feed motor

Rear side

One-way clutch (locked)

Spring clutch

(Stops the drive for the clutch when the

pickup roller reaches its upper limit position)

Pickup roller (lifted up)

Front side

Motor rotating clockwise to transport original

(2) Feed motor rotating counterclockwise (as seen from the front side)

Feed motor

Rear side

One-way clutch (slipped)

Front side

Motor rotating counterclockwise to transport original

Pickup roller (Down)

October 2000 © TOSHIBA TEC MR-3011/3012 SECTIONAL VIEW

3-2

Page 12

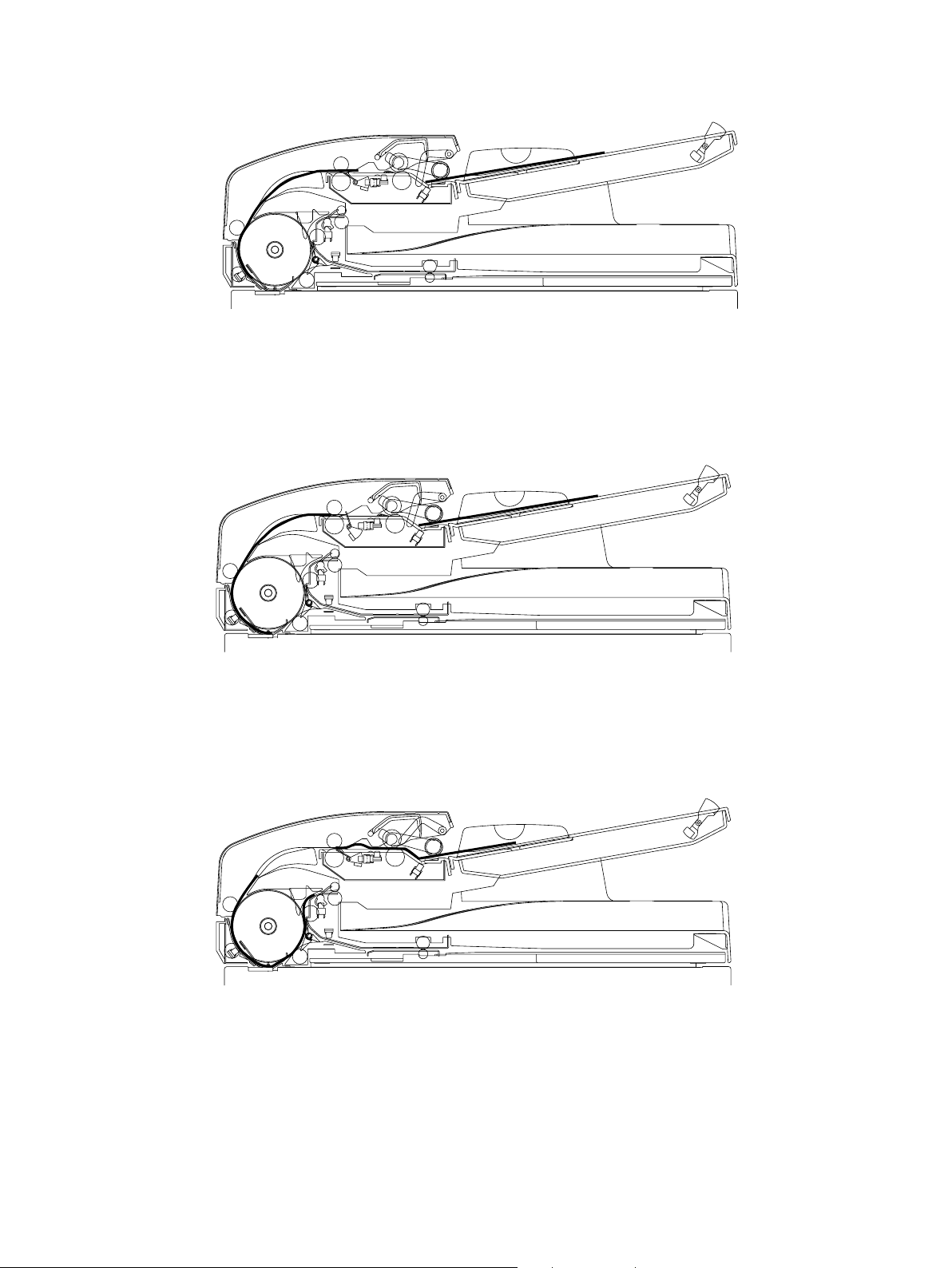

(3) Read motor rotating clockwise (as seen from the front side)

Reverse motor

Read motor

Rear side

Reverse motor rotating clockwise

to carry original to the reverse path.

Reverse roller

Exit roller

Front side

Transportation, scanning and original exit

(read motor rotating clockwise)

Read roller

(4) Read motor rotating counterclockwise (as seen from the front side)

Reverse motor

Read motor

Rear side

Reverse motor rotating counterclockwise

for back side registration and original discharge.

One-way gear

Reverse roller

Exit roller

Front side

Read motor rotating counterclockwise

to transport mixed sized originals.

Read roller

October 2000 © TOSHIBA TEC MR-3011/3012 SECTIONAL VIEW

3-3

One-way gear

Page 13

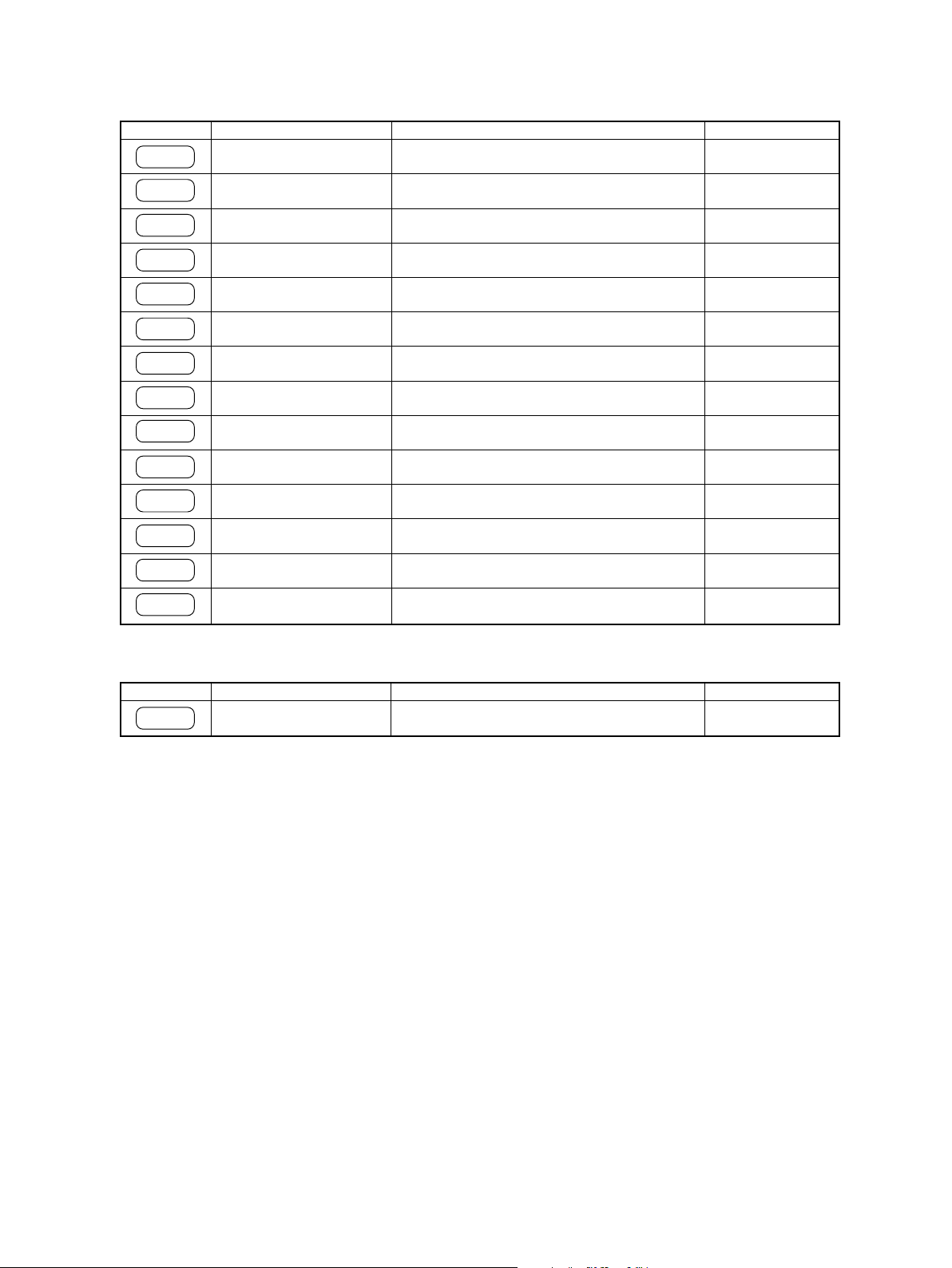

4. SYMBOLS AND LAYOUT OF ELECTRICAL PARTS / DIAGRAM OF SIGNAL BLOCKS

4.1 Symbols

(1) Motors

Symbol

RDMOT

RVMOT

FMOT

FAN

(2) Solenoid

Symbol

RSOL

Name

RDMOT

(Read motor)

RVMOT

(Reverse motor)

FMOT

(Feed motor)

FAN

(Fan motor)

Name

RSOL

(Reverse solenoid)

Function

Drives transportation roller and exit roller

Drives reverse roller

Drives pickup roller, feed roller and registration

roller

Cools down read motor

Function

Switches flapper

Remarks

Pulse motor

Pulse motor

DC motor

Fan motor

Remarks

DC solenoid

October 2000 © TOSHIBA TEC MR-3011/3012 SYMBOLS

4-1

Page 14

(3) Switches and Sensors

Symbol

JAMSW

OPNSW

EMPS

REGS

EXITS

SIZES1

SIZES2

SIZES3

TRYS

OPNSN

MCLK

LENGS

READS

RVRS

Name

JAM-SW

(Jam access cover switch)

RADF-OPN-SW

(RADF open/close switch)

EMP-SNS

(Empty sensor)

REG-SNS

(Registration sensor)

EXIT-SNS

(Exit sensor)

SIZE-SNS 1

(Original width sensor 1)

SIZE-SNS 2

(Original width sensor 2)

SIZE-SNS 3

(Original width sensor 3)

TRY-SNS

(Tray sensor)

RADF-OPN-SNS

(RADF open/close sensor)

MCLK-SNS

(Feed motor clock sensor)

LENG-SNS

(Original length sensor)

Read-SNS

(Read sensor)

RVR-SNS

(Reverse sensor)

Function

Switch to detect if jam access cover for feeding

unit is opened/closed

Switch to detect if RADF unit is opened/closed

Sensor to detect original on original tray

Sensor to detect original at registration position

Sensor to deteat original at exit area

Original width detection sensor 1

Original width detection sensor 2

Original width detection sensor 3

Sensor to detect length of original on original

tray

Sensor to detect if RADF unit is opened/closed

Detection sensor for feed motor clock

Sensor to detect length of original

Sensor to detect leading edge of original at

scanning position

Sensor to detect original at reverse position

Remarks

Microswitch

Microswitch

Semiconductive

optical sensor

Semiconductive

optical sensor

Semiconductive

optical sensor

Semiconductive

optical sensor

Semiconductive

optical sensor

Semiconductive

optical sensor

Semiconductive

optical sensor

Semiconductive

optical sensor

Semiconductive

optical sensor

Semiconductive

optical sensor

Semiconductive

optical sensor

Semiconductive

optical sensor

(4) PC board

Symbol

PWA-DF

PWA-LGC-RADF

(PC board)

Function

Drives feeding and transportation

RemarksName

October 2000 © TOSHIBA TEC MR-3011/3012 SYMBOLS

4-2

Page 15

4.2 Layout of Electrical Parts

JAMSW

TRYS

FMOT

RDMOT

FAN

OPNSW

MCLK

RVRS

READS

RVMOT

EMPS

OPNS

SIZES1

SIZES3

REGS

EXITS

LENGS

SIZES2

RSOL

RDMOT Read motor

RVMOT Reverse motor

FMOT Feed motor

FAN Fan motor

RSOL Reverse solenoid

JAMSW Jam access cover switch

OPNSW RADF open/close switch

EMPS Empty sensor

REGS Registration sensor

EXITS Exit sensor

SIZE 1 Original width sensor 1

SIZE 2 Original width sensor 2

SIZE 3 Original width sensor 3

TRYS Tray sensor

OPNS RADF open/close sensor

MCLK Feed motor clock sensor

LENGS Orignal length sensor

READS Read sensor

RVRS Reverse sensor

October 2000 © TOSHIBA TEC MR-3011/3012 SYMBOLS

4-3

Page 16

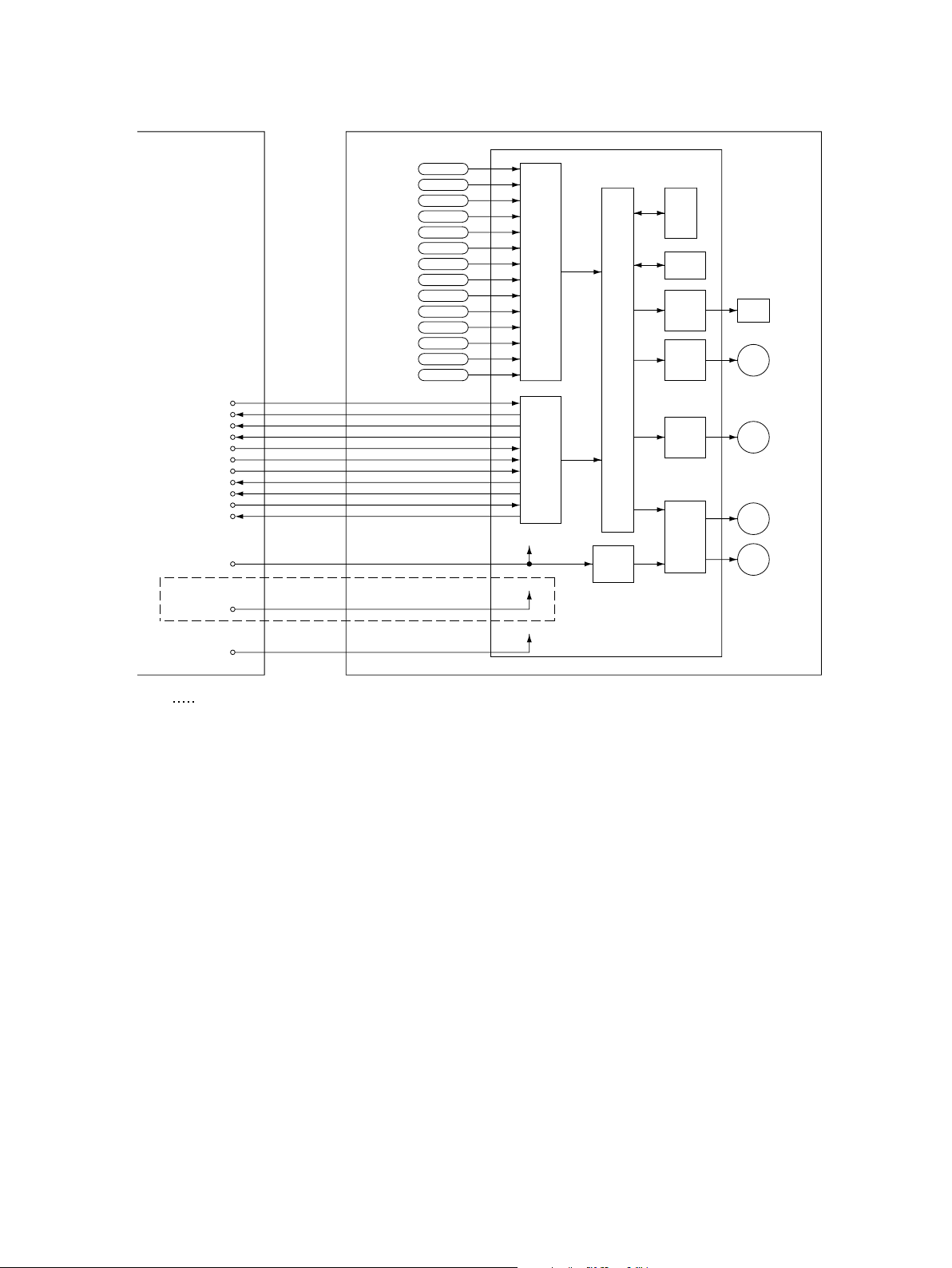

4.3 Diagram of Signal Blocks

PPC (copier)

ACK

VARID

EMPTY

RxD

SGND

TxD

SGND

DF-ACK

DF-REQ

REQ

RADFCNT

DC+24V

(Supplied from copier)

*1

P+5V

(

Supplied from copier

DC+5V

Supplied from copier

(

RADF (Reversing Automatic Document Feeder)

JAMSWJAM-SW

OPNSWRADF-OPN-SW

EMPSEMP-SNS

REGSREG-SNS

EXITSEXIT-SNS

SIZES1SIZE-SNS1

SIZES2SIZE-SNS2

SIZES3SIZE-SNS3

TRYSTRY-SNS

OPNSRADF-OPN-SNS

MCLKMCLK-SNS

LENGSLENG-SNS

READSREAD-SNS

RVRSRVR-SNS

PWA-LGC-F513

Sensor

input

circuit

Communication

circuit

DC+24V

P+5V

CPU

Irruptive

current

control

circuit

ROM

EEPROM

Driver

Driver

Driver

Driver

RSOL

RSOL

FAN

FAN

FMOT FMOT

RDMOT

RDMOT

RVMOT

RVMOT

)

DC+5V

)

*1 Available only for MR-3011

October 2000 © TOSHIBA TEC MR-3011/3012 SYMBOLS

4-4

Page 17

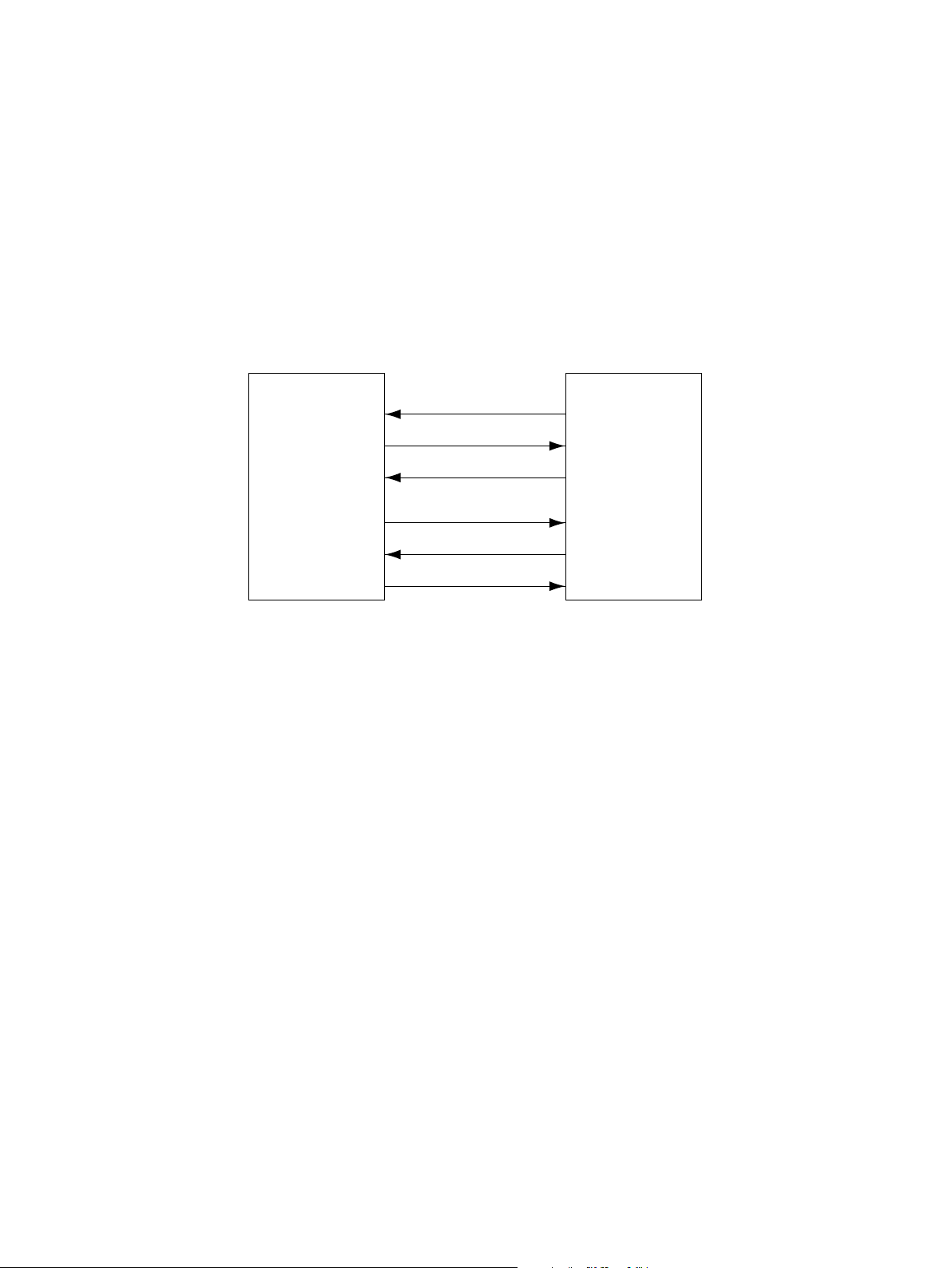

4.4 Description of Interface Signals

The following 6 lines are used to send/receive signals between the copier and the RADF.

REQ ............. Communication request signal (from copier to RADF)

DF-REQ ....... Communication request signal (from RADF to copier)

DF-ACK........Response signal for communication request signal (from RADF to copier)

ACK..............Response signal for communication request signal (from copier to RADF)

TxD ..............Data sent from copier to RADF

RxD ..............Data sent from RADF to copier

Data communication (RxD and TxD) between the scanner and RADF has adopted the serial communication

system which does not allow checking using testing devices to see whether the signals are sent/received

properly in the field.

RADF Copier

REQ

DF-ACK

TxD

DF-REQ

ACK

RxD

October 2000 © TOSHIBA TEC MR-3011/3012 SYMBOLS

4-5

Page 18

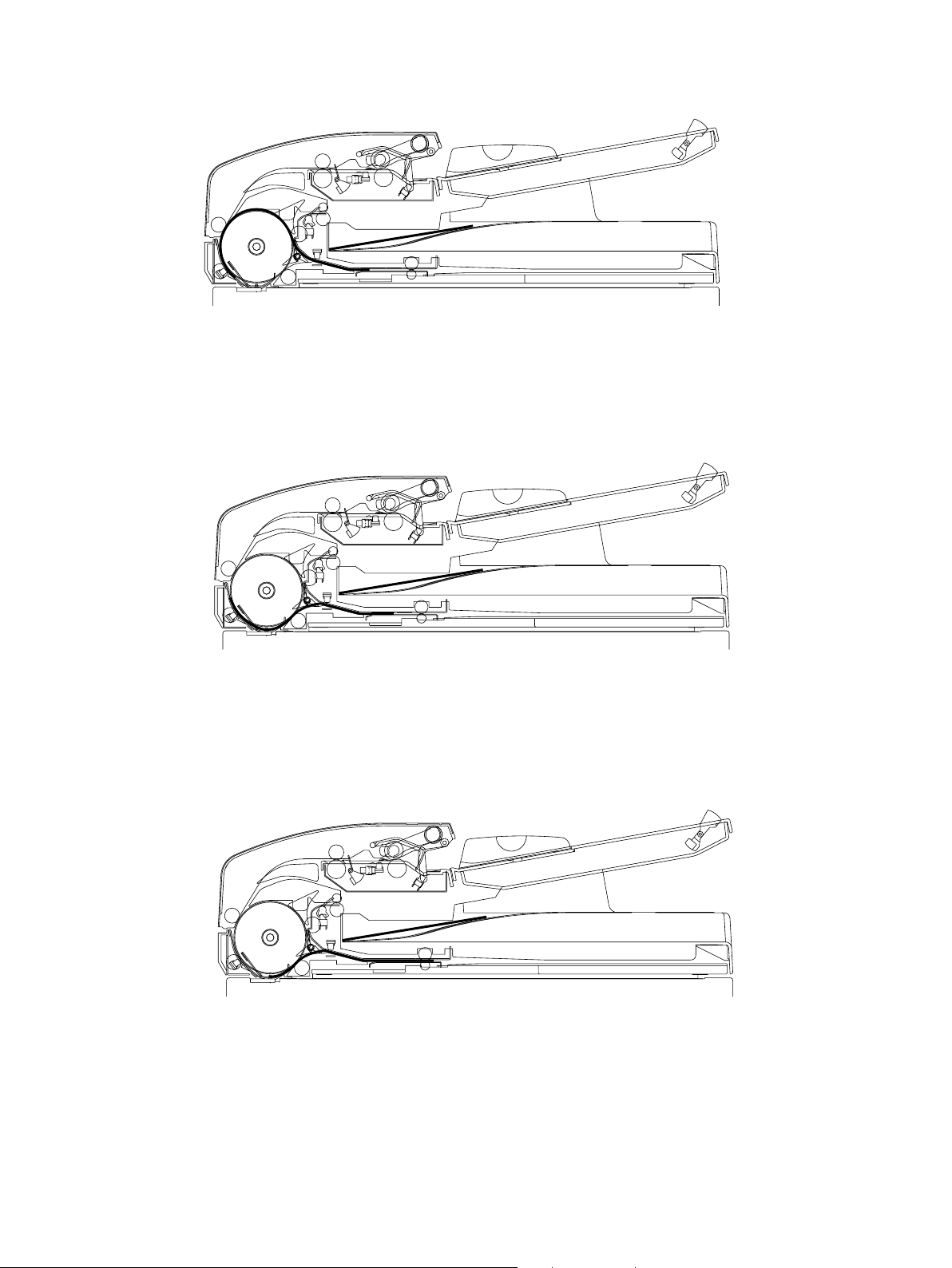

5. DESCRIPTION OF OPERATIONS

5.1 Single Side Feeding

(A4, registration ratio 100%)

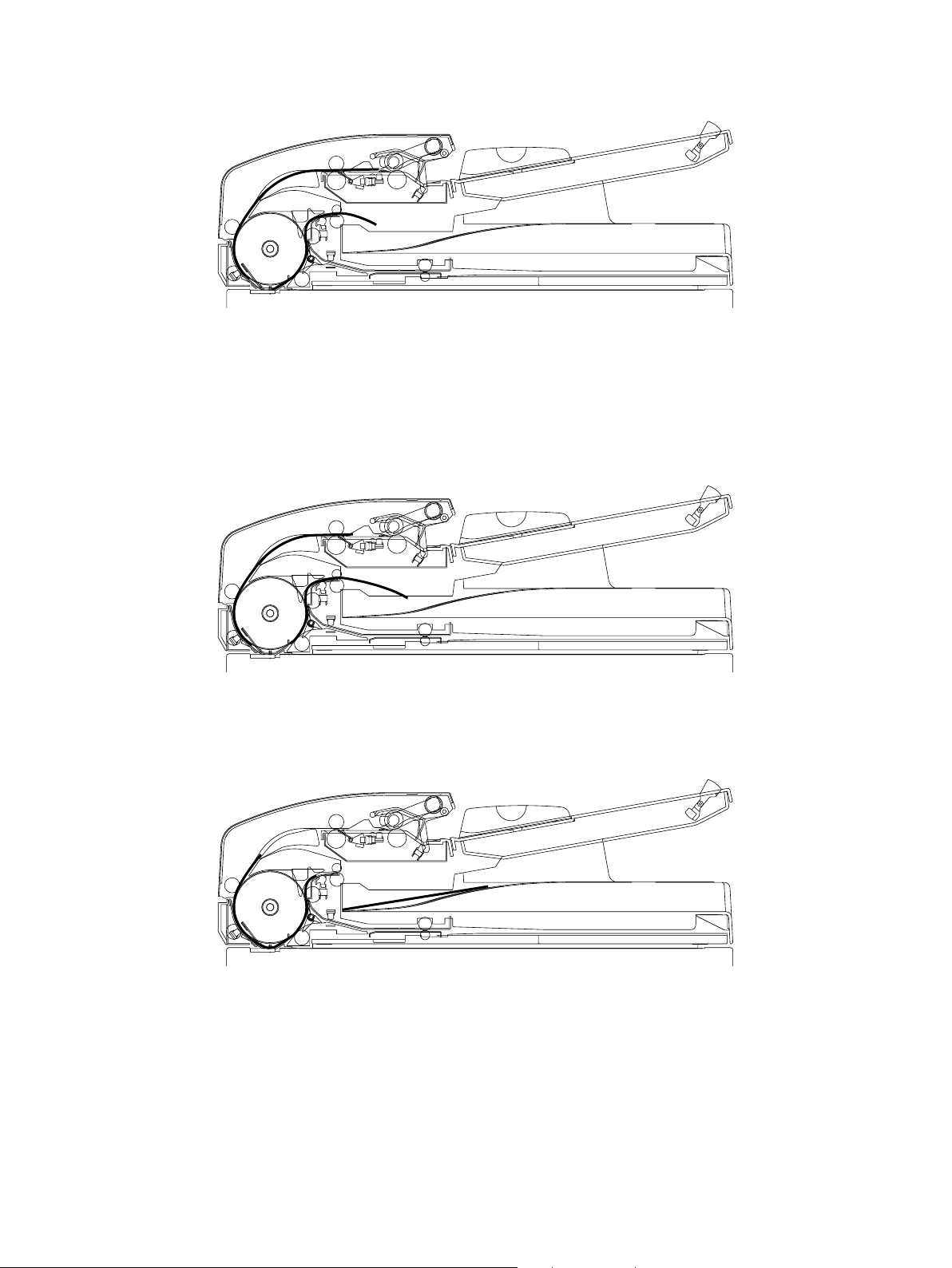

(1) Setting original

The original is set on the tray and the empty sensor is turned ON.

The original set signal becomes ON.

(2) Start of pre-feeding operation n Completion of pre-feeding operation

A feed signal is sent from the main unit, and the feed motor rotates the pickup roller and feed motor to start

feeding the original (pre-feeding operation).

(3) Start of feeding operation n Original length sensor OFF

The feed motor starts to rotate in reverse and the read motor rotates forward to rotate the registration roller and

the read roller while the original is waiting in front of the registration roller and read roller starts to be transported.

The feed motor is stopped after the original length sensor is turned OFF.

October 2000 © TOSHIBA TEC MR-3011/3012 DESCRIPTION OF OPERATION

5-1

Page 19

(4) Original length sensor OFF n Completion of sending operation

If the next original is waiting in the tray, the pickup roller is lowered after the feed motor which has started to

rotate forward rotates for a cer tain number of pulses. (The pickup roller waits for the next pre-feeding operation in

that lowered position.)

The read motor rotates for a certain number of pulses and stops after the read sensor is turned ON. (The leading

edge of the original reaches the pre-scanning position.)

(5) Start of scanning operation n Star t of pre-feeding operation for next original

The original transport signal is sent from the main unit, and the read motor starts to rotate forward. The read

roller and exit roller are rotated to start scanning the original. The feed motor rotates the pickup roller and feed

roller after the trailing edge of the original has passed the registration roller to start the pre-feeding operation for

the next original.

(6) Start of pre-feeding operation for next original n Completion of pre-feeding operation

After the registration sensor has detected the leading edge of the original. The feed motor transports the original

for a certain number of pulses, performs registration and stops.

October 2000 © TOSHIBA TEC MR-3011/3012 DESCRIPTION OF OPERATION

5-2

Page 20

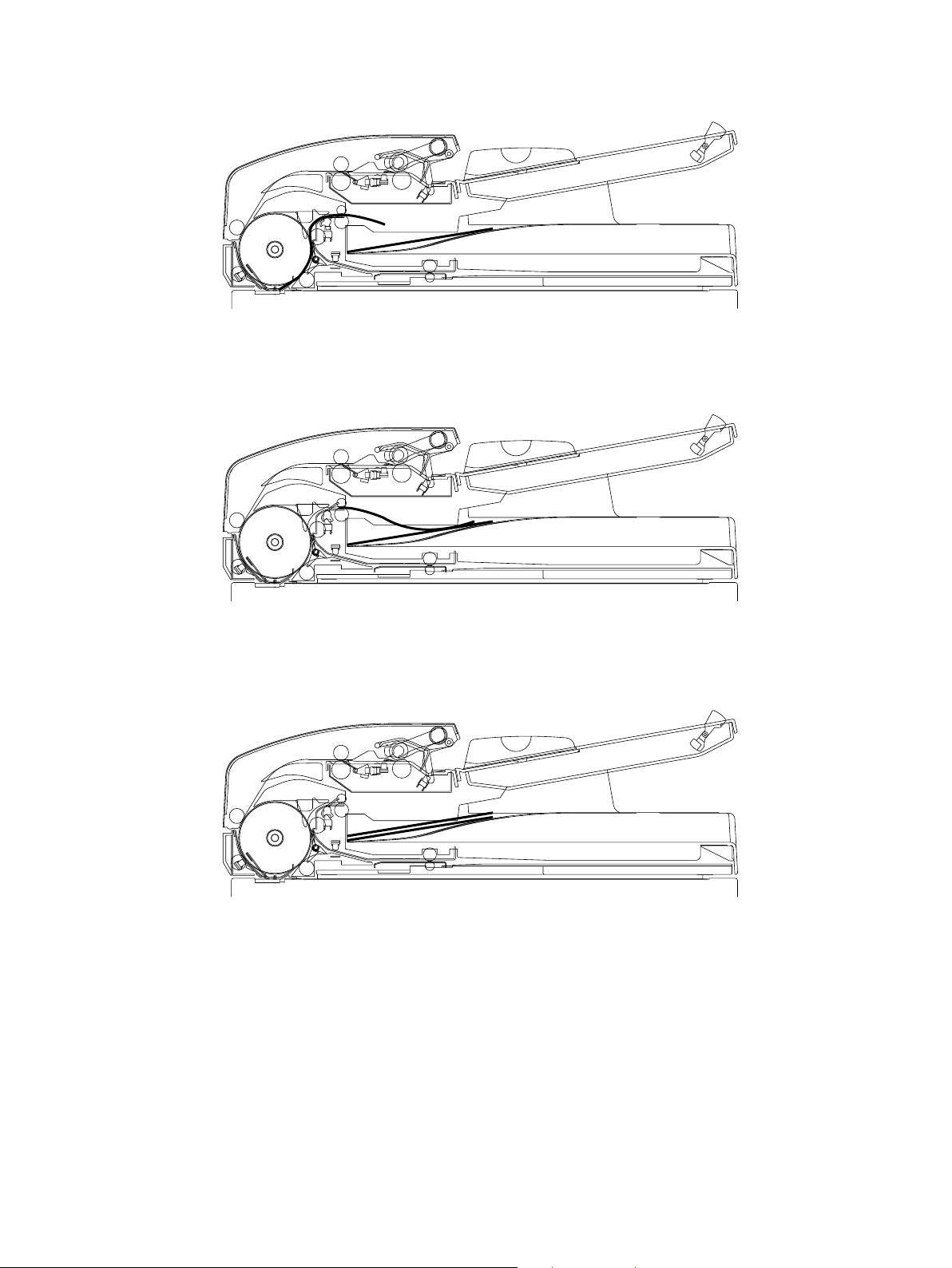

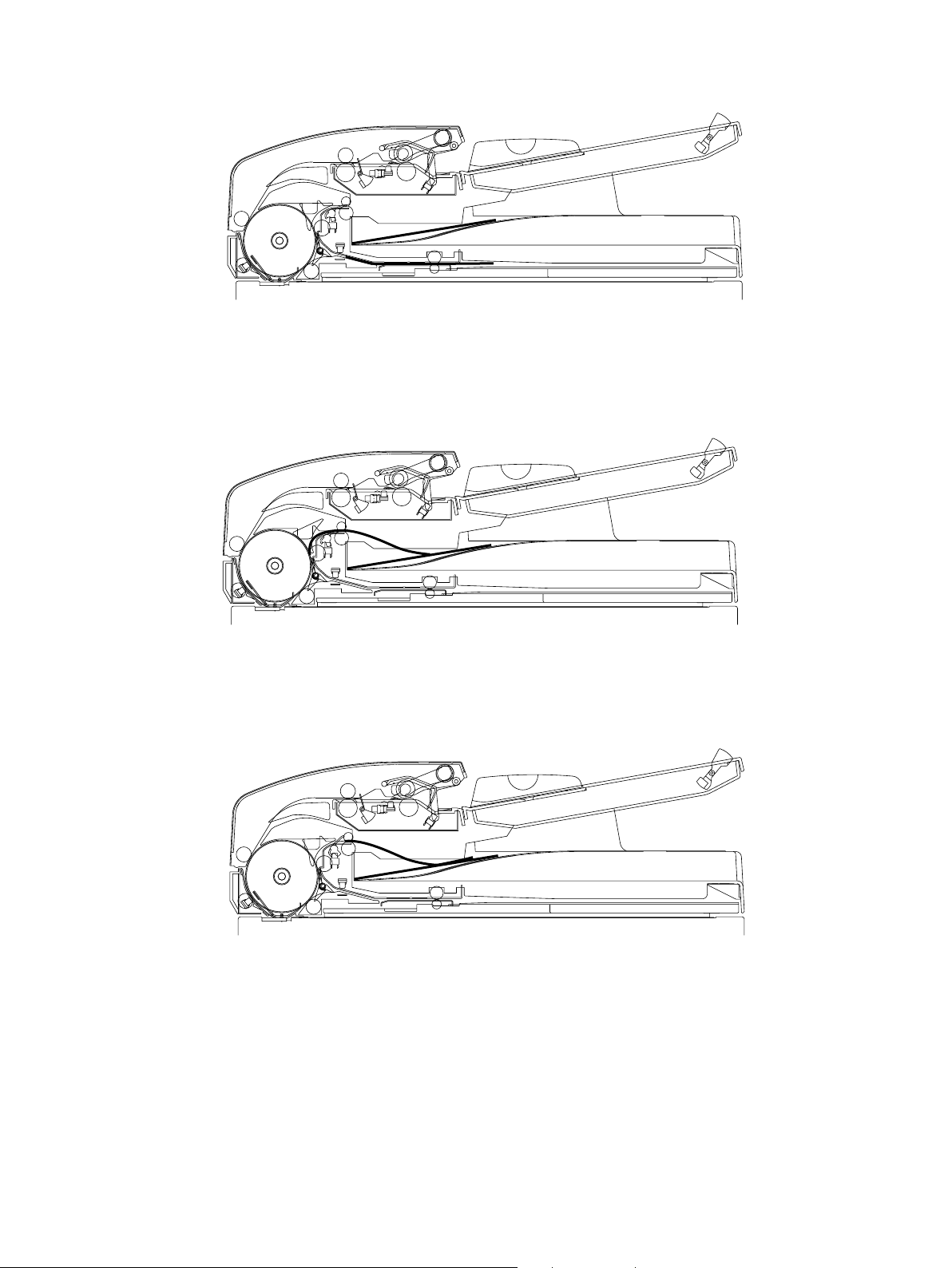

(7) Start of feeding operation for next original n Completion of scanning operation

The feed motor starts to rotate in reverse, it rotates the registration roller to feed the next original waiting in front

of the registration roller and read roller.

The original set signal is reset when the empty sensor is turned OFF. The feed motor is stopped after the original

length sensor is turned OFF.

The scanning operation is completed when the trailing edge of the original being scanned has passed the

scanning position.

(8) Completion of scanning operation n Completion of feeding operation for next original

The read motor rotates for a certain number of pulses and stops after the read sensor is turned ON.

(The leading edge of the next original reaches the pre-scanning position.)

(9) Start of scanning operation for next original n Completion of original discharge

The read motor starts to rotate forward, it rotates the read roller and exit roller to start scanning the next original.

Original discharge is completed when the trailing edge of the original has passed the exit roller.

October 2000 © TOSHIBA TEC MR-3011/3012 DESCRIPTION OF OPERATION

5-3

Page 21

(10)Completion of scanning operation for next original

Scanning is completed when the trailing edge of the next original has passed the scanning position and the

original is carried toward the receiving tray.

(11)Exit sensor OFF (next original)

After the exit sensor is turned OFF, the feed motor rotates for a certain number of pulses till the original is

completely discharged.

(12) Completion of or iginal discharge (next original)

The read motor is stopped when the next original is completely discharged into the receiving tray.

October 2000 © TOSHIBA TEC MR-3011/3012 DESCRIPTION OF OPERATION

5-4

Page 22

5.2 Duplex Feeding

(A4, reproduction ratio 100%)

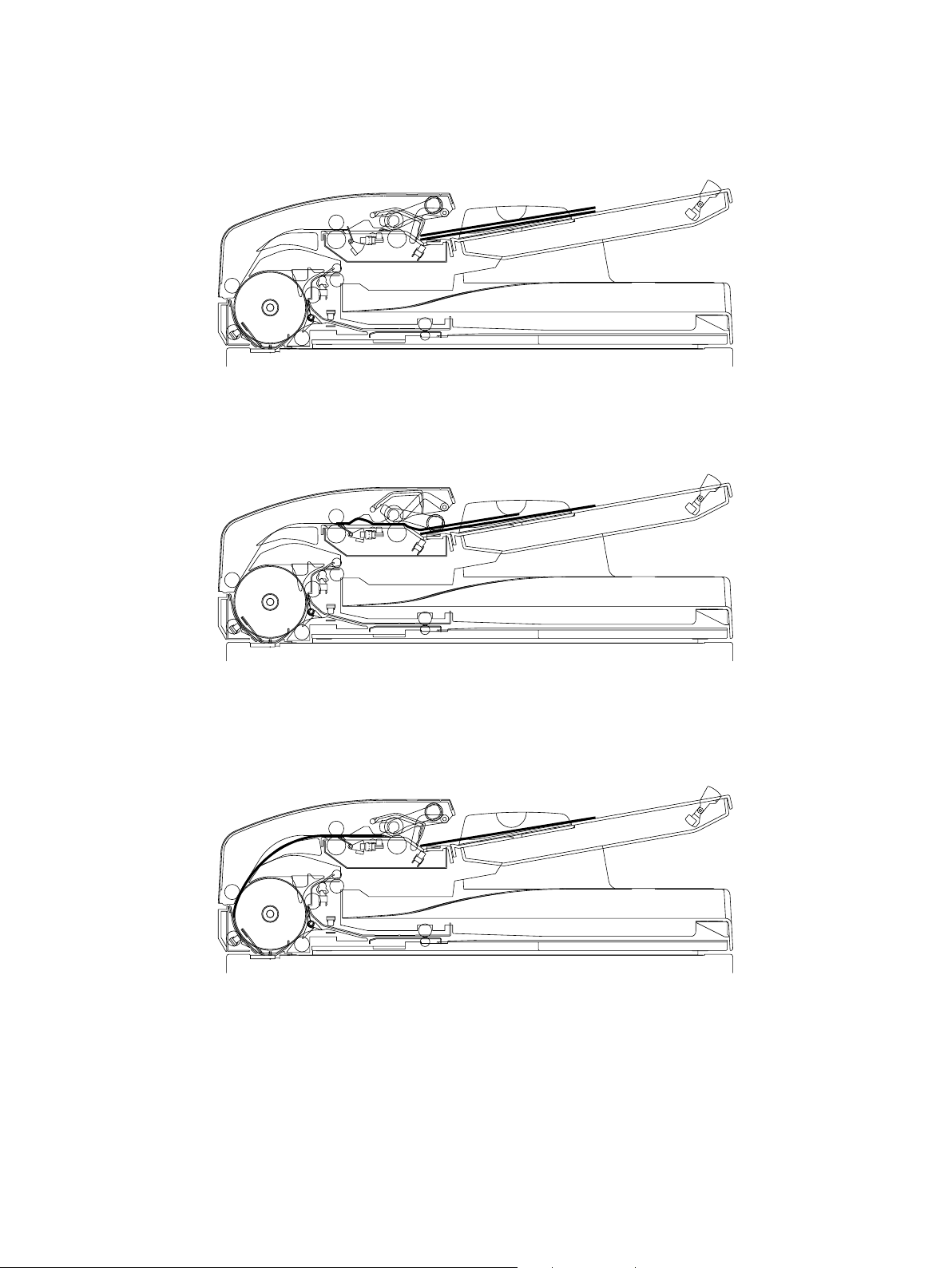

(1) Setting original

The original is set on the tray and the empty sensor is turned ON.

The original set signal becomes ON.

(2) Start of pre-feeding operation n Completion of pre-feeding operation

A feed signal is sent from the main unit, and the feed motor starts to rotate forward and rotates the pickup roller

and feed roller to start the pre-feeding operation. After the registration sensor detected the leading edge of the

original, the feed motor transports the original for a certain number of pulses, performs registration and stops.

(3) Start of feeding operation n Original length sensor OFF

The feed motor starts to rotate in reverse and the read motor starts to rotate forward to start feeding the original

waiting in front of the registration roller and the read roller. The feed motor is stopped after the original length

sensor is turned OFF.

October 2000 © TOSHIBA TEC MR-3011/3012 DESCRIPTION OF OPERATION

5-5

Page 23

(4) Original length sensor OFF n Completion of feeding operation

If the next original is waiting on the tray, the pickup roller is lowered after the feed motor started to rotate forward

rotates for a certain number of pulse. (The pickup roller waits for next pre-feeding operation in that lowered

position.)

The read motor rotates for a certain number of pulses and stops after the read sensor is turned ON. (The leading

edge of the original reaches the pre-front side scanning position.)

(5) Start of front side scanning operation n Star t of pre-feeding operation for next original

An original transport signal is sent from the main unit, and the read motor and reverse motor start to rotate

forward. The read roller, exit roller and reverse roller are then rotated. The reverse flapper is switched toward the

reverse position by turning ON the reverse solenoid and the front side of the original, star ts to be scanned.

The feed motor rotates the pickup roller and feed roller after the trailing edge of the original has passed the

registration roller, to start the pre-feeding operation for the next original.

(6) Start of pre-feeding operation for next original n Completion of pre-feeding operation n Completion of front-

side scanning operation

After the registration sensor has detected the leading edge of the next original, the feed motor transports the

original for a certain number of pulses, performs registration and stops. Scanning of the front side of original is

completed when the trailing edge of the original being scanned has passed the scanning position.

October 2000 © TOSHIBA TEC MR-3011/3012 DESCRIPTION OF OPERATION

5-6

Page 24

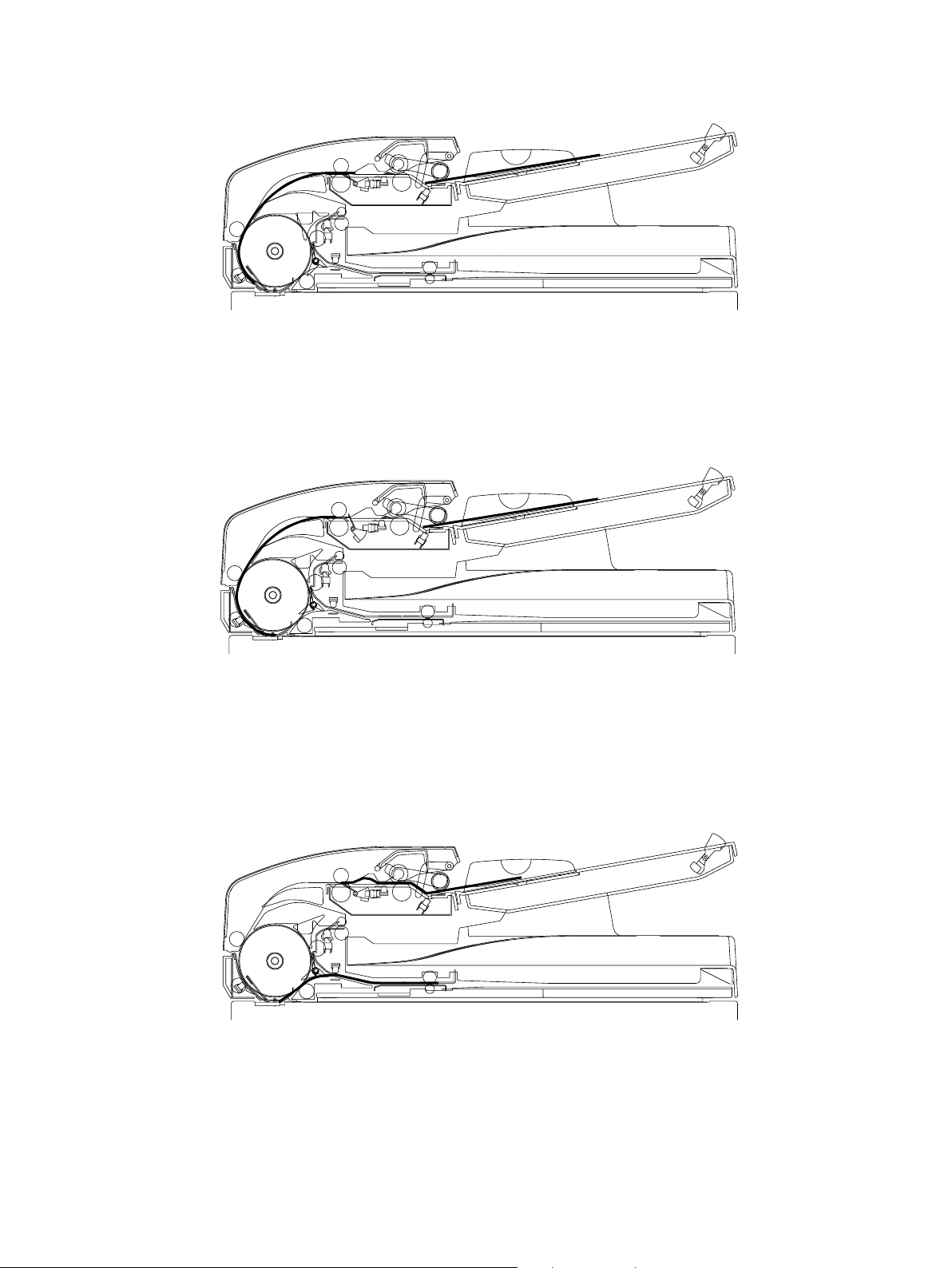

(7) Completion of transport operation for front side of original (original paused at reverse position)

The read motor and reverse motor are stopped after the reverse sensor is turned OFF to complete transpor tation of the front side of the original.

(8) Start of back side registration operation n Completion of registration

The reverse motor starts to rotate in reverse and rotates the reverse roller in reverse to start the registration

operation for the back side of the original pausing at the reverse position.

After the reverse sensor has detected the trailing edge of the original, the feed motor transpor ts the or iginal for a

certain number of pulses, performs registration and stops.

(9) Start of reverse feeding operation n Completion of reverse feeding operation

The read motor starts to rotate forward and the reverse motor starts to rotate in reverse. The read roller, exit

roller and reverse roller are rotated to start the reverse feeding operation for the original waiting at the back side

registration position. The read motor and reverse motor rotate for a cer tain number of pulses and stop after the

read sensor is turned ON. (The leading edge of the original reaches the pre-back side scanning position.)

October 2000 © TOSHIBA TEC MR-3011/3012 DESCRIPTION OF OPERATION

5-7

Page 25

(10)Start of back side scanning operation n Or iginal passing reverse position

An original transport signal is sent from the main unit, and the read motor starts to rotate forward and reverse

motor starts its reverse rotation activated by read rotate in reverse to rotate the read roller, exit roller and reverse

roller. The reverse flapper is switched toward the reverse position by turning ON the reverse solenoid to start

scanning the back side of the original.

The reversal motor rotates for a cer tain number of pulses and stops after the trailing edge of the original has

passed the reverse roller.

(11)Original passing reverse position n Completion of back side scanning operation

The reversal motor starts to rotate forward and rotates the reverse roller to be ready for the leading edge of the

original to come into the reverse position.

The scanning operation for the back side of the original is completed when the trailing edge of the original has

passed the scanning position.

(12)Completion of transport operation for back side of original (original paused at reverse position)

The read motor and reverse motor are stopped after the reverse sensor is turned OFF to complete transpor tation of the back side of the original.

The reverse flapper is switched to the exit side by turning OFF the reverse solenoid.

October 2000 © TOSHIBA TEC MR-3011/3012 DESCRIPTION OF OPERATION

5-8

Page 26

(13)Start of reverse discharge n Start of feeding operation for next original n Original length sensor OFF

The read motor starts to rotate forward and the reverse motor starts to rotate in reverse. The read roller, exit

roller and reverse roller are rotated to start reverse discharge of the original paused at the reverse position. The

feed motor rotates for a certain number of pulses after the reverse sensor is turned ON. It then starts to rotate in

reverse to rotate the registration roller, and starts the feeding operation for the next original waiting in front of the

read roller and registration roller.

The original set signal is reset when the empty sensor is turned OFF.

The reverse motor is stopped after the reverse sensor is turned OFF.

The feed motor is stopped after the original length sensor is turned OFF.

(14)Original length sensor OFF n Completion of feeding operation for next original

The read motor rotates for a certain number of pulses and stops after the read sensor is turned ON. (The leading

edge of the next original reaches the pre-scanning position for front side of original.)

(15)Start of front side scanning operation pre-scanning position for front side of original n Completion of

reverse discharge operation

The read motor and reverse motor start to rotate forward to rotate the read roller, exit roller and reverse roller.

The reverse flapper is switched toward the reverse position by turning ON the reverse solenoid to star t the

scanning of the front side of next original.

The reverse discharge operation is completed when the trailing edge of the original has passed the exit roller.

October 2000 © TOSHIBA TEC MR-3011/3012 DESCRIPTION OF OPERATION

5-9

Page 27

(16)Completion of front side scanning operation

The scanning operation for the front side of the original is completed when the trailing edge of next original has

passed the scanning position.

(17)Completion of transport operation for the front side of next original (original paused at reverse position)

The read motor and reverse motor are stopped when the reverse sensor is turned OFF to complete the transpor t

operation for the front side of the original.

(18)Start of back side registration n Completion of back side registration

The reverse motor starts to rotate in reverse and the reverse roller rotates in reverse to start the registration of

the next original paused at the reverse position.

After the reverse sensor has detected the leading edge of the original, the reverse motor transpor ts the original

for a certain number of pulses, performs registration and stops.

October 2000 © TOSHIBA TEC MR-3011/3012 DESCRIPTION OF OPERATION

5-10

Page 28

(19)Start of reverse feeding operation for next original n Completion of reverse feeding operation

The read motor starts to rotate forward and the revese motor starts to rotate in reverse. The read roller, exit roller

and reverse roller are rotated to start the reverse feeding operation for the next original waiting at the back side

registration position. The read motor and reverse motor rotate for a cer tain number of pulses and stop after the

read sensor has been turned ON.

(The leading edge of next original reaches the pre-scanning position for the back side of the original.)

(20)Start of back side scanning operation n Or iginal passing reverse position

The read motor starts to rotate forward and the reverse motor starts to rotate in reverse to rotate the read roller,

exit roller and reverse roller. The reverse flapper is switched toward the reverse position by tur ning ON the

reverse solenoid to start scanning the back side of the next original.

The reverse motor rotates for a cer tain number of pulses and stops after the trailing edge of the next original has

passed the reverse roller.

(21)Next original passing reverse position n Completion of back side scanning

The reverse motor starts to rotate forward and the reverse roller is rotated to be ready for the leading edge of the

next original to come into the reverse position.

The scanning of the back side of the original is completed when the trailing edge of the next original has passed

the scanning position.

October 2000 © TOSHIBA TEC MR-3011/3012 DESCRIPTION OF OPERATION

5-11

Page 29

(22)Completion of transport operation for back side of next original (original paused at reverse position)

The read motor and reverse motor stop after the reverse sensor is turned OFF to complete transpor tation of the

back side of the original. The reverse flapper is switched to the exit side by turning OFF the reverse solenoid.

(23)Start of reverse discharge operation of next original n Start of feeding operation for next original n Or iginal

length sensor OFF

The read motor starts to rotate forward and the reverse motor starts to rotate in reverse. The read roller, exit

roller and reverse roller are rotated to start the reverse discharge of the next original paused at the reverse

position. The reverse motor stops after the reverse sensor has been turned OFF.

(24)Exit sensor OFF

After the exit sensor has been turned OFF, read motor rotates for a certain number of pulses till the next original

has completely discharge.

October 2000 © TOSHIBA TEC MR-3011/3012 DESCRIPTION OF OPERATION

5-12

Page 30

(25)Completion of reverse discharge operation for next original

The read motor is stopped when the next original is completely discharged into the original receiving tray to

terminate the reverse discharge operation.

October 2000 © TOSHIBA TEC MR-3011/3012 DESCRIPTION OF OPERATION

5-13

Page 31

5.3 Single Side Feeding (for Mixed Sized Originals)

(Mixture of A4-R and FOLIO (LTR/LG), reproduction ratio 100%)

(1) Setting original

An original is set on the tray and the empty sensor is turned ON.

The original set signal becomes ON.

(2) Start of pre-feeding operation n Completion of pre-feeding operation

The feed signal is sent from the main unit, and the feed motor starts to rotate forward. The pickup roller and feed

roller are rotated to start the pre-feeding operation. After the registration sensor has detected the leading edge of

the original, the feed motor transports the original for a cer tain number of pulses, performs registration and

stops.

(3) Start of feeding operation n Completion of feeding operation

The feed motor starts to rotate in reverse and the read motor starts to rotate forward. The registration roller and

read roller, exit roller are rotated to star t feeding the original waiting in front of the registration roller and read

roller.

The feed motor stops and the read motor rotates for a certain number of pulses and stops when the read sensor

is turned ON. (The leading edge of the original reaches the pre-scanning position)

October 2000 © TOSHIBA TEC MR-3011/3012 DESCRIPTION OF OPERATION

5-14

Page 32

(4) Start of transpor t operation n Original length sensor OFF

The read motor starts to rotate forward and rotates the read roller and exit roller to start transportation of the

original paused at the scanning position. (The original is transported to determine its lengthwise size along the

feeding direction.)

(5) Original length sensor OFF n Completion of downswing operation of pickup roller

The pickup roller is lowered after the feed motor has started to rotate forward and has rotated for a certain

number of pulses. (The pickup roller waits for the next pre-feeding operation in the lowered position.)

(6) Completion of downswing operation of pickup roller n Pre-reverse position for mixed sized original

The read motor rotates for a certain number of pulse and stops after the original length sensor has been turned

OFF. (The trailing edge of the original reaches the pre-reverse position.)

October 2000 © TOSHIBA TEC MR-3011/3012 DESCRIPTION OF OPERATION

5-15

Page 33

(7) Start of reverse operation for mixed sized originals n Completion of reverse operation

The gate for the reverse path is switched after a certain period of time. The read motor starts to rotate in reverse

and rotates the read roller and exit roller in reverse to star t the reverse operation.

The read motor rotates for a certain number of pulses and stops after the read sensor has been turned OFF.

(8) Start of transpor tation n Completion of transpor tation

The read motor starts to rotate forward and rotates the read roller and exit roller to start the transportation of the

original to the pre-scanning position.

The read motor rotates for a certain number of pulses and stops after the read sensor has been turned ON. (The

leading edge of the original reaches the pre-scanning position.)

(9) Start of scanning operation n Star t of pre-feeding operation for next original n Completion of pre-feeding

operation

A transport signal is sent from the main unit, and the read motor star ts to rotate forward. The read roller and exit

roller is rotated to start scanning the or iginal. The feed motor rotates pickup roller and feed roller to start the prefeeding operation for the next original.

After the registration sensor has detected the leading edge of the original, the feed motor transports the original

for a certain number of pulses, performs registration and stops.

October 2000 © TOSHIBA TEC MR-3011/3012 DESCRIPTION OF OPERATION

5-16

Page 34

(10) Completion of scanning operation

Scanning is completed when the trailing edge of the original has passed the scanning position.

(11)Exit sensor OFF n Start of feeding operation for next original

The feed motor starts to rotate in reverse after the exit sensor has been turned OFF and rotates the registration

roller to start feeding the next original waiting in front of the registration roller and read roller.

The original discharge operation is completed when the trailing edge of the original has passed the exit roller.

(12)Completion of feeding operation for next original

The feed motor stops and the read motor rotates for a certain number of pulses and stops when the read sensor

has been turned ON. (The leading edge of the next original reaches the pre-scanning position.)

October 2000 © TOSHIBA TEC MR-3011/3012 DESCRIPTION OF OPERATION

5-17

Page 35

(13)Start of transportation of next original n Original length sensor OFF

The read motor starts to rotate forward and rotates the read roller and exit roller to transport the next original

paused at the scanning position.

(The original is transported to deter mine its lengthwise size along the feeding direction.)

The original set signal is reset when the empty sensor is turned OFF.

(14)Original length sensor OFF (for next original) n Pre-reverse position for mixed sized originals

The read motor rotates for a certain number of pulses and stops after the original length sensor has been turned

OFF. (The trailing edge of the next original reaches the pre-reverse position.)

(15)Start of reverse operation for the next mixed sized original n Completion of reverse operation

The gate for the reverse path is switched after a certain period of time. The read motor starts to rotate in reverse

and rotates the read roller and exit roller in reverse to star t the reverse operation.

The read motor rotates for a certain number of pulses and stops after the read sensor has been turned OFF.

October 2000 © TOSHIBA TEC MR-3011/3012 DESCRIPTION OF OPERATION

5-18

Page 36

(16)Start of transportation of next original n Completion of transportation

The read motor starts to rotate forward and rotates the read roller and exit roller to start the transportation of the

next original to the pre-scanning position.

The read motor rotates for a certain number of pulses and stops after the read sensor has been turned ON. (The

leading edge of the next original reaches the pre-scanning position.)

(17)Start of scanning operation for next original

A transport signal is sent from the main unit and the read motor star ts to rotate forward. The read roller and exit

roller is rotated to start scanning the next original.

(18)Completion of scanning operation for next original

Scanning is completed when the trailing edge of the next original has passed the scanning position.

October 2000 © TOSHIBA TEC MR-3011/3012 DESCRIPTION OF OPERATION

5-19

Page 37

(19)Exit sensor OFF n Completion of discharge operation for next or iginal

After the exit sensor has been turned OFF, the read motor rotates for a certain number of pulses till the next

original is completely discharge into the tray. The read motor is stopped when the next original is completely

discharge into the receiving tray to complete the original discharge operation.

None: (Duplex feeding of mixed-sized originals)

The reverse mechanism detects the size of the mixed-sized originals consisting of A4-R/FOLIO or LT-R/

LG, then the scanning operation is started.

October 2000 © TOSHIBA TEC MR-3011/3012 DESCRIPTION OF OPERATION

5-20

Page 38

6. JAMMING

6.1 Feeding Jam

(1) Original not reaching registration sensor

• Jam detection:

Jam detection is performed after the feed motor starts to rotate forward to start the pre-feeding operation,

until the leading edge of the original has reaches the registration sensor.

• Jam timer setting

The setting value of thrice the amount of time after the original turns on the empty sensor till it reaches the

registration sensor is set for the jam timer.

6.2 Transport Jam

(1) Original jamming at registration sensor

• Jam detection for single-sided/duplex originals:

Jam detection is performed after the read motor starts to rotate forward to start scanning the front side of

the original, until the trailing edge of the original has passed the registration sensor.

• Jam pulse setting

[In the normal mode]

Assume that the longest original (LD) is at the pre-scanning position. The setting value of an added

+30mm to the distance till the trailing edge of the original has passed the registration sensor is set as the

jam pulse.

[In the length is irregularly long mode]

Assume then the longest original (original length approx. 1m) is at the pre-scanning position. The setting

value of an added +50mm to the distance till the trailing edge of the original has passed the registration

sensor is set as the jam pulse.

(2) Original not reaching read sensor (1)

• Jam detection for single-sided/duplex originals:

Jam detection is performed after the leading edge of the original reaches the first small roller of the read

roller during the pre-feeding operation, until it has reached the read sensor.

• Jam pulse setting

The setting value of an added +60mm to the distance from the first small roller of the read roller to the

position where the read sensor is turned ON is set as the jam pulse.

(3) Original not reaching read sensor (2)

• Jam detection for duplex originals:

Jam detection is performed after the read motor starts to rotate forward to start switchback feeding, until

the leading edge of the original has reached the read sensor.

• Jam pulse setting

The setting value of an added +30mm to the distance from the back side registration position (= the

position where the 4th small roller of the read sensor is located) till the read sensor is turned ON is set as

the jam pulse.

(4) Original jamming at read sensor (1)

• Jam detection for single-sided/duplex originals:

Jam detection is performed after the trailing edge of the original has passed the registration sensor during

the pre-feeding operation, until it has passed the read sensor.

• Jam pulse setting

The setting value of an added +30mm to the distance from the position where the registration sensor is

turned OFF till the read sensor is turned OFF is set as the jam pulse.

(5) Original jamming at read sensor (2)

• Jam detection for duplex originals:

Jam detection is performed after the original waiting at the back side registration position reaches the read

sensor during the reverse feeding operation, until the trailing edge of the original has passed the read

sensor during scanning.

• Jam pulse setting

The setting value of an added +30mm to the distance till the longest original (LD) passes the read sensor

is set as the jam pulse.

October 2000 © TOSHIBA TEC MR-3011/3012 JAMMING

6-1

Page 39

(6) Original not reaching exit sensor (1)

• Jam detection for single-sided/duplex originals:

Jam detection is performed after the read motor starts to rotate forward to start scanning the original

waiting at the pre-front side scanning position, until the leading edge of the original has reached the exit

sensor.

• Jam pulse setting

The setting value of an added +30mm to the distance from the pre-scanning position till the exit sensor is

turned ON is set as the jam pulse.

(7) Original not reaching reverse sensor (1)

• Jam detection for duplex originals:

Jam detection is performed after the read motor starts to rotate forward to start scanning the front side of

the original, until the leading edge of the original has reached the reverse sensor.

• Jam pulse setting

The setting value of an added +30mm to the distance from the pre-scanning position till the reverse sensor

is turned ON is set as the jam pulse.

6.3 Exit Jam

(1) Original jamming at exit sensor (1)

• Jam detection for duplex originals:

Jam detection is performed after the trailing edge of original paused at the reverse position has passed the

reverse sensor during the reverse operation, until it has passed the exit sensor.

• Jam pulse setting

The setting value of an added +60mm to the distance from the position where the reverse sensor is turned

OFF till the exit sensor is turned OFF is set as the jam pulse.

(2) Original jamming at exit sensor (2)

• Jam detection for single-sided/duplex originals:

Jam detection is performed after the trailing edge of the original waiting at the pre-front side scanning

position has passed the read sensor during the scanning operation, until it has passed the exit sensor.

• Jam pulse setting

The setting value of an added +60mm to the distance from the position where the read sensor is turned

OFF till the exit sensor is turned OFF is set as the jam pulse.

6.4 Reversing Jam

(1) Original not reaching exit sensor (2)

• Jam detection for duplex originals:

Jam detection is performed after the leading edge of the original paused at the reverse position has

reached the reverse sensor during the reverse discharge operation, until it has reached the exit sensor.

• Jam pulse setting

The setting value of an added +30mm to the distance from the position where the reverse sensor is turned

ON till the exit sensor is turned ON is set as the jam pulse.

(2) Original not reaching reverse sensor (2)

• Jam detection for duplex originals:

Jam detection is performed after reverse motor star ts rotating in reverse to start the reverse operation for

the original paused at the reverse position, until the leading edge of the original has reached the reverse

sensor.

• Jam pulse setting

The setting value of an added +30mm to the distance from the pre-reverse position till the reverse sensor

is turned ON is set as the jam pulse.

(3) Original jamming at reverse sensor (1)

• Jam detection for duplex originals:

Jam detection is performed after the trailing edge of the original being scanned has passed the read

sensor, until it has passed the reverse sensor.

• Jam pulse setting

The setting value of an added +30mm to the distance from the position where the read sensor is turned

OFF till the reverse sensor is turned OFF is set as the jam pulse.

October 2000 © TOSHIBA TEC MR-3011/3012 JAMMING

6-2

Page 40

(4) Original jamming at reverse sensor (2)

• Jam detection for duplex originals:

Jam detection is performed after the leading edge of the original paused at the reverse position has

reached the reverse sensor during the reverse discharge operation, until the trailing edge of the original

has passed the reverse sensor.

• Jam pulse setting

The setting value of an added +30mm to the distance till the longest original (LD) passes the reverse

sensor is set as the jam pulse.

October 2000 © TOSHIBA TEC MR-3011/3012 JAMMING

6-3

Page 41

7. ORIGINAL SIZE DETECTION

Original size is detected when it is sent out of the tray, and informed (unit:mm) to the copier before the star t of

the scanning of the original.

7.1 Method of Original Size Detection (for Standard Sized Originals)

1) Width

When the original waiting at the pre-feeding position has started to be fed and its leading edge reaches the

first small roller of the read roller, its width of the original is detected using the original width sensors 1 and 3

and the size data are saved in EPROM.

2) Size along feeding direction

When the trailing edge of the original (original size: LT of smaller) is detected by the original length sensor

before the read sensor detects the leading edge of the original, or when the original length sensor has

already detected the original (original size: B5-R or larger) when the read sensor detects the leading edge of

the original, the original size along the feeding direction is assumed with the width size data saved in

EPROM, then the size data are sent to the copier. At this time, the date for the size along the feeding

direction are sent first.

With an original whose length is irregularly long, if the size along the feeding direction is not determined by

the scanning operation is started, the read motor counts the of distance pulses after the scanning operation

is started till the trailing edge of the original is detected by original length sensor. Then the motor sends the

measured value to the copier.

Original size: LT or smaller

1) Timing to determine width

2) Timing to determine size along feeding direction

October 2000 © TOSHIBA TEC MR-3011/3012 SIZE DETECTION

7-1

Page 42

Size: B5-R or larger

1) Timing to determine width

2) Timing to determine size along feeding direction

October 2000 © TOSHIBA TEC MR-3011/3012 SIZE DETECTION

7-2

Page 43

7.2 Relation between Status of Sensor and Original Size (for Standard Sized

Originals)

[For JE]

(mm)

Original

width

sensor 1

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

[For UC]

Original

width

sensor 1

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

Original

width

sensor 2

OFF

OFF

OFF

OFF

OFF

ON

ON

ON/OFF

ON/OFF

Original

width

sensor 2

OFF

OFF

OFF

OFF

OFF

ON

ON

ON/OFF

ON/OFF

Original

width

sensor 3

OFF

OFF

ON

ON

ON

ON/OFF

ON/OFF

ON/OFF

ON/OFF

Original

width

sensor 3

OFF

OFF

ON

ON

ON

ON/OFF

ON/OFF

ON/OFF

ON/OFF

Tray

sensor

ON/OFF

ON/OFF

ON/OFF

OFF

ON

ON/OFF

ON/OFF

ON/OFF

ON/OFF

Tray

sensor

ON/OFF

ON/OFF

ON/OFF

OFF

ON

ON/OFF

ON/OFF

ON/OFF

ON/OFF

Original length

sensor

OFF

ON

OFF

ON

ON

OFF

ON

OFF

ON

Original length

sensor

OFF

ON

OFF

ON

ON

OFF

ON

OFF

ON

Original size

data

(Widthwise

direction)

148

182

297

210

210

257

257

297

297

Original size

data

(Widthwise

direction)

140

280

216

216

216

280

258

280

280

Original size

data

(Feeding

direction)

210

257

210

297

330

182

364

210

420

Original size

data

(Feeding

direction)

216

432

216

280

356

216

356

216

432

Original

size

detected

A5R

B5R

A4

A4R

FOLIO

B5

B4

A4

A3

(mm)

Original

size

detected

STR

LD

8.5 × 8.5

LTR

LG

LT

COMPUTER

LT

LD

October 2000 © TOSHIBA TEC MR-3011/3012 SIZE DETECTION

7-3

Page 44

7.3 Method of Original Size Detection (for Mixed Sized Original)

1) Width

Width is detected by original width sensors 1,2 and 3 and the size data are saved when an original waiting

at the pre-feeding position has started to be fed and its leading edge reaches the first small roller of the read

roller.

2) Size along the feeding direction

With original whose width is any of 210mm/216mm, if the original length sensor has already detected the

original when the read sensor detects the leading edge of the original, reverse operation is performed to

determine the size along the feeding direction. The read motor counts the pulse of the distance pulses till the

original length sensor detects the trailing edge of the original. Original size is determined by the result of

counting and threshold of size along the feeding direction, then size data are sent to the copier. At this time,

data of the size along the feeding direction are sent first.

The size along the feeding direction of B5-R or smaller originals is determined as with other standard sized

originals. (reverse operation is performed after the size is determined.)

1) Timing to determine the width

2) Timing to determine the size along the feeding direction

October 2000 © TOSHIBA TEC MR-3011/3012 SIZE DETECTION

7-4

Page 45

7.4 Relation between Status of Sensor and Original Size (for Mixed Sized Originals)

[For JE]

Original

width

sensor 1

OFF

OFF

[For UC]

Original

width

sensor 1

OFF

OFF

Original

width

sensor 2

OFF

Threshould of size along feeding direction

OFF

Original

width

sensor 2

OFF

OFF

Original

width

sensor 3

ON

ON

Original

width

sensor 3

ON

Threshould size of feeding direction

ON

Tray

sensor

OFF

ON

Tray

sensor

OFF

ON

Original

length

sensor

ON

ON

Original

length

sensor

ON

ON

Original size

data

(Widthwise

direction)

210

210

Original size

data

(Widthwise

direction)

216

216

Original size

data

(Feeding

direction)

297

313.5

330

Original size

data

(Feeding

direction)

280

318

356

Original

detected

FOLIO

Original

detected

(mm)

size

A4R

(mm)

size

LTR

LG

October 2000 © TOSHIBA TEC MR-3011/3012 SIZE DETECTION

7-5

Page 46

8. FLOW CHART

8.1 Power ON

Standby

nn

n Completion of Discharge for Last Original Carried Out

nn

Power ON

Cover opened?

NO

All sensors OFF?

YES

Initialization

started

YES

NO

Jam

Initialization

completed?

YES

Empty sensor

ON?

YES

Feed signal

“H” level?

YES

A

(Feeding Operation)

NO

NO

NO

Standby

October 2000 © TOSHIBA TEC MR-3011/3012 FLOW CHART

8-1

Page 47

A

NO

Jam

E

Original

is on tray?

YES

Separation

started

Separation

completed?

YES

Ready for

feeding?

YES

Feeding

operation started

NO

NO

Mixed

original signal

“H” level?

YES

D

Switchback

possible?

YES

Switchback

started?

Switchback

completed?

YES

NO

NO

NO

Transport

signal

“H” level?

YES

Duplex

mode signal

“H” level?

NO

NO

YES

C

B

Feeding

operation

completed?

YES

October 2000 © TOSHIBA TEC MR-3011/3012 FLOW CHART

NO

8-2

(Scanning

one side

of original)

(Scanning

two sides of

original)

Page 48

B

Scanning of one

side started

Next original

is on tray?

YES

Ready for

separation?

YES

D

(Separation)

NO

Scanning

completed?

YES

Last original

carried out?

YES

Standby

NONO

NO

October 2000 © TOSHIBA TEC MR-3011/3012 FLOW CHART

8-3

Page 49

C

Scanning of

front side of

original started

Next original

is on tray?

YES

Ready for

separation?

YES

Separation

started

Separation

completed?

YES

NO

NO

NO

Reverse feeding

started

Reverse

feeding completed?

YES

Transport signal

“H” level?

YES

Scanning of back

side of original

started

Back side scanning

completed?

YES

NO

NO

NO

Reverse discharge

Scanning of

front side

completed?

YES

Registration for

back side of

original started

Back side

registration

completed?

YES

October 2000 © TOSHIBA TEC MR-3011/3012 FLOW CHART

NO

NO

8-4

started

Is there

a separated

original ?

YES

E

(Feeding operation)

NO

Last original

finished

YES

Standby

NO

Page 50

8.2 Initialization Control

Initialization

control

Registration

sensor ON?

NO

Original length

sensor ON?

NO

Original

width sensor

ON?

NO

Feed motor

reverse rotation

Feed motor rotates

for a certain

number of pulses

YES

YES

YES

Reverse sensor

ON?

NO

Reverse motor

reverse rotation

Read sensor

ON?

NO

Exit sensor

ON?

NO

Read motor

forward rotation

YES

YES

YES

All sensors

OFF?

YES

Initialization

control

completed

NO

Jam

Feed motor

braked

Certain period

of time

Feed motor

stopped

Certain period

of time

Read motor

rotates for a certain

number of pulses

Read motor

stopped

Reverse motor

rotates for a certain

number of pulses

Reverse motor

stopped

October 2000 © TOSHIBA TEC MR-3011/3012 FLOW CHART

8-5

Page 51

8.3 Control for Operation of Pickup Roller

Control

Empty sensor

ON?

YES

Feed motor

forward rotation

Feed motor rotates

for a certain

number of pulses

Feed motor

braked

NO

Certain period

of time

Feed motor

stopped

Control for pickup

roller operation

completed

October 2000 © TOSHIBA TEC MR-3011/3012 FLOW CHART

8-6

Page 52

8.4 Control for Feeding Operation

Feeding operation

control

Feed motor

stopped?

YES

Feed motor

reverse rotation

First page?

YES

Read motor

forward rotation

Feed motor

rotates for a certain

number of pulses

NO

NO

Original length

sensor OFF?

YES

Feed motor

braked

Certain period

of time

Feed motor

stopped

Pickup roller

lowered

NO

Feed motor

braked

Certain period

of time

Feed motor

reverse rotation

October 2000 © TOSHIBA TEC MR-3011/3012 FLOW CHART

8-7

Read sensor

ON?

YES

Read motor

rotates for a certain

number of pulses

Read motor

stopped

Control for feeding

operation completed

NO

Page 53

8.5 Control for Separation

Control for

separation

Feed motor

stopped?

YES

Feed motor

forward rotation

Registration

sensor ON?

YES

Feed motor rotates

for a certain

number of pulses

NO

NO

Feed motor

braked

Certain period

of time

Feed motor

stopped

Control separation

completed

October 2000 © TOSHIBA TEC MR-3011/3012 FLOW CHART

8-8

Page 54

8.6 Control for Switchback Operation

Switchback

control

Read motor

forward rotation

Original length

sensor OFF?

YES

Read motor rotates

for a certain

number of pulse

Read motor

stopped

Certain period

of time

NO

Read motor

stopped

Read motor

forward rotation

Read sensor

ON?

YES

Read motor rotates

for a certain

number of pulse

Read motor

stopped

NO

Read motor

reverse rotation

Read sensor

OFF?

YES

Read motor

rotates for a certain

number of pulse

October 2000 © TOSHIBA TEC MR-3011/3012 FLOW CHART

NO

8-9

Control for

switchback

operation completed

Page 55

8.7 Control for One Side Scanning

One side scanning

control

Read motor

forward rotation

Read motor rotates

for a certain

number of pulses

Scanning

started

Exit sensor

ON?

YES

Read sensor

OFF?

NO

NO

Exit sensor

OFF?

YES

Last original?

YES

Read motor rotates

for a certain

number of pulses

Read motor

stopped

Control for one

side scanning

completed

NO

NO

YES

Read motor rotates

for a certain

number of pulses

Scanning

completed

October 2000 © TOSHIBA TEC MR-3011/3012 FLOW CHART

8-10

Page 56

8.8 Control for Front Side Scanning

Front side

scanning control

Reverse solenoid

ON

Read motor

forward rotation

Read motor rotates

for a certain

number of pulses

Scanning

completed

Read motor rotates

for a certain

number of pulses

Scanning

started

Reverse sensor

ON?

YES

Read motor rotates

for a certain

number of pulses

NO

Reverse sensor

OFF?

YES

Read motor

stopped

Reverse motor

rotates for a certain

number of pulses

Reverse motor

stopped

Certain period

of time

NO

Reverse motor

forward rotation?

Control for

front side

scanning completed

Read sensor

OFF?

YES

October 2000 © TOSHIBA TEC MR-3011/3012 FLOW CHART

NO

8-11

Page 57

8.9 Control for Reverse Feeding

Reverse

feeding control

Read motor

forward rotation

Reverse motor

reverse rotation

Read sensor

ON?

YES

Read motor and

reverse motor

rotate for a certain

number of pulses

Read motor

and reverse

motor stopped

Control for

reverse

feeding completed

NO

October 2000 © TOSHIBA TEC MR-3011/3012 FLOW CHART

8-12

Page 58

8.10 Control for Back Side Registration

Back side

registration command

Reverse motor

reverse rotation

Reverse sensor

ON?

YES

Reverse motor

rotates for a certain

number of pulses

Reverse motor

stopped

Certain period

of time

NO

Control for back side

registration completed

October 2000 © TOSHIBA TEC MR-3011/3012 FLOW CHART

8-13

Page 59

8.11 Control for Back Side Scanning

Control for

back side scanning

Read motor

foward rotation

Reverse motor

reverse rotation

Read motor

rotates for a certain

number of pulses

Scanning

started

Reverse motor

rotates for a certain

number of pulses

Reverse motor

stopped

Reverse sensor

OFF?

YES

Read motor

stopped

Reverse solenoid

OFF

Reverse motor

rotates for a certain

number of pulses

Reverse motor

stopped

Certain period

of time

NO

Reverse motor

forward rotation

Read sensor

OFF?

YES

Read motor rotates

for a certain

number of pulses

Scanning

completed

October 2000 © TOSHIBA TEC MR-3011/3012 FLOW CHART

NO

8-14

Control for

back side scanning

completed

Page 60

8.12 Control for Reverse Discharge

Control for

reverse discharge

Reverse motor

reverse rotation

Exit sensor

OFF?

NO

Read motor

forward rotation

Reverse sensor

ON?

YES

Reverse motor

rotates for a certain

number of pulses

Last original?

NO

Feeding operation

started

NO

YES

YES

NO

Last original?

YES

Read motor

rotates for a certain

number of pulses

Read motor

stopped

Control for

reverse discharge

completed

Reverse sensor

OFF?

YES

Reverse motor

stopped

October 2000 © TOSHIBA TEC MR-3011/3012 FLOW CHART

NO

8-15

Page 61

9. TIMING CHART

9.1 DP1600 Three A4 sheets single-side feeding

Exposure timeExposure time

00

4.71

0.08

2.93

0.08

4.38

0.08

2.93

0.08

4.38

0.180.181.68

0.08

0.08

0.08

0.490.08

2.970.550.55

0.74

0.17

1.73

0.49

2.94

4.39

2.23

3.69

4.74

0.21

0.21

0.24

0.24

2.930.564.382.001.460.27

4.381.971.421.971.423.41

2.530.092.530.093.991.56

3.500.720.512.101.950.37

2.65

Exposure time

H

PRE-FED

2.00

LHL

H

SCN-STR

ORG-FAC

1.58

1.581.48

1.48

0.10

0

LHL

H

DF-ACT

ORG-IN

1.58

L

H

H

ORG-STP

1.94

L

ORG-TR

October 2000 © TOSHIBA TEC MR-3011/3012 TIMING CHART

3.19

2.02

1.86

1.66

1.50

1.46

0.93

0.43

0.39

0.17

L

STOP

CW(H)

CW(L)

CCW(L)

CCW(M)

CCW(H)

FMOT

1.64

CW(H)

1.68

0.45

STOP

CW(L)

RDMOT

CW(L)

CW(H)

STOP

CCW(L)

RVMOT

CCW(H)

ON

RSOL

OFF

ON

OFF

ON

OFF

REG-SNS

LENG-SNS

ON

OFF

ON

READ-SNS

ON

OFF

EXIT-SNS

RVR-SNS

OFF

OFF

ON

EMP-SNS

9-1

Page 62

9.2 DP1600 Two A4 sheets duplex feeding

00000

2.52

Exposure timeExposure timeExposure timeExposure time

2.83

2.83

2.73

2.73

2.45

2.45

2.35

2.35

2.93

2.55

2.83

2.45

2.45

0.94

0.94

3.17

2.78

1.58

2.36

2.48

2.42

2.08

2.80

0.92 0.92

1.03

2.841.52

2.46

0.66

0.66

0.95

0.95

1.05

1.05

2.84

1.54

4.04

4.50

2.801.44

2.022.02

0.952.460.951.68

2.361.981.470.27

2.381.502.381.50

2.001.120.923.983.181.120.923.582.001.100.903.983.181.120.922.80

5.162.745.242.865.162.744.001.58

2.752.181.970.37

2.28

0.10

1.05

0.95

2.80

1.64

CW(M)

CW(H)

0.92

0.92

STOP

CW(L)

1.03

2.84

1.52

1.68

0.45

0.66

0.66

1.05

0.95

CW(L)

CW(H)

2.84

1.54

STOP

4.50

3.28

CCW(L)

2.80

1.44

CCW(M)

CCW(H)

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

0.94

2.83

2.83

2.73

1.59

1.49

H

2.93

2.83

2.73

1.69

1.59

1.49

LHL

1.94

1.59

L

L

H

H

3.16

0.94

2.19

1.94

2.00

LHL

H

1.66

1.46

1.50

0.43

0.39

0.17

L

H

CW(H)

CW(L)

STOP

CCW(L)

0.93

CCW(M)

CCW(H)

ORG-IN

DF-ACT

ORG-TR

ORG-STP

ORG-FAC

PRE-FED

SCN-STR

FMOT

October 2000 © TOSHIBA TEC MR-3011/3012 TIMING CHART

RDMOT

9-2

RVMOT

RSOL

REG-SNS

LENG-SNS

RVR-SNS

READ-SNS

EMP-SNS

EXIT-SNS

Page 63

9.3 DP2500 Three A4 sheets single-side feeding

Exposure timeExposure timeExposure time

000

3.47

0.07

3.66

0.07

3.66

0.07

3.66

0.07

3.66

0.170.171.681.58

0.07

0.07

0.07

0.36

0.07

2.17

1.78

1.78

0.52

0.14

1.09

0.34

3.68

2.12

3.63

1.61

3.47

0.12

0.12

0.14

0.14

2.143.621.931.460.27

0.41

3.231.421.061.421.062.96

1.850.041.850.043.381.56

0.540.510.372.051.890.37

1.94

0.10

H

ORG-IN

1.58

1.48

1.58

1.48

LHL

H

DF-ACT

L

H

ORG-TR

ORG-STP

1.88

L

H

PRE-FED

1.92

LHL

H

SCN-STR

ORG-FAC

3.11

2.62

2.02

1.86

1.66

1.50

1.46

0.43

0.390.17

L

STOP

CW(H)

CW(L)

CCW(M)

CCW(H)

CCW(L)

FMOT

0.93

1.64

CW(H)

CW(L)

RDMOT

1.68

0.45

STOP

CW(L)

CW(H)

STOP

CCW(L)

RVMOT

CCW(H)

ON

RSOL

OFF

ON

OFF

ON

LENG-SNS

ON

OFF

READ-SNS

REG-SNS

OFF

OFF

ON

RVR-SNS

ON

OFF

ON

EXIT-SNS

OFF

EMP-SNS

October 2000 © TOSHIBA TEC MR-3011/3012 TIMING CHART

9-3

Page 64

9.4 DP2500 Two A4 sheets duplex feeding

00000

2.34

Exposure timeExposure timeExposure timeExposure time

2.66

2.66

2.56

2.56

2.29

2.29

2.19

2.19

2.76

2.39

2.66

2.29

2.29

0.76

0.77

2.92

2.542.93

1.40

2.19

1.90

2.34

2.26

0.762.650.77

0.90

1.38 2.702.31

0.48

0.48

0.76

0.76

0.86

0.86

2.701.38

3.46

2.65 3.92

1.26

1.84