Page 1

SERVICE MANUAL

MULTIFUNCTIONAL DIGITAL SYSTEMS

e-STUDIO161

MR-2015

MY-1022

File No. SME03003100

R03112148300-TTEC

VerB1_2003-12

Page 2

© 2003 TOSHIBA TEC CORPORATION

All rights reserved

Parts marked with " " are important for maintaining the safely of the machine. Be sure to replace these

parts with the replacement parts specified to maintain the safety and performance of the machine.

This document has been published to be used for after sales service only.

The contents are subject to change without notice.

Page 3

GENERAL PRECAUTIONS REGARDING THE INSTALLATION AND

SERVICE FOR e-STUDIO161

The installation and service should be done by a qualified service technician.

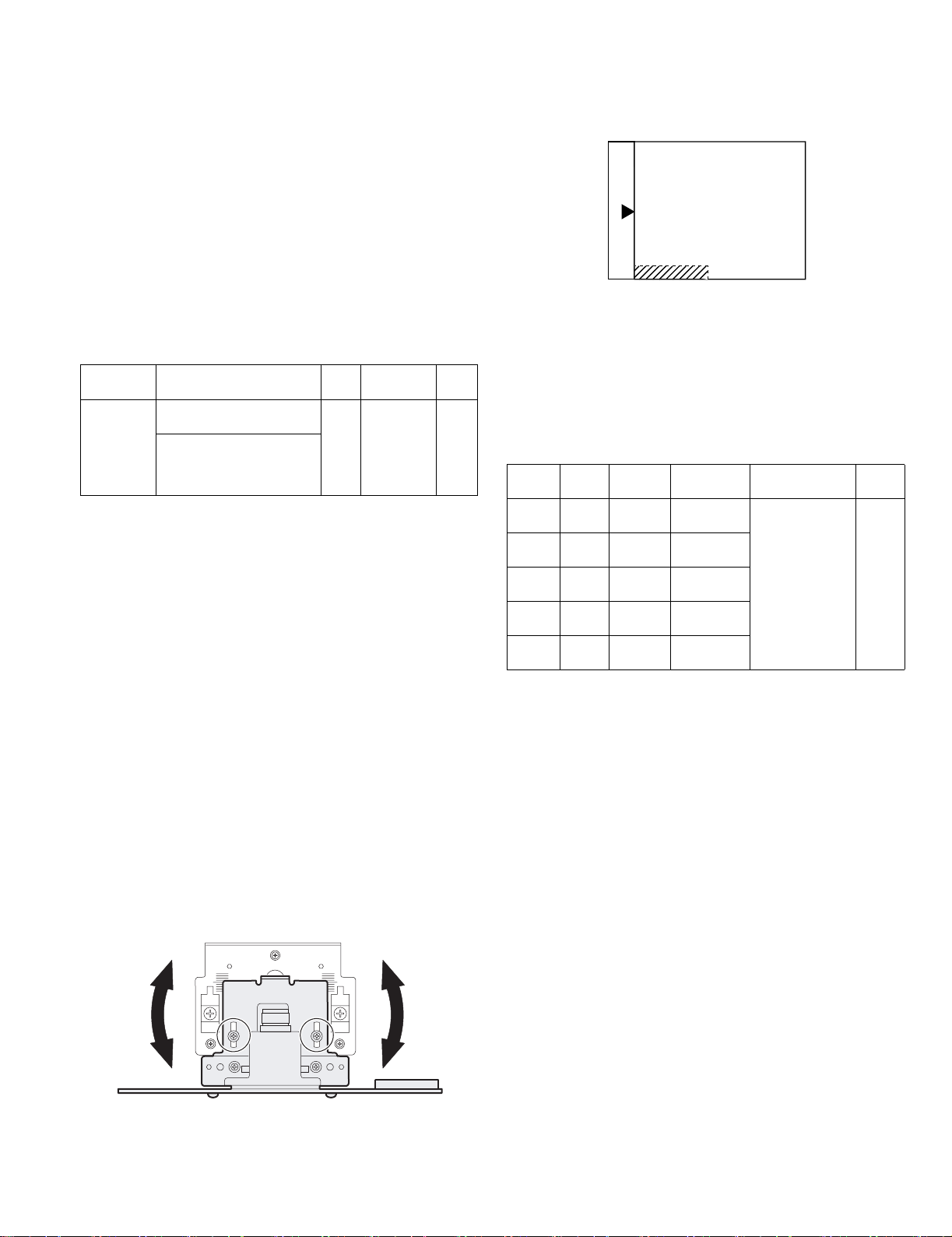

1. Transportation/Installation

• When transporting/installing the machine, employ two persons and be sure to use the positions as

indicated below.

The machine is quite heavy and weighs approximately 30kg (14.3 lb.), therefore pay full attention

when handling it.

• Be sure to use a dedicated outlet with AC 110A, 115V or 127V/10A, 220V-240V or 240V/5A) for its

power source.

• The machine must be grounded for safety.

Never ground it to a gas pipe or a water pipe.

• Select a suitable place for installation.

Avoid excessive heat, high humidity, dust, vibration and direct sunlight.

• Also provide proper ventilation as the machine emits a slight amount of ozone.

• The socket-outlet shall be installed near the machine and shall be easily accessible.

2. Service of Machines

• Basically, be sure to turn the main switch off and unplug the power cord during service.

• Be sure not to touch high-temperature sections such as the exposure lamp, the fuser unit and their

periphery.

• Be sure not to touch high-voltage sections such as the chargers and the high-voltage transformer.

Especially, the board of these components should not be touched since the electric charge may

remain in the capacitors, etc. on them even after the power is turned OFF.

• Be sure not to touch rotating/operating sections such as gears, belts, pulleys, fan, etc.

• Be careful when removing the covers since there might be the parts with very sharp edges underneath.

• When servicing the machines with the main switch turned on, be sure not to touch live sections and

rotating/operating sections. Avoid exposure to laser radiation.

• Use suitable measuring instruments and tools.

• Avoid exposure to laser radiation during servicing.

- Avoid direct exposure to the beam.

- Do not insert tools, parts, etc. that are reflective into the path of the laser beam.

- Remove all watches, rings, bracelets, etc. that are reflective.

• Unplug the power cable and clean the area around the prongs of the plug once a year or more.

A fire may occur when dust lies on this area.

Page 4

3. Main Service Parts for Safety

• The breaker, door switch, fuse, thermostat, thermofuse, thermistor, etc. are particularly important

for safety. Be sure to handle/install them properly. If these parts are shorted circuit and/or made

their functions out, they may burn down, for instance, and may result in fatal accidents. Do not allow

a short circuit to occur. Do not use the parts not recommended by Toshiba TEC Corporation.

4. Cautionary Labels

• During servicing, be sure to check the rating plate and the cautionary labels such as “Unplug the

power cord during service”, “Hot area”, “Laser warning label” etc. to see if there is any dirt on their

surface and whether they are properly stuck to the machine.

5. Disposition of Consumable Parts, Packing Materials

• Regarding the recovery and disposal of the machine, supplies, consumable parts, packing materials,

follow the relevant local regulations or rules.

6. When parts are disassembled, reassembly is basically the reverse of disassembly unless

otherwise noted in this manual or other related documents. Be careful not to reassemble

small parts such as screws, washers, pins, E-rings, star washers in the wrong places.

7. Basically, the machine should not be operated with any parts removed or disassembled.

8. Precautions Against Static Electricity

• The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband,

because the ICs on it may become damaged due to static electricity.

Caution: Before using the wristband, pull out the power cord plug of the machine and make

sure that there are no uninsulated charged objects in the vicinity.

Page 5

Page 6

CONTENTS

[1] GENERAL

1. Note for servicing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

[2] SPECIFICATIONS

1. Copy mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

[3] CONSUMABLE PARTS

1. Supply system table . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

2. Environmental conditions . . . . . . . . . . . . . . . . . . . . . . . .3-2

3. Production number identification . . . . . . . . . . . . . . . . . .3-2

[4] EXTERNAL VIEWS AND INTERNAL STRUCTURES

1. Appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

2. Internal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

3. Operation Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4. Motor, solenoid, clutch . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

5. Sensor, switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

6. PWB unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

7. Cross sectional view . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

[5] UNPACKING AND INSTALLATION

1. Installing conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

2. Removal of protective material and fixing screw . . . . . .5-1

3. Installing procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

4. Removal and storage of fixing screw . . . . . . . . . . . . . . .5-2

5. Changing a tray’s paper size setting . . . . . . . . . . . . . . .5-3

[6] ADJUSTMENTS

1. Adjustment item list . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

2. Copier adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

[7] SIMULATIONS

1. Entering the simulation mode. . . . . . . . . . . . . . . . . . . . .7-1

2. Canceling the simulation mode . . . . . . . . . . . . . . . . . . .7-1

3. List of simulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

4. Contents of simulations . . . . . . . . . . . . . . . . . . . . . . . . .7-2

[8] USER PROGRAMS

1. List of user programs . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

2. Setting the user programs. . . . . . . . . . . . . . . . . . . . . . . 8-3

3. Toner cartridge life . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

[9] TROUBLE CODE LIST

1. Trouble code list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

2. Details of trouble codes . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] MAINTENANCE

1. Maintenance table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

2. Maintenance display system. . . . . . . . . . . . . . . . . . . . . 10-2

3. Note for replacement of consumable parts . . . . . . . . . . 10-2

[11] DISASSEMBLY AND ASSEMBLY

1. High voltage section / Duplex transport section . . . . . . 11-1

2. Optical section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

3. Fusing section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

4. Paper exit section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-6

5. MCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-8

6. Optical frame unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-8

7. LSU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

8. Tray paper feed section / Paper transport section . . . . . 11-9

9. Manual multi paper feed section . . . . . . . . . . . . . . . . . . 11-11

10. Power section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-13

11. Developing section . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-14

12. Process section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-15

13. Others. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-15

[12] FLASH ROM VERSION UP PROCEDURE

1. Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

2. Download procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1

3. Installation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

[13] ELECTRICAL SECTION

1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

2. Circuit descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-2

3. Actual wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 13-5

[14] OPTION MY-1022 (250 sheets paper feed unit)

[15] OPTION MR-2015 (ADF)

Page 7

[1] GENERAL

1. Note for servicing

Pictogram

The label ( ) in the fusing area of the machine indicates the

following:

: Caution, risk of danger

: Caution, hot surface

•poorly ventilated

A. Warning for servicing

•The fusing area is hot. Exercise care in this area when removing misfed

paper.

•Do not look directly at the light source. Doing so may damage your eyes.

B. Cautions for servicing

•Do not switch the machine rapidly on and off. After turning the machine

off, wait 10 to 15 seconds before turning it back on.

•Machine power must be turned off before installing any supplies.

•Place the machine on a firm, level surface.

•Do not install the machine in a humid or dusty location.

•When the machine is not used for a long time, for example, during

prolonged holidays, turn the power switch off and remove the power

cord from the outlet.

•When moving the machine, be sure to turn the power switch off and

remove the power cord from the outlet.

•Do not cover the machine with a dust cover, cloth or plastic film while the

power is on. Doing so may prevent heat dissipation, damaging the

machine.

•Use of controls or adjustments or performance of procedures other than

those specified herein may result in hazardous laser radiation

exposure.

•The socket-outlet shall be installed near the machine and shall be easily

accessible.

•Be careful when removing the covers since there might be the parts with

very sharp edges underneath.

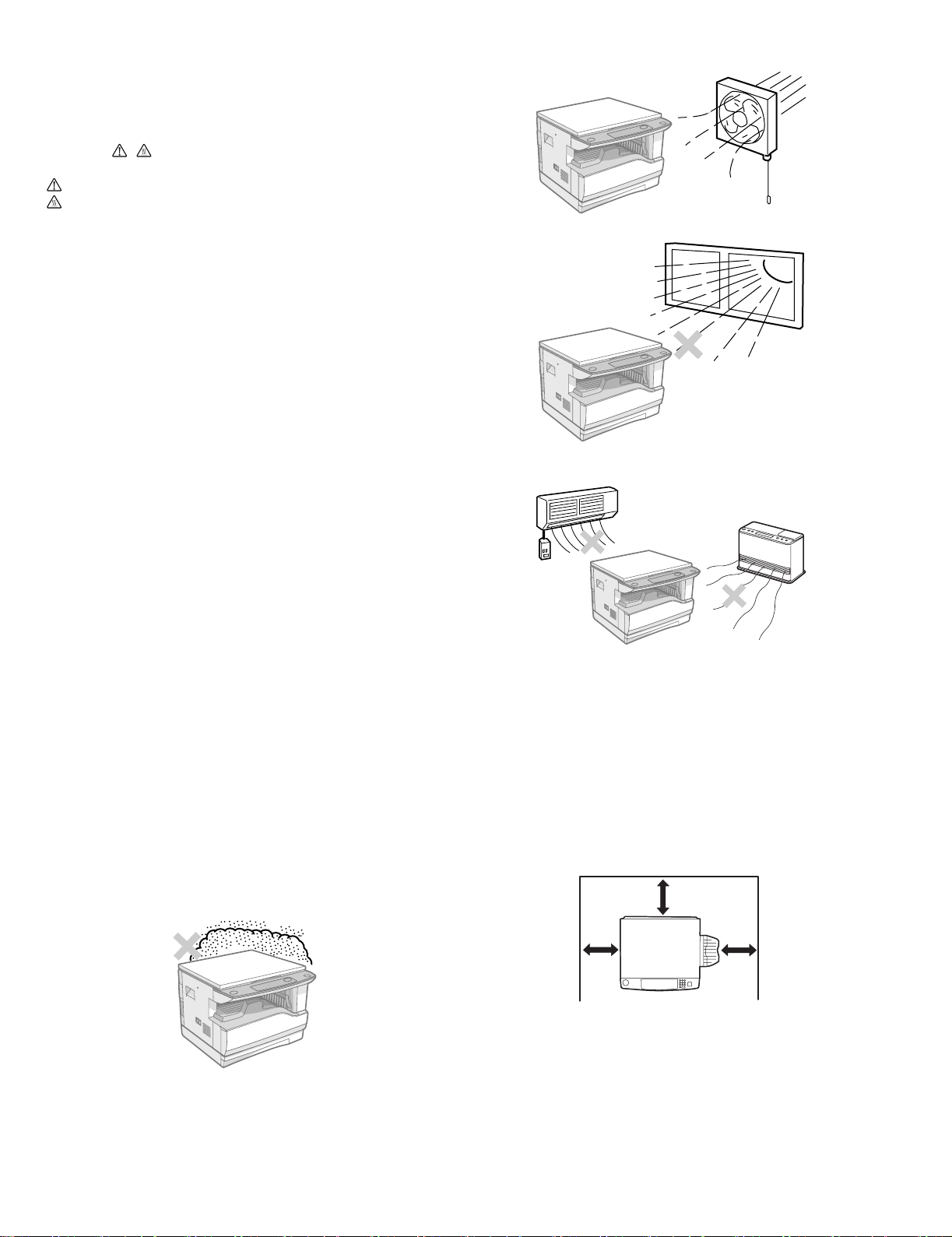

C. Note for installation place

Improper installation may damage the machine. Please note the

following during initial installation and whenever the machine is moved.

Caution : If the machine is moved from a cool place to a warm place,

condensation may form inside the machine. Operation in this

condition will cause poor copy quality and malfunctions. Leave

the machine at room temperature for at least 2 hours before

use.

Do not install your machine in areas that are:

•damp, humid, or very dusty

•exposed to direct sunlight

•subject to extreme temperature or humidity changes, e.g., near an air

conditioner or heater.

The machine should be installed near an accessible power outlet for

easy connection and disconnection.

Be sure to connect the power cord only to a power outlet that meets the

specified voltage and current requirements. Also make certain the outlet

is properly grounded.

Note : Connect the machine to a power outlet which is not used for other

electric appliances. If a lighting fixture is connected to the same

outlet, the light may flicker.

Be sure to allow the required space around the machine for servicing

and proper ventilation.

8" (20 cm)

DP-1620 GENERAL 1-1

8"

(20 cm)

8"

(20 cm)

Page 8

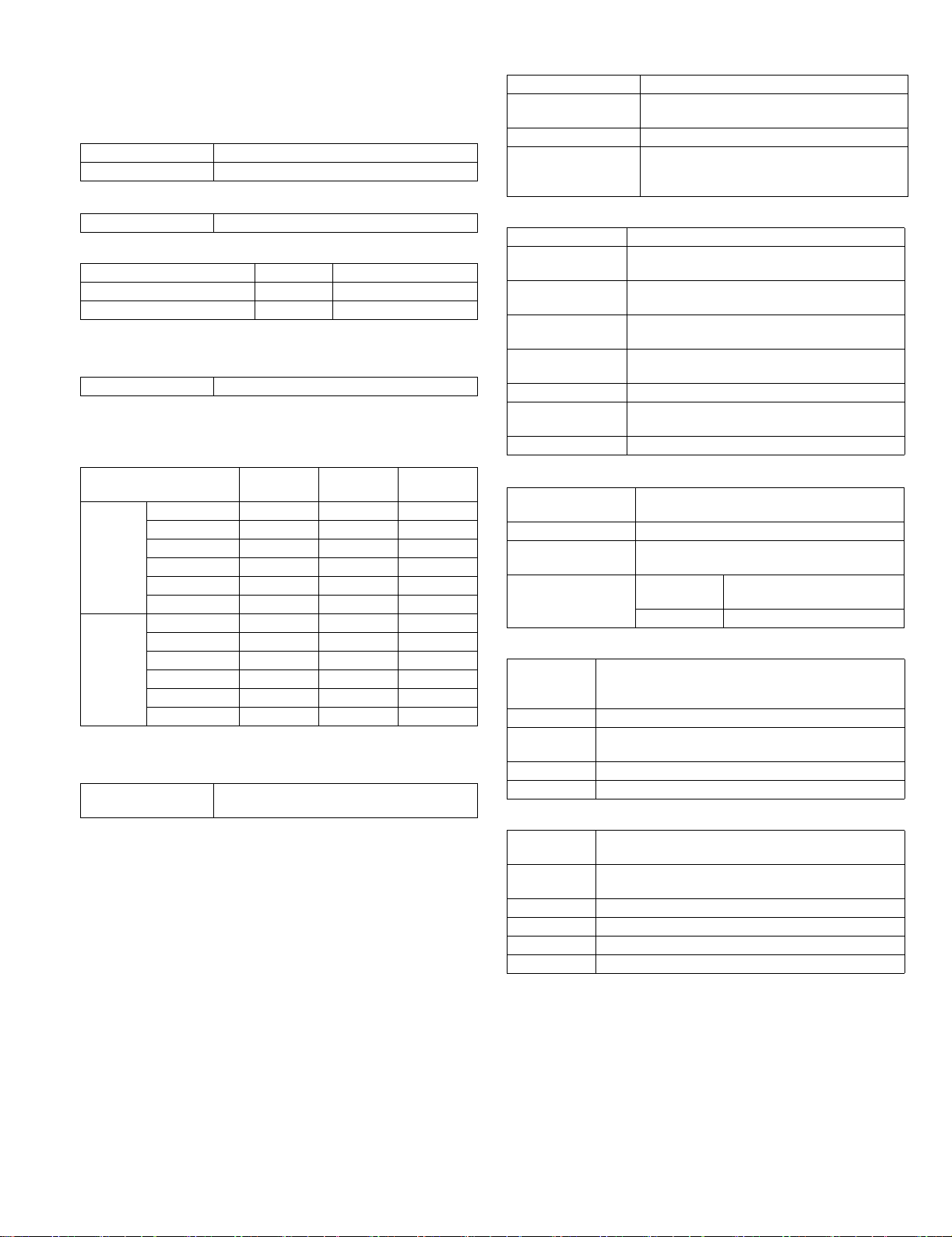

[2] SPECIFICATIONS

1. Copy mode

A. Type

Type Desk-top

Paper exit Wing less

B. Machine composition

DP-1620 16-CPM multi function model

(1) Option

Machine Model

250 sheets paper feed unit MY-1022

ADF MR-2015

C. Copy speed

(1) Scan One Print many

DP-1620 Available

Condition: Copy speed in the normal copy from all the paper feed ports

including the manual paper feed port.

(2) Continuous copy speed (Sheets/min)

Paper size Normal

A3 9 9 9

B4 10 10 10

A4 16 16 16

AB

system

Inch

system

A4R 121212

B5 16 16 16

B5R 141414

LD 9 9 9

LG 10 10 10

8.5" X 13" 11 11 11

LT 16 16 16

LT-R 12 12 12

ST 16 16 16

Enlargement

(200%)

D. First copy time

(1) Basic speed

First copy time 7.2sec (A4, 8.5" X 11"/1st tray/with OC)

(Polygon motor ready state)

Reduction

(50%)

E. Document

Max. document size A3, LD

Document reference

position

Detection (Platen) None

Detection size A3, B4, A4, A4R, B5, B5R, A5

Left side center

LD, LG, 8.5" X 13", LT, ST

(8.5" X 13" is detected by key input.)

(1) ADF

Standard/Option Option : MR-2015

Document load

capacity

Document size

(Max. ~ Min.)

Document

replacement speed

Document set/Paper

feed direction

Document weight 56 ~ 90g/m², 15 ~ 21 lbs

Document size

detection

Document mixture Not Available

40 sheets (Thickness 4mm or less)

A3 ~ A5

LD ~ LT

16 sheets/min

(A4 , 8.5" x 11" normal copy)

Face up, Center reference,

Paper feed from the top

On the document feed tray

F. Pa pe r f ee d

Copy size

(Max. ~ Min.)

Paper feed system 1 cassette + Multi manual paper feed

Paper feed capacity 250 x 1 (Paper feed tray)

Remaining quantity

detection

(1) Paper feed section of the copier

Paper feed

size

Side front Front

Paper feed

capacity

Weight 56 ~ 90g/m² (15 lbs. ~ 21 lbs.)

Special paper Recycled paper

(2) Manual paper feed section

Paper feed

size

Paper feed

capacity

Detection Size detection not available

Weight 56 ~ 200g/m² (15 ~ 34 lbs.)

Special paper Recycled paper, OHP film, labels

Paper feed Single except for recycled paper

A3 ~ A5, Post card

LD ~ LT

+ 100 (Multi bypass feed tray)

Cassette

section

Manual tray Only empty detection available

A3, B4, A4, A4R, B5, B5R, A5, 16K, 16KR, 8K

LD, LG, 8.5" x 13", LT, ST,

(For A5 and LT, only No. 1 tray available.)

250 sheets

(56 ~ 90g/m² equivalent) (15 ~ 21 lbs.)

A3 ~ A6, Post card, LD ~ LT

100 sheets(56 ~ 80g/m²)

Only empty detection available

DP-1620 SPECIFICATIONS 2-1

Page 9

(3) Option paper feed unit

1-step paper feed unit

Model MY-1022

Paper feed size A3, B4, A4, A4R, B5, B5R

Capacity

(56 ~ 80gm²)

Paper weight 56 ~ 90 g/m² (15 ~ 21 lbs.)

Moisture preserving

heater

Paper empty detection Available

Paper size setting User setting

External dimensions

(W x D x H)

Weight About 4.7kg

Special paper Recycled paper

Power Supplied from the machine

Condition:With SPF/RSPF A4/Letter Normal 1cassette

LD, LG, 8.5" x 13", LT, ST

About 250 sheets x

1 step

None

Paper size detection:None

590 x 471 x 88mm

G. Multi copy

Max. number of multi copy 999 sheets

H. Warm-up time

Warm-up time 45 sec

Pre-heat Available

Jam recovery Within 45 sec

I. Copy magnification ratio

Fixed

magnification

ratio

Zooming 25 ~ 400%

Independent

zooming(vertical)

Independent zooming

(horizontal)

AB system:

50, 71, 82, 86, 100, 115, 122, 141, 200%

Inch system:

50, 65, 78, 95, 100, 121, 129, 141, 200%

ADF(50 ~ 200%)

Available (25 ~ 400%)

ADF(50 ~ 200%)

Available (25 ~ 400%)

ADF(50 ~ 200%)

J. Print density

Density mode Auto / Text / Photo

No. of manual

adjustment

Resolution Writing: 600 x 600dpi

Gradation Reading: 256 gradations

Toner save mode Set by the user program

5 steps (Text / Photo)

Reading: 600 (main) x 600 (sub) (PHOTO mode)

600 (main) x 300 (sub) (AE mode)

Writing: Binary

K. Void width

Void area Lead edge 1 ~ 4mm,

Image loss 4mm or less

rear edge 4mm or less,

both sides 4mm or less

L. Paper exit / finishing

Paper exit section capacity Face down 250 sheets

Full detection None

Finishing None

M. Additional functions

APS O

AMS O

Auto tray switching O

Memory copy O

Independent

zooming

1 set 2 copy O Enlargement invalid/ADF invalid

Black/white

reverse

Preheating O The conditions are set by the user

Auto shut-off O The conditions are set by the user

User programming O

Total counter O Supports Total counter, Scan counter, and

Coin vendor

support

Auditor support X

Toner save O

Department

management

O : Available X : Not available

O

(Patent rotation)

X

program.

program.

Copy counter.

X

O (Copy: 20 Dept.)

N. Other specifications

Photoconductor type OPC (Organic Photo Conductor)

Photoconductor drum dia. 30mm

Copy lamp Cold cathode fluorescent lamp (CCFL)

Developing system Dry 2-component magnetic brush

development

Charging system Saw teeth charging

Transfer system (+) DC corotron

Separation system (-) DC corotron

Fusing system Heat roller

Process speed 88mm/s

O. Package form

Body Body / Accessories

P. External view

External dimensions

(W x D x H)

Occupying area

(W x D)

Weight About 31.3kg

590 x 577 x 470 mm

590 x 531mm

(When the manual tray is installed.)

Q. Power source

Voltage AC100V, 110V, 120V, 127V, 230(240)V

Frequency 50/60Hz common

R. Power consumption

Max. power consumption 1200W

* EnergyStar conformity

Average power consumption in

operation

Power consumption when

standby

Energy consumption efficiency Less than 25W

Less than 550W

5W(Not include option)

DP-1620 SPECIFICATIONS 2-2

Page 10

S. Digital performance

Resolution Reading 600 x 600dpi (PHOTO mode)

Writing 600 x 600dpi

Gradation Reading 256 gradations

Writing Binary

Memory 16MB

Hard disk None

600 x 300dpi (AE mode)

T. Printing function

Print speed 12ppm

Data resolution 600dpi

First print 7.2sec

Duplex print None

Paper feed system Paper feed tray and Manual paper feed tray

Support OS Windows 95/98/ME/2000/NT4.0/XP

Emulation GDI

Interface IEEE1284(ECP, Compatible)/USB1.1

PnP support Support on Windows 95/98/ME/2000/XP

Software Status monitor

DP-1620 SPECIFICATIONS 2-3

Page 11

[3] CONSUMABLE PARTS

1. Supply system table

A. USA / CANADA / Latin America

NO Name Content Life Product name Remark

1 Toner cartridge(Black) Toner

(Toner: Net Weight 537g)

Vinyl bag

2 Developer Developer

(Developer : Net Weight 400g)

3 Drum kit Drum

Drum fixing plate

B. Europe / East Europe

NO Name Content Life Product name Remark

1 Toner cartridge(Black) Toner

(Toner: Net Weight 537g)

Vinyl bag

2 Developer Developer

(Developer : Net Weight 400g)

3 Drum kit Drum

Drum fixing plate

C. Asia / Oceania / Saudi Arabia

NO Name Content Life Product name Remark

1 Toner cartridge(Black) Toner

(Toner: Net Weight 537g)

Vinyl bag

2 Developer Developer

(Developer : Net Weight 400g)

3 Drum kit Drum

Drum fixing plate

x10

160K PS-ZT-1620 Life setting by A4 6% document

x10

x10 500K PS-ZD-1620

x10

500K PS-OD-1620

x10

x10

160K PS-ZT-1620E Life setting by A4 6% document

x10

x10 500K PS-ZD-1620

x10

500K PS-OD-1620

x10

x10

160K PS-ZT-1620D Life setting by A4 6% document

x10

x10 500K PS-ZD-1620

x10

500K PS-OD-1620

x10

DP-1620 CONSUMABLE PARTS 3-1

Page 12

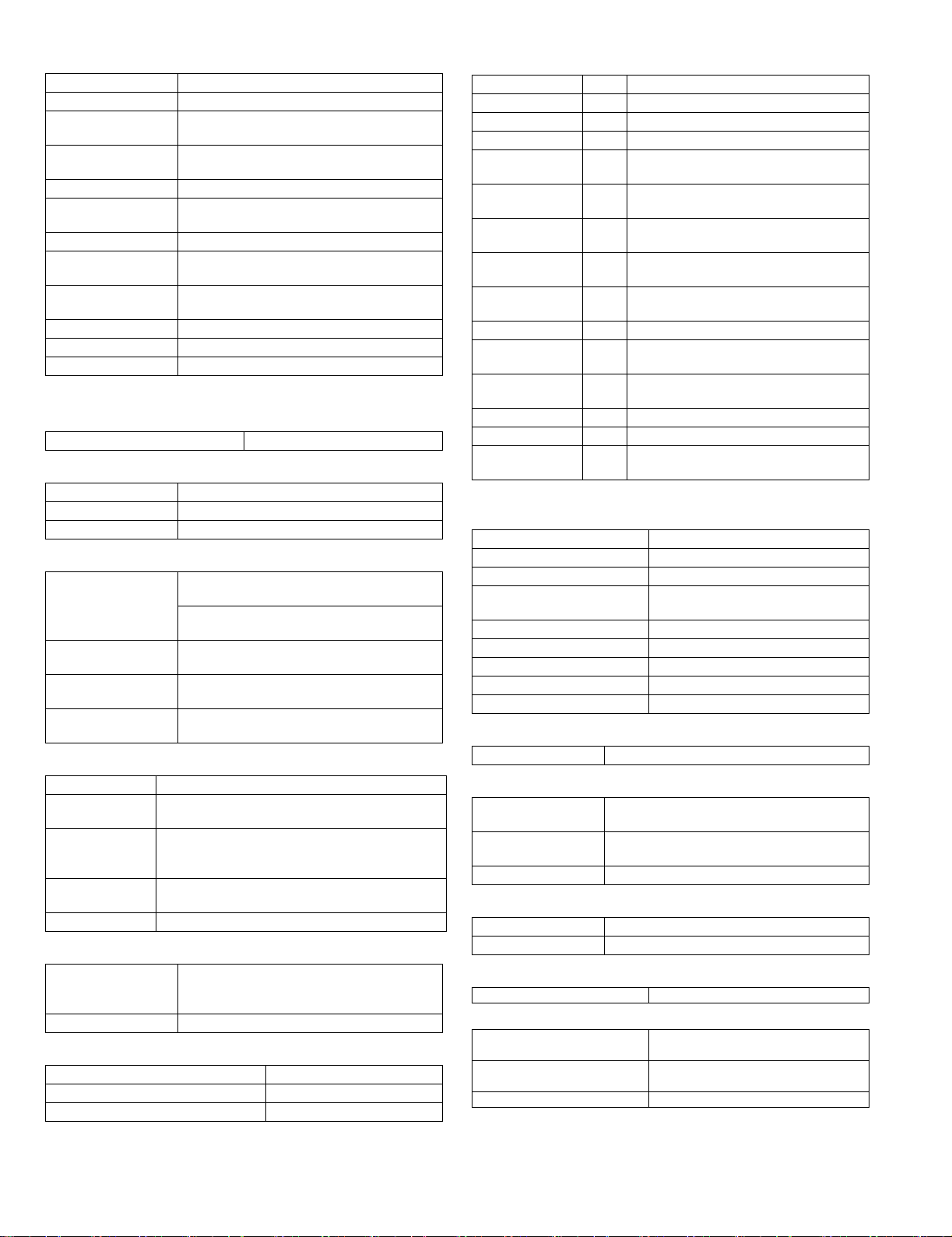

2. Environmental conditions

A. Transport conditions

(1) Transport conditions

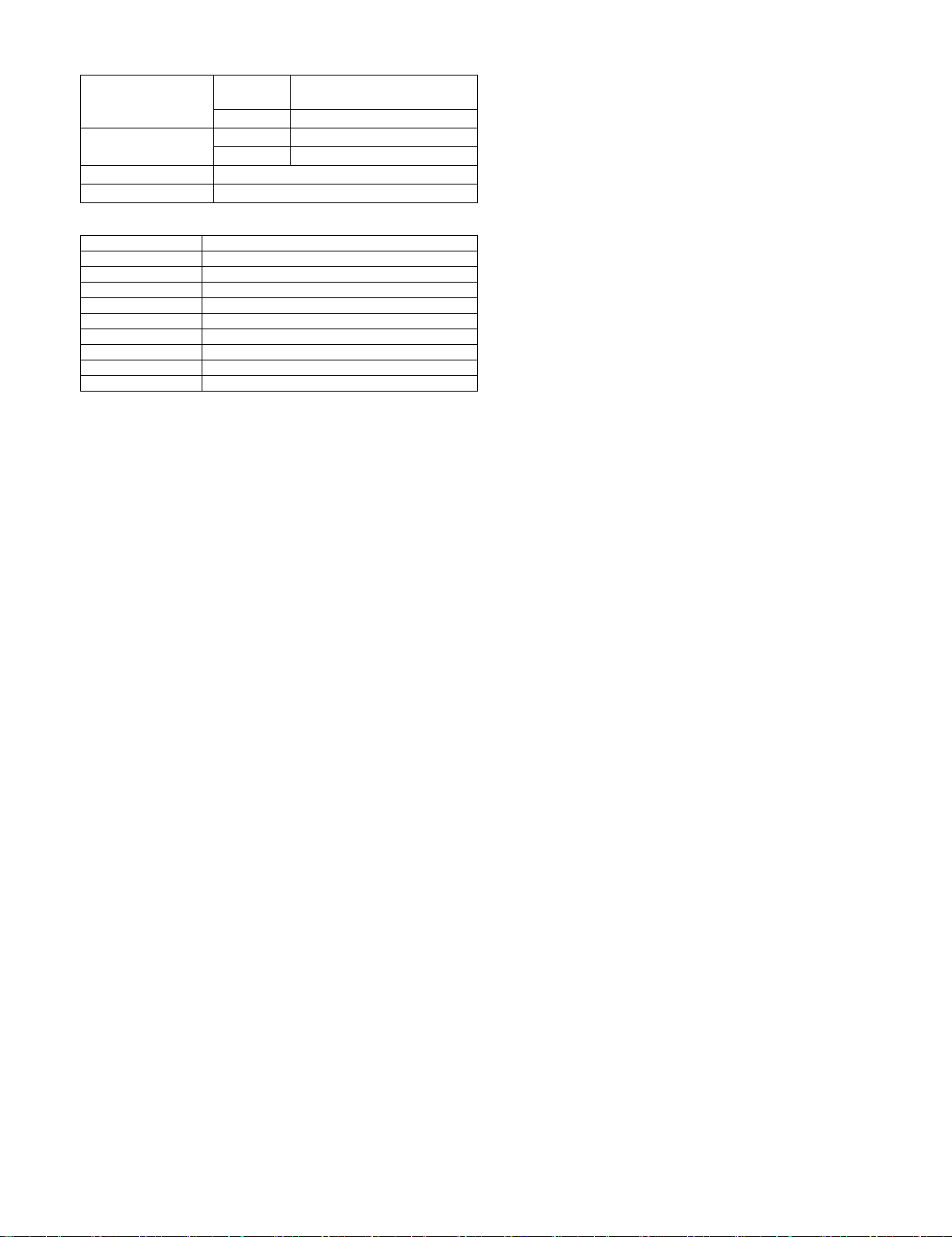

3. Production number identification

<Toner cartridge>

The label on the toner cartridge shows the date of production.

Humidity (%)

(2) Storage conditions

Humidity (%)

Temperature

Temperature

Ver.No.Production

place

Serial

number

Year/

Month/

Day

<Drum cartridge>

The lot number, printed on the front side flange, is composed of 6 digits,

each digit showing the following content:

123456

B. Use conditions

Use environment

conditions

Humidity (%)

Temperature

C. Life(packed conditions)

Photoconductor drum (36 months from the production month)

Developer, toner (24 months from the production month)

1 Alphabet

Indicates the model conformity code. A for this model.

2 Number

Indicates the end digit of the production year.

3 Number or X, Y, Z

Indicates the month of packing.

X stands for October, Y November, and Z December.

4/5 Number

Indicates the day of the month of packing.

6 Alphabet

Indicates the production factory. "A" for Nara Plant, “C“ for

SOCC

DP-1620 CONSUMABLE PARTS 3-2

Page 13

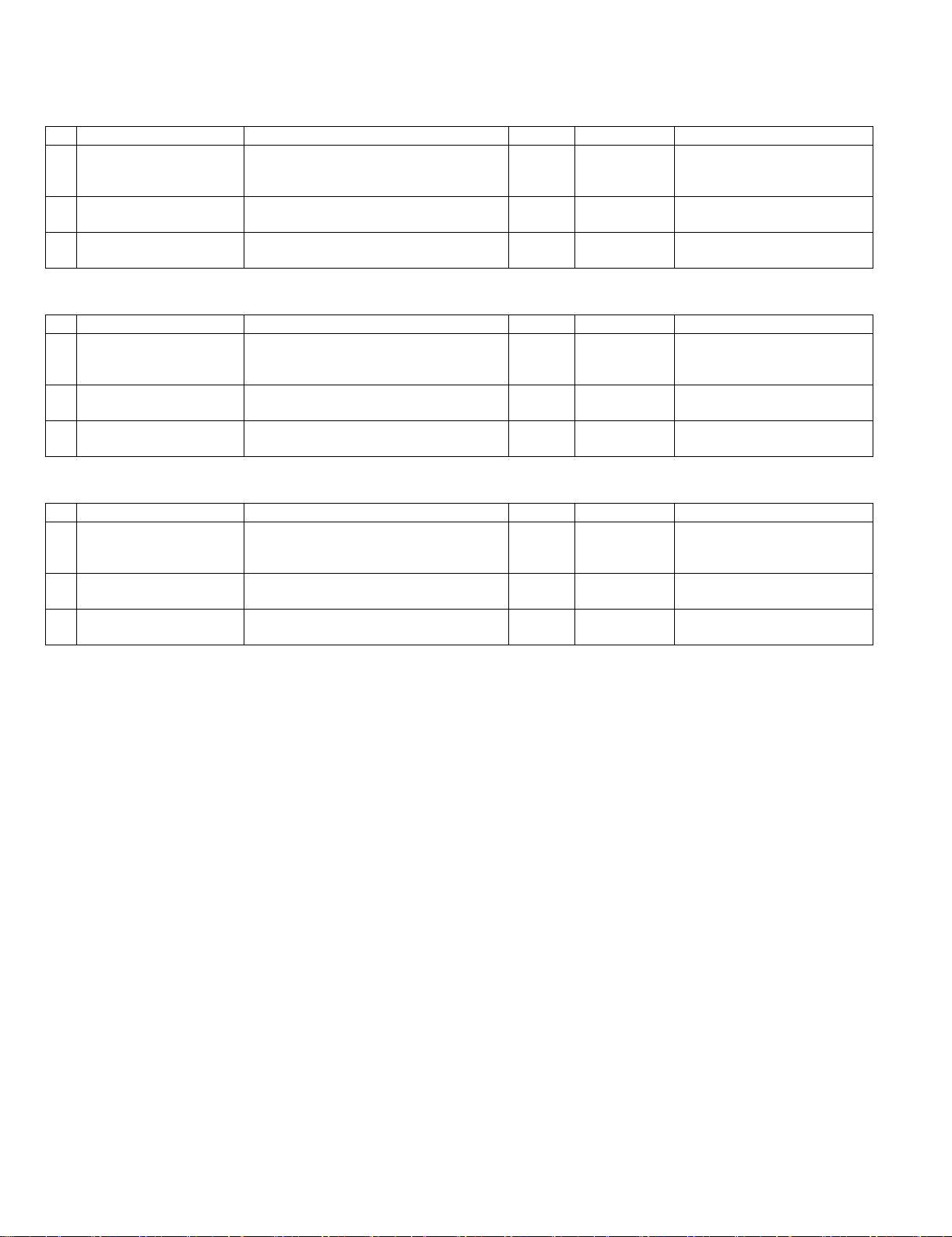

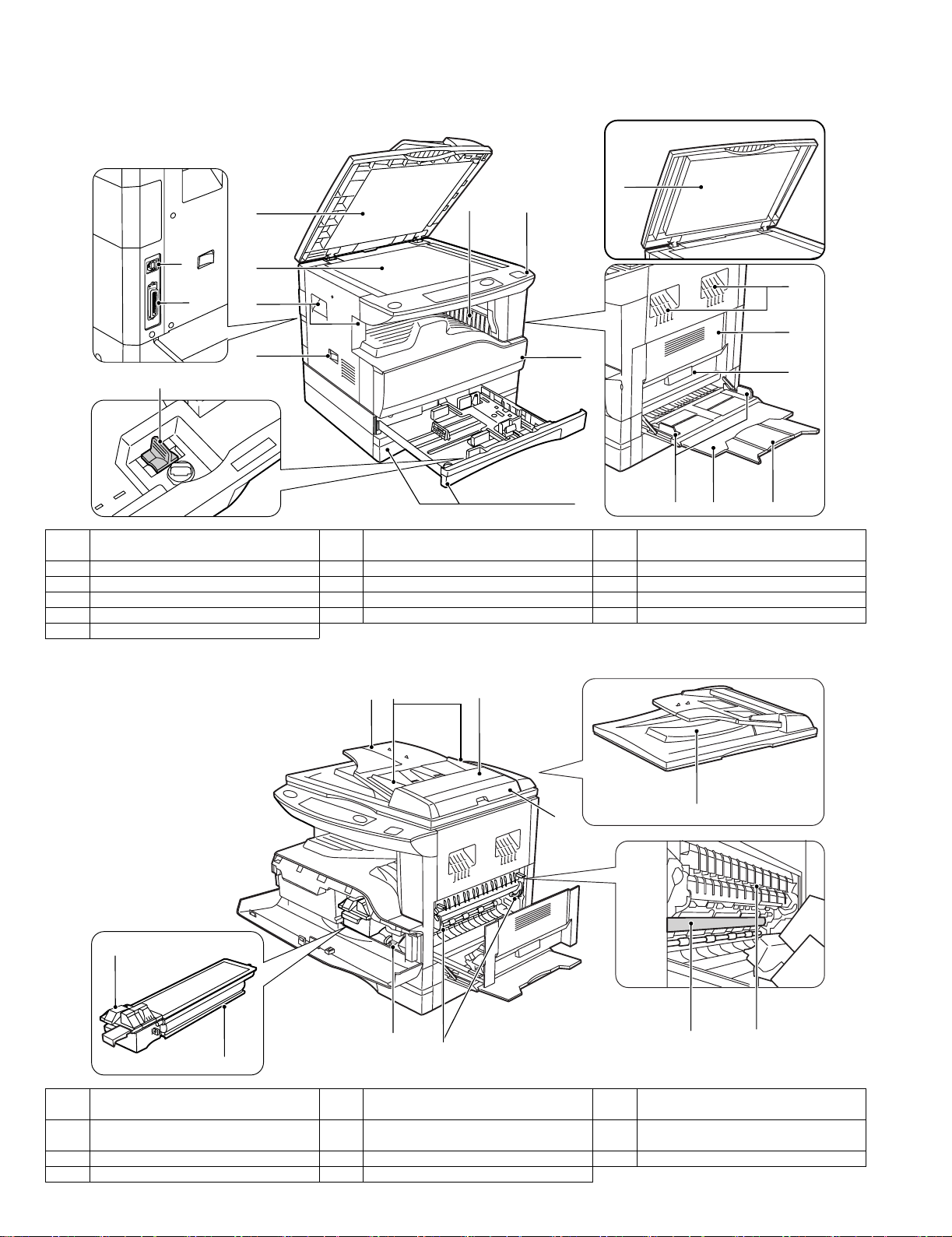

[4] EXTERNAL VIEWS AND INTERNAL STRUCTURES

1. Appearance

1

6

5

1

15

16

2

3

4

7

14

8

1 Document feeder cover (when the ADF

is installed) /document cover

4 Power switch 5 Operation panel 6 Paper output tray

7 Front cover 8 Paper trays 9 Side cover

10 Side cover handle 11 Bypass tray guides 12 Bypass tray

13 Bypass tray extension 14 Charger cleaner 15 USB 1.1 connector

16 Parallel connector

2 Document glass 3 Handles

11

2. Internal

18

1917

3

9

10

12 13

20

21

22

24

25

2726

23

17 Document feeder tray

(when the ADF is installed)

20 Right side cover

(when the ADF is installed)

23 Toner cartridge 24 Roller rotating knob 25 Fusing unit release levers

26 Photoconductive drum 27 Fusing unit paper guide

DP-1620 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-1

18 Original guides

(when the ADF is installed)

21 Exit area

(when the ADF is installed)

19 Feeding roller cover

(when the ADF is installed)

22 Toner cartridge lock release lever

Page 14

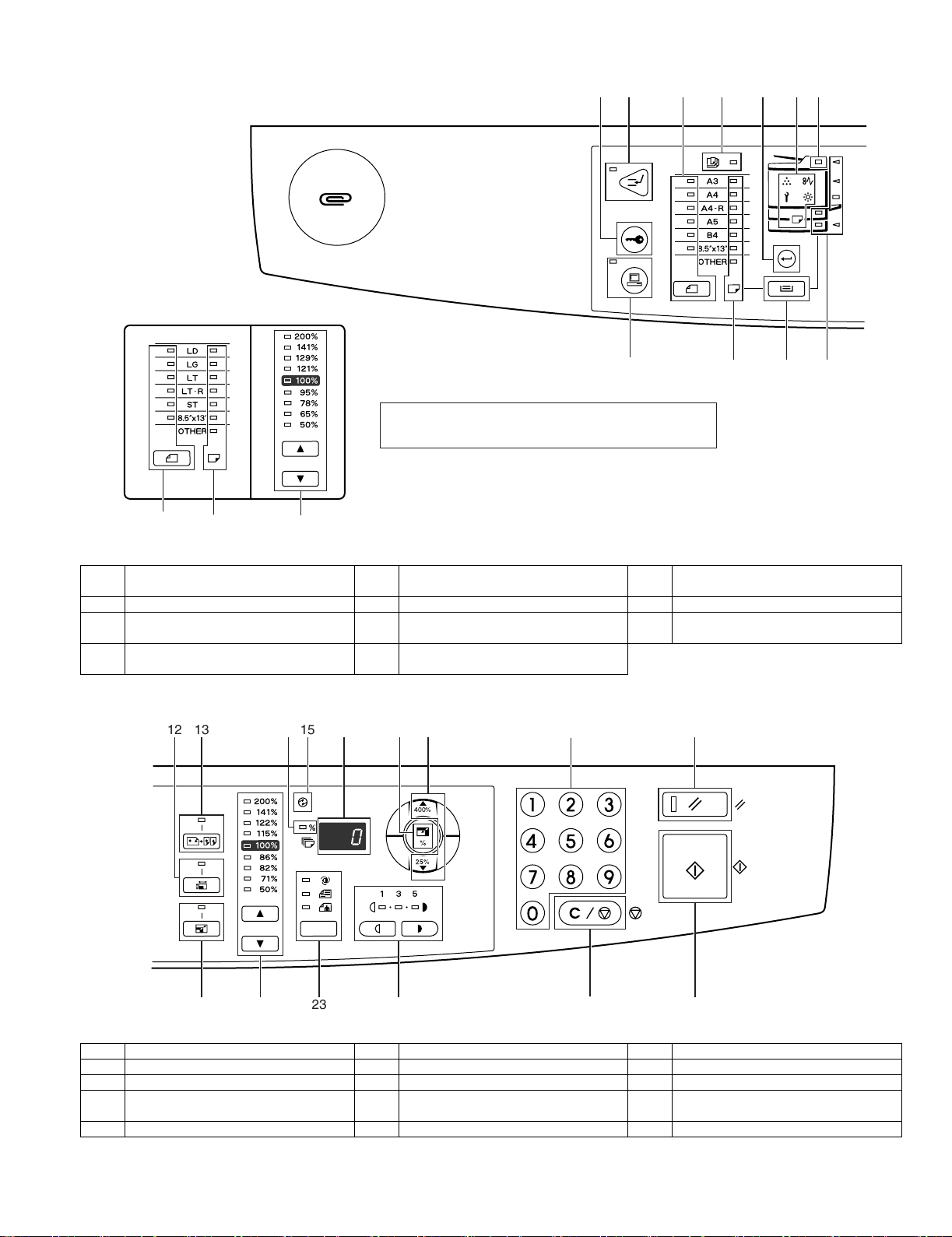

3. Operation Section

The example of a display of inch series

2

1

35

8 9 10 11

The indications of the operation panel may differ

depending on the country and the region.

6

4

7

39 22

1 AUDIT CLEAR key 2 INTERRUPT key / indicator 3 ORIGINAL SIZE ENTER key /

4 AUTO PAPER SELECT indicator 5 PAPER SIZE ENTER key 6 Alarm indicators

7ADF indicator

(when the SPF is installed)

10 TRAY SELECT key 11 Paper feed location / misfeed location

1312 15

8 ON LINE key/indicator 9 PAPER SIZE indicators

indicators

16

1714 18

"

#

19

ORIGINAL SIZE indicators

20

23

12 XY-ZOOM key/indicator 13 DUAL PAGE COPY key/indicator 14 ZOOM indicator

15 POWER SAVE indicator 16 Display 17 Copy ratio display key

18 Zoom keys 19 Numeric keys 20 RESET key

21 AUTO IMAGE key / indicator 22 PRESET RATIO selector keys /

24 Light and Dark keys / indicators 25 CLEAR STOP key 26 START key / indicator

DP-1620 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-2

2421 22

indicators

25

26

23 AUTO/TEXT/PHOTO key / indicators

Page 15

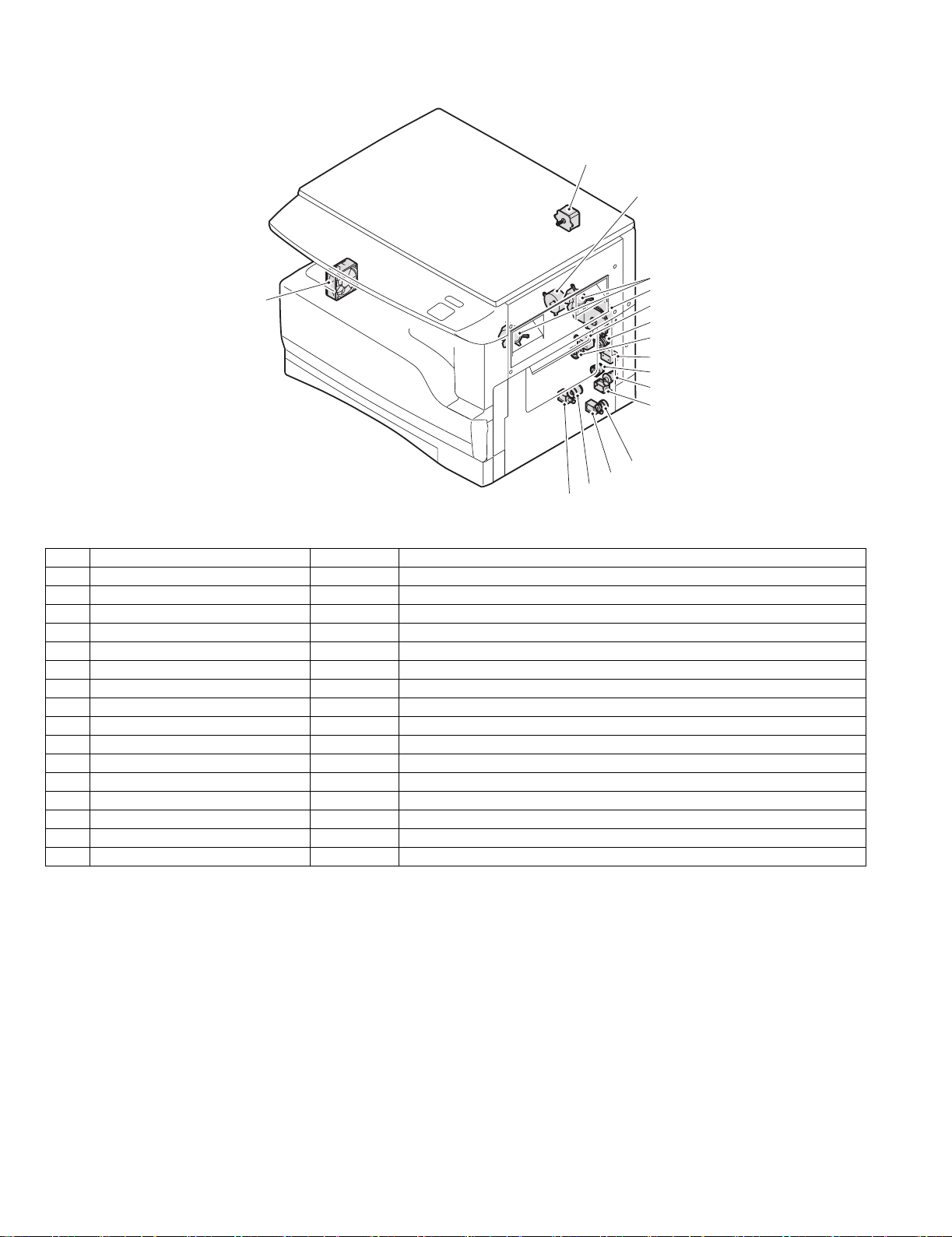

4. Motor, solenoid, clutch

16

15

1

14

13

2

3

4

5

6

7

8

9

10

11

12

No.

1 Mirror motor MRM Drives the optical mirror base (scanner unit).

2 Toner motor TM Toner supply

3 Cooling fan motor CFM Cools the inside of the machine.

4 Main motor MM Drives the machine.

5 1st tray paper feed clutch CPFC1 Drive the pick up roller

6 PS clutch RRC Drives the resist roller

7 Paper feed solenoid CPSOL1 Solenoid for paper feed from cassette

8 Resist roller solenoid RRS Resist roller rotation control solenoid

9 Manual paper transport clutch MPTC Drives the manual paper transport roller.

10 Manual paper feed clutch MPFC Drives the manual paper feed roller.

11 Manual paper feed solenoid MPFS Manual paper feed solenoid

12 2nd tray transport clutch CPFC2 Drives the 2nd tray transport roller.

13 2nd tray transport solenoid FSOL1 2nd tray transport solenoid

14 2nd tray paper feed clutch CPFC1 Drives the 2nd tray paper feed roller.

15 2nd tray paper feed solenoid PSOL2 2nd tray transport solenoid

16 Exhaust fan motor VFM Cools the inside of the machine.

Name

Code

Function operation

DP-1620 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-3

Page 16

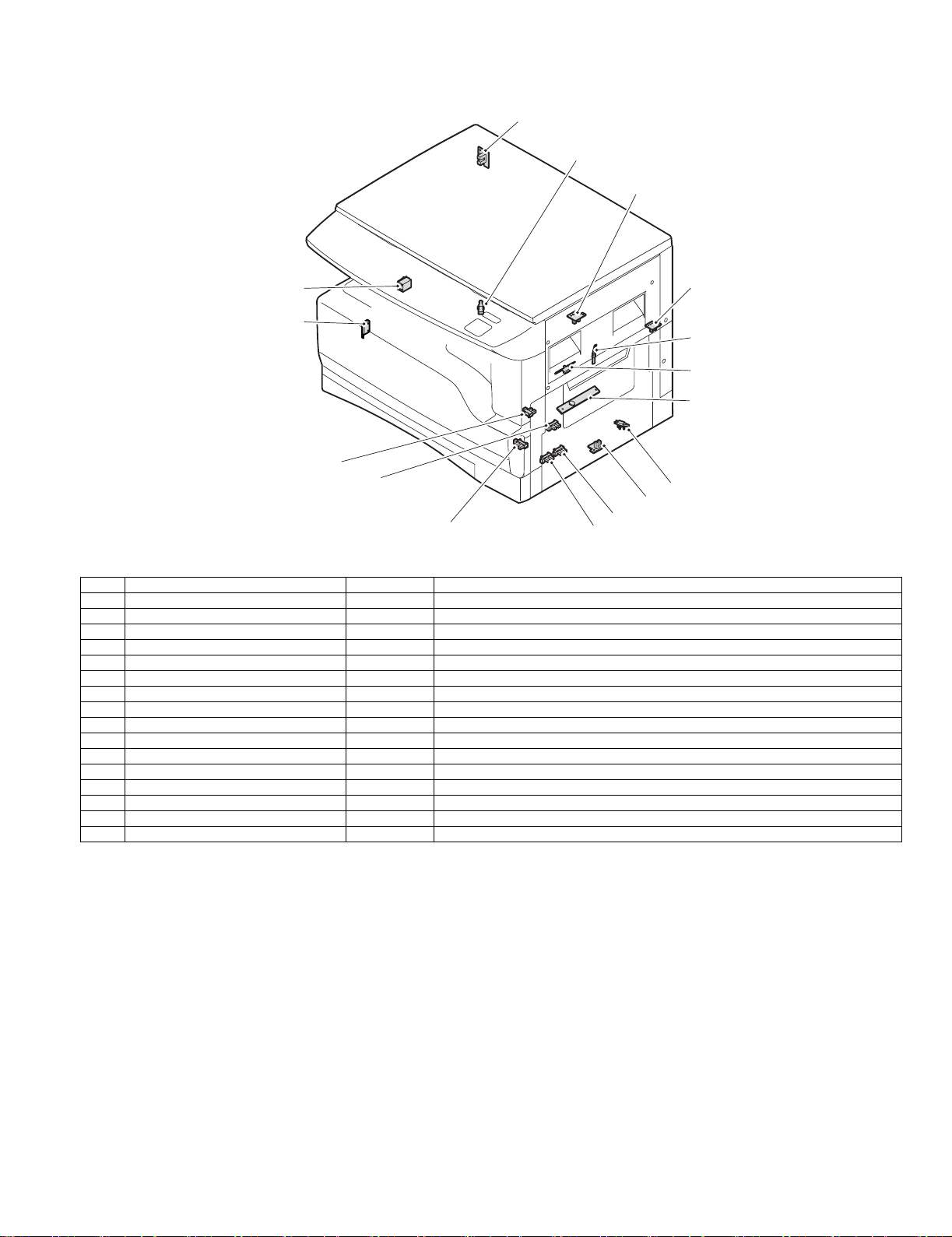

5. Sensor, switch

1

2

3

16

4

15

5

6

7

14

13

8

9

12

No. Name Code Function operation

1 Mirror home position sensor MHPS Detects the mirror (scanner unit) home position.

2 Side door switch DSWR Side door open detection

3 Paper exit sensor (paper exit side) POD1 Detects paper exit.

4 Paper exit sensor PDPX Paper transport detection

5 Thermistor RTH Fusing section temperature detection

6 Thermostat Fusing section abnormally high temperature detection

7 Toner density sensor TCS Toner quantity detection

8 2nd tray detection switch 2nd tray detection

9 Manual sensor MPED Manual transport detection

10 2nd tray door open/close sensor DRS2 2nd tray door open/close detection

11 2nd tray door paper pass sensor PPD2 2nd tray paper entry detection

12 2nd tray paper empty sensor CSS2 2nd tray paper empty detection

13 Paper in sensor PIN Paper transport detection

14 Cassette empty Tray paper entry detection

15 Front cover SW Front cover open detection

16 Power switch MAIN SW Turns ON/OFF the main power source.

10

11

DP-1620 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-4

Page 17

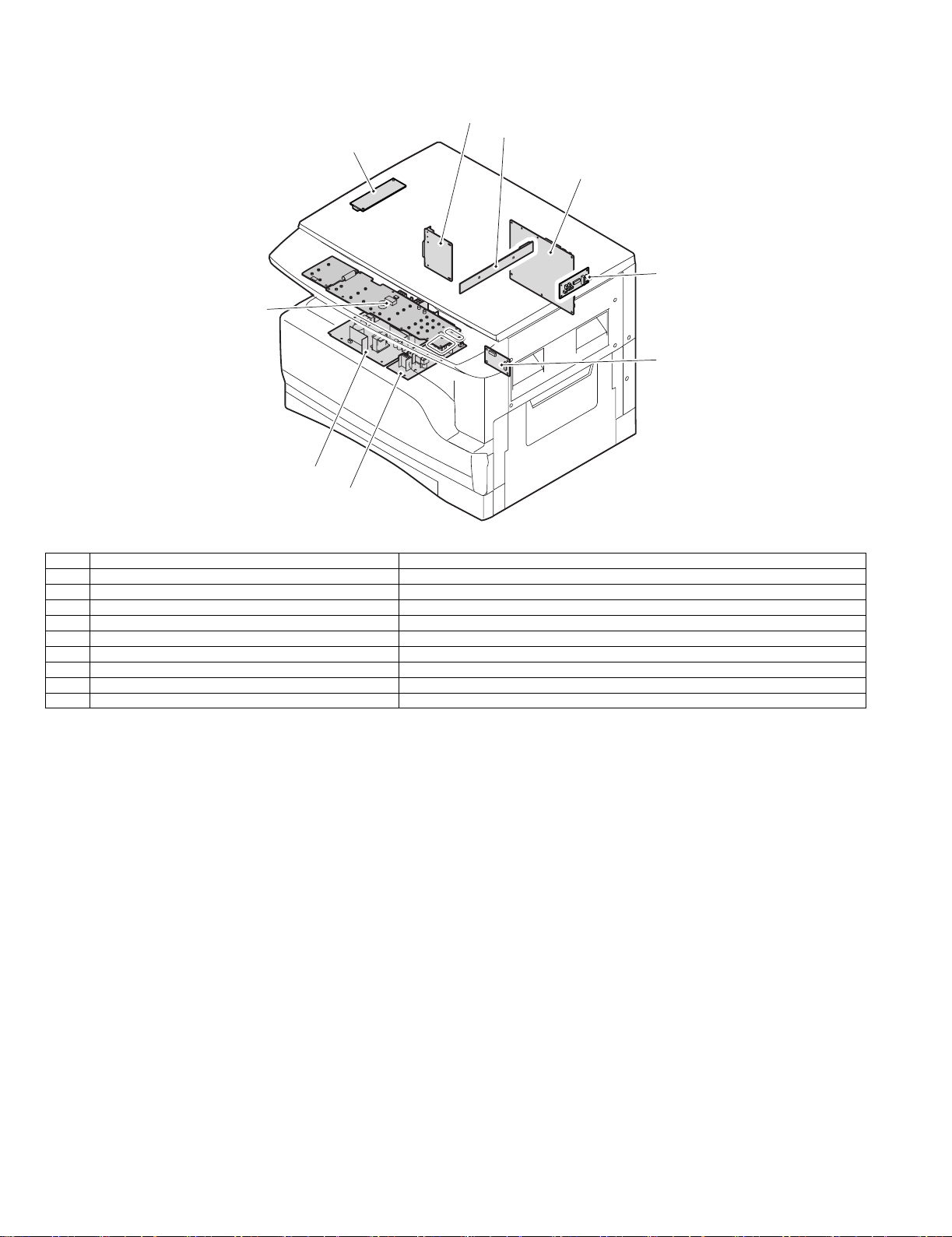

6. PWB unit

2

3

1

4

5

9

6

8

7

No. Name Function operation

1 Copy lamp Inverter PWB Copy lamp control

2 I / F PWB USB1.1, IEEE1284 I/F

3 CCD sensor PWB Image scanning

4 Main control PWB Main control PWB

5 Tray PWB Shifter motor control

6 2nd cassette PWB 2nd cassette control

7 High voltage PWB High voltage control

8 Power PWB AC power input/DC power control

9 Operation main PWB Operation panel input/Display, operation panel section control

DP-1620 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-5

Page 18

7. Cross sectional view

18

1 4

2

53

6

7

8

9

10

11

12

13

14

15

16171920212223

No. Name Function/Operation

1 Copy lamp Image radiation lamp

2 Copy lamp unit Operates in synchronization with No. 2/3 mirror unit to radiate documents

3 LSU unit Converts image signals into laser beams to write on the drum.

4 Lens unit Reads images with the lens and the CCD.

5 MC holder unit Supplies negative charges evenly on the drum.

6 Paper exit roller Used to discharge paper.

7 Transport roller Used to transport paper.

8 Upper heat roller Fuses toner on paper (with the teflon roller).

9 Lower heat roller Fuses toner on paper (with the silicon rubber roller).

10 Waste toner transport roller Transports waste toner to the waste toner box.

11 Drum unit Forms images.

12 Transfer charger unit Transfer images (on the drum) onto paper.

13 DUP follower roller

14 Duplex transport roller Transports paper for duplex .

15 Resist roller Takes synchronization between the paper lead edge and the image lead edge.

16 Manual paper feed tray Manual paper feed tray

17 Manual paper pick up roller Picks up paper in manual paper feed.

18 No. 2/3 mirror unit Reflects the images from the copy lamp unit to the lens unit.

19 Manual transport roller Transports paper from the manual paper feed port.

20 2nd tray paper transport roller Transports paper from the 2nd tray.

21 2nd tray paper pick up roller

(semi-circular roller)

22 1st tray paper feed roller

(semi-circular roller)

23 MG roller Puts toner on the OPC drum.

sequentially.

Picks up paper from the 2nd tray.

Picks up paper from the 1st tray.

DP-1620 EXTERNAL VIEWS AND INTERNAL STRUCTURES 4-6

Page 19

[5]UNPACKING AND INSTALLATION

1.Installing conditions

A.Copier installation

Do not install your copier in areas that are:

•damp, humid, or very dusty

•exposed to direct sunlight

•poorly ventilated

•subject to extreme temperature or humidity changes, e.g., near an air

conditioner or heater.

•Be sure to allow the required space around the machine for servicing

and proper ventilation.

B.Power source

•Use an exclusive-use power outlet. If the power plug of this machine is

inserted into a power outlet commonly used with other illumination

units, flickers of the lamp may be result. Use a power outlet which is not

used commonly with any illumination units.

•Avoid complex wiring.

C.Grounding wire connection.

•To avoid danger, be sure to connect a grounding wire. If no grounding

wire is connected and a leakage occurs, a fire or an electric shock may

be result.

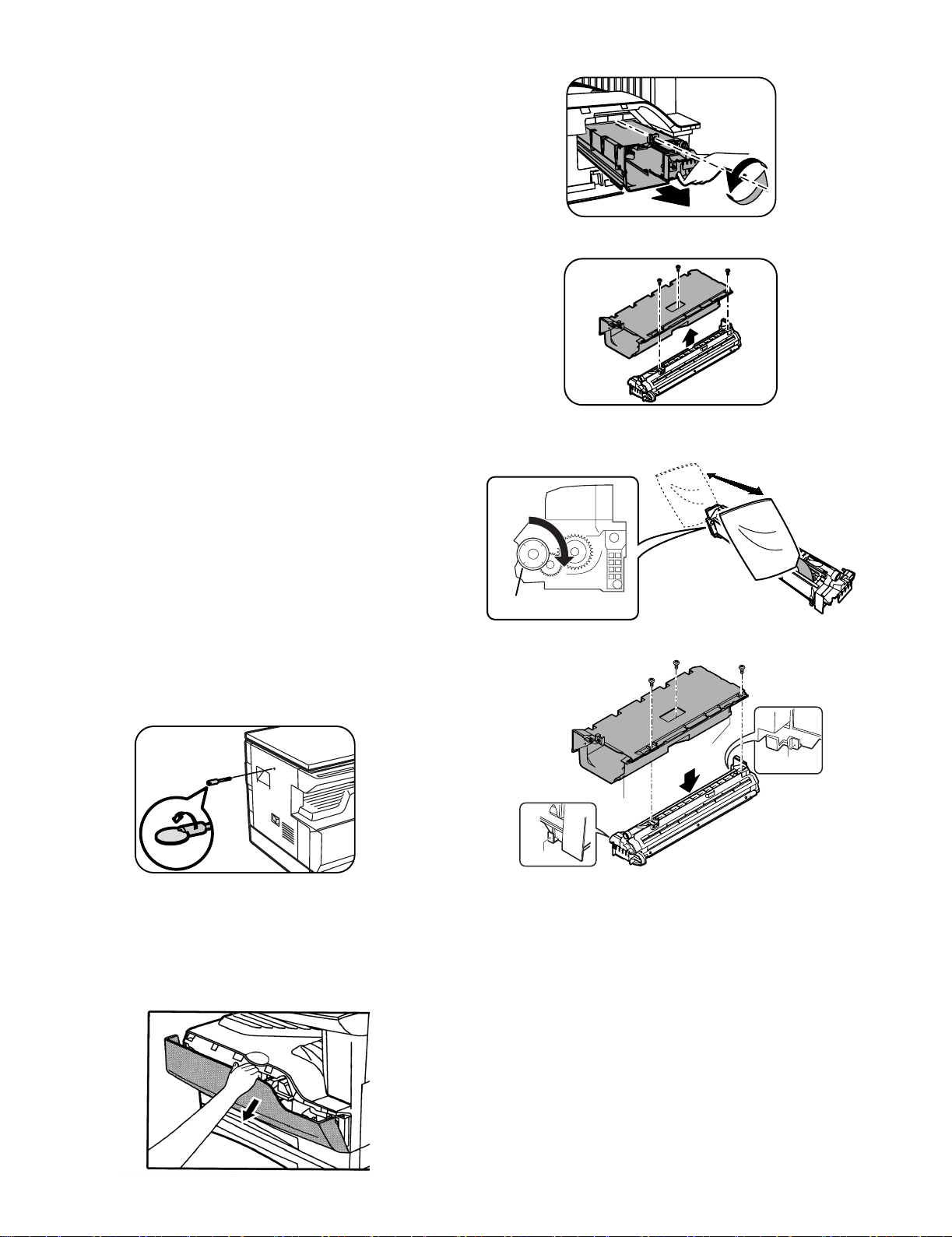

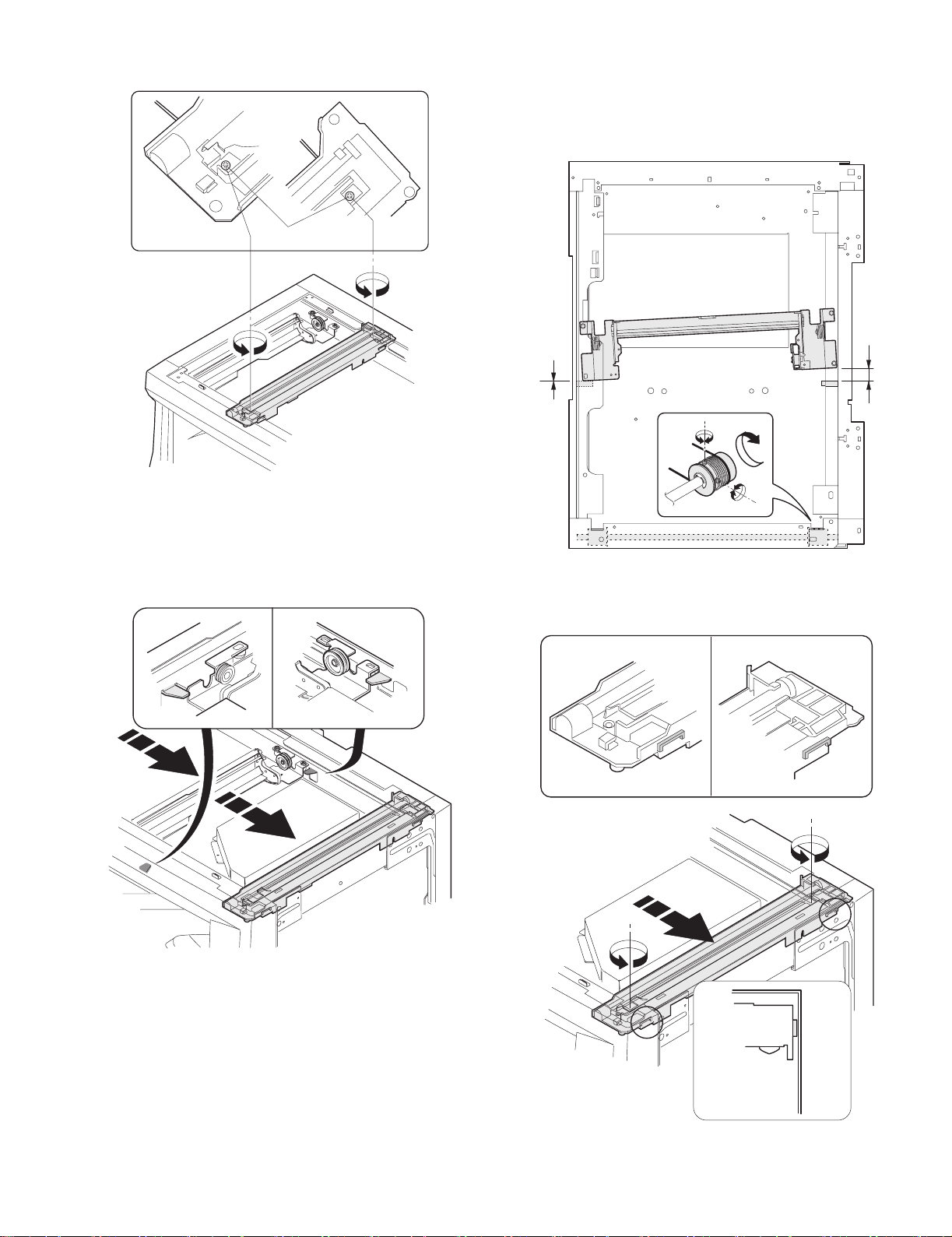

2) Loosen the screw and remove the developer cartridge.

3) Remove the developer tank from the developer cartridge.

4) Supply developer into the developer tank while rotating the MG roller

in the arrow direction.

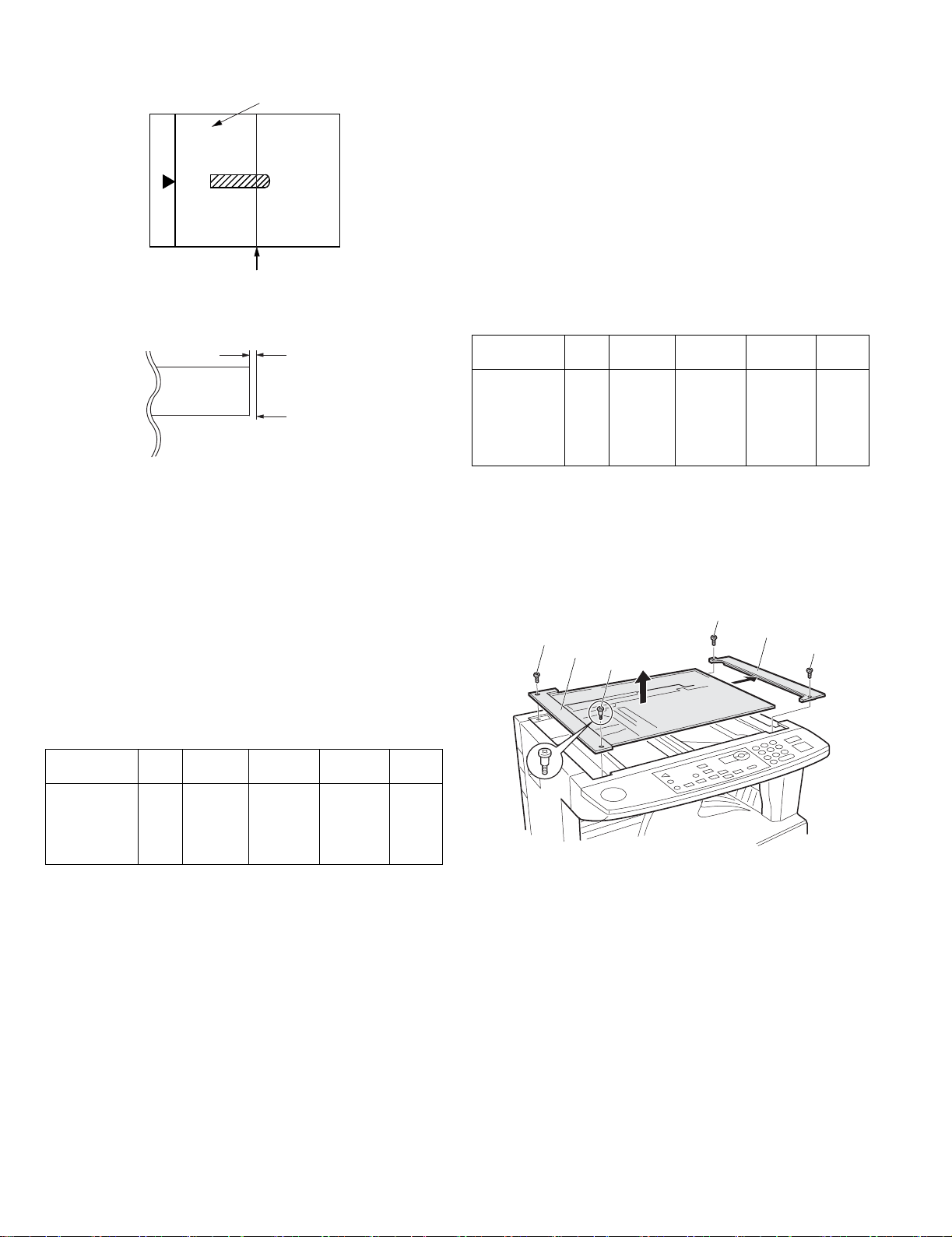

2.Removal of protective material and fixing screw

1) Remove all tapes and protective material.

•Remove all tapes, then open the document cover and remove the

protective material of sheet shape

2) Remove the fixing screw.

•Use a coin to remove the fixing screw.

•The fixing screw is required when transporting the machine. Keep it in

the tray. (Refer to the later description.)

3.Installing procedure

A.Developer cartridge installation

1) Open the front cover.

•Pull on the top center of the front cover to open.

MG roller

* Shake the developer bag enough before opening it.

Hole

Hook

Hole

Hook

Note:Check that the DV seal is free from developing agent. If developing

agent is attached to the DV seal, clean it carefully.

Check to insure that the hook is engaged in two positions.

5) Attach the developer tank to the developer cartridge.

* After supplying developer into the developer cartridge, do not tilt or

shake the developer cartridge.

6) Attach the developer cartridge to the copier, and fix it with the screw.

DP-1620 UNPACKING AND INSTALLATION 5-1

Page 20

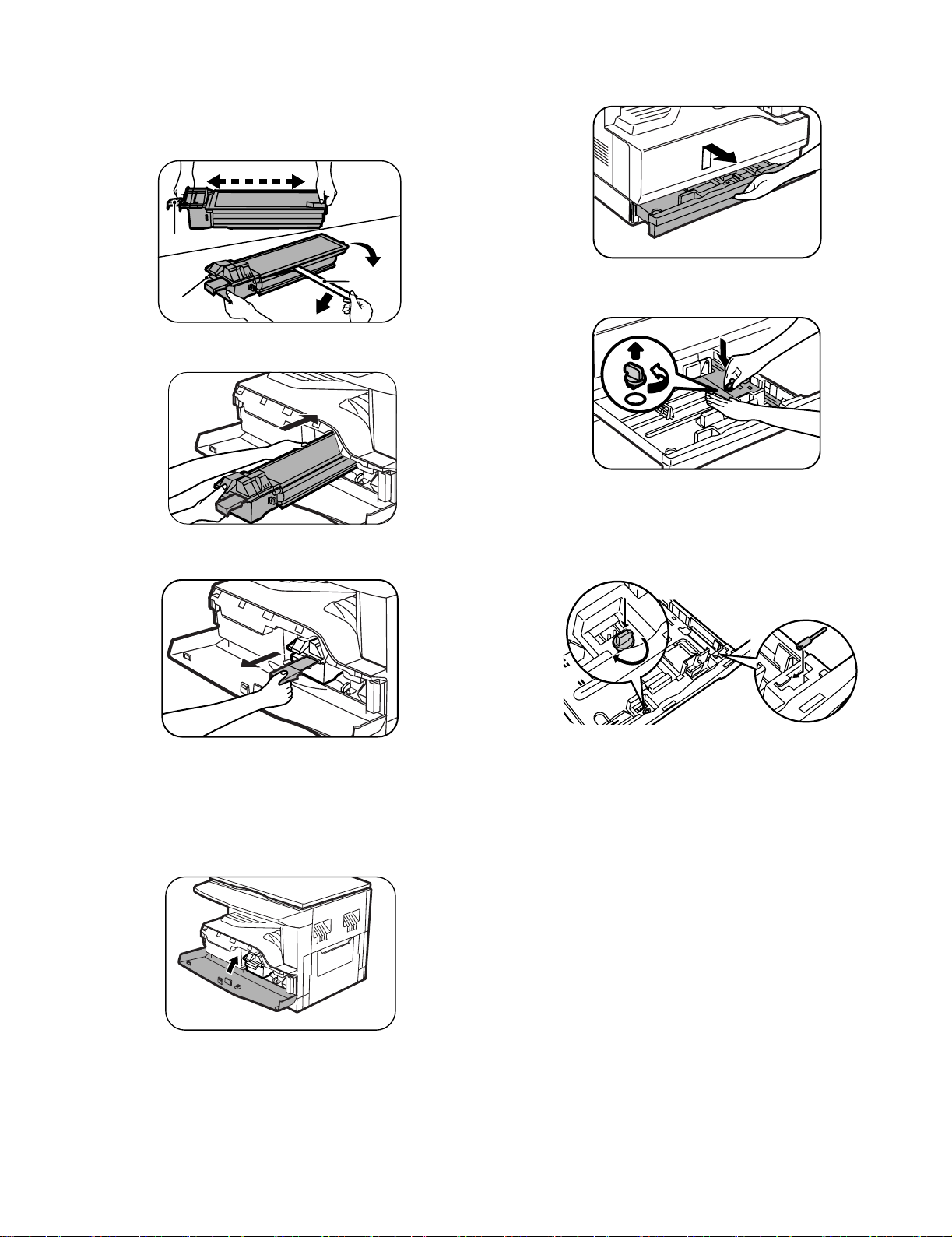

B.Toner cartridge installation

1) Shake the toner cartridge several times horizontally, and remove the

tape.

* Do not hold the shutter lever when shaking.

* After removing the tape, do not tilt or shake the toner cartridge.

4 or 5 times

Shutter

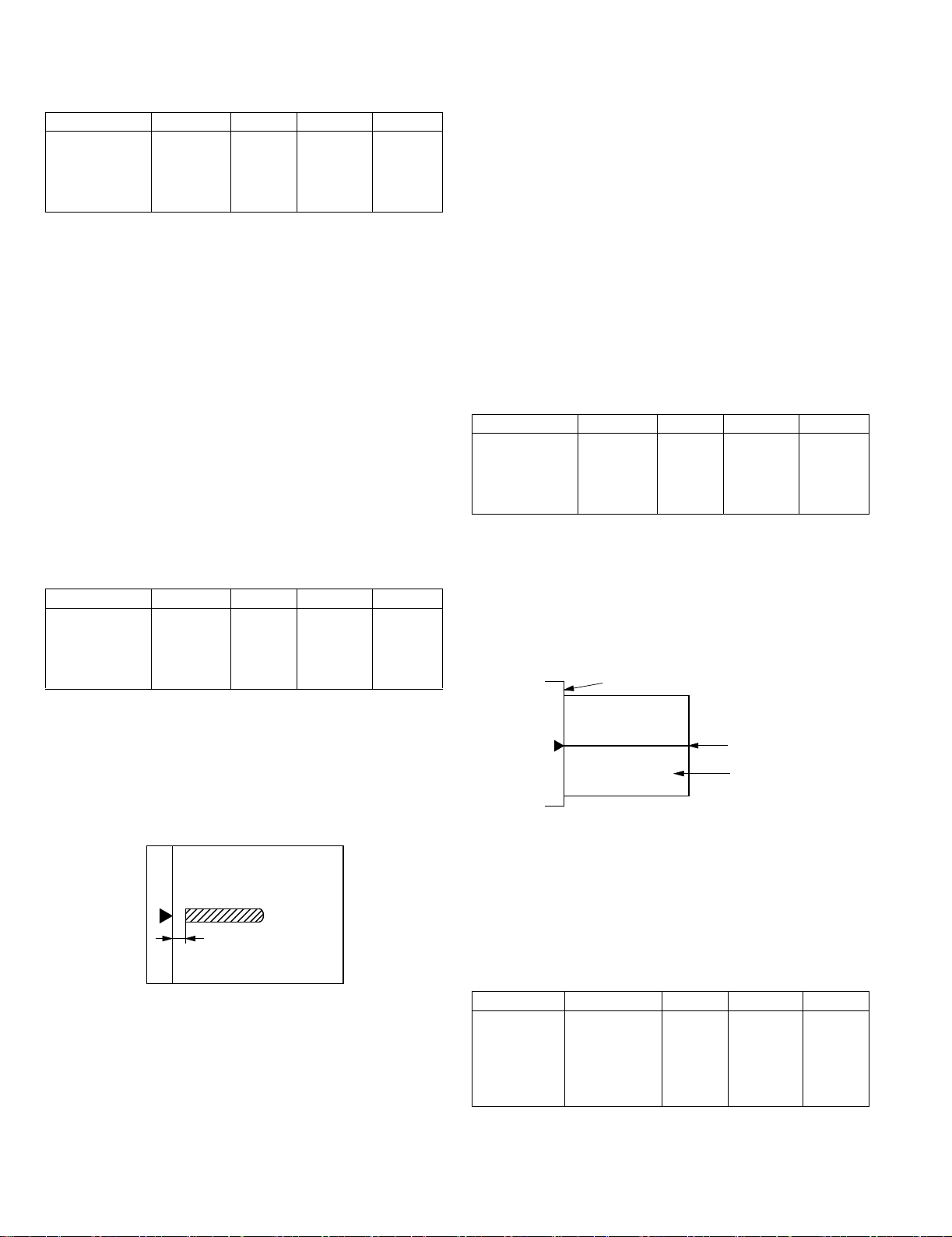

4.Removal and storage of fixing screw

1) Lift the knob and gently pull out the tray.

Handle

2) Attach the toner cartridge to the copier.

3) Pull the shutter lever.

Tape

2) Hold the paper pressure plate and turn the fixing screw in the arrow

direction.

3) Store the fixing pin and the fixing screw in the tray.

•Store the fixing screw which was removed in the above procedure 2 and

the fixing screw which was removed in procedure 2 of 2.

•Removal of protective material and fixing screw in the storage place in

the tray.

Close the front cover A, then close the side cover B.

•When closing the front cover, gently press the both sides.

•When closing the side cover, hold the knob.

•When closing the covers, be sure to close the front cover first, then

close the side cover. If closed in a wrong sequence, the covers may be

broken.

DP-1620 UNPACKING AND INSTALLATION 5-2

Page 21

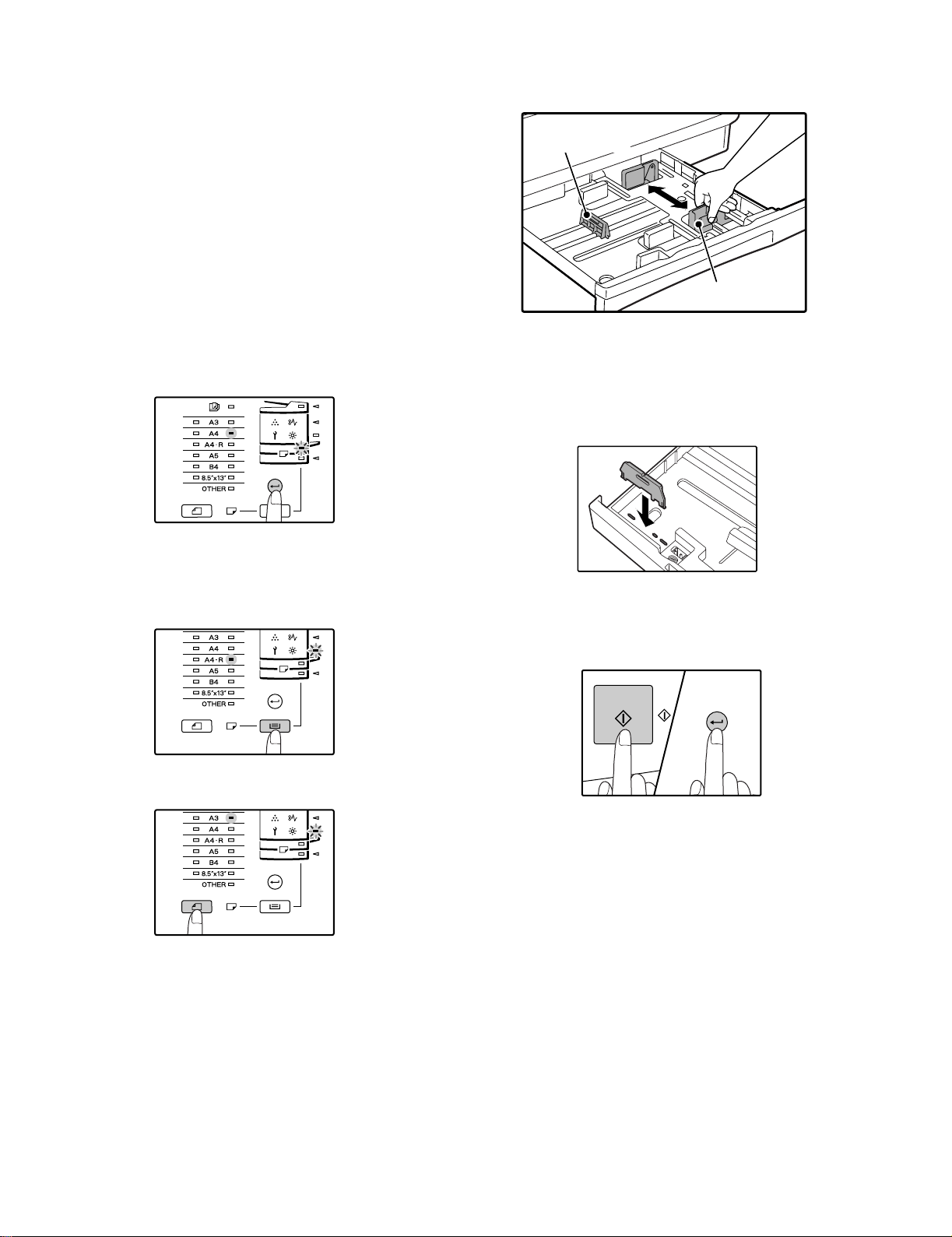

5. Changing a tray's paper size setting

Follow these steps to change a tray's paper size setting.

Note:

•The paper size setting cannot be changed when the machine has

stopped temporarily due to running out of paper or a misfeed, or during

interrupt copying.

•During printing (even in copy mode), the paper size setting cannot be

changed.

•A5 (ST) size paper can only be selected in upper paper tray.

•Do not load paper that is a different size than the paper size setting.

Copying will not be possible.

4) Squeeze the lock lever of the front guide and slide the front guide to

match the width of the paper, and move the left guide to the

appropriate slot as marked on the tray.

Left guide

1) Hold down the [PAPER SIZE ENTER] key for more than 5 seconds to

set the selected paper size.

The currently selected paper feed location indicator will blink and the

corresponding paper size (which is currently set) indicator will light

steadily.

All other indicators will go out.

2) If the machine has two paper trays, use the [TRAY SELECT] key to

select the paper tray for which you wish to change the paper size

setting.

Each time the [TRAY SELECT] key is pressed, a paper tray will be

indicated with a blinking paper feed location indicator.

Front guide

•The front guide is a slide-type guide. Grasp the locking knob on the

guide and slide the guide to the indicator line of the paper to be loaded.

•The left guide is an insert-type guide. Remove it and then insert it at the

indicator line of the paper to be loaded.

•When using LD sized paper store the left guide in the slot at the left front

of the paper tray.

5) Press the [START] key and then the [PAPER SIZE ENTER] key.

To change the paper size setting of another tray, repeat steps 2) to 5)

after pressing the [START] key.

3) Use the [ORIGINAL SIZE ENTER] key to select the paper size.

The indicator of the selected paper size lights up.

DP-1620 UNPACKING AND INSTALLATION 5-3

Note:Affix the paper size label for the paper size selected in step 3) to

the label position on the right end of the tray.

Important points when using the printer mode

•Make sure that the tray's paper size setting is the same as the tray's

paper size setting in the printer driver. For example, if the tray's paper

size setting is A4R (LT-R), set "Setting Paper Size" to "A4-R". For more

information, see "CONFIGURING THE PRINTER DRIVER" in the

"Software Setup Guide".

Page 22

[6]ADJUSTMENTS

1.Adjustment item list

Section Adjustment item Adjustment procedure/SIM No.

A Process

section

B Mechanism

section

C Image density

adjustment

(1) Developing doctor gap adjustment Developing doctor gap adjustment

(2) MG roller main pole position adjustment MG roller main pole position adjustment

(3) Developing bias voltage check

(4) Main charger voltage check

(1) Image position adjustment SIM-50

(2) Main scanning direction (FR direction) distortion balance

adjustment

No. 2/3 mirror base unit installing position adjustment

Copy lamp unit installing position adjustment

(3) Main scanning direction (FR direction) distortion adjustment Rail height adjustment

(4) Sub scanning direction (scanning direction) distortion

Winding pulley position adjustment

adjustment

(5) Main scanning direction (FR direction) magnification ratio

SIM 48-1

adjustment

(6) Sub scanning direction (scanning direction) magnification ratio

adjustment

OC mode in copying (SIM 48-1)

SPF mode in copying (SIM 48-5)

(7) Off center adjustment OC mode (SIM 50-12)

SPF mode (SIM 50-12)

(8) SPF white correction pixel position adjustment

(

required in an SPF model when replacing the lens unit)

SIM63-7

(1) Copy mode SIM 46-1

2.Copier adjustment

A.Process section

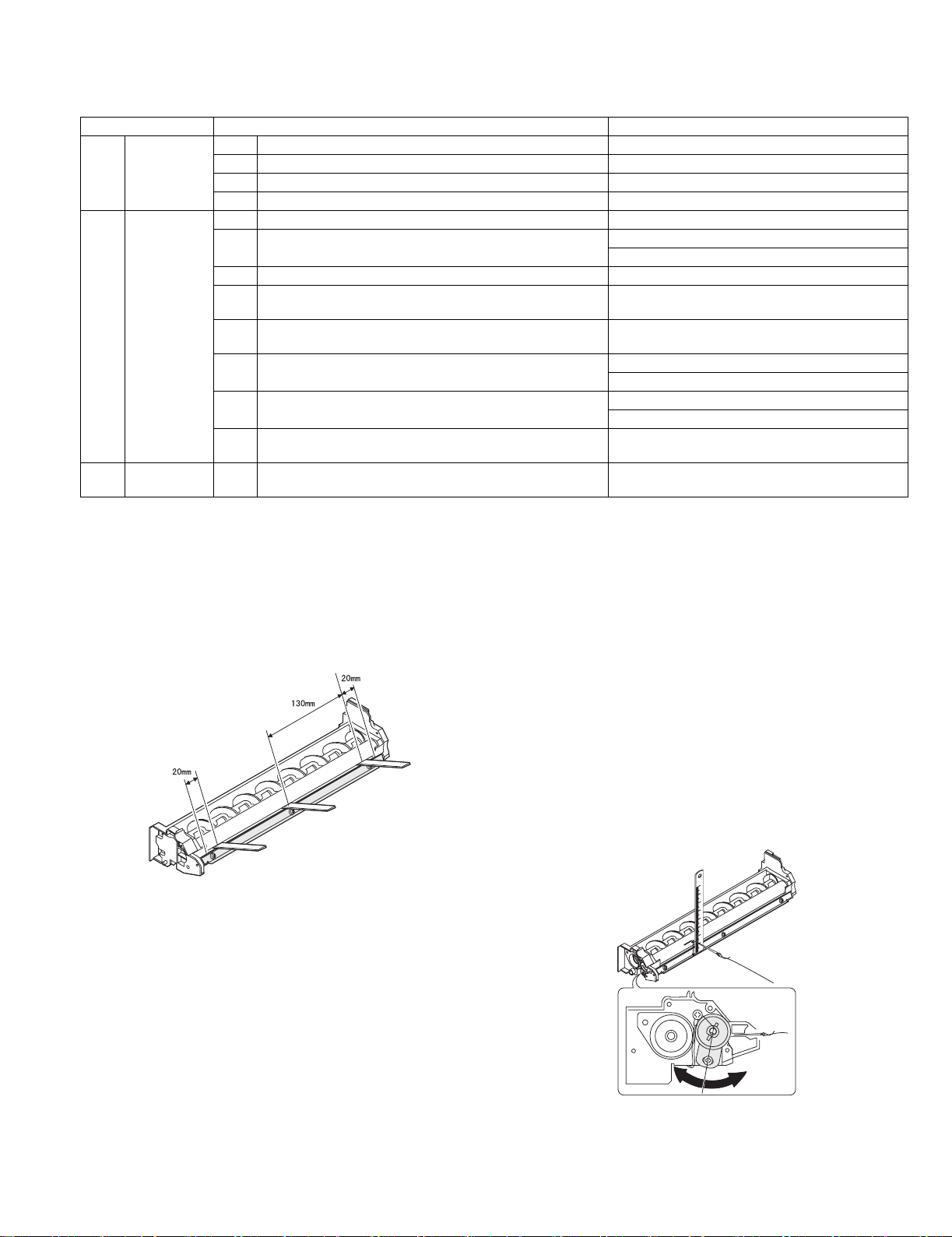

(1) Developing doctor gap adjustment

1) Loosen the developing doctor fixing screw A.

2) Insert a thickness gauge of 1.5mm to the three positions at 20mm

and 130mm from the both ends of the developing doctor as shown.

3) Push the developing doctor in the arrow direction, and tighten the

developing doctor fixing screw. (Perform the same procedure for the

front and the rear frames.)

4) Check the clearance of the developing doctor. If it is within the

specified range, then fix the doctor fixing screw with screw lock.

* When inserting a thickness gauge, be careful not to scratch the

developing doctor and the MG roller.

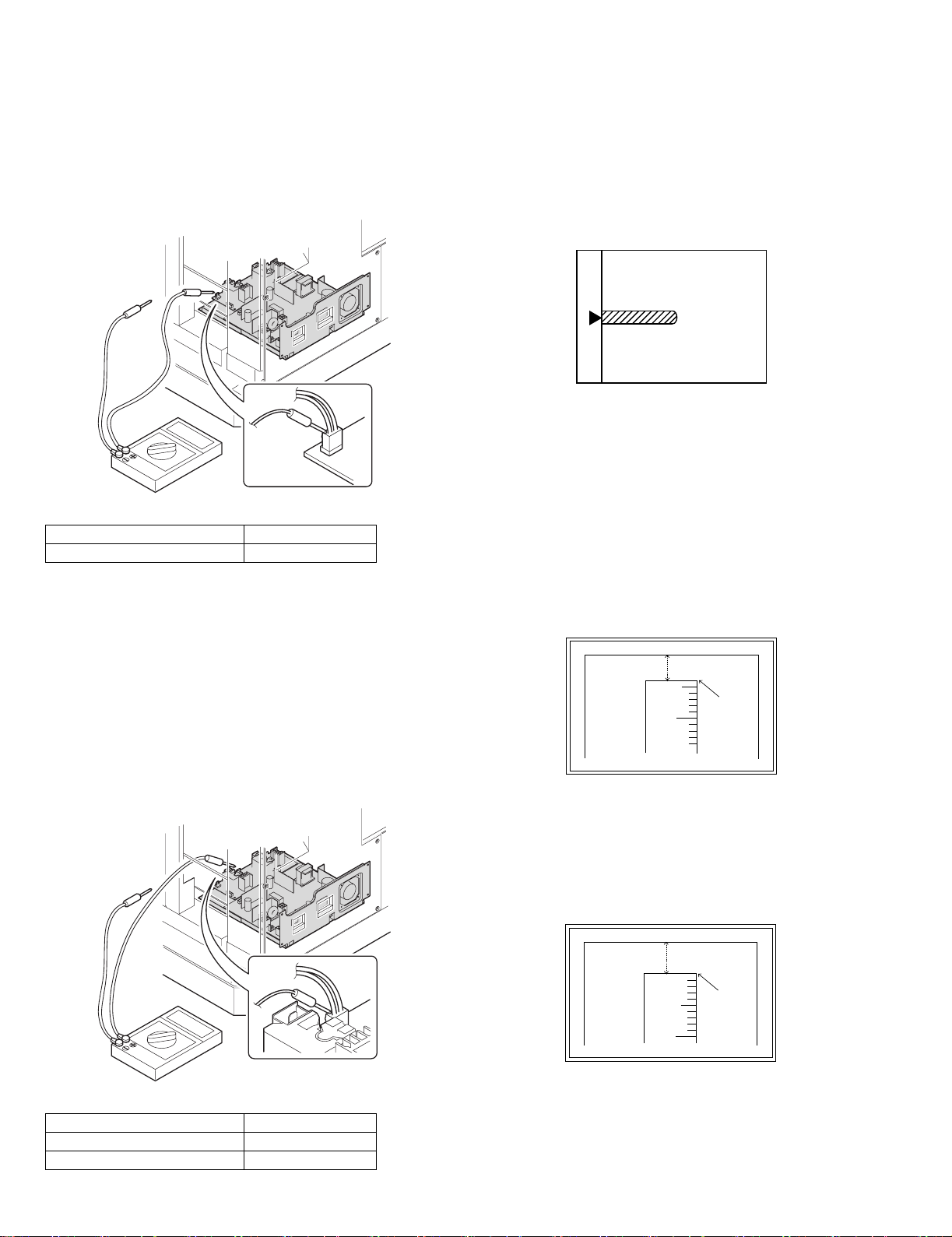

(2) MG roller main pole position adjustment

1) Remove and separate the waste toner box and put the developing

unit on a flat surface.

2) Tie a string to a needle or a pin.

3) Hold the string and bring the needle close to the MG roller

horizontally. (Do not use paper clip, which is too heavy to make a

correct adjustment.) (Put the developing unit horizontally for this

adjustment.)

4) Do not bring the needle into contact with the MG roller, but bring it to

a position 2 or 3mm apart from the MG roller. Mark the point on the

MG roller which is on the extension line from the needle tip.

5) Measure the distance from the marking position to the top of the

doctor plate of the developing unit to insure that it is 18mm.

If the distance is not within the specified range, loosen the fixing

screw A of the main pole adjustment plate, and move the adjustment

plate in the arrow direction to adjust.

<Adjustment specification>

Developing doctor gap

Both ends (20mm from the both ends) :

C (Center) (150mm from the both ends) :

+0.1

1.5 mm

- 0.15

+0.15

1.55 mm

- 0.2

DP-1620 ADJUSTMENT 6-1

Page 23

(3)Developing bias voltage check

Note:Use a digital multi-meter with an internal resistance of 10MΩ or

more.

1) Set the digital multi-meter range to DC700V.

2) Put the test rod of the digital multi-meter on the developing bias

voltage output check pin.

3) Turn on the power, execute SIM25-1.

<Specification>

Mode Specification

Developing bias voltage DC - 400±8V

(4) Grid bias voltage check

Note:Use a digital multi-meter with an internal resistance of 10MΩ or

more.

B.Mechanism section

Note: If a jam error or paper empty occurs during copying in the

adjustment by the simulation, the image data are not saved, and

therefore recopying is required.

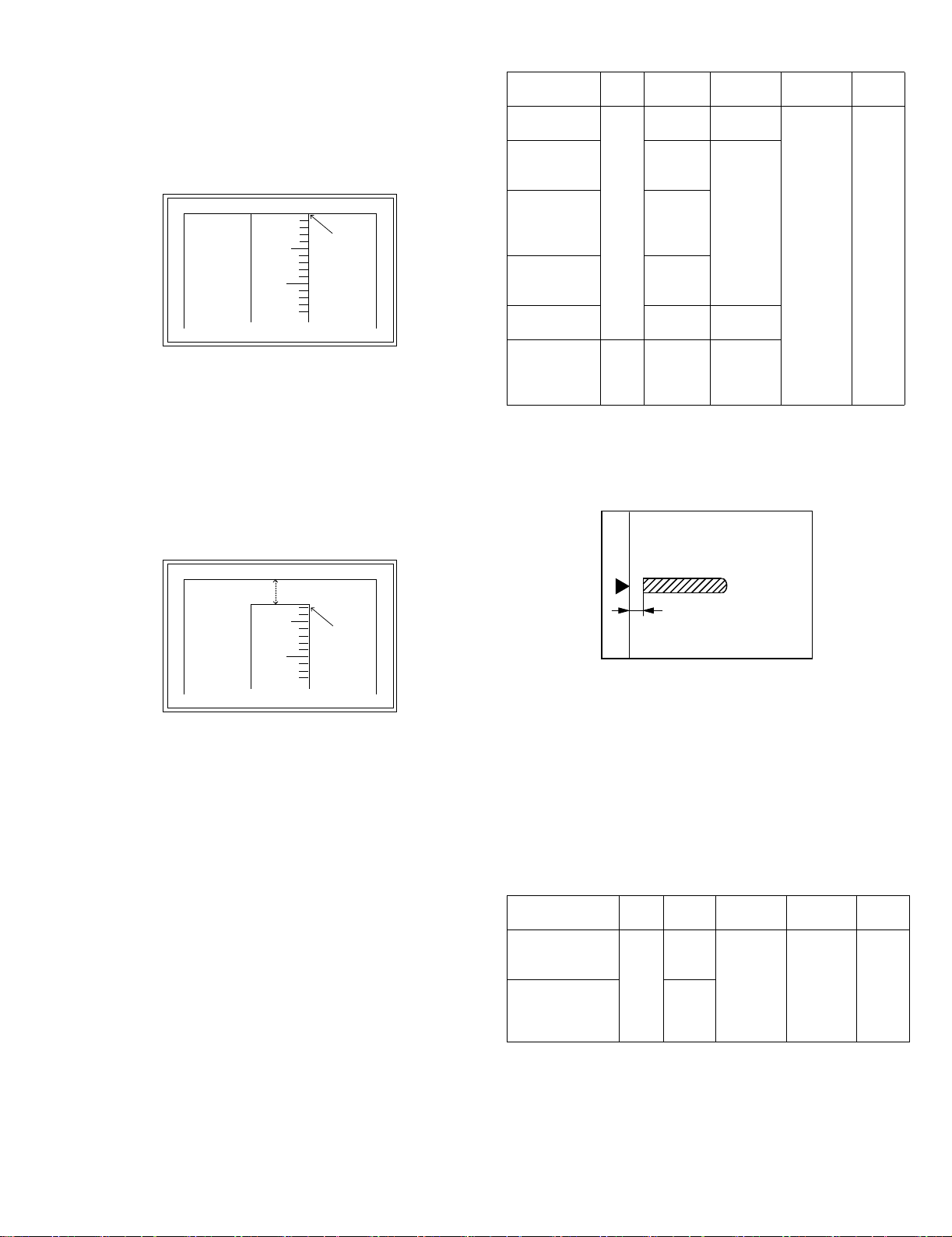

(1)Image position adjustment

a.OC image lead edge position adjustment (SIM 50-1)

Note:In advance to this adjustment, the sub scanning magnification ratio

adjustment must be performed.

1) Set a scale on the OC table as shown below.

2) Make a copy.

3) Check the copy output. If necessary, perform the following

adjustment procedures.

4) Execute SIM 50-1.

5) Set the OC lead edge position set value (Exposure display

<<PHOTO>> ON) to [1]

The OC image scanning start position is shifted inside the document

edge.

6) Set the main cassette lead edge void adjustment value (Exposure

display <<TEXT>> ON) * to [1]

The lead edge void becomes the minimum.

7) Set the main cassette print start position value (Exposure display

<<AUTO+MAIN CASSETTE LAMP>> ON) to [1] and make a copy.

The print start position is shifted inside the document edge.

1) Set the digital multi-meter range to DC700V.

2) Put the test rod of the digital multi-meter on the grid bias voltage

output check pin.

3) Turn on the power.

(The voltage is outputted in the grid bias High output mode during

warming up, and in the grid bias Low output mode when warming up

is completed.)

<Specification>

Mode Specification

Grid bias LOW DC - 400±8V

Grid bias HIGH DC - 525±10V

5mm

5

10

*The dimension varies depending on the model.

4mm

8) Measure the image loss R of the copied image. Enter the set value of

the image scanning lead edge position (Exposure display

<<PHOTO>> ON) again.

•1 step of the set value corresponds to about 0.1mm shift.

•Calculate the set value from the formula below.

R/0.1(mm) = Image loss set value

<R: Image loss measurement value (mm)>

5mm

5

10

* The scanning edge is set.

(A line may be printed by scanning the document edge.)

0mm

Example: 4/0.1 = 40 = about 40

Note:If the set value is not obtained from the above formula, perform the

fine adjustment.

DP-1620 ADJUSTMENT 6-2

Page 24

9) Measure the distance H between the paper lead edge and the image

print start position. Set the image print start position set value

(Exposure display <<AUTO+MAIN CASSETTE LAMP>> ON) again.

•1 step of the set value corresponds to about 0.1mm shift.

•Calculate the set value from the formula below.

H/0.1(mm) = Image print start position set value

<H: Print start position measurement value (mm)>

0mm

5

10

0mm

<Adjustment specification>

Adjustment

mode

OC image lead

edge position

Main cassette

print start

position

2nd cassette

print start

position

SIM LED Set

value

SIM

PHOTO R/0.1 Lead edge

50-1

AUTO

B/0.1

+

MAIN

AUTO

+

2nd

CASSETTE

Multi bypass

tray print start

position

AUTO

+

MULTI

Lead edge void TEXT B/0.05

Spec

value

void:

1 - 4mm

Image loss:

3mm or

less

Set

range

1 ~ 99

*Fit the print edge with the paper edge, and perform the

lead edge adjustment.

Example: 5/0.1 = 50 = about 50

Note:If the set value is not obtained from the above formula, perform the

fine adjustment.

10) Set the lead edge void adjustment value (Exposure display

<<TEXT>> ON)* again.

•1 step of the set value corresponds to about 0.1mm shift.

•Calculate the set value from the formula below.

B/0.05 (mm) = Lead edge void adjustment value

<B: Lead edge void (mm)>

2.5mm

5

10

2.5mm

Example: When setting the lead edge void to 2.5mm

:2.5 /0.05 = about 50

Note:If the set value is not obtained from the above formula, perform the

fine adjustment.

* 2nd cassette lead edge void adjustment: Exposure display <<AUTO

+ TEXT + PHOTO>>

Multi bypass tray lead edge void adjustment: Exposure display

<<TEXT + PHOTO>>

OC 2nd print

surface lead

SIM

50-19*

PHOTO 1 step:

0.1mm shift

edge position

adjustment

* (Set to S → D mode for before execution)

b.SPF image lead edge position adjustment (SIM50-6)

1) Set a scale on the OC table as shown below.

Note:Since the printed copy is used as a test chart, put the scale in

paralled with the edge lines.

2) Make a copy, Then use the copy output as an original to make an

SPF copy again.

3) Check the copy output. If necessary, perform the following

adjustment procedures.

4) Execute SIM 50-6.

5) Set the SPF lead edge position set value (Exposure display

<<AUTO>> ON) so that the same image is obtained as that obtained

in the previous OC image lead edge position adjustment.

<Duplex mode adjustment>

OC 2nd print surface (Auto duplex) lead edge position adjustment:

SIM50-19 <<PHOTO>>

* For the adjustment procedure, set to S → D mode before execution.

Note:Before performing the 2nd print surface lead edge position

adjustment and the lead edge void adjustment, be sure to perform

the 1st print surface lead edge position adjustment in advance, and

be sure to perform the 2nd print surface lead edge position

adjustment and then the lead edge void adjustment in this

sequence.

DP-1620 ADJUSTMENT 6-3

<Adjustment specification>

Adjustment mode SIM LED Set value Spec value Set

range

SPF image lead

edge position

(1st print surface)

SIM

50-6

AUTO 1 step:

0.1mm shift

Lead edge

void:

1 - 4mm

1 ~ 99

(2nd print surface) TEXT

Image loss:

3mm or

less

Page 25

c.Rear edge void adjustment (SIM50-1, SIM50-19)

1) Set a scale as shown in the figure below.

A4(8.5" x 11")

Paper rear edge

2) Set the document size to A4 (8.5" x 11"), and make a copy at 100%.

3) If necessary, perform the following adjustment procedure.

Void amount (Standard value: 4mm or less)

Scale image

Paper rear edge

4) Execute SIM 50-1 and set the density mode to AUTO + TEXT +

PHOTO (Rear edge void).The currently set adjustment value is

displayed.

5) Enter the set value and press the start key. The correction value is

stored and a copy is made.

<Duplex mode adjustment>

* 1st print surface (auto duplex) rear edge void adjustment:

SIM50-19 <<AUTO>>

* 2nd print surface (auto duplex) rear edge void adjustment:

SIM50-19<<TEXT>>

*Set to S → D mode before execution.

Note:Before performing the 2nd print surface rear edge void adjustment,

be sure to perform the 2nd print surface lead edge position

adjustment. Never reverse the sequence.

<Adjustment specification>

Mode SIM LED Set value Specifi-

Rear edge void SIM

50-1

AUTO

+

1 step:

0.1mm shift

cation

4mm or

less

Set

range

1 ~ 99

TEXT

+

PHOTO

e.Side edge void area adjustment (SIM26-43)

Note:Before performing this adjustment, be sure to check that the paper

off center adjustment (SIM 50-10) is completed.

1) Set a test chart on the document table.

2) Select a paper feed port and make two copies. Compare the 2nd

copy and the test chart. If necessary, perform the following

adjustment procedure.

* The 1st copy does not show the void. Be sure to check the 2nd copy.

3) Execute SIM 26-43 and set the density mode to AUTO(right edge

void) + TEXT (Left edge void).

The currently set adjustment value is displayed.

4) Enter the set value and press the start key. The correction value is

stored.

<Adjustment specification>

ode SIM LED Set value Specifi-

Left edge void SIM

26-43

AUTO

(right

1 step:

0.5mm shift

cation

0.5 ~ 4mm 1 ~ 99

Set

range

edge)

+

TEXT

(left edge)

* The void adjustment values on the right and the left must be the

same.

(2) Main scanning direction(FR direction) distortion balance

adjustment

1) Remove the OC glass and the right cabinet.

(3)

(1)

(2)

(1)

(4)

(3)

d. Paper off center adjustment (SIM50-10)

1) Set a test chart on the document table.

2) Select a paper feed port and make a copy. Compare the copy and

the test chart. If necessary, perform the following adjustment

procedure.

3) Execute SIM 50-10. After completion of warm-up, shading is

performed and the currently set off center adjustment value of each

paper feed port is displayed.

4) Enter the set value and press the start key. The correction value is

stored and a copy is made.

DP-1620 ADJUSTMENT 6-4

Page 26

2) Loosen the copy lamp unit wire fixing screw.

Wire fixing screw

3) Manually turn the mirror base drive pulley and bring No. 2/3 mirror

base unit into contact with the positioning plate. At that time, if the

front frame side and the rear frame side of No. 2/3 mirror base unit

are brought into contact with the positioning plate at the same time,

the mirror base unit parallelism is proper. If one of them is in contact

with the positioning plate, perform the adjustment of 4).

4) Loosen the set screw of the scanner drive pulley which is not in

contact with No. 2/3 mirror base unit positioning plate.

5) Without moving the scanner drive pulley shaft, manually turn the

scanner drive pulley until the positioning plate is brought into contact

with No. 2/3 mirror base unit, then fix the scanner drive pulley.

6) Put No. 2/3 mirror base unit on the positioning plate again, push the

projections on the front frame side and the rear frame side of the

copy lamp unit to the corner frame, and tighten the wire fixing screw.

DP-1620 ADJUSTMENT 6-5

Page 27

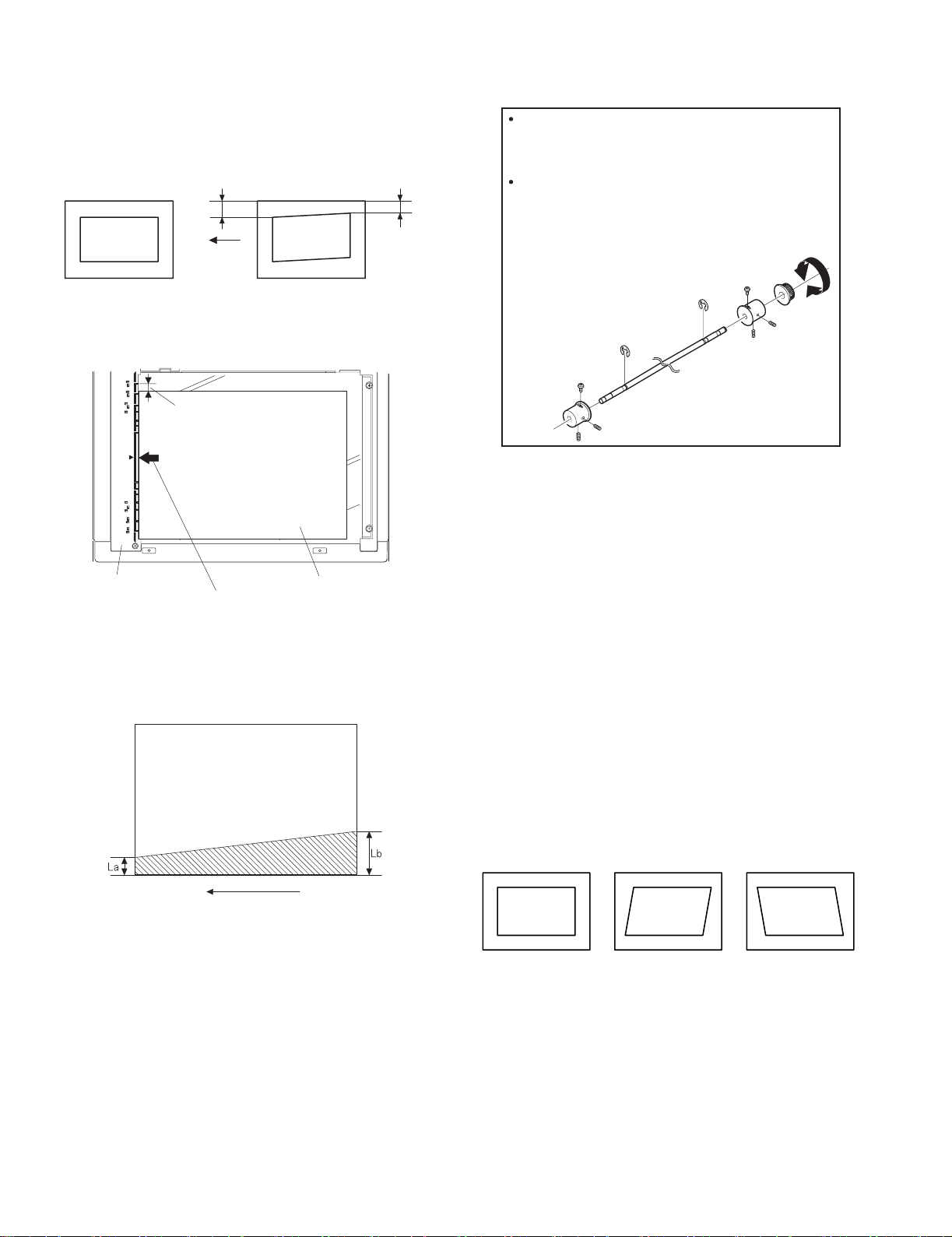

(3)Main scanning direction (FR direction) distortion

adjustment

This adjustment must be performed in the following cases:

•When the mirror base drive wire is replaced.

•When the lamp unit, or No. 2/3 mirror holder is replaced.

•When a copy as shown is made.

La

Paper exit

direction

Original

Copy

1) Set A3 (11" x 17") white paper on the original table as shown below.

Allow a little space.

Lb

4) Loosen the mirror base drive pulley fixing screw on the front frame

side or on the rear frame side.

When La < Lb

Turn the mirror base drive pulley on the front frame side in the

arrow direction A.

(Do not move the mirror base drive pulley shaft.)

When La > Lb

Turn the mirror base drive pulley on the front frame side in the

arrow direction A.

(Do not move the mirror base drive pulley shaft.)

Rear side

A

B

Front side

5)Tighten the mirror base drive pulley fixing screw.

Glass holding plate

Fit the paper edge and

the glass holding plate edge.

A3 (11" x 17") white paper

2) Open the original cover and make a normal (100%) copy.

3) Measure the width of the black background at the lead edge and at

the rear edge.

Paper exit direction

La: Lead edge black background width

Lb: Rear edge black background width

If the width (La) of the black background at the lead edge is equal that

(Lb) at the rear edge, there is no need to execute the following

procedures of 4) ~ 7).

<Adjustment specification>

La = Lb

6) Execute the main scanning direction (FR) distartion balance

adjustment previously described in 2) again.

(4) Sub scanning direction (scanning direction) distortion

adjustment

When there is no skew copy in the mirror base scanning direction and

there is no horizontal error (right angle to the scanning direction), the

adjustment can be made by adjusting the No. 2/3 mirror base unit rail

height.

Before performing this adjustment, be sure to perform the horizontal

image distortion adjustment in the laser scanner section.

This adjustment must be performed in the following cases:

•When the mirror base wire is replaced.

•When the copy lamp unit or No. 2/3 mirror unit is replaced.

•When the mirror unit rail is replaced or moved.

•When a following copy is made.

Original

Copy A Copy B

DP-1620 ADJUSTMENT 6-6

Page 28

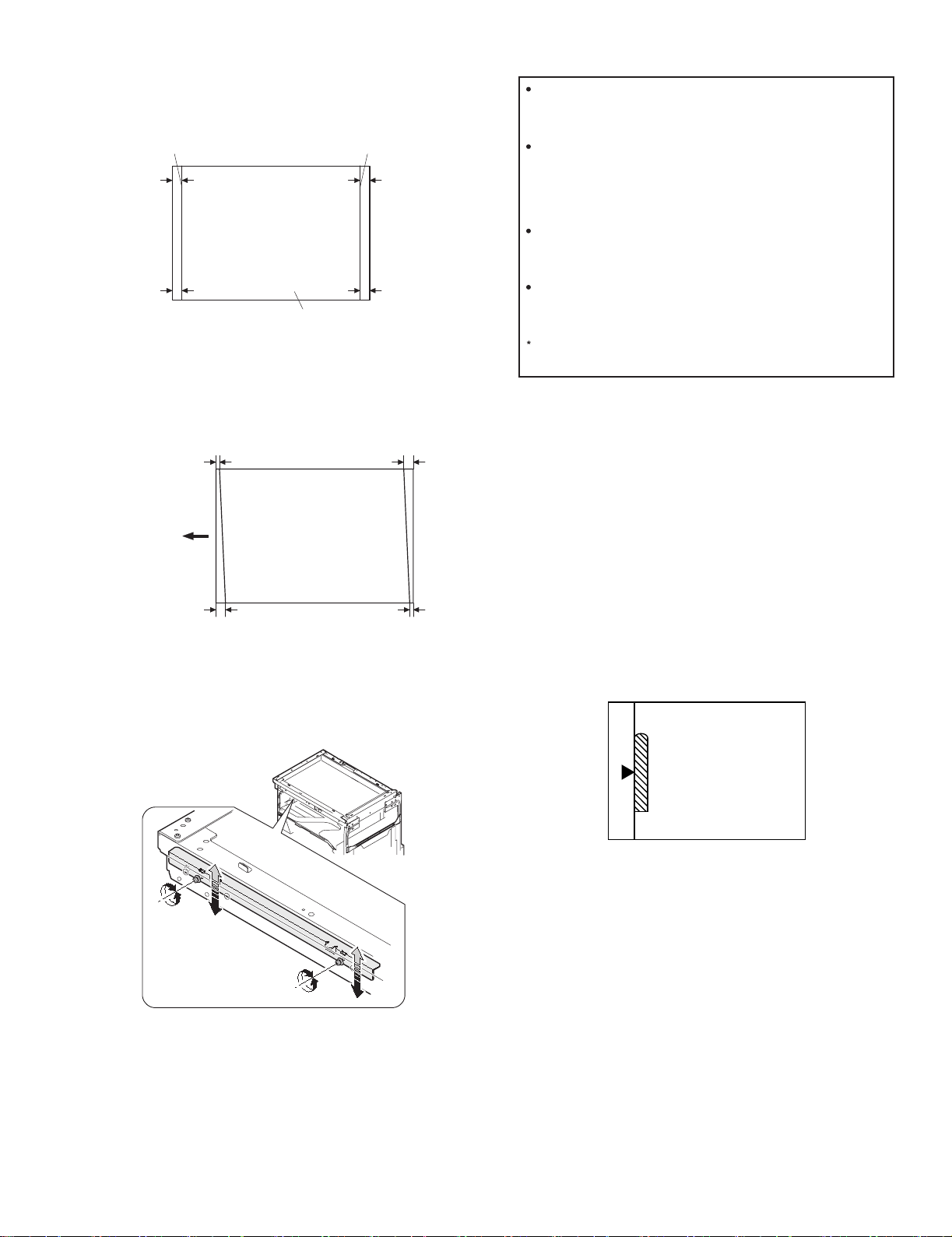

1) Making of a test sheet

Make test sheet by drawing parallel lines at 10mm from the both

ends of A3 (11" x 17") white paper as shown below. (These lines

must be correctly parallel to each other.)

When La > Lb

Shift the mirror base B rail upward by the half of the

difference of La - Lb.

Parallel line

10mm

10mm

White paper

Parallel line

10mm

10mm

2) Make a normal (100%) copy of the test sheet on A3 (11" x 17")

paper. (Fit the paper edge with the glass holding plate edge.)

3) Measure the distances (La, Lb, Lc, Ld) at the four corners as shown

below.

Paper exit

direction

La

Lb Ld

Lc

When La < Lb

Shift the mirror base B rail downward by the half of the

difference of Lb - La.

Example: When La = 12mm and Lb = 9mm, shift the mirror

base B rail upward by 1.5mm.

When Lc > Ld

Shift the mirror base B rail downward by the half of the

difference of Lc - Ld.

When Lc < Ld

Shift the mirror base B rail downward by the half of the

difference of Ld - Lc.

When moving the mirror base rail, hold the mirror base rail

with your hand.

<Adjustment specification>

La = Lb, Lc = Ld

5) After completion of adjustment, manually turn the mirror base drive

pulley, scan the mirror base A and mirror base B fully, and check that

the mirror bases are not in contact with each other.

* If the mirror base rail is moved extremely, the mirror base may be in

contact with the frame or the original glass. Be careful to avoid this.

(5) Main scanning direction (FR direction) magnification

ratio adjustment (SIM 48-1)

Note:Before performing this adjustment, be sure to check that the CCD

unit is properly installed.

When La = Lb and Lc = Ld, no need to perform the procedures 4) and 5).

4) Move the mirror base F rail position up and down (in the arrow

direction) to adjust.

Note:If the rear side rail is used for the adjustment, the scanning position

of the white balance sheet is shifted and "E7-04" may occur only

when scanning with the SPF. Therefore it is advisable to use the

front side rail for the adjustment.

1) Put a scale on the original table as shown below.

2) Execute SIM 48-1.

3) After warm-up, shading is performed and the current set value of the

main scanning direction magnification ratio is displayed on the

display section in 2 digits.

4) Select the mode and press the start key again.

5) Manual correction mode (TEXT lamp ON)

Enter the set value and press the start key.

The set value is stored and a copy is made.

DP-1620 ADJUSTMENT 6-7

Page 29

<Adjustment specification>

Note: A judgment must be made with 200mm width, and must not be

made with 100mm width.

Mode Specification SIM Set value Set range

Main scanning

direction

magnification

ratio

At normal:

±1.0%

SIM 48-1 Add 1:0.1%

increase

Reduce 1:

0.1%

1 ~ 99

decrease

(6) Sub scanning direction (scanning direction)

magnification ratio adjustment (SIM 48-1, SIM 48-5)

a. OC mode in copying (SIM48-1)

Note:Before performing this adjustment, be sure to check that the CCD

unit is properly installed.

1) Put a scale on the original table as shown below, and make a normal

(100%) copy.

2) Compare the scale image and the actual image. If necessary,

perform the following adjustment procedures.

3) Execute SIM 48-1.<<PHOTO>>

4) After warm-up, shading is performed and the current set value of the

main scanning direction magnification ratio is displayed on the

display section in 2 digits.

5) When the photo lamp is lighted by pressing the density selection key,

the current magnification ratio correction value in the sub scanning

direction is displayed in lower 2 digits of the display section.

6) Enter the set value and press the start key.

The set value is stored and a copy is made.

<Adjustment specification>

Mode Specification SIM Set value Set range

Sub scanning

direction

magnification

ratio

(OC mode)

b. RSPF sub scanning direction magnification ratio (SIM48-5)

Note:

•Before performing this adjustment, be sure to check that the CCD unit is

properly installed.

•Before performing this adjustment, the OC mode adjustment in copying

must be completed.

1) Put a scale on the original table as shown below, and make a normal

(100%) copy to make a test chart.

Normal

±1.0%

SIM 48-1

(PHOTO)

Add 1:0.1%

increase

Reduce 1:

0.1%

decrease

1 ~ 99

Note:Since the printed copy is used as a test chart, put the scale in

parallel with the edge lines.

2) Set the test chart on the SPF and make a normal (100%) copy.

3) Compare the scale image and the actual image. If necessary,

perform the following adjustment procedures.

4) Execute SIM 48-5.

5) After warm-up, shading is performed.

The auto density lamp lights up and the current front surface sub

scanning direction magnification ratio correction value is displayed in

two digits on the display section.

6) Enter the set value and press the start key.

The set value is stored and a copy is made.

7) Change the mode from the duplex original mode to the simplex

original mode.

"MANUAL" lamp lights up and the current back surface sub scanning

direction magnification ratio is displayed in two digits on the display

section.

8) Enter the set value and press the start key.

The set value is stored and a copy is made.

<Adjustment specification>

Mode Specification SIM Set value Set range

Sub scanning

direction

magnification

ratio

(SPF mode)

Normal

±1.0%

SIM 48-5 Add 1:0.1%

increase

Reduce 1:

0.1%

decrease

1 ~ 99

(7) Off center adjustment (SIM 50-12)

a. OC mode (SIM50-12)

1) Make a test chart as shown below and set it so that its center line is

fit with the original guide center mark.

* To make a test chart, draw a line on A3 or 11" x 17" paper at the

center in the paper transport direction.

Original guide

Center

Copy paper

(A3 or 17" x 11")

2) Make a normal copy from the manual paper feed tray, and compare

the copy and the test chart.

If necessary, perform the following adjustment procedures.

3) Execute SIM 50-12.

4) After warm-up, shading is performed and the current set value of the

off center adjustment is displayed on the display section in 2 digits.

5) Enter the set value and press the start key.

The set value is stored and a copy is made.

<Adjustment specification>

Mode Specification SIM Set value Set range

Original off

center mode

(OC mode)

DP-1620 ADJUSTMENT 6-8

Single:

Center ±2.0mm

SIM 50-12

(AE lamp

ON)

Add 1:

0.1mm shift

to R side

Reduce 1:

0.1mm shift

to L side

1 ~ 99

Page 30

b. SPF original off-center adjustment (SIM50-12)

Note:Before performing this adjustment, be sure to check that the paper

off center is properly adjusted.

1) Make a test chart for the center position adjustment and set it on the

SPF.

<Adjustment specification>

Draw a line on a paper in the scanning direction.

2) Make a normal copy from the manual paper feed tray, and compare

the copy and the original test chart.

If necessary, perform the following adjustment procedures.

3) Execute SIM 50-12.

4) After warm-up, shading is performed and the current set value of the

off center adjustment at each paper feed port is displayed on the

display section in 2 digits.

5) Enter the set value and press the start key.

The set value is stored and a copy is made.

<Adjustment specification>

Mode Specification SIM Set value Set

range

Original off

center

mode

(SPF mode)

Single:

Center ±3.0mm(TEXT lamp)

Duplex:

Center ±3.5mm(

PHOTO lamp

)

SIM

50-12

Add 1:

0.1mm shift

to R side

Reduce 1:

0.1mm shift

to L side

1 ~ 99

(8) SPF white correction pixel position adjustment(SIM63-7)

(required in an SPF model when replacing the lens unit)

1) Fully open the SPF.

2) Execute SIM 63-7.

3) When the operation panel displays "COMPLETE,"the adjustment is

completed.

4) If the operation panel displays "ERROR,"perform the following

measures.

•When the display is 0:

Check that the SPF is open.

Check that the lamp is ON.(If the lamp is OFF,check the MCU connector.)

Check that the CCD harness is properly inserted into the MCU

connector.

•When the display is 281 or above:

1) Remove the table glass.

2) Remove the dark box.

3) Slide the lens unit toward the front side and attach it,then execute

SIM.

•When the display is 143 or below:

1) Remove the table glass.

2) Remove the dark box.

3) Slide the lens unit toward the rear side and attach it,then execute

SIM.

C.Image density adjustment

(1)Copy mode (SIM 46-1)

1)Set a test chart on the OC table as shown below.

2) Put several sheets of A3 or 11" x 17" white paper on the test chart.

3) Execute SIM 46-1.

4) After warm-up, shading is performed and the current set value of the

density level is displayed on the display section in 2 digits.

For mode selection, use the density select key.

5) Change the set value with the 10-key to adjust the copy image

density.

6) Make a copy and check that the specification below is satisfied.

<Adjustment specification>

Density

mode

Auto Auto - "2" is slightly

Text Text 3 "3" is slightly

Photo Photo 3 "2" is slightly

Toner

save

Toner

save

Display

lamp

Text/

Photo

Auto/

Photo

Exposure

level

Sharp Gray

Chart output

copied.

copied.

copied.

3 "3" is slightly

copied

- "2" is slightly

copied

Set value Set

The greater the

set value is the

greater the

density is The

smaller the set

value is the

smaller the

density is.

range

1 ~ 99

F

* When the lens unit is moved,execute the OC main scanning

magnification ratio auto adjustment,SIM 48-1-1,IM48-3 and the PF

original off-center adjustment.

* This adjustment is basically O.K.with IM 63-7.

R

DP-1620 ADJUSTMENT 6-9

Page 31

[7] SIMULATIONS

1. Entering the simulation mode

The initial "C" key AUTO/TEXT/PHOTO key "C" key

AUTO/TEXT/PHOTO key sequence must be performed quickly with

no more than a second between key strokes.

Main code Start key Sub code Start key.

2. Canceling the simulation mode

When the clear all key is pressed, the simulation mode is cancelled.

When the interruption key is pressed, the process is interrupted and the

screen returns to the sub code entering display.

* After canceling the simulation mode, be sure to turn OFF/ON the

power and check the operation.

Note: If the machine is terminated by a jam error or paper empty during

copying in the adjustment by the simulation, recopying is required.

3. List of simulations

Main

Sub

code

code

01 01 Mirror scanning operation

02 Mirror home position sensor (MHPS) status display

06 Mirror scanning operation aging

02 01 Single paper feeder (SPF) aging

02 SPF sensor status display

03 SPF motor operation check

08 SPG paper feed solenoid operation check

11 SPF PS release solenoid operation check

05 01 Operation panel display check

02 Fusing lamp and cooling fan operation check

03 Copy lamp lighting check

06 01 Paper feed solenoid operation check

02 Resist roller solenoid operation check

10 Cassette semi-circular roller cleaning

07 01 Warm-up display and aging with jam

06 Intermittent aging

08 Shifting with warm-up display

08 01 Developing bias output

02 Main charger output (Grid = HIGH)

03 Main charger output (Grid = LOW)

06 Transfer charger output

10 - Toner motor operation

14 - Trouble cancel (except for U2)

16 - U2 trouble cancel

20 01 Maintenance counter clear

21 01 Maintenance cycle setting

02 Mini maintenance cycle setting

22 01 Maintenance counter display

02 Maintenance preset display

03 Jam memory display

04 Jam total counter display

05 Total counter display

06 Developing counter display

07 Mini maintenance preset display

08 SPF counter display

09 Paper feed counter display

12 Drum counter display

13 CRUM type display

14 P-ROM version display

15 Trouble memory display

17 Copy counter display

18 Printer counter display

21 Scanner counter display

22 SPF jam counter display

Contents

Main

code

Sub

code

24 01 Jam total counter clear

02 Trouble memory clear

04 SPF counter clear

06 Paper feed counter clear

07 Drum counter clear

08 Copy counter clear

09 Printer counter clear

13 Scanner counter clear

14 SPF jam total counter clear

15 Scanner mode counter clear

25 01 Main motor operation check

10 Polygon motor operation check

26 02 Size setting

05 Count mode setting

06 Destination setting

07 Machine condition check (CPM)

18 Toner save mode setting

30 CE mark conformity control ON/OFF

36 Cancel of stop at maintenance life over

37 Cancel of stop at developer life over

38 Cancel of stop at drum life over

39 Memory capacity check

42 Transfer ON/OFF timing control setting

43 Side void amount setting

51 Copy temporary stop function setting

30 01 Paper sensor status display

42 01 Developing counter clear

43 01 Fusing temperature setting

12 Standby mode fusing fan rotation setting

13 Fusing paper interval control allow/inhibit setting

44 34 Transfer current setting

40 Setting of rotation time before toner supply

46 01 Copy density adjustment (300dpi)

02 Copy density adjustment (600dpi)

09 Copy exposure level adjustment, individual setting

(Text) 300dpi

10 Copy exposure level adjustment, individual setting

(Text) 600dpi

11 Copy exposure level adjustment, individual setting

(Photo) 600dpi

18 Image contrast adjustment (300dpi)

19 Exposure mode setting

(Gamma table setting/AE operation mode setting/

Photo image process setting)

20 SPF exposure correction

29 Image contrast adjustment (600dpi)

30 AE limit setting

31 Image sharpness adjustment

48 01 Main/sub scanning magnification ratio adjustment

05 SPF/RSPF mode sub scanning magnification ratio

adjustment in copying

49 01 Flash ROM program writing mode

12 Standby mode fusing fan RPM setting

50 01 Image lead edge adjustment

06 Copy lead edge position adjustment (SPF/RSPF)

10 Paper off-center adjustment

12 Document off-center adjustment

51 02 Resist amount adjustment

53 08 SPF scanning position automatic adjustment

61 03 HSYNC output check

63 01 Shading check

07 SPF automatic correction

64 01 Self print

Contents

DP-1620 SIMULATIONS 7-1

Page 32

4. Contents of simulations

Main

Sub

code

code

01 01 Mirror scanning operation When the [START] key is pressed, the home position is checked in the first place, and the mirror

02 Mirror home position sensor

(MHPS) status display

06 Mirror scanning operation aging When the [START] key is pressed, the mirror base performs A3 full scanning at the set magnification

02 01 Single paper feeder (SPF) aging When the [START] key is pressed, the set magnification ratio is acquired and document transport

02 SPF sensor status display (In order to receive the sensor change notification, the load must be decreased.)

03 SPF motor operation check When the [START] key is pressed, the motor rotates for 10 sec at the speed corresponding to the set

08 SPG paper feed solenoid

operation check

11 SPF PS release solenoid operation

check

Contents Details of operation

base performs A3 full scanning once at the set magnification ratio speed. During this scanning, the

set magnification ratio is displayed. The mirror home position sensor status is displayed with the

photoconductor cartridge replacement lamp.

(The lamp lights up when the mirror is in the home position.)

During scanning, the copy lamp lights up.

When the [Interrupt] key is pressed, the operation is interrupted to go to the sub code input standby

mode.

Used to monitor the mirror home position sensor. When the sensor is ON, the photoconductor

cartridge replacement lamp is lighted. During that time, the display section displays the sub code.

When the [Interrupt] key is pressed, the machine goes to the sub code input standby mode.

(When the CA key is pressed, the simulation is terminated.)

ratio speed. During scanning, the set magnification ratio is displayed. After 3 seconds, the mirror

base performs full scanning again. During scanning, the set magnification ratio is displayed.

* When the [START] key is pressed again, the ready lamp turns and remains off.

The DV replacement/OPC drum cartridge replacement lamp displays the status of the mirror

home position sensor. (The lamp lights up when the mirror is in the home position.)

During aging, the copy lamp lights up. When the [Interrupt] key is pressed, the operation is

interrupted if operating, and the machine goes into the sub code input standby mode.

operation of single surface is performed in the case of SPF or document transport operation of

duplex surfaces is performed. During operation, the LED on the display section corresponding to the

selected magnification ratio lights up, and the magnification ratio is displayed on the 7-seg display.

When the [Interrupt] key is pressed at that time, the machine goes to the sub code input standby

mode. When the [CA] key is pressed, the simulation is terminated.

The sensor status (ON/OFF) in the SPF can be checked with the following lamps.

When a sensor detects paper, it turns on. The open/close detection sensor turns on when the

machine is opened.

Display lamp Sensor

Toner supply lamp

Copier jam lamp

The DV replacement/OPC drum cartridge

replacement lamp

Paper empty lamp

SPF jam lamp

Manual paper feed lamp

Tray jam lamp

AE lamp

TEXT lamp

PHOTO lamp

When the [Interrupt] key is pressed, the machine goes to the sub code input standby mode.

When the [CA] key is pressed, the simulation is terminated.

magnification ratio. When the [Interrupt] key is pressed, the machine stops operation and goes to the

sub code input standby mode. When the [CA] key is pressed, the simulation is terminated.

The SPF paper feed solenoid (PSOL) is turned ON for 500msec and OFF for 500msec.

This operation is repeated 20 times.

After completion of the process, the machine goes to the sub code input standby mode.

When the [Interrupt] key is pressed during the process, the machine goes to the sub code input

standby mode. When the [CA] key is pressed, the simulation is terminated.

The SPF PS release solenoid (CLH) is turned ON for 500msec and OFF for 500msec. This operation

is repeated 20 times.

After completion of the process, the machine goes to the sub code input standby mode. When the

[Interrupt] key is pressed during the process, the machine goes to the sub code input standby mode.

When the [CA] key is pressed, the simulation is terminated.

SPF document set sensor

SPF document transport sensor

SPF unit (OC cover) open/close sensor

SPF paper exit sensor

SPF paper feed cover open/close sensor

SPF paper length sensor 1

SPF paper length sensor 2

SPF paper feed width sensor (small)

SPF paper feed width sensor (middle)

SPF paper feed width sensor (large)

DP-1620 SIMULATIONS 7-2

Page 33

Main

code

Sub

code

Contents Details of operation

05 01 Operation panel display check <<LED check mode (ALL ON/Individual ON)>>

When the [START] key is pressed in the sub code input mode, all the LED's (including the 7-seg

lamps) are turned ON. After 5 sec of all ON, the machine goes to the sub code input standby mode.

When the [Mode select] key is pressed during all ON, the lighting mode is shifted to the individual ON

mode, where the LED's are individually lighted from the left top, to the left bottom, to the next line top,

to the bottom, and so on. (For the 7-seg lamps, the 3-digit lamps are lighted at once.)

After completion of lighting of all the lamps, the mode is shifted to the all ON mode.

After 5 sec of all ON mode, the machine goes to the sub code input standby mode.

Individual ON mode cycle: 300ms for ON 20ms for OFF

When the [Interrupt] key is pressed in the LCD check mode, the machine goes back to the sub code

input standby mode.

When the [CA] key is pressed, the simulation is terminated.

When the [START] key is pressed with all the lamps ON, the machine goes back to the key input

check mode.

<< Key input check mode>>

When the machine goes into the key input check mode, [- - -] is displayed on the copy quantity

display. Every time when a key on the operation panel is pressed, the input value is added on the

copy quantity display.

[- - -] [ 1] [ 2] •••.

When a key is pressed once, it is not counted again.

When the [START] key is pressed, the input number is added and displayed for 3 sec, and the

machine goes into the LED lighting check mode (LED all ON state). When the [Interrupt] key is

pressed for the first time, it is counted. When the key is pressed for the second time, the machine

goes into the sub code input mode. When the [CA] key is pressed for the first time, it is counted.

When the key is pressed for the second time, the simulation is terminated. (Note for the key input

check mode).

•Press the [START] key at the end. (When the key is pressed during the process, the machine goes

into the LED lighting check mode (all ON state).).

•When two or more keys are pressed simultaneously, they are ignored.

02 Fusing lamp and cooling fan

operation check

When the [START] key is pressed, the fusing lamp turns ON for 500ms and OFF for 500ms.

The operation is repeated 5 times. During this process, the cooling fan motor rotates.

After completion of the process, the machine goes into the sub code input standby mode.

03 Copy lamp lighting check When the [START] key is pressed, the copy lamp lights up for 5 sec. After completion of lighting, the

machine goes into the sub code input mode.

When the [Interrupt] key is pressed, the process is interrupted and the machine goes into the sub

code input standby mode. When the [CA] key is pressed, the simulation is terminated.

06 01 Paper feed solenoid operation

check

When this simulation is executed, the sub code is displayed on the 7-seg LED and the lamp

corresponding to the solenoid lights up.

Select a solenoid with the tray select key (the lamp corresponding to the solenoid lights up) and

press the [START] key, and the machine repeats operation of ON for 500ms and OFF for 500ms.

This operation is repeated 20 times.

After that, the machine goes into the sub code entry standby mode.