Page 1

AUTOMA TIC DOCUMENT FEEDER

MR-2012

File No. 31100013

Page 2

General Precautions for Installation/Servicing/Maintenance for the MR-2012

The installation and service should be done by a qualified service technician.

1. When installing the MR-2012 to the Plain Paper Copier , be sure to follow the instructions described in

the “Unpacking/Set-Up Procedure for the MR-2012” booklet which comes with each unit of the

MR-2012.

2. The MR-2012 should be installed by an authorized/qualified person.

3. Before starting installation, servicing or maintenance work, be sure to turn off and unplug the copier

first.

4. When servcing or maintaining the MR-2012, be careful about the rotating or operation sections such

as gear, pulleys , sproc k ets, cams , belts, etc.

5. When parts are disassembled, reassembly is basically the reverse of disassemb ly unless otherwise

noted in this manual or other related materials. Be careful not to reassemble small parts such as

screws, washers, pins, E-rings, toothed washers to the wrong places .

6. Basically, the machine should not be operated with any parts removed or disassembled.

7. Delicate parts for preventing safety hazard problems (such as breakers, thermofuses, fuses, door

switches, sensors, etc. if any) should be handled/installed/adjusted correctly .

8. Use suitable measuring instruments and tools.

9. During servicing or maintenance work, be sure to check the serial No. plate and other cautionary

labels (if any) to see if they are clean and firmly fixed. If not, take appropriate actions.

10. The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband,

because the ICs on it may be damaged due to static electricity . Before using the wrist band, pull out

the power cord plug of the copier and make sure that there is no uninsulated charged objects in the

vicinity.

11. For the recovery and disposal of used MR-2012, consumable par ts and packing materials, it is

recommended that the relevant local regulations/rules should be follo wed.

12. After completing installation, servicing and maintenance of the MR-2012, return the MR-2012 to its

original state, and check operation.

Copyright 2000

TOSHIBA TEC CORPORATION

Page 3

CONTENTS

1. SPECIFICATIONS....................................................................................................... 1-1

2. OUTLINE..................................................................................................................... 2-1

2.1 Names of Various Components........................................................................................ 2-1

2.2 Layout of Electrical Parts ................................................................................................. 2-2

2.3 Harness Connection Diagram .......................................................................................... 2-4

2.4 Board Assembly ............................................................................................................... 2-5

3. OPERATIONAL DESCRIPTION .................................................................................. 3-1

3.1 General Operation............................................................................................................ 3-1

3.2 Block Diagram.................................................................................................................. 3-1

3.3 Detection of Abnormal Status ..........................................................................................3-2

3.3.1 Cover open/Close detection.................................................................................. 3-2

3.3.2 Feeder jam detection ............................................................................................ 3-2

3.3.3 ADF registration sensor stay jam detection .......................................................... 3-2

3.3.4 ADF read sensor unreached jam detection........................................................... 3-2

3.3.5 ADF read sensor stay jam detection..................................................................... 3-2

3.3.6 ADF exit sensor unreached jam detection ............................................................ 3-2

3.4 Flow Chart........................................................................................................................ 3-3

4. MECHANICAL DESCRIPTION................................................................................... 4 - 1

4.1 Paper Feed System.......................................................................................................... 4-1

4.2 Document Size Detection Method.................................................................................... 4-2

4.3 Drive System.................................................................................................................... 4-4

5. CIRCUIT DESCRIPTION ............................................................................................ 5-1

5.1 PWA Block Diagram......................................................................................................... 5-1

5.2 Detection Circuit............................................................................................................... 5-1

5.3 ADF Read Sensor Input Circuit........................................................................................ 5-2

5.4 ADF Motor Drive Circuit ................................................................................................... 5- 3

5.5 Meaning of Signals........................................................................................................... 5-4

5.6 Timing Chart .................................................................................................................... 5-5

6. DISASSEMBLY AND REPLACEMENT...................................................................... 6-1

October 2000 © TOSHIBA TEC 1 MR-2012 CONTENTS

Page 4

1. SPECIFICATIONS

Function : Auto document feeder

No. of originals loaded : Up to 50 originals (13 to 29 lb)

Document size : A5-R (Min.) to A3 (Max.)

Dimensions : 530 (W) x 450 (D) x 120 (H) mm

Weight : Approx. 5.4 kg

Pow er supply : 5V, 24V (Supplied from copier)

October 2000 © TOSHIBA TEC 1 - 1 MR-2012 SPECIFICATIONS

Page 5

2. OUTLINE

2.1 Names of Various Components

Document guide R

Connection Cable

Document tray

Document guide F

ADF top cover

ADF 02-01-01

October 2000 © TOSHIBA TEC 2 - 1 MR-2012 OUTLINE

Page 6

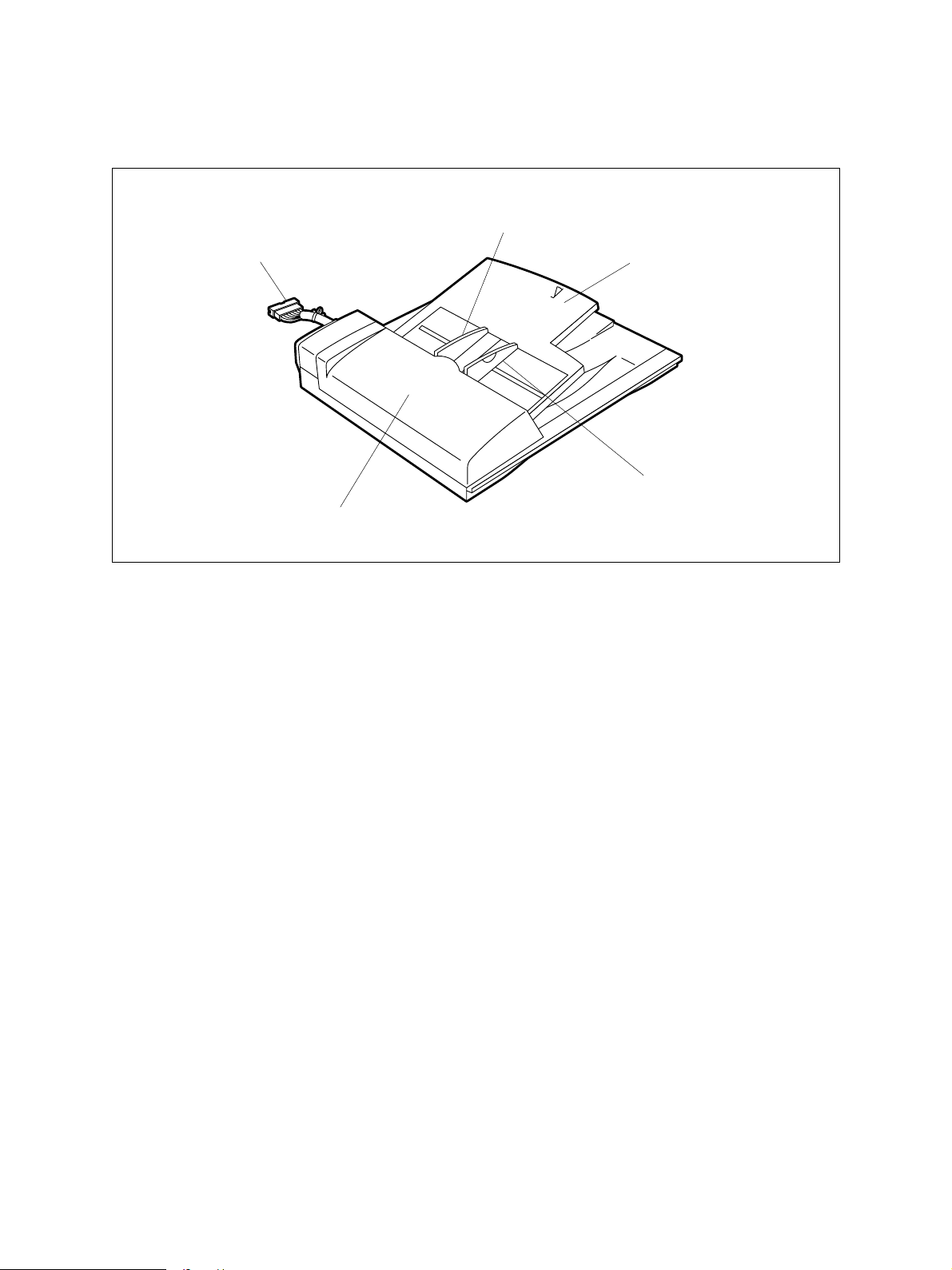

2.2 Layout of Electrical Parts

SEN4

SEN2

VR1

SEN3

SEN6

SEN5

SW1

SEN1

ADF 02-02-01

ADF PWA

M1

ADF 02-02-02

MR-2012 OUTLINE 2 - 2 October 2000 © TOSHIBA TEC

Page 7

Symbols and functions of various devices

Symbol

SW1

VR1

SEN1

SEN2

SEN3

SEN4

SEN5

SEN6

ADF

Name

ADFCOV-SW

ADF top cover open switch

WIDTH-VR

Document width sensor

ADFOPN-SEN

ADF open sensor

SIZE-SEN

Document length sensor

EMPTY-SEN

Document empty sensor

REGST-SEN

ADF registration sensor

POS-SEN

ADF read sensor

HAISI-SEN

ADF exit sensor

ADF PWA

Function

Detects the open/close state of the top cover

during jamming processing, etc.

Detects the width of document.

Detects the open/close state of the ADF unit.

Detects the length of document.

Detects the loading of document.

Detects the aligning position of document.

Detects the document scanning start position.

Detects the ejection of document.

PWA which relays the sensor signals and motor

M1

ADF-MOT

ADF motor

drive signals.

Drives the roller to transport originals.

October 2000 © TOSHIBA TEC 2 - 3 MR-2012 OUTLINE

Page 8

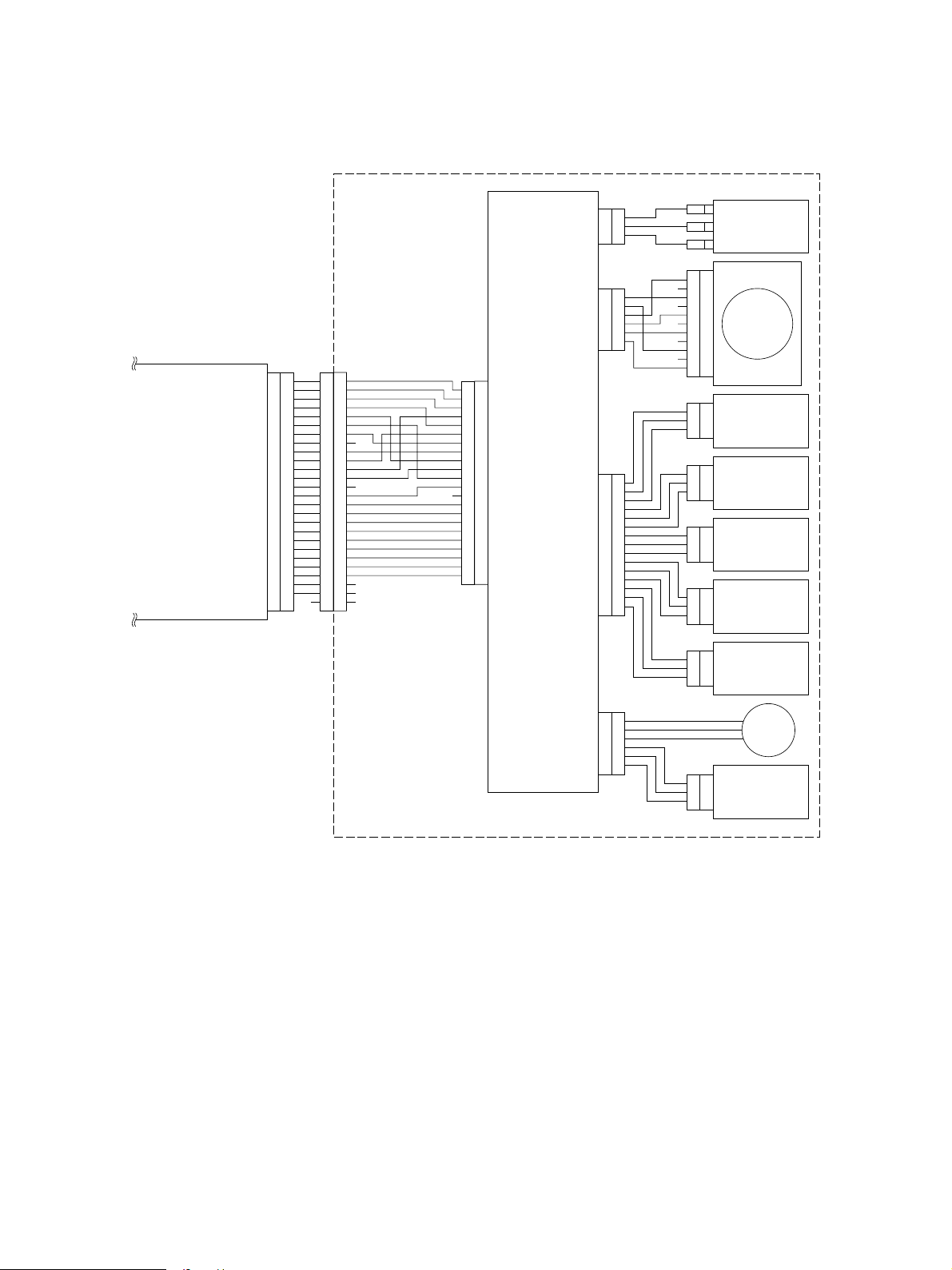

2.3 Harness Connection Diagram

ADF

CN2

MOT+24V

+24V

COVER

1

2

3

N.O.

COM

top cover open switch

N.C.

ADF

Scanner control PWA

CN6

+24V 1

+24V

2

/AA34

/BB56

PG 7

PG

8

+5V 9

D/A

10

POS 11

REGST/ACK

12

VALID/DFFAN 13

5VPS

14

EMPTY 15

DF OPN

16

COVER/RXD 17

SG

18

WIDTH/TXD 19

SG

20

HAISI/DF-ACK 21

SIZE2/DF-REQ

ADF CNT/REQ 23

22

RADF CNT

24

SG 25

NC FG FG

26

CN3

1

MOT+24V

2

MOT+24V

3

A

4

/A

5

B

6

/B

1

2

3

4

5

6

7

8

NC

9

10

11

12

13

NC

14

15

16

17

18

19

20

21

22

23

24

NC

25

NC

26

NC

CN1

1

2

3

4

5

6

7

8

9

10

11

12

ADF PWA

13

14

15

16

17

18

19

20

21

22

CN4

HAI+5V

HAISI

POS

REG+5V

REGST

EMP+5V

EMPTY

OPN+5V

DF_OPN

CN5

WIDTH+5V

WIDTH

SIZE+5V

SIZE

1

2

SG

3

4

+5V

5

6

D/A

7

8

SG

9

10

11

SG

12

13

14

SG

15

1

2

3

SG

4

5

SG

6

1

2

NC

3

NC

4

5

6

NC

NC

NC

CN12

CN6

CN9

CN10

CN11

CN12

ADF motor

7

8

9

10

11

3

2

ADF exit sensor

1

3

2

ADF read sensor

1

3

ADF registration

2

1

3

2

Document empty sensor

1

3

2

ADF open sensor

1

3

2

Document length sensor

1

sensor

Document

width

sensor

ADF 02-03-01

MR-2012 OUTLINE 2 - 4 October 2000 © TOSHIBA TEC

Page 9

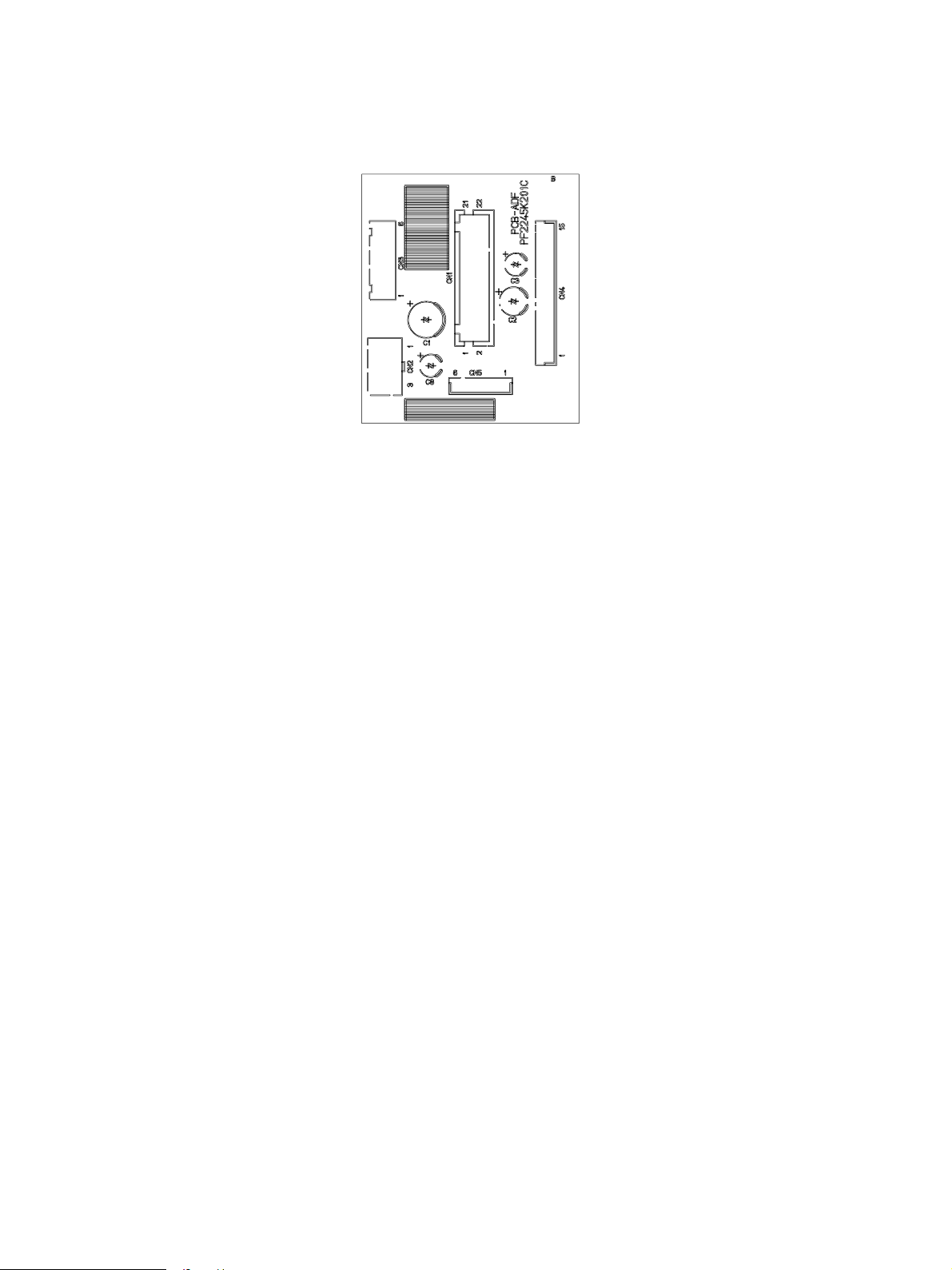

2.4 Board Assembly

ADF 02-04-01

October 2000 © TOSHIBA TEC 2 - 5 MR-2012 OUTLINE

Page 10

3. OPERATIONAL DESCRIPTION

3.1 General Operation

The ADF is an auto document feed unit capable of accommodating a maximum of 50 originals. The

originals loaded are fed and scanned one by one and stacked on the e xit tray. The ADF has a mechanical

section for document transport, sensors to detect the position of document, etc., and a motor for transport. It also has one PWA where comparator IC’s only are installed and the other signals simply pass.

For this reason, all control and processing are performed by the scanner PWA.

3.2 Block Diagram

ADF

Scanner

PWA

CN6

CN1

ADF

PWA

CN4CN5

CN2CN3

ADF read sensor

ADF open cover sensor

ADF registration sensor

Document empty sensor

ADF exit sensor

Document length sensor

Document width sensor

ADF top cover open switch

ADF motorM

ADF 03-02-01

October 2000 © TOSHIBA TEC 3 - 1 MR-2012 OPERA TIONAL DESCRIPTION

Page 11

3.3 Detection of Abnormal Status

3.3.1 Cover open/Close detection

When the ADF top cover is opened, the contact of the ADF top cover open switch changes to cut the

supply of 24V to the motor and sends a cover open detection signal to the scanner PWA.

3.3.2 Feeder jam detection

The number of pulses (time) equivalent to the distance ( ) from the document set position to the ADF

registration sensor ON position plus 300 mm is regarded as timing for detecting a jam. When the time

from the moment of starting paper feed to the moment when the ADF registration sensor is turned ON

exceeds that value, a jam in the feeder will be detected.

3.3.3 ADF registration sensor stay jam detection

The number of pulses (time) equivalent to the distance obtained by subtracting 115 mm ( + ) from

the document length plus 30 mm (1115 mm for long mode) is regarded as timing for detecting a jam.

When the time from the moment when the ADF exit sensor is turned ON to the moment when the ADF

registration sensor is turned OFF exceeds that value, a ADF registration sensor stay jam will be detected.

3.3.4 ADF read sensor unreached jam detection

The number of pulses (time) equivalent to the distance ( ) from the ADF registration sensor to the ADF

read sensor plus 30 mm is regarded as timing for detecting a jam. When the time from the moment of

starting the transport of the document having reached the ADF registration sensor to the moment when

the ADF read sensor is turned ON exceeds that value, an ADF read sensor unreached jam will be

detected.

3.3.5 ADF read sensor stay jam detection

The number of pulses (time) equivalent to the distance ( ) from the ADF registration sensor to the ADF

read sensor plus 30 mm is regarded as timing for detecting a jam. When the time taken after the end of

the document passes the ADF registration sensor exceeds that v alue , an ADF read sensor stay jam will

be detected.

3.3.6 ADF exit sensor unreached jam detection

The number of pulses (time) equivalent to the distance ( ) from the moment when the ADF read sensor

is turned ON to the moment when the exit sensor is turned ON plus 35 mm is regarded as timing for

detecting a jam. When the time tak en after the top of the document passes the ADF read sensor exceeds

that value, an ADF exit sensor unreached jam will be detected.

ADF registration sensor

ADF read sensor

Document empty sensor

ADF exit sensor

adf 03-03-06

MR-2012 OPERATIONAL DESCRIPTION 3 - 2 October 2000 © T OSHIBA TEC

Page 12

3.4 Flow Chart

Start button ON

Document feed from ADF

Scanning of document

Cassette feed

Copy

Ejection

NO

Scanning of

final document

YES

End

October 2000 © TOSHIBA TEC 3 - 3 MR-2012 OPERA TIONAL DESCRIPTION

Page 13

4. MECHANICAL DESCRIPTION

4.1 Paper Feed System

Document length sensor

ADF 04-01-01

ADF registration sensor

Registration roller

Read roller

Document empty sensor

Feed roller

ADF read sensor

Pickup roller

Flow of document

Exit roller

ADF exit sensor

Document width sensor

Transport of Document

When a document is placed in the tray, the document empty sensor detects the presence of a document.

When the Start button is pressed on the copier while in ADF mode, the ADF motor operates to lower the

pickup roller and pull in the document. Where there are more than one document, they are separated by

the separation pad under the feed roller and transported one by one.

The document transported by the feed roller is detected by the ADF registration sensor and then stopped

when the leading edge of the document reaches the registration roller after being fed f or a certain distance.

This feed amount can be adjusted by the aligning amount adjustment (05-354).

Then, the read roller rotates and the scanner starts scanning when the document reaches the ADF read

sensor.

The scanned document passes over the ADF exit sensor, then is ejected by the exit roller.

October 2000 © TOSHIBA TEC 4 - 1 MR-2012 MECHANICAL DESCRIPTION

01/05

Page 14

4.2 Document Size Detection Method

The size of document is found by detecting the document width by the document width sensor, and the

document length by the document length sensor. When documents of different sizes are placed in the

tray, this detection method allows the maximum size of the documents to be detected. The document

size is detected according to the timing with which the document empty sensor is turned ON, the timing

with which the document width sensor changes, and the timing with which the document length sensor

changes. The detected size is sent to the copier.

When the ADF is on standby or the document empty sensor is ON, the document width sensor is

checked e very 100 ms and the value obtained is compared with that of the last time. If the value is found

changed as a result of the comparison, the document size will be detected and sent to the copier when

in ADF active mode. When this unit receives a command accompanied by a document size notice

request from the copier, it will also detect and send the document size to the copier.

Document empty

sensor

Document width

sensor

Document length

sensor

ADF as viewed from top

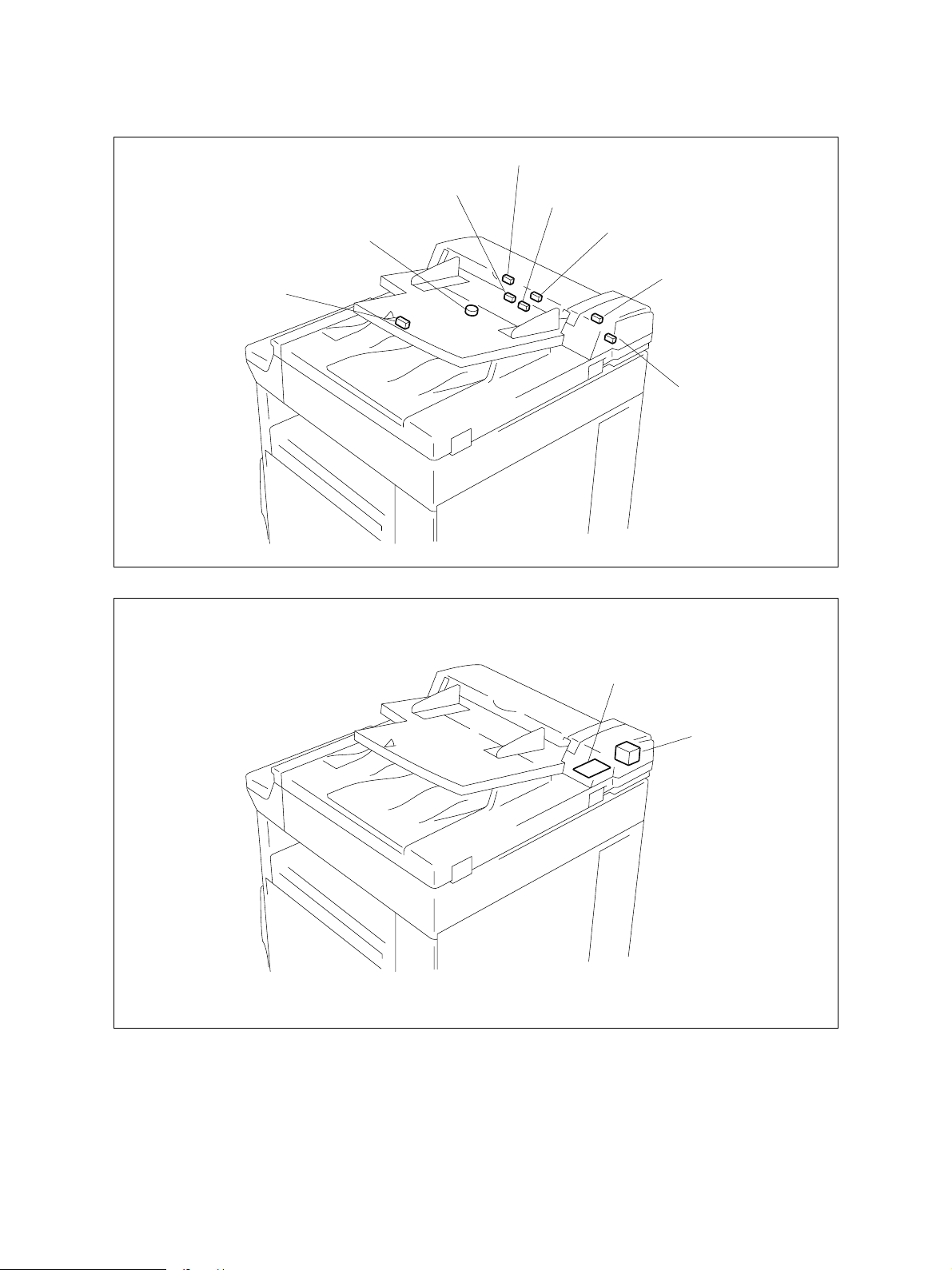

The detection results of the document size sensors are listed below . (Unit: mm)

A4 series

Document width Document length sensor (*1)

OFF ON

129.40 - 165.99 A5R (148 x 210)

166.00 - 196.99 B5R (182 x 257)

197.00 - 233.99 A4R (210 x 297) FOLIO (210 x 330)

234.00 - 277.99 B5 (257 x 182) B4 (257 x 364)

278.00 - 310.00 A4 (297 x 210) A4 (297 x 420)

(*1: ON for a document length of 306 mm)

adf 04-02-01

MR-2012 MECHANICAL DESCRIPTION 4 - 2 October 2000 © TOSHIBA TEC

Page 15

L T series

Document width Document length sensor (*1)

OFF ON

129.40 - 177.99 STR (139.7 x 215.9)

178.00 - 236.99 LTR (215.9 x 279.4) LG (215.9 x 355.6)

237.00 - 268.99 COMPUTER (257.2 x 356)

269.00 - 310.00 LT (279.4 x 215.9) LD (279.4 x 431.8)

(*1: ON for a document length of 306 mm)

October 2000 © TOSHIBA TEC 4 - 3 MR-2012 MECHANICAL DESCRIPTION

Page 16

4.3 Drive System

Pickup roller

Front side

Spring Clutch

Rear side

ADF motor

One-way clutch

Feed roller

Read roller

ADF 04-03-01

The driving force of the ADF motor is transmitted to each roller through the gears and belts. It is transmitted to the feed rollers through the timing belt and gears (3 pcs.) and further transmitted to the pickup roller

through the timing belt. The driving f orce is transmitted to the read roller through the two timing belts and

the gears connecting them. The shaft part of the read roller is provided with a one-way clutch allo wing the

driving force of the ADF motor to be transmitted only in the transport direction (counterclockwise) for

rotation.

Document Feed

The document is fed as the ADF motor turns clockwise as viewed from the front (in the direction of the

black arrow). When the ADF motor turns clockwise, the pickup roller lowers to pull in the document. At

this time, the read roller does not turn due to the function of the one-way clutch.

Document Transport

The document is transported as the ADF motor turns counterclockwise as viewed from the front (in the

direction of the white arrow). When the ADF motor turns counterclockwise, the pickup roller ascends

causing the spring clutch mounted on the feed roller shaft to slip so that the driving force is no longer

transmitted.

MR-2012 MECHANICAL DESCRIPTION 4 - 4 October 2000 © TOSHIBA TEC

Page 17

5. CIRCUIT DESCRIPTION

5.1 PWA Block Diagram

ADF PWA

+24V

1

2

3

A

4

POS

5

/A

6

D/A

7

+5V

PG

8

B

9

REGST

10

/B

Relay PWA

11

CN1

P+5V

12

13

NC

EMPTY

14

DF-OPN

15

COVER

16

17

WIDTH

18

19

HAISI

20

21

SIZE

22

SG

1

MOT+24V

+24V

2

CN2

COVER

Q1

SG

IC1

-

1

+

-

2

+

-

13

+

-

14

+

+5V

6

7

4

5

10

11

+5V

R2

R4

SG

8

9

3

1

2

3

4

CN3CN4CN5

5

6

1

2

3

HAISI

4

5

6

7

REG+5V

8

9

P+5V

10

11

12

13

OPN+5V

14

15

SG

+5V

1

2

3

4

5

6

SIZE

SG

ADF

top cover open switch

ADF motor

ADF exit sensor

ADF read sensor

ADF registration sensor

Document empty sensor

ADF open sensor

Document

width

sensor

Document length sensor

ADF 05-01-01

5.2 Detection Circuit

The ADF top cover open s witch detects the open or close state of the ADF top cov er. 24V is supplied to

the motor when the cover is closed, and switches to the tr ansistor Q1 side when open. The output of Q1

turns to “Low” level when the cover is open and the detection signal is sent to the scanner PWA from

CN1.

The document width sensor uses a variable resistor for its detection element. It divides the v oltage of 5V

through the variable resistor and sends the output to the scanner PW A. The scanner PW A A-D conv erts

the input voltage to calculate the document width.

The outputs of the ADF exit sensor, ADF registration sensor, ADF open sensor, and document length

sensor each are input to the IC1 comparator. The reference voltage obtained by dividing 5V though R2

and R4 is input to the other input of the comparator. The detection level of each sensor is stabilized

according to this reference voltage value and output from the comparator. Since the document empty

sensor does not require accuracy for detecting the presence of a document, its output signal simply

passes through the ADF PWA.

October 2000 © TOSHIBA TEC 5 - 1 MR-2012 CIRCUIT DESCRIPTION

Page 18

5.3 ADF Read Sensor Input Circuit

ADFScanner

+5V

5

POS_DA

REF_DA

IPOS

POS_AD

The ADF read sensor input circuit is installed on the scanner PWA. The ADF PWA only allo ws the signal

+

IC7

6

-

3

+

IC7

2

-

R23

7

IC8

R18

7

1

5

+

6

-

R22

C19

Q2

R19

R17

C16C17

ADF 05-03-01

only to pass through. Therefore, this section describes the ADF read sensor input circuit on the scanner

PWA.

The ADF read sensor is a mirror reflective type sensor and consists of a pair of a infrared LED and a PTr

(phototransistor) each having an optical axis in the same direction. A mirror is provided on an extended

line of the optical axis of the sensor. When there is no document between the sensor and the mirror, an

infrared light emitted from the LED is reflected to PTr at high reflectance. When there is a document

between them, the emission to the mirror and the reflected light from the mirror are obstructed by the

document so that the reflected light incident on PTr becomes extremely low. When a quantity of light

incident on PTr is large (no document present), photoelectric current flowing through PTr increases and

a drop in voltage due to R17 causes the voltage at pin 6 of IC8 to rise.

IC8 is a comparator which compares the reference voltage input to pin 5 (non-inverting input) with the

signal voltage at pin 6 (inv erting input). When the voltage at pin 6 is higher , the output (pin 7 of IC8) turns

to “Low” level. Conversely, when a quantity of light incident on PTr is small (a document present), the

voltage at pin 6 of IC8 becomes low and as a result pin 7 of IC8 turns to “High” level.

An automatic sensitivity adjusting function is also provided to control variations in sensor sensitivity.

When the sensor sensitivity adjust mode is selected, the automatic adjustment measures the output

voltage (analog value) of PTr at the A-D input terminal on the scanner side, changes the D-A output

voltage on the scanner side to make the PTr output voltage become the required v oltage, and adjusts the

LED current through the voltage-current conversion circuit consisting of IC7, Q2, R20, etc.

MR-2012 CIRCUIT DESCRIPTION 5 - 2 October 2000 © TOSHIBA TEC

Page 19

5.4 ADF Motor Drive Circuit

Scanner control PWA

IC1

Scanner MPU

+24V

1,2

CPUA0~19

CPUD0~15

5,16

2,13

6

17

3

14

IC10

Motor driver

+5V

2

1

Q1

5

R5C6C7

SG PGSGSG

A

13

/A

84

B

11 5

/B

18

9

10

R1,R2

R3,R4

IC4

Motor

control IC

76

74

77

78

72

75

APWM

ACKO

ASTB

ADTA

ADTB

AENB

R8 R7 R6

The ADF motor operates according to the driving signals from the scanner PWA. The signals only pass

ADF top cover open switch

1,2

3

CN6

CN1

5

9

6

11

CN2

21

ADF PWA

1,2

ADF motor

3

CN3

4

5

6

A

/A

B

/B

ADF 05-04-01

through the ADF PWA. Therefore, this section describes the ADF motor drive circuit on the scanner

PWA.

The ADF motor is driven by amplifying the pulse motor driving pattern signals output from the gate array

through the IC10 motor driver. These signals control the motor rotational direction and speed. The PWM

signal is input to APWM and converted to a certain voltage through the resistor and capacitor. The

voltage is input to IC10 (pins 3 and 14) to set the current value for the motor.

The current value for the motor can be set as desired b y changing the duty of the PWM signal. AENB is

a signal to control the output of the motor driver. When the signal is at “High” level, the output of the driver

becomes effective.

October 2000 © TOSHIBA TEC 5 - 3 MR-2012 CIRCUIT DESCRIPTION

Page 20

5.5 Meaning of Signals

Signal name

COVER

DF_OPN

SIZE

WIDTH

EMPTY

REGST

POS

HAISI

Part name

ADF top cover

open switch

ADF open

sensor

Document

length sensor

Document width

sensor

Document

empty sensor

ADF registration

sensor

ADF read

sensor

ADF exit sensor

Functional description

Detects the open/close state

of the top cover during jamming processing, etc.

Detects the open/close state

of the ADF unit.

Detects the length of document.

Detects the width of document.

Detects the loading of document.

Detects the aligning position

of document.

Detects the document scanning start position.

Detects the ejection of document.

Status

-

Low: Open

Low: Document present

-

Low: Document present

Low: Document present

Low: Document present

Low: Document present

Note

Microswitch

Photo sensor

Photo sensor

Variable resistor

Photo sensor

Photo sensor

Photo sensor

Photo sensor

The ADF top cover open s witch detects the open or close state of the cover and uses a 2-circuit microswitch.

24V is supplied to the motor when the cover is closed, and cut when open.

The ADF open sensor detects the open/close state of the ADF unit. A photo sensor is used for the

sensor.

The document length sensor detects the length of the document placed in the document tray. A photo

sensor is used for the sensor. It turns ON when the document length exceeds 306 mm.

The document width sensor detects the width of the document. A v ariable resistor is used f or the sensor.

The resistive value changes as the document width guide is slid.

The ADF empty sensor detects the document placed in the document tray. A photo sensor is used for

the sensor.

The ADF registration sensor detects the document position in the transport path. A photo sensor is used

for the sensor. It detects a paper jam in combination with other sensors.

The ADF read sensor detects the document scanning start position. A mirror reflective type photo

sensor is used for the sensor. It detects the presence or absence of a document according to the

strength of reflected light from the mirror.

The document exit sensor detects the ejection of a document. A photo sensor is used for the sensor.

MR-2012 CIRCUIT DESCRIPTION 5 - 4 October 2000 © TOSHIBA TEC

Page 21

5.6 Timing Chart

(14)

(11)

Pre-feed Paper-feed Scan Eject

(12) (13)

(11)

(3) (4) (5) (1) (3) (4) (5) (6)

(10) (10)

(9) (9)

(2) (2)

ON

(8) (8)

OFF

ON

OFF

ON

OFF

ON

(1)

Forward

OFF

OFF

Reverse

ADF motor

October 2000 © TOSHIBA TEC 5 - 5 MR-2012 CIRCUIT DESCRIPTION

Document

empty sensor

ADF registration

sensor

ADF read sensor

ADF exit sensor

ADF 05-06-01

Page 22

6. DISASSEMBLY AND REPLACEMENT

[A] ADF unit

1. Release 2 hooks, and detach ADF cover.

2. Release the clamp and detach one connector.

3. Open ADF unit and take it out by lifting.

Hook

ADF cover

ADF unit

Connector

Fig. 6-1

Fig. 6-2

Clamp

160

161

[B] Document tray assembly

1. Open ADF top cover.

2. Remove one screw, release 3 hooks, and detach ADF cover R.

3. Detach one connector from ADF PWA (CN5).

ADF top cover

162

Fig. 6-3

ADF cover R

Screw

Hook

ADF PWA

Hook

CN5

Connector

163

Fig. 6-4

October 2000 © TOSHIBA TEC 6 - 1 MR-2012 DISASSEMBLY AND REPLACEMENT

Page 23

4. Remove one scre w and remove document tr ay

support.

5. Detach document tray support from the harness.

6. Move document tray assembly in the direction

of the arrow and remove it.

Document tray

assembly

Document

tray support

[C] Document tray cover

1. Remove ADF. (See Fig. 6-1 and 6-2)

2. Remove document tra y assembly. (See Fig. 6-3

to 6-5)

3. Remove 3 screws and detach document tray

cover.

[D] Document width sensor assembly

1. Remove ADF. (See Fig. 6-1 and 6-2)

2. Remove document tra y assemb ly.

(See Fig. 6-3 to 6-5)

3. Detach document tray co v er . (See Fig. 6-6)

4. Release the harness from the clamp and detach the document length sensor harness.

Document width

volume assembly

Harness

Fig. 6-5

Screw

Fig. 6-6

Screw

Document

tray cover

Screw

164

165

5. Remove one screw, release the hook, and re-

Clamp

move document width sensor assembly.

Clamp

166

Fig. 6-7

Notes: 1. Align the arrow ( ↑ ) mark of sensor

holder with that of document guide

Sensor holder

Document guide

rack

gear.

2. Align the cut part of document guide rack

with the triangle mark ( ) of document

guide gear.

Document

guide gear

Document guide

rack

MR-2012 DISASSEMBLY AND REPLACEMENT 6 - 2 October 2000 © TOSHIBA TEC

Fig. 6-8

167

Page 24

[E] ADF top cover assembly

1. Remove document tra y assembly . (See Fig. 6-3

to 6-5)

2. Detach 2 stop rings, release the tab, and remove ADF top cov er assemb ly.

Stop ring

ADF top cover

assembly

Stop ring

[F] ADF pickup roller assembly/ADF pic kup roller/

ADF pickup feed roller

1. Open ADF top cover . (See Fig. 6-3)

2. Remove 2 screws , and remove ADF document

guide.

3. Remove two each of stop ring and bushing and

remove ADF pickup roller assemb ly.

ADF document guide

Fig. 6-9

Fig. 6-10

Stop ring

Bushing

168

Screw

169

Stop ring

170

4. Detach 2 stop rings and remove shutter stop-

ADF pickup roller

assembly

ADF holder F

Fig. 6-11

Stop ring

per.

5. Slide ADF holder F in the direction of the arrow

Straight Pin

Shutter Stopper

and draw out pin.

Shutter Stopper

171

Fig. 6-12

October 2000 © TOSHIBA TEC 6 - 3 MR-2012 DISASSEMBLY AND REPLACEMENT

Page 25

6. Remove Spring, ADF holder F, and washers in

this order, and remov e timing belt.

7. Remove ADF pickup roller and ADF pickup f eed

roller.

Note: Apply 0.1g of Sumitec 505 No . 1 (white) to

the outer circumference of the spring.

ADF pickup

feed roller

Spring

Washer

ADF pickup roller

Timing belt

[G] ADF pad/brake pad

1. Open ADF top cover. (See Fig. 6-3)

2. Release the hook and remove ADF pad unit.

3. Release the tab and remove ADF pad.

Hook

ADF holder F

Fig. 6-13

Hook

Fig. 6-14

Tab

172

ADU pad unit

Hook

173

ADF pad

174

Fig. 6-15

4. Remove the old brak e pad, wipe off the mount-

Brake pad

ing surface, and mount a new br ake pad to the

position shown below .

Brake pad

175

Fig. 6-16

MR-2012 DISASSEMBLY AND REPLACEMENT 6 - 4 October 2000 © TOSHIBA TEC

Page 26

[H] ADF PWA

1. Open ADF top cover . (See Fig. 6-3)

2. Remove one screw, release 3 hooks, and detach ADF cover R.

Screw

ADF cover R

Hook

Hook

3. Detach all the connectors from ADF PWA.

4. Remove 2 screws and remov e ADF PWA.

[I] ADF feed guide assembly

1. Remove document tra y assemb ly.

(See Fig. 6-3 to 6-5)

2. Remove ADF top cov er assemb ly.

(See Fig. 6-9)

3. Detach the connectors from ADF PWA (CN2CN4), remove one screw , and detach the ground

Fig. 6-17

176

Screw

ADF PWA

177-1

Fig. 6-18

Connector

ADF PWA

CN2 CN3

CN4

wire.

Ground wire

Fig. 6-19

4. Remove 4 screws, release 2 hooks , and remove

ADF feed guide assembly.

Hook

ADF feed guide assembly

Screw

Hook

Fig.6-20

October 2000 © TOSHIBA TEC 6 - 5 MR-2012 DISASSEMBLY AND REPLACEMENT

Screw

177-2

Screw

Hook

178

Page 27

Note: Mount ADF feed guide assemb ly with mylar

on exit pinch roller up.

[J] ADF feed motor assembly

1. Remove document tra y assemb ly.

(See Fig. 6-3 to 6-5)

2. Remove ADF top cov er assemb ly.

(See Fig. 6-9)

3. Remove ADF f eed guide assembly.

(See Fig. 6-19 and 6-20)

4. Detach one connector from platen sensor, and

release the harness of ADF feed motor assembly from the clamp.

5. Remove one screw and detach the ground wire .

Mylar

Exit pinch roller

Harness

Clamp

Fig. 6-21

Ground wire

Platen sensor

Fig. 6-22

ADF feed guide

assembly

179

Screw

Connector

180

6. Remove 3 scre ws, release timing belt 166, and

remove ADF f eed motor assembly.

7. Remove tension spring 2.

Tension spring

Screw

Fig. 6-23

Screw

ADF feed

motor assembly

Timing belt 166

181

MR-2012 DISASSEMBLY AND REPLACEMENT 6 - 6 October 2000 © TOSHIBA TEC

Page 28

Notes: Installation procedure for timing belt 166

1. While hooking timing belt 166 around

feed pulley M-66, secure ADF feed motor assembly with 2 screws.

2. Mount tension spring 2 and secure the

Screw

ADF feed motor

assembly

Timing belt 166

Tension spring 2

Fig. 6-24

Screw

Feed pully M-66

182

belt bracket 2 with one scre w.

[K] Read roller shaft assembly/ Read r oller shaft

1. Remove document tra y assemb ly.

(See Fig. 6-3 to 6-5)

2. Remove ADF top cov er assemb ly.

(See Fig. 6-9)

3. Remove ADF feed guide assemb ly.

(See Fig. 6-19 and 6-20)

4. Remove ADF feed motor assemb ly.

(See Fig. 6-22 and 6-23)

5. Remove one screw, release 2 hooks, and de-

Belt bracket 2

Screw

Fig. 6-25

Screw

Fig. 6-26

183

Sensor cover R

Hook

184

tach sensor cover R.

October 2000 © TOSHIBA TEC 6 - 7 MR-2012 DISASSEMBLY AND REPLACEMENT

01/05

Page 29

6. Remove one scre w and remo v e e xit plate .

Screw

Exit plate

7. Release 4 hooks and detach harness cover .

8. Remove one screw and remo ve the ground wire

and ADF registration sensor brack et.

Hook

Harness cover

ADF registration

sensor bracket

Fig. 6-27

Fig. 6-28

Screw

185

Hook

186

Ground wire

187

Fig. 6-29

9. Remove one screw and remo ve the ground wire

and ADF exit/read sensor bracket while push-

Screw

Ground wire

ADF exit/read sensor bracket

ing the part indicated by the arrow.

Fig. 6-30

MR-2012 DISASSEMBLY AND REPLACEMENT 6 - 8 October 2000 © TOSHIBA TEC

188-1

Page 30

10. Remove the mylar sheet.

Mylar sheet

188-2

Fig. 6-31

Note: Before attaching the mylar sheet, wipe the

surface to be attached. Attach the mylar

sheet by holding it to the two ends. Attach

the sheet securely with no portion lifted.

11. Detach the E-ring and remove f eed pulley M-66.

Mylar sheet

188-3

Fig. 6-32

Feed pulley M-66

E-ring

Fig. 6-33

189

12. Detach the E-r ing, slide bearing inwards, and

remove Read roller shaft assembly.

Bearing

E-ring

Read roller shaft assembly

Bearing

190

Fig. 6-34

October 2000 © TOSHIBA TEC 6 - 9 MR-2012 DISASSEMBLY AND REPLACEMENT

01/05

Page 31

13. Detach the E-r ing from Read roller shaft and

remove bearing.

14. Detach ADF knob from Read roller shaft and

remove bearing and spring.

E-ring

Spring

Read roller shaft

E-ring

Bearing

Jam dial

[L] ADF front cover

1. Open ADF unit.

2. Release 3 screws and hook and detach ADF

front cover by sliding it in the direction of the

arrow.

Bearing

Fig. 6-35

Fig. 6-36

ADF front cover

Screw

191-1

191-2

MR-2012 DISASSEMBLY AND REPLACEMENT 6 - 10 October 2000 © TOSHIBA TEC

01/05

Page 32

1-1, KANDA NISHIKI-CHO , CHIYODA-KU, TOKYO , 101-8842 JAPAN

Loading...

Loading...