Page 1

SERVICE MANUAL

LARGE CAPACITY FEEDER

MP-4003

File No.31100203

2002-06

Page 2

Copyright 2002

TOSHIBA TEC CORPORATION

Page 3

GENERAL PRECAUTIONS FOR INSTALLATION/SERVICE/ MAINTENANCE FOR LARGE CAPACITY FEEDER MP-4003

1. When installing the Large Capacity Feeder MP-4003 to the Copier, be sure to follow the instructions

described in the “Unpacking/Set-Up Procedure for the MP-4003” booklet which comes with each

unit of the MP-4003.

2. Installed only by an authorized/qualified person.

3. When transporting/installing the MP-4003, employ two persons. The MP-4003 is fairly heavy and

weights approximately 40 kg (89 lb), therefore pay full attention when handling it.

4. Before starting installation, servicing or maintenance work, be sure to turn off and unplug the

copier first.

5. Supplied with power from the copier, requiring no additional power source.

6. Grounded to the specified positions on the machine frame.

7. When serving or maintaining, be careful about the rotating or operating sections such as gears,

pulleys, sprockets, cams, belts, etc.

8. When parts are disassembled, reassembly is basically the reverse of disassembly unless otherwise

noted in this manual or other related documents. Be careful not to reassemble small parts such as

screws, washers, pins, E-rings, toothed washers to the wrong places.

9. Basically, the machine should not be operated with any parts removed or disassembled.

10. Delicate parts for preventing safety hazard problems (such as thermofuses, door switches sensors,

etc. if any) should be handled/installed/adjusted correctly.

11. During servicing or maintenance work, be sure to check the nameplate and other cautionary labels (if

any) to see if they are clean and firmly stuck. If not, take appropriate actions.

12. Use suitable measuring instruments and tools.

13. The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband,

because the ICs on it may be damaged due to static electricity.

Caution: Before using the wrist band, pull out the power cord plug of the copier and make sure that

there is no uninsulated objects in the vicinity.

14. For the recovery and disposal of used the large capacity feeder, consumable parts, packing materials,

used batteries, and RAM-ICs including litium batteries, it is recommended that the relevant local

regulations/rules.

Page 4

CONTENTS

1. SPECIFICATIONS .......................................................................................... 1-1

2. OUTLINE OF THE MACHINE......................................................................... 2-1

2.1 Front Sectional View ...................................................................................................... 2-1

2.2 Electrical Parts Layout................................................................................................... 2-2

2.3 Electrical Parts ..............................................................................................................2-4

3. GENERAL OPERATION ................................................................................. 3-1

3.1 Description of Operation ................................................................................................ 3-1

3.2 Error Detection............................................................................................................... 3-2

3.3 Flow Chart ..................................................................................................................... 3-3

3.4 Timing Chart .................................................................................................................. 3-5

4. DISASSEMBLY AND REPLACEMENT/ADJUSTMENT................................... 4-1

4.1 Covers ........................................................................................................................... 4-1

4.2 Tray Unit ......................................................................................................................... 4-2

4.3 Feeder Unit..................................................................................................................... 4-3

4.4 Electrical Parts .............................................................................................................. 4-4

4.5 Rollers ............................................................................................................................ 4-6

4.6 Side Guides / End Guide ................................................................................................ 4-7

4.7 Tray wire ......................................................................................................................... 4-8

4.8 Sidewise Deviation Adjustment .................................................................................... 4-11

4.9 Stopper Adjustment ..................................................................................................... 4-11

5. ELECTRICAL CIRCUIT .................................................................................. 5-1

5.1 Harness Diagram ........................................................................................................... 5-1

5.2 Circuit Diagram .............................................................................................................. 5-2

5.3 PC Board........................................................................................................................ 5-5

6. PERIODIC MAINTENANCE ........................................................................... 6-1

JUNE 2002 © TOSHIBA TEC I MP-4003 CONTENTS

Page 5

1. SPECIFICATIONS

Function

Replenishing method ......Front loading method

Paper .............................. Size: A4, B5, LT

Thickness: 64~209g/m2 (17~110lbs. Index)

Capacity of tray .............. 4,000 papers (Stack height: within 428mm)

Dimensions .....................326 (W) X 599 (D) X 617 (H) mm (when connected to the copier)

Weight ............................ Approx. 40kg (89lbs)

Power supply................... DC5V, 24V (supplied from the copier)

JUNE 2002 © TOSHIBA TEC 1 - 1 MP-4003 SPECIFICATIONS

Page 6

2. OUTLINE OF THE MACHINE

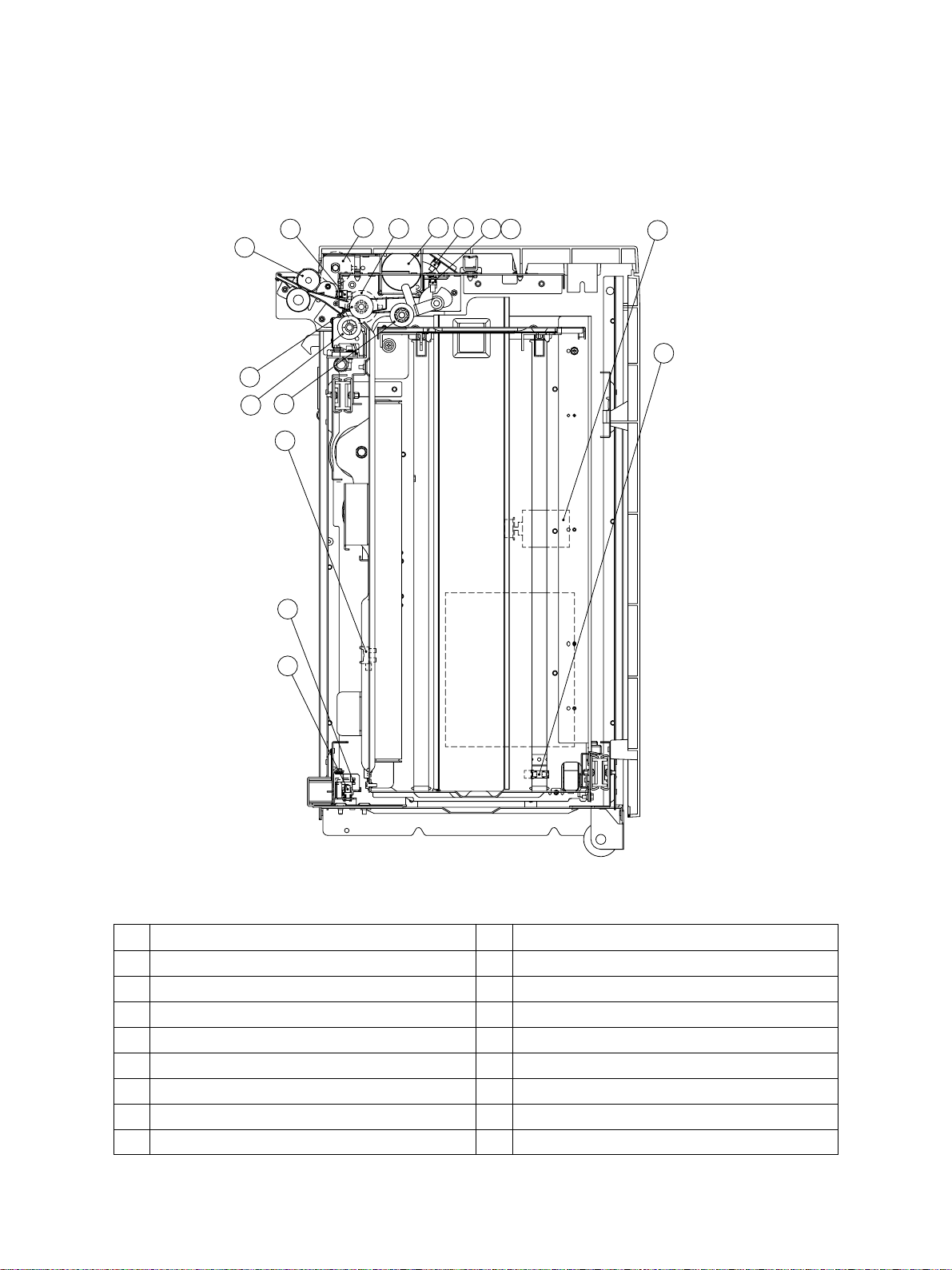

2. 1 Front Sectional View

16

14

15

13

12

9

11

7

3

1

4

8

6

5

2

10

NO. NAME NO. NAME

1 Transport motor (M1) 9 Tray sensor (S5)

2 Tray motor (M2) 10 Tray bottom sensor (S6)

3 Transport clutch (CL1) 11 LCF set sensor (S7)

4 Feed clutch (CL2) 12 Door switch (SW1)

5 Empty sensor (S1) 13 Pickup roller

6 Tray-up sensor (S2) 14 Feed roller

7 Feed sensor (S3) 15 Separation roller

8 FG-pulse sensor (S4) 16 Transport roller

JUNE 2002 © TOSHIBA TEC 2 - 1 MP-4003 OUTLINE OF THE MACHINE

Page 7

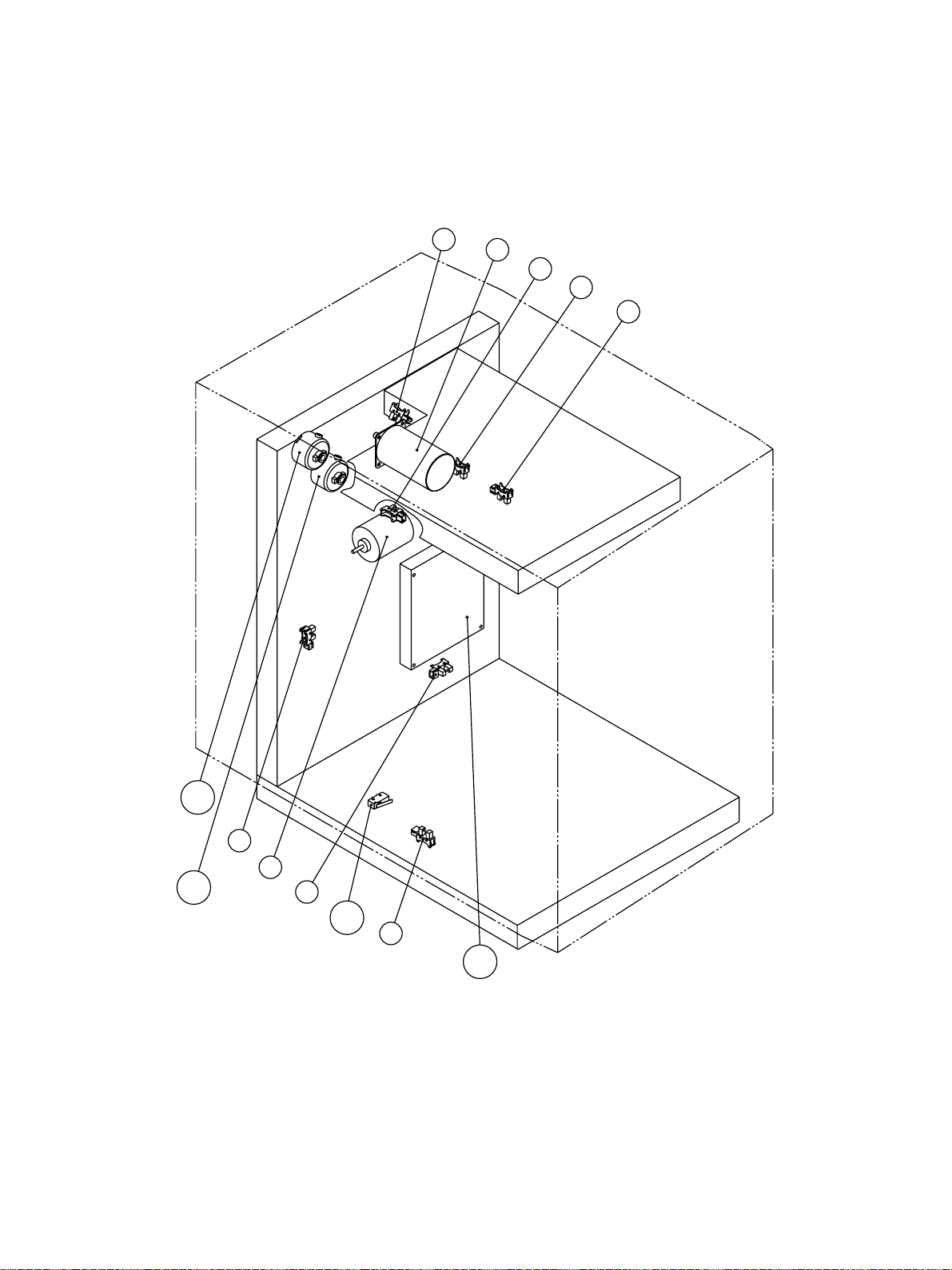

2. 2 Electrical Parts Layout

CL1

CL2

S5

M2

S6

SW1

S7

S4

M1

S3

S1

S2

S4

M1

S3

S1

S2

CL1

S5

M2

CL2

JUNE 2002 © TOSHIBA TEC 2 - 2 MP-4003 OUTLINE OF THE MACHINE

S6

SW1

S7

PWPWA

Page 8

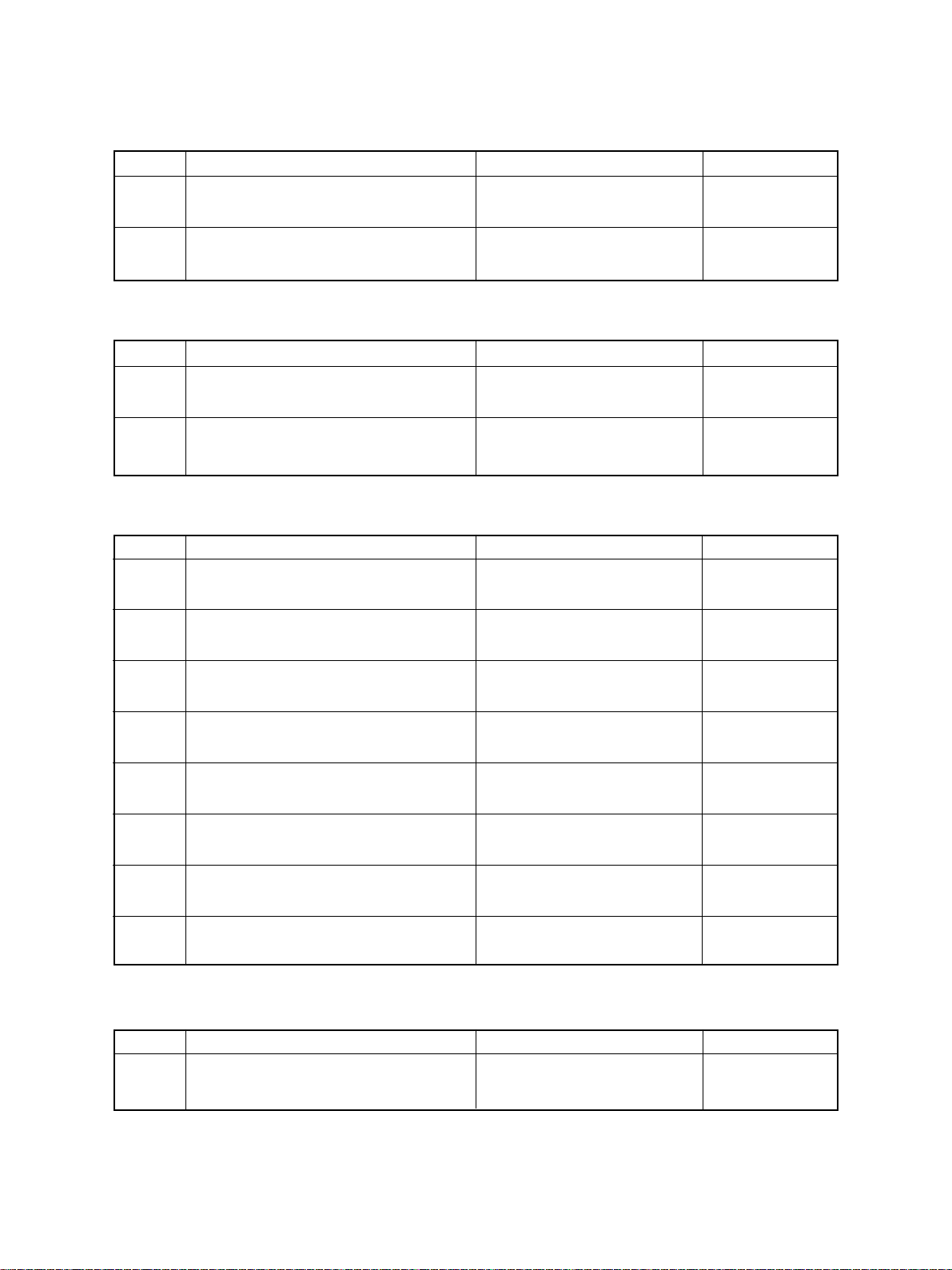

2. 3 Electrical Parts

(1) Motors

SYMBOL NAME FUNCTION REMARKS

M1 TR-MTR Driving of the feeding and Brush motor

Transport motor transportation

M2 TRY-MTR Lifting/Lowering of the tray Brush motor

Tray motor

(2) Electromagnetic clutches

SYMBOL NAME FUNCTION REMARKS

CL1 TR-CLT Driving of the transportation

Transport clutch

CL2 FED-CLT Driving of the feeding

Feed clutch

(3) Switches/Sensors

SYMBOL NAME FUNCTION REMARKS

S1 EMP-SNR Detection of the presence or Photo interrupter

Empty sensor absence of paper

S2 TRY-UP-SNR

Tray-up sensor

S3 FED-SNR Detection of the paper Photo interrupter

Feed sensor transportation

S4 FG-PULS-SNR

FG-pulse sensor rotation number

S5 TRY-SNR Detection of the drawer Photo interrupter

Tray sensor installed

S6 TRY-BTM-SNR

Tray bottom sensor

S7 LCF-SET-SNR Detection of the LCF installed Photo interrupter

LCF-set sensor to the copier

SW1 DOOR-SW Safety switch Pushing switch

Door switch

Detection of the tray upper limit

position

Detection of the transport motor

Detection of the tray lower limit

position

Photo interrupter

Photo interrupter

Photo interrupter

(4) PC Board

SYMBOL NAME FUNCTION REMARKS

PWA PWA-F-LCF-555 Driving of the feeding

PC board Control of the tray driving

JUNE 2002 © TOSHIBA TEC 2 - 3 MP-4003 OUTLINE OF THE MACHINE

Page 9

3. GENERAL OPERATION

3. 1 Description of Operation

[A] From power ON to standby

(1) When the copier is turned ON, power is also supplied to the feed unit from the copier to start the pre-

running operation. The tray motor (M2) starts to rotate forward to lift the tray.

The tray motor (M2) stopped rotating and lifting the tray when the tray has been lifted and the tray-up

sensor (S2) has been turned ON (H: Sensor light path blocked by the actuator sensor). Papers are

assessed to be present when the empty sensor (S1) is turned ON (L:Passing the sensor light path )

while they are assessed to be absent when the empty sensor (S1) is turned OFF (H: Sensor light path

blocked).

(2) When the LCF is not being installed to the copier (LCF set sensor (S7): OFF) or when the drawer is

being pulled out (Tray sensor (S5): OFF), the tray lifting operation is not carried out. In this case, the

tray starts to be lifted and the same operation which is until the detection of the paper presense or

absense is carried out when it is installed to the copier and the drawer is inserted.

(3) When the feed sensor (S3) is turned ON (L: Passing the sensor light path), that is, when the paper is

remaining at the transport path, the LCF detects it as a paper jam and cannot operate.

[B] Standby state

(1) When a paper is detected to be present by the above-described operation, the LCF gets into a standby

state.

(2) When the tray unit is pulled out, the tray is automatically lowered because of its structure, and when it

is inserted once again, it is lifted.

[C] Feeding/Transporting operation from the start to the finish of the printing

(1) The [START] key is pressed when the copier decides that the feeding from the the LCF. Then, the

transport motor (M1) starts to drive after the feed motor of the copier has been turned ON.

(2) The feed clutch (CL2) is turned ON and pickup and feed rollers start to drive to feed a paper from the

tray.

(3) After the feeding starts, the transport clutch (CL1) is turned ON and the transport roller starts to drive

to transport the paper.

(4) When the leading edge of the paper has turned ON the feed sensor (S3), the feed clutch (CL2) is turned

OFF and stops the feeding operation. The paper transported by the transport roller is sent to the copier

side, where it is transported by the feed unit.

(5) When a specified time has passed after the trailing edge of the paper turned OFF the feed sensor (S3),

next paper can be fed.

(6) When carrying out a continuous printing, the above steps from (2) to (5) are repeated as many papers

as printed.

(7) When the printing has been finished, the feed motor of the copier stops rotating and the transport motor

(M1) is turned OFF to finish the feeding/transporting operation.

JUNE 2002 © TOSHIBA TEC 3 - 1 MP-4003 GENERAL OPERATION

Page 10

[D] Tray operation during printing

(1) When 10~20 sheet of paper have been fed from the tray, the pickup roller is lowered down to a

specified height. The tay-up sensor (S2) detects this and the tray motor (M2) rotates forward to lift

the tray.

3. 2 Error Detection

[A] Jam detection

In the following cases, the feed jam takes place.

(1) When the feed sensor (S3) is not turned ON in a specified time after the feeding has started.

(2) When each transport sensor of the copier does not operate (ON/OFF) in a specified time after the

feeding has started at the copier side.

[B] Call for service

(1) When the tray-up sensor (S2) is not turned ON in a specified time after the tray has started to be lifted.

JUNE 2002 © TOSHIBA TEC 3 - 2 MP-4003 GENERAL OPERATION

Page 11

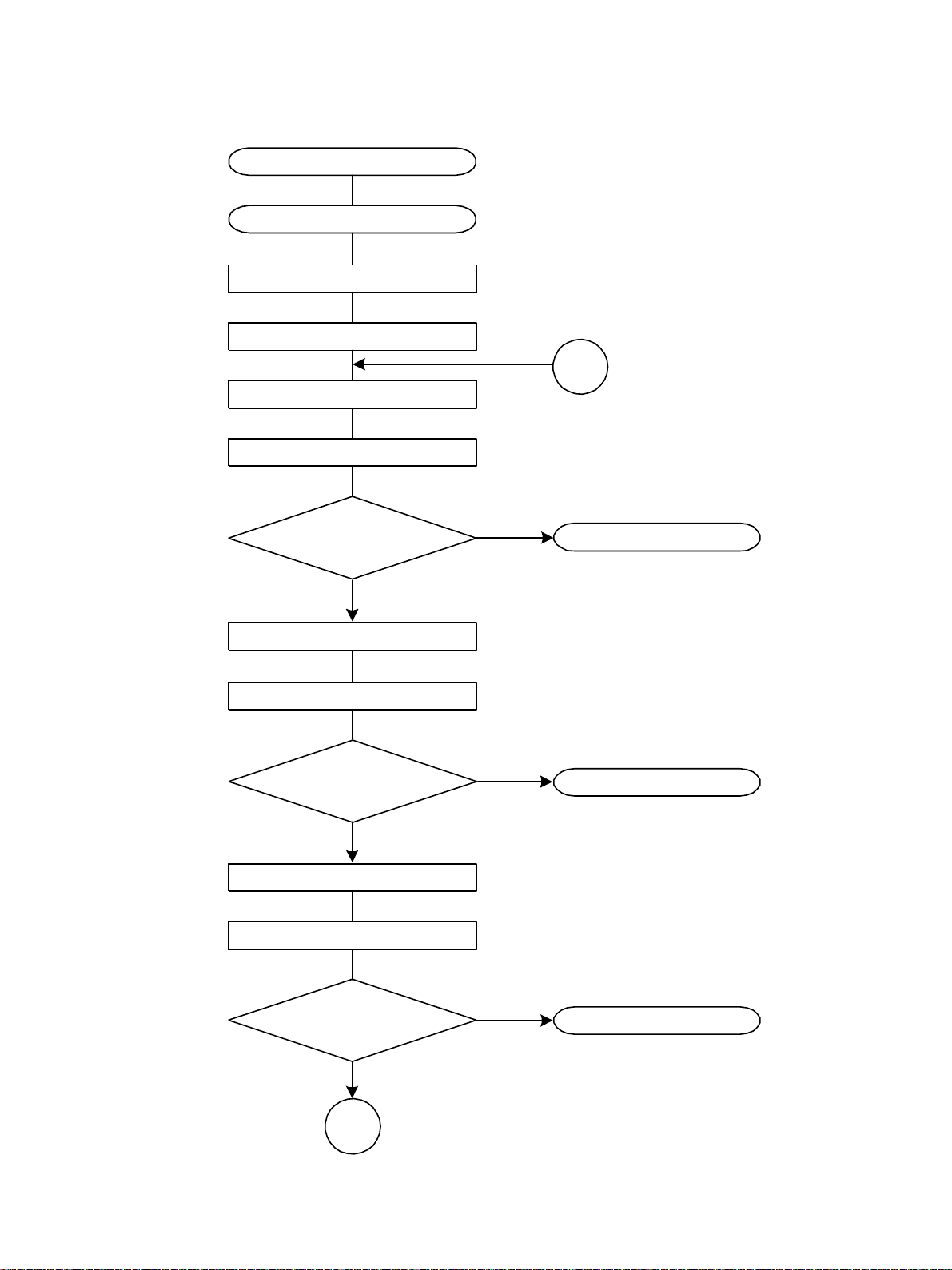

3. 3 Flow Chart

Press the [START] key

Transport system controlling

Copier feed motor ON

LCF transport motor ON

LCF feed clutch ON

LCF transport clutch ON

Is the LCF feed sensor ON?

YES

B

NO

Paper jam

(E19)

Copier intermediate transport clutch ON

LCF feed sensor ON

Is the copier intermediate

transport sensor ON?

YES

LCF feed sensor OFF

LCF transport clutch OFF

Is the copier registration

sensor ON?

YES

NO

Paper jam

(E25)

NO

Paper jam

(E25)

A

JUNE 2002 © TOSHIBA TEC 3 - 3 MP-4003 GENERAL OPERATION

Page 12

A

Copier intermediate transport clutch ON

Copier registration motor ON

Copier registration motor OFF

Is there no remaining copy?

YES

Is the copier fuser unit

exit sensor ON?

YES

Is the copier fuser unit

exit sensor OFF?

YES

LCF transport motor OFF

Copier feed motor OFF

NO

NO

NO

B

Paper jam

(E01)

Paper jam

(E02)

Standby

JUNE 2002 © TOSHIBA TEC 3 - 4 MP-4003 GENERAL OPERATION

Page 13

3. 4 Timing Chart

(1) Timing at the LCF feeding: A4, 1 copy

3700

(unit: ms)

1650

1410

OFF

800

ON

OFF

800

690

570

385

180

75

0

ON

OFF

ON

OFF

ON

OFF

180

ON

OFF

ON

Transport motor

JUNE 2002 © TOSHIBA TEC 3 - 5 MP-4003 GENERAL OPERATION

Feed clutch

Transport clutch

Feed sensor

Copier intermediate

transport sensor

Copier registration sensor

Page 14

(2) Timing at the LCF feeding: A4, 2 copies

4450

(unit: ms)

2410

1740

1660

1345

900 1185

745

400

200

70

0

865

710

200

1435 1520 2170

585

1760

825 1675

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

ON

OFF

Transport motor

JUNE 2002 © TOSHIBA TEC 3 - 6 MP-4003 GENERAL OPERATION

Feed clutch

Transport clutch

Feed sensor

Copier intermediate

transport sensor

OFF

Copier registration

sensor

Page 15

(3) Timing at the LCF feeding: B5, 1 copy

3640

(unit: ms)

1605

1370

820

740

630

400

OFF

190

ON

190

75

0

ON

OFF

ON

OFF

ON

OFF

570

ON

OFF

ON

OFF

Transport motor

JUNE 2002 © TOSHIBA TEC 3 - 7 MP-4003 GENERAL OPERATION

Feed clutch

Transport clutch

Feed sensor

Copier intermediate

transport sensor

Copier registration sensor

Page 16

(4) Timing at the LCF feeding: B5, 2 copies

4390

(unit: ms)

1665

1560

2340

2100

1760

1515

OFF

1370

585

ON

OFF

825 1610

ON

OFF

1325

790

680 830 1160

400

200

OFF

80

ON

OFF

ON

0

ON

OFF

640

200

ON

Transport motor

JUNE 2002 © TOSHIBA TEC 3 - 8 MP-4003 GENERAL OPERATION

Feed clutch

Transport clutch

Feed sensor

Copier intermediate

transport sensor

Copier registration

sensor

Page 17

(5) Timing at the LCF feeding: LT, 1 copy

3750

(unit: ms)

1700

1460

835

725

590

415

OFF

210

ON

OFF

ON

210

OFF

70

ON

OFF

ON

0

ON

OFF

830

ON

OFF

Transport motor

JUNE 2002 © TOSHIBA TEC 3 - 9 MP-4003 GENERAL OPERATION

Feed clutch

Transport clutch

Feed sensor

Copier intermediate

transport sensor

Copier registration sensor

Page 18

(6) Timing at the LCF feeding: LT, 2 copies

4450

(unit: ms)

2420

1750

1650

1450 1520 2185

1330

910 1170

755

400

195

80

0

870

715

585

195

1765

825 1690

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

ON

OFF

Transport motor

JUNE 2002 © TOSHIBA TEC 3 - 10 MP-4003 GENERAL OPERATION

Feed clutch

Transport clutch

Feed sensor

Copier intermediate

transport sensor

OFF

Copier registration

sensor

Page 19

4.

DISASSEMBLY AND REPLACEMENT

/ADJUSTMENT

4. 1 Covers

[A] Front cover

(1) Pull out the drawer.

(2) Remove 4 screws and take off the front cover.

Front cover

Note: When installing the front cover, fit the arm on the

latch lever.

[B] Rear cover

(1) Remove 4 screws and take off the rear cover.

Arm

Rear cover

[C] Upper cover

(1) Pull out the drawer.

(2) Remove the rear cover.

(3) Loosen 4 screws and take off the upper cover.

Upper cover

JUNE 2002 © TOSHIBA TEC 4 - 1 MP-4003 DISASSEMBLY AND REPLACEMENT

Page 20

[D] Right cover

(1) Remove 2 screws and take off the right cover

sliding it toward the front side.

4. 2 Tray Unit

(1) Pull out the drawer.

(2) Remove 1 screw and take off the stopper.

Right cover

(3) Remove 4 screws (2 for the left side and 2 for

the right side) and take off the tray unit pulling it

upward.

Stopper

Left side

Right side

JUNE 2002 © TOSHIBA TEC 4 - 2 MP-4003 DISASSEMBLY AND REPLACEMENT

Page 21

4. 3 Feed Unit

(1) Remove the upper cover.

(2) Remove the lever.

(3) Disconnect 2 connectors (for tray motor, PC

boad).

Lever

(4) Remove 3 screws for each at the front and

rear sides and take off the feed unit upward.

Connector

Feed unit

Front side

Rear side

JUNE 2002 © TOSHIBA TEC 4 - 3 MP-4003 DISASSEMBLY AND REPLACEMENT

Page 22

4. 4 Electric Parts

[A] PC board

(1) Remove the rear cover.

(2) Disconnect 4 connectors and remove 1 screw

to take off the PC board.

[B] Tray motor

(1) Remove the rear cover.

(2) Disconnect 1 connector and remove 3 screws

to take off the tray motor.

[C] Transport motor

(1) Remove the upper cover.

(2) Disconnect 1 connector and remove 2 screws

to take off the transport motor.

[D] Tray sensor

(1) Remove the rear cover.

(2) Disconnect 1 connector and take off the tray

sensor.

Connector

Connector

Tray sensor

JUNE 2002 © TOSHIBA TEC 4 - 4 MP-4003 DISASSEMBLY AND REPLACEMENT

Page 23

[E] FG-pulse sensor, Tray-up sensor, Empty

sensor, Feed sensor

(1) Remove the upper cover.

(2) Remove 1 screw and disconnect 1 connector

for each sensor and take off the sensor with

the bracket. (FG-pulse sensor, tray-up sensor,

empty sensor, feed sensor)

Feed sensor

Tray-up sensor

[F] LCF set sensor, Door switch

(1) Remove the right cover and pull out the tray

unit.

(2) Remove 1 screw and take off the cover.

(3) Remove 1 screw and dissconnect 3

connectors, and take off the LCF set sensor

and door switch with the bracket.

Note: Be careful not to connect the connector of the

door switch to the wrong place.

Empty sensor

FG-pulse sensor

Red

Orange

Not

used

Door switchLCF set sensor

[G] Tray bottom sensor

Tray bottom sensor

(1) Remove 1 screw and take off the actuator.

(2) Disconnect 1 connector and unhook the hook

of the sensor from the rear side to take off the

tray bottom sensor.

Actuator

JUNE 2002 © TOSHIBA TEC 4 - 5 MP-4003 DISASSEMBLY AND REPLACEMENT

Page 24

[H] Transport clutch

(1) Remove the feed unit.

(2) Remove 2 screws and take off the bracket.

Then disconnect 1 connector and take off the

transport clutch.

Note: When installing the clutch, put the stopper of

clutch in the boss of flame conmpetely.

Transport clutchBracket

Stopper

[I] Feed clutch

(1) Remove the transport clutch.

(2) Disconnect 1 connector and remove 2

setscrews to take off the feed clutch.

Note: When installing the clutch, put the stopper of

clutch in the boss of flame conmpetely.

4. 5 Rollers

(1) Pull out the LCF away from the copier.

(2) Remove 1 clip and take off the separation roller

while pushing it down.

Feed clutch

Stopper

Separation roller

Clip

(3) Remove 2 screws and take off the right cover

sliding it toward the front side.

(4) Remove 1 clip and take off the weight (A). Then

Pull out the weight (B) with the shaft and take

off the pickup roller.

Clip

JUNE 2002 © TOSHIBA TEC 4 - 6 MP-4003 DISASSEMBLY AND REPLACEMENT

(A)

Pickup roller

(B)

Page 25

(5) Remove 1 clip and take off the feed roller.

4. 6 Side Guides / End Guide

[A] Rear side guide

(1) Pull out the drawer.

(2) Remove 1 screw and take off the stopper.

(3) Remove 2 screws and adapt the groove and

screw hole to the paper size. Then screw it

shut.

Clip

Stopper

Feed roller

A4

LT

B5

[B] Front side guide

Pickup lever guide

(1) Pull out the drawer.

(2) Remove 1 screw and take off the pickup lever

guide.

JUNE 2002 © TOSHIBA TEC 4 - 7 MP-4003 DISASSEMBLY AND REPLACEMENT

Page 26

(3) Remove 2 screws and adapt the groove and

screw hole to the paper size. Then screw it

shut.

[C] End guide guide

(1) Remove 4 screws and take off the tray unit.

(2) Remove 4 screws and adapt the groove and

screw hole to the paper size. Then screw it

shut.

Note: For a B5 size paper, an exclusive end guide is

needed.

A4

LT

B5

4. 7 Tray Wire

(1) Remove the tray unit.

(2) Remove the front cover.

(3) Remove both the rear and front side guides.

(4) Remove 1 screw and 3 clips and take off the

front side wire tensioner (same for the rear side).

(5) Remove the tray.

End guide

Clip

Tensioner

Tr a y

JUNE 2002 © TOSHIBA TEC 4 - 8 MP-4003 DISASSEMBLY AND REPLACEMENT

Page 27

(6) Release the latches and take off 4 wire stoppers

and tray wires.

Wire stopper

Wire stopper

(7) Release the latches and take off the wire clamps.

Note: Pay attention to the length and direction of the

wires when installing the wire clamps.

(8) Remove 7 screws and take off the brake unit.

Front side Rear side

촞

End of wire

촞

Short wire

Long wire

Wire clamp

End of wire

Long wire

Short wire

Wire clamp

Brake unit

(9) Remove 1 E-ring and take off the front side

pully.

E-ring

Front side pulley

JUNE 2002 © TOSHIBA TEC 4 - 9 MP-4003 DISASSEMBLY AND REPLACEMENT

Page 28

(10)

Release the latches and take off the flange of

the front side pulley.

Long wire

Note: Pay attention to the length of the wires when

installing the flange.

(11)

Pull out the rear side pulley with shaft. Release

the latches and take off the flange of rear side

pulley.

Note: Pay attention to the length of the wires when

installing the flange.

Flange

Latch

Short wire

Latch

Front side pulley

Flange

Long wire

Short wire

Rear side pulley

Wire layout

JUNE 2002 © TOSHIBA TEC 4 - 10 MP-4003 DISASSEMBLY AND REPLACEMENT

Page 29

4. 8 Sidewise Deviation Adjustment

When the tray position is out of alignment, adjust it

taking the following procedure.

(1) Pull out the tray unit.

(2) Remove 2 screws and take off the bracket.

(3) Loosen 2 screws and move the adjustment

board to the right position. Then screw it shut.

Brecket

Tray moves toward

the front side.

Tray moves toward

the rear side.

Note: After the tray position adjustment, re-adjust the

front cover position. Adjustment; loose 4 screws

and slide the front cover front or rear side.

4. 9 Stopper Adjustment

Compensate the slant of LCF by the adjusting the

stoppers.

(1) Pull out the LCF from the copier.

(2) Turn 2 screws and adjust the stoppers.

Turn left: Stopper moves upward.

Turn right: Stopper moves downward.

Note: When moving the copier, need to move the

stoppers upward.

JUNE 2002 © TOSHIBA TEC 4 - 11 MP-4003 DISASSEMBLY AND REPLACEMENT

Page 30

5. ELECTRIC CIRCUIT

5. 1 Harness Diagram

PWA-F-LCF

VDD

LC-FGSIG

SG

VDD

LC-PEMP

SG

VDD

LC-TRYUP

SG

VDD

LC-PICK

SG

LCFDM-B

LCFDM-A

LCTRM-B

LCTRM-A

LC-PCLT

+24V

LC-FCLT

+24V

VDD

LC-SET

SG

VDD

LC-CST

SG

VDD

LC-BTM

SG

24V-SW

+24V

+24V-SW

FG-PULSE

SCSWA-0

RETS-7

RETS-6

RETS-5

RETS-4

RETS-3

RETS-2

RETS-1

RETS-0

VDD

SG

RST-0

DG

DG

CLKC-1

DRV-7

DRV-6

DRV-5

DRV-4

DRV-3

DRV-2

DRV-1

DRV-0

+24V-SW

[HRNS-LCF-UP-555]

A1

A1

A2

A2

A3

A3

A4

A4

A5

A5

A6

A6

A7

A7

A8

A8

A9

A9

A10

A10

A11

A11

J802

A12

A12

B10

B11

B12 B12

B1

B1

J802

B2

B2

B3

B3

B4

B4

B5

B5

B6

B6

B7

B7

B8

B8

B9

B9

B10

B11

[HRNS-LCF-RLY-555]

1

1

2

2

3

3

J803

4

4

5

5

J803

6

6

7

7

8

8

9

9

J804

1

1

J804

2

2

[HRNS-LCF-RLY-555]

[HRNS-LCF-MAIN-555]

A1

A1

A2

A2

A3

A3

A4

A4

A5

A5

A6

A6

A7

A7

A8

A8

A9

A9

A10

A10

A11

A11

A12

A12

J801

A13

A13

B10

B11

B12

B13

B1

B1

J801

B2

B2

B3

B3

B4

B4

B5

B5

B6

B6

B7

B7

B8

B8

B9

B9

B10

B11

B12

B13

VDD

LC-FGSIG

SG

VDD

LC-PEMP

SG

VDD

LC-TRYUP

SG

VDD

LC-PICK

SG

N.C.

N.C.

N.C.

LCFDM-B

LCFDM-A

LCTRM-B

LCTRM-A

LC-PCLT

+24V

LC-PCLT

+24V

N.C.

VDD

LC-SET

SG

VDD

LC-CST

SG

VDD

LC-BTM

SG

24V-SW

24V

+24V-SW

FG-PULSE

SCSWA-0

RETS-7

RETS-6

RETS-5

RETS-4

RETS-3

RETS-2

RETS-1

RETS-0

VDD

SG

RST-0

DG

DG

CLKC-1

DRV-7

DRV-6

DRV-5

DRV-4

DRV-3

DRV-2

DRV-1

DRV-0

+24V-SW

J809

1

2

FG-PULS-SNR (S4)

3

J810

1

2

EMP-SNR (S1)

3

1

2

3

4

2

1

2

1

2

3

J812

FED-SNR (S3)

1

2

J815

TRY-MOT (M2)

1

2

J817

FE D-CLT (CL2)

J811

TRY-UP-SNR (S2)

J814

TR-MOT (M1)

J816

TR-CLT (CL1)

[HRNS-LCF-INSW-555]

1

2

J819

1

2

CST-SW

3

(S5)

3

4

5

6

1

2

6

5

J823

4

3

J823

J823-1

2

1

[HRNS-LCF-INSW-555]

J821

1

J821

2

1

2

3

J818

1

2

3

J820

TRY-BTM-SNR (S6)

faston J807

faston J808

DOOR-SW (SW1) 24V

(DE2L-BALB)

LCF-SET-SNR (S7)

PPC(LGC)

FG

11

13

15

17

19

21

23

25

27

28

26

24

22

20

18

16

14

12

10

N.C. N.C.

1

1

3

3

5

5

7

7

9

9

11

13

15

17

19

21

23

25

J822

27

28

J822

26

24

22

20

18

16

14

12

10

8

8

6

6

4

4

2

2

13

12

11

10

9

8

7

6

5

4

3

2

1

26

25

24

23

22

21

20

19

18

17

16

15

14

J346

13

12

11

10

9

8

7

6

5

4

3

2

1

26

J346

25

24

23

22

21

20

19

18

17

16

15

14

+24VC

LCINT-0

SCSWA-0A

RETS[7]

RETS[6]

RETS[5]

RETS[4]

RETS[3]

RETS[2]

RETS[1]

RETS[0]

VDD

SG

RST-0

DG

DG

CLKC-1A

RCDRV[7]

RCDRV[6]

RCDRV[5]

RCDRV[4]

RCDRV[3]

RCDRV[2]

RCDRV[1]

RCDRV[0]

+24VC

JUNE 2002 © TOSHIBA TEC 5 - 1 MP-4003 ELECTRIC CIRCUIT

Page 31

5. 2 Circuit Diagram (1)

(1/3)

JUNE 2002 © TOSHIBA TEC 5 - 2 MP-4003 ELECTRIC CIRCUIT

Page 32

5. 2 Circuit Diagram (2)

(2/3)

JUNE 2002 © TOSHIBA TEC 5 - 3 MP-4003 ELECTRIC CIRCUIT

Page 33

5. 2 Circuit Diagram (3)

(3/3)

JUNE 2002 © TOSHIBA TEC 5 - 4 MP-4003 ELECTRIC CIRCUIT

Page 34

5. 3 PC Board

JUNE 2002 © TOSHIBA TEC 5 - 5 MP-4003 ELECTRIC CIRCUIT

Page 35

6. PERIODIC MAINTENANCE

Symbols used in the checklist

Cleaning Coating Replacing Date

A: Cleaning with alcohol

W: White grease

(Molycoat)

500: every 500K copies

: Replace if deformed or

damaged.

General Maintenance Checklist

Item to check Cleaning Coating Replacing Remarks

x 1000

Pickup roller A 500

Feed roller A 500

Separation roller A 500

Drive gears (tooth face) W

* Operational interval of the periodic maintenance (PM) is different among the copiers.

e-STUDIO 550: every 400K copies

e-STUDIO 650: every 460K copies

e-STUDIO 810: every 500K copies

User’s name

Serial No.

Inspector’s name

Remarks

JUNE 2002 © TOSHIBA TEC 6 - 1 MP-4003 PERIODIC MAINTENANCE

Page 36

R02032112200-TTEC

1-1, KANDA NISHIKI-CHO, CHIYODA-KU, TOKYO, 101-8442, JAPAN

Loading...

Loading...