Toshiba MMY-MAP1404HT8-E, MMY-MAP1404HT8Z-E, MMY-MAP0804HT8ZG-E, MMY-MAP0804HT8-E, MMY-MAP1204HT8-E User Manual

...

AIR CONDITIONER (MULTI TYPE)

Installation manual

Outdoor Unit

Model name:

<Heat Pump Model>

MMY-MAP0804HT8-E

MMY-MAP1004HT8-E

MMY-MAP1204HT8-E

MMY-MAP1404HT8-E

MMY-MAP1604HT8-E

MMY-MAP0804HT8Z-E

MMY-MAP1004HT8Z-E

MMY-MAP1204HT8Z-E

MMY-MAP1404HT8Z-E

MMY-MAP1604HT8Z-E

MMY-MAP0804HT8ZG-E

MMY-MAP1004HT8ZG-E

MMY-MAP1204HT8ZG-E

MMY-MAP1404HT8ZG-E

MMY-MAP1604HT8ZG-E

<Cooling Only Model>

MMY-MAP0804T8-E

MMY-MAP1004T8-E

MMY-MAP1204T8-E

MMY-MAP1404T8-E

MMY-MAP1604T8-E

MMY-MAP0804T8Z-E

MMY-MAP1004T8Z-E

MMY-MAP1204T8Z-E

MMY-MAP1404T8Z-E

MMY-MAP1604T8Z-E

MMY-MAP0804T8ZG-E

MMY-MAP1004T8ZG-E

MMY-MAP1204T8ZG-E

MMY-MAP1404T8ZG-E

MMY-MAP1604T8ZG-E

Not accessible to the general public

For commercial use

Vente interdite au grand public

Kein öffentlicher Zugang

Non accessibile a clienti generici

No destinado al público en general

Não acessível ao público em geral

Niet geschikt voor huishoudelijk gebruik

Μη προσβάσιμο από το γενικό κοινό

Недоступен для посторонних

Genel erişime açık değildir

Installation manual

English

1-EN 2-EN

SMMS-i

Installation Manual

–1–

SMMS-i

Installation Manual

Original instruction

ADOPTION OF NEW REFRIGERANT

This Air Conditioner uses R410A an environmentally friendly refrigerant.

Contents

1 PRECAUTIONS FOR SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 ACCESSORY PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 INSTALLATION OF NEW REFRIGERANT AIR CONDITIONER . . . . . . . . . . . . . . . . . 4

4 SELECTION OF INSTALLATION PLACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5 CARRYING IN THE OUTDOOR UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6 INSTALLATION OF THE OUTDOOR UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7 REFRIGERANT PIPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

8 ELECTRIC WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

9 ADDRESS SETTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

10 TEST RUN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

11 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

12 MACHINE CARD AND LOGBOOK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Thank you for purchasing this Toshiba air conditioner.

This Installation Manual describes the installation method of the outdoor unit. For installation of indoor units, follow the

Installation Manual supplied with the indoor unit.

Moreover, as this installation manual includes the important articles concerning the “Machinery” Directive (Directive 2006/42/

EC), please read through the manual and make sure you understand it. After installation, give this Installation Manual, the

Owner’s Manual and the Installation Manual supplied with the indoor unit to the customer and tell the customer to keep them

safe.

Prepare an exclusive power source for indoor units, independent to that for outdoor units.

Y-shaped branching joints or a branching header (separately purchased) are required for connecting pipes between indoor and

outdoor units. Choose either of them considering the system capacity concerning piping. For installing branching pipes, refer to

the installation manual of the Y-shaped branching unit or branching header (separately purchased).

Outdoor connecting branching joints are required for connecting between outdoor units.

Generic Denomination: Air Conditioner

Definition of Qualified Installer or Qualified Service Person

The air conditioner must be installed, maintained, repaired and removed by a qualified installer or qualified service person.

When any of these jobs is to be done, ask a qualified installer or qualified service person to do them for you.

A qualified installer or qualified service person is an agent who has the qualifications and knowledge described in the table

below.

Agent Qualifications and knowledge which the agent must have

• The qualified installer is a person who installs, maintains, relocates and removes the air conditioners made by

Toshiba Carrier Corporation. He or she has been trained to install, maintain, relocate and remove the air

conditioners made by Toshiba Carrier Corporation or, alternatively, he or she has been instructed in such

operations by an individual or individuals who have been trained and is thus thoroughly acquainted with the

knowledge related to these o perations.

• The qualified installer who is a llowed to do the electrical work in volved in installation, relocation and removal has

the qualifications pertaining to this electrical work as stipulated by the local laws and regulations, and he or she is

a person who has been trained in matters relating to electrical work on the air conditioners made by Toshiba Carrier

Corporation or, alternatively, he or she has been instructed in such matters by an individual or individuals who have

Qualified installer

Qualified service

person

been trained and is thus thoroughly acquainted with the knowledge related to this work.

• The qualified installer who is allowed to do the refrigerant handling and piping work involved in installation,

relocation and removal has the qualification s pertaining to this refrigerant handling an d piping work as stipulated

by the local laws and regulations, and he or she is a person who has been trained in matters relating to refrigerant

handling and piping work on the air conditioners made by Toshiba Carrier Corporation or, alternatively, he or she

has been instructed in such matters by an individual or individuals who have been trained and is thus thoroughly

acquainted with the knowledge related to this work.

• The qualified installer who is allowed to work at heights has been trained in matters relating to working at heights

with the air conditioners made by Toshiba Carrier Corporation or, alternatively, he or she has been instructed in

such matters by an individu al or individuals who have been trained and is thus thorou ghly acquainted with the

knowledge related to this work.

• The qualified service person is a person who installs, repairs, maintains, relocates and removes the air conditioners

made by Toshiba Carrier Corporation. He or she has been trained to install, repair, maintain, relocate and remove

the air conditioners made by Toshiba Carrier Corporation or, alternatively, he or she has been instructed in such

operations by an individual or individuals who have been trained and is thus thoroughly acquainted with the

knowledge related to these o perations.

• The qualified service person who is allowed to do the electrical work involved in installation, repair, relocation and

removal has the qualifications pertaining to this electrical work as stipulated by the local laws and regulations, and

he or she is a person who has been trained in matters relating to electrical work on the air conditioners made by

Toshiba Carrier Corporation or, alternatively, he or she has been instructed in such matters by an individual or

individuals who have been trained and is thus thoroughly acquainted with the knowledge related to this work.

• The qualified service person who is allowed to do the refrigerant handling and piping work involved in installation,

repair, relocation and removal has the qualifications pertaining to this refrigerant handling and piping work as

stipulated by the local laws and regulations, and he or she is a person who has been trained in matters relating to

refrigerant handling and piping work on the air conditioners made by Toshiba Carrier Corporation or, alternatively,

he or she has been instructed in such matters by an individual or individuals who have been trained and is thus

thoroughly acquainted with the knowledge related to this work.

• The qualified service person who is allowed to work at heights has been trained in matters relating to working at

heights with the air conditioners made by Toshiba Carrier Corporation or, alternatively, he or she has been

instructed in such matters by an individual or individuals who have been trained and is thus thoroughly acquainted

with the knowledge related to this work.

Definition of Protective Gear

When the air conditioner is to be transported, installed, maintained, repaired or removed, wear protective gloves and ‘safety’

work clothing.

In addition to such normal protective gear, wear the protective g ear described below when undertaking the special work detailed

in the table below.

Failure to wear the proper protective gear is dangerous because you will be more susceptible to injury, burns, electric shocks

and other injuries.

SMMS-i

Installation Manual

SMMS-i

Installation Manual

Work undertaken Protective gear worn

All types of work

Electrical-related

work

Work done at heights

(50 cm or more)

Transportation of

heavy objects

Repair of outdoor unit Gloves to provide protection for electricians and from heat

Protective gloves

‘Safety’ working clothing

Gloves to provide protec tion for electricians and from heat

Insulating shoes

Clothing to provide protection from electr ic shock

Helmets for use in industry

Shoes with additional protective toe cap

Warning Indications on the Air Conditioner Unit

Warning indication Description

WARNING

ELECTRICAL SHOCK HAZARD

Disconnect all remote

electric power supplies

before servicing.

WARNING

Moving parts.

Do not operate unit with grille

removed.

Stop the unit before the servicing.

CAUTION

High temperature parts.

You might get burned

when removing this panel.

CAUTION

Do not touch the aluminum

fins of the unit.

Doing so may result in injury.

CAUTION

BURST HAZARD

Open the service valves before

the operation, otherwise there

might be the burst.

CAUTION

Do not climb onto the

fan guard.

Doing so may result in injury.

WARNING

ELECTRICAL SHOCK HAZARD

Disconnect all remote electric power supplies before servicing.

WARNING

Moving parts.

Do not operate unit with grille removed.

Stop the unit before the servicing.

CAUTION

High temperature parts.

You might get burned when removing this panel.

CAUTION

Do not touch the aluminium fins of the unit.

Doing so may result in injury.

CAUTION

BURST HAZARD

Open the service valves before the operation, otherwise there might be the

burst.

CAUTION

Do not climb onto the fan guard.

Doing so may result in injury.

1 PRECAUTIONS FOR SAFETY

WARNING

General

• Before starting to install the air conditioner, read through the Installation Manual carefully, and follow its instructions to install

the air conditioner. Otherwise, falling down of the unit may occur, or the unit may cause noise, vibration or water leakage.

• Only a qualified installer(*1) or qualified service person(*1) is allowed to do installationwork. If installation is carried out by

an unqualified individual, a fire, electric shocks, injury, water leakage, noise and/or vibration may result.

• If using separately sold products, make sure to use Toshiba specified products only. Using unspecified products may cause

fire, electric shock, water leak or other failure.

• Before opening the service panel of the outdoor unit, set the circuit breaker to the OFF position. Failure to set the circuit

breaker to the OFF position may result in electric shocks through contact with the interior parts. Only a qualified installer(*1)

or qualified service person(*1) is allowed to remove the service panel of the outdoor unit and do the work required.

• Before carrying out the installation, maintenance, repair or removal work, be sure to set the circuit breakers for both the

indoor and outdoor units to the OFF position. Otherwise, electric shock may result.

• Place a “Work in progress” sign near the circuit breaker while the installation, maintenance, repair or removal work is being

carried out. There is a danger of electric shocks if the circuit breaker is set to ON by mistake.

• Only a qualified installer(*1) or qualified service person(*1) is allowed to undertake work at heights using a stand of 50 cm

or more or to remove the intake grille of the indoor unit to undertake work.

• Wear protective gloves and safety work clothing during installation, servicing and removal.

• Do not touch the aluminium fin of the outdoor unit. You may injure yourself if you do so. If the fin must be touched for some

reason, first put on protective gloves and safety work clothing, and then proceed.

• Do not climb onto or place objects on top of the outdoor unit. You may fall or the objects may fall off of the outdoor unit and

result in injury.

• When working at height, put a sign in place so that no-one will approach the work location before proceeding with the work.

Parts or other objects may fall from above, possibly injuring a person below. Also, be sure that workers put on helmets.

• When cleaning the filter or other parts of the outdoor unit, set the circuit breaker to OFF without fail, and place a “Work in

progress” sign near the circuit breaker before proceeding with the work.

• When working at heights, put a sign in place so that no-one will approach the work location, before proceeding with the

work. Parts and other objects may fall from above, possibly injuring a person below.

• The refrigerant used by this air conditioner is the R410A.

• You shall ensure that the air conditioner is transported in stable condition. If you find any part of the product broken, contact

your dealer.

• Do not disassemble, modify, repair or move the product yourself. Doing so may cause fire, electric shock, injury or water

leaks. Ask a qualified installer or qualified service person to do any repairs or to move the product.

Selection of installation location

• If you install the unit in a small room, take appropriate measures to prevent the refrigerant from exceeding the limit

concentration even if it leaks. Consult the dealer from whom you purchased the air conditioner when you implement the

measures. Accumulation of highly concentrated refrigerant may cause an oxygen deficiency accident.

• Do not install in a location where flammable gas may leaks are possible. If the gas should leak and accumulate around the

unit, it may ignite and cause a fire.

• When transporting the air conditioner, wear shoes with protective toe caps, protective gloves and other protective clothing.

• When transporting the air conditioner, do not take hold of the bands around the packing carton. You may injure yourself if

the bands should break.

• Install the indoor unit at least 2.5 m above the floor level since otherwise the users may injure themselves or receive electric

shocks if they poke their fingers or other objects into the indoor unit while the air conditioner is running.

• Do not place any combustion appliance in a place where it is directly exposed to the wind of air conditioner, otherwise it may

cause imperfect combustion.

• Places where the operation sound of the outdoor unit may cause a disturbance. (Especially at the boundary line with

a neighbour, install the air conditioner while considering the noise.)

Installation

• Follow the instructions in the Installation Manual to install the air conditioner. Failure to follow these instructions may cause

the product to fall down or topple over or give rise to noise, vibration, water leakage or other failure.

• The designated bolts (M12) and nuts (M12) for securing the outdoor unit must be used when installing the unit.

• Install the outdoor unit property in a location that is durable enough to support the weight of the outdoor unit. Insufficient

durability may cause the outdoor unit to fall, which may result in injury.

• Install the unit in the prescribed manner for protection against strong wind and earthquake. Incorrect installation may result

in the unit falling down, or other accidents.

• Be sure to fix the screws back which have been removed for installation or other purposes.

EN

3-EN 4-EN

–2–

5-EN 6-EN

SMMS-i

Installation Manual

–3–

SMMS-i

Installation Manual

Refrigerant piping

• Install the refrigerant pipe securely during the installation work before operating the air conditioner. If the compressor is

operated with the valve open and without refrigerant pipe, the compressor sucks air and the refrigeration cycles is over

pressurized, which may cause a injury.

• Tighten the flare nut with a torque wrench in the specified manner. Excessive tighten of the flare nut may cause a crack in

the flare nut after a long period, which may result in refrigerant leakage.

• Ventilate the air if the refrigerant gas leaks during installation. If the leaked refrigerant gas comes into contact with fire, toxic

gas may be produced.

• After the installation work, confirm that refrigerant gas does not leak. If refrigerant gas leaks into the room and flows near a

fire source, such as a cooking range, noxious gas may be generated.

• When the air conditioner has been installed or relocated, follow the instructions in the Installation Manual and purge the air

completely so that no gases other than the refrigerant will be mixed in the refrigerating cycle. Failure to purge the air

completely may cause the air conditioner to malfunction.

• Nitrogen gas must be used for the airtight test.

• The charge hose must be connected in such a way that it is not slack.

• If refrigerant gas has leaked during the installation work, ventilate the room immediately. If the leaked refrigerant gas comes

in contact with fire, noxious gas may be generated.

Electrical wiring

• Only a qualified installer(*1) or qualified service person(*1) is allowed to carry out the electrical work of the air conditioner.

Under no circumstances must this work be done by an unqualified individual since failure to carry out the work properly may

result in electric shocks and/or electrical leaks.

• When connecting the electrical wires, repairing the electrical parts or undertaking other electrical jobs, wear gloves to

provide protection for electricians and from heat, insulating shoes and clothing to provide protection from electric shocks.

Failure to wear this protective gear may result in electric shocks.

• When executing address setting, test run, or troubleshooting through the checking window on the electric parts box, put on

insulated heat-proof gloves, insulated shoes and other clothing to provide protection fr om electric shock. Otherwise you may

receive an electric shock.

• Use wiring that meets the specifications in the Installation Manual and the stipulations in the local regulations and laws. Use

of wiring which does not meet the specifications may give rise to electric shocks, electrical leakage, smoking and/or a fire.

• Check that the product is properly earthed. (grounding work)

Incomplete earthing may cause electric shock.

• Do not connect the earth line to a gas pipe, water pipe, lightning conductor, or a telephone earth line.

• After completing the repair or relocation work, check that the ground wires are connected properly.

• Install a circuit breaker that meets the specifications in the installation manual and the stipulations in the local regulations

and laws.

• Install the circuit breaker where it can be easily accessed by the agent.

• When installing the circuit breaker outdoors, install one which is designed to be used outdoors.

• Under no circumstances must the power cable be extended. Connection trouble in the places where the cable is extended

may give rise to smoking and/or a fire.

• Electrical wiring work shall be conducted according to law and regulation in the community and installation manual.

Failure to do so may result in electrocution or short circuit.

• Do not supply power from the power terminal block equipped on the outdoor unit to another outdoor unit. Capacity overflow

may occur on the terminal block and may result in fire.

• When carrying out electric connection, use the wire specified in the Installation Manual and connect and fix the wires

securely to prevent them applying external force to the terminals. Improper connection or fixing may result in fire.

Test run

• Before operating the air conditioner after having completed the work, check that the electrical parts box cover of the indoor

unit and service panel of the outdoor unit are closed, and set the circuit breaker to the ON position. You may receive an

electric shock if the power is turned on without first conducting these checks.

• When you have noticed that some kind of trouble (such as when an error display has appeared, there is a smell of burning,

abnormal sounds are heard, the air conditioner fails to cool or heat or water is leaking) has occurred in the air conditioner,

do not touch the air conditioner yourself but set the circuit breaker to the OFF position, and contact a qualified service

person. Take steps to ensure that the power will not be turned on (by marking “out of service” near the circuit breaker, for

instance) until qualified service person arrives. Continuing to use the air conditioner in the trouble status may cause

mechanical problems to escalate or result in electric shocks or other failure.

• After the work has finished, be sure to use an insulation tester set (500V Megger) to check the resistance is 2 MΩ or more

between the charge section and the non-charge metal section (Earth section). If the resistance value is low, a disaster such

as a leak or electric shock is caused at user’s side.

• Upon completion of the installation work, check for refrigerant leaks and check the insulation resistance and water drainage.

Then conduct a test run to check that the air conditioner is operating properly.

Explanations given to user

• Upon completion of the installation work, tell the user where the circuit breaker is located. If the user does not know where

the circuit breaker is, he or she will not be able to turn it off in the event that trouble has occurred in the air conditioner.

• If you have discovered that the fan grille is damaged, do not approach the outdoor unit but set the circuit breaker to the OFF

position, and contact a qualified service person(*1) to have the repairs done. Do not set the circuit breaker to the ON position

until the repairs are completed.

• After the installation work, follow the Owner’s Manual to explain to the customer how to use and maintain the unit.

Relocation

• Only a qualified installer(*1) or qualified service person(*1) is allowed to relocate the air conditioner. It is dangerous for the

air conditioner to be relocated by an unqualified individual since a fire, electric shocks, injury, water leakage, noise and/or

vibration may result.

• When carrying out the pump-down work shut down the compressor before disconnecting the refrigerant pipe. Disconnecting

the refrigerant pipe with the service valve left open and the compressor still operating will cause air or other gas to be suck ed

in, raising the pressure inside the refrigeration cycle to an abnormally high level, and possibly resulting in rupture, injury or

other trouble.

• Never recover the refrigerant into the outdoor unit. Be sure to use a refrigerant recovery machine to recover the refrigerant

when moving or repairing. It is impossible to recover the refrigerant into the outdoor unit. Refrigerant recovery into the

outdoor unit may result in serious accidents such as explosion of the unit, injury or other accidents.

(*1) Refer to the “Definition of Qualif ied Installer or Qualified Service Per son.”

CAUTION

New Refrigerant Air Conditioner Installation

• THIS AIR CONDITIONER ADOPTS THE NEW HFC REFRIGERANT (R410A) WHICH DOES NOT DESTROY OZONE

LAYER.

• The characteristics of R410A refrigerant are; easy to absorb water, oxidizing membrane or oil, and its pressure is approx.

1.6 times higher than that of refrigerant R22. Accompanied with the new refrigerant, refrigerating oil has also been changed.

Therefore, during installation work, be sure that water, dust, former refrigerant, or refrigerating oil does not enter the

refrigerating cycle.

• To prevent charging an incorrect refrigerant and refrigerating oil, the sizes of connecting sections of charging port of the

main unit and installation tools are changed from those for the conventional refrigerant.

• Accordingly the exclusive tools are required for the new refrigerant (R410A).

• For connecting pipes, use new and clean piping designed for R410A, and please care so that water or dust does not enter.

To Disconnect the Appliance from Main Power Supply.

• This appliance must be connected to the main power supply by means of a switch with a contact separation of at least 3 mm.

The installation fuse (all type can be used) must be used for the power supply line of this conditioner.

SMMS-i

Installation Manual

SMMS-i

Installation Manual

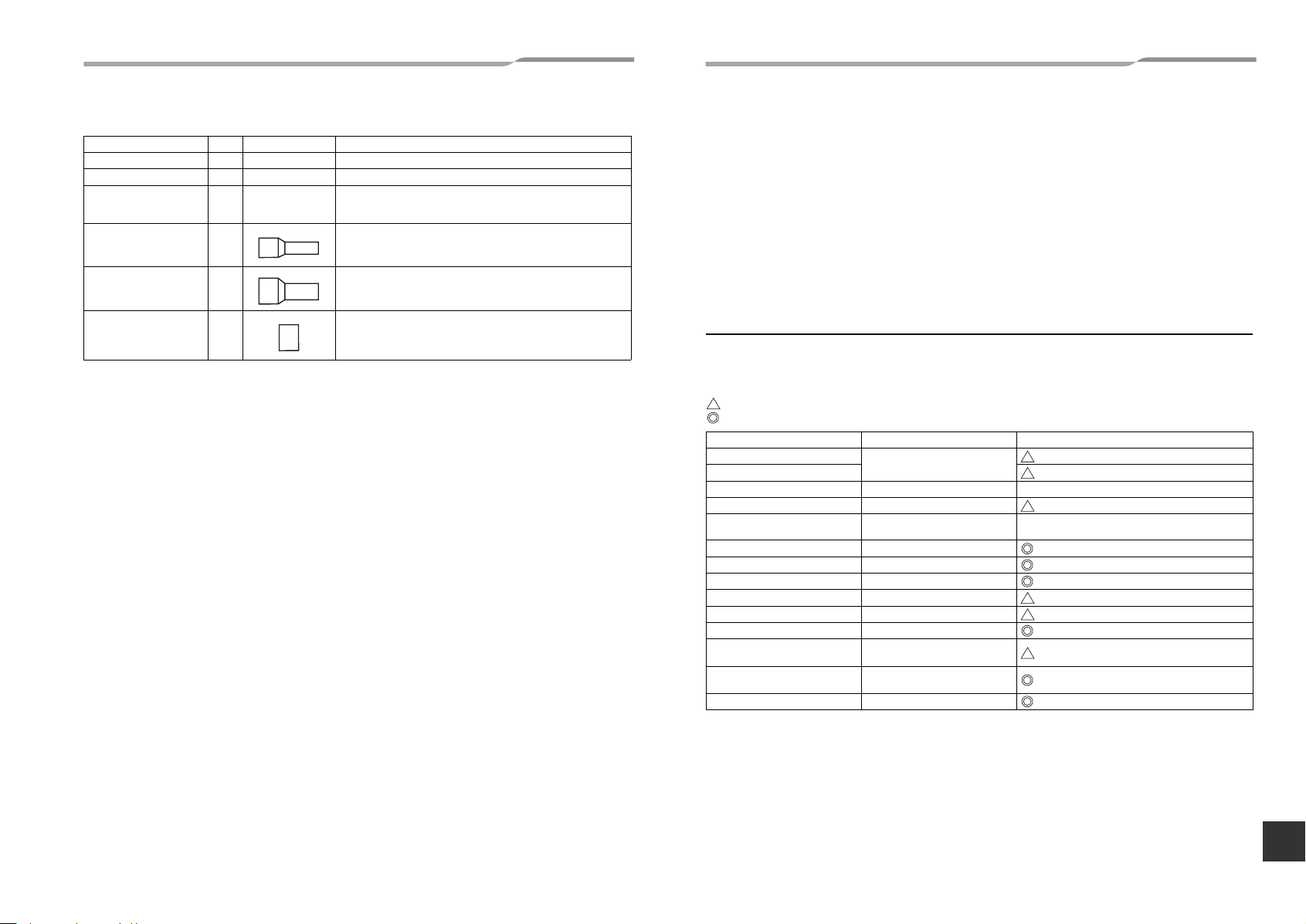

2 ACCESSORY PARTS

Part name Q’ty Shape Usage

Owner’s Manual 1 – (Be sure to hand it to the customers.)

Installation Manual 2 – (Be sure to hand it to the customers.)

CD-ROM

(Owner’s manual,

Installation manual)

Attached pipe

(for Ø22.2)

Attached pipe

(for Ø28.6)

F-GAS label 1 Fill the items on the label after adding refrigerant.

1–

1

1

For other languages that do not appear in this Installation Manual,

Please refer to the enclosed CD-ROM.

Connecting pipe for gas side piping

(MAP080, MAP100 type)

Connecting pipe for gas side piping

(MAP120, MAP140, MAP160 type)

3 INSTALLATION OF NEW REFRIGERANT

AIR CONDITIONER

This air conditioner adopts the new HFC refrigerant (R410A) which does not deplete the ozone layer.

• R410A refrigerant is vulnerable to impurities such as water, oxidizing membranes, or oils because the pressure

of R410A refrigerant is higher than that of the former refrigerant by approximately 1.6 times.

As well as the adoption of the new refrigerant, the refrigerating oil has been also changed. Therefore, pay

attention so that water, dust, former refrigerant, or refrigerating oil does not enter the refrigerating cycle of the

new refrigerant air conditioner during installation.

• To prevent mixing of refrigerant or refrigerating oil, the size of the charge port of the main unit or connecting

section of the installation tool differs to that of an air conditioner for the former refrigerant.

Accordingly, exclusive tools are required for the new refrigerant (R410A) as shown below.

• For connecting pipes, use new and clean piping materials so that water or dust does not enter.

Required Tools and Cautions on handling

It is necessary to prepare the tools and parts for installation as described below. The tools and parts which will be newly prepared in the following items should be restricted to exclusive use.

Explanation of symbols

: Newly prepared (It is necessary to use it exclusively with R410A, separately from those for R22 or R407C.)

: Former tool is available.

Gauge manifold

Charging hose Exclusive to R410A

Charging cylinder Charging refrigerant Unusable (Use the Refrigerant charging balance.)

Gas leak detector Checking gas leak Exclusive to R410A

Vacuum pump Vacuum drying

Vacuum pump with counterflow Vacuum drying R22 (Existing article)

Flare tool Flare processing of pipes Usable by adjusting size

Bender Bending processing of pipes R22 (Existing article)

Refrigerant recovery device Recovering refrigerant Exclusive to R410A

Torque wrench Tightening flare nut Exclusive to Ø12.7mm and Ø15.9mm

Pipe cutter Cutting pipes R22 (Existing article)

Refrigerant canister Charging refrigerant

Welding machine/Nitrogen gas

cylinder

Refrigerant charging balance Charging refrigerant R22 (Existing article)

Used tools Usage Proper use of tools/parts

Vacuuming, charging refrigerant

and operation check

Welding of pipes R22 (Existing article)

Exclusive to R410A

Usable if a counter-flow preventive adapter is

attached

Exclusive to R410A

Enter the refrigerate name for identification

EN

7-EN 8-EN

–4–

9-EN 10-EN

SMMS-i

Installation Manual

–5–

SMMS-i

Installation Manual

4 SELECTION OF INSTALLATION PLACE

Upon customer’s approval, install the air conditioner in a place which satisfies the following conditions:

• Place where it can be installed horizontally.

• Place which can reserve a sufficient service space for safe maintenance or checks.

• Place where there is no problem even if the drained water overflows.

Avoid the following places:

• Salty places (seaside area) or places with much gas sulfide (hot spring area) (If selecting such a place, special

maintenance is required.)

• Places where oil (including machine oil), steam, oil smoke or corrosive gas is generated.

• Places where an organic solvent is used.

• Chemical plants with a cooling system using liquid carbon dioxide.

• Places where a device generating high frequency (inverter, non-utility generator, medical apparatus, or

communication equipment) is set. (Malfunction or abnormal control of the air conditioner, or interference to

devices listed above may occur.)

• Places where discharged air from the outdoor unit blows against the windows of a neighbour's house.

• Places unable to bear the weight of the unit.

• Places with poor ventilation.

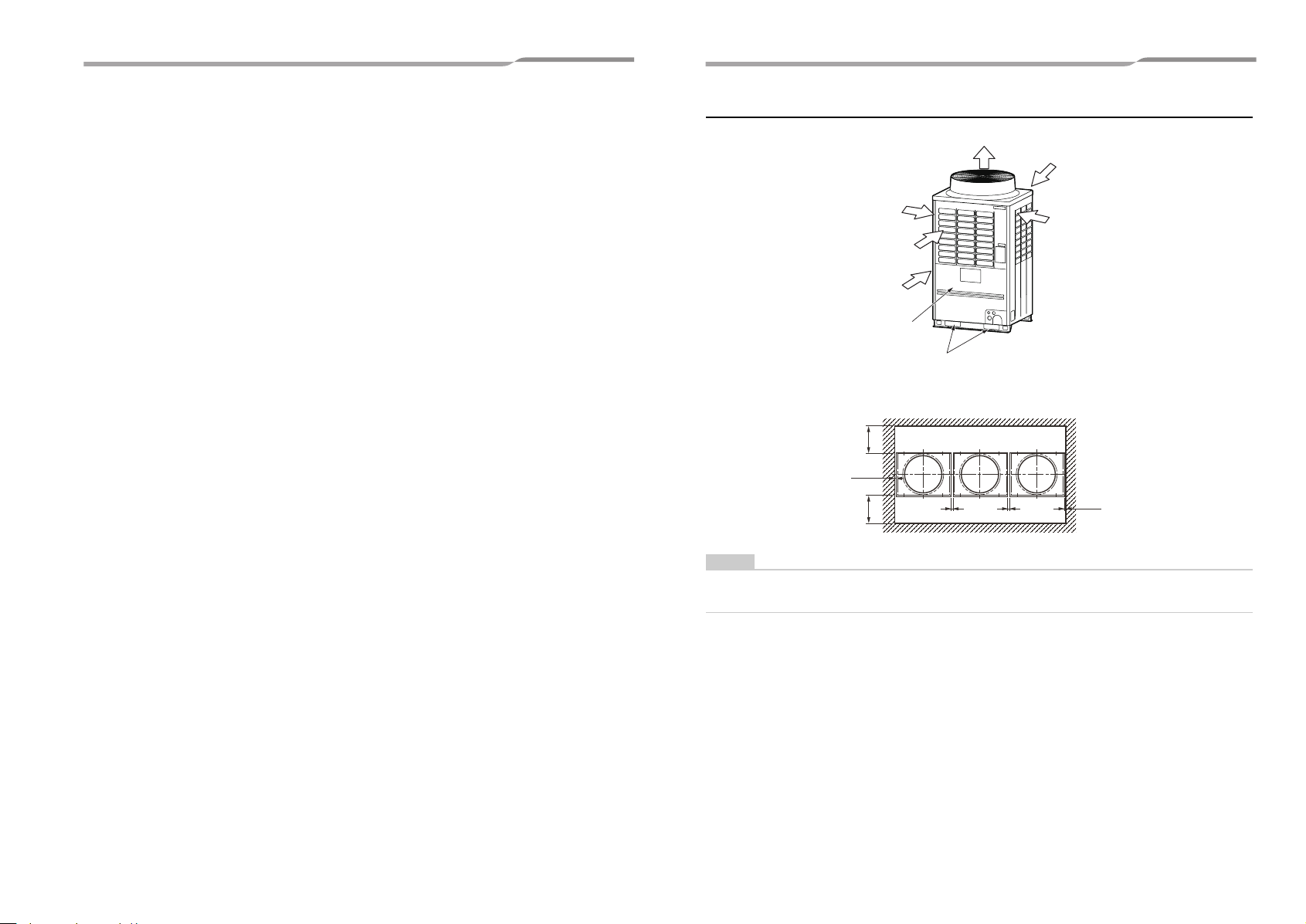

Installation space

Leave space necessary for running, installation and servicing.

Air intake

Air intake

Installation/servicing

500mm or more

(Rear side)

10mm or more

500mm or more

(Front side)

surface

20mm or more

Square hole for

handling

Outdoor unit top view

Air discharge

20mm or more

Air intake

Air intake

10mm or more

NOTE

• If there is an obstacle above the outdoor unit, leave a space of 2000mm or more to the top end of the outdoor unit.

• If there is a wall around the outdoor unit, make sure that its height does not exceed 800mm.

SMMS-i

Installation Manual

SMMS-i

Installation Manual

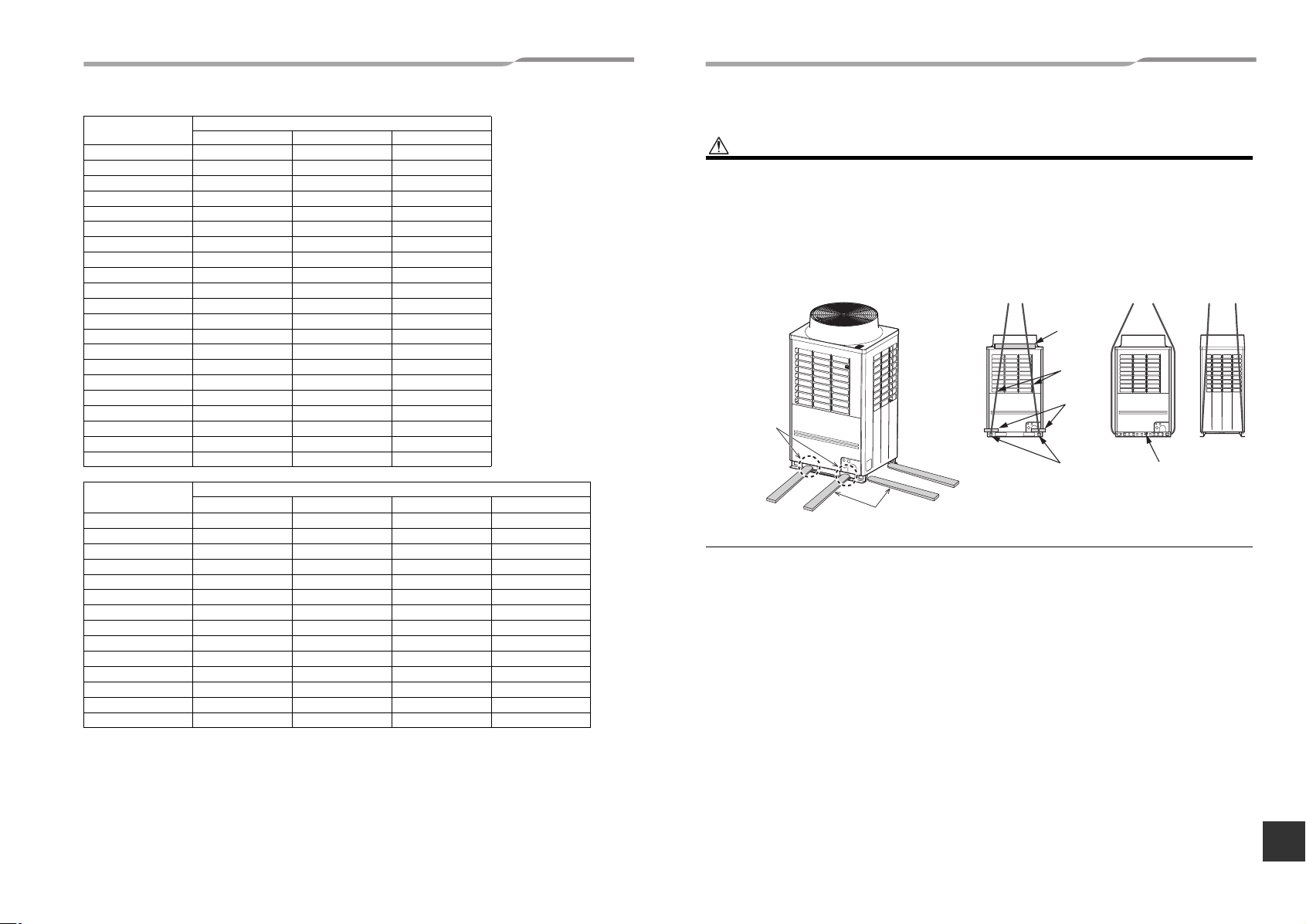

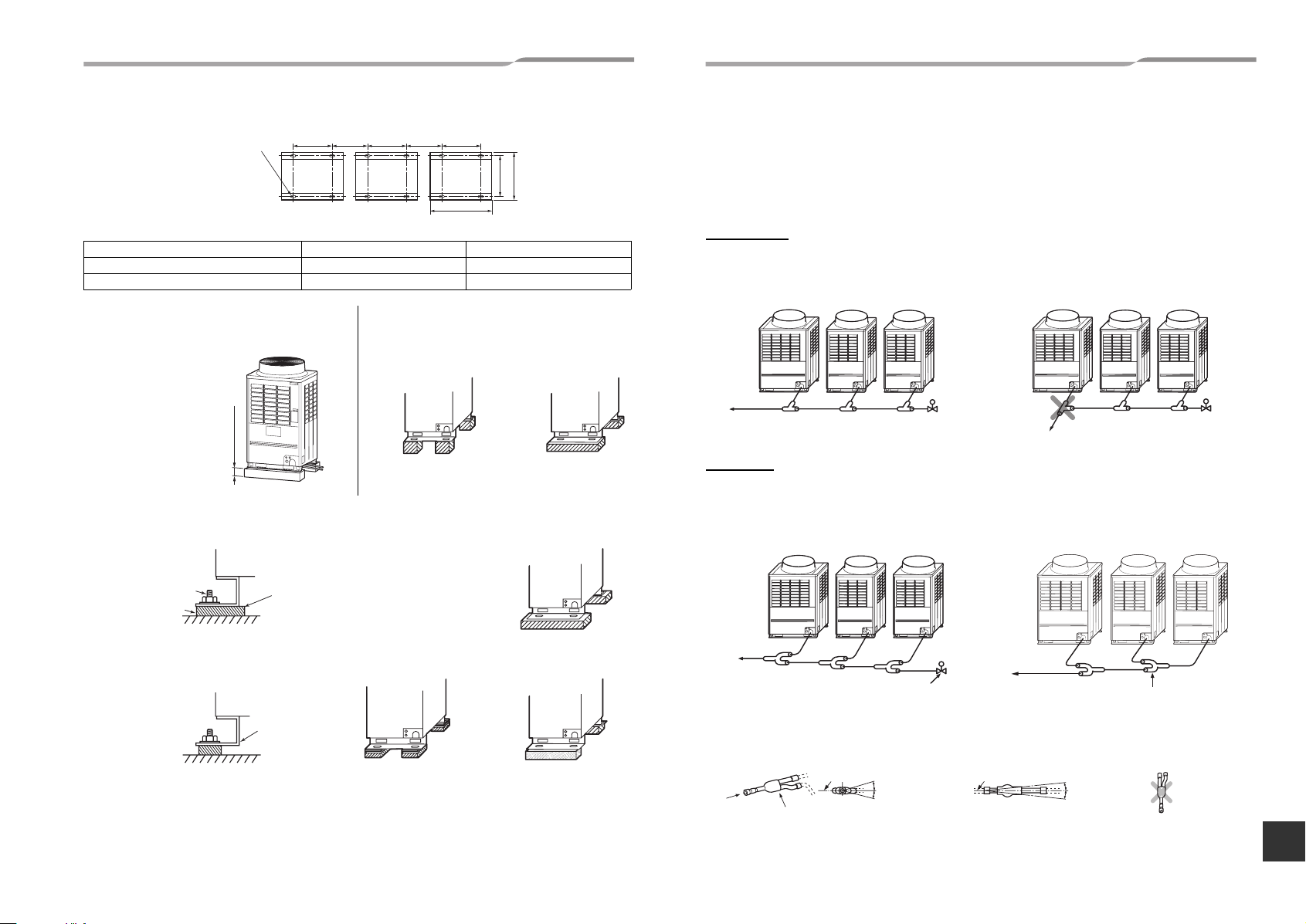

▼ Combination of outdoor units

Model name

(Standard type)

MMY-MAP0804* MMY-MAP0804* – –

MMY-MAP1004* MMY-MAP1004* – –

MMY-MAP1204* MMY-MAP1204* – –

MMY-MAP1404* MMY-MAP1404* – –

MMY-MAP1604* MMY-MAP1604* – –

MMY-AP1814* MMY-MAP1004* MMY-MAP0804* –

MMY-AP2014* MMY-MAP1004* MMY-MAP1004* –

MMY-AP2214* MMY-MAP1204* MMY-MAP1004* –

MMY-AP2414* MMY-MAP1204* MMY-MAP1204* –

MMY-AP2614* MMY-MAP1604* MMY-MAP1004* –

MMY-AP2814* MMY-MAP1604* MMY-MAP1204* –

MMY-AP3014* MMY-MAP1604* MMY-MAP1404* –

MMY-AP3214* MMY-MAP1604* MMY-MAP1604* –

MMY-AP3414* MMY-MAP1204* MMY-MAP1204* MMY-MAP1004*

MMY-AP3614* MMY-MAP1204* MMY-MAP1204* MMY-MAP1204*

MMY-AP3814* MMY-MAP1604* MMY-MAP1204* MMY-MAP1004*

MMY-AP4014* MMY-MAP1604* MMY-MAP1204* MMY-MAP1204*

MMY-AP4214* MMY-MAP1604* MMY-MAP1404* MMY-MAP1204*

MMY-AP4414* MMY-MAP1604* MMY-MAP1604* MMY-MAP1204*

MMY-AP4614* MMY-MAP1604* MMY-MAP1604* MMY-MAP1404*

MMY-AP4814* MMY-MAP1604* MMY-MAP1604* MMY-MAP1604*

Model name

(High Efficiency Model)

MMY-AP1624* MMY-MAP0804* MMY-MAP0804* – –

MMY-AP2424* MMY-MAP0804* MMY-MAP0804* MMY-MAP0804* –

MMY-AP2624* MMY-MAP1004* MMY-MAP0804* MMY-MAP0804* –

MMY-AP2824* MMY-MAP1004* MMY-MAP1004* MMY-MAP0804* –

MMY-AP3024* MMY-MAP1004* MMY-MAP1004* MMY-MAP1004* –

MMY-AP3224* MMY-MAP0804* MMY-MAP0804* MMY-MAP0804* MMY-MAP0804*

MMY-AP3424* MMY-MAP1004* MMY-MAP0804* MMY-MAP0804* MMY-MAP0804*

MMY-AP3624* MMY-MAP1004* MMY-MAP1004* MMY-MAP0804* MMY-MAP0804*

MMY-AP3824* MMY-MAP1004* MMY-MAP1004* MMY-MAP1004* MMY-MAP0804*

MMY-AP4024* MMY-MAP1004* MMY-MAP1004* MMY-MAP1004* MMY-MAP1004*

MMY-AP4224* MMY-MAP1204* MMY-MAP1004* MMY-MAP1004* MMY-MAP1004*

MMY-AP4424* MMY-MAP1204* MMY-MAP1204* MMY-MAP1004* MMY-MAP1004*

MMY-AP4624* MMY-MAP1204* MMY-MAP1204* MMY-MAP1204* MMY-MAP1004*

MMY-AP4824* MMY-MAP1204* MMY-MAP1204* MMY-MAP1204* MMY-MAP1204*

Unit 1 Unit 2 Unit 3

Unit 1 Unit 2 Unit 3

Cooperating outdoor unit

Cooperating outdoor unit

Unit 4

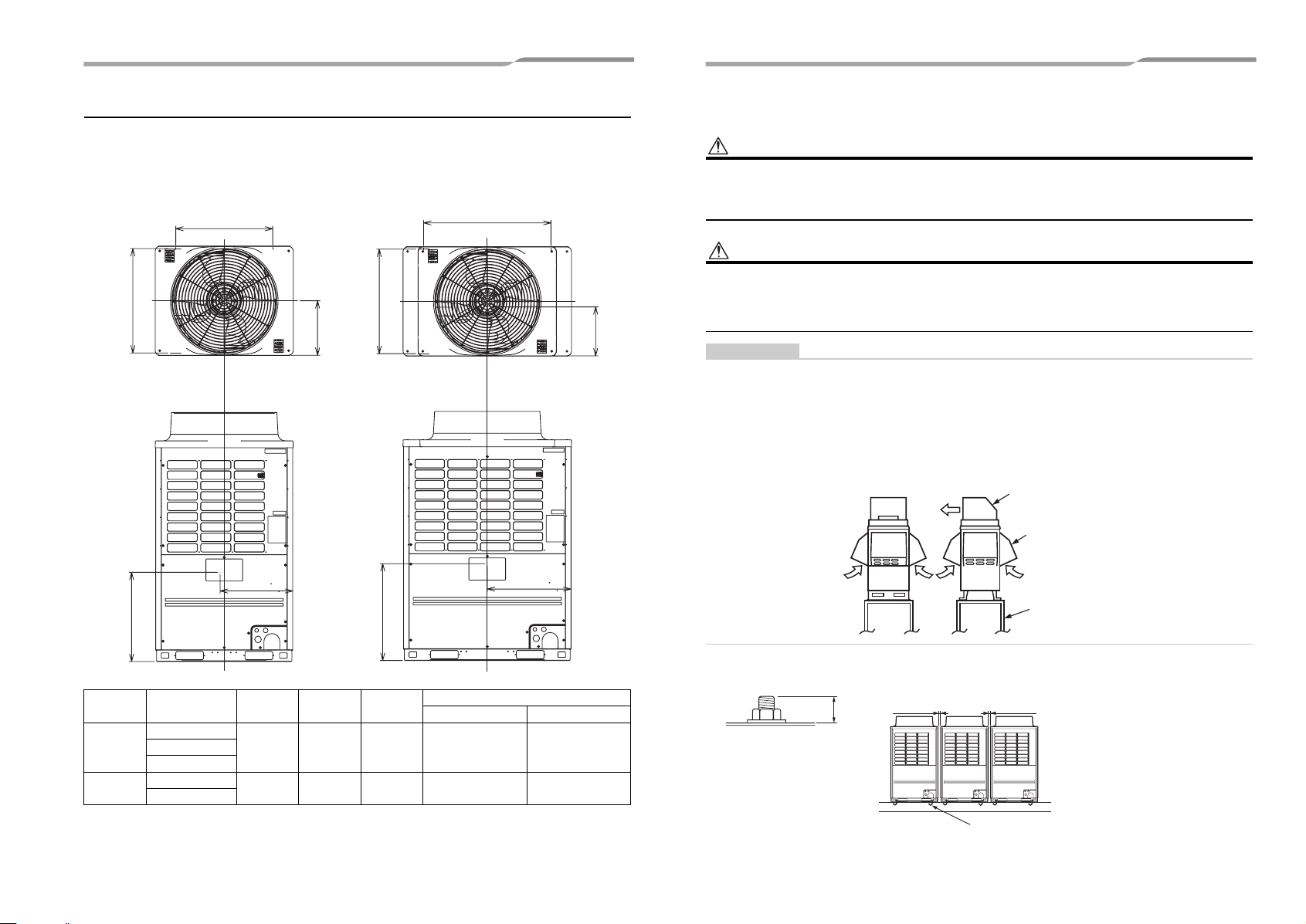

5 CARRYING IN THE OUTDOOR UNIT

CAUTION

Handle the outdoor unit carefully, observing the following items.

• When using a forklift or other machinery for loading/unloading in transportation, insert the prongs of the forklift

into the rectangular holes for handling as shown below.

• When lifting up the unit, insert a rope able to bear the unit’s weight into the rectangular holes for handling, and

tie the unit from 4 sides.

(Apply padding in positions where the rope comes into contact with the outdoor unit so that no damage is caused

to the outer surface of the outdoor unit.)

(There are reinforcing plates on the side surfaces, so the rope cannot be passed through.)

GOOD NO GOOD NO GOOD

Plaster

Rope

Rectangular

holes for

handling

Front /Back

GOOD

Side

NO GOOD

Prongs of the

forklift

Plaster

Rectangular

holes for

lifting

Reinforcing

plate

EN

11-EN 12-EN

–6–

13-EN 14-EN

SMMS-i

Installation Manual

–7–

SMMS-i

Installation Manual

Weight centre and weight

◆ Weight centre of an outdoor unit

(A)

Anchor bolt position

700

755

Anchor bolt position

Y

6 INSTALLATION OF THE OUTDOOR UNIT

WARNING

(B)

Anchor bolt position

920

755

Anchor bolt position

Y

• Be sure to install the outdoor unit in a place able to bear its weight.

If strength is insufficient, the unit may fall down resulting in human injury.

• Perform specified installation work to protect against strong wind and earthquakes.

If the outdoor unit is imperfectly installed, an accident by falling or dropping may be caused.

CAUTION

• Drain water is discharged from the outdoor unit. (Especially while heating)

Install the outdoor unit in a place with good drainage.

• For installation, be careful of the strength and level of the foundation so that abnormal sounds (vibration or noise)

are not generated.

REQUIREMENT

Installation in a snowfall area

1. Install the outdoor unit on a higher foundation than the snowfall or set up a stand to install the unit so that snowfall

will not affect the unit.

• Set up a stand higher than the snowfall.

• Apply an angled structure to the stand so that drainage will not be prevented. (Avoid using a stand with a flat

surface.)

2. Mount a snowfall-hood onto the air inlet and the air outlet.

• Leave enough space for the snowfall-hood so that it will not be an obstacle for the air inlet and the air outlet.

Snowfall-hood for air

outlet (locally procured)

Snowfall-hood for air

outlet

(4 faces)

(locally procured)

X

Z

No. Model type X (mm) Y (mm) Z (mm)

MAP080

(A)

(B)

MAP120

MAP140

MAP160

500 390 645 242 241MAP100

605 350 700 330 330

Z

X

Weight (kg)

Heat pump model Cooling only model

Stand

(locally procured)

1. To install multiple outdoor units, arrange them with 20mm or more spaces in between. Fix each outdoor unit with M12 anchor bolts at 4 positions. 20mm projection is appropriate for an anchor bolt.

20

20mm or more

20mm or more

M12 anchor bolt

4 positions/unit

SMMS-i

Installation Manual

SMMS-i

Installation Manual

• Anchor bolt positions are as shown below:

Continuous hole

(15 x 20 long hole)

310 or

more

A A A

Model type A B

MAP080*, MAP1000*, MAP120* 700 990

MAP1404*, 1604* 920 1210

2. When drawing out the refrigerant pipe from the

underside, set the height of the stand to 500mm or

310 or

more

755

790

B

(Unit: mm)

3. Do not use 4 stands on the corner to support the outdoor unit.

more.

NO GOOD GOOD

500mm or more

4. Mount the vibration-proof rubber (including vibration-proof blocks) so that it fits under the whole clamping leg.

GOOD GOOD

Install the vibration-proof

rubber so that the bent part

Anchor bolt

Vibration-proof rubber

of the fixing leg is

grounded.

5. Be careful of the connecting arrangement of the header unit and follower units. Set the outdoor units in order of

capacity from the one with the largest capacity. (A (Header unit) ≥ B ≥ C ≥ D)

• Be sure to use a header unit for the leading outdoor unit to be connected to the main pipe. (Figure 1 and 3)

• Be sure to use a T-shaped branch joint (RBM-BT14E/RBM-BT24E: separately purchased) to connect each

outdoor unit.

• Be careful of the direction of the Outdoor unit connection piping kit for the liquid side. (As shown in Figure 2, a

Outdoor unit connection piping kit cannot be attached so that the refrigerant of the main pipe flows directly into

the header unit.)

Liquid piping

▼ Figure 1 ▼ Figure 2

GOOD

Header unit AFollower unit BFollower unit

Main pipe

To the indoor unit

C

NO GOOD

Header unit AFollower unit BFollower unit

NO GOOD

Main pipe

To the indoor unit

C

Gas piping

▼ Figure 3 ▼ Figure 4

GOOD

Header unit AFollower unit BFollower unit

C

[Inverse connection of a gas-side branch unit]

NO GOOD

Header unit AFollower unit

B

Follower unit

C

Main pipe

NO GOOD NO GOODNO GOOD

The bent part of the

fixing leg is not

grounded.

To the indoor unit

Extension valve

• When attaching a Y-shaped branch unit for the gas side, attach it level with the ground (Be sure not to exceed

Main pipe

To the indoor unit

To gas-side branch

unit

±15 degrees.). Regarding a T-shape branch joints for the liquid side, there is no restriction for its angle.

(Horizontal line)

A

B

(A arrow view)

Within ±15 degrees

(Horizontal line)

(B arrow view)

Within ±15

degrees

Do not connect

a branch unit

vertically.

At a level position

EN

15-EN 16-EN

–8–

17-EN 18-EN

SMMS-i

Installation Manual

–9–

SMMS-i

Installation Manual

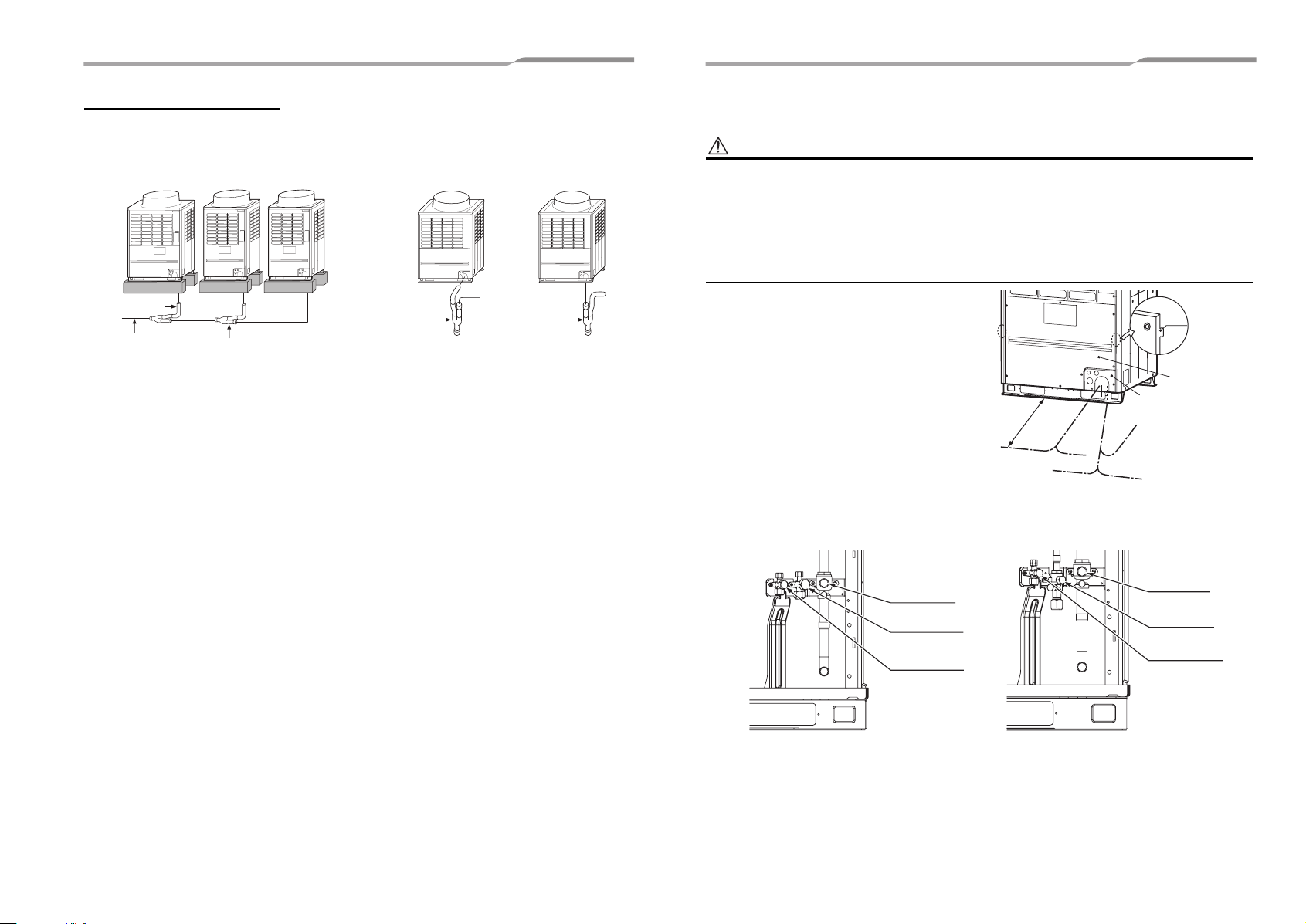

When drawing pipes downward

▼ Figure 5 ▼ Figure 6

GOOD

Header unit AFollower unit BFollower unit

L-shaped

pipe

To gas-side branch

unit

C

To gas-side branch

unit

• Adding only one follower unit is possible. Install the additional unit so that its position is opposite to the header

unit. Use an extension valve for installation (See the figure above.).

Specify the pipe diameter in advance to allow for adding another unit.

[Vertical connection of branch units]

NO GOOD

To gas-side

branch unit

To gas-side

branch unit

7 REFRIGERANT PIPING

WARNING

• If the refrigerant gas leaks during installation, ventilate the room.

If the leaked refrigerant gas comes into contact with fire, noxious gas may be generated.

• After installation, check that the refrigerant gas does not leak.

If the refrigerant gas leaks into the room and comes into contact with fire such as a fan heater, stove, or kitchen range,

noxious gas may be generated.

Connection of refrigerant pipe

• The refrigerant pipe connecting section is set in the

outdoor unit. Remove the front panel and the piping/

wiring panel. (M5: 9 pcs.)

• As shown in the illustration on the right, the hooks are

at the right and left sides of the front panel. Lift up and

remove the front panel.

• Pipes can be drawn out forward or downward from the

outdoor unit.

• When drawing out the pipe forward, draw it out to the

outside via the piping/wiring panel, and leave a space

of 500mm or more from the main pipe connecting the

outdoor unit with the indoor unit, considering service

work or other work on the unit. (For replacing the

compressor, 500mm or more space is required.)

• When drawing out the pipe downward, remove the

knockouts on the base plate of the outdoor unit, draw

o

m

m

0

e

r

0

o

5

m

D

r

a

w

(Left piping)

r

i

n

(Left

piping)

g

o

u

t

f

o

r

w

(Right

piping)

a

r

d

Drawing out

downward

the pipes out of the outdoor unit, and perform piping on

the right/left or rear side. Downward length of the balance pipe should be 5m or less.

Hook

Front panel

Piping/wiring panel

(Rear piping)

(Right piping)

Ball valve of gas

side

Packed valve of liquid

side

Packed valve of

balance pipe

(MAP080, MAP100, MAP120) (MAP140, MAP160)

Ball valve of gas

side

Ball valve of liquid

side

Packed valve of

balance pipe

SMMS-i

Installation Manual

SMMS-i

Installation Manual

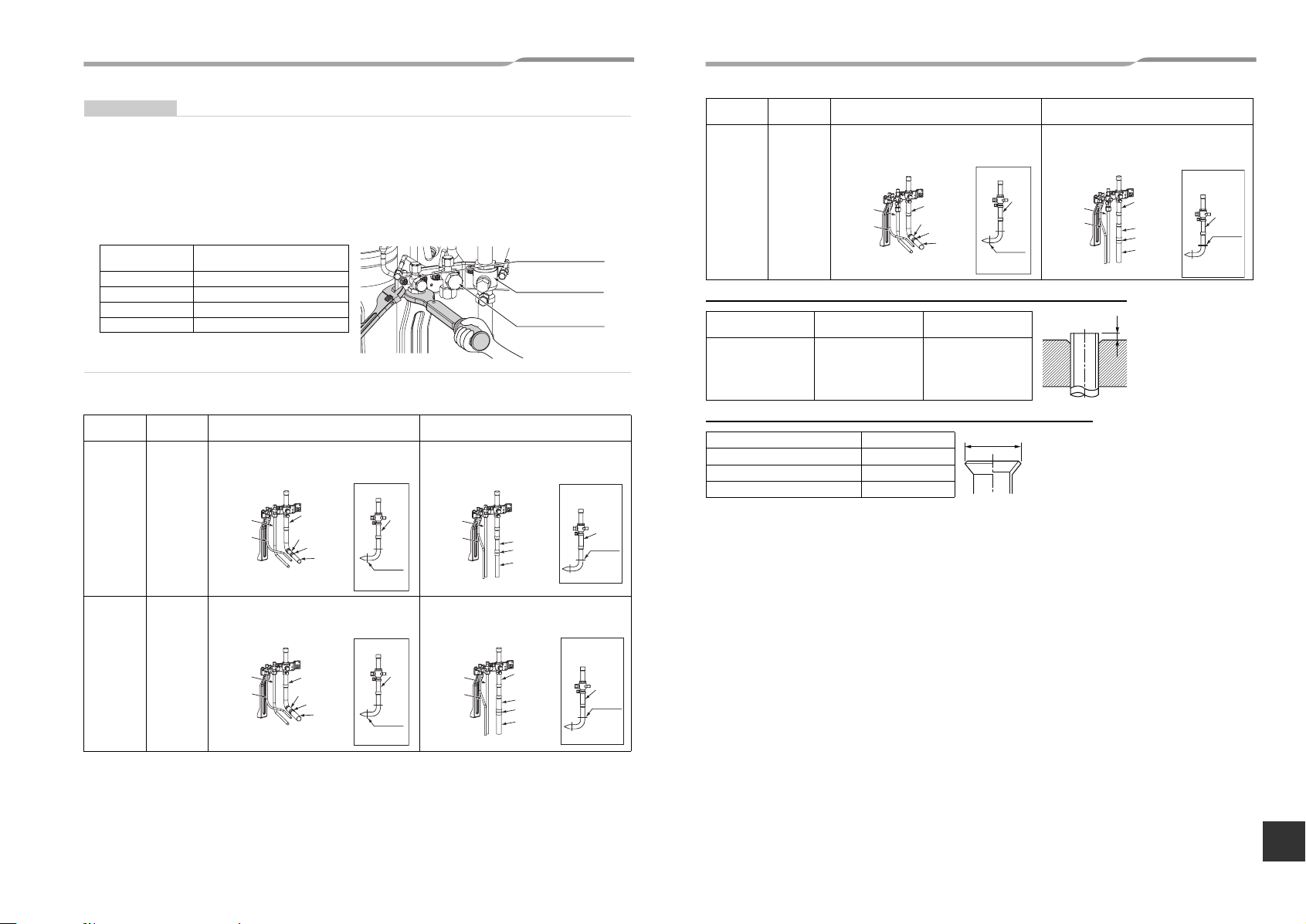

REQUIREMENT

• For a welding work of the refrigerant pipes, be sure to use nitrogen gas in order to prevent oxidation of the inside

of the pipes; otherwise clogging of the refrigerating cycle due to oxidized scale may occur.

• Use clean and new pipes for the refrigerant pipes and perform piping work so that water or dust does not

contaminate the refrigerant.

• Be sure to use a double spanner to loosen or tighten the flare nut. If a single spanner is used, the required level

of tightening cannot be obtained. Tighten the flare nut with the specified torque. (If it is hard to loosen or tighten

the flare nut of the balance pipe or packed valve of the liquid side with a double spanner, loosen or tighten the

flare nut while holding the valve mounting plate with a spanner.)

Packed valve of

Outer dia. of

copper pipe

6.4 mm 14 to 18 (1.4 to 1.8 kgf•m)

9.5 mm 33 to 42 (3.3 to 4.2 kgf•m)

12.7 mm 50 to 62 (5.0 to 6.2 kgf•m)

15.9 mm 63 to 77 (6.3 to 7.7 kgf•m)

Tightening torque (N•m)

balance pipe

Ball valve of gas side

Packed valve of liquid

side

Pipe connection method of valve at the gas side (Example)

Type

MAP080

MAP100

Pipe

diameter

Ø22.2

Draw-out forward Draw-out downward

Cut the L-shaped pipe at the horizontal straight

section, then braze the supplied attachment

pipe and the socket and pipe procured locally.

Gas

Liquid

pipe

Balance

pipe

Cut the L-shaped pipe at the horizontal straight

section, then braze the supplied attachment

pipe and the socket and pipe procured locally.

Gas pipe

Attachment

pipe

Socket

Pipe

pipe

Section to be

cut

Cut the L-shaped pipe at the vertical straight

section, then braze the supplied attachment

pipe and the socket and pipe procured locally.

Liquid

pipe

Balance

pipe

Cut the L-shaped pipe at the vertical straight

section, then braze the supplied attachment

pipe and the socket and pipe procured locally.

Gas pipe

Attachment

pipe

Socket

Pipe

Gas

pipe

Section

to be cut

Type

MAP140

MAP160

Pipe

diameter

Ø28.6

Draw-out forward Draw-out downward

Cut the L-shaped pipe at the horizontal straight

section, then braze the supplied attachment

pipe, and the socket and pipe procured locally.

Gas

Liquid

pipe

Balance

pipe

Gas pipe

Attachment pipe

Socket

Pipe

pipe

Section

to be cut

Cut the L-shape pipe at the vertical straight

section, then braze the supplied attachment

pipe, and the socket and pipe procured locally.

Liquid

pipe

Balance

pipe

Gas pipe

Attachment

pipe

Socket

Pipe

Gas

pipe

Section

to be cut

Extruding margin of copper pipe with flare machining: B (Unit: mm)

Copper pipe outer

dia.

9.5

12.7

15.9

When using R410A

tool

0 to 0.5 1.0 to 1.5

When using

conventional tool

B

Extruding margin of copper pipe with flare tools: A (Unit: mm)

Copper pipe outer dia. A

9.5 13.2

12.7 16.6

15.9 19.7

* When using the conventional flare tool, to connect R410A pipes with flaring, make a margin approx. 0.5mm

longer than that of an R22 pipe so that the flare size matches the one specified. It is convenient to use a copper

pipe gauge for size adjustment of the extruding margin.

+0

-0.4

A

MAP120

Ø28.6

pipe

Balance

pipe

Gas pipe

Attachment pipe

Socket

Pipe

Gas

pipeLiquid

Section to be

cut

Liquid

pipe

Balance

pipe

Gas pipe

Attachment

pipe

Socket

Pipe

Gas

pipe

Section

to be cut

EN

19-EN 20-EN

–10–

21-EN 22-EN

SMMS-i

Installation Manual

–11–

SMMS-i

Installation Manual

Coupling size of brazed pipe

Connected section

External size Internal size

K

ØC

G

ØF

(Unit: mm)

Connected section

Standard outer dia.

of connected

copper pipe

6.35 6.35 (±0.03) 6.45 ( ) 7 6 0.06 or less 0.50

9.52 9.52 (±0.03) 9.62 ( ) 8 7 0.08 or less 0.60

12.70 12.70 (±0.03) 12.81 ( ) 9 8 0.10 or less 0.70

15.88 15.88 (±0.03) 16.00 ( ) 9 8 0.13 or less 0.80

19.05 19.05 (±0.03) 19.19 ( ) 11 10 0.15 or less 0.80

22.22 22.22 (±0.03) 22.36 ( ) 11 10 0.16 or less 0.82

28.58 28.58 (±0.04) 28.75 ( ) 13 12 0.20 or less 1.00

34.92 34.90 (±0.04) 35.11 ( ) 14 13 0.25 or less 1.20

38.10 38.10 (±0.05) 38.31 ( ) 15 14 0.27 or less 1.26

41.28 41.28 (±0.05) 41.50 ( ) 15 14 0.28 or less 1.35

External size Internal size

Standard outer dia.

(Allowable difference)

CFKG

+0.04

-0.02

+0.04

-0.02

+0.04

-0.02

+0.04

-0.02

+0.03

-0.03

+0.03

-0.03

+0.06

-0.02

+0.04

-0.04

+0.08

-0.02

+0.08

-0.02

Min. depth of

insertion

Oval value

Min. thickness

of coupling

Selection of pipe size

◆ Capacity code of indoor and outdoor units

Selection of pipe material

• For the indoor unit, the capacity code is decided at each capacity rank. (Table 1)

• The capacity codes of the outdoor units are decided at each capacity rank. The maximum number of connectable

indoor units and the total value of capacity codes of the indoor units are also decided. (Table 2)

NOTE

Compared with the capacity code of the outdoor unit, the total value of capacity codes of the connectable indoor units differs

based on the height difference between the indoor units.

• When the height difference between the indoor units is 15m or less: Up to 135% of the capacity code (Equivalent

to HP) of the outdoor unit (Equivalent to HP) of the outdoor unit

• When the height difference between the indoor units is over 15m: Up to 105% of the capacity code

Table 1

Indoor unit

capacity rank

007 0.8 2.2

009 1 2.8

012 1.25 3.6

015 1.7 4.5

018 2 5.6

024 2.5 7.1

027 3 8

030 3.2 9

036 4 11.2

048 5 14

056 6 16

072 8 22.4

096 10 28

Equivalent to HP

Capacity code

Equivalent to

capacity

Table 2

Outdoor unit

model name

(Standard model)

MMY-MAP0804∗ 822.413— — ——

MMY-MAP1004∗ 10 28 16 — — — —

MMY-MAP1204∗ 12 33.5 20 — — — —

MMY-MAP1404∗ 14 40 23 — — — —

MMY-MAP1604∗ 16 45 27 MMY-AP1624∗ 16 45 27

MMY-AP1814∗ 18 50.4 30 — — — —

MMY-AP2014∗ 20 56 33 — — — —

MMY-AP2214∗ 22 61.5 37 — — — —

MMY-AP2414∗ 24 68 40 MMY-AP2424∗ 24 68 40

MMY-AP2614∗ 26 73 43 MMY-AP2624∗ 26 73 43

MMY-AP2814∗ 28 78.5 47 MMY-AP2824∗ 28 78.5 47

MMY-AP3014∗ 30 85 48 MMY-AP3024∗ 30 85 48

MMY-AP3214∗ 32 90 48 MMY-AP3224∗ 32 90 48

MMY-AP3414∗ 34 96 48 MMY-AP3424∗ 34 96 48

MMY-AP3614∗ 36 101 48 MMY-AP3624∗ 36 101 48

MMY-AP3814∗ 38 106.5 48 MMY-AP3824∗ 38 106.5 48

MMY-AP4014∗ 40 112 48 MMY-AP4024∗ 40 112 48

MMY-AP4214∗ 42 118 48 MMY-AP4224∗ 42 118 48

MMY-AP4414∗ 44 123 48 MMY-AP4424∗ 44 123 48

MMY-AP4614∗ 46 130 48 MMY-AP4624∗ 46 130 48

MMY-AP4814∗ 48 135 48 MMY-AP4824∗ 48 135 48

Capacity code

Equivalent to HPEquivalent to

capacity

No. of

indoor

units

Outdoor unit

model name

(High Efficiency

model)

Capacity code

Equivalent to HPEquivalent to

capacity

No. of

indoor

units

* For combination of the outdoor units, refer to “Combination of outdoor units”.

SMMS-i

Outdoor unit

(3) Main

piping

Header

unit A

(8)

(2)

(6)

First branch

Y-shape

branching joint

Follower

Follower

unit B

unit C

(8)

(8)

(2)

(8) Outdoor unit connection piping kit (For linking of outdoor units)

(4)

(6)

Follower

unit D

(1)(1)(1)

(4) Branching pipe

(5) Indoor unit connecting pipe

Indoor unit

(4)

Indoor unit

(2) Balance pipes Ø9.5

(1) Outdoor unit connecting pipes

(7) Branching header

(5) (5) (5) (5)

(6)

(6)

(4)

(6) Y-shaped branching joint

(4)

(6)

(4)

Installation Manual

(5)(5)(5)(5)(5)

SMMS-i

No.

Piping parts Name Selection of pipe size Remarks

Connecting pipe size of outdoor unit

Type Gas side Liquid side

Outdoor unit

È

(1)

Outdoor unit

connection piping

kit

Between Outdoor

unit connection

(2)

piping kits

Outdoor unit

connection piping

kit of header unit

(3)

È

First branching

section

Branching section

È

(4)

Branching section

Outdoor unit

connecting pipe

Main connecting

piping between

outdoor units

Main piping

Branching pipe

MAP080 Ø22.2 Ø12.7

MAP100 Ø22.2 Ø12.7

MAP120 Ø28.6 Ø12.7

MAP140 Ø28.6 Ø15.9

MAP160 Ø28.6 Ø15.9

Pipe size for connecting piping between outdoor units

Total capacity codes of

outdoor units at the

downstream side

Equivalent to HPEquivalent to

16 to below 22

22 to below 26

26 to below 36

36 or more 101.0 or more Ø41.3 Ø22.2

Size of main piping

Total capacity codes of all

capacity

45.0 to below

61.5

61.5 to below

73.0

73.0 to below

101.0

outdoor units

Equivalent to HPEquivalent to

8 to below 12 22.4 to below 33.5 Ø22.2 Ø12.7

12 to below 14 33.5 to below 38.4 Ø28.6 Ø12.7

14 to below 22 38.4 to below 61.5 Ø28.6 Ø15.9

22 to below 36

36 to below 46

46 or more 130.0 or more * Ø41.3 Ø22.2

* Maximum equivalent length of main pipe is 70m or less (The actual

length is 50m or less.).

Pipe size between branching sections *1

Total capacity codes of indoor

units at downstream side

Equivalent to HP

Below 2.4 Below 6.6 Ø12.7 Ø9.5

2.4 to below 6.4 6.6 to below 18. 0 Ø15.9 Ø9.5

6.4 to below 12.2 18.0 to below 34.0 Ø22.2 Ø12.7

12.2 to below 20.2 34.0 to below 56 .5 Ø28.6 Ø15.9

20.2 to below 35.2 56.5 to below 98.5 Ø34.9 Ø19.1

35.2 or more 98.5 ore more Ø41.3 Ø22.2

61.5 to below

101.1 to below

Equivalent to

capacity

101.0

130.0

capacity

Gas

Liquid

side

side

Ø28.6 Ø15.9

Ø34.9 Ø19.1

Ø34.9 Ø19.1

Gas

side

Ø34.9 Ø19.1

Ø41.3 Ø22.2

Gas

side

Balanc

e pipe

Ø9.5

Liquid

side

Liquid

side

Installation Manual

Same as connecting

pipe size of the

outdoor unit.

Pipe size differs based

on the total capacity

code value of outdoor

units at the

downstream side.

(See Table 2.)

Pipe size differs based

on the capacity code

of the outdoor unit.

(See Table 2.)

Pipe size differs based

on the total capacity

code value of indoor

units at the

downstream side. If

the total value

exceeds the capacity

code of the outdoor

unit, apply the

capacity code of the

outdoor unit. (See

Table 1 and 2.)

*1: If exceeding the main pip e size, set the size to the same as the

main pipe size.

23-EN 24-EN

–12–

EN

25-EN 26-EN

SMMS-i

No.

Piping parts Name Selection of pipe size Remarks

Connecting pipe size of indoor unit

Capacity rank Gas side

Branching section

È

(5)

Indoor unit

Indoor unit

connecting pipe

007 to 012 type

015 to 018 type Ø12.7 Ø6.4

024 to 056 type Ø15.9 Ø9.5

072 to 096 type Ø22.2 Ø12.7

Selection of branching section (Y-shaped branching joint)

15m or less real length Ø9.5 Ø6.4

Real length exceeds 15m Ø12.7 Ø6.4

Installation Manual

Liquid

side

Total capacity code of indoor units

Model name

Branching section

(6)

Y-shaped

branching joint

Equivalent to HP

Below 6.4 Below 18.0 RBM-BY55E

Y-shape

branching joint

Selection of branching section (Branching header)

6.4 to below 14.2 18.0 to below 40.0 RBM-BY105E

14.2 to below 25.2 40.0 to below 70.5 RBM-BY205E

25.2 or more 70.5 or more RBM-BY305E

Equivalent to

capacity

Total capacity code of indoor units

Model name

*3

Model name

Branching section Branching header

(7)

Outdoor unit

Branching section

(8)

connection piping

kit (For linking of

outdoor units)

Equivalent to HP

For 4

*2

Branching header

*2: Up to a total of 6.0 maximum equivalent to HP capacity codes is connectable to one line

after branching of header. When the total capacity codes of all outdoor units are 12 to below

26 (equivalent to HP) and you use a branching header for the first branching section, use

a RBM-HY2043E or RBM-HY2 083E regardless of the total capacity codes of outdo or units

at downstream side. In addition, you cannot use a branching header for the first branching

section when the total capacity codes of all outdoor units are over 26 (equivalent to HP).

Outdoor unit connection piping kit (For linking of outdoor units)

branches

For 8

branches

Below 14.2 Below 40.0 RBM-HY1043E

14.2 to below 25.2 40.0 to below 70.5 RBM-HY2043E

Below 14.2 Below 40.0 RBM-HY1083E

14.2 to below 25.2 40.0 to below 70.5 RBM-HY2083E

Equivalent to

capacity

Total capacity code of outdoor units

Equivalent to

capacity

Outdoor unit

connection piping

kit (For linking of

outdoor units)

Equivalent to HP

Below 26.0 Below 73.0 RBM-BT14E

26.0 or more Above 73.0 RBM-BT24E

–13–

SMMS-i

Installation Manual

Allowable length of refrigerant pipes and allowable height

difference between units

D

Follower unit

Outdoor unit

A

B

Height

difference

between

outdoor

units

H3 ≤ 5 m

Height

difference

between

outdoor

and indoor

units:

H1 ≤ 70 m

Header

Follower

unit

La

LA

Outdoor unit connection piping kit

(For linking of outdoor units)

The longest piping between outdoor units:

L0 ≤ 25 m

Main piping L1

First branching

section

unit

Lb

LB

L3

Y-shaped

branching joint

C

Follower

unit

Ld

Lc

Outdoor unit connecting pipes

Branching header

Indoor unit connecting

pipe

Indoor unit

abcde

The longest piping length: L ≤ 235 m

The longest piping length fr om the first branch: Li ≤ 90 m

L4

f

g

Indoor unit

L7

L5

L6

h

Y-shaped branching

joint

i

j

(j)

Height

difference

between

indoor units:

H2 ≤ 40 m

*3: Downstream side when regarding the main piping as the start point

SMMS-i

Installation Manual

SMMS-i

Installation Manual

◆ System restriction

Outdoor unit combination Up to 4 units

Total capacity of outdoor units Up to 48 HP

Indoor unit connection Up to 48 units

Total capacity of indoor units

(varies depending on the height difference between

indoor units.)

H2 ≤ 15m 135% of outdoor units’ capacity

15m < H2 105% of outdoor units’ capacity

◆ Cautions for installation

• Set the outdoor unit first connected to the bridging pipe to the indoor units as the header unit.

• Install the outdoor units in order of their capacity codes: A (header unit) ≥ B ≥ C ≥ D

• When connecting gas pipes to indoor units, use Y-shaped branching joints to keep pipes level.

• When piping to outdoor units using Outdoor unit connection piping kits, intersect the pipes to the outdoor unit

and those to indoor units at a right angle as shown in figure 1 on “6. INSTALLATION OF THE OUTDOOR UNIT”.

Do not connect them as in figure 2 on “6. INSTALLATION OF THE OUTDOOR UNIT”.

◆ Allowable length and allowable height difference of refrigerant piping

Item

Total extension of

pipe (liquid pipe,

real length)

Farthest piping length L (*1)

Main piping length

Pipe length

Height

difference

*1: Farthest outdoor unit from the first branch: (D), farthest indoor unit: (j)

*2: If the total capacity of outdoor units is 46HP or more, make the equivalent length 7 0m (real length 50m) or less .

*3: Make the difference 65m or less if the height difference between outdoor and indoor units (H1) is more than 3m.

*4: Make the difference 50m or less if the height difference between indoor units (H2) is more than 3m.

*5: Make the difference 30m or less if the height difference between indoor units (H2) is more than 3m.

Farthest equivalent piping length from the first branch Li

(*1)

Farthest equivalent piping length between outdoor units L0

(*1)

Maximum equivalent piping length of pipes connected to

outdoor units

Maximum real length of pipes connected to indoor units 30m a, b, c, d, e, f, g, h, i, j

Maximum equivalent length betwee n branching sections 50m L2, L3, L4, L5, L6, L7

Height between outdoor and indoor

units H1

Height between indoor units H2 40m –

Height between indoor units H3 5m –

Less than 96kW

96kW or more 34HP or more 500m

Less than 34HP or

less

Equivalent length 235m

Real length 190m

Equivalent length 120m (*2)

Real length 100m (*2)

Upper outdoor

units

Lower outdoor

units

Allowable

value

300m

LA + LB + La + Lb + Lc + Ld + L1 + L2 + L3 + L4

+ L5 + L6 + L7 + a + b + c + d + e + f + g + h + i + j

LA + LB + Ld + L1 + L3 + L4 + L5 + L6 + j

90m (*3) L3 + L4 + L5 + L6 + j

25m LA + LB + Ld (LA + Lb, LA + LB + Lc)

10m La, Lb, Lc, Ld

70m (*4) –

40m (*5) –

Pipes

L1

Airtightness test

After the refrigerant piping has been finished, execute an airtight test.

For an airtight test, connect a nitrogen gas canister as shown in the figure on the next page and apply pressure.

• Be sure to apply pressure from the service ports of the packed valves (or ball valves) at the liquid side, gas side

and balance pipe side.

• An airtight test can only be performed at the service ports at the liquid side, gas side and balance pipe side on

header unit.

• Close the valves fully at the gas side, liquid side and balance pipe side. As there is a possibility that the nitrogen

gas will enter into the cycle of outdoor units, re-tighten the valve rods at the liquid side and balance pipe side

before applying pressure.

(When using MAP140 or MAP160, you do not have to re-tighten the liquid side valve rod as their valves at the

liquid side are ball valves.)

• For each refrigerant line, apply pressure gradually in steps at the liquid side, gas side and balance pipe side.

Be sure to apply pressure at the gas side, liquid side, and balance pipe side.

WARNING

Never use oxygen, flammable gases, or noxious gases in an airtight test.

VLV

Copper

pipe

High pressure

gauge

Gauge

H

manifold

Reducing

valve

Nitrogen

gas

Connected to indoor unit

Main piping

Packed valve details

To gauge manifold

Liquid-side service port

Liquid-side valve

Balance

service port

Balance valve

Piping at site

To

outdoor

unit

Piping at site

To outdoor unit

Gas-side valve

To

outdoor

unit

Gas-side

service port

Piping at site

Connected to other follower units

Brazed

Fully

closed

Fully

closed

Able to detect a serious leakage

1. Apply pressure 0.3MPa (3.0kg/cm²G) for 5 minutes or more.

2. Apply pressure 1.5MPa (15kg/cm²G) for 5 minutes or more.

Available to detect slow leakage

3. Apply pressure 3.73MPa (38kg/cm²G) for approx. 24 hours.

Gas side valve fully closed

Header outdoor unit

Service port

Service port

Liquid valve fully closed

Service port

Balanced pipe side valve

fully closed

Low pressure

gauge

Copper pipe

• If there is no pressure decrease after 24 hours, the test is passed.

EN

27-EN 28-EN

–14–

29-EN 30-EN

SMMS-i

Installation Manual

–15–

SMMS-i

Installation Manual

NOTE

However, if the environmental temperature changes from the moment of applying pressure to 24 hours after that, the pressure

will change by about 0.01MPa (0.1kg/cm²G) per 1°C. Consider the pressure change when checking the test result.

REQUIREMENT

When pressure decrease is detected in steps 1-3, check the leakage at the connecting points.

Check the leakage using a foaming agent or other measures and seal the leak with re-brazing, flare retightening or other

methods. After sealing, execute an airtight test again.

Vacuum drying

• Be sure to perform vacuuming from both liquid and gas sides.

• Be sure to use a vacuum pump equipped with the counter-flow prevention function so that oil in the pump will

not flow back into piping for air conditioners. (If oil in the vacuum pump enters in the air conditioner with R410A

refrigerant, a problem may be caused in the refrigerating cycle.)

After finishing the airtight test and discharging nitrogen gas, connect the gauge manifold to the service ports of the liquid side,

gas side, and balance pipe side and connect a vacuum pump as shown in the figure below. Be sure to perform vacuuming for

the liquid, gas, and balance pipe sides.

Low pressure

gauge

Service port

Service port

Packed valve details

To gauge manifold

Liquid-side service port

Liquid-side valve

valve

To

outdoor

unit

Piping at site

Balance

service port

Balance

To

outdoor

unit

Piping at site

Main pipe

To outdoor unit

Gas-side valve

Gas-side

service port

Piping at site

Connected to indoor unit

Brazed

Fully

closed

Fully

closed

Follower units

Packed valve fully closed

(gas side)

Header outdoor unit

Service port

Packed valve fully closed

(liquid side)

Packed valve fully closed

(balance)

• Use a vacuum pump with a high vacuuming degree [-100.7kPa (5Torr, -755mmHg)] and large exhaust gas

amount (40L/minute or larger).

• Perform vacuuming for 2 or 3 hours, though the time differs depending on the pipe length. Check that all the

packed valves at the liquid side, gas side, and balance pipe side are fully closed.

• If the pressure does not reach -100.7kPa or less, continue vacuuming for 1 hour or more. If the pressure does

not reach -100.7kPa after 3 hours of vacuuming, stop vacuuming and check for air leakage.

• If the pressure reaches -100.7kPa or less after vacuuming for 2 hours or more, close the valves VL and VH on

the gauge manifold fully and stop the vacuum pump. Leave it as it is for 1 hour to confirm that the vacuuming

degree does not change.

If the degree of vacuum loss is large, moisture may remain in the pipes. In that case, inject dry nitrogen gas and

apply pressure to 0.05MPa and perform vacuuming again.

• After finishing the above procedure of vacuuming, exchange the vacuum pump with a refrigerant canister and

advance to the additional charging of refrigerant.

High pressure

gauge

VL VH

Vacuum pump

Gauge

manifold

P

SMMS-i

Installation Manual

SMMS-i

Installation Manual

Adding refrigerant

After finishing vacuuming, exchange the vacuum pump with a refrigerant canister and start additional charging of refrigerant.

Calculation of additional refrigerant charge amount

Refrigerant charge amount at shipment from the factory does not include the refrigerant for pipes at the local site.

For refrigerant to be charged in pipes at the local site, calculate the amount and charge it additionally.

NOTE

If the additional refrigerant amount indicates minus as the result of calculation, use the air conditioner without additional

refrigerant.

Heat pump

type

Cooling only

type

Additional refrigerant charge

amount at local site

Table 1

Liquid pipe dia. (mm) 6.4 9.5 12.7 15.9 19.1 22.2

Additional refrigerant amount/1m liquid

pipe (kg/m)

Outdoor unit type MAP080 MAP100 MAP120 MAP140 MAP160

Charging amount (kg) 11. 5

Outdoor unit type MAP080 MAP100 MAP120 MAP140 MAP160

Charging amount (kg) 10.5 10.5 10.5 11.5 11.5

Real length of liquid pipe

=

0.025 0.055 0.105 0.160 0.250 0.350

Additional refrigerant charge

amount per 1m liquid pipe

×

(Table 1)

Corrective amount of refrigerant

depending on HP of co-

+

operating outdoor units

(Table 2)

Table 2

C (Corrective amount

of refrigerant) (kg)

Standard type

High Efficiency type

Combined HP (HP) Combined outdoor units (HP)

88HP––– 1.5

10 10HP – – – 2.5

12 12HP – – – 3.5

14 14HP – – – 8.5

16 16HP – – – 10.5

18 10HP 8HP – – 0.0

20 10HP 10HP – – 3.0

22 12HP 10HP – – 5.0

24 12HP 12HP – – 7.5

26 16HP 10HP – – 8.5

28 16HP 12HP – – 9.5

30 16HP 14HP – – 11.5

32 16HP 16HP – – 12.5

34 12HP 12HP 10HP – 3.0

36 12HP 12HP 12HP – 4.0

38 16HP 12HP 10HP – 6.0

40 16HP 12HP 12HP – 7.0

42 16HP 14HP 12HP – 8.0

44 16HP 16HP 12HP – 10.0

46 16HP 16HP 14HP – 12.0

48 16HP 16HP 16HP – 14.0

16 8HP 8HP – – 0.0

24 8HP 8HP 8HP – -4.0

26 10HP 8HP 8HP – -4.0

28 10HP 10HP 8HP – -2.0

30 10HP 10HP 10HP – 0.0

32 8HP 8HP 8HP 8HP -6.0

34 10HP 8HP 8HP 8HP -6.0

36 10HP 10HP 8HP 8HP -6.0

38 10HP 10HP 10HP 8HP -6.0

40 10HP 10HP 10HP 10HP -5.0

42 12HP 10HP 10HP 10HP -4.0

44 12HP 12HP 10HP 10HP -2.0

46 12HP 12HP 12HP 10HP 0.0

48 12HP 12HP 12HP 12HP 2.0

Charging of refrigerant

• Keeping the valve of the outdoor unit closed, be sure to charge the liquid refrigerant into the service port at the

liquid side.

• If the specified amount of refrigerant cannot be charged, fully open the valves of the outdoor unit at liquid and

gas sides, operate the air conditioner in COOL mode, and then charge refrigerant into service port at the gas

side. In this time, choke the refrigerant slightly by operating the valve of the canister to charge liquid refrigerant.

• The liquid refrigerant may be charged suddenly, therefore be sure to charge refrigerant gradually.

EN

31-EN 32-EN

–16–

33-EN 34-EN

SMMS-i

Installation Manual

–17–

SMMS-i

Installation Manual

Full opening of the valve

Open the valves of the outdoor unit fully.

MAP080

MAP100

MAP120

Packed valve

Using a 4mm-hexagonal wrench,

fully open the valve rods.

Liquid side

Balance pipe

Gas side

Balance packed valve

Using a 4mm-hexagonal wrench, fully open the valve rods.

Ball valve

Using a minus screwdriver, turn it counterclockwise by 90° until it hits the stopper.

(Full open)

MAP140

MAP160

Ball valve

Using a flathead screwdriver, turn it counterclockwise by 90° until it hits the

stopper. (Full open)

Service

port

Valve unit

Using flathead

screwdriver, turn it

counterclockwise by

(1)

(2)

90° until it hits the

stopper. (Full open)

Flare nut

Position of screwdriver slot

Fully closed

* When opened fully, do not apply

excessive torque after the screwdriver hits

the stopper; otherwise a problem may be

caused on the valve. (5 N•m or less)

Fully opened

Slot

F-GAS label

This product contains fluorinated greenhouse gases covered by the Kyoto Protocol

• Chemical Name of Gas R410A

• Global Warming Potential (GWP) of Gas 1975

CAUTION

1. Stick the enclosed refrigerant label adjacent to the charging and/or recovering location.

2. Clearly write the charged refrigerant quantity on the refrigerant label using indelible ink. Then, place the included

transparent protective sheet over the label to prevent the writing from rubbing off.

3. Prevent emission of the contained fluorinated greenhouse gas. Ensure that the fluorinated greenhouse gas is

never vented to the atmosphere during installation, service or disposal. When any leakage of the contained

fluorinated greenhouse gas is detected, the leak shall be stopped and repaired as soon as possible.

4. Only qualified service personnel are allowed to access and service this product.

5. Any handling of the fluorinated greenhouse gas in this product, such as when moving the product or recharging

the gas, shall comply under (EC) Regulation No. 842/2006 on certain fluorinated greenhouse gases and any

relevant local legislation.

6. Periodical inspections for refrigerant leaks may be required depending on European or local legislation.

7. Contact dealers, installers, etc., for any questions.

Pre-charged Refrigerant at Factory [kg],

R410A

specified in the nameplate

kg

Additional Charge on Installation Site

[kg]

kg

kg

Fully closed

Fully opened

Heat insulation for pipe

• Apply heat insulation of pipe separately at the liquid, gas, and balance sides.

• Be sure to use thermal insulator resistant up to 120°C or higher for pipes at the gas side.

Finishing after connecting pipes

• After piping connection work has been finished, cover the opening of the piping/wiring panel with the piping

cover, or fill silicon or putty into the space between the pipes.

• In case of drawing-out the pipes downward or sideward, also close the openings of the base plate and the side

plate.

• Under the opened condition, a problem may be caused due to the entering of water or dust.

SMMS-i

Installation Manual

SMMS-i

Installation Manual

When using the piping cover When not using the piping cover

Piping/wiring panel

Drawing-out

frontward

Drawing-out

downward

Drawing-out sideward

Close the opening with the

pipe cover.

Piping/wiring panel

Drawing-out

frontward

Drawing-out

downward

◆ Pipe holding bracket

Attach pipe holding brackets following the table below.

Diameter of pipe (mm) Interval

Ø15.9 - Ø19.1 2m

Ø22.2 - Ø41.3 3m

Drawing-out sideward

Fill silicon or putty into the

periphery of the pipes.

8 ELECTRIC WIRING

WARNING

The appliance shall be installed in accordance with national wiring regulations.

Capacity shortages of the power circuit or an incomplete installation may cause an electric shock or fire.

CAUTION

• Perform wiring of power supply complying with the rules and regulations of the local electric company.

• Do not connect 380V - 415V power to the terminal blocks for control cables (U1, U2, U3, U4, U5, U6); otherwise,

the unit may break down.

• Be sure that electric wiring does not come into contact with high-temperature parts of piping; otherwise, the

coating of cables may melt and cause an accident.

• After connecting wires to the terminal block, take off the traps and fix the wires with cord clamps.

• Follow the same structure for both the control wiring and refrigerate piping.

• Do not conduct power to indoor units until vacuuming of the refrigerant pipes has finished.

• For the wiring of power to indoor units and that between indoor and outdoor units, follow the instructions in the

installation manual of each indoor unit.

Power supply specifications

Do not bridge the power between outdoor units

through the equipped terminal blocks (L

N).

1, L2, L3,

Power supply for

outdoor units

NO GOOD

◆ Power wiring selection

Standard model

Model

MMY-MAP0804*

MMY-MAP1004*

MMY-MAP1204*

MMY-MAP1404*

MMY-MAP1604*

MMY-AP1814*

MMY-AP2014*

MMY-AP2214*

MMY-AP2414*

MMY-AP2614*

MMY-AP2814*

MMY-AP3014*

MMY-AP3214*

35-EN 36-EN

–18–

Phase and frequency Nominal Voltage

3N~ 50Hz 380-400-415V

3N~ 50Hz 380-400-415V

Power Supply

MOCP: Maximum Overcurrent Protection (Amps)

MCA: Minimum Circuit Amps

MCA

(A)

23.5

25.5

28.5

33.2

36.5

49.0

51.0

54.0

57.0

62.0

65.0

69.7

73.0

MOCP

(A)

32

32

40