Engineering Data

Fresh Air Intake

Indoor Unit Type

Tentative

Indoor Unit

MMD-AP0481HFE

MMD-AP0721HFE

MMD-AP0961HFE

Contents

1. System summary

2. Specifications

3. Dimensions

4. Center of gravity

5. Electrical current characteristics

6. Wiring diagrams

7. Fan characteristics

8. Sound characteristics (NC Curve)

1. System summary

Fresh Air Intake Indoor Unit Type

1. Outline of fresh air intake unit

• Type: Concealed Duct High Static Pressure type

Three models (5HP, 8HP, 10HP) are prepared.

• Connectable outdoor unit

Three series (MMY-MAPXXXXT8, MAPXXXXHT8, MAPXXXXHT7) of Cooling/Heating selecting

Super module multi type outdoor unit.

• Corresponding system

Corresponds to a system in which there are the fresh air intake units and the indoor air

conditioners.

(For the fresh air intake units, up to 2 units for one system and also within 30% to capacity of the

connectable indoor air conditioners are allowed.)

• Definition

The fresh air intake unit means an air controller for taken-in fresh air.

Intake of the fresh air often influences on the system so that the normal control of the air conditioner

becomes difficult or gives a large load upon air controller and cooling performance.

Therefore it is frequently adopted to handle the fresh air to a certain condition before the fresh air

will enter in the main air conditioner.

This handling device is called a fresh air intake unit.

NOTE:

The Fresh Air Intake unit is an air conditioner provided to handle the fresh air load and is not to control

the room temperature. For correspondence to the load of the indoor air controller, set an air

conditioner separately.

22

1. System summary

Fresh Air Intake Indoor Unit Type

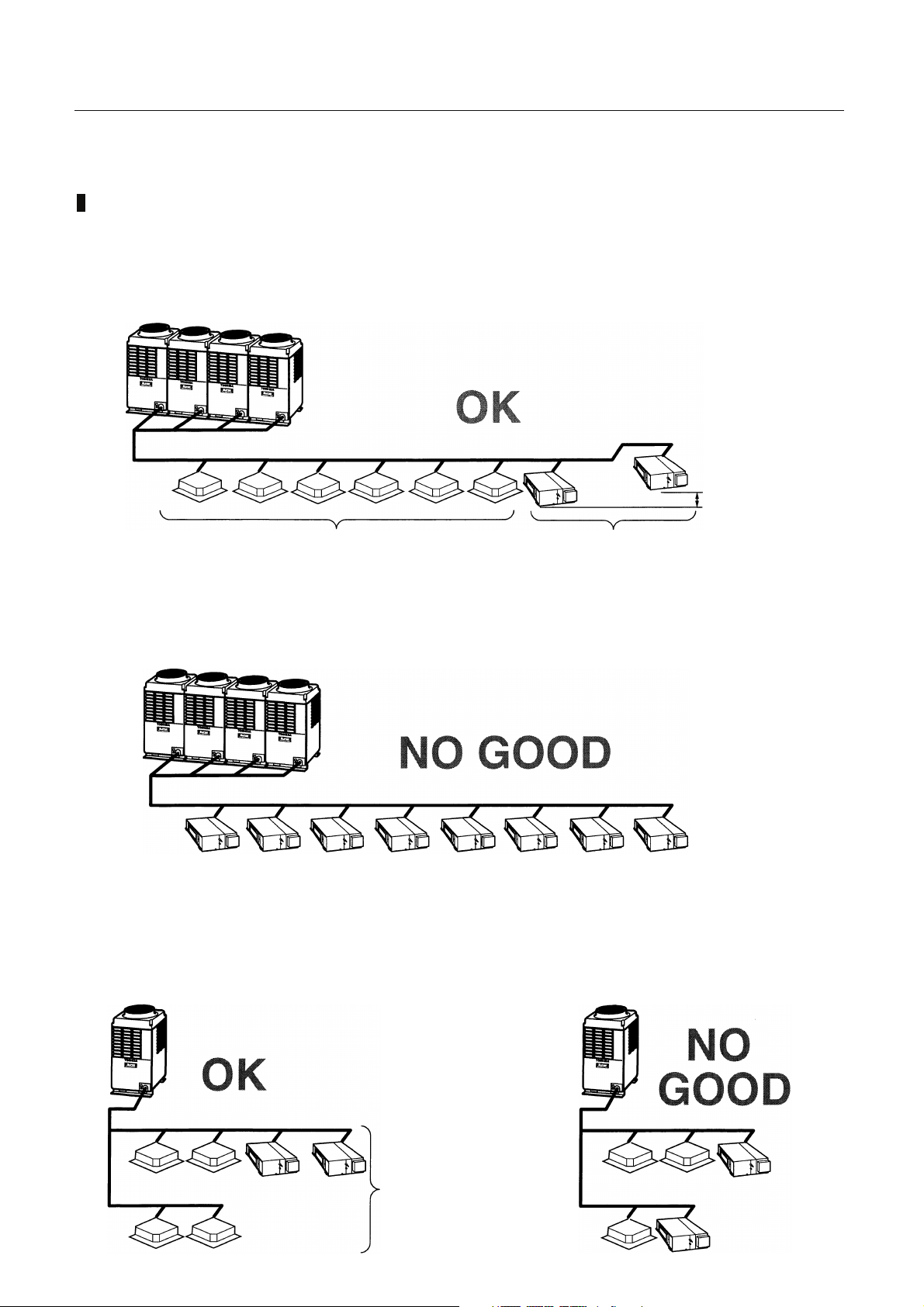

2. System able to be combined

The fresh air intake unit is connectable to S-MMS (Super Modular Multi system).

However this is not connectable to S-HRM (Super Heat Recovery Multi system).

0.5m or less

80 to 100% to capacity of the outdoor

Keep the height difference between the fresh air intake units to 0.5m or less.

Up to two fresh air intake

units occupy 30% or less

· The fresh air intake unit is usually used together with the indoor units on one line of the multi system.

The fresh air intake unit only cannot be connected.

· The total capacity of the indoor units and the fresh air intake units is restricted to 80% to 100%

against the capacity of the outdoor units. (This restriction should be strictly kept for correct control

of the refrigerant.)

· Up to two fresh air intake units can be connected on one line of the multi system.

The allowable total capacity of the two fresh air intake units shall be 30% or less against the total

capacity of the indoor units (including the fresh air intake units).

Connection which stretches

over two floors is unavailable

Height difference:

0.5m or more

33

1. System summary

Fresh Air Intake Indoor Unit Type

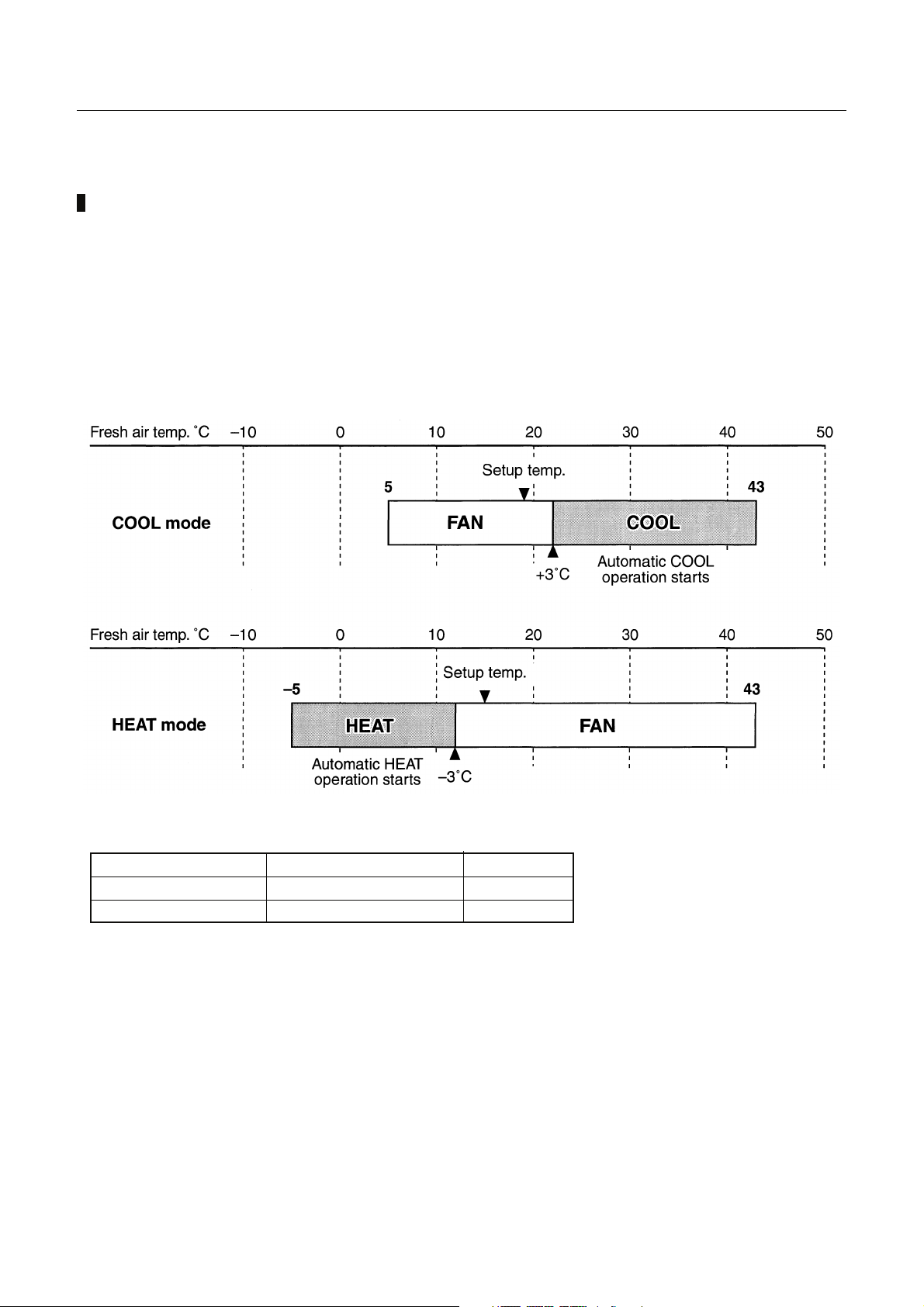

3. Use Conditions

· In COOL mode, if temperature of the fresh air is under the setup temp. +3°C, FAN status is

automatically made. When temperature of the fresh air is under 19°C, FAN status is also made

regardless of the setup temperature.

· In HEAT mode, if temperature of the fresh air is over the setup temp. -3°C, FAN status is

automatically made. When temperature of the fresh air is over 15°C, FAN status is also made

regardless of the setup temperature.

• Operable mode and discharge temp setup range

Operation mode

COOL

HEAT

• Special mentions

1. The fan operation of the Fresh Air Intake unit stops during defrosting.

However the fan operation is enabled to continue by selection.

2. When a central controller is used, divide zone setup of indoor air conditioner and fresh air intake

unit.

3. The standard is to control the discharge temperature. However the priority is given to the capacity

control for the indoor air conditioner in a system in which the normal indoor air conditioner

concurrently operated.

4. The fresh air intake unit cannot be connected with remote controller group of the indoor air

conditioner.

5. In heating operation, if the temperature is below –5°C, the operation stops automatically. (FAN stop)

(To protect the refrigerant cycle)

6. In cooling operation, if the temperature is below 5°C, the operation stops automatically. (FAN stop)

At shipment from factory Setup range

18°C 16 to 27°C

25°C 16 to 27°C

44

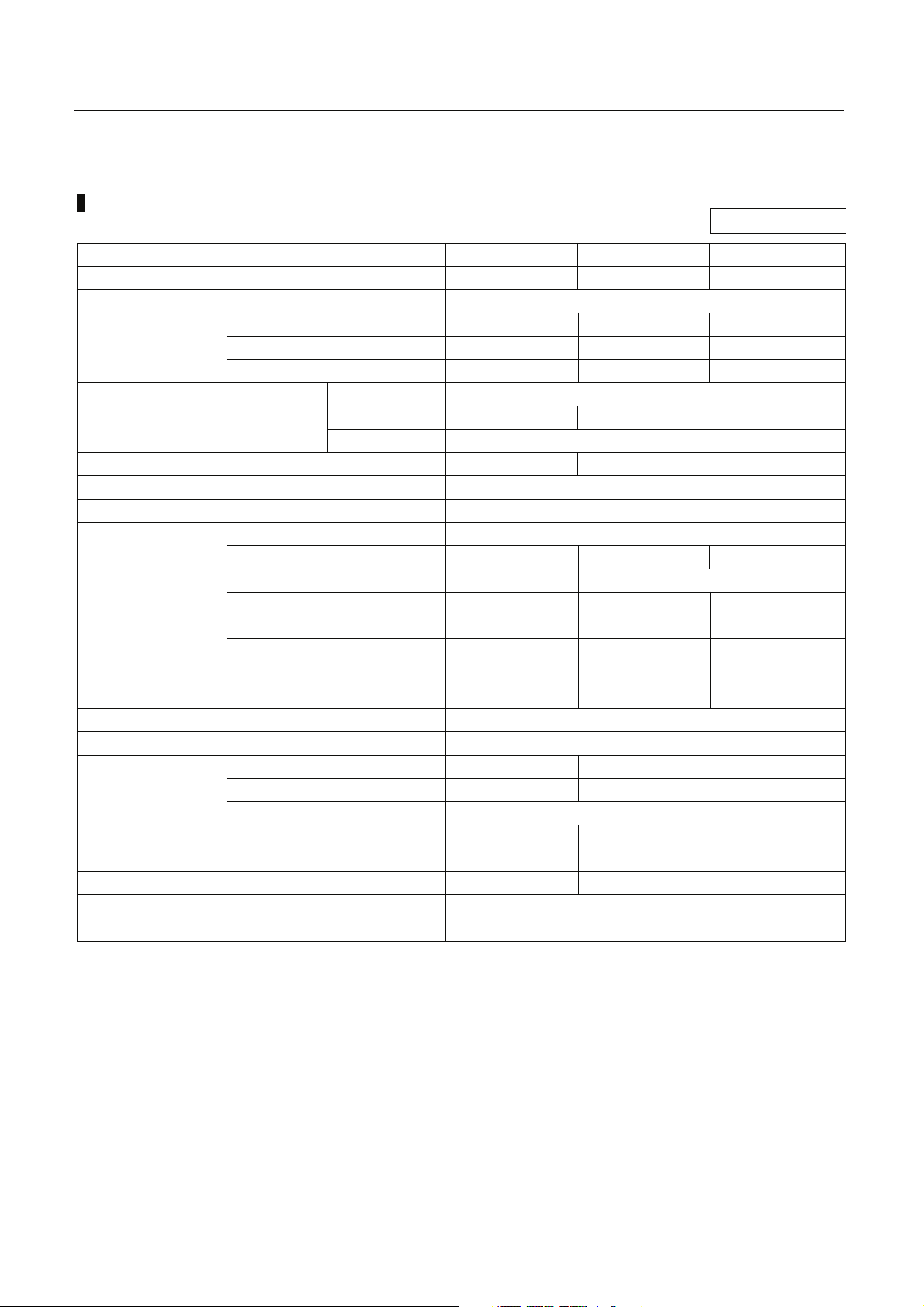

2. Specifications

Fresh Air Intake Indoor Unit Type

50Hz

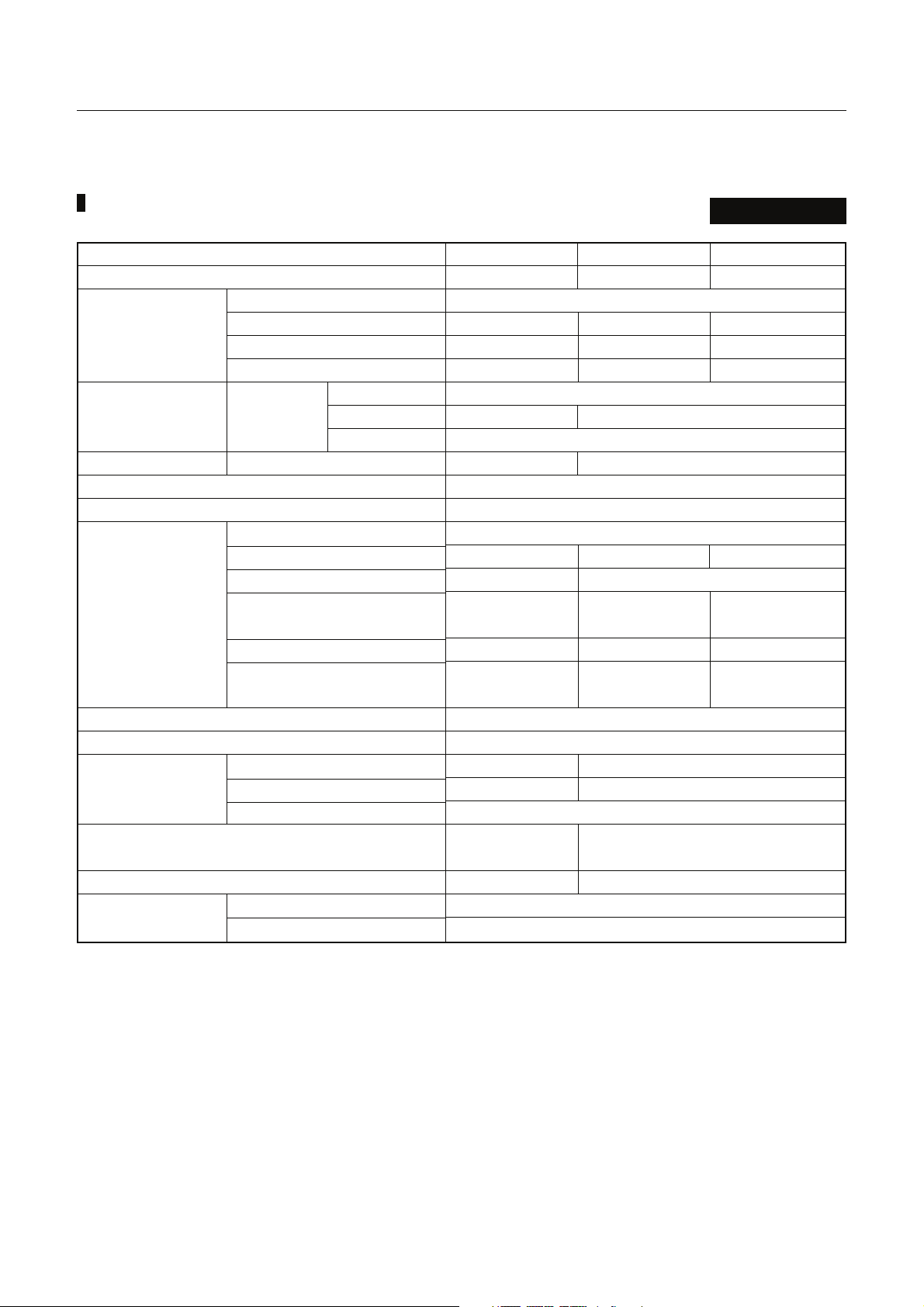

Model name

Cooling/Heating capacity (Note 1) (kW)

Electical

characteristics

Outer

dimension

Total weight

Heat exchanger

Soundproof / Heat-insulating material

Fan unit

Air filter

Controller

Connecting pipe

Sound pressure level (Note 2) (dB(A))

(High/Med./Low)

Sound power level (High/Med./Low) (dB(A))

Operation range

Power supply

Running current (A)

Power consumption (kW)

Starting current (A)

Main unit Height (mm)

Width (mm)

Depth (mm)

Main unit (kg)

Fan

Standard air flow (m3/h)

Motor (W)

External static pressure

(factory setting)

External static pressure

Air flow limit (m3/h)

Lower limit/Upper limit

Gas pipe (mm)

Liquid pipe (mm)

Drain pipe

Cooling (Note 3) (°C)

Heating (Note 4) (°C)

MMD-AP0481HFE MMD-AP0721HFE MMD-AP0961HFE

14.0/8.9 22.4/13.9 28.0/17.4

1 phase 50Hz 230V (220-240V)

1.43 2.52 2.73

0.28 0.45 0.52

3.50 7.00 7.00

492

892 1,392

1,262

93 144

Finned tube

Non-flammable insulation

Centrifugal fan

1,080 1,680 2,100

160 160 x 2

210 165 190

170-210-230 140-165-180 160-190-205

756 1,176 1,470

Option or field supply

Wired remote controller

15.9 22.2

9.5 12.7

R1

45/43/41 46/45/44

65/63/61 66/65/64

5 - 43

-5 - 43

* The setting temperature is 16 - 27°C(standard FCU…18 - 29°C).

* An option humidifier is not available with Fresh Air Intake Indoor unit.

* Height difference between Fresh Air Intake Indoor units must be within 0.5m.

Height difference between Fresh Air Intake Indoor unit and standard FCU must be within 30m.

Note 1: Rated conditions Cooling : Outdoor air temperature 33°C DB/28°C WB setting temperature 18°C

Heating : Outdoor air temperature 0°C DB/-2.9°C WB setting temperature 18°C

Piping : Length 7.5m / Height 0m

Note 2: The sound level are measured in an anechoic chamber in accordance with JIS B8616. Normally, the

values meausured in the actual operating environment become large than the indicated values due to

the effects of external sound.

Note 3: * When supply air temperature is “setting temperature + 3°C” or less, Fresh Air Intake unit operates as

FAN mode.

* When supply air temperature is 19°C or less, Fresh Air Intake Indoor unit operates as FAN mode.

Note 4: * When supply air temperature is “setting temperature - 3°C” or over, Fresh Air Intake unit operates as

FAN mode.

55

2. Specifications

Fresh Air Intake Indoor Unit Type

Model name

Cooling/Heating capacity (Note 1) (kW)

Electical

characteristics

Outer

dimension

dimension

Total weight

Heat exchanger

Soundproof / Heat-insulating material

Fan unit

Air filter

Controller

Connecting pipe

Sound pressure level (Note 2) (dB(A))

(High/Med./Low)

Sound power level (High/Med./Low) (dB(A))

Operation range

Power supply

Running current (A)

Power consumption (kW)

Starting current (A)

Main unit

Main unit (kg)

Fan

Standard air flow (m3/h)

Motor (W)

External static pressure

(factory setting)

External static pressure

Air flow limit (m3/h)

Lower limit/Upper limit

Gas pipe (mm)

Liquid pipe (mm)

Drain pipe

Cooling (Note 3) (°C)

Heating (Note 4) (°C)

Height (mm)

Width (mm)

Depth (mm)

60Hz

MMD-AP0481HFE MMD-AP0721HFE MMD-AP0961HFE

14.0/8.9 22.4/13.9 28.0/17.4

1 phase 60Hz 220V

1.66 2.75 3.12

0.34 0.55 0.65

3.40 6.80 6.80

492

892 1,392

1,262

93 144

Finned tube

Non-flammable insulation

Centrifugal fan

1,080 1,680 2,100

160 160 x 2

215 210 180

115-215-260 150-210-235 80-180-220

1,188 1,848 2,310

Option or field supply

Wired remote controller

15.9 22.2

9.5 12.7

R1

45/43/41 46/45/44

65/63/61 66/65/64

5 - 43

-5 - 43

* The setting temperature is 16 - 27°C(standard FCU…18 - 29°C).

* An option humidifier is not available with Fresh Air Intake Indoor unit.

* Height difference between Fresh Air Intake Indoor units must be within 0.5m.

Height difference between Fresh Air Intake Indoor unit and standard FCU must be within 30m.

Note 1: Rated conditions Cooling : Outdoor air temperature 33°C DB/28°C WB setting temperature 18°C

Heating : Outdoor air temperature 0°C DB/-2.9°C WB setting temperature 18°C

Piping : Length 7.5m / Height 0m

Note 2: The sound level are measured in an anechoic chamber in accordance with JIS B8616. Normally, the

values meausured in the actual operating environment become large than the indicated values due to

the effects of external sound.

Note 3: * When supply air temperature is “setting temperature + 3°C” or less, Fresh Air Intake unit operates as

FAN mode.

* When supply air temperature is 19°C or less, Fresh Air Intake Indoor unit operates as FAN mode.

Note 4: * When supply air temperature is “setting temperature - 3°C” or over, Fresh Air Intake unit operates as

FAN mode.

66

3. Dimensions

Fresh Air Intake Indoor Unit Type (MMD-AP***HFE)

Service

space

Over 1000

Space necessary for service

Service space

200

Over

Fresh air

intake

unit

200

Check port (600 )

Long hole for M10 hanging bolt

Type

0481

0721, 0961

Hole dia.-Wideth x Length

4- 12 x 40

4- 12 x 92

(185)

30

Drain piping work

example at local site

A

B (Hanging bolt pitch)

(65)

Refrigerative piping work

example at local site

1328

1288 (Hanging bolt pitch)

1262

600

Check port

100

600

X

Filter direction

X

Drain port

(When drain-up kit is mounted)

For vinyl chloride pipes

(Nominal dia 25 : Inner dia 32)

Drain piping work

example at local site

41

37081

C

Blow-off port

Discharge port connecting flange (K)

ED F

Discharge temp sensor

492

360

23

60

61

(Accessory for main unit of product)

38

40638

GHI J

A

Z View

Pre-filter

Refrigerant piping work

example at local site

(205)

(250)

47

Drain port (R1) (Main uint of product)

35

406

51

G IH J

Suction port connecting flange (L)

(Accessory for main unit of product)

X - X detail diagram

Refrigerant pipe

connecting port

(Gas side M)

150

216

850

1262

Suction port

Refrigerant pipe

connecting port

(Liquid pipe N)

704

Electric parts box (With cover)

Filter chamber

High-performance

filter

Pre-filter

Z

292

AP0961HFE

AP0721HFE

AP0481HFE

Model MMD-

1392

1392

892

A

1260

1260

810

250250 250 250 250250250 250 10-M6

215

CB

107.5

D

107.5

E

215

GIJK

F

250250250 250250250

H

250 250

250250

77

10-M6

8-M6

10-M6

10-M6

6-M6

22.2 brazing

22.2 brazing

LM N

12.7 flare

12.7 flare

9.5 flare15.9 flare

r

3. Dimensions

Fresh Air Intake Indoor Unit Type (MMD-AP***HFE)

Work example

Canvas duct

Ceiling

High-performance filter

Over

50

Fresh air

intake unit

Over

Check port

Pre-filter

Air intake duct

100

Filter chamber

Canvas duct

Outside ai

<Installation Notice>

1 The check port should be 600 x 600mm.

2 A slope the piping outside of the unit downward at 1/100.

Be sure to do heat insulating to the connecting peat with the indoor unit. In complete heat insulating may cause

dewing.

3 Check the water drainage is surely performed at the trial operation.

4 Do not install the air conditioner in a salty place such as seaside area and a place where sulfurous gasgenerated

such as in a spa.

5 Please clean the drain plate before the season of cooling air conditioning.

Water overflows from the drain plate when the drain plate and the drain poart are dirty, and the ceiling might be wet.

6 The air filter is not built into the Fresh Air intake indoor unit.

Please remove the dust that enters from air by installing optional Filter chamber, Pre-filter, and High Efficiency Filter.

If no air filter is installed, dust will collect in the heat exchanger, which may cause the air conditioner to fail or to leak.

(local prpcure)

7 Place where the unit cane installed horizontally.

8 Set the canvas duct at air inlet port and air supply port. It is to avoid conveyance of vibration, abnormal resonance

sound and also to make easy the disassembly of the main unit in service time.

9 Be sure to connect the wire and connection cable while matching the terminal.

Please refer to the wiring diagram for details.

10 Please note that the size is different because of MMD-AP0481HFE and MMD-AP0721HFE/MMD-AP0961HFE in the

electric part box.

11 The heat insulator is pasted to externals of the main body of the product. (Bottom board thickness : 16mm, other

thickness : 6mm)

12 Be sure to set the duct at air filter with descending inclination because the suction duct of the this unit is exposed to

outdoors and therefore rainwater, leaves and birds are easy to enter in if it is set horizontally.

Attching wire netting and others to end of the suction duct is also recommended.

13 Set the air inlet duct at descending inclination so that water can be drained even if rainwater enters in.

14 The balloon entrance connection flange and the inhalation mouth connection flange are installed in the main body

of the product.

Please use it detaching it when you connect the duct.

Please obtain Filter chamber directly in the main body of the product when you install Filter chamber and obtain

installation Air intake port connecting flange for C side of A.

15 Connect the ducts directly so that the ducts do not weight on the main unit.

Moreover, please do not damage, and do not knock down air supply temperature sensor when you connect the air

supply duct.

16 Be sure to apply heat insulation for the duct to prevent dewing.

Especially, when it is inhaled to heat it, the be dewy on the surface of the outside of the duct because cold air enters.

Please put the heat insulator.

17 When installing the drain pump and filter chamber sold separately, refer to attachment installation manual.

88

3. Dimensions

Fresh Air Intake Indoor Unit Type (MMD-AP***HFE)

Discharge port connecting flange

MMD-AP0481HFE MMD-AP0721HFE, AP0961HFE

12

65

775

215 215215

65

25

65

12

250

1130

250250250

65

25

394

370

12

25

8- 8

725

344

25

25

Suction port connecting flange

MMD-AP0481HFE MMD-AP0721HFE, AP0961HFE

65

25 25 25

430

12 406 12

630

250 250

2525

580

380

6- 8

NOTE 1)

The left figure shows MMD-AP0721HFE / AP0961HFE.

For MMD-AP0481HFE, one fan motor and one fan are provided.

65

394

430

370

12

406 12

12

25

10- 8

65

250 250 250 250

1080

10- 8

1080

25

344

1130

65

25 25

25

380

25

99

4. Center of gravity

p

Fresh Air Intake Indoor Unit Type

Model name MMD-

AP0481HFE

AP0721HFE

AP0961HFE

Y

X (mm) Y (mm) Z (mm) Weight (kg)

670 480 220 93

670 770 220 144

X

Electric

arts box

Z

1010

5. Electrical current characteristics

Fresh Air Intake Indoor Unit Type

Model name

S-MMS(50Hz)

S-MMS(60Hz)

Model name

MMD-AP0481HFE

MMD-AP0721HFE

MMD-AP0961HFE

MMD-AP0481HFE

MMD-AP0721HFE

MMD-AP0961HFE

Nominal Voltag e

(V-Ph-Hz)

230-1-50

220-1-60

Voltage Range Fan Motor Power supply

Min. Max. kW FLA MCA MOCP

198 264 0.16 0.28 0.35 15

198 264 0.16 x 2 0.45 0.56 15

198 264 0.16 x 2 0.52 0.65 15

198 264 0.16 0.34 0.43 15

198 264 0.16 x 2 0.55 0.69 15

198 264 0.16 x 2 0.65 0.81 15

1111

6. Wiring diagrams

Fresh Air Intake Indoor Unit Type (5HP)

MMD-AP0481HFE

PMV

2

5

3

6

4

1

2

5

3

6

4

1

EXCT

FILTER

3

2

2

2

1

1

1

(WHI)

CN080

(GRN)

CN073

(RED)

CN070

CN081

MCC-1403

FS

for Indoor Unit

Control P.C. Board

RY001

RY002

RY005

RY006

RY004

P301

CN304(GRY)

CN309

1

3

11

(YEL)

3

(BLK)

3

3

5

6

2

3

1

4

5

6

2

3

5

4

Power

Fuse

1

1

supply

~

250V

CN067(BLK)

T5.0A

33

4

(BLU)

CN082

circuit

CN066(WHI)

1

1

1

CN060(WHI)

(WHI)

CN032

CN061(YEL)

(WHI)

CN075

CN074(WHI)

CN050(WHI)

CN041(BLU)

CN040

(BLU)

CN044(BRW)

2

2

423 56 1 4212356 1 423 56

1

3

1

13245

3

2

1

2

1

12

FAN OPTION

DRIVE

T10

1423 56

3

1

3

1

RC

2

1

OC

EMG

CN02

1423 56

(YEL)

1423 56

BLK

BLK

BLU

BLU

CN01

(WHI)

MCC-1520

1423 56

1423 56

Sub P.C.Board

B

A

U2

U1

Line Filter

TR1

Remote

Controller

Board

AB

Remote

Controller

U2

U1

Unit

Outdoor

TF

TC2 TC1

TCJ

TA

(Option)

DP

RED

LM

DP

2

1

3

1

2

1

2

1

2

1

3

1

CN033

CN068

31

797

FAN

PNL

2

1

2

1

(GRN)

CN103

32

(BRW)

CN100

1

2

1

(BLK)

CN101

2

1

(RED)

CN102

2

1

(YEL)

CN104

3

(RED)

CN030

1 2

(GRN)

3

1

(BLU)

31

3 1

5

CN083(WHI)

BLK

ULL

M

H

RY007

WHI

6

RED

~

T10A, 250V

F1

43F1

RED

3

F3 F4

BLK

ORN

F1 F2

BLU

A

RC

4P

(WHI)

GRY

3 4

4

2134

2

RED

1

WHI

FAN1

GRY

RED

WHI

BLK

2

ORN

1

BLU

FM

4P

(WHI)

GRY

GRY

2134

2134

RED

RED

WHI

WHI

Note

At shipment from factory

G&Y

wiring

Fan moter

Blue(50/60Hz)

Black(50/60Hz)

Orange(50/60Hz)

Terminal block No.

F4

F1(Low static pressure tap)

F2(Intermediate static Pressure tap)

F3(High static pressure tap)

43F1

3

5

YEL

Connector

Closed-end

spark killer

43F1

8

7

WHI

BLU

wiring diagram

Fan motor inside

ORN

BLK

WHI

49F

GRY

RED

ACIN

WHI

RED

protection switch

Motor over heating

COLOR

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

IDENTIFICATION

WHI

RED

RED

WHI

3

1

Connector

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

BRW : BROWN

1212

RED

S(N)

R(L)

Unit

Earth

Indoor

Screw

G&Y : GREEN&YELLOW

50Hz

~

60Hz

~

220V

Power Supply

220-240V

Fan Moter

Parts Name

Running Capacitor

RC

FM

Symbol

number as figure and lead wire's color of fan motor.

exchange the lead wire of arrow( ) position after check the terminal

the froat switch connector to CN030 connector.

Letter at inside indicates the terminal number.

4. When installing the drain pump connect

5. A position is connected to terminal block when change to static pressure.

3. indicates the control P.C board.

2. A dotted line and broken line indicate the wiring at site.

1. indicates the terminal block.

Sold

Separately

Transformer

Temp sensor

Blow temp. sensor

Intake air temp. sensor

Fan Motor Control Relay

007

~

TF

TA

TR1

RY005

TC1,TC2,TCJ

Drain Control Relay

RY002

Drain Pump Motor

Pulse Motor Valve

Fuse for Fan Motor

Fan Motor Control Relay

F1

DP

43F1

PMV

Float Switch

FS

6. Wiring diagrams

Fresh Air Intake Indoor Unit Type (8-10HP)

MMD-AP0721HFE

MMD-AP0961HFE

PMV

2

5

3

1

6

4

2

5

3

1

4

6

EXCT

FILTER

3

(GRN)

CN080

1

CN073

2

(RED)

1

CN070

2

(WHI)

2

1

CN081

MCC-1403

FS

for Indoor Unit

Control P.C. Board

RY001

RY002

RY005

RY006

RY004

P301

CN304(GRY)

CN309

(YEL)

3

1

1

8

8

7

WHI

WHI

5

3

4

(BLK)

Fuse

313

1

3

1

ACIN

RED

6

6

supply

Power

~

250V

T5.0A

3

WHI

5

2

3

1

4

5

2

3

1

4

(BLU)

CN082

3456

2

CN060(WHI)

2

1

FAN OPTION

DRIVE

(WHI)

CN032

3456 1

2

CN061(YEL)

T10

(WHI)

CN075

3456 1

3456

circuit

2

2

1

1

13

13

CN074(WHI)

345

2

CN050(WHI)

31

3

121

CN041(BLU)

RC

2

121

CN040

(BLU)

OC

2

1

EMG

CN044(BRW)

CN066(WHI)

CN067(BLK)

2

1

2

1

CN02

3456

2

1

(YEL)

3456

2

1

MCC-1520

Sub P.C.Board

BLK

BLK

BLU

BLU

Line Filter

CN01

3456

2

1

B

A

U2

U1

(WHI)

3456

2

1

TR1

Remote

Controller

B

Board

A

Remote

Controller

U2

U1

Unit

Outdoor

~

T10A, 250V

F1

RED RED

WHI

RED

RED

WHI

1

3

TF

TC2 TC1

TCJ

TA

(Option)

DP

RED

RED

21

1

3

1

21

21

21

3

LM

CN033

DP

CN068

13

FAN

6

RED

7

PNL

2

1

12

(GRN)

CN103

123

(BRW)

CN100

12

(BLK)

CN101

12

(RED)

CN102

12

(YEL)

CN104

(RED)

CN030

123

(GRN)

13

(BLU)

13

UL

15

L

HM

7

93

RY007

CN083(WHI)

BLK

spark killerspark killer

43F243F1

7

7

6

6

RED

~

T10A, 250V

F2

RED

8

RED

RED

ORN

43F1

ORN

43F2

5

WHI

4

4

43F1

Unit

Indoor

WHI

3

5

Earth

Screw

BLU ORN BLK

FAN1

(WHI)

4321

RED

WHI GRY

F1 F2 F3 F4

BLU ORN BLK

A

FAN2

(BLU)

4321

GRY

RED

WHI

Connector

Closed-end

50Hz

~

60Hz

~

220V

Power Supply

220-240V

123

BLU ORN BLK

4P

(WHI)

4321

4321

GRY

RED

RED

WHI

WHI GRY

123

BLU ORN BLK

4P

(WHI)

4321

4321

GRY

GRY

RED

RED

WHI

WHI

F1 F2 F3 F4

A

RC1

4P

4321

GRY

RED

WHI

RC2

4P

4321

GRY

RED

WHI

YEL

S(N)

R(L)

Note

FM1

G&Y

FM2

G&Y

wiring

Fan moter

Blue(50/60Hz)

At shipment from factory

Black(50/60Hz)

Orange(50/60Hz)

Terminal block No.

F4

F1(Low static pressure tap)

F2(Intermediate static Pressure tap)

F3(High static pressure tap)

number as figure and lead wire's color of fan motor.

exchange the lead wire of arrow( ) position after check the terminal

the froat switch connector to CN030 connector.

Letter at inside indicates the terminal number.

4. When installing the drain pump connect

5. A position is connected to terminal block when change to static pressure.

3. indicates the control P.C board.

2. A dotted line and broken line indicate the wiring at site.

1. indicates the terminal block.

BLU

wiring diagram

Fan motor inside

ORN

BLK

WHI

GRY

49F

RED

protection switch

Motor over heating

COLOR

RED : RED

WHI : WHITE

YEL : YELLOW

BLU : BLUE

IDENTIFICATION

Connector

BLK : BLACK

GRY : GRAY

PNK : PINK

ORN : ORANGE

BRW : BROWN

1313

G&Y : GREEN&YELLOW

Fan Moter

Parts Name

Running Capacitor

FM1 2

RC1 2

Symbol

Transformer

Temp sensor

Blow temp. sensor

Intake air temp. sensor

Fan Motor Control Relay

007

~

TF

TA

TR1

RY005

TC1,TC2,TCJ

Sold

Drain Pump Motor

Pulse Motor Valve

Fuse for Fan Motor

Drain Control Relay

Fan Motor Control Relay

DP

F1 2

PMV

RY002

43F1 2

Separately

Float Switch

FS

7. Fan characteristics

Fresh Air Intake Indoor Unit Type

<220V>

50Hz

MMD-AP0481HFE (5HP)

Standard air volume: 1080m3/h

2.0

High static pressure tap

1.5

1.0

Mid static pressure tap

Low static pressure tap

High static pressure tap

Low static pressure tap

Fan motor current (A)External static pressure (Pa)

0.5

350

300

250

200

Mid static pressure tap

150

100

50

MMD-AP0721HFE (8HP)

Standard air volume: 1680m3/h

3.0

High static pressure tap

2.5

Fan motor current (A)External static pressure (Pa)

2.0

1.5

350

300

High static pressure tap

250

200

150

Low static pressure tap

100

50

Low static

pressure tap

Mid static

pressure tap

Mid static pressure tap

0

Air volume (m3/h)

MMD-AP0961HFE (10HP)

Standard air volume: 2100m3/h

Fan motor current (A)External static pressure (Pa)

3.5

Mid static pressure tap

3.0

2.5

2.0

350

300

250

200

150

Mid static pressure tap

100

High static pressure tap

High static pressure tap

Low static pressure tap

Low static

pressure tap

120011001000900800

0

1800160014001200

Air volume (m3/h)

50

0

Air volume (m3/h)

23002100190017001500

1414

7. Fan characteristics

Fresh Air Intake Indoor Unit Type

<220V>

60Hz

MMD-AP0481HFE (5HP)

Standard air volume: 1080m3/h

2.0

High static pressure tap

1.5

M

Fan motor current (A)External static pressure (Pa)

id static pressure

1.0

0.5

350

300

250

200

150

Low static pressure tap

100

50

tap

Low static pressure tap

High static pressure tap

Mid static

pressure tap

MMD-AP0721HFE (8HP)

Standard air volume: 1680m3/h

3.0

High static pressure tap

2.5

Mid static pressure tap

2.0

Low static pressure tap

High static pressure tap

Fan motor current (A)External static pressure (Pa)

1.5

350

300

250

200

Mid static

pressure tap

150

Low static pressure tap

100

50

0

Air volume (m3/h)

MMD-AP0961HFE (10HP)

Standard air volume: 2100m3/h

3.5

High static pressure tap

3.0

Fan motor current (A)External static pressure (Pa)

2.5

Low static pressure tap

2.0

350

300

250

200

150

Low static

pressure tap

100

Mid static pressure tap

High static

pressure tap

Mid static

pressure tap

120011001000900800

0

1800160014001200

Air volume (m3/h)

50

0

Air volume (m3/h)

23002100190017001500

1515

7. Fan characteristics

Fresh Air Intake Indoor Unit Type

<230V>

50Hz

MMD-AP0481HFE (5HP)

Standard air volume: 1080m3/h

2.0

High static pressure tap

1.5

1.0

Mid static pressure tap

Low static pressure tap

Low static pressure tap

Fan motor current (A)External static pressure (Pa)

0.5

350

High static pressure tap

300

250

200

Mid static pressure tap

150

100

50

MMD-AP0721HFE (8HP)

Standard air volume: 1680m3/h

3.0

High static pressure tap

2.5

Fan motor current (A)External static pressure (Pa)

2.0

1.5

350

300

High static pressure tap

250

200

150

Low static pressure tap

100

50

Low static

pressure tap

Mid static

pressure tap

Mid static pressure tap

0

Air volume (m3/h)

MMD-AP0961HFE (10HP)

Standard air volume: 2100m3/h

Fan motor current (A)External static pressure (Pa)

3.5

Mid static pressure tap

3.0

2.5

2.0

350

300

250

200

Mid static pressure tap

150

100

High static pressure tap

High static pressure tap

Low static pressure tap

Low static

pressure tap

120011001000900800

0

1800160014001200

Air volume (m3/h)

50

0

Air volume (m3/h)

23002100190017001500

1616

7. Fan characteristics

Fresh Air Intake Indoor Unit Type

<240V>

50Hz

MMD-AP0481HFE (5HP)

Standard air volume: 1080m3/h

2.0

High static pressure tap

1.5

1.0

Fan motor current (A)External static pressure (Pa)

Mid static pressure tap

0.5

350

High static pressure tap

300

250

200

Low static pressure tap

150

100

50

Low static pressure tap

Mid static pressure tap

MMD-AP0721HFE (8HP)

Standard air volume: 1680m3/h

3.0

High static pressure tap

2.5

Mid static pressure tap

2.0

Low static pressure tap

1.5

Fan motor current (A)External static pressure (Pa)

350

300

High static pressure tap

250

Mid static pressure tap

200

150

Low static pressure tap

100

50

0

Air volume (m3/h)

MMD-AP0961HFE (10HP)

Standard air volume: 2100m3/h

Fan motor current (A)External static pressure (Pa)

3.5

Mid static pressure tap

3.0

2.5

2.0

350

300

250

200

150

100

High static pressure tap

Low static pressure tap

High static pressure tap

Mid static

pressure tap

Low static

pressure tap

120011001000900800

0

1800160014001200

Air volume (m3/h)

50

0

Air volume (m3/h)

23002100190017001500

1717

8. Sound characteristics (NC Curve)

Fresh Air Intake Indoor Unit Type

Measureing

Center

1.5m

MMD-AP0721HFE

MMD-AP0961HFE

Microphon

MMD-AP0481HFE

Fan tap

Sound pressure

level (dB(A))

Octave band sound pressure (dB)

Audibility limits of

continuous white

HML

45 43 41

Fan tap

Sound pressure

level (dB(A))

Octave band sound pressure (dB)

Audibility limits of

continuous white

HML

46 45 44

Octave band center frequency (Hz)

Octave band center frequency (Hz)

1818

Fresh Air Intake Indoor Unit Type

Engineering Data

May, 2007 First Edition

Loading...

Loading...