Toshiba MMD-AP0276HP-E, MMD-AP0246HP-E, MMD-AP0566HP-E, MMD-AP0186HP-TR, MMD-AP0246HP-TR Service Manual

...

FILE NO. SVM-15032

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

SERVICE MANUAL

AIR-CONDITIONER

MULTI TYPE

INDOOR UNIT

< Concealed Duct High Static Pressure Type >

MMD-AP0186HP-E

MMD-AP0246HP-E

MMD-AP0276HP-E

MMD-AP0366HP-E

MMD-AP0486HP-E

MMD-AP0566HP-E

MMD-AP0186HP-TR

MMD-AP0246HP-TR

MMD-AP0276HP-TR

MMD-AP0366HP-TR

MMD-AP0486HP-TR

MMD-AP0566HP-TR

R410A

CONTENTS

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

PRECAUTIONS FOR SAFETY ................................................................................ 6

1. SPECIFICATIONS .................................................................................................. 13

2. AIR DUCTING WORK............................................................................................. 15

3. CONSTRUCTION VIEWS (EXTERNAL VIEWS).................................................... 17

4.

WIRING DIAGRAMS............................................................................................... 20

5.

PARTS RATING....................................................................................................... 21

6.

REFRIGERANT CYCLE DIAGRAM ........................................................................ 22

7.

CONTROL OUTLINE............................................................................................... 23

8. APPLIED CONTROL AND FUNCTIONS

(INCLUDING CIRCUIT CONFIGURATION) ........................................................... 29

8-1. Indoor controller block diagram ........................................................................................ 29

8-1-1. In Case of Connection of Wired (Simple) Remote Controller ............................. 29

8-1-2. In Case of Connection of Wireless Remote Controller ....................................... 30

8-1-3. Connection of Both Wired (Simple) Remote Controller and Wireless Remote

Controller ................................................................................................................ 31

8-2. Indoor Print Circuit Board MCC-1631 ............................................................................... 32

8-3. Optional connector specifications of indoor P.C. board ................................................ 33

8-4. Test operation of indoor unit .............................................................................................34

8-5. Method to set indoor unit function DN code .................................................................... 35

8-6. Applied control of indoor unit ........................................................................................... 38

9.

TROUBLESHOOTING............................................................................................. 54

9-1. Overview .............................................................................................................................. 54

9-2. Troubleshooting method ................................................................................................... 55

9-3. Troubleshooting based on information displayed on remote controller ....................... 61

9-4. Check codes displayed on remote controller and SMMS outdoor unit

(7-segment display on I/F board) and locations to be checked .................................... 66

9-5. Sensor characteristics ....................................................................................................... 85

10.

P.C. BOARD EXCHANGE PROCEDURES.......................................................... 86

10-1. Replacement of indoor P.C. boards................................................................................. 86

11.

DETACHMENTS................................................................................................... 92

12.

EXPLODED VIEWS AND PARTS LIST ............................................................... 98

– 2 –

Original instruction

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Please read carefully through these instructions that contain important information which complies with the

“Machinery” Directive (Directive 2006/42/EC), and ensure that you understand them.

Generic Denomination: Air Conditioner

Definition of Qualified Installer or Qualified Service Person

The air conditioner must be installed, maintained, repaired and removed by a qualified installer or qualified

service person. When any of these jobs is to be done, ask a qualified installer or qualified service person to do

them for you.

A qualified installer or qualified service person is an agent who has the qualifications and knowledge

described in the table below.

Agent Qualifications and knowledge which the agent must have

• The qualified installer is a person who installs, maintains, relocates and removes the air

conditioners made by Toshiba Carrier Corporation. He or she has been trained to install,

maintain, relocate and remove the air conditioners made by Toshiba Carrier Corporation or,

alternatively, he or she has been instructed in such operations by an individual or individuals

who have been trained and is thus thoroughly acquainted with the knowledge related to these

operations.

• The qualified installer who is allowed to do the electrical work involved in installation, relocation

and removal has the qualifications pertaining to this electrical work as stipulated by the local

laws and regulations, and he or she is a person who has been trained in matters relating to

electrical work on the air conditioners made by Toshiba Carrier Corporation or, alternatively, he

Qualified installer

or she has been instructed in such matters by an individual or individuals who have been

trained and is thus thoroughly acquainted with the knowledge related to this work.

• The qualified installer who is allowed to do the refrigerant handling and piping work involved in

installation, relocation and removal has the qualifications pertaining to this refrigerant handling

and piping work as stipulated by the local laws and regulations, and he or she is a person who

has been trained in matters relating to refrigerant handling and piping work on the air

conditioners made by Toshiba Carrier Corporation or, alternatively, he or she has been

instructed in such matters by an individual or individuals who have been trained and is thus

thoroughly acquainted with the knowledge related to this work.

• The qualified installer who is allowed to work at heights has been trained in matters relating to

working at heights with the air conditioners made by Toshiba Carrier Corporation or,

alternatively, he or she has been instructed in such matters by an individual or individuals who

have been trained and is thus thoroughly acquainted with the knowledge related to this work.

Qualified service

person

• The qualified service person is a person who installs, repairs, maintains, relocates and removes

the air conditioners made by Toshiba Carrier Corporation. He or she has been trained to install,

repair, maintain, relocate and remove the air conditioners made by Toshiba Carrier Corporation

or, alternatively, he or she has been instructed in such operations by an individual or individuals

who have been trained and is thus thoroughly acquainted with the knowledge related to these

operations.

• The qualified service person who is allowed to do the electrical work involved in installation,

repair, relocation and removal has the qualifications pertaining to this electrical work as

stipulated by the local laws and regulations, and he or she is a person who has been trained in

matters relating to electrical work on the air conditioners made by Toshiba Carrier Corporation

or, alternatively, he or she has been instructed in such matters by an individual or individuals

who have been trained and is thus thoroughly acquainted with the knowledge related to this

work.

• The qualified service person who is allowed to do the refrigerant handling and piping work

involved in installation, repair, relocation and removal has the qualifications pertaining to this

refrigerant handling and piping work as stipulated by the local laws and regulations, and he or

she is a person who has been trained in matters relating to refrigerant handling and piping work

on the air conditioners made by Toshiba Carrier Corporation or, alternatively, he or she has

been instructed in such matters by an individual or individuals who have been trained and is

thus thoroughly acquainted with the knowledge related to this work.

• The qualified service person who is allowed to work at heights has been trained in matters

relating to working at heights with the air conditioners made by Toshiba Carrier Corporation or,

alternatively, he or she has been instructed in such matters by an individual or individuals who

have been trained and is thus thoroughly acquainted with the knowledge related to this work.

– 3 –

Definition of Protective Gear

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

When the air conditioner is to be transported, installed, maintained, repaired or removed, wear protective

gloves and ‘safety’ work clothing.

In addition to such normal protective gear, wear the protective gear described below when undertaking the

special work detailed in the table below.

Failure to wear the proper protective gear is dangerous because you will be more susceptible to injury, bur ns,

electric shocks and other injuries.

Work undertaken

All types of work

Electrical-related work

Work done at heights

(50 cm or more)

Transportation of heavy objects

Repair of outdoor unit

Protective gloves

‘Safety’ working clothing

Gloves to provide protection for electricians

Insulating shoes

Clothing to provide protection from electric shock

Helmets for use in industry

Shoes with additional protective toe cap

Gloves to provide protection for electricians

Protective gear worn

The important contents concerned to the safety are described on the product itself and on this Service

Manual.

Please read this Service Manual after understanding the described items thoroughly in the following contents

(Indications / Illustrated marks), and keep them.

[Explanation of indications]

Indication Explanation

DANGER

WARNING

CAUTION

Indicates contents assumed that an imminent danger causing a death or serious injury of

the repair engineers and the third parties when an incorrect work has been executed.

Indicates possibilities assumed that a danger causing a death or serious injury of the

repair engineers, the third parties, and the users due to troubles of the product after work

when an incorrect work has been executed.

Indicates contents assumed that an injury or property damage (*) may be caused on the

repair engineers, the third parties, and the users due to troubles of the product after work

when an incorrect work has been executed.

* Property damage: Enlarged damage concerned to property, furniture, and domestic animal / pet

[Explanation of illustrated marks]

Indication Explanation

Indicates prohibited items (Forbidden items to do)

The sentences near an illustrated mark describe the concrete prohibited contents.

Indicates mandatory items (Compulsory items to do)

The sentences near an illustrated mark describe the concrete mandatory contents.

Indicates cautions (Including danger / warning)

The sentences or illustration near or in an illustrated mark describe the concrete cautious contents.

– 4 –

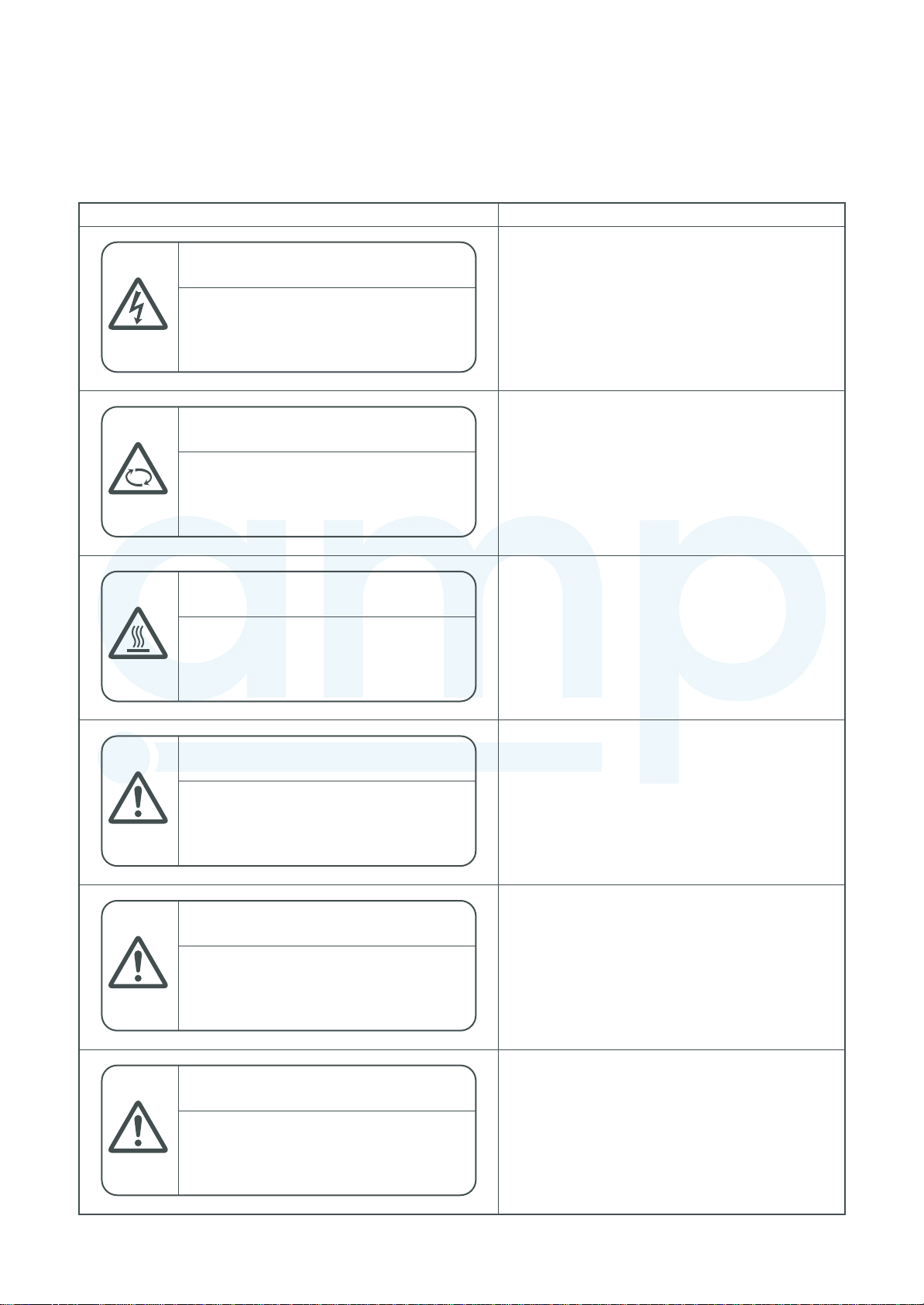

Warning Indications on the Air Conditioner Unit

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

[Confirmation of warning label on the main unit]

Confirm that labels are indicated on the specified positions

If removing the label during parts replace, stick it as the original.

Warning indication Description

WARNING

ELECTRICAL SHOCK HAZARD

Disconnect all remote electric

power supplies before servicing.

WARNING

Moving parts.

Do not operate unit with grille removed.

Stop the unit before the servicing.

CAUTION

High temperature parts.

You might get burned when removing

this panel.

WARNING

ELECTRICAL SHOCK HAZARD

Disconnect all remote electric power supplies

before servicing.

WARNING

Moving parts.

Do not operate unit with grille removed.

Stop the unit before the servicing.

CAUTION

High temperature parts.

You might get burned when removing this panel.

CAUTION

Do not touch the aluminium fins of the unit.

Doing so may result in injury.

CAUTION

BURST HAZARD

Open the service valves before the

operation, otherwise there might be the

burst.

CAUTION

Do not climb onto the fan guard.

Doing so may result in injury.

CAUTION

Do not touch the aluminium fins of the unit.

Doing so may result in injury.

CAUTION

BURST HAZARD

Open the service valves before the operation,

otherwise there might be the burst.

CAUTION

Do not climb onto the fan guard.

Doing so may result in injury.

– 5 –

PRECAUTIONS FOR SAFETY

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

The manufacturer shall not assume any liability for the damage caused by not observing the description of this

manual.

DANGER

Before carrying out the installation, maintenance, repair or removal work, be sure to set the circuit

breaker for both the indoor and outdoor units to the OFF position. Otherwise, electric shocks may

result.

Before opening the electrical box cover of the indoor unit or service panel of the outdoor unit, set the

circuit breaker to the OFF position. Failure to set the circuit breaker to the OFF position may result in

electric shocks through contact with the interior parts. Only a qualified installer (*1) or qualified service

person (*1) is allowed to remove the intake grille of the indoor unit or service panel of the outdoor unit

and do the work required.

Before opening the suction board cover, set the circuit breaker to the OFF position.

Failure to set the circuit breaker to the OFF position ma y result in injury through contact with the rotation parts.

Only a qualified installer (*1) or qualified service person (*1) is allowed to remove the suction board

Turn off

braeaker

Electric

shock hazard

Prohibition

Stay on

protection

cover and do the work required.

Before starting to repair the outdoor unit fan or fan guard, be absolutely sure to set the circuit breaker

to the OFF position, and place a “Work in progress” sign on the circuit breaker.

When cleaning the filter (sold separately) or other parts of the indoor unit, set the circuit breaker to OFF

without fail, and place a

When you have noticed that some kind of trouble (such as when an error display has appeared, there

is a smell of burning, abnormal sounds are heard, the air conditioner fails to cool or heat or water is

leaking) has occurred in the air conditioner, do not touch the air conditioner yourself but set the circuit

breaker to the OFF position, and contact a qualified service person. Take steps to ensure that the

power will not be turned on (by marking “out of service” near the circuit breaker, for instance) until

qualified service person arrives. Continuing to use the air conditioner in the trouble status may cause

mechanical problems to escalate or result in electric shocks or other failure.

When you access inside of the service panel to repair electric parts, wait for about five minutes after turning

off the breaker. Do not start repairing immediately.Otherwise you may get electric shock by touching

terminals of high-voltage capacitors. Natur al discharge of the capacitor tak es about five minutes.

When checking the electric parts, removing the cover of the electric parts box of Indoor Unit and/or

service panel of Outdoor Unit inevitably to determine the failure, use gloves to provide protection for

electricians, insulating shoes, clothing to provide protection from electric shock and insulating tools. Be

careful not to touch the live part. Electric shock may result. Only “Qualified service person” is allowed to

do this work.

Place a “Work in progress” sign near the circuit breaker while the installation, maintenance, repair or

removal work is being carried out.

There is a danger of electric shocks if the circuit breaker is set to ON by mistake.

When checking the electric parts, removing the cover of the electric parts box of Indoor Unit and/or

front panel of Outdoor Unit inevitably to determine the failure, put a sign “Do not enter” around the site

before the work. Failure to do this may result in third person getting electric shock.

Before operating the air conditioner after having completed the work, check that the electrical parts box

cover of the indoor unit and service panel of the outdoor unit are closed, and set the circuit breaker to

the ON position.

You may receive an electric shock if the power is turned on without first conducting these checks.

If, in the course of carrying out repairs, it becomes absolutely necessary to check out the electrical

parts with the electrical parts box cover of one or more of the indoor units and the service panel of the

outdoor unit removed in order to find out exactly where the trouble lies, wear insulated heat-resistant

gloves, insulated boots and insulated work overalls, and take care to avoid touching any live parts.

You may receive an electric shock if you fail to heed this warning. Only qualified service person (*1) is

allowed to do this kind of work.

“Work in progress” sign near the circuit breaker before proceeding with the work.

– 6 –

W ARNIG

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

General

Before starting to repair the air conditioner, read carefully through the Service Manual, and repair the

air conditioner by following its instructions.

Only qualified service person (*1) is allowed to repair the air conditioner.

Repair of the air conditioner by unqualified person may give rise to a fire, electric shocks, injury, water

leaks and / or other problems.

Do not use any refrigerant different from the one specified for complement or replacement.

Otherwise, abnormally high pressure may be generated in the refrigeration cycle, which may result in a

failure or explosion of the product or an injury to your body.

Only a qualified installer (*1) or qualified service person (*1) is allowed to carry out the electrical work

of the air conditioner.

Under no circumstances must this work be done by an unqualified individual since failure to carry out

the work properly may result in electric shocks and / or electrical leaks.

When the air conditioner is to be transported, installed, maintained, repaired or removed, wear

protective gloves and ‘safety’ work clothing.

To connect the electrical wires, repair the electrical parts or undertake other electrical jobs, wear gloves

to provide protection for electricians, insulating shoes and clothing to provide protection from electric

shocks. Failure to wear this protective gear may result in electric shocks.

Electrical wiring work shall be conducted according to law and regulation in the community and

installation manual. Failure to do so may result in electrocution or short circuit.

Use wiring that meets the specifications in the Installation Manual and the stipulations in the local

regulations and laws. Use of wiring which does not meet the specifications may give rise to electric

shocks, electrical leakage, smoking and/or a fire.

Only a qualified installer (*1) or qualified service person (*1) is allowed to undertake work at heights

using a stand of 50 cm or more or to remove the intake gr ille of the indoor unit to undertake work.

When working at heights, use a ladder which complies with the ISO 14122 standard, and follow the

procedure in the ladder’s instructions.

Also wear a helmet for use in industry as protective gear to undertake the work.

Before working at heights, put a sign in place so that no-one will approach the work location,

before proceeding with the work. Parts and other objects may fall from above, possibly injur ing a

person below. While carrying out the work, wear a helmet for protection from falling objects.

When executing address setting, test run, or troubleshooting through the checking window on the

electric parts box, put on insulated gloves to provide protection from electric shock. Otherwise you may

receive an electric shock.

Do not touch the aluminum fin of the outdoor unit.

You may injure yourself if you do so. If the fin must be touched for some reason, first put on protective

gloves and safety work clothing, and then proceed.

Do not climb onto or place objects on top of the outdoor unit.

You may fall or the objects may fall off of the outdoor unit and result in injury.

Use forklift to carry in the air conditioner units and use winch or hoist at installation of them.

When transporting the air conditioner, wear shoes with protective toe caps, protective gloves and other

protective clothing.

When transporting the air conditioner, do not take hold of the bands around the packing carton.

You may injure yourself if the bands should break.

Be sure that a heavy unit (10 kg or heavier) such as a compressor is carried by four persons.

This air conditioner has passed the pressure test as specified in IEC 60335-2-40 Annex EE.

Before troubleshooting or repair work, check the earth wire is connected to the earth terminals of the main unit,

otherwise an electric shock is caused when a leak occurs.If the earth wire is not correctly connected,

contact an electric engineer for rework.

Check earth

wires.

After completing the repair or relocation work, check that the ground wires are connected properly.

Be sure to connect earth wire. (Grounding work) Incomplete grounding causes an electric shock.

Do not connect ground wires to gas pipes, water pipes, and lightning rods or ground wires for

telephone wires.

– 7 –

Prohibition of

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

modification.

Use specified

parts.

Do not bring

a child close

to the

equipment.

Insulating

measures

No fire

Refrigerant

Do not modify the products.Do not also disassemble or modify the parts.

It may cause a fire, electric shock or injury.

When any of the electrical parts are to be replaced, ensure that the replacement par ts satisfy the

specifications given in the Service Manual (or use the parts contained on the parts list in the

Service Manual).

Use of any parts which do not satisfy the required specifications may give rise to electric shocks,

smoking and / or a fire.

If, in the course of carrying out repairs, it becomes absolutely necessary to check out the electrical

parts with the electrical parts box cover of one or more of the indoor units and the service panel of the

outdoor unit removed in order to find out exactly where the trouble lies, put a sign in place so that noone will approach the work location before proceeding with the work. Third-par ty individuals may enter

the work site and receive electric shocks if this warning is not heeded.

Connect the cut-off lead wires with crimp contact, etc., put the closed end side upward and then apply

a watercut method, otherwise a leak or production of fire is caused at the users’ side.

When performing repairs using a gas burner, replace the refrigerant with nitrogen gas because the oil

that coats the pipes may otherwise burn.

When repairing the refrigerating cycle, take the following measures.

1) Be attentive to fire around the cycle. When using a gas stove, etc., be sure to put out fire bef ore w ork;

otherwise the oil mixed with refrigerant gas may catch fire.

2) Do not use a welder in the closed room. When using it without ventilation, carbon monoxide

poisoning may be caused.

3) Do not bring inflammables close to the refrigerant cycle, otherwise fire of the welder may catch the

inflammables.

The refrigerant used by this air conditioner is the R410A.

Check the used refrigerant name and use tools and materials of the parts which match with it.

For the products which use R410A refrigerant, the refrigerant name is indicated at a position on the

outdoor unit where is easy to see. To prevent miss-charging, the route of the service port is changed

from one of the former R22.

Do not use any refrigerant different from the one specified for complement or replacement.

Otherwise, abnormally high pressure may be generated in the refrigeration cycle, which may result in a

failure or explosion of the product or an injury to your body.

For an air conditioner which uses R410A, never use other refr igerant than R410A. For an air

conditioner which uses other refrigerant (R22, etc.), never use R410A.

If different types of refrigerant are mixed, abnormal high pressure generates in the refrigerating cycle

and an injury due to breakage may be caused.

When the air conditioner has been installed or relocated, follow the instructions in the Installation

Manual and purge the air completely so that no gases other than the refrigerant will be mixed in the

refrigerating cycle.

Failure to purge the air completely may cause the air conditioner to malfunction.

Do not charge refrigerant additionally. If charging refrigerant additionally when refrigerant gas leaks, the

refrigerant composition in the refrigerating cycle changes resulted in change of air conditioner

characteristics or refrigerant over the specified standard amount is charged and an abnormal high

pressure is applied to the inside of the refrigerating cycle resulted in cause of breakage or injury.

Therefore if the refrigerant gas leaks, recover the refrigerant in the air conditioner, execute vacuuming,

and then newly recharge the specified amount of liquid refrigerant.

In this time, never charge the refrigerant over the specified amount.

When recharging the refrigerant in the refrigerating cycle, do not mix the refrigerant or air other than

R410A into the specified refrigerant. If air or others is mixed with the refrigerant, abnormal high

pressure generates in the refrigerating cycle resulted in cause of injury due to breakage.

After installation work, check the refrigerant gas does not leak. If the refrigerant gas leaks in the room,

poisonous gas generates when gas touches to fire such as fan heater, stove or cocking stove though

the refrigerant gas itself is innocuous.

Never recover the refrigerant into the outdoor unit. When the equipment is moved or repaired, be sure

to recover the refrigerant with recover ing device.

The refrigerant cannot be recovered in the outdoor unit; otherwise a serious accident such as breakage

or injury is caused.

– 8 –

Assembly /

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Wiring

Insulator

check

Ventilation

Compulsion

Check after

repair

After repair work, surely assemble the disassembled parts, and connect and lead the removed wires as before .

Perform the work so that the cabinet or panel does not catch the inner wires.

If incorrect assembly or incorrect wire connection was done, a disaster such as a leak or fire is caused

at user’s side.

After the work has finished, be sure to use an insulation tester set (500 V Megger) to check the resistance is

1 MΩ or more between the charge section and the non-charge metal section (Earth position).

If the resistance value is low, a disaster such as a leak or electric shock is caused at user’s side.

When the refrigerant gas leaks during work, execute ventilation.

If the refrigerant gas touches to a fire, poisonous gas generates. A case of leakage of the refrigerant

and the closed room full with gas is dangerous because a shortage of oxygen occurs. Be sure to

execute ventilation.

If refrigerant gas has leaked during the installation work, ventilate the room immediately.

If the leaked refrigerant gas comes in contact with fire, noxious gas may generate.

After installation work, check the refrigerant gas does not leak. If the refrigerant gas leaks in the room,

poisonous gas generates when gas touches to fire such as fan heater, stove or cocking stove though

the refrigerant gas itself is innocuous.

When the refrigerant gas leaks, find up the leaked position and repair it surely.

If the leaked position cannot be found up and the repair work is interrupted, pump-down and tighten the

service valve, otherwise the refrigerant gas may leak into the room.

The poisonous gas generates when gas touches to fire such as fan heater , stove or cocking stove though

the refrigerant gas itself is innocuous.

When installing equipment which includes a large amount of charged refrigerant such as a multi air

conditioner in a sub-room, it is necessary that the density does not the limit even if the refrigerant leaks.

If the refrigerant leaks and exceeds the limit density, an accident of shortage of oxygen is caused.

Tighten the flare nut with a torque wrench in the specified manner.

Excessive tighten of the flare nut may cause a crack in the flare nut after a long period, which may

result in refrigerant leakage.

Nitrogen gas must be used for the airtight test.

The charge hose must be connected in such a way that it is not slack.

For the installation / moving / reinstallation work, follow to the Installation Manual.

If an incorrect installation is done, a trouble of the refrigerating cycle, water leak, electric shoc k or fire is caused.

Once the repair work has been completed, check for refrigerant leaks, and check the insulation

resistance and water drainage.

Then perform a trial run to check that the air conditioner is running properly.

After repair work has finished, check there is no trouble. If check is not executed, a fire, electric shock

or injury may be caused. For a check, turn off the power breaker.

After repair work (installation of front panel and cabinet) has finished, execute a test run to check there

is no generation of smoke or abnormal sound.

If check is not ex ecuted, a fire or an electric shock is caused. Bef ore test run, install the front panel and cabinet.

Be sure to fix the screws back which have been removed for installation or other purposes.

Check the following matters before a test r un after repairing piping.

• Connect the pipes surely and there is no leak of refrigerant.

• The valve is opened.

Do not

operate the

unit with the

valve closed.

Check after

reinstallation

Running the compressor under condition that the valve closes causes an abnormal high pressure

resulted in damage of the parts of the compressor and etc. and moreover if there is leak of refrigerant

at connecting section of pipes, the air is sucked and causes further abnormal high pressure resulted in

burst or injury.

Only a qualified installer (*1) or qualified service person (*1) is allowed to relocate the air conditioner. It

is dangerous for the air conditioner to be relocated by an unqualified individual since a fire, electric

shocks, injury, water leakage, noise and / or vibration may result.

Check the following items after reinstallation.

1) The earth wire is correctly connected.

2) The power cord is not caught in the product.

3) There is no inclination or unsteadiness and the installation is stable.

If check is not executed, a fire, an electric shock or an injury is caused.

When carrying out the pump-down work shut down the compressor before disconnecting the refrigerant pipe.

Disconnecting the refrigerant pipe with the service valve left open and the compressor still operating

will cause air, etc. to be sucked in, raising the pressure inside the refrigeration cycle to an abnormally

high level, and possibly resulting in reputing, injury, etc.

– 9 –

Cooling check

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Installation

When the service panel of the outdoor unit is to be opened in order for the compressor or the area

around this part to be repaired immediately after the air conditioner has been shut down, set the circuit

breaker to the OFF position, and then wait at least 10 minutes before opening the service panel.

If you fail to heed this warning, you will run the risk of burning yourself because the compressor pipes

and other parts will be very hot to the touch. In addition, before proceeding with the repair work, wear

the kind of insulated heat-resistant gloves designed to protect electricians.

Take care not to get burned by compressor pipes or other parts when checking the cooling cycle while

running the unit as they get heated while running. Be sure to put on gloves providing protection for heat.

When the service panel of the outdoor unit is to be opened in order for the fan motor, reactor, inverter

or the areas around these parts to be repaired immediately after the air conditioner has been shut

down, set the circuit breaker to the OFF position, and then wait at least 10 minutes before opening the

service panel.

If you fail to heed this warning, you will run the risk of burning yourself because the fan motor, reactor,

inverter heat sink and other parts will be very hot to the touch.

In addition, before proceeding with the repair work, wear the kind of insulated heat-resistant gloves

designed to protect electricians.

Only a qualified installer or service person is allowed to do installation work. Inappropriate installation

may result in water leakage, electric shock or fire.

Before starting to install the air conditioner, read carefully through the Installation Manual, and follow its

instructions to install the air conditioner.

Be sure to use the company-specified products for the separately purchased parts. Use of nonspecified products may result in fire, electric shock, water leakage or other failure. Have the installation

performed by a qualified installer.

Do not supply power from the power terminal block equipped on the outdoor unit to another outdoor unit.

Capacity overflow may occur on the terminal block and may result in fire.

Do not install the air conditioner in a location that may be subject to a risk of expire to a combustible gas .

If a combustible gas leaks and becomes concentrated around the unit, a fire may occur.

Install the indoor unit at least 2.5 m above the floor level since otherwise the users may injure

themselves or receive electric shocks if they poke their fingers or other objects into the indoor unit

while the air conditioner is running.

Install a circuit breaker that meets the specifications in the installation manual and the stipulations in

the local regulations and laws.

Install the circuit breaker where it can be easily accessed by the qualified service person (*1).

If you install the unit in a small room, take appropriate measures to prevent the refrigerant from

exceeding the limit concentration even if it leaks. Consult the dealer from whom you purchased the air

conditioner when you implement the measures. Accumulation of highly concentrated refrigerant may

cause an oxygen deficiency accident.

Do not place any combustion appliance in a place where it is directly exposed to the wind of air

conditioner, otherwise it may cause imperfect combustion.

Explanations given to user

If you have discovered that the fan grille is damaged, do not approach the outdoor unit but set the circuit

breaker to the OFF position, and contact a qualified service person to have the repairs done.

Do not set the circuit breaker to the ON position until the repairs are completed.

Relocation

• Only a qualified installer (*1) or qualified ser vice person (*1) is allowed to relocate the air conditioner.

It is dangerous for the air conditioner to be relocated by an unqualified individual since a fire, electric shocks,

injury, water leakage, noise and / or vibration may result.

• When carrying out the pump-down work shut down the compressor before disconnecting the refrigerant pipe.

Disconnecting the refrigerant pipe with the service valve left open and the compressor still operating will

cause air, etc. to be sucked in, raising the pressure inside the refrigeration cycle to an abnormally high level,

and possibly resulting in reputing, injury, etc.

(*1) Refer to the “Definition of Qualified Installer or Qualified Service Person”

– 10 –

Declaration of Conformity

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Manufacturer:

Authorized Representative / Nick Ball

TCF holder: Toshiba EMEA Engineering Director

Hereby declares that the machinery described below:

Generic Denomination: Air Conditioner

Model / type: Indoor unit

TOSHIBA CARRIER (THAILAND) CO., LTD.

144 / 9 Moo 5, Bangkadi Industrial Park, Tivanon Road, Tambol Bangkadi,

Amphur Muang, Pathumthani 12000, Thailand

Toshiba Carrier UK Ltd.

Porsham Close, Belliver Industrial Estate,

PLYMOUTH, Devon, PL6 7DB.

United Kingdom

<Concealed Duct High Static Pressure Type>

MMD-AP0186HP-E,

MMD-AP0246HP-E,

MMD-AP0276HP-E,

MMD-AP0366HP-E,

MMD-AP0486HP-E,

MMD-AP0566HP-E

MMD-AP0186HP-TR,

MMD-AP0246HP-TR,

MMD-AP0276HP-TR,

M

MD-AP0366HP-TR,

MMD-AP0486HP-TR,

MMD-AP0566HP-TR

Commercial name: Super Modular Multi System Air Conditioner

Super Heat Recovery Multi System Air Conditioner

MiNi-Super Modular Multi System Air Conditioner (MiNi-SMMS series)

Complies with the provisions of the “Machinery” Directive (Directive 2006/42/EC) and the regulations

transposing into national law

“Declaration of incorporation of partly completed machinery”

Must not be put into service until the final machinery into which it is to be incorporated has been declared in

conformity with the provisions of this Directive, where appropriate.

NOTE

This declaration becomes invalid if technical or operational modifications are introduced without the

manufacturer’s consent.

– 11 –

Specifications

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

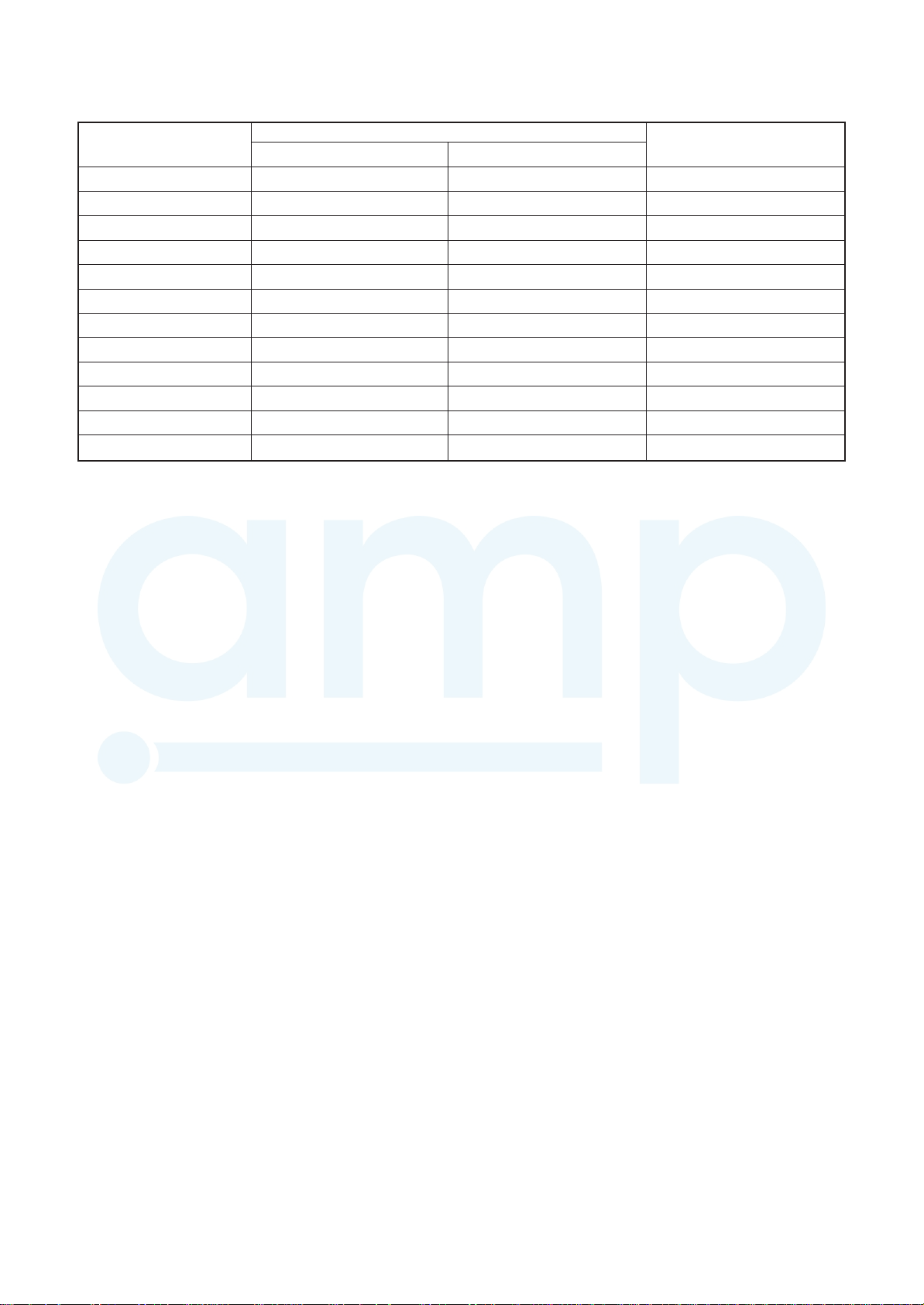

Model

MMD-AP0186HP-E

MMD-AP0246HP-E

MMD-AP0276HP-E

MMD-AP0366HP-E

MMD-AP0486HP-E

MMD-AP0566HP-E

MMD-AP0186HP-TR

MMD-AP0246HP-TR

MMD-AP0276HP-TR

MMD-AP0366HP-TR

MMD-AP0486HP-TR

MMD-AP0566HP-TR

: Under 70 dBA

∗

Sound pressure level (dBA)

Cooling Heating

∗

∗

∗

∗

∗

∗

∗

∗

∗

∗

∗

∗

∗

∗

∗

∗

∗

∗

∗

∗

∗

∗

∗

∗

Weight (kg)

Main unit

34

34

34

43

43

43

34

34

34

43

43

43

– 12 –

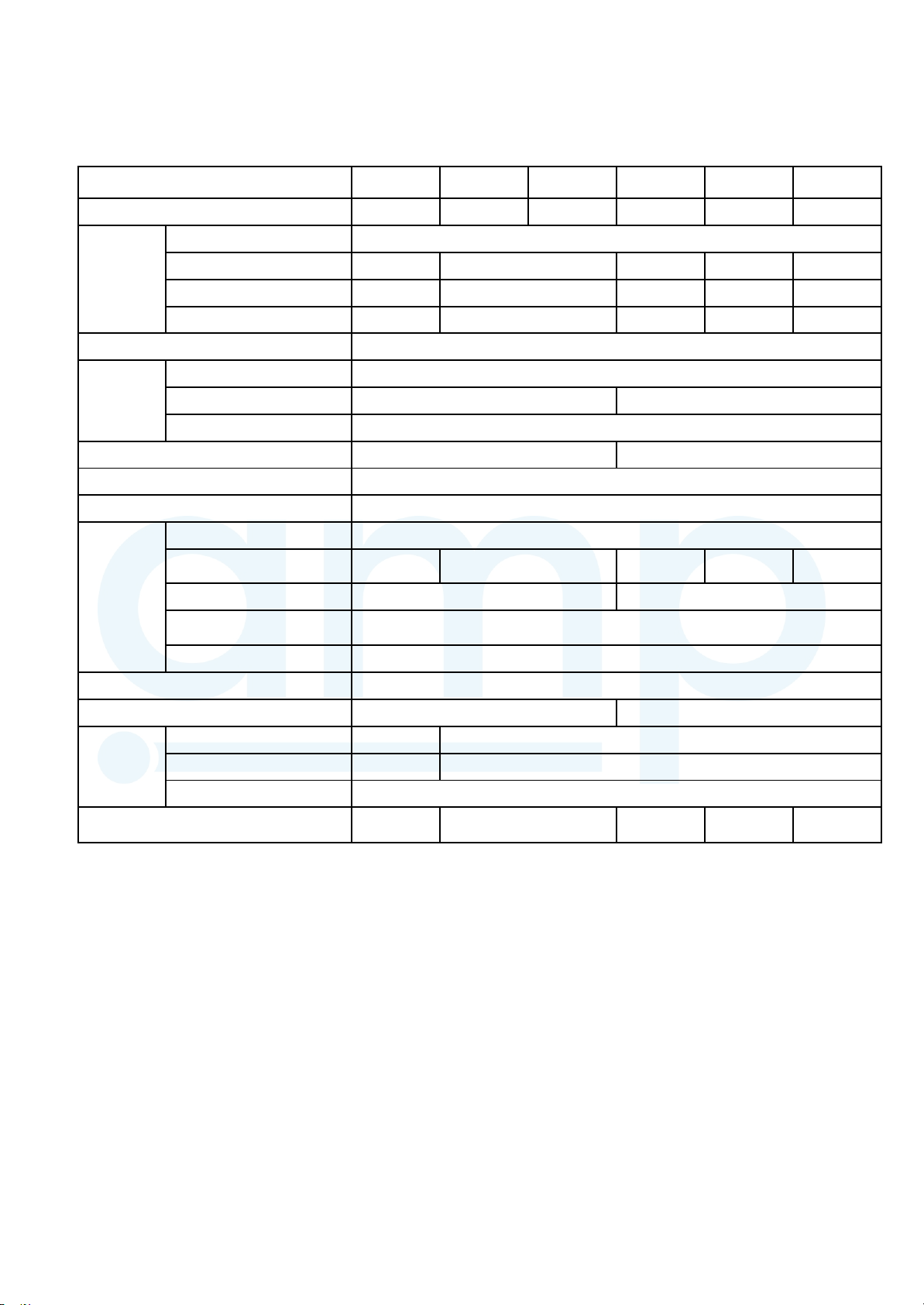

1. SPECIFICATIONS

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Concealed Duct High Static Pressure Type

Model name MMD-

Cooling/Heating capacity (Note 1) (kW)

Electrical Power supply

characteristics Running current (A) 0.52 0.70 1.17 1.34 1.68

Power consumption (kW) 0.085 0.115 0.198 0.230 0.290

Starting current (A) 0.78 1.05 1.75 2.01 2.51

Appearance

Dimension Height (mm)

Width (mm)

Depth (mm)

Total weight (kg)

Heat exchanger

Soundproof / Heat-insulating meterial

Fan unit Fan

(m3/h) 800 1,200 1,920 2,100 2,400Standard air flow

(Med./Low) (660/550) (970/800) (1560/1340) (1740/1420) (2040/1660)

Motor output (W)

External static pressure

(factory setting)

External static pressure (Pa)

Controller

Air filter

(Pa)

AP0186

HP-E(TR)

5.6/6.3 7.1/8.0 8.0/9.0 11.2/12.5 14.0/16.0 16.0/18.0

Sold separately (TCB-LK801D-E) Sold separately (TCB-LK1401D-E)

AP0246

HP-E(TR)

1000

34

250 350

AP0276

HP-E(TR)

1phase 50Hz 230V(220V-240V)

Zinc hot dipping steel plate

Finned tube

Polyethlene foam

Centrifugal fan

50-75-100-125-150-175-200 (7steps)

Remote controller

AP0366

HP-E(TR)

298

750

100

AP0486

HP-E(TR)

1400

43

AP0566

HP-E(TR)

(50Hz)

Connecting Gas side (mm) 12.7

pipe Liquid side (mm) 6.4

Drain port (mm)

Sound pressure level (Note 2)

(High/Med./Low) (32/30) (34/31) (37/34) (40/35) (42/37)

Note 1 : The cooling capacities and electrical characteristics are measured under the conditions specified by JIS B 8615 based

on the reference piping.

The reference piping consists of 5m of main piping and 2.5m of branch piping connected with 0 meter height.

Note 2 : The sound level are measured in an anechoic chamber in accordance with JIS B 8616.

Normally, the values measured in the actual operating environment become larger than the indicated valves due to the

effects of external sound.

Note: Rated conditions Cooling: Indoor air temperature 27℃ DB/19℃ WB, Outdoor air temperature 35℃ DB

Heating: Indoor air temperature 20℃ DB, Outdoor air temperature 7℃ DB/6℃ W B

(dB(A)) 37 38 41 42 45

25(Polyvinyl chloride tube)

15.9

9.5

– 13 –

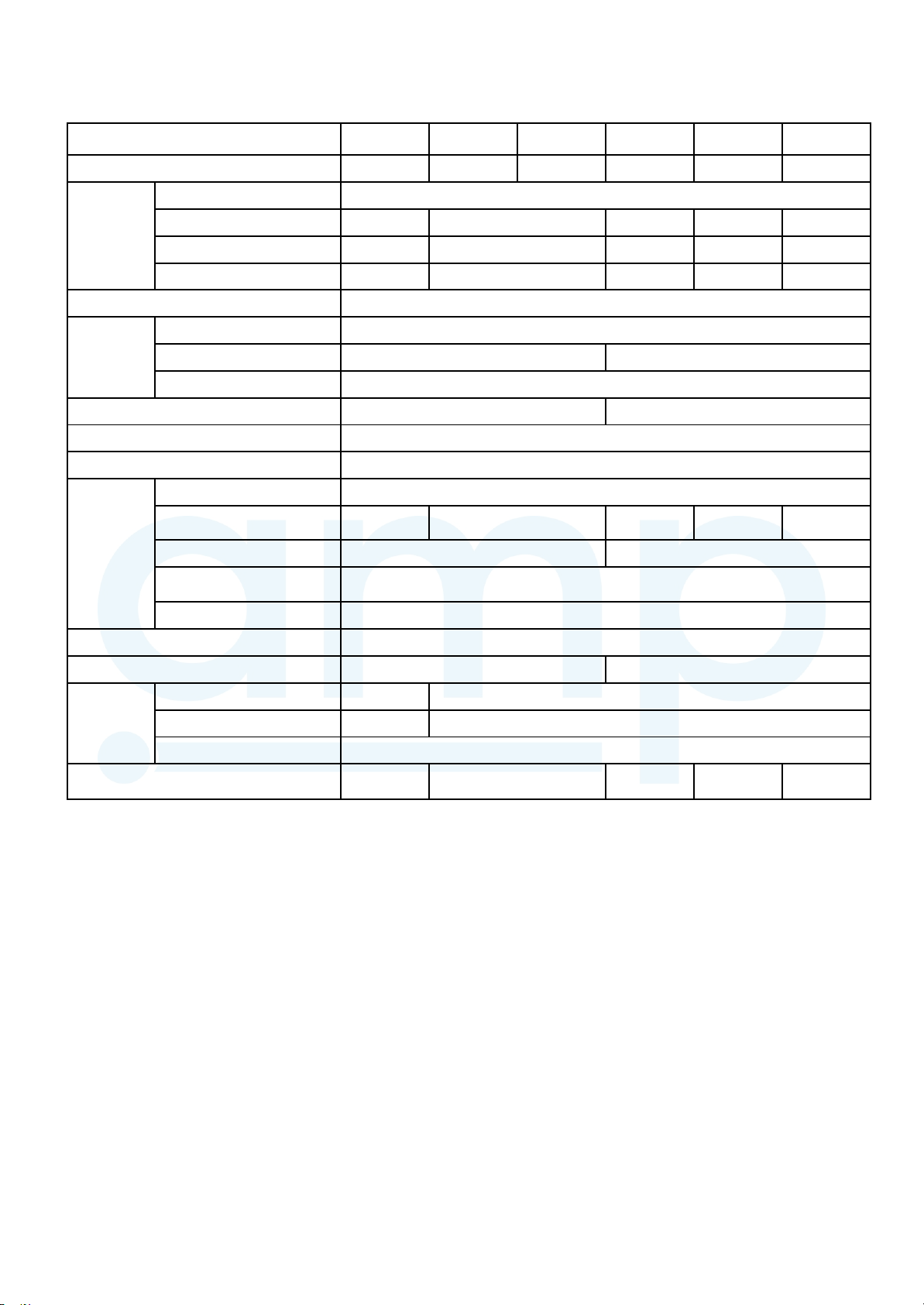

(60Hz)

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Model name MMD-

Cooling/Heating capacity (Note 1) (kW)

AP0186

HP-E

5.6/6.3 7.1/8.0 8.0/9.0 11.2/12.5 14.0/16.0 16.0/18.0

Electrical Power supply

characteristics Running current (A) 0.54 0.73 1.22 1.40 1.75

Power consumption (kW) 0.085 0.115 0.198 0.230 0.290

Starting current (A) 0.81 1.10 1.83 2.10 2.63

Appearance

Dimension Height (mm)

Width (mm)

Depth (mm)

Total weight (kg)

Heat exchanger

Soundproof / Heat-insulating meterial

Fan unit Fan

(m3/h) 800 1,200 1,920 2,100 2,400Standard air flow

(Med./Low) (660/550) (970/800) (1560/1340) (1740/1420) (2040/1660)

Motor output (W)

External static pressure

(Pa)

(factory setting)

External static pressure (Pa)

Controller

Air filter Sold separately (TCB-LK801D-E) Sold separately (TCB-LK1401D-E)

AP0246

HP-E

AP0276

HP-E

AP0366

HP-E

AP0486

1phase 60Hz 220V

Zinc hot dipping steel plate

298

1000 1400

750

34 43

Finned tube

Polyethlene foam

Centrifugal fan

250 350

100

50-75-100-125-150-175-200 (7steps)

Remote controller

HP-E

AP0566

HP-E

Connecting Gas side (mm) 12.7

pipe Liquid side (mm) 6.4

Drain port (mm)

Sound pressure level (Note 2)

(dB(A)) 37 38 41 42 45

25(Polyvinyl chloride tube)

15.9

9.5

(High/Med./Low) (32/30) (34/31) (37/34) (40/35) (42/37)

Note 1 : The cooling capacities and electrical characteristics are measured under the conditions specified by JIS B 8615 based

on the reference piping.

The reference piping consists of 5m of main piping and 2.5m of branch piping connected with 0 meter height.

Note 2 : The sound level are measured in an anechoic chamber in accordance with JIS B 8616.

Normally, the values measured in the actual operating environment become larger than the indicated valves due to the

effects of external sound.

Note: Rated conditions Cooling: Indoor air temperature 27℃ DB/19℃ WB, Outdoor air temperature 35℃ DB

Heating: Indoor air temperature 20℃ DB, Outdoor air temperature 7℃ DB/6℃ W B

– 14 –

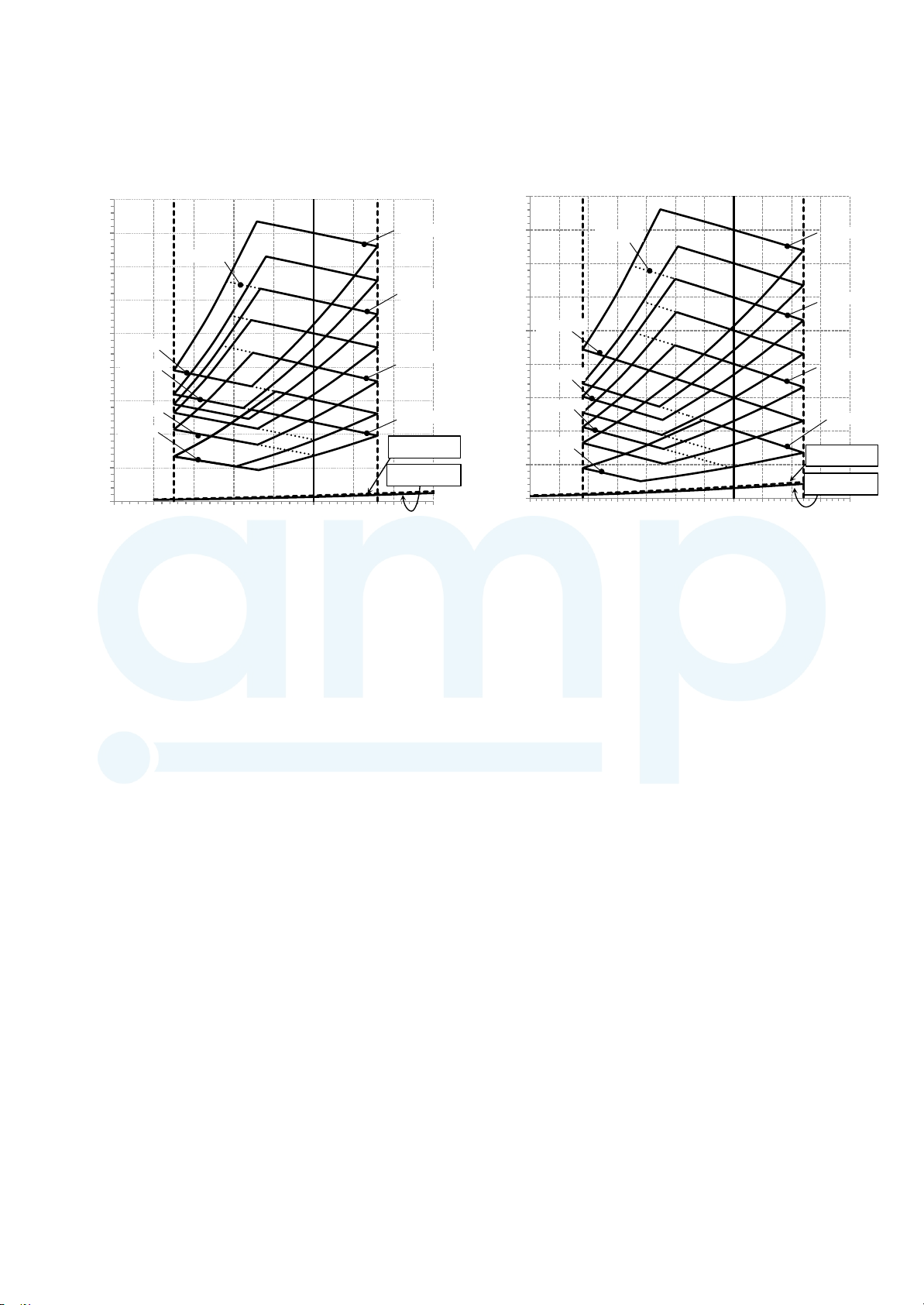

2. AIR DUCTING WORK

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

AP0186 type

225

200

175

150

125

200Pa-Low

150Pa-Low

100

Static Pressure (Pa)

75

100Pa-Low

50Pa-Low

50

25

0

300

400

200Pa-Mid

500

Air Flow (m3/h)

Standard Air Flow 800m3/h

600

700

AP0246, 0276 type

225

200Pa-High

200

200Pa-Mid

175

150Pa-High

100Pa-High

50Pa-High

Spigod Flange

pressure loss (option)

Filter set.

pressure loss (option)

150

200Pa-Low

125

100

75

50

150Pa-Low

100Pa-Low

50Pa-Low

Static Pressure (Pa)

25

0

500

600

800

900

1000

1100

700

Standard Air Flow 1,200m3/h

800

900

Air Flow (m3/h)

1000

200Pa-High

150Pa-High

100Pa-High

50Pa-High

Spigod Flange

pressure loss (option)

Filter set.

pressure loss (option)

1100

1200

1300

1400

1500

1600

– 15 –

AP0366 type AP0486 type

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

250

Standard Air Flow 1,920m3/h

250

Standard Air Flow 2,100m3/h

225

200

175

150

200Pa-Low

125

150Pa-Low

100

Static Pressure (Pa)

75

100Pa-Low

50

25

50Pa-Low

0

600

AP0566 type

250

225

200

225

200Pa-Mid

200Pa-High

200

200Pa-Mid

200Pa-High

175

150Pa-High

150

200Pa-Low

150Pa-High

125

100Pa-High

150Pa-Low

100

Static Pressure (Pa)

100Pa-High

75

50Pa-High

Spigod Flange

pressure loss (option)

Filter set.

pressure loss (option)

800

1000

1200

1400

1600

1800

2000

2200

2400

Air Flow (m3/h)

Standard Air Flow 2,400m3/h

200Pa-Mid

2600

200Pa-High

50

25

0

100Pa-Low

50Pa-Low

800

1000

1200

1400

1600

Air Flow (m3/h)

1800

2000

2200

50Pa-High

Spigod Flange

pressure loss (option)

Filter set.

pressure loss (option)

2400

2600

2800

Static Pressure (Pa)

175

150

125

100

75

50

25

0

200Pa-Low

150Pa-Low

100Pa-Low

50Pa-Low

1000

150Pa-High

100Pa-High

50Pa-High

Spigod Flange

pressure loss (option)

Filter set.

pressure loss (option)

1200

1400

1600

1800

2000

2200

2400

2600

2800

Air Flow (m3/h)

3000

– 16 –

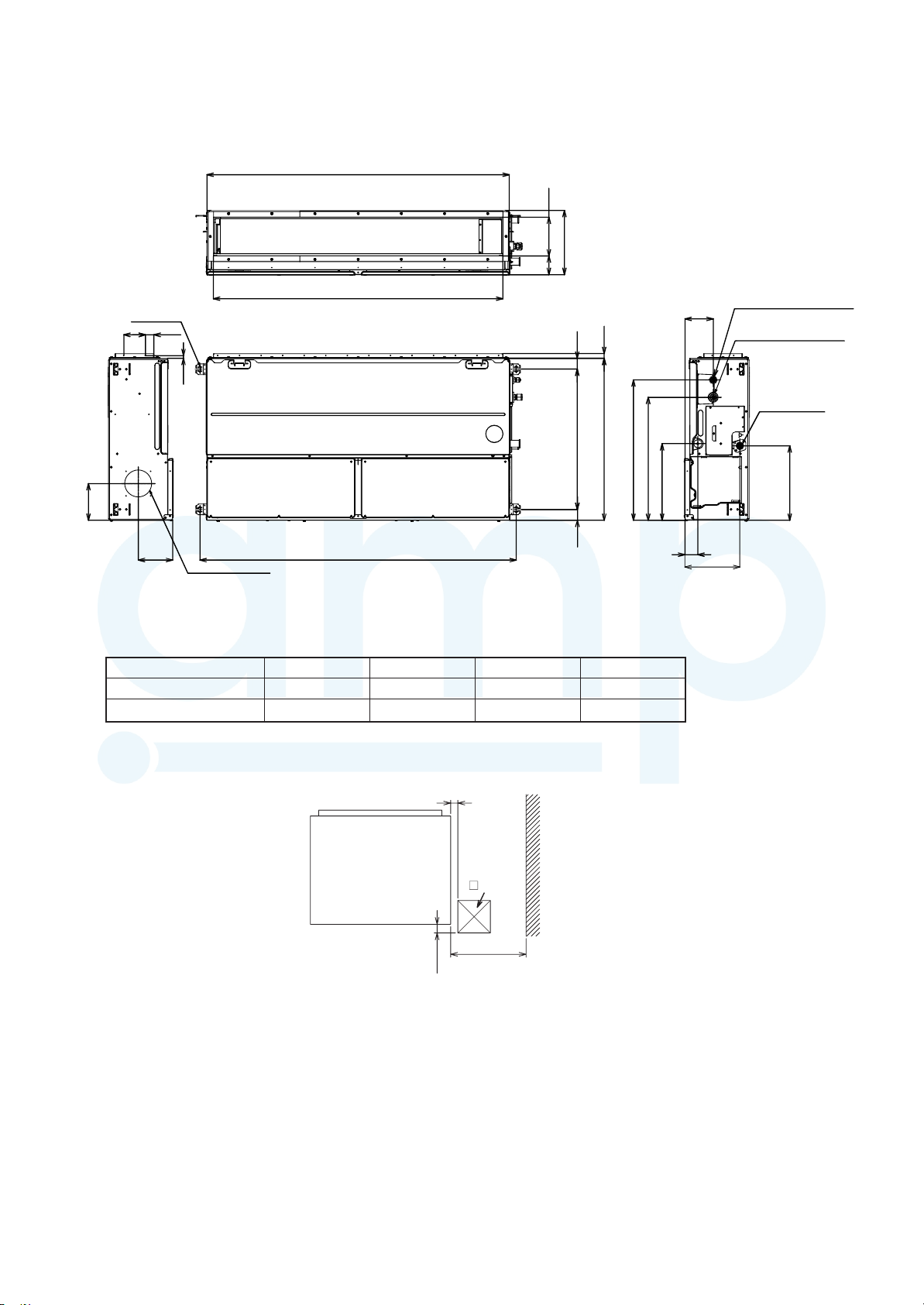

3. CONSTRUCTION VIEWS (EXTERNAL VIEWS)

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Main unit dimension A

180

298

87

Hole for hanging bolt

(4-Φ12×30)

170

Dimension

AP018~027 type

AP036~056 type

40100

13

160

Φ125 K nockout hole

For Auxi liary fresh ai r flan ge

(Sold se parate ly)

External dimension C

22

750

650 5050

Hanging bolt mounting pitch

Hanging bolt mounting pitch B

650

570

355

ABCD

1000 1065 940

1400 1465 1340

500

700

Refrigerant pipe

131

60

connecting port (Liquid side)

Refrigerant pipe

connecting port (Gas side)

Drain pipe

connecting port

255

345

Air discharge

100 or more

Check port

450

120

D

Service space

(D for maintenance of air filter(Sold separately))

– 17 –

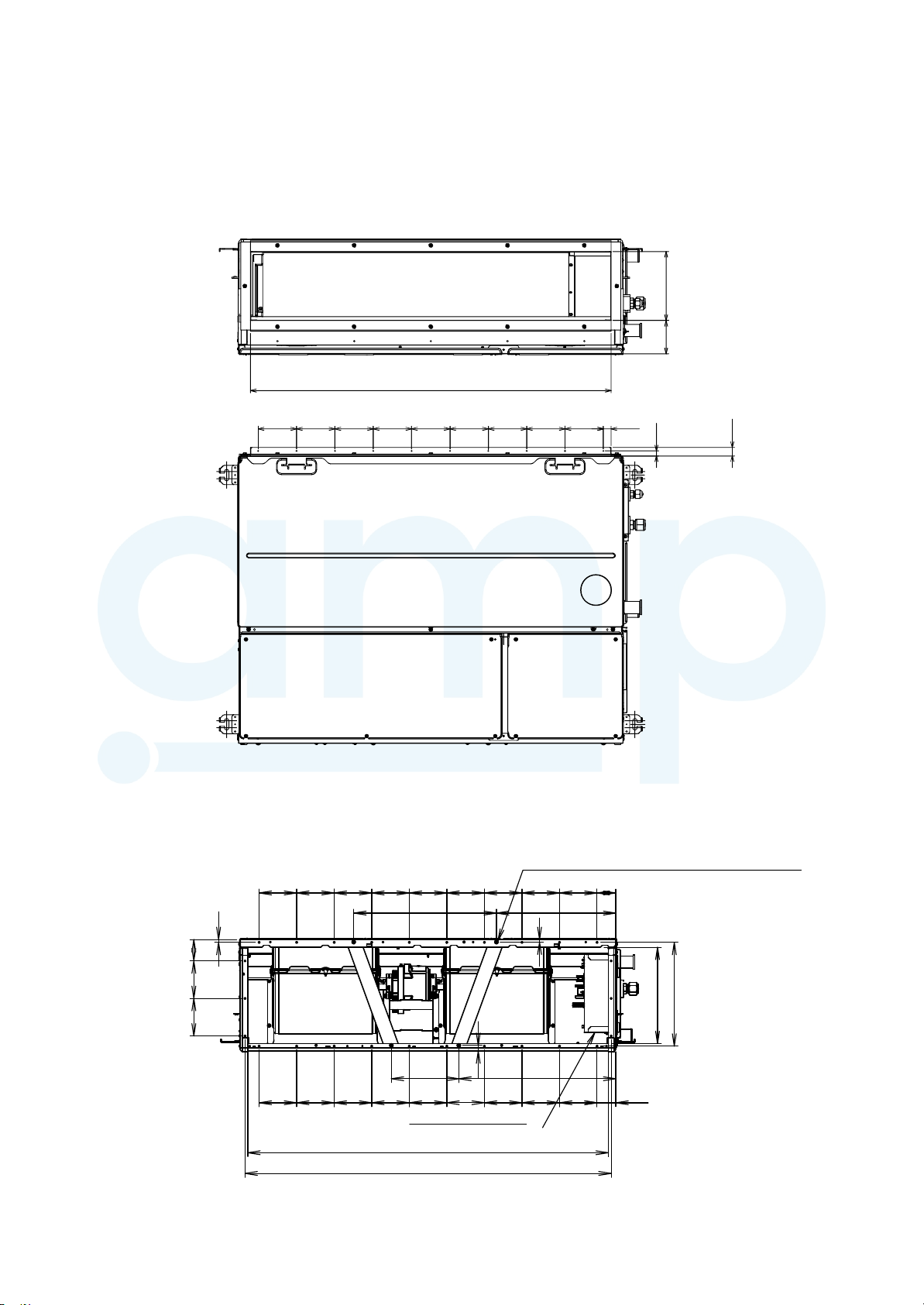

Duct arrangement

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

AP0186, AP0246, AP0276

<Air outlet>

940

(Outside)

87 180

(Outside)

<Air inlet>

100 100 100 100

8

There are the head of the screw(n=4).

Make a hole at the installation of inlet duct.

100 100 100 100 100 50

380 318

7

20100100100100100100100100100

13

22

100 57

100

15

100

100 100 100 100 100

Electrical control box

960

975

– 18 –

276

256

418 180

100 100 100

50

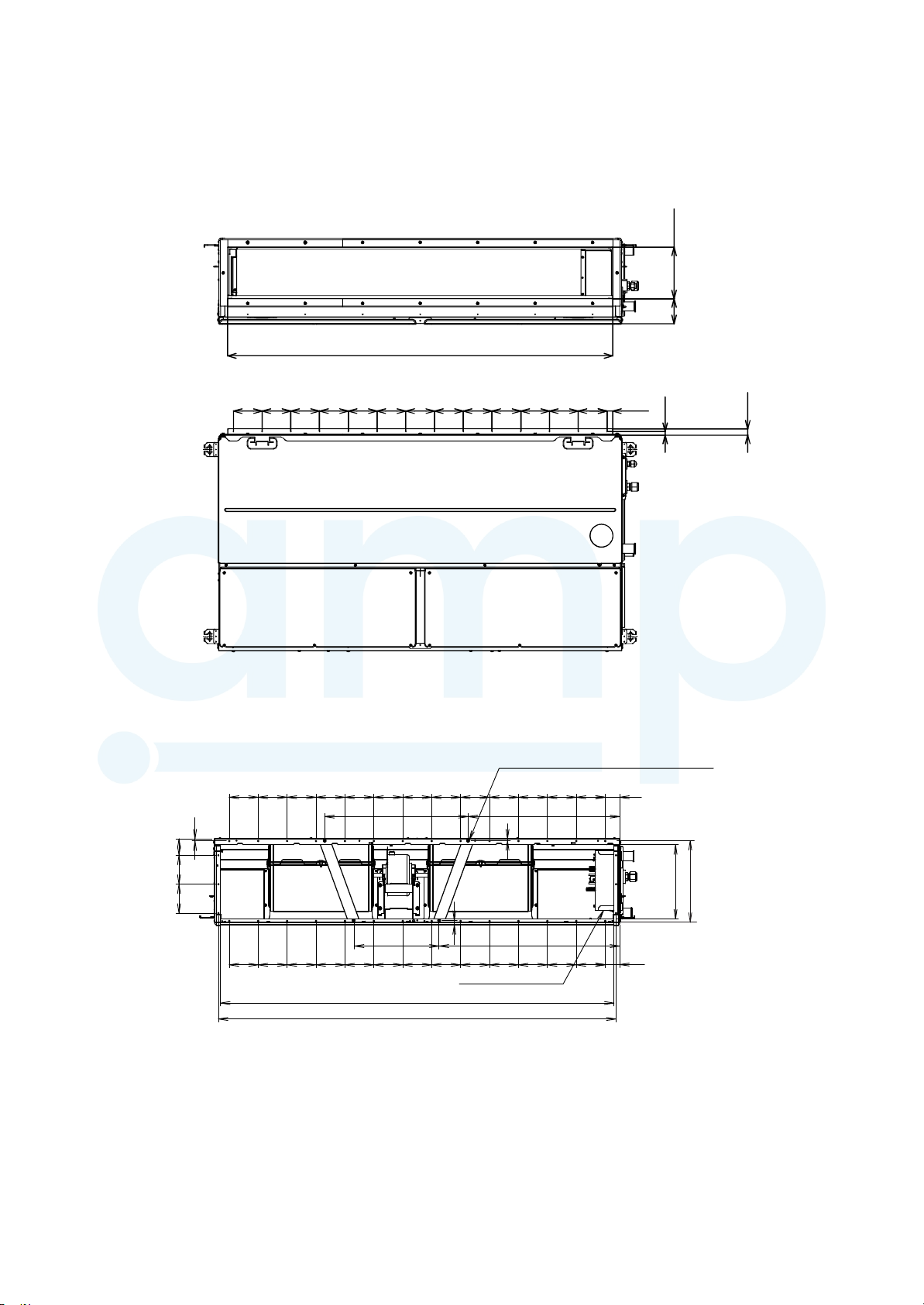

AP0366, AP0486, AP0566

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

<Air outlet>

1340

(Outside)

(Outside)

180

87

20100100100100100100100100100100100100100

13

(Unit : mm)

22

8

100 100 57

<Air inlet>

There are the head of the screw(n=4).

Make a hole at the installation of inlet duct.

100 100 100 100 100 100 100 100 100 100 100 100 100

496 524

7

15

100

Electrical control box

1360

1375

624 293

50

276

256

100 100 100 100 100 100 100 100 100 100 100 100

50

–

19 –

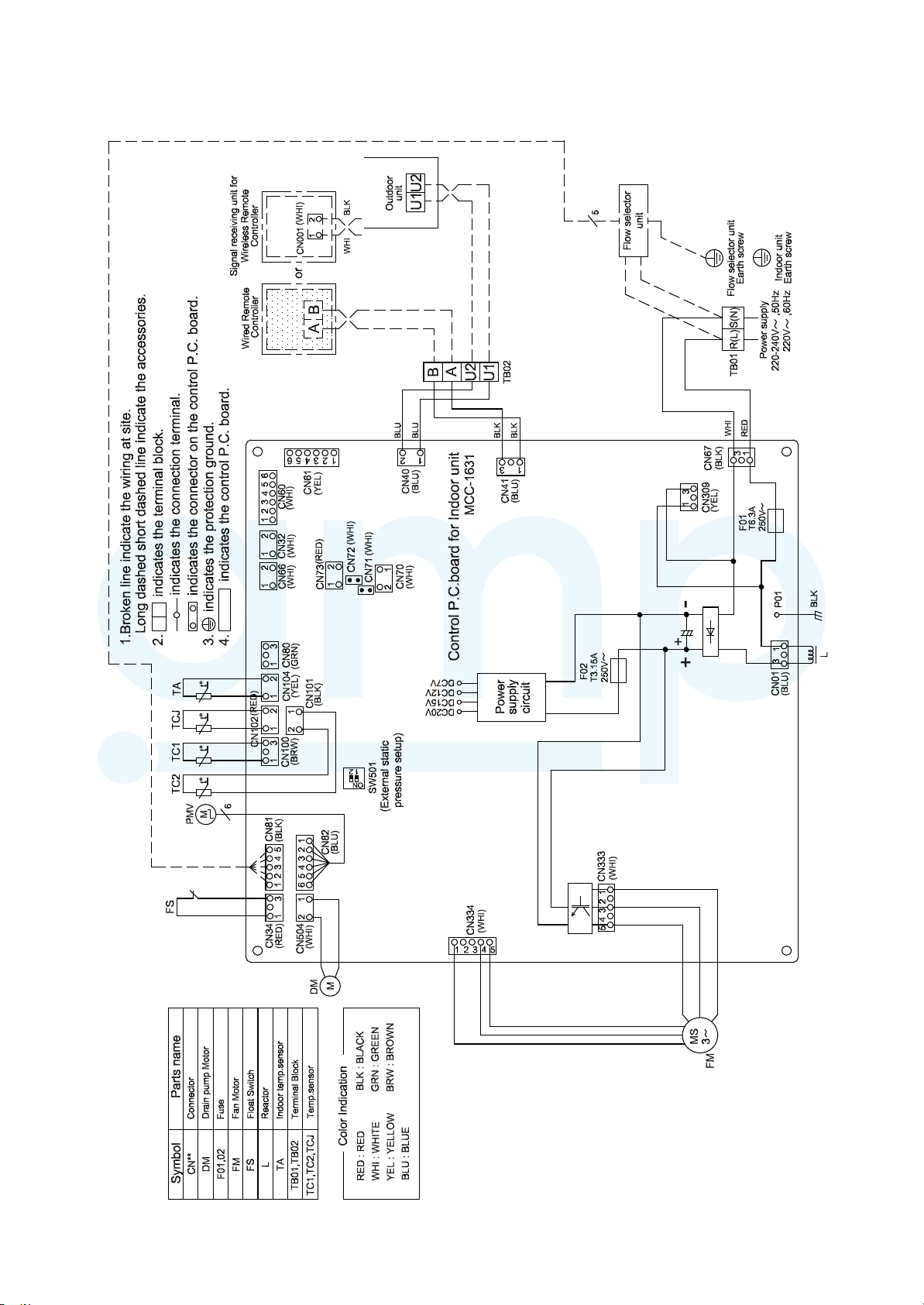

4.WIRING DIAGRAMS

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

–

20 –

5. PARTS RATING

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Model MMD-AP 0186HP* 0246HP* 0276HP* 0366HP* 0486HP* 0566HP*

Fan motor

Drain pump motor

Float switch

Pulse motor

Pulse motor valve

TA sensor

TC1 sensor

TC2 sensor

TCJ sensor

ICF-340W250-2 MF-340W350-1

MDP-1401, PMD-08D12TF-1

FS-1A-31-3

EFM-MD12TF-1

EFM-60YGTCTH-1EFM-40YGTF-1

Lead wire length:230mm

∅4 size lead wire length:1000mm Vinyl tube (Blue)

∅6 size lead wire length:1000mm Vinyl tube (Black)

∅6 size lead wire length:1000mm Vinyl tube (Red)

–

21 –

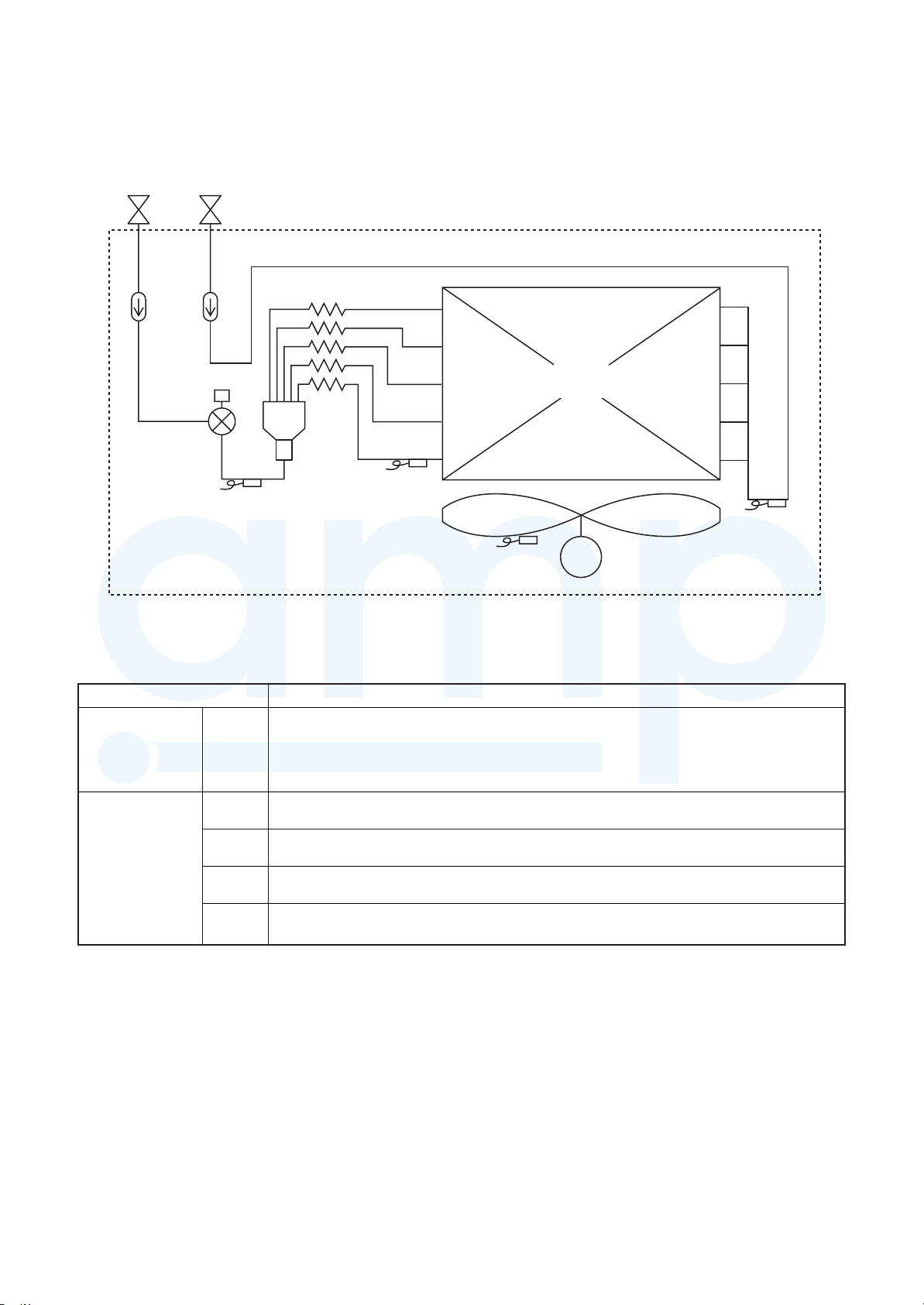

6. REFRIGERANT CYCLE DIAGRAM

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Indoor unit

Gas sideLiquid side

Strainer

Pulse Motor

Valve (PMV)

Sensor

(TC2)

Capillary tube

Strainer

Sensor

(TCJ)

Explanation of functional parts in indoor unit

Functional part name

Pulse Motor Valve

PMV

Temp. Sensor (Connector CN104 (2P): Yellow)

1.TA

2.TC1

3.TC2

4.TCJ

(Connector CN082 (6P): Blue)

1) Controls super heat in cooling operation

2) Controls under cool in heating operation

3) Recovers refrigerant oil in cooling operation

4) Recovers refrigerant oil in heating operation

1) Detects indoor suction temperature

(Connector CN100 (3P): Brown)

1) Controls PMV super heat in cooling operation

(Connector CN101 (2P): Black)

1) Controls PMV under cool in heating operation

(Connector CN102 (2P): Red)

1) Controls PMV super heat in cooling operation

Heat exchanger

at indoor side

Fan

Sensor

(TA)

Functional outline

M

Sensor

(TC1)

Fan motor

–

22 –

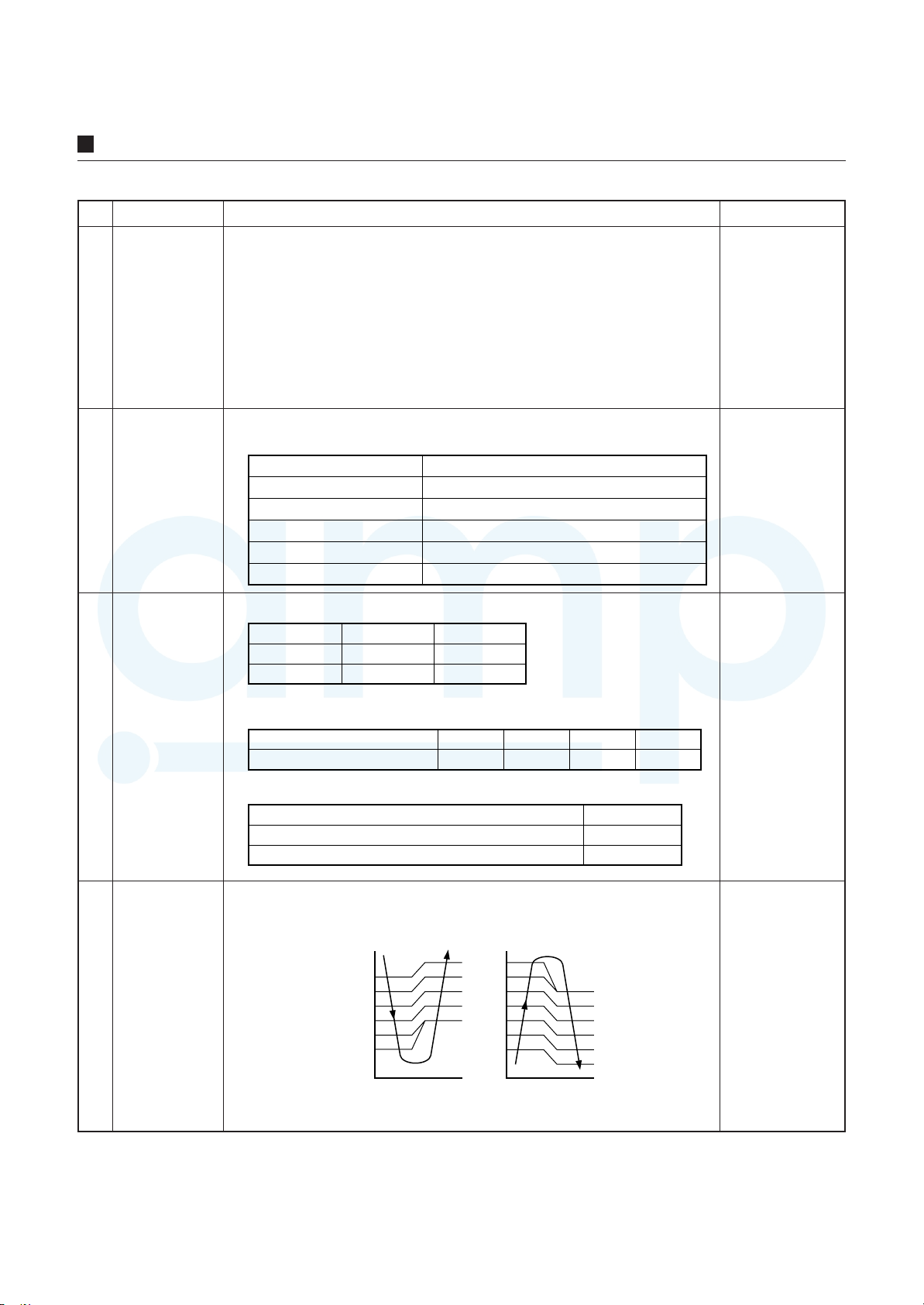

7. CONTROL OUTLINE

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Indoor unit

Control specifications

NO.

1

2

3

Item Specification outline Remarks

Upon power

supply reset

1. Identification of outdoor unit

When the power supply is reset, the outdoor unit is identified, and control

is redirected according to the identification result.

2. Indoor fan speed and air flow direction control availability settings

Settings such as indoor fan speed and air flow direction control availability

are replaced on the basis of EEPROM data.

3. If power supply reset is performed in the wake of a fault, the check code

is cleared.

If the abnormality persists after the Start / Stop button on the remote

controller is pressed to resume operation, the check code is redisplayed

on the remote controller.

Operation

selection

Room temp.

control

1. The operation mode changes in response to an operation selection

command issued via the remote controller.

Remote controller command Control outline

STOP Air conditioner shutdown

FAN Fan operation

COOL Cooling operation

DRY Drying operation

HEAT Heating operation

1. Adjustment range - remote controller temperature setting (°C)

COOL / DRY HEAT

Wired type 18~29 18~29

Wireless type 18~30 16~30

2. In heating operation, the temperature setting may be fine-tuned via the

Ts: Temperature

Ta: Room

Shift in heating

suction

temperature

(not applicable to

remote controller

thermo

operation)

DN code “06”.

SET DATA 0 2 4 6

Temperature setting adjustment +0 ˚C +2 ˚C +4 ˚C +6 ˚C

setting

temperature

Automatic

capacity control

4

Factory default

Model type SET DATA

Floor standing (standard, concealed, cabinet) 0

Other model 2

1. The outdoor unit determines the operational capacities of indoor units

according to the difference between Ta and Ts.

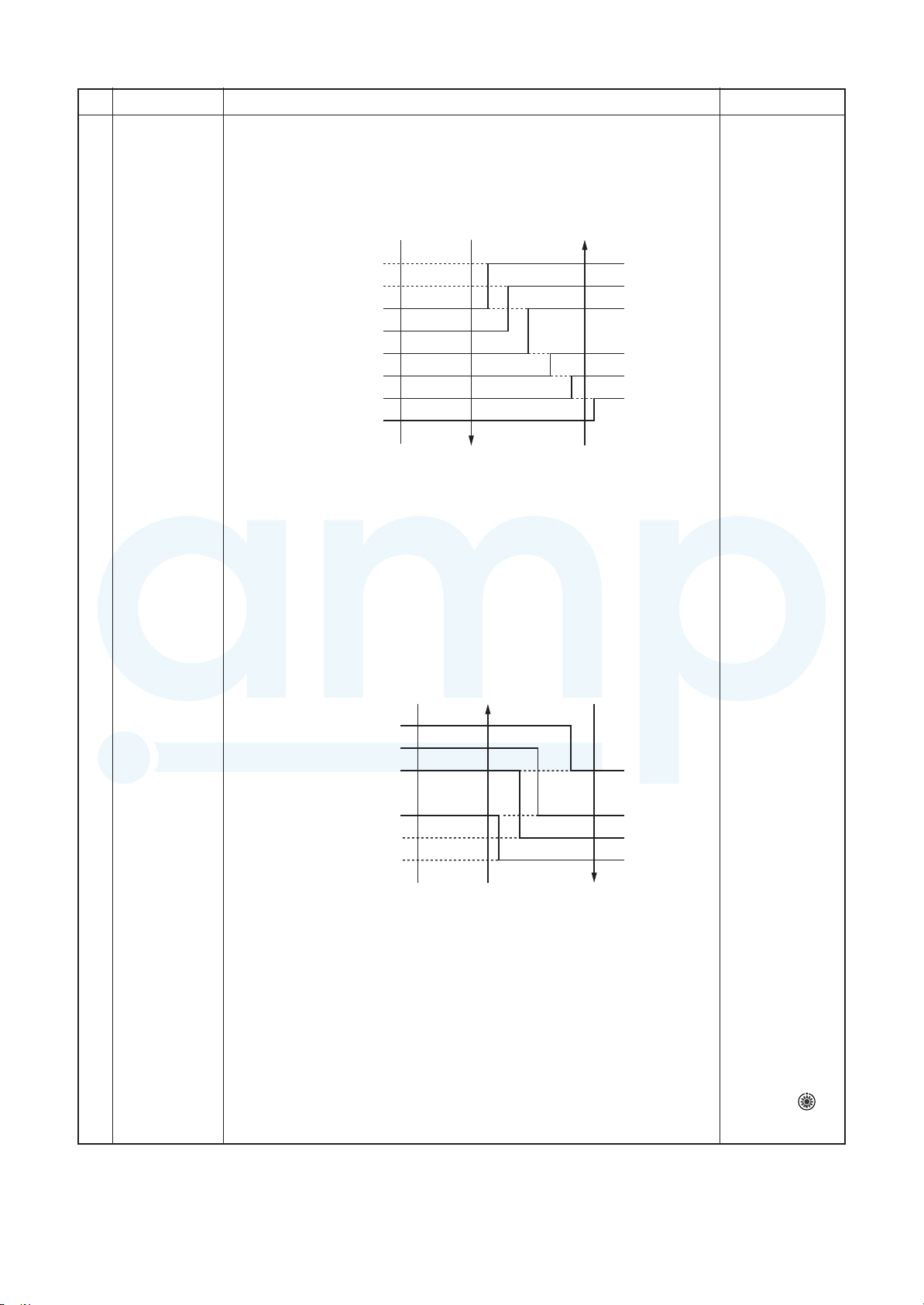

Cooling Heating

Ta

(˚C)

+2

+1

Ts

–1

SD

SB

S9

S7

S5

S3

S0

Ta

(˚C)

+1

Ts

–1

–2

S3

S5

S7

S9

SB

SD

SF

S0

Ts: Temperature

setting

Ta: Room

temperature

–

23 –

NO. Item Specification outline Remarks

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Fan speed

control

1. The fan operates in one of the four speed modes of “HIGH (HH)”, “MED

(H)”, “LOW (L)” and “AUTO” on the basis of a command issued via the

remote controller. (Concealed duct high static pressure type: HH only)

2. In AUTO fan speed mode, the air speed changes according to the

difference between Ta and Ts.

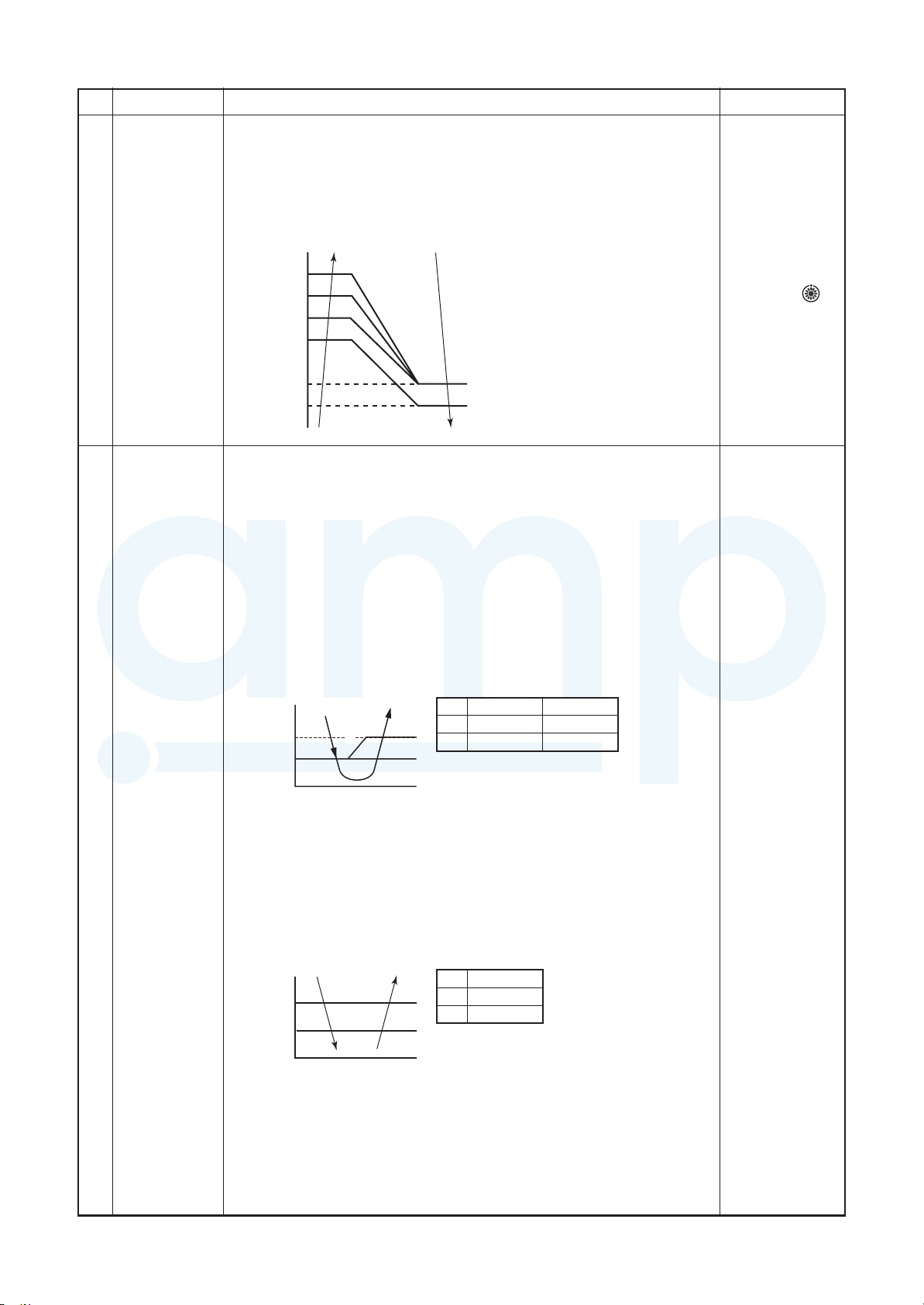

<Cooling>

Ta (˚C)

+3.0

+2.5

+2.0

+1.5

+1.0

+0.5

Tsc

–0.5

HH <HH>

H+ <HH>

H <HH>

L+ <H+>

L <H>

L <H>

L <L+>

A

B

C

D

E

F

G

HH > H+ > H >

L+ > L > UL

or LL

• Control is identical in remote controller thermo and body thermo

operation.

Speed modes shown in < > apply to cooling operation under AUTO air

conditioner operation mode.

• In AUTO fan speed mode, the fan speed remains the same for 3 minutes

each time a speed change occurs.

5

However, a speed change command issued via the remote controller can

override this, and the fan speed changes accordingly.

• At the beginning of cooling operation, a higher speed (steeper downward

temperature gradient) is chosen.

• As long as the temperature difference remains on a boundary line, the

fan speed stays the same.

<Heating>

Ta (˚C)

(–0.5) –1.0

(0) Tsh

(+0.5) +1.0

(+1.0) +2.0

(+1.5) +3.0

(+2.0) +4.0

Figures inside ( ) applies to remote controller thermo operation.

Figures outside ( ) applies to body thermo operation.

Speed modes shown in < > apply to heating operation under AUTO air

conditioner operation mode.

• In AUTO fan speed mode, the fan speed remains the same for 1 minute

each time a speed change occurs.

However, a speed change command issued via the remote controller can

override this, and the fan speed changes accordingly.

• At the beginning of heating operation, a higher speed (steeper upward

temperature gradient) is chosen.

• As long as the temperature difference remains on a boundary line, the

fan speed stays the same.

• When TC2 ≥ 60 °C, the fan speed is raised by one step.

3. If the air conditioner goes thermo OFF during heating operation, the fan

speed drops down to LL (breeze).

L <L+>

L+ <H>

H <H+>

H+

<HH>

HH

<HH>

E

D

C

B

A

DN code “32”

“0000”: Body

thermo

“0001”: Remote

controller thermo

TC2: Indoor heat

exchanger sensor

temperature

“HEATING

STANDBY

displayed

”

–

24 –

NO. Item Specification outline Remarks

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Cold air

discharge

prevention

control

1. In heating operation, the upper limit of the fan tap is set according to the

lower of whichever is the higher between TC2 sensor and TCJ sensor

temperatures, on the one hand, and TC1 sensor temperature, on the

other.

• If the fan continuously operates in zone B for 6 minutes, it automatically

moves into zone C.

• During defrosting, the control point is shifted by +6 °C.

TCJ: Indoor heat

exchanger

sensor

temperature

•In zones D and E,

priority is given

to the remote

controller fan

6

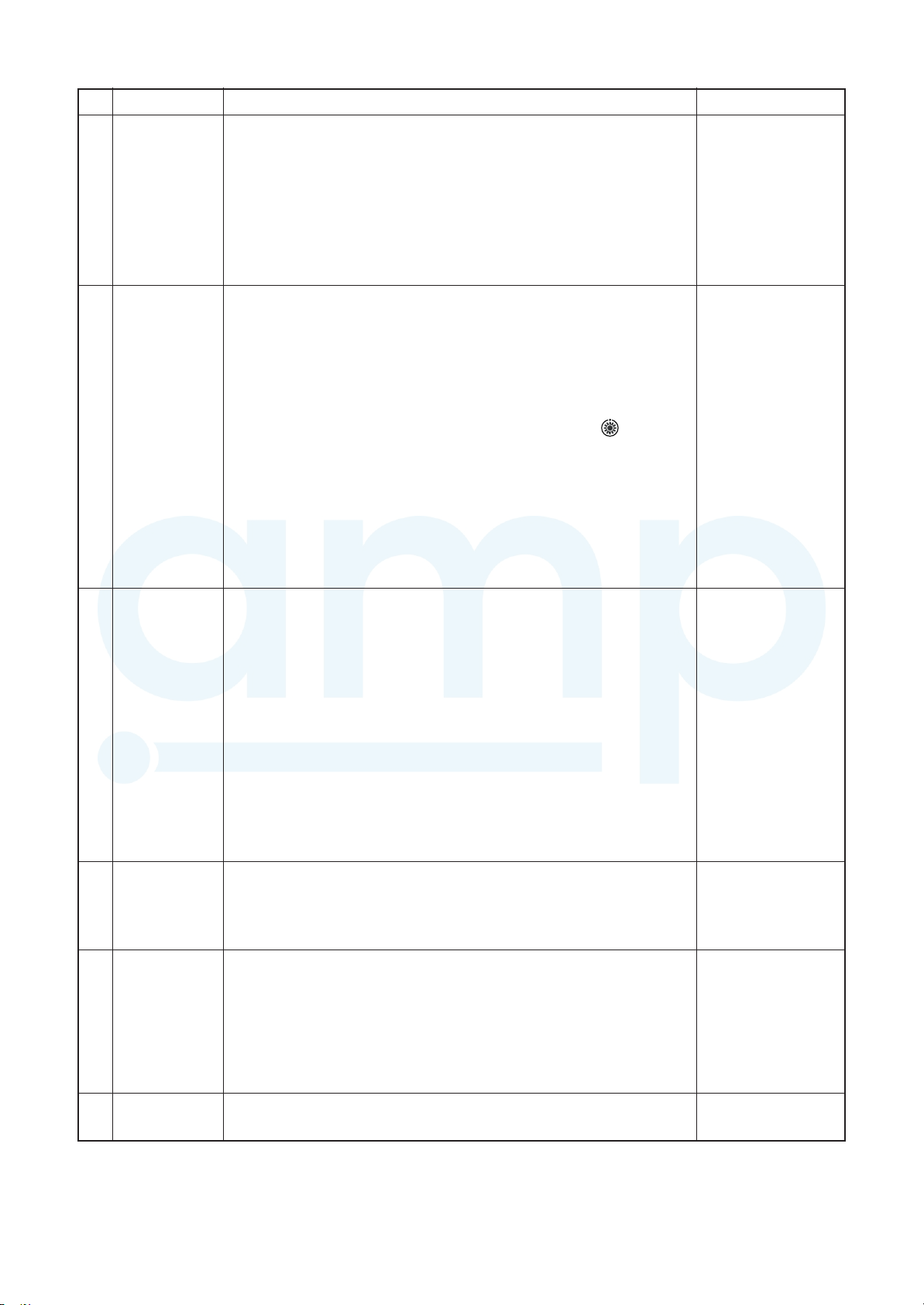

32

30

28

D

C

E

26

20

16

˚C

A zone: OFF

B zone: 26˚C or above and

C zone: 28˚C or above and

D zone: 30˚C or above and

B

E z

A

below 28˚C

breeze

below 30˚C

Lo

below 32˚C

Medium

one: High

w

speed setting.

•In zone A,

“HEATING

STANDBY

is displayed.

”

Freeze

prevention

control (low

temp. release)

7

1. During cooling, the air conditioner is operated in the manner described

below according to the temperature readings of the TC1, TC2 and TCJ

sensors.

• If zone J operation is detected for 5 minutes, the air conditioner is forced

into thermo OFF.

• In zone K, the timer is put on pause, with the current timer count

retained.

• If zone I operation is detected, the timer count is cleared, and the air

conditioner returns to normal operation.

• If continuous zone J operation forces the air conditioner into thermo OFF,

the indoor fan is operated in breeze mode until it moves into zone I.

The control is terminated under the following conditions:

Termination conditions

1) TC1 ≥ 12 °C, TC2 ≥ 12 °C, and TCJ ≥ 12 °C

(˚C)

P1

Q1

P1

I

K

J

a

Q1

TC1

10˚C (5˚C)

0˚C

TC2, TCJ

–10˚C

–14˚C

2) Passage of 20 minutes after stoppage

2. During cooling, the air conditioner is operated in the manner described

below according to the temperature readings of the TC2 and TCJ sensors.

• If zone M operation is detected for 45 minutes, the air conditioner is

forced into thermo OFF.

• In zone N, the timer is put on pause, with the current timer count

retained.

• When the air conditioner goes back into zone M, timer count is resumed

from the retained value.

TC1:

Indoor heat

exchanger

sensor

temperature

(˚C)

P2

Q2

• If zone L operation is detected, the timer count is cleared, and the air

conditioner returns to normal operation.

Reset conditions

1) TC1 ≥ 12 °C, TC2 ≥ 12 °C and TCJ ≥ 12 °C

2) Passage of 20 minutes after stoppage

L

N

M

P2

Q2

TC2, TCJ

5

–2.0

* With models

without TC2,

TC2 is not

part of the

control

parameters.

–

25 –

NO. Item Specification outline Remarks

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Cooling oil

(refrigerant)

recovery control

8

Heating

refrigerant (oil)

recovery

control

9

While the outdoor unit is recovering cooling oil (refrigerant), the indoor

units perform the following control tasks:

[common for operational (cooling thermo ON / thermo OFF / FAN), as

well as nonoperational indoor units]

1)Open the indoor PMV to a certain degree.

2)Engage in recovery control for a specified period of time and return

to normal cooling operation at the end of this period upon

terminating the control.

3)Operate the drain pump throughout the recovery control period and

for about 1 minute after it.

While the outdoor unit is recovering heating refrigerant (oil), the indoor

units perform the following control tasks:

1)Open the indoor PMV to a certain degree.

2)Control the indoor fan according to the operation mode.

[Indoor units operating in heating thermo ON / OFF state]

Let the indoor fan continue operating, but turn it off if the temperature

of the indoor heat exchanger drops.

[Indoor units operating in FAN mode]

Turn off the indoor fan and display “HEATING STANDBY

remote controller.

[Non-operational indoor units]

Keep the indoor fan turned off.

3)Terminate the recovery operation depending on the TC2

temperature reading.

The timing of termination is determined by each indoor unit.

4)Operate the indoor fan and drain pump for about 1 minute after the

termination of the recovery operation. (Applicable to compact 4-way

cassette type and 1- way cassette type)

” on the

• Recovery operation

normally takes

place roughly every

2 hours.

• The opening

position of the

indoor PMV

depending on the

type and capacity

of the indoor unit.

• Recovery

operation

normally takes

place roughly

every hour .

• The opening

position of the

indoor PMV

depending on the

type and capacity

of the indoor unit.

Defrosting

control

10

Short

intermittent

operation

11

compensation

control

Drain pump

control

12

While the outdoor unit is engaged in defrosting control, the indoor units

perform the following control tasks:

1)Open the indoor PMV to a certain degree.

2)Control the indoor fan according to the operation mode.

[Indoor units operating in heating thermo ON / OFF state]

Let the indoor fan continue operating for a while, but turn it off as the

temperature of the indoor heat exchanger drops.

[Indoor units operating in FAN mode]

Let the indoor fan continue operating.

[Non-operational indoor units]

Keep the indoor fan turned off.

3)As defrosting control comes to an end, it gives way to heating

refrigerant (oil) recovery control.

(For control details, see “9. Heating refrigerant (oil) recovery control” abov e.)

1. For 5 minutes after startup, the system is forced to continue operating

even if it reaches the thermo OFF region.

2. However, priority is given to cooling / heating selection, operation

standby, and protective control, so that there is no overriding of

thermo OFF in these cases.

1. During cooling (including DRY operation), the drain pump is operated

at all times.

2. If the float switch is activ ated while the dr ain pump is in operation, the

drain pump continues operating, with the rele vant check code displayed.

3. If the float switch is activ ated while the drain pump is turned off, thermo

OFF is forced on the air conditioner, with the drain pump put into

operation. If the float switch continues to be activated for about 5 minutes,

the drain pump is turned off, with the relevant check code displayed.

• For defrosting

commencement

conditions, see 5

Control Outline “10.

Defrosting control

(reverse defrosting

method)” in SMMS-i

Outdoor Unit

Service Manual

A10-005 above.

• The opening

position of the

indoor PMV

depending on the

type and capacity

of the indoor unit.

Check code [P10]

Elimination of

13

residual heat

1. When the air conditioner is turned off after engaging in heating operation,

the indoor fan is operated for about 30 seconds in “breeze” mode.

–

26 –

NO. Item Specification outline Remarks

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Filter sign

display

(not applicable

to wireless type)

*Provided in

14

the separately

mounted type,

TCB-AX32E2

Operation

standby

Heating standby

15

1. The indoor fan’s cumulative hours of operation are counted, and when

these exceed the prescribed value (2500H), a filter replacement signal

is sent to the remote controller to display a filter sign on it.

2. When a filter reset signal is received from the remote controller, the

timer measuring cumulative hours is cleared. If the prescribed hours

have been exceeded, the hours count is reset, with the sign on the

remote controller display erased.

2500HFilter service life

<Operation standby> .......... Displayed on remote controller

1. When any of the DN codes listed below is displayed

• “P05” - Detection of an open phase in the power supply wiring

• “P10” - Detection of indoor flooding in at least one indoor unit

• “L30” - Detection of an interlock alarm in at least one indoor unit

2. Forced thermo OFF

• “COOL / DRY” operation is unavailable because at least one indoor

unit is operating in “HEAT” mode.

• “HEAT” operation is unavailable because at least one indoor unit is

operating in

“COOL / DRY” mode under pr iority cooling setting (bit 1 of SW11 on

outdoor I/ F P.C. board ON).

3. All indoor units not able to engage in any of the above operations

stand by in thermo OFF state.

4. The indoor fan has been turned off because the system is engaged in

a heat refrigerant (oil) recovery operation.

<Heating standby> .......... Displayed on remote controller

1. Normal thermo OFF

• During heating, the indoor unit goes ther mo OFF as the heating

temperature setting is reached.

2. During heating, the fan rotates at a breeze speed (UL or lower) or

remains stationary to prevent cold air from being discharged

(including defrosting operation).

3.Forced thermo OFF

• “HEAT” operation is unavailable because at least one indoor unit is

operating in

“COOL / DRY” mode under pr iority cooling setting (bit 1 of SW11 on

outdoor I/ F P.C. board ON).

“FILTER

” display ed

• “OPERATION

STANDBY

displayed

No display

provided on

wireless remote

controller

• “HEATING

STANDBY

displayed

”

”

Selection of

central control

mode

16

1. The range of operations that can be performed via an indoor unit

remote controller can be determined through the setting of the central

controller.

2. Setting details

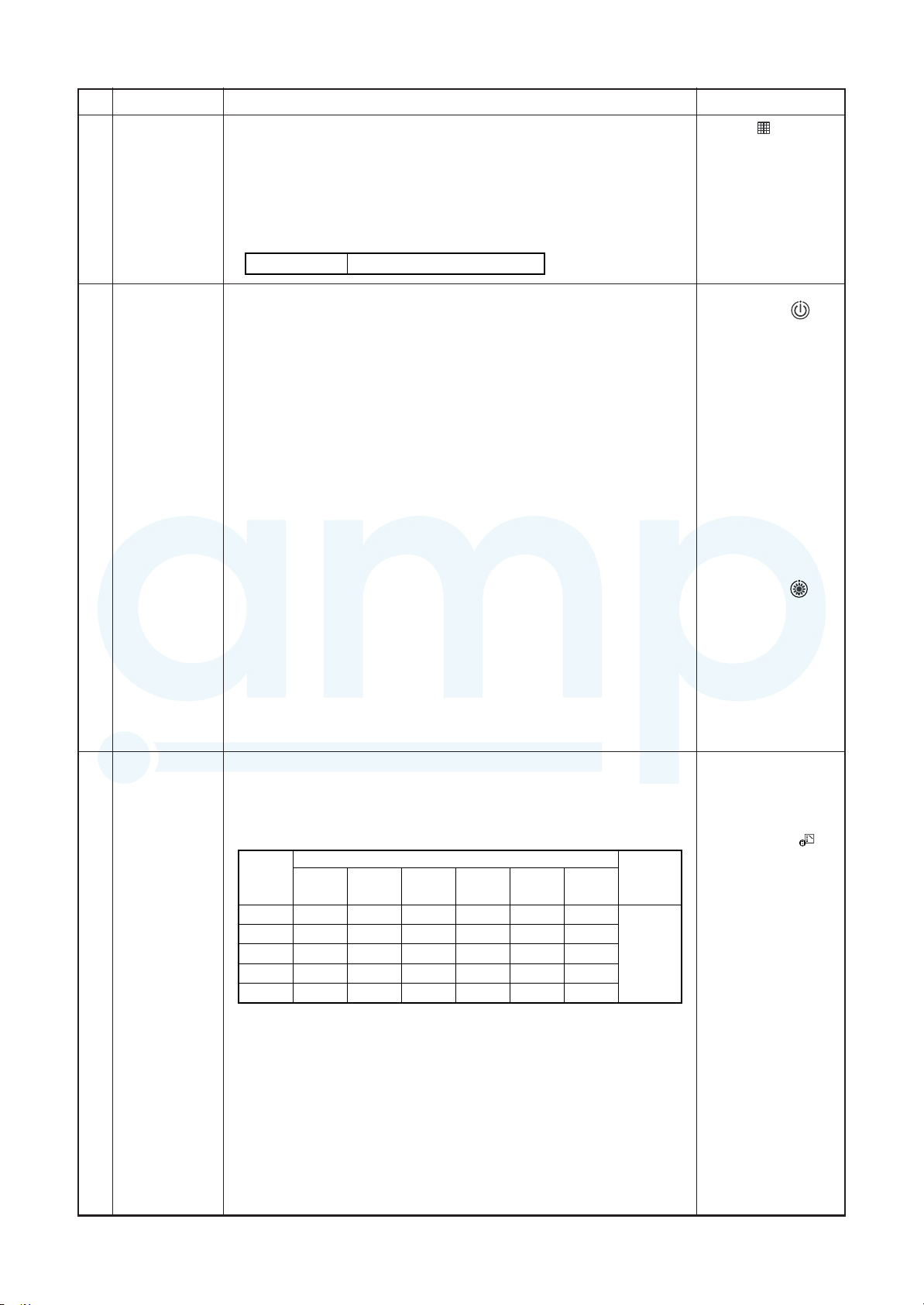

TCC-Link central control

Operation

via TCCLink

Individual

Central 1

Central 2

Central 3

Central 4

(

{

Start / stop

central

control

selection

{

×

×

{

: Accessible × : Inaccessible)

{

Operation on RBC-AMT32E

Operation

mode

selection

{

{

Timer

setting

{

×

×

×

×

×

{

{

Temperature

setting

{

{

×

×

{

Fan speed

setting

{

{

{

{

{

Air flow

direction

setting

{

{

{

{

{

RBC-

AMT32E

display

“CENTRAL

CONTROL

PROGRESS”

• In the case of a

wired remote

controller,

“CENTRAL

CONTROL IN

PROGRESS

”

is displayed (lit up)

while in central

control mode.

• The display blinks

when a control

function

IN

inaccessible to a

remote controller is

chosen.

• A wireless remote

controller has the

same set of control

functions, although

there is no display.

When a control

operation is

performed via a

wireless remote

controller while in

central control

mode, a peep

sound alert (5

times) is provided.

–

27 –

NO. Item Specification outline Remarks

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

DC motor 1) When the fan operation has started, positioning of the stator and the

17

Power saving

mode

18

Frequency

fixed

operation

(Test run)

rotor are performed.

(Moves slightly with tap sound)

2) The motor operates according to the command from the indoor

controller.

Notes)

• When the fan rotates while the air conditioner stops due to entering of

outside air, etc, the air conditioner may operate while the fan motor

stops.

• When a fan lock is found, the air conditioner stops, and an error is

displayed.

• If static pressure of the used duct does not match with the setup value of

static pressure, which was decided in the static pressure setting code No.

[5D], the air conditioner may stop or an error code may be displayed.

SAVE

1. Push the

2. The “

3. The requirement capacity ratio is limited to approximately 75 %.

4. If the power saving operation is enabled, the settings are retained

when the operation is stopped, when the mode is changed, or when

the power is reset. The power saving operation will be enabled the

next time the operation starts.

<In case of wired remote controller>

1) When pushing [CHK] button for 4 seconds or more, [TEST] is displayed

on the display screen and the mode enters in Test run mode.

2) Push [ON/OFF] button.

3) Using [MODE] button, set the mode to [COOL] or [HEAT].

• Do not use other mode than [COOL]/[HEAT] mode.

• During test run operation, the temperature cannot be adjusted.

• An error is detected as usual.

• A frequency fixed operation is performed.

4) After the test run, push [ON/OFF] button to stop the operation.

(Display in the display part is same as the procedure in Item 1.)

5) Push [CHK] button to clear the test run mode.

([TEST] display in the display part disappears and the status returns

to the normal stop status.)

button on the remote controller

“ segment lights up on the wired remote controller display.

Check code “P12”

The power saving

operation cannot be

set by the wireless

remote controller or

wired remote

controller of

AMT31E or older.

Command frequency

is approximately [S7]

19

<In case of wireless remote controller>

1) When TEMPORARY button is pushed for 10 seconds or more, “Pi!”

sound is heard and the operation changes to test run. After approx. 3

minutes, a cooling operation starts forcedly.

Check cool air starts blowing. If the operation does not start, check

wiring again.

2) To stop a test operation, push TEMPORARY button once again

(Approx. 1 second).

Check wiring / piping of the indoor and outdoor units in test run.

TEMPORARY button

–

28 –

8. APPLIED CONTROL AND FUNCTIONS

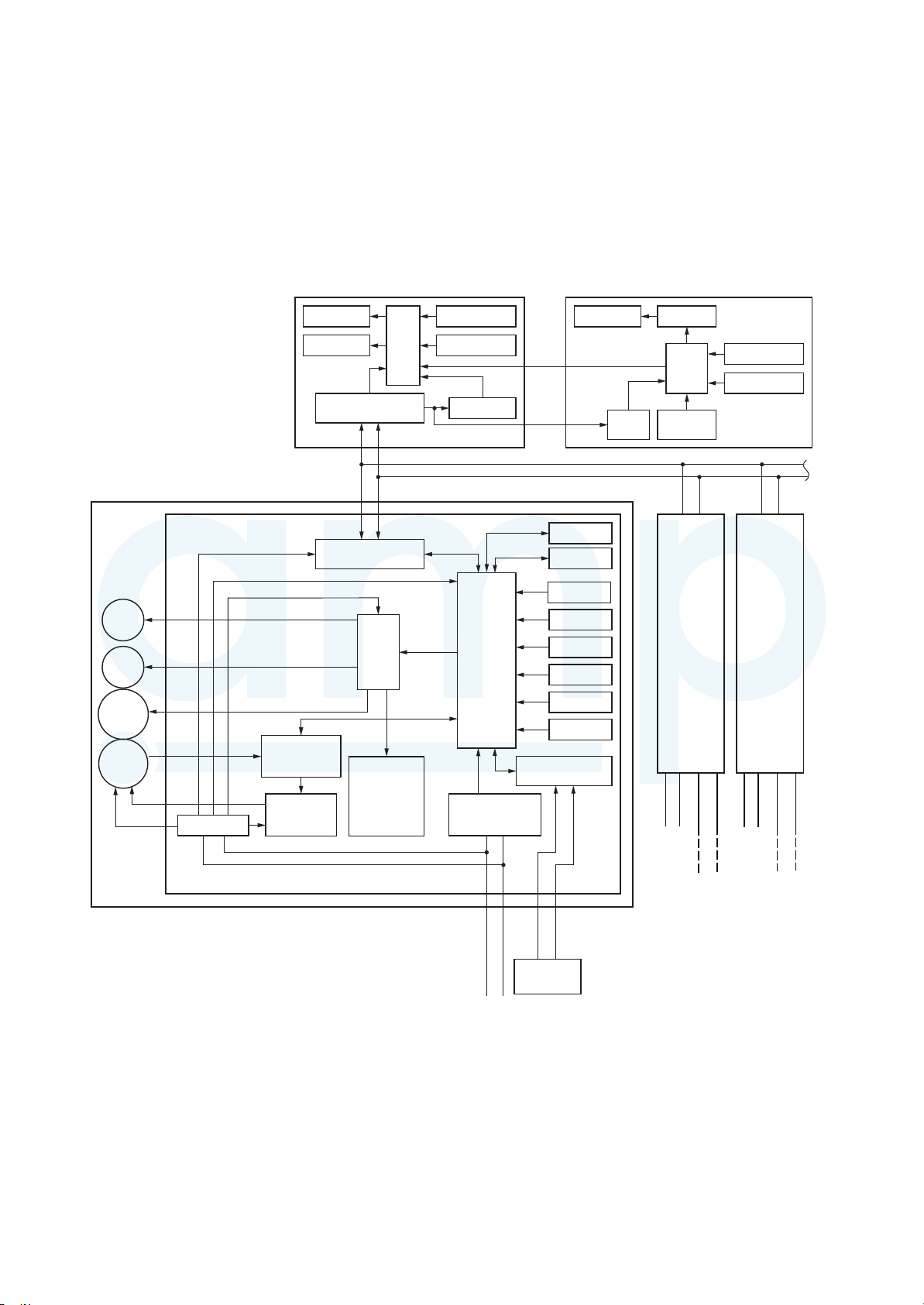

Wired (Simple) heder remote controller (Max. 2 units) Schedule remote controller

Outdoor unit

NU1U2

U1 U2

L

Up to 8 units are connectable.

∗1 It is unavailable to connect the Schedule remote

controller to the simple wired remote controller.

Same as left

#3

(Follower)

A B

AB

Same as left

CPU

H8/36109

DC12V

DC5V

DC20V

External

output

Remote controller

communication circuit

Display LCD Function setup

Key switch

CN2

CN1

∗1

CPU

Display LED

Display LCD LCD driver

CPU

Remote controller

communication circuit

Function setup

Key switch

Power circuit

Power circuit

Fan motor

control circuit

CPU

TMP88CH47FG

(TMP88PH47FG)

EEPROM1

EEPROM2

TA sensor

TC1 sensor

TC2 sensor

TCJ sensor

Float input

HA

Run

Alarm

Defrost

Thermo. ON

COOL

HEAT

FAN

BUS

comunication circuit

AC

synchronous

signal input circuit

Power supply

1

∅

, 220-240V, 50Hz

1

∅

, 220V, 60Hz

Power

circuit

Secondary

battery

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

(INCLUDING CIRCUIT CONFIGURATION)

8-1. Indoor controller block diagram

8-1-1. In Case of Connection of Wired (Simple) Remote Controller

Indoor unit

#1 (Heder)

Drain

pump

PMV

Flow

Selector

Unit

Indoor

fan motor

DC280V

DC5V

Indoor control P.C. board (MCC-1631)

Driver

DC5V

#2

(Follower)

A B

N

L

Power

Supply

L

Power

Supply

N

–

29 –

Outdoor

unit

Outdoor

unit

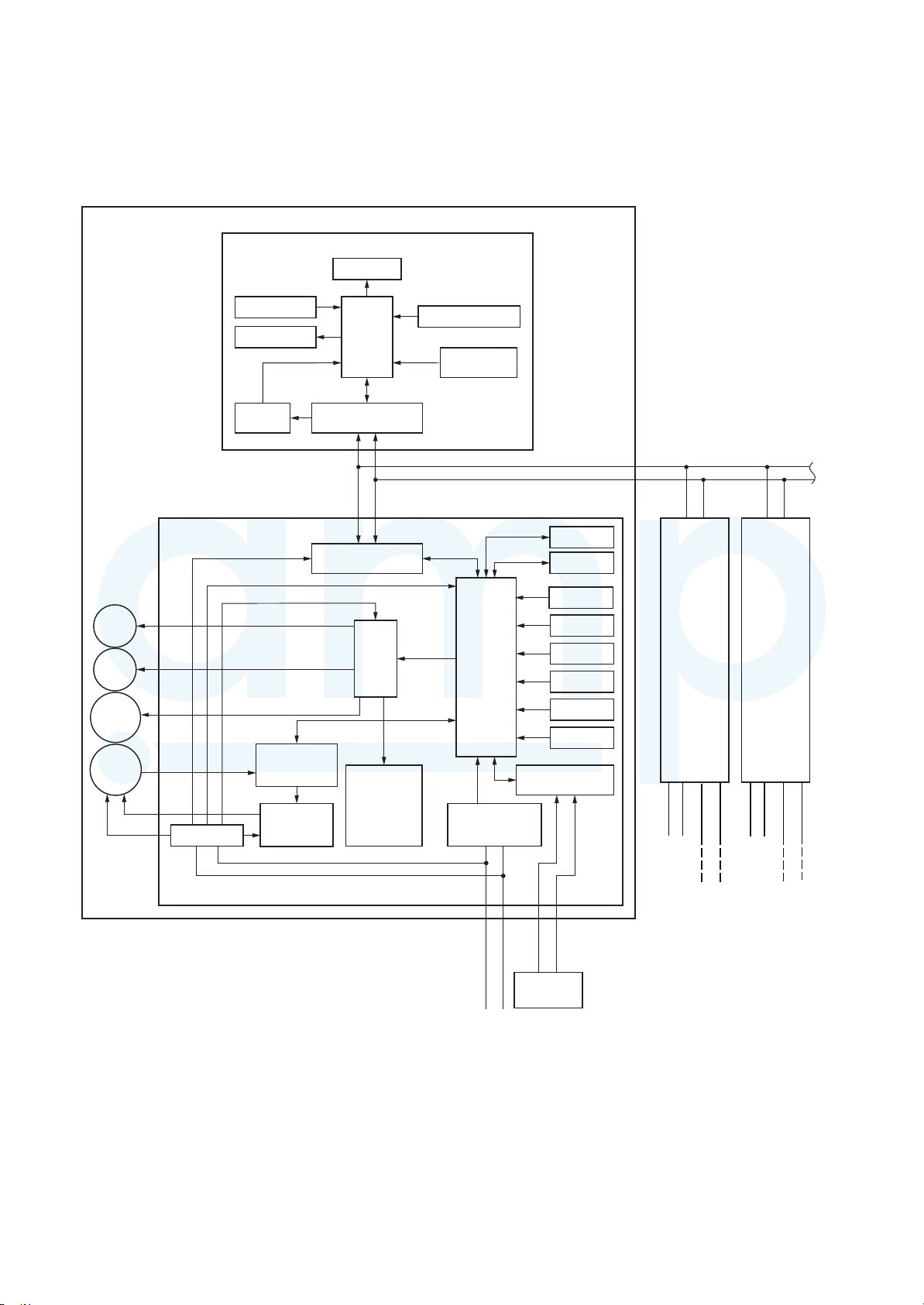

8-1-2. In Case of Connection of Wireless Remote Controller

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Indoor unit

#1 (Heder)

Wireless remote controller

Receiver P.C. board

Display LED

Drain

pump

PMV

Flow

Selector

Unit

Indoor

fan motor

DC280V

Receive circuit

Buzzer

DC5V

Power

circuit

Indoor control P.C. board (MCC-1631)

DC20V

DC5V

DC12V

TMP88CH47FG

(TVP88PH47FG)

Fan motor

Power circuit

control circuit

Remote controller

communication circuit

Remote controller

communication circuit

CPU

CPU

AB

Driver

External

output

Run

Alarm

Defrost

Thermo. ON

COOL

HEAT

FAN

Function setup SW

Temporary

operation SW

CPU

H8/36109

AC

synchronous

signal input circuit

EEPROM2

EEPROM1

TA sensor

TC1 sensor

TC2 sensor

TCJ sensor

Float input

HA

BUS

comunication circuit

#2

(Follower)

A B

Same as left

N

L

Power

Supply

#3

(Follower)

A B

Same as left

N

L

Power

Supply

L

Power supply

∅

, 220-240V, 50Hz

1

1

∅

, 220V, 60Hz

–

30 –

NU1U2

U1 U2

Outdoor unit

Outdoor

unit

Up to 8 units are connectable.

Outdoor

unit

Loading...

Loading...