Page 1

GENERAL PRECA UTIONS FOR INSTALLATION/SERVICING/

MAINTENANCE

1. When installing the Large Capacity Feeder KD-1010 to the Copier, be sure to follow the instructions

described in the “Unpacking/Set-Up Procedure for the KD-1010” booklet which comes with each unit of

the KD-1010.

2. The KD-1010 should be installed by an authorized/qualified person.

3. When transporting/installing the KD-1010, employ two persons and be sure to use the positions as

indicated below . The KD-1010 is f airly heavy and weights appro ximately 23 kg (51 lb), therefore pa y full

attention when handling it.

4. Before starting installation, servicing or maintenance work, be sure to turn off and unplug the copier

first.

5. The KD-1010 is supplied with power from the copier , requiring no additional power source.

6. The KD-1010 should be grounded to the specified positions on the machine frame.

7. When servicing or maintaining the KD-1010, be careful about the rotating or operating sections such as

gears, pulleys, sprockets, cams, belts, etc.

8. When parts are disassembled, reassembly is basically the rev erse of disassembly unless otherwise

noted in this manual or other related documents. Be careful not to reassemble small parts such as

screws, washers, pins, E-rings, toothed washers to the wrong places.

9. Basically, the machine should not be operated with any parts removed or disassemb led.

10. Delicate parts for preventing safety hazard problems (such as thermofuses, door switches sensors,

etc. if any) should be handled/installed/adjusted correctly.

11. During servicing or maintenance work, be sure to check the nameplate and other cautionary labels (if

any) to see if they are clean and firmly stuck. If not, take appropriate actions.

12. Use suitable measuring instruments and tools.

13. The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband,

because the ICs on it may be damaged due to static electricity.

Caution: Before using the wrist band, pull out the power cord plug of the copier and make sure that

there is no uninsulated objects in the vicinity.

14. For the recov ery and disposal of used KD-1010, consumable parts and packing materials, it is recommended that the relevant local regulations/rules should be followed.

© Copyright 2000

TOSHIBA TEC CORPORA TION

Page 2

CONTENTS

1. SPECIFICATIONS ......................................................................................... 1-1

2. OVERVIEW .................................................................................................... 2-1

2.1 Front Sectional Vie w ....................................................................................................... 2-1

2.2 Layout of Electrical Parts................................................................................................ 2-2

2.3 Electrical Parts ............................................................................................................... 2-4

2.4 Harness Diagram ............................................................................................................ 2- 6

2.5 Circuit Diagram ............................................................................................................... 2- 7

2.6 Installation of PC Board .................................................................................................. 2- 8

2.7 Timing Chart ................................................................................................................... 2- 9

3. GENERAL OPERATION ................................................................................ 3-1

3.1 Description of Operation ................................................................................................. 3-1

3.2 Error Detection................................................................................................................ 3- 3

3.3 Flow Chart ...................................................................................................................... 3- 4

4. DRIVE SYSTEM AND FEEDING OPERATION............................................. 4-1

4.1 Configuration and Drive System...................................................................................... 4-1

5. DISASSEMBLY AND REPLACEMENT ......................................................... 5-1

5.1 Top Co ver ....................................................................................................................... 5-1

5.2 Installation and Removal of LCF Cassette and Covers ................................................... 5-1

5.3 Paper Guides.................................................................................................................. 5- 3

5.4 Standby Side Paper Mis-stacking Sensor ....................................................................... 5-5

5.5 End Fence Home P osition Sensor/Standby Side Empty Sensor ..................................... 5-5

5.6 End Fence Stop P osition Sensor .................................................................................... 5-6

5.7 LCF Transport Motor Unit ................................................................................................ 5- 6

5.8 PC Board........................................................................................................................ 5-7

5.9 T ra y-up Motor/End Fence Motor...................................................................................... 5- 7

5.10 Feed Clutch/Transport Clutch.......................................................................................... 5- 7

5.11 Side Cover Open/Close Switch ....................................................................................... 5-8

5.12 Feeding Unit ................................................................................................................... 5- 8

5.13 Feeding Side Paper Stock Sensor/Tray Bottom Sensor................................................. 5-10

5.14 Cassette Detection Switch............................................................................................ 5-10

5.15 Disassembly for Supplies ............................................................................................. 5-10

6. PERIODIC MAINTENANCE .......................................................................... 6-1

October 2000 © TOSHIBA TEC I KD-1010 CONTENTS

Page 3

Page 4

1. SPECIFICATIONS

Feeding method T andem tra y

Paper Size: A4,L T

Thickness: 64 - 80g/m

Transportation speed Approx. 260mm/sec. (Model with a DP2500)

Approx. 400mm/sec. (Models with a DP4500/3500)

Capacity of cassette Stack height: 137.5mm

Dimensions 530 (W) X 536 (D) X 305 (H) mm

(627 (W) X 618 (D) X 305 (H) mm : Including the stabilizer)

Weight Approx. 23 kg

Po wer supply 5V , 24V (supplied from the copier)

2

October 2000 © TOSHIBA TEC 1 - 1 KD-1010 SPECIFICATION

Page 5

Page 6

2. OVERVIEW

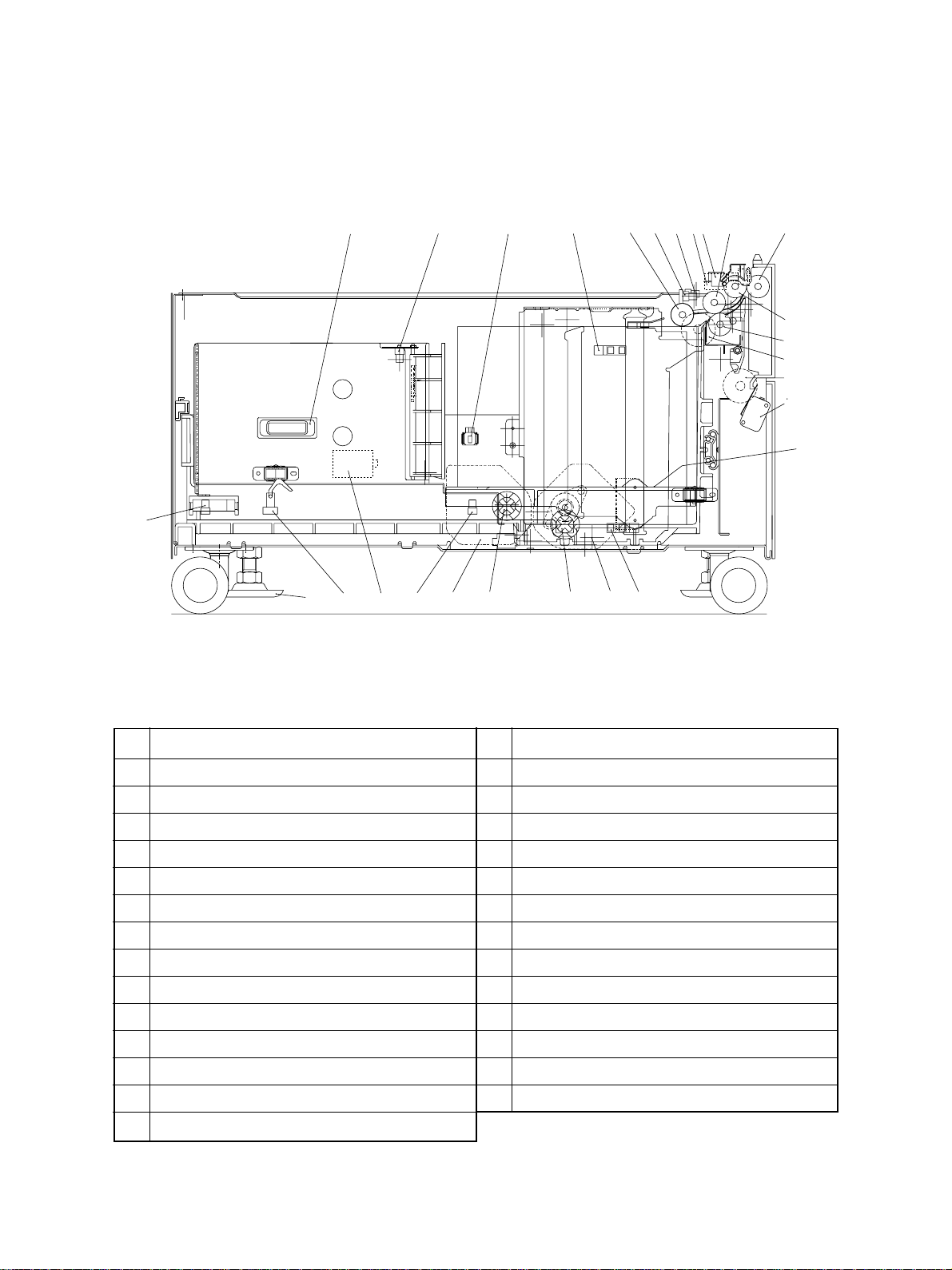

2.1 Front Sectional View

20

24 21 15 14 8 2 1 3 6 4

27

1312111817192225

26

5

7

9

10

23

16

NO. NAME NO . NAME

1 T r ay-up sensor (S3)

2 Feeding side paper empty sensor (S7)

3 Feed sensor (S2)

4 Side cover roller

5 T ransport roller

6 Feed roller

7 Separation roller

8 Pickup roller

9 Feed clutch (C2)

10 T ransport clutch (C1)

11 T ray-up coupling

12 T ray-up motor (M2)

1 3 Tray bottom sensor (S4)

1 5 Cassette detection switch (S10)

1 6 Elevator tray

1 7 End fence motor (M3)

18 End fence coupling

1 9 End fence stop position sensor (S5)

2 0 End fence home position sensor (S6)

2 1 Standby side paper mis-stacking sensor (S11)

2 2 Standby side empty sensor (S8)

2 3 Side cover open/close switch (S1)

24 Drawer connector

25 Adjuster

26 Pickup solenoid (SOL1)

27 End fence solenoid (SOL2)

1 4 Feeding side paper stock sensor (S9)

October 2000 © TOSHIBA TEC 2 - 1 KD-1010 OVERVIEW

Page 7

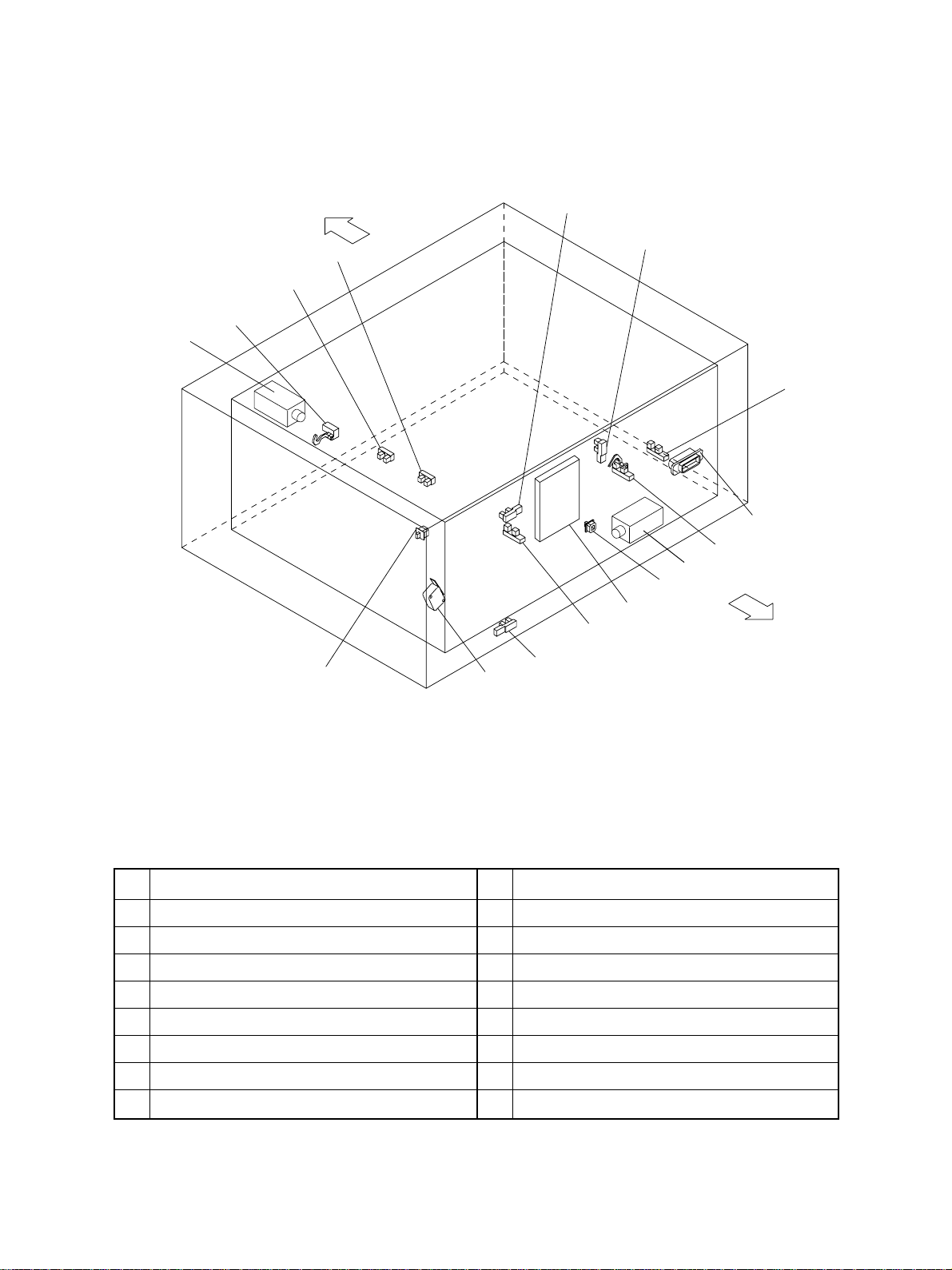

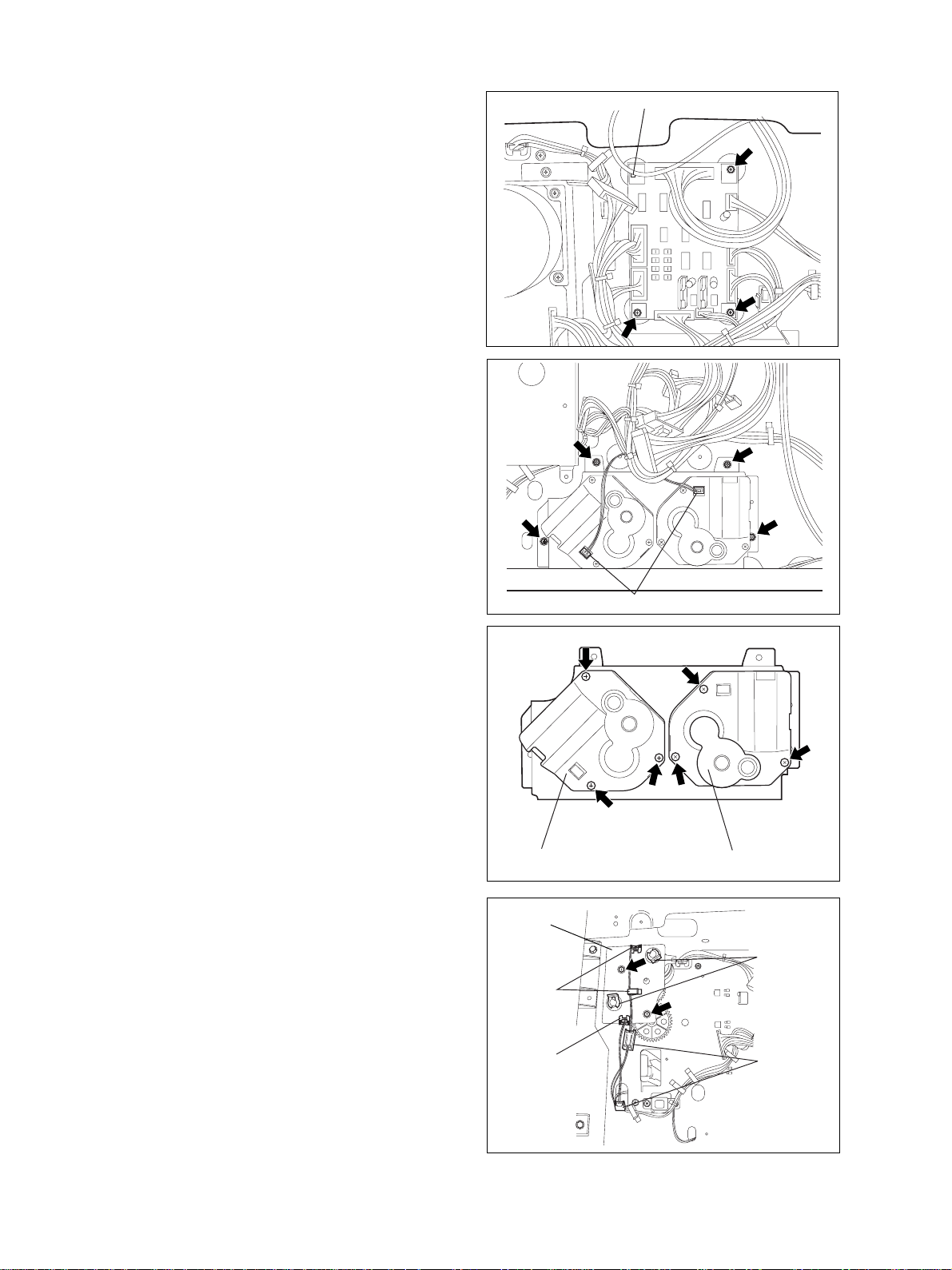

2.2 Layout of Electrical Parts

14

Front Side

1

2

3

4

12

11

13

10

15

8

16

9

Rear Side

7

6

5

NO . NAME NO . NAME

1 Tray-up sensor (S3)

2 Feeding side paper empty sensor (S7)

3 Feed sensor (S2)

4 Feeding side paper stock sensor (S9)

5 Tray bottom sensor (S4)

6 Side cover open/close switch <24V> (S1)

7 Side cover open/close switch <5V>

8 Cassette detection switch (S10)

9 End fence stop position sensor (S5)

1 0 Standby side empty sensor (S8)

1 1 End fence home position sensor (S6)

1 2 Standby side paper mis-stacking sensor (S11)

13 Drawer connector

14 Pickup solenoid (SOL1)

15 End fence solenoid (SOL2)

16 PC board (PWA)

KD-1010 OVERVIEW 2 - 2 October 2000 © TOSHIBA TEC

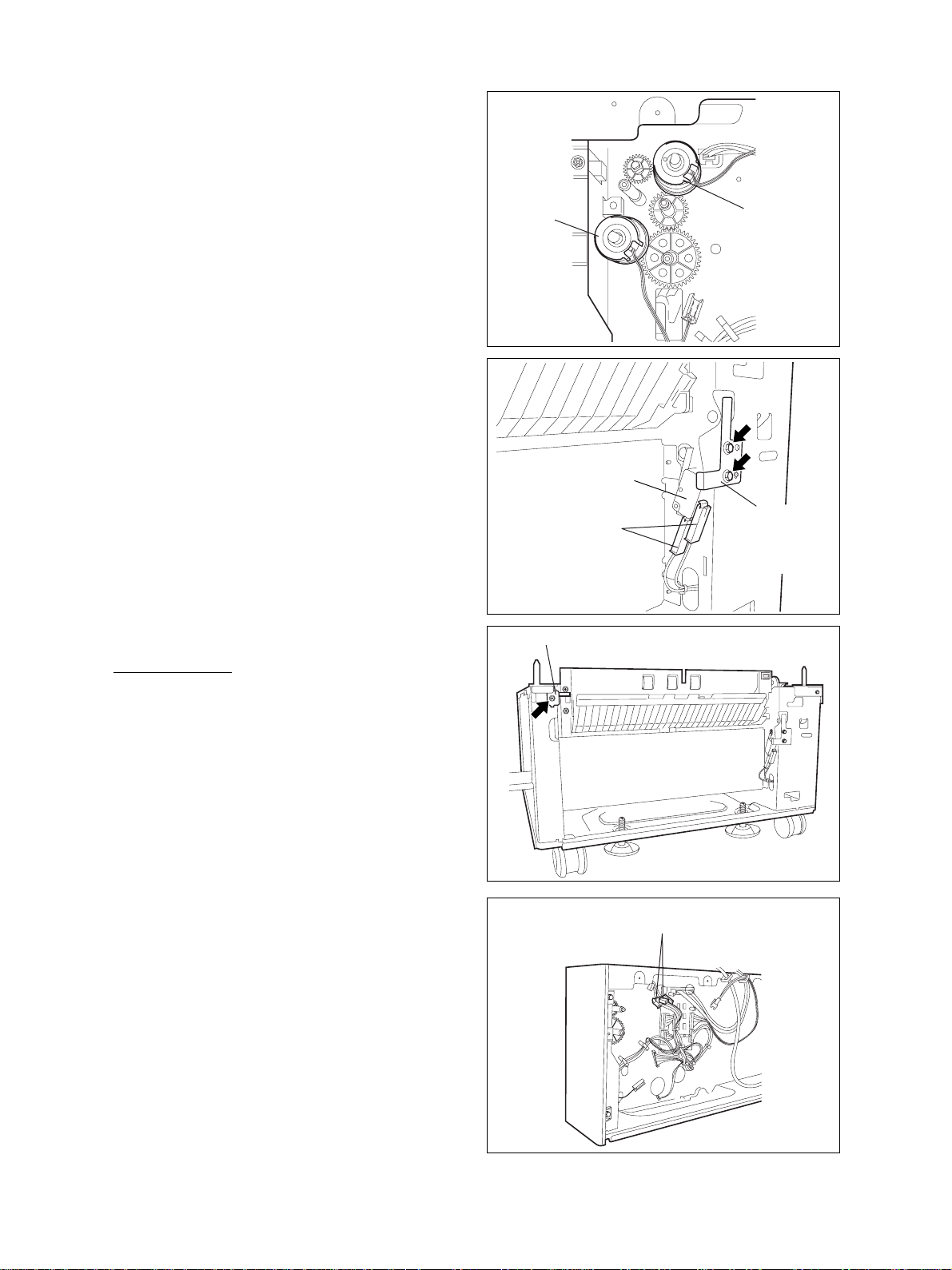

Page 8

LCF

Cassette

1

LCF

2

3

4

5

NO. NAME NO. NAME

1 LCF transport motor (M1)

2 End fence motor (M3)

4 Feed clutch (C2)

5 Transport clutch (C1)

3 Tray-up motor (M2)

October 2000 © TOSHIBA TEC 2 - 3 KD-1010 OVERVIEW

Page 9

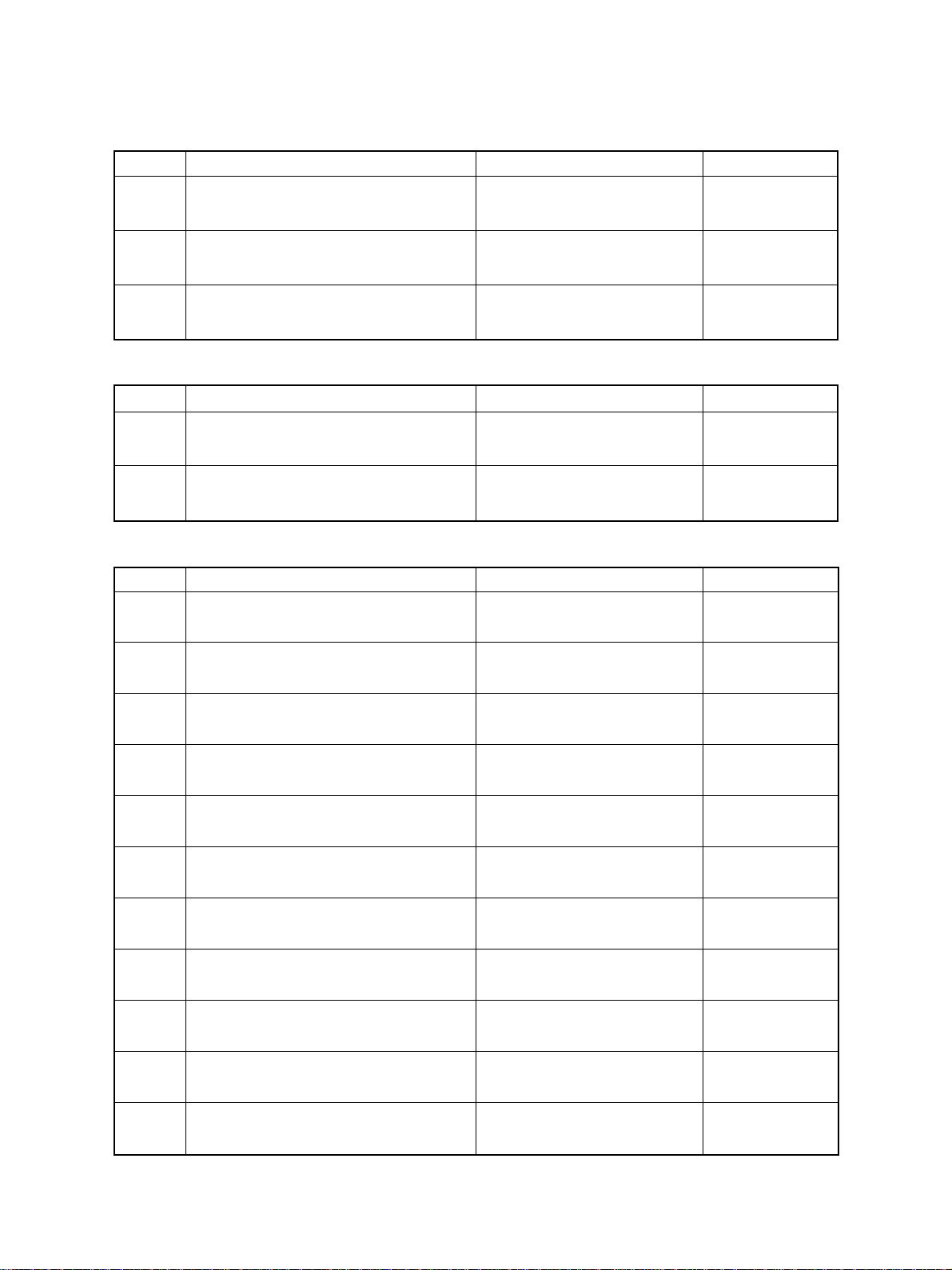

2.3 Electrical Parts

(1) Motor

SYMBOL NAME FUNCTION REMARKS

(M1) LCF-MTR Drives feeding and Brushless motor

LCF transport motor transportation

(M2) T -UP-MTR Lifts up the elevator tray Brush motor

Tray-up motor

(M3) END-F-MTR Drives the movement of the end Brush motor

End fence motor fence

(2) Electromagnetic clutch

SYMBOL NAME FUNCTION REMARKS

(C1) TR-CL T Drives the transportation

Transport clutch

(C2) FED-CL T Drives the roller to pick up

Feed clutch from the elevator tray

(3) Switches or sensors

SYMBOL NAME FUNCTION REMARKS

(S1) SIDE-COV -SW Side cover open/close Push switch

Side cover open/close switch detection

(S2) FED-SNR Detects paper from the Photo interrupter

Feed sensor elevator tray

(S3) T OP-SNR Detects if the elevator Photo interrupter

Tray-up sensor tray has been raised

(S4) TRY-BTM-SNR Detects the home position Photo interrupter

Tray bottom sensor of the elevator tray

(S5) END-F-STP-SNR Detects the stop position Photo interrupter

End fence stop position sensor of the end fence

(S6) END-F-HP-SNR Detects the home position Photo interrupter

End fence home position sensor of the end fence

(S7) EMP-SNR-FS Detects lack of paper Photo interrupter

Feeding side paper empty sensor of the feed side

(S8) EMP-SNR-SS Detects lack of paper Photo interrupter

Standby side paper empty sensor of the standby side

(S9) PST -SNR-FS Detects that the paper Photo interrupter

Feeding side paper stock sensor stock is going short

(S10) CST-SW Detects the availability Push switch

Cassette detection switch of the cassette

(S11) PR-MST-SS Detects mis-stacking of paper Photo interrupter

Standby side paper mis-stacking sensor in the standby side cassette

KD-1010 OVERVIEW 2 - 4 October 2000 © TOSHIBA TEC

Page 10

(4) PC Board

SYMBOL NAME FUNCTION REMARKS

PWA PW A-F-PFP-523 Drives the feeding and moves

PC board the tray

(5) Solenoids

SYMBOL NAME FUNCTION REMARKS

(SOL1) PICKUP-SOL Lifts up the pickup roller

Pickup solenoid

(SOL2) END-F-SOL Moves the lever to detect mis-

End fence solenoid stacking of paper in the standby

side cassette

October 2000 © TOSHIBA TEC 2 - 5 KD-1010 OVERVIEW

Page 11

KD-1010 OVERVIEW 2 - 6 October 2000 © TOSHIBA TEC

Page 12

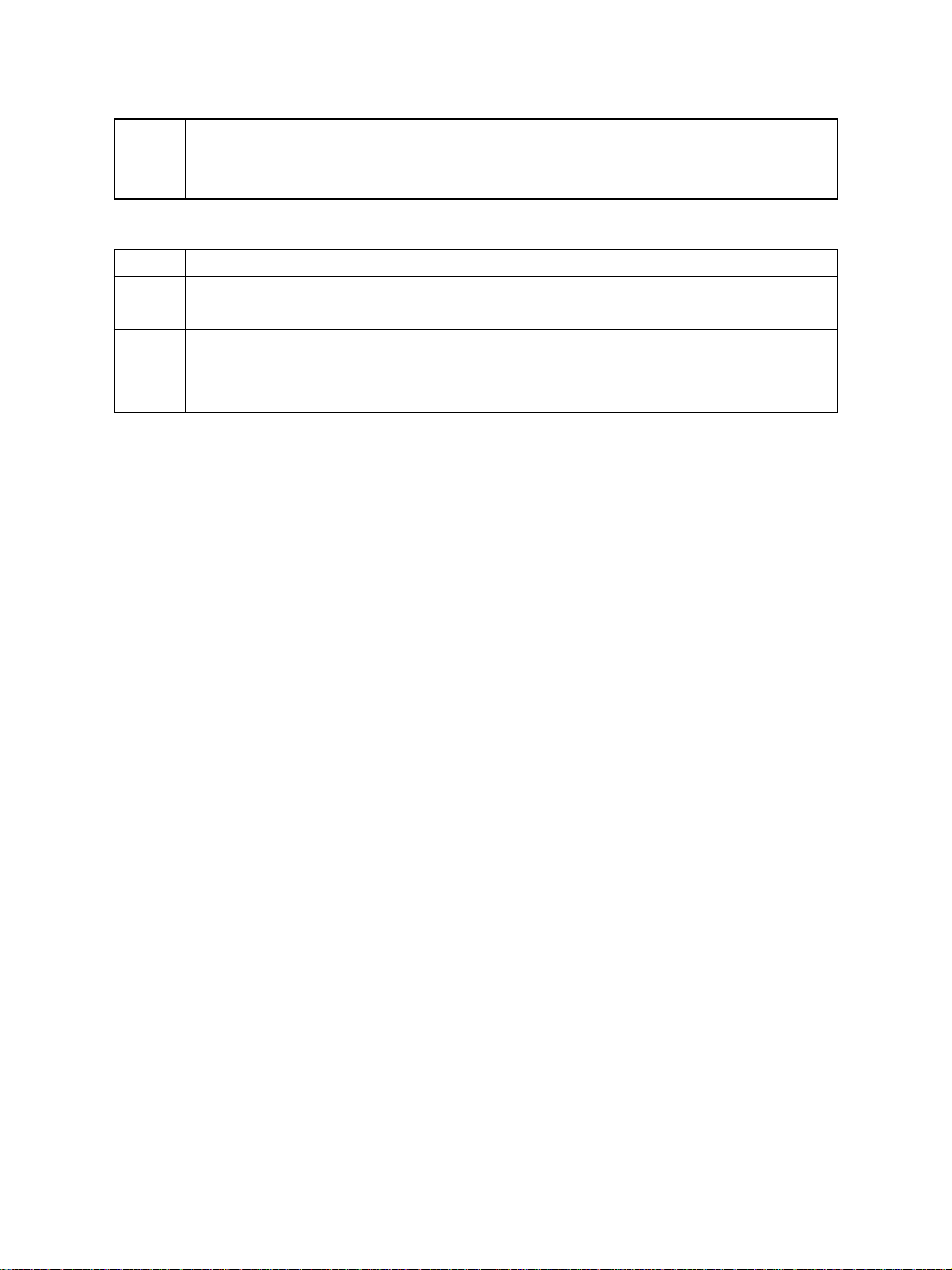

2.4 Harness Diagram

October 2000 © TOSHIBA TEC 2 - 7 KD-1010 OVERVIEW

Page 13

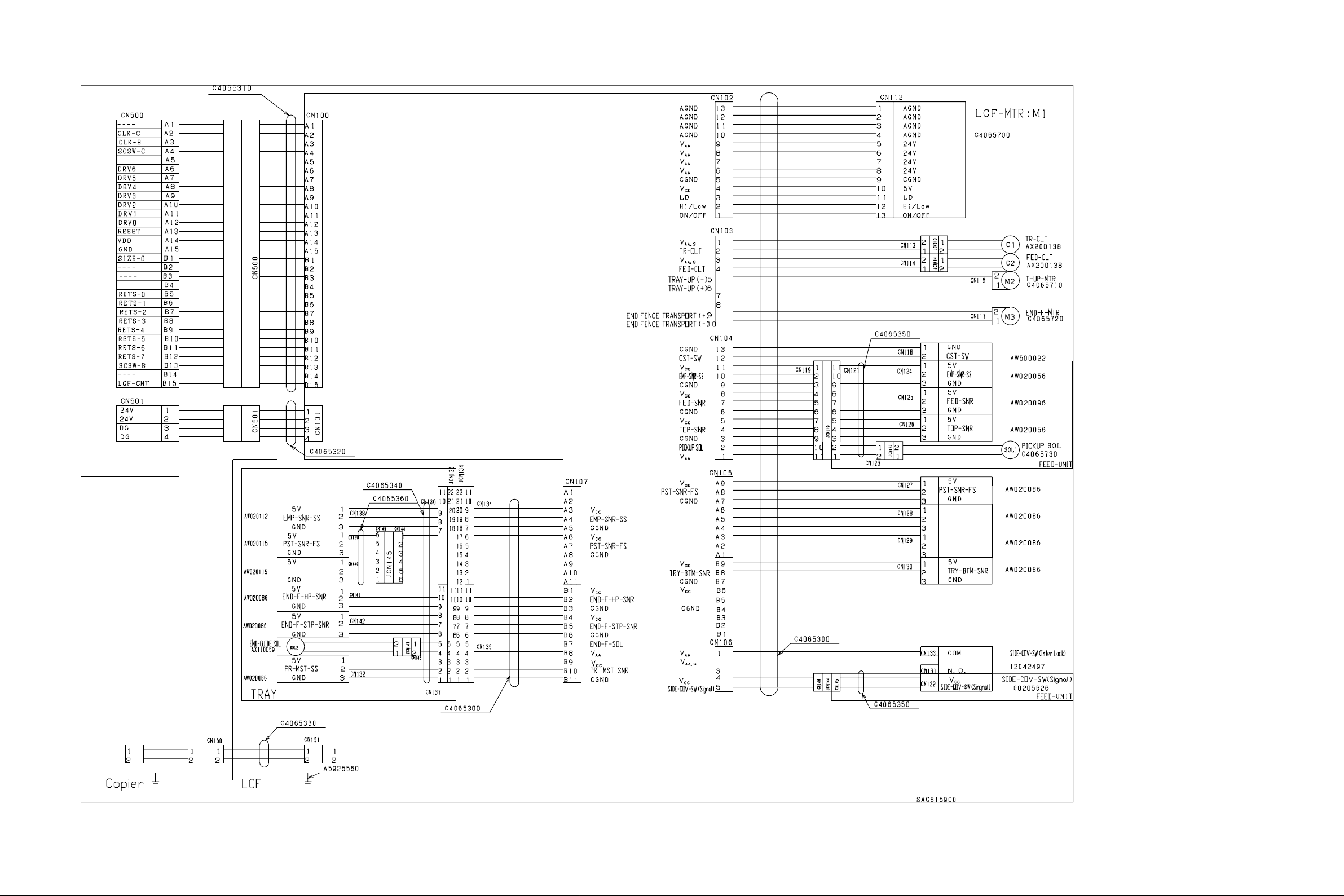

2.5 Circuit Diagram

KD-1010 OVERVIEW 2 - 8 October 2000 © TOSHIBA TEC

Page 14

2.6 Installation of PC Board

October 2000 © TOSHIBA TEC 2 - 9 KD-1010 OVERVIEW

Page 15

2.7 Timing Chart

(1 ) DP2500 (A4 sized sheet fed from the LCF)

KD-1010 OVERVIEW 2 - 10 October 2000 © TOSHIBA TEC

Page 16

(2 ) DP4500/3500 (A4 sized sheet fed from the LCF)

October 2000 © TOSHIBA TEC 2 - 11 KD-1010 OVERVIEW

Page 17

Page 18

3. GENERAL OPERATION

3.1 Description of Operation

[A] From power ON to standby

(1) When the copier is turned ON, power is also supplied to the feeding unit to start the pre-running

operation. The tray-up motor (M2) starts to rotate forw ard and raises the tray. The tr ay-up motor (M2) is

turned OFF when the tray turns ON the tray-up sensor (S3), then the tray is stopped. At this time, it is

judged that there is paper in the feeding side cassette when the feeding side empty sensor (S7) is ON.

On the other hand, the absence of paper in the feeding side cassette is assumed when the sensor (S7)

is OFF, and the standby side empty sensor (S8) is subsequently checked. When the standby side

empty sensor (S8) is OFF, that means that paper is absent in the standby side cassette, and it is

therefore assumed that there is no paper in the LCF. When the standby side empty sensor (S8) is ON,

the paper in the standby side cassette is mov ed to the f eeding side cassette . The tray-up motor (M2)

is rotated in rev erse and lowers the tra y of the feeding side . The lowered tra y turns ON the tray bottom

sensor (S4), and the tray-up motor (M2) is turned OFF to stop the tray. The end fence solenoid and

pickup solenoid are then turned ON. The end fence motor (M3) rotates forward and the paper in the

standby side cassette is mov ed onto the tray of the f eeding side. The end fence motor (M3) is stopped

for a second when the end fence stop position sensor (S5) is turned ON, and the motor (M3) immediately starts to rotate in reverse to return the end fence to the position where the home position sensor

(S6) is turned ON. When the returning operation is started, the end fence solenoid and pickup solenoid

are turned OFF, and the tray-up motor (M2) is rotated forward to r aise the tra y . The tr ay-up motor (M2)

is turned OFF when the tray being raised turns ON the tray-up sensor (S3) and stops the tr a y. At this

time, the presence of paper is judged when the feeding side empty sensor (S7) is ON.

(2 ) If the power is turned ON when the cassette has been removed, the tray-up motor for that cassette is

not turned ON. The tray is raised as soon as the cassette is installed, and it detects if there is paper

in the cassette.

(3) If either of the feed sensor (S2) is ON (there is paper in the transportation path) when the power is

turned ON, that means a paper jam has occurred and the operation is disabled until the paper is

removed.

October 2000 © TOSHIBA TEC 3 - 1 KD-1010 GENERAL OPERATION

Page 19

[B] Standby status

(1 ) T ra ys detect the paper as described abov e, and the copier goes into the standb y status .

(2 ) The tray goes down automatically when the cassette is removed and is raised as soon as the cassette

is reinstalled it then checks if there is paper in the cassette.

[C] From the start to the end of copying

(1 ) The main motor of the copier is turned ON when the START ke y is pressed. The LCF transport motor

(M1) are turned ON to drive.

(2 ) When the copier judges that the LCF is ready f or f eeding paper , it turns ON the feed clutch (C2) of the

selected cassette. This clutch drives the pic kup roller and feed roller to feed paper from the tra y.

(3 ) About 0.02 sec (DP4500/3500: 0.05 sec), after the feeding started transport clutch (C1) are turned ON

to drive the transport roller.

(4 ) The leading edge of the paper turns the feed sensor (S2) ON. These are located right ne xt to the e xit

side of the selected cassette. The feed clutch (C2) is turned OFF and feeding from the cassette is

completed.

(5 ) The paper is tr ansported to the copier by the LCF transport roller. If the trailing edge of the pre viously

sent sheet still remains at the feed sensor when the leading edge of the paper reaches the feed sensor

(S2), the transport clutch (C1) is turned OFF to stop the transport of the paper.

(6 ) The trailing edge of the paper turns the feed sensor (S2) OFF. These are located right next to the exit

side of the selected cassette. LCF then becomes ready for feeding the next sheet of paper, and the

procedures (2) to (5) are repeated.

(7) When the copying operation is completed, the main motor, LCF transport motor (M1) and transport

clutch (C1) are turned OFF and the transport roller is stopped.

KD-1010 GENERAL OPERATION 3 - 2 October 2000 © TOSHIBA TEC

Page 20

3.2 Error Detection

[A] Jam detection

(1 ) A paper jam (E19, E33, E36) [DP4500/3500: (E19, E3C, E3D, E3E)] occurs in the following cases.

a. Feed sensor (S2) is not turned ON within 0.5 seconds after the feeding is started.

b . The leading edge of the paper does not pass the feed sensor (S2) in the transport path within a fixed

time.

(2 ) Open the side co ver of the paper feeder and remo ve all the paper remaining on the transport path and

close the side cover to clear the jammed paper. If either of the f eed sensors (S2) is still ON when the

side cover is closed, it is determined that there is still paper on the transport path and the paper jam

status is not canceled.

(3 ) When a paper jam occurs in the paper feeder during multiple copying, the sheet that was fed before the

jam is copied normally .

[B] Call Service

(1 ) When the tray-up sensor (S3) is not turned ON even through 8 seconds (DP4500/3500: 10 seconds)

have passed since the tr ay started to be raised, it is assumed that the cassette cannot be used (there

is no paper) and the corresponding message is displayed on the control panel.

(2) When the tray bottom sensor (S4) is not turned ON even through 8 seconds (DP4500/3500: 10 seconds)

have passed since the tray started to be lowered, it is assumed that the cassette cannot be used

(there is no paper) and the corresponding message is displayed on the control panel.

(3) When the end fence stop position sensor (S5) is not turned ON even through 8 (DP4500/3500: 5

seconds) seconds have passed since the end fence started to move the paper in the standby side

cassette, it is assumed that the cassette cannot be used (there is no paper) and the corresponding

message is displayed on the control panel.

(4) When the end fence home position sensor (S6) is not turned ON even through 8 seconds (DP4500/

3500: 5 seconds) ha ve passed since the end f ence started to move the paper in the standby side , it is

assumed that the cassette cannot be used (there is no paper) and the corresponding message is

displayed on the control panel.

(5 ) The states (1) to (4) are cleared by removing the cassette.

October 2000 © TOSHIBA TEC 3 - 3 KD-1010 GENERAL OPERATION

Page 21

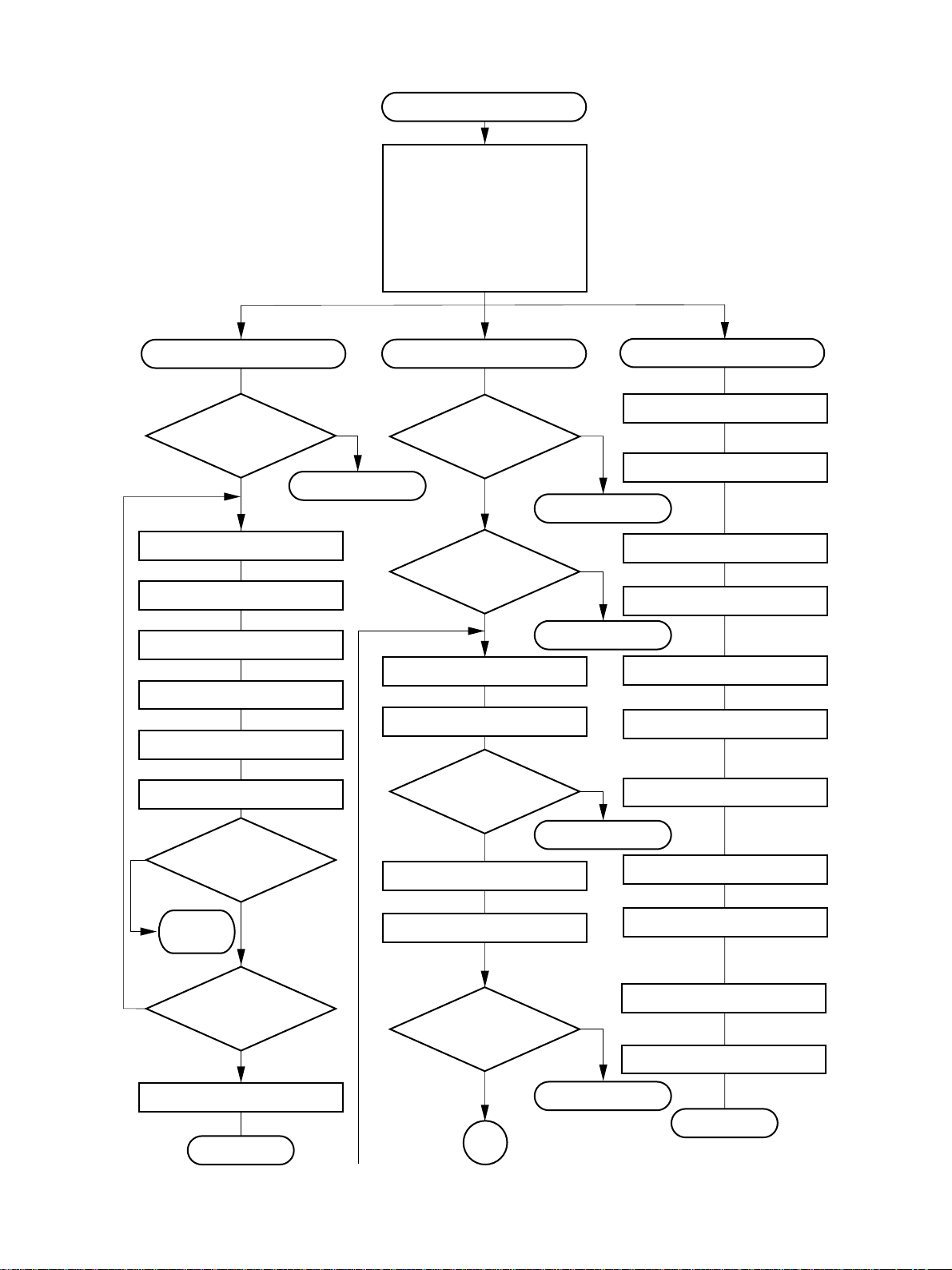

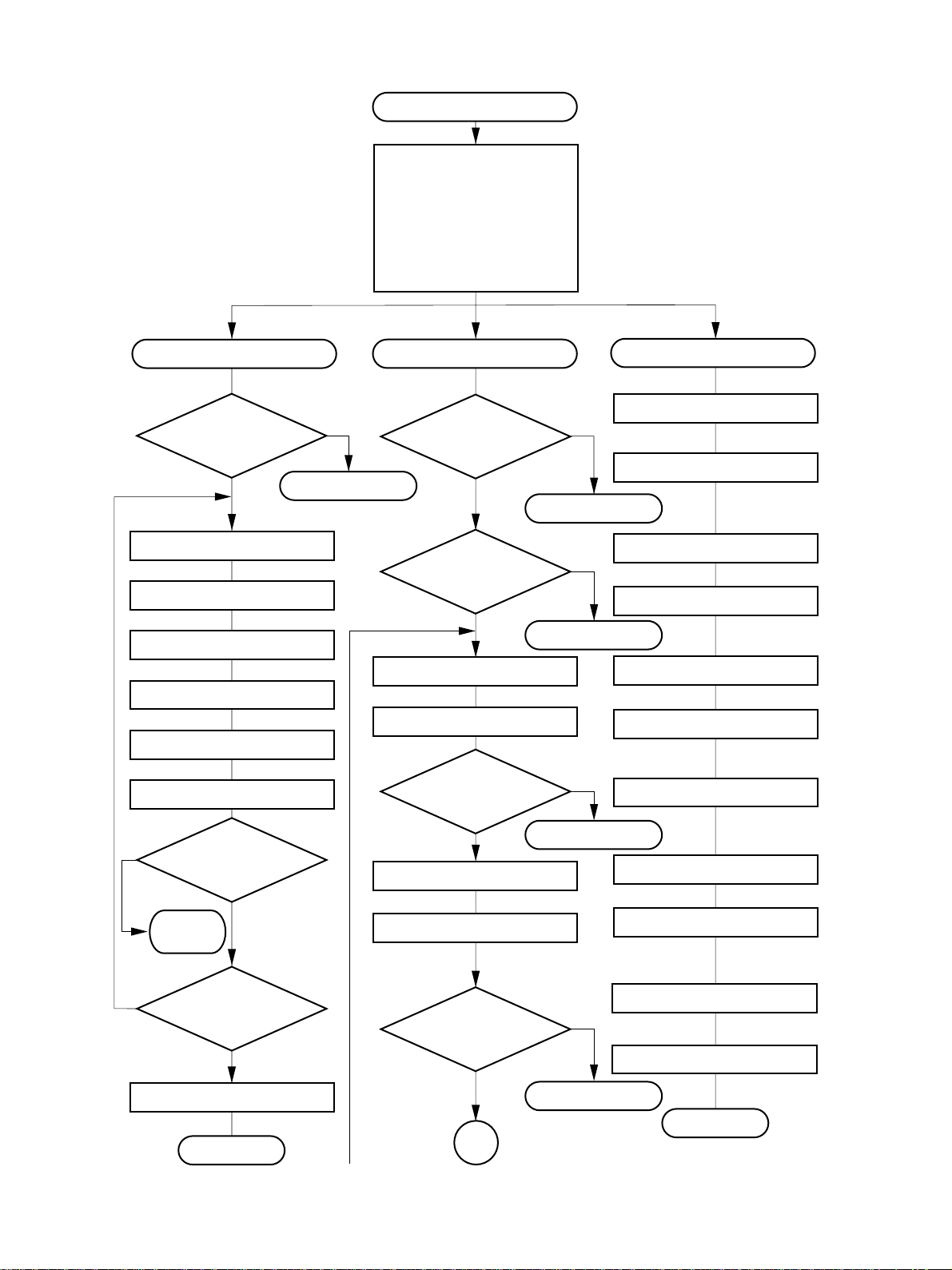

3.3 Flow Chart

(1) DP2500

START key ON

Main motor ON

LCF transport motor ON

Polygonal motor ON

Developer bias ON

Separation charger ON

Main charger ON

Discharge lamp ON

Processing control

Polygonal motor

rotating normally?

YES

Call for Service

Laser ON

Transfer charger ON

Transfer guide bias ON

Laser OFF

Transfer charger OFF

Transfer-guide bias OFF

NO

"CA1"

Transpor t system control

Main motor

rotating normally?

YES

LCF transport

motor rotating

normally?

YES

LCF feed clutch ON

LCF transport clutch ON

LCF feed

sensor ON?

Carriages move backward

NO

Call for Service

"C01"

NO

Call for Service

"C1B "

NO

Scanner system control

Black shading

Exposure lamp ON

Carriages Stopped

Carriages move forward

White shading

Scanning

NO

H-Sync OK?

Call for

Service

YES

LCF feed clutch OFF

YES

Copier’s transport clutch ON

Paper jam

"E19"

Carriages stopped

Exposure lamp OFF

"CA2"

NO

Remaining number

of copies=0?

Copier’s feed

NO

Carriages move backward

sensor ON?

YES

Polygonal motor OFF

YES

Paper jam

"E36"

Processing con-

trol completed

KD-1010 GENERAL OPERATION 3 - 4 October 2000 © TOSHIBA TEC

B

Carriages stopped

Scanner system

control completed

Page 22

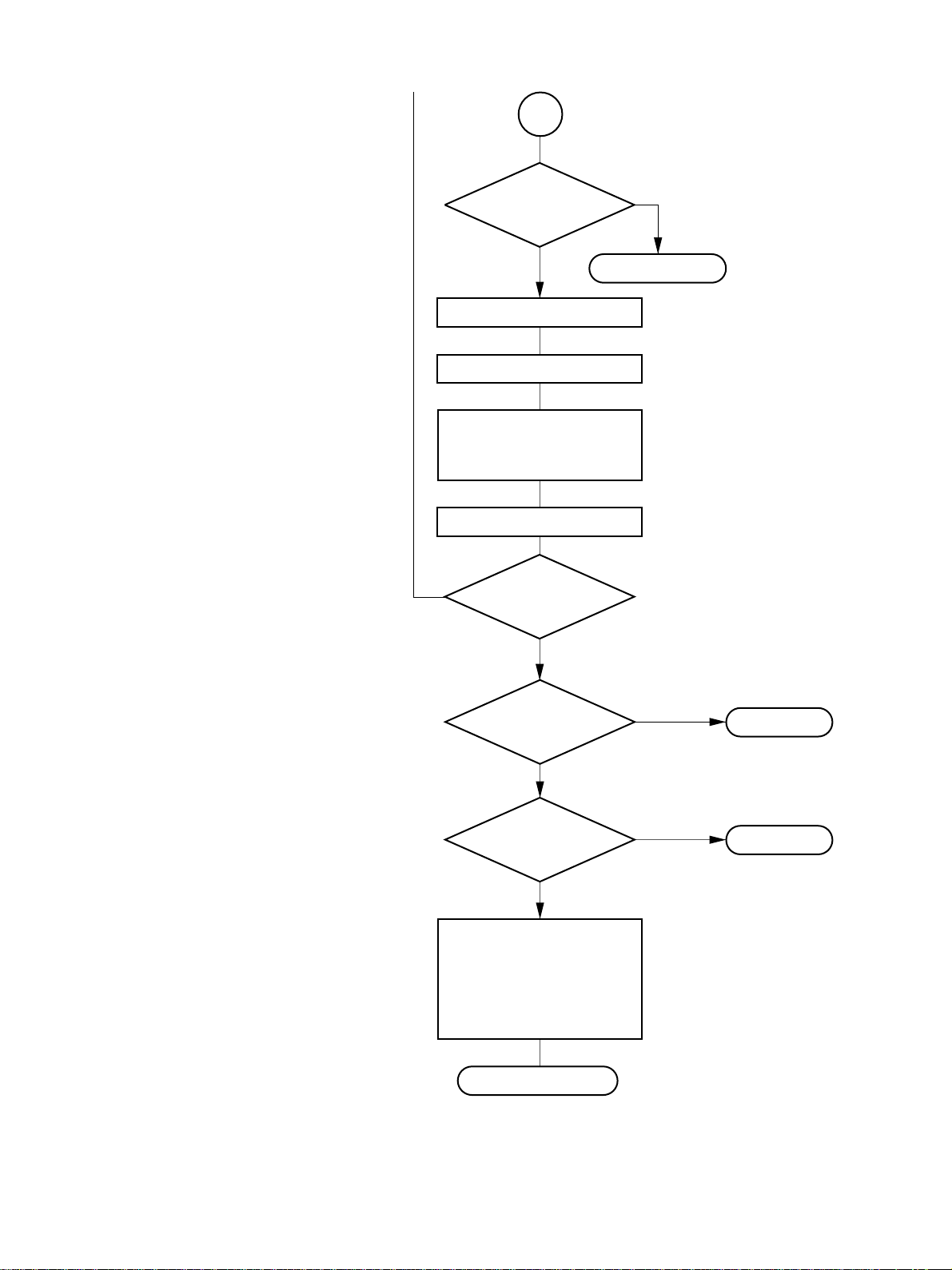

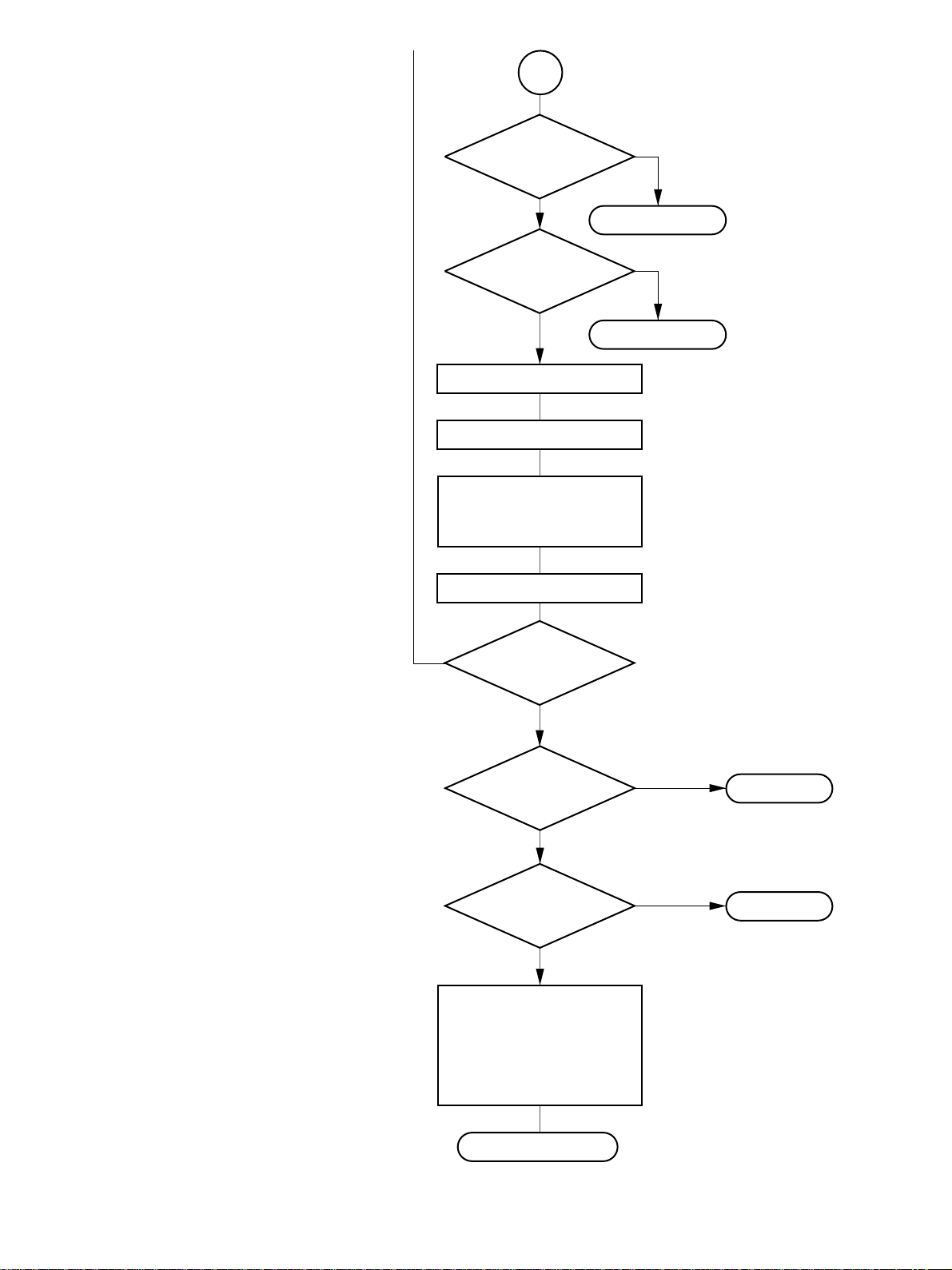

B

Copier’s registration

sensor ON?

YES

LCF transport clutch OFF

Copier’s transport clutch OFF

Copier’s registration clutch ON

Copier’s transport clutch ON (Low)

Counter ON

Copier’s registration clutch OFF

NO

Remaining number

of copies = 0?

YES

NO

Paper jam

"E33"

Exit

sensor 1

ON?

YES

Exit

sensor 2

ON?

YES

Main charger OFF

Main motor OFF

LCF transport motor OFF

Developer bias OFF

Separation charger OFF

Discharge lamp OFF

Standby

NO

NO

Paper jam

"E01"

Paper jam

"E02"

October 2000 © TOSHIBA TEC 3 - 5 KD-1010 GENERAL OPERATION

Page 23

(2) DP4500/3500

START key ON

Main motor ON

LCF transport motor ON

Polygonal motor ON

Developer bias ON

Separation charger ON

Main charger ON

Discharge lamp ON

Processing control

Polygonal motor

rotating normally?

YES

Call for Service

Laser ON

Transfer charger ON

Transfer guide bias ON

Laser OFF

Transfer charger OFF

Transfer-guide bias OFF

NO

"CA1"

Transpor t system control

Main motor

rotating normally?

YES

LCF transport

motor rotating

normally?

YES

LCF feed clutch ON

LCF transport clutch ON

LCF feed

sensor ON?

Carriages move backward

NO

Call for Service

"C01"

NO

Call for Service

"C1B"

NO

Scanner system control

Black shading

Exposure lamp ON

Carriages Stopped

Carriages move forward

White shading

Scanning

NO

H-Sync OK?

Call for

Service

YES

LCF feed clutch OFF

YES

Copier’s transport clutch ON

Paper jam

"E19"

Carriages stopped

Exposure lamp OFF

"CA2"

NO

Remaining number

of copies=0?

Copier’s lower

NO

Carriages move backward

feed sensor ON?

YES

Polygonal motor OFF

YES

Paper jam

"E3E"

Processing con-

trol completed

KD-1010 GENERAL OPERATION 3 - 6 October 2000 © TOSHIBA TEC

B

Carriages stopped

Scanner system

control completed

Page 24

B

Copier’s upper feed

sensor ON?

YES

Paper jam

Copier’s registration

sensor ON?

YES

Paper jam

LCF transport clutch OFF

Copier’s transport clutch OFF

Copier’s registration clutch ON

Copier’s transport clutch ON (Low)

Counter ON

Copier’s registration clutch OFF

NO

"E3D"

NO

"E3C"

NO

Remaining number

of copies = 0?

Exit

sensor 1

ON?

Exit

sensor 2

ON?

Main charger OFF

Main motor OFF

LCF transport motor OFF

Developer bias OFF

Separation charger OFF

Discharge lamp OFF

YES

YES

YES

NO

NO

Paper jam

"E01"

Paper jam

"E02"

Standby

October 2000 © TOSHIBA TEC 3 - 7 KD-1010 GENERAL OPERATION

Page 25

Page 26

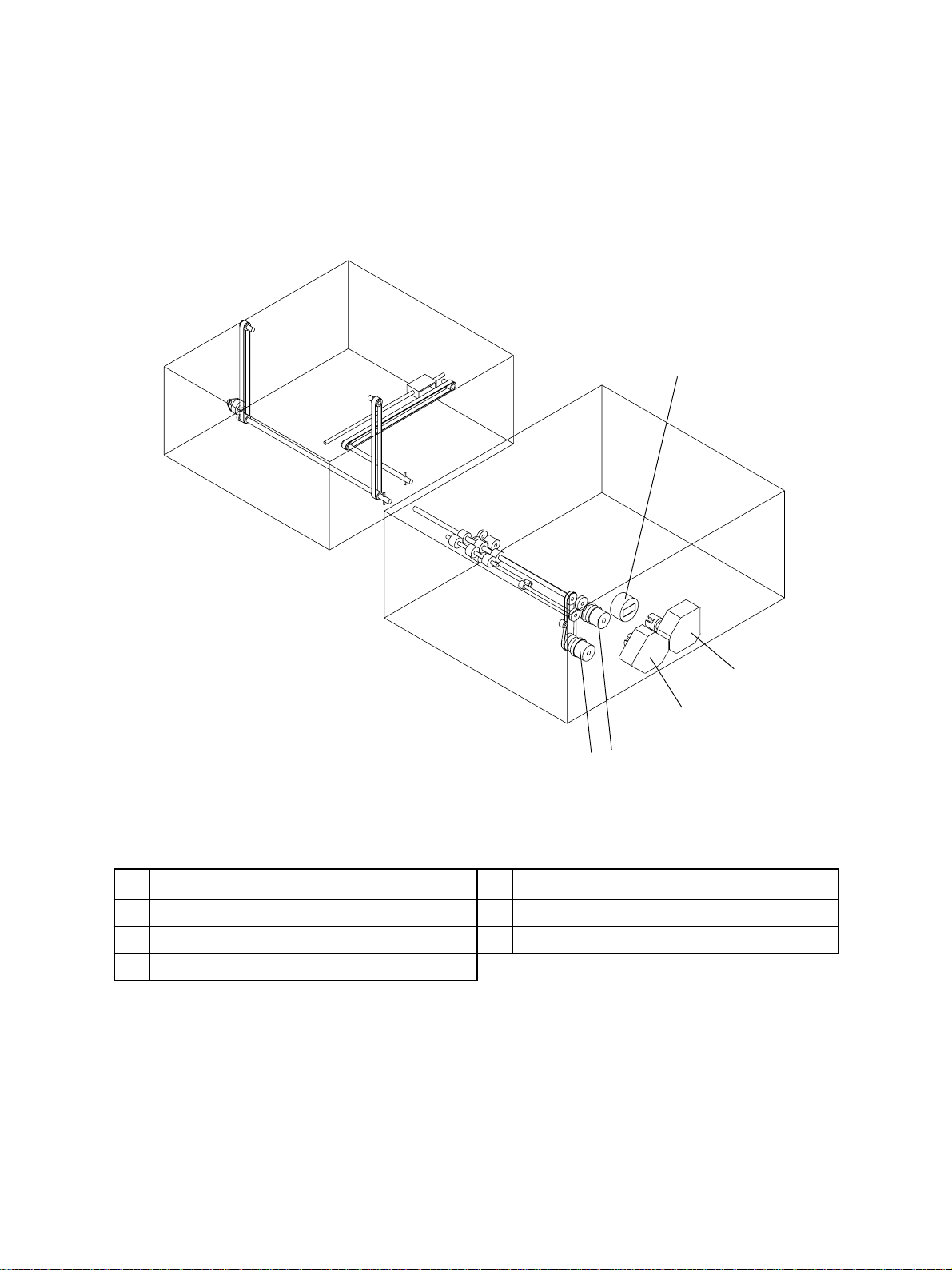

4. DRIVE SYSTEM AND FEEDING OPERATION

4.1 Configuration and Drive System

The Large Capacity Feeder (LCF) mainly consists of the LCF cassette, pic kup roller, f eed roller, separ ation

roller, tr ansport roller and drive system for these components.

• Feeding/Transport system

The LCF transport motor drives the pickup roller, f eed roller , separation roller and transport roller which

are located in the feeding area.

• Cassette tray system

This system raises and lowers the tray.

• End fence system

This system movement of the end fence.

Feed roller

LCF cassette

Transpor t roller

Pickup roller

LCF transport motor

LCF

End fence motor

Tray-up motor

Feed clutch

Transpor t clutch

October 2000 © TOSHIBA TEC 4 - 1 KD-1010 DRIVE SYSTEM

Page 27

Page 28

5.

Disassembly and Replacement

5.1 Top cover

Remove 5 screws and take off the top cover.

5.2 Installation and Removal of the LCF

Cassette and Covers

[A] LCF cassette

(1 ) Draw out the LCF cassette toward you.

(2) Remove one screw and take off the stopper

bracket at the left side of the LCF cassette.

Top cover

Stopper bracket

(3) Pull out the LCF cassette while pressing the plate

spring at the right side of the LCF cassette.

[B] Front cover

Remove 2 scre ws and tak e off the front cover.

LCF cassette

Plate spring

October 2000 © TOSHIBA TEC 5 - 1 KD-1010 DISASSEMBLE/REPLACE

Page 29

[C] Rear cover

Remove 3 scre ws and tak e off the rear co v er.

[D] Feeding side rear cover

Remove 2 screws and take off the feeding side

rear cover .

[E] Feeding side front cover

Remove 2 screws and take off the feeding side

front cover.

[F] Side cover

(1 ) Open the side cover and take the protrusion at

the front side of the side cover out of the hole of

the frame while pushing the cover to the rear

side.

(2) Remove the side cover.

Feeding side rear cover

Front side

Feeding side front cover

Rear side

Fulcrum of the front side

KD-1010 DISASSEMBLE/REPLACE 5 - 2 October 2000 © TOSHIBA TEC

Page 30

5.3 Paper Guides

[A] Feeding side front guide

(1 ) Remove one screw fixing the feeding side front

guide.

(2 ) Lift up the paper guide slightly and place it into

the slots for the appropriate size. Confirm the

position of the screwhole and insert a screw into

it.

Punch mark

[B] Feeding side rear guide

(1 ) Remove one screw fixing the feeding side rear

guide.

(2 ) Lift up the paper guide slightly and place it into

the slots for the appropriate size. Confirm the

position of the screwhole, and insert a screw

into it.

LTA4

Punch mark

LT A4

October 2000 © TOSHIBA TEC 5 - 3 KD-1010 DISASSEMBLE/REPLACE

Page 31

[C] Standby side front guide

(1 ) Remove one screw fixing the standby side front

guide and slide the guide in the direction of the

arrow .

(2 ) Lift up the paper guide slightly and place it into

the slots for the appropriate size. Cconfirm the

position of the screw hole, and insert a screw

into it.

LT

A4

[D] Standby side rear guide

(1 ) Remove one screw fixing the standby side rear

guide and slide the guide in the direction of the

arrow .

(2 ) Lift up the paper guide slightly and place it into

the slots for the appropriate size. Confirm the

position of the screwhole, and insert a screw

into it.

Note: When the position of the standby side rear

guide is changed (A4−>LT or LT−>A4),

remember that the direction of the rear guide

stopper to be assembled is also changed

(See the following figure).

[A4 size] [LT size]

Rear guide

stopper

Fixing screw

Rear guide

stopper

Fixing screw

LT A4

KD-1010 DISASSEMBLE/REPLACE 5 - 4 October 2000 © TOSHIBA TEC

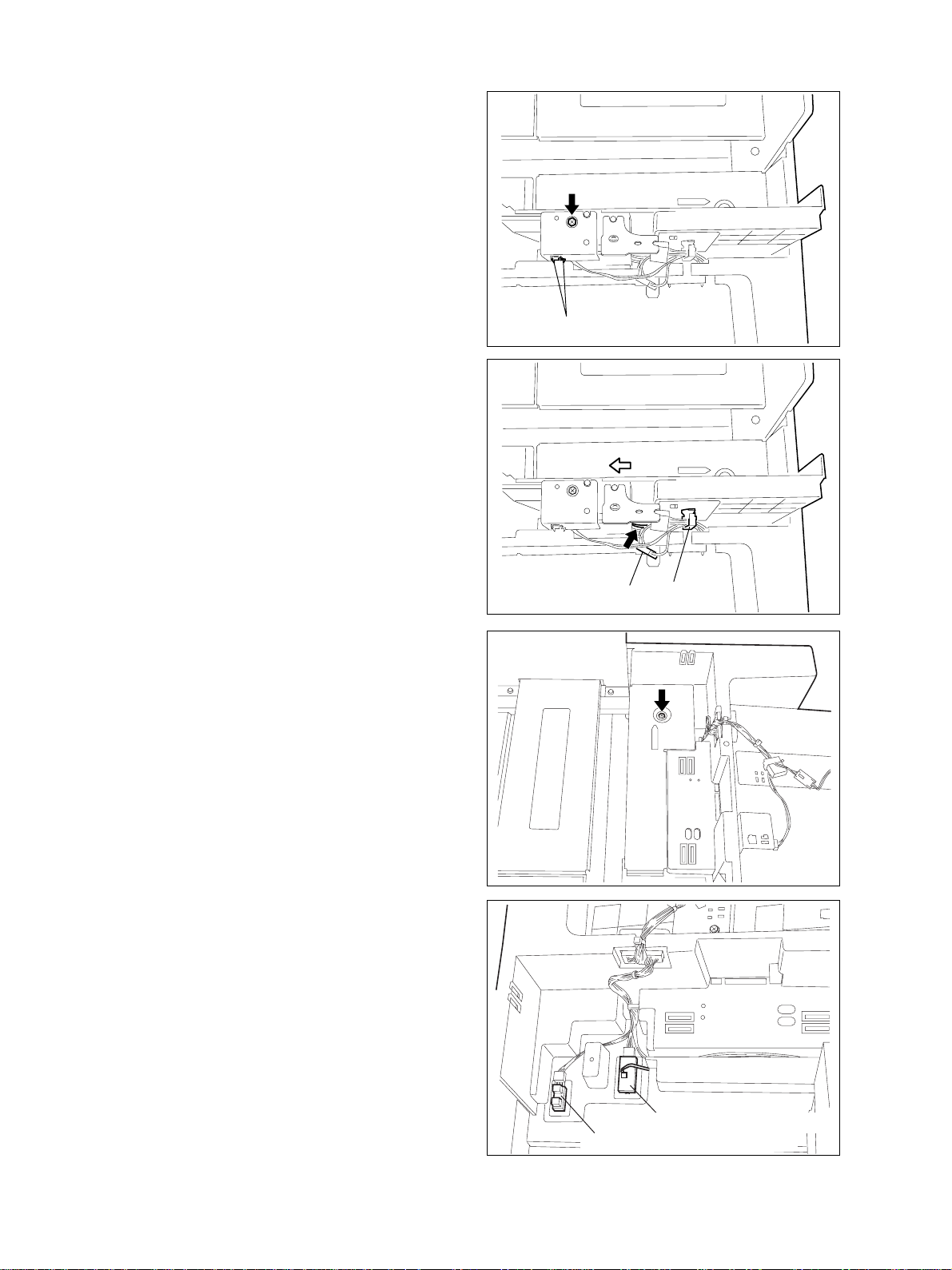

Page 32

5.4 Standby side Paper Mis-stacking

Sensor

(1) Remove one screw and take off the sensor

bracket.

(2 ) Disconnect one connector.

(3 ) Release the latch and remove the sensor .

5.5 End Fence Home Position Sensor /

Standby Side Empty Sensor

(1 ) Disconnect one connector, and release the har-

ness from the clamp.

(2 ) Remove one screw fixing the standby side rear

guide, then slide the guide in the direction of the

arrow to take it out.

Latch

(3 ) Remove one screw and take off the bracket.

(4 ) Disconnect the connector.

(5) Release the latch to remove the end-fence home

position sensor and the standby side paper

empty sensor from the backside of the LCF cas-

sette.

Connector

Clamp

Standby side paper empty sensor

End fence home position sensor

October 2000 © TOSHIBA TEC 5 - 5 KD-1010 DISASSEMBLE/REPLACE

Page 33

5.6 End Fence Stop Position Sensor

(1) Disconnect one connector, remove one screw

and take off the bracket.

(2 ) Release the latch to remove the sensor.

Note: The positions to attach the end fence stop

position sensor differ according to each

paper size.

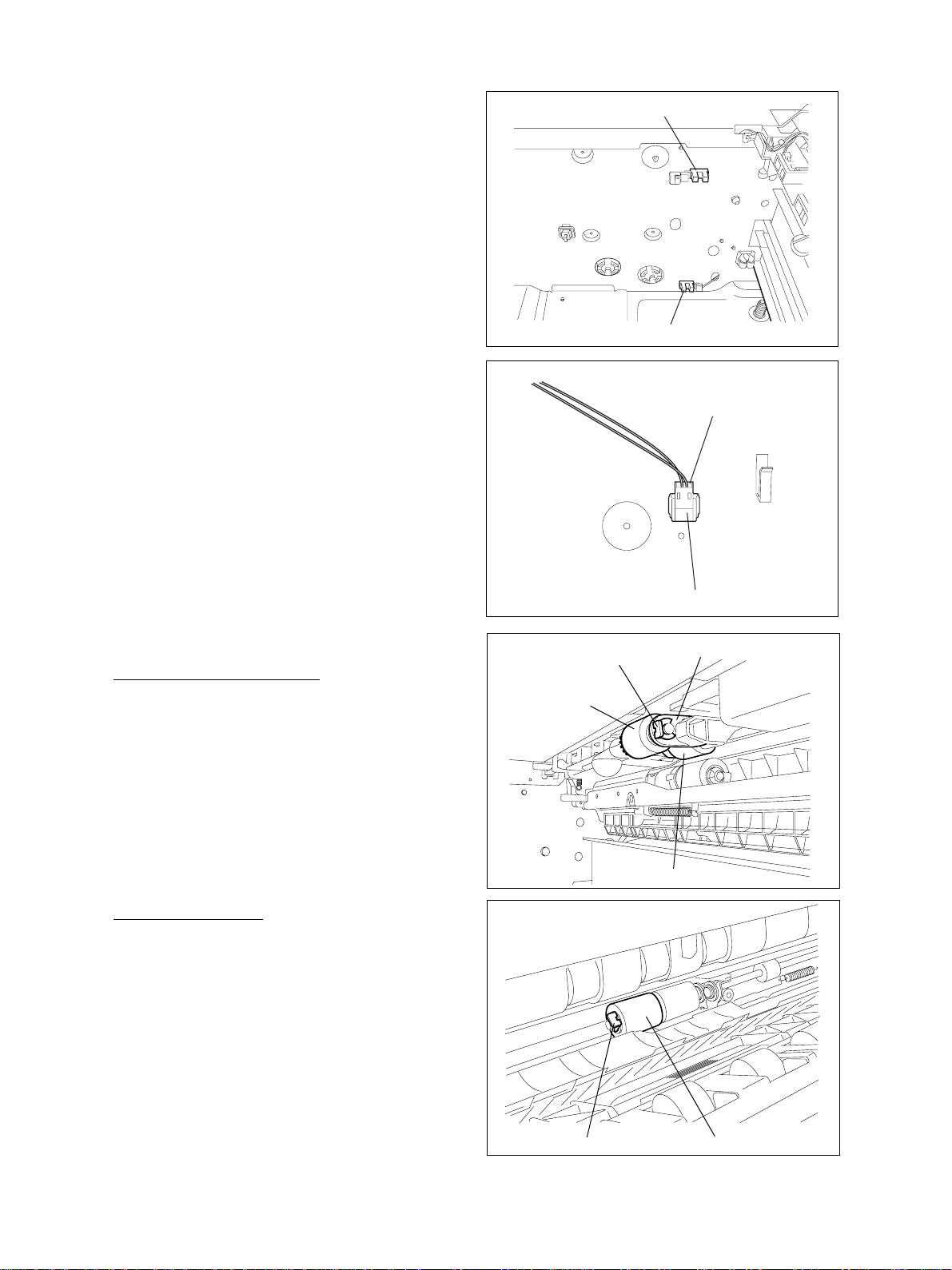

5.7 LCF T ransport Motor Unit

(1 ) Disconnect one connector.

(2) Remove 3 screws and take off the LCF trans-

port motor along with the bracket.

[A4 size] [LT size]

End fence stop position

sensor

Bracket

Feeding side

Standby side

Connector

(3) Remove 6 screws and take off the motor from

the bracket.

KD-1010 DISASSEMBLE/REPLACE 5 - 6 October 2000 © TOSHIBA TEC

Page 34

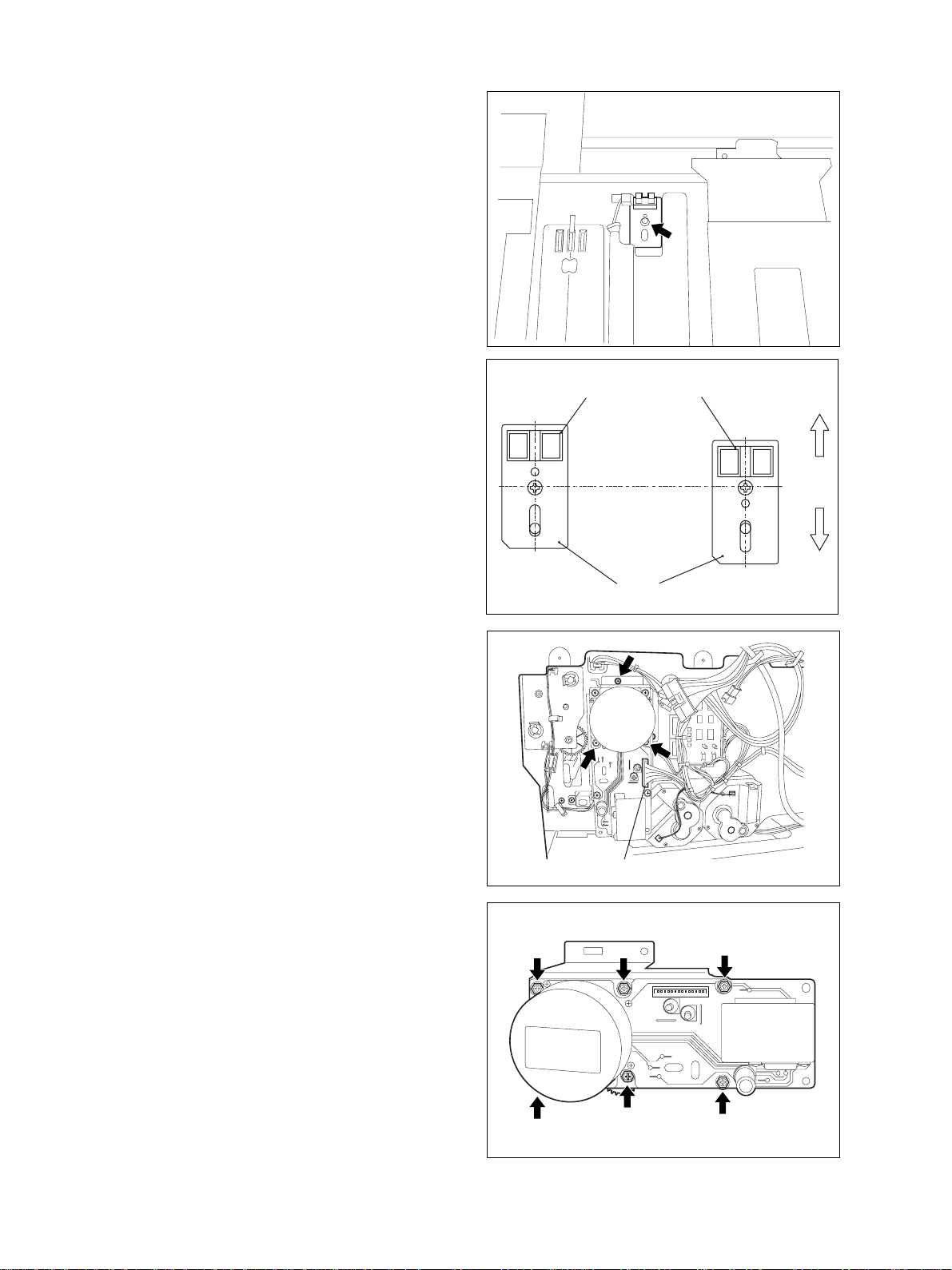

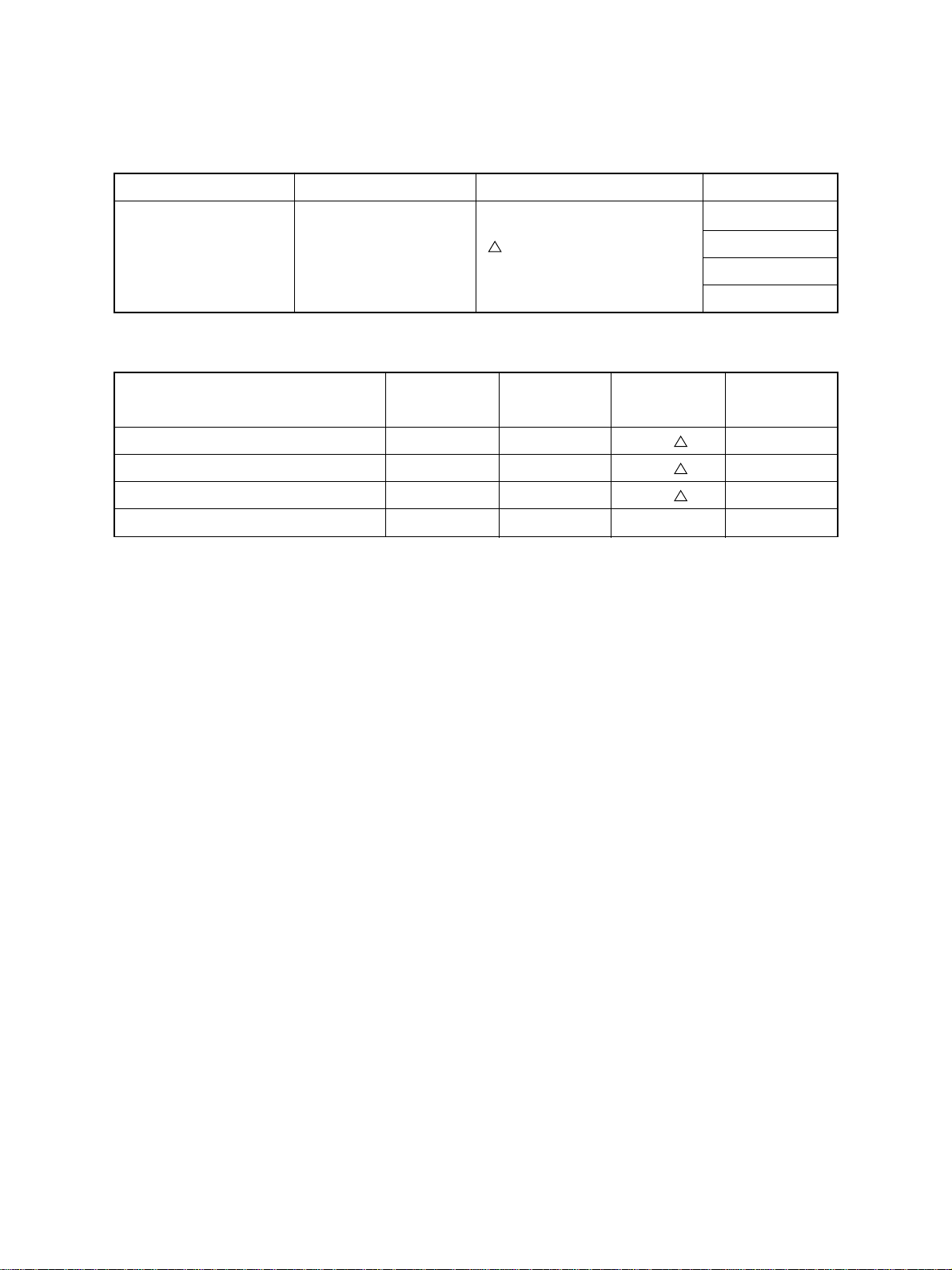

5.8 PC Board

(1 ) Disconnect 8 connectors.

(2) Remove one lock support and 3 screws. Take

off the PC board.

5.9 Tray-up Motor / End Fence Motor

(1 ) Disconnect 2 connectors.

(2) Remove 4 screws and take out the tray-up motor

/ end fence motor along with the bracket.

Lock support

(3 ) Remove 6 screws and take off the tray-up motor

and the end-fence motor to detach the motors

from the bracket.

5.10 Feed Clutch / Transport Clutch

(1 ) Relase the harness from 3 clamps and discon-

nect 2 connectors.

(2) Remove 2 clips and 2 screws. Take off the

bracket.

Connector

Tray-up motor

Bracket

Clamps

Clamp Connectors

End fence motor

Clips

October 2000 © TOSHIBA TEC 5 - 7 KD-1010 DISASSEMBLE/REPLACE

Page 35

(3) Remove the feed clutch and transport clutch.

5.11 Side Cover Open/Close Switch

(1 ) Disconnect 2 connectors.

(2) Remove 2 screws and the plate spring for the

tension pulley.

(3 ) Remove the side cover open/close switch.

5.12 Feeding Unit

[A] Feeding unit

Transpor t

clutch

Slide cover open/

close switch

Connectors

Side cover open/close lock pin

Feed clutch

Plate spring of the

tension pulley

(1 ) Remove one screw and pull out the side cover

open/close lock pin for the feeding unit.

(2 ) Disconnect 2 connectors.

Connectors

KD-1010 DISASSEMBLE/REPLACE 5 - 8 October 2000 © TOSHIBA TEC

Page 36

(3 ) Release the latch from the groove on the shaft,

and take off the gear .

(4 ) Remove the clip and take off the belt to remove

the feeding unit drive gear .

(5) Remove 2 screws fixing the feeding unit, and

take off the unit upward while pushing it in the

direction of the arrow .

Feeding Unit drive gear

Clip

Gear

[B] Feed sensor

(1) Remove one screw and take off the sensor

bracket.

(2 ) Disconnect one connector and release the latch

to remove the sensor.

[C] Feeding side paper empty sensor / Tray-up sensor

(1) Disconnect the connectors of the sensor (one

each).

(2) Release the latches and remove the feeding side

paper empty sensor and the tray-up sensor .

Connector

Tray-up sensor

Latch

Feeding side paper

empty sensor

LatchLatch

October 2000 © TOSHIBA TEC 5 - 9 KD-1010 DISASSEMBLE/REPLACE

Page 37

5.13 Feeding Side Paper Stock Sensor

/ T r ay bottom sensor

(1 ) Disconnect the connectors of the sensor.

(2 ) Release the latch from the rear side and remove

the sensors toward the front side.

5.14 Cassette Detection Switch

Feeding side paper stock sensor

Tray bottom sensor

(1 ) Disconnect one connector.

(2 ) Release the latch and remove the switch toward

the front side.

5.15 Disassembly for Supplies

[A] Pickup roller/Feed roller

(1) Pull out the LCF cassette.

(2) Remove the clip and take off the pickup arm.

(3) Remove the pickup roller and feed roller from

the shaft.

Pickup roller

Connector

Cassette detection switch

Clip

Pickup arm

Feed roller

[B] Separation roller

(4 ) Open the side cover.

(5) Remove the clip and take off the separation roller .

Clip Separation roller

KD-1010 DISASSEMBLE/REPLACE 5 - 10 October 2000 © TOSHIBA TEC

Page 38

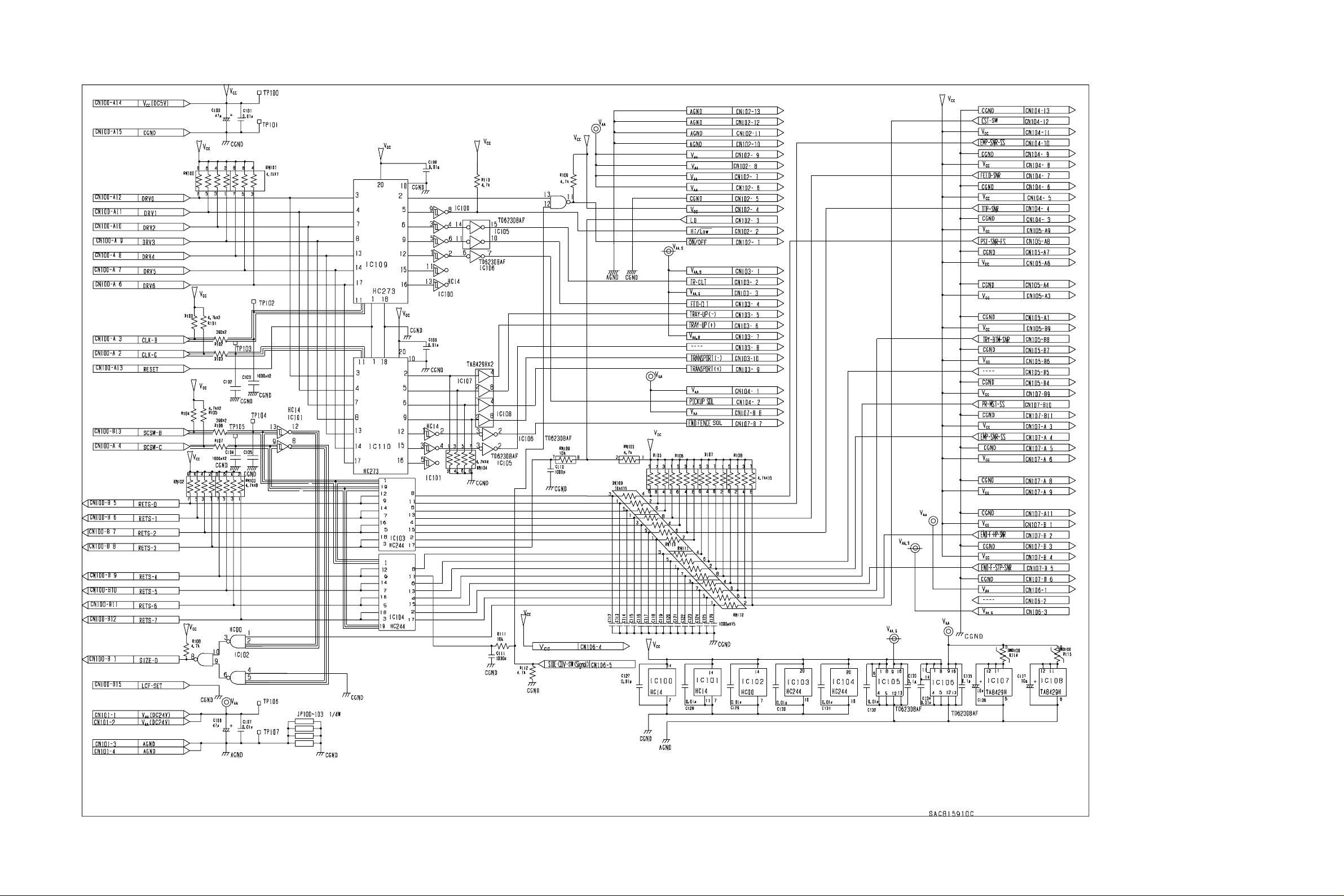

6. PERIODIC MAINTENANCE

Symbols used in the checklist

Cleaning Coating Replacing Date

A Cleaning with alcohol

General Maintenance Checklist

Item to inspect Cleaning Coating Replace every Remarks

Pickup roller(Upper/Lower) A 16 0

Feed roller(Upper/Lower) A 1 60

Separation roller(Upper/Lower) A 1 60

Drive gears(tooth face) W

*The above par ts are to be replaced depending on the number of the sheets of paper used in each

cassette.

W: White grease

(Molycoat)

A V: Alvania No. 2

8 0 Every 80K copies

Replace if deformed or

damaged

1K copies

User’s name

Serial No

Inspector’s name

Remarks

October 2000 © TOSHIBA TEC 6 - 1 KD-1010 PERIODIC MAINTENANCE

Page 39

MEMO

Page 40

MEMO

Page 41

MEMO

Loading...

Loading...