Page 1

GENERAL PRECA UTIONS FOR INSTALLATION/SERVICING/

MAINTENANCE

1. When installing the Paper Feed Pedestal KD-1009 to the Copier, be sure to follow the instructions

described in the “Unpacking/Set-Up Procedure for the KD-1009” booklet which comes with each unit of

the KD-1009.

2. The KD-1009 should be installed by an authorized/qualified person.

3. When transporting/installing KD-1009, employ two persons and be sure to use the positions as indicated below. KD-1009 is fairly heavy and weight approximately 17 kg (37.5 lb), therefore pay full

attention when handling it.

4. Before starting installation, servicing or maintenance work, be sure to turn off and unplug the copier

first.

5. The KD-1009 is supplied with power from the copier , requiring no additional power source.

6. The KD-1009 should be grounded to the specified positions on the machine frame.

7. When servicing or maintaining the KD-1009, be careful about the rotating or operating sections such as

gears, pulleys, sprockets, cams, belts, etc.

8. When parts are disassembled, reassembly is basically the reverse of disassembly unless otherwise

noted in this manual or other related documents. Be careful not to reassemble small parts such as

screws, washers, pins, E-rings, toothed washers to the wrong places.

9. Basically, the machine should not be operated with any parts removed or disassemb led.

10. Delicate parts for preventing safety hazard problems (such as thermofuses, door switches sensors,

etc. if any) should be handled/installed/adjusted correctly.

11. During servicing or maintenance work, be sure to check the nameplate and other cautionary labels (if

any) to see if they are clean and firmly stuck. If not, take appropriate actions.

12. Use suitable measuring instruments and tools.

13. The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband,

because the ICs on it may be damaged due to static electricity.

Caution: Before using the wrist band, pull out the power cord plug of the copier and make sure that

there is no uninsulated objects in the vicinity.

14. For the recov ery and disposal of used KD-1009, consumable parts and packing materials, it is recommended that the relevant local regulations/rules should be followed.

© Copyright 2000

TOSHIBA TEC CORPORA TION

Page 2

CONTENTS

1. SPECIFICATIONS ........................................................................................... 1-1

2. OVERVIEW ...................................................................................................... 2-1

2.1 Front Sectional Vie w ......................................................................................................... 2-1

2.2 Layout of Electrical Parts.................................................................................................. 2-2

2.3 Electrical Parts ................................................................................................................. 2-3

2.4 Harness Diagram .............................................................................................................. 2 -5

2.5 Circuit Diagram ................................................................................................................. 2- 9

2.6 Assembly of PC Board ..................................................................................................... 2- 12

2.7 Timing Chart ..................................................................................................................... 2-13

3. GENERAL OPERATION .................................................................................. 3-1

3.1 Description of Operation ................................................................................................... 3-1

3.2 Error Detection.................................................................................................................. 3- 2

3.3 Flow Chart .................................................................................................................. ...... 3- 3

4. DRIVE SYSTEM AND FEEDING OPERATION............................................... 4-1

4.1 Configuration and Drive System........................................................................................ 4- 1

5. DISASSEMBLY AND REPLACEMENT ........................................................... 5-1

5.1 Installation and Removal of Cassettes and Covers ........................................................... 5- 1

5.2 PC Board .......................................................................................................................... 5 -2

5.3 Upper and Lower Transport Roller (Plastic Rollers) ............................................................ 5-2

5.4 Motors .............................................................................................................................. 5-3

5.5 Feed/Separation/Pickup Roller .......................................................................................... 5 -4

5.6 Switches and Sensors ...................................................................................................... 5-6

6. PERIODIC MAINTENANCE ............................................................................ 6-1

October 2000 © TOSHIBA TEC I KD-1009 CONTENTS

Page 3

Page 4

1. SPECIFICATIONS

Feeding method Automatic feeding: 1 cassette installed from the front

(One extra cassette (option) are available for the models with a DP2500, DP4500/

3500)

Paper Size: A5 – A3

Thickness: 64 – 80g/m

Transportation speed Approx. 260mm/sec. (Models with a DP1600/2500)

Approx. 400mm/sec. (Models with a DP4500/3500)

Capacity of cassette Stack height: 60.5mm (approx. 550 sheets)

Dimensions 530 (W) × 536 (D) × 305 (H) mm

Weight Approx. 17 kg (one cassette)

Po wer supply 5V, 24V (supplied from the copier)

2

October 2000 © TOSHIBA TEC 1 - 1 KD-1009 SPECIFICATION

Page 5

Page 6

2. OVERVIEW

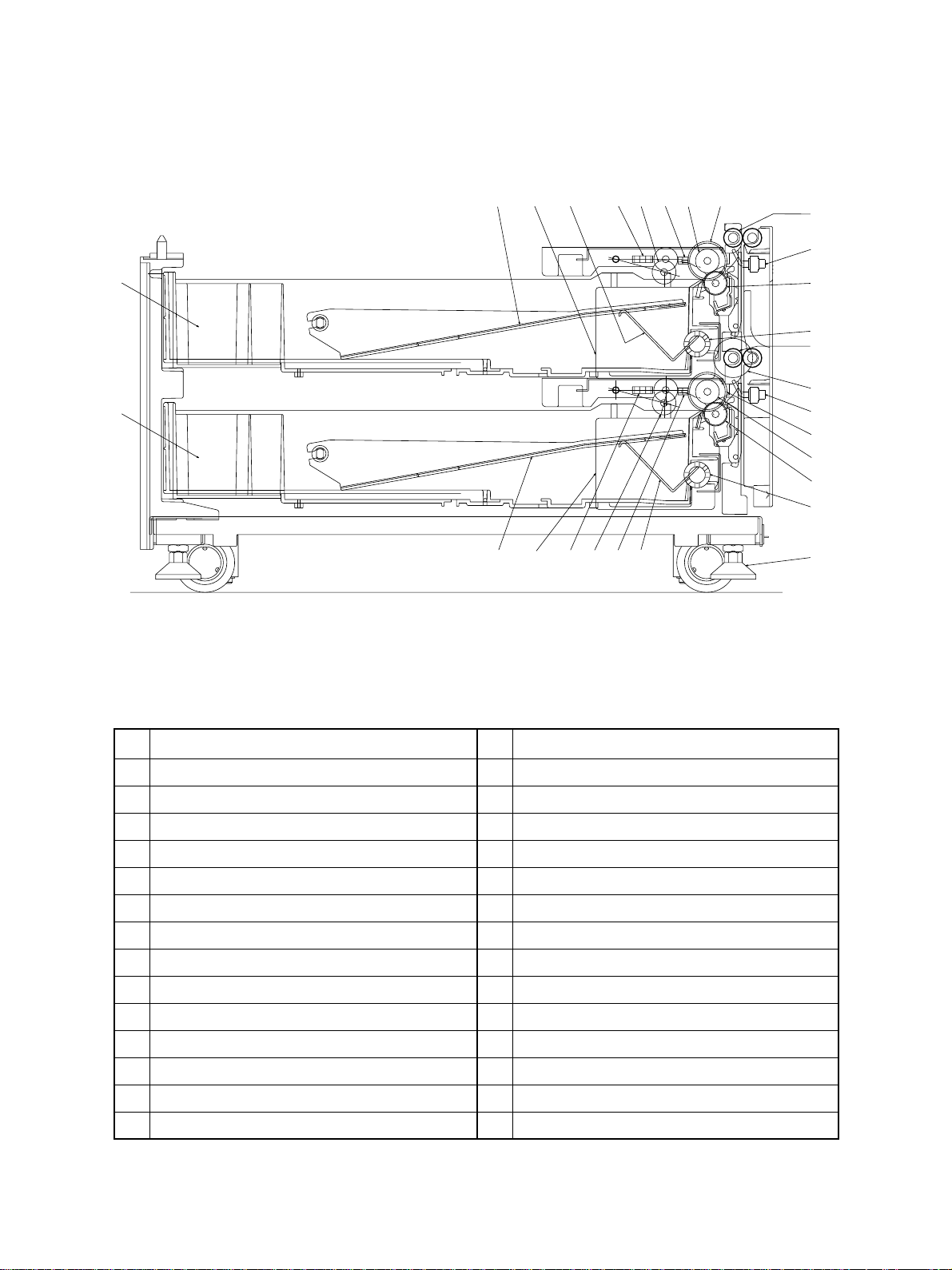

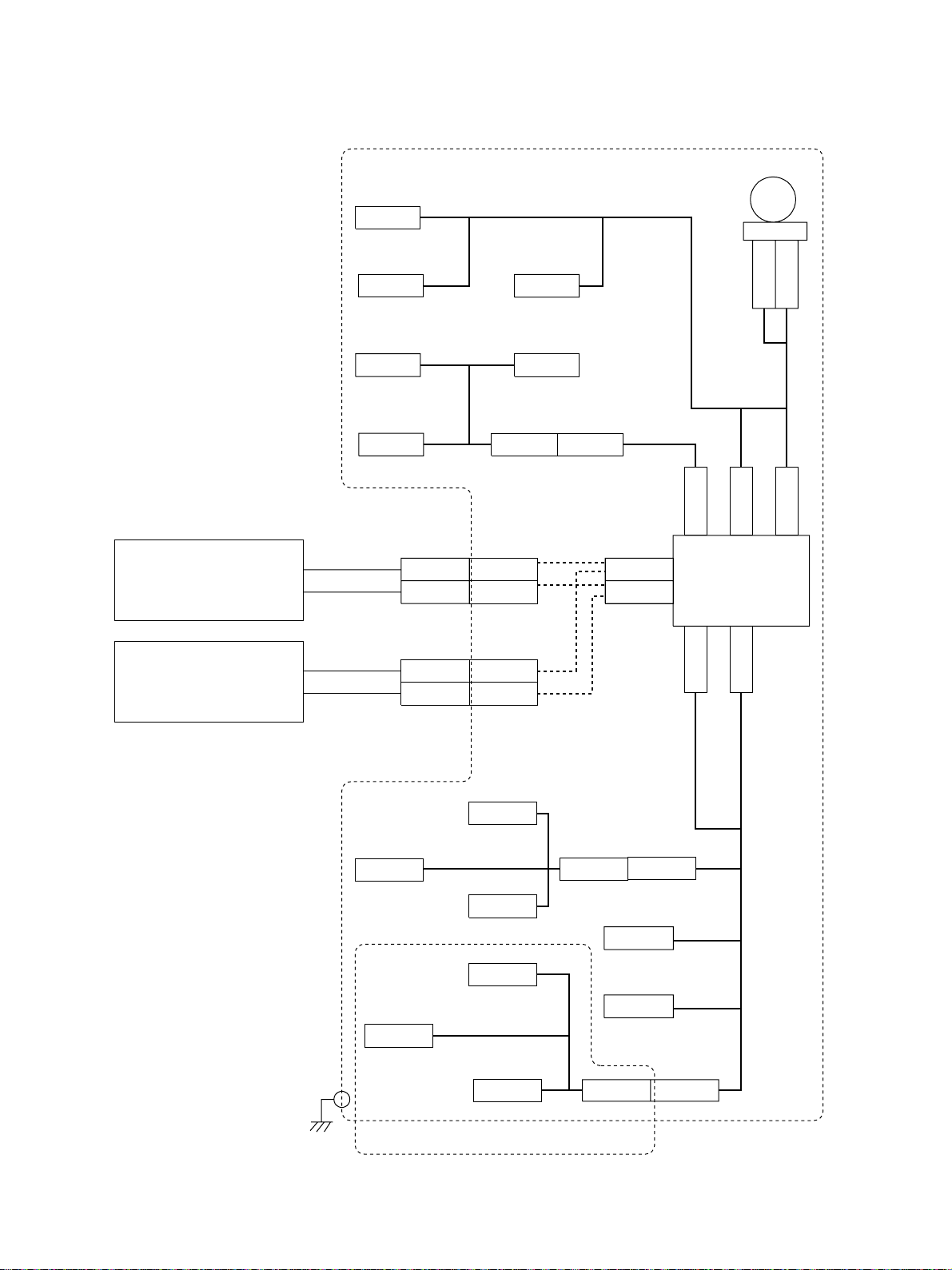

2.1 Front Sectional View

10

16 17

8

9

15

261823192524

12

56

4

3

7

12

13

14

11

20

21

22

27

28

NO . NAME NO. NAME

1 Upper cassette tray-up sensor (S4)

2 Upper cassette paper empty sensor (S6)

3 Upper feed sensor (S2)

4 Upper transport roller

5 Upper cassette feed clutch (C2)

6 Upper cassette feed roller

7 Upper cassette separation roller

8 Upper cassette

9 Lower cassette

10 Upper cassette tray-up motor (M2)

11 Lower feed sensor (S3)

12 Upper cassette elevator coupling

13 Lower transport roller

14 T ransport clutch (C1)

October 2000 © TOSHIBA TEC 2 - 1 KD-1009 OVERVIEW

1 5 Upper cassette pickup roller

1 6 Upper cassette tray

17 Upper cassette elevator

18 Lower cassette tray-up sensor (S5)

1 9 Lower cassette paper empty sensor (S7)

2 0 Lower cassette feed clutch (C3)

21 Lower cassette feed roller

22 Lower cassette separation roller

2 3 Lower cassette pickup roller

2 4 Lower cassette tray

25 Lower cassette tray-up motor (M3)

26 Lower cassette elevator

27 Lower cassette elevator coupling

28 Adjuster

Page 7

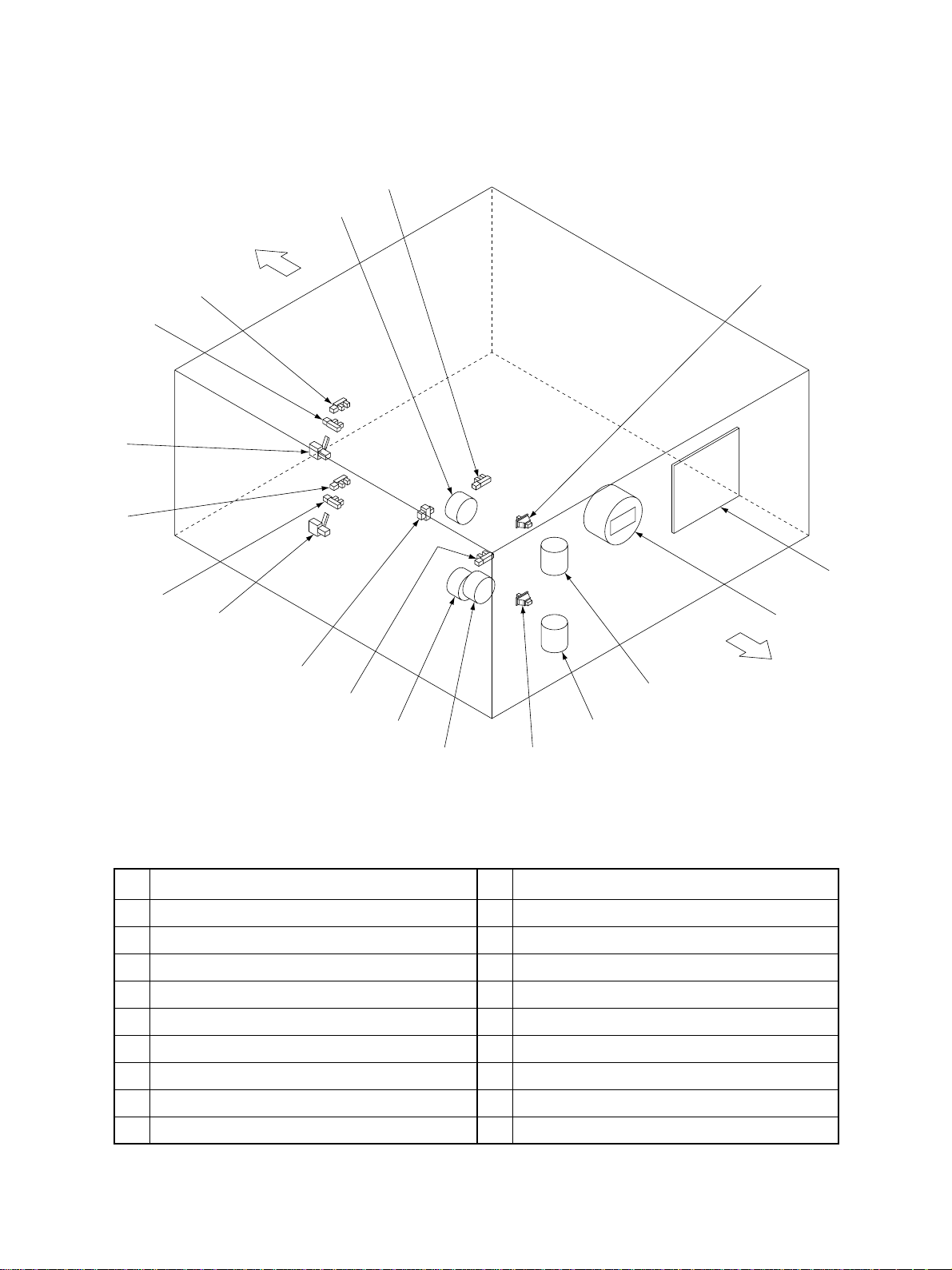

2.2 Layout of Electrical Parts

*

16

Front side

8

2

6

4

9

18

7

11

5

15

1

*

17

12

10

NO. NAME NO. NAME

1 Side cover open/close switch (S1)

2 Upper cassette detection switch (S8)

3 Lower cassette detection switch (S9)

4 Upper feed sensor (S2)

5 Lower feed sensor (S3)

6 Upper cassette tray-up sensor (S4)

7 Lower cassette tray-up sensor (S5)

8 Upper cassette paper empty sensor (S6)

9 Lower cassette paper empty sensor (S7)

*16 Upper cassette paper stock sensor (S10)

*17 Lower cassette paper stock sensor (S11)

3

10 T ransport clutch (C1)

1 1 Upper cassette feed clutch (C2)

1 2 Lower cassette feed clutch (C3)

13 Upper cassette tray-up motor (M2)

14 Lower cassette tray-up motor (M3)

1 5 PFP motor (M1)

18 PC board (PWA)

14

13

* for the DP4500/3500 only

Rear side

KD-1009 OVERVIEW 2 - 2 October 2000 © TOSHIBA TEC

Page 8

2.3 Electrical Parts

(1) Motor

SYMBOL NAME FUNCTION REMARKS

(M1) PFP-MTR Drives feeding and trans- Brushless motor

PFP motor portation

(M2) T-UP-U-MTR Lifts up the upper cassette tray Brush motor

Upper cassette tray-up motor

(M3) T-UP-L-MTR Lifts up the lower cassette tray Brush motor

Lower cassette tray-up motor

(2) Electromagnetic clutch

SYMBOL NAME FUNCTION REMARKS

(C1) TR-CLT Drives transportation

Transport clutch

(C2) FED-U-CL T Drives roller to pick up paper

Upper cassette feed clutch from the upper cassette

(C3) FED-L-CL T Drives roller to pick up paper

Lower cassette feed clutch from the lower cassette

(3) Switches and Sensors

SYMBOL NAME FUNCTION REMARKS

(S1) SIDE-COV -SW Side cover open/close Push switch

Side cover open/close switch detection

(S2) FED-U-SNR Detects paper from the upper Photo interrupter

Upper feed sensor cassette

(S3) FED-L-SNR Detects paper from the lower Photo interrupter

Lower feed sensor cassette

(S4) T OP-U-SNR Detects if the upper cassette Photo interrupter

Upper cassette tray-up sensor has been raised

(S5) TOP-L-SNR Detects if the lower cassette Photo interrupter

Lower cassette tray-up sensor has been raised

(S6) EMP-U-SNR Detects lack of paper in the Photo interrupter

Upper cassette paper empty sensor upper cassette

(S7) EMP-L-SNR Detects lack of paper in the Photo interrupter

Lower cassette paper empty sensor lower cassette

(S8) CST -U-SW Detects the availability of the Push switch

Upper cassette detection switch upper cassette

(S9) CST -L-CST Detects the availability of the Push switch

Lower cassette detection switch lower cassette

October 2000 © TOSHIBA TEC 2 - 3 KD-1009 OVERVIEW

Page 9

* for the DP4500/3500 only

SYMBOL SPEC. NAME FUNCTION REMARKS

*(S10) PST-U-SNR Detects that the paper stock is Photo interrupter

Upper cassette paper stock sensor going short of the upper cassette

*(S11) PST-L-SNR Detects that the paper stock is Photo interrupter

Lower cassette paper stock sensor going short of the lower cassette

(4) PC board

SYMBOL SPEC. NAME FUNCTION REMARKS

PWA PWA-F-PFP-519 Drives feeding and moves trays

PC board

KD-1009 OVERVIEW 2 - 4 October 2000 © TOSHIBA TEC

Page 10

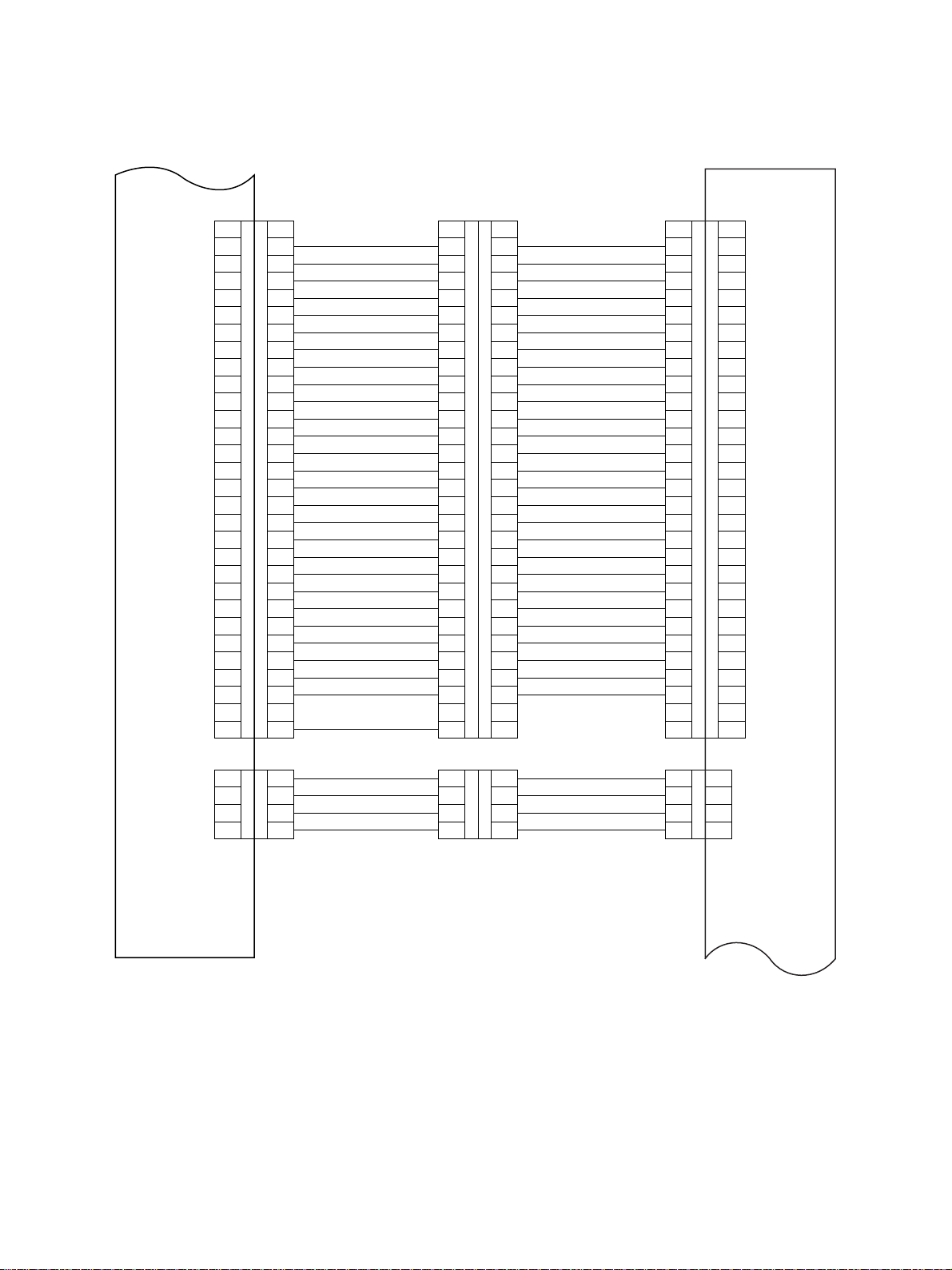

2.4 Harness Diagram

Copier

Copier

(PREMAGE165/255)

(DP1600/2500)

PFP

CN508

TR-CLT

CN507

T-UP-U-MTR

CN511

FED-U-SNR

CN510 CN520 CN520

FED-L-SNR

CN500

CN501

CN505

T-UP-L-MTR

CN509

SIDE-COV-SW

CN500

CN501

CN241

CN242

PFP-MTR

M

CN503

CN243CN247

CN244

PFP

PC board

CN502

CN246

Copier

Copier

(DP4500/3500)

(PREMAGE455/355)

CN318

FED-U-CLT

PFC

CN318

FED-L-CLT

CN567

CN568

TOP-U-SNR

CN567

CN568

CN314

CN316 CN516

ADPT

CN315

EMP-U-SNR

CN314

TOP-L-SNR

EMP-L-SNR

CN315 CN316 CN517

CN335

CST-U-SW

CN336

CST-L-SW

ADPT

CN248

October 2000 © TOSHIBA TEC 2 - 5 KD-1009 OVERVIEW

Page 11

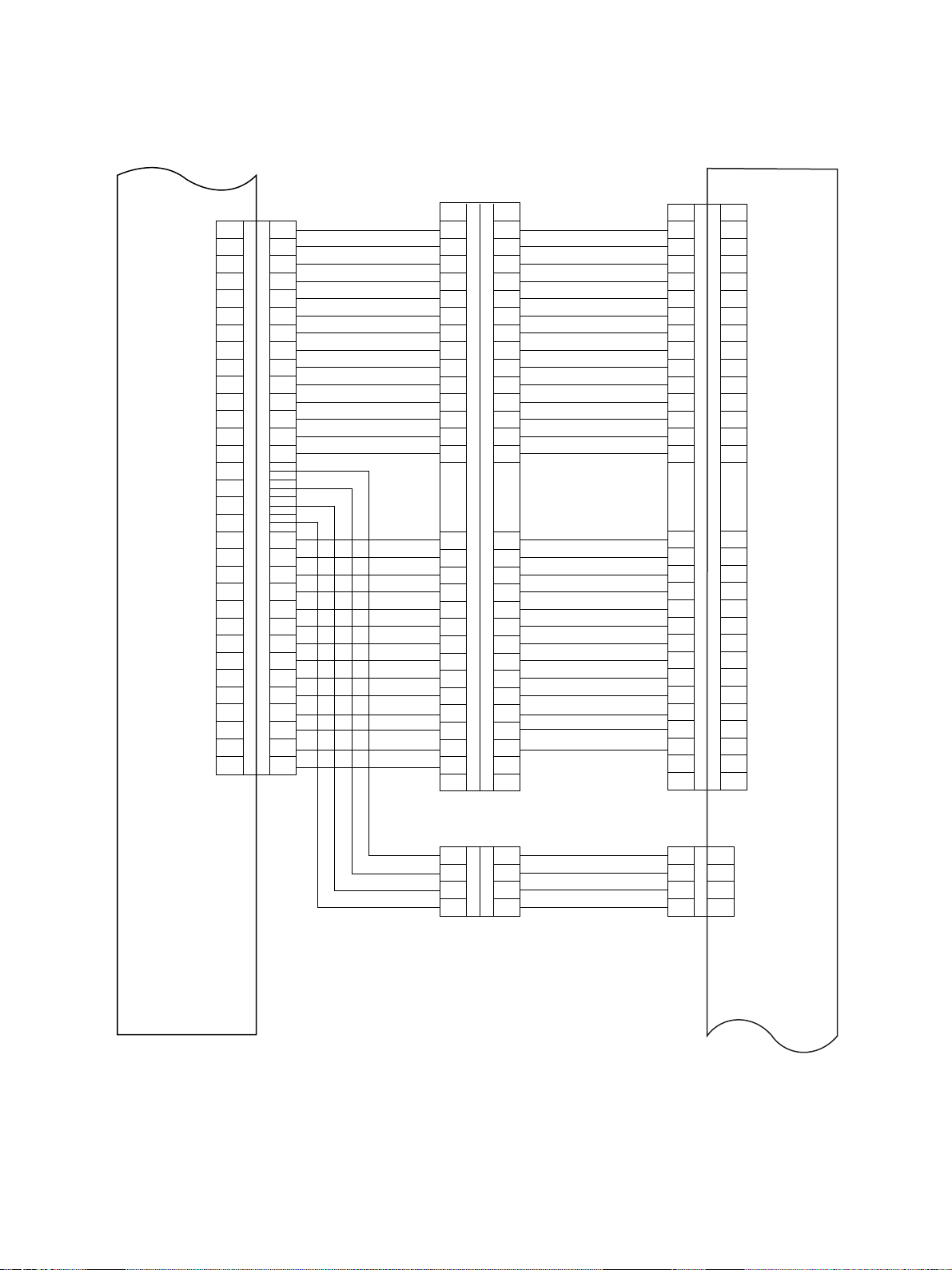

A1

CLK-C

A2

CLK-B

A3

SCSW-C

PFPRST

SCSW-B

Copier (DP1600/2500)

LCFCNT

DRV7

DRV6

DRV5

DRV4

DRV3

DRV2

DRV1

DRV0

VDD

GND

SIZE-0

SIZE-1

SIZE-2

SIZE-3

RETS-0

RETS-1

RETS-2

RETS-3

RETS-4

RETS-5

RETS-6

RETS-7

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

CN206

CN206

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

Copier (PREMAGE 165/255)

+24V

+24V

DG

DG

1

2

3

4

CN207

CN207

1

2

3

4

11

13

15

17

19

21

23

25

27

29

30

28

26

24

22

20

18

16

14

12

10

1

3

5

7

9

8

6

4

2

1

2

3

4

CN500

CN500

CN501

CN501

11

13

15

17

19

21

23

25

27

29

30

28

26

24

22

20

18

16

14

12

10

1

3

5

7

9

8

6

4

2

+24V

1

+24V

2

GND

3

GND

4

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

1

2

3

4

CN241

CN242

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

CN241

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

+24V

1

+24V

2

DG

3

DG

4

PFPCNT

CLK-C

CLK-B

SCSW-C

DRV7

DRV6

DRV5

DRV4

DRV3

DRV2

DRV1

DRV0

PFPRST

VDD

GND

SIZE-0

SIZE-1

SIZE-2

SIZE-3

RETS-0

RETS-1

RETS-2

RETS-3

RETS-4

RETS-5

RETS-6

RETS-7

SCSW-B

PFP

PC board

KD-1009 OVERVIEW 2 - 6 October 2000 © TOSHIBA TEC

Page 12

CLK-C

A1

CLK-B

A2

SCSW-C

PFPRST

Copier (DP4500/3500)

SCSW-B

Copier (PREMAGE 455/355)

DRV7

DRV6

DRV5

DRV4

DRV3

DRV2

DRV1

DRV0

VDD

GND

+24V

+24V

DG

DG

SIZE-0

SIZE-1

SIZE-2

RETS-0

RETS-2

RETS-3

RETS-4

RETS-5

RETS-7

RETS-5

RETS-6

RETS-7

LCCNT

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16 B16

CN312

CN312

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

11

13

15

17

19

21

23

25

27

29

30

28

26

24

22

20

18

16

14

12

10

1

3

5

7

9

8

6

4

2

CN567

CN567

11

13

15

17

19

21

23

25

27

29

30

28

26

24

22

20

18

16

14

12

10

PFPCNT

CN241

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

CN241

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

CLK-C

CLK-B

SCSW-C

DRV7

DRV6

DRV5

DRV4

DRV3

DRV2

DRV1

DRV0

PFPRST

VDD

GND

SIZE-0

SIZE-1

SIZE-2

RETS-0

RETS-2

RETS-3

RETS-4

RETS-5

RETS-7

RETS-5

RETS-6

RETS-7

SCSW-B

1

3

5

7

9

8

6

4

2

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

1

2

3

4

CN568

CN568

+24V

1

+24V

2

GND

3

GND

4

1

2

3

4

1

CN242

2

3

4

+24V

+24V

DG

DG

PFP

PC board

October 2000 © TOSHIBA TEC 2 - 7 KD-1009 OVERVIEW

Page 13

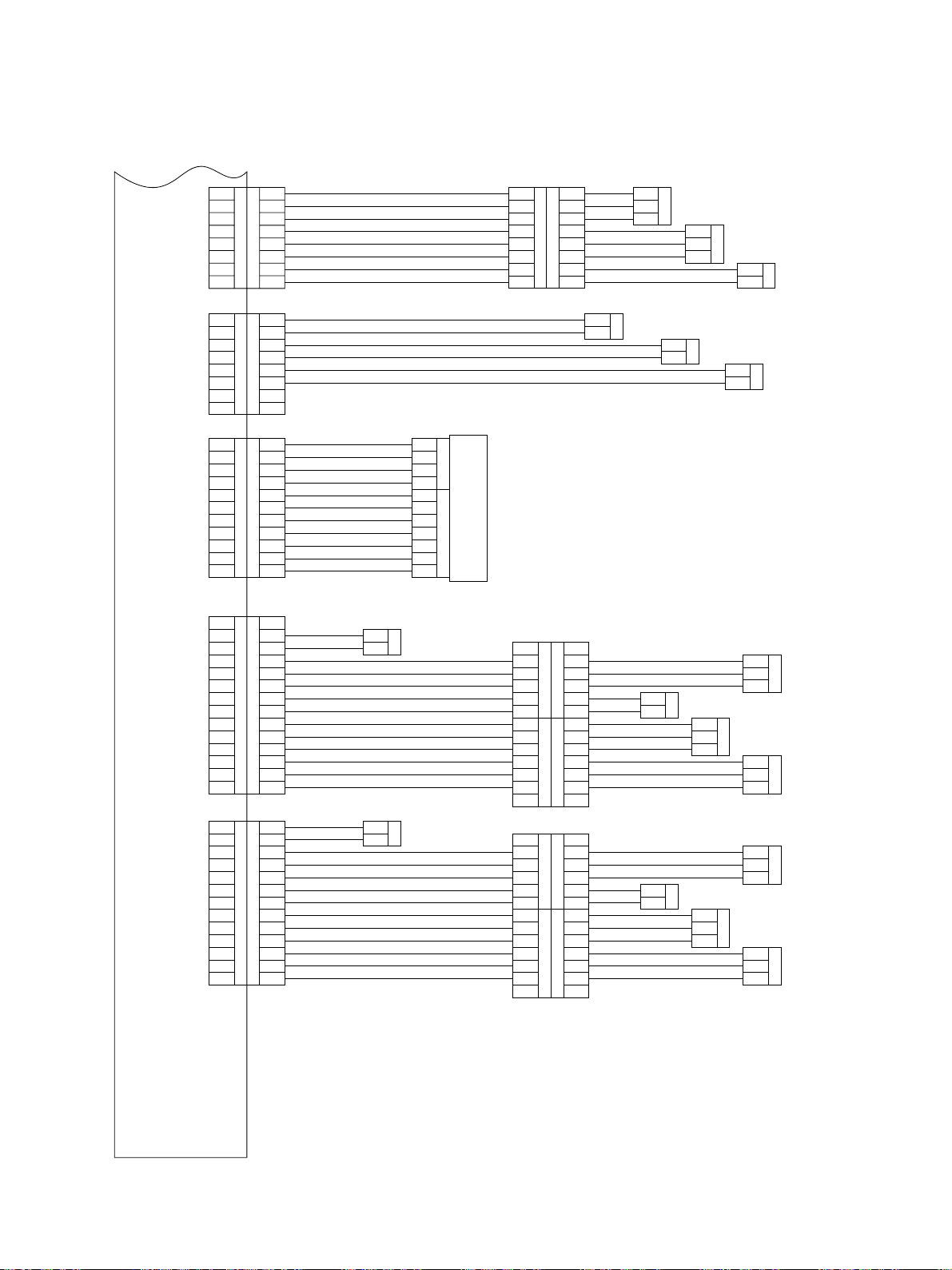

GND

FEDU

VDD

GND

FEDL

VDD

GND

COV-SW

1

2

3

4

5

6

7

8

CN243

CN243

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

CN520

1

2

3

4

5

CN520

6

7

8

GND

FEDU

VDD

GND

FEDL

VDD

GND

COV-SW

CN511

3

2 FED-U-SNR

1

CN510

3

2 FED-L-SNR

1

2

1

CN509

SIDE-COV-SW

CN244

CN244

CN246

CN246

CN247

CN247

CN248

CN248

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

14

GND

13

CST

12

11

10

9

8

7

6

5

4

3

2

1

GND

13

CST

12

11

10

9

8

7

6

5

4

3

2

1

TRMU-B

1

TRMU-A

2

TRMU-B

3

TRMU-A

4

+24V

5

FEDCLT

6

+24V

FEDCLT35

MOT-BRK

7

8

DG

1

DG

2

+24

3

+24

4

5

VDD

6

DIR

7

PLLOK

8

99

MOT-OFF

10 10

GND

11 11

14

13

GND

12

SIZCUO

11

VDD

10

PHU1

9

GND

8

+24V

7

PCLTU

VDD

6

TUPU

5

GND

4

VDD

3

PEMPU

2

GND

1

PFP PC Board

GND

13

12

SIZCUO

VDD

11

PUL1

10

GND

9

8

+24V

7

PCLTU

VDD

6

TUPU

5

GND

4

VDD

3

PEMPU

2

GND

1

1

2

1

2

CN335

CST-U-SW

CN336

CST-L-SW

4

3

2

1

7

6

5

4

3

2

1

CN502 CN503

PFP-MTR

(6)

1

CN516B

2

3

CN316B

4

5

1

2

CN516A

3

4

5

CN316A

6

(7)

(6)

1

CN517B

2

3

CN316B

4

5

1

2

CN517A

3

4

5

CN316A

6

(7)

(1)

(1)

(1)

(1)

CN505

1

T-UP-L-MTR

2

VCC

6

PHU1

5

GND

4

+24V

3

PCLTU

2

VCC

7

LPSON

6

GND

5

VCC

4

PESON

3

GND

2

VCC

6

PHU1

5

GND

4

+24V

3

PCLTU

2

VCC

7

LPSON

6

GND

5

VCC

4

PESON

3

GND

2

1

2

1

2

CN507

1

T-UP-U-MTR

2

CN318

FED-U-CLT

1

2 TOP-U-SNR

3

CN318

FED-L-CLT

1

2 TOP-L-SNR

3

CN508

1

2

1

2

3

CN314

1

2

3

1

2

3

CN314

1

2 EMP-L-SNR

3

TR-CLT

CN344

*PST-U-SNR

CN315

CN344

*PST-L-SNR

CN315

* for the DP4500/3500 only

KD-1009 OVERVIEW 2 - 8 October 2000 © TOSHIBA TEC

Page 14

2.5 Circuit Diagram

October 2000 © TOSHIBA TEC 2 - 9 KD-1009 OVERVIEW

Page 15

KD-1009 OVERVIEW 2 - 10 October 2000 © TOSHIBA TEC

Page 16

October 2000 © TOSHIBA TEC 2 - 11 KD-1009 OVERVIEW

Page 17

2.6 Assembly of PC Board

CN243 CN242

18

711

M3

CN244

18

11

14

C3

10/50

R1

IC1

8428KS

C4

10/50

IC4

8428KS

IC3

CN246

IC6

62308FT

1

IC7

MC74HC273AFL

CN247

C1

47/50

10K

MC74HC273AFL

PD

RV

CN241

A1

B15

CN248

M3

1114

HC244FL

HC244FL

HC244FL

A1

B1

C2

100/25

IC2

IC5

IC8

M3

5161

CN249 CN250

13

KD-1009 OVERVIEW 2 - 12 October 2000 © TOSHIBA TEC

Page 18

2.7 Timing Chart

(1 ) DP1600 (A4 sized sheet fed from the upper cassette)

ON

CW

CCW

CCW

MAIN-MTR

PFP-MTR

October 2000 © TOSHIBA TEC 2 - 13 KD-1009 OVERVIEW

OFFONOFFONOFFONOFF

OFF

TR-CLT

FED-U-CLT

FED-U-SNR

PFU-FED-CLT

ON

CW

ON

OFF

PFU-FED-SNR

RGST-SNR

ON

RGST-CL T

OFF

ON

OFF

EXIT-SNR

Page 19

(2 ) DP2500 (A4 sized sheet fed from the upper cassette)

CW

CW

CCW

CCW

MAIN-MTR

PFP-MTR

ON

ON

OFF

OFFONOFFONOFFONOFF

TR-CLT

FED-U-CLT

FED-U-SNR

PFU-FED-CLT

ON

OFF

PFU-FED-SNR

RGST-SNR

ON

OFF

RGST-CL T

ON

OFF

EXIT-SNR

KD-1009 OVERVIEW 2 - 14 October 2000 © TOSHIBA TEC

Page 20

(3 ) DP4500/3500 (A4 sized sheet fed from the upper cassette)

CCW

CW

CW

MAIN-MTR

ON

OFF

CCW

PFP-MTR

FED-U-CLT

ON

OFFONOFFONOFFONOFF

TR-CLT

FED-U-SNR

PFU-FED-CLT

ON

ON

OFF

PFU-FED-SNR

RGST-SNR

OFF

RGST-CL T

ON

EXIT-SNR

OFF

October 2000 © TOSHIBA TEC 2 - 15 KD-1009 OVERVIEW

Page 21

Page 22

3. GENERAL OPERATION

3.1 Description of Operations

[A] From power ON to standby

(1) When the copier is turned ON, power is also supplied to the feeder unit. Tray-up motor (M2)/(M3) is

turned ON to raise tray. Tray-up sensor (S4)/(S5) is turned ON correspondingly , then the tra y-up motor

(M2)/(M3) is turned OFF to stop the tray. If the empty sensor (S6)/(S7) is OFF (H) at this time, it is

judged that there is no paper in the cassette. If the empty sensor is ON (L), it is assumed that there is

paper in the cassette, and the tray stay in the raised position until the cassette is pulled out.

(2 ) If the power is turned ON when the cassette has been removed, the tray-up motor for that cassette is

not turned ON. The tray is r aised as soon as the cassette is installed, and it detects if there is paper

in the cassette.

(3 ) If either of the feed sensors (S2), (S3) is ON (there is paper in the transportation path) when the power

is turned ON, that means paper jam has occurred and operation is disabled until the paper is removed.

[B] Standby status

(1 ) T ra ys detect the paper as described abov e, and the copier goes into standb y status .

(2) The tray goes down automatically when the cassette is removed and it is raised as soon as the

cassette is installed again and checks if there is paper in the cassette.

[C] From the start to the end of copying

(1 ) The main motor of the copier is turned ON when the START key is pressed. About 0.1 sec. later , the

PFP motor (M1) and the transport clutch (C1) are turned ON to drive the transport rollers.

(2 ) When the copier judges that PFP is ready for feeding paper , it turns ON the feed clutch (C2)/(C3) of the

selected cassette. This clutch drives the pickup roller and feed roller to feed paper from the tr ay.

(3 ) The leading edge of the paper turns the feed sensor (S2)/(S3) ON. These are located right ne xt to the

exit side of the selected cassette. The feed clutch (C2)/(C3) is turned OFF and feeding from the

cassette is completed.

(4 ) The paper is transported to the copier by the PFP transport roller. If the trailing edge of the pre viously

sent sheet still remains at the feed sensor when the leading edge of the paper reaches the feed sensor

(S2)/(S3), the transport clutch (C1) is turned OFF to stop the transport of the paper. (In case of DP4500/

3500, the transport cluch (C1) is not turned OFF until the registration operation is completed regardless

of the size of the paper .)

(5 ) The trailing edge of the paper turns the feed sensor (S2)/(S3) OFF. These are located right next to the

exit side of the selected cassette. PFP then becomes ready for feeding the next sheet of paper, and

the procedures (2) to (4) are repeated.

(6 ) When the copying operation is completed, the main motor , PFP motor (M1) and transport clutch (C1)

are turned OFF and the transport roller is stopped.

October 2000 © TOSHIBA TEC 3 - 1 KD-1009 GENERAL OPERATION

Page 23

3.2 Error Detection

[A] Jam detection

(1) Paper jams (E15), (E16) and (E32, E34, E35) [DP4500/3500: (E15, E16) (E30~E36)] occurs in the

following cases.

a. Feed sensor (S2)/(S3) is not turned ON within 0.4 second after the feeding is started.

b . The leading edge of the paper does not pass the feed sensor (S2)/(S3) in the transport path within

a fixed time.

(2 ) Open the side cover of the paper feeder and remo ve all the paper remaining on the transport path and

close the side cover to clear the jammed paper . If either of the feed sensors (S2)/(S3) is still ON when

the side cover is closed, it is determined that there is still paper on the transport path and the paper jam

status is not canceled.

(3 ) When a paper jam occurs in the paper feeder during multiple copying, the sheet that was fed before the

jam is copied normally .

[B] Call Service

(1 ) The tray is raised when the power is turned ON or the cassette is inserted or removed.

If the tray-up sensor (S4)/(S5) is not turned ON within 8 (DP4500/3500: 12 seconds) seconds after the

tray has started to raise, a message to the effect that the selected cassette of that level cannot be

used is displayed in the control panel.

(2) The state (1) are cleared by removing the cassette. (This state cannot be cleared by opening and

closing the side cover)

KD-1009 GENERAL OPERATION 3 - 2 October 2000 © TOSHIBA TEC

Page 24

3.3 Flow Chart

(1) DP1600/2500

START key ON

Main motor ON

PFP motor ON

Polygonal motor ON

Developer bias ON

Separation charger ON

Main charger ON

Discharge lamp ON

Processing control

Polygonal motor

rotating normally?

YES

Call for Service

Laser ON

Transfer charger ON

Transfer guide bias ON

Laser OFF

Transfer charger OFF

Transfer-guide bias OFF

NO

"CA1"

Transpor t system control

Main motor

rotating normally?

YES

Call for Service

"C01"

PFP motor

rotating normally?

YES

Call for Service

"C04"

Upper cassette feed clutch ON

PFP

Upper feed

sensor ON?

Scanner system control

Carriages move backward

NO

Black shading

Exposure lamp ON

NO

Carriages Stopped

Carriages move forward

White shading

NO

Scanning

NO

H-Sync OK?

YES

Copier’s

Lower feed

sensor ON?

YES

NO

Call for

Service

"CA2"

YES

Remaining number

of copies=0?

YES

Registration

sensor ON?

YES

Polygonal motor OFF

Processing con-

trol completed

October 2000 © TOSHIBA TEC 3 - 3 KD-1009 GENERAL OPERATION

B

Paper jam

"E15"

NO

Paper jam

"E34"

NO

Paper jam

"E32"

Carriages stopped

Exposure lamp OFF

Carriages move backward

Carriages stopped

Scanner system

control completed

Page 25

B

Upper cassette feed clutch OFF

Registration clutch ON

Counters ON

Registration clutch OFF

NO

Remaining number

of copies = 0?

sensor 1

ON?

Exit

sensor 2

ON?

Main charger OFF

Main motor OFF

PFP motor OFF

Developer bias OFF

Separation charger OFF

Discharge lamp OFF

Exit

YES

YES

YES

NO

NO

Paper jam

"E01"

Paper jam

"E02"

Standby

KD-1009 GENERAL OPERATION 3 - 4 October 2000 © TOSHIBA TEC

Page 26

(2) DP4500/3500

START key ON

Main motor ON

PFP motor ON

Polygonal motor ON

Developer bias ON

Separation charger ON

Main charger ON

Discharge lamp ON

Processing control

Polygonal motor

rotating normally?

YES

Call for Service

Laser ON

Transfer charger ON

Transfer guide bias ON

Laser OFF

Transfer charger OFF

Transfer-guide bias OFF

NO

"CA1"

Transpor t system control

Main motor

rotating normally?

YES

Call for Service

"C01"

PFP motor

rotating normally?

YES

Call for Service

Upper cassette feed clutch ON

PFP transport clutch ON

PFP

Upper feed

sensor ON?

NO

NO

"C04"

NO

Scanner system control

Carriages move backward

Black shading

Exposure lamp ON

Carriages Stopped

Carriages move forward

White shading

Scanning

NO

H-Sync OK?

Call for

Service

YES

Upper cassette feed clutch OFF

YES

Copier’s transport clutch ON

Paper jam

"E15"

Carriages stopped

Exposure lamp OFF

"CA2"

NO

Remaining number

of copies=0?

Copier’s lower

NO

Carriages move backward

feed sensor ON?

YES

Polygonal motor OFF

YES

Paper jam

"E32"

Processing con-

trol completed

October 2000 © TOSHIBA TEC 3 - 5 KD-1009 GENERAL OPERATION

B

Carriages stopped

Scanner system

control completed

Page 27

B

Copier’s upper feed

sensor ON?

YES

Paper jam

Copier’s registration

sensor ON?

YES

Paper jam

PFP transport clutch OFF

Copier’s transport clutch OFF

Copier’s registration clutch ON

Copier’s transport clutch ON (up)

Counter ON

Copier’s registration clutch OFF

NO

"E31"

NO

"E30"

NO

Remaining number

of copies = 0?

sensor 1

ON?

Exit

sensor 2

ON?

Main charger OFF

Main motor OFF

PFP motor OFF

Developer bias OFF

Separation charger OFF

Discharge lamp OFF

Exit

YES

YES

YES

NO

NO

Paper jam

"E01"

Paper jam

"E02"

Standby

KD-1009 GENERAL OPERATION 3 - 6 October 2000 © TOSHIBA TEC

Page 28

4. DRIVE SYSTEM AND FEEDING OPERATION

4.1 Configuration and Drive System

The Paper F eed Pedestal (PFP) mainly consists of the cassette , pickup roller , feed roller , separation roller ,

transport roller and drive systems for these components.

• Feeding/Transport system

The PFP motor drives the pickup roller , feed roller , separation roller and tr ansport roller which are located

in the feeding area.

• Cassette tray system

This system raises and lowers the trays.

Upper/Lower cassette pickup roller

Upper/Lower cassette feed roller

Upper transport roller

Lower transport roller

Upper/Lower cassette

tray-up motor

Upper cassette

feed clutch

PFP motor

Transpor t clutch

Lower cassette feed clutch

October 2000 © TOSHIBA TEC 4 - 1 KD-1009 DRIVE SYSTEM

Page 29

Page 30

5. DISASSEMBLY AND RE-

PLACEMENT

5.1 Installation and Removal of Cas-

settes and Covers

[A] Cassettes

(1) Pull out the cassette fully and remove it while

lifting it up.

[B] Slot cover

(1 ) Pull out the upper cassette.

(2) Remove 2 screws and take off the slot co ver.

[C] Rear cover

(1) Remove the 5 screws fixing the rear cov er.

(2 ) Remove the rear cover while lifting it up.

[D ] Feeding-side front cover and Feeding-side

rear cover

(1 ) Remove 2 screws and take off the feeding-side

front cover.

(2 ) Remove 2 screws and take off the feeding-side

rear cover .

Slot cover

Rear cover

Feeding-side front cover Feeding-side rear cover

October 2000 © TOSHIBA TEC 5 - 1 KD-1009 DISASSEMBLY

Page 31

[E] Side cover

(1) Open the side cover. Loosen the belt and re-

move it.

(2 ) Disconnect one connector.

(3) Remove the side cover.

Connector

Belt

5.2 PC Board

(1 ) Remove the rear cov er .

(2 ) Disconnect 7 connectors and detach 4 lock sup-

ports to remove the PC board.

5.3 Upper and Lower T ransport Rollers

(Plastic Rollers)

(1) Remove the side cover and the feeding-side front

cover .

(When the upper transport roller is also removed,

take off the feeding-side front cover of the

copier.)

(2 ) Detach the springs and bushings from the front

and rear sides and take off the rollers.

Lock supports

Springs

Plastic rollers

Springs

KD-1009 DISASSEMBLY 5 - 2 October 2000 © TOSHIBA TEC

Page 32

5.4 Motors

[A] Tray-up motor unit

(1 ) Remove the rear cov er .

(2 ) Remove the harness from the 2 clamps.

(3 ) Disconnect 3 connectors.

(4) Remove 5 screws and take off the tray-up

motor unit.

Note: Tray-up motor unit is connected with the

copier with other harness. Do not disconnect

them and place the unit nearby the copier .

Connector

Tray-up

motor unit

Connector

Connector

Clamps

[B] PFP motor unit

(1 ) Disconnect 2 connectors.

(2) Remove 2 screws and take off the PFP motor.

(3 ) Remove one screw and take off the lever shaft

bracket.

(4) Remove 4 screws and take off the PFP motor

unit bracket.

Note: The positions to attach the

shift lever bracket and lever

DP4500/3500

(Lever position: HIGH)

shaft bracket differ according

to each model.

Lever shaft

bracket

(4) (4)

(3)

(2)

(4)

(4)

DP1600/2500

(Lever position: LOW)

Connectors

(5 ) Remove the clip and pull out the lever shaft.

(6) T ak e off the shift lever br acket. Remove the gears

and belt from the PFP motor unit bracket.

Gears

October 2000 © TOSHIBA TEC 5 - 3 KD-1009 DISASSEMBLY

Shift lever blacket

Clip

Gear

Belt

Lever shaft

Page 33

5.5 Feed/Separation/Pickup Rollers

[A] Feed unit

(1) Pull out the cassette.

(2) Remove one screw and take out the feed unit

toward the front side.

[B] Feed clutch

(1 ) Disconnect one connector.

(2) Remove 2 screws and take off the clutch bracket.

(3 ) Loosen one setscrew.

(4 ) Remove the feed clutch.

Feed unit

Clutch bracket

Connector

[C] Separation roller

(1 ) Remove one screw and take off the separation

roller holder.

(2) Remove the lever from the holder and take off

the separation roller along with its shaft.

(3) Remove the cover , arbor, clutch spring, and then

the separation roller from the shaft.

Separation roller

KD-1009 DISASSEMBLY 5 - 4 October 2000 © TOSHIBA TEC

Page 34

Note:

When reassembling the pickup roller , feed roler and

separation roller, pa y attention to the f ollowings:

1. Put a pin into the pulley.

2. Set the timing belt securely on the pulleys.

3. The “lock” direction of each one-way clutch is

different.

CLUTCH-6-L

CLUTCH-6-R

L

O

C

K

LOCK

LOCK

4. Fit the clips securely into the groove on the shaft.

5. Confirm that there is no oil staining etc. on the

surface of the timing belt, pulleys and rollers.

6. Pay attention to the mounting direction of the

Holder

Arbor

Lever

Cover

Clutch spring

Separation roller

Shaft

Spring

Arbor

Spring

rollers.

[D] Pickup roller

(1) Remove the pickup roller from the pickup arm

and take off the belt.

Paper

Pickup arm

Paper feed roller

Separation roller

One-way clutch

Pickup

roller

Pickup roller

Belt

Pickup arm

October 2000 © TOSHIBA TEC 5 - 5 KD-1009 DISASSEMBLY

Page 35

[E] Feed roller

(1) Remove the clip and take off the feed roller in

the direction of the arrow .

Clip

One-way clutch

Feed roller

5.6 Switches and Sensors

[A] Side cover open/close sensor

(1) Remove the side cove r .

(2) Release the latches and remove the sensor

cover.

(3 ) Disconnect one connector.

(4 ) Release the latches and remove the sensor .

[B] Upper/lower feed sensors

(1) Relase the latches and remove the sensor cov er.

(2 ) Disconnect one connector.

(3 ) Release the latches and remove the sensor .

Note: Upper and lower switches can be removed

with the same procedure.

Sensor cover

Latches

Side cover open/

close sensor

Latches

Sensor cover

Latches

Feed sensor

[C] Upper/lower cassette detection switches

(1) Pull out the cassette.

(2 ) Remove the rear cov er .

(3) Take off the tray-up motor unit and PFP motor

Connectors

unit.

(4) Disconnect the connectors connected to the cas-

sette detection switch.

(5 ) Release the latches and remove the switch from

the front side.

KD-1009 DISASSEMBLY 5 - 6 October 2000 © TOSHIBA TEC

Page 36

[D] Tray-up sensor and Paper empty sensor

(1) Disconnect the connector and release the latches

and remove the tr ay-up sensor .

(2) Disconnect the connector and release the latches

and remove the empty sensor .

[E] Paper stock sensor (for the DP4500/3500 only)

(1 ) Release the latches and remove the sensor .

(2 ) Disconnect one connector.

Tray-up sensor

Latch

Latch

Paper empty sensor

Paper stock sensor

October 2000 © TOSHIBA TEC 5 - 7 KD-1009 DISASSEMBLY

Page 37

Page 38

6. PERIODIC MAINTENANCE

Symbols used in the checklist

Cleaning Coating Replacing Date

A: Cleaning

with

alcohol

General Maintenance Checklist

Pickup roller(Upper/Lower) A 81

Feed roller(Upper/Lower) A 81

Separation roller(Upper/Lower) A AV 81 Note)

Drive gears(tooth face) W

*The above par ts are to be replaced depending on the number of the sheets of paper used in each

cassette.

Note: Apply the appropriate amount

of the grease as specified in the

right figure.

W: White grease (Molycoat)

A V: Alvania No. 2

Item to inspect Cleaning Coating Replace every Remarks

8 1 Every 81K copies

Replace if deformed or

damaged

1K copies

User’s name

Serial No

Inspector’s name

Remarks

Apply the grease on the

inside entirely

October 2000 © TOSHIBA TEC 6 - 1 KD-1009 PERIODIC MAINTENANCE

Page 39

MEMO

Page 40

MEMO

Page 41

MEMO

Loading...

Loading...