Toshiba HWS-P804XWHM3-E1, HWS-P804HR-E1, HWS-P804XWHT6-E1, HWS-P1104HR-E1, HWS-P804XWHT9-E1 Service Manual

...Page 1

AIR TO WATER HEAT PUMP

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Service Manual

Model name:

FILE No. A10-1503

Hydro unit

HWS-P804XWHM3-E1(TR)

HWS-P804XWHT6-E1(TR)

HWS-P804XWHT9-E1

HWS-P1104XWHM3-E1(TR)

HWS-P1104XWHT6-E1(TR)

HWS-P1104XWHT9-E1(TR)

Outdoor unit

HWS-P804HR-E1(TR)

HWS-P1104HR-E1(TR)

Page 2

Contents

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

1 Safety precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Refrigerant (R410A). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-1.Safety during installation and service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-2.Installing refrigerant pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2-2-1.Steel pipe and joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2-2-2.Processing of piping materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-3.Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-3-1.Necessary tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-4.Recharging of refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-5.Brazing of pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2-5-1.Materials of brazing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2-5-2.Flux . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2-5-3.Brazing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 Outside drawing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4-1.Hydro unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4-2.Outdoor unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4-3.Hot water cylinder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5 Wiring diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5-1.Hydro unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5-2.Outdoor unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5-3.Hot water cylinder unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6 Key electric component rating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6-1.Hydro unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6-2.Outdoor unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6-3.Hot water cylinder unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6-4.Water heat exchange control board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6-5.Outdoor control board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

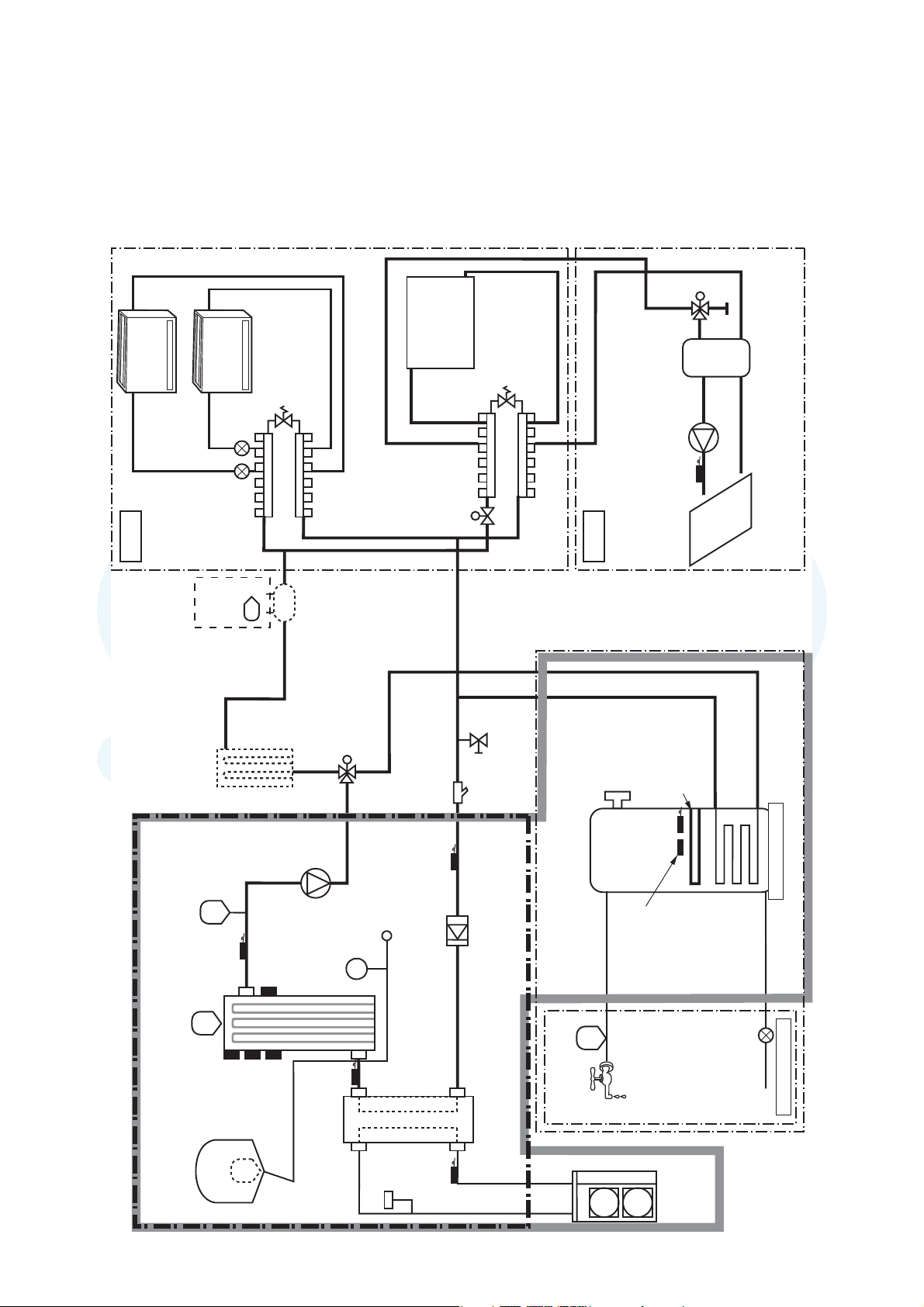

7 Refrigeration cycle / Water system diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7-1.Water system diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7-2.Refrigeration cycle system diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

1

Page 3

8 Operational description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

9 Method of defect diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

9-1.Matters to be confirmed first. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

9-1-1.Check the power supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

9-1-2.Check for any miswiring of the connection cables between the hydro unit and the

outdoor unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

9-1-3.About the installation of the temperature sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

9-2.Non-defective operation (pro gr am op er at i on ) … No fault code display appears.. . . . . . . . . . . . . . 75

9-3.Outline of the determination diagr am . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

9-3-1.Procedure of defect diagnosis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

9-3-2.How to determine from the check code on the remote controller . . . . . . . . . . . . . . . . . . . 76

9-3-3.How to cancel a check code on the remote controller . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

9-3-4.How to diagnose by error code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

9-4.Diagnosis flow chart for each error code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

9-4-1.Hydro unit failure detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

9-4-2.Outdoor unit failure detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

9-4-3.Temperature sensor, temperature-resistance characteristic table . . . . . . . . . . . . . . . . . 113

9-5.Operation check by PC board switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

9-5-1.Operation check mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

9-6.Brief method for checking the key components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

9-6-1.Hydro unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

9-6-2.Outdoor unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

10 Hydro unit and outdoor unit settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

11 Replacement of the service PC board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

12 How to exchange main parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

13 For cooling installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

14 Periodic inspection items. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

15 Part exploded view, part list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

2

Page 4

1 Safety precautions

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

The unit and this service guide list very important safety precautions.

Understand the following details (indications and symbols) before reading the body text, and follow the instructions.

[About indication]

Indication Meaning of Indication

DANGER

WARNING

CAUTION

*Property damage indicates extended damage to property, furniture, livestock, or pets.

Indicates that a wrong operation may cause a service engineer and the third persons

around to get fatal or serious injuries.

Indicates that a wrong operation may cause a service engineer and the third persons

around to get fatal or serious injuries, or that unit defective after the operation may cause

a user to have a similar serious accident.

Indicates that a wrong operation may cause a service engineer and the third persons

around to get injuries or may cause property damage*, or that unit defective after the

operation may cause a user to have a similar accident.

[About symbols]

Symbols Meaning of Symbols

Indicates a forbidden action.

Specific forbidden actions are des c ribed in text near the symbol.

Indicates a forcible (must do) action.

Specific forcible actions are described in text near the symbol.

Indicates a caution (including danger and warning).

Specific cautions are described in picture or text inside or near the symbol.

DANGER

<Turn off the power breaker>

Turn off the power breaker before removing the front panel and cabinet.

• Failure to do so may cause a high voltage electric shock, leading to death or injury.

• During an operation, the second side circuit of high pressure transmission(*) are applied with a high voltage of 230 V

or higher.

• Touching the circuit even with an electrical insulator, let alone a bare hand or body, causes an electric shock.

∗: For details, see the schematic.

<Discharge between terminals>

When the front panel and cabinet are removed, make short-circuit current to discharge between high pressure

capacitor terminals.

• Failure to do so may cause a high voltage electric shock, leading to death or injury.

• After the power is turned off, the high pressure capacitor is still charged with high voltage.

<Forbidden>

Do not turn on the power breaker after removing the front panel cabinet.

• Failure to do so may cause a high voltage electric shock, leading to death or injury.

WARNING

<Check earth ground>

Before starting failure diagnosi s or re pa ir , check that the earth wire (∗) is connected to the unit ground terminal.

• An unconnected earth wire could cause an electric shock if electric leakage occurs.

• If the earth ground is not properly connected, ask an electrical worker for rework of the ground connection.

∗: Earth wire of class D grounding

3

Page 5

WARNING

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

<No modification>

Do not modify the unit.

• Do not disassemble or modify the parts also.

• A fire, an electric shock, or an injury may occur.

<Use specified parts>

Use the specified parts (∗) when replacing them.

• Using parts other than specified ones may cause a fire or an electric shock.

∗: For details, see the parts price list.

<Keep children away from unit>

Keep any person (including children) oth er than service eng ineers away from a fail ure diagnosis or repa iring place.

• A tool or disassembled parts may cause an injury.

• Advise the customer to keep the third persons (including children) away from the unit.

<Insulation treatment>

After connecting a cut lead with a crimp contact, discharge by facing the closed side upward.

• Connect lead wires with crimping terminals and turn the closed end upwards to avoid exposure to water.

<Watch out for fire>

Observe the following instructions when repairing the refrigerant cycle.

(1) Watch out for surrounding fire. Always put out the fire of stove burner or other devices before starting the repair.

Should the fire fail to be put out, the oil mixed with refrigerant gas could catch fire.

(2) Do no use a welder in a closed room.

A room with no ventilation may cause carbon monoxide poisoning.

(3) Keep away flammable materials.

The materials may catch the fire of a welder.

<Use refrigerant carefully>

Check the refrigerant name to use the tools and members appropriate for the re frigerant.

• A product using the refrigerant R410A has the refrigerant name prominently displayed on its outdoor unit. In

addition, the diameter of the service port is changed from that of the conventional R22 to prevent incorrect filling.

Never use refrigerant other than R410A for Air to Water Heat Pump using R410A. Also, never use R410A for Air to

Water Heat Pump using other refrigerant (such as R22).

• A mixture of R410A with different ones excessively raises the pressure in the refrigerant cycle, leading to an injury

due to burst.

Do not make additional charge of the refrigerant.

• An additional charge when refrigerant gas leaks changes the refrigerant composition in the refrigerant cycle,

causing the characteristics change of the Air to Water Heat Pump or excessive high pressure in the refrigerant

cycle with more than the specified amount of refrigerant charged. This may cause burst or an injury. If the

refrigerant gas leaks, perform refrigerant recovery or other operation to make the Air to Water Heat Pump contain

no refrigerant, and then perform vacuuming. After that, refill the unit with the defined amount of liquid refrigerant.

Never charge refrigerant exceeding the amount specified.

When the refrigerant cycle is refilled with refrigerant, do not enter air or refrigerants other than the specified

refrigerant, R410A.

• A mixture of R410A with air or an inappropriate substance causes excessive high pressure inside the refrigerant

cycle, leading to an injury due to burst.

Check that there is no refrigerant gas leak after the installation is completed.

• If it catches fire of a fan heater, a space heater, or a stove, poisonous gases may be produced.

<Be careful with wiring>

After a repair is completed, be sure to reassemble the parts and put the wiring back to its original s tate. In additio n,

be careful with the internal wiring not to be caught in a cabinet or panel.

• A defective assembly or wiring may cause a disaster at a customer site due to electrical leakage or a fire.

<Check for water leak>

After the repair of a water pathway is completed, check that there is no water leak.

• In using the product, water leak may cause a fire at a customer site due to electrical leakage or an electric shock.

4

Page 6

WARNING

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

<Check insulation>

After the work is completed, check with an insulating-resistance tester (500V) that the insulation resistance between

the live and dead-metal parts is 2 MΩ or higher.

• A low insulation resistance may cause a disaster at a customer site due to electrical leakage or an electric shock.

<Ventilate>

Ventilate if refrigerant gas leaks during service work.

• Should refrigerant gas catch fire, poisonous gases may be produced. A closed room full of leaking refrigerant

results in the absence of oxygen; it is dangerous. Make sure to ventilate.

<Caution: electric shock>

When checking a circuit while energized if necessary, use rubber gloves not to contact the live part.

• Contact with the live part may cause an electric shock.

• The unit contains high-voltage circuits. Contact with a part in the control board with your bare hand may cause an

electric shock. Take enough care to check circuits.

<Turn off the power breaker>

Because the electrical components are energized with high voltage, always turn off the power breaker before

starting to work.

• Failure to do so may cause an electric shock.

<Always do>

Should refrigerant gas leak, find where the gas leaks and properly re pair it.

• To stop the repair work because the leakage location cannot be identified, perform refrigerant recovery and close

the service valve. Failure to do so may cause the refrigerant gas to leak in a room. Although refrigerant gas alone

is harmless, if it catches fire of a fan heater, a space heater, or a stove, poisonous gases may be produced.

When installing the unit or re-installing it after relocation, follow the installation guide for proper operation.

• A defective installation may cause a refrigerant cycle defective, a water leak, an electric shock, or a fire.

<Check after repair>

After a repair is completed, check for any abnormality.

• Failure to do so may cause a fire, an electric shock, or an injury.

• Turn off the power breaker to perform check.

After a repair is completed (and the front panel and cabinet are placed), make a test run to check for any abnormality

such as smoke or abnormal sound.

• Failure to do so may cause a fire or an electric shock. Place the front panel and cabinet before making a test run.

<Check after re-installation>

Check that the following are properly performed after re-installation.

(1) The earth wire is properly connected.

(2) The installation is stable without any tilt or wobbles.

Failure to check them may cause a fire, an electric shock, or an injury.

CAUTION

<Wear gloves>

Wear gloves (∗) when performing repair.

• Failure to do so may cause an injury when accidentally contacting the parts.

∗: Thick gloves such as cotton work gloves

<Cooling check>

Perform service work when the unit becomes cool enough after the operation.

• High temperature of compressor piping or other equipment after a cooling or heating operation may cause burn.

<Tighten with torque wrench>

Tighten a flare nut with a torque wrench in the specified method.

• A flare nut tightened too much might crack after a long period, causing refrigerant leak.

5

Page 7

2 Refrigerant (R410A)

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

This Air to Water Heat Pump adopts a refrigerant HFC (R410A) to prevent destruction of the ozone layer.

The working pressure of R410A refrigerant is 1.6 times higher than that of the conventional refrigerant R22.The

refrigerant oil is also changed for the new refrigeration. Therefore, during installation or service work, be sure that

water, dust, former refrigerant, or refrigeration machine oil does not enter the refrigerant cycle of the new type

refrigerant Air to Water Heat Pump. A wrong installation or service operation may cause a serious accident.

Read carefully the following instructions to use the tools or members for R410A for safety work.

2-1. Safety during installation and service

• Use only the refrigerant R410A for Air to Water Heat Pump using R410A.

A mixture of R410A with different ones excessively raises the pressure in a refrigerant cycle, leading to an injury

due to burst.

• Check the refrigerant name to use the tools and members appropriate for the refrigerant.

A product using the refrigerant R410A has the refrigerant name prominently displayed on its outdoor unit. In

addition, the diameter of the service port is changed from that of the conventional R22 to prevent incorrect filling.

• Ventilate if refrigerant gas leaks during service work.

Should refrigerant gas catch fire, poisonous gases may be produced. A closed room full of leaking refrigerant

results in the absence of oxygen; it is dangerous. Make sure to ventilate.

• When the refrigerant cycle is refilled with refrigerant, do not mix air or refrigerants other than the specified

refrigerant, R410A.

A mixture of R410A with air or an inappropriate substance causes exce ssive high pressure inside the refrig erant

cycle, leading to an injury due to burst.

• Check that no refrigerant gas leaks after the installation is completed.

Should a refrigerant gas leak in a room and catch fire, poisonous gases may be produced.

• When installing the unit that contains lar ge amount of refrigerant such as Air to Water Heat Pump, take measures

to prevent the refrigerant from exceeding the threshold concentration in case it leaks.

Should leaking refrigerant exceed the threshold concentration could cause an accident due to oxygen deficient.

• When installing the unit or re-installing it after relocation, follow the installation guide for proper operation.

A defective installation may cause a refrigerant cycle defective, a water leak, an electric shock, or a fire.

• Do not modify the product. Do not disassemble or modify the parts also.

A fire, an electric shock, or an injury may occur.

6

Page 8

2-2. Installing refrigerant pipe

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

2-2-1. Steel pipe and joint

For refrigerant piping, steel pipe and joints are mainly used. Select those comply with JIS (Japanese Industrial

Standards) for a service work. Also, use such clean piping materials that less im purities attach to the inside of pipe

and joints.

Copper pipe

Use copper pipe of the “copper and copper alloy seamless pipe” type with attach oil quantity of 40 mg / 10 m or less.

Do not use pipe that is cracked, distorted, or discoloured (especially inside).The expansion valve or capillary may

get clogged with impurities.

Considering that Air to Water Heat Pump using R410A is higher in pressure than those using the conventional R22,

be sure to select the material that comply with the standard.

Table 2-1 shows the thickness of copper pipe used for R410A.

Never use commercially available thin-walled copper pipe of 0.8 mm thick or less.

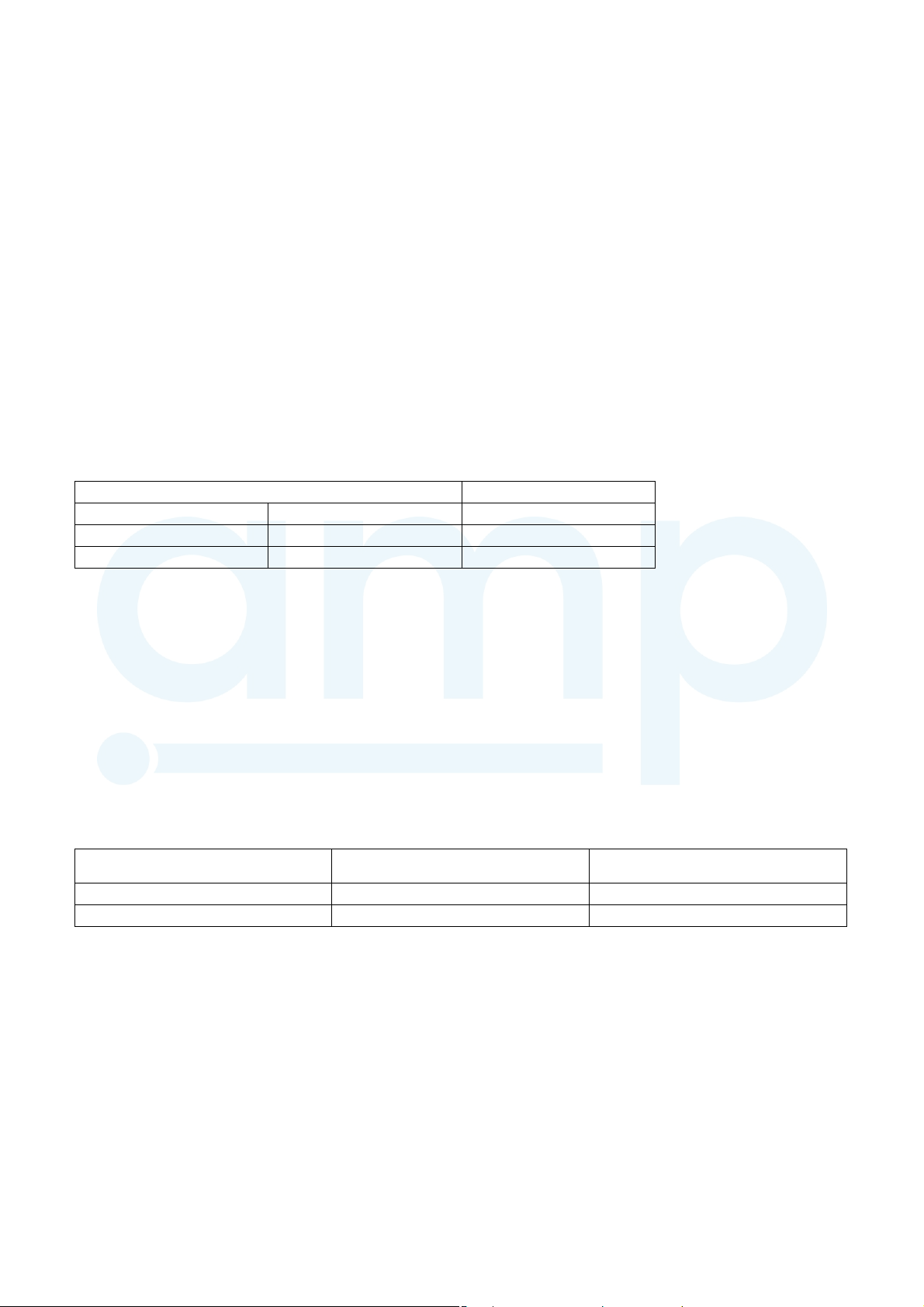

Table 2-1 Wall thickness of copper pipe

Wall thickness (mm)

Nominal diameter Outer diameter R410A

3/8 9.52 0.80

5/8 15.88 1.00

Joints

For the joint of copper pipe, flared joint and socket joint are used. Remove impurities from a joint before using it.

• Flared joint

A flared joint cannot be used for the copper pipe whose outer diameter is 20 mm or larger. A socket join t can be

used instead in that case.

Table 2-2-3 and 2-2-4 show the dimension s of flare pipe, the end of flared joint, and flare nuts.

• Socket joint

A socket joint is used to connect the thick-walled pipe of mainly 20 mm or larger in diameter.

Table 2-2 shows the wall thickness of socket joints.

Table 2-2 The minimum wall thickness of socket joints

Nominal diameter

3/8 9.52 0.80

5/8 15.9 1.00

Reference of outer diameter of

copper pipe connected (mm)

Minimum joint wall thickness

(mm)

7

Page 9

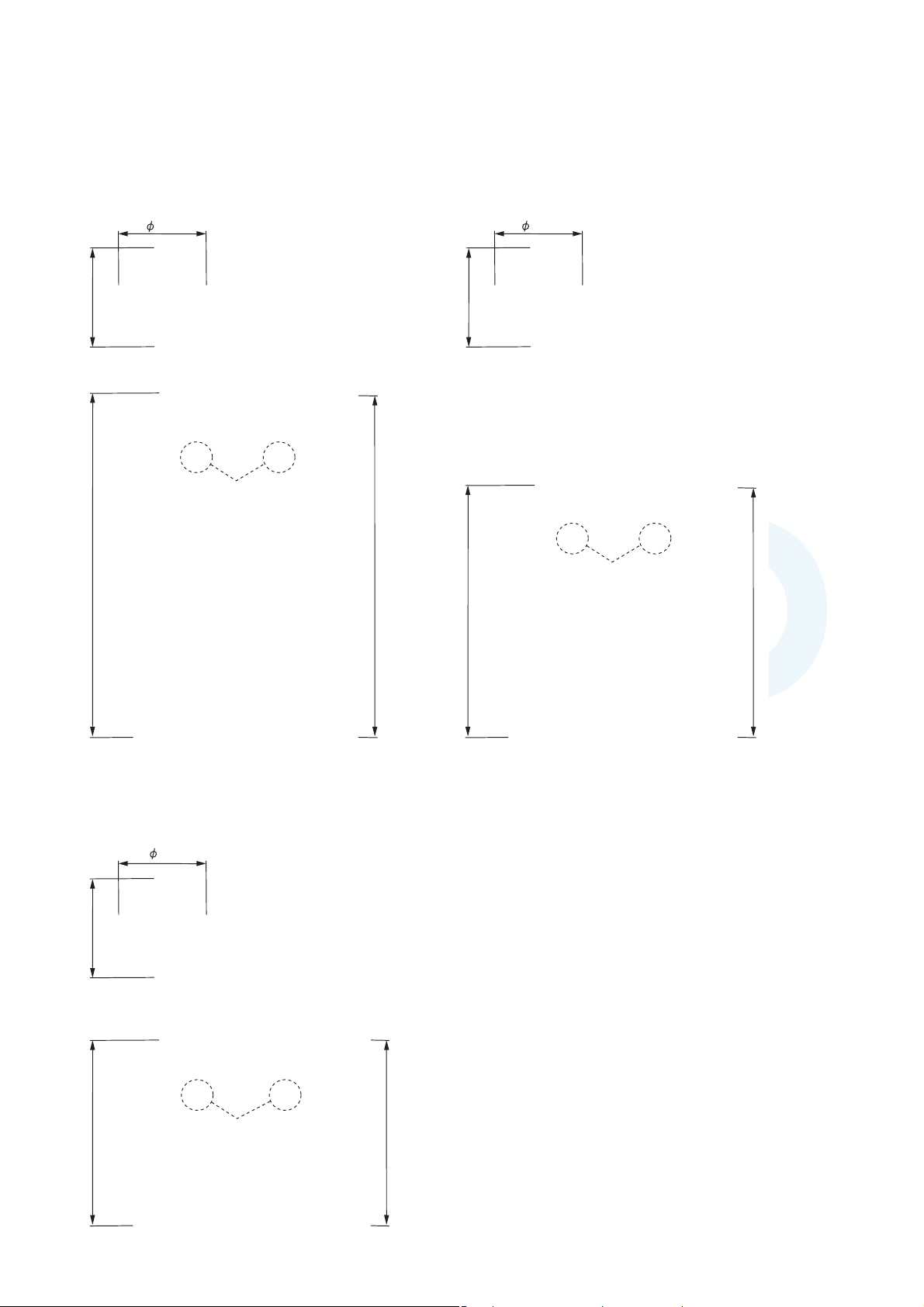

2-2-2. Processing of piping materials

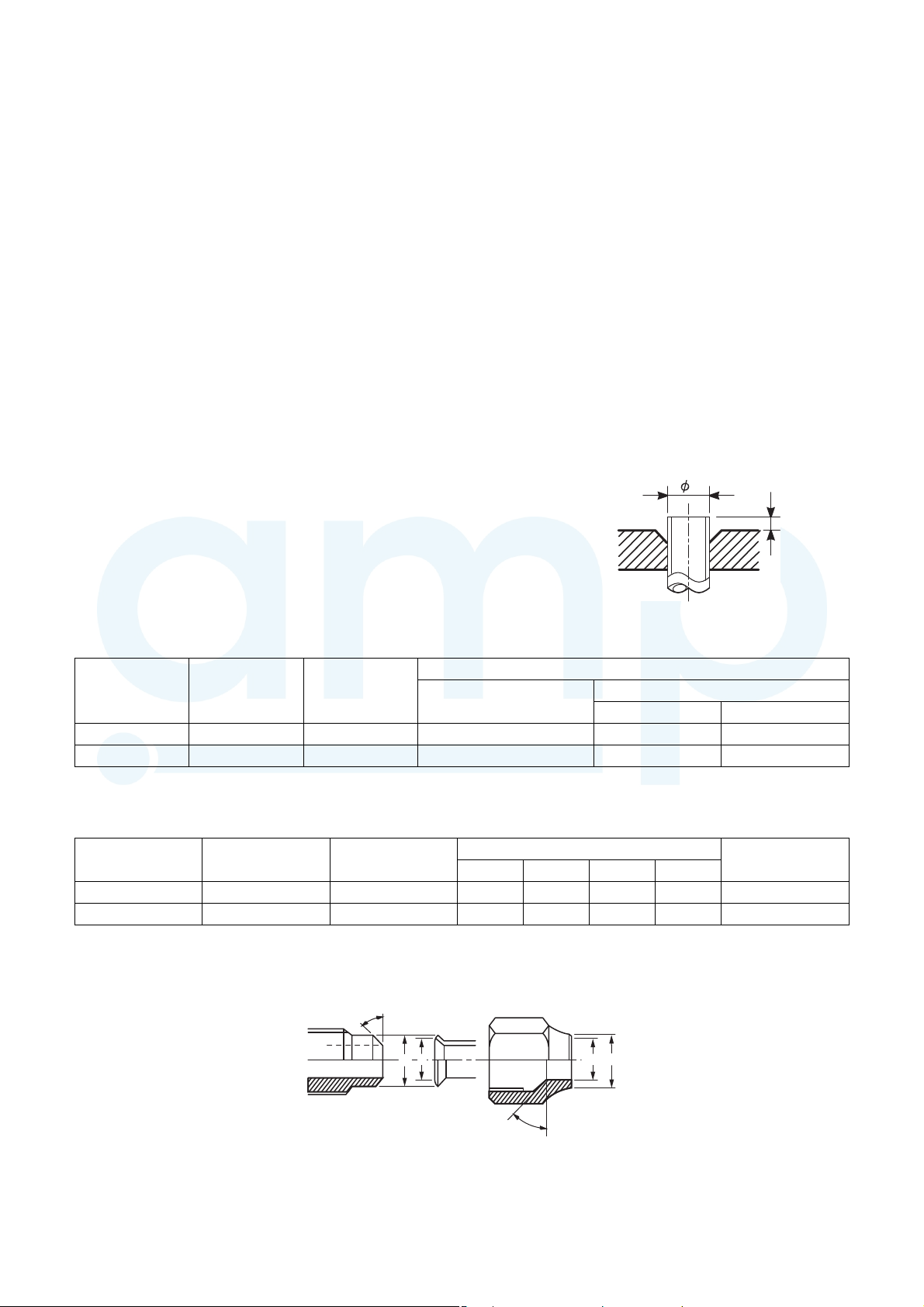

Figure 2-2-1

Flare dimension

DCB A

45° - 46°

43° - 45°

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

When installing refrigerant pipe, prevent water or dust from entering the pipe, and do not use oil other than lubricant

used for Air to Water Heat Pump. Make sure that no refrigerant leak occurs.

If piping needs lubrication, use lubricating oil whose water content is removed.

After the oil is put in, be sure to seal the container with air proof cover or other covers.

Flare and precautions

1) Cut a pipe.

Cut slowly with a pipe cutter so that the pipe is not distorted.

2) Remove burr and flaw.

A burr or flaw in a flare part may cause refrigerant leak. Remove carefully all the burrs, and clean up the

cut ends before installation.

3) Insert a flare nut.

4) Flare

Check that the clasps and copper pipe are clean. Flare

correctly using the clasp. Use a flare tool for R410A or the

conventional one. Flare processing dimension varies

depending on the flare tool type. When using the

conventional flare tool, use a gauge for size adjust me n t

to secure the A dimension.

D

A

Table 2-2-3 Flare processing related dimension for R410A

Nominal

diameter

3/8 9.52 0.8 0 to 0.5 1.0 to 1.5 2.0 to 2.5

5/8 15.9 1.0 0 to 0.5 1.0 to 1.5 2.0 to 2.5

Outer diameter

(mm)

Wall thickness

(mm)

Flare tool for R410A

clutch type

Table 2-2-4 Dimension of flare for R410A and flare nut

Nominal

diameter

3/8 9.52 0.8 13.0 13.2 9.7 20 18

5/8 15.9 1.0 19.1 19.7 15.9 24.5 26

Outer diameter

(mm)

Wall thickness

(mm)

ABCD

Dimension (mm)

Figure 2-2-2 Relationship between flare nut and flare surface

A (mm)

Conventional flare tool

Clutch type Butterfly-nut type

Flare nut width

(mm)

8

Page 10

Flare connecting procedure and precautions

NOTE

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

1) Make sure that the flare and connecting portions do not have any flaw and dust.

2) Correctly align the flared surface and the connecting axis.

3) Tighten the flare with designated torque by mean s of a torq ue wre nch. The tightenin g to rque for R4 10A is

the same as that for the conventional R22. If the torque is weak, gas leakage may occur. If it is too strong,

the flare nut may crack and may be made non-removable. When choosing the tightening toque, comply

with values designated by products. Table 2-2-5 shows reference values.

When applying oil to the flare surface, be sure to use oil designated by the product. Us ing any other oil deteriorates

the lubricating oil, possibly causing the compressor to burn out.

Table 2-2-5 Tightening torque of flare for R410A (Reference values)

Nominal diameter Outer diameter (mm) Tightening torque N•m (kgf•m)

3/8 9.52 33 to 42 (3.3 to 14.2)

5/8 15.9 66 to 82 (6.8 to 8.2)

9

Page 11

2-3. Tools

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

2-3-1. Necessary tools

In Air to Water Heat Pump using R410A, the service port diameter of packed valve of the outd oor un it is change d

to prevent mixing of other refrigerant. To reinforce the pressure resistance, flare dimensions and opposite side

dimensions of flare nut (For Ø 12.7 copper pipe) of the refrigerant piping are lengthened.

Because the refrigerating machine oil is changed, mixing of oil may generate sludge, clog capillary, or cause other

problems. Accordingly, the tools to be used include:

• tools dedicated for R410A (Those that cannot be used for the conventional refrigerant, R22)

• tools dedicated for R410A, but can be also used for the conventional refrigerant, R22

• tools that can be used for the conventional refrigerant, R22.

The following table shows the tools dedicated for R410A and their interchangeability.

Tools dedicated for R410A (The following tools must be for R410A)

Tools whose specifications are changed for R410A and their interchangeability

R410A Air to Water Hear Pump

No. Tool to be used Usage

1 Flare tool Pipe flaring Yes *(Note 1) Yes

2

3 Torque wrench (For Ø15.9) Connection of flare nut Yes No No

4 Gauge manifold

5 Charge hose

6 Vacuum pump adapter Vacuum evacuating Yes No Yes

7

8 Refrigerant cylinder Refrigerant charge Yes No No

9 Leakage detector Gas leakage check Yes No Yes

10 Charging cylinder Refrigerant charge *(Note 2) No No

Copper pipe gauge for

adjusting projection margin

Electrical balance for

refrigerant charging

Flaring by conventional

flare tool

Evacuating, refrigerant

charge, run check, etc.

Refrigerant charge Yes No Yes

For R410A

Existence of new

equipment

installation

Conventional

equipment can be

used

Yes *(Note 1) *(Note 1)

Yes No No

Conventional refrigerant

Air to Water Heat Pump

installation

New equipment can be

used with conventional

refrigerant

* (Note 1) Flaring for R410A by using the conventional flare tool requires projection margin adjustment. This

adjustment requires copper pipe gauge or other instrument.

* (Note 2) A charging cylinder for R410A is currently under development.

General tools (Conventional tools are available)

In addition to the above dedicated tools, the following equipment also available for R22 is necessary as the general

tools.

1. Vacuum pump

Use this by attaching vacuum pump

adapter.

2. Torque wrench (For Ø6.35) 7. Screwdriver (+, –) 11. Tape measure

3. Pipe cutter 8. Spanner or Monkey wrench 12. Metal saw

Also prepare the following equipment for other work methods or run check.

1. Clamp meter 3. Insulation resistance meter

2. Thermometer 4. Electroscope

4. Reamer 9. Hole co re drill (Ø65)

5. Pipe bender 10. Hexagon wrench

(Opposite side 4 mm)6. Level vial

10

Page 12

2-4. Recharging of refrigerant

NOTE

(For refrigerant charging, see the figure below)

Recover the refrigerant, and check that no

refrigerant remains in the refrigerant cycle.

Connect the charge hose to packed valve service

port on the outdoor unit's gas side.

Connect the charge hose to the vacuum pump

adapter.

Open fully both packed valves on the liquid and

gas sides.

Open fully the handle of gauge manifold Lo, turn on the

vacuum pump, and then perform vacuum evacuating.

When the compound gauge's pointer indicates

-0.1 MPa (-76 cmHg), close fully the handle Lo and turn

off the vacuum pump.

Let the equipment stay as it is for one to two minutes

and check that the compound gauge pointer does not

return.

Place the refrigerant cylinder to the electronic balance,

connect the connecting hose to the cylinder and the

connecting port of the electronic balance, and then

charge liquid refrigerant.

(Hydro unit)

(Outdoor unit)

Open

Open

Service port

Check valve

Open/close valve

for charging

Electronic balance for refrigerant charging

CloseOpen

Refrigerant cylinder (with siphon)

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Recharge, if necessary, the specified amount of new refrigerant according to the following procedure.

• Never charge refrigerant exceeding the specified amount.

• If the specified amount of refrigerant cannot be charged, charge it a little at a time while running refrigerant

recovery (pump down).

• Do not make additional charging.

An additional charge when refrigerant leaks changes the refrigerant composition in the refrigerant cycle,

causing the characteristics change of the Air to Water Heat Pump or excessive high pressure in the refrigerant

cycle with more than the specified amount of refrigerant charged. This may cause burst or an injury.

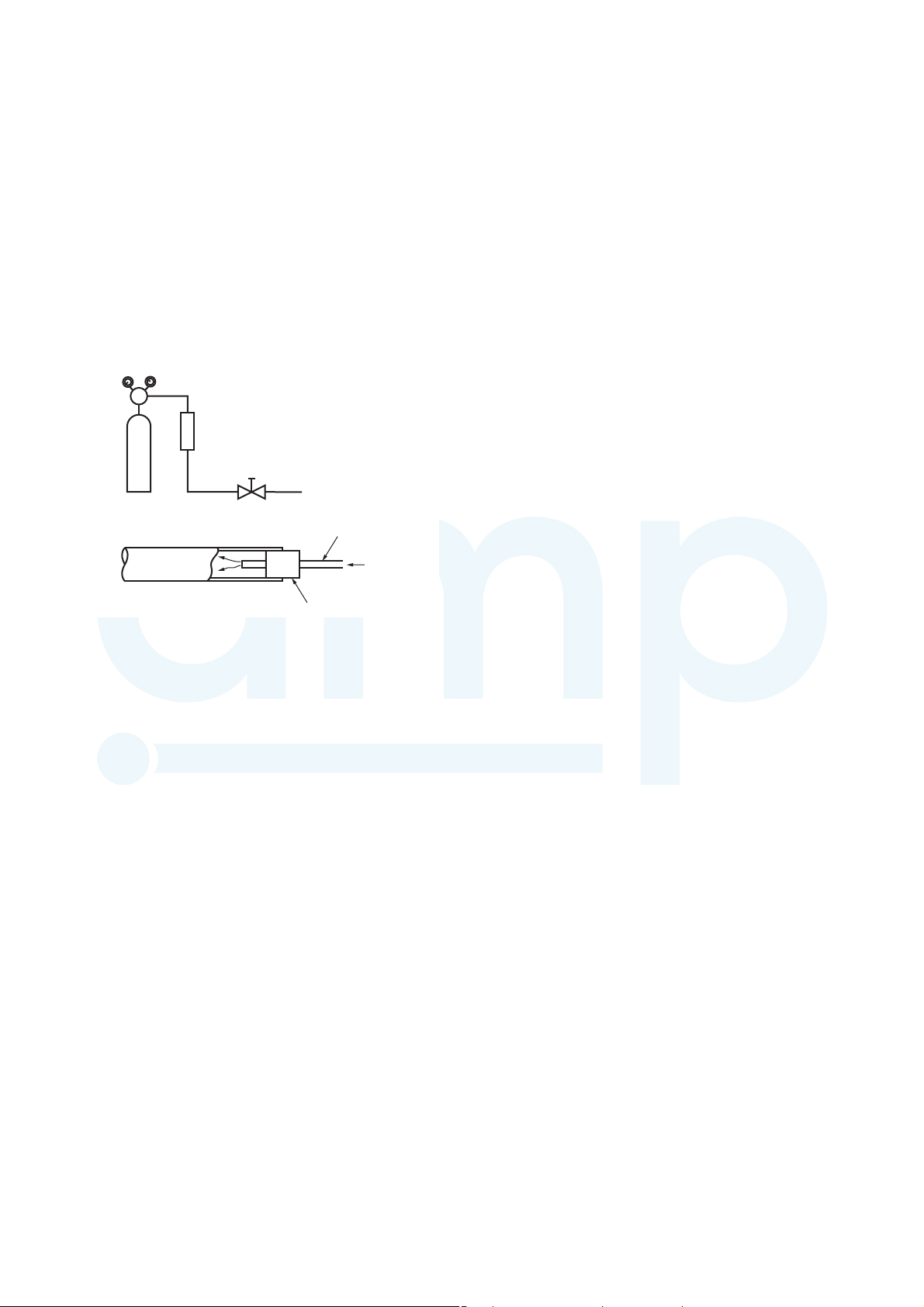

Fig. 2-4-1 Configuration of refrigerant charging

11

Page 13

NOTE

• Make sure that the setting is appropriate so that liquid can be charged.

NOTE

[Cylinder with siphon]

[Cylinder without siphon]

Gauge manifold

Outdoor unit

Refrigerant

cylinder

Electronic balance

Gauge manifold

Outdoor unit

Refrigerant

cylinder

Electronic balance

Siphon pipe

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

• A cylinder with siphon enables liquid to be charged without the cylinder turned upside down.

• Because R410A is HFC mixed refrigerant, charging with gas changes the charged refrigerant composition,

causing the equipment characteristics to change.

12

Page 14

2-5. Brazing of pipes

NOTE

NOTE

NOTE

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

2-5-1. Materials of brazing

Silver brazing metal

Silver brazing metal is an alloy mainly composed of

silver and copper.

It uses iron, copper, or copper alloy, and is relatively

expensive though it excels in soldering.

Phosphor bronze brazing metal

Phosphor bronze brazing metal is generally used to

join copper or copper alloy.

Low temperature brazing metal

Low temperature brazing metal is generally called

solder, and is an alloy of tin and lead. Do not u se it for

refrigerant piping because its adhesive ca pacity is low.

• Phosphor bronze brazing metal tends to react with

sulfur, producing a fragile compound water solution.

This may cause gas leakage. Therefore, use other

type of brazing metal at a hot spring resort or similar

place, and coat the surface with coatings.

• To braze the pipe again while performing service

work, use the same type of brazing metal.

2-5-2. Flux

Type of flux

• Non-corrosive flux

It is generally a compound of borax and boric acid.

It is effective when brazing temperature is higher

than 800 °C.

• Active solvent

Most of this type of flux is generally used for silver

brazing.

It features the increase of oxide film while moving the

capability to the borax-boric acid compound to add

compounds such as potassium fluoride, potassium

chloride, or sodium fluoride.

Piping materials for brazing and brazing

metal / flux

Piping material

Copper - Copper Phosphor copper Do not use

Copper - Iron Silver Paste flux

Iron - Iron Silver Vapour flux

• Do not enter flux into the refrigerant cycle.

• If chlorine contained in the flux remains within the

pipe, the lubricating oil deteriorates. Because of

this, use a flux that does not contain chlorine.

• When adding water to the flux, use water that does

not contains chlorine. (e.g. distilled water or ion

exchange water)

• Remove the flux after brazing.

Brazing metal to be

used

Flux to be used

Why flux is necessary

• Removing all the oxide film and any foreign matter

on the metal surface assists the flow of brazing

metal.

• Flux prevents the metal surface from being oxidized

in the course of brazing.

• Reducing the brazing metal's surface tension

enables the brazing metal to adhere for better metal

processing.

Characteristics of flux

• The activation temperature of flux matches the

brazing temperature.

• A wide effective temperature range makes flux hard

to carbonize.

• It is easy to remove slag after brazing.

• The corrosive action to the treate d metal and brazing

metal is minimum.

• The good performance of flux gives no harm to a

human body.

Since flux works in a complicated manner as

described above, select an appropriate type of flux

according to metal treatment ty pe, brazing metal and

brazing method, or other conditions.

2-5-3. Brazing

Brazing must be performed by a person qualified and

experienced with theoretical knowledge since the

operation requires sophisticated techniques.

Perform brazing while flowing dry nitrogen gas (N2) to

prevent oxide film from forming during brazing

application to the inside of the pipe.

• Never use gas other than nitrogen ga s.

Brazing method to prevent oxidation

1) Attach a reducing valve and a flow meter to the

nitrogen cylinder.

2) Use a copper pipe to direct the piping material,

and attach the flow meter to the balance.

3) Apply a mark to the clearance between the

piping material and the copper pipe filled with

nitrogen to prevent the back flow of the

nitrogen gas.

4) If the nitrogen gas flows out, be sure to keep

open the piping end.

13

Page 15

5) Use the reducing valve to adjust the nitrogen

M

Flow meter

Stop valve

From nitrogen cylinder

Nitrogen gas

Robber plug

Pipe

Nitrogen gas cylinder

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

3

gas flow speed to 0.05 m

2

(0.2 kgf/cm

).

/hour or 0.02 MPa

6) After the steps above, keep the nitrogen gas

flowing until the pipe cools down to a certain

extent. (Temperature where the pipe is cool

enough to be touched by hands)

7) Remove the flux completely after brazing.

Fig 2-5-1

Prevention of oxidation during brazing

14

Page 16

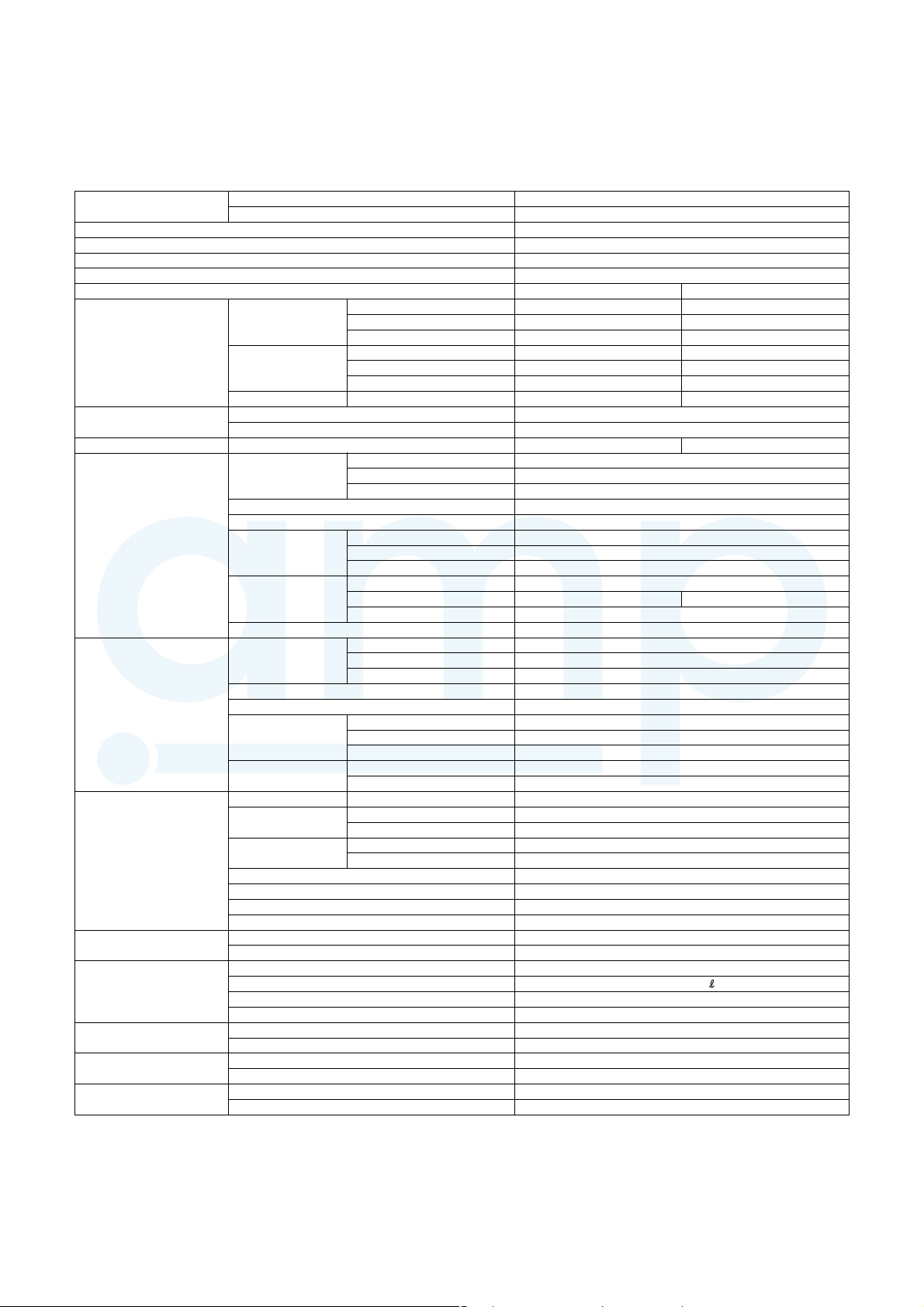

3 Specifications

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Unit name Hydro unit HWS-P804XWHM3-E1, P804XWHT6-E1, P804XWHT9-E1

Heating capacity *1 (kW) 8.0

Cooling capacity *2 (kW) 6.0

Variable range of compressor frequency 10 - 70 Hz

Power source Single phase 50 Hz 220-230 V

Operation mode Heating Cooling

Electric characteristic *1 *2 Hydro unit Current (A) 0.44 0.44

Operating noise sound power level Hydro unit (dB (A)) 41

Coefficient of performance *1 *2 4.76 3.66

Hydro unit Outer dimension Height (mm) 925

Outdoor unit Outer dimension Height (mm) 1340

Refrigerant piping Connection method Flare connection

Refrigerant Refrigerant name R410A

Water piping Pipe diameter R1 1/4

Operating temperature range Hydro unit (°C) *5 5-32

Operating humidity range Hydro unit (%) 15-85

Wiring connection Power wiring 3 wires: including earth wire (Outdoor unit)

*1 Heating performance measurement conditions: outside air temperature 7 °C, water supply temperature 30 °C, outlet temperature 35 °C, refrigerant piping length 7.5 m (no height

difference).

*2 Cooling performance measurement conditions: outside air temperature 35 °C, wa ter supply temperature 12 °C, outlet temperature 7 °C, refrigerant piping length 7.5 m (no height

difference).

*3 • The remote controller should be shipped with the hydro unit.

• Use two 1.5-meter wires to connect the hydro unit with the remote controller.

*4 Check the water piping for le akage under the maximum operating pressure.

*5 Do not leave the hydro unit at 5 °C or below.

Outdoor unit HWS-P804HR-E1

Power (kW) 0.06 0.06

Outdoor unit Current (A) 7.57 7.39

Total Running current (A) 8.01 7.83

Outdoor unit (dB (A)) 66

Net weight (kg) 49

Color Silky shade (Munsell 1Y8.5/0.5)

Remote controller

Outer dimension *3

Circulating pump Motor output (W) 125 (MAX)

Heat exchanger Plate-type heat exchange

Net weight (kg) 92

Color Silky shade (Munsell 1Y8.5/0.5)

Compressor Motor output (W) 2500

Fan motor Sta ndard air capacity (m

Hydro unit Liquid Ø9.52

Outdoor unit Liquid Ø9.52

Maximum length (m) 30

Maximum chargeless length (m) 30

Maximum height difference (m) ±30

Minimum length (m) 5

Charge amount (kg) 2.7

Maximum length (m) None (Need the flow rate 13 /min or more)

Maximum height difference (m) ±7

Maximum working water pressure (kPa) *4 300

Outdoor unit (°C) -25-43

Outdoor unit (%) 15-100

Connecting line 4 wires: including earth wire

Power factor (%) 59.3 59.3

Power (kW) 1.62 1.58

Power factor (%) 93 93

Width (mm) 525

Depth (mm) 355

Height (mm) 120

Width (mm) 120

Depth (mm) 16

Flow rate (L/min) 22.9 17.2

Type Non-self-suction centrifugal pump

Width (mm) 900

Depth (mm) 320

Type Twin rotary type with DC-inverter variable speed control

Model DA422A3F-26M

Motor output (W) 100 × 2

Gas Ø15.9

Gas Ø15.9

3

/min) 103.0

15

Page 17

Unit name Hydro unit HWS-P1104XWHM3-E1, P1104XWHT6-E1, P1104XWHT9-E1

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Heating capacity *1 (kW) 11.2

Cooling capacity *2 (kW) 10.0

Variable range of compressor frequency 10 - 90 Hz

Power source Single phase 50 Hz 220-230 V

Operation mode Heating Cooling

Electric characteristic *1 *2 Hydro unit Current (A) 0.66 0.66

Operating noise sound power level Hydro unit (dB (A)) 43

Coefficient of performance *1 *2 4.88 3.00

Hydro unit Outer dimension Height (mm) 925

Outdoor unit Outer dimension Height (mm) 1340

Refrigerant piping Connection method Flare connection

Refrigerant Refrigerant name R410A

Water piping Pipe diameter R1 1/4

Operating temperature range Hydro unit (°C) *5 5-32

Operating humidity range Hydro unit (%) 15-85

Wiring connection Power wiring 3 wires: including earth wire (Outdoor unit)

*1 Heating performance measurement conditions: outside air temperature 7 °C, water supply temperature 30 °C, outlet temperature 35 °C, refrigerant piping length 7.5 m (no height

difference).

*2 Cooling performance measurement conditions: outside air temperature 35 °C, wa ter supply temperature 12 °C, outlet temperature 7 °C, refrigerant piping length 7.5 m (no height

difference).

*3 • The remote controller should be shipped with the hydro unit.

• Use two 1.5-meter wires to connect the hydro unit with the remote controller.

*4 Check the water piping for leakage under the maximum operating pressure.

*5 Do not leave the hydro unit at 5 °C or below.

Outdoor unit HWS-P1104HR-E1

Power (kW) 0.09 0.09

Outdoor unit Current (A) 10.33 14.99

Total Running current (A) 10.99 15.65

Outdoor unit (dB (A)) 66

Net weight (kg) 52

Color Silky shade (Munsell 1Y8.5/0.5)

Remote controller

Outer dimension *3

Circulating pump Motor output (W) 190 (MAX)

Heat exchanger Plate-type heat exchange

Net weight (kg) 92

Color Silky shade (Munsell 1Y8.5/0.5)

Compressor Motor output (W) 2500

Fan motor Standard air capacity (m3/min) 103.0

Hydro unit Liquid Ø9.52

Outdoor unit Liquid Ø9.52

Maximum length (m) 30

Maximum chargeless length (m) 30

Maximum height difference (m) ±30

Minimum length (m) 5

Charge amount (kg) 2.7

Maximum length (m) None (Need the flow rate 18 /min or more)

Maximum height difference (m) ±7

Maximum working water pressure (kPa) *4 300

Outdoor unit (°C) -25-43

Outdoor unit (%) 15-100

Connecting line 4 wires: including earth wire

Power factor (%) 59.2 59.2

Power (kW) 2.21 3.24

Power factor (%) 93 94

Width (mm) 525

Depth (mm) 355

Height (mm) 120

Width (mm) 120

Depth (mm) 16

Flow rate (L/min) 32.1 28.9

Type Non-self-suction centrifuga l pump

Width (mm) 900

Depth (mm) 320

Type Twin rotary type with DC-inverter variable speed control

Model DA422A3F-26M

Motor output (W) 100 × 2

Gas Ø15.9

Gas Ø15.9

16

Page 18

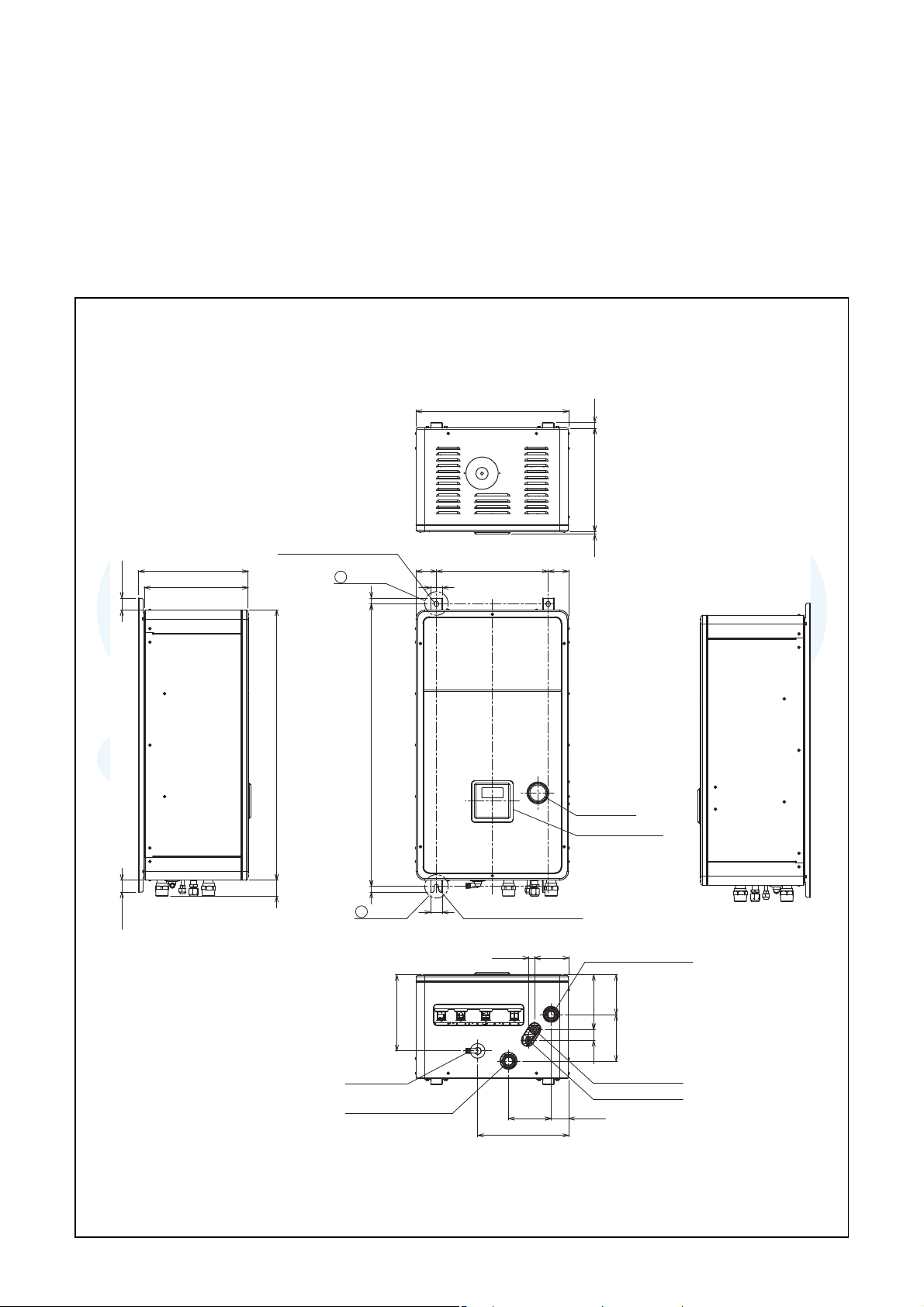

4 Outside drawing

960

Anchor bolt long hole pitch

B leg part

40

380

40

2020

72.5 72.5

2-dia.12x17 long hole

(for dia.8-10 anchor bolt)

2-dia.12x17 U-shape hole

(for dia.8-10 anchor bolt)

A leg part

Remote controller

135.5

158

186.5

59.5144.5

11619.5

352

37.5

92054

Hot water outlet

connecting pipe 1 1/4"

Water inlet

connecting pipe 1 1/4"

Gas line dia.15.88

Liquid line dia.9.52

309.5

259

Drain nipple

371.5

355

4040

9

Anchor bolt

long hole pitch

Manometer

525

19.5

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

4-1. Hydro unit

HWS-P804XWHM3-E1, P804XWHT6-E1, P804XWHT9-E1

HWS-P1104XWHM3-E1, P1104XWHT6-E1, P1104XWHT9-E1

17

Page 19

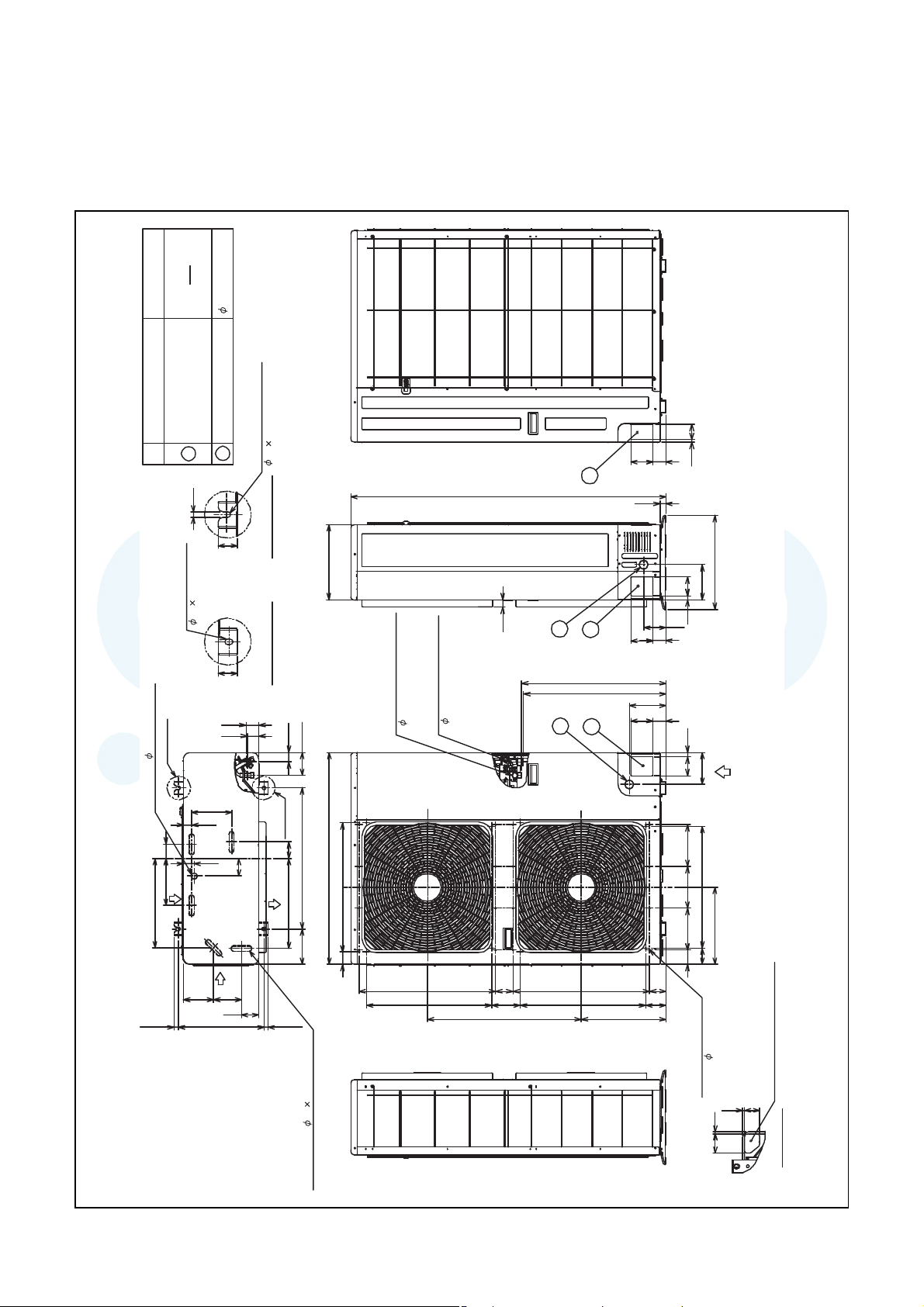

4-2. Outdoor unit

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

HWS-P804HR-E1, P1104HR-E1

Description

38 knockout hole

Name

Refrigerant piping outlet

Indoor and outdoor

connecting line outlet

Power source intake hole

2

1

12

40

Mounting bolt hole

( 12 17 long hole)

40

Portion B

Mounting bolt hole

( 12 17 U-shape hole)

Details of portion B

Details of portion A

54

48

39

64

9555

1

1340

320

30

( 15.9 flare)

Refrigerant gas connection

( 9.5 flare)

96

Refrigerant liquid connection

1

2

613

605

1

2

12

24

400

151

80

18

94

55

95

155

55

95

1880

Z

135

Drain hole ( 25 burring hole)

60

200

380

17.5

Air intake

170

34

46

75

Air intake

128118

74

Portion A

70

600

900

Air

discharge

383

150

52 550

17.5 365

5-Drain hole ( 20 88 burring hole)

53412153485

360 655

518

327

178 178 178

60

68

70 581 74 581

(24- 3 embossed)

Optional mounting hole

7

83

Knockout for lower part of piping

65

7

Z arrow view

18

Page 20

4-3. Hot water cylinder

550

5952066.6

2040

550

5951114

1090

5951497.6

1474

550

Specification

for UK only

Specification

for UK only

Specification

for UK only

HWS-3001CSHM3-E(-UK)

HWS-2101CSHM3-E(-UK)

HWS-1501CSHM3-E(-UK)

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

19

Page 21

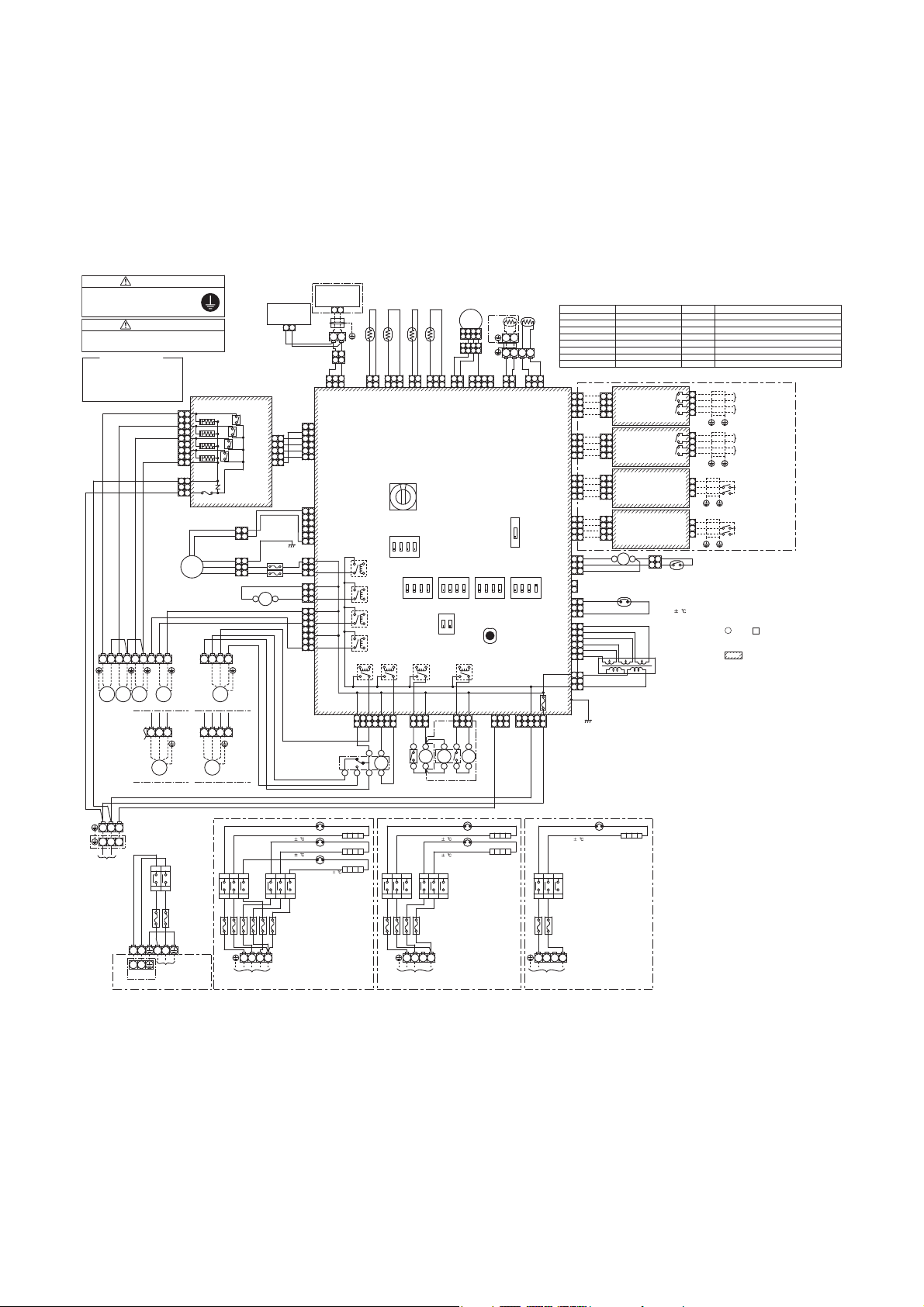

5 Wiring diagram

Remote

controller

(HWS-AMS11E)

AB

GRY

WHI

AB

Remote

controller

(HWS-AMS11E)

*Option

TB 07

GRY

WHI

BLK

BLK

BLK

BLK

BLK

BLK

BLK

BLK

1

3

2

1

34

22

2

111

3

2

1

1

2

2

3

1

1

3

1

2

1

2

1

2

1

2

1

1

2

3

3

2

1

3

2

1

3

1

2

1

2

*Option

THOTWOTWITC

LPS

RED

RED

BRW

BRW

RED

WHI

BLK

TFI

TTW

TB 06

CN208

(BLU)

CN213

(WHI)

CN214

(WHI)

CN206

(WHI)

CN205

(RED)

CN204

(BRW)

CN203

(YEL)

CN41

(BLU)

CN501

(YEL)

CN207

(BLU)

CN212

(WHI)

CN102

(WHI)

CN101

(WHI)

CN202

(YEL)

CN201

(WHI)

CN200

(RED)

CN211

(BLK)

CN210

(RED)

CN209

(GRN)

RY607RY606RY605RY604

RY601RY600RY603 RY602

CN601

(RED)

CN603

(YEL)

CN602

(WHI)

WHI

YEL

WHI

RED

RED

BRW BRW BRW

BLU BLU

WPM

RY

05

A1

A2

P.C.board

(MCC-1511)

SW10 SW11 SW12 SW13

SW06

SW07

SW14

SW01

SW02

12 43

ON

ON

1234 1234 12341234

ON ON21ON

ON

OFF

ON

3

5

7

1

313

1

313

22

1

1221

313

1

5

7

1

TB 04

MIXV

TB 04TB 05

RED

RED

ORN

PNK

WHI

WHI

YEL

RED

ORN

WHI

PNK

WHI WHI

YEL

BLU

BRW

WHI

RED

WHI

YEL

BH 3WV

2WV

WPM

TB 05

525

1

5

3

5

4

5

6

5

5

5

7

5

9

5

8

4

2

4

1

4

3

4

4

4

4

4

3

4

2

4

1

MIXV

5

9

5

8

5

7

3WV

RED

PNK

ORN

468

2

7

5

RY

06

A1

A2

648

7

A2

A1

4

6

RY

01

WHI WHI

RY

02

RY04RY

03

*

1

*

1

HWS-P804XWHT6-E1 : Installed

HWS-P1104XWHT6-E1 : Installed

HWS-P804XWHT9-E1 : Installed

HWS-P1104XWHT9-E1 : Installed

HWS-P804XWHM3-E1 : Not installed

HWS-P1104XWHM3-E1 : Not installed

*

1

HWS-P804XWHT6TR : Installed

HWS-P1104XWHT6TR : Installed

HWS-P1104XWHT9TR : Installed

HWS-P804XWHM3TR : Not installed

HWS-P1104XWHM3TR : Not installed

RED

WHI

GRY

RED

WHI

BLK

YE

L

WHI

ORN

WHI

PNK

CN604

(BLU)

CN605

(YEL)

CN606

(BLU)

CN305

(GRN)

CN100

(WHI)

3

1

3

1

7

7

5

5

3

1

1

3

1

3

1

3

1

3

33

3

1

1

5

F100

Fuse

T5A

250V~

WHI

WHI

P100

BLK

ORN

ORN

RED

RED

BRW

BRW

RED

YEL

GRN

BLK

BLK

11

1

2

3

4

5

6

1

1

1 1

4

5

6

2

3

1

2

3

414

2

3

1

2

3

414

2

3

1

2

3

414

2

3

1

2

3

414

2

3

1

2

3

414

2

3

1

2

3

414

2

3

1

2

3

414

2

3

1

2

3

414

2

3

33

323

1 1

2

2

33

1

2

2 2

1

T

ransformer

3

1

2

3

1

2

4

3

1

2

4

3

1

2

GRN

GRN

GRN

GRN

GRN

GRN

GRN

GRN

YEL

YEL

YEL

YEL

YEL

YEL

YEL

YEL

*Option p.c.board

Emergency stop I/P

Hot water tank thermostat I/P

Cooling thermostat I/P

Heating thermostat I/P

Compressor operation

O/P

Defrost O/P

Boiler control O/P

Alerm O/P

7

8

RY

01

Flow switch

Thermal protector

(auto)

75 5

PJ20

TB1

K1

K2

K1

K2

PJ20

TB1

PJ17

TB1

PJ17

TB1

Photocoupler input

p.c.board

(MCC-1214)

Relay

p.c.board

(MCC-1217)

Relay

p.c.board

(MCC-1217)

Photocoupler input

p.c.board

(MCC-1214)

WHI

RED

GRY

TB 01

Outdoor unit

3

3

12

12111

3

4

2

6

515

4

3

2

2

2

1

CN500

(BLU)

3

4

2

66

5

1

1

55

11

4

3

3

4

RED

BLU

GRN

ORN

BRW

CN02

(WHI)

Relay

p.c.board

(MCC-1431)

F01 (5A)

CN01

(WHI)

3

11

2

3

2

11

3

4

55

6

9

787

9

RED

WHI

WHI

BLU

BRW

YEL

YEL-GRN

YEL-GRN

BLU

BRW

BRW

BLU

BLU

CN10

(WHI)

RY

10

CR10

CR11

CR12

CR13

RY

11

RY

12

RY

13

1

6

D

6

C

6

B

6

A

AB

7

B

7

A

Type 1

(3-wire SPDT type)

Type 1

(2-wire spring return)

Type 2

(3-wire SPST type)

Type 2

(3-wire SPST type)

Type 3

(3-wire SPDT type)

2

4

3

2

3

4

2

4

3

2

1

3

4

*See DIP SW13_1

Power supply

220 - 230V~ 50Hz

or

380 - 400V~ 50Hz

1. The one-dot chain line indicates

wiring at the local site, and th e

dashed line indicates accessories

sold separately and service wires,

respectively.

2.

, and indicates the terminal

board and the numerals indicate the

terminal numbers.

3.

indicates P.C. board.

* Be sure to fix the electric

parts cover surely with screws.

(Otherwise water enters into the box

resulting in malfunction.)

Symbol

WPM Water pump motor

2WV 2-way valve (local)

Booster heater

Relay01~Relay06

BH

RY01~RY06

TWI

THO

TWO

TC

TTW

TFI

Parts name

3WV 3-way valve (local)

MIXV Mixing valve (local)

LPS Low pressure sensor

Heater AC230V, 3kWBackup heater1, 2, 3

Water heat exchanger temperature sensor

Water heat exchanger inlet temperature sensor

Terminal block

Parts nameSymbol

TB

Floor heating inlet temperature sensor

Hot water cylinder temperature sensor

Water heat exchanger outlet temperature sensor

Backup heater outlet temperature sensor

BLK : BLACK

BRW : BROWN

GRY : GRAY

PNK : PINK

WHI : WHITE

BLU : BLUE

GRN : GREEN

ORN : ORANGE

RED : RED

YEL : YELLOW

Color identification

33

12

N

L

12

TB 03

Power supply

220 - 230V~ 50Hz

Hot water cylinder

*Option

BRW

BLU

BRW

BLU

BRW

BLU

YEL/GRN

F1 F2

F1, F2

Fuse

AC250V

T30A

RY05

2T1

1L1

4T2

3L2

F9, F10

AC250V

T3.15A

95 5

95 5

2T1

1L1

4T2

3L2

6T3

5L3

6T3

2T1

4T2

1L12L3

5L3

F3~8

Fuse

AC250V

T30A

RY02

F3F4F6F5F8

F7

BLU

GRY

GRY

BLU

BLU

BLU

BRW

BLU

BRW

BLU

BLK

BLK

TB 02

L1 L2

L3

N

Power supply

380 - 400V 3N~ 50Hz

HWS-P804XWHT9-E1

HWS-P1104XWHT9-E1

HWS-P1104XWHT9TR

RY04

Backup heater 2

Backup heater 1

Backup heater 3

Thermal protector

(Single operation)

Thermal protector

(Single operation)

(Single operation)95 5

Thermal protector

95 5

95 5

F3~6

Fuse

AC250V

T30A

BRW

BLU

BRW

BLU

BLU

BLK

BLK

BLU

RY02

6T3

5L3

4T22T1 6T3

3L51L12L3

1L1 3L2

2T1 4T2

RY04

F3 F6

F5

F4

TB 02

Power supply

380 - 400V 3N~ 50Hz

1L 2L

L3

N

HWS-P804XWHT6-E1

HWS-P1104XWHT6-E1

HWS-P804XWHT6TR

HWS-P1104XWHT6TR

Thermal protector

(Single operation)

(Single operation)

Thermal protector

Backup heater 1

Backup heater 2

95 5

F3,F4

Fuse

AC250V

T30A

RY02

6T32T1 4T2

5L31L1 3L2

Thermal protector

(Single operation)

Backup heater 1

F4

F3

BRW

BLU

BRW

BLU

LN

TB 02

Power supply

220 - 230V~ 50Hz

HWS-P804XWHM3-E1

HWS-P1104XWHM3-E1

HWS-P804XWHM3TR

HWS-P1104XWHM3TR

WARNING

Perform the grounding from the

earth terminal in the terminal

block of the outdoor unit.

CAUTION

Electric shock may happen.

Don't touch the electric parts.

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

5-1. Hydro unit

20

Page 22

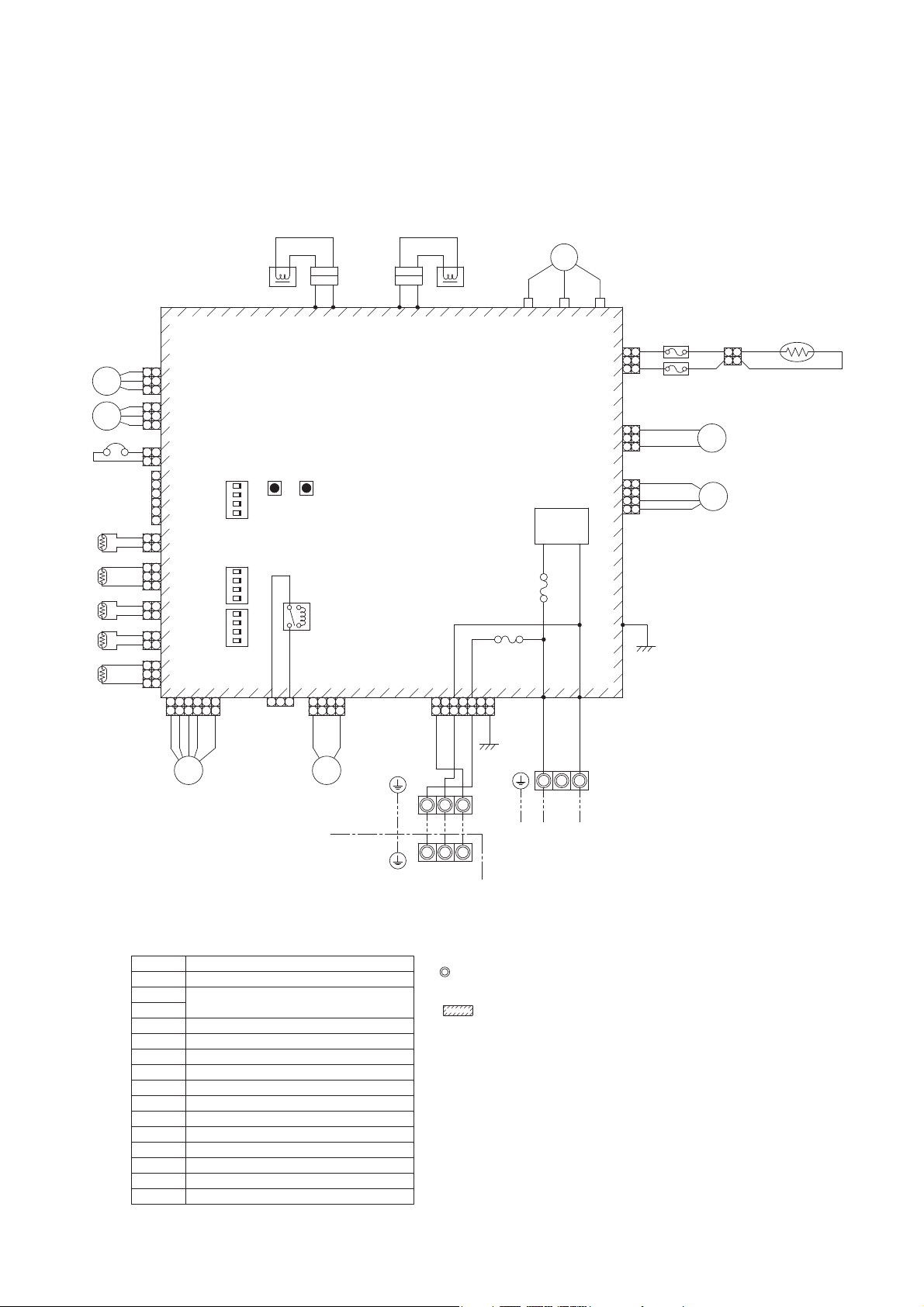

5-2. Outdoor unit

1. indicates the terminal block. Alphanumeric characters

in the cycle indicate the terminal No.

2.The two-dot chain line indicates the wiring procured locally.

3. indicates the P.C. board.

4.For the hydro unit circuit, refer to the wiring diagram

of the hydro unit.

Symbol

CM

FM01

FM02

PMV

TD

TS

TE

TL

TO

20SF

SV

PD

49C

RY

L/F

Part name

Compressor

Fan motor

Pulse motor valve

Pipe temperature sensor(Discharge)

Pipe temperature sensor(Suction)

Heat exchanger sensor 1

Heat exchanger sensor 2

Outside temperature sensor

4-way valve coil

2-way valve coil

Pressure sensor

Compressor case thermostat

Relay

Line Filter

SW802

CN600

(White)

CN710

(White)

CN704

(Blue)

CN701

(White)

SW803

CN601

(White)

CN602

(Yellow)

CN603

(White)

CN604

(White)

RY704

CN04

(White)

CN609

(Blue)

SW800

CN610

(Yellow)

SW804

SW801

CN300

(White)

Fuse, F01

T25 A, 250 V ~

CN202

CN201

CN200

P07P06

L/F

(Black)

(Red) (White)

(Red) (White) (Black)

P.C. board

MCC-1571

Fuse, F03

T10 A, 250 V ~

(White) (White)

(Gray) (Gray)

P04 P05

Power Supply

220 V - 230 V ~ 50 Hz

Earth

screw

Earth

screw

Earth

screw

(Red)

(White)

(Gray)

(Black)

Hydro

unit

Outdoor

unit

Reactor Reactor

CM

U

VW

1

2

3

1

2

3

FM02

49C

121

2

1

2

3

4

5

6

TL

TD

TO

TE

TS

121

2

11

2

33

121

2

121

2

11

2

33

12

3

4

5

6

12

346

PMV

1

3

1

4

1

4

20SF

1

3

5

1

3

5

7

7

P01 P02

12

3

12

3

LN

P09

ON

12

3

4

ON

12

3

4

ON

12

3

4

CN400

(White)

1

2

3

1

2

3

FM01

SV

(Red)

(White)

(Black)

PD

(Gray)

3

CN703

3

11

Heater

T3.15 A 250 V ~

Fuse

T3.15 A 250 V ~

Fuse

2 2

11

(White)

3

CN702

3

11

(Red)

3

CN606

3

11

4 4

2

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

HWS-P804HR-E1, HWS-P1104HR-E1

21

Page 23

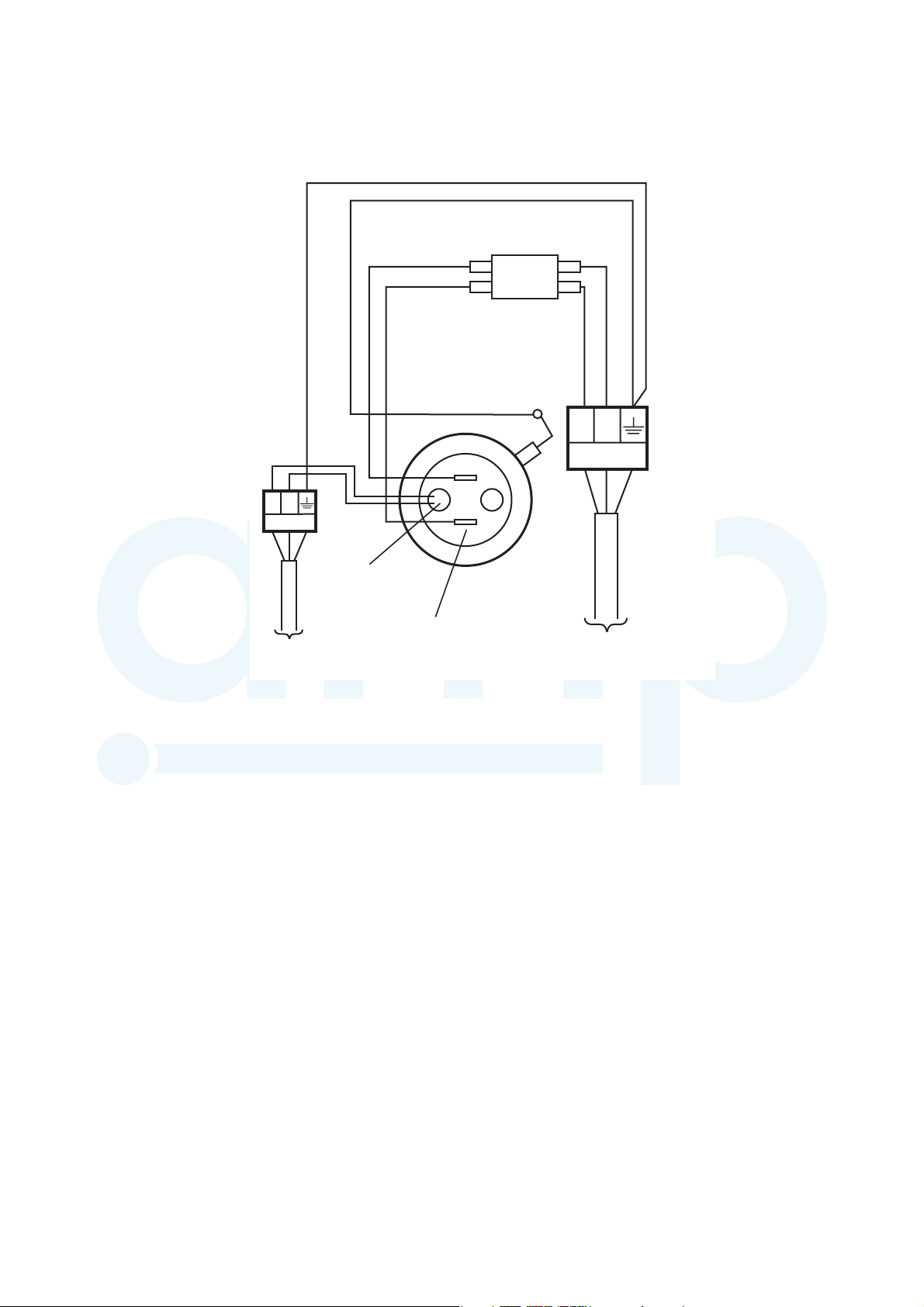

5-3. Hot water cylinder unit

12

TB03 (230 V)

AB

TB06 (TTW)

Supply 220 - 230 V from hydro unit

Cable size 1.5 mm

2

(minimum)

To hydro unit

Green /

Yellow

Blue

Double pole thermal cut out

Blue

Brown

Brown

TTW sensor

Hot water cylinder heater

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

22

Page 24

6 Key electric component rating

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

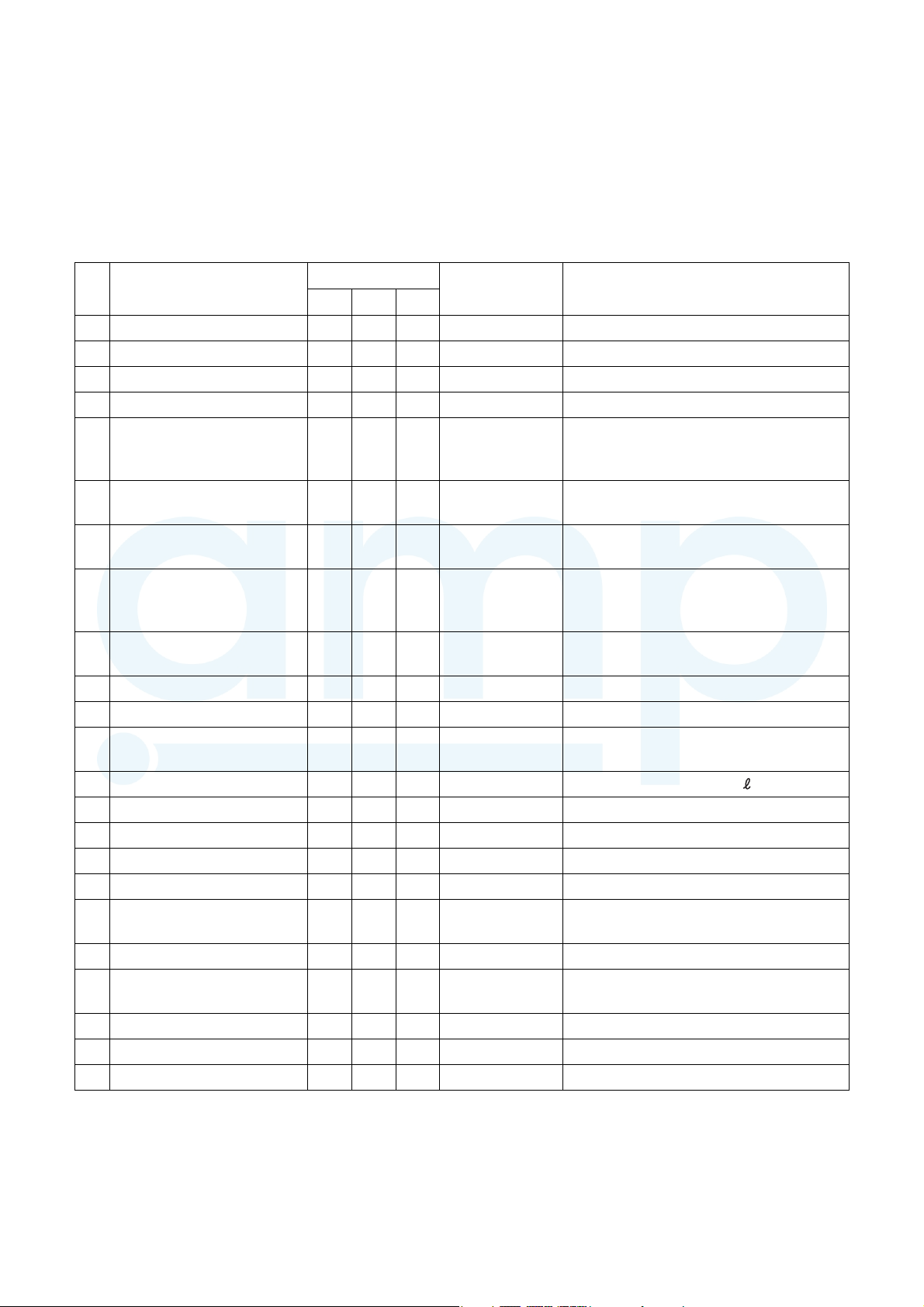

6-1. Hydro unit

HWS-P804XWHM3-E1, T6-E1, T9-E1

No. Component name

1

Circulating pump

2

Backup heater 3 kW

3

Backup heater 6 kW

4

Backup heater 9 kW

Water heat exchange

5

temperature sensor

(TC sensor)

Water inlet temperature sensor

6

(TWI sensor)

Water outlet temperature sensor

7

(TWO sensor)

Heater outlet water temperature

8

sensor

(THO sensor)

Floor inlet temperature sensor

9

(TFI sensor)

10

Low pressure sensor

11

Bimetal thermostat (auto)

Bimetal thermostat (singl e

12

operation)

13

Flow switch

14

Output board (OP)

15

Input board (OP)

16

Remote controller (Main)

17

Remote controller (Sub)

Water 3-way valve terminal

18

19

Water 2-way valve terminal

Mixing valve terminal

20

21

Circulating pump terminal

22

Booster heater terminal

23

Fuse

Model name

Type name Rating

M3-E1 T6-E1 T9-E1

OOOUPM 2K 25-60 130

O SA3-23652B

O SA3-23652B

O SA3-23652B

OOO –

OOO –

OOO –

OOO –

OOO –

OOO –

OOO –

OOO –

OOO –

OP OP OP

OP OP OP

OOO

OP OP OP

OOO –

OOO –

OOO –

OOO –

OOO –

OOO –

TCB-PCIN3E AC230 V 0.5 A, DC24 V 1 A

TCB-PCM03E Contact input

HWS-AMS11E

HWS-AMS11E

AC230 V 0.40 A (MAX)

AC230 V 3 kW

AC400 V (3N) 6 kW

AC400 V (3N) 9 kW

10 kΩ (25 °C)

10 kΩ (25 °C)

10 kΩ (25 °C)

10 kΩ (25 °C)

10 kΩ (25 °C)

Operating pressure 0.20 MPa

Operating temperature 75±3 °C DC12 V / 0.2 A

Operating temperature 95±5 °C AC250 V / 16 A

Operating flowing quantity 13 /min

AC230 V 0.1 A

2Wire, 3Wire SPST, SPDT type mountable

AC230 V 0.1 A 2Wire type mountable

AC230 V 0.1 A

3Wire SPST, SPDT type mountable

AC230 V 1.0 A

AC230 V 1.0 A

AC250 V 30 A

O······· Applied

OP····· Optional accessory

23

Page 25

HWS-P1104XWHM3-E1, T6-E1, T9-E1

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

No. Component name

1

Circulating pump

2

Backup heater 3 kW

3

Backup heater 6 kW

4

Backup heater 9 kW

Water heat exchange

5

temperature sensor

(TC sensor)

Water inlet temperature sensor

6

(TWI sensor)

Water outlet temperature sensor

7

(TWO sensor)

Heater outlet water temperature

8

sensor

(THO sensor)

Floor inlet temperature sensor

9

(TFI sensor)

10

Low pressure sensor

11

Thermal protector (auto)

Thermal protector (single

12

operation)

13

Flow switch

14

Output board (OP)

15

Input board (OP)

16

Remote controller (Main)

17

Remote controller (Sub)

Water 3-way valve terminal

18

19

Water 2-way valve terminal

Mixing valve terminal

20

21

Circulating pump terminal

22

Booster heater terminal

23

Fuse

Model name

M3-E1 T6-E1 T9-E1

OOO

O

O

OOO –

OOO –

OOO –

OOO –

OOO –

OOO –

OOO –

OOO –

OOO –

OP OP OP

OP OP OP

OOO

OP OP OP

OOO –

OOO –

OOO –

OOO –

OOO –

OOO –

Type name Rating

UPM GEO 25-85 130

AC230 V 0.66 A (MAX)

SA3-23652B AC230 V 3 kW

SA3-23652B AC400 V (3N) 6 kW

O

SA3-23652B AC400 V (3N) 9 kW

10 kΩ (25 °C)

10 kΩ (25 °C)

10 kΩ (25 °C)

10 kΩ (25 °C)

10 kΩ (25 °C)

Operating pressure 0.20 MPa

Operating temperatur e 75 ± 3 °C D C4 2 V / 0.2 A

Operating temperature 95±5 °C AC250 V 16 A

Operating flowing quantity 18 L/min

TCB-PCIN3E AC230 V 0.5 A, DC24 V 1 A

TCB-PCM03E Contact input

HWS-AMS11E

HWS-AMS11E

AC230 V 0.1 A

2Wire, 3Wire SPST, SPDT type mountable

AC230 V 0.1 A 2Wire type mountable

AC230 V 0.1 A

3Wire SPST, SPDT type mountable

AC230 V 1.0 A

AC230 V 1.0 A

AC250 V 30 A

O······· Applied

OP····· Optional accessory

24

Page 26

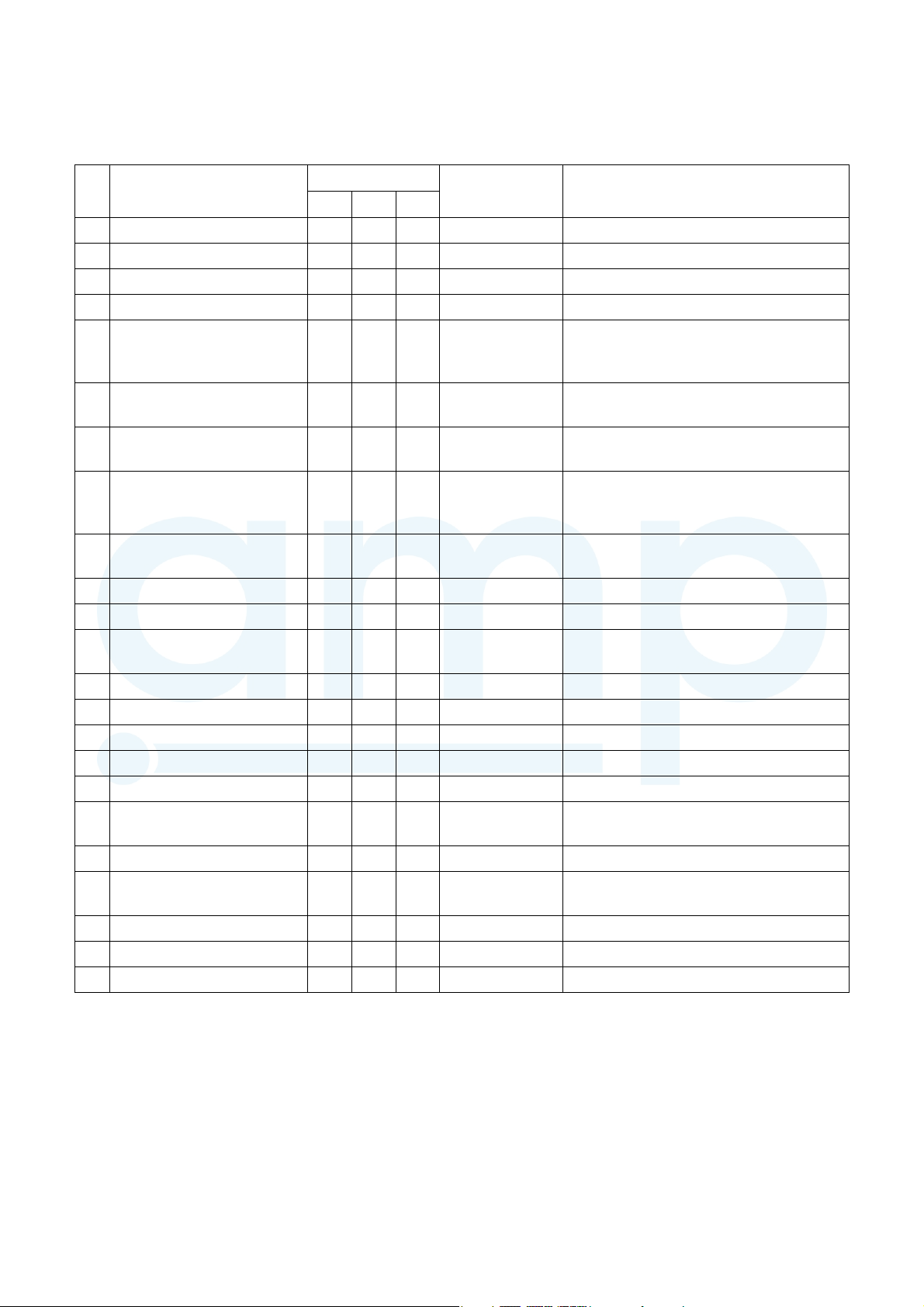

6-2. Outdoor unit

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

HWS-P804HR-E1, P1104HR-E1

No. Component name Type name Rating

1

Compressor DA422A3F-26M

2

Outdoor fan motor (x2) ICF-280-A100-1 Output 100 W

3

Reactor (x2) CH-44 1.4 mH, 25 A

4

4-way valve coil AC220 - 230 V full-wave rectifier input, alive time 10 sec or less

5

Pulse motor valve (PMV) coil UKV-A038 DC12 V

6

Board MCC-1560 Input 3Ø, AC230 V±23 V, 50/60 Hz

7

Compressor case thermostat US-622KXTMQO-SS OFF = 125 ± 4 °C, ON = 90 ± 5 °C

8

PC board MCC-1571 Input 1Ø, AC220 - 230 V ± 10%, 50/60 Hz

9

High pressure sensor NSK-BH042D-430 0 ~ 4.15 MPa

10

2-way valve coil VPV-MOAJ510B0 AC220 - 240 V

25

Page 27

6-3. Hot water cylinder unit

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Model name

1501

2101

No. Component name

1

Hot water cylinder heater

Hot water cylinder temperature

2

sensor

(TTW sensor)

Thermal cut-out

3

O······· Applied

CSH

M3-E

M3-E

(-UK)

(-UK)

OOO

OOO

OOO

CSH

3001

CSH

M3-E

(-UK)

Type name Rating

– AC230 V 2.7 kW

10 kΩ (25 °C)

–

–

Operating temperature

Manual reset 82 °C (+3k/-2k)

26

Page 28

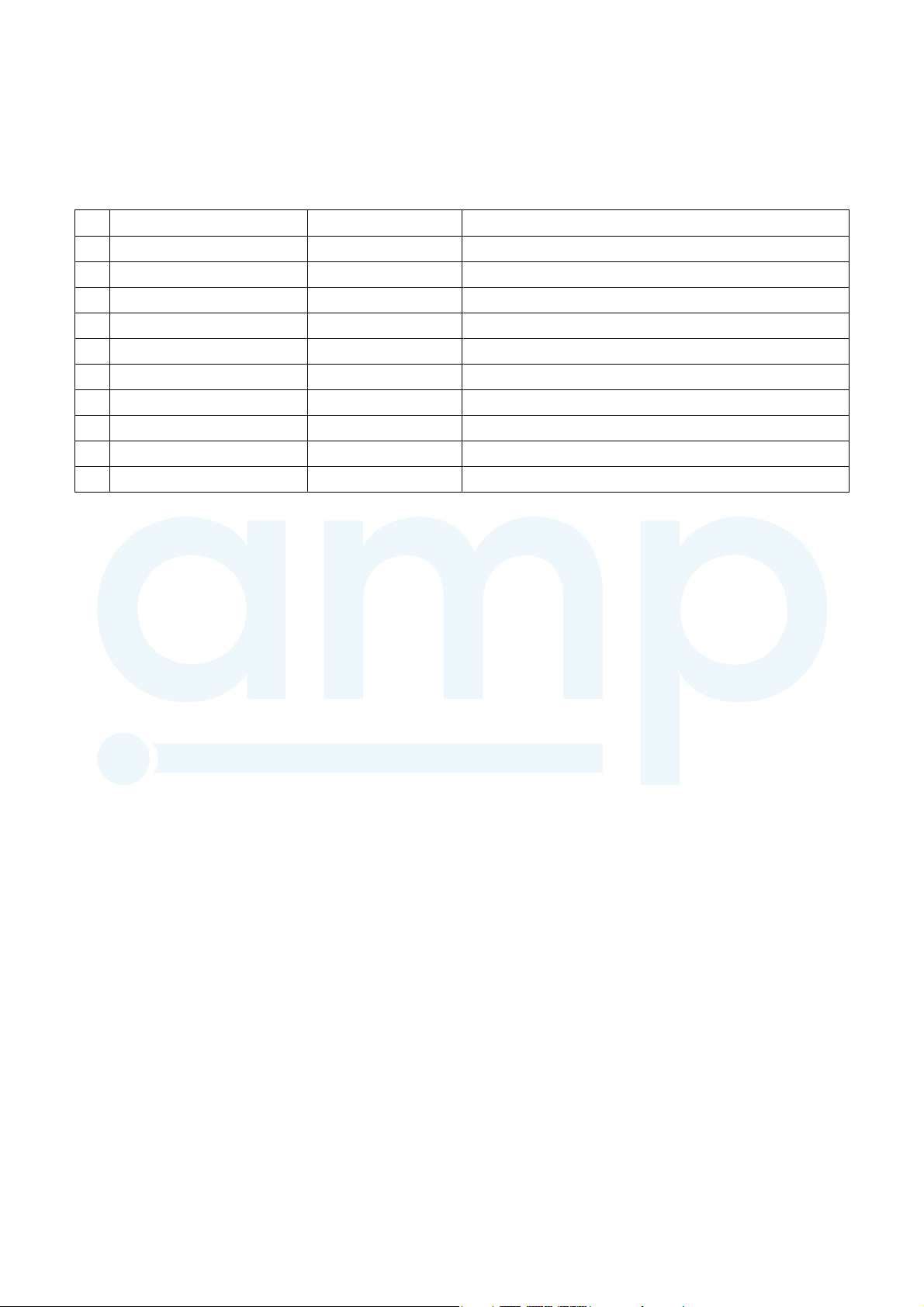

6-4. Water heat exchange control board

PWM signal line

connector

CN500

Transformer input connector

CN101

AC power supply connector

CN100

Serial input connector

CN305

Backup heater 2 drive connector

CN606

3WV drive connector

CN602

Transformer connector

CN102

Flow switch connector

CN200

Overheat protection thermostat

input connector

CN202

TWO sensor connector

CN205

TWI sensor connector

CN204

THO sensor connector

CN206

TTW sensor connector

CN214

Low pressure sensor connector

CN207, CN212

Remote controller

connector

CN41

TC sensor connector

CN203

TFI sensor

connector

CN213

Backup heater 1 drive

connector

CN605

Mixing valve drive

connector

CN604

Hot water cylinder

drive connector

CN601

Built-in pump

connector

CN603

Relay board

connector

CN501

Option board

connector

CN208-CN211

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

HWS-P804XWHM3-E1, P804XWHT6-E1, P804XWHT9-E1

HWS-P1104XWHM3-E1, P1104XWHT6-E1, P1104XWHT9-E1

27

Page 29

6-5. Outdoor control board

Fan motor output (Upper)

CN400(White)

Fan motor output (Lower)

CN300(White)

Case thermostat connector

CN609(Blue)

Power circuit protection

fuse

F100(250 V, 3.15 A,

plastic case)

4-way valve connector

CN701(White)

Compressor ON output

connector

CN704(Blue)

Heater output

connector

CN703(Grey)

External input connector

CN610(Yellow)

Special operation switches

SW801

SW804

Display change-over

switches

SW800

SW803

PMV connector

CN710(White)

PD sensor

CN606(Red)

2-way valve

CN702(White)

Initialization switch

SW802

4-way valve protection fuse

F700(250 V, 3.15 A

plastic case)

Power supply protection fuses

F01

(250 V, 25 A)

Earth lead wire

P09(Black)

Connecting cable connector

CN04(White)

Connecting cable protection fuse

F03(250 V, 10 A)

Electrolytic capacitorsCompressor output terminals

CN202

CN201

CN200

Power supply connection

lead wires

P01(Red)

P02(White)

P03(Black)

Temperature sensor

connectors

TL CN604(White)

TD CN603(White)

TO CN602(Yellow)

TE CN601(White)

TS CN600(White)

Alive, abnormal display LEDs

D800 804(Yellow)

D805(Green)

Hydro-outdoor communication

signal LEDs

D503 (Green, Outdoor =>Hydro)

D502 (Amber, Hydro => Outdoor)

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

HWS-P804HR-E1, P1104HR-E1

28

Page 30

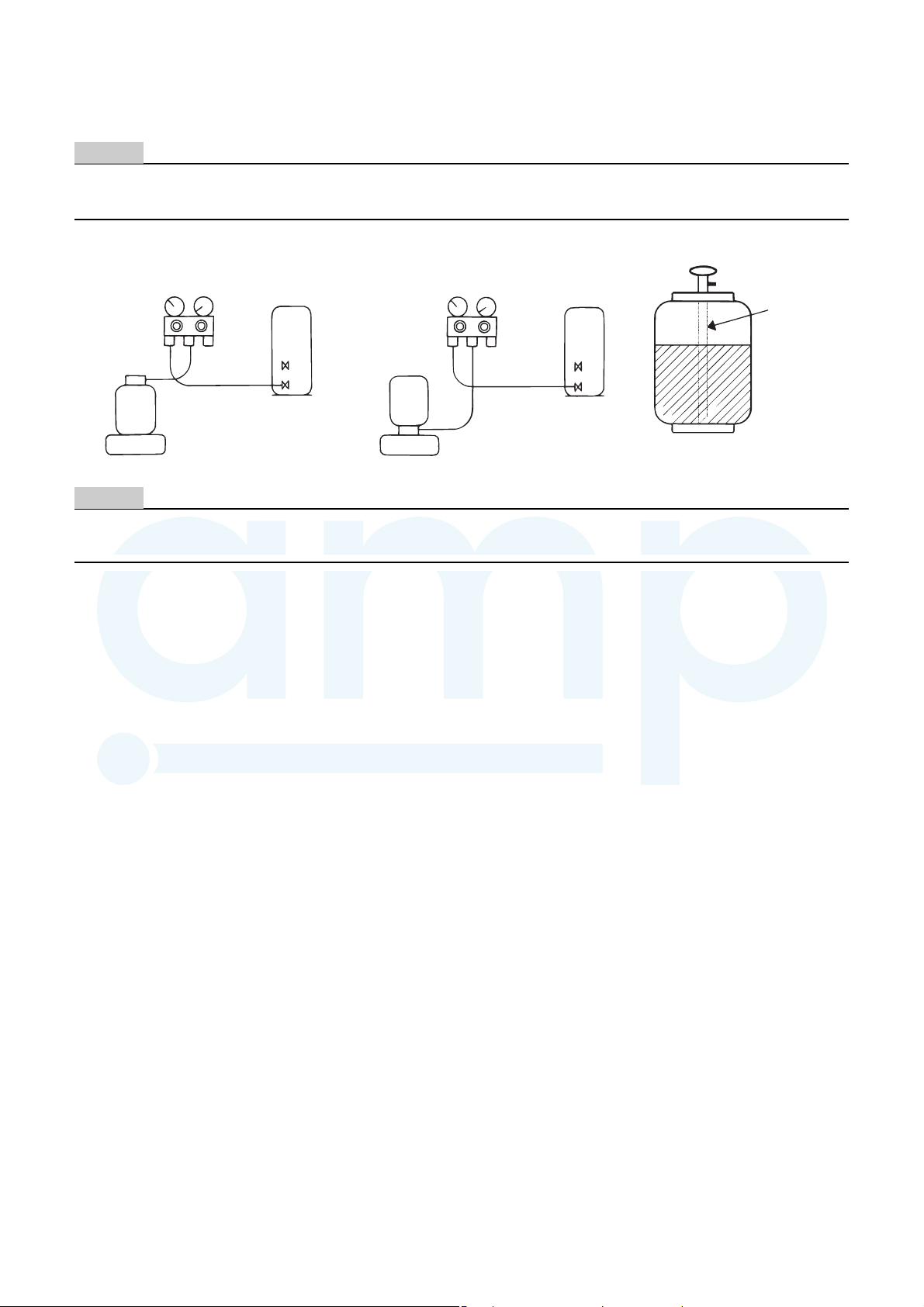

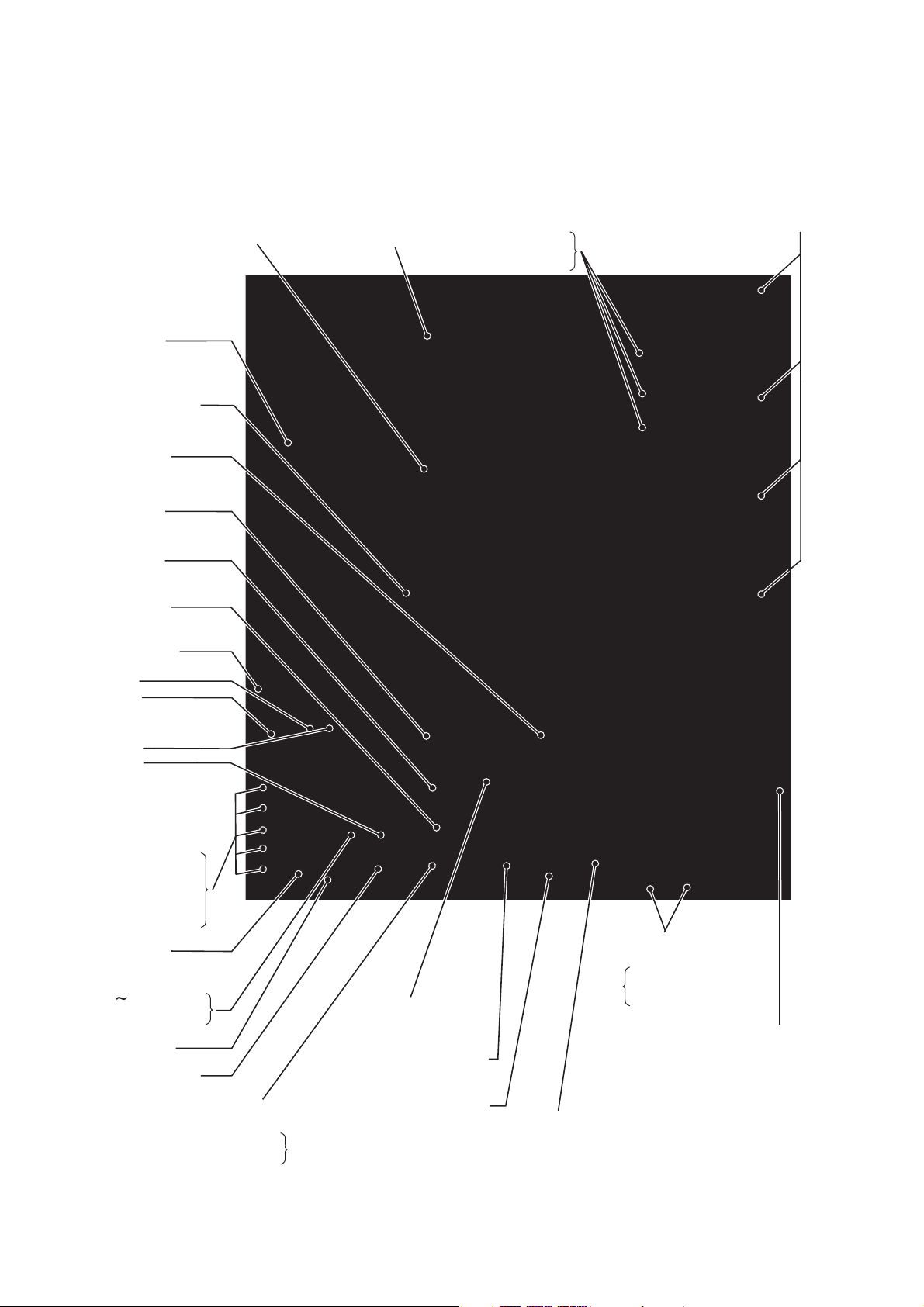

7 Refrigeration cycle / Water system diagram

M

M

Fan coil unit

Radiator unit

Floor

heating

By-pass valve

(locally procured)

By-pass valve

(locally procured)

Motorized mixing valve

(locally procured)

AC230 V

Buffer tank (locally procured)

AC pump

(locally procured)

Circulation

pump

max : 10 bar

Strainer

(locally procured)

40 mesh

Motorized 3-way valve

(locally procured)

AC230 V

Booster heater

(local)

2-way valve for

cooling mode

(locally procured)

AC230 V

Safety valve

set : 3.5bar

Boiler

(local)

Drain cock for water charge

(locally procured)

Cylinder heater

Ø

1 : 2.7 kW

Relief valve(UK)

90 °C

10 bar

Water outlet

Water inlet

Reducing

valve (UK)

3.5 bar

Pressure relief

Set value : 7 bar (UK)

Water heat exchanger

max : 10bar

Backup heater

Ø

1 : 3 kWØ3 : 6 kWØ3 : 9 kW

Flow sw

Thermal protector

(auto)

set : 75 ± 3 °C

Thermal protector

Single operation

set : 95 ± 5 °C

Low pressure sensor

Expansion vessel

set : 1bar

Pressure relief valve

set : 3bar

Manometer

gage : - 6bar

Water vent

valve

Air vent valve

Outdoor unit

Thermal cut-out

(manual reset)

82 °C (+3k/-2k)

zone1

zone2

TFI

TTW

TC

TWO

THO

TWI

Hot water cylinder

Local hot water system

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

7-1. Water system diagram

29

Page 31

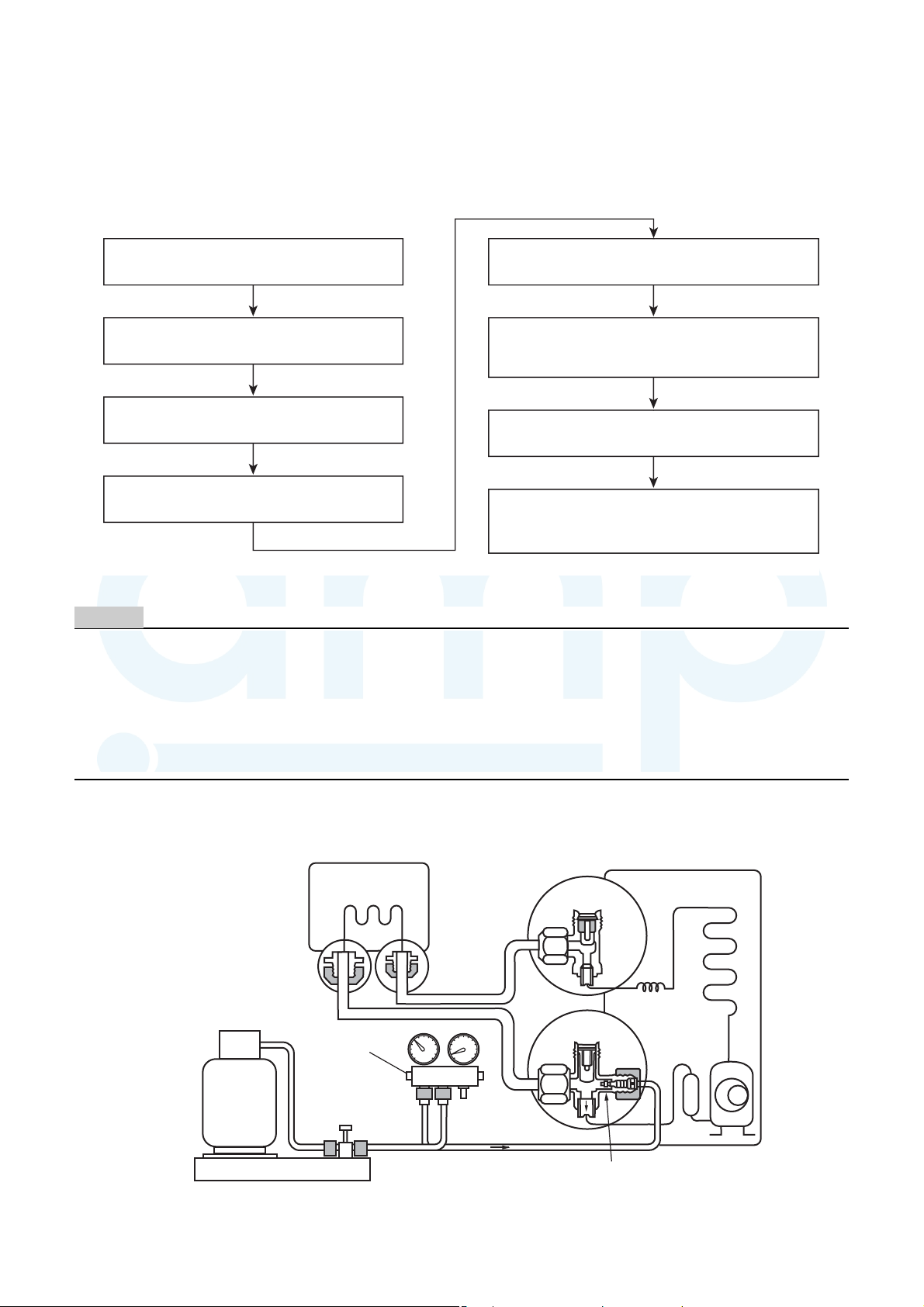

Installation example of water circuit

(1) (2)

(3) (4)

(5) (6)

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

The water flowing for a system without buffer tank ((1), (2), (3), (5)) r equires18 /min (P804XWH 1 3 /min) or more.

This water flowing requires 5 or more branches of Floor heating or Radiator etc.

Less than 5 branches may cause a flow deficien cy. In this case, please provide a buffer tank and secondary pumps

as shown in (4).

Please check how to install the boiler (See page 41)

30

Page 32

7-2. Refrigeration cycle system diagram

Outdoor unit

TS

TD

Accumulator

(2500 cc)

PMV

TO

Flow switch

Plate-type

water hea t

exchanger

Air vent valve

Manometer

P

Expansion vessel

High press ure

sensor (PD)

TE

Low pressure

sensor

TWO

Water vent valve

Safety valve

Backup heater

TWI

Circulat ing pump

8 kW…UPM 2K 25 - 60 130

11 kW…UPM GEO 25 - 85 130

THO

TL

4-way valve

(STF-H0404)

TC

Hydro unit

Outdoor heat exc hanger

Compressor

(DA422A3F-26M)

2-way valve

Heati ng / Hot water s upply

Defrosting / Cooling

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

HWS-P804XWHM3-E1, HWS-P804XWHT6-E1, HWS-P804XWHT9-E1,

HWS-P1104XWHM3-E1, HWS-P1104XWHT6-E1, HWS-P1104XWHT9-E1 /

HWS-P804HR-E1, HWS-P1104HR-E1

[

[

31

Page 33

8 Operational description

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

This chapter describes the working circuit and control of Air to Water Heat Pump about the following operations.

8-1

8-2

8-3

8-4

Item

8-1. Basic Operation

1) Operation control

2) Hot water supply operation

3) Heating operation

4) Cooling operation

8-2. Operation Mode and Control Method

1) Heat pump operation range of hot water supply, heating and cooling

2) Hot water supply operation

3) Heating operation

4) Cooling operation

5) Simultaneous operations of "hot water supply" and "heating"

6) Simultaneous operations of "hot water supply" and "cooling"

7) Boiler control

8) Hot water boost operation

9) Anti bacteria (ANTI BACTERIA) operation

10) Night set back (NIGHT SET BACK) operation

11) FROST PROTECTION operation

12) AUTO operation

13) Night time low-noise operation

8-3. Hydro Unit Control

1) Capacity control (compressor, high-temperature release, low-temperature release)

2) Heater control

3) Circulation pump control

4) Control by the flow switch

5) Mixing Valve control (2-temperature heating control)

6) Room temperature cont rol

7) Room temperature cont rol w ith th e th e rm o s ta t

8) Hot water cylinder thermostat control

9) Control of force stop and restart

10) Control of limit of heat pump operation

11)Output signal control 1

12)Output signal control 2

13) Q-H characteristics of hydro unit

14) Automatic restart control

15) Piping freeze prevention control

16) High return water protect control

8-4. Outdoor unit control

1) PMV (Pulse motor valve) control

2) Discharge temperature release control

3) Current release control

4) Current releases shift control

5) Outdoor fan control

6) Defrosting control

7) Winding heating control

8) Short circuit operation prevention control

9) Over current protection control

10) High pressure release control

11) Compressor case thermostat

12) Bottom plate heater control

13) 2-way valve control

14) Start up from hibernation

Page

33 to 35

36 to 47

48 to 64

65 to 73

32

Page 34

Item Operation flow and applicable data, etc. Operation description

Operation

condition selection

Serial signals

transmit and receive

Heating: Run/Stop

Hot water supply: Run/Stop

Cooling: Run/Stop

Serial signals transmit

and receive

Serial signals

transmit and receive

Remote controller settings

<Heating> Temperature setting

<Hot water supply > Temperature setting

<Cooling> Temperature setting

Auto Temp

Anti Bacteria

Frost protection

Hot waterboost

Water heat

exchange

Sub board

Outdoor

unit control

Serial signals

transmit and receive

Outdoor unit control

Inverter frequency control

Waveform synthesis function

Calculation function (Temperature calculation)

AD conversion function

Rapid heating function

Compressor restart

Delay function

G-Tr overcurrent prevention function

Defrosting operation function

Hydro

unit

Outdoor

unit

Compressor

Outdoor fan motor

PD sensor

TD sensor

TS sensor

TE sensor

TO sensor

PMV

4-way valve

2-way valve

Thermostat (Cooling/Heating)

Forcible stop input

Error Alarm stop output

Defrosting output