Toshiba HWS-G1901CNMR-E, HWS-G1901CNRR-E, HWS-G1901ENXR-E, HWS-G1901CNXR-E, HWS-G2601CNRR-E Service Manual

...Page 1

FILE No. EU-SVM-18001 R01

AIR TO WATER HEAT PUMP

Service Manual

Domestic Hot Water Heat Pump

Model name:

HWS-G1901CNMR-E HWS-G1901CNRR-E HWS-G1901CNXR-E

HWS-G1901ENXR-E HWS-G2601CNMR-E HWS-G2601CNRR-E

HWS-G2601CNWR-E HWS-G2601ENXR-E

Page 2

Domestic Hot Water Heat Pump Service Manual

1

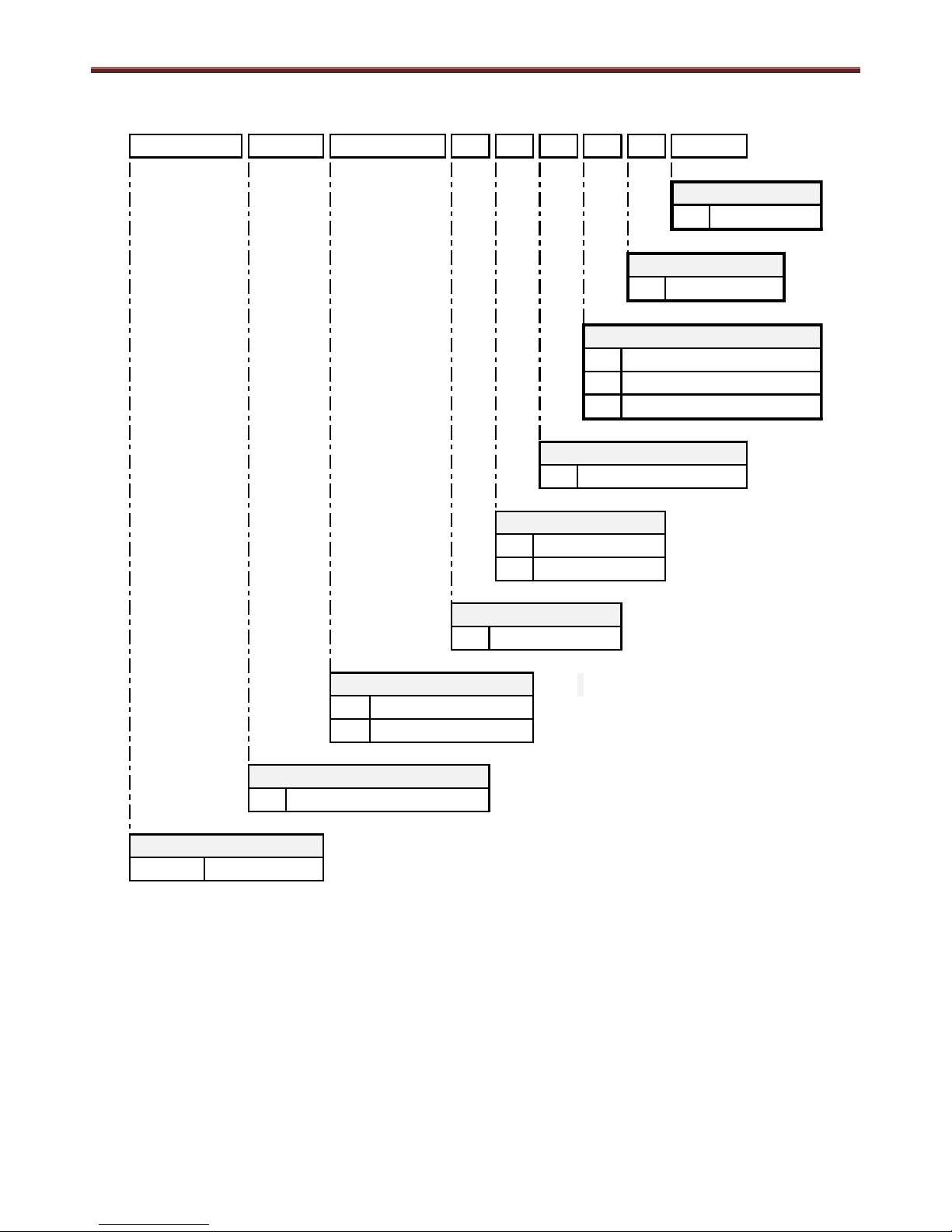

Model naming convention:

H W S - G 1 9 0 1 C N M R - E

E

R

M

R

X

N

C

E

1

190

260

G

Europe

Area

Tank Type

Factory

HWS

Thermodynamic HWS

Model Type

A2W

TCEU

Standard Tank (45°)

180° variant tank

Deluxe PCB

Type

Coil Type

Coil

Extra coil

190l Capacity

260l Capacity

Enamelled Steel

Tank Material

Series Number

Series 1

Water Tank Capacity

Page 3

Domestic Hot Water Heat Pump Service Manual

2

Contents

1.0

Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

2.0

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

3.0

DHW-HP Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

4.0

Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 PC Board and connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 4.2 Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10

5.0

Key electric component rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11

6.0

Refrigerant cycle / water system diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Refrigeration cycle system diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12

6.2 Water system diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12

7.0

Operational description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 P1 AUTO mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15

7.2 P2 ECO mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16 7.3 P3 BOOST mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17

7.4 P4 BACKUP mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18

7.5 P5 SILENT mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19

7.6 P6 HOLIDAY mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19

7.7 B4 Hot on time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20 7.8 B3 Low tariff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20

7.9 B1 Ventilation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21

7.10 B5 Photovoltaic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22

7.10.1 PV ECO operation in AUTO mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25

7.10.2 PV ECO operation in BOOST mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26

7.10.3 PV Storage operation in BOOST mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27 7.11 D26 Extra function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28

7.11.1 B6 Solar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28

7.11.2 B7 Floor / B8 Floor T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29

7.11.3 B9 Cooling / Cooling T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30

7.12 D27 SG Ready . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31

7.13 D29 External control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

33 7.14 Defrost operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

35

7.15 Legionella operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

36

8.0

Modbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

38

8.1 Monitoring functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

40

8.2 Read & write functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

41

9.0

Method of defect analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Matters to be confirmed first . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

44

9.1.1 Check the power supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

44

9.1.2 Check the cold water supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

44

9.2 In the event of error – how to operate BACK-UP mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

45

9.3 Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

45

9.4 Error code analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

45 9.4.1 Er1 ~ Er5 – Temperature sensor error analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46

9.4.2 Er HP – High pressure switch error analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46

9.4.3 Er Evap – Evaporator temperature error analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

47

9.4.4 Er H Evap – High evaporator temperature error analysis . . . . . . . . . . . . . . . . . . . . . . . . .

47

9.4.5 Er C Evap – Low evaporator temperature error analysis . . . . . . . . . . . . . . . . . . . . . . . . .

48

9.4.6 Er Filter – Change filter error analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

48 9.5 Resetting of error code & BACK-UP mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

48

10.0

DHWHP Settings

10.1 Home view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

49

10.1.1 Information menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50

10.1.2 Mode of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

51

10.1.3 Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

52

10.1.4 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

53 10.1.5 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

54

10.1.6 Installer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

55

11.0

Periodic inspection items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

58

11.1 Environmental requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

58

11.2 Heating system and fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

58 11.3 Condensation and condensate drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

58

Page 4

Domestic Hot Water Heat Pump Service Manual

3

11.4 Water circulation and tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.1 Pressure relief valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

58

11.4.2 Anode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

59

12.0

Part exploded view, part list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

60

13.0

Main components replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1 Open & remove the front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

61

13.2 Remove the top shell & top cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

62

13.3 Remove the evaporator housing top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

63

13.4 Replace the heating element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

63

13.5 Replace the safety breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

64

13.6 Replace the anode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

64 13.7 Replace the solenoid valve, coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

65

13.8 Replace the fan kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

66

13.9 Replace the BT1 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

66

13.10 Replace the BT2 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

67

13.11 Replace the BT3 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

67

13.12 Replace the BT4 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

68 13.13 Replace the Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

69

13.14 Replace the Tube kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

70

13.15 Replace the PCB Board standard & deluxe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

71

13.16 Replace the display & frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

71

Page 5

Domestic Hot Water Heat Pump Service Manual

4

1.0 Safety precautions

The product shall be installed, commissioned, repaired only by qualified technicians. Incorrect installation can

result in damage to property and/or injuries to people and animals.

The unit shall be disconnected from the power supply when the cover is off.

The unit shall not be used by children or people with limited physical or mental capacity.

Children should be supervised to ensure that they do not play with the appliance.

Cleaning and maintenance shall not be made by children without supervision.

Do not place flammable materials in contact or close to the unit.

The water system and the air system should be installed as stated in the manual.

When in service, the unit should not be placed in sub-zero temperature areas.

When not in service, the unit can be placed in sub-zero temperature areas, but all the water in the tank or in the

condensate drain should be removed.

Hot water can cause serious burns if directly connected to the taps. The installation of a mixing valve is suggested.

The unit should be used only for its specified use. The manufacturer is not liable for any damages due to failure to

observe this manual.

Take all the possible precautions to avoid incidents.

The product contains HFC-R134a

The electrical supply, for the domestic hot water heat pump, must be protected by an earth leakage breaker and an

overcurrent protection device (fuse or circuit breaker).

Failure to comply with this precaution may result in electric shock or fire

This unit must be connected to the main power supply using a circuit breaker or switch with a contact separation of

at least 3mm

Introduction

The aim of this manual is to give information, instructions and warnings on the domestic hot water heat pump. The

manual is to be used by service engineers, since it contains important safety, diagnosis and operational indications.

The manual is a part of the domestic hot water heat pump and it is to be conserved with care, since it contains

important installation and maintenance instructions that can be useful to assure a long life time and an efficient

operation.

About the product

The product is a domestic hot water heat pump (DHWHP) that has been designed according to EU directives. The

product is intended for hot water production for domestic use or for similar applications. The unit has been designed to

be ready for installation.

General

The domestic hot water heat pump is composed of a water tank, a refrigerant circuit, a cabinet and a display

connected to a control board. The main scope of the appliance is to heat water stored in a tank.

Operation

The unit is programmed to start heating the water inside the tank when its temperature falls below a predetermined

level, BBT3 (T Tank Top) is 5K<SP. The unit stops when the water temperature reaches a set point (SP) that can be

regulated by the user. In general, the appliance is designed to produce enough hot water to cover the need of a

household of 4 persons or more.

There are two ways in which the DHW-HP can heat the water:

1) Heat pump operation

In the operation with heat pump, a heating cycle utilizes the operation of a compressor and the extraction of the

heat from the air to heat the water in the tank. This is the standard way used to heat the domestic hot water, since

it leads to lower electricity consumption, hence also lower running costs.

2) Electric heater operation

The water is heated using an electric heater. An electric resistance is powered to heat the water in a safe, fast and

flexible way. However, using the electrical heater can become an expensive way to produce hot water. This

operation should be used as a back-up or as integration of the standard operation.

Page 6

Domestic Hot Water Heat Pump Service Manual

5

The electric heater is activated in case of:

Failure of the heat pump operation, this requires an override command from the end user to be confirmed

Too high or too low air temperature

The quantity of hot water produced is not enough.

Note: The amount of water heated by the electric heater is at a reduced volume; see the performance data for

these values.

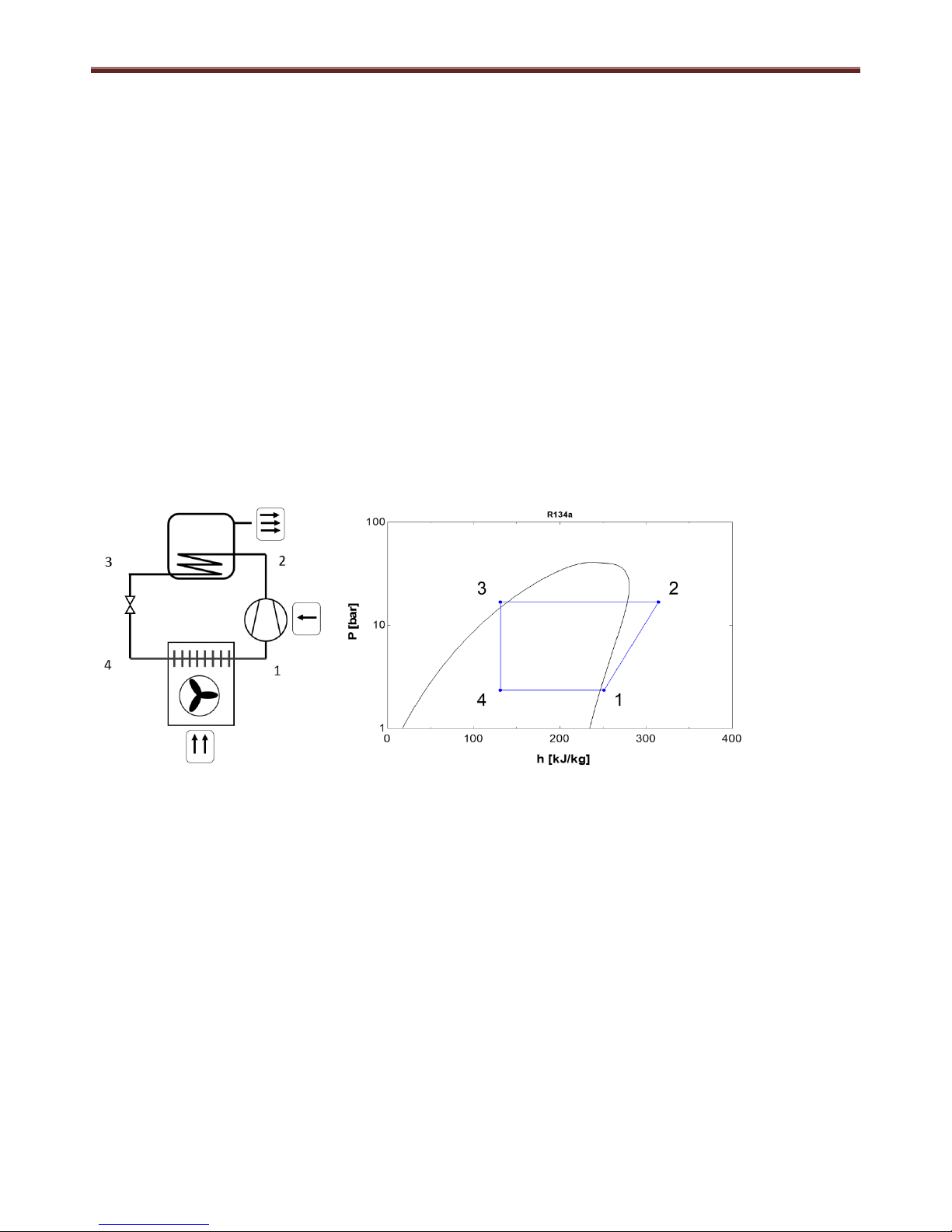

Heating circuit

As depicted in the figure below, the heat pump cycle can be divided in four main processes: compression (1-2),

condensation 2-3), expansion (3-4) and evaporation (4-1) described below.

At the suction of the compressor (1) the superheated gas refrigerant enters the compressor at a low pressure.

In the compressor, the gas is compressed to a higher pressure and temperature level (2).

The gas is first de-superheated and condensed in the condenser, exchanging heat with the water stored in the

tank.

The refrigerant exits the condenser in a subcooled, liquid form (3)

Through the thermostatic expansion valve the pressure of the refrigerant is lowered to allow its evaporation at a

lower temperature (4)

The refrigerant is evaporated in the fin-coil heat exchanger that uses forced air as a heat source (1)

The process goes on until the power supply to the compressor is stopped.

Note: the extensive use of the electric heater leads to a higher electricity consumption and it may lead to high

electricity bills. The operation with the heat pump normally consumes more than 3 times less electricity than the

operation with electric heater. The energy released to the condenser (2-3) is, in fact, the sum between the free energy

extracted from the air in the evaporator (1-4) and the energy supplied to the compressor (2-1). On average, the energy

absorbed by the evaporator is more than double of the energy used to run the compressor.

Safety instructions – Heating circuit

Only skilled and trained technicians shall carry out repair and service of the heat pump circuit.

Before opening the heating circuit, discharge the refrigerant to a level that allows safe working conditions.

The refrigerant can be toxic if inhaled or if in high concentrations.

Special attention should be given if the work is carried out with an open flame.

Page 7

Domestic Hot Water Heat Pump Service Manual

6

2.0 Specifications

Physical data

Domestic Hot Water Heat Pump

HWS-G1901CN*R-E

HWS-G2601CN*R-E

HWS-G1901ENXR-E

HWS-G2601ENXR-E

Dimensions (Height x Diameter)

mm

1600x620

1960x620

1600x620

1960x620

Weight (dry / wet)

kg

91 / 281

106/356

107/297

126/376

Nominal insulation thickness

mm

50

50

50

50

Refrigerant R134A

R134A

R134A

R134A

Refrigerant charge

kg

1.2

1.28

1.2

1.28

Refrigerant charge CO2 equivalent

ton

1.70

1.80

1.70

1.80

Water connections (cold & hot water)

inch

3/4

3/4

3/4

3/4

Water connections (entry angle)

deg.

45 / 180

45 / 180

45 / 180

45 / 180

Condensates water connections

mm

Ø19

Ø19

Ø19

Ø19

Max water side operating pressure

Mpa

0.6

0.6

0.6

0.6

Power supply

V-ph-Hz

230-1-50

230-1-50

230-1-50

230-1-50

Performance data

Domestic Hot Water Heat Pump

HWS-G1901CN*R-E

HWS-G2601CN*R-E

HWS-G1901ENXR-E

HWS-G2601ENXR-E

Energy Class - A+

A+

A+

A+

COP at Air7°C W10°C-52,9°C (EN16147)

-

3.57

3.69

3.57

3.69

Heat up time (A7°C W10°C-53,5°C)

hh:mm

06:27

09:12

06:27

09:12

COP at Air20°C W10°C-52,9°C (EN16147)

-

4.13

4.2

4.13

4.2

Heat up time (A20°C W10°C-53,5°C)

hh:mm

05:15

07:09

05:15

07:09

Cylinder volume

l

190

260

184

252

V40 volume (W52.9°C)

l

247

347

234

331

Maximum Qty of water by electric heater

only

l (%)

75 (40%)

130 (50%)

75 (40%)

130 (50%)

Maximum water temperature

°C

60

60

60

60

Corrosion protection

Magnesium anode

Magnesium anode

Magnesium anode

Magnesium anode

Heat pump operating range (min/max)

°C

-7 / +40

-7 / +40

-7 / +40

-7 / +40

Electrical heater Power

W

1500

1500

1500

1500

Maximum Power input

W

2185

2185

2185

2185

Auxiliary Power input (Paux)

W

1.61

1.61

1.61

1.61

Standby Power input (Pes)

W

17

20

17

20

Sound power level - Air7°C W10°C-52,9°C

(EN16147)

dB(A)

49

49

49

49

Sound power level - Air20°C W10°C-52,9°C

(EN16147)

dB(A)

55.6

55.6

55.6

55.6

Airflow rate nominal (min - max)

m3/h

450 (0 - 800)

450 (0 - 800)

450 (0 - 800)

450 (0 - 800)

Maximum fan power

W

85

85

85

85

Maximum external static pressure

Pa

200

200

200

200

Air duct connections

mm

Ø160

+Ø160

Ø160

Ø160

Minimum room volume (non-ducted unit)

m3

60

60

60

60

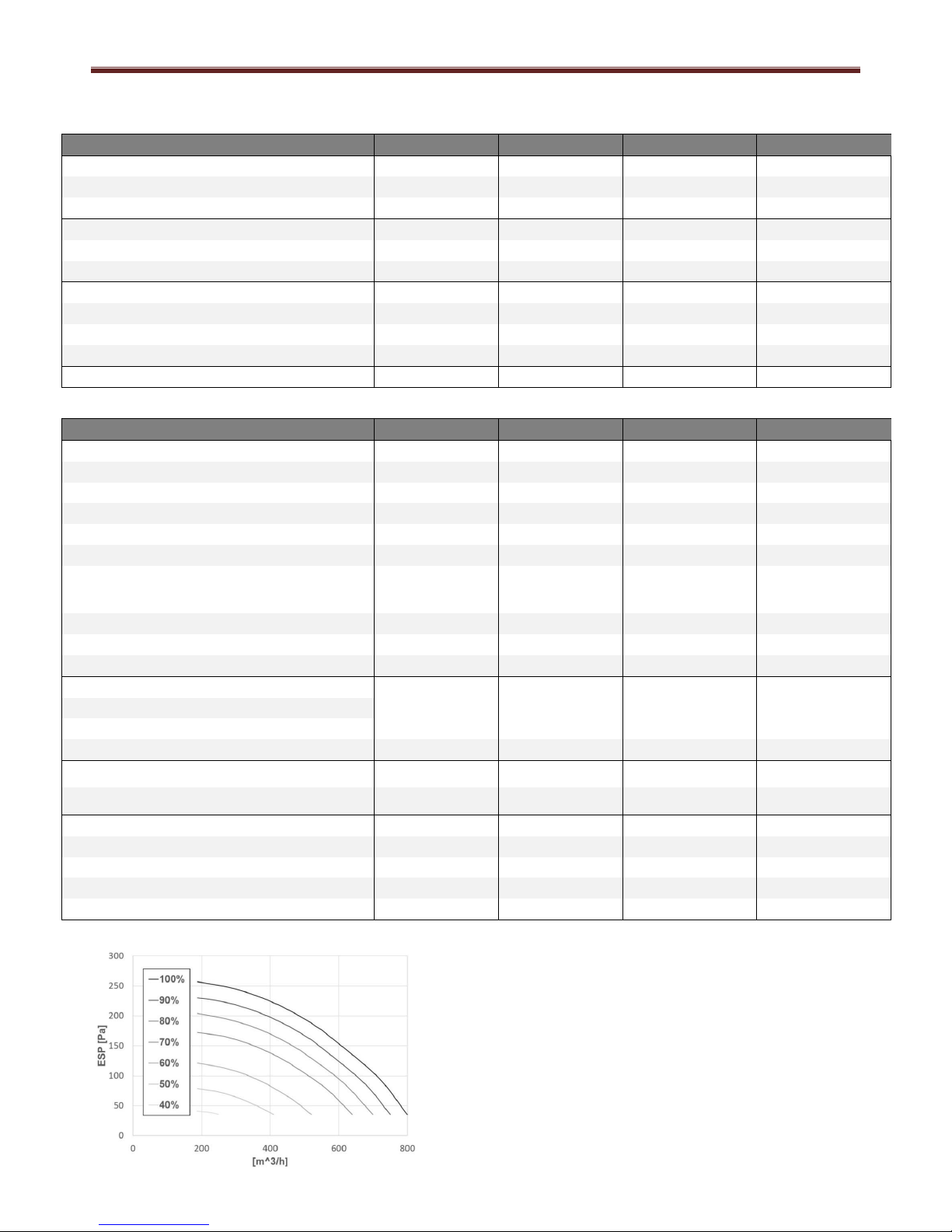

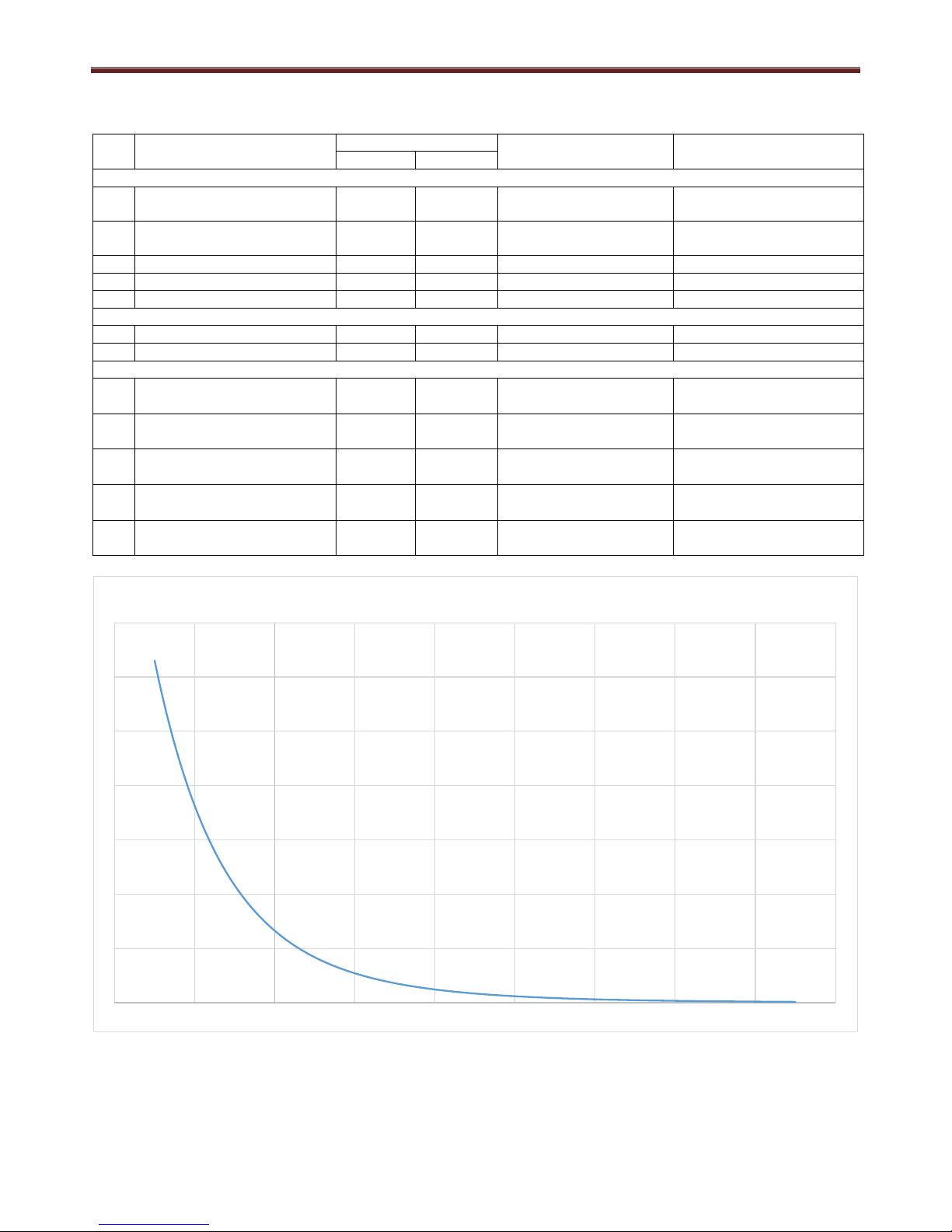

Fan Curve

The graph shows the external static pressure vs airflow

at different fan speeds.

In order to assure an efficient operation, it is suggested

to keep the external pressure drops below 200 Pa.

Page 8

Domestic Hot Water Heat Pump Service Manual

7

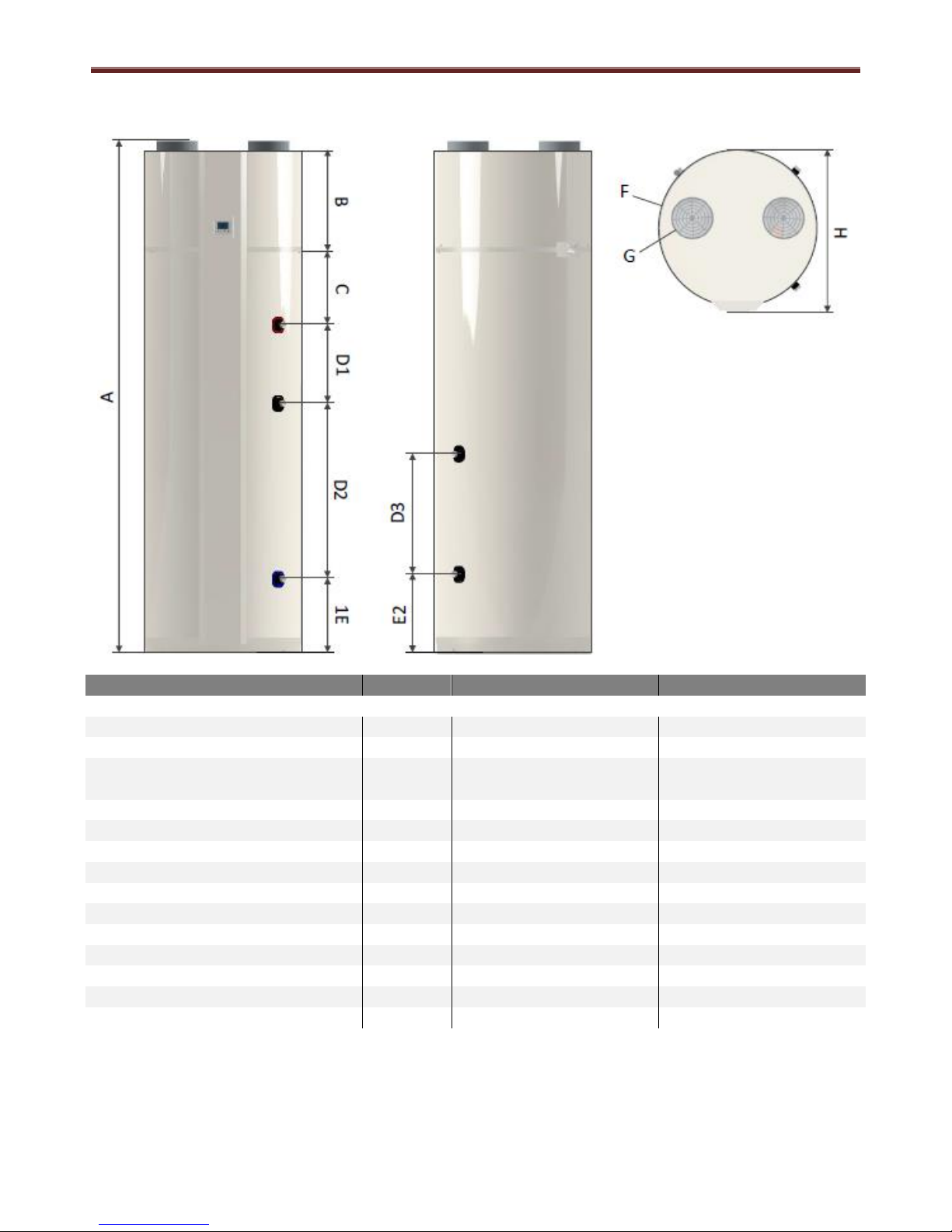

3.0 DHW-HP drawing

Parameter

Unit

HWS-G1901***R-E

HWS-G2601***R-E

Dimensional Data

A – Height

mm

1610

1960

B

mm

385

385

C

mm

280

280

D1

mm

180

300

D2

mm

435

670

D3

mm

375

375

E1

mm

285

285

E2

mm

305

305

F – Diameter

mm

603

603

G – Diameter

mm

160

160

H – Max Diameter

mm

620

620

Height required for installation

mm

1700

2040

Standard DHW-HP weight dry/wet

kg

94 / 284

100 / 350

Additional coil DHW-HP weight dry/wet

Kg

100/300

120/370

Nominal insulation thickness

mm

50

50

Page 9

Domestic Hot Water Heat Pump Service Manual

8

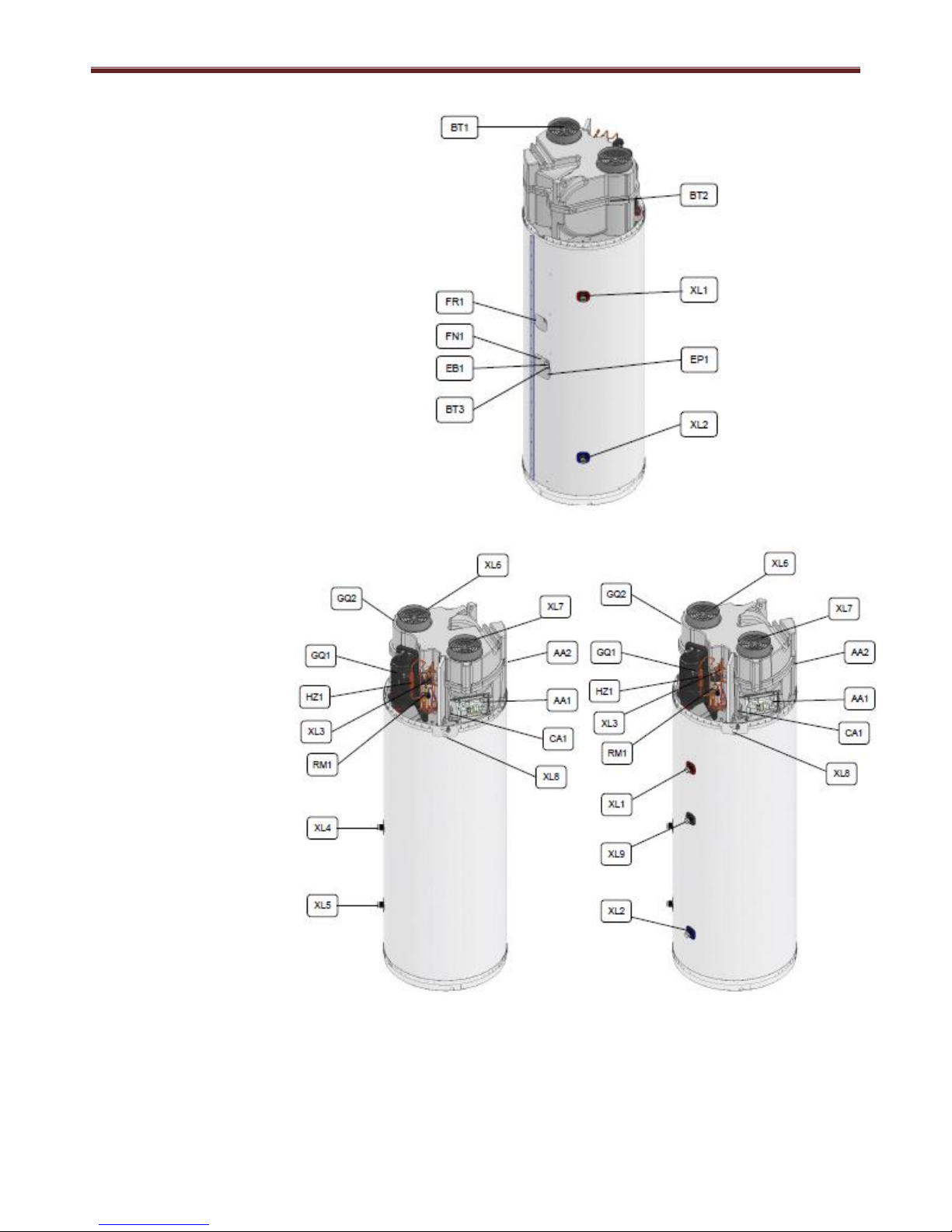

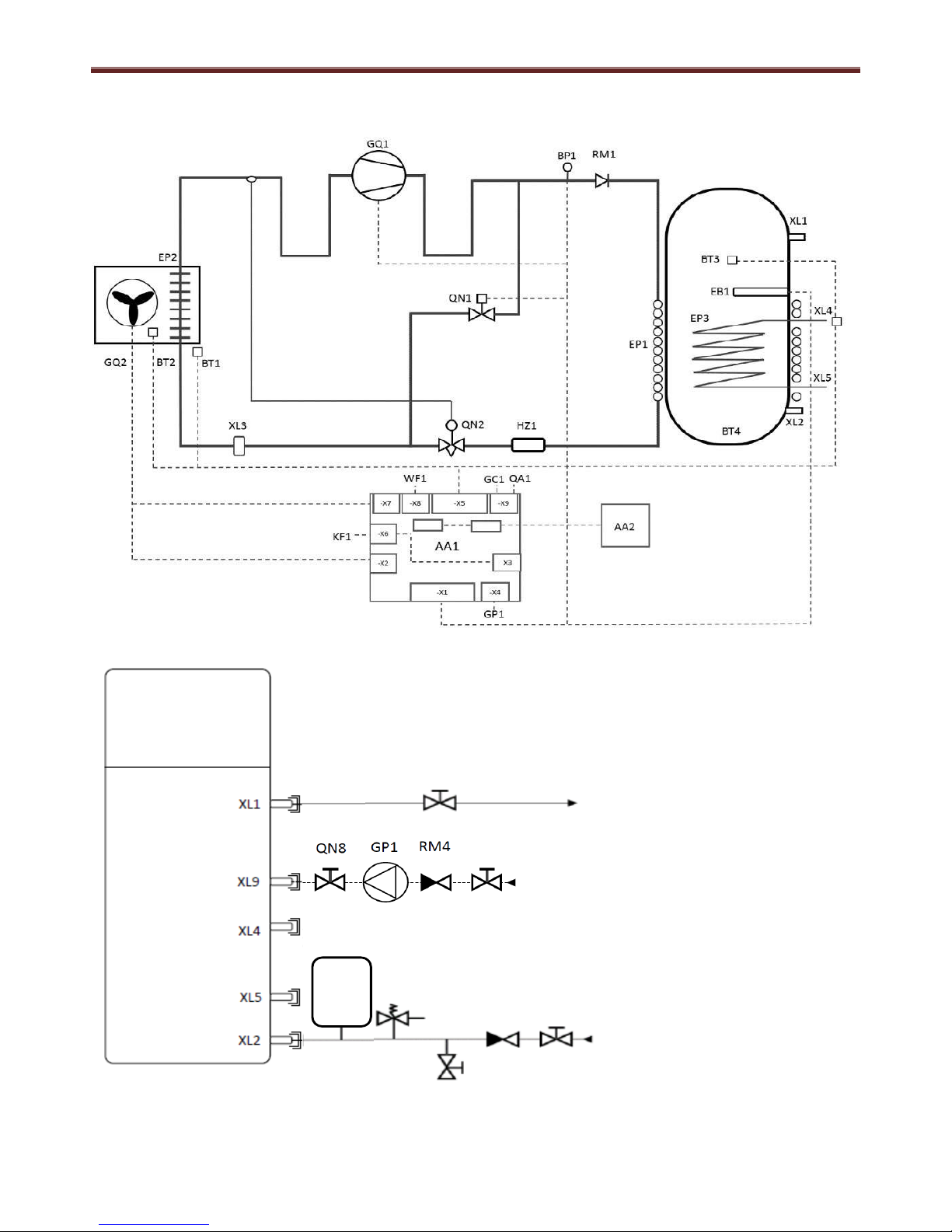

Refrigerant circuit

GQ1: Compressor

GQ2: Fan

RM1: Check valve

EP1: Condenser

EP2: Evaporator

HZ1: Filter drier

QN1: Solenoid valve

QN2: Thermostatic expansion valve

XL3: Service valve

Water circuit

XL1: Water outlet

XL2: Water inlet

XL4*: Coil top

XL5*: Coil bottom

XL6: Air outlet

XL7: Air inlet

XL8: Condensate outlet

XL9*: Hot water circulation

EP3*: Coil

EB1: Electric heater

FR1: Anode

FN1: Thermal protection

The items with * are optional.

Figure 4 – Design of the heating circuit and the main components

Sensors

BBT1: Air inlet temperature

BBT2: Evaporator temperature

BBT3: Tank water temperature

BBT4*: Additional temperature

BBT5*: Additional temperature

(not included)

BP1: Pressostat

Electric components

AA1: Main printed circuit board

AA2: Display circuit board

WF1: Modbus port

GC1*: Solar 0-3V/10V

QA1*: SG-ready port

GP1*: Additional supply to pump

or damper

The items with * are optional.

Figure 5 – Design of tank, condenser and related components

Nomenclature according to standard

IEC 81346-1 and 81346-2.

Page 10

Domestic Hot Water Heat Pump Service Manual

9

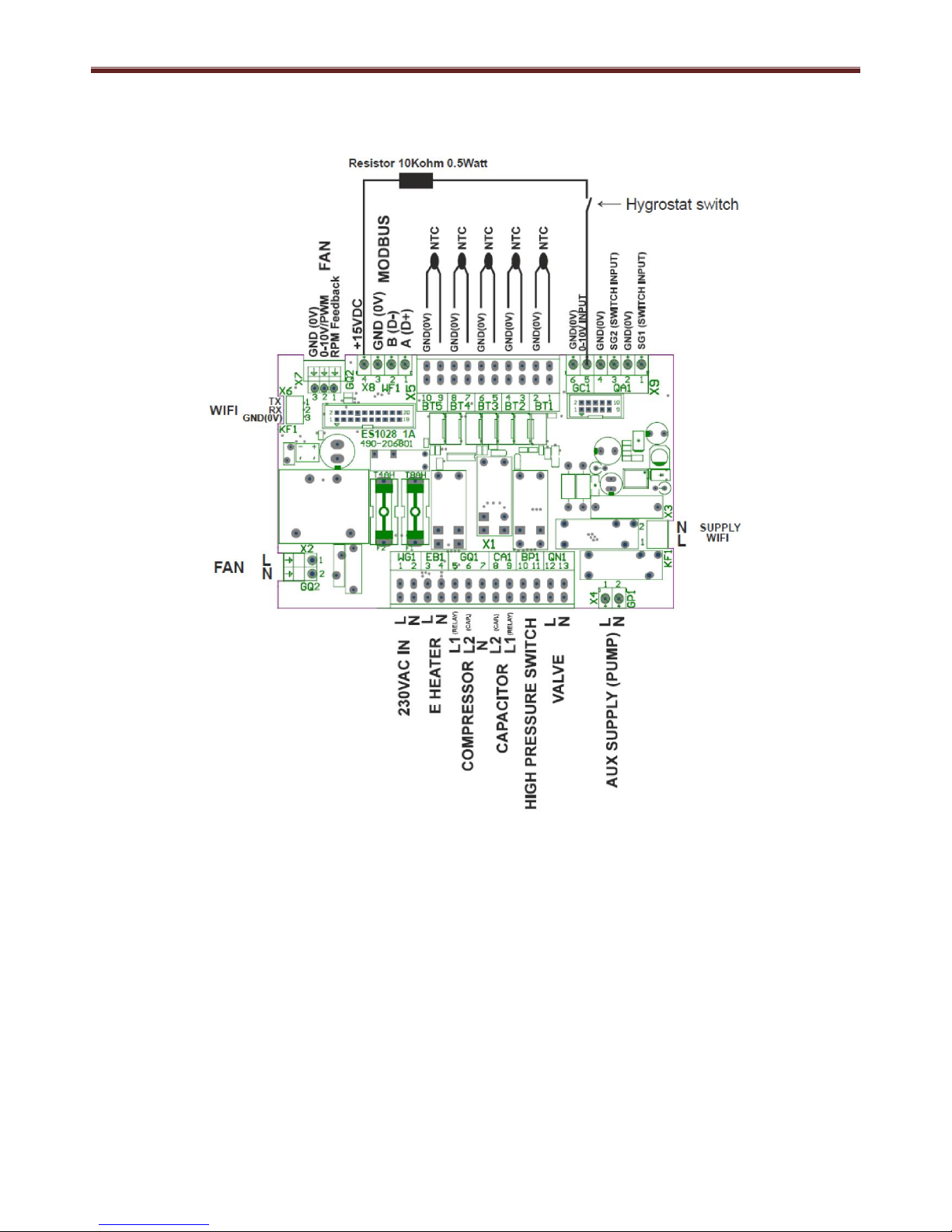

4.0 Wiring diagram

4.1 PC Board and connections

Page 11

Domestic Hot Water Heat Pump Service Manual

10

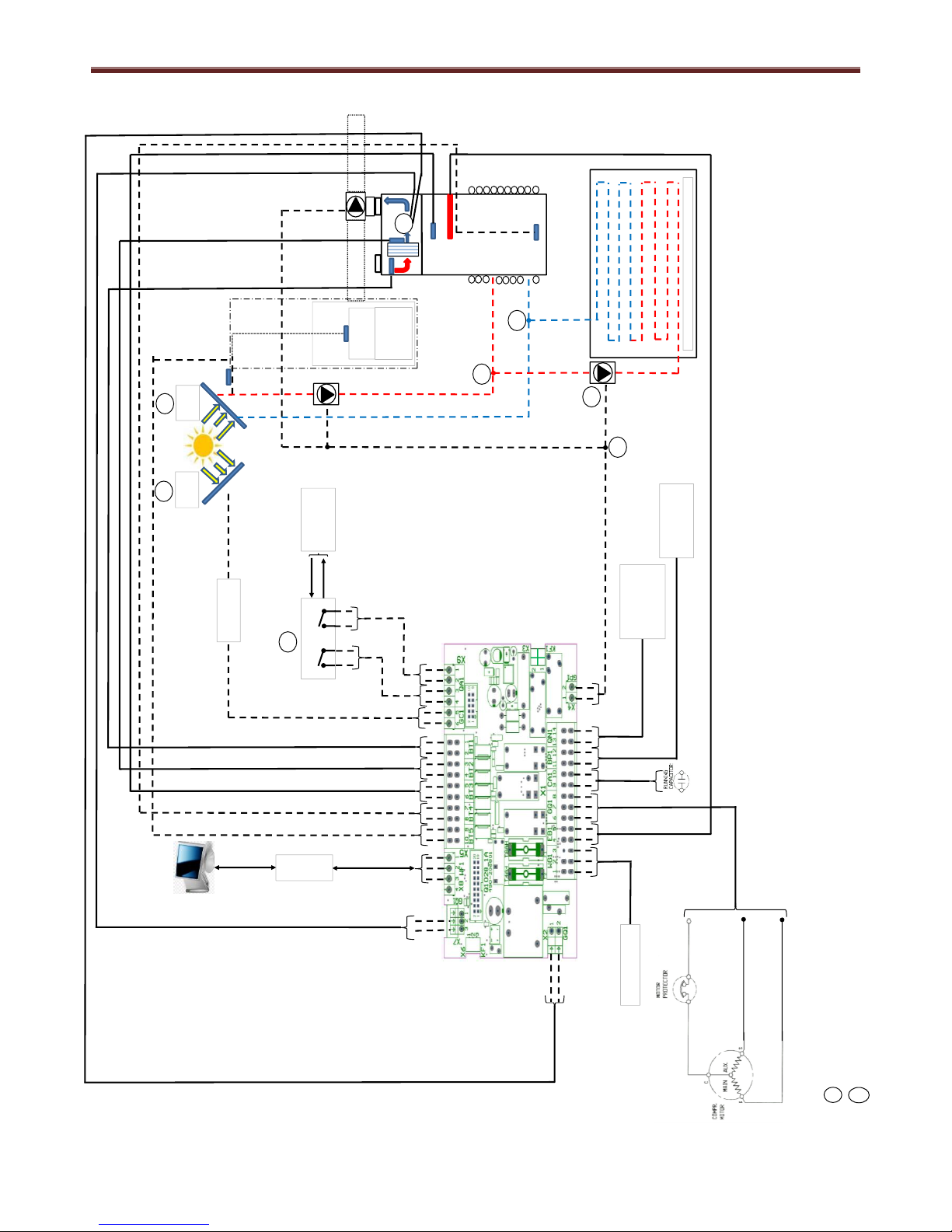

4.2 Schematic

= Schematic shows all available options connected to the DHWHP PCB. In reality it is not possible to connect the solar thermal panel / circuit at the same time as the underfloor heating circuit.

It is only possible to connect one of these options to the DHWHP at any one time

= Schematic shows all available options connected to the DHWHP PCB. These options are only available with the deluxe model DHWHP units only.

BLU

B (D-)

L

N

L

N

0V

0V

L

L

0V

0~10V

Input

BT3

EB1

0V

0V

0V

FM

BT2

BT1

0V

0V

L

N

PE

230VAC ~ 50Hz

0V

A (D+)

0V BLU

0~10V PWM

YEL

High pressure switch.

Compressor STOP when

Pd ≥ 2.0MPa

Solenoid valve.

Solenoid ON for 2 min

before compressor

starts and during

system defrost

BRN

BLK

N

BLU

BLK

BRN

BRN

BLU

#1

Energy Meter

Communication to

/ from power grid

SG2

SG1

0V

0V

#2

#2

Modbus

communication

Inverter

#2

Solar

PV

BT4

#1#1#2

BT5

Under floor

heating

or

Cooling

Room

temperature

Under floor heating circuit

#2

Solar

Thermal

BT5

#1

Page 12

Domestic Hot Water Heat Pump Service Manual

11

5.0 Key electric component rating

No.

Component Name

Model

Type

Rating

Standard

Deluxe

Refrigeration

1

Highly compressor

ο

ο

WHP01900BUV-H8JU

Winding resistance

4.82/6.22Ω (at 20°C)

2

Case thermostat

ο

ο

B110-160-241E

Contact open: 160±10°C

Contact Close: 70±10°C

3

Fan motor

ο

ο

R3G220-RC05-17

230V / 0.7A / 50-60Hz

4

Solenoid

ο

ο

FDF2.5A 08

230V / 50-60Hz

5

High pressure switch

ο

ο

UL1015 18AWG

Open press: 20±1 bar

Electrical

6

Heating element

ο

ο

Kanthal D or 0Cr23AI5

230V / 1500W

7

Heater thermostat (x2)

ο

ο

El Matik KB

80±3°C

Sensors

8

BBT1 Motron

ο

ο

AHC3.782.244-65A

(L=400mm)

R25=22.00k +/-1%, -30

to +105°C

9

BBT2 Motron

ο

ο

AHC3.782.244-65B

(L=900mm)

R25=22.00k +/-1%, -30

to +105°C

10

BBT3 Motron

ο

ο

AHC3.782.244-65C

(L=2200mm)

R25=22.00k +/-1%, -30

to +105°C

11

BBT4 Motron

-

ο

AHC3.782.244-65D

(L=2700mm)

R25=22.00k +/-1%, -30

to +105°C

12

BBT5 Motron

-

ο

AHC3.782.244-65D

(L=2700mm)

R25=22.00k +/-1%, -30

to +105°C

0

50000

100000

150000

200000

250000

300000

350000

-40 -20 0 20 40 60 80 100 120 140

R-ntc [ohm] vs Temperature [C]

Page 13

Domestic Hot Water Heat Pump Service Manual

12

6.0 Refrigerant cycle / water system diagram

6.1 Refrigerant cycle

6.2 Water system cycle

XL1: Water outlet pipe connection

XL2: Water inlet pipe connection

XL4: Coil top*

XL5: Coil bottom*

XL9: Water circulation connection*

QN3: Shut-off valve water outlet

QN4: Shut-off valve water inlet

QN5: Drain valve

QN6: Safety valve**

QN7: Expansion tank**

QN8: Shut-off valve pump inlet*

QN9: Shut-off valve pump outlet*

RM3: Check valve

RM4: Check valve water circulation*

GP1: Water circulation pump*

* Optional additional coil

** Safety equipment required for the

installation to be locally sourced (i.e.

safety group, expansion vessel)

QN7

QN5

QN6

QN3

RM3 QN4

QN3

QN9

Page 14

Domestic Hot Water Heat Pump Service Manual

13

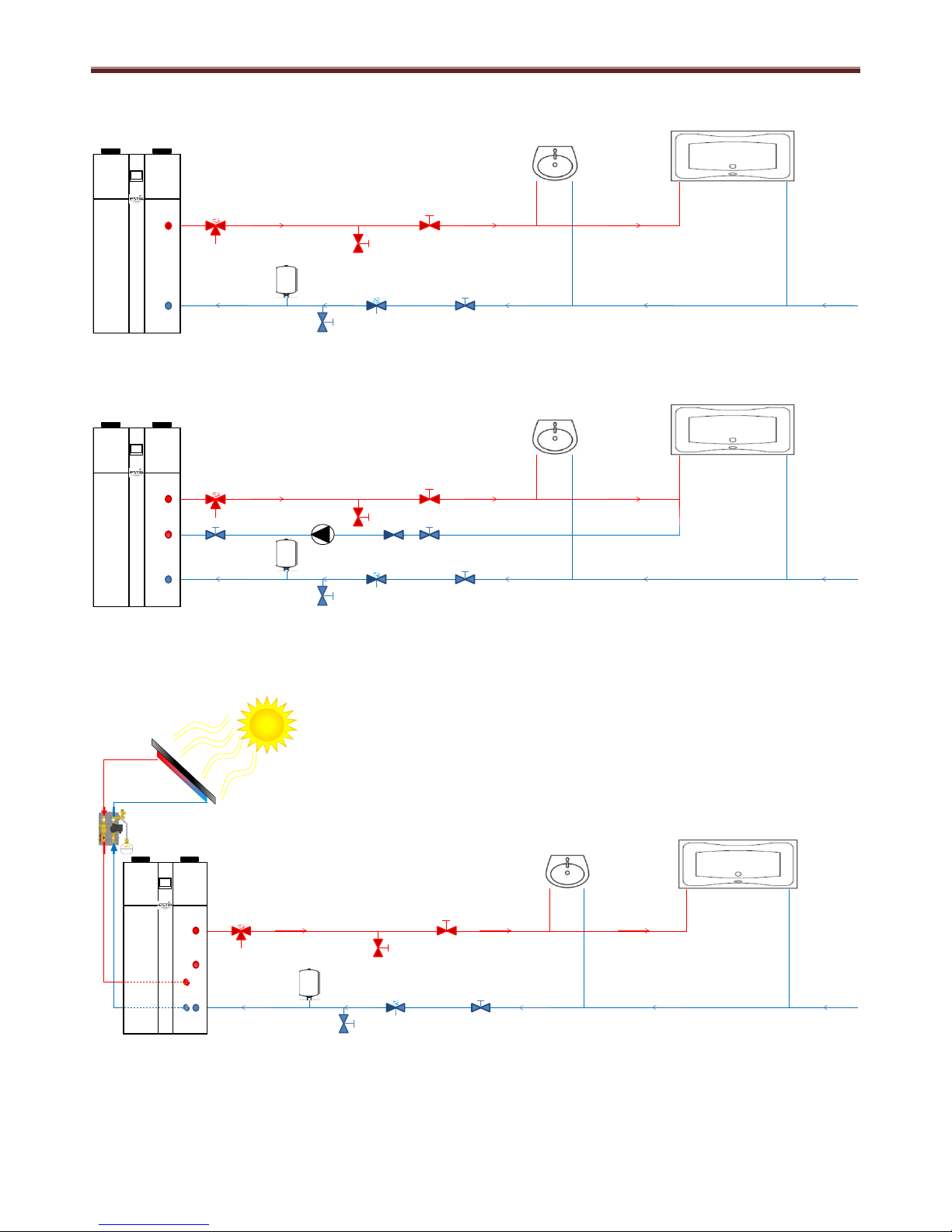

Example of a standard circuit with the DHW-HP installation

Example of a circulation circuit with the DHW-HP installation

Example of solar thermal circuit with the DHW-HP installation

2 1

8 9 11

10

6

7 4 3

5

TOSHIBA

2

1

8 9

11

10

16

15

14

13 12

6

7 4

3

5

TOSHIBA

17

18

2

1

8 9

11

10

16

6

7 4

3

5

TOSHIBA

19

20

Page 15

Domestic Hot Water Heat Pump Service Manual

14

Example of underfloor heating circuit with the DHW-HP installation

21 22

2

1

8 9

11

10

16

6

7 4

3

5

TOSHIBA

19

20

1

Bath

12

Isolation valve return flow

2

Sink

13

Check valve

3

Cold water supply shut off valve

14

Circulation pump

4

Safety group

15

Isolation valve circulation

5

Cold water supply drain valve

16

Water circulation connection point

6

Expansion vessel

17

Solar thermal collectors

7

Cold water supply pipe connection

18

Pump & expansion vessel

8

Hot water outlet pipe connection

19

Extra coil inlet

9

Temperature & pressure relief valve (6 bar / 90°C)

20

Extra coil outlet

10

Hot water supply drain valve

21

Circulation pump

11

Hot water supply shut off valve

22

Underfloor heating circuit

Page 16

Domestic Hot Water Heat Pump Service Manual

15

7.0 Operational description

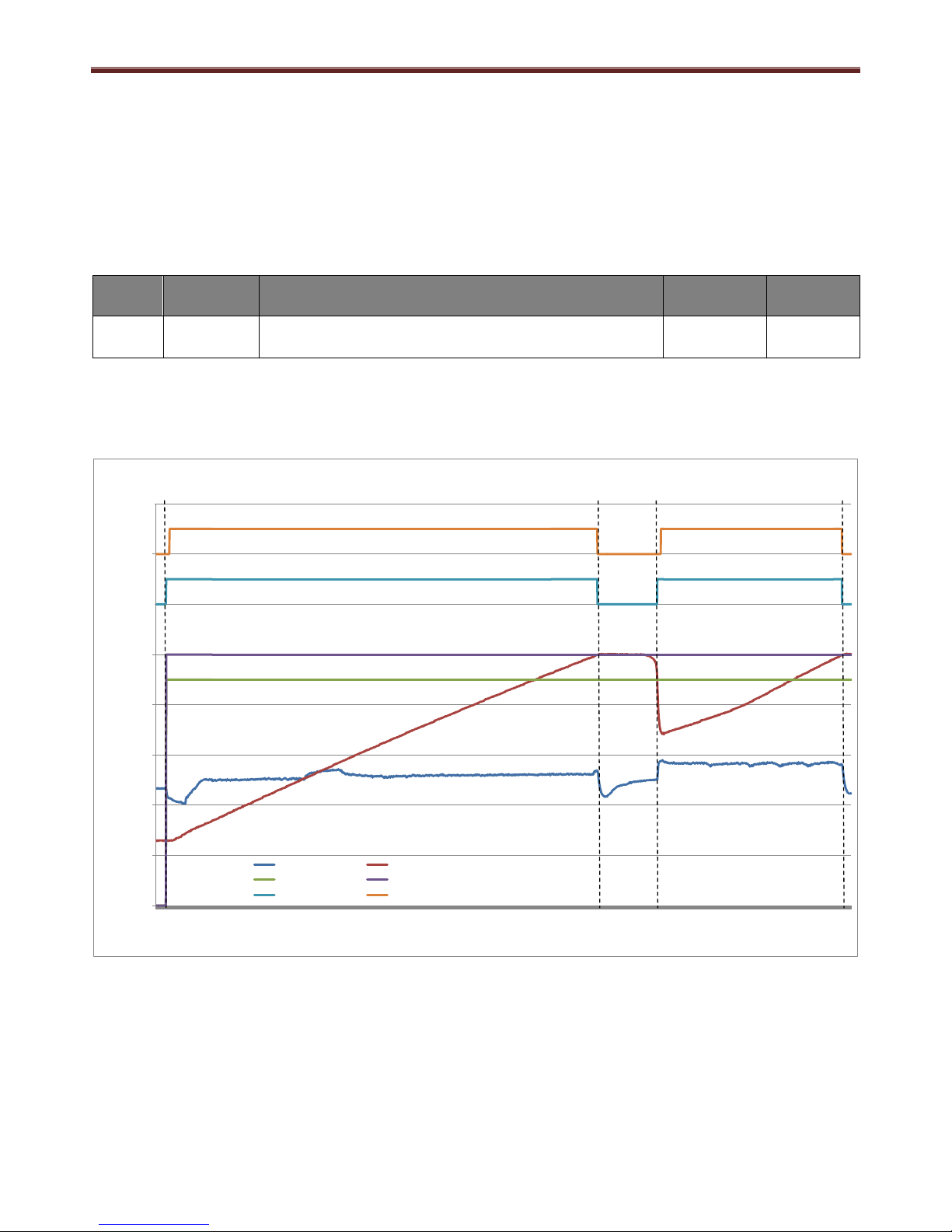

7.1 P1 AUTO mode

This is the standard operation mode for the domestic hot water heat pump.

The temperature is set from main menu, by pressing the ’OK’ button.

Select ‘A Temperatures’ and then A1 AUTO to set temperature for auto mode, default set point is

53°C.

As long as the air inlet temperature, BT1, is within the specified temperature range, default -7 ~

+40°C then the DHW-HP will operate normally, if BT1 temperature is outside of its operating range

then the water will be heated using the electrical heater only.

Code

Set Point

Name

Description

Range

Factory

setting

A1

T AUTO

The temperature level at which the DHW-HP

heats the water when AUTO mode is selected.

50 ~ 60

53.5

The DHW-HP will then heat the water to set point using the heat pump only.

If the water temperature, BT3, reduces by 5°C then the DHW-HP will start to reheat the water

temperature back to set point.

DHW-HP starts operation on selection of AUTO mode, T AUTO <SP -5k

DHW-HP stops when BT3 = T AUTO SP (53.5°C factory setting)

DHW-HP restarts when T AUTO = SP -5k

DHW-HP stops when BT3 = T AUTO SP (53.5°C factory setting)

0

10

20

30

40

50

60

70

80

00:00:00

00:07:40

00:15:20

00:23:00

00:30:40

00:38:20

00:46:00

00:53:40

01:01:20

01:09:00

01:16:40

01:24:20

01:32:00

01:39:40

01:47:20

01:55:00

02:02:40

02:10:20

02:18:00

02:25:40

02:33:20

02:41:00

02:48:40

02:56:20

03:04:00

03:11:40

03:19:20

03:27:00

03:34:40

03:42:20

03:50:00

03:57:40

04:05:20

04:13:00

04:20:40

04:28:20

04:36:00

04:43:40

04:51:20

04:59:00

05:06:40

05:14:20

05:22:00

05:29:40

05:37:20

05:45:00

05:52:40

06:00:20

06:08:00

06:15:40

06:23:20

06:31:00

06:38:40

06:46:20

T1 T air in T3 T water top

HP_OnTemp HP_OffTemp

R3 Fan R4 Comp

Fan Off

Fan On

Comp Off

Comp On

Page 17

Domestic Hot Water Heat Pump Service Manual

16

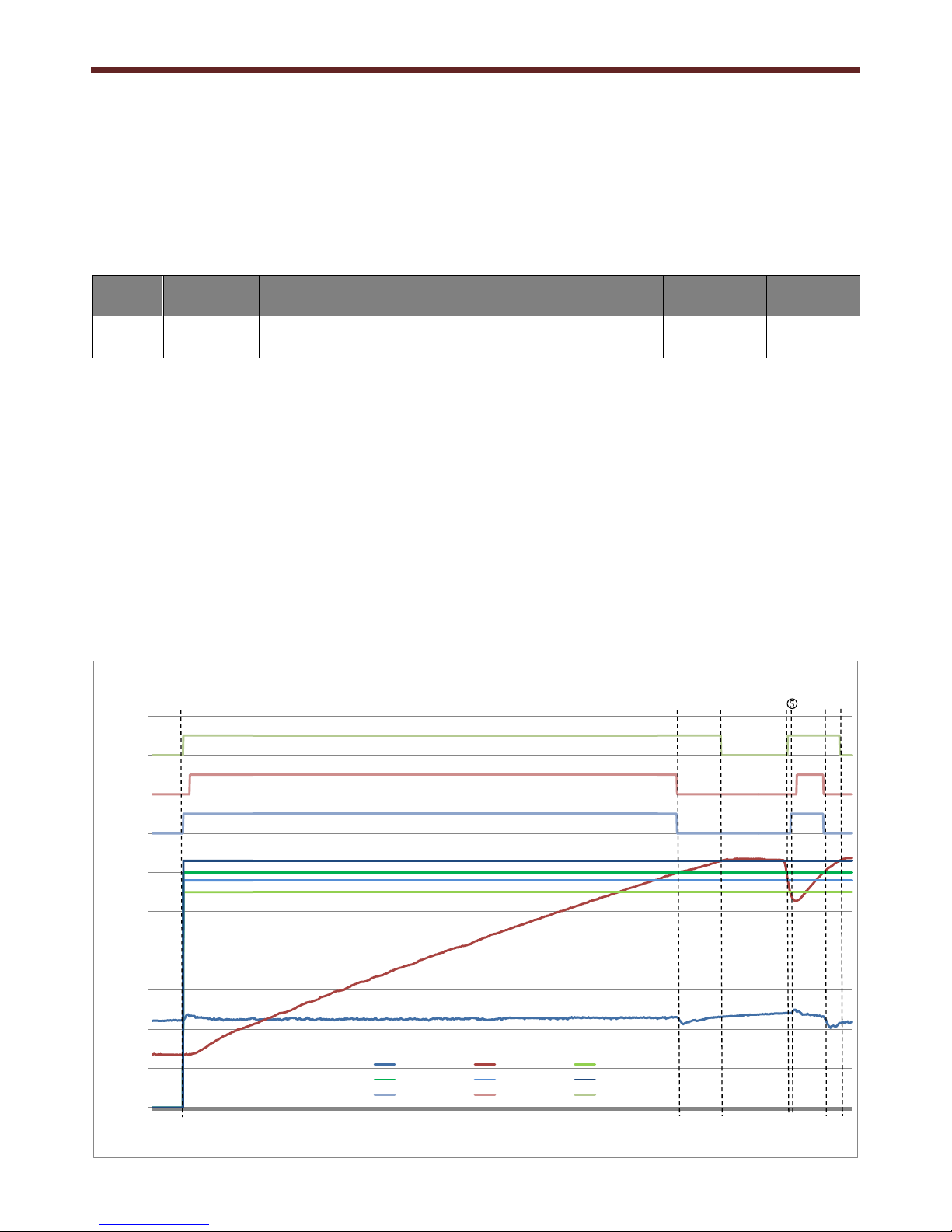

7.2 P2 ECO mode

This is the standard operation mode for the domestic hot water heat pump.

The temperature is set from main menu, by pressing the ’OK’ button.

Select ‘A Temperatures’ and then A2 ECO to set temperature for eco mode, default set point is

50°C.

As long as the air inlet temperature, BT1, is within the specified temperature range, default -7 ~

+40°C then the DHW-HP will operate normally, if BT1 temperature is outside of its operating range

then the water will be heated using the electrical heater only.

Code

Set Point

Name

Description

Range

Factory

setting

A2

T ECO

The temperature level at which the DHW-HP

heats the water when ECO mode is selected.

50 ~ 55

50

The DHW-HP will then heat the water to set point using the heat pump only.

If the water temperature, BT3, reduces by 5°C then the DHW-HP will start to reheat the water

temperature back to set point.

DHW-HP starts operation on selection of ECO mode, T ECO <SP -5k

DHW-HP stops when BT3 = T ECO SP (50°C factory setting)

DHW-HP restarts when T ECO = SP -5k

DHW-HP stops when BT3 = T ECO SP (50°C factory setting)

0

10

20

30

40

50

60

70

80

00:00:00

00:07:40

00:15:20

00:23:00

00:30:40

00:38:20

00:46:00

00:53:40

01:01:20

01:09:00

01:16:40

01:24:20

01:32:00

01:39:40

01:47:20

01:55:00

02:02:40

02:10:20

02:18:00

02:25:40

02:33:20

02:41:00

02:48:40

02:56:20

03:04:00

03:11:40

03:19:20

03:27:00

03:34:40

03:42:20

03:50:00

03:57:40

04:05:20

04:13:00

04:20:40

04:28:20

04:36:00

04:43:40

04:51:20

04:59:00

05:06:40

05:14:20

05:22:00

05:29:40

05:37:20

05:45:00

05:52:40

06:00:20

06:08:00

06:15:40

06:23:20

06:31:00

06:38:40

06:46:20

T1 T air in T3 T water top

HP_OnTemp HP_OffTemp

R3 Fan R4 Comp

Fan Off

Fan On

Comp Off

Comp On

Page 18

Domestic Hot Water Heat Pump Service Manual

17

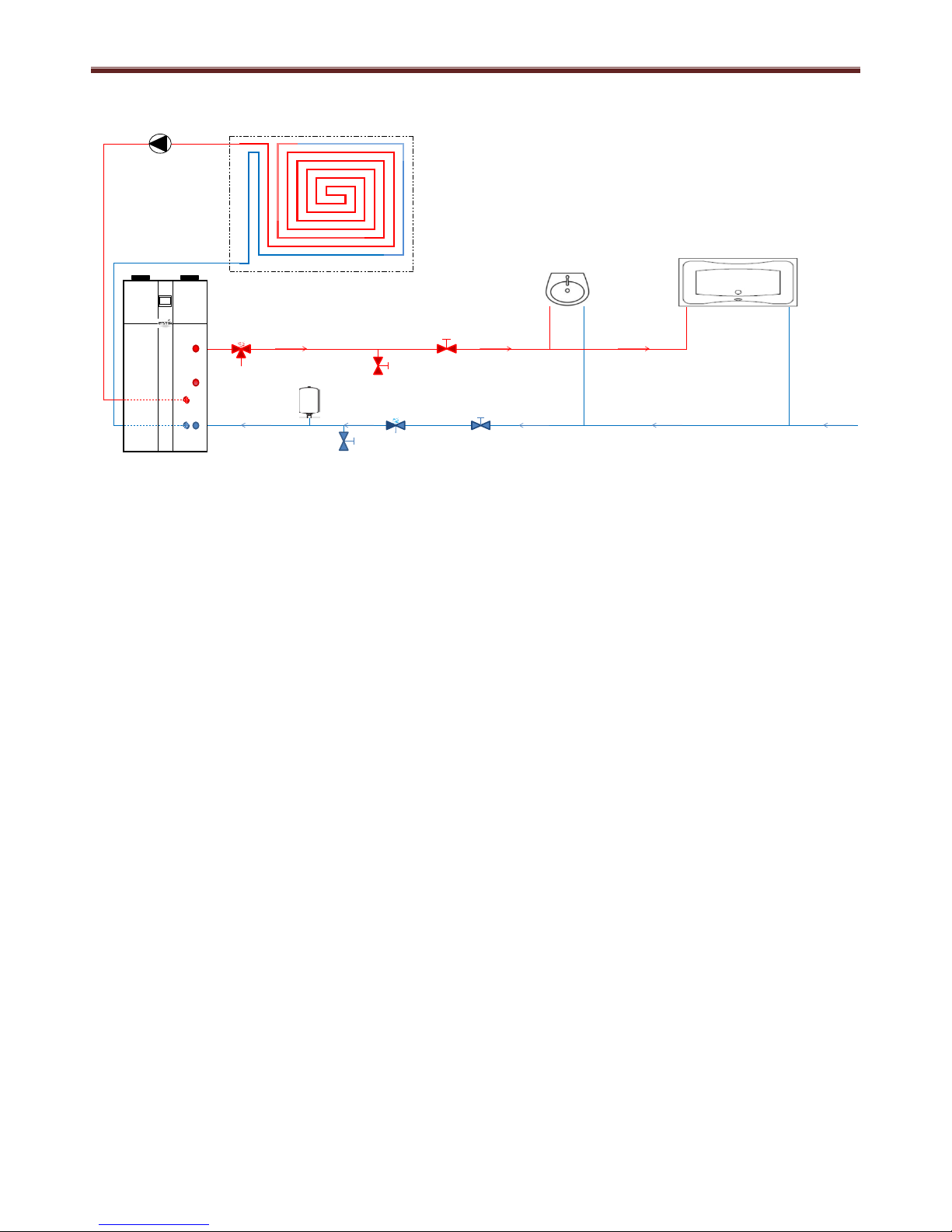

7.3 P3 BOOST mode

This is the standard operation mode for the domestic hot water heat pump.

The temperature is set from main menu, by pressing the ’OK’ button.

Select ‘A Temperatures’ and then A2 ECO to set temperature for eco mode, default set point is

50°C.

As long as the air inlet temperature, BT1, is within the specified temperature range, default -7 ~

+40°C then the DHW-HP will operate normally, if BT1 temperature is outside of its operating range

then the water will be heated using the electrical heater only.

Code

Set Point

Name

Description

Range

Factory

setting

A3

T BOOST

The temperature level at which the DHW-HP

heats the water when BOOST mode is selected.

50 ~ 65

55

The DHW-HP will then heat the water to set point using the heat pump and the electrical heater

together.

If A3 T BOOST temperature is set higher than D33 (Temp HP max – default 60°C) then the

remaining temperature above this set point is reached by electrical heater only operation

If the water temperature, BT3, reduces by 5°C then the EL heater will start to reheat the water

temperature back to set point.

The HP requires the BT3 temperature to reduce to 5°C below D33 (Temp HP Max SP)

In this case 8°C below BOOST mode temperature set point (A3 = 63°C).

NOTE: A3 T BOOST set to 63°C for illustration purposes.

NOTE: Volume of water heated by EL heater is only a percentage of the full water volume, as

follows: 190l = 75l (40%)

260l = 130l (50%)

0

10

20

30

40

50

60

70

80

90

100

00:00:00

00:04:20

00:08:40

00:13:00

00:17:20

00:21:40

00:26:00

00:30:20

00:34:40

00:39:00

00:43:20

00:47:40

00:52:00

00:56:20

01:00:40

01:05:00

01:09:20

01:13:40

01:18:00

01:22:20

01:26:40

01:31:00

01:35:20

01:39:40

01:44:00

01:48:20

01:52:40

01:57:00

02:01:20

02:05:40

02:10:00

02:14:20

02:18:40

02:23:00

02:27:20

02:31:40

02:36:00

02:40:20

02:44:40

02:49:00

02:53:20

02:57:40

03:02:00

03:06:20

03:10:40

03:15:00

03:19:20

03:23:40

03:28:00

03:32:20

03:36:40

03:41:00

03:45:20

03:49:40

Temperature (°C)

T1 T air in T3 T water top HP_OnTemp

HP_OffTemp E_HeatOnTemp E_HeatOffTemp

R3 Fan R4 HP R5 El Heater

Fan OFF

Fan ON

HP OFF

HP ON

EL Heat OFF

EL Heat ON

Page 19

Domestic Hot Water Heat Pump Service Manual

18

DHW-HP starts operation on selection of BOOST mode, T BOOST <SP -5k

HP stops operation at Temp HP Max SP (D33) 60°C

DHW-HP continues heating water using EL only until SP (63°C)

Electric Heater restart is based on SP (63°C) -5k (58°C)

HP restart is based on Temp HP Max (D33 = 60°C) -5k (55°C)

HP stops operation at Temp HP Max SP (D33) 60°C

DHW-HP continues heating water using EL only until SP (63°C)

7.4 P4 BACKUP mode

This is an emergency mode. The water is heated up by the electric heater only at a lower set

temperature. The water temperature set point is set in the installer menu, D12 (Backup T).

In the case of an error, a message is displayed on the LCD display requesting if Back Up mode is

required. There is a yes/no input selection required to activate or disable.

The legionella control remains active.

Code

Set Point

Name

Description

Range

Factory

setting

D12

Backup T

The temperature level at which the El heater

heats the water when BACK UP mode is

activated /selected

0 ~ 65

35

EL starts when BBT3 (T Tank t) < D12 (BACKUP T) -5°C

EL stops when BBT3 (T Tank t) = D12 (BACKUP T)

Note: Back up mode can only be deactivated after rectifying the cause of the fault. Once the fault

has been repaired a power cycle (Off/ On) is required to reset the error code. Normal operation

can be resumed by pressing the arrow, up or down, buttons to select the required operating mode.

If an error occurs, using the up or down buttons, select Yes or No, if no is selected the unit has No

operation.

If Yes is selected the DHW-HP changes to BACKUP operation and the unit operates at the

BACKUP mode temperature setting from D12.

After fault rectification and power reset, using the mode selection screen, choose operation mode.

Page 20

Domestic Hot Water Heat Pump Service Manual

19

7.5 P5 SILENT mode

This mode decreases the fan speed to D5 (Min fan speed) in order to minimize the sound

emissions

The DHW-HP is controlled by the A1 AUTO operation mode

The unit starts when BBT3 (T Tank t) < A1 (T AUTO) -5°C

The unit stops when BBT3 (T Tank t) = A1 (T AUTO)

System operating in AUTO mode

Operating mode changed to SILENT.

Fan speed lowers from D6 (AUTO Speed) SP of 57% (factory set point) to D5 (Min Fan Speed)

SP of 40% (factory set point)

Operating mode returned to AUTO mode

Fan speed raises from D5 (Min Fan Speed) SP of 40% to D6 (AUTO speed) of 57%

Note: In SILENT mode the controlled temperature set point is from AUTO mode.

7.6 P6 HOLIDAY mode

DHW-HP does not start when the water heating is required. The HP is OFF except during

Legionella control, which is still activated once a week on the selected day from D15 (Legionella

date).

The HOLIDAY mode is connected to B4 (Hot on Time). After the HOLIDAY period is completed,

the unit goes back to the previous mode of operation.

0

10

20

30

40

50

60

70

80

90

00:00:00

00:00:40

00:01:20

00:02:00

00:02:40

00:03:20

00:04:00

00:04:40

00:05:20

00:06:00

00:06:40

00:07:20

00:08:00

00:08:40

00:09:20

00:10:00

00:10:40

00:11:20

00:12:00

00:12:40

00:13:20

00:14:00

00:14:40

00:15:20

00:16:00

00:16:40

00:17:20

00:18:00

00:18:40

00:19:20

00:20:00

00:20:40

00:21:20

00:22:00

00:22:40

00:23:20

00:24:00

00:24:40

00:25:20

00:26:00

00:26:40

00:27:20

00:28:00

00:28:40

00:29:20

00:30:00

00:30:40

00:31:20

Temperature (°C)

T1 T air in T2 air out T3 T water top

FanSpeedSet R3 Fan R4 HP

Fan OFF

Fan ON

Comp OFF

Comp ON

Page 21

Domestic Hot Water Heat Pump Service Manual

20

7.7 B4 Hot on time

The unit can be programmed to deliver hot water from 1 to 30 days from the moment in which the

function is activated and the HOLIDAY mode is selected.

The unit switches to A1 AUTO mode after the desired number of days is reached. If OFF is

selected the function is not active.

i.e. To set a 7 day Hot on Time function

1. Push the ‘OK’ button for the main menu

2. Use the Up or Down arrows to highlight ‘B Functions’ menu and push the ‘OK’ button

3. Use the Up or Down arrows to highlight ‘B4 Hot on Time’ and push the ‘OK’ button.

4. Use the Up and Down arrows to select the number of days required for the unit to switch on to

A1 AUTO mode and push the ‘OK’ button.

The duration of the HOLIDAY mode is now set.

Note: This function is not activated until ‘HOLIDAY’ is selected from the mode selection screen,

accessed by pushing the Up or Down arrow from the home screen.

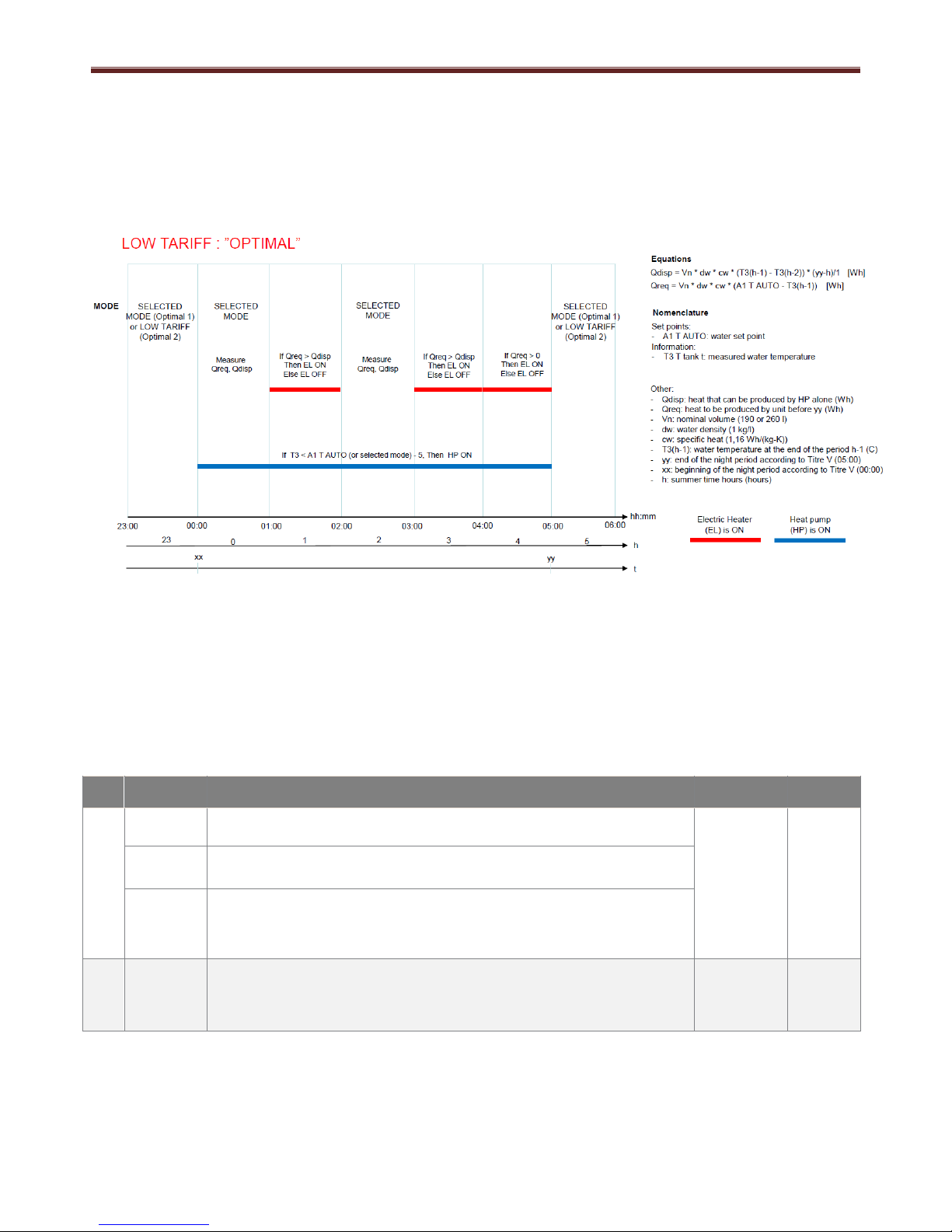

7.8 B3 Low Tariff

The low tariff allows the electric heater and the heat pump to run only during periods with low

electricity prices, according to the menu item that regulate the program of the low tariff D17/ D18

(Low tariff weekday/weekends). The unit runs only during pre-defined hours of the day.

Code

Set point

name

Description

Range

Factory

setting

B3

Low Tariff

Standard

If the PV function (B5) is active, this allows the electric heater and the heat

pump to run outside the low tariff period.

OFF/

Standard/

Optimal 1/

Optimal 2

OFF

Low Tariff

Optimal 1

This function allows the maximum exploitation of the lower electricity price

during the night periods between 00:00 and 05:00

Low Tariff

Optimal 2

This function allows the maximum exploitation of the lower electricity price

during the night periods between 00:00 and 05:00.

During the day, the unit works according to Low Tariff periods D17 and D18

Electric heater operation (Optimal 1 and Optimal 2)

The EL can operate only at night, between 01:00 and 05:00

The EL starts operating when the amount of heat that can be produced by the HP (Qdisp) is not

sufficient to cover the amount of heat needed to reach the water temperature set point by 5:00

(Qreq).

The EL cannot operate more than3 hours/day. 2 other hours are used to calculate the Qreq and

Qdisp (normallybetween00:00-01:00 and 02:00-03:00) and EL cannot be used in these periods.

The EL, if activated, works for at least one continuous hour.

If the water set point temperature has not been reached by 4:00, EL will operate for the last

hour(until05:00), or until the water temperature set point is reached.

In normal conditions, the EL is activated only if also the HP is active.

If the heat pump is not operating, the EL will be activated only in case the external ambient

conditions don’t allow HP operation (Inlet air temperaturebelow-7°C or above40 °C.

Page 22

Domestic Hot Water Heat Pump Service Manual

21

Heat pump operation (Optimal 1 and Optimal 2)

If the water temperature is below set point temperature minus hysteresis, the HP starts its operation

(normally at 00:00).

Optimal 1: The HP is allowed to run also during the day(according to MODE of operation

Optimal 2: The HP is always allowed to run in the night period(between00:00 and 5:00) plus it is

allowed to run in the periods described by D17/D18 (Low tariff period weekday/weekend)

7.9 B1 Ventilation

This mode is used for the ventilation of air from a room and distributed either into the DHW-HP

room location or ducted outside of the building.

Using the function B1 (Ventilation) the DHW-HP can be set to 3 operation modes, Off, single

speed or 2 speed

To complete the ventilation mode setup B2 (Ventilation Fan Speed) can be set.

Code

Set point

name

Description

Range

Factory

setting

B1

Ventilation

OFF

The fan switches off when the heat pump does not run.

OFF/

Single

Speed/

2Speeds

OFF

Single

speed

The fan is always running at a single fixed speed (B2 Fan speed), both

when the heat pump is operating and when it is not.

2 Speeds

The fan is always in operation but it runs normally at a higher speed D6

(Fan AUTO Speed) when the heat pump starts operating and at (B2 Fan

speed) when it is not operating.

B2

Fan speed

The main fan speed regulation for the ventilation function. There are

three ventilation level that can be selected: LOW D5 (Min Fan Speed),

MEDIUM D4 (Fan medium speed) HIGH D3 (Max fan speed).

LOW/

MEDIUM/

HIGH

HIGH

Page 23

Domestic Hot Water Heat Pump Service Manual

22

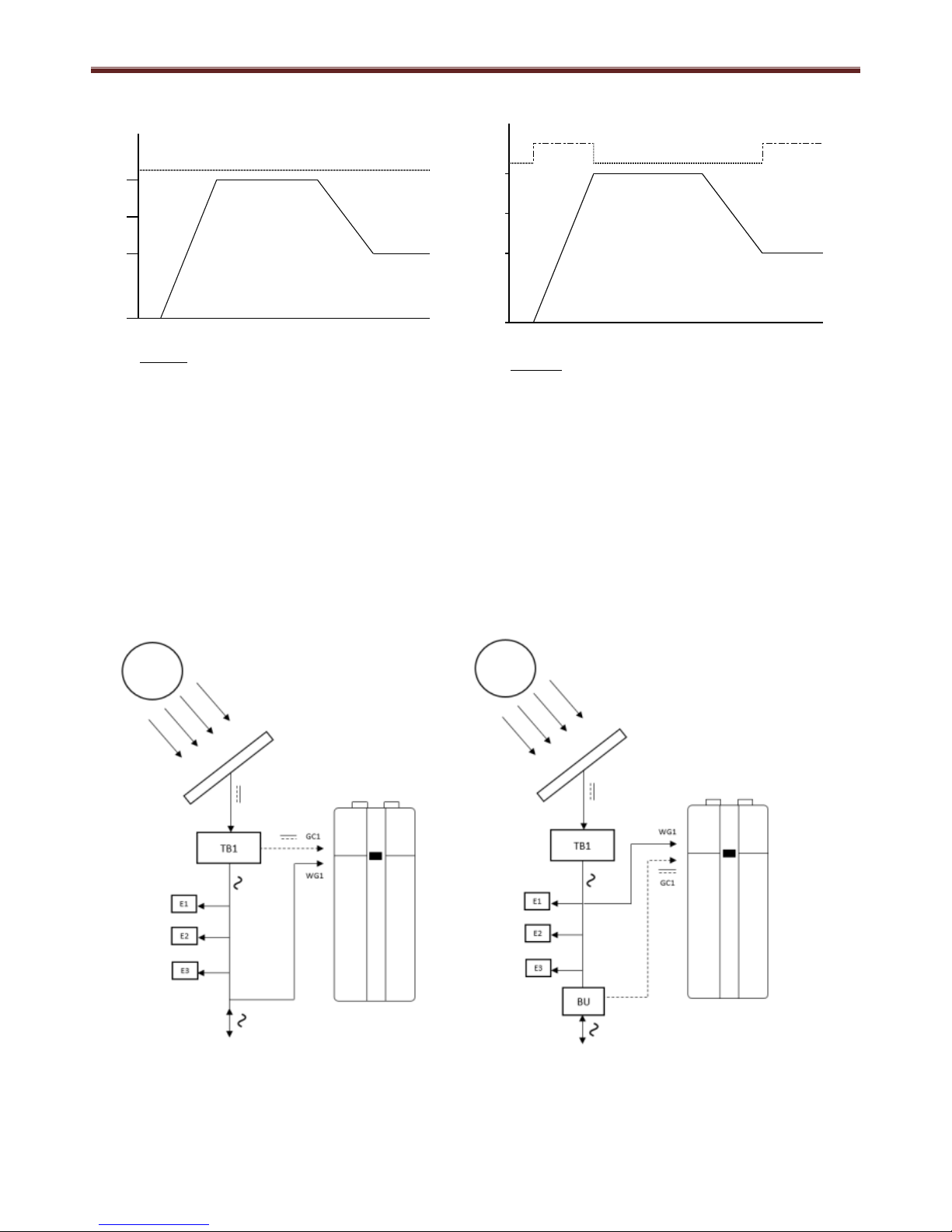

Single Speed Operation 2 Speed Operation

7.10 B5 Photovoltaic

The domestic hot water heat pump (DHWHP) can be controlled by a signal from a solar

photovoltaic (PV) converter or an energy meter, either as simple start/stop via a potential free

contact or by a variable signal.

The diagrams below represent possible installation configurations with or without energy meter.

Using the variable signal option, a certain output (VDC or mA) from the (PV) inverter or the

energy meter corresponds to a given amount of excess power for use in the DHWHP. This

excess power can be used to activate either the electrical immersion heater, the heat pump (HP)

or both.

PV installation 1: control signal from inverter. PV installation 2: control signal from energy meter.

\

T3:Temperature Tank Top

DHW AUTO mode set point of 53°C

Ventilation ON

Ventilation fan speed LOW

Ventilation mode single speed

Note: This may have an impact on performance due to fan reduction in DHW mode

Temperature °C

Fan

Auto

Low5350

48

12

T3:Temperature Tank Top

DHW AUTO mode set point of 53°C

Ventilation ON

Ventilation fan speed LOW

Ventilation mode 2 speed

Auto

4812Low

Fan

Temperature °C

53

50

TB1: DC/AC Inverter

BU: Energy meter

E1-2-3: Electric loads

WG1: Heat pump

power supply

GC1: Photovoltaic

function input

signal (0-10

VDC 0-3 VDC,

4-20 mA).

Page 24

Domestic Hot Water Heat Pump Service Manual

23

A graph to convert the signal input to % is available in figure 21

Conversion table of the controller input signal to percentage

The following schematic shows the electrical connections for the Solar PV operation

BLU

B (D-)

N

L

0V

0V

L

L

0V

0~10V

Input

BT3

EB1

0V0V0V

FM

BT2

BT1

0V

0V

L

N

PE

230VAC ~ 50Hz

0V

A (D+)

0V BLU

0~10V PWM

YEL

High pressure switch.

Compressor STOP when

Pd ≥ 2.0MPa

Solenoid valve.

Solenoid ON for 2 min

before compressor

starts and during

system defrost

BRN

BLK

N

BLU

BLK

BRN

BRN

BLU

Inverter

Solar

PV

BT4

Page 25

Domestic Hot Water Heat Pump Service Manual

24

PV operation is set up using a combination of the following functions:

Code

Set point

name

Description

Range

Factory

setting

B5

OFF

The PV function is not active. If this function is activated, the heat pump

and the electric heater can start only if the input voltage in GC1 (0-10V)

is higher than D20/D21 (PV min Voltage HP/EL) for longer than D22 (PV

min time).

OFF/ ECO/

STORAGE

ECO

PV ECO

The PV function allows for water heating only with the heat pump until

temperature set point defined by the MODE of operation is reached.

PV STORAGE

The PV function allows for water heating to the maximum temperature

level, giving priority to the operation of the heat pump if the BOOST or

BACK UP mode is not active. The heat pump operates alone until the

max allowed temperature for the heat pump operation D33 (T HP Max)

is reached. The electric heater operates only from D33 to the maximum

allowable temperature D9 (Water T max).

D20

PV min

Voltage HP

The minimum voltage (V) required to start the HP

when the PV function is active.

0-10

0

D21

PV min

Voltage EL

The minimum voltage (V) required to start the electric heater when

the PV function is active.

0-10

0

D22

PV min time

The minimum time (minutes) at which the input voltage from the PV

panel should be above the set point D20/D21 (PV min Voltage HP/EL)

in order to start the electric heater or heat pump when the PV function

is active D22 also regulates the minimum heat pump operational time

when started by the PV function.

1-120

15

The following operational charts have these settings applied:

i) D20 (PV min voltage HP) set to 5V

ii) D21 (PV min voltage EL) set to 8V

iii) D22 (PV min time) set to 5mins

iv) PV mode selected from B5 dependant on operation required (ECO or STORAGE)

Page 26

Domestic Hot Water Heat Pump Service Manual

25

7.10.1 PV ECO operation in AUTO mode

When the photovoltaic mode is set to PV ECO and the DHW-HP mode is set to AUTO, there is no

operation of the electrical heater, even if the 0~10V input rises above the D21 (PV Min Voltage EL)

set point.

0~10V input raised in small steps until >5V, set from D20 (PV Min Voltage HP)

HP starts after 5 minutes delay, set from D22 (PV Min Time)

In ECO / AUTO mode the heater should not operate, Voltage raised to >8V D21 (PV Min Voltage

EL)

0~10V input decreased until <5V, set from D20 (PV Min Voltage HP)

HP stops after 5 minutes delay, set from D22 (PV Min Time)

Note: If water set point temperature is achieved then the heat pump stops operation.

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

0

10

20

30

40

50

60

70

80

90

00:00:00

00:01:20

00:02:40

00:04:00

00:05:20

00:06:40

00:08:00

00:09:20

00:10:40

00:12:00

00:13:20

00:14:40

00:16:00

00:17:20

00:18:40

00:20:00

00:21:20

00:22:40

00:24:00

00:25:20

00:26:40

00:28:00

00:29:20

00:30:40

00:32:00

00:33:20

00:34:40

00:36:00

00:37:20

00:38:40

00:40:00

00:41:20

00:42:40

00:44:00

00:45:20

00:46:40

00:48:00

00:49:20

00:50:40

00:52:00

00:53:20

00:54:40

00:56:00

00:57:20

00:58:40

01:00:00

01:01:20

01:02:40

01:04:00

01:05:20

01:06:40

01:08:00

Voltage

Temperature

Time

T3 T water top R3 Fan R4 HP

R5 El heater V in (0-10V)

Fan Off

Fan On

HP Off

HP On

El H Off

El H On

Fan Off

Fan On

HP Off

HP On

El H Off

El H On

Fan Off

Fan On

HP Off

HP On

El H Off

El H On

Page 27

Domestic Hot Water Heat Pump Service Manual

26

7.10.2 PV ECO operation in BOOST mode

When the photovoltaic mode is set to PV ECO and the DHW-HP mode is set to BOOST, there is no

operation of the electrical heater, even if the 0~10V input rises above the D21 (PV Min Voltage EL)

set point.

0~10V input raised until >8V, set from D20 (PV Min Voltage HP) & D21(PV Min Voltage EL)

HP starts after 5 minutes delay, set from D22 (PV Min Time). Electric heater does not start due to

PV ECO mode being selected.

0~10V input decreased until <5V, set from D20 (PV Min Voltage HP)

HP stops after 5 minutes delay, set from D22 (PV Min Time)

Note: If water set point temperature is achieved then the heat pump stops operation.

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

0

10

20

30

40

50

60

70

80

90

00:00:00

00:01:10

00:02:20

00:03:30

00:04:40

00:05:50

00:07:00

00:08:10

00:09:20

00:10:30

00:11:40

00:12:50

00:14:00

00:15:10

00:16:20

00:17:30

00:18:40

00:19:50

00:21:00

00:22:10

00:23:20

00:24:30

00:25:40

00:26:50

00:28:00

00:29:10

00:30:20

00:31:30

00:32:40

00:33:50

00:35:00

00:36:10

00:37:20

00:38:30

00:39:40

00:40:50

00:42:00

00:43:10

00:44:20

00:45:30

00:46:40

00:47:50

00:49:00

00:50:10

00:51:20

00:52:30

00:53:40

00:54:50

00:56:00

00:57:10

00:58:20

00:59:30

01:00:40

01:01:50

Voltage

Temperature

Time

T3 T water top R3 Fan R4 HP R5 El heater V in (0-10V)

Fan Off

Fan On

HP Off

HP On

El H Off

El H On

Page 28

Domestic Hot Water Heat Pump Service Manual

27

7.10.3 PV Storage operation in BOOST mode

When the photovoltaic mode is set to PV STORAGE and the DHW-HP mode is set to BOOST, the

HP operates when the 0~10V input rises above the D20 (PV Min Voltage HP) and the electrical

heater operates when the 0~10V input rises above the D21 (PV Min Voltage EL) set point.

0~10V input raised in small steps until >5V, set from D20 (PV Min Voltage HP)

HP starts after 5 minutes delay, set from D22 (PV Min Time)

0~10V input raised in small steps until >8V, set from D21 (PV Min Voltage EL)

EL starts after 5 minutes delay, set from D22 (PV Min Time)

0~10V input decreased until <8V, set from D20 (PV Min Voltage HP)

EL stops after 5 minutes delay, set from D22 (PV Min Time)

0~10V input decreased until <5V, set from D20 (PV Min Voltage HP)

HP stops after 5 minutes delay, set from D22 (PV Min Time)

Note: If water set point temperature is achieved then the heat pump stops operation.

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

0

10

20

30

40

50

60

70

80

90

00:00:00

00:01:10

00:02:20

00:03:30

00:04:40

00:05:50

00:07:00

00:08:10

00:09:20

00:10:30

00:11:40

00:12:50

00:14:00

00:15:10

00:16:20

00:17:30

00:18:40

00:19:50

00:21:00

00:22:10

00:23:20

00:24:30

00:25:40

00:26:50

00:28:00

00:29:10

00:30:20

00:31:30

00:32:40

00:33:50

00:35:00

00:36:10

00:37:20

00:38:30

00:39:40

00:40:50

00:42:00

00:43:10

00:44:20

00:45:30

00:46:40

00:47:50

00:49:00

00:50:10

00:51:20

00:52:30

00:53:40

00:54:50

00:56:00

00:57:10

00:58:20

00:59:30

01:00:40

01:01:50

Voltage

Temperature

Time

T3 T water top R3 Fan

R4 HP R5 El heater

V in (0-10V)

Fan Off

Fan On

HP Off

HP On

El H Off

El H On

Page 29

Domestic Hot Water Heat Pump Service Manual

28

7.11 D26 Extra Function (Only available with the deluxe DHW-HP)

There are 3 additional modes available for the Deluxe model DHW-HP, solar, floor heating and

cooling functions. These are activated from D26 Extra Function accessed within the Installer

menu.

NOTE: It is only possible to connect one of these options to the DHW-HP at any time.

Code

Set point

name

Description

Range

Factory

setting

D26

Extra function

The desired extra function is selected here. The possible functions are

Solar, Floor or Cooling. Once the function is activated, move to the function

menu and adjust the set point as desired.

OFF/

Solar/

Floor/

Cooling

OFF

7.11.01 B6 Solar

The Solar function allows the water to be heated up by the solar collector, activating a water pump

controlled by the extra relay (GP1).

The setup of the solar function is carried out using the function menu and B6 (Solar)

Code

Set point

name

Description

Range

Factory

setting

B6

Solar

The Solar function allows the water to be heated up by the solar collector,

activating a water pump controlled by the extra relay (GP1). The pump

starts when BT5 > BT3 + D24 (Solar DT min). The pump stops if the

temperature in the tank goes above D23 (Solar T max) or if BT5 is below

BT3.

OFF/ON

OFF

The following schematic shows the electrical connections for the Solar Thermal operation

BLU

B (D-)

N

L

0V

0V

L

L

0V

0~10V

Input

BT3

EB1

0V0V0V

FM

BT2

BT1

0V

0V

L

N

PE

230VAC ~ 50Hz

0V

A (D+)

0V BLU

0~10V PWM

YEL

High pressure switch.

Compressor STOP when

Pd ≥ 2.0MPa

Solenoid valve.

Solenoid ON for 2 min

before compressor

starts and during

system defrost

BRN

BLK

N

BLU

BLK

BRN

BRN

BLU

Solar

Thermal

BT5

BT4

Page 30

Domestic Hot Water Heat Pump Service Manual

29

7.11.02 B7 Floor / B8 Floor T

The floor heating function activates an external circulation pump, controlled by the extra relay

(GP1)

The setup of the floor heating function is carried out using the function menu and B7 (Floor) & B8

(Floor T)

Code

Set point

name

Description

Range

Factory

setting

B7

Floor

If the temperature at the bottom of the tank BT4 (T water b) is higher than

the setting menu D25 (Floor T start) the floor heating function is activated.

If the extra temperature BT5 (T Extra) is higher than the floor heating

temperature (B8 T floor) the circulation pump (Extra relay GP1) stops.

OFF/ON

OFF

B8

Floor T

The desired floor heating temperature in °C with hysteresis of 1K.

15 - 40

35

The following schematic shows the electrical connections for the underfloor heating operation

ON

OFF

PUMP

22

2112292330

Tank Temperature °C

Floor Temperature °C

T4: Temperature Tank Bottom Control

T5: Floor Temperature

Based on following set conditions

Installer menu

D24: Floor Set Start = 30°C (T4)

D26: Extra Function = Floor

Function menu

B7: Floor = ON

B8: Floor Temp = 22°C (T5)

BLU

B (D-)

N

L

0V

0V

L

L

0V

0~10V

Input

BT3

EB1

Room Temperature

0V0V0V

FM

BT2

BT1

0V

0V

L

N

PE

230VAC ~ 50Hz

0V

A (D+)

0V BLU

0~10V PWM

YEL

High pressure switch.

Compressor STOP when

Pd ≥ 2.0MPa

Solenoid valve.

Solenoid ON for 2 min

before compressor

starts and during

system defrost

BRN

BLK

N

BLU

BLK

BRN

BRN

BLU

BT5

BT4

Page 31

Domestic Hot Water Heat Pump Service Manual

30

7.11.03 B9 Cooling / B10 Cooling T

The cooling function activates a three-way damper, which directs the cold exhaust air to a room

with cooling requirements. The two functions operate the damper in opposite directions.

The Cooling function allows an area to be cooled up by the DHW-HP exhaust air, activating a

damper motor controlled by the extra relay (GP1).

The setup of the cooling function is carried out using the function menu B9 (Cooling) & B8

(Cooling T) and installer menu D28 m(Cooling type)

Code

Set point

name

Description

Range

Factory

setting

B9

Cooling

The Cooling function can be activated. See installer menu D28 (Cooling

type).

OFF/ON

OFF

B10

Cooling T

The air temperature set point (°C) below which the heat pump stops,

when the unit is in the Cooling function.

10 - 30

21

D28

Cooling 1

The fan and heat pump run until the additional temperature sensor, BT5,

placed in the room environment is below a certain level. The water

temperature can only reach the maximum temperature allowed in the tank

D33 (T HP max). The cooling function activates a three-way damper, which

directs the cold exhaust air to a room with cooling requirements. The two

functions operate the damper in opposite directions

Cooling1 /

Cooling2

Cooling1

Cooling 2

Cooling 1 (2). If BT5 is higher than B10 T Cooling, the extra relay that

operates the damper (GP1) switches ON (OFF).

If BT5 is lower than B10 (T Cooling), the extra relay that operate the

damper (GP1) switches OFF (ON).

The following schematic shows the electrical connections for the cooling operation

BLU

B (D-)

N

L

0V

0V

L

L

0V

0~10V

Input

BT3

EB1

0V0V0V

FM

BT2

BT1

0V

0V

L

N

PE

230VAC ~ 50Hz

0V

A (D+)

0V BLU

0~10V PWM

YEL

High pressure switch.

Compressor STOP when

Pd ≥ 2.0MPa

Solenoid valve.

Solenoid ON for 2 min

before compressor

starts and during

system defrost

BRN

BLK

N

BLU

BLK

BRN

BRN

BLU

BT5

Underfloor

heating

or

Cooling

Room

temperature

BT4

Page 32

Domestic Hot Water Heat Pump Service Manual

31

7.12 D27 SG Ready

A smart grid is an electrical grid which includes a variety of operational and energy

measures including smart meters, smart appliances, renewable energy resources,

and energy efficient resources. Electronic power conditioning and control of the

production and distribution of electricity are important aspects of the smart grid.

The DHW-HP is controlled based on inputs received from the Smart Grid energy

meter on QA1and set up using installer menu D27.

Code

Set point

name

Description

Range

Factory

setting

D27

SG

Ready

The SG ready function can be activated by the installer here. Three

possible modes can be selected. This function allows the start of the heat

pump from an external access (See QA1).

OFF

OFF

The heat pump and electric heater must start, if below the max water

temperature allowed in the tank. Both Heat Pump and Electric heater are

forced to operate (SG1 ON and SG2 ON).

SG

BOOST

The heat pump operates minimizing costs, only the heat pump is activated

(SG1 OFF, SG2 ON).

SG ECO

The unit can be stopped even if there is a need for hot water (SG1 ON,

SG2 OFF).

SG

BLOCK

OFF

<53

19

ON

T Extra Temperature °C

Tank T °C

25

21

HP Operation

20

65

53

DHW

Set Point

>53

OFF

Aux

ON

T3:Temperature Tank Top

T5: Temperature Extra (Room)

Cooling

Type 1

Cooling temperature set point 20°C

Note: If DHW temperature is greater than Auto set point (>53°C)

then HP OFF when Cool satisfied

If cooling demand during this time then HP start at 65°C set point

CAUTION: DHW temperature could be hot 60°C

DHW AUTO mode set point of 53°C

Tank T °C

T Extra Temperature °C

252120

DHW

Set Point

Aux

OFF

65

ON

53

19

HP Operation

<53

ON

>53

OFF

T3:Temperature Tank Top

T5: Temperature Extra (Room)

Cooling

Type 2

Cooling temperature set point 20°C

Note: If DHW temperature is greater than Auto set point (>53°C)

then HP OFF when Cool satisfied

If cooling demand during this time then HP start at 65°C set point

CAUTION: DHW temperature could be hot 60°C

DHW AUTO mode set point of 53°C

Page 33

Domestic Hot Water Heat Pump Service Manual

32

The following schematic shows the electrical connections for the SG Ready operation

BLU

B (D-)

N

L

0V

0V

L

L

0V

0~10V

Input

BT3

EB1

Energy Meter

Communication to

/ from power grid

SG2

SG1

0V0V0V0V0V

FM

BT2

BT1

0V

0V

L

N

PE

230VAC ~ 50Hz

0V

A (D+)

0V BLU

0~10V PWM

YEL

High pressure switch.

Compressor STOP when

Pd ≥ 2.0MPa

Solenoid valve.

Solenoid ON for 2 min

before compressor

starts and during

system defrost

BRN

BLK

N

BLU

BLK

BRN

BRN

BLU

#2

TB1: DC/AC Inverter

BU: Energy meter

E1-2-3: Electric loads

WG1: Heat pump power supply

GC1: Photovoltaic function

input signal (0-10 VDC 03 VDC, 4-20 mA).

____: represents the cables to

the switch inputs SG1 &

SG2

E1

E2

E3

BU - Smart Grid

Energy Meter

GC1

WG1

TB1

From the Grid

SG1

SG2

TOSHIBA

Page 34

Domestic Hot Water Heat Pump Service Manual

33

DHW-HP normal operation

SB Block – SG switch positions: SG1 ON, SG2 Off – DHW-HP stops operation

SG Boost – SG switch positions; SG1 On, SG2 On – DHW-HP operates with HP & EL Heater

SG Eco – SG Switch positions; SG1 Off, SG2 On – DHW-HP operates with HP only

When DHW-HP reaches mode set point (AUTO mode = 53.5°C), DHW-HP stops operation

7.13 D29 External control

This function allows for the external control of the ventilation function using a 0 ~ 10 Volt input.

Using the installer menu, D29 (External control) function.

Code

Set point

name

Description

Range

Factory

setting

D29

OFF

Normal operation.

OFF/

Hygrostat/

Ventilation

Max/

Start-Stop

OFF

Hygrostat

The fan always runs according to the input signal in GC1 (0-10V) from an

external hygrostat, CO2 – sensor or similar appliances.

1. If the voltage is between 0-3.0V the fan speed id D5 (Fan min speed)

2. If the voltage is between 3.0-8.0V the fan speed is D4 (Fan medium

speed)

3. If the voltage is higher than 8V the fan speed is D3 (Fan max speed)

Ventilation

max

If the ventilation function is already selected,

a signal higher of 2V to GC1 leads to maximum air flow.

Start/

Stop

If GC1 receives a signal higher than 2V, the unit operation is stopped.

0

20

40

60

80

100

120

11:56:00

11:59:00

12:02:00

12:05:00

12:08:00

12:11:00

12:14:00

12:17:00

12:20:00

12:23:00

12:26:00

12:29:00

12:32:00

12:35:00

12:38:00

12:41:00

12:44:00

12:47:00

12:50:00

12:53:00

12:56:00

12:59:00

13:02:00

13:05:00

13:08:00

13:11:00

13:14:00

13:17:00

13:20:00

13:23:00

13:26:00

13:29:00

13:32:00

13:35:00

13:38:00

13:41:00

13:44:00

13:47:00

13:50:00

13:53:00

13:56:00

13:59:00

14:02:00

14:05:00

14:08:00

14:11:00

14:14:00

14:17:00

14:20:00

14:23:00

14:26:00

14:29:00

T3 T water top R4 HP R5 El Heate r

SG1 input SG2 input SG state

HP_OnTemp HP_OffTemp

HP Off

HP On

EL Off

EL On

SG1 Off

SG1 On

SG2 Off

SG2 On

SG Off

SG Block

SG1 Eco

SG1 Boost

Page 35

Domestic Hot Water Heat Pump Service Manual

34

Hygrostat Function – fan speed control

The air flow is automatically adjusted depending on the ambient air conditions or by manual

adjustments.

The fan constantly runs changing the speed level depending on the 0~10V input signal from

external humidity sensors, CO2 sensors or human interface panel:

When the input signal is from 0 to 3.3V, the fan switches to minimum speed level (from D5)

When the input signal is from 3.3 to 8V, the fan switches to medium speed level (from D4)

When the input signal is from 8 to 10V, the fan switches to high speed level (from D3)

Humidity / CO2 Sensor

Human Interface

Humidity / CO2 Sensor

Receiver

Room 1

Room 2

BLU

B (D-)

N

L

0V

0V

L

L

0V

0~10V

Input

BT3

EB1

0V0V0V

FM

BT2

BT1

0V

0V

L

N

PE

230VAC ~ 50Hz

0V

A (D+)

0V BLU

0~10V PWM

YEL

High pressure switch.

Compressor STOP when

Pd ≥ 2.0MPa

Solenoid valve.

Solenoid ON for 2 min

before compressor

starts and during

system defrost

BRN

BLK

N

BLU

BLK

BRN

BRN

BLU

Page 36

Domestic Hot Water Heat Pump Service Manual

35

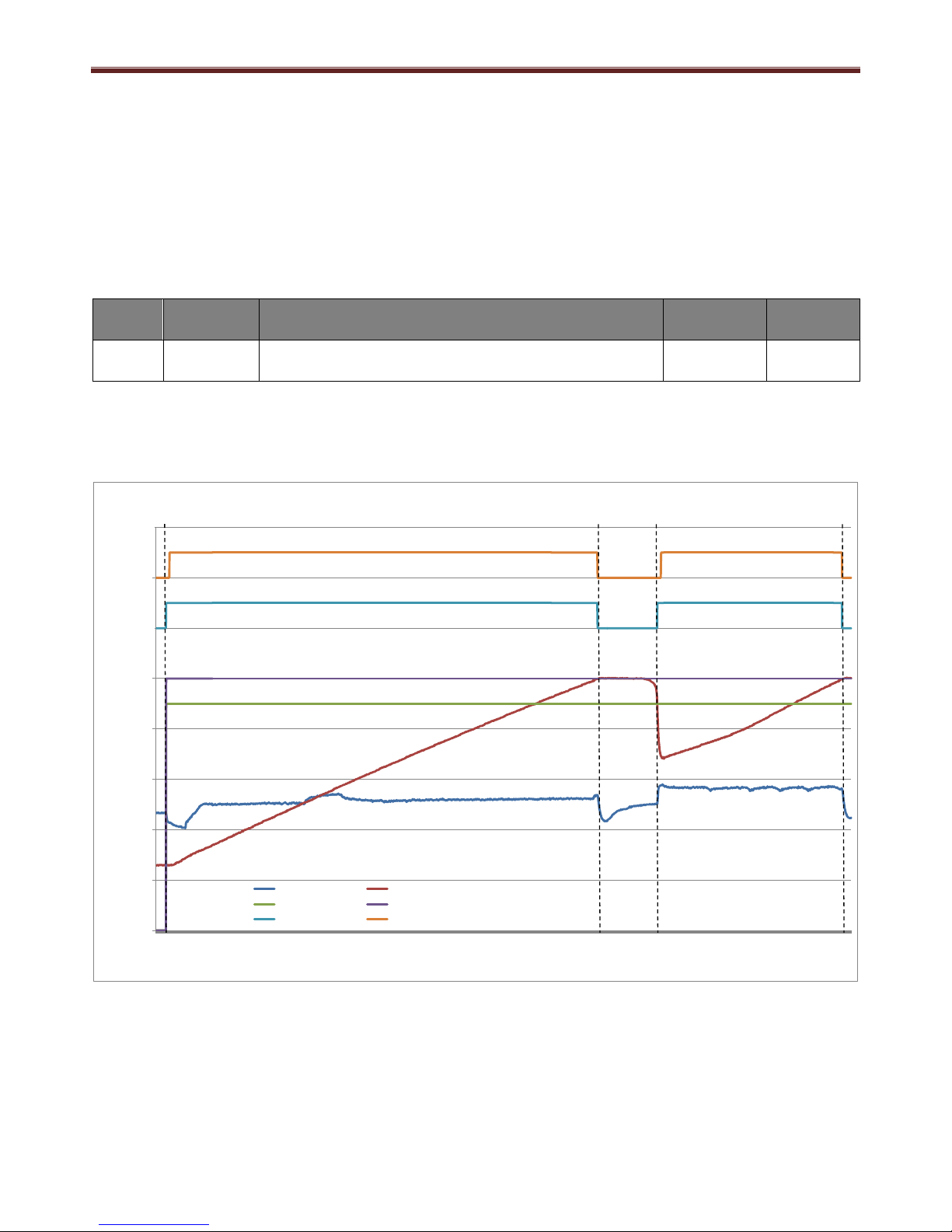

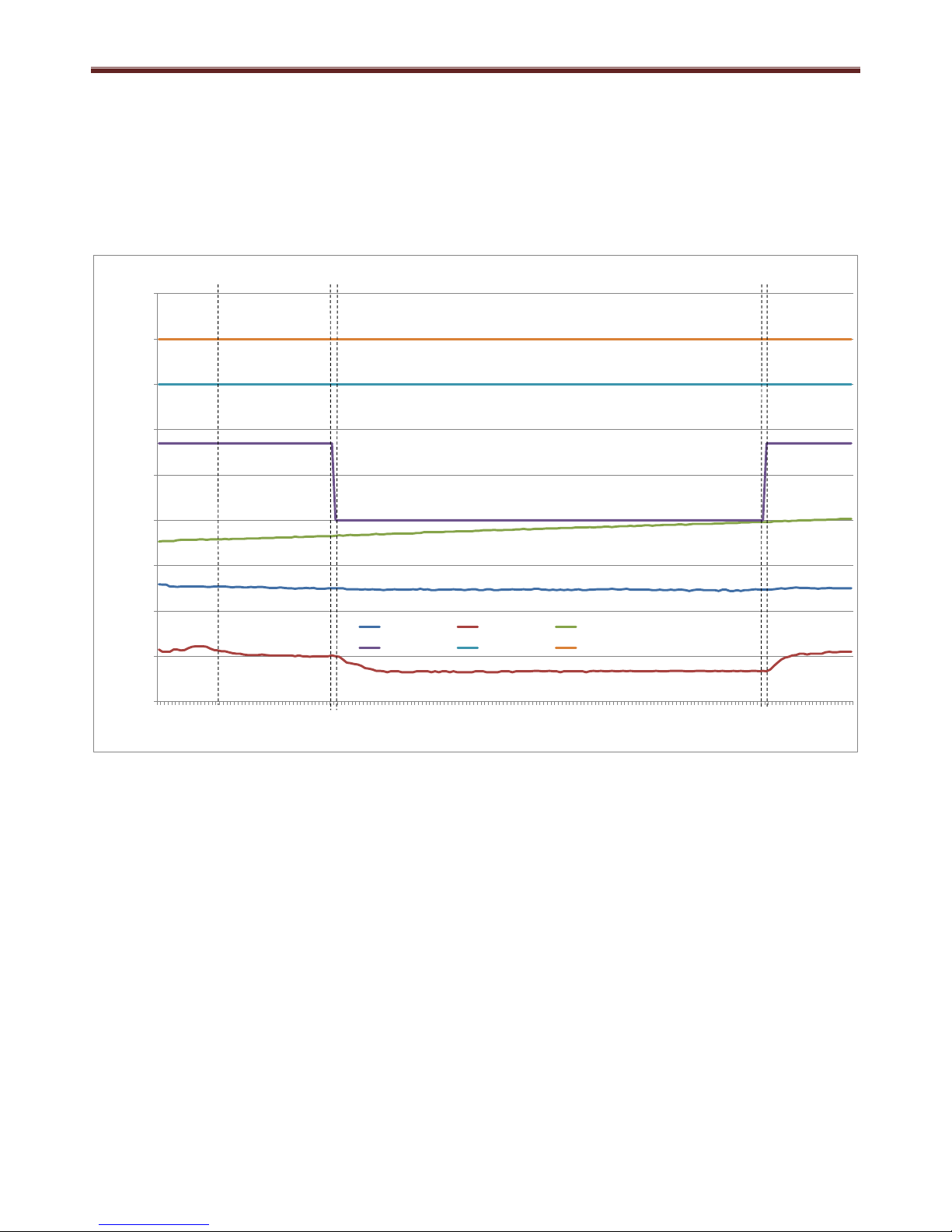

7.14 Defrost operation

When the evaporation temperature (BT2) falls below 0°C, the evaporator starts to accumulate ice

on its fins. In order to maintain the unit reliability and performance, an automatic defrosting

operation is activated.

Defrosting can occur between 60 minutes and 120 minutes from the last defrosting or from the

last moment in which the evaporation temperature was above 0°C.

Defrosting can occur with two different strategies according to the conditions of the inlet air.

1) If the air temperature is above 4°C, then the defrosting occurs running both compressor and

fan. The fan runs at speed D3 (Fan max speed).

2) If the air temperature is below 4°C, then the defrosting occurs running the compressor and

stopping the fan.

Before defrosting is completed the fan stops for a short period to allow the excess water in the

unit to leave the unit from the condensate drain.

Defrosting automatically stops when the temperature of the evaporator (BT2)

becomes higher than the set point (D10).

-5

5

15

25

35

45

55

65

75

85

95

00:00:00

00:05:50

00:11:40

00:17:30

00:23:20

00:29:10

00:35:00

00:40:50

00:46:40

00:52:30

00:58:20

01:04:10

01:10:00

01:15:50

01:21:40

01:27:30

01:33:20

01:39:10

01:45:00

01:50:50

01:56:40

02:02:30

02:08:20

02:14:10

02:20:00

02:25:50

02:31:40

02:37:30

02:43:20

02:49:10

02:55:00

03:00:50

03:06:40

03:12:30

03:18:20

03:24:10

03:30:00

03:35:50

03:41:40

03:47:30

03:53:20

03:59:10

04:05:00

04:10:50

04:16:40

04:22:30

04:28:20

04:34:10

04:40:00

04:45:50

04:51:40

Temperature (°C)

T1 T air in T2 air out

T3 T water top FanSpeedSet

R2 Defrost DefrostState

Defrost Valve

ON

Defrost Valve

OFF

Defrost OFF

Defrost Timer

Defrost ON

Fan OFF

Fan Auto

Speed

Fan Max

Speed

Page 37

Domestic Hot Water Heat Pump Service Manual

36

System start up with BT1 (Air Inlet Temp) at 3°C

After 60 minute operation the defrost countdown timer is activated

After a further 60 minutes, the DHW-HP enters defrost operation

The solenoid valve opens and because the BT1 temperature is <4°C the compressor stays on

and the fan stops operation

Defrost operation stops after a maximum time limit of 12 minutes or when BT2 (T Air Out),

evaporator temperature, becomes higher than the set point of D10 (Defrosting Temp Stop),

factory set to 4°C.

BT1 (Air Inlet Temp) raised to 4.2°C

After a further 60 minutes, the DHW-HP enters defrost operation

The solenoid valve opens and because the BT1 temperature is >4°C the compressor and fan

operate. The fan increases operation to Max Fan Speed, D3 (Fan Speed Max) set point.

Defrost operation stops after a maximum time limit of 12 minutes or when BT2 (T Air Out),

evaporator temperature, becomes higher than the set point of D10 (Defrosting Temp Stop),

factory set to 4°C.