Toshiba HWS-804XWHM3-E, HWS-804XWHT6-E, HWS-804XWHT9-E, HWS-1404XWHM3-E, HWS-1404XWHT6-E Owner's Manual

...

AIR TO WATER HEAT PUMP

Owner’s Manual

Hydro Unit

Model name:

HWS-804XWHM3-E

HWS-804XWHT6-E

HWS-804XWHT9-E

HWS-1404XWHM3-E

HWS-1404XWHT6-E

HWS-1404XWHT9-E

English

Hydro Unit

Thank you very much for purchasing TOSHIBA Air to Water Heat Pump.

Please read this owner’s manual carefully before using the system.

• Be sure to obtain the “Owner’s manual” and “Installation manual” from constructor (or dealer).

Request to constructor or dealer

• Please clearly explain the contents of the Owner’s manual before handing it over to the Customer.

Owner’s Manual

ADOPTION OF NEW REFRIGERANT

This Air to Water Heat Pump is a new type which adopts a new refrigerant HFC (R410A) instead of the

conventional refrigerant R22 in order to prevent destruction of the ozone layer.

Contents

1 Safety precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Names and functions of parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 How to use functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 User maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Air to Water Heat Pump operations and performance. . . . . . . . . . . . . . . . . . . . . . . 12

6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1-EN

–1–

Hydro Unit

DANGER

WARNING

CAUTION

Owner’s Manual

1 Safety precautions

• Do not attempt to install this unit yourself.

• This unit requires a qualified installer.

• Do not attempt to repair the unit yourself.

• This unit has no components which you can repair.

• Opening or removing the cover will expose you to dangerous voltages.

• Turning off the power supply will prevent potential electric shock.

Installation warnings

• Be sure to ask a dealer or a store specialized in electrical work to install the Air to Water Heat Pump.

• The Air to Water Heat Pump should be installed by a suitably qualified installer, if not; this may lead to problems such as

water leaks, electric shock, fire, etc.

• Ensure the correct grounding procedures are applied when installing the Air to Water Heat Pump.

• Do not connect the earth wire to gas pipes, water pipes, lightning rods or telephone earth wires.

• Should the Air to Water Heat Pump be improperly grounded, this could lead to an electric shock.

• Serious damage can occur if there is water leak. Therefore, the Hydro Unit is recommended to be installed in a room with

waterproof flooring and drainage systems.

• Products and parts to be used in combination with this product must be specified products and parts that meet prescribed

specifications. If unspecified products or parts are used, a failure, smoke, fire, or electric shock may be caused.

Operation warnings

• Avoid injury or damage to the outdoor unit by never inserting fingers or sticks into the air discharge or air intake of the

outdoor unit, during operation the fans run at a high speed.

• Should you notice something unusual with the Air to Water Heat Pump (such as a burning smell or low heating power),

immediately turn off the main switch and circuit breaker from the main power supply to stop the Air to Water Heat Pump,

and contact the dealer.

• If there is a suspected problem with the operation of the Air to Water Heat Pump, continuous operation is not recommended,

operational failures may lead to machine breakdown, electric shock, a fire, etc.

• Do not spill water or other liquid onto the Hydro Unit.

• If the unit is wet, it could cause an electric shock.

Warnings at movement and repair

• Do not attempt to move or repair the unit yourself.

• Due to the presence of high voltage, removal of any covers may result in an electric shock.

• Should there be any requirements for the Air to Water Heat Pump to be moved, always consult the dealer or qualified

installer.

• Should the Air to Water Heat Pump be improperly installed, it may lead to electric shock or fire.

• Whenever the Air to Water Heat Pump requires repair, request assistance from the dealer.

• Should the Air to Water Heat Pump be improperly repaired, the result may lead to electric shock or fire.

This appliance is not intended for use by person (including children) with reduced physical sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

To disconnect the appliance from the main power supply

This appliance must be connected to the main power supply using a circuit breaker or switch with a contact separation

of at least 3 mm.

Installation cautions

• Be sure to connect the Air to Water Heat Pump to a dedicated power supply using the rated voltage.

Failure to do so may cause the unit to break down or cause a fire.

• Do not install the unit in a place where there is a risk that flammable gas may leak.

• An accumulation of flammable gases around the unit may result in a fire.

Operation cautions

• To ensure satisfactory performance, please read this manual carefully before operating the Air to Water Heat Pump system.

• Do not install the Air to Water Heat Pump in special-purpose rooms such as a ship or any kind of vehicle.

Doing so could harm machine performance.

–2–

2-EN

Hydro Unit

• When the Air to Water Heat Pump is operated together with a combustion device in the same place, pay careful attention

to ventilation and let fresh air into the room.

Owner’s Manual

Poor ventilation can cause an oxygen shortage.

• When the Air to Water Heat Pump is used in a closed room, pay careful attention to the ventilation of the room.

Poor ventilation can cause an oxygen shortage.

• Do not put a container with water, such as a vase, on the unit, should water enter the unit the result may lead to an electric

shock, this would be due to deterioration in the electric insulation.

• Perform occasional checks to the concrete supports underneath the outdoor unit.

If the base is left damaged or deteriorated, the unit may topple over which could result in possible injury.

• Check from time to time that the unit mounts are not damaged.

If the mounts are left damaged, the unit may drop or topple over, resulting in possible injury.

• Do not wash the unit with water. This could cause an electric shock.

• Do not use alcohol, benzene, thinner, glass cleaner, polishing powder, or other solvent for cleaning the unit because they

can deteriorate and damage the Air to Water Heat Pump.

• Before cleaning the unit, be sure to turn off the main switch or circuit breaker.

• Do not place anything, or step, on the unit, this could cause the unit to fall or topple over which may result in possible injury.

• To achieve maximum performance, the Air to Water Heat Pump must operate within the temperature range specified in the

instructions.

Failure to do so may cause malfunction, break down, or water to leak from the unit.

• Clear away snow before it accumulates on the outdoor unit.

Accumulated snow can lead to malfunction and damage.

• Do not locate other electric appliances or furniture underneath the unit.

Water may drip from the unit, which could lead to rust, unit failure and damage to property.

• Do not allow the obstruction of air flow around the outdoor unit; Do not place any items within the specified installation

service space requirements.

Obstructed air flow can lower performance and cause damage.

• Check for water leaks. In communal housing, leaking water may damage lower floors.

Check for water leaks everyday.

• Do not touch the water pipes, refrigerant pipes, or joints. These may become extremely hot.

Do not drink water produced by the Air to Water Heat Pump.

• After extended use, fresh water may become contaminated by the Hydro Unit, due to deterioration of pipe materials, etc.

• If fresh water contains solid matter, is discolored, turbid or smells, DO NOT DRINK IT.

• Call for equipment inspection immediately.

• Use source water that satisfies water quality standard.

• When the unit will not be used for a long period of time, ask your dealer or a qualified service shop to drain the water inside

the Hydro Unit in order to prevent the water quality from changing.

• When restarting use, ask your dealer or a qualified service shop to charge the unit with water and perform a test run.

• Ask your dealer or a qualified service shop to periodically clean the strainer.

• Ask your dealer or a qualified service shop to confirm that the relief valve is operating correctly.

• Do not hit the manometer, because it is made of glass. It is breakable.

3-EN

–3–

Hydro Unit

NOTE

17

16

1

2

3

4

76

89 11

12

15

14

13

5

▼ Fig. 2-01

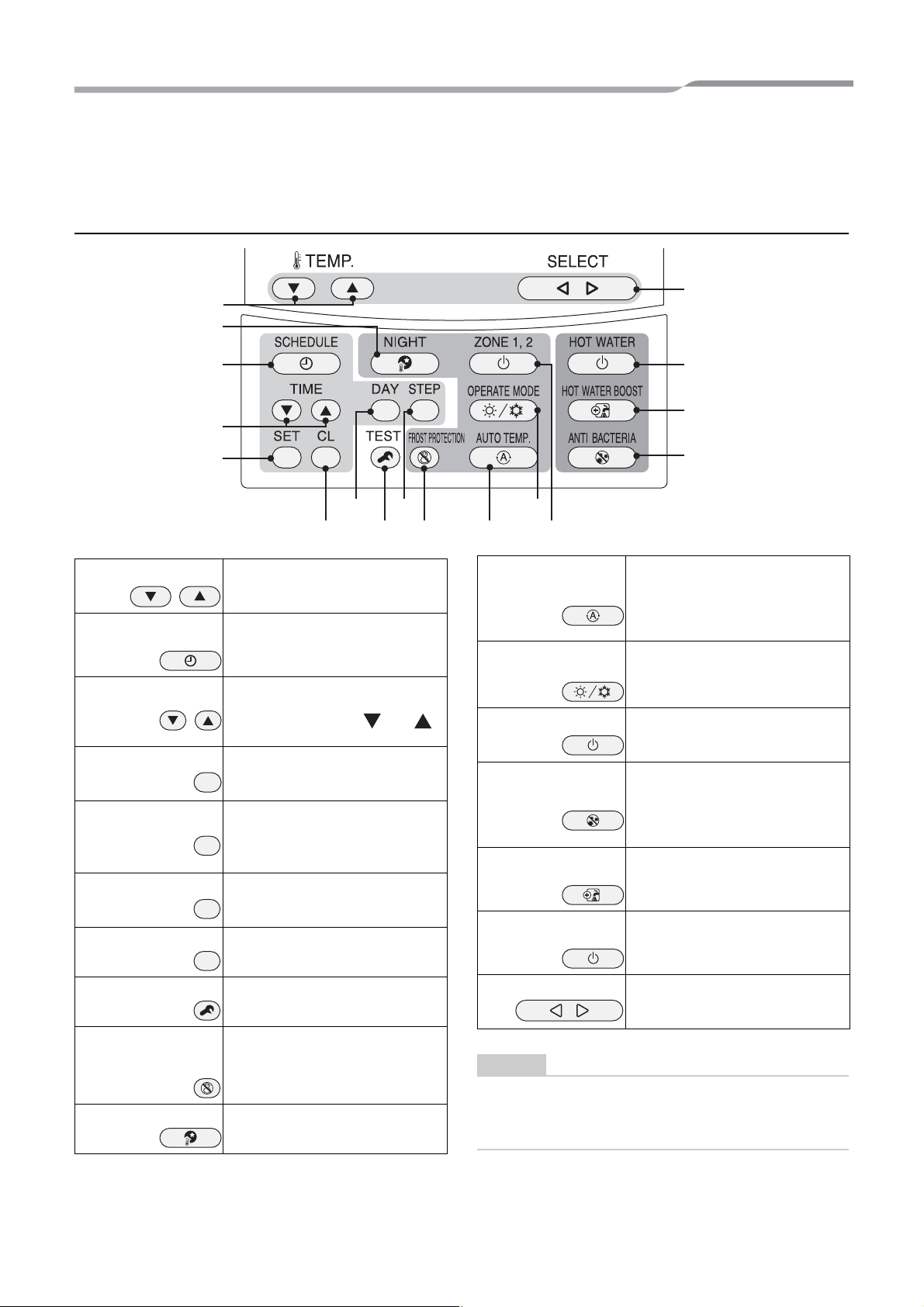

2 Names and functions of parts

Buttons

Owner’s Manual

1. TEMP. button:

2. SCHEDULE

button:

3. TIME button:

4. SET button:

5. CL button:

6. DAY button:

7. STEP button:

8. TEST button:

9. FROST

PROTECTION

button:

10. NIGHT button:

Changes the set temperature for

each operation mode (ZONE1/2

hot water) by 1°C step.

Sets the current time and

scheduled weekly operation.

Changes time for current time

setting and scheduled weekly

operation setting with and

buttons.

Determines the entered current

time setting and scheduled weekly

operation setting.

Clears settings for the current time

and scheduled weekly operation.

Cancels audible alarm in the event

of a system fault.

Sets days of the week for current

time setting and scheduled weekly

operation setting.

Specifies switching STEP number

in a day for weekly schedule.

Used for test run or service.

Controls minimum operation for

unused period (going out, absence,

etc.) for anti freezing.

Controls the night set back

operation.

11. AUTO TEMP.

button:

12. OPERATE MODE

button: Selects ZONE1/2 operation mode

13. ZONE1, 2 button:

14. ANTI BACTERIA

button:

15. HOT WATER

BOOST button:

16. HOT WATER

button:

17. SELECT button:

Switches setting temperature

automatically according to outside

temperature. (Pressing this button

long changes the mode to data

setting mode.)

(heating or cooling).

Turns on/off the zone (floor

heating/radiator/Fan Coil Unit)

operation.

Regularly increases the hot water

temperature in the tank for

sterilization. (Pressing this button

long changes the mode to data

setting mode.)

Boosts boiling when high tapping

temperature is required

temporarily.

Turns on/off hot water operation.

Selects an operation mode when

changing the set temperature of

each operation mode.

Some functions are not provided depending on the

system specifications in use.

For details, contact the installation company.

–4–

4-EN

Loading...

Loading...