Toshiba HD-XE1KE, HD-XE1KY Service Manual

SERVICE MANUAL

HD DVD PLAYER

HD-XE1KE

FILE NO. 810-200695GR

HD-XE1KY

The above models are classified as green products (*1), as indicated by the underlined serial numbers.

This Service Manual describes replacement parts for the green products. When repairing these green

product(s), use the part(s) described in this manual and lead-free solder (*2).

For (*1) and (*2), see the next page.

Dec., 2006 GREEN

(*1) GREEN PRODUCT PROCUREMENT

The EC is actively promoting the WEEE & RoHS Directives that define standards for recycling

and reuse of Waste Electrical and Electronic Equipment and for the Restriction of the use of

certain Hazardous Substances. From July 1, 2006, the RoHS Directive will prohibit any marketing of new products containing the restricted substances.

Increasing attention is given to issues related to the global environmental. Toshiba Corporation

recognizes environmental protection as a key management tasks, and is doing its utmost to

enhance and improve the quality and scope of its environmental activities. In line with this,

Toshiba proactively promotes Green Procurement, and seeks to purchase and use products,

parts and materials that have low environmental impacts.

Green procurement of parts is not only confined to manufacture. The same green parts used in

manufacture must also be used as replacement parts.

(*2) LEAD-FREE SOLDER

This product is manufactured using lead-free solder as a part of a movement within the consumer products industry at large to be environmentally responsible. Lead-free solder must be

used in the servicing and repair of this product.

WARNING

This product is manufactured using lead free solder.

DO NOT USE LEAD BASED SOLDER TO REPAIR THIS PRODUCT !

The melting temperature of lead-free solder is higher than that of leaded solder by 86°F to

104°F (30°C to 40°C). Use of a soldering iron designed for lead-based solders to repair product

made with lead-free solder may result in damage to the component and or PCB being soldered.

Great care should be made to ensure high-quality soldering when servicing this product especially when soldering large components, through-hole pins, and on PCBs as the level of heat

required to melt lead-free solder is high.

SERVICE SHOULD NOT BE ATTEMPTED BY ANYONE UNFAMILIAR WITH THE NECESSARY

SSARY PRECAUTIONS TO BE

SAFETY INSTRUCTIONS

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "SAFETY PRECAUTION"

AND "PRODUCT SAFETY NOTICE"INSTRUCTIONS BELOW.

SAFETY PRECAUTION

WARNING:

PRECAUTIONS ON THIS RECEIVER. THE FOLLOWING ARE THE NECE

OBSERVED BEFORE SERVICING THIS CHASSIS.

・An isolation transformer should be connected in the power line between the receiver and the AC line before any service

is performed on the receiver.

・When replacing a chassis in the cabinet, always be certain that all the protective devices are put back in place, such as;

nonmetallic control knobs, insulating covers, shields, isolation resistor-capacitor network etc.

・Always advise users to keep children away. There is danger of injury to children from tools, disassembled products, etc.

・Always disconnect the power plug before starting work whenever power is not required. Failure to disconnect the power

plug before starting work can result in electrical shock.

・Depending on the model, use an insulation transformer or wear gloves when servicing with the power on, and disconnect

the power plug to avoid electrical shock when replacing parts. In some cases, alternating current is also impressed in

the chassis, so electrical shock is possible if the chassis is contacted with the power on.

・Always use the replacement parts specified for the particular model when making repairs. The parts used in products

have the necessary safety characteristics such as inflammability, voltage resistance, etc. ; therefore, use only

replacement parts that have these same characteristics. Use only the specified parts when the mark is

include in a circuit diagram or parts list.

・Parts mounting and routing of the wiring should be the same as that used originally. For safety purposes, insulating materials

such as tubing or tape is sometimes used and printed circuit boards are sometimes mounted floating. Also make sure that

wiring is routed and clamped to avoid parts that generate heat and which use high voltage. Always follow the original scheme.

・After a repair has been completed, reassemble all disassembled pars, and route and reconnect the wiring, in accordance with

the original scheme. Do not allow internal wiring to be pinched by cabinets, panels, etc. Any error in reassembly or wiring

can result in electrical leakage, flame, etc.,and may be hazardous.

・Never remodel the product in any way. Remodeling can result in improper operation, malfunction, or electrical leakage and

flame, which may be hazardous.

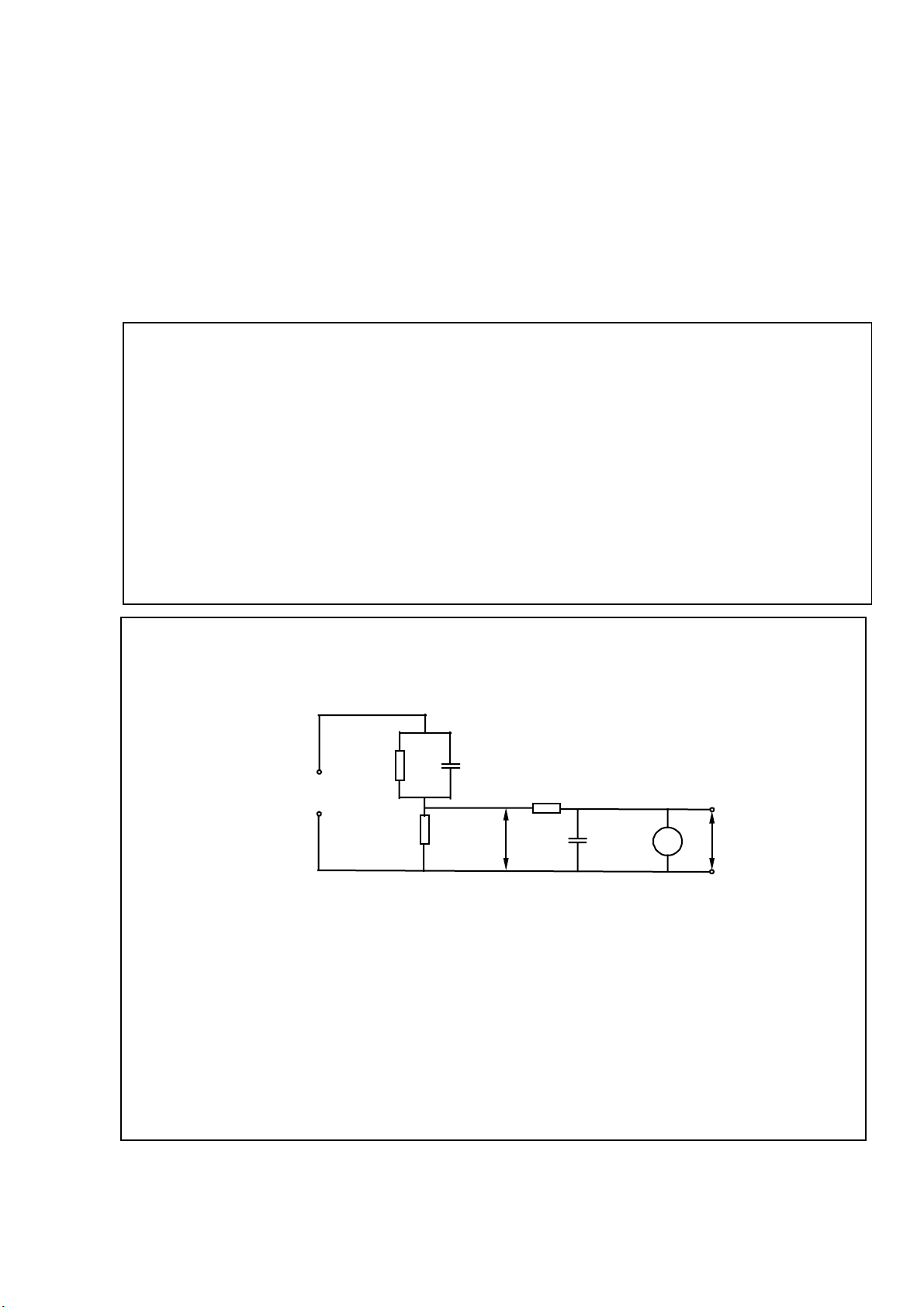

Touch current check

(After completing the work, measure touch current to prevent an electric shock.)

・Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check..

・Connect a measuring network for touch currents between each exposed metallic part on the set and a good earth

ground such as a water pipe, as shown in Figure D.1

・The potential at any point(TOUCH CURRENT) expressed as voltage U

The part or contact of a TERMINAL is not HAZARDOUS LIVE if:

a) the open-circuit voltage does not exceed 35 V (peak) a.c or 60 V d.c.,

or,if a)is not met,

b) the measurement of the TOUCH-CURRENT shall be carried out in accordance with IEC 60990, with the measuring network

described in annex D of this standard.

The TOUCH CURRENT expressed as voltages U

- for a.c.:U

- for d.c.:U

NOTE 5 -The limit values of U

mA 2,0mA d.c.

The limit value U

1

= 35 V(peak)and U2=0.35 V (perk);

1

= 1,0 V,

2

=0.35 V (peak) for a.c. and U1=1.0 V for d.c. correspond, to the values 0,7mA (peak) a.c. and 2,0

1

= 35 V (peak) for a.c. corresponds to the value 70mA (peak) a.c. for frequencies greater than 100 kHz.

1

and U2 does not exceed the following value:

1

and U2, does not exceed the following values:

Measuring network for TOUCH CURRENTS

Annex D

(normative)

Test TERMINALS

A

B

Rs=

1 500Ω

b

R

500Ω

=

Cs=

0.22uF

10kΩ

U

1

0.022uF

V

(V)

U

2

Resistance values in ohms(Ω)

V: Voltmeter or oscilloscope

(r.m.s or peak reading)

Input resistance: ≧1 MΩ

Input capacitance: ≦ 200 pF

Frequency range: 15 Hz to 1 MHz and d.c. respectively

NOTE-Appropriate measures should be taken to obtain the correct value in case of non-sinusoidal waveforms.

2

The measuring instrument is calibrated by comparing the frequency factor of U

with the solid line in figure F.2 of

IEC 60990 at various frequencies. A calibration curve is constructed showing the deviation of U

curve as a function of frequency.

TOUCH CURRENT=U2/500(peak value)

IEC 802/96

2

from the ideal

Fig.D.1

PRODUCT SAFETY NOTICE

The use of substitute replacement parts which do not have the same safety characteristics as specified in the parts list

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These characteristics

are often passed unnoticed by a visual inspection and the protection afforded by them cannot necessarily be obtained by

using replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in this manual and its supplements; electrical components having such features are

identified by the international hazard symbols on the schematic diagram and the parts list.

Before replacing any of these components, read the parts list in this manual carefully.

may create shock, fire, or other hazards.

The lightning flash with arrowhead symbol, within an equilateral triangle, is intended to alert the user

to the presence of uninsulated “ dangerous voltage ” within the products enclosure that may be of

sufficient magnitude to constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is intended to alert the user to the presence of

important operating and maintenance (servicing) instructions in the literature accompanying the

appliance.

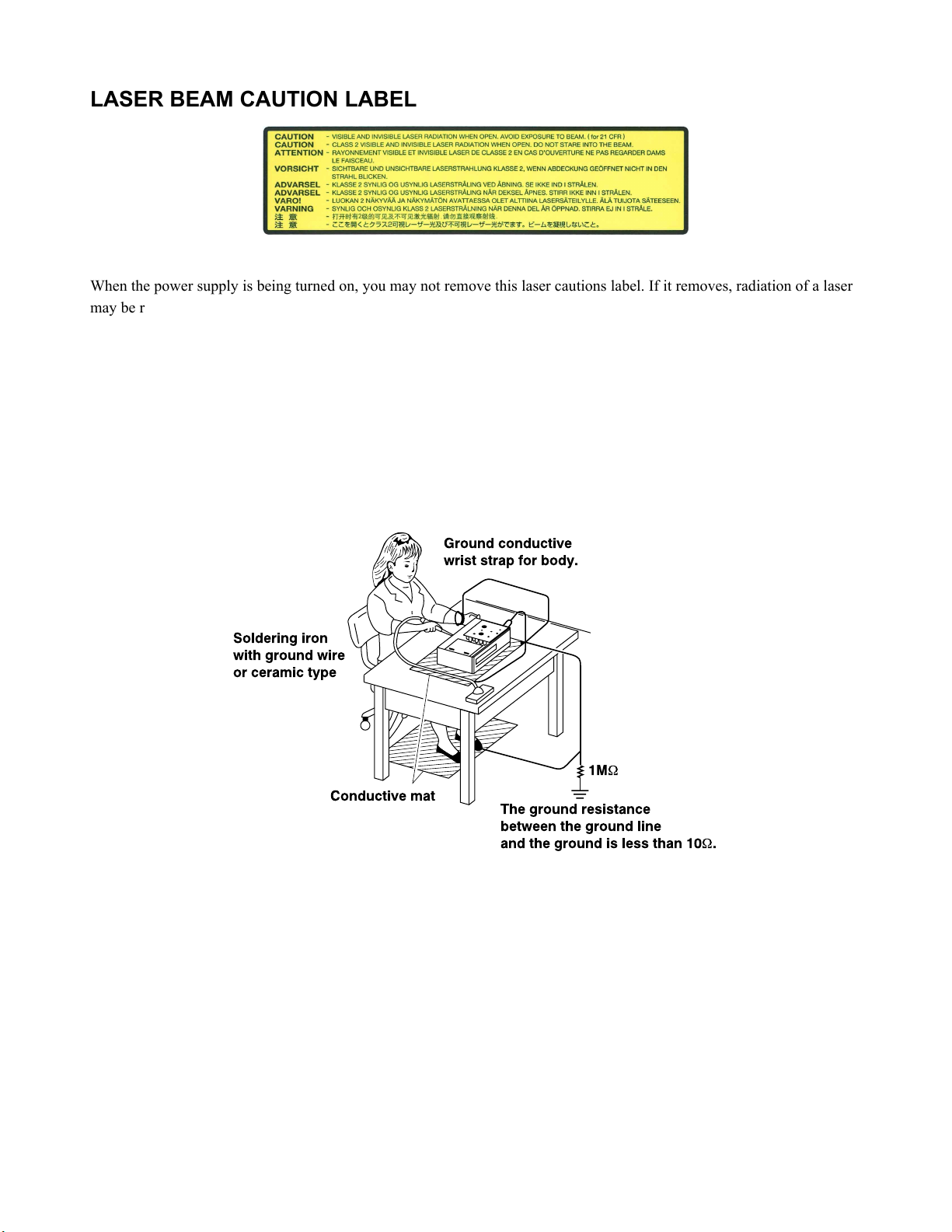

LASER BEAM CAUTION LABEL

When the power supply is being turned on, you may not remove this laser cautions label. If it removes, radiation of a laser

may be received.

PREPARATION OF SERVICING

Pickup Head consists of a laser diode that is very susceptible to external static electricity.

Although it operates properly after replacement, if it was subject to electrostatic discharge during replacement,

its life might be shortened. When replacing, use a conductive mat, soldering iron with ground wire, etc. to

protect the laser diode from damage by static electricity.

And also, the LSI and IC are same as above.

9

Dolby features manufactured under license from Dolby Laboratories. Dolby and the double-D symbol are trademarks of Dolby Laboratories.

·

DTS features manufactured under license from Digital Theater Systems, Inc. U.S. Pat. No's. 5,451,942; 5,956,674; 5,974,380; 5,978,762; 6,226,616;

·

6,487,535 and other U.S. and world-wide patents issued and pending. "DTS" and "DTS Digital Surround" are registered trademarks of Digital Theater

Systems, Inc.

Copyright 1996, 2003 Digital Theater Systems, Inc. All Rights Reserved.

HDMI, the HDMI logo and High-Definition Multimedia Interface are trademarks or registered trademarks of HDMI Licensing LLC.

·

SHARC is a registered trademark and Melody is a trademark of Analog Devices, Inc.

·

All other brand and product names mentioned in this manual are trademarks and/or registered trademarks of their respective holders.

·

9

1. OPERATING INSTRUCTIONS

CONTENTS

SECTION 1

GENERAL DESCRIPTIONS

2. LOCATION OF MAIN PARTS

2-1. Location of Main Parts

2-2. Location of PC Boards

1. REPLACEMENT OF MECHANICAL PARTS

1-1. Front Panel, Front PC Boards

1-2. Main/Power PC Boards

1-3. DVD Drive

1. CIRCUIT SYMBOLS AND

SUPPLEMENTARY EXPLANATION

1-1. Precautions for Part Replacement

1-2. Solid Resistor Indication

1-3. Capacitance Indication

1-4. Inductor Indication

1-5. Waveform and Voltage Measurement

1-6. Others

2. PRINTED WIRING BOARD AND

SCHEMATIC DIAGRAM

3. BLOCK DIAGRAMS

4. CIRCUIT DIAGRAMS

4-1. Power Supply Circuit Diagram

4-2. Front Circuit Diagram

4-2-1. Front FIP Circuit Diagram

4-2-2. Power Switch Circuit Diagram

4-2-3. Front Switch/USB Circuit Diagram

4-2-4. Front D-Light Circuit Diagram

4-3. RS232C Circuit Diagram

PART REPLACEMENT PROCEDURES

SECTION 2

2. WIRING CONNECTION DIAGRAM

2-1. Wiring Connection Diagram

2-2. Supplementary Instructions for Reassembling

SECTION 3

SERVICING DIAGRAMS

4-4. Main Circuit Diagram

4-4-1. AV Output Circuit Diagram

4-4-2. Timer Circuit Diagram

4-4-3. Video Scaller Circuit Diagram

4-4-4. Video Output Circuit Diagram

4-5. ATAPI Conversion Circuit Diagram

5. PC BOARDS

5-1. Front FIP PC Board

5-2. Power Switch PC Board

5-3. Front Switch/USB PC Board

5-4. ATAPI PC Board

5-5. D-Light PC Board

5-6. RS232C PC Board

SAFETY PRECAUTION

NOTICE

ABBREVIATIONS

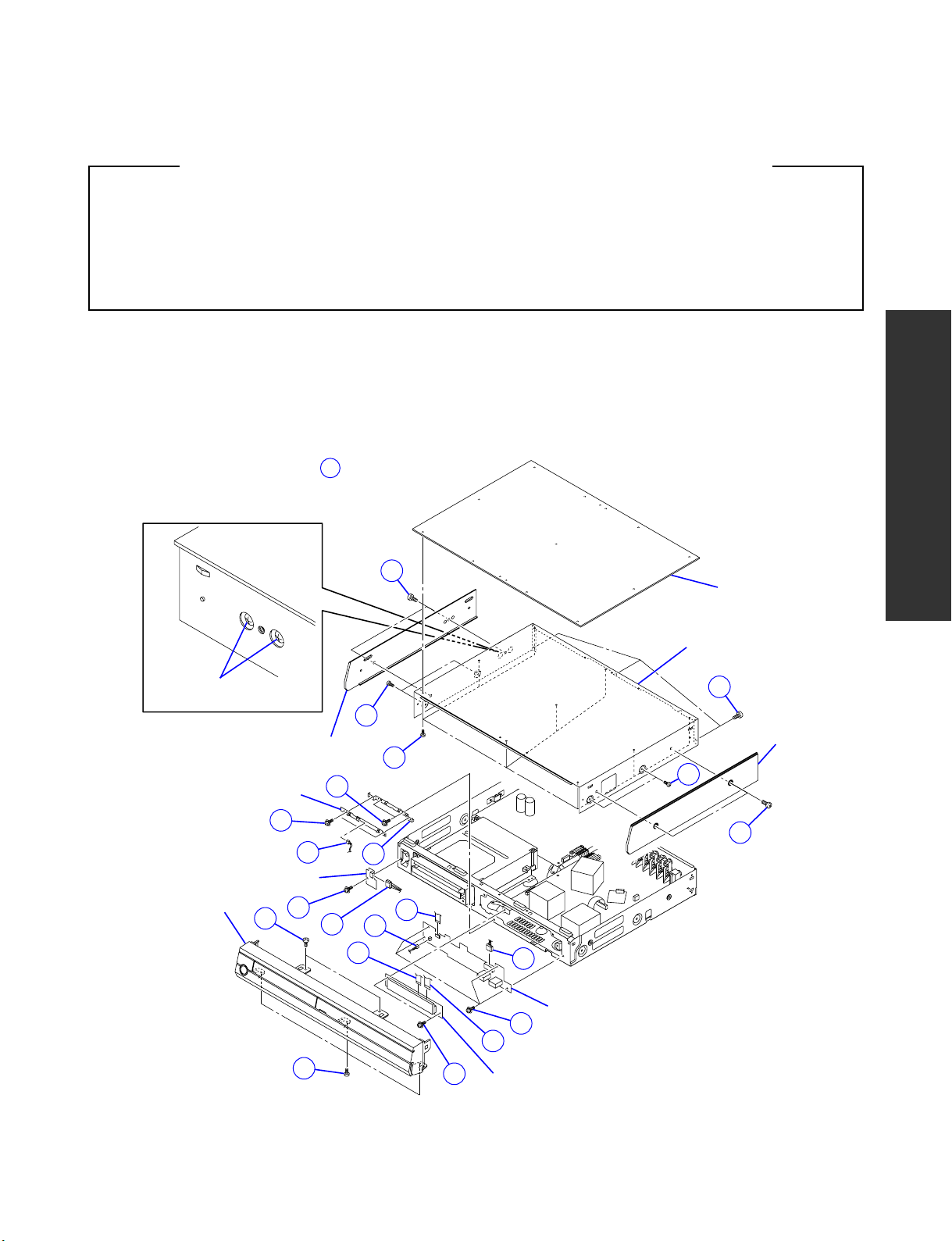

1. EXPLODED VIEWS

1-1. Packing Assembly

1-2. Chassis Assembly

2. PARTS LIST

SUPPLEMENT1. Firmware Version Update

SUPPLEMENT2. Error Code

SUPPLEMENT3. TROUBLESHOOTING

3-1. Standby LED (red) does not light.

3-2. LED (green) does not light at power on.

3-3. CPU FAN does not work.

3-4. Indicator does not light. (“WELCOME” does not light at

startup.)

3-5. System does not run. (“WELCOME” displayed and key

operation disabled)

3-6. No picture appears.

3-6-1. No output from HDMI.

SECTION 4

PARTS LIST

SUPPLEMENT

3-7. No audio is played back.

3-8. Buzzer does not sound.

3-9. Extension port does not work.

3-10. Front panel keys/remote control are disabled.

3-11. Other Symptoms

3-12. Power Circuit Troubleshooting

GENERAL DESCRIPTIONS

SECTION 1

GENERAL DESCRIPTIONS

1. OPERATING INSTRUCTIONS

Please refer to the owner's manual about the contents.

SECTION 1

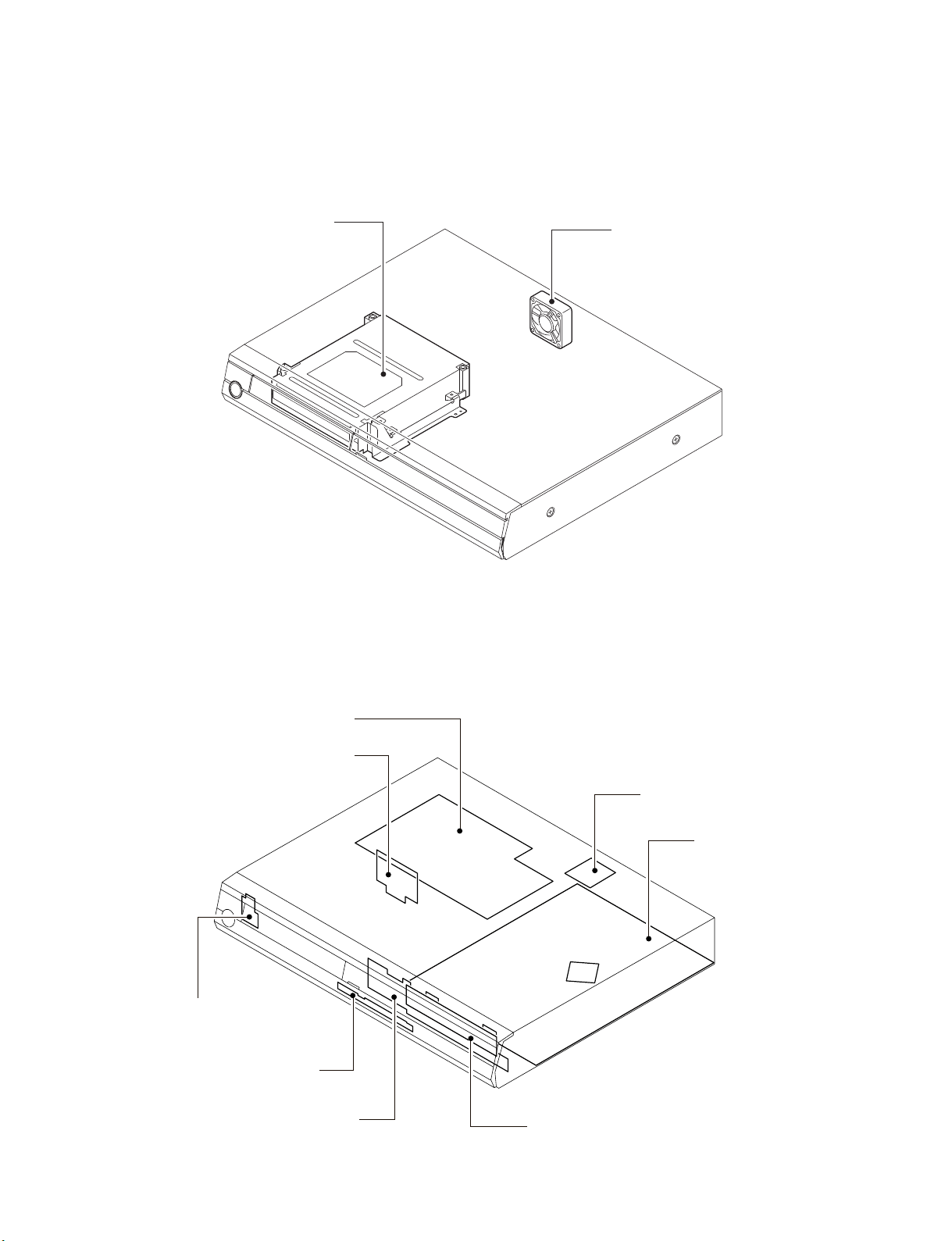

2. LOCATION OF MAIN PARTS

2-1. Location of Main Parts

RAM1 DVD Drive

FAN1 Fan

Fig. 1-2-1

2-2. Location of PC Boards

PWR1 Power PC board

U003 ATAPI PC board

PSW1 Power Switch PC board

LED1 Front D-Light PC board

FSW1 Front Switch/USB PC board

FRS1 RS232C PC board

U001 Main PC board

U002 Front FIP PC board

Fig. 1-2-2

SECTION 2

PART REPLACEMENT PROCEDURES

CAUTIONS BEFORE STARTING PART REPLACEMENT

Electronic parts are susceptible to static electricity and may easily damaged, so do not forget to ground as required.

Many screws are used inside the unit. To prevent the screws from missing or dropping, etc. always use a magnetized

screwdriver in servicing. Several kinds of screws are used and some of them need special cautions. That is, take care of

the tapping screws securing molded parts and fine pitch screws used to secure metal parts. If they are used improperly,

the screw holes will be easily damaged and the parts can not be fixed.

1. REPLACEMENT OF MECHANICAL PARTS

Note:

• Circled numbers in the figure show the main disassembly procedure. Refer to them when disassembling.

1-1. Front Panel, Front PC Boards

PART REPLACEMENT PROCEDURES

SECTION 2

Note: Do not tighten up the screws too much.

(Tightening torqne: 1.0kg • cm (0.098N • m))

Do not remove the screws

when disassembling.

Side panel L

Front D-Light PC board

Power Switch PC board

Front panel

2

16

1

3

16

8

7

6

5

9

4

12

Top panel

Top cover

2

Side panel R

3

1

13

10

2

11

Fig. 2-1-1

14

Front Switch/USB PC board

15

10

Front FIP PC board

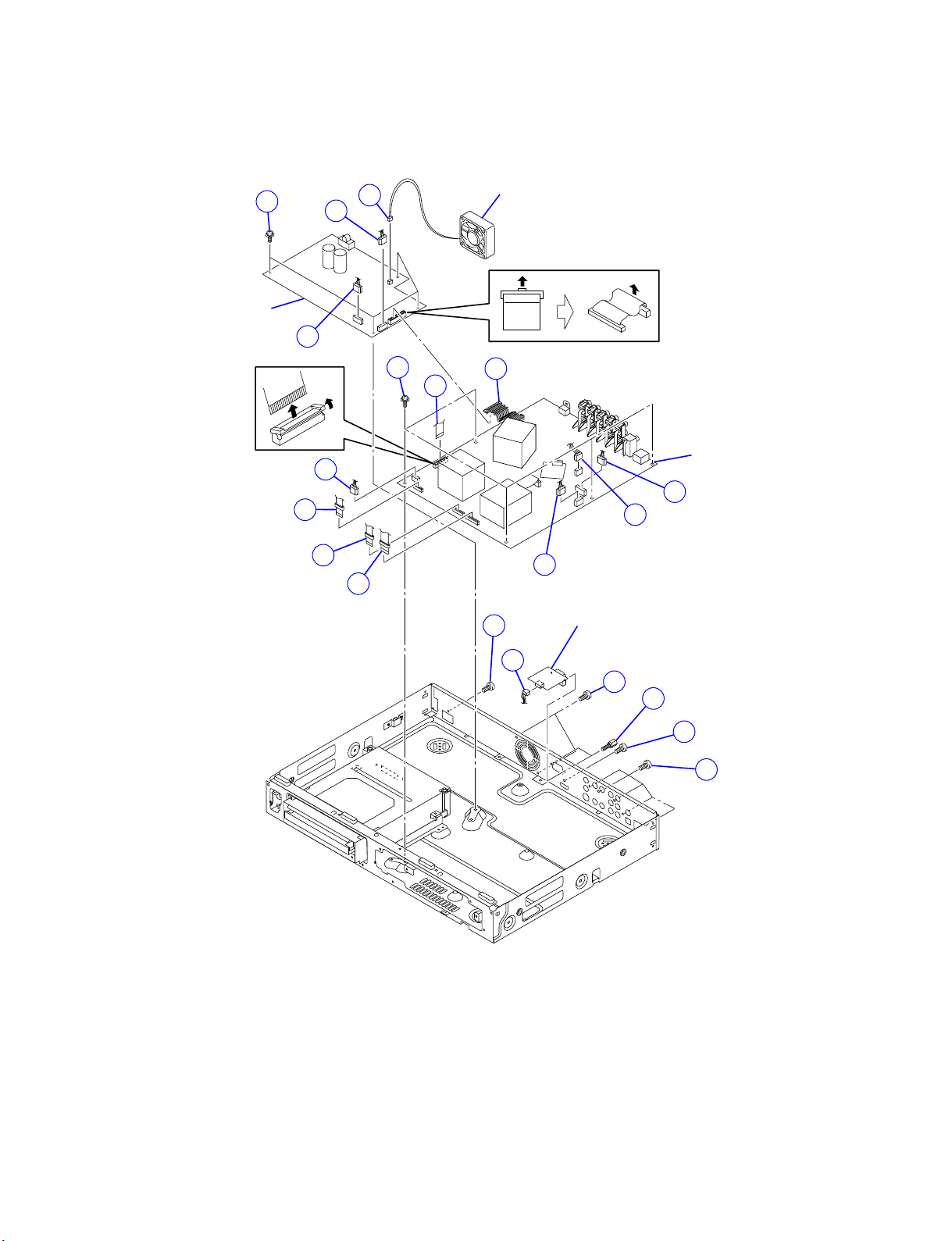

1-2. Main/Power PC Boards

Power PC Board

6

1

3

Fan

3

10

4

7

Main PC Board

8

8

7

7

8

8

7

5

RS232C PC Board

Fig. 2-1-2

11

2

12

9

9

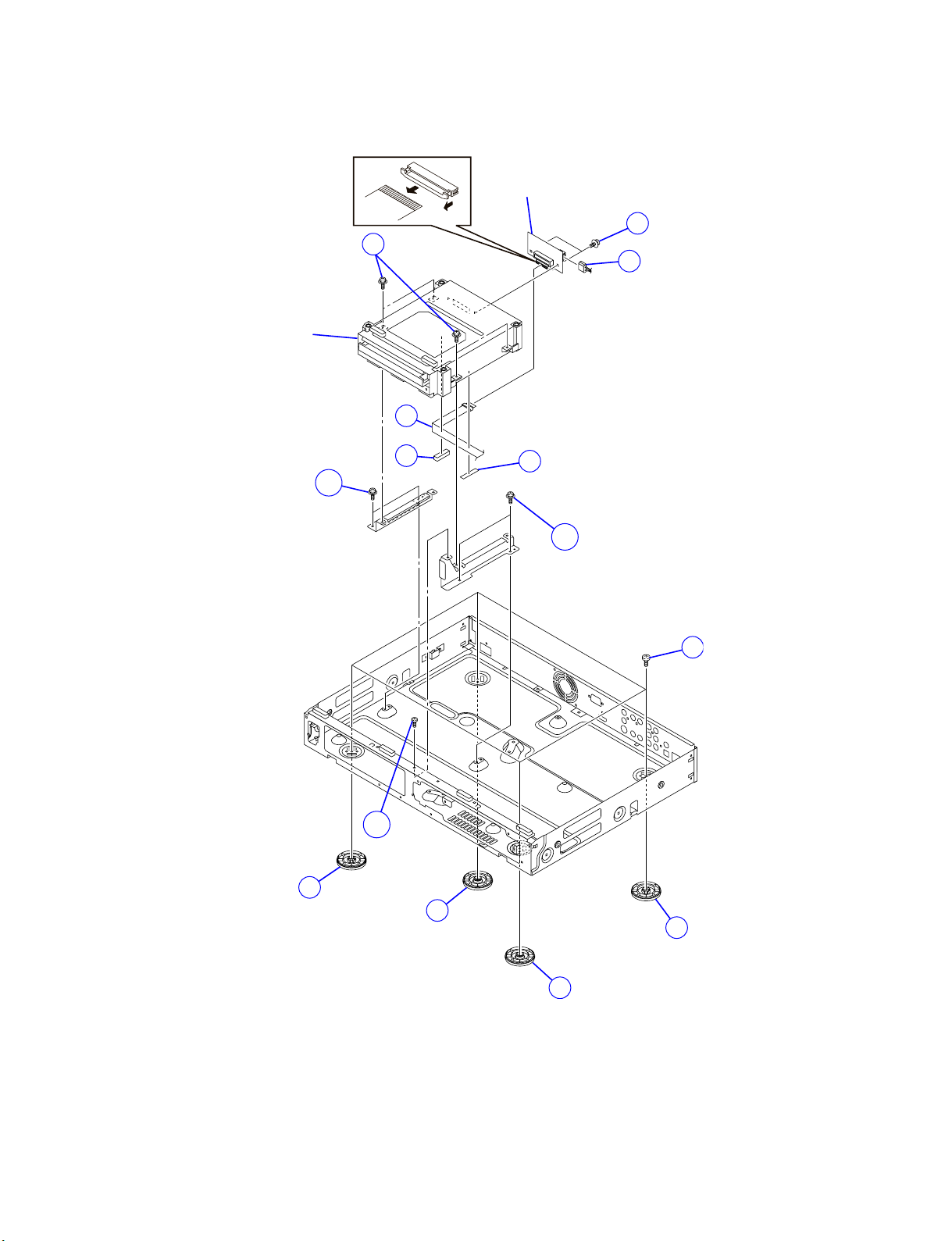

1-3. DVD Drive

ATAPI PC Board

6

1

5

DVD Drive

3

2

4

1

1

7

1

8

9

9

Fig. 2-1-3

8

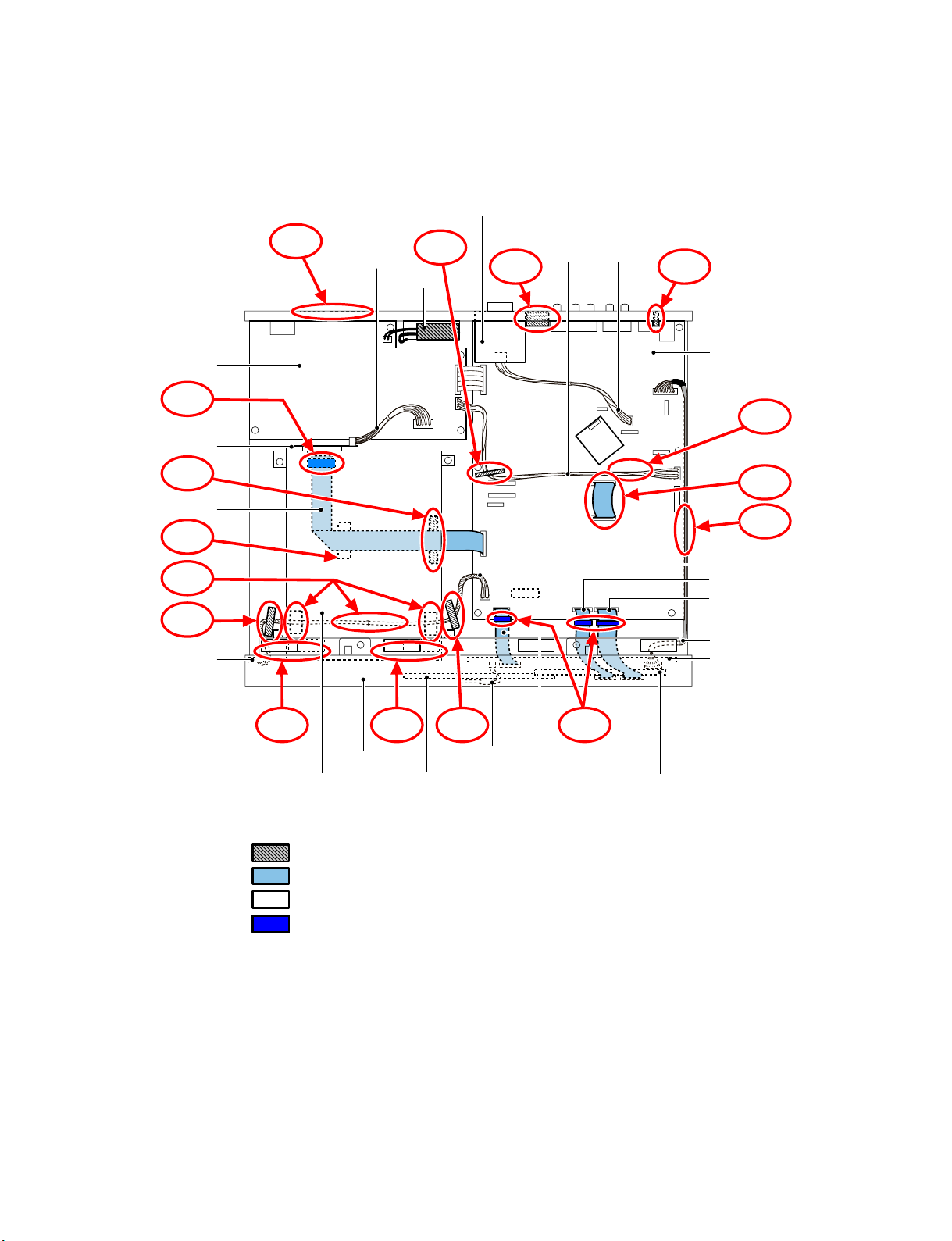

2. WIRING CONNECTION DIAGRAM

2-1. Wiring Connection Diagram

After the servicing is complete, return the wiring to its original state by using the diagram below as a reference.

RS232C PC board

Power PC board

B-4

ATAPI PC board

A-2

W004

B-2

D-3

A-1

Power Switch PC board

D-1

W102

A-3

Fan

W104 W105

D-1 D-1

Main PC board

D-6

D-5

D-4

W103

W003

W002

W101

Front Switch/USB PC board

B-3

DVD Drive

: Tape

: Flexible cable

: Gasket

: Ferrite core

B-3

Front panel

Front D-Light PC board

A-1 C-2

W001W106

Front FIP PC board

Fig. 2-2-1

2-2. Supplementary Instructions for Reassembli ng

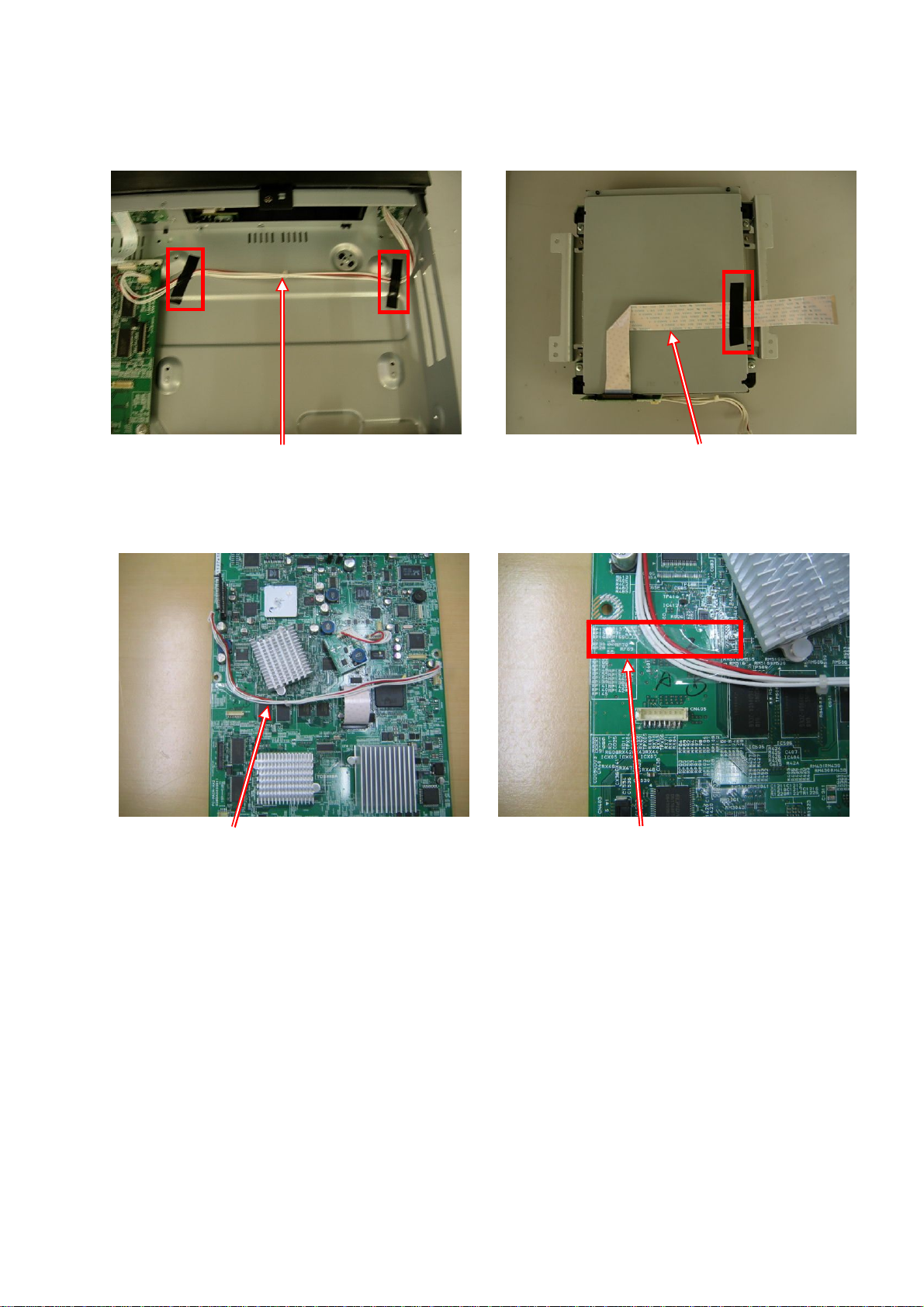

A-1. Fix the wire (W103) with two tapes (TAPE-PET-W10-L50).

A-2. Fix the FFC (W104) with the tape (TAPE-PET-W10-L50).

W103 W104

A-3. Fix the wire (W004) with the tape (TAPE-PET-W10-L50).

(Fixed position : Between CN405 and C60 D)

W004 Fix (Between CN405 and C60D)

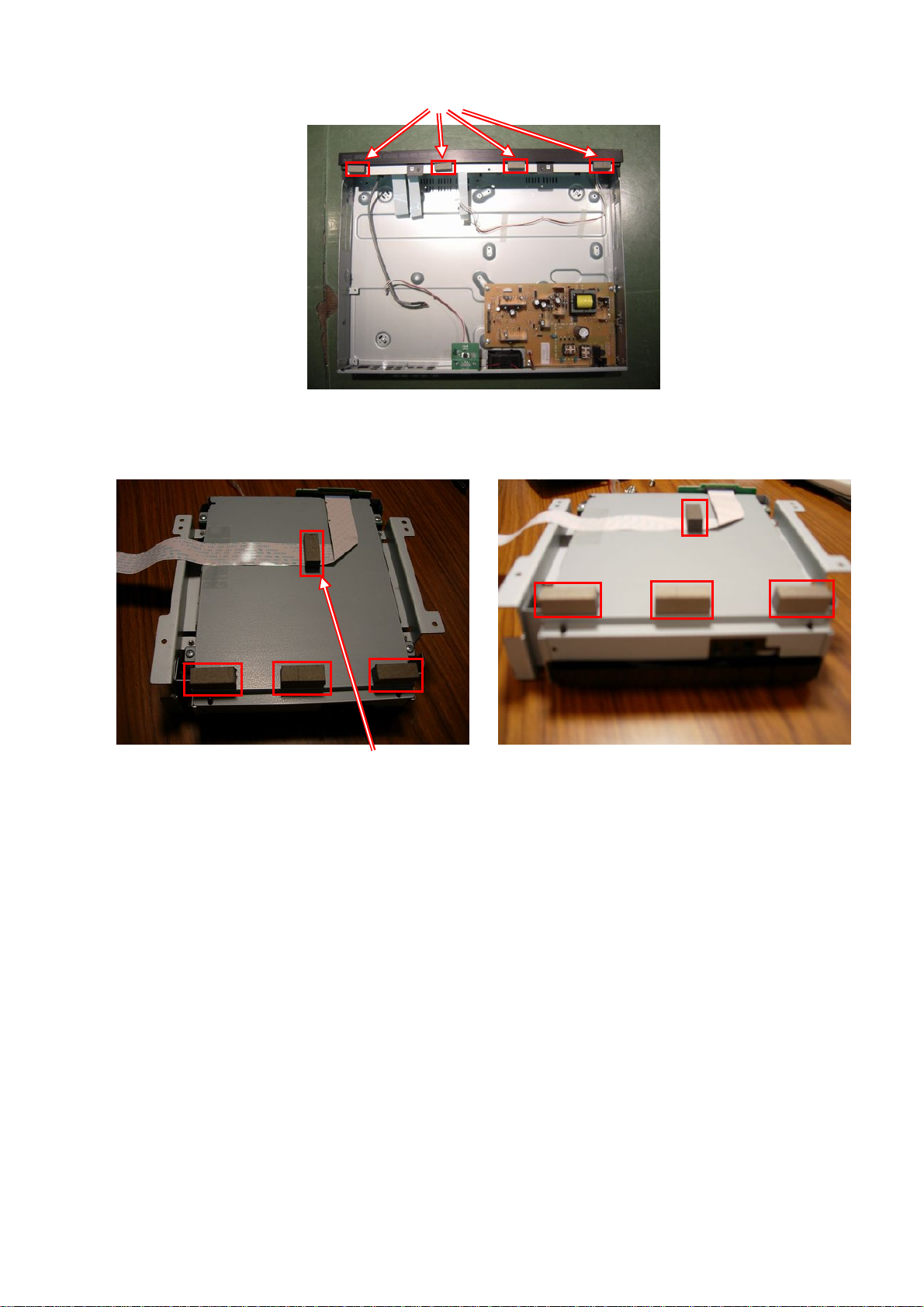

B-1. Paste the gasket to 4 places of the upper surface of front panel.

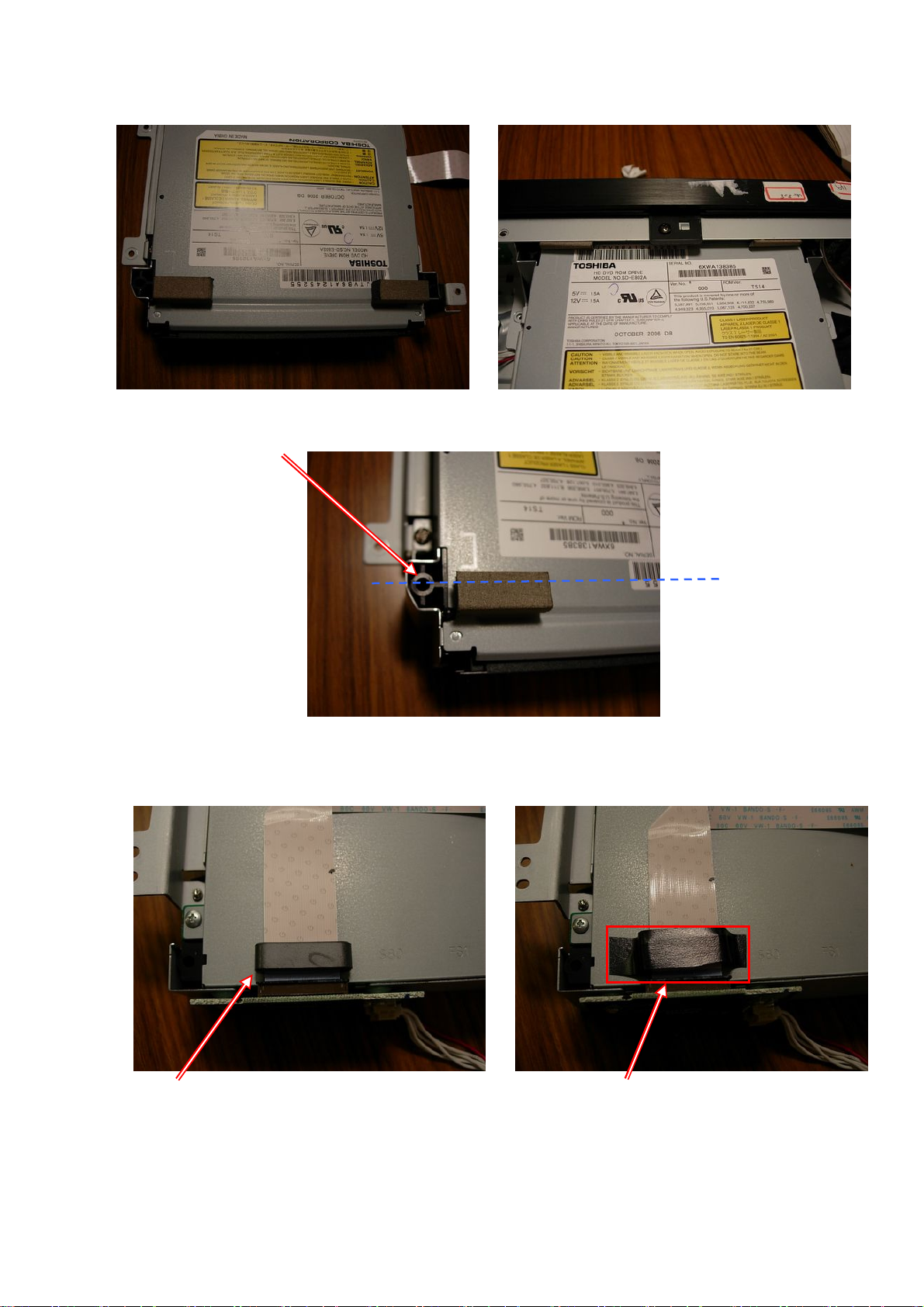

B-2. Paste gaskets to the following positions in the lower side of DVD drive.

(Gasket : SSTG10-10 L25HC(GD9D00000080)

Paste the gasket just behind folded FFC.

B-3. Paste gaskets to the following positions in the upper side of DVD drive.

(Gasket : SSTG10-10 L25HC(GD9D00000080)

Paste gasket to the position where a semicircle part of the hole of molde this DVD drive corre sp ond to the edge

of Gasket.

B-4. Attatch ferrite core (HF70SH22*0.8*7:PM000969 1010) to FFC betwee n DVD drive and m ain board.

(fixed position : just behind PC board side of DVD drive, Use TAPE-PET-W10-L50)

ferrite core (HF70SH22*0.8*7:PM0009691010) TAPE-PET-W10-L50

C-1.Attach ferrite core Z001F(PM0007982010:ZCAT2132-1130) to the power code. Roll the power code twice.

(HD-XE1KE has two power codes. Attach ferrite core on each power code.)

Fixed

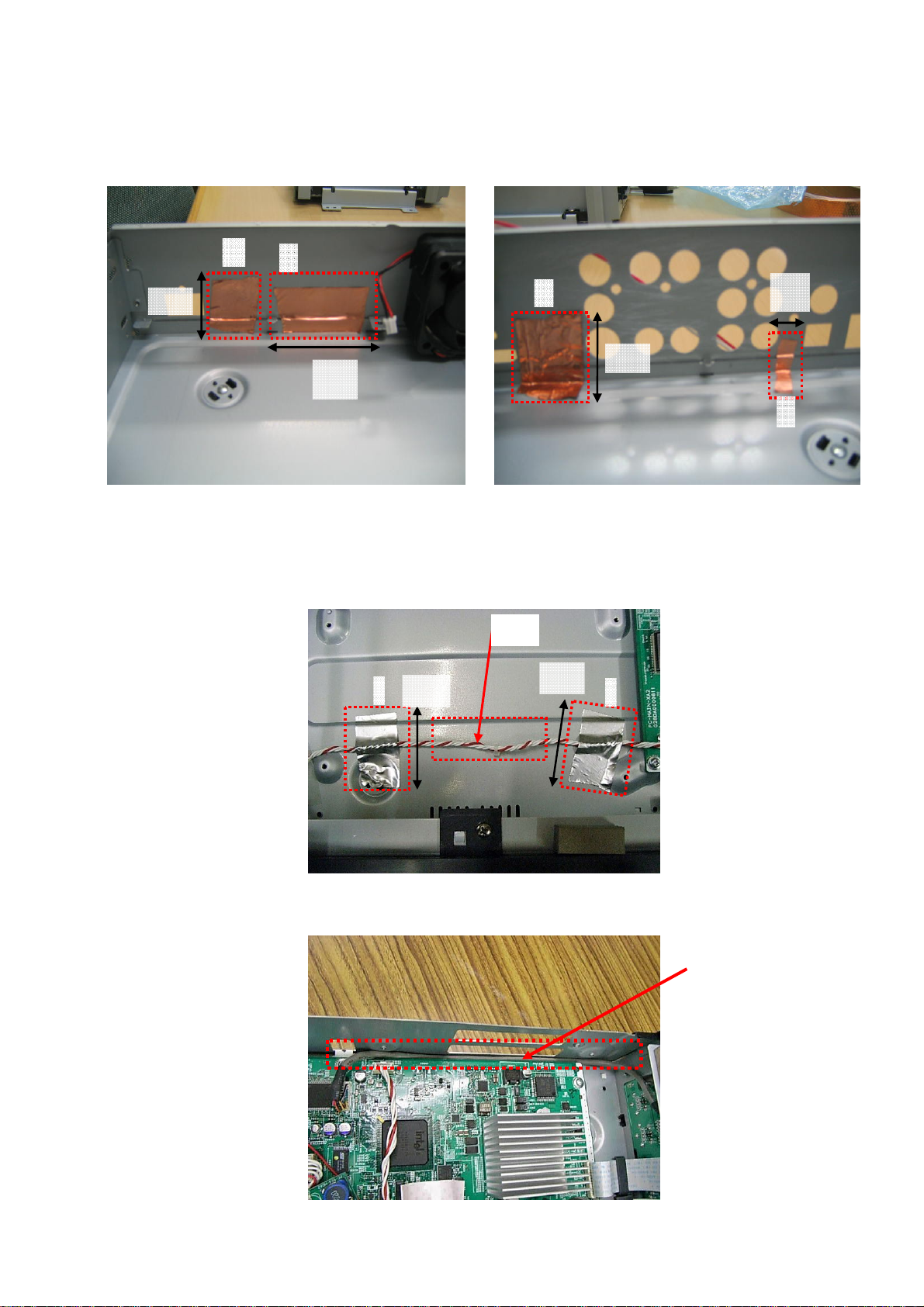

C-2.Attach ferrite cores(HF70SH22*0.8*7:PM0009691010) for FFC(W001,W002,W003) of between Front and Main.

Fix three cores with the tape respectively (TAPE-PET-W10-L50).

(Fixed position : Main side)

C-3.Fix right and left both sides of top cover with the screw. (Screw : BITTS 3x6)

D-1.Paste the aluminum tapes to the position of A, B, and C.

A

Position A : 25mm(Tape Width) X 30mm

Position B : 25mm(Tape Width) X 50mm

Position C : 25mm(Tape Width) X 7mm

A

B

30mm

30mm

50mm

D-2.Twist W103.

D-3.Fix the wire (W103) to the following position (A and B) with t wo aluminum tap es

(GY4D00000030, Parts Name: AL-25T, Tape Width : 40mm).

W103

40mm

40mm

A

B

7mm

C

D-4.Insert the USB wire (W101) to the space of main uni t and chassi s.

W101

Loading...

Loading...