Page 1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Document: VF00W103 Rev. 7

INSTRUCTION MANUAL

INSTALLATION - OPERATION - MAINTENANCE

HCV-5HA 7.2kV, 400A-7.0kA (4.5kA@7.2kV)

HCV-5HAL 7.2kV, 400A-7.0kA (4.5kA@7.2kV)

Manufactured in the USA

MAY 2008

Page 2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

MAY 2008

Page 3

INTRODUCTION Page 2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

READ THIS MANUAL carefully for important information about safety, handling, and

maintenance, for general-purpose NEMA Class E magnetic controllers.

This manual and all accompanying drawings should be considered a permanent

part of the equipment. They should be readily available for review and reference at

all times.

DIMENSIONS shown in the manual are in metric and/or their English equivalent.

These instructions are not intended to cover all details, combinations, or variations

of the equipment, storage, or installation.

PROBLEMS OR QUESTIONS should be addressed to:

Field Service Department

Toshiba International Corporation

13131 West Little York Road

Houston, Texas 77041 USA

Telephone: (713) 466-0277

(800) 231-1412

(800) 527-1204 (Canada)

FAX: (713) 466-8773

Use only Toshiba-authorized replacement parts.

This equipment is designed and built in accordance with

applicable safety standards in effect on the date of

manufacture. Unauthorized modifications can result in

severe injury, death and property damage. Do not make

any modifications to this equipment without the written

approval of Toshiba.

MAY 2008

Page 4

TABLE OF CONTENTS Page 3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page

SAFETY DATA 4

Safety Data Information 4

GENERAL 6

Recommended Procedure 6

RECEIVING & HANDLING 7

Receiving 7

Handling 7

Storage 7

GENERAL DESCRIPTION 8

Application 8

Load Data 8

Location Condition 8

Ratings 9

Construction 10

MAINTENANCE 17

General Inspection 17

Vacuum Interrupter 18

Bearing 19

Closing Coils 19

Latch Mechanism 19

Auxiliary Switch 19

VACUUM INTERRUPTER 20

Replacement Procedure 20

Removing 20

Mounting 21

Adjustment of Contacts 21

Operation Check 21

TROUBLESHOOTING 22

OUTLINE DIAGRAM 23

WARRANTY AND LIMITATION

OF LIABILITY 24

PRE-OPERATION SET-UP 11

Application Precautions 11

Installation 11

Controls 12

Power Connections-Standard 13

Power Connections-Latched 13

Drive Unit Configuration 14

Standard Circuit Diagram 14

Latched Circuit Diagrams 15

Trial Operation 16

Page

Page 5

Page 4 SAFETY DATA

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

QUALIFIED OPERATORS ONLY

Only qualified persons are to install, operate, or service this equipment

according to all applicable codes and established safety practices.

A qualified person must:

1) Carefully read the entire instruction manual.

2) Be skilled in the installation, construction or operation of the

equipment and aware of the hazards involved.

3) Be trained and authorized to safely energize, de-energize, clear,

ground, lockout and tag circuits in accordance with established safety

practice.

4) Be trained and authorized to perform the service, maintenance or

repair of this equipment.

5) Be trained in the proper care and use of protective equipment such as

rubber gloves, hard hat, safety glasses, face shield, flash clothing, etc.

in accordance with established practices.

6) Be trained in rendering first aid.

SAFETY CODES

Toshiba medium voltage controllers are general purpose, Class E, magnetic

controllers designed and built in accordance with the latest applicable

provisions of NEMA ICS 3 Part 2, UL 347 and the National Electrical Code.

Installations must comply with all applicable state and local codes, adhere to

all applicable National Electric Code (NFPA 70) standards and instructions

provided in this manual.

Page 6

SAFETY DATA Page 5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

IMPORTANT MESSAGES

Read this manual and follow its instructions. Signal words such as

DANGER, WARNING, CAUTION, and NOTE will be followed by important

safety information that must be carefully reviewed.

Indicates a situation which will result in death,

serious injury, and severe property damage if you

do not follow instructions.

Means that you might be seriously injured or killed

if you do not follow instructions. Severe property

damage might also occur.

Means that you might be injured if you do not

follow instructions. Equipment damage might also

occur.

NOTE Gives you helpful information.

READ SAFETY SIGNS

To avoid injury, you must read and follow the instructions in this manual and

on the safety signs located on the equipment.

Keep the safety signs visible and in good shape.

Never remove, damage, or cover any safety sign.

Page 7

Page 6 GENERAL

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Please read this manual and all accompanying documentation in its entirety prior to installation and

operation. These instructions are not intended to cover all details, combinations or variations of the

equipment, storage or installation.

Toshiba medium voltage open vacuum type magnetic motor controllers are UL recognized and built in

accordance with the latest applicable provisions of NEMA ICS 3 Part 2, UL 347 and the National Electrical

Code.

There is a hazard of shock or

burn whenever working on or near

electrical equipment.

ALL POWER supplying the

equipment should be turned off

before starting work, and

disconnecting means should be

locked out and/or tagged out in

accordance with NFPA 70 E, Part II

and ANSI Z244.1.

Where it is not feasible to de-energize the unit, the following precautions should be taken;

A. Persons working near exposed parts that are or may be energized should be instructed to

and should use practices (including appropriate apparel, equipment and tools) in

accordance with NFPA 70 E, Part II.

B. Persons working on exposed parts that are or may be energized should, in addition to A, be

qualified persons who have been trained to work on energized equipment.

RECOMMENDED PROCEDURE

The successful and safe operation of medium voltage control equipment is dependent upon handling,

installation, operation and maintenance by qualified personnel. Failure to follow fundamental installation and

maintenance recommendations could lead to personal injury and damage to the equipment and other

property. When referred to in this manual and on product labels, a qualified person is one who is familiar

with installation, construction or operation of the equipment and the hazards involved. In addition, this

person should have the following qualifications;

1) Is trained and authorized to energize, de-energize, clear, ground and tag circuits in

accordance with established safety practices.

2) Is trained in the proper care and use of protective equipment such as rubber gloves, hard

hat, safety glasses or face shields, flash clothing, etc. in accordance with established

practices.

3) Is trained in rendering first aid.

Page 8

KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 9

RECEIVING & HANDLING Page 7

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

RECEIVING

Upon receipt of the equipment, make an immediate inspection for any damages which may have occurred

during shipment. When the contactor is received it should be unpacked sufficiently to inspect for concealed

damage and to determine that the shipment is complete and correct. If any damage is found it should be

noted prior to accepting the shipment if possible.

Check for things such as, damage to the container, water seepage or moisture on the contactor. Check the

nameplate to confirm that the ratings meet the intended application.

If any parts are damaged or missing, file a claim immediately with the carrier and notify the Toshiba sales

office. Try to give as much information as possible when filing a claim.

HANDLING & STORAGE

Vacuum contactors should be handled with care to avoid damage. Contactors should be kept in an upright

position and moved with suitable equipment.

If the contactor is to be stored over any length of time, the packing material should be restored for protection

during that period. Where conditions permit, the packing should be left intact until the contactor is ready for

installation. Store the contactor in a dry and dust free area. It should not be left outdoors or in adverse

conditions. If unprotected, corrosion, rust and insulation deterioration will occur.

Page 10

Page 8 GENERAL DESCRIPTION

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

SERVICE CONDITIONS

Application Condition

The type HCV vacuum contactor is manufactured in accordance with IEC 60470 (1974), NEMA ICS 3 Part 2

(1993). The vacuum contactor should be used in the following conditions.

Table 1

Normal Service Conditions

- Altitude: Less than 2,000 m

(6600 ft)

Above 2,000 m consult factory

-Ambient temperature: -5°C min. to +40°C max.

Its average over a period of

24 hr does not exceed +35°C.

-Relative humidity: 45% min. to 85% max.

-Vibration: 20 Hz - 1G or less

-Shock 30G

-Weight 43 lbs.

Latched type 44 lbs.

If the contactor is to be used in conditions other than those specified above, please consult Toshiba

International Corporation.

Table 2

General Application and Load Data

System

Voltage

2.2-2.5kV

3.0-3.3kV

4.0-5.0kV

6.0-6.6kV

The above table is based on general load data and standard application. Lower limitations may apply on

specific applications (i.e. applications above 6600 feet elevations).

Location condition

The location where the contactor is to be installed should be free from dust, corrosive gas and moisture.

When it is to be used in a chemical plant or in outdoor applications, take necessary precautions against

corrosion, water seepage and condensation.

0.8PF Ind/Syn

Motor

1750HP

2250HP

3000HP

4500HP

1.0PF Syn Motor 3 Phase

Transformer

2000HP

2500HP

3500HP

5000HP 4000kVA 2000kVAR

1500kVA 1500kVAR

2000kVA 2000kVAR

3000kVA 2000kVAR

3 Phase Capacitor

Page 11

GENERAL DESCRIPTION Page 9

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

CONTACTOR RATINGS

HCV-5HA

Rated Voltage 7200 Volts

Rated Current 400 Amps

Interrupting Capacity 7000A RMS Symmetrical @5000V Max.

4500A RMS Symmetrical @7200V Max.

Permissible Switching Frequency 1200/Hour

Mechanical Life 2,500,000 Operations

Electrical Life 250,000 Operations

Closing Time 75-100 ms

Opening Time * 20-30 ms

Arcing Time 10 ms or less

Pick-Up Voltage AC or DC 85% Rated (Hot) - 70% Rated (Cold)

Drop-Out Voltage AC or DC 50% Rated (Hot) - 40% Rated (cold)

Rated Control Voltage AC 115/120 or 230/240 V 50/60 Hz

Rated Control Voltage DC 120/125 or 240/250 V

Coil Circuit Inrush 670 VA AC (700 W DC)

Coil Circuit Holding 85 VA AC (85 W DC)

Auxiliary Contact Arrangement 3 N.O. - 3 N.C.

Auxiliary Contact Rating 10 A, 600 V (NEMA Class A600)

* - DC switching, opening terminals 3 & 4.

HCV-5HAL (Latched Type Only)

Permissible Switching Frequency 300/Hour

Mechanical Life 250,000 Operations

Tripping Voltage 40-60% Rating DC

Tripping Current 4.8 A DC Max

Page 12

Page 10 STRUCTURE

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

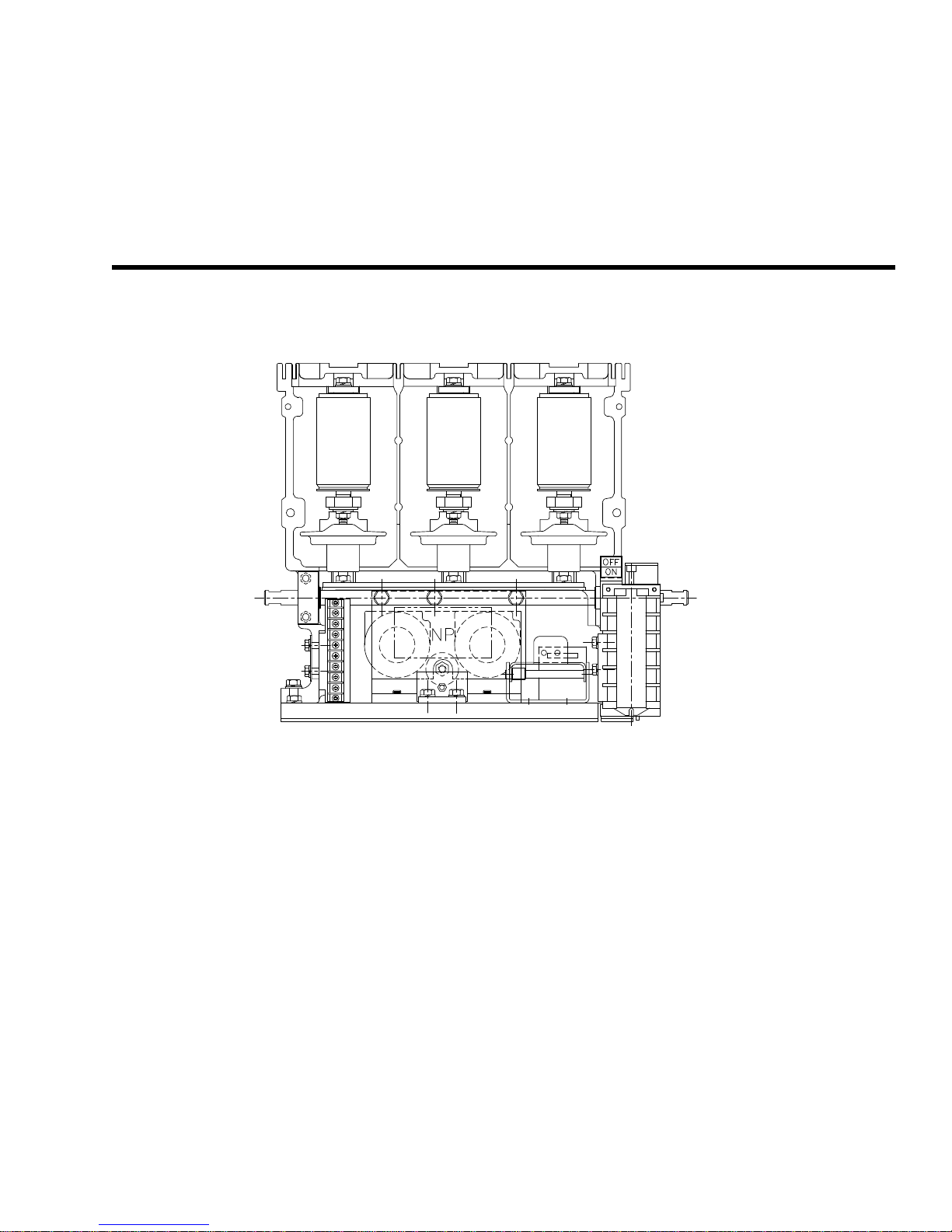

Fig. 1 Construction of HCV-5HA & HCV-5HAL

Page 13

PRE-OPERATION SET-UP Page 11

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

APPLICATION PRECAUTIONS

1) Verify that the voltage and current applied is within the specified ratings. (See application

table, page 5).

2) When the contactor is used with an induction heater facility, the switching life of the vacuum

interrupter is approximately 250,000 operations. The vacuum interrupter should be replaced

after 250,000 operations.

3) When the contactor is applied to a capacitor load, be sure to use a space heater to keep

the temperature above the dew point and prevent condensation. Be sure to use a heater

adequately sized for the compartment in which the contactor is installed. The contactor

should always be applied with a protective power fuse.

INSTALLATION

During installation, protect the contactor from dust and falling debris.

The following precautions should be taken,

1) The mounting surface should be horizontal (level: ±1 mm). If the mounting surface is not

level, adjust with spacers or shims.

2) The contactor base has four (4) mounting holes. Use M8 or 5/16 bolts to securely mount

the contactor.

3) In wiring the main circuit, wires should be gi ven sufficient length to be flexible for service.

The ground wires should be #10 AWG or larger.

4) Avoid touching the surface of the vacuum interrupter with soiled hands. You can damage

the silicon finish on the interrupter. If the interrupter becomes dirty, simply clean it with a

non-tracking cleaner such as rubbing alcohol.

Page 14

Page 12 PRE-OPERATION SET-UP

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

CONTROLS

The drive unit for the closing coil assembly is installed in a cavity in the molded frame housing. The

closing circuit can be operated by applying either AC or DC to this drive unit. The optional latch trip

circuit uses DC as standard. When a latched contactor is operated using AC power, it is

recommended that a capacitor trip device be used.

The standard control voltage (factory preset) is 120V AC. To operate at other ratings see the

selection chart below.

Fig. 2 Control Voltage Selection for Closing Coils

The following is a list of the available trip coil voltages for a latched type contactor:

24 V DC 32 V DC 48 V DC

125 V DC 250 V DC

Page 15

PRE-OPERATION SET-UP Page 13

pply

(

)

(

)

pply

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

CONNECTION OF CONTROL POWER SUPPLY

Figures 3 and 4 show the internal connections of the magnetically held (normally energized) type

and the latched type respectively. Connect control power and open/close control signals according

to these connection diagrams.

Note: Connections are the same for 100V and 200V

class. Only the drive unit settings should be changed

to match the application control voltage.

Jumper or

2 Relay

Contacts

Power

Su

Closing Coils

Control Terminal Block

Drive Unit is Attached

Fig. 3 Connections for Magnetically Held Type.

Note: Terminals 3 and 4 are rated for 4.8A DC max. A wire jumper (14 AWG or larger) can be used

instead of a relay on 3 and 4.

Note: Connections are the same for 100V and 200V

class. Only the drive unit settings should be changed

to match the application control voltage.

Contactor Auxiliary Switch Contact

Trip

Power

Supply

Fig. 4 Connections for Mechanically Latched Type.

Jumper or

2 Relay

Contacts

Power

Su

Control Terminal Block

Drive Unit is Attached

Closing Coils Trip Coil

Note: Terminals 3 and 4 are rated for 4.8A DC max. A wire jumper (14 AWG or larger) can be used

instead of a relay on 3 and 4.

Page 16

Page 14 CONTROLS

V

(

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

C

ONTRO Page 14 LS

Contacts or

Jumper Wire

Fig. 5 Internal Configuration of Drive Unit.

STANDARD OPERATION CIRCUIT

The following figures illustrate the vacuum contactor and its auxiliary circuits (control and

monitoring). Fig. 6 represents the standard operation circuit diagram of the normally

energized type and Fig. 7 (a & b) the latched type. Wiring should be implemented

100-125V AC/DC

200-250V AC/DC

Fig. 6 Standard Operation Circuit Diagram of Normally Energized Type.

according to these circuit diagrams.

Remote

Operation

Switch

CR

STOP

INTERLOCK

CONTROL

RELAY

OFF

OFF

ON

START

INTERLOCK

DOOR

SWITCH

2E

OVERLOAD)

ON

REMOTE

DU

CR

ACUUM CONTACTOR

Page 17

LATCHED CIRCUIT Page 15

S

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Fig. 7a Standard Operation Circuit Diagram of Latched Type Using Shunt Trip

REMOTE OPERATION

ON

DC

CONTROL

ON

START

INTERLOCK

LOCAL

REMOTE

CR

DU

2E

Fig. 7b Standard Operation Circuit Diagram of Latched Type Using Capacitor Trip Device

AC

ON ON

START

INTERLOCK

CONTROL

RELAY

LOCAL

REMOTE

REMOTE OPERATION

WITCH

DU

CR

OFF OFF

VCTT

2E

CTD

P

Page 18

Page 16 TRIAL OPERATION

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

TRIAL OPERATION

MAKE SURE MAIN POWER IS OFF.

After mounting and wiring of the vacuum contactor, make the following inspections.

1) Check for any loose connections.

2) Check for any wiring errors. Perform this test with only the control circuit energized.

Confirm that the operation is correct. For the latched type contactor, check that the latch

correctly engages and trips when the close/trip signals are applied. Also, manually trip the

contactor using the trip lever to verify proper operation. For latch kit adjustment and

maintenance please refer to manual no. 6F9G0132 - Installation Instructions of Latch Kits

for HCV-5HA.

Page 19

MAINTENANCE Page 17

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

GENERAL INSPECTION

MAINTENANCE AND INSPECTION

The following maintenance and inspections are recommended to maintain the performance level

and extend the operational life of the vacuum contactor.

BEFORE CONDUCTING MAINTENANCE AND INSPECTIONS, MAKE SURE

ITEMS FOR INSPECTION

Table 3

INSPECTED

PARTS TO BE

MAIN CIRCUIT

SECTION

MECHANISM

THAT ALL POWER IS TURNED OFF.

INSPECTION

ITEM

VACUUM

INTERRUPTER

MOVABLE

CONDUCTOR

UPPER &

LOWER

TERMINALS

MOLDED

FRAME

INSULATION

FLANGE

BEARING

CRACKS

DISCOLORATION

OO

OO

OOO

OO

RUST

CONTAMINATION

WEAR

OPERATION

INCOMPETE

LOOSE PARTS

SOUND

VIBRATION

OOO O

OO

INTERVALS

INSPECTION

CLOSING COIL

ARMATURE &

MAGNET

ELECTRO-

LATCH

MECHANISM

OTHERS

NOTE

CORE

AUXILIARY

SWITCH

TRIP COIL

ROLLER

BOLTS & NUTS

INSULATION

WIRE

THE LIFE EXPECTANCY OF THE ELECTRICAL PARTS (VACUUM INTERRUPTER,

OO O

OOOO

O

AUXILIARY SWITCH) IS 250,000 OPERATIONS

O

OO

O

O

VISUAL CHECK ONCE A YEAR OR EVERY 20,000 OPERATIONS

Page 20

Page 18 MAINTENANCE

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Make Sure Power Is Turned Off.

MAINTENANCE

Location Maintenance Procedure

Vacuum

Interrupter

Check the upper and lower flanges and interrupter shaft to see if they are

contaminated or corroded.

If contaminated...use a clean cloth

UPPER

FLANGE

and rubbing alcohol.

If corroded.........replace with a

new interrupter.

NOTE: Avoid touching the ceramic surface.

Skin oils may harm the silicon

varnish.

LOWER

FLANGE

SHAFT

Check the main contact wear in the

vacuum interrupter.

If the wear gauge can be inserted,

WEAR

GAUGE

then there is sufficient contact material

available for continued use.

If the gauge cannot be inserted, replace

2.7mm

MINIMUM

the interrupter.

NOTE: This check is made with the

INSULATING

FLANGE

contactor closed.

Check vacuum in the vacuum interrupter. Fig. 8 Vacuum Interrupter

Apply 10kVAC between the upper and lower terminals for one minute.

If there is no voltage breakdown, the vacuum interrupter is acceptable for continued use.

If there is voltage breakdown, replace with a new vacuum interrupter before continued

use.

NOTE: If there is a vacuum failure, it can be confirmed by pushing down on the insulating

flange below the vacuum interrupter. If the interrupter shaft can easily be moved, then the

interrupter has lost vacuum.

Page 21

MAINTENANCE Page 19

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Location

Vacuum

Interrupter

Bearing

C l os in g Co il

Latch

Mechanism

Maintenanc e P r oc edure

Ga p/ Wip e St andard Values (contactor in new condi tion)

Contac tor Contact Gap W ipe (new) Allowable Wear

Normally

Energized Type

L atche d Type 4.0-4.2mm >2.1mm 1.6mm

* Chec k for l oos e mounting bolts. Tight en i f loose.

Torque M6 bo lt s to 48 in-lb.

* Check f or discoloration.

Ye llow (Gold) …… av ailable for cont inued us e.

Dark Brown or Black …… replace with new coil.

If the cl osing coil is ov er heating, contact Toshib a.

* Chec k that the holding la tch re liably engages.

N ote: To ma nuall y c lose th e latch, hold the centra l area of th e ro tating

* Check t he condition of the roller. It should be smooth.

* Lubr icat e the rotating par ts wi th a mo ly bden um dis ulfide

or gear lubric ant.

* Ve r i fy that the re is remainin g auxiliary shaft travel.

Ap prox imate ly 2.3 - 2.5mm .

* Chec k for bur nt or wo r n c ont ac ts.

4.0-4.2mm >2.3mm 1. 8mm

shaf t w i t h a wren c h an d operate it .

Auxiliary

Switch

Replace if bur nt or w or n.

* Chec k if aux iliar y s witch i s mounted at an inc line or if

mounting plate is l oose. If inclined or loos e, correct it.

(Reference) Values for gap and wipe

C ontact Type

Nor m ally Op en Contac t

No r ma lly Closed Co ntact

Del ayed N. C. Contac t (For latched

ty pe contactor onl y . Contacts 16- 26)

Contact Gap Wipe

4mm +/- 0.4 3mm +/- 0.3

4mm +/- 0.4 3mm +/- 0.3

2.5mm +/- 0.3 4.5mm +/- 0.5

Page 22

Page 20 MAINTENANCE

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

PROCEDURE FOR REPLACING VACUUM INTERRUPTERS

When a vacuum interrupter has reached a specified life (250,000 operations) or when it is

damaged, it is recommended that it be replaced in the following sequence:

“B”

(M8 BOLT)

Removing

CONDUCTIVE

COLLAR

1) Hold the insulating flange with one hand and

loosen nut "A" (below the flexible conductor)

with a wrench.

VACUUM

INTERRUPTER

UPPER

TERMINAL

2) Turn the insulating flange clockwise by hand

until it comes off the movable shaft of the

vacuum interrupter.

3) With the vacuum interrupter held in one hand,

CONDUCTIVE

NUT

FLEXIBLE

CONDUCTOR

loosen and remove bolt “B” (above the

interrupter) with a wrench.

“A”

(M8 NUT)

4) While pushing down on the insulating flange,

pull the vacuum interrupter forward to remove

it.

At this time, the conductive collar can also be

INSULATING

FLANGE

REMOVE

removed. Keep the collar for later use.

Fig. 9 Mounting of Vacuum Interrupter.

Page 23

MAINTENANCE Page 21

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

MOUNTING

1) Remove the conductive nut from the vacuum interrupter

being replaced and attach it to the new vacuum

interrupter as shown in Fig. 10.

2) Put the conductive collar on the upper part of the

vacuum interrupter (stationary terminal) and assemble

the vacuum interrupter.

3) Hold the vacuum interrupter and fasten bolt "B" (torque

to 120kg-cm or 102in-lb).

CONDUCTIVE NUT

0.5-1.0mm

4) Push down the insulating flange and align the insulating

flange stud with the movable shaft of the vacuum

interrupter. Then, while turning the flange counterclockwise, insert it. (Install the insulating flange with only

3 to 4 turns, then stop).

Fig. 10

ADJUSTING THE MAIN CONTACT GAP OF THE VACUUM INTERRUPTER

1) With the control circuit energized, close the

vacuum contactor. Check that the armature is

attracted to the coil cores.

VACUUM

INTERRUPTER

WEAR

GAUGE

(SUPPLIED)

2) As shown in Fig. 11, turn the insulating flange until

the distance is 41.5mm or use the wear gauge

supplied.

3) With the adjustment made, hold the insulating

flange still with the hand and secure nut "A".

CONDUCTIVE

NUT

Note: -Arrange so that the movable conductor is

straight and flat.

41.5mm

-Check that the conductive nut does not rotate.

"A"

(M8 NUT)

4) Turn off the control circuit power supply.

INSULATING

FLANGE

5) Operate manually to confirm that the vacuum

interrupters close simultaneously.

6) Operate the contactor electrically and check that

Fig. 11 Adjusting the Main Contact Gap.

the main contact gap is 4mm +0.2mm. If

necessary, loosen nut “A” and turn the insulating

flange (clockwise or counterclockwise as

necessary) until the correct contact gap is

achieved. Then tighten nut “A”.

OPERATION CHECK

In a no-load condition, electrically operate the contactor through 20 operations to confirm normal

operation.

Page 24

Page 22 MAINTENANCE

g

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

TROUBLESHOOTING

Turn off main power before any inspections

are conducted.

Table 4

SYMPTOM

Conduct investigation with

(Latch type).

Contactor does not open

Contactor does not close.

Trip coil overheated.

Closing coil overheated.

Latch does not engage.

00 0

00000

00

00 0

Bad connection and/or loose

00

SOURCE OF

TROUBLE/PROBLEM

main power "OFF".

Control power supply is low.

Incorrect control voltage. Apply proper rating.

Defective control circuit. Check connection diagram.

connection.

Bad control switch contact. Clean or replace device.

countermeasure is difficult,

inform Toshiba immediately.

increase the voltage to 90%

SOLUTION

If inspection and/or

Lower the voltage drop to

or more of the ratin

Make proper connection.

.

00 0

00

00

00

000

00

0

0

Incorrect terminal

connection.

Blown power supply fuse(s).

Disconnected coil.

Faulty drive unit. Replace drive unit.

Defective latch mechanism.

Mechanism jammed.

Incorrect auxiliary

adjustment.

Bad auxiliary contact.

Connect correctly.

Remove cause of fault and

replace fuse(s).

Survey cause and reconnect

Excite closing coil and check

latch hook.

Lubricate corresponding

portion.

Adjust delayed N.C. contact

gap to 2.5mm +/- 0.3mm when

connected.

Clean or replace auxiliary

contact block.

coil.

Page 25

OUTLINE Page 23

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Fig. 12 Types HCV-5HA, HCV-5HAL

Page 26

Page 24 WARRANTY AND LIMITATION OF LIABILITY

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Toshiba International Corporation ("Company") warrants that all equipment and parts described herein will

be free from defects in materials and workmanship. THIS WARRANTY WILL EXPIRE EIGHTEEN (18)

MONTHS AFTER THE DATE ON WHICH SUCH EQUIPMENT AND PARTS (EXCLUDING REPAIRED OR

REPLACEMENT EQUIPMENT AND PARTS FURNISHED PURSUANT TO THIS WARRANTY) ARE

SHIPPED BY THE COMPANY TO THE INITIAL PURCHASER OR TWELVE (12) MONTHS AFTER SUCH

EQUIPMENT AND PARTS (EXCLUDING REPAIRED OR REPLACEMENT EQUIPMENT AND PARTS

FURNISHED PURSUANT TO THIS WARRANTY) ARE FIRST PLACED IN OPERATION, WHICHEVER

PERIOD FIRST EXPIRES.

The Company will, at its option, repair or replace such equipment or part which is defective under the terms

of the foregoing warranty, free of charge; provided

writing of such defect, and (2) furnishes the Company satisfactory proof thereof, and (3) establishes that the

equipment or part has been properly installed, maintained and operated within the limits of rated capacity

and normal usage and in accordance with this manual, and (4) if requested by the Company, returns the

defective equipment or part to the Company and pays all expenses incurred in connection with such return.

The repaired or replacement equipment or part will be delivered, free of charge, to the purchaser F.O.B. the

Company's warehouse or, at the Company's option, F.O.B. a Company authorized service shop, not loaded

on truck or other carrier. The purchaser will pay the costs applicable to the equipment or part following such

delivery, including, without limitation, all handling, transportation, assembly, insurance, testing and inspection

charges.

THE FOREGOING OBLIGATION TO REPAIR OR REPLACE EQUIPMENT PARTS SHALL BE THE SOLE

AND EXCLUSIVE REMEDY OF THE PURCHASER, ITS CUSTOMERS AND USERS OF THE

EQUIPMENT AND PARTS FOR BREACH OF THE FOREGOING WARRANTY. THE COMPANY WILL

HAVE NO OBLIGATIONS TO DISASSEMBLE ANY EQUIPMENT OR PART WHICH IS DEFECTIVE

WITHIN THE TERMS OF THE ABOVE WARRANTY OR TO INSTALL ANY REPAIRED OR

REPLACEMENT PART OR EQUIPMENT OR TO PAY ANY COSTS INCURRED IN CONNECTION WITH

ANY SUCH DISASSEMBLY OR INSTALLATION. THE COMPANY, TOSHIBA CORPORATION AND

THEIR SUPPLIERS AND SUBCONTRACTORS HEREBY DISCLAIM ALL OTHER EXPRESS,

STATUTORY AND IMPLIED WARRANTIES, INCLUDING, WITHOUT LIMITATION, ALL EQUIPMENT

AND PARTS FURNISHED PURSUANT TO THE FOREGOING WARRANTY AND ALL IMPLIED

WARRANTIES OF MERCHANTABILITY.

The total liability of the Company, Toshiba Corporation and their suppliers and subcontractors for any

loss, damage or claim, whether in contact, tort (including negligence and liability without fault), or

otherwise, arising out of, connected with or resulting from the equipment and parts described in this

manual or the performance or breach of any contract for the sale or supply of such equipment and parts,

or from the design, manufacture, sale, delivery, resale, installation, technical direction or supervision of

installation, inspection, testing, repair, replacement, operation, maintenance or use of any such

equipment or part or any service relating thereto furnished by the Company shall not in any event exceed

the price allocable to the equipment, part or service which gives claim, loss or damage. In no event,

whether as a breach of contract or warranty, alleged negligence, liability without fault, or otherwise, shall

the Company, Toshiba Corporation or their suppliers or subcontractors be liable for special or

consequential damages, including, without limitation, loss or profits or revenue, loss of equipment

described herein or any associated equipment, cost of capital, cost of substitute equipment or parts,

facilities or services, down-time costs, labor costs or claims of customers of the purchaser for such

damages.

the purchaser (1) promptly notifies the Company in

Loading...

Loading...